Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2234 results about "Laser engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser engraving, which is a subset of laser marking, is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

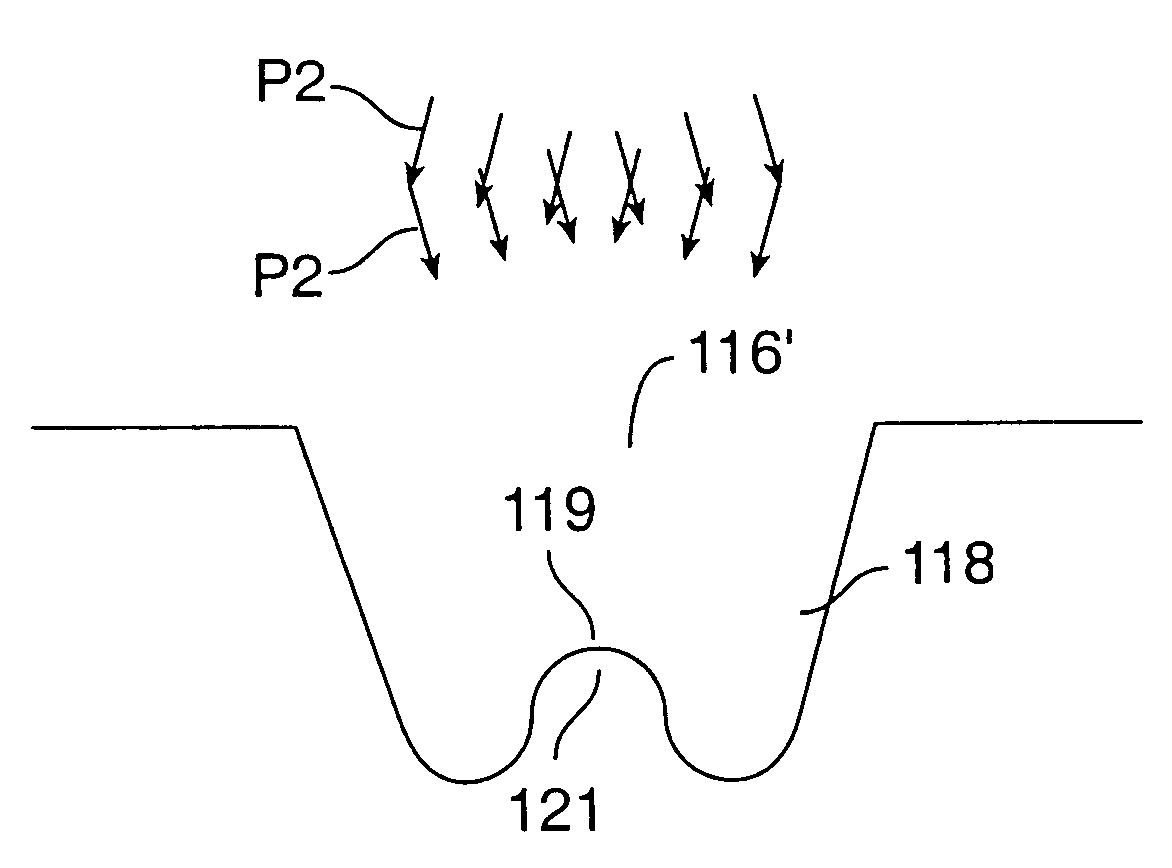

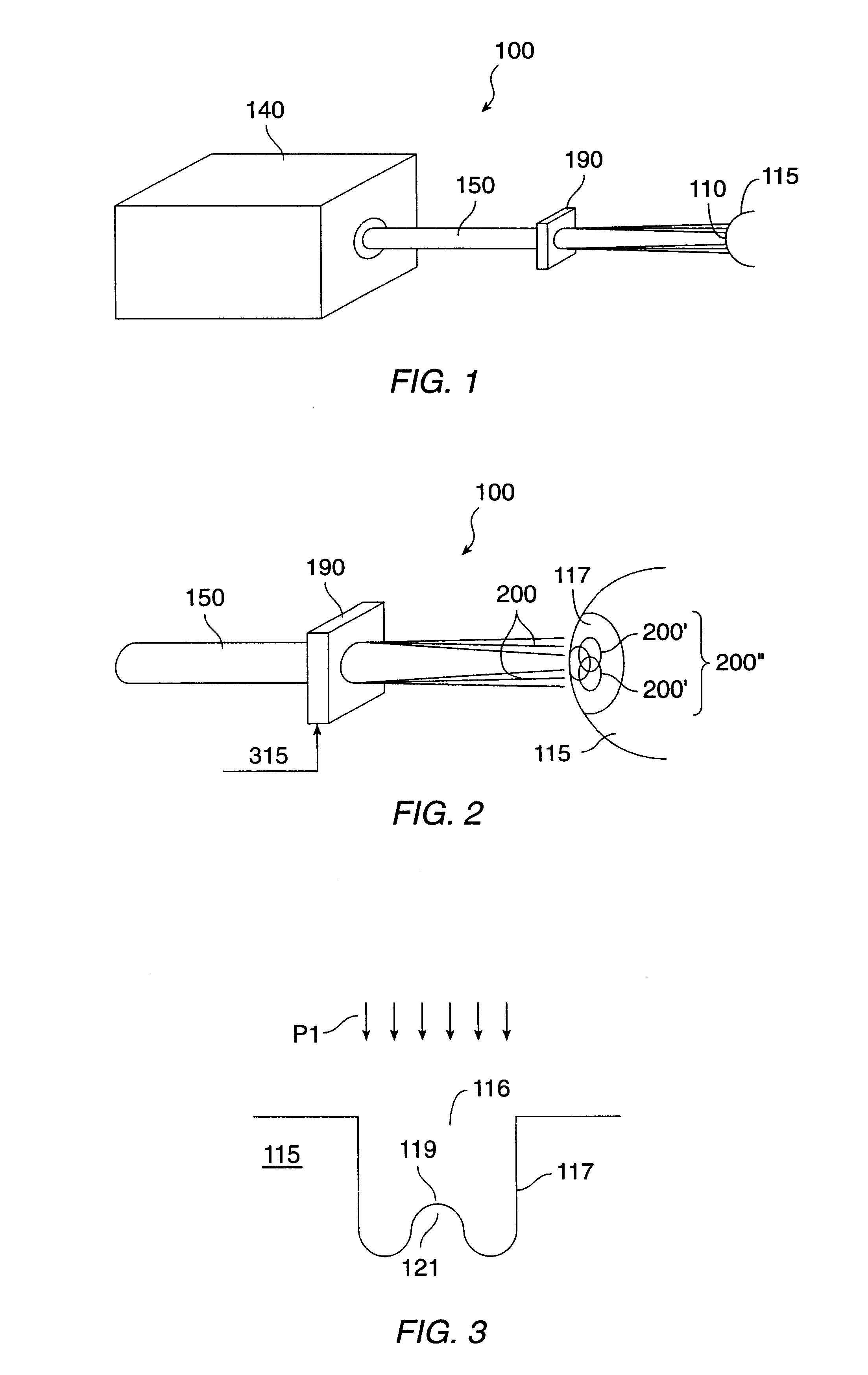

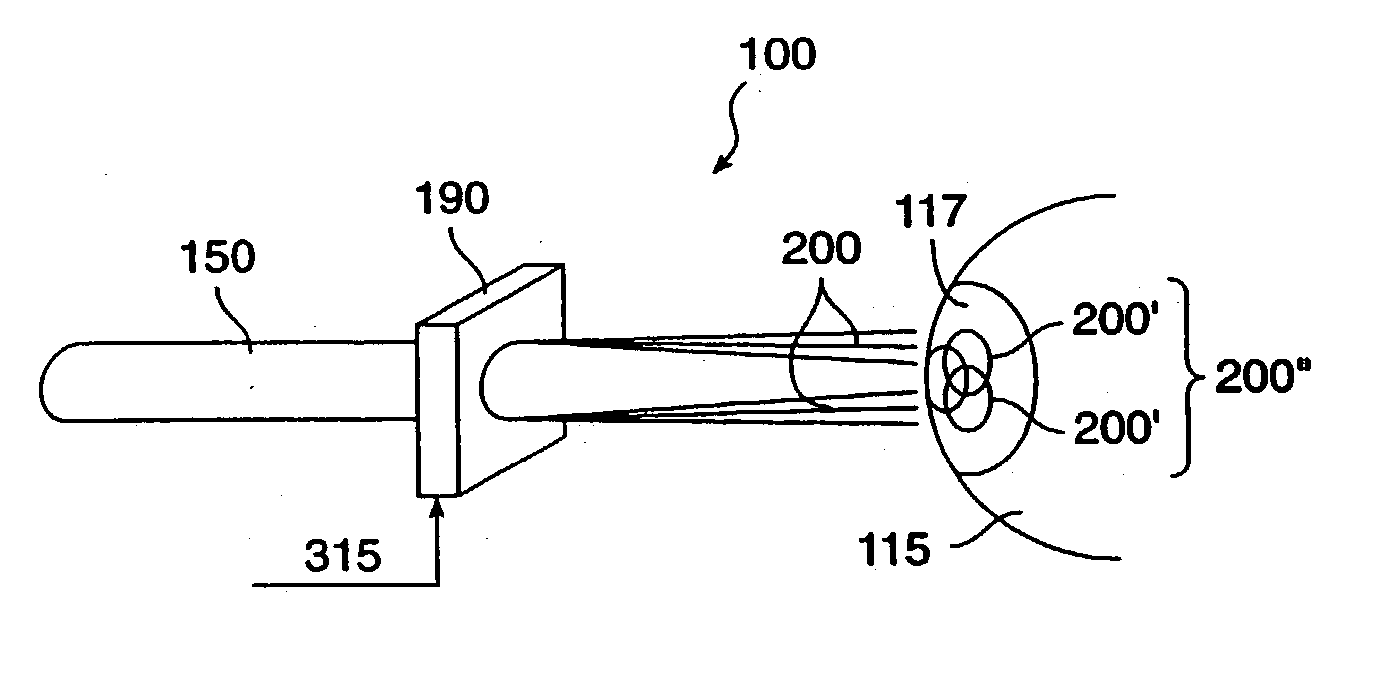

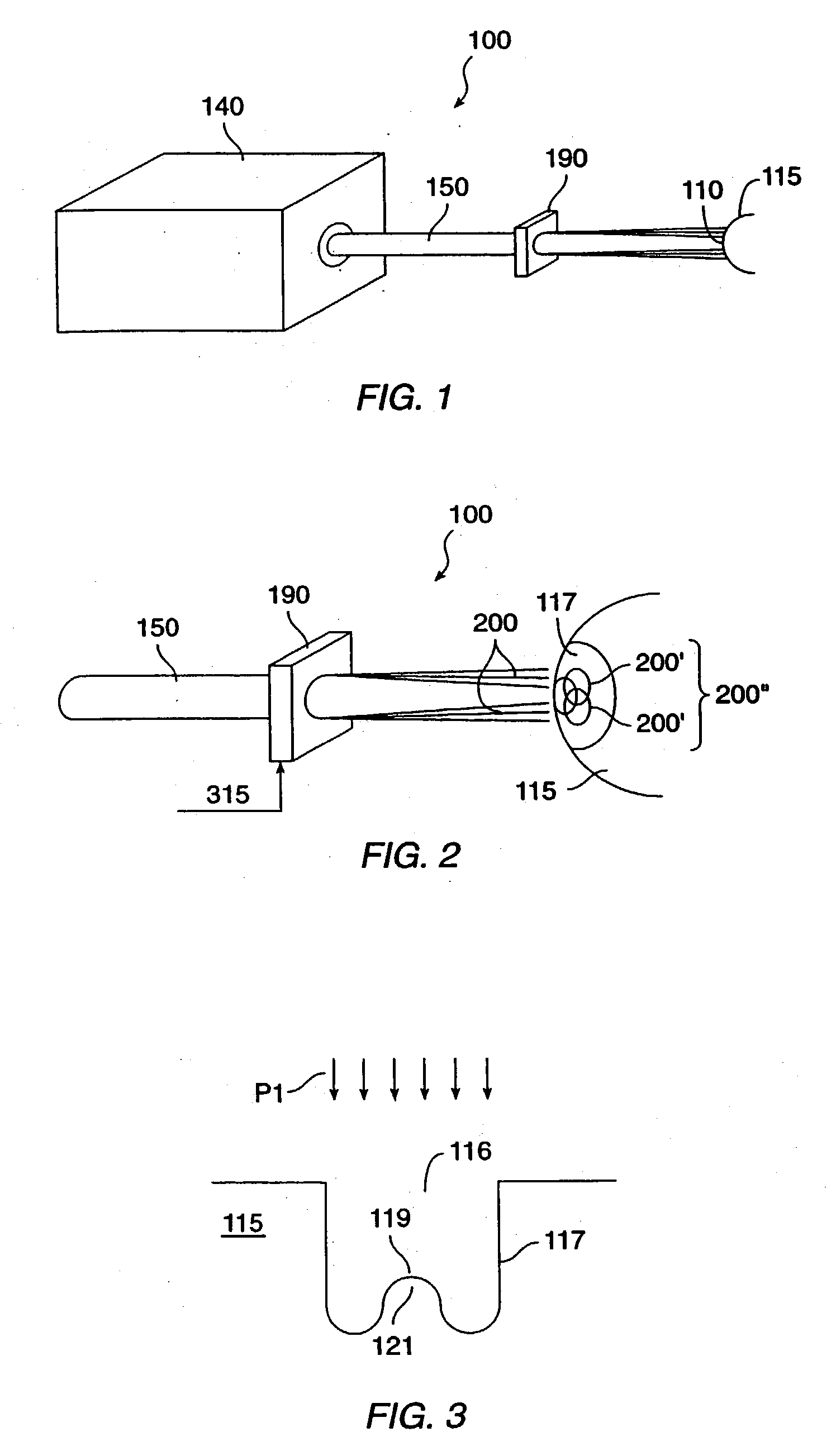

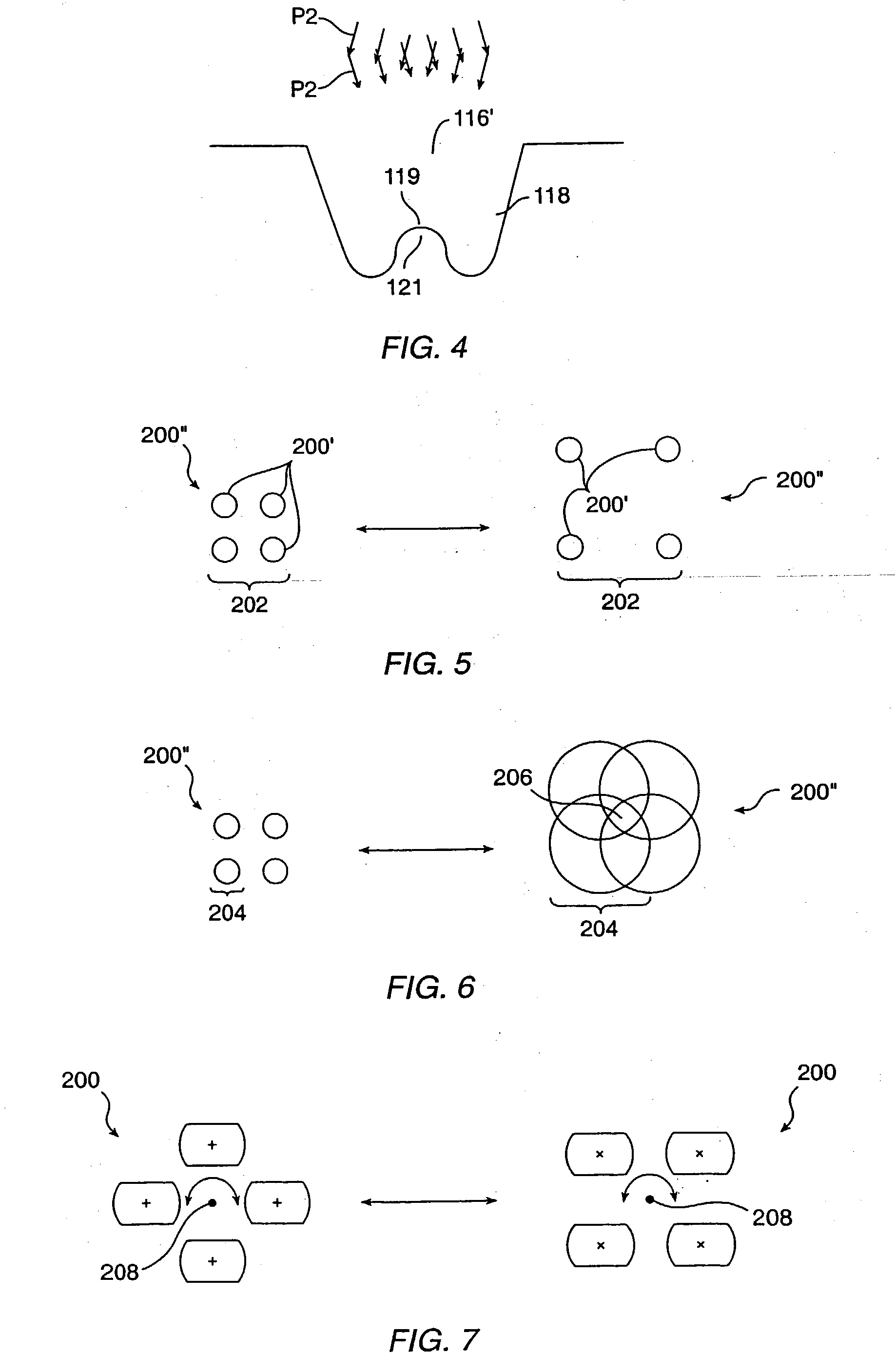

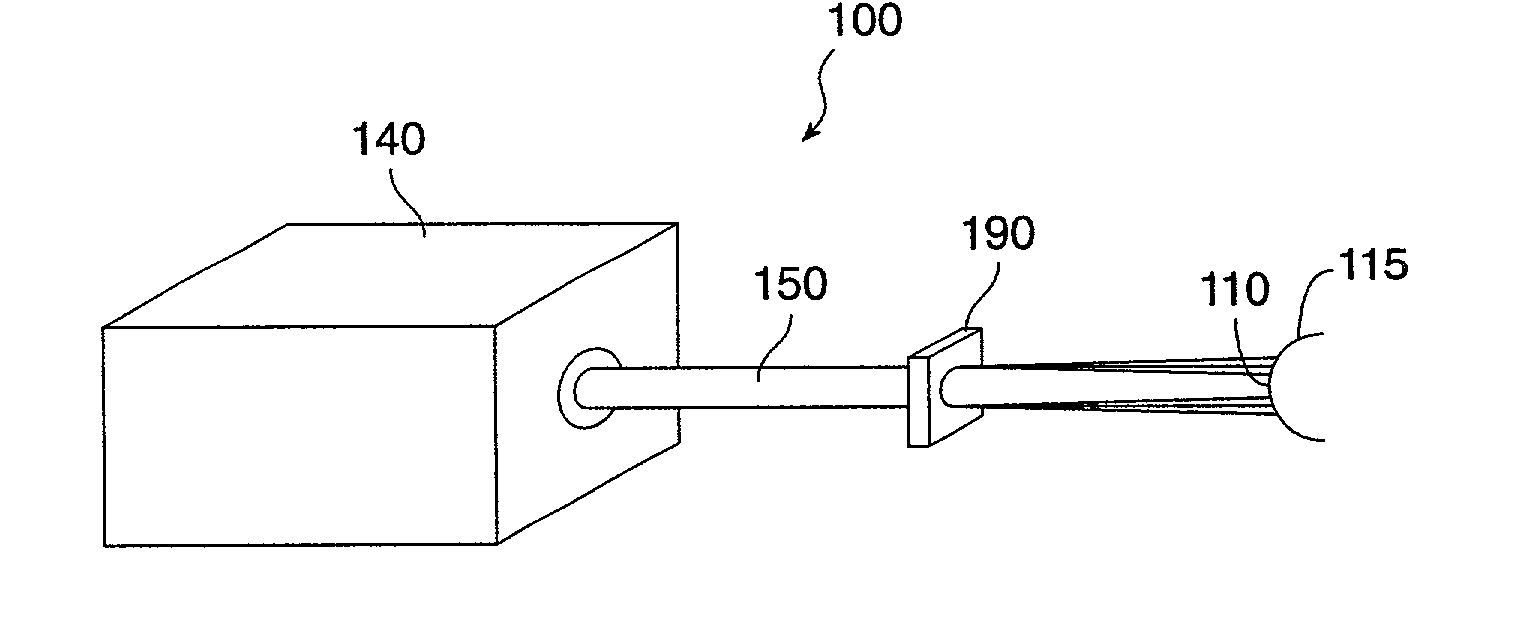

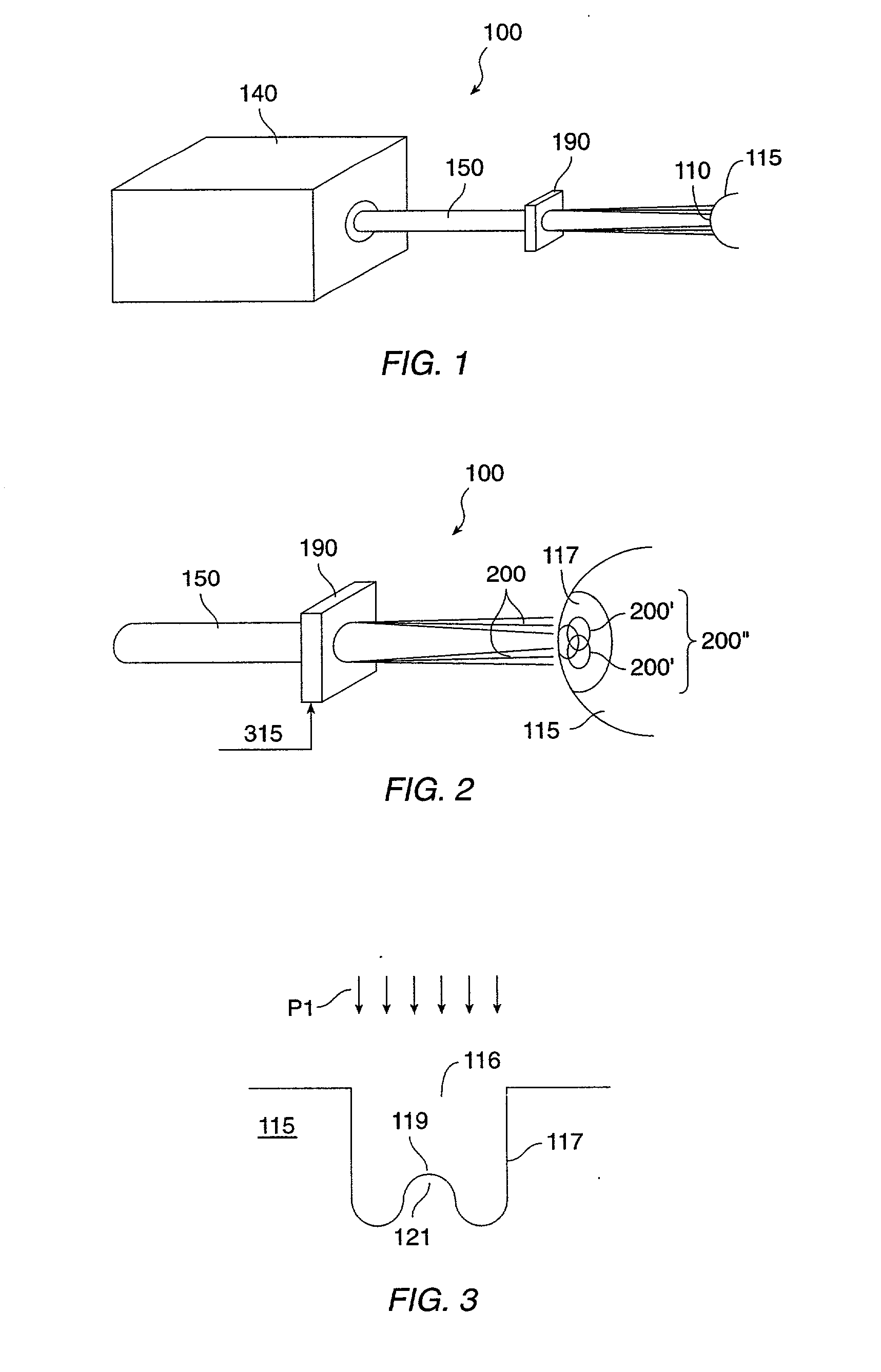

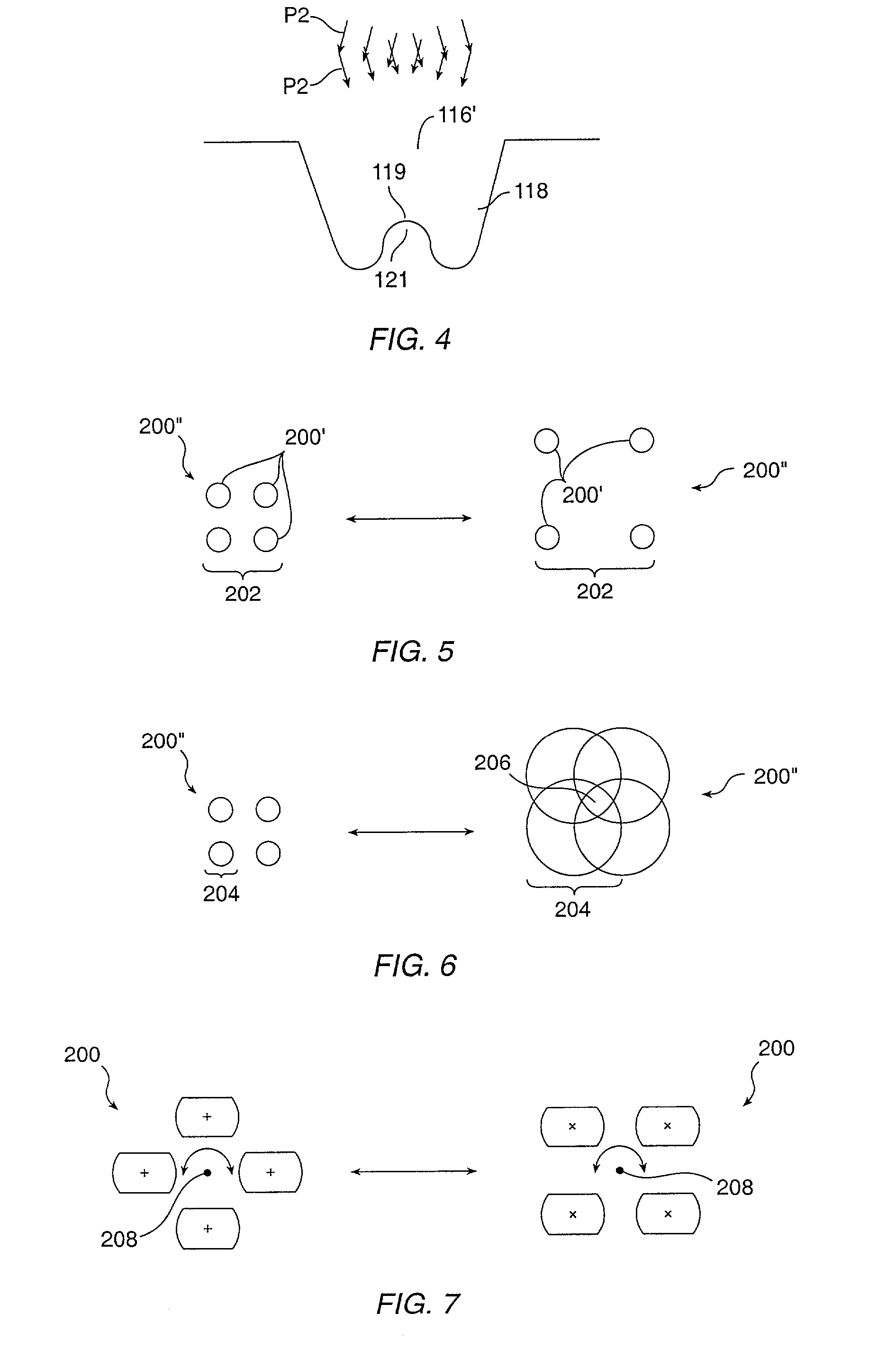

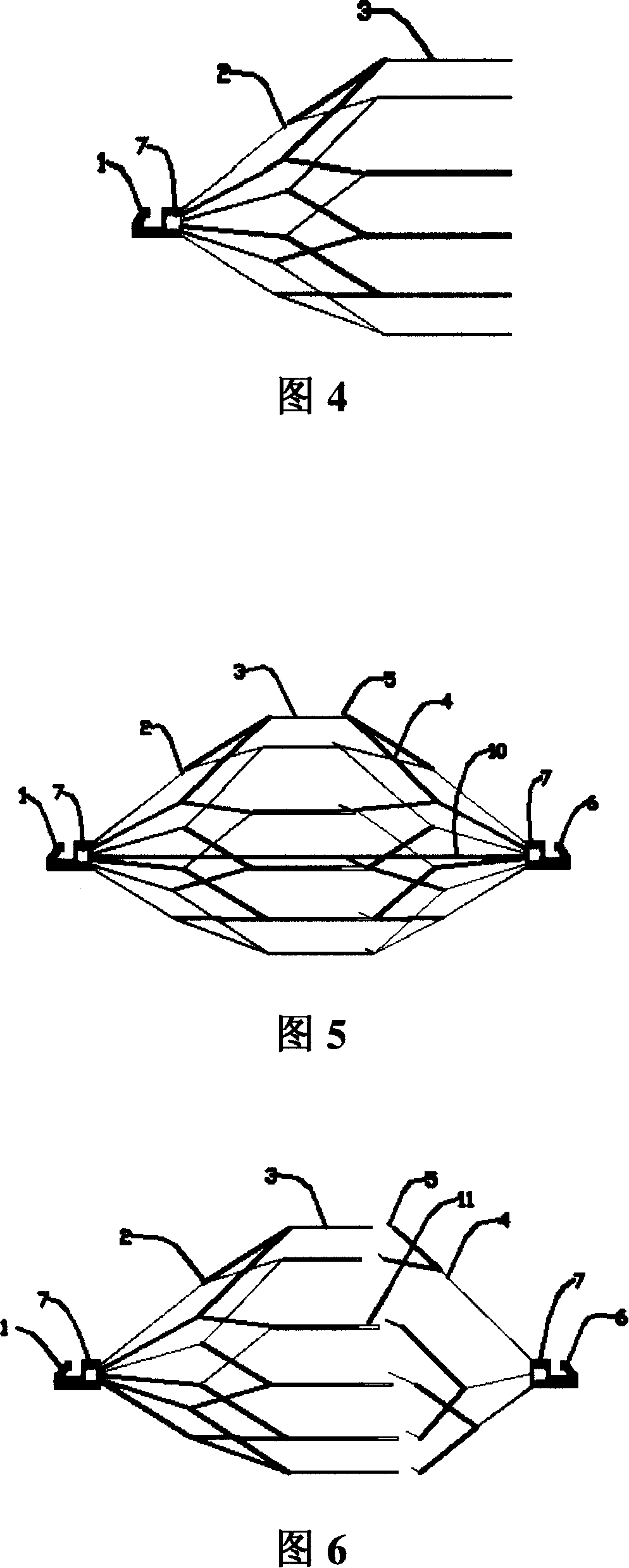

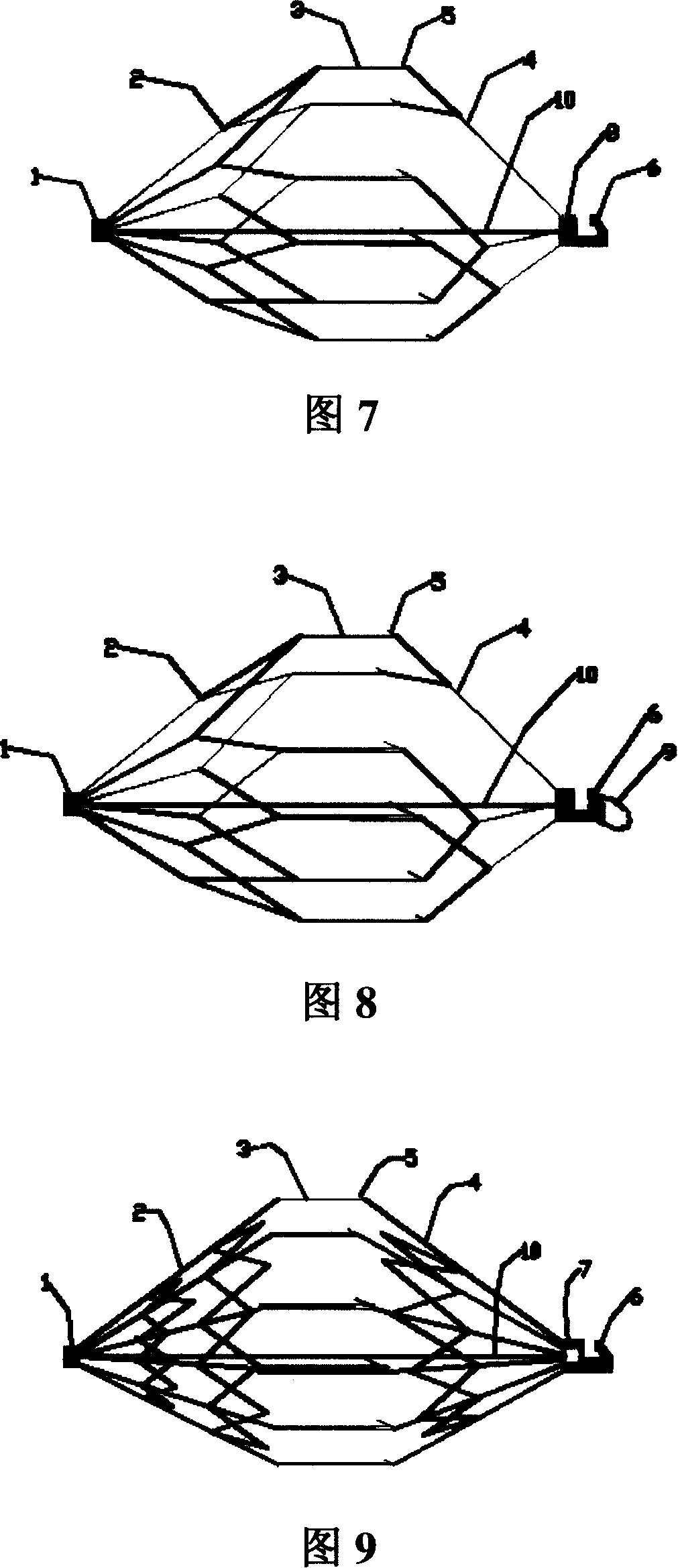

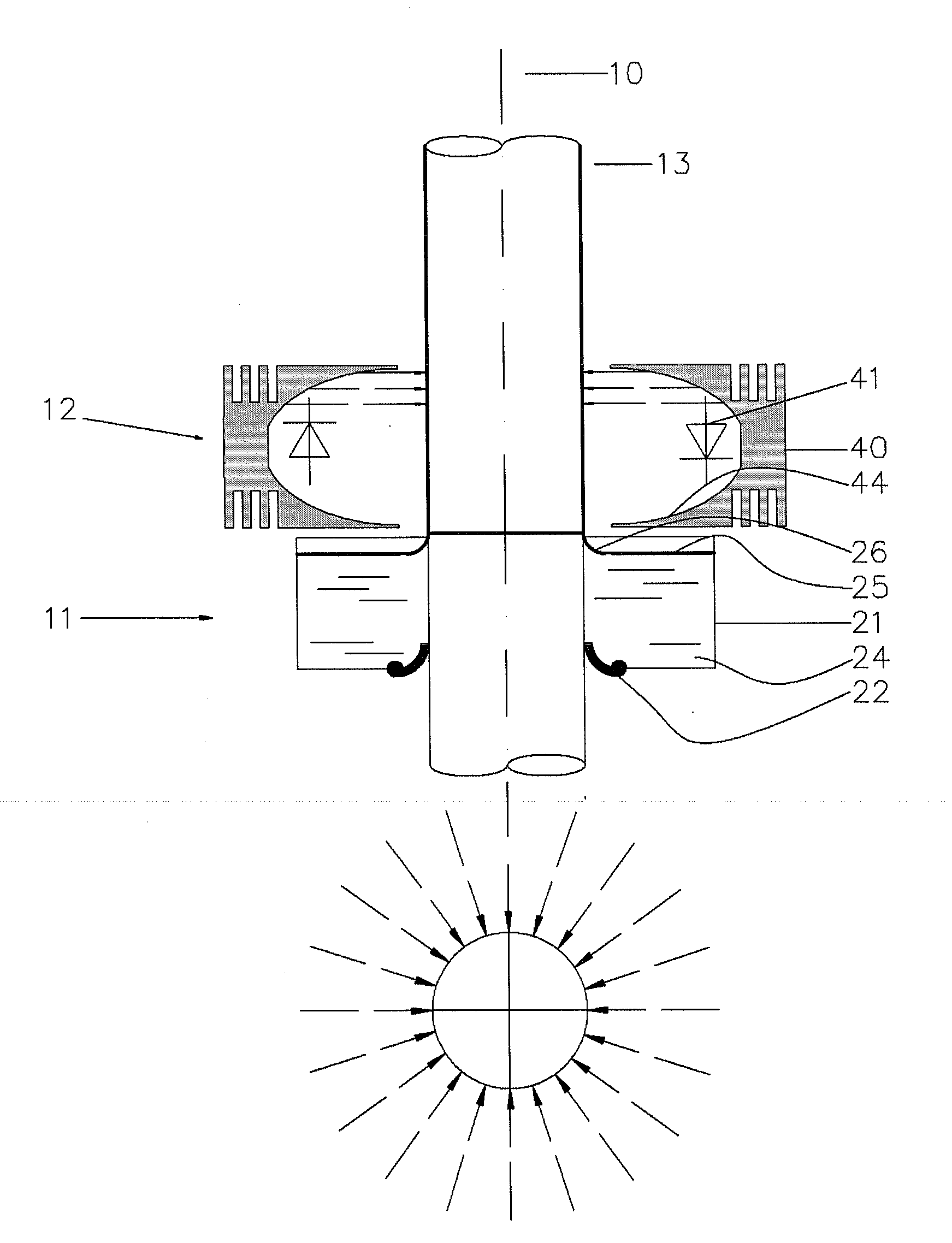

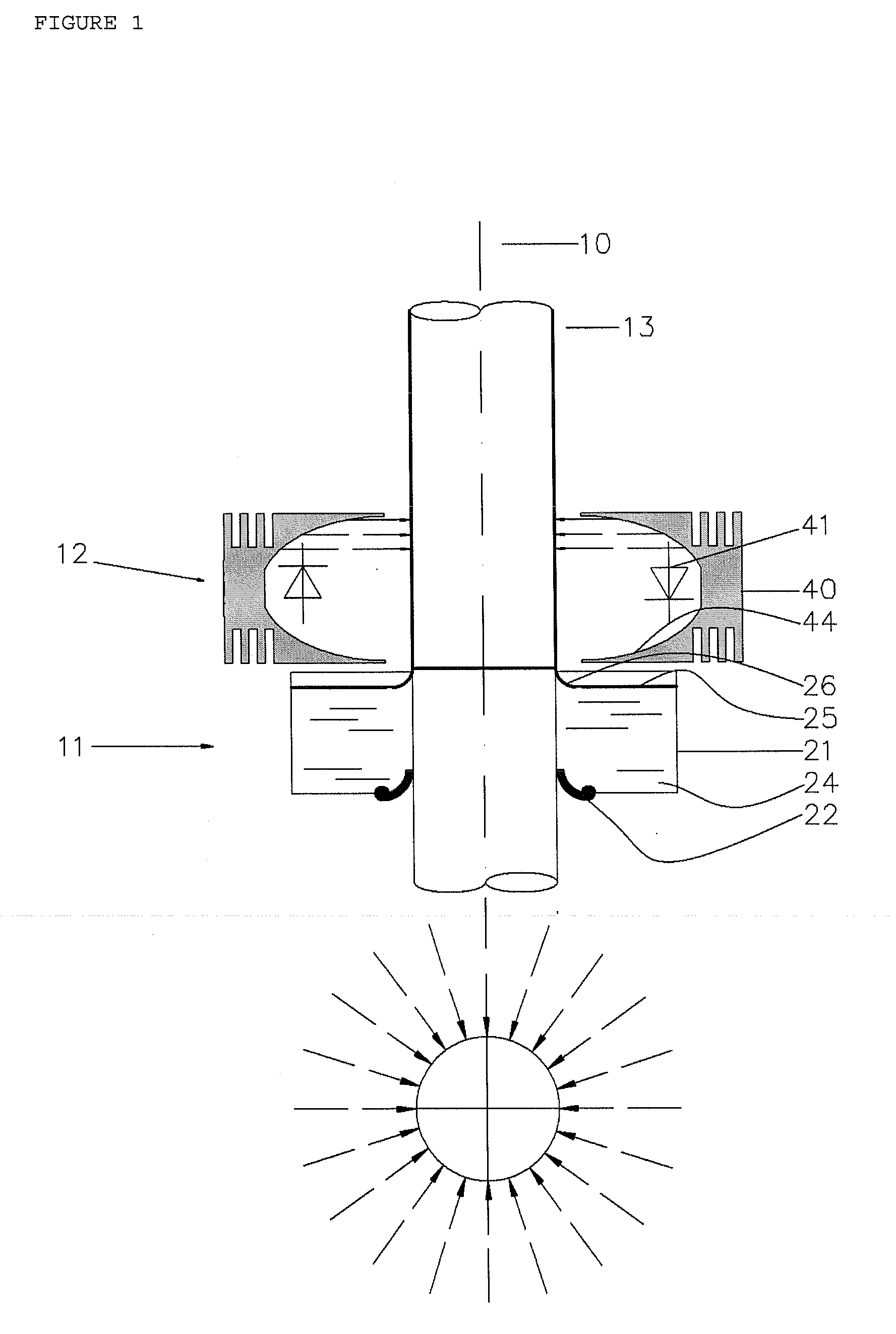

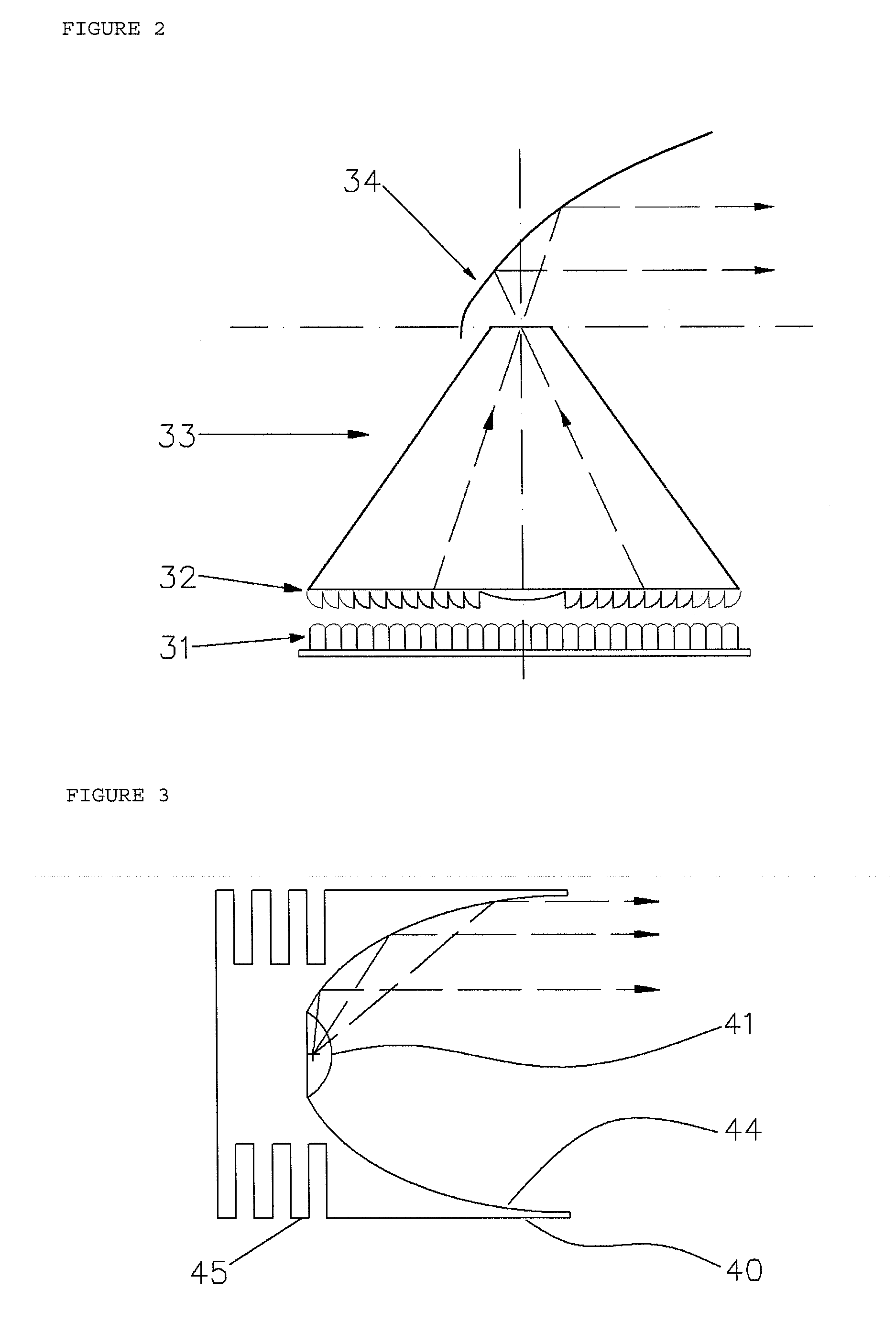

Multiple beam laser sculpting system and method

The invention improves the laser sculpting of a region of a material to a predetermined shape by improving the smoothness and accuracy of surfaces formed by the sculpting technique. The technique includes projecting plurality of partially overlapping beams toward the region. The invention includes blurring an edge of an ablation to smooth an internal portion of the ablation that is separate from the edge. The blurred edge may be formed by the partially overlapping beams. Using a computer controlled laser delivery system, the position and shape of the overlapping beams may be precisely controlled to sculpt the material to a desired shape according to a laser treatment table.

Owner:AMO MFG USA INC

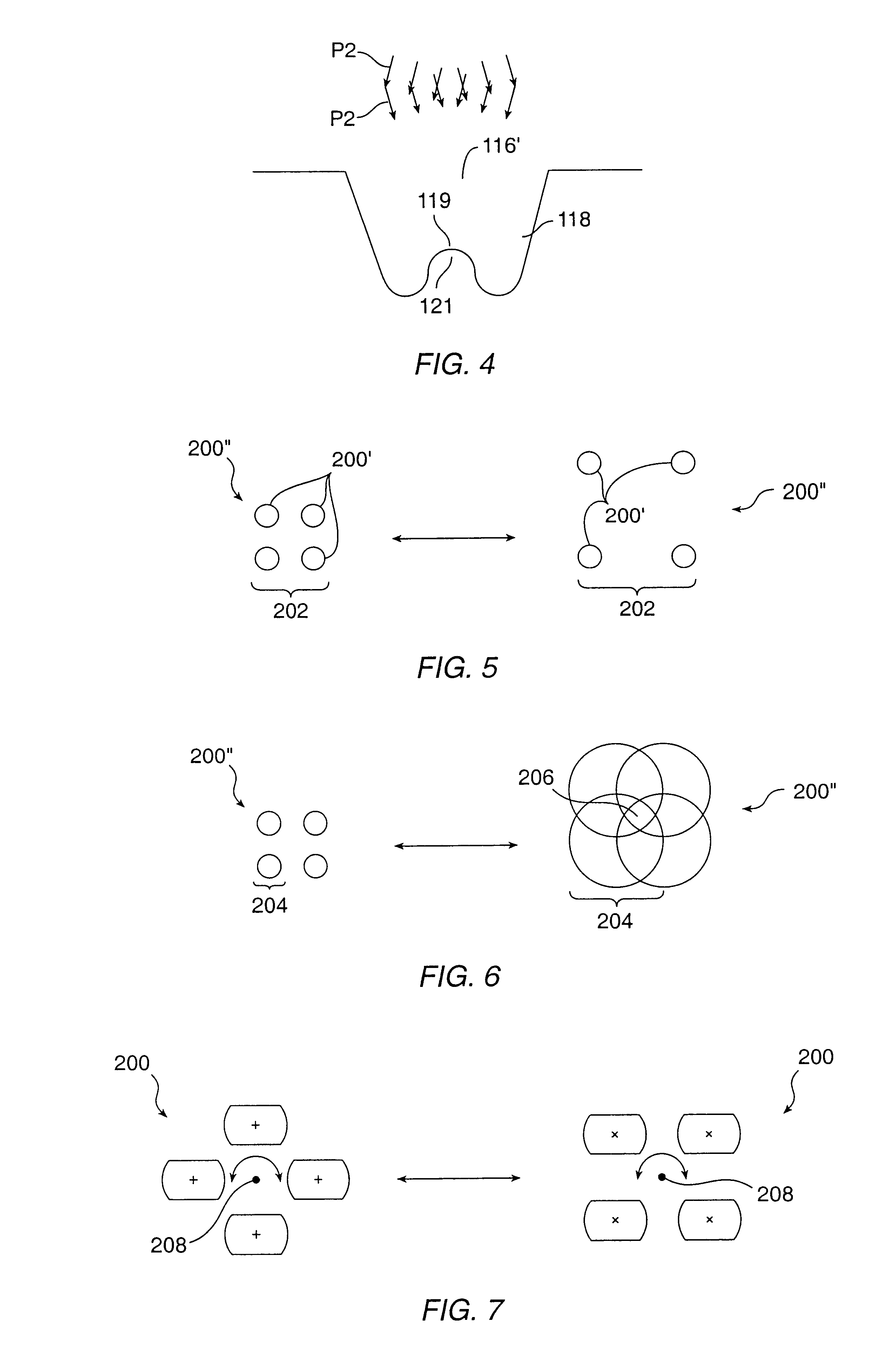

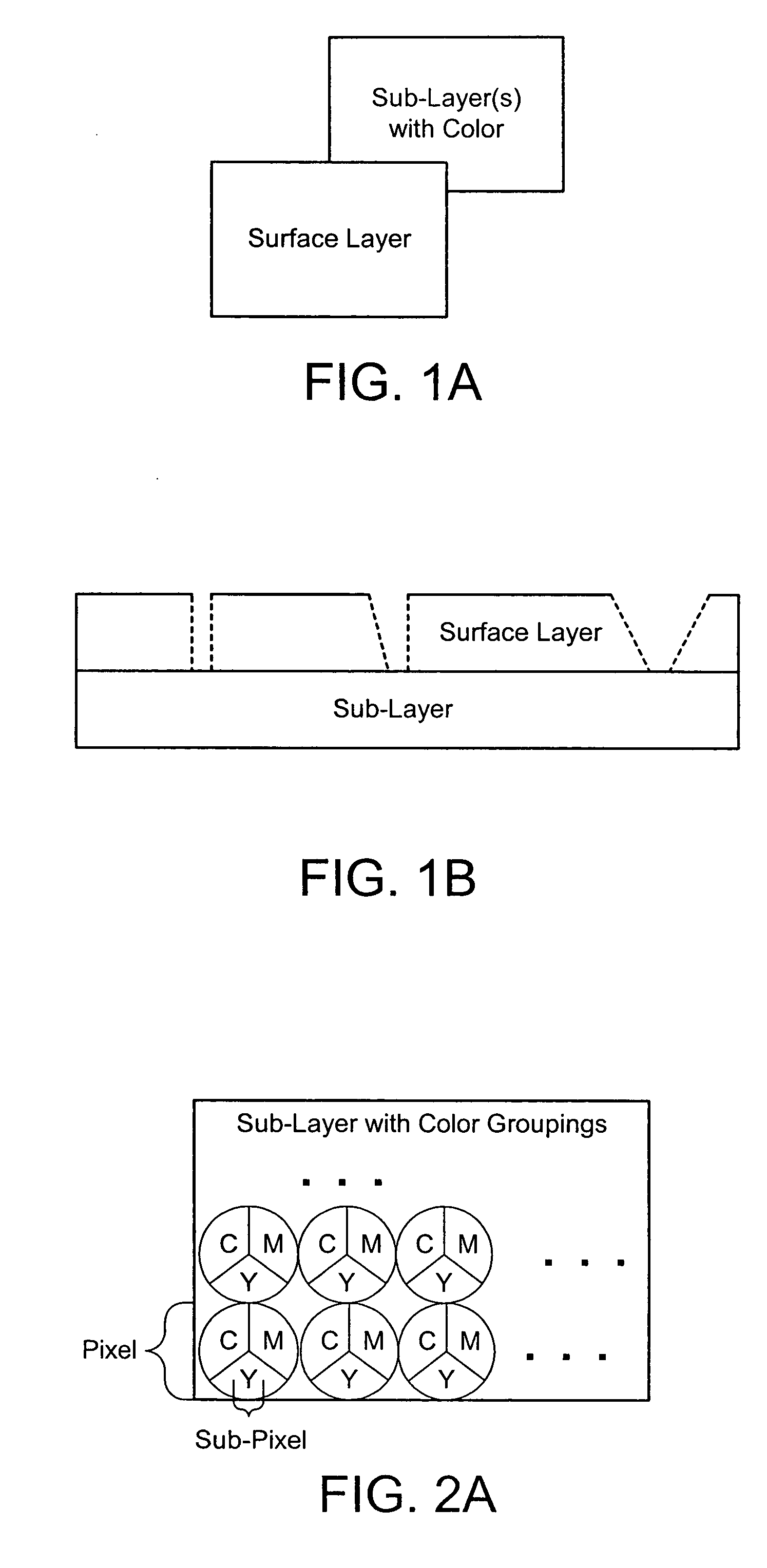

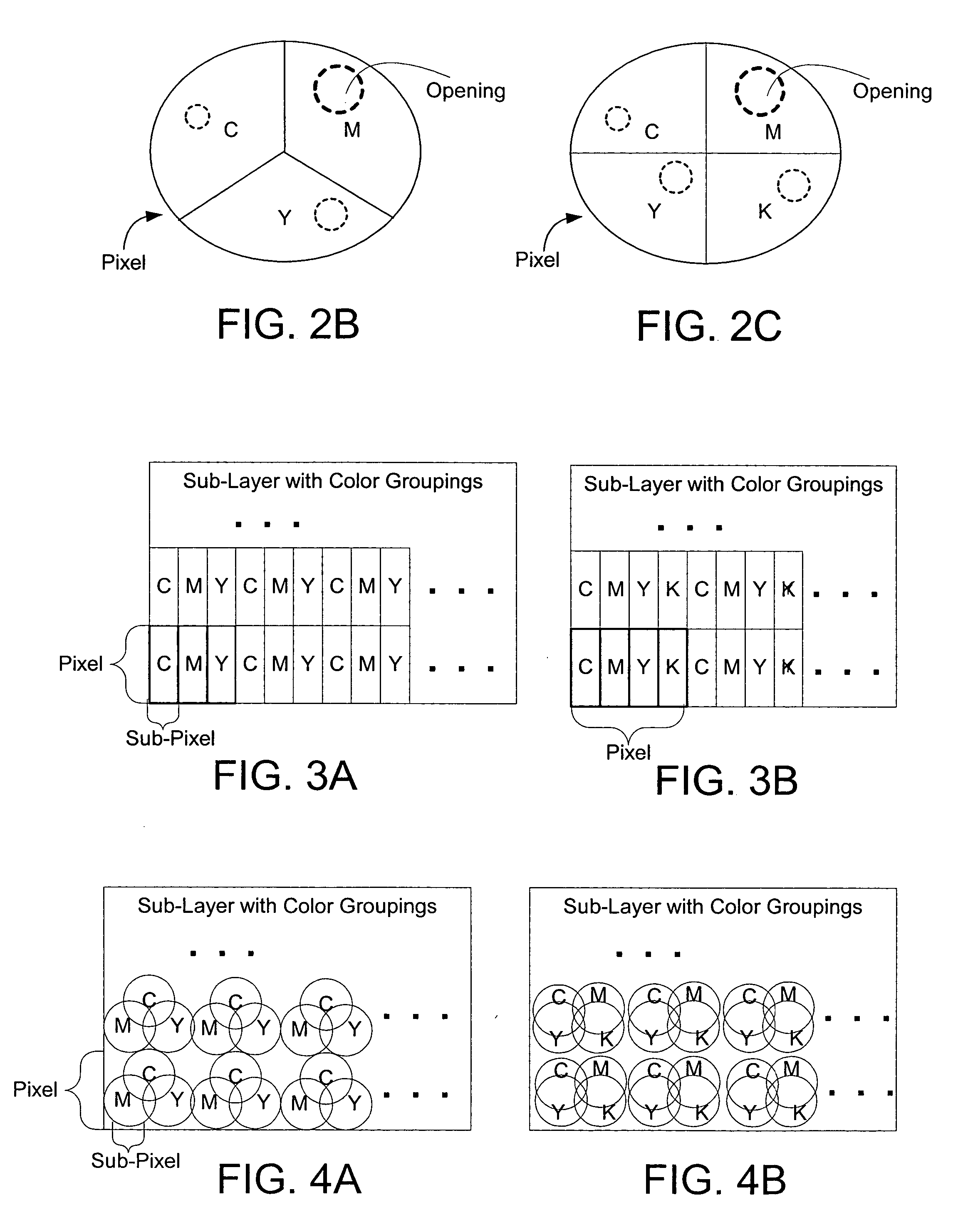

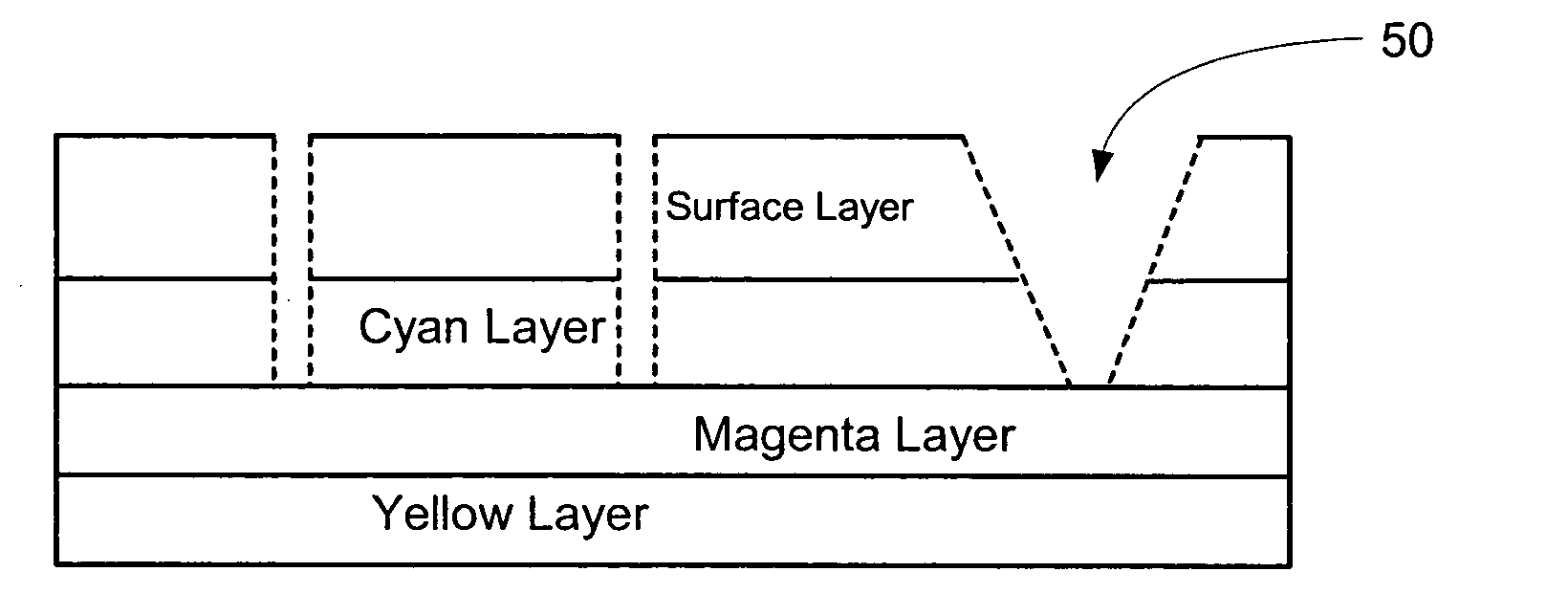

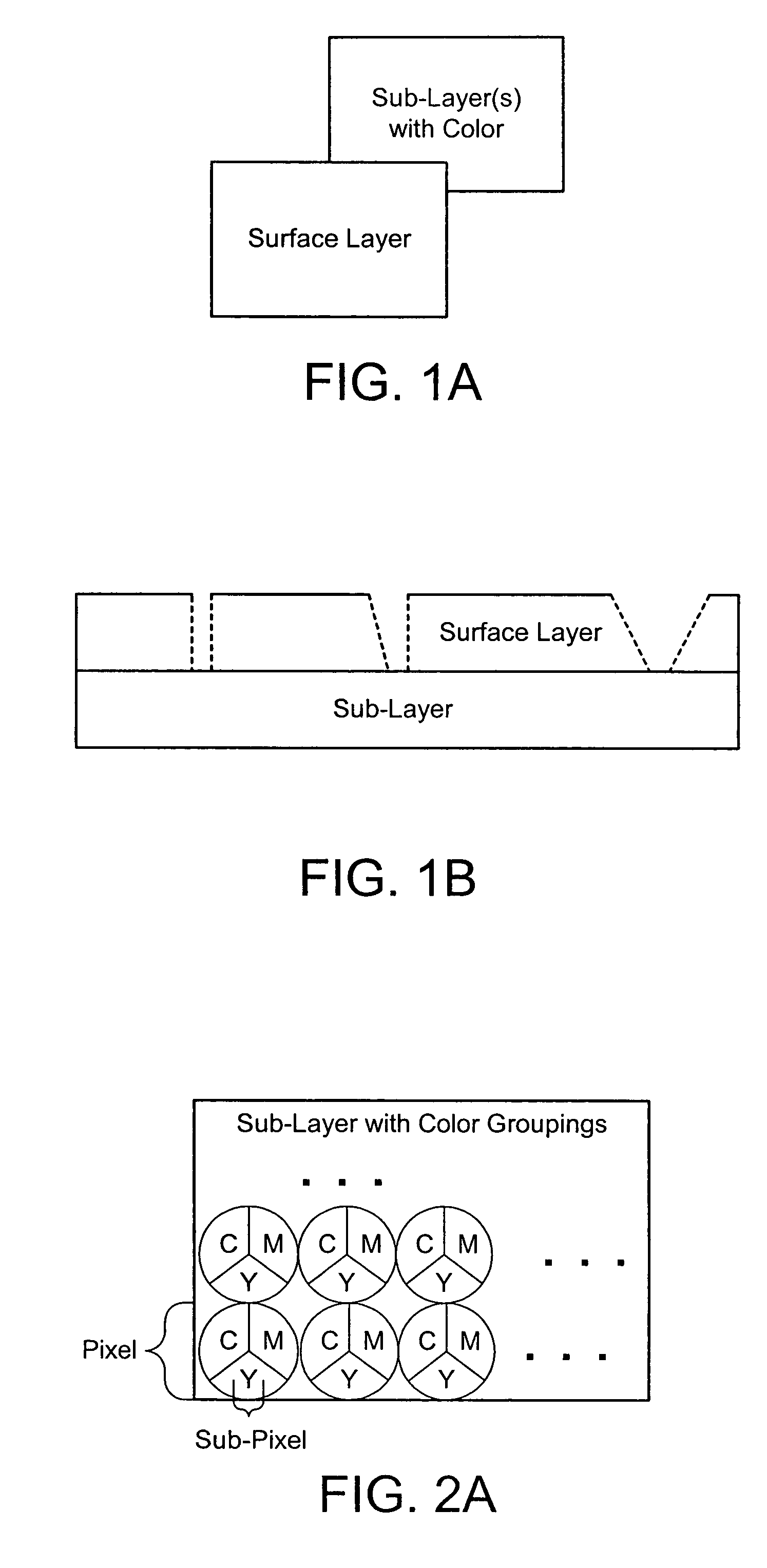

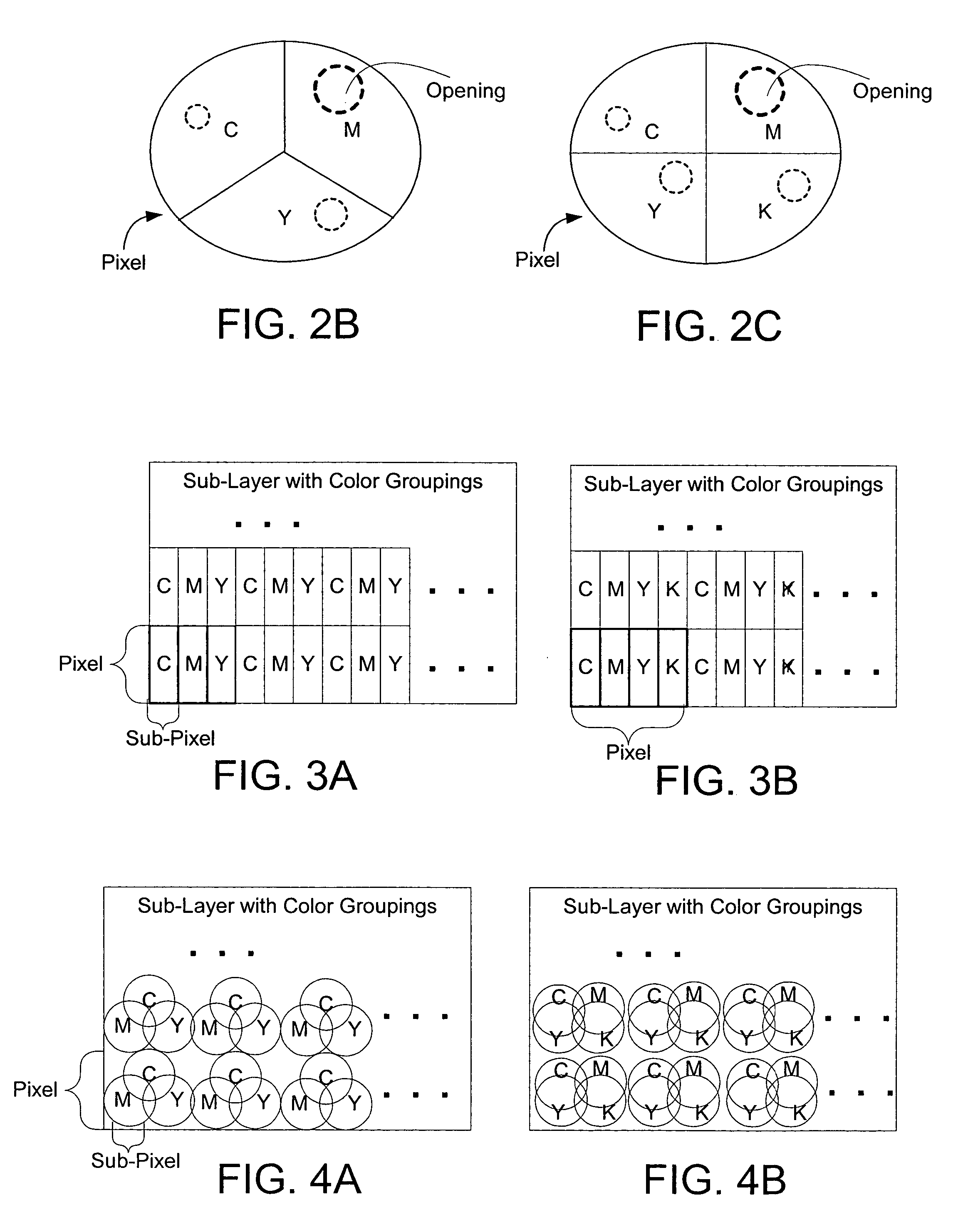

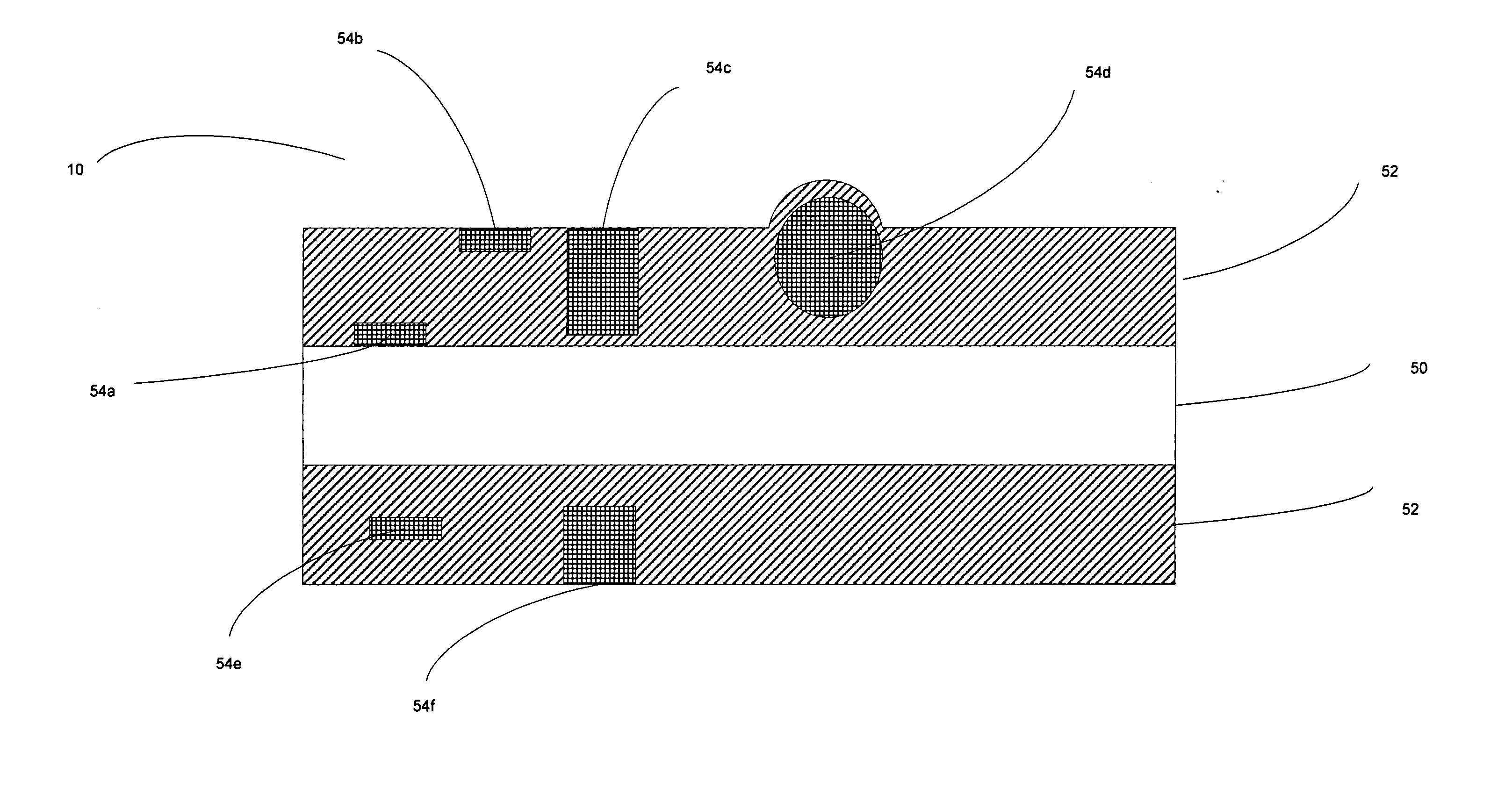

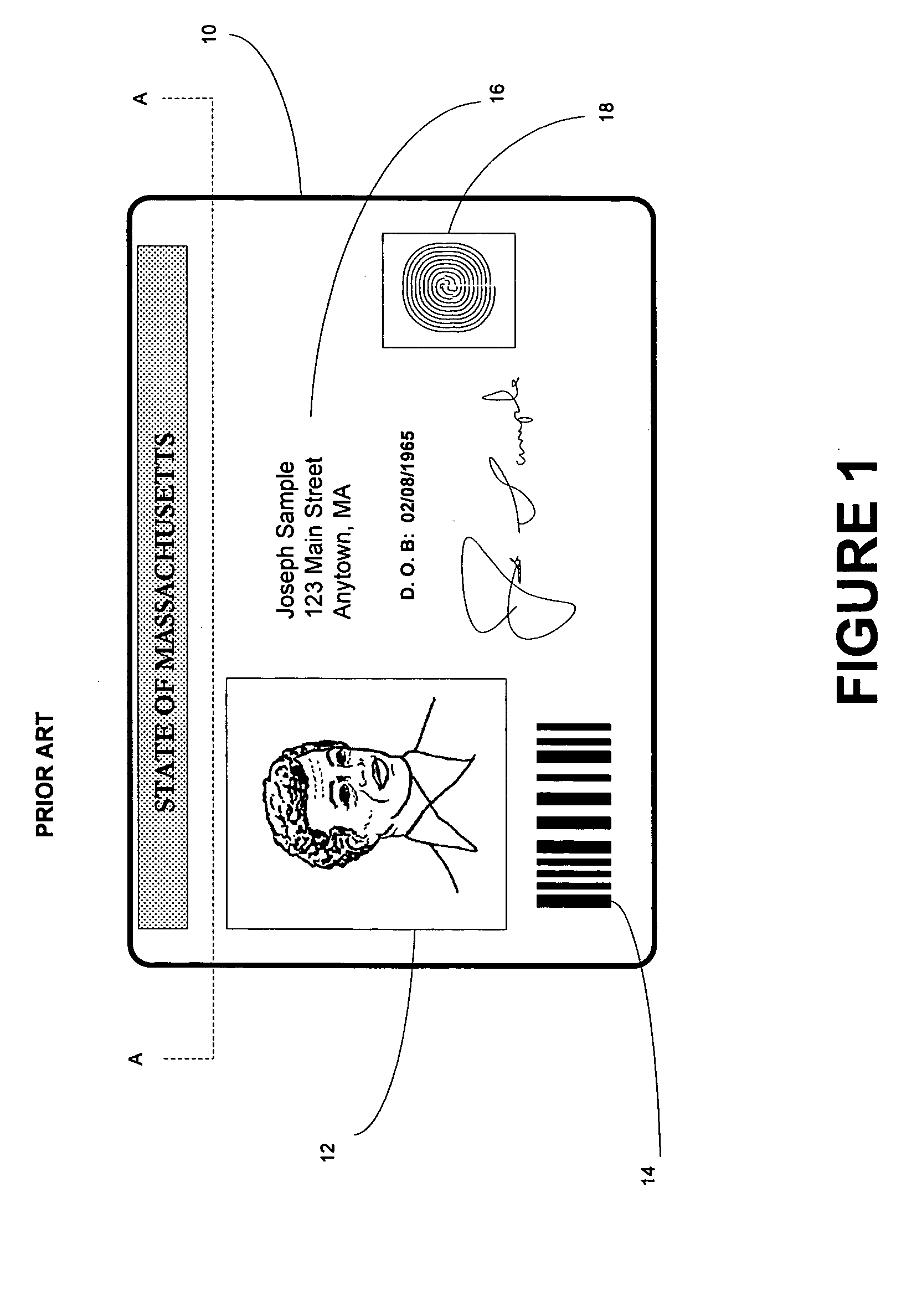

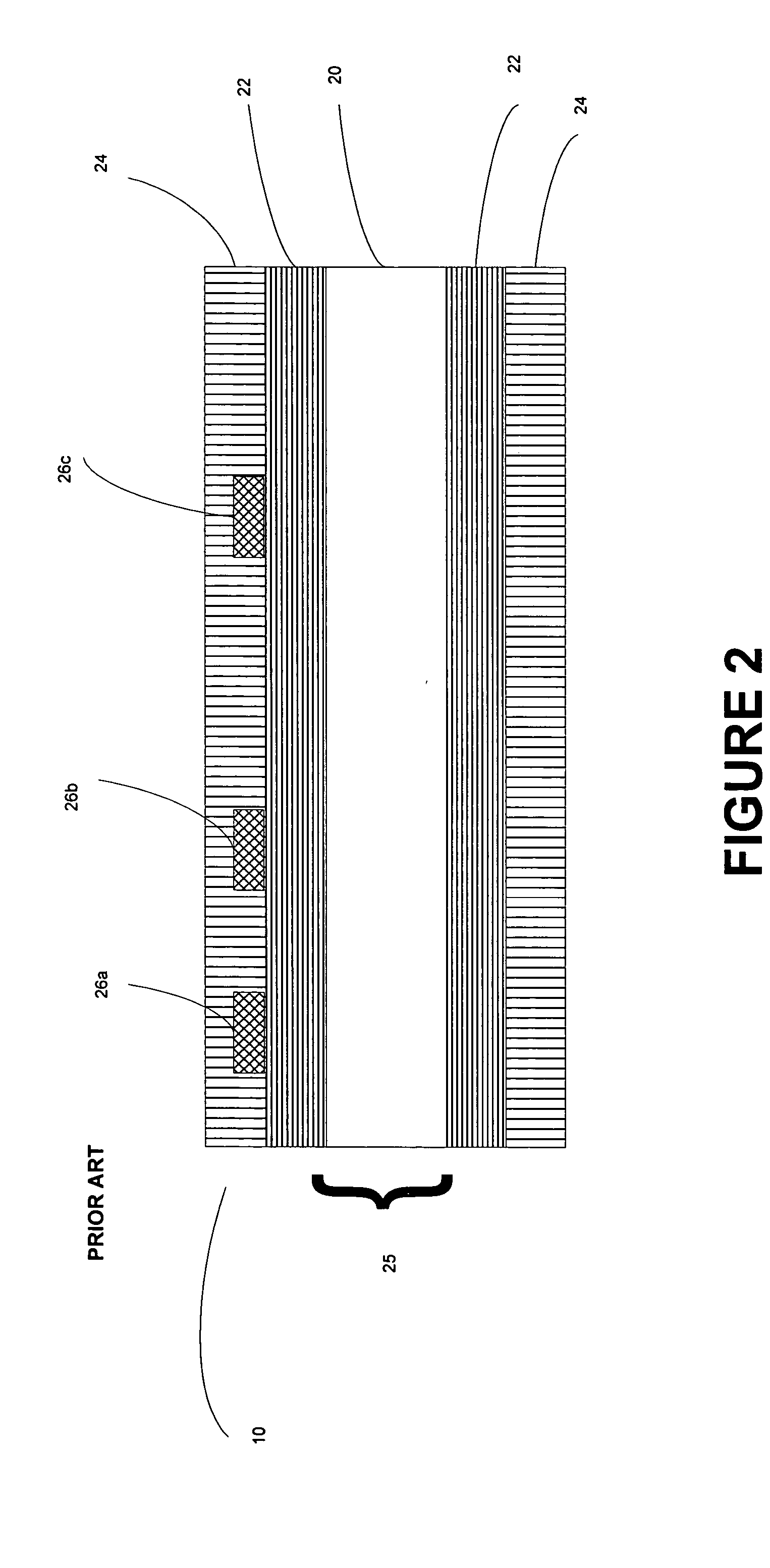

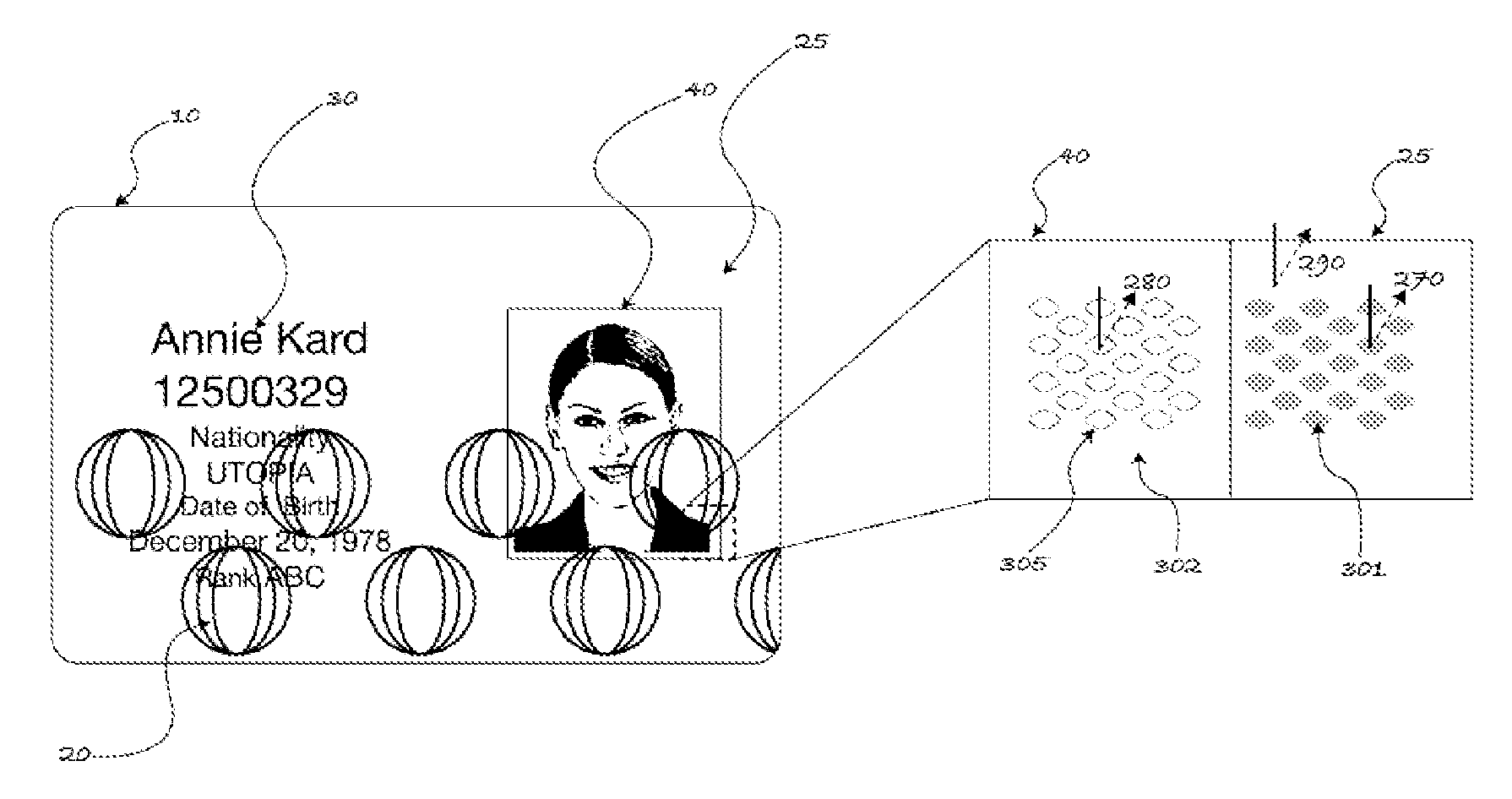

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

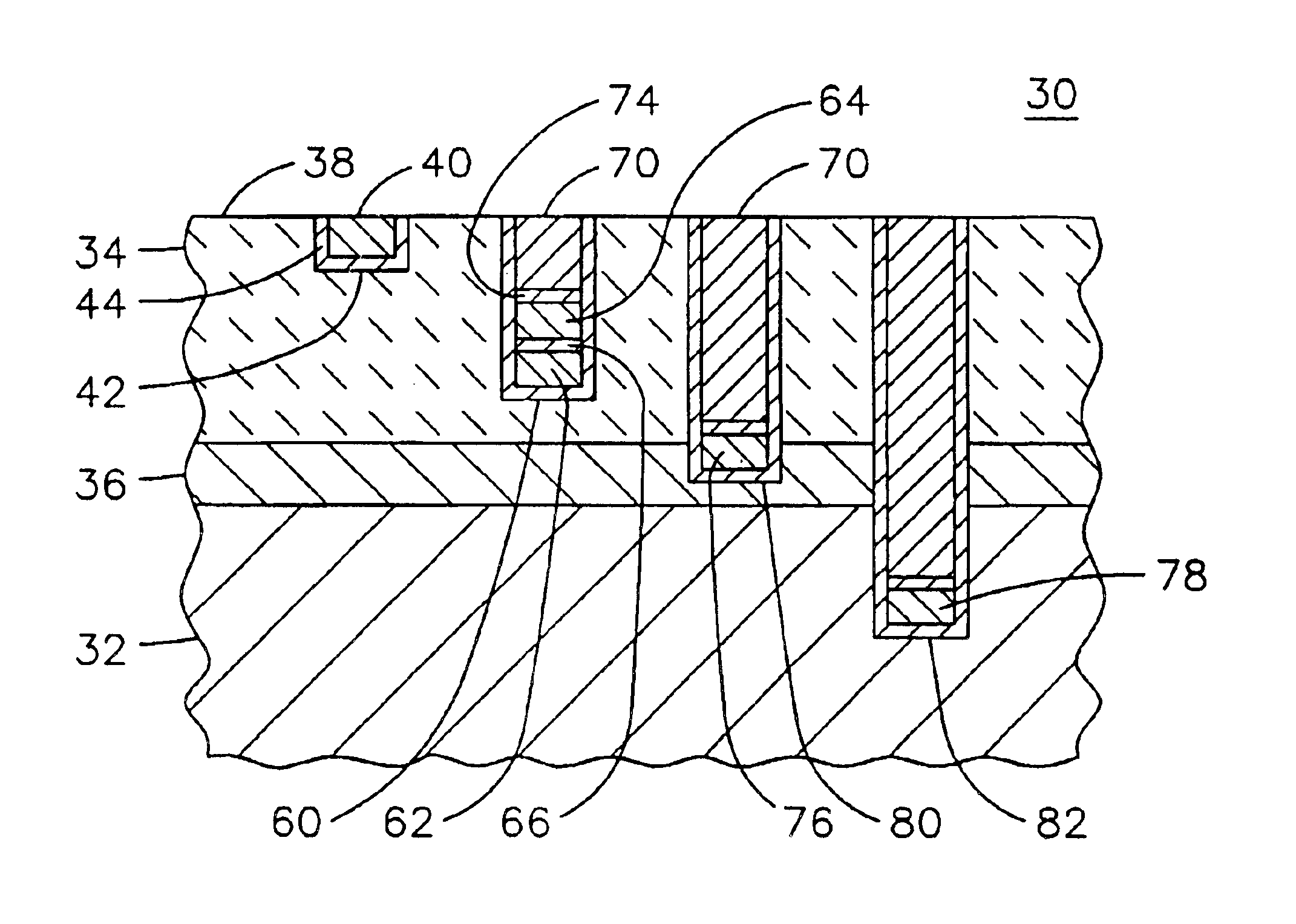

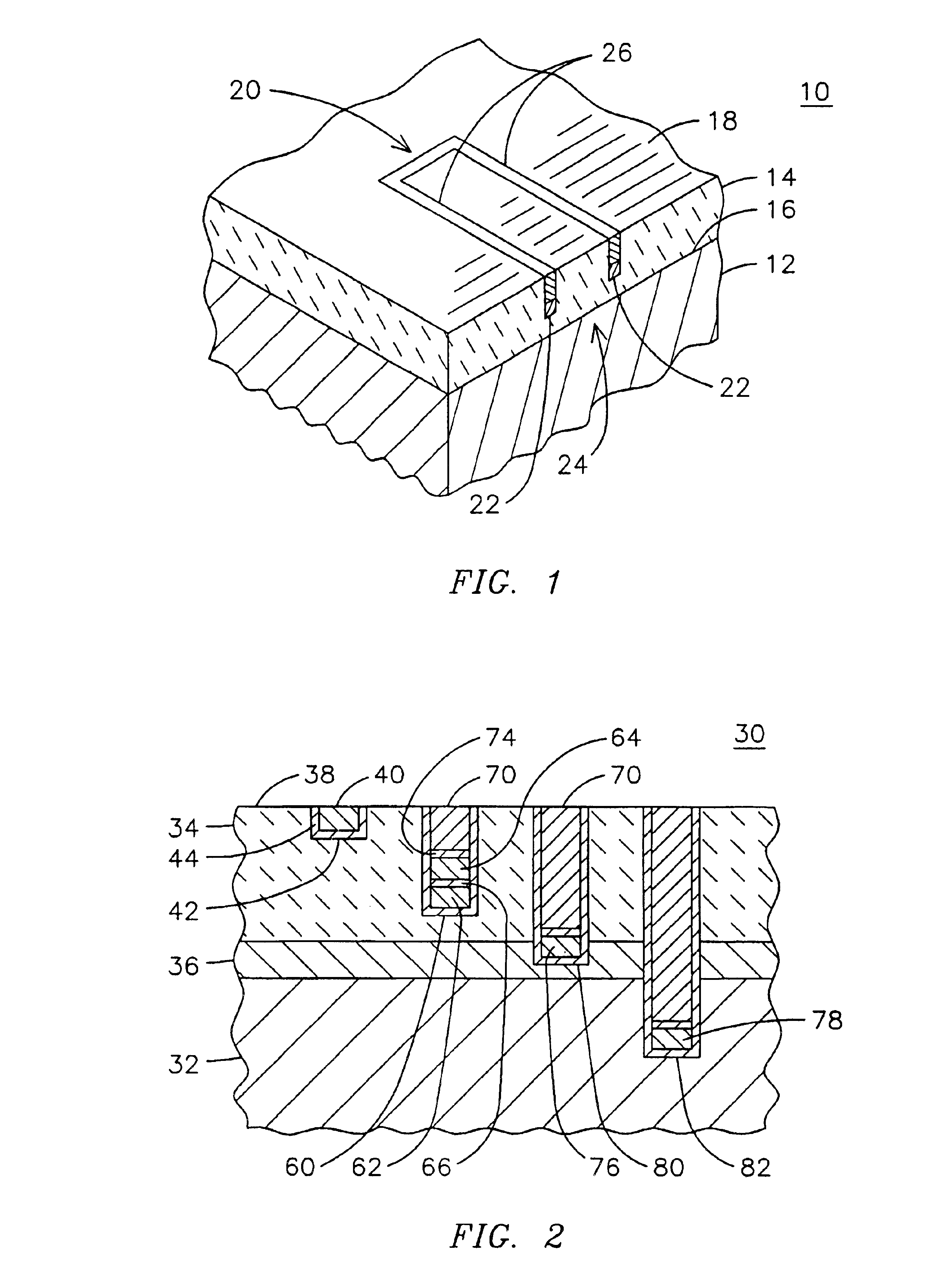

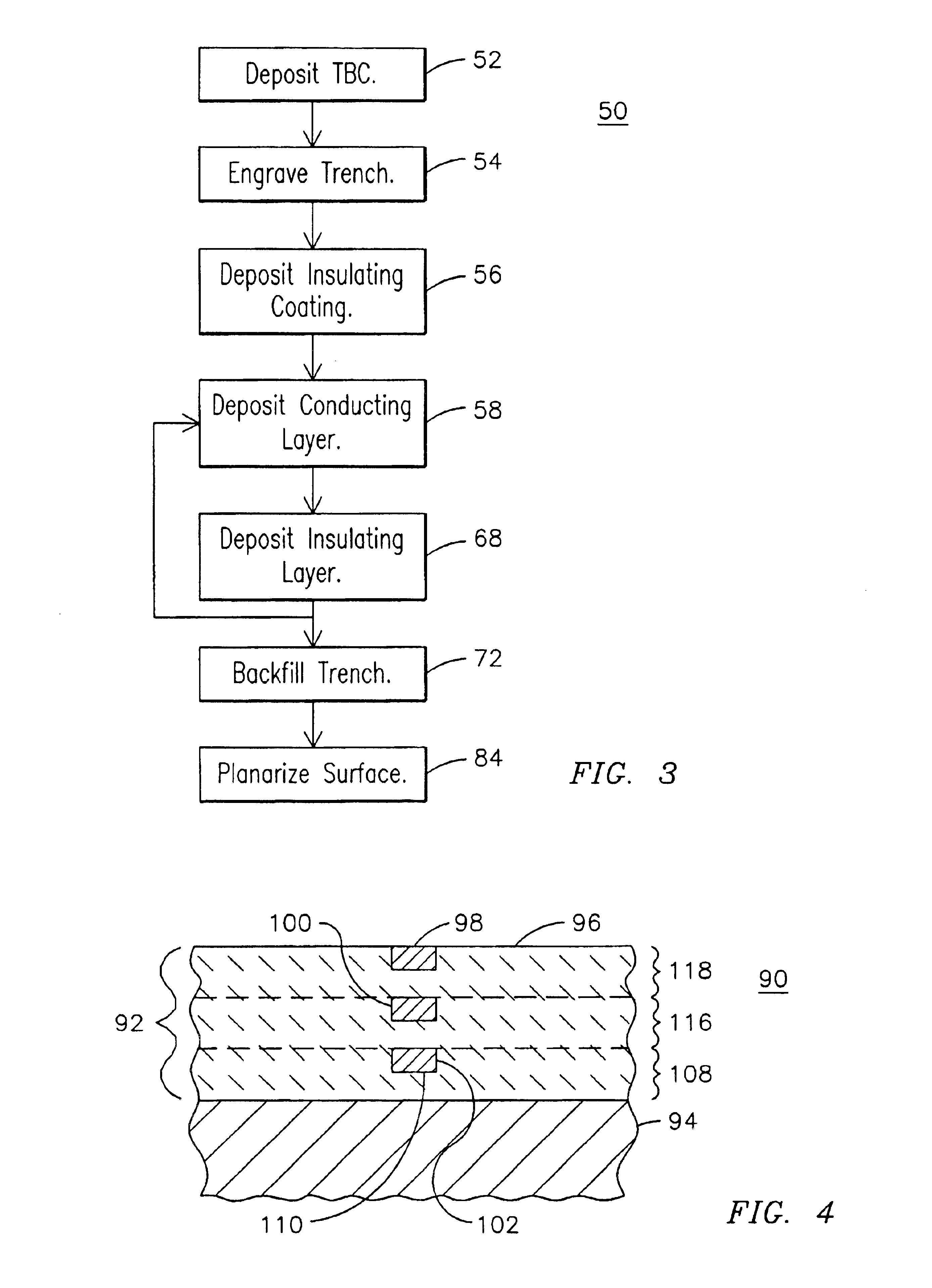

Method and apparatus for instrumenting a gas turbine component having a barrier coating

InactiveUS6838157B2Molten spray coatingVacuum evaporation coatingSelective laser meltingElectrical conductor

A method (50) of instrumenting a component (10) having a barrier coating (14). A sensor (76) is embedded within or below the coating. Material forming the sensor is deposited within a trench (80) formed into the barrier coating. The trench is then backfilled with material (70) to protect the sensor from the environment within which the component is operating. In this manner, the sensor may be embedded at any desired location and any desired depth within a barrier coating on a previously fabricated component. An array of sensors (98, 100, 102) may be embedded across the depth of the coating to provide signals indicative of operating conditions across the coating. The signals may be conducted to a connection location (24) by conductors (62, 64) that are deposited within the trench. The trench may be formed with a laser engraving process (54) and the material for the sensor and conductors may be deposited with a selective laser melting process (58).

Owner:SIEMENS ENERGY INC

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

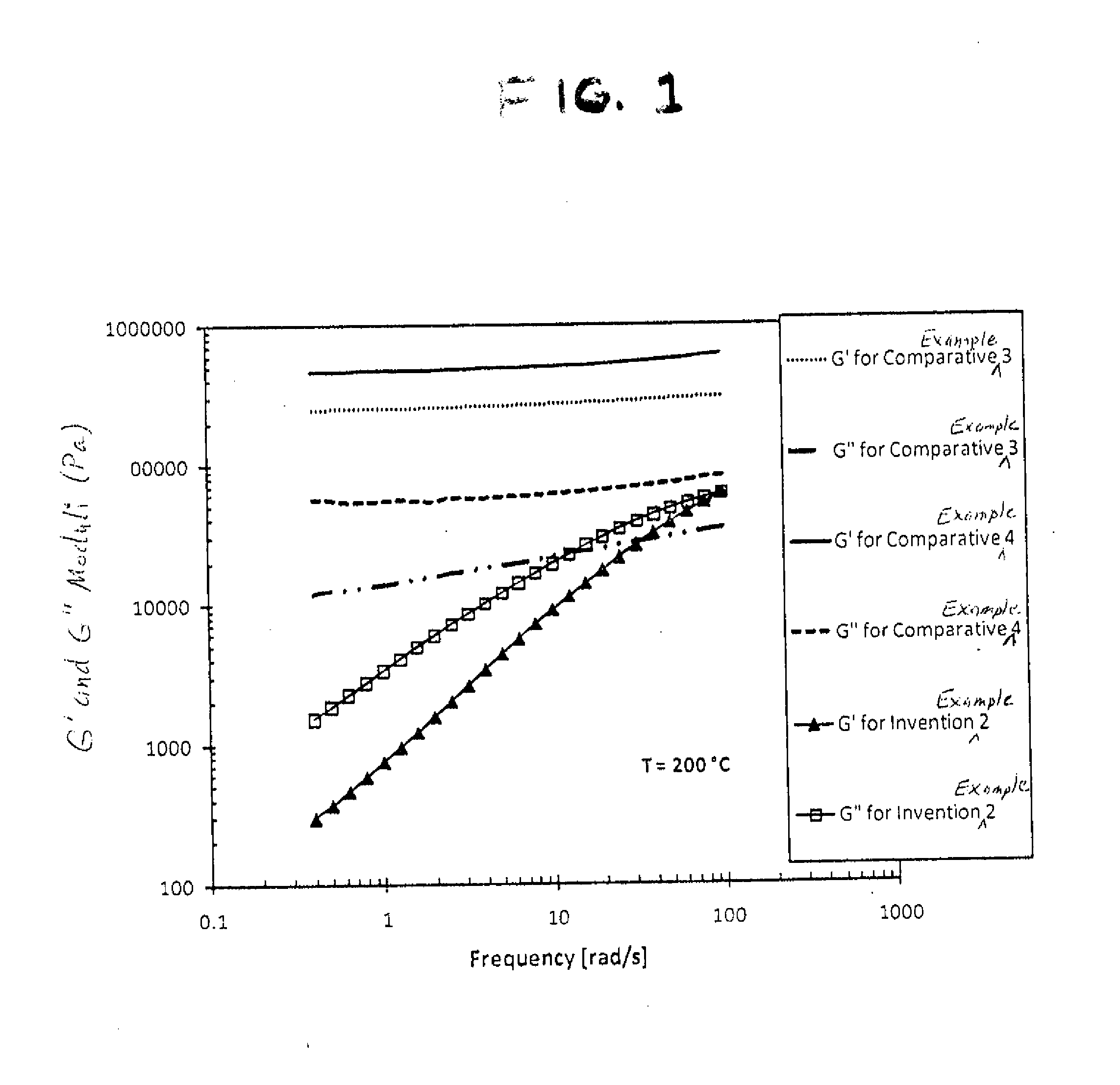

Laser engraving methods and compositions, and articles having laser engraving thereon

ActiveUS20050095408A1Not easy to counterfeitDifficult to alterRadiation applicationsDecorative surface effectsThioester synthesisBarium sulphide

The invention provides a composition having laser engraving properties, comprising a host material and an effective amount of a laser enhancing additive. The laser enhancing additive comprises a first quantity of least one of copper potassium iodide (CuKI3) or Copper Iodide (CuI), and a second quantity at least one substance selected from the group consisting of zinc sulfide (ZnS), barium sulfide (BaS), alkyl sulfonate, and thioester. The composition can be engraved with grayscale images by an Nd:Yag laser and can be added to laminates or coatings. The composition can be used during the manufacture of many articles of manufacture, including identification documents.

Owner:L 1 SECURE CREDENTIALING

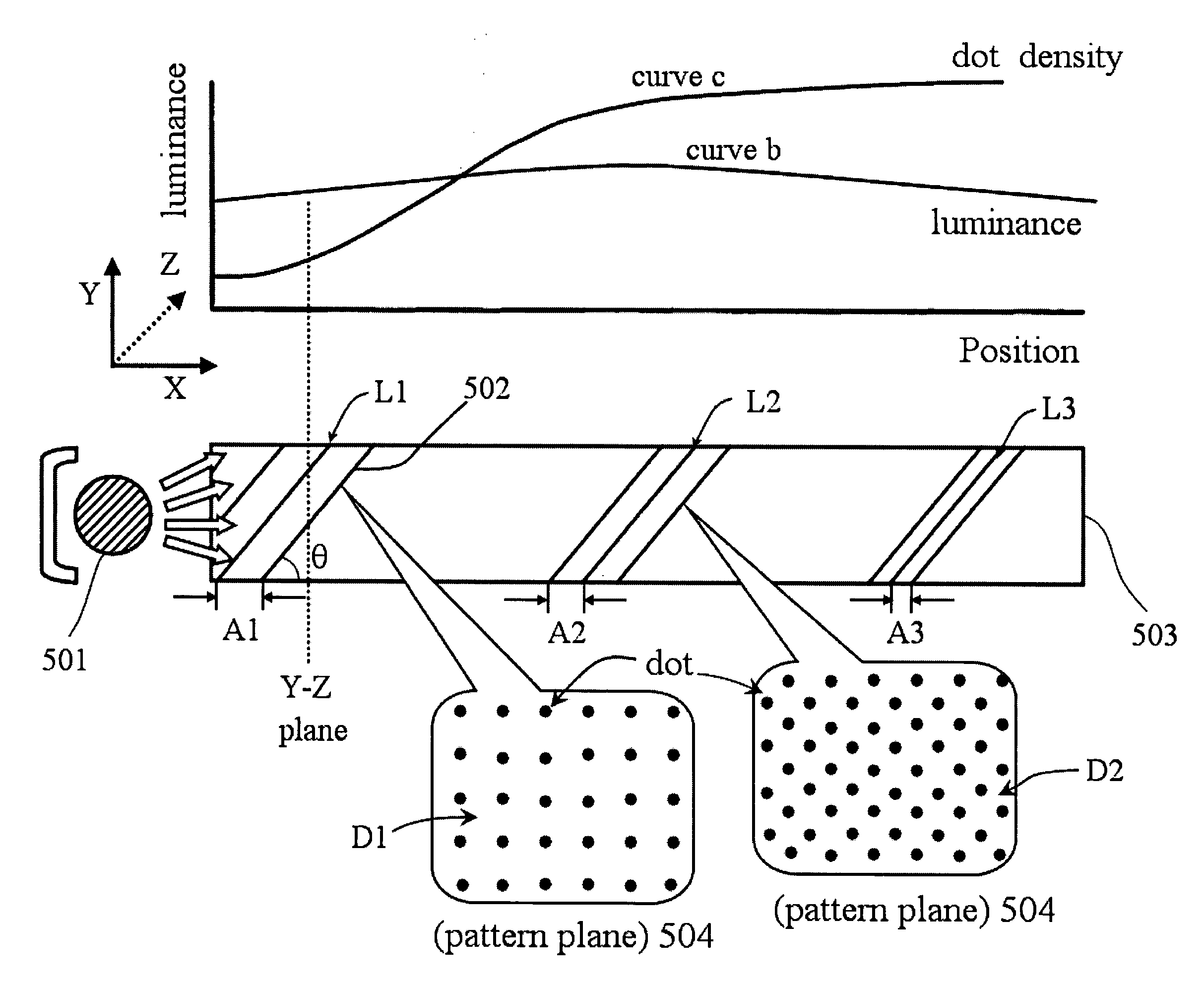

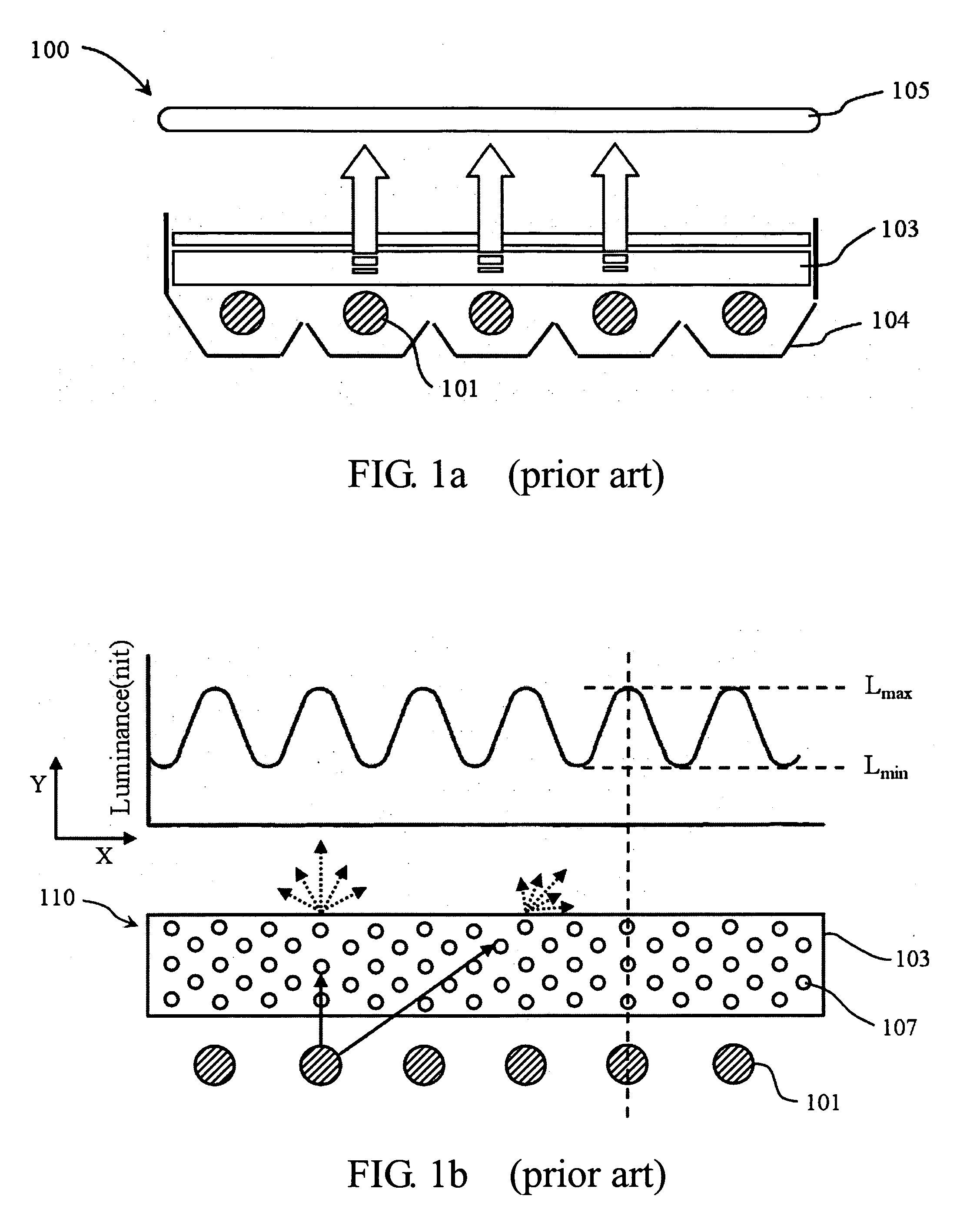

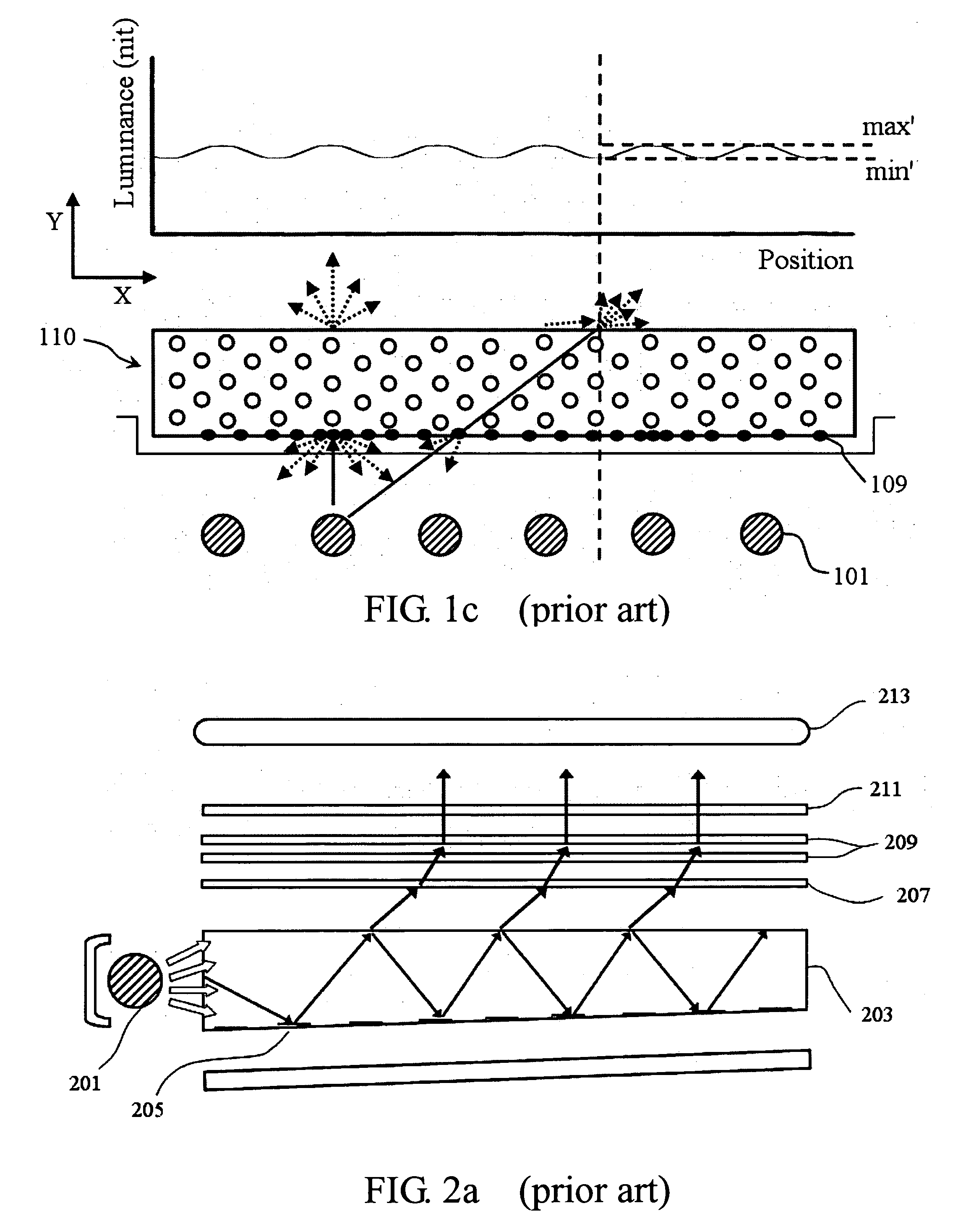

Method of forming light-scattering dots inside the diffusion plate and light guide plate by laser engraving

InactiveUS20090067178A1Improve brightness uniformityAccurate methodOptical light guidesLaser beam welding apparatusLight guideComputer module

The present invention discloses a method of forming internal scattering pattern in the diffusion plate and light guide plate used in backlight module by laser engraving. In the present invention, the distribution and density of the engraved dots can be controlled and modulated depending on the position of the light source and the distribution of luminance to obtain higher luminance and better luminance uniformity.

Owner:KISMART

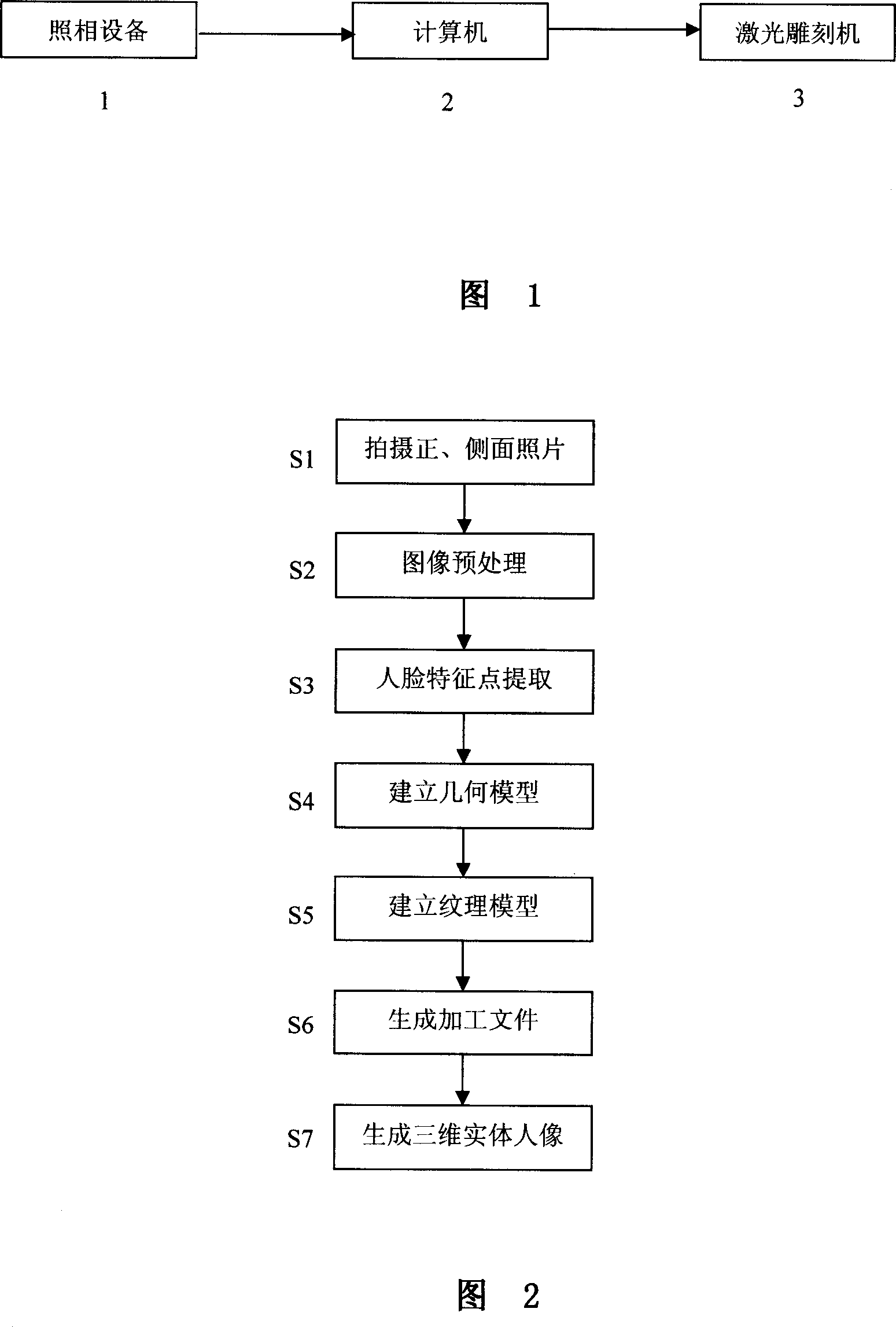

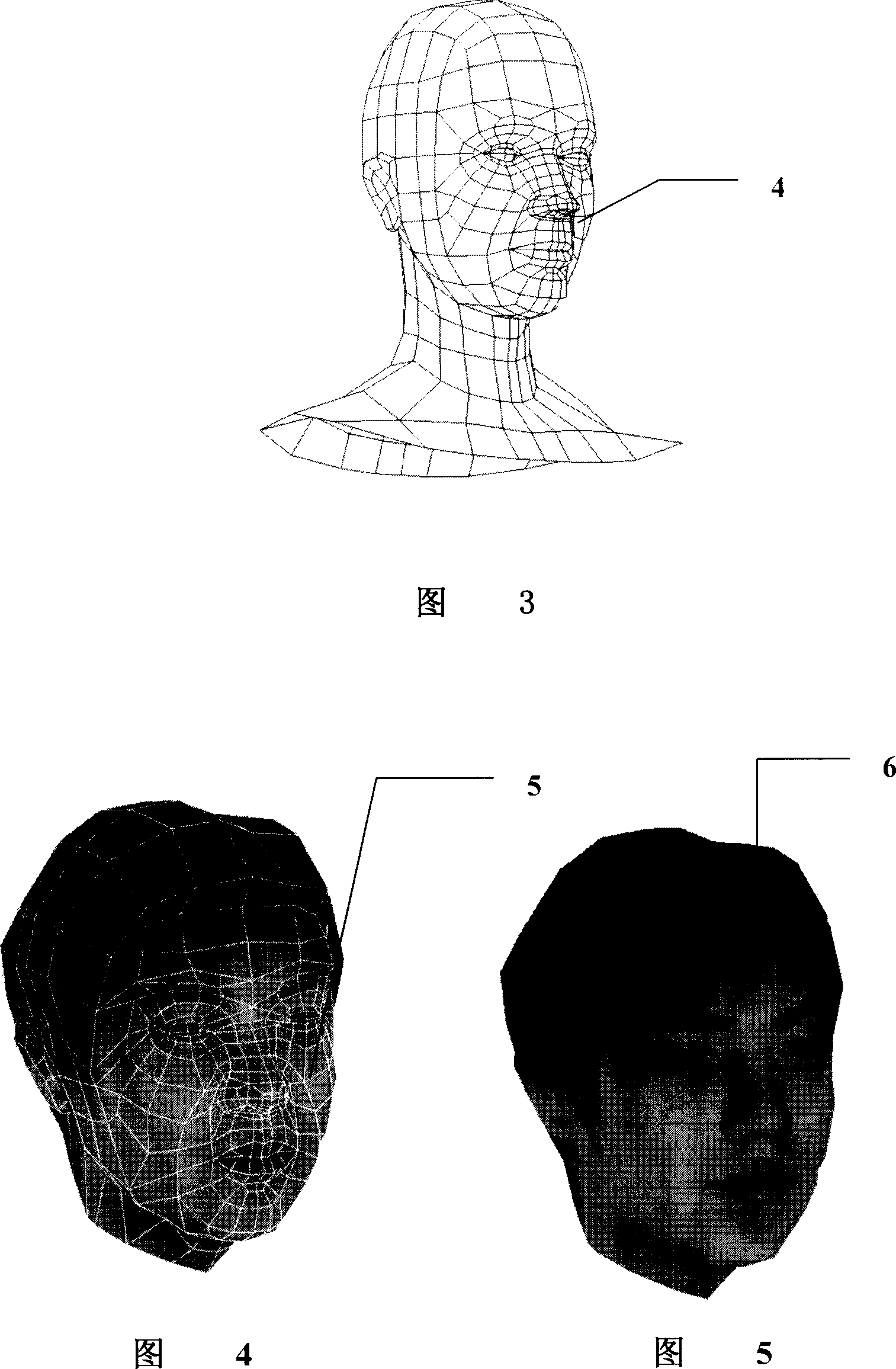

Three-dimensional portrait photograph system and realizing method thereof

InactiveCN101082765AHard textureNew Visual EnjoymentPrintersProjectorsContinuous toneLaser engraving

The invention discloses a three-dimensional portrait shooting system and realizing method, which comprises the following steps: using common camera to shoot positive and lateral photos of portrait; adopting computer visual algorism to acquire three-dimensional geometrical model of head; projecting the photo as texture on the three-dimensional mould according to the projecting relationship of photo and geometrical model; obtaining the three-dimensional portrait model with photo-grade true sense; using spatial semi-tone method to modulate the space of texture grey image continuously; printing binary image approaching three-dimensional image on the visual observing effect in the artificial crystal through laser carving machine; forming the three-dimensional entity head portrait with true sense.

Owner:高宏 +1

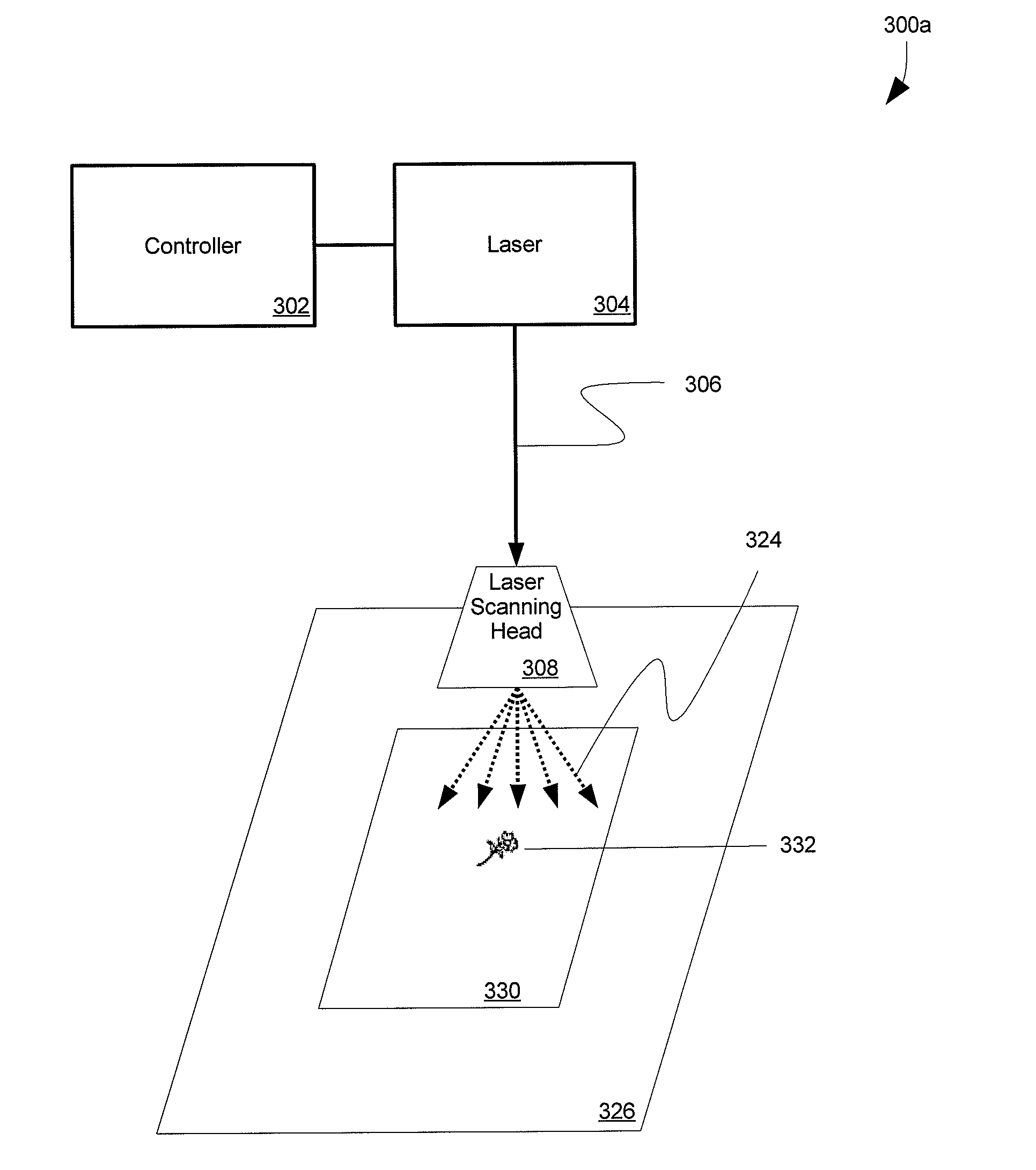

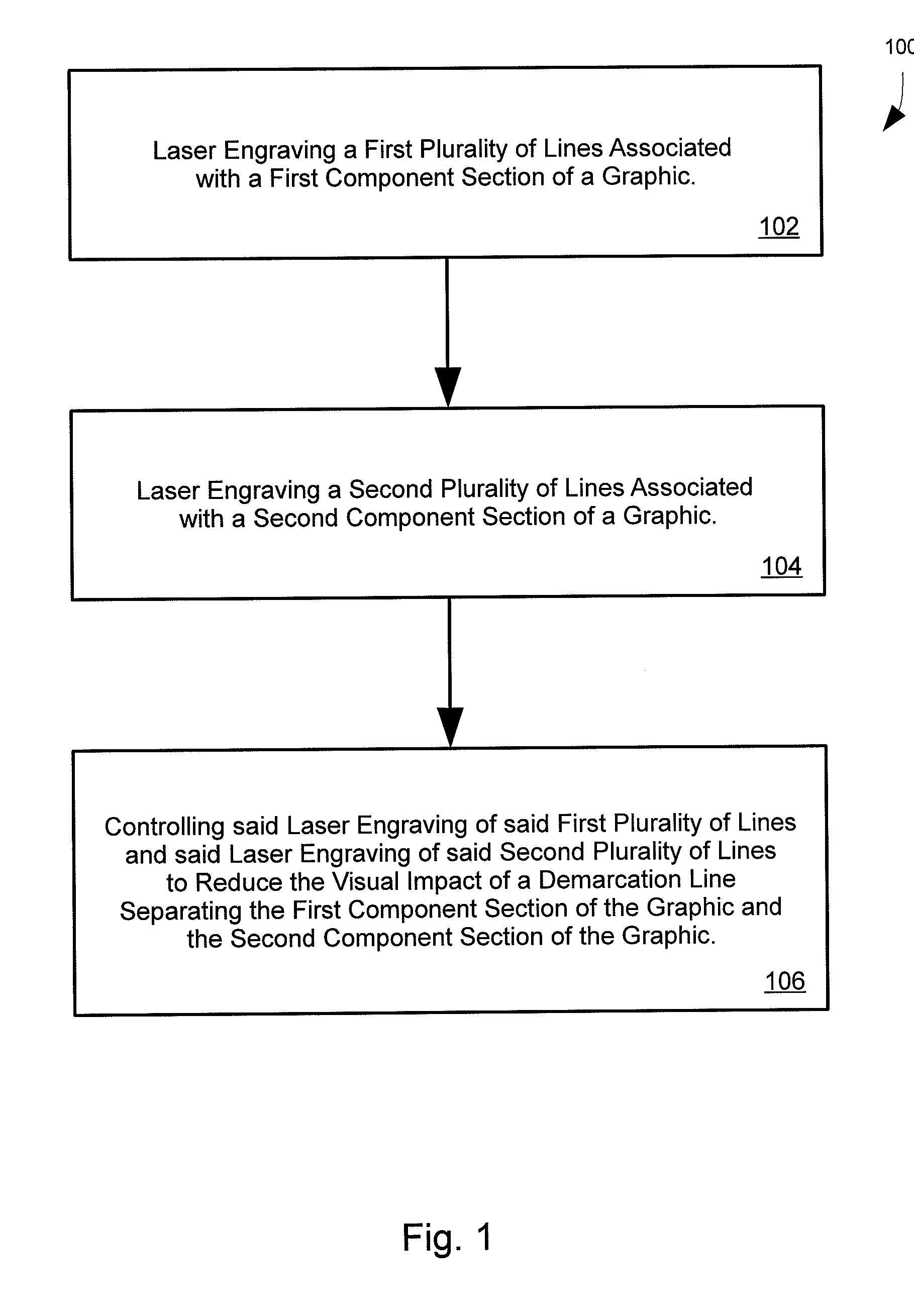

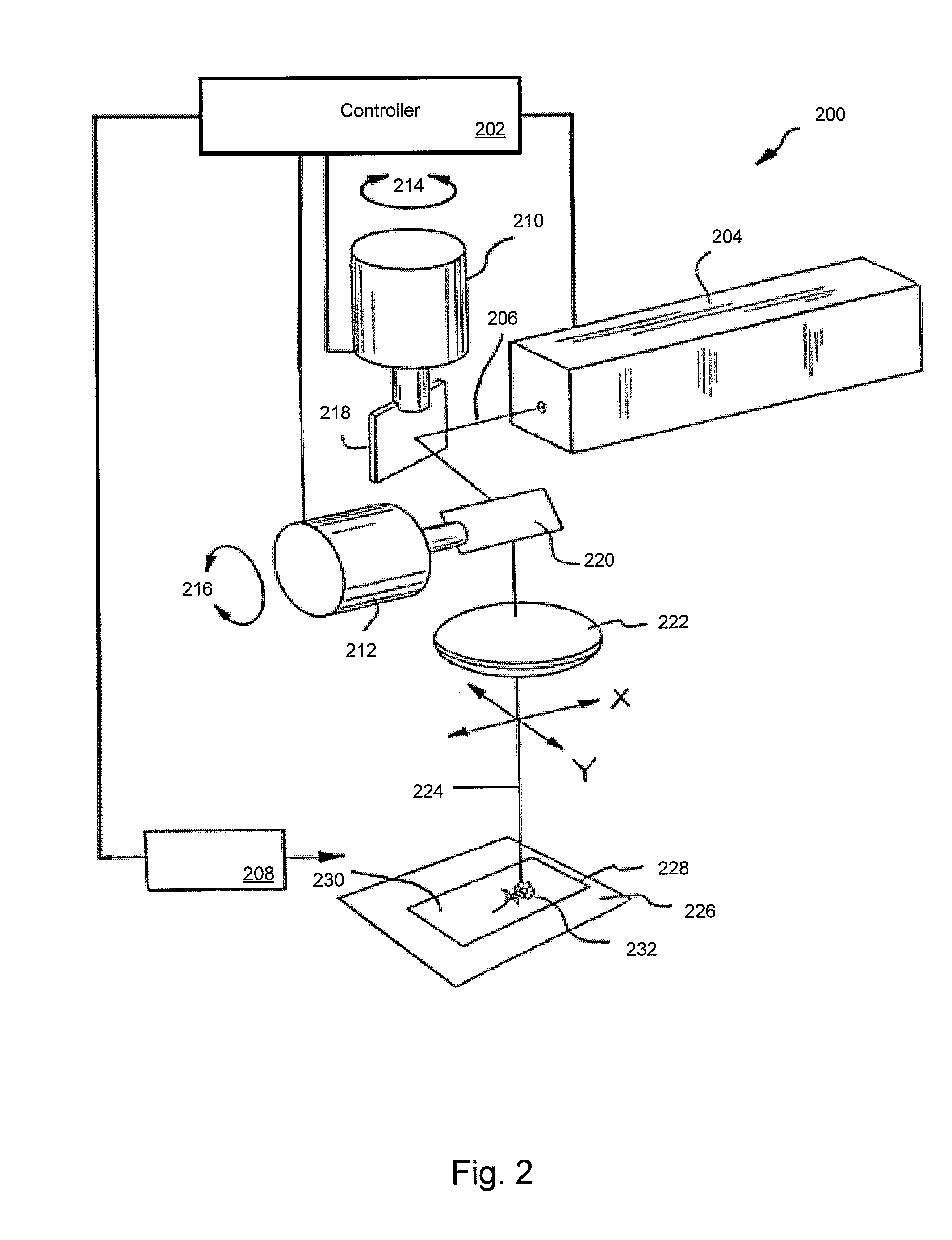

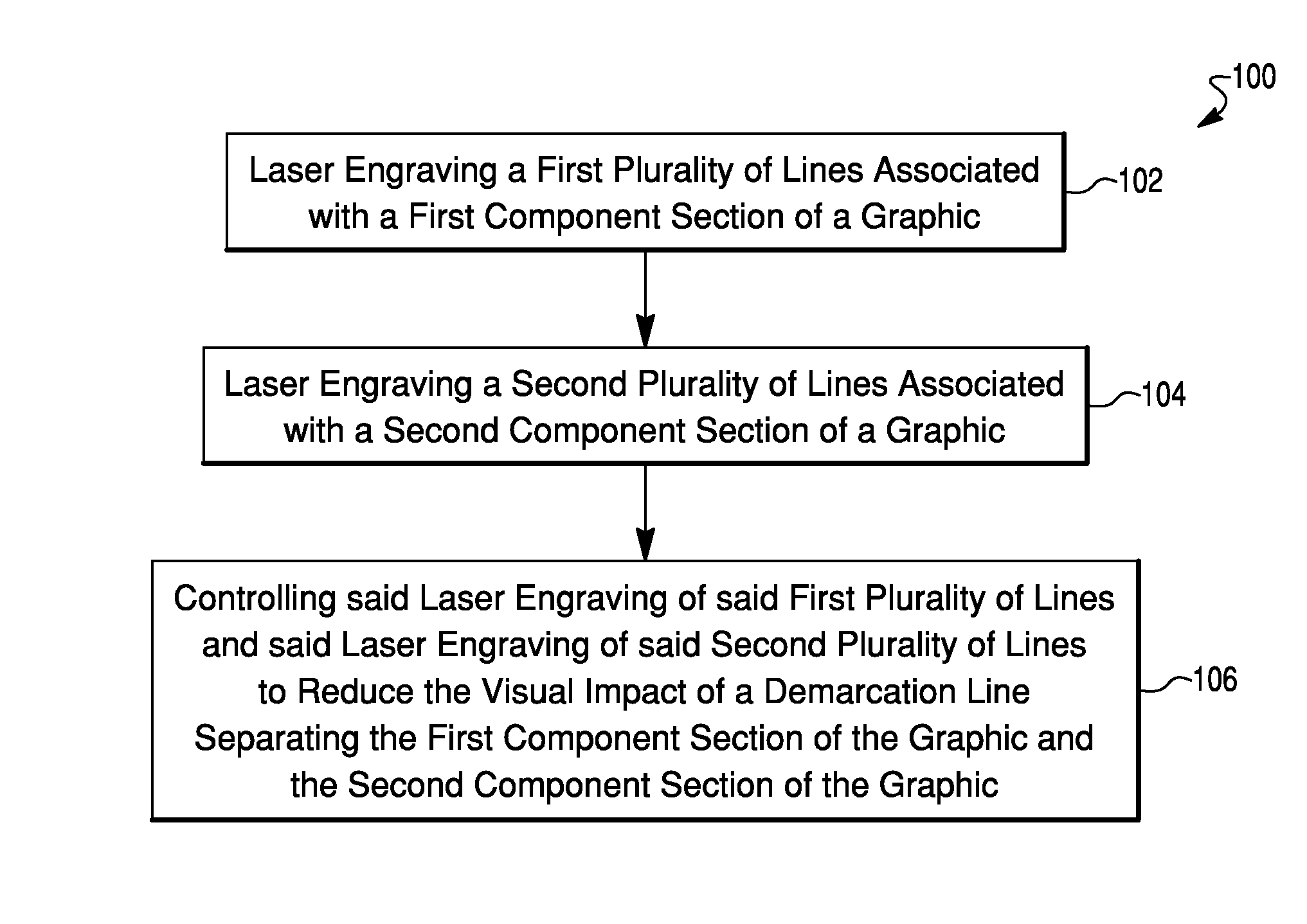

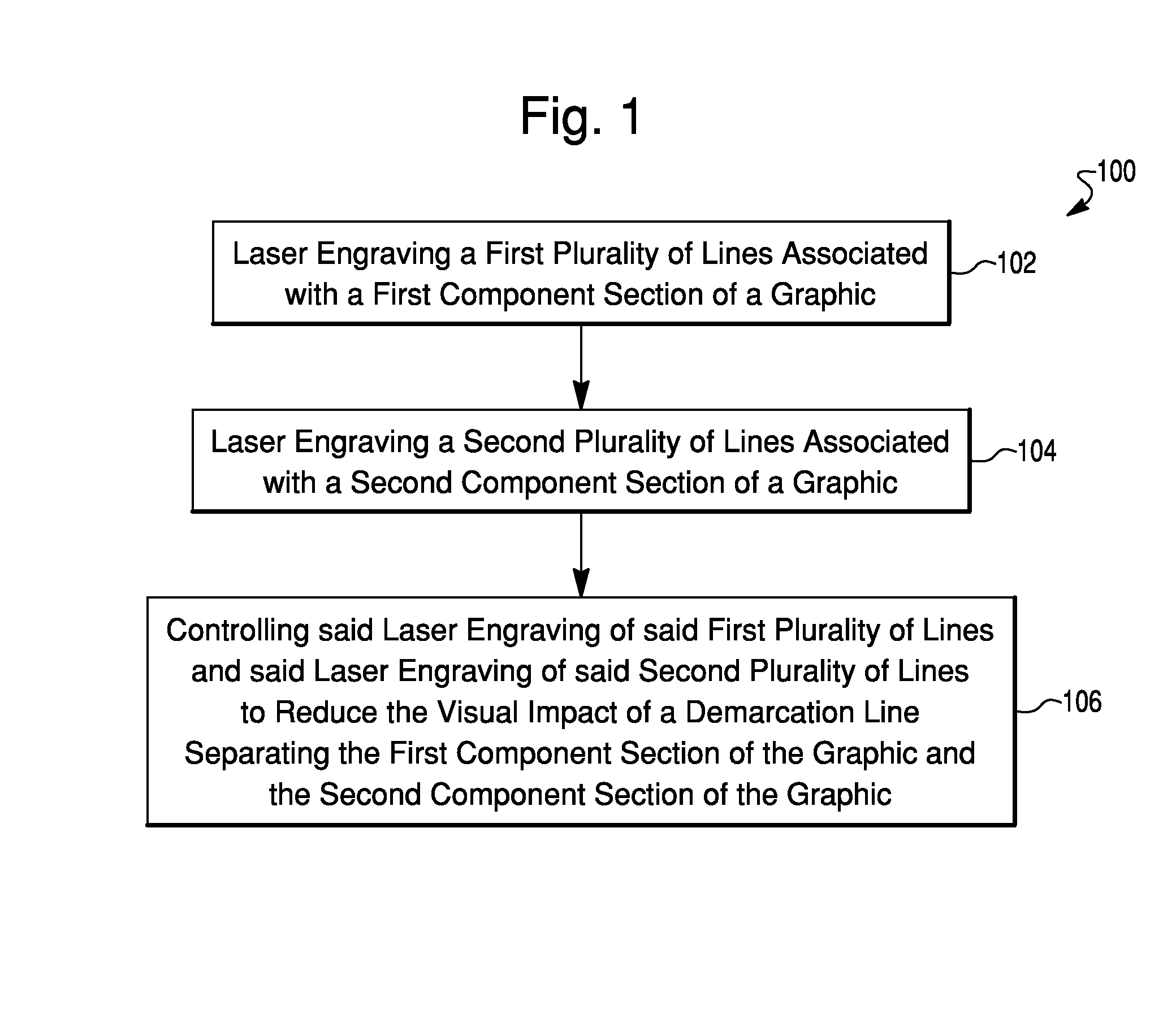

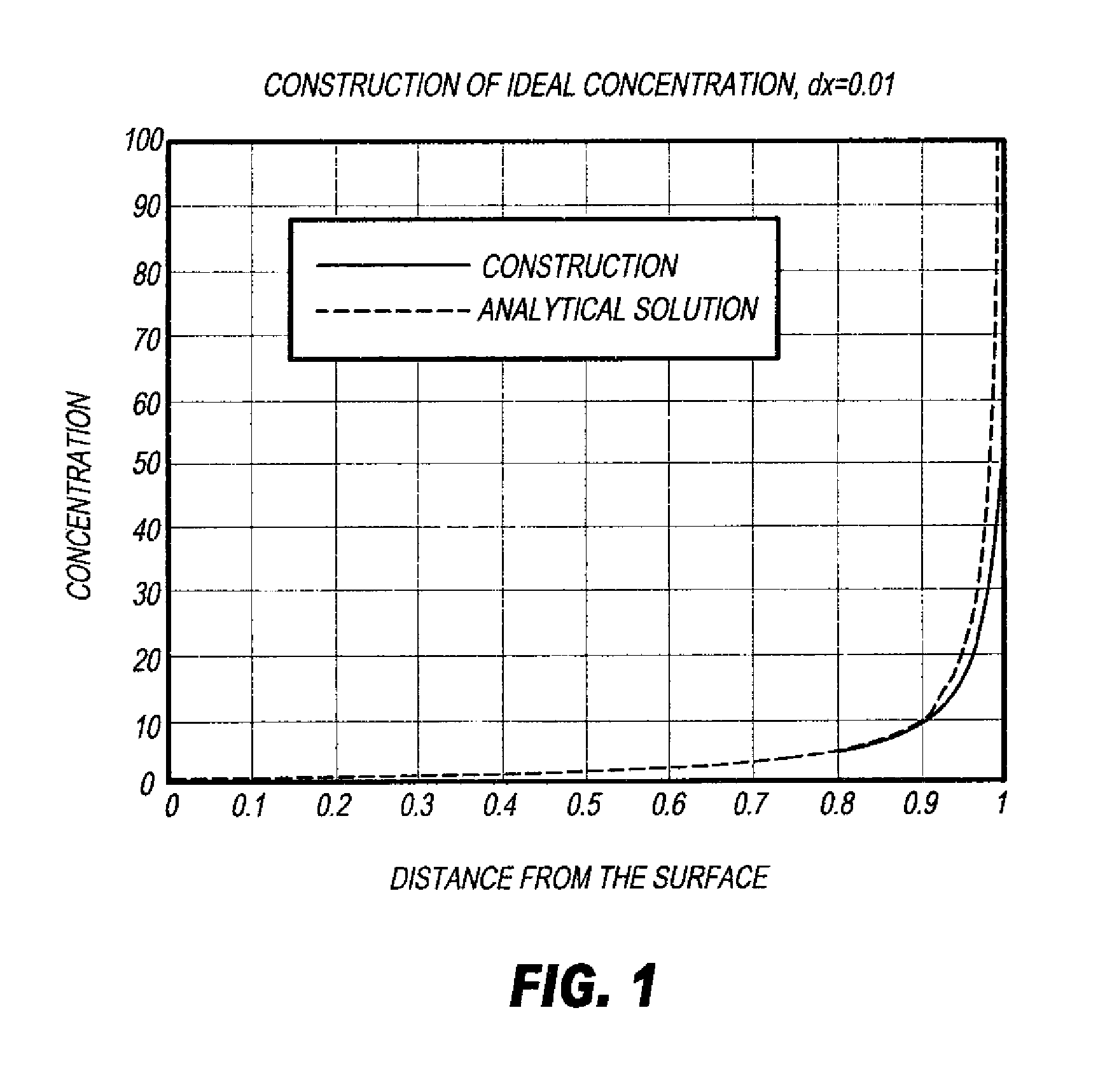

Staggered laser-etch line graphic system, method and articles of manufacture

InactiveUS20100272961A1Reduce visual impactReduce the impactVacuum gauge using ionisation effectsDecorative surface effectsGraphicsLaser etching

A staggered laser-etch line graphic system, method, and articles of manufacture are provided. One described method includes the steps of laser engraving a first plurality of lines associated with a first component section of a graphic on a surface of an article; laser engraving a second plurality of lines associated with a second component section of the graphic on the surface of the article; and controlling said laser engraving of the first plurality of lines and said laser engraving of second plurality of lines to reduce the visual impact of a demarcation line separating the first component section of the graphic and the second component section of the graphic.

Owner:REVOLAZE LLC

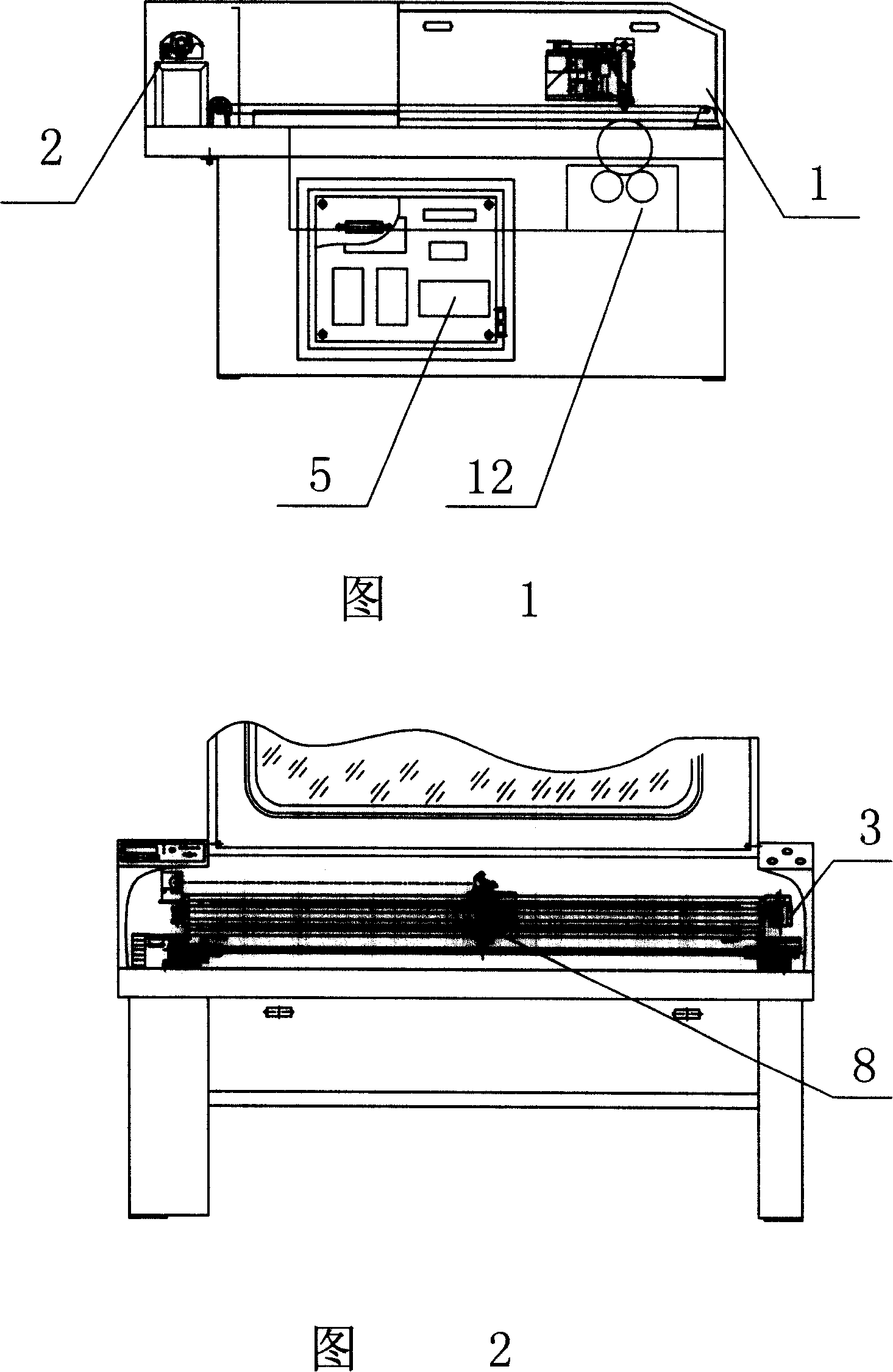

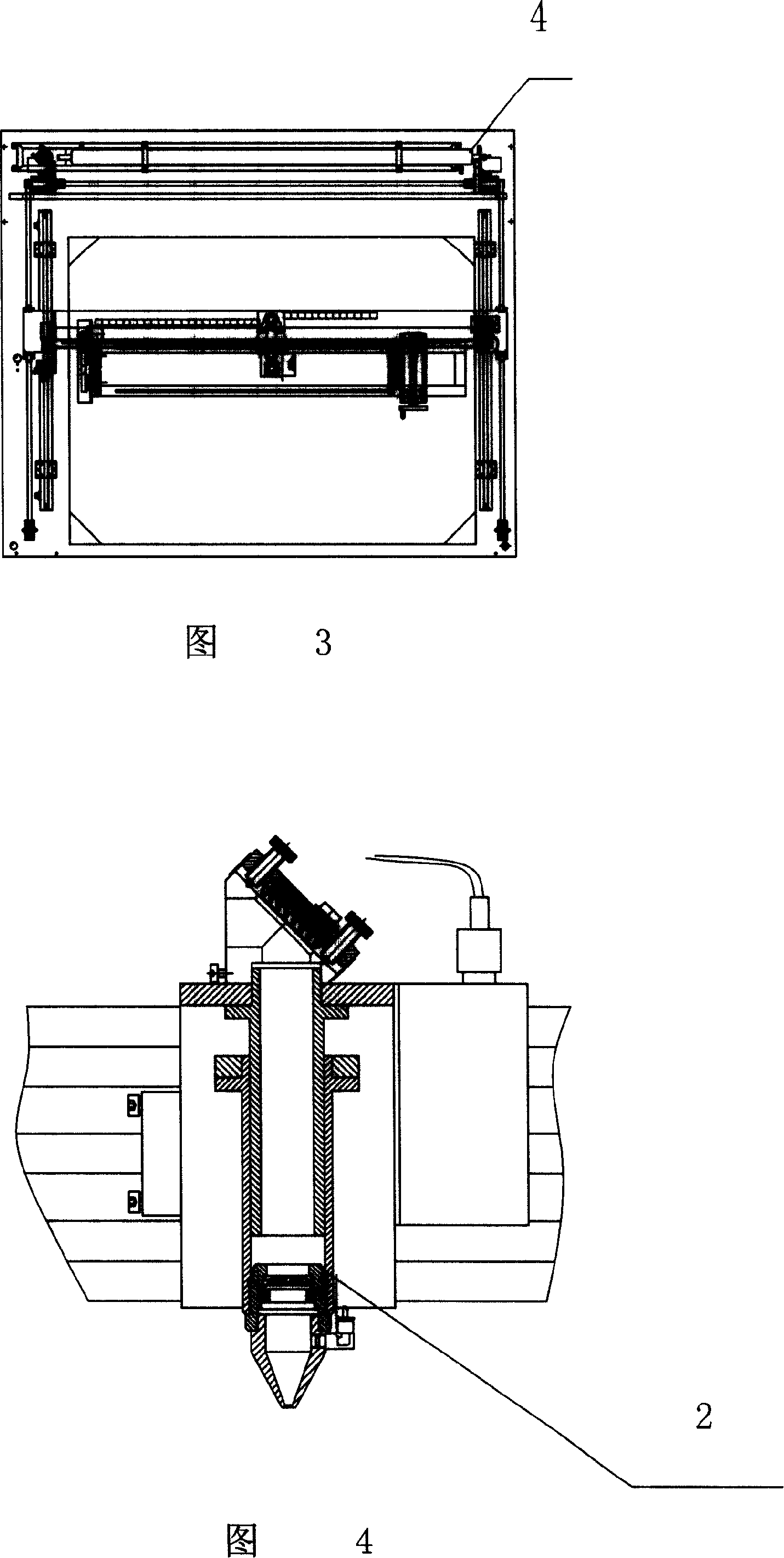

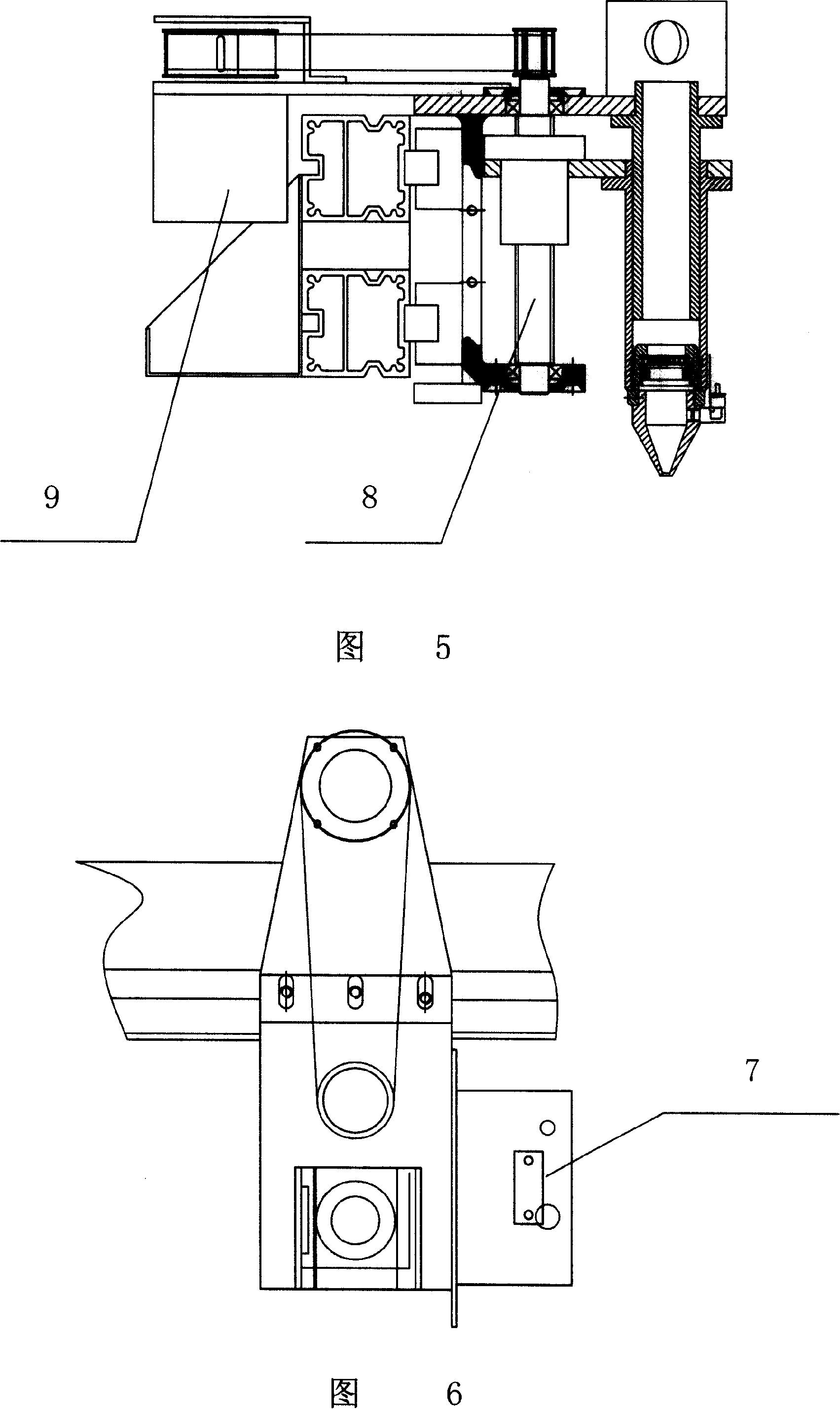

Profile modeling laser engraving process method and laser carving machine thereof

InactiveCN101138926ARealize dynamic focusRealize special-shaped plane engravingComputer controlProgramme control in sequence/logic controllersPid control algorithmLaser engraving

A method of form copying laser carving processing belongs to the laser carving processing field. The method uses a CCD laser displacement sensor to detect the distance between a laser head and a workpiece for processing to generate a three-dimensional relief map of the material for carving; a PID control arithmetic is used to control the position of the laser head to ensure that a focus of the laser falls at the surface of the workpiece for processing, so as to realize laser cutting and carving towards irregular materials. A laser carving machine is also provided, including a machine frame, a leaser head, an X-axial and Y-axial flying mechanism which is connected with the laser head, a Z-axial driving mechanism which is vertical with the surface of the workpiece, a CCD laser displacement sensor and an upper controller which is used for controlling form copying carving. The present invention provides a method of form copying laser carving processing which can realize dynamic focusing and real-time focusing during the course of carving and can realize plane carving of the irregular materials, and also provides the laser carving machine of the method.

Owner:ZHEJIANG FORESTRY ACAD +1

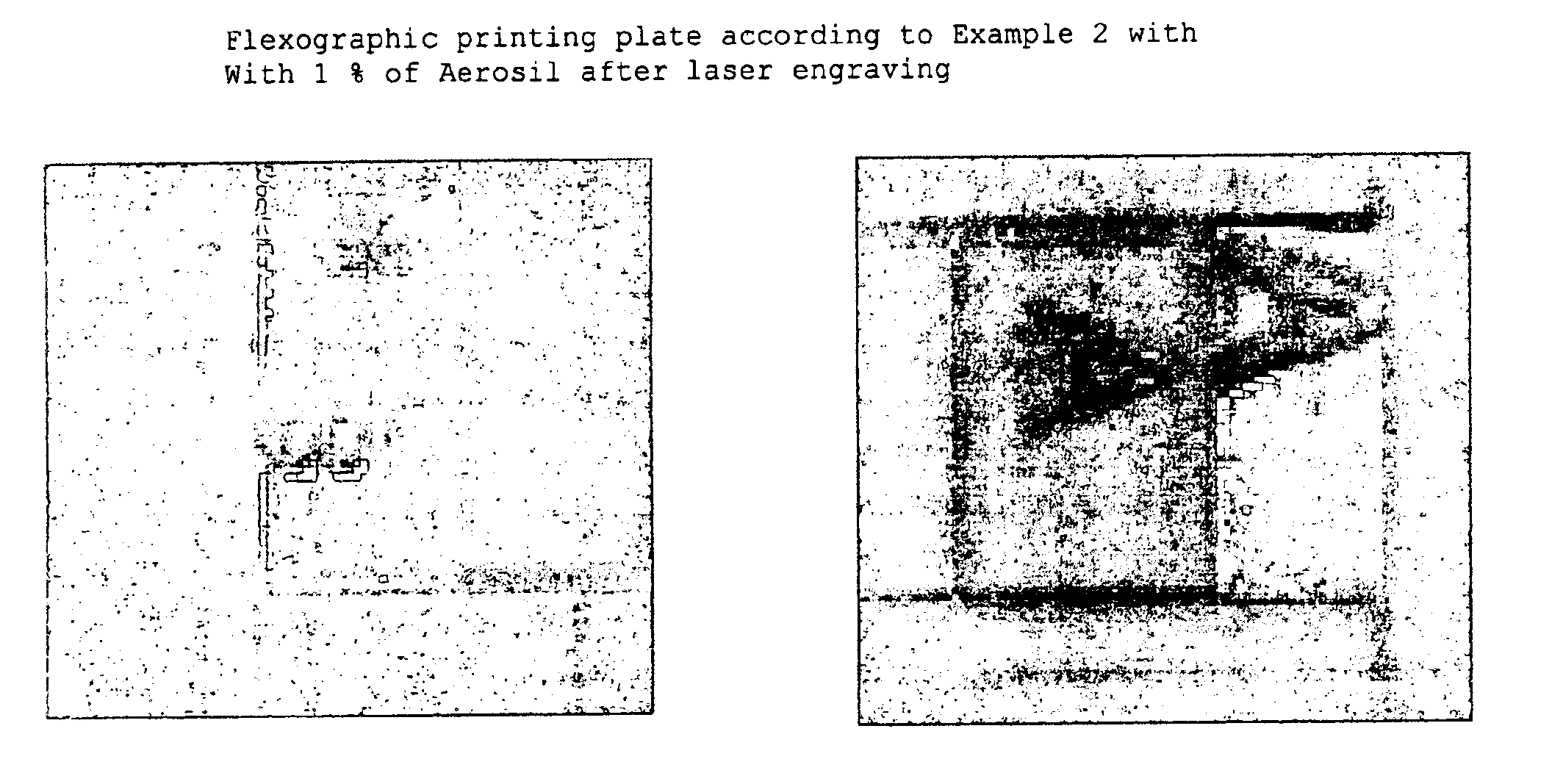

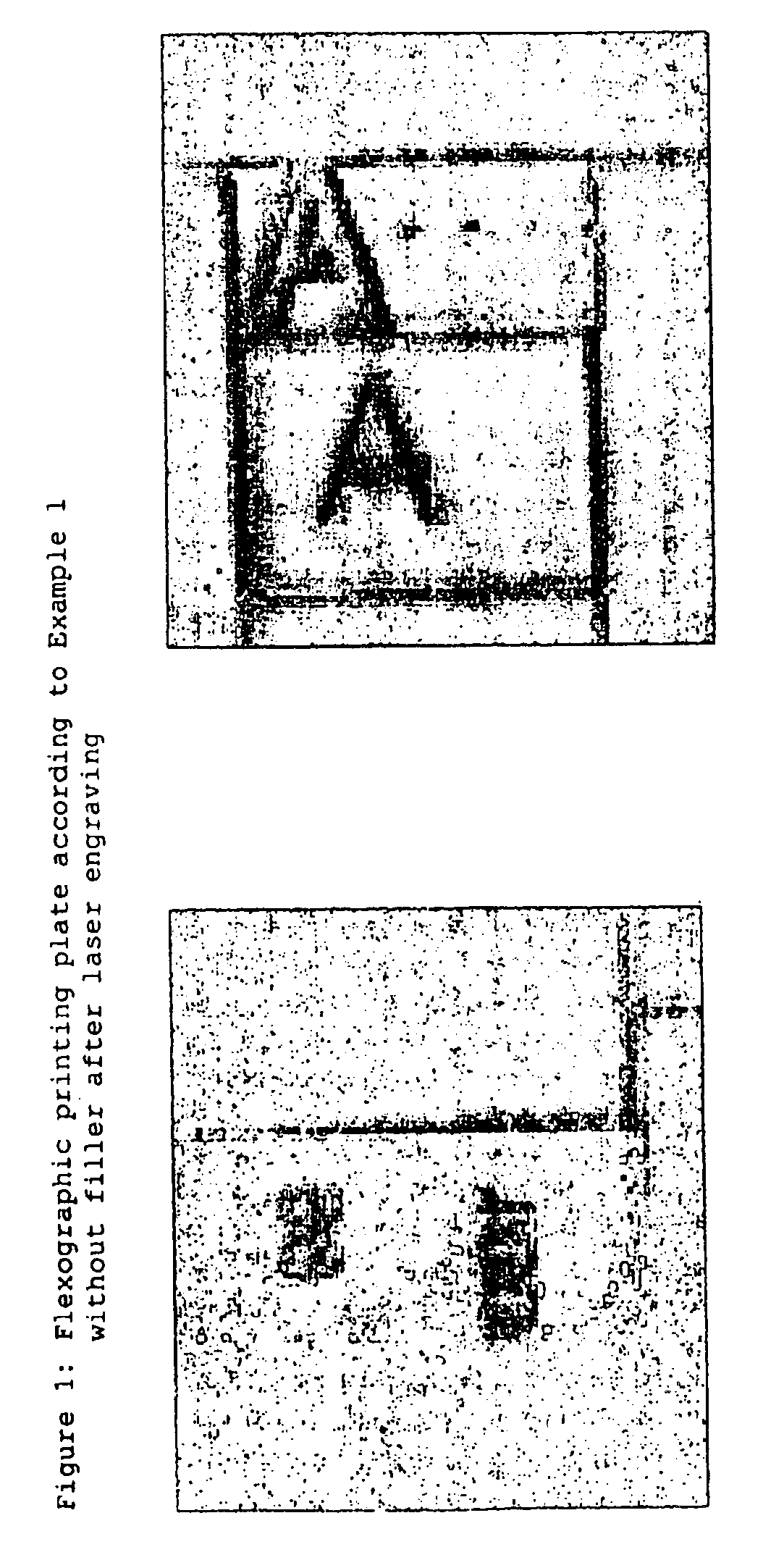

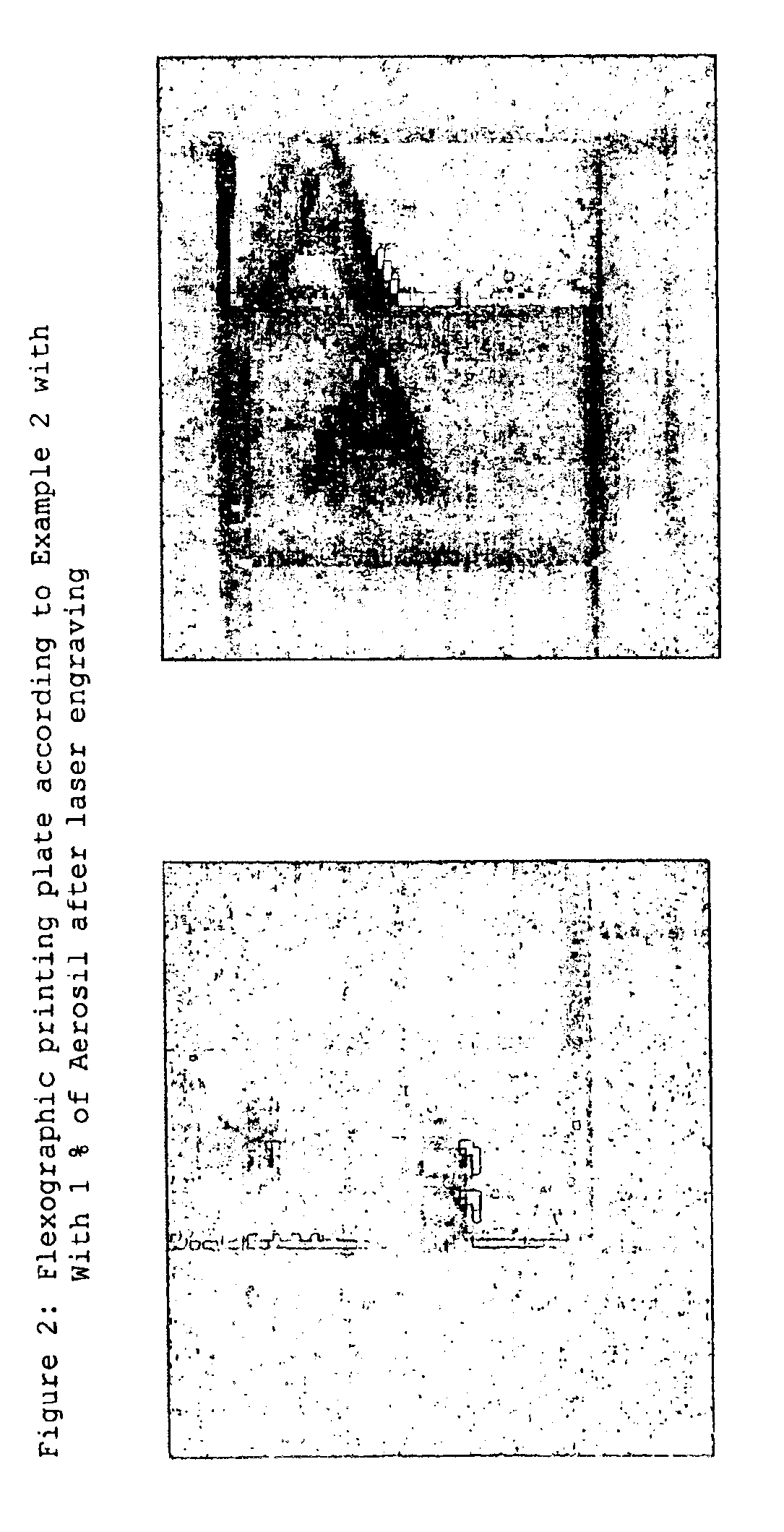

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

Multiple beam laser sculpting system and method

The invention improves the laser sculpting of a region of a material to a predetermined shape by improving the smoothness and accuracy of surfaces formed by the sculpting technique. The technique includes projecting plurality of partially overlapping beams toward the region. The invention includes blurring an edge of an ablation to smooth an internal portion of the ablation that is separate from the edge. The blurred edge may be formed by the partially overlapping beams. Using a computer controlled laser delivery system, the position and shape of the overlapping beams may be precisely controlled to sculpt the material to a desired shape according to a laser treatment table.

Owner:AMO MFG USA INC

Multiple beam laser sculpting system and method

The invention improves the laser sculpting of a region of a material to a predetermined shape by improving the smoothness and accuracy of surfaces formed by the sculpting technique. The technique includes projecting plurality of partially overlapping beams toward the region. The invention includes blurring an edge of an ablation to smooth an internal portion of the ablation that is separate from the edge. The blurred edge may be formed by the partially overlapping beams. Using a computer controlled laser delivery system, the position and shape of the overlapping beams may be precisely controlled to sculpt the material to a desired shape according to a laser treatment table.

Owner:AMO MFG USA INC

Laser-engravable flexographic printing element containing a conductive carbon black and method for production of flexographic printing forms

ActiveUS7223524B2Improve accuracySuitable for usePhotosensitive materialsRadiation applicationsLaser engravingEngineering

In a laser-engravable flexographic printing element, the relief-forming layer comprises a conductivity carbon black having a specific surface area of at least 150 m2 / g and a DBP number of at least 150 ml / 100 g. Flexographic printing plates are produced by a process in which a printing relief is engraved into said flexographic printing element by means of a laser system.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

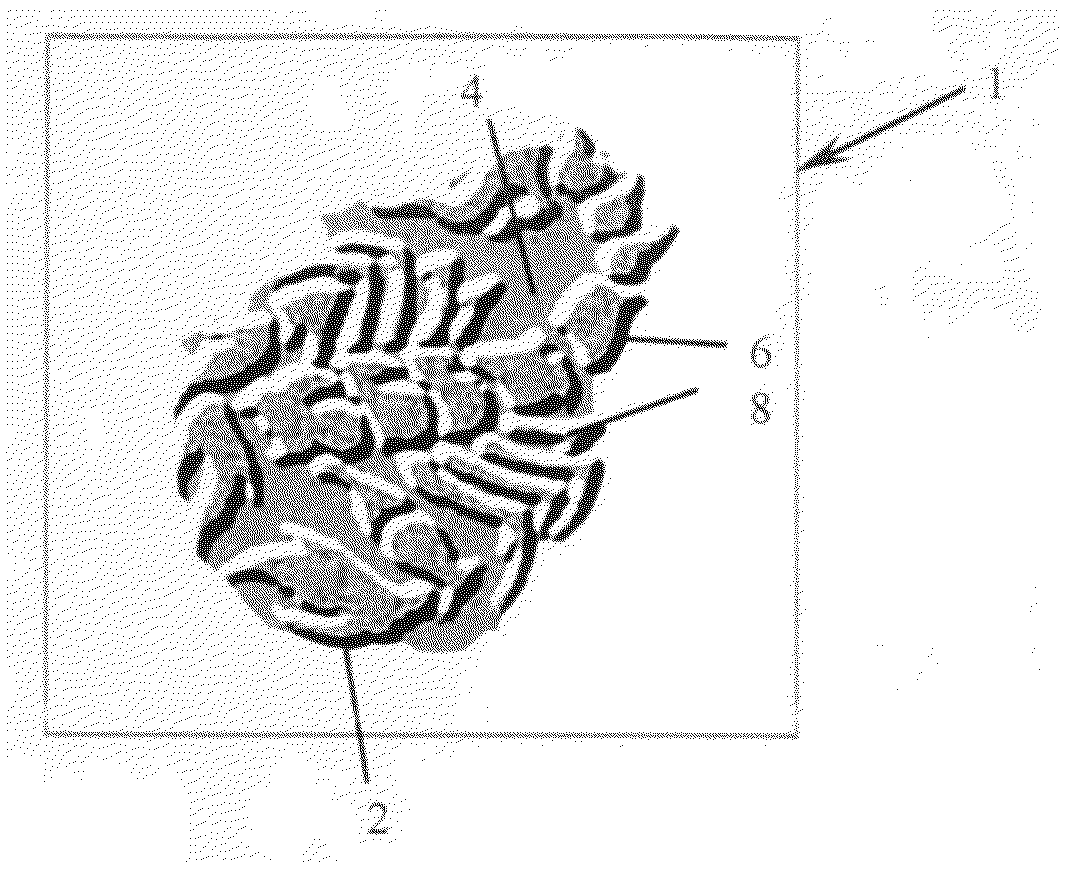

Controllable released biological ceramic thrombus filter and manufacturing method thereof

InactiveCN101147705ANo connection pointPermanent placementBlood vessel filtersThrombusLaser engraving

The present invention relates to a controllably-released bioceramic thrombus filter and its preparation method. Said thrombus filter is made up by using laser engraved metal tube, its end portion is equipped with a combination portion matched with a conveying portion, its centre is equipped with an elastic wire and its surface is convered with a layer of bioceramic membrance. It can be temporarily placed into blood vessel of human body, also can be permanently placed in the blood vessel of human body. Said invention also provides the concrete working principle of said thrombus filter.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Ovd containing device

InactiveUS20090251749A1Good optical performanceOther printing matterSynthetic resin layered productsVisibilityMetal coating

A holographic overlay is provided, including: a polycarbonate substrate having a first side and a second side, a diffractive structure cast upon the first side of the polycarbonate substrate, and a reflection-enhancing coating on at least a part of the diffractive structure; wherein the second side of the polycarbonate substrate provides a substantially flat external surface of the overlay capable of fusing to a conforming surface in the presence of heat and pressure without an adhesive. Optionally, the overlay is laser-engraved so as to form ablated voids in the metal coating and carbonize the laser engravable polycarbonate under the ablated voids. According to another aspect of the invention, a metal coating on a hologram is made substantially transparent using a laser to form a transparent portion of a hologram. Optionally, it is done after applying the hologram to an object such as a card, a document, etc., in register with underlying information to ensure its visibility and continuity of the hologram.

Owner:OPSEC SECURITY GROUP

Laser-engraveable flexographic printing precursors

InactiveUS20120240802A1Enhance the imageIncrease elasticityMaterial nanotechnologyLayered productsElastomerPolyolefin

A laser-engravable flexographic printing precursor or other patternable material can be laser-engraved to provide a relief image. The relief image is formed in an elastomeric, relief-forming, laser-engravable layer comprising a thermoplastic elastomeric nanocrystalline polyolefin that is melt processable. The laser-engraveable composition can be readily recycled and reformed into another flexographic printing plate precursor.

Owner:EASTMAN KODAK CO

Laser engraving methods and compositions, and articles having laser engraving thereon

InactiveUS20050003297A1Not easy to counterfeitDifficult to alterRadiation applicationsLayered productsThioester synthesisBarium sulphide

The invention provides a composition having laser engraving properties, comprising a host material and an effective amount of a laser enhancing additive. The laser enhancing additive comprises a first quantity of least one of copper potassium iodide (CuKI3) or Copper Iodide (CuI), and a second quantity at least one substance selected from the group consisting of zinc sulfide (ZnS), barium sulfide (BaS), alkyl sulfonate, and thioester. The composition can be engraved with grayscale images by an Nd:Yag laser and can be added to laminates or coatings. The composition can be used during the manufacture of many articles of manufacture, including identification documents.

Owner:L 1 SECURE CREDENTIALING

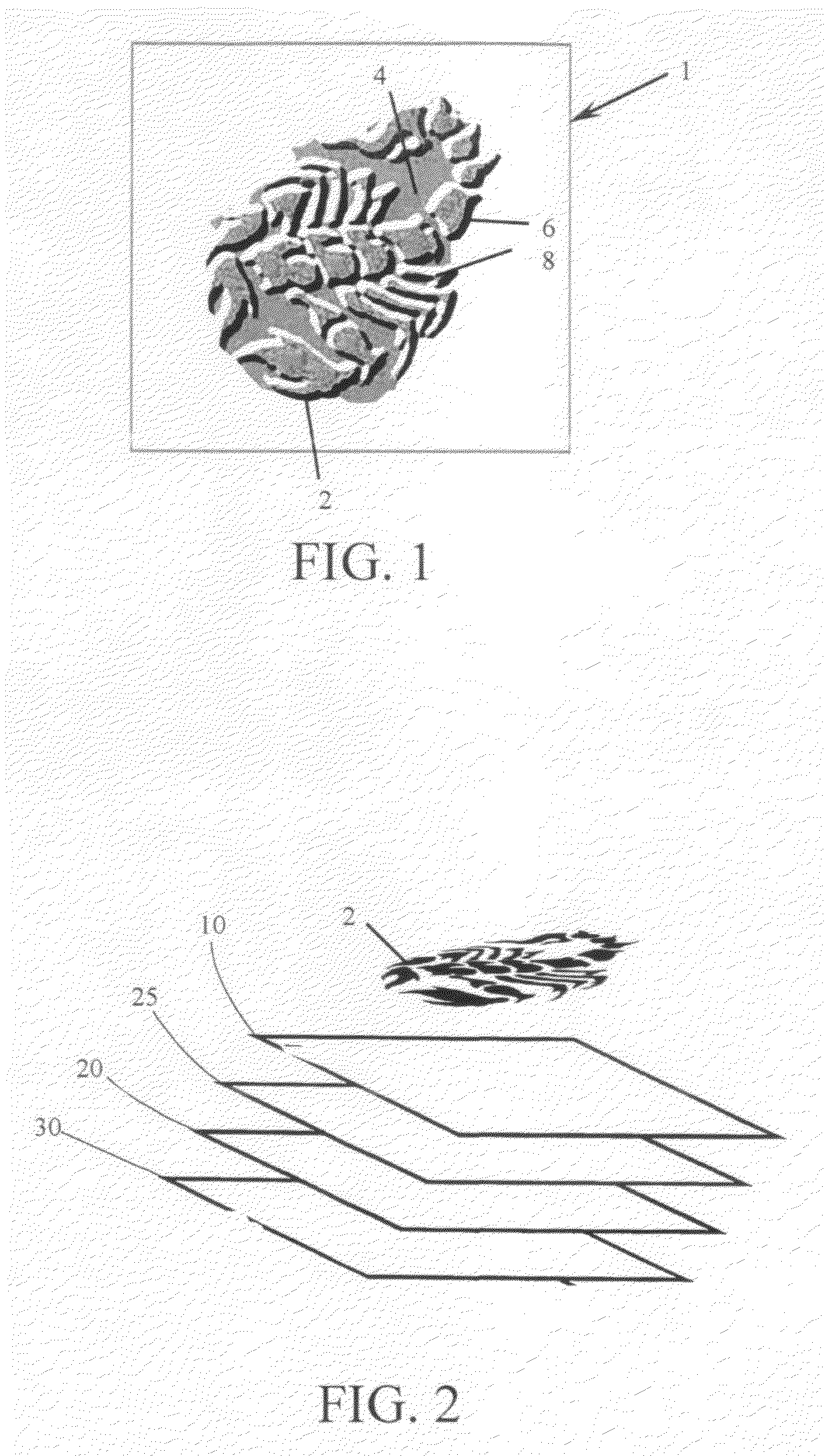

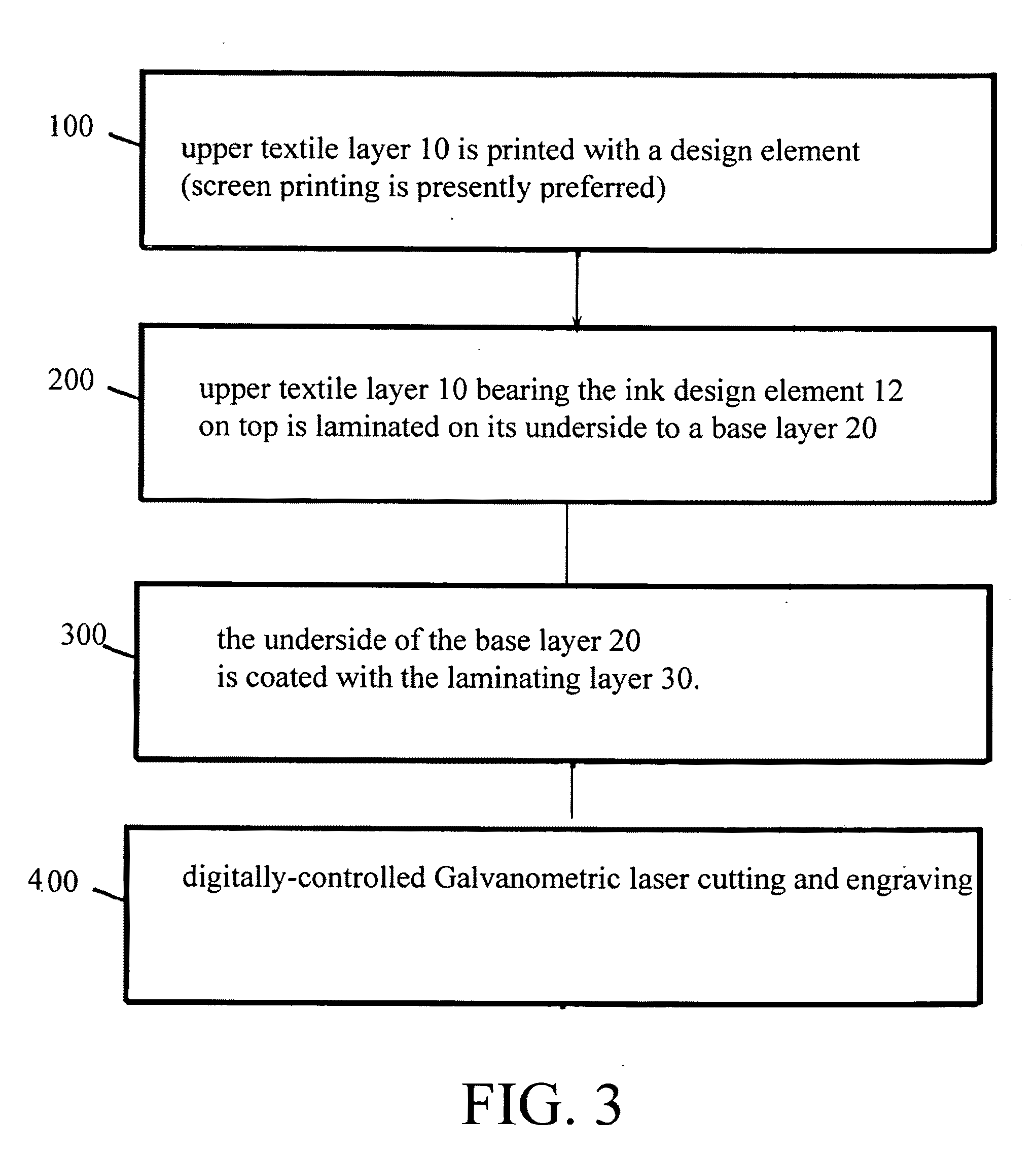

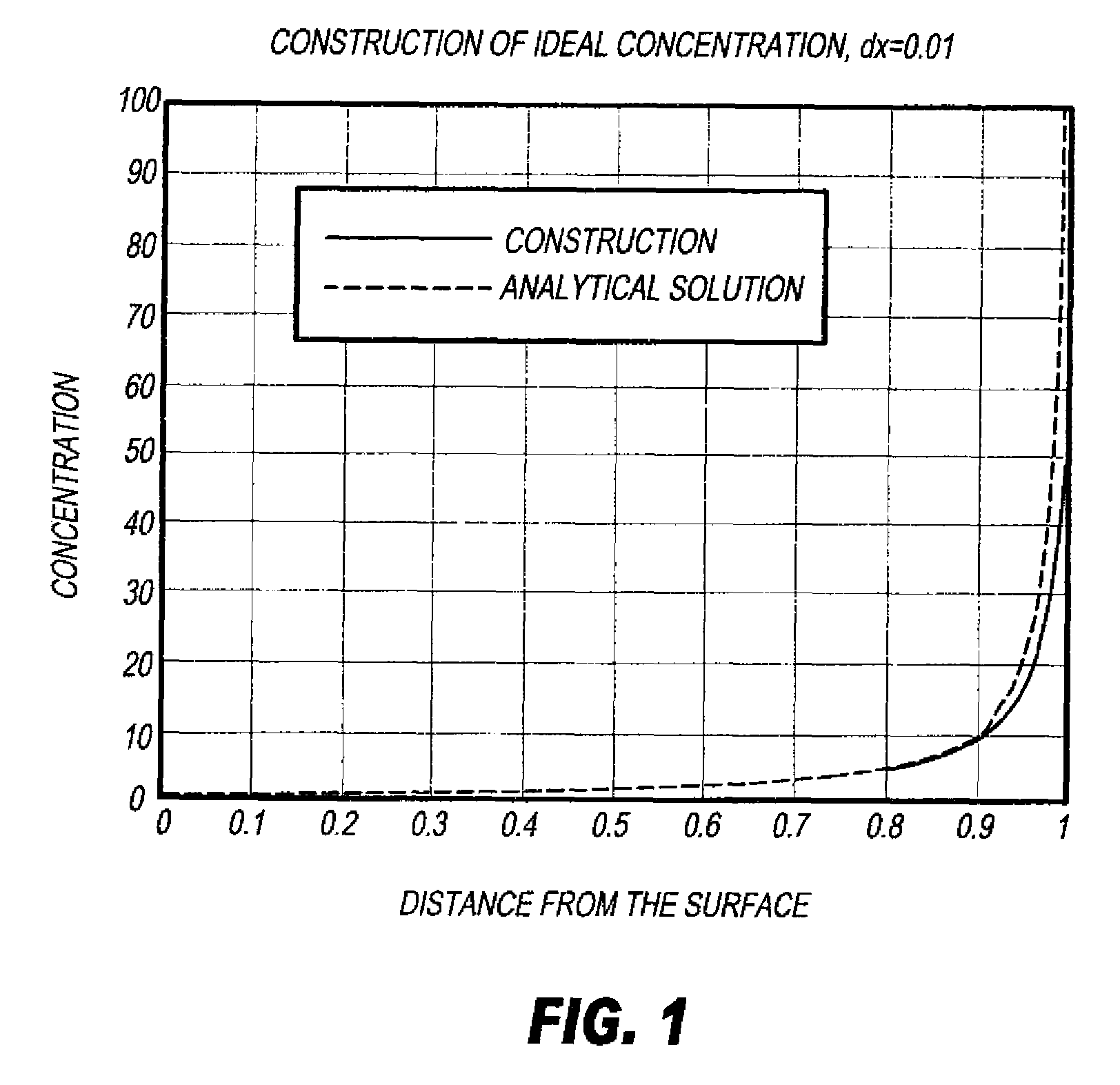

Appliqué having dual color effect by laser engraving

A product and process for producing heat-transfers having a contrasting-color 3D appearance comprising a printed layer of woven fabric substrate adhered to a colorfast textile substrate. The woven fabric substrate includes a top substrate printed with a design logo. The underlying substrate is a solid color. The design logo / is engraved away in patterned designs using a galvanometric laser to reveal the contrasting substrate in desired areas, giving a layered embroidery 3D visual effect. These heat activated appliqués of the present invention are particularly suitable for use in forming decorations for apparel, bags and home furnishings. Their soft tactile hand feel does not cause discomfort to the wearer. The resulting product has superior care and durability characteristics, is more wash fast and can be ironed, and has superior appearance characteristics to other types of heat transfer appliqués. The heat transfer capability of the appliqué allows for fast customization of finished garments.

Owner:LION BROS CO INC

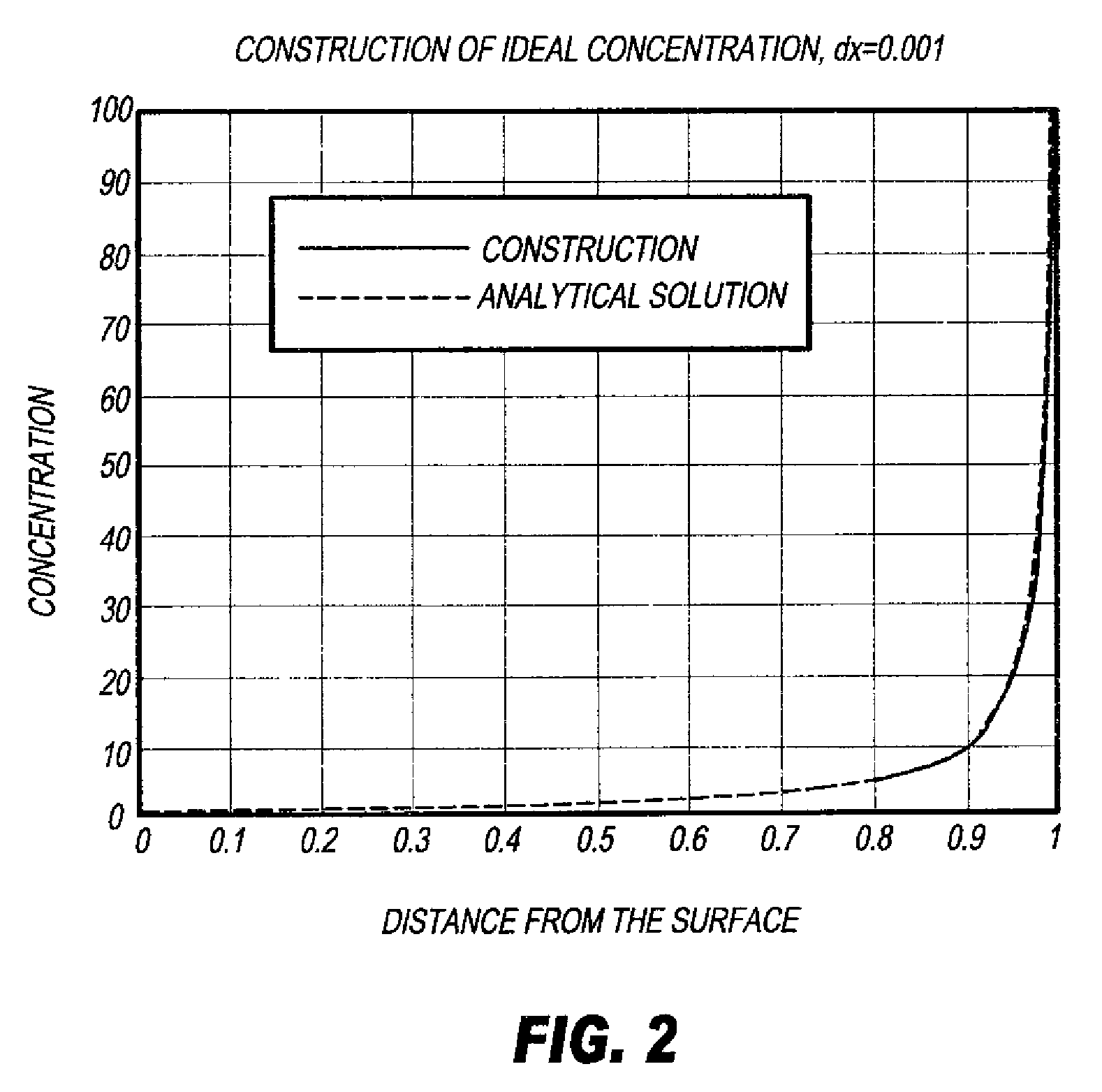

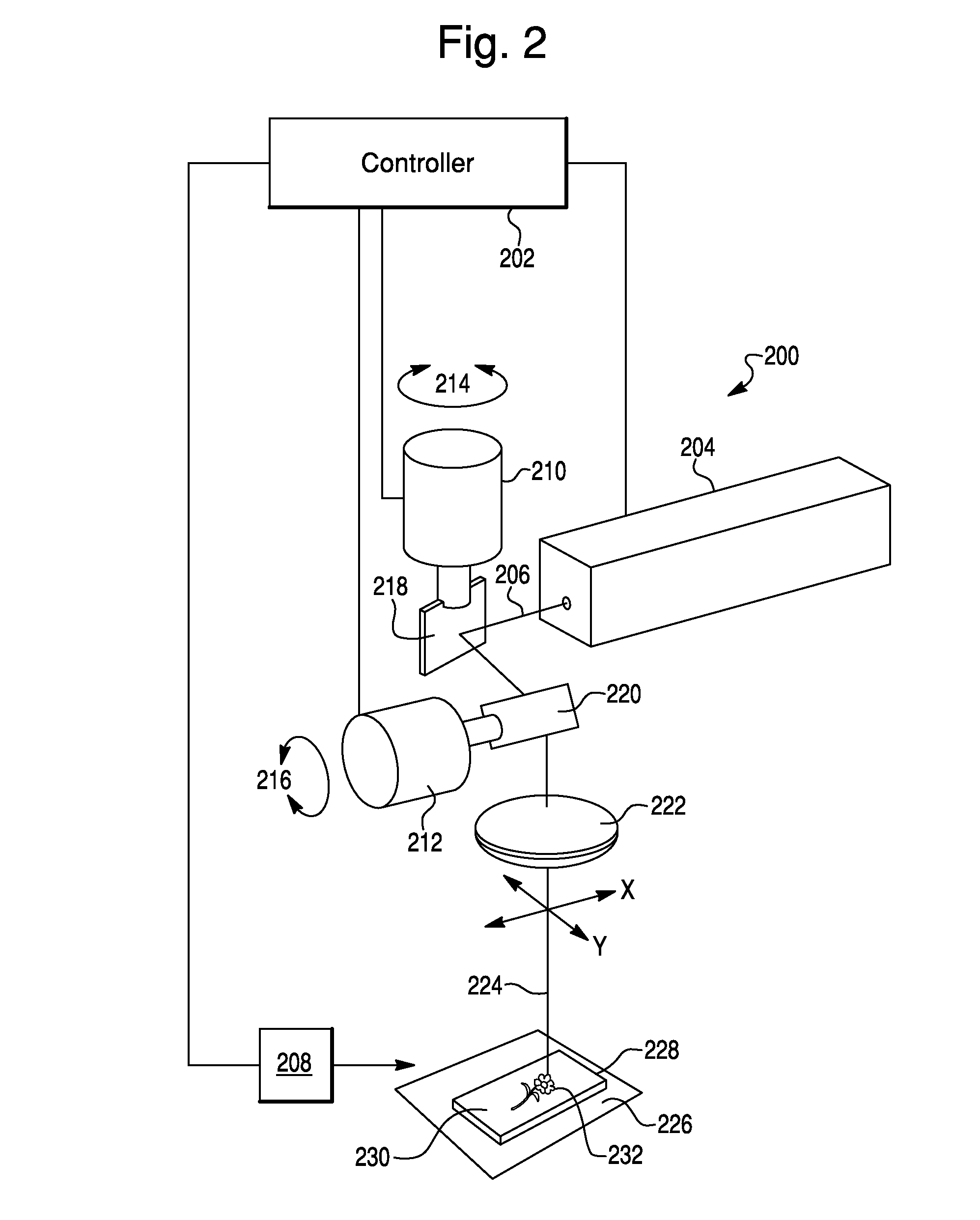

Laser-ablatable elements and methods of use

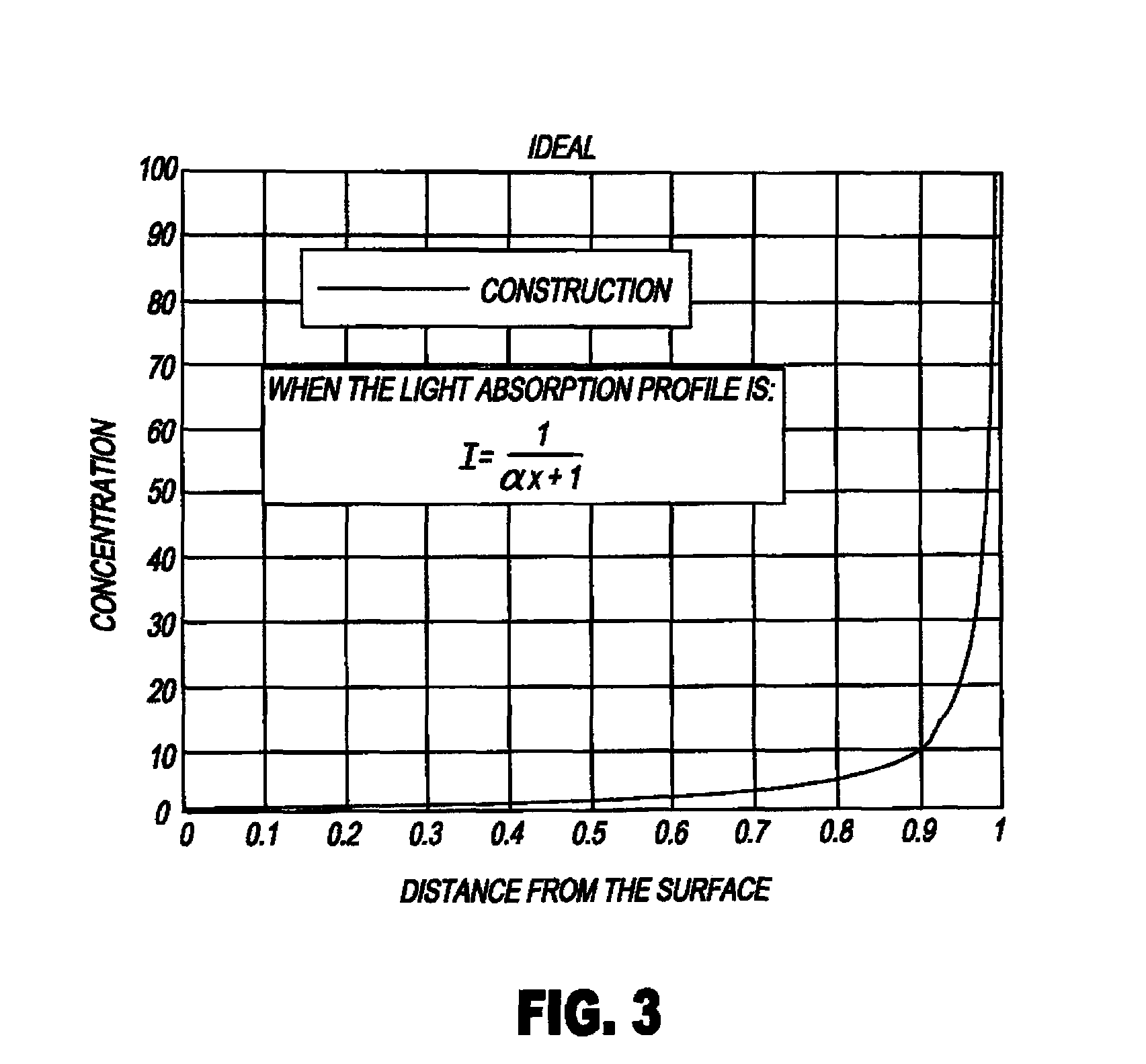

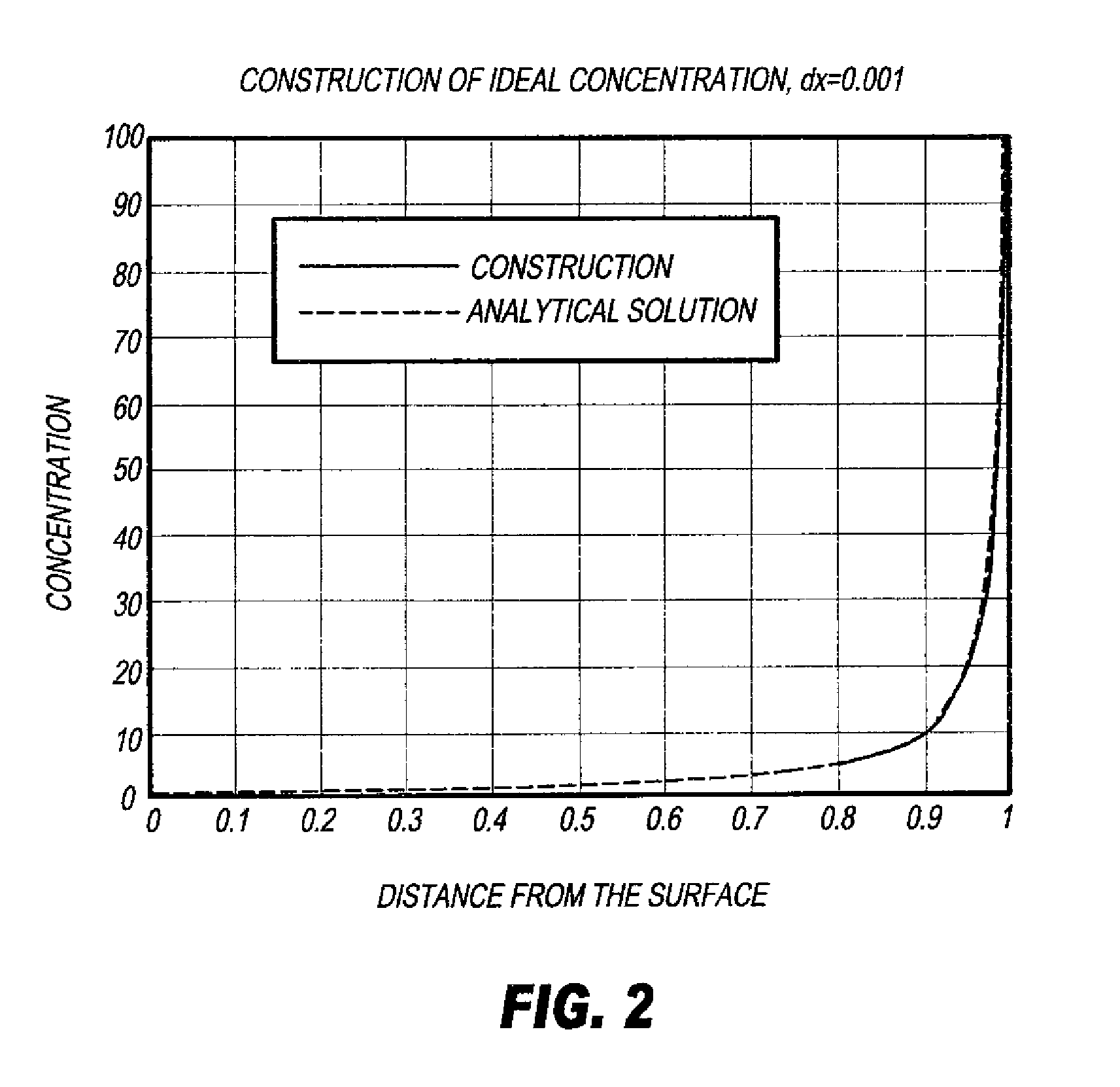

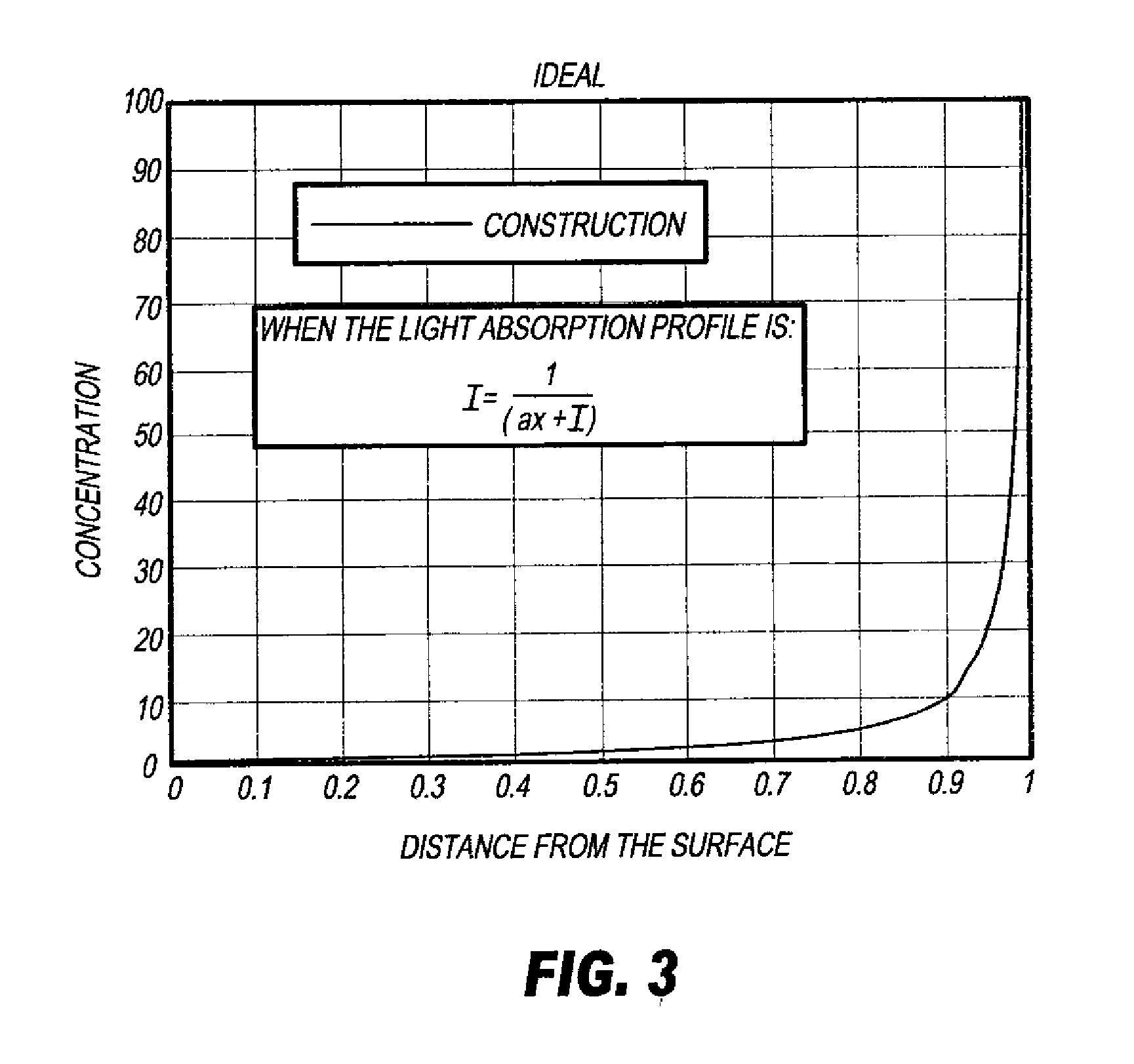

ActiveUS8114572B2Improve ablation efficiencyReduce concentrationPhotosensitive materialsRadiation applicationsLaser engravingLaser exposure

A laser-ablatable element for direct laser engraving has a laser-ablatable, relief-forming layer that has a relief-image forming surface and a bottom surface. This relief-forming layer includes a laser-ablatable polymeric binder and an infrared radiation absorbing compound that is present at a concentration profile such that its concentration is greater near the bottom surface than the image-forming surface. This arrangement of the infrared radiation absorbing compound provides improved ablation efficiency, particularly when laser exposure is carried out adiabatically.

Owner:MIRACLON CORP

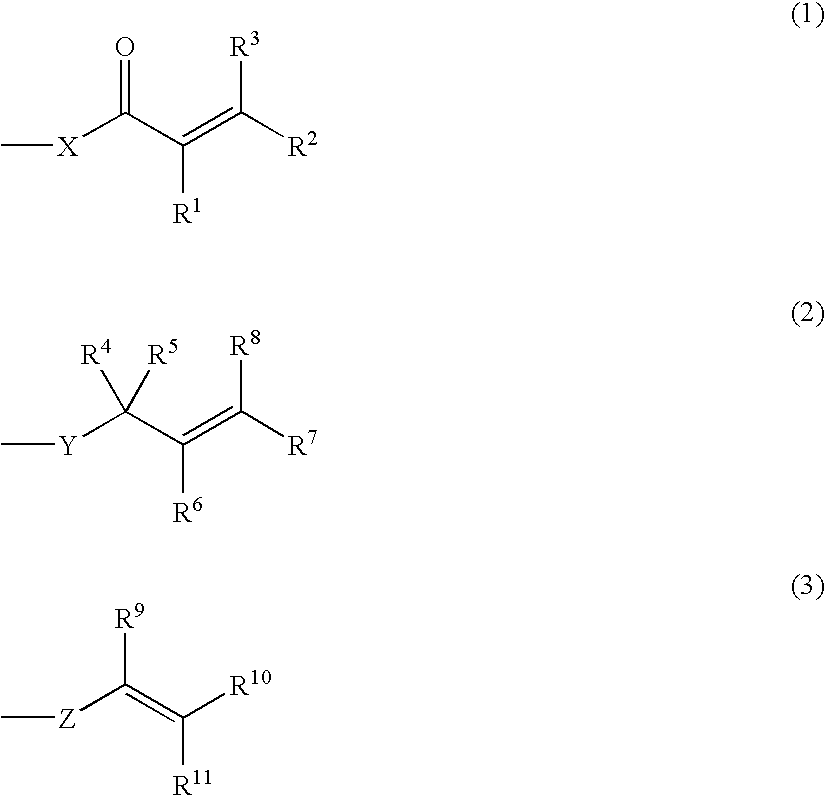

Flexographic printing forme precursor for laser engraving

InactiveUS20100009285A1Suppress formationPhotosensitive materialsDuplicating/marking methodsOligomerMeth-

A method of making a flexographic printing form precursor for laser engraving including the steps of(i) providing at least one layer of a curable composition on a substrate;(ii) curing the at least one layer; wherein the curable composition defining an outermost layer includesat least 0.5% by weight relative to the total weight of the composition of an organo-silicon compound including at least one polymerizable group; and a urethane (meth)acrylate oligomer having three or less polymerizable groups.

Owner:AGFA NV

Staggered laser-etch line graphic system, method and articles of manufacture

InactiveUS8460566B2Reduce visual impactReduce impactVacuum gauge using ionisation effectsDecorative surface effectsLaser etchingGraphics

A staggered laser-etch line graphic system, method, and articles of manufacture are provided. One described method includes the steps of laser engraving a first plurality of lines associated with a first component section of a graphic on a surface of an article; laser engraving a second plurality of lines associated with a second component section of the graphic on the surface of the article; and controlling said laser engraving of the first plurality of lines and said laser engraving of second plurality of lines to reduce the visual impact of a demarcation line separating the first component section of the graphic and the second component section of the graphic.

Owner:REVOLAZE LLC

Laser-ablatable elements and methods of use

ActiveUS20110089609A1Improve ablation efficiencyPromote recombinationPhotosensitive materialsRadiation applicationsLaser engravingLaser exposure

A laser-ablatable element for direct laser engraving has a laser-ablatable, relief-forming layer that has a relief-image forming surface and a bottom surface. This relief-forming layer includes a laser-ablatable polymeric binder and an infrared radiation absorbing compound that is present at a concentration profile such that its concentration is greater near the bottom surface than the image-forming surface. This arrangement of the infrared radiation absorbing compound provides improved ablation efficiency, particularly when laser exposure is carried out adiabatically.

Owner:MIRACLON CORP

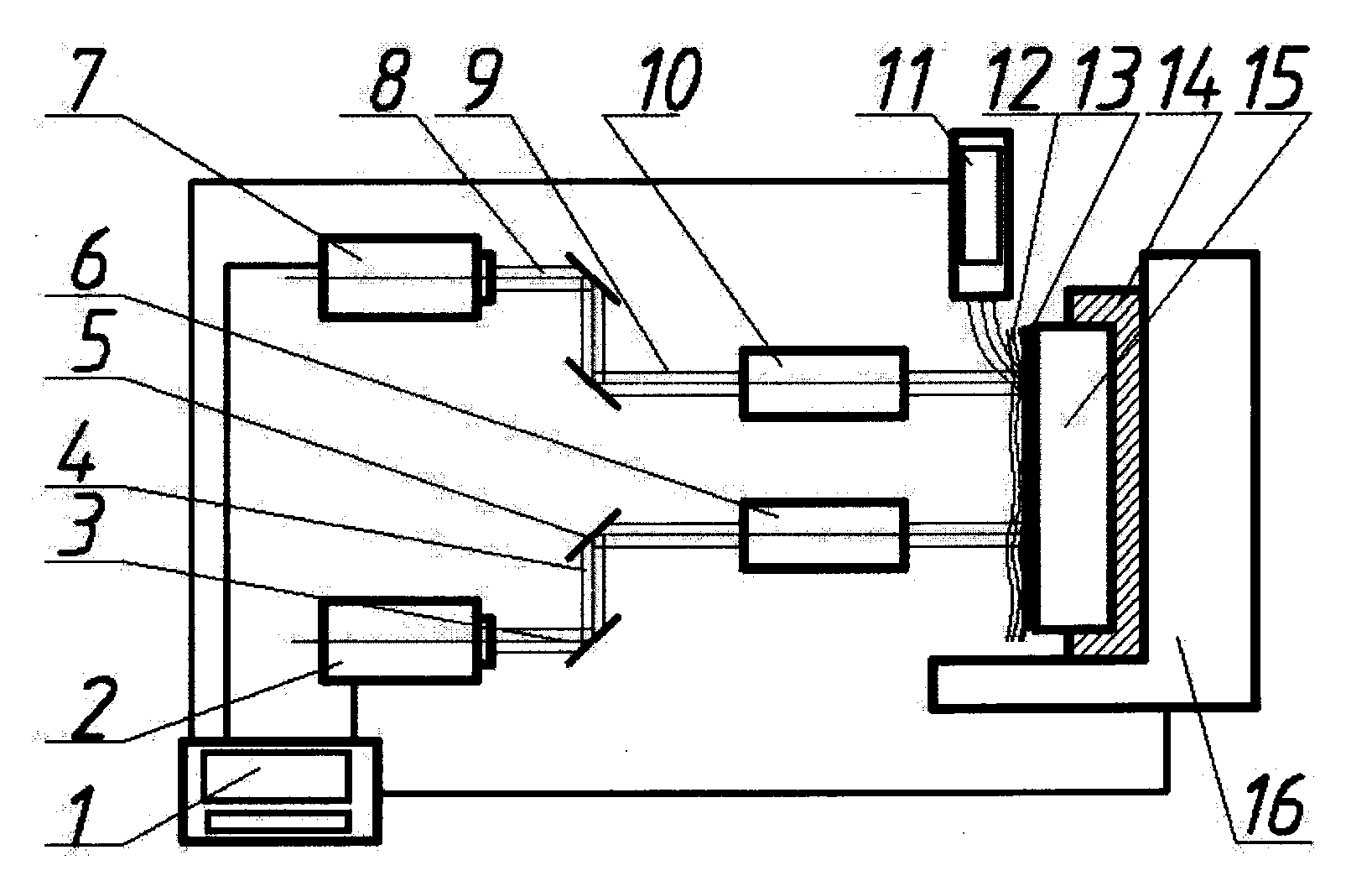

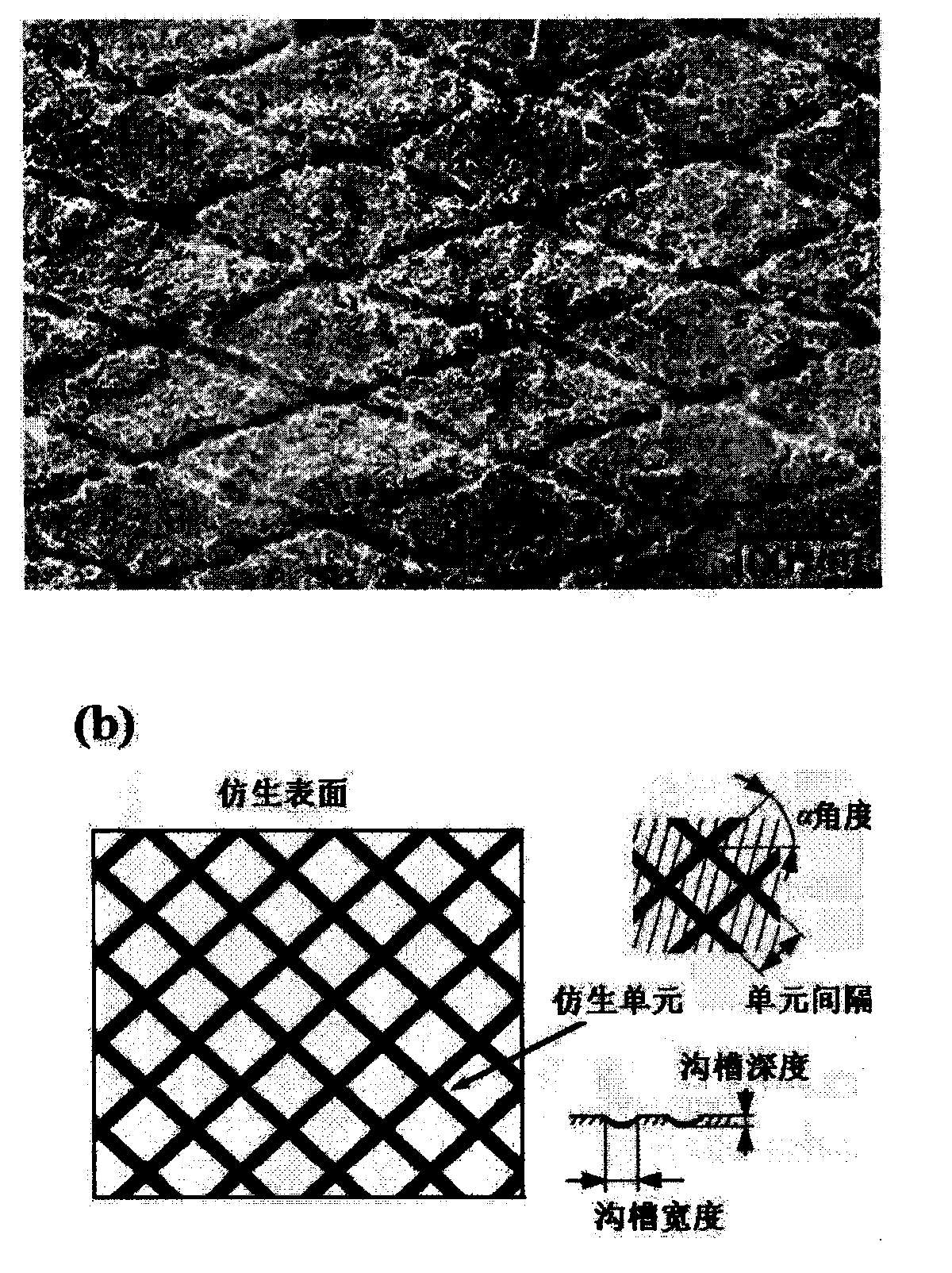

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569ANo wearNo consumptionLaser beam welding apparatusLight spotVolumetric Mass Density

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing a regular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

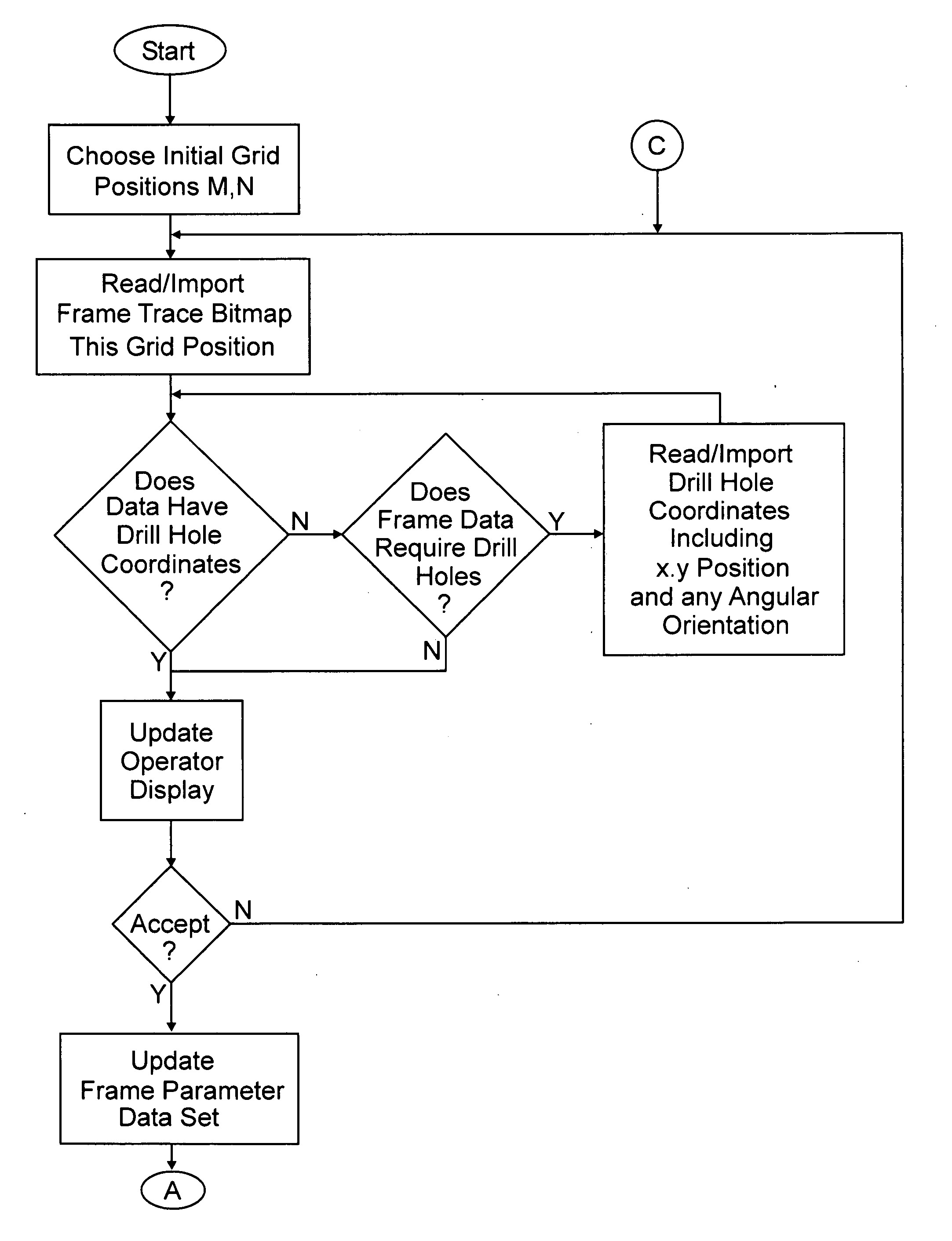

Automated laser cutting of optical lenses

InactiveUS20060011617A1Many optionsImprove carryMicrowave heatingLaser beam welding apparatusAngle of incidenceLaser engraving

A laser engraving device is adapted to process a plurality of lens blanks in a single processing run. The lens blanks are cut or edged serially where the laser cutter path for each blank is calculated by software which interprets lens blank optical parameters, prescription parameters and frame trace parameters, all of which can vary for each blank being edged. Minor adjustment of the angle of incidence between the laser cutter and the target blank is accomplished by a tiltable blank holder. More aesthetically appealing “rimless” lens are achieved by cutting the lens to have a frame-shaped edge from a single monolithic piece of blank material. Such shaping of the edge portion provides more ornamentation options on “rimless” eyeglasses. The manipulation of laser power, velocity, and number of passes over given position on the lens results in cutting depth variability which can be selected to further ornament the edge region and allow for the carrying of dyes or tints to a greater degree than an untreated or polished lens surface.

Owner:MEANDRE

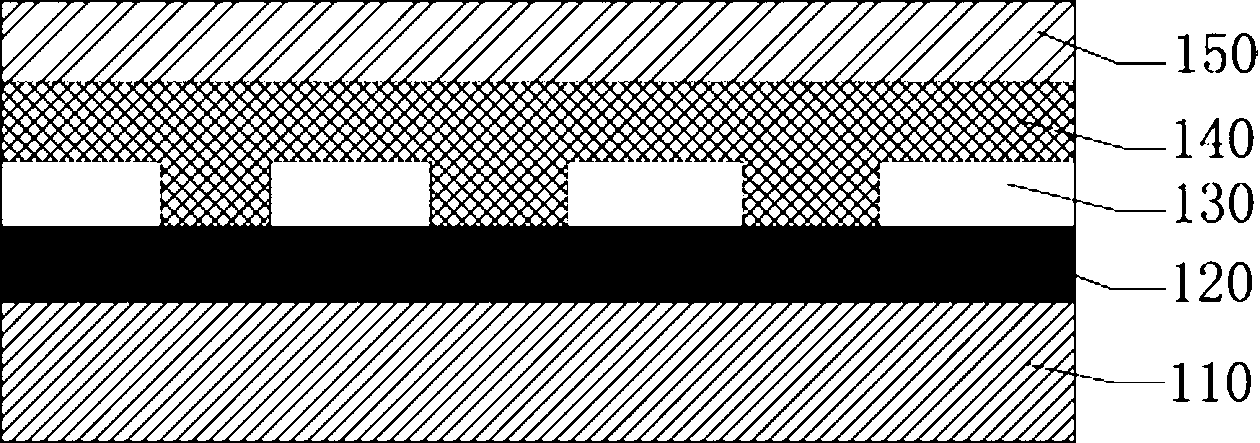

Preparation method of ceramic circuit board

ActiveCN102695370AGood choiceImprove bindingInsulating substrate metal adhesion improvementLiquid/solution decomposition chemical coatingChemical platingHemt circuits

The invention relates to a ceramic surface modifying technology, particularly relates to a method for metalizing the surface of a ceramic profiled bar, and specifically provides a preparation method of a ceramic circuit board... The preparation method of the ceramic circuit board comprises the preparation steps of: (1) preparing a ceramic substrate; (2) engraving a required circuit pattern with laser on the surface of the ceramic substrate; (3) in chemical plating, and chemically plating copper on the ceramic substrate obtained in the step (2) to realize bottoming; and (4) chemically plating nickel or chemically plating gold or silver on the surface of a plated layer, so as to prevent copper from being oxidized. According to the preparation method of the ceramic circuit board provided by the invention, a laser engraving technology is combined with chemical copper plating, so that the ceramic board is selectively coated with copper, and the good selectivity is achieved. By using the laser engraving technology, the binding force of a conductive layer with a ceramic base body is good; production equipment is cheap and easy to obtain. Furthermore, the three-dimensional ceramic circuit board can be easily produced; the circuit pattern design is very simple; and the circuit precision is high. Moreover, compared with the other technologies, the preparation method provided by the invention has the advantage that the 'three wastes' emission in a production process is reduced.

Owner:黄石星河电路有限公司

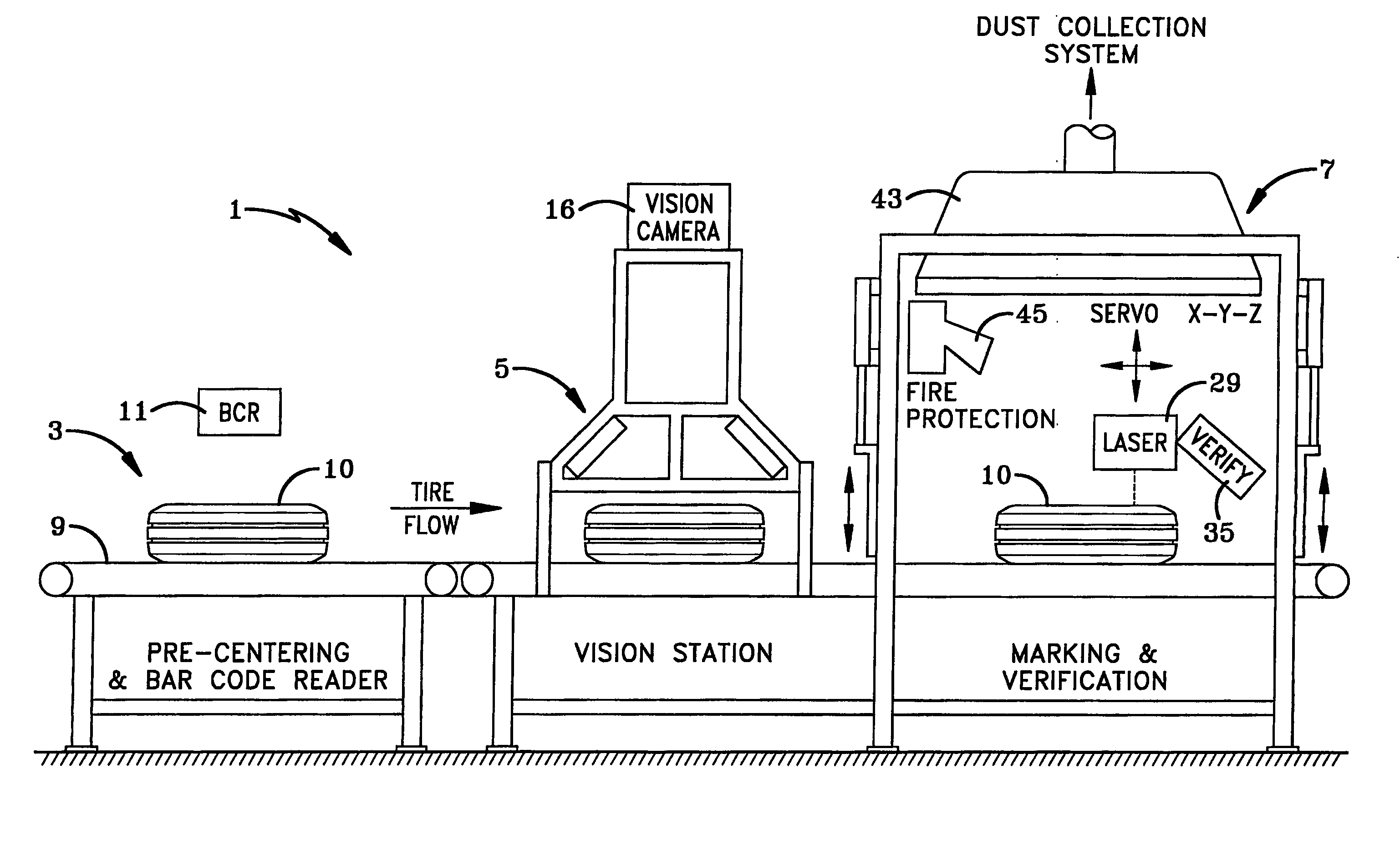

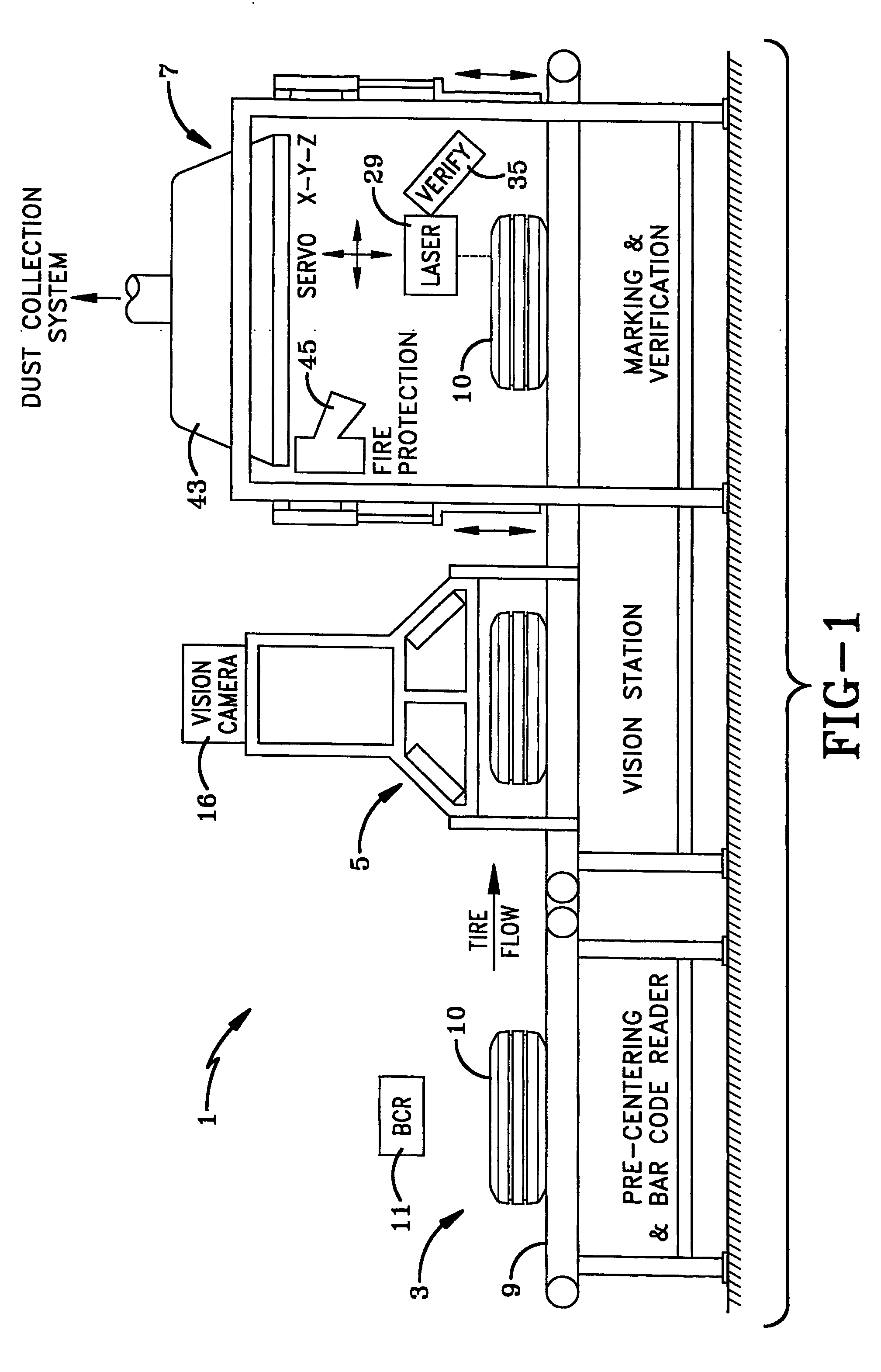

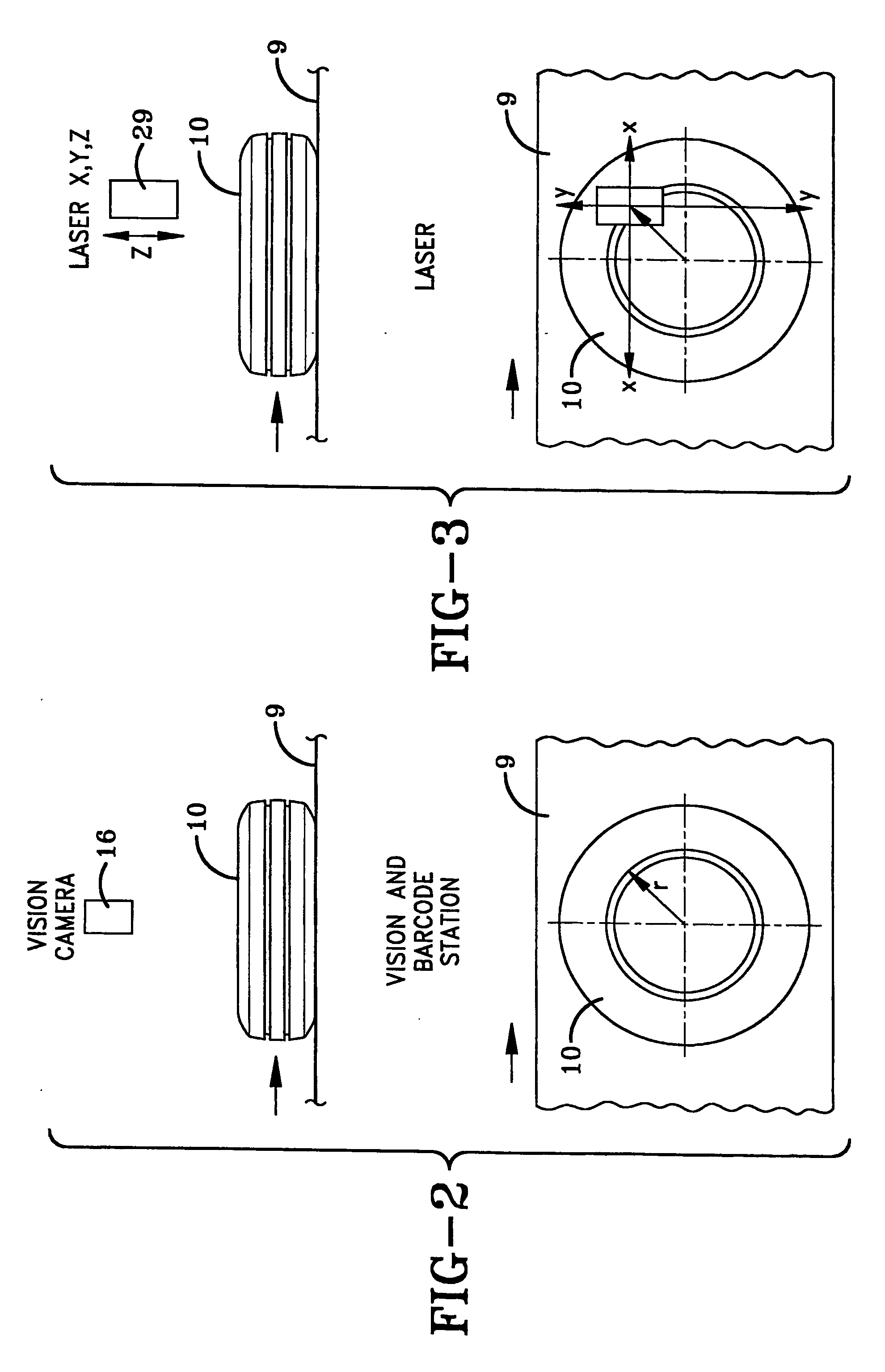

Method and system for marking tires

A system and associated method of marking a molded vehicle tire with laser engraved information to provide both human visible and machine readable data concerning the tire. Information contained in a barcode on the tire is read at a first station and supplied to a control unit. The physical location of human visible information previously molded into the tire is read from the tire at a second station and supplied to the control unit which uses this information to position a laser located at a third station for engaging additional human visible information pertaining to the manufacture of the tire adjacent the existing visible information to satisfy the Department of Transportation (DOT) tire marking requirements. The additional information also can be laser engraved into the tire in a machine readable encoded format, such as 2D symbols, for subsequent control and verification throughout the life of the tire.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

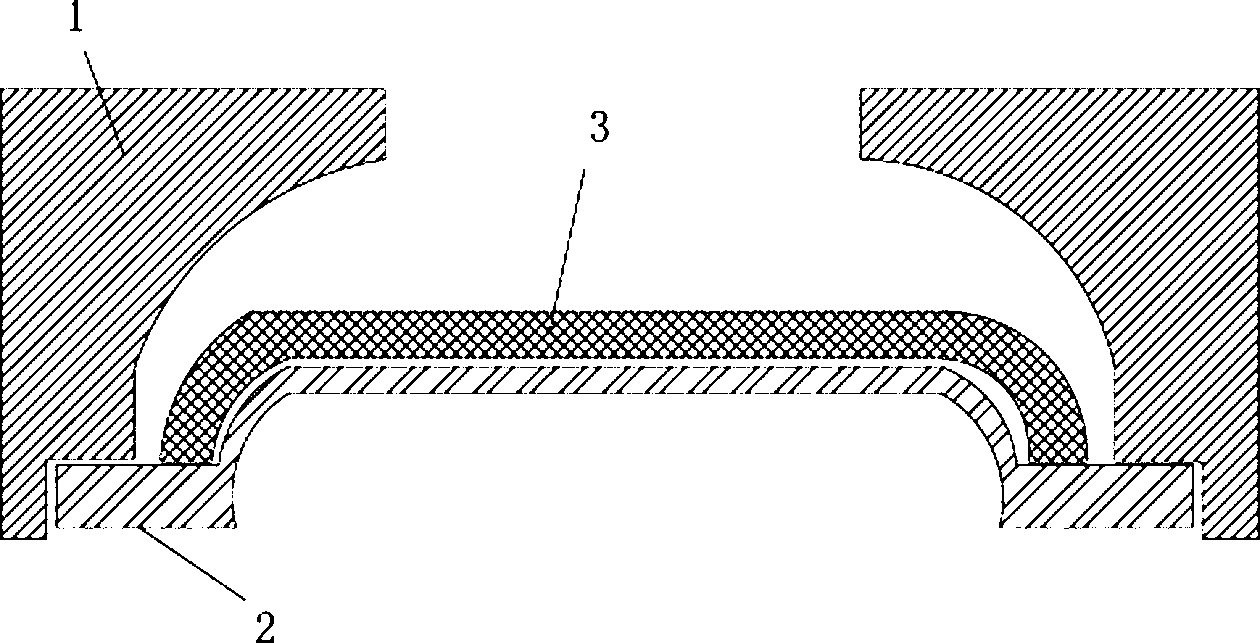

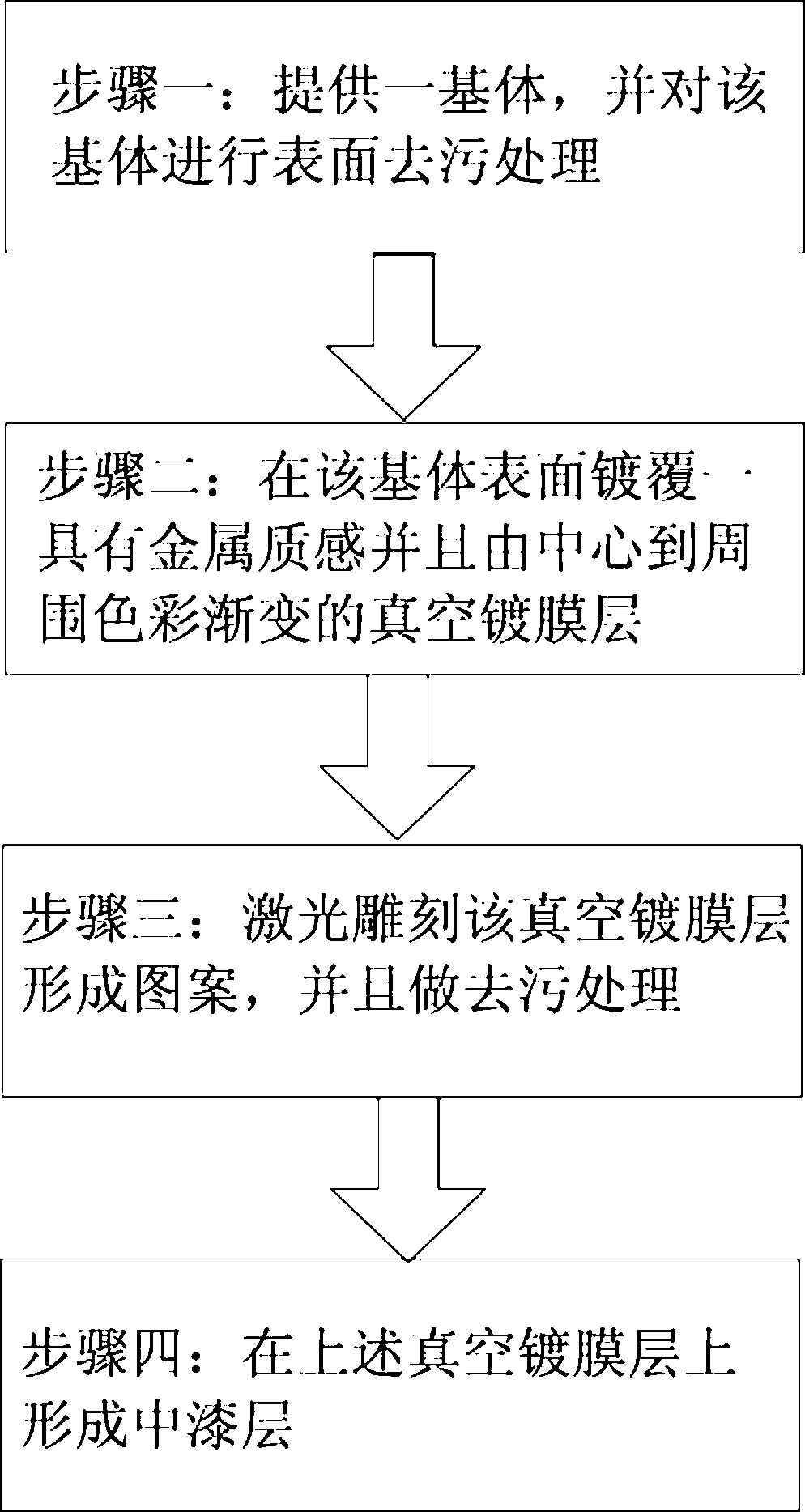

Electronic product shell and manufacturing method thereof

ActiveCN102858100AMeet the needs of colorVacuum evaporation coatingSpecial ornamental structuresLaser engravingVacuum coating

The invention discloses an electronic product shell which comprises a base body, a vacuum coating layer and a middle paint layer, wherein the vacuum coating layer is formed on the surface of the base body and has metal texture and color gradient from the center to the periphery; the middle paint layer is formed on the vacuum coating layer; and patterns are formed on the vacuum coating layer. The invention also provides a manufacturing method of the electronic product shell. According to the electronic product shell and the manufacturing method thereof provided by the invention, the middle paint layer is formed after the laser engraving of the vacuum coating layer, and the cleaning process can be performed after the laser engraving; and since the vacuum coating layer has color gradient from the center to the periphery, the needs for colors of people are met.

Owner:BYD CO LTD

Pigmented Images on Stone

ActiveUS20080160254A1High power outputRealistic and aesthetically pleasing resultRadiation applicationsDecorative surface effectsLaser engravingComputer science

A method of creating a pigmented image on a monument stone substrate includes positioning the stone relative to a laser engraving apparatus, masking the stone substrate in an image area in which the image is to be created with a first mask layer, operating the laser engraving apparatus in a pattern over the masked area at a sufficient power level to burn through the mask and pit the stone substrate with a first set of pits, applying a first layer of pigment over the image area to any remaining first mask layer in the image area and to the first set of pits, curing the first layer of pigment and removing any remaining first mask layer. Additional colors or pigment layers can be added by repeating the masking, burning and applying steps, and the final such step can be a dithered image, followed by an edge defining cutting step in which the border of the image is defined. All pigment layers are rooted in the stone. The final pigmented image is preserved with protective coatings.

Owner:OM STONE INC

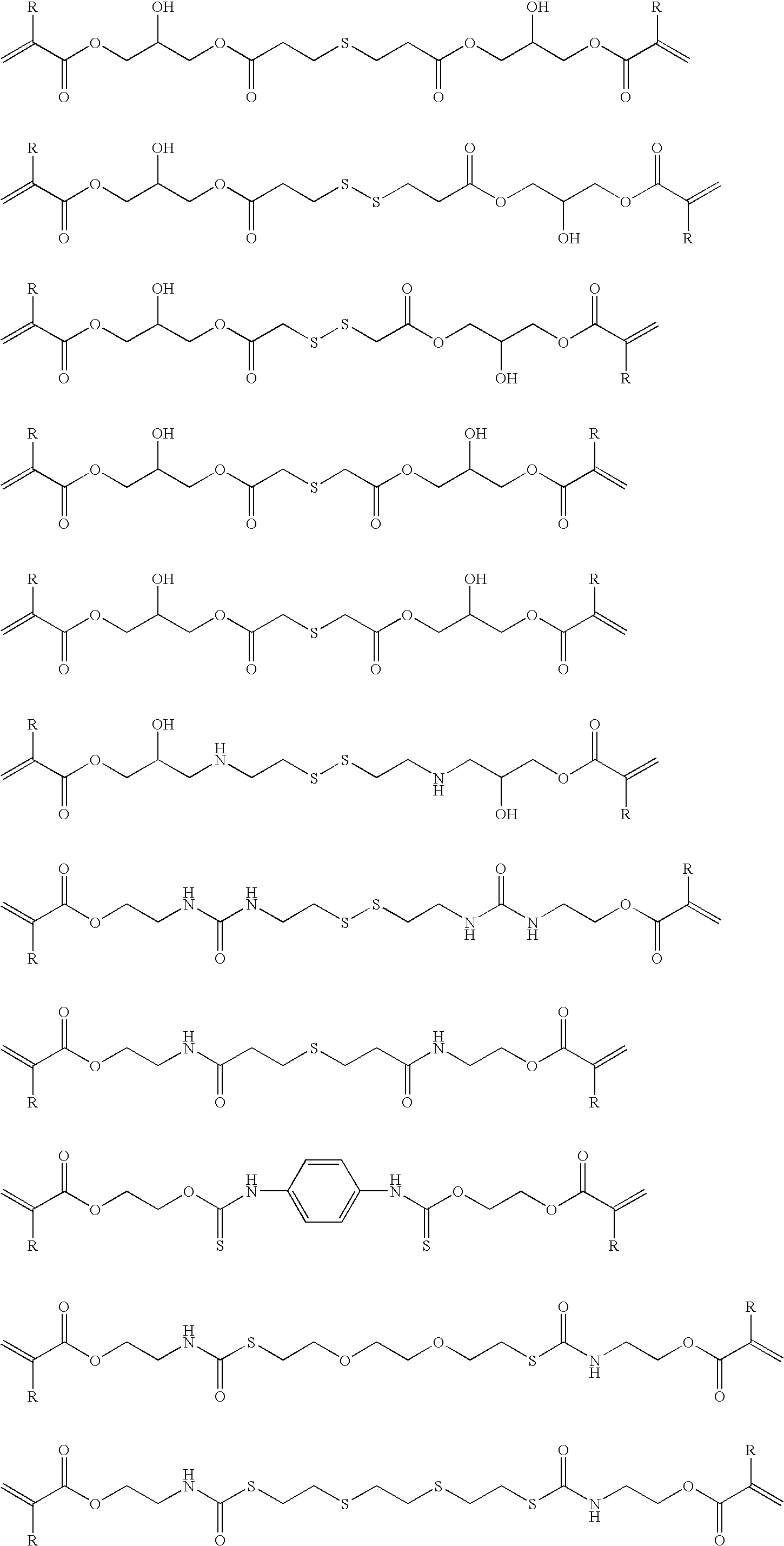

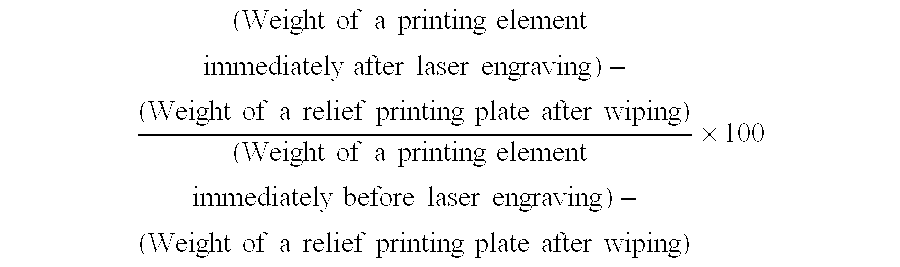

Resin composition for laser engraving, image forming material, relief printing plate precursor for laser engraving, relief printing plate, and method of manufacturing relief printing plate

InactiveUS20090246469A1High engraving sensitivityHigh sensitivityPhotosensitive materialsLayered productsSulfurLaser engraving

The invention provides a resin composition for laser engraving, containing at least (A) a polymerizable compound having two or more ethylenic unsaturated bonds, a carbon-sulfur bond being contained at the site where two among the two or more ethylenic unsaturated bonds are connected and (B) a binder polymer. The invention further provides an image forming material containing the resin composition, a relief printing plate precursor having a relief forming layer which contains the resin composition, a relief printing plate precursor having a relief forming layer which contains a product formed by subjecting the resin composition to cross-linking, a method for manufacturing a relief printing plate including subjecting the relief printing plate precursor having the relief forming layer which contains the resin composition to cross-linking, and a relief printing plate manufactured by the manufacturing method.

Owner:FUJIFILM CORP

Photosensitive resin composition for original printing plate capable of being carved by laser

InactiveUS20050227165A1Accurate imagingImprove wear resistanceSemiconductor/solid-state device manufacturingPlate printingSimple Organic CompoundsLaser engraving

A photosensitive resin composition for forming a laser engravable printing element, comprising: (a) 100 parts by weight of a resin which is in a solid state at 20° C., wherein the resin has a number average molecular weight of from 5,000 to 300,000, (b) 5 to 200 parts by weight of an organic compound having a number average molecular weight of less than 5,000 and having at least one polymerizable unsaturated group per molecule, and (c) 1 to 100 parts by weight of an inorganic porous material having an average pore diameter of from 1 to 1,000 nm, a pore volume of from 0.1 to 10 ml / g and a number average particle diameter of not more than 10 μm. A laser engravable printing element formed from the above-mentioned resin composition. A method for producing a laser engraved printing element by using the above-mentioned photosensitive resin composition.

Owner:ASAHI KASEI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com