Environment-friendly steel pickling waste liquor treatment system and method for producing PFC (Polymerization Ferric Chloride) through electrochemical process

A technology for iron and steel pickling waste liquid and environmental protection treatment, which is applied in the field of green environmental protection and circular economy, can solve the problems of safety and environmental protection hidden dangers, harsh reaction conditions, low extraction efficiency, etc., achieve exquisite technology, extremely low production cost, and optimize the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

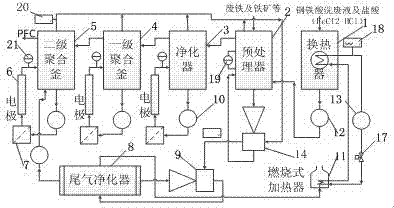

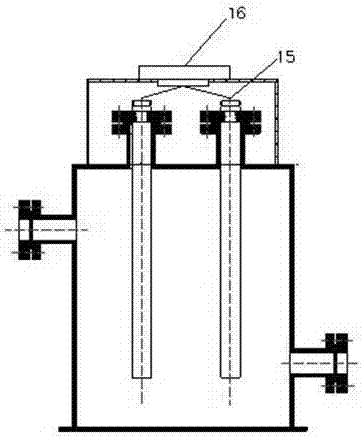

[0029] Such as Figure 1 to Figure 2 As shown, the PFC environmental protection treatment system for the electrochemical production of iron and steel pickling waste liquid includes a heat exchanger 1, a preprocessor 2, a purifier 3, a primary polymerization kettle 4, a secondary polymerization kettle 5 and an exhaust gas purifier 6. The water inlet of the heat exchanger 1 is connected to a fluid heat source through a hot water circulation pump, the heat exchanger 1 is connected to the preprocessor 2, the preprocessor 2 is connected to the purifier 3, and the purifier 3 is connected to the primary polymerization tank 4. The first-stage polymerizer 4 is connected to the second-stage polymerizer 5, and the gas discharged from the preprocessor 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com