Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Sulfur concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur concrete is a composite construction material, composed mainly of sulfur and aggregate (generally a coarse aggregate made of gravel or crushed rocks and a fine aggregate such as sand). Cement and water, important compounds in normal concrete, are not part of sulfur concrete. The concrete is heated above the melting point of sulfur ca. 140 °C. After cooling the concrete reaches a high strength, not needing a prolonged curing like normal concrete. Sulfur concrete is resistant to some compounds like acids which attack normal concrete. Sulfur concrete was developed and promoted as building material to get rid of large amounts of stored sulfur produced by hydrodesulfurization of gas and oil. Sulfur concrete is also a possible building material for a lunar base. As of 2011, sulfur concrete has only been used in small quantities when fast curing or acid resistance is necessary.

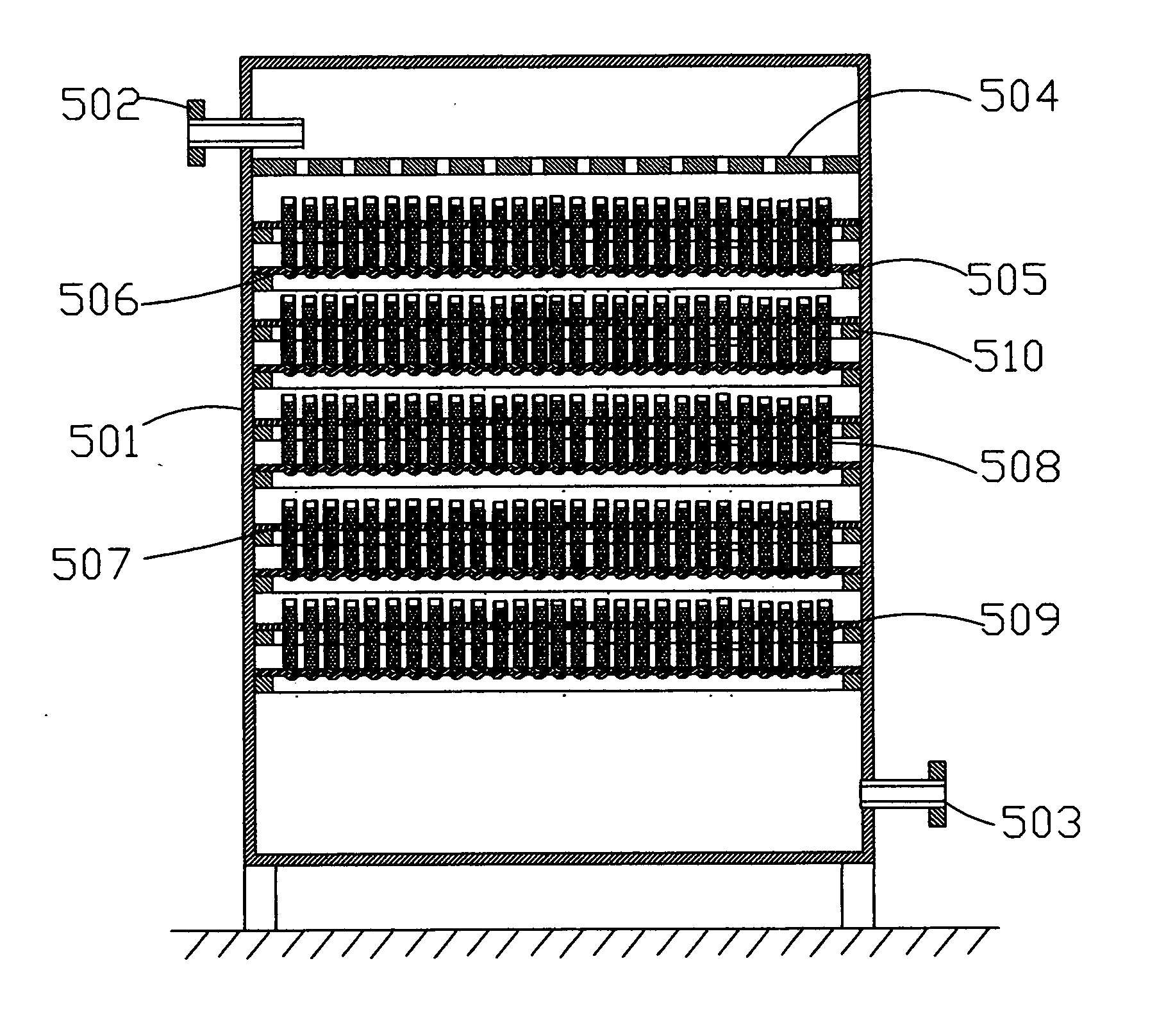

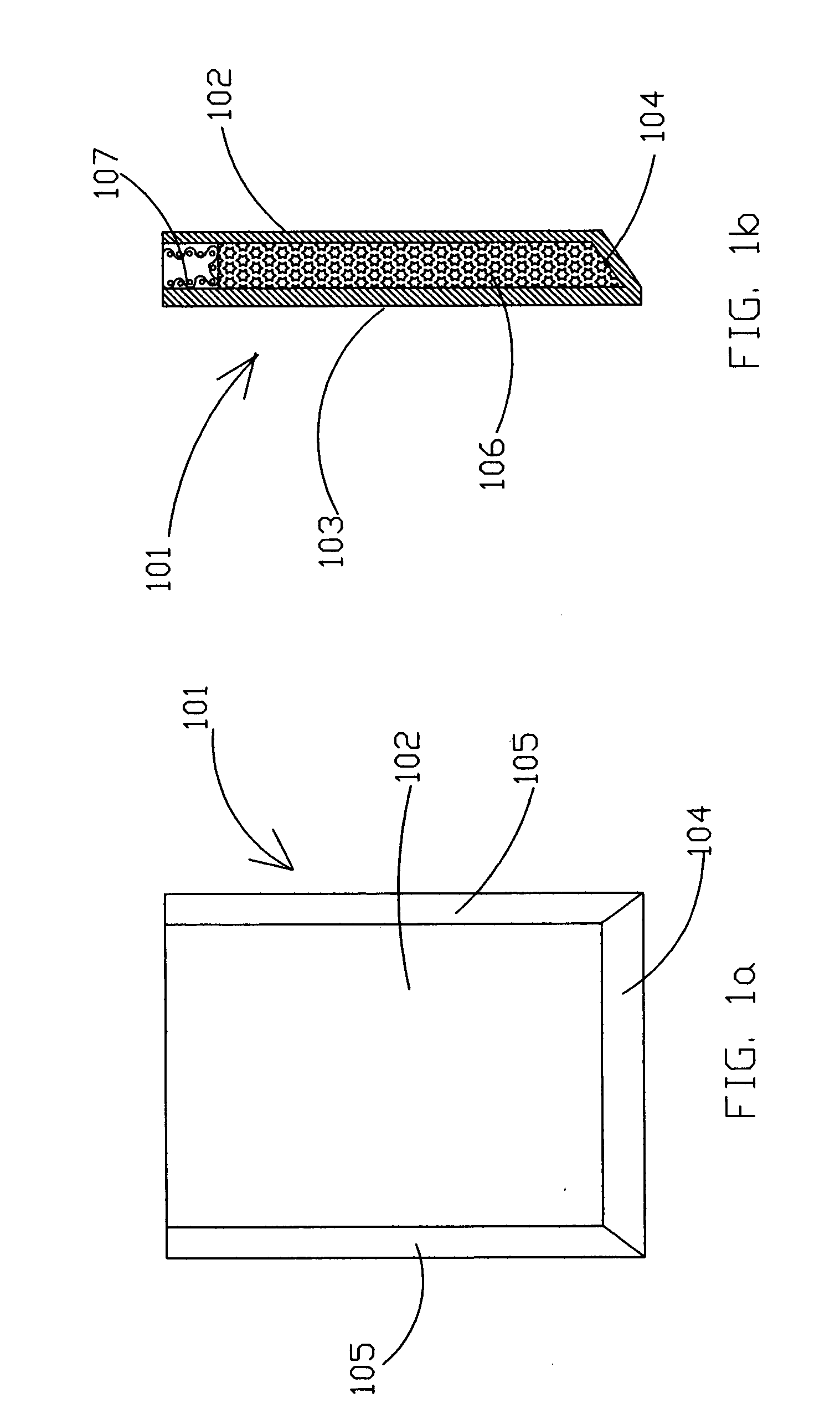

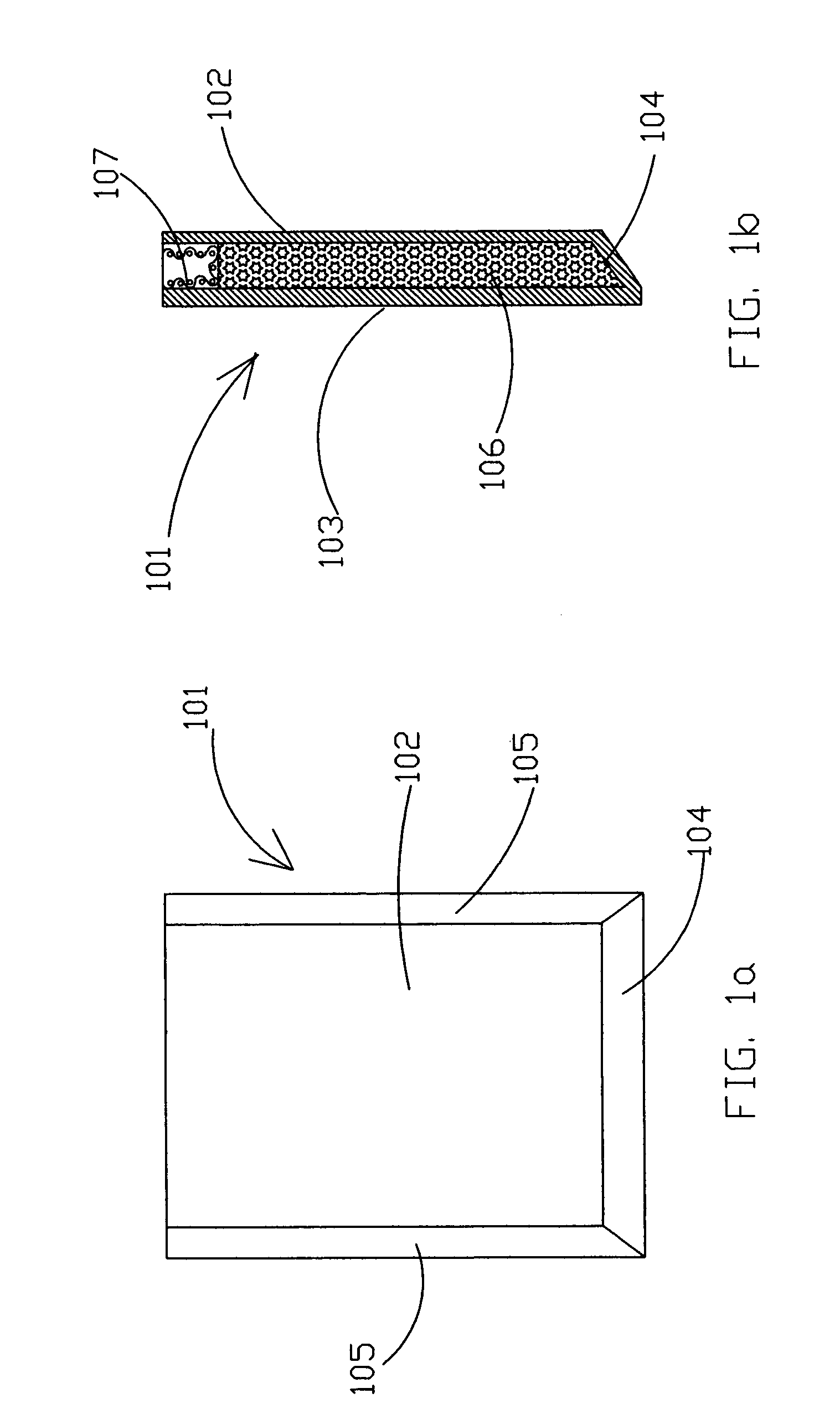

Heat and cold storage multistage tower with application of PCM

InactiveUS20060225863A1Inhibition formationImprove thermal conductivityMilk preservationHeat storage plantsEngineeringThermal management system

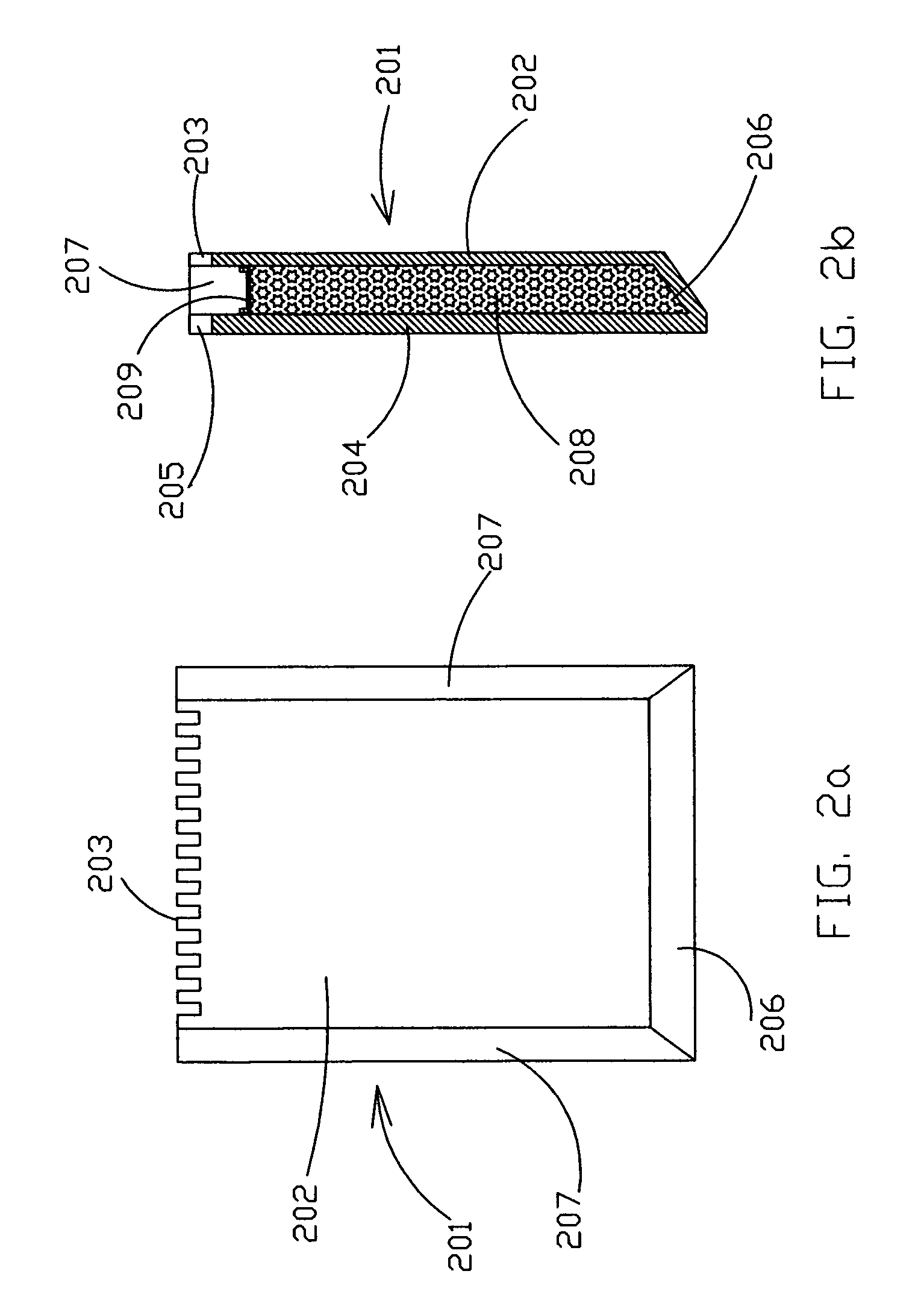

This invention relates to the area of heat management systems and, specifically, to the heat management systems, which include application of phase change materials (PCM). Proposed heat or cold storage multistage tower comprises a housing with a multistage system of flat rigid containers; significant fraction of internal space of each container is filled with PCM; these containers are fabricated from ceramics, glass, glass ceramics or sulfur concrete. Another version of the heat or cold storage tower is based on application of multi-channel blocks from ceramics, glass, glass ceramics or sulfur concrete; the parallel internal vertical channels of the blocks are open and sealed at their bottoms alternatively, and the channels with the sealed bottoms are filled partially with PCM. The proposed invention allows to achieve effective heat transfer between a heat transfer fluid (HTF) and PCM in the processes of charging and discharging of the containers with heat or cold.

Owner:LEVIN ALEXANDER

Heat and cold storage multistage tower with application of PCM

InactiveUS7222659B2Inhibition formationImprove thermal conductivityMilk preservationHeat storage plantsThermal management systemHeat transfer fluid

A heat management system include including application of phase change materials (PCM). A heat or cold storage multistage tower has a housing with a multistage system of flat rigid container. A significant fraction of internal space of each container is filled with PCM; these containers are fabricated from ceramics, glass, glass ceramics or sulfur concrete. Another version of the heat or cold storage tower is based on application of multi-channel blocks from ceramics, glass, glass ceramics or sulfur concrete; the parallel internal vertical channels of the blocks are open and sealed at their bottoms alternatively, and the channels with the sealed bottoms are filled partially with PCM. The tower achieves effective heat transfer between a heat transfer fluid (HTF) and PCM in the processes of charging and discharging of the containers with heat or cold.

Owner:LEVIN ALEXANDER

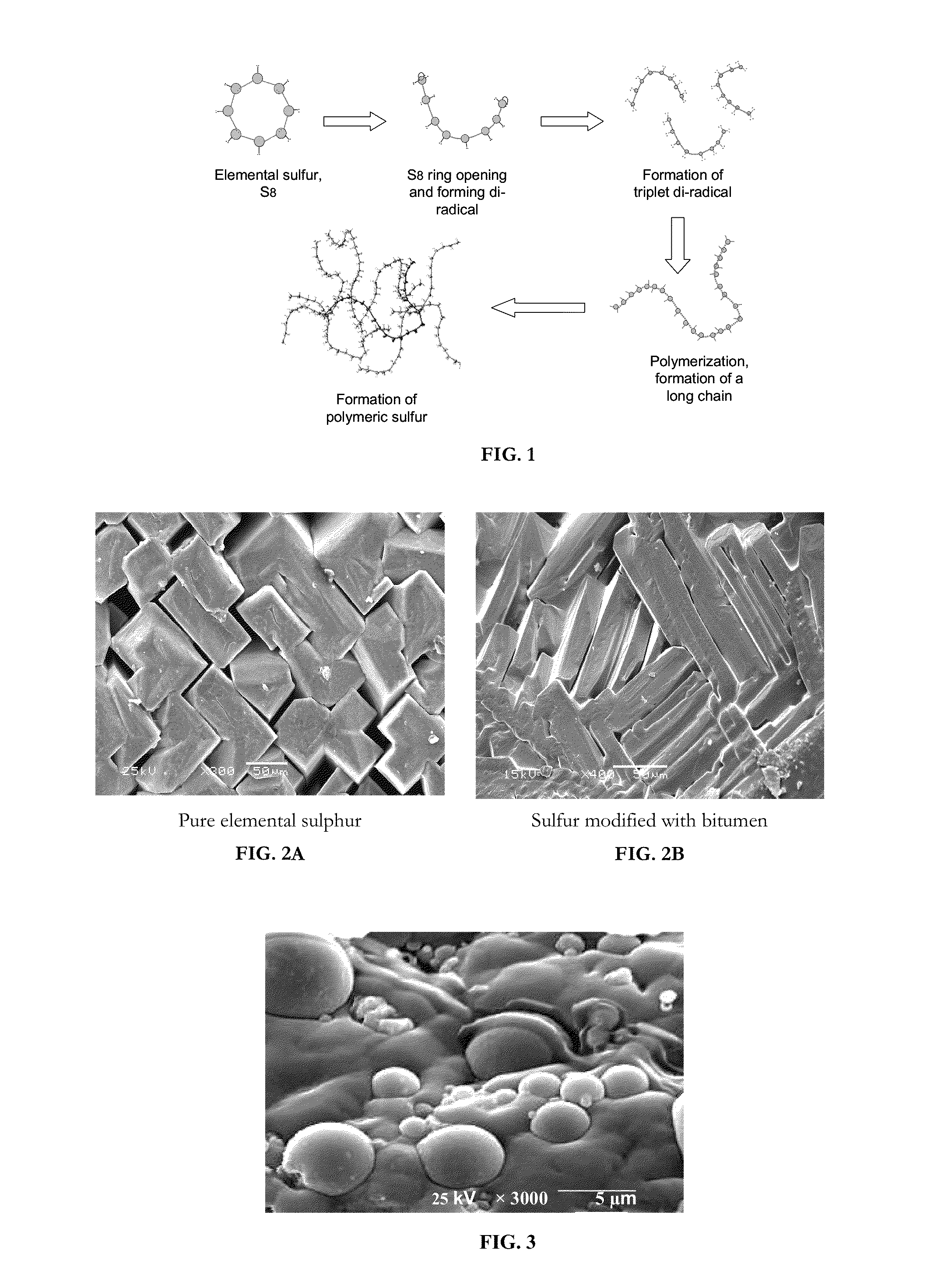

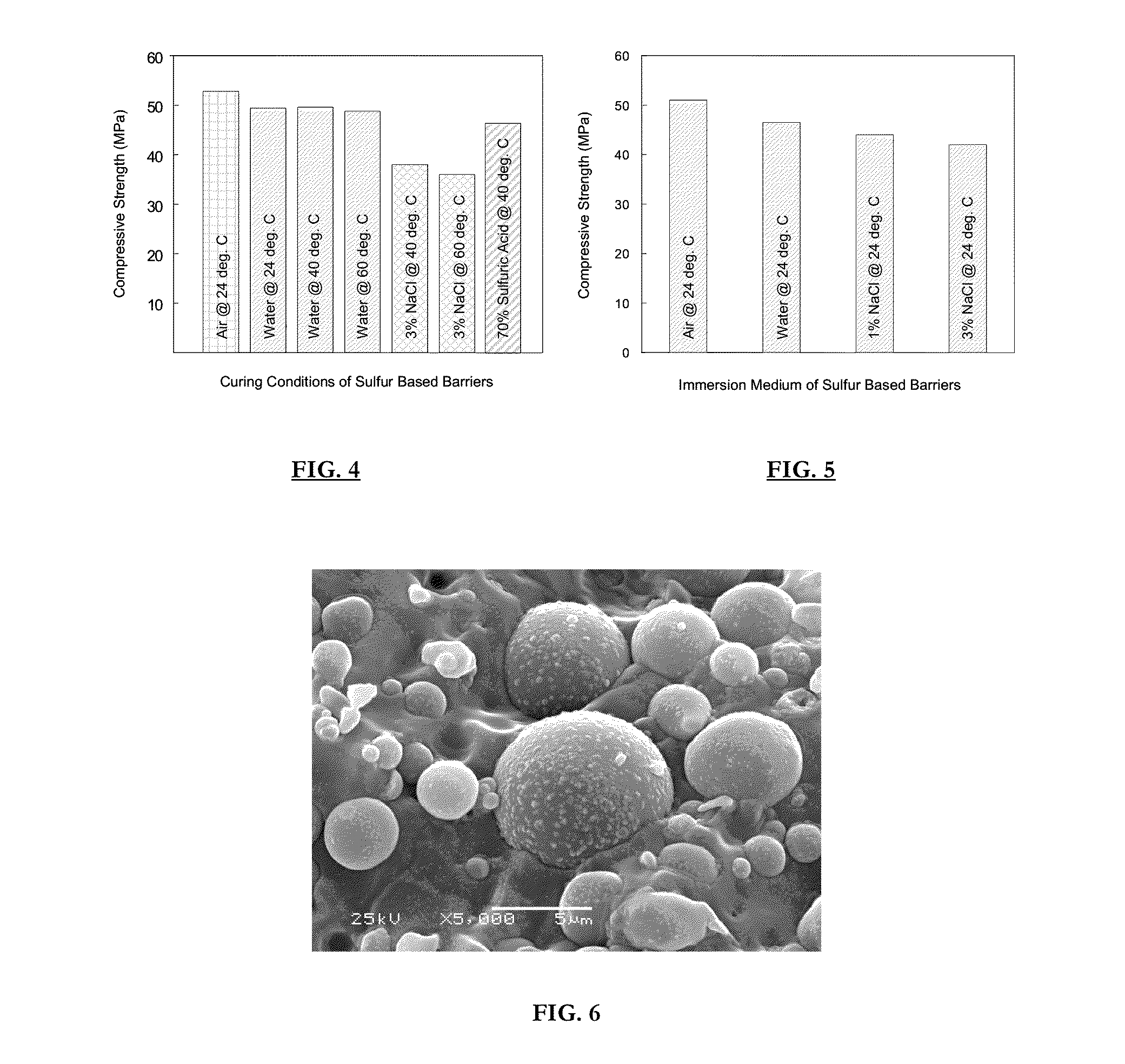

Use of surfactant in the preparation of modified sulfur and sulfur cement

ActiveUS8859719B2Excellent property in term of strength and durability and leachabilityEasy to useSolid waste disposalSulfur preparation/purificationSulfur concreteMaterials science

Owner:UNITED ARAB EMIRATES UNIVERSITY

Use of surfactant in the preparation of modified sulfur and sulfur cement

ActiveUS20110263755A1Restrict permeationImprove hydraulic conductivitySolid waste disposalSulfur compoundsSulfur concreteNon ionic

Owner:UNITED ARAB EMIRATES UNIVERSITY

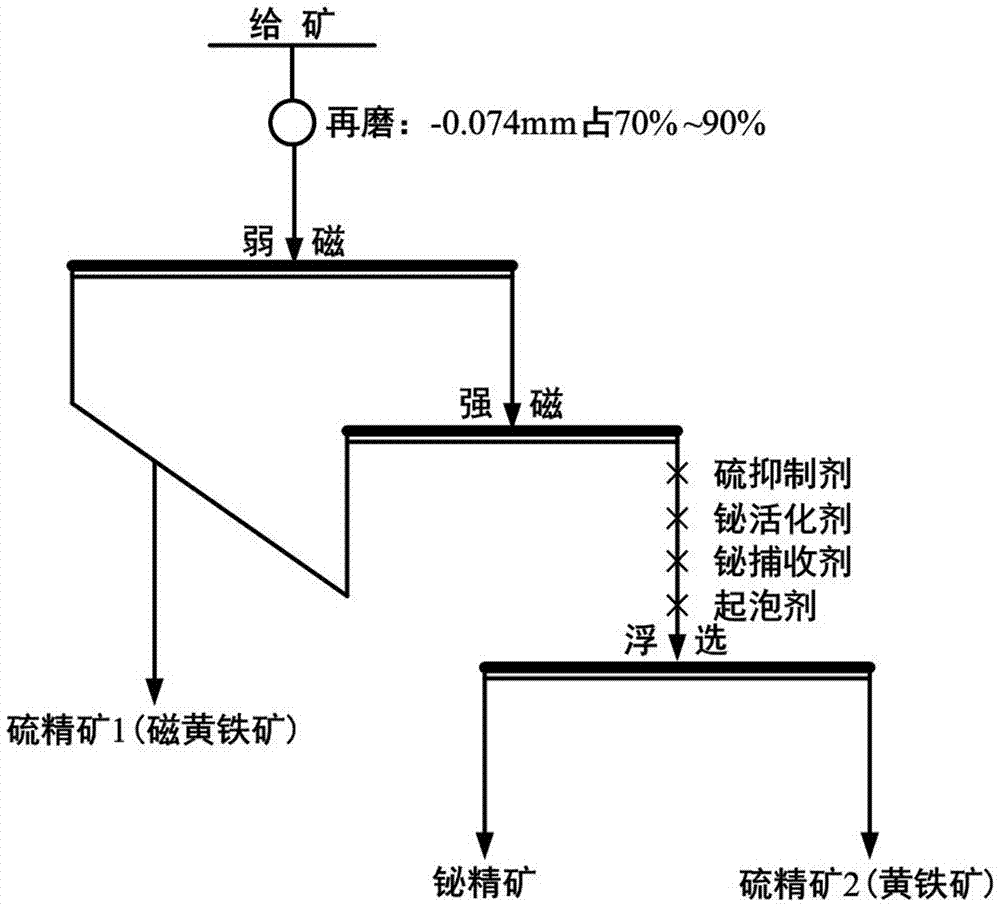

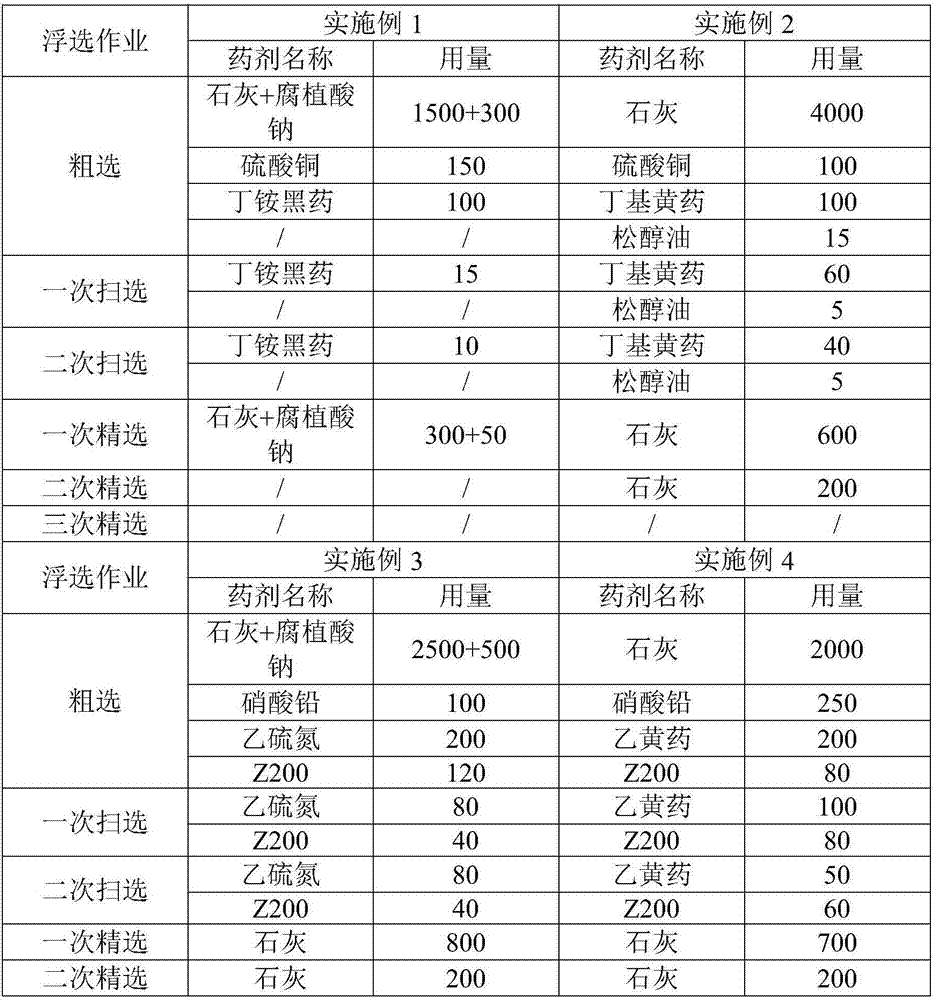

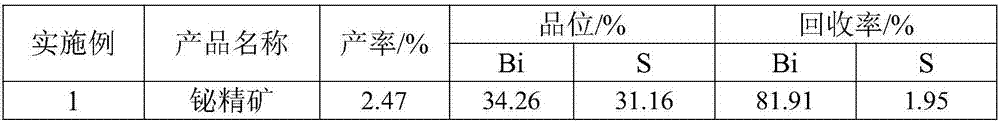

Mineral beneficiation method for separating bismuth and sulfide from bismuth-sulfide concentrate

ActiveCN107971127AGuaranteed separation effectGreat tasteSolid separationBismuth sulfideFoaming agent

The invention discloses a mineral beneficiation method for separating bismuth and sulfide from bismuth-sulfide concentrate. The method comprises the steps of firstly, separating out pyrrhotite with strong magnetism from the bismuth-sulfide concentrate through weak magnetic separation in advance and then separating out pyrrhotite with weak magnetism from the bismuth-sulfide concentrate through strong magnetic separation; secondly, combining the pyrrhotite with the strong magnetism and the pyrrhotite with the weak magnetism into sulfur concrete 1 mainly comprising the pyrrhotite; adding a sulfurinhibitor, a bismuth activating agent, a bismuth collecting agent and a foaming agent to magnetic separation tailings to conduct flotation to obtain bismuth concrete and sulfur concrete 2 mainly comprising pyrite. The mineral beneficiation method has the advantages that the bismuth-sulfur separation effect is good; the grade of obtained bismuth concrete is high; the recovery rate is high, and isapplicable to separation of the bismuth-sulfur concrete and particularly suitable for separation of bismuth-sulfur concrete with the high pyrrhotite content.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

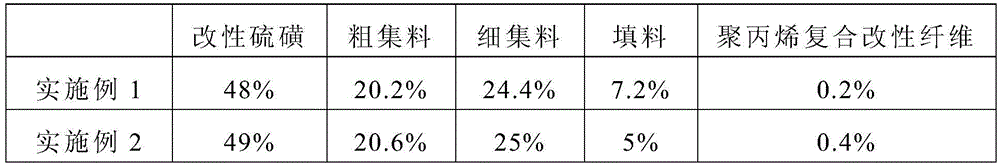

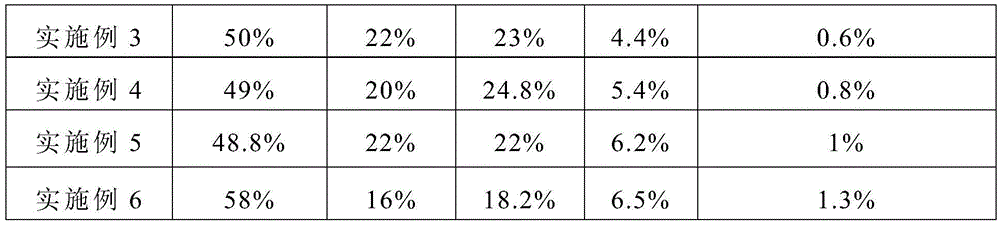

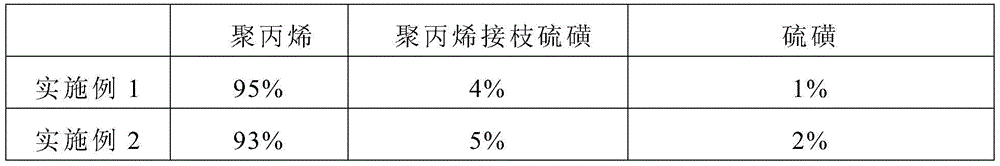

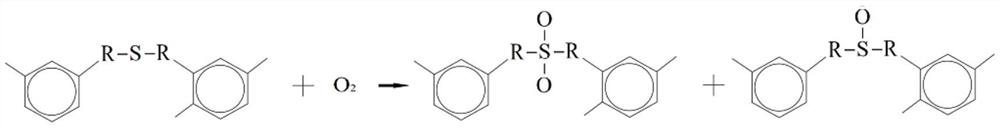

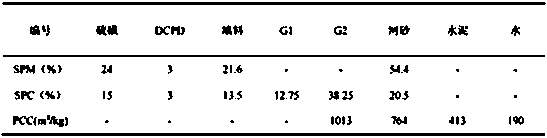

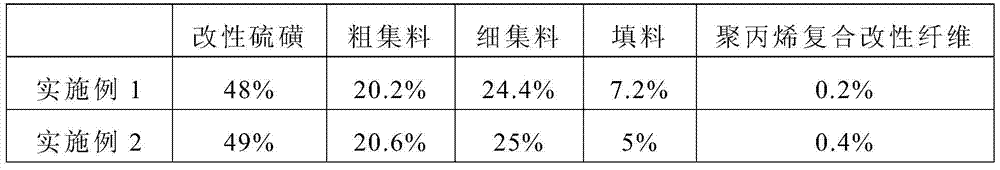

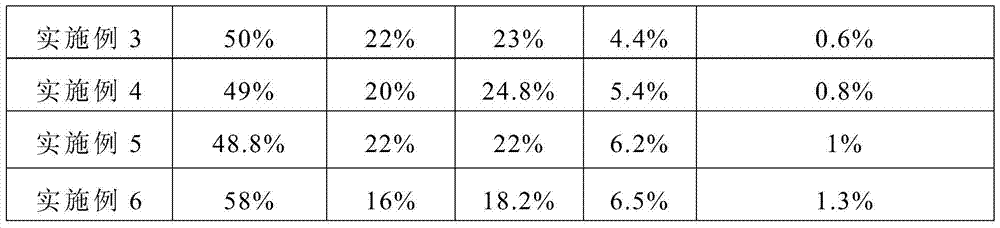

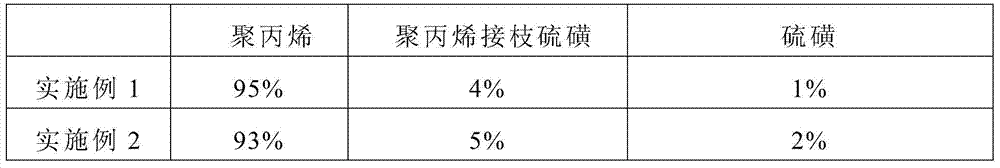

Sulfur-containing polypropylene composite fiber enhanced sulfur concrete and preparation method thereof

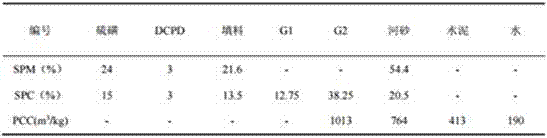

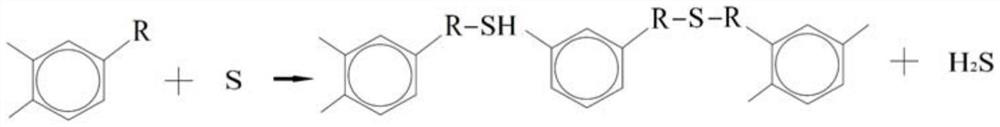

The invention discloses sulfur-containing polypropylene composite fiber enhanced sulfur concrete and a preparation method thereof. The concrete is prepared from the following ingredients in percentage by mass: 40 to 60 percent of modified sulfur, 15 to 25 percent of coarse aggregate, 10 to 25 percent of fine aggregate, 1 to 10 percent of fillings and 0.1 to 1.5 percent of polypropylene composite modified fiber. The preparation method sequentially comprises the following steps of 1, preparing polypropylene grafted sulfur; 2, preparing polypropylene composite modified fiber; 3, preparing modified sulfur; 4, taking the coarse aggregate, the fine aggregate, the fillings, the modified sulfur and the polypropylene composite modified fiber according to the designed quantity, and sufficiently and uniformly stirring the materials to obtain fiber enhanced sulfur concrete. Practice proves that the sulfur-containing polypropylene composite fiber enhanced sulfur concrete has the advantages that the mechanical property is excellent; the corrosion performance is high; the anti-cracking performance is good, and the like, wherein the bonding performance between the polypropylene composite fiber and the sulfur concrete interface is good; in addition, the operation of the preparation method is simple; the cost is low.

Owner:HUBEI UNIV OF TECH

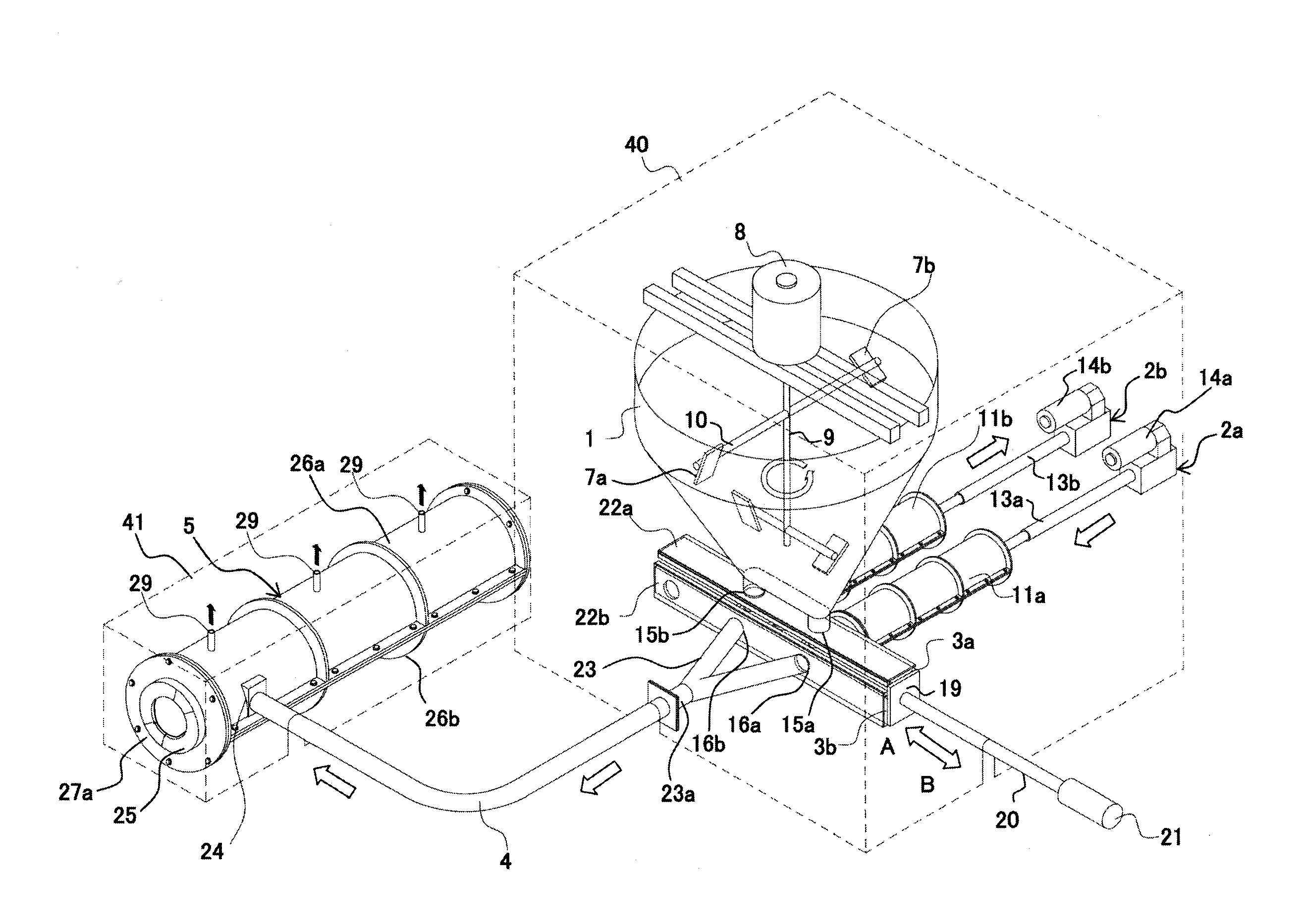

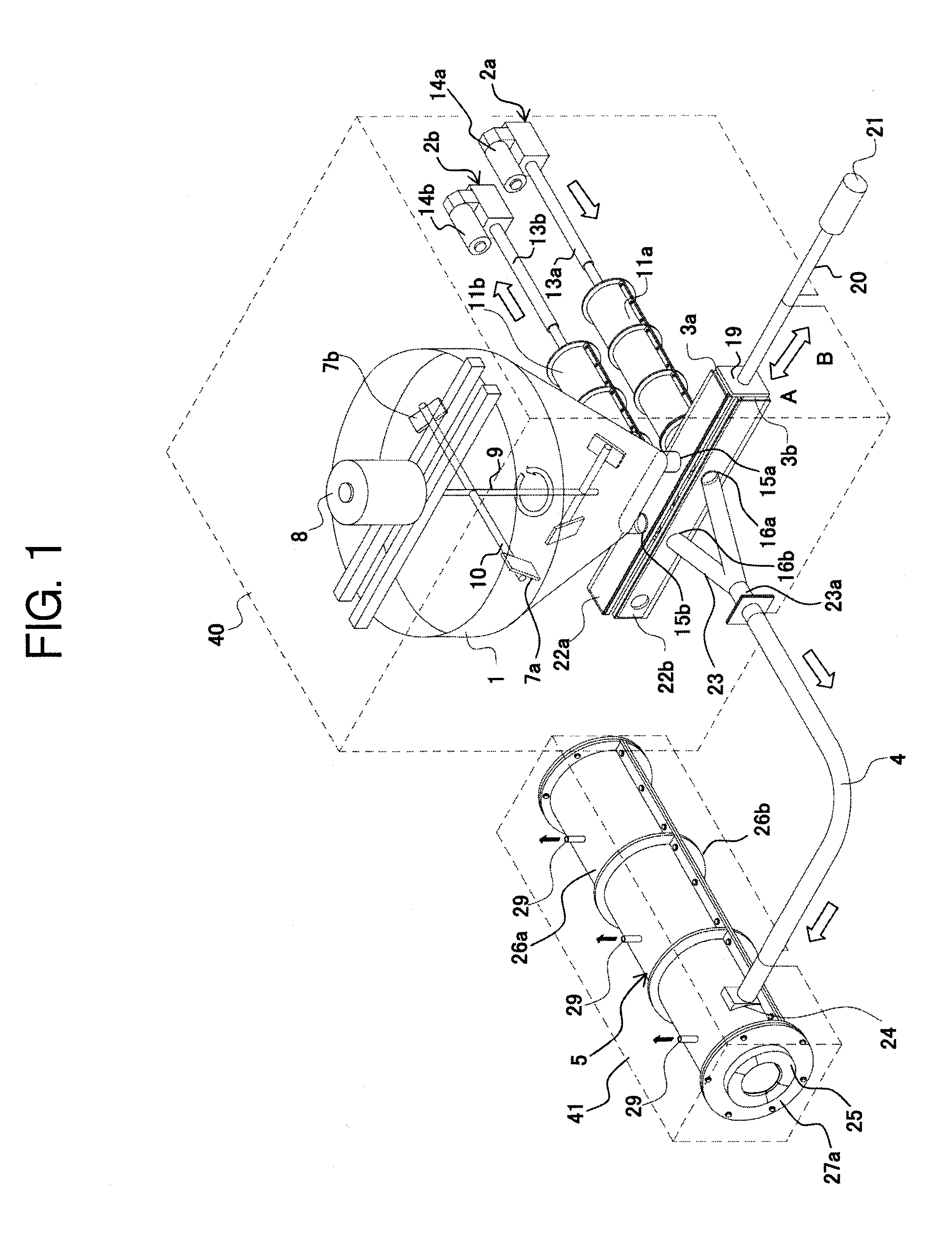

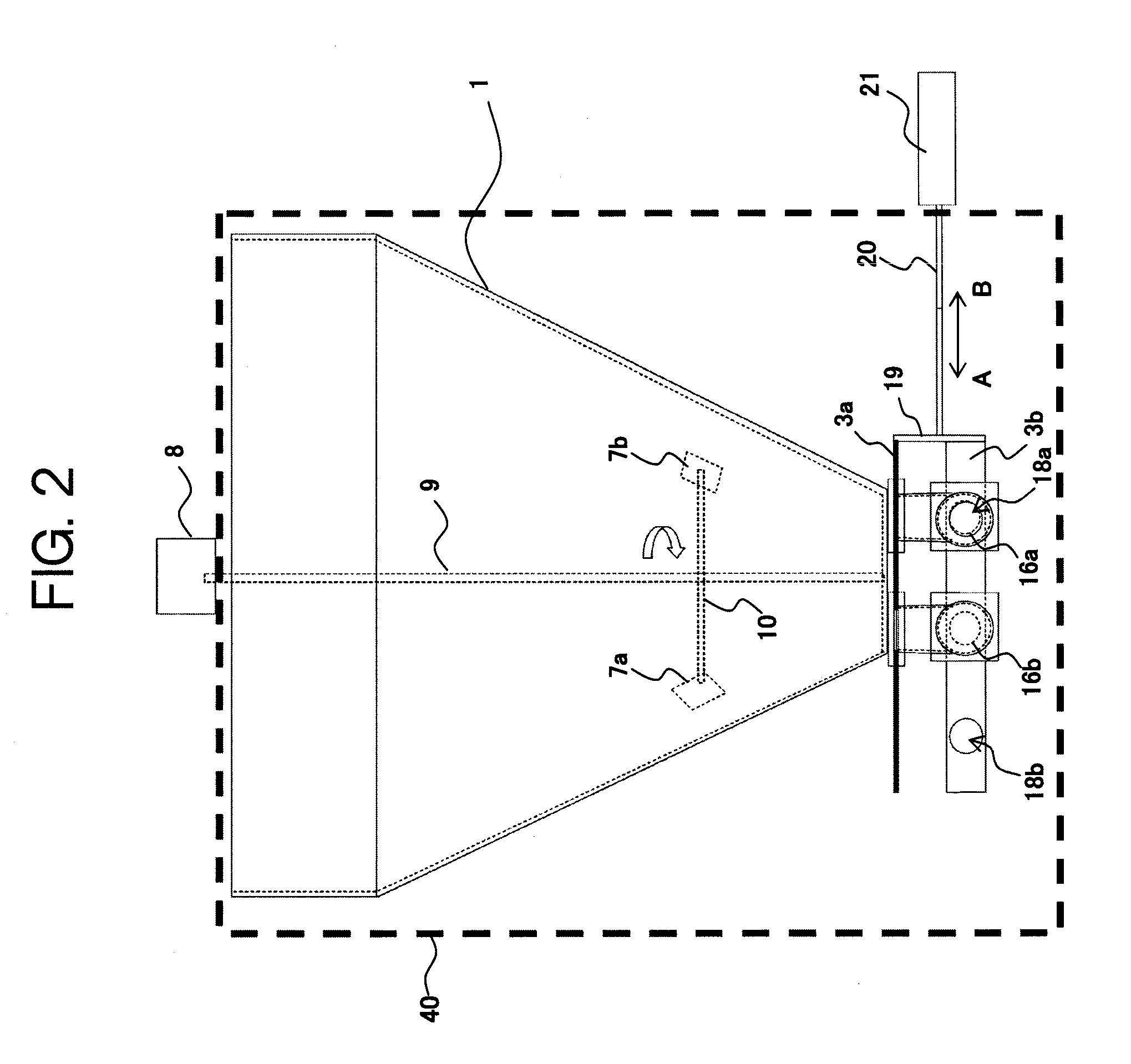

Molding Apparatus for Modified Sulfur Concrete Substance Product

InactiveUS20110064841A1Maintain temperatureIncrease valueSolid waste managementFeeding arrangmentsLower limitShell molding

In the present invention, as a sulfur-containing material fully filled into a cavity of a mold body in which the inside of an outer mold having the cavity which can be hermetically sealed is heated to a temperature within a preset temperature range of which a lower limit is equal to or above a melting point of sulfur is cooled and contracted in the cavity, the sulfur-containing material stored in a filling tank in which a cover is attached to an upper end opening of filling tank, so that the inside of filling tank can be hermetically sealed, and also, the inside of filling tank is pressurized to a predetermined pressure, and the inside of filling tank is heated to a temperature within the preset temperature range, is replenished into the cavity by a pressure in filling tank to mold a modified sulfur concrete substance product.

Owner:NIPPON OIL CORP +1

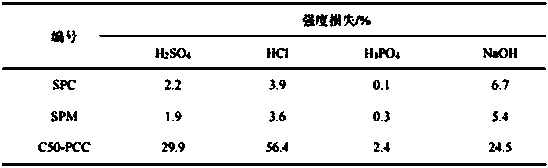

Application of modified sulphur to improvement of compressive strength, corrosion resistance and/or penetration resistance performance of sulphur concrete or sulphur mortar

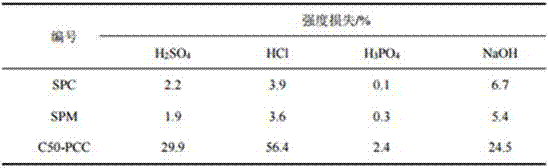

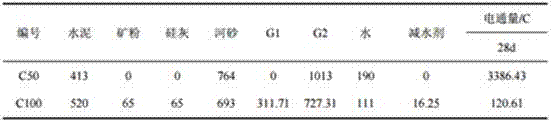

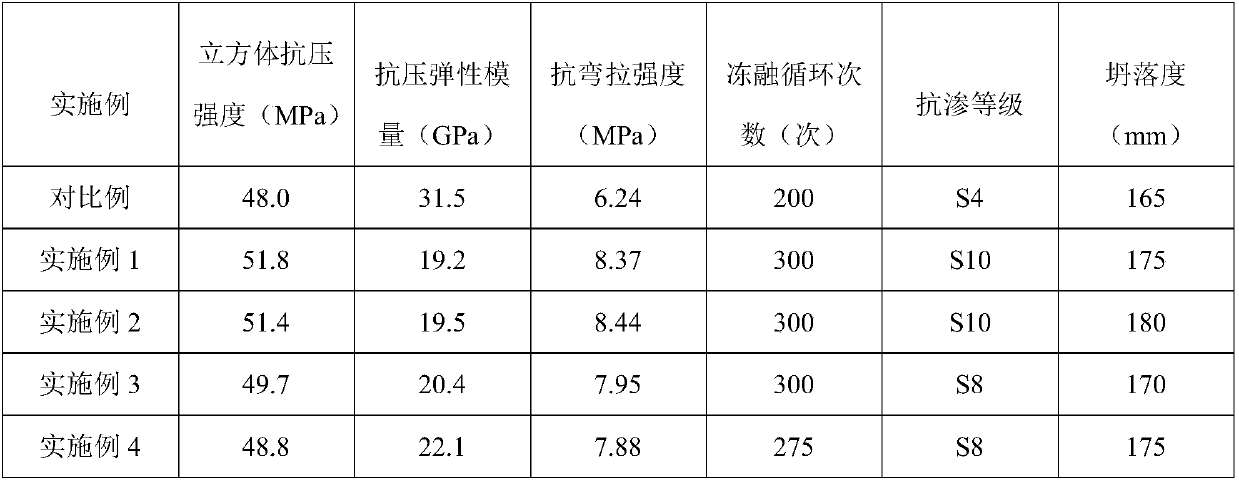

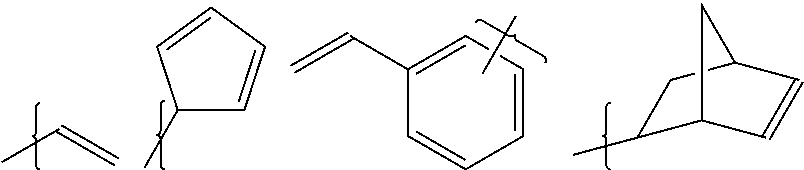

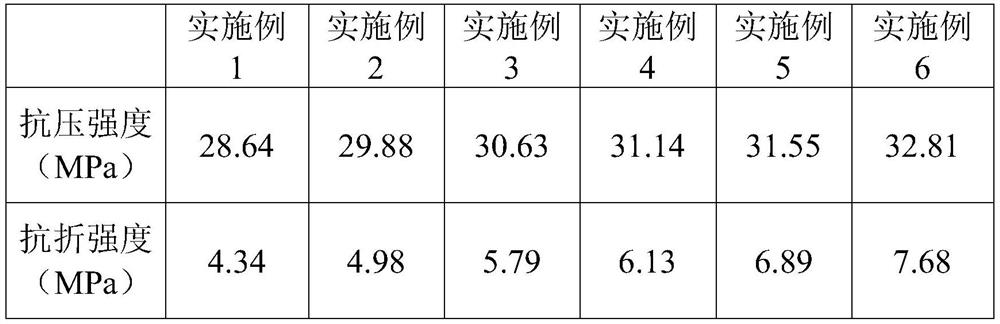

ActiveCN107540336AHigh compressive strengthImprove flexural strengthAcid corrosionCompressive strength

The invention discloses an application of modified sulphur to improvement of compressive strength, corrosion resistance and / or penetration resistance performance of sulphur concrete or sulphur mortar.Modified sulphur is formed by a modifier dicyclopentadiene modified sulphur; The modified sulphur concrete comprises the following raw materials in percentages by mass: 15-20% of modified sulphur, 12-27% of a filling material, 50-60% of stone, and 18-28% of sand; the modified sulphur mortar comprises the following raw materials in percentages by mass: 20-37% of modified sulphur, 15-48% of the filling material, and 50-75% of sand. Compared with silicate concrete, the modified sulphur concrete and modified sulphur mortar have extremely good compressive strength, acid corrosion resistance and / orpenetration resistance, in the preparation process, water and maintenance are not needed, coagulation speed is extremely fast, and pouring work can be carried out in a freezing environment; the gelling material sulphur is a petroleum by-product, and the material can be completely recycled and reused.

Owner:JINAN UNIVERSITY

Coal tar modified durable sulfur concrete and preparation method thereof

InactiveCN111875323ASolve the land environmentSolve the pollution of the environmentSlagCrushed stone

The invention discloses coal tar modified durable sulfur concrete and a preparation method thereof. Each cubic meter of the coal tar modified durable sulfur concrete comprises the following componentsby mass: 1080 kg of industrial sulfur particles; 600 kg of granular crushed stone; 72 kg of fly ash; 41 kg of granulated blast furnace slag; 342 kg of quartz sand; 29 kg of waste ceramic fine aggregate; 24 kg of waste glass micro powder; 36kg of stone chip powder; 36kg of volcanic ash; 65 kg of rubber particles; and 30kg of glass fiber; wherein the mass of the modifier is 1-5% of the mass of theindustrial sulfur particles; the mass of the thickening agent is 0.1-0.5% of the total mass of the sulfur concrete; and the mass of the coupling agent is 0.3-2% of the mass of the industrial sulfur particles. According to the invention, the durability problem caused by material embrittlement and volume shrinkage due to sulfur solid-phase transformation is solved, the cost problem that the traditional sulfur concrete is generally high in price is solved, and the problems that wastes occupy land and pollute the natural environment are also solved.

Owner:INNER MONGOLIA UNIV OF TECH

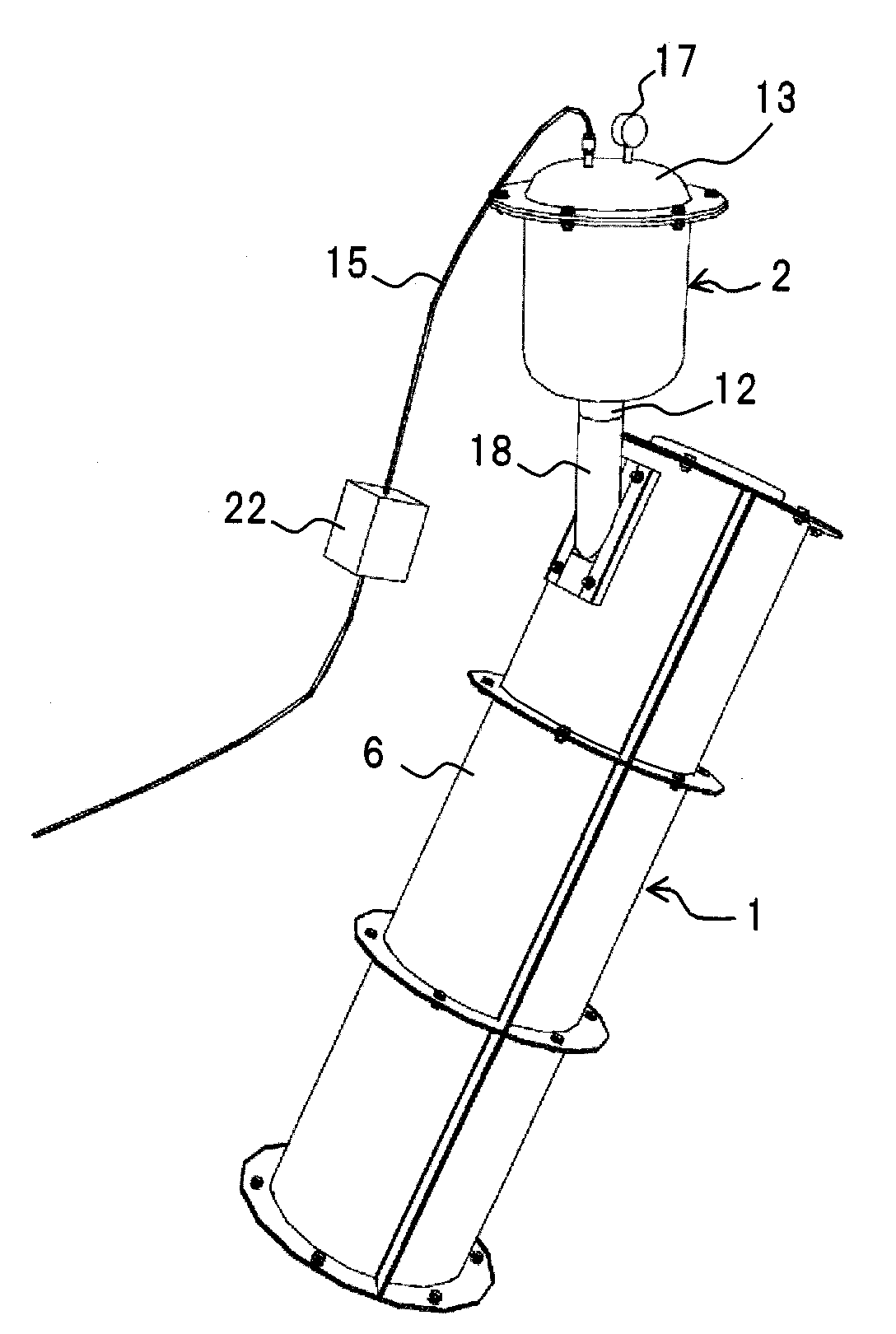

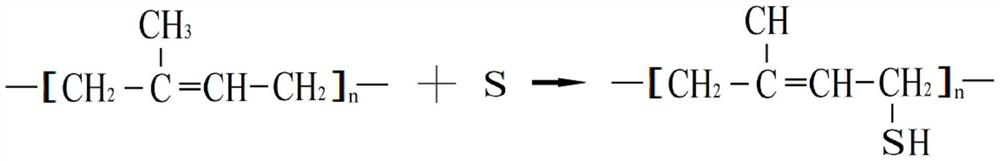

System for production of solid modified sulfur products

InactiveCN101189107ASafe and easy to manufactureEasy to transportSulfur compoundsPretreatment controlSulfur productHazardous substance

A reformed sulfur solidified substance producing system of the present invention includes a reformed sulfur producing tank 3 which receives and mixes molten sulfur from a molten sulfur tank 1 and sulfur reforming agent from a sulfur reforming agent tank 2 to thereby produce reformed sulfur, and at the same time, which heats the inside accommodated substance to a predetermined temperature or higher, a reformed sulfur intermediate material tank 5 which receives and mixes reformed sulfur from the reformed sulfur producing tank 3 and a fine aggregate from a fine aggregate hot bin 4 to thereby produce reformed sulfur intermediate material, and at the same time, which heats an inside accommodated substance to a predetermined temperature or higher, a mulling device 7 which receives and mulls reformed sulfur intermediate material from the reformed sulfur intermediate material tank 5 and a coarse aggregate from a coarse aggregate hot bin 6, and further, heats an inside mulled substance to a predetermined temperature or higher, and a pouring device 8 which receives and stores the raw material mulled by the mulling device 7 and heats the same to a predetermined temperature or higher, and further, measures the inside raw material and pours the same into a mold form 36. With this, it is possible to produce a reformed sulfur solidified substance which can be handled as a non-dangerous substance (here, the non-dangerous substance is a substance which does not have ignitability or an incombustible substance), and which can be easily transferred.

Owner:NIPPON OIL CO LTD +1

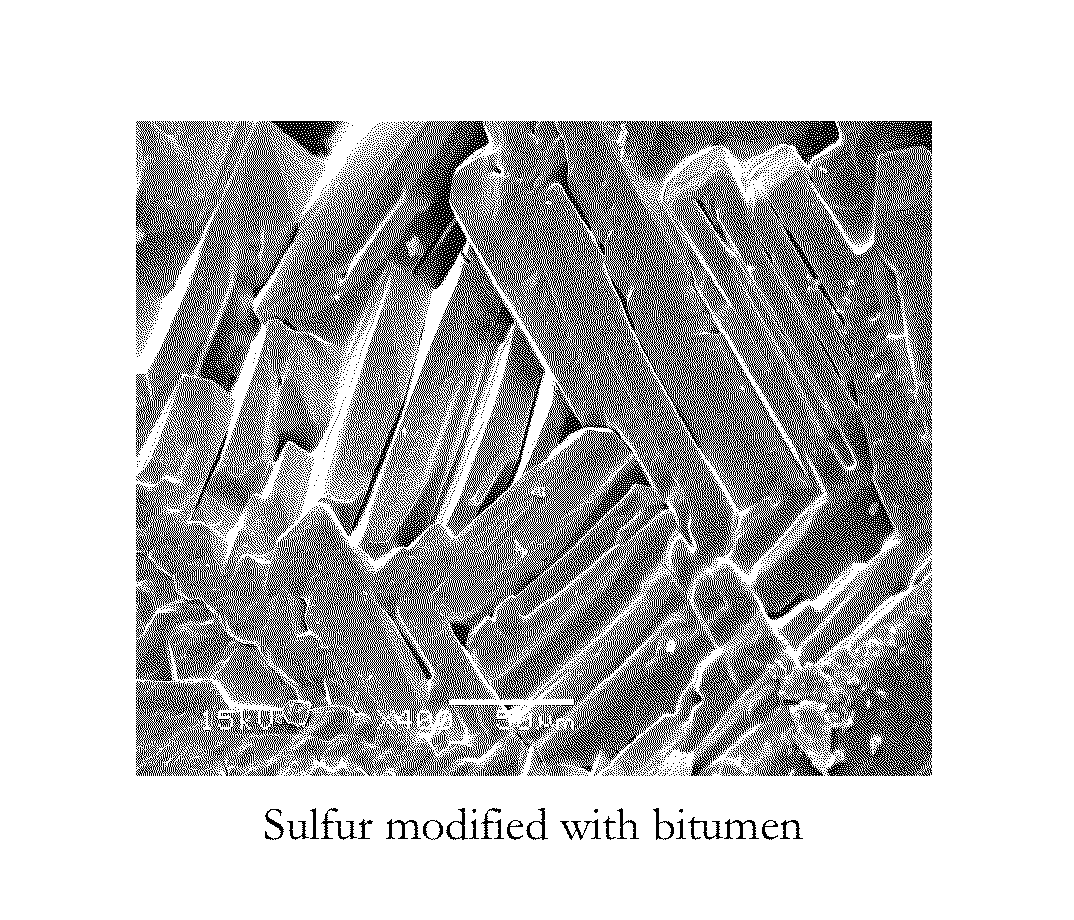

Fire-resistant sulfur concrete

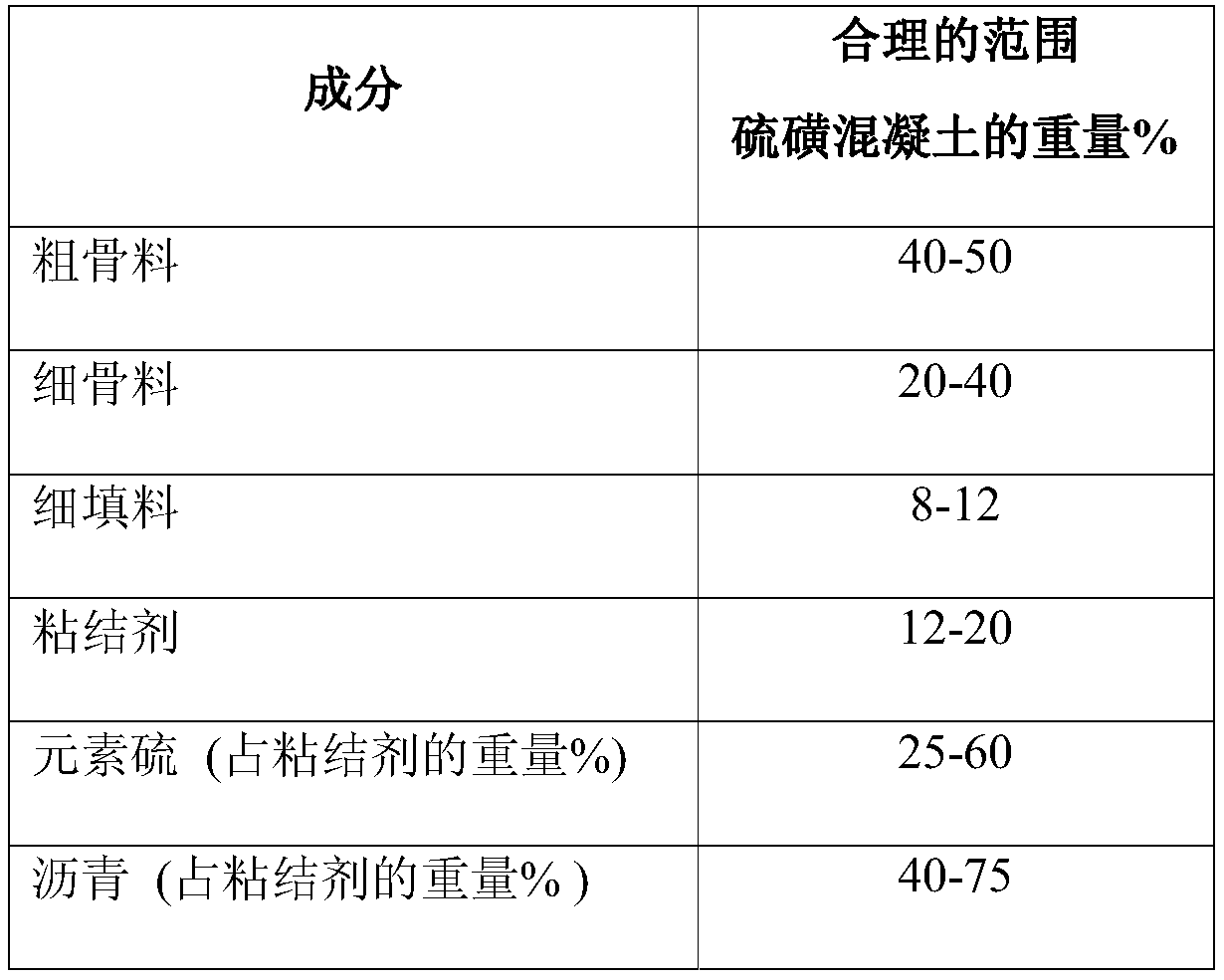

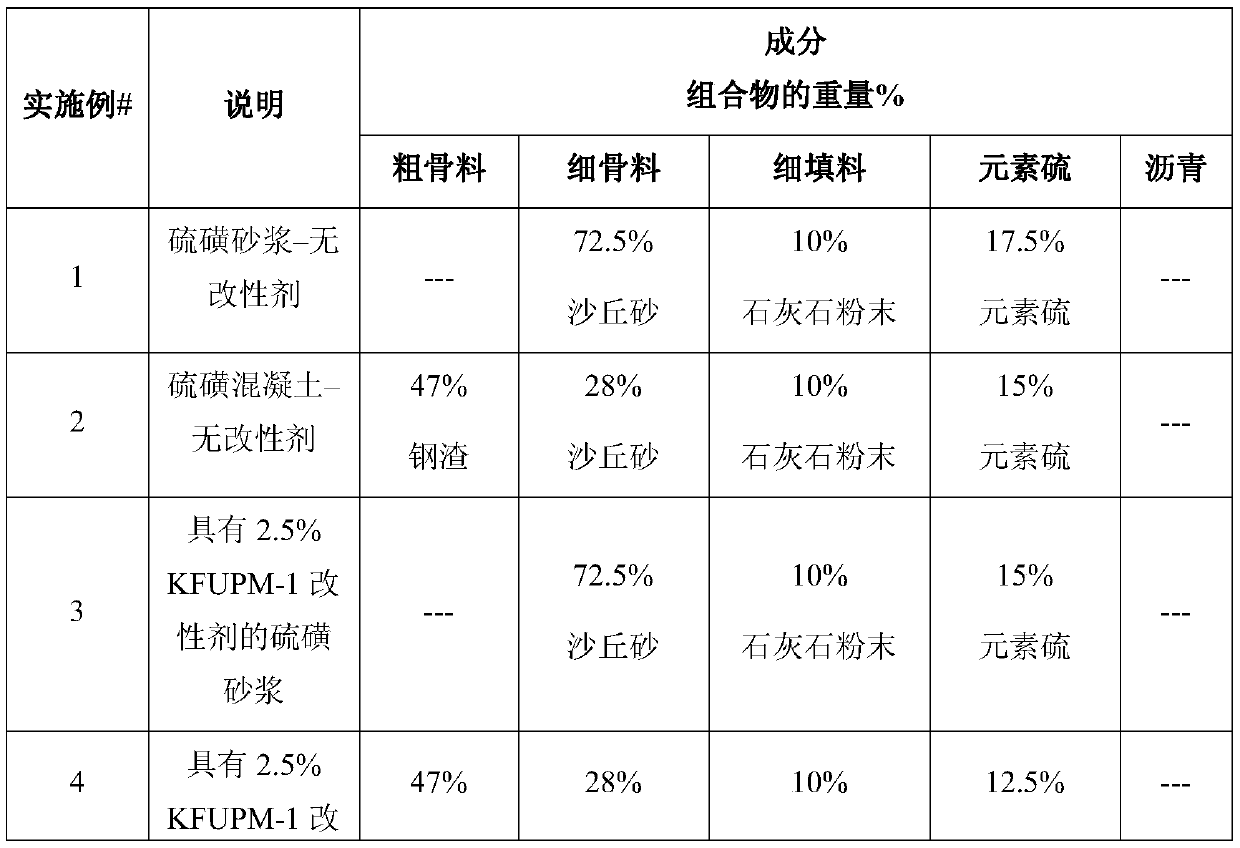

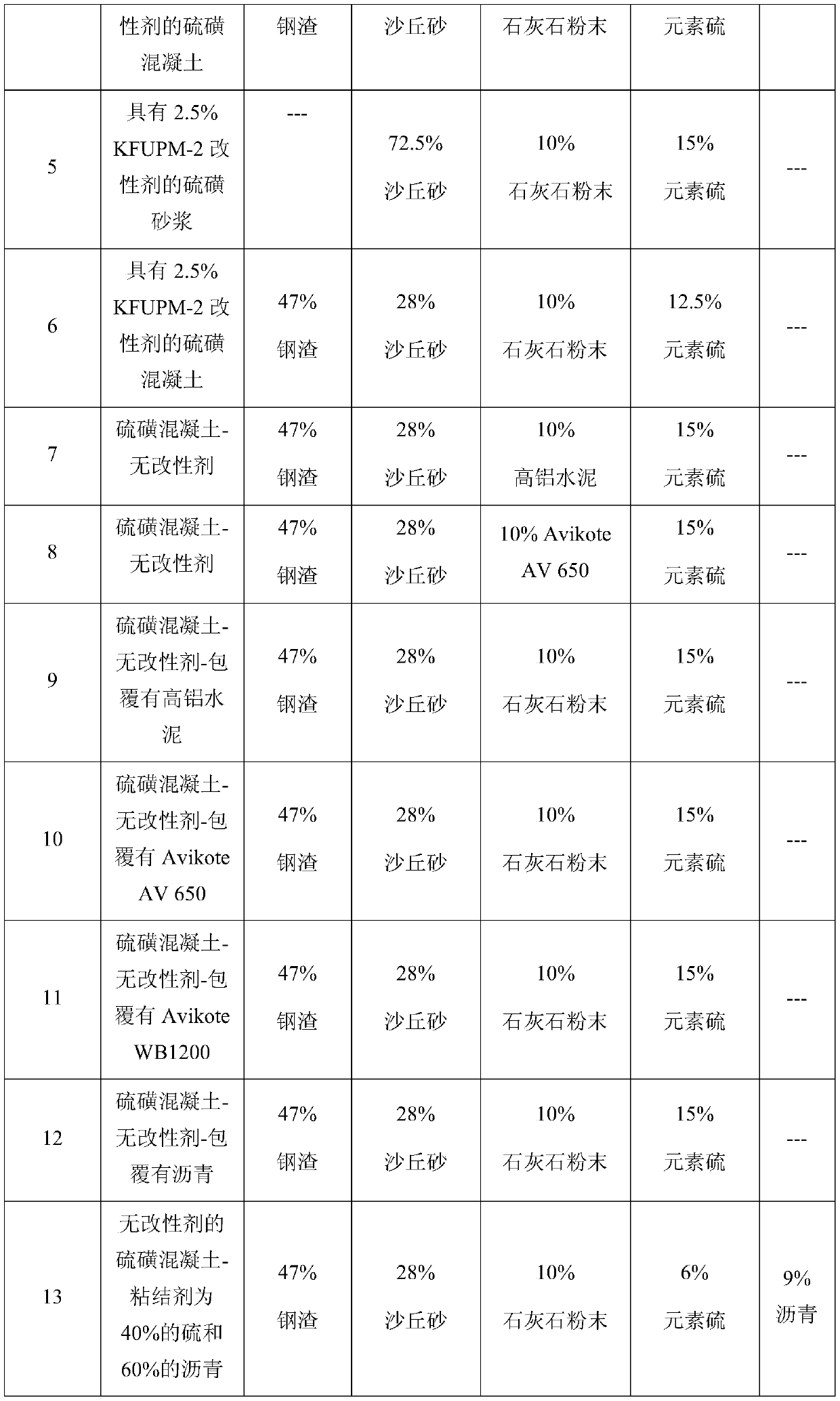

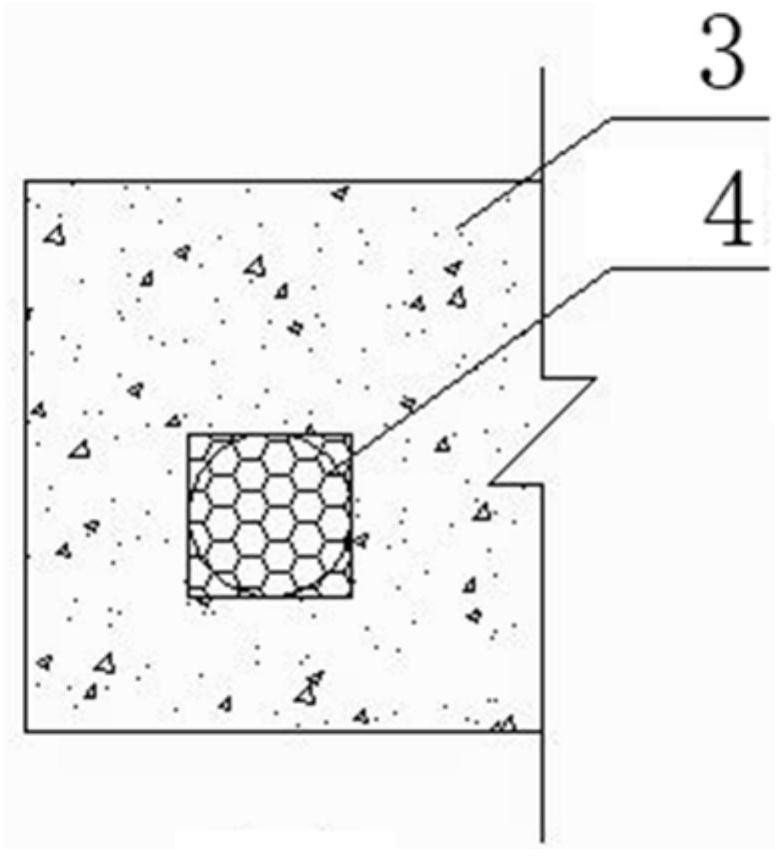

A sulfur concrete has constituents that include a coarse aggregate in an amount in a range of 40-50 wt % of the weight of the sulfur concrete, a fine aggregate in an amount in a range of 20-40 wt % of the weight of the sulfur concrete, a fine filler in an amount in a range of 8-12 wt % of the weight of the sulfur concrete, and a binder in an amount in a range of 12-20 wt % of the weight of the sulfur concrete. The binder includes elemental sulfur in an amount in a range of 25-60 wt % of the weight of the binder and asphalt in an amount in a range of 40-75 wt % of the weight of the binder.

Owner:SAUDI ARABIAN OIL CO +1

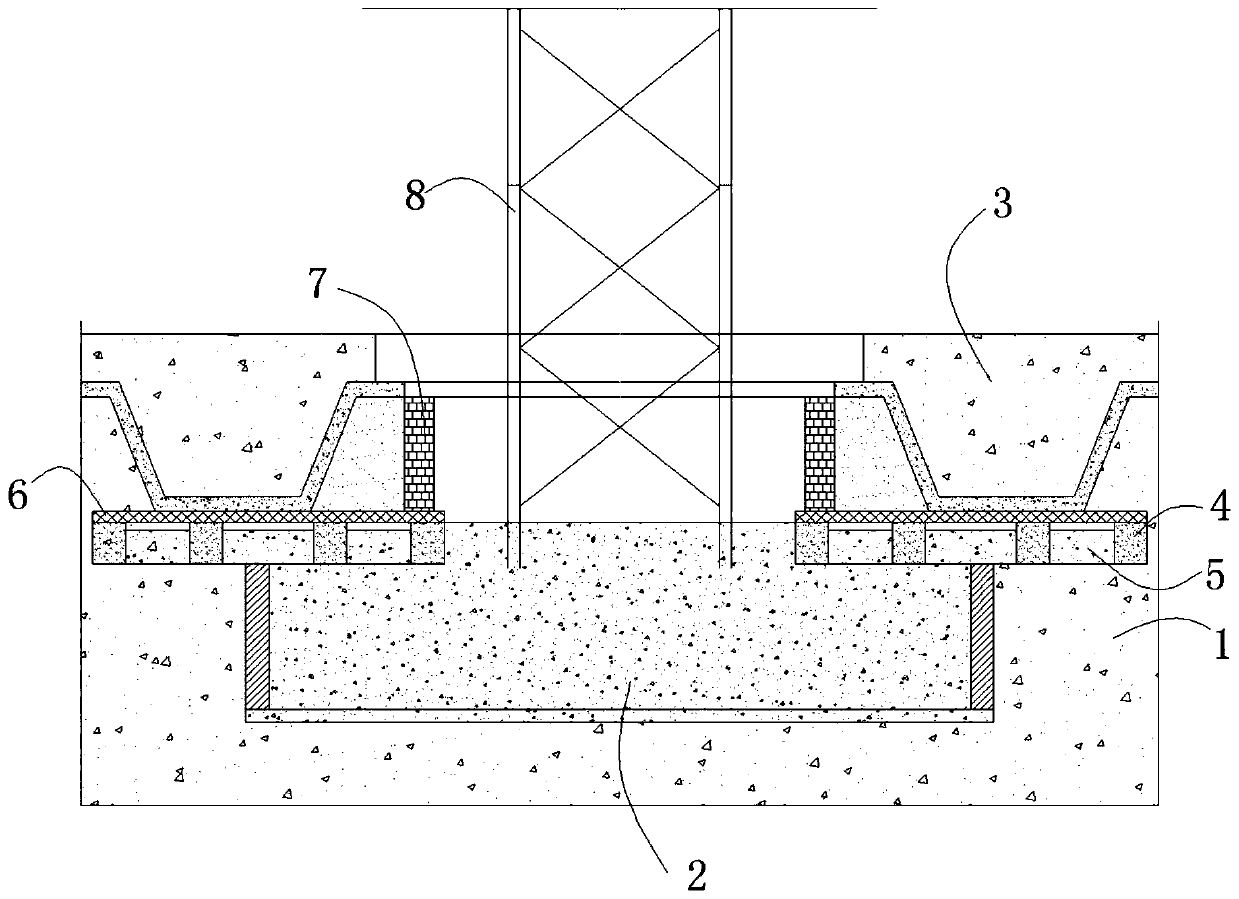

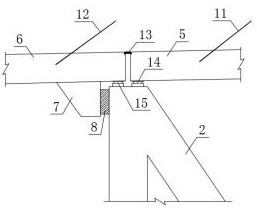

Method for building underground parking waterproof facilities by means of tower crane

ActiveCN110552546AWarranty requirementsGuaranteed waterproof requirementsFoundation engineeringTowersStructural engineeringTower crane

The invention relates to a method for building underground parking waterproof facilities by means of a tower crane. Removal of a tower crane body is carried out after the completion of off-wall liningmasonry, a sulfur concrete temporary support is constructed between a tower crane foundation and an independent foundation in advance to absorb the vibration generated in the working process of the tower crane body, vibration damage is stopped on the sulfur concrete temporary support, through the way of removing the sulfur concrete temporary support, a concrete body permanent support can be utilized to realize the way of permanent support after pouring, unstable support of the damaged sulfur concrete temporary support to the independent foundation is removed, and thus under the condition of ensuring the strength requirement and waterproof requirement of a basic foundation of an underground garage, the transport capacity of the tower crane can be better utilized to achieve the purpose of energy saving and emission reduction.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Use of surfactant in the preparation of modified sulfur and sulfur cement

ActiveUS20150027345A1Excellent property in term of strength and durability and leachabilityEasy to useSolid waste disposalSulfur compoundsActive agentPhysical chemistry

Owner:UNITED ARAB EMIRATES UNIVERSITY

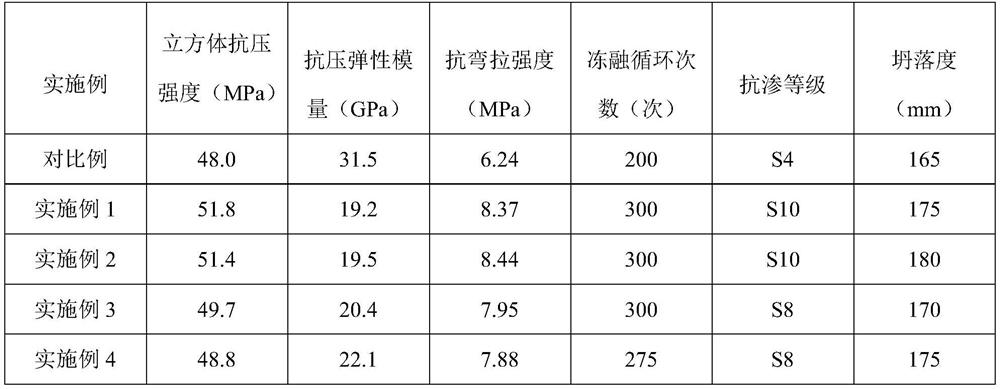

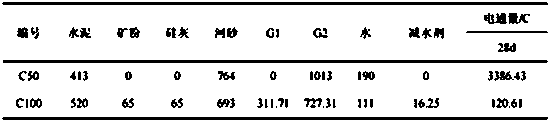

High-performance sulfur concrete and preparation method thereof

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

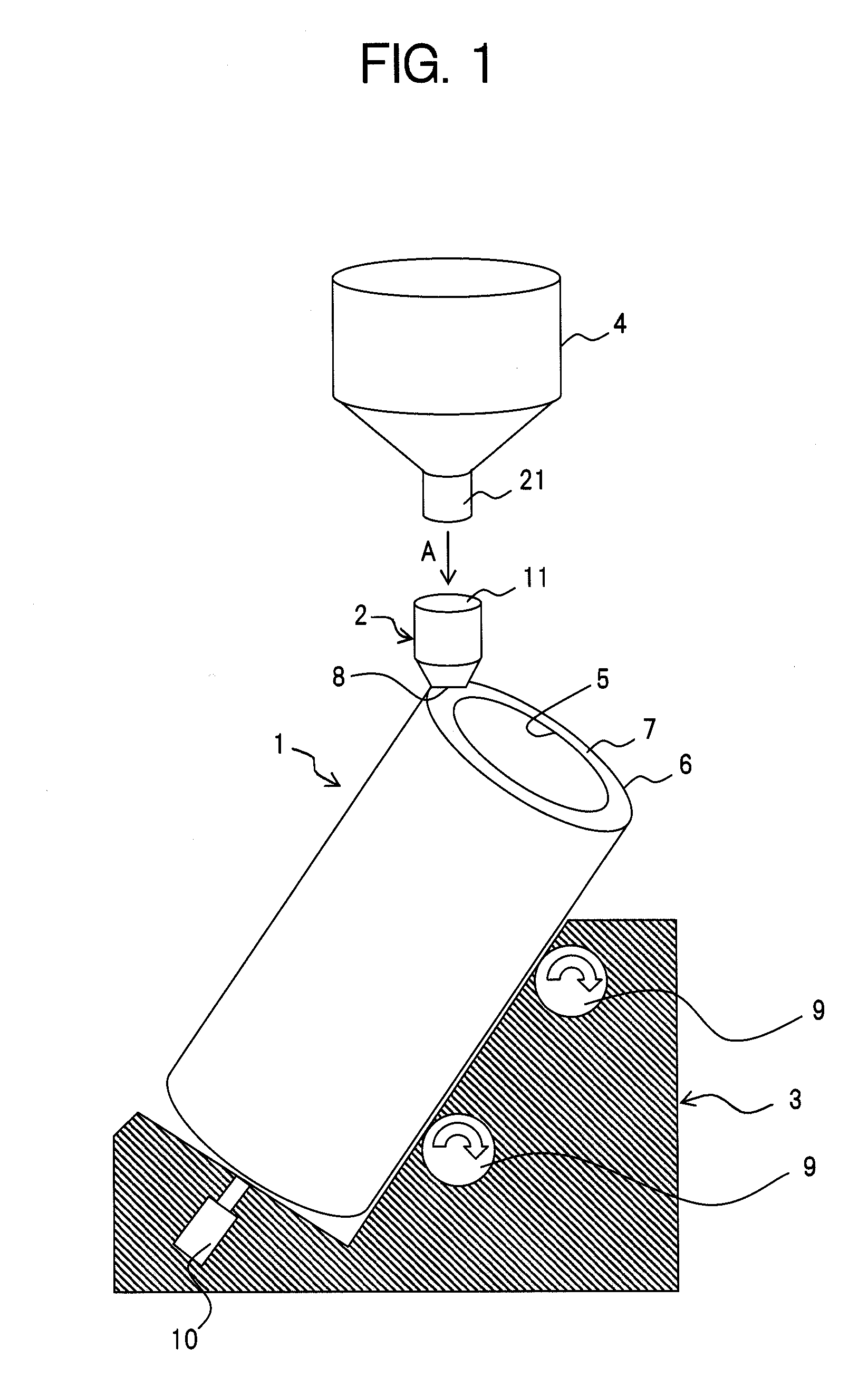

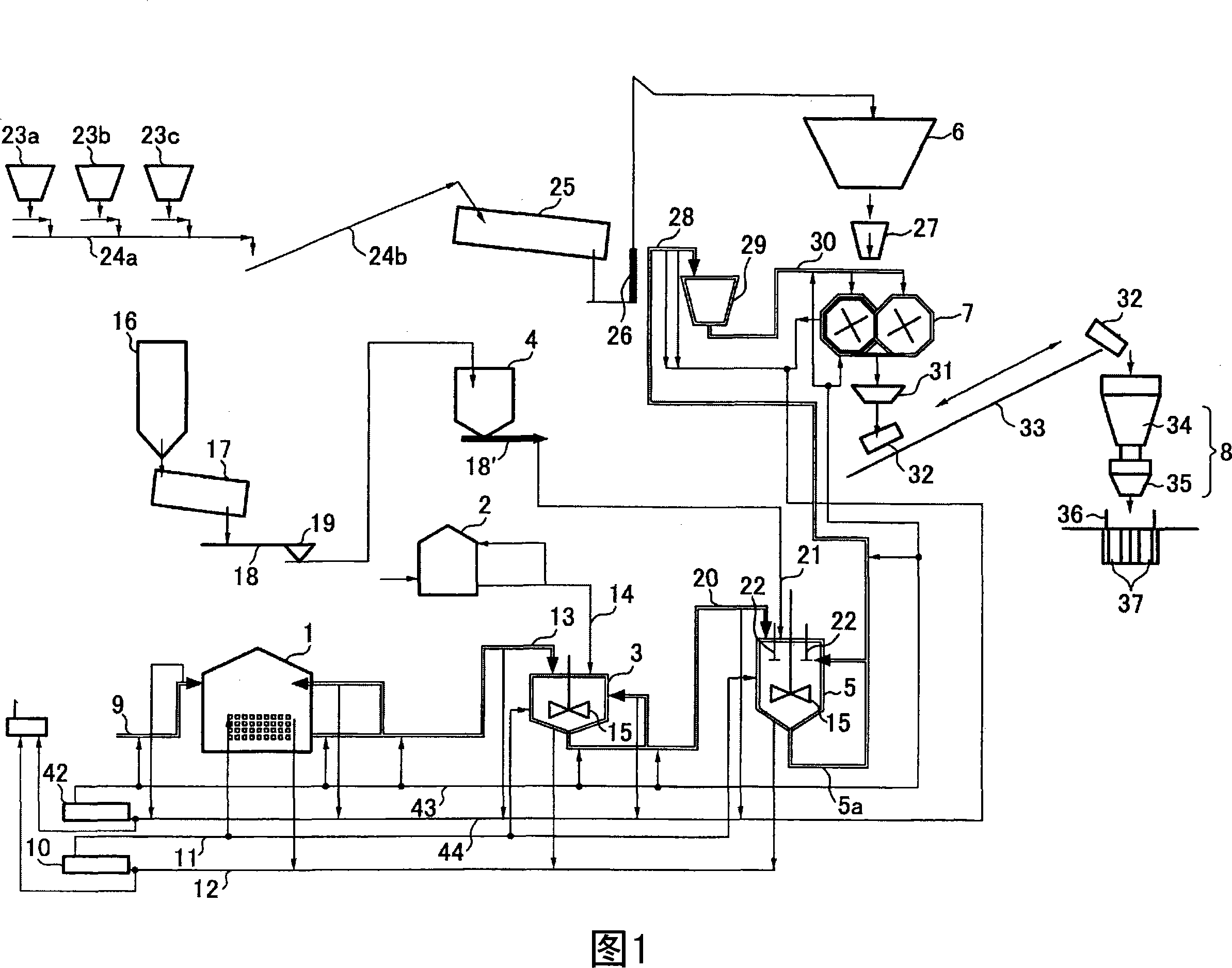

Apparatus for producing a sulfur concrete substance

InactiveUS8235705B2Improve accuracyAvoid separationDischarging apparatusMixing operation control apparatusLower limitMolten state

A sulfur-containing material in a melt state is stored in material hopper 1 heated to a temperature within a preset temperature range of which a lower limit is equal to or above a melting point of sulfur. The stored sulfur-containing material is sucked by pressure generators 2a, 2b and pulled out into cylinders 11a, 11b heated to a temperature within the preset temperature range. The pulled out sulfur-containing material is pushed out from the cylinders under predetermined pressure applied by the pressure generator, and thereafter, the resultant material is injected from injection port 24 into mold 5 having therein a cavity which can be hermetically sealed and the mold being heated to a temperature within the preset temperature range. The injection port of the mold after the sulfur-containing material is fully injected in the cavity is closed. By stopping heating of the mold, the sulfur-containing material injected in the cavity is slowly cooled. After that, a modified sulfur concrete substance formed by cooling and solidifying the sulfur-containing material in the cavity is taken out from the mold.

Owner:NIPPON OIL CORP +1

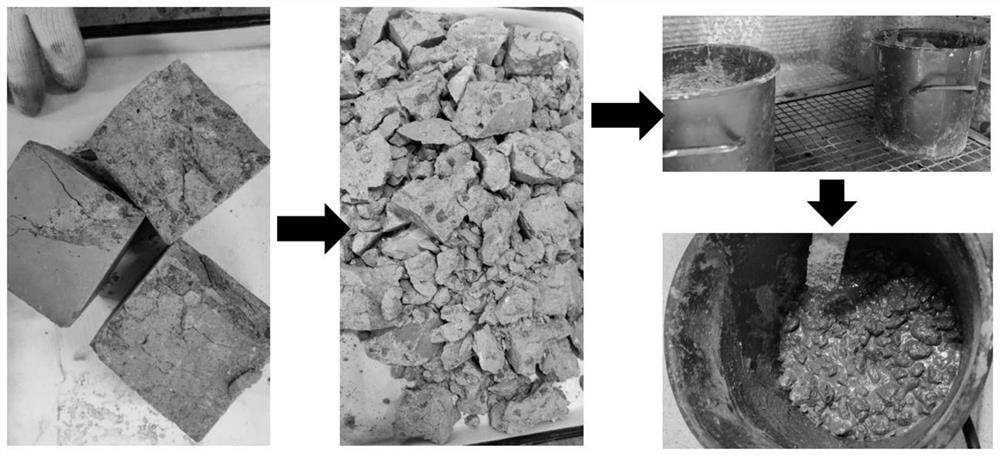

Concrete composition

InactiveUS20120272871A1Shorten hardening timeLow water absorptionSolid waste managementWood working apparatusStructural engineeringSulfur concrete

A concrete composition comprising a mouldable mixture of aggregate, binder and liquid vehicle, wherein the aggregate comprises sulphur concrete-derived aggregate and wherein the binder comprises hydraulic binder. The use of crushed sulphur concrete as aggregate in cement-based concrete reduces the hardening time of the concrete.

Owner:SHELL OIL CO

Microwave-excitation-based self-broken concrete as well as preparation method and application thereof

The invention relates to microwave-excitation-based self-broken concrete as well as a preparation method and application thereof. The concrete contains the following components in parts by weight: 250-300 parts of sulfur, 100-150 parts of Portland cement, 150-200 parts of fine aggregates, 350-500 parts of coarse aggregates, 10-20 parts of paraffin, 30-50 parts of a microwave absorbent and 20-30 parts of a mineral filler; and the density of the concrete is 1850kg / m<3>-2900kg / m<3> after being mixed and blended. By virtue of the interaction and cooperation of the components, the concrete has thecharacteristics of high strength, corrosion resistance, permeation resistance and high hardening speed of existing sulfur concrete and further has the advantages of lightness and high heated volume swelling speed of light aggregate concrete. The concrete is reasonable in design, low in cost and easy in preparation process. A component prepared from the concrete has good mechanical properties. Whenbeing dismounted, the component can be automatically cracked and broken under an external microwave field, so that the difficulty of dismounting construction is reduced, and the popularization and use are promoted.

Owner:SHENYANG JIANZHU UNIVERSITY

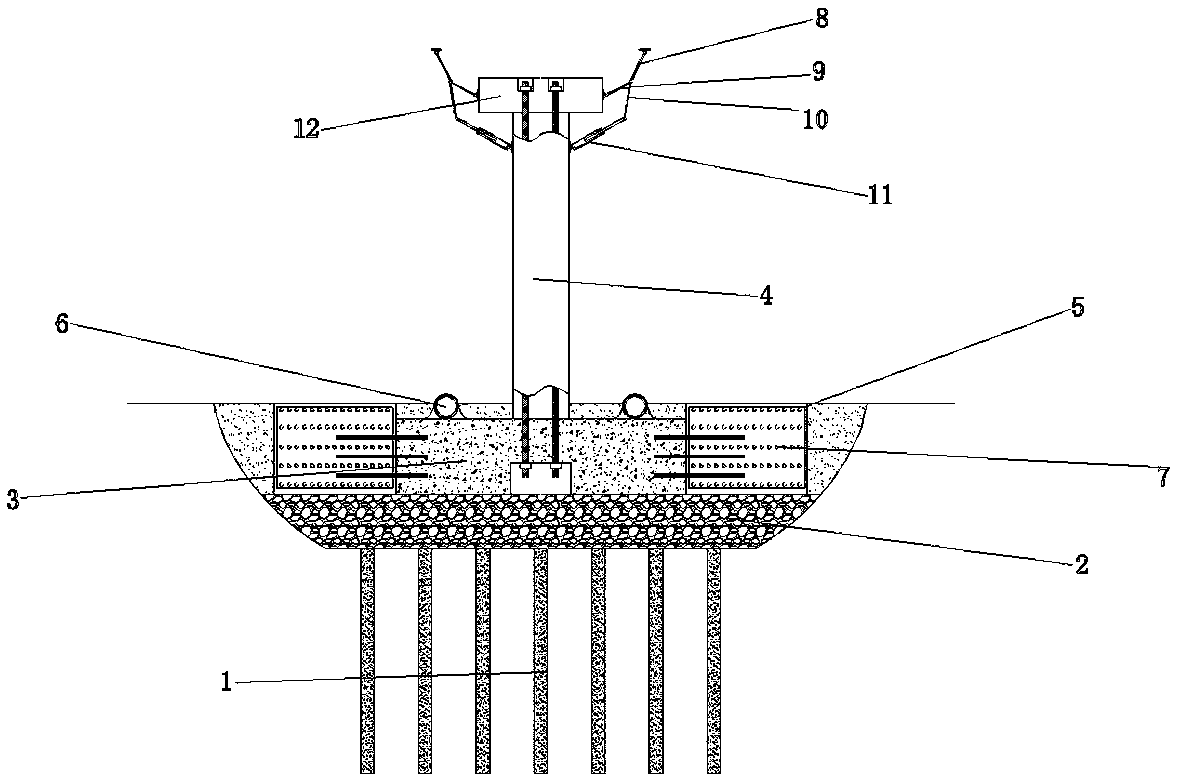

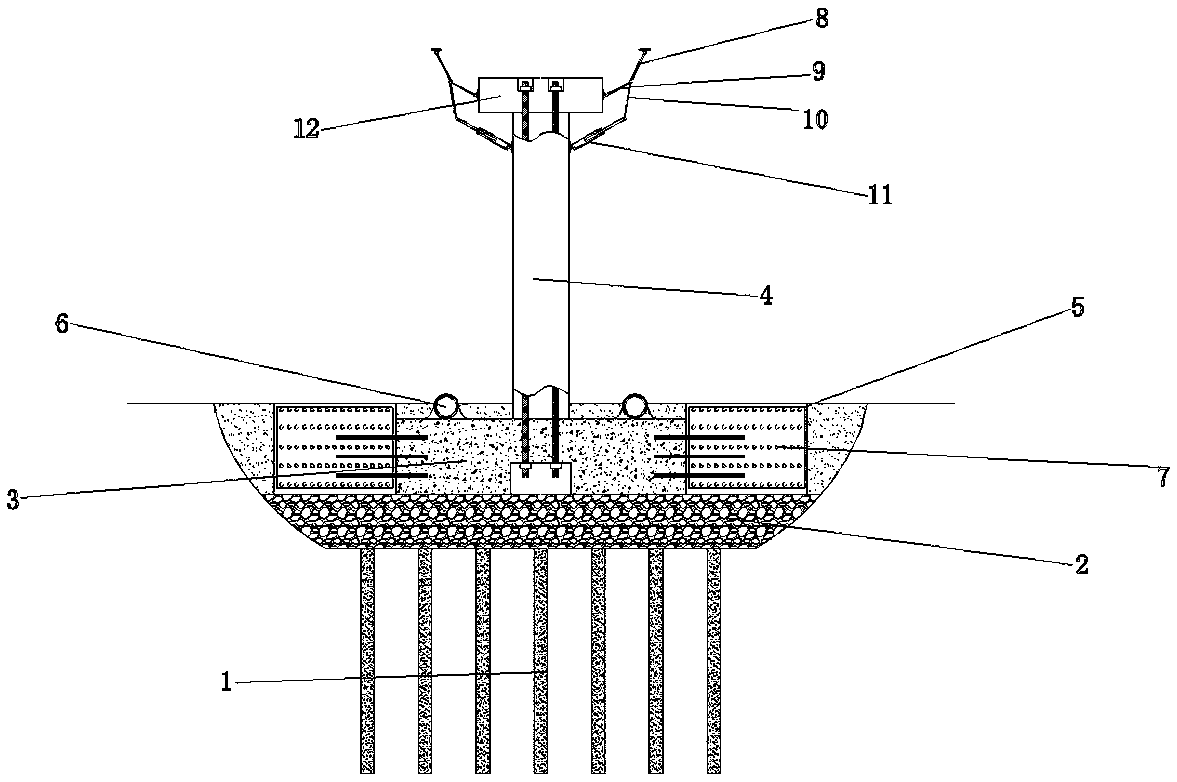

Super-tough concrete bridge shock-proof system

ActiveCN109653234AImprove shock resistanceReduce shockProtective foundationBridge structural detailsStructural engineeringEngineering

The invention discloses a super-tough concrete bridge shock-proof system which comprises a pile group arranged on a foundation soil layer. The upper portion of the pile group is covered with a gravellayer, a pouring bearing platform is arranged on the upper portion of the gravel layer, the upper portion of the pouring bearing platform is connected with a bridge pier, a capping beam is arranged atthe top of the bridge pier, a fluctuating power generation device is arranged on the pouring bearing platform, sulfur concrete boxes are arranged on the periphery of the pouring bearing platform, sulfur concrete is poured into the sulfur concrete boxes, heating wires are embedded into the sulfur concrete and electrically connected with piezoelectric crystals, and a hydraulic connecting rod mechanism is arranged between the bridge pier and a bridge. Energy generated by an earthquake is transformed into electric energy by the fluctuating power generation device, the hydraulic connecting rod mechanism at the tops of the sulfur concrete and the bridge pier is further used for comprehensively absorbing the energy, the system is reasonable in design, the earthquake energy absorption capacity ofa bridge structure is greatly improved, and impact of the earthquake energy on the bridge pier is reduced.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

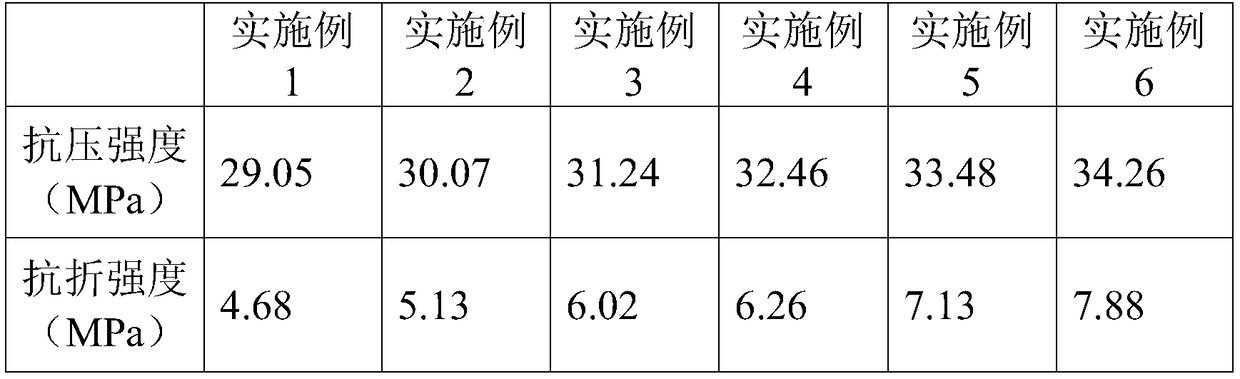

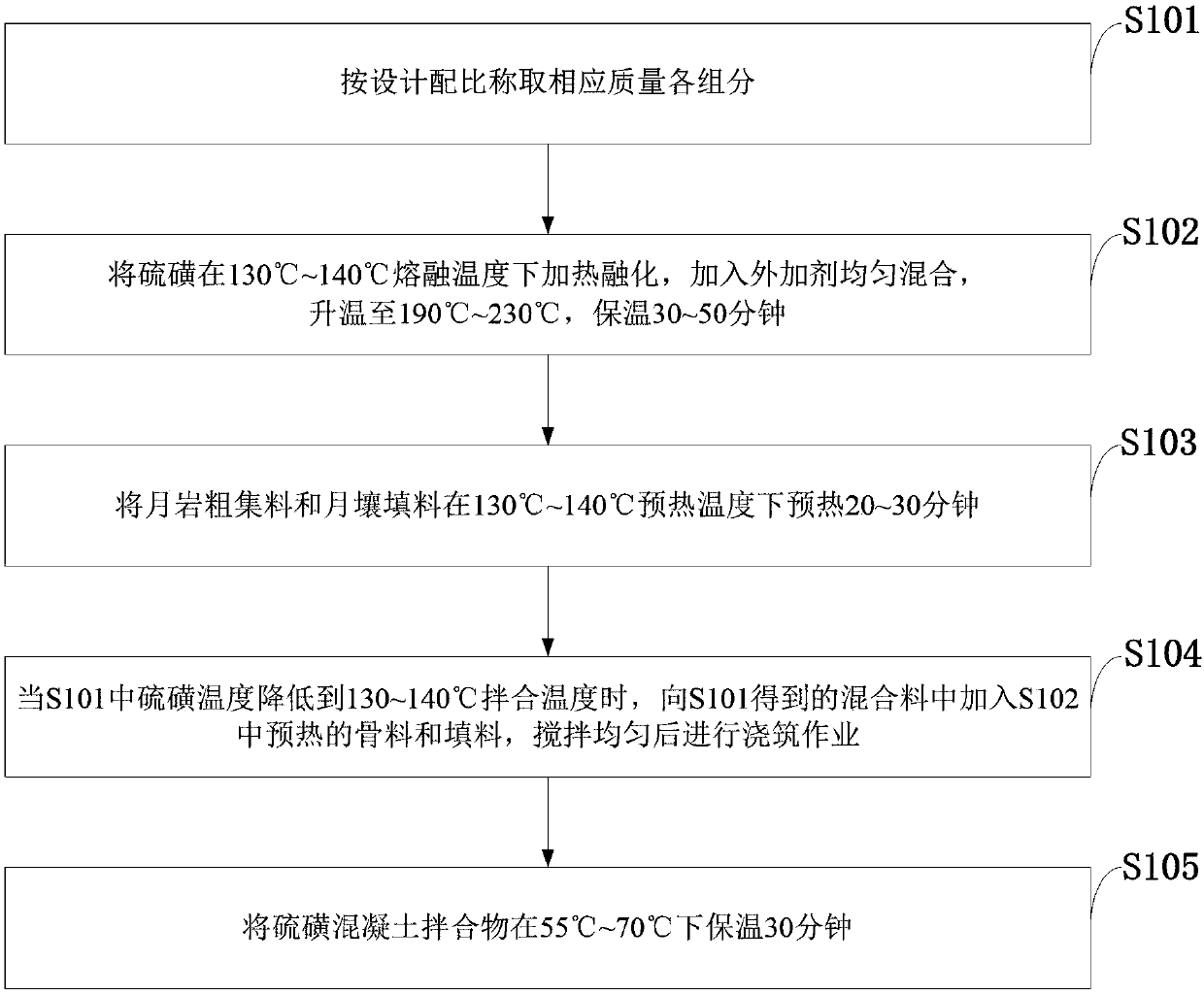

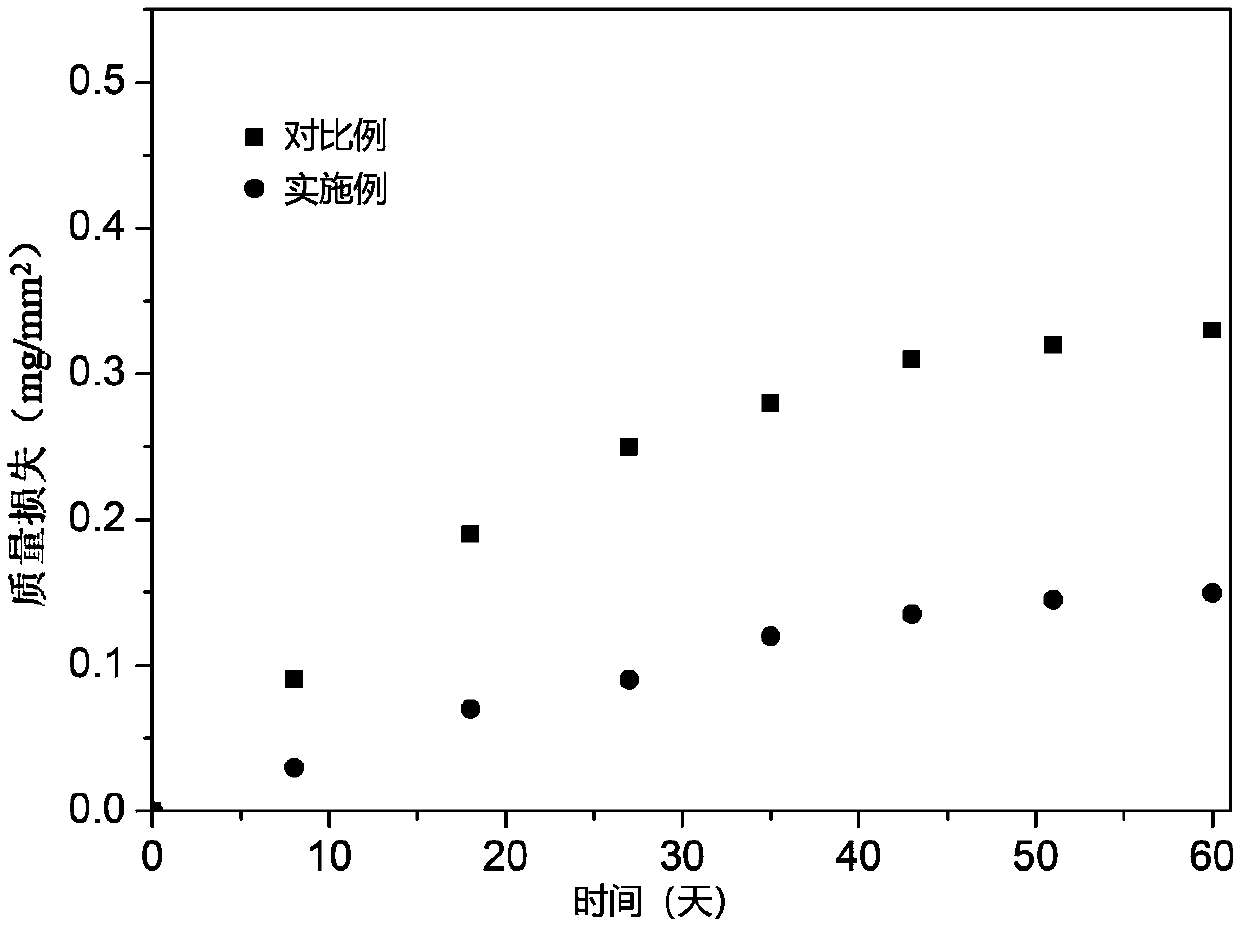

Sulfur concrete with sublimation corrosion resistance and preparation method thereof

The invention belongs to the technical field of macromolecule materials, and discloses sulfur concrete with sublimation corrosion resistance and a preparation method thereof. The sulfur concrete is prepared from, by mass, 15-20% of sulfur, 0.2-0.6 % of an additive, 55-65% of lunar rock coarse aggregate and 14-26% of lunar soil filler. The additive is prepared by mixing magnesium stearate, polystyrene fluoride and carbon tetrafluoride at the mass ratio of 1:5:20, and the addition amount of the additive is 1-4% of sulfur. The additive is used for pre-modifying sulfur, the sublimation rate of sulfur components in sulfur concrete under high vacuum conditions is effectively reduced, the durability of sulfur concrete under high vacuum conditions is improved, and the preparation technology is simple and easy to operate, the construction efficiency is high, and the sulfur concrete is easy to produce and use under high vacuum conditions such as the moon.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Fire-resistant sulfur concrete

A sulfur concrete has constituents that include a coarse aggregate in an amount in a range of 40-50 wt% of the weight of the sulfur concrete, a fine aggregate in an amount in a range of 20-40 wt% of the weight of the sulfur concrete, a fine filler in an amount in a range of 8-12 wt% of the weight of the sulfur concrete, and a binder in an amount in a range of 12- 20 wt% of the weight of the sulfurconcrete. The binder includes elemental sulfur in an amount in a range of 25-60 wt % of the weight of the binder and asphalt in an amount in a range of 40-75 wt % of the weight of the binder.

Owner:SAUDI ARABIAN OIL CO +1

Door sealing structure and construction method used in shield launching and receiving construction

A door-sealing structure and its construction method used in shield launching and receiving construction. The underground diaphragm wall is composed of a steel cage embedded in concrete as a skeleton. Steel plate, two side steel plates of the same size as the bottom steel plate are vertically welded on the left and right sides of the bottom steel plate to form a square upper opening steel formwork, and the corresponding vertical steel bars on the reinforcement cage are welded to the upper and lower surfaces of the bottom steel plate. A number of steel bars are welded horizontally between the two side steel plates; the length of the above-mentioned bottom steel plate is the diameter of the tunnel plus 1m, the thickness is 2cm to 5cm, and the width is equal to the thickness of the underground diaphragm wall; sulfur concrete is poured in the upper opening steel formwork, and the upper opening steel The underground continuous wall other than the formwork is poured with ordinary concrete; the invention solves the problems of traditional shield tunneling methods such as winding the cutter head, head-to-head contact between the cutter head and the steel bar, and pulling the surrounding concrete, and has the characteristics of reducing the loss of the shield machine cutter head and improving the efficiency of the shield tunneling machine .

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of high-performance sulfur concrete and its preparation method

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

Reinforced sulphur concrete

InactiveUS8753444B2Improve adhesionEnhanced interactionCeramic shaping apparatusBuilding reinforcementsSulfur concreteMetal

Owner:SHELL OIL CO

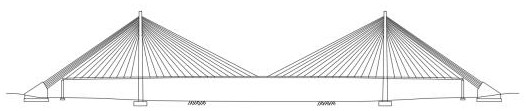

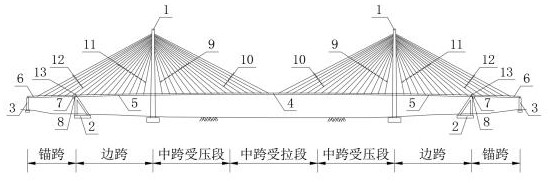

Ultra -large-span cable-stayed bridge with thrust piers and construction method thereof

PendingCN111996896AReasonable forceBeautiful shapeCable-stayed bridgeBridge structural detailsArchitectural engineeringSulfur concrete

The invention provides an ultra-large-span cable-stayed bridge with thrust piers. The bridge comprises cable bent towers, the thrust piers, transition piers, mid-span main beams, side-span main beams,anchor span main beams, stay cables and expansion joints. The mid-span main beams and the side-span main beams are continuous, and the expansion joints are arranged between the anchor-span main beamsand the side-span main beams; the thrust piers are arranged between the side span main beams and the anchor span main beams, brackets are arranged at the positions, at the thrust piers, of the bottoms of the anchor span main beams, and anti-thrust supports are arranged between the brackets and the thrust piers. In the construction process, temporary support padstones which are made of sulfur concrete and internally provided with electric heating wires are arranged on the side span sides of the thrust piers, temporary brackets are arranged at the positions, at the thrust piers, of the bottomsof the side span main beams, and temporary anti-thrust supports are arranged between the temporary brackets and the temporary support padstones. The thrust piers are used for bearing the horizontal force of the anchor span main beams and serve as support for counteracting the horizontal force of the side span and anchor span main beams in the construction stage, expensive ground anchors can be omitted, and a cantilever construction method can be conveniently used for installing the mid-span main beams and converting a system after mid-span folding.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTHEAST UNIV CO LTD

Application of a modified sulfur in improving the compressive strength, anti-corrosion and/or anti-permeability of sulfur concrete and sulfur mortar

ActiveCN107540336BHigh compressive strengthImprove flexural strengthMining engineeringAcid corrosion

The invention discloses an application of modified sulphur to improvement of compressive strength, corrosion resistance and / or penetration resistance performance of sulphur concrete or sulphur mortar.Modified sulphur is formed by a modifier dicyclopentadiene modified sulphur; The modified sulphur concrete comprises the following raw materials in percentages by mass: 15-20% of modified sulphur, 12-27% of a filling material, 50-60% of stone, and 18-28% of sand; the modified sulphur mortar comprises the following raw materials in percentages by mass: 20-37% of modified sulphur, 15-48% of the filling material, and 50-75% of sand. Compared with silicate concrete, the modified sulphur concrete and modified sulphur mortar have extremely good compressive strength, acid corrosion resistance and / orpenetration resistance, in the preparation process, water and maintenance are not needed, coagulation speed is extremely fast, and pouring work can be carried out in a freezing environment; the gelling material sulphur is a petroleum by-product, and the material can be completely recycled and reused.

Owner:JINAN UNIVERSITY

A self-shattering concrete based on magnetothermal excitation, its preparation method and its application

A self-shattering concrete based on magneto-thermal excitation, preparation method and application thereof according to the present invention, each component of the concrete comprises: 250-300 parts of sulfur, 100-150 parts of Portland cement, and 150 parts of fine aggregate ~200 parts, 350~500 parts of coarse aggregate, 10~20 parts of paraffin, 30~50 parts of magnetic powder, 20~30 parts of mineral filler, the density after mixing is 2050~2850kg / m 3 . The mutual cooperation and synergy of various components makes the present invention not only have the characteristics of high strength, corrosion resistance, penetration resistance and quick setting of the existing sulfur concrete, but also have the advantages of light weight and fast volume expansion speed of lightweight aggregate concrete . The invention has reasonable design, low cost and simple preparation process. The components made of the concrete have good mechanical properties. When dismantling, the component can expand and crack by itself under the action of an external alternating magnetic field, which reduces the difficulty of dismantling and construction, and is suitable for popularization and use.

Owner:上海隧港建筑材料有限公司

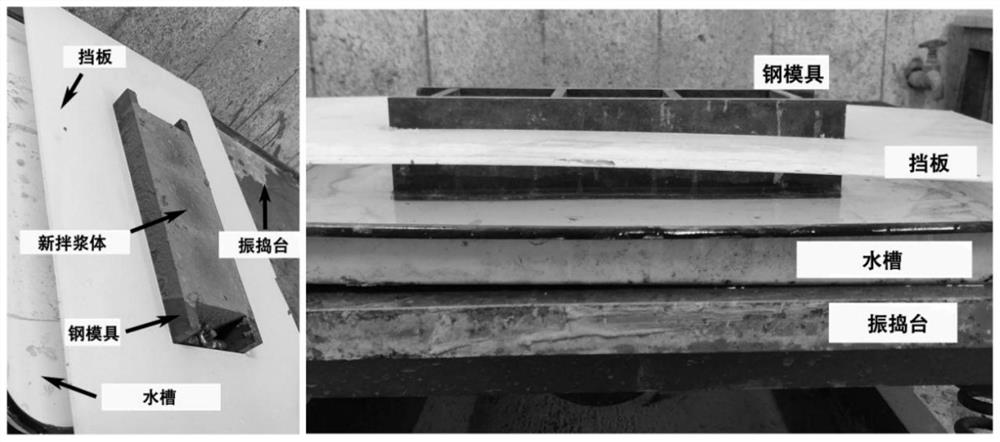

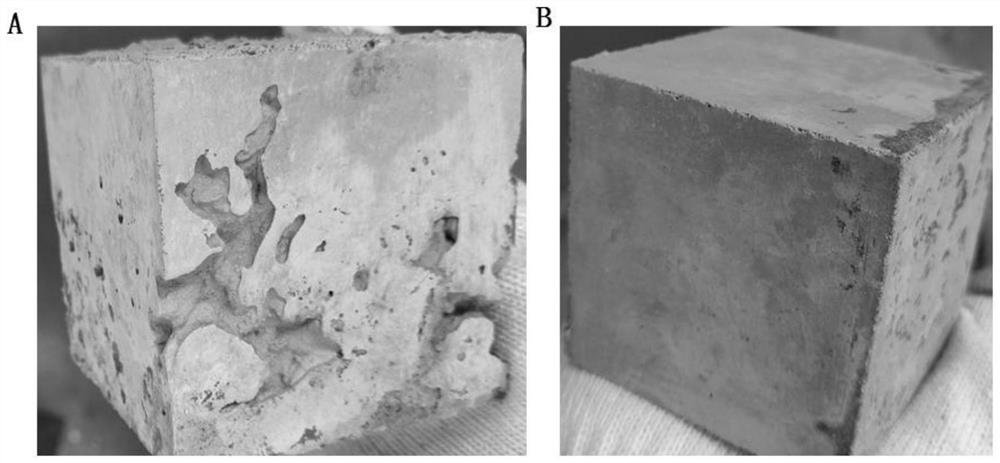

A process for preparing high-strength modified sulfur concrete by cold-water bath vibrating molding method

ActiveCN113199593BImprove compactnessReduce intensityCeramic shaping apparatusCement mixing apparatusSulfur concreteCompressive strength

The invention belongs to the technical field of building materials, and in particular relates to a process for preparing high-strength modified sulfur concrete by a cold-water bath vibrating molding method. The compactness of the sulfur matrix is improved to a large extent, that is, the adverse effects on the strength caused by the holes formed by the cooling and shrinkage of the sulfur matrix are avoided, and the operation is simple and the device is simple to manufacture. The compressive strength is as low as 77MPa, there are very few holes in the test block, the density is high, the strength dispersion between the test blocks is low, and the compressive strength is stable. At the same time, the invention also optimizes the optimal ratio of the sulfur concrete premix before the molding stage, and the compressive strength of the modified sulfur concrete prepared by the optimal concrete ratio combined with the cold-water bath vibrating molding process is averaged. up to 87MPa.

Owner:JINAN UNIVERSITY

A shock-absorbing system for super-tough concrete bridges

ActiveCN109653234BImprove shock resistanceReduce shockProtective foundationBridge structural detailsSulfur concreteSeismic energy

The invention discloses a super-tough concrete bridge shock-proof system which comprises a pile group arranged on a foundation soil layer. The upper portion of the pile group is covered with a gravellayer, a pouring bearing platform is arranged on the upper portion of the gravel layer, the upper portion of the pouring bearing platform is connected with a bridge pier, a capping beam is arranged atthe top of the bridge pier, a fluctuating power generation device is arranged on the pouring bearing platform, sulfur concrete boxes are arranged on the periphery of the pouring bearing platform, sulfur concrete is poured into the sulfur concrete boxes, heating wires are embedded into the sulfur concrete and electrically connected with piezoelectric crystals, and a hydraulic connecting rod mechanism is arranged between the bridge pier and a bridge. Energy generated by an earthquake is transformed into electric energy by the fluctuating power generation device, the hydraulic connecting rod mechanism at the tops of the sulfur concrete and the bridge pier is further used for comprehensively absorbing the energy, the system is reasonable in design, the earthquake energy absorption capacity ofa bridge structure is greatly improved, and impact of the earthquake energy on the bridge pier is reduced.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

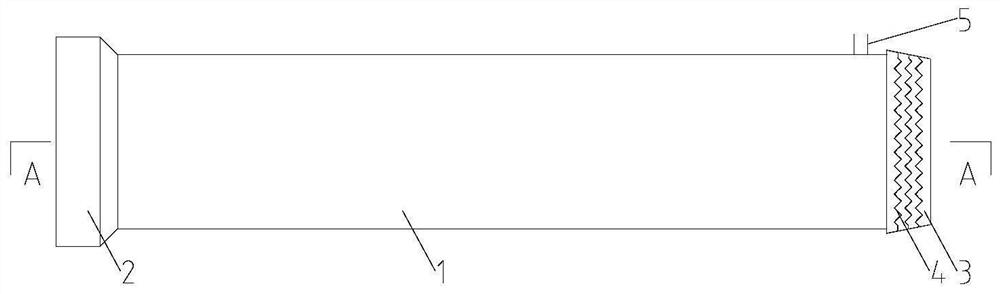

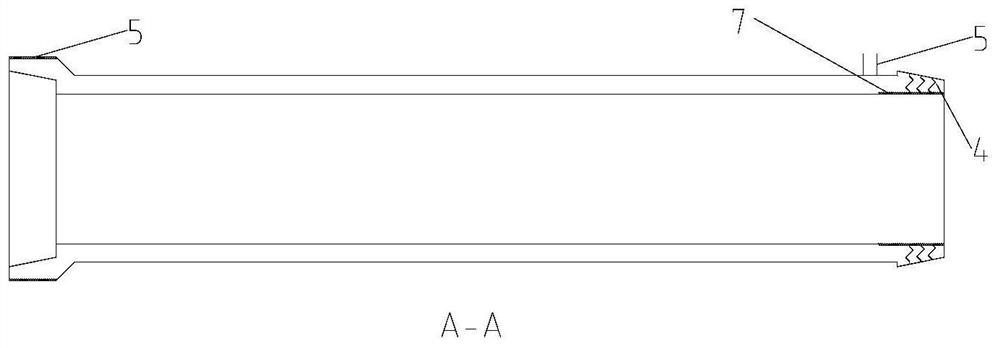

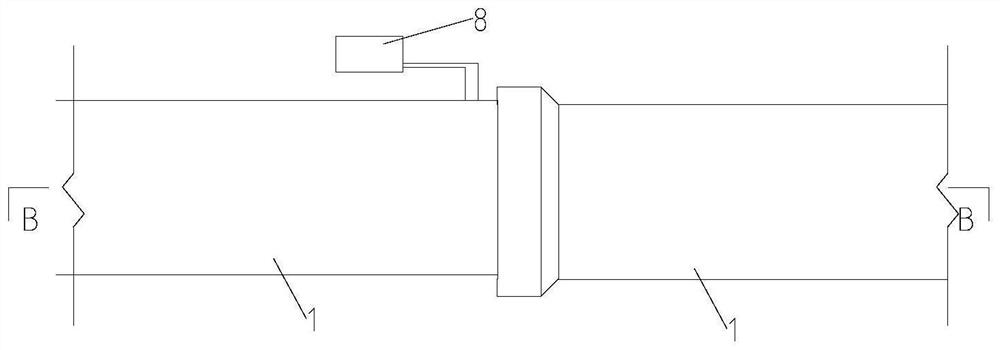

Electric heating fusion connection type modified sulfur concrete pipe and manufacturing method thereof

PendingCN111706722AGood mechanical propertiesHigh compressive strengthAuxillary shaping apparatusRigid pipesPipe fittingStructural engineering

The invention discloses an electric heating fusion connection type modified sulfur concrete pipe and a manufacturing method thereof. The electric heating fusion connection type modified sulfur concrete pipe comprises a plurality of pipe fitting segments which are sequentially connected in an inserted manner, wherein one end of each pipe fitting segment is a conical socket, the other end of each pipe fitting segment is a conical spigot, the conical socket of the front pipe fitting is connected with the conical spigot of the corresponding back pipe fitting in a sleeving manner, electric heatingmetal wires are wound around the outer periphery of the conical spigots, and after the electric heating metal wires are electrified, the electric heating metal wires emit heat to enable the front pipefitting and the corresponding back pipe fitting to be fixed together through hot fusion. The pipe fitting is made of the material of the following modified sulfur concrete formula with a heating andpouring formation method. The modified sulfur concrete formula comprises, by mass, 15%-24% of modified sulfur, 12%-21% of filler, 46%-55% of stone and 18%-27% of sand. The modified sulfur concrete pipe material achieves connection in an electric heating fusion manner; and compared with a common concrete pipe material, the modified sulfur concrete pipe material has the advantages that the connection manner is simple and reliable, seal performance is good, and the construction efficiency can be greatly improved.

Owner:CCCC FOURTH HARBOR ENG INST +2

Sulfur-containing polypropylene composite fiber reinforced sulfur concrete and preparation method thereof

The invention discloses sulfur-containing polypropylene composite fiber enhanced sulfur concrete and a preparation method thereof. The concrete is prepared from the following ingredients in percentage by mass: 40 to 60 percent of modified sulfur, 15 to 25 percent of coarse aggregate, 10 to 25 percent of fine aggregate, 1 to 10 percent of fillings and 0.1 to 1.5 percent of polypropylene composite modified fiber. The preparation method sequentially comprises the following steps of 1, preparing polypropylene grafted sulfur; 2, preparing polypropylene composite modified fiber; 3, preparing modified sulfur; 4, taking the coarse aggregate, the fine aggregate, the fillings, the modified sulfur and the polypropylene composite modified fiber according to the designed quantity, and sufficiently and uniformly stirring the materials to obtain fiber enhanced sulfur concrete. Practice proves that the sulfur-containing polypropylene composite fiber enhanced sulfur concrete has the advantages that the mechanical property is excellent; the corrosion performance is high; the anti-cracking performance is good, and the like, wherein the bonding performance between the polypropylene composite fiber and the sulfur concrete interface is good; in addition, the operation of the preparation method is simple; the cost is low.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com