Antifreezing speed-sealing film and preparation method thereof

A technology of film and polypropylene film, which is applied in the field of antifreeze quick-sealing film and its preparation, can solve the problems of inability to play a packaging role, poor mechanical properties of packaging bags, and reduced protection performance of packaging bags, and achieve excellent antifreeze Cold resistance, good shelf effect, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

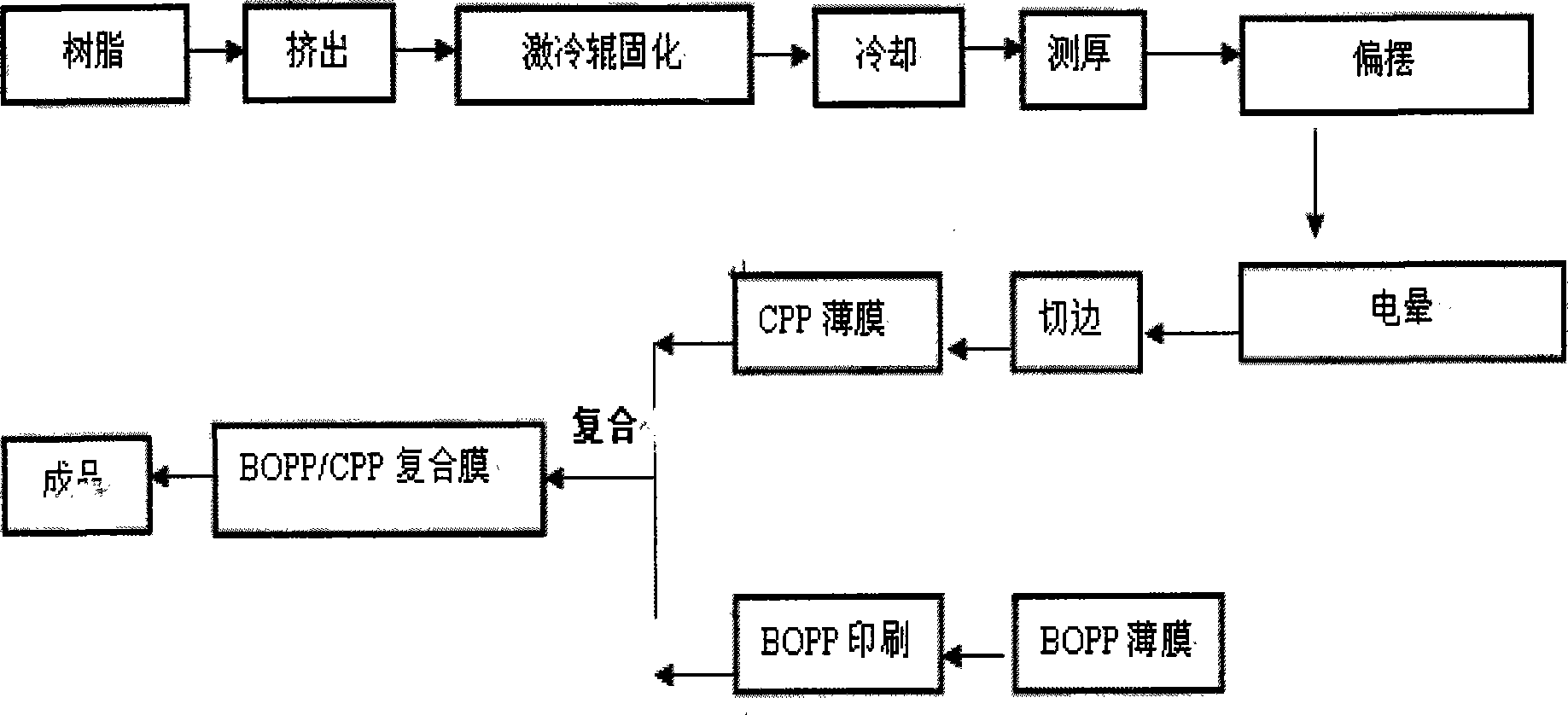

[0068] Extrusion process, chilled roll solidification process, cooling process, thickness measurement process, corona process, deflection process, edge trimming process, compound process of BOPP and CPP, slitting into roll film process, the thickness of CPP film is 40μm.

[0069] In the extrusion process, the temperature of the resin is 220-280°C

[0070] In the cooling and setting process, the temperature of the chilled roll is 20-40°C.

[0071] Traction speed 20-40m / min

[0072] In the lamination process, lamination is carried out by a dry lamination machine, the operating concentration of the adhesive used is controlled at No. 3 Zahn cup for 17 seconds, the drying temperature is 70°C, and the speed of the lamination machine is 130m / min.

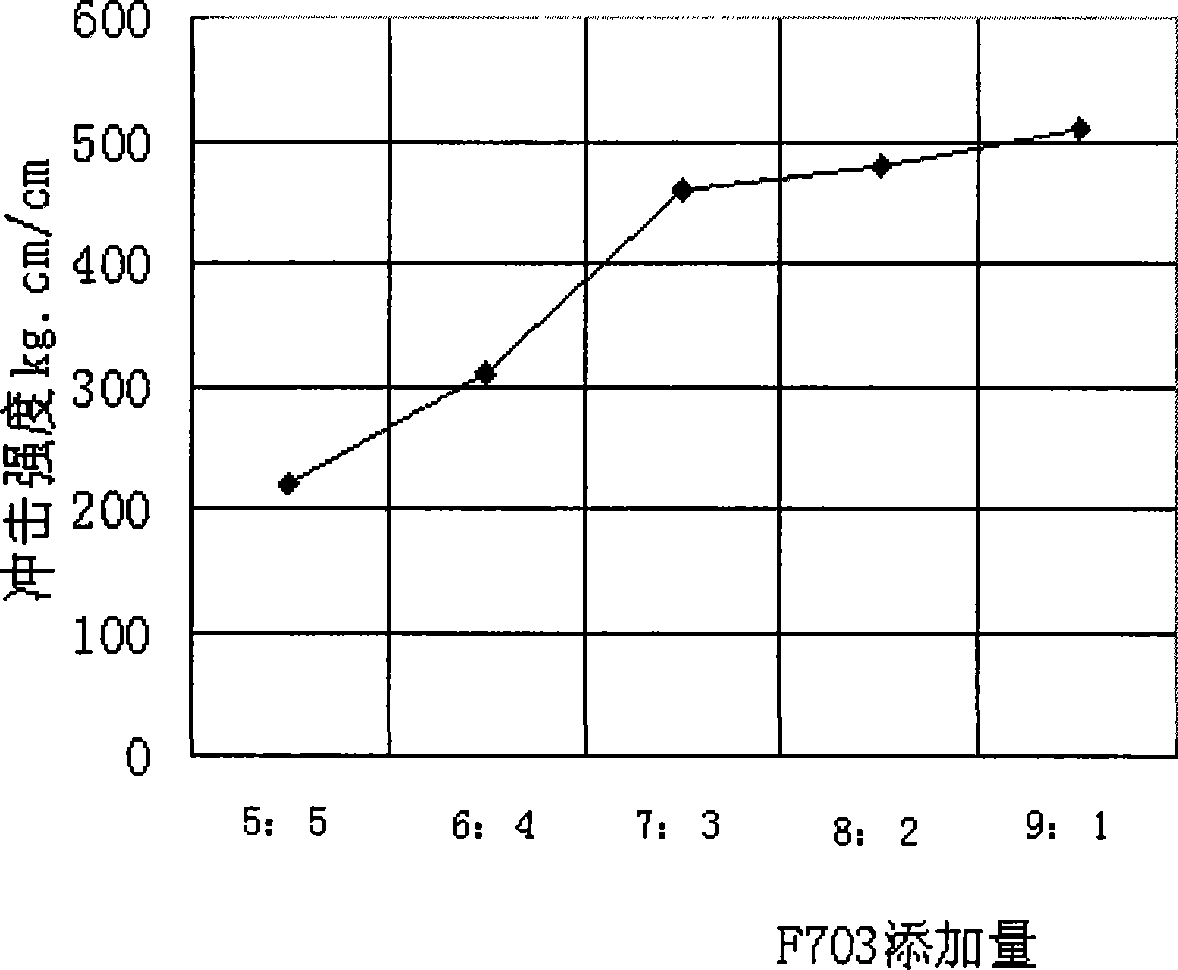

[0073] The resin of the corona layer is a mixed resin of F703 and A-4085S, and the weight ratio of F703 and A-4085S is 9:1;

[0074] The resin of the middle layer is a mixed resin of BC3HF and A-4085S, and the weight ratio of BC3HF and A...

Embodiment 2

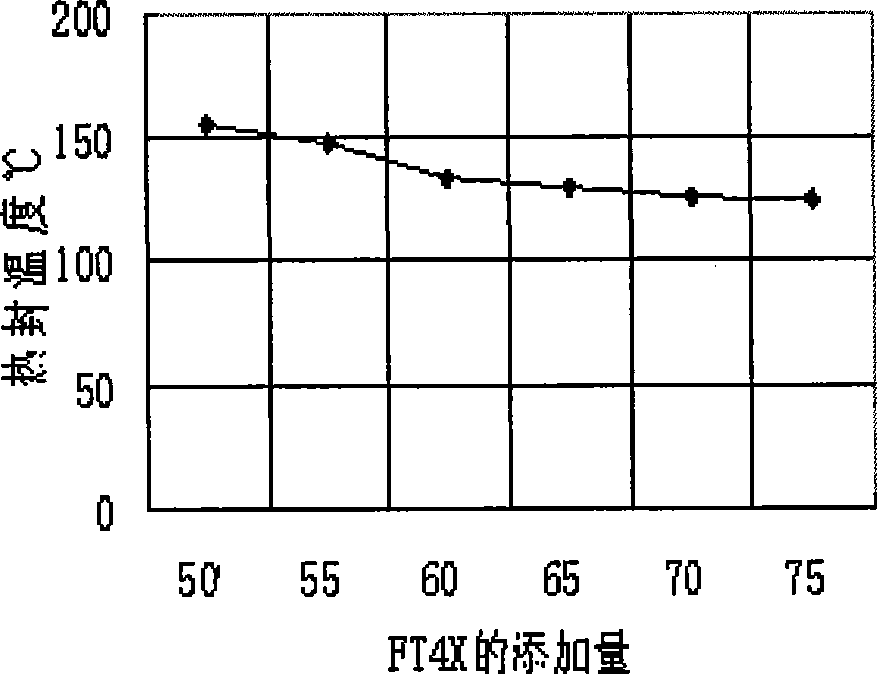

[0079] Except that the weight ratio of FX4T, A-4085S, ABPP10S, and SL07PP in the resin of the heat-sealing layer is 50:20:2:1.5, the rest is the same as that of Example 1.

Embodiment 3

[0081] Except that the weight ratio of FX4T, A-4085S, ABPP10S, and SL07PP in the resin of the heat-sealing layer is 55:20:2:1.5, the rest is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com