Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Reduce sulfur dioxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated method for simultaneously realizing denitrification, desulfurization and heavy metal removal from flue gas, and special equipment suitable for the method

ActiveCN102188882ASimple systemEasy to implementDispersed particle separationAir quality improvementAmmonium sulfateFertilizer

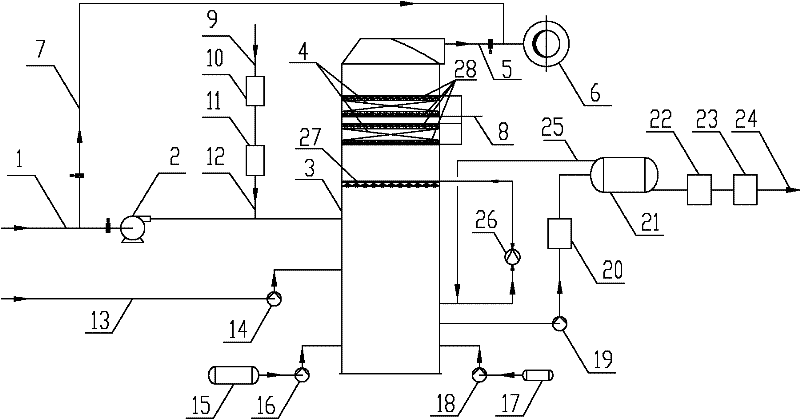

The invention relates to an integrated method for simultaneously realizing denitrification, desulfurization and heavy metal removal from flue gas, and special equipment suitable for the method. The integrated method is characterized in that an acidic gas capture agent adopted by the invention captures SO2 and / or highly charged nitrogen oxides NOx in raw flue gas and thus ammonium sulfate as a by-product and / or ammonium nitrate as a by-product is obtained finally, and the acidic gas capture agent adsorbs heavy metals in the raw flue gas simultaneously, wherein the above processes are carried out in a same absorbing device. The special equipment suitable for the method of the invention comprises an absorbing tower, a raw flue gas input pipeline having an external connection with the absorbing tower body, a purified flue gas output pipeline having an external connection with the absorbing tower body, a system for supplying the acidic gas capture agent and absorbents, a demisting water input pipeline, an absorption liquid cycling system, a slurry discharge system, and a separation and treatment system, wherein the raw flue gas input pipeline is provided with a supercharging system anda forced oxidation system. Through the method of the invention, the integrated purification processes of denitrification, desulfurization and heavy metal removal from flue gas can be completed in a same device and by-products from the integrated purification processes are ammonium sulfate and ammonium nitrate, wherein ammonium sulfate and ammonium nitrate can be utilized as components of fertilizers. Through the method, waste water and waste residue are not produced in the integrated purification processes and the integrated purification processes have the advantages of simple system, low cost, high recovery rate, etc.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Low-salt pickled fermented Allium chinense and processing method thereof

InactiveCN101926446ARich flavorPreserve the crispnessFood preparationAcetic acidSodium metabisulfite

The invention relates to a low-salt pickled fermented Allium chinense and a processing method thereof. The pickled fermented Allium chinense is prepared by the steps of: taking a fresh Allium chinense; removing fibrous roots and washing; adding table salt, drinking water, glacial acetic acid, citric acid and sodium metabisulfite to carry out primary fermentation for 10 to 12 days; taking the fermented Allium chinense; adding the table salt, the drinking water, the glacial acetic acid and the citric acid to carry out secondary fermentation for 30 to 60 days; proportionally mixing the fermented Allium chinense in the second time with soup; then adding dried red pepper rings; and sterilizing and cooling. The product of the invention has stable quality and low content of sulfur dioxide with preferable preservation of color, brittleness and nutritious elements of the Allium chinense, and has longer shelf life.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

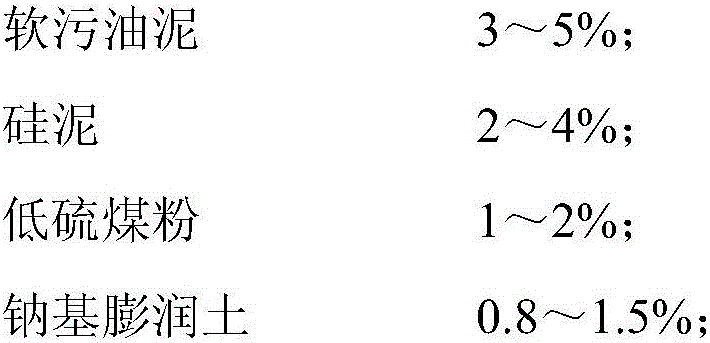

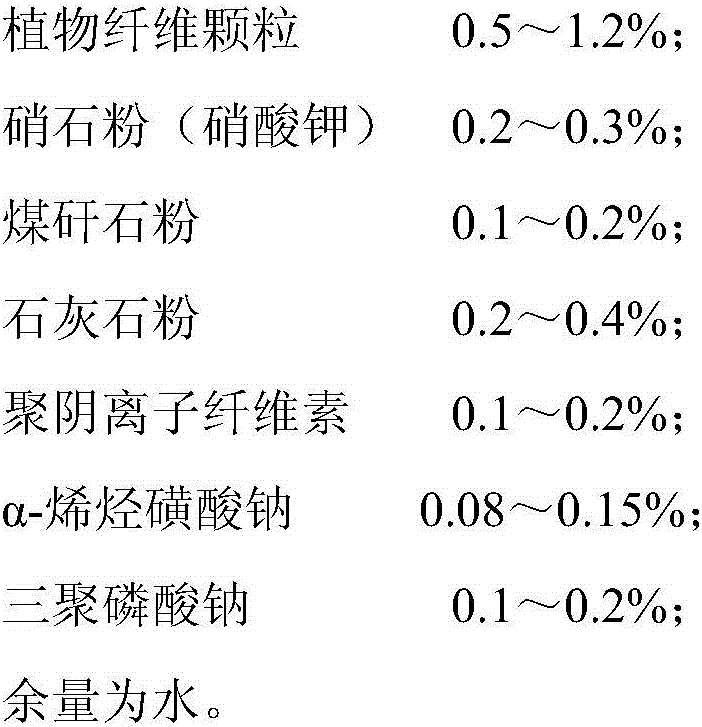

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

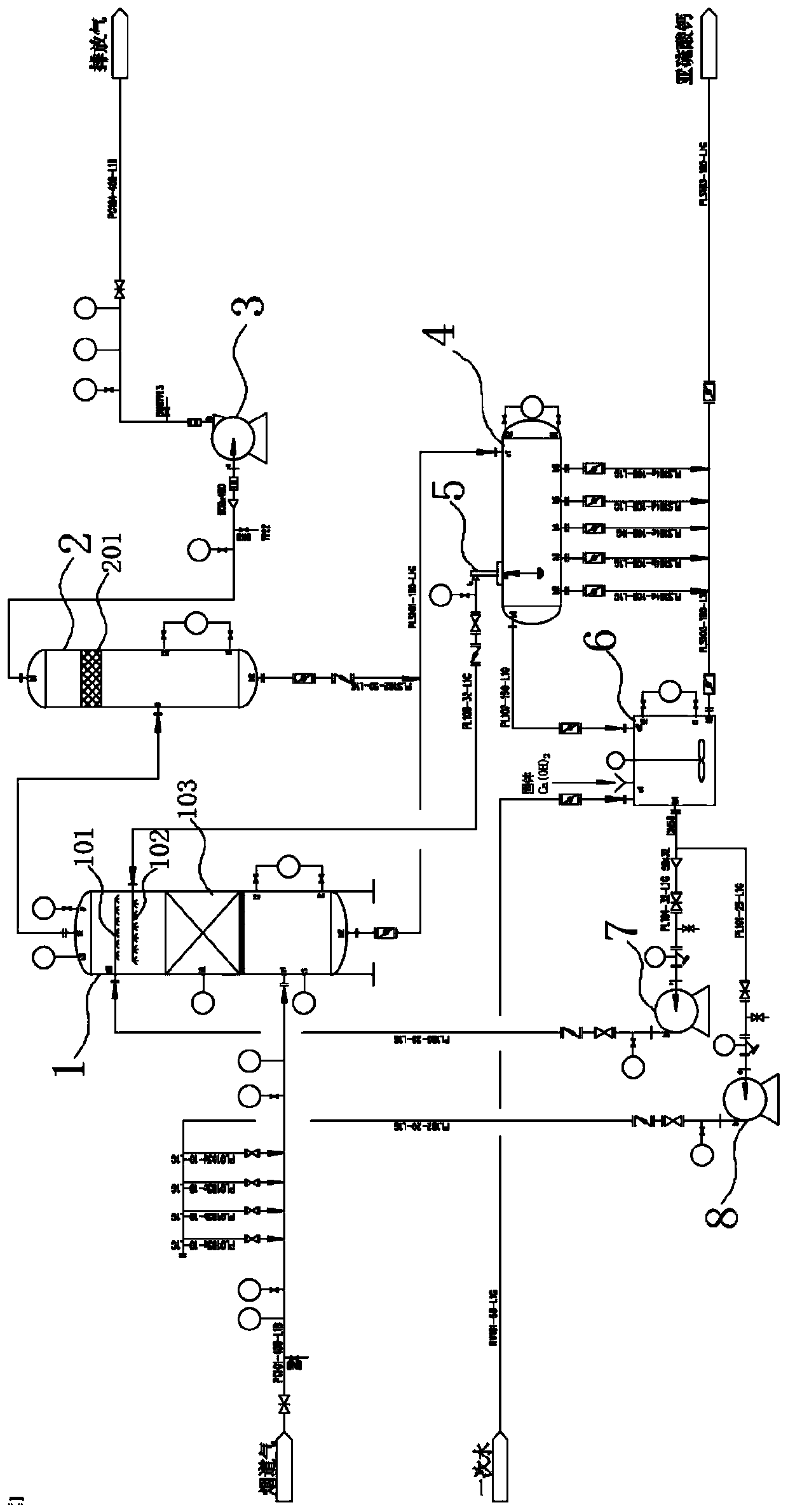

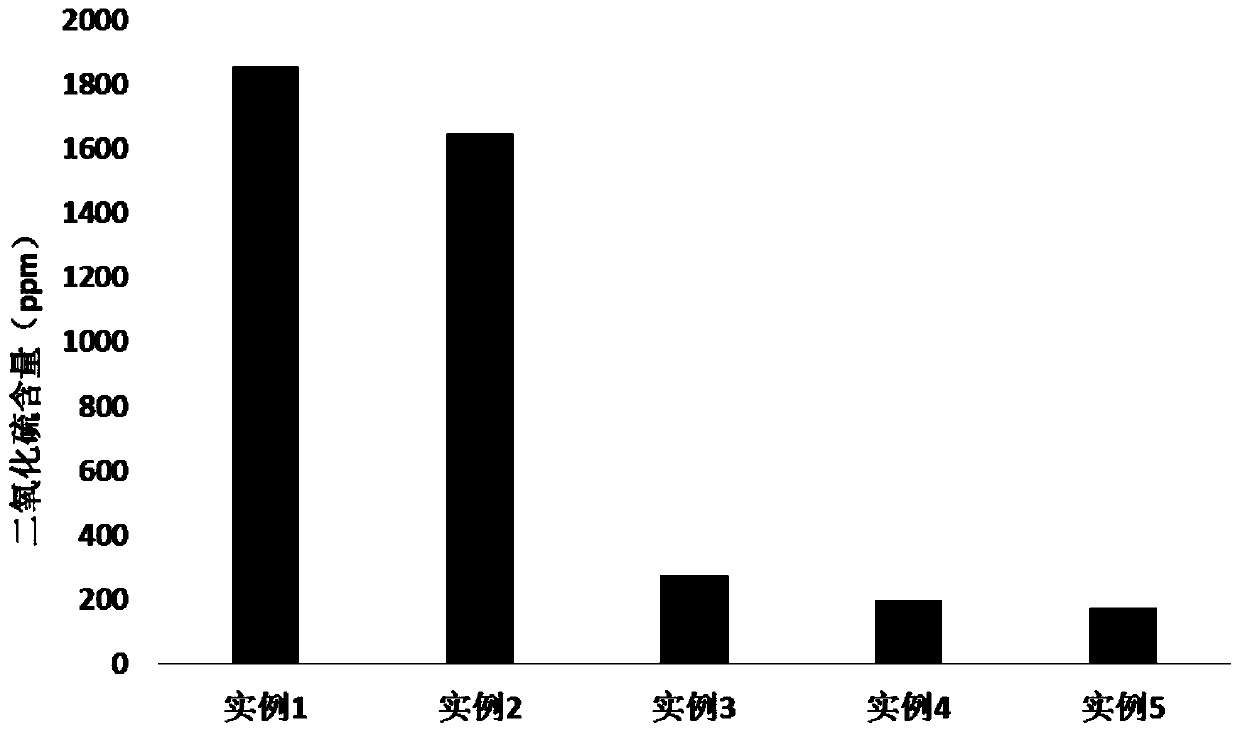

swsr-1 sulfur recovery process

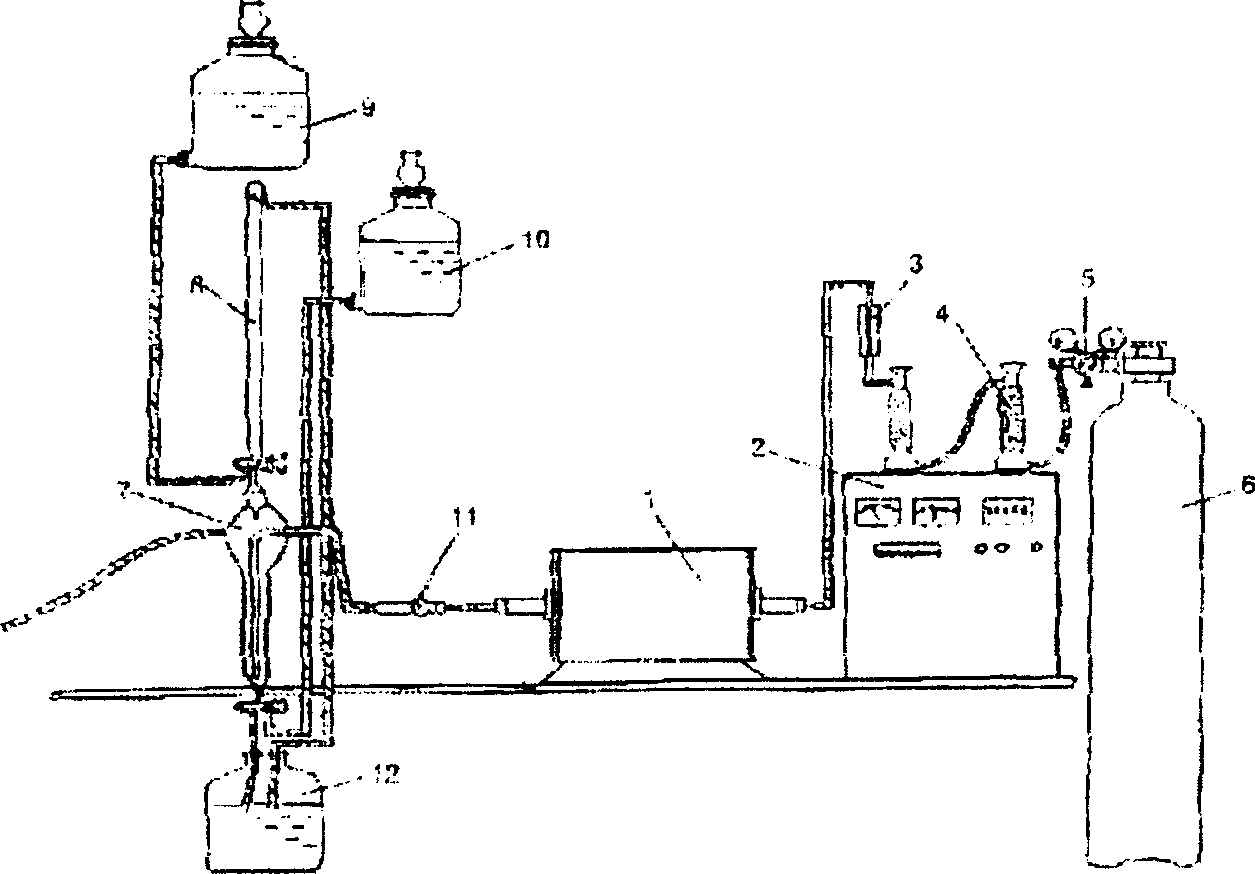

ActiveCN103482583BReduce sulfur dioxide contentThe effect achieved is excellentDispersed particle separationSulfur preparation/purificationAntioxidantIonic liquid

The invention relates to an SWSR (SunWay Sulfur recovery)-1 device and technique. The invention relates to a tail gas treatment combination device and technique by adopting Claus sulfur recovery and ionic liquid cycle absorption process. The device comprises a sulfur production burning furnace, a Claus reaction system, a sulfur production tail gas incinerator, a rich SO2 process gas heat exchanger, an SO2 absorption tower, a rich liquid pump, a lean and rich liquid heat exchanger, an SO2 regeneration tower and a lean liquid feed pump. The technique comprises the steps: (1) enabling hydrogen sulfide-containing acid gas to generate a Claus reaction, and recovering sulfur and heat energy in the reaction process; (2) burning sulfur production tail gas to generate SO2; (3) removing SO2 from rich SO2 process gas through an ionic liquid absorption tower; and (4) feeding rich SO2 ionic liquid into a regeneration tower for separating and regenerating sulfur. The ionic liquid is an aqueous solution which takes organic positive ions and inorganic anions as main components and a little amount of activating agent and antioxidant as additives. The SWSR-1 device and technique are low in equipment investment, high in material safety, short in technique flow, safe and reliable in technique processes, high in SO2 recovery rate, and the content of SO2 in effluent gas can be reduced by 50ppm below which can meet the national regulation requirement.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD +1

Manufacturing method of crimson brown granulated sugar

InactiveCN102703611AHigh color ratioColoring effect is stableSugar productsFood preparationSucroseCaramel Flavor

The invention discloses a manufacturing method of crimson brown granulated sugar, which comprises the steps of: raw material juicing in white granulated sugar manufacturing process, sugar juice defecation, evaporation, sugar cooking, assisted crystallization, purging and drying, and is characterized in that edible caramel pigment is added during the growth period of granulated sugar crystal sucrose-absorption crystal from the triose cooking working procedure to the assisted crystallization working procedure in the later-stage working procedure of three-stage sugar cooking, so that the granulated sugar crystal sugar and the caramel pigment are synchronously absorbed; and the edible caramel pigment is at least one of double caramel pigment or single caramel pigment. Compared with the prior art, the crimson brown granulated sugar obtained by the manufacturing method of the crimson brown granulated sugar has the advantages of high color ratio, stable and controllable color ratio, reliable quality and longer shelf life.

Owner:广西柳州中嘉知识产权服务有限公司 +1

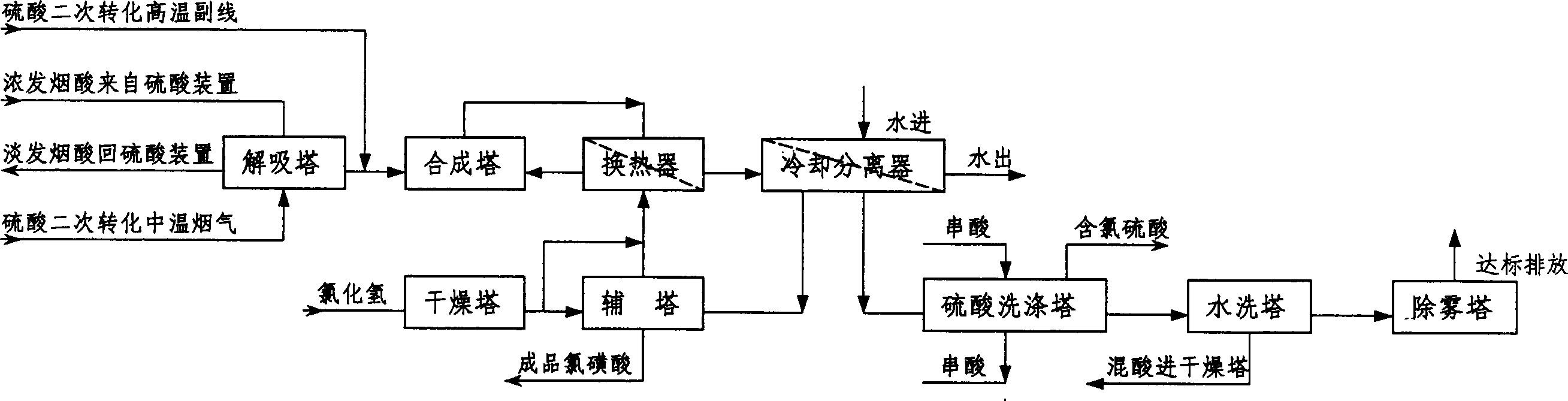

Technology of synthesizing high concentration chlorosulfonic acid using low concentration salfur trioxide

InactiveCN1410347AReduce manufacturing costLower working temperatureSulfur-halogen-hydrogen-oxygen compoundsHigh concentrationSulfur trioxide

A process for synthesizing high-concentration chlorosulfonic acid from low-concentration SO2 features that the SO3 generated by directly decomposing the fuming sulfuric acid by the fume converted from sulfuric acid and the hydrogen chloride are used as raw materials. Its advantages are wide range of the concentrations for hydrogen chloride, and little environmental pollution.

Owner:顾林建

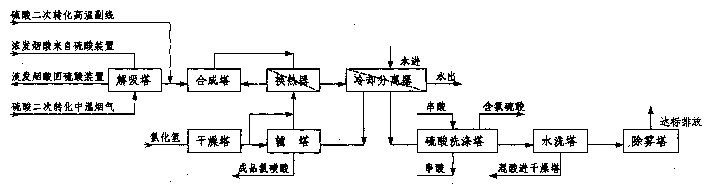

Technique for extracting vanadium pentoxide by tunnel kiln calcification roasting

InactiveCN101265522AEasy to stackReduce sulfur dioxide contentProcess efficiency improvementTunnel kilnBrick

The invention relates to a method for extracting vanadium pentoxide by calcification and calcination of tunnel kiln coal gas, which comprises the steps of: mixing mineral soil and calcium oxide at a proper proportion, crushing, squeezing to obtain bricks, stacking on a kiln cart, placing into a coal gas tunnel kiln, calcinating at a certain temperature, pulverizing the calcinated bricks with a ball mill, placing the obtained powder into a large stirring tank, leaching with low concentration sulphuric acid solution under stirring to obtain slurry, press filtering with a press filter, washing, separating, transferring the filtrate to a ion-exchange column for exchange and enrichment, purifying to obtain ammonium metavanadate, and performing thermal decomposition with an electrothermal burning furnace to obtain vanadium pentoxide. The inventive method has the advantages of low production equipment investment, convenient and accurate process condition control, low production operating cost, high product extraction yield (mean value about 75%), and high product purity (over 99%). The exhaust gas emission meets the standards, the waste water is recycled and reused without external discharge, and the waste residues are integrally utilized to produce bricks, so as to realize clean and environmentally friendly production.

Owner:闫国正

Environment-friendly biomass particle fuel and processing method

The invention relates to the technical field of biomass fuel and specifically relates to environment-friendly biomass particle fuel and a processing method. The particle fuel is prepared from the following raw materials in parts by weight: 45 to 65 parts of woodwork waste mixture, 10 to 20 parts of mulberry stalk, 5 to 15 parts of straw, 5 to 8 parts of tobacco stem, 3 to 5 parts of flame accelerator, 2 to 3 parts of anti-slagging agent and 1 to 2 parts of sulfur fixing agent. The invention further discloses the processing method of the particle fuel. The processing method comprises the steps of preparing the flame accelerator, the anti-slagging agent and the sulfur fixing agent according to selected parts by weight; mixing and smashing; drying: drying an obtained wood pellet mixture at high temperature; extrusion forming: sending the dried solid fuel into a granulator to be extruded and granulated and finally cooling to obtain the environment-friendly biomass particle fuel. The environment-friendly biomass particle fuel and the processing method disclosed by the invention have reliable performance, and the environment-friendly biomass particle fuel can meet the requirement of energy conservation and environmental friendliness and meanwhile has long combustion time and high combustion ratio.

Owner:云南省福仑木业有限公司

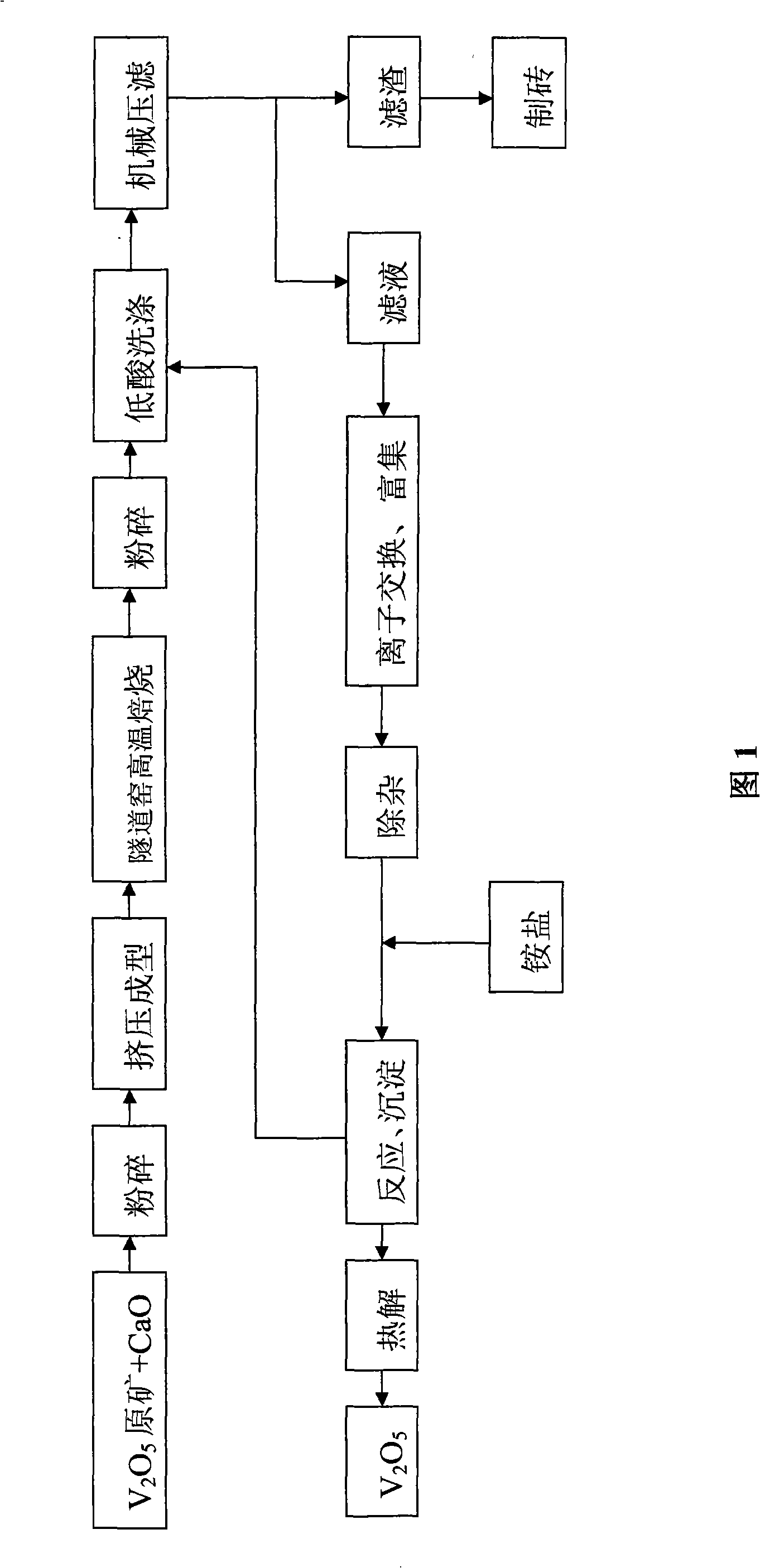

Method for automatically clearing syrup in conveying and storing processes

InactiveCN104313193AAdd cleaning functionReduce sulfur dioxide contentPurification using chemicalsThermodynamicsEconomic benefits

The invention provides a method for automatically clearing syrup in conveying and storing processes. After syrup is discharged from the former procedure, the syrup is firstly heated to a temperature of 80-85 DEG C and then discharged into a syrup box on +_0.000 layer. Then, the syrup is conveyed into a syrup storage box at the top layer of a sugar boiling building through a main and auxiliary pipeline, and a high-molecular flocculant is added before the syrup enters the syrup storage box. On the +_0.000 layer, gas is absorbed and dissolved through an online pipeline air breather and pressure formed by liquid level height difference. After the syrup enters the syrup storage box at the top layer of the sugar boiling building, impurities and air bubbles in the syrup rise to the top of the syrup storage box and are discharged out, and pure syrup is discharged from the bottom of the syrup storage box. The function of automatically clearing the syrup is increased under the condition of storing the syrup by the syrup storage box. The impurities are effectively removed from the syrup, the syrup purity is improved, the syrup conversion losses are reduced, the quality of a white granulated sugar product is effectively improved, and the economical benefit of a sugar making industry is improved.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

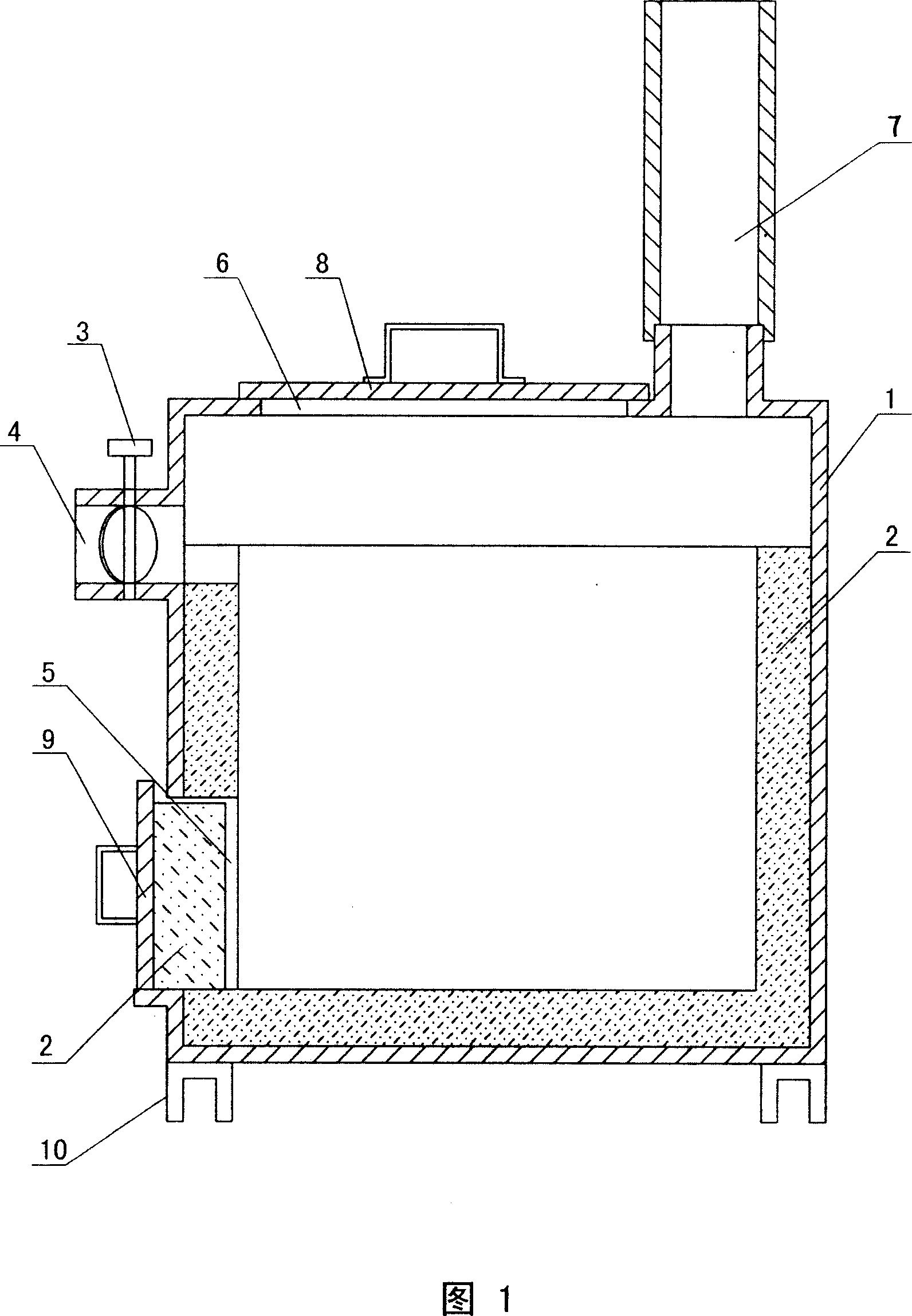

Small indoor biological material hidden-burning heating stove

InactiveCN1936427AReduce pollutionReduce sulfur dioxide contentDomestic stoves or rangesLighting and heating apparatusFilling materialsSulfur dioxide

This invention provides a small indoor biological material hidden burning heating stove including a cavity surrounded by a stove with a heat preservation layer characterizing in adding an inlet with an adjusting valve and connected to the cavity, an ash exhaust port, a feed port, a chimney and a cover covering on the feeding port, in which, the chimney is set at a side of the top of the stove, the inlet is set at the top of the side wall of the stove far away from the chimney, the feed port is set on the top of the stove, the exhaust port is set at the bottom of the side wall of the stove and an exhaust sliding door is put at the exhaust port, when filling materials, we should press them tightly and cover a certain thickness of hidden burning ash or burning ash on the surfaces apart from the inflaming place to form the hidden burning quickly and develop steadily.

Owner:SHANDONG UNIV OF TECH

Seasoning hot pepper for steaming fish and processing method thereof

InactiveCN101617809AGood colorImprove crispnessFood preparationMonosodium glutamateAdditive ingredient

The invention relates to a seasoning hot pepper for steaming fish and a processing method thereof. The seasoning hot pepper is prepared by the steps: taking the desulfurated pickled capsicum frutescens and the pickled hot green pepper to be matched with other ingredients of ginger, mild water with the temperature of 65 DEG C, citric acid, monosodium glutamate, sodium cyclamate, Acesulfame-K, disodium 5'-Inosine monophosphate, disodium 5'-guanosine monophosphate and ethyl maltol; stirring, standing and sterilizing the substances to obtain the seasoning hot pepper. The seasoning hot pepper has stable quality and low content of sulfur dioxide, better retains the fragility, color and lustre of the hot pepper, as well as the nutrition of the hot pepper, and has longer time and shelf life.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Flue gas adsorption catalytic reaction high-precision desulfurization method

InactiveCN110585919AOptimize mass transfer channelsBalanced Partial Pressure HighGas treatmentDispersed particle separationFlueExhaust gas

The invention discloses a flue gas adsorption catalytic reaction high-precision desulfurization method. The method comprises the following steps: A, pretreating flue gas and cooling; B, enabling the cooled flue gas to flow through an adsorption catalyst solid bed layer arranged in a desulfurization tower; then introducing alkali liquor into the desulfurization tower, and enabling the alkali liquorto flow through the adsorption catalyst solid bed layer, and carrying out a reaction with gas molecules adsorbed in the adsorption catalyst solid bed layer; C, carrying out solid-liquid separation onthe desulfurization solution to obtain a clear solution and a solid phase; D, allowing one part of the clear liquid to return to the desulfurization tower, swashing the adsorption catalyst solid bedlayer, and regenerating the adsorption catalyst solid bed layer; and supplementing an alkali into the other part of the clear liquid to adjust the pH, and then feeding the other part of the clear liquid into the desulfurization tower for recycling as alkali liquor; and E, carrying out gas-liquid separation to remove a liquid phase in the desulfurized flue gas, and thus obtaining exhaust gas. The method has the advantages that deep desulfurization of sulfur dioxide gas in the flue gas is realized, and the production process is simplified.

Owner:宋强

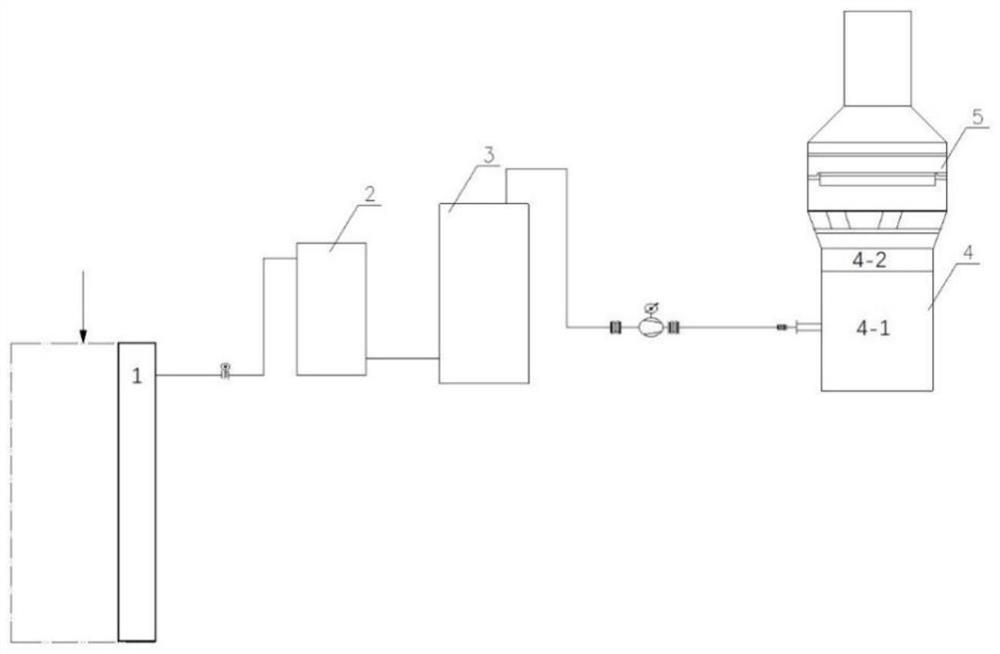

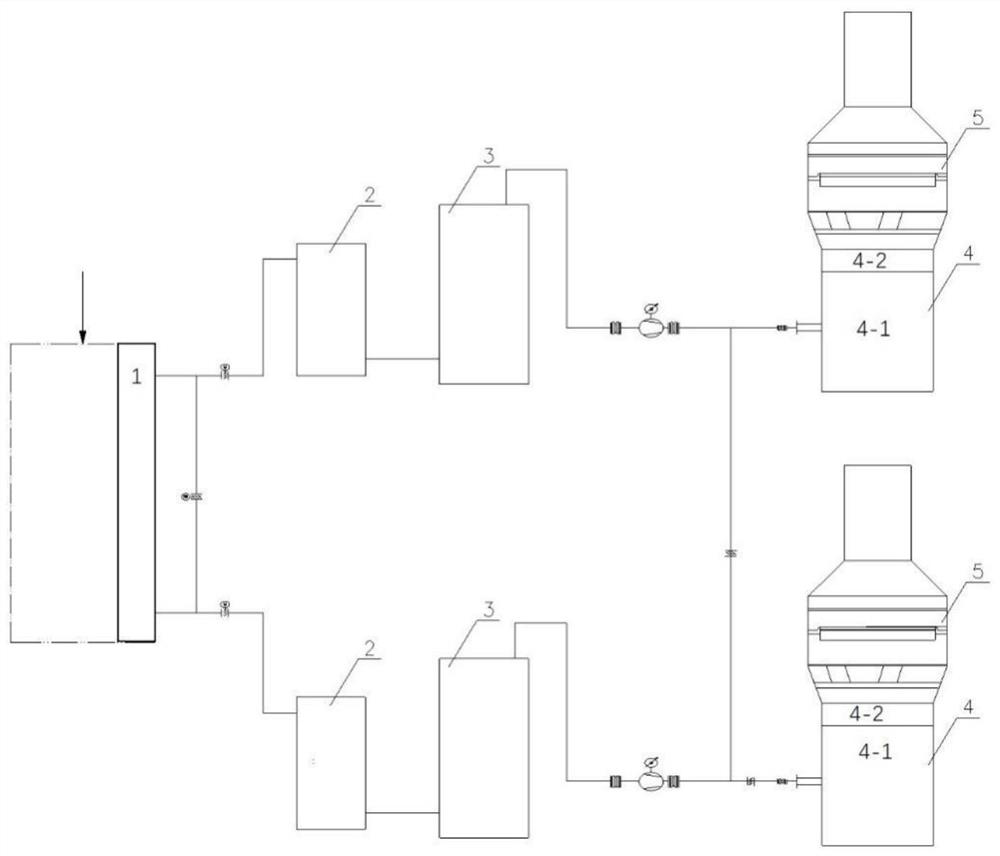

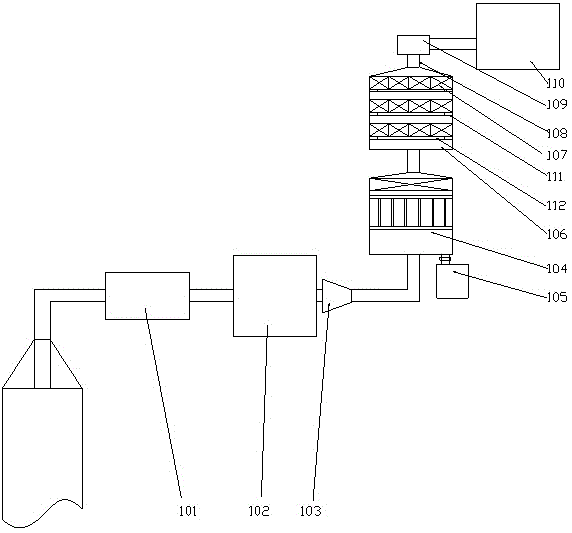

SWSR (Sunway Sulfur Recovery)-7 technology and SWSR-7 device

ActiveCN105692563AHigh recovery rateReduce sulfur dioxide contentChemical industrySulfur preparation/purificationCombustionFlue gas

The invention belongs to the technical field of sulfur recovery and tail gas treatment, in particular relates to an SWSR (Sunway Sulfur Recovery)-7 technology and an SWSR-7 device. The SWSR-7 technology comprises the following steps of (1) generating sulfur and sulfur-making tail gas through a sulfur-making combustion furnace and a Claus reaction system by an acid gas containing hydrogen sulfide, and recovering and feeding the sulfur into a liquid sulfur storage facility; (2) mixing the sulfur-making tail gas with air after enabling the sulfur-making tail gas to pass through or not pass through a tail gas hydrogenation reduction or oxidation system, feeding the mixed gas into a tail gas incineration system for being incinerated, converting all sulfur-containing media into SO2, forming SO2 flue gas, and then enabling heat energy to enter a flue gas purifying tower through recovery; (3) enabling SO2-containing flue gas to be in contact with an absorbent, i.e. hydrogen peroxide, in the flue gas purifying tower, absorbing the SO2 in the SO2-containing flue gas by the absorbent, circulating the absorbent, enabling the absorbent to enter the tower bottom, and feeding purified flue gas having no SO2 into a chimney for being discharged; (4) a system for preparing and conveying the absorbent. According to the SWSR-7 technology disclosed by the invention, the technological process is safe and reliable, and the content of the SO2 in discharged gas can be reduced to below 50 mg / Nm<3> and can meet the requirements regulated by the nation.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Appetizing hot pepper and processing method thereof

The invention relates to an appetizing hot pepper which is prepared by mixing, stirring, standing, sterilizing and cooling 50-53 percent ( by weight) of desulphurized pickled green capsicum, 9-11.5 percent of pickled millet chilli and other ingredients comprising 2.2-3.8 percent of ginger, 2.5-3 percent of garlic bulb, 31-32.5 percent of warm water at 65 DEG C, 0.068-0.07 percent of citric acid, 0.4-0.45 percent of aginomoto, 0.1-0.11 percent of chicken essence, 0.34-0.37 percent of seafood sauce, 0.013-0.133 percent of sodium cyclamate and 0.012-0.015 percent of ethyl maltol. The product has stable quality, unique ingredient and low sulfur dioxide content, better preserves the brittleness and color of the hot pepper and the characteristics of nutrients in the hot pepper and has longer quality guarantee period.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Composite fuel coal sulfur fixing agent and its prepn

InactiveCN1252229CReduce sulfur dioxide contentSolve the problem of clean useFuel additivesSulfurSulfide

The composite fuel coal sulphur fixing agent is added into burning coal to reduce released harmful gas SO2. It consists of mixed complex carbonate, calcium carbonate, calcium oxide and magnesium carbonate crushed to 1 mm below size. In different burning temperature, the sulphur fixing agent absorbs SO2 produced by burning coal to produce sulfide staying in cinder, and reduces the exhausted SO2 ans decrease environmental pollution. Using the sulphur fixing agent as clean coal additive is convenient and high in effect.

Owner:朱常先

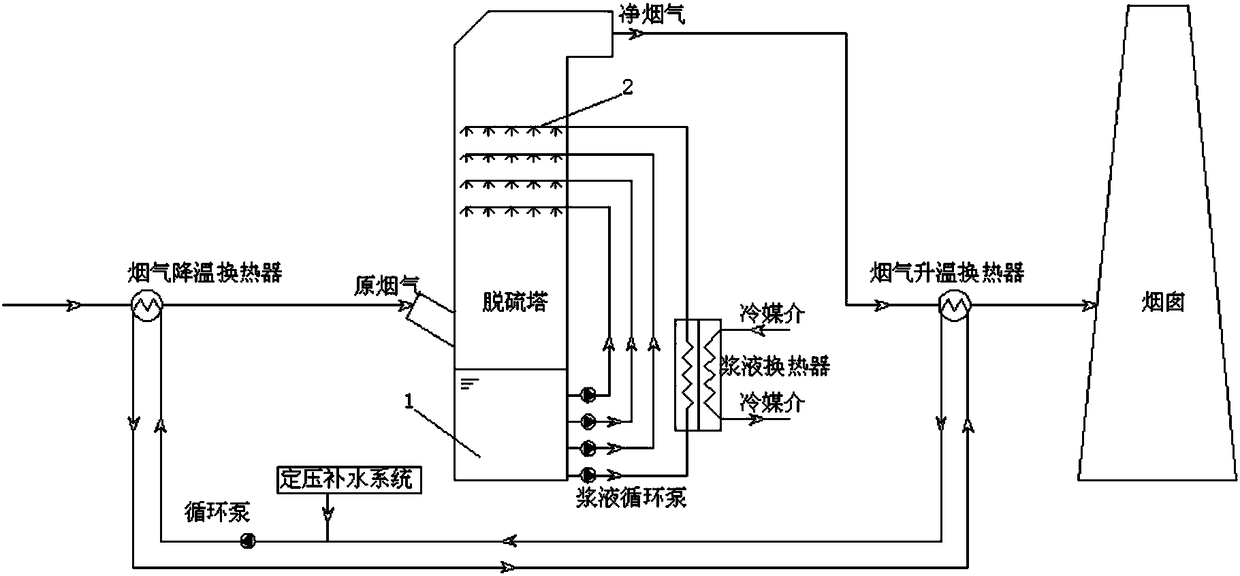

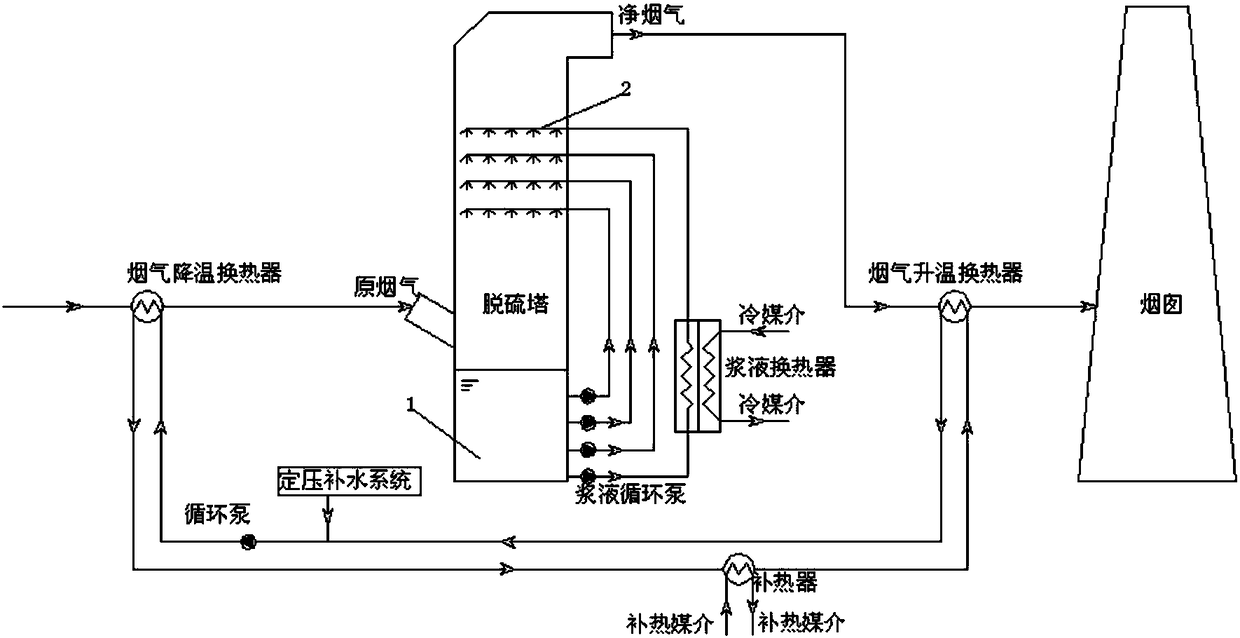

Wet desulfurization flue gas gypsum rain eliminating system and wet desulfurization flue gas gypsum rain eliminating method

PendingCN108499350AReduce entrainmentReduce sulfur dioxide contentGas treatmentLighting and heating apparatusWater circulationGypsum

The invention provides a wet desulfurization flue gas gypsum rain eliminating system and a wet desulfurization flue gas gypsum rain eliminating method, and relates to a flue gas desulfurization and flue gas gypsum rain eliminating system and a flue gas desulfurization and flue gas gypsum rain eliminating method. The wet desulfurization flue gas gypsum rain eliminating system comprises a flue gas cooling heat exchanger, a desulfurization tower equipped with a slurry cooler, a flue gas heating heat transfer and a heat medium water circulation system. According to the wet desulfurization flue gasgypsum rain eliminating system, in the flue gas cooling heat exchanger, heat medium water recovers the waste heat of the flue gas and reduces the temperature of the flue gas, wherein the cooled fluegas can improve the dust removal and desulfurization efficiency; in the slurry cooler, the desulfurization slurry is cooled, and the cooled slurry is used for the wet removal and desulfurization of the flue gas; and in the flue gas heating heat exchanger, the heat medium water recovering the waste heat of the flue gas heats the desulfurized flue gas so as to increase the superheat degree. With thesystem and the method of the present invention, the desulfurization efficiency is improved while the flue gas gypsum rain is eliminated, and the investment on the whole desulfurization process systemis reduced.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

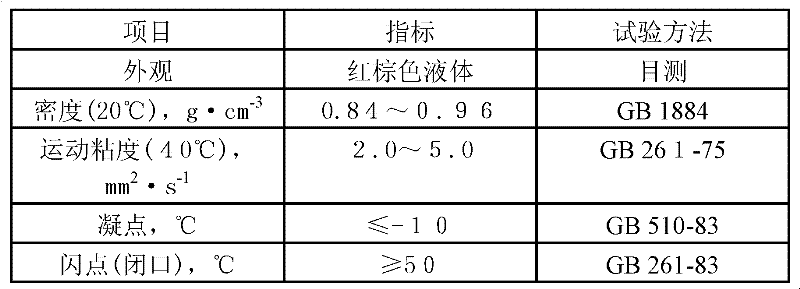

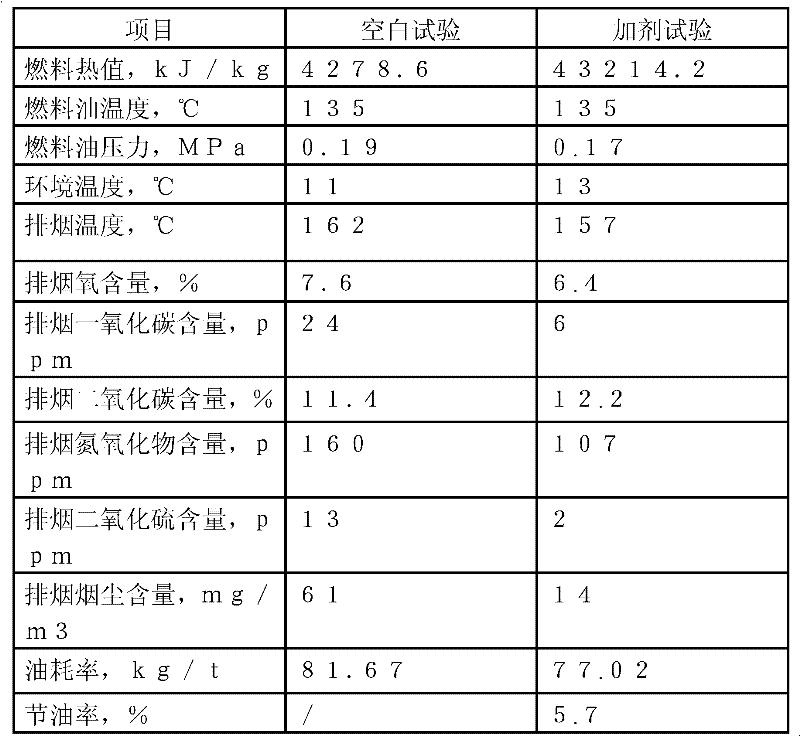

Multifunctional ashless combustion accelerant of heavy oil

InactiveCN102199458AHigh thermal efficiencyReduce consumptionLiquid carbonaceous fuelsAir quality improvementFuel oilNitric oxide

The invention relates to a multifunctional ashless combustion accelerant of heavy oil. The multifunctional ashless combustion accelerant is characterized by comprising a free oxygen generating agent, a catalyst, a dispersing agent and a solvent. The invention aims at solving the technical problem of providing a multifunctional ashless combustion accelerant, which has the advantages of combustion acceleration (oil saving), smoke abatement and reduced emission of harmful gases. According to the multifunctional ashless combustion accelerant of the heavy oil, the calorific value of a fuel can be increased, and the discharged smoke content and the oil consumption are reduced; the fuel oil undergoes a more complete combustion after the multifunctional ashless combustion accelerant of the heavy oil is added; in addition, the nitric oxide content and the sulfur dioxide content in discharged smoke are remarkably reduced, and the atmospheric pollution can be improved after the multifunctional ashless combustion accelerant of the heavy oil is added. When the addition amount of the multifunctional ashless combustion accelerant of the heavy oil is 0.3 percent, the oil saving ratio can reach more than 5 percent.

Owner:JIANGSU KECHUANG PETROCHEM

Method for reducing sulfur dioxide residues in caramel pigment

PendingCN109907212APreserve the coloring functionControl sulfur dioxide contentFood scienceFiltrationSulfite

The invention discloses a method for reducing sulfur dioxide residues in caramel pigment. The method is characterized by including steps: feeding syrup and a sulfite catalyst into a reaction kettle, and adjusting a pH value; heating for pressurized reaction in the reaction kettle, and controlling a proper heating temperature and heating duration; after water adding, cooling and diluting, filteringthrough a conventional filter bag and an organic oxidation filter membrane; pumping a filtered material into a blending tank, and blending according to related technical indexes to obtain a final product. By acidity, high temperature, organic membrane oxidation filtration and control of parameters including a ratio of a catalyst to a sugar raw materials, a pH value of a reaction system, a pH value of a final product and temperature, pressure and the like in a reaction process, the content of sulfur dioxide in the final productcaramel pigment is reduced while the coloring performance and otherphysical and chemical properties of the caramel pigment are guaranteed.

Owner:上海爱普食品工业有限公司

Plant purification method for reducing SO2 concentration in air of industrial area

InactiveCN101695628AHigh absorption and enrichmentBCFDispersed particle separationAir quality improvementHigh absorptionPurification methods

The invention discloses a plant purification method for reducing SO2 concentration in air of an industrial area, which comprises the following process steps: planting one or a combination of oleanders, sycamores and weeping willows serving as roadside tree species at intervals of between 150 and 200 cm in plant areas and peripheral regions, performing lawn planting on Lucerne, gardenias, China roses in a hunk of space areas or planting the combination of the Lucerne, the gardenias, the China roses into a lawn, planting the oleanders, the sycamores and the weeping willows alternately for matching, and planting small trees among the plants sporadically; loosening and ploughing a ground substance at intervals of half a month during planting, appropriately introducing animals, such as earthworms and the like to loosen the ground substance, spraying and washing the dust on leaves of the planted plants, adding biological growth promoters into the plants or inoculating part of mycorrhiza organisms, watering fertilizers of leaf surfaces supplementarily, and harvesting the leaves shed naturally at any time. The plant purification method has the characteristics of no secondary pollution to environment and high absorption enrichment amount of the sulfur dioxide, soil and water loss prevention and control, environment beautification and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for removing sulfur dioxide from fruit distilled wine

ActiveCN102851191AImprove clearanceEfficient removalAlcoholic beverage preparationSulfur dioxideDistillation

The invention provides a method for removing sulfur dioxide from a fruit distilled wine, particularly relates to a method for removing sulfur dioxide from a fruit (such as grape, apple, cherry, plum and the like) distilled wine in a distillation procedure, and aims to solve the problem that a base wine, wine leftovers or fermented peel dregs in preparation of a fruit distilled wine contain too much sulfur dioxide or a corresponding fruit fermented wine is not suitable for being sold on the market due to quality and other factors and is suitable for preparation of a distilled wine. The invention first uses calcium oxide in the process of removing sulfur dioxide from the fruit distilled wine, effectively reduces the sulfur dioxide content in the fruit distilled wine, and improves the utilization ratio and quality of the fruit wine. Besides, the invention improves the situation that the distilled wine containing sulfur dioxide is wasted, develops a new method for treating the fruit distilled wine containing sulfur dioxide, and provides a reference to the further research and development of the fruit wine and processed products thereof.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method of decontaminating sulfur dioxide in smoke using honeycomb ceramic

InactiveCN1442228AReduce sulfur dioxide contentImprove desulfurization effectDispersed particle separationBrickHoneycomb

A process for removing SO2 from the fume in sinterting plane is characterized by use of the porous honeycomb ceramics as absorbing carrier whose pore surface adsorbing the lime milk as desulfurizing agent and the lime milk are dropped in for continuously supplement fresh lime milk. Its advantages are high desulfurizing rate up to more than 80%, and low cost.

Owner:UNIV OF SCI & TECH BEIJING

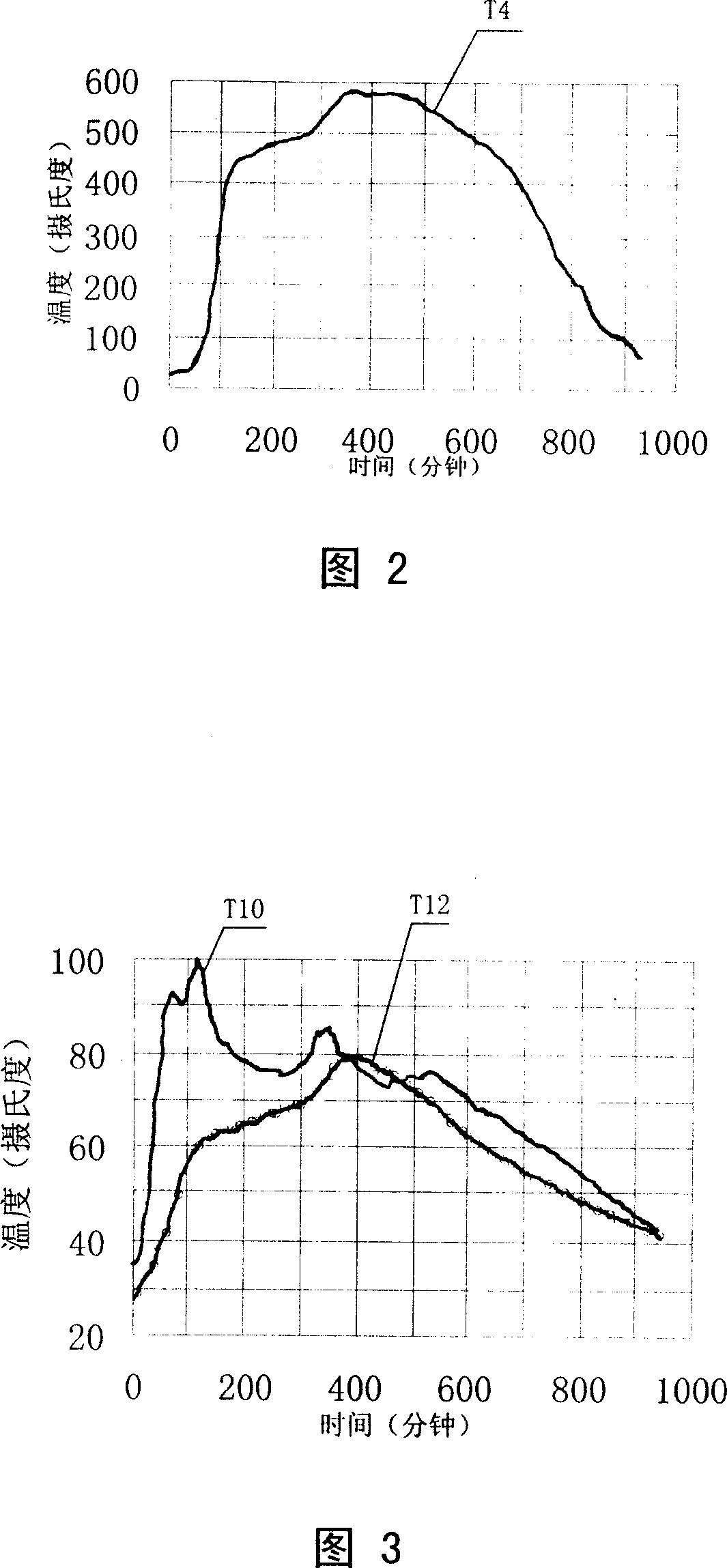

Fructus lycii processing methodn

The invention discloses a Chinese wolfberry processing method. The processing method comprises the following steps of: 1, dewaxing; 2, preheating a drying room: preheating the drying room to temperature of 35-45 degrees centigrade; 3, placing Chinese wolfberries into trays and then placing the trays on shelves; 4, drying: dividing the drying process into four stages: at a first stage, drying temperature is 40-45 degrees centigrade and drying time is 2-4 hours; at a second stage, drying temperature is 45-50 degrees centigrade and drying time is 4-6 hours; at a third stage, drying temperature is 50-55 degrees centigrade and drying time is 9-11 hours; at a fourth stage, drying temperature is 55-60 degrees centigrade and drying time is 1-3 hours; 5, cooling: closing a hot air gate of a furnace in the drying room, continuing to open a moisture discharge window and a fan for 1.5-2 hours to naturally cool the drying room, and removing baked trays at less than 40 degrees centigrade of the drying room temperature; 6, classification filtrating; 7, color sorting; 8, packaging. The processing method has the advantages of high efficiency, cleanness, and low cost.

Owner:湖北金贵中药饮片有限公司

Method and system for purifying flue gas of carbon roasting furnace

PendingCN113304591AReduce sulfur dioxide contentReduce emission concentrationGas treatmentElectrostatic separationNitrogen oxidesFlue gas

The invention discloses a method and a system for purifying flue gas of a carbon roasting furnace. The method comprises the steps of denitration, cooling, tar removal, desulfurization and demisting, dust removal and the like. A dry powder denitration agent direct injection method is adopted for denitration, a water mist spraying method is adopted for cooling, an electrical tar precipitator is adopted for tar removal, and wet desulfurization is adopted for desulfurization. The system comprises a denitration unit, a cooling unit, a tar removal unit, a desulfurization and demisting unit and a dust removal unit. By adopting the method and the system, pollutants such as nitrogen oxides, tar, sulfur dioxide, fog drops, dust and the like in the flue gas of the carbon roasting furnace can be removed below emission limits, and the method and the system are simple, practical, high in efficiency and low in operation cost.

Owner:北京铝能清新环境技术有限公司

Sulphur condensing and separating deice of sulphur recovering device

ActiveCN103213951AReduce pollutionReduce spill pollutionSulfur preparation/purificationEngineeringSteam heating

The invention relates to a combined device for condensing and separating sulphur of a sulphur recovering device. The combined device is combined by a process gas condensing cooler and a liquid sulphur separator. The liquid sulphur separator is directly connected below the end socket of the process gas condensing cooler and forms an integral space together with the end socket. A steam heating facility is arranged outside the end socket of the process gas condensing cooler and the liquid sulphur separator. The liquid sulphur separator is internally provided with a filler layer section and a liquid sulphur collecting section. The filler layer is in a normal filler structure. A process gas outlet is provided with a liquid sulphur capturer and is connected with a next stage reaction or condensing cooling system. The liquid sulphur separator is provided with a liquid sulphur outlet valve which controls the liquid sulphur to flow out. The liquid sulphur outlet valve is connected to a liquid sulphur middle tank through a liquid sulphur outlet line. According to the combined device provided by the invention, the investment on devices is reduced and the environment and a human body are not damaged, the content of hydrogen sulfide entrained by liquid sulphur treated is low, and the content of sulphur dioxide in exhaust gas is low, so that the environmental pollution is reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Method for drying medlar

InactiveCN102599230BRapid contractionReduce lossesFruits/vegetable preservation by dehydrationWaxEngineering

The invention relates to a method for drying medlar. The method is characterized by comprising the following steps: (1) pre-treating, (2) breaking wax, (3) drying, (4) taking down from a frame, (5) screening, (6) performing color selection, and (7) finely selecting, wherein a steam hot-air circulating and low-temperature drying method is adopted in a drying chamber. According to the method, the cost of equipment investment is low, the drying temperature is easily controlled, the fresh fruit is quickly contracted in the drying chamber, the loss of nutrient content is less, the drying quality is high, the content of sulfur dioxide in the medlar dried according to the method is less than 10mg / kg, and the medlar can be directly eaten.

Owner:GANSU JINQI FUYUAN BIOLOGICAL PROD DEV

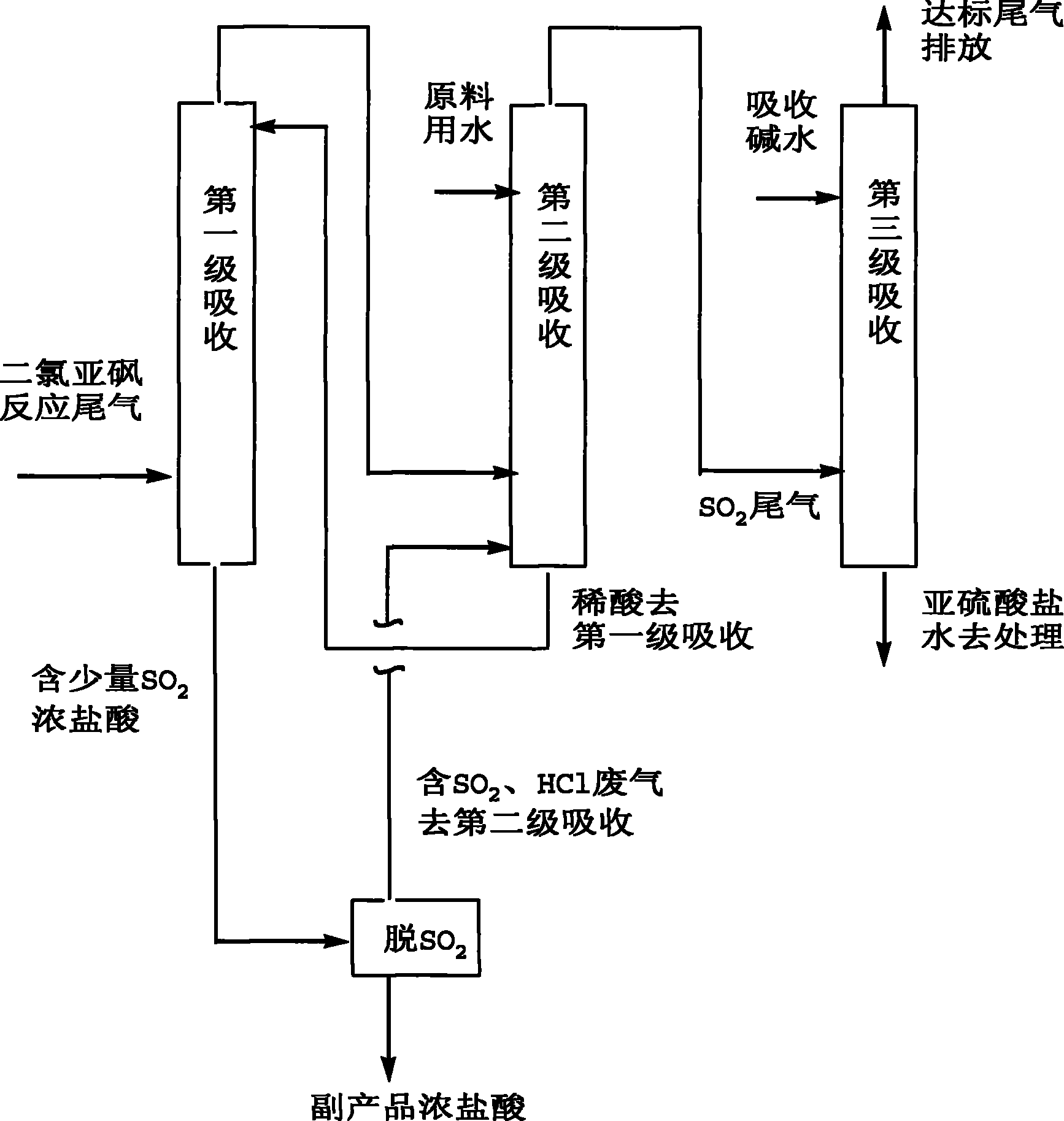

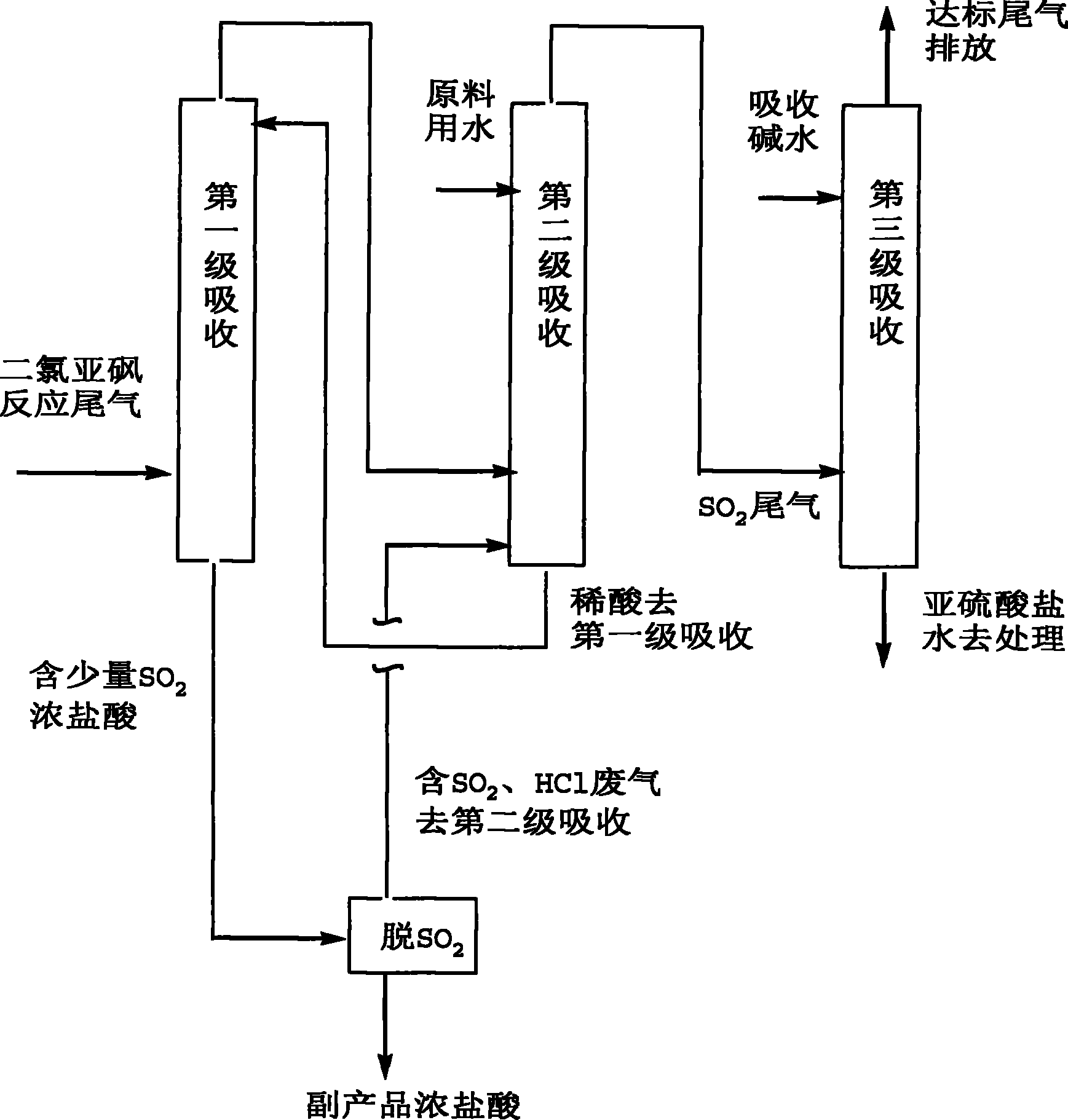

Method for treating tail gas of thionyl chloride chlorination

InactiveCN101121094BFully absorbedReduce dosageChlorine/hydrogen-chlorideSulfur-halogen-hydrogen-oxygen compoundsSulfite saltSulfur dioxide

The present invention discloses a disposal method of a tail gas, which is produced from a thionyl chloride used in a chlorination reaction. The cost of the prior traditional tail gas disposal method is high because of large consumption of alkali, and a high environmental protection pressure is resulted from a plurality of finally produced waste water which contains heteroions. Firstly, the present invention uses water to absorb the hydrogenchloride of the tail gas by controlling the water consumption, and a first grade absorption obtains a concentrated hydrochloric acid, the a hydrogenchloride content of which is approximately saturated and little sulfur dioxide is contained; a second grade absorption is that water is used to process the tail gas after the first grad absorption for the second grade absorption, which is that the added water is not discharged to obtain a diluted hydrochloric acid which contains little hydrogenchloride and little sulfur dioxide, and the diluted hydrochloric acid is used as a liquid of raw material used for the first grade absorption; then the alkali or alkaline water is used to process the tail gas after the second grade absorption for a third grade absorption to absorb the sulfur dioxide in the tail gas and obtain a quite pure sodium sulfite aqueous solution. The disposal efficiency of the present invention is high, and the tail gas absorption is complete, which reduces the environmental protection pressure.

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

Desulfurizing and dedusting system

InactiveCN107213764ARealize environmentally friendly emissionsReduce sulfur dioxide contentGas treatmentUsing liquid separation agentSulfurBiochemical engineering

The invention discloses a desulfurizing and dedusting system. The desulfurizing and dedusting system comprises a tower body, a flue gas inlet, a discharging outlet, a first-stage desulfurizing layer, a second-stage desulfurizing layer, a third-stage desulfurizing layer and a circulating water system, wherein the flue gas inlet is formed in one side of the bottom part of the tower body; the first-stage desulfurizing layer, the second desulfurizing layer and the third-stage desulfurizing layer are arranged in the tower body from bottom to top; the circulating water system is respectively connected with the first-stage desulfurizing layer, the second desulfurizing layer and the third-stage desulfurizing layer; the third-stage desulfurizing layer is a biological membrane layer. The third-stage desulfurizing layer is filled with a biological membrane, and the biological membrane is small in gaps, so that flue gas is in full contact reaction with liquid medicine, dust is not easy to pass, and the liquid medicine attached to the biological membrane can drop down after being adhered to the dust; the biological membrane layer is 1 to 2 m in height, the adsorption effect is good, exhaust gas passing through the biological membrane is greatly purified, and national standard is met.

Owner:FOSHAN XINLICHENG MECHANICAL & ELECTRICAL EQUIP CO LTD

Sulfur-free konjak slice and processing method thereof

The invention discloses a processing method of a sulfur-free konjak slice. The processing method comprises the following steps of (1) washing the konjak; (2) rubbing the peel of the konjak bulb; (3) slicing and collecting the konjak bulb; (4) blanching the konjak slice by steam, deactivating enzyme, and inhibiting the activity of polyphenol oxidase; (5) treating the konjak slice by konjak powder,so as to coat one layer of konjak powder onto the surface of the konjak slice; (6) drying the konjak slice by microwaves. The processing method of the sulfur-free konjak slice has the advantages thatthe fresh konjak is used as the raw material; the special processing method is adopted, so as to obtain the sulfur-free konjak slice.

Owner:HUNAN BOJIA MOLI AGRI SCI & TECH +1

Chemical tail gas deodorization device and deodorization method

InactiveCN105056728AHigh purityReduce sulfur dioxide contentDispersed particle separationExhaust gasProcess engineering

The invention discloses a chemical tail gas deodorization device. The device comprises a high-pressure gas dissolution pump connected with chemical equipment through a pipeline, the high-pressure gas dissolution pump is connected with an airtight water tank through a pipeline, a jet pump is arranged at the output end of the airtight water tank, the output end of the jet pump is connected with a gas-liquid separation chamber, and a gas-liquid separator is arranged in the gas-liquid separation chamber; a liquid storage tank is arranged at the lower end of the separation chamber, and a one-way valve connected with a desulfuration chamber is arranged at the upper end of the gas-liquid separation chamber; an adsorption layer is arranged in the desulfuration chamber and adopts a honeycomb structure, a calcification desulfuration agent is arranged on the surface of the adsorption layer, a gas outlet is formed in the end, away from the one-way valve, of the desulfuration chamber, a steam purifier is arranged at the gas outlet, and the output end of the steam purifier is connected with the gas storage tank through a gas sucking pump. The chemical tail gas deodorization device is simplified, and ammonia and sulfur are separated.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

Processing process of low-sugar and low-sulfur preserved Laiyang pears

InactiveCN106260414ALow in sugarReduce sulfur dioxide contentConfectionerySweetmeatsBiotechnologyNutrition

The invention relates to a processing process of low-sugar and low-sulfur preserved Laiyang pears, and belongs to the technical field of a health-care preserved fruit processing process. The processing process comprises the following steps: 1, washing and peeling; 2, dicing; 3, cooking at low temperature, so that pear dices are 80 percent cooked; 4, cooling; 5, smouldering by sulfur; 6, comprehensively desulfurizing; 7, boiling sugar; 8, sugaring; 9, drying at low temperature; 10, producing composite syrup; 11, coating with sugar; 12, baking the sugar. The processing process provided by the invention is reasonable in formula design; the preparation process is simple and convenient; Laiyang pears, Chinese herbal medicines capable of nourishing yin and moistening lung, and a nutritional supplement capable of improving the body immune function are combined, and the low-sugar and low-sulfur preserved Laiyang pears which are low in sugar content and sulfur dioxide content, can keep nutrients in the Laiyang pears to a relatively great extent and improve the body immune function, and prevent organism damages caused by PM2.5 (Particulate Matter 2.5) are prepared.

Owner:李新民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com