Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

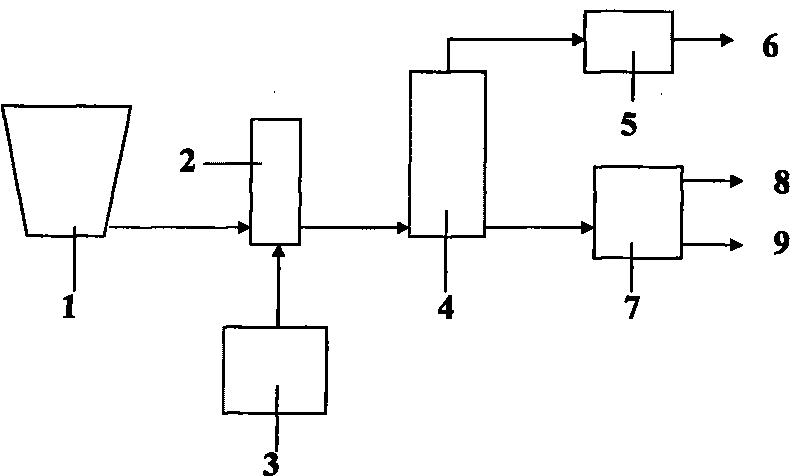

925results about How to "Increase gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming agents for use in coal seam reservoirs

InactiveUS6915854B2Increase productionGood oil wetting characteristicOther chemical processesFluid removalFoaming agentHydrogen

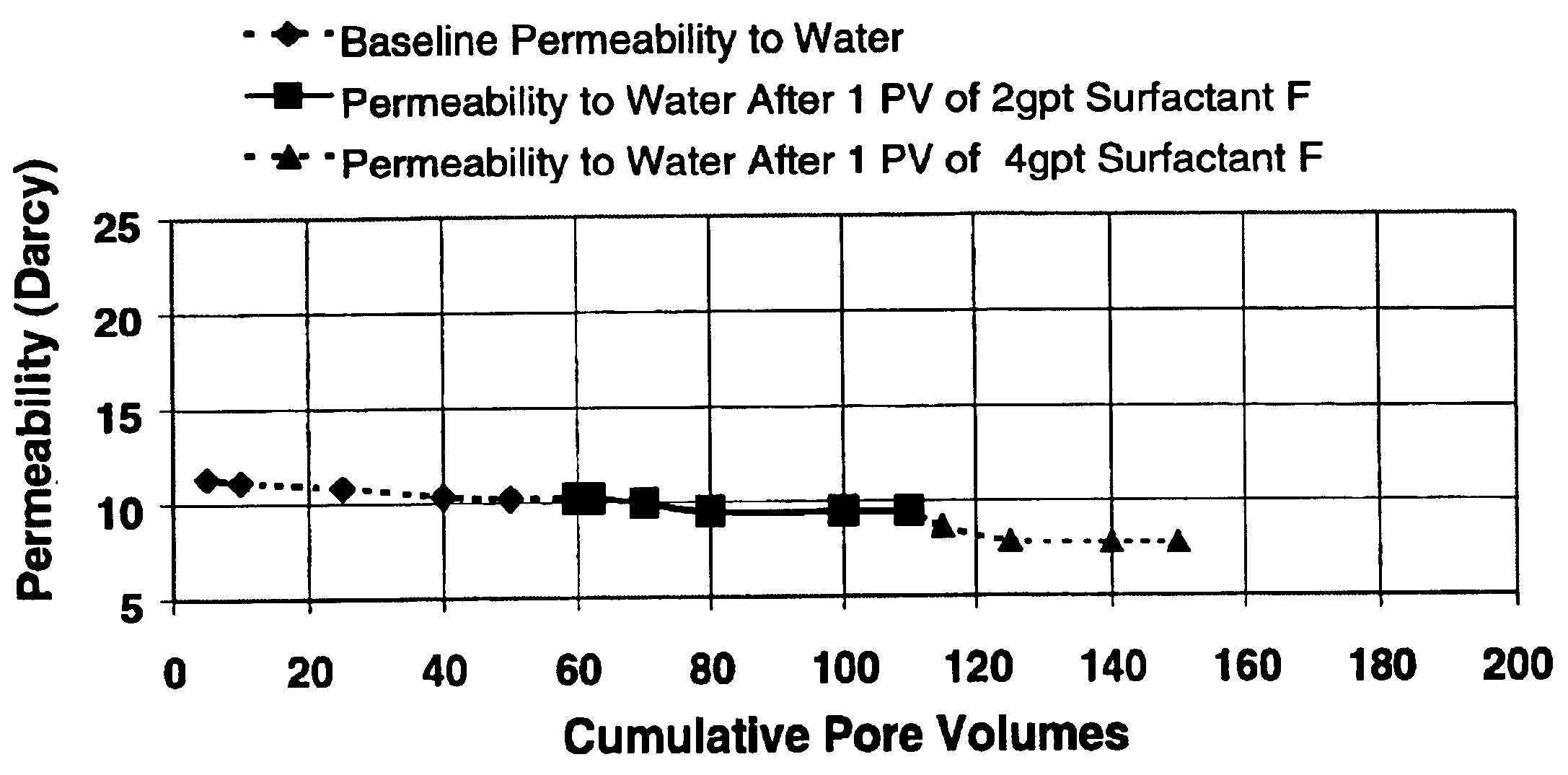

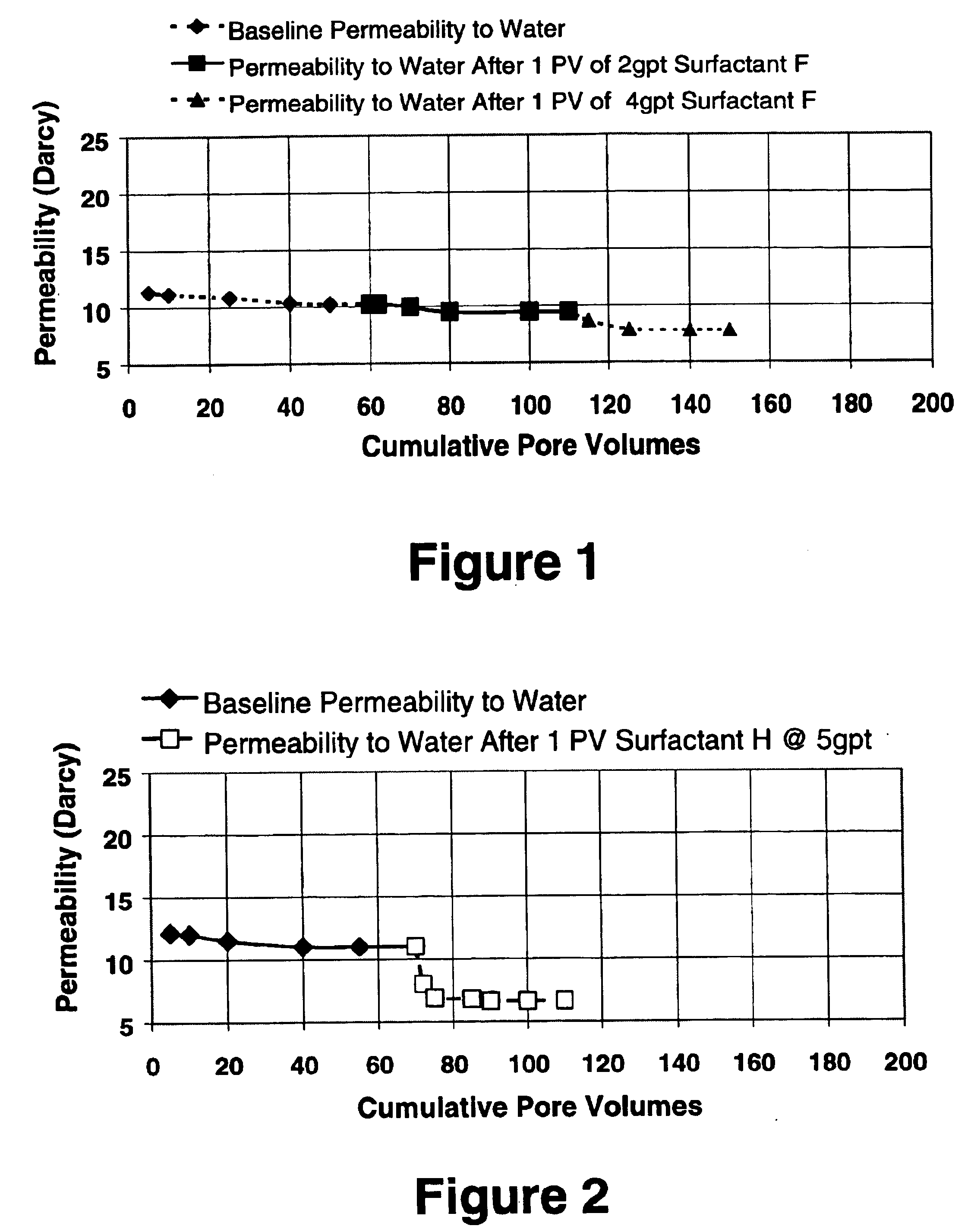

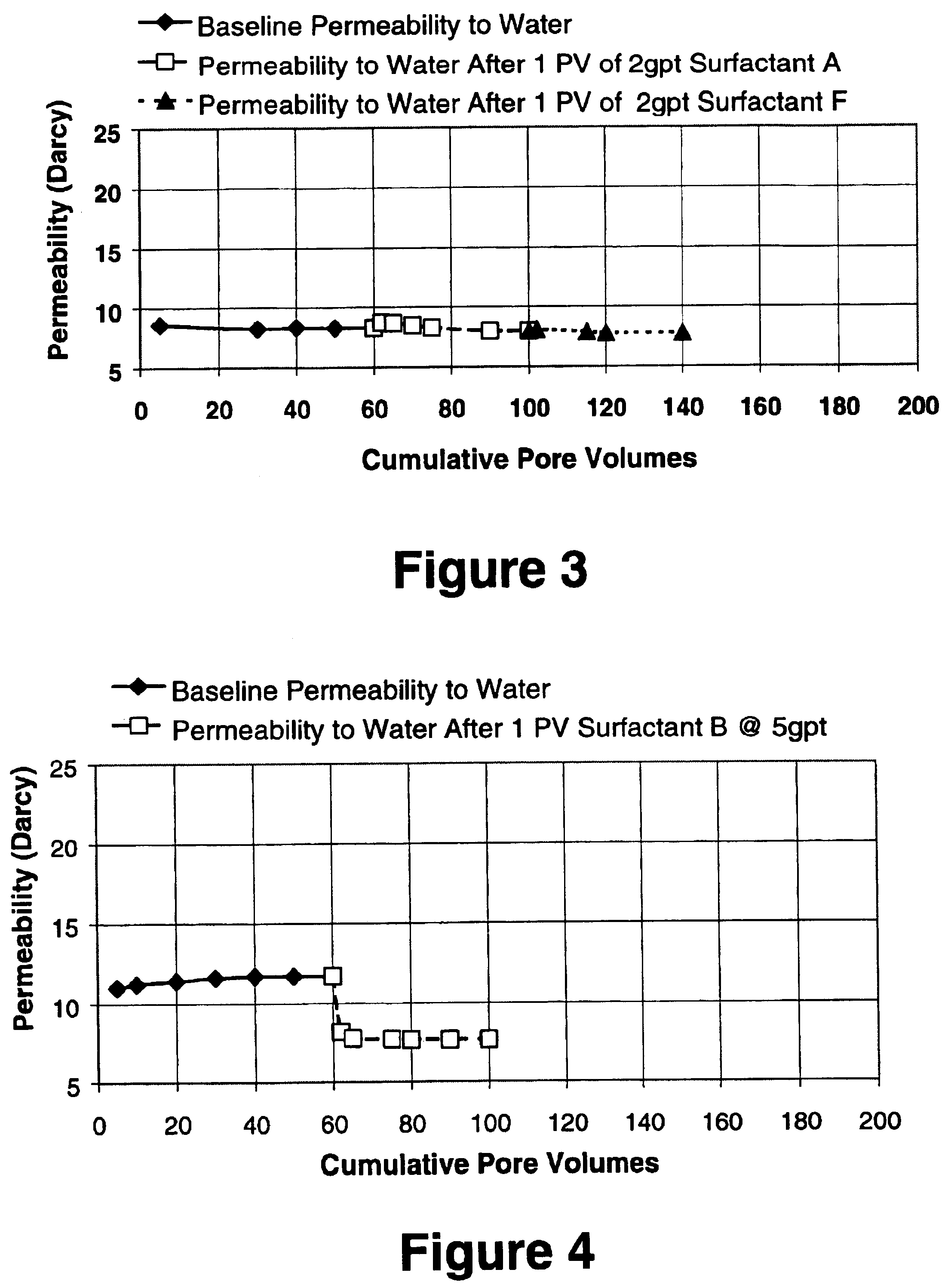

A well treatment fluid composition that comprises a carrier fluid and an amphoteric surfactant, and optionally a viscosifying agent and proppant, is well suited for use in fracturing coal beds to stimulate methane production. The composition preferably is a foam that comprises a gas such as nitrogen or air. Preferably, the surfactant has the formulaR—NH2—(CH2)n—C(O)OXwherein R is a saturated or unsaturated alkyl group having from 6-20 carbon atoms, n is from 2-6, and X is hydrogen or a salt forming cation.

Owner:SCHLUMBERGER TECH CORP

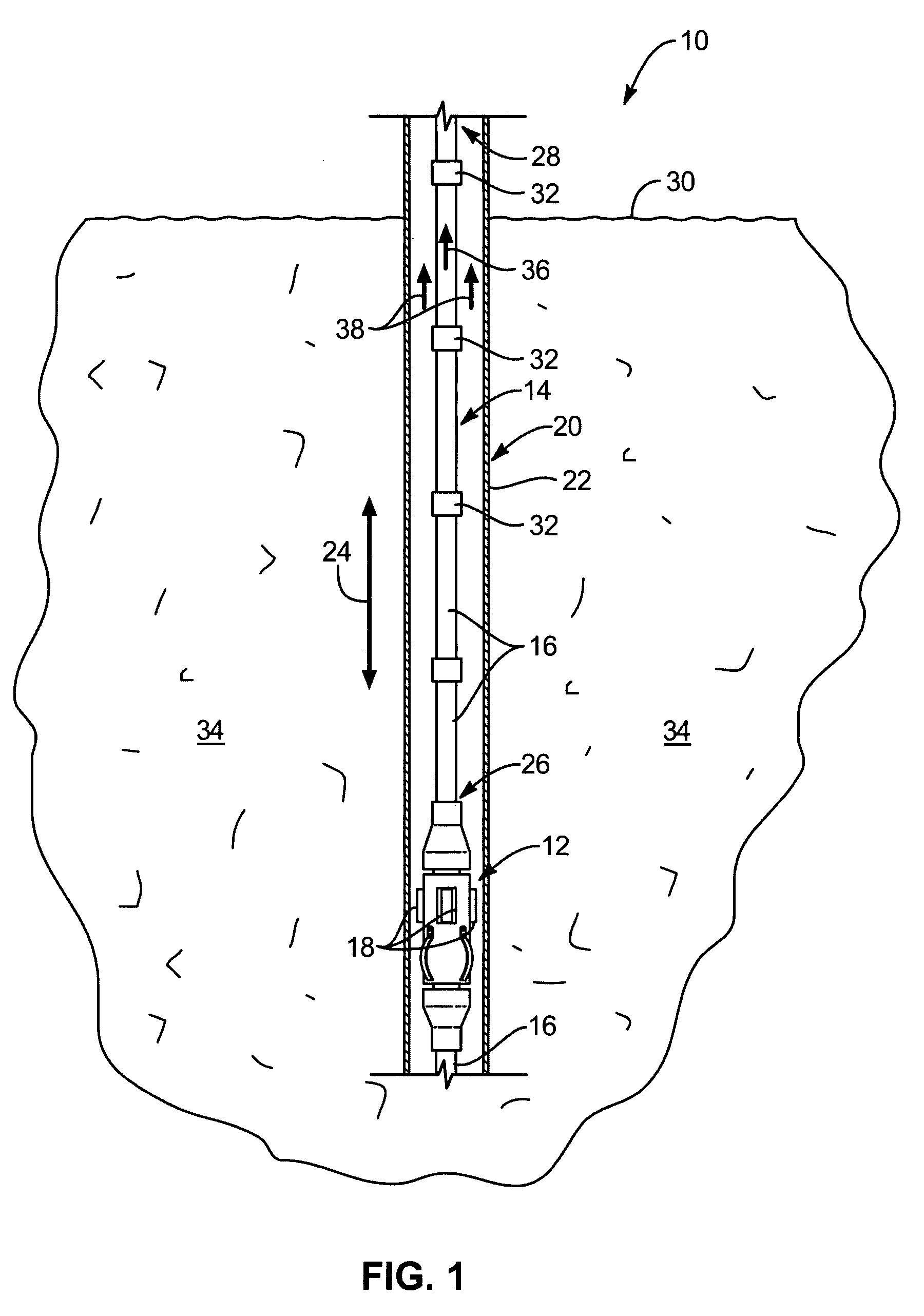

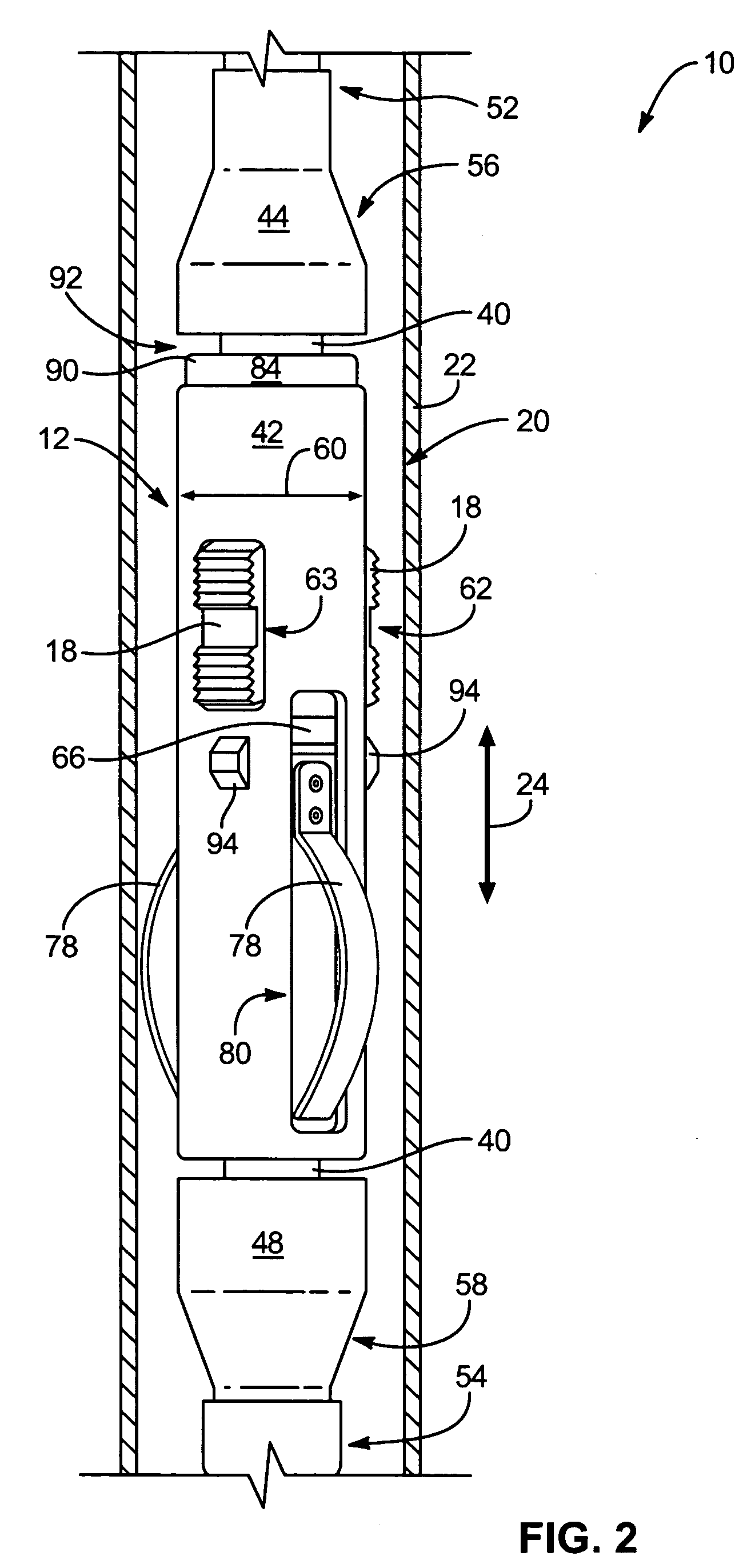

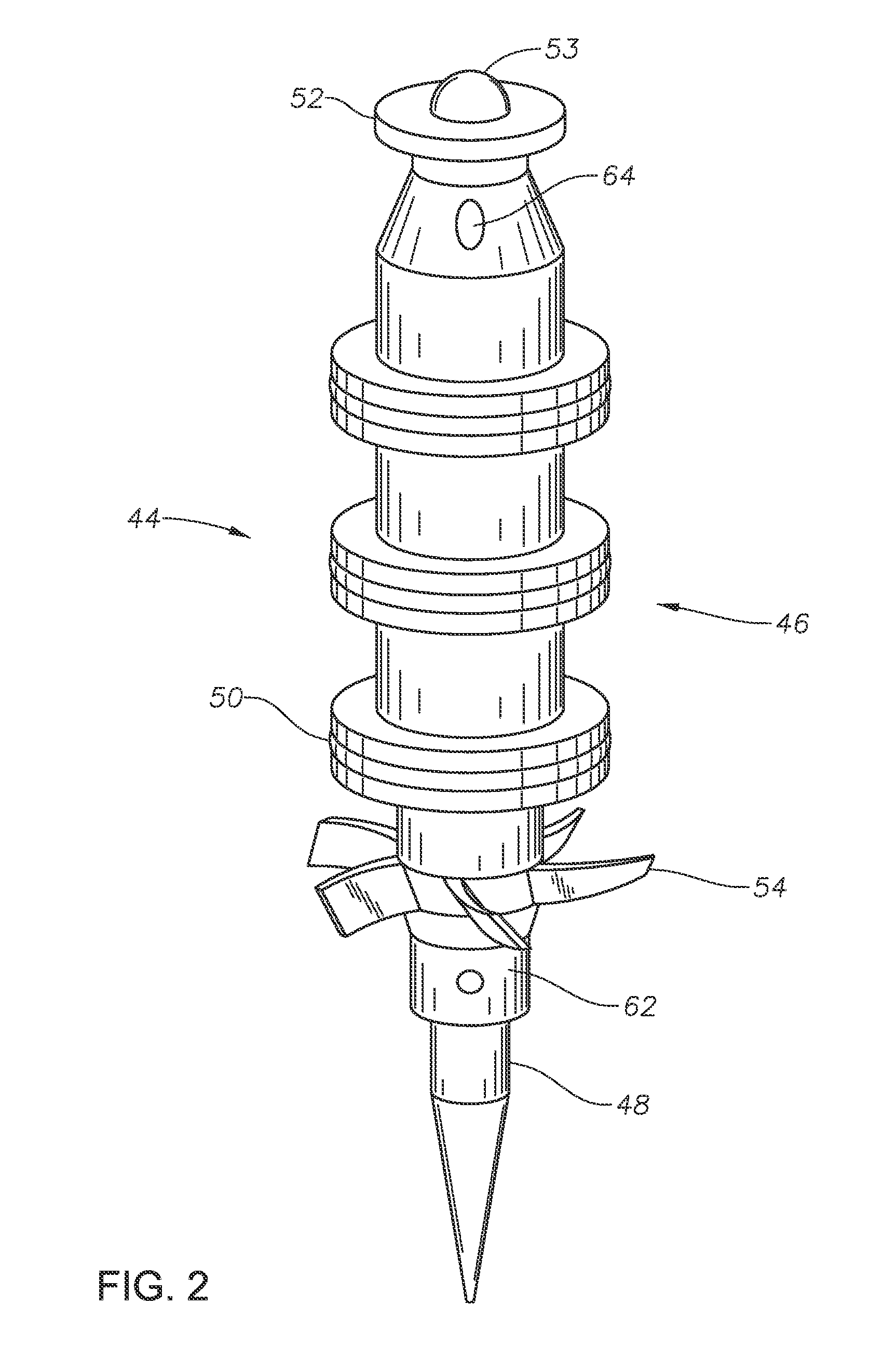

Hydrodynamic, down-hole anchor

ActiveUS7255172B2Facilitate their admittanceIncrease gas productionDrilling rodsFluid removalMechanical engineeringWellbore

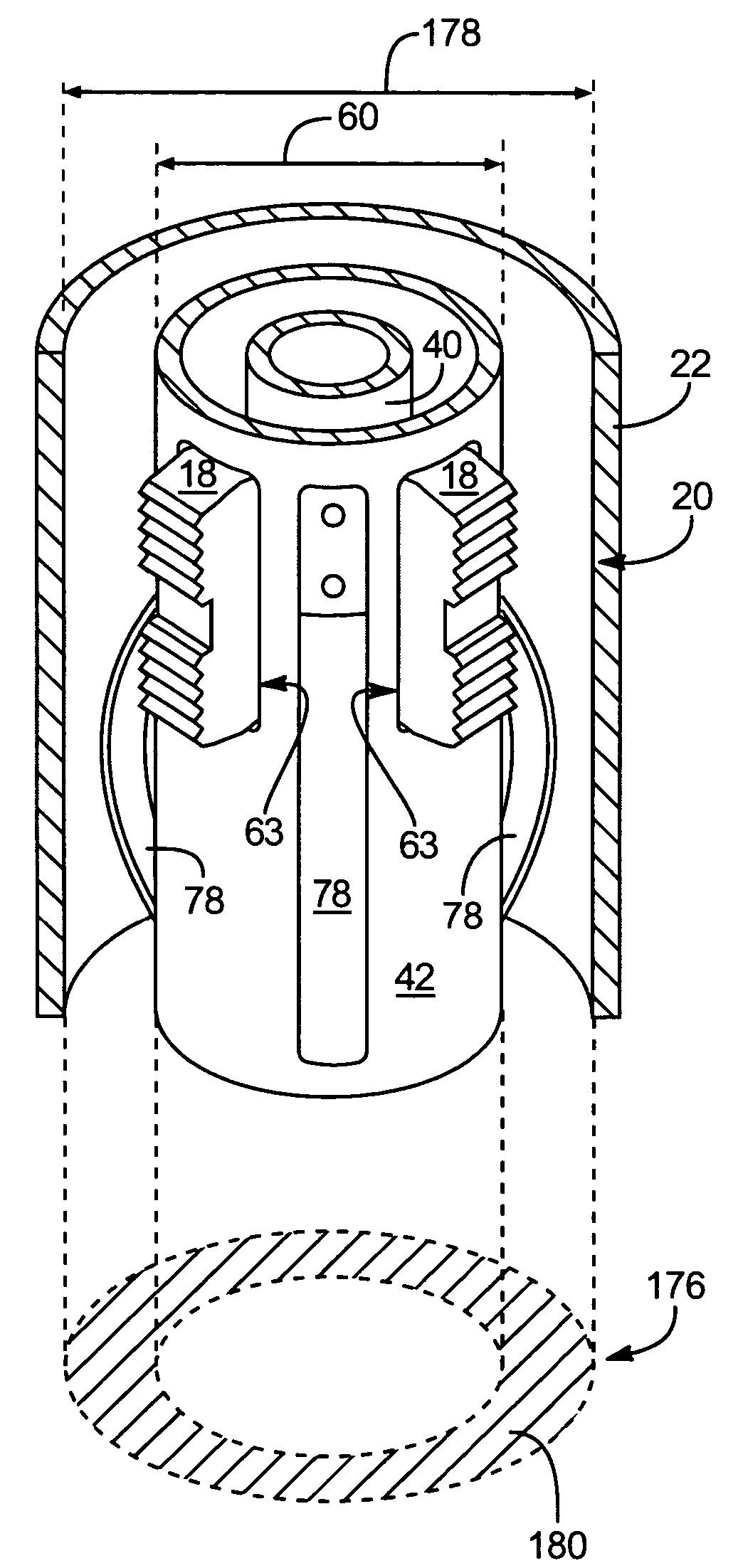

A method of removably anchoring well tubing in a well bore may include selecting a well having a bore diameter and an anchor positioned therein. The anchor may have a housing defining an anchor diameter and extension members extending therefrom toward the bore diameter. The bore diameter and anchor diameter may be spaced apart a distance defining an annulus therebetween and extending along the well. A tool sized to cut substantially exclusively within the annulus may be selected. The tool may be positioned within the annulus, rotated, and advanced to drive past the housing to remove the extension members between the housing and the bore diameter to free the anchor.

Owner:TECH TAC

Open well plunger-actuated gas lift valve and method of use

InactiveUS6907926B2Increase gas productionReduce hydrostatic pressureFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

A system is provided for unloading accumulated liquids and enhancing the recovery of gas from a reservoir having diminished pressure. An annulus between a tubing string and casing is isolated by a packer and continually pressurized with a slipstream of compressed gas while the well continues to produce. A unique valve positioned in the tubing string is shuttled between a production position in which production fluids are permitted to bypass the valve to the surface and a lift position in which the bypass is blocked and an unloading port is opened to vent high pressure annulus gas to the tubing string above the valve, lifting accumulated liquids with it. Preferably, the valve is actuated to the lift position by the impact of a plunger dropped from a lubricator at the wellhead, when the pressure in the annulus has reached a predetermined threshold. When the gas has been vented and the pressure in the annulus drops, the valve is actuated to the uphole production position as a result of the higher reservoir pressure.

Owner:G BOSLEY OILFIELD SERVICES

Method of optimizing production of gas from vertical wells in coal seams

ActiveUS7445045B2Maximize interferenceIncrease gas productionSurveyDisloding machinesProduct gasCoal

The present invention is directed to a method for producing gas from a subterranean formation containing a coal seam. The method includes the steps of drilling a substantially vertical well bore into the subterranean formation, which intersects the coal seam and fracturing the coal seam using a hydrajetting tool to produce at least one pair of opposed bi-wing fractures substantially along a plane of maximum stress. One or more horizontal well bores may also be drilled into the coal seam along which the coal seam can be further fractured.

Owner:HALLIBURTON ENERGY SERVICES INC

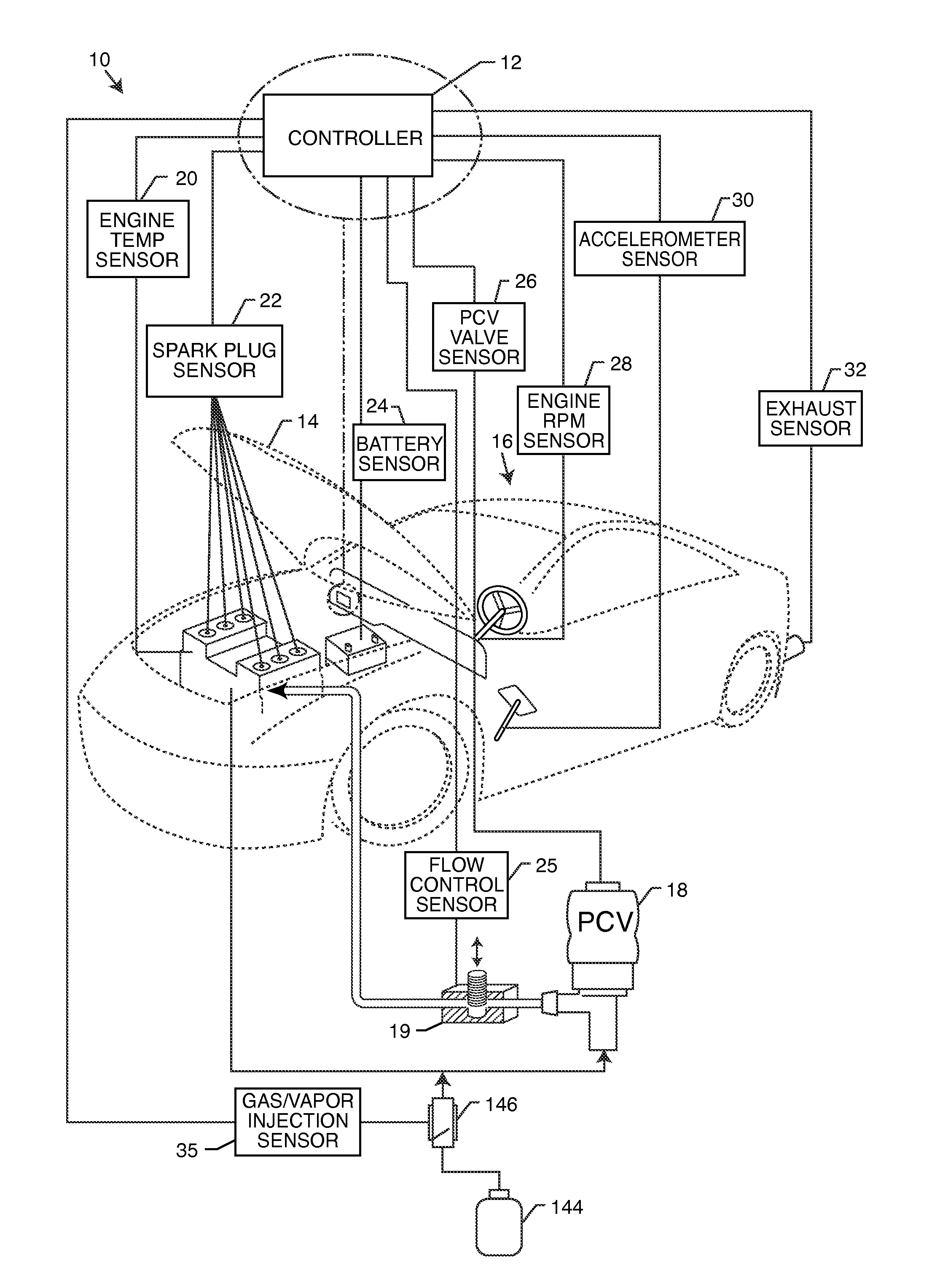

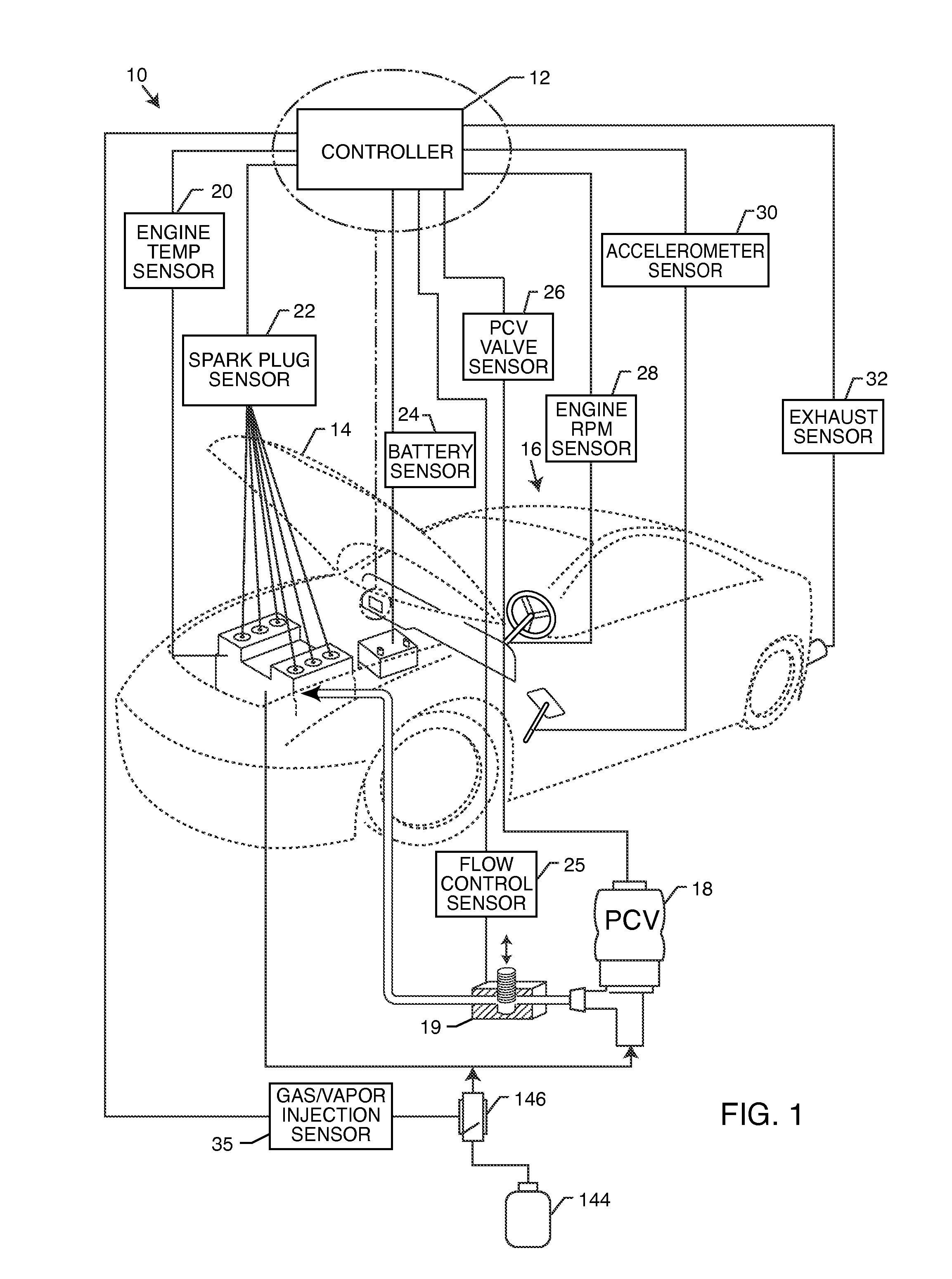

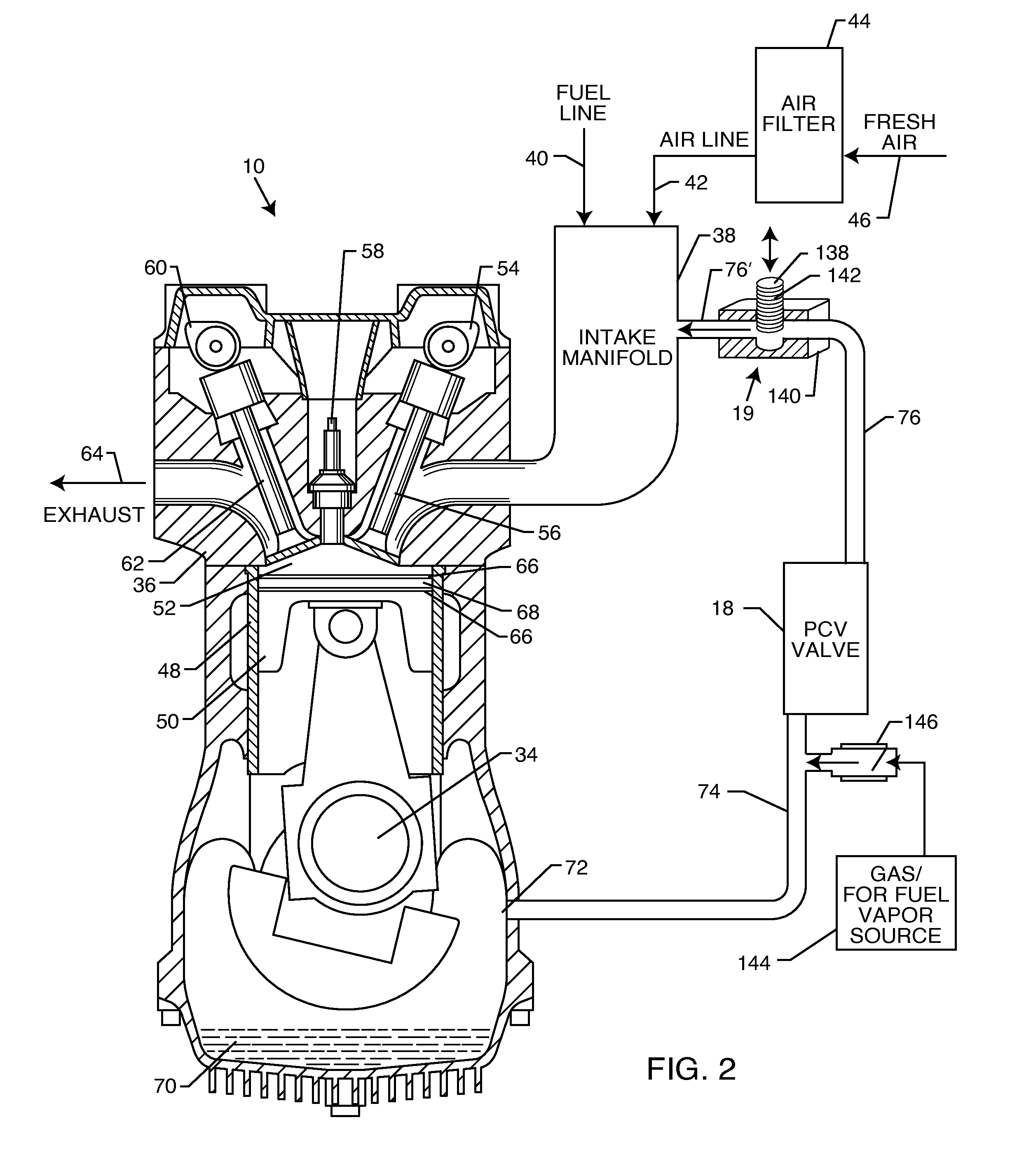

Pollution control system

ActiveUS20100076664A1Reduce fluid flow rateIncrease fluid velocityAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

Method for promoting sludge to be reduced by ozone

InactiveCN101708937ASmall particle sizeLow mineralization rateSludge treatment by oxidationWaste based fuelBrickBiological filter

The invention relates to a method for promoting sludge to be reduced by ozone, in particular to a technology used for pretreating the sludge and accelerating anaerobic sludge digestion speed by utilizing ozone oxidation technique, which is widely applied to the sludge treatment technique of a sewage plant. The method comprises: the residual sludge of the sewage plant is concentrated and then treated by a sludge pretreatment reactor; due to the strong oxidizing property of ozone, the cell wall and the cell membrane of microorganism inside the sludge are broken, and a great deal of organic matter is released out of cells; after being treated by the ozone, the sludge enters into an anaerobic digestion reactor, and anaerobic digestion can be carried out in a closed anaerobic state; gas generated by digestion is treated by a gas purifying device, and methane can be obtained; after anaerobic digestion, the sludge is treated by flocculation and dehydration, and dewatering sludge can be obtained; then, final treatment can be carried out, for example, the sludge can be used for manufacturing agricultural fertilizer, bricks, porcelain granules or auxiliary fuel of fire coal; and anaerobic supernate is treated by biological filtering bed technique, so that the organic matter, ammonia and nitrogen in the solution can be removed.

Owner:NANJING UNIV OF TECH

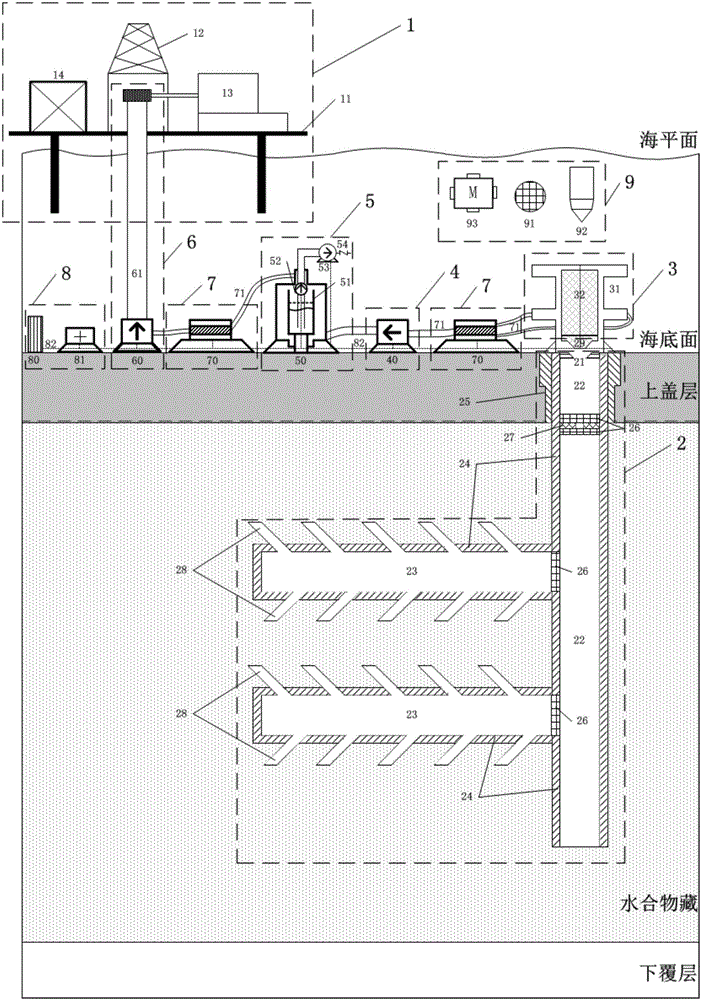

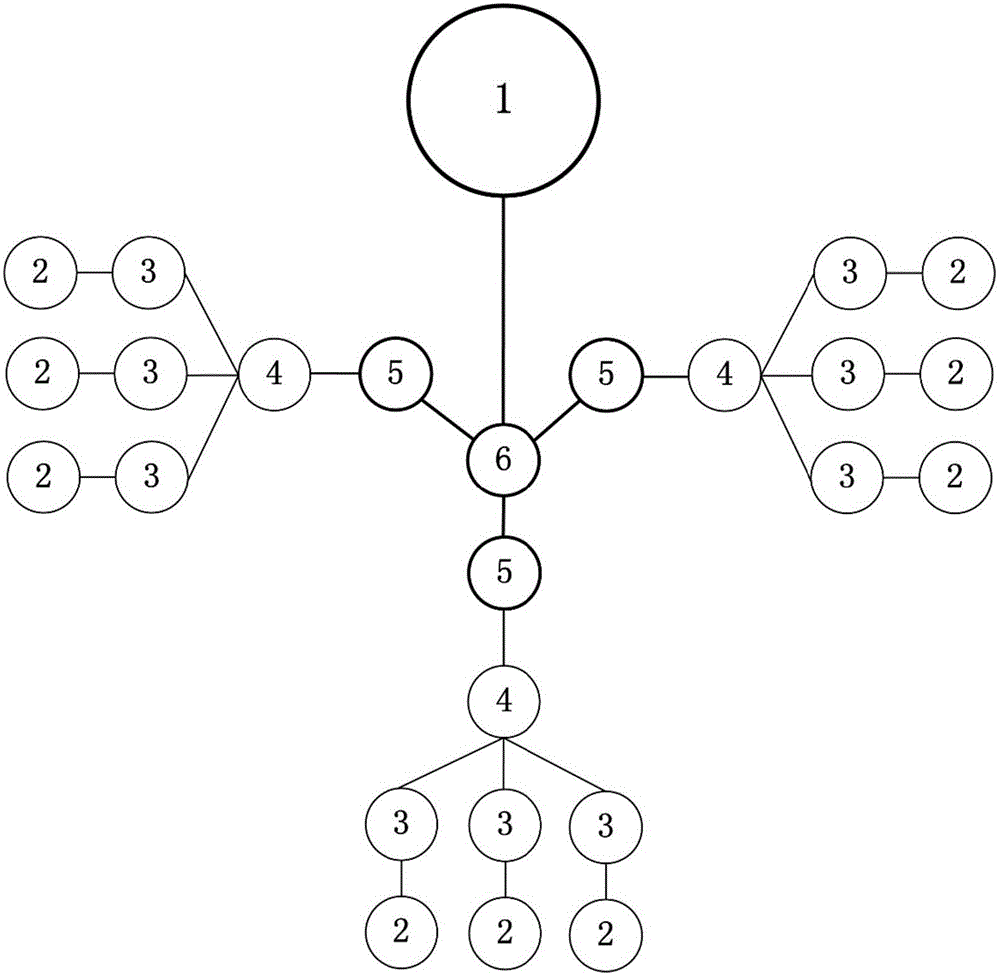

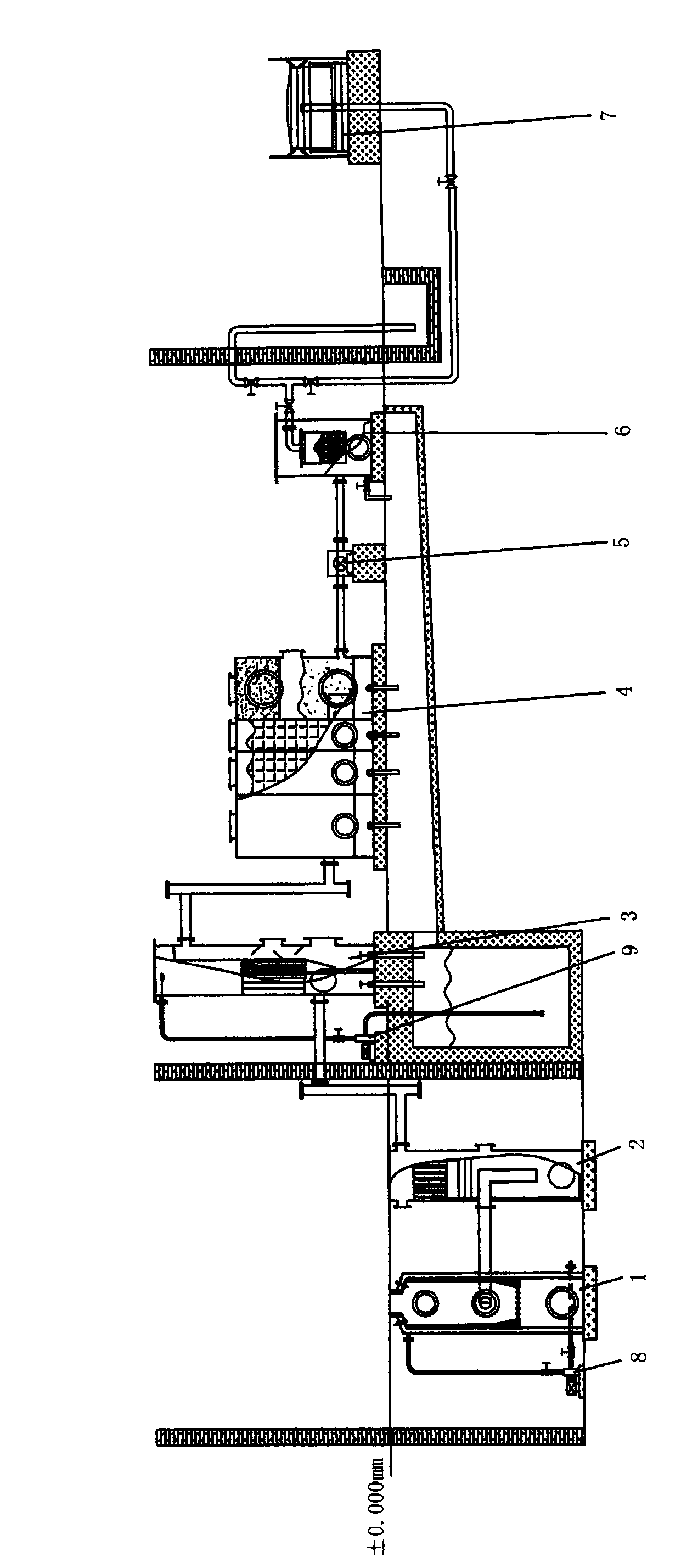

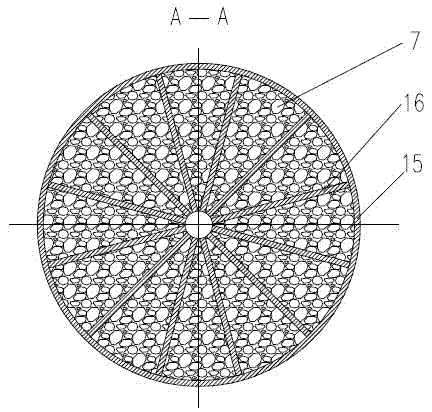

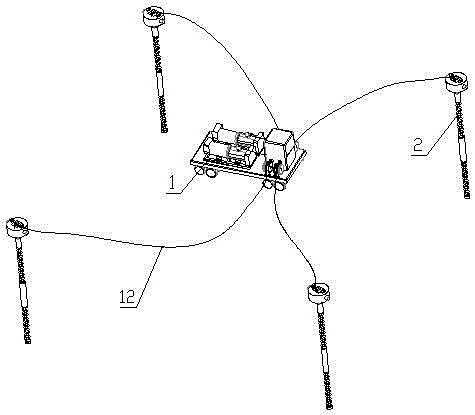

Decompression marine natural gas hydrate mining method and submarine mining system

The invention relates to a decompression marine natural gas hydrate mining method and a submarine mining system. The submarine mining system comprises a semi-submersible offshore platform, a mining well with multiple shower holes, a wellhead gas and water acquisition tree, a gas and water mixed delivery system, a submarine gas and water separating device, a gas delivery system, a pipeline system, a power and communication system and an auxiliary device. The decompression marine natural gas hydrate mining method and the submarine mining system have the advantages that submarine natural gas hydrate reservoirs can be safely, efficiently and economically mined; the submarine mining system is complete, and various portions of the submarine mining system are high in modularization, low in manufacturing cost and short in manufacturing cycle and can be reused; most devices are positioned in submarine environments and are controlled via the offshore platform, only natural gas is delivered offshore, and accordingly the submarine mining system is low in extra energy consumption; owing to a technology for forming the multiple shower holes in the mining well, missed mining regions can be effectively reduced, and the gas yield can be effectively increased owing to multiple horizontal wells; the submarine mining system has functions of well blocking prevention, well blowout prevention, hydrate secondary generation and the like, and accordingly safety production can be guaranteed; various main devices can flexibly move and are used with one another, and accordingly movable regional production operation can be implemented.

Owner:DALIAN UNIV OF TECH

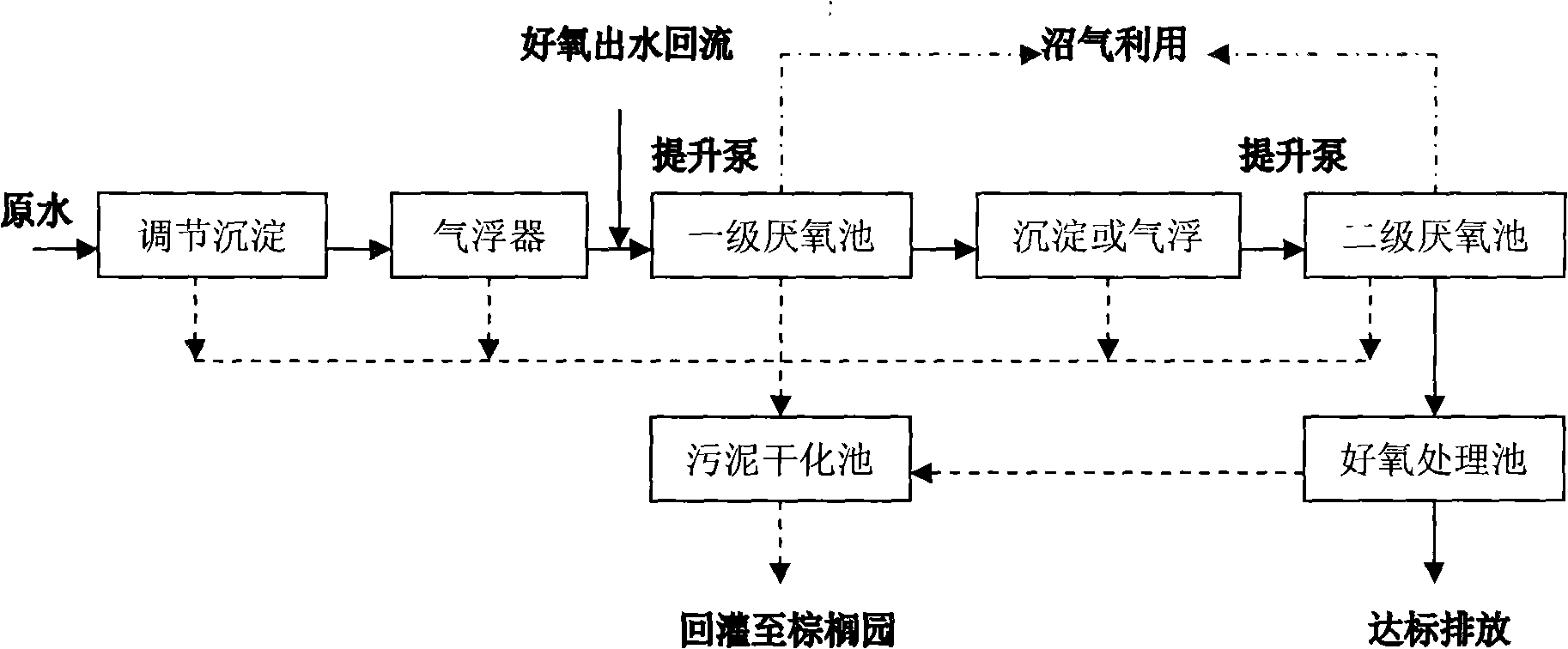

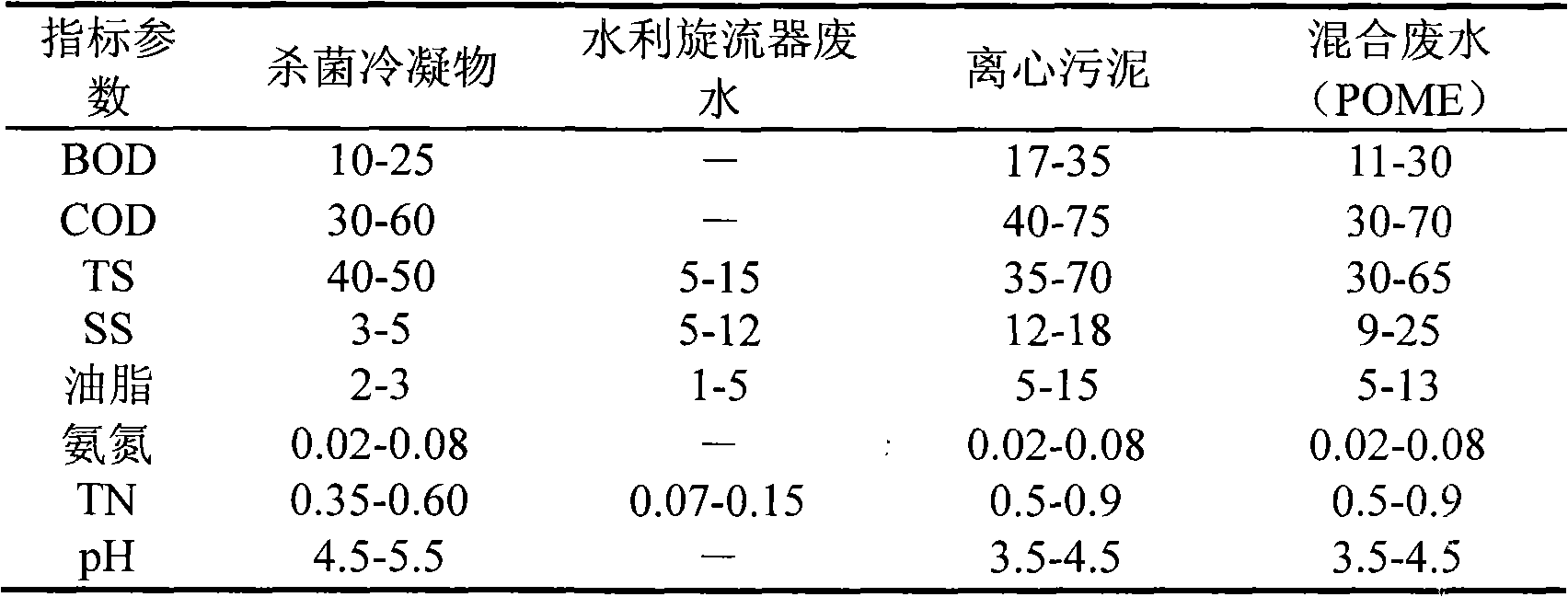

Method for processing palm oil waste water and use thereof

InactiveCN101302071AAchieve recyclingEmission reductionFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesOil and greaseMonosodium glutamate

The invention provides a method for treating palm oil wastewater and an application of the method. The method particularly adopts a process combining pretreatment, primary anaerobic treatment, precipitation, secondary anaerobic treatment and aerobic treatment. The details can be seen in the specification. The method and the application of the method have the advantages of high load, small occupied area, good treatment effect and high treatment efficiency. Most organic substances in the wastewater can be transformed into biogas which can be used as new energy after centralized collection; and the primary anaerobic treatment is controlled in a hydrolytic acidification section, thereby not only reducing the content of SS and grease in the wastewater, but also improving the treatment effect and the gas production of a secondary methanogenic aerobic reactor. The application of the method is as follows: the method not only has excellent treatment effect to the palm oil wastewater, but also can effectively treat similar fermentations (such as factory effluent of bioethanol, vintage, monosodium glutamate, starch and so on), food production, dairy products, livestock and poultry breeding and other industries; meanwhile, the process has excellent digestion effect to excess sludge for a sewage plant, in particular a municipal sewage plant.

Owner:中节能铁汉盖雅(北京)环境科技有限公司

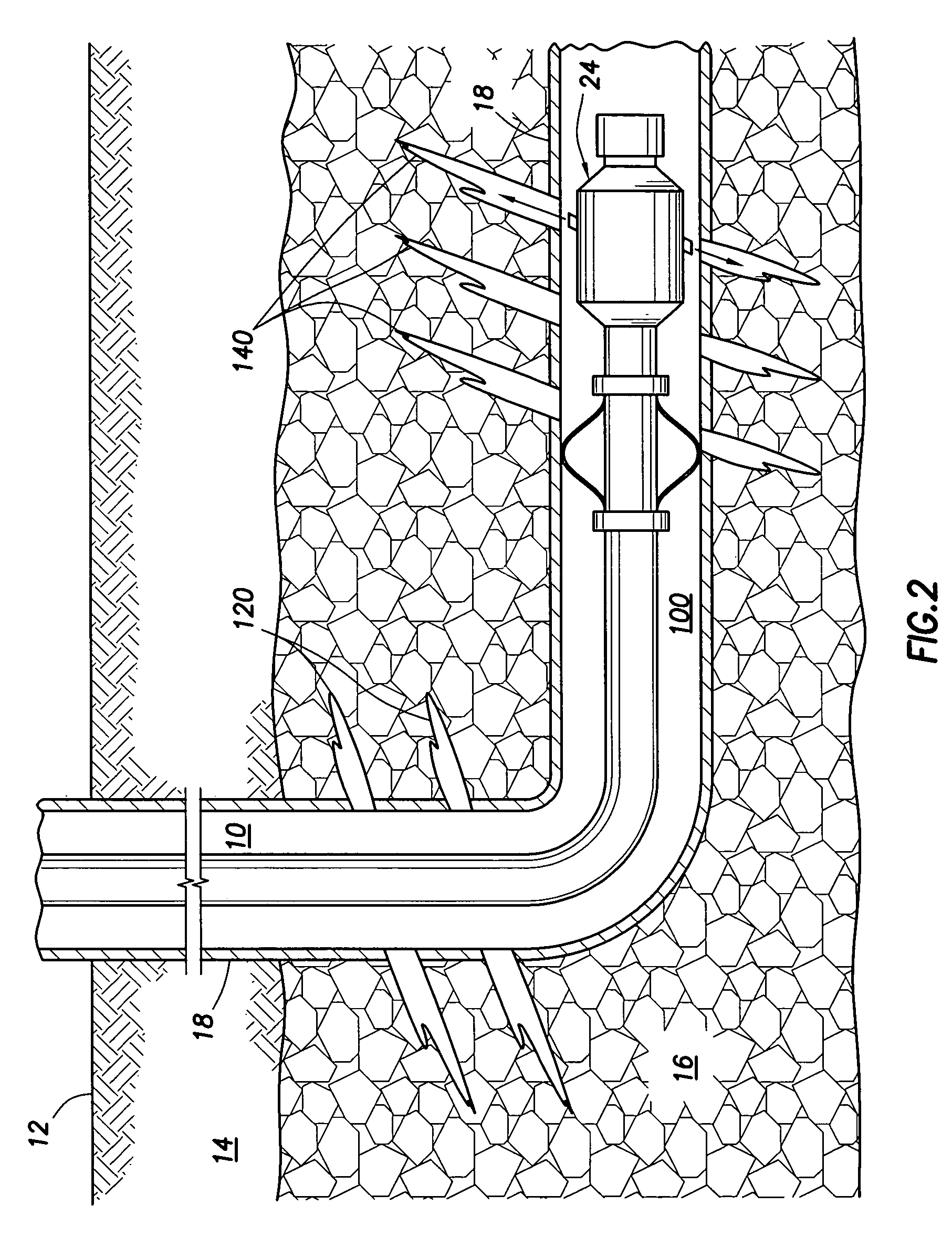

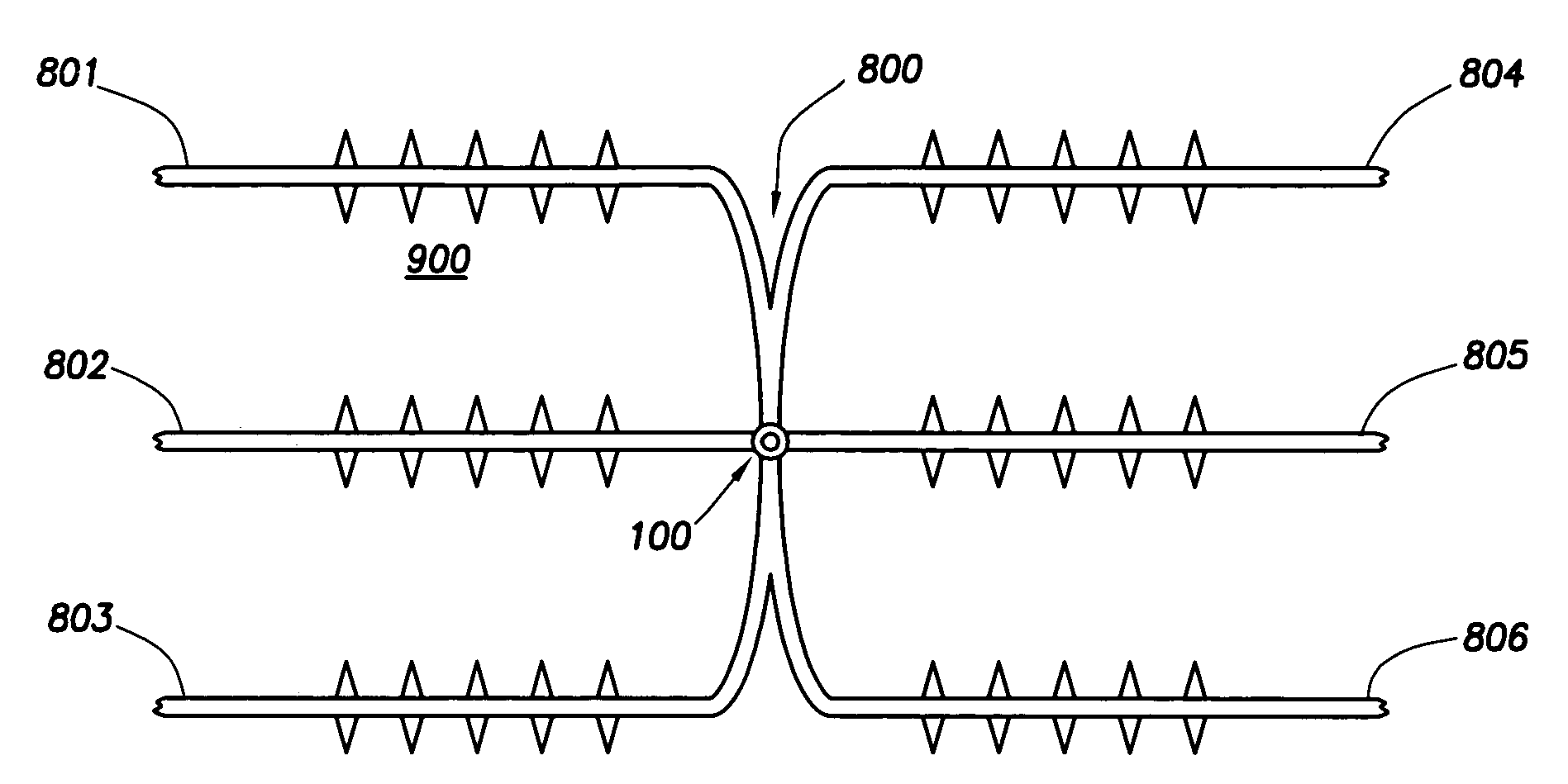

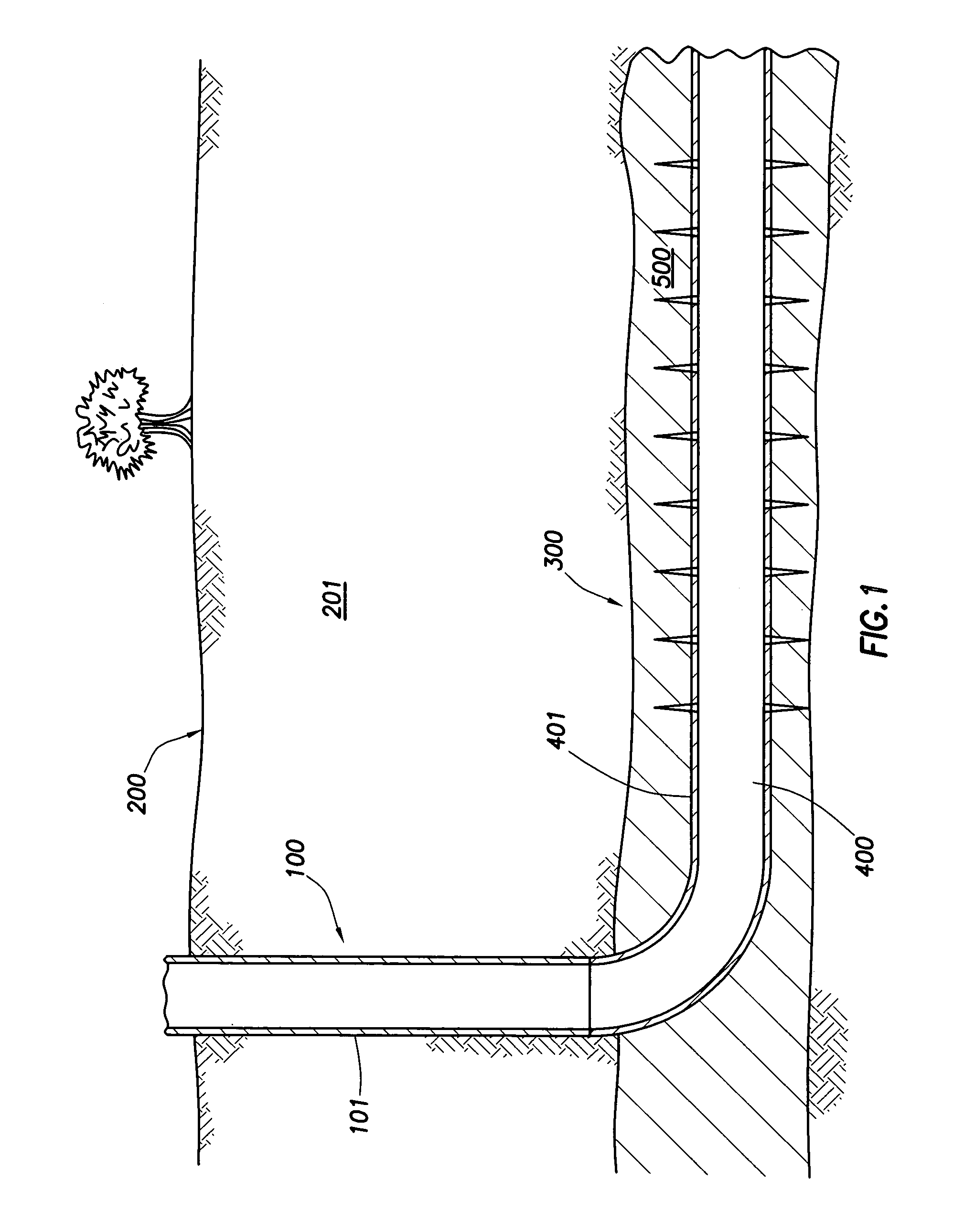

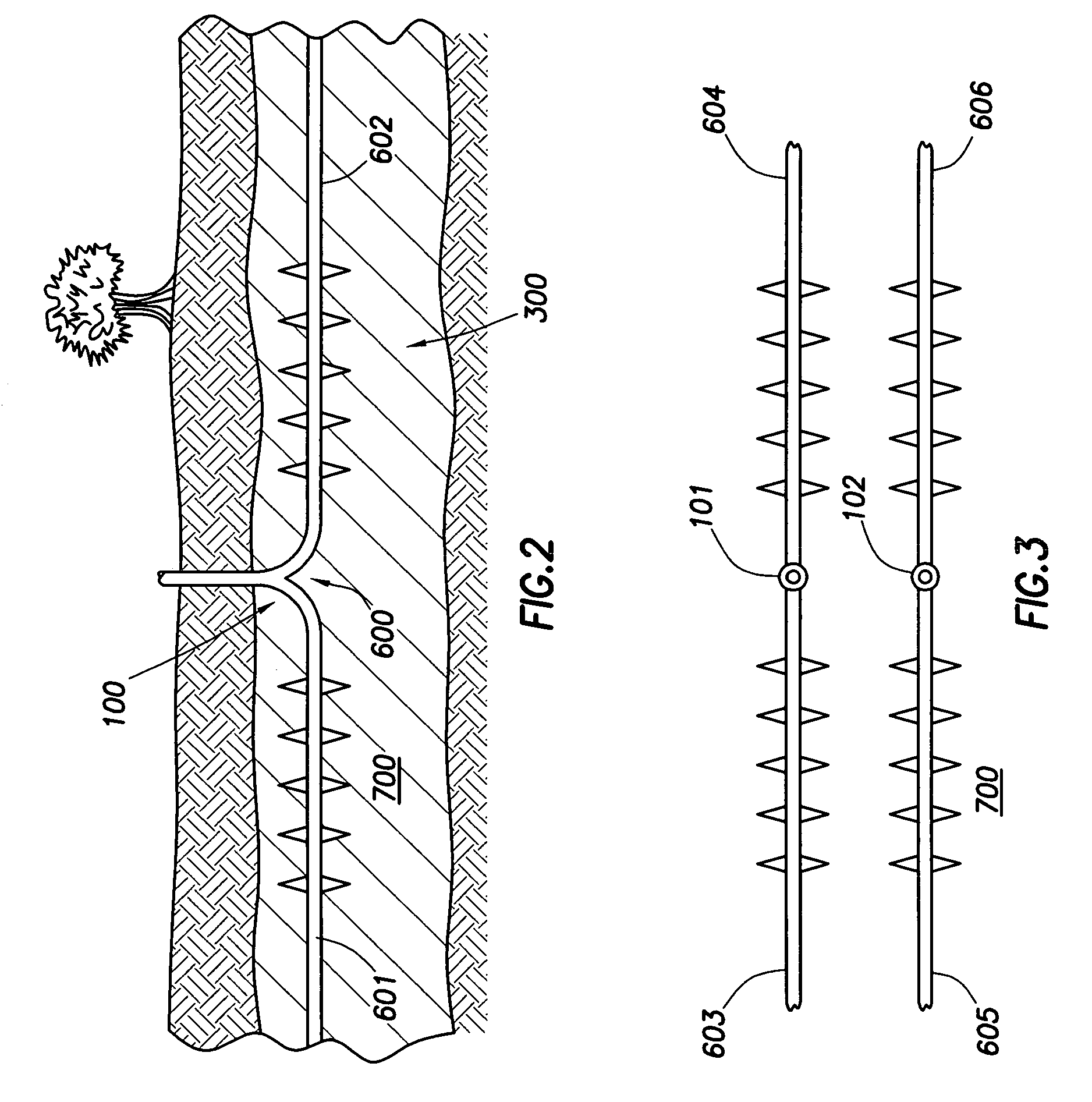

Method of optimizing production of gas from subterranean formations

InactiveUS20050121193A1Maximize interferenceIncrease gas productionArtificial islandsSurveyCoalWellbore

The present invention relates generally to subterranean well construction, and more particularly, to improved methods for producing gas from subterranean formations that include coal seams. The method according to the present invention includes the steps of drilling at least one substantially vertical well bore intersecting the coal seam, drilling at least one substantially horizontal well bore disposed substantially within the coal seam and exiting from the at least one substantially vertical well bore, and fracturing the coal seam along the at least one substantially horizontal well bore using a hydrajetting tool to produce a plurality of fractures. The plurality of fractures is spaced to maximize interference between the fractures and enhances the production of gas from the coal seam of the subterranean formation. A plurality of substantially horizontal well bores can also be drilled. The plurality of substantially horizontal well bores can be spaced to maximize interference between the substantially horizontal well bores.

Owner:HALLIBURTON ENERGY SERVICES INC

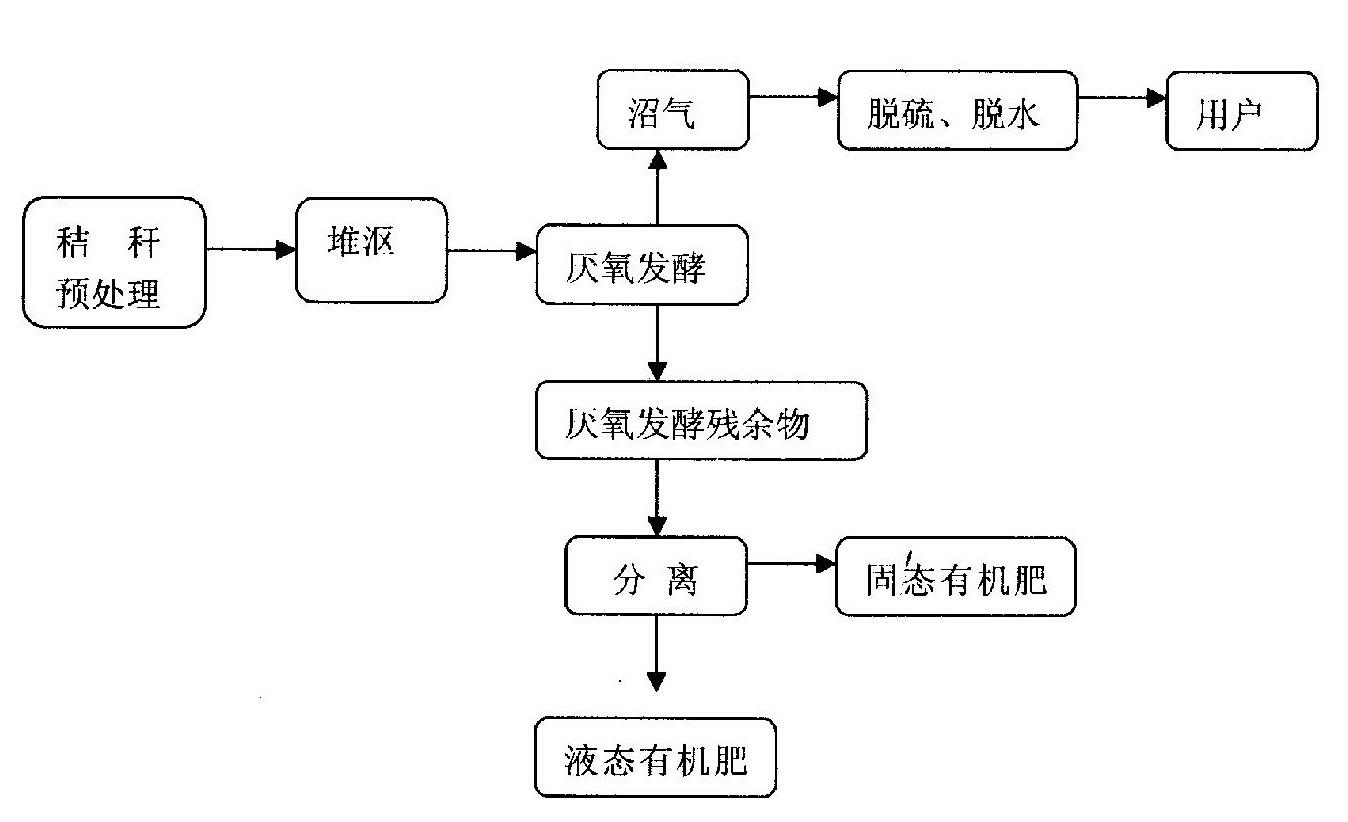

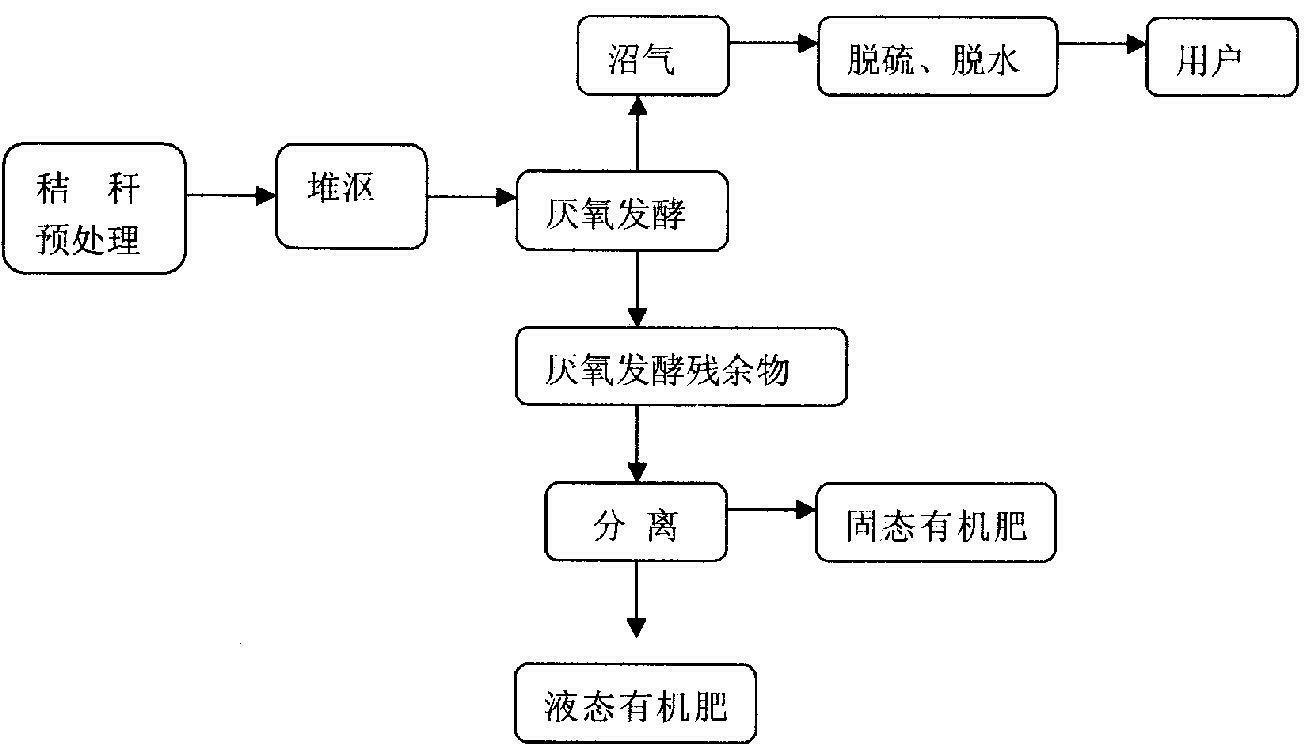

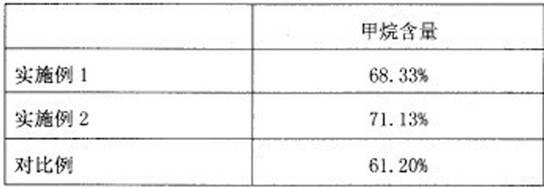

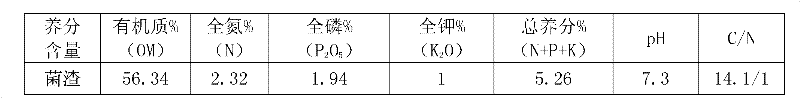

Method for manufacturing biogas and organic fertilizer by straw

InactiveCN102321677AFacilitate the use of anaerobic microorganismsImprove degradation rate and gas productionBio-organic fraction processingClimate change adaptationBiogasAgricultural crops

The invention relates to the technical field of renewable energy resources, and especially relates to a method for manufacturing biogas and organic fertilizer by straw. The invention comprises the following steps of: (1) straw pretreatment; (2) straw retting; (3) anaerobic fermentation; (4) utilization of fermentation products. The invention significantly increases the degradation rate and biogas yield of straw, stabilizes the pH value of the fermentation system by combining with the bactericide pretreatment, facilitates the normal proceeding of anaerobic fermentation, and thus increases the methane content in the biogas. The invention greatly saves cost, and has almost no sewage discharge; the utilization rate of renewable energy resources is increased; the biogas produced by crop straw anaerobic fermentation is treated by purification procedures of desulphurization and dehydration, and thus can be used as fuel for resident cooking or for power generation; on the other hand, residues produced by straw anaerobic fermentation are separated into biogas residues and biogas slurry which can be prepared into solid and liquid organic fertilizer, and the organic fertilizer is easy to be absorbed by crops, and can greatly increase the comprehensive utilization rate of straw resources.

Owner:雷震

Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

ActiveCN103967472AFor precise controlSolving the Difficulties of Directional DrillingFluid removalSoil scienceDrill

The invention relates to a horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing. In order to solve the problems that hole forming performance of horizontal drilling in a coal bed is poor and buried drill accidents can happen easily and to achieve the forced gas drainage effect on tectonic soft coal, the well track of a horizontal well is controlled in mudstone or sand stone with a certain range above a coal bed top boundary, and the horizontal well is docked with a drainage vertical well at a far end. An ultra deep penetration perforating technology is used, according to the requirement for certain hole density and orientation, orientated perforating is conducted downwards on the horizontal well section in a segmented mode, a steel sleeve, a well cementation cement ring and a mudstone top plate are penetrated, and the horizontal well is communicated with a target coal layer below. Then, a clear water sand carrying fracturing technology is used, staged fracturing is conducted on the target coal bed according to the requirements for large discharge capacity, large liquid amount, high prepad fluid ratio, large sand amount and middle sand ratio, and the purpose of increasing production is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method of optimizing production of gas from subterranean formations

The present invention relates generally to subterranean well construction, and more particularly, to improved methods for producing gas from subterranean formations that include coal seams. The method according to the present invention includes the steps of drilling at least one substantially vertical well bore intersecting the coal seam, drilling at least one substantially horizontal well bore disposed substantially within the coal seam and exiting from the at least one substantially vertical well bore, and fracturing the coal seam along the at least one substantially horizontal well bore using a hydrajetting tool to produce a plurality of fractures. The plurality of fractures is spaced to maximize interference between the fractures and enhances the production of gas from the coal seam of the subterranean formation. A plurality of substantially horizontal well bores can also be drilled. The plurality of substantially horizontal well bores can be spaced to maximize interference between the substantially horizontal well bores.

Owner:HALLIBURTON ENERGY SERVICES INC

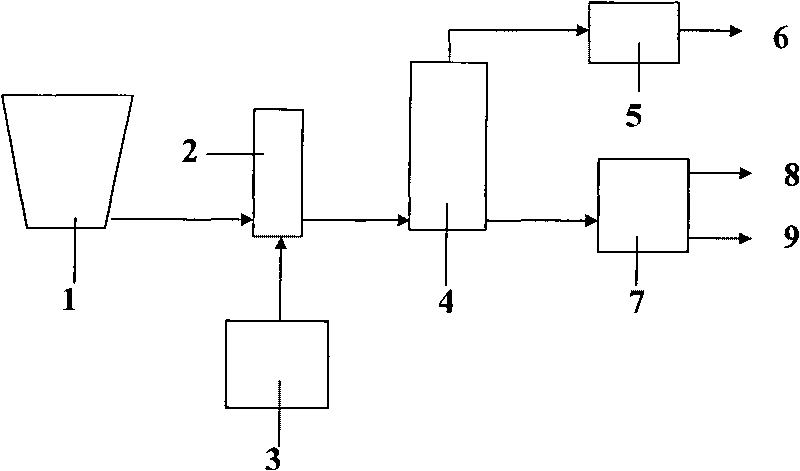

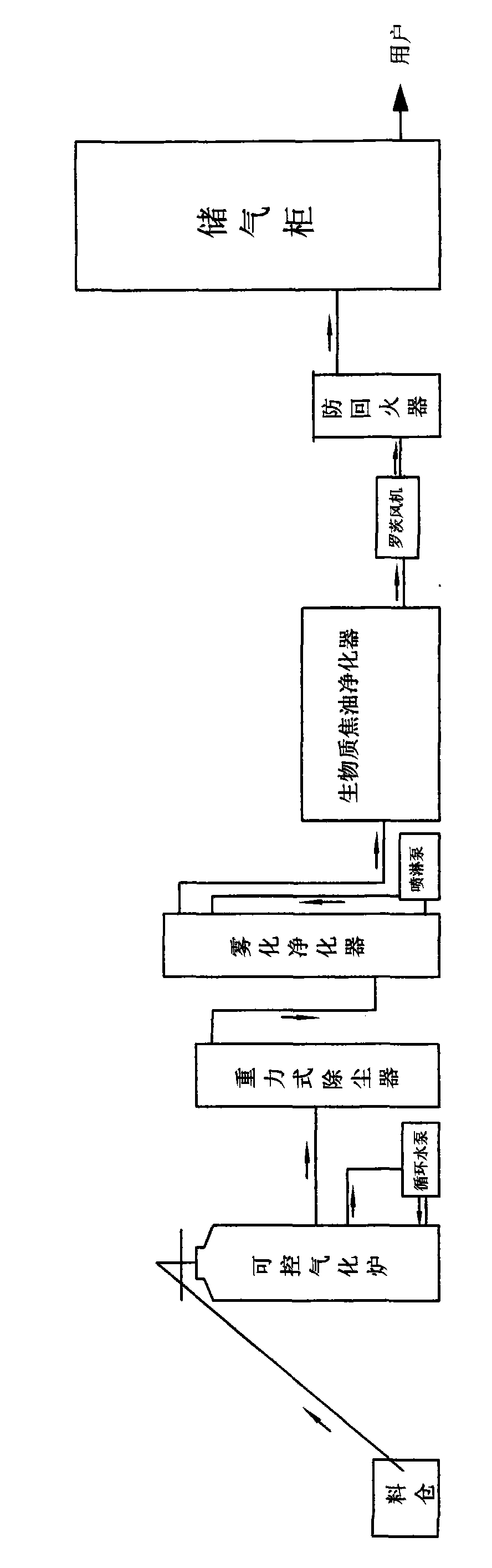

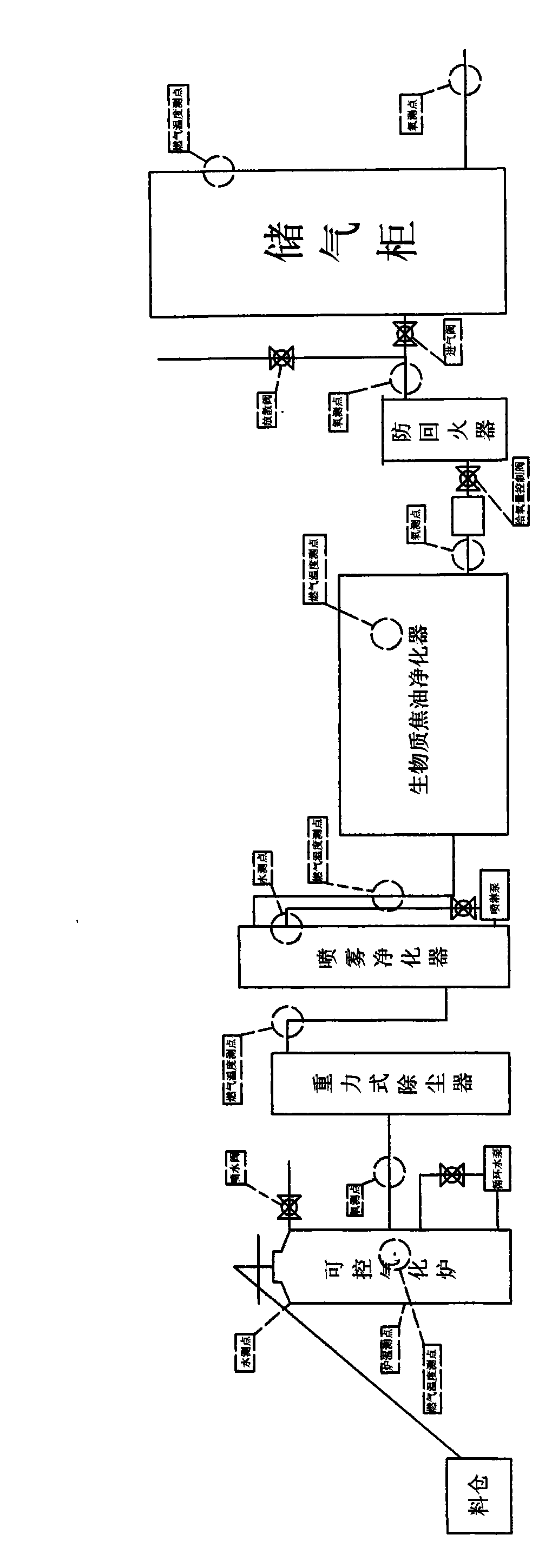

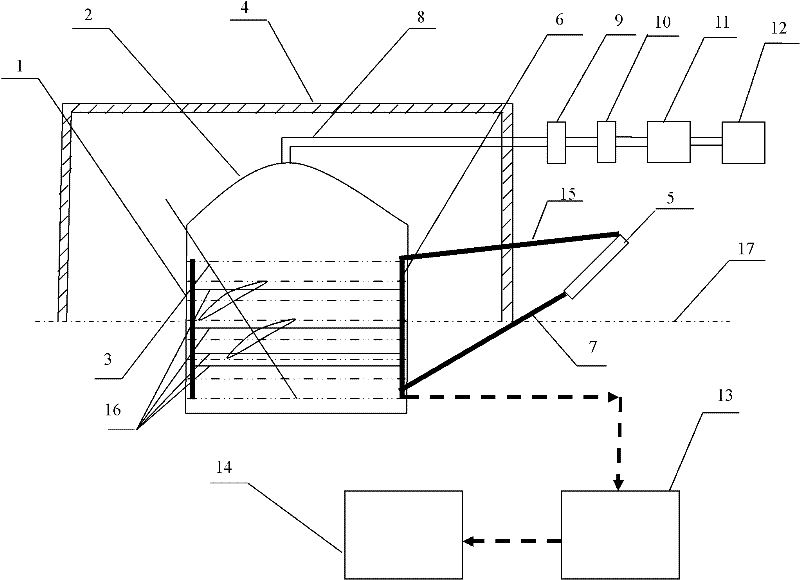

Method for preparing fuel gas by gasifying biomass materials and device thereof

InactiveCN101649226AReduce cloggingSolve the blockageCombined combustion mitigationCombustible gas productionTarProcess engineering

The invention relates to a method for preparing fuel gas by gasifying biomass materials and a device thereof, belonging to the technical fields of methods for preparing fuel gas by solid biomass materials in a gasifying process and the devices thereof. The method comprises the following steps: feeding, gasifying, dedusting, spraying and purifying, detarring, pumping front-end gases and conveying rear-end fuel gas by a Roots blower, and conveying the fuel gas to a fuel gas storage cabinet through a tempering preventing device. The device realizing the method comprises a feeding mechanism, a controllable gasifying furnace and a circulation water pump, a gravity deduster, a spraying purifier and a spraying pump, a biomass tar purifier, the Roots blower, the tempering preventing device and thefuel gas storage cabinet. The device is used for transforming the solid biomass materials of straws and the like into the fuel gas with less impurities and high heat value and supplying the fuel gasfor users centrally.

Owner:ZHENYU COMPLETE SET ELECTRIC EQUIP GROUP BEIJING

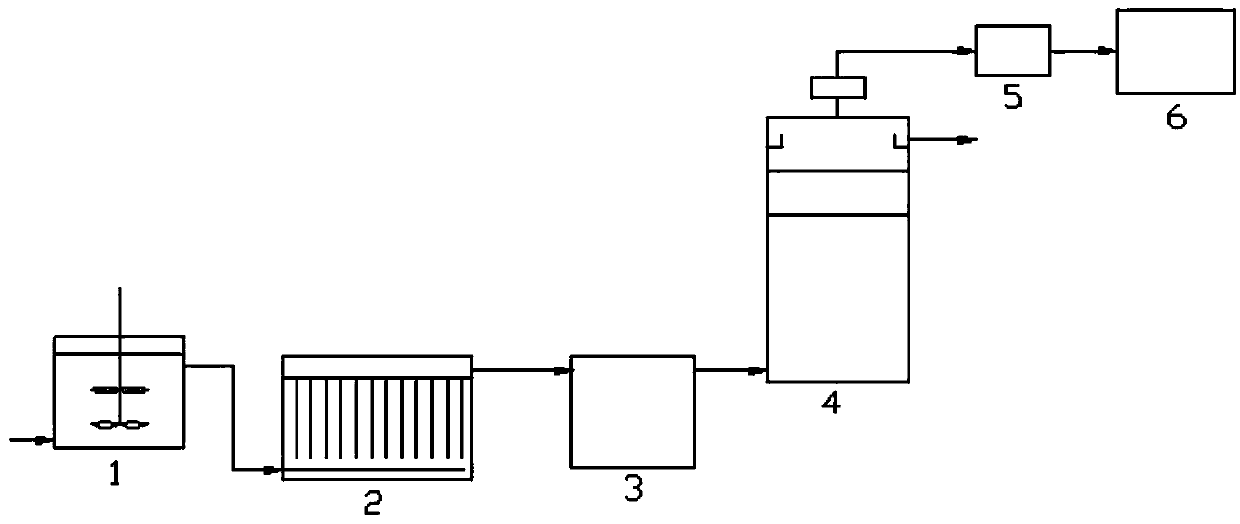

Method and device for recycling edible mushroom residues

ActiveCN102174586AImprove filtration efficiencyIncrease gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsRed mudNew energy

The invention relates to a method and device for recycling edible mushroom residues. The method mainly comprises the steps of placing waste mushroom residues and maize straws or excrements from a cattle farm into an anaerobic reactor for united fermentation to produce biogas, and covering a red-mud plastic head cover on the anaerobic reactor, wherein an inclined stirrer is arranged and is beneficial to feeding / discharging of mushroom residue raw materials and avoidance of crusting. The produced biogas is used for power generation and agriculture, biogas residues are used for manufacturing organic fertilizers, biogas slurry is prepared into foliar fertilizer for fruits or vegetables, and thus, new energy sources, namely the biogas and the organic fertilizers, are obtained while the mushroom residues are treated. The method and the device in the invention are mainly used in major edible mushroom producing areas, a solar-panel greenhouse and a solar heat supply device are assorted for the device, a composite microbial inoculum is assorted for the method, and the anaerobic reactor can be normally used all the year round.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

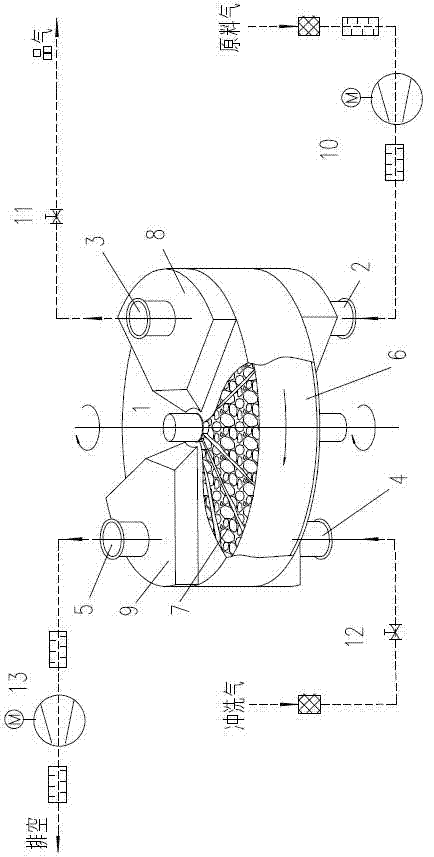

Rotor type pressure swing adsorption gas separation device

InactiveCN102755810AReduce dosageLess investmentGas treatmentOxygen/ozone/oxide/hydroxideSorbentDesorption

The invention discloses a rotor type pressure swing adsorption gas separation device, wherein a rotor is arranged in a shell; an adsorption region and a desorption region are divided according to formed different pressures; the rotor comprises a disc with a plurality of empty grids which is formed by a plurality of partition plates; the empty grids are filled with an adsorbent and are sealed by using porous plates or nets at the two ends in the axial direction; during work, the rotor rotates, an adsorbent is driven to continuously move and circulate at the adsorption region and the desorption region; feed gas and / or flushing gas regionally pass (passes) through the adsorbent layer in direction crossed with the adsorbent movement direction, so that the feed gas is continuously separated and purified at the adsorption region; and saturated adsorbent is continuously decompressed or / and flushed and regenerated at the desorption region, so that product gas is continuously and stably produced. The rotor type pressure swing adsorption gas separation device has the advantages of overcoming the defect of frequent switching of an adsorption tower existing in the conventional pressure swing adsorption gas separation device, low energy consumption, high yield, easiness in running and operation, small land occupation and small using amount of the adsorbent, is extremely suitable for the fields of oxygen enriched combustion, oxygen enriched and pure oxygen application of industrial kilns and can also be used for separation and purification industries of other gases.

Owner:南京圣火环境科技有限公司

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

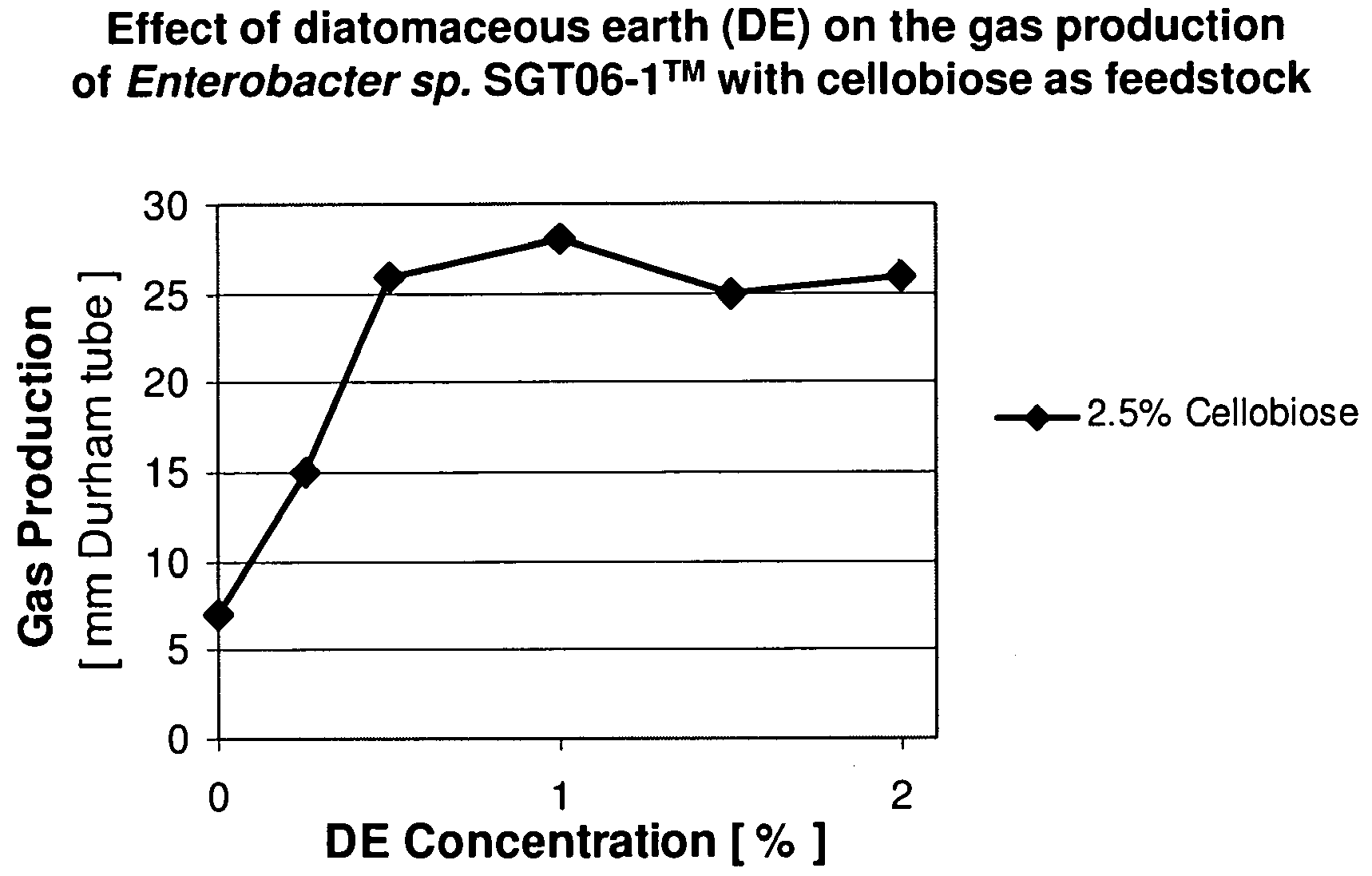

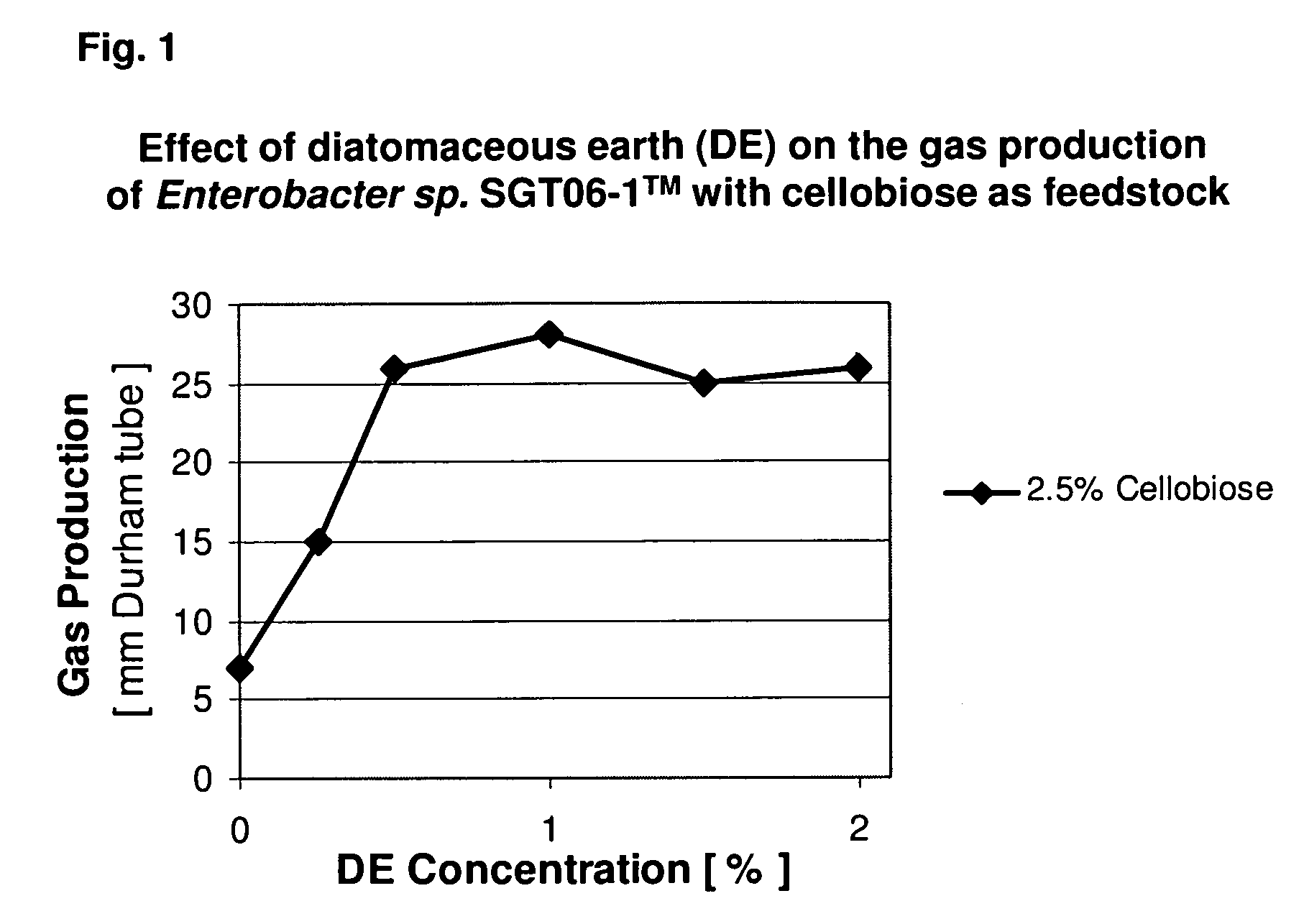

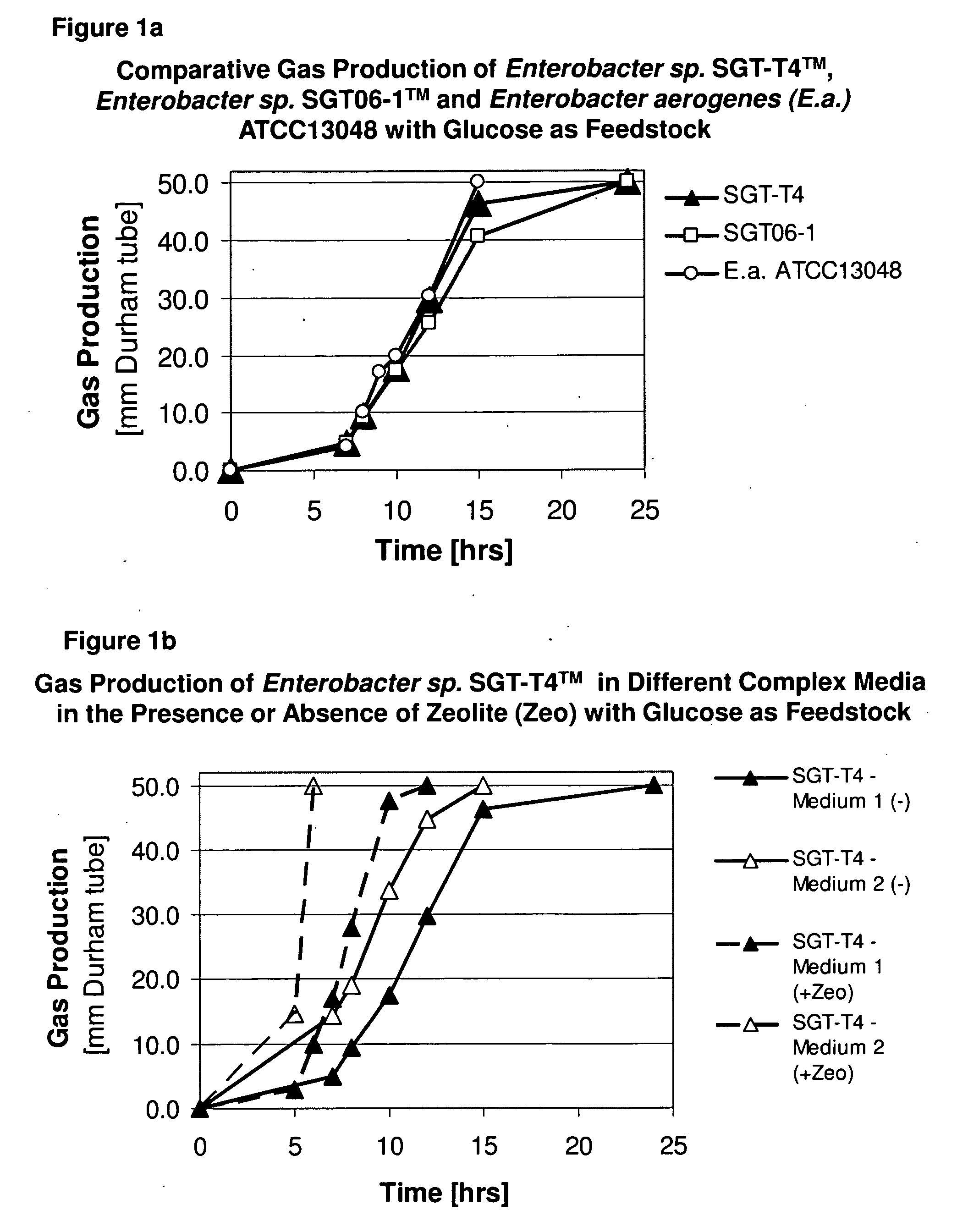

Microorganisms and methods for increased hydrogen production using diverse carbonaceous feedstock and highly absorptive materials

The disclosed invention relates to an isolated hydrogen gas producing microorganism, termed Enterobacter sp. SGT-T4™ and derivatives thereof. Compositions and methods comprising the disclosed microorganisms are also provided. The disclosed invention also relates to a method to increase the hydrogen production rate and yield of hydrogen gas producing microorganism in the presence of diatomaceous earth and other absorptive materials. Further, the disclosure relates to the production of high microalgal biomass and microalgal oils suitable for economical industrial scale bio-diesel production from processed bacterial fermentation wastes as feedstock using the green microalga Chlorella protothecoides.

Owner:SUSTAINABLE GREEN TECH

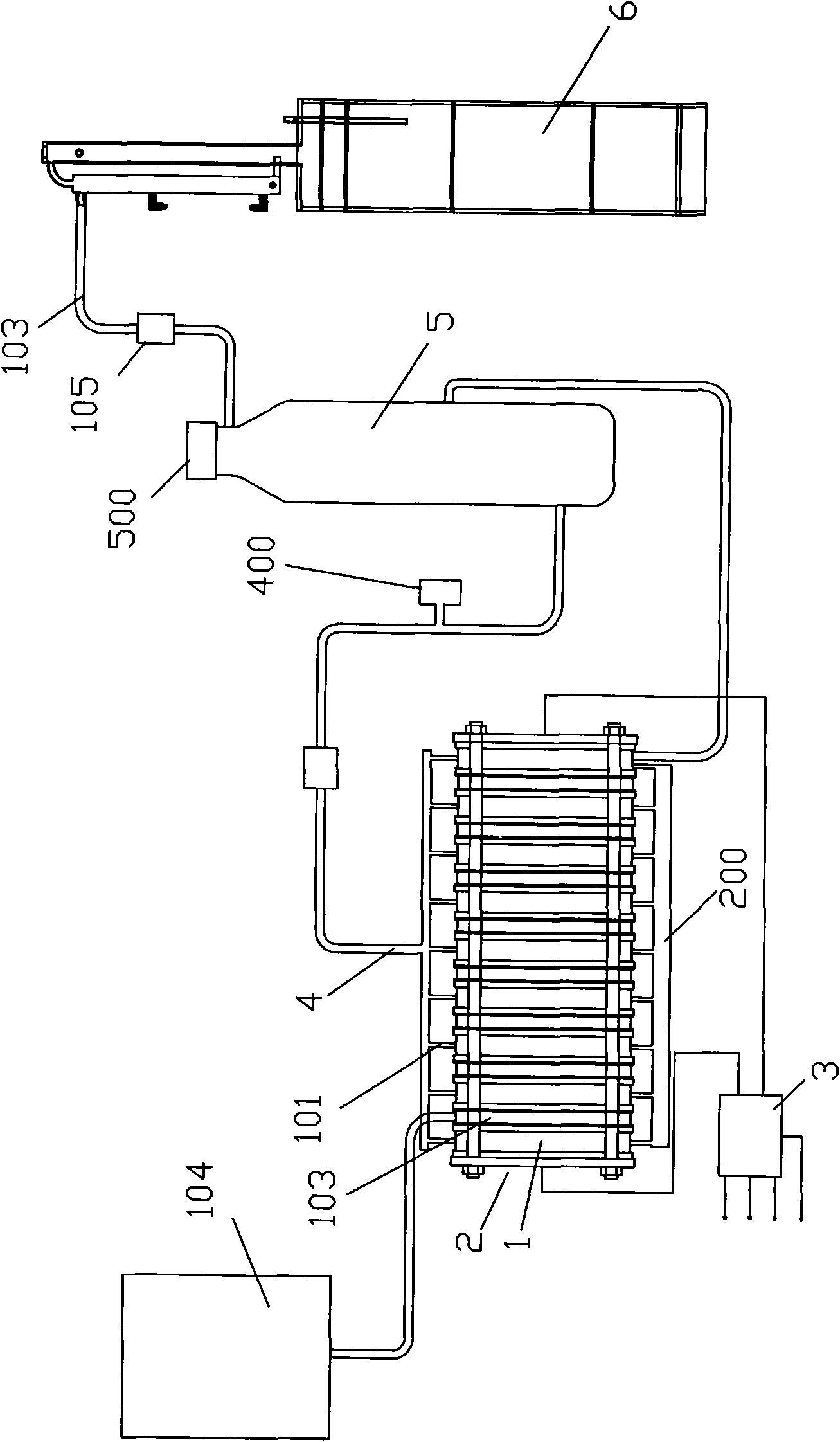

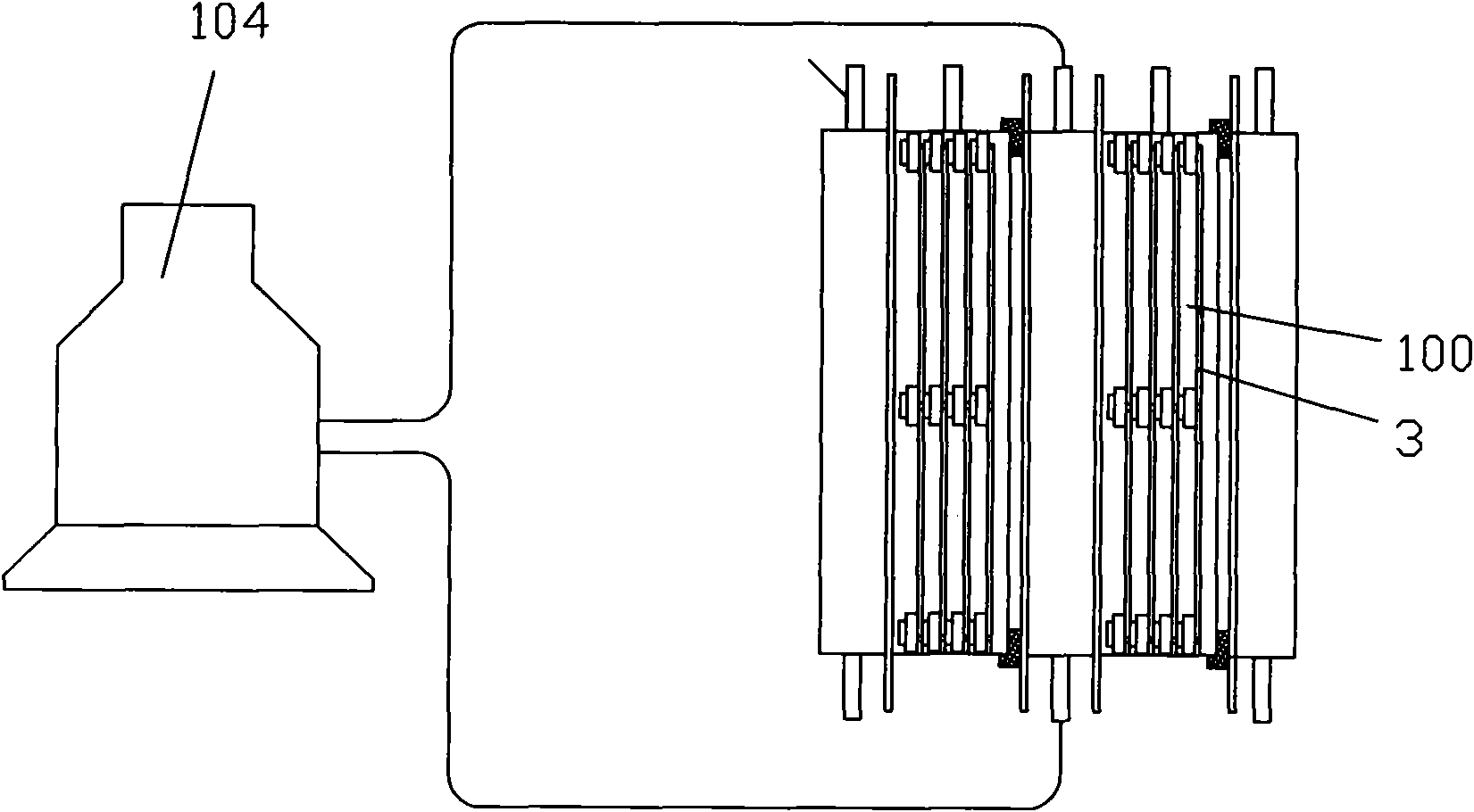

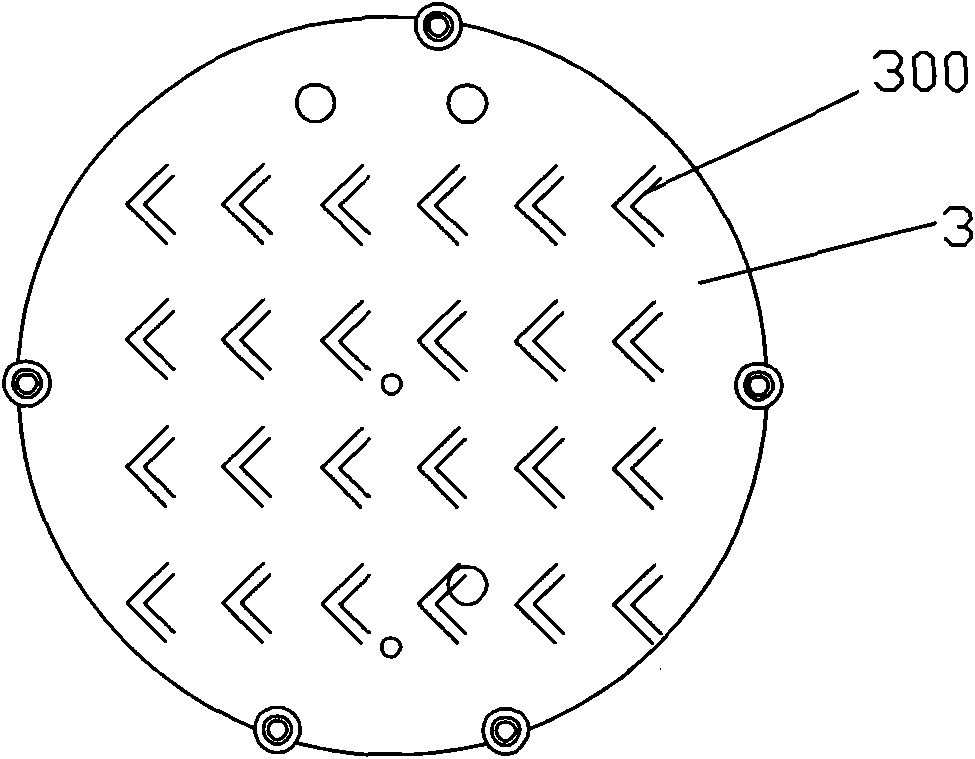

Hydrogen-oxygen mixed gas generator

The present invention discloses a hydrogen-oxygen mixed gas generator, including electrolytic tank combined by a plurality of electrolytic chambers connecting in series, the electrolytic chamber is cut into a plurality of small electrolytic chambers by a plurality of polar plates, on which is provided with rhombic concave-convex groove; positive and negative polar plate of the electrolytic tank is connected with corresponding electrode of the electrolysing power supply; top of the electrolytic chamber is arranged with vent-pipe which connecting to gas busbar, air-out end of the gas busbar is connected with built-in water block, which is connected with external water block via airway; external side of the electrolytic chamber is arranged with cooling cycle apparatus. Employing multi-chamber electrolysis can make full use of electric energy efficiency, and heating dissipating impression of the water-cooling circulating device set outside the electrolytic tank is obvious, improving quality of hydrogen-oxygen mixture, assuring stabilization of working level, assuring use impression of long time machine opening. The electrolytic tank of entrails uses easily broken bubbles, and electrode plate of concave-convex rough groovy for increasing electrolysis effective area, large gas production.

Owner:广州中氢能源科技有限公司

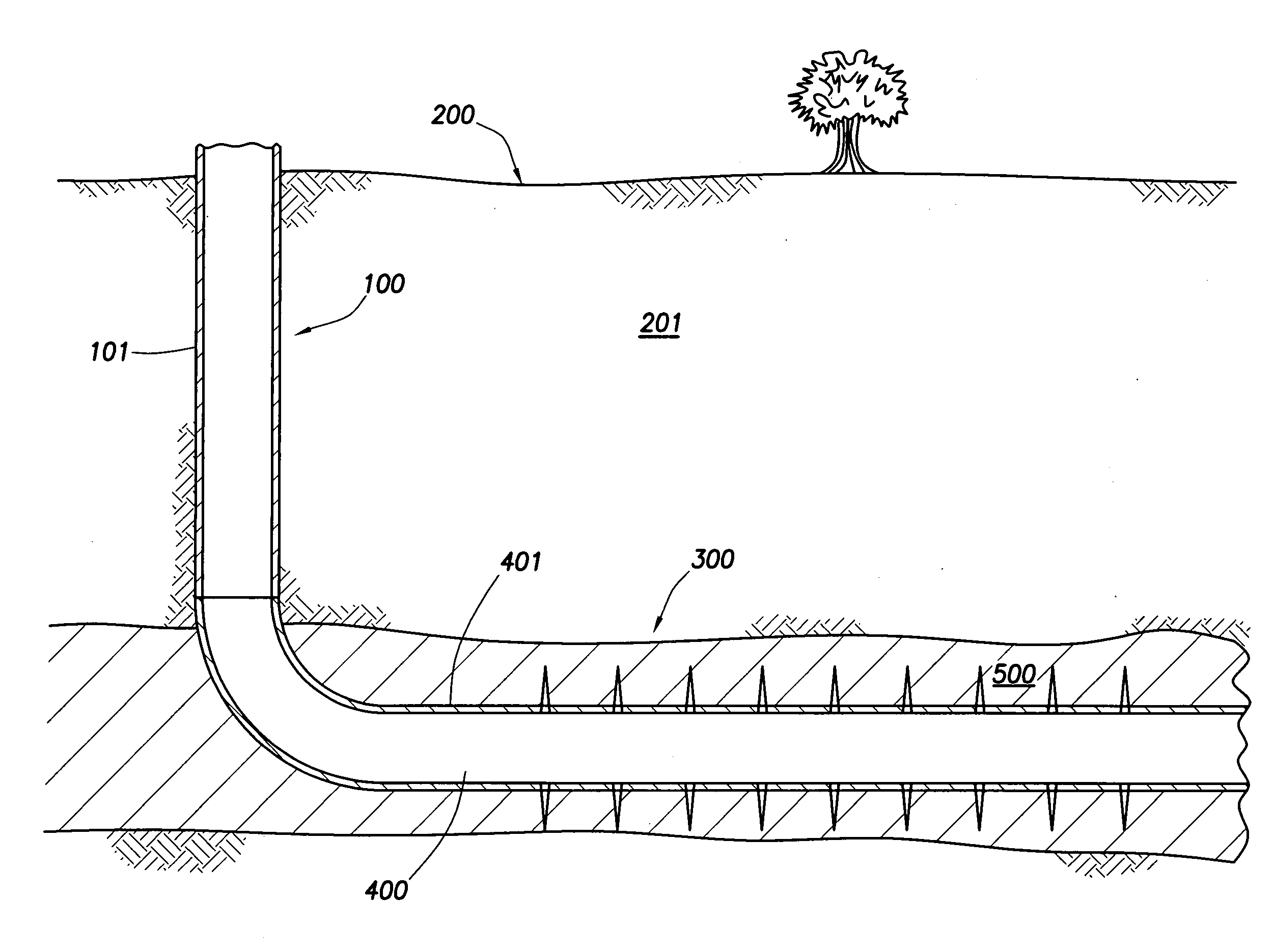

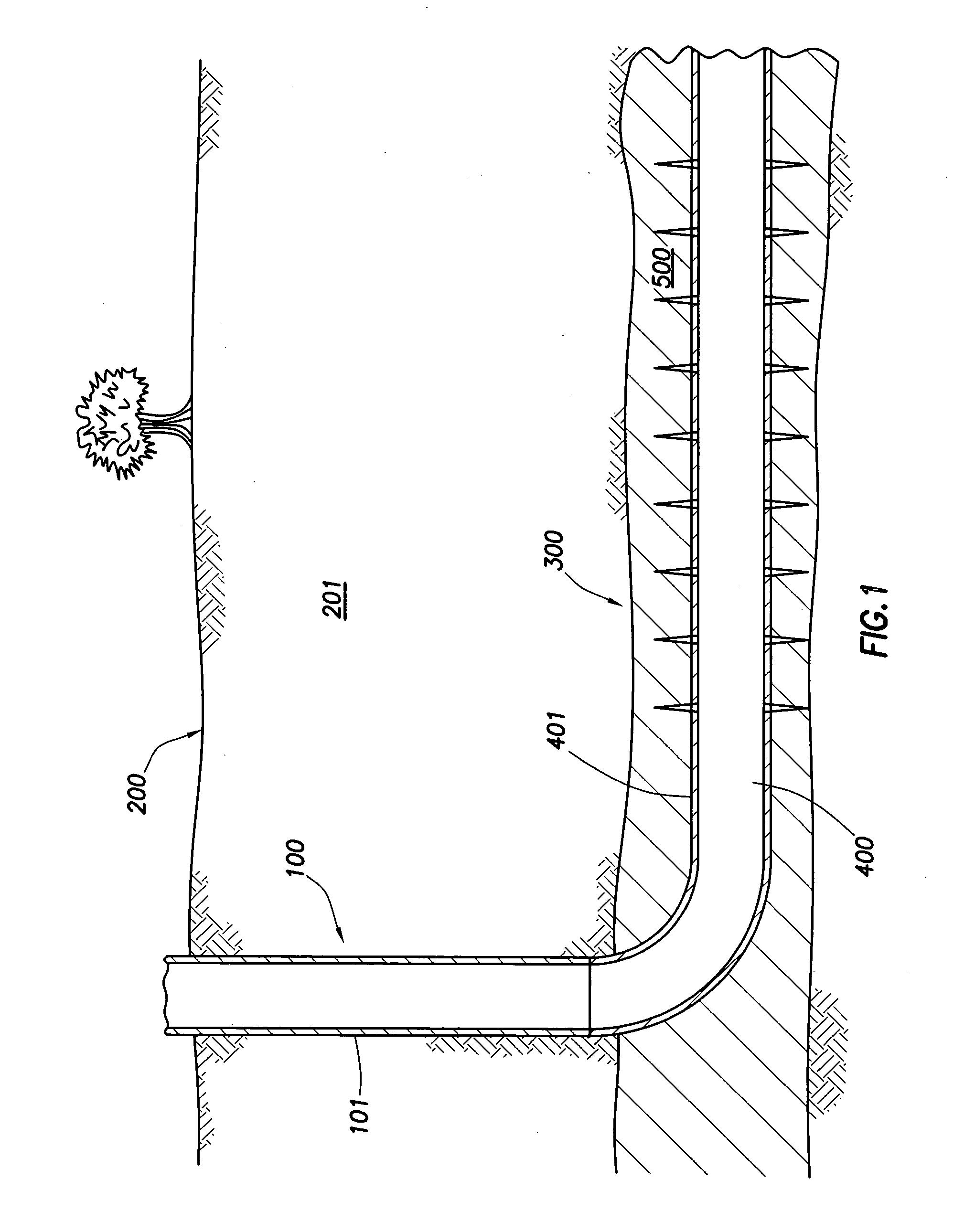

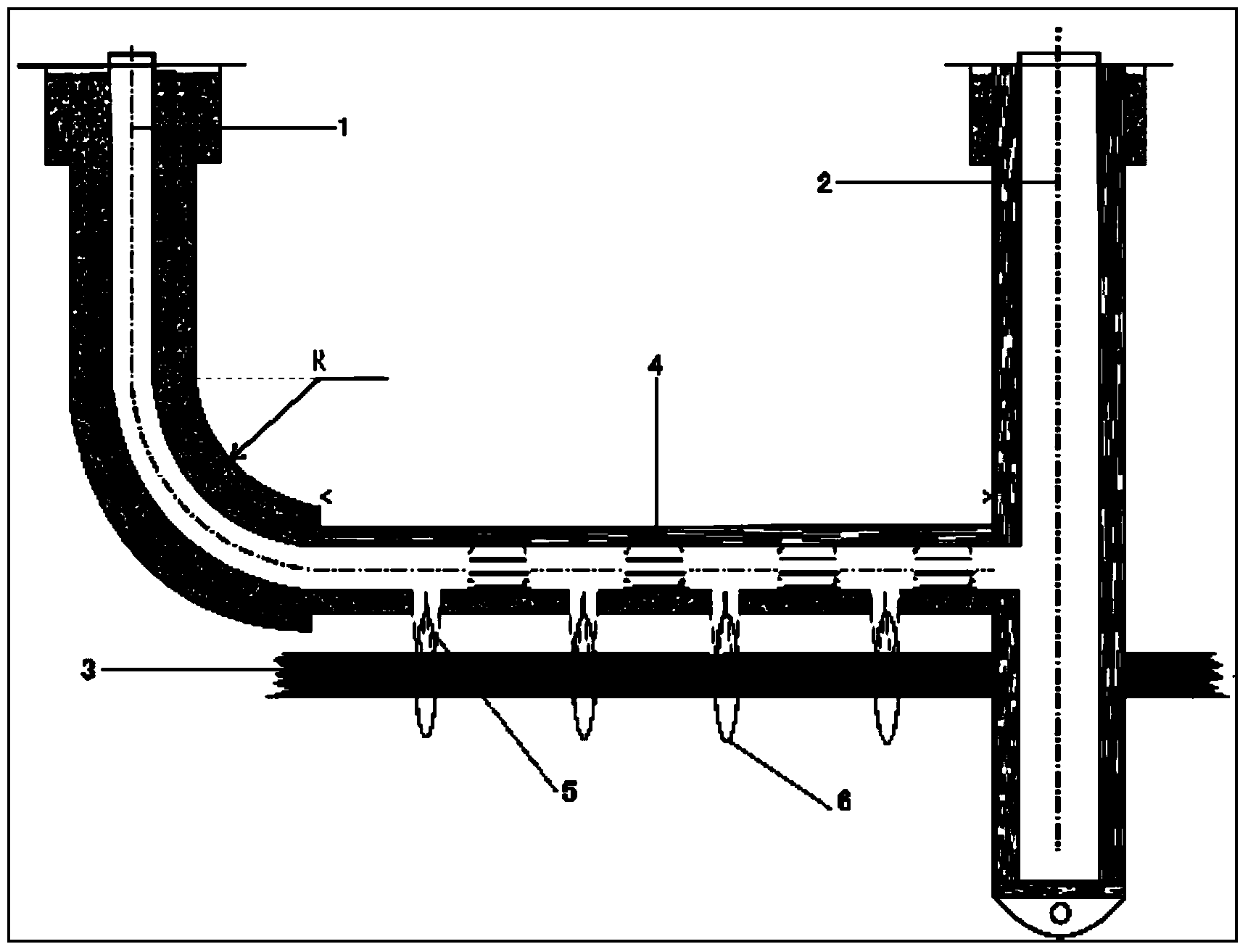

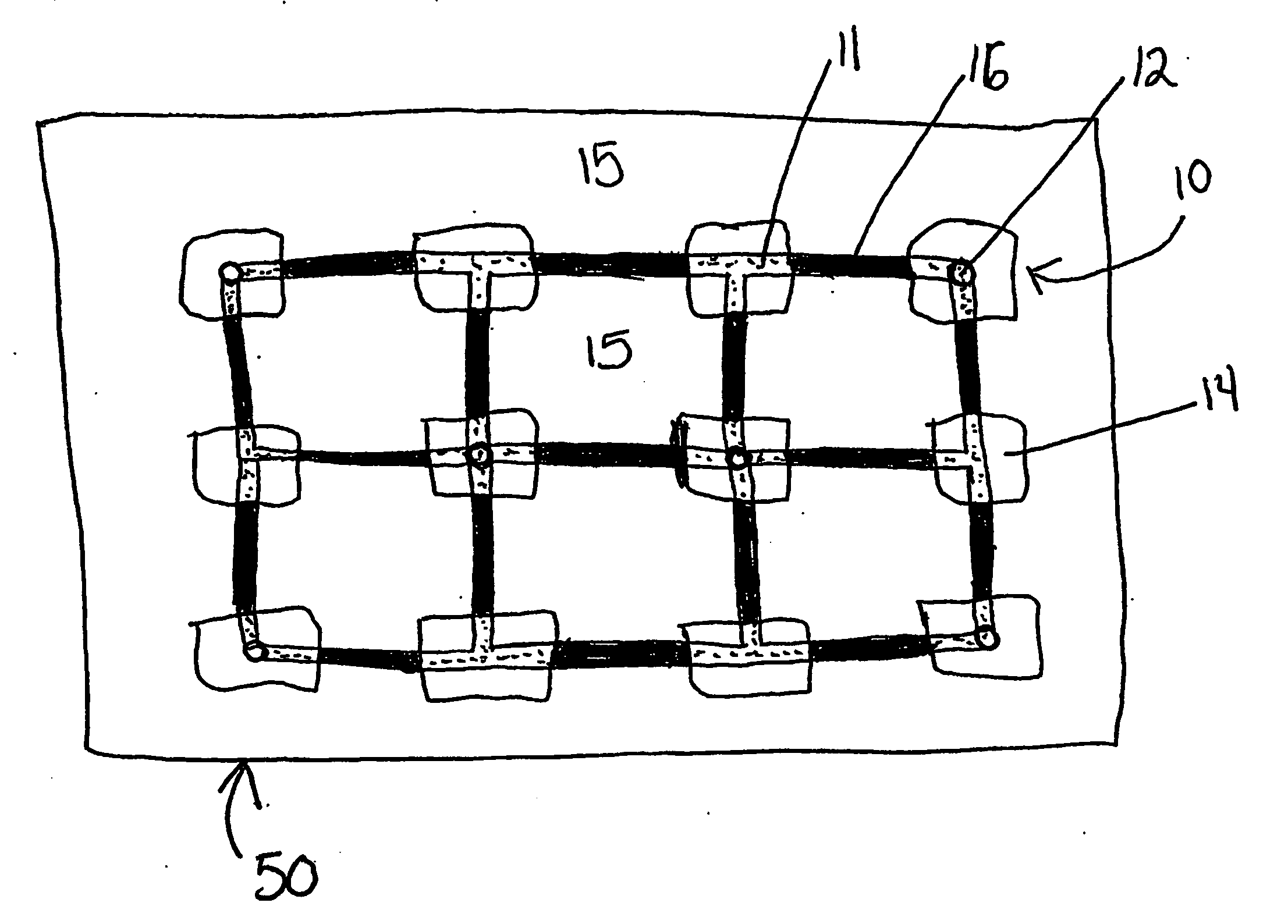

Aerobic and anaerobic waste management systems and methods for landfills

ActiveUS20060222464A1Promote degradationFast settlementSolid waste disposalContaminated soil reclamationDisposal wasteEnvironmental engineering

The invention provides systems and methods for creating, managing and staging aerobic and / or anaerobic landfills. The invention provides systems and methods for collecting liquids from and recirculating liquids into landfills and systems and methods for collecting gases from and introducing gases into landfills. The invention also provides a novel conduit for conveying liquids and gases which comprises a first pipe coaxially disposed within a second pipe.

Owner:CASELLA WASTE SYSTEMS

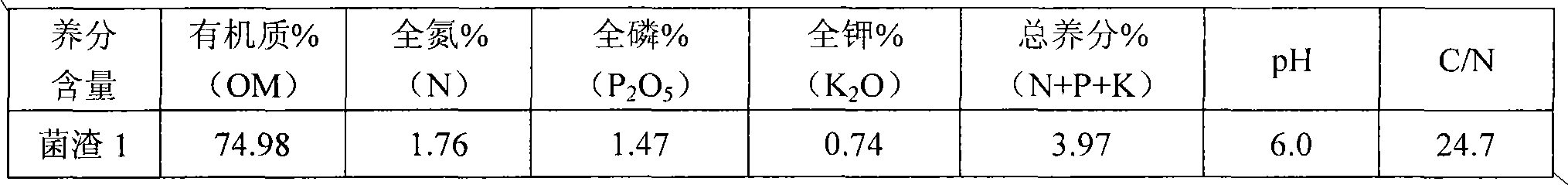

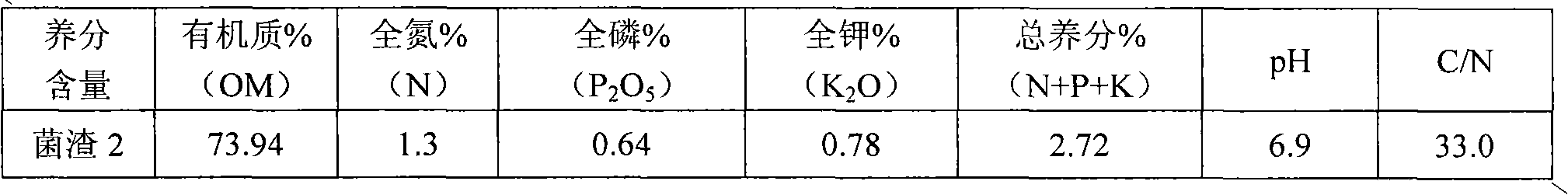

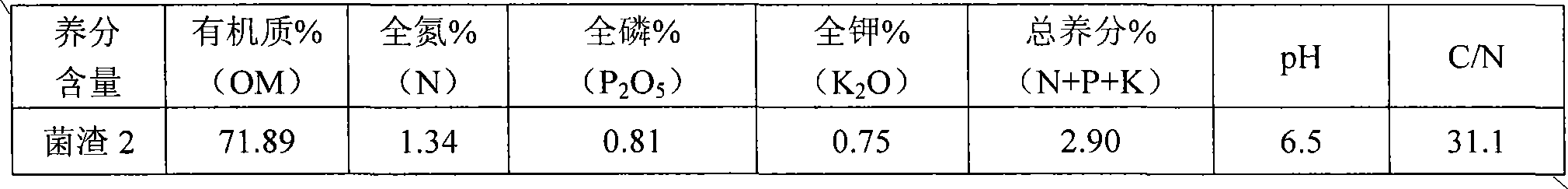

Method for producing marsh gas by utilizing corn cob fungi slag as raw material through anaerobic fermentation

InactiveCN102153261AIncrease profitSolve the problem of random discarding and polluting the environmentBio-organic fraction processingWaste based fuelBiotechnologySlag

The invention discloses a method for producing marsh gas by utilizing corn cob fungi slag as a raw material through anaerobic fermentation. The method comprises the following steps: mixing the fungi slag wasted after corn cob is used as a main raw material to cultivate edible fungus with pig manure or cow dung, adding a methane reagent, and carrying out pile fermentation; and putting fermentationraw materials in a household methane-generating pit or an anaerobic reactor, wherein the addition amount of the raw materials is 80-130 kg per cubic meter of pit volume. In the invention, generation of methane via anerobic fermentation is achieved by carrying out reasonable proportioning, pretreatment, pile outside the pit, fermentation starting and the like on the fermentation raw materials, thereby effectively solving the problem that the pollution is caused by discarding the fungi slag at random and simultaneously turning waste into wealth. After the method is utilized, the gas can be normally generated by the fungi slag in the household, and the method is simple with no need of special equipment and can be applied and disseminated in edible fungus cultivating households.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Treatment method of antibiotic fermenting bacterial residues

ActiveCN104212840ATake advantage ofReduce pollutionMicroorganism based processesFermentationResource utilizationSmall footprint

The invention discloses a treatment method of antibiotic fermenting bacterial residues. The treatment method comprises the following steps: uniformly mixing the fermenting bacterial residues of lincomycin hydrochloride and gentamicin with water, and preparing a suspension; performing anaerobic fermentation treatment on the suspension. The treatment method is an efficient fermentation treatment process of the fermenting bacterial residues of lincomycin hydrochloride and gentamicin and belongs to the technical field of resource utilization of the bacterial residues. By adopting the method disclosed by the invention, the toxicity, the harm and an inhibition effect of residual antibiotics to fermenting bacteria in an anaerobic fermentation process of the traditional antibiotic bacterial residues are overcome, the problems of blockage, short flow and the like which are produced when a traditional filler is fed are simultaneously avoided, the biomass of a hydrolysis acidification pool and an L-fermentation tank is ensured, the gas production is improved and the method further has the advantages of low treatment cost, easiness in control of operation process, high load of a reactor matched with the method, small occupied area and the like.

Owner:ZHENGZHOU UNIV

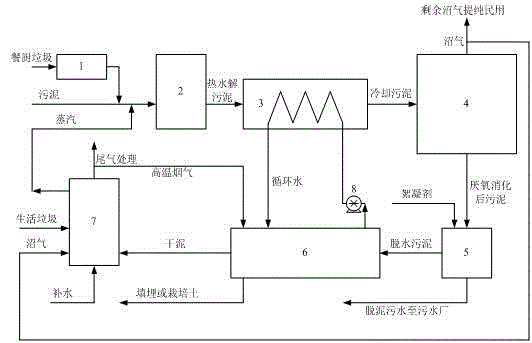

Energy-saving recycling treatment disposal system and energy-saving recycling treatment disposal process for organic solid waste

InactiveCN104944732AImproved anaerobic biodegradabilityImprove the efficiency of anaerobic digestionSludge treatment by de-watering/drying/thickeningSolid waste disposalExternal energyWaste treatment

The invention relates to an energy-saving recycling treatment disposal system and an energy-saving recycling treatment disposal process for an organic solid waste. The energy-saving recycling treatment disposal process mainly comprises a continuous sludge pyrohydrolysis anaerobic digestion section, a sludge dehydration heat drying section and a dry sludge, domestic garbage and biogas mixing incineration section. Due to the energy-saving recycling treatment disposal system and process disclosed by the invention, the innocent treatment of kitchen garbage, municipal sludge and the domestic garbage can be thoroughly realized by combining a high-temperature sludge anaerobic digestion technology with the high-organic matter characteristic of the kitchen garbage by utilizing respective characteristics of three solid wastes, applying a solid waste high-temperature incineration technology of mixed biogas, adopting a reasonable energy resource integrated means and applying an advanced high-temperature continuous pyrohydrolysis pretreatment technology. In addition, the energy-saving recycling treatment disposal process disclosed by the invention can also be used for realizing the recycling of the three solid wastes, improving the energy resource utilization efficiency of an integrated system, effectively reducing the input of external energy resources and reducing the operation cost. The energy-saving recycling treatment disposal process disclosed by the invention is capable of realizing the continuous operation of solid waste treatment, simple and reliable, simple in equipment, small in initial investment and has good environmental and economic benefits.

Owner:TONGJI UNIV

High sulfur natural gas purifying process modeling and optimizing method based on extreme learning machine

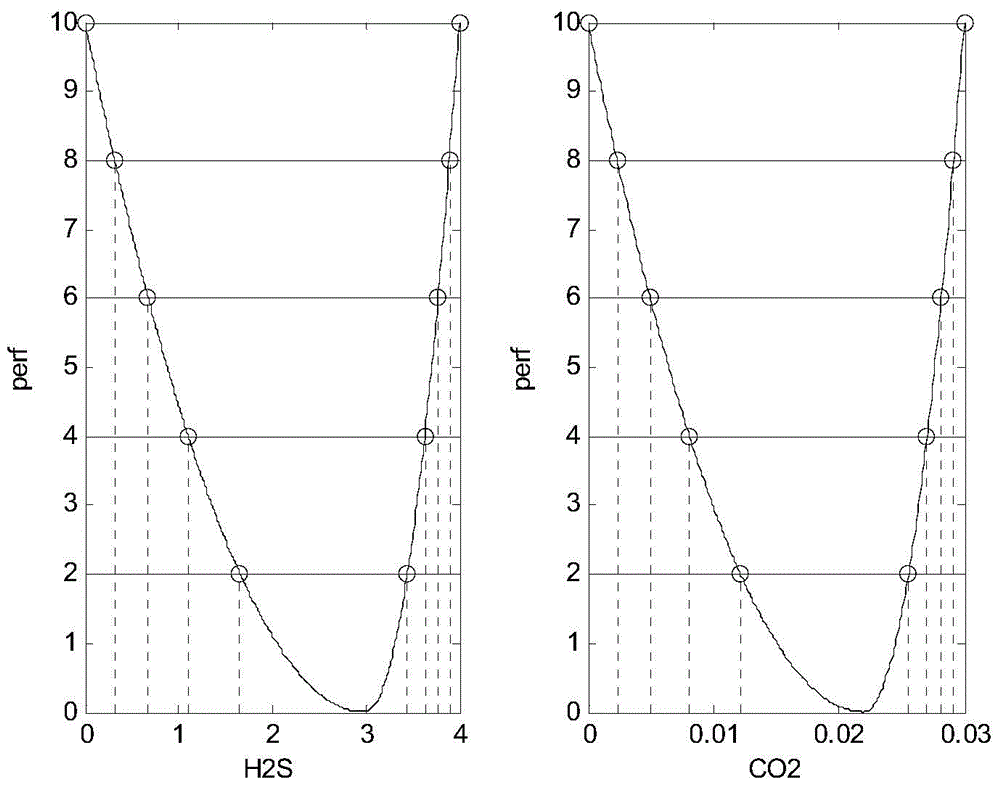

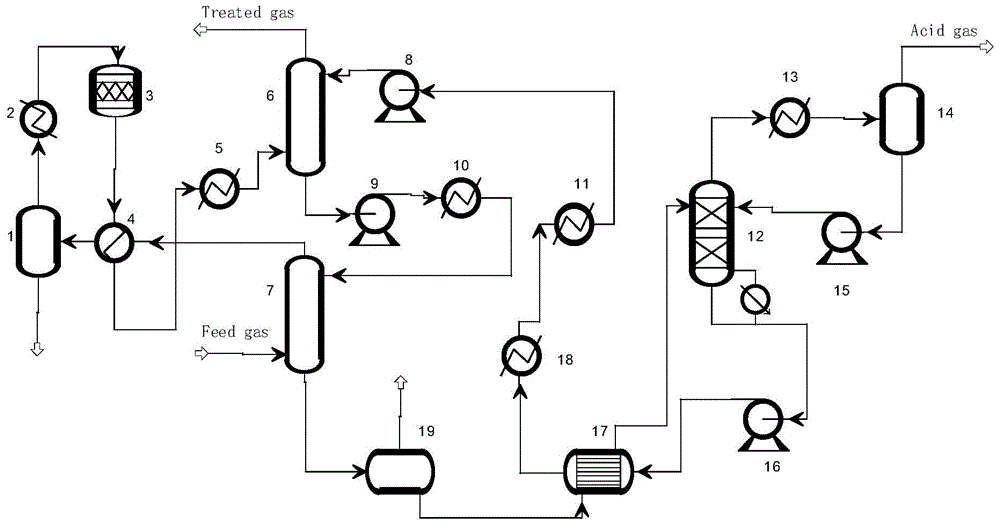

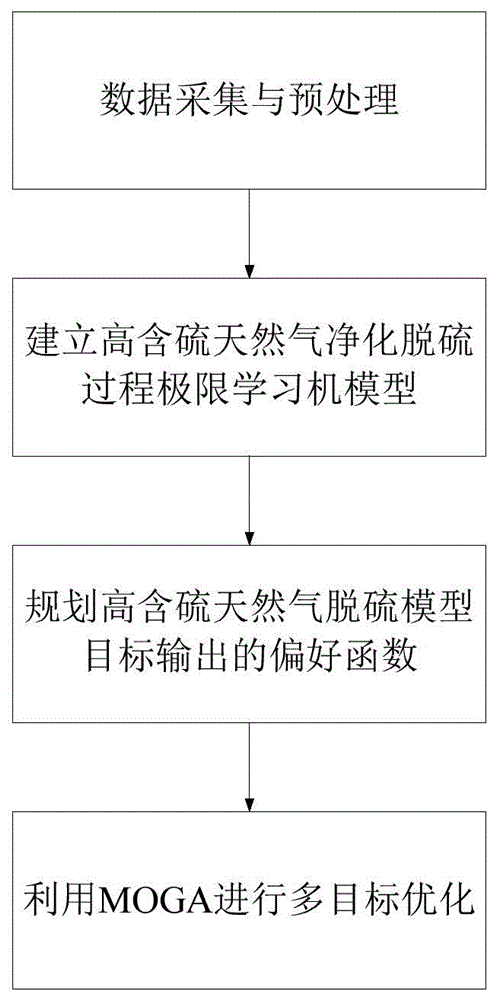

InactiveCN104636600AImprove model accuracyFast learningPhysical realisationSpecial data processing applicationsPre treatmentGenetic algorithm

The invention discloses a high sulfur natural gas purifying process modeling and optimizing method based on an extreme learning machine. The method comprises the steps of determining the input variable of a model; acquiring production process data; preprocessing the production process data; conducting data normalization; conducting data modeling by means of the extreme learning machine to obtain a model of technological operation parameters to H2S and CO2 content; designing a preference function according to two output variables of the extreme learning machine model, and optimizing the input variable by means of the multi-objective genetic algorithm; applying input variable optimal solution sets to the extreme learning machine model in sequence to calculate two output values, namely the content of H2S and the content of CO2, of the model at the moment, comparing the output values with an average sample value, and observing the optimization effect. By the adoption of the method, an accurate and reliable high sulfur natural gas purification and desulfurization industrial process model can be established quickly, the yield of finished gas can be increased on this basis, energy consumption during desulfurization can be reduced, and the method has important practical significance in guiding actual industrial production.

Owner:SINOPEC ZHONGYUAN OILFIELD PUGUANG BRANCH +1

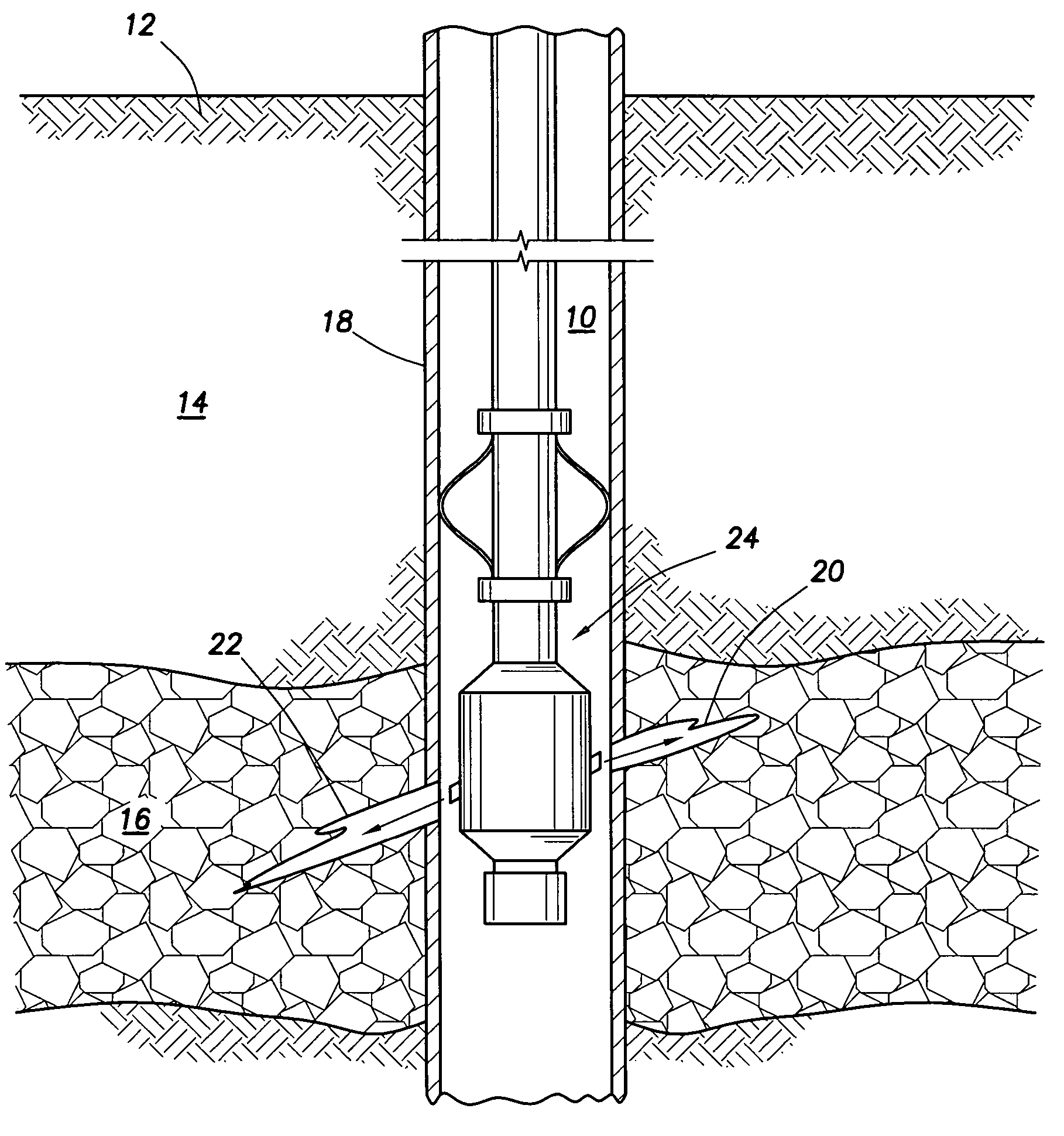

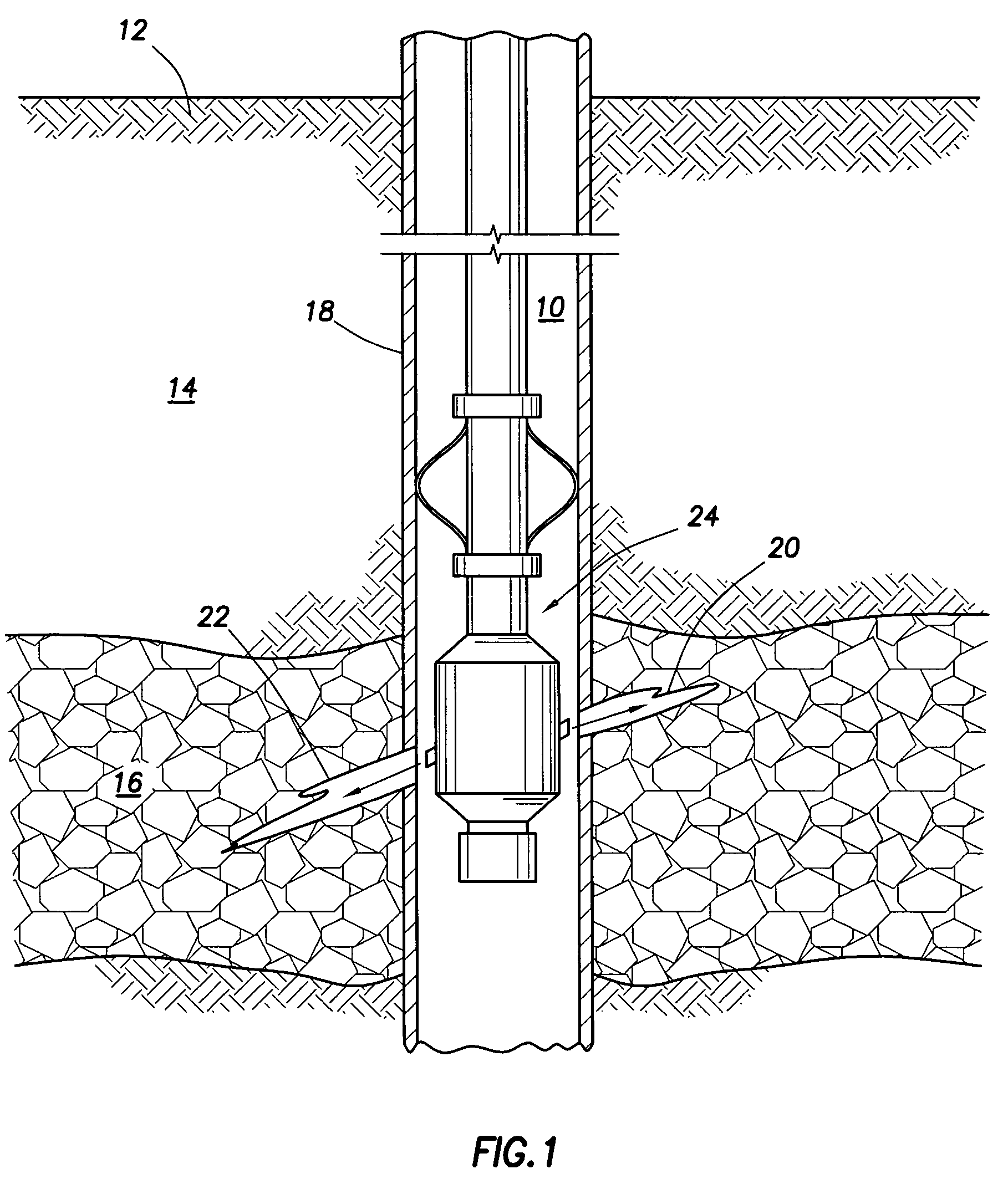

Apparatus and method for enhancing productivity of natural gas wells

ActiveUS6991034B2Extend product lifeReducing bottomhole pressureSurveyDrilling rodsProduct gasProcess engineering

A natural gas production system prevents liquid accumulation in the wellbore and minimizes friction loading in the wellbore by maintaining production gas velocity above a critical minimum velocity. A pressurized gas is injected into the well to supplement the flow of production gas such that the velocity of the total gas flow up the well exceeds the critical velocity. A choke is fitted to the gas injection line, and total gas flows are measured by a flow meter. A flow controller compares the measured total gas flow rate against the critical flow rate, and determines a minimum gas injection rate required to maintain the total gas flow rate at or above the critical flow rate. The flow controller then adjusts the choke to achieve the desired gas injection rate. The injection gas may be recirculated production gas from the well, or a gas from a separate source.

Owner:OPTIMUM PROD TECH INC

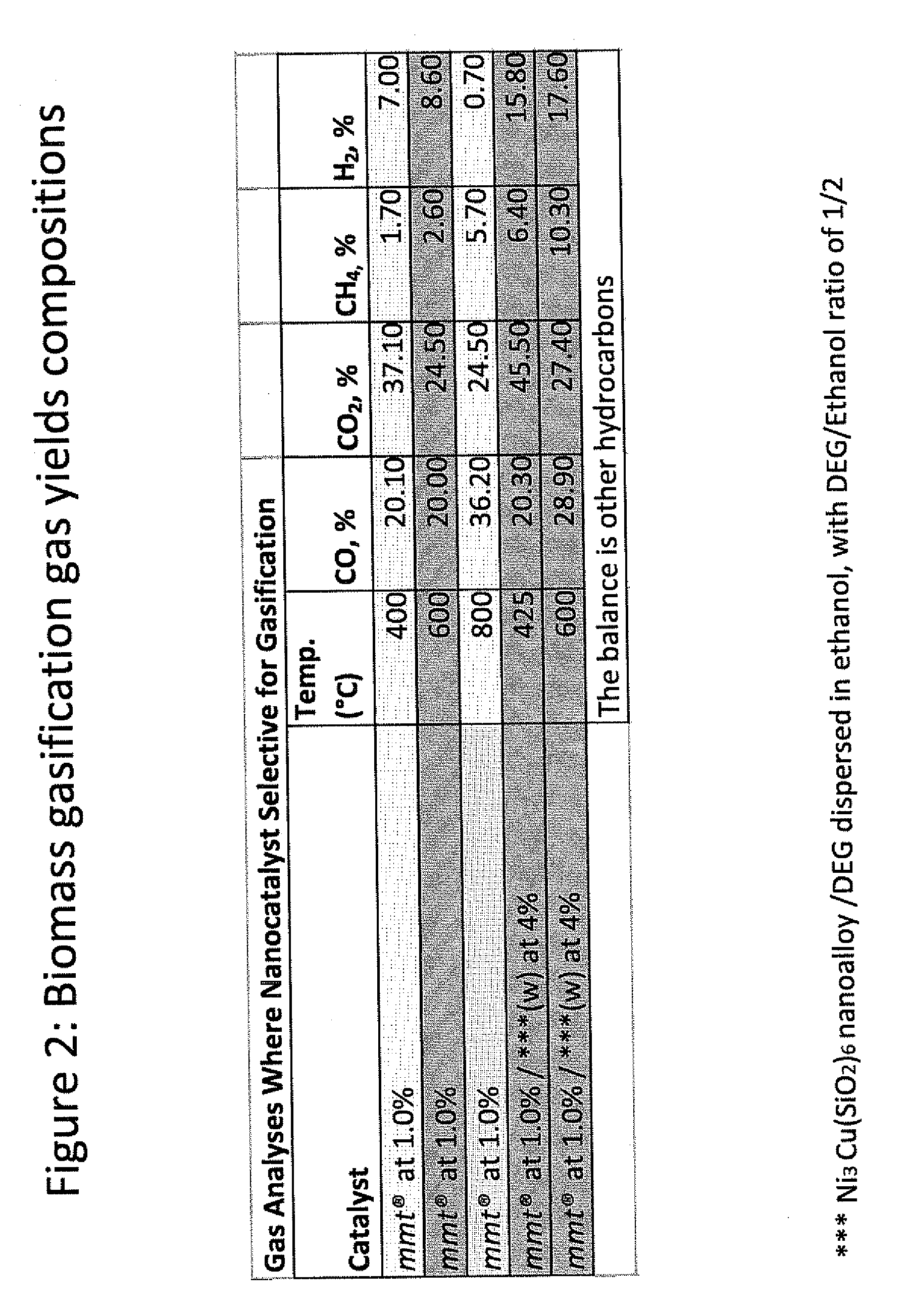

Nanoparticle Catalyst Compounds and/or Volatile Organometallic Compounds and Method of Using the Same for Biomass Gasification

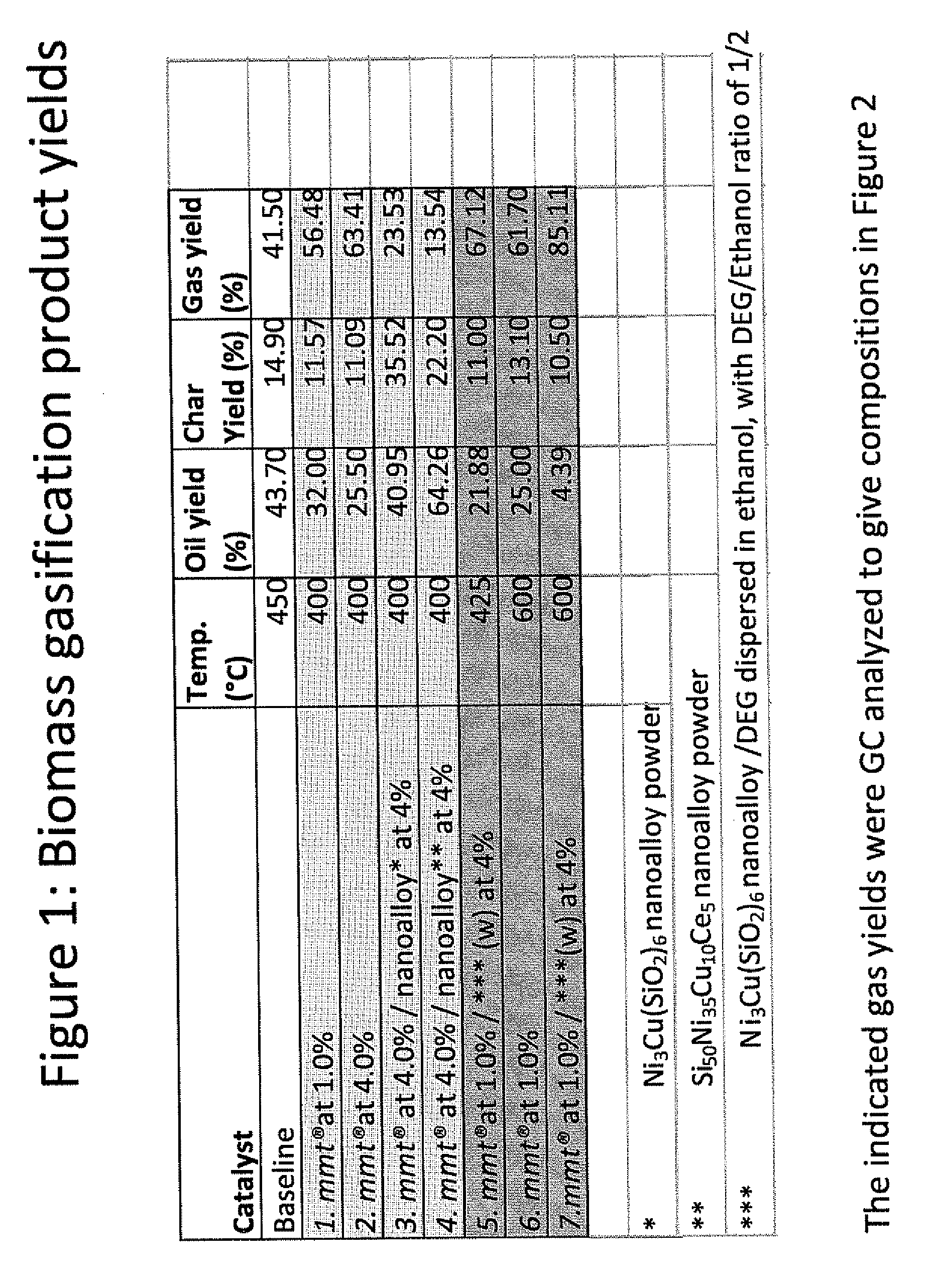

InactiveUS20100299990A1Improve gasificationHigh gas yieldBiofuelsWaste based fuelNano catalystOil production

A nanocatalyst, dual catalyst and methods for improving the efficiency and output of a biomass gasification process are provided where the catalysts comprise a volatile organometallic compound(s) and / or a nanoalloy catalyst. By the catalyst and method, a very high biomass gasification conversion efficiency of over 85% can be achieved. The subject nanocatalyst cracks and gasifies lignin, which is generally inert in conventional gasification, at relatively low gasification temperatures. The subject disclosure also provides a means to increase gas yields and lower lignin content in the resulting product relative to conventional gasification. Alternatively, oil production may be increased, if desired. Moreover, the resulting gas may achieve a Fischer-Tropsch reactor favorable H2:CO ratio of about 9:1. The energy input to the gasification is correspondingly reduced to reduce costs and the environmental impact associated with the gasification process.

Owner:AFTON CHEMICAL

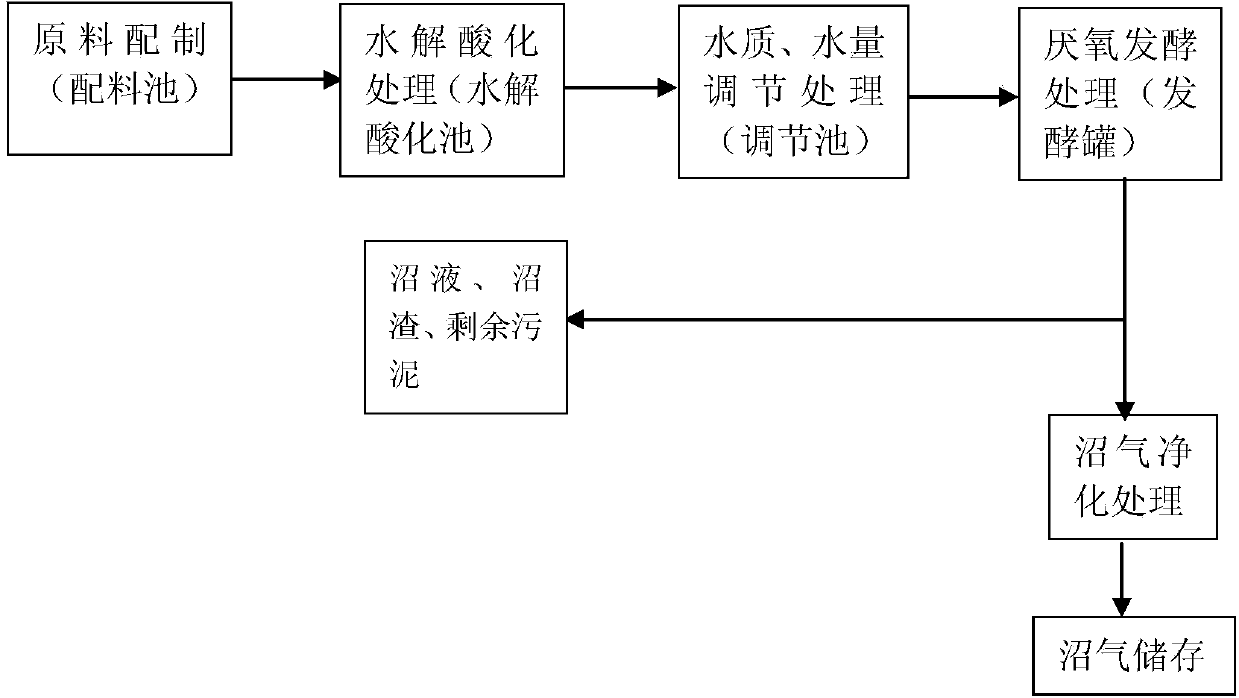

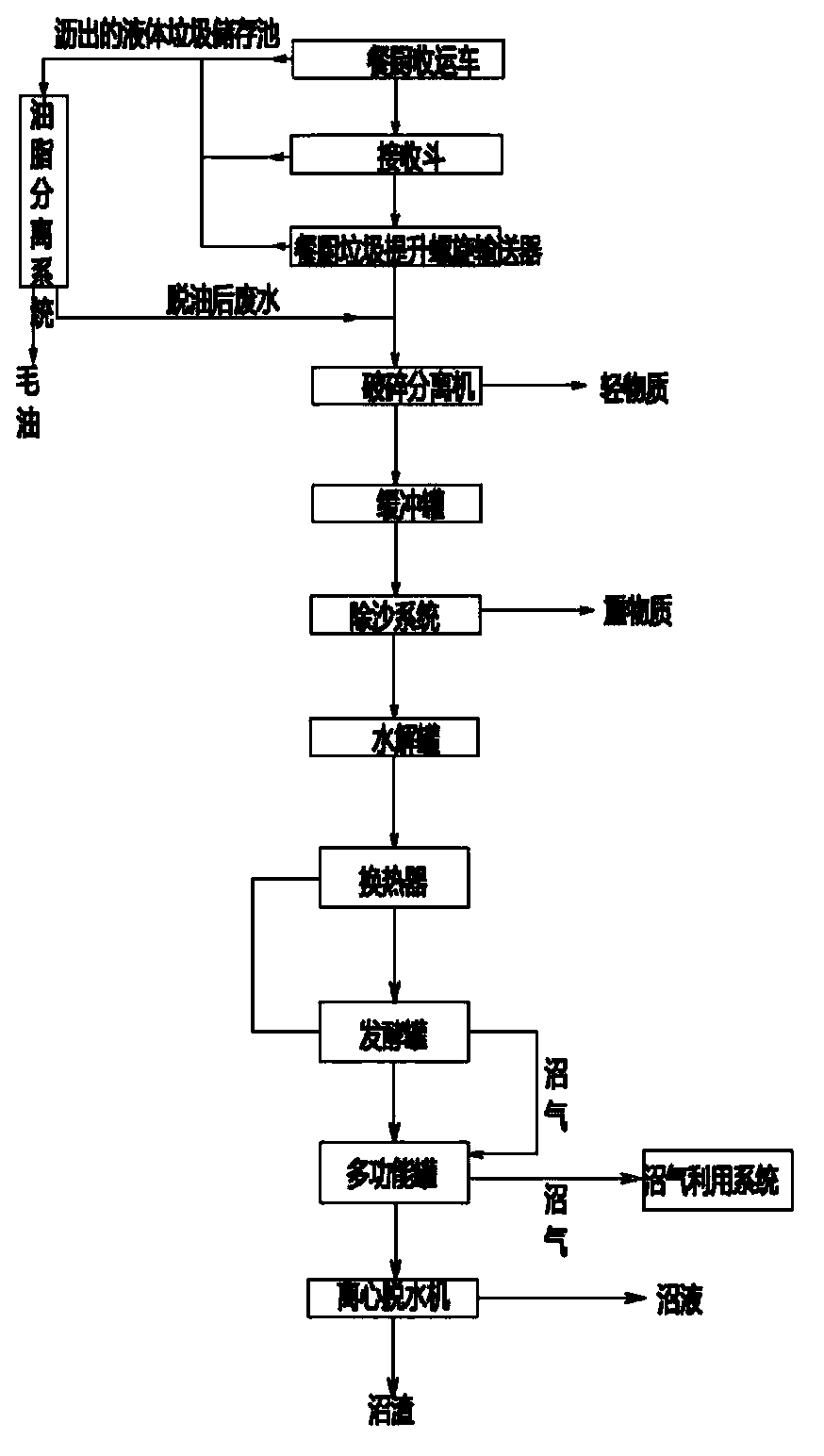

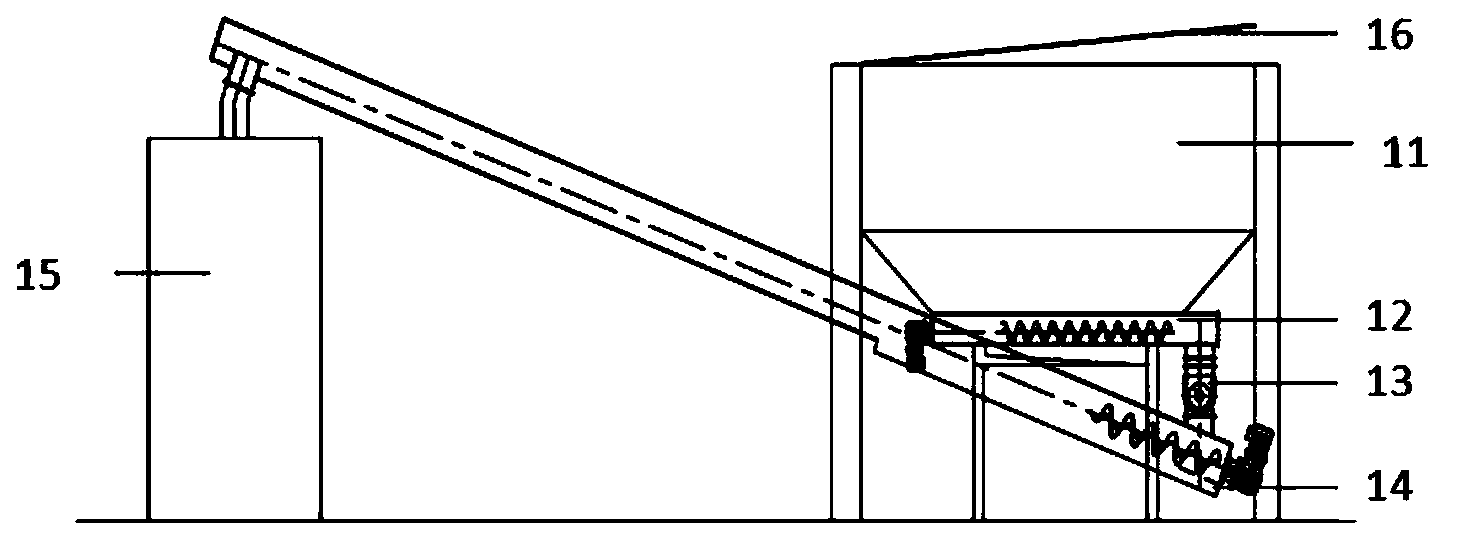

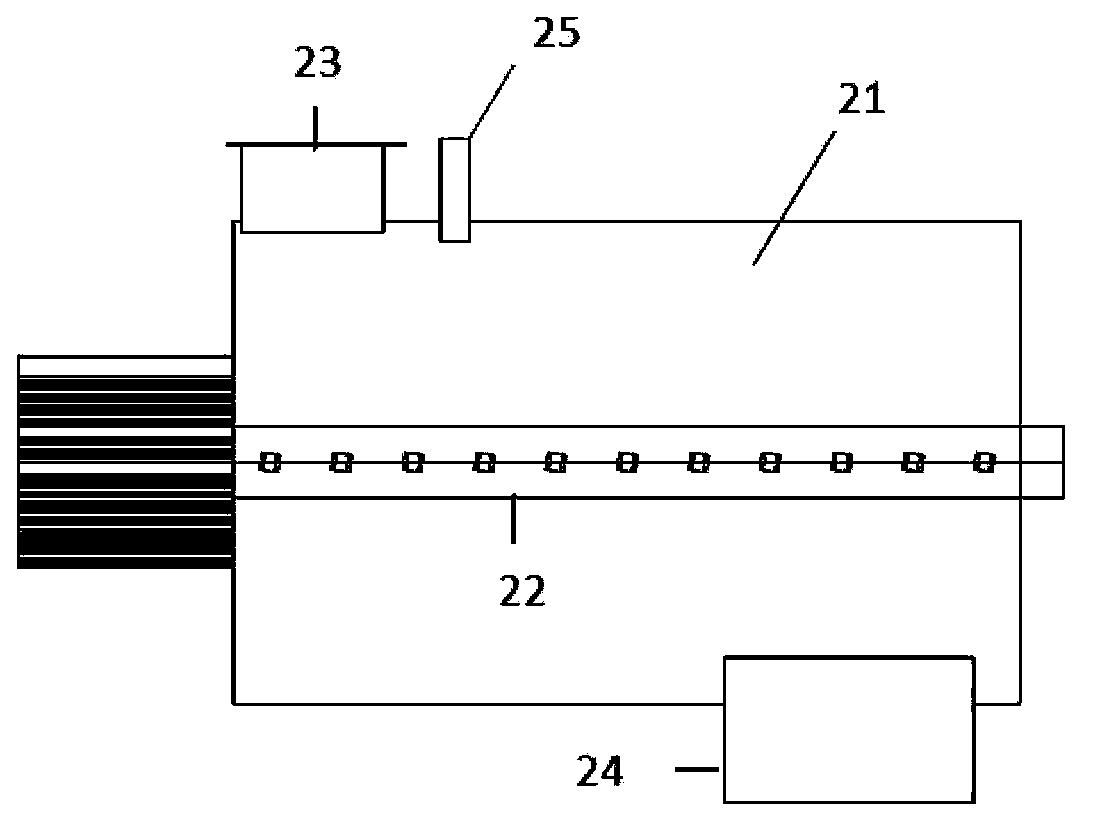

Two-phase anaerobic fermentation method for kitchen waste

ActiveCN103695472AReduce outputImprove organic degradation rateBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationOil and grease

The invention relates to the kitchen waste treatment field, in particular to a two-phase anaerobic fermentation method for kitchen waste. The two-phase anaerobic fermentation method for kitchen waste includes the steps of: 1) sending leached oil water into a grease separation system to undergo grease separation, recovering the separated grease, and carrying the separated wastewater and the kitchen waste conveyed by a lifting screw conveyor to a crushing separation system; 2) carrying out crushing and separation; 3) conducting hydrolytic acidification; 4) inputting the waste slurry subjected to hydrolytic acidification in a hydrolysis tank into a heat exchanger, performing heating, then sending the waste slurry into a fermentation tank to undergo anaerobic fermentation; 5) conducting re-fermentation, and subjecting biogas to desulfurization treatment; and 6) recovering biogas residue and biogas. The method provided by the invention applies the two-phase anaerobic technology to the kitchen waste industry, and can effectively avoid the easy acidification phenomenon of high concentration organic waste anaerobic fermentation. The multifunctional tank integrating gas production, gas storage and desulfurization is adopted in the invention, and the gas production efficiency is improved.

Owner:北京时代桃源环境科技股份有限公司

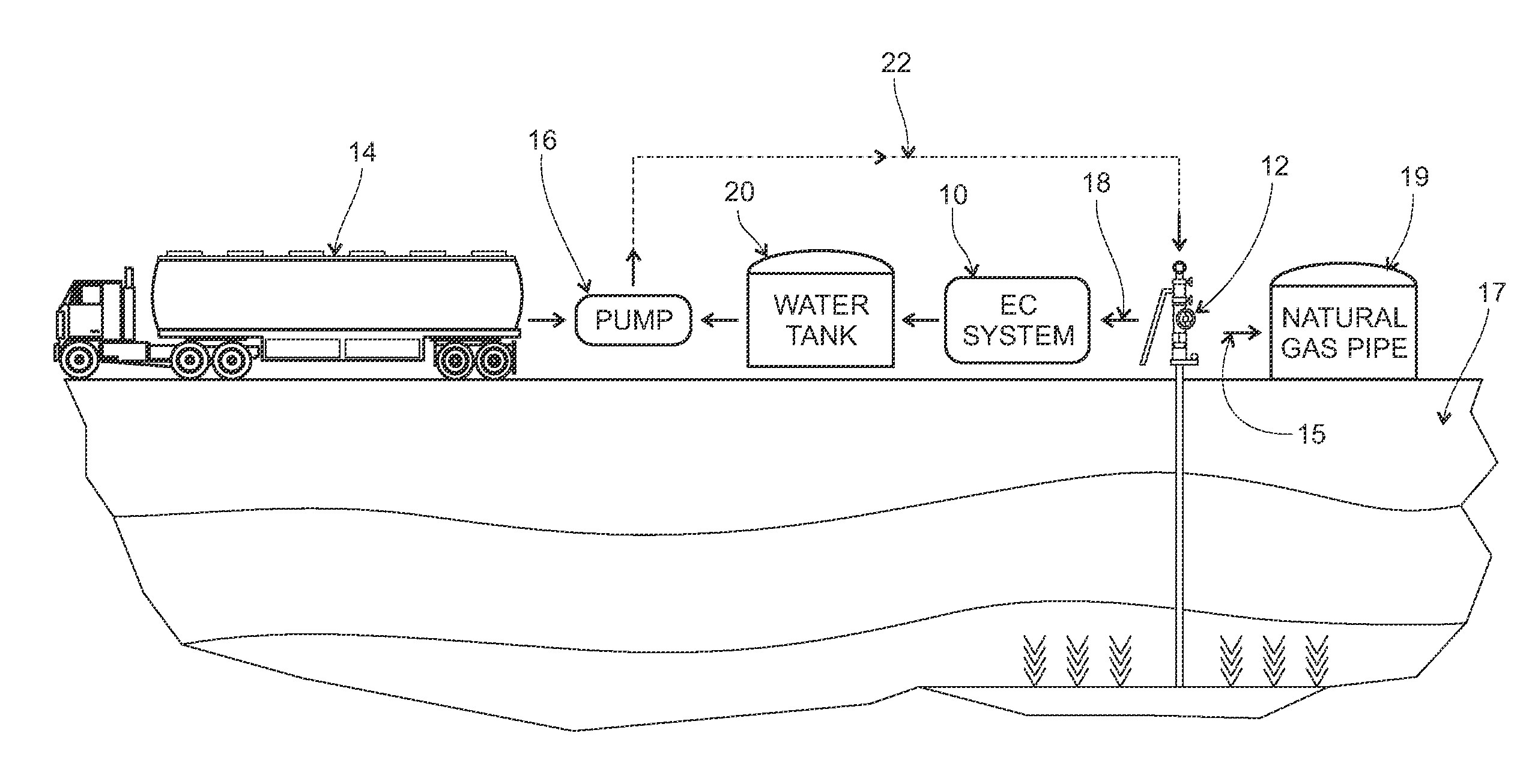

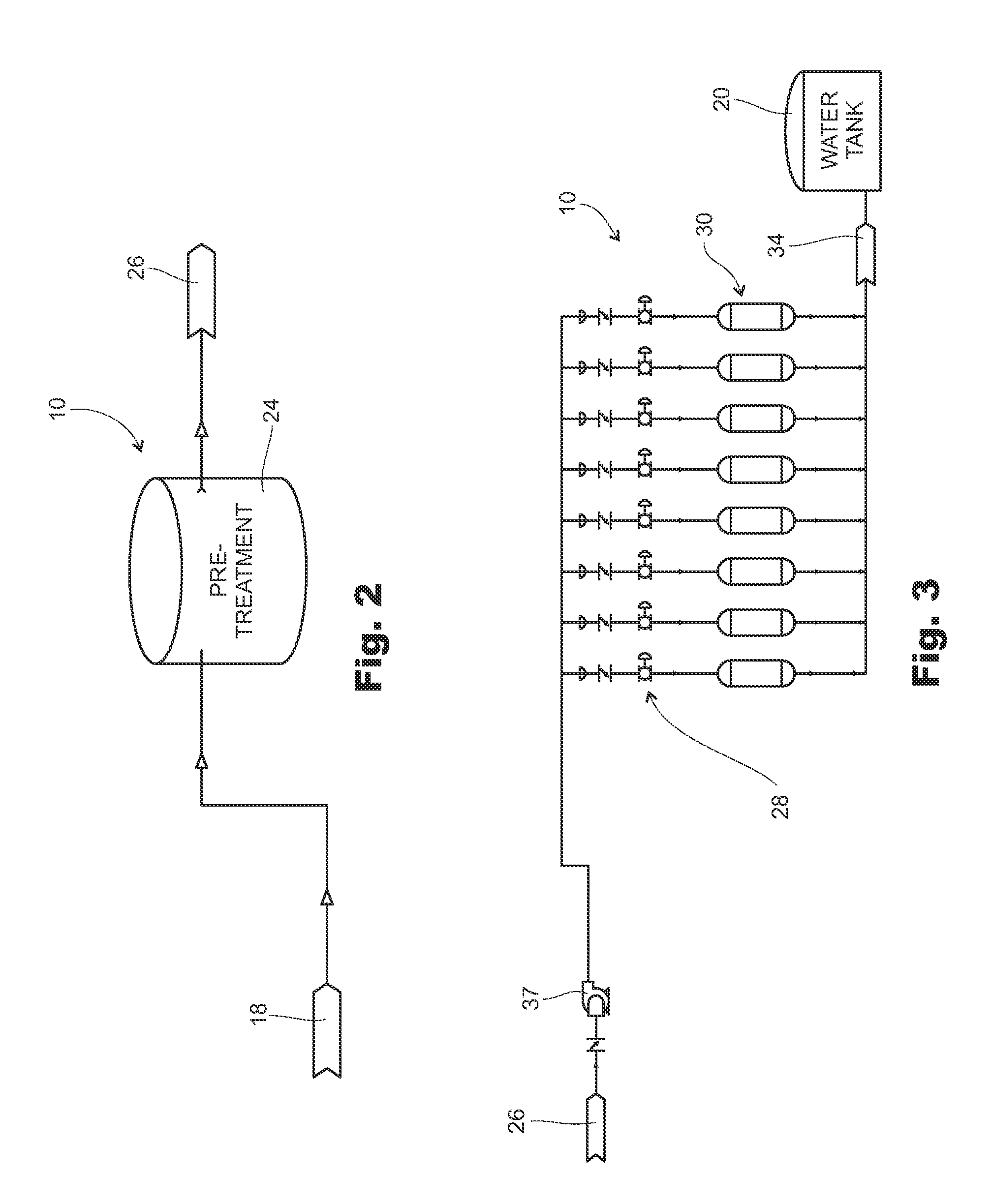

Method For Improving Hydraulic Fracturing Efficiency And Natural Gas Production

ActiveUS20110180263A1Reduce conventional transportationReduce disposal costsWaste water treatment from quariesLiquid separation by electricityElectrocoagulationFracturing fluid

A method of improving natural gas release from a well via an enhanced hydraulic fracturing operation. The method includes capturing or retrieving the flow back from the well following the fracturing operation. The flow back or other source water is introduced to an electrocoagulation (“EC”) treatment process. EC treatment separates the water from other fracturing fluid components in the flow back and also removes bacteria and other contaminants. Thereafter, the EC-treated fluid is recycled for subsequent fracturing operations. The process may also be used to treat all source water, including fresh water delivered to the well before it is used as a fracturing fluid.

Owner:WATER TECTONICS

Coal-bed gas well electric pulse blockage releasing and permeation enhancing method

ActiveCN106593388AUnblock the problemImprove connectivityFluid removalVibration devicesHydraulic fracturingElectrical impulse

A coal-bed gas well electric pulse blockage releasing and permeation enhancing method is suitable for high-efficient mining of coal-bed gas wells. According to the blockage releasing and permeation enhancing method, a positive electrode coal-bed gas well shaft and a negative electrode coal-bed gas well shaft are constructed from the ground to a coal bed; cracks in the coal bed are closed gradually or blocked by granular impurities along with coal bed gas extraction after hydrofracturing, so that the gas yield is reduced; at the moment, a conductive ion solution is injected into the positive electrode coal-bed gas well shaft, and the portion, between the positive electrode coal-bed gas well shaft and the negative electrode coal-bed gas well shaft, of the coal bed is filled with the conductive ion solution; then a positive electrode and a negative electrode are put downwards to the coal bed permeation forecast increasing portions in the positive electrode coal-bed gas well shaft and the negative electrode coal-bed gas well shaft correspondingly; the portion, between the positive electrode and the negative electrode and filled with the conductive ion solution, of the coal bed is broken down through discharging of high voltage electropulses, great energy forms impact waves to act on the coal bed, the closed cracks in the coal bed are opened again and extend, the granules blocking the cracks are removed, the number of the cracks in the coal bed is effectively increased, and crack connectivity is improved.

Owner:CHINA UNIV OF MINING & TECH

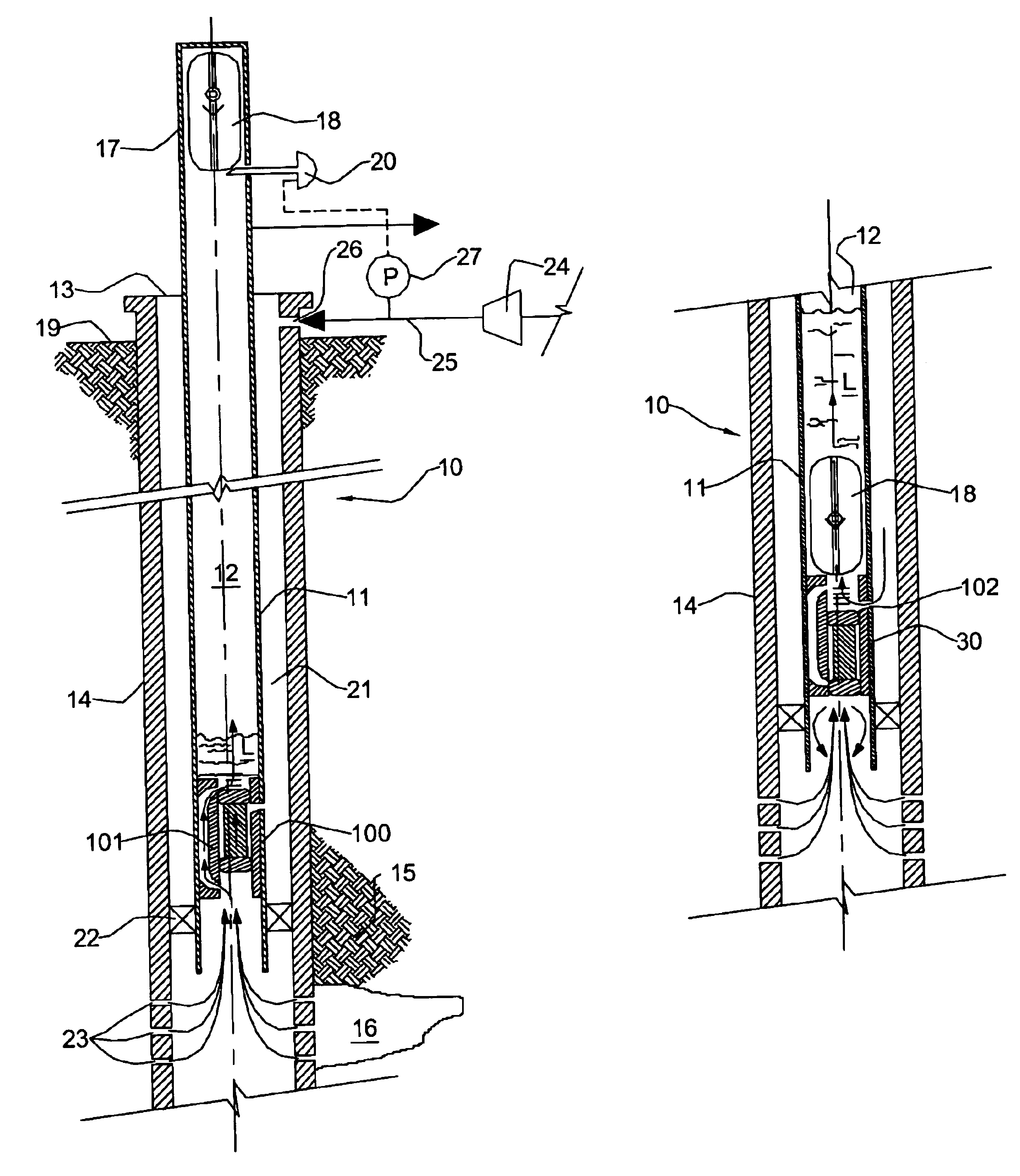

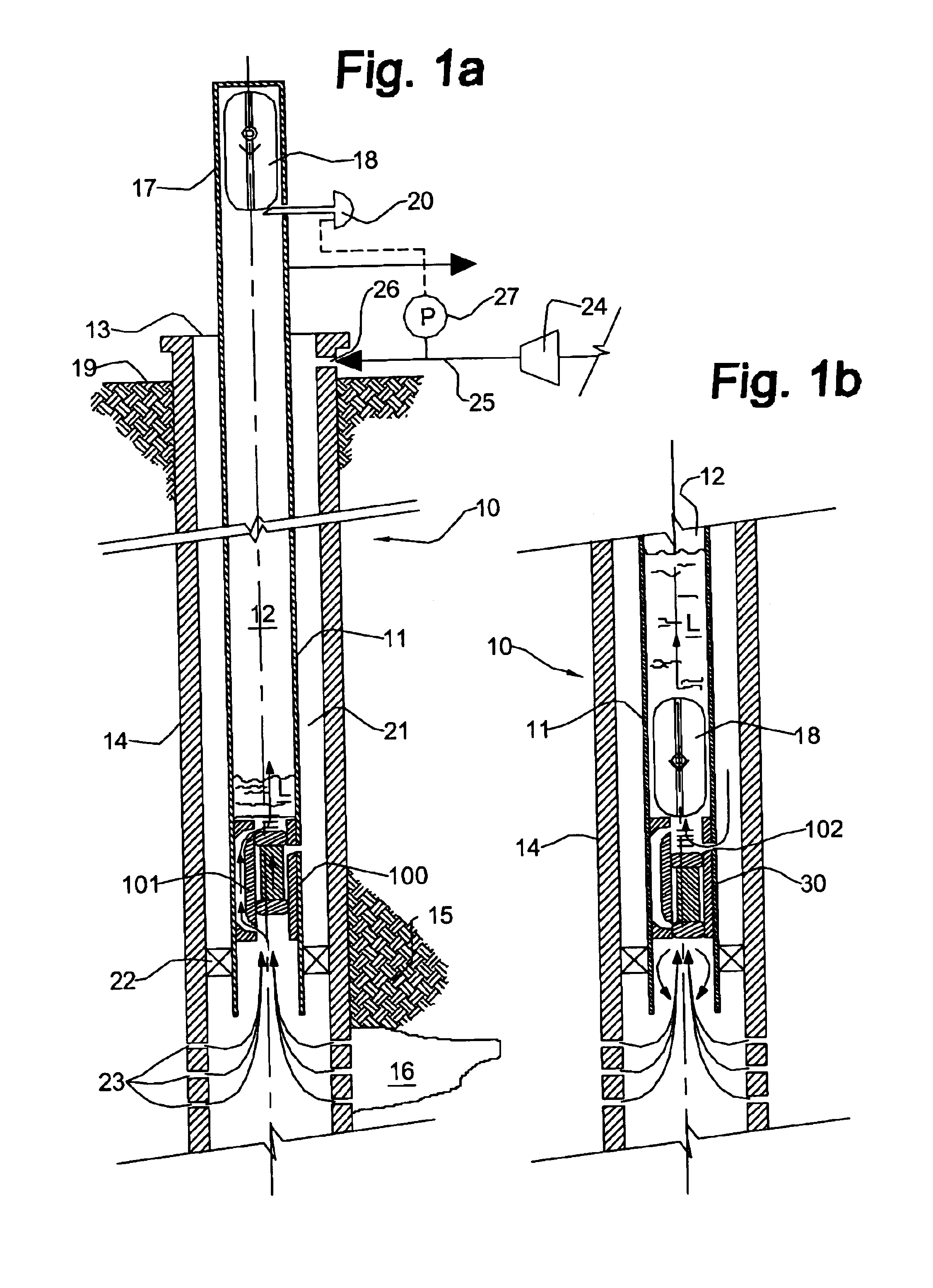

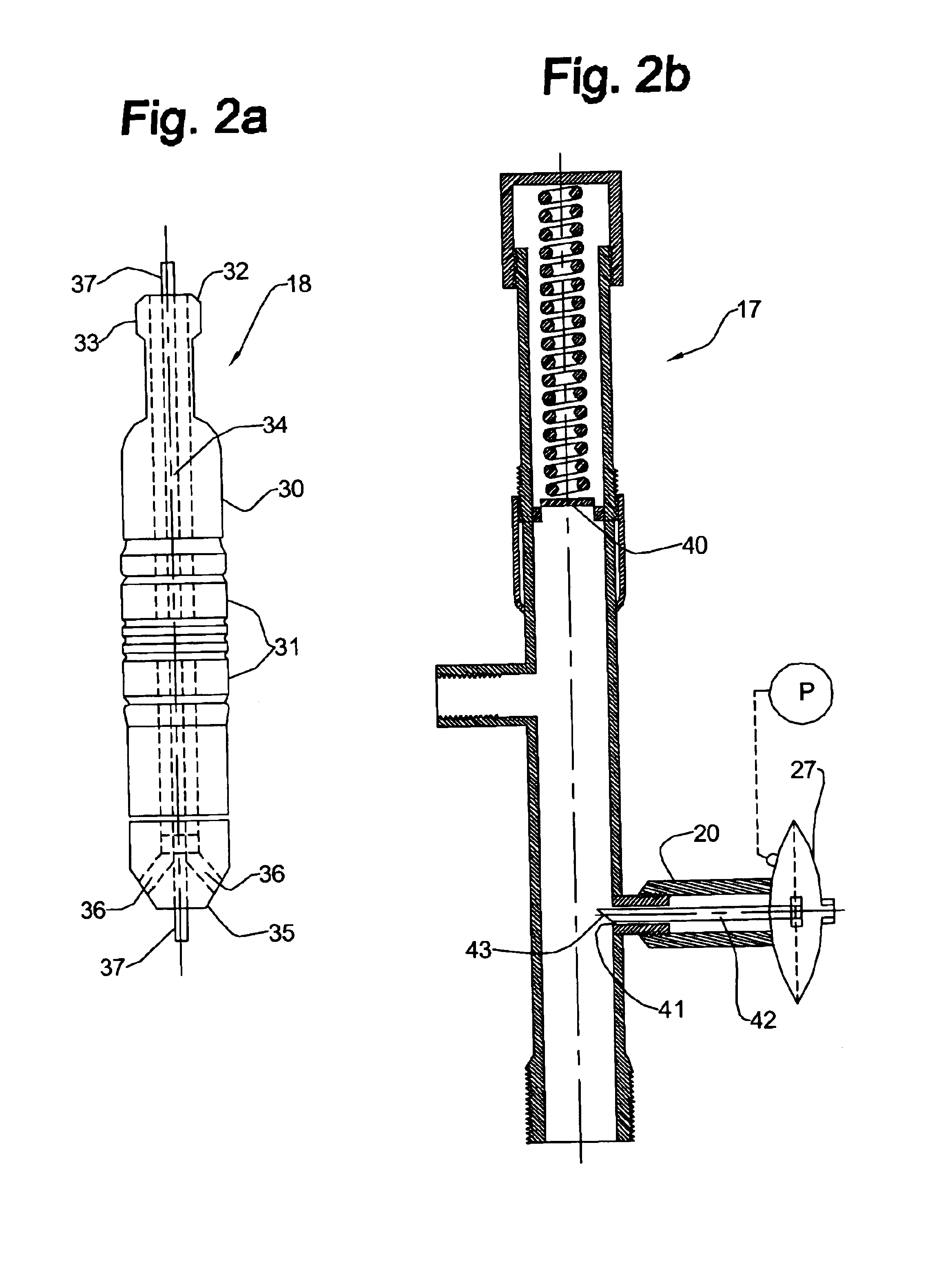

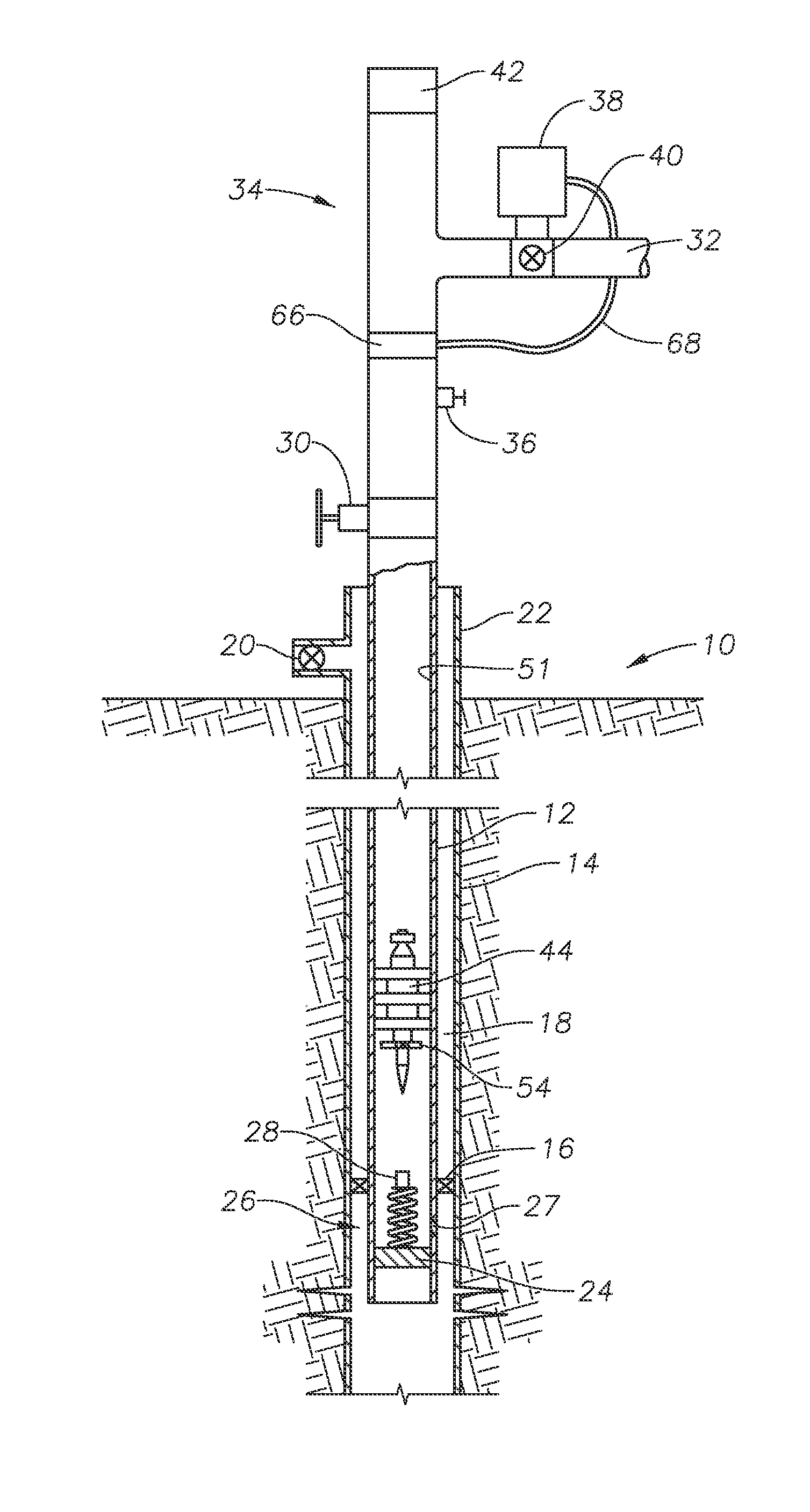

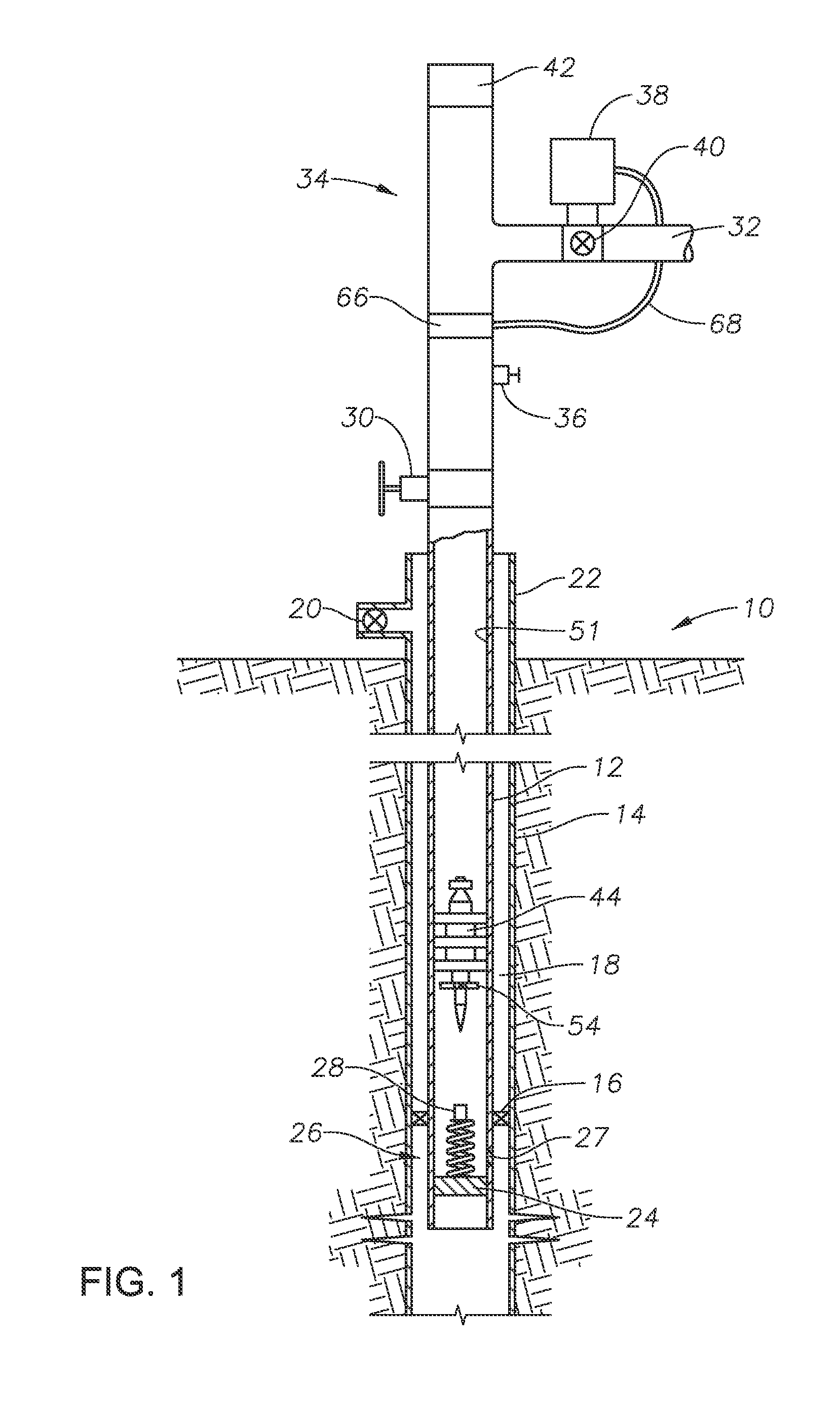

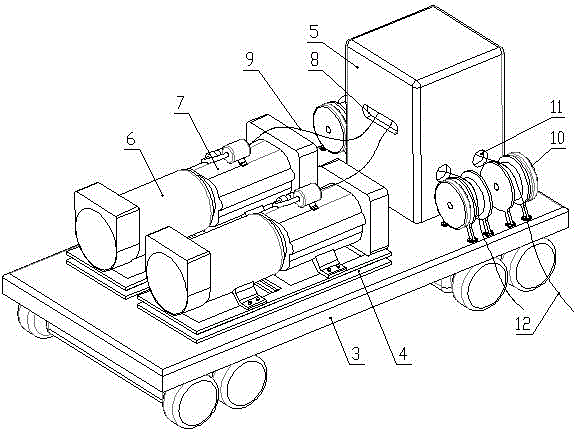

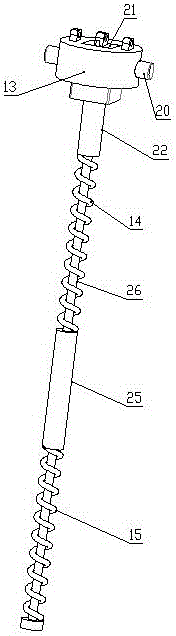

Downhole fluid transport plunger with thruster

A method for lifting fluids within a subterranean well includes lowering an elongated plunger to a lower region of a bore of the subterranean well. The plunger includes a motor assembly operably connected to a propeller. A seal can be created between the plunger and an inner surface of the bore of the subterranean well. A thruster, such as motor assembly connected to a propeller, generates thrust to lift the plunger to a plunger retainer located proximate to a wellhead of the subterranean well.

Owner:SAUDI ARABIAN OIL CO

Resistance wire type coal seam heating device

ActiveCN106223916AGuaranteed power generation efficiencyGuaranteed power supplyFluid removalGas removalFracturing fluidEngineering

The invention provides a resistance wire type coal seam heating device. The device comprises a mobile ground power generation system and a plurality of downhole heaters, wherein the mobile ground power generation system provides electric energy for the downhole heaters; each downhole heater comprises a coal seam upper permanent joint, a reinforcement pipe, an upper resistance wire and a lower resistance wire; the coal seam upper permanent joint is formed by an upper cylinder and a lower square cylinder; a square groove is formed in the top of the cylinder; an installing hole is formed in the square cylinder; two fracturing fluid inlet pipe joints are connected at the side parts of the coal seam upper permanent joint; a square joint is assembled in the square groove; the lower end face of the square joint is connected with an installing pipe penetrating through the installing hole; the upper resistance wire is arranged at the upper part of the reinforcement pipe in a sleeving manner and the lower resistance wire is arranged at the lower part of the reinforcement pipe in a sleeving manner. The device has the beneficial effects that the device adopts the method of injecting thermal fracturing fluid; the resistance wires are adopted by heating equipment for heating; a mobile ground power supply vehicle is adopted as main power supply equipment; the device has the advantages of convenience in operation, diverse functions, safety and reliability and capability of fully increasing the gas output.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com