Vacuum glass with metal edge-sealing structure and making method thereof

A technology of vacuum glass and metal, applied in the field of vacuum glass structure and vacuum glass, can solve the problem that the metal edge sealing technology is not suitable for the large-scale, convenient and low-cost production of vacuum glass, and achieve good sealing and widen application. Scope and the effect of realizing industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

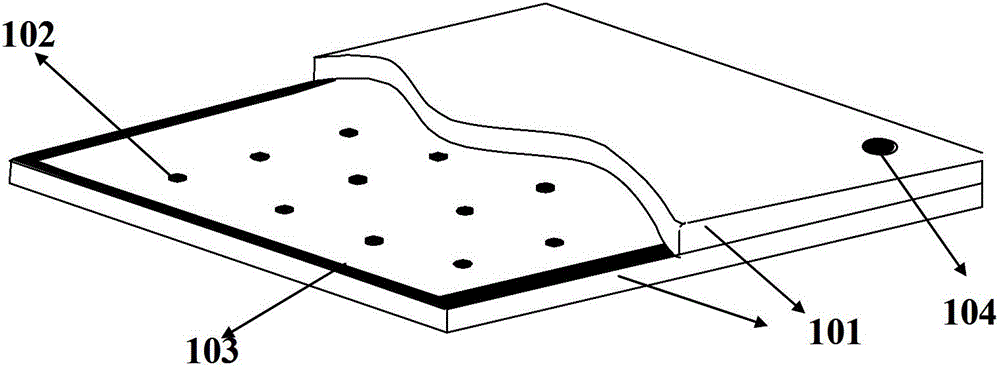

[0042] Figure 2A , Figure 2B is a schematic diagram of the metal edge sealing structure of the vacuum glass of the present invention, wherein Figure 2A An example diagram of the platform sealing structure, Figure 2B It is an example diagram of the staggered sealing structure. In these two structures, a layer of metal transition layer 201 is first solidified on the sealing surfaces of the two flat glass original sheets 101, and then a low-melting-point metal solder 202 is used for fusion welding and sealing between the two metal transition layers 201. Thereby forming a sealed structure of vacuum glass.

[0043] Specifically, in Figure 2A In the sealing structure of the platform shown, the two flat glass original sheets 101 are aligned and placed at the edge, and at the sealing place around the edges of the two glasses, on the lower su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com