Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

284 results about "Plastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plastomer is a polymer material which combines qualities of elastomers and plastics, such as rubber-like properties with the processing ability of plastic. As such, the word plastomer is a portmanteau of the words plastic and elastomer. Significant plastomers are ethylene-alpha olefin copolymers.

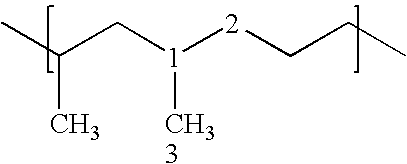

Process for producing propylene based polymer compositions

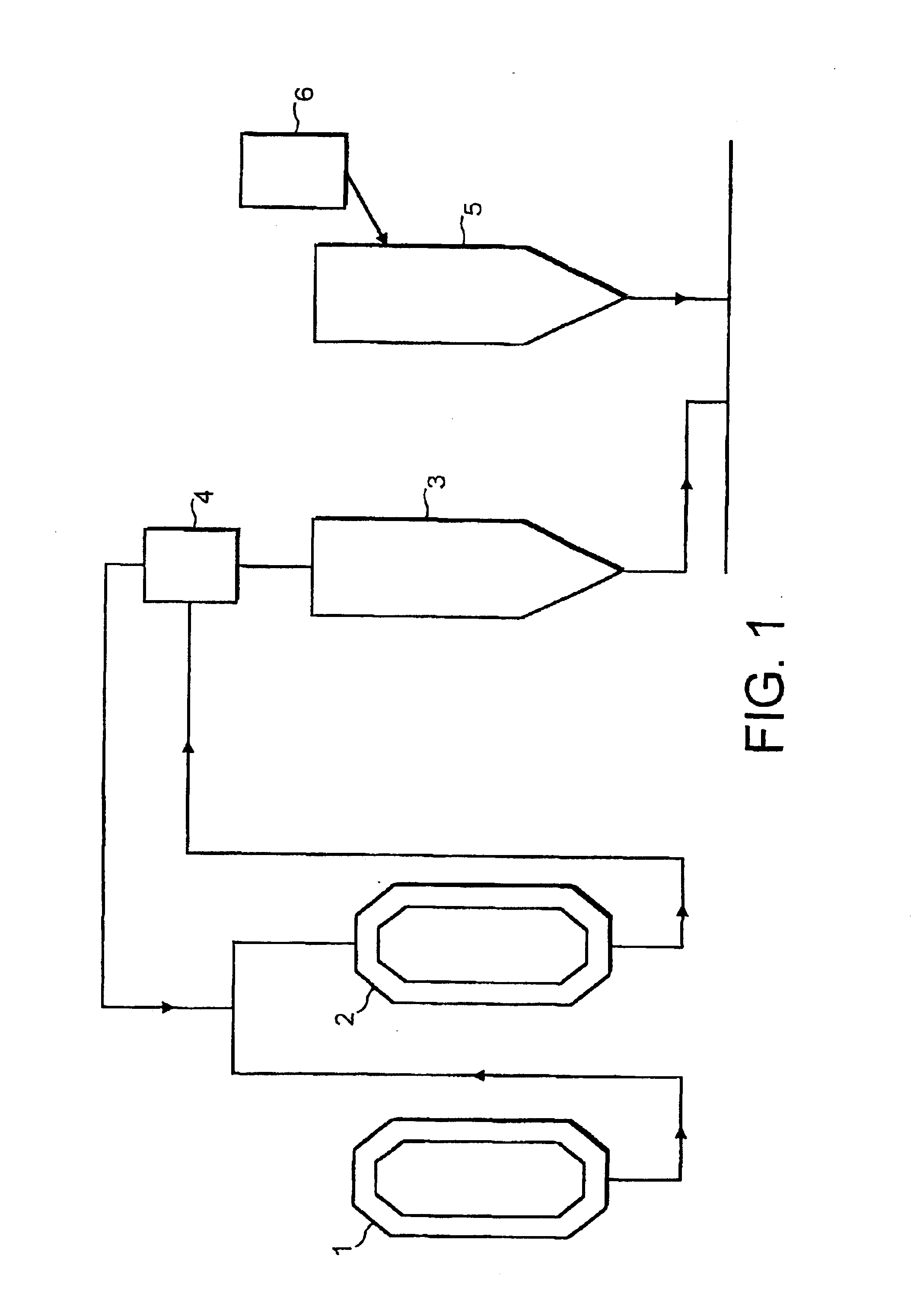

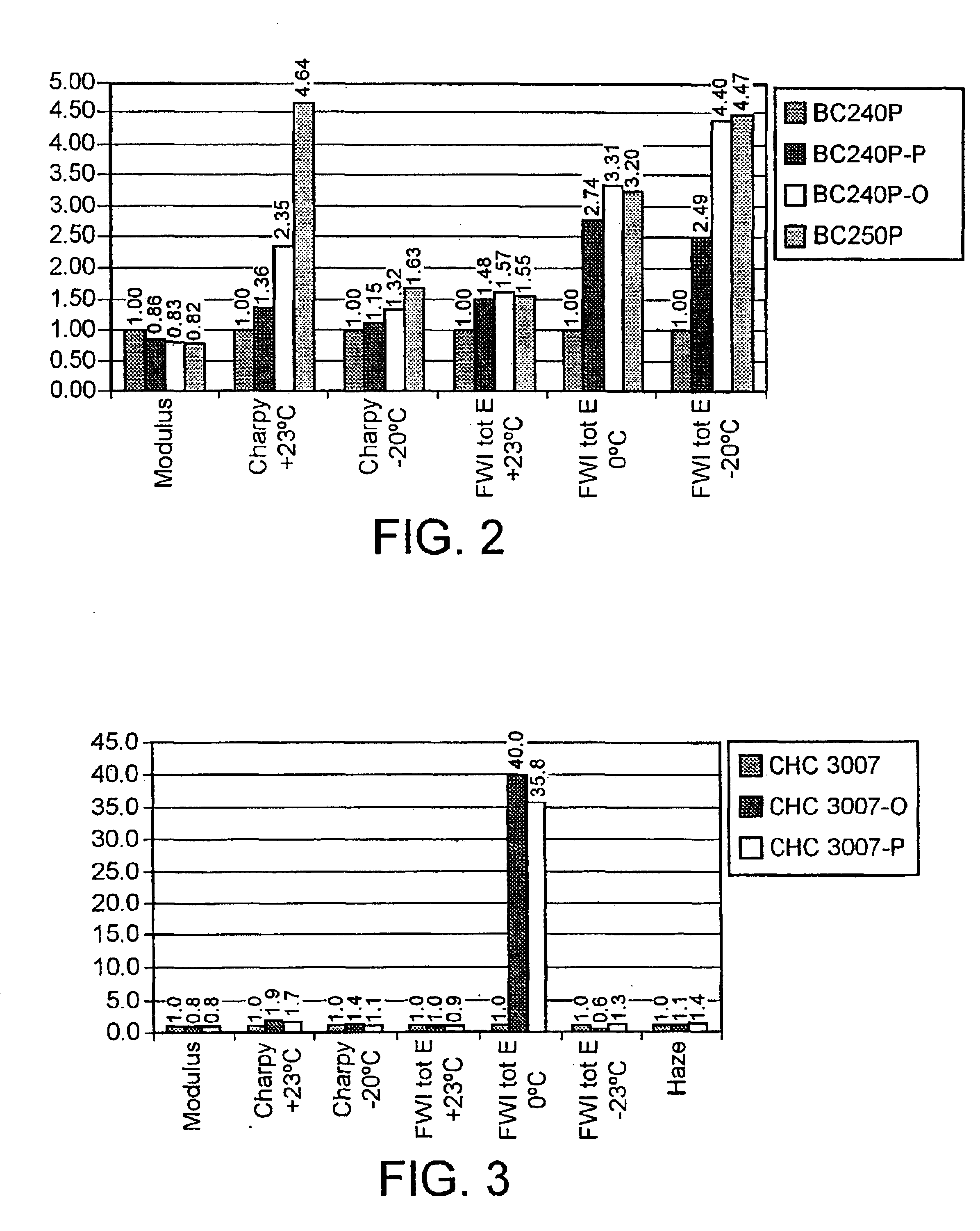

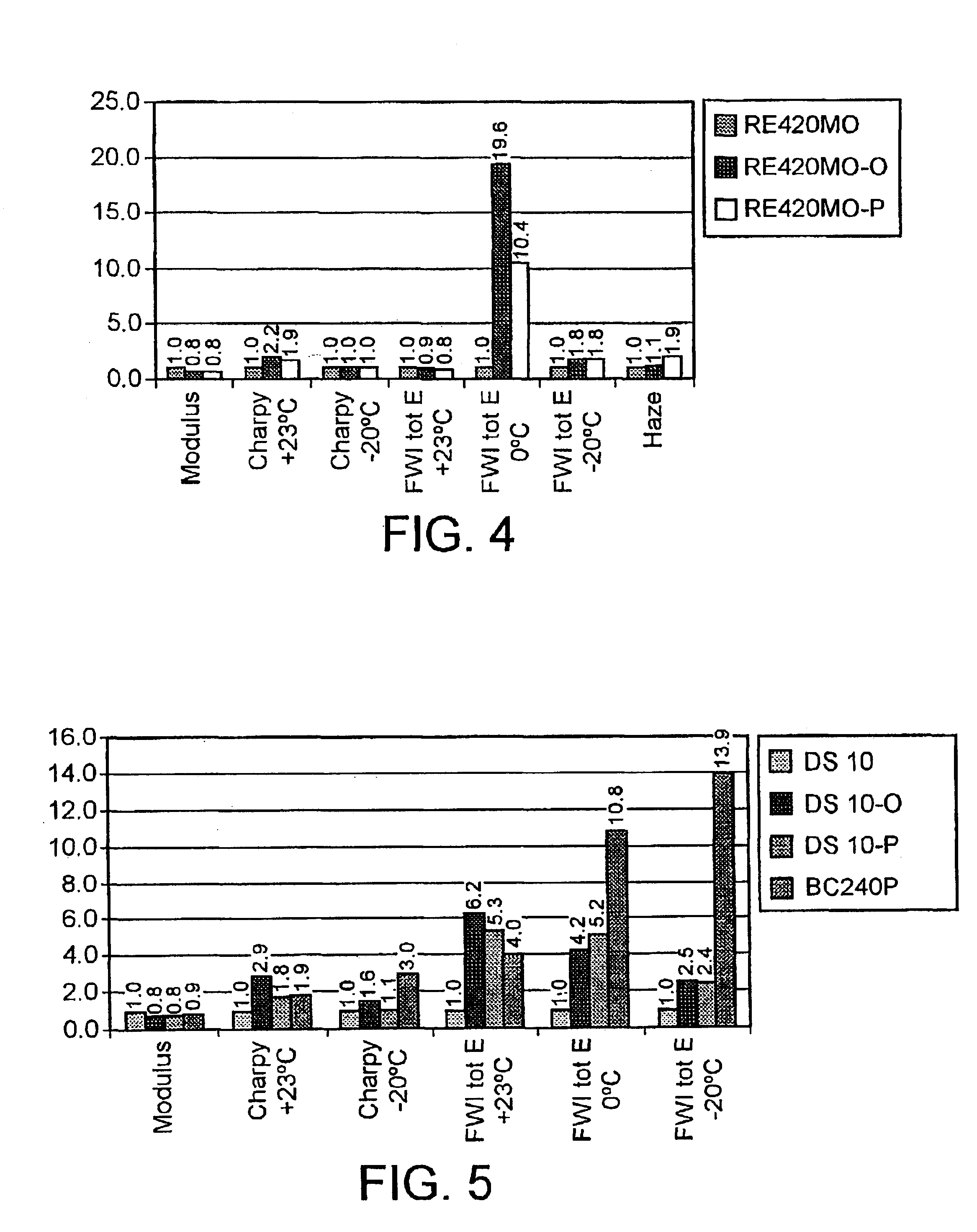

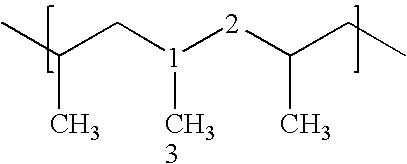

A process for the production of a propylene based polymer, the process comprising the following steps: (a) a first polymerization stage comprising homopolymerizing propylene or copolymerizing propylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce a polypropylene component; (b) a second polymerization stage comprising copolymerizing ethylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce an ethylene / alpha-olefin copolymer component; and (c) blending the polymer components produced in steps (a) and (b) whereby to produce a polymer blend, wherein the first and second polymerization stages are effected in separate polymerization reactors connected in parallel. Also provided are polymer compositions comprising: (i) 30 to 97% by weight, based on the total weight of the polymer composition, of a propylene based polymer; and (ii) 3 to 70% by weight, preferably 5 to 20% by weight, based on the total weight of the polymer composition, of an ethylene copolymer plastomer (e.g., an ethylene-propylene plastomer) containing at least 60% by weight ethylene.

Owner:BOREALIS TECH OY

Nonwoven fabric and fibers

InactiveUS20070173162A1High strengthFuzzing levels can be controlledWoven fabricsNon-woven fabricsElastomerPlastomer

The present invention relates to nonwoven webs or fabrics. In particular, the present invention relates to nonwoven webs having superior abrasion resistance and excellent softness characteristics. The nonwoven materials comprise fibers made from of a polymer blend of isotactic polypropylene, reactor grade propylene based elastomers or plastomers, and optionally, a homoge-neously branched ethylene / alpha olefin plastomer or elastomer. The isotactic polypropylene can be homopolymer polypropylene, and random copolymers of propylene and one or more alpha-olefins. The reactor grade propylene based elastomers or plastomers plastomer have a molecular weight distribution of less than about 3.5, and a heat of fusion less than about 90 joules / gm. In particular, the reactor grade propylene based elastomers or plastomers contains from about 3 to about 15 percent by weight of units derived from an ethylene, and a melt flow rate of from about 2 to about 200 grams / 10 minutes. The present invention also relates to cold drawn textured fibers comprising of a polymer blend of isotactic polypropylene and reactor grade propylene based elastomers or plastomers.

Owner:ETHIOPIA SAMUEL +7

Heat-shrinkable polymeric films

InactiveUS6908687B2High and predictable and controlled shrinkage characteristicGood optical claritySynthetic resin layered productsSausage casingsOptical transparencyControl layer

The present invention relates to oriented or hot-blown shrink films which may be manufactured from by a number of processes. The oriented films may be manufactured by double bubble, LISIM, tape bubble, trapped bubble or tenter framing processes. The films of the present invention are useful as a shrink film to package and label a variety of products. The films exhibit a high degree of MD shrinkage in a very controlled and consistent manner while providing a number of other positive characteristics such as optical clarity, puncture and abrasion resistance, controlled gauge, and superior web winding and handling characteristics. The shrink control layers of the films of the present invention contain a modifier component selected from plastomers and / or metallocene catalyzed ethylene-propylene copolymers and blends thereof.

Owner:JINDAL INNOVATION CENT SRL

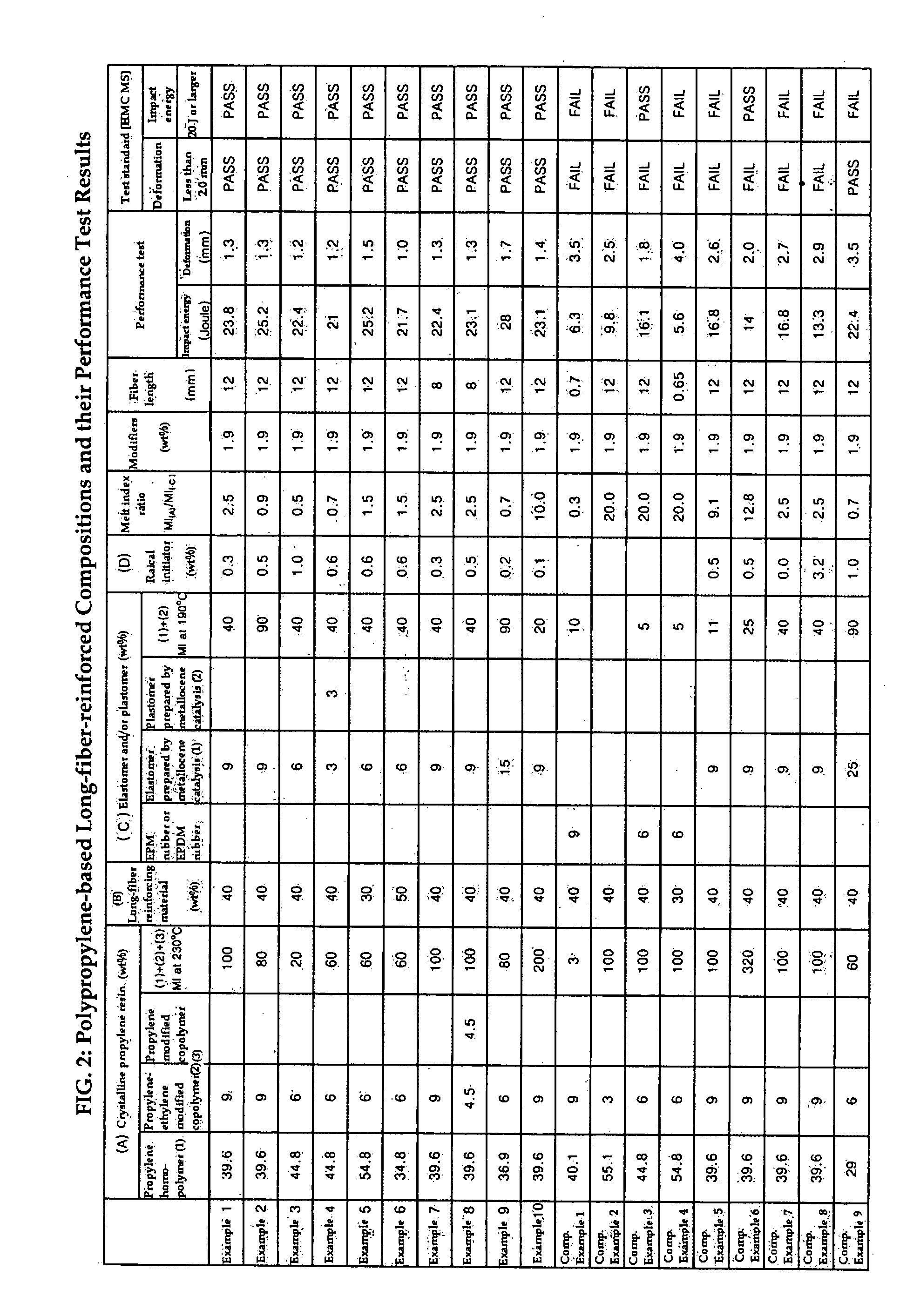

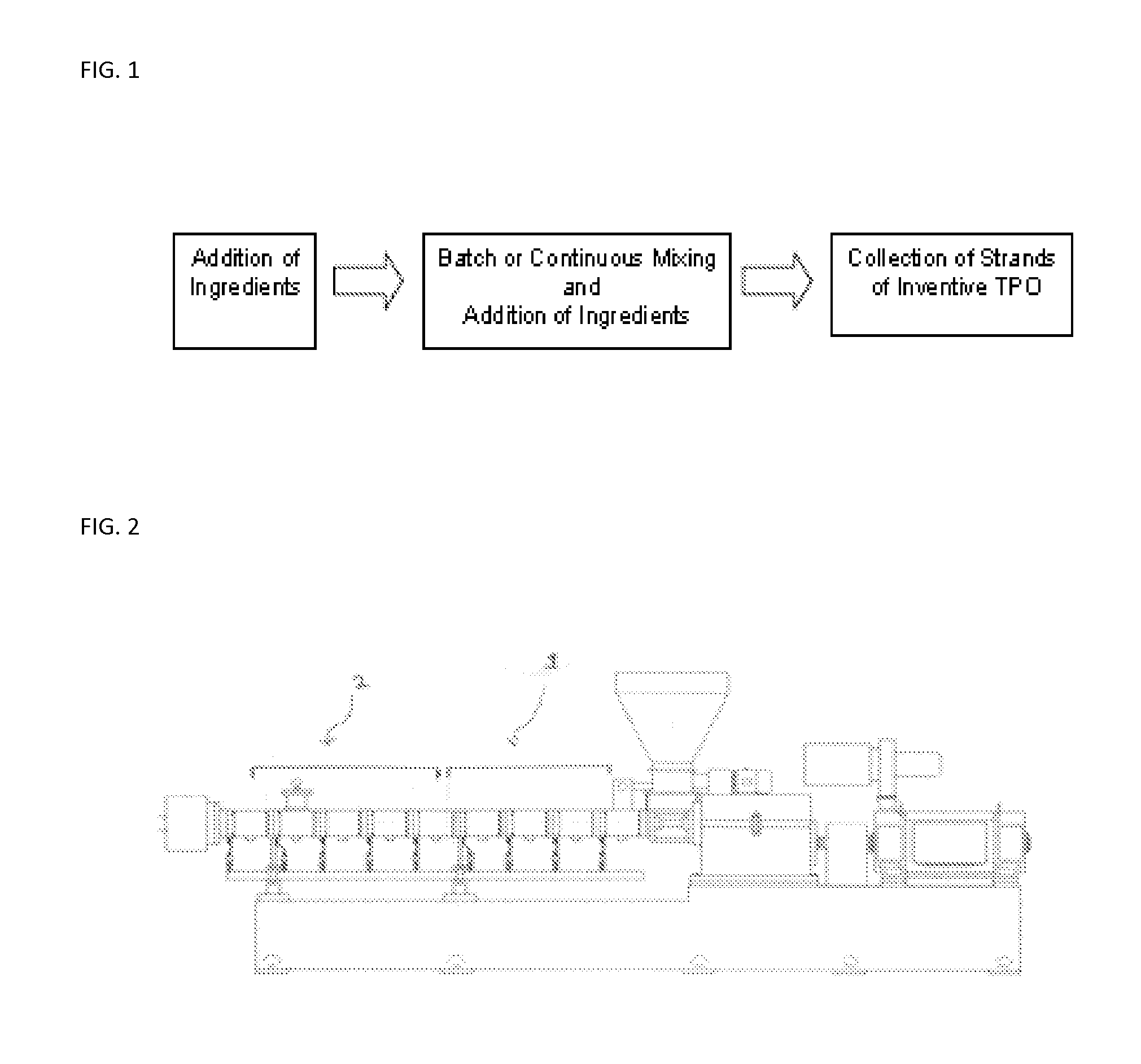

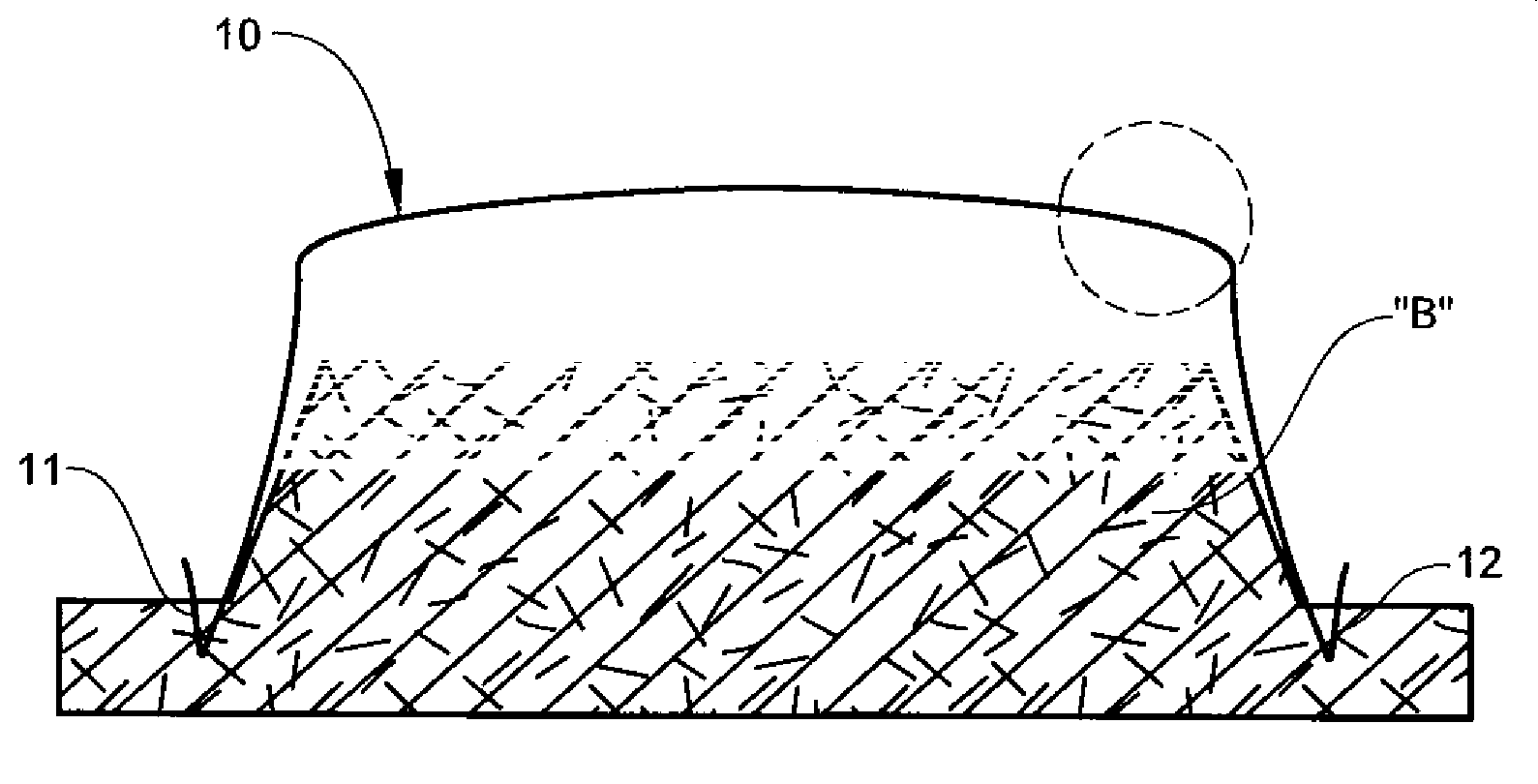

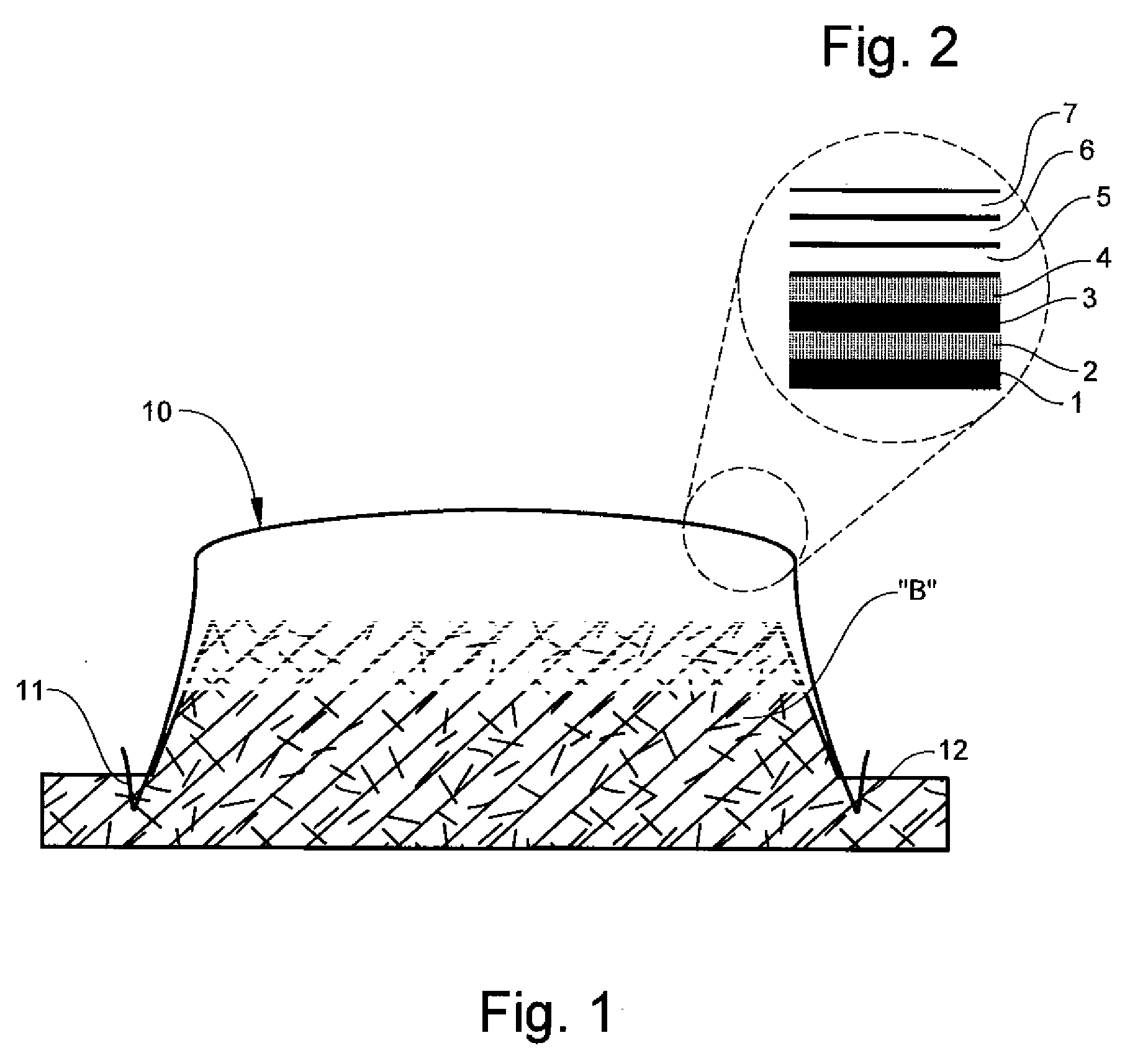

Flexible polypropylene roofing membrane

InactiveUS20060046084A1Good flexibilityExcellent heat welding strengthRoof covering using flexible materialsSynthetic resin layered productsElastomerPolyolefin

A thermoplastic polyolefin (TPO) roofing membrane is made by blending a new polypropylene based elastomer (PBE) or plastomer (PBP) and polyolefin copolymers. The new PBE or PBP offers superior flexibility over conventional polypropylene roofing membranes for easy installation. The new narrow molecular weight distribution and broad crystallinity distribution of the PBE or PBP results in excellent heat welding strength and wide heat welding windows of the said TPO membrane.

Owner:BUILDING MATERIALS INVESTMENT

Stiff polypropylene composition with excellent elongation at break

Polypropylene composition comprising (a) a high melt strength polypropylene having a melt flow rate MFR 2 (230 °C) of equal or below 15 g / l 0min and a branching index g' of below 1.0, (b) a first heterophasic propylene copolymer comprising €¢ a polypropylene having a melt flow rate MFR 2 (230 °C) in the range of 50 to 500 g / 10min and an elastomeric propylene copolymer having a propylene content in the range of 50 to 80 wt.-% and €¢ an intrinsic viscosity (IV) of equal or more than 2.5 dl / g, (c) a second heterophasic propylene copolymer comprising €¢ a random propylene copolymer having a melt flow rate MFR 2 (230 °C) in the range of 1 to 40 g / 10min, a branching index g' of 1.0, and a comonomer content of more than 0.5 wt.-%,and €¢ an elastomeric propylene copolymer having a propylene content in the range of 50 to 80 wt.-%, and an intrinsic viscosity (IV) of equal or below 2.4 dl / g, (d) a polyethylene plastomer having an ethylene content of at least 50 wt.-%, and (e) a mineral filler (F).

Owner:BOREALIS AG

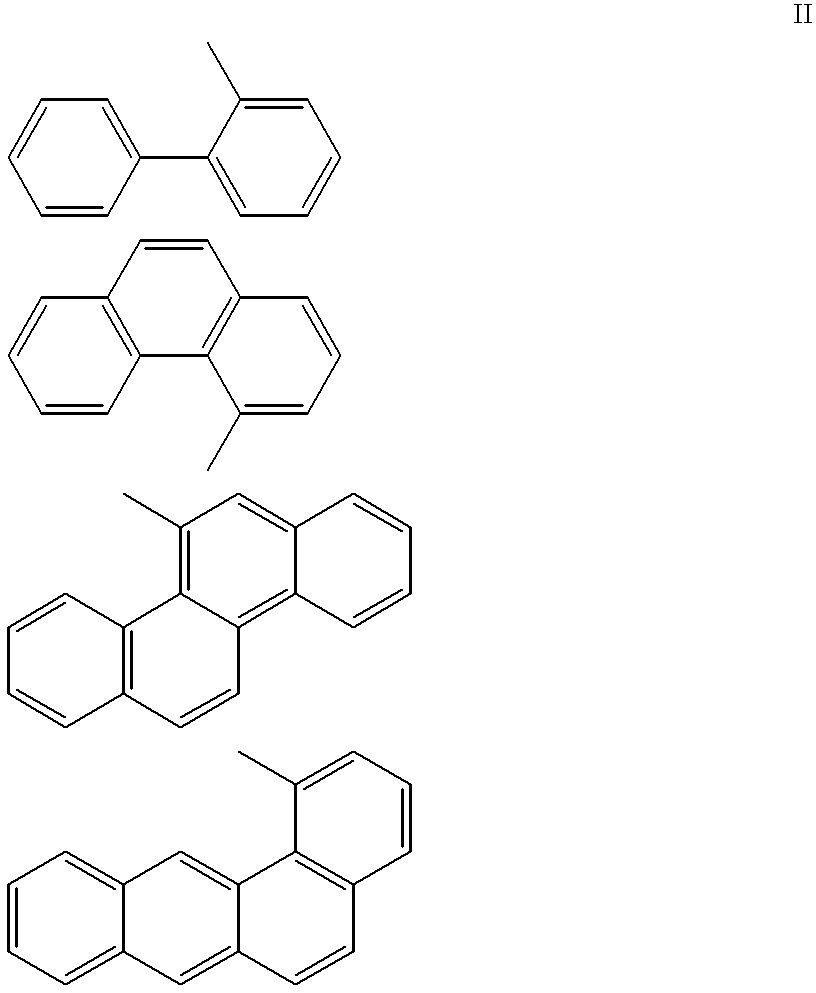

Polymerization process for olefin copolymers using bridged hafnocene compounds

InactiveUS6218488B1High Mooney viscosityIncrease pointsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerSide chain

The invention is a polymerization process for ethylene copolymers having a density less than 0.915 comprising contacting ethylene, one or more alpha-olefin monomer, and optionally one or more diene monomer, with a catalyst composition comprising the reaction product of at least one organometallic Group 4 metallocene compound derived from a bridged, fused-ring ligand containing biscyclopentadienyl hafnocene, said bridge being a substituted or unsubstituted carbon or silicon atom connecting the biscyclopentadienyl ligands, and a salt of a Group 13 element anionic complex having halogenated aromatic ligands in an essentially tetrahedral structure wherein the aromatic groups are polycyclic fused or pendant aromatic rings. The process is particularly suitable for the preparation of high comonomer content and high molecular weight ethylene-alpha-olefin plastomers and ethylene-propylene or ethylene-propylene-diene monomer elastomers.

Owner:EXXONMOBIL CHEM PAT INC

Elastomeric compositions

A composition comprising: (i) at least one low molecular weight polyolefin; (ii) at least one block copolymer obtainable by selectively hydrogenating a block copolymer having terminal polymeric blocks of a vinyl aromatic monomer and a mid-block prepared originally with an olefin and subsequently hydrogenated; (iii) at least one polypropylene; and (iv) at least one plastomer, wherein the plastomer is an ethylene based polymer having a density of 0.86 g / cc to about 0.910 g / cc or a propylene based polymer having a heat of fusion (Hf) of 70 J / g or less.

Owner:EXXONMOBIL CHEM PAT INC

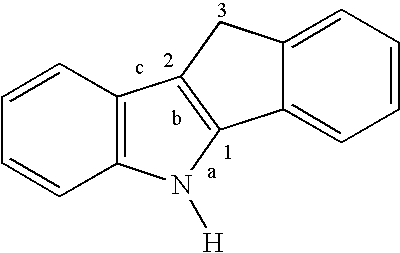

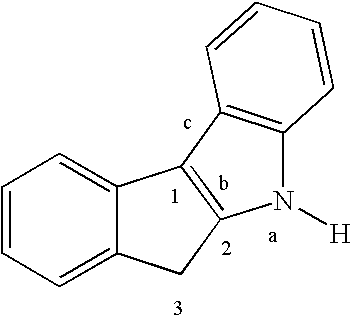

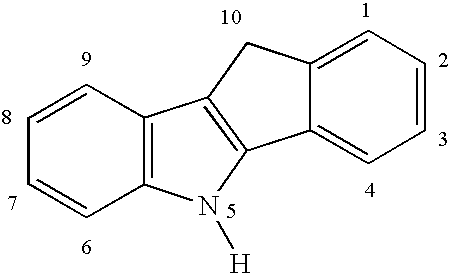

Method for making polyolefins

A method for making ethylene polymers and copolymers is disclosed. The method uses a catalyst system comprising a low level of an aluminum-containing activator, a bridged indenoindolyl transition metal complex, and a treated silica support. The method enables economical preparation of ethylene copolymers having very low density. The silica-supported, bridged complexes incorporate comonomers efficiently and are valuable for a commercial slurry loop process. Use of a bridged indeno[2,1-b]indolyl complex provides exceptionally efficient comonomer incorporation, and gives polymers with a substantial and controlled level of long-chain branching. The method facilitates the production of a wide variety of polyolefins, from HDPE to plastomers.

Owner:EQUSR CHEM LP

Flame retardant crosslinkable compositions and articles

InactiveUS20070027250A1Synthetic resin layered productsGlass/slag layered productsPolyolefinPolymer science

Owner:EQUSR CHEM LP

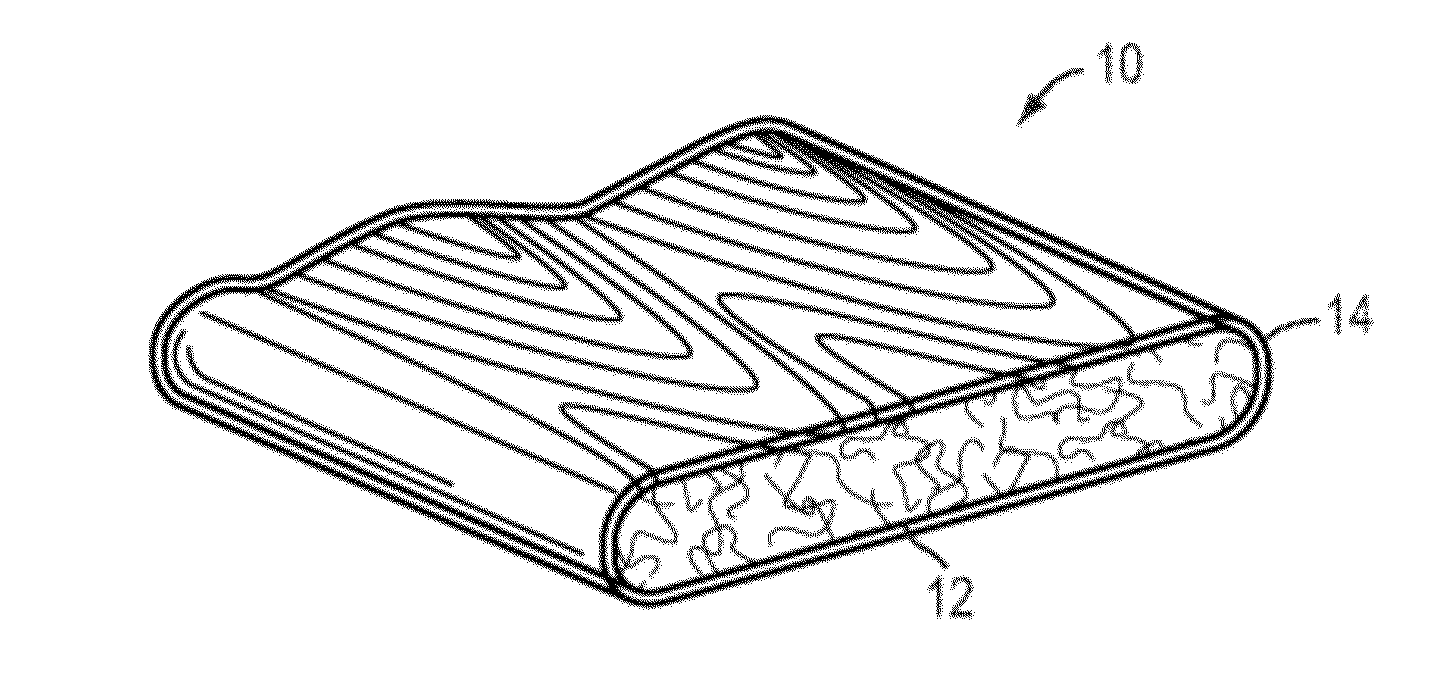

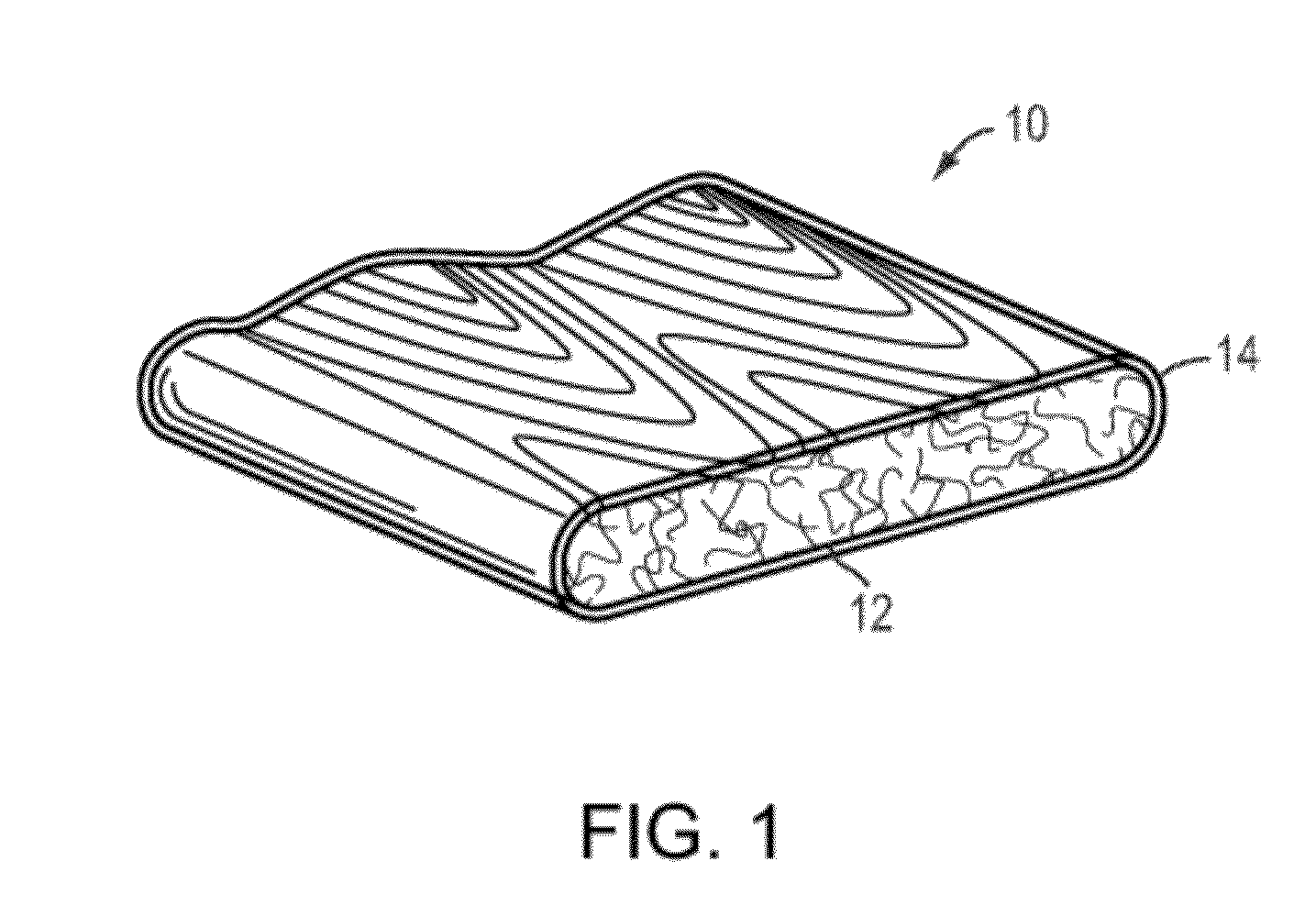

Post-Bonded Grooved Elastic Materials

An elastic nonwoven laminate that contains an elastic film laminated to one or more nonwoven facings is provided. The nonwoven facing contains a conventional polyolefin and can also contain a polyolefin-based plastomer. The laminate is activated by grooving to decouple the nonwoven facing from the elastic film. To reduce fiber-pull out that can result due to activation by grooving, the laminate can be post-bonded at room or elevated temperatures and a specific range of pressures to compact the fibers of the facing and minimize fiber pull-out / fuzziness while not sacrificing the softness, elasticity, and feel of the laminate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Modified asphalt compositions

ActiveUS20050101702A1Broad PG ratingReduction in dust formationIn situ pavingsBuilding insulationsElastomerPolymer science

A modified asphalt composition is provided comprising-at least one plastomer, at least one elastomer, at least one crosslinking agent and asphalt. More specifically, a modified asphalt composition is provided comprising an oxidized polyethylene, a styrene-butadiene-styrene block copolymer, sulfur, and asphalt. A hot mix asphalt composition is also provided comprising the modified asphalt composition and aggregate. Processes for producing the modified asphalt composition and the hot mix asphalt composition are also provided as well as articles produced from these inventive compositions.

Owner:PRI ASPHALT TECH LLC +1

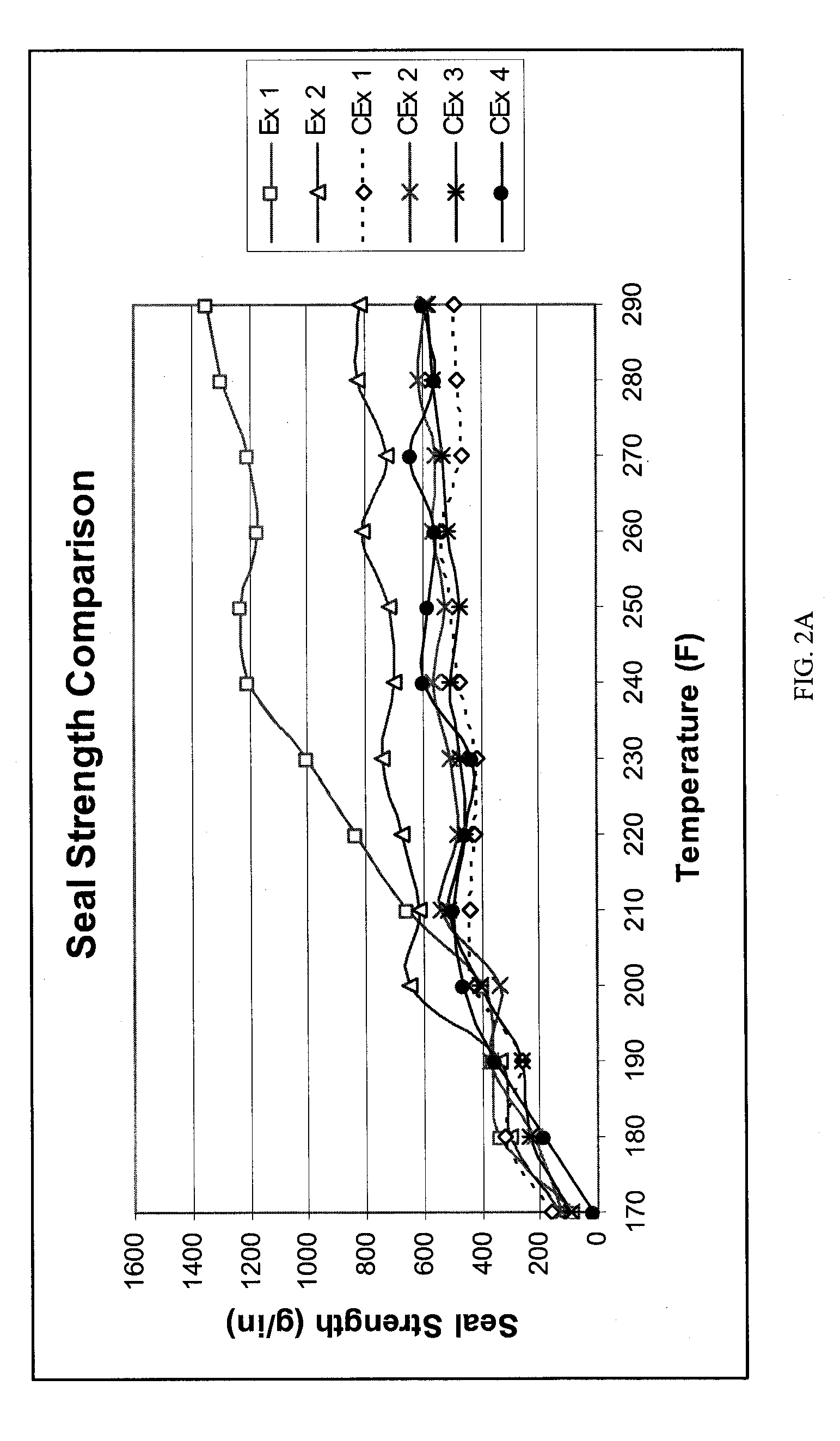

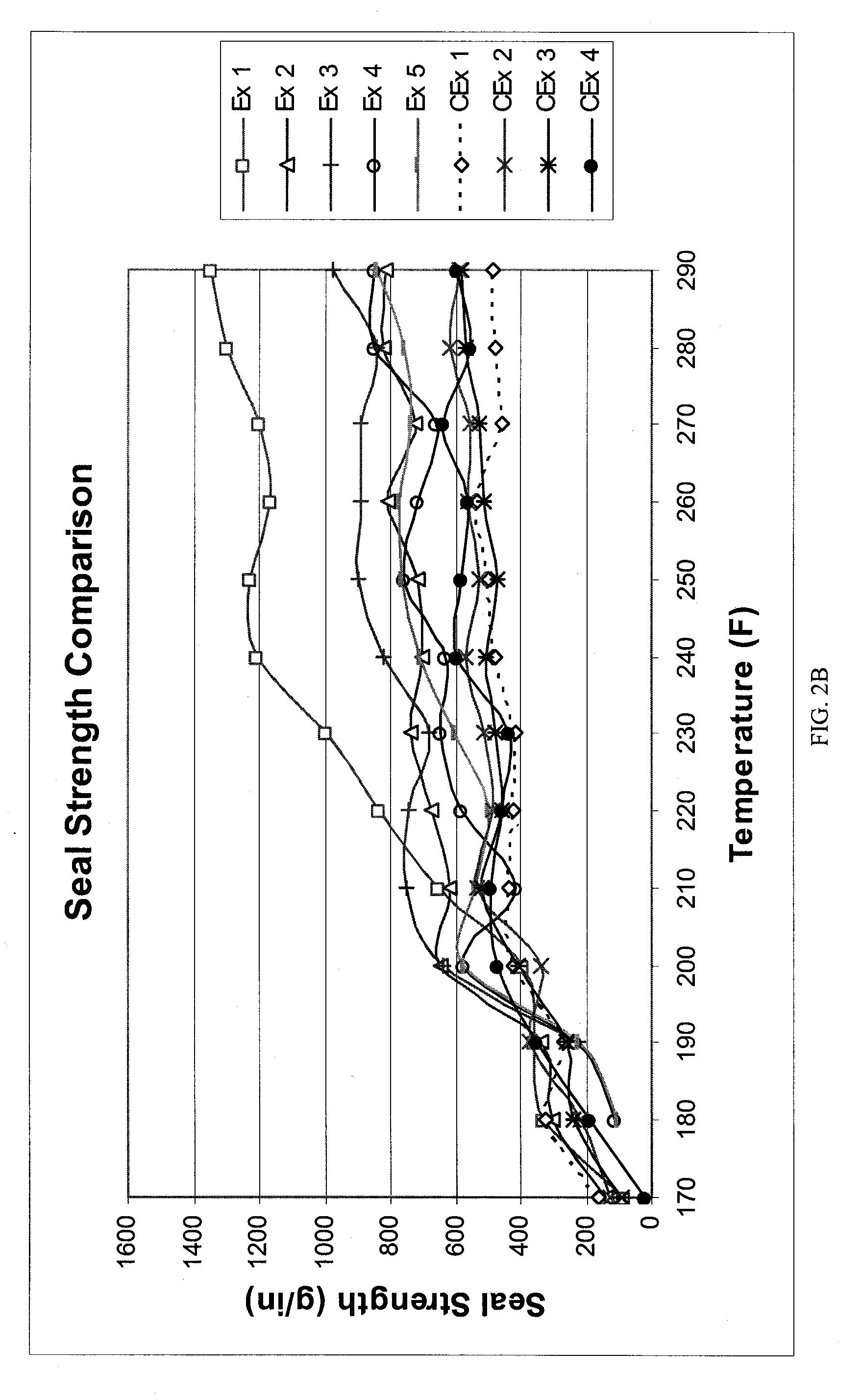

Biaxially oriented polypropylene film with high heat seal strength

ActiveUS20090087648A1Easy to processImprove seal strengthLamination ancillary operationsLayered product treatmentPolyolefinThermoplastic elastomer

A laminate film including a first polyolefin heat sealable resin layer and a second core layer including of a blend of 5-15 wt % of a metallocene-catalyzed butene-propylene or ethylene-propylene thermoplastic elastomer or ethylene-propylene plastomer or blends thereof which exhibit an isothermal crystallization temperature of 60° C. or less and 95-85 wt % of a crystalline propylene homopolymer is disclosed. The laminate film may include additional layers such as a third polyolefin resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

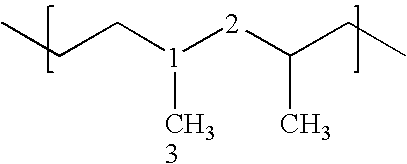

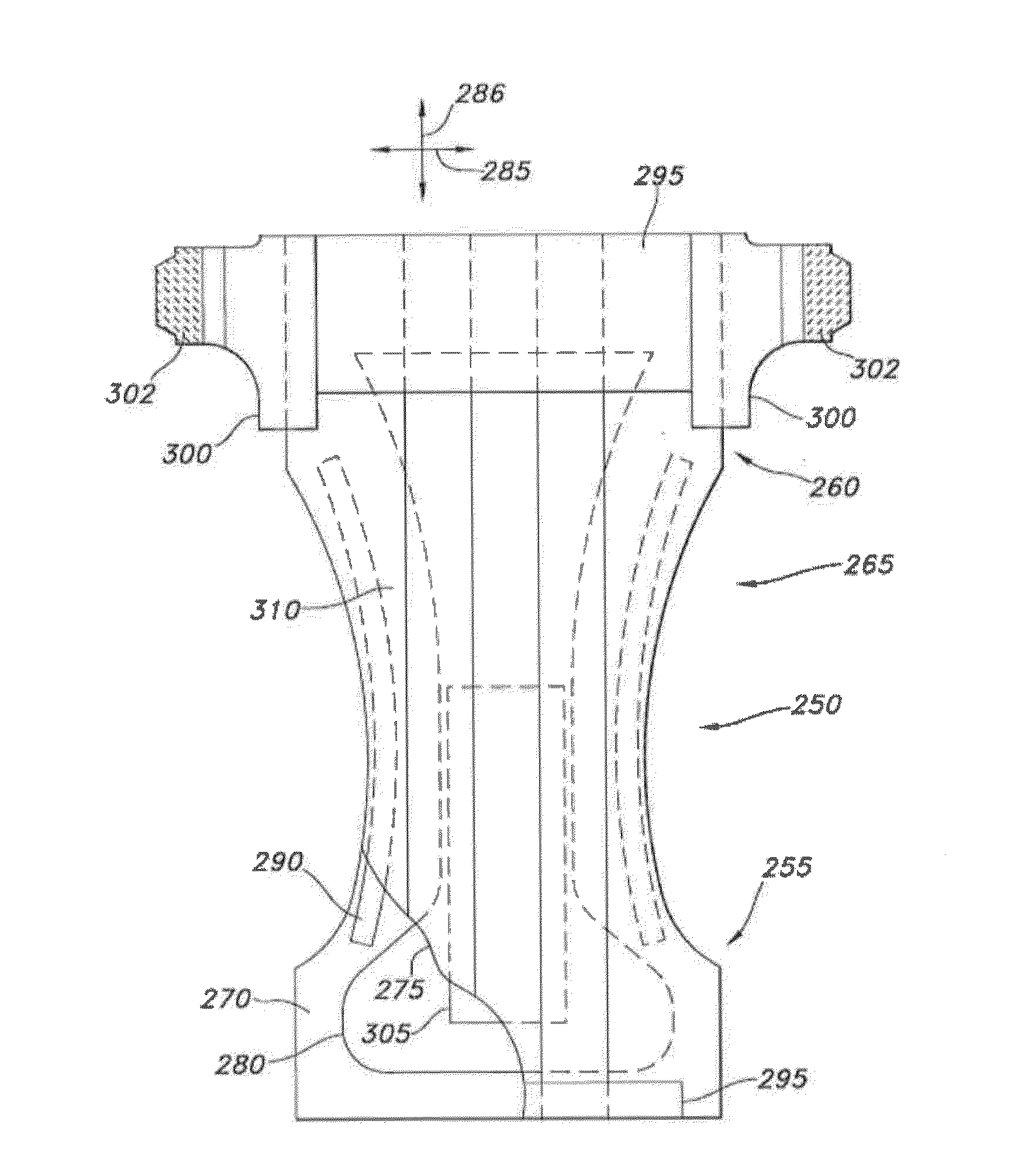

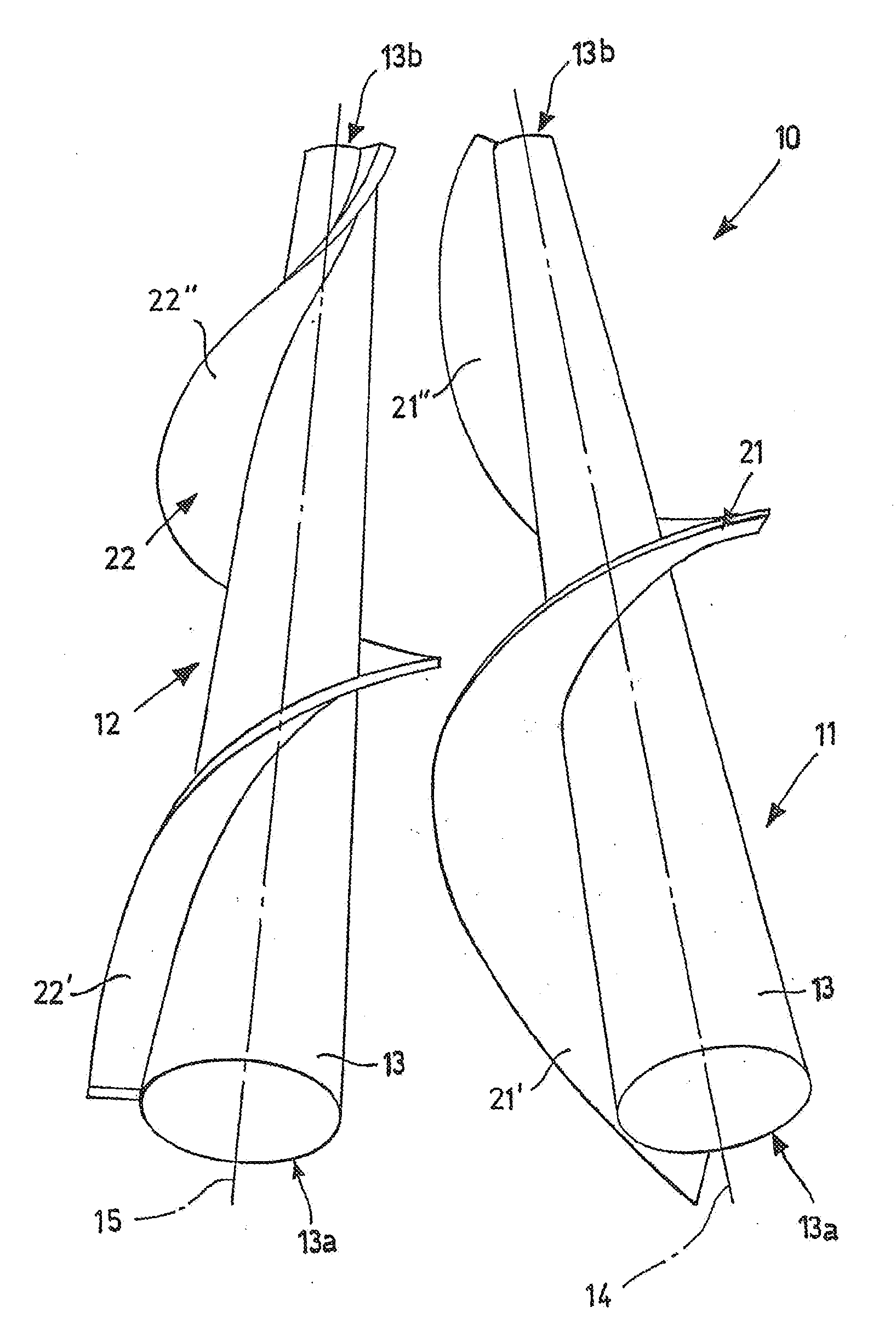

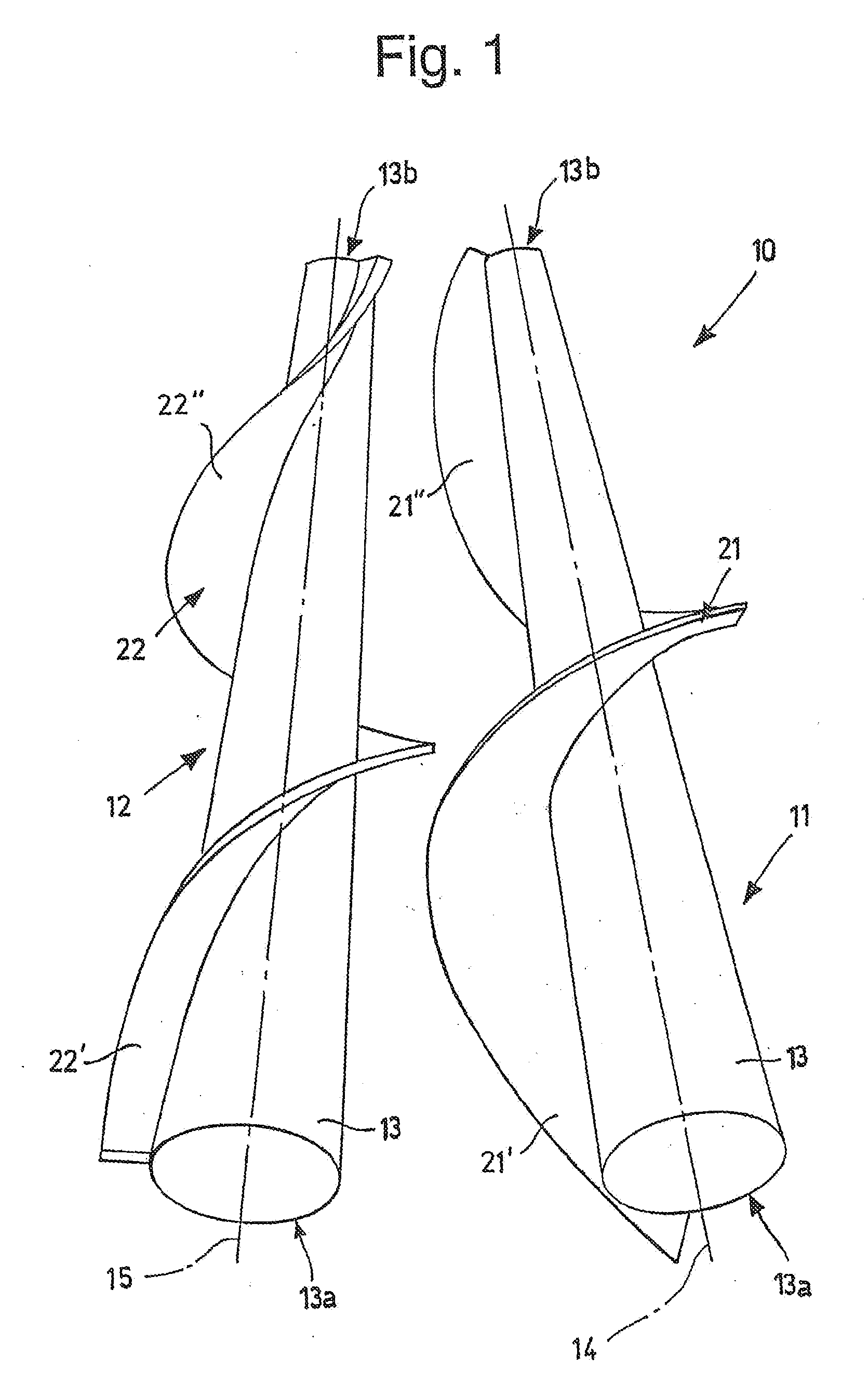

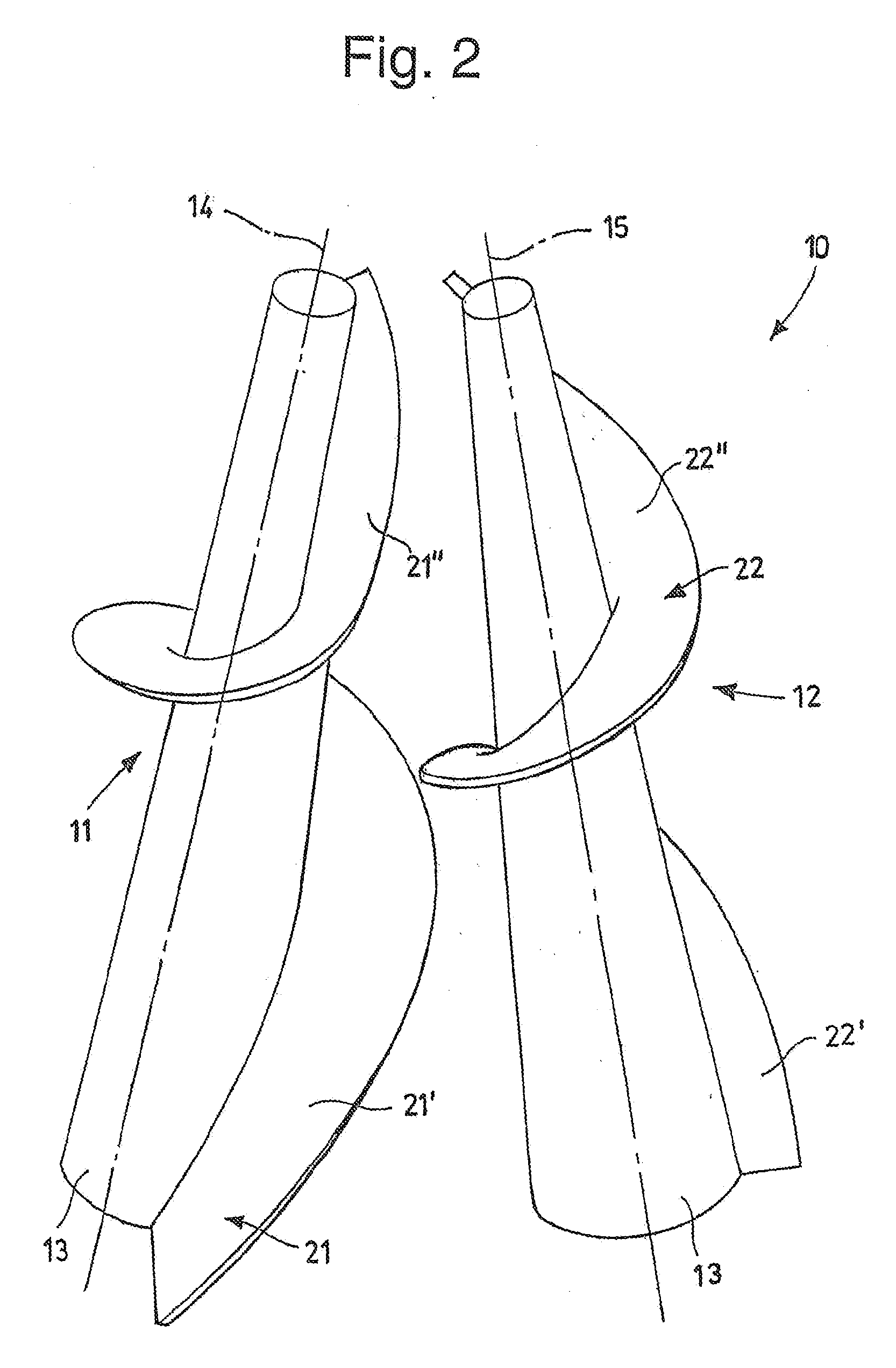

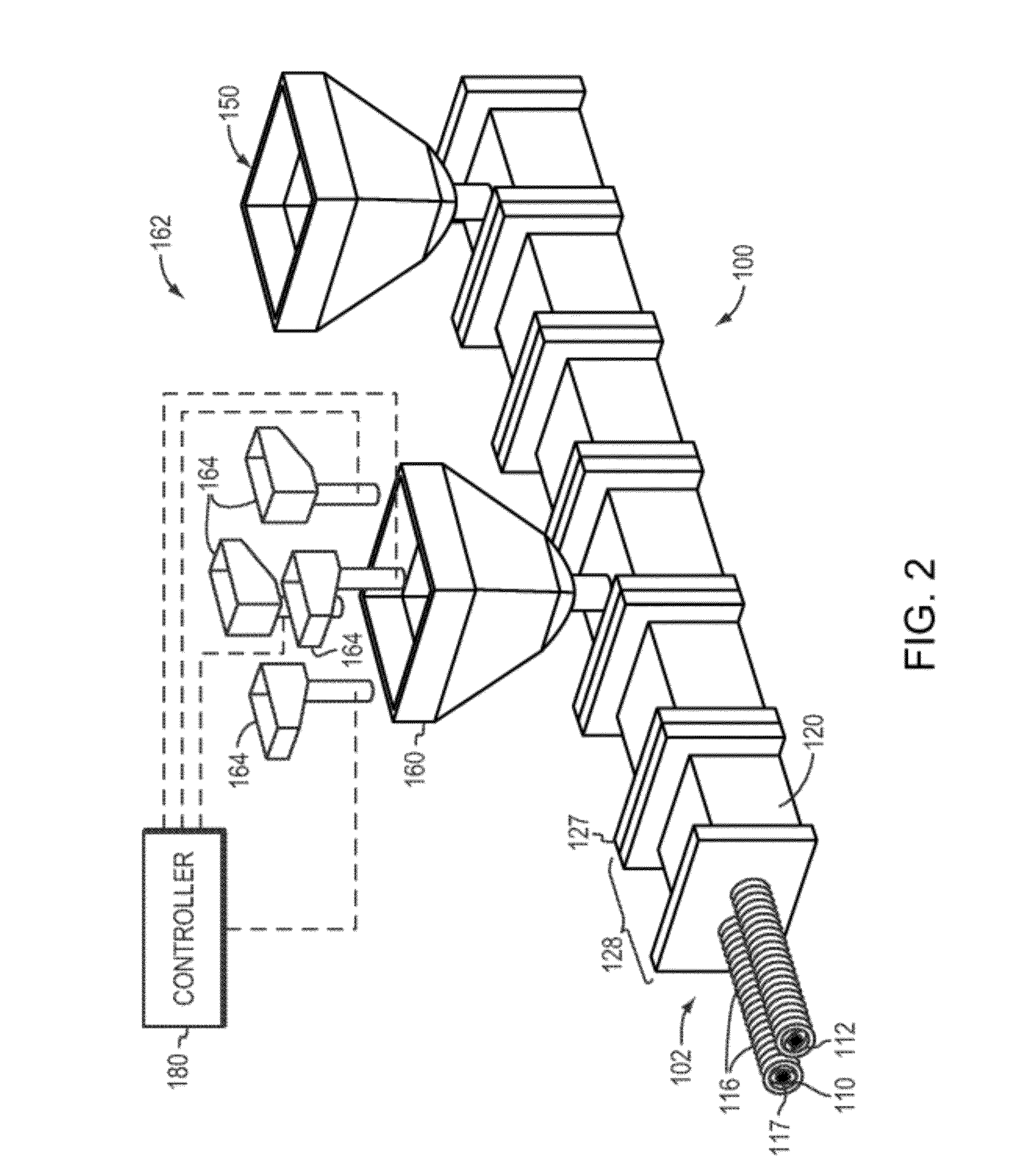

Extruder with twin converging screws for extruding plastomers, elastomers and viscous liquids in general

The invention relates to an extruder with two screws, a first screw and a second screw each comprising a threaded conical shaft having a first end with a bigger diameter and a second tapered end, said screws being arranged converging towards each other for the extrusion of plastomers, elastomers and viscous liquids in general. According to the invention, said first screw has a corresponding thread with a first portion which is diametrically larger than a corresponding first portion of the thread of the second screw.

Owner:POMINI RUBBER & PLASTICS SRL

Polyolefin film for use in cold seal cohesive applications

A polyolefin multilayer film containing a polyolefinic core layer and a first polyolefin skin layer of a blend, wherein the first polyolefin skin layer does not contain a thermoplastic or natural rubber and provides a cold seal receptive surface for a cold seal adhesive is disclosed. The blend includes an ethylene propylene random copolymer at 50-90 wt. % of the skin layer and metallocene catalyzed plastomer at 10-50% wt. % of the skin layer, a metallocene catalyzed isotactic polypropylene polymer or a butene propylene copolymer that contains from 5 wt % to 22 wt % of butene.

Owner:TORAY PLASTICS AMERICA

High flow filled propylene polymer compositions having improved impact and dimensional properties

InactiveUS20040092631A1Maintain good propertiesReadily controlled and maintainedFibre treatmentSpecial tyresPolymer sciencePlastomer

Owner:EQUSR CHEM LP

Blends of Styrene Butadiene Copolymers with Ethylene Acrylate Copolymers and Ethylene Based Wax for Asphalt Modification

The present invention is a polymer-modified asphalt composition comprising an elastomeric polymer blend, a low molecular weight plastomer and an un-modified asphalt. Asphalt compositions of the present invention demonstrate improved elasticity and stiffness compared to conventional polymer-modified asphalt compositions.

Owner:PERFORMANCE MATERIALS NA INC

Blends of epdm and metallocene plastomers for wire and cable applications

Power cable coating compounds are disclosed, the coating compounds including an ethylene alpha-olefin diene elastomeric terpolymer, and an ethylene alpha-olefin copolymer having a Melt Index Ratio I10 / I2 of at least 7 and / or a Melt Index Ratio I21 / I2 of at least 20. In various embodiments, the ethylene alpha-olefin copolymer can be present in the coating compound in amounts up to 90 percent by weight, based on the weight of the ethylene alpha-olefin diene elastomeric terpolymer and the ethylene alpha-olefin copolymer. Also disclosed are electrical devices including extruded coating compounds, the extruded compounds having low surface roughness at high extrusion rates.

Owner:EXXONMOBIL CHEM PAT INC

Modified asphalt compositions

ActiveUS7202290B2Good dispersionBroad ratingIn situ pavingsBuilding insulationsElastomerPolymer science

A modified asphalt composition is provided comprising at least one plastomer, at least one elastomer, at least one crosslinking agent and asphalt. More specifically, a modified asphalt composition is provided comprising an oxidized polyethylene, a styrene-butadiene-styrene block copolymer, sulfur, and asphalt. A hot mix asphalt composition is also provided comprising the modified asphalt composition and aggregate. Processes for producing the modified asphalt composition and the hot mix asphalt composition are also provided as well as articles produced from these inventive compositions.

Owner:PRI ASPHALT TECH LLC +1

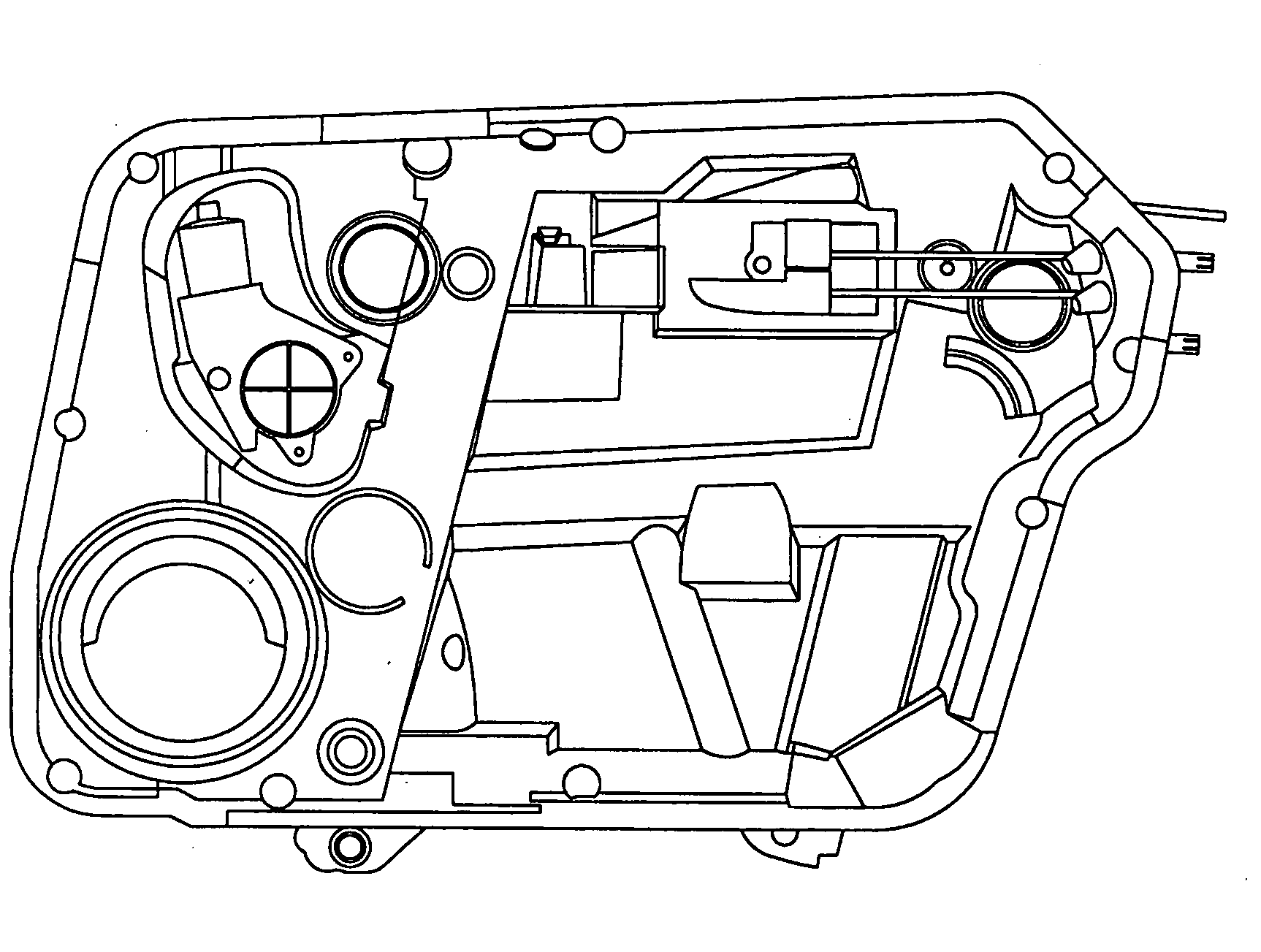

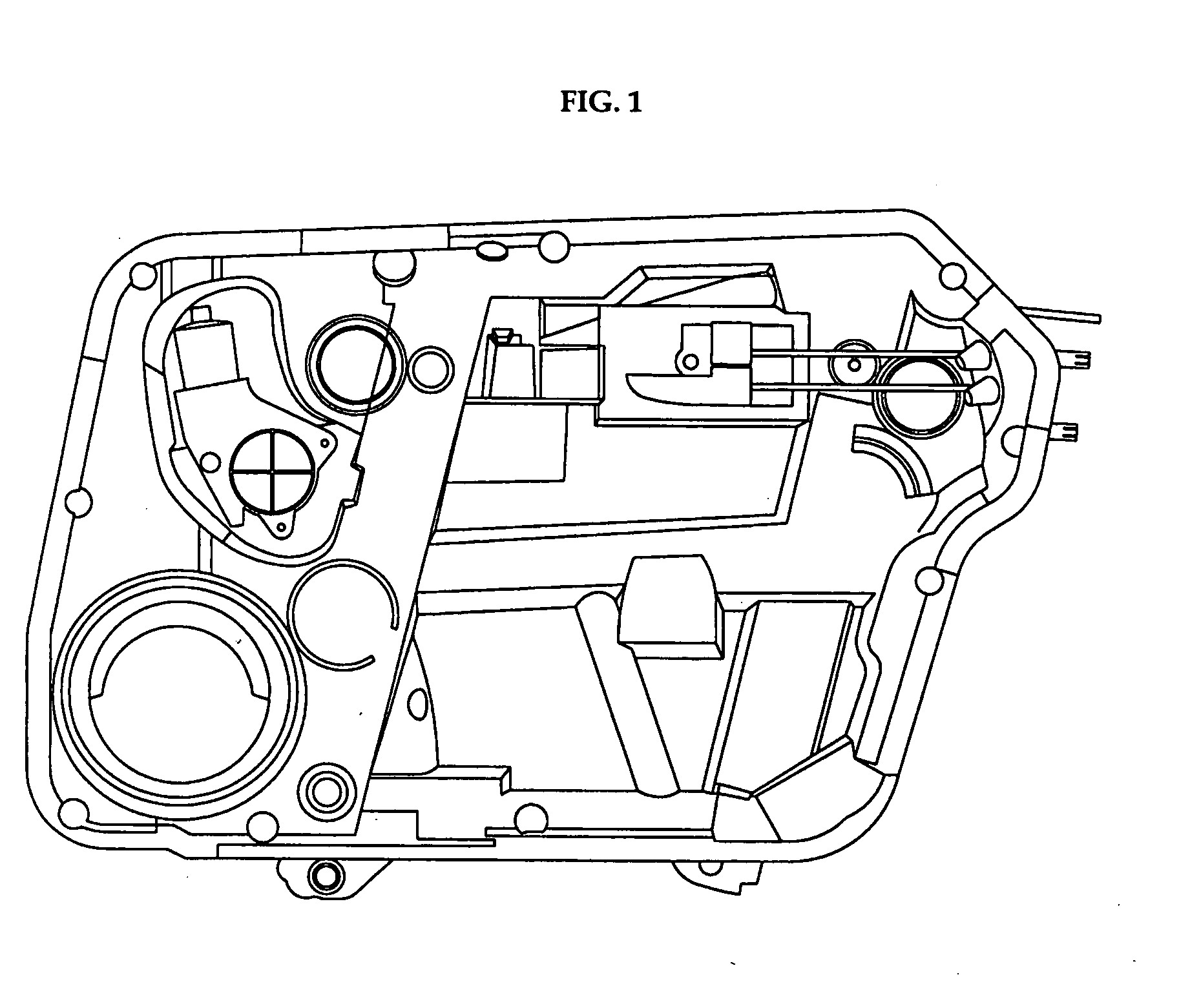

Long-fiber-reinforced polypropylene compositions and door shield module plate produced with the same

ActiveUS20070087193A1Improve resistance to damageImprove impact resistanceFilm/foil adhesivesSynthetic resin layered productsElastomerPlastomer

The present invention provides long-fiber reinforced polypropylene compositions comprising: (a) about 29-77 wt % of a crystalline polypropylene resin comprising about 50-100 wt % of a propylene homopolymer; (b) about 20-50 wt % of a long-fiber reinforcing material having an average fiber length of about 3-50 mm and an average diameter of about 4-30 μm; (c) about 2-20 wt % of an elastomer, a plastomer, or a mixture thereof having a melt index as measured at 190° C. of about 20-150 g / 10 min, wherein said elastomer, plastomer, or mixture thereof was polymerized by a metallocene-based catalyst; and (d) about 0.01-3 wt % of a radical initiator, wherein the ratio of the melt index as measured at 230° C. of the crystalline polypropylene resin to the melt index as measured at 190° C. of the elastomer, the plastomer, or the mixture thereof is in the range of about 0.5 to about 10.

Owner:HYUNDAI MOTOR CO LTD +1

Films having enhanced sealing characteristics and packages containing same

InactiveUS7056593B2Highly desirable sealing characteristicSacrificing advantageous seal propertyLayered product treatmentSynthetic resin layered productsElastomerIonomer

Films containing a sealant layer composition comprising:(1) polyethylene homopolymer, and ethylene / alpha-olefin copolymer, ethylene vinyl acetate copolymer, and ethylene / acrylate copolymer; and(2) elastomer, plastomer, ionomer, and carboxyl-modified polyethylene;when sealed to another outer film layer comprising at least one member selected from the group consisting of ionomer, ethylene / acid copolymer, ethylene / vinyl acetate copolymer and ethylene / acrylate copolymer, have been discovered to provide a seal strength comparable to an ionomer to ionomer seal.

Owner:CRYOVAC ILLC

Polypropylene compounds with enhanced haptics and methods of making same

InactiveUS20140163154A1Enhanced hapticsSimple processFilm/foil adhesivesSpecial tyresAntioxidantThermoplastic elastomer

Polypropylene compositions with enhanced haptics and a process for making the same are disclosed comprising a blend of reactor TPO, and filler. The compositions may further comprise homopolymer polypropylene, random copolymer polypropylene, polyamide 6, ethylene-C4-8 α-olefin plastomer, plastomer propylene-ethylene copolymer, SEBS triblock thermoplastic elastomer, maleic anhydride grafted PP, anti-scratch additives, antioxidants, UV stabilizers, and colorants. A process is also disclosed for preparing the polypropylene compositions with enhanced haptics.

Owner:ASAHI KASEI PLASTICS NORTH AMERICA

Photosensitive resin compositive for printing plate precursor capable of laser engraving

InactiveUS7029825B2Highly uniform thicknessSmall surface tackRadiation applicationsSemiconductor/solid-state device manufacturingLaser engravingPlastomer

Disclosed is a photosensitive resin composition for forming a laser engravable printing element, comprising: (a) 100 parts by weight of a resin which is a plastomer at 20° C., wherein the resin has a number average molecular weight (Mn) of from 1,000 to 100,000 and has a polymerizable unsaturated group in an amount such that the average number of the polymerizable unsaturated group per molecule is at least 0.7, (b) 5 to 200 parts by weight, relative to 100 parts by weight of resin (a), of an organic compound having an Mn of less than 1,000 and having at least one polymerizable unsaturated group per molecule, and (c) 1 to 100 parts by weight, relative to 100 parts by weight of resin (a), of an inorganic porous material. Also disclosed is a laser engravable printing element formed from the above-mentioned resin composition.

Owner:ASAHI KASEI CHEM CORP

Adhesive and coating compositions

The instant invention concerns a composition that is useful as an adhesive in laminating applications. The composition comprises a segmented copolyesterether and a metallocene-catalyzed polyethylene-co-alpha-olefin plastomer, wherein the alpha-olefin comonomer can be a C3-C12 alpha-olefin. The adhesive heterophase blend is substantially free of external compatibilizers.

Owner:HENKEL CORP

Adhesives for fluoropolymer films and structures containing same

InactiveUS6838520B2Synthetic resin layered productsThin material handlingElastomerLinear low-density polyethylene

Adhesives useful for adhering fluoropolymers are provided. The adhesives are a blend of linear low density polyethylene, ethylene polymer plastomer, polyolefin elastomer and modified polyolefin having acid or acid derivative functionality. Composite fluoropolymer / adhesive structures are also provided.

Owner:EQUSR CHEM LP

Modified asphalt compositions

InactiveUS20060223916A1Good dispersionBroad ratingIn situ pavingsBuilding insulationsElastomerPolymer science

A modified asphalt composition is provided comprising at least one plastomer, at least one elastomer, and asphalt. More specifically, a modified asphalt composition is provided comprising an oxidized polyethylene, a styrene-butadiene-styrene block copolymer, and asphalt. A hot mix asphalt composition is also provided comprising the modified asphalt composition and aggregate. Processes for producing the modified asphalt composition and the hot mix asphalt composition is also provided as well as articles produced from these inventive compositions.

Owner:WESTLAKE LONGVIEW

Barrier Agricultural Fumigation Film

InactiveUS20070298197A1Slowing down escapeTight gripWrappers shrinkageShrinkage connectionsLow-density polyethyleneLinear low-density polyethylene

A film that provides a fumigant barrier on a raised crop bed includes a barrier material for restricting the flow of a fluid fumigant, and an elastic polymer material for providing elasticity in the film so that the film can be stretched around the crop bed. The barrier material can be a combination of a polyamide, such as copolyamide 6 / 66, and an amorphous nylon resin. The elastic polymer can be a plastomer, such as an ethylene based octene plastomer or a polyolefin plastomer. The film can also include a polyethylene resin, such as a linear low density polyethylene, to provide strength to the film. The film can be made utilizing a blown film extrusion process.

Owner:RIJNLANDSE PLASTICS GROEP

Composites Utilizing Polymeric Capstocks and Methods of Manufacture

InactiveUS20120315471A1Improve skid resistanceIncrease coefficient of frictionSynthetic resin layered productsCellulosic plastic layered productsElastomerFilling materials

An extruded composite adapted for use as a building material includes a core having a base polymer and a filler material in a substantially homogeneous mixture and a polymeric capstock modified with an elastomer and / or a plastomer. To improve adherence of the polymeric capstock to the base polymer, the capstock can include a capstock polymer that is similar or substantially similar the base polymer. Additionally, various additives may be mixed with the capstock material to improve visual aesthetics of the product and performance of the building material, especially over time.

Owner:MANCOSH DOUGLAS +1

Plasticized polyolefin compositions

The present invention relates to plasticized polyolefin compositions comprising a polyolefin and a non-functionalized plasticizer; wherein the non-functionalized plasticizer may comprise C6 to C200 paraffins (including branched and normal paraffins) having a pour point of less than −5° C. In one embodiment, the non-functionalized plasticizer is an isoparaffin comprising C6 to C25 isoparaffins. In another embodiment the non-functionalized plasticizer is a polyalphaolefin comprising C10 to C100 n-paraffins. The polyolefin may be a polypropylene homopolymer, copolymer, impact copolymer, or blends thereof, and may include a plastomer. Non-limiting examples of desirable article of manufacture made from compositions of the invention include films, tubes, pipes, sheets, fibers, woven and nonwoven fabrics, automotive components, furniture, sporting equipment, food storage containers, transparent and semi-transparent articles, toys, tubing and pipes, and medical devices.

Owner:EXXONMOBIL CHEM PAT INC

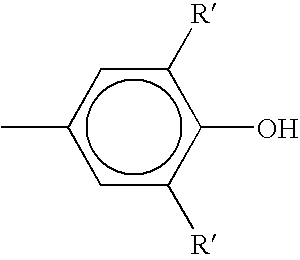

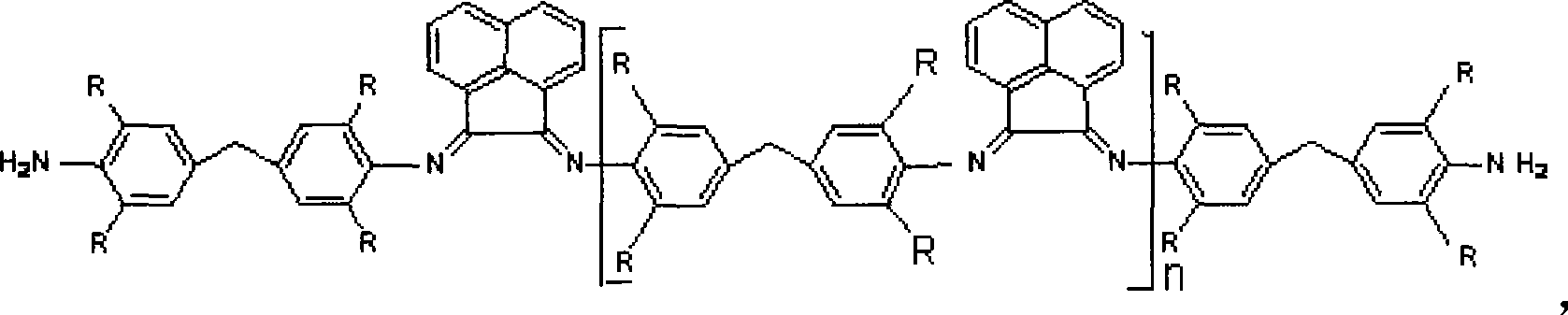

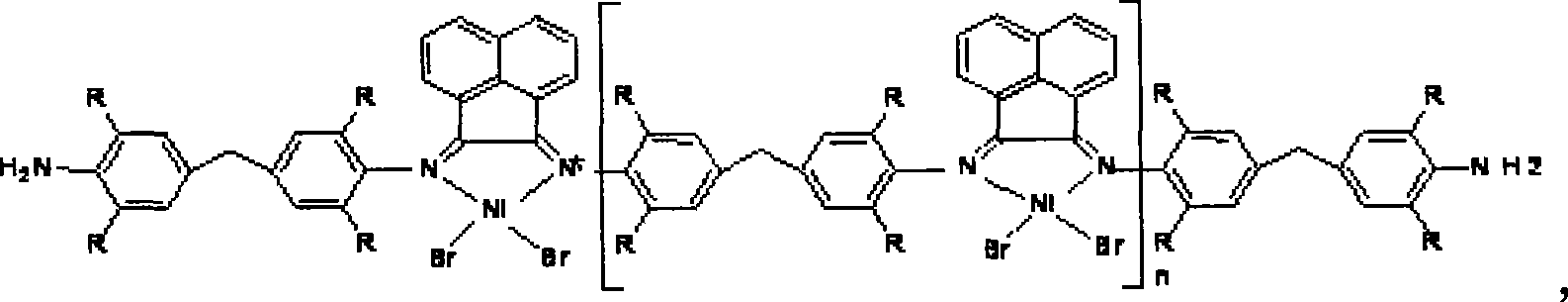

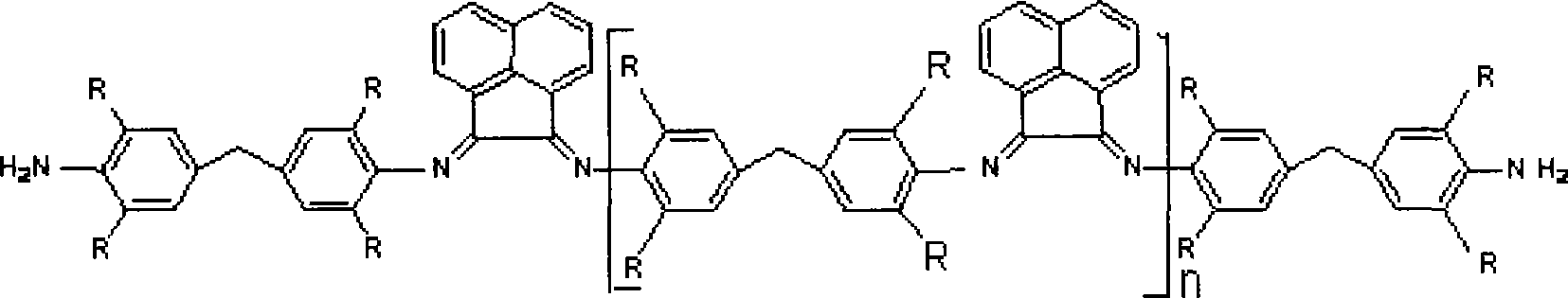

Polynuclear nickel(II) acenaphthenequinonediimine catalyst for synthesizing branched polyethylene and preparation method thereof

InactiveCN101531724AEasy to shapeLow degree of branchingBulk chemical productionLow-density polyethyleneElastomer

The invention provides a polynuclear nickel(II) acenaphthenequinonediimine catalyst for synthesizing branched polyethylene, comprising a main catalyst and a co-catalyst, characterized in that: the main catalyst is formed by loading the polynuclear nickel bromide acenaphthenequinonediimine complexes on the MgCl2 / AlRm(OEt)[3-m] carrier formed by aluminium trialkyl modified MgCl2-C2H5OH complexes; the co co-catalyst is the AlEt2Cl and the catalyst for synthesizing branched polyethylene by ethane polymerization is formed by the main catalyst and the co-catalyst, and the mol ratio is that: Ni[(n+1)]L[(n)]Br[2(n+1)]:AlEt[2]Cl is 1:100-1000. The advantages of the invention are that: the prepared catalyst only uses general AlEt[2]Cl as co-catalyst without using expensive MAO or boron compounds, and the catalysis for ethylene polymerization is high active, thus the branched high branching degree and low density polyethylene plastomer and lower density elastomer is prepared; the carrier uses the modified MgCl2-C2H5OH complexes, thus the prepared polyethylene product has good form. The catalyst is suitable for being generalized and used in industrial production with notable advantage.

Owner:NANCHANG HANGKONG UNIVERSITY

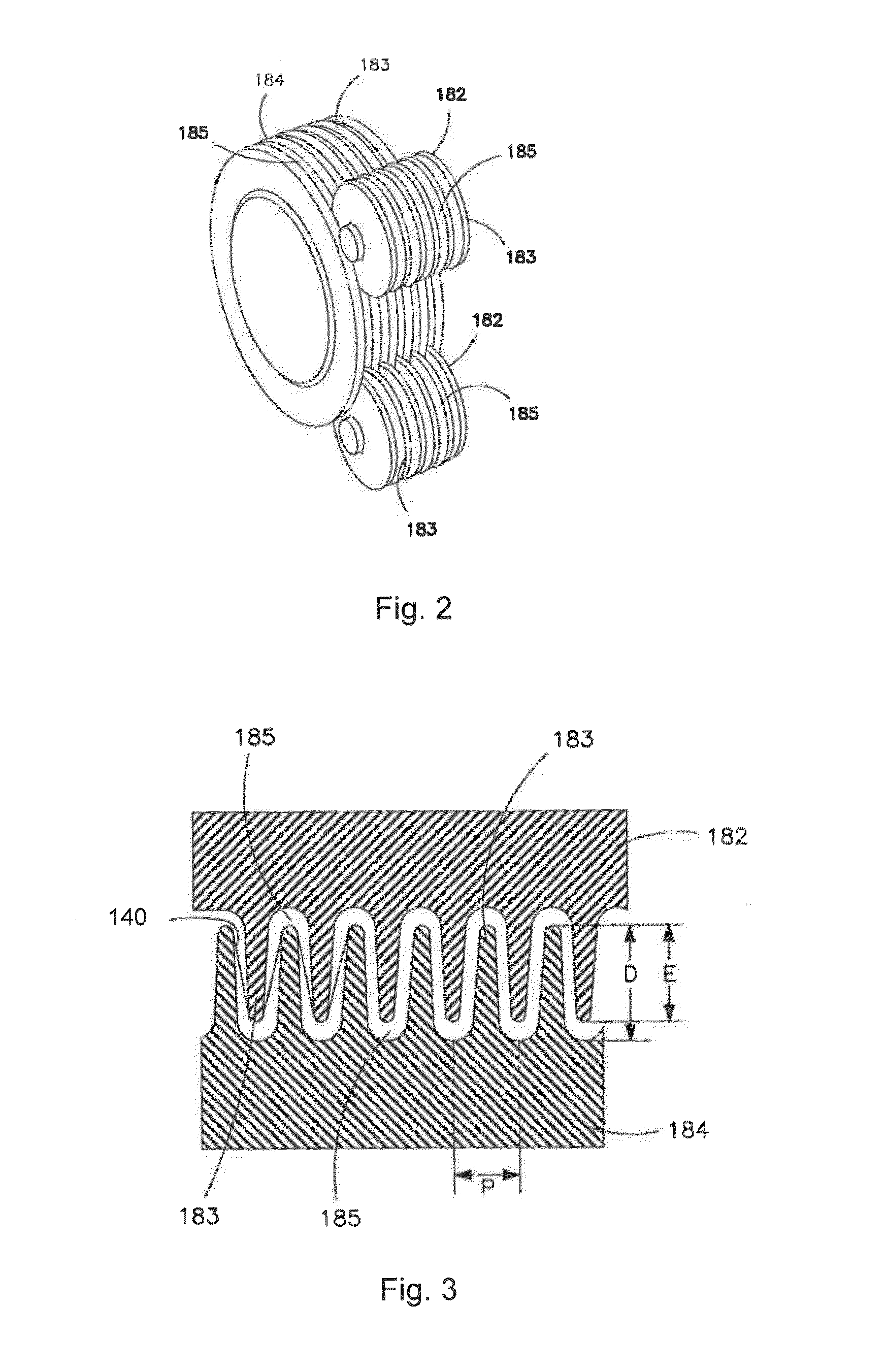

Toothed Belt for Use with Oil and Relative Timing Control System

Toothed belt for use with oil comprising a body and a plurality of teeth extending from at least a surface of the body; the teeth are covered by a coating fabric. The toothed belt comprises a plurality of resistant inserts produced from at least a first and a second material. Preferably, the resistant inserts are constituted by glass fibres and carbon fibres. Preferably, a resistant layer is made to adhere over the coating fabric, said layer comprising a fluorine based plastomer with the addition of an elastomeric material, wherein the plastomer is present in a greater amount than the elastomeric material. The elastomeric material forming the body of the belt is preferably a copolymer obtained from a diene monomer and a monomer containing nitrile groups, wherein the nitrile groups are between 33% and 49%, preferably 39 weight % with respect to the copolymer.

Owner:DAYCO EURO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com