Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

699results about How to "Improve seal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

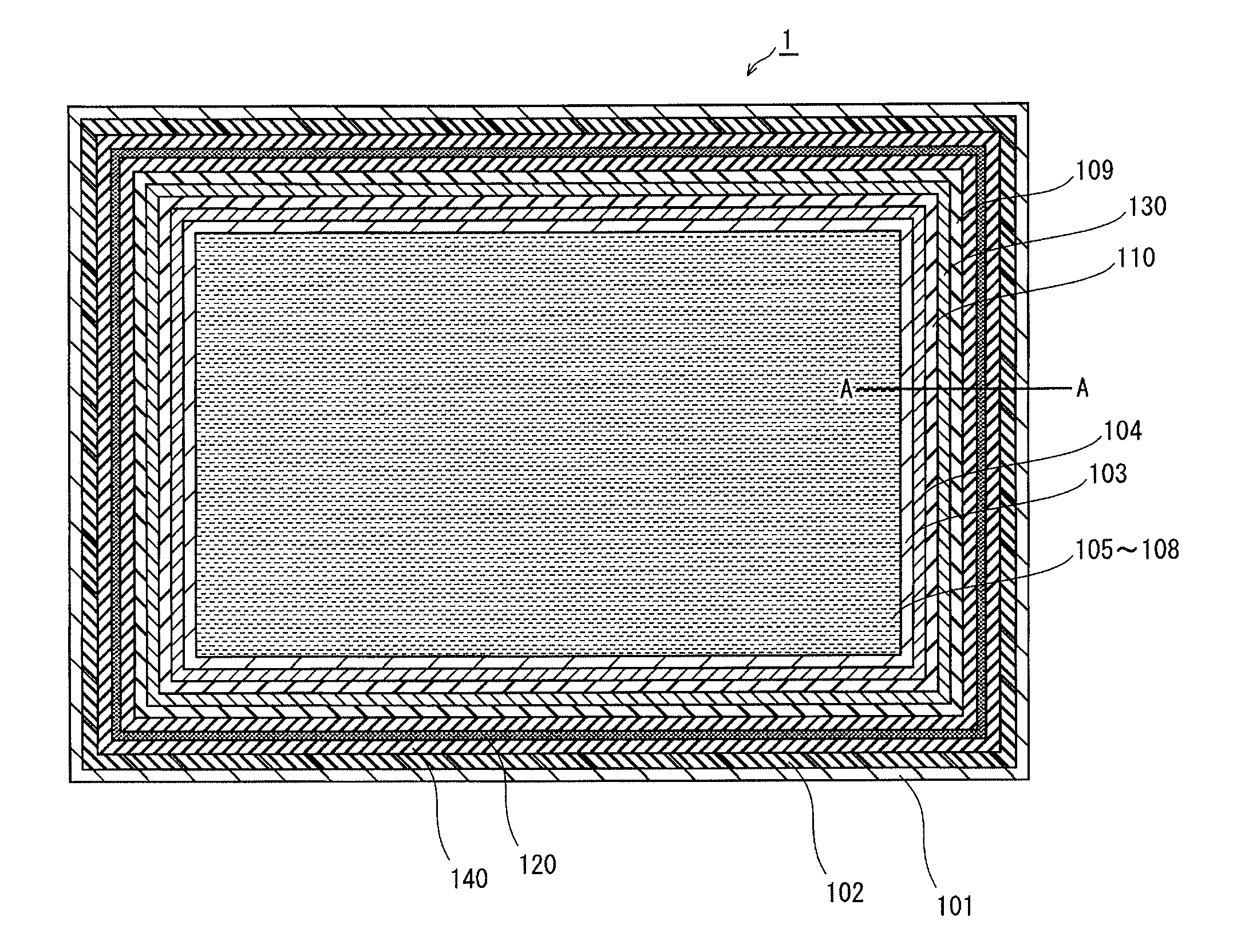

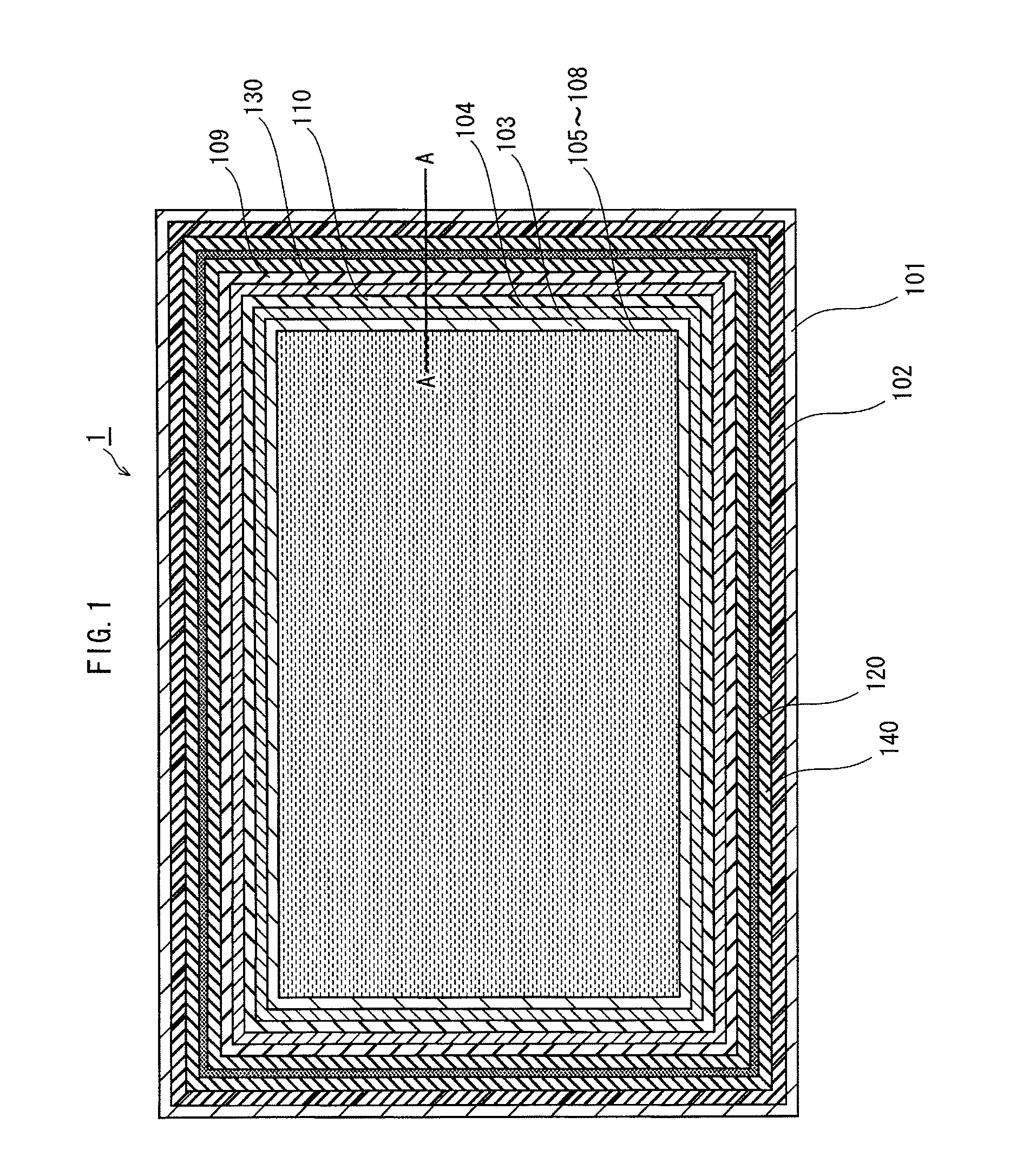

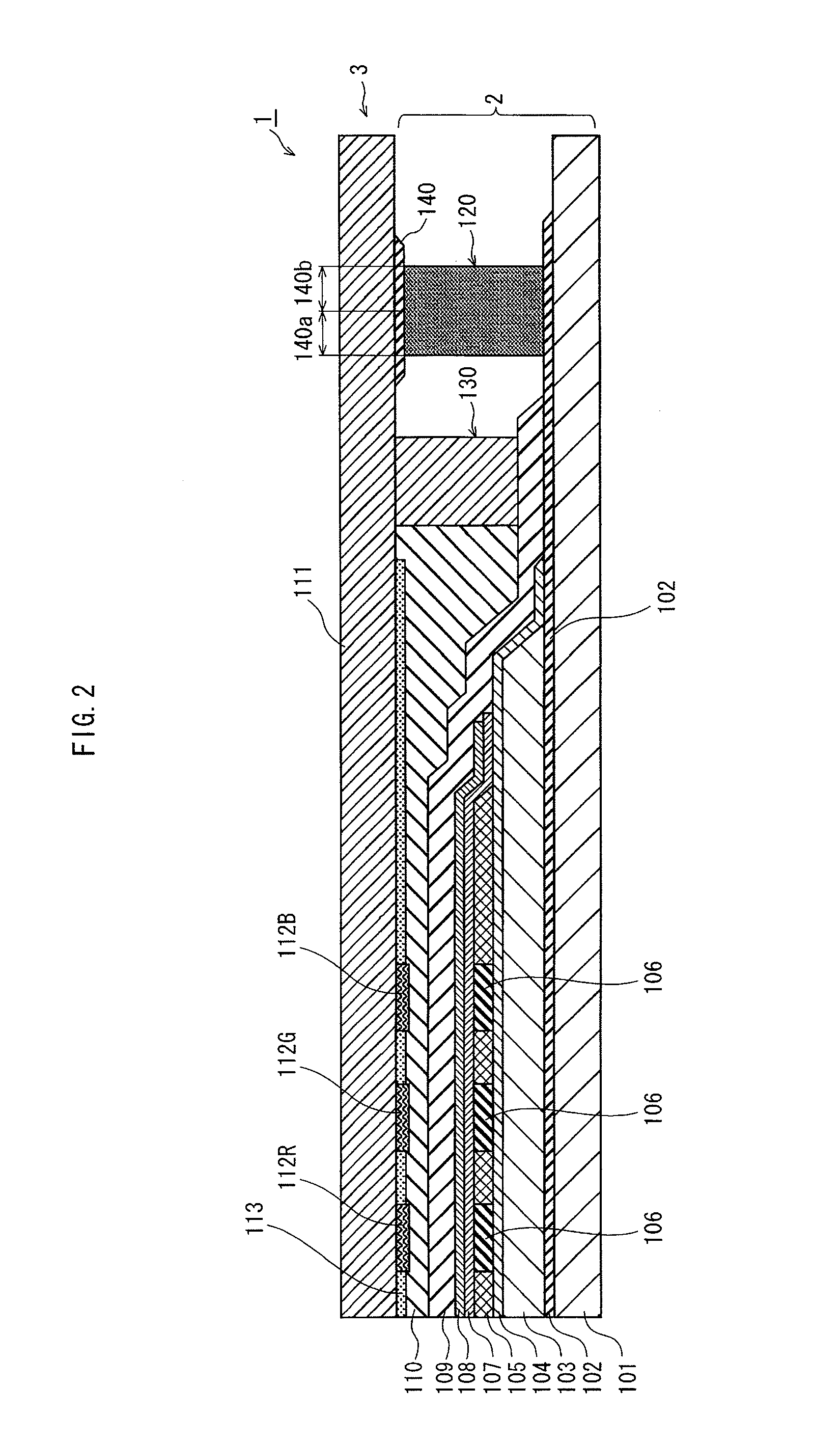

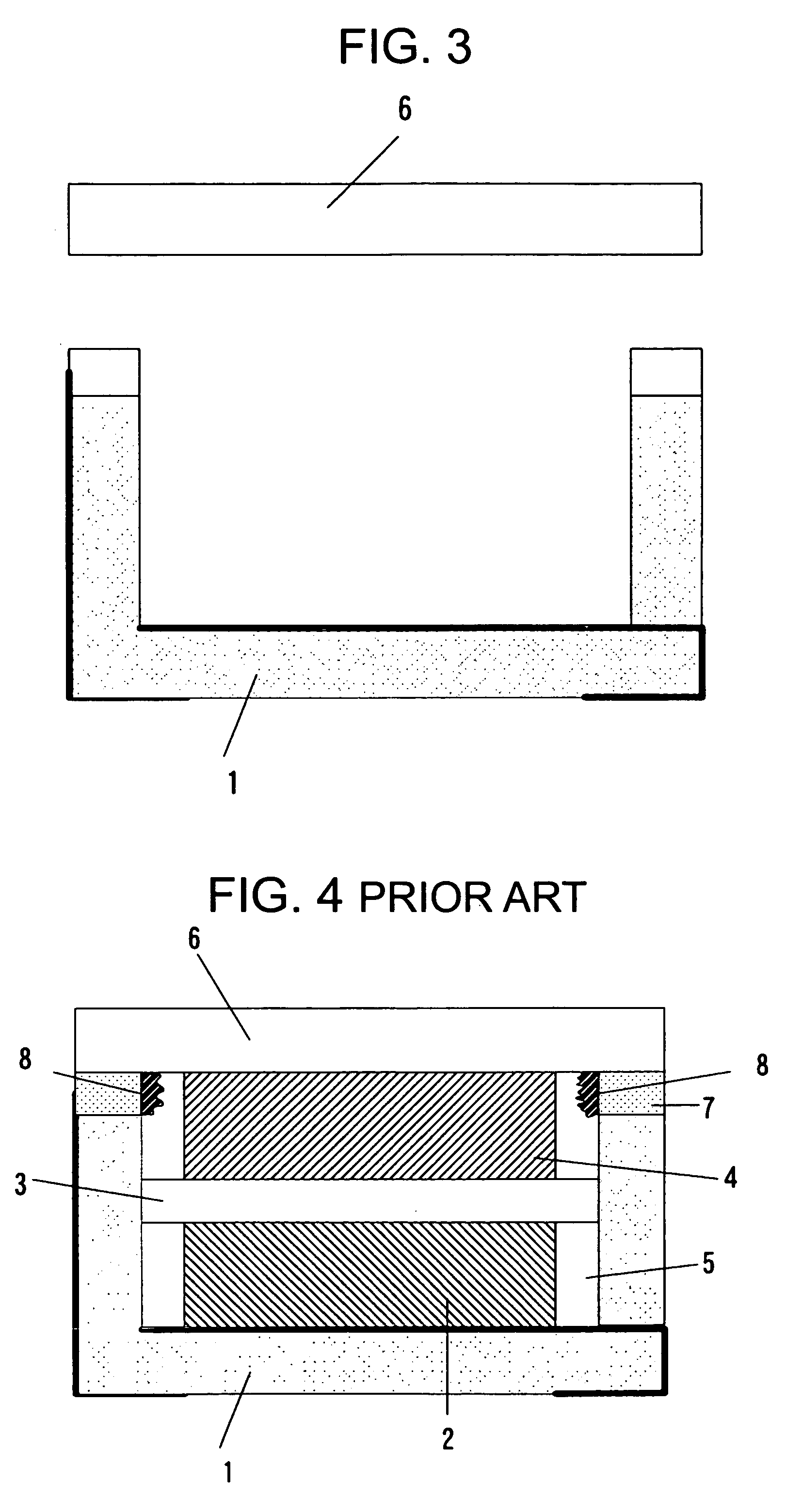

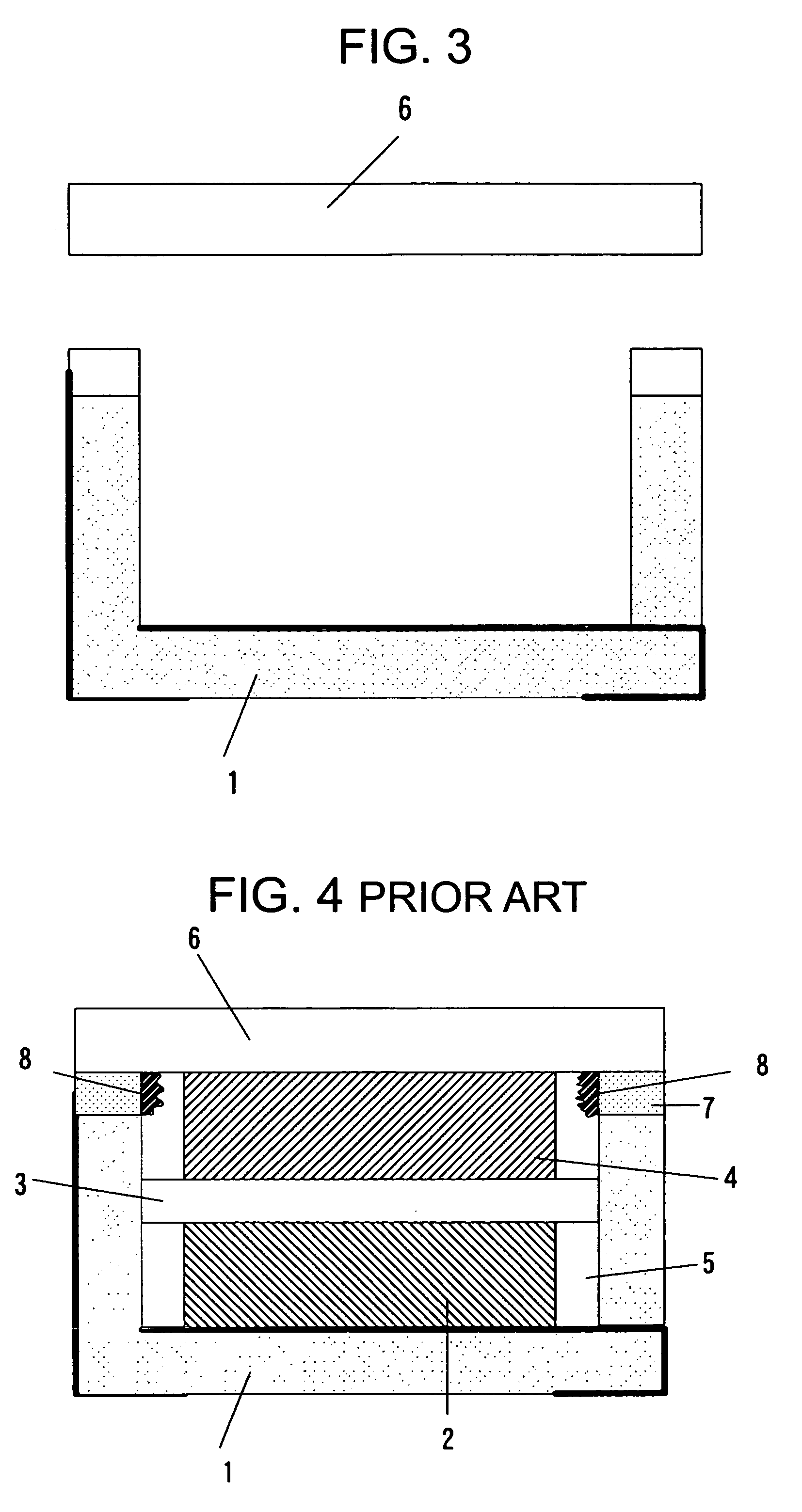

Display panel and production method thereof

ActiveUS20120287026A1Improve deteriorationReduced Surface Flatness RequirementsLamination ancillary operationsStatic indicating devicesPhoto irradiationHermetic seal

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

Electrochemical cell

InactiveUS20060035143A1Prevent oxidationInhibition capacityHybrid capacitor electrodesFinal product manufactureOrganic solventInternal resistance

In a conventional electrochemical cell, since a welding between a container and a sealing plate is performed in the atmospheric air, a weld zone is oxidized and a corrosion resistance decreases. For this reason, impurities are eluted from the weld zone into an electrolyte, and this causes an internal resistance increase and a capacity decrease of the electrochemical cell. Further, there is a possibility that an organic solvent in the electrolyte is oxidized by the welding. According to the invention, in order to solve the above problems, the seal welding between the container and the sealing plate of the electrochemical cell is performed under an inert atmosphere.

Owner:SEIKO INSTR INC

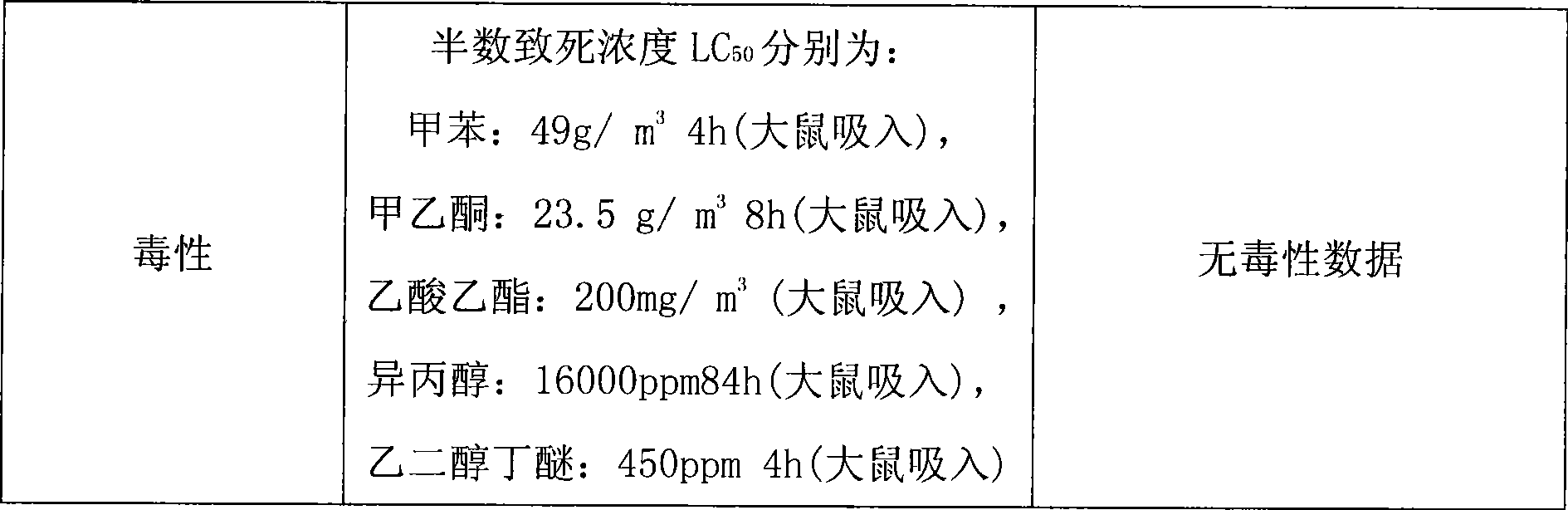

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

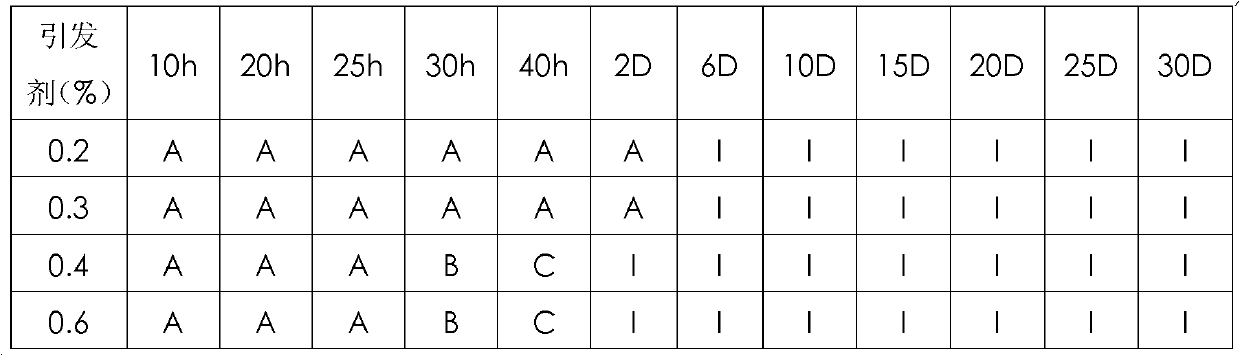

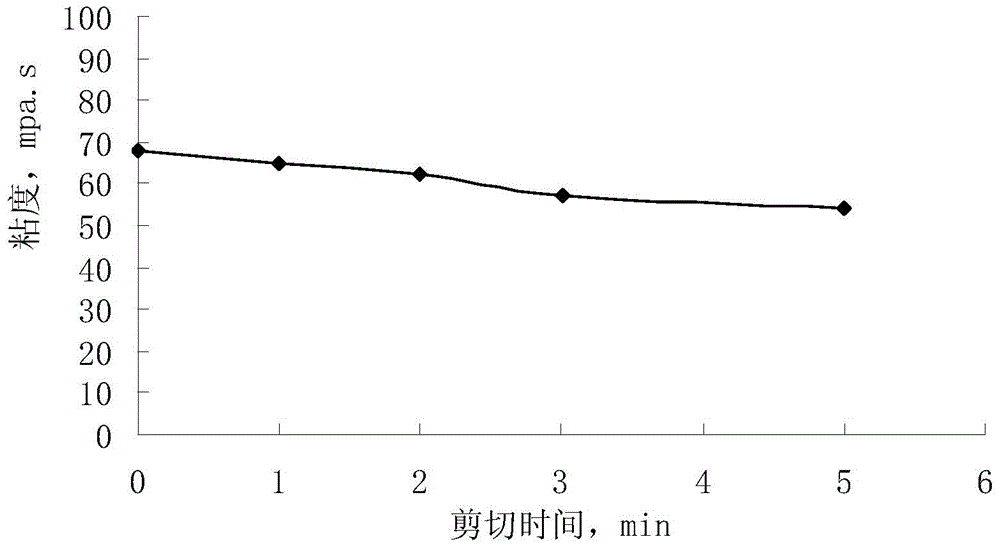

Gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs

InactiveCN102382244AGood instant solubilityConvenient dispensing operationDrilling compositionSynaeresisVisual observation

The invention relates to a gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs, which consists of 5 to 7 percent by weight of main agent, 1 to 2 percent by weight of solubilizer, 1 to 2 percent by weight of cross-linking agent, 0.1 to 0.8 percent by weight of initiator and the balance of water, the main agent consists of monomer A and monomer B, the mass ratio of the monomer A to the monomer B is 3:1 to 5:1, the monomer A is acrylamide, and the monomer B is ester. Under high temperature, the pumping time of the gel is relatively longer, the gelation time canbe controlled at 20 to 72 hours under 120 DEG C, the final set strength can reach visual observation code level I, the synaeresis of the gel does not take place in 90 days, and the gel can be used inwater shutoff operation for high-temperature reservoirs under 90 DEG C to 140 DEG C. Because the gel has the advantages of good pumping property, high plugging strength, long service life, simple construction process and the like, the gel has a broad application prospect in chemical profile modification and water shutoff for oil fields.

Owner:SOUTHWEST PETROLEUM UNIV

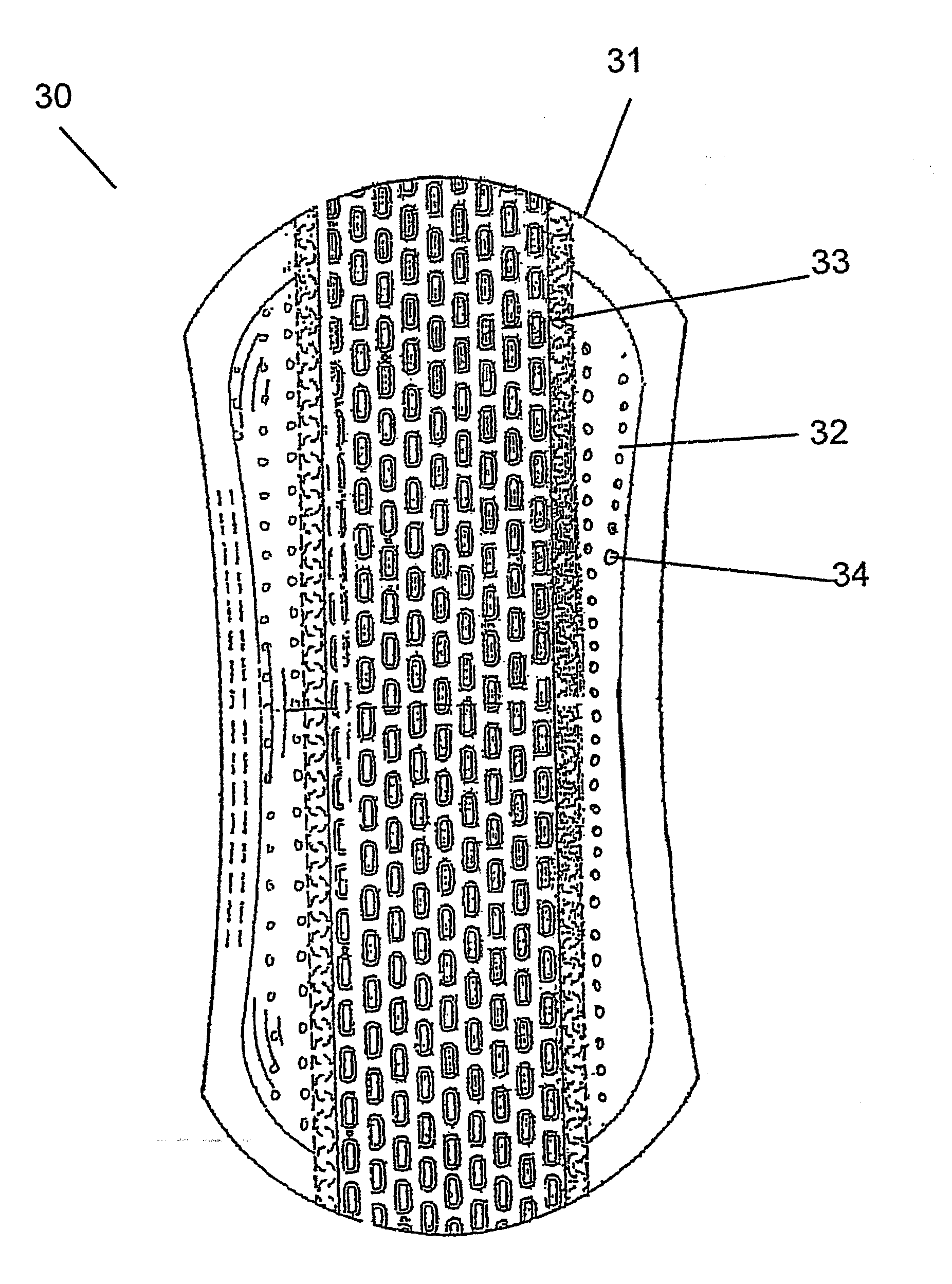

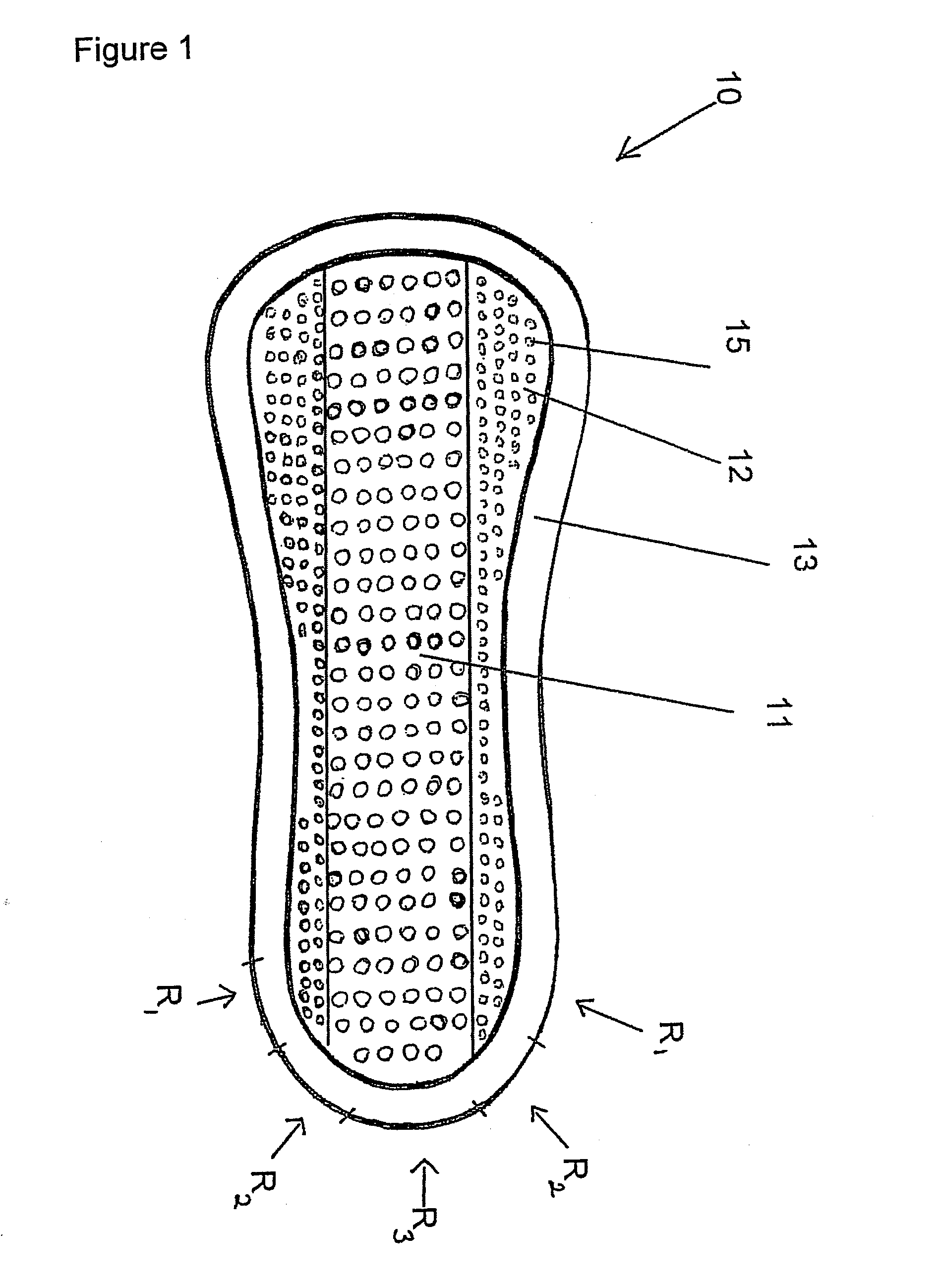

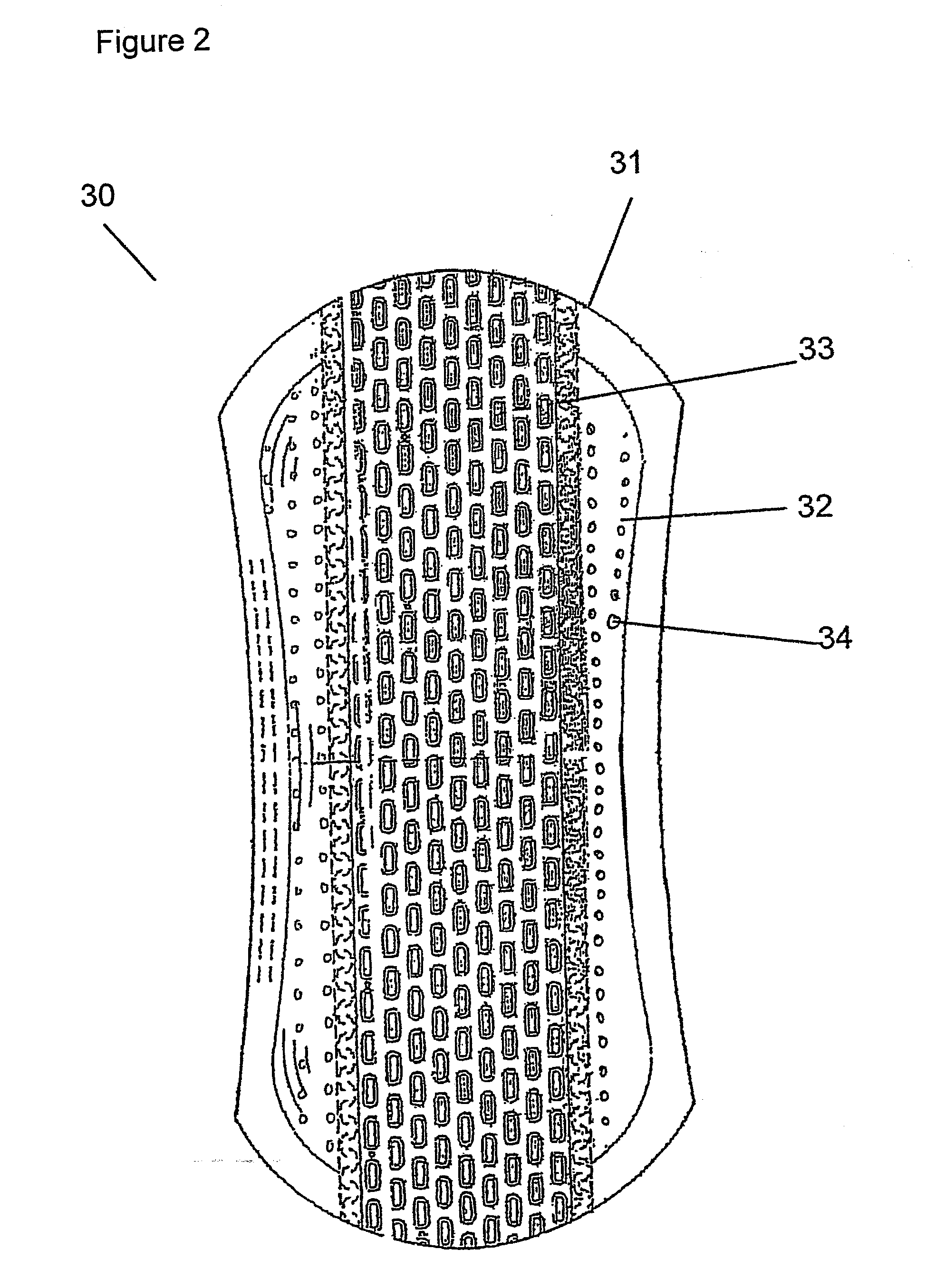

Absorbent product

InactiveUS20110106036A1Increased free volumeDistanceSanitary towelsBaby linensMechanical engineeringMoisture

The invention refers to an absorbent product including a liquid permeable apertured top sheet facing the wearer during use, and a liquid-impermeable back sheet facing away from the wearer during use, whereby longitudinally extending textile-like edges are positioned on both longitudinal sides of the top sheet whereby the textile-like edges comprise apertures. Hereby, the textile-like edges will amongst others have the capacity to transport moisture that is formed at the interface between the textile-like edges and the wearer skin. Further, the apertures will allow a certain acquisition, i.e., liquid can be transported to the absorbent structure of the product.

Owner:SCA HYGIENE PROD AB

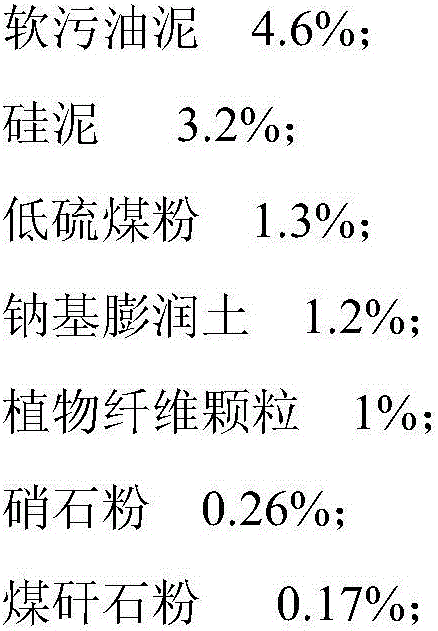

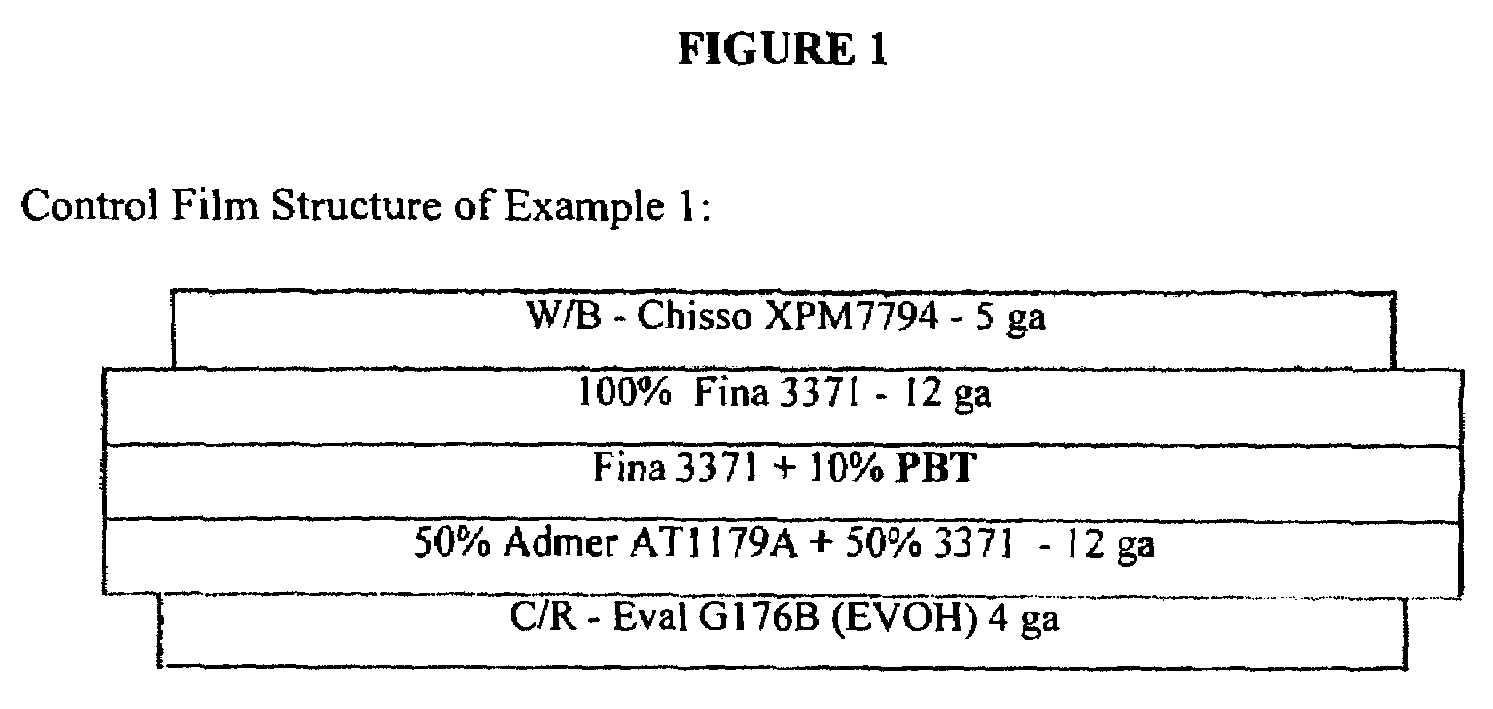

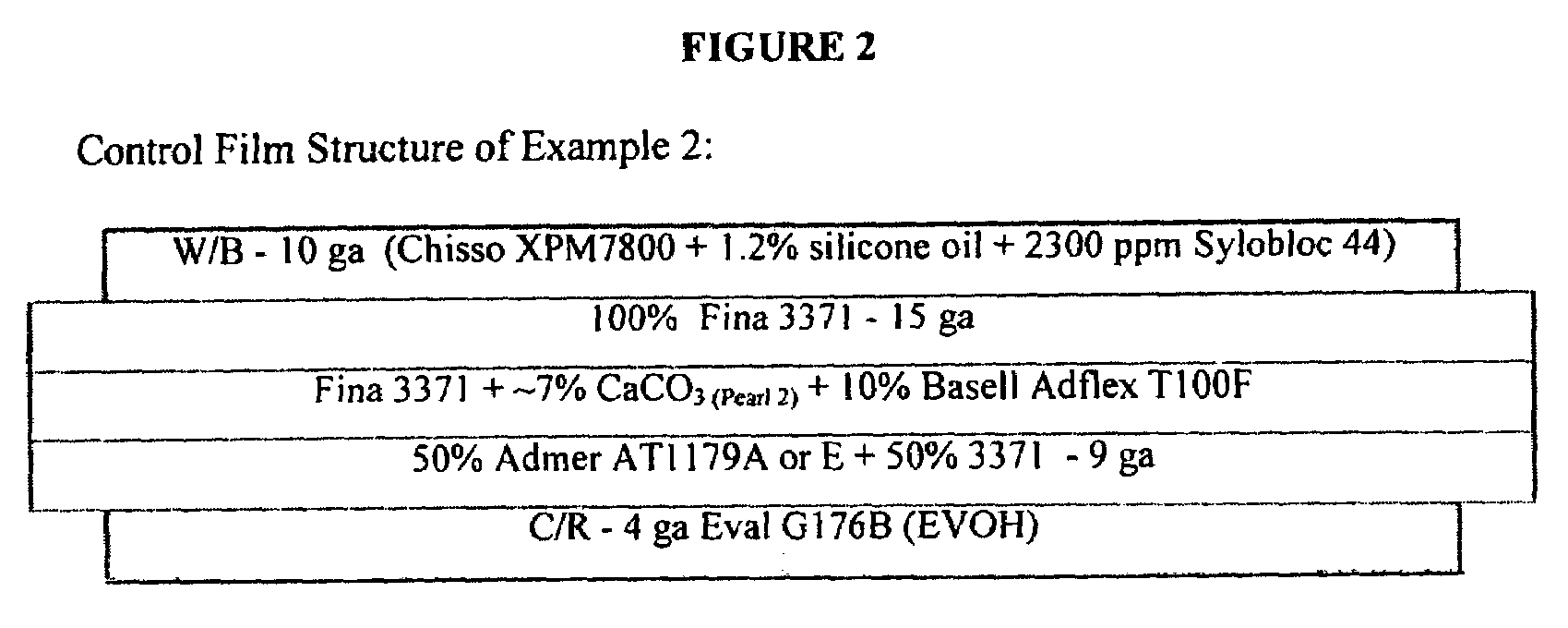

Heat sealable monoaxially oriented propylene-based film with directional tear

InactiveUS20100055429A1Maintain good propertiesImprove seal strengthLamination ancillary operationsSynthetic resin layered productsButeneElastomer

A monoaxially oriented film including heat sealable layer including an ethylene-propylene impact copolymer and a metallocene-catalyzed propylene-butene elastomer. The heat sealable layer may include a metallocene-catalyzed ethylene-butene elastomer. The film is oriented at least 4 times in the machine direction and exhibits excellent linear directional tear properties in the machine direction and excellent heat seal performance. This film formulation and orientation is suitable for pouch applications requiring an “easy-tear” linear tear feature and excellent hermetic seal properties, particularly for retort pouches.

Owner:TORAY PLASTICS AMERICA

Sealing material

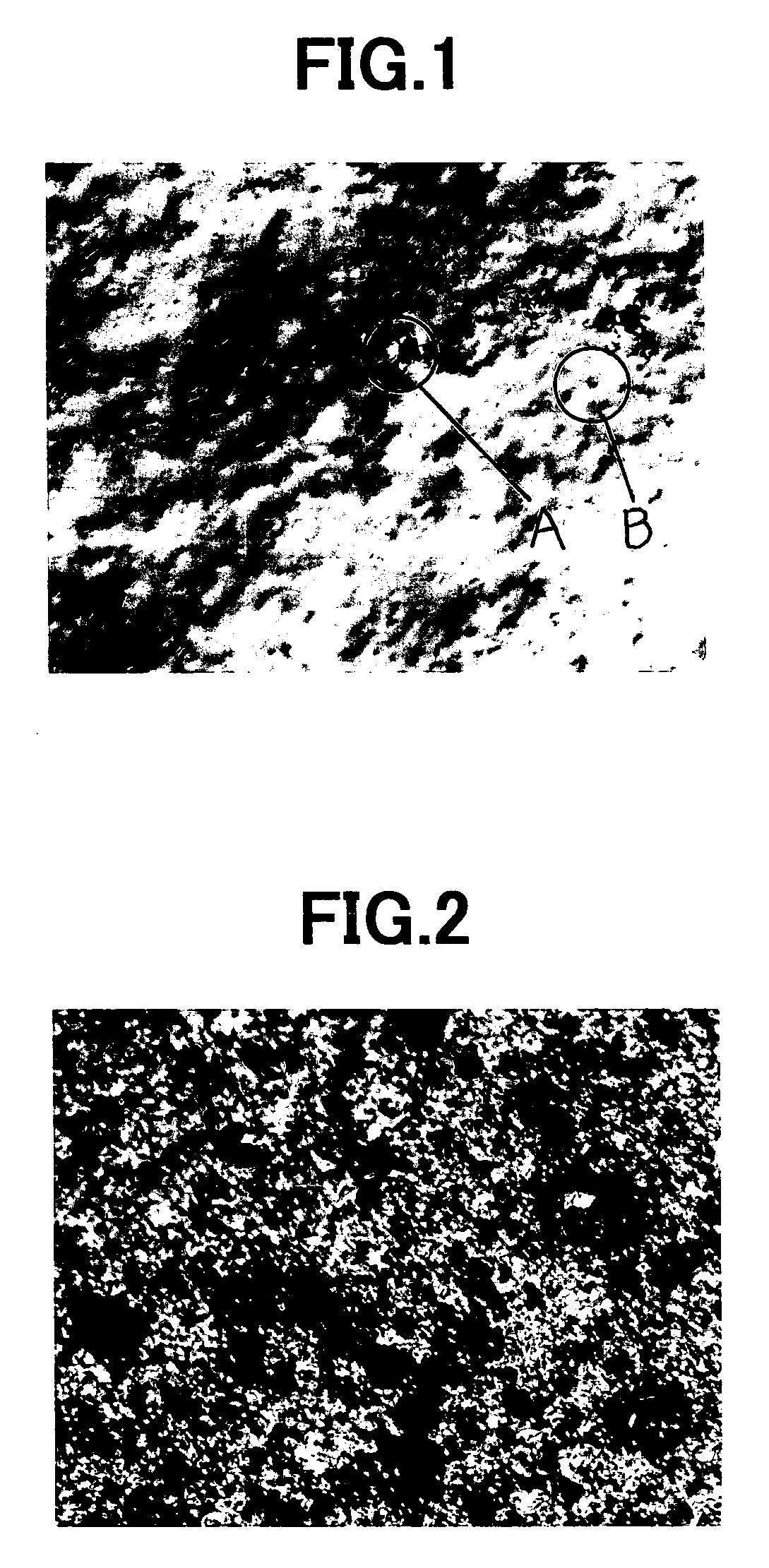

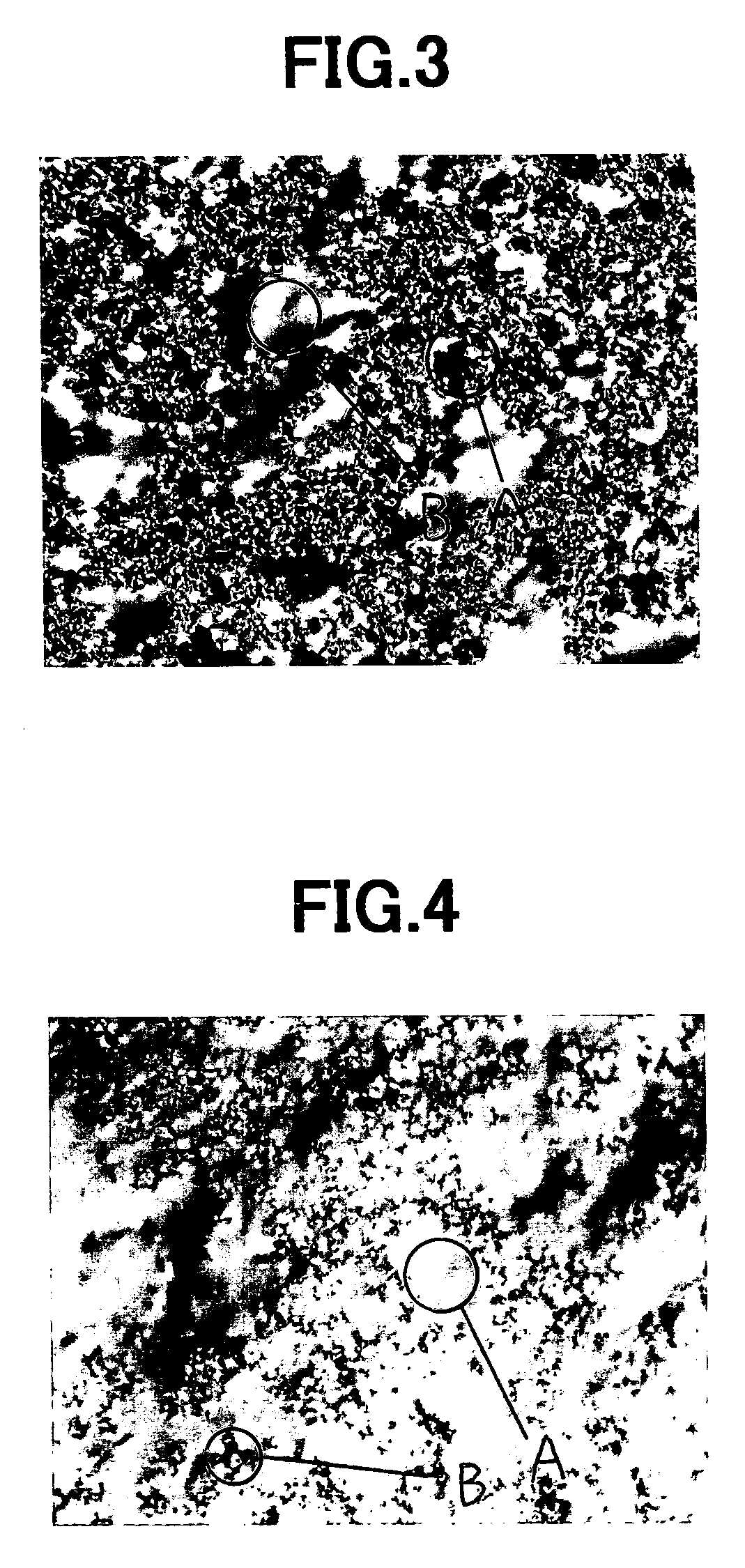

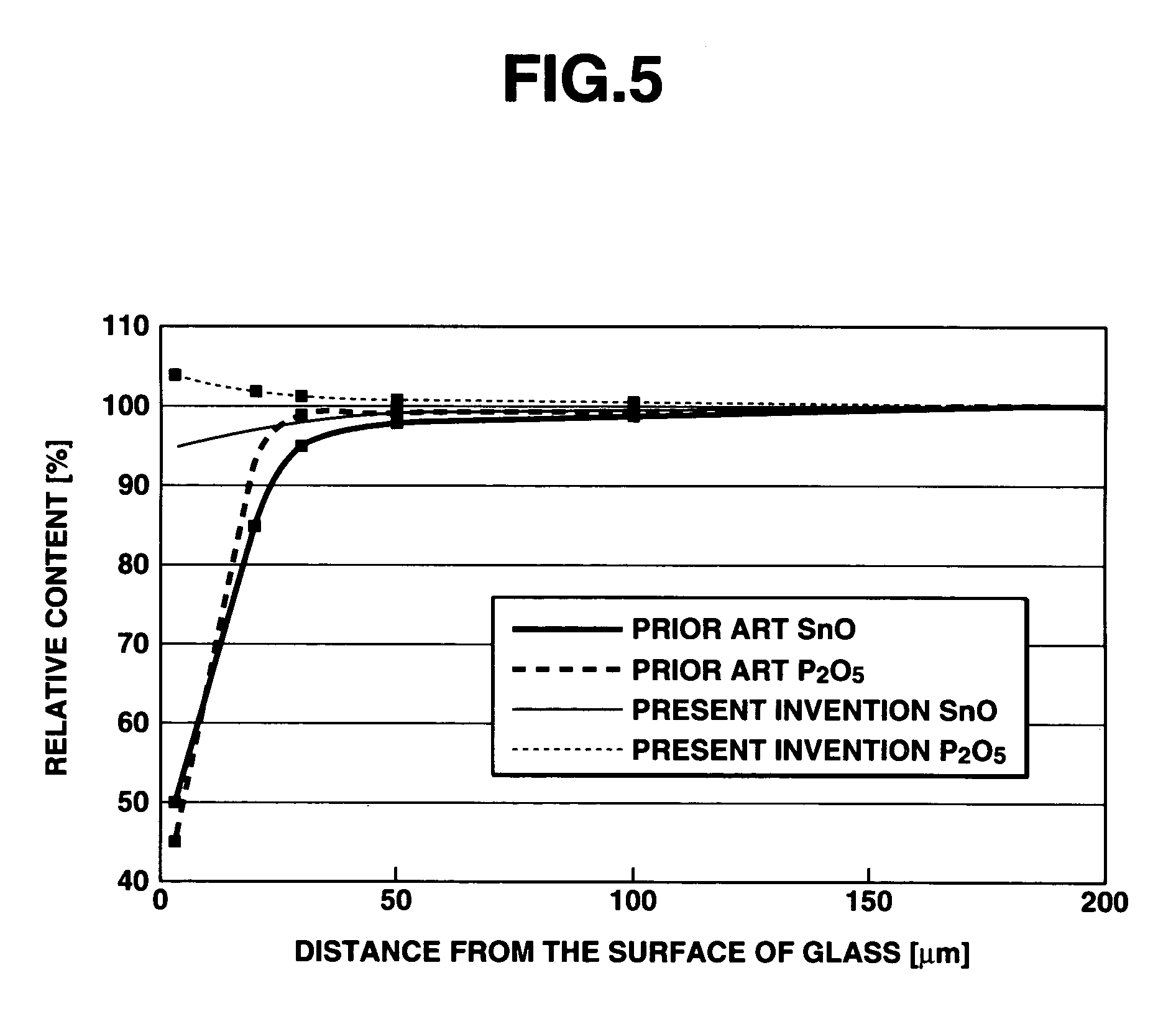

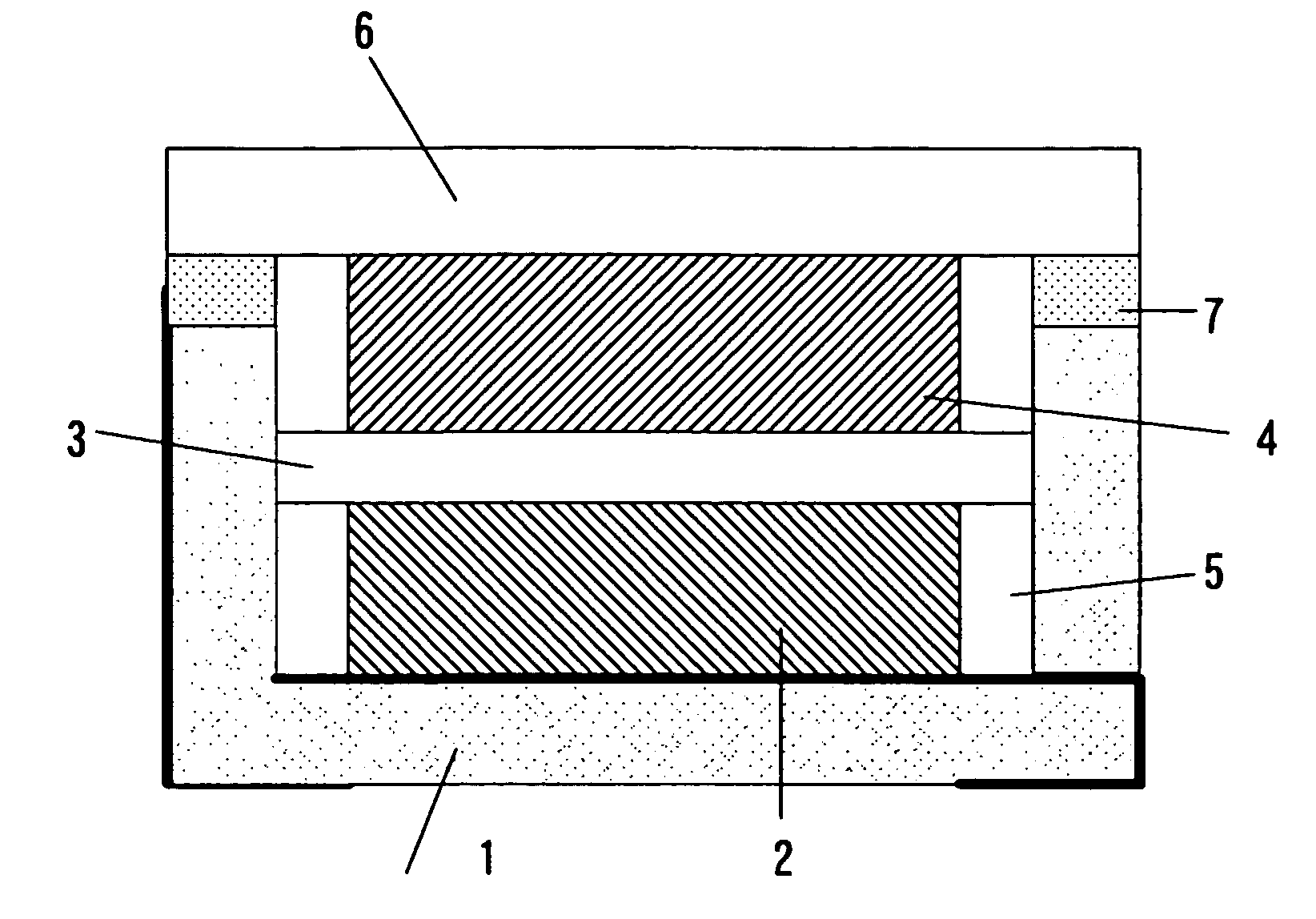

InactiveUS7214429B2Improve seal strengthAvoid instabilityCathode-ray/electron-beam tube vessels/containersTube sealing materialsThermal expansionCeramic

A sealing material for sealing an envelope of an electron tube. The sealing material comprises 0.01˜2.0 wt % of fine particle selected from the group consisting of SiO2, Al2O3 and ZrO2 having a particle diameter of 0.001˜0.1 μm, P2O5—SnO type low melting glass and thermal expansion-controlling low melting ceramics.

Owner:FUTABA CORPORATION

Electrochemical cell

InactiveUS7883796B2Inhibition capacityInternal resistanceHybrid capacitor electrodesFinal product manufactureEngineeringElectrochemical cell

An electrochemical cell has a container having a main surface and a cavity containing therein a positive electrode, a negative electrode, a separator separating the positive and negative electrodes from one another, and an electrolyte. A sealing plate that seals the cavity of the container is bonded to the main surface of the container with an unoxidized weld.

Owner:SEIKO INSTR INC

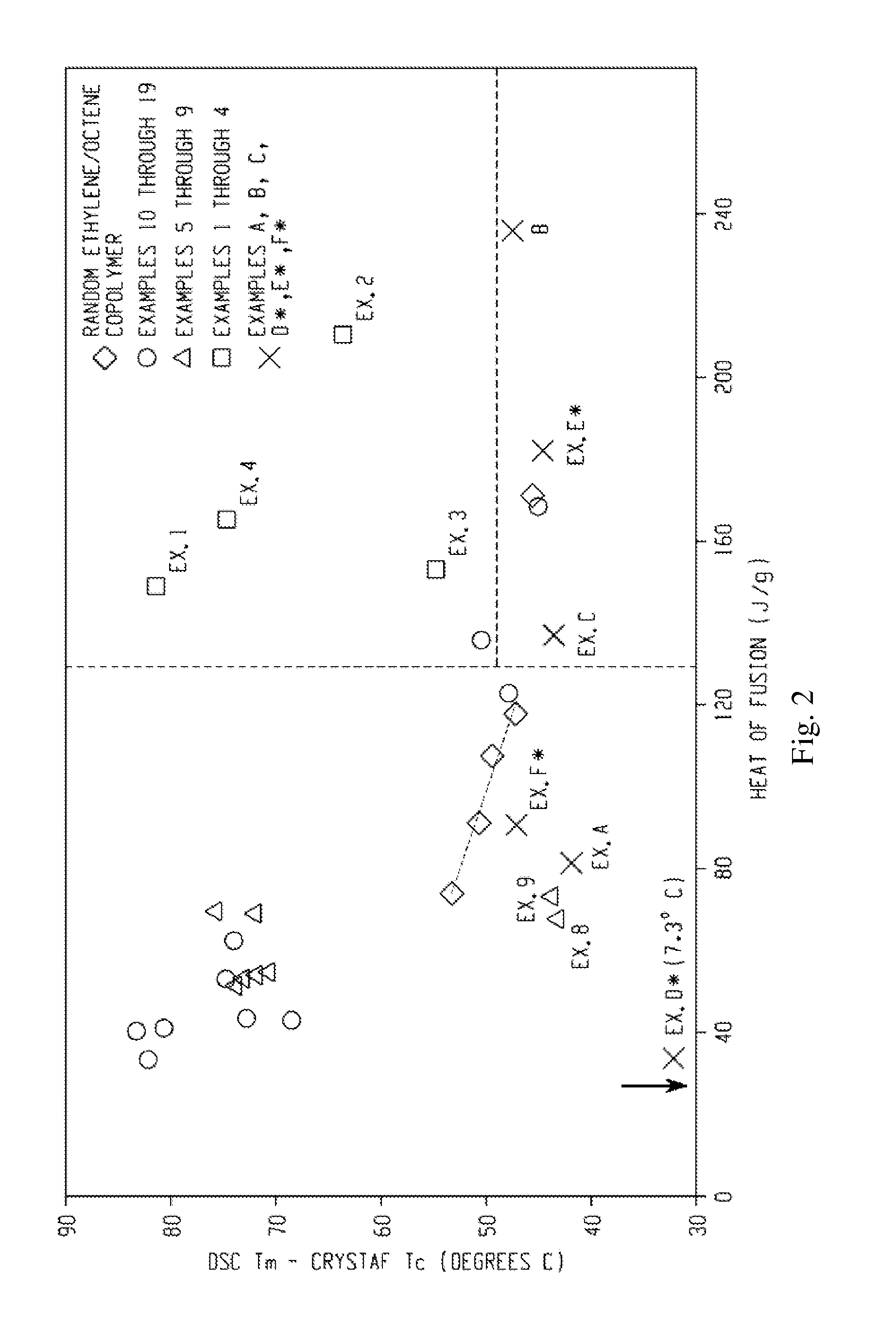

Oriented Films Comprising Ethylene/a-Olefin Block Interpolymer

InactiveUS20110039082A1Good packaging appearanceHigh sealing strengthSynthetic resin layered productsThin material handlingPolymer compositionMelting point

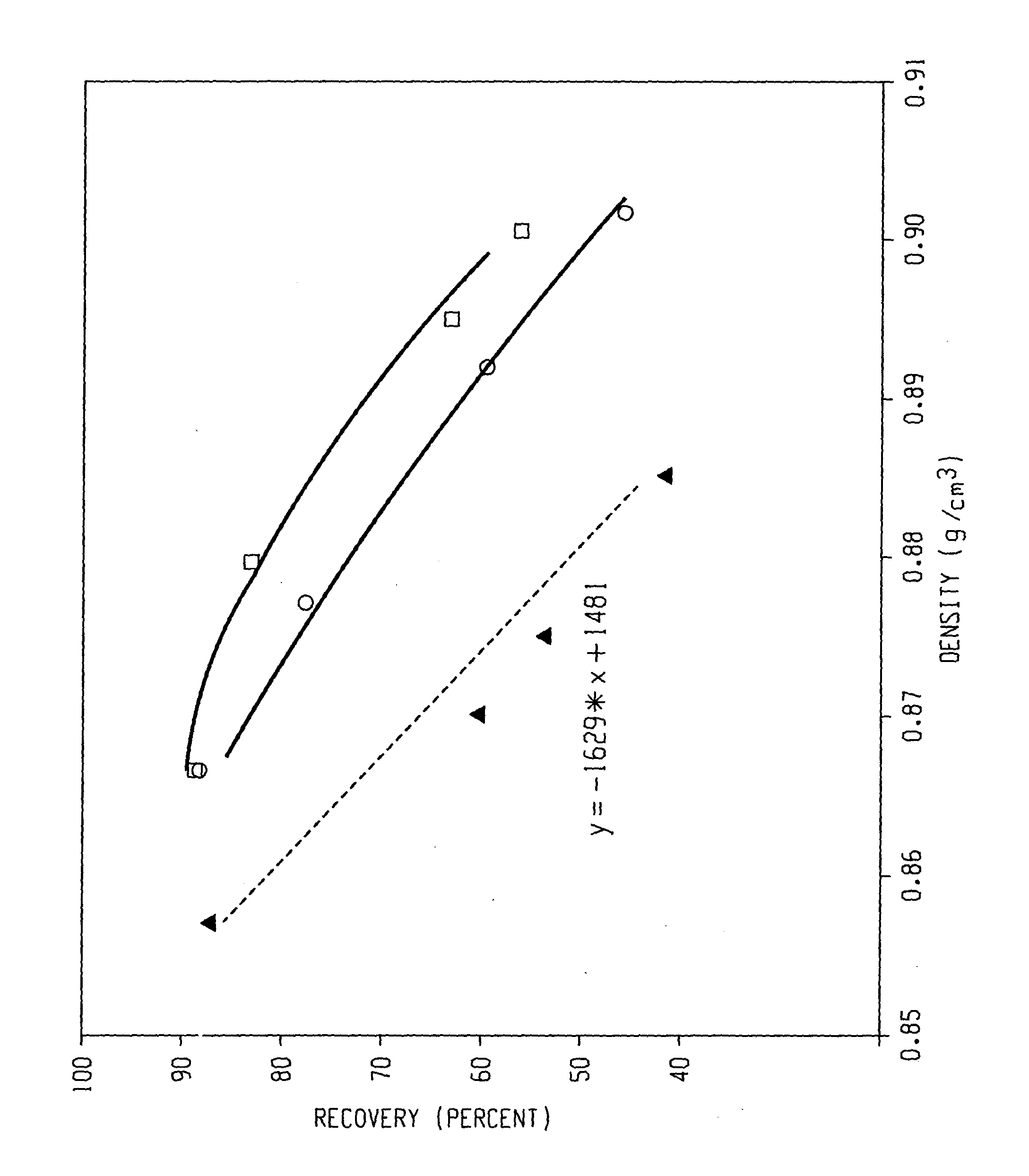

The present invention relates to oriented films having improved shrinkage force, shrinkage temperature, tear strength, seal strength and / or bubble stability. For example, the shrink tension of the oriented film stretched at 110° C. is less than 3 MPa. The oriented film comprises a polymer composition comprising at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship: Tm>−6553.3+13735(d)−7051.7(d)2.

Owner:THE DOW CHEM CO

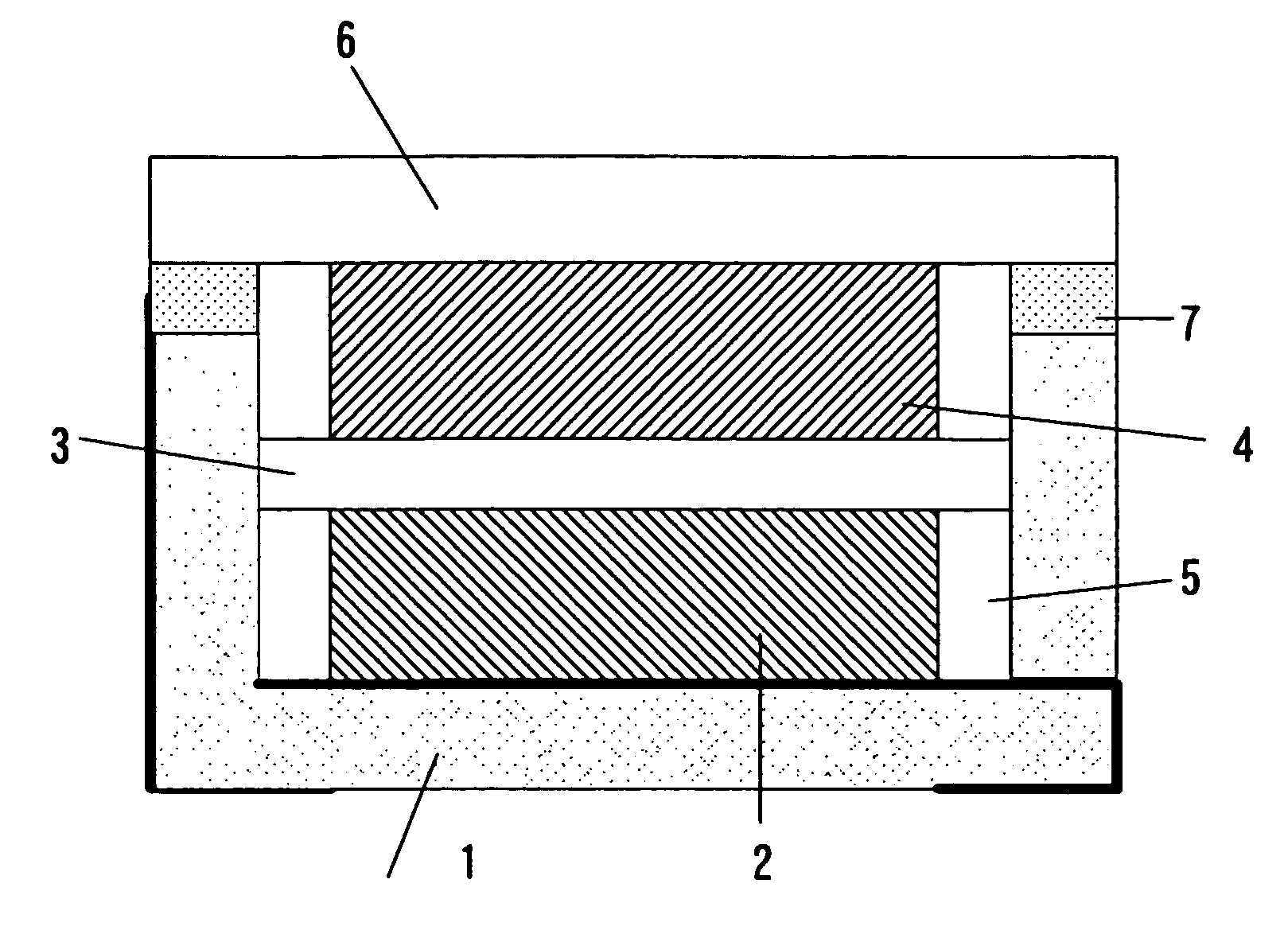

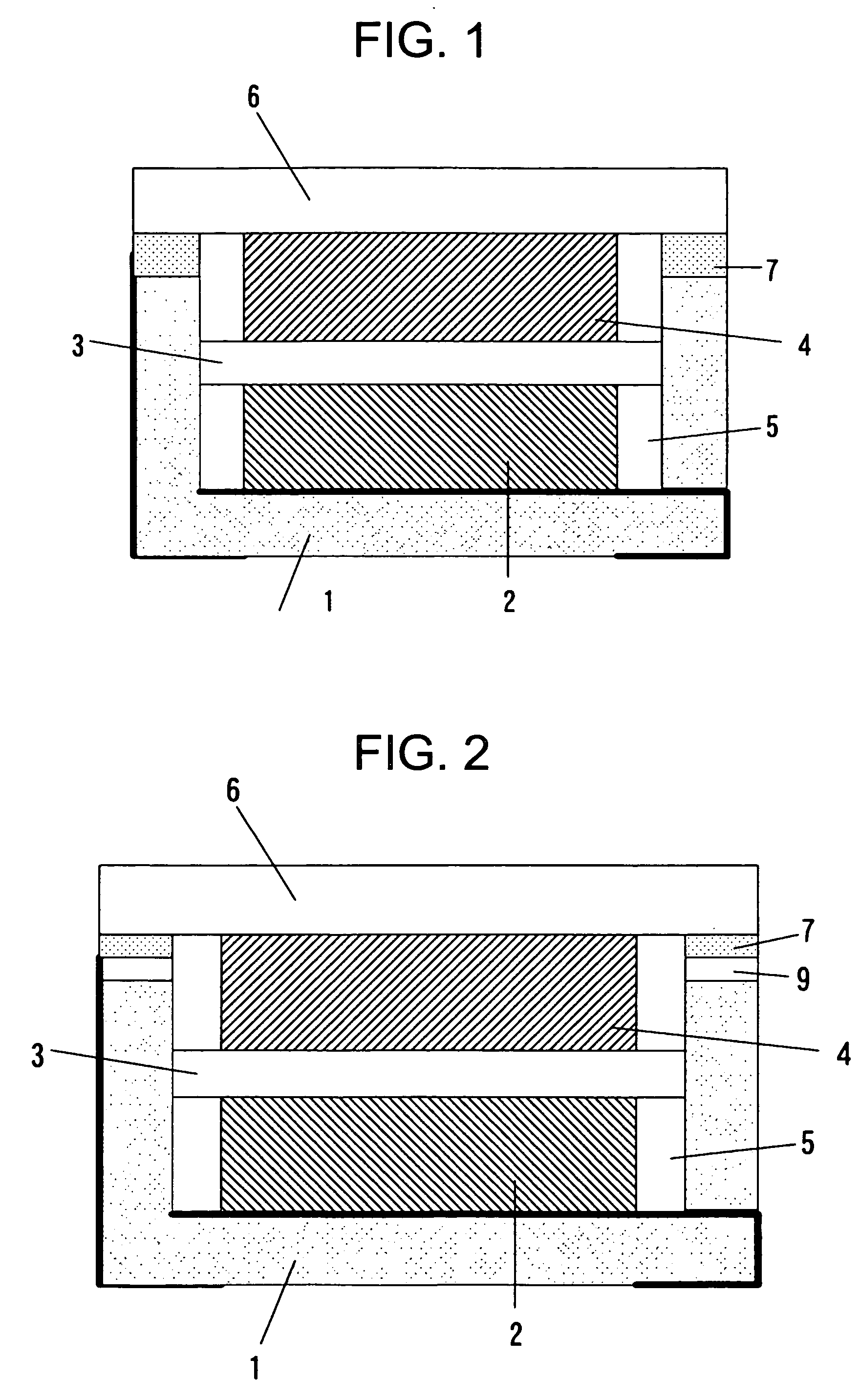

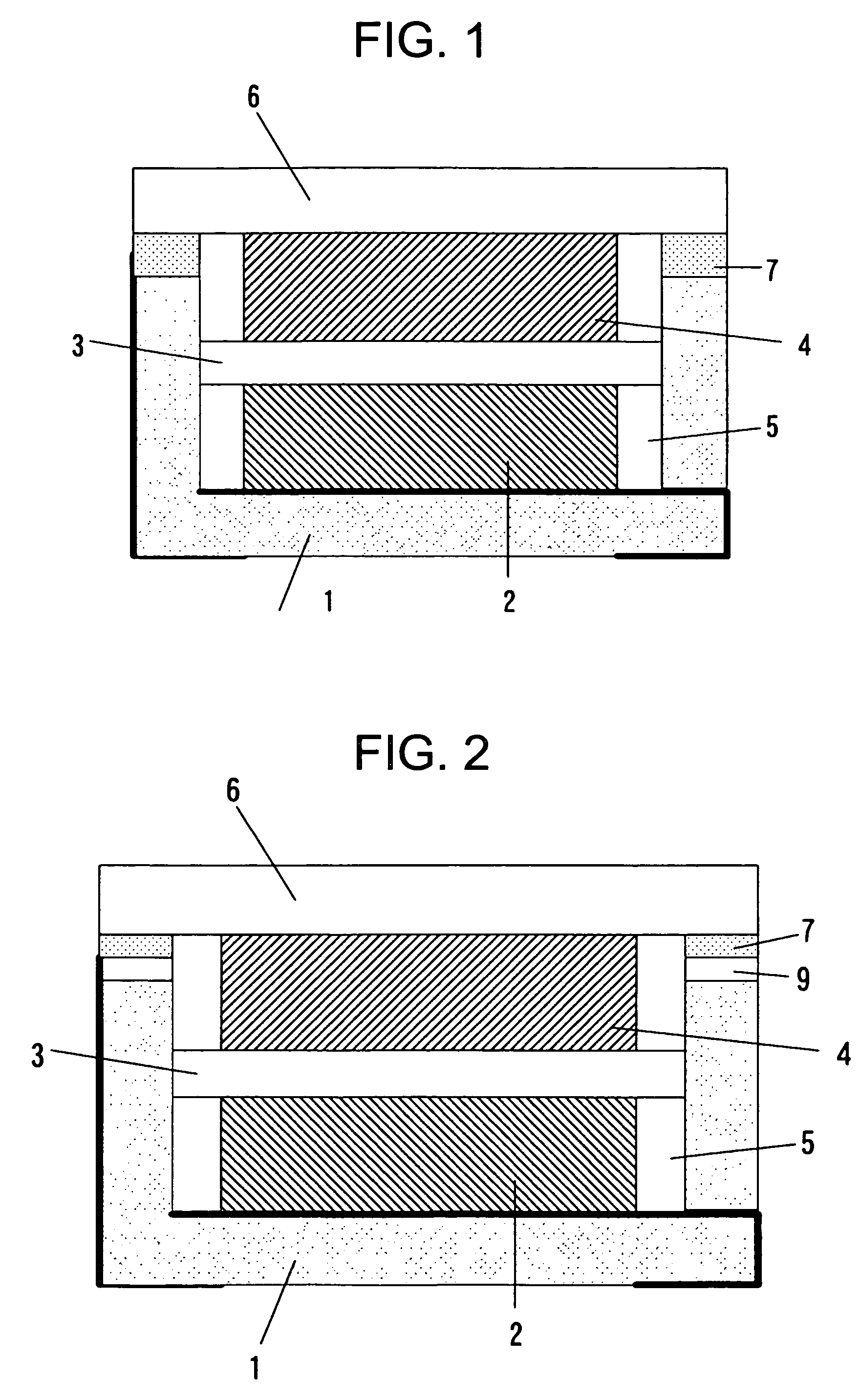

Display panel and method of manufacturing the same

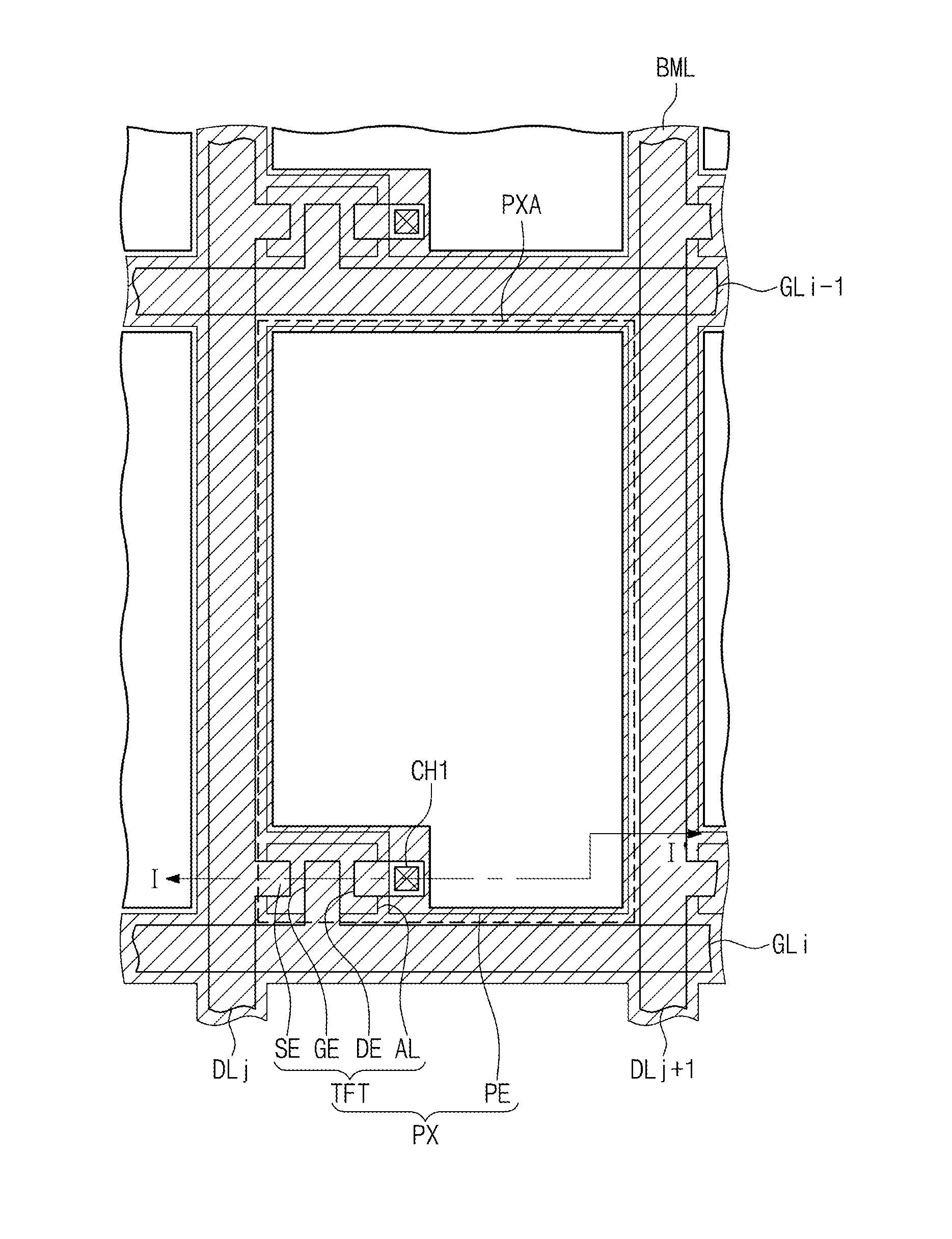

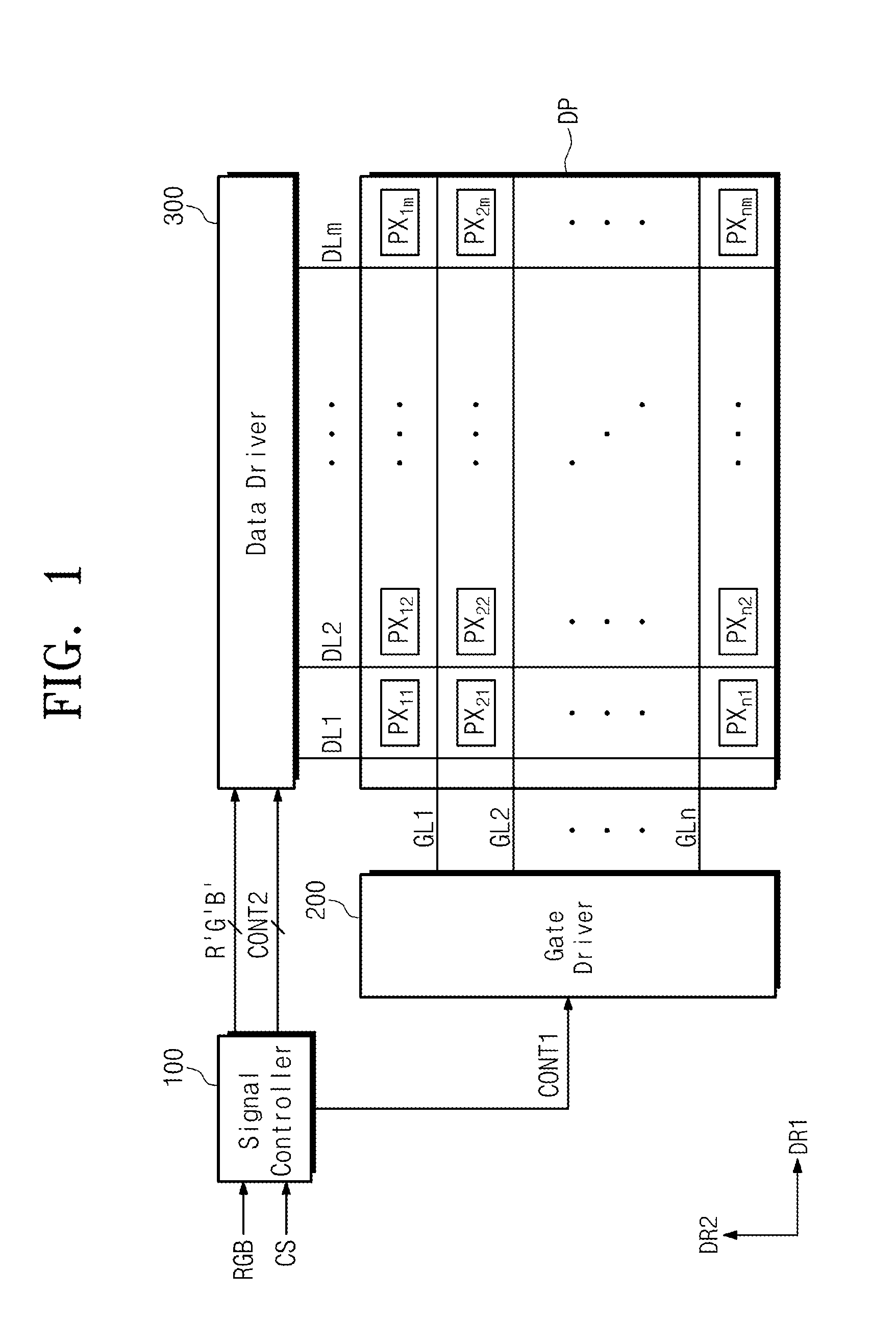

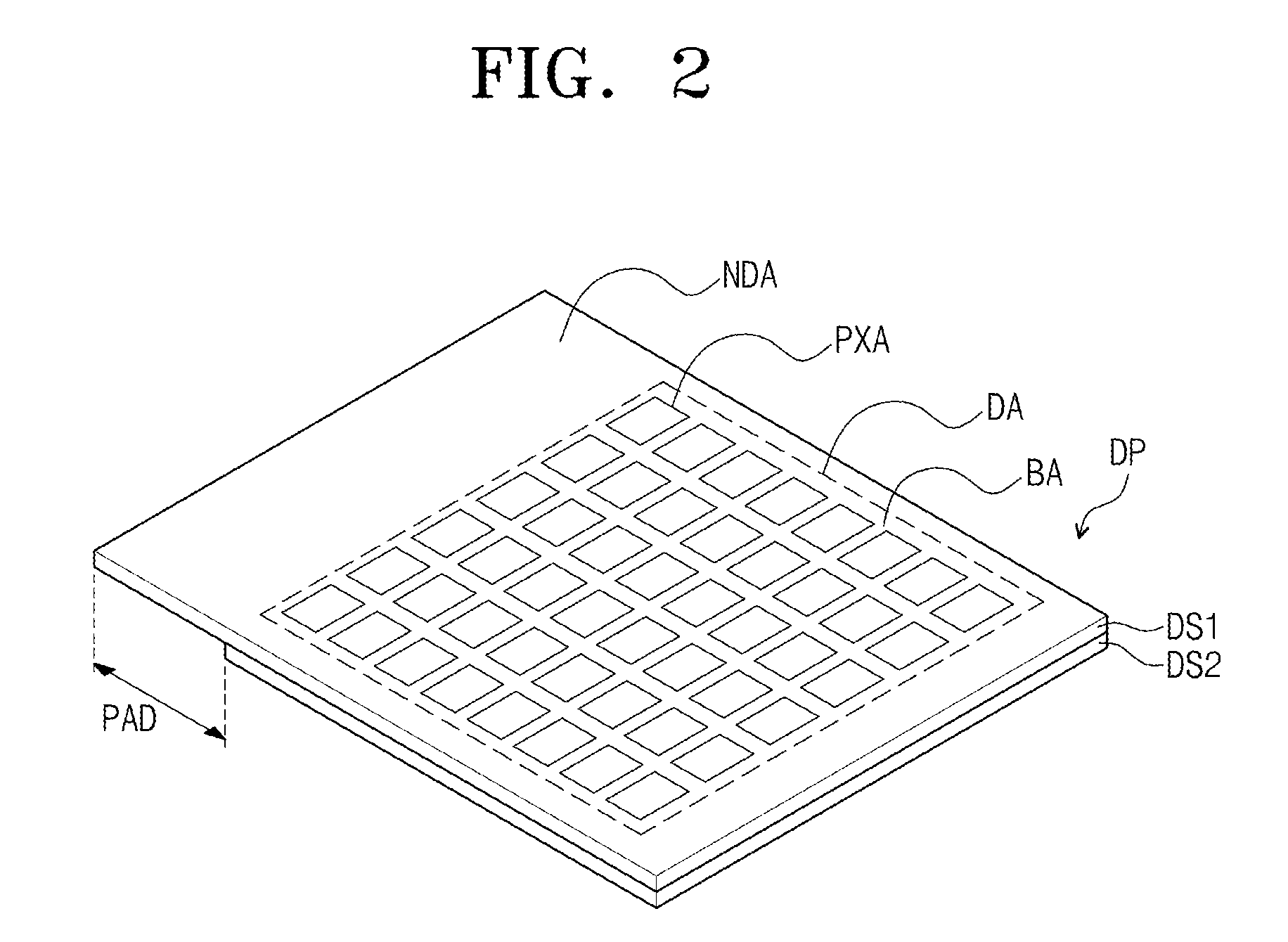

ActiveUS20150187800A1Improve seal strengthHigh bonding strengthTransistorSolid-state devicesReflective layerComputer science

A display panel includes a first base substrate that includes an upper surface to which an external light is incident and a lower surface facing the upper surface and includes a plurality of pixel areas and a peripheral area adjacent to the pixel areas when viewed in a plan view, a plurality of pixels disposed on the lower surface of the first base substrate to respectively correspond to the pixel areas, and a black matrix layer disposed between the pixels and the lower surface of the first base substrate to overlap the peripheral area. The black matrix layer includes a low reflection layer disposed on the lower surface of the first base substrate and a light blocking layer disposed on the low reflection layer.

Owner:SAMSUNG DISPLAY CO LTD

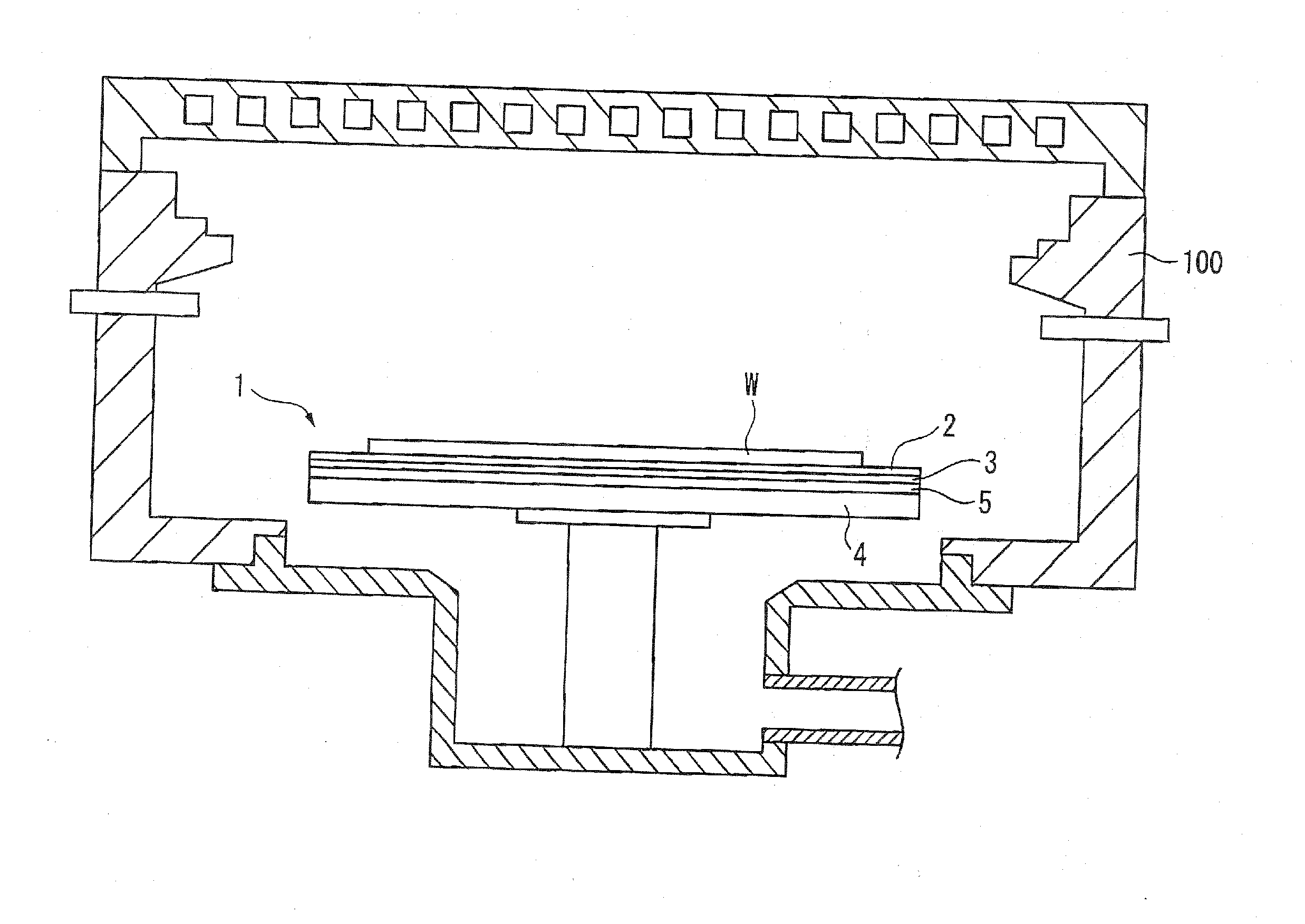

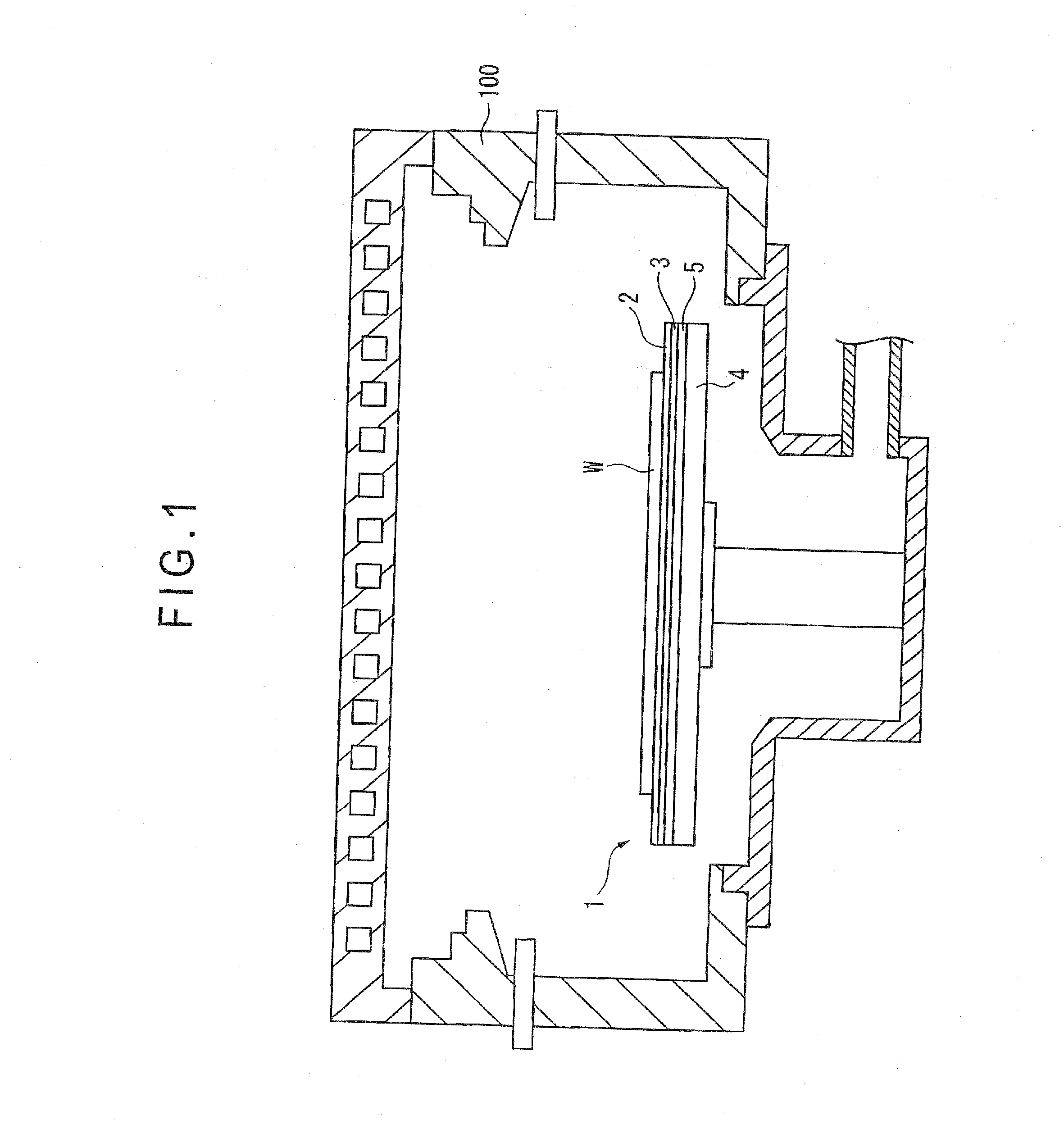

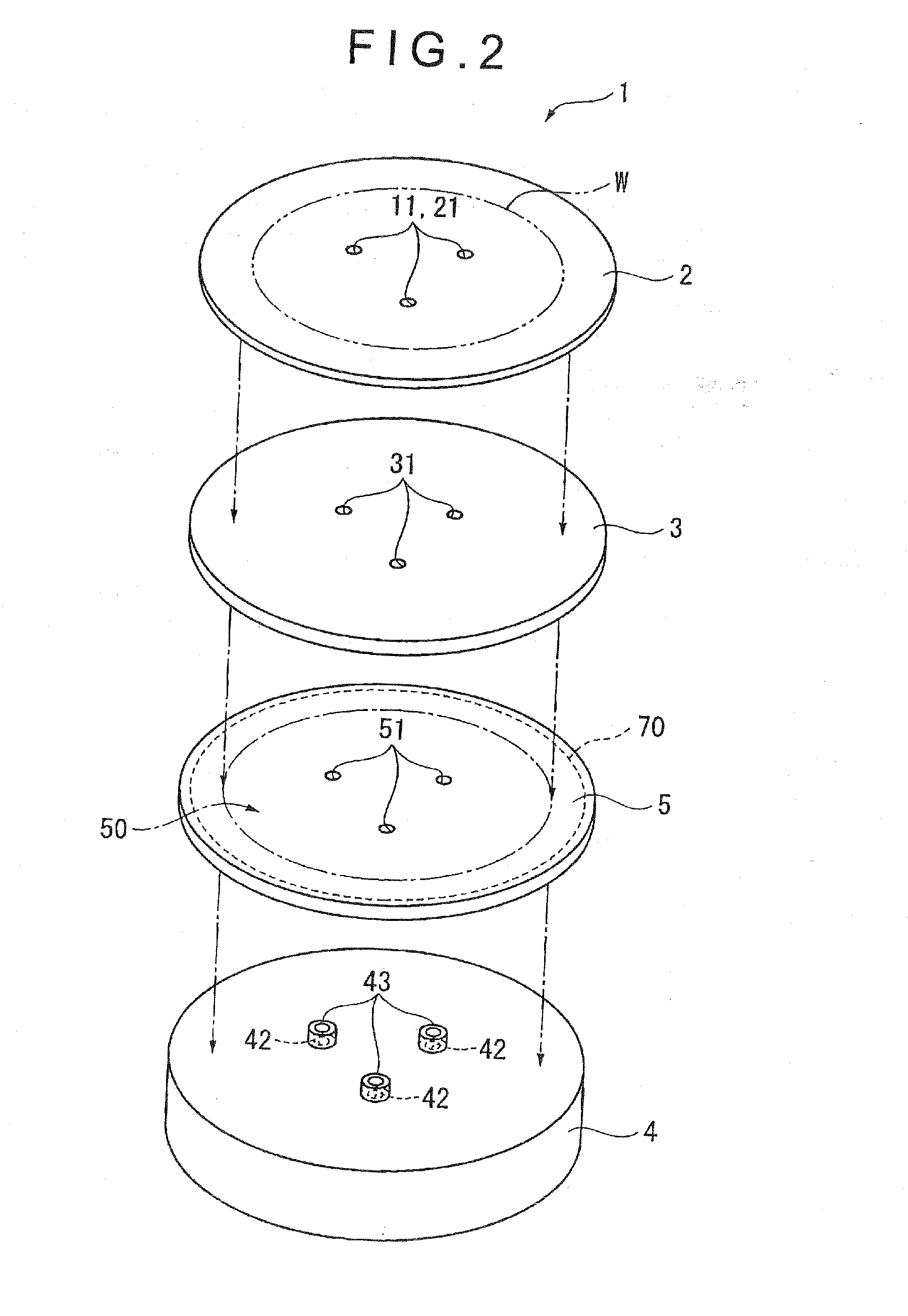

Temperature control device

InactiveUS20130098068A1Increasing the thicknessImprove seal strengthMachines using electric/magnetic effectsTemperature controlAdhesive

A temperature control device includes: a top plate; a heat exchanger plate; a thermoelectric module including a temperature-control-side electrode disposed near the top plate, a heat-exchanger-side electrode disposed near the heat exchanger plate and a thermoelectric element of which one side is connected with the temperature-control-side electrode and the other side is connected with the heat-exchanger-side electrode; and a polyimide film provided on the thermoelectric module near the top plate. The thermoelectric module is spaced apart from and surrounded by a seal wall having a ceramic outer circumference and disposed between the polyimide film and the heat exchanger plate. An adhesion sheet or an adhesive is interposed between the seal wall and the polyimide film.

Owner:KELK LTD

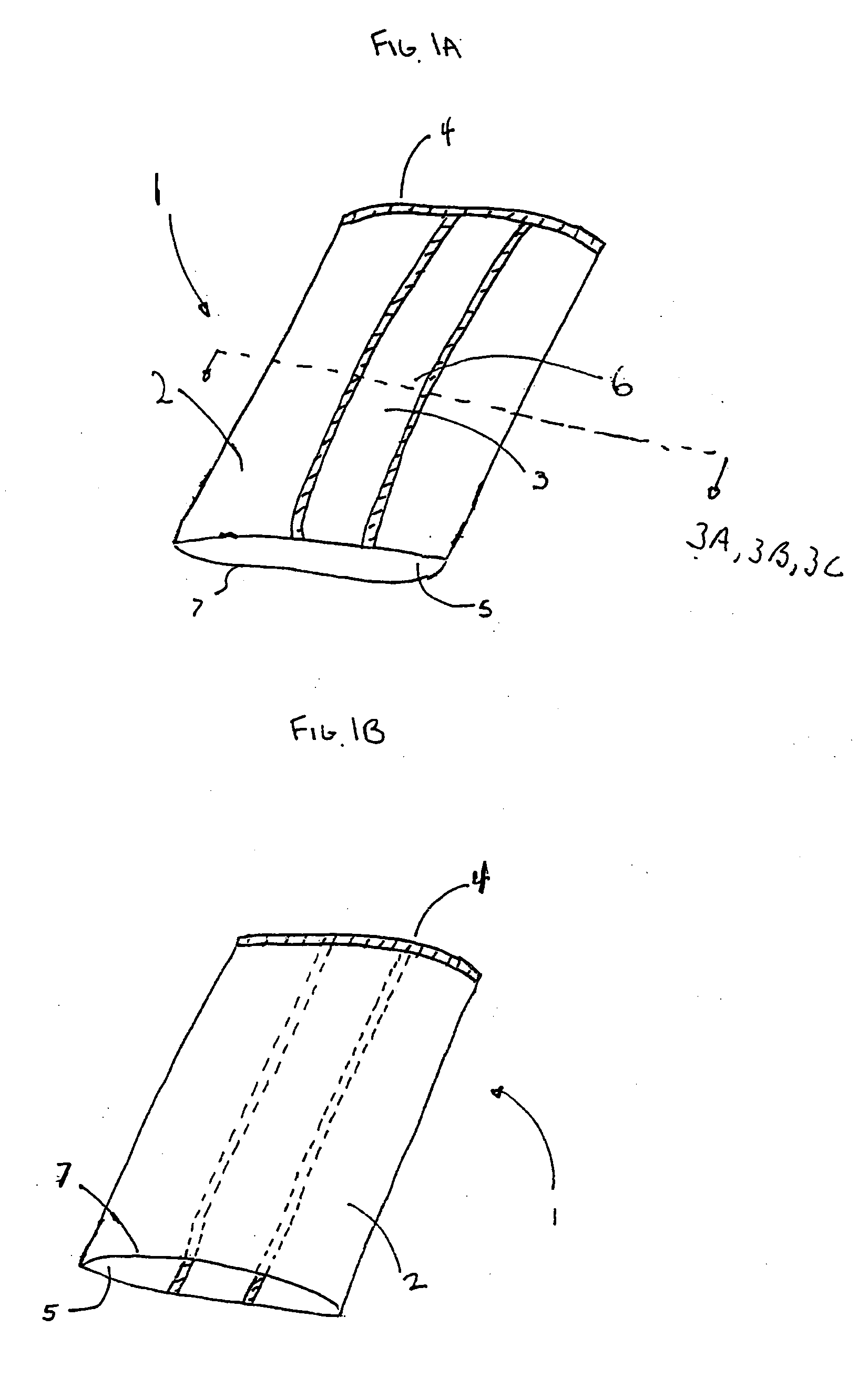

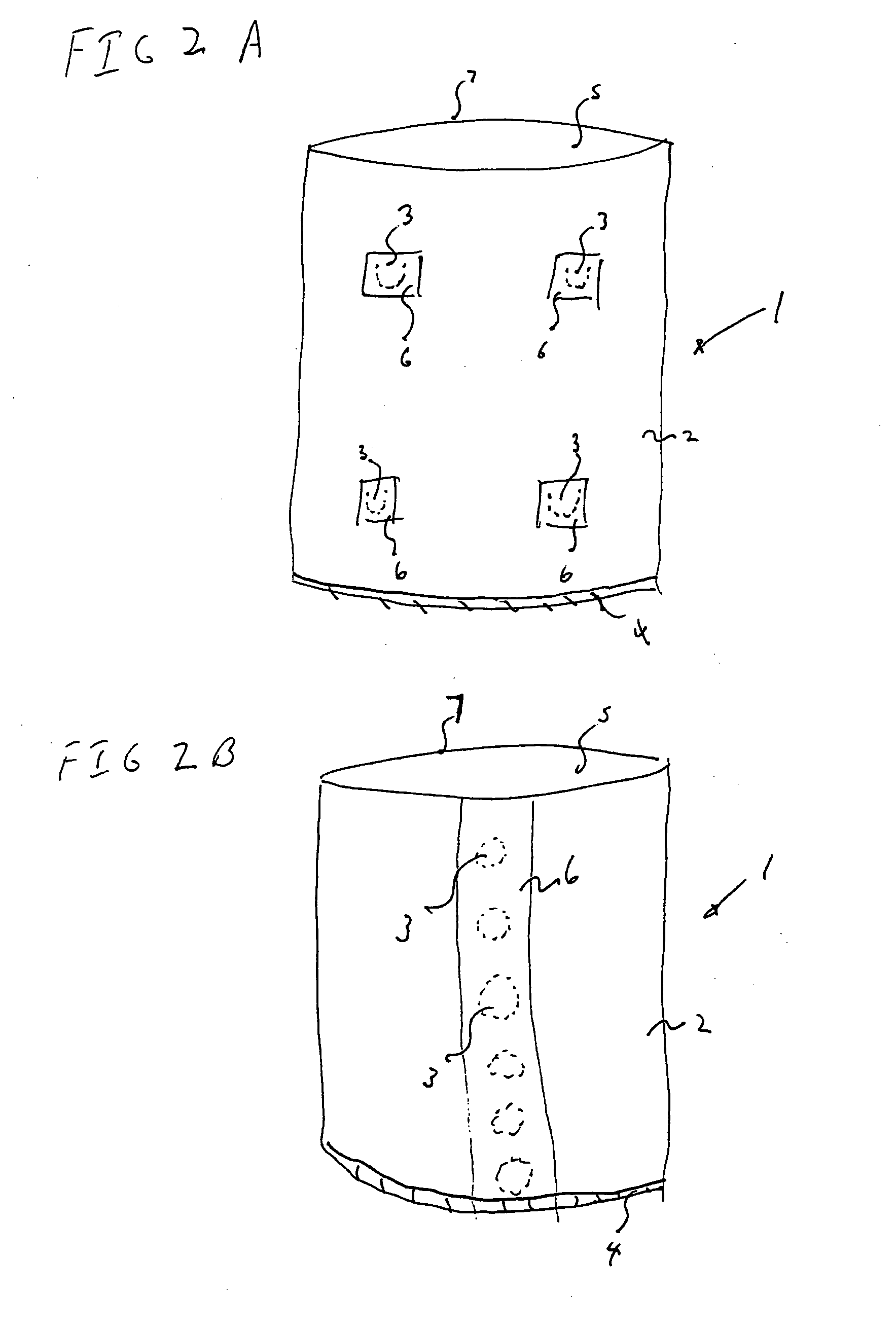

High temperature venting bags

InactiveUS20070134382A1Increases salable weightImpose sealMicrowave heatingDomestic containersEngineeringFood products

Provided are high temperature, venting food preparation bags used to package food products for storage, transportation, and preparation and methods for making and using the same. High temperature, venting food preparation bags are composed of a sealed end, an open end, at least one side wall composed of a first thermoplastic film having a vent, and a vent seal composed of a second thermoplastic film. The vent seal is fused to the sidewall via a non-adhesive seal thereby closing the vents. At elevated temperatures, the vent seal at least partially detaches from the side wall thereby opening the vents. Opening of the at least one vent is not dependent upon the accumulation of internal fluid or gaseous pressure, and is compatible with vacuum packaging techniques. Vented cooking techniques are provided that permit browning and crisping of beef and poultry without manipulating the food preparation bag during cooking.

Owner:M&Q IP LEASING

Films having enhanced sealing characteristics and packages containing same

InactiveUS7056593B2Highly desirable sealing characteristicSacrificing advantageous seal propertyLayered product treatmentSynthetic resin layered productsElastomerIonomer

Films containing a sealant layer composition comprising:(1) polyethylene homopolymer, and ethylene / alpha-olefin copolymer, ethylene vinyl acetate copolymer, and ethylene / acrylate copolymer; and(2) elastomer, plastomer, ionomer, and carboxyl-modified polyethylene;when sealed to another outer film layer comprising at least one member selected from the group consisting of ionomer, ethylene / acid copolymer, ethylene / vinyl acetate copolymer and ethylene / acrylate copolymer, have been discovered to provide a seal strength comparable to an ionomer to ionomer seal.

Owner:CRYOVAC ILLC

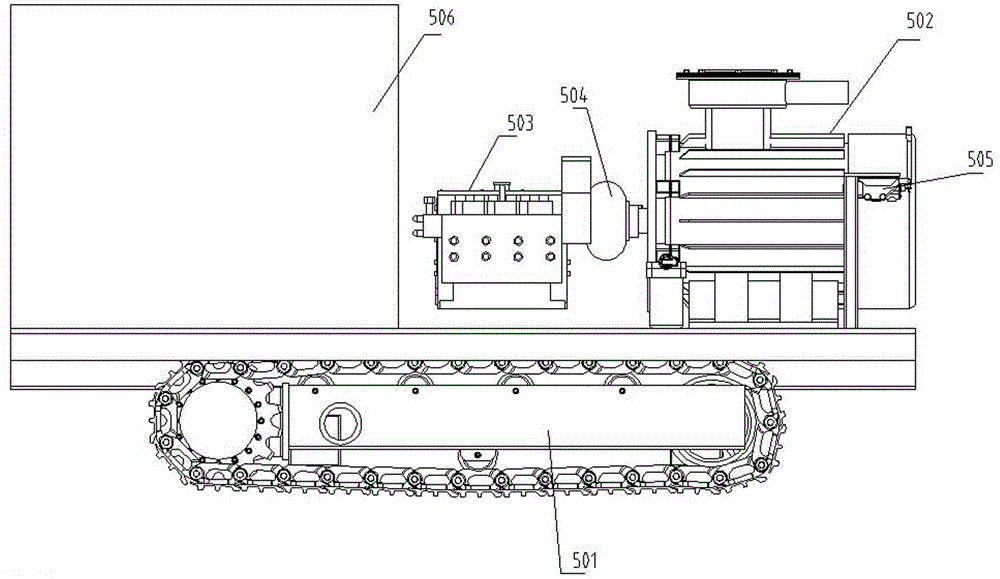

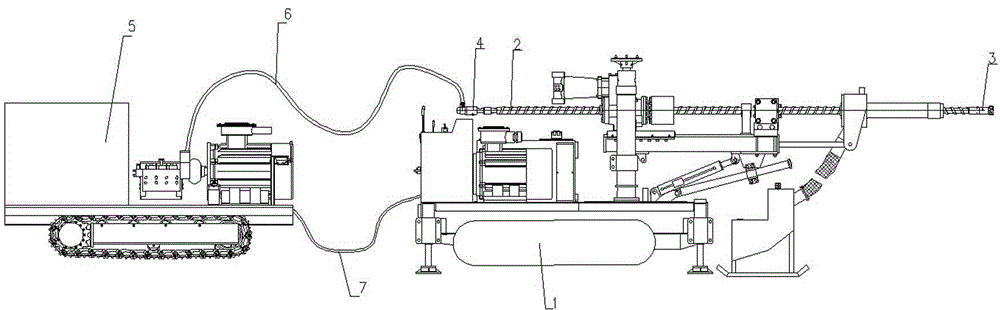

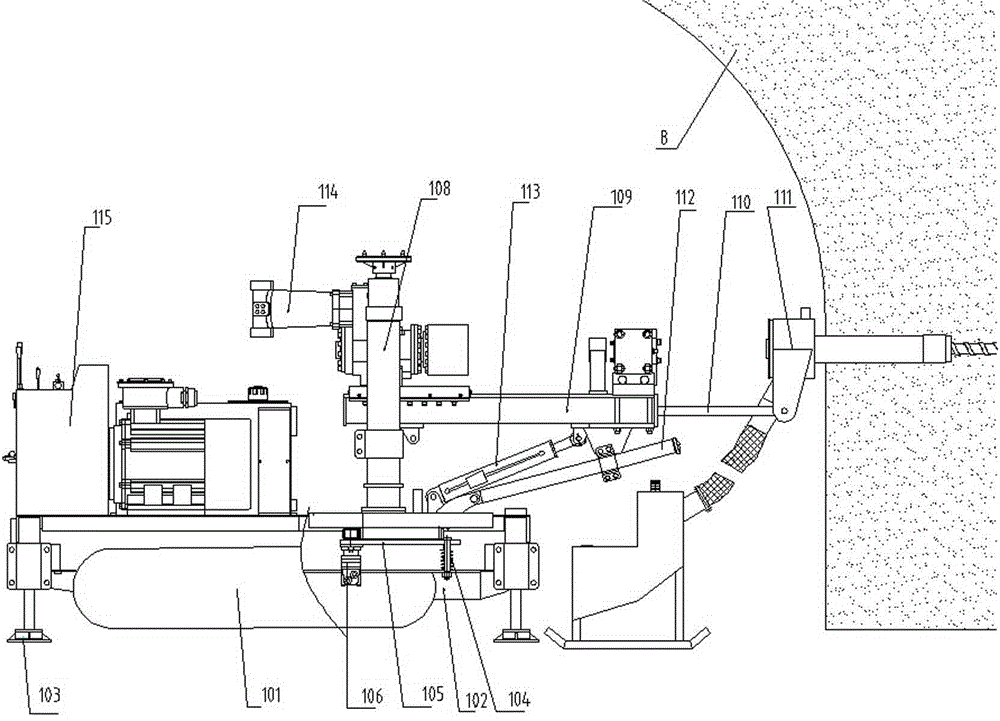

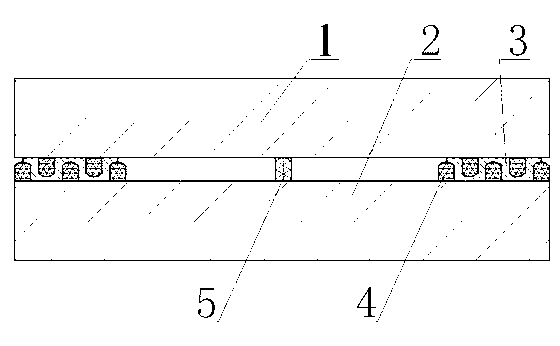

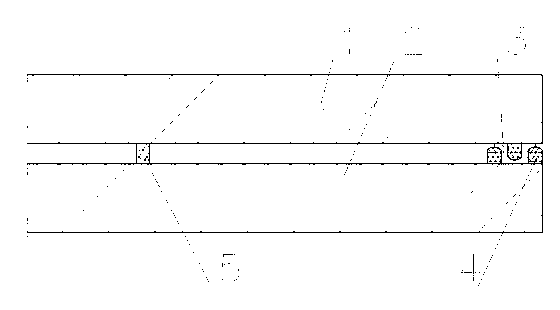

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

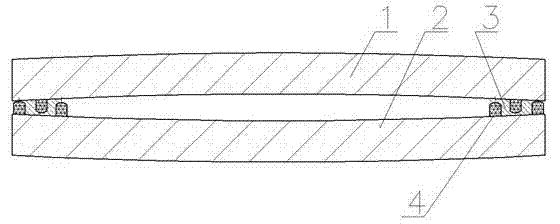

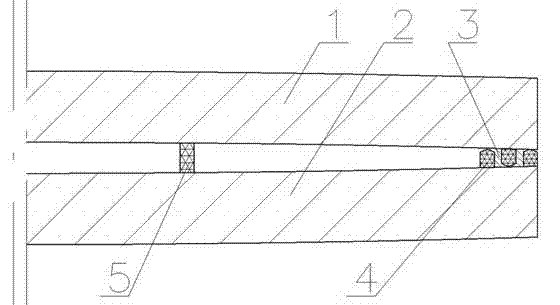

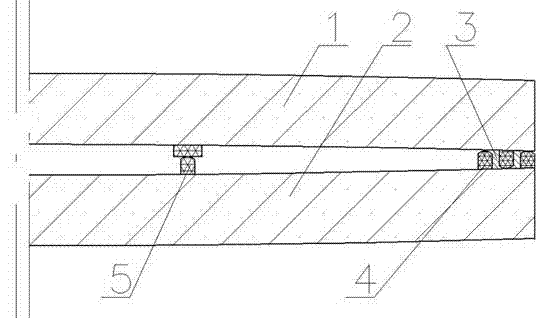

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

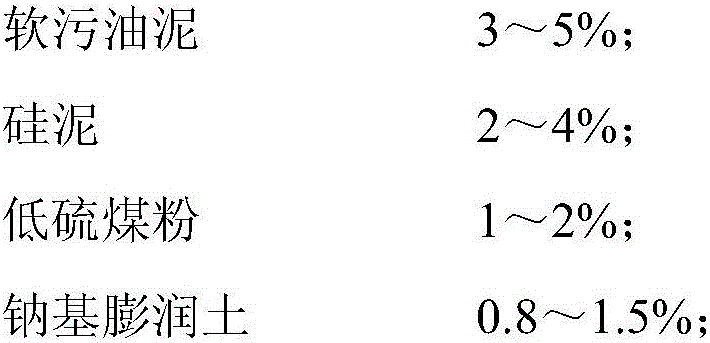

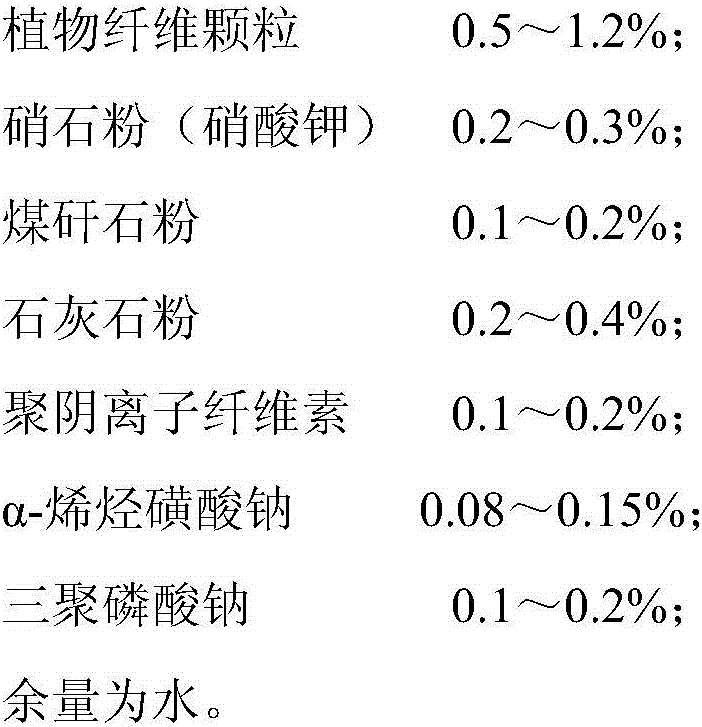

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

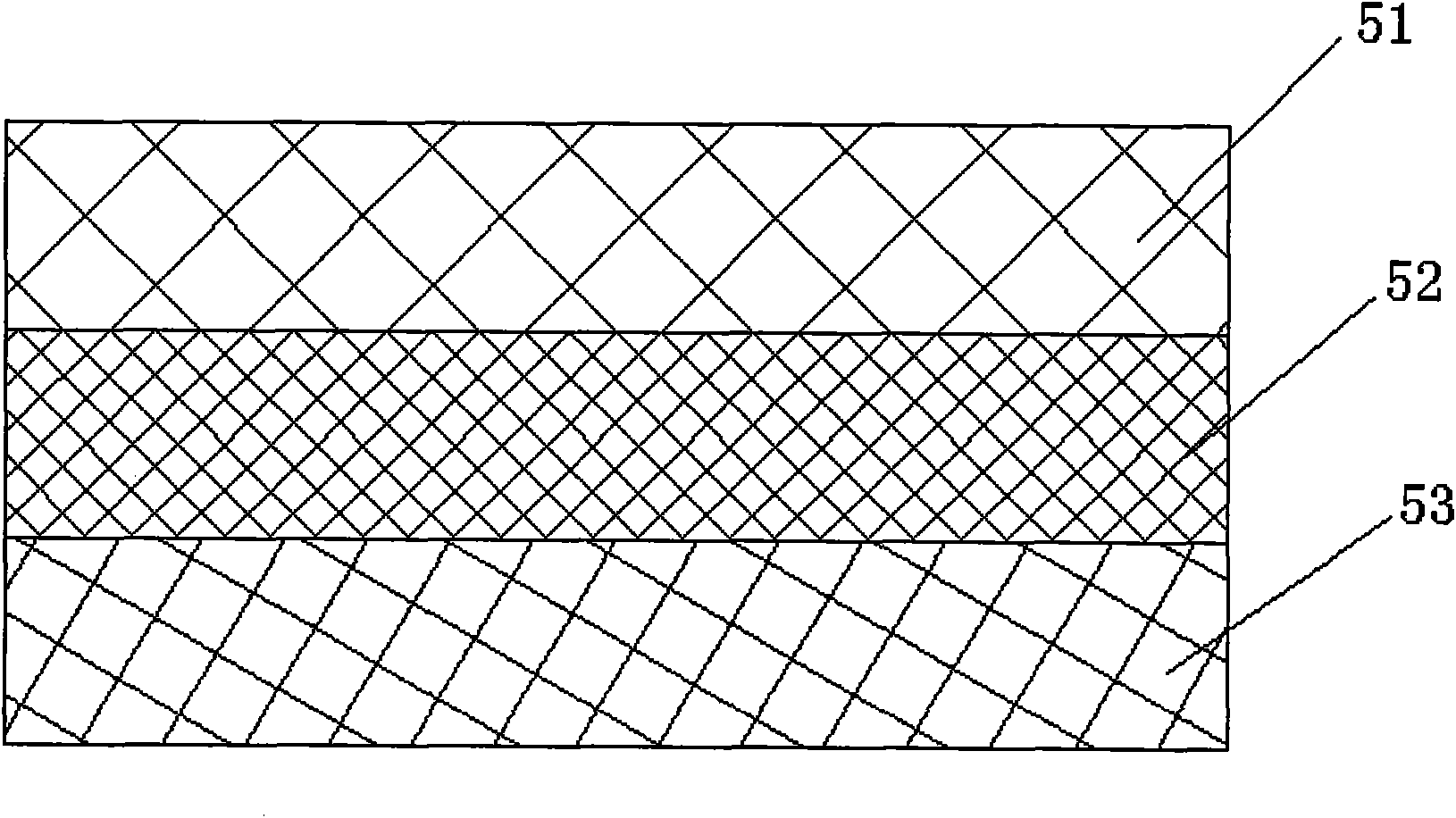

Multi-layer films having improved sealing properties

InactiveUS7537829B2Improving seal strength and impact strength and resilience and hermeticityReduced-temperature sealabilitySynthetic resin layered productsLaminationEngineeringPolymer

Multi-layer films that are suitable for packaging and having improved sealing properties are disclosed. Some embodiments may also provide a lower minimum sealing temperature. A soft polymer is blended in a core layer and a tie layer comprising the soft polymer and, optionally, another polymer. A sealable layer is provided on the side of the tie layer opposite the core layer. The multi-layer films may be transparent, contain a cavitating agent, or are pigmented to form an opaque film. Also, the multi-layer film may be metallized or coated with a barrier coating.

Owner:JINDAL FILMS AMERICAS LLC

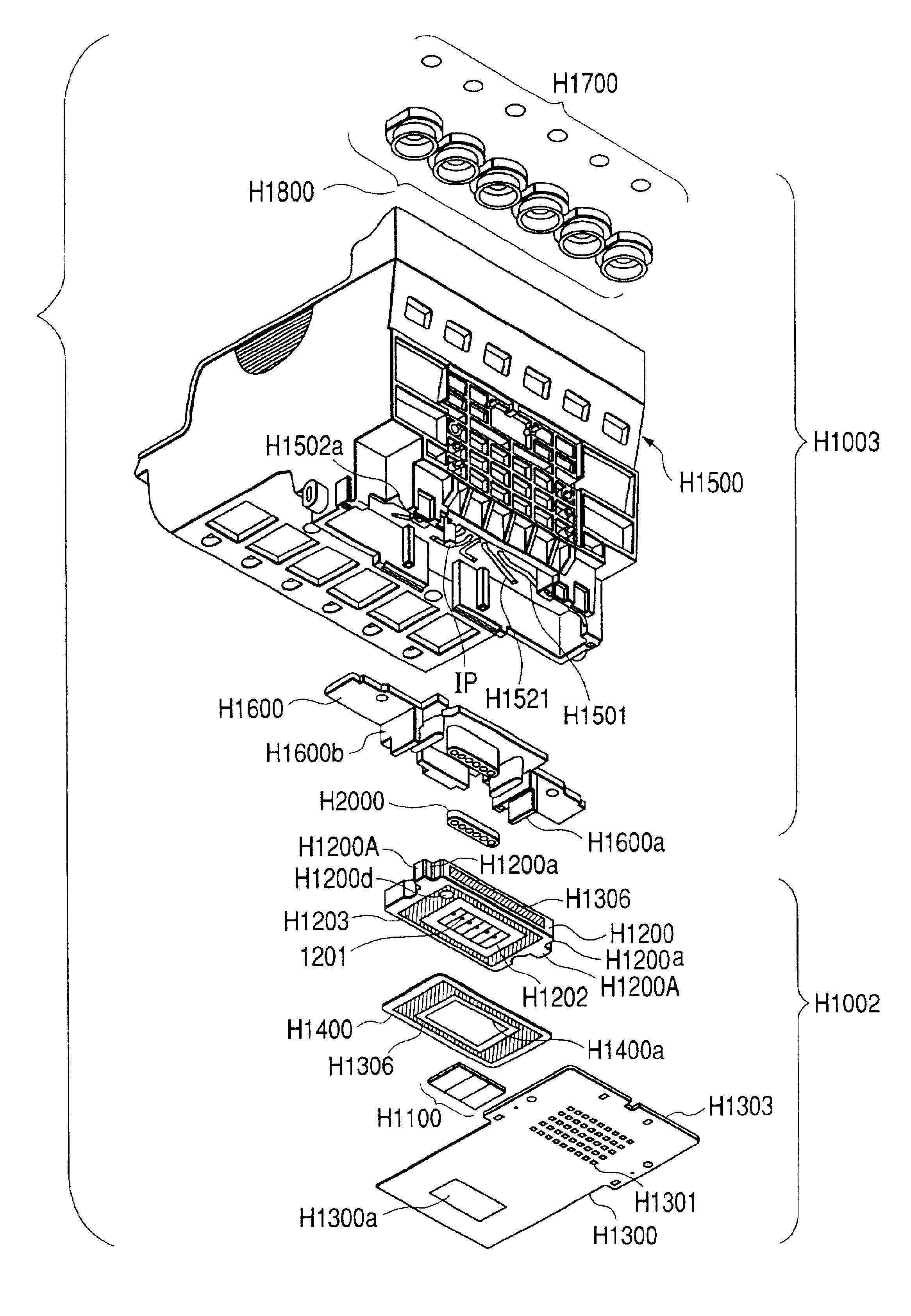

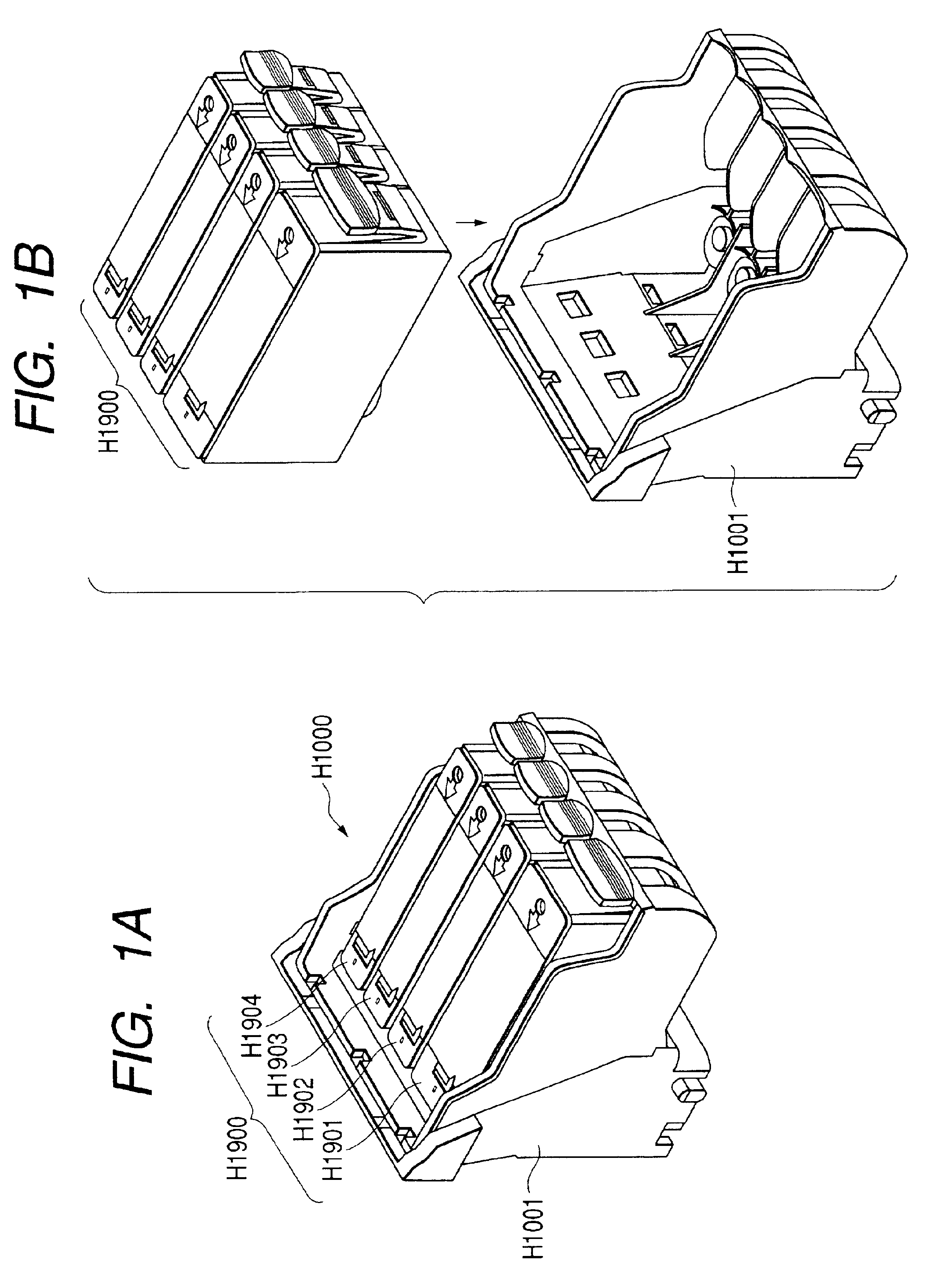

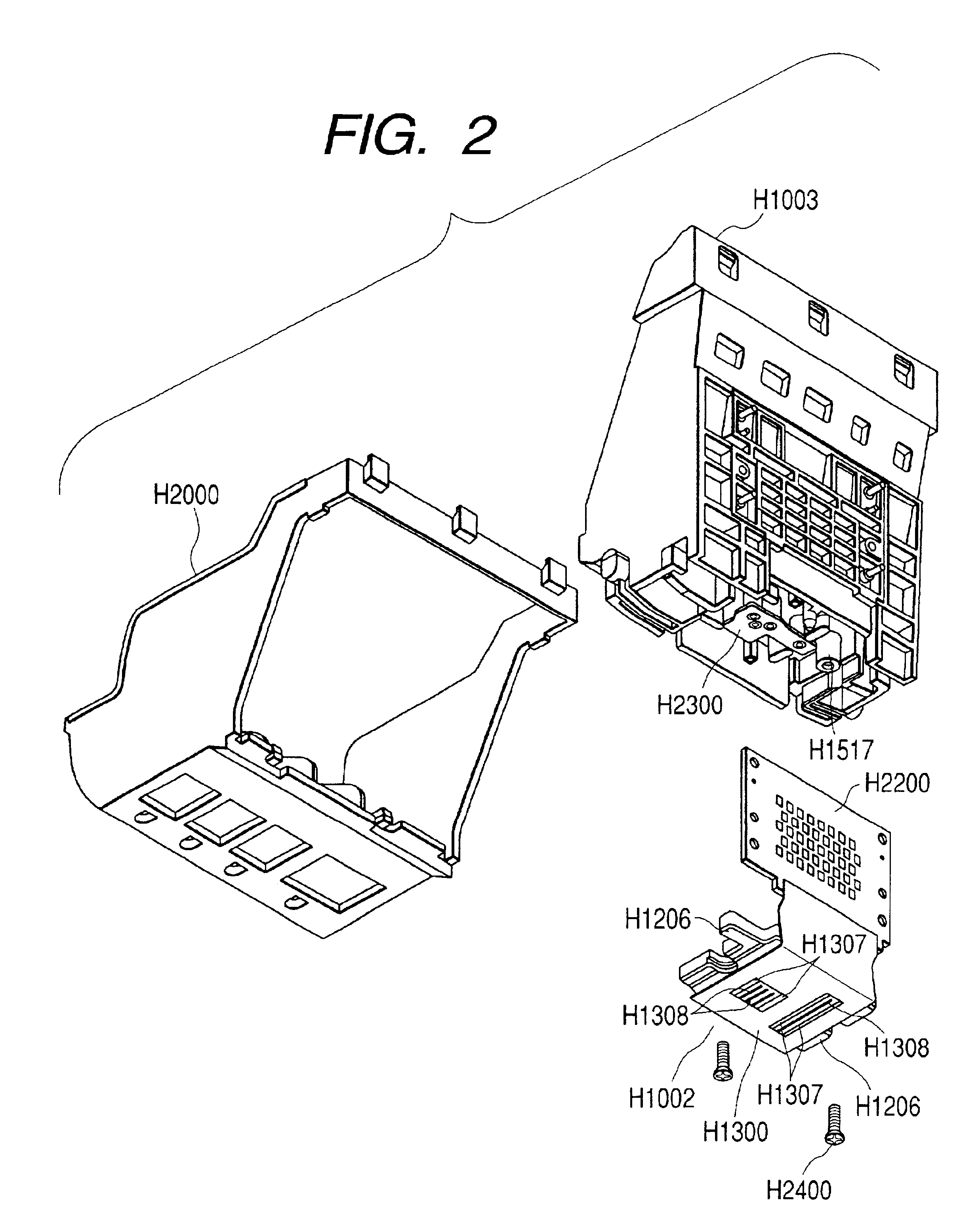

Liquid discharge recording head cartridge and liquid discharge recording apparatus

A liquid discharge head cartridge includes a recording element unit having a plate member with liquid supply paths for supplying liquid to a recording element base plate for recording by discharging the liquid; a liquid supply unit portion having a communication passage for conducting liquid from a liquid supply source; and an elastic sealing member that forms a seal between one end portion of the liquid supply paths of the plate member and an end portion of the communication passage facing the one end portion of the liquid supply paths. The elastic sealing member is provided with liquid flow paths communicating with the liquid supply paths and the communication passage. The liquid supply unit portion and the recording element unit are adhesively bonded with each other at locations other than those having the elastic sealing member arranged thereon.

Owner:CANON KK

Self-decomposition temporary plugging agent for workover fluid and using method of temporary plugging agent

InactiveCN105086973AWith self-blocking functionImprove protectionDrilling compositionFiberWater based

The invention discloses a self-decomposition temporary plugging agent for a workover fluid and a using method of the temporary plugging agent. The self-decomposition temporary plugging agent comprises 10-40 parts of particles I with the particle size ranging from 1 mm to 10 mm by mass, 20-60 parts of particles II with the particle size ranging from 20 meshes to 40 meshes by mass, 0.2-1 part of staple fibers with the length ranging from 3 mm to 10 mm by mass and 18-40 parts of superfine powder with the particle size ranging from 100 meshes to 300 meshes by mass; the particles I, the particles II, the staple fibers and the superfine powder are any one of or a mixture of several of polylactic acid, poly lactic-glycolic acid and polycaprolactone in any ratio. The using method of the agent comprises steps as follows: the staple fibers are evenly mixed in the water-based workover fluid, other components of the self-decomposition temporary plugging agent are added, and the mixture is evenly mixed. The self-decomposition temporary plugging agent for the workover fluid can be completely degraded into carbon dioxide and water in an aqueous solution and causes no damage to stratums, and the using method of the agent is suitable for on-site preparation.

Owner:CNPC BOHAI DRILLING ENG

Powder for ceramic metallizing paste and its prepn

The powder for ceramic metallizing paste and its preparation process belongs to the field of ceramic metallizing material applying technology. The ceramic metallizing powder consists of molybdenum powder in 60-80 weight portions and glass phase component in 20-40 weight portions. The powder for ceramic metallizing paste has reasonable composition, proper metal titanium content, capacity of strengthening activity of the metallizing layer and ceramic, raised sealing strength of metallized ceramic, metallizing sintering temperature lowered to 1400-1450 deg.c and expanded compact sintering temperature range.

Owner:CHANGSHU CITY YINYANG CERAMIC CO LTD

Vacuum glass with metal edge-sealing structure and making method thereof

Belonging to the field of vacuum glass and its edge-sealing technologies, the invention relates to a vacuum glass with a metal edge-sealing structure and a making method thereof. The vacuum glass comprises two flat glass sheets, a plurality of supports and a sealing layer. A metal transition layer is respectively cured on a sealing surface of the two flat glass sheets, and the two metal transition layers are fused and sealed by a metal layer formed by a low-melting-point metal welding material, and the fused and sealed metal transition layers and the metal layer form the low-melting-point metal sealing layer. The technical scheme involved in the invention not only can realize convenient and low-cost metal edge-sealing of vacuum glass, is easy to realize large-scale production, but at the same time also can realize low temperature (130DEG C-400DEG C) sealing of vacuum glass and lead-free manufacturing. Therefore, the vacuum glass and the method provided by the invention have great significance in reducing the production cost of vacuum glass and broadening the application scope of vacuum glass.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

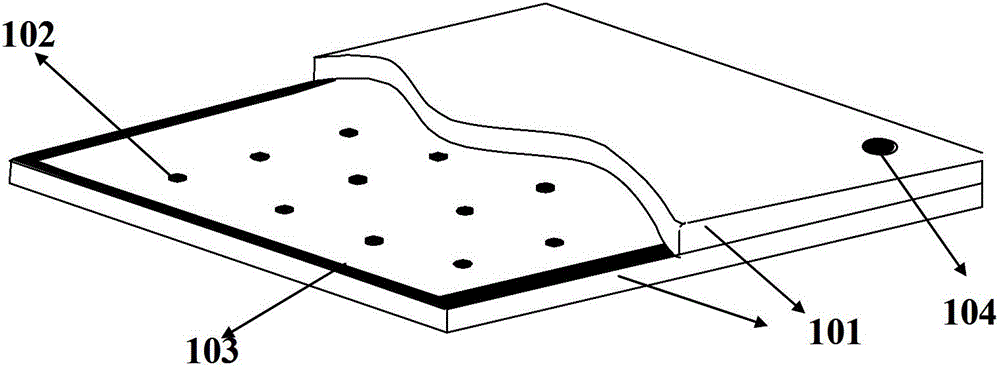

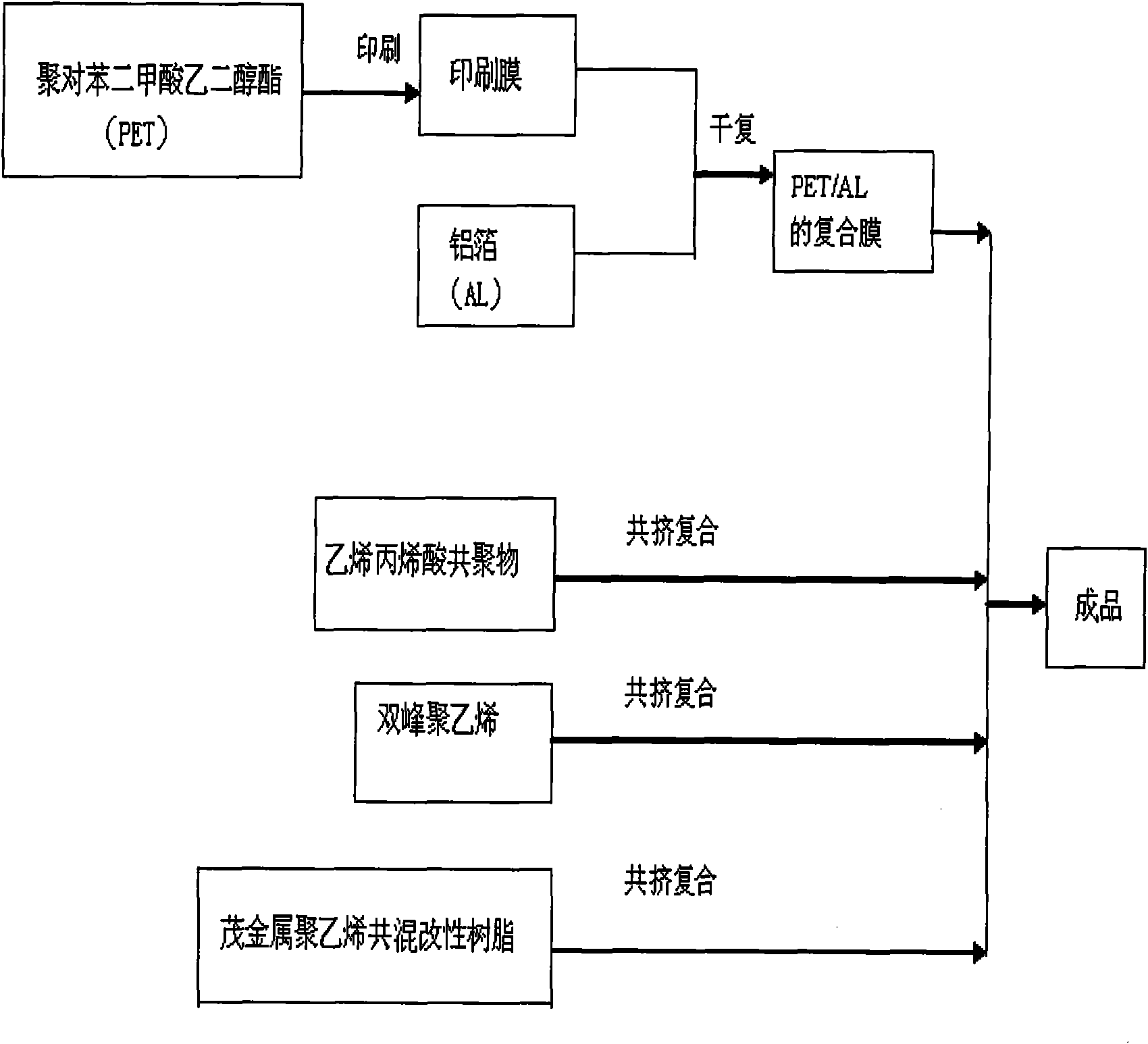

Composite membrane for sauce and preparation method thereof

ActiveCN101624112AGood fragrance retentionGood low temperature heat sealabilityFlexible coversWrappersLow-density polyethylenePolyethylene terephthalate

The invention discloses a composite membrane for sauce and a preparation method thereof. The composite membrane sequentially comprises a polyethylene glycol terephthalate layer, an aluminum foil layer, an ethylene acrylic multipolymer layer, a double-peak low-density polyethylene layer and a metallocene polyethylene blending and modifying resin layer. The preparation method is characterized by comprising the following steps: dry compounding, preparing the metallocene polyethylene blending and modifying resin layer and blending and compounding. Compared with the prior art, the composite membrane for sauce has high sealing strength, short hot seal time, good sealing effect, good sealing planeness, good pollution resistance, medium resistance, low cost, no delamination, and the like.

Owner:HUANGSHAN NOVEL

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Composite temporary plugging agent for refracturing of horizontal well and temporary plugging method

ActiveCN107245330AImprove seal strengthImprove the blocking effectDrilling compositionSealing/packingFiberPolyester

The invention provides a composite temporary plugging agent for refracturing of a horizontal well. The composite temporary plugging agent comprises a component A and a component B, wherein the component A is selected from at least one type of polyester polymers; the component B is selected from at least one type of acrylamide polymers, polymethyl fibers and polyvinyl alcohol. The composite temporary plugging agent has quick temporary plugging and lasting temporary plugging functions.

Owner:北京斯迪莱铂油气技术有限公司

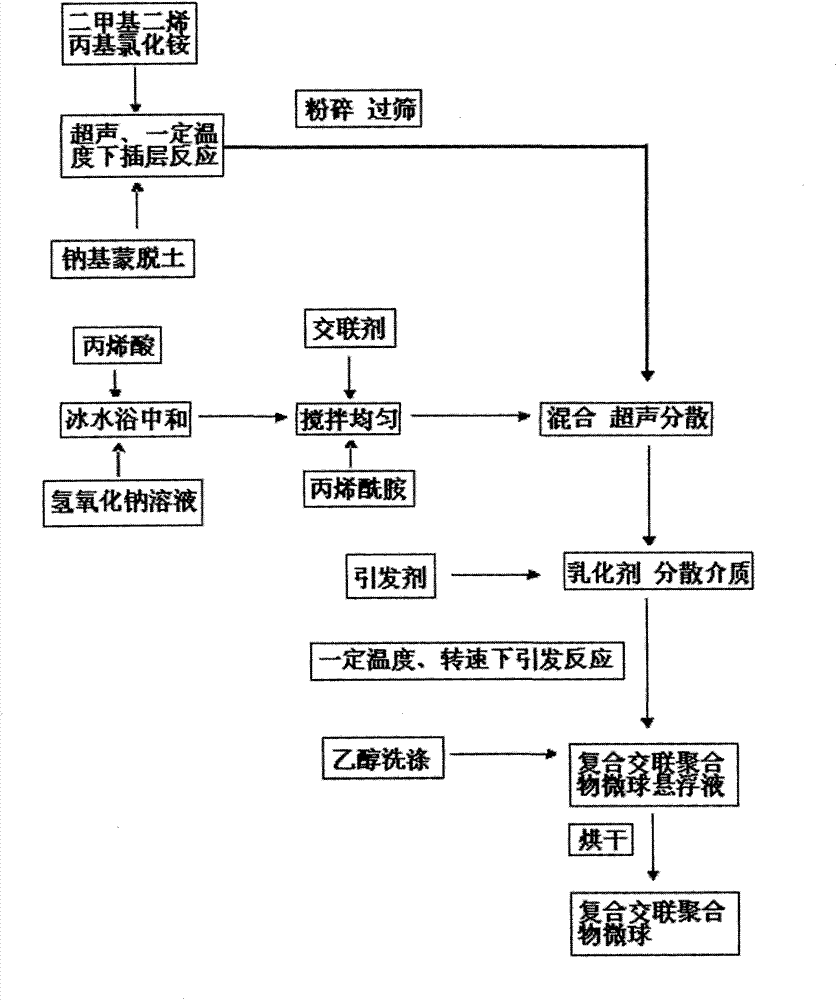

Inorganic montmorillonoid composited cross-linked polymer microsphere as well as preparation method and application thereof

InactiveCN103570859AGood expansion performanceImprove seal strengthDrilling compositionPolymer scienceMicrosphere

The invention discloses an inorganic montmorillonoid composite cross-linked polymer microsphere, which comprises the following components in parts by weight: 0.1 to 10 parts of compound monomer, 10 to 50 parts of crylic acid monomer, 5 to 65 parts of acrylamide, 0.01 to 1 part of crosslink agent and 0.01 to 0.4 part of initiator; the initiator is a mixture of water-soluble initiator and oily initiator, and the compound monomer is the compound monomer of inorganic montmorillonoind and dimethyl diallyl ammonium chloride. The invention also provides a preparation method of the cross-linked polymer microsphere and an application of the prepared cross-linked polymer microsphere which is used as a profile control agent for sealing a high-permeability belt and a large pore in an oil reservoir in the oil field exploitation.

Owner:CHINA PETROLEUM & CHEM CORP +1

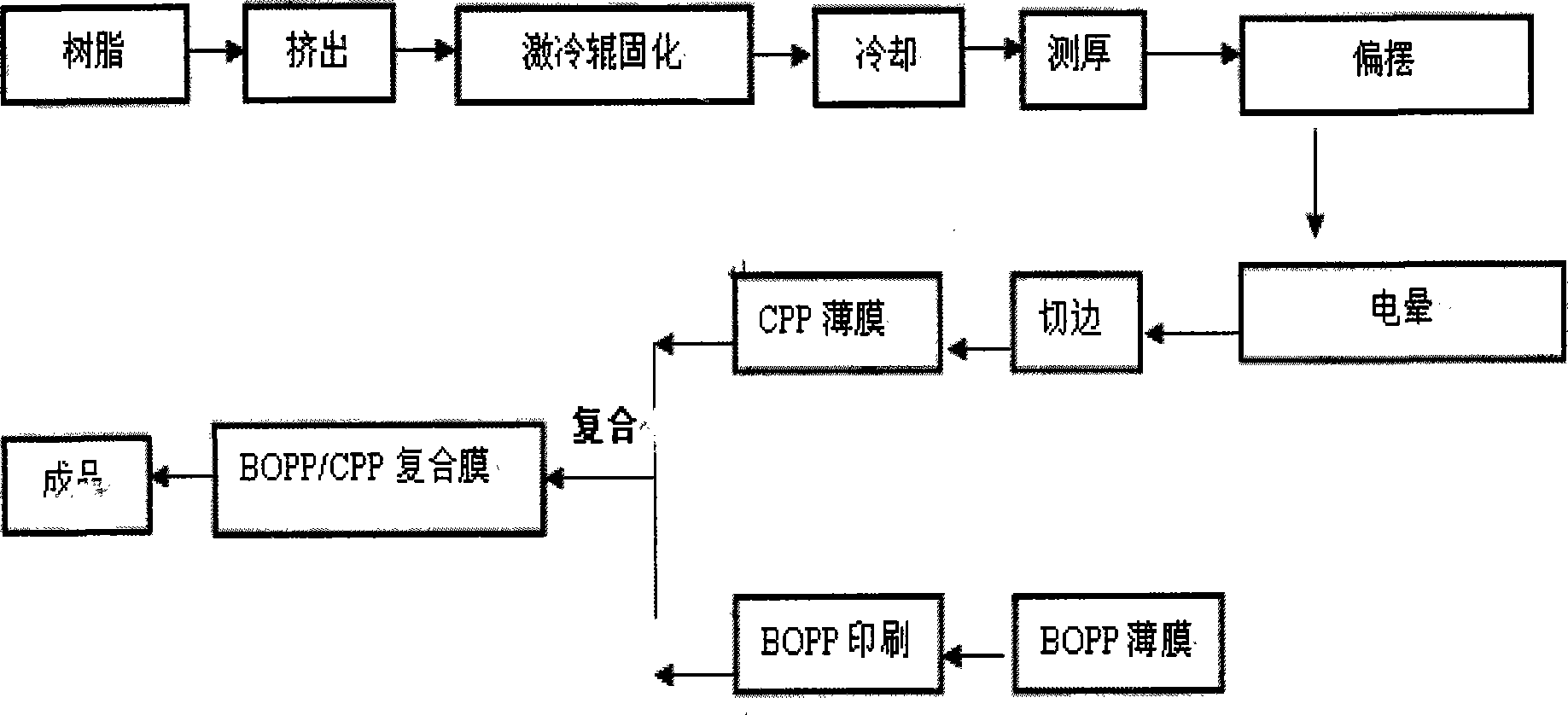

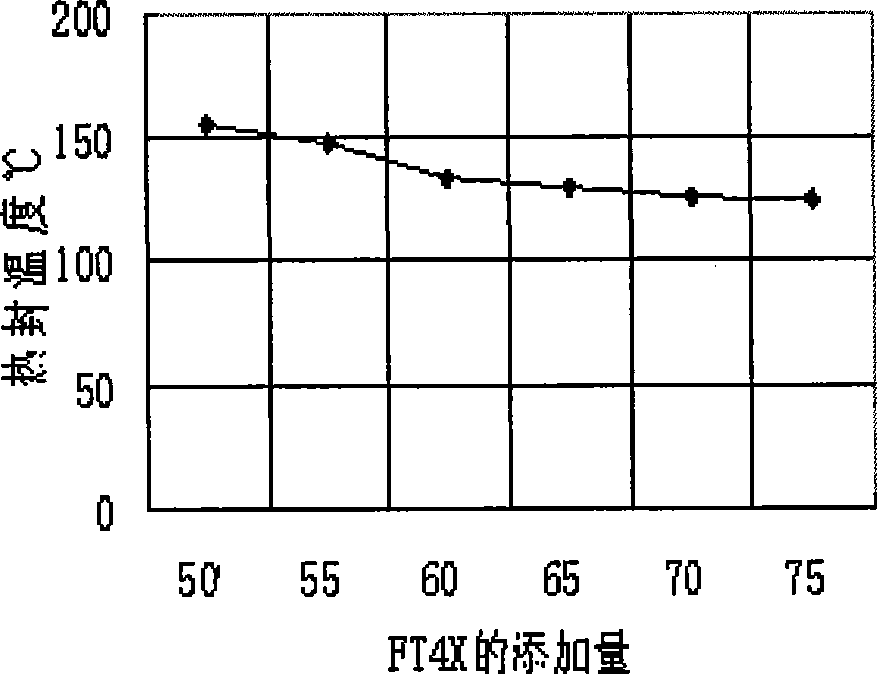

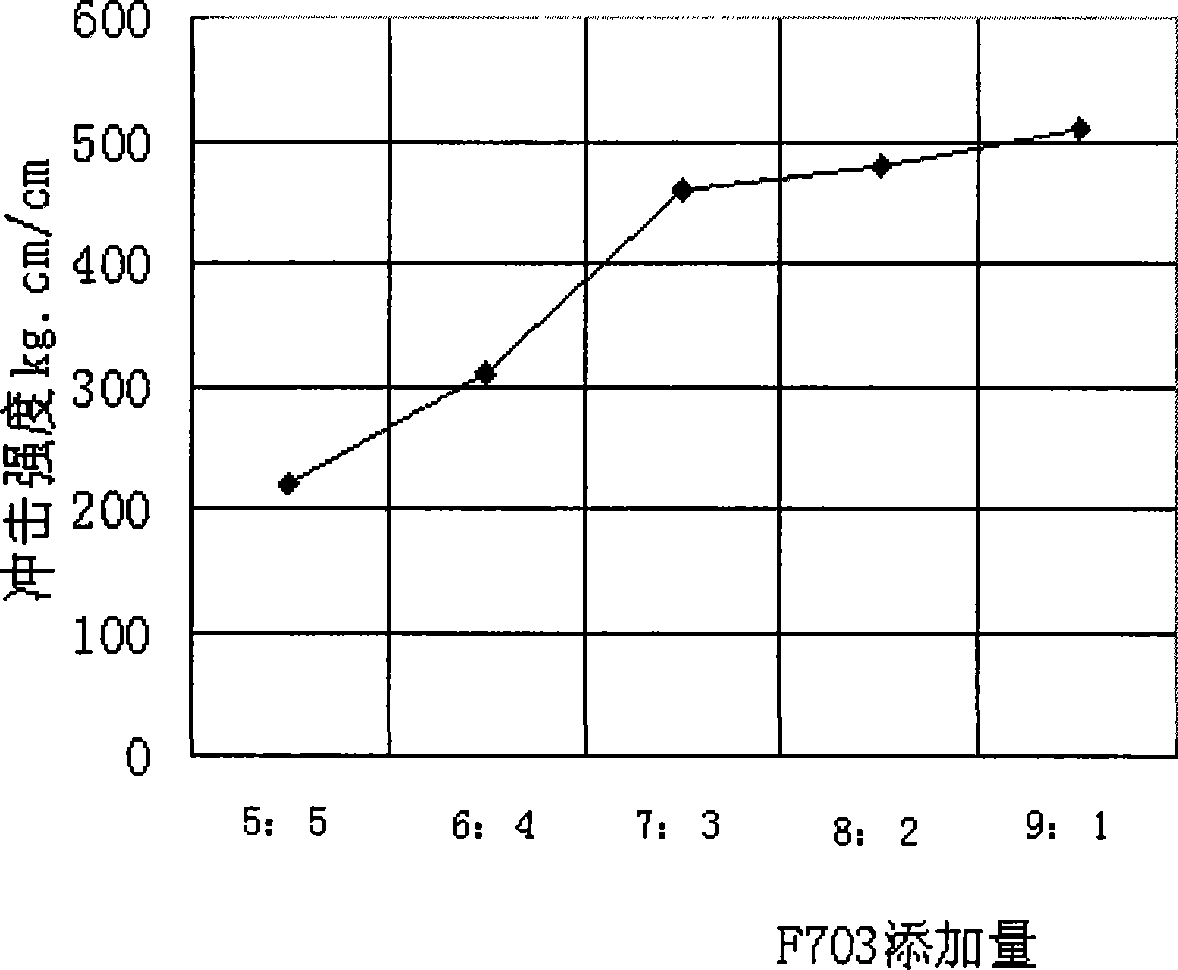

Antifreezing speed-sealing film and preparation method thereof

The invention discloses an anti-freezing film capable of being quickly sealed and a preparation method thereof. The film is formed by composition of biaxial tension polypropylene and a polypropylene film, wherein the polypropylene film consists of a corona layer, an intermediate layer and a heat-sealing layer; the heat-sealing layer comprises metallocene three-element blocking polypropylene, an ethylene elastomer, an antitackiness agent and a slip agent the weight ratio of which is 50-86.5: 18-20: 1-2: 1-1.5. The preparation method comprises the following steps in turn: a step of extrusion, a step of solidifying a sharp cooling roller, a step of cooling, a step of thickness measurement, a step of corona, a step of swing, a step of edge cutting, a step of composition of BOPP and CPP and a step of forming a spiral-wound film through cutting. Compared with the prior art, the anti-freezing film capable of being quickly sealed has the characteristics of good anti-freezing property, cold resistance and mechanical performance, obvious shock resistance effect and penetration resistance effect, low initial sealing temperature, short heat-sealing time and high sealing intensity, and is suitable for a modern quick automatic packaging unit.

Owner:HUANGSHAN NOVEL

High-strength aluminum oxide ceramic metalized paste and preparation method thereof

The invention discloses high-strength aluminum oxide ceramic metalized paste and a preparation method thereof. The metalized paste disclosed by the invention is prepared from the following substances by weight percent: 70-85% of molybdenum powder, 5-15% of manganese powder, 5-15% of Al2O3 powder; 5-10% of silica powder, 0.2-1.2% of calcium oxide, 0.2-1.5% of magnesium oxide, 0.2-1.5% of zirconium oxide powder, and 0.2-1.0% of titanium dioxide powder. The preparation method comprises the steps of respectively putting the substances into an oven according to the ratio; baking for 1-2 hours at the temperature of 100-110 DEG C; putting the molybdenum powder into a ball grinder; adding absolute ethyl alcohol to grind for 24-48 hours; baking at 100-110 DEG C; and putting the manganese powder, the Al2O3 powder, the silica powder, the calcium oxide, the magnesium oxide, the zirconium oxide powder and the titanium dioxide powder into the ball grinder to grind for 4-6 hours; adding the grinded molybdenum powder to grind for 36-48 hours, so as to obtain the mixed powder of the materials; and adding a binder to the mixed powder to grind for 24-48 hours, so as to obtain the metalized paste.

Owner:JINZHOU METAL CERAMICS

Flexible gel particle and flexible gel particle plugging agent prepared from the same

ActiveCN104910882ALow costSimple preparation processDrilling compositionPlasticizerMiddle molecular weight

The present invention provides a flexible gel particle and a flexible gel particle plugging agent prepared from the same. The raw materials for preparing the gel particle comprise, by weight, 6-12wt% of acrylamide, 3-12wt% of temperature tolerant monomer, 5-15wt% of alkali and salt resistant monomer, 0.2-1wt% of partially hydrolyzed polyacrylamide with high and middle molecular weight, 0.02-0.08wt% of an initiator, 0.04-0.1wt% of a crosslinking agent, 0.01-0.1wt% of a retarder, 1-8wt% if a plasticizer and the balance of water. The temperature tolerant monomer includes Si-O bond monomer; the alkali and salt resistant monomer includes acrylate monomer; and the partially hydrolyzed polyacrylamide with high and middle molecular weight has number-average molecular weight of 8-16 million. The flexible gel particle is prepared into a suspension with certain concentration by water or polyacrylamide solution, so as to prepare the flexible gel particle plugging agent. The flexible gel particle plugging agent provided by the invention has the advantages of environment-friendliness, low cost, little pollution to the stratum, no toxicity, and simple preparation process.

Owner:PETROCHINA CO LTD

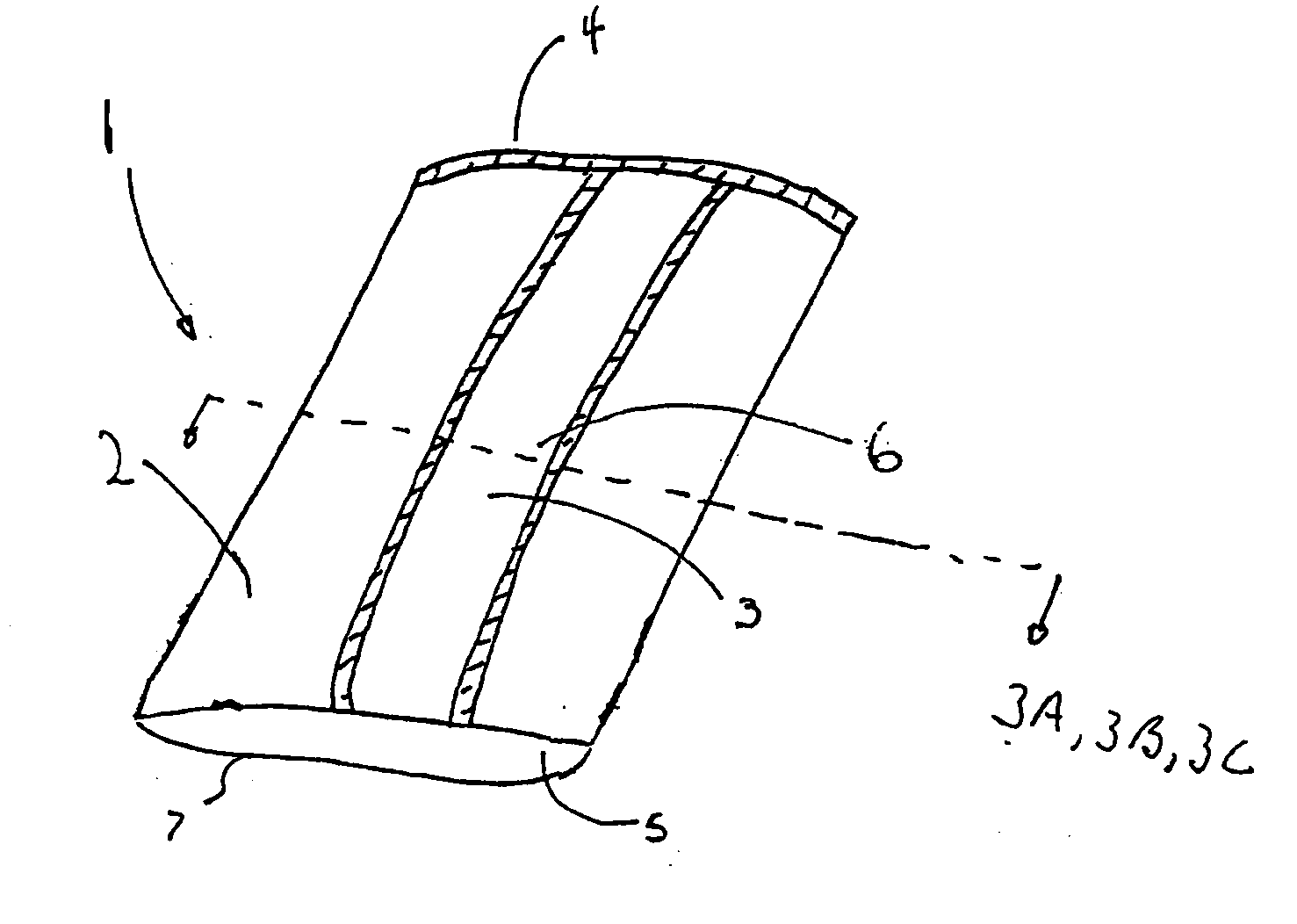

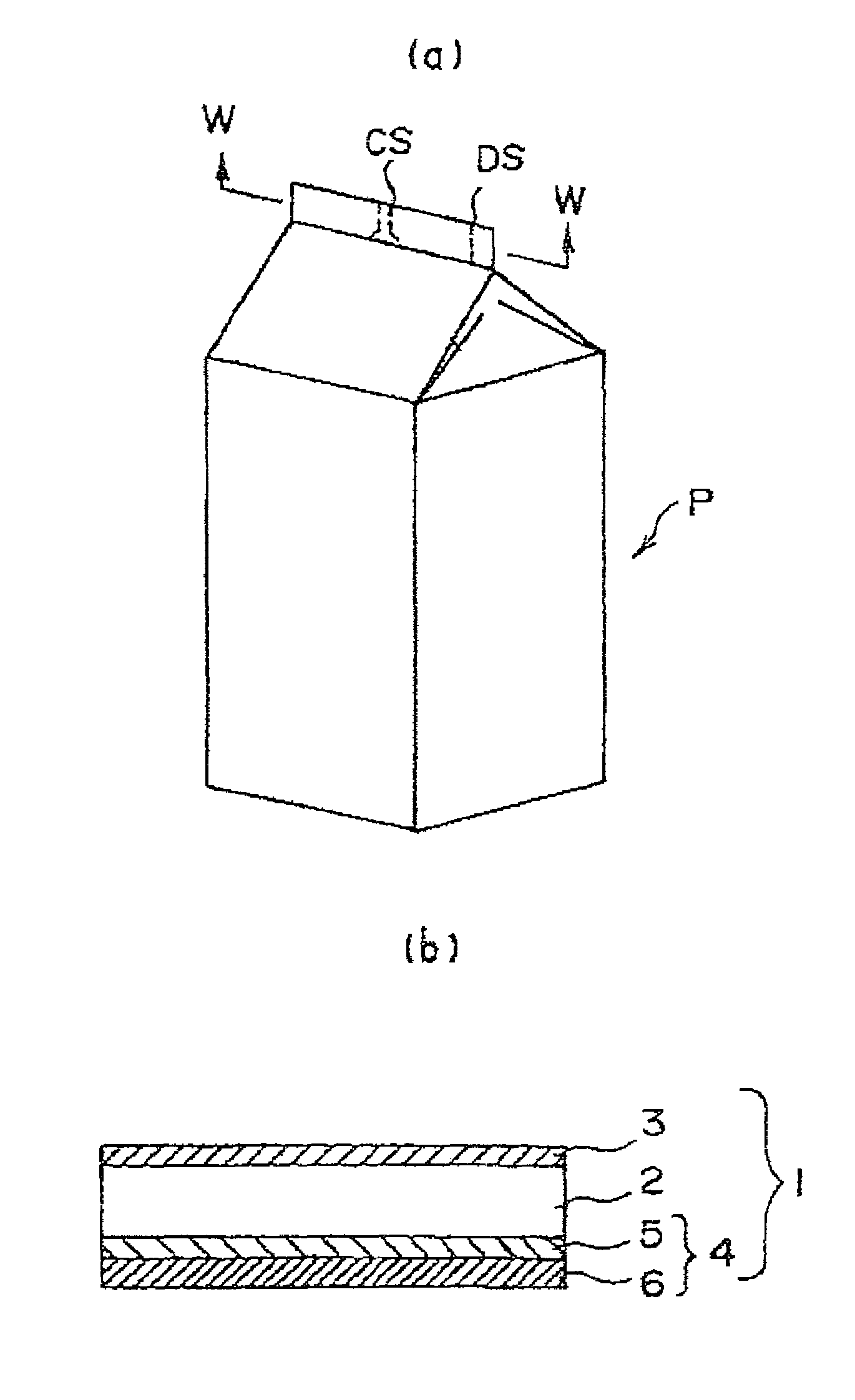

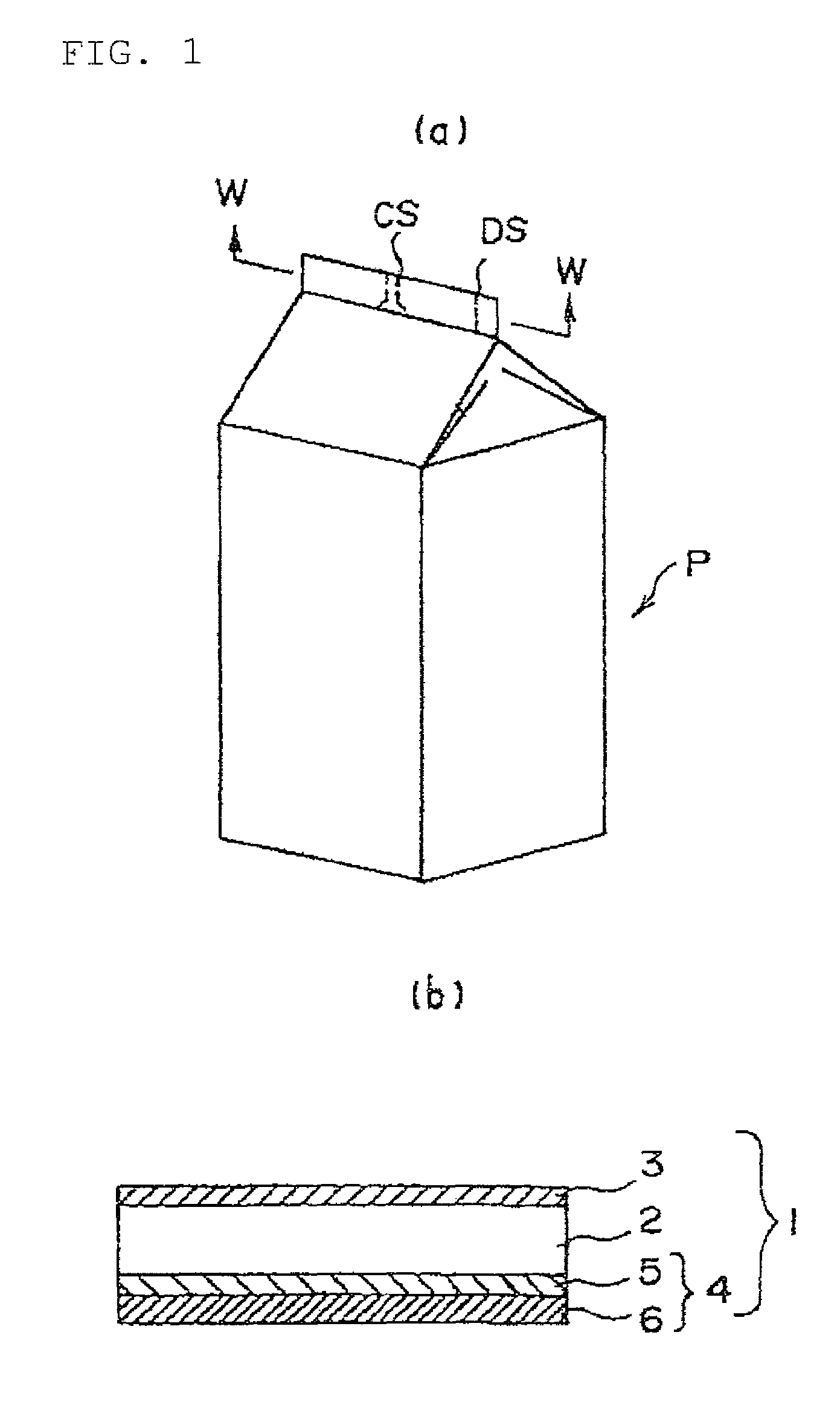

Paper container for liquid

InactiveUS8544718B2Improve propertiesHigh strengthSynthetic resin layered productsThin material handlingLow-density polyethyleneLinear low-density polyethylene

The aim is to provide a paper container for liquid that has a strength to prevent breakage or leakage due to a shock in a long-distance transportation and also has no problems in opening the container when used.This invention is a paper container for liquid which comprises a laminated body which comprises a paper as base material thereof and a heat-sealant layer which is placed inner side of the container than the paper and which comprises a reinforcement layer and a liquid-contacting layer which is the side of contacting the liquid, wherein the reinforcement layer is a layer made of linear low-density polyethylene and the liquid-contacting layer is a layer made of low-density polyethylene and thickness ratio of the reinforcement layer and the liquid-contacting layer (thickness of reinforcement layer 5 / thickness of liquid-contacting layer 6) that form the heat-sealant layer is in the range of 0.2-5. Moreover, it is characterized in that the density of the linear low-density polyethylene is in a range of 0.900-0.945 g / cm3. Furthermore, it is characterized in that the linear low-density polyethylene and the low-density polyethylene are additive-free resins to which no additives have been added.

Owner:DAI NIPPON PRINTING CO LTD

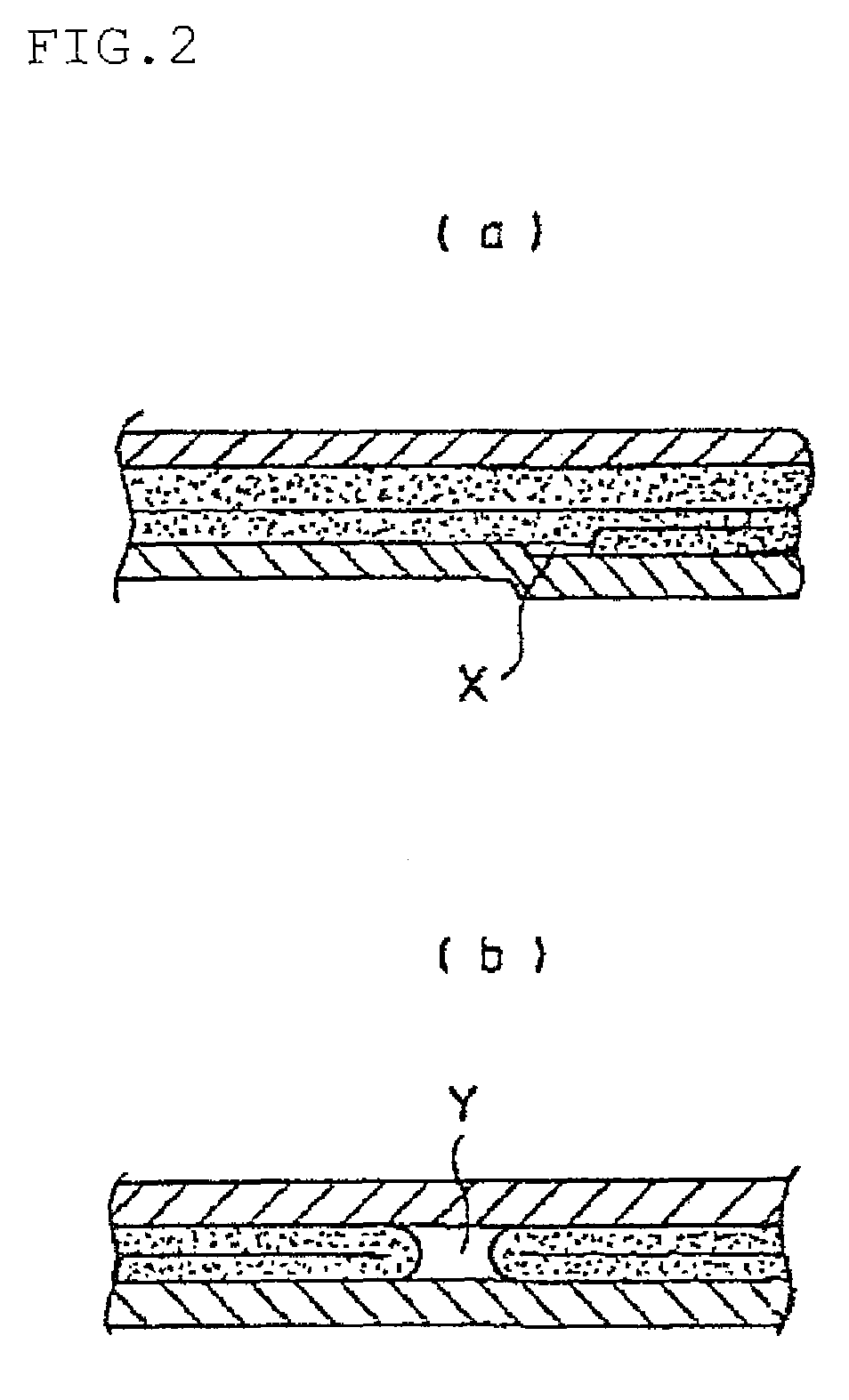

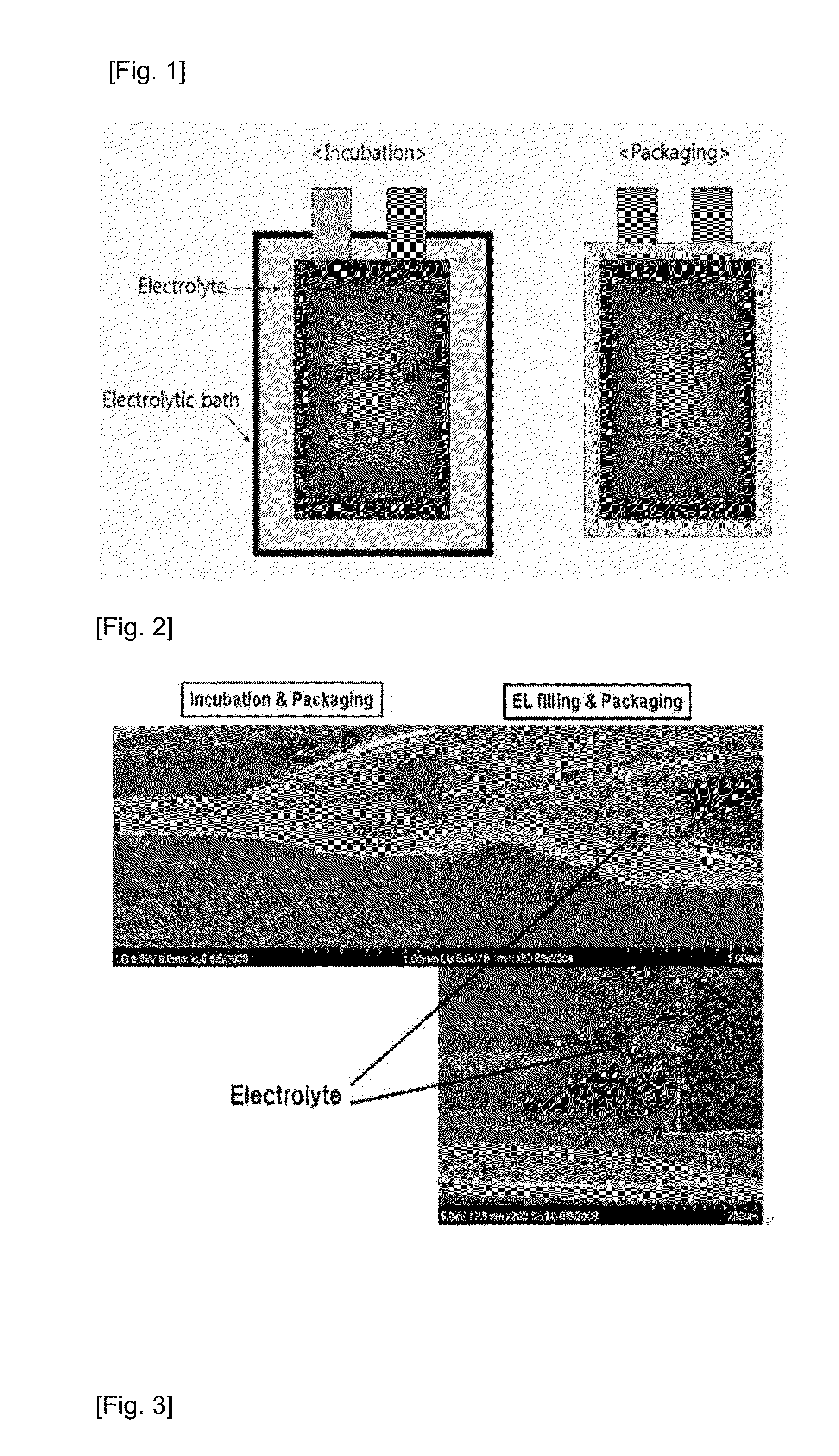

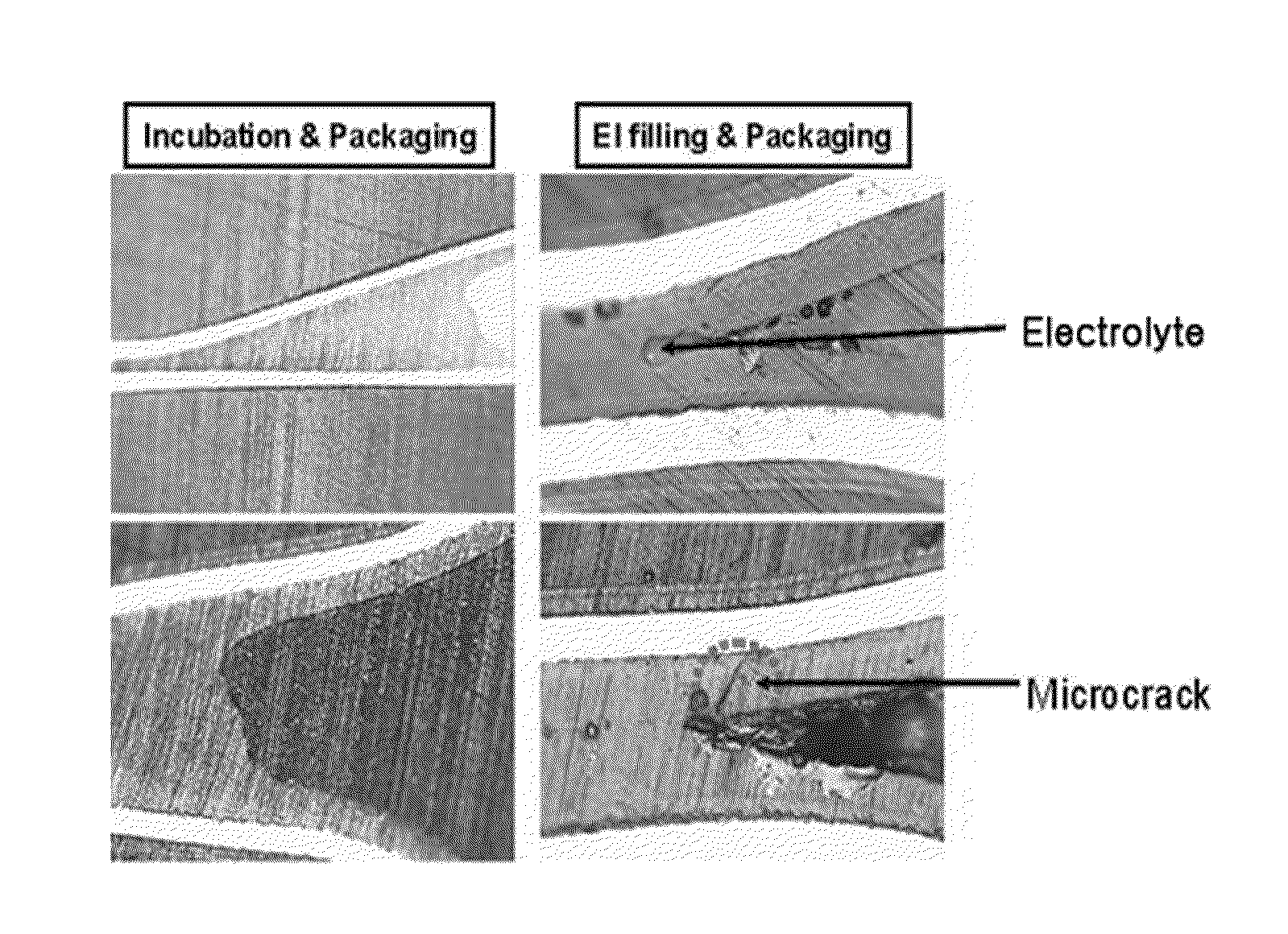

Method for manufacturing lithium ion polymer battery, battery cell, and lithium ion polymer battery including the same

ActiveUS20110097630A1Improve seal strengthLiquid surface applicatorsFinal product manufacturePhysical chemistryLithium-ion battery

A method for manufacturing a lithium ion polymer battery is provided in which in injecting electrolyte into a lithium ion polymer battery, the battery cell is immersed in an electrolyte impregnation bath to allow the electrolyte to be impregnated into the cell. The electrolyte can be impregnated simultaneously, and as the battery cell is activated, the electrolyte is settled down in the interior of the battery cell. Thus, when the battery cell is sealed, a phenomenon that the electrolyte is present at the sealed portion can be prevented.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com