Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Loss of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enteric composition for the manufacture of soft capsule wall

ActiveUS20060165778A1Loss of strengthLoss of viscosityOrganic active ingredientsPeptide/protein ingredientsHard CapsuleBiomedical engineering

Owner:PATHEON SOFTGELS INC

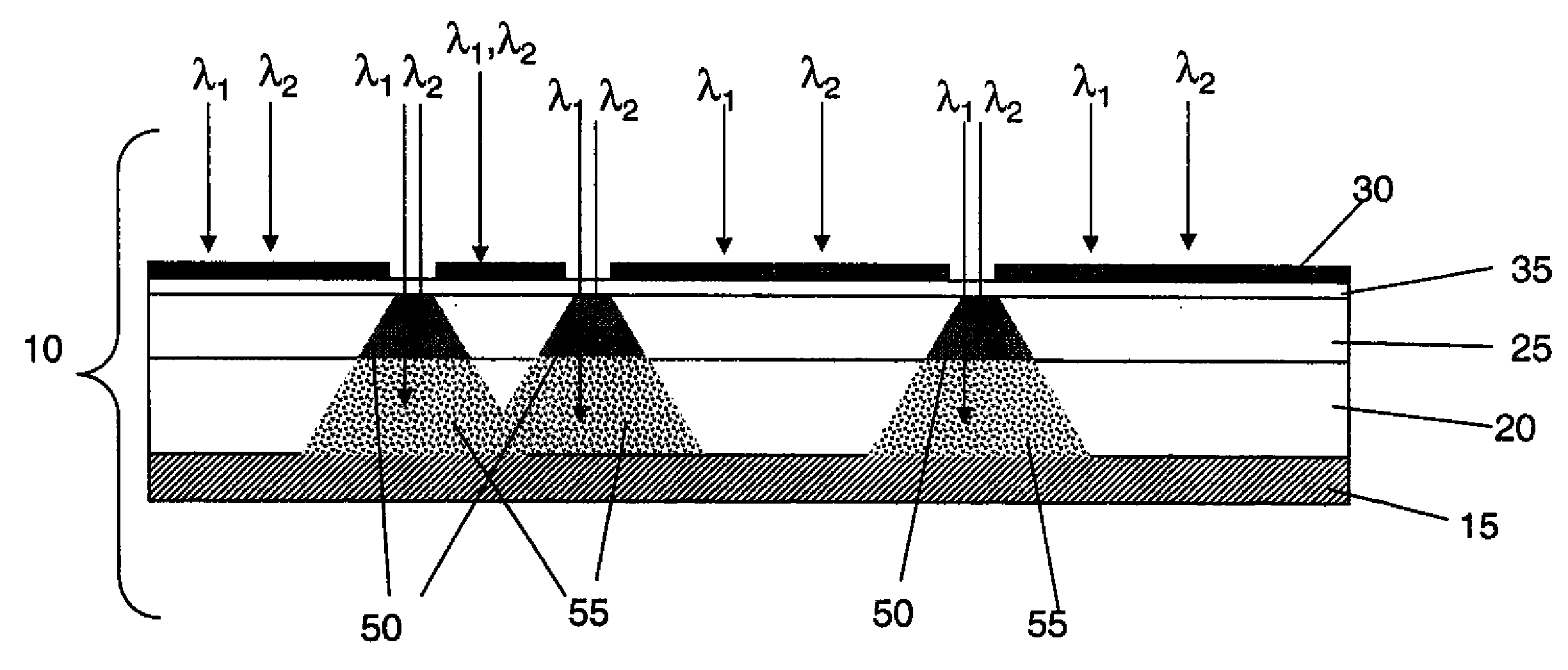

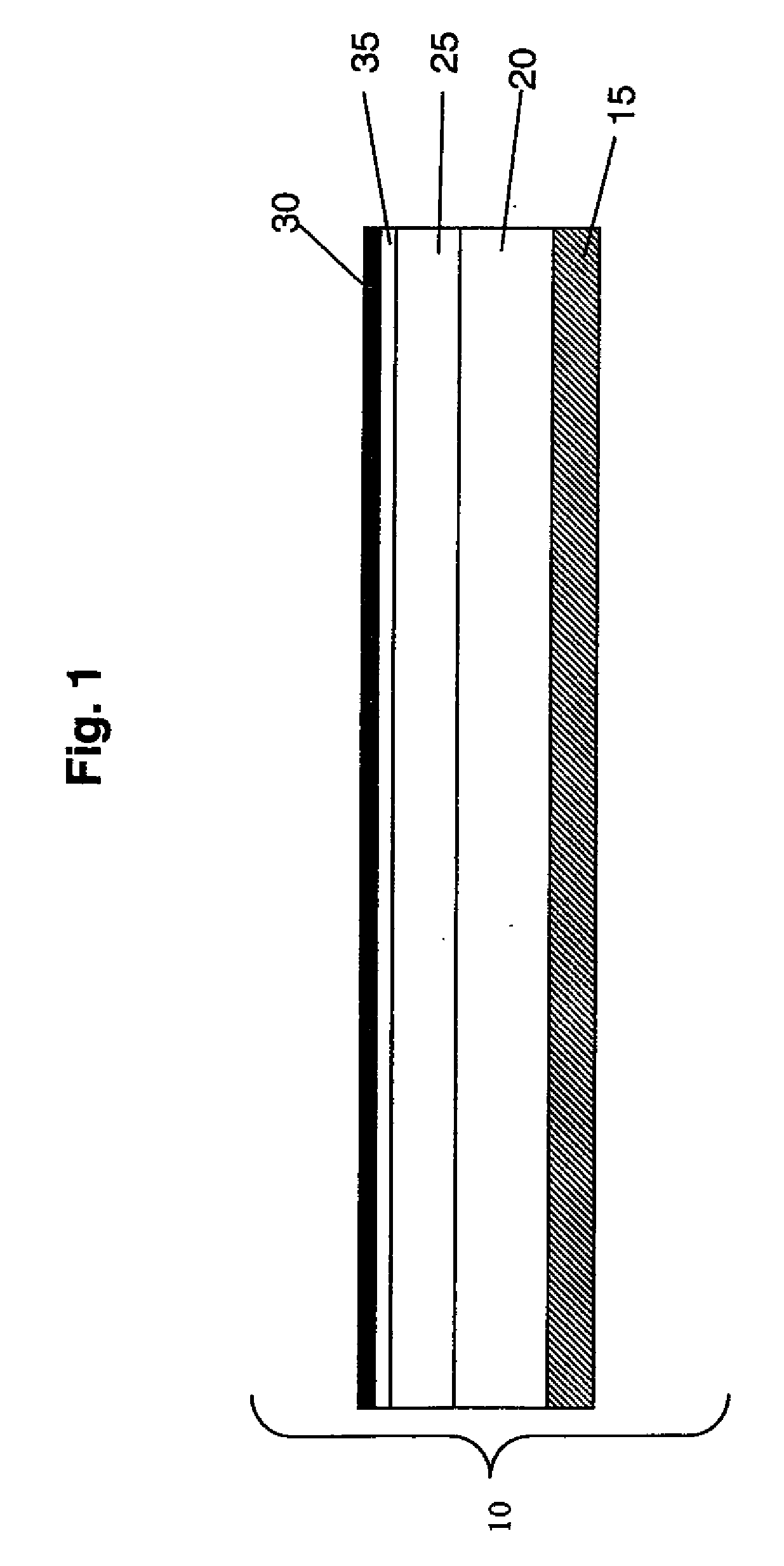

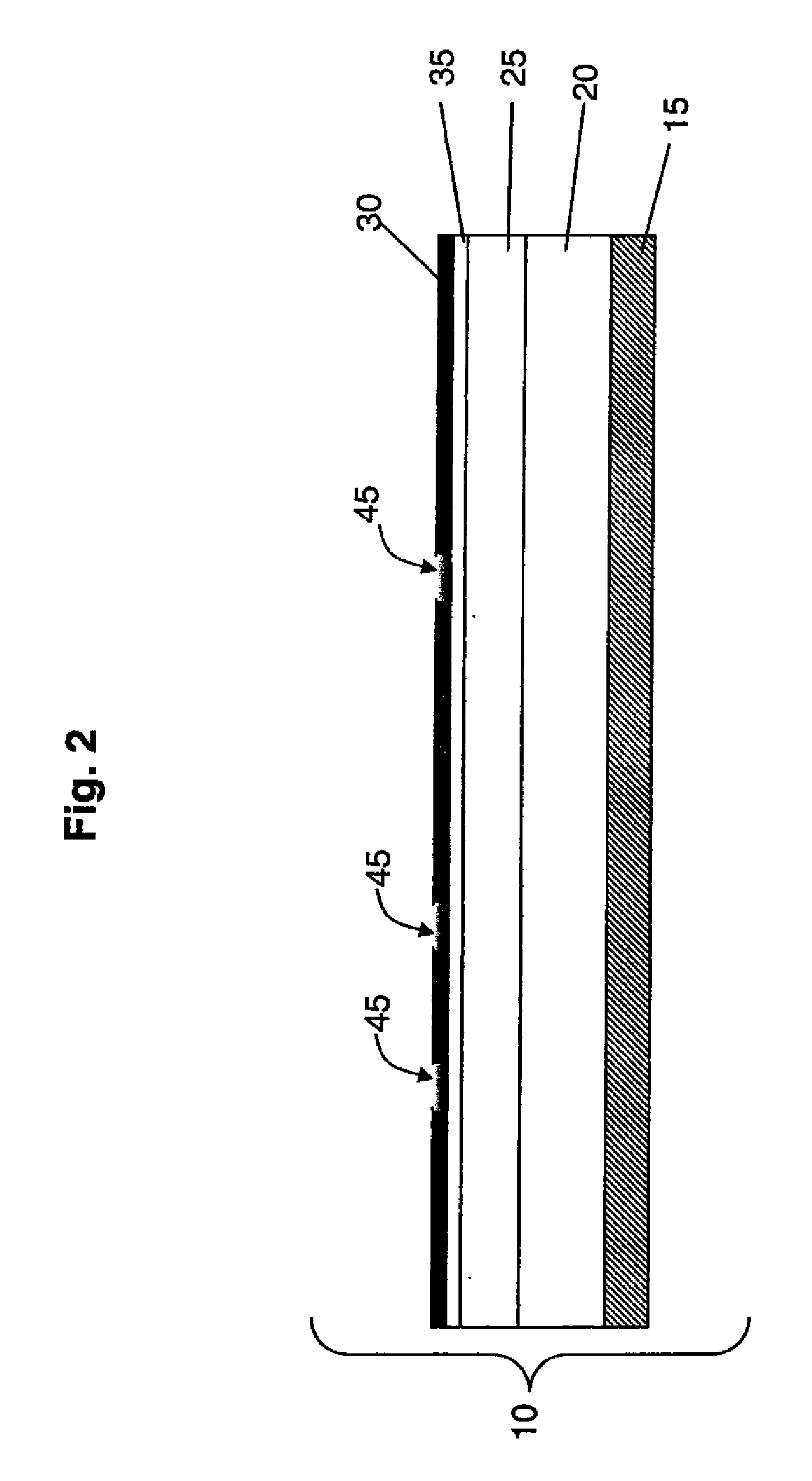

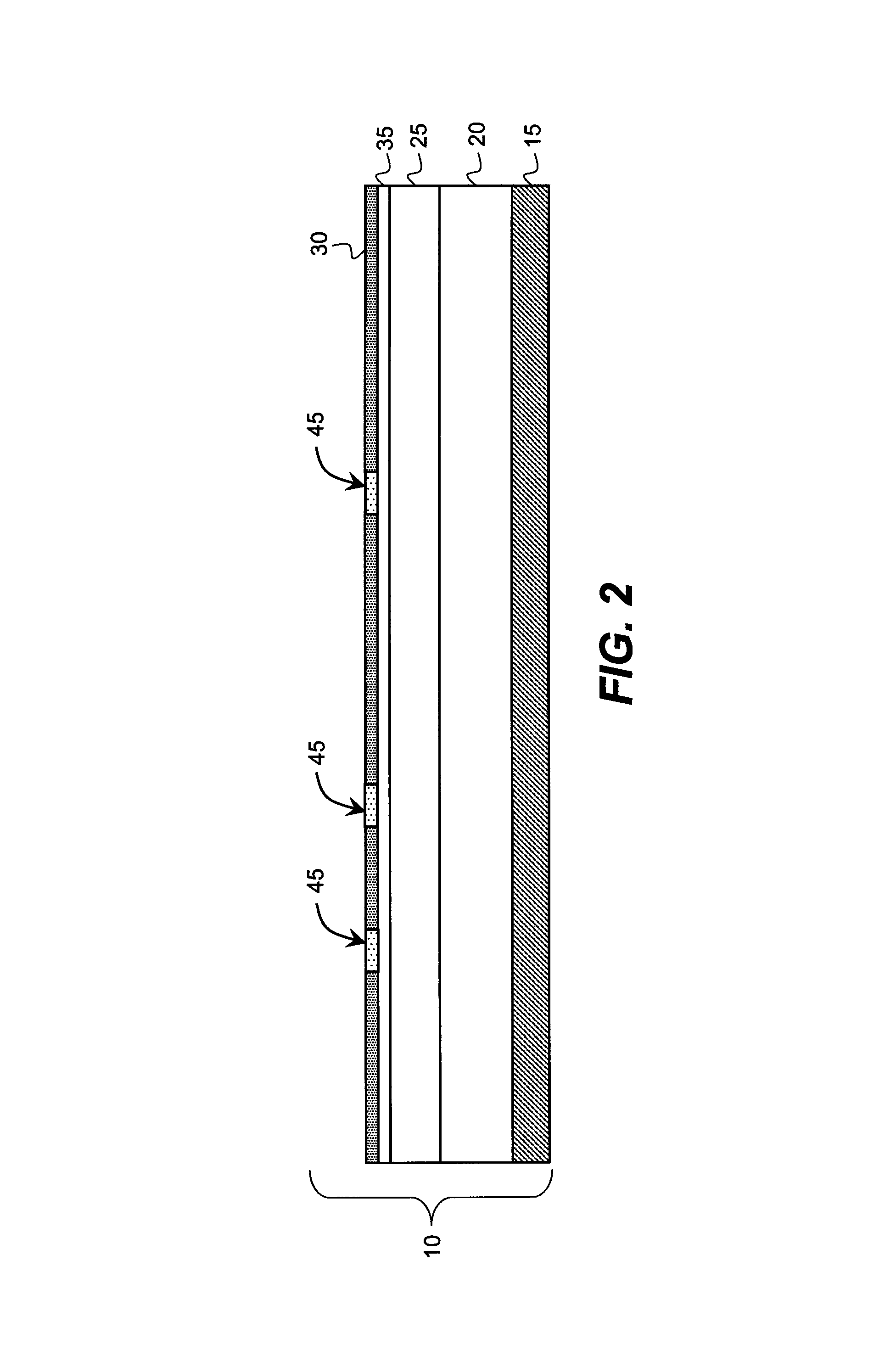

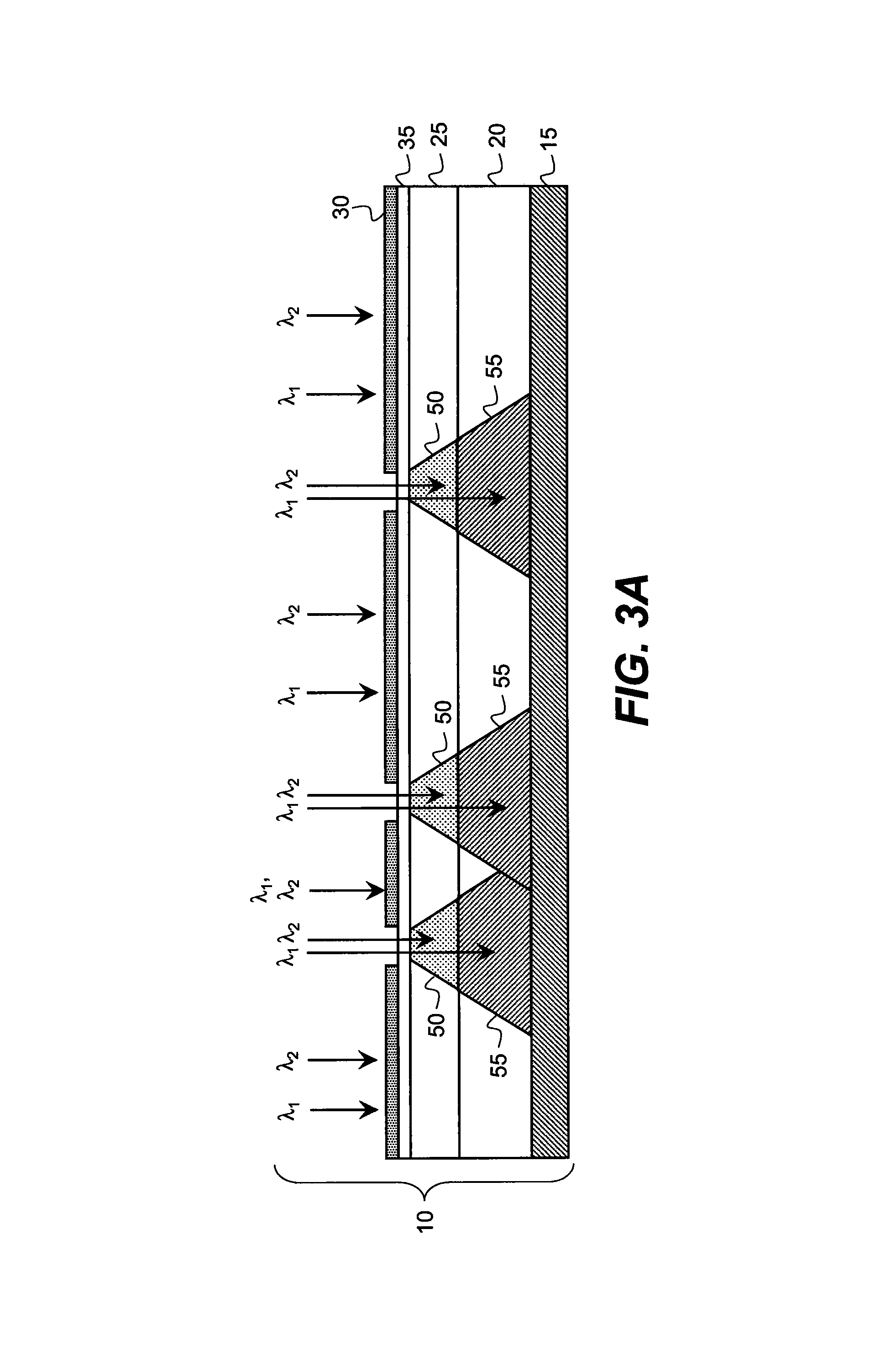

Flexographic element and method of imaging

InactiveUS20100143840A1Without any loss in strengthEnhance the imagePhotosensitive materialsSemiconductor/solid-state device manufacturingRelief printingPhysics

A relief (or flexographic) printing precursor has first and second radiation-sensitive layers, or a plurality of radiation-sensitive layers. The first radiation-sensitive layer is sensitive to a first imaging radiation having a first λmax. The second radiation-sensitive layer is disposed on the first radiation-sensitive layer and is sensitive to a second imaging radiation having a second λmax that differs from the first λmax by at least 25 nm. An infrared radiation ablatable layer can be present and is opaque or insensitive to the first and second imaging radiations and contains an infrared radiation absorbing compound. These relief printing precursors can be used to prepare flexographic printing plates, cylinders, or sleeves where the ablatable layer is used to form an integral mask on the element. Use of the invention provides a relief image without any loss in the strength of the small dots and can be carried out using multiple irradiation steps using the same apparatus.

Owner:EASTMAN KODAK CO

Process for macromolecularizing phenolic compounds etc. and use thereof

InactiveUS20010007762A1Prevent rustLoss of strengthAntibacterial agentsOrganic active ingredientsPoulticeAdhesive

A process for macromolecularizing phenolic compounds or aromatic amine compounds by the action of a catalyst comprising an enzyme having a polyphenol oxidizing activity in the alkali region; applications of the compounds obtained by the above process to thickeners, stabilizers, coagulants, emulsifiers, dispersants, water retainers, antioxidants, adhesives, concrete admixtures, dyes, coating materials, petroleum recovering agent, soil conditioner, a blow-applied seed bearing surface soil stabilizer, deodorants, smell eliminators, agricultural chemical spreaders, feeding stuff binders, bactericides, antimicrobial agents, viral infection inhibitors, bioadhesion preventives, biotic repellents, insecticides, poultices, ink bases or wood treating agents; and method of waste water disposal, a method of deoxygenation and a method of treating wood, concrete or soil in which use is made of the above reaction.

Owner:SDS BIOTECH CO LTD

Enteric composition for the manufacture of soft capsule wall

ActiveUS8685445B2Loss of strengthLoss of viscosityOrganic active ingredientsPeptide/protein ingredientsHard CapsuleBiomedical engineering

Owner:PATHEON SOFTGELS INC

Flexographic element and method of imaging

InactiveUS8153347B2Loss of strengthAvoid the needPhotosensitive materialsSemiconductor/solid-state device manufacturingUltimate tensile strengthRelief printing

Owner:EASTMAN KODAK CO

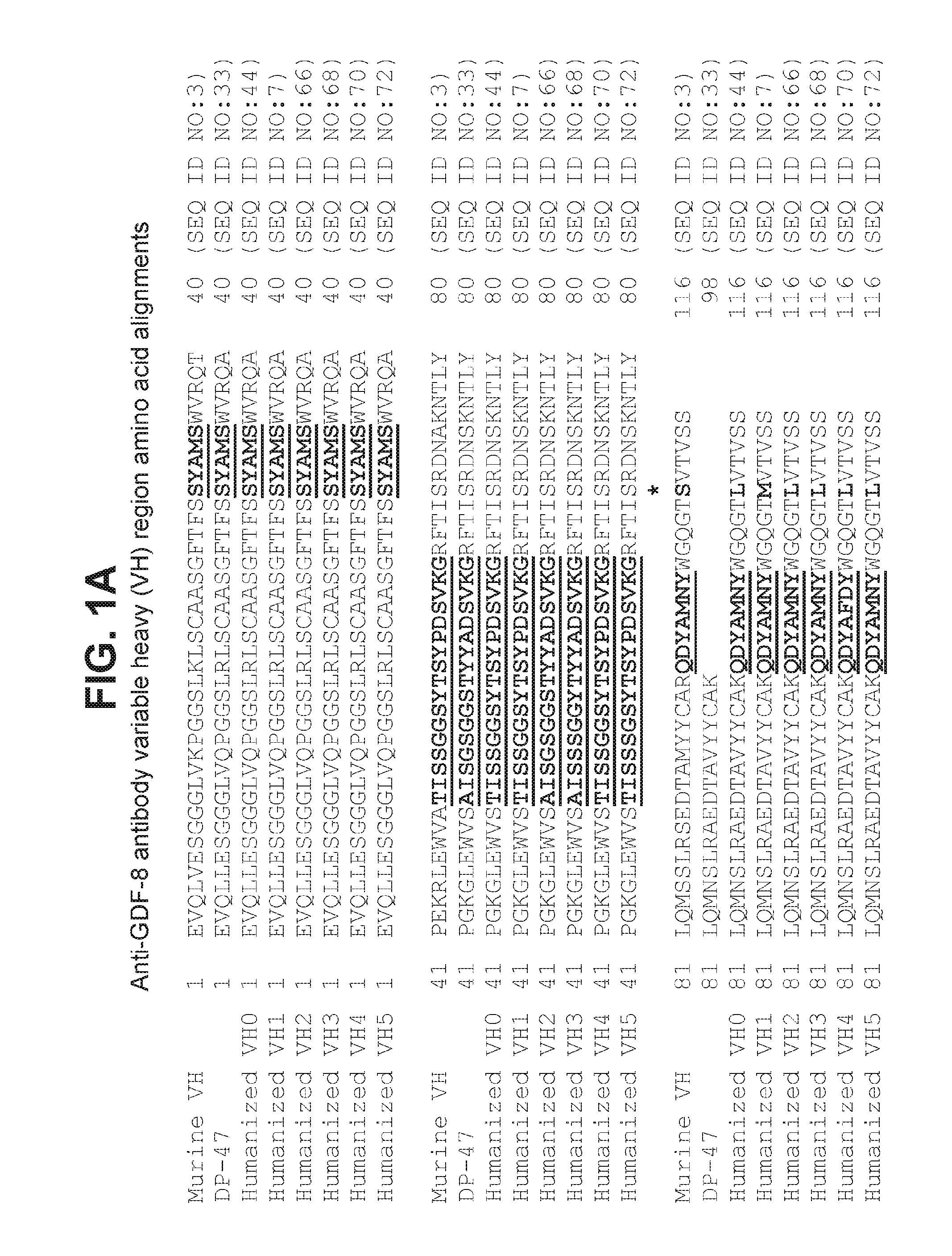

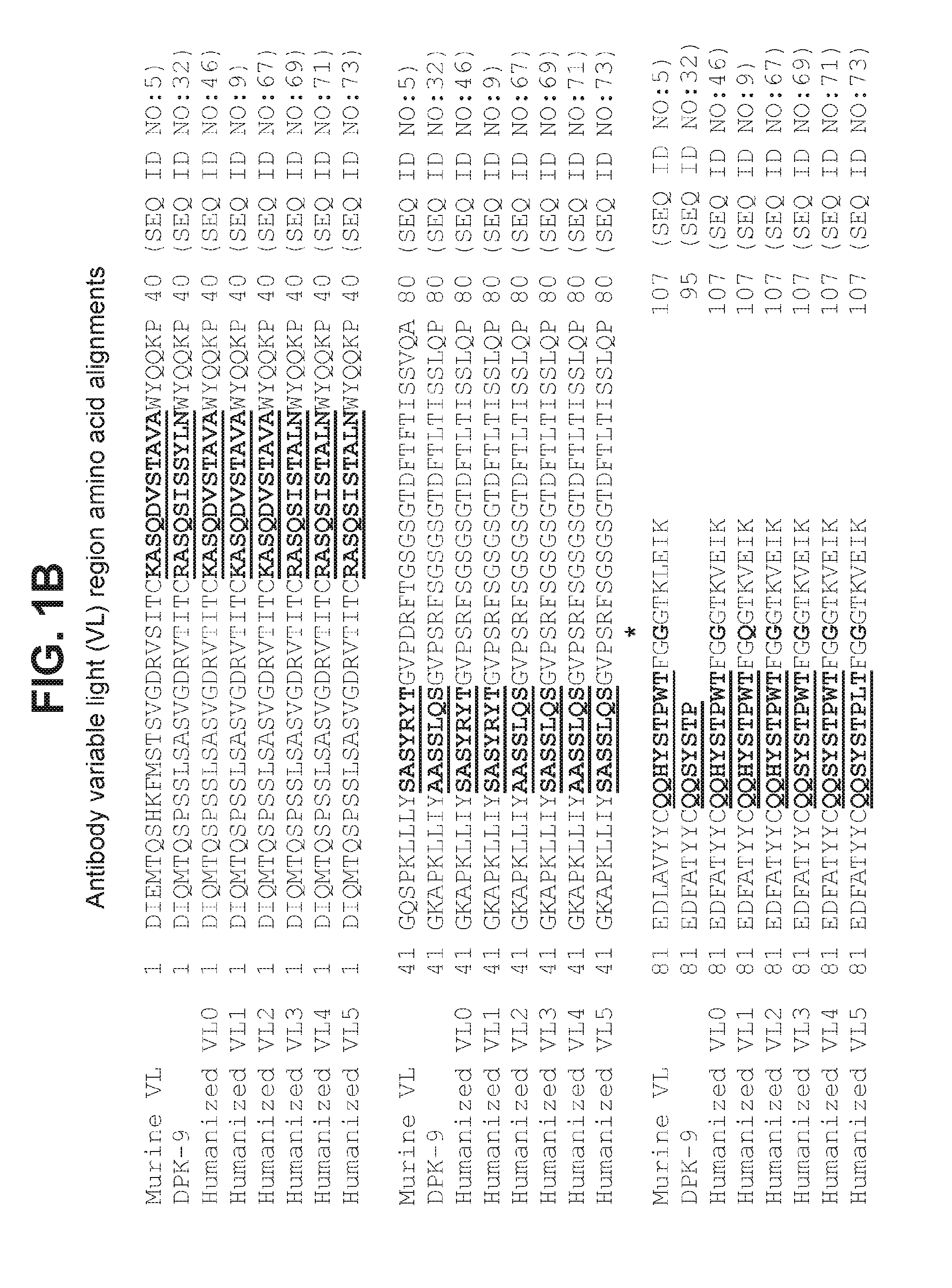

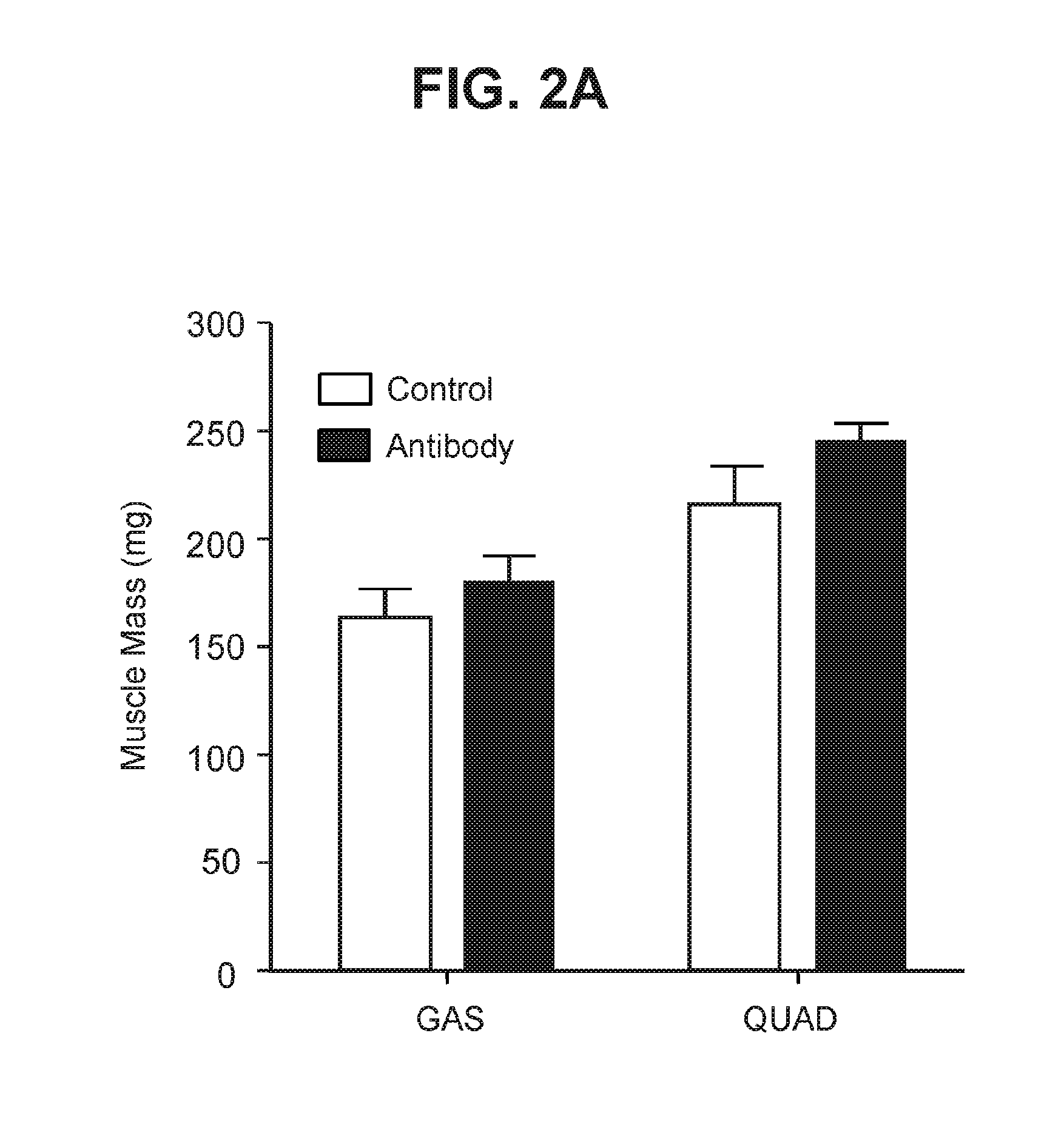

Antagonist antibodies against gdf-8 and uses therefor

InactiveUS20130336982A1Improve performanceLoss of massSugar derivativesMetabolism disorderDiseaseNeuromuscular disease

The disclosure provides improved neutralizing anti-GDF-8 antibodies capable of substantially higher levels of expression in host cells compared to previous anti-GDF-8 antibodies. Also provided are methods of using compositions comprising such antibodies to increase muscle mass or strength, and to treat or prevent muscular disorders, neuromuscular disorders, metabolic disorders, adipose tissue disorders or bone disorders.

Owner:PFIZER INC

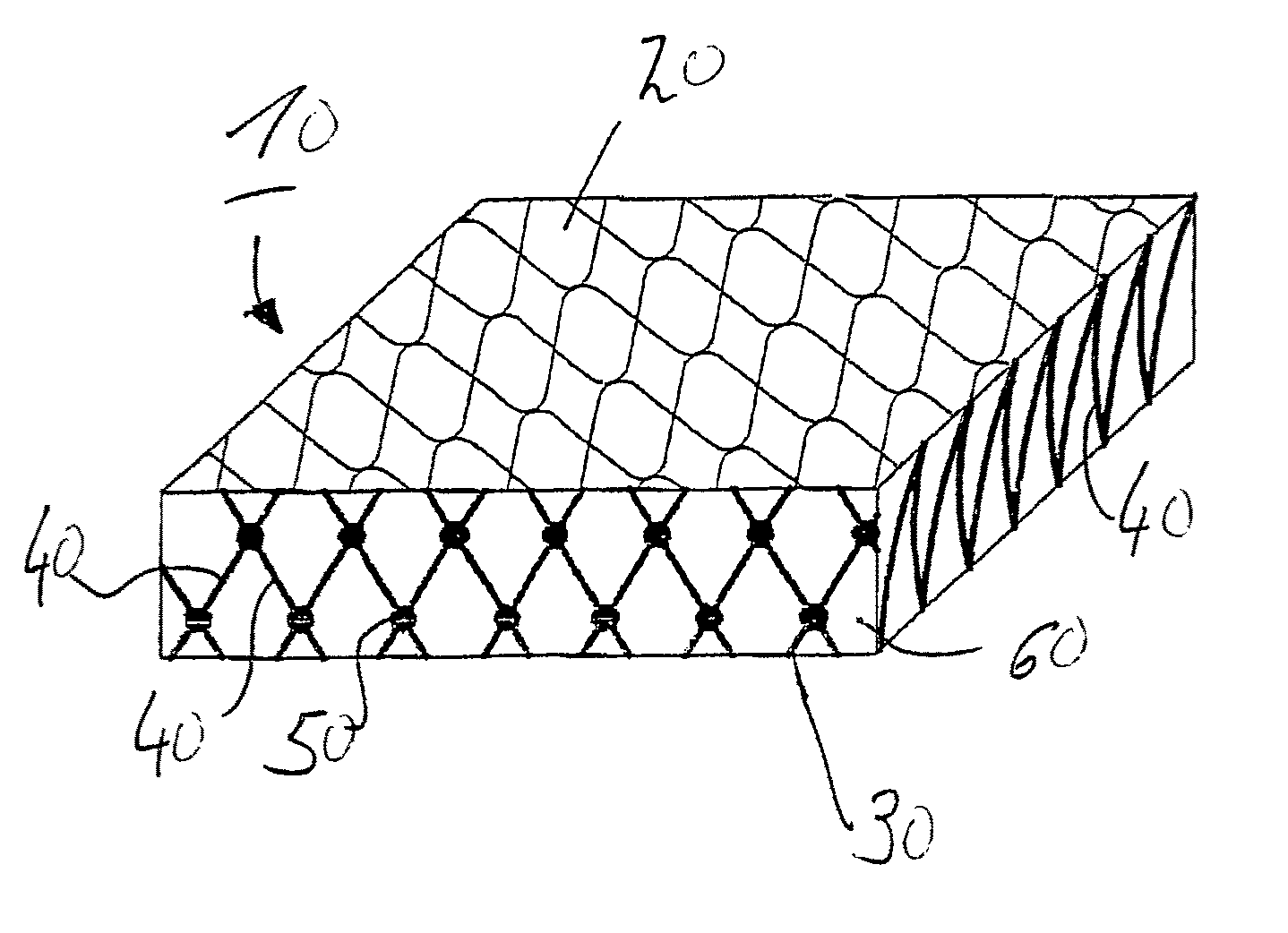

Knitted spacer fabric and method for the production thereof

InactiveUS20090049870A1Improved shear and compressive strengthLoss of strengthOrnamental textile articlesBed linenEngineeringMechanical engineering

A knitted spacer fabric includes an upper textile, a lower textile and mutually crossing supporting threads arranged between the upper textile and the lower textile which connect the upper and the lower textiles to one another. Portions of the supporting threads are connected to one another at crossing points.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

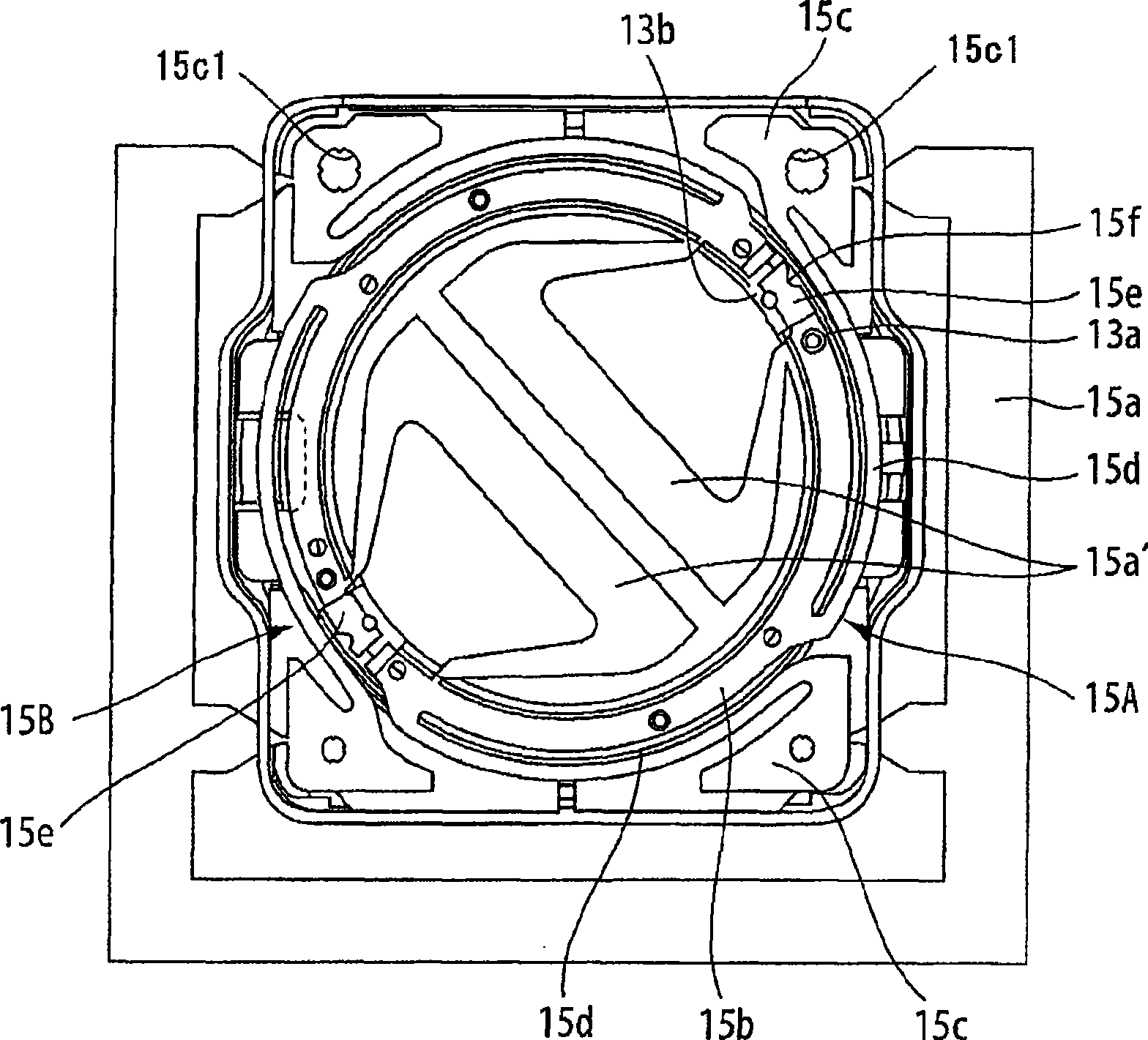

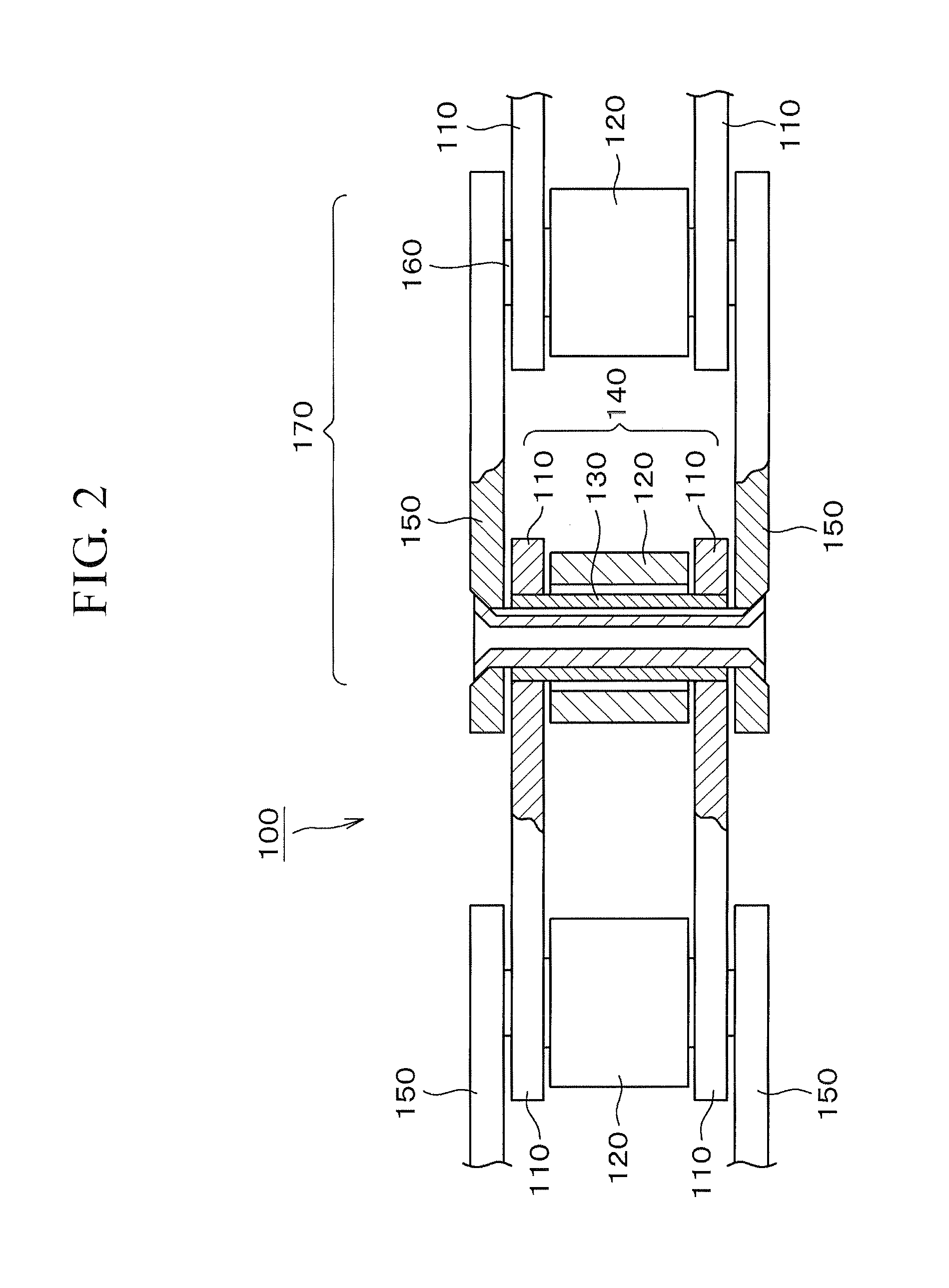

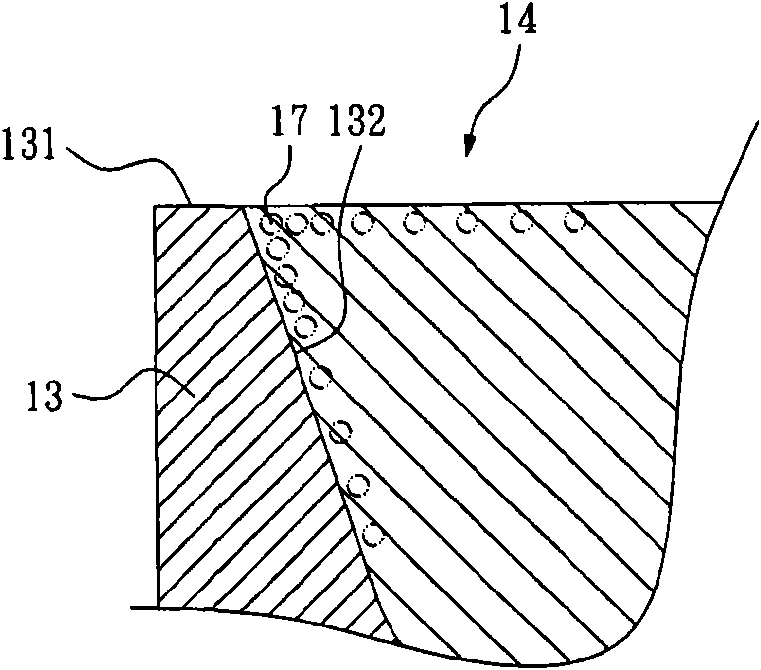

Lens drive device, spring member and manufacturing methods therefor

InactiveCN101435908AFacilitate thinningEnsure intervalDynamo-electric machinesMountingsElectricityEngineering

A lens drive device, spring member and manufacturing method thereof prevents narrow space of soldering tin of part wherein braze welding is implemented in a designed space to accelerate the device to be slim. The lens drive device (1) includes a movable body (sleeve 13) movable in an optical axis direction, a support body (maintaining element 19) supporting the movable body through a spring member and a magnetic drive mechanism having a coil (18) on the movable body and driving the movably body along the optical axis, the spring element (second plate spring) which may include spring pieces (15A, 15B) electrically separated from each other, formed with a coil connecting part (15e) to which one of a winding start part and a winding end part of the coil is electrically connected. The movablebody is provided with an accommodating part (13b) for accommodating the coil connecting part (15e) bended.

Owner:NIDEC SANKYO CORP

Knitted spacer fabric and method for the production thereof

InactiveUS7779654B2Improved shear and compressive strengthLoss of strengthOrnamental textile articlesWarp knittingEngineeringMechanical engineering

A knitted spacer fabric includes an upper textile, a lower textile and mutually crossing supporting threads arranged between the upper textile and the lower textile which connect the upper and the lower textiles to one another. Portions of the supporting threads are connected to one another at crossing points.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

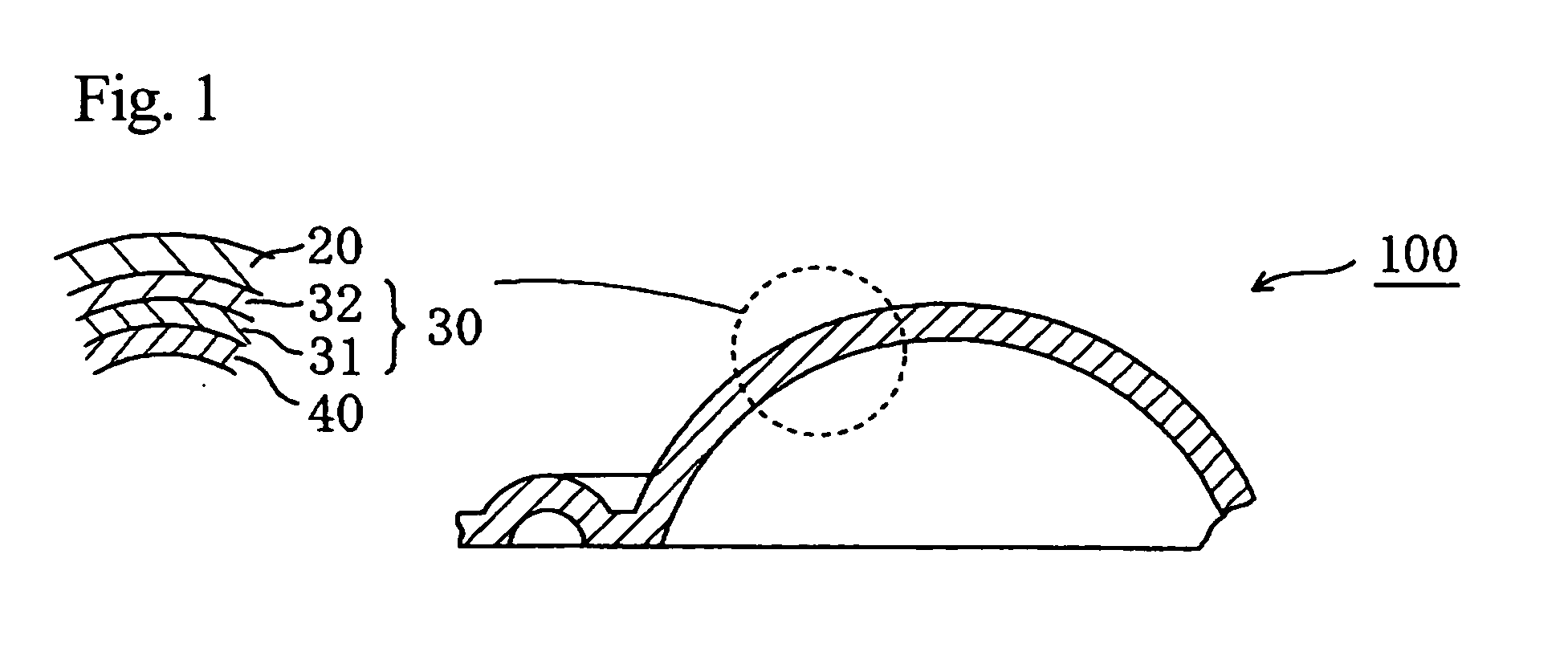

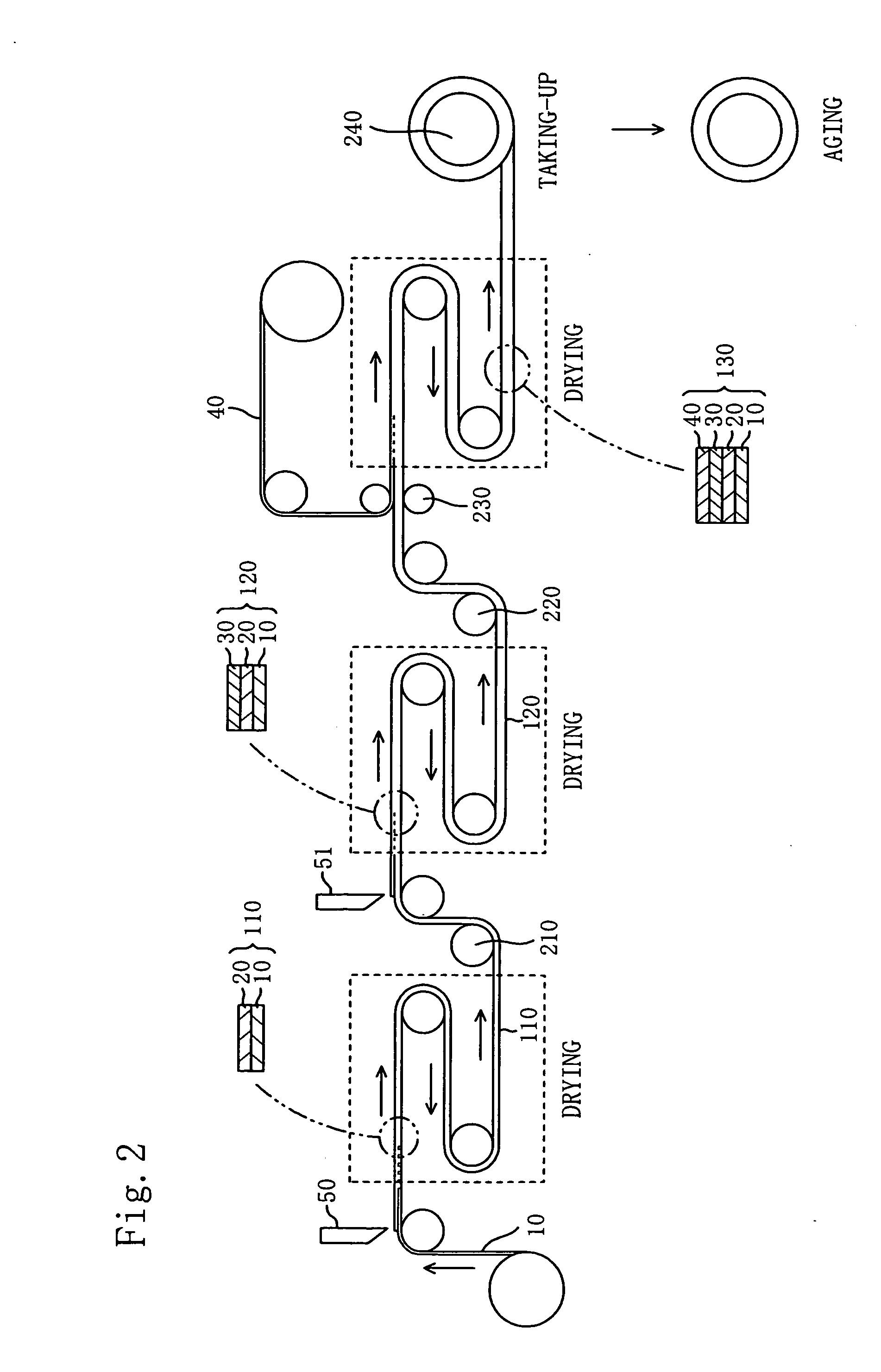

Speaker member and method for manufacturing the same

InactiveUS20060281381A1Light weightLoss of strengthEngine sealsOther chemical processesAdhesiveLoudspeaker

The speaker member includes: a base material; and a resin film layer laminated on the base material through an adhesive layer. The adhesive layer has a heat shrinkage ratio of 0.5 to 1.0%; the resin film layer has a heat shrinkage ratio of 0.8 to 1.3%; and the heat shrinkage ratio of the adhesive layer is smaller than the heat shrinkage ratio of the resin film layer. The method of manufacturing a speaker comprises the steps of: applying a predetermined resin composition on a release material; drying the resin composition, so as to form a resin film layer on the release material; applying a predetermined adhesive on the resin film layer, so as to form an adhesive layer; attaching together the resin film layer formed on the release material and a base material through the adhesive layer, so as to form a laminate; subjecting the laminate to aging; and molding the laminate subjected to aging by using a metal mold having a predetermined shape.

Owner:ONKYO KK

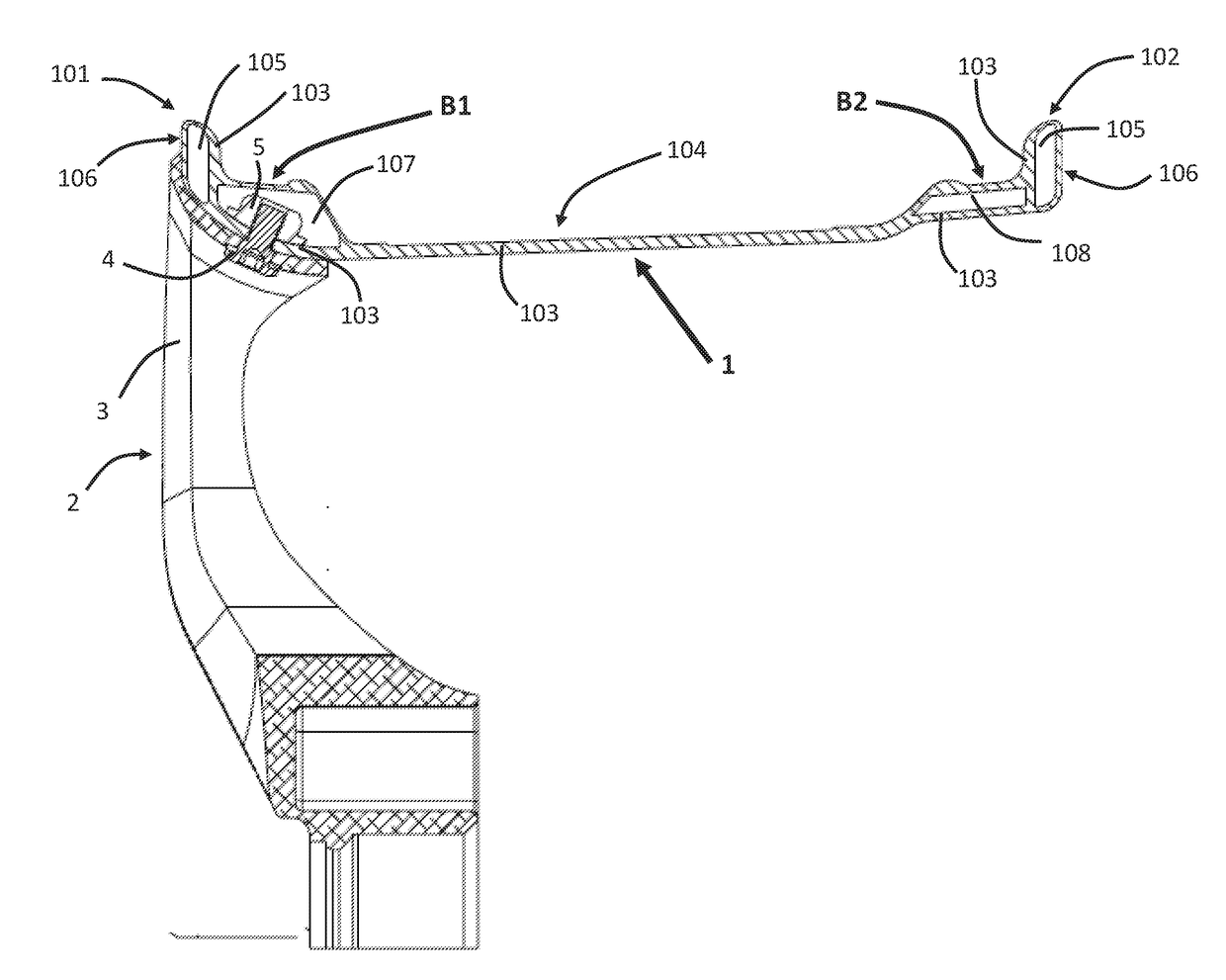

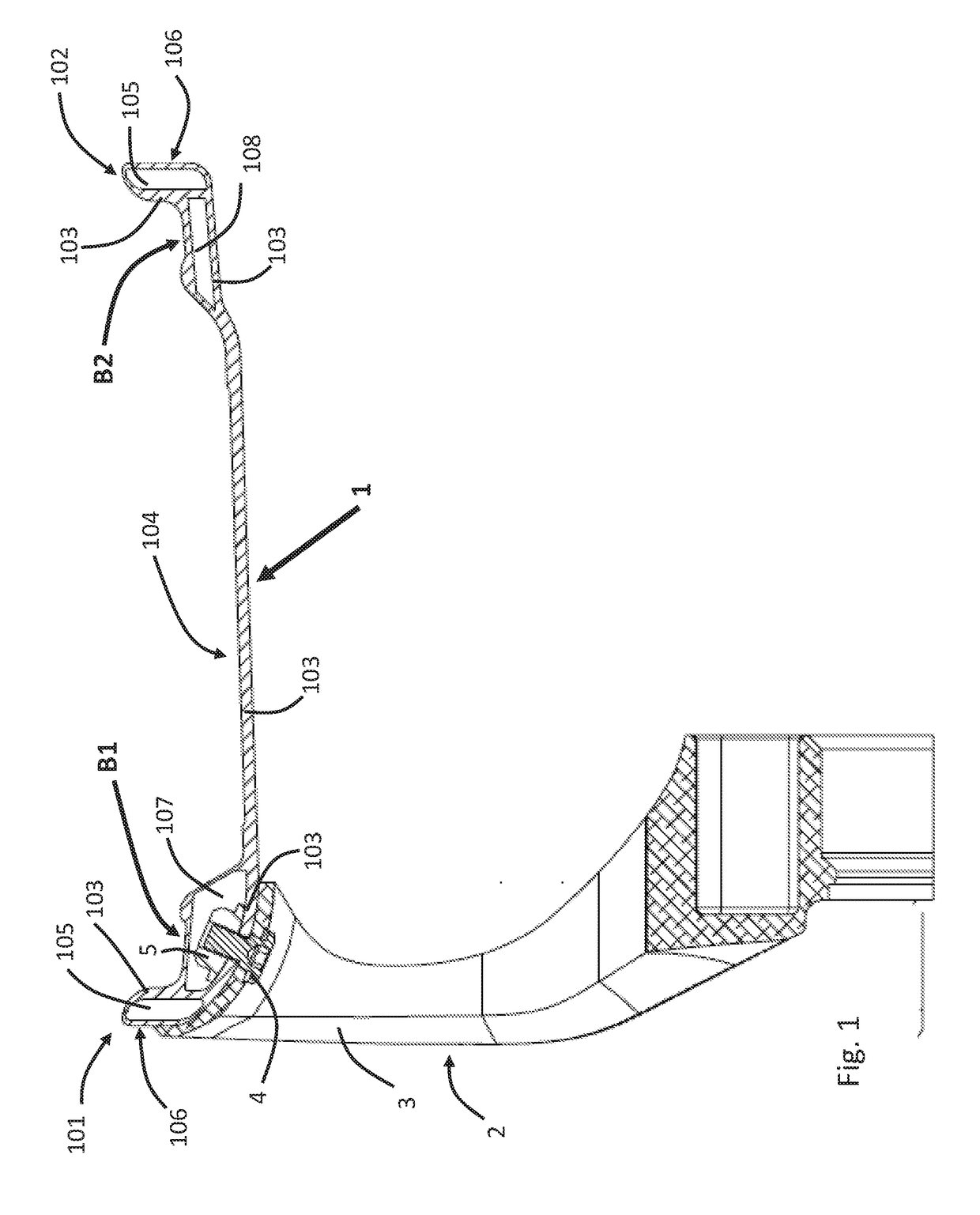

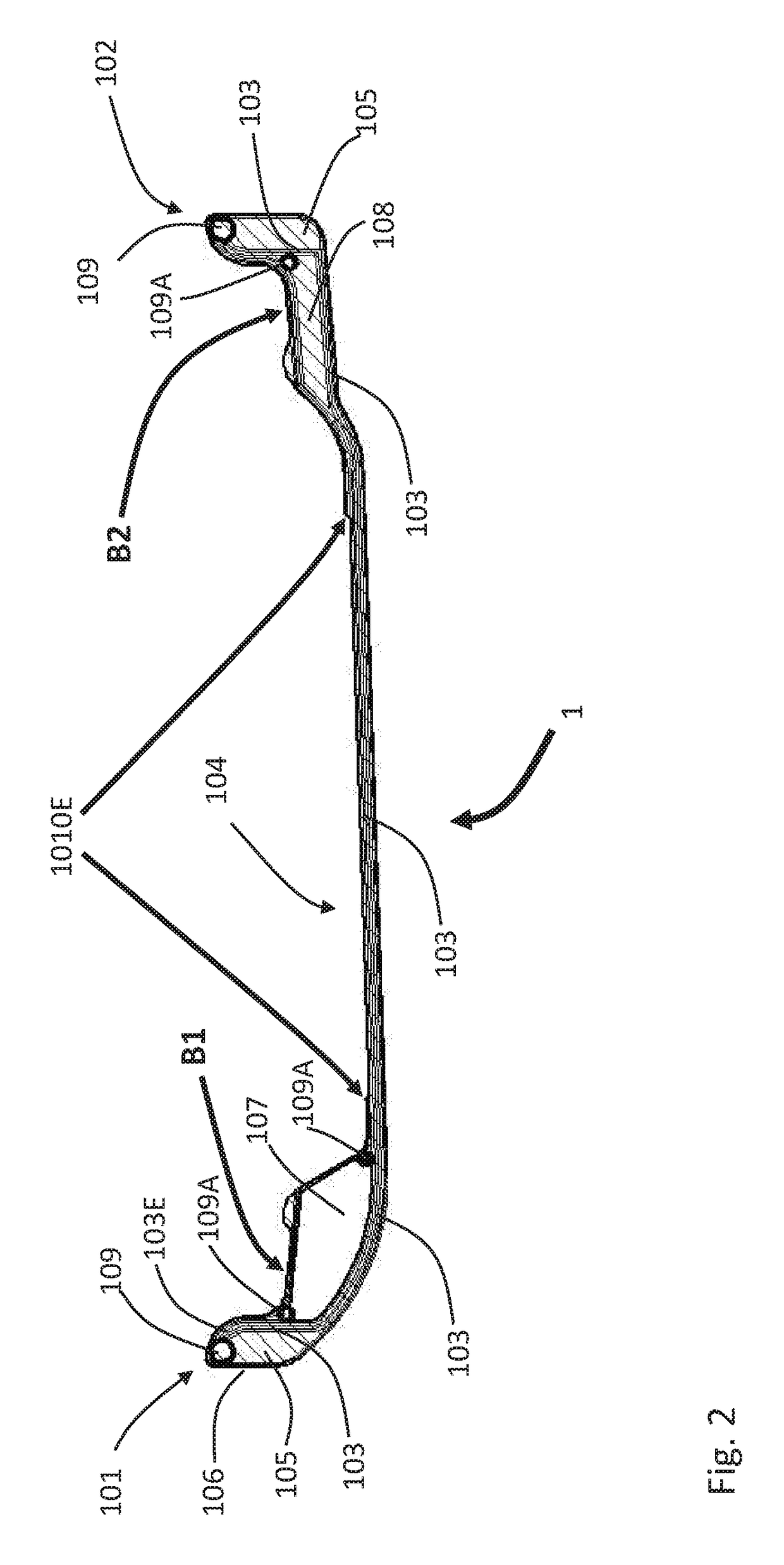

Rim for a wheel

ActiveUS20170087929A1Improve impact resistanceIncrease stiffnessRimsNon-metallic wheel bodyEngineeringPolymer

Herein is described a non-metallic rim for a wheel, the rim comprising:a barrel having first and second flanges extending radially outward from opposing edges of the barrel, and the barrel comprising a first bead seat and a second bead seat arranged axially inwardly, respectively, of the first and second flanges,whereina primary structural component extends at least through the first flange and the barrel, the primary structural component being capable of bearing the majority of the radial and / or lateral load that, in use, would be borne by the rima protective insert is disposed between an outer face of the first flange and the primary structural component and / orat least a portion of the first bead seat is spaced apart from the primary structural component andthe primary structural component, bead seat and, if present, the protective insert are bound by a polymer matrix.

Owner:DYMAG GRP LTD

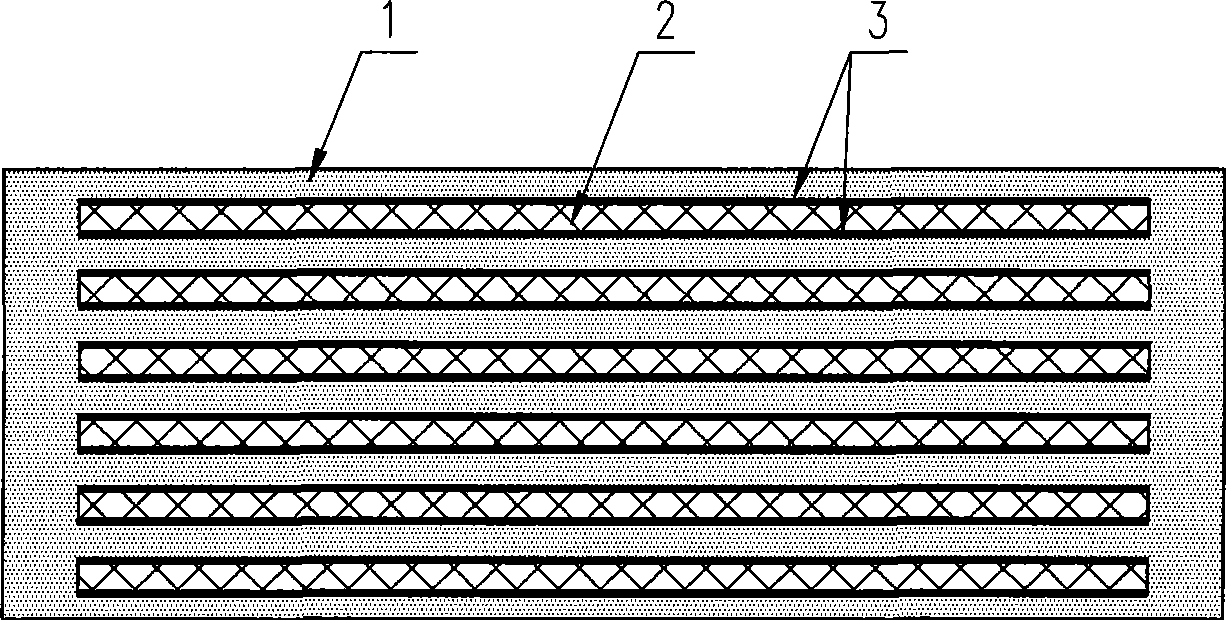

FRP reinforced rubber vibration isolator and method of producing the same

ActiveCN101469758AImprove carrying capacityGuaranteed flexibilityNon-rotating vibration suppressionEpoxyPolyester

A FRP reinforced rubber vibration isolator and manufacturing method thereof, relate to a vibration isolator and a manufacturing method thereof. The vibration isolator is formed by a rubber layer and a FRP plate with adhesive layers arranged on the upper and lower surfaces which are staggeredly superposed, vulcanized and bonded, wherein the FRP plate is made of fiber reinforced materials and a resin substrate, the fiber reinforced material is one or more of glass fiber, high-strength glass fiber, carbon fiber, aramid fiber, basalt fiber or polyester fiber, the resin substrate is one of the epoxy resin, unsaturated polyester resin, phenolic resin or vinyl ester resin, the FRP plate is formed by superposing 1 to 50 single layer plate which have different principal directions. The manufacturing method comprises preparing FRP plate, arranging adhesive layer, superposing, vulcanization molding. The vibration isolator has higher bearing capacity and excellent damping performance, durability, corrosion resistance, and has simple and applicable manufacturing method.

Owner:LIUZHOU OVM MASCH CO LTD +2

Method for manufacturing multi-component structural members

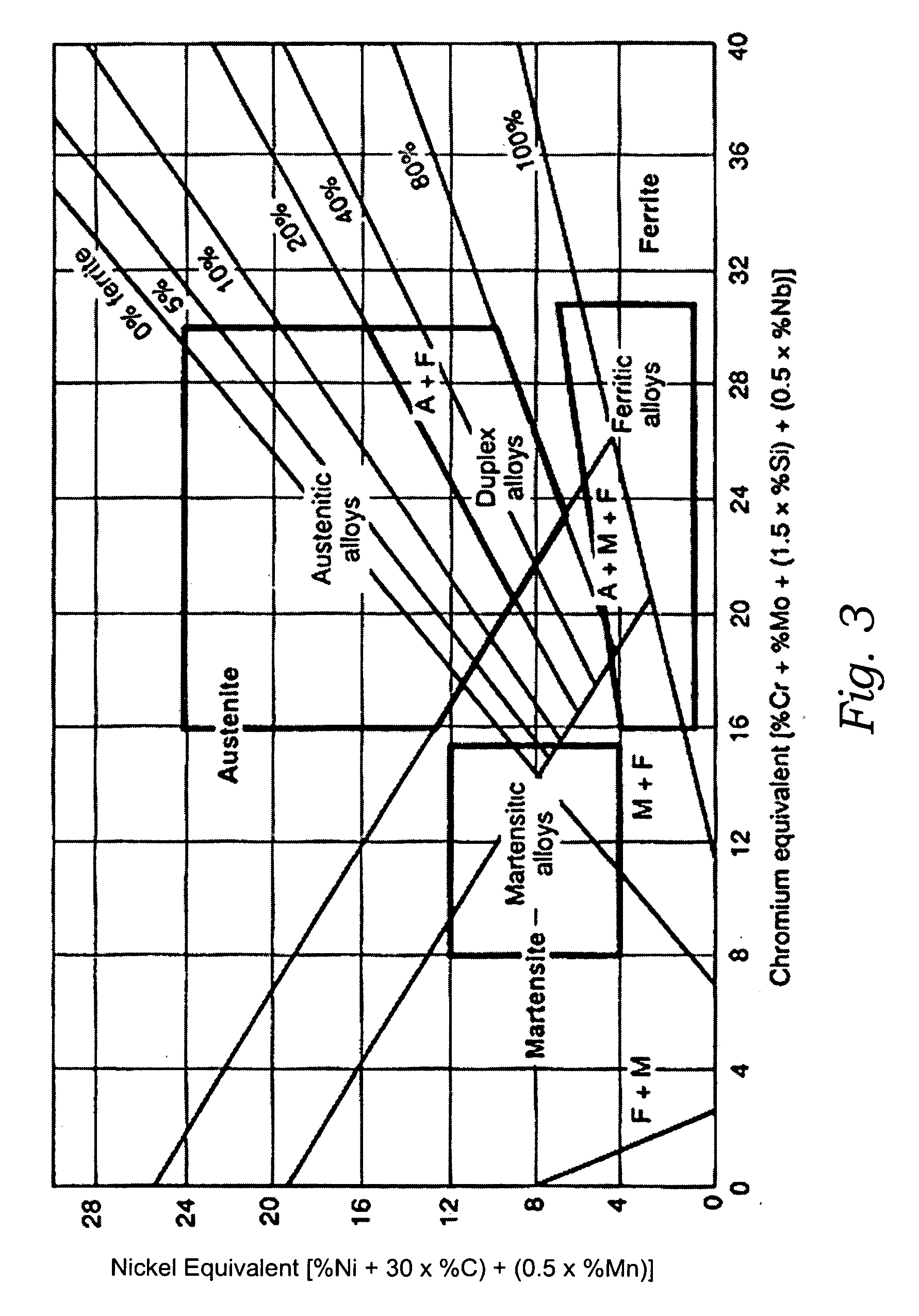

InactiveUS20070012748A1Improve ductilityLoss of hardness and strengthCooking-vessel materialsArc welding apparatusMartensitic stainless steelStructural element

A method for fabricating multi-component structural members includes brazing a first component of air-hardenable martensitic stainless steel to a second component made of ferrous, stainless or nickel alloy steels. The martensitic stainless steel first component is preferably type 410, 420 or 440 and formed while in the annealed condition. The martensitic stainless steel component is simultaneously brazed and hardened to the second structural component by heating both components to between 950° C. and 1100° C. while depositing a brazing compound between the structural components to form a joint. The structural members are then cooled at a rate of 25° C. per minute or greater so as to transform the air-hardenable martensitic stainless steel to a predominantly martensitic state.

Owner:KVA

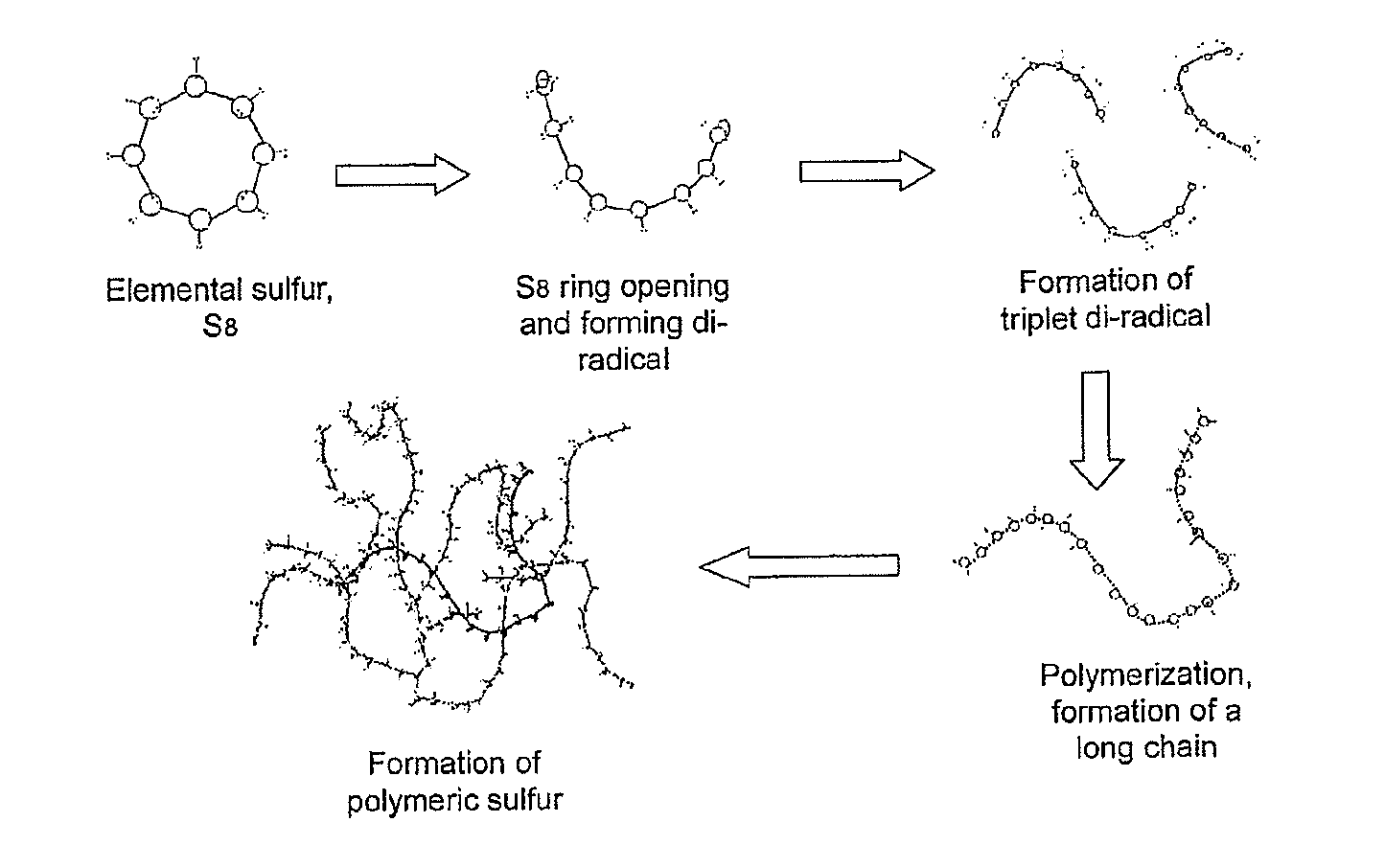

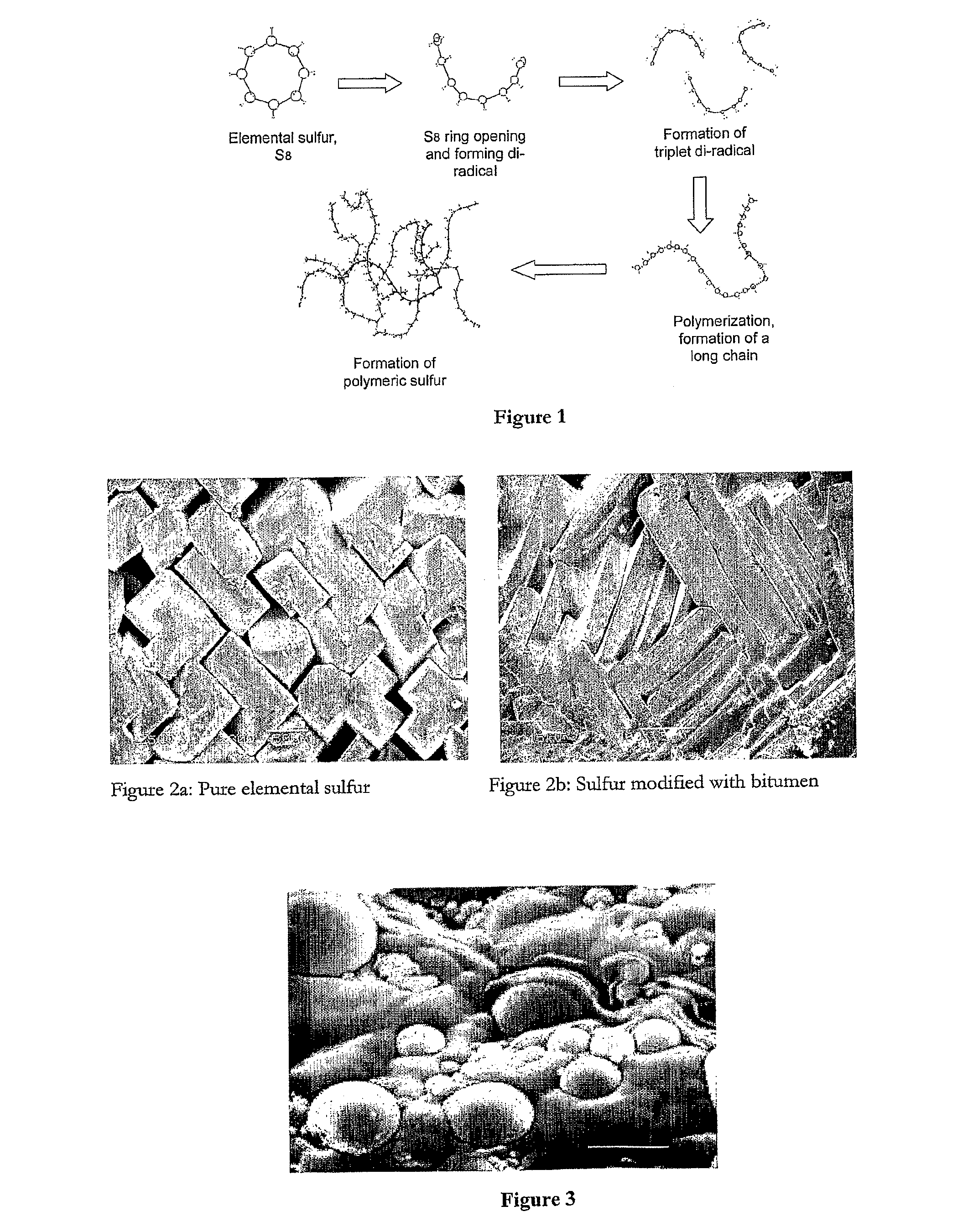

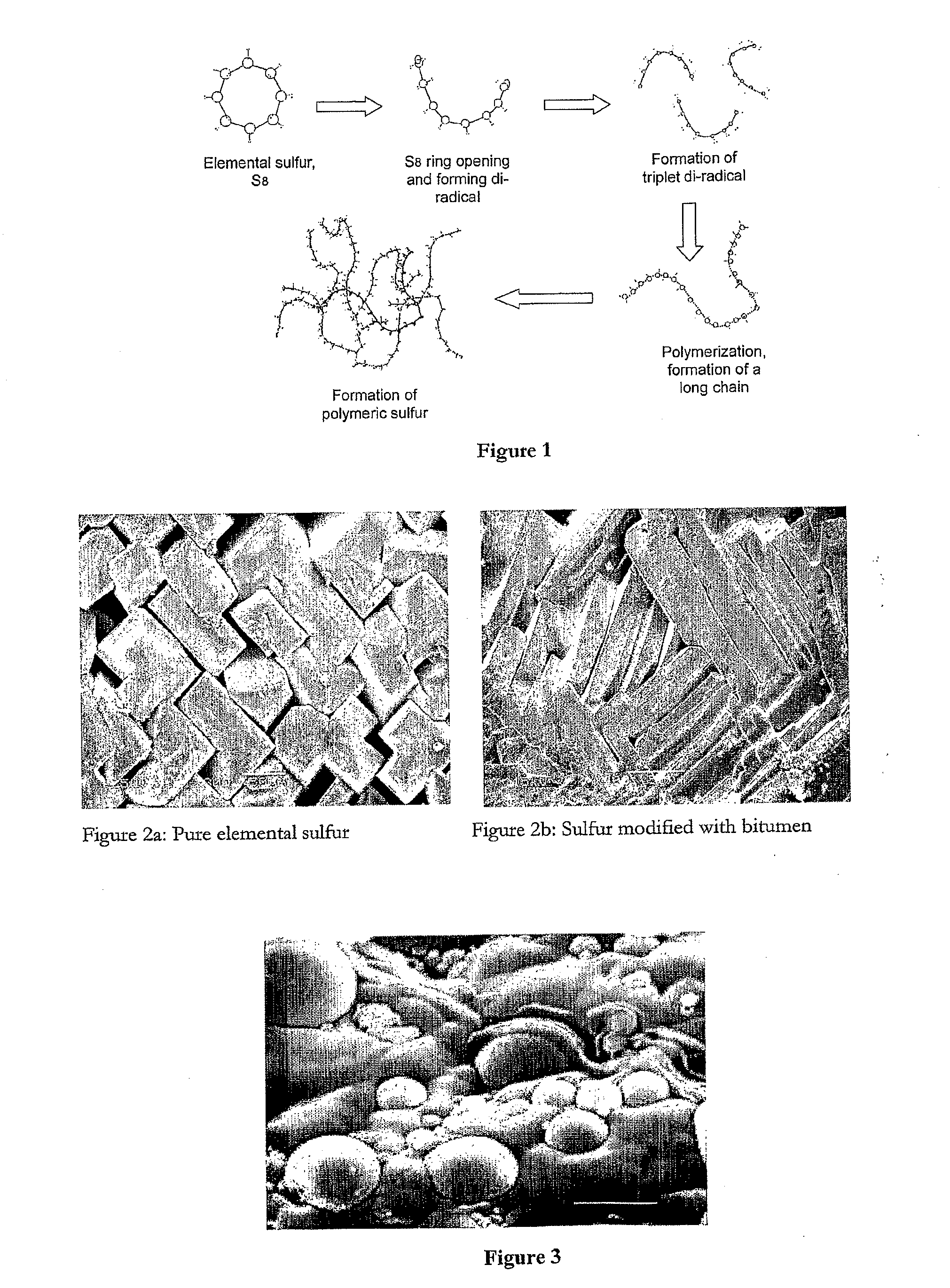

Use of surfactant in the preparation of modified sulfur and sulfur cement

ActiveUS8859719B2Excellent property in term of strength and durability and leachabilityEasy to useSolid waste disposalSulfur preparation/purificationSulfur concreteMaterials science

Owner:UNITED ARAB EMIRATES UNIVERSITY

Enzymatic opacifying composition for paper, pulp or paperboard, processes using same and pulp, paper or paperboard produced therefrom

InactiveUS20070029059A1High opacityHigh strengthMicroorganism/enzyme additionVegetable material additionPorosityPaperboard

An organic agent for enhancing opacity in paper, paperboard or pulp comprises a hydrolase or an oxido-reductase; this enzymatic opacifying agent overcomes drawbacks associated with traditional organic and inorganic opacifying agents but also serves to provide increased strength and reduced porosity in paper and paperboard.

Owner:TRI TEX

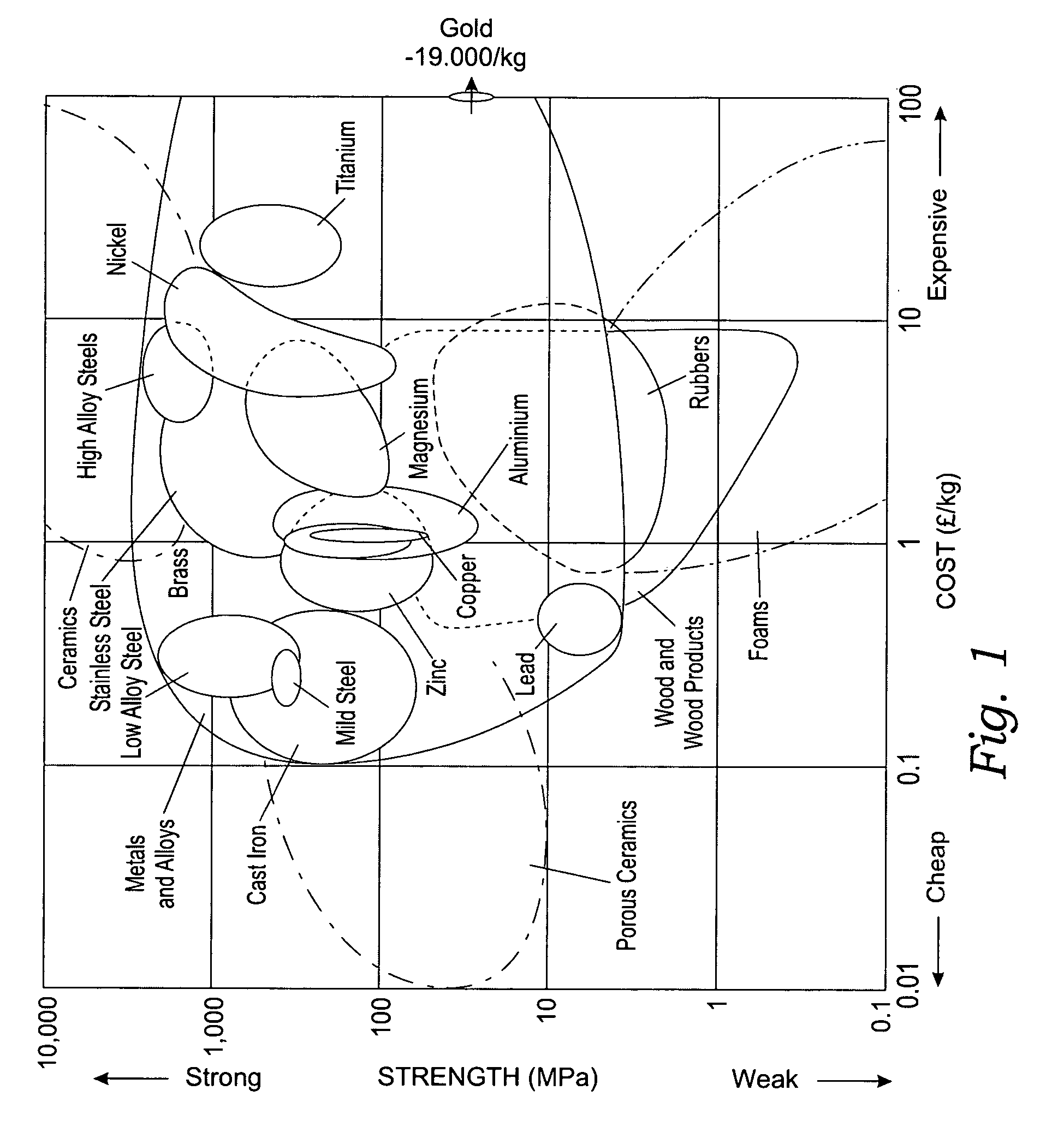

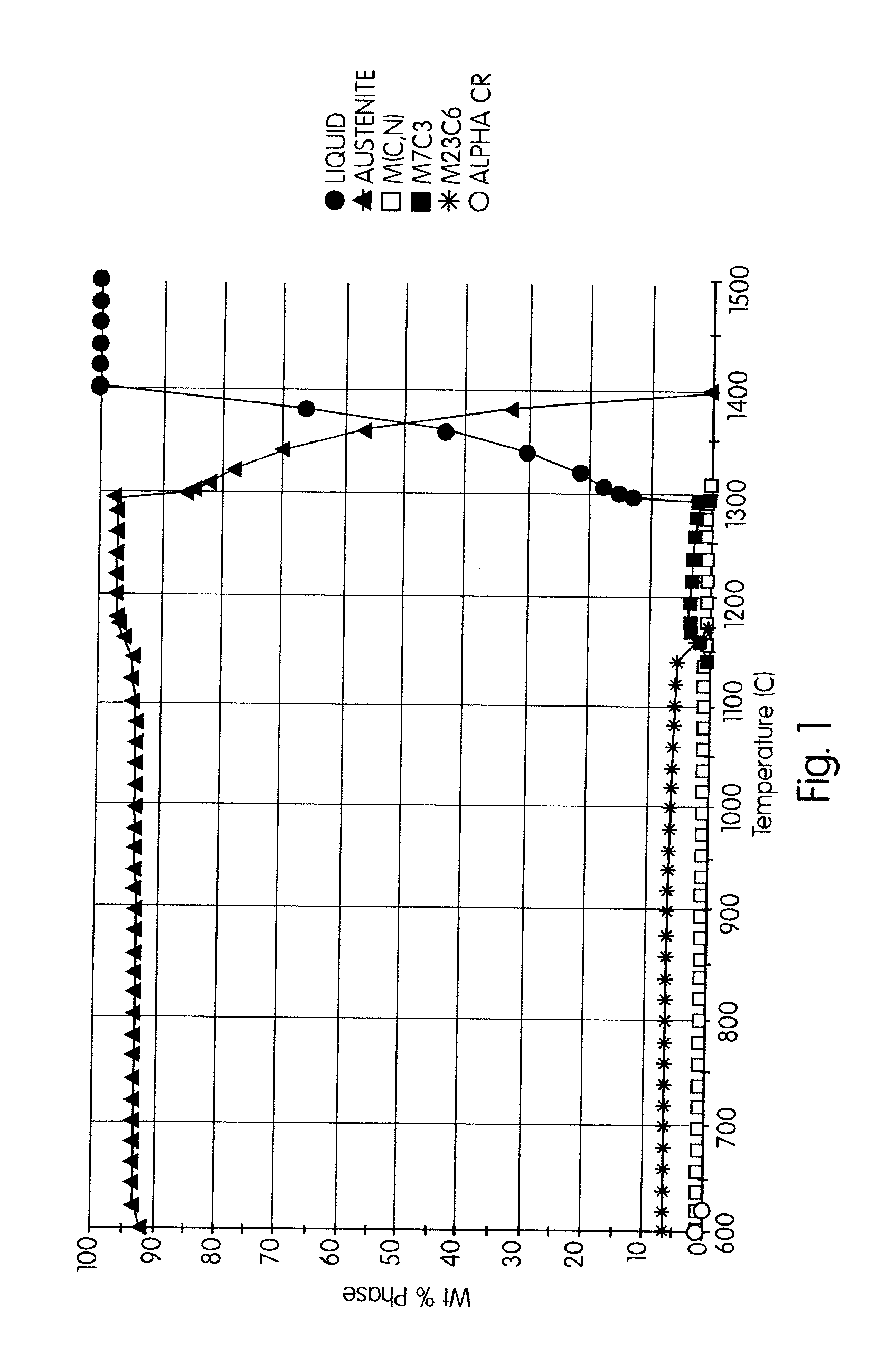

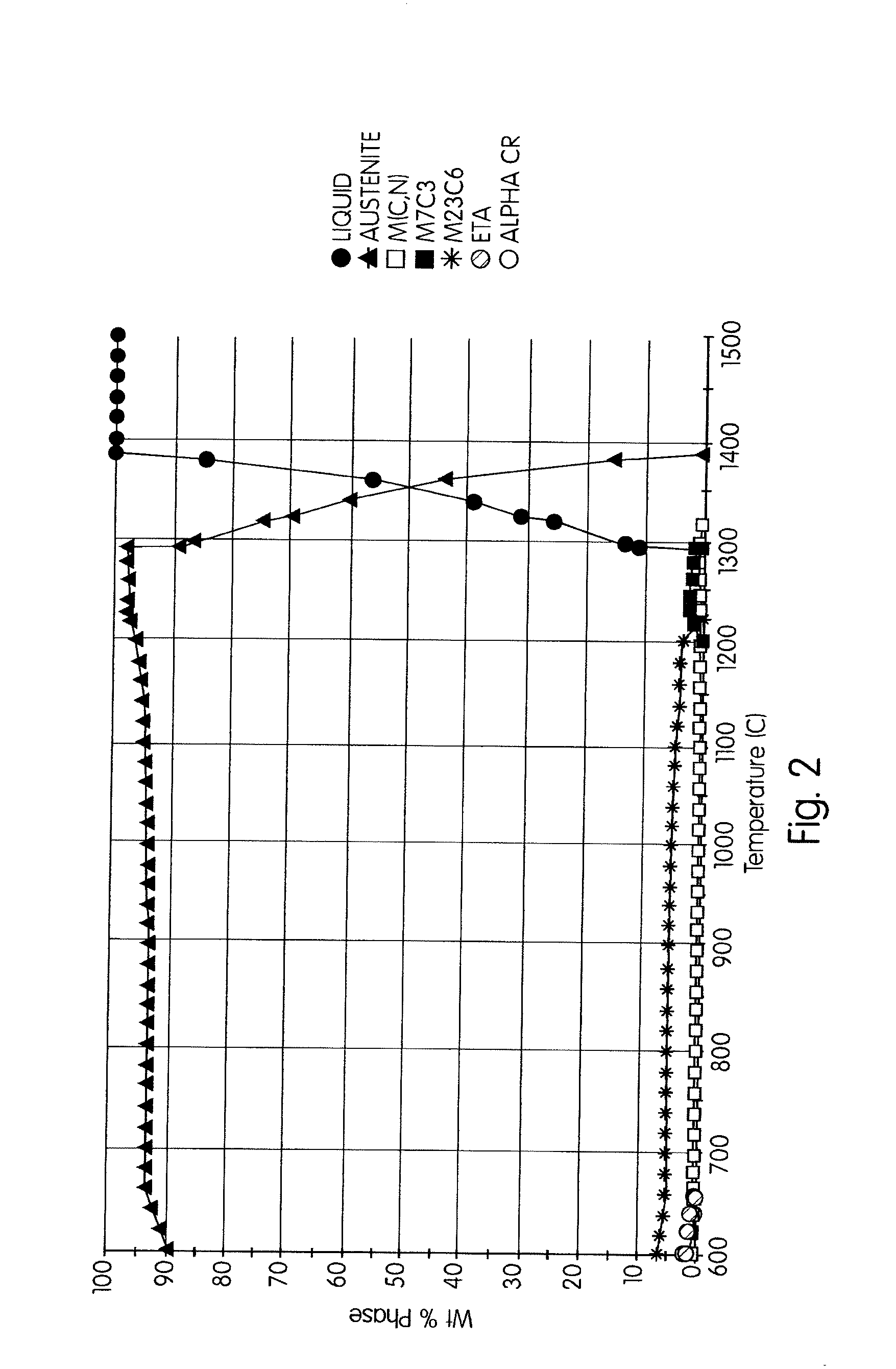

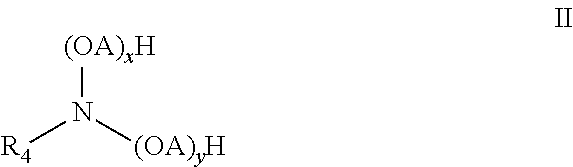

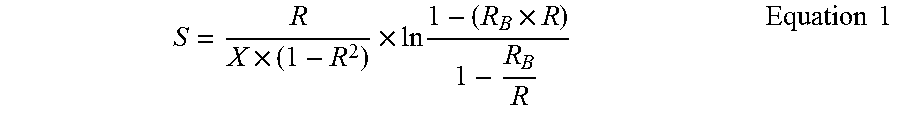

Cast Heat-Resistant Austenitic Steel with Improved Temperature Creep Properties and Balanced Alloying Element Additions and Methodology for Development of the Same

InactiveUS20100303669A1Improve creep-resistanceImprove stabilityTesting metalsAlloyUltimate tensile strength

The present invention addresses the need for new austenitic steel compositions with higher creep strength and higher upper temperatures. The present invention also discloses a methodology for the development of new austenitic steel compositions with higher creep strength and higher upper temperatures.

Owner:UT BATTELLE LLC

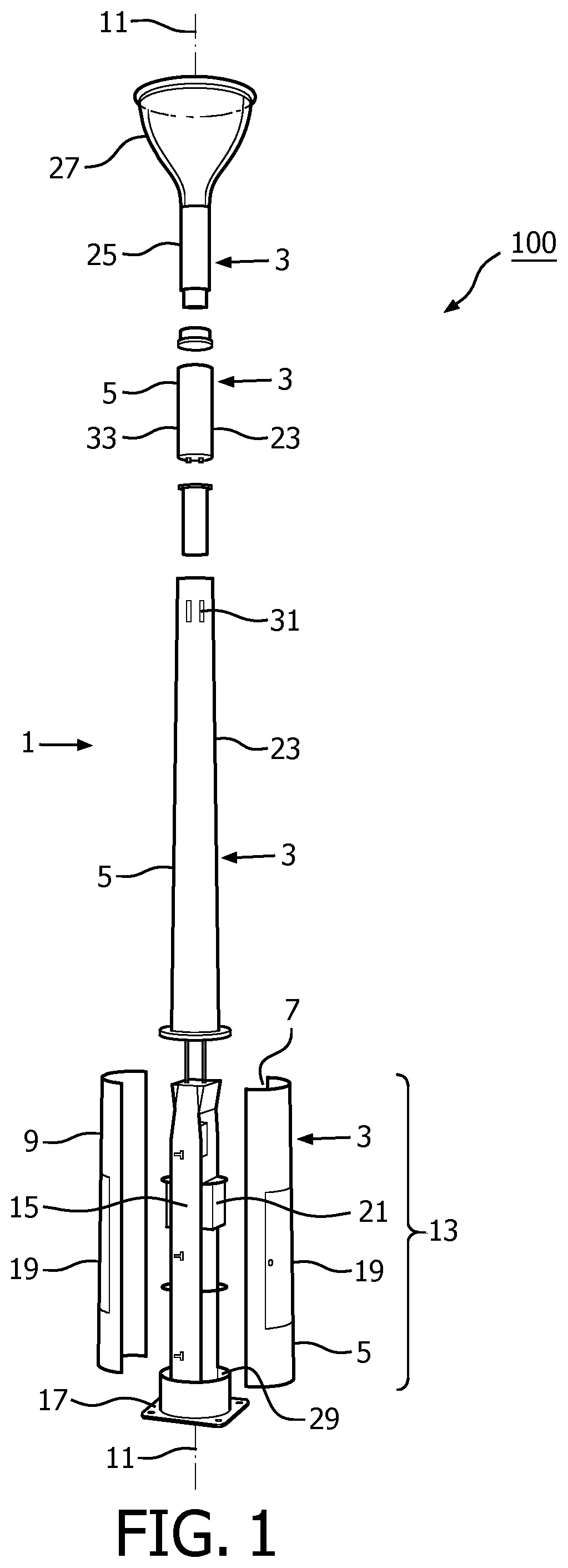

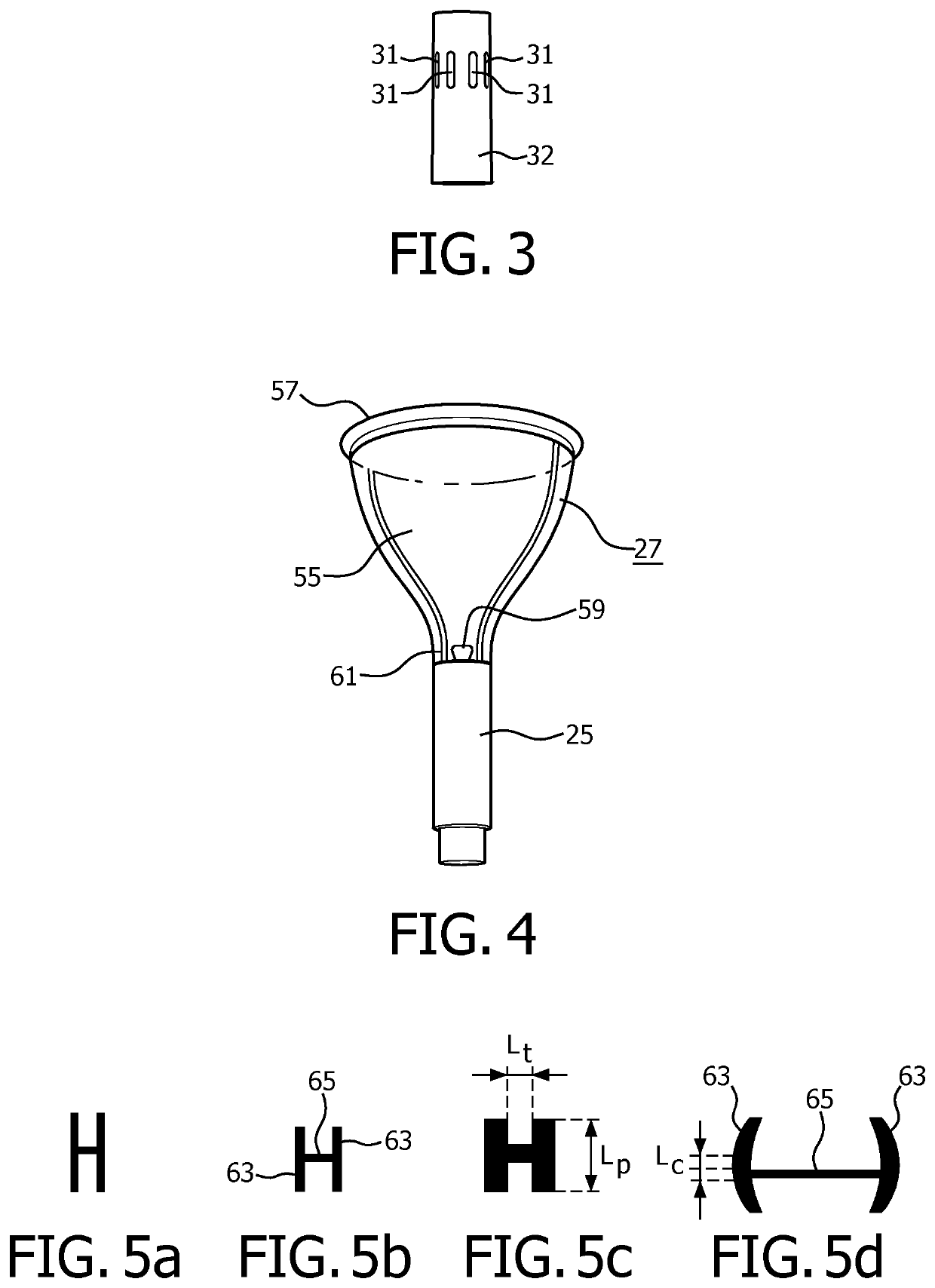

Elongated structure

ActiveUS20200116318A1Less vulnerable to damageImprove cooling effectMechanical apparatusLighting support devicesClassical mechanicsStructural engineering

The invention provides an elongated structure comprising a pole having a wall around a hollow core as a tubular body part extending along a length axis. A base section of the wall of the tubular body part is connected to an H-shaped frame extending from a foot of the pole along the length axis, said H-shaped frame being arranged in the core. The wall at the location of the H-shaped frame is provided with a door, said door in closed position being flush with the wall and in opened position providing access to the core.

Owner:SIGNIFY HLDG BV

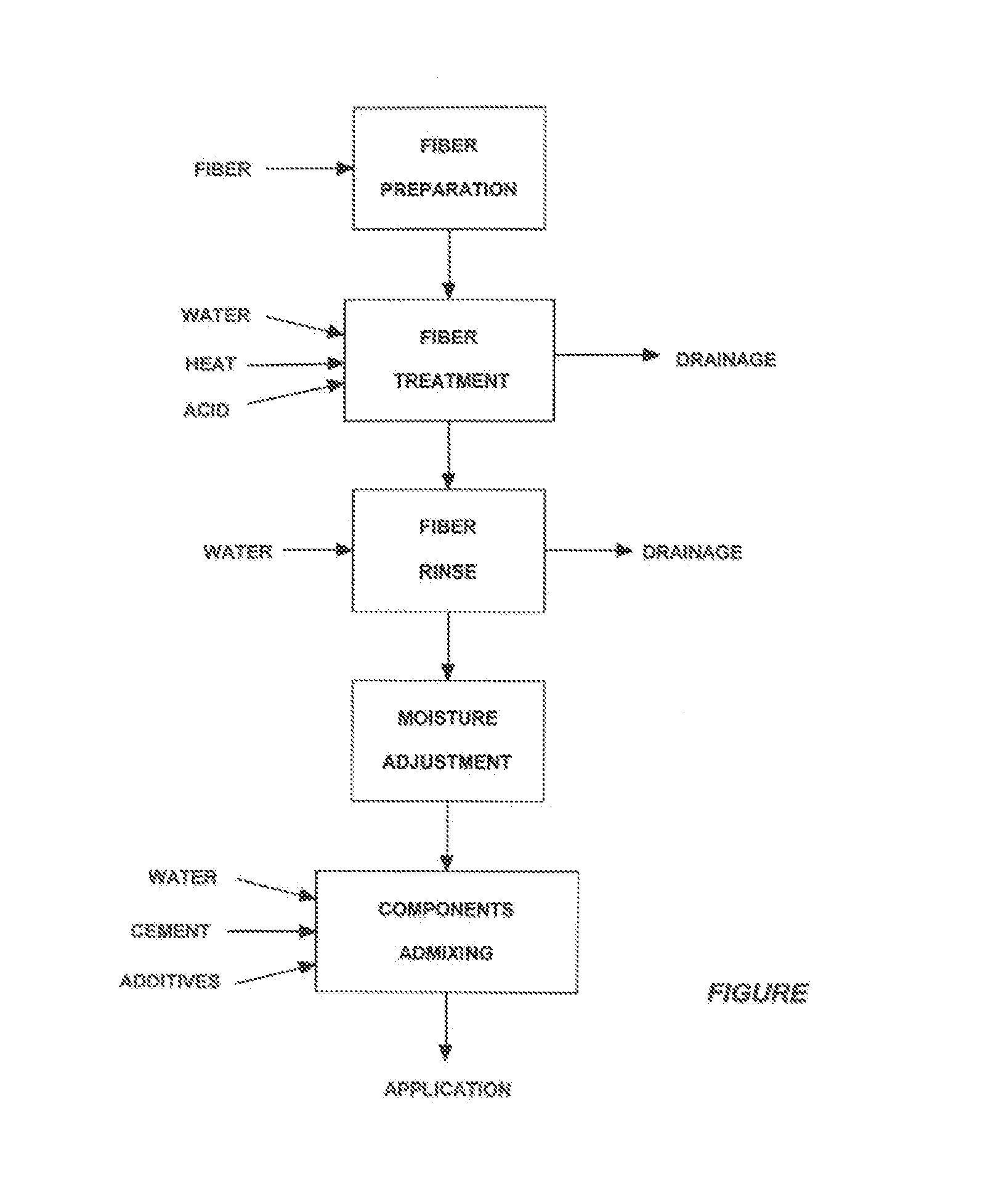

Compositions and Methods For Making of a Concrete-Like Material Containing Cellulosic Derivatives

InactiveUS20140352578A1Reduce materialLoss of strengthSolid waste managementCellulose fiberMaterials science

A composition includes an admixture of a cementitious component and a cellulosic component. The cellulosic component includes a cellulosic fibrous material and water. The admixture is suitable for mixing with a second amount of water to form a hardened material. A method includes reducing a cellulosic fiber material to produce a fiber fragment material, treating the fiber fragment material, and rinsing the treated fiber fragment product with water to form a rinsed fiber fragment material. Treating the fiber fragment material includes admixing the fiber fragment material and water to form an admixture, heating the admixture, agitating the admixture, and separating a treated fiber fragment product from the admixture. The method is effectively controlled so that the rinsed fiber fragment material is suitable for reacting with a cementitious component to form a hardened material.

Owner:SANDROCK VENTURES

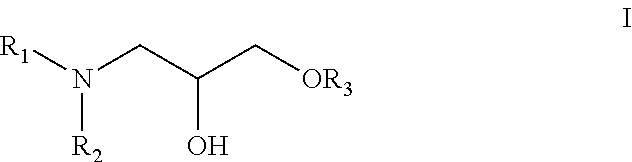

Heur thickener and process for its preparation

ActiveUS20150119525A1Improve rheologyExcellent flow/leveling and gloss propertyThixotropic paintsAllophanePolymer science

The present invention is a process for preparing an aqueous solution of a hydrophobically modified alkylene oxide poly(urethane-urea-allophanate) thickener by contacting isocyanate reactive groups with a stoichiometric excess of a diisocyanate, followed by reaction with water. The thickener surprisingly shows a maintenance or improvement in hiding in paint formulations while maintaining other critical rheological properties.

Owner:ROHM & HAAS CO

Process for producing high-molecular-weight phenolic compounds with myrothecium

InactiveUS6190891B1Prevent rustLoss of strengthAntibacterial agentsOrganic active ingredientsAdhesivePoultice

A process for macromolecularizing phenolic compounds or aromatic amine compounds by the action of a catalyst comprising an enzyme having a polyphenol oxidizing activity in the alkali region; applications of the compounds obtained by the above process to thickeners, stabilizers, coagulants, emulsifiers, dispersants, water retainers, antioxidants, adhesives, concrete admixtures, dyes, coating materials, petroleum recovering agent, soil conditioner, a blow-applied seed bearing surface soil stabilizer, deodorants, smell eliminators, agricultural chemical spreaders, feeding stuff binders, bactericides, antimicrobial agents, viral infection inhibitors, bioadhesion preventives, biotic repellents, insecticides, poultices, ink bases or wood treating agents; and method of waste water disposal, a method of deoxygenation and a method of treating wood, concrete or soil in which use is made of the above reaction.

Owner:SDS BIOTECH CO LTD

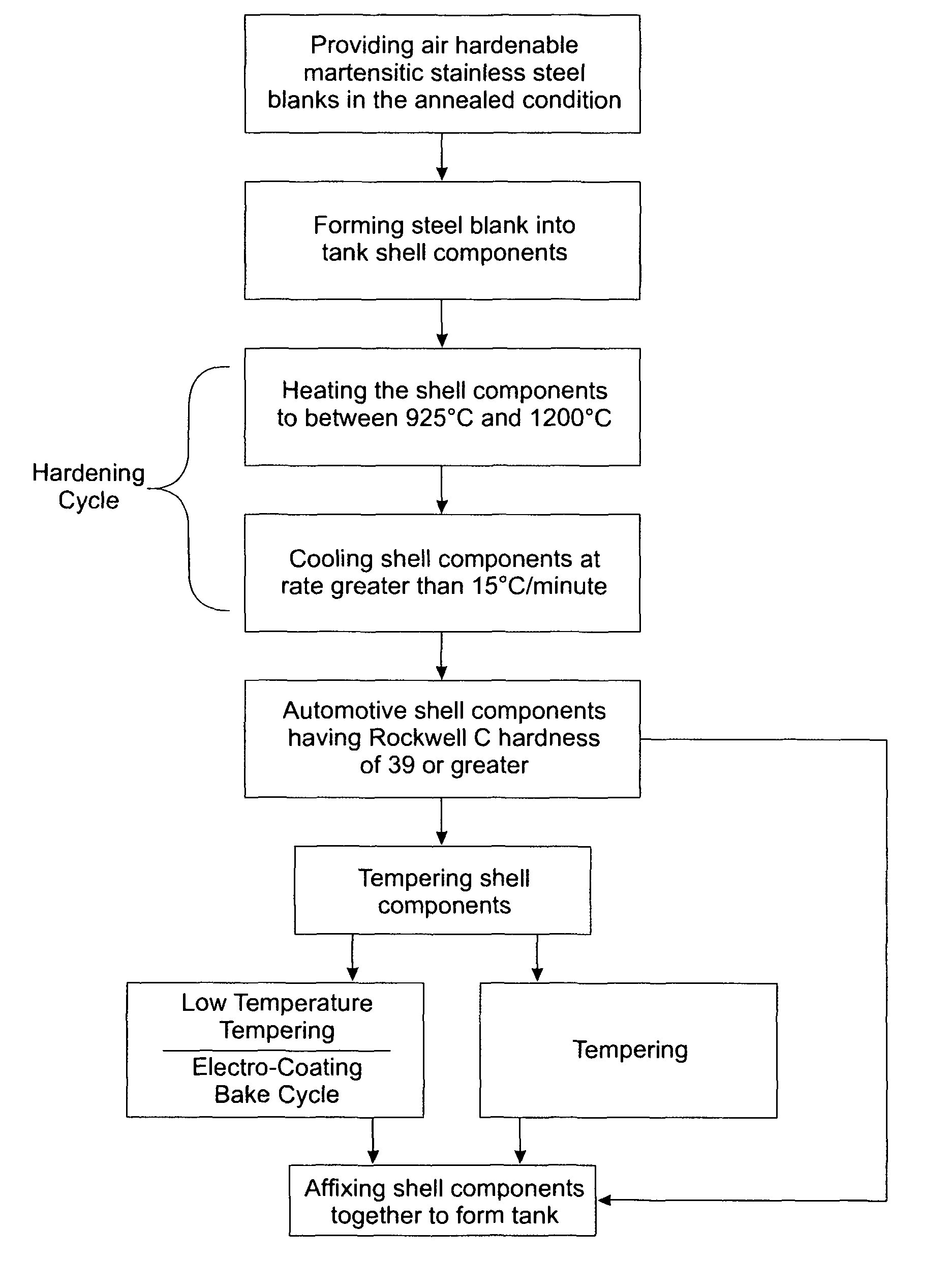

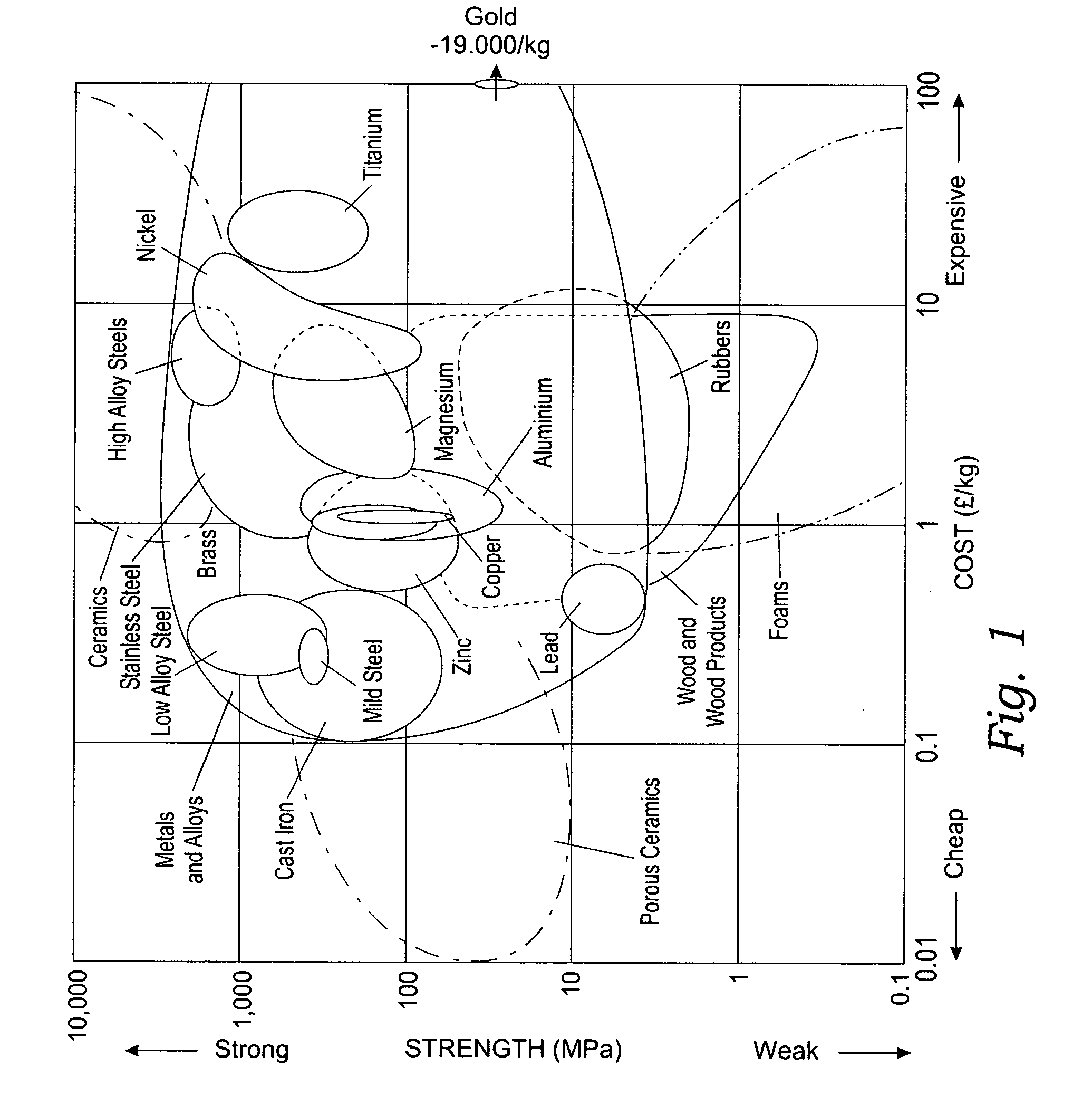

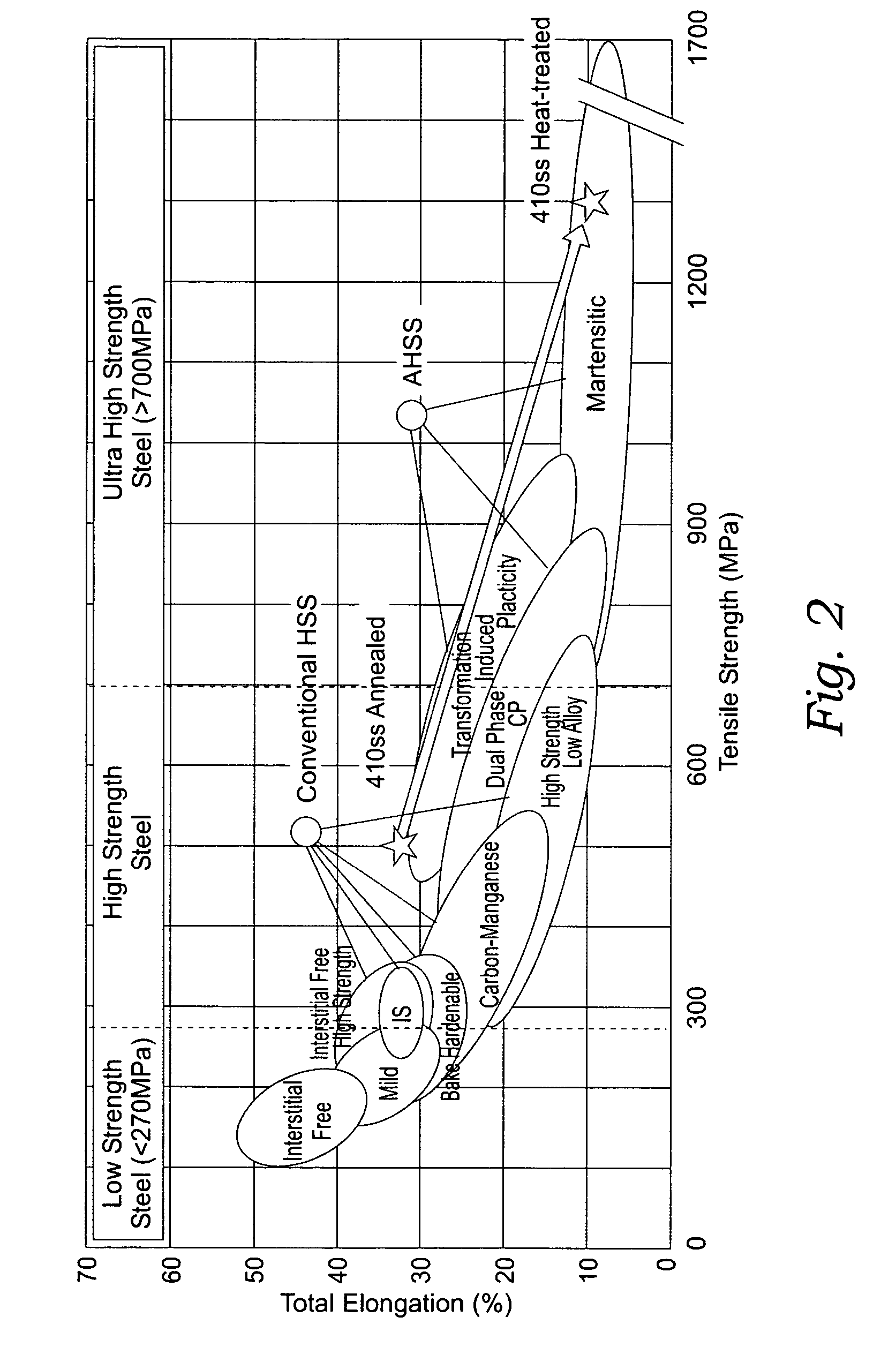

Method for manufacturing gas and liquid storage tanks

InactiveUS20070045384A1Reduce brittlenessImprove ductilityCooking-vessel materialsMetal-working apparatusMartensitic stainless steelLiquid storage tank

A method for making gas and liquid storage tanks such as automotive fuel tanks includes providing two or more blanks of air hardenable martensitic stainless steel in the annealed condition. The steel blanks have a thickness in the range of 0.5-5.0 mm., and are formed utilizing stamping, forging, pressing, or roller forming techniques or the like into the form of a tank shell components. The shell components are hardened and assembled into a storage tank. The shell components are hardened by application of heat, preferably to between 950° C. and 1100° C. for standard air hardenable martensitic stainless steels. Thereafter, the automotive fuel tank is preferably cooled at a rate greater than 25° C. per minute to achieve a Rockwell C hardness of at least 39. The automotive fuel tank may undergo additional heat treating processes including high temperature or low temperature tempering processes which may incorporate electro-coating.

Owner:KVA

Cast heat-resistant austenitic steel with improved temperature creep properties and balanced alloying element additions and methodology for development of the same

The present invention addresses the need for new austenitic steel compositions with higher creep strength and higher upper temperatures. The present invention also discloses a methodology for the development of new austenitic steel compositions with higher creep strength and higher upper temperatures.

Owner:UT BATTELLE LLC +1

Use of surfactant in the preparation of modified sulfur and sulfur cement

ActiveUS20110263755A1Restrict permeationImprove hydraulic conductivitySolid waste disposalSulfur compoundsSulfur concreteNon ionic

Owner:UNITED ARAB EMIRATES UNIVERSITY

Method of using landplaster as a wallboard filler

ActiveUS20080160340A1High strengthAvoid strength lossLaminationLamination apparatusSlurryCalcium Sulfate Dihydrate

A gypsum slurry includes calcium sulfate hemihydrate, water and calcium sulfate dihydrate, where the calcium sulfate dihydrate is added downstream of the mixer.In an optional embodiment, the a gypsum slurry includes calcium sulfate hemihydrate, a polycarboxylate dispersant, water and coated calcium sulfate dihydrate. In this case, the hydrophilic, dispersible coating is selected to serve as a modifier to enhance the ability of the dispersant to fluidize the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

Enteric soft capsules

InactiveUS20140348879A1Loss of strengthLoss of viscosityOrganic active ingredientsPeptide/protein ingredientsBiomedical engineeringMedicine

Owner:PATHEON SOFTGELS INC

Method for manufacturing gas and liquid storage tanks

InactiveUS7926180B2Reduce brittlenessImprove ductilityCooking-vessel materialsMetal-working apparatusMartensitic stainless steelLiquid storage tank

A method for making gas and liquid storage tanks such as automotive fuel tanks includes providing two or more blanks of air hardenable martensitic stainless steel in the annealed condition. The steel blanks have a thickness in the range of 0.5-5.0 mm., and are formed utilizing stamping, forging, pressing, or roller forming techniques or the like into the form of a tank shell components. The shell components are hardened and assembled into a storage tank. The shell components are hardened by application of heat, preferably to between 950° C. and 1100° C. for standard air hardenable martensitic stainless steels. Thereafter, the automotive fuel tank is preferably cooled at a rate greater than 25° C. per minute to achieve a Rockwell C hardness of at least 39. The automotive fuel tank may undergo additional heat treating processes including high temperature or low temperature tempering processes which may incorporate electro-coating.

Owner:KVA

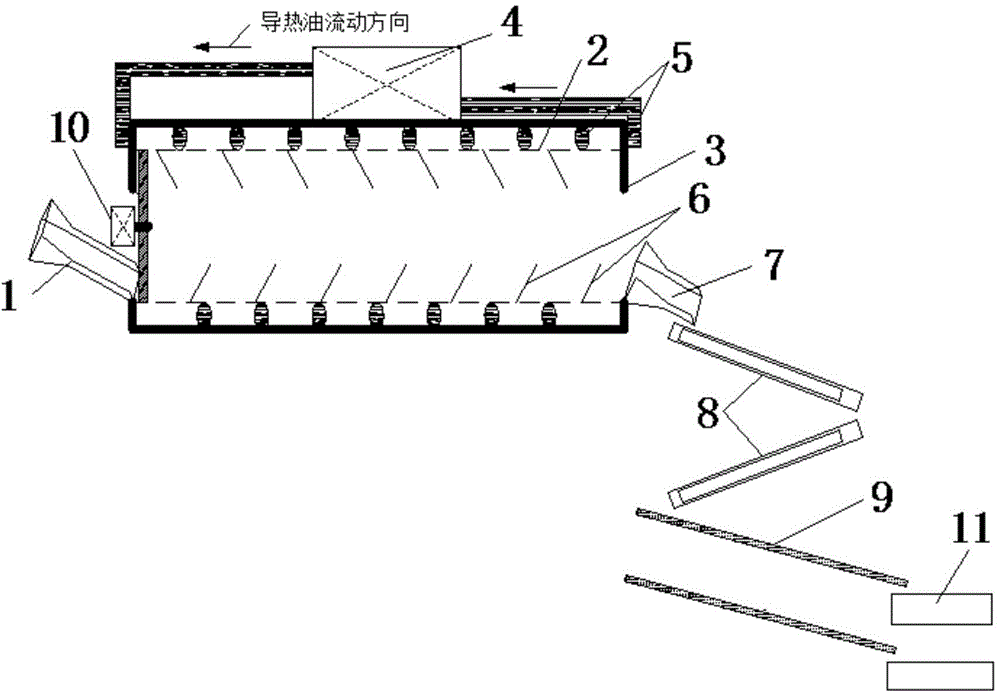

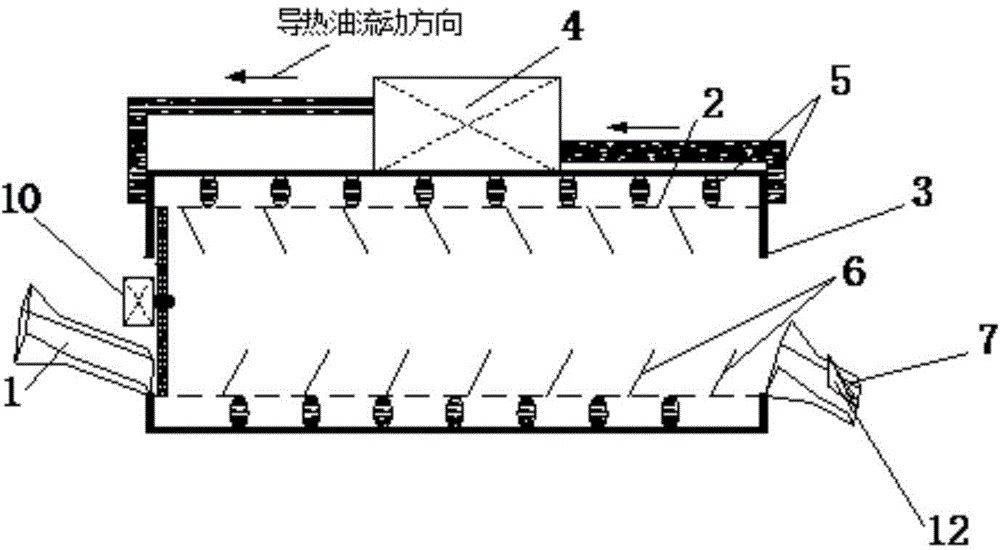

Extruded asphalt pavement milling material crushing and screening device

InactiveCN104480832AHeating evenlyGuaranteed heating temperatureRoads maintainenceRoad surfaceMix proportion

The invention discloses an extruded asphalt pavement milling material crushing and screening device which comprises a heating and conveying system and a crushing and screening system, wherein the heating and conveying system comprises a drum; a milling material is rotationally conveyed from a feed chute in the rear end of the drum to a discharge chute in the front end of the drum by virtue of the drum, and a heating device for heating the milling material is arranged on the drum; the crushing and screening system is arranged below the discharge chute and is obliquely arranged; the crushing and screening system comprises a crushing operation group consisting of multiple rotatable crushing units; and the milling material dropping onto the crushing operation group is extruded by the rotating crushing units and is collected by a screen. According to the device disclosed by the invention, a single and extensive RAP treatment mode in pavement hot regeneration in the conventional highway reconstruction and expansion can be effectively improved, further, the mix proportion design of hot recycled asphalt mixtures is further conveniently realized, and the pavement performance of the regenerated asphalt mixture is improved.

Owner:CHANGAN UNIV

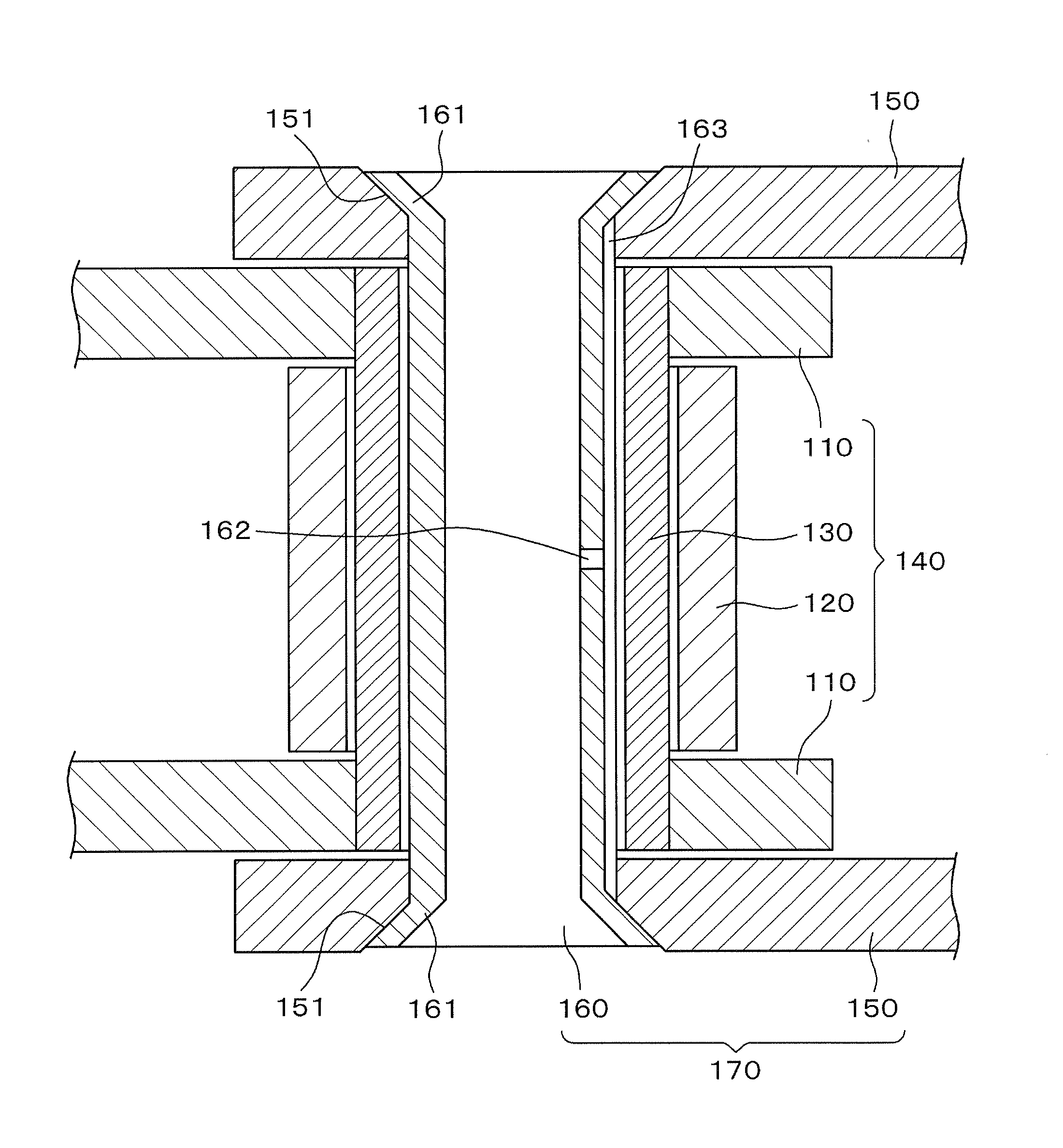

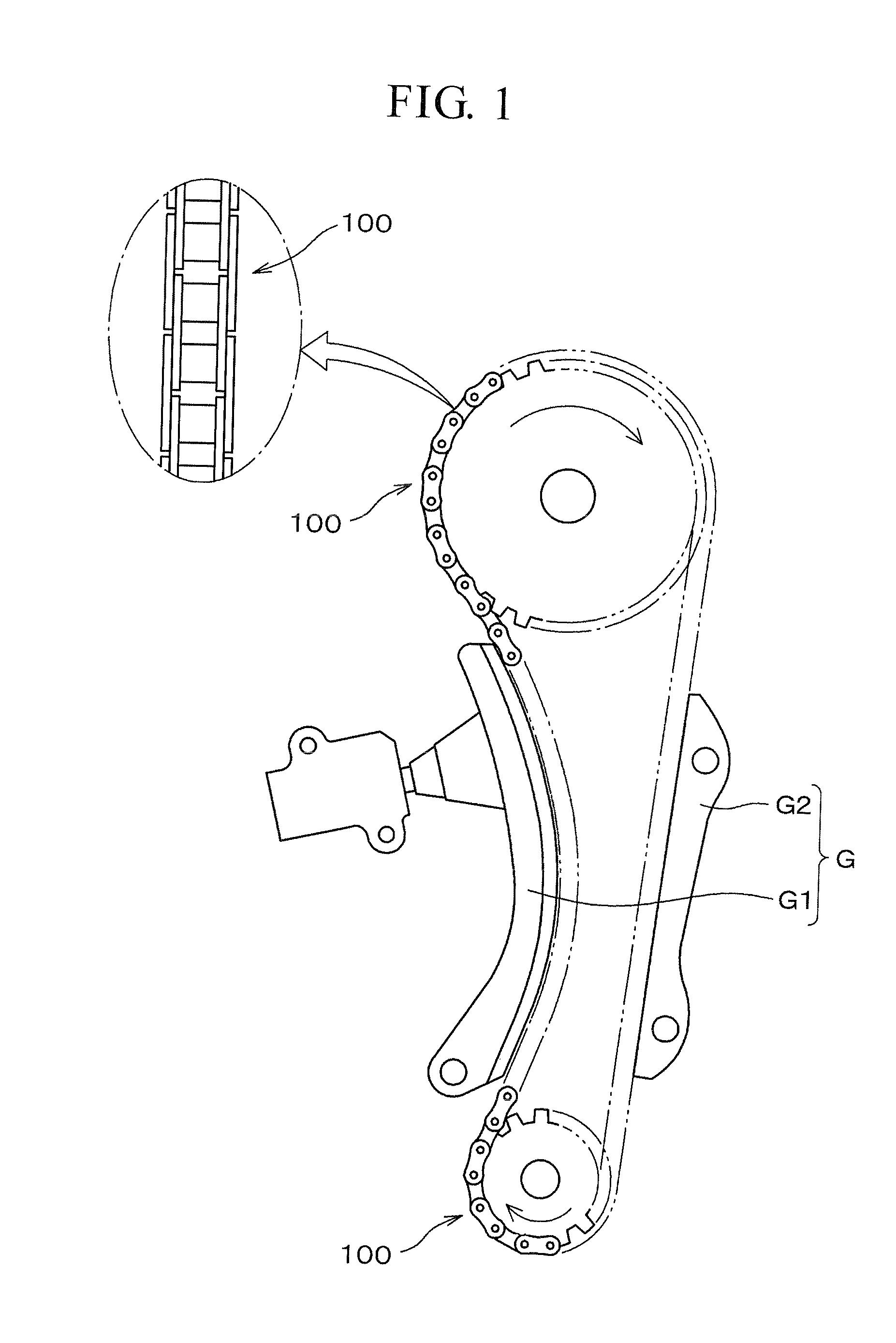

Transmission chain

InactiveUS20100304906A1Improve collectionLoss of strengthGear lubrication/coolingDriving chainsEngineeringRoller chain

In a roller chain or rollerless bushing chain for transmission of power, hollow connecting pins are swaged to the plates of the outer links. Each pin has at least one oil conducting passage extending from its hollow interior to its exterior whereby lubricating oil can flow through the pin from the ends thereof and into the clearance between the pin and its surrounding bushing.

Owner:TSUBAKIMOTO CHAIN CO

Embedded substrate provided with side-inclined plane line layer assembly and manufacturing method thereof

ActiveCN101888738AAvoid sharp cornersLoss of strengthElectrical connection printed elementsPrinted element electric connection formationEngineeringCopper

The invention relates to an embedded substrate provided with side-inclined plane line layer assembly and a manufacturing method thereof. The embedded substrate comprises a dielectric layer and a line layer assembly. The dielectric layer is provided with an upper surface and a containing slot. The line layer assembly is arranged in the containing slot. The line layer assembly is provided with an upper surface, a chemical copper layer, an electroplated copper layer and a side-inclined plane. The upper surface is higher or lower the upper surface of the dielectric layer. The chemical copper layer is provided with palladium (Pd). The electroplated copper layer is arranged on the chemical copper layer. The side-inclined layer is arranged closed to the hole wall of the containing slot on the upper surface of the line layer assembly and is extended downward to the hole wall of the containing slot from the upper surface of the line layer assembly. Thus, the side-inclined plane of the line layer assembly can avoid that electrons are aggregated on the point angle of the line layer assembly in the prior art.

Owner:ADVANCED SEMICON ENG INC

Curing agent composition and method for making the same

ActiveCN101456661AGood curing effectFast Hard Early Strong GoodSludge treatment by de-watering/drying/thickeningSolid waste managementSodium silicateSodium sulfate

The invention relates to a rapid high-strength hardener composition for a pelitization substance of mudstone of a laneway base plate of a mine and a method for preparing the same. The composition is prepared through mixing and grinding sulphate aluminium cement clinker, hydrated gypsum, hydrated lime, sodium sulfate, sodium silicate, aluminum potassium sulfate and sodium hydroxide into powder with specific surface area of between 200m<2> / kg and 900m<2> / kg. The rapid high-strength hardener composition carries out reinforcing treatment on the pelitization substance of mudstone and has the advantages of short time for forming a condensate and high strength of the formed condensate.

Owner:CHINA SHENHUA ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com