Lyophobic and oleophylic micro nano-coatings applied to of oil filtering dehydration and preparation method thereof

A filtration dehydration, micro-nano technology, applied in the direction of mechanical dehydration/demulsification, filtration separation, separation method, etc., can solve the problems of thick coating, easy to block mesh, poor lipophilicity, etc., and achieve the distribution of coating film. Uniform, good hydrophobic effect and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a hydrophobic and lipophilic micro-nano coating for oil filtration and dehydration: comprising the following steps:

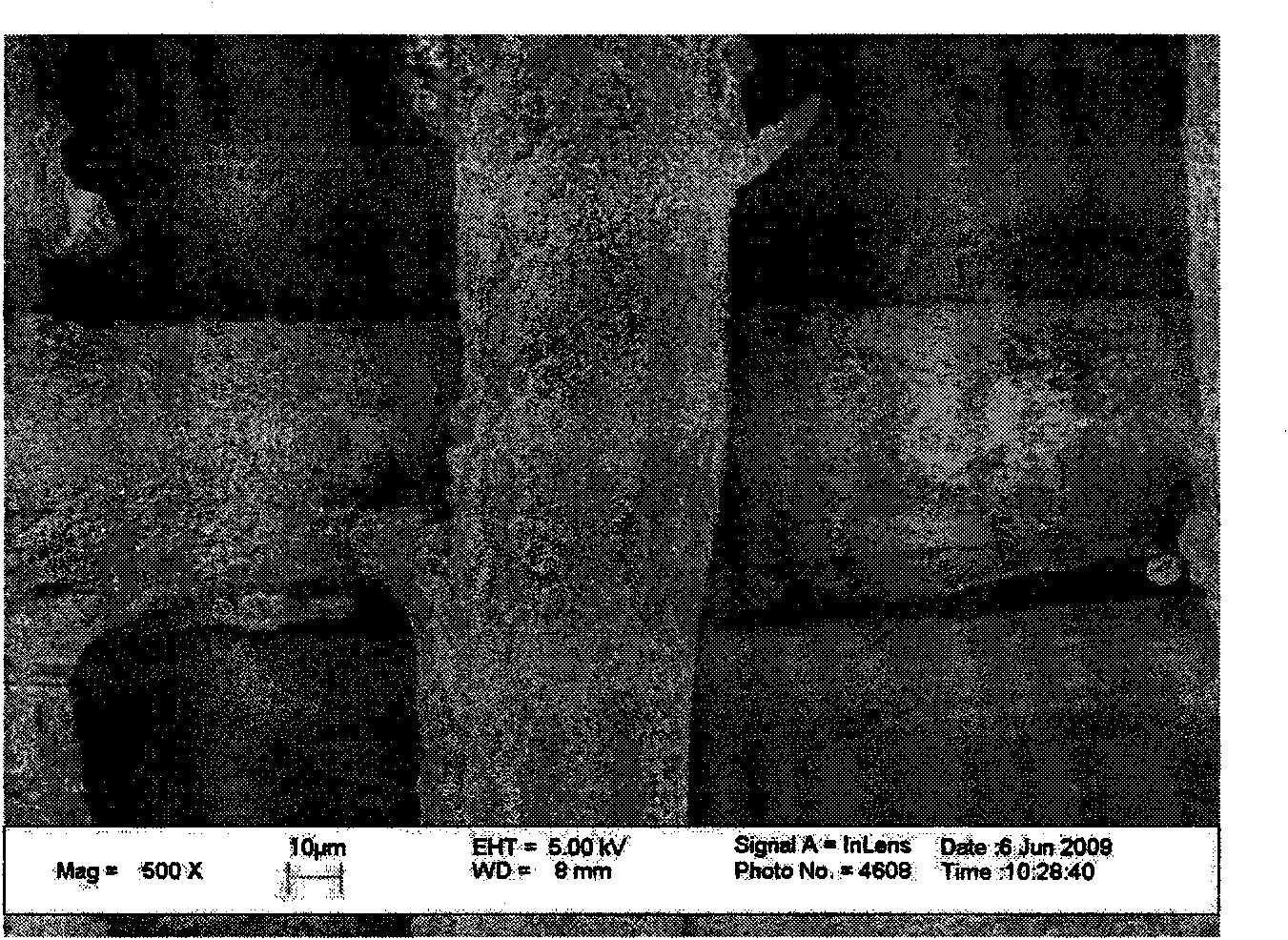

[0035] The first step is to immerse the 300-mesh stainless steel braided mesh in petroleum ether, ultrasonically clean it for 20 minutes, and put it into the mixed solution of hydrochloric acid, sulfuric acid, ethanol, hexamethylenetetramine, hydrogen peroxide and water after drying, among them, hydrochloric acid, sulfuric acid, The mass ratio of ethanol, hexamethylenetetramine, hydrogen peroxide and water is 300:220:120:2:250:150; soak at room temperature for 5 minutes to remove rust, make the surface of the stainless steel mesh smooth, and then wash it with a large amount of distilled water until neutral , and finally dried at 60°C for later use;

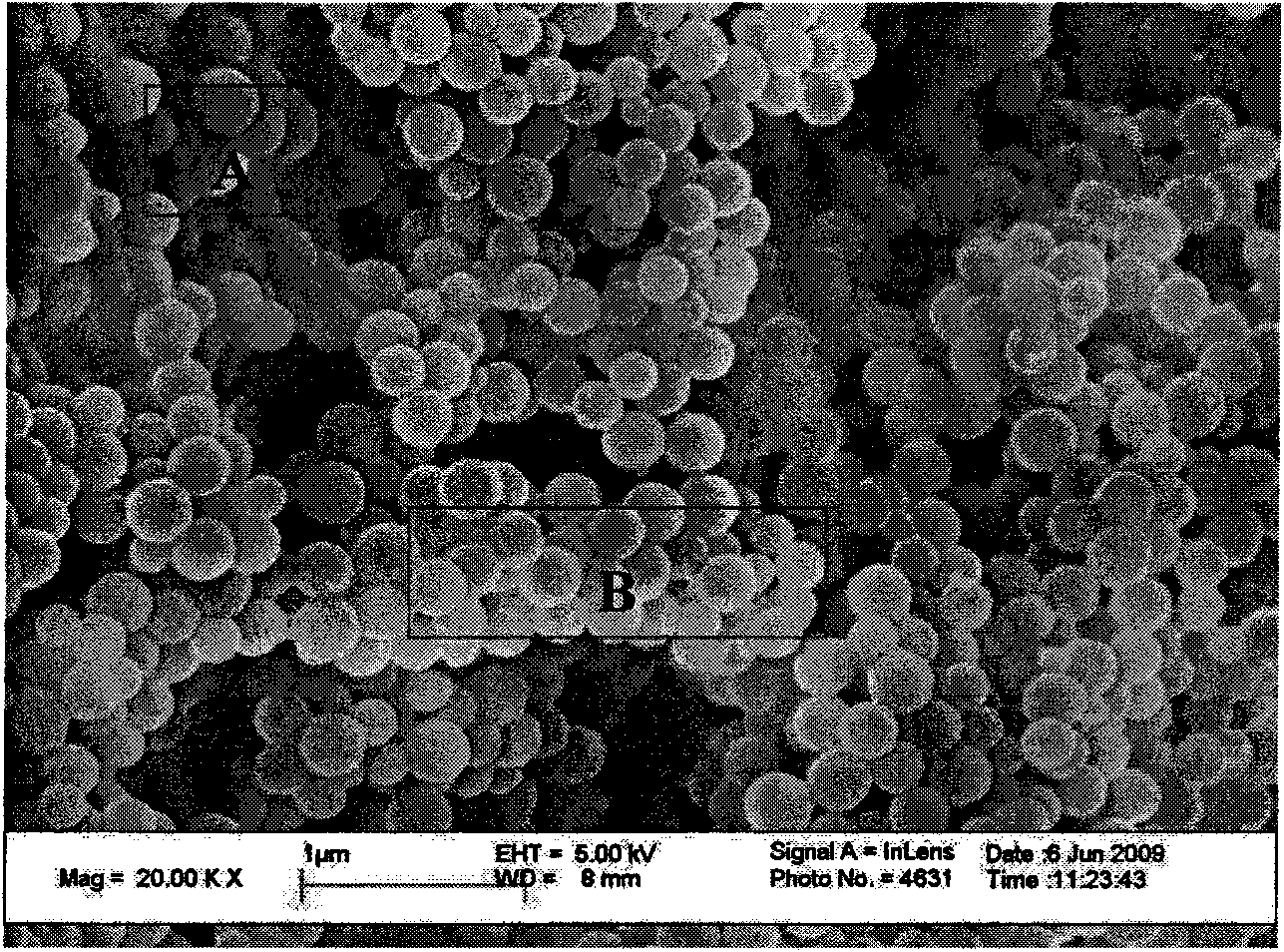

[0036] In the second step, in parts by weight, add 6 parts of methyl orthosilicate, 6 parts of ammonia water, 12 parts of water and 100 parts of ethanol in the reaction vessel, and rea...

Embodiment 2

[0042] A method for preparing a hydrophobic and lipophilic micro-nano coating for oil filtration and dehydration: comprising the following steps:

[0043] The first step is to immerse the 50-mesh copper net in gasoline, ultrasonically clean it for 20 minutes, put it into the mixed solution of sulfuric acid, nitric acid and sodium chloride after drying, and the mass ratio of sulfuric acid, nitric acid and sodium chloride is 700:300:4 ; Soak at 40°C for 10 minutes to remove rust, make the surface of the copper mesh smooth, then wash with a large amount of distilled water until neutral, and finally dry at 60°C for later use;

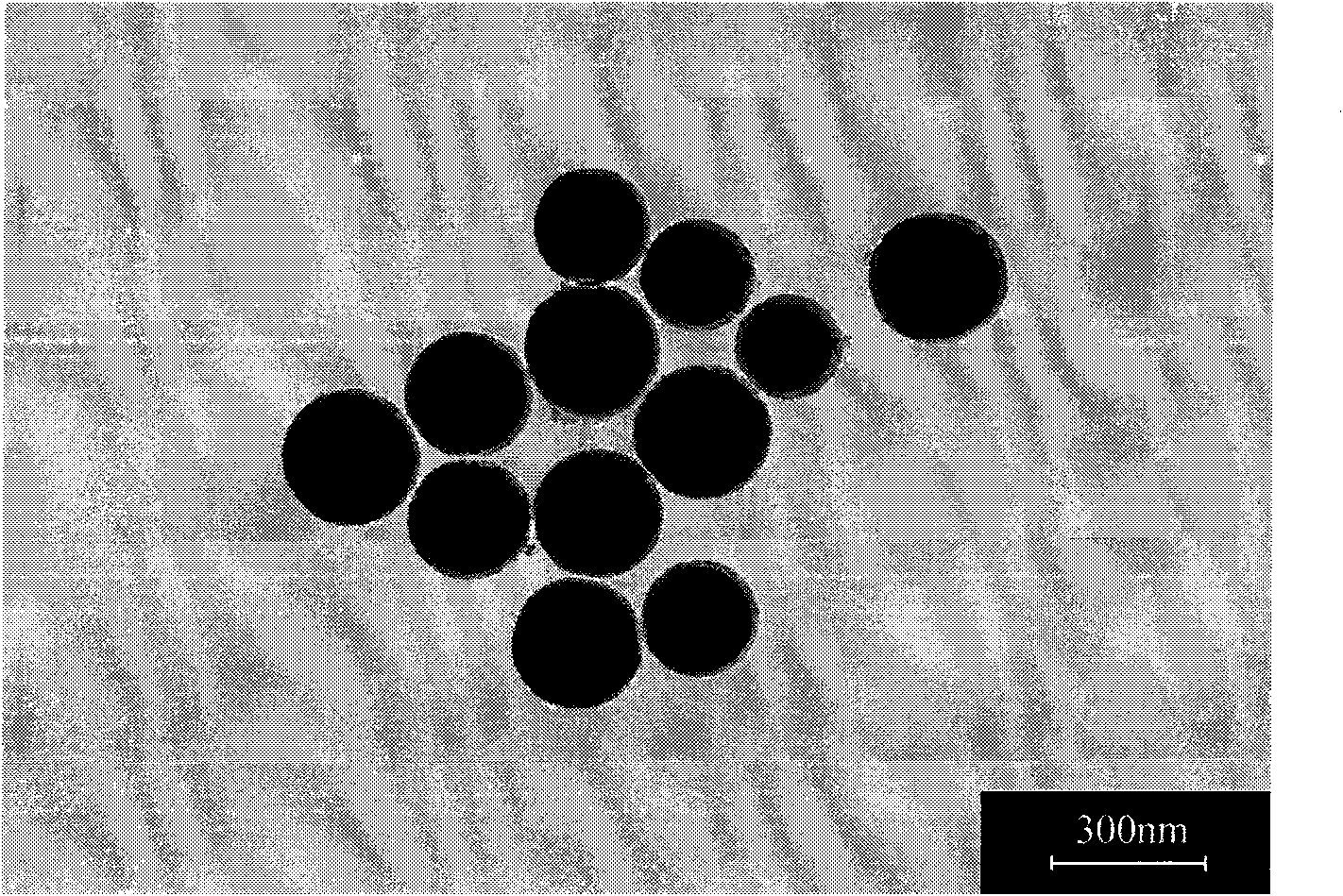

[0044] In the second step, 10 parts of tetraethyl orthosilicate, 8 parts of ammonia water, 0 parts of water, and 50 parts of methanol were added to the reaction vessel in parts by weight, and reacted at 30°C for 0.5h to obtain 500nm monodisperse silica Sol;

[0045] In the third step, add 1 part of dodecyltrimethoxysilane to the reaction vessel described i...

Embodiment 3

[0048] A method for preparing a hydrophobic and lipophilic micro-nano coating for oil filtration and dehydration: comprising the following steps:

[0049] The first step is to immerse the 1800-mesh iron net in the mixed solvent of methanol and acetone, ultrasonically clean it for 20 minutes, put it into the mixed solution of phosphoric acid and chromic acid after drying, and the mass ratio of phosphoric acid and chromic acid is 8.5:15. Soak in ℃ for 2 minutes to remove rust, make the surface of steel mesh smooth, then wash with a large amount of distilled water until neutral, and finally dry at 60 ℃ for later use;

[0050] In the second step, in parts by weight, add 4 parts of ethyl orthosilicate, 2 parts of ammonia water, 18 parts of water, 200 parts of propanol in the reaction vessel, and react at 70°C for 1 hour to obtain a 90nm monodisperse silica sol ;

[0051] In the third step, add 3 parts of isobutyltriethoxysilane to the reaction vessel described in the second step, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com