Method and device for compositely preparing surface-layer biomimetic structure by laser

A control device and surface layer technology, which is applied to the processing of bionic surfaces and friction pair surfaces, based on the mechanical effects of laser engraving and laser shock to prepare surface bionic structures, can solve the problems affecting the wear resistance of materials, and achieve uniform effects. Improved surface roughness and better beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

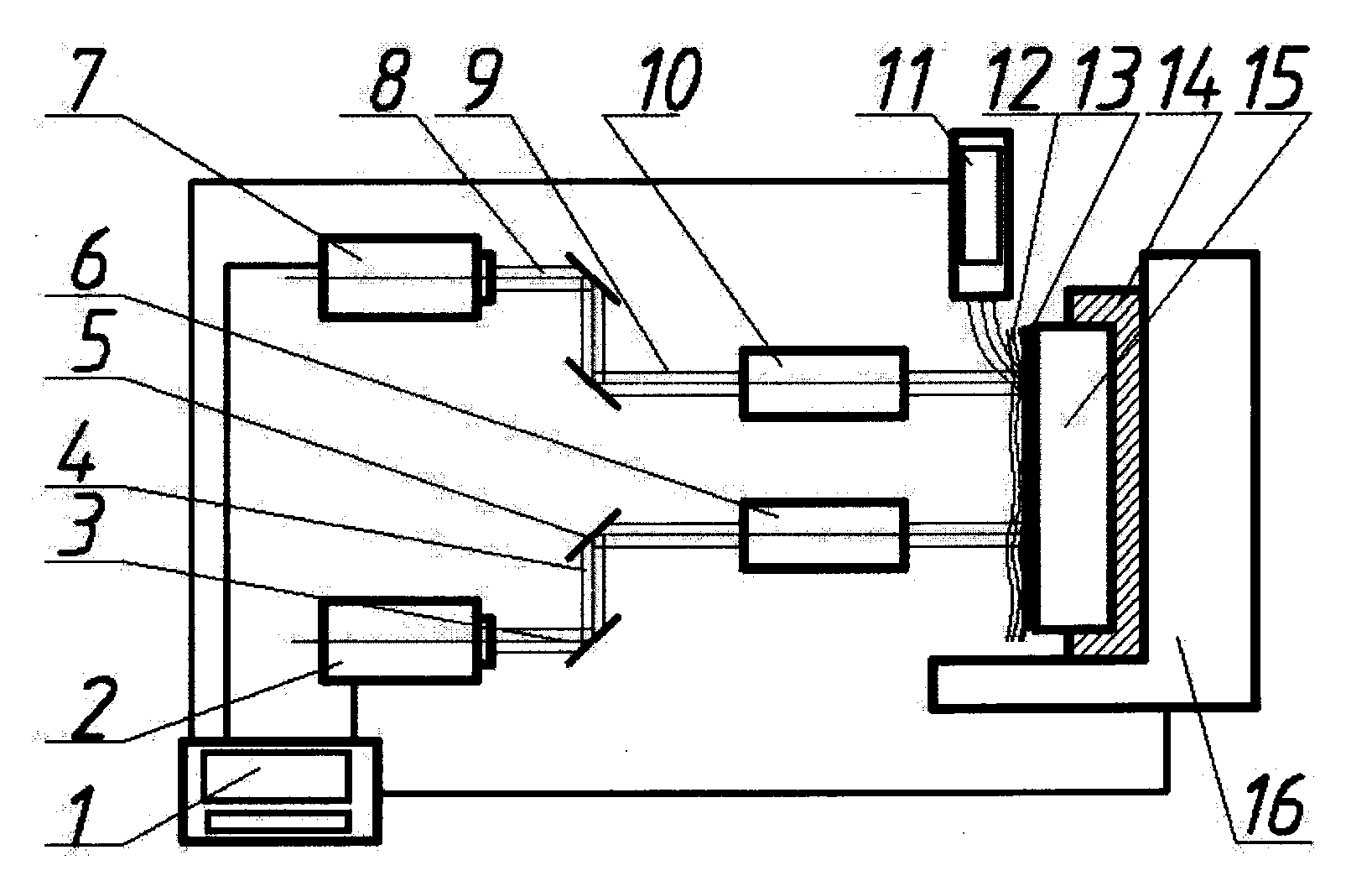

[0024] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The device for preparing a bionic structure by laser compounding according to the present invention includes a control device (1), an optical path system I or an optical path system II, an automatic spraying device (11), a constrained layer (12), an absorbing layer (13), and a tool holder connected in sequence System (14), workpiece (15) and five-axis workbench (16). The optical path system I and the optical path system II are parallel structures, wherein the optical path system I includes a nanosecond laser generator (2), a laser beam I (3), a light guide tube I (4), a total reflection mirror (5), The spot size adjustment device I (6), the optical path system II includes a fiber laser (7), a laser beam II (8), a light guide tube II (9), a total reflection mirror (5), and a spot size adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com