Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

646 results about "Roll film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rollfilm or roll film is any type of spool-wound photographic film protected from white light exposure by a paper backing, as opposed to film which is protected from exposure and wound forward in a cartridge. The term originated in contrast to sheet film. Confusingly, roll film was originally often referred to as "cartridge" film because of its resemblance to a shotgun cartridge.

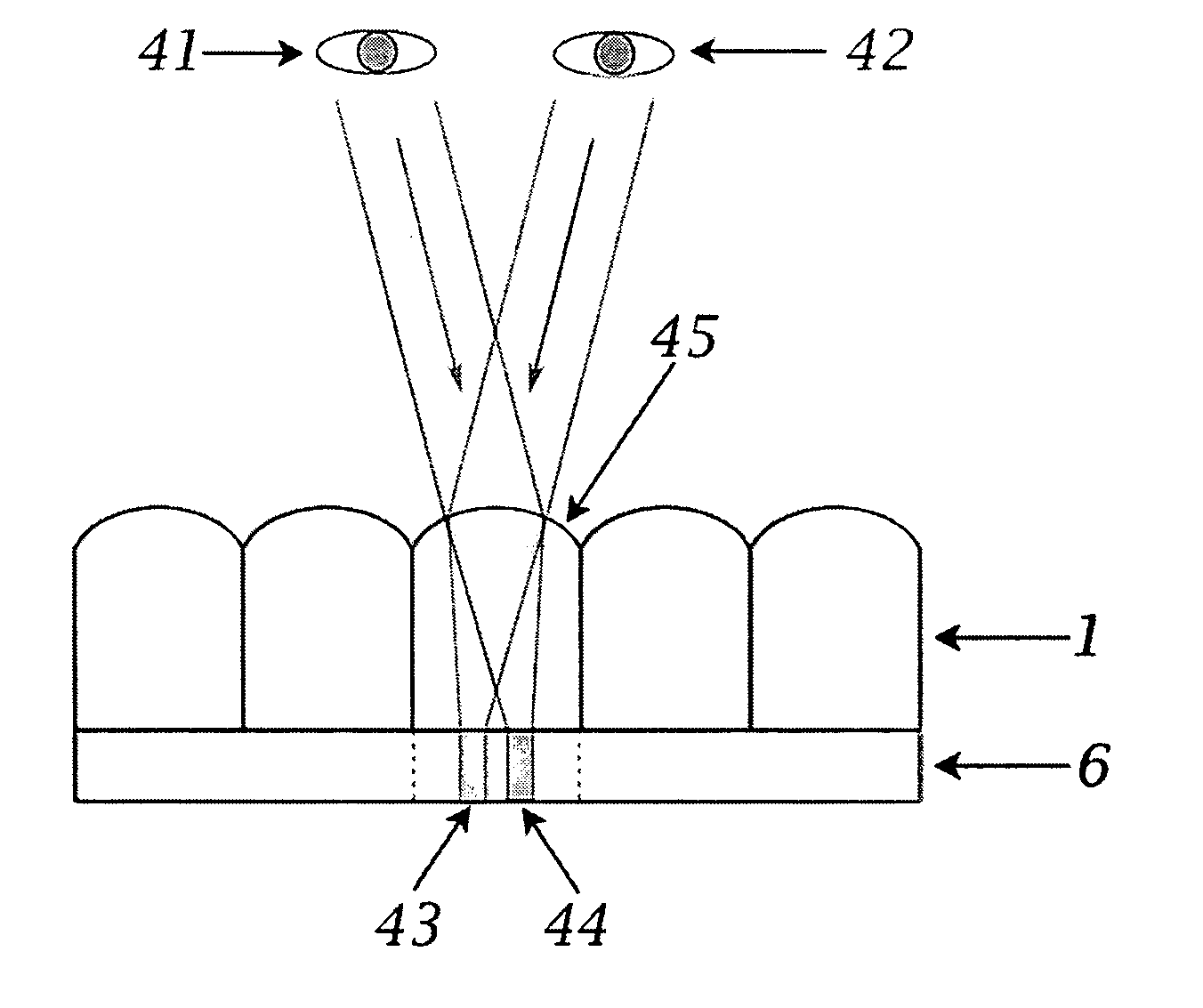

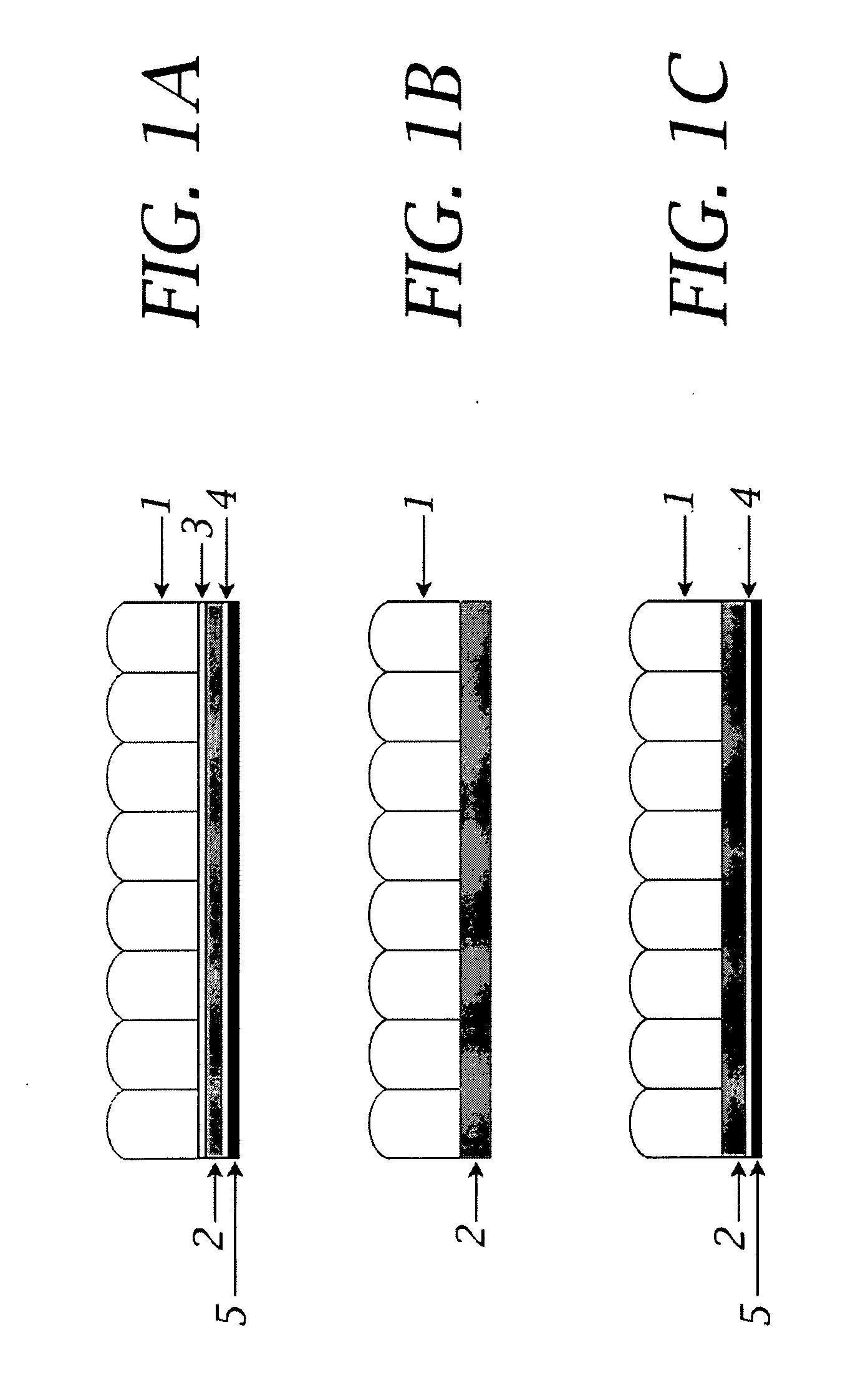

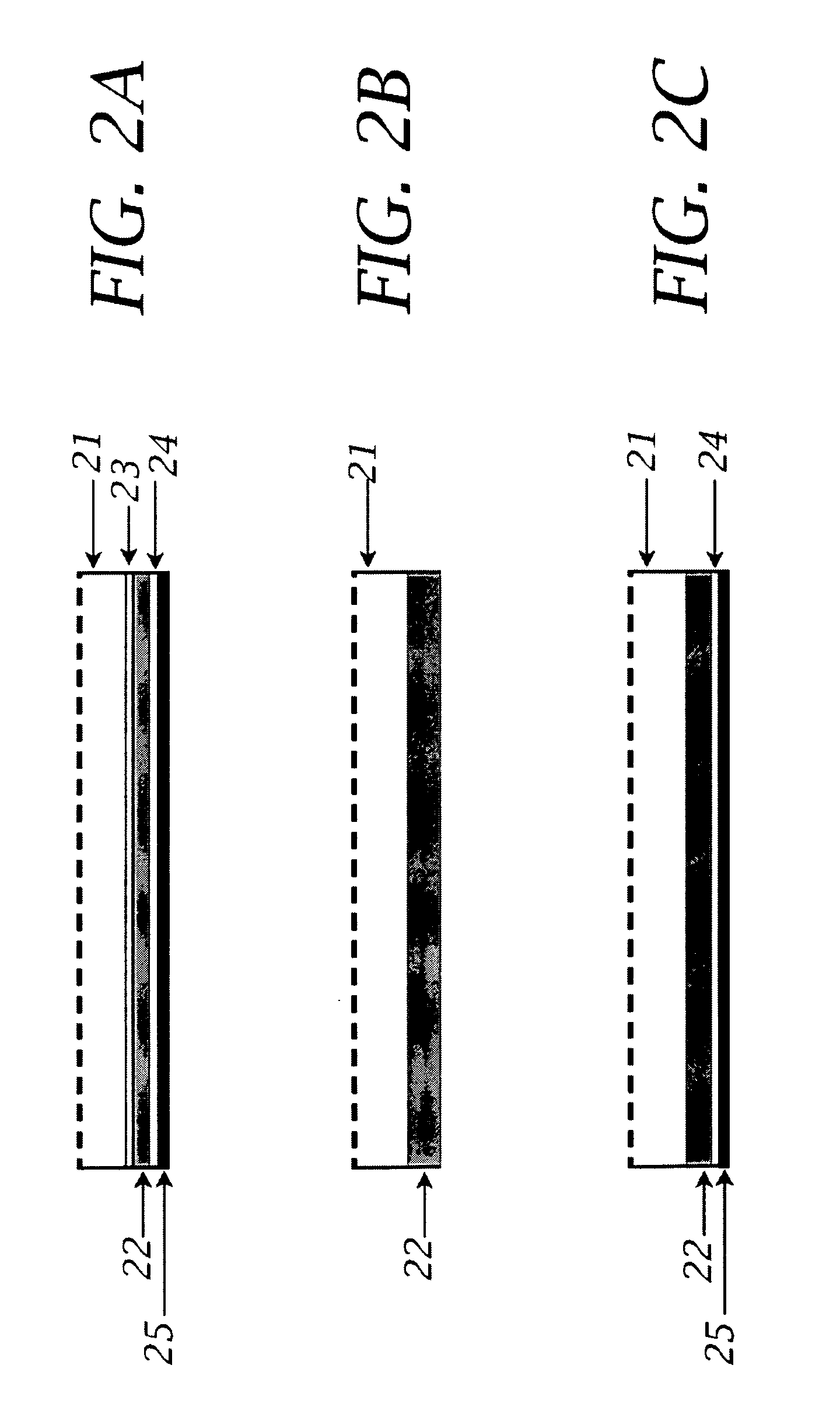

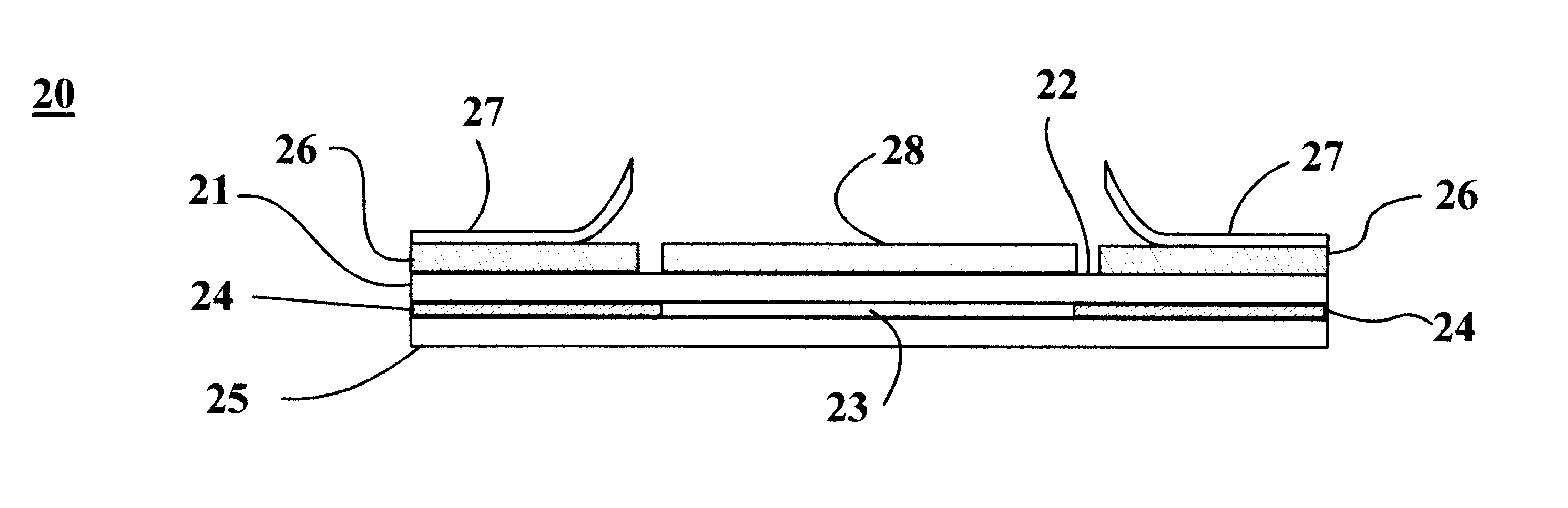

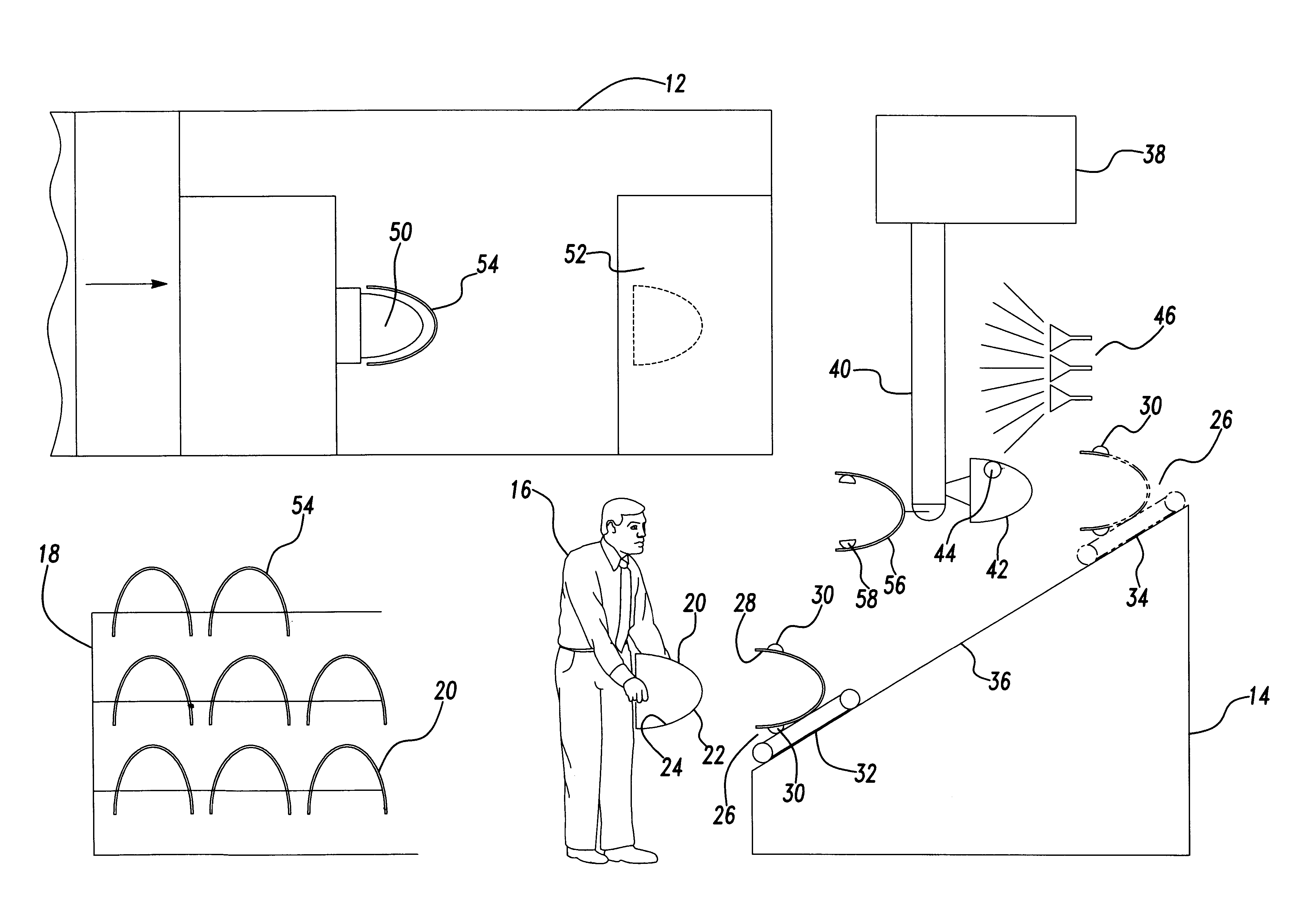

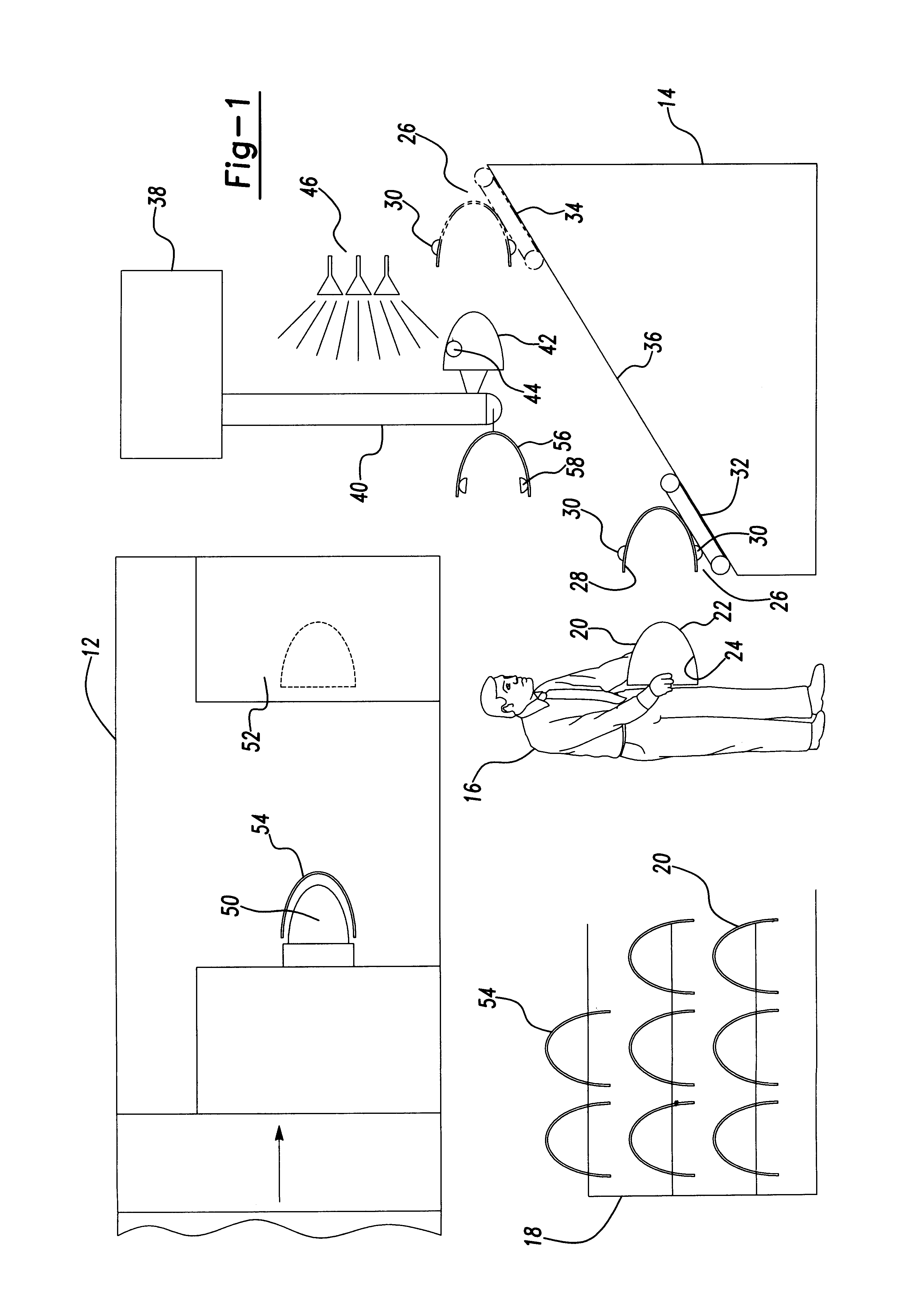

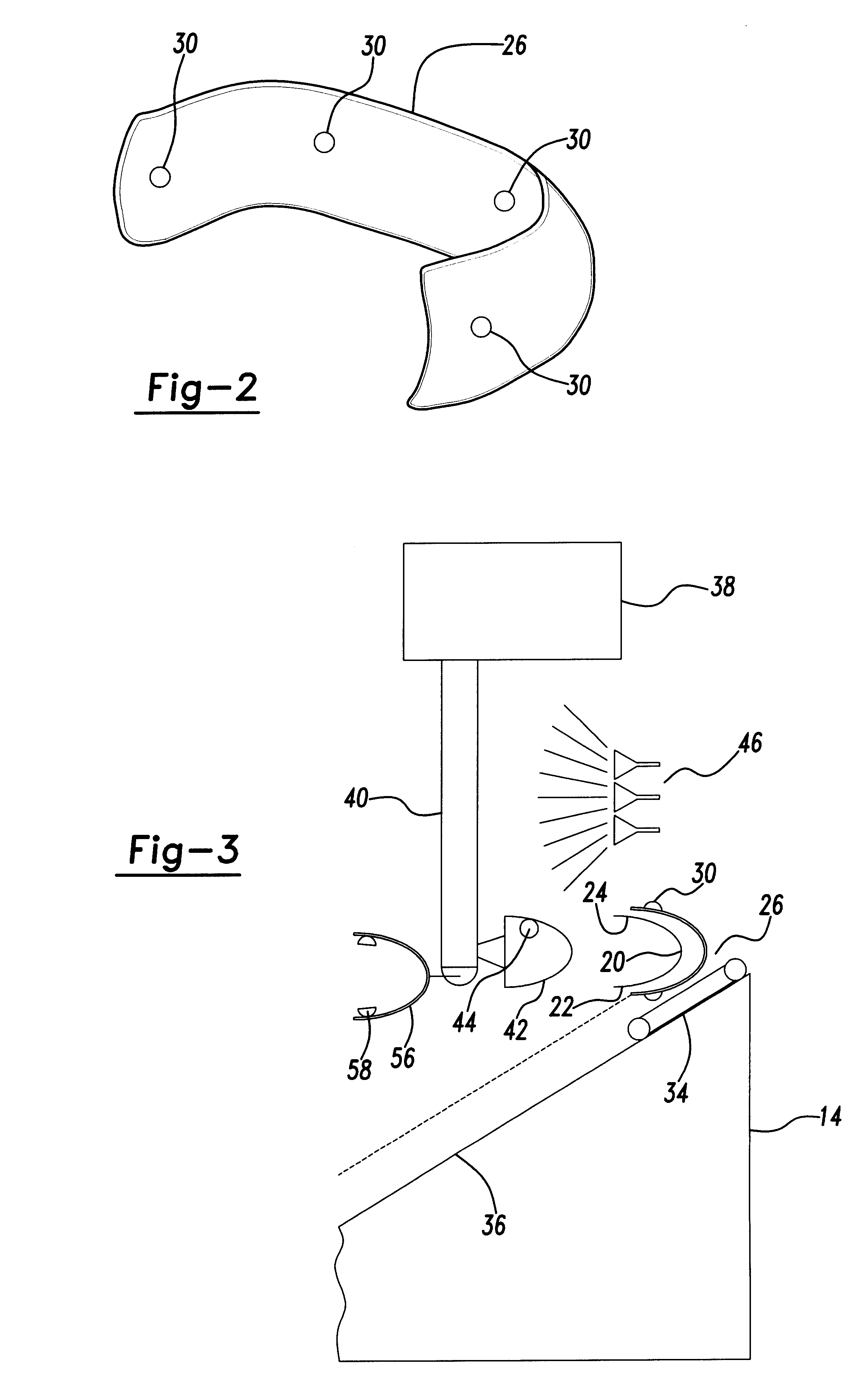

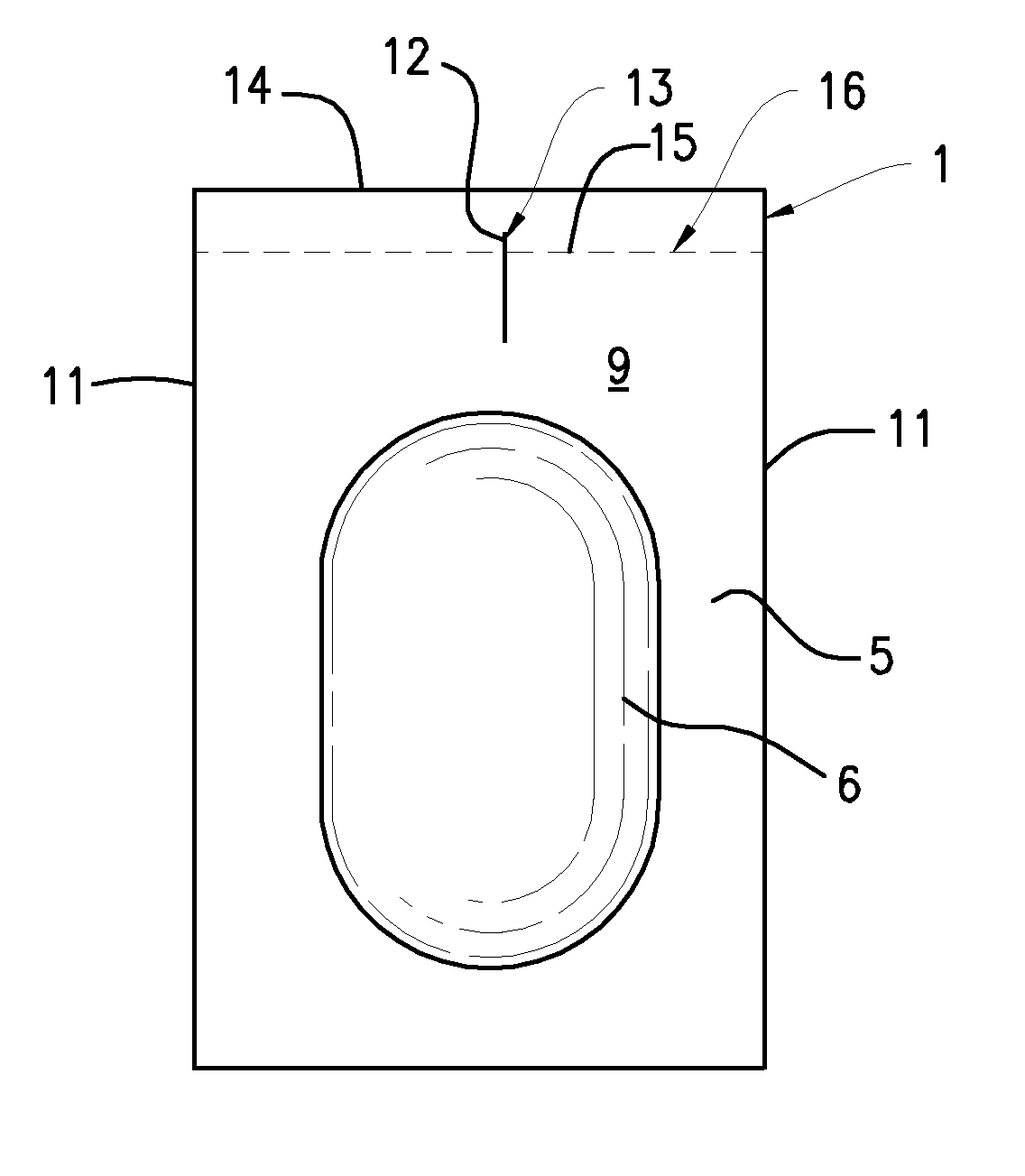

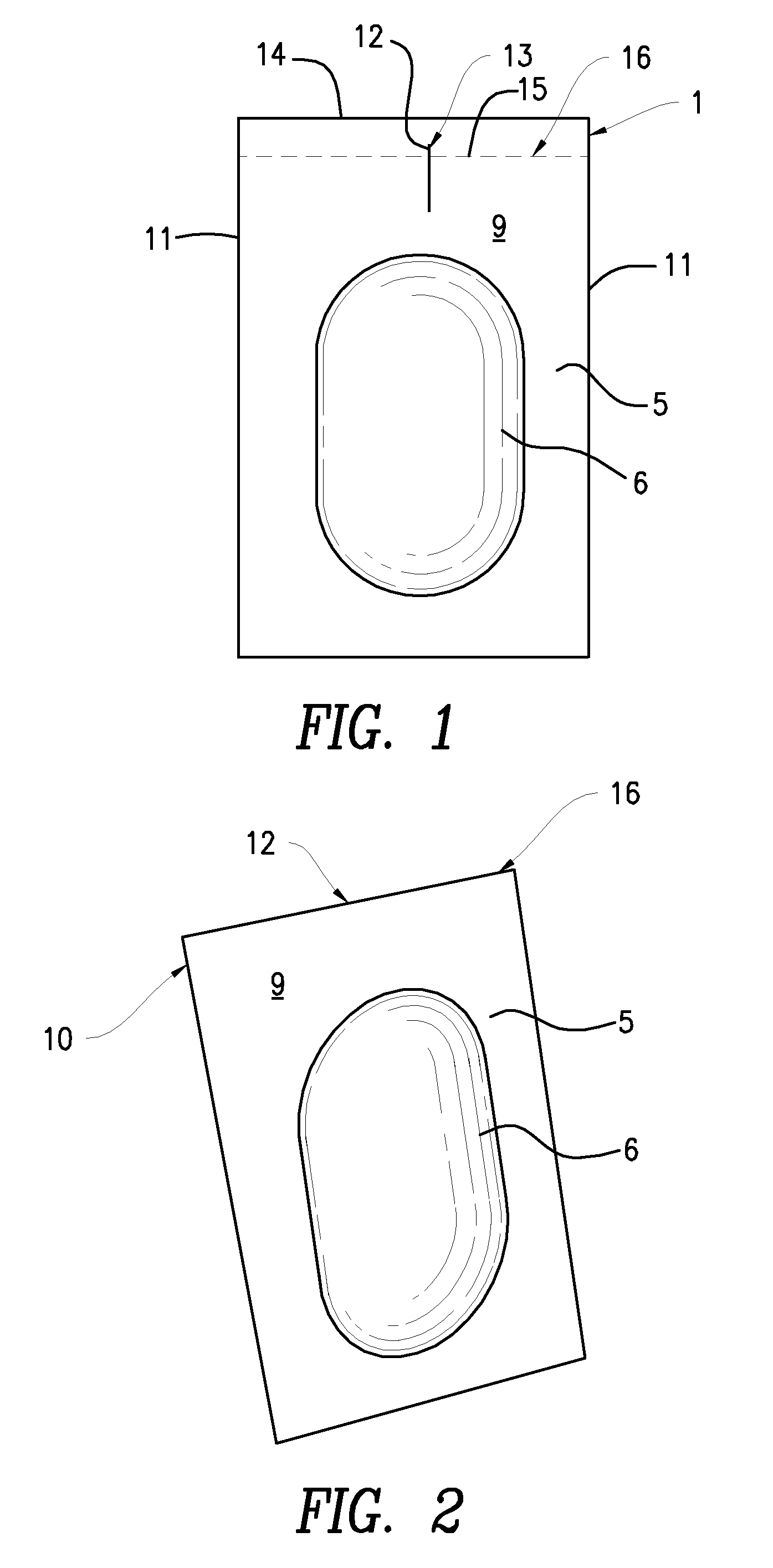

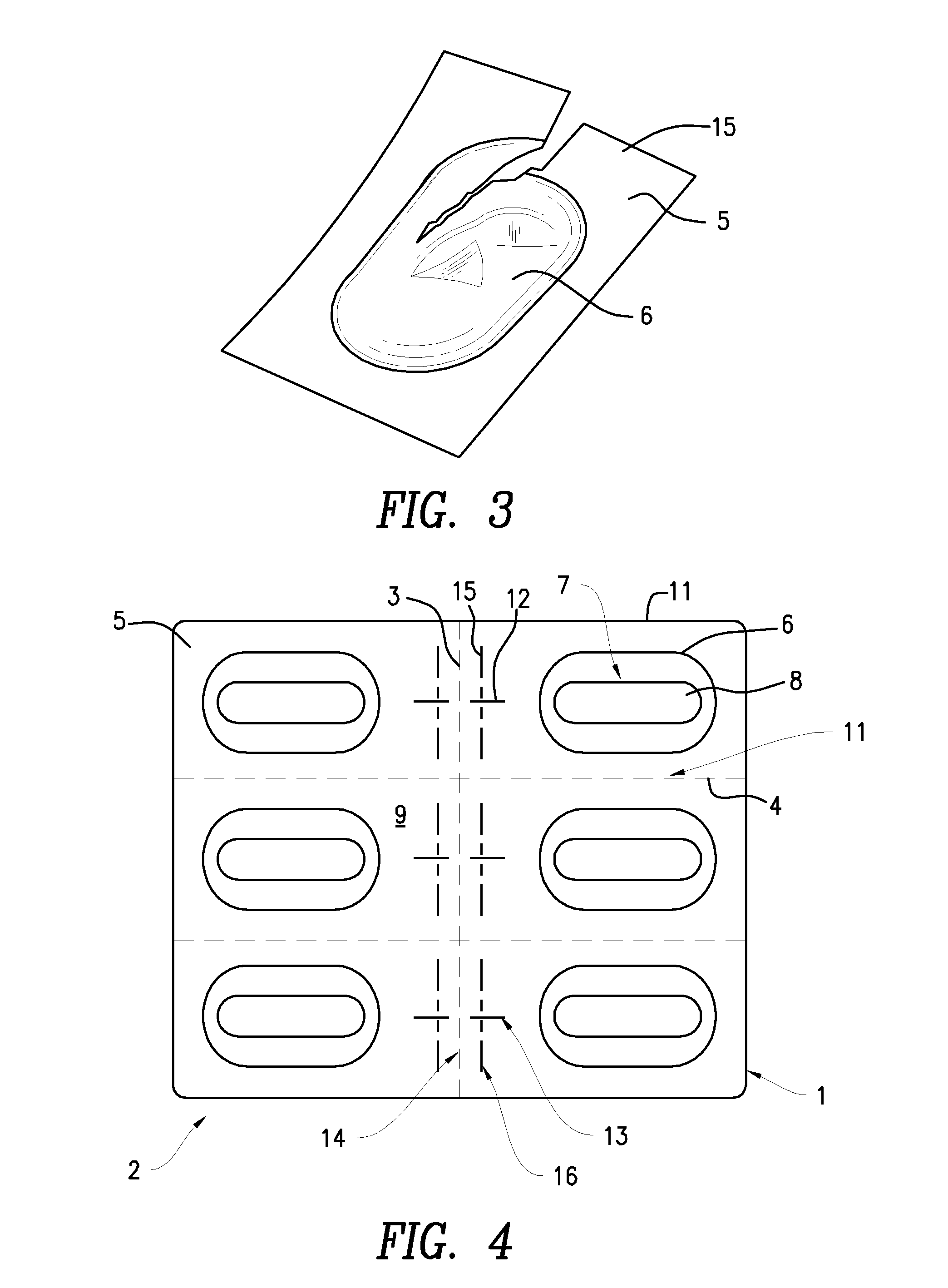

Method and system for automated production of autostereoscopic and animated prints and transparencies from digital and non-digital media

InactiveUS20060023197A1Correct keystone distortionStereoscopic photographyPhotographic printingComputer printingDisplay device

A method and system for automated production of stereoscopic and animated images and hardcopies can utilize a light-sensitive lenticular material employing a conventional or non-conventional photographic emulsion or an instant-developing material. An automated printer can produce autostereoscopic and animated hardcopies in multiple formats from digital and non-digital sources, including single images, stereopairs, and multiple-image sets of negatives, transparencies, or prints. The printer, which includes a projection device and a material plate that can rotate around two perpendicular axes, can utilize software to automate viewing angle calculation, printer control, multiple-image alignment, distortion correction, and image processing and conversion. A digital camera can capture stereoscopic and animated images and record them digitally or on photographic film. A non-digital camera can record stereoscopic and animated images directly onto light-sensitive lenticular material employing a conventional or non-conventional photographic emulsion or an instant-developing material. The printer and cameras can utilize autostereoscopic monitors to preview parallax.

Owner:VOLUGRAPHICS

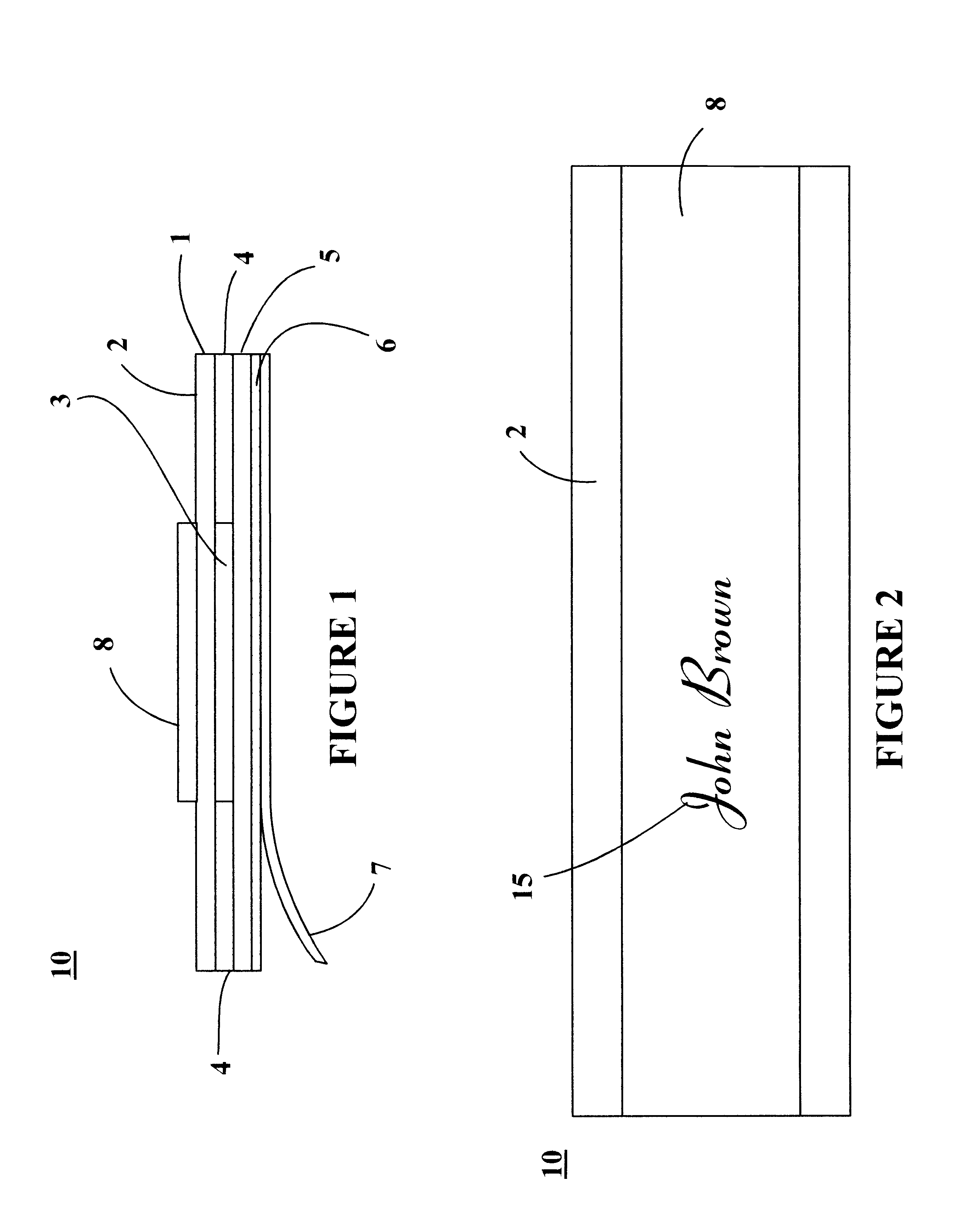

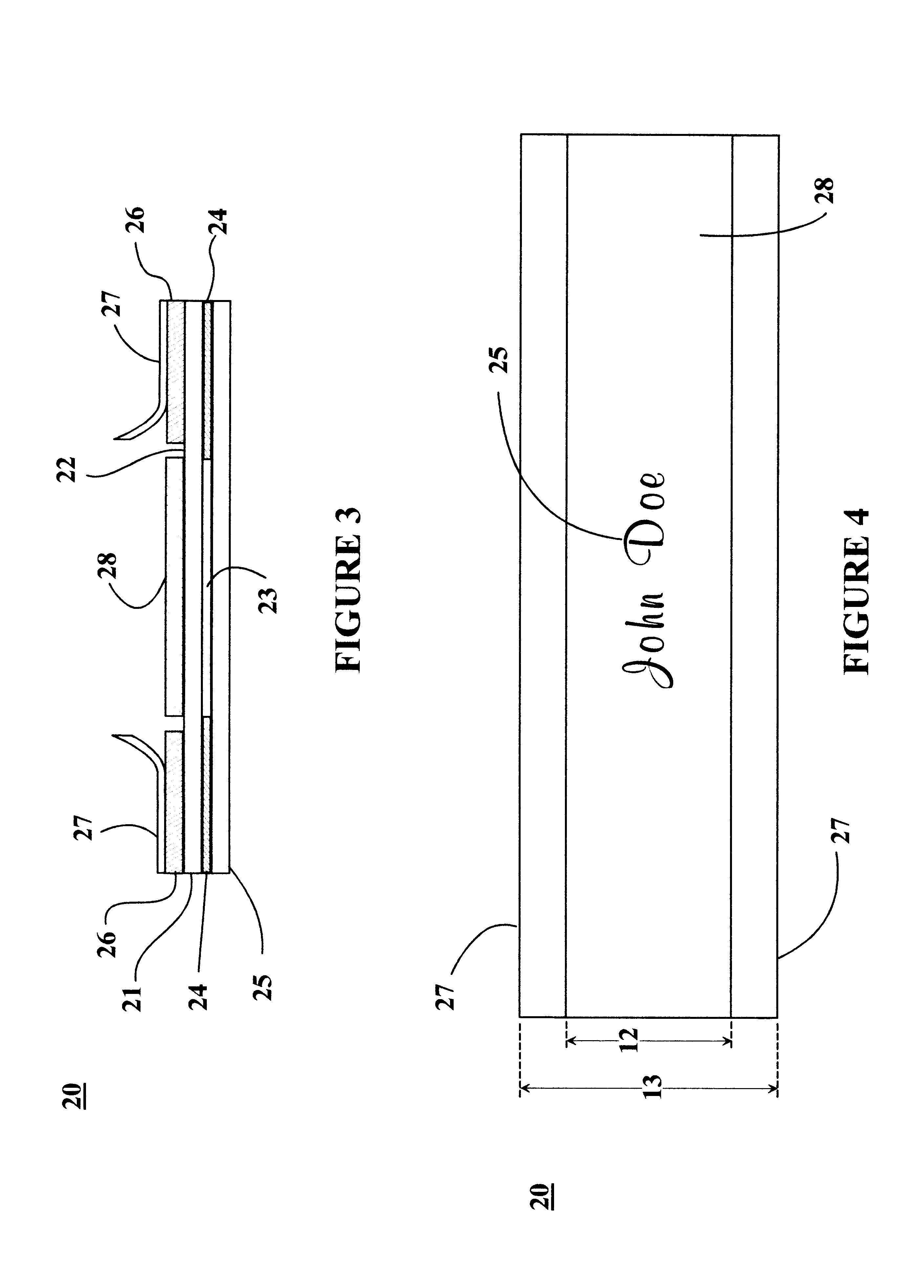

X-ray labeling tape

A marking tape for transferring information written thereon to a film when the film is exposed to x-rays. The tape is a laminate of an upper film, a radiopaque emulsion, and a lower film. The top surface of the upper film is partially coated with a writable ink, and the ink coating positioned directly over the radiopaque emulsion. Pressure exerted by the user while writing on the ink surface causes the underlying emulsion to part. When the marking tape is affixed to a film cassette, x-rays penetrate the marking tape in those areas where the emulsion has been parted, the underlying film is exposed, and the information entered on the marking tape is thereby transferred to the film. The marking tape can be made in different sizes and radiopacities that can be distinguished by color-coding the writable surface.

Owner:DESENA DANFORTH

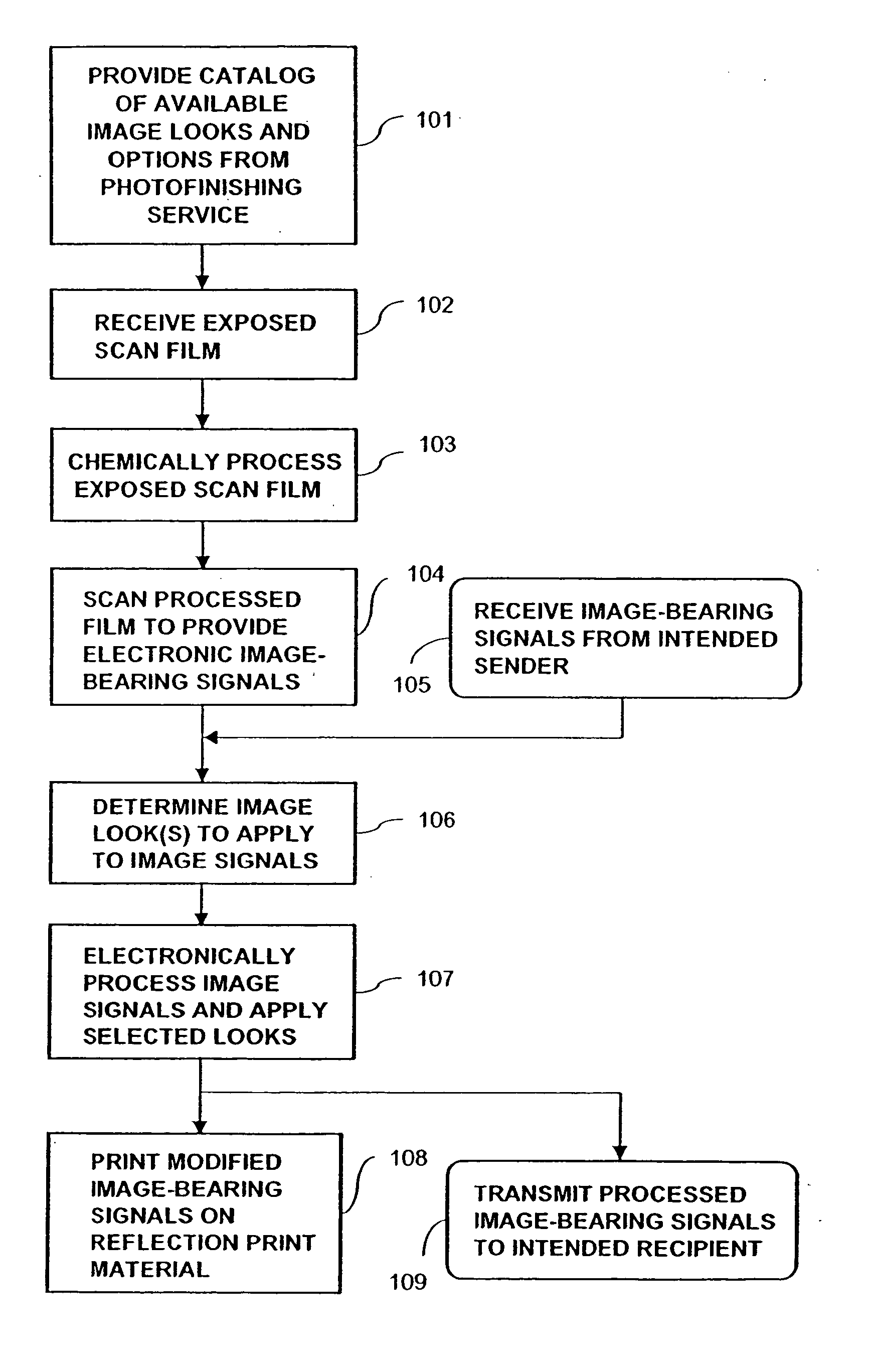

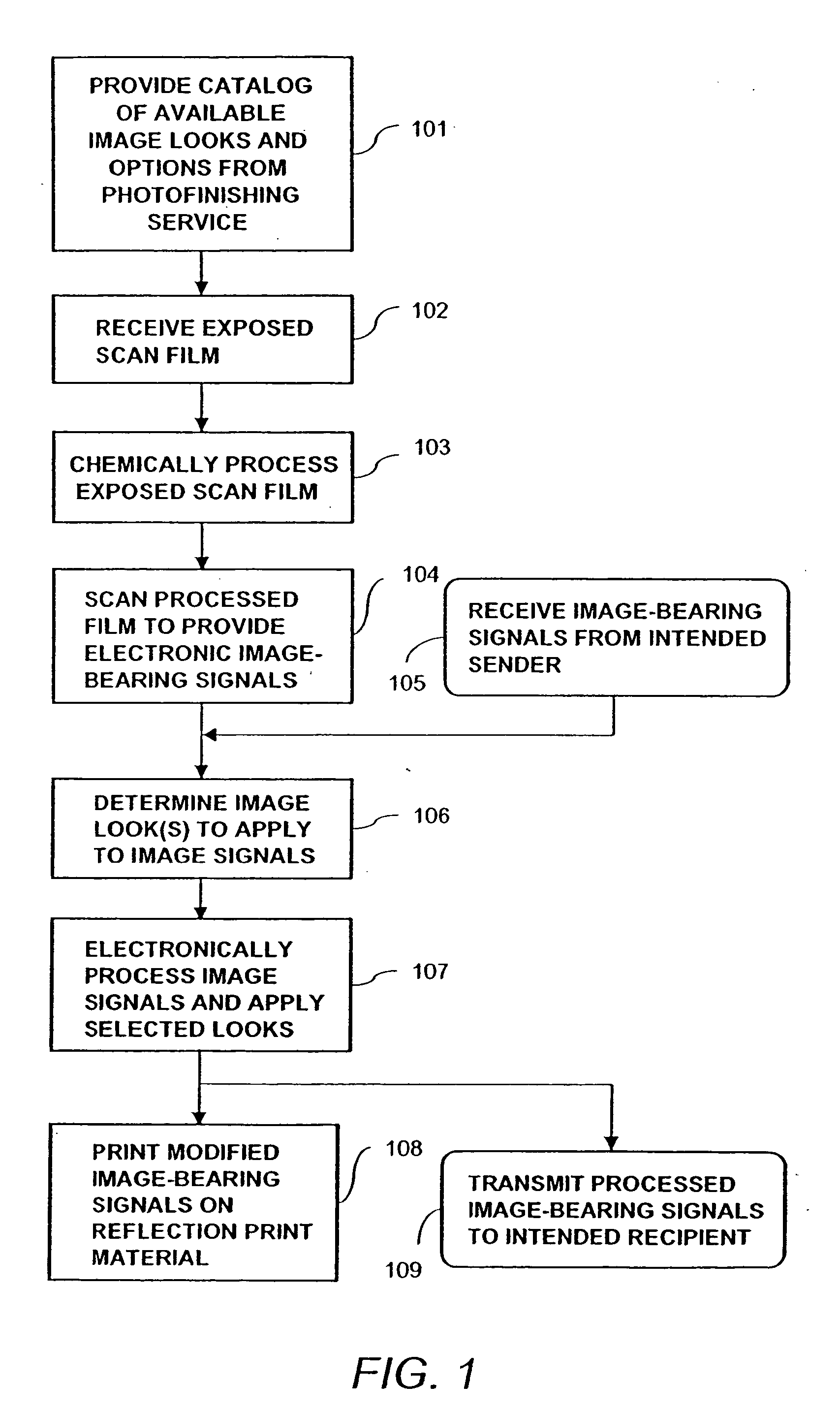

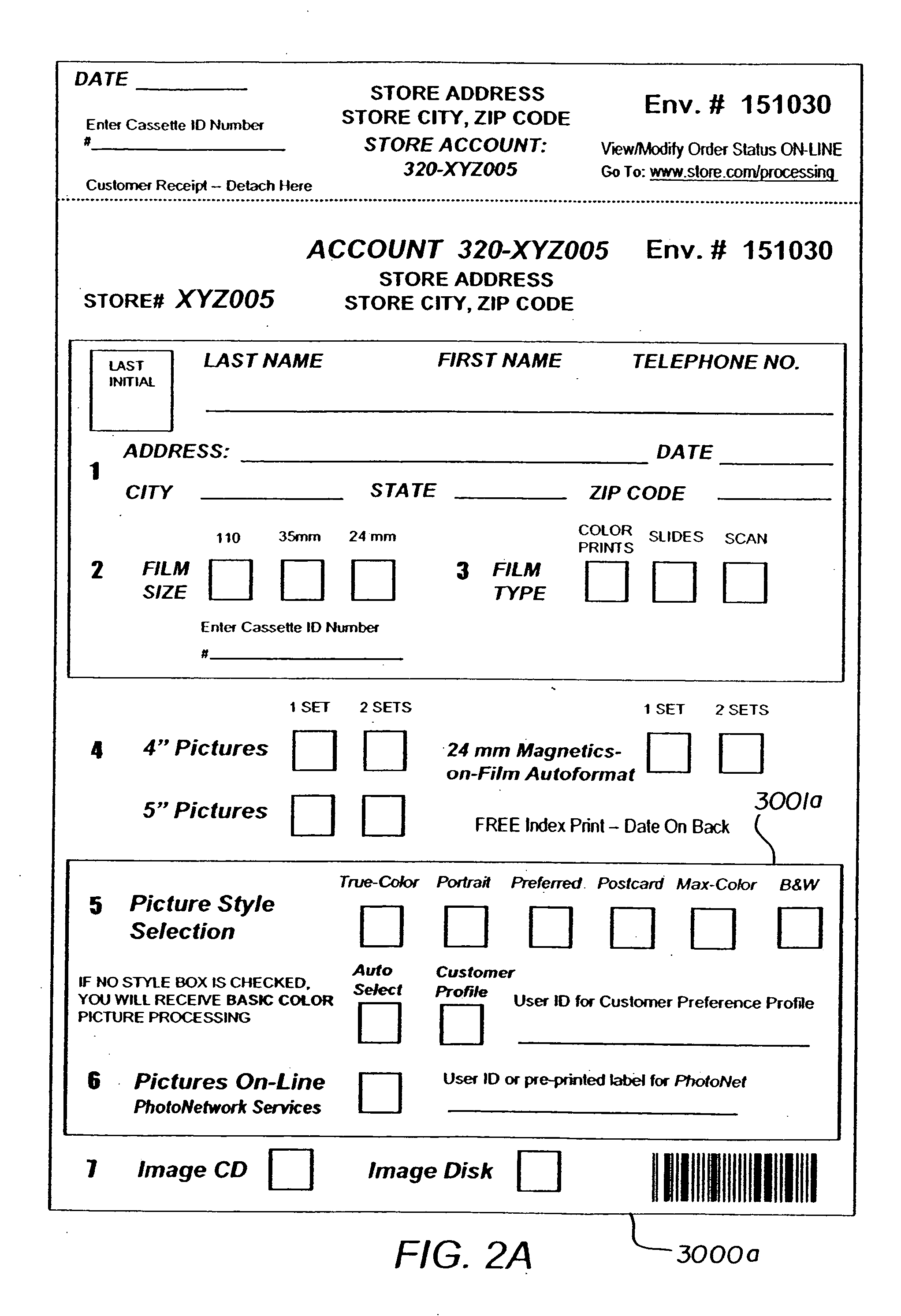

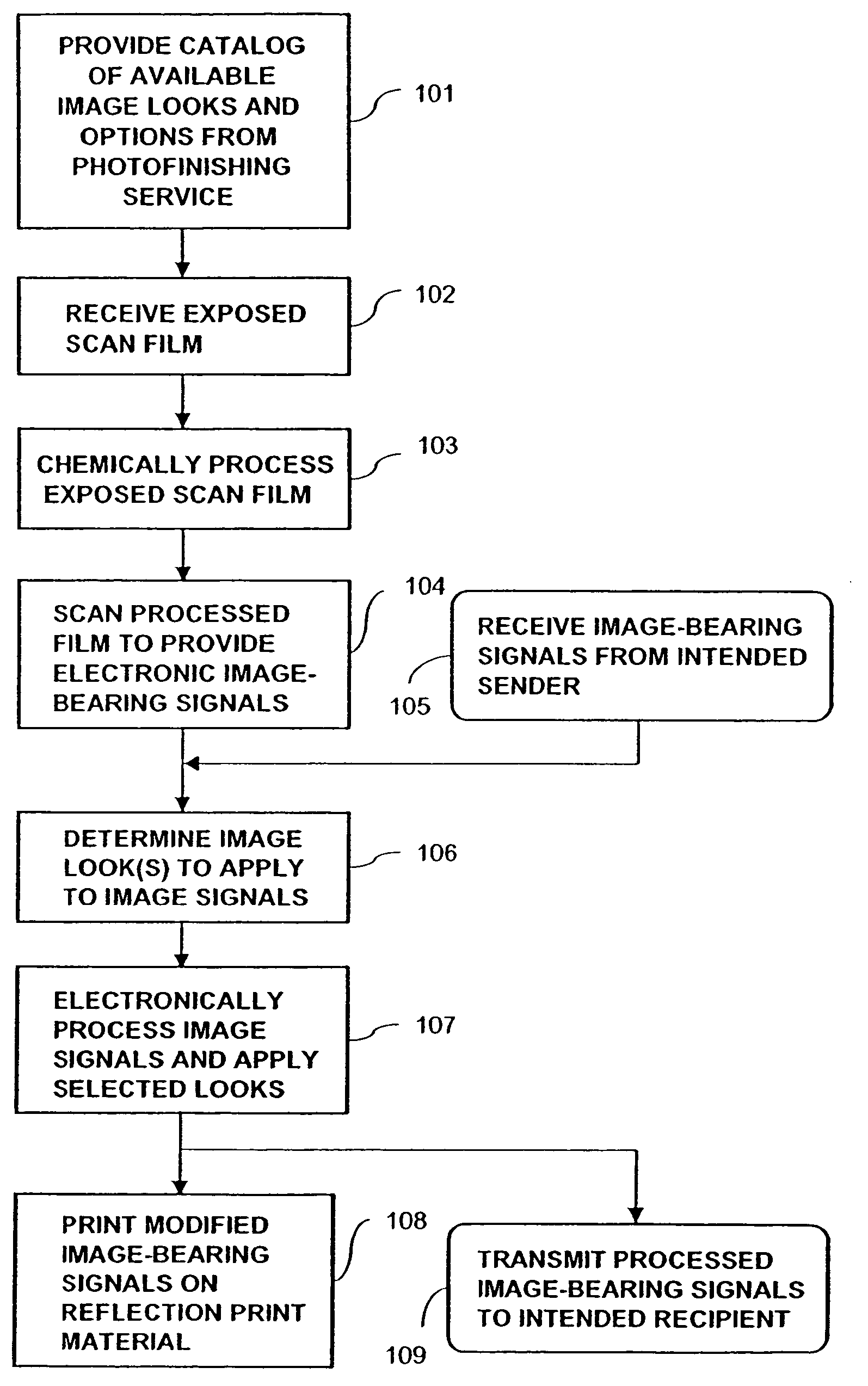

Plurality of picture appearance choices from a color photographic recording material intended for scanning

InactiveUS20050174591A1Maximum flexibilityDigitally marking record carriersDigital computer detailsComputer graphics (images)Digital image

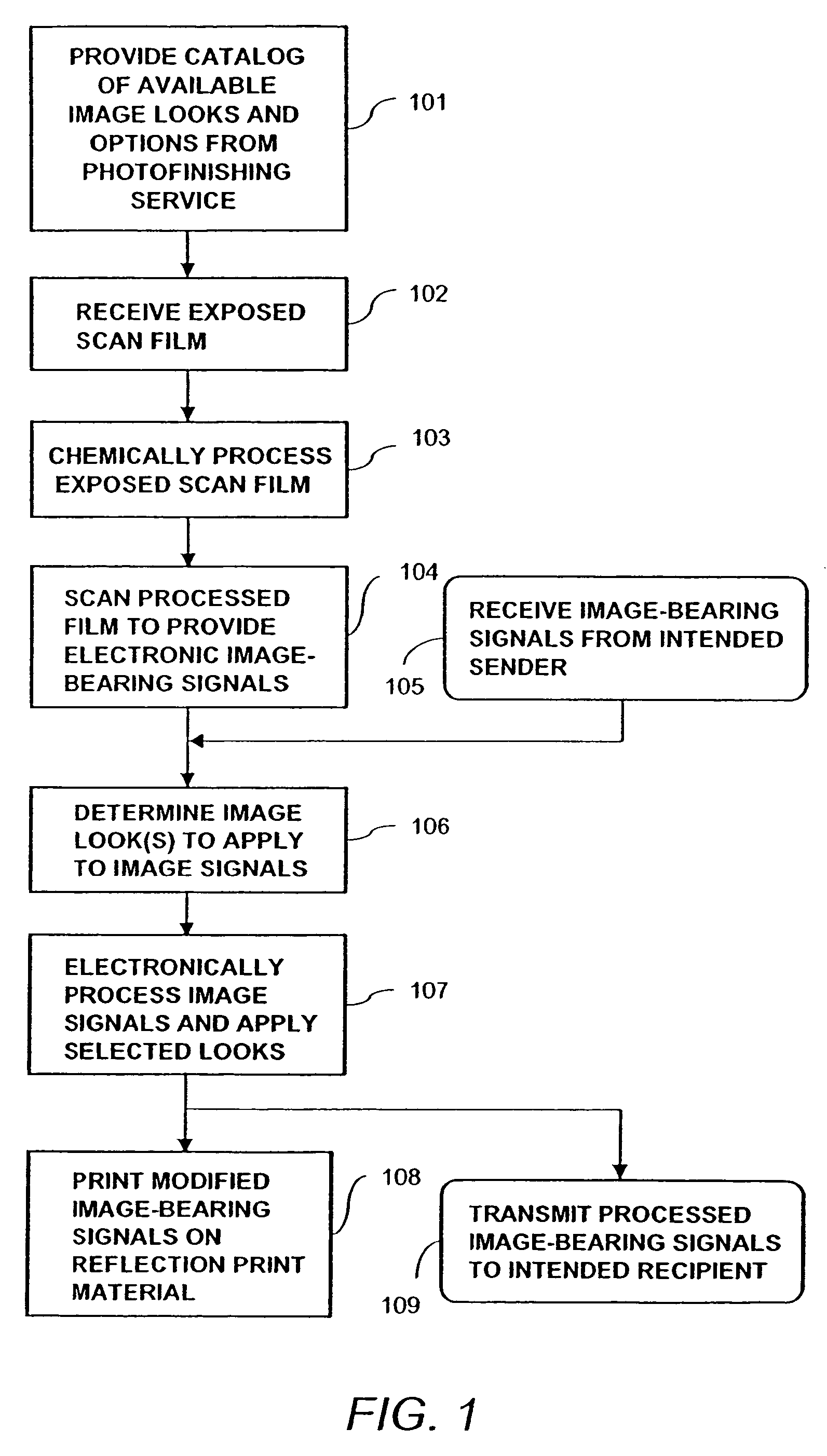

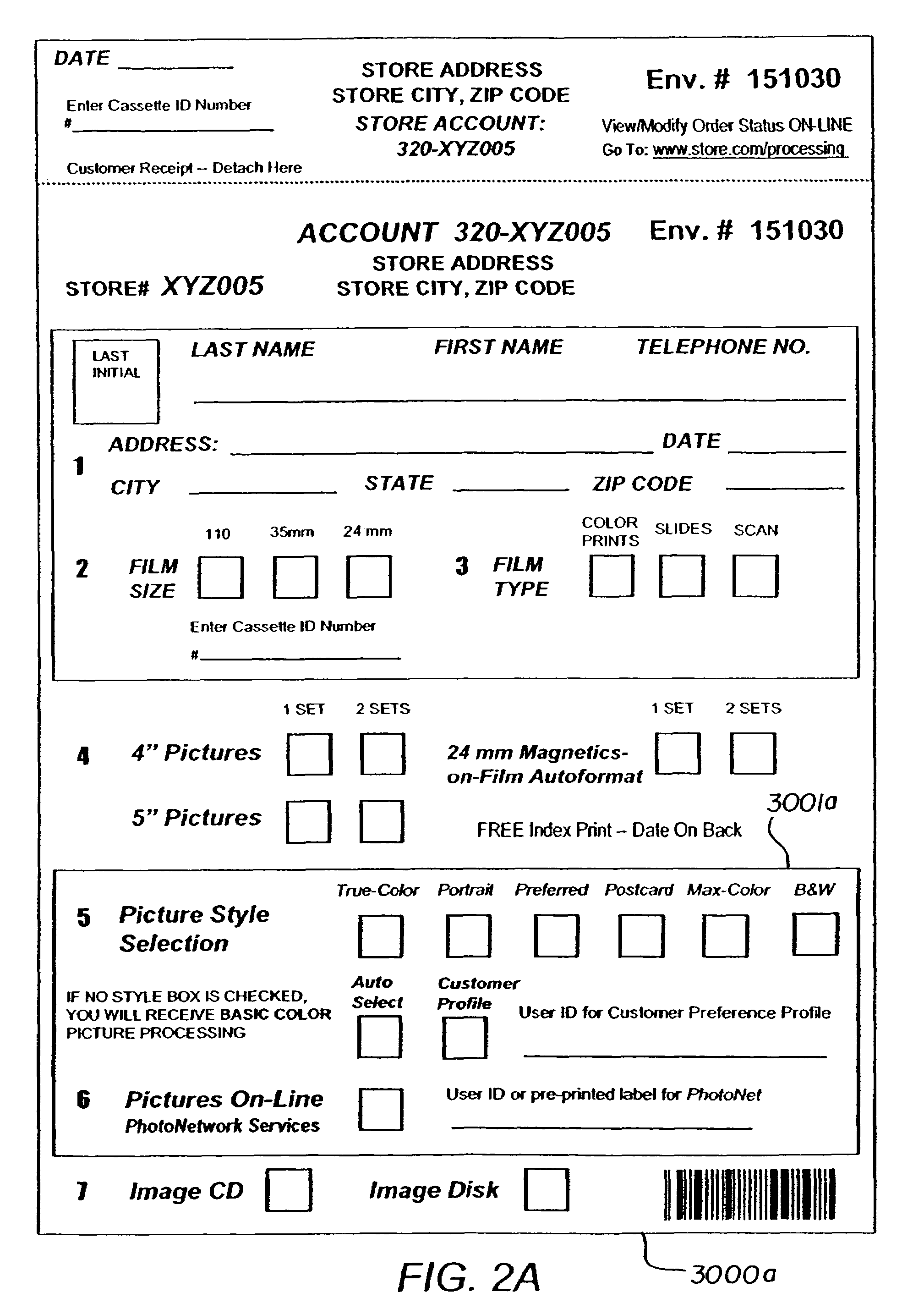

A system and method of offering photofinishing services involves receiving an exposed photographic film from a customer; developing and scanning the film to produce a digital image; displaying examples of a plurality of looks on a color display medium to a customer; receiving a selection of a preferred look from the customer; and applying the selected look to the digital image to produce a processed digital image having the preferred look.

Owner:KODAK ALARIS INC

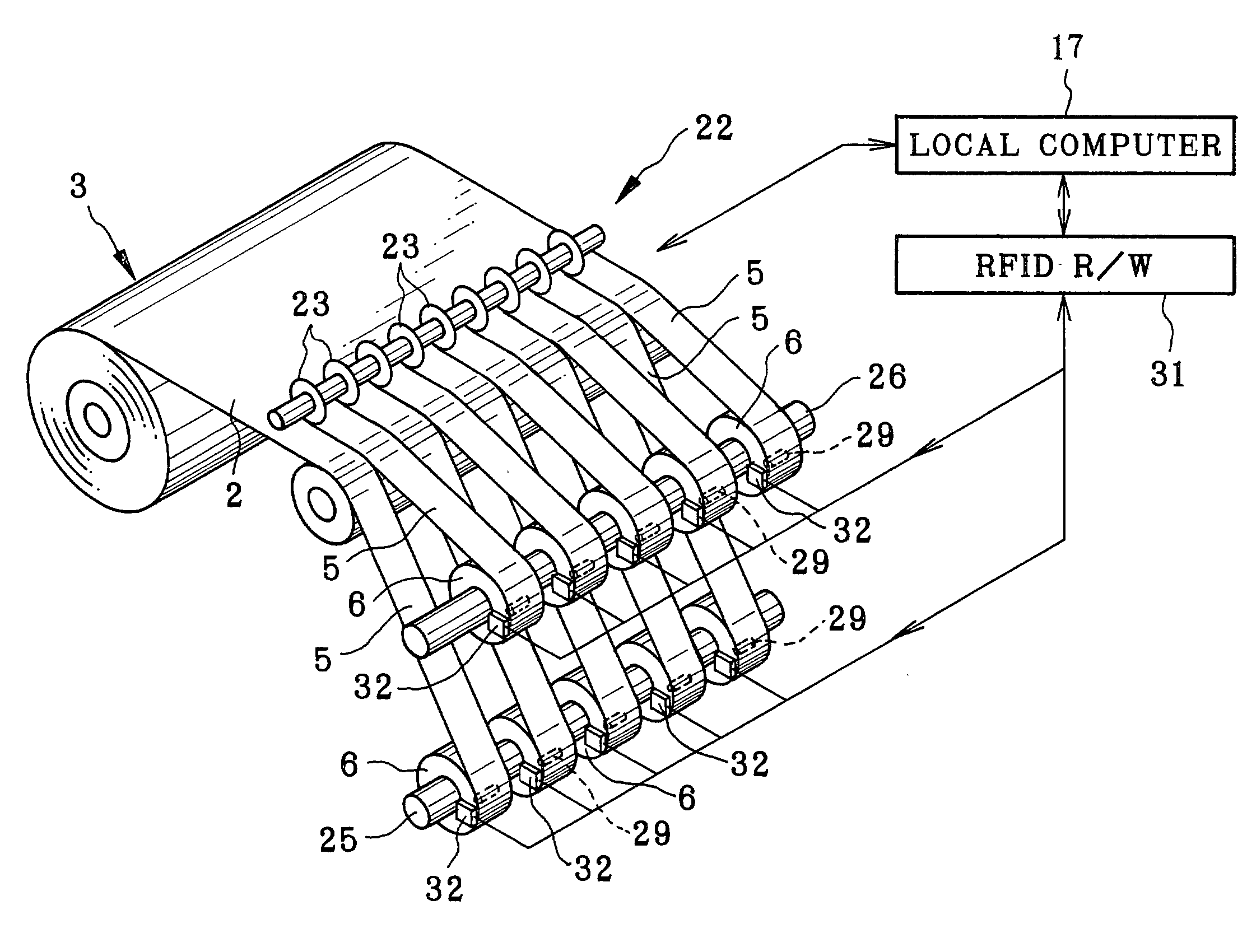

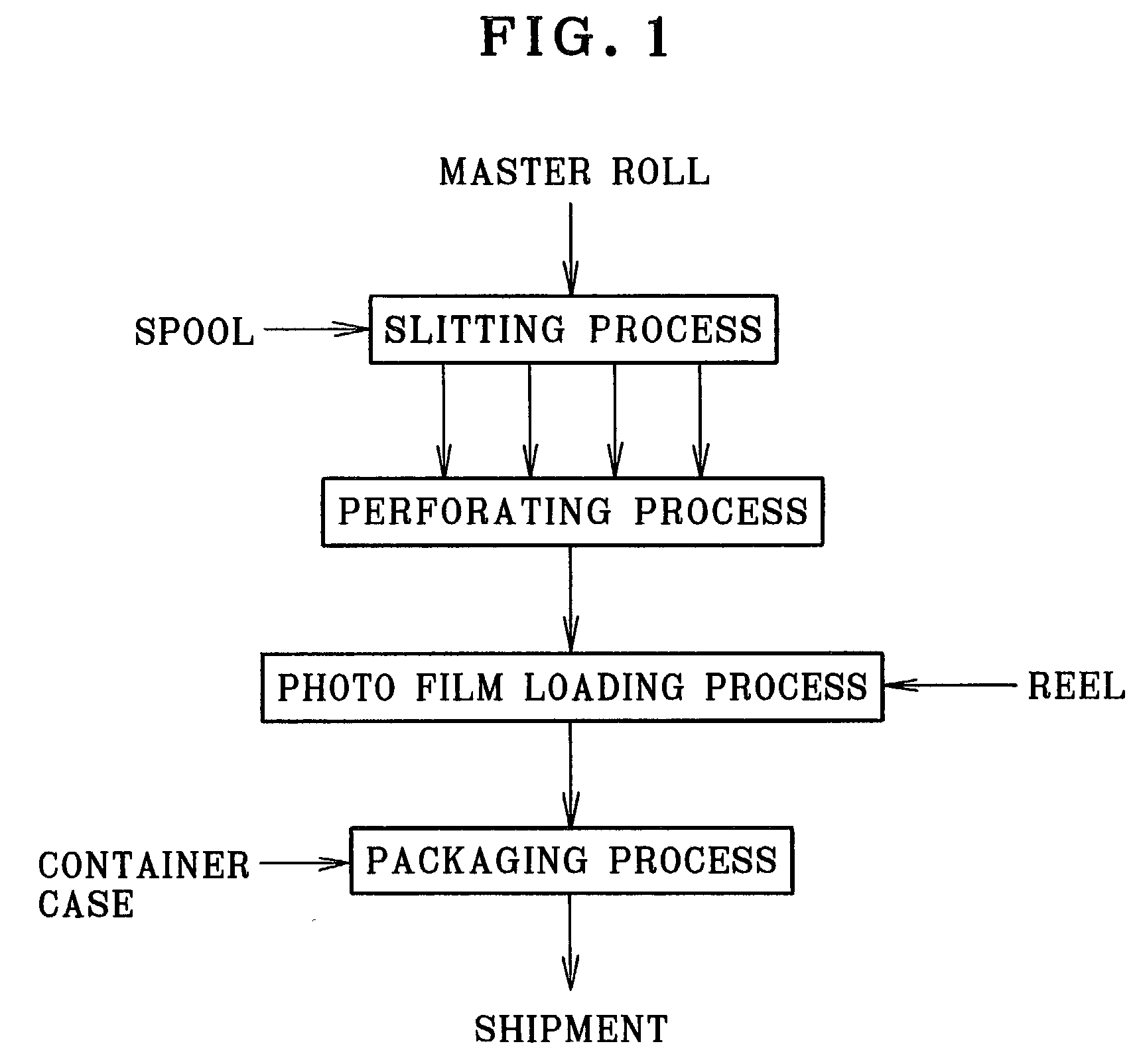

Production managing method for photo film production

InactiveUS20030025027A1Improve product qualityProne to defectPhotosensitive materialsMachines/enginesSheet filmEngineering

A production managing method for production of motion picture photo film is provided. At first, film web is slitted to produce continuous photo film having a predetermined width. Production managing information is written to an RFID (radio frequency identification) tag, and includes a roll number and slitting number, which are related to the film web and the continuous photo film. The continuous photo film is cut to produce motion picture photo film. The production managing information is stored in association with the motion picture photo film. The motion picture photo film is checked. If the motion picture photo film has a defect, the production managing information may be referred to for detecting a portion of the film web or the continuous photo film from which the defect derives. Other motion picture photo films with a defect will be traced.

Owner:FUJIFILM HLDG CORP +1

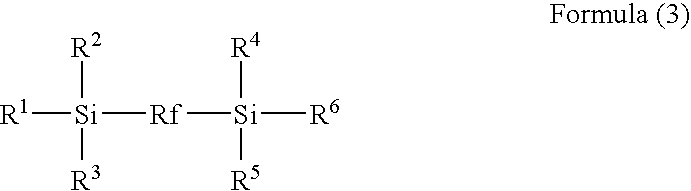

Gas barrier laminate film, method for producing the same and image display device utilizing the film

InactiveUS20050238846A1High yieldAvoid crackingSynthetic resin layered productsRecord information storageWrinkle skinRoll film

In a gas barrier laminate film comprising a gas barrier layer laminated on at least one surface of a support, the surface of the support on the side opposite to the surface laminated with the gas barrier layer is made to have an Ra value of 1 to 20 nm. A gas barrier laminate film that can prevent cracks generated by displacement of rolled film, slacks and wrinkles during rolling up and transportation in the production process of the film and thus can be produced with a high yield, a method for producing the same and an image display device utilizing the film are provided.

Owner:FUJIFILM CORP

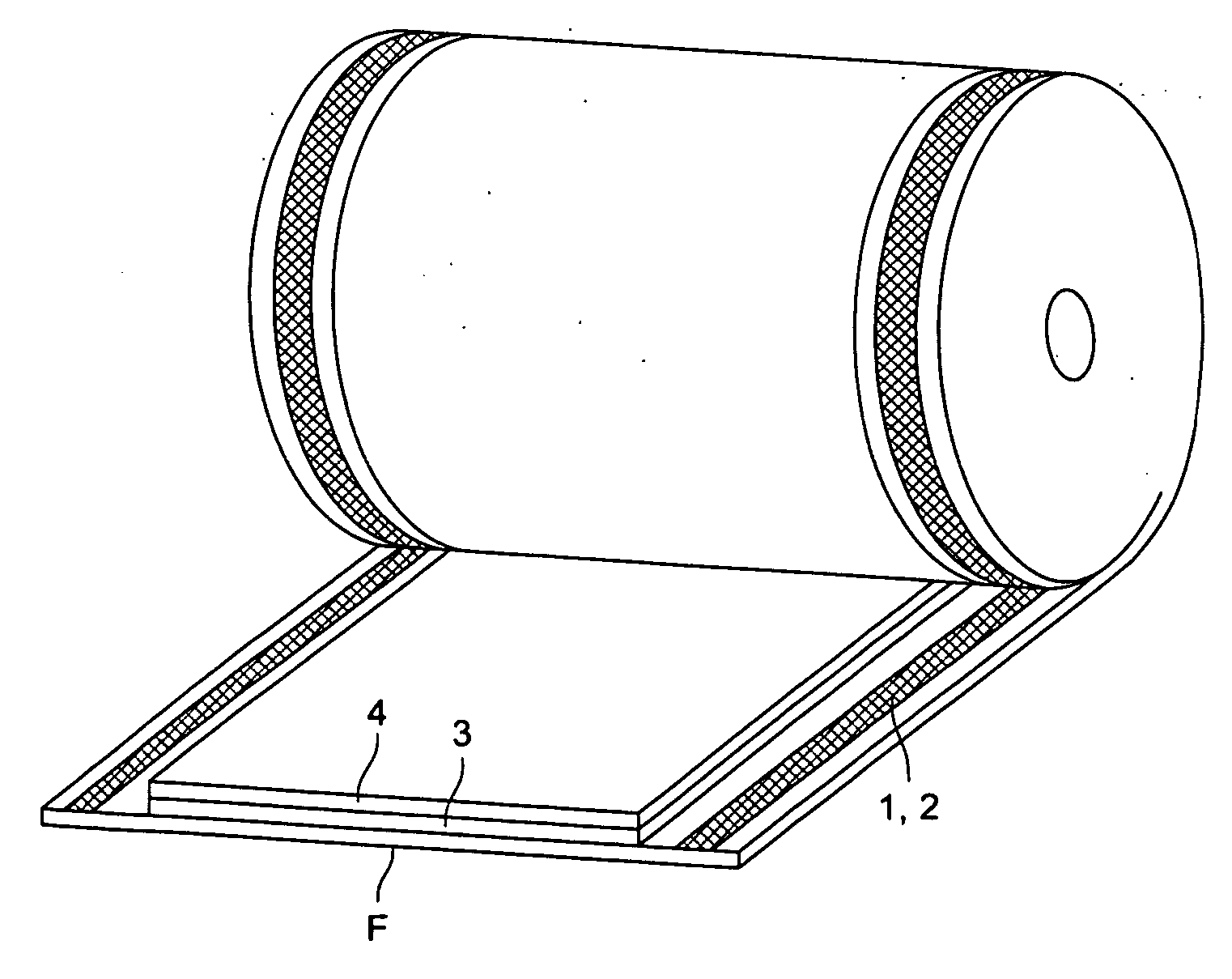

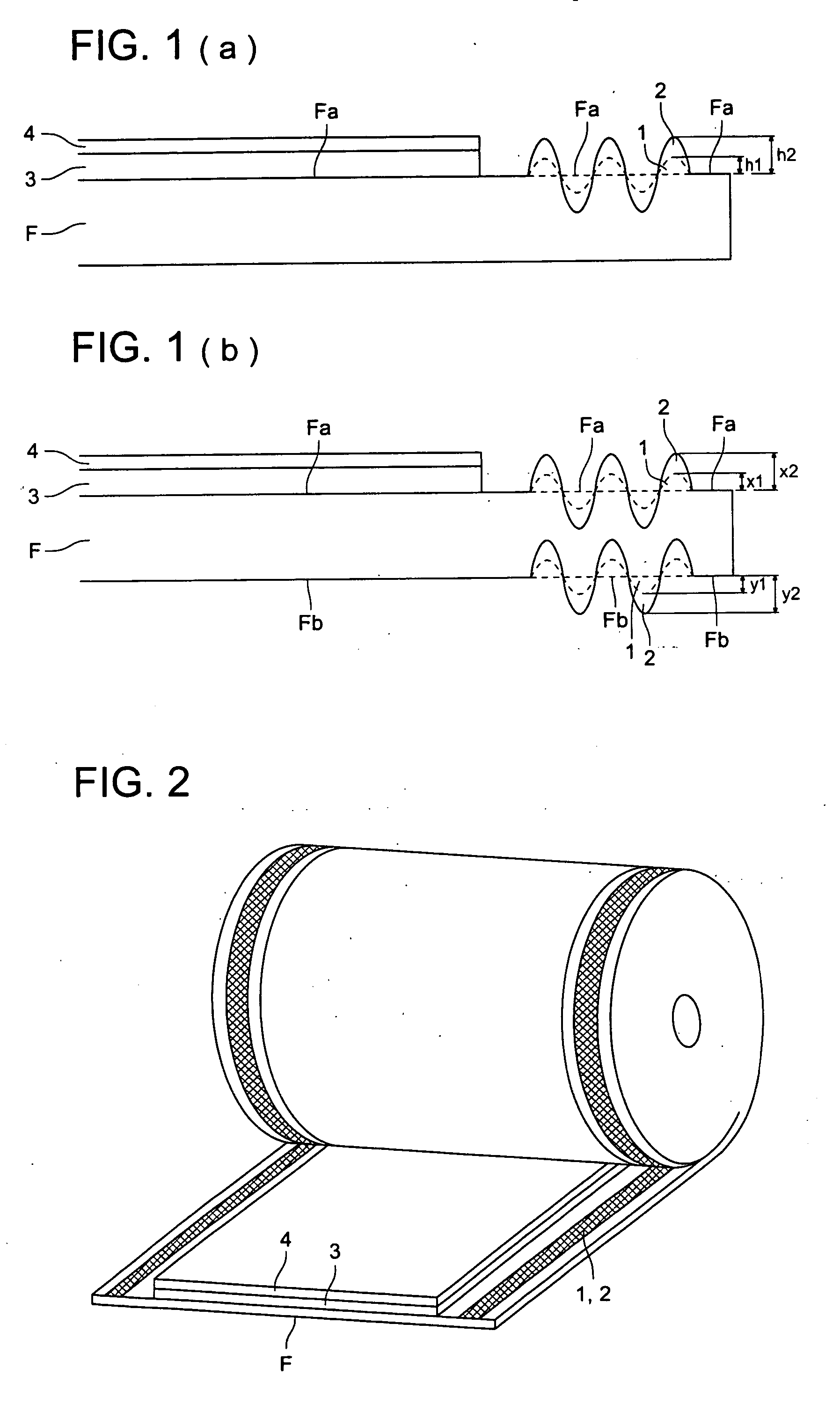

Production method of rolled optical film having coating layer, rolled optical film, polarizing plate and liquid crystal display

InactiveUS20060198991A1Less frizzSmall differencePretreated surfacesPolarising elementsLiquid-crystal displayEngineering

A method for producing a roll film provided with a coat layer comprising the steps of: (i) producing a roll film; (ii) applying a first embossing treatment along a longitudinal direction of the roll film on a part of a lateral direction of the roll film; (iii) applying a coat layer on the roll film; (iv) applying a second embossing treatment along a longitudinal direction of the roll film on a part of a lateral direction of the roll film; (v) heat treating the roll film at a temperature of 50 to 150° C. for a duration of 1 to 30 days while the roll film is rolled in a roll.

Owner:KONICA MINOLTA OPTO

Plurality of picture appearance choices from a color photographic recording material intended for scanning

InactiveUS7218776B2Maximum flexibilityCharacter and pattern recognitionImage data processing detailsComputer visionDigital image

A system and method of offering photofinishing services involves receiving an exposed photographic film from a customer; developing and scanning the film to produce a digital image; displaying examples of a plurality of looks on a color display medium to a customer; receiving a selection of a preferred look from the customer; and applying the selected look to the digital image to produce a processed digital image having the preferred look.

Owner:KODAK ALARIS INC

Printer and projector equipped with micromirror device

InactiveUS6900825B2Small sizeIncrease speedDigitally marking record carriersDigital computer detailsComputer printingImaging data

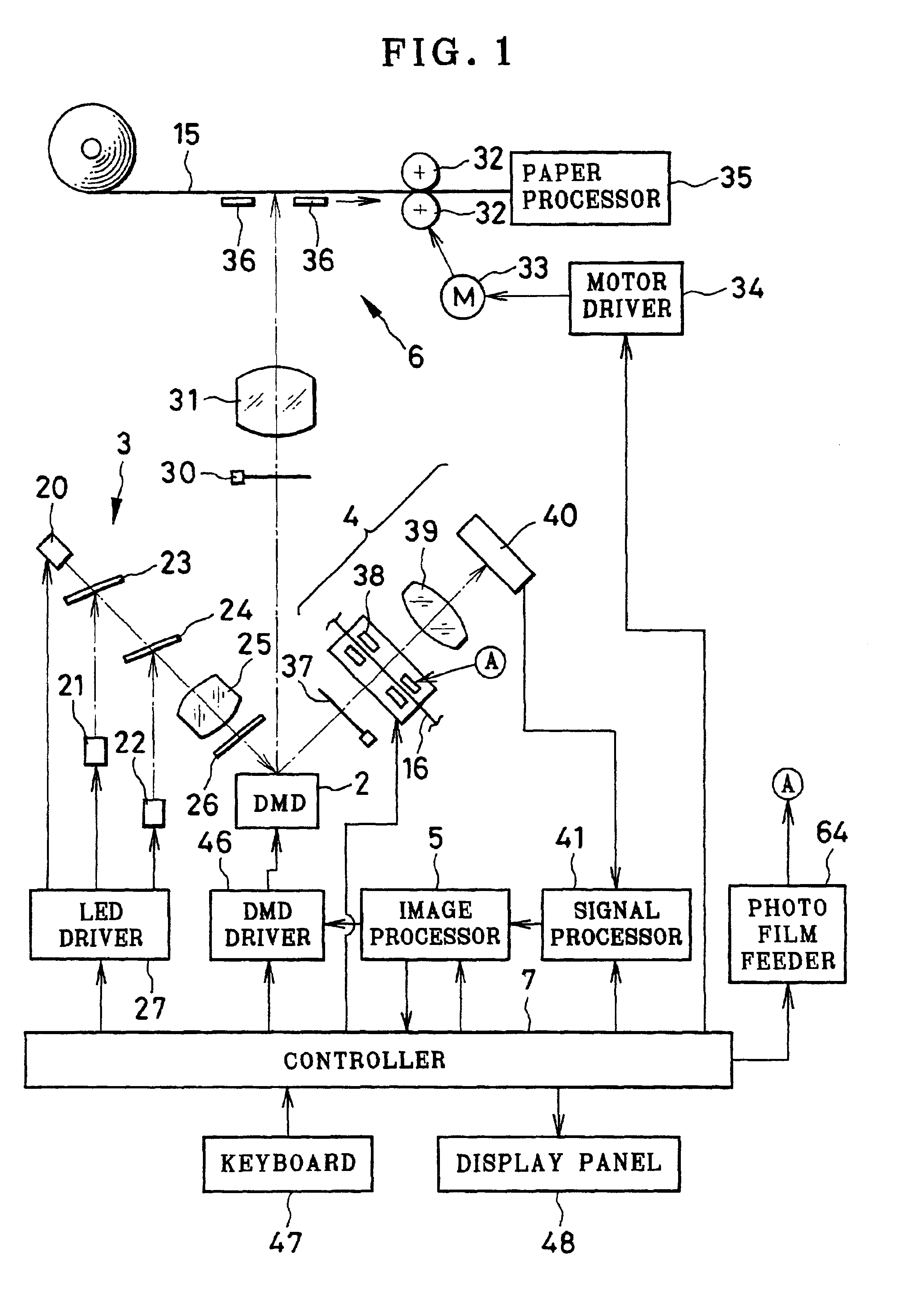

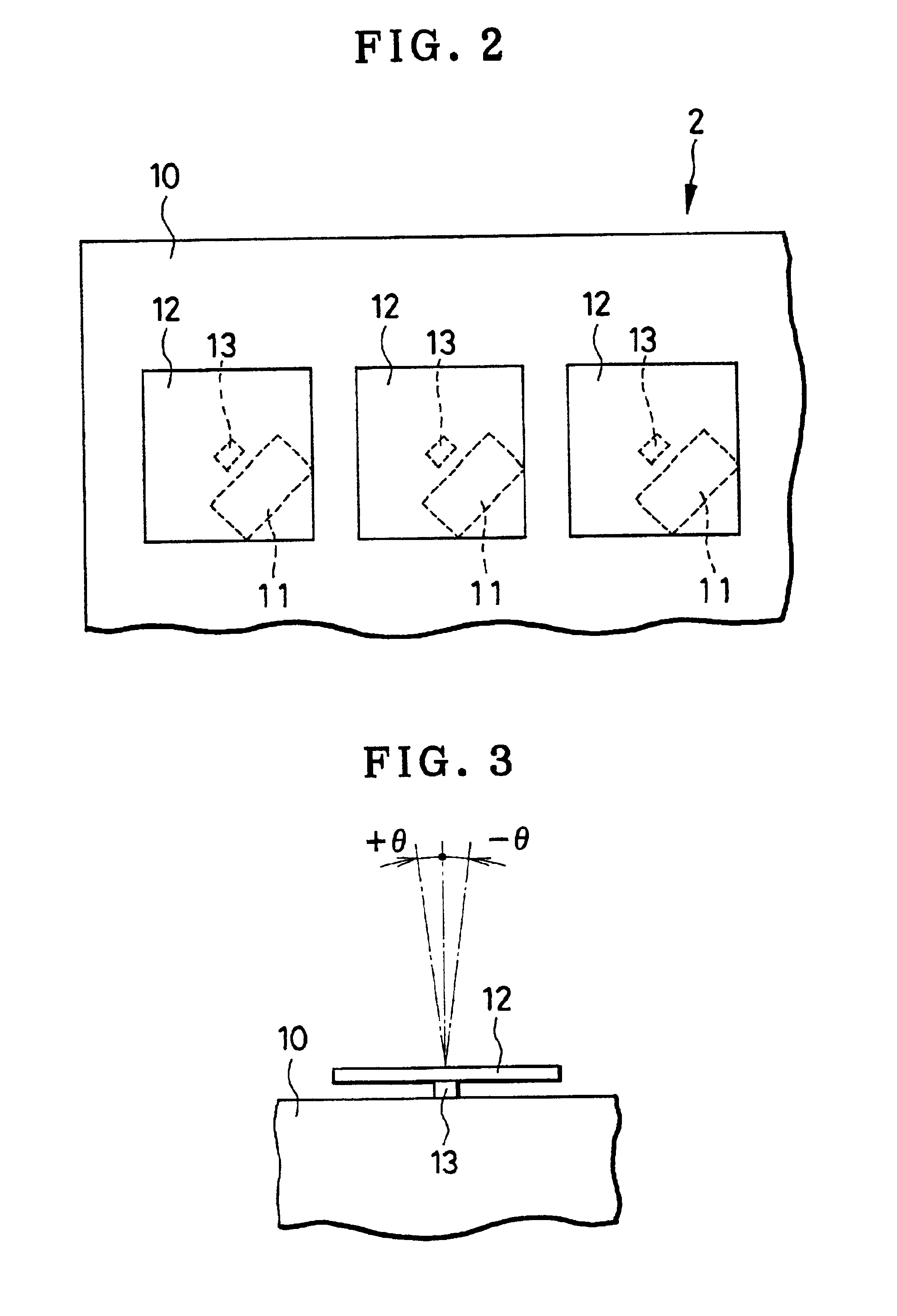

A printer includes an image area sensor for picking up a picture frame in photo film to output image data. A printing projecting lens focuses and records a print frame to color photographic paper. Three LED light sources generate light. A digital micromirror device (DMD) is disposed in a traveling path of the light, includes plural micromirrors arranged in at least one array. The plural micromirrors are individually shiftable between first and second positions different in a direction, and when in the first position, direct the light to the photo film by reflection, and when in the second position, direct the light to the printing projecting lens by reflection. A controller initially sets the plural micromirrors in the first position, to illuminate the picture frame in the photo film while the image area sensor is operated. According to the image data, the controller sets micromirrors in one first group in the DMD to the first position, and sets micromirrors in a second group in the DMD to the second position except for the first group, to modulate the light by reflection on the second group. Thus, the print frame is printed with the printing projecting lens.

Owner:FUJIFILM HLDG CORP +1

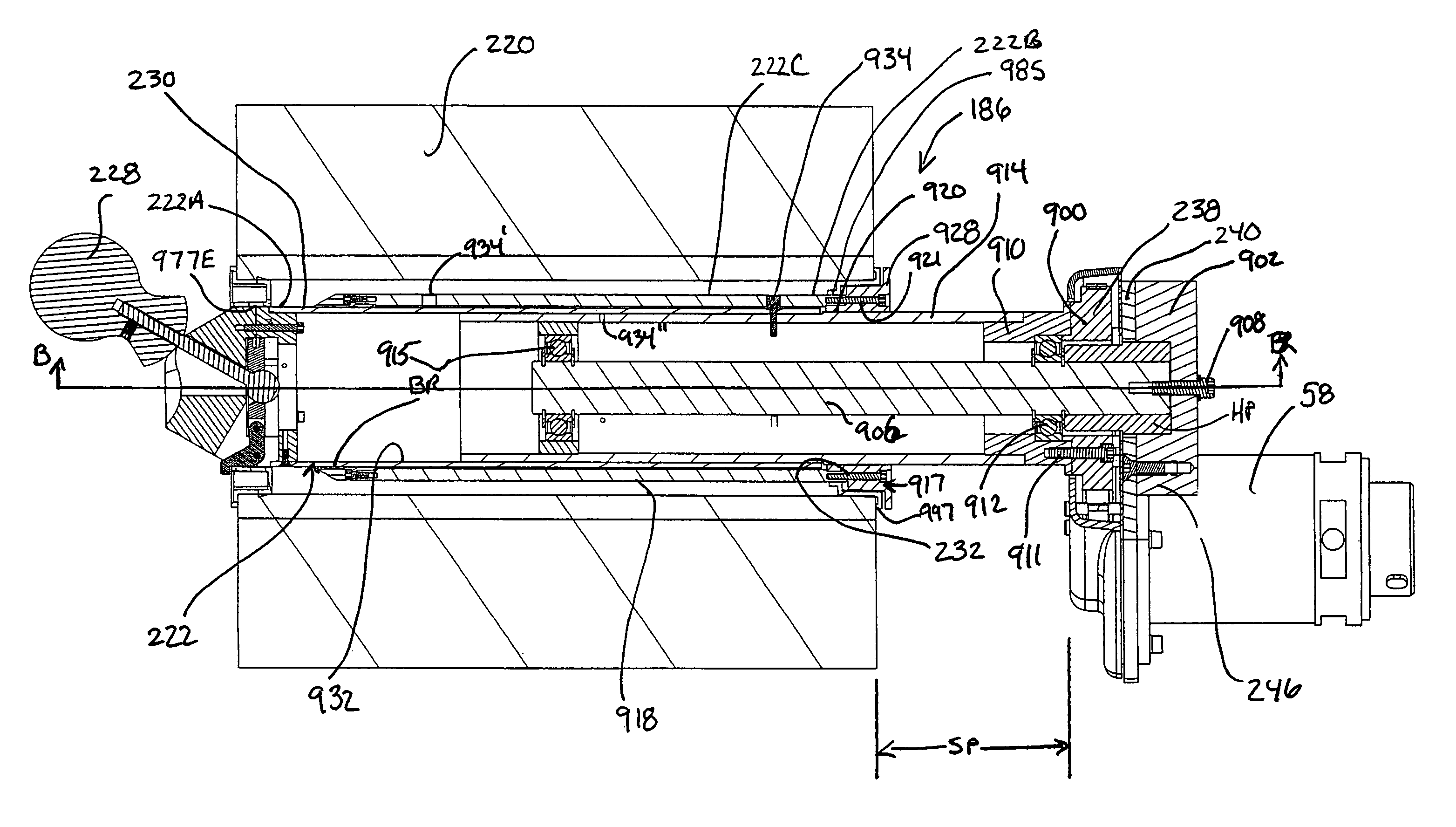

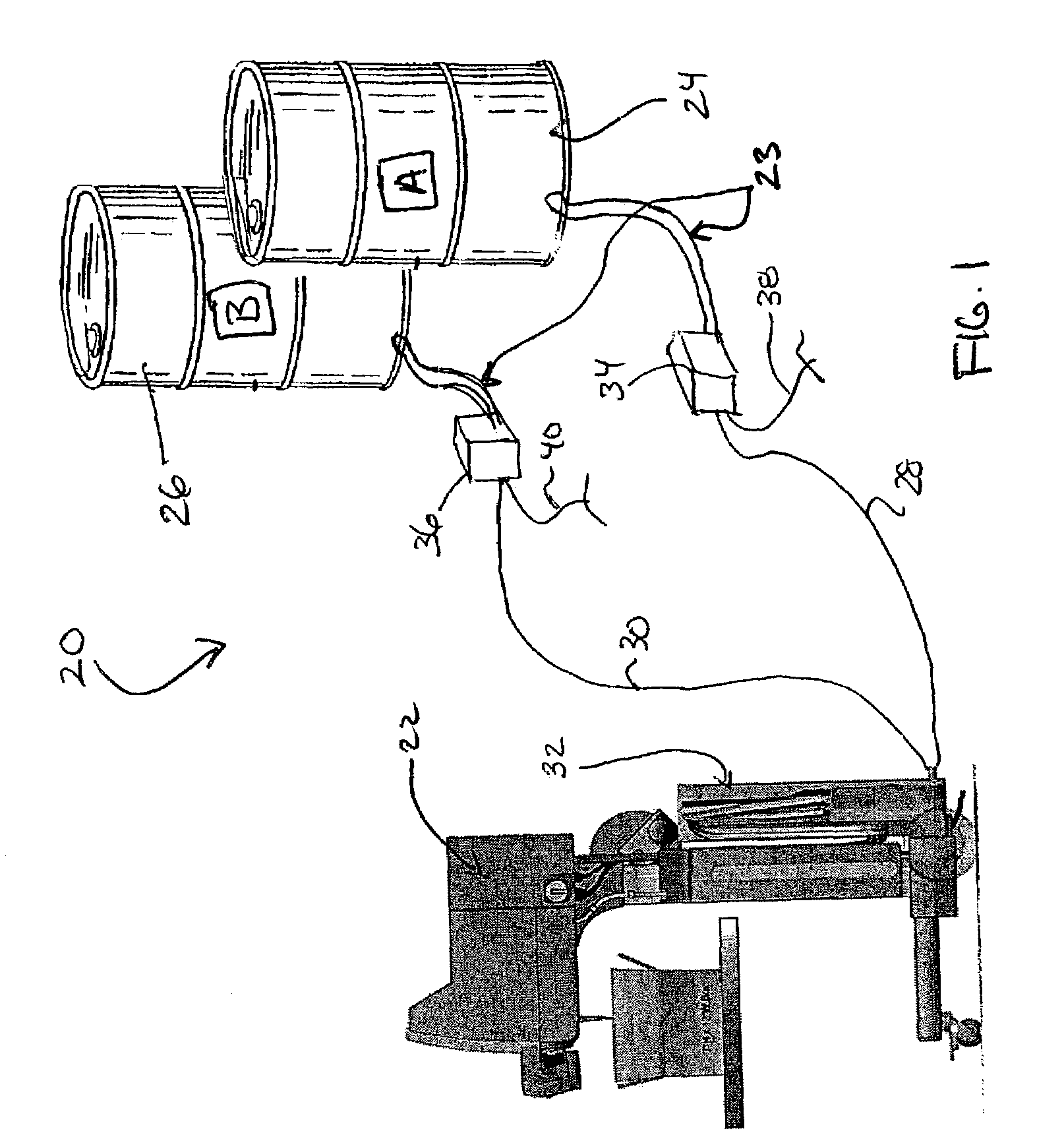

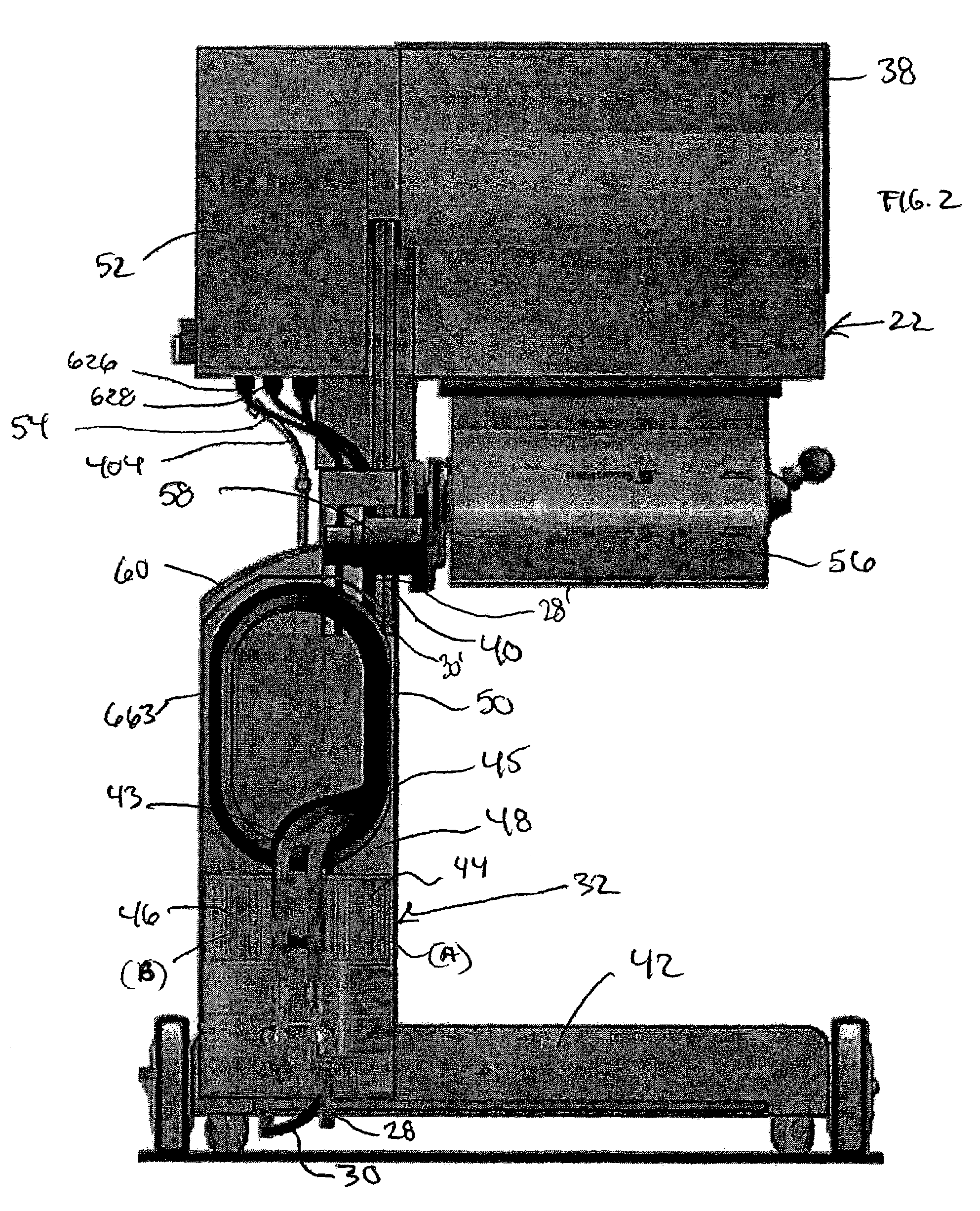

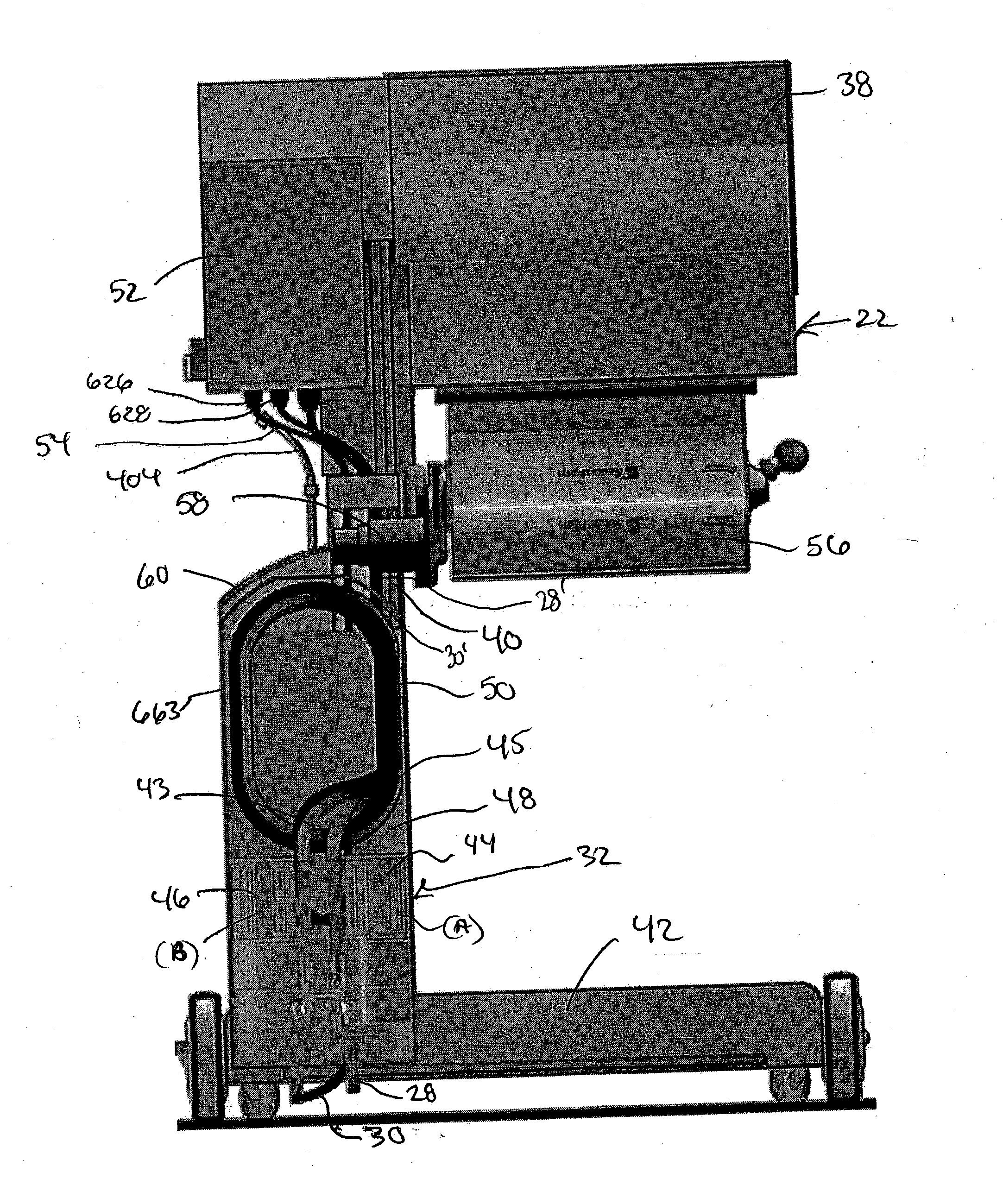

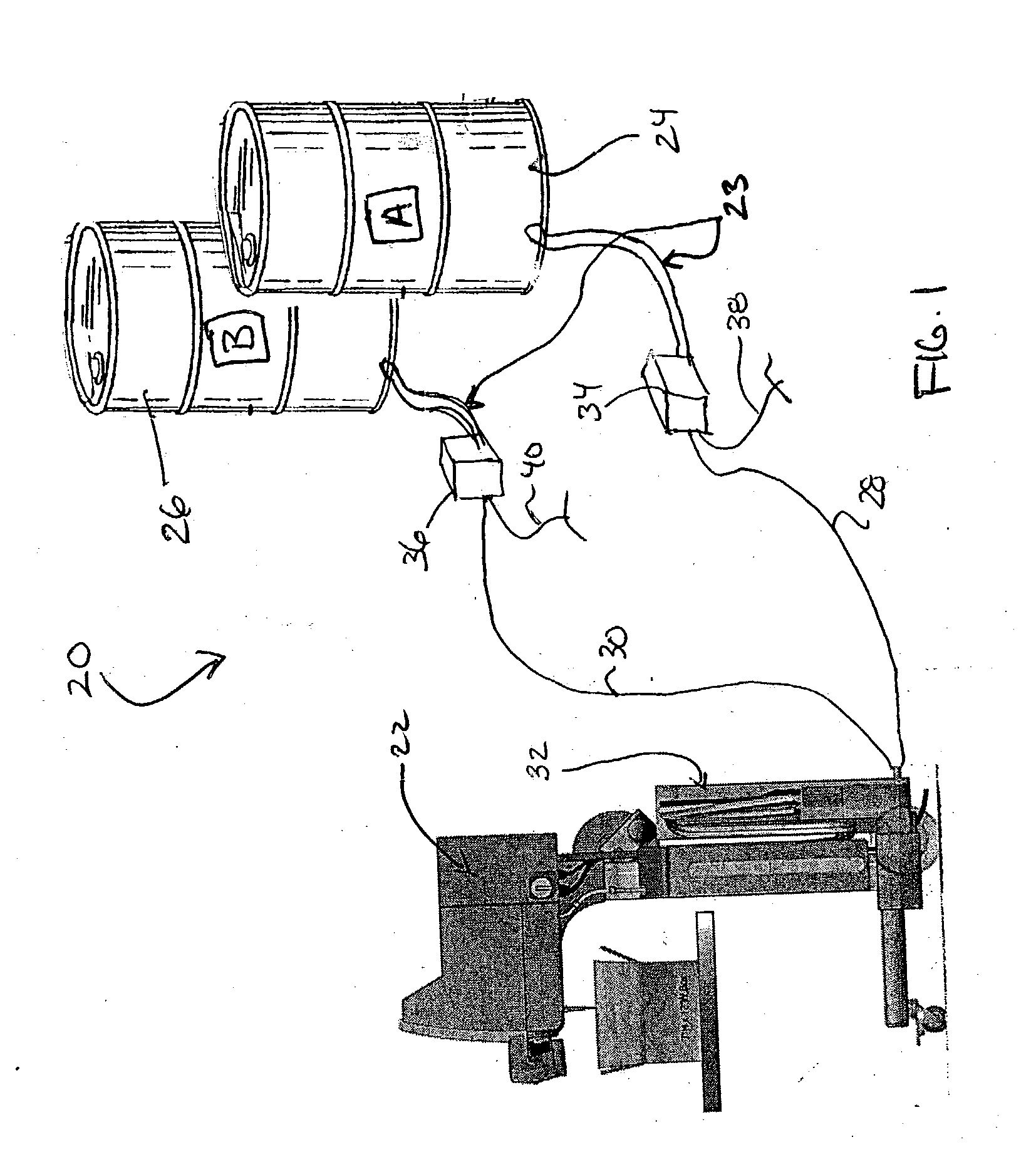

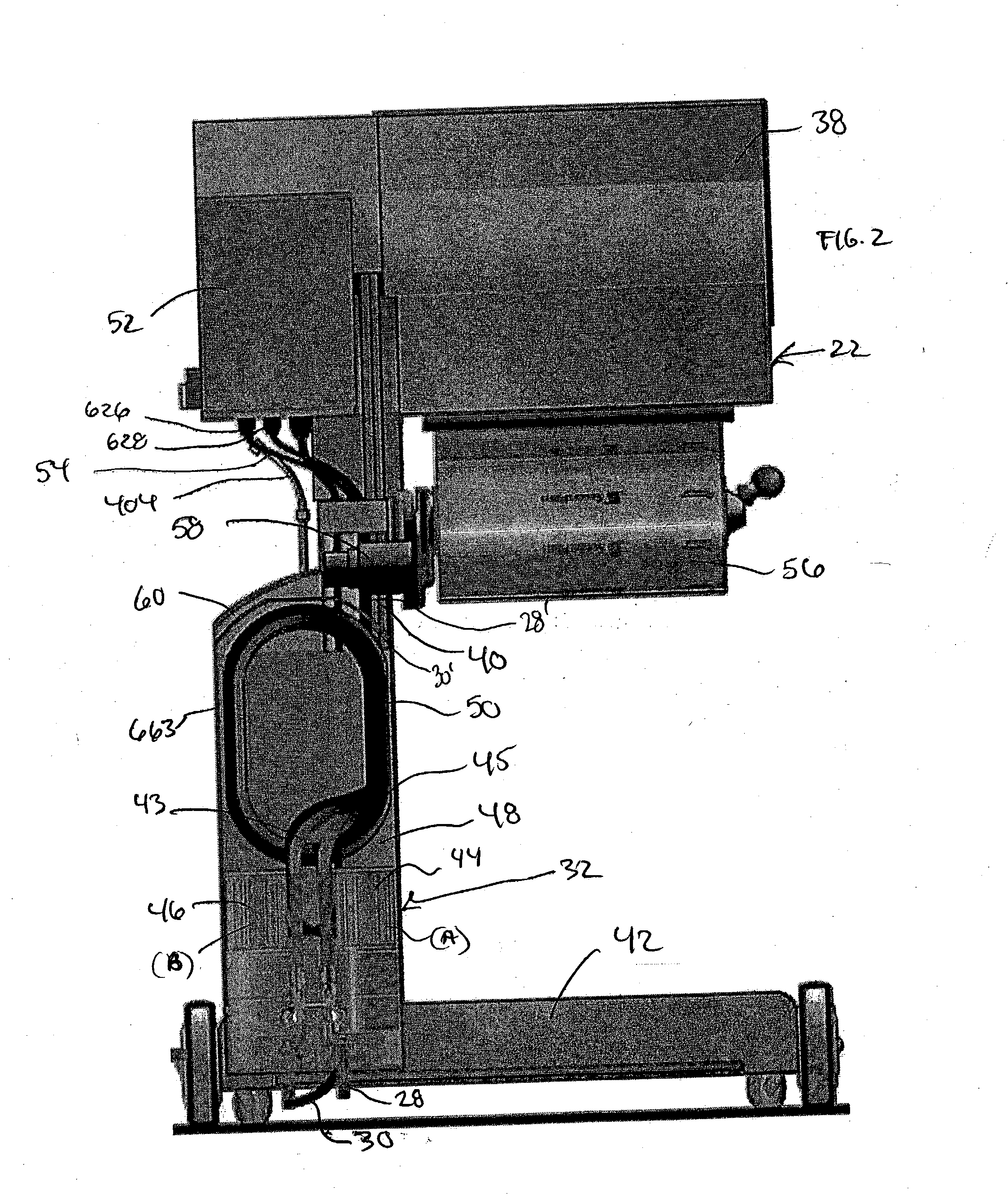

Film unwind system with hinged spindle and electronic control of web tension

A film supply apparatus supplying film in a foam-in-bag system having a film feeding device for feeding film from a film source to a location for bag formation, a bag forming apparatus, a foam material dispenser positioned for feeding foam material for reception in a bag of the bag forming apparatus, and a web tensioning system with a web tensioning driver in driving communication with the film source and which is in communication with a controller for monitoring the film feed and web tension states and directing adjustments in the web tension system. The web tensioning driver is arranged to move film backwards or in a direction opposite to a direction of film feed induced by the film feeding means and with the film source including a roll of film and the web tensioning system including a drive transmission in communication with the roll of film for rotational driving of the roll of film and also in communication with web tensioning driver. There is further featured a spindle support for supporting the roll of film and a roll film core drive insert.

Owner:PREGIS INTELLIPACK CORP

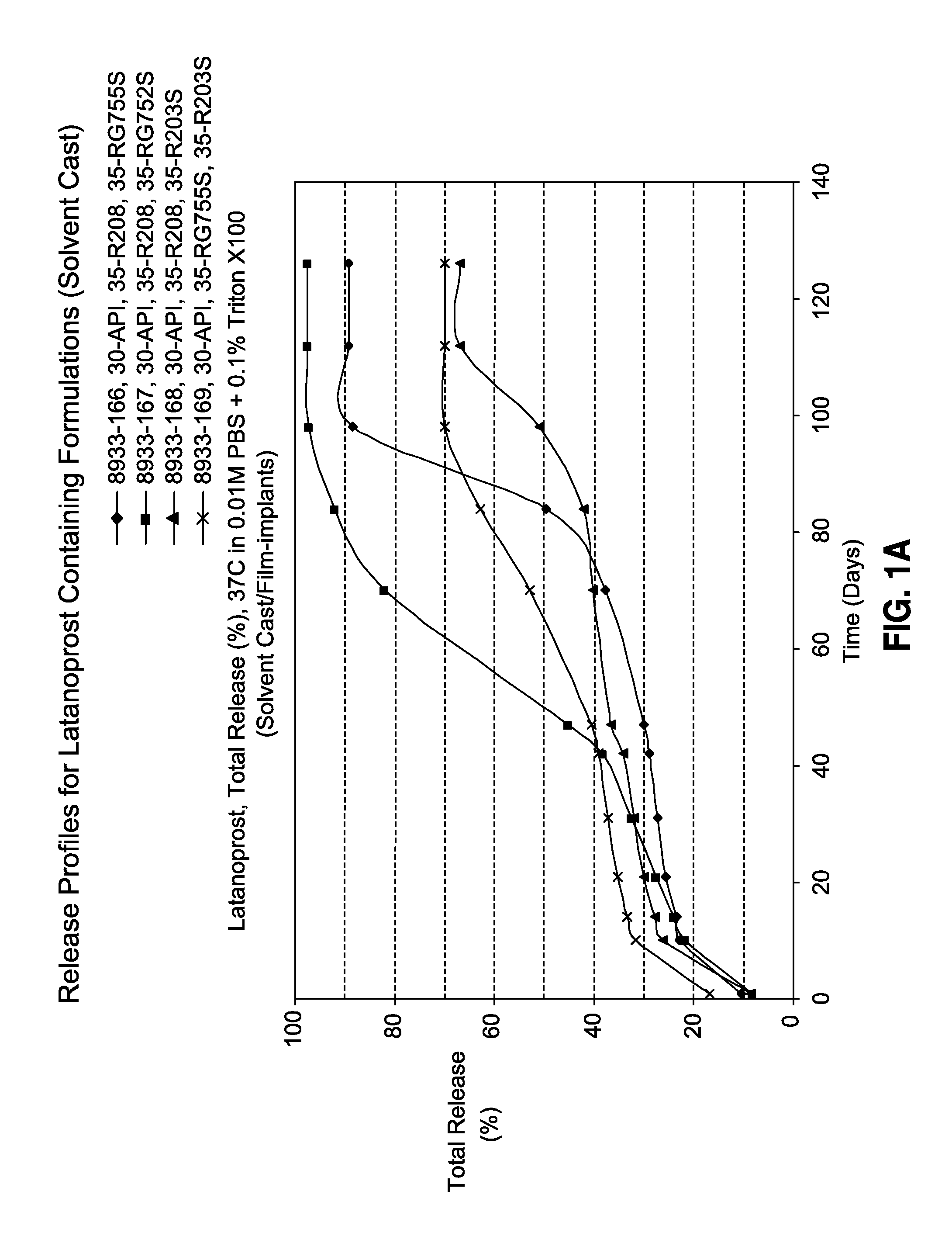

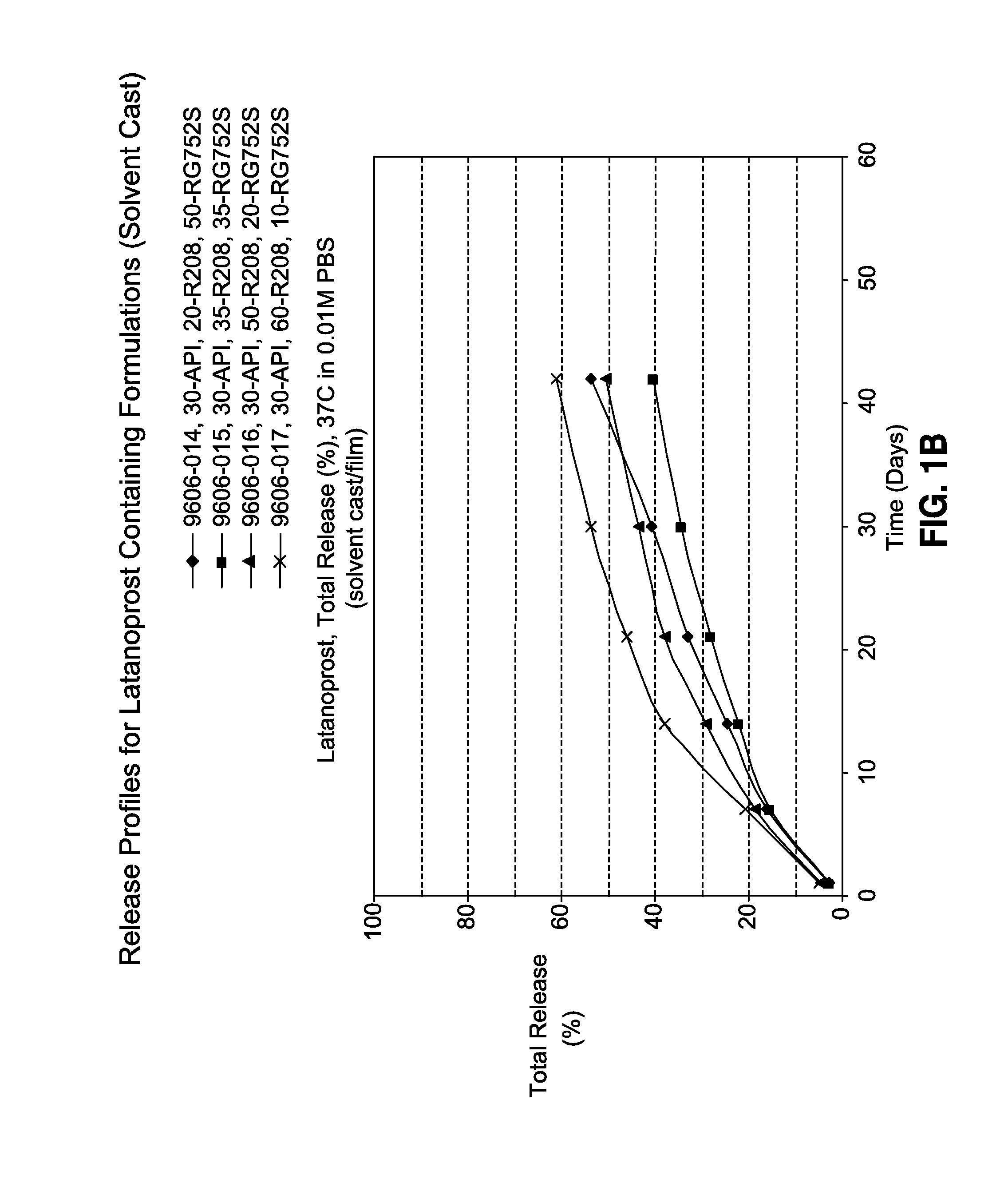

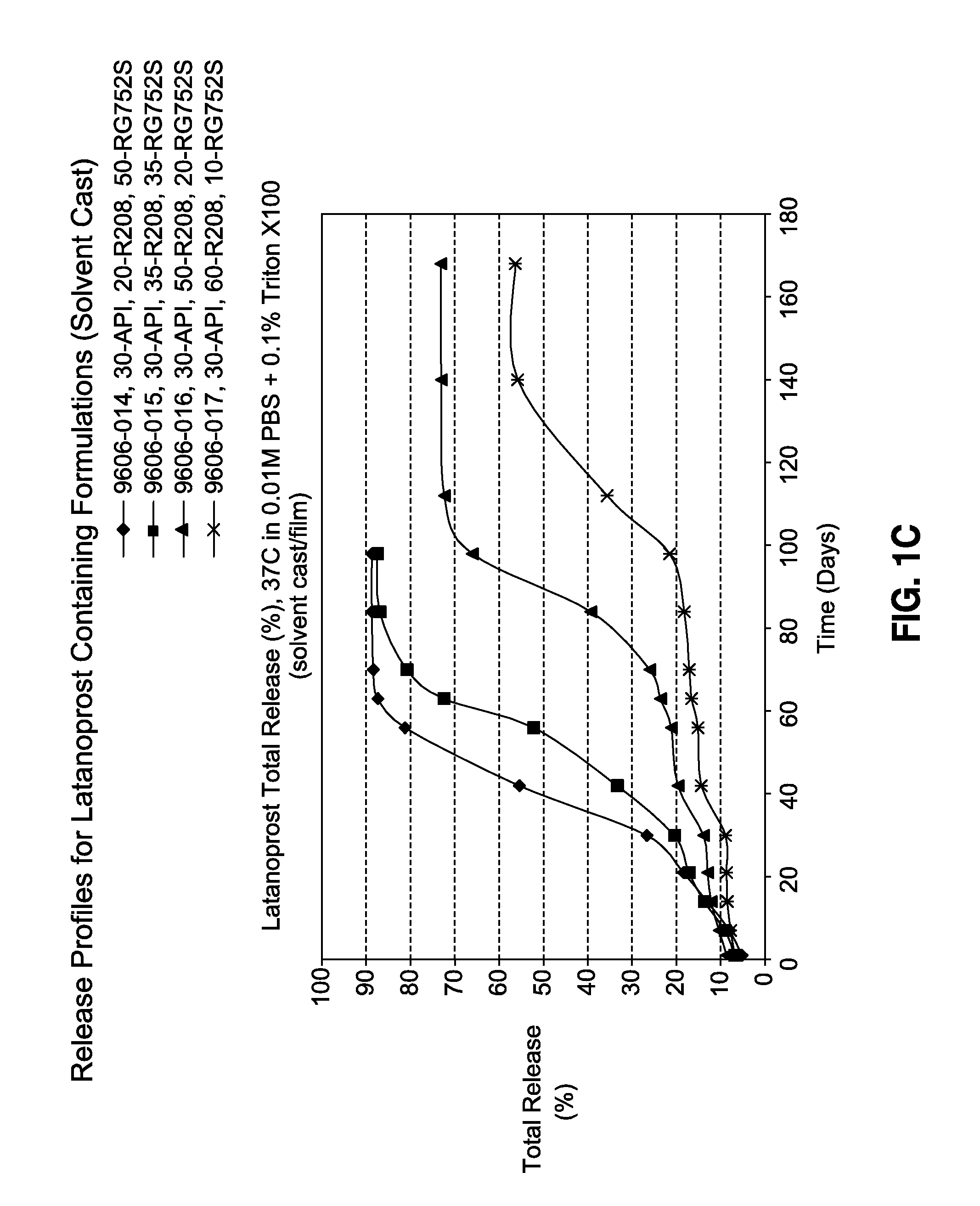

Sustained release latanoprost implant

InactiveUS20120276186A1Preserve latanoprost activityOrganic active ingredientsBiocideLatanoprostProstate implant

The present invention provides a sustained release, biodegradable intraocular latanoprost implant for reducing elevated intraocular pressure in an individual in need thereof. The implant can be configured as a film (e.g., a rolled film) or extruded filament, either of which can be inserted into the eye of the individual to provide for extended release of latanoprost for several days. Upon insertion into the eye, a rolled film may unroll to provide a film having a high surface area to volume ratio for drug diffusion.

Owner:ALLERGAN INC

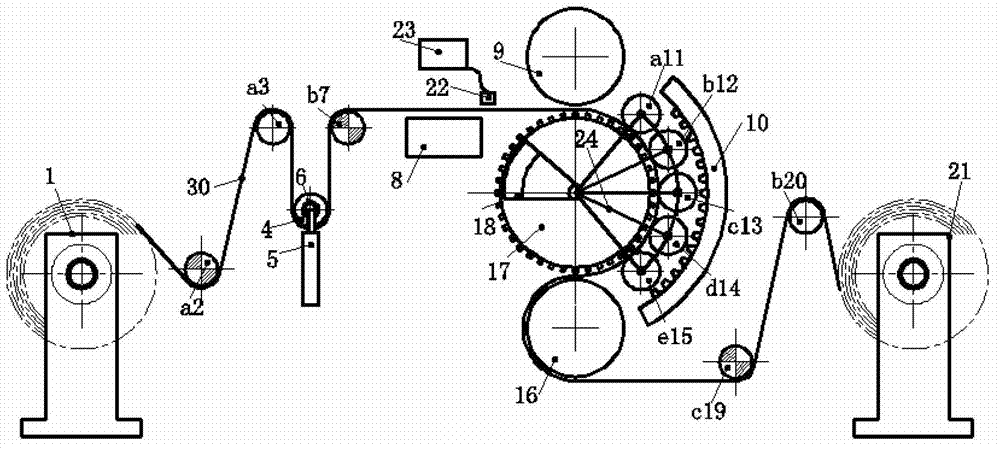

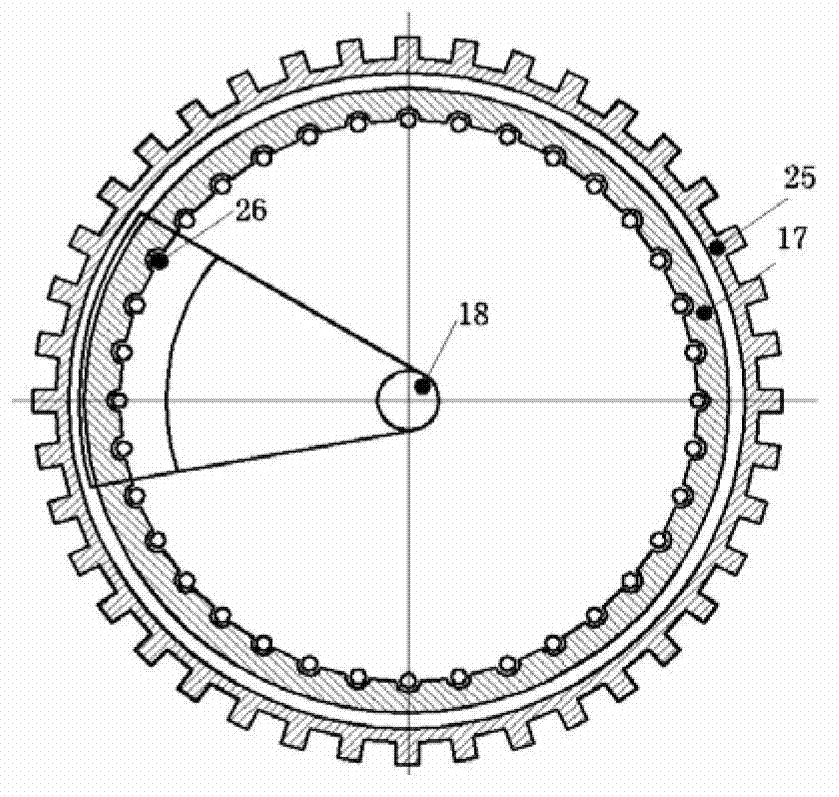

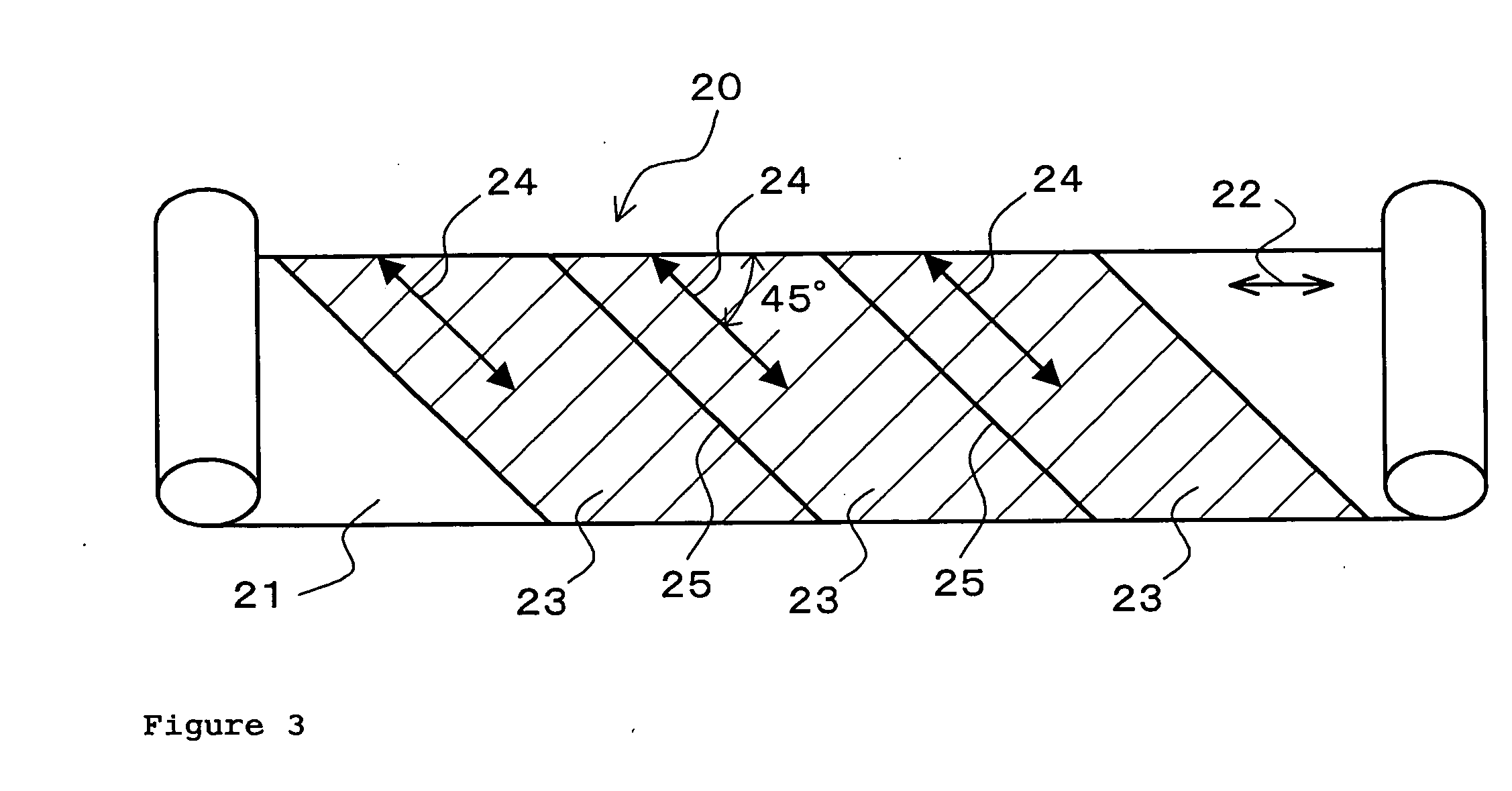

Device and method for processing polymer film surface microstructure based on roll-to-roll hot rolling

The invention relates to device and method for processing a polymer film surface microstructure based on roll-to-roll hot rolling. The method comprises the following six steps: unrolling, pre-heating, hot-rolling, conforming, cooling and rolling. The unrolling step includes continuously drawing a polymer film from a rolled material and removing static electricity on the surface of the film. After the pre-heating step, the polymer film is heated to a temperature below the glass transition temperature thereof to get ready for the hot-rolling step. The local heating treatment is conducted on a plate roller to allow only the temperature of the stamping surface to rise above the glass transition temperature, so as to roll-form the preheated film. The conforming step enables the rolled film in close contact with the surface of the plate roller, so that the film is completely deformed. The formed film is subjected to both cooling and conforming to cause rapid curing of the surface microstructure and reduce rebound. Compared with the prior art, the device and method have the advantages of reducing the risk of rebound and deformation, improving the forming precision of the microstructure, making demoulding easier and increasing the processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

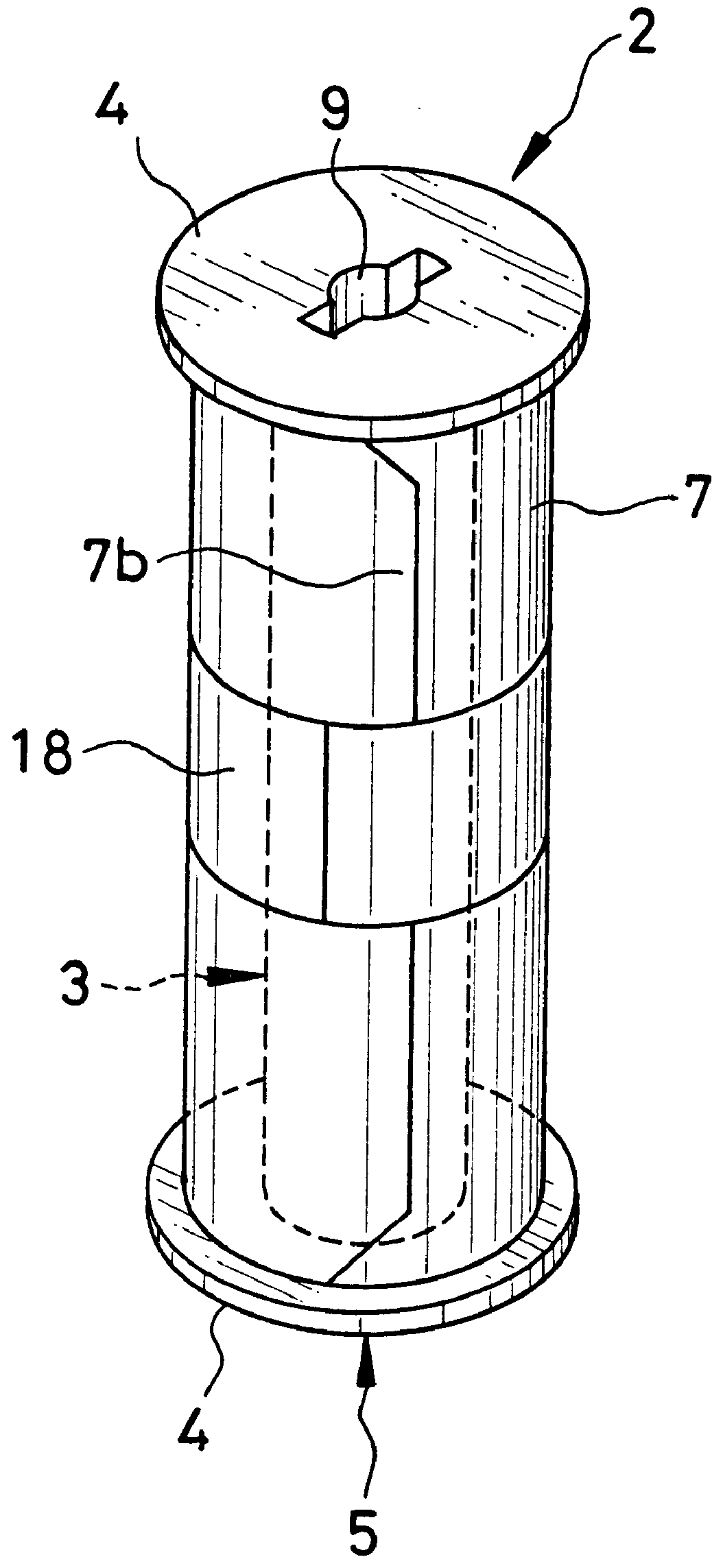

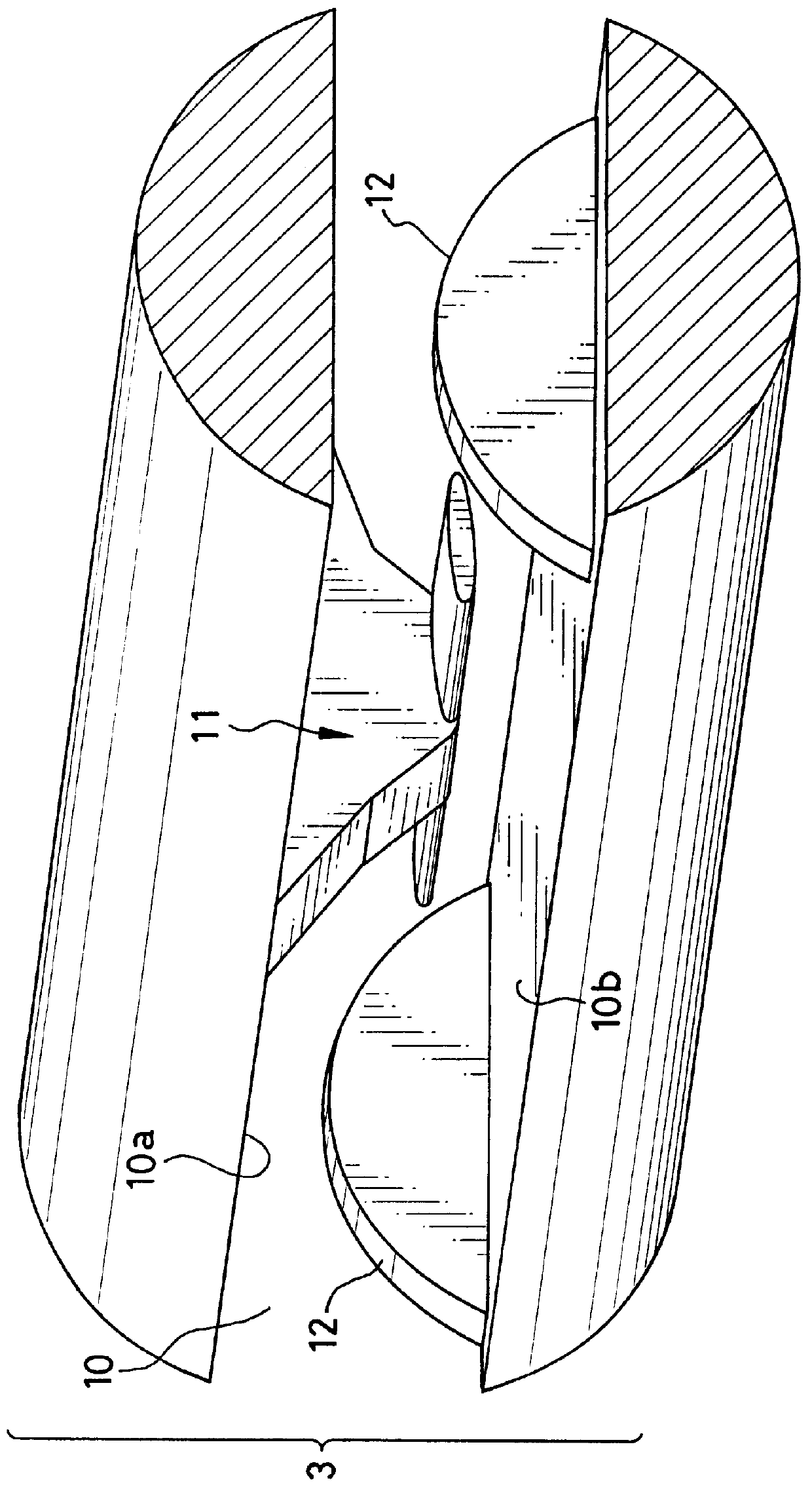

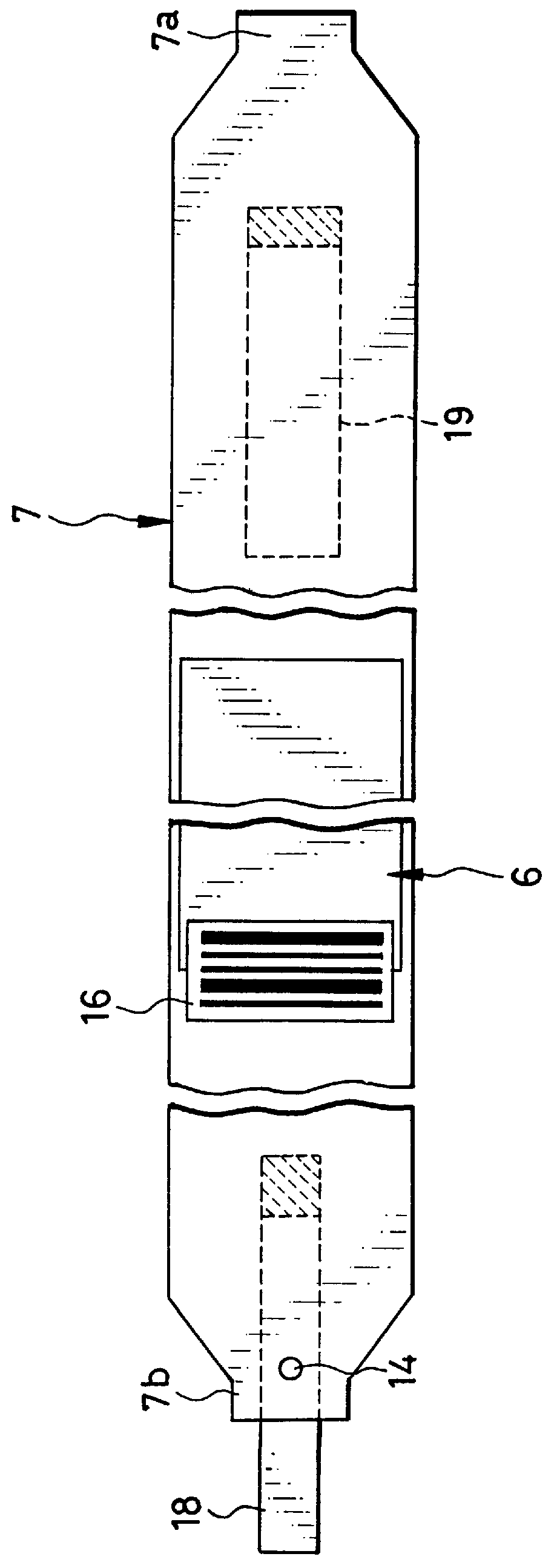

Film cassette, rack and relief trolley for the film cassette, and method of handling the film cassette

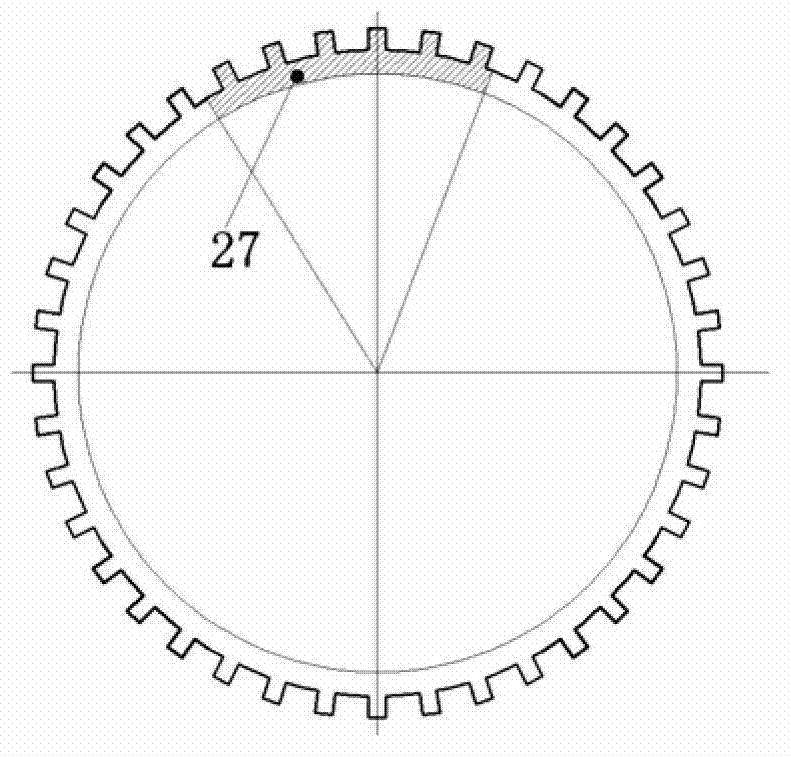

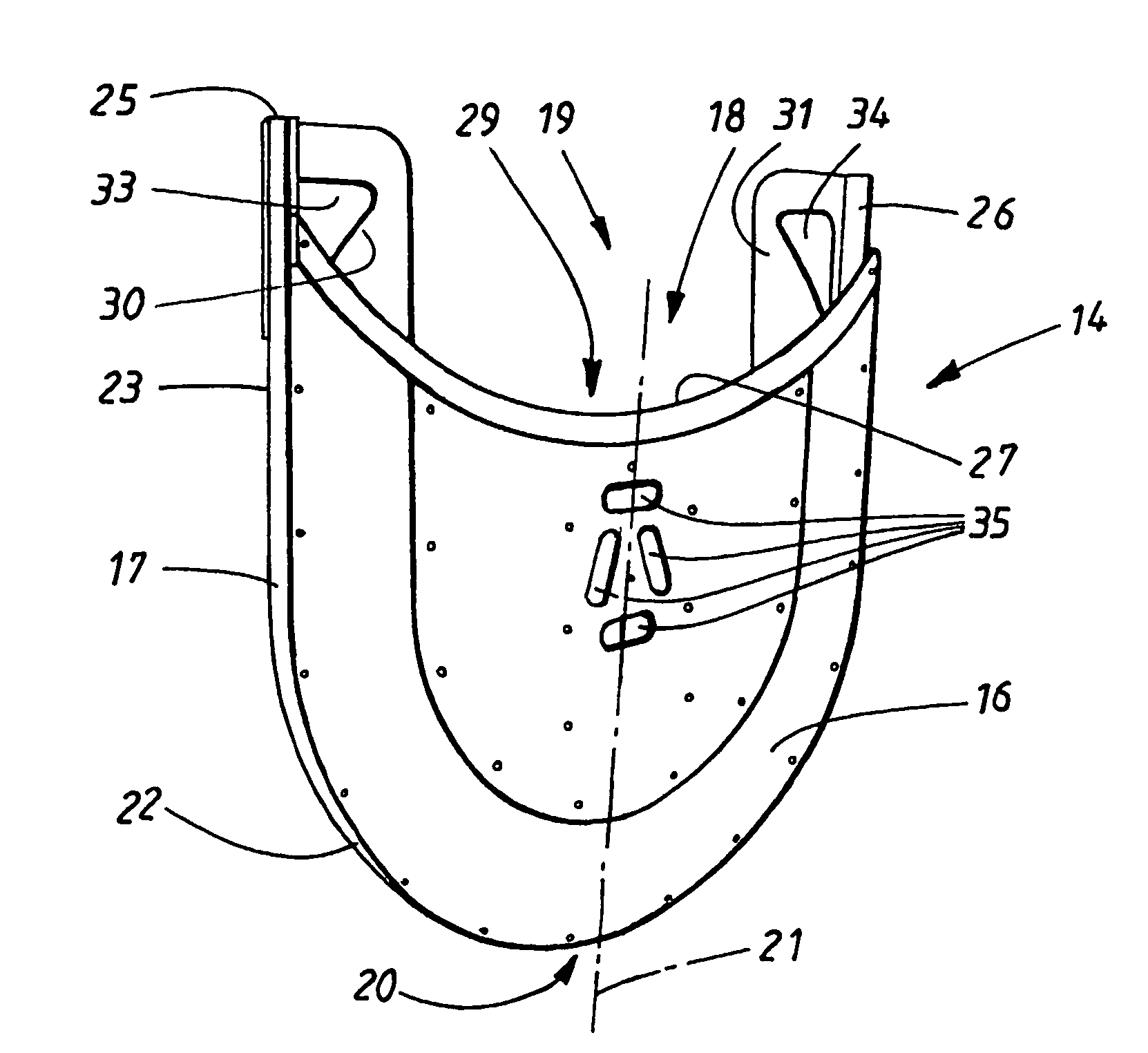

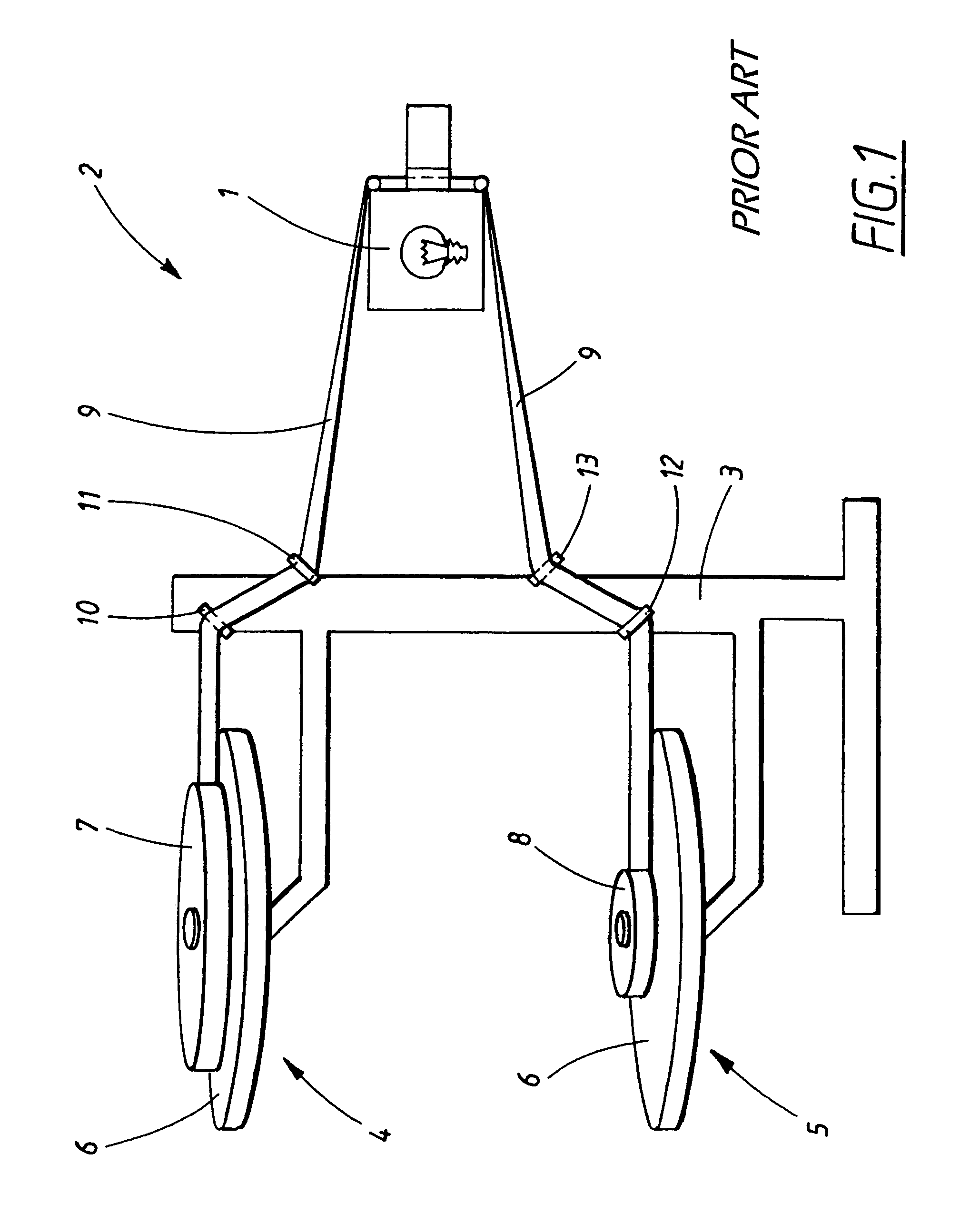

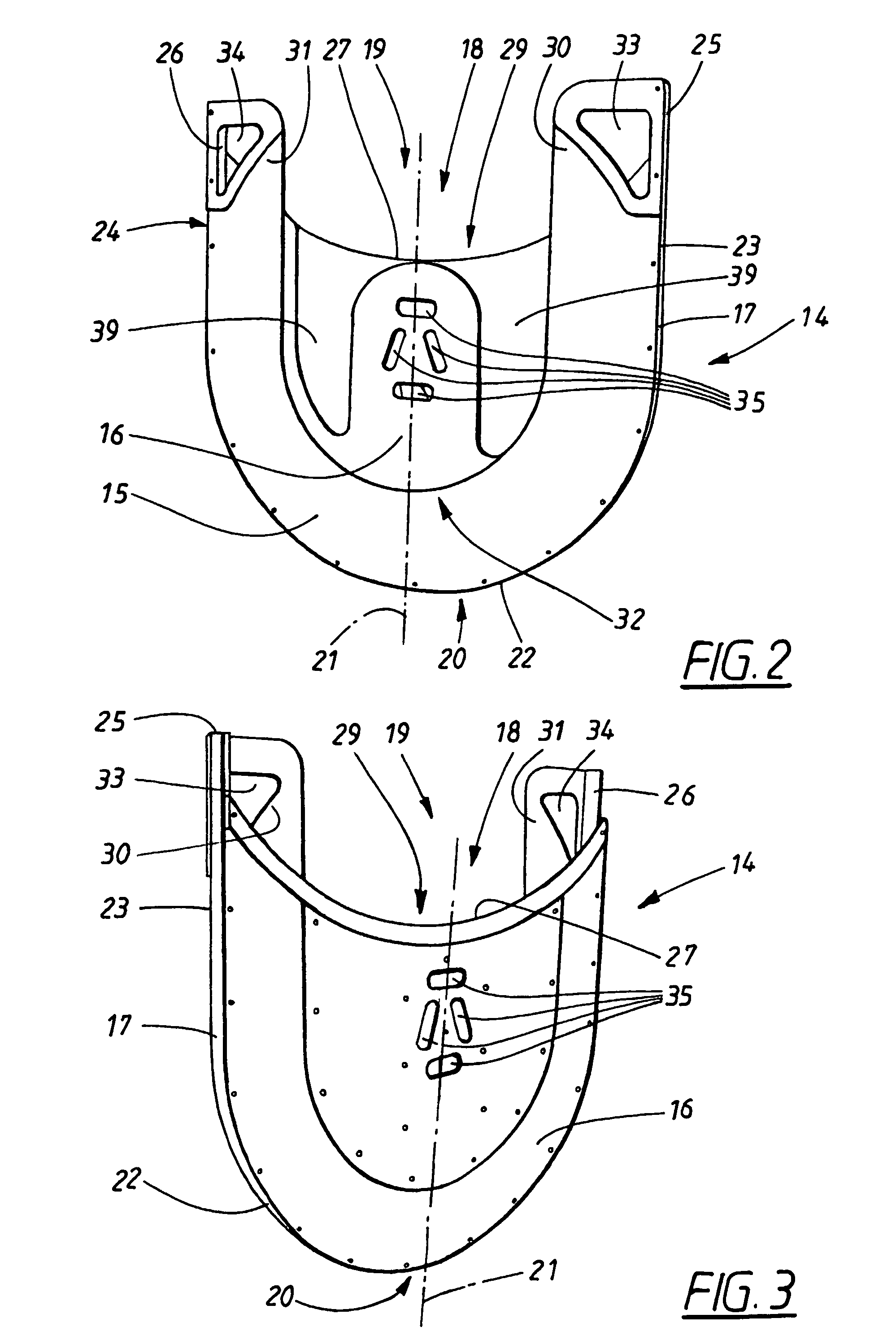

The present invention relates to a cassette for storing cinema film rolls (7). The cassette (14) comprises a first portion (15) and a second portion (16) which are essentially plane-parallel and separated by a spacing which exceeds the thickness of a cinema film roll (7) and connected by a connecting part (17). The cassette (14) also has an opening (18). The invention is characterized in that the cassette (14) comprises bearing supports (25, 26) for weight-relief against a horizontal circular table (4, 5) when the film roll (7) is moved between the cassette (14) and the circular table (4, 5). The invention also relates to a method of transferring a cinema film roll (7) between a storage cassette (14) and an essentially horizontal circular table (4, 5). The cassette is positioned so that bearing supports (25, 26) of the cassette (14) bear against the circular table (4, 5) and so that a contact edge (27) of the cassette (14) is fitted against the peripheral edge (28) of the circular table (4, 5). In this position, the film is moved between the cassette and the circular table. The present invention also relates to a rack (40) and a relief trolley (46) intended for cassettes (14) as described above.

Owner:CARLSSON EQUIP

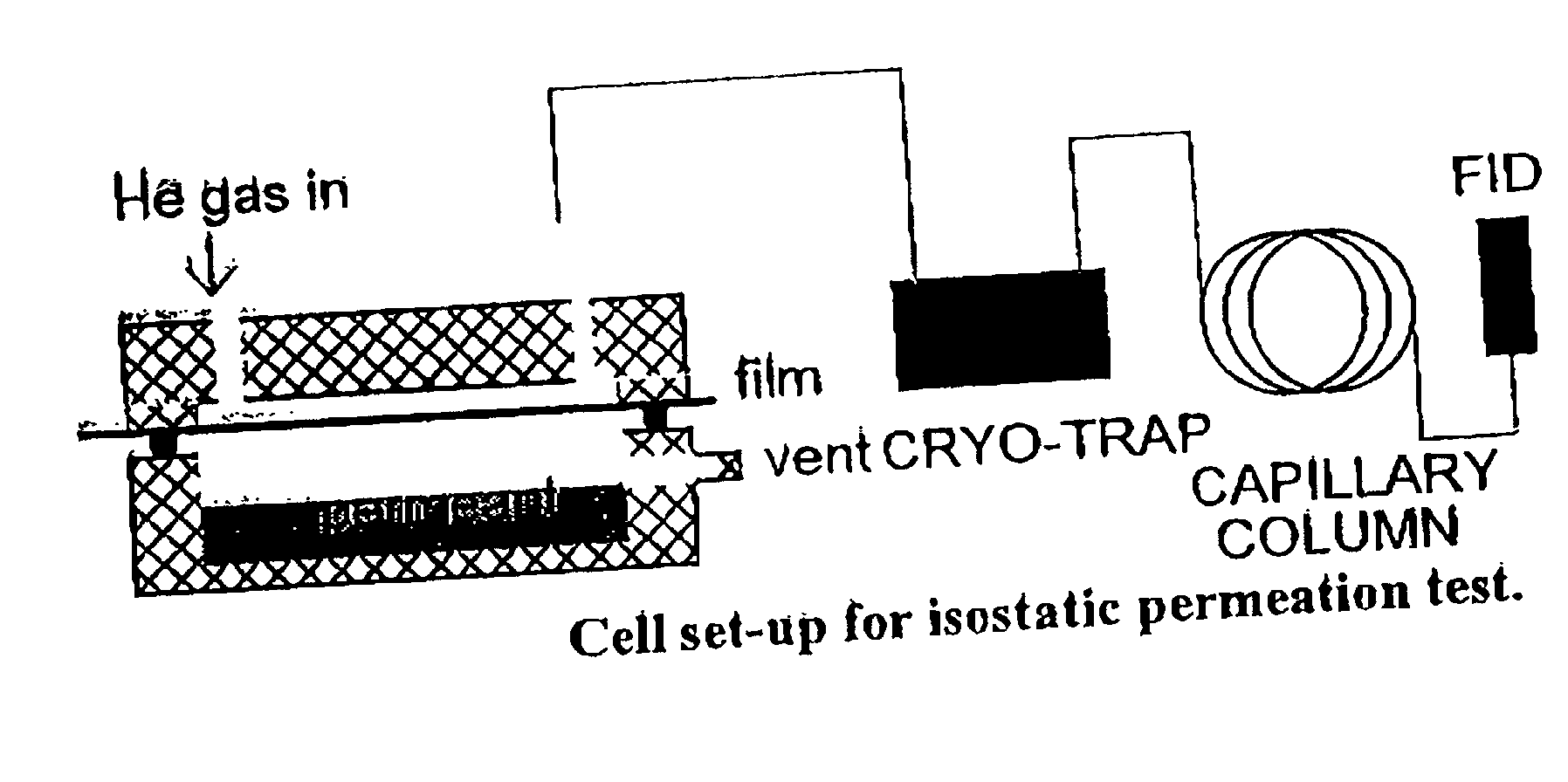

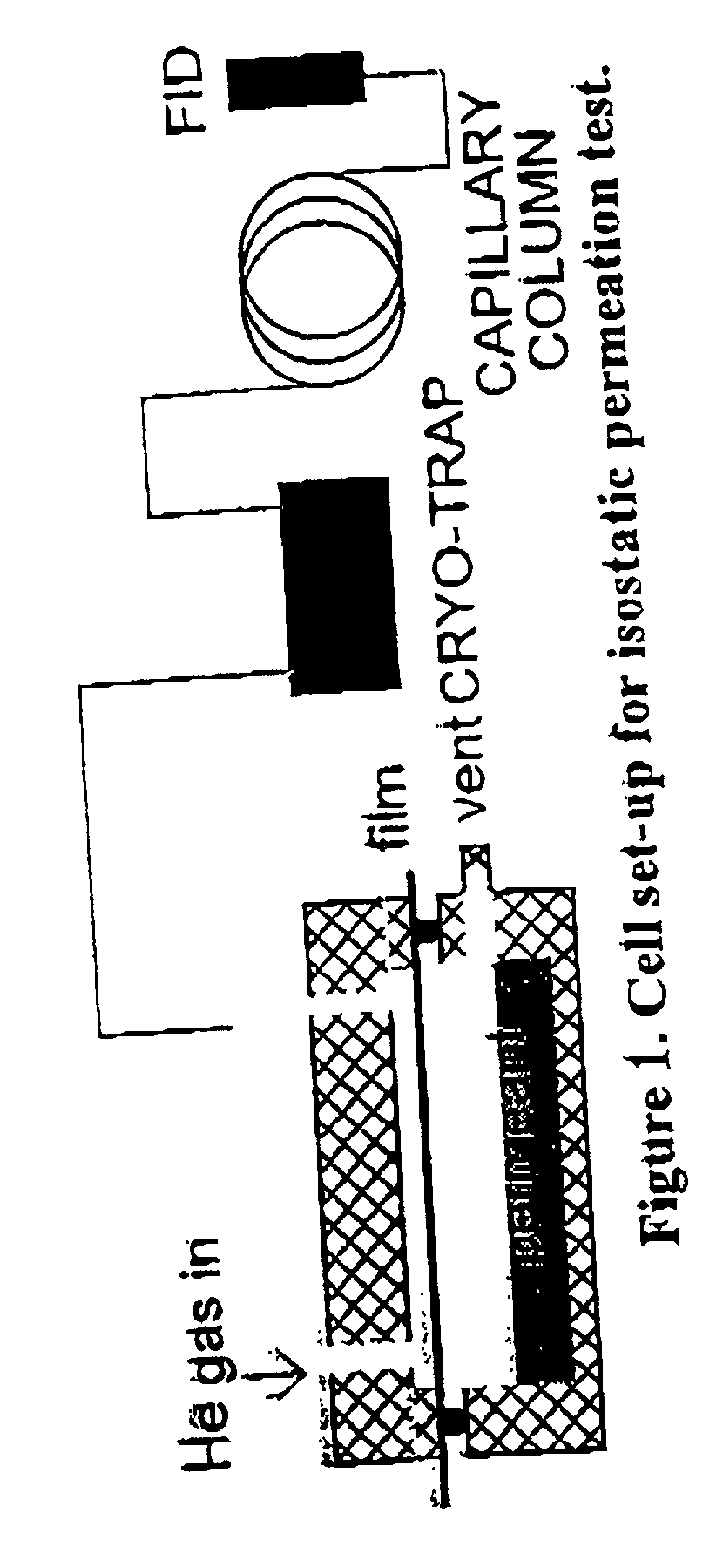

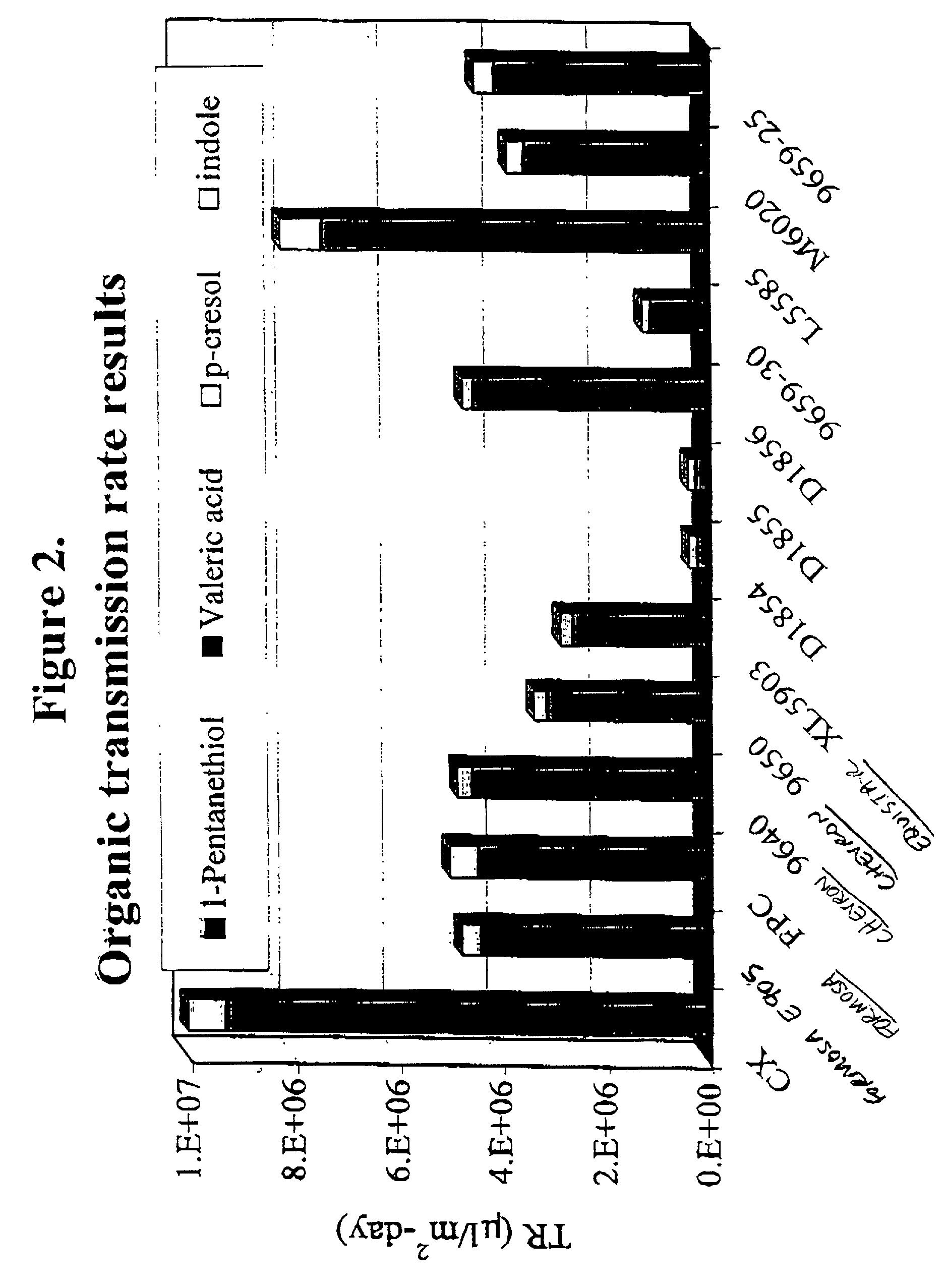

Odor control cassette

InactiveUS20030131569A1Reduce odorInexpensive and easy to manufactureRefuse receptaclesContainer/bottle contructionHigh-density polyethyleneEngineering

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:PLAYTEX PROD INC

Method of manufacturing a film coated article

InactiveUS6221304B1Low costPrecise positioningTailstocks/centresConfectioneryShell moldingEngineering

A method and apparatus for manufacturing a film coated article by placing a pre-molded film into a loading station. The film has a decorative surface and a backing surface. The decorative surface is positioned juxtaposed the loading station. The film is transferred to a loader. The loader is positioned juxtaposed the backing surface. The loader and film are positioned in an open mold press between a cavity and a core. The film is transferred from the loader to the cavity. The decorative surface of the film is positioned juxtaposed the cavity. The cavity mates with the film and retains the film in position during the molding operation. The press is closed and a polymeric material is injected against the backing surface of the film. The polymeric material produces a molded article having a rigid substrate fused to the backing of the film and displaying the decorative surface. The press is opened and the molded article is transferred from the cavity to an unloader. The decorative surface of the article is positioned juxtaposed the unloader. The molded article is transferred to an unloading station and the unloader releases the molded article.

Owner:VISTEON GLOBAL TECH INC

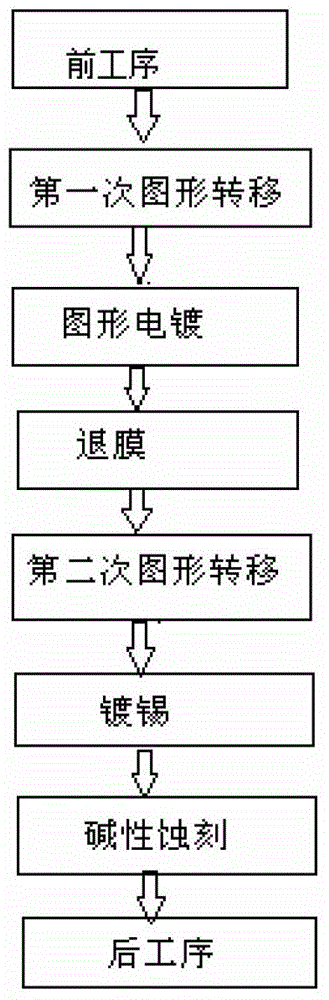

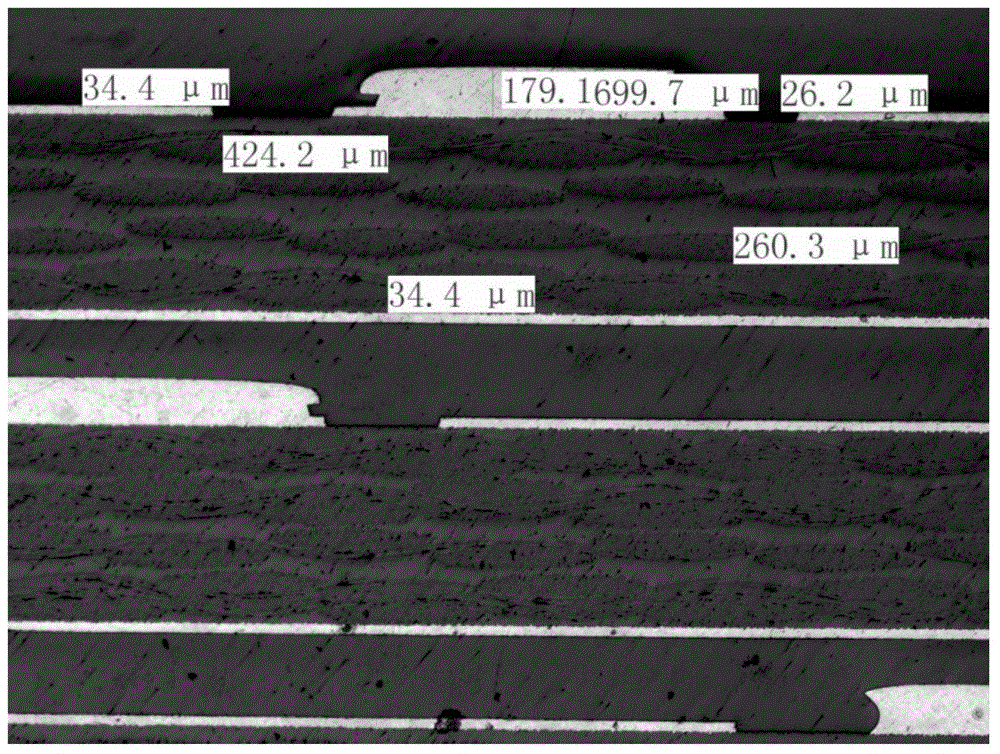

Heavy-copper step circuit board and preparation method thereof

ActiveCN103338595AOptimize grinding plateOptimizing the etch processConductive material chemical/electrolytical removalTinningAlkaline etching

The invention discloses a heavy-copper step circuit board and a preparation method thereof. The preparation method comprises the working procedures of primary pattern transfer, pattern electroplating, film removal, secondary pattern transfer, tinning and alkaline etching. The preparation method solves the quality problem of a clamping film and the quality problems such as circuit nicks and unclean etching due to the fact that an anti-corrosion layer cannot be closely bonded with a circuit by a dry film technology by utilizing the production capacity of the available equipment and optimizing roll film, board grinding and etching processes; the whole preparation process is compatible with the traditional circuit board technology; and the quality and the cost can be compatible effectively.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

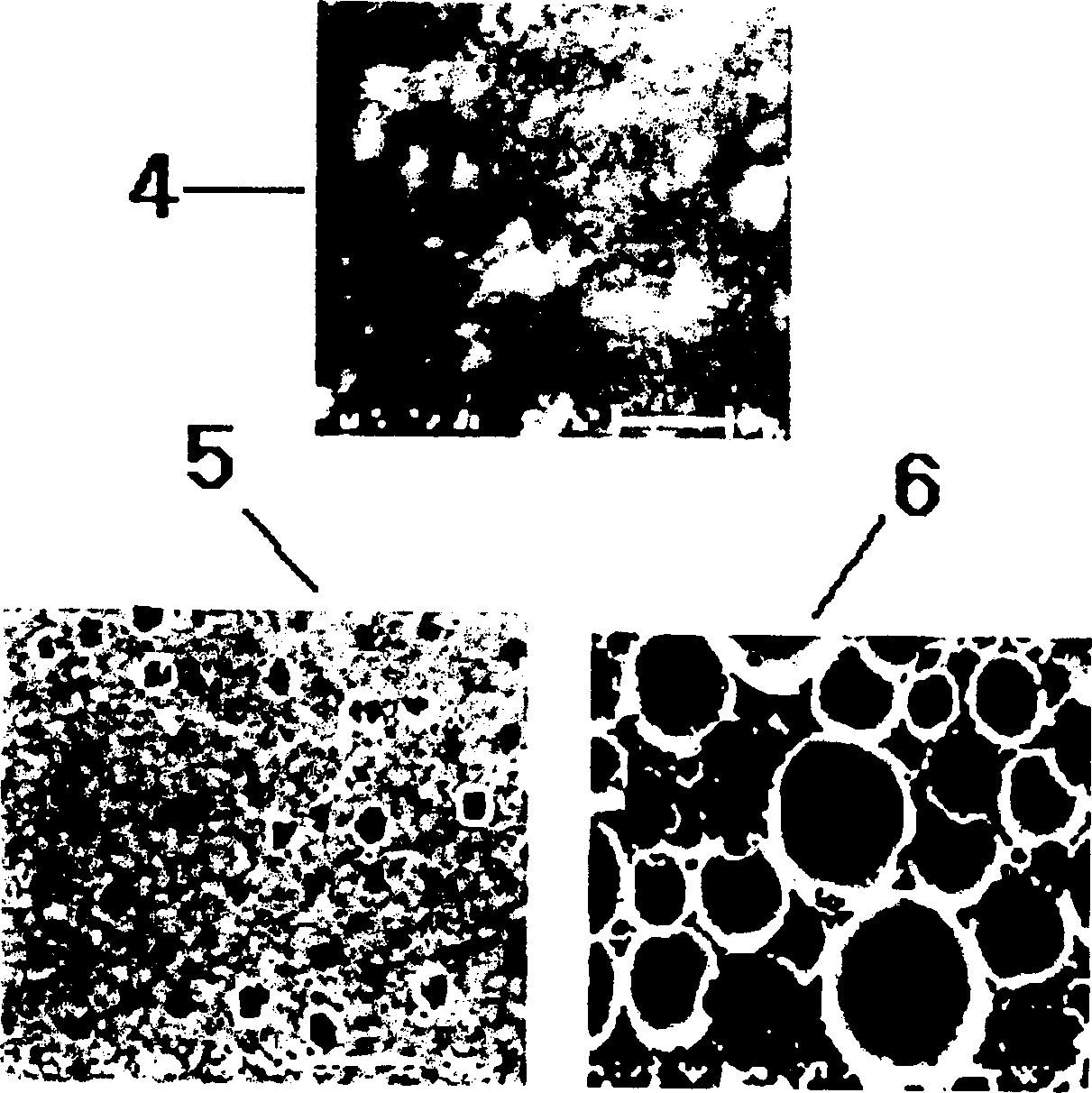

Multilayer polyporous foam dressing material and its producing method

The present invention relates to a multimicroporous foamed dressing with multilayer structure and its preparation method. The thickness of said dressing is 1-7 mm, and its structure contains the following three layers: first layer is outside protective film layer whose thickness is 10-90 micrometer, second layer is internal absorption foamed layer with several holes whose diameter is 80-400 micrometer and third layer is wound-contacting layer with several microfine pores whose average diameter is below 60 micrometer, and its thickness is 0.1-200 micrometer. Its preparation process is simple and includes the following steps: firstly, mixing 40-75 wt% of polyurethane prepolymer, 15-45 wt% of foaming agent, 5-35 wt% of cross-linking agent and 0.5-15wt% of additive containing surfactant, humectant, releasing agent, bactericide and pigment, stirring them, injecting them into mould, foaming and moulding.

Owner:株式会社界优维

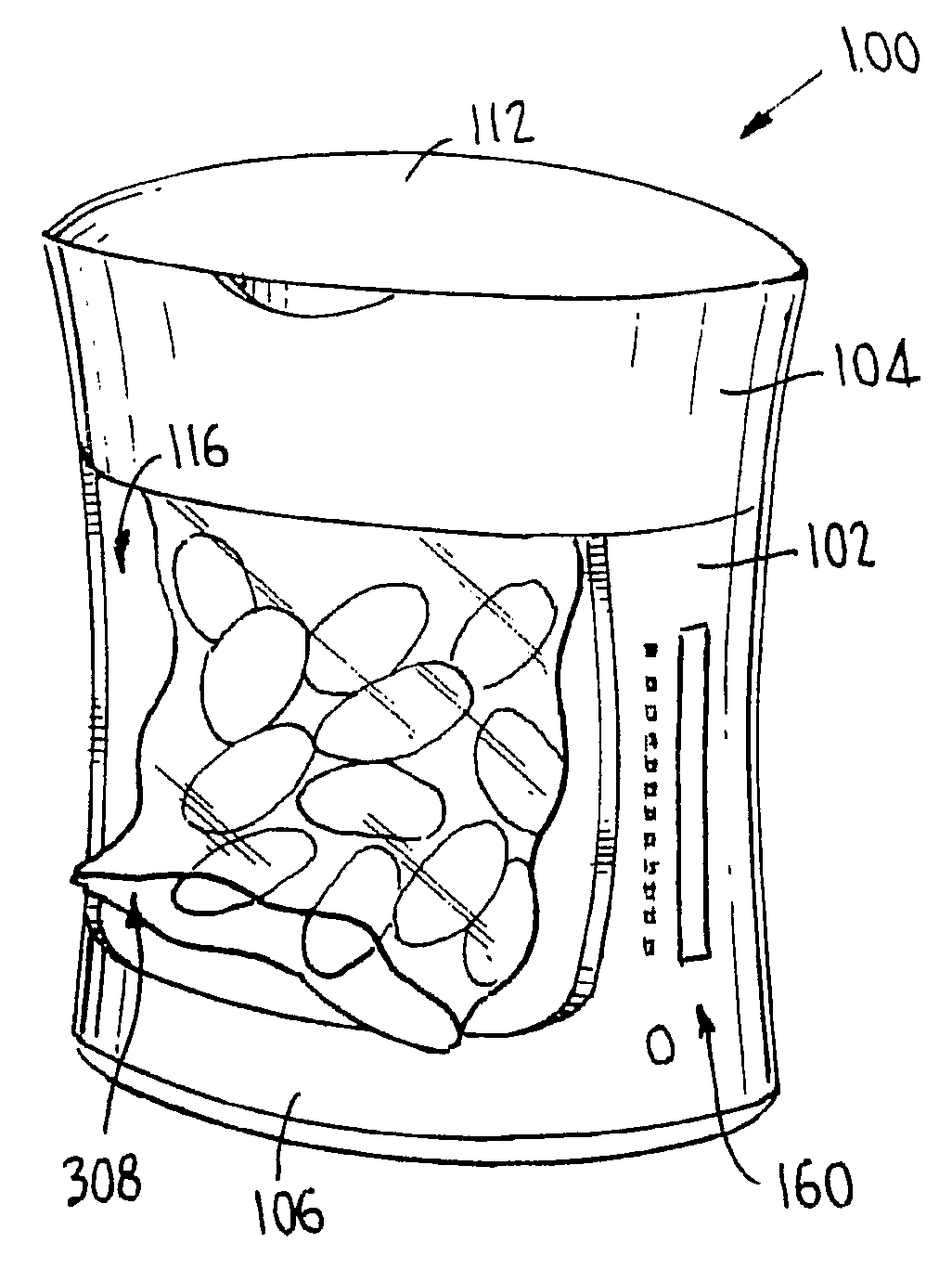

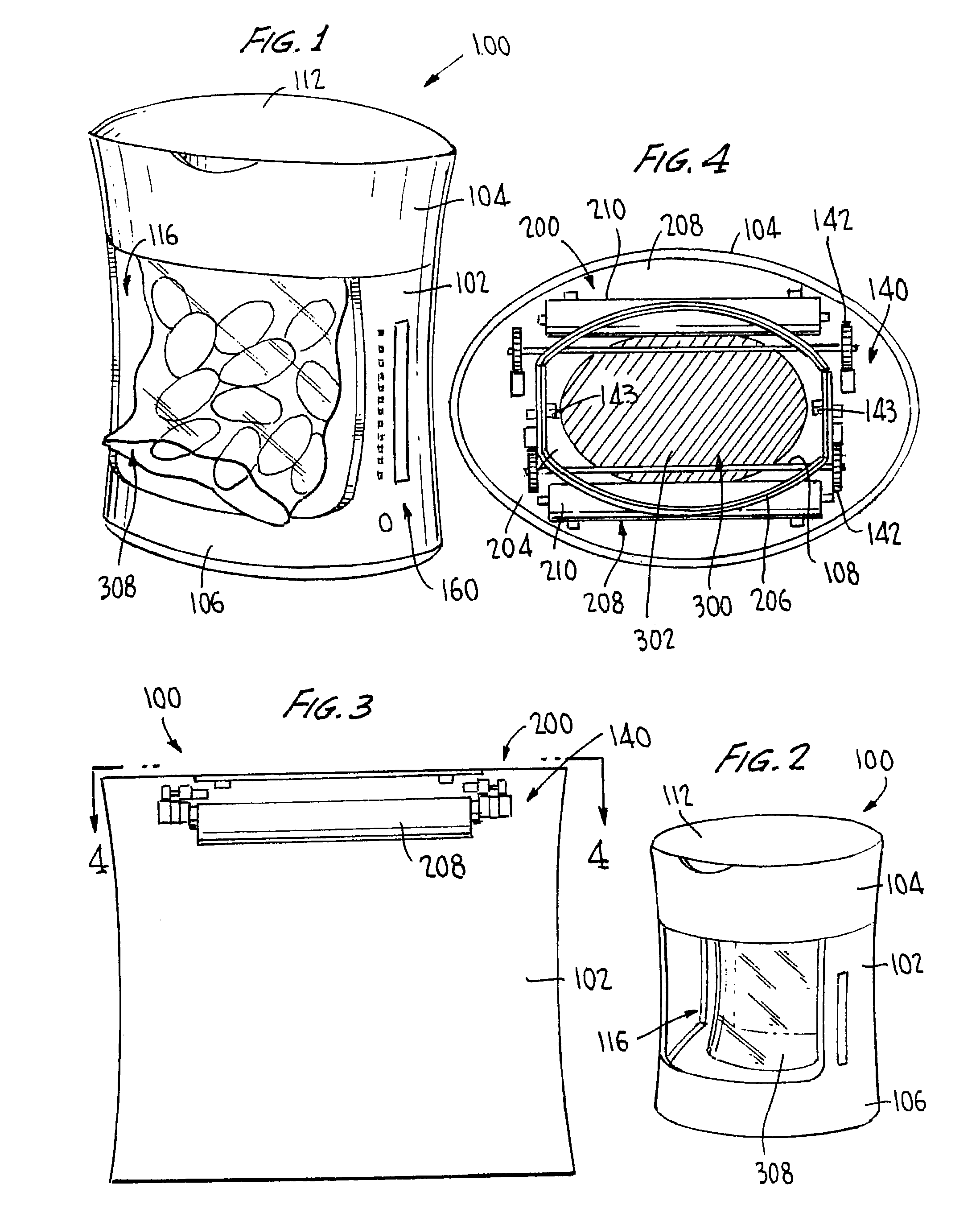

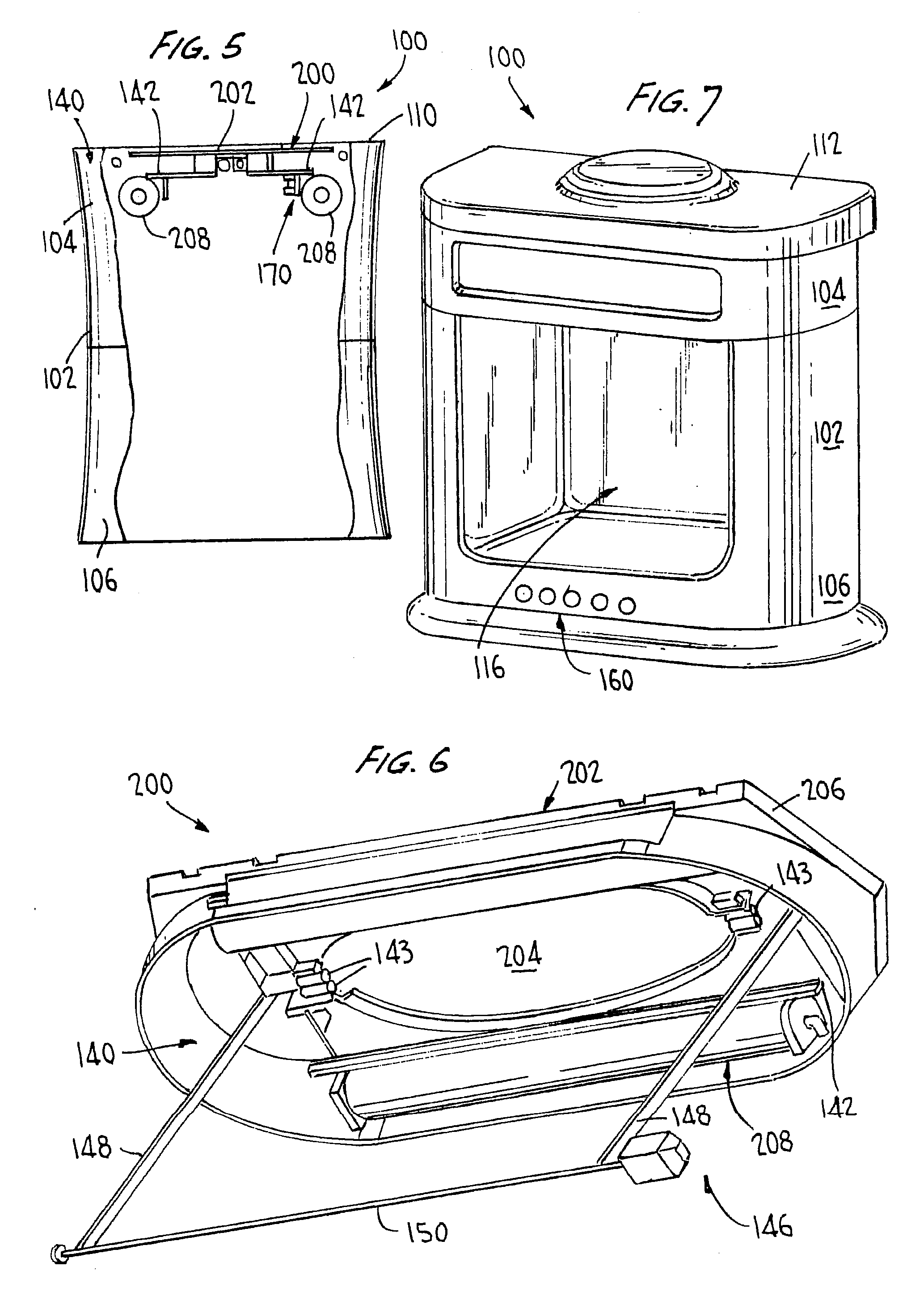

Vacuum sealer apparatus and a film cartridge for a vacuum sealer and a means of operating the vacuum sealer and the film cartridge

InactiveUS20080000204A1Easy and fast packingImprove freshnessPackaging by pressurising/gasifyingEngineeringVacuum pump

A vacuum sealer for packaging, sealing and storing items and a film cartridge for a vacuum sealer is disclosed. The vacuum sealer has a means to feed, form, seal and cut film bags for storing items. The vacuum sealer preferably includes a body, a top portion, a base portion, a film cartridge, a drive mechanism, a sealing and cutting mechanism and a vacuum / pump mechanism. The film cartridge is operatively positioned in a feed opening in a top portion of the vacuum sealer. The film cartridge houses film for forming film bags for use in the vacuum sealer. The film cartridge may have tubular film contained in a collapsed state or may have two film rolls which are brought together and sealed at the edges. The vacuum sealer may be used in a vertical orientation or optionally in a horizontal or angled orientation.

Owner:SC JOHNSON & SON INC

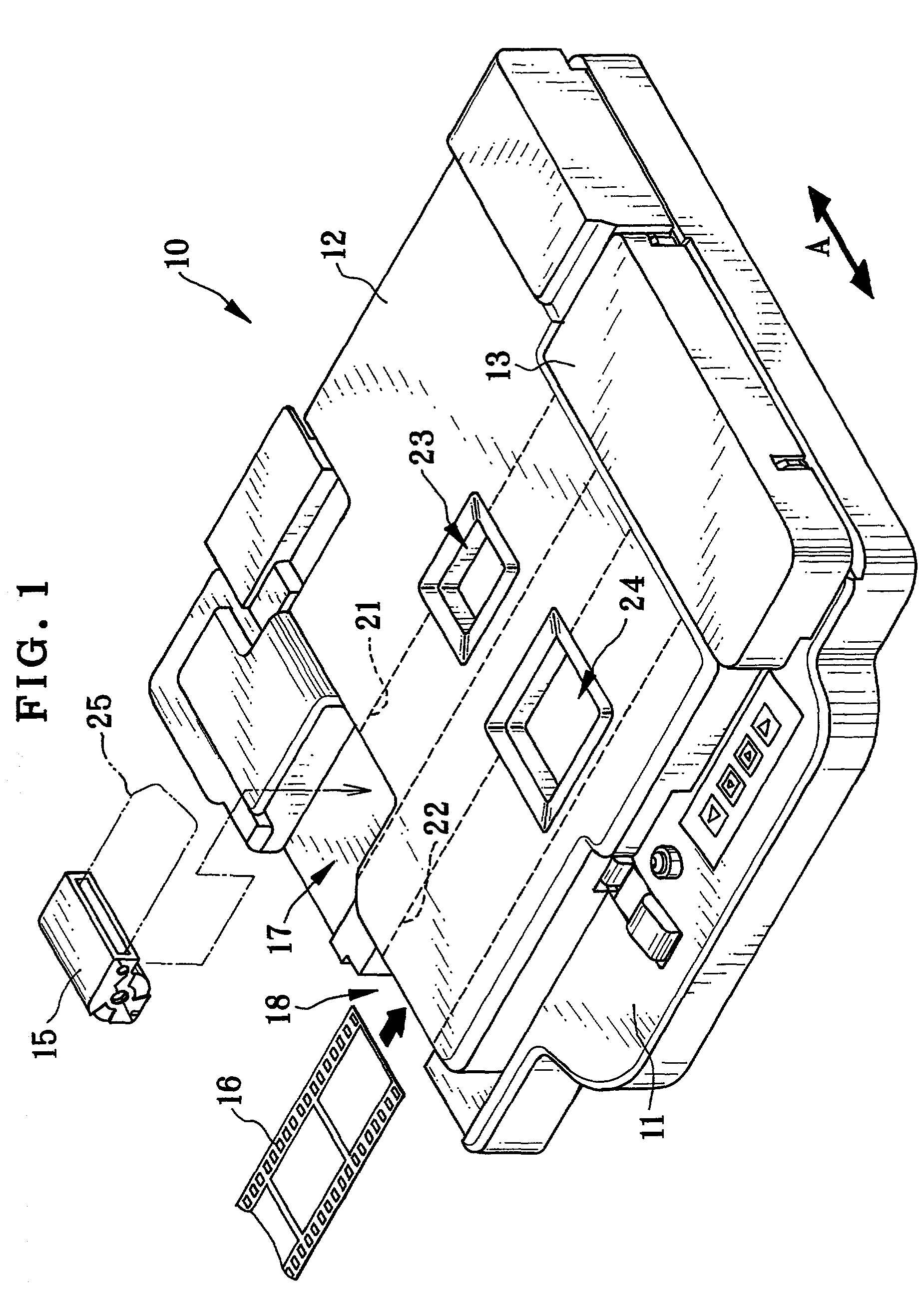

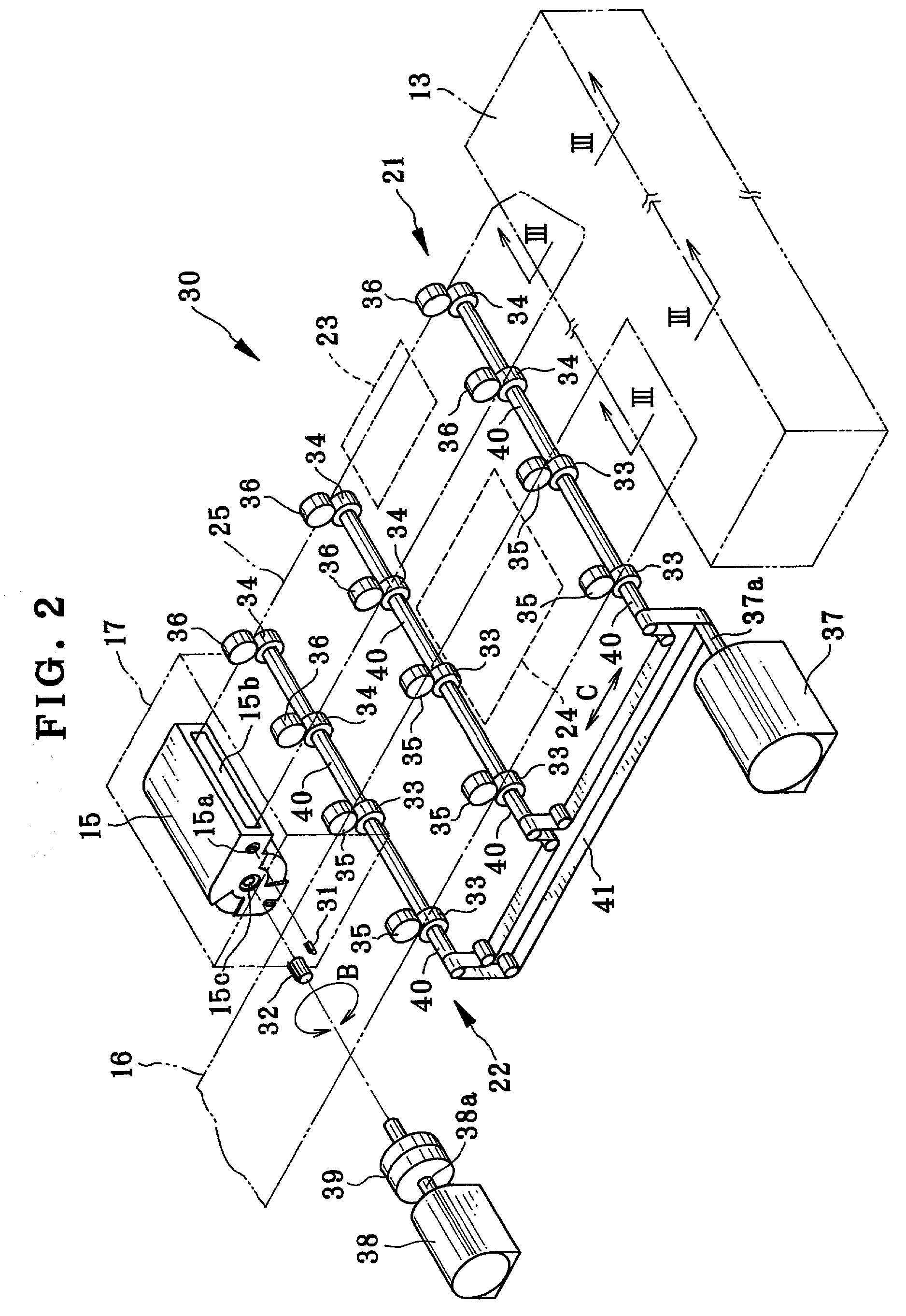

Winding method and device for photo film and photo film carrier

InactiveUS20020130212A1Eliminate loosenessProjector film strip handlingCamera film strip handlingRoll filmEngineering

Owner:FUJIFILM CORP +1

Film container

ActiveUS7866474B2Easy to creasingEasy to carrySmall article dispensingFlexible coversThin membraneStructural engineering

Owner:BOEHRINGER INGELHEIM INT GMBH

Thermoplastic resin film and process for producing the same

InactiveUS7166342B2Increase opennessMaintain good propertiesWrappers shrinkagePretreated surfacesPolymer scienceNitrogen

A heat-shrinkable resin film which has heat shrinkage in the maximum shrinkage direction of 20% or higher when a 10 cm×10 cm square sample cut out thereof is immersed in hot water at 85° C. for 10 seconds, pulled out, subsequently immersed in water at 25° C. for 10 seconds, and then pulled out, characterized in that a content of nitrogen atoms in a surface of the film is 0.1% to 3.0% and the surface of the film has wet tension of 36 mN / m or higher; and a film roll obtained by winding up the heat-shrinkable resin film characterized in that when the rolled film is sampled at a first sampling part located up to 2 m apart from the end of the rolled film and at other sampling parts located after the first sampling part at intervals of about 100 m and an average content of nitrogen atoms of each sample is calculated, then the content of nitrogen atoms of each sample is within the ±0.8% range based on the above average content of nitrogen atoms.

Owner:TOYOBO CO LTD

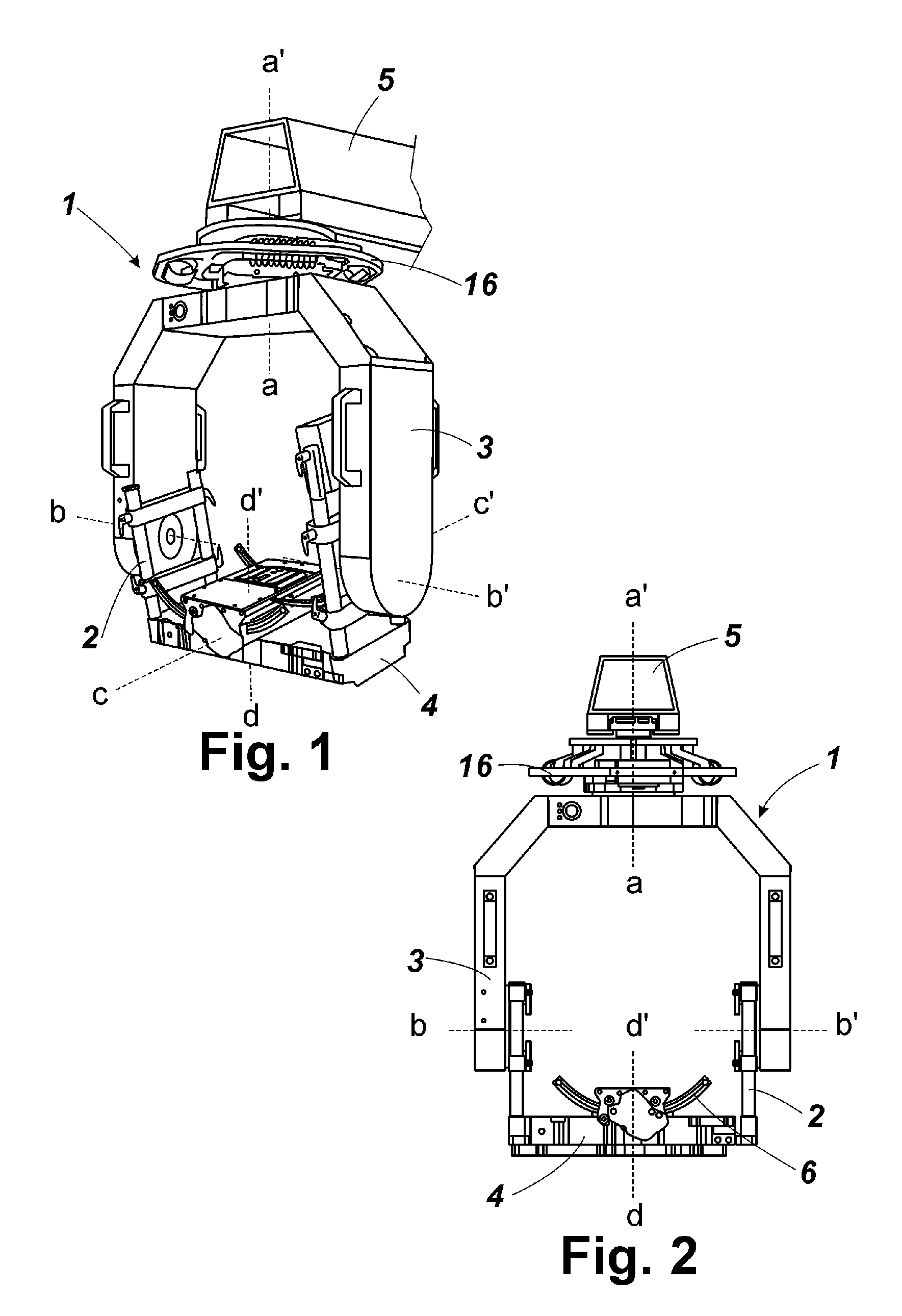

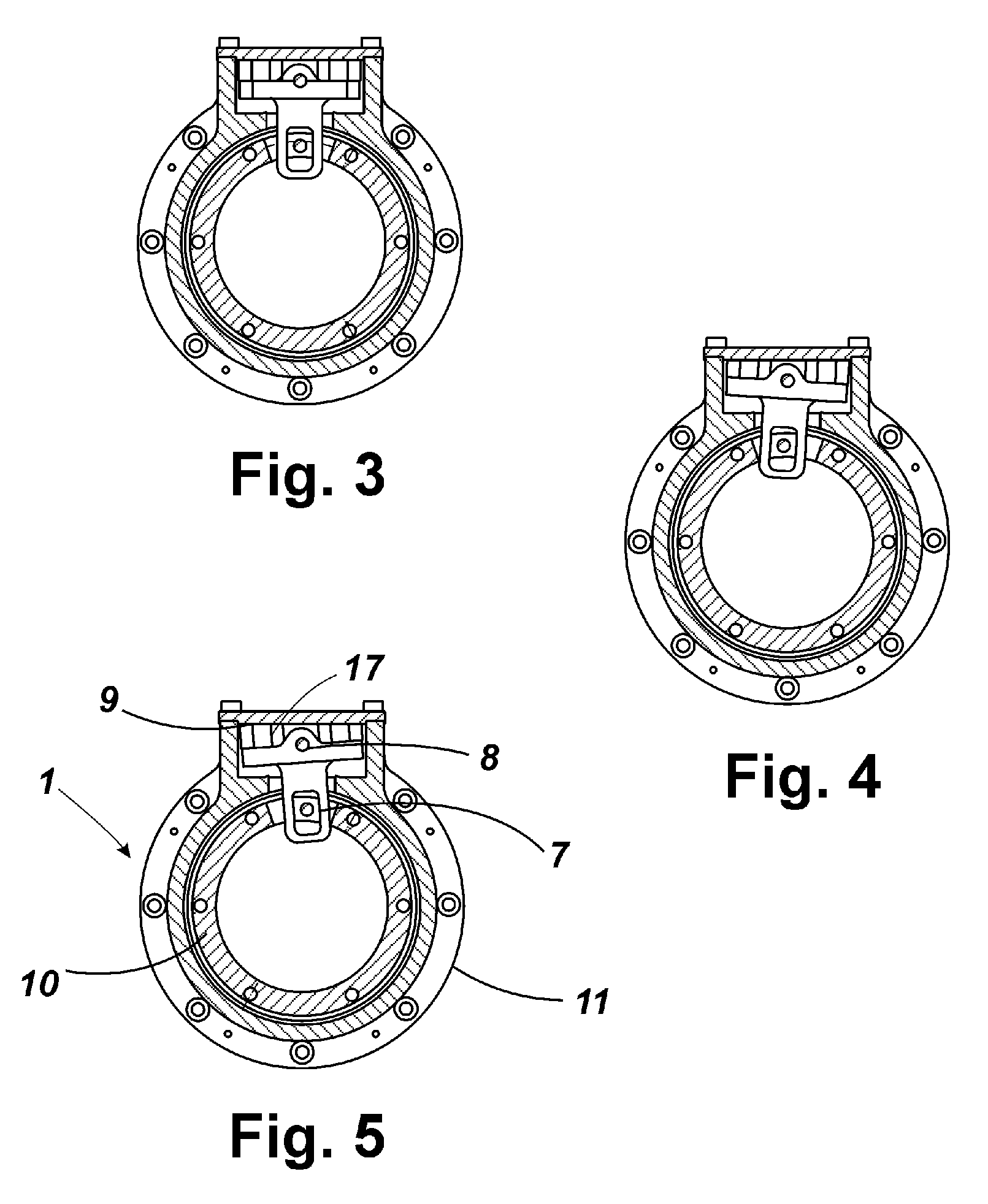

Film camera head

InactiveUS20090148150A1Reduce impactPossible movementStands/trestlesKitchen equipmentSheet filmEngineering

Owner:VALLES NAVARRO ANDRES +1

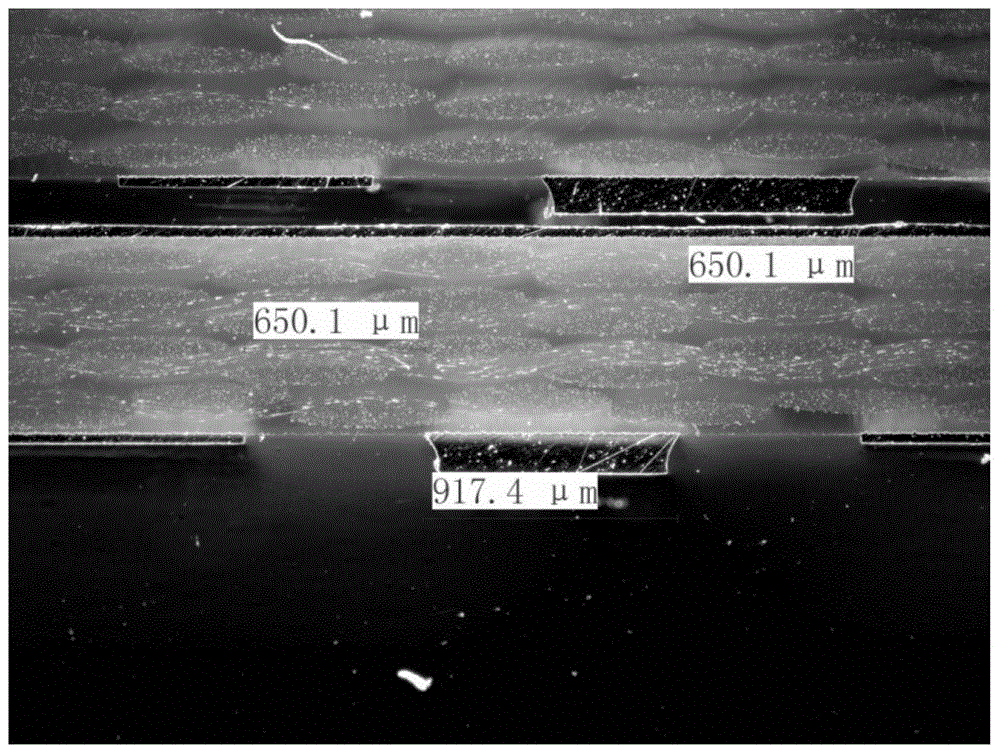

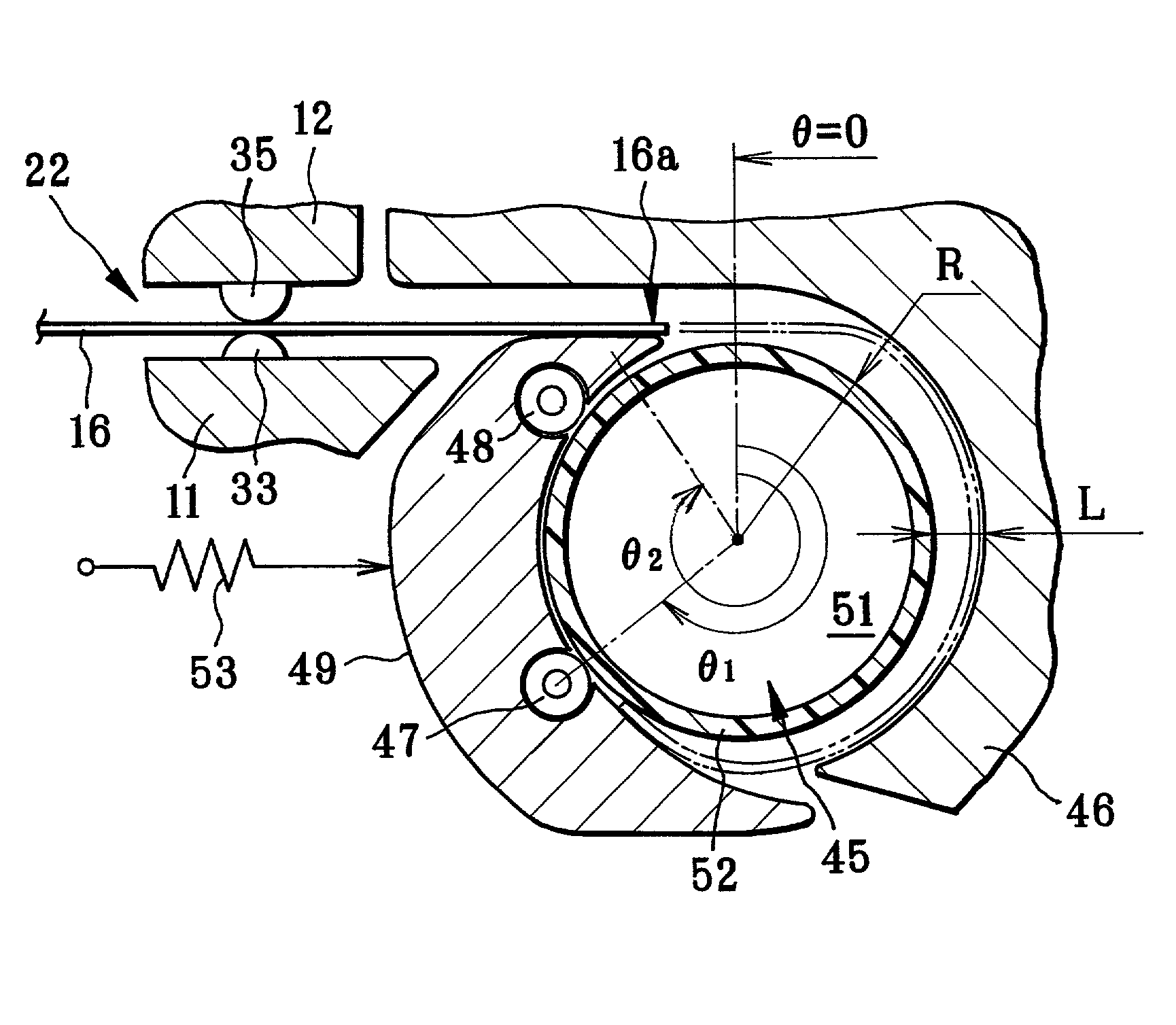

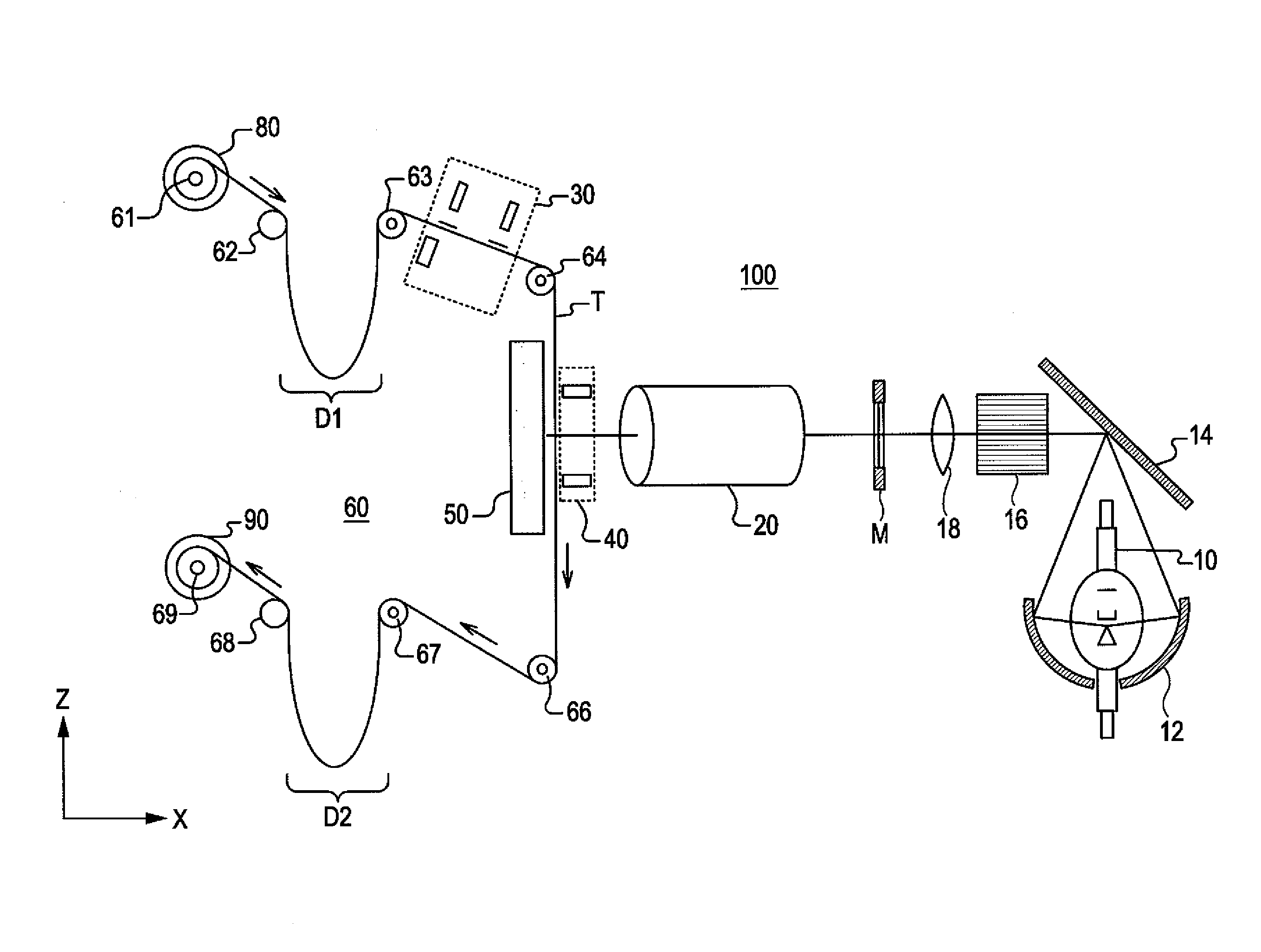

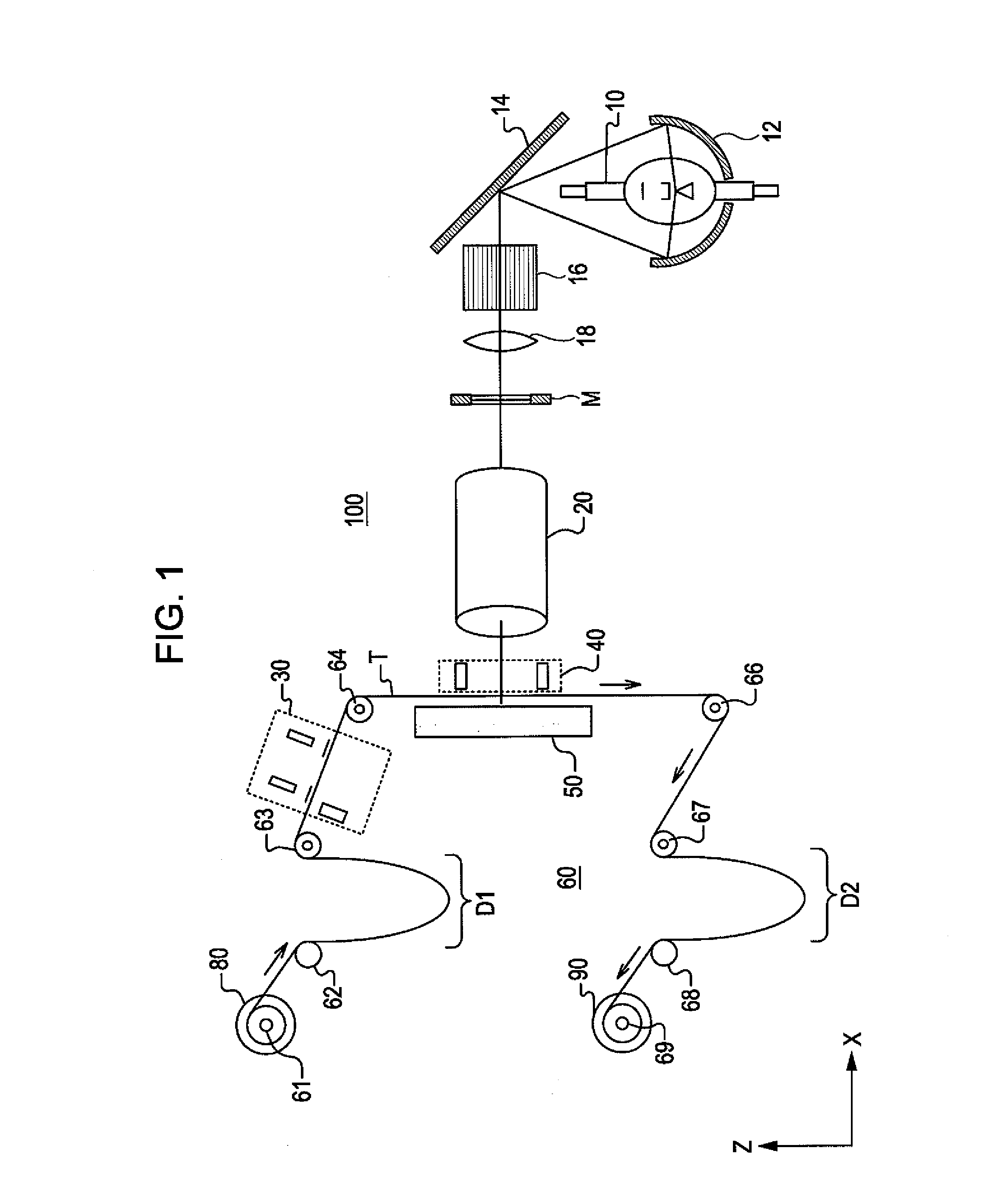

Exposure device with mechanism for forming alignment marks and exposure process conducted by the same

ActiveUS20090059195A1Accurate transferReduce riskPrinted circuit aspectsSolid-state devicesEngineeringRoll film

The present invention relates to an exposure device for transferring circuit patterns of a mask to a roll-film-shaped object. The exposure device includes a supply reel rotation section that is constituted by a supply reel around which the object is wound and that feeds the object by rotating the supply reel, at least one guide roller for guiding the object fed from the supply reel rotation section, an exposure stage on which the circuit patterns are transferred to the object guided by the guide roller, and an alignment mark forming section which forms, on the object, alignment marks that are used to align the mask with the object and which is positioned between the guide roller and the exposure stage.

Owner:ORC MFG

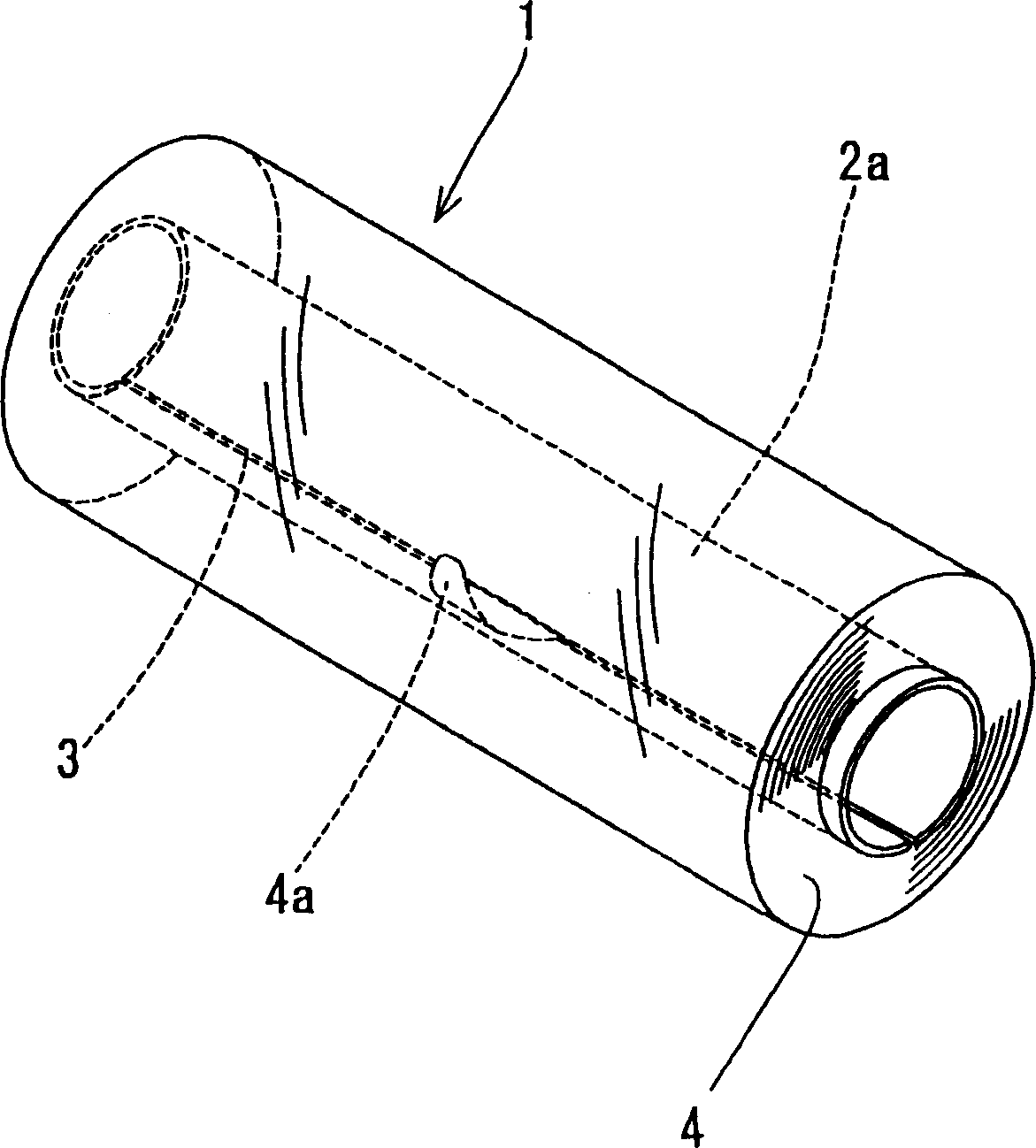

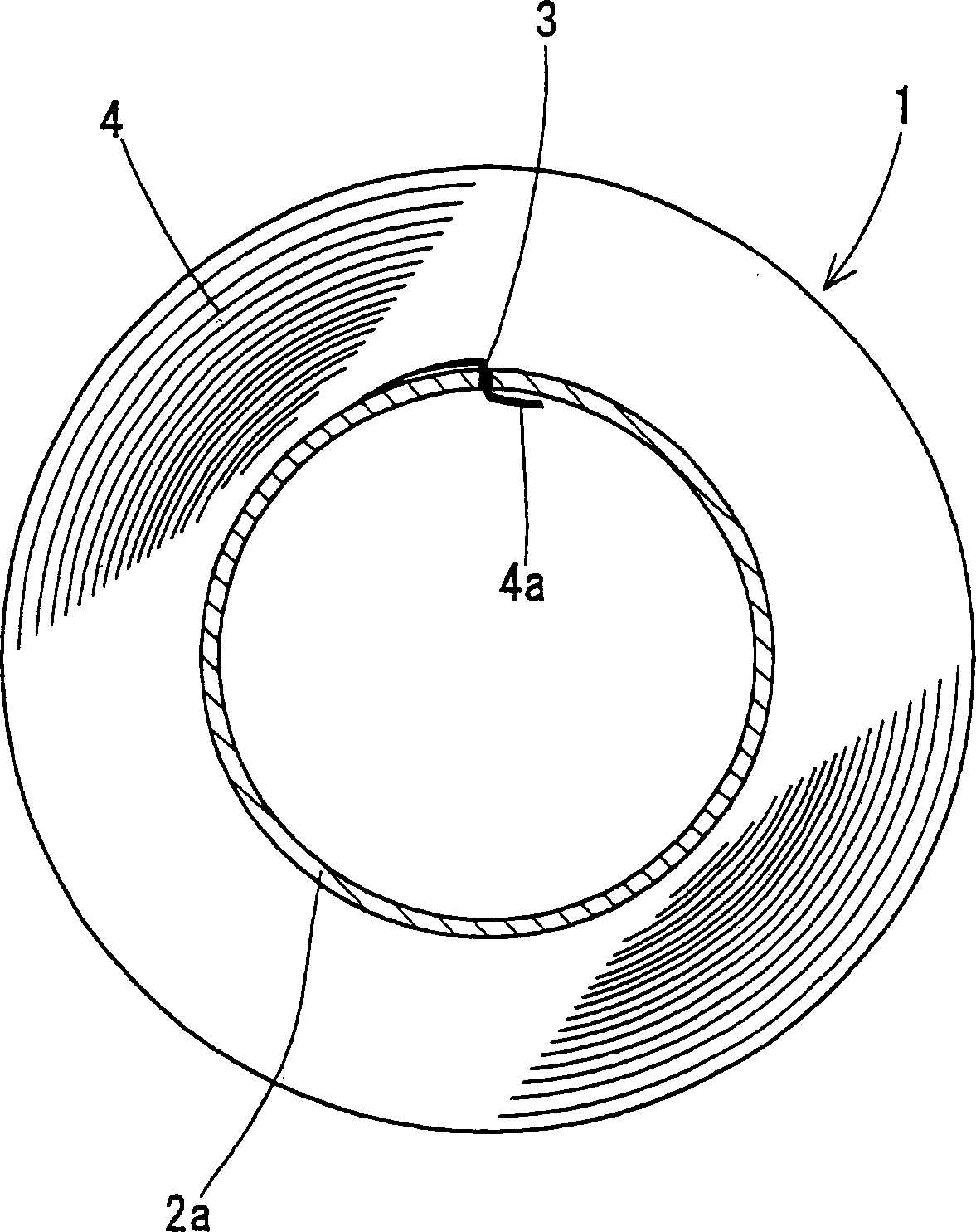

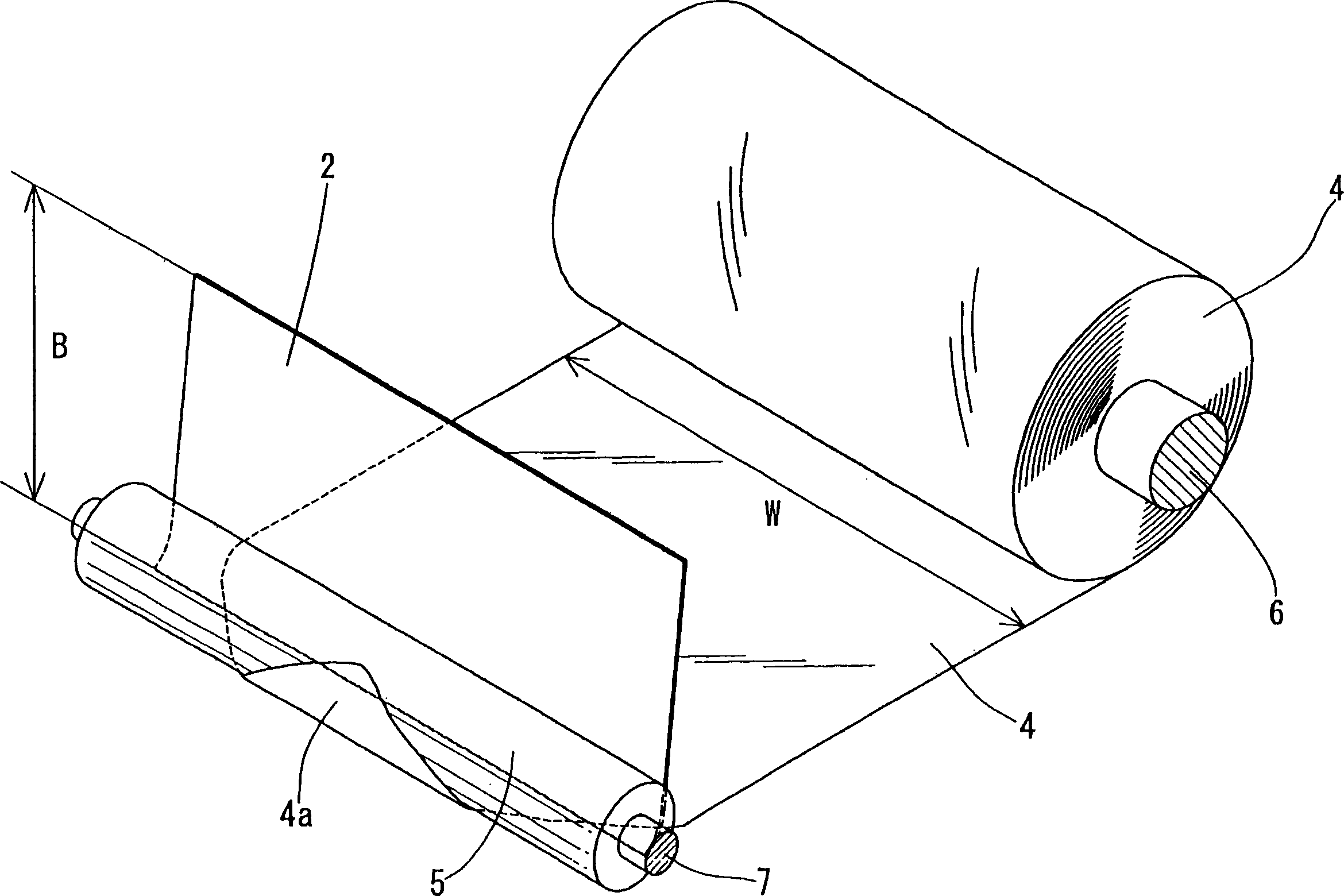

Wound product and its winding method

An improved roll-to-roll product that rolls long strips of film or sheet onto cores that can be scrapped without effort when ordinary paper tubes are not used. The core is formed by bending a flat sheet of cardboard into a tube. The side edges of the panels can be split, butted or overlapped. The sides may or may not be connected together. The end of the film is stuck on the side edge of the flat plate. This device allows the film to be used to the last inch under the condition of applying a certain tension and without damaging the core or winding displacement. Ends can be fitted with caps to improve core shape retention.

Owner:TAIKA INDS

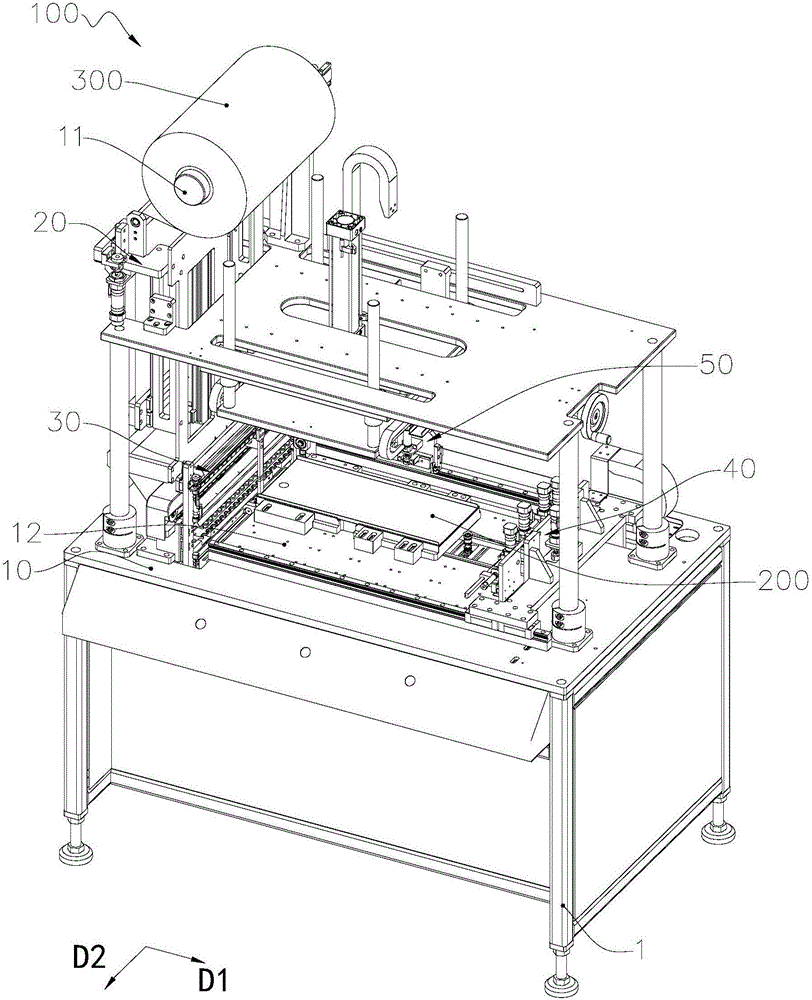

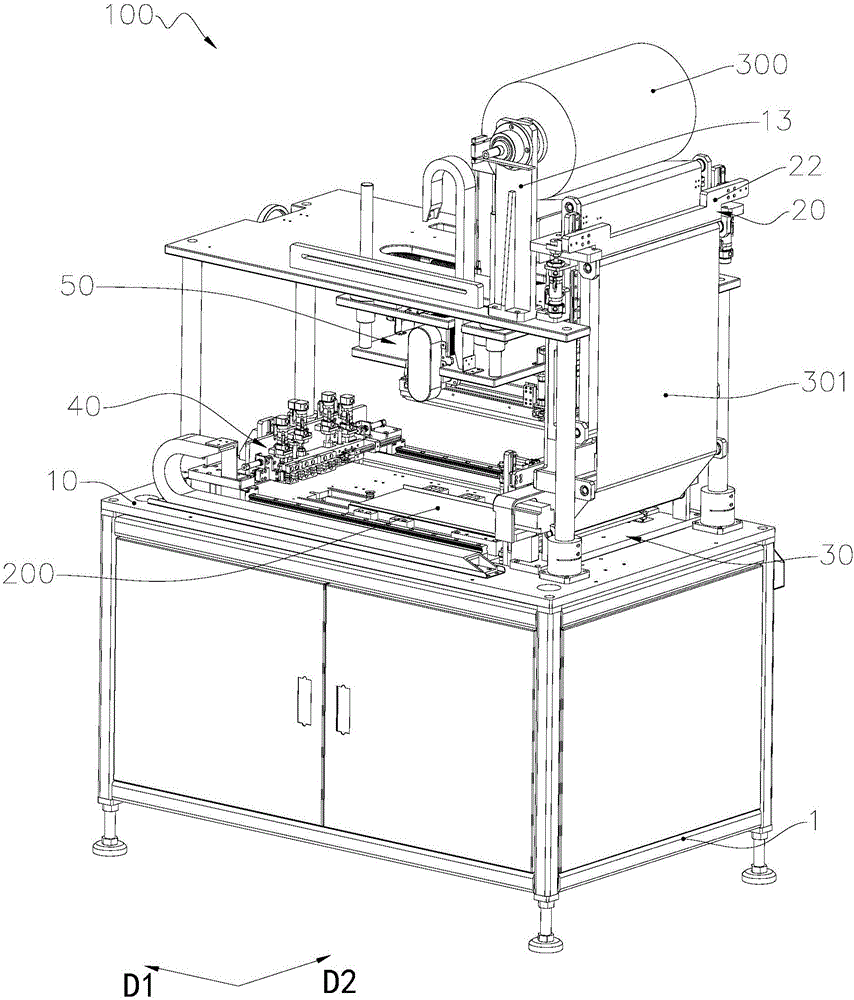

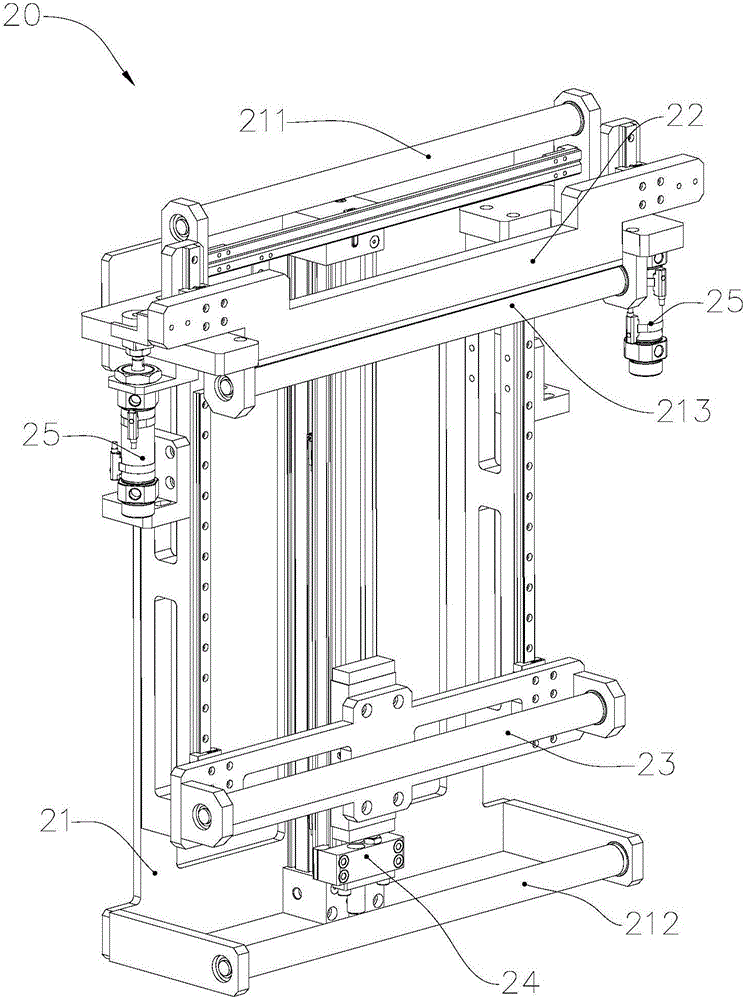

Film sticking machine

ActiveCN105958101ARealize automatic film applicationImprove yield rateAssembling battery machinesFinal product manufactureEngineeringUltimate tensile strength

The invention relates to the technical field of battery film sticking, and provides a film sticking machine. The film sticking machine comprises a base plate for placing a workpiece waiting for film sticking and a film shaft for mounting a rolled film, wherein the surface of the base plate is provided with a transverse direction and a longitudinal direction which are vertical to each other. The film sticking machine also comprises a film pulling device, a film cutting device and a film sticking device which are mounted on the base plate. The film pulling device is used for picking up the film edge of the rolled film, and the film is pulled by a preset distance along the direction parallel to the transverse direction; the film cutting device is used for clamping the film after the film is pulled by the film pulling device for the preset distance and cutting the film positioned between the film pulling device and the film cutting device; and the film sticking device is used for adhering the film positioned between the film pulling device and the film cutting device onto the workpiece waiting for film sticking. Compared with the prior art, the film sticking machine provided by the invention realizes automatic film sticking on the surface of the workpiece waiting film sticking, so that the labor intensity is reduced, the capacity is high, the production efficiency is high, the yield of film sticking finished products can be effectively improved, and the production quality is guaranteed.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

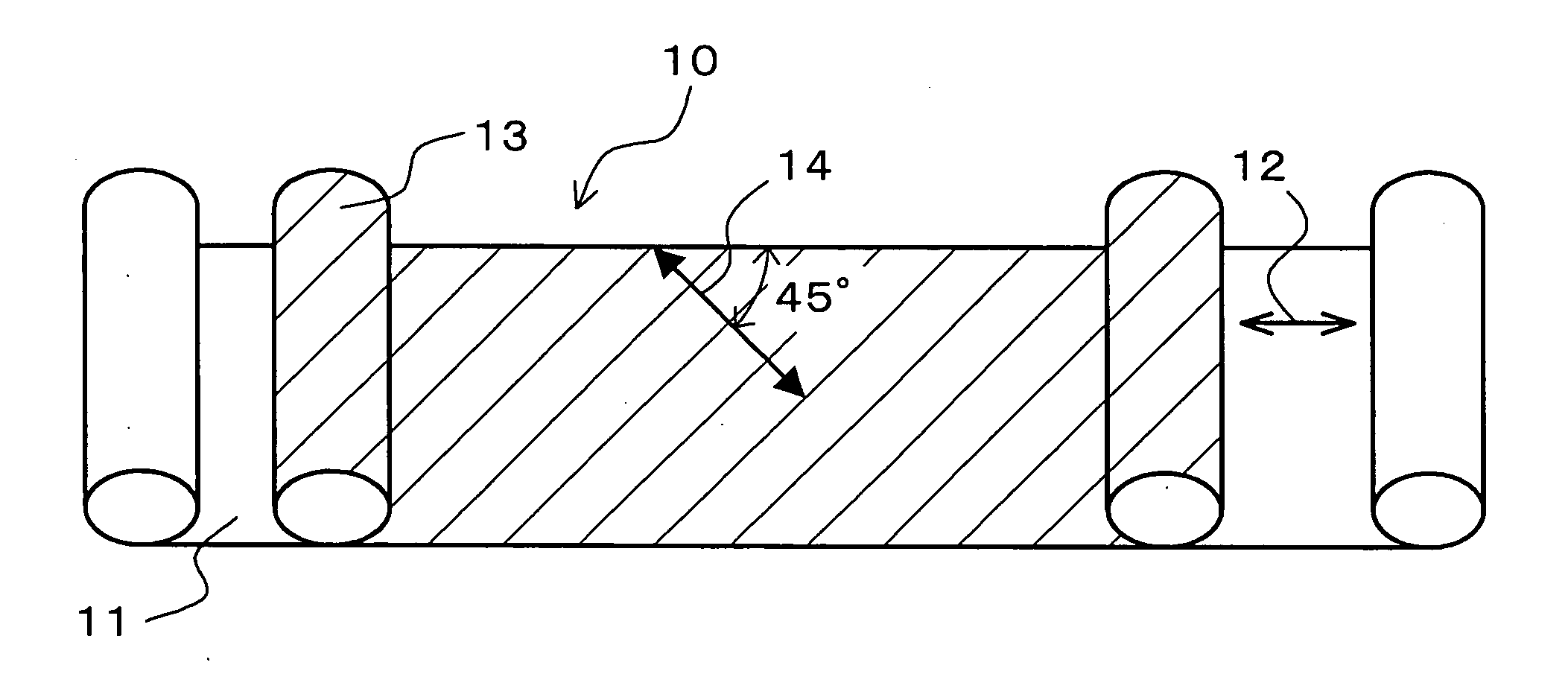

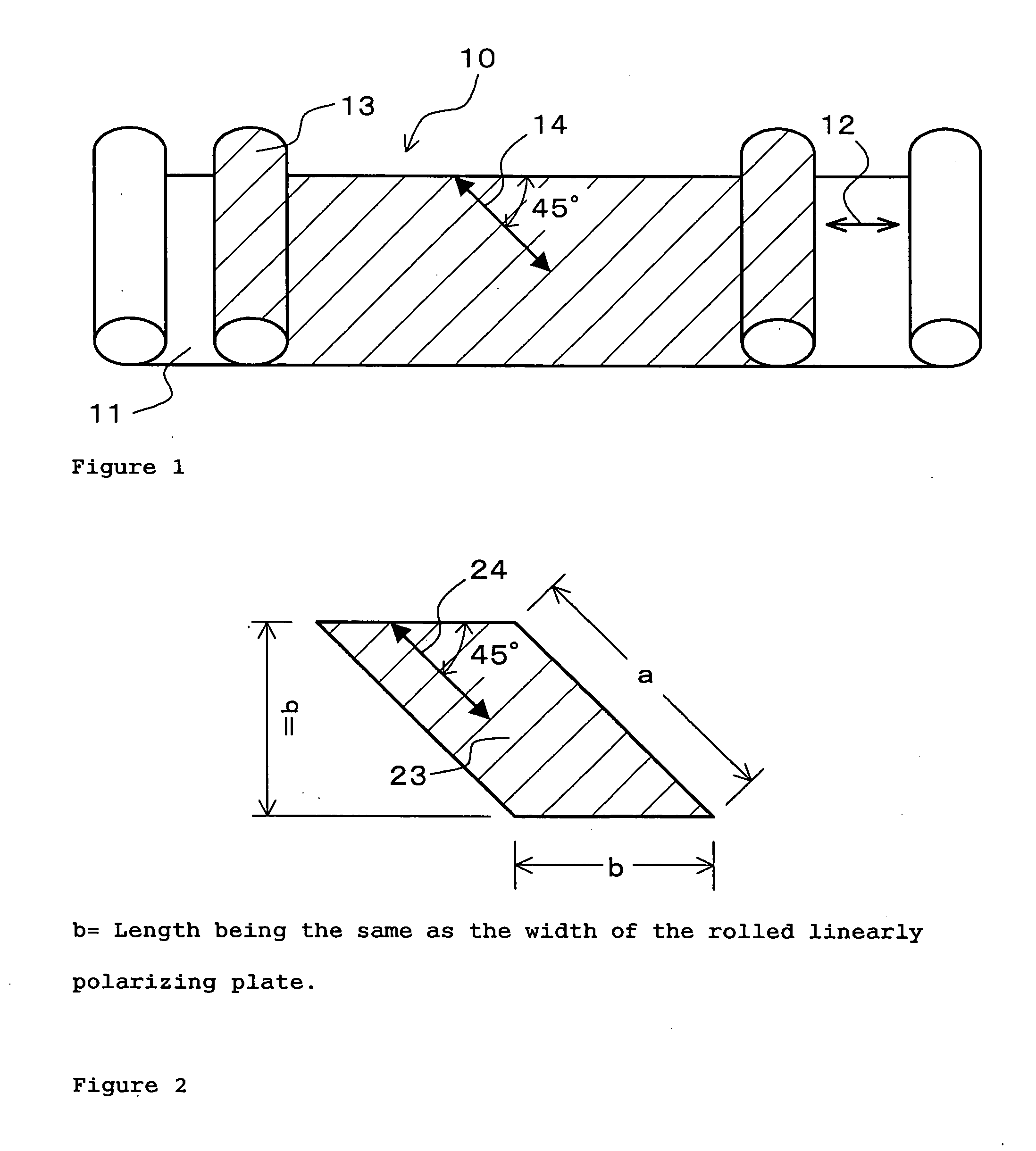

Elliptically polarizing plate and method of producing the same

InactiveUS20070128382A1Improve efficiencyHigh yieldLiquid crystal compositionsPolarising elementsRoll-to-roll processingEngineering

A rolled elliptically polarizing plate that is made by laminating a compensation film 13 having a coated layer made by a coating agent performing a compensation function on the surface of a rolled linear polarizing plate, the compensation film being a rolled film formed by application of a coating agent performing a compensation function to the surface of a transparent substrate, the linear polarizing plate and the compensation film being laminated by means of roll to roll processing by making the respective longitudinal directions approximately in parallel, or the above compensation film being formed by application of a coating agent performing a compensation function to the surface of the rolled linear polarizing plate.

Owner:SUMITOMO CHEM CO LTD

Method and apparatus for producing roll photo film

InactiveUS6079654AHigh precisionPicture changing apparatusProjector film strip handlingEngineeringFixed position

A roll photo film includes a spool which has a cylindrical core. A light-shielding sheet has a front end portion and a rear end portion. The front end portion is secured to the core. A first end of a photo filmstrip is secured to one securing position on the light-shielding sheet. The photo filmstrip is wound about the core in a roll form with the light-shielding sheet. A roll photo film producing apparatus includes a punch / die set, which has a trimming punch and a trimming die, and trims the rear end portion with a reduced width. A hole-forming punch and a hole-forming die are incorporated in the punch / die set, and cut a retaining hole through the rear end portion simultaneously with trimming of the rear end portion.

Owner:FUJIFILM HLDG CORP +1

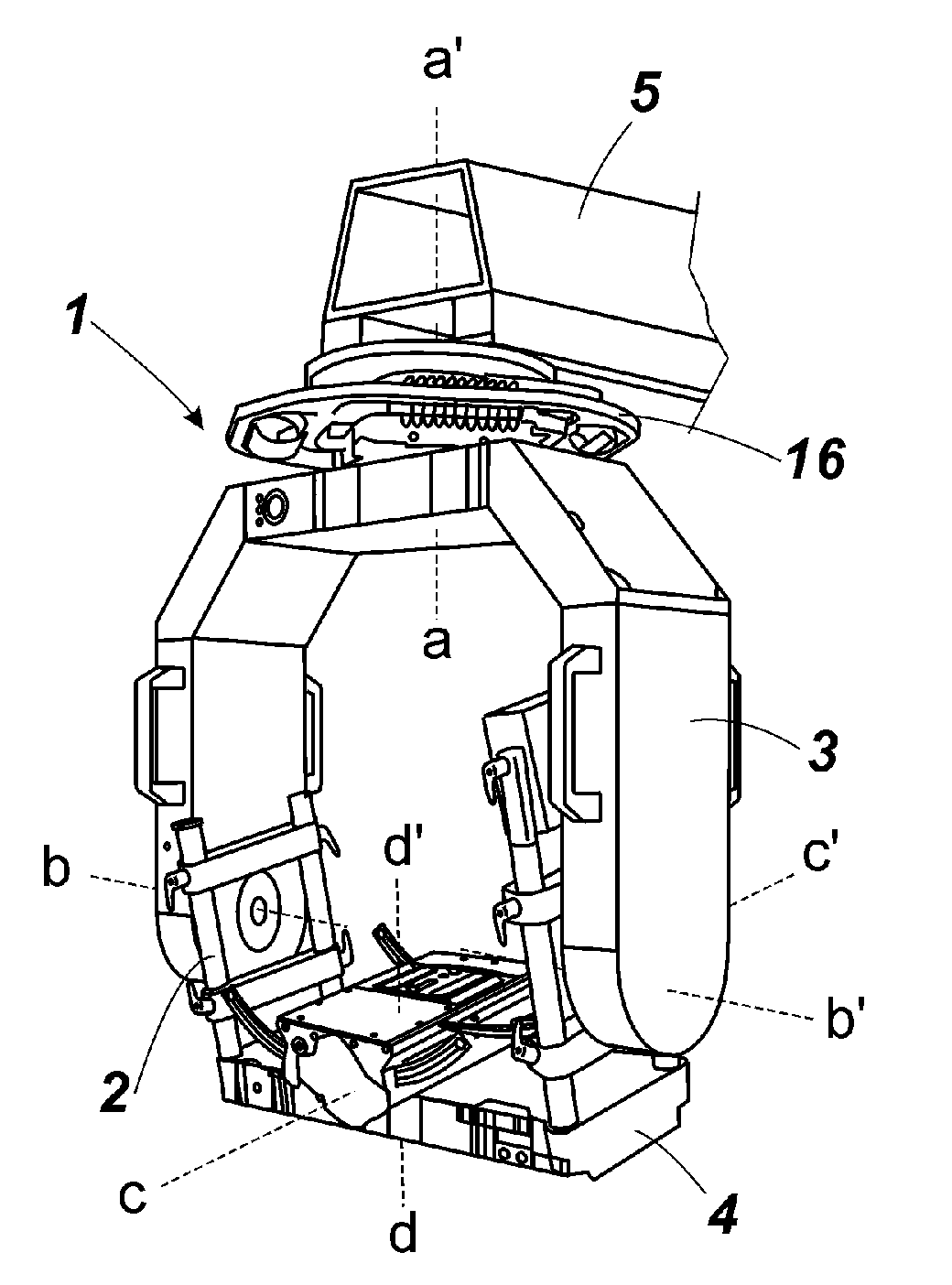

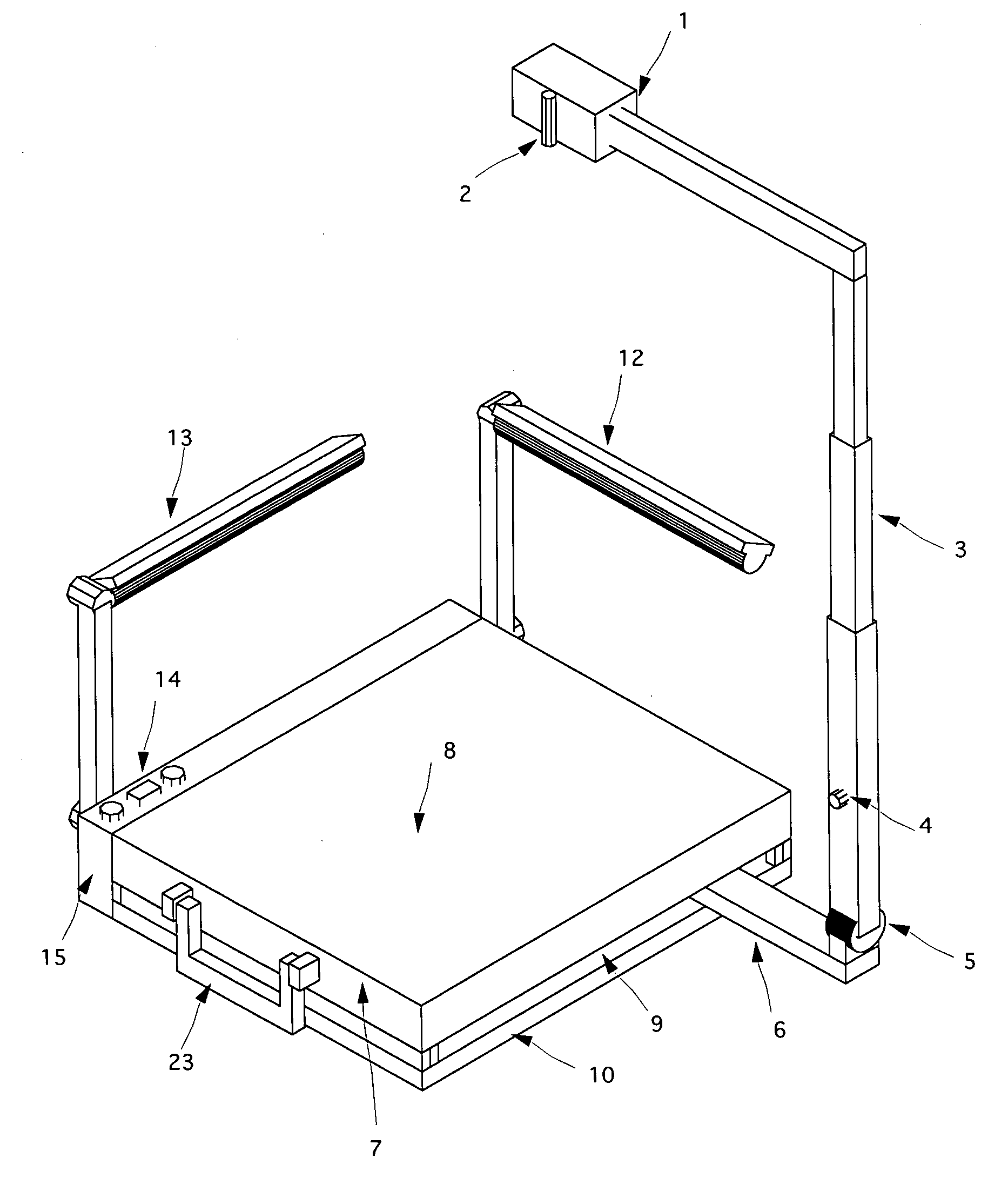

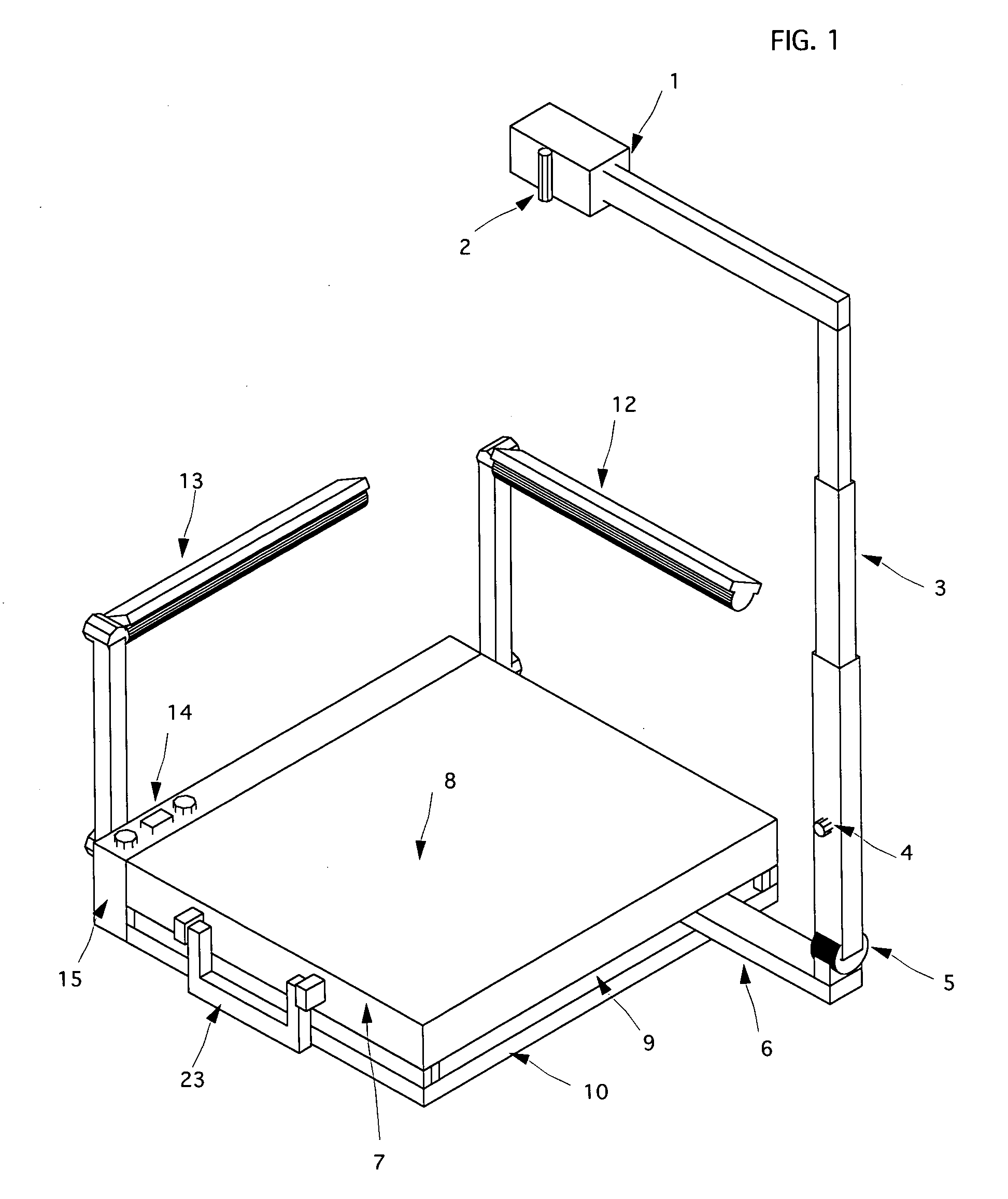

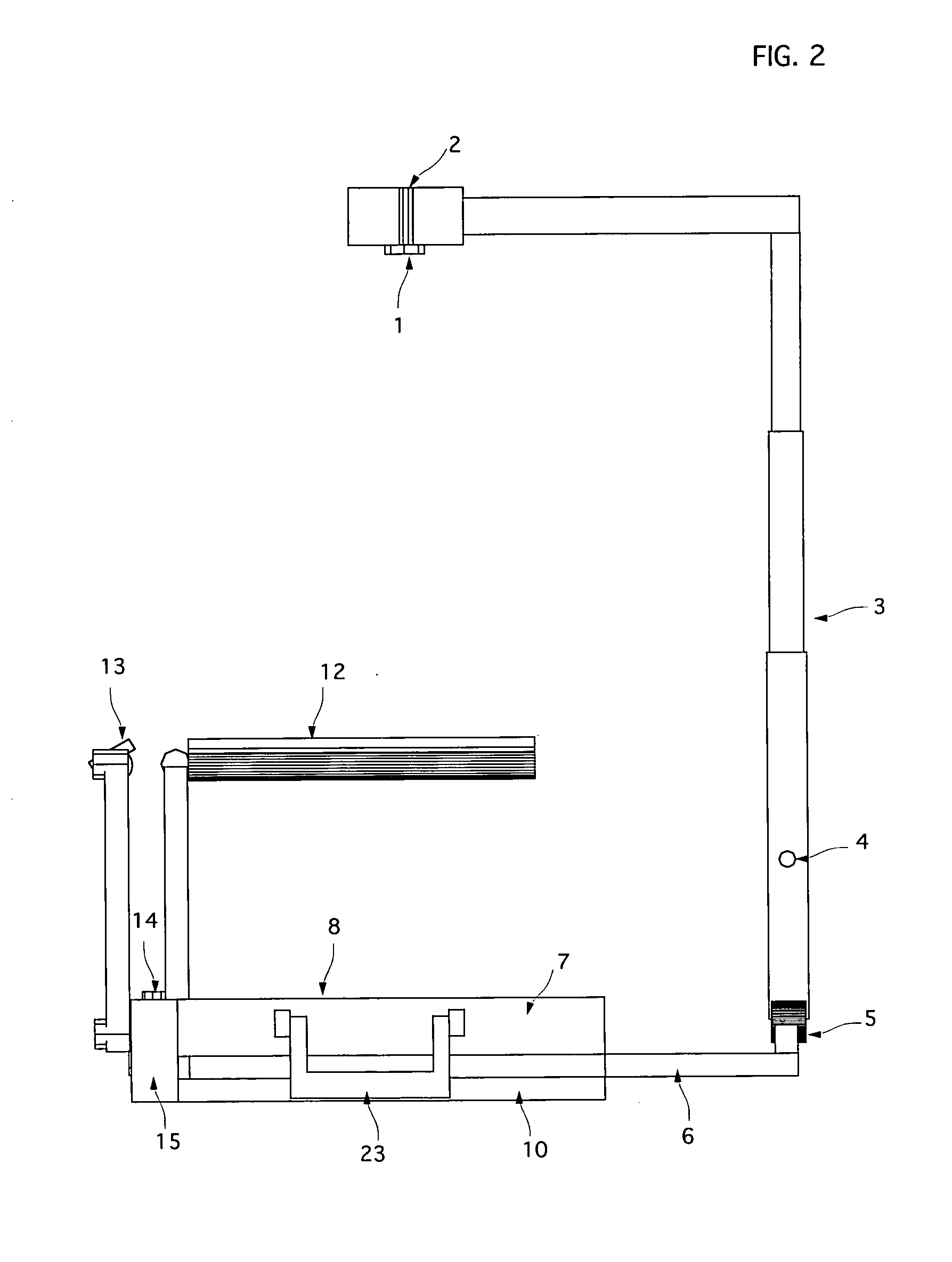

Portable digital visual presenter specially designed to be used with 14 x 17 inches films on which the MRI and CAT scans are commonly printed

A Portable Digital Visual Presenter specially designed to be used with 14×17 inches films on which the MRI and CAT scans are commonly printed. The present invention allows the whole film (commonly including between 8 and 50 images) and each individual image to be included in the shooting area of the digital camera, making the use simple, and friendly. The position of the film with respect to the digital camera is variable in order to allow each individual image to be situated at the centre of the camera's shooting area, fulfilling the said camera's shooting area. Since each member can be folded, it is possible to make the Portable Digital Visual Presenter compact so that users can conveniently carry such a novel Portable Digital Visual Presenter to different conference rooms.

Owner:FERNANDEZ ALBERTO ANGEL

Thermoplastic resin film and process for producing the same

InactiveUS20050095379A1Improve ink adhesionMaintain good propertiesWrappers shrinkagePretreated surfacesPolymer scienceNitrogen

A heat-shrinkable resin film which has heat shrinkage in the maximum shrinkage direction of 20% or higher when a 10 cm×10 cm square sample cut out thereof is immersed in hot water at 85° C. for 10 seconds, pulled out, subsequently immersed in water at 25° C. for 10 seconds, and then pulled out, characterized in that a content of nitrogen atoms in a surface of the film is 0.1% to 3.0% and the surface of the film has wet tension of 36 mN / m or higher; and a film roll obtained by winding up the heat-shrinkable resin film characterized in that when the rolled film is sampled at a first sampling part located up to 2 m apart from the end of the rolled film and at other sampling parts located after the first sampling part at intervals of about 100 m and an average content of nitrogen atoms of each sample is calculated, then the content of nitrogen atoms of each sample is within the ±0.8% range based on the above average content of nitrogen atoms.

Owner:TOYOBO CO LTD

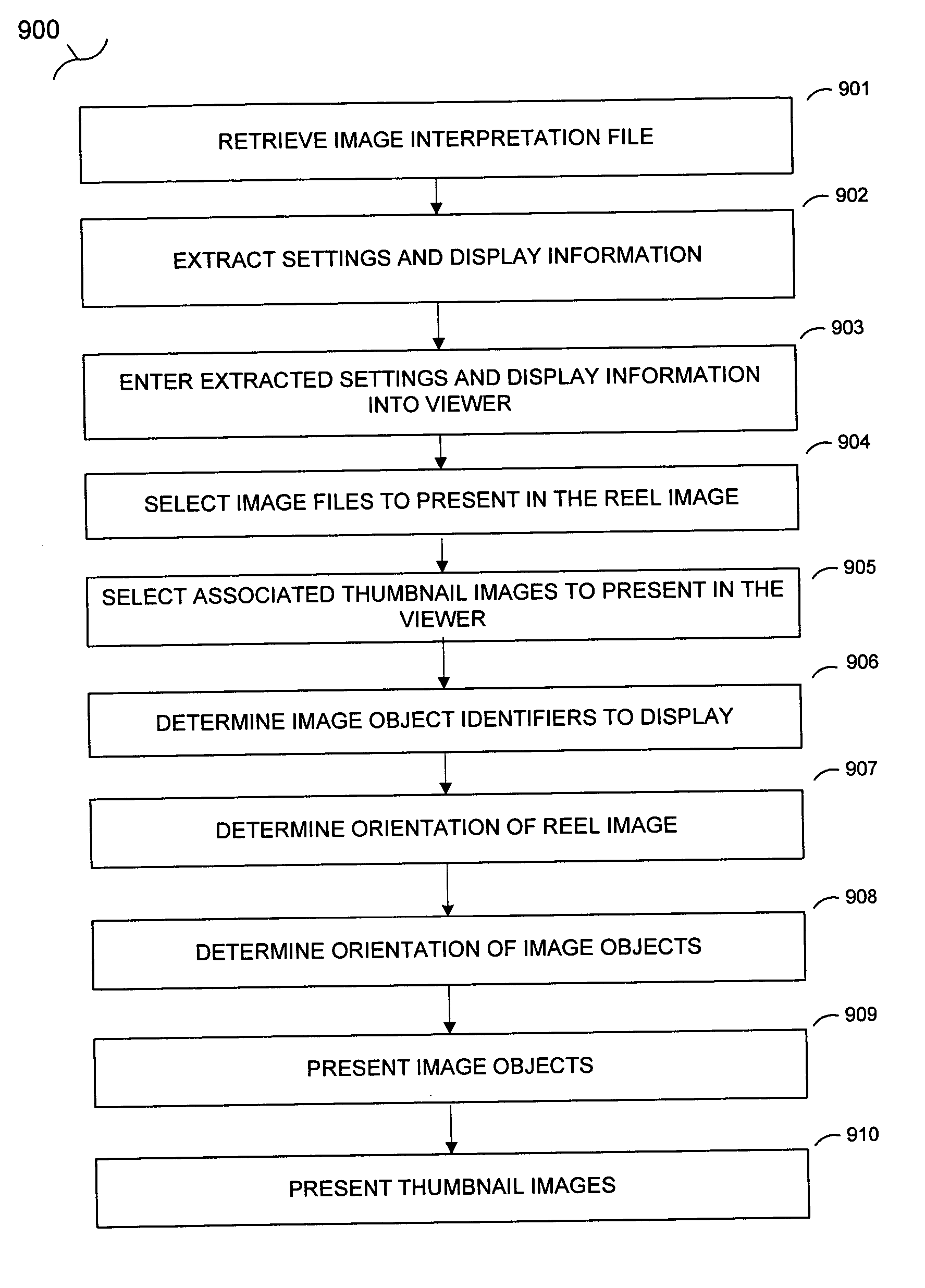

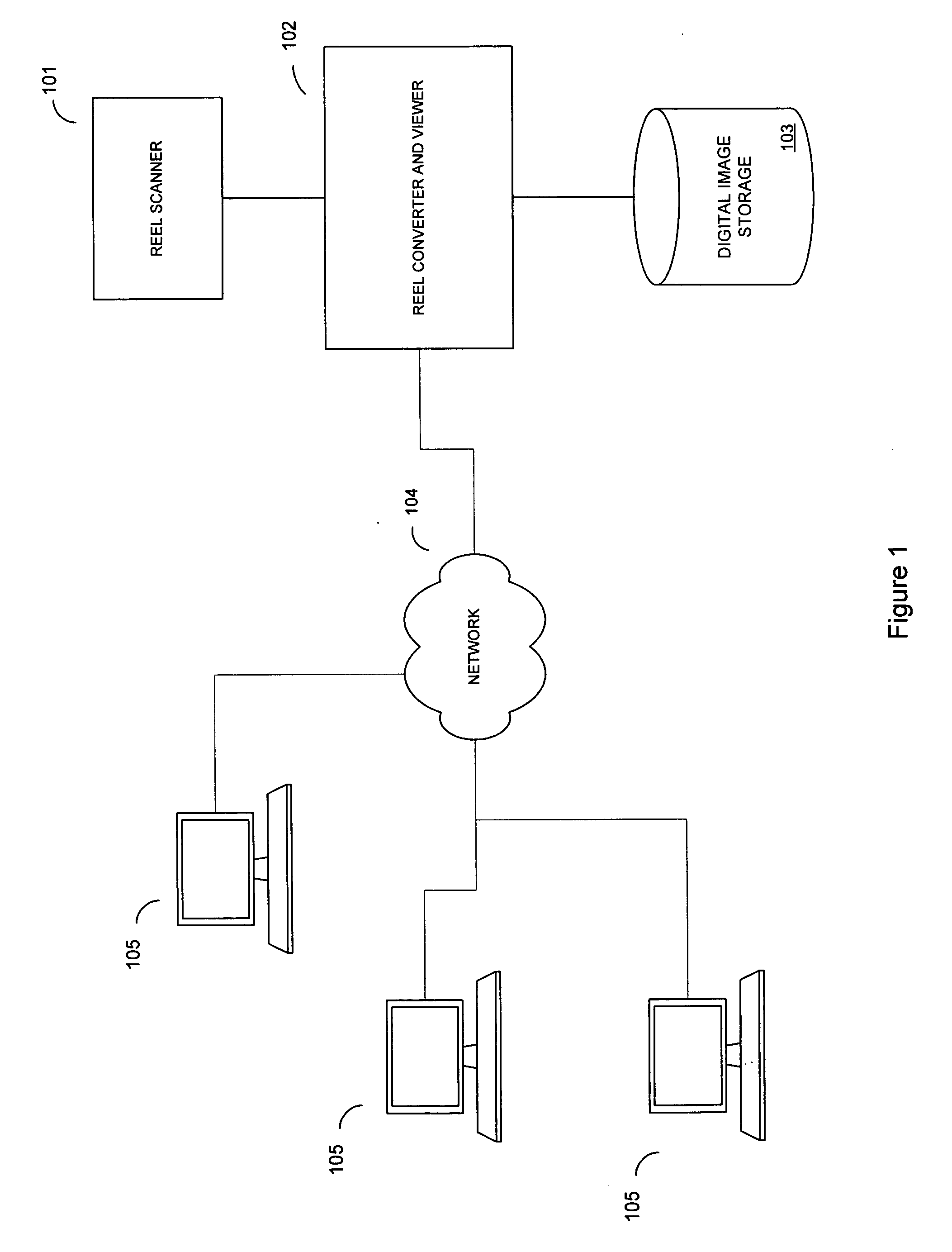

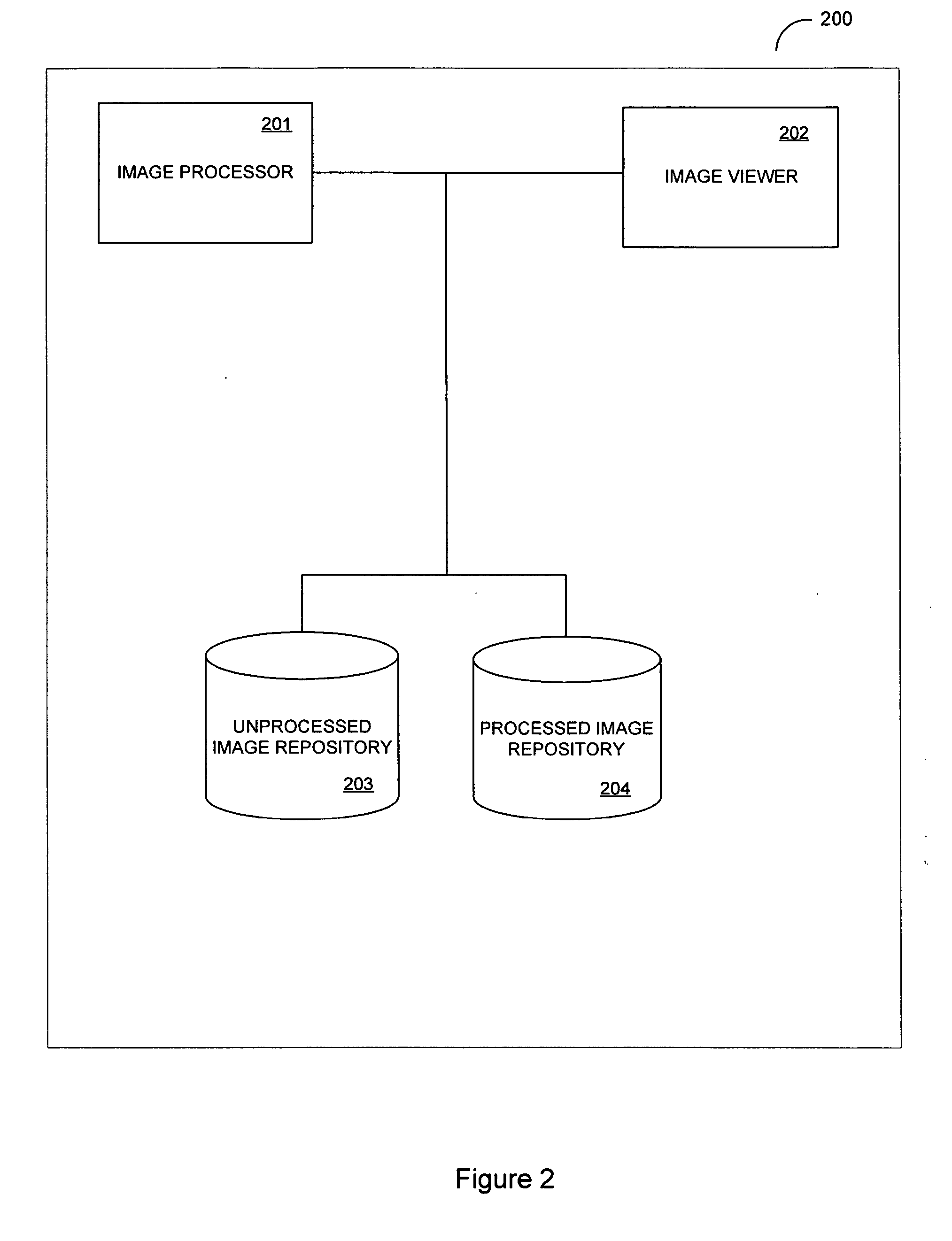

Method and system of viewing digitized roll film images

InactiveUS20060204134A1Character and pattern recognitionPictoral communicationComputer graphics (images)Data file

One example embodiment provides a method and system presenting digital images files output from a roll scanner in a roll format. A viewer receives a meta-data file including orientation, positioning, presentation and / or identification information of image objects and associated image files. Presentation, orientation, and / or identification information is extracted from the meta-data file and loaded into the viewer, which presents the image objects in accordance with the extracted settings and presentation information.

Owner:MODRALL JAMES +2

Film unwind system with hinged spindle and electronic control of web tension

A film supply apparatus supplying film in a foam-in-bag system having a film feeding device for feeding film from a film source to a location for bag formation, a bag forming apparatus, a foam material dispenser positioned for feeding foam material for reception in a bag of the bag forming apparatus, and a web tensioning system with a web tensioning driver in driving communication with the film source and which is in communication with a controller for monitoring the film feed and web tension states and directing adjustments in the web tension system. The web tensioning driver is arranged to move film backwards or in a direction opposite to a direction of film feed induced by the film feeding means and with the film source including a roll of film and the web tensioning system including a drive transmission in communication with the roll of film for rotational driving of the roll of film and also in communication with web tensioning driver. There is further featured a spindle support for supporting the roll of film and a roll film core drive insert.

Owner:PREGIS INTELLIPACK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com