Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1113results about How to "Solve the pollution of the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological deodorization and purification agent, and its use

A biologic deodoring and cleaning agent for treating the refuse to prepare fertilizer and cleaning and activating water area contains high-safety yeast, lactobacillus, nitrogen-fixing bacteria, functional bacillus, and photosynthetic bacteria.

Owner:CHINA AGRI UNIV

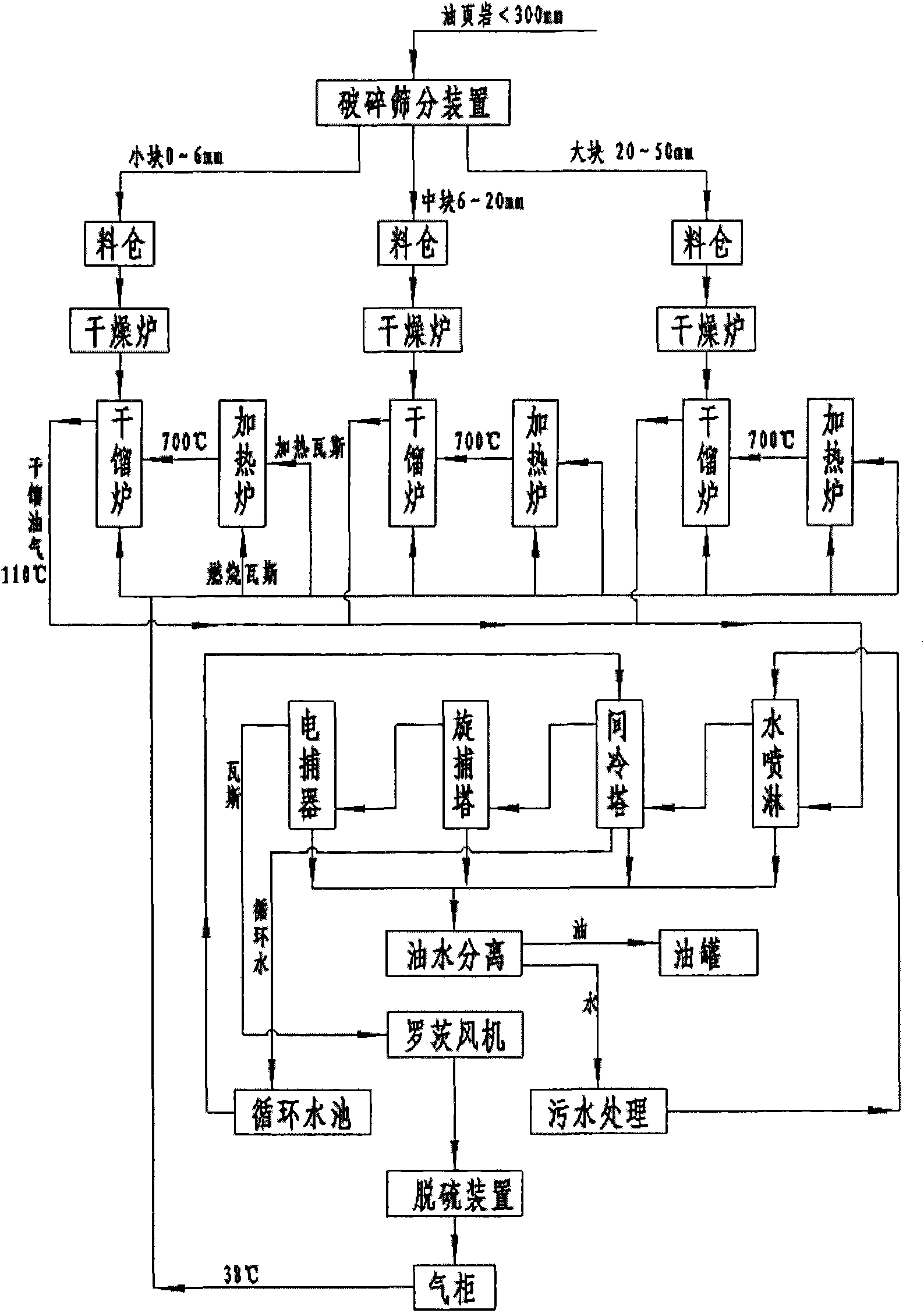

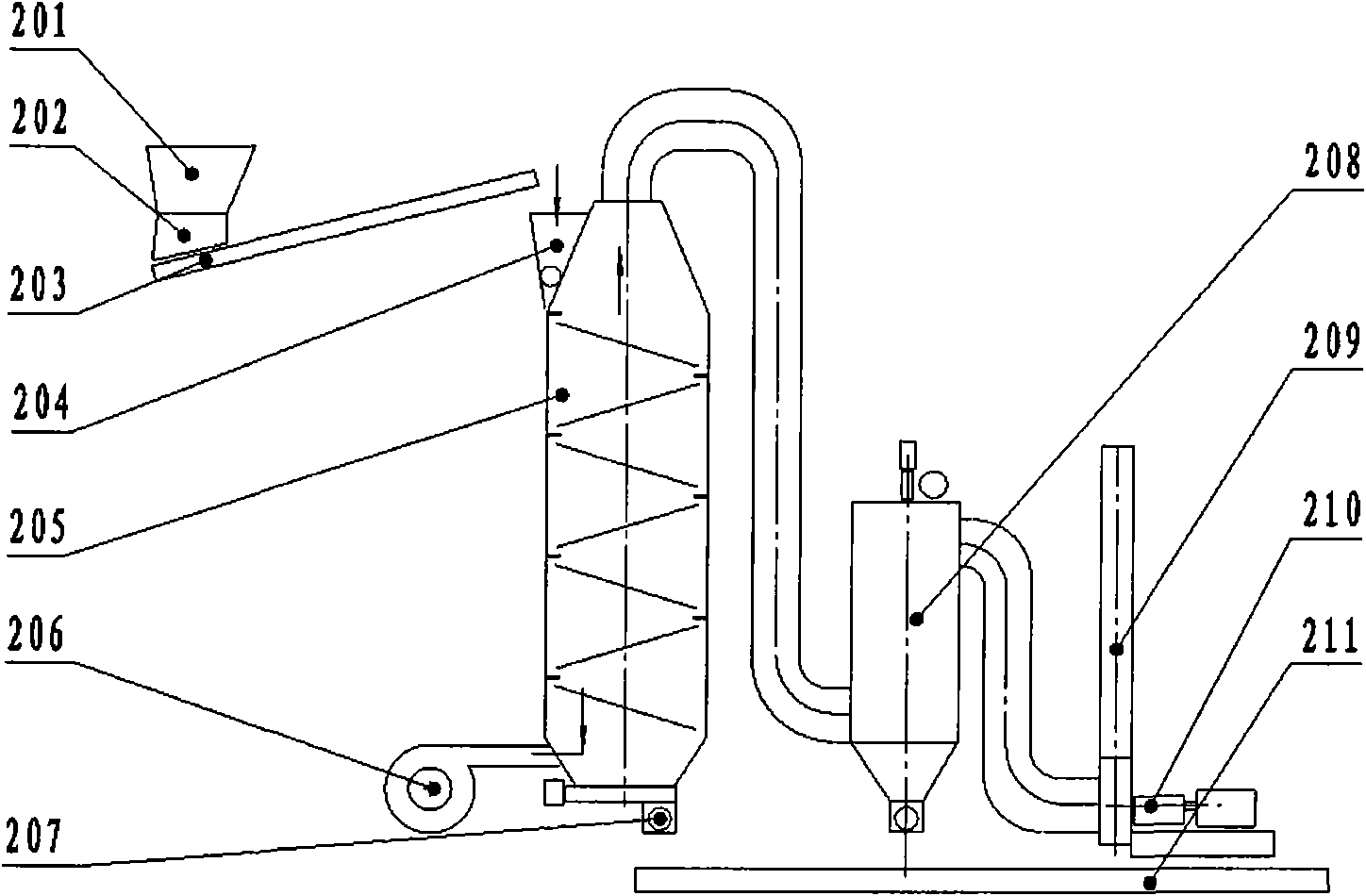

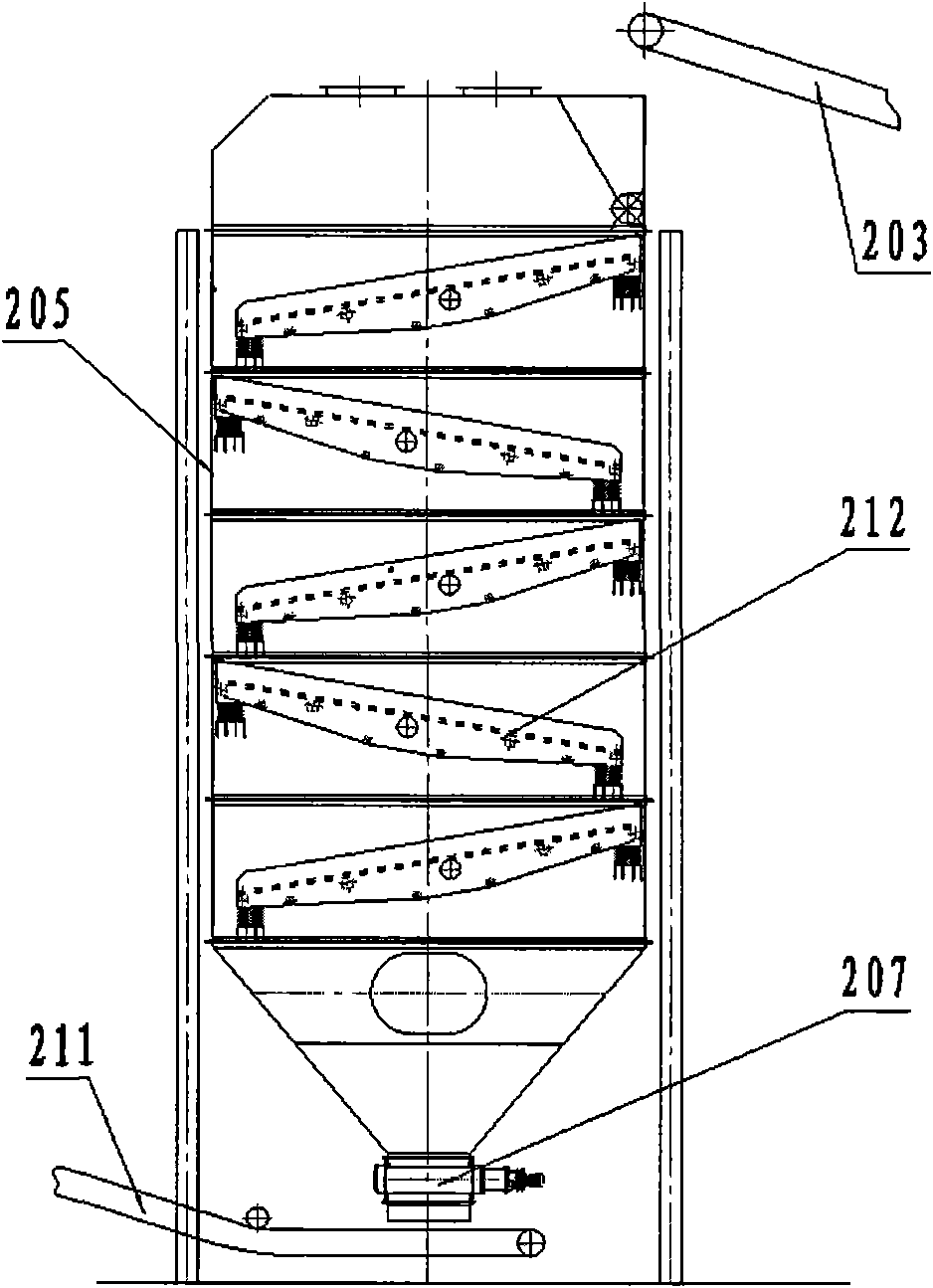

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

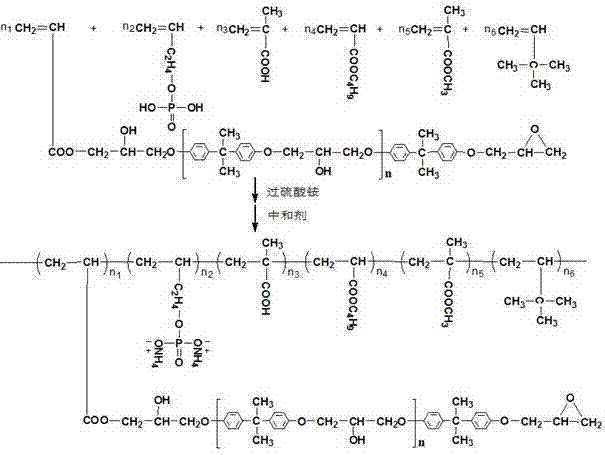

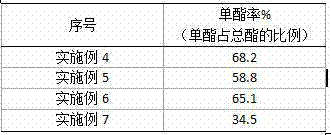

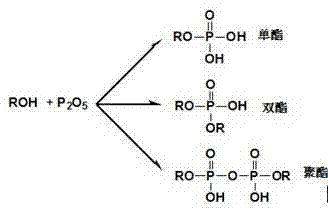

Single-component self-phosphatizing antirust acrylic emulsion, and preparation method and application thereof

InactiveCN102924667AImprove anti-corrosion performanceSolve the repeatabilityAnti-corrosive paintsWater basedEpoxy

The invention discloses a single-component self-phosphatizing antirust acrylic emulsion, and a preparation method and application thereof. Self-made epoxy monoacrylate and acrylic phosphate used as monomers are subjected to radical copolymerization with acrylic acid monomer; and a seed emulsion semicontinuous method is utilized to obtain the emulsion. The emulsion used as a film forming material is matched with related pigment, filler and assistants to obtain water-based paint. When being used on the automobile leaf spring surface, the water-based paint can be cured at 80 DEG C within 20 minutes to form a film, of which the adhesive force is Grade 0, the hardness is 3H and the salt-fog resistance is 1000 hours. The method solves the problems of poor water resistance, salt-fog resistance, weather resistance and storage stability of the coated film of the existing antirust emulsion; and the method also solves the problems of incapability of recycling ground waste, and poor antirust capacity of unit coating thickness in the existing automobile leaf spring application process, and omits the procedure of phosphatizing on the substrate surface before application due to the introduction of the phosphate monomer.

Owner:武汉海源九天新材料有限公司 +1

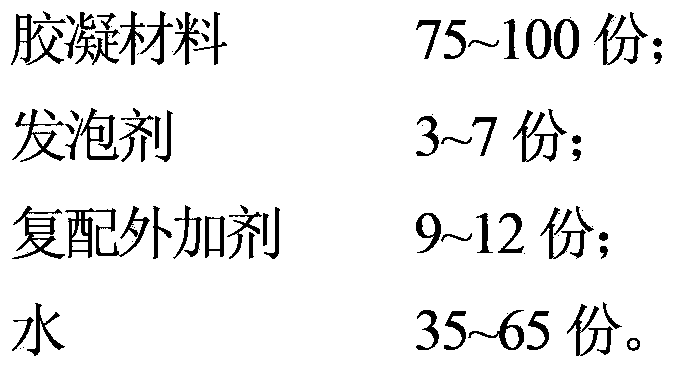

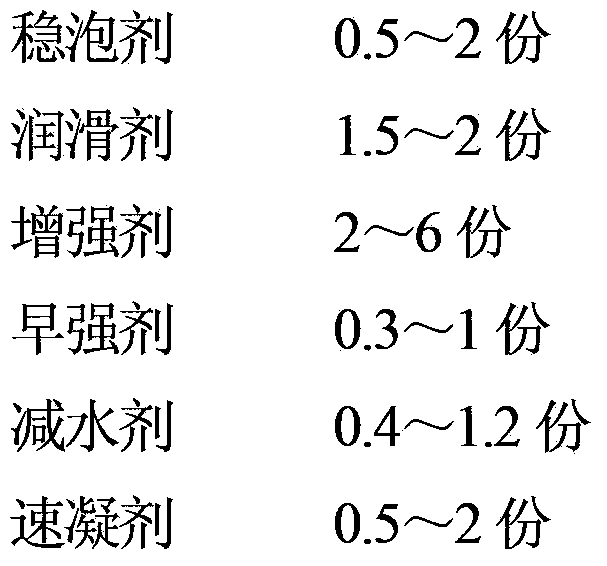

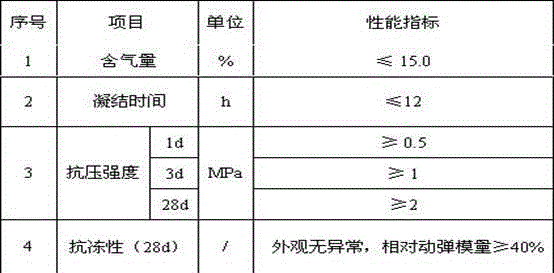

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

Nano antibacterial and controllable photodegradation and biodegradation polyethylene plastic film and method for preparing same

InactiveCN1631958AGood antibacterial and bactericidal effectConducive to the protection of the environmentChemistryNanometre

Disclosed are a polyethylene nm antibacterial biological couple degradable plastic film and its preparing method. It is comprised of the following components with the mass ratio: starch: photo sensitizer: plasticizer: coupling agent: polyethylene: modifier =10~100:0.1~30:0.5~30:0.3~35:0.1~10:0.5~25:130~26:0.1~53. With antibacterial effect and can be broken down faster by the effects of both light and biologic, the invention has replaced the conventional product with much loss of plastic, it can solve environment pollution existing in the usual plastic film, benefiting for environmental protection. It has the advantaged not existing in the present plastic film, simplified productive technique and low cost.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for producing alcohol and feed by utilizing seaweed chemical waste material

InactiveCN101024847AEconomic Industrial TechnologyEnvironmental Industrial TechnologyAnimal feeding stuffMicroorganism based processesLiquid wasteChemical industry

The invention discloses a method for producing alcohol and feed by alga chemical waste, i.e. using the cellulose-containing waste residues as raw materials formed in the course of producing sodium alginate, mannitol, I or trehalose glue products in the alga chemical industry, making enzymatic hydrolysis by cellulase and anaerobic fermentation by brewing yeast or double fermentation by cellulase producing bacteria and brewing yeast, then making solid-liquid separation and obtaining alcohol and feed. And the invention provides economic, environmental protection and effective industrial technique for waste residues and waste liquid in the alga chemical industry, able to turn waste into wealth and provide important technical support for full and high value utilization of alga resources and development of alga circulating economy.

Owner:SHANDONG UNIV

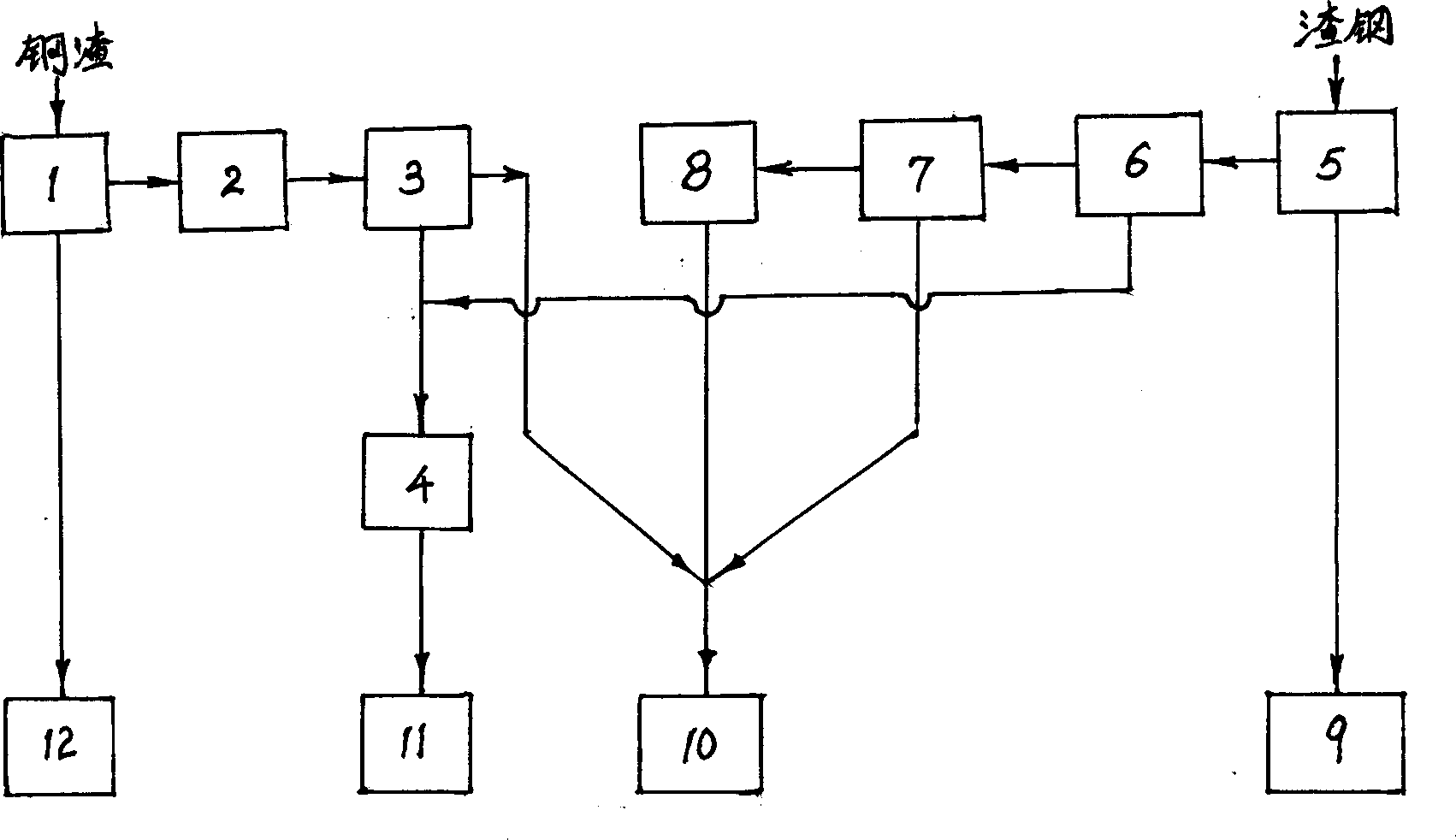

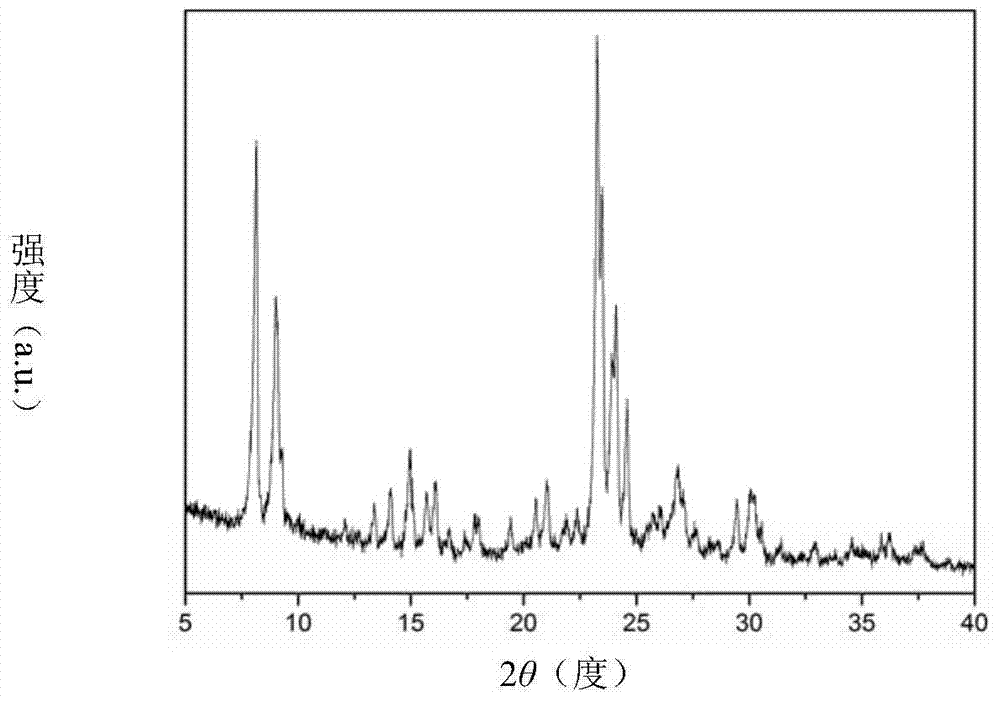

Process for treating steel slag

InactiveCN1390795AIncrease added valueSolve the pollution of the environmentRecycling and recovery technologiesProcess efficiency improvementIron powderSlag

A process for reclaiming the steel slags includes such steps as preparing steel slags and residual steel as raw material, sieving, ball grinding, magnetic separating, and wind classifying to obtain 4 products: high-quality waste steel used for smelting steel, refined iron powder used for smelting iron, micro slag powder used as high-activity additive of concrete, and steel slag aggregate used for slag-asphalt-concrte pavement of highway.

Owner:北京科美隆科技发展有限公司

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

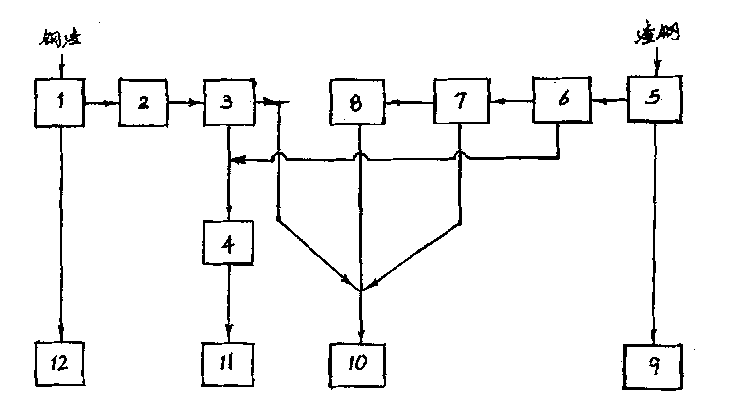

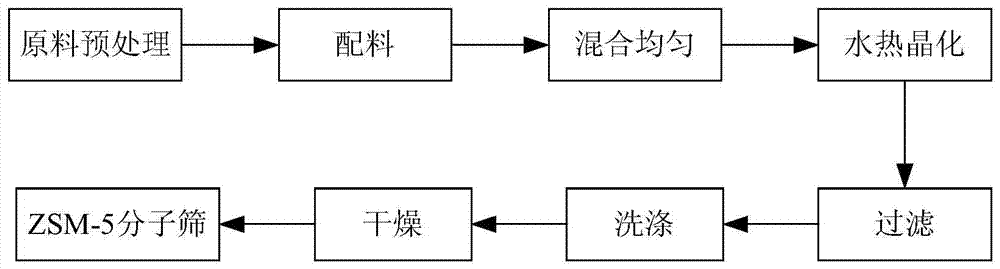

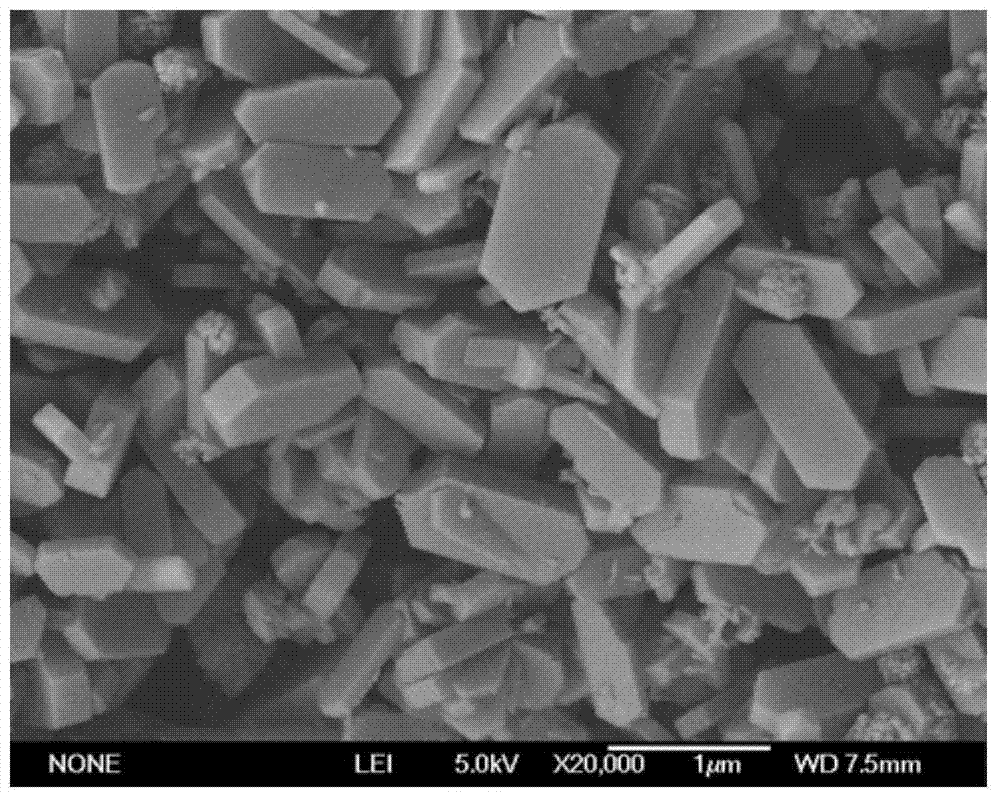

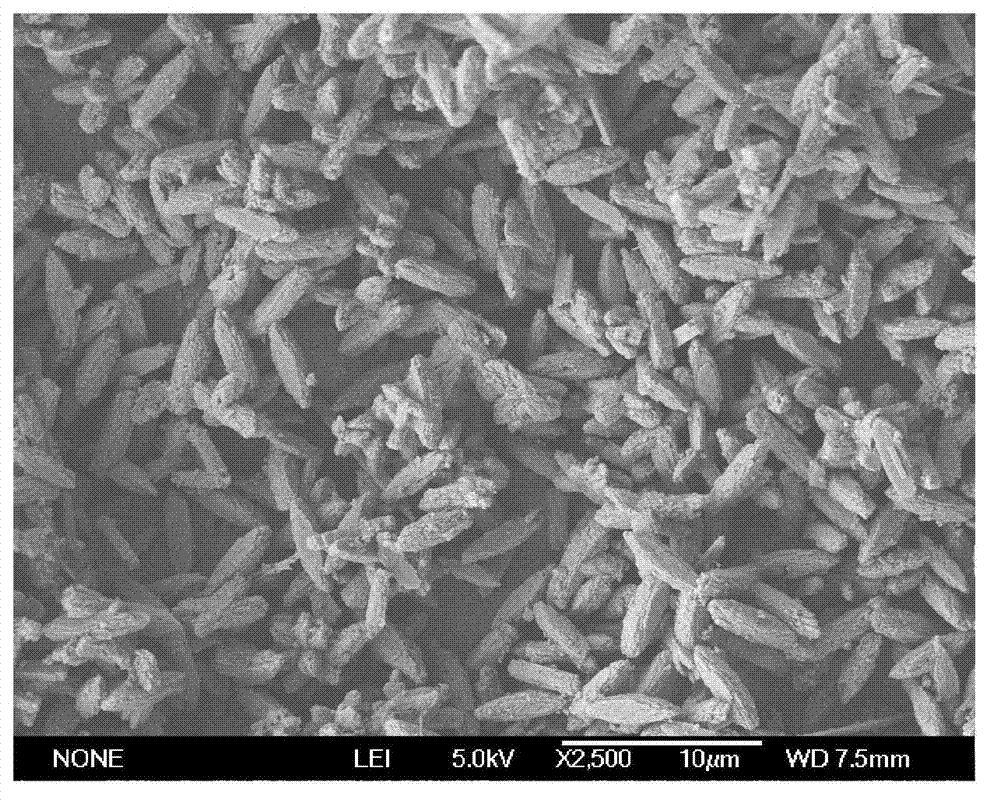

ZSM-5 molecular sieve and preparation method thereof

ActiveCN104743573AHigh value-added utilizationReduce manufacturing costPentasil aluminosilicate zeoliteSlurryNatural mineral

1)pretreating mineral raw materials containing silicon and aluminium to obtain a solid predecessor; 2)mixing the solid predecessor, sodium hydroxide and water to obtain a mixture, adding the ZSM-5 molecular sieve seeds, uniformly mixing, then grinding to obtain an uniform slurry, standing for aging; and 3)placing the slurry in a reaction vessel for a hydrothermal crystallization reaction, after reaction is finished, filtering, washing filter residue, and drying to obtain the ZSM-5 molecular sieve. According to the invention, a template is added in a synthetic method of the ZSM-5 molecular sieve, calcination is not be carried out for removing the template, the natural mineral raw materials containing silicon and aluminium are employed, technology is simplified, cost is reduced, and the preparation method has the advantages of environmental protection and energy saving. The ZSM-5 molecular sieve has high crystallization degree, and the particle size is submicron.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Edible fungus cultivating material prepared by utilizing waste Chinese medicinal residues and preparation method thereof

The invention relates to an edible fungus cultivating material prepared by utilizing waste Chinese medicinal residues and a preparation method thereof in the technical field of plant cultivation. The edible fungus cultivating material comprises the following components in part by weight: 50 to 70 parts of Chinese medicinal residue, 10 to 20 parts of cotton seed hull, 5 to 10 parts of corn flour, 2 to 5 parts of calcium oxide, 5 to 10 parts of nitrogenous fertilizer, 2 to 4 parts of monopotassium phosphate, 0.1 to 0.2 part of miconazole, 0.4 to 0.8 part of microelements and 0.2 to 0.4 part of molysite. The method solves the problem of environmental pollution of the waste Chinese medicinal residue, relieves the pollution treatment burden of enterprises, solves the problems of shortage and price rise of the edible fungus cultivating material, saves the production cost and produces high-quality functional edible fungus products.

Owner:SHANGHAI JIAO TONG UNIV +1

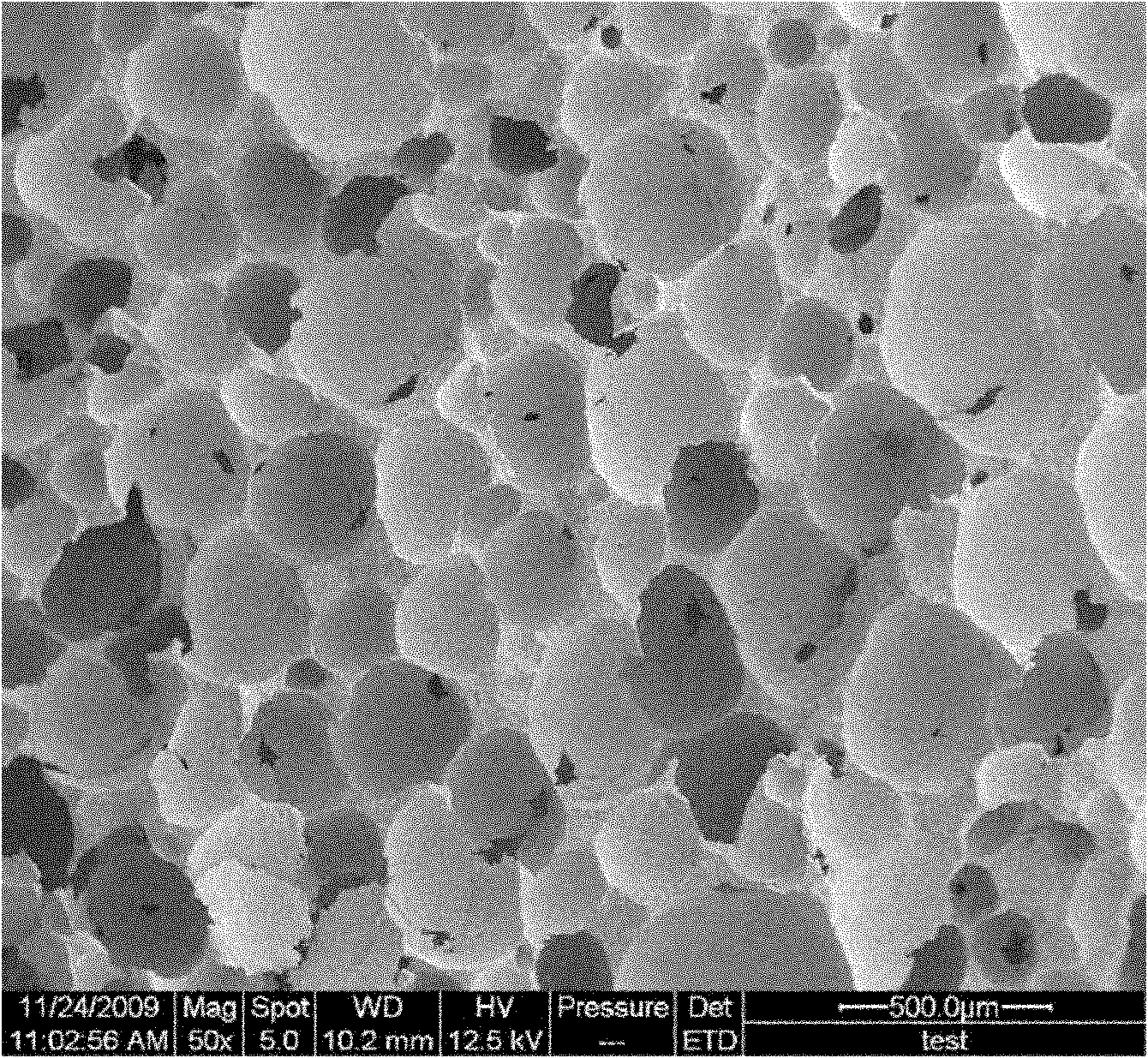

Protein foaming method for preparing porous ceramics composite material

InactiveCN101967064ASolve health problemsSolve the pollution of the environmentCeramicwareCeramic compositeHazardous substance

The invention discloses a protein foaming method for preparing a porous ceramics composite material, and relates to a method for preparing a composite material. The method solves the problem that toxic gas is generated to harm human health and pollute environment when a foaming agent is volatilized in a foaming method for preparing porous ceramics. The method comprises the following steps of: 1, preparing slurry; 2, preparing a sample; and 3, processing the sample into a required shape, sintering in a sintering furnace, and cooling with the furnace to room temperature to obtain the porous ceramics composite material. Compared with other methods, the method has the advantages that: a microstructure is controllable and is molded simply; and toxic gas and harmful substances polluting environment are not generated when proteins are decomposed. Polysaccharide macromolecules and water molecules form hydrogen bonds to keep the foaming stability; meanwhile, the polysaccharide macromolecules have net structures to improve the blank strength, adjust the fluidity of the slurry, improve the rheological properties of the slurry and make the foaming uniform.

Owner:HARBIN INST OF TECH

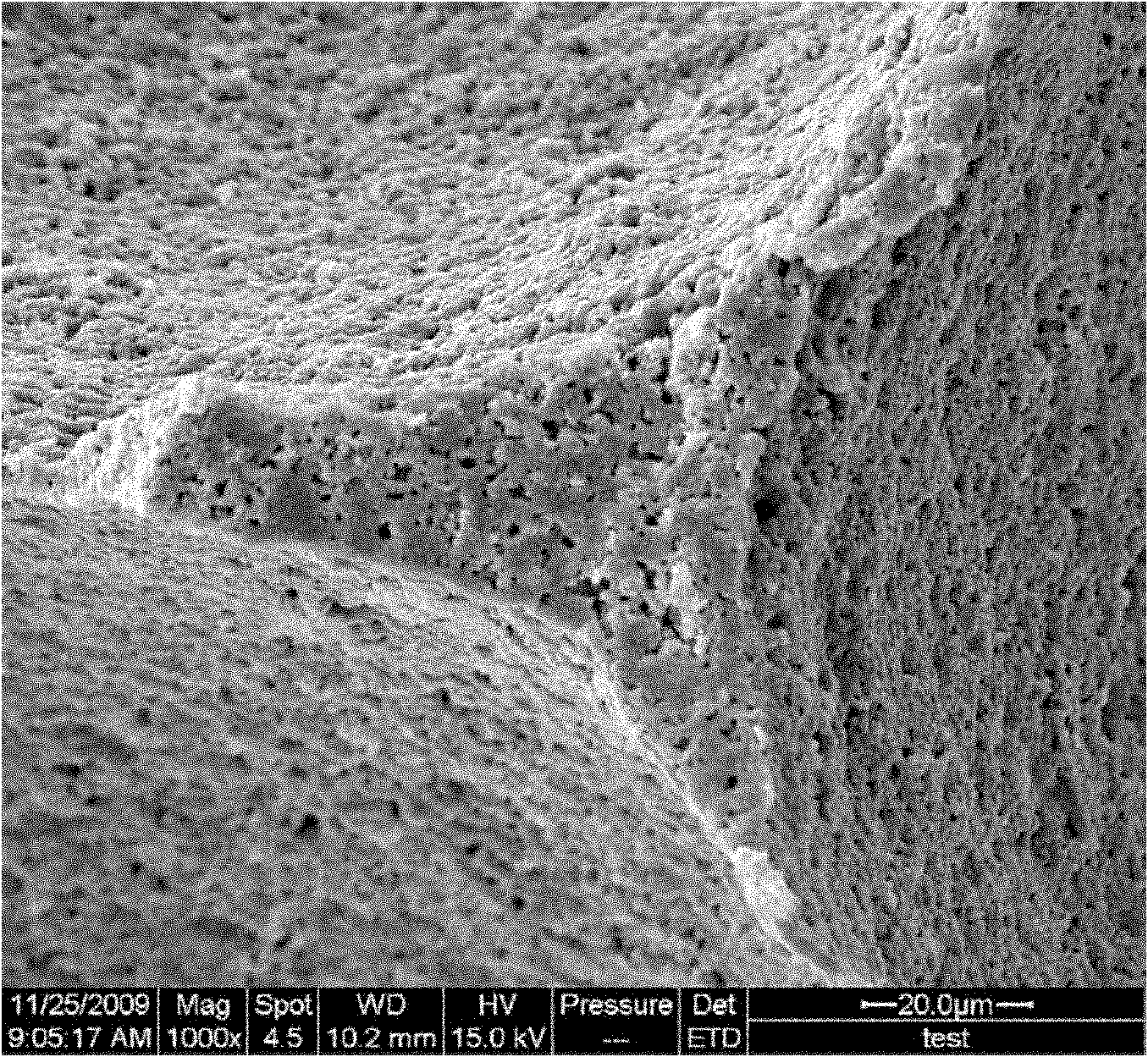

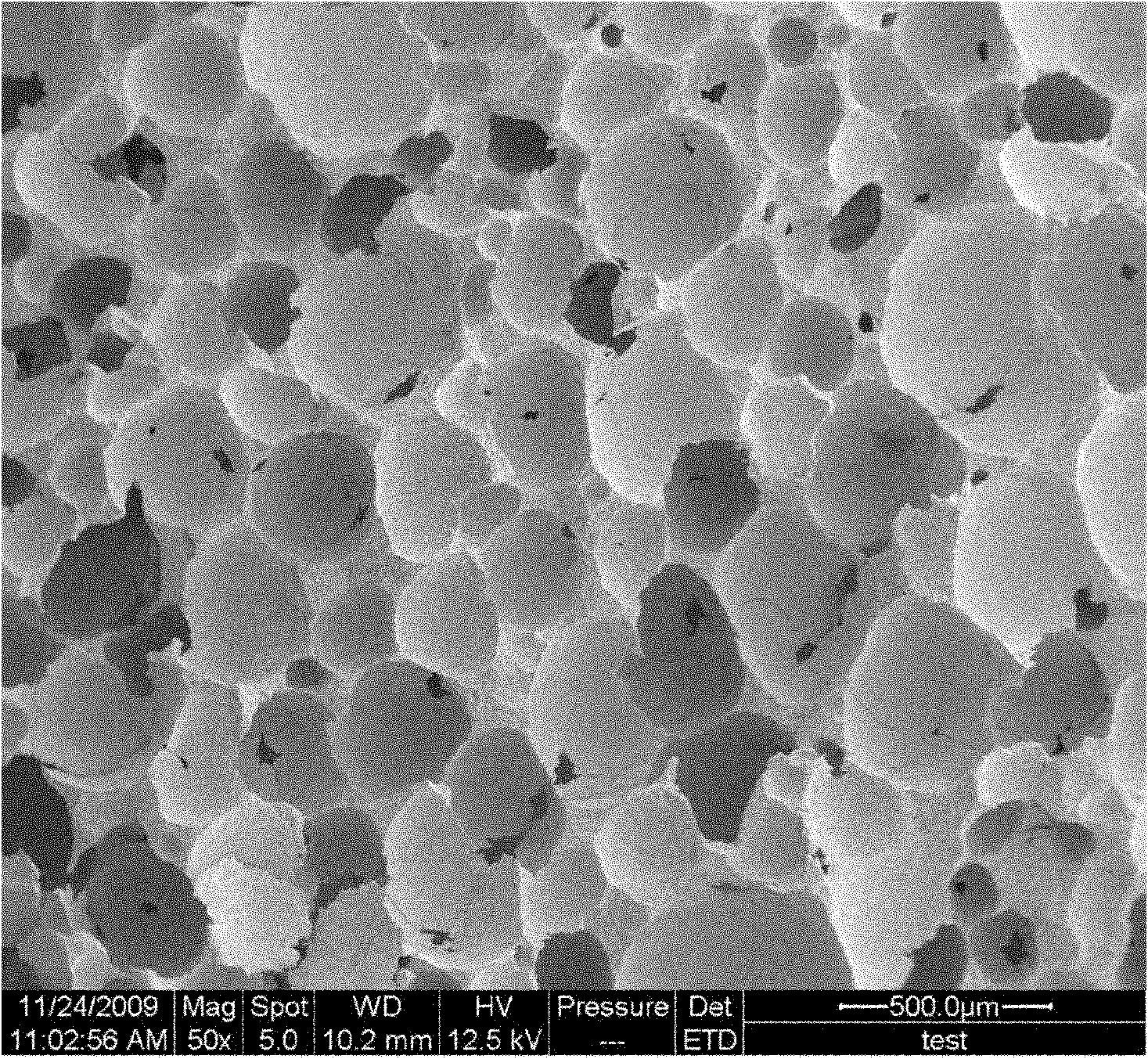

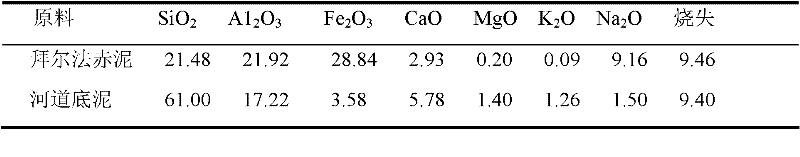

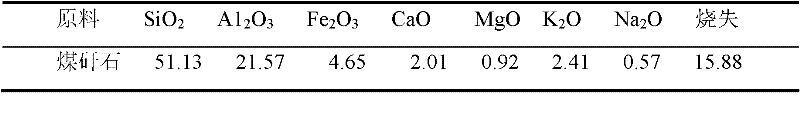

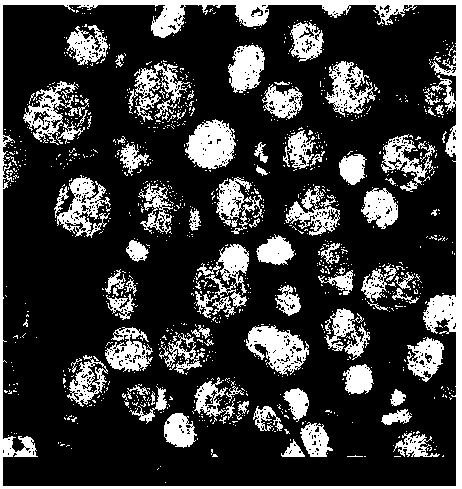

Preparation method of ceramsite filter material for water treatment

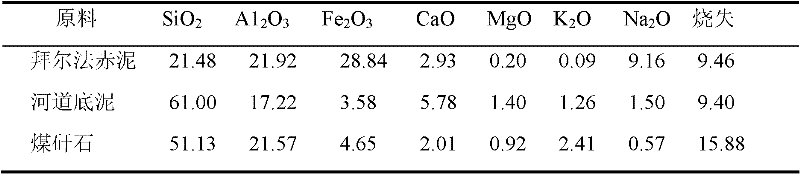

The invention provides a preparation method for a ceramsite filter material for water treatment. The method is characterized by comprising the following steps: (1) mixing Bayer red mud powder in aluminum manufacturers in Shangdong province, river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province, gangue powder and a pore forming agent according to a mass ratio of 40-50:40-50:0-5:5-10 to obtain a mixture; (2) putting the mixture into a pan granulator and adding water, the mass of which is 20 to 25% of the mixture, for granulation into spherical particles with phi being 3 to 10 mm; (3) sintering and cooling the spherical particles after drying so as to obtain the ceramsite filter material. According to the invention, Bayer red mud powder in aluminum manufacturers in Shangdong province and river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province are used as the main raw materials and added at an equal or substantially equal amount, and a small amount of the pore forming agent is blended for the preparation of the ceramsite filter material; therefore, low cost is realized, the problem of flood passage capability of rivers is overcome, and environment pollution and land occupation caused by accumulation of Bayer red mud are simultaneously eliminated.

Owner:SHANDONG UNIV OF TECH

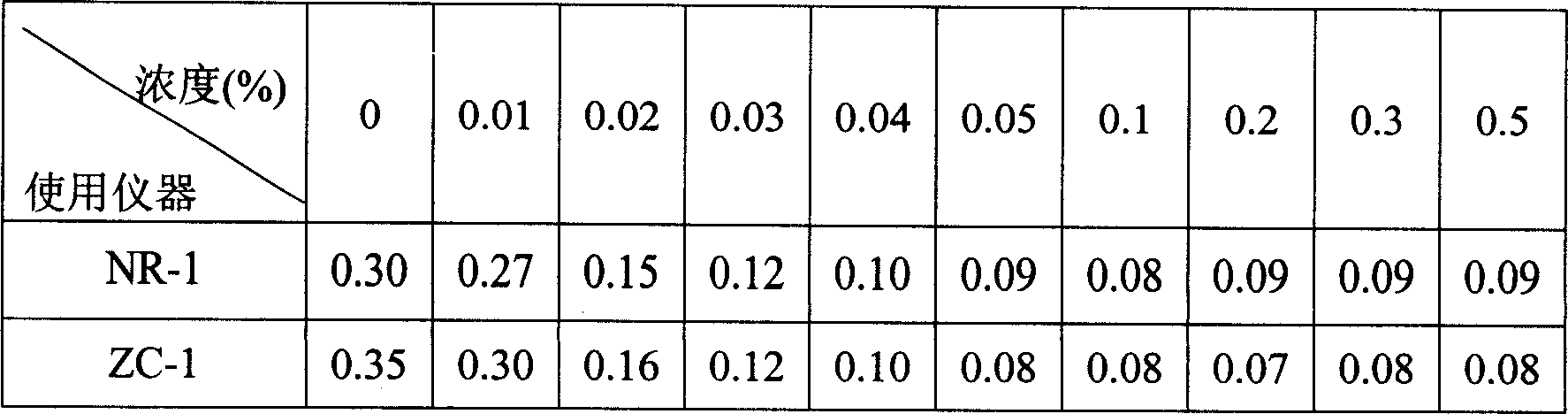

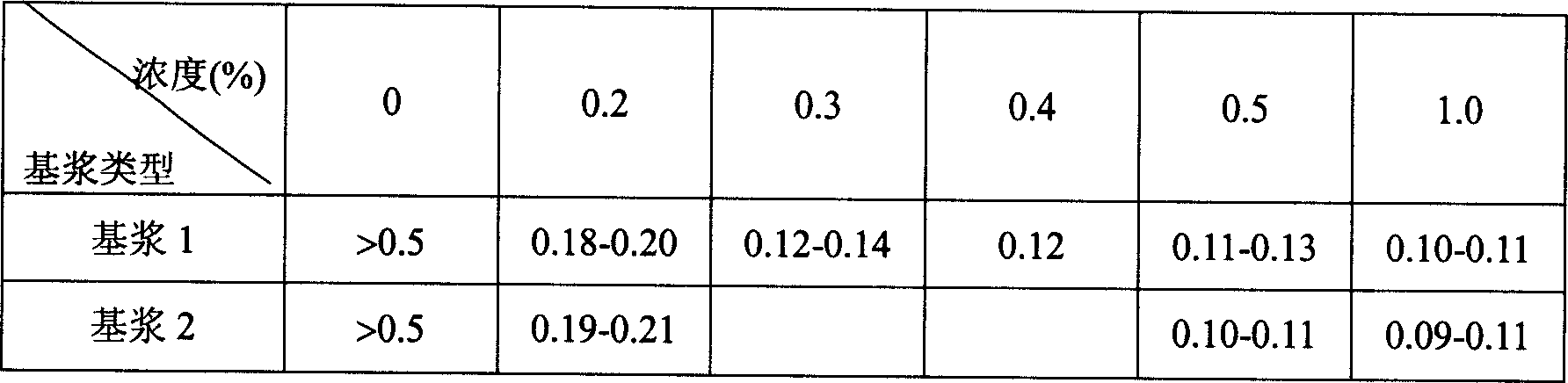

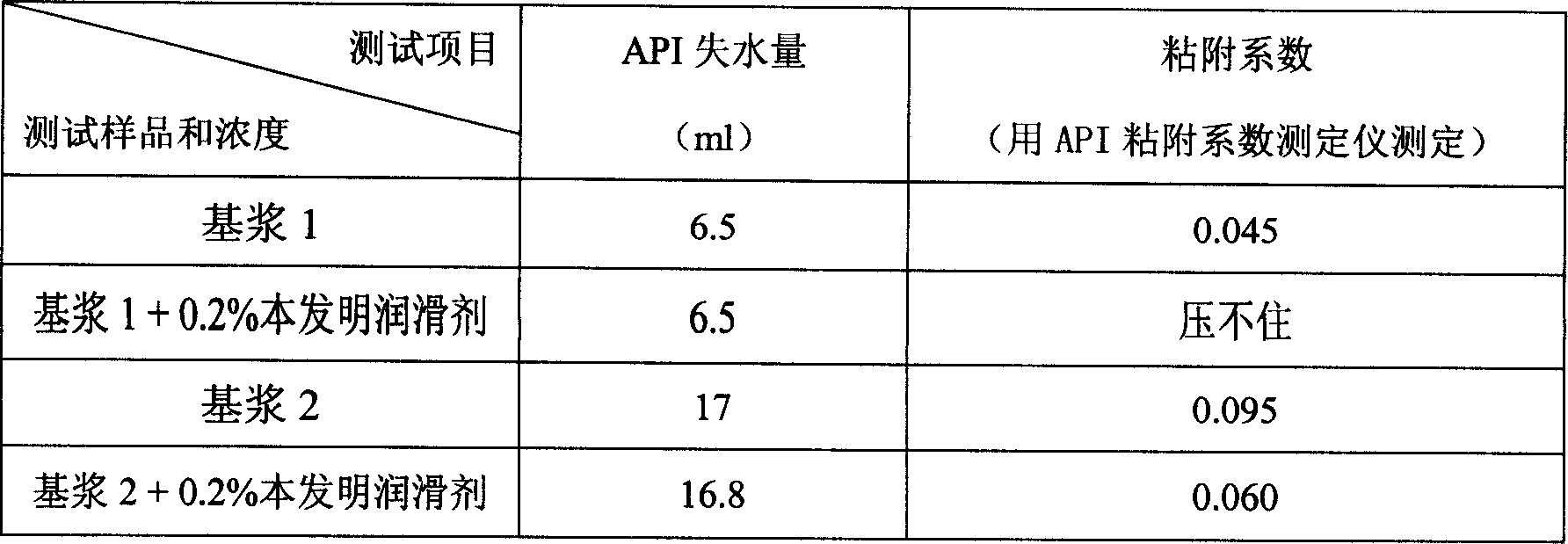

Drilling fluid lubricating additive and its preparing method

InactiveCN1743404AGood water solubilityGood lubrication and drag reductionDrilling compositionVegetable oilSurface-active agents

This invention relates to a drilling fluid lubricating additive and its preparation method characterizing that the proportion of the compositions is: offal of vegetable oil: 20%-40%, TEA: 1%-2%, NaOH: 4%-8%, 0P-10: 0.5%-0.8% and water, which utilizes the offal when refining food vegetable oil to replace petroleum-kind products to form a lubricating additive integrating anion surface active agent and non-ion surface active agent, having good lubricating efficiency and strong ability of anti-erosion against salt and Ca ions by two steps of saponification, further more, such additive does not contain any abialogical degradation mineral oil substances.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Total nutrient safe instant fish meat broth production technology

ActiveCN102309027ASolve potential safety hazardsSolve the pollution of the environmentFood preparationFiltrationBottle

The invention relates to a food production technology, specifically to a total nutrient safe instant fish meat broth production technology. The production technology provided by the invention comprises the following steps of: (1) washing fish, cutting heads, removing internal organs and removing scales; (2) collecting meat, rinsing and dewatering, followed by fine filtration to obtain small granular pure fish meat; (3) boiling to obtain a safe nutritional pure primitive fish meat broth; (4) boiling to obtain a fish collagen protein broth; (5) mixing the safe nutritional pure primitive fish meat broth and the fish collagen protein broth for complex formulation: mixing the soups obtained from Step (3) and Step (4) to obtain a total nutrient safe fish meat broth; filling the broths obtained from Step (3), Step (4) and Step (5) into bottles and carrying out second sterilization to obtain the corresponding instant primitive broth. In comparison with the prior art, the invention has solved the potential safety problem of fishbone to eaters when they drink fish broth, solved production technological problems of the fishbone-free safe instant fish broth product without industrialization, solved the problem that only the pure fish broth is drunk with high-quality protein in fish meat being wasted, and solved the problem of short shelf-life of the fish broth prepared at home.

Owner:王星

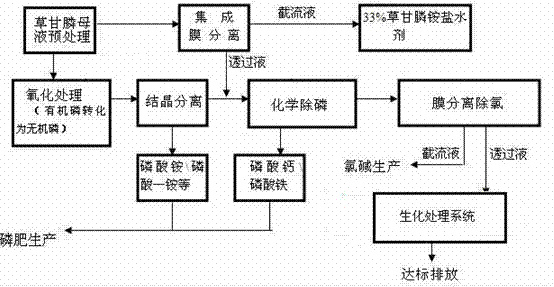

Integrated process for recycling glyphosate mother liquor

ActiveCN102786187AImprove use valueOvercome limitationsGroup 5/15 element organic compoundsChemical industryPre treatmentPhosphate fertilizer

The purpose of the invention is to provide an integrated process for processing mother liquor generated in the process of preparing glyphosate to solve the problems of higher cost and resource solution in glyphosate mother liquor processing. The process comprises the steps of: pre-treatment of mother liquor, integrated film separation, oxidation treatment, crystal separation, chemical phosphorus removal, film separation dechlorination and biochemical treatment. According to the sales condition of water aqua, the dosage of the mother liquor going into a film separation system is adjusted; the market demand is adapted; meanwhile, the cost is controlled; the influences of device maintenance and the like are avoided, and normal operation of a glyphosate production device is guaranteed. The glyphosate obtained from integrated film separation can be used for producing 33% of glyphosate ammonium salt agent; organic phosphorus obtained from crystal separation and chemical phosphorus removal can be applied to phosphate fertilizer production; sodium chloride solution obtained from film separation can be applied to chlor-alkali production, and the other parts can go into biochemical treatment and be discharged with standards.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

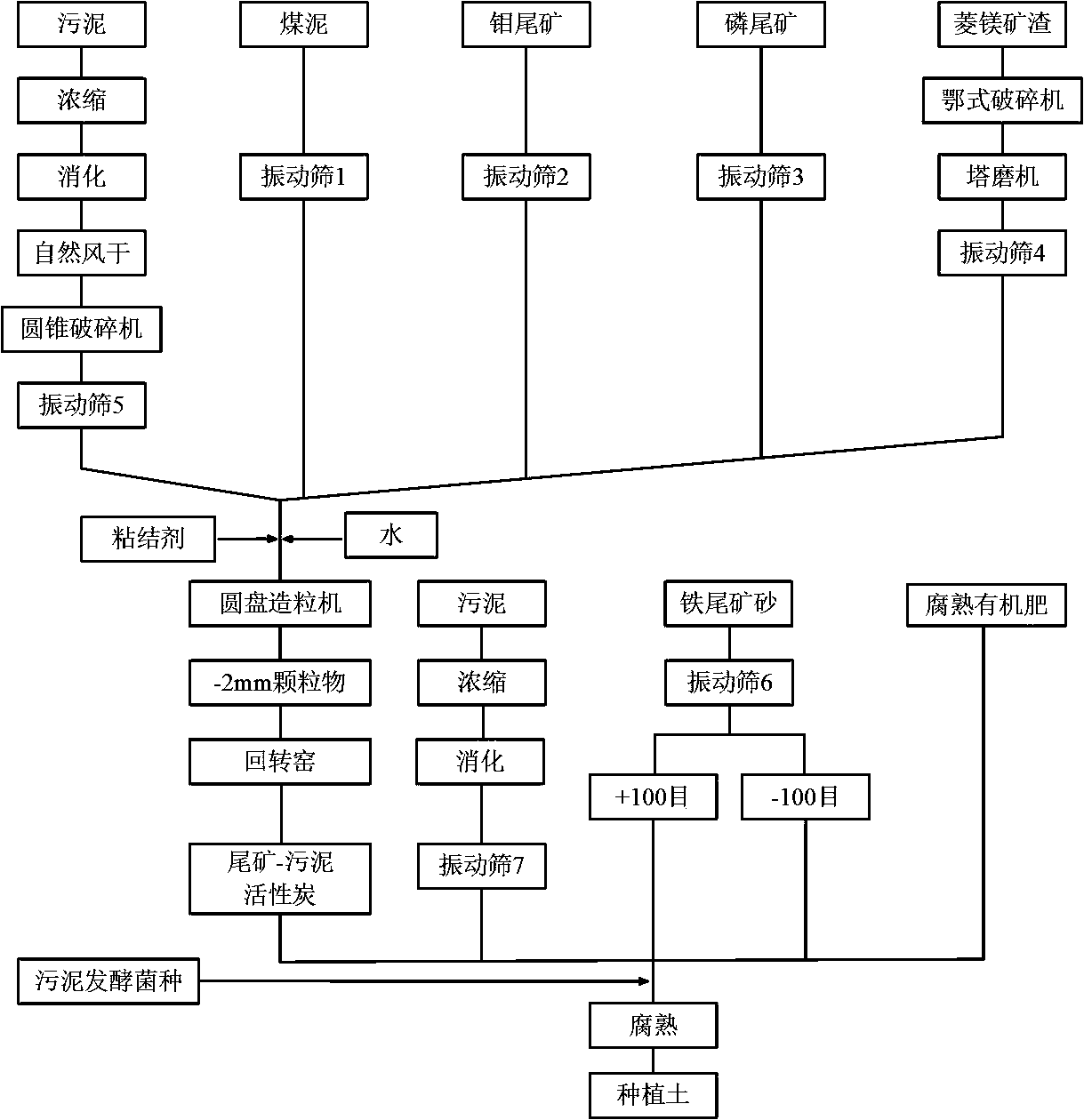

Planting soil and preparation method thereof

ActiveCN107821090ASolve the occupation of land resourcesSolve the pollution of the environmentBio-organic fraction processingMagnesium fertilisersLand resourcesMass ratio

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Particulate ferric oxide red pigment and method for producing the same

InactiveCN1521220ASolving Dispersion ProblemsSolve the problem of easy cakingPigmenting treatmentPolyvinyl alcoholSulfate

The present invention is granular iron oxide red pigment of grain size of 5-100 mesh and its preparation process. The preparation process includes the following steps: compounding water solution of additive in the concentration of 0.3-10 % and heating to 30-100 deg.c; spraying the water solution to iron oxide red in a pelletizing machine to form the granular pigment gradually with the weight ratio of iron oxide red to the water solution being 100 to 15-40; and vibration sieving and stoving to obtain the product. The additive is the combination of two or more of CMCNa, PVA, sodium silicate, glutin, sodium lignosulfonate and ferrous sulfate. The granular iron oxide red pigment has the same performance and use effect as the powdered iron oxide red pigment and is favorable to prevent dust pollution, and may be used to replace powdered iron oxide red pigment.

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

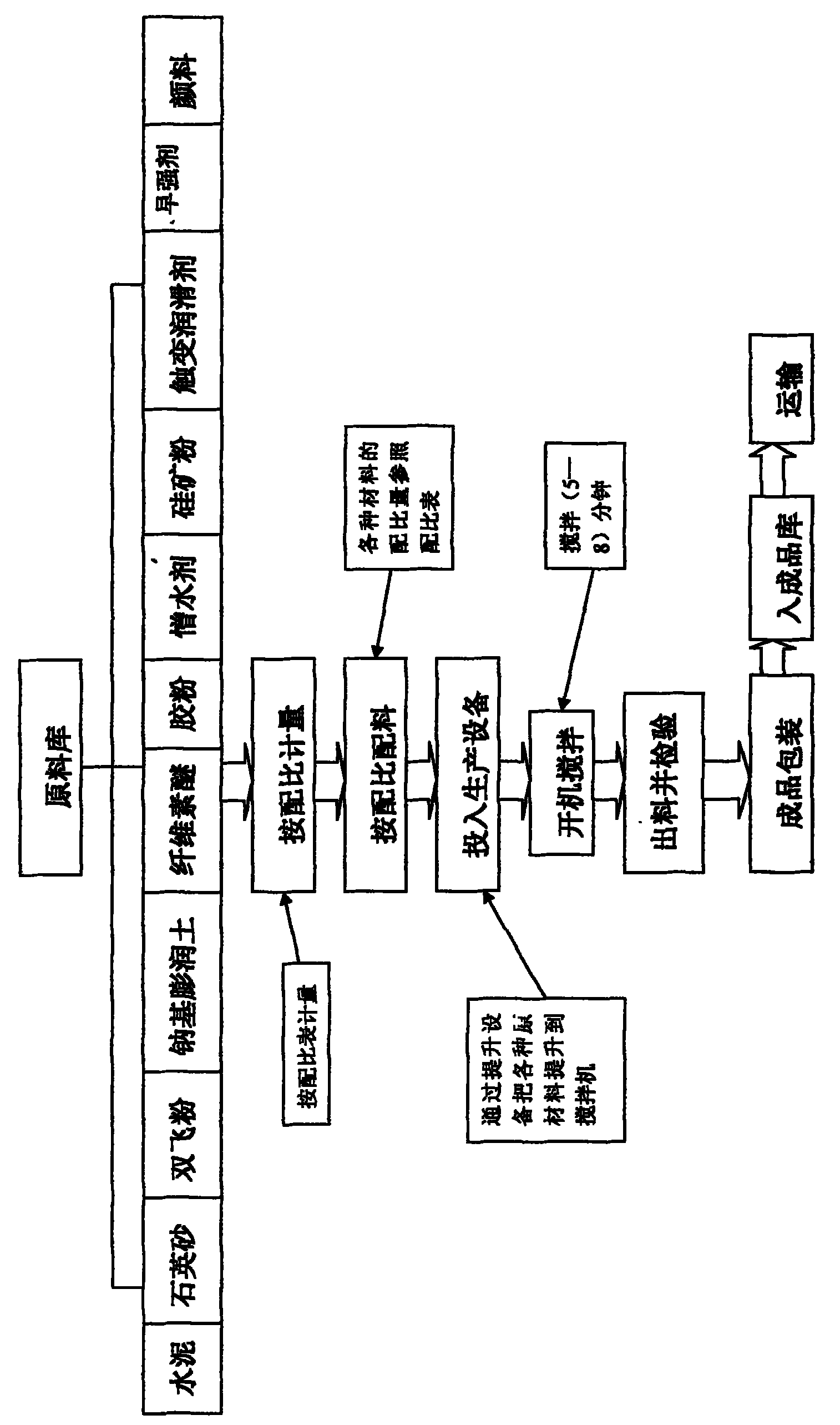

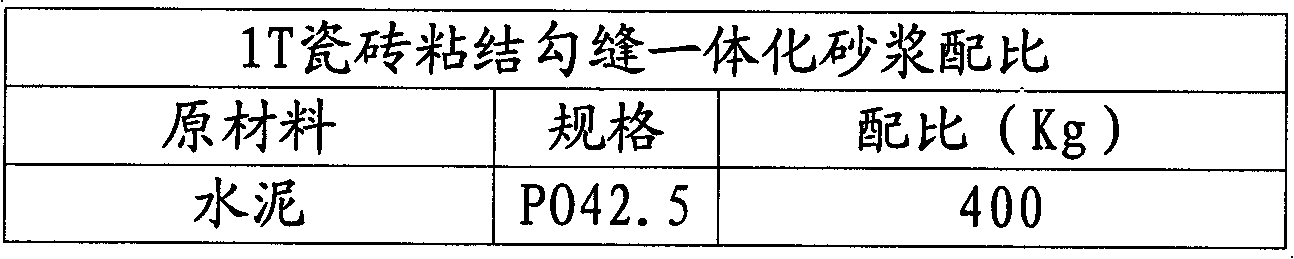

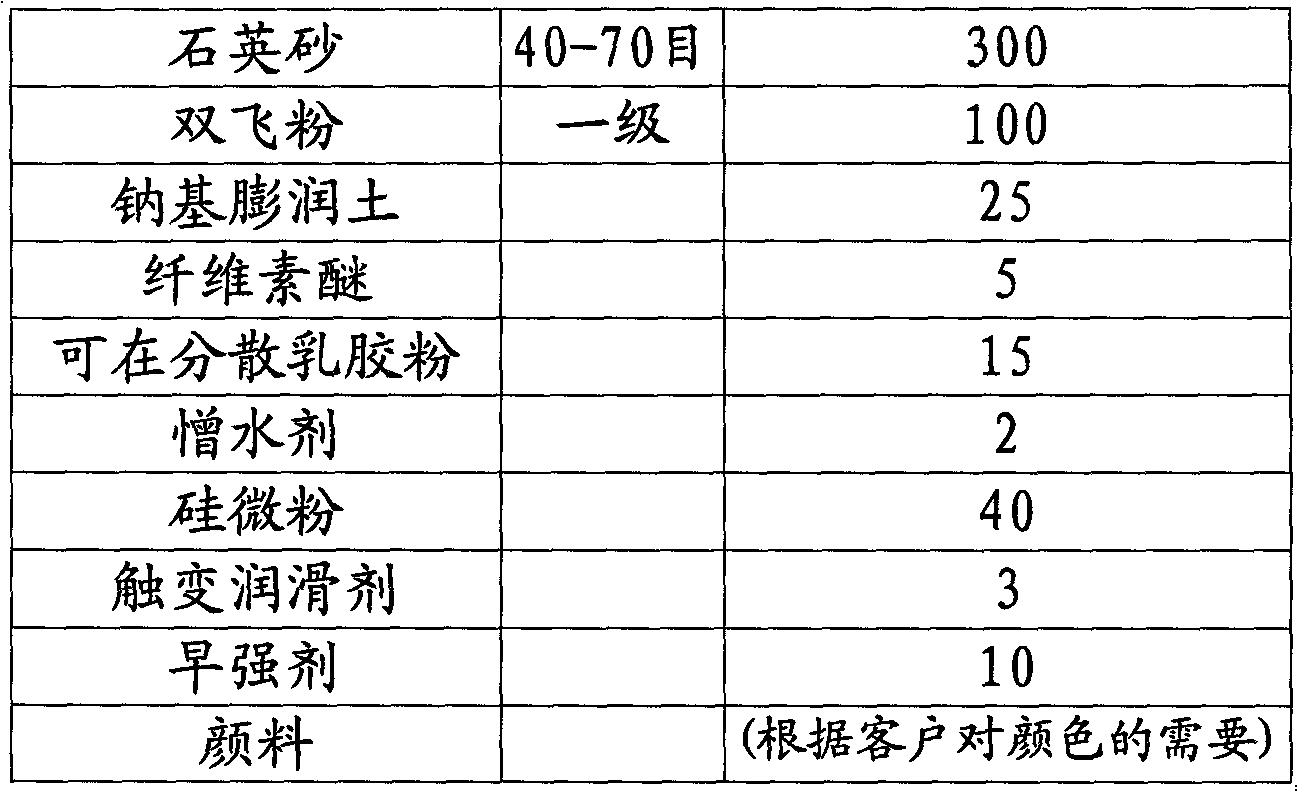

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

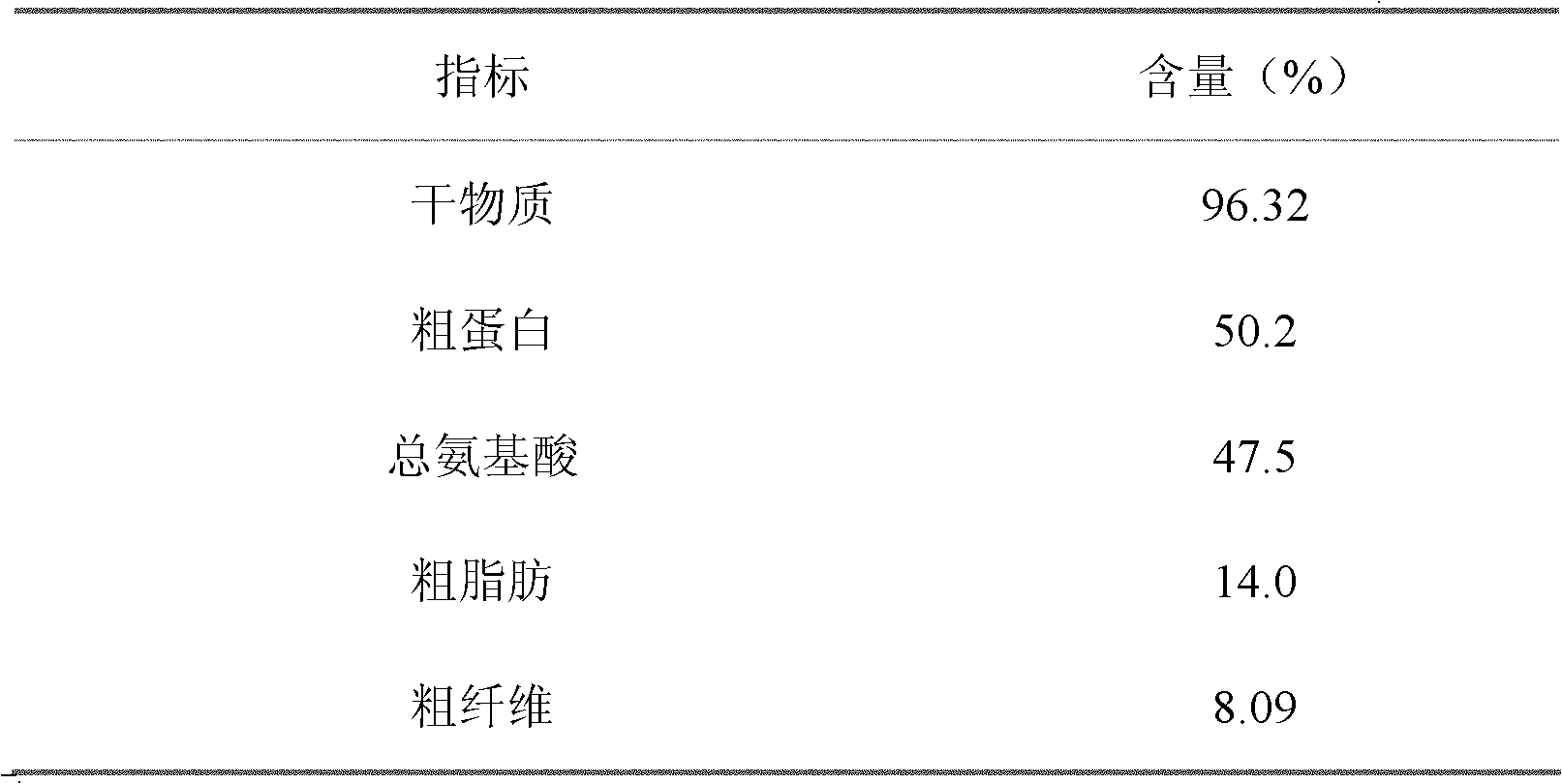

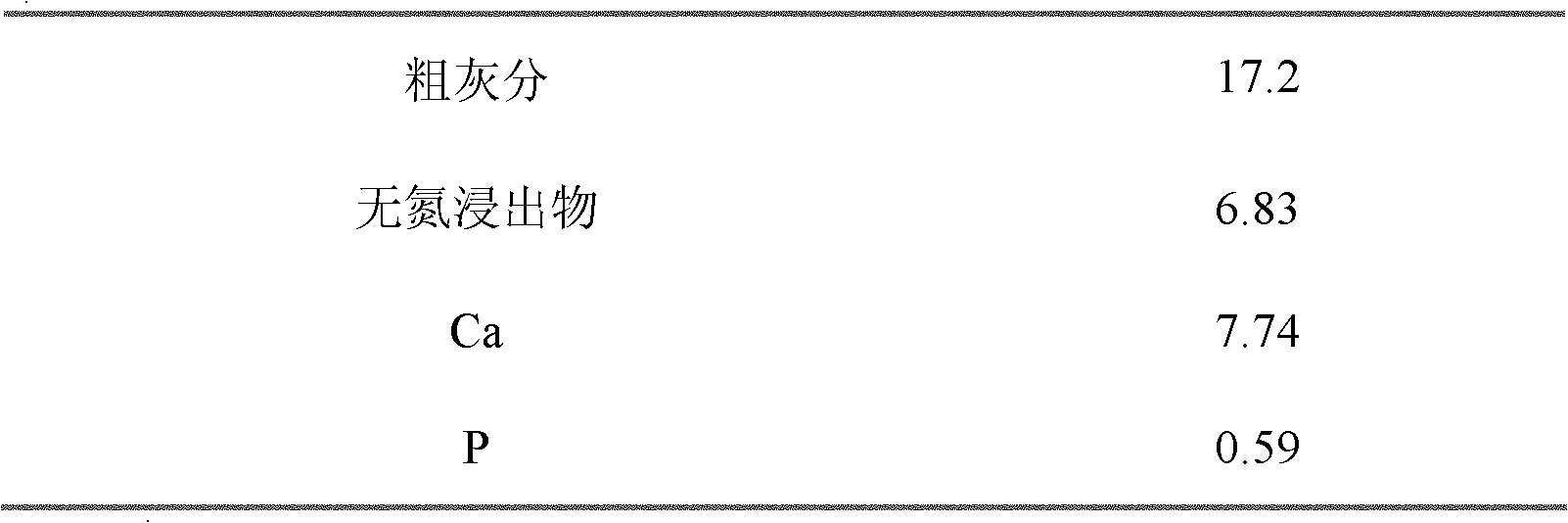

Method for producing insect protein feed through treating livestock and poultry manure by utilizing ptecticus aurife

InactiveCN102058039ASolve the pollution of the environmentTake advantage ofAnimal feeding stuffFecesPoultry manure

The invention discloses a method for producing an insect protein feed through treating livestock and poultry manures by utilizing ptecticus aurife, comprising the following steps of: (1) placing a cultivated 3-year larva of ptecticus aurife into wet livestock and poultry manures for sub-culturing and growing; and (2) when the 3-year larva of ptecticus aurife grows into a mature larva, collecting mature larva, firstly treating the mature larva with hot water or steam, then drying in the sun, drying in the air or drying and pulverizing to obtain a high quality insect protein feed. The method for producing the insect protein feed through treating the livestock and poultry manures by utilizing the ptecticus aurife promotes the effective utilization of insect protein on the animal husbandry and aquaculture and becomes one way to solve the shortage of protein feed resources in China and also solve the problem of serious pollution of the livestock and poultry manures.

Owner:AGRI BIO TECH INST GUANGDONG ACADEMY OF AGRI SCI +3

Road slope silt curing agent and preparation method thereof

The invention relates to a road slope silt curing agent and a preparation method thereof. The road slope silt is prepared from the following components in percentage by weight: 50-90% of silt and 10-50% of a curing agent, wherein the curing agent is prepared from the following components in percentage by weight: 40-70% of cement, 10-30% of coal ash, 5-10% of an expanding agent, 0.5-4% of a high polymer, 0.1-2% of a super plasticizer, 1-3% of an early strength agent, 0.001-0.1% of a retarder, 0.01-1% of a thickener, 0.1-3% of fibers and the balance of grass seeds. According to the curing agent provided by the invention, the expanding agent and fibers are introduced. Compared with a curing agent in the prior art, the road slope silt curing agent has the advantages that the shrinkage rate of cured sandy soil is reduced by 40%, so that the crack resistance of a curing body is improved. A pore structure can be controlled, so as to provide a growing space for plants. By adopting low-grade coal ash, turning waste into wealth and environmental friendliness are facilitated.

Owner:JIANGSU DINGTAI ENG MATERIAL

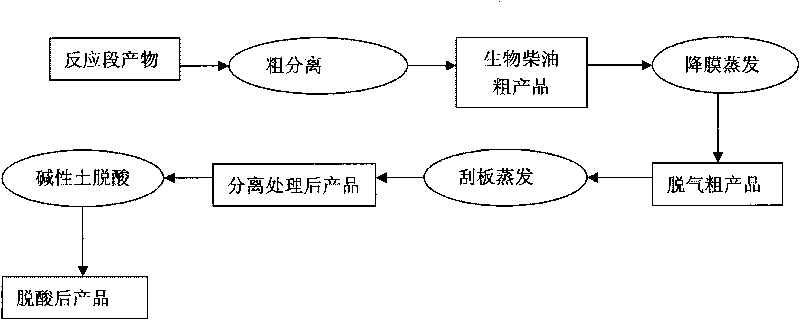

Method for separating and purifying biodiesel

InactiveCN101735845AReduce manufacturing costHigh purityBiofuelsLiquid hydrocarbon mixture productionChemistryGlycerol

The invention discloses a method for separating and purifying biodiesel. The method comprises the steps of: 1) performing degassing and distillation operation on a crude biodiesl product by a film evaporator to obtain the biodiesl of which the content of methyl ester is over 96 percent; and 2) performing alkaline soil deacidification on a product of separation treatment in the step 1) to obtain purified biodiesel of which an acid value satisfies the national standard. By the method, alkaline solution is absorbed on the surface of alkaline soil for a deacidification reaction, which effectively avoids emulsification; the method has simple operation conditions, does not need to strictly control conditions such as stirring and the like; components such as glycerol and soap can be absorbed after the reaction is finished; the obtained methyl ester does not need to be purified again, does not need to be dehydrated, is easy to separate, and has high yield; and a purified product has high quality. The method has the advantages of simple process flow, low equipment cost and energy consumption, and no wastewater pollution, and is suitable to be popularized and applied in a large area.

Owner:BEIJING UNIV OF CHEM TECH

Perfumed mosquito repellent composition

ActiveCN101669529ANo side effectsSolve efficiency problemsBiocidePest repellentsEucalyptus oilAdditive ingredient

The invention discloses a perfumed mosquito repellent composition, characterized in that the composition is prepared by the following ingredients, based on percent by weight, of: 0.1-1% of wild lemonleaf oil, 0.1-2% of eucalyptus oil, 0.5-3% of tea tree oil, 1-10% of eucalyptus citriodora leaf oil, 0-0.5% of clove oil, 0-0.2% of linaloe wood oil, 0-0.5% of dementholised peppermint oil and the balance as diluent of alkane C14. The mosquito repellent composition makes full use of three mosquito repellent essential oils including eucalyptus oil, tea tree oil and eucalyptus citriodora leaf oil, which all have no pesticide ingredients contained, but are excellent in repelling mosquito, bugs and ants, thus achieving ideal mosquito repellent effect and acceptance for human body and generating noside effect to human body, besides, the cost of the composition is low.

Owner:广州百花香料股份有限公司

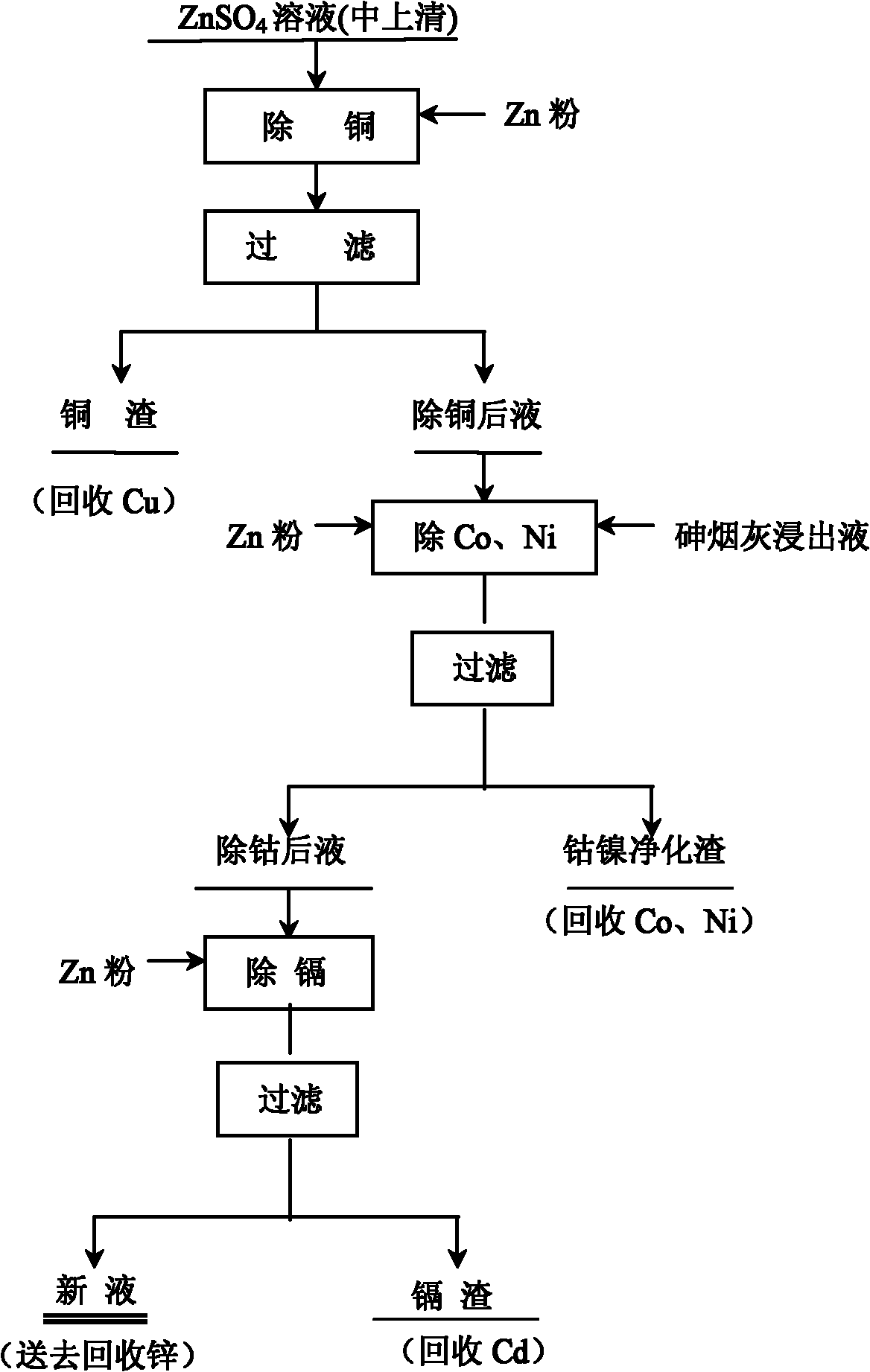

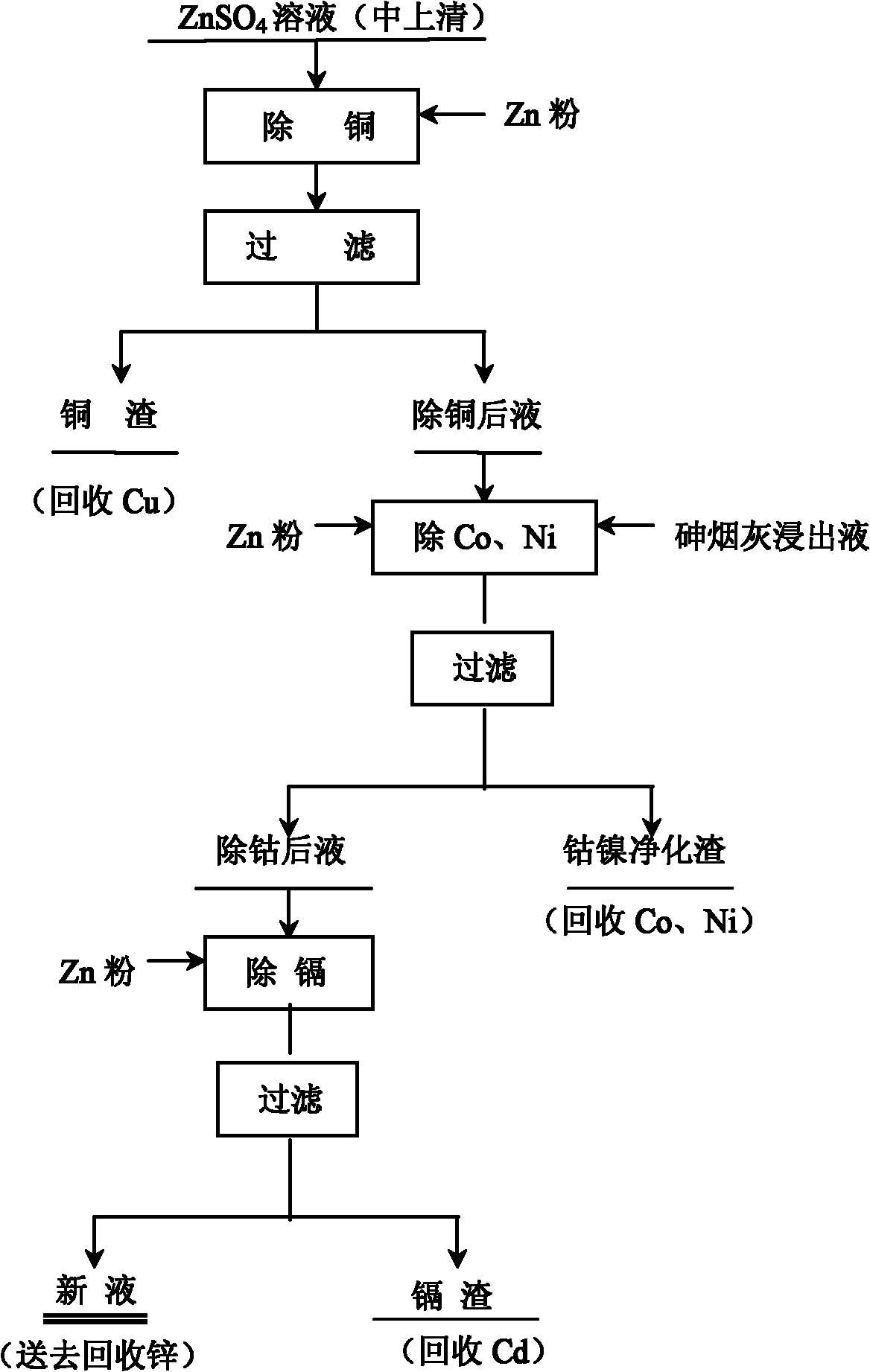

Method for purifying zinc sulfate solution and removing cobalt by using arsenic ash lixivium

ActiveCN101994005ASolve the pollution of the environmentAvoid the Cons of PollutionProcess efficiency improvementPregnant leach solutionSulfate

The invention discloses a method for purifying a zinc sulfate solution and removing cobalt by using arsenic ash lixivium. The invention aims at providing a method for purifying the zinc sulfate solution and removing the cobalt by using the arsenic ash lixivium, which is characterized by comprising the following steps of: A, adding zinc powder to remove copper: adding the zinc powder in a ZnSO4 solution to remove the copper, filtering to obtain copper residue and a copper-removed solution, controlling the copper content of the copper-removed solution to 150-300mg / L; B, removing cobalt and nickel: adding the zinc powder and arsenic ash lixivium into the copper-removed solution obtained in the step A to remove the cobalt and the nickel, filtering to obtain a cobalt-removed solution and cobalt and nickel purified residue; and C, removing cadmium: adding the zinc powder into the cobalt-removed solution obtained in the step B to remove the cadmium, stirring and filtering to obtain a new solution, recovering zinc from the new solution and recovering the cadmium from the cadmium residue . The invention is mainly used for purifying the zinc sulfate solution and removing the cobalt in a wet-process zinc-smelting plant.

Owner:ZHUZHOU SMELTER GRP

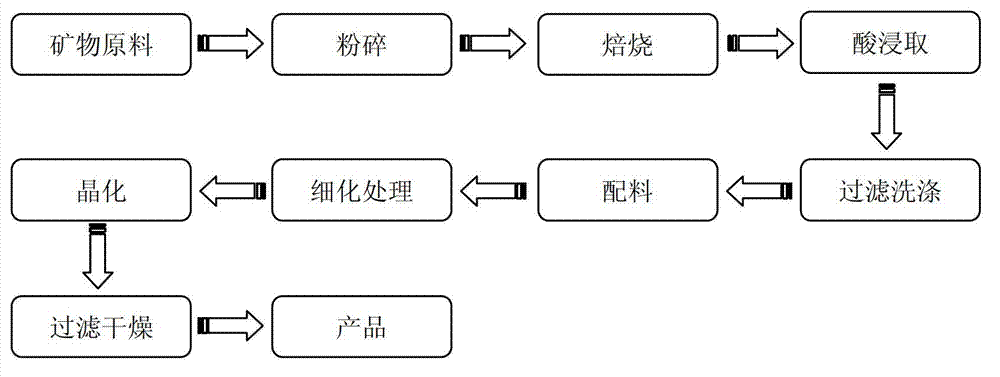

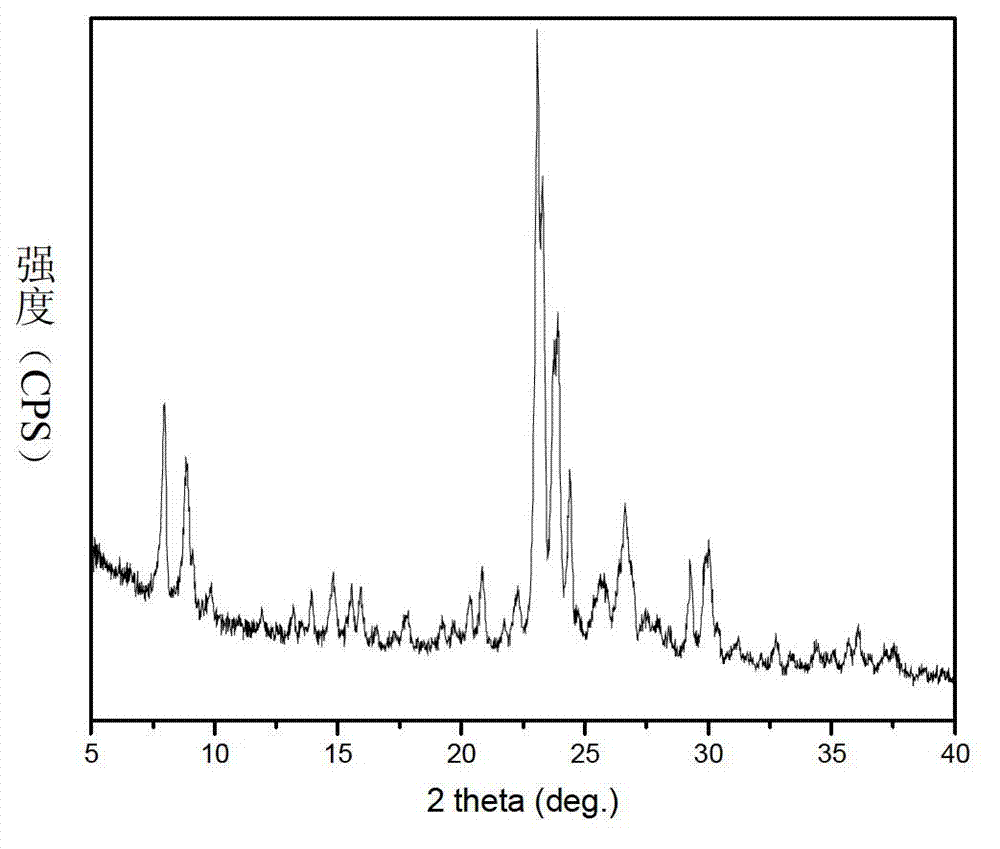

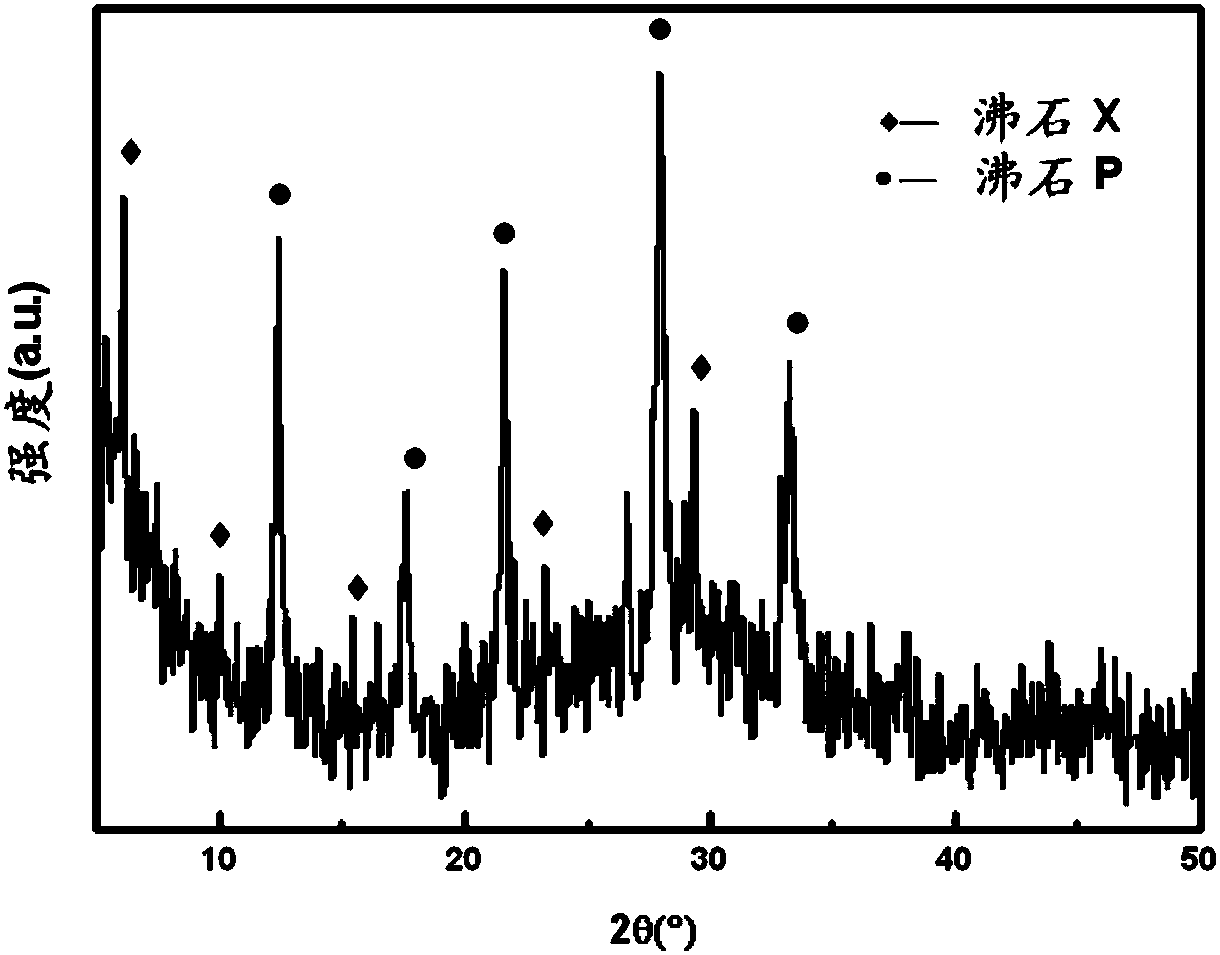

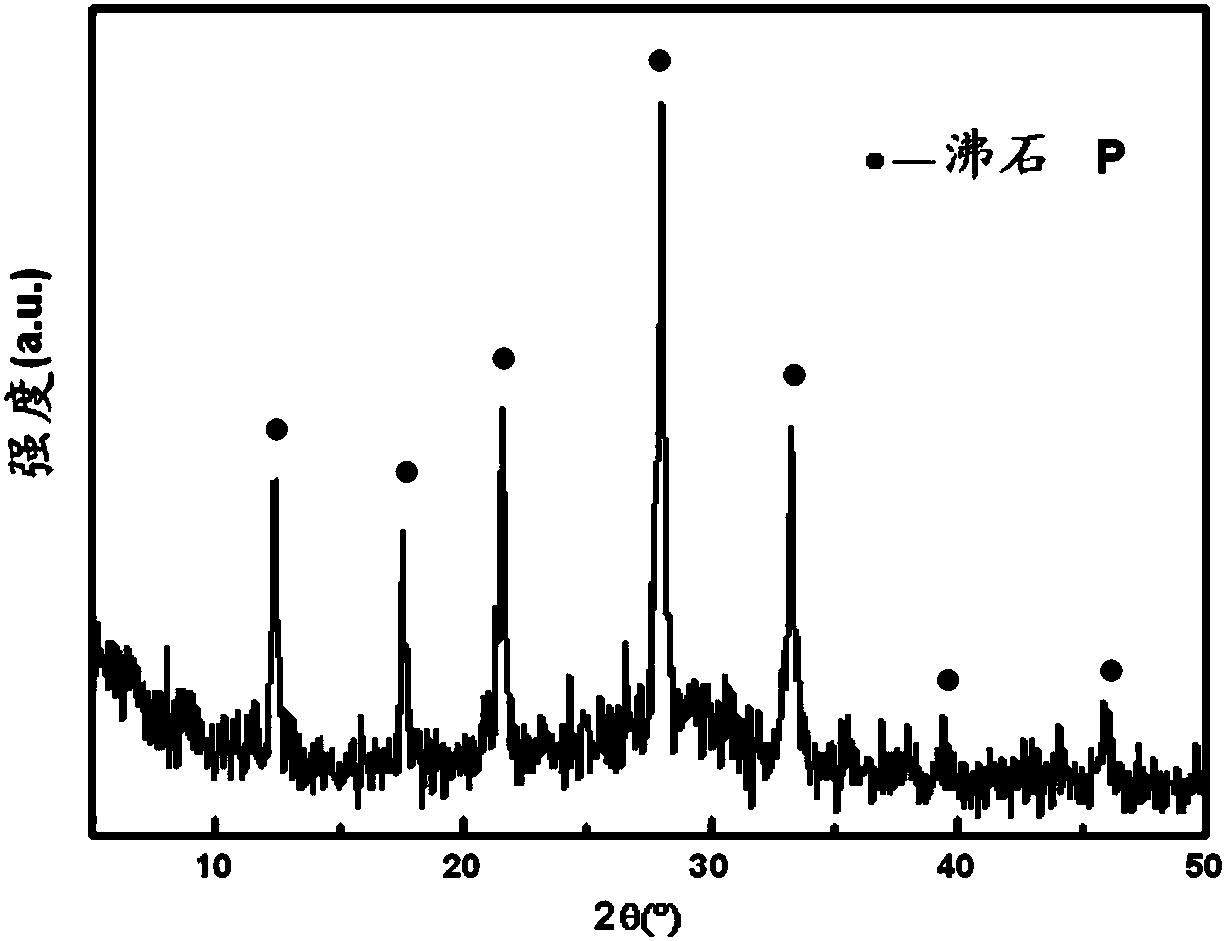

Method for preparing ZSM-5 molecular sieve without template agent

ActiveCN102963908AEasy to controlIncrease added valuePentasil aluminosilicate zeoliteSilicon oxideSubstance amount

The invention relates to a method for preparing a ZSM-5 molecular sieve without template agent. The method comprises the following steps of: smashing the mineral resource containing silicon oxide and aluminum oxide into powder, and roasting; leaching the roasted powder with acid liquor, regulating the amount of substance ratio of the silicon oxide to the aluminum oxide in solid phase to be (14:1)-(85:1), separating the solid phase, and removing impurities from the solid phase; mixing the obtained solid phase, the alkali and the water in the mass ratio of 1:(0.05-0.5):(5-30), carrying out hydrothermal reaction at 130-220 DEG C to crystallize for at least 18 hours, and removing impurities, thus obtaining the ZSM-5 molecular sieve. The method has the characteristics of adding no template agent, adding no additional silicon source or aluminum source, and saving the cost; the technology is simple to operate, the conditions are easy to control, and high value added utilization of waste resources is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

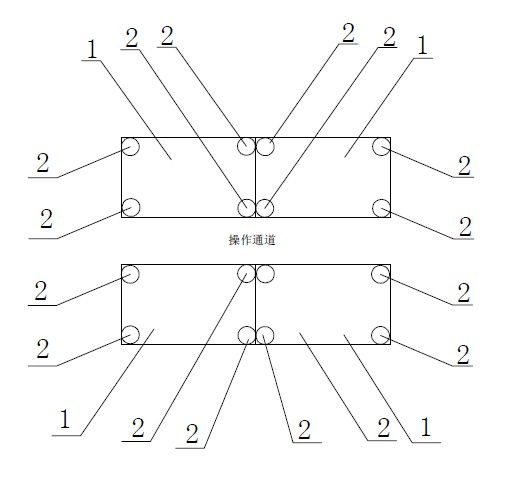

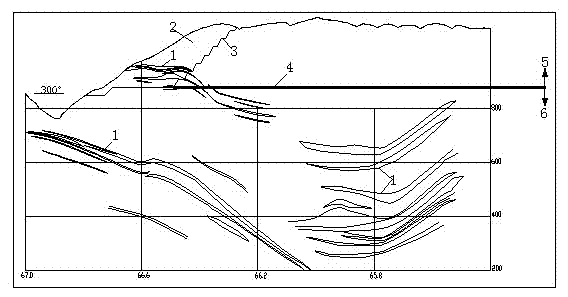

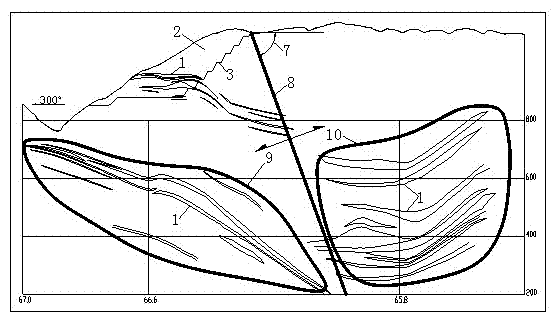

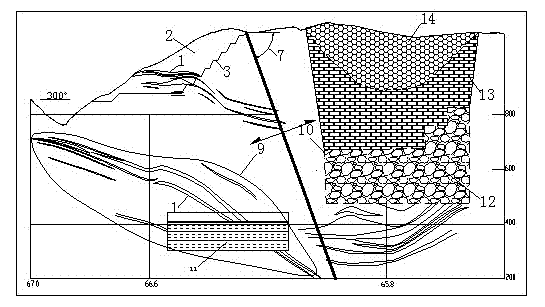

Open pit and underground space-time synchronous mining method for multiple-ore body

ActiveCN103590830ASafe miningGuaranteed thicknessUnderground miningSurface miningOpen-pit miningTime space

The invention discloses an open pit and underground space-time synchronous mining method for a multiple-ore body. According to the technical scheme, the method comprises the following steps: marking the demarcation line of the ore bodies at the shallow and deep positions so as to divide the multiple-ore body into a shallow-position ore body and a deep-position ore body according to an economical and reasonable stripping ratio; delineating the demarcation line of an open-pit mining protection zone according to a moveable angle (7) determined by underground mining by taking the largest demarcation ring of the open-pit mining as a protection line, wherein the deep-position ore body in the protection zone is a filling-process mining zone section (9) and the deep-position ore body outside the protection zone is a caving-process mining zone section (10); filling the waste stone stripped in open pit back to a waste stone back filled region (14) in a rubber belt conveying manner and carrying out cemented filling on the dead zone of the filling-process mining zone section (9) with tailings so as to form a tailings cemented filling region (11). According to the method, the technological characteristics of different mining manners such as open-pit mining, filling-process milling and caving-process mining are organically combined, so that the open-pit, underground space-time synchronous, environment-friendly and efficient mining of the multiple-ore body can be realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for comprehensively utilizing fine coal gasification slag

ActiveCN107857496AHigh activityImprove adsorption capacityOther chemical processesSolid waste managementCycloneSlag

The invention discloses a method for preparing an adsorption material from fine coal gasification slag. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation,collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, and collecting the obtained light separation product to obtain a carbon-rich composite slurry; and 3, carrying out solid-liquid separation and drying on the carbon-rich composite slurry to obtain the carbon-rich adsorption material, and further preparing other products from the remaining silicon-rich composite slurry. The method realizes the high-added value recycling of the fine coal gasification slag.

Owner:鄂尔多斯市慧恒科技有限责任公司

Porcelain granules containing carbon and preparation method thereof

InactiveCN101580349AReduce manufacturing costLight weightSolid waste disposalThermal insulationExpanded clay aggregate

The invention discloses a preparation method for porcelain granules containing carbon. According to the weight percentage, 5%-40% of carbon powder, 5%-25% of gold mine tailing powder and 35%-70% of fly ash make up main raw materials. The preparation method comprises the steps of: (1) the gold mine tailing powder is dipped in a HCl solution; (2) the carbon powder, the fly ash and the modified mine tailing powder are uniformly blended; and then water is added for wet mixing; (3) the wet material is prepared into spheric granules with the grain diameter of 5-20mm; (4) the spheric granules are dried and sintered to obtain the porcelain granules containing carbon. The porcelain granules containing carbon are multifunctional porcelain granules with the functions of adsorption, light weight, high strength, heat preservation, thermal insulation, etc.

Owner:ZHEJIANG UNIV

Method for preparing Y-type molecular sieve from FCC waste catalyst by microwave heating

InactiveCN108190910AEfficient use ofSolve the problem of massive emissions polluting the environmentFaujasite aluminosilicate zeoliteChemical recyclingMolecular sieveMicrowave power

The invention relates to a method for preparing a Y-type molecular sieve from an FCC waste catalyst by microwave heating, and belongs to the technical field of secondary resource comprehensive recovery and utilization. The method comprises the following steps: first, removing toxic metals, namely, vanadium, nickel and iron, from the FCC waste catalyst by soaking for 10 to 60 minutes at 50 to 120 DEG C by a chemical method, wherein a molecular sieve framework structure must be remained simultaneously; taking metal-removed reactivated FCC waste catalyst as an aluminium source, performing seed crystal growth for 10 to 60 minutes at the microwave power of 400 to 1,600 W at 80 to 140 DEG C in the situation of externally adding a silicon source, a sodium source, water and a guiding agent, cooling to 60 to 120 DEG C, crystallizing for 0.5 to 3 hours at the microwave power of 400 to 1,600 W, and drying to obtain the Y-type molecular sieve. According to the method, the problem of massive discharging of the FCC waste catalyst can be solved, high-efficiency and quick utilization of the FCC waste catalyst can also be realized, and the problem about the aluminium source required in a preparation process is also solved.

Owner:KUNMING UNIV OF SCI & TECH +1

Method for reclaiming ferric oxide from coal ash and coal gangue

The invention discloses a method of recovering an iron oxide from a fly ash and a gangue. The method adopts the process of grinding and roasting the fly ash and the gangue, the process of immersing and carbon dioxide decomposing the alumina, the process of acidizing and separating the silica and the process of obtaining iron oxide by the method of hydroxide precipitation. The purity of the iron oxide made by the method is high and the extraction rate of the iron oxide in the fly ash and the gangue can reach to 86 percent. The whole process is carried out under the pressure condition, so the method has low requirements to the equipment. The method solves the problems of land occupation and environment pollution caused by residue stacking after alumina extraction, also solves the problems of large amount of residue and low added value of the residue. The whole process realizes recycling of resources and can not cause new pollution to the surrounding environment.

Owner:北京蔚然欣科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com