Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

334 results about "Relief printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relief printing is a family of printing methods where a printing block, plate or matrix that has had ink applied to its surface, but not to any recessed areas, is brought into contact with paper. The areas of the printing plate with ink will leave ink on the paper, whereas the recessed areas of the printing plate will leave the paper ink-free. A printing press may not be needed, as the back of the paper can be rubbed or pressed by hand with a simple tool such as a brayer or roller.

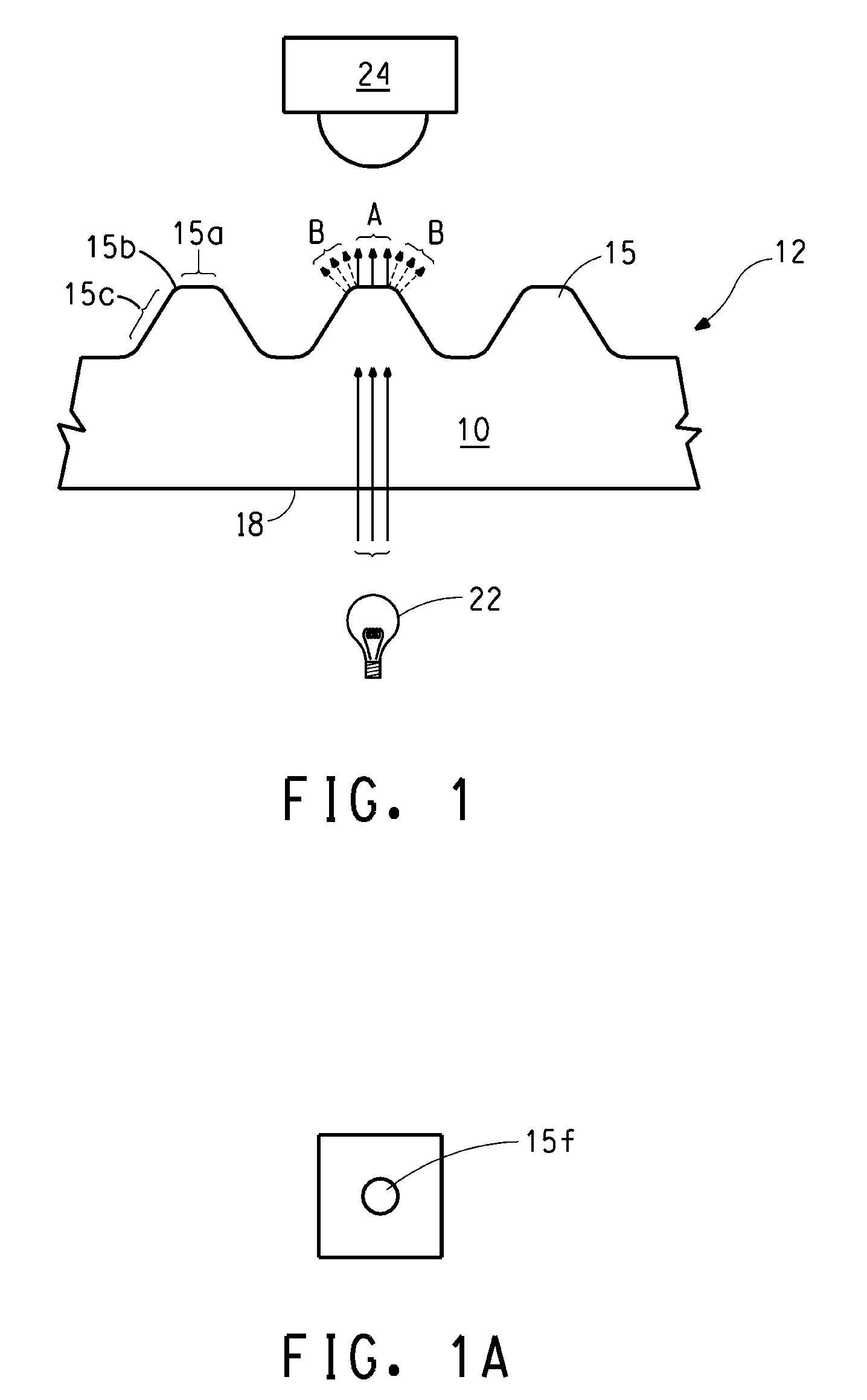

Enhanced relief printing plate

ActiveUS20100143841A1Improve accuracyOptimization rangePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringImage area

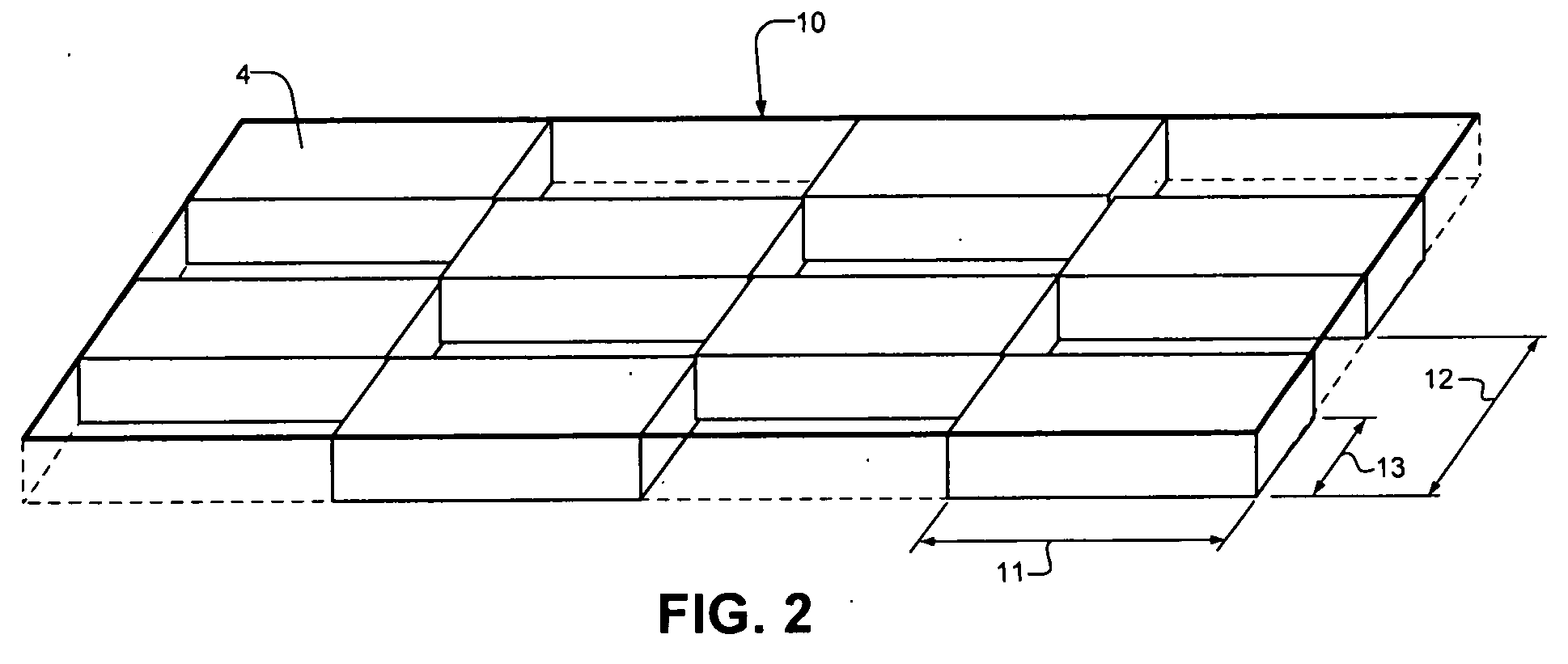

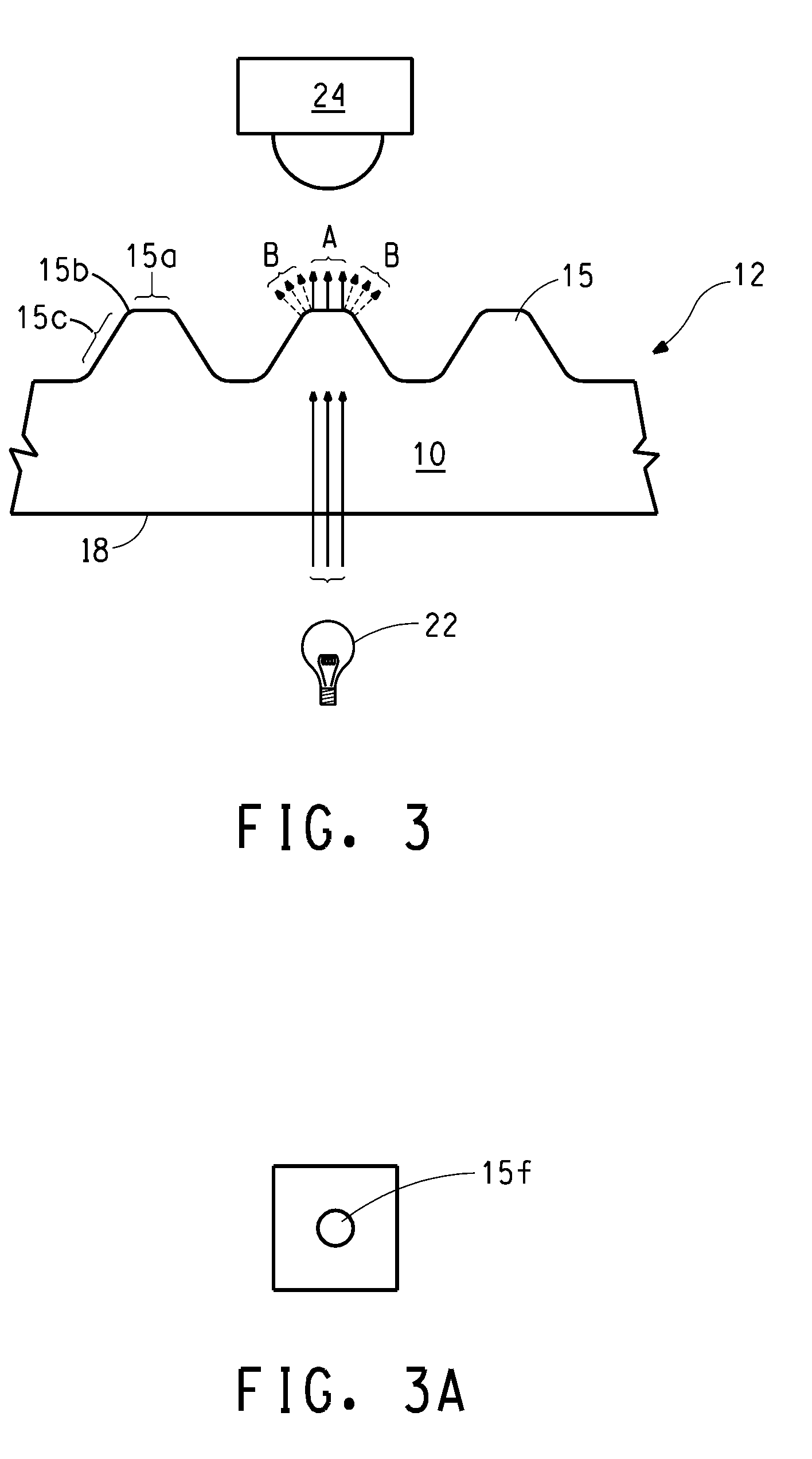

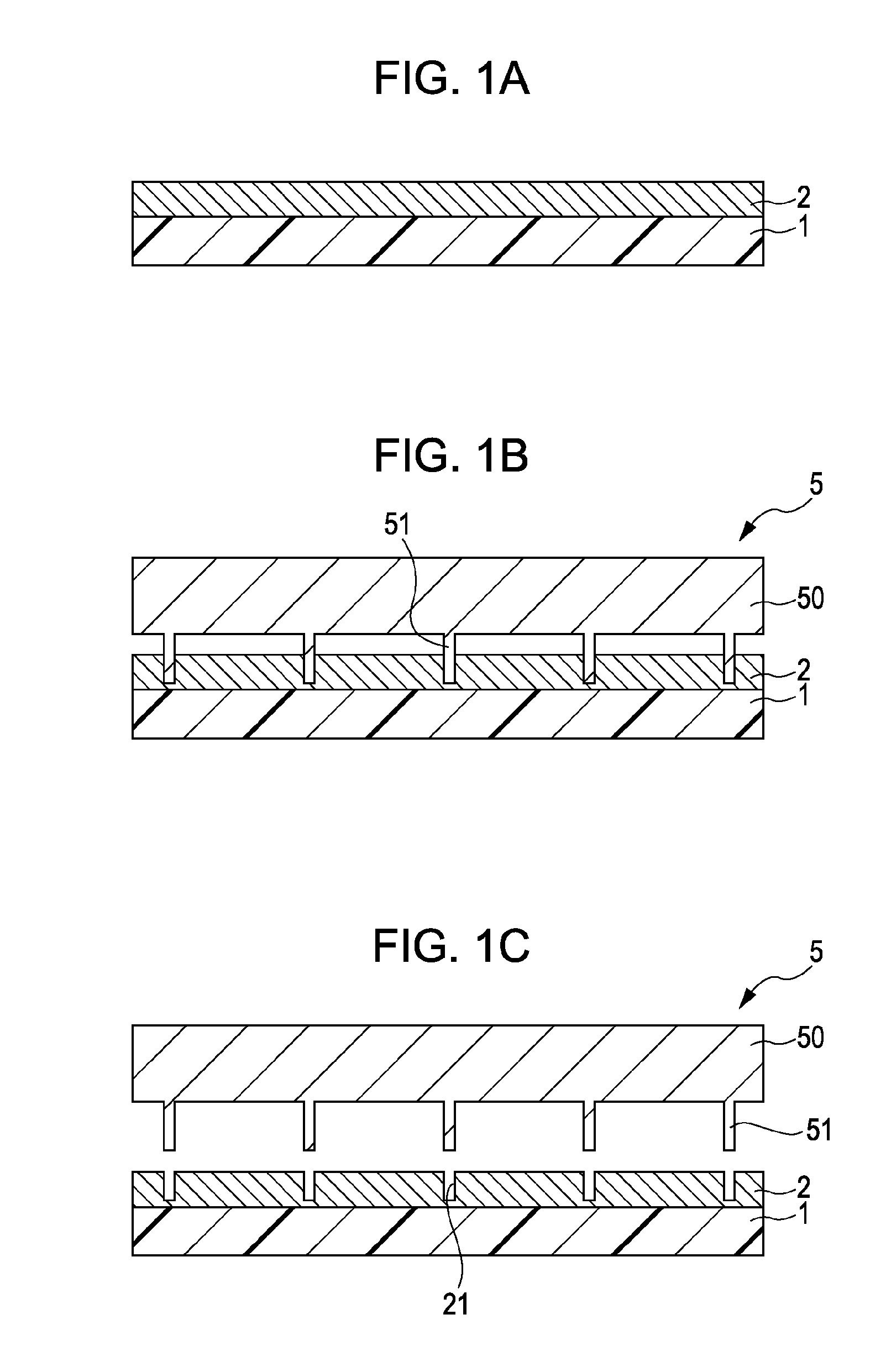

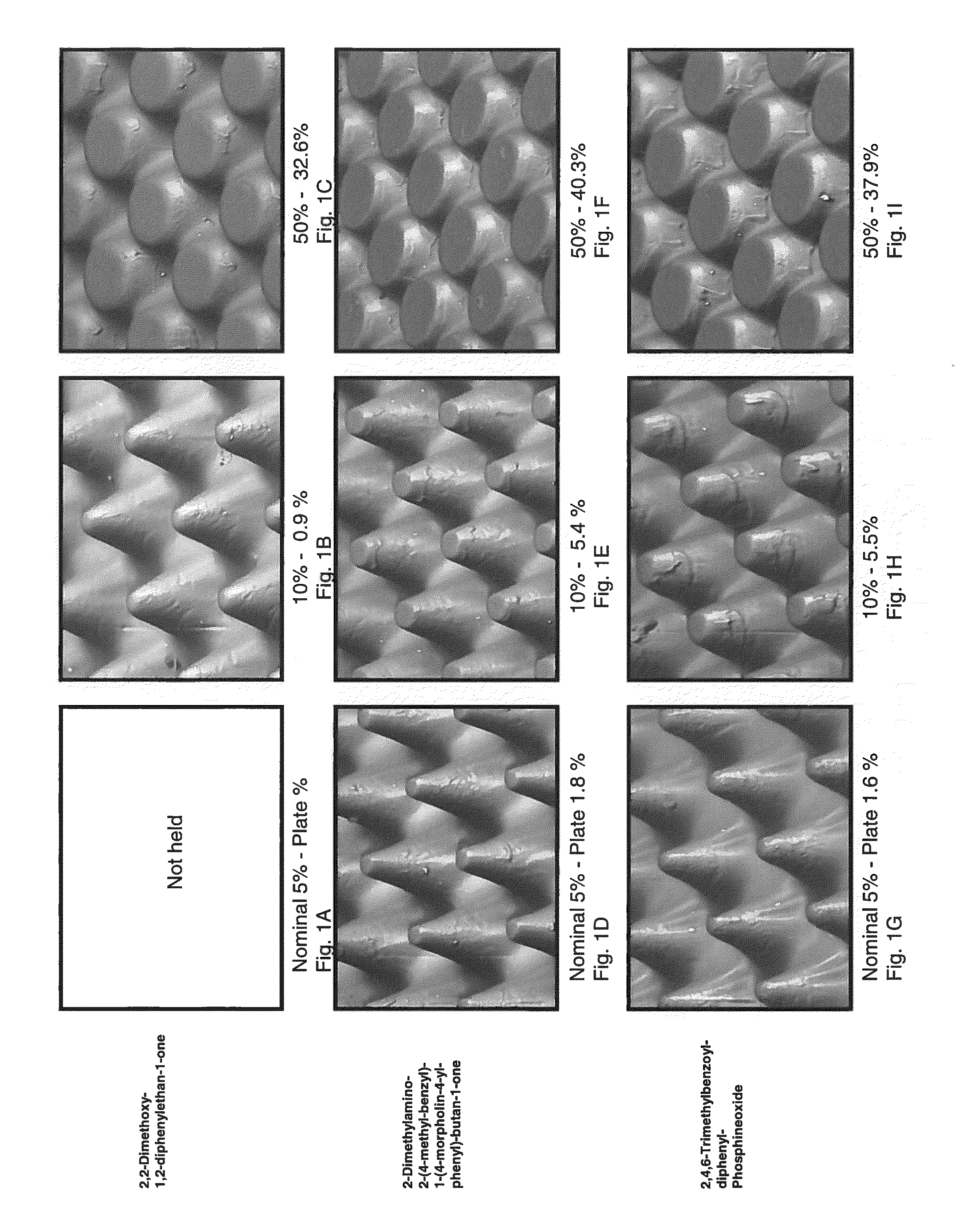

An improved relief printing plate and method for producing said plate is disclosed. Substantially all sizes of relief features resolve a fixed pattern which improves print quality. The pattern is applied to image areas in halftone data used to produce an image mask that is subsequently used to convert a plate precursor into a relief plate. The accuracy, ink density and tonal response of printed images corresponding to relief features that include the pattern are comparable or better than relief features produced without the pattern.

Owner:MIRACLON CORP

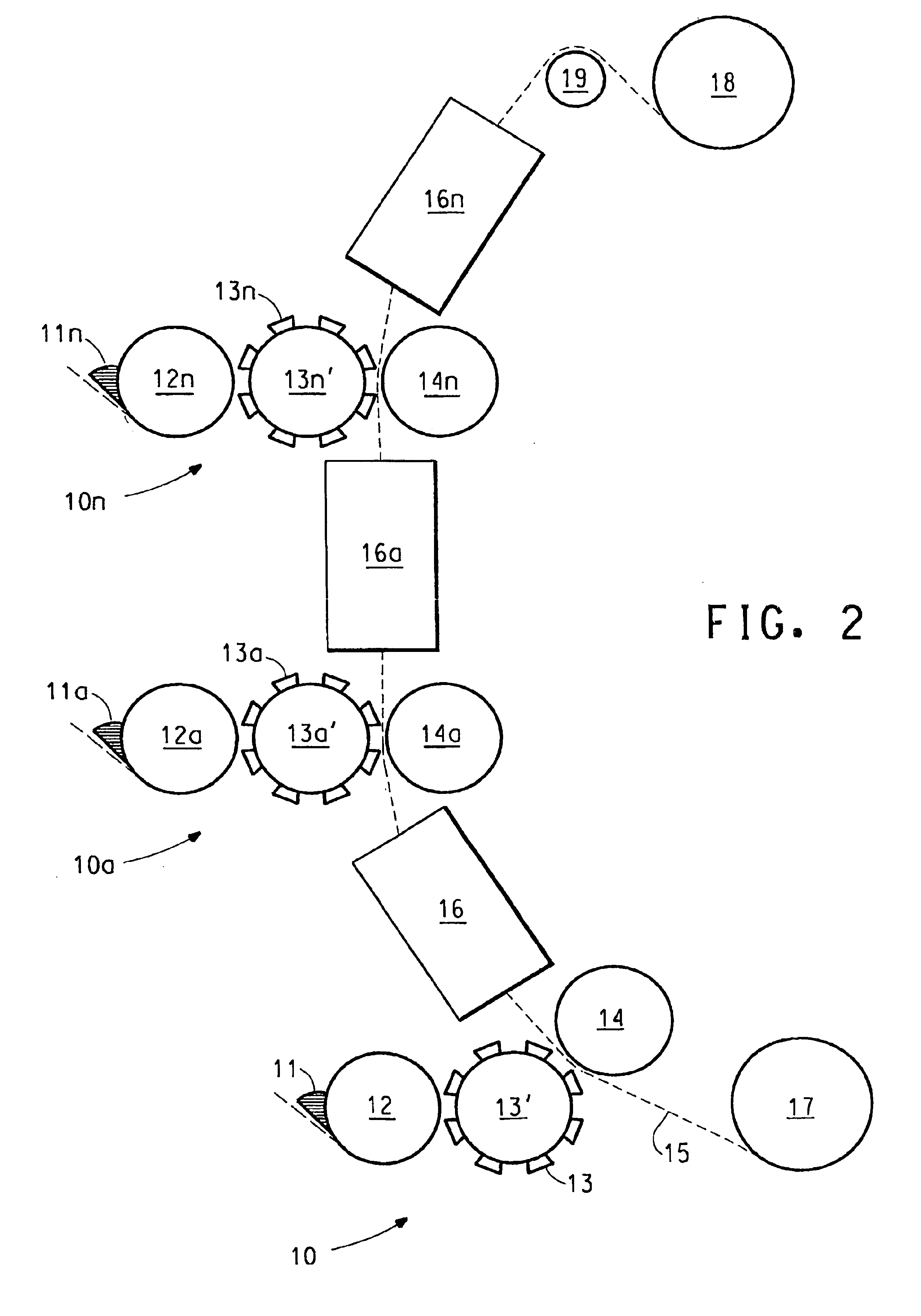

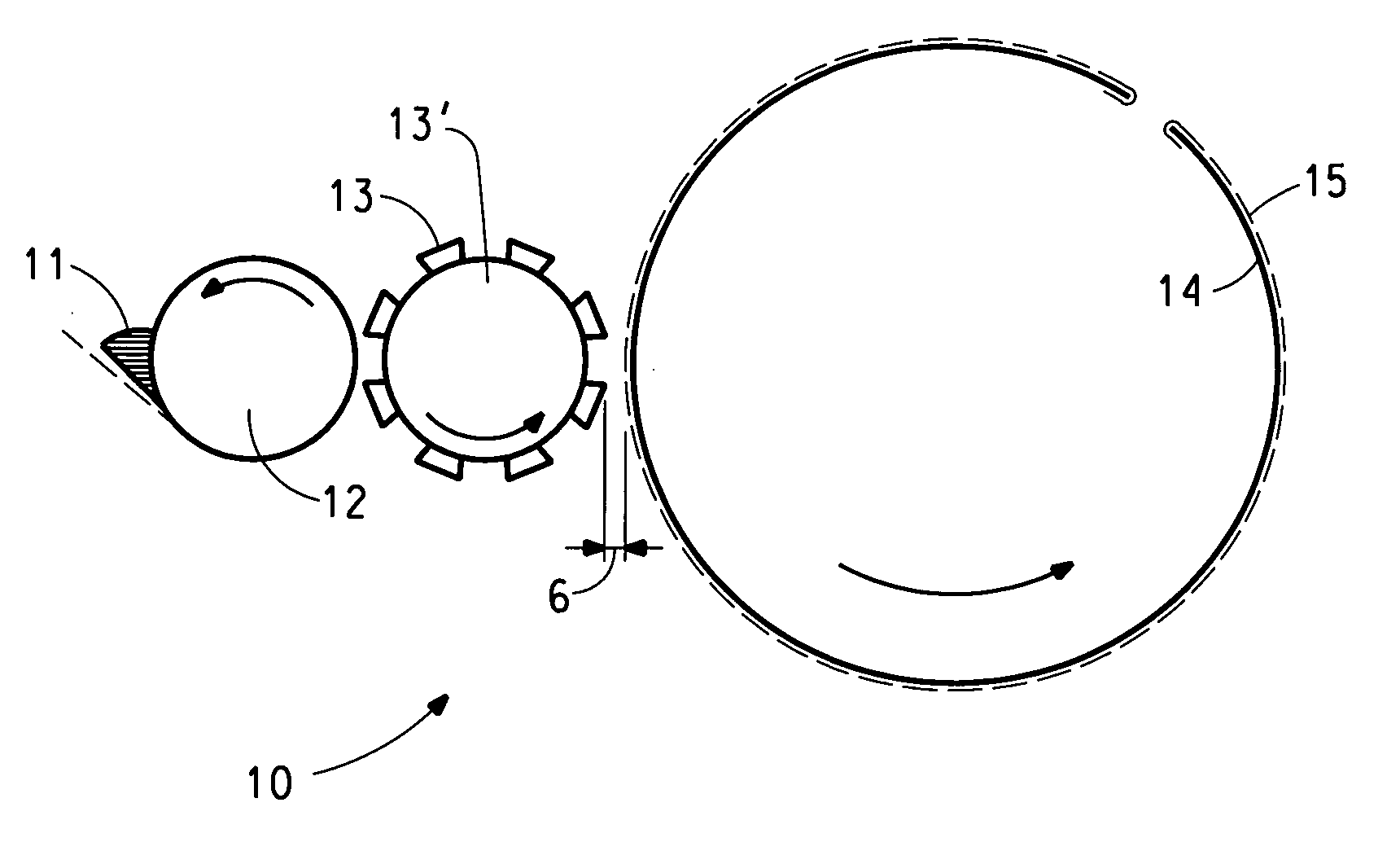

Method for printing a pattern on a substrate

ActiveUS20090186308A1Photosensitive materialsSemiconductor/solid-state device manufacturingPaperboardEngineering

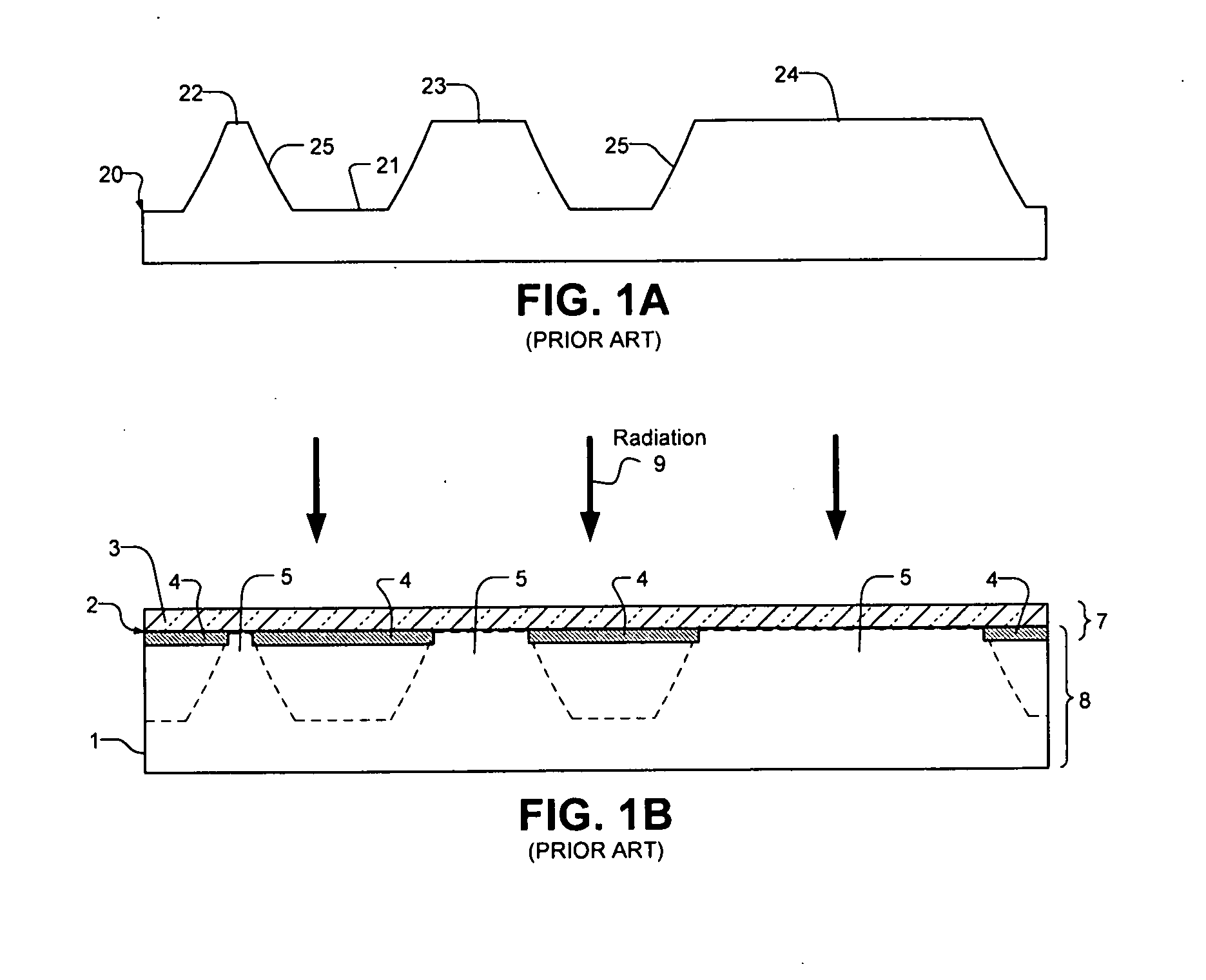

The invention provides a method for printing a pattern of ink on a substrate, such as corrugated paperboard, with a relief printing form made from a photosensitive element. The method includes forming an in-situ mask for the photosensitive element, exposing the element to actinic radiation through the in-situ mask in an environment having an inert gas and a concentration of oxygen between 190,000 and 100 ppm, and treating the exposed element to form the relief printing form having a pattern of printing areas. Printing is accomplished by securing the relief printing form to a print press, applying the ink to the printing areas on the printing form, and contacting the ink from the printing areas to the substrate to transfer the pattern of ink onto the substrate.

Owner:DUPONT ELECTRONICS INC

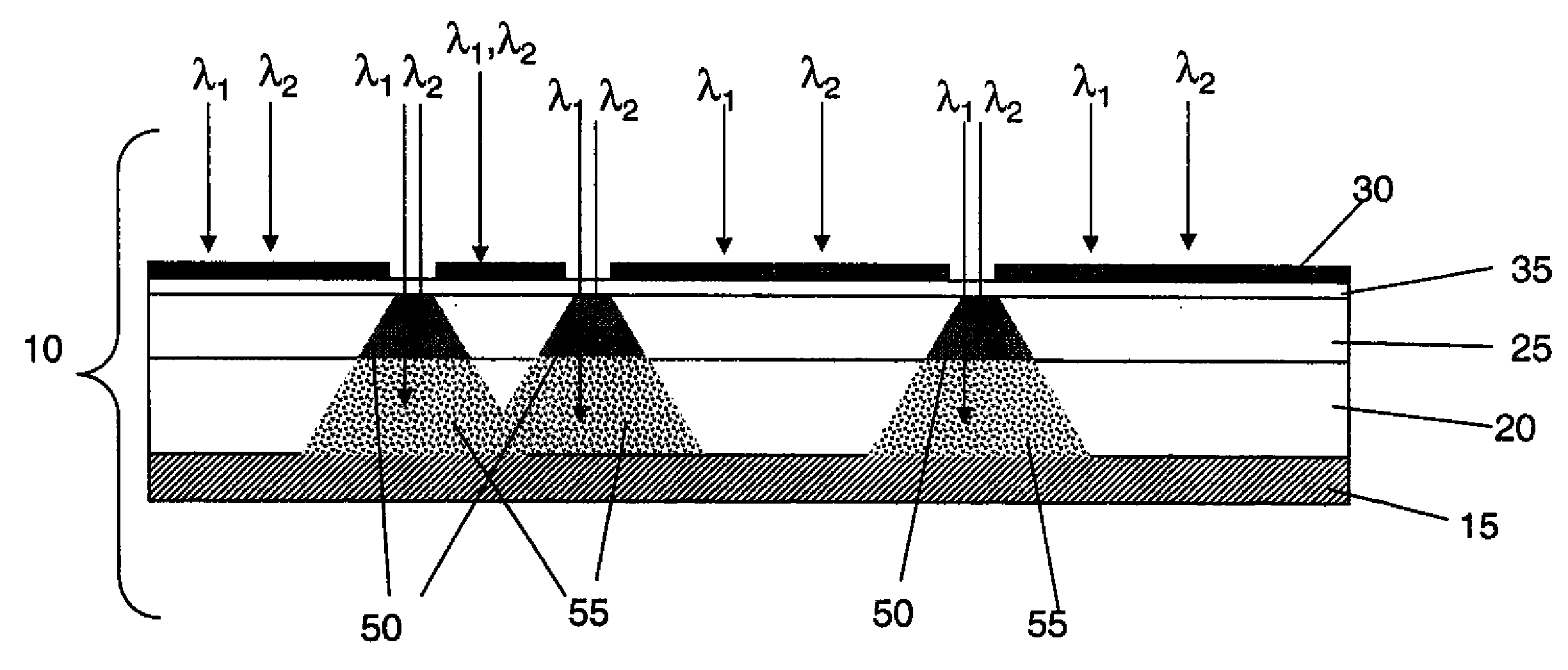

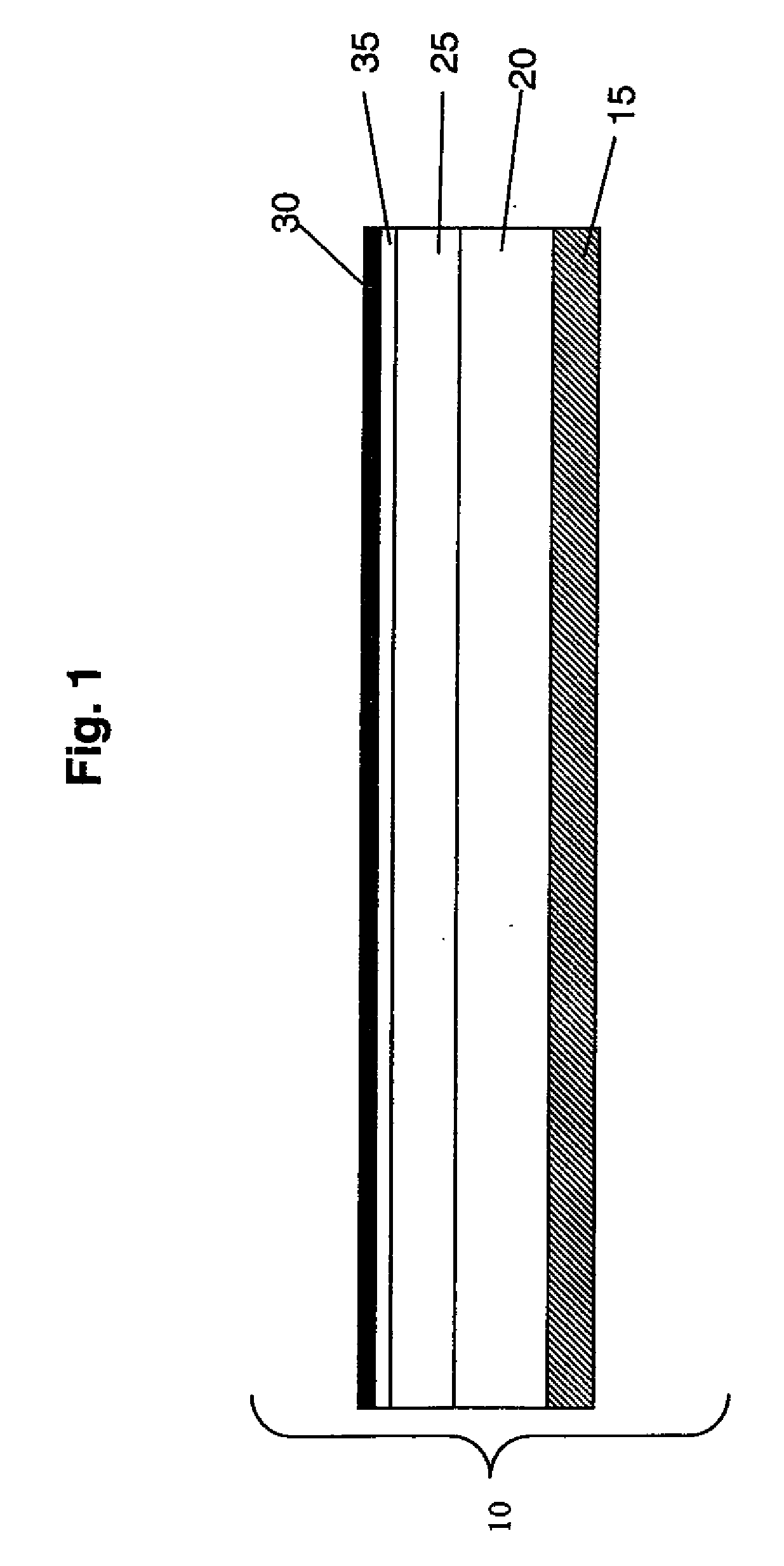

Flexographic element and method of imaging

InactiveUS20100143840A1Without any loss in strengthEnhance the imagePhotosensitive materialsSemiconductor/solid-state device manufacturingRelief printingPhysics

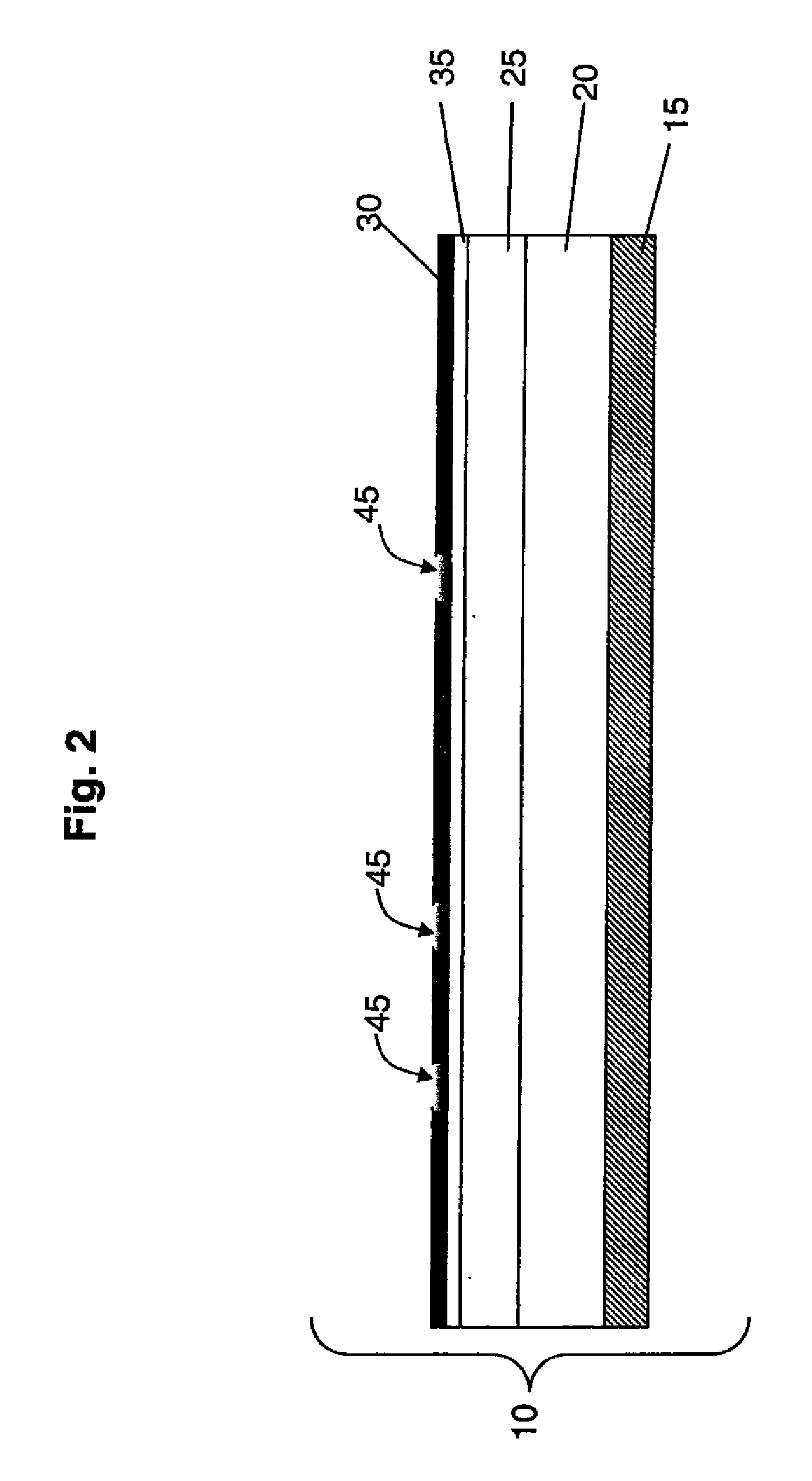

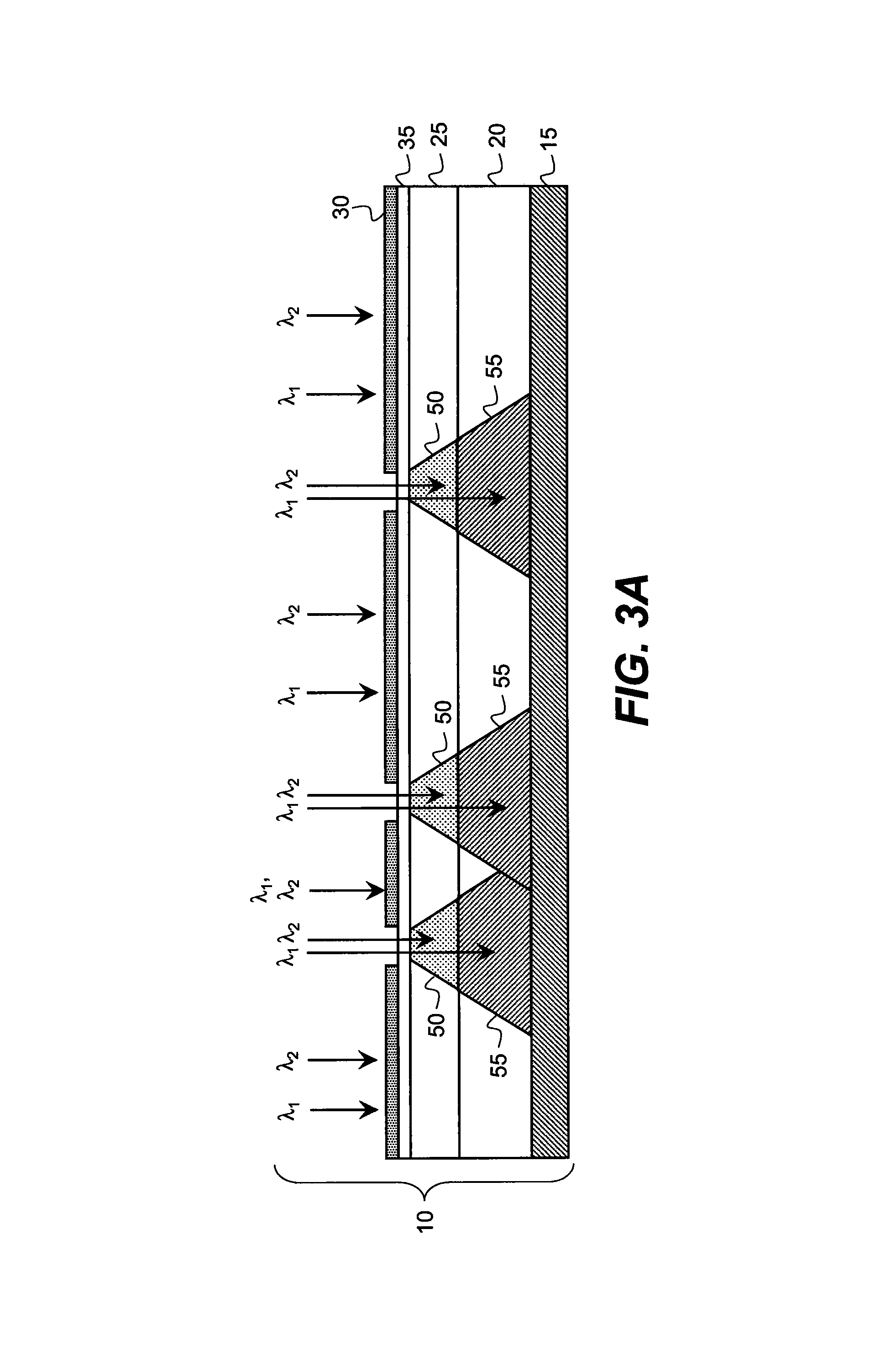

A relief (or flexographic) printing precursor has first and second radiation-sensitive layers, or a plurality of radiation-sensitive layers. The first radiation-sensitive layer is sensitive to a first imaging radiation having a first λmax. The second radiation-sensitive layer is disposed on the first radiation-sensitive layer and is sensitive to a second imaging radiation having a second λmax that differs from the first λmax by at least 25 nm. An infrared radiation ablatable layer can be present and is opaque or insensitive to the first and second imaging radiations and contains an infrared radiation absorbing compound. These relief printing precursors can be used to prepare flexographic printing plates, cylinders, or sleeves where the ablatable layer is used to form an integral mask on the element. Use of the invention provides a relief image without any loss in the strength of the small dots and can be carried out using multiple irradiation steps using the same apparatus.

Owner:EASTMAN KODAK CO

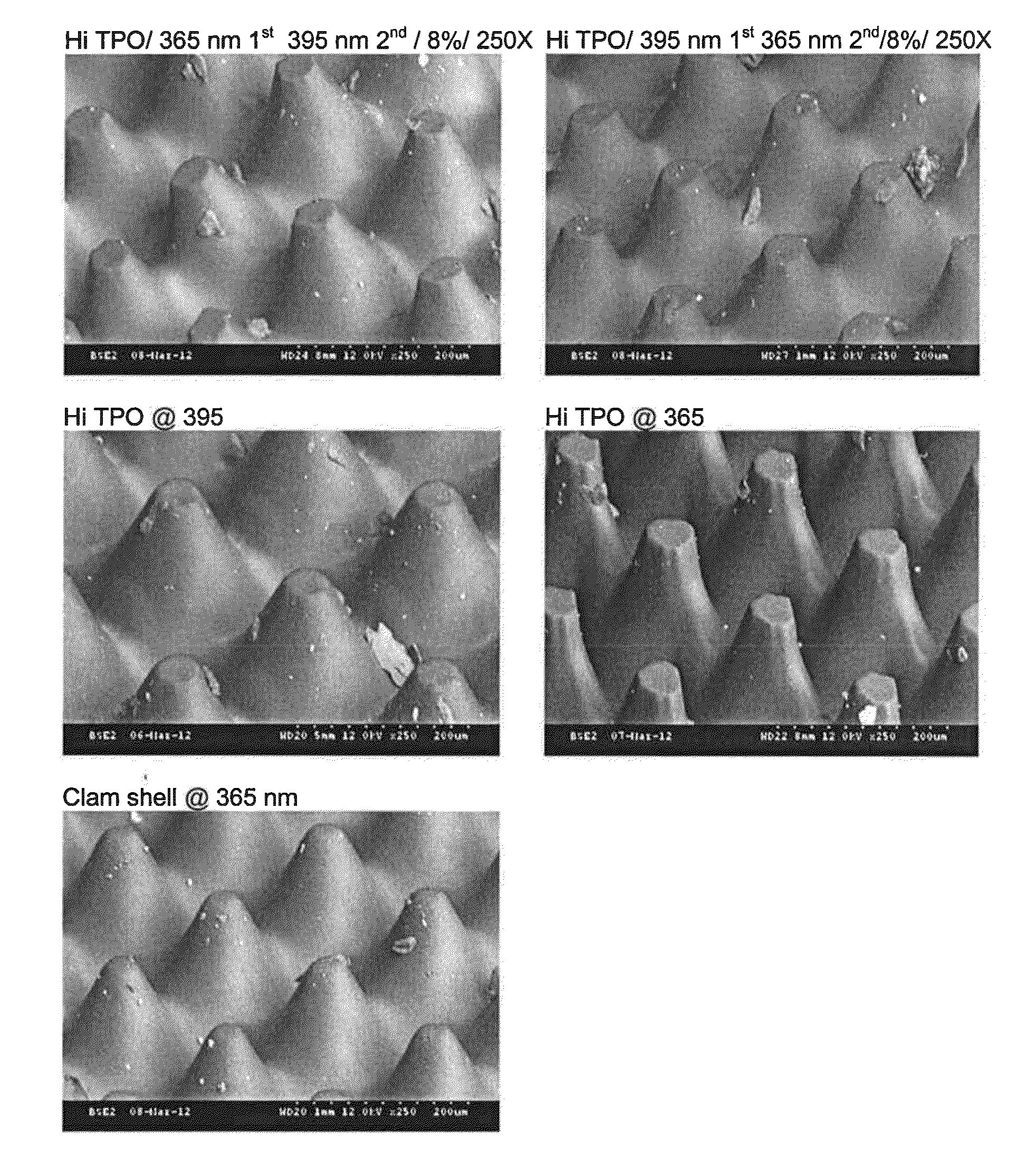

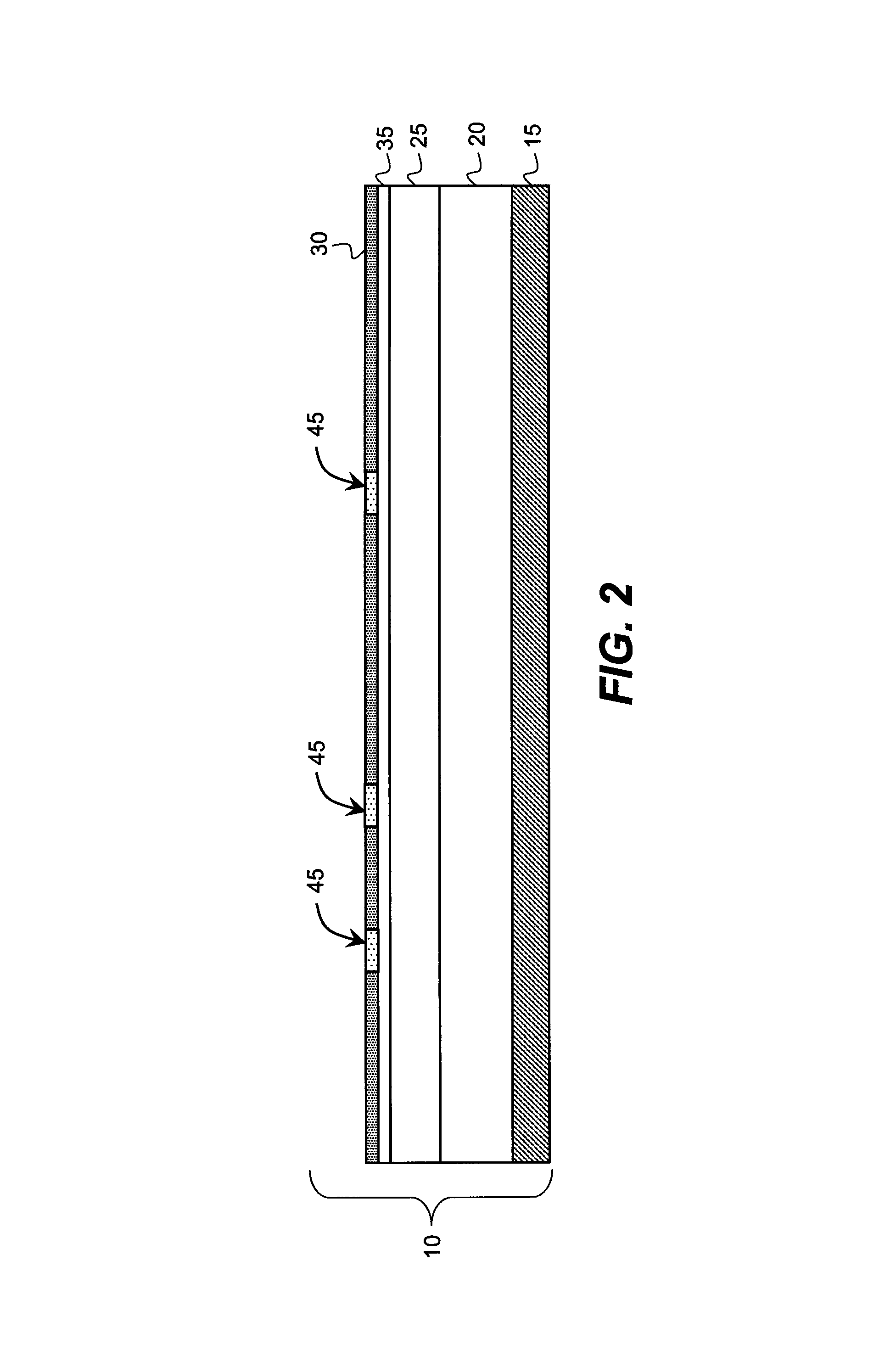

Method of Improving Print Performance in Flexographic Printing Plates

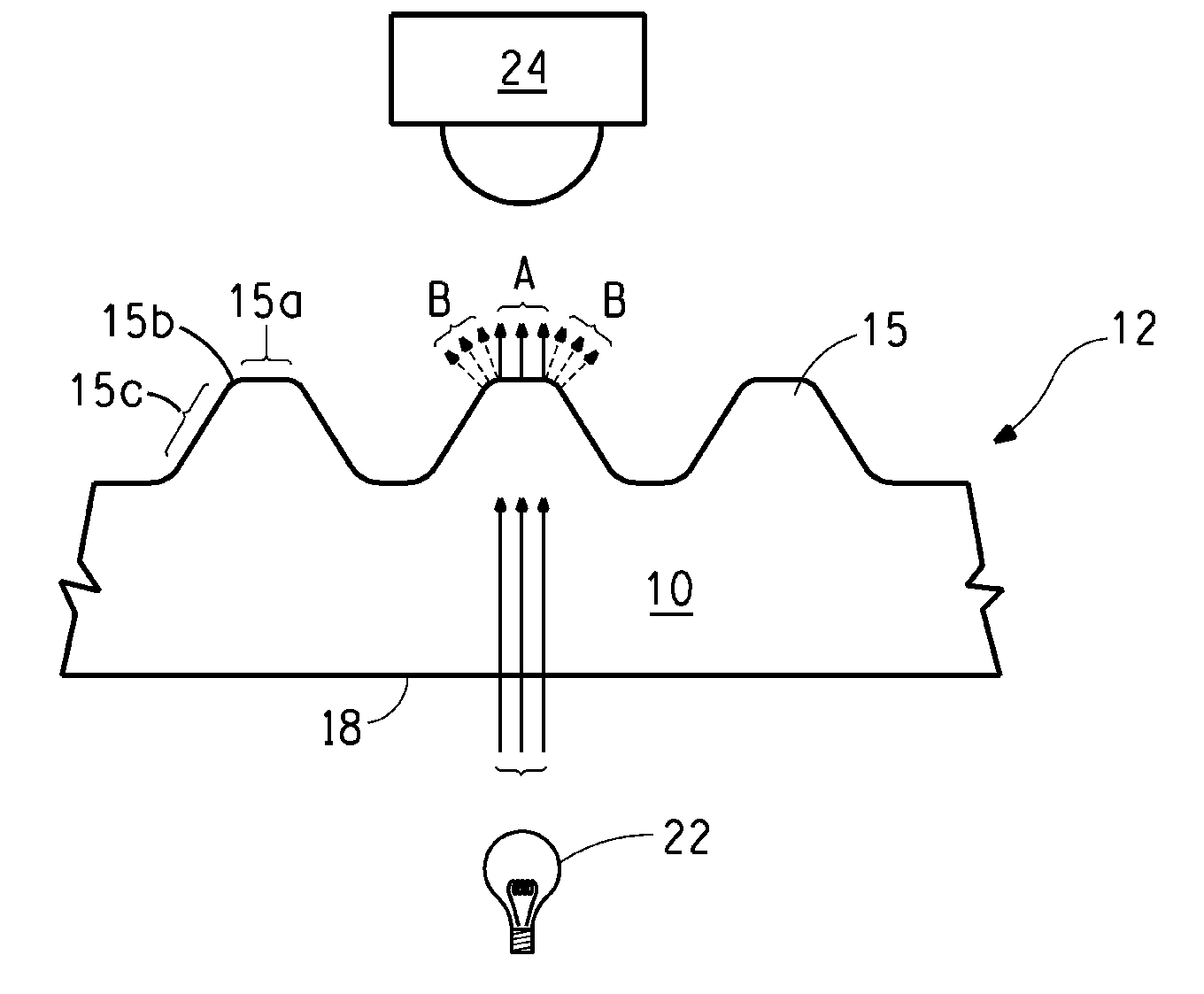

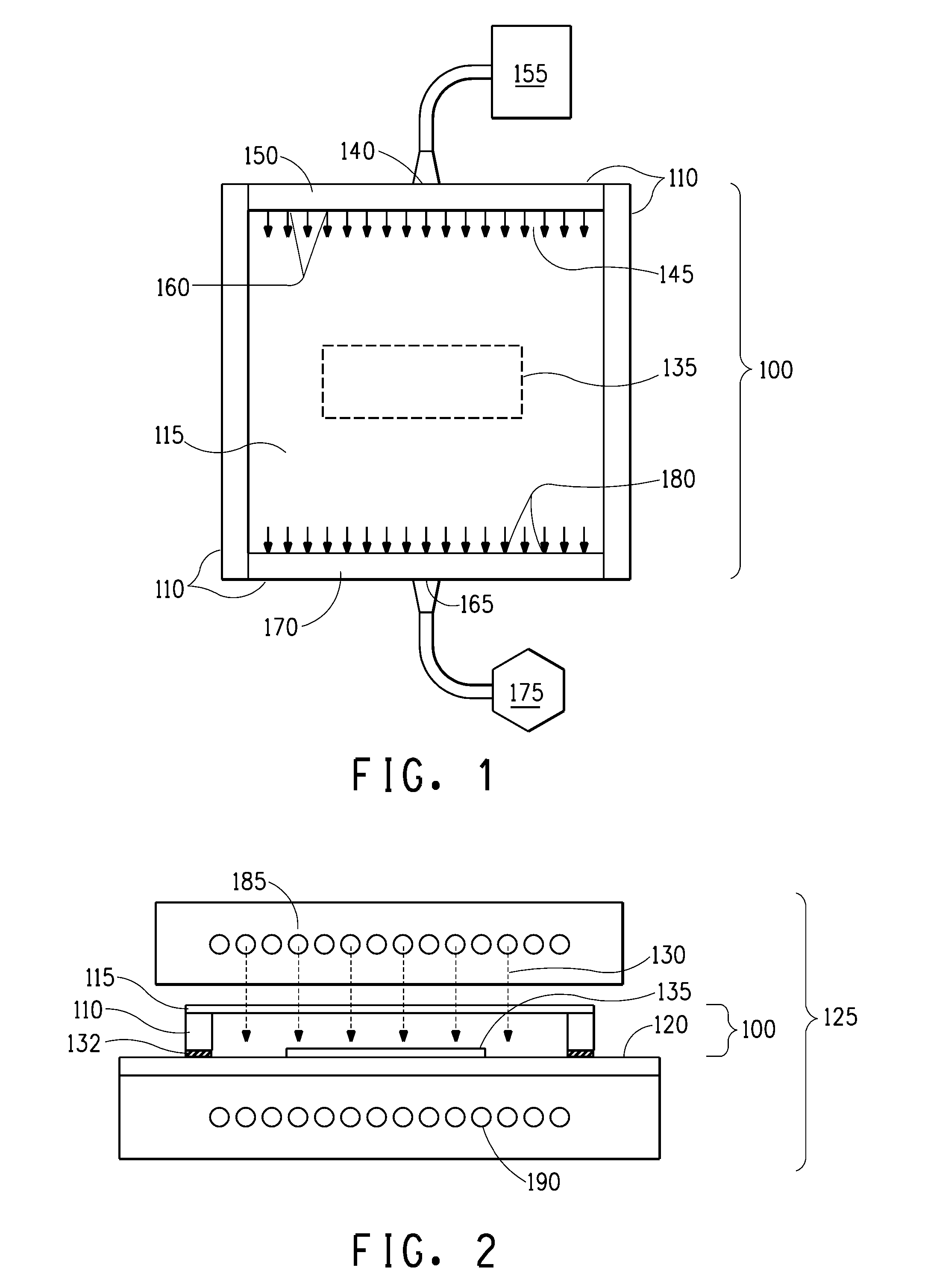

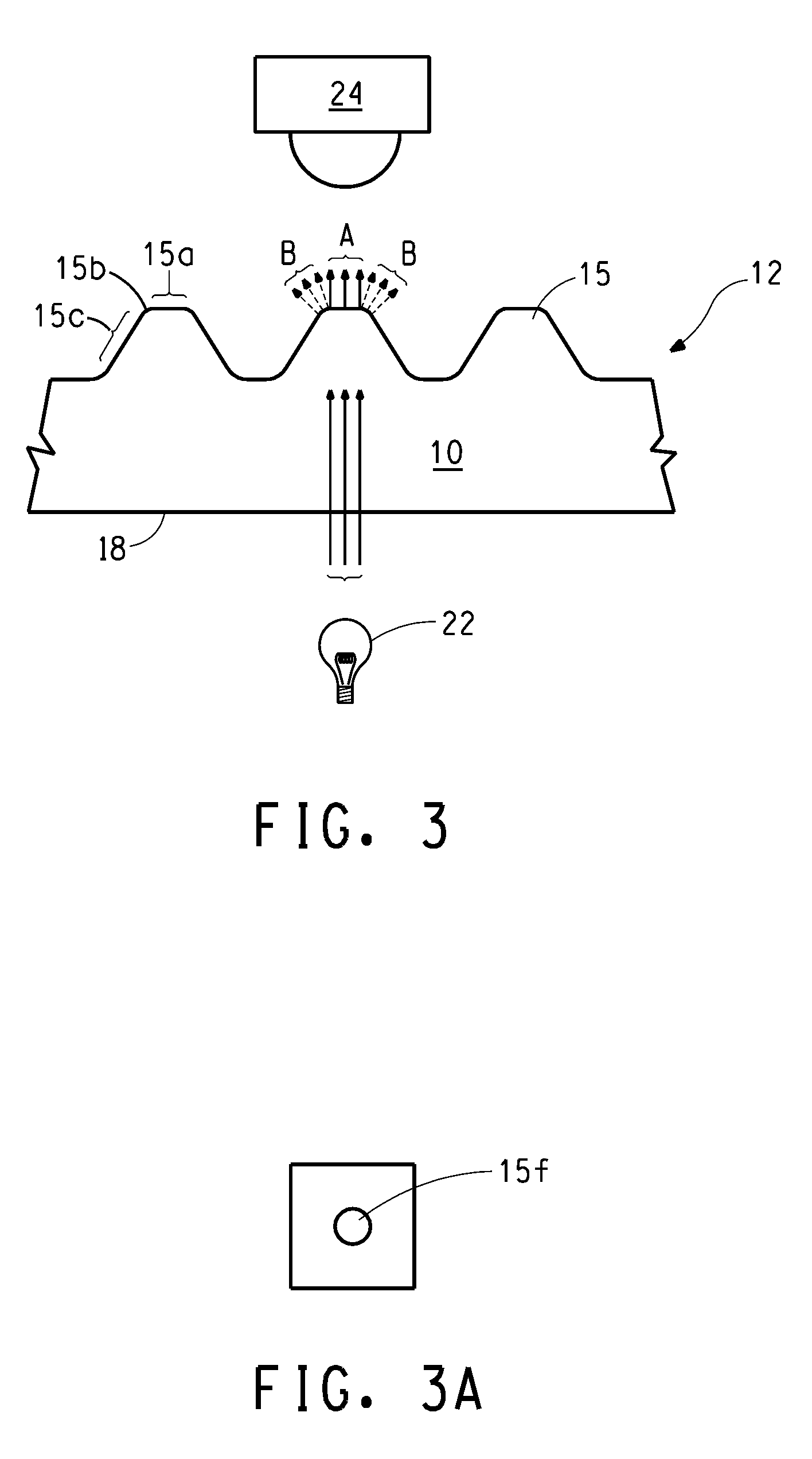

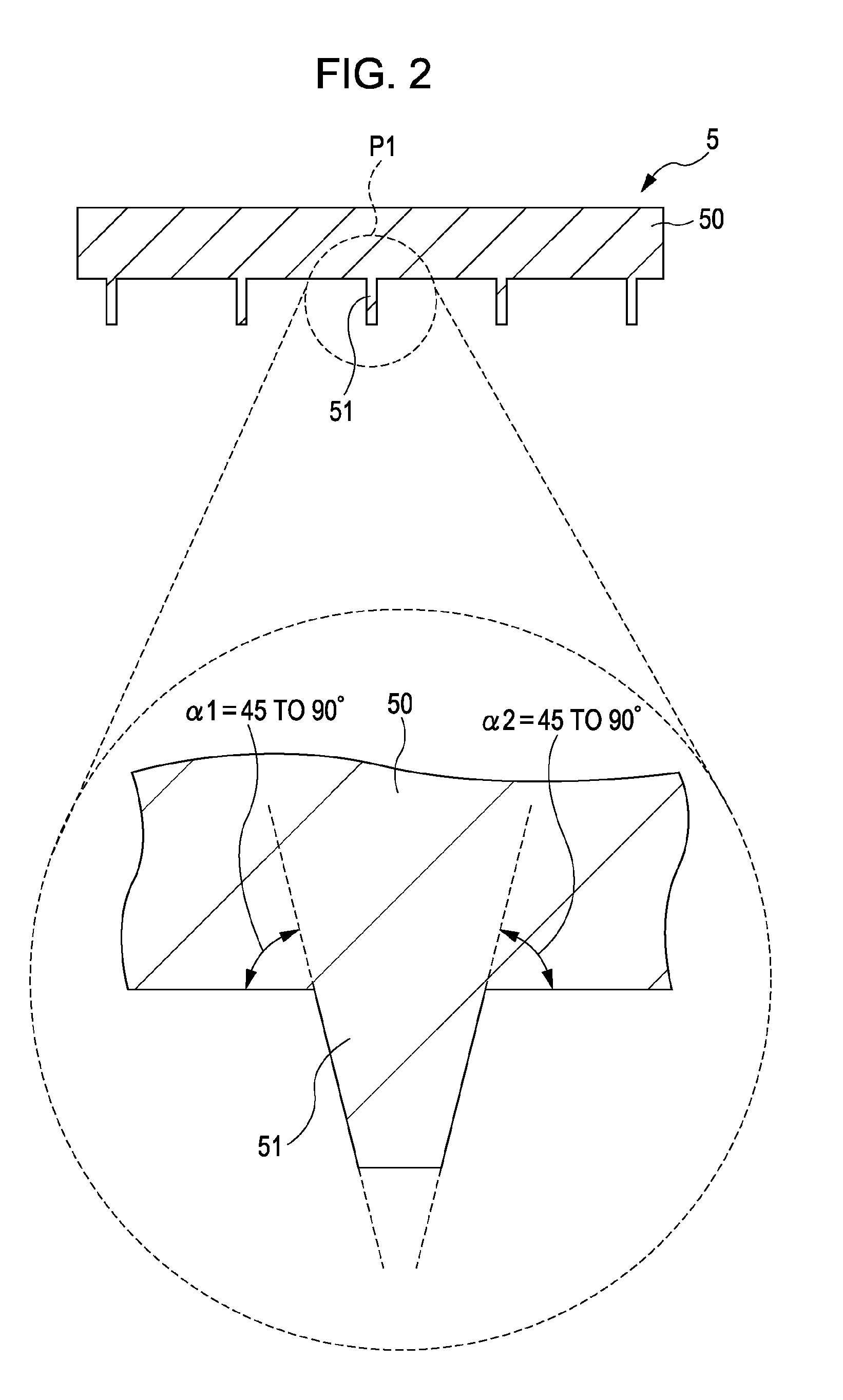

ActiveUS20140057207A1Easy to printSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringLED lamp

A method of tailoring the shape of a plurality of relief printing dots created in a photosensitive printing blank during a platemaking process is provided. The photocurable layer is exposed to actinic radiation using an array of UV LED light assemblies and the use of the array of UV LED light assemblies produces relief printing dots having at least one geometric characteristic selected from the group consisting of a desired planarity of a top surface of the relief printing dots, a desired shoulder angle of the relief printing dots and a desired edge sharpness of the relief printing dots.

Owner:MACDERMID PRINTING SOLUTIONS

Flexographic element and method of imaging

InactiveUS8153347B2Loss of strengthAvoid the needPhotosensitive materialsSemiconductor/solid-state device manufacturingUltimate tensile strengthRelief printing

Owner:EASTMAN KODAK CO

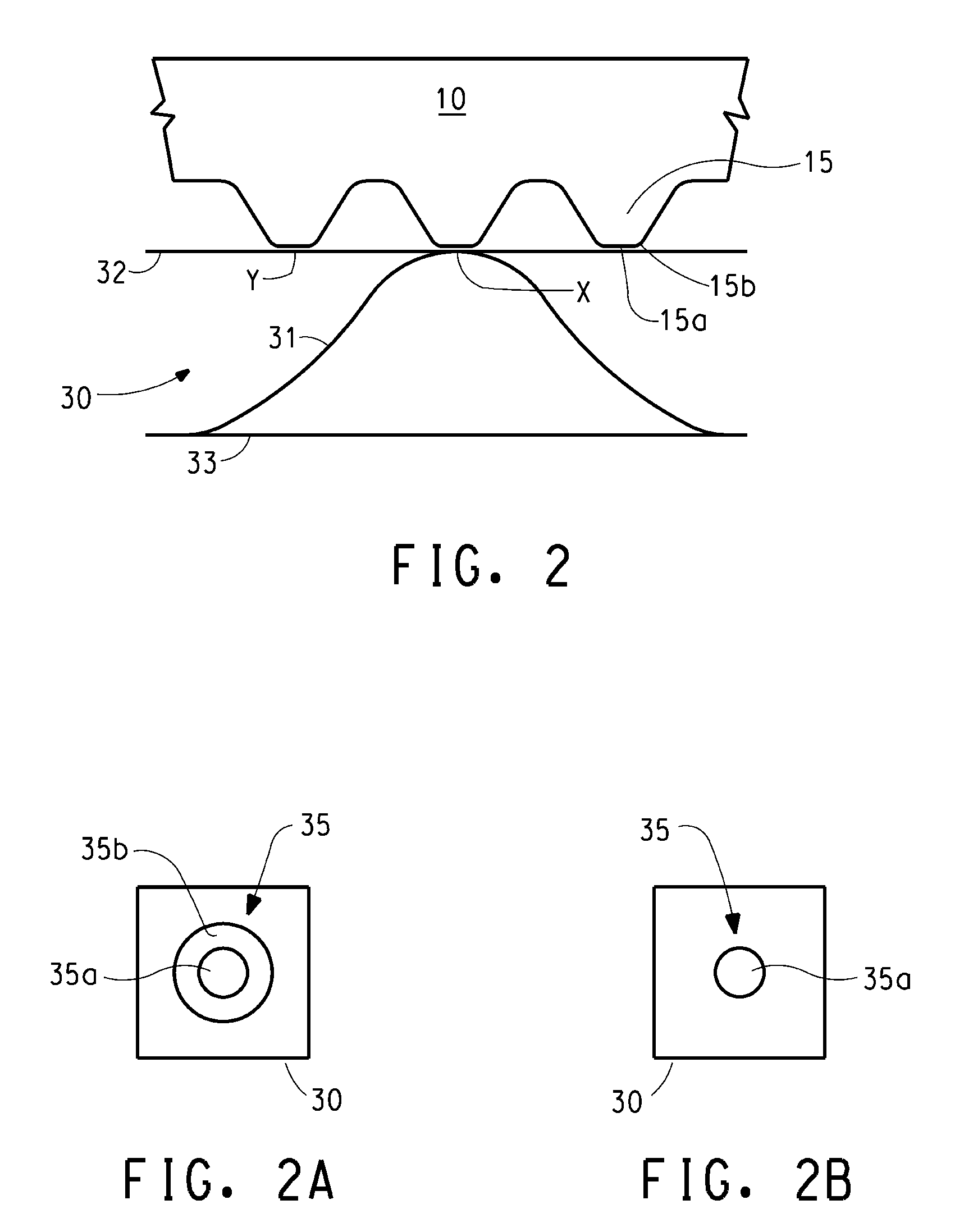

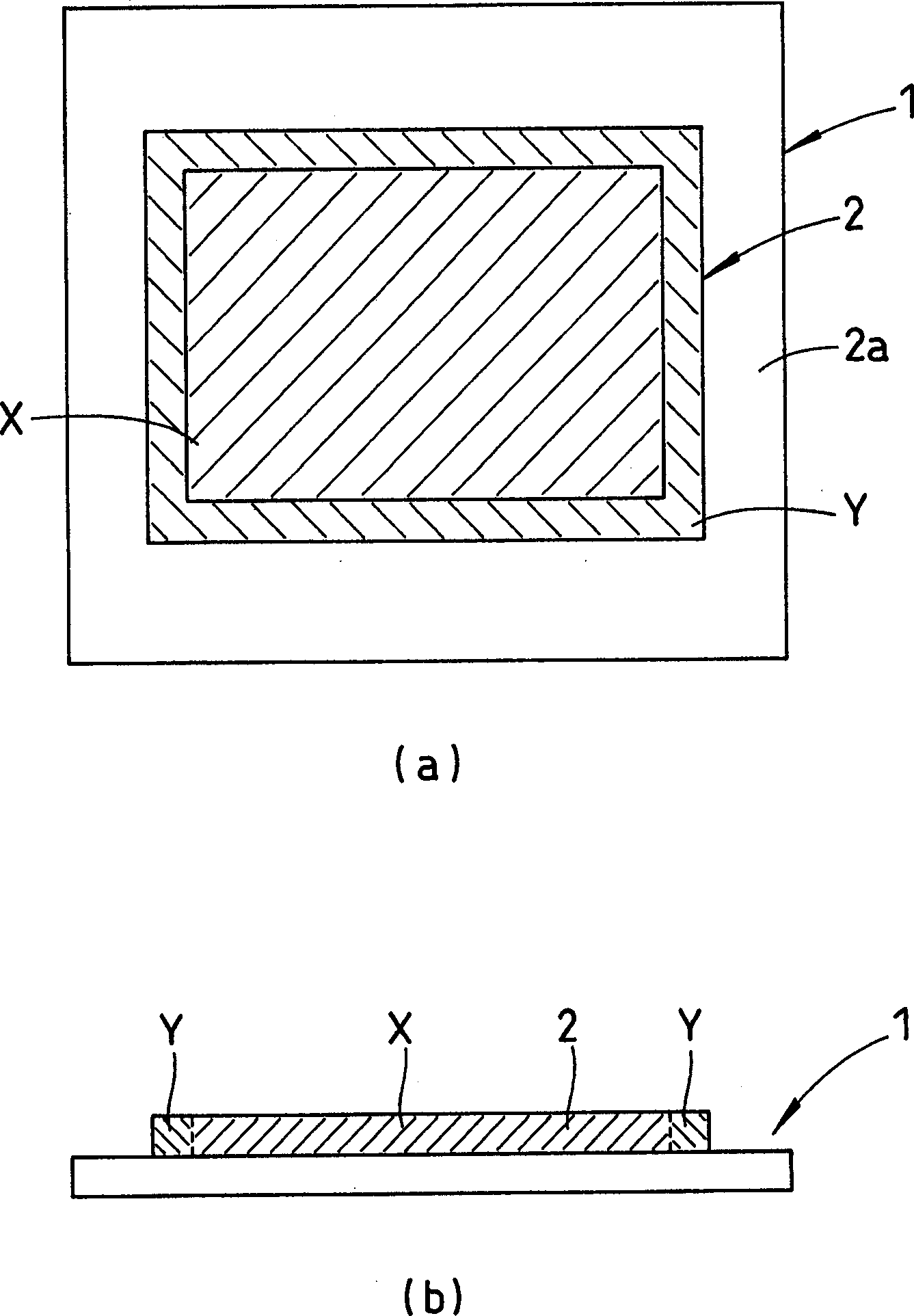

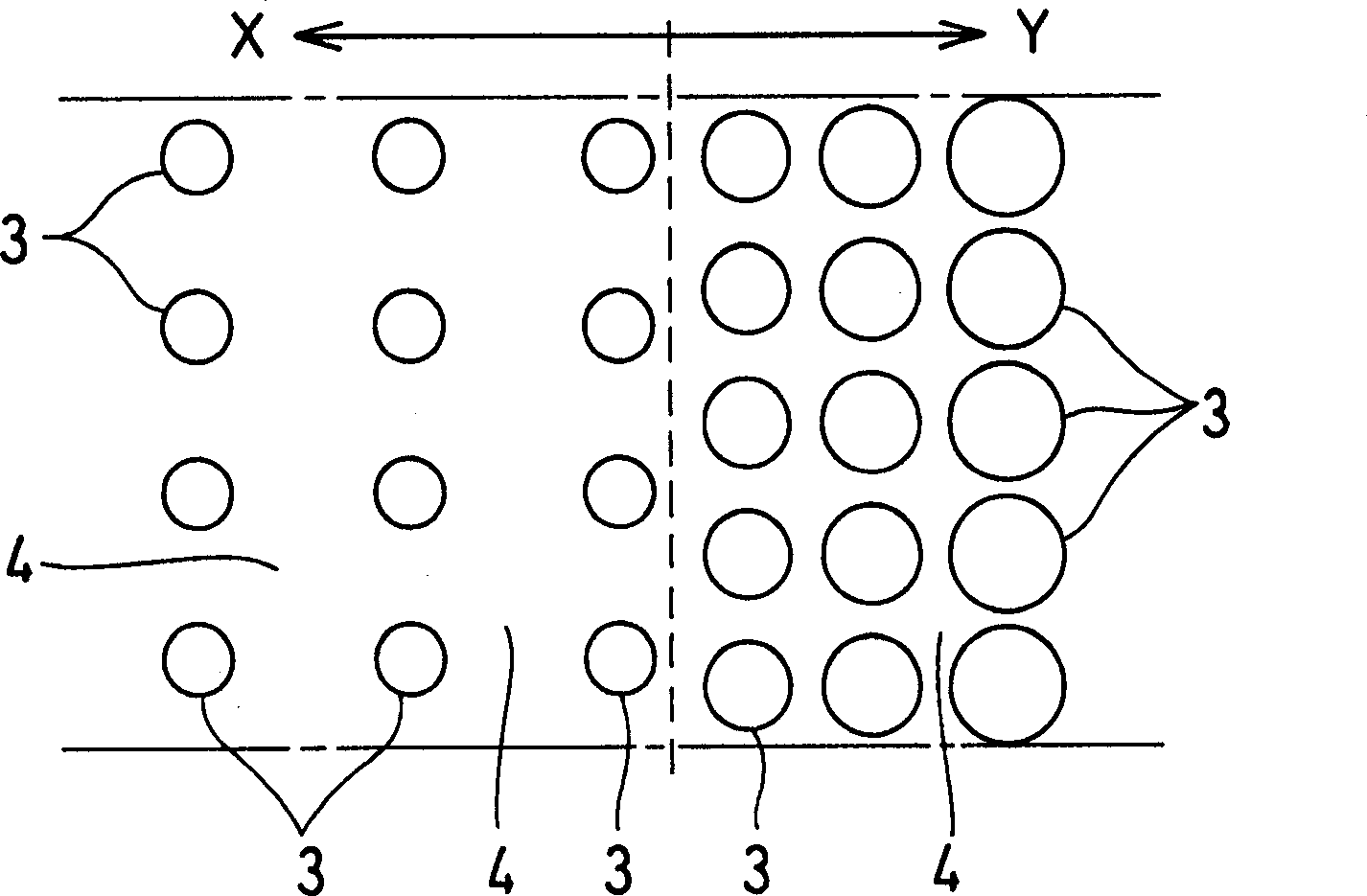

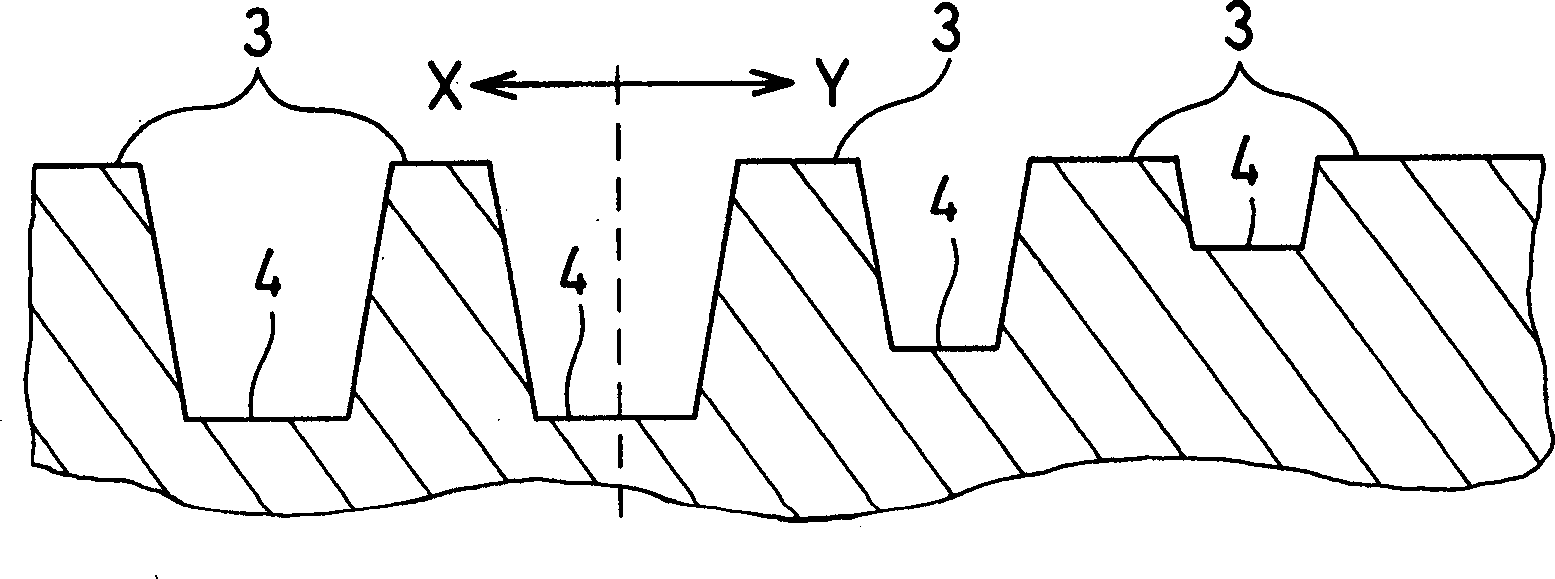

Resin relief plate for forming film

InactiveCN1378917ASuppression of marginal phenomenaUniform film thicknessPhotomechanical apparatusPlate printingEngineeringVolumetric Mass Density

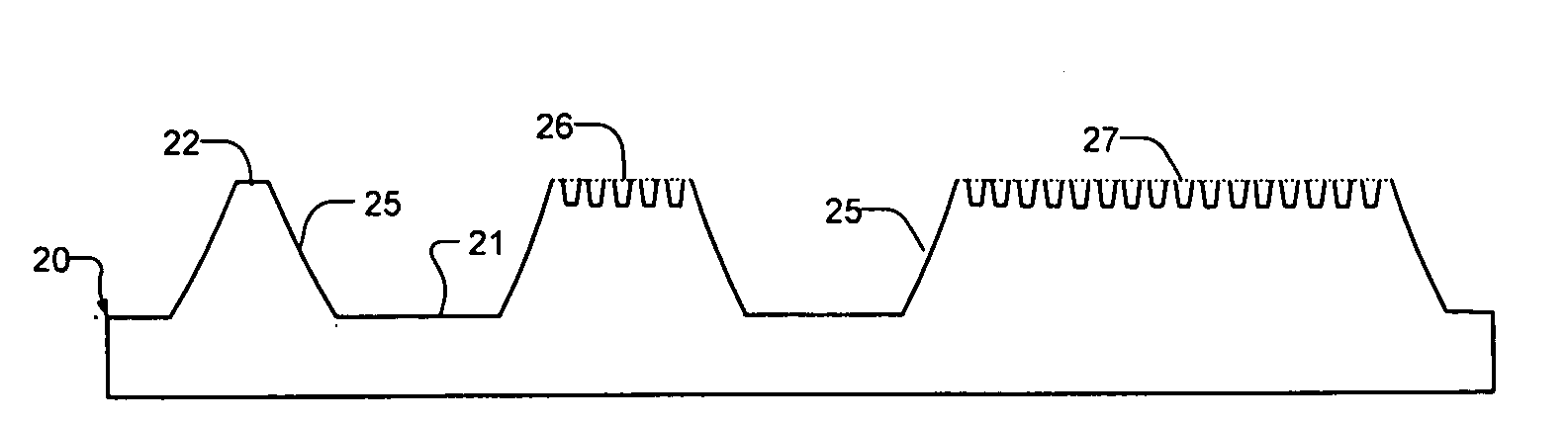

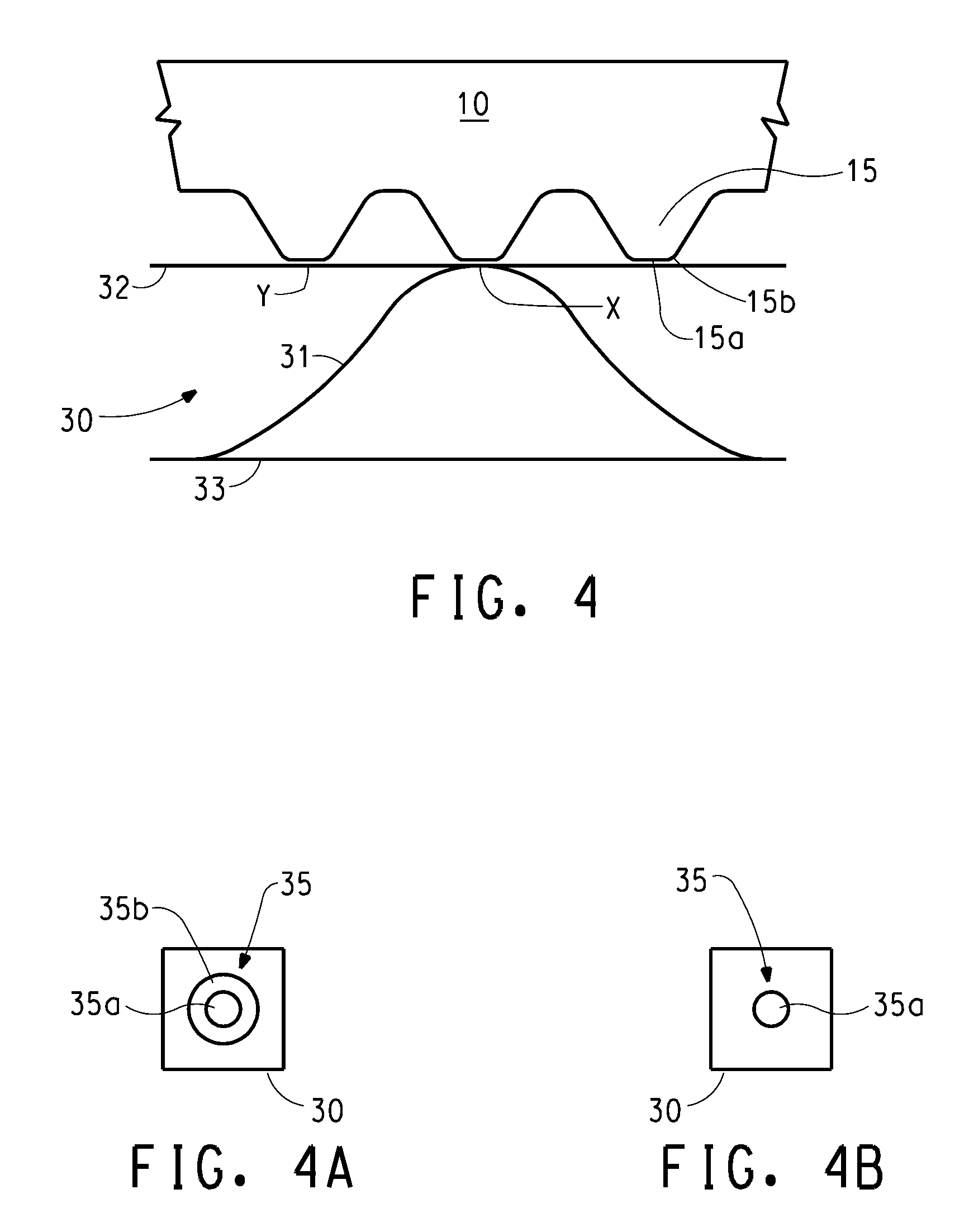

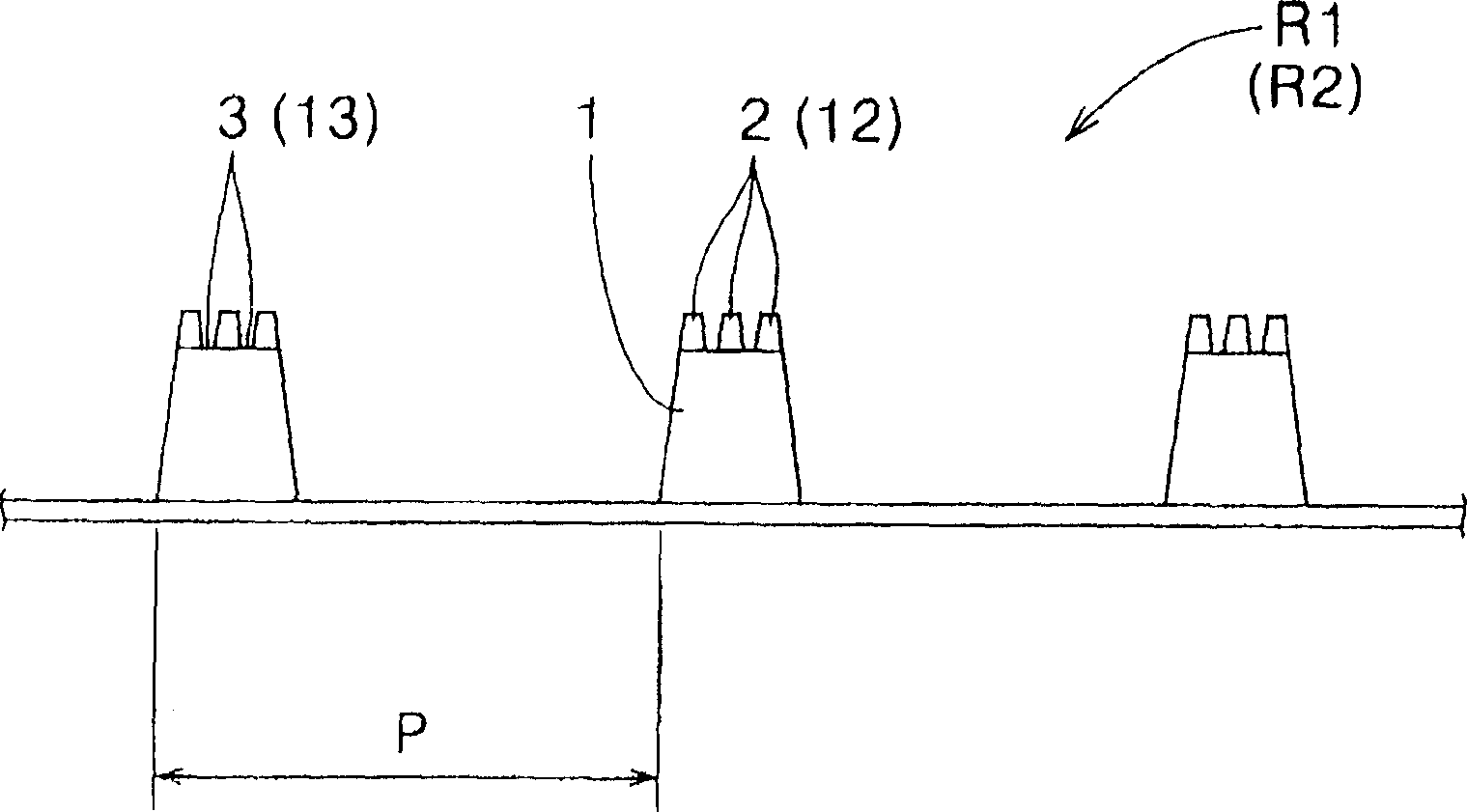

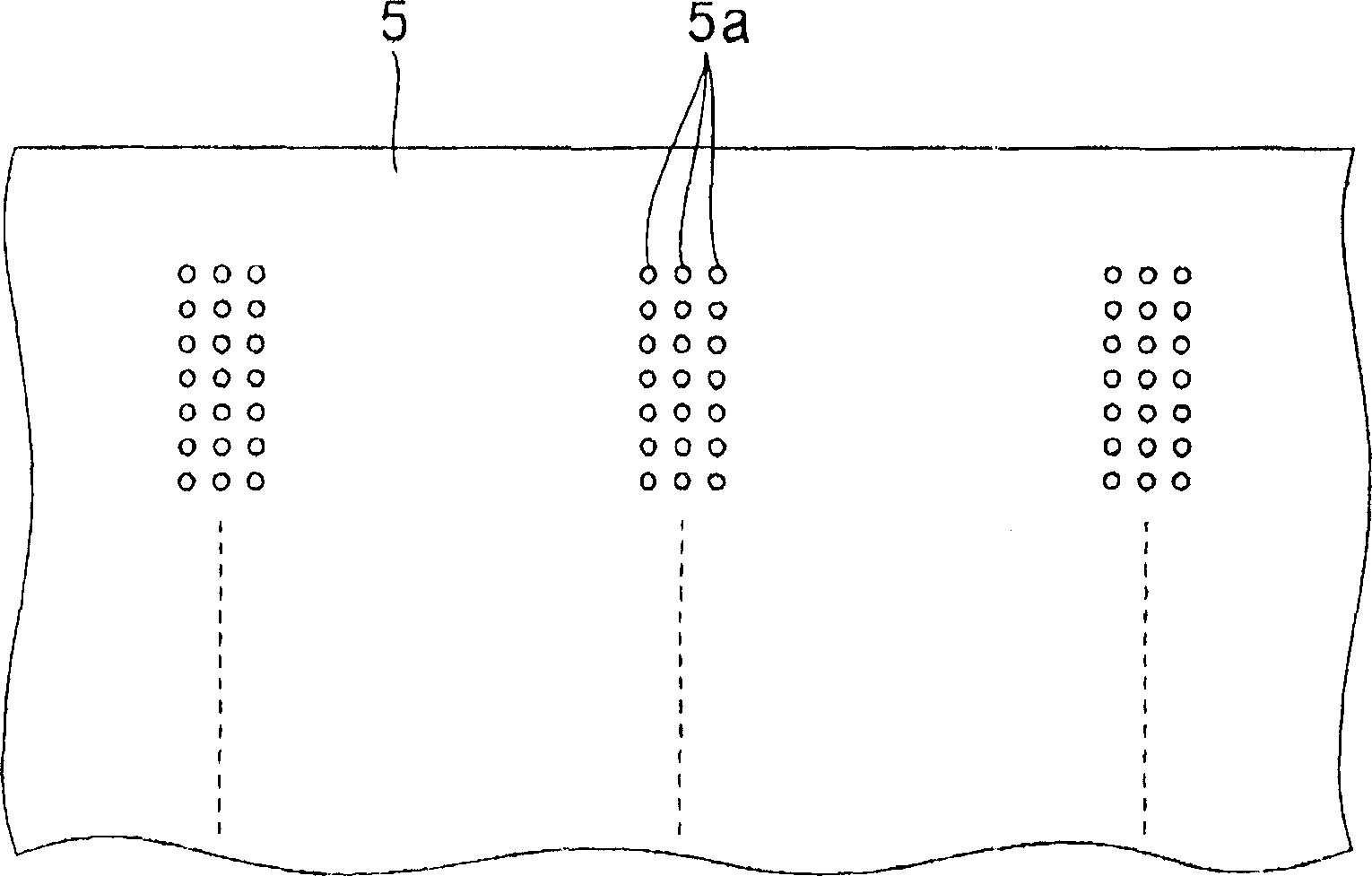

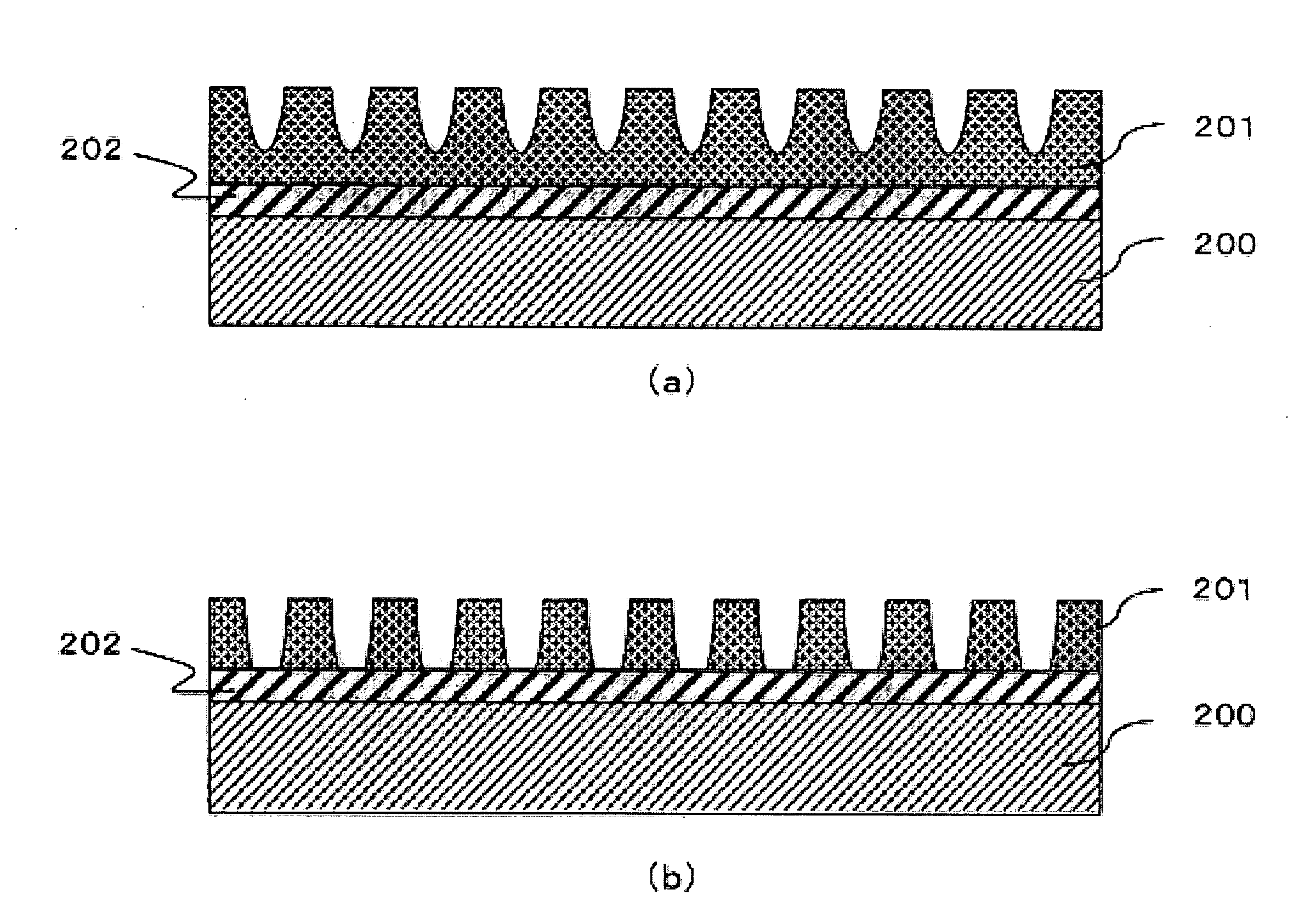

PURPOSE: To provide a resin relief printing plate for forming a thin film by which a marginal phenomenon is prevented from being generated and an oriented film with a uniform film thickness can be formed. CONSTITUTION: In the resin relief printing plate for forming the thin film used for transferring a coating liquid applied on projected parts 2 for printing onto a body to be printed and printing, channel parts 4 for holding the coating liquid are formed among adjoining micro-projections 3 by distributing and forming a number of the micro-projections 3 on the whole face of the projected parts 2 for printing. In addition, in the central regions X of the projected parts 2 for printing, the adjoining micro-projections 3 are uniformly formed and in the peripheral regions Y of the projected parts 2 for printing, distribution densities of the micro-projections 3 are higher than those of the central regions X. In addition, the occupied area ratio of the micro-projections 3 becomes gradually higher as the regions approach toward the end parts in the peripheral regions Y.

Owner:KOMURA TECH

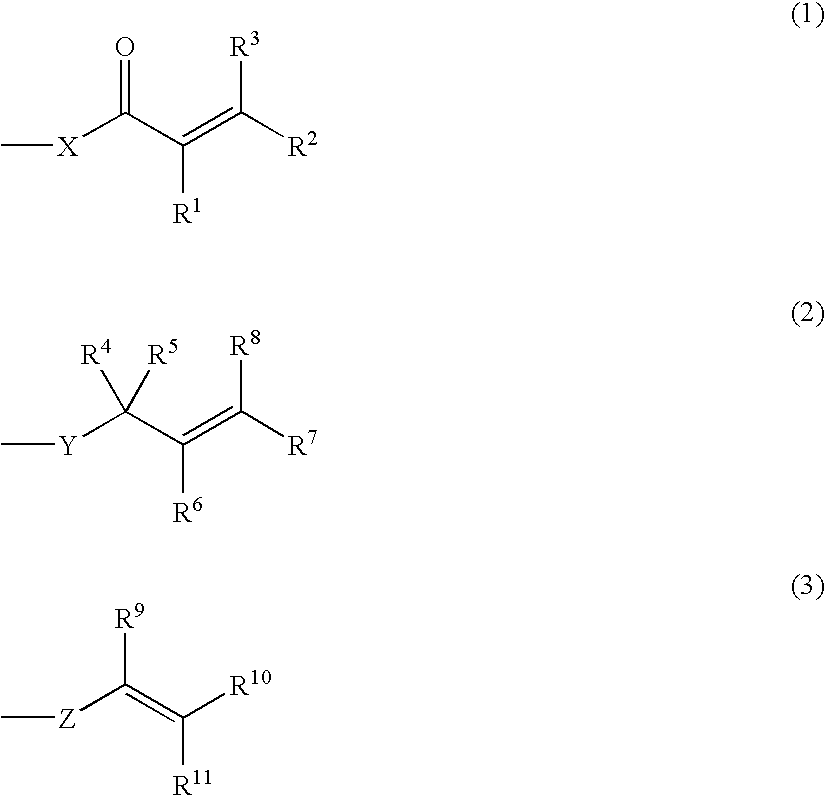

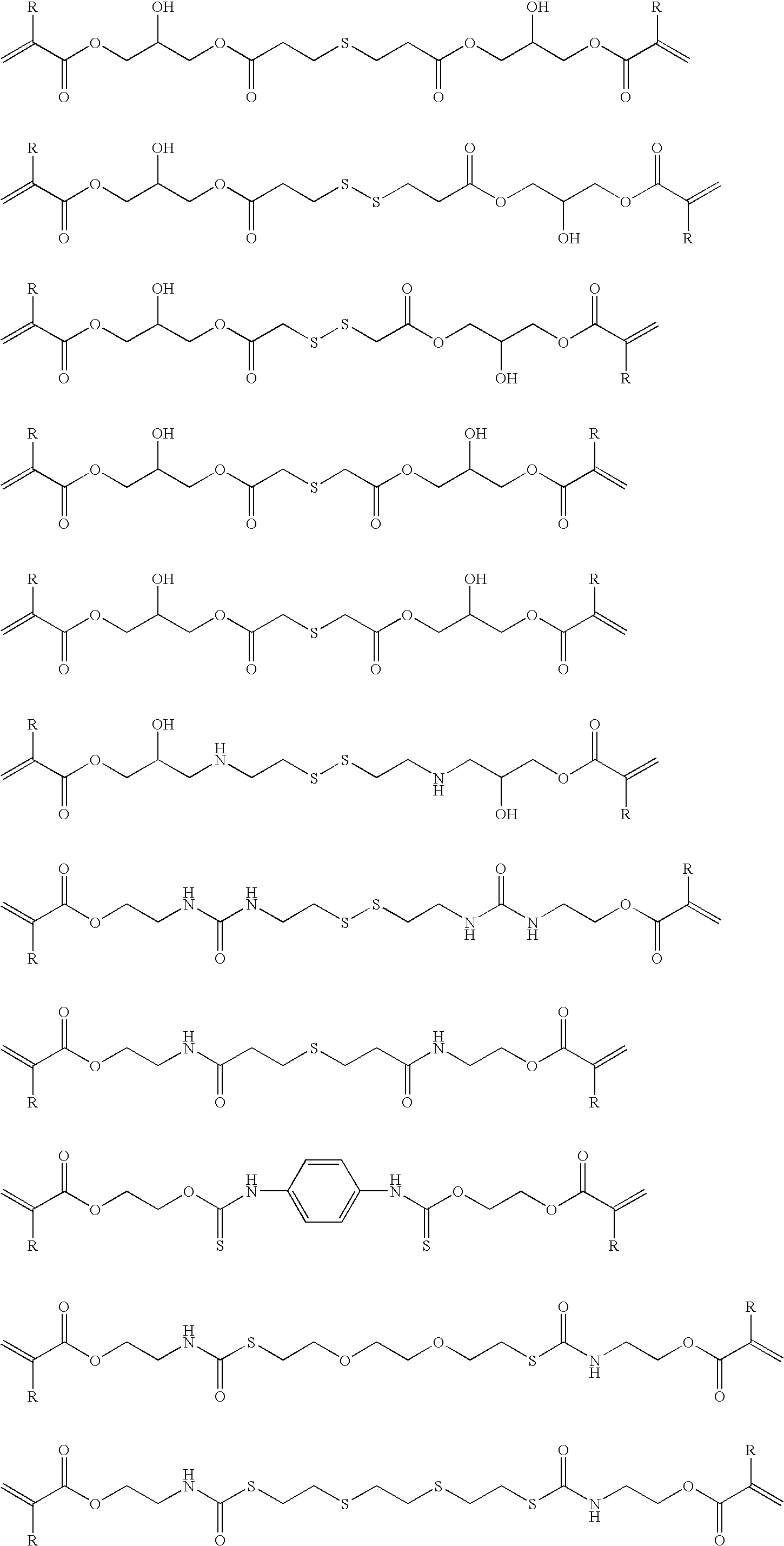

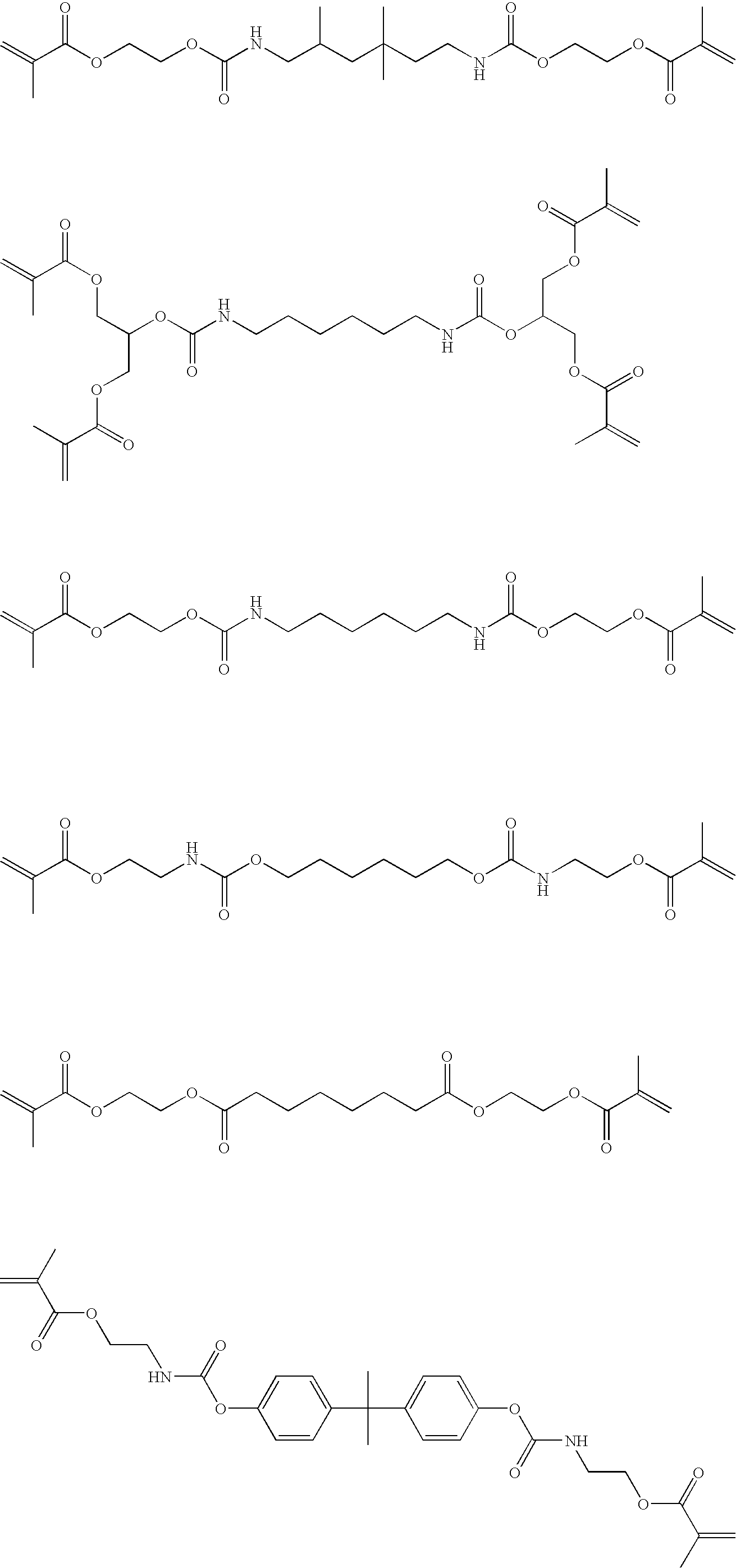

Resin composition for laser engraving, image forming material, relief printing plate precursor for laser engraving, relief printing plate, and method of manufacturing relief printing plate

InactiveUS20090246469A1High engraving sensitivityHigh sensitivityPhotosensitive materialsLayered productsSulfurLaser engraving

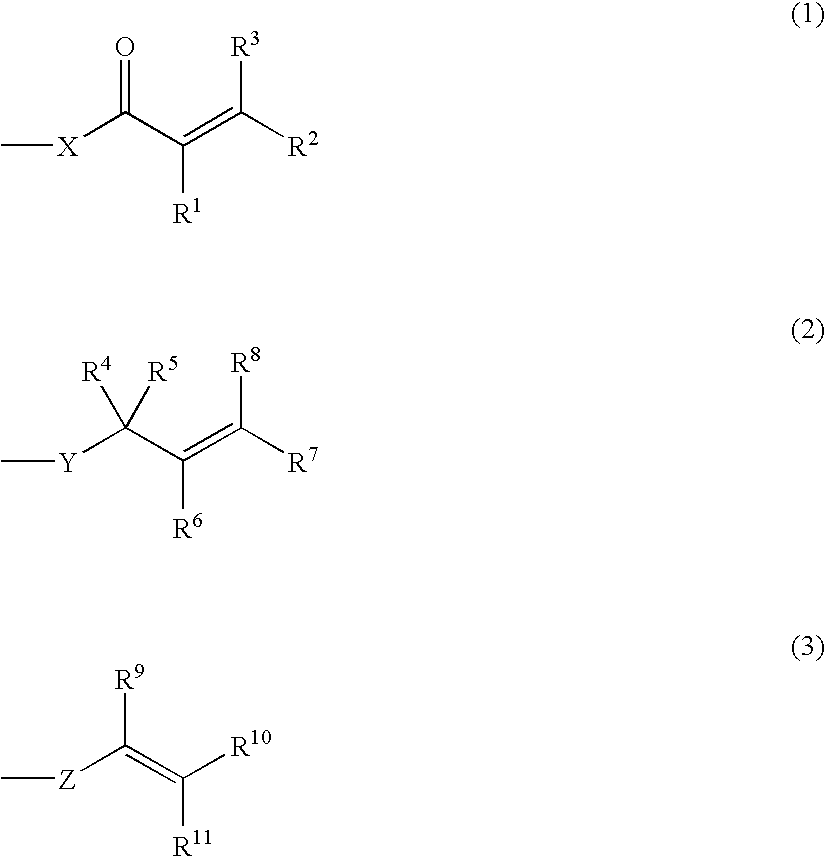

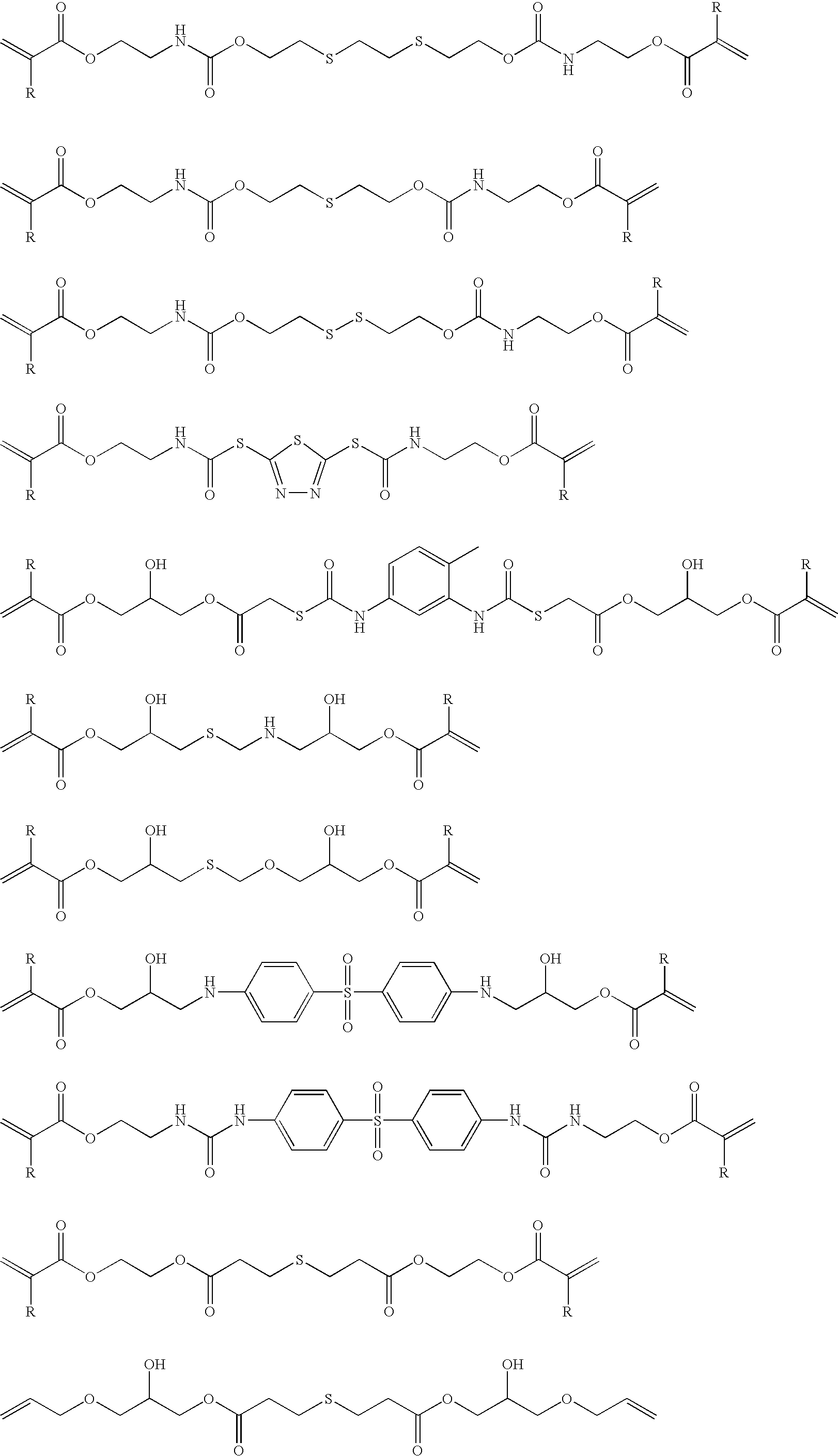

The invention provides a resin composition for laser engraving, containing at least (A) a polymerizable compound having two or more ethylenic unsaturated bonds, a carbon-sulfur bond being contained at the site where two among the two or more ethylenic unsaturated bonds are connected and (B) a binder polymer. The invention further provides an image forming material containing the resin composition, a relief printing plate precursor having a relief forming layer which contains the resin composition, a relief printing plate precursor having a relief forming layer which contains a product formed by subjecting the resin composition to cross-linking, a method for manufacturing a relief printing plate including subjecting the relief printing plate precursor having the relief forming layer which contains the resin composition to cross-linking, and a relief printing plate manufactured by the manufacturing method.

Owner:FUJIFILM CORP

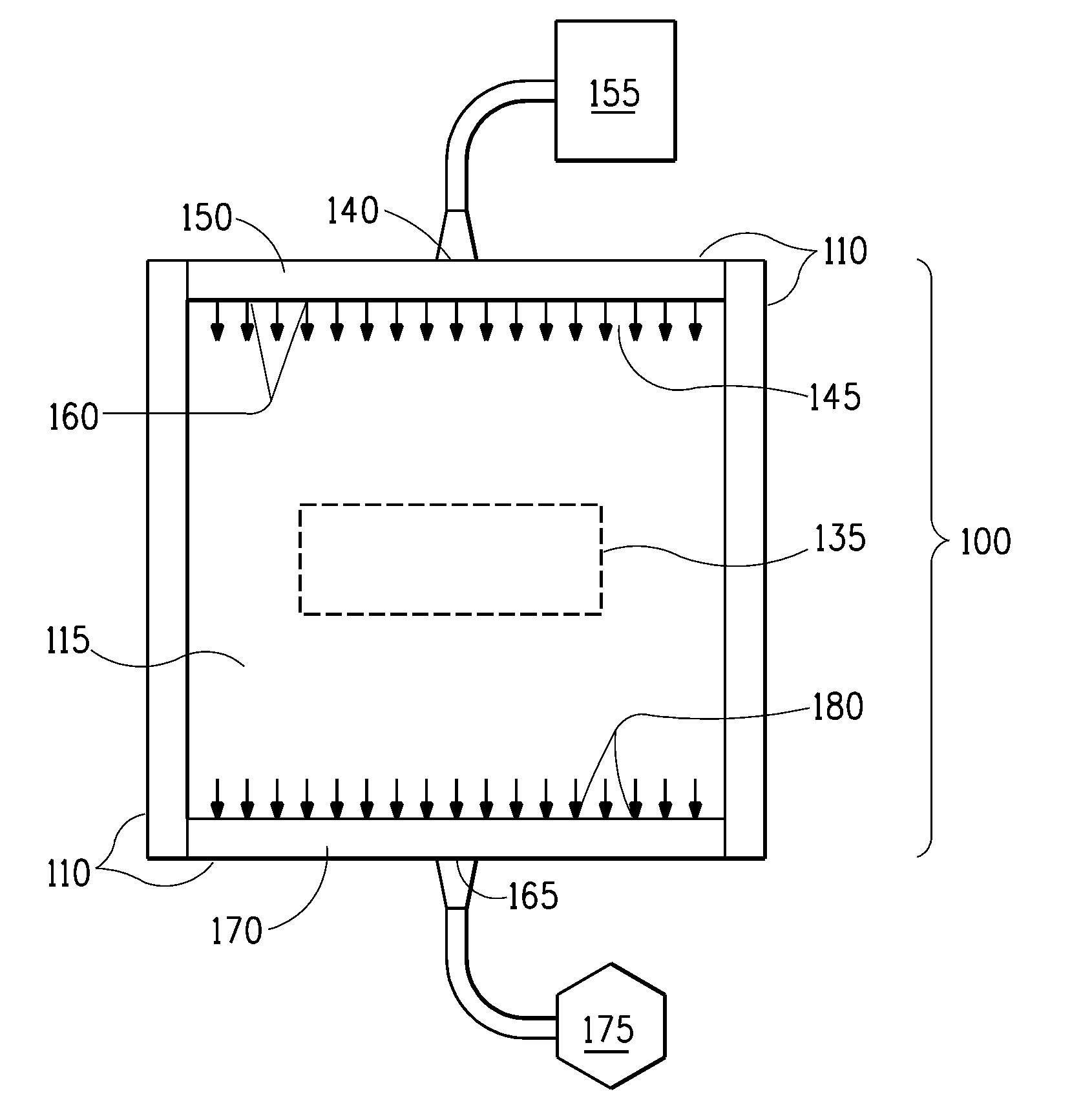

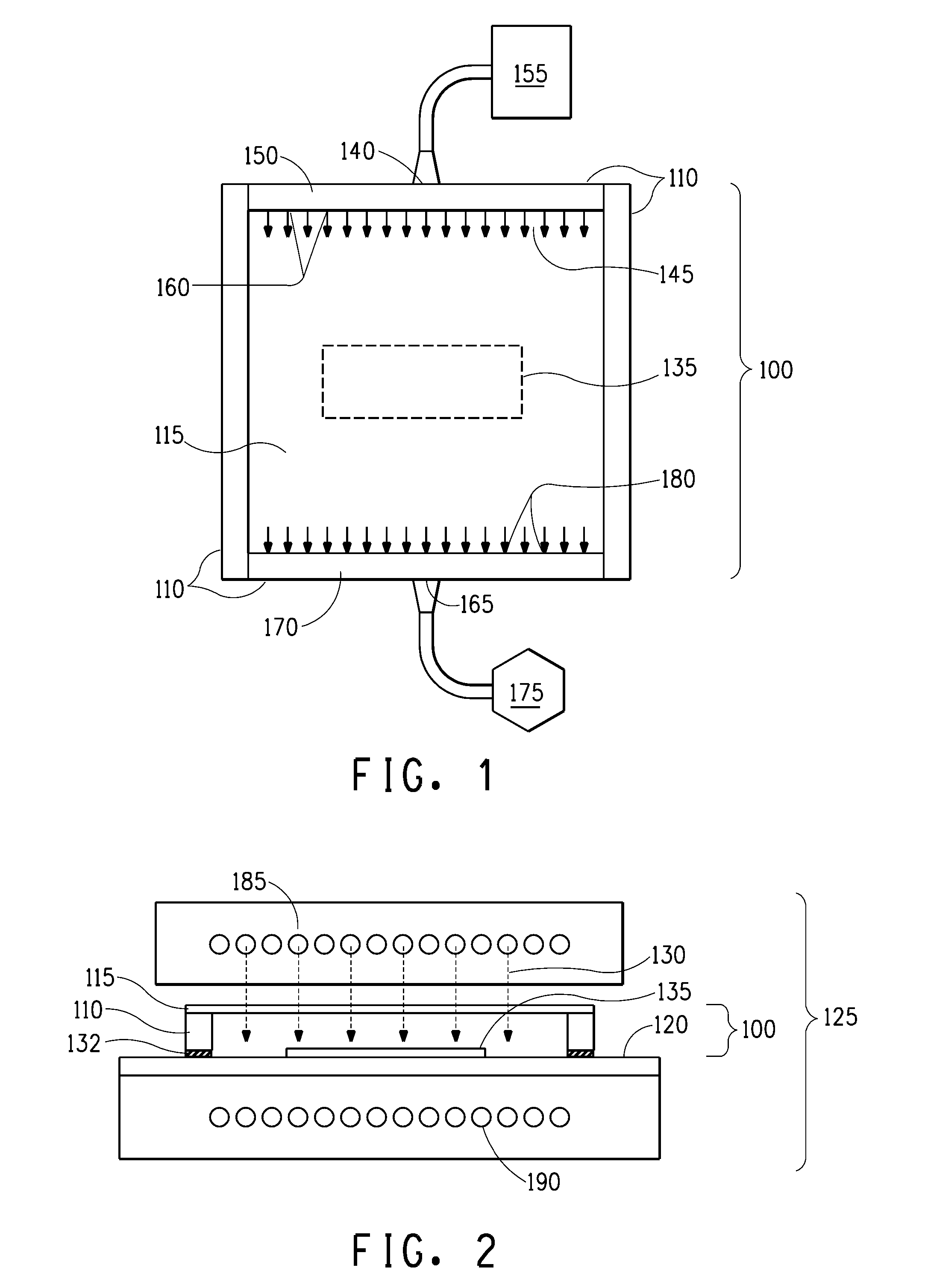

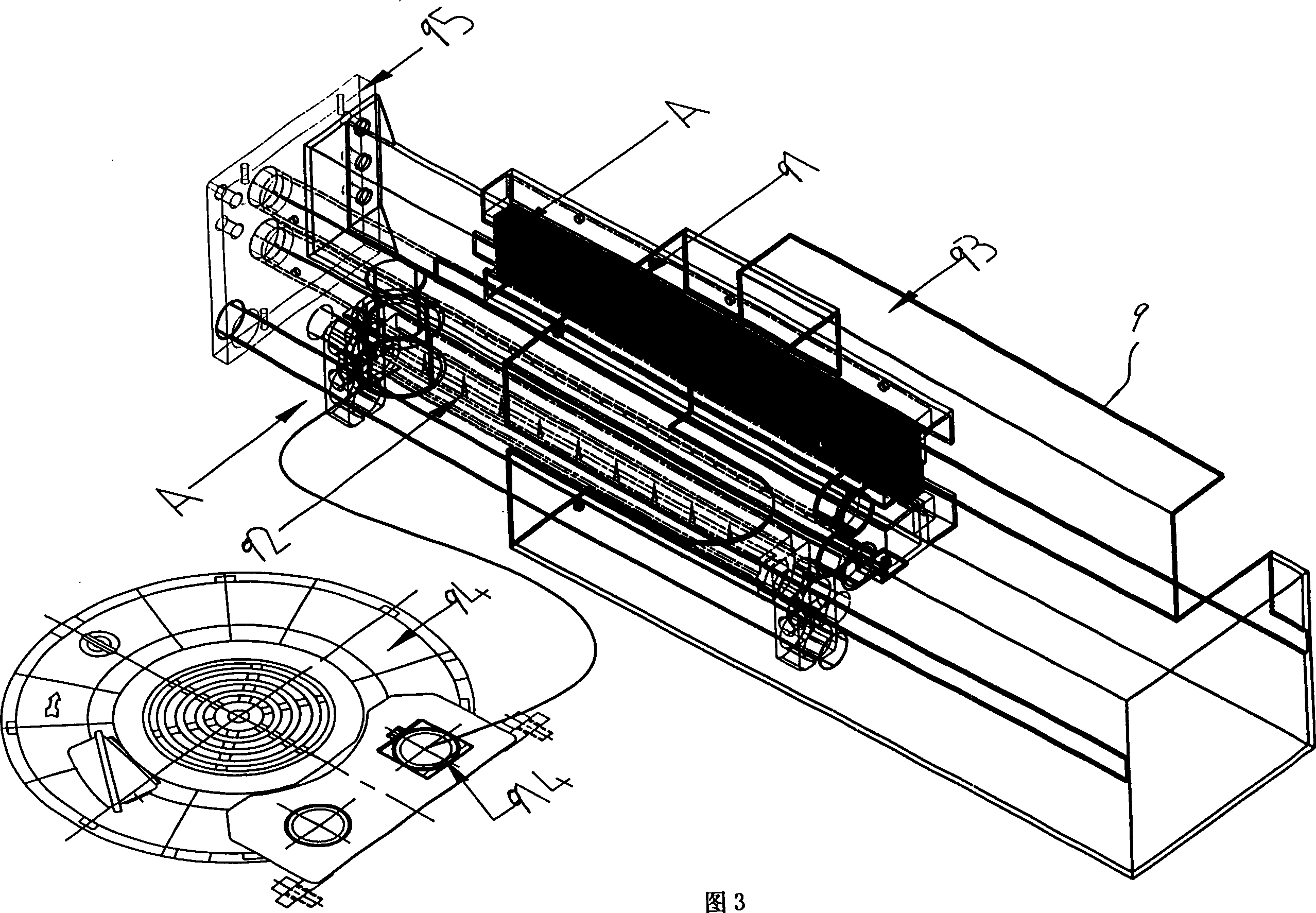

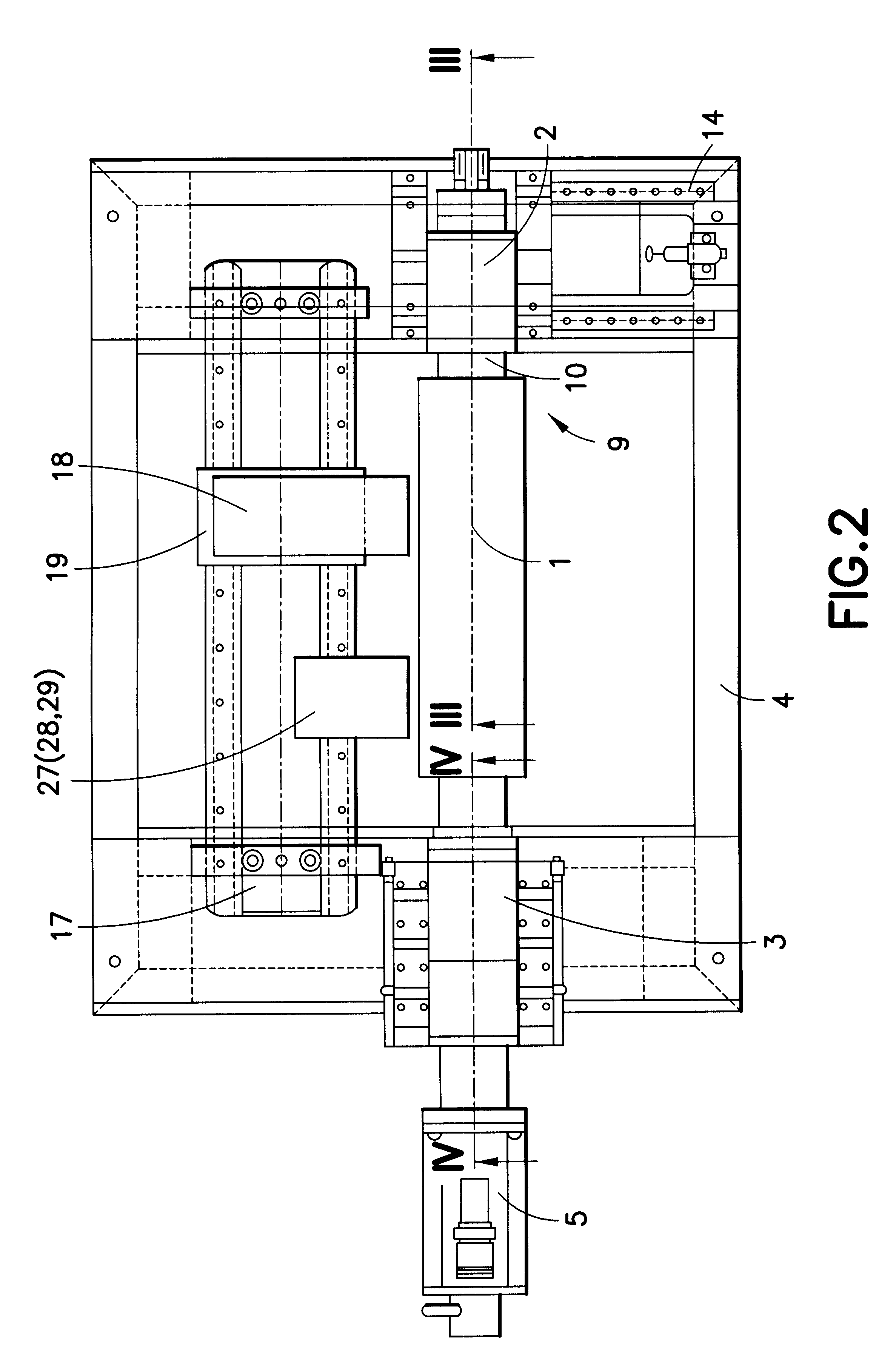

Device and method for preparing relief printing form

The invention provides a method and an apparatus for preparing a relief printing form from a photosensitive element. More specifically, this invention describes a method and an apparatus for preparing a relief form in an environment having controlled oxygen concentration during exposure to actinic radiation. The method includes forming an in-situ mask on a photosensitive element, exposing the element to actinic radiation through the in-situ mask in an environment having an inert gas and a concentration of oxygen between 190,000 and 100 ppm, and treating the exposed element to form the relief printing form having a pattern of raised surface areas.

Owner:DUPONT ELECTRONICS INC

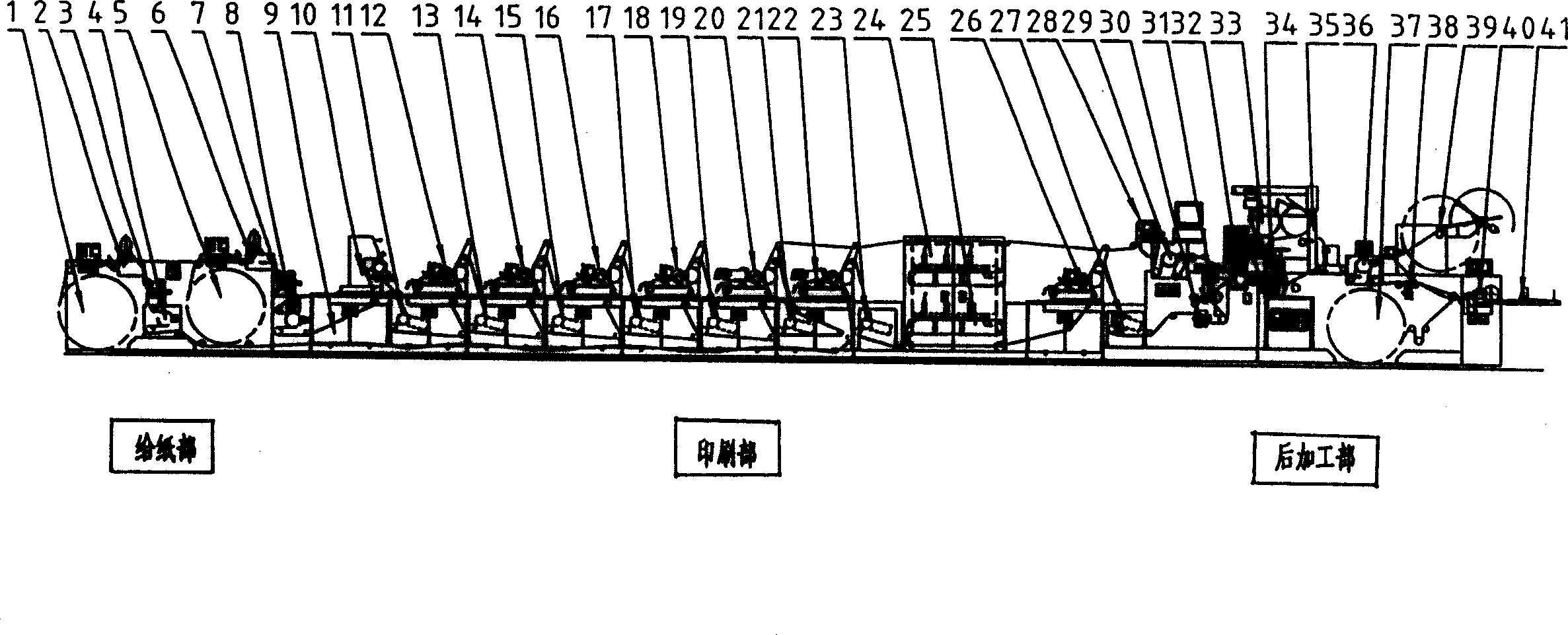

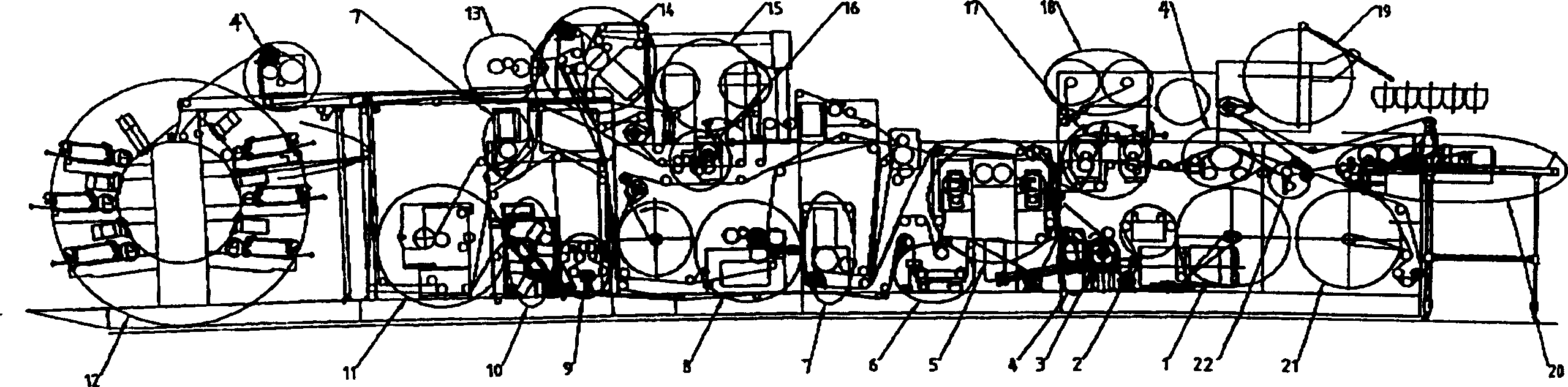

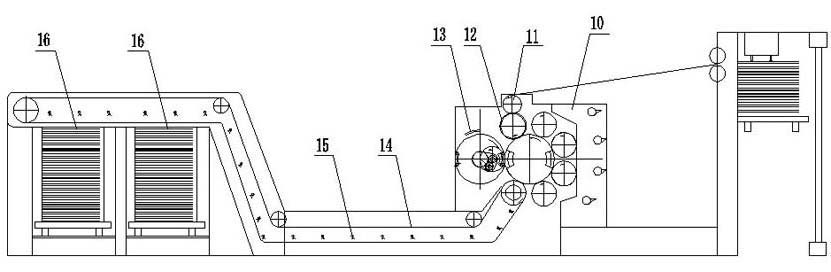

Label wheel rotary printing machine

InactiveCN101054011AImprove matchDry in timeLamination plant layoutStampsPlastics industryEngineering

The invention relates to a label rotary printing which is characterized by that: it is mainly comprised by paper feeding device, printing section, post-process portion, and can be linked with relief printing, flexographic printing, offset printing, and can be further linked with code spray, silicon oil coating, hot melting glue coating to make multi-layer anti-counterfeiting label, and two paper feeding portions can simultaneously print two rolls of stocks, and coats hot melting glue between the two rolls of stocks, and compounds them to obtain the non-drying glue label, and the invention is applicable in plastic industry for plastic film printing, and can be also used in printing commercial table and printing non-carbon impact paper; because the invention has five flexo printing color classes, it can be regarded as a pure five-color rotary flexo printing used in commercial packing printing field. The advantage of the invention is that: the invention can print single roll of stock as well as two rolls of stocks and can compound the two rolls of stocks, multi-layer non-drying glue label can be processed by multiple printings and ink jet printing on same device.

Owner:SHANGHAI XINMIN TAIYO KIKAI

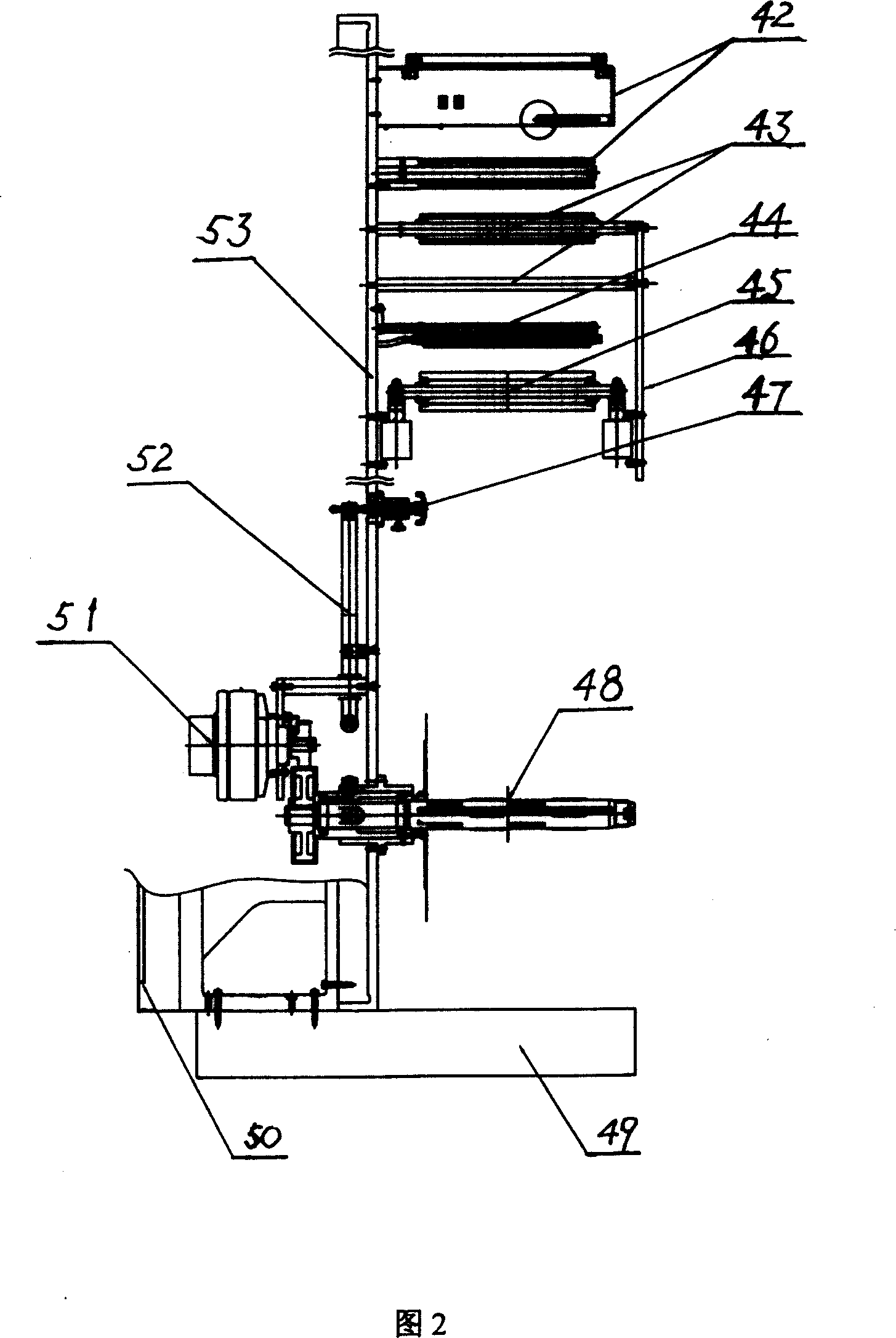

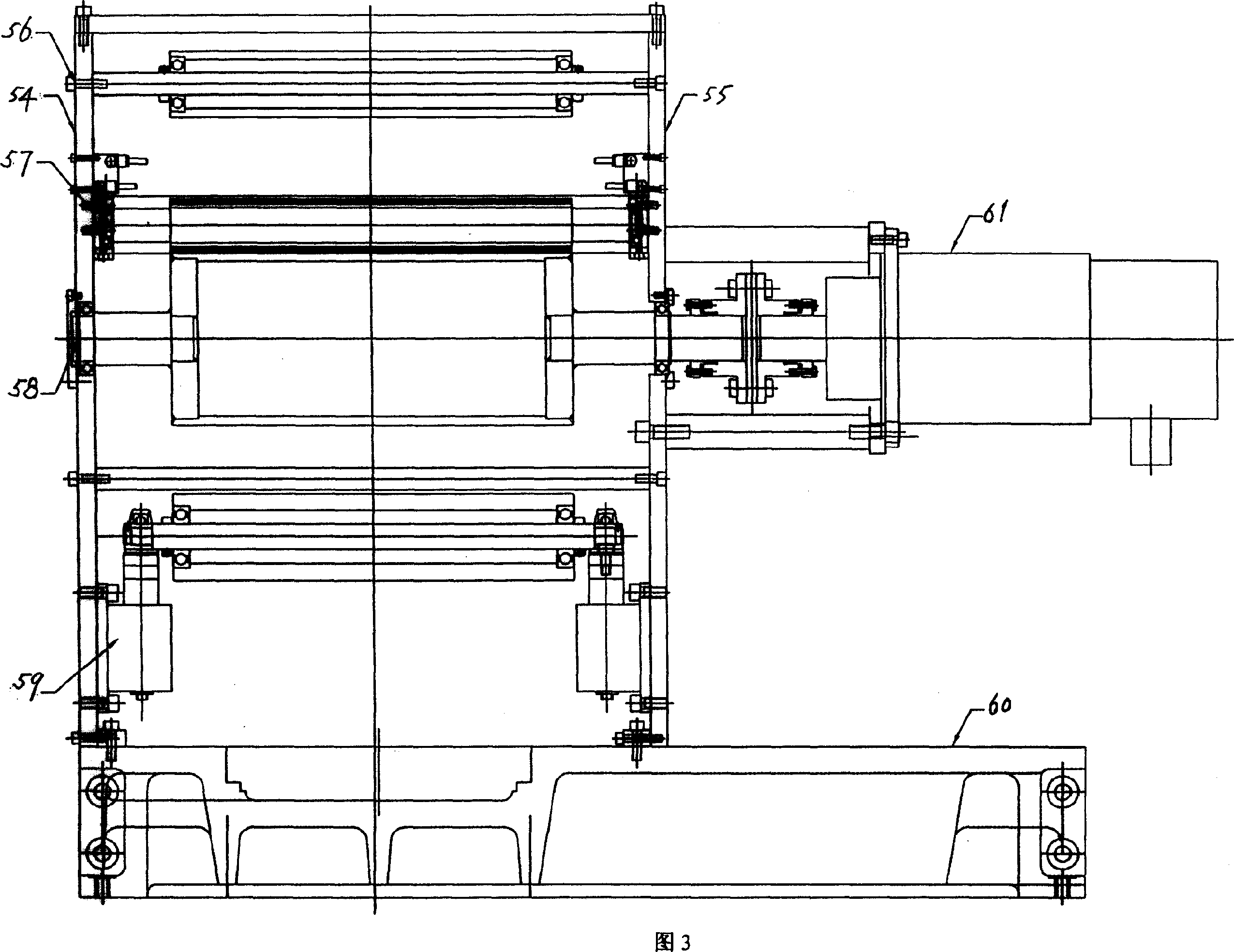

Adhensive rotary printer

A rotary press for printing on non-drying adhesive matter is composed of paper feeder, paper receiver, speed reducer, AC servo tension control and tract unit, platen unit, skew corrector, servo motor cooling and driving unit, flexible plate printing unit, paper chip and static electricity remover, corona unit, silk screen printing unit, satellite relief printing unit, gilded film sticking-UV baking-cooling driver, golden foil feeder, reel, gilded film cutting unit, etc.

Owner:SHANGHAI XINMIN TAIYO KIKAI

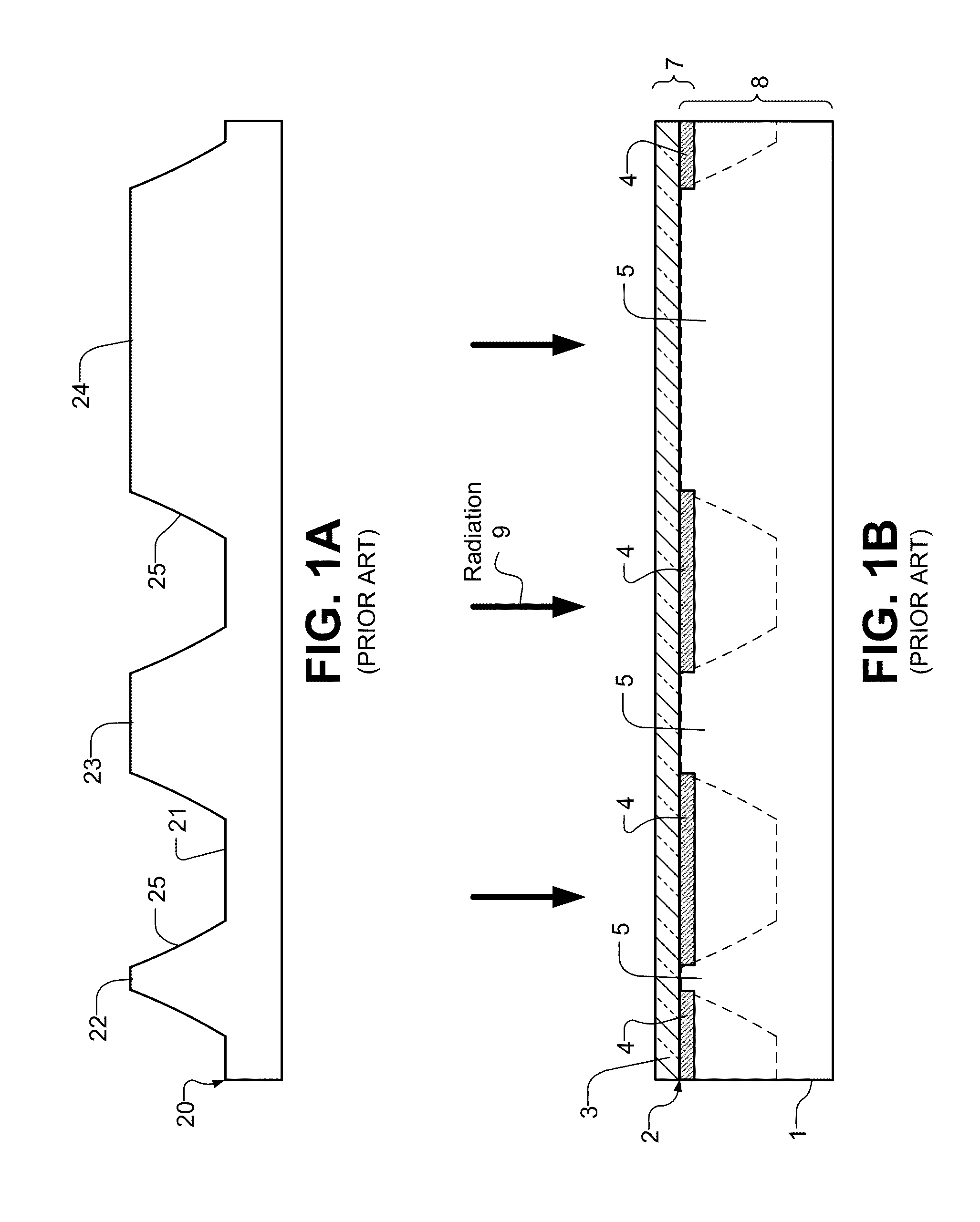

Production of catalyst coated membranes

A method for the production of catalyst coated membranes, especially catalyst coated membranes for use in fuel cells, includes raised relief printing a catalyst coating composition (11) onto the surface of an ion exchange membrane (16) to form at least one electrode layer.

Owner:EI DU PONT DE NEMOURS & CO

Fluoropolymer film made by printing

InactiveUS20060134323A1Quantity minimizationOvercome problemsMaterial nanotechnologyPattern printingThin membraneDisplay device

Disclosed is a process for forming a patterned fluoropolymer film on a substrate by raised relief printing a fluoropolymer solution with a patterned raised relief printing plate, and drying the solvent from the solution to form the patterned fluoropolymer film. Such fluoropolymer films are useful as antireflective or hydrophobic layers on substrates used in optical displays.

Owner:EI DU PONT DE NEMOURS & CO

Relief printing plate precursor for laser engraving, method of producing the same, relief printing plate obtainable therefrom, and method of producing relief printing plate

A relief printing plate precursor for laser engraving, including a relief forming layer that includes a peroxide and a binder polymer, and includes a crosslinked structure.

Owner:FUJIFILM CORP

Device and method for preparing relief printing form

Owner:DUPONT ELECTRONICS INC

Resin composition for laser engraving, relief printing plate precursor for laser engraving, relief printing plate and method of producing the same

The present invention provides a resin composition for laser engraving, containing at least an inorganic porous material, a binder polymer, a thermopolymerization initiator and a polymerizable compound; a relief printing plate precursor for laser engraving using the same; a relief printing plate; and a method of producing the relief printing plate.

Owner:FUJIFILM CORP

Photosensitive resin printing plate original, process for producing the same and process for producing resin relief printing plate therewith

ActiveUS20060008729A1Semiconductor/solid-state device manufacturingPhotosensitive material processingWater dispersibleWater insoluble

An object of the present invention is to provide a photosensitive resin printing plate precursor capable of forming a protruding relief pattern without using any original pattern film. Specifically, the present invention relates to a photosensitive resin printing plate precursor including: a photosensitive resin layer (A) containing a water-soluble or water-dispersible resin and an ultraviolet-curable monomer; and a water-insoluble heat-sensitive mask layer (C) containing an infrared-absorbing material, deposited in that order on a support. By introducing a crosslinked structure or a hydrophobic constituent to the heat-sensitive mask layer (C) so as to be insoluble in water, difference in polarity is produced between the layers (A) and (C) and, thus, mass transfer between the two layers can be prevented. Also, the scratch resistance of the heat-sensitive mask layer (C) can be dramatically enhanced and, thus, the printing plate precursor becomes easy to handle.

Owner:TORAY IND INC

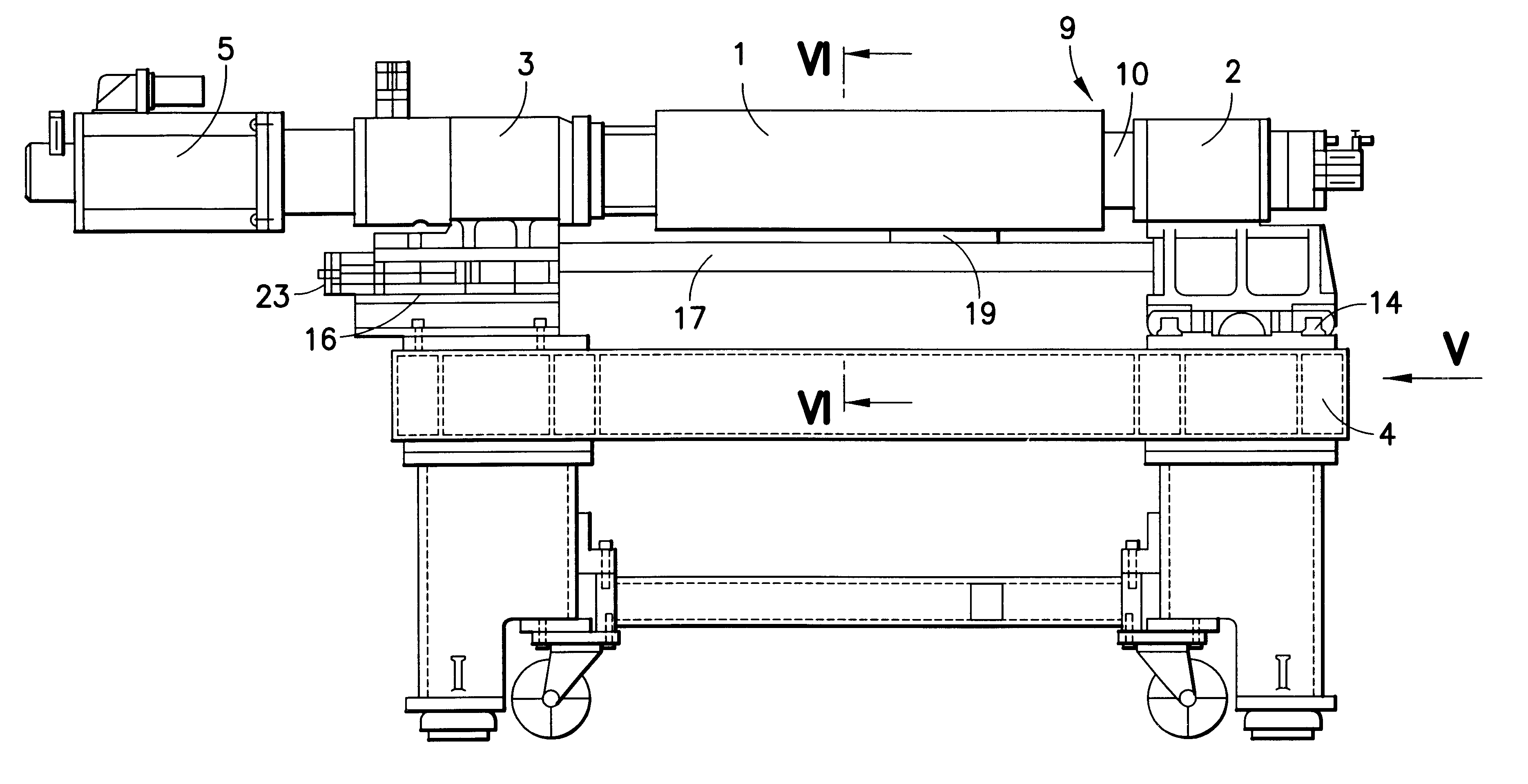

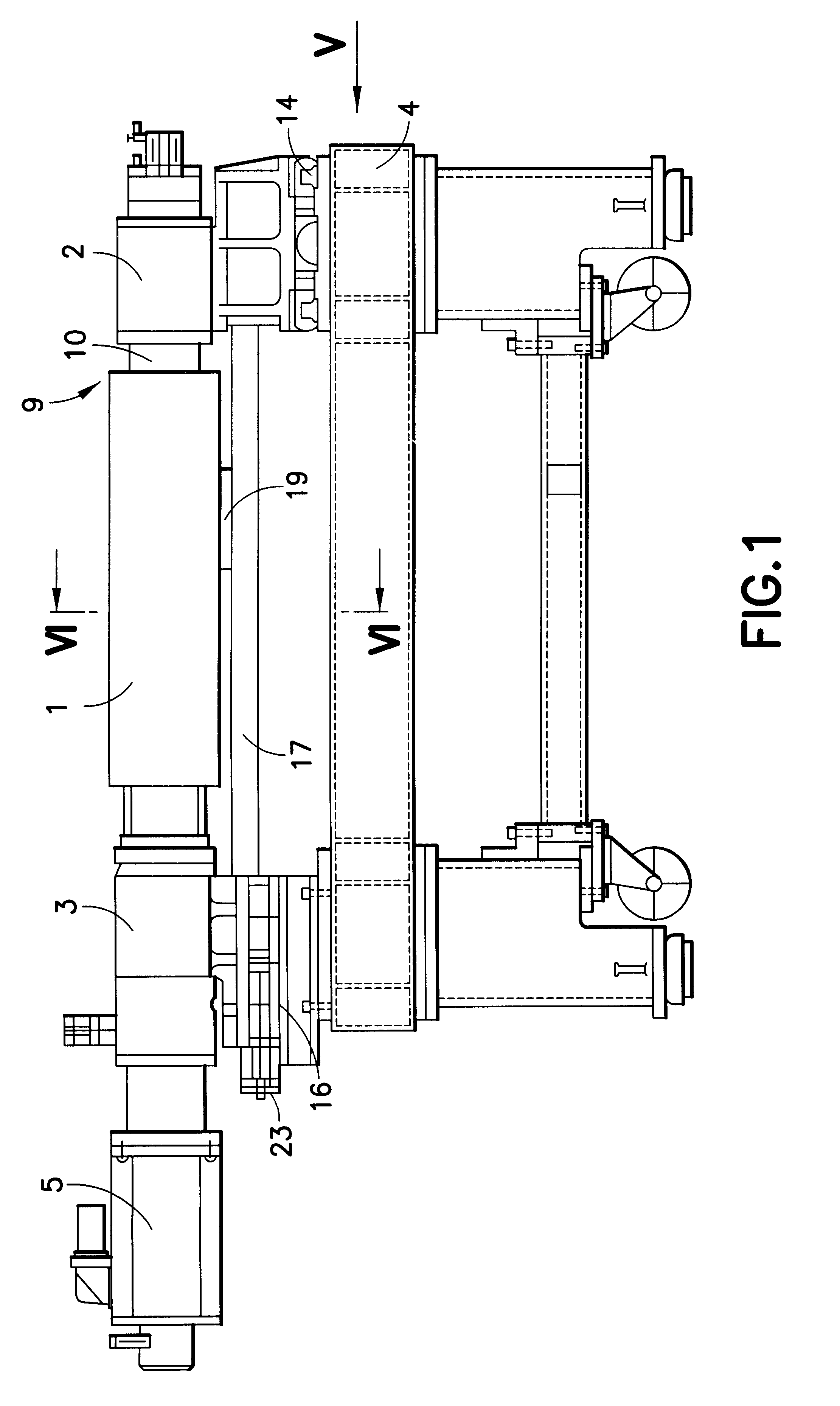

Apparatus for producing printing plates having movable journal for axial removal of plate

Owner:MANROLANAD AG

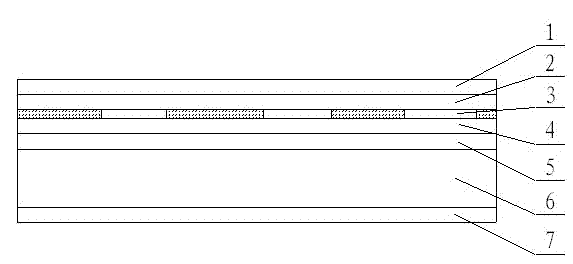

Transfer hollow-out-out sprayed metallic paper or card paper and production process thereof

InactiveCN102535258AHighlight the packaging effectHighlight the noble packaging effectSpecial paperPaper/cardboardAdhesive gluePlastic film

The invention discloses a piece of transfer hollow-out sprayed metallic paper or card paper which is characterized by sequentially comprising a strippable coating (2), a hollow-out sprayed metallic layer (3), a glue layer (4) and a piece of paper (6) from top to bottom; and besides the four layers, the transfer hollow-out metalized paper also can comprise any one or more of a surface coating (bright oil layer) (1), a coloring layer (5) and a back coating (7). In the invention, through adopting a relief printing process principle, a low-surface tension coating which contains pre-designed patterns and / or characters is printed on a plastic film which is coated with the strippable coating; then vacuum spraying is carried out to obtain a metallic layer which cannot be deposited on the low-surface tension coating and can be deposited on other places without the low-surface tension coating coated; the hollow-out metallic layer is composited with the paper by use of glue; and the plastic film is processed by resurgence or back coating after being stripped to obtain the sprayed metallic paper or card paper with hollow-out patterns and / or characters.

Owner:YANTAI BOYUAN TECH MATERIALS

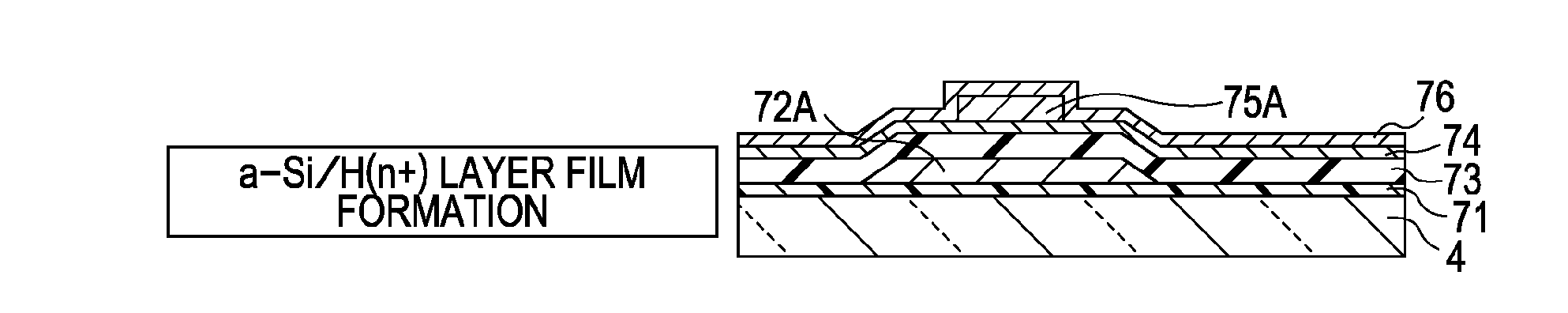

Method for manufacturing organic thin-film transistor with plastic substrate

InactiveUS20060030067A1Simple preparation procedureReduce material costsFinal product manufactureSolid-state devicesEngineeringSemiconductor

A method for manufacturing an organic thin-film transistor with a plastic substrate, comprising steps of: providing a mold and a plastic substrate, said mold being provided with a relief printing structure; imprinting said plastic substrate by said mold so as to define source / drain electrode regions on said plastic substrate; forming a first electrode layer so as to form source / drain electrodes on said source / drain electrode regions on said plastic substrate; forming a plurality of semiconductor mesas, each of said semiconductor mesas covering a pair of said source / drain electrodes; forming an insulating layer; forming a second electrode layer, being separated from and on said semiconductor mesas by said insulating layer; and forming a passivation layer.

Owner:IND TECH RES INST

Relief for forming layer

Owner:KOMURA TECH

Resin composition for laser engraving, resin printing plate precursor for laser engraving, relief printing plate and method for production of relief printing plate

InactiveUS20090220753A1High engraving sensitivityHigh sensitivityPhotosensitive materialsDecorative surface effectsPolyesterLaser engraving

Owner:FUJIFILM CORP

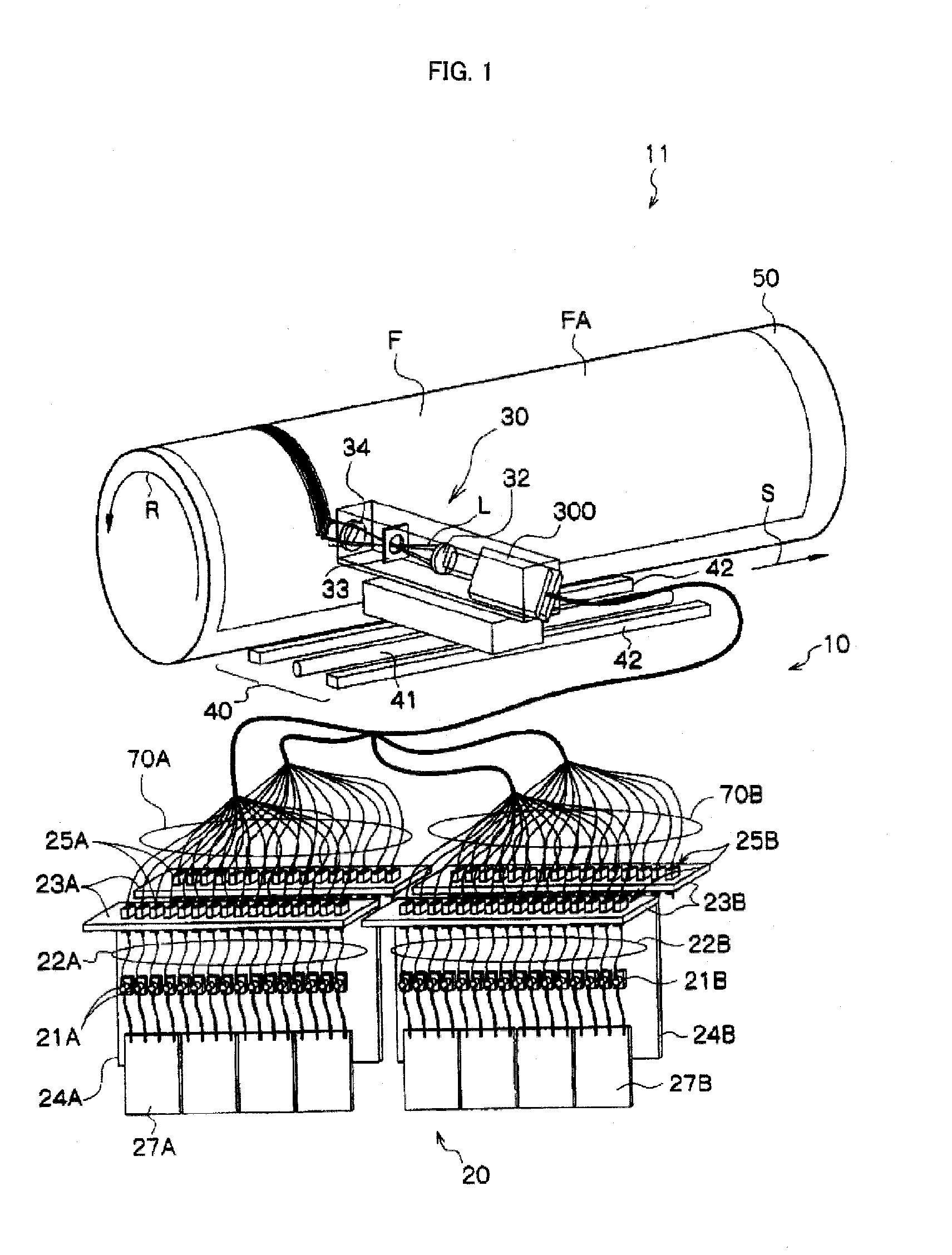

Printing method and display apparatus manufacturing method

InactiveUS20100173553A1Easy to cutAccurate printingCylinder pressesPlaten pressesRelief printingElectrical and Electronics engineering

A printing method including the steps of, forming a transfer layer on a blanket, forming a groove portion on the transfer layer by pressing a protrusion portion of a mold member including the protrusion portion having a predetermined pattern against the transfer layer, the groove portion having the pattern corresponding to the protrusion portion, forming a print pattern layer on the blanket by causing the transfer layer on the blanket and a relief printing plate including a convex portion having a pattern corresponding to a reverse pattern of the protrusion portion to face each other and pressure-contacting them so that a portion on the transfer layer corresponding to the convex portion is selectively eliminated, and transferring the print pattern layer onto a substrate to be printed by causing the print pattern layer on the blanket and the substrate to be printed to face each other and pressure-contacting them.

Owner:SONY CORP

Enhanced relief printing plate

ActiveUS8399177B2Improve accuracyOptimization rangePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringImage area

Owner:MIRACLON CORP

Polychrome connection silk screen printing process and equipment thereof

ActiveCN101982319AImprove anti-counterfeiting performanceSolve process problemsScreen printersPattern printingScreen printingPrinting ink

The invention discloses a polychrome connection silk screen printing process and equipment thereof, and relates to the technical field of sheet-fed rotary screen printing. The printing process comprises the following steps: transferring the printing ink to relief printing plates on four color mould drums by utilizing a four-color-group ink supply unit in satellite-type layout; converging the different colors onto the color gathering rubber blankets of a double-diameter impression cylinder in different zones by different color mould relief printing plates; transmitting the different colors onto a connection cylinder printing plate in a silk screen cylinder by combining a special money printing connection process through a big neutral position to form an accurate printing ink pattern; and finally rolling the printing ink pattern onto the paper sheet through the silk screen plate to form a polychrome connection pattern. The invention can realize the connection silk screen printing process of different-color counterfeiting inks, such as OVI and OVMI, and also can realize a puzzle connection silk screen printing process and a mixed-color silk screen printing process of common printing ink, OVI, OVMI and colorless fluorescent ink and the like. The printing production has high yield and accurate connection, and is convenient in operations of washing, replacing and tightening the silk screen plates.

Owner:CHENGDU BANKNOTE PRINTING +1

Preparation method and use method for paper for textile fabric printing

ActiveCN103184706AQuality improvementReduce wasteNatural cellulose pulp/paperTransfer printing processFiberCellulose

The invention discloses a preparation method and a use method for paper for textile fabric printing. The preparation method comprises the following steps of: 1) producing paper pulp: placing 60-100 parts of fibre paper pulp plates and not greater than 40 parts of raw wood pulp plates in a pulp-producing stirring pool and uniformly mixing, adding 0.5-1% of starch and 3-10% of sodium carboxymethylcellulose, and uniformly stirring; 2) producing adhesive film solution: stirring and mixing water-soluble resin with cellulose, adding 65 parts of water in 35 parts of the mixture, stirring, heating to 80 DEG C, and when the liquid becomes transparent, adding an adhesive and auxiliaries, and mixing and stirring; and 3) applying an adhesive film layer according to an adhesive-applying dry base unit weight of 30 g per square meter, drying and pressure-polishing, and then producing the paper for printing. According to the use method disclosed by the invention, patterns can be printed by adopting an intaglio printing plate, a flat plate, a relief printing plate, a flexible printing plate or printing equipment, and the patterns are transferred on various fibre textile fabrics, metals, woods, ceramics and leathers by a cold-transferring method or a heat-transferring method. The preparation method and the use method are suitable for being used in the wide industries of textile, clothing, home decoration, furniture, advertisement, gift production and the like.

Owner:HUBEI COLOR ROOT TECH CO LTD

Relief printing plate, and method for manufacturing electronic circuit pattern, organic electroluminescence device and organic electronic device by using the same

An embodiment of the present invention is a relief printing plate for forming a high-definition pattern by a printing method, having a convex part comprising a resin layer, a base material supporting the convex part and a light reflection controlling layer, the light wave length being in range of 400 nm-800 nm, and the layer being between the convex part and the base material.

Owner:TOPPAN PRINTING CO LTD

Dye liquid crystal anti-glare vehicle rearview mirror

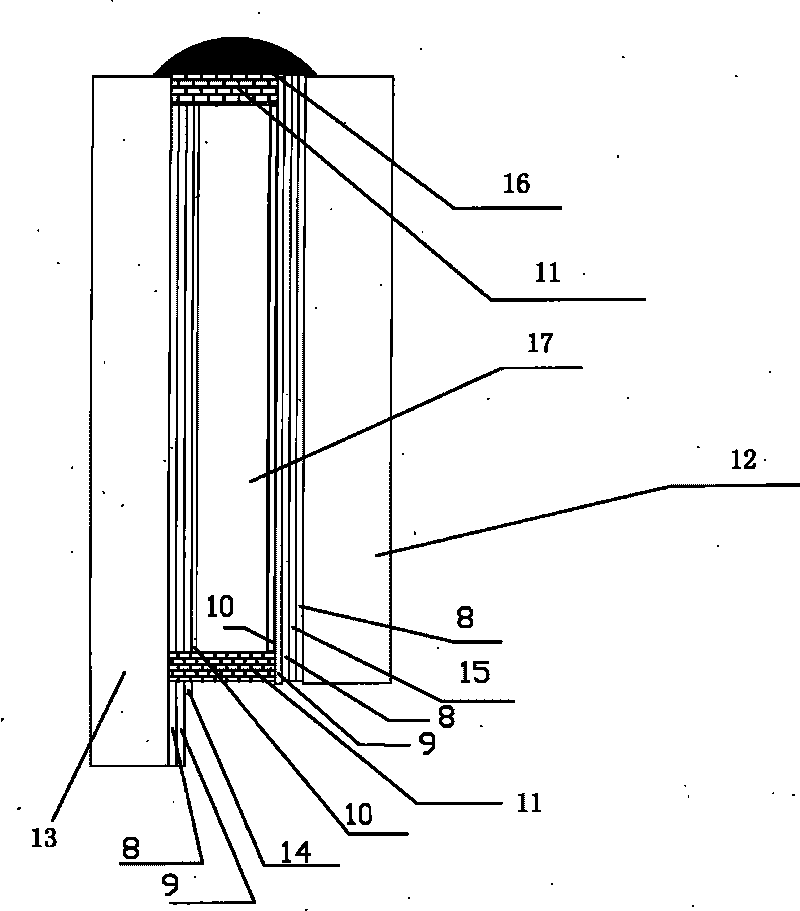

The invention discloses a dye liquid crystal anti-glare vehicle rearview mirror, which is formed by overlaying a substrate A and a plane B at intervals according to the pattern of an ITO electrode, and then forms a close box body with peripheral sealing frames. The inner surface of a substrate B is sequentially provided with a SiO2 film, an Al film, a SiO2 film, a transparent conducting film and an orientation layer, and the inner surface of the substrate B is provided with the SiO2 film, the transparent conducting film and the orientation layer. The substrate A and the substrate B are separated by a separation material, and an insulating film in a special structure is designed by using a relief printing method, thereby simplifying manufacturing process. A specific box structure is utilized by utilizing a built-in Al dielectric film mode, without the need of etching the substrate B. When the vehicle rearview mirror is not powered up, the reflectivity of the rearview mirror can be up to about 75%, while the dark-state reflectivity is 10%-13% when powered up. The vehicle rearview mirror has the characteristic of high performance-price ratio and great competitive advantage.

Owner:浙江富申科技有限公司

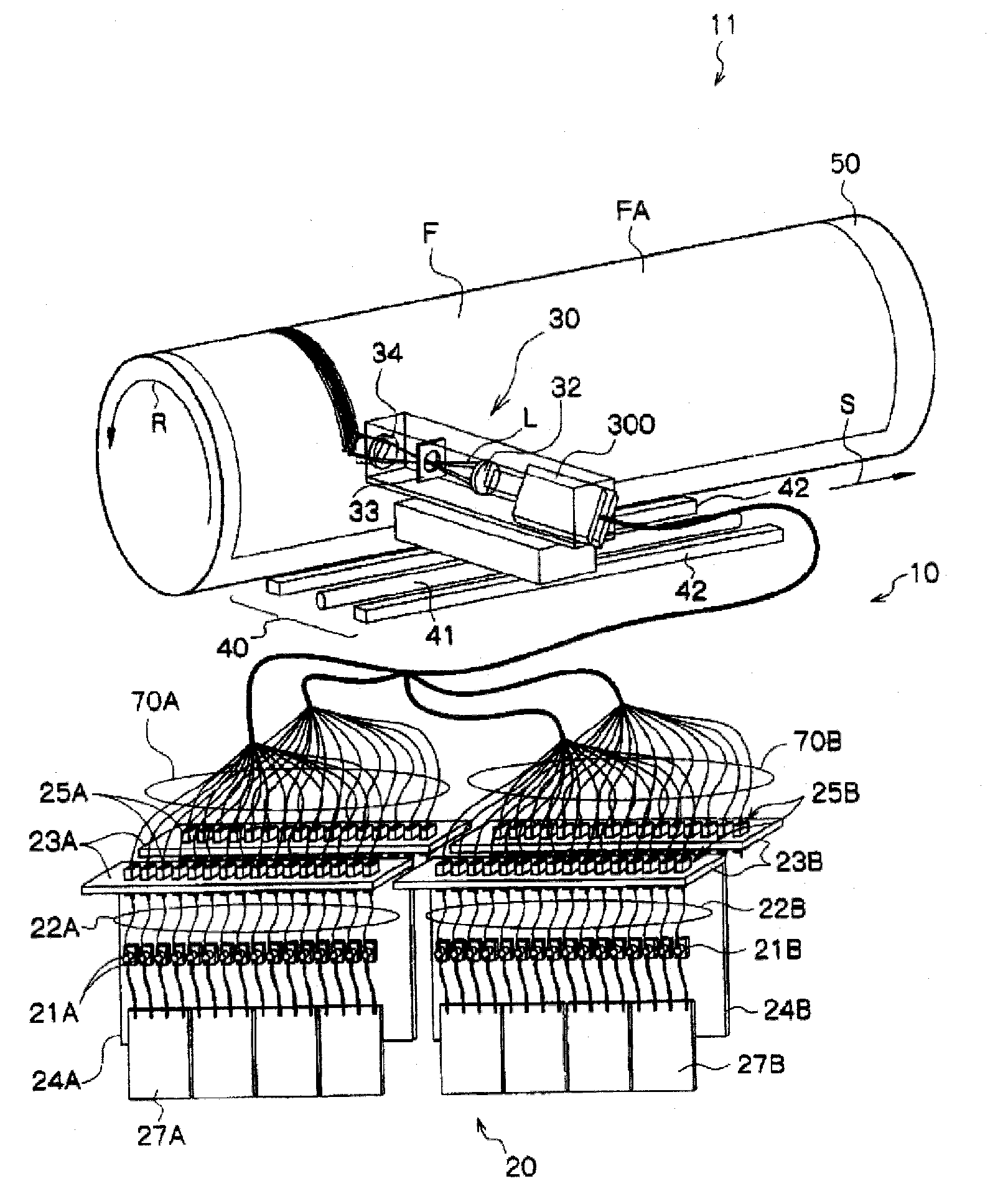

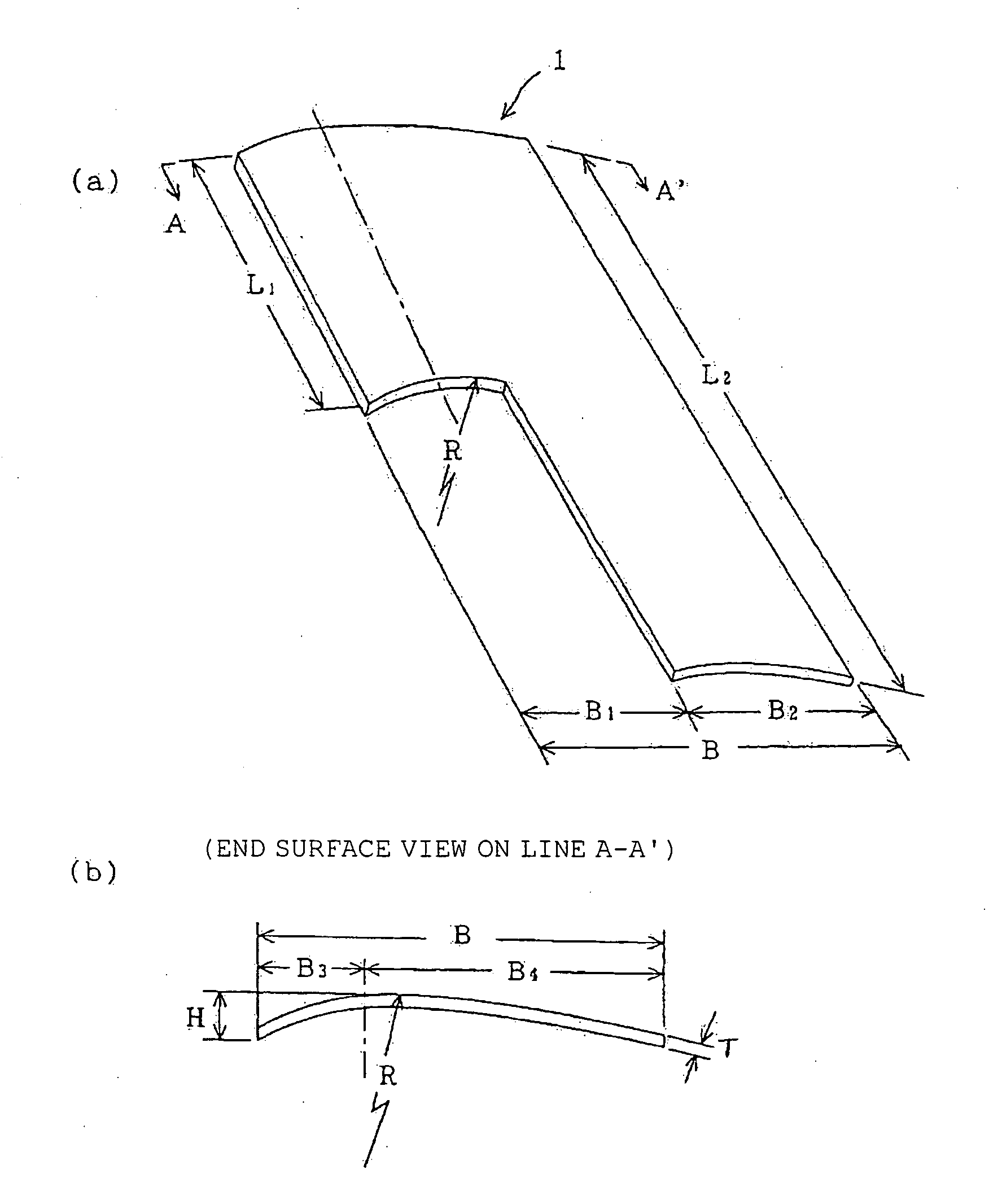

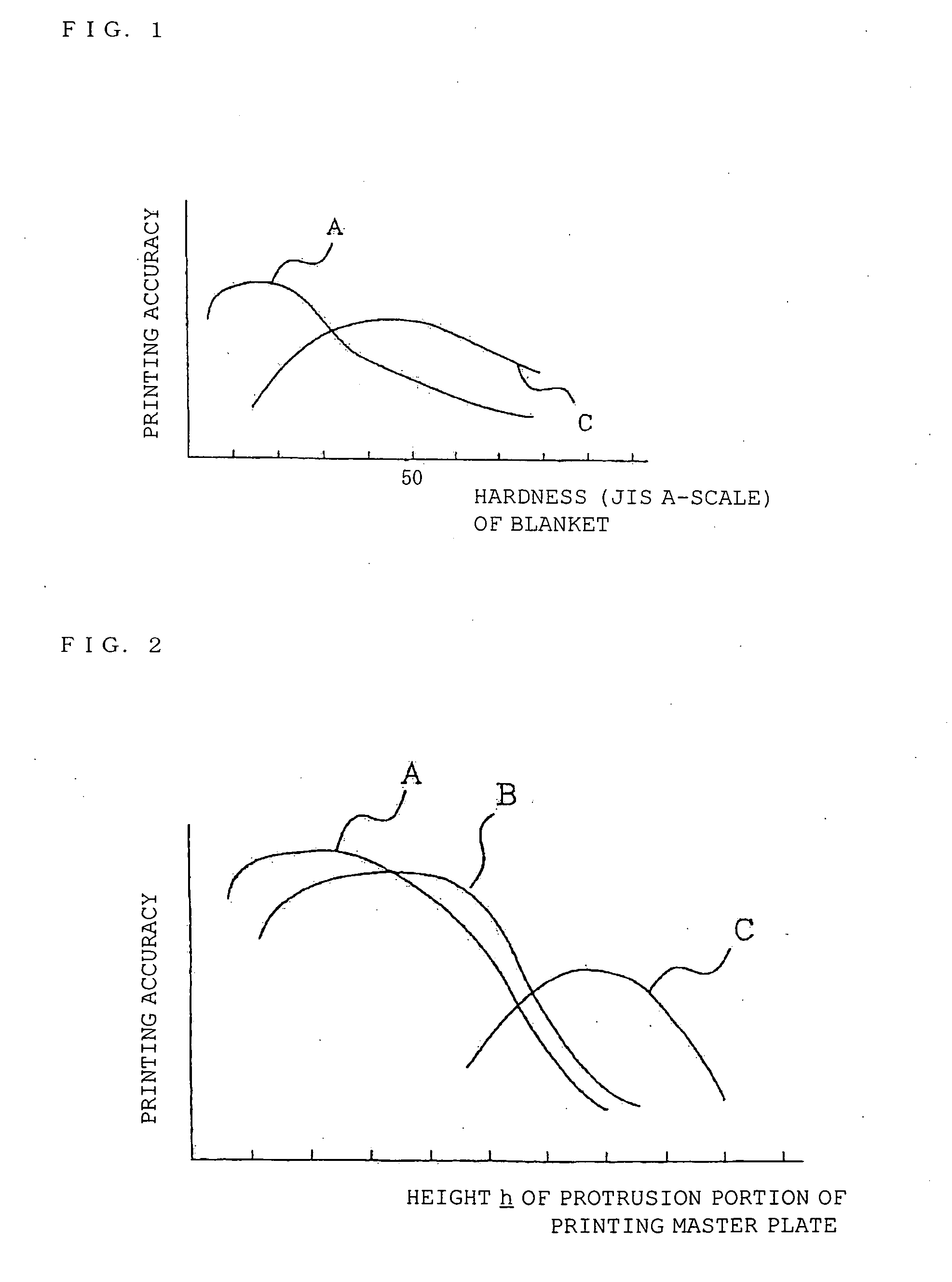

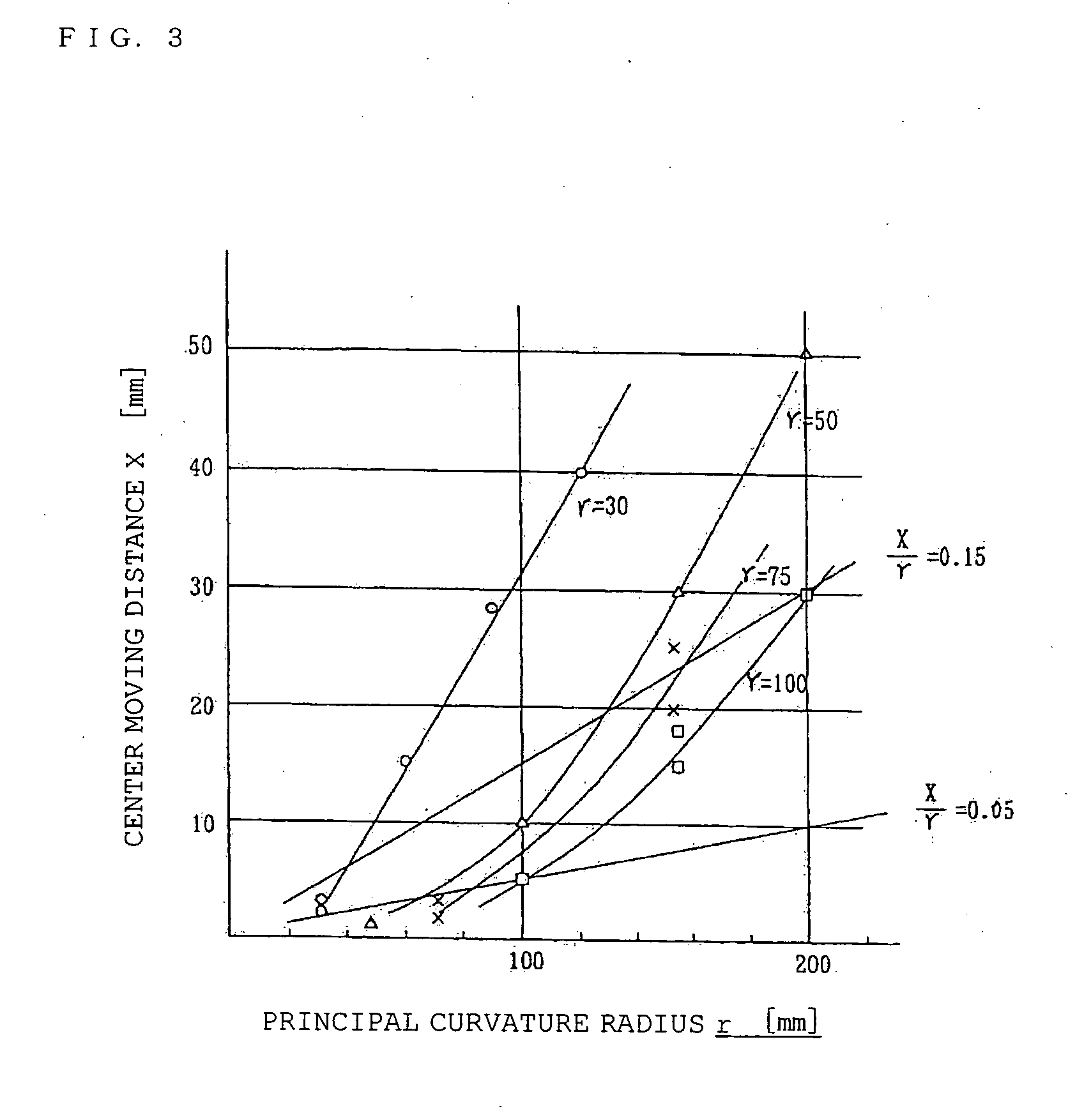

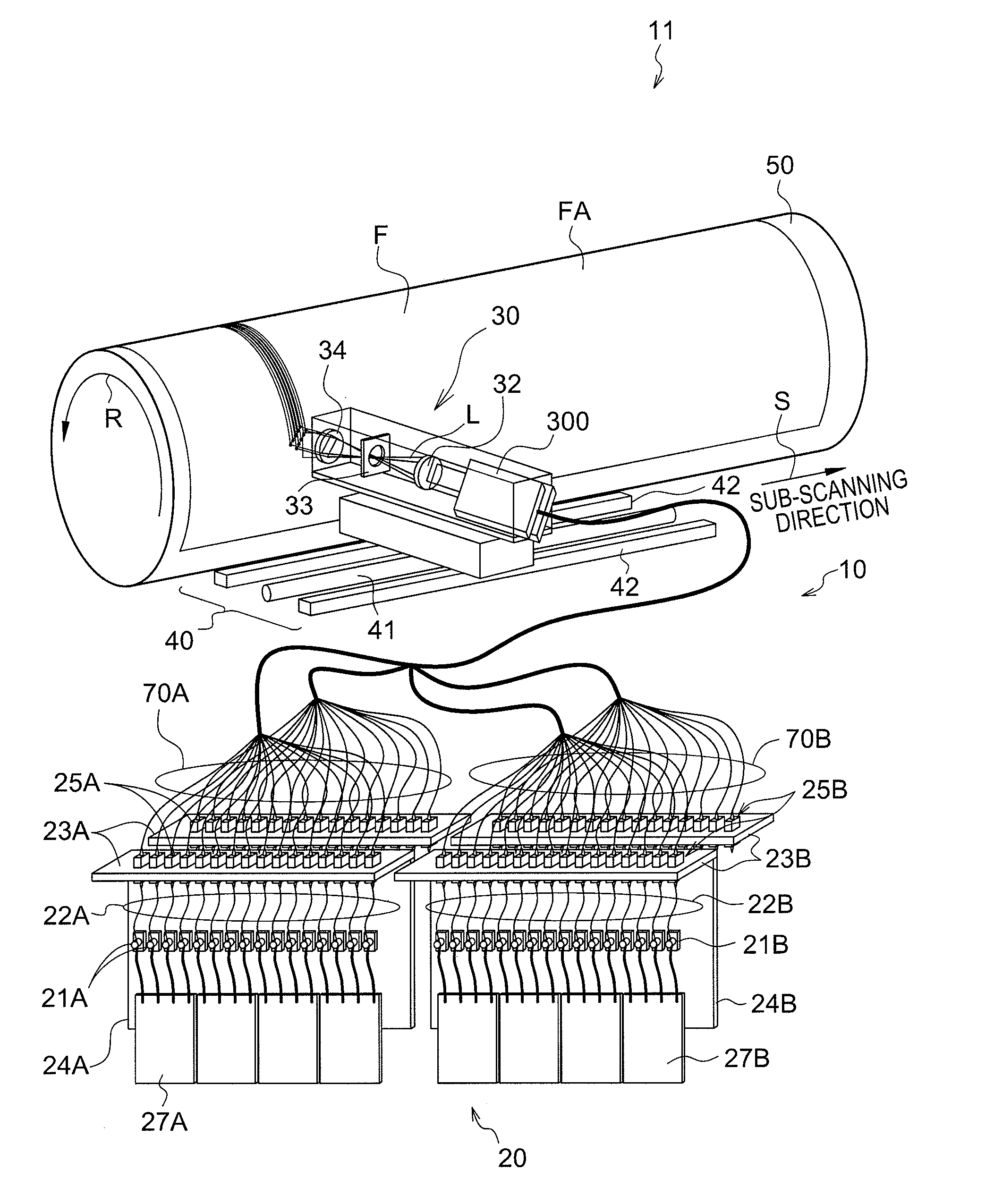

Printing Method on Curved Surface and Curved Surface Body Printed by that Method

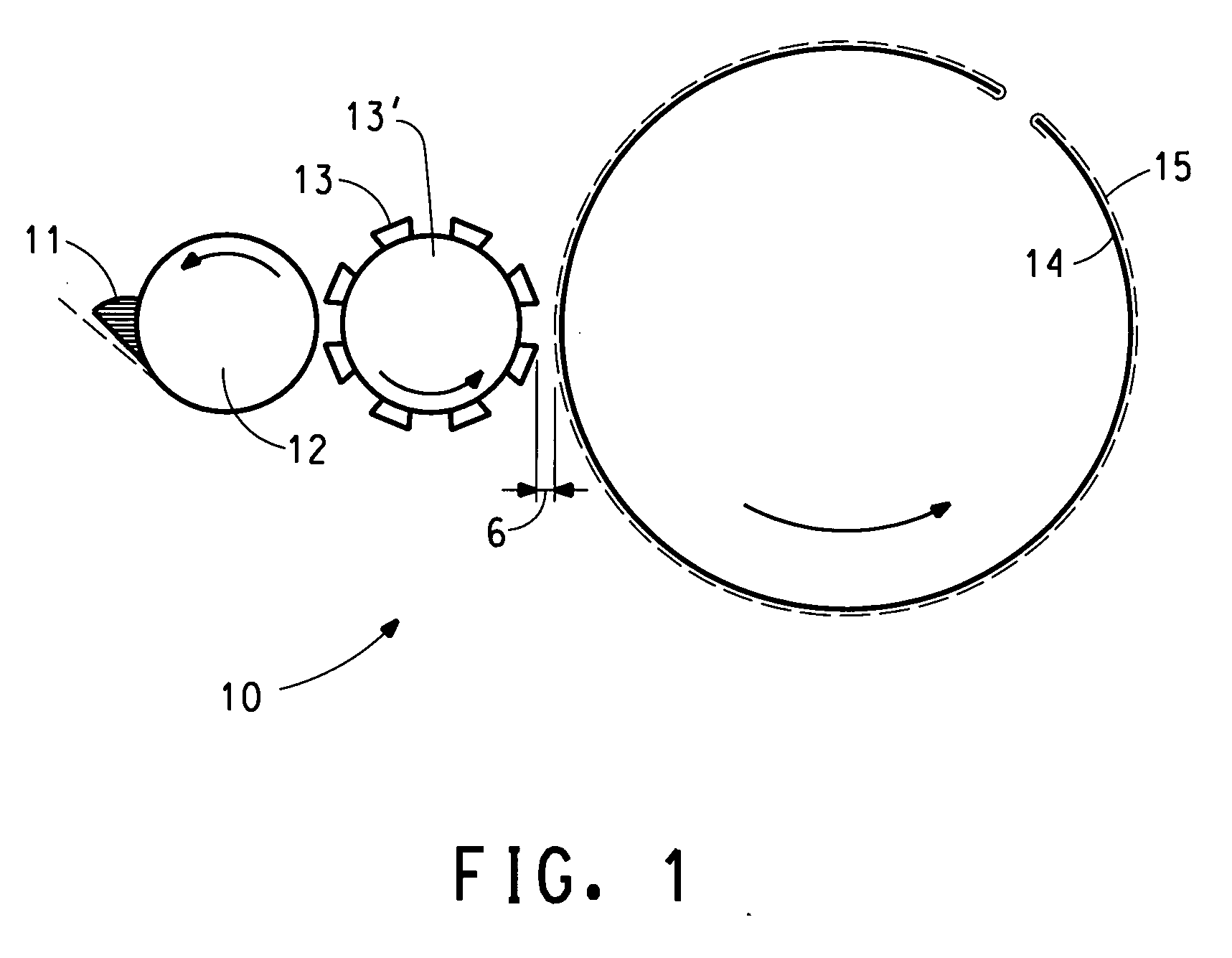

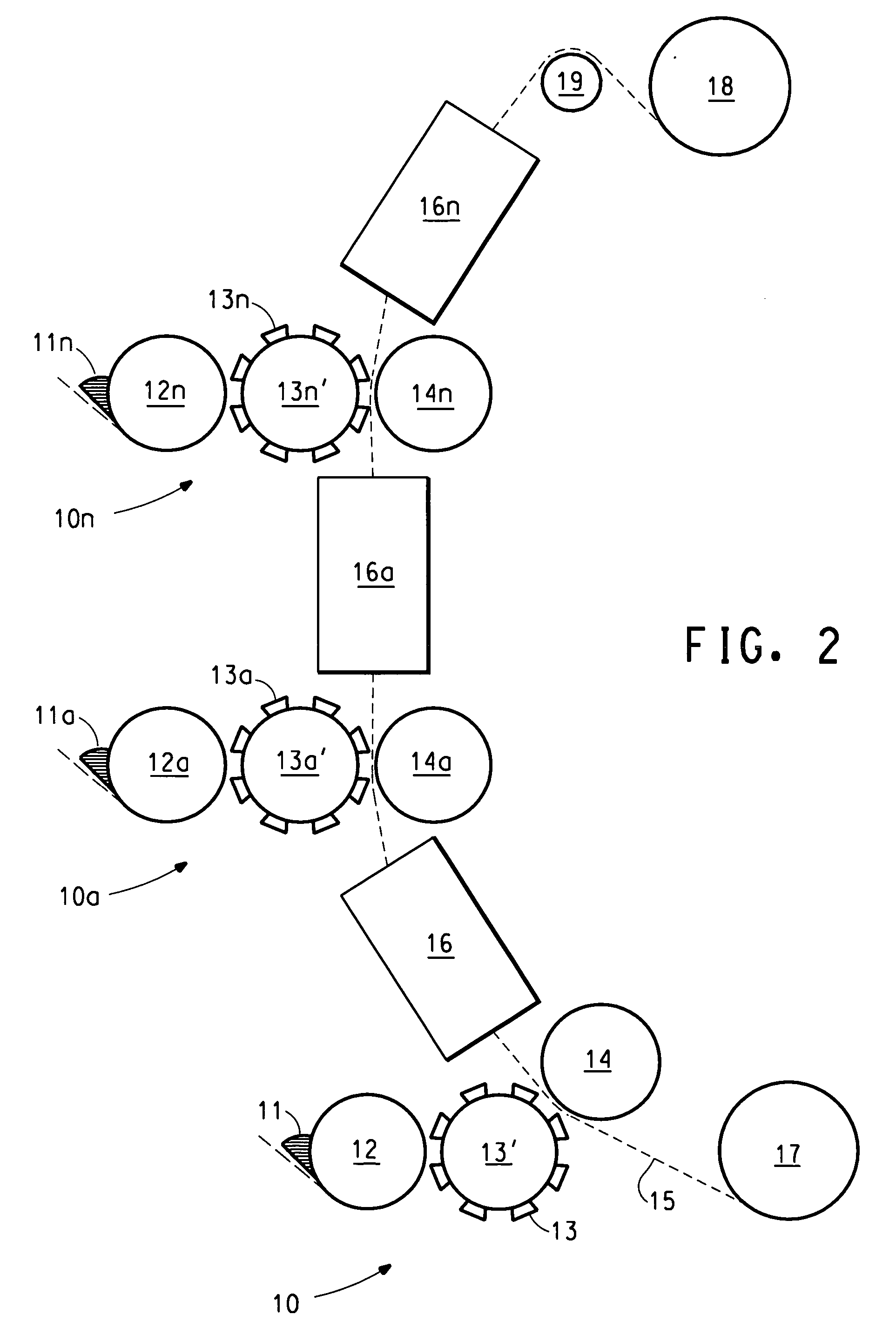

A method for printing on a curved surface and a printed curved surface body using the method. The method includes the steps of: applying printing ink having a viscosity of 5-500 PaS, preferably 5-250 PaS, to a protrusion portion of a relief printing master plate 3 which is a flat plate with the protrusion portion 0.1-50 μm high, preferably 0.1-25 μm high in height h; pressing a rubber or rubbery roll-like elastic blanket 2 having an elastic portion whose thickness T has a relation of 2H≦T≦8H with respect to a level difference H of a to-be-printed curved surface body 10 and which has a hardness (JIS A-scale) of 3-40, preferably 3-20, onto the relief printing master plate 3 supplied with the printing ink while applying constant pressure to the roll-like elastic blanket 2 and smoothly rotating the roll-like elastic blanket 2, so as to transfer the printing ink to an outer circumferential surface of the roll-like elastic blanket 2; and moving the roll-like elastic blanket 2 having the printing ink transferred thereto, and bringing the roll-like elastic blanket 2 into rotational pressure contact with a surface of the to-be-printed curved surface body 10 so as to perform printing thereon.

Owner:SHUHOU

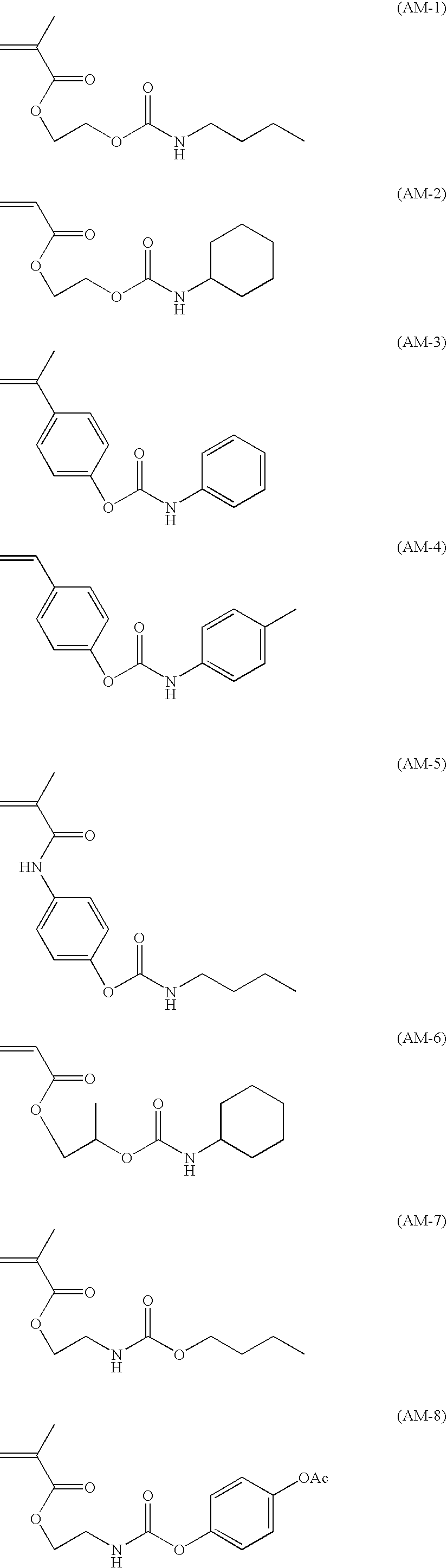

Resin composition for laser engraving, relief printing plate precursor for laser engraving and method for producing the same, and relief printing plate and method for making the same

InactiveUS20110076613A1Photosensitive materialsSemiconductor/solid-state device manufacturingTotal solid contentLaser engraving

A resin composition for laser engraving, including at least a phenol derivative (A) represented by the following Formula (A), a binder polymer (B), and a crosslinking agent (C), wherein the content of the phenol derivative (A) with respect to the total solid content of the resin composition is from 5% by mass to 50% by mass:

Owner:FUJIFILM CORP

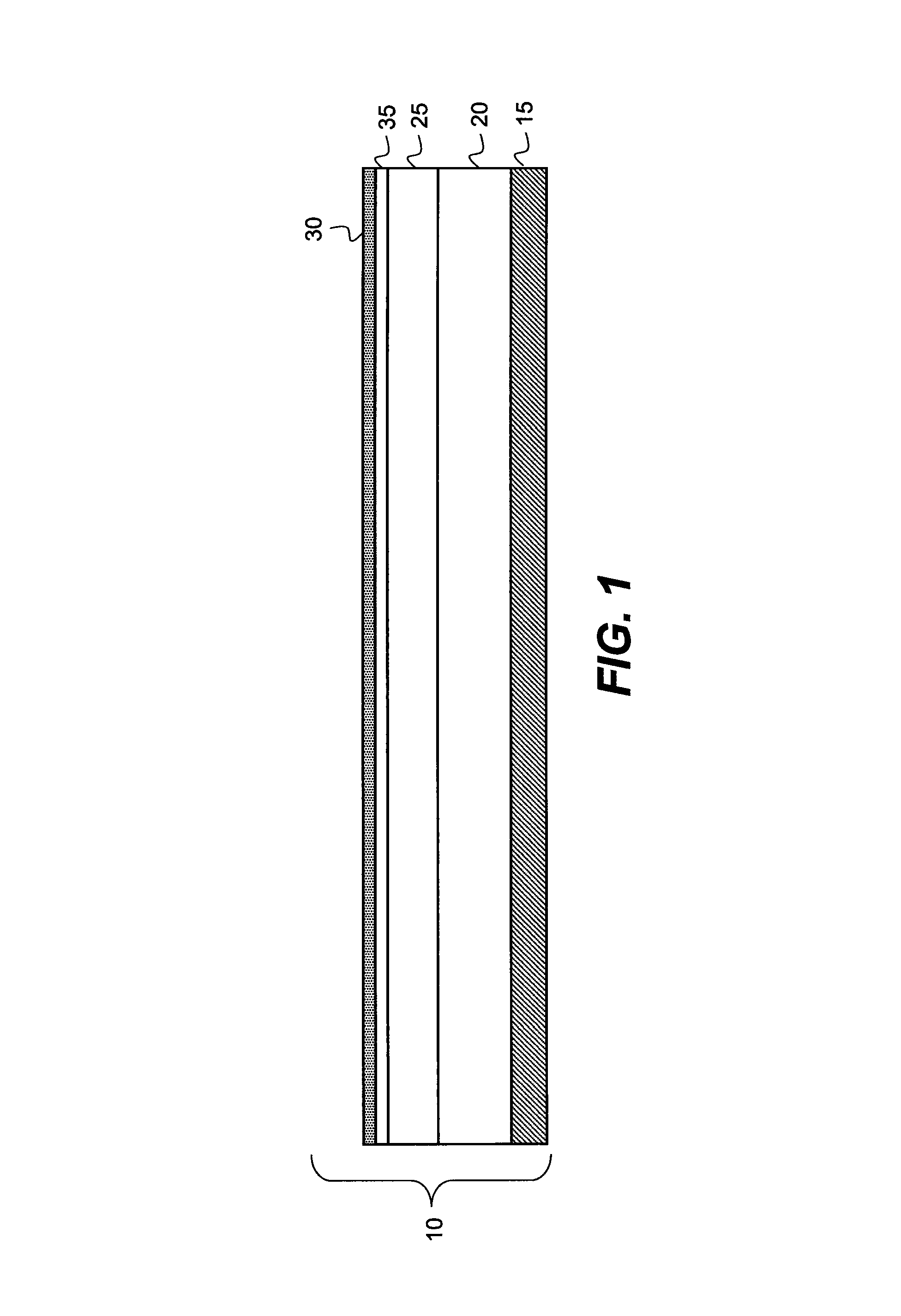

Flexographic Printing Plate with Improved Cure Efficiency

ActiveUS20160131973A1Improved photocurable compositionDesired characteristicPhotosensitive materialsSemiconductor/solid-state device manufacturingQuantum yieldEngineering

A method of making a relief image printing element comprising a plurality of relief printing dots. The method includes the steps of: (a) providing at least one photocurable layer disposed on the backing layer, the at least one photocurable layer being capable of being selectively crosslinked and cured upon exposure to actinic radiation, (b) imagewise exposing the at least one photocurable layer to actinic radiation to selectively crosslink and cure portions of the at least one photocurable layer; and (c) developing the relief image printing element to separate and remove uncrosslinked and uncured portions of the at least one photocurable layer to reveal the relief image therein. The at least one photocurable layer comprises (i) an ethylenically unsaturated monomer; (ii) a binder; and (iii) a photoinitiator exhibiting a quantum yield of initiation (Qi) of more than 0.05 at a 365 nm wavelength.

Owner:MACDERMID PRINTING SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com