Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

353 results about "Deep penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

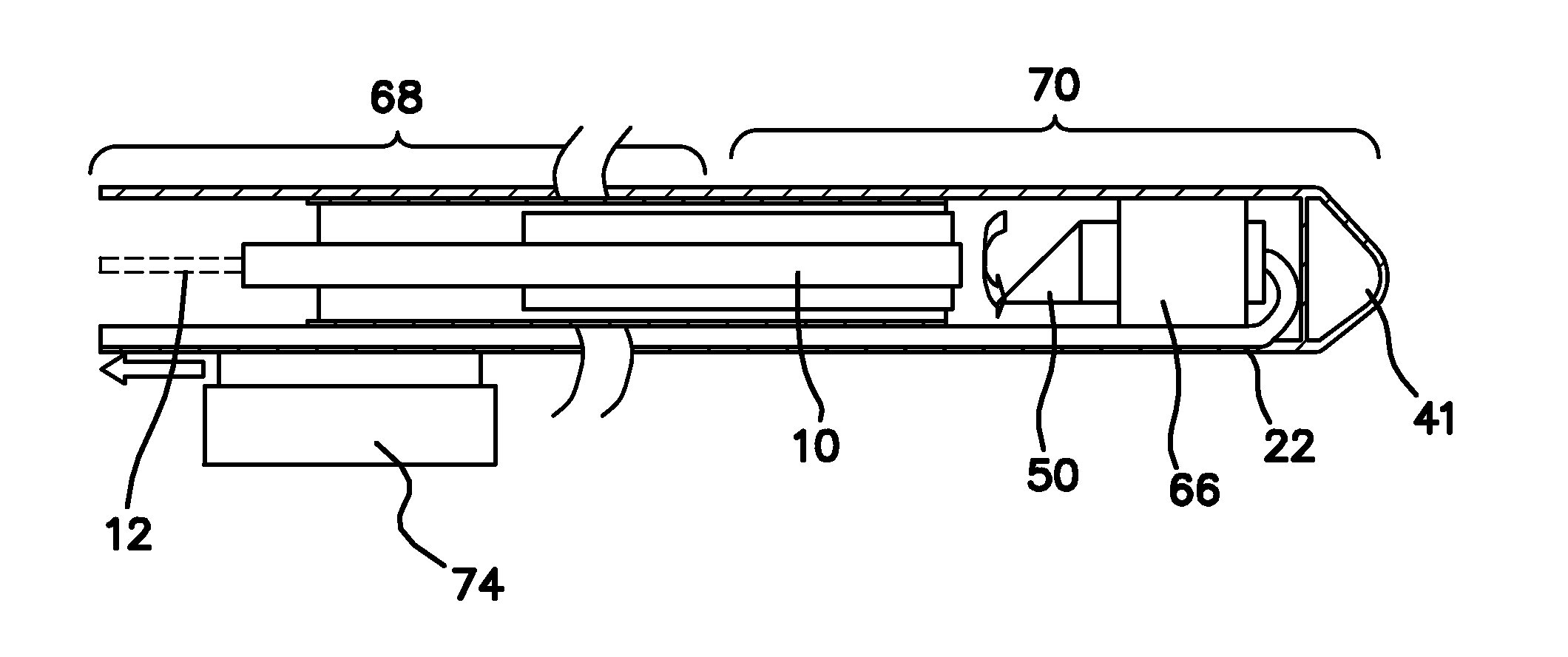

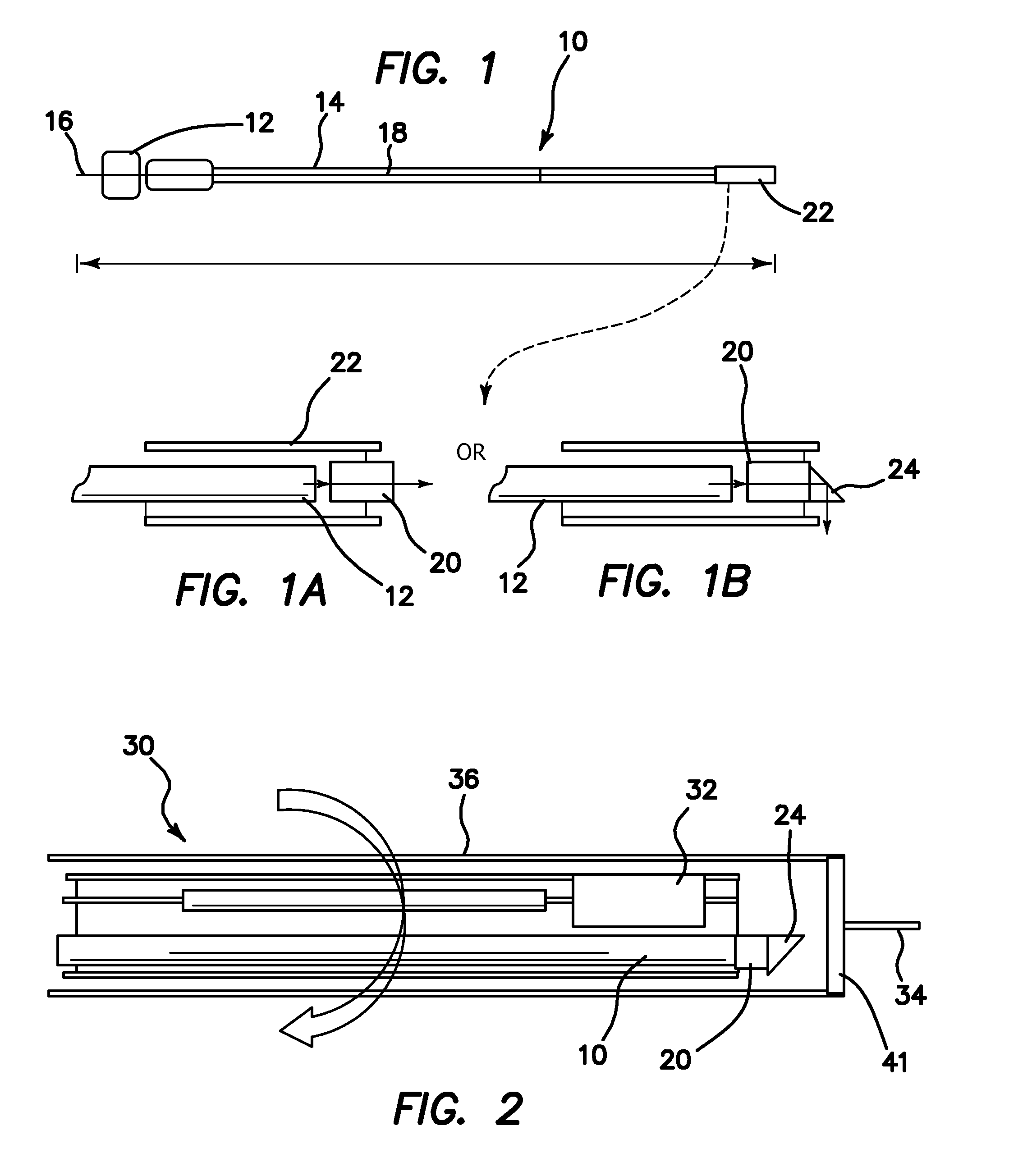

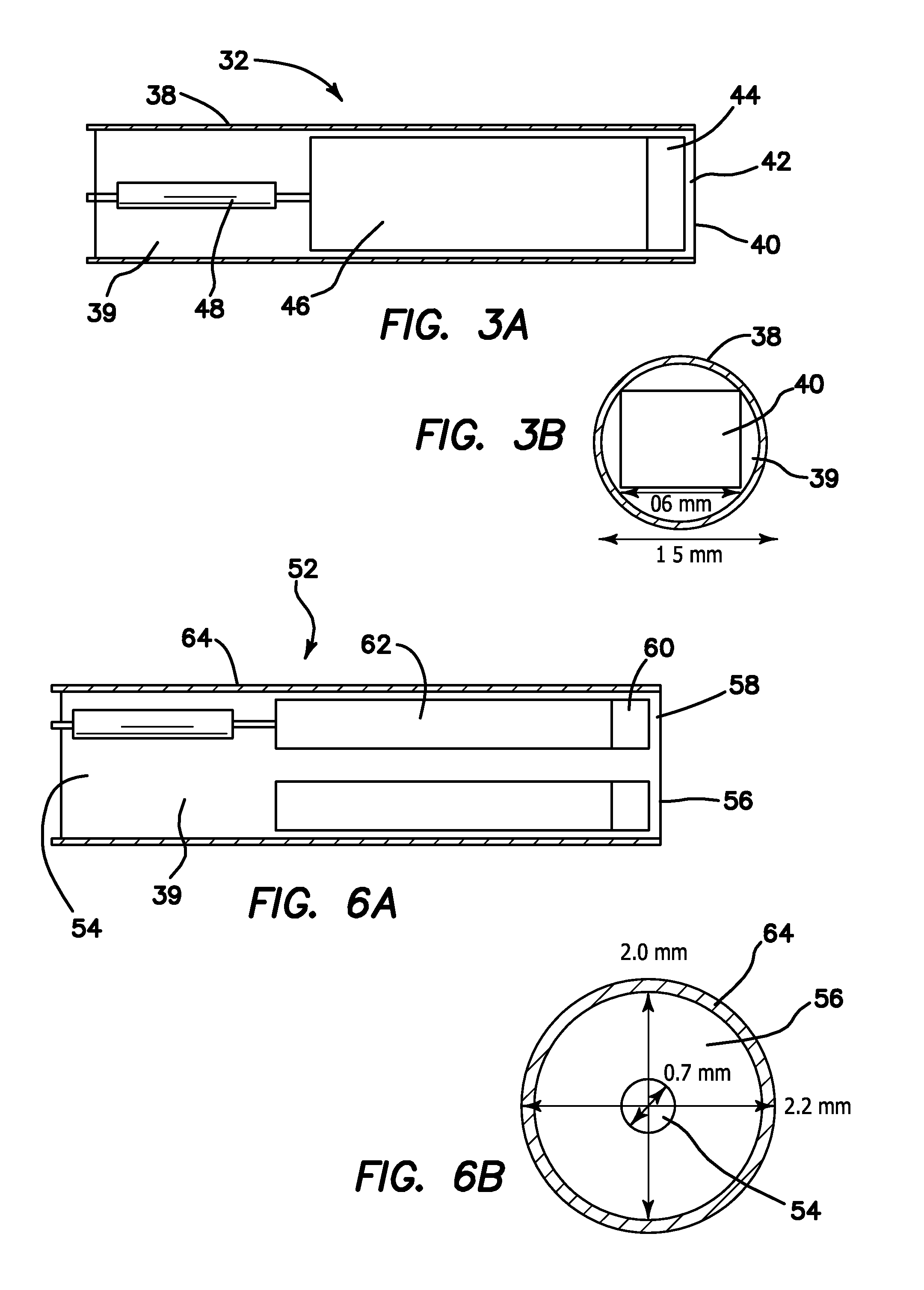

Ultrasound guided optical coherence tomography, photoacoustic probe for biomedical imaging

ActiveUS20110098572A1High resolution imagingEasy accessUltrasonic/sonic/infrasonic diagnosticsCatheterDiagnostic Radiology ModalityHigh resolution imaging

An imaging probe for a biological sample includes an OCT probe and an ultrasound probe combined with the OCT probe in an integral probe package capable of providing by a single scanning operation images from the OCT probe and ultrasound probe to simultaneously provide integrated optical coherence tomography (OCT) and ultrasound imaging of the same biological sample. A method to provide high resolution imaging of biomedical tissue includes the steps of finding an area of interest using the guidance of ultrasound imaging, and obtaining an OCT image and once the area of interest is identified where the combination of the two imaging modalities yields high resolution OCT and deep penetration depth ultrasound imaging.

Owner:RGT UNIV OF CALIFORNIA

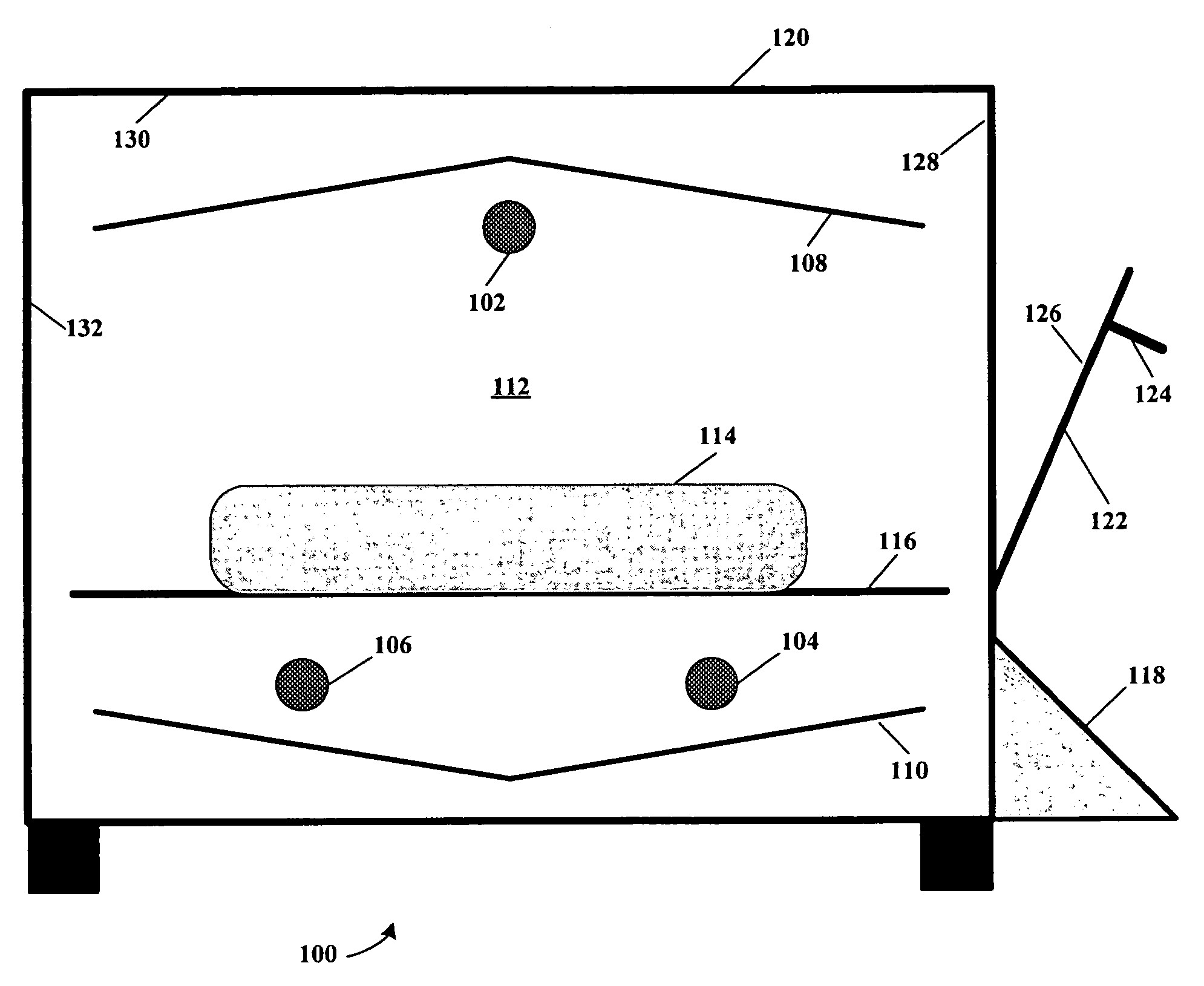

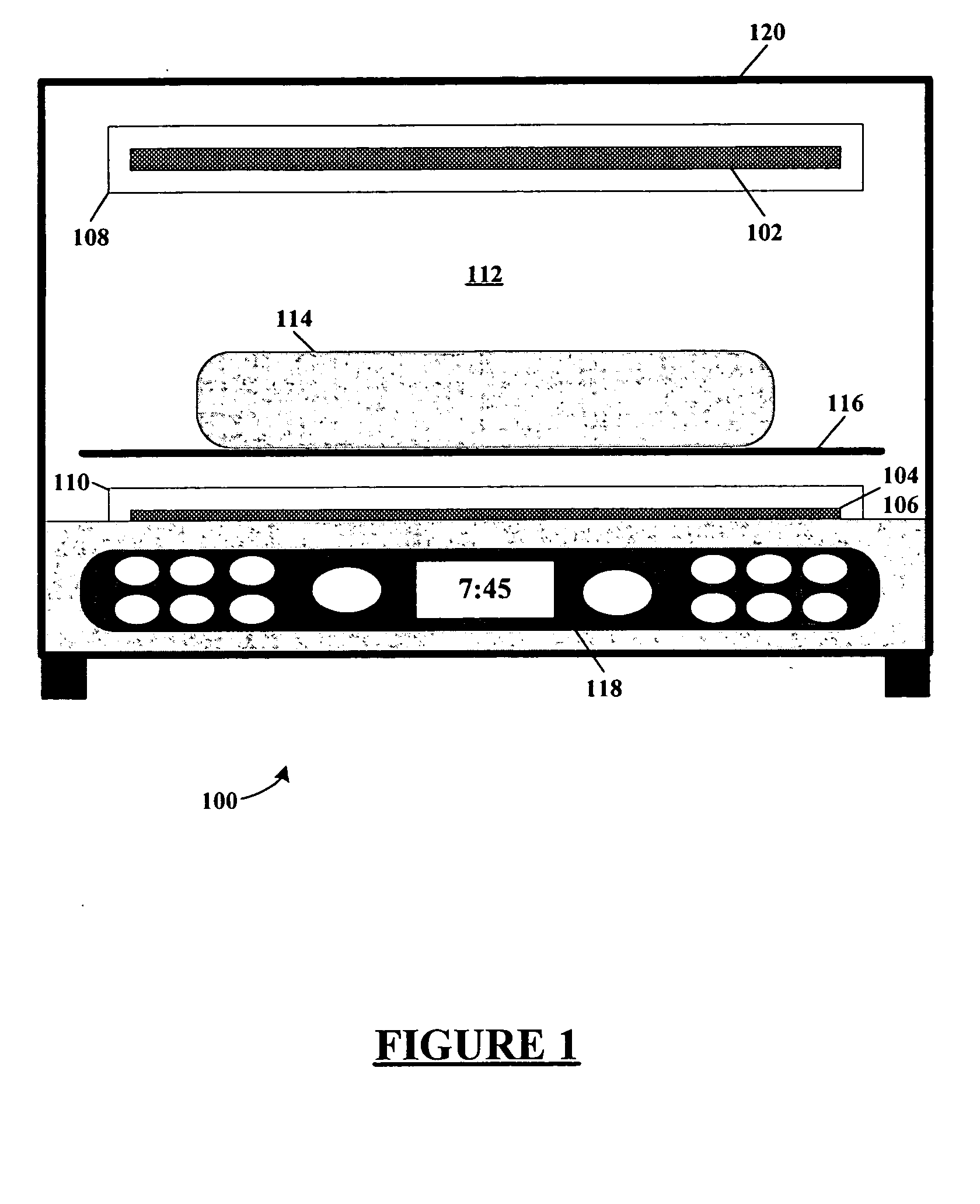

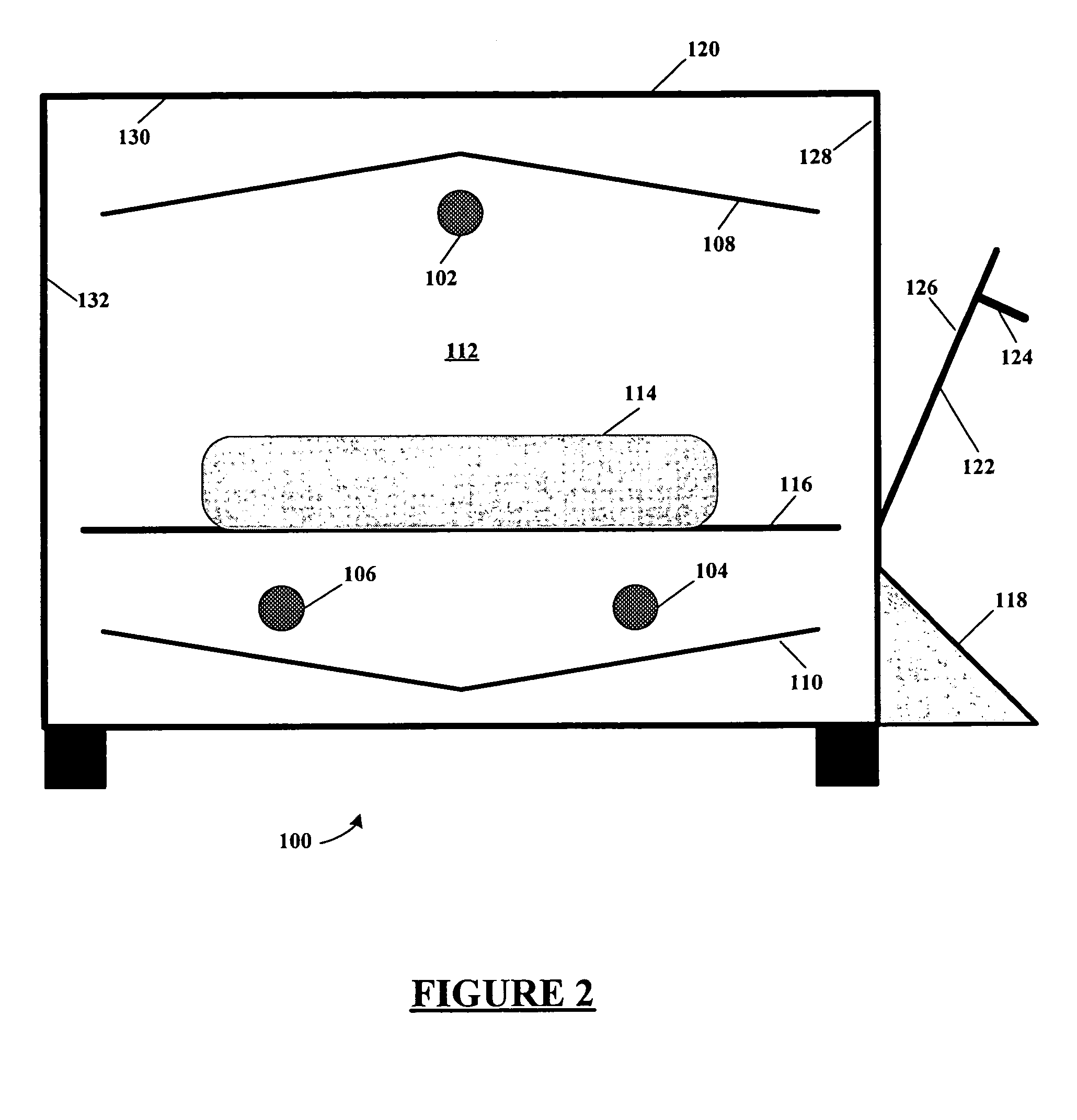

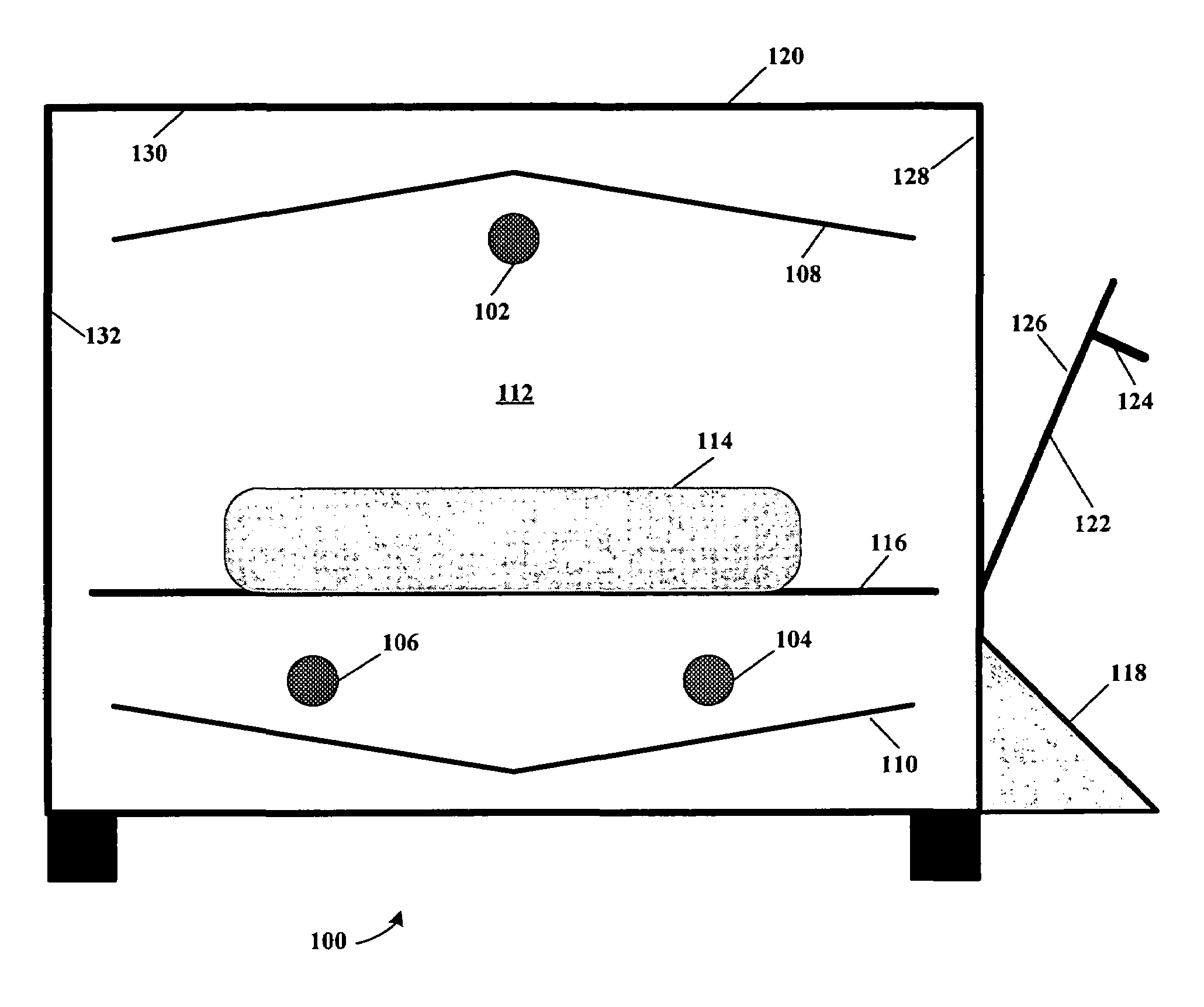

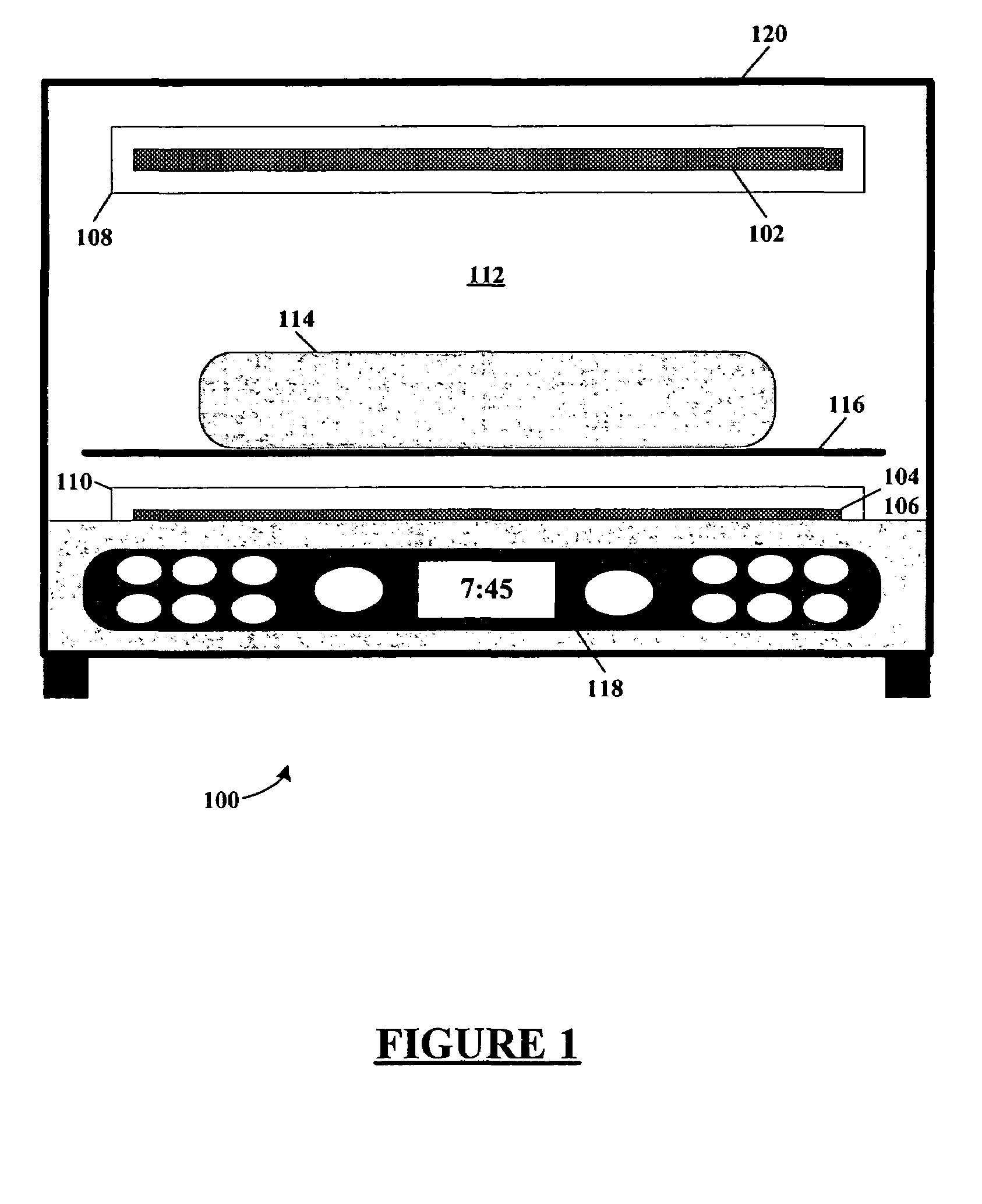

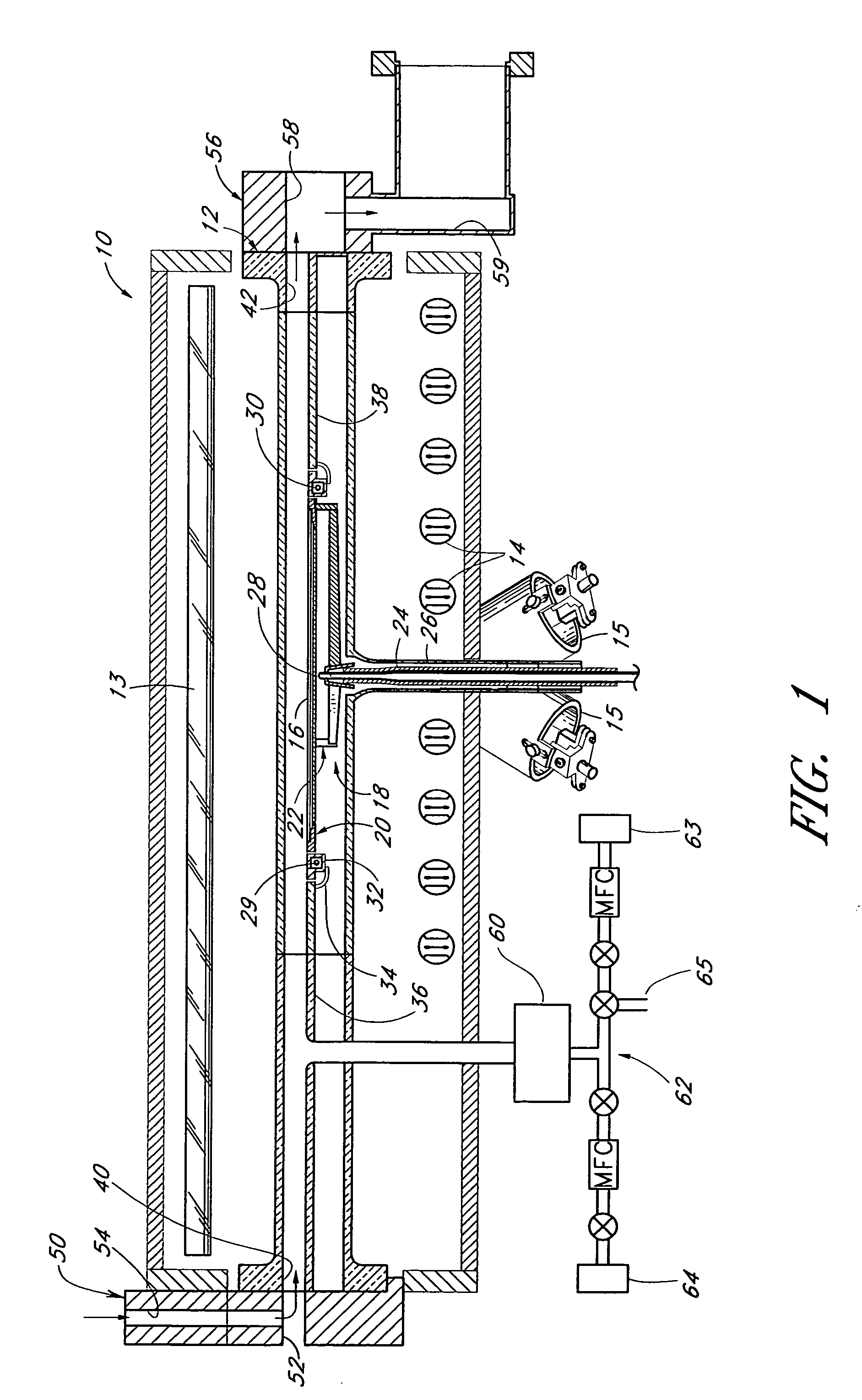

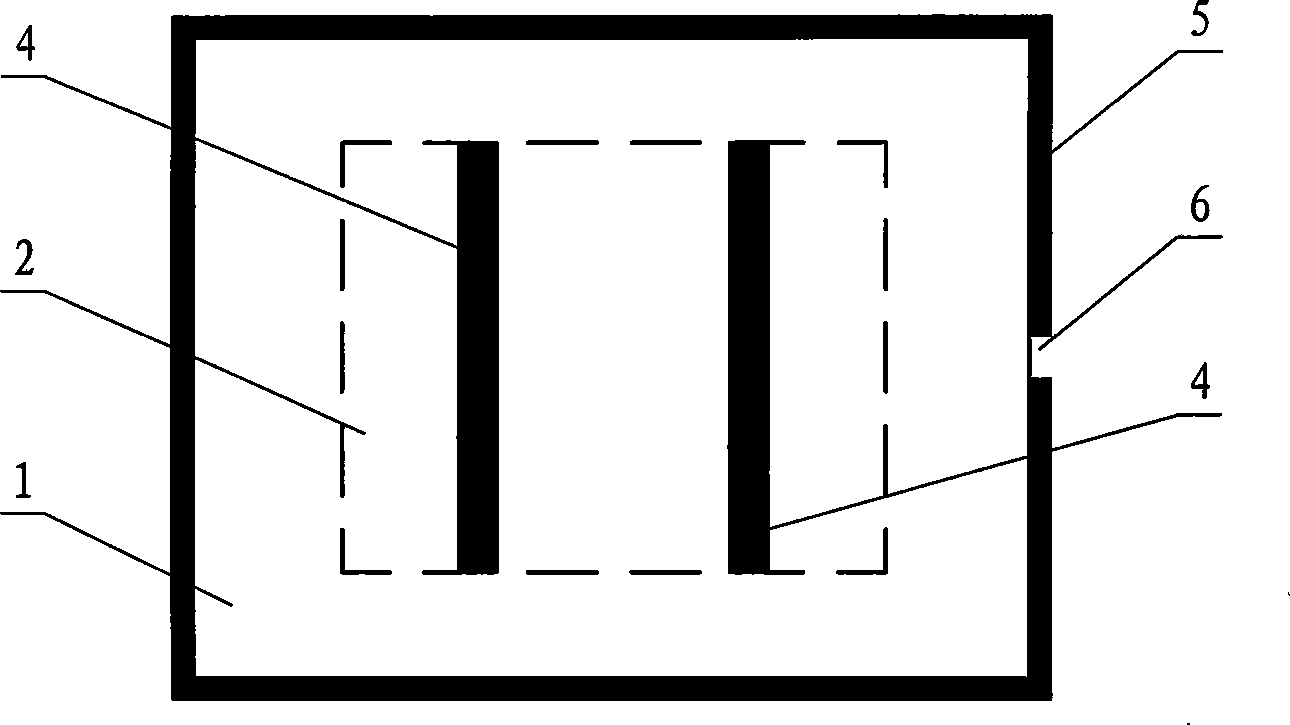

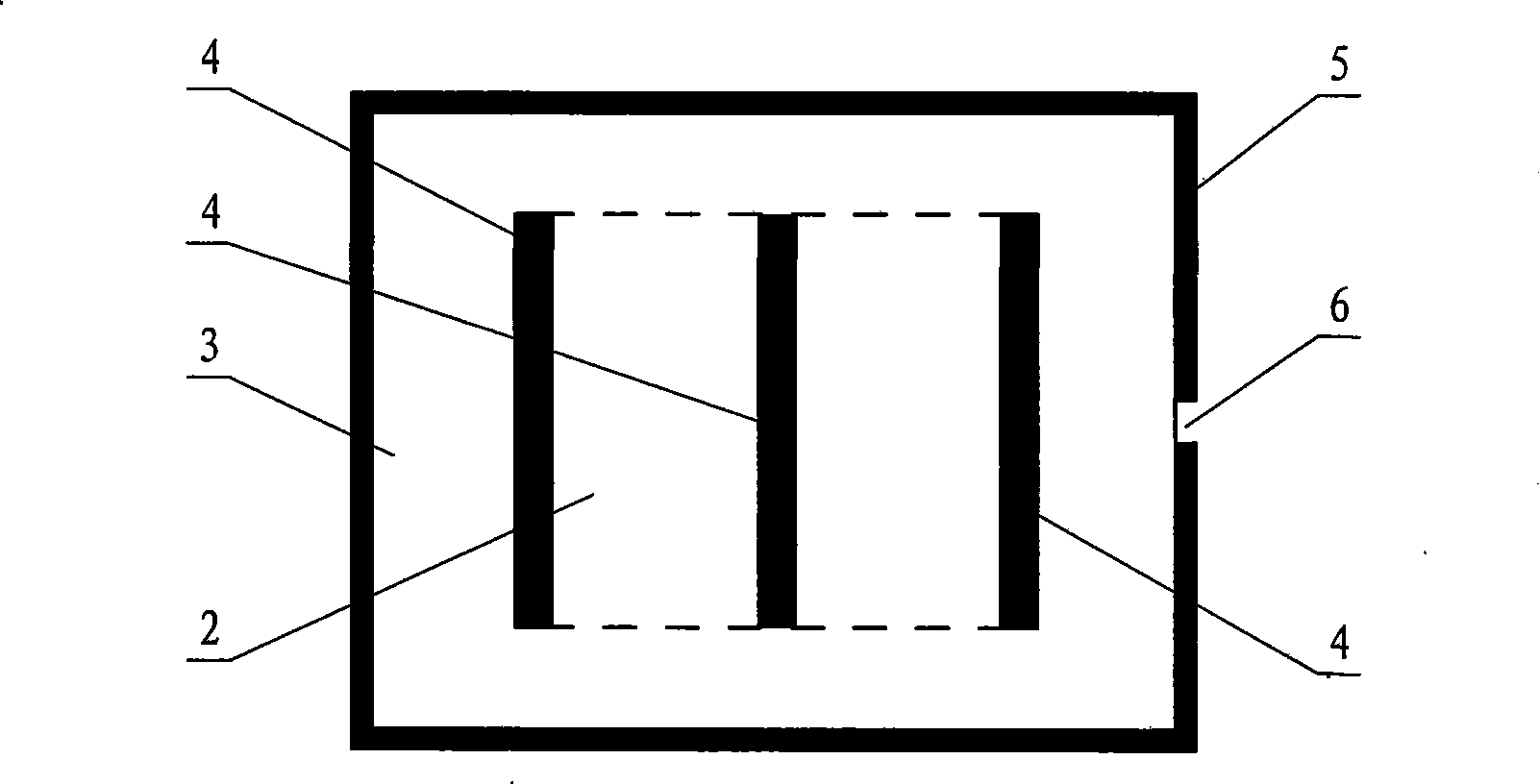

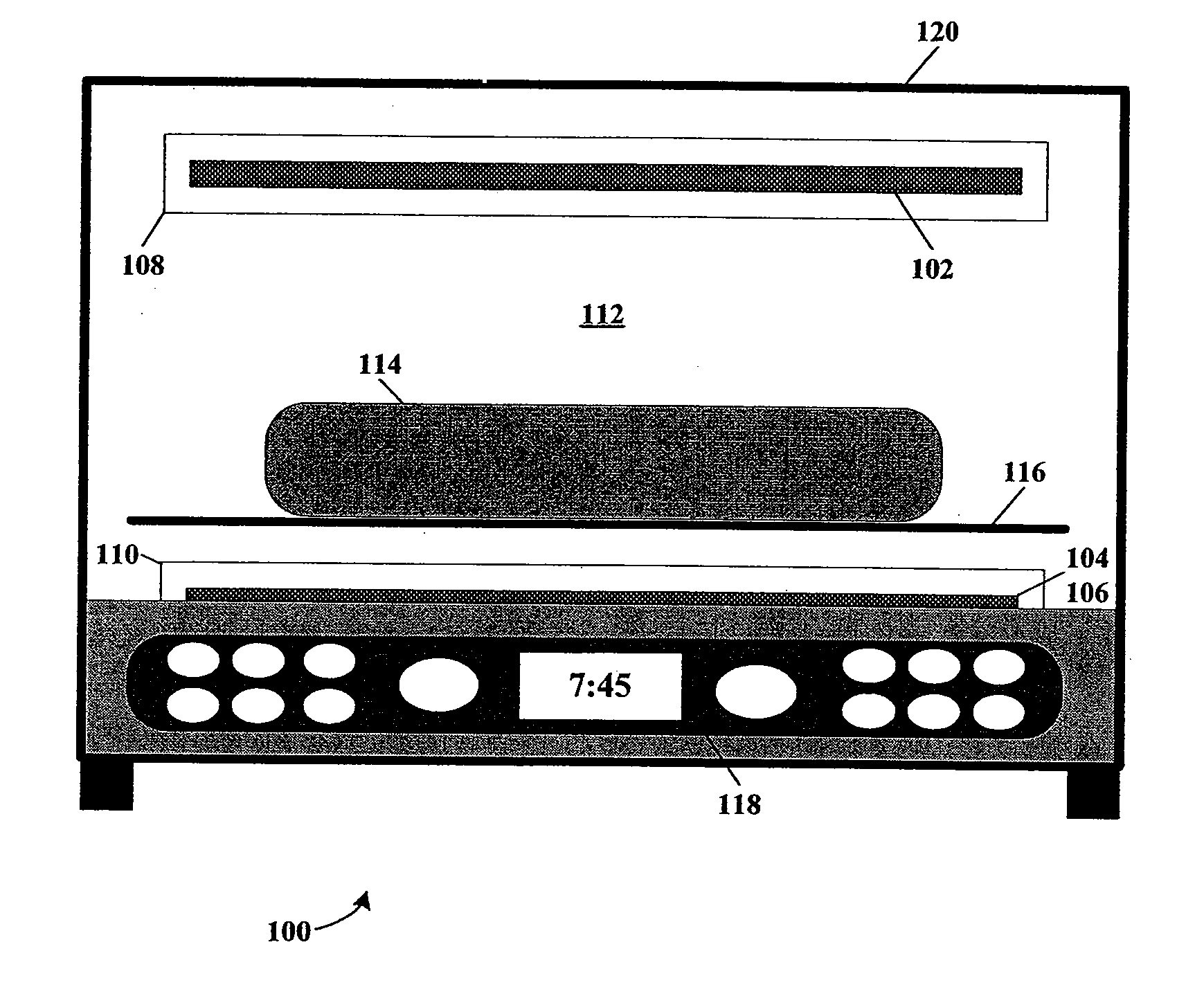

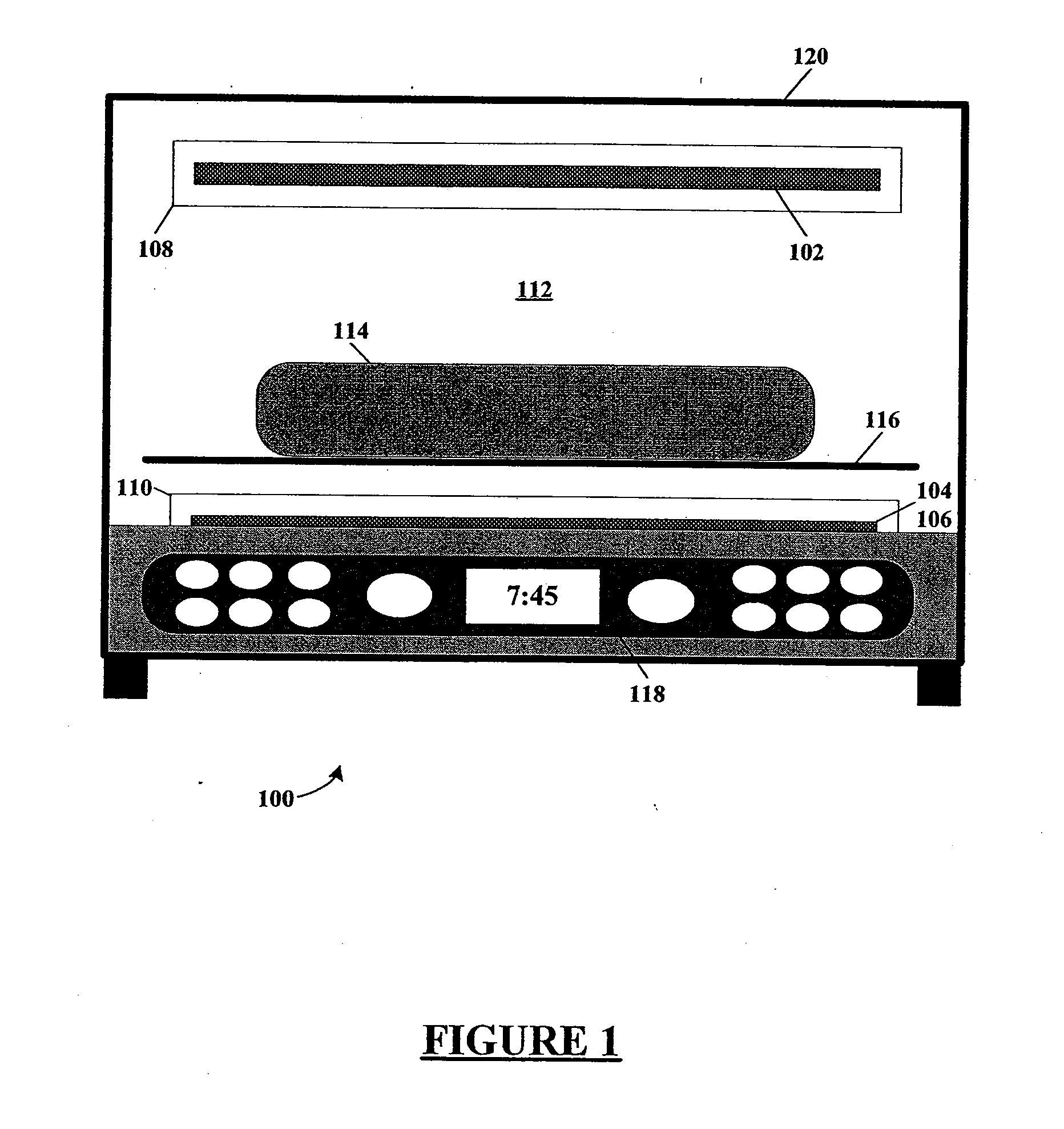

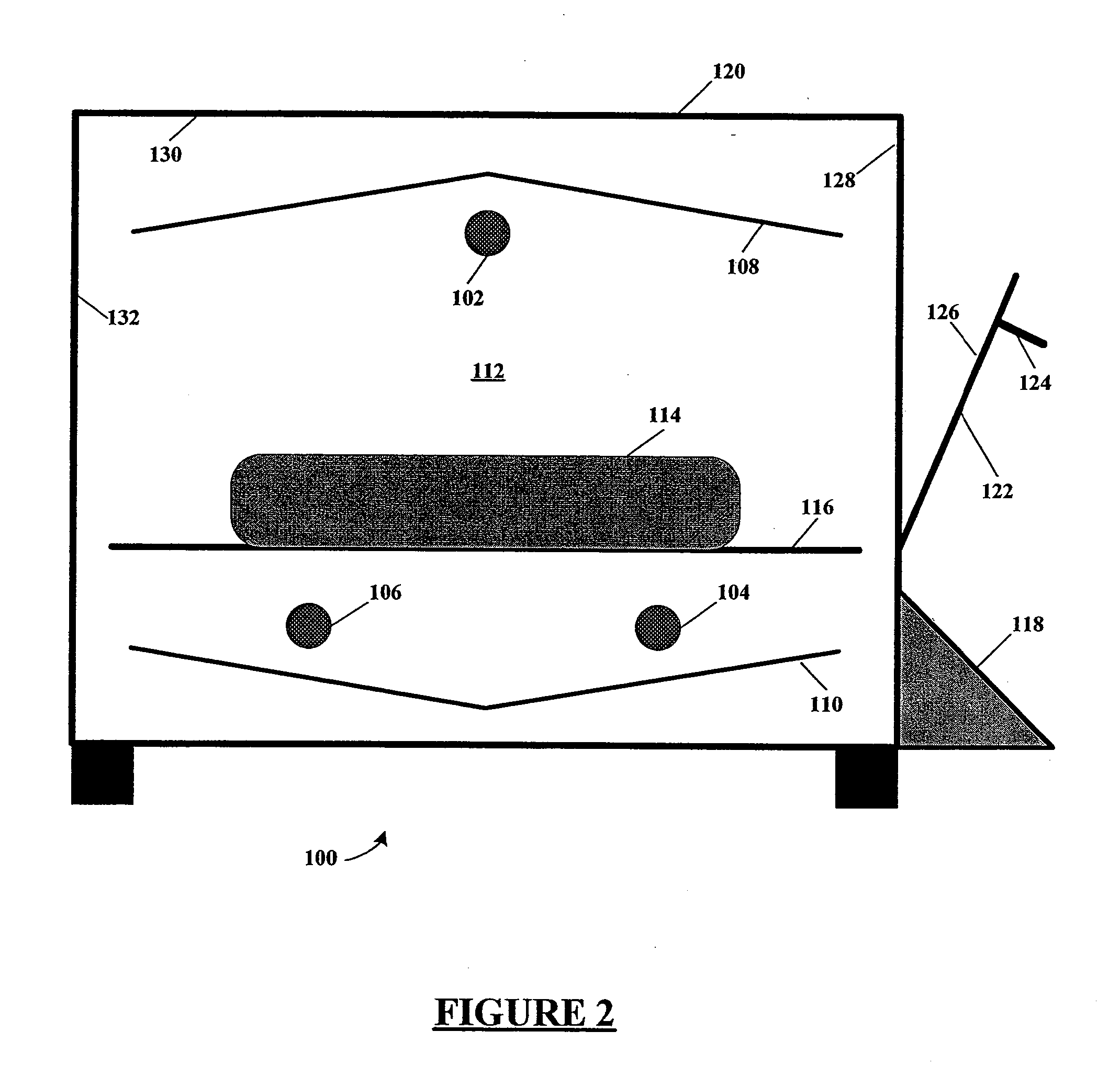

Multi-purpose oven using infrared heating for reduced cooking time

ActiveUS20050173400A1Quality improvementHigh speedDomestic stoves or rangesElectrical heating fuelThermal energyCooked food

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and re-heats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

Multi-purpose oven using infrared heating for reduced cooking time

ActiveUS7323663B2High speedEfficient use of powerRadiation pyrometryDomestic stoves or rangesThermal energyRadiant heat

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and re-heats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

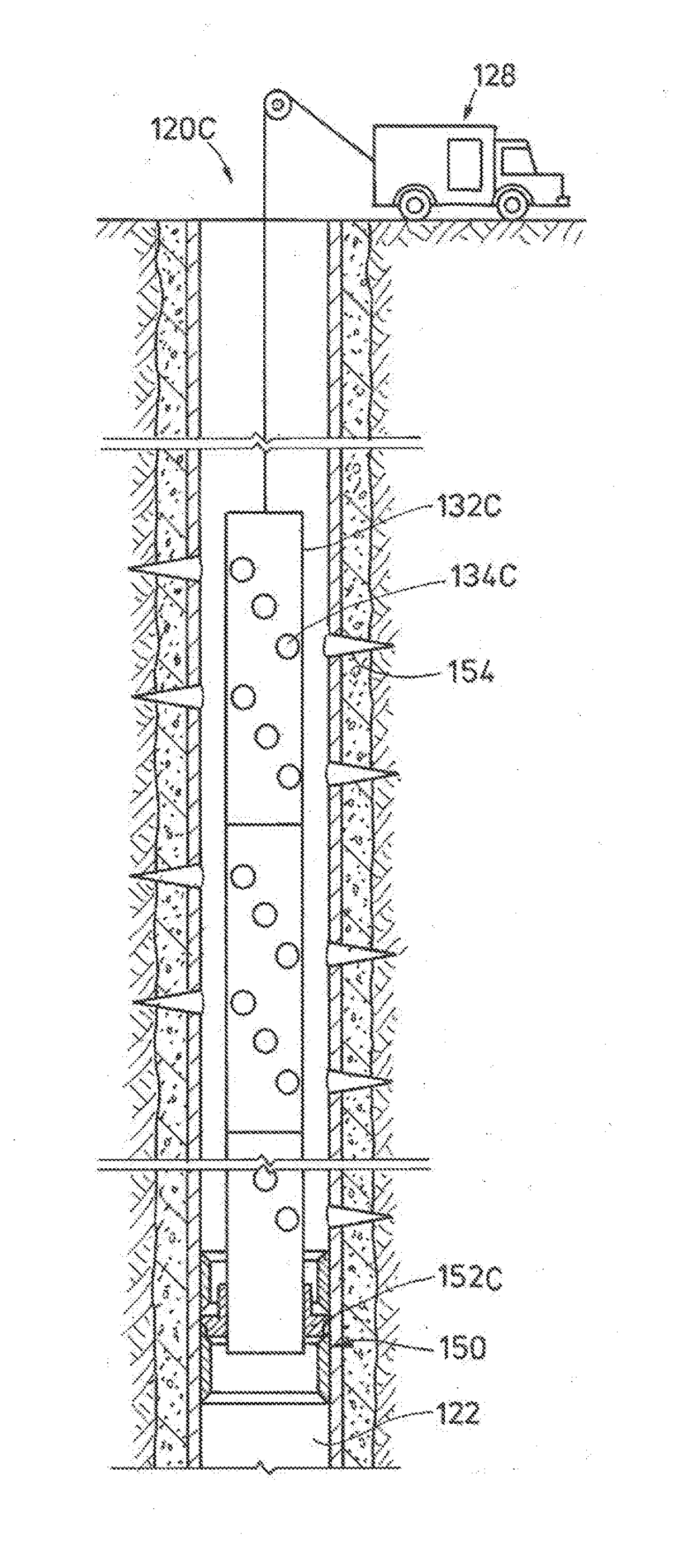

Subterranean Formation Shock Fracturing Charge Delivery System

InactiveUS20180030334A1Maximizes development and production and captureReduce stepsExplosive chargesBlasting cartridgesDetonationHydraulic fracturing

Owner:INNOVATIVE DEFENSE

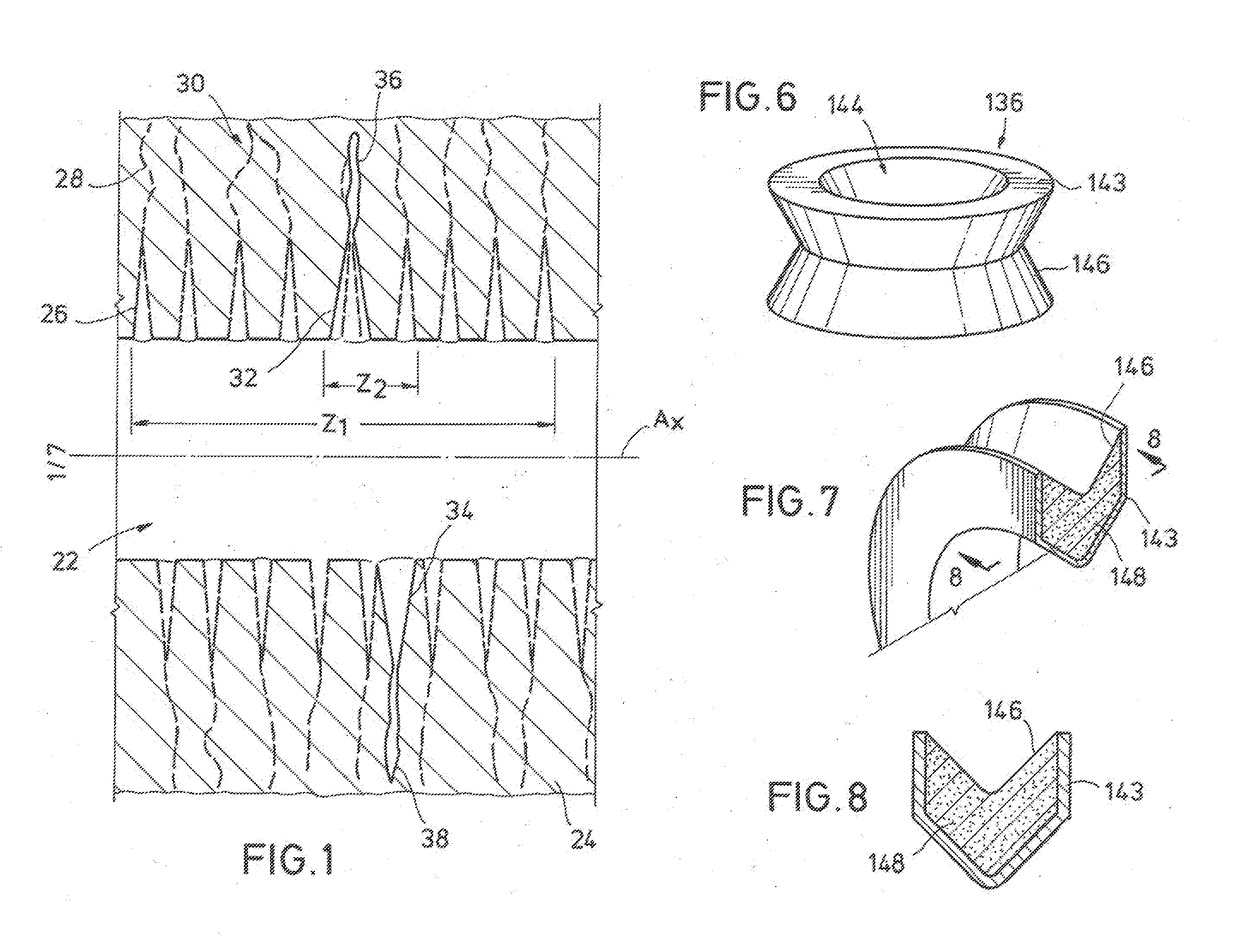

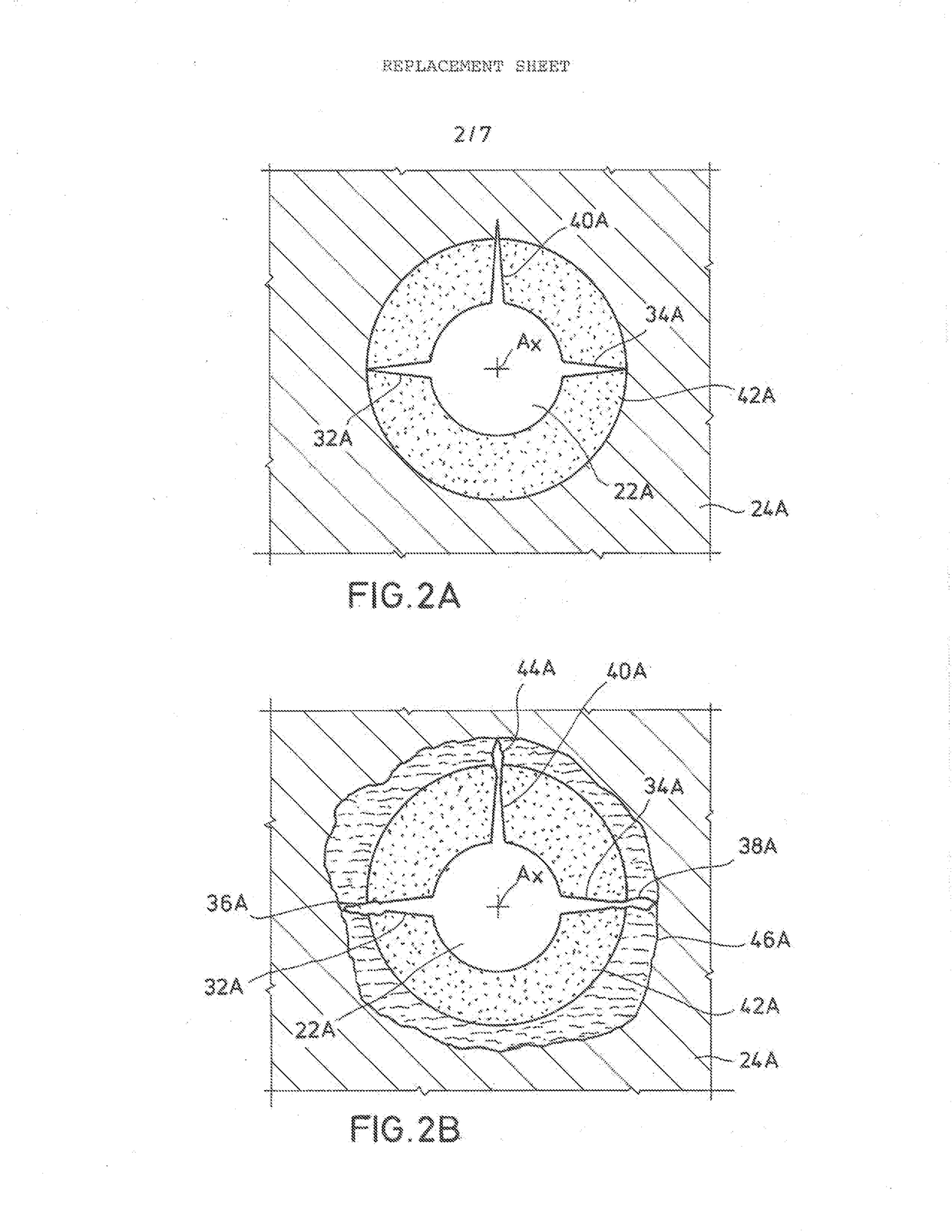

Band saw blade

The present disclosure relates to band saw blades often used for cutting wood at a sawmill. A band saw blade has teeth, and at least one tooth has a back angle that is greater than the back angle of conventional band saw blades. The greater back angle results in teeth having a smaller tooth angle so that the teeth make deeper penetration into wood or other materials that are cut by the blade.

Owner:COOKS SAW MFG

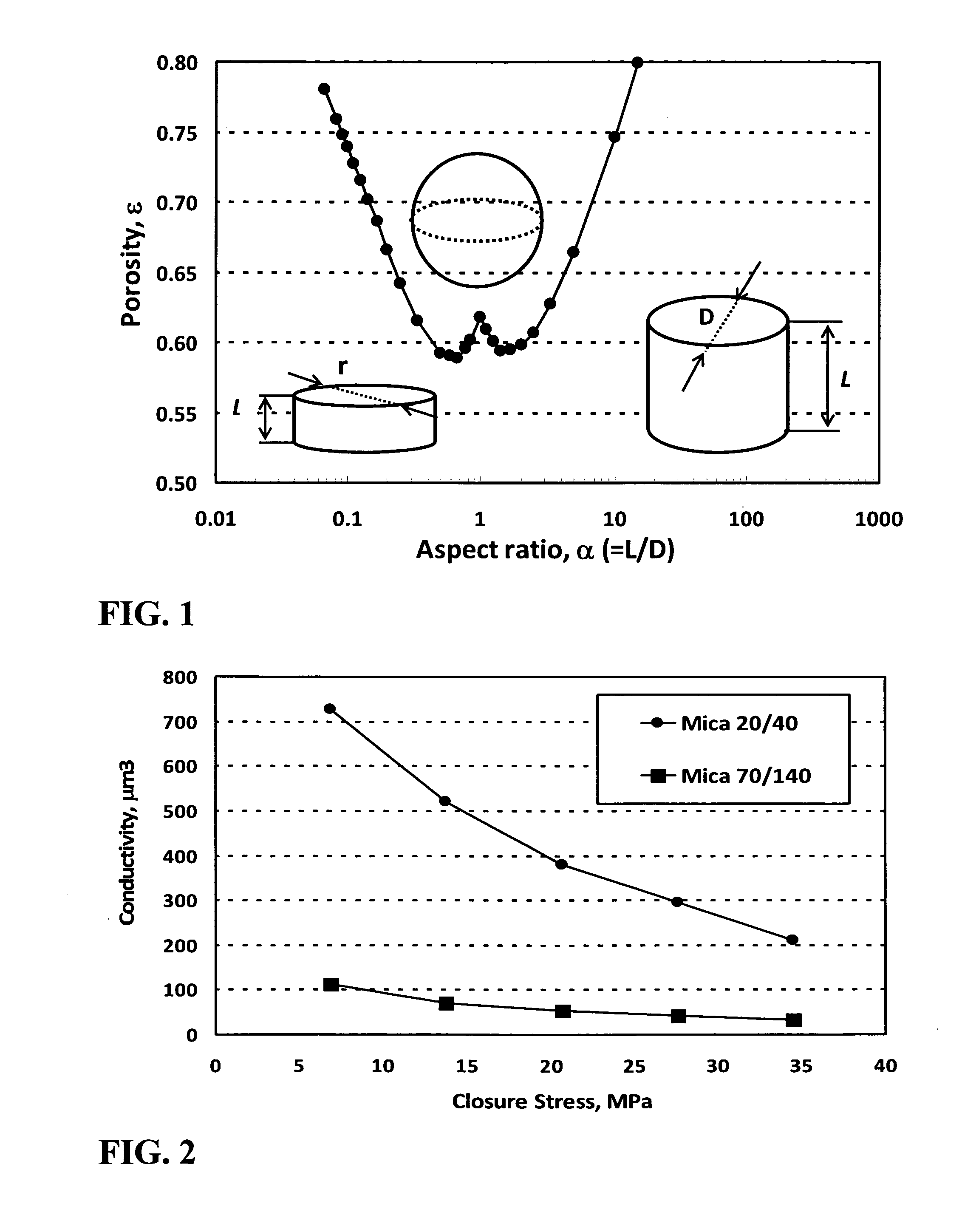

Hydraulic Fracturing Proppants

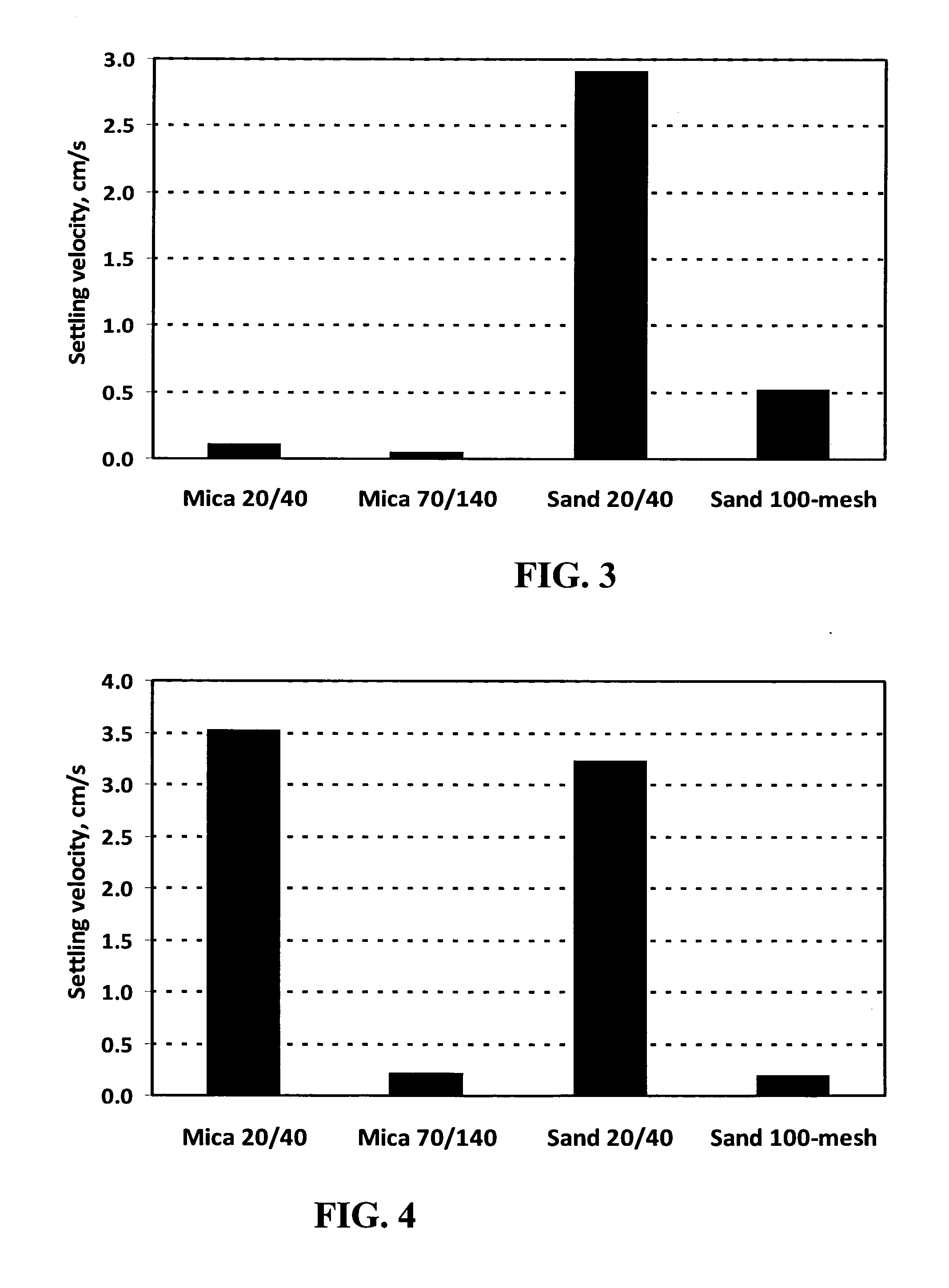

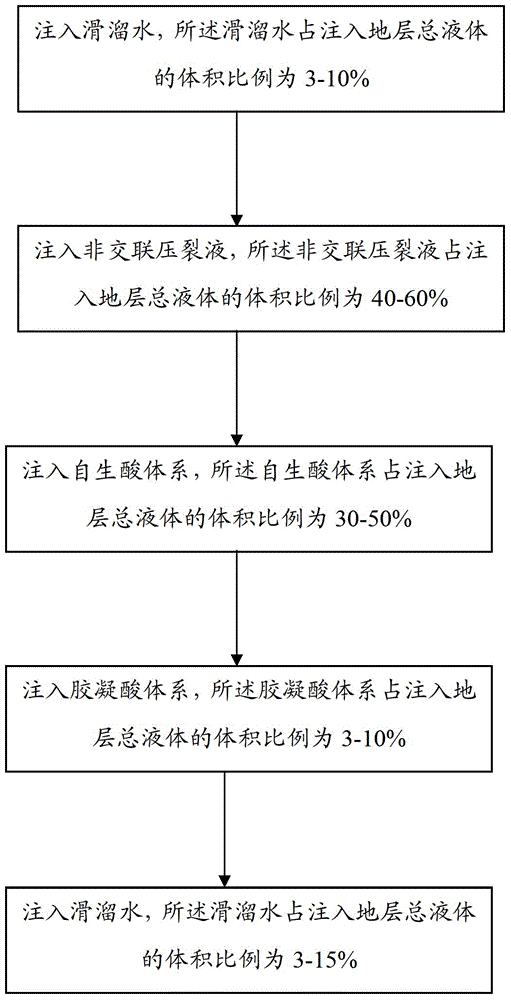

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

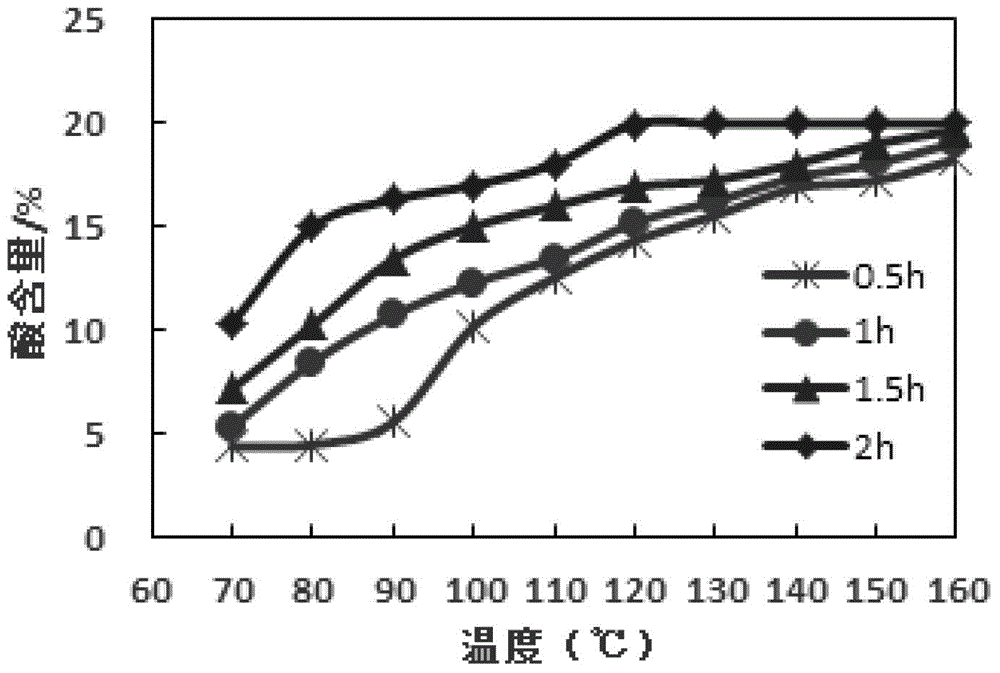

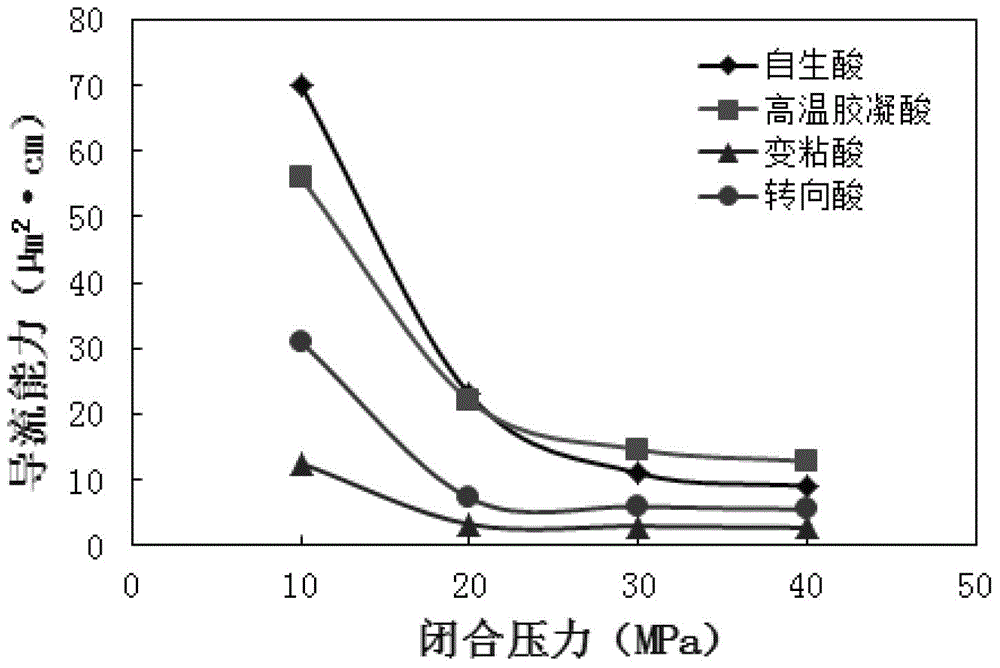

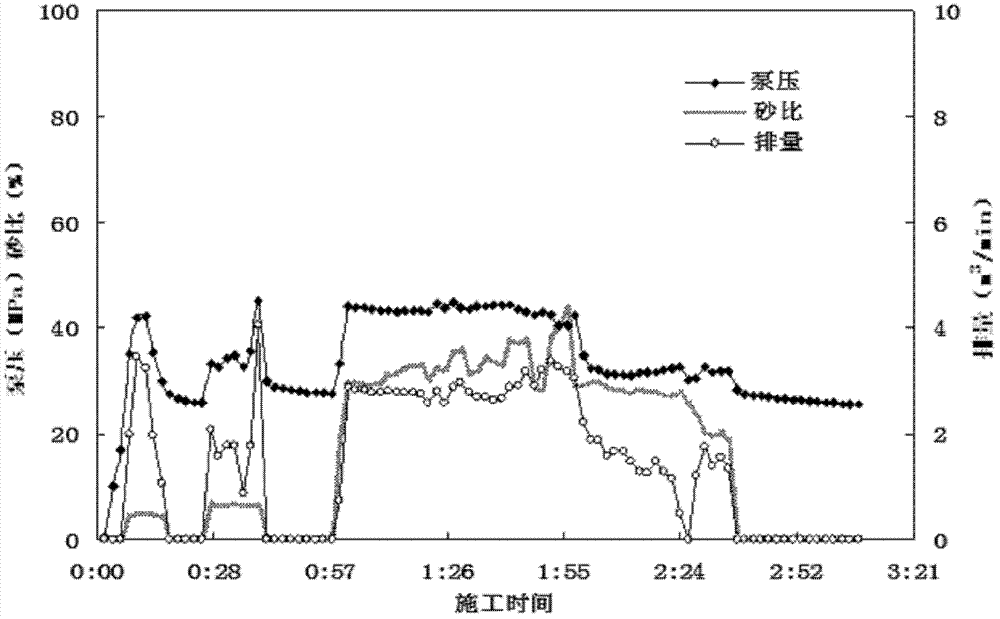

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

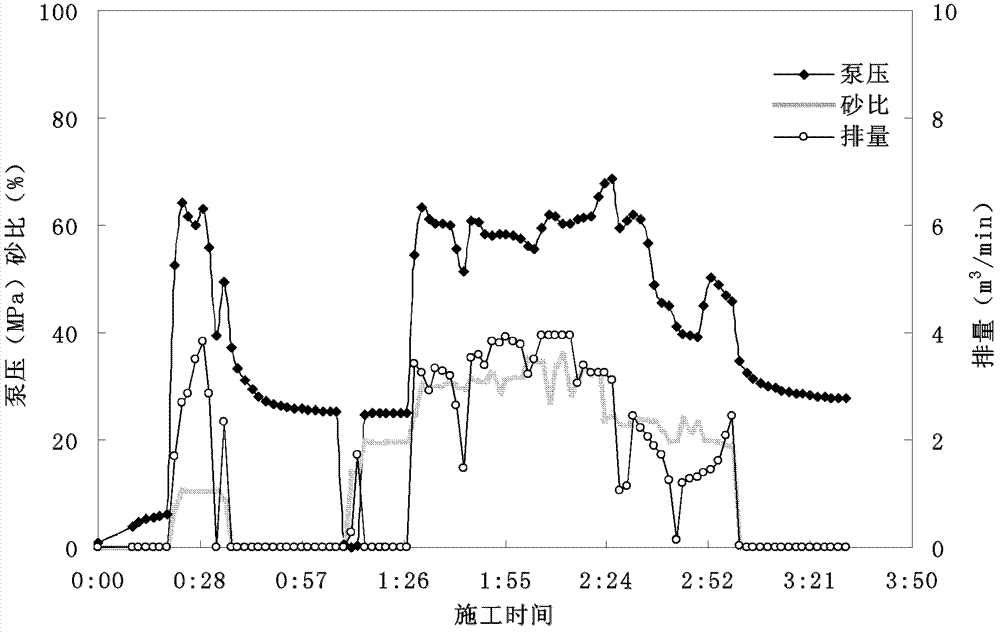

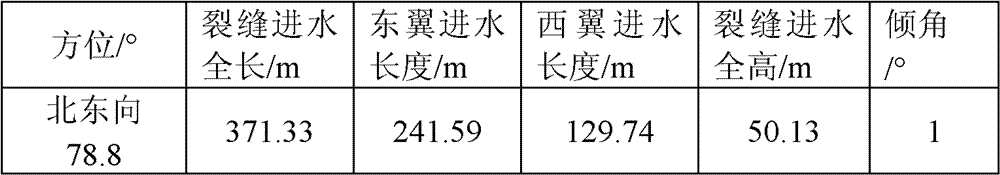

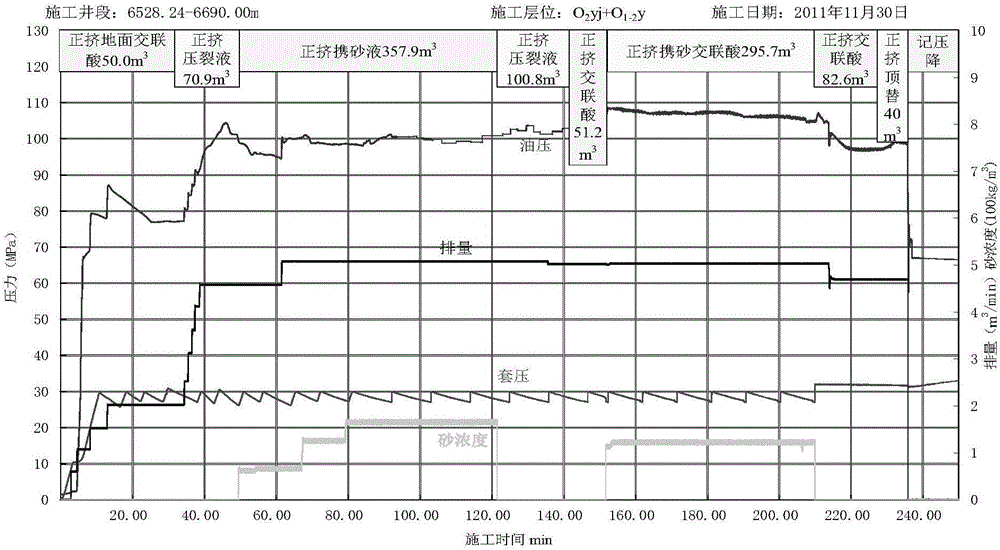

Cross-linked acid and sand-carrying acid-fracturing method for ground with argillaceous dolomites

ActiveCN103089228AImprove diversion capacityImprove well productivityFluid removalAcid etchingCross-link

The invention discloses a cross-linked acid and sand-carrying acid-fracturing method for a ground with argillaceous dolomites. Cross-linked acid-fracturing for the ground is combined with cross-linked acid sand-carrying acid-fracturing for the ground in the method, and in other words, the cross-linked acid and sand-carrying acid-fracturing method includes performing the cross-linked acid-fracturing in a prepad fluid stage; and performing the cross-linked acid sand-carrying acid-fracturing for the ground in a main sand feeding stage. The cross-linked acid and sand-carrying acid-fracturing method has the advantages that the process is simple, operation is facilitated, and a construction effect is obvious; the method can be widely applied to transformation construction for complex lithologic oil and gas reservoirs with argillaceous dolomites and the like; a deep-penetration prop fracture with durable flow conductivity can be formed to the greatest extent under the combined effect of acid-fracturing and sand-feeding acid-fracturing technologies, acid etching and propping effects are played for the fracture, and the flow conductivity of the artificial fracture and the productivity of an oil well are greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

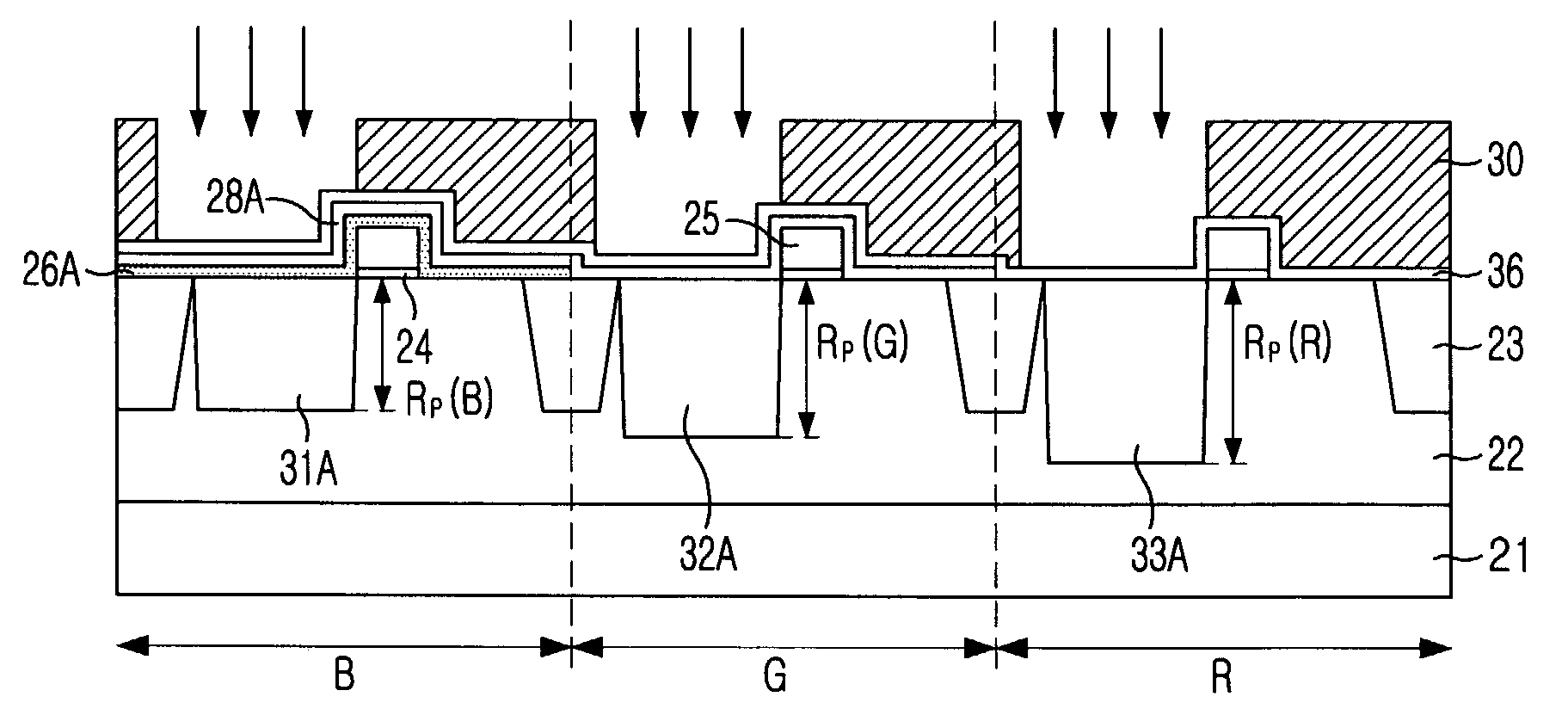

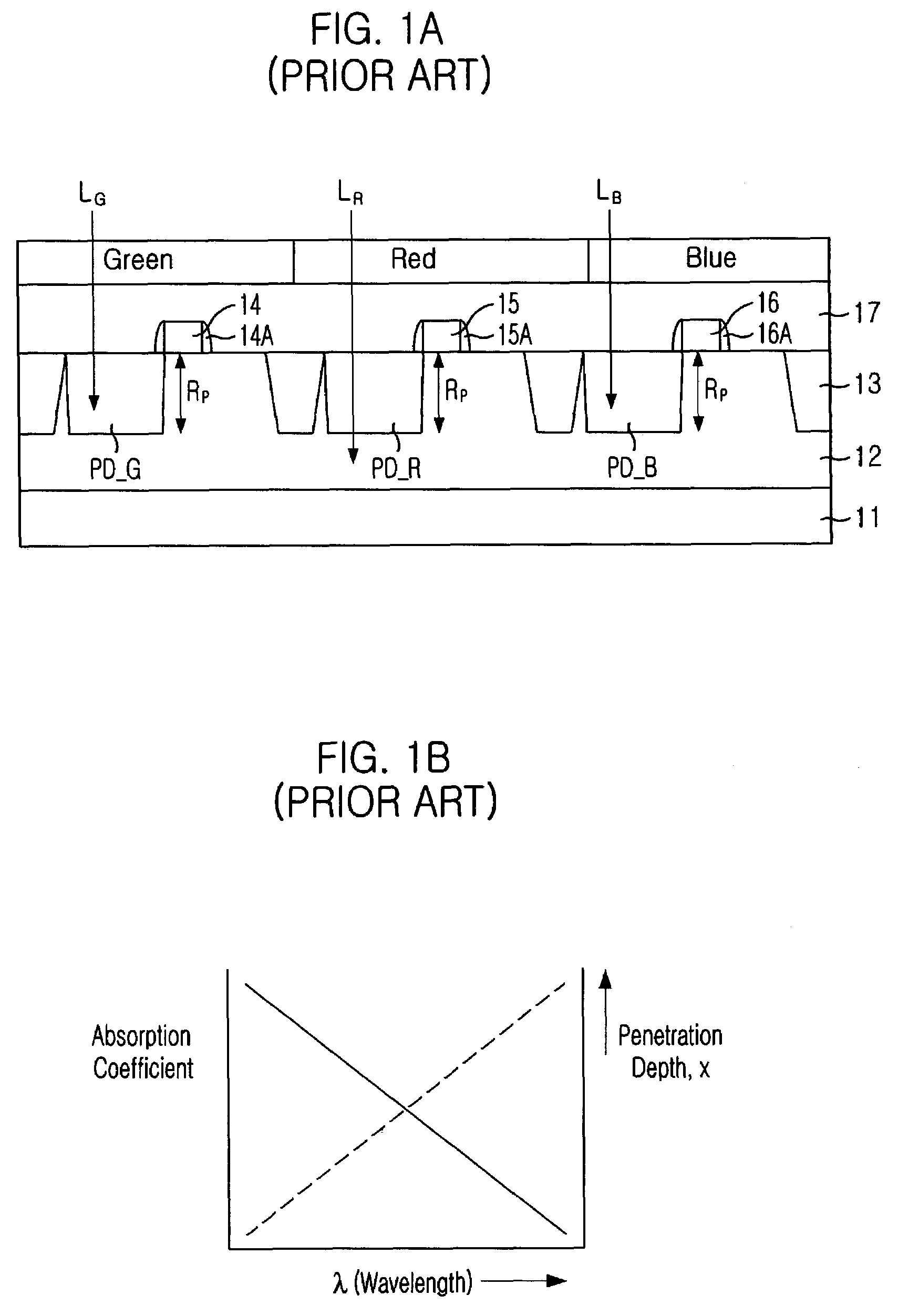

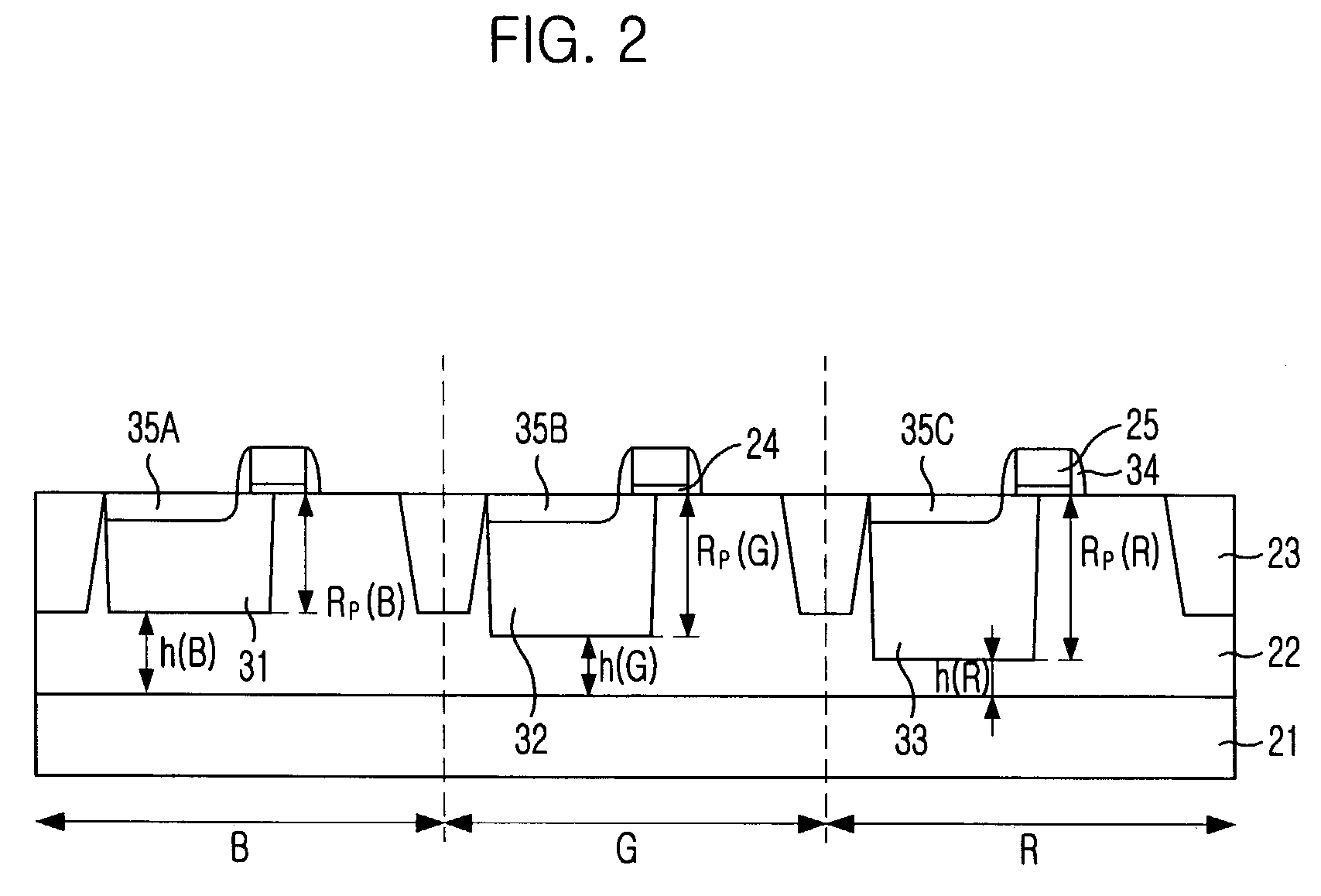

CMOS image sensor including photodiodes having different depth according to wavelength of light

InactiveUS7345703B2Avoid crosstalkReduction factorTelevision system detailsTelevision system scanning detailsCMOSGreen-light

An image sensor capable of preventing the cross-talk phenomenon due to a deep penetration depth and a low absorption coefficient of red light in a photodiode region and a method for fabricating the same, wherein the photodiode for collecting incident light has different depths in accordance with the wavelength of the incident light. The photodiode for receiving red light, which has the longest wavelength, has the deepest depth, the photodiode for receiving blue light has the least depth, and the photodiode for receiving green light, which has a wavelength between the red light and the blue light has an intermediate depth.

Owner:INTELLECTUAL VENTURES II

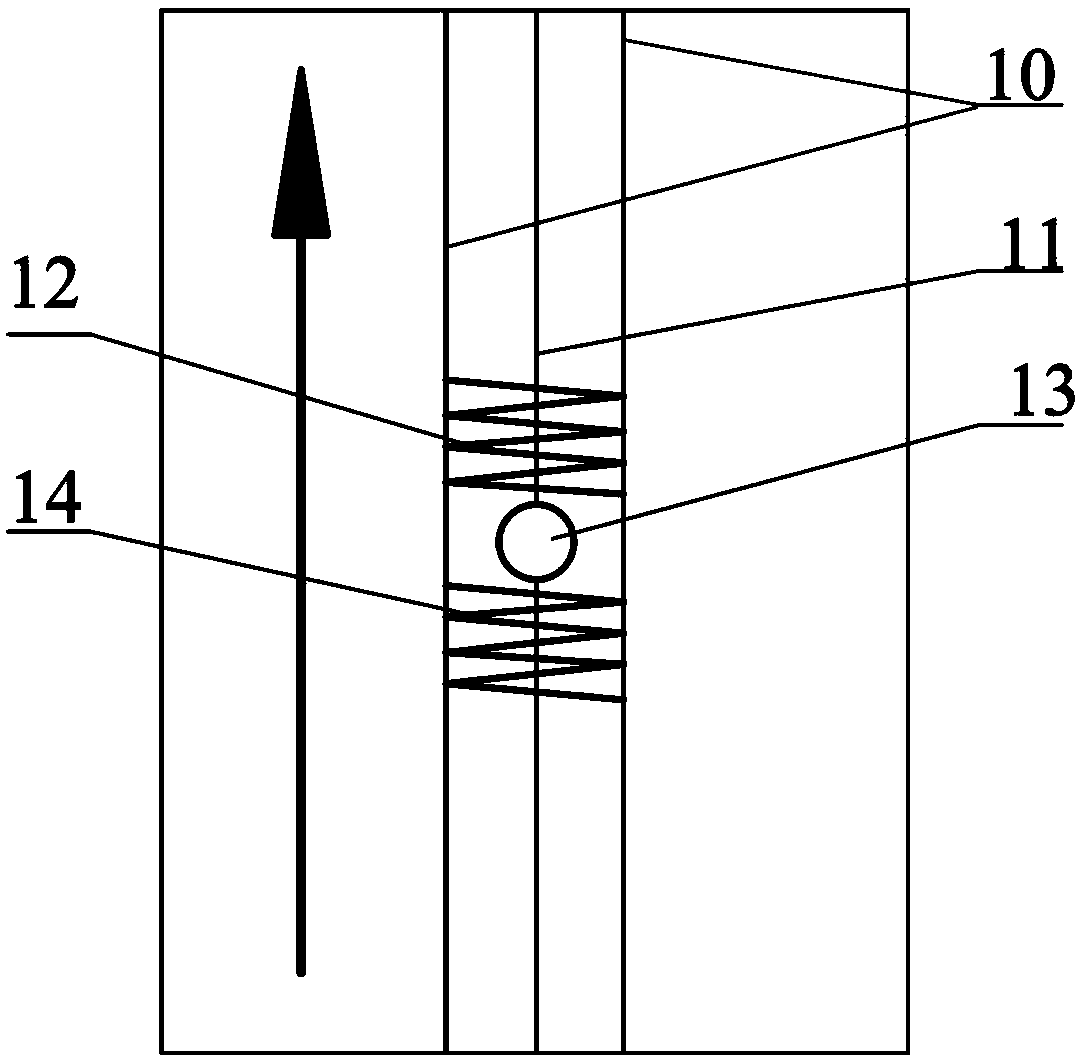

Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

ActiveCN103967472AFor precise controlSolving the Difficulties of Directional DrillingFluid removalSoil scienceDrill

The invention relates to a horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing. In order to solve the problems that hole forming performance of horizontal drilling in a coal bed is poor and buried drill accidents can happen easily and to achieve the forced gas drainage effect on tectonic soft coal, the well track of a horizontal well is controlled in mudstone or sand stone with a certain range above a coal bed top boundary, and the horizontal well is docked with a drainage vertical well at a far end. An ultra deep penetration perforating technology is used, according to the requirement for certain hole density and orientation, orientated perforating is conducted downwards on the horizontal well section in a segmented mode, a steel sleeve, a well cementation cement ring and a mudstone top plate are penetrated, and the horizontal well is communicated with a target coal layer below. Then, a clear water sand carrying fracturing technology is used, staged fracturing is conducted on the target coal bed according to the requirements for large discharge capacity, large liquid amount, high prepad fluid ratio, large sand amount and middle sand ratio, and the purpose of increasing production is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

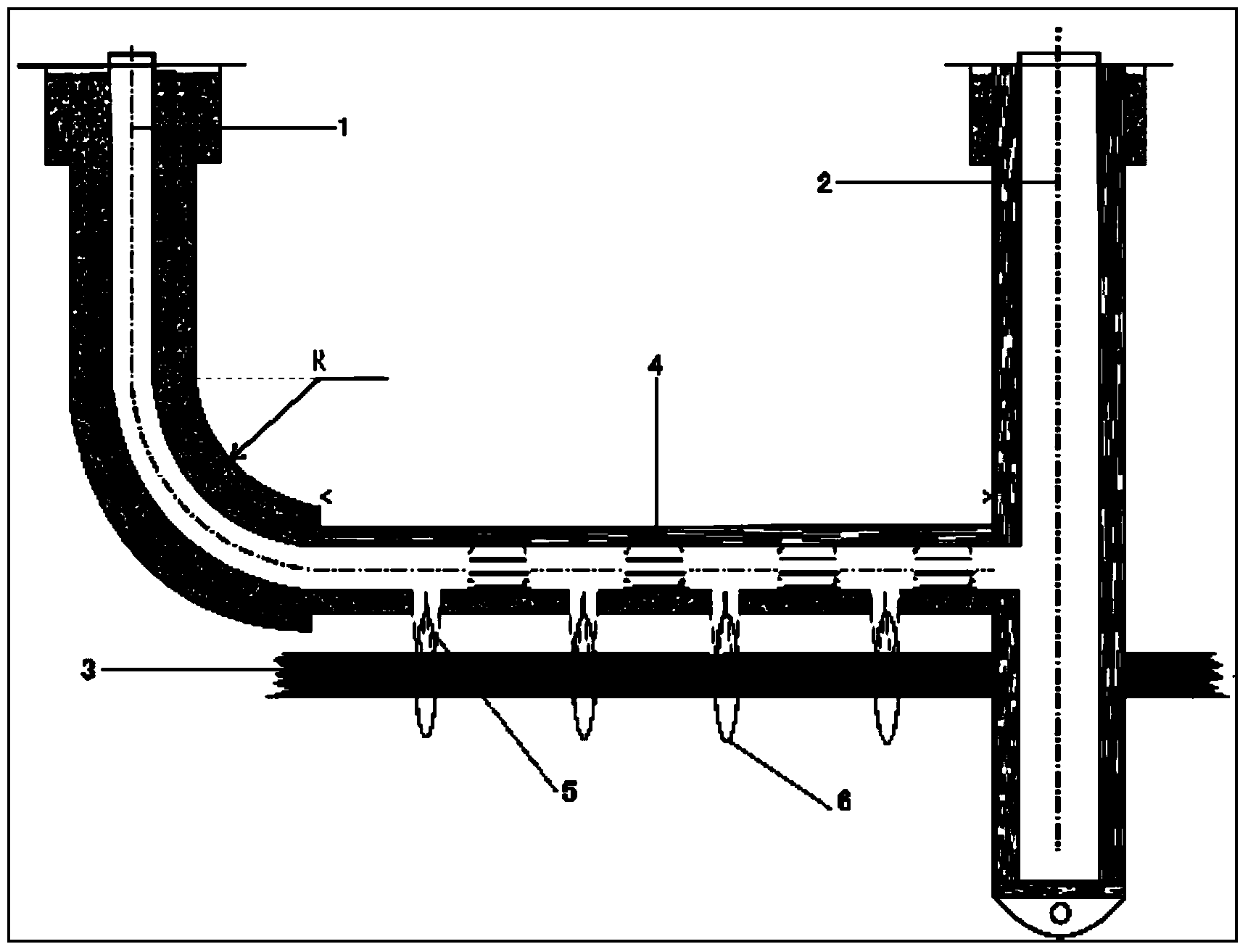

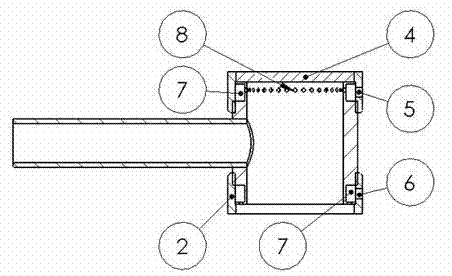

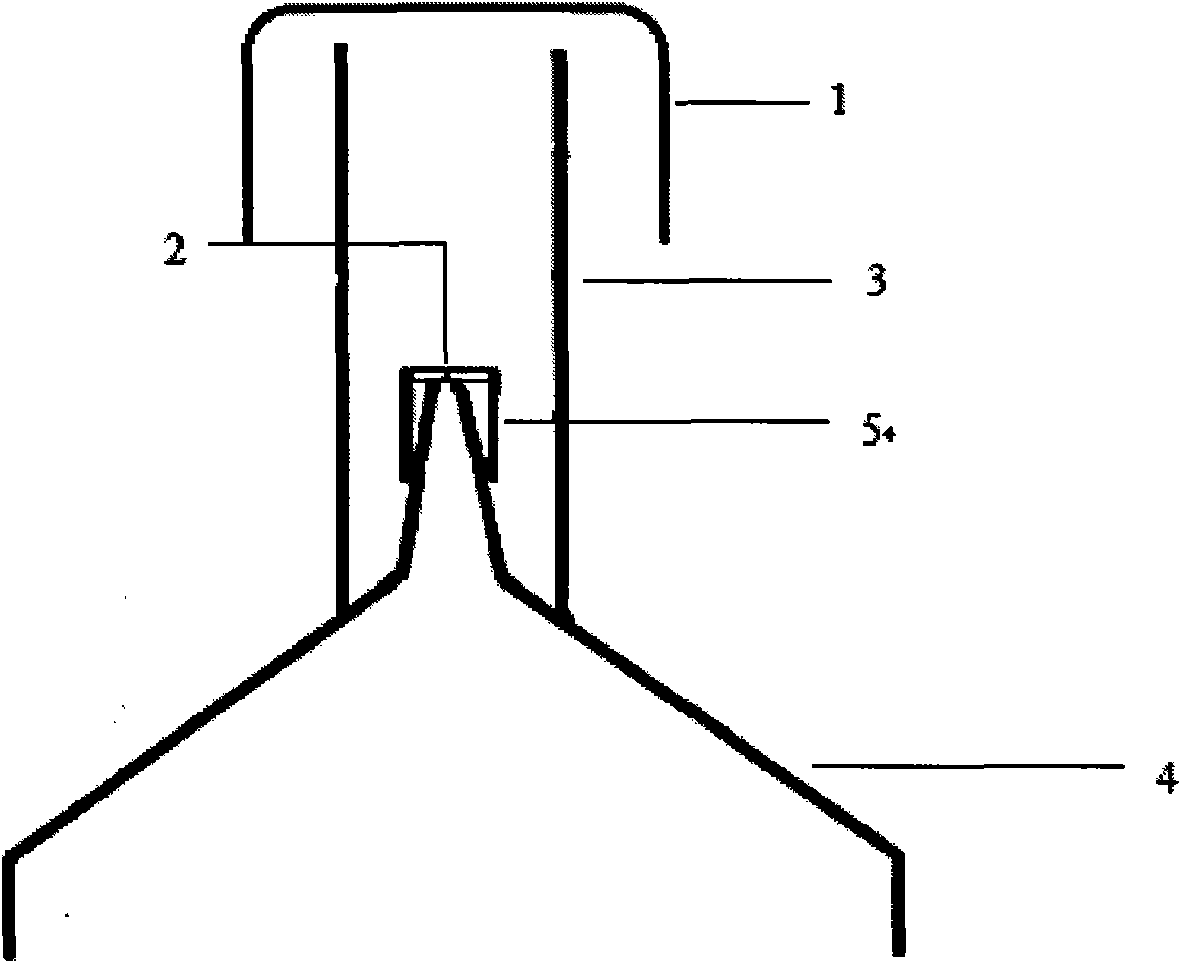

Plasma-side-suction negative pressure device for laser welding

InactiveCN102642085AUnlimited sizeImprove welding qualityLaser beam welding apparatusHigh power lasersClosed chamber

The invention relates to a plasma-side-suction negative pressure device for laser welding. The plasma-side-suction negative pressure device can be mounted on any laser welding gun head. A negative pressure chamber device is fixed with the laser welding gun head and can move relative to a workpiece to be welded; and the negative pressure chamber device is arranged above a welding puddle area on the surface of the workpiece to be welded and is used for quickly exhausting, so that local negative pressure lower than the normal atmospheric pressure is generated in a closed chamber fixed in the laser welding gun head, and a negative pressure environment can be formed around a welding puddle. With the adoption of the plasma-side-suction negative pressure device for laser welding, the plasma generation during the process of high-power laser deep penetration welding can be effectively inhibited, and the weld-seam deep-layer air holes caused by a keyhole effect are eliminated. The plasma-side-suction negative pressure device for laser welding has the advantages of no restriction of workpiece size, flexibility and convenience in use, good stability, higher welding quality and increased stability in a welding process.

Owner:SHANGHAI JIAO TONG UNIV

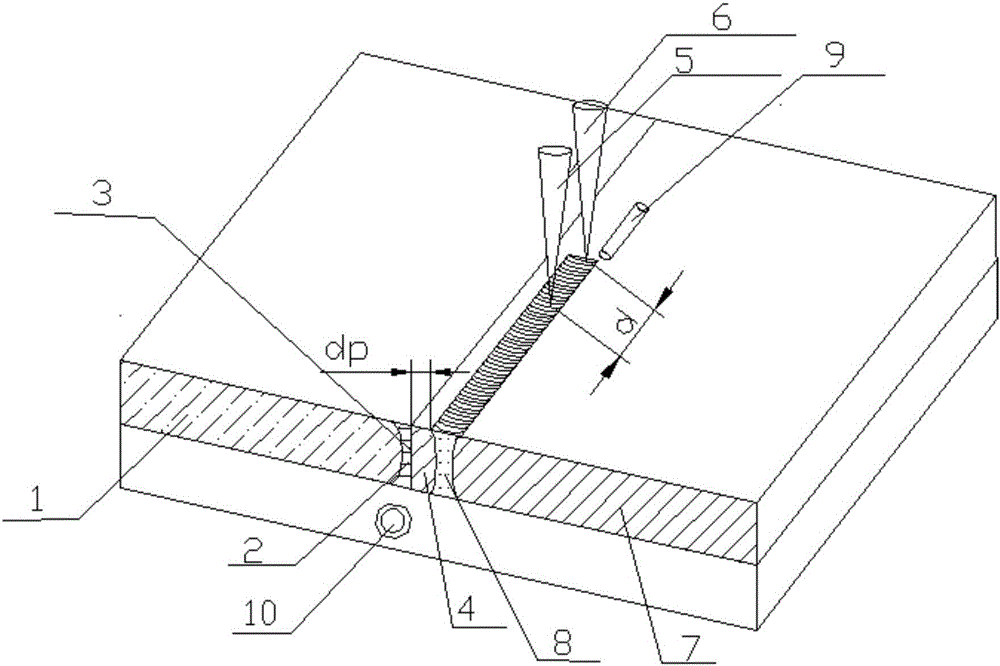

Double-beam laser deep penetration brazing method applicable to moderately thick plate aluminum/steel dissimilar alloy connection

InactiveCN106513892APremium connectionMeet welding needsSoldering apparatusWelding/soldering/cutting articlesForms of energyThick plate

The invention provides a double-beam laser deep penetration brazing method applicable to moderately thick plate aluminum / steel dissimilar alloy connection, and belongs to the field of laser machining of dissimilar alloy connection. According to the double-beam laser deep penetration brazing method, two laser beams with different forms of energy are arranged in series, and act on the steel side; through the main laser beam, deep penetration is achieved on the steel side; a solid-state steel intermediate layer is acquired by controlling the offset dp of the laser beams with a steel / aluminum interface and the heat input on a regulating joint interface, the heat input for welding is transferred through the solid-state steel intermediate layer, an aluminum alloy is molten, and the molten aluminum alloy is wetted and spread, thereby achieving laser deep penetration brazing of an aluminum / steel dissimilar alloy; when the auxiliary laser beam goes before, the stability of laser deep penetration welding is improved and the effect of preheating treatment before welding is achieved; and when the auxiliary laser beam follows after, the wetting and spreading properties of aluminum are improved, and the effect of heat treatment after welding on the joint interface is achieved. By adoption of the double-beam laser deep penetration brazing method provided by the invention, the distribution of welding temperature fields can be controlled, the interfacial intermetallic compound distribution and thickness uniformity can be improved, and the high-quality and efficient dissimilar alloy connection can be achieved.

Owner:BEIJING UNIV OF TECH

Dedicated welding active agent for deep penetration TIG welding and using method

InactiveCN103990919ASimple welding processIncrease productivityArc welding apparatusWelding/cutting media/materialsActive agentMechanical property

The invention discloses a dedicated welding active agent for deep penetration TIG welding. The welding active agent is composed of, by mass, five percent to 15 percent of NaCl powder, 10 percent to 20 percent of CaO powder, 15 percent to 20 percent of MgF2 powder, 10 percent to 15 percent of Fe2O3 powder, seven percent to 10 percent of SiO2 powder, eight percent to 10 percent of TiO2 powder, 17 percent to 20 percent of Cr2O3 powder, four percent to five percent of La2O3 powder and four percent to five percent of Y2O3 powder. The using method of the active agent comprises the steps that calculation is carried out according to the mass percent, 92 percent to 95 percent of the powder of the dedicated welding active agent for deep penetration TIG welding is mixed with five percent to eight percent of acetone to form the pasty or grease-shaped welding active agent, the surface of a workpiece is evenly coated with the welding active agent through a brush, and welding is carried out after the acetone is fully volatilized. According to the welding active agent, complete penetration is achieved on AISI316 austenitic stainless steel and X70 pipeline steel with the thickness of 14 mm through deep penetration TIG welding, the welding process is simplified, a coarse structure is avoided, the mechanical property of a welding joint is improved, production efficiency is improved, and production cost is lowered.

Owner:ZHANGJIAGANG HUABAO MACHINERY MFG

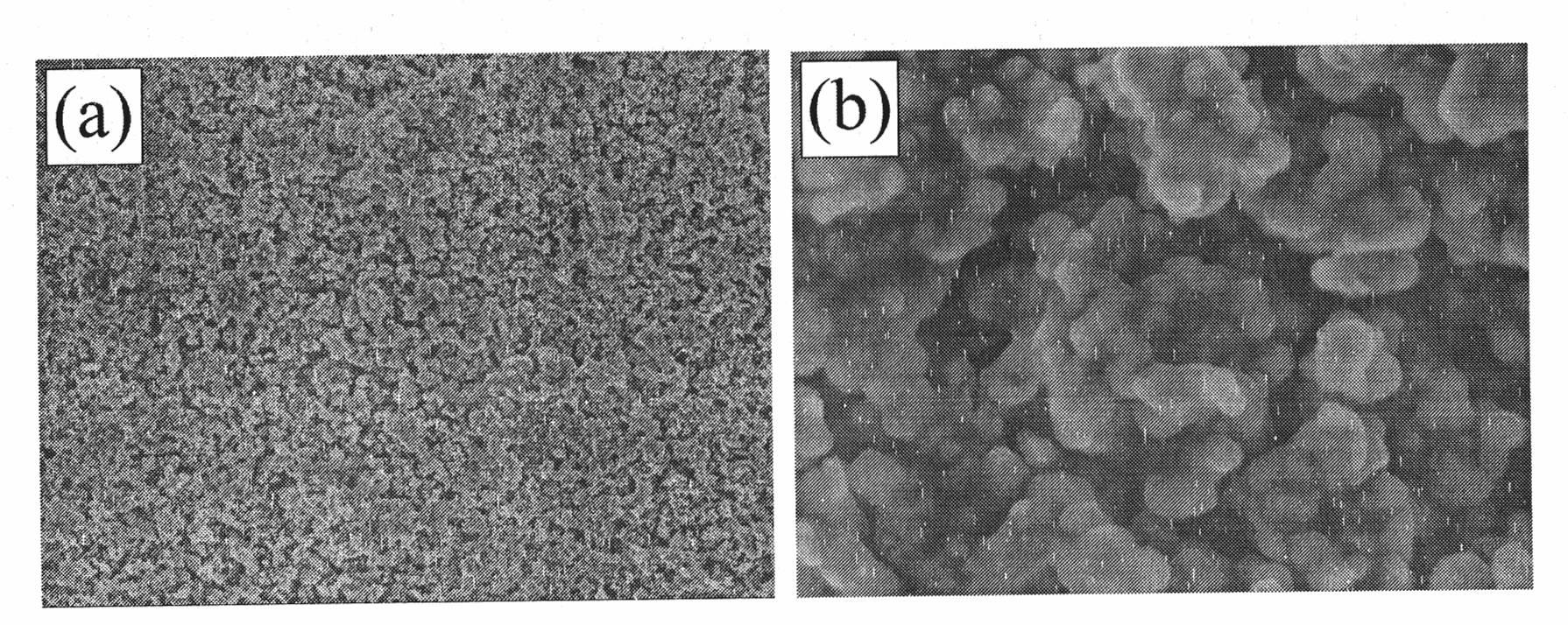

Preparation method and device for nano porous metal or ceramic

InactiveCN101851709ASmall apertureLarge specific surface areaCeramicwareGlass containerMelting point

The invention discloses a preparation method and a preparation device for nano porous metal or ceramic, and relates to the field of porous materials. The preparation method comprises the following steps of: adhering micron-sized metal powder to a processed substrate by using abietic resin; standing and air drying the substrate; controlling the temperature of the surface of the irradiated powder by adjusting laser processing parameters in different atmospheres with laser deep penetration welding technology and heating the micron-sized metal powder to be in the proximity of the melting point; and quickly melting and adhering the heated powder, curing and thinning the heated powder and volatizing the abietic resin to produce the nano porous metal or ceramic. The preparation device comprises a workbench, a glass container, a laser spot energy optimization device, a laser, a high-temperature-resistant temperature measurement probe or embedded temperature measurement line, a high-accuracy full-automatic computer temperature measurement and acquisition system and the like. The method and the device have the advantages of simple process, low cost, easy implementation of automation and suitability for batch production.

Owner:JIANGSU UNIV

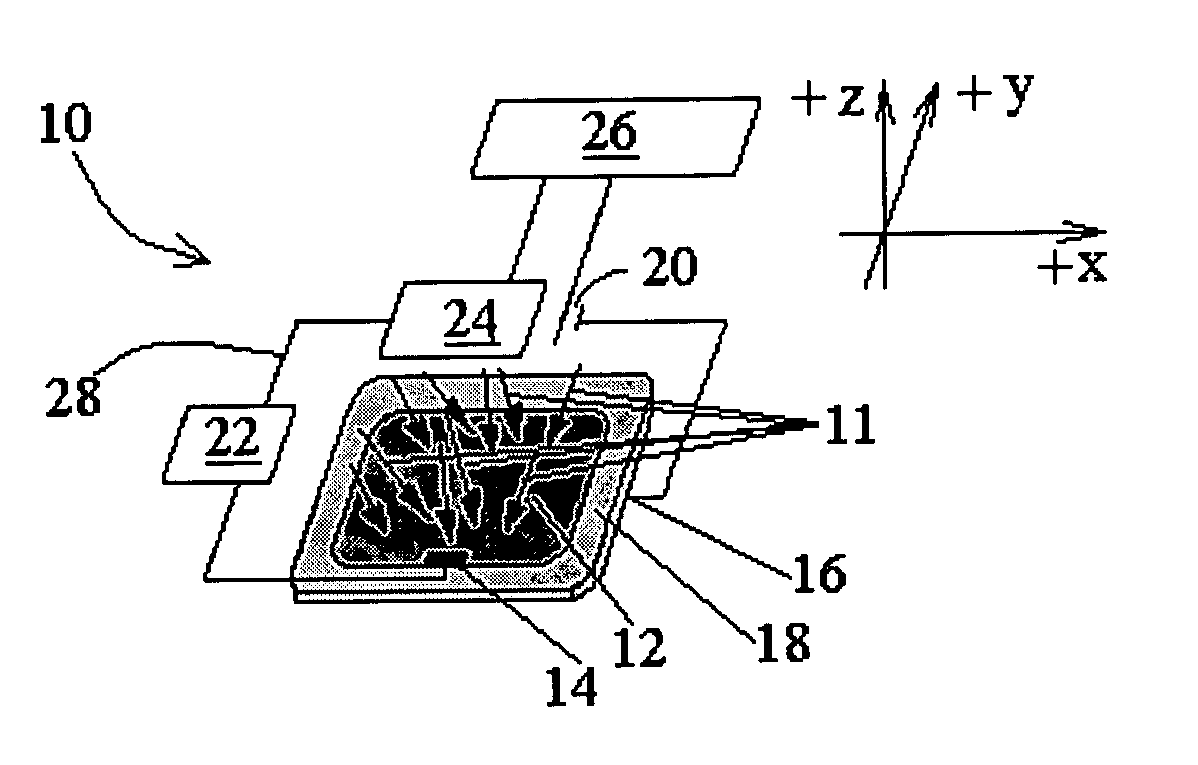

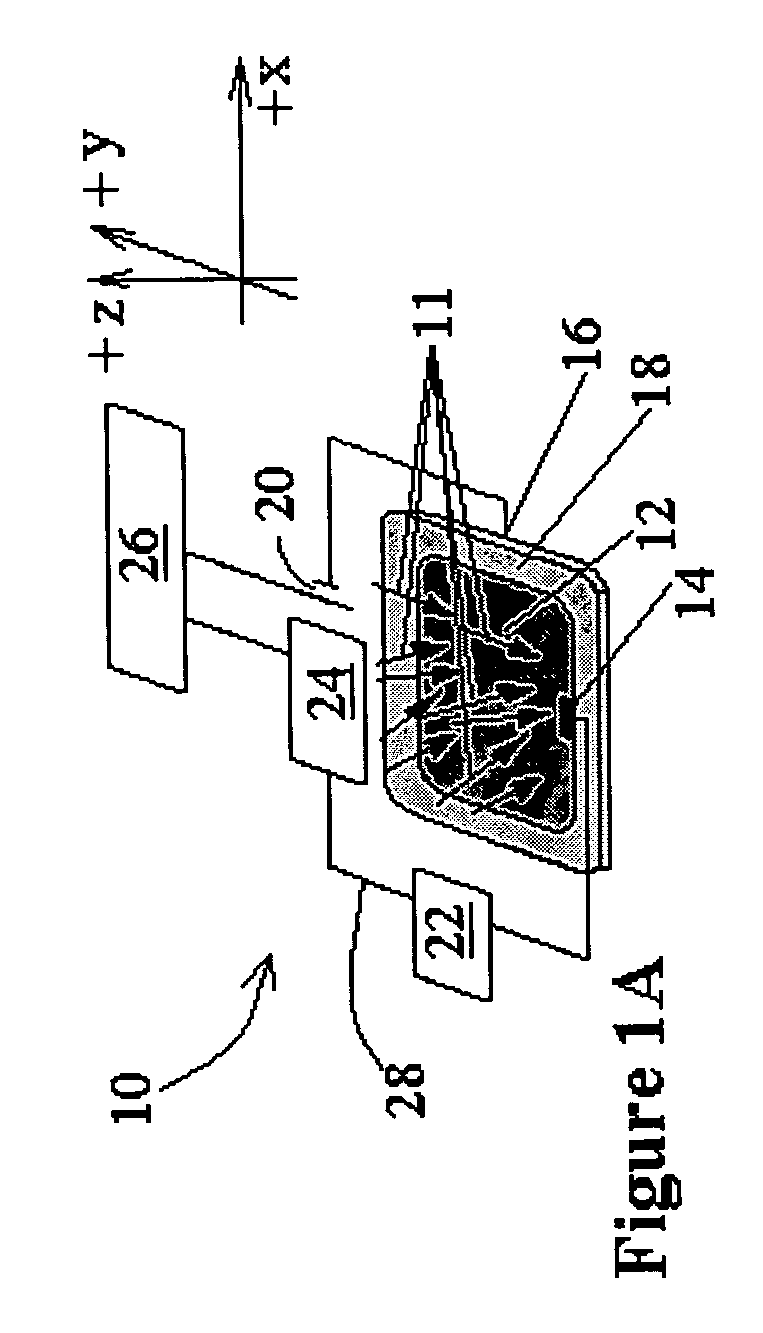

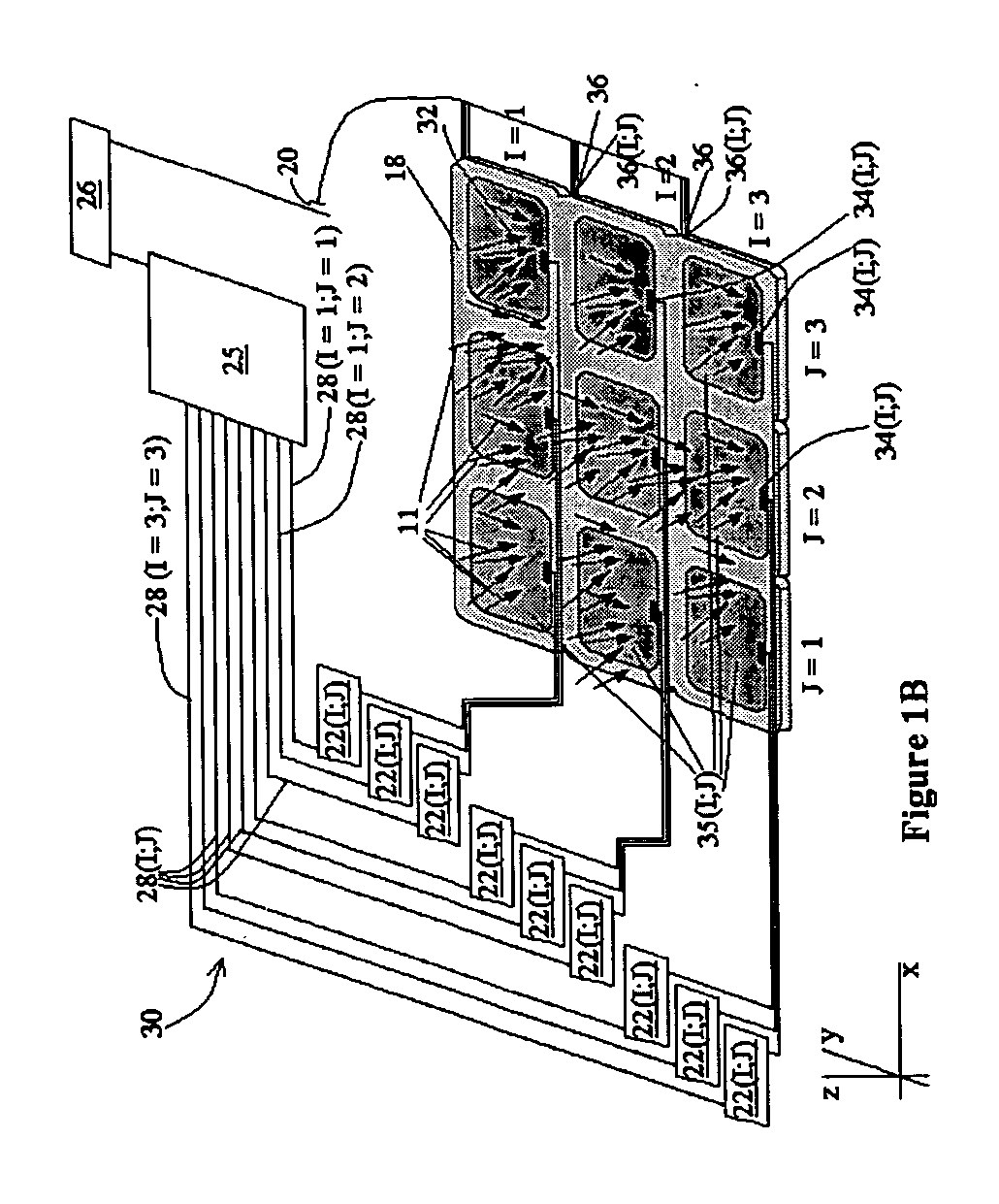

Low-voltage, solid-state, ionizing-radiation detector

InactiveUS20060033029A1Low working voltageIncreased manufacturing flexibilitySolid-state devicesMaterial analysis by optical meansLow voltageHigh pressure

A stratified, solid-state detector for ionizing radiation, is provided, wherein an operating bias is applied in parallel to all the strata. Since the bias required for accelerating electrons away from holes in a solid-state material is generally a function of material thickness, a stack of thin solid-state-material layers, connected in parallel, will operate at only a fraction of the bias required for a single, thick layer of solid-state-material of an equivalent thickness. Thus, stratification allows for reduced operating voltage and improved manufacturing flexibility. Additionally, a high-voltage power supply need not be used, thus increasing the safety of the detector. Stratification may further provide information on incident-radiation energy, based on depth penetration into the detector, wherein the layers may operate as “depth pixels.” Generally, the higher the incident radiation energy, the greater the probability for deep penetration into the solid state material. The stratified, solid-state detector may be designed as a stack of relatively thin solid-state-material layers, each with dedicated electrical contacts, and electrical insulation between layers. Alternatively, the stratified detector may be designed as a stack of relatively thin solid-state-material layers, with thin electrode layers, alternating between positive and negative senses, between them. Alternatively, the stratified detector may be designed as a stack of relatively thin solid-state-material layers, with thin electrode strips between them, wherein the electrode strips form a weave: at one layer the electrode strips are positive, running in a first direction, and at another, the electrode strips are negative, and running in a direction orthogonal to the positive strips. In effect, the weave electrode structure forms a pixel-like structure from single-pixel solid-state-material layers. The incident radiation may be orthogonal to or parallel with the stack of solid-state-material layers.

Owner:V TARGET TECH

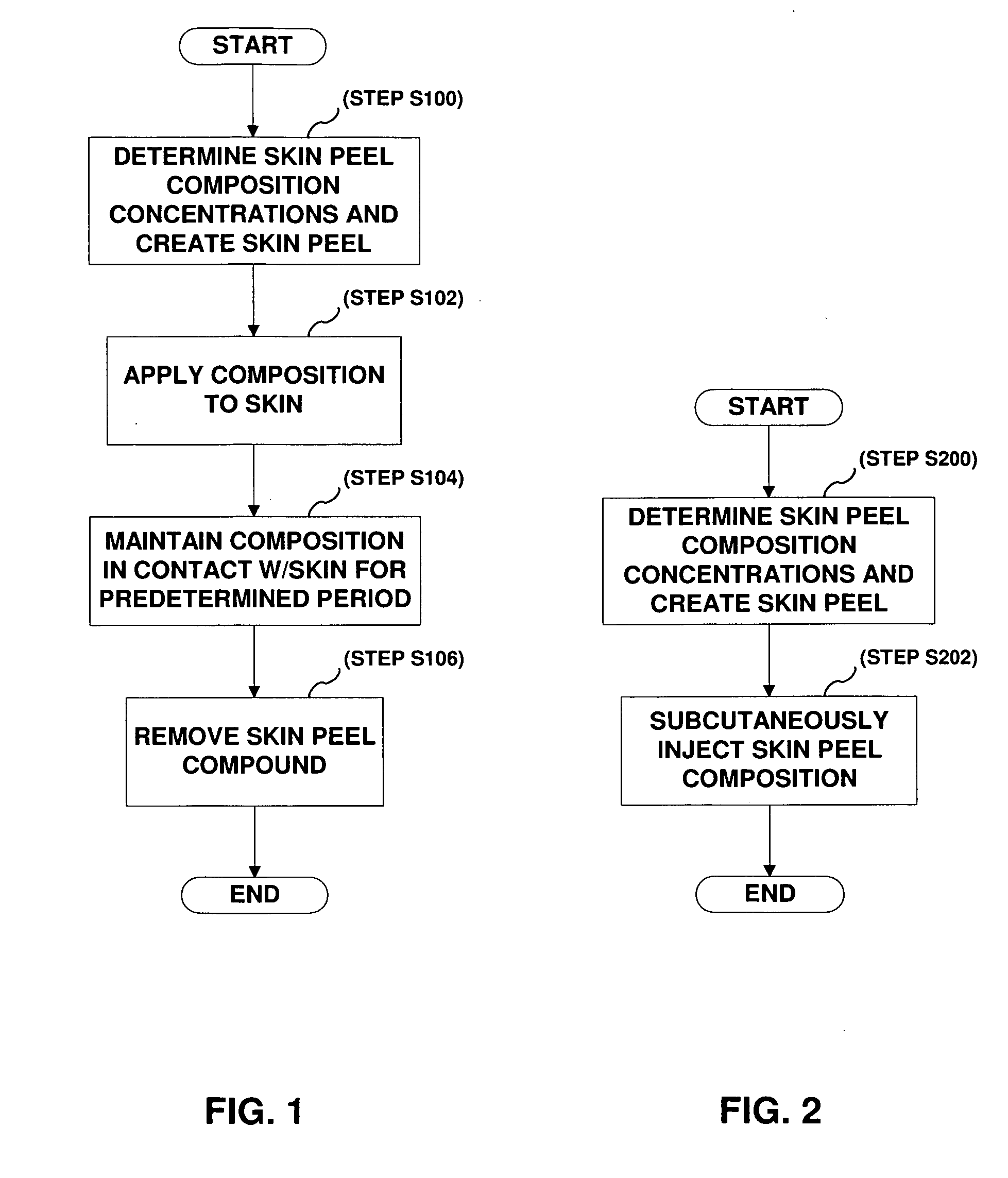

Method and compound for skin chemical peel

The present invention provides a skin peel composition including a plurality of keratolytic substances, such as trichloroacetic acid and salicylic, and a post inflammatory hyper pigmentation reducing substance such as retinoic acid. In addition, the skin peel composition may further include ascorbic acid (vitamin C), as well as vitamins A and E. Application of the skin peel composition may be either topically in the form of a cream or gel, and may further be injected subcutaneously into the skin to achieve deeper penetration of the composition within the skin layers of the area to be treated.

Owner:KALIL ENTERPRISES

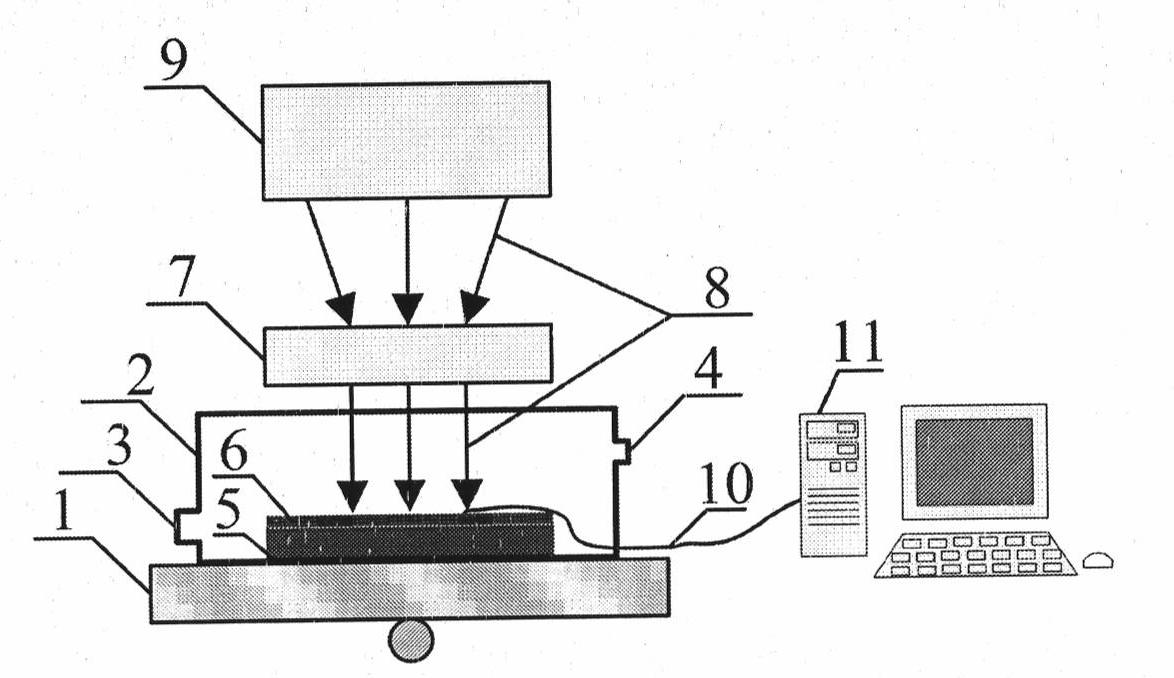

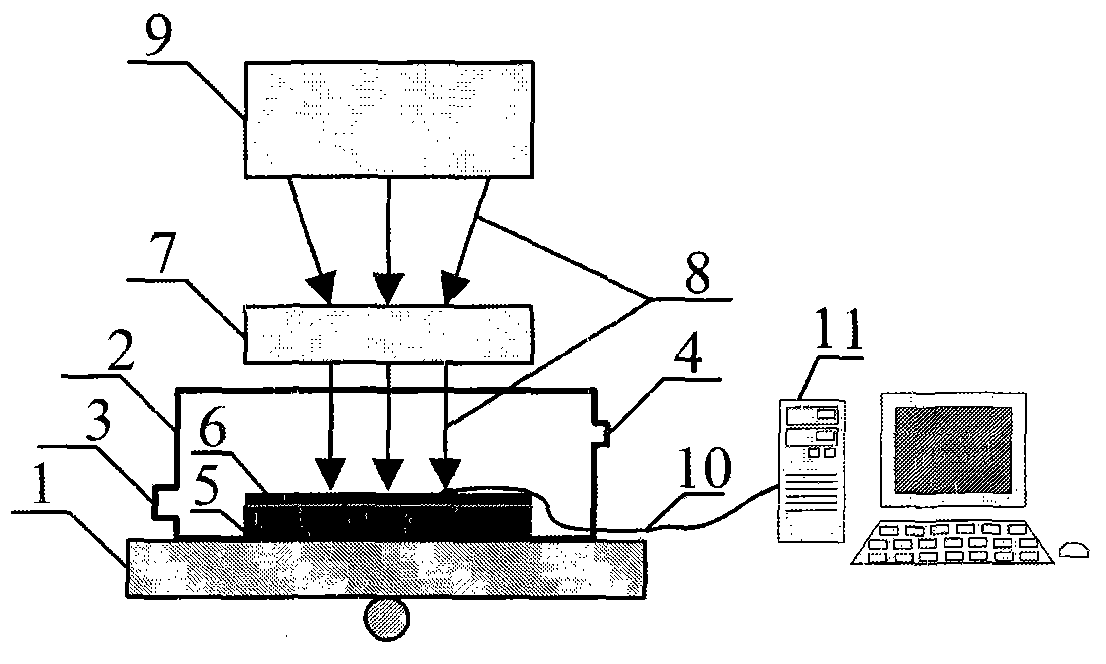

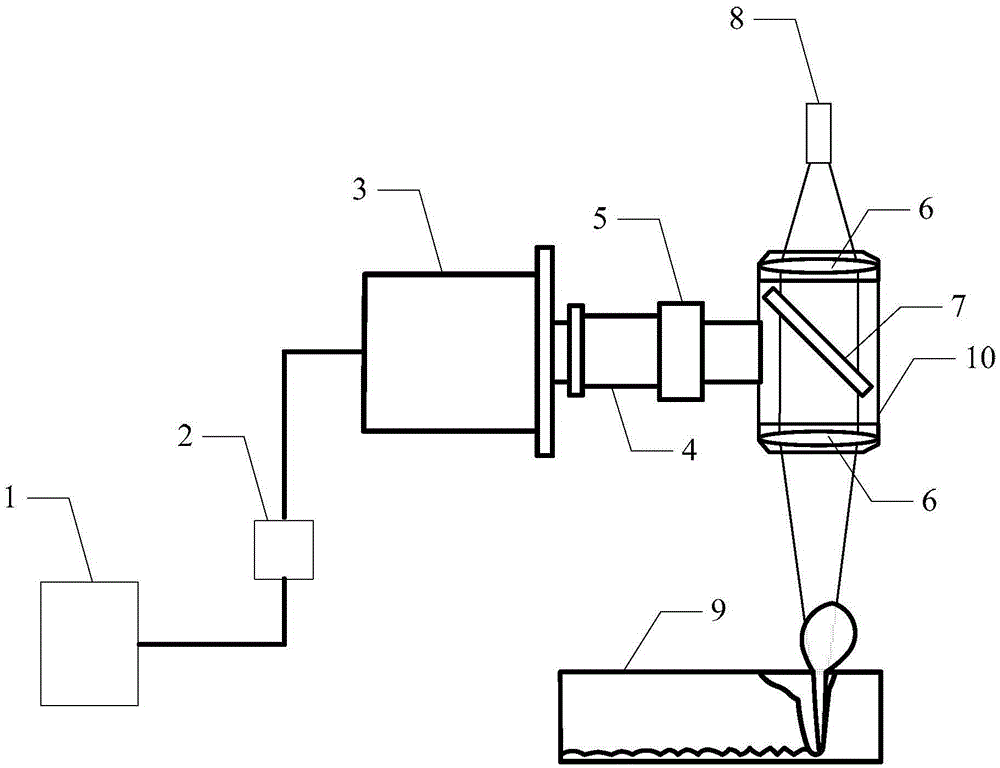

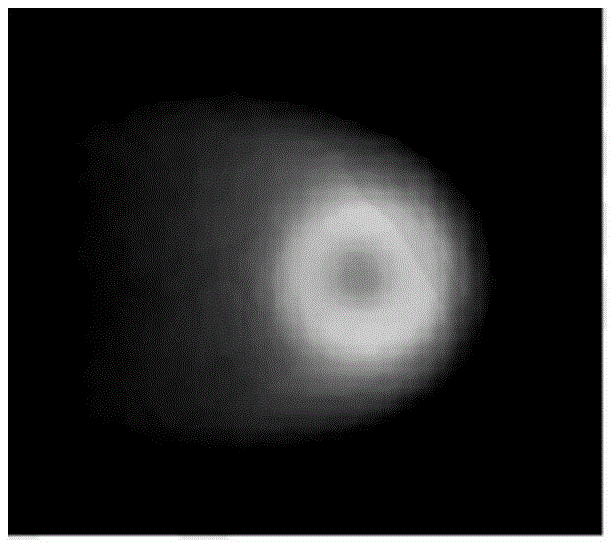

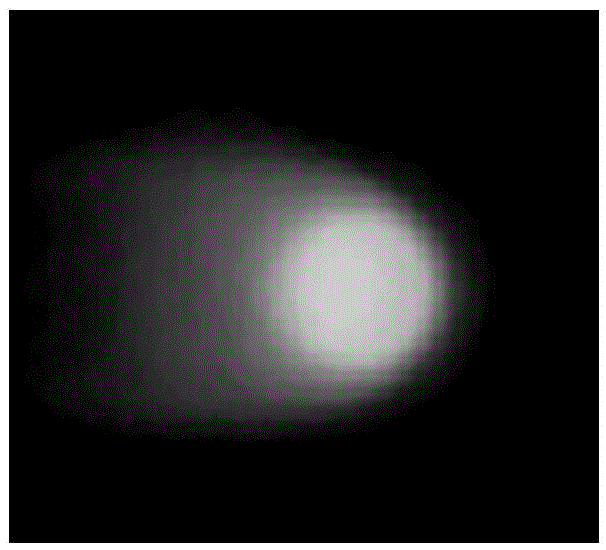

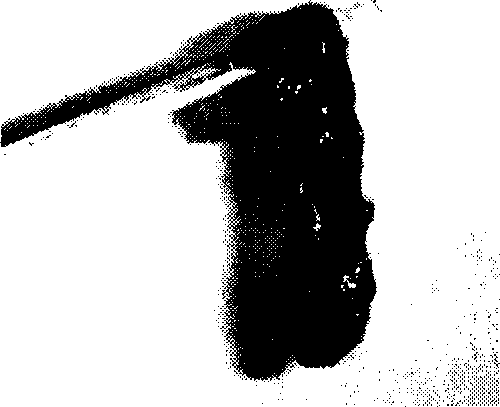

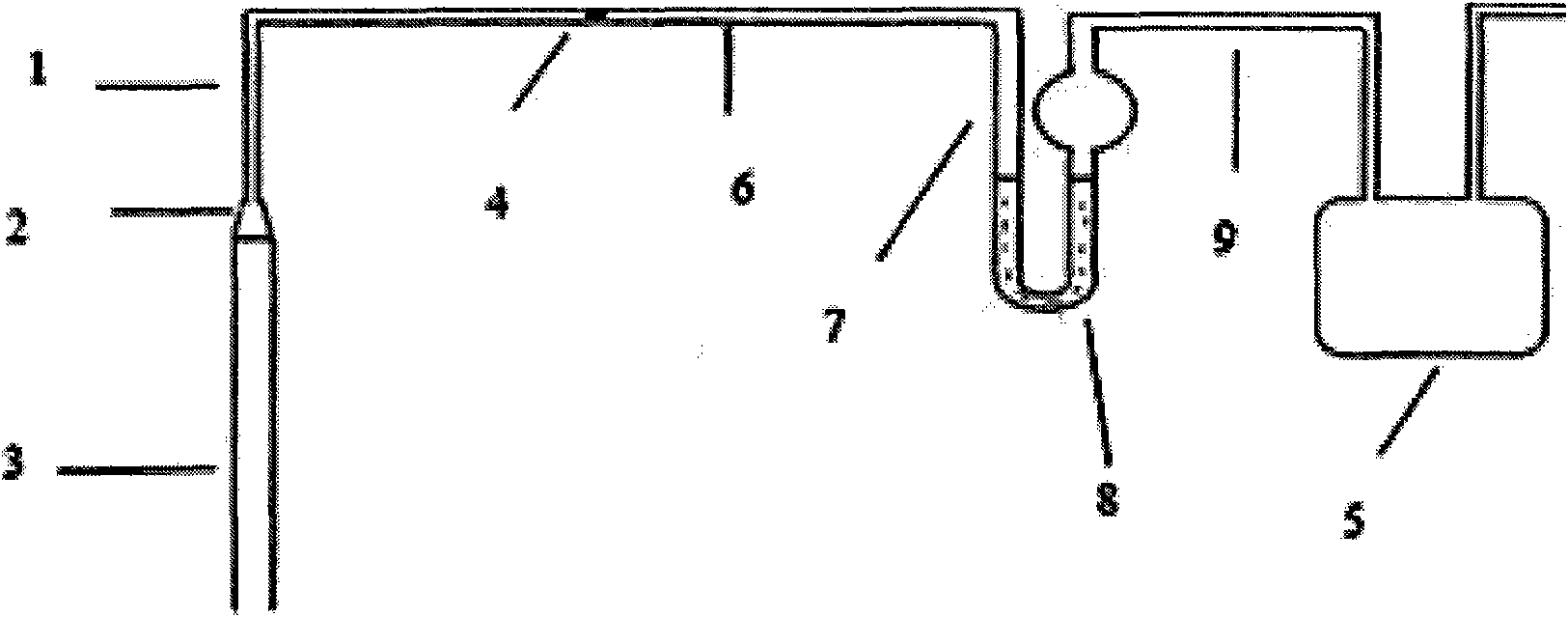

Real-time monitoring system and monitoring method for judging welding type of laser deep penetration welding by using high-speed camera

InactiveCN105458490AUnderstanding Spatial FeaturesAvoid placingLaser beam welding apparatusStereo cameraObservation method

The invention discloses a real-time monitoring system and a monitoring method for judging a welding type of laser deep penetration welding by using a high-speed camera, relates to the field of detection of laser deep penetration welding technology, and aims to solve the problem of incapability of directly judging if workpieces use deep penetration welding in a traditional welding process observation method. An image acquisition card is used for acquiring image signals shot by the camera to a PC; after the welding process is stabilized through the PC, the camera acquires images in the welding process; then, the PC is used for preprocessing the images acquired by the camera; and finally, the deep penetration welding is judged according to morphology of key holes and molten pools in the images preprocessed in the step 2. The real-time monitoring system and monitoring method have the following beneficial effects: the monitoring method of the real-time monitoring system for judging the welding type of laser deep penetration welding by using the high-speed camera has higher advancement and accuracy, and is suitable for detecting of the laser deep penetration welding technology.

Owner:HARBIN INST OF TECH

High resolution imaging using near-infrared-ii fluorescence

ActiveUS20150297086A1Powder deliveryGroup 1/11 element organic compoundsInfraredDiagnostic Radiology Modality

Disclosed are methods for imaging lumen-forming structures such as blood vessels using near-infrared fluorescence in the NIR-II region of 1000-1700 nm. The fluorescence is created by excitation of solubilized nano-structures that are delivered to the structures, such as carbon nanotubes, quantum dots or organic molecular fluorophores attached to hydrophilic polymers. These nanostructures fluoresce in the NIR-II region when illuminated through the skin and tissues. Fine anatomical vessel resolution down to −30 μm and high temporal resolution up to 5-10 frames per second is obtained for small-vessel imaging with up to 1 cm penetration depth in mouse hind limb, which compares favorably to tomographic imaging modalities such as CT and MRI with much higher spatial and temporal resolution, and compares favorably to scanning microscopic imaging techniques with much deeper penetration.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Acid liquor gel for acidified fracturing, as well as preparation method and use thereof

InactiveCN101481607AIncrease viscositySuitable for acid fracturingDrilling compositionPolymer dissolutionPolymer science

The invention relates to an acidulating fracturing acid liquor gel, a preparation method and the application thereof. The acid liquor gel comprises the components based on the mass percentage: 5-40% of acid, 0.3-2.0% of polyacrylamides polymer, 0.03-1.5% of inorganic cross linker, 0.03-1.5% of organic cross linker and the rest of water. The polyacrylamides polymer is dissolved in aqueous solution containing the acid and stirred for 2-5hr until the polymer is completely dissolved, so that uniform sticky liquid is obtained and added with the organic cross linker and the inorganic cross linker at last. The acidulating fracturing acid liquor gel can be used for acidulating and fracturing the oil field at the high temperature of 70-120 DEG C. The gel has high viscocity and good elasticity, and can carry sand, thus realizing the aims of deep penetration of acid liquor, acid manufacture and slit pressing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

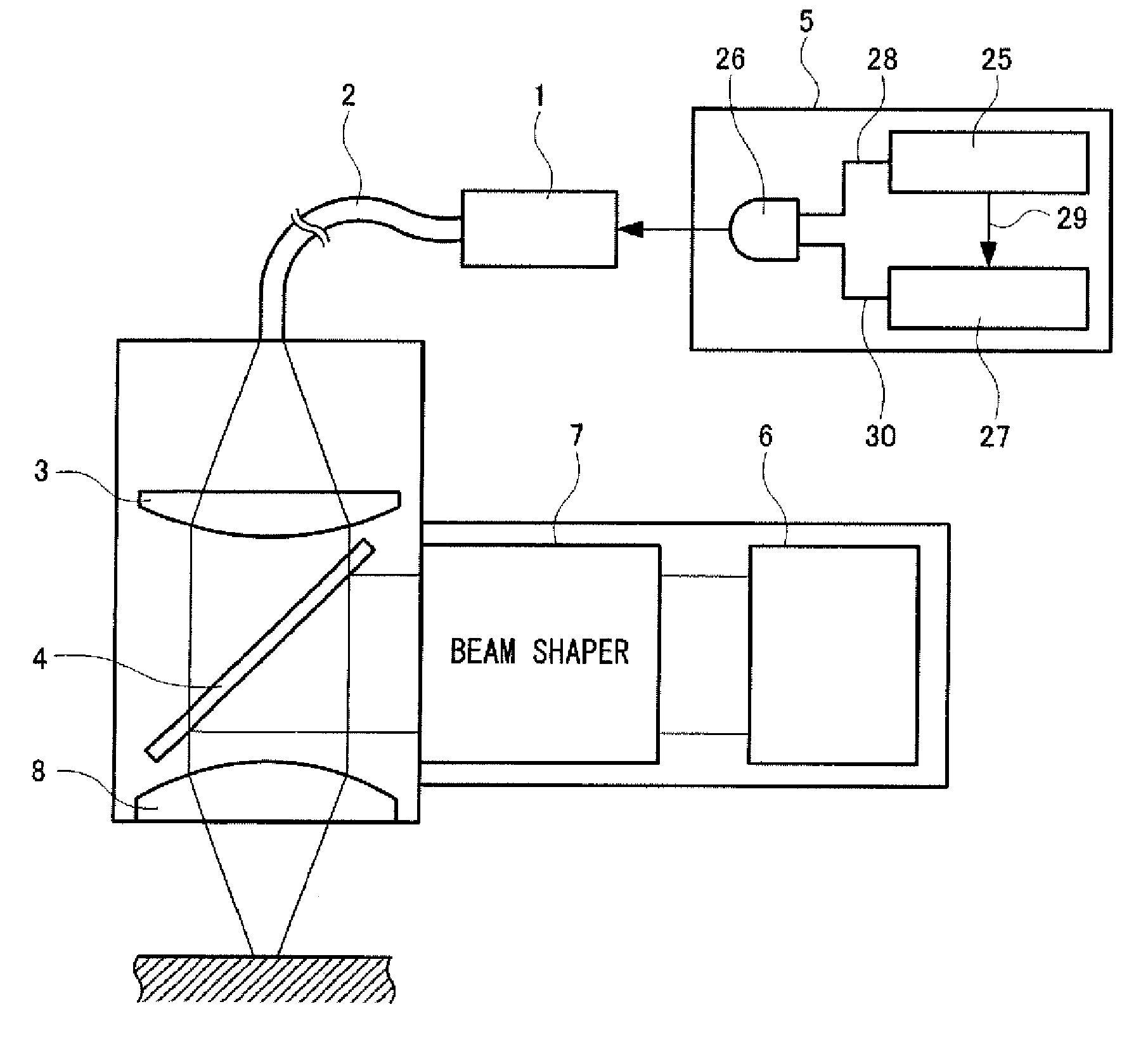

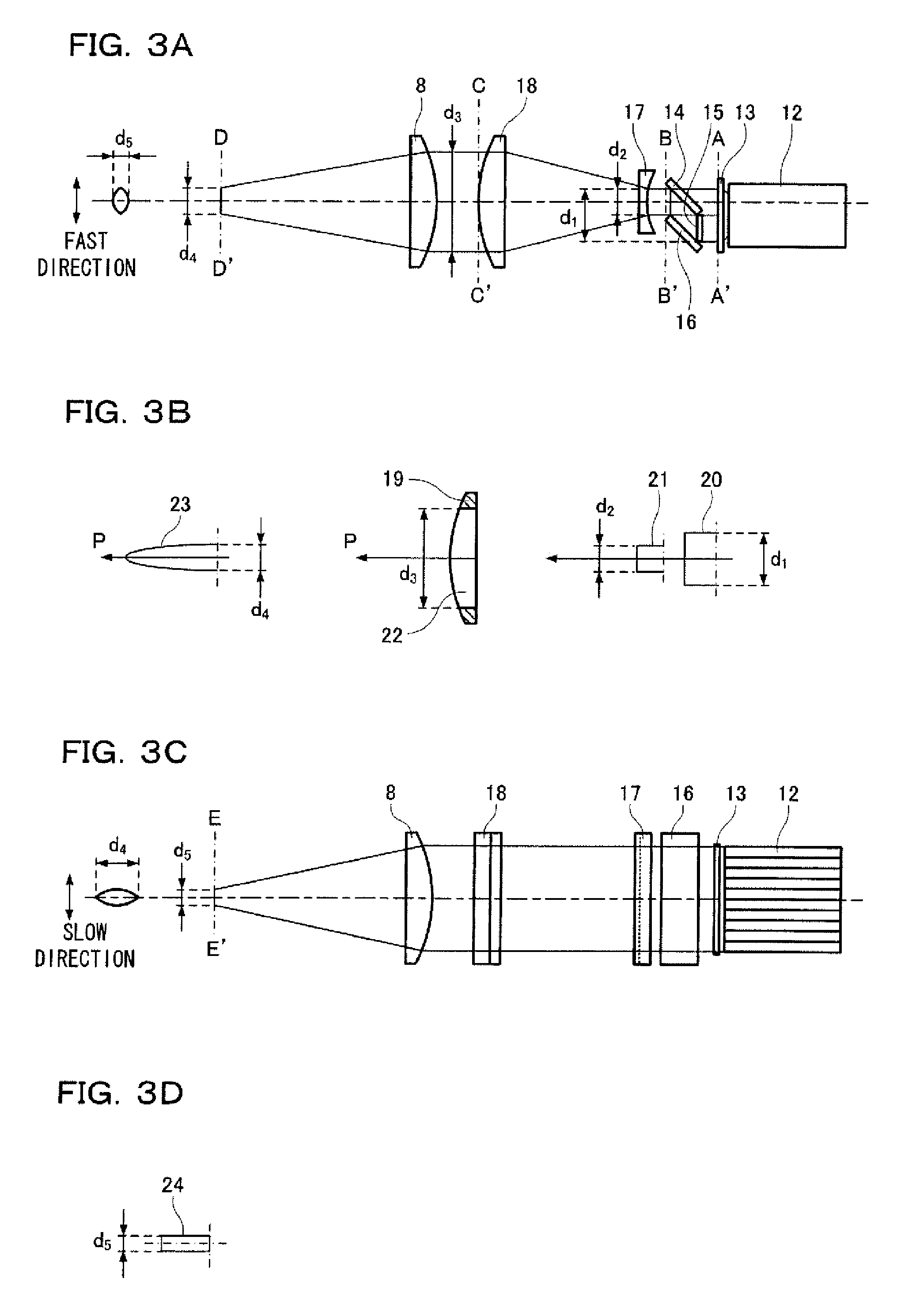

Laser apparatus and manufacturing method of a battery

InactiveUS20080253410A1Reduced stabilityReduction in welding speedLaser detailsNanobatteriesMetallic materialsOptoelectronics

A laser apparatus is provided which is capable of achieving deep penetration into an aluminum-like metal material without causing welding defects such as spatters or cracks and performing high-speed pulse seam welding. The laser apparatus includes a pulse power source that generates a current signal and a mask signal for masking a fluctuation component included in the current signal, and which supplies a current signal in which a fluctuation component has been masked by the mask signal to a YAG pulsed laser oscillator. In addition, the laser apparatus sets the spot shape of a CW laser light oscillated by a CW laser oscillator to a rhombic streamlined shape, and causes a focus spot of the CW laser light to include a circular focus spot of a pulsed laser light.

Owner:PANASONIC CORP

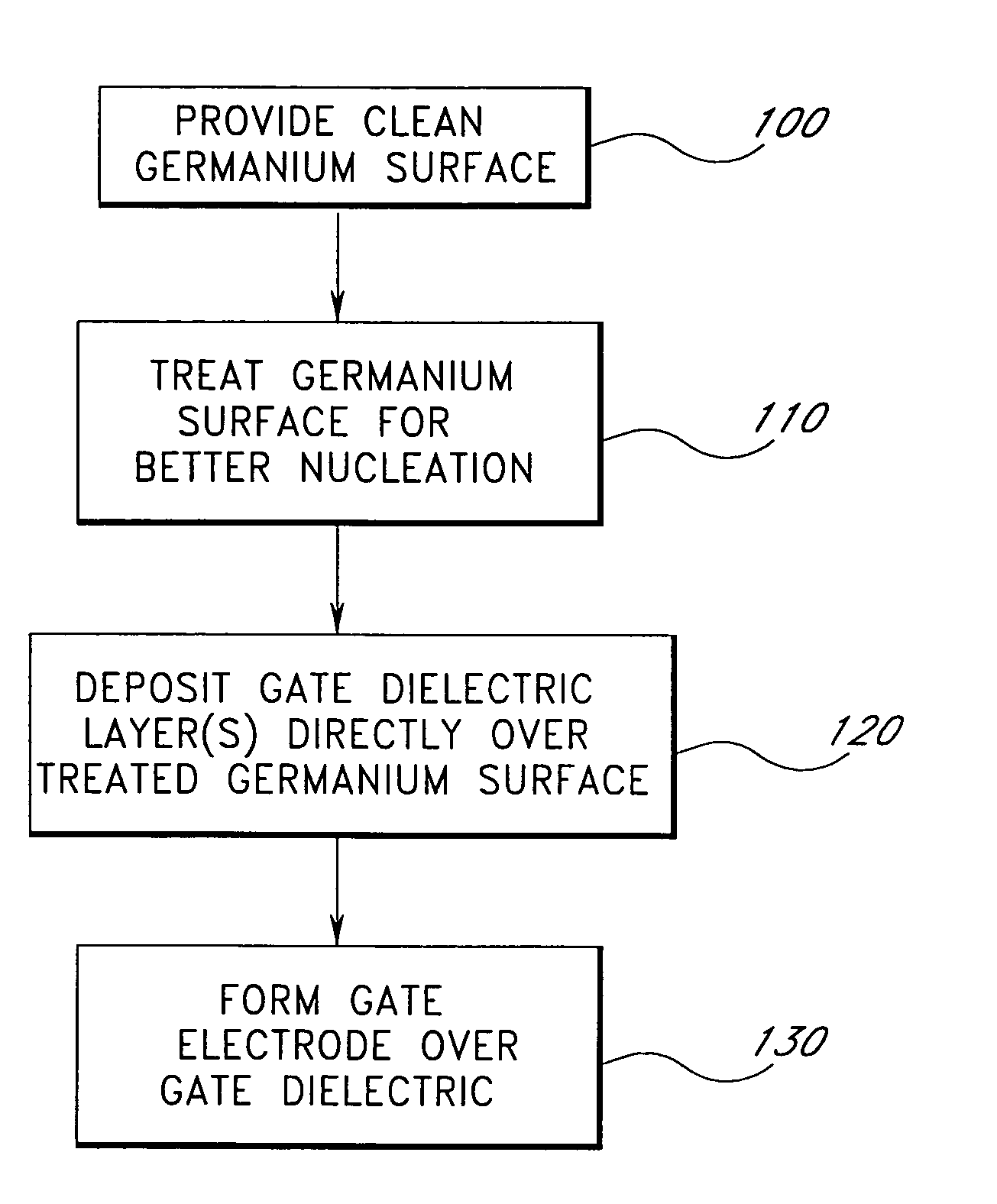

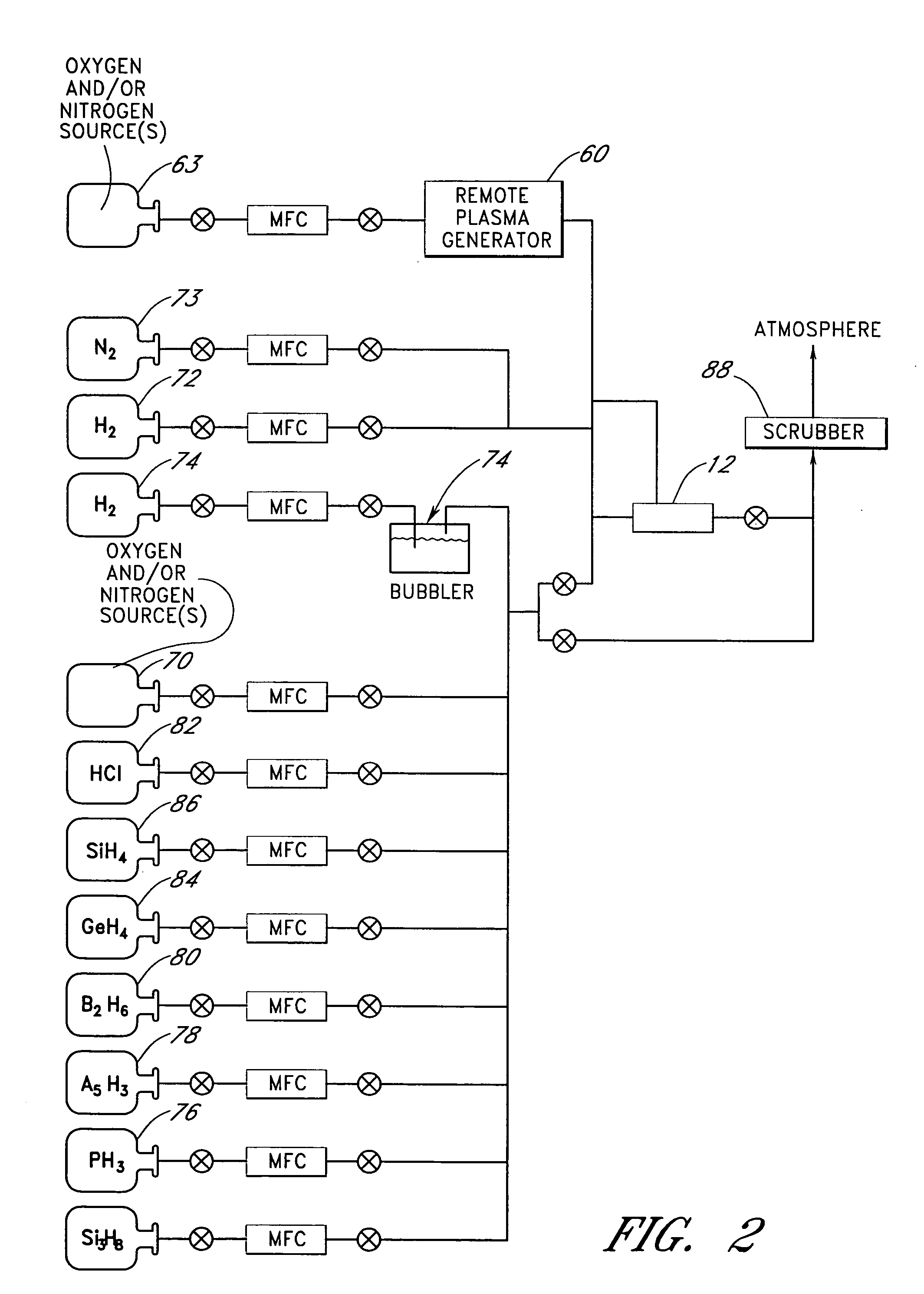

Surface preparation prior to deposition on germanium

ActiveUS7202166B2Increase speedImprove efficiencyVacuum evaporation coatingSputtering coatingGate dielectricNitrogen

Owner:ASM IP HLDG BV

Proppant-carrying acid fracturing method for high-temperature ultra-deep carbonate reservoir

InactiveCN106321044ASimple processEasy to operateFluid removalDrilling compositionAcid fracturingFracturing fluid

The invention provides a proppant-carrying acid fracturing method for a high-temperature ultra-deep carbonate reservoir. The proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir comprises the following steps that (1) fracture forming is conducted through fracturing fluid; (2) ground crosslinked acid is adopted and is made to react with rock, so that an acid-etched fracture is generated in a formed fracture, and a proppant is carried with the ground crosslinked acid for supporting the acid-etched fracture; and (3) linear glue is used for replacement, and thus acid fracturing is completed. According to the proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir, the technique is simple, operation is convenient, and the construction effect is remarkable; and the proppant-carrying acid fracturing method is suitable for transforming construction of deep well carbonatite at the high temperature of 150-170 DEG C, a supporting fracture which has deep penetration and longer flow conductivity can be formed in a stratum, the productivity is increased and the production time is prolonged after acid fracturing and well fracturing, and the length of the formed fracture is larger than 120 m.

Owner:CHINA PETROLEUM & CHEM CORP +1

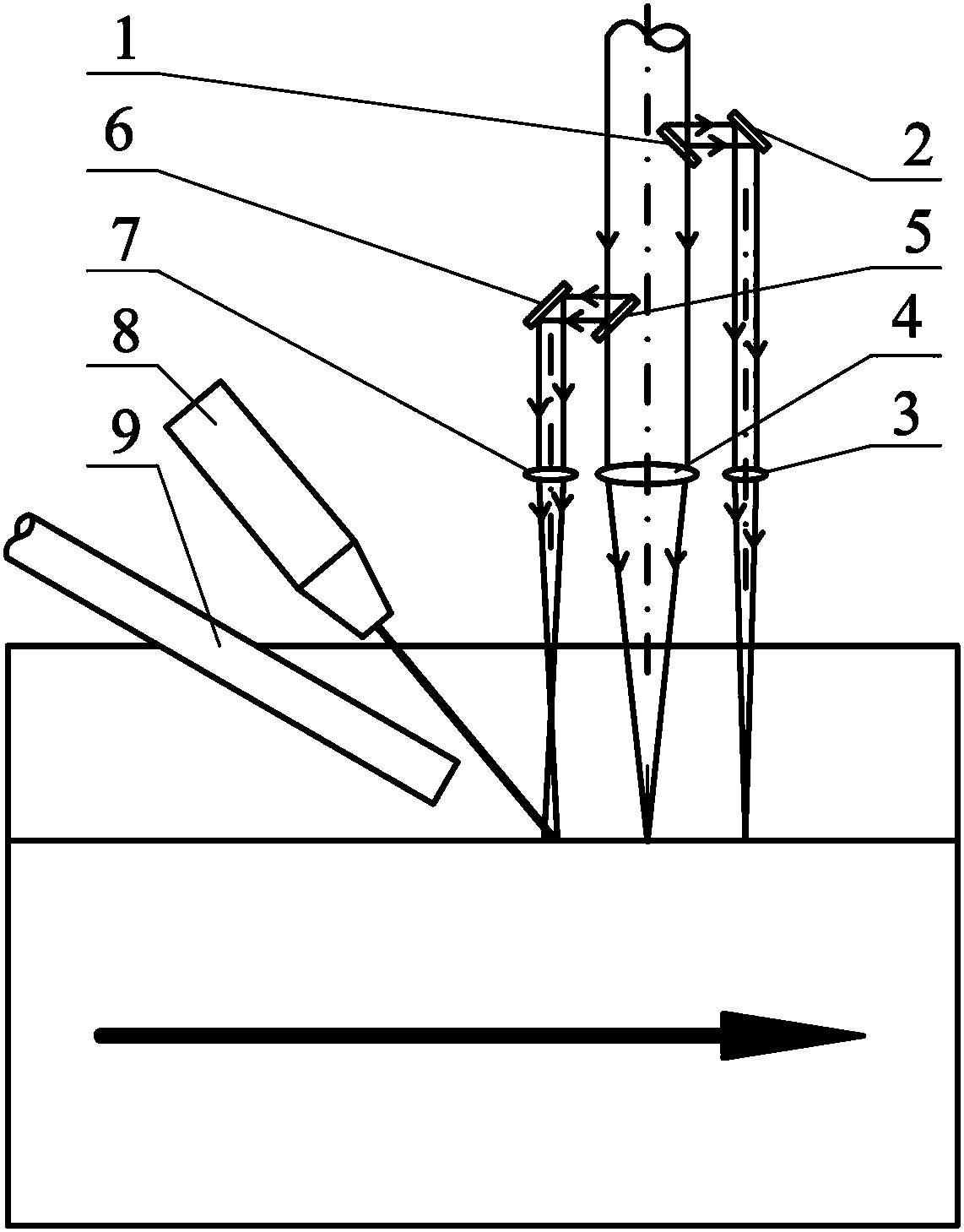

Thick plate ultra-narrow gap laser wire-filling welding device and method

ActiveCN107813049AQuality assuranceSolve the problem that it is difficult to effectively clean deep and narrow groovesLaser beam welding apparatusThick plateLight beam

The invention discloses a thick plate ultra-narrow gap laser wire-filling welding method. Main light beams are divided into a cleaning light beam, a deep penetration light beam and a wire-filling light beam. A laser cleaning technology is applied to cleaning of a thick plate ultra-narrow gap groove and compounded with a laser deep penetration wire-filling welding technology, and the problem that it is difficult to effectively clean the deep and narrow groove by means of an existing method is solved. The laser deep penetration welding and the laser wire-filling welding are effectively combined,and the thick plate ultra-narrow gap laser wire-filling welding method has the advantages of a large penetration depth, good bridging ability and expandable thickness and the like. Welding stabilityis improved, laser cleaning and laser welding are performed simultaneously, welding quality can be greatly improved, and the connector quality is guaranteed. The invention further provides a welding device adopting the method, the laser cleaning and the laser welding are performed simultaneously, and welding efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

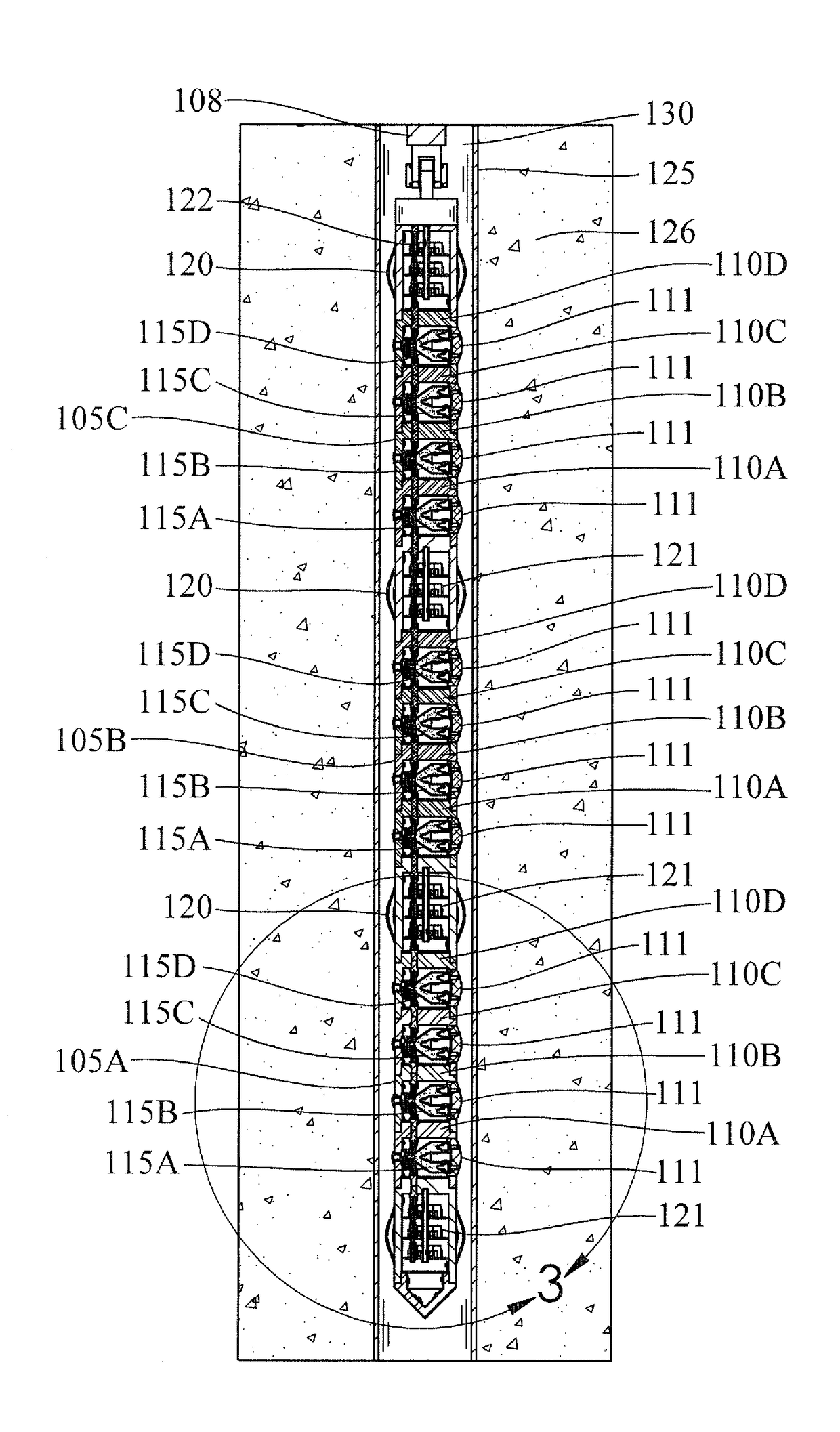

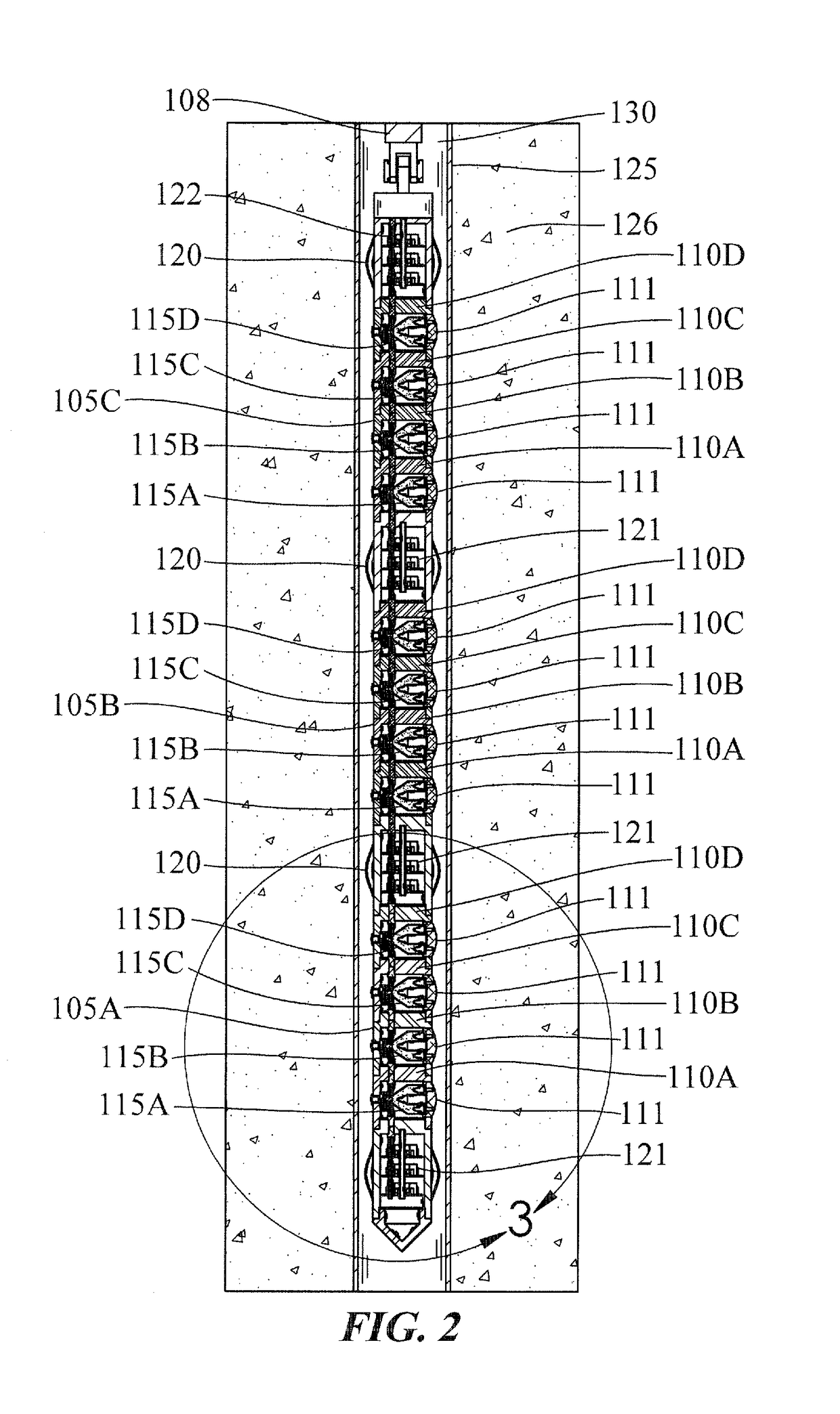

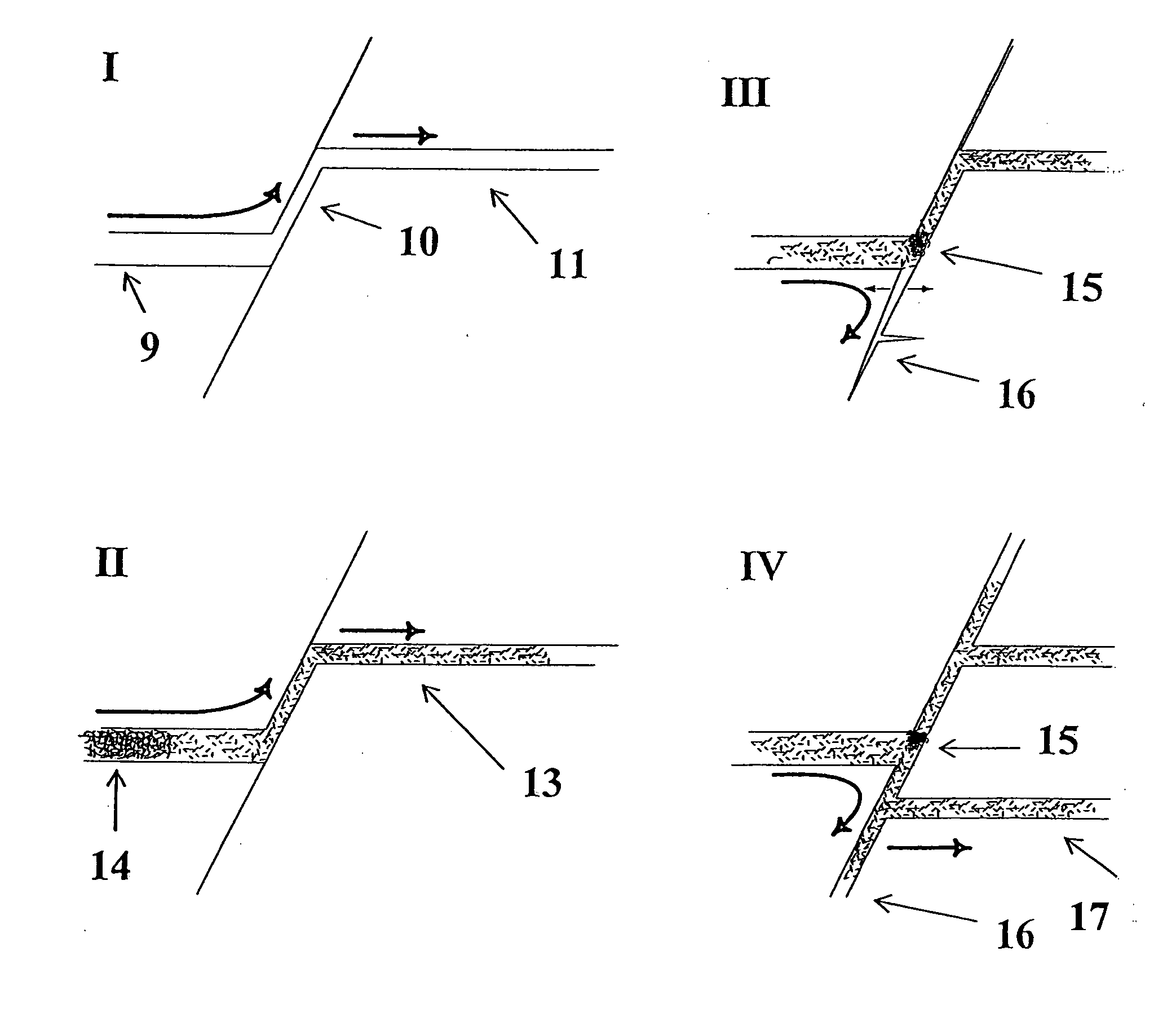

System and Method for Perforating a Wellbore

A system and method for stimulating hydrocarbon production from a wellbore that perforates the formation around the wellbore in strategic locations so that fractures can be formed in the formation having specific orientations. The system includes deep penetration perforators that extend past a portion of the formation adjacent the wellbore having locally high internal stresses (a stress cage); and big hole perforators that form perforations with a larger entrance diameter. The perforators form perforations in the formation that are axially consolidated along the wellbore. After perforating, the wellbore is hydraulically fractured with high pressure fluid, which creates fractures in a formation surrounding the wellbore that extend radially outward from the perforations. Creating perforations that are axially consolidated reduces the chances of forming competing fractures in the formation during fracturing.

Owner:BAKER HUGHES INC

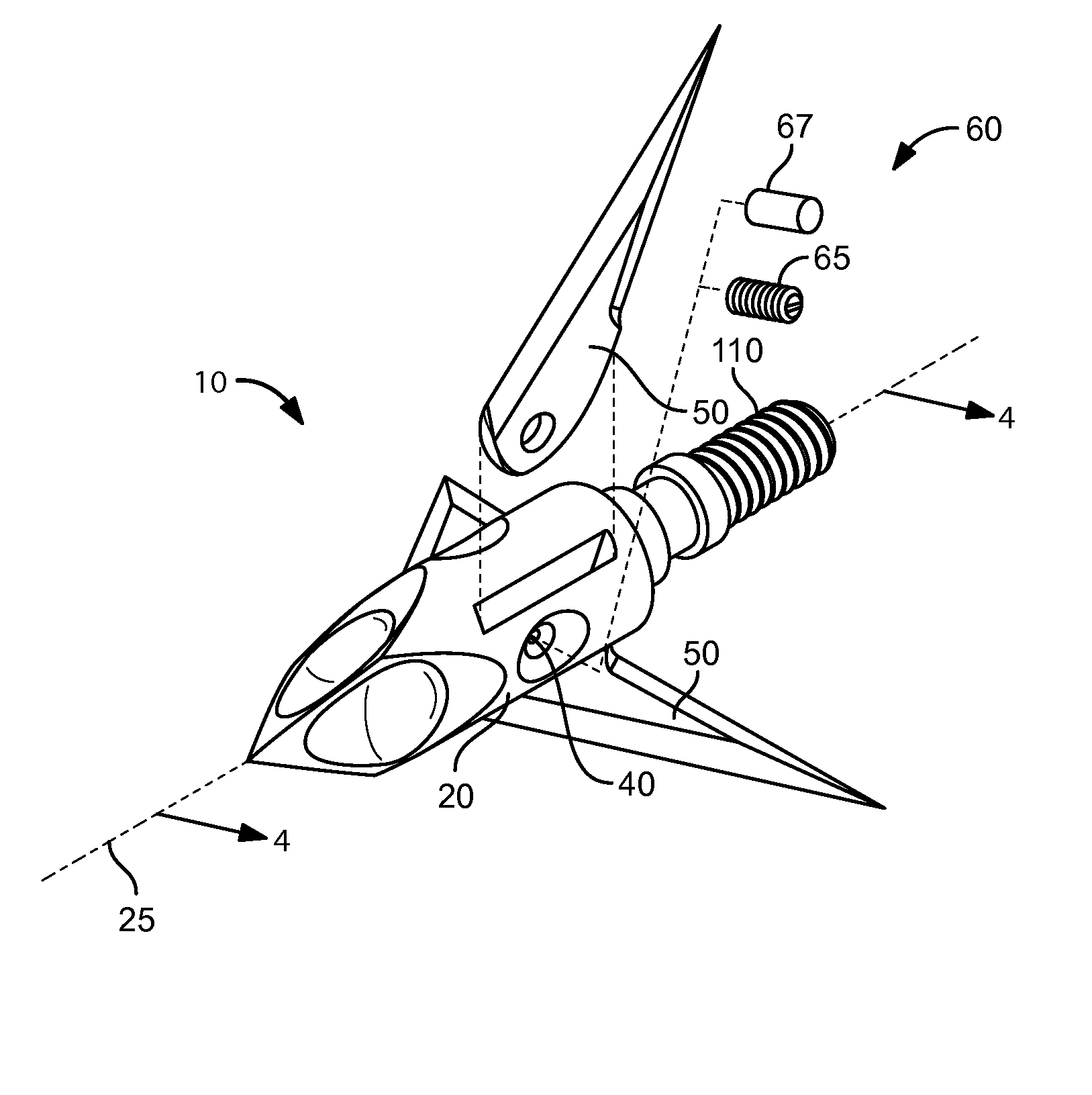

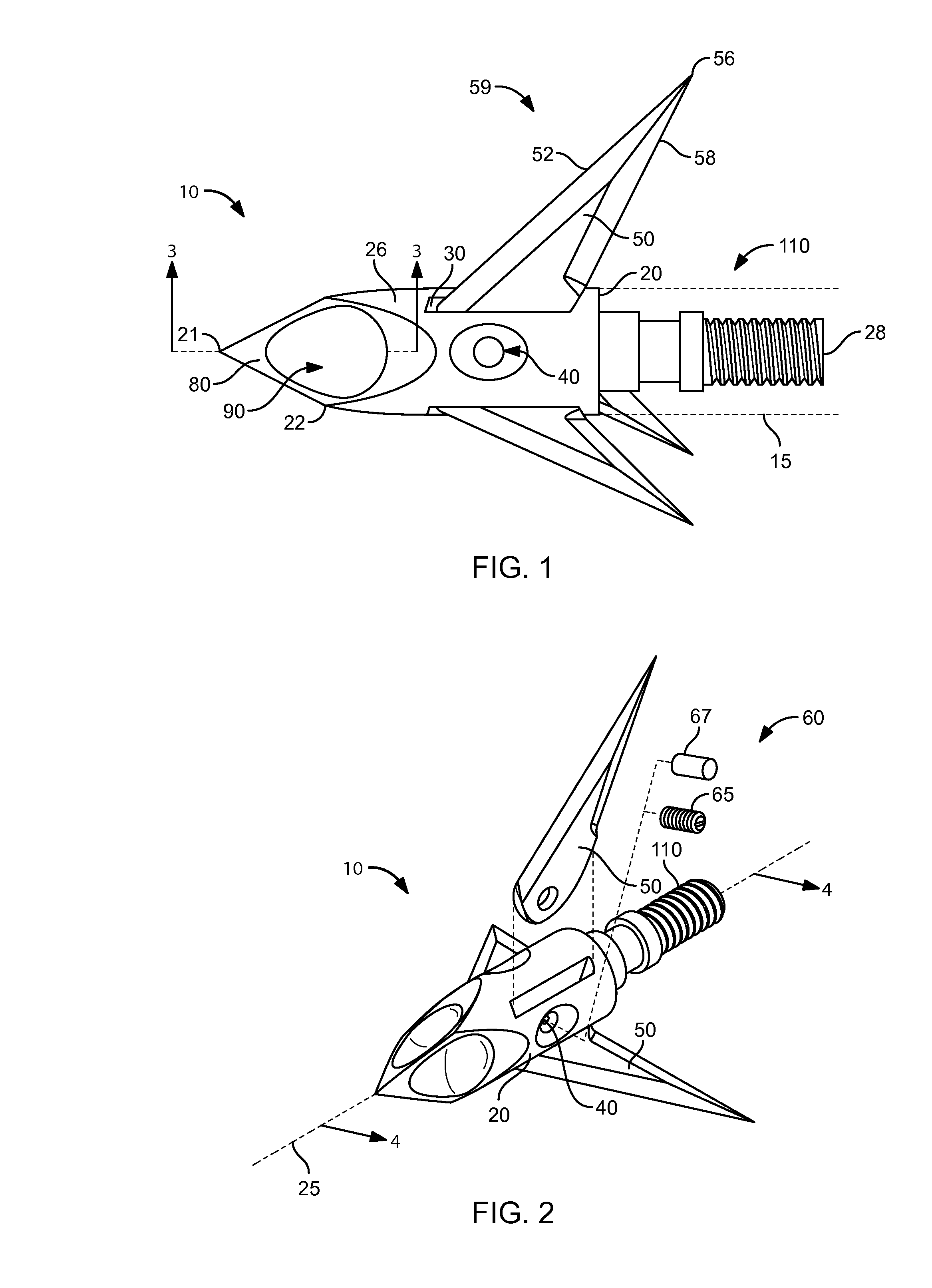

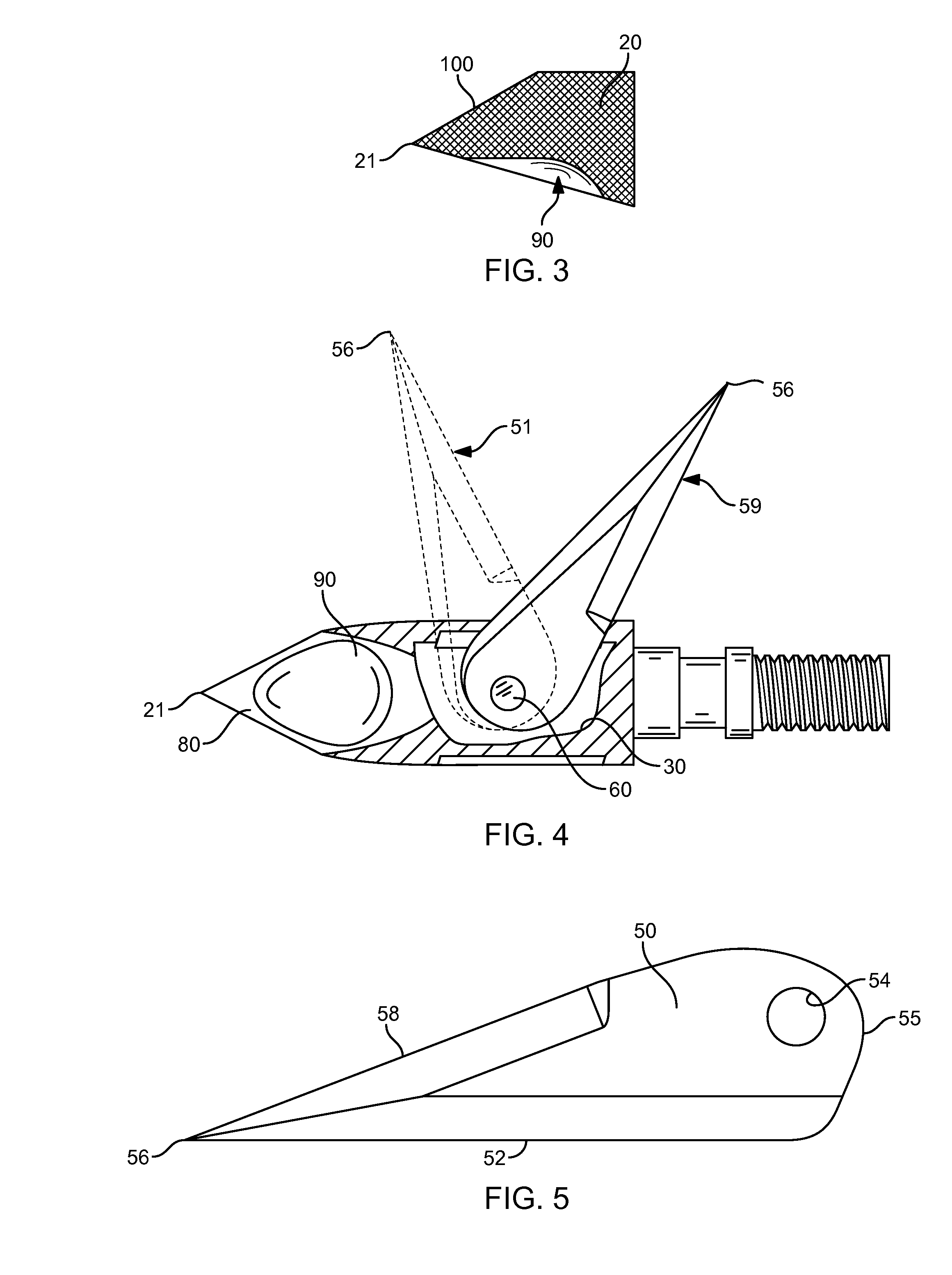

Pivoting-blade deep-penetration arrowhead

A broadhead for an archery arrow is disclosed. The broadhead includes a substantially cylindrical body having a forward cutting end, a rearward attachment end, and a side wall. The forward cutting end terminates in a point and further includes a plurality of pointed faces, each of which has a concave scoop formed therein. A cutting edge is formed between each pointed face. The side wall of the body, in one embodiment, includes a plurality of longitudinal slots. The broadhead in such an embodiment further includes a plurality of blades each having a forward cutting edge and preferably a rearward cutting edge. Each edge meets at a distal point. Each blade further includes a slot engaging edge opposite the distal point, and each blade may be pivotally fixed in one slot.

Owner:RAMCAT LLC

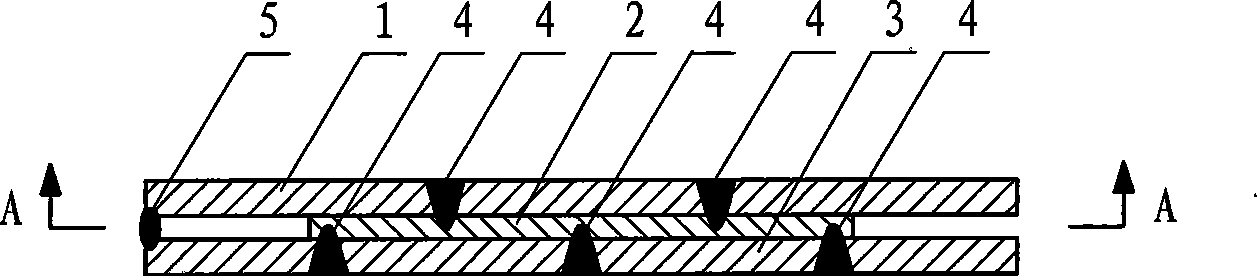

Method for producing GH4169 high-temperature alloy multiply laminate structure

InactiveCN101412155AShort manufacturing timePracticalArc welding apparatusLaser beam welding apparatusRoom temperatureAlloy

The invention provides a method for manufacturing the GH4169 high-temperature alloy sandwich panel structure, which belongs to the field of material processing. The aim of the invention is to solve the problems in manufacturing the GH4169 high-temperature alloy with a multi-layer structure by SPF / DB. The method comprises the following steps: 1. the ultrasonic cleaning is performed; 2. by adopting the laser deep penetration welding, various workpieces are welded together; 3. by adopting the argon-arc welding, a sealed space is formed, and only a vent hole is reserved; 4. the welded workpieces are placed in a die; 5. the die is placed in a heating furnace, heated at a temperature of between 950 and 980 DEG C and subjected to heat preservation for 25 and 40 minutes; 6. the inert gas is filled in for the superplastic bulging treatment; and 7. the die is cooled down to the room temperature. In the invention, by adopting the laser connection / superplastic bulging combined technique, the GH4169 high-temperature alloy sandwich panel structure is successfully manufactured; and by utilizing the quickness and the accuracy in the laser connection, the manufacturing time of the sandwich panel is shortened.

Owner:HARBIN INST OF TECH

Spiral seam submerged arc welded pipe manufacturing process

ActiveCN102284550ASmall sizeReduce cooling rateArc welding apparatusShielded metal arc weldingVisual inspection

The invention provides a manufacturing process of a spiral seam submerged arc welded pipe. The purpose of the present invention is achieved in this way: 1) raw material inspection, 2) stock preparation, 3) uncoiling, 4) leveling, 5) steel strip alignment, 6) disc shearing, 7) edge milling, 8) steel strip Delivery, 9) Steel strip edge pre-bending, 10) Forming, 11) Forming inspection, 12, 13) Internal and external automatic welding, 14, 15) Initial inspection, internal inspection, 16) Steel pipe cutting, 17) Manual repair welding, 18) X-ray inspection, 19) water pressure, 20) water pressure test inspection, 21) ultrasonic inspection, 22) magnetic particle inspection, 23) chamfering, 24) physical and chemical inspection of products, 25) finished product inspection, 26) spray marking. Submerged arc automatic welding can use large welding current, the arc heat is concentrated, the penetration depth is large, and the welding wire can be fed continuously, so its production efficiency is 5-10 times higher than that of manual arc welding; it saves materials and electric energy, and is environmentally friendly and harmless to the human body.

Owner:TIANJIN JINGHAI COUNTY XINGDA PIPE MFG

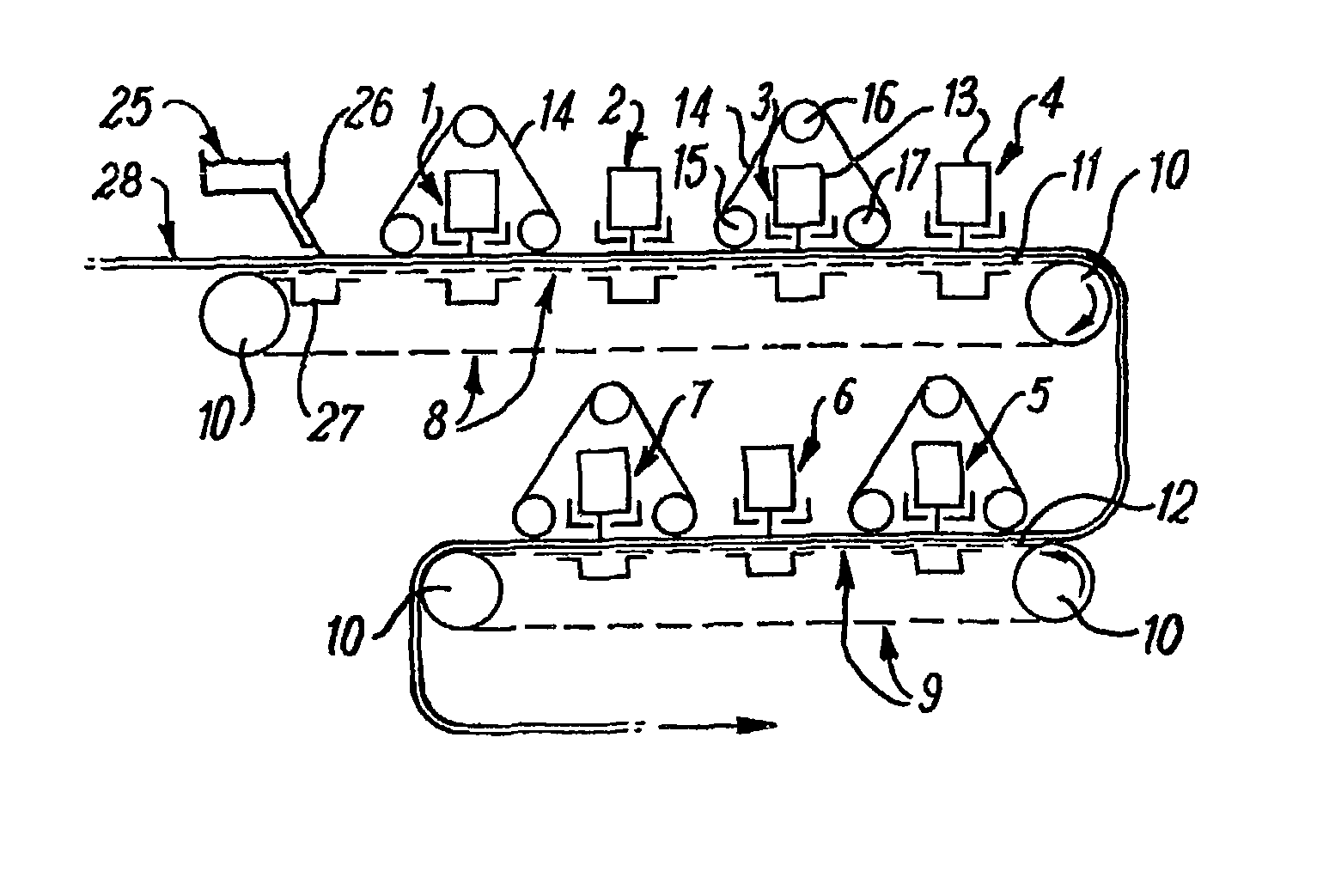

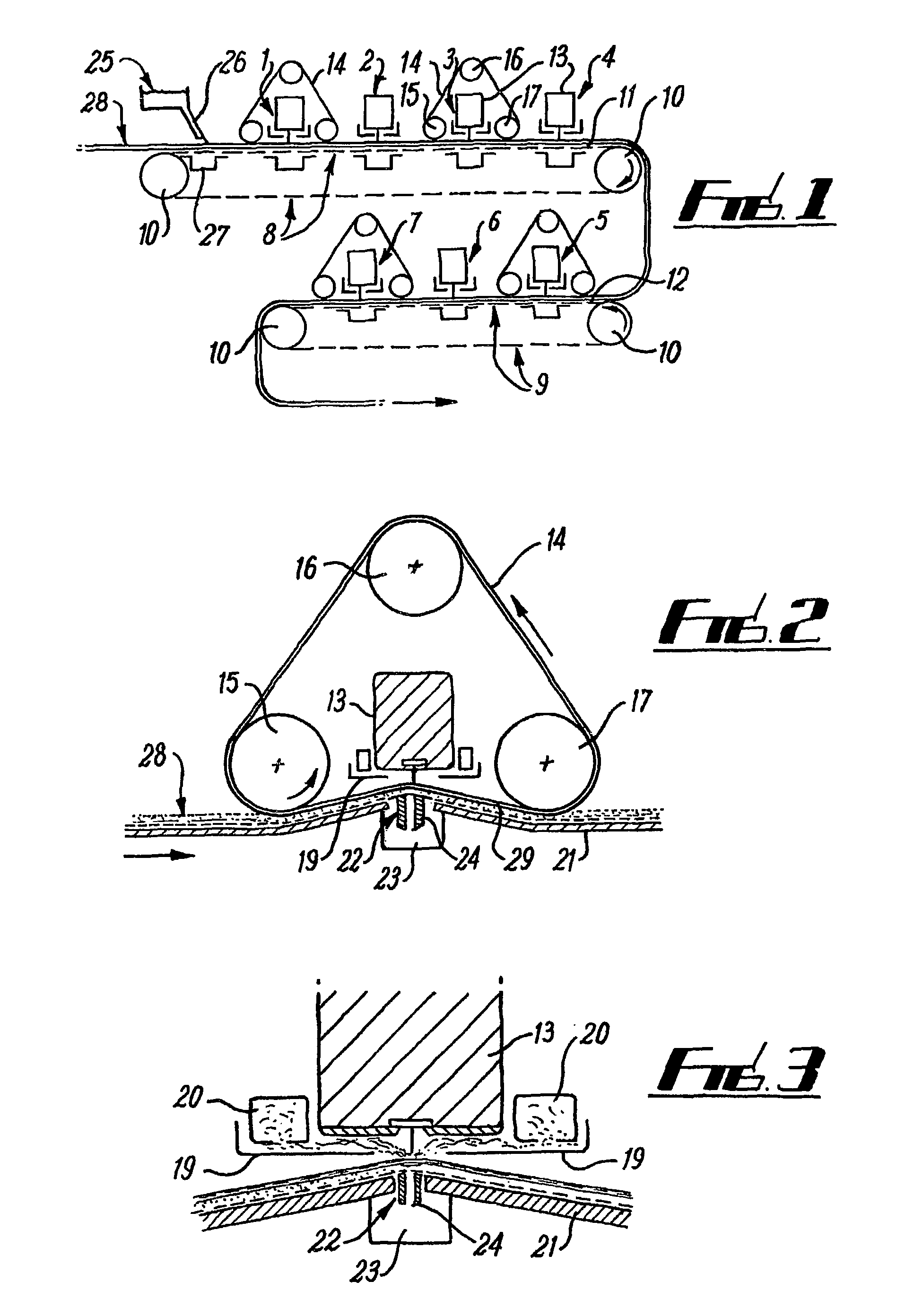

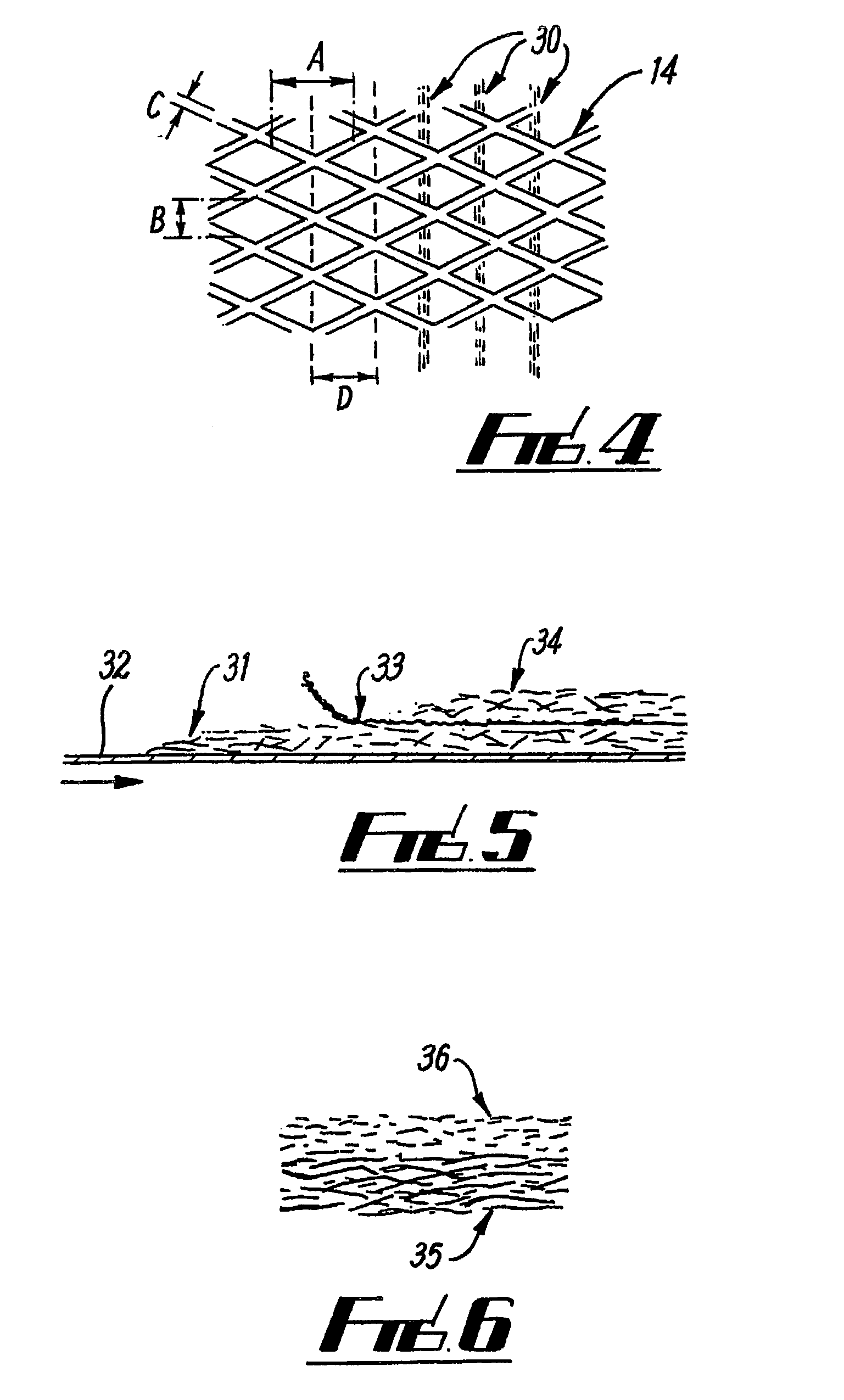

Formation of sheet material using hydroentanglement

Artificial leather sheet material is made by hydroentanglement of waste leather fibers. A web of the fibers is advanced on a porous belt high pressure water jet heads in a number of successive hydroentanglement steps. Screens have apertures which allow deep penetration of the water jets into the web while thin screen portions between the apertures act to interrupt the jets allow deep penetration of the water jets into the web while thin screen portions between the apertures act to interrupt the jets and limit formation of furrows. Deflector plates are provided alongside water jet heads to remove re-bounding water.

Owner:E-LEATHER LTD +1

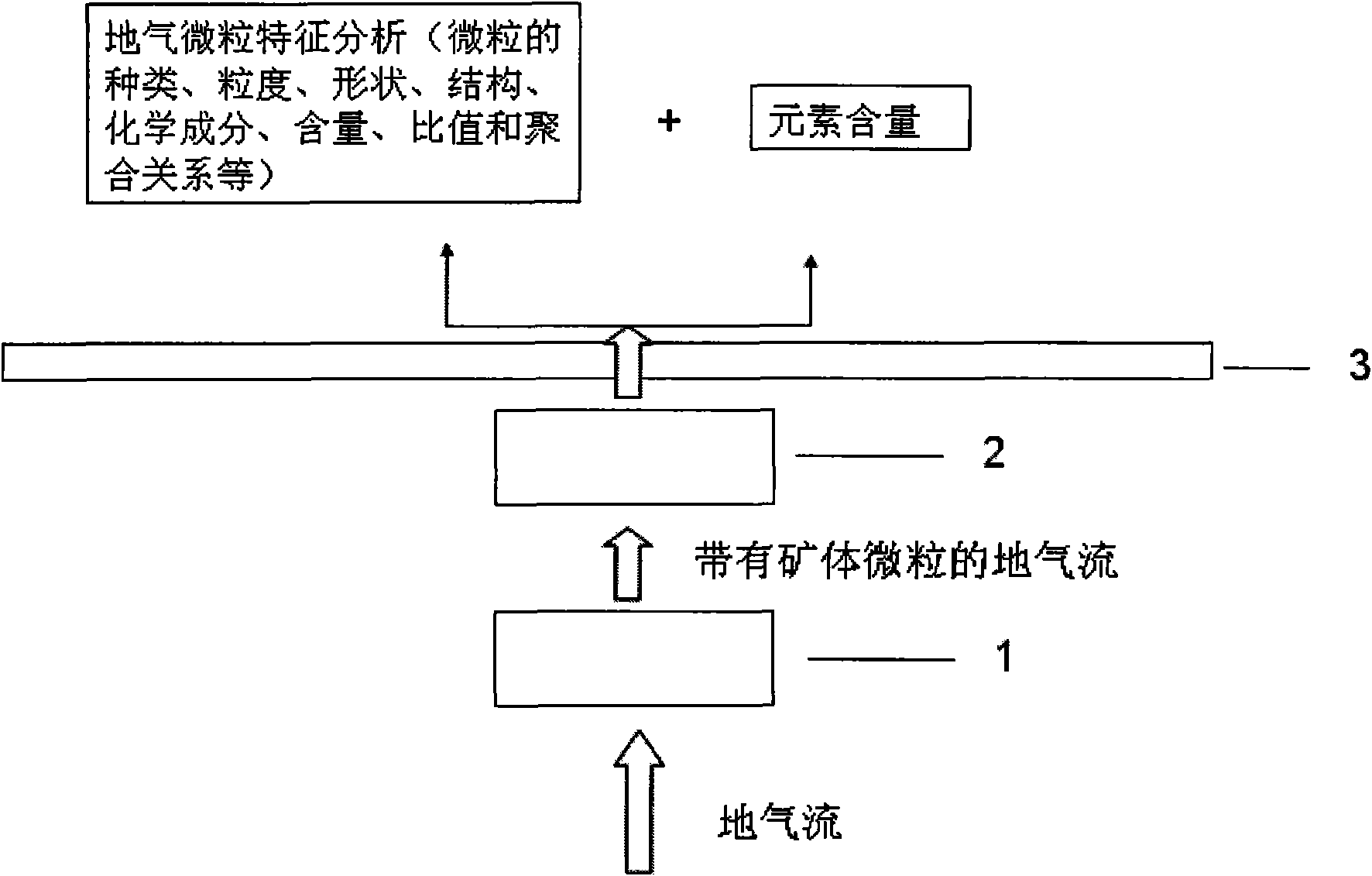

Method for prospecting by using geo-gas particles

ActiveCN101819169AHigh precisionImprove accuracyMaterial analysis using wave/particle radiationWithdrawing sample devicesCarbon filmMicroparticle

The invention belongs to the field of geology and relates to a method for prospecting through deep penetration inside the earth. The method comprises the following steps of: collecting and analyzing geo-gas particles; after a molybdenum mesh to which a carbon film is attached serving as a sampling carrier adsorbs geo-gas particle samples brought by underground air stream, detecting the geo-gas particle samples on the molybdenum mesh by using a transmission electron microscope; and analyzing the particles on the microscope in a single particle state to judge the characteristic of a concealed ore body. Due to the adoption of the method, the test accuracy is enhanced, a test object reaches geo-gas nano-scale single particles, and the concealed ore body is comprehensively explored by analyzing characteristics, such as components, granularity and shape of particle ore, ratio and polymerization of various particles and the like, chemical components (including major elements and microelements), content, structural forms and mineralization types.

Owner:SUN YAT SEN UNIV

Method for cooking a food with infrared radiant heat

ActiveUS20080029503A1High speedEfficient use of powerDomestic stoves or rangesElectrical heating fuelThermal energyProcess engineering

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and reheats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com