Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

283results about How to "Meet welding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

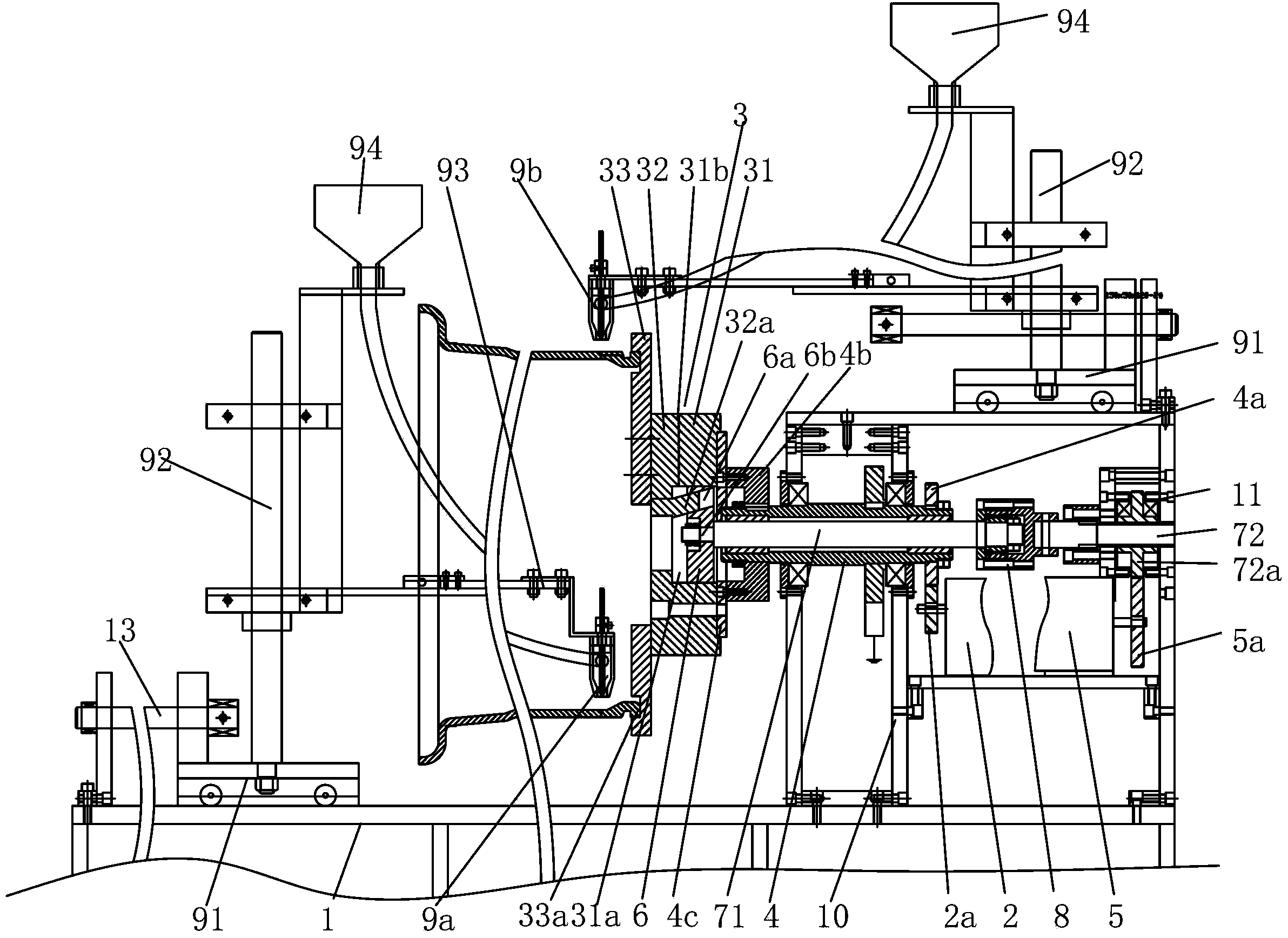

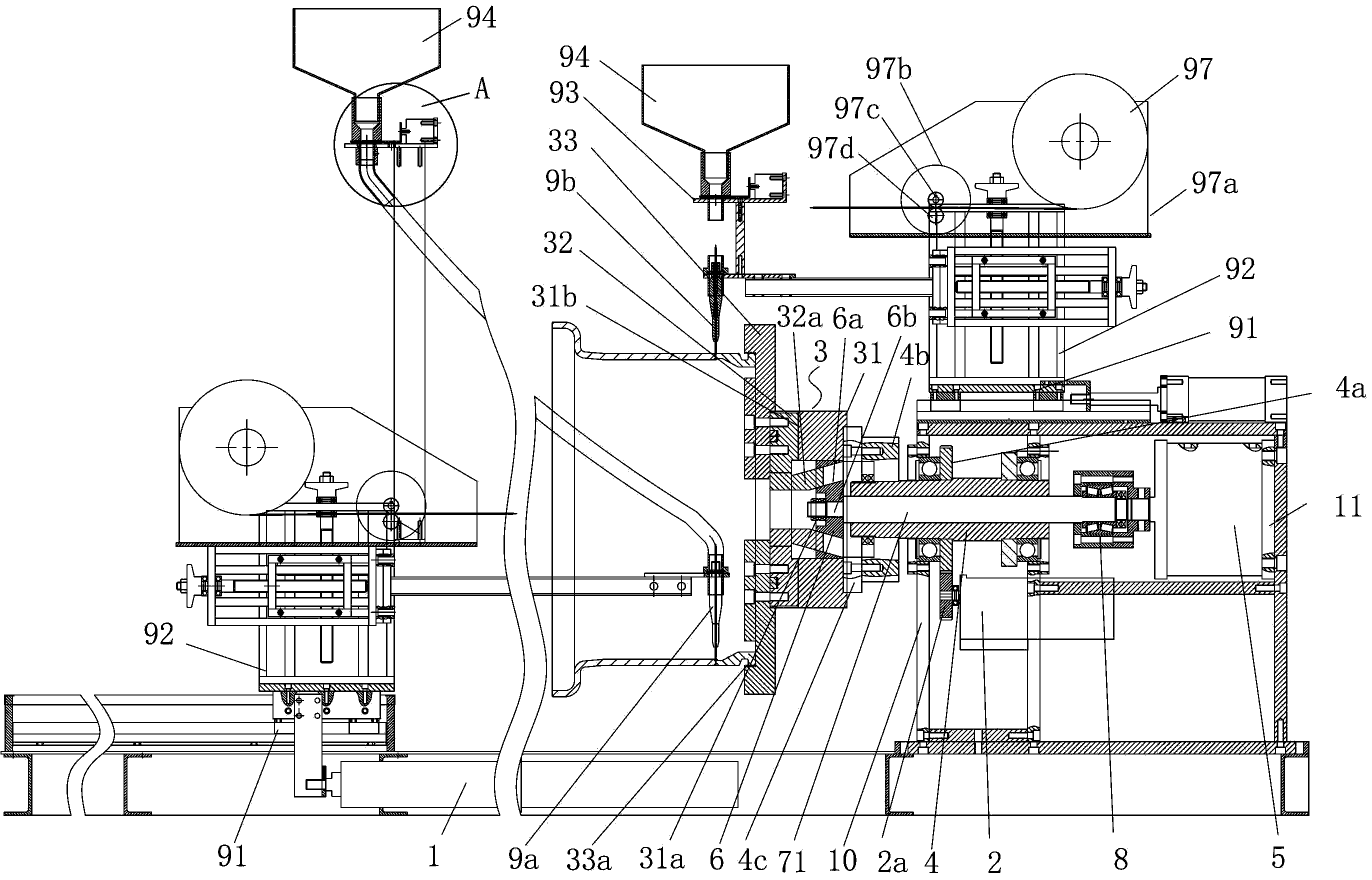

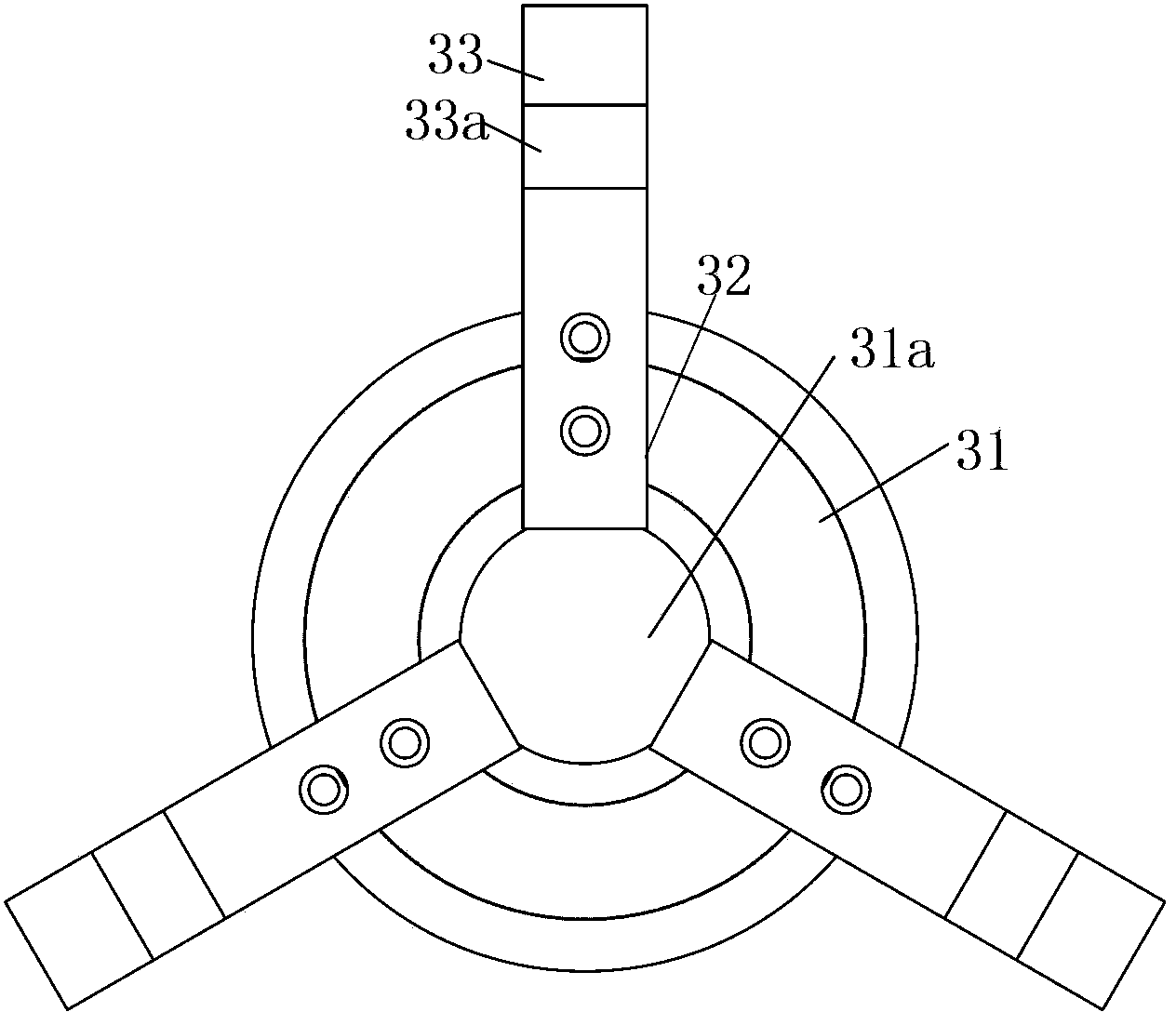

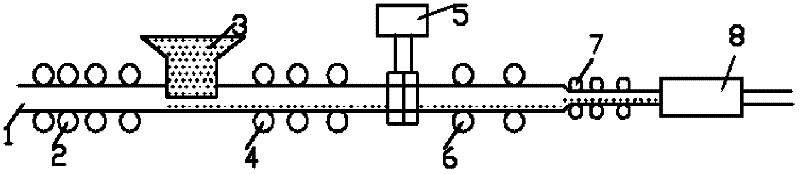

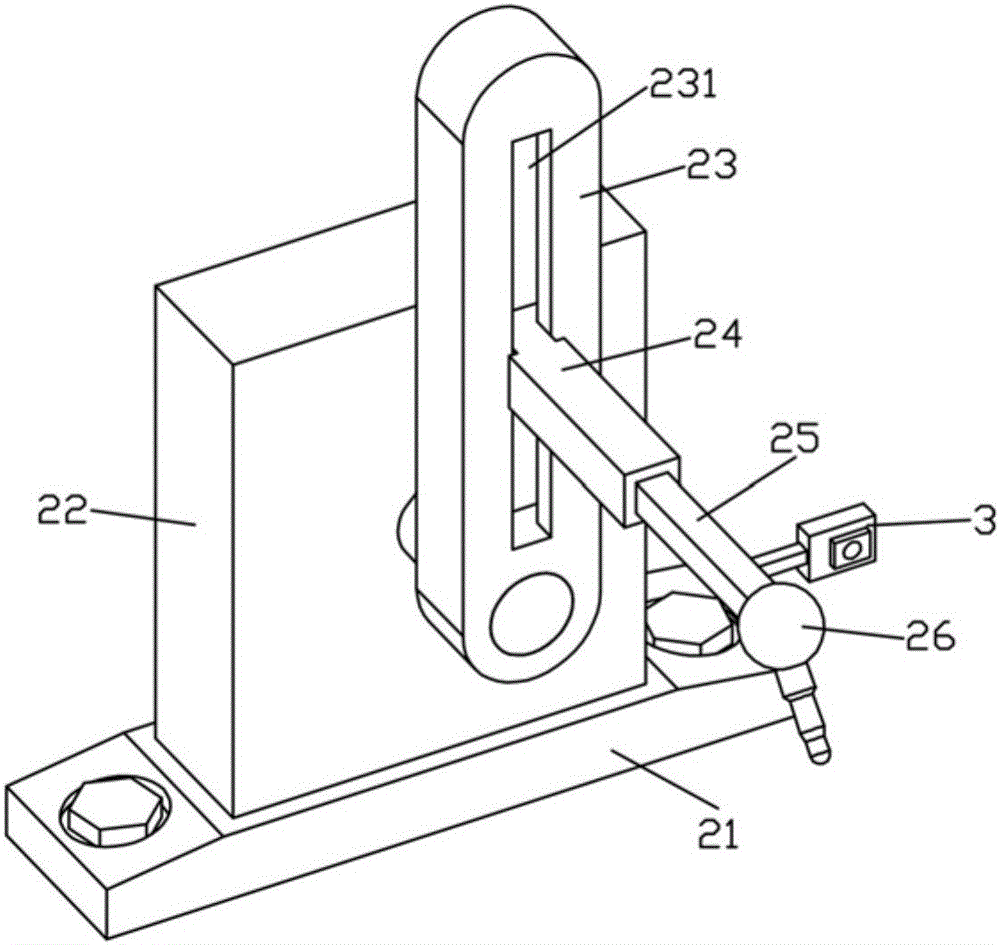

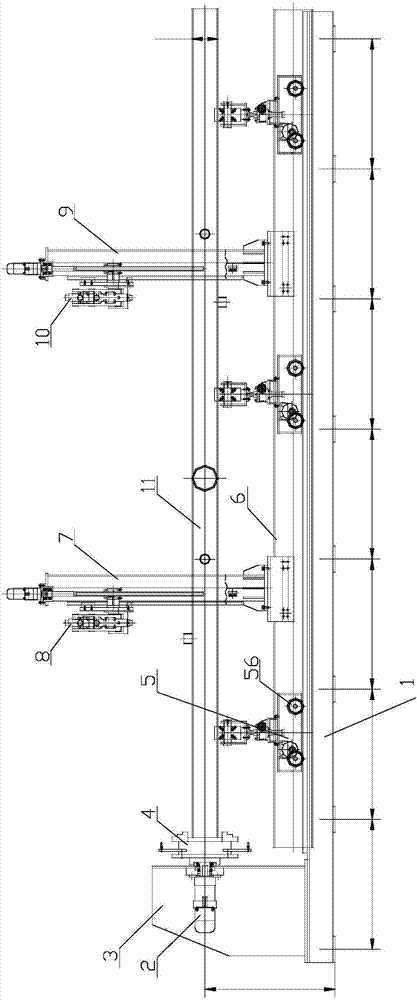

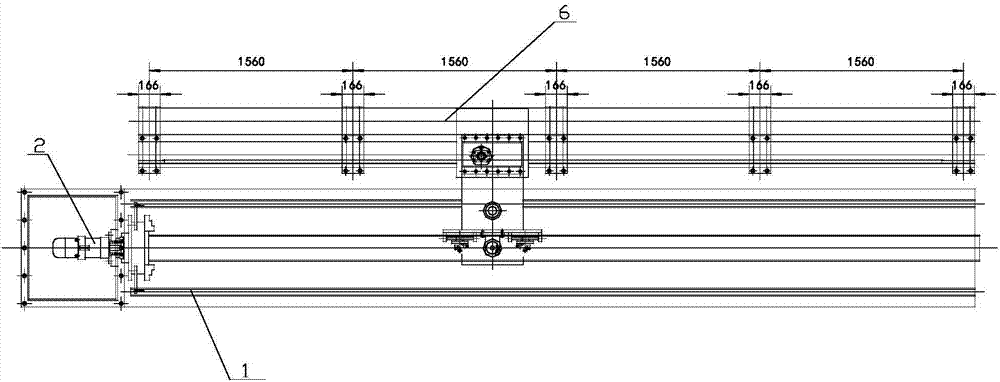

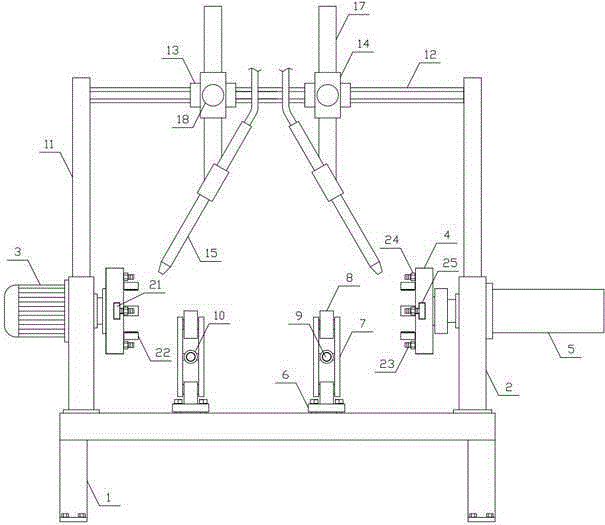

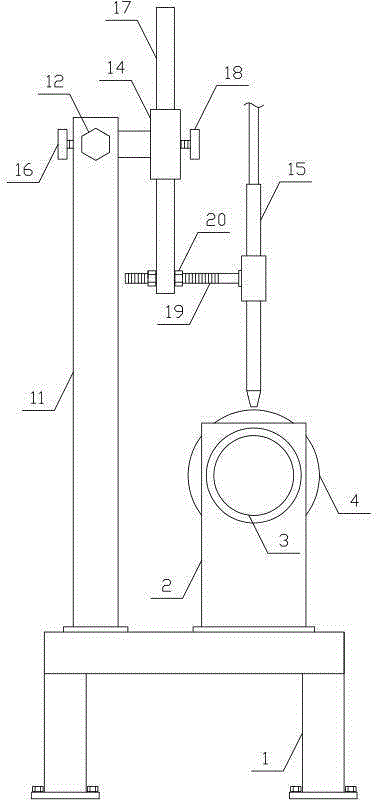

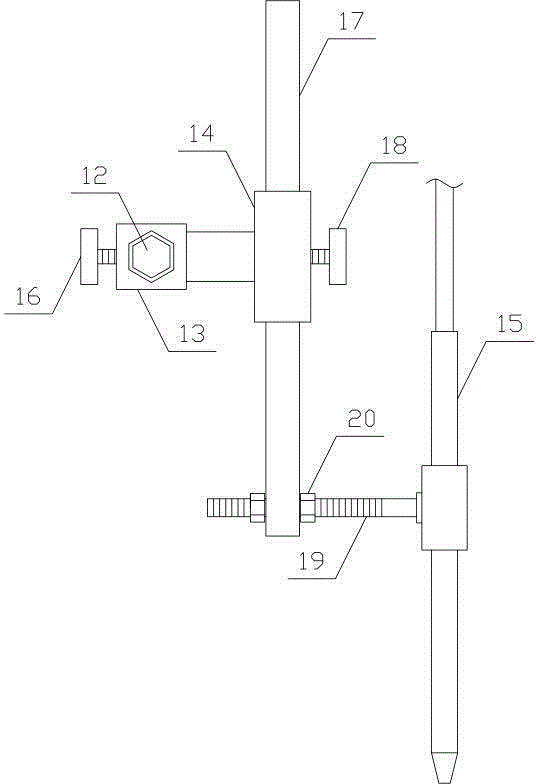

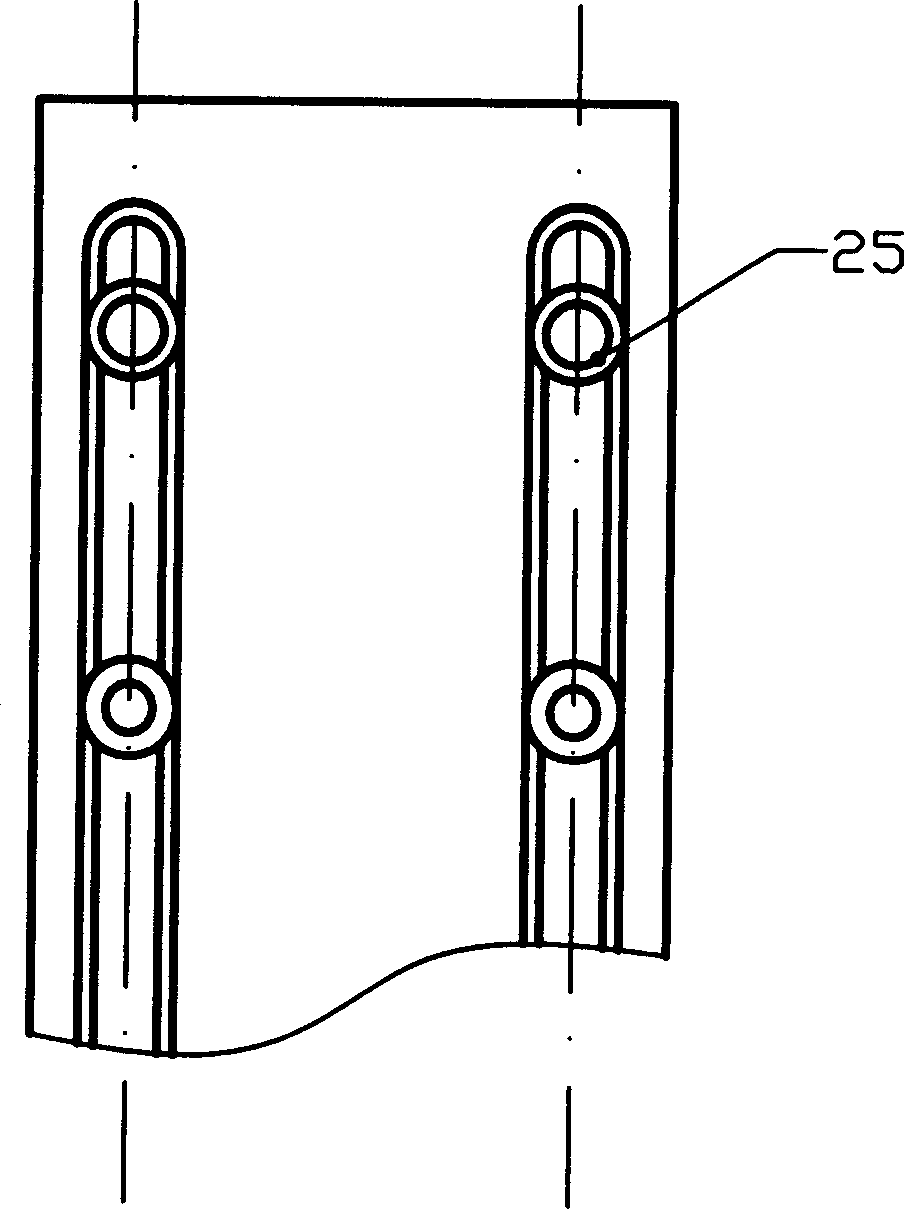

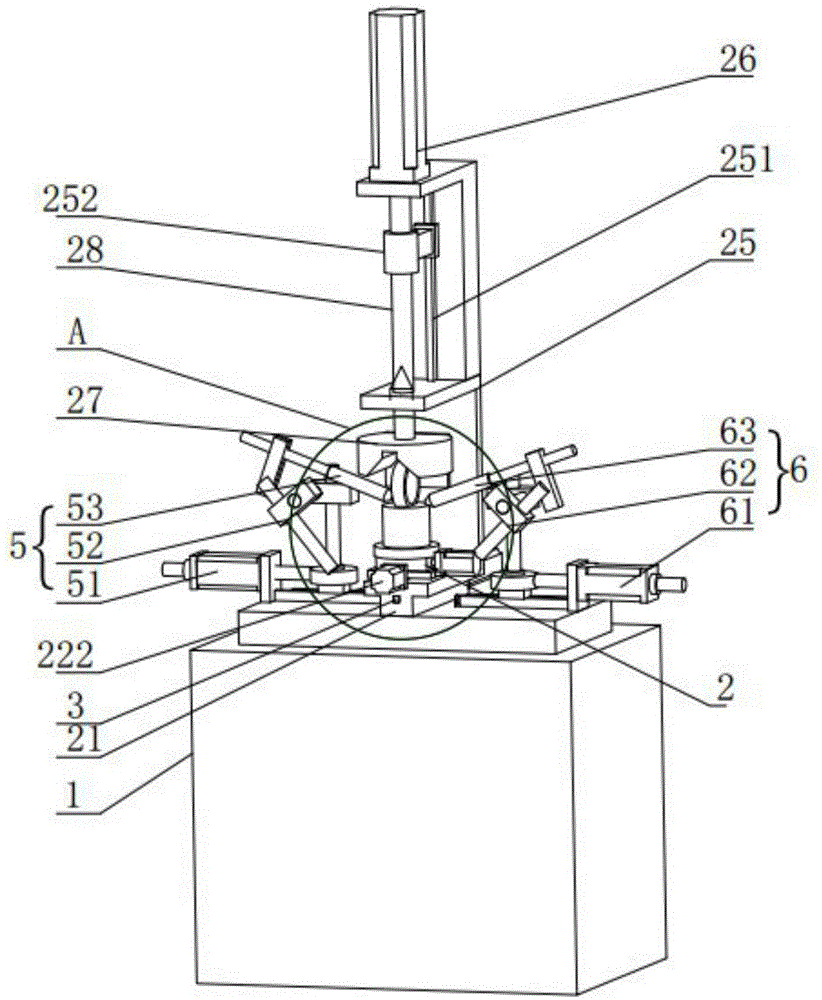

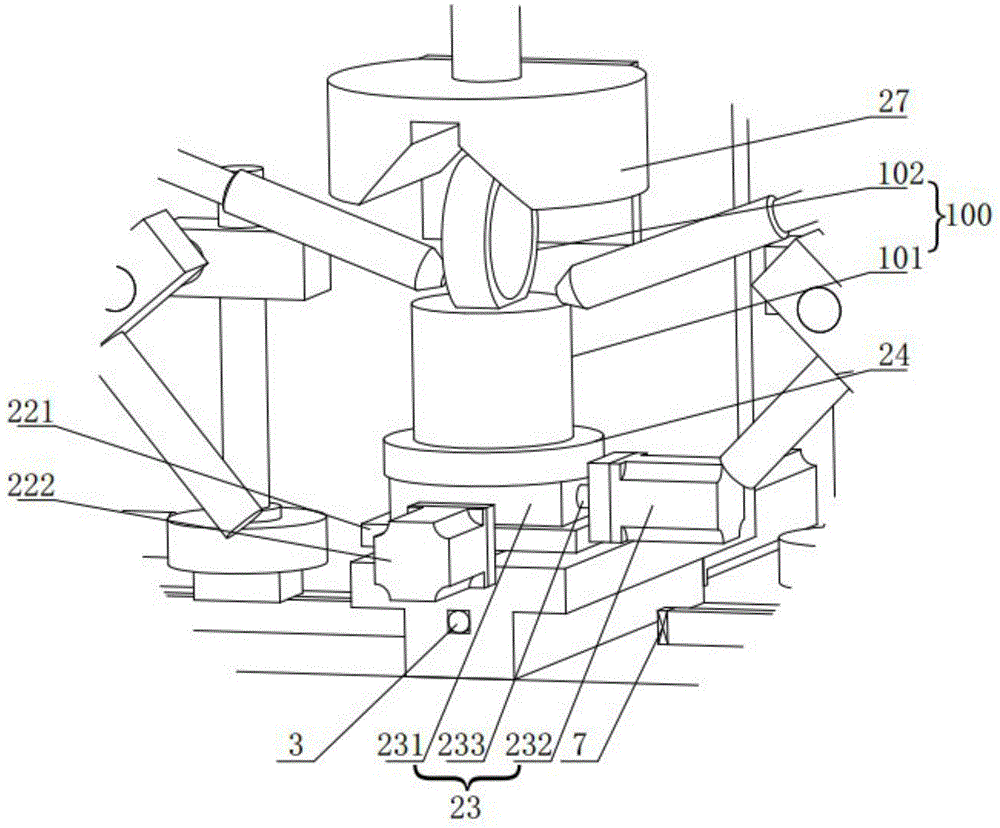

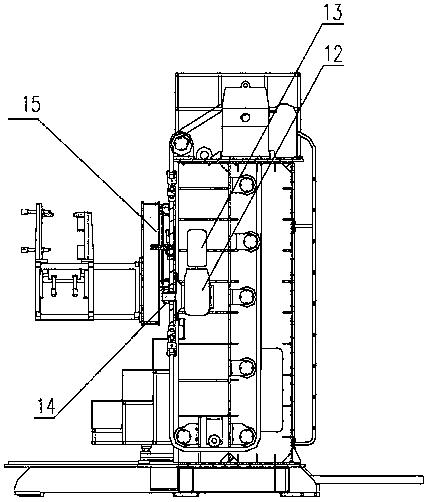

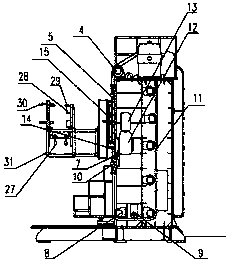

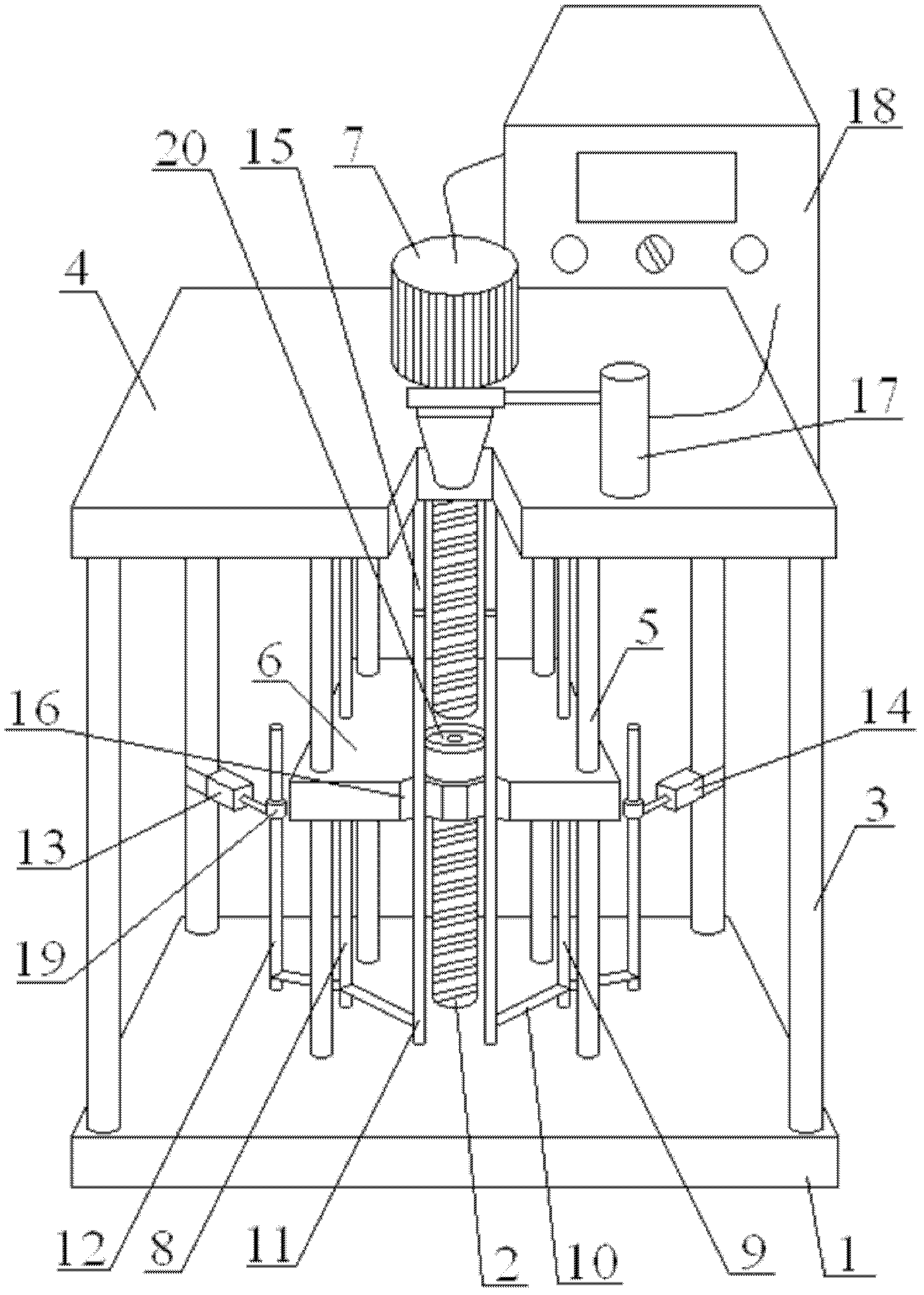

Inner and outer circumference welding machine for cylinder

ActiveCN104289791AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses an inner and outer circumference welding machine for a cylinder. The inner and outer circumference welding machine is characterized by comprising a power device (2) mounted on a base (1), a clamp (3), an inner welding gun and an outer welding gun (9a and 9b), wherein the clamp (3) is used for clamping a cylinder and connected with the power device (2) through a transmission mechanism to bring convenience for driving the cylinder to rotate under driving of the power device; the inner welding gun and the outer welding gun (9a and 9b) are respectively arranged on the base through a welding gun support device, respectively positioned on the inner side and the outer side of the cylinder and aligned with the same circumferential weld on the cylinder to bring convenience for welding the inner side and the outer side of the circumferential weld when the cylinder rotates. The inner and outer circumference welding machine can achieve girth welding of the inner circumferential surface and the outer circumferential surface of the cylinder at the same time, the weld quality is good, workpieces can be mounted and dismounted very conveniently, and the welding speed can be controlled to meet the requirements for welding different workpieces.

Owner:杭州润德车轮制造有限公司

Manufacturing method of seamless flux-cored wire

InactiveCN102310302AMeet welding needsWelding/cutting media/materialsSoldering mediaHydrogen contentHigh intensity

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

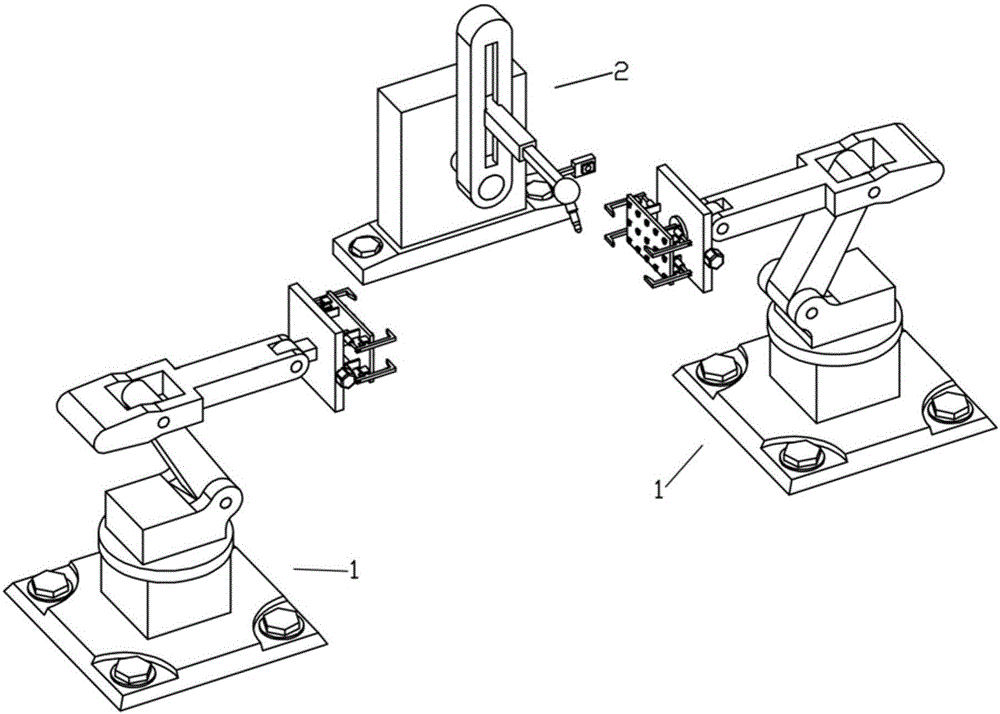

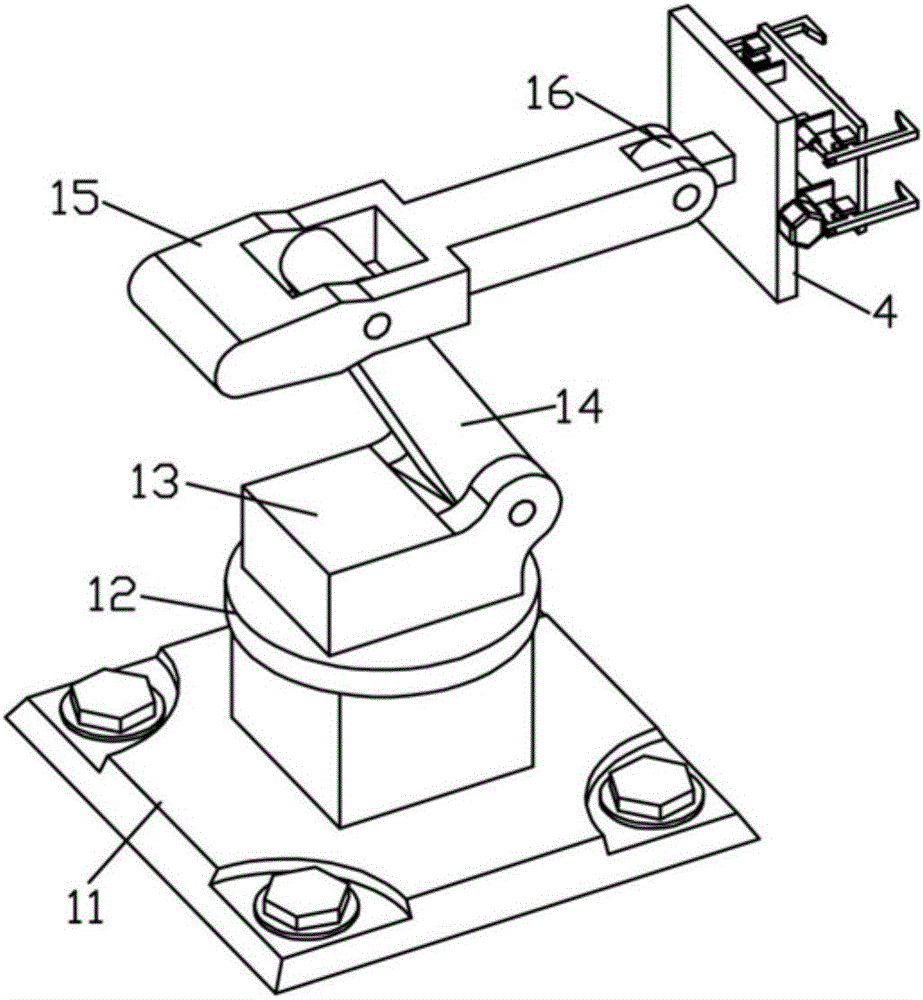

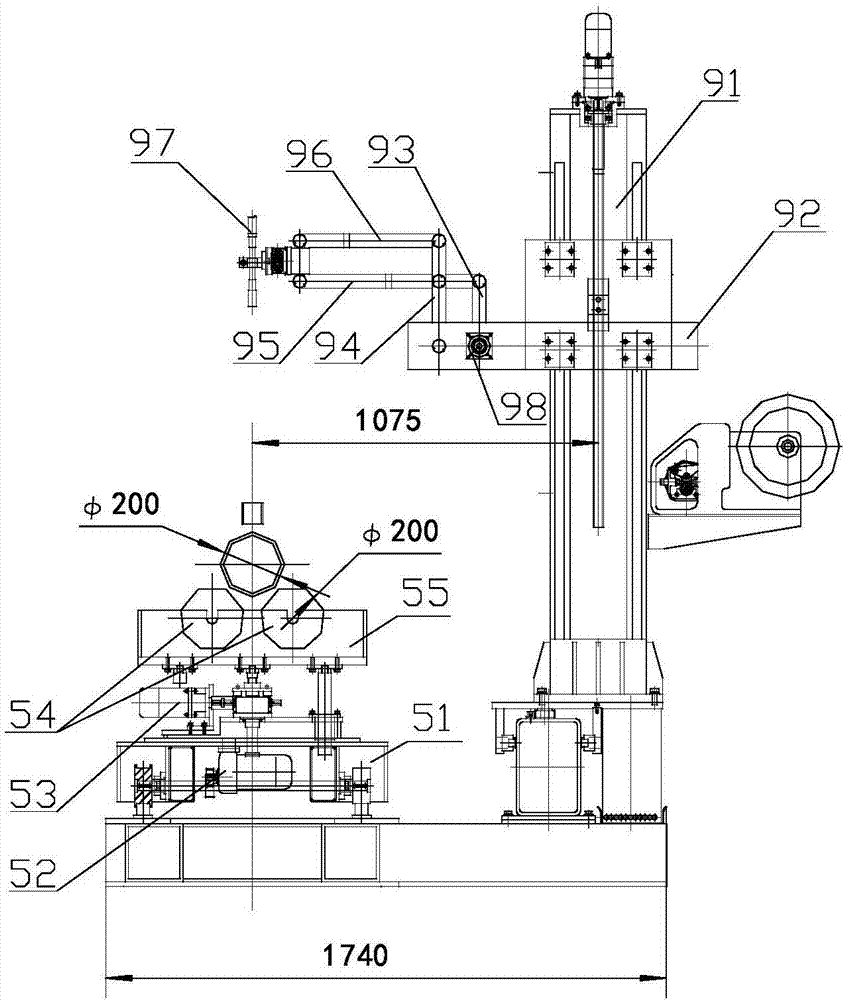

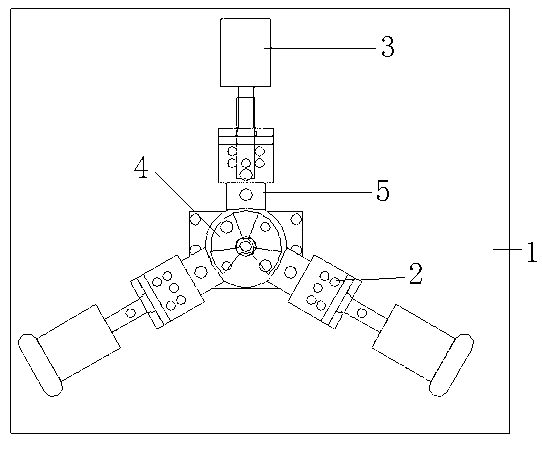

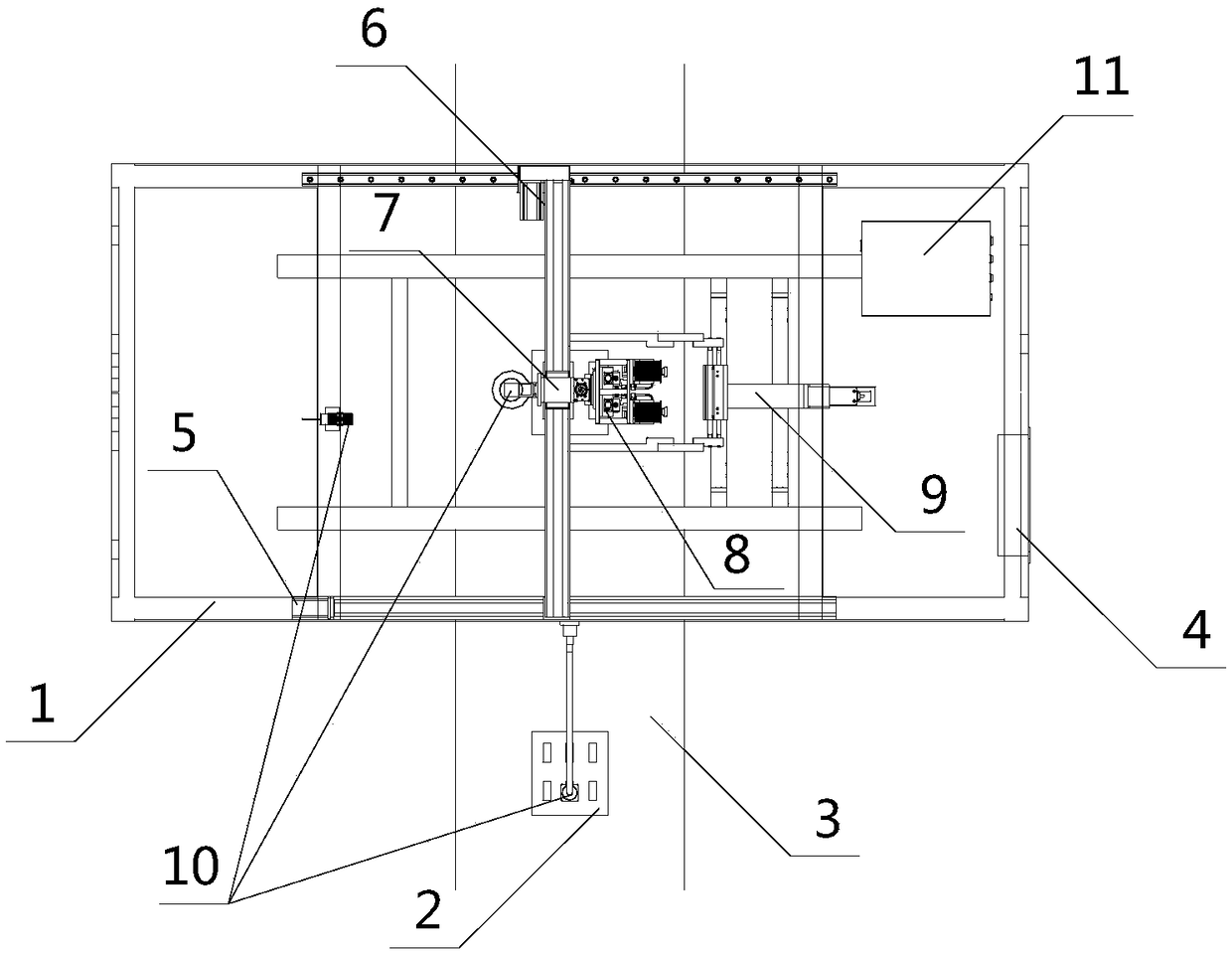

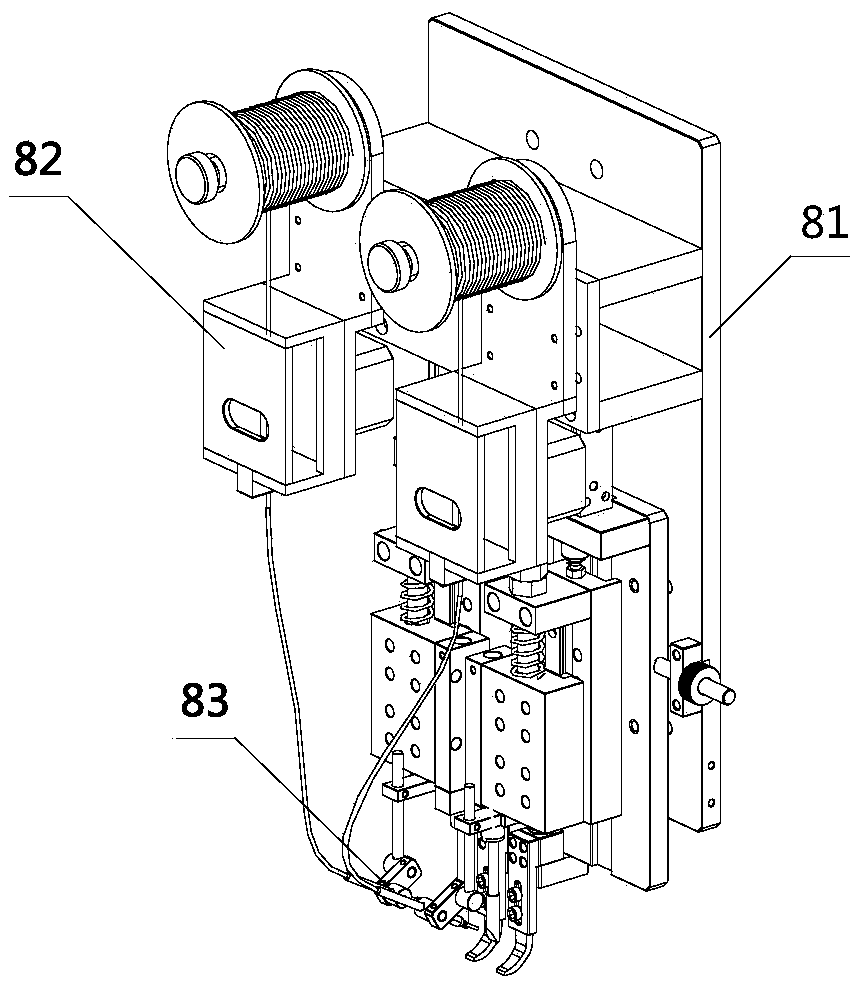

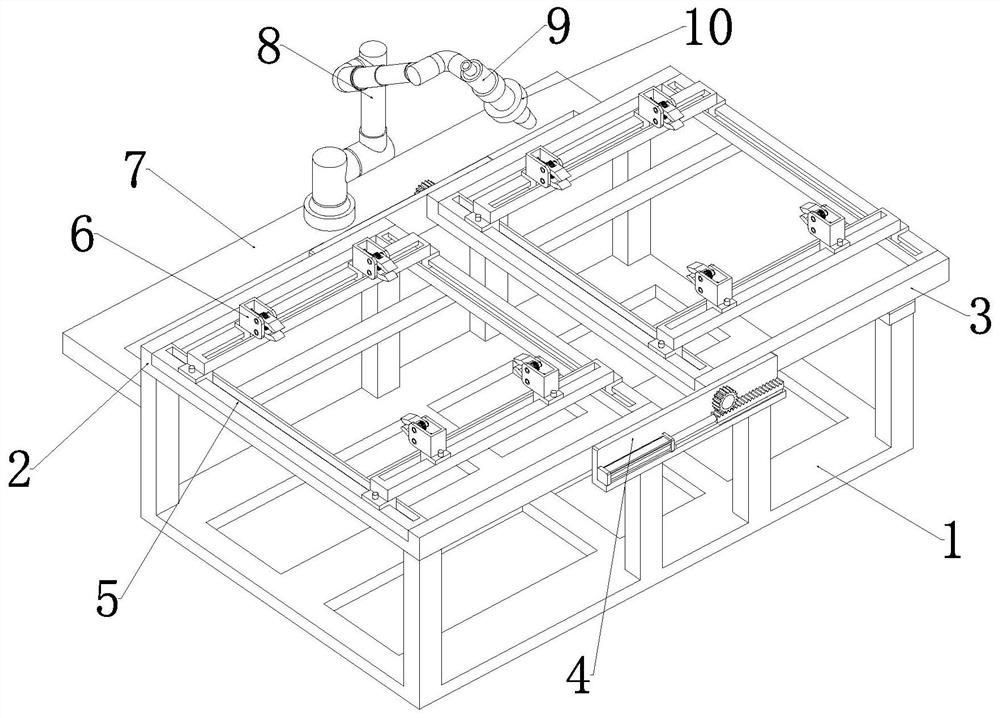

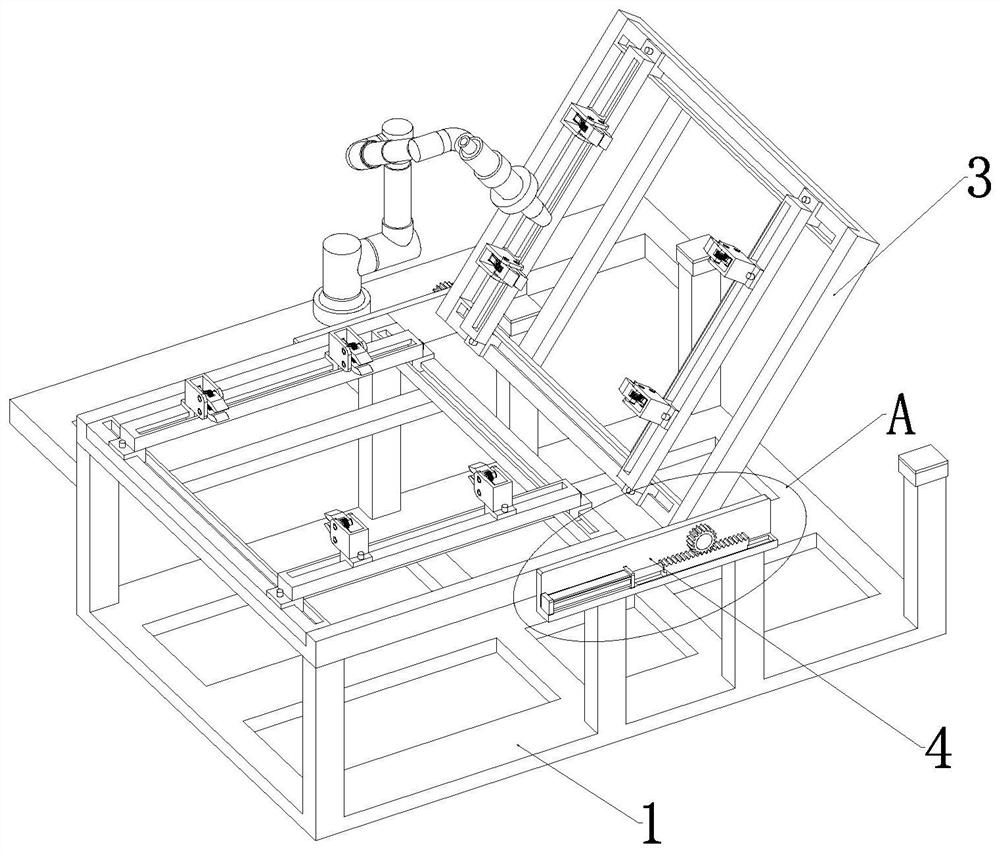

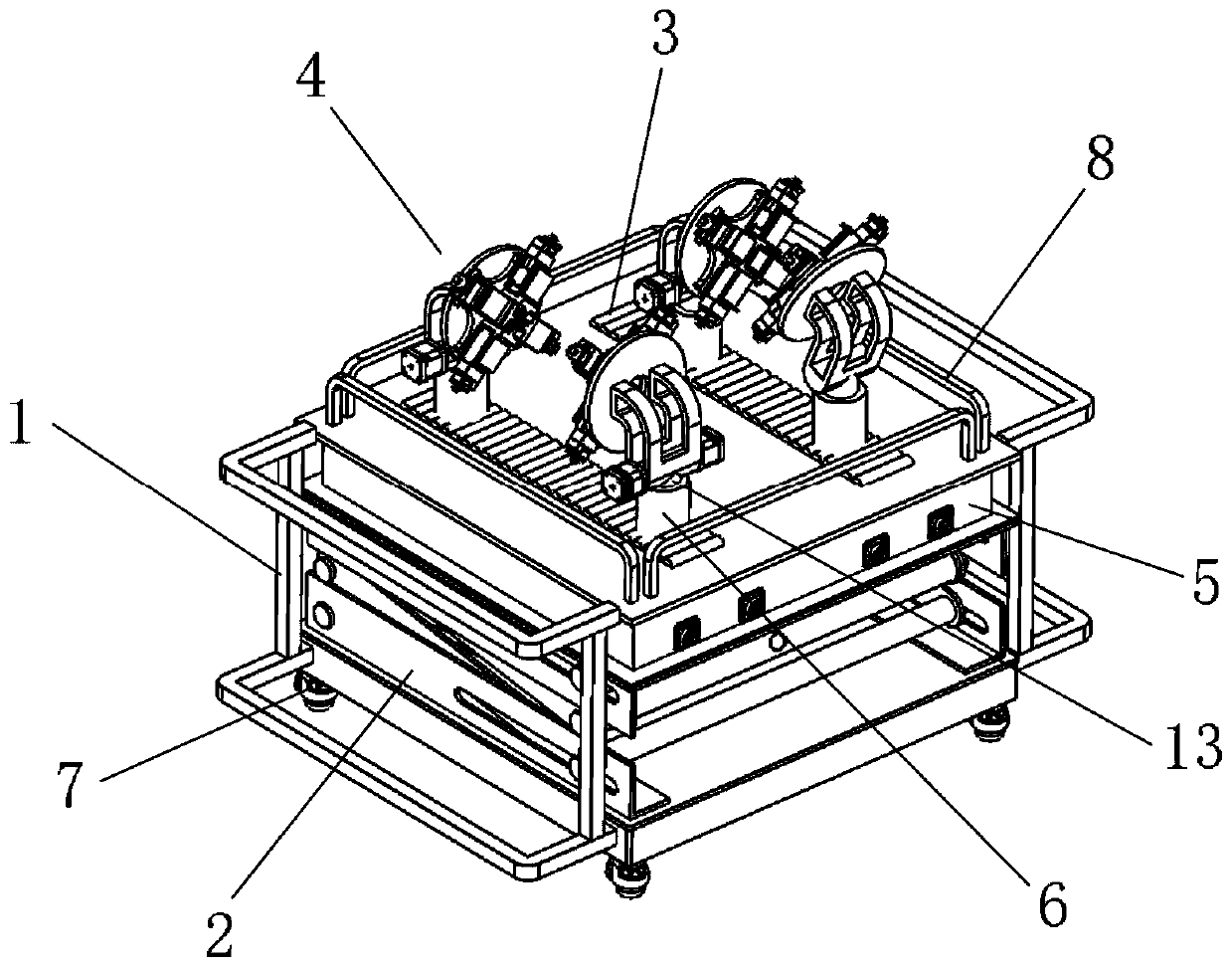

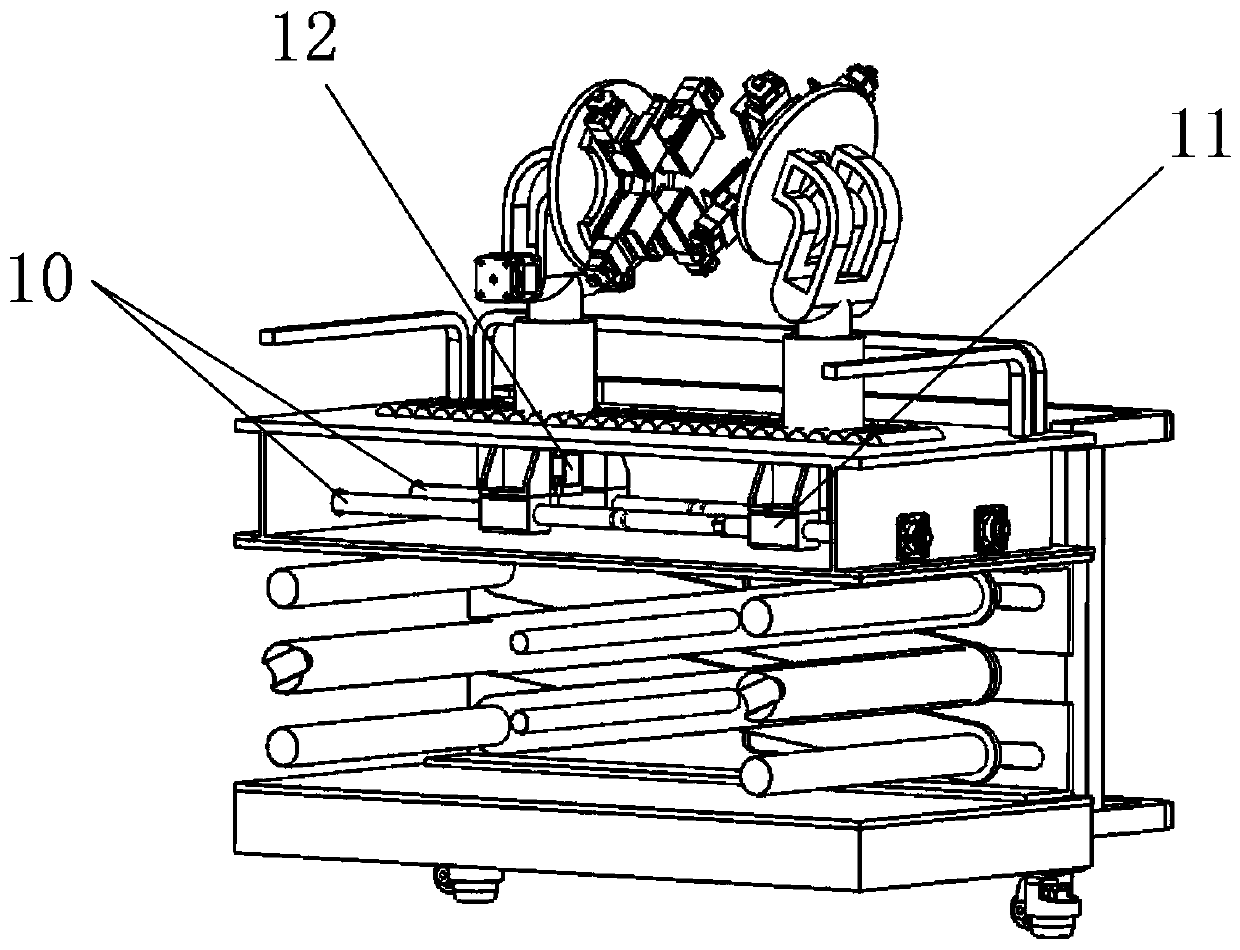

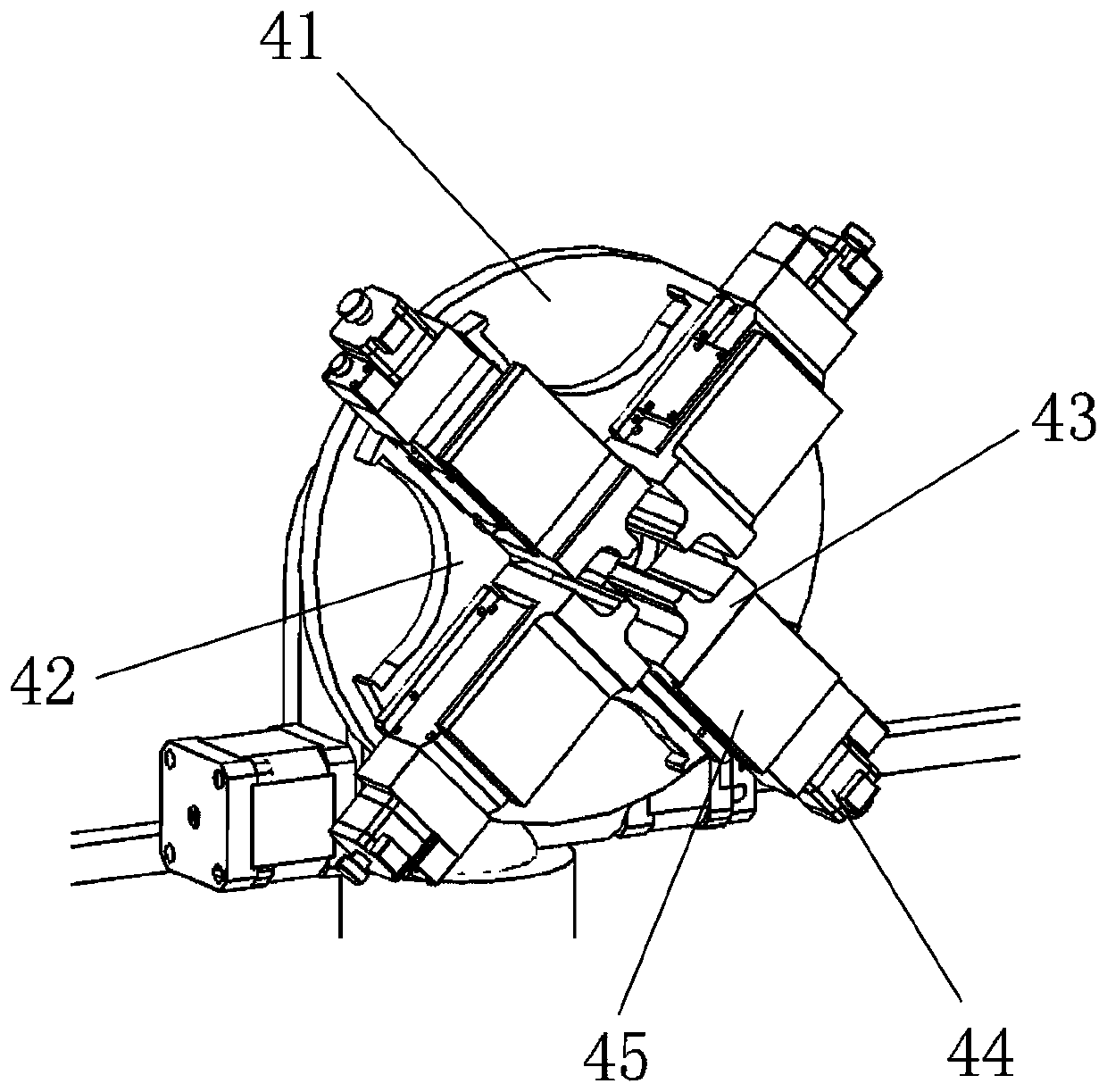

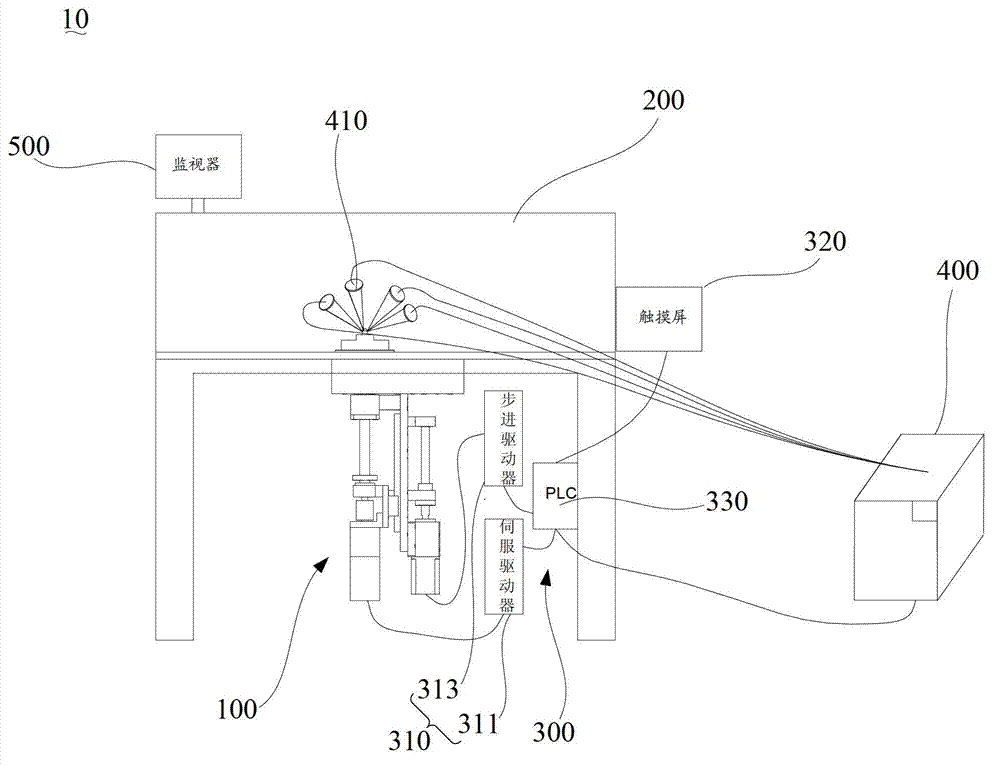

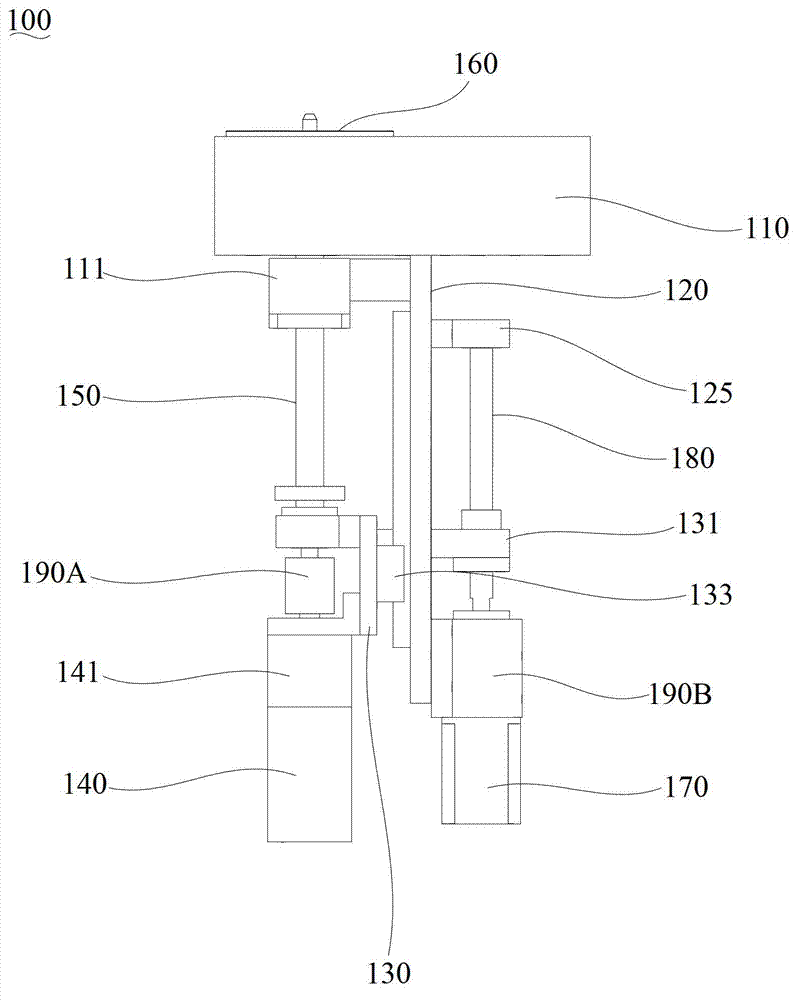

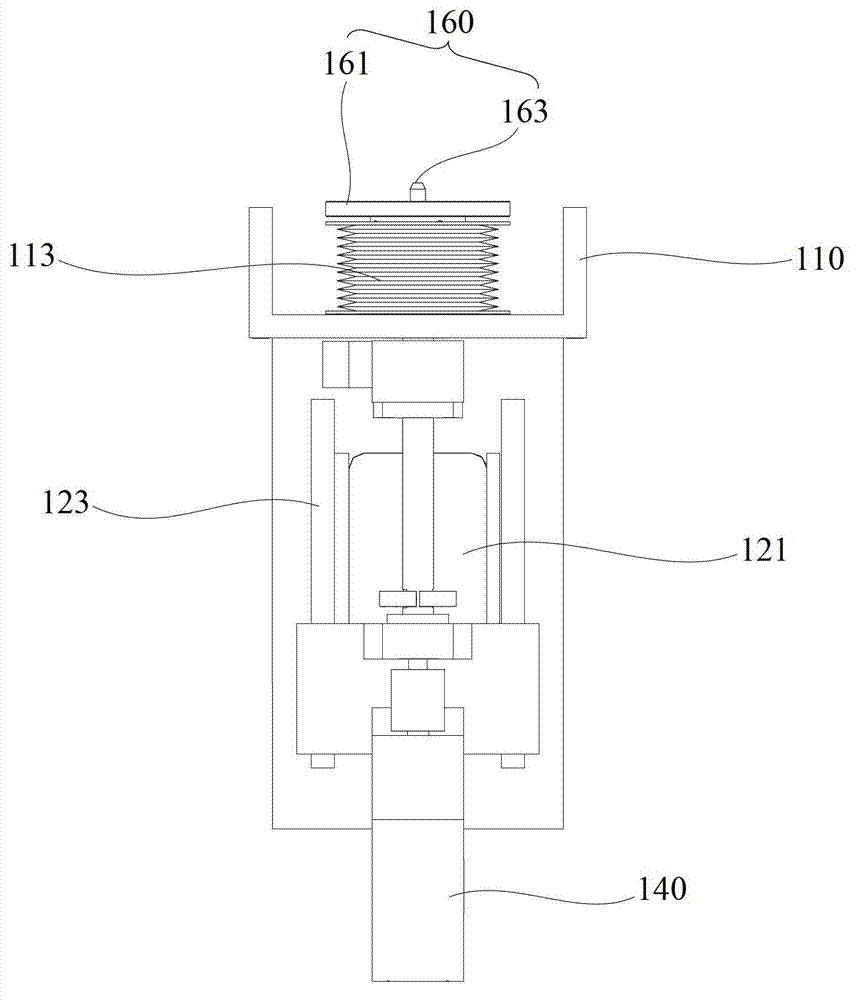

Intelligent welding robot

ActiveCN105855769AImprove replacement efficiencyMeet welding needsWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerDisplay device

The invention discloses an intelligent welding robot which comprises a pair of opposite welding fixtures, a welding manipulator, a CCD (charge coupled device) camera and a control mechanism. The welding fixtures, the welding manipulator and the CCD camera are electrically connected with the control mechanism, the welding manipulator is positioned between the two opposite welding fixtures, the CCD camera is positioned on the upper portion of the welding manipulator, the control mechanism comprises an upper computer, a PLC (programmable logic controller) and a display, the welding fixtures and the welding manipulator can act under the constant control of the PLC, the CCD camera can move along with the welding manipulator and can photograph workpieces in welding procedures, the workpieces can be fixedly firmly grasped by the welding fixtures in the welding procedures, and welding operation can be carried out on the workpieces by the welding manipulator. The intelligent welding robot has the advantages that the intelligent welding robot is provided with the two structurally identical welding fixtures, the workpiece changing efficiency can be improved by the two welding fixtures, welding requirements of the welding manipulator can be met, and the welding efficiency can be greatly improved.

Owner:江门市盛誉金属制品有限公司

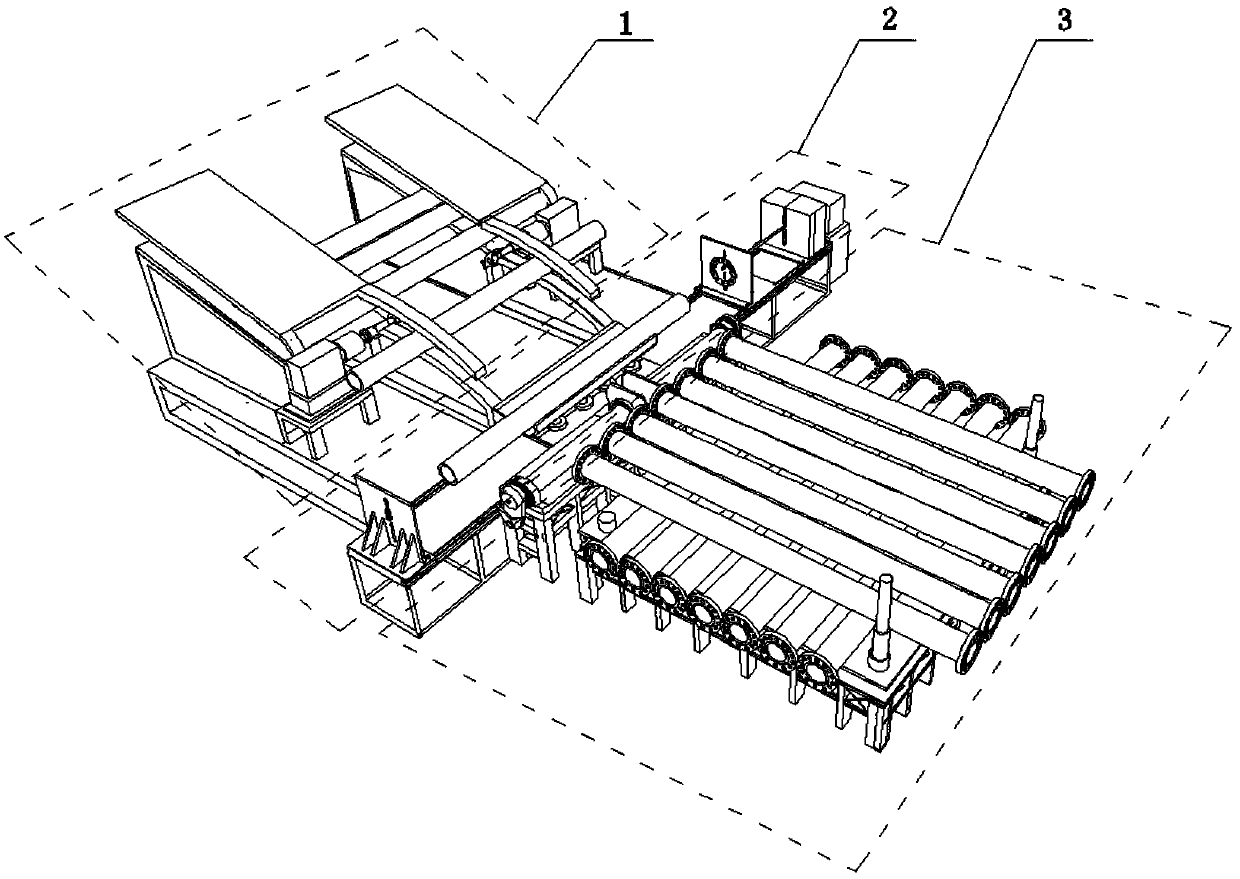

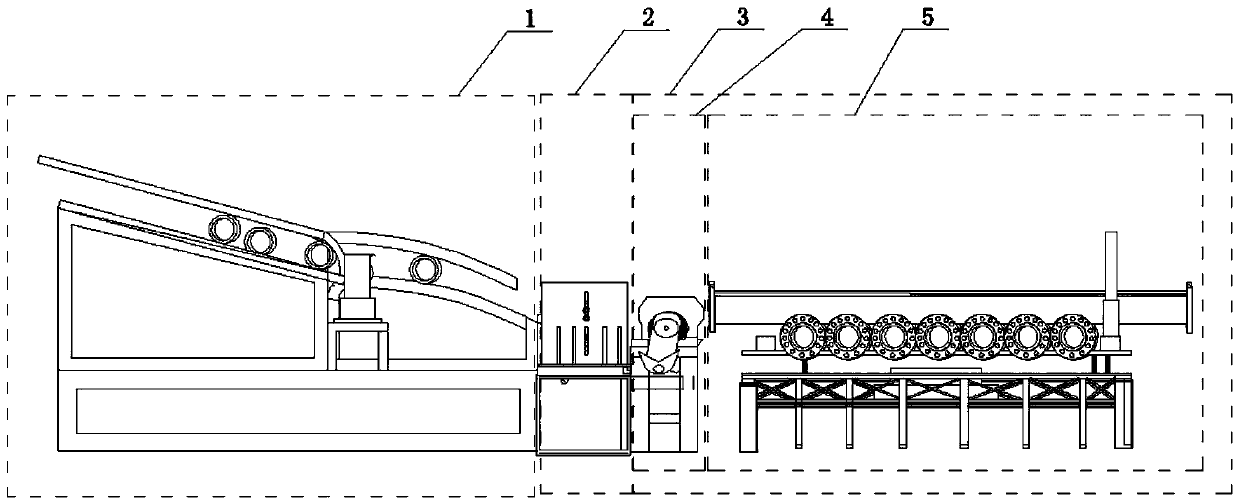

Pipe cutting and welding all-in-one machine

InactiveCN107052656AAchieve weldingImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesMotor driveWire cutting

The invention discloses a pipe cutting and welding all-in-one machine. A clamping chuck is arranged on the end face of a driving headstock and connected with a rotary servo motor driving the clamping chuck to rotate. A plurality of movable lifting brackets are mounted on a fixed base. Each movable lifting bracket comprises a movable lifting base, a lifting riding wheel fixed to the movable lifting base, a traveling driving motor driving the movable lifting base to move along a linear guide rail, and a lifting driving motor driving the lifting riding wheel to move vertically. A cutting assembly comprises a cutting head supporting plate and a cutting head fixed to the cutting head supporting plate. A welding assembly comprises a welding gun head supporting plate and a welding gun head which is fixed to the welding gun head supporting plate. The cutting head supporting plate and the welding gun head supporting plate are both arranged on a movable sliding base and can move along the movable sliding base. The pipe cutting and welding all-in-one machine is suitable for pipes with different diameters and different lengths, a main pipe and a branch pipe can be welded together, two main pipes can also be welded together, and the applicability is high.

Owner:DONGTAI YAOQIANG MACHINERY MFG

Round tube welding device

InactiveCN105215561AGuarantee welding qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderMachining

The invention discloses a round tube welding device and belongs to the field of machining equipment. The round tube welding device comprises a main support, a round tube containing mechanism and a welding mechanism. The round tube containing mechanism is horizontally arranged on one side above the main support. The welding mechanism is vertically arranged on one side of the round tube containing mechanism. The round tube containing mechanism comprises a containing support, a rotary motor, round tube fixing boards, a horizontally-moving hydraulic cylinder and tube bearing mechanisms. The rotary motor is horizontally arranged on one side of the containing support. The horizontally-moving hydraulic cylinder is horizontally arranged on the other side of the containing support. The two round tube fixing boards are vertically and symmetrically arranged. Multiple round tube clamping mechanisms are symmetrically arranged on the round tube fixing boards in the radial direction. The tube bearing mechanisms are vertically and symmetrically arranged at the portion, between the two round tube fixing boards, of the main support. The welding mechanism comprises a welding support, a horizontally-moving rod, horizontally-moving sleeves, lifting sleeves and round tube welding guns. The round tube welding device is simple in structure, round tubes can be rapidly and efficiently welded, round tube welding efficiency and quality are improved, and the production requirement is met.

Owner:魏俊杰

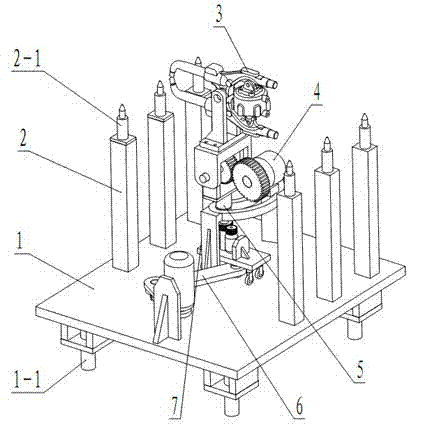

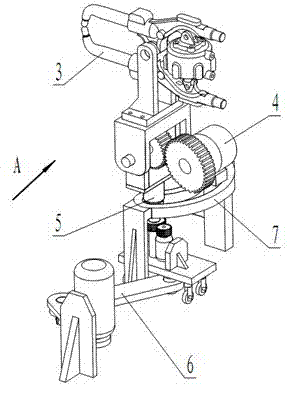

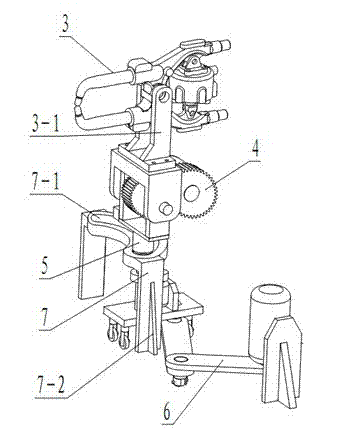

Gas protection method and apparatus for rotating arc narrow gap welding

The invention relates the gas protection method and device used for rotating arc narrow gap welding. The method comprises the following steps: adopting the symmetrical reentrant fan nozzles distributed on the two sides of arc, leading the protection gas from the nozzles along the two sides of rotating arc to protect the welding seam; when ignition tip being close to the work surface or out of fusion face, adopting external telescopic nozzles. The invention has good practicability and low cost, and the observability of arc and fused bath is good. The device possesses simple structure and convenient maintenance.

Owner:JIANGSU UNIV OF SCI & TECH

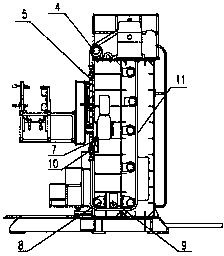

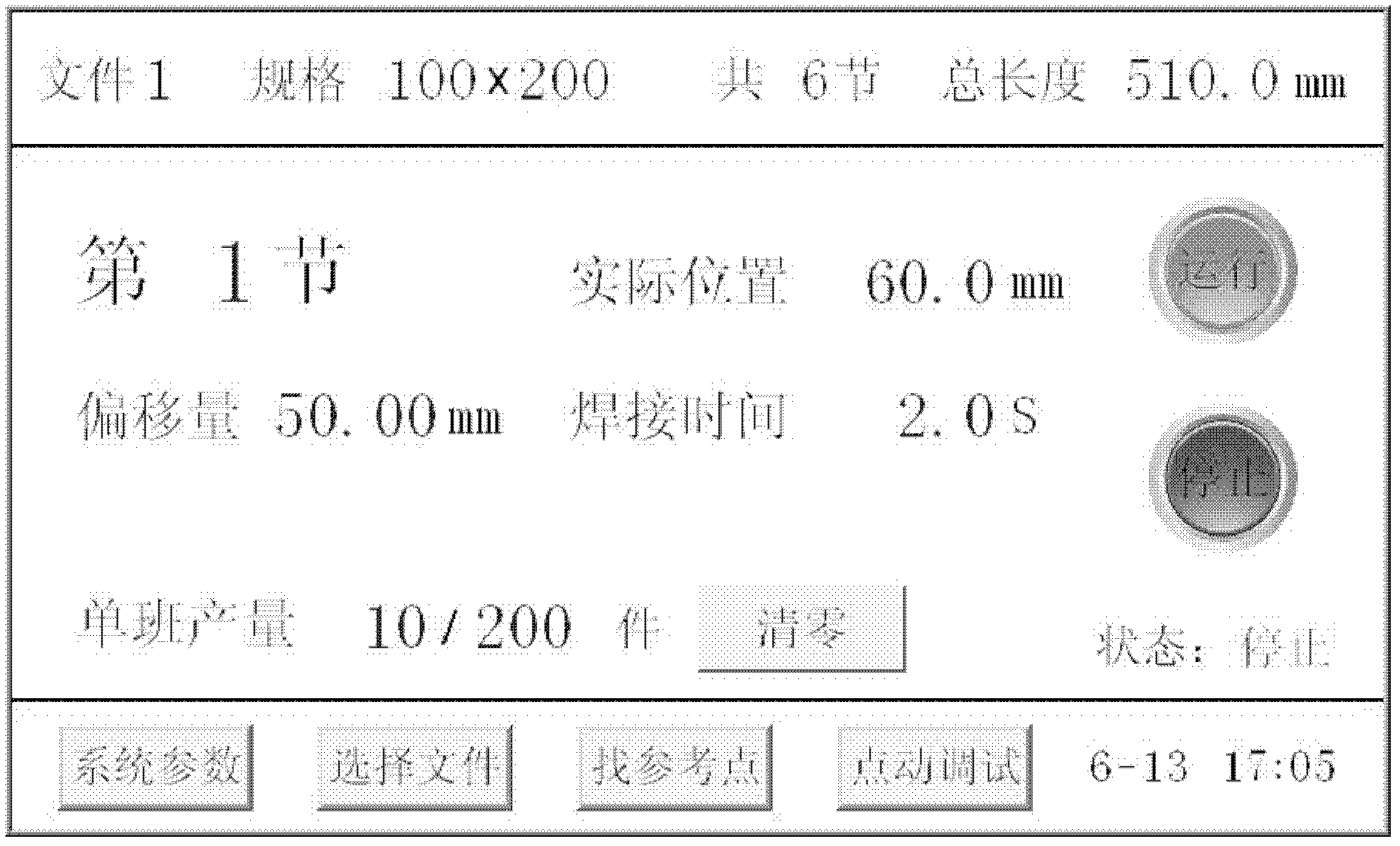

Automatic welding machine and automatic welding method thereof

ActiveCN104690464AImprove welding efficiencyReduce welding costsWelding/cutting auxillary devicesAuxillary welding devicesManipulatorEngineering

The invention relates to an automatic welding machine which comprises a base station, a clamp device, a first ball screw, a first servo motor, a first welding gun component and a second welding gun component. The clamp device is mounted on the base station, the first ball screw is penetratingly mounted in the clamp device and connected with the first servo motor which is fixedly mounted on the base station, the first servo motor drives the first ball screw to drive the clamp device to be in linear motion on the base station, the first welding gun component and the second welding gun component are positioned on two sides of the clamp device respectively, a first cylinder drives a first welding gun rack to adjust position of a first welding gun, and a second cylinder drives a second welding gun rack to adjust position of a second welding gun. The automatic welding machine has the advantages that welding needs on oil storage cylinders and dustproof covers of dampers diverse in structure can be met; the automatic welding machine can replace manual welding, so that welding efficiency is improved; the automatic welding machine can replace welding of a manipulator, so that welding quality is guaranteed while welding cost is lowered.

Owner:无锡乔尼威尔铁路设备科技有限公司

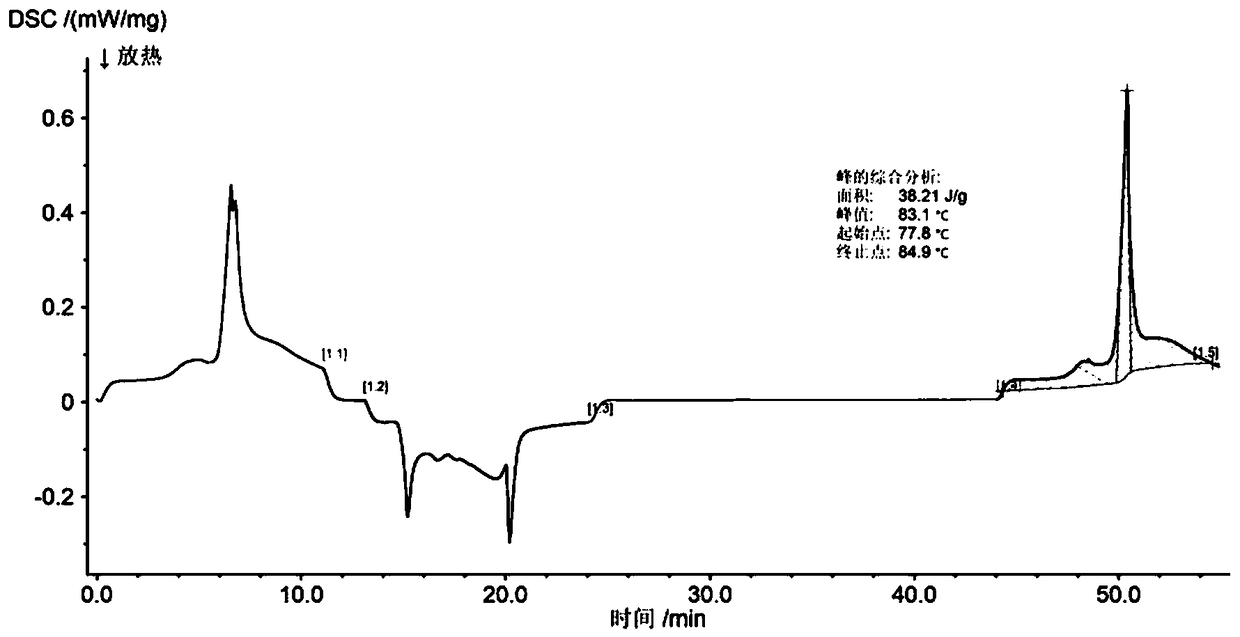

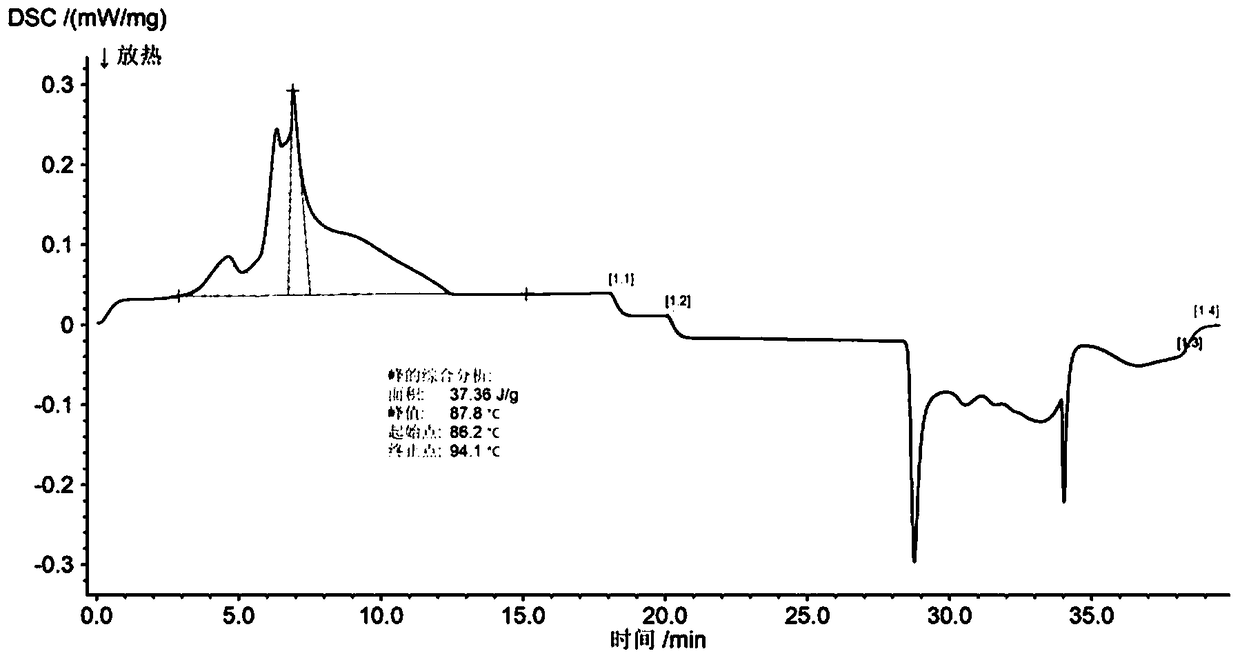

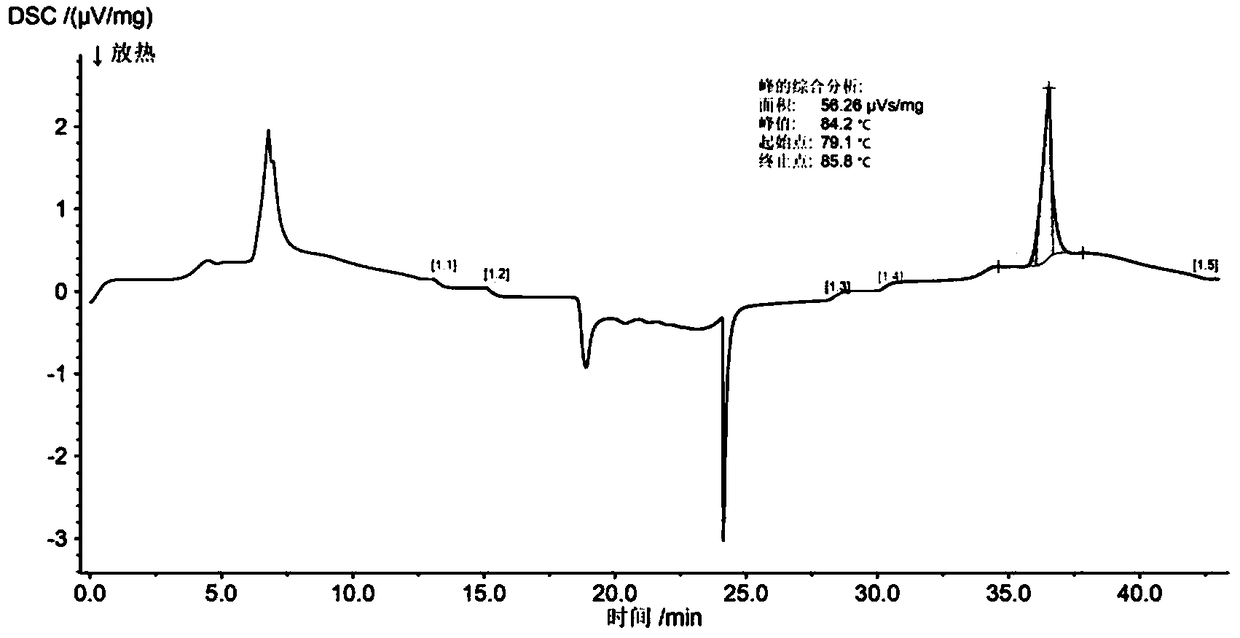

Environment-friendly and low-temperature residue-free solder paste and preparing method thereof

ActiveCN107088716AMeet welding needsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaAlloySolid solution

The invention relates to environment-friendly and low-temperature residue-free solder paste and a preparing method thereof. According to the technical scheme, the environment-friendly and low-temperature residue-free solder paste is characterized in that the solder paste comprises, by weight, 41.0%-60.0% of Sn, 26.6%-37.7% of Bi, 2.1%-4.4% of a third element alloy and 9.0%-19.0% of scaling powder; and the scaling powder comprises, by weight, 67.0%-75.0% of a carrier, 14.8%-18.8% of an activating agent, 4.6%-8.72% of a thixotropic agent, 0.32%-3.2% of a surface active agent and 1.48%-3.5% of corrosion inhibitor. The environment-friendly and low-temperature residue-free solder paste is provided, halogen-free components are adopted in a formula, volatile components are avoided in the tin paste, and smells are avoided during using. After welding, residues are colorless and transparent, and the effect of replacing Pb containing tin paste or halogen-containing tin paste is achieved. Under the low-temperature welding condition, nano aluminum powder is added, a high-temperature solid solution is formed during welding to serve as an auxiliary part for supplementary welding, poor welding of a Sn-Bi alloy is effectively improved, and the welding requirement for aluminum components on the surface of an electronic component can be met; and meanwhile, the storage period of the tin paste is prolonged, and better wettability is brought.

Owner:中山翰华锡业有限公司

Multifunctional industrial robot for intelligent manufacturing automatic production line

ActiveCN108436343AGuaranteed rotational freedomIncrease freedomProgramme-controlled manipulatorWelding/cutting auxillary devicesInterference fitProduction line

The invention relates to the field of robot equipment, and discloses a multifunctional industrial robot for an intelligent manufacturing automatic production line. The multifunctional industrial robotcomprises a bottom plate, wherein a welding manipulator is fixed to the bottom plate, and a small wheel unit is arranged on the lower portion of the bottom plate; the welding manipulator which linearly moves along a first guide rail group is arranged on a first rack and the first guide rail group, the welding manipulator comprises a welding platform, supporting legs are arranged under the weldingplatform, and the supporting legs are slidably arranged on the first guide rail group; a first gear is coaxially connected to an output shaft of a first motor, the first gear is meshed with the firstrack, an installing rod is arranged on one side of the first motor, a supporting wheel is arranged at the bottom of the installing rod, and the supporting wheel makes rolling contact with the bottomplate; and a rotating disc is installed on a welding platform, the rotating disc is sleeved with a gear ring, the inner side of the gear ring is in interference fit with the outer side face of the rotating disc, and a second gear is meshed with the gear ring. The multifunctional industrial robot for the intelligent manufacturing automatic production line has the advantages of being wide in application range, low in cost, accurate in transmission control and the like.

Owner:聊城锐利机械设备有限公司

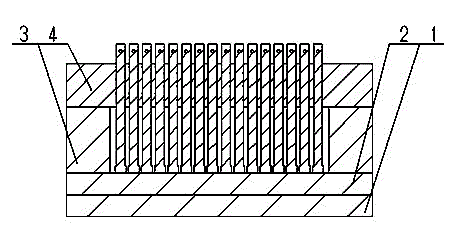

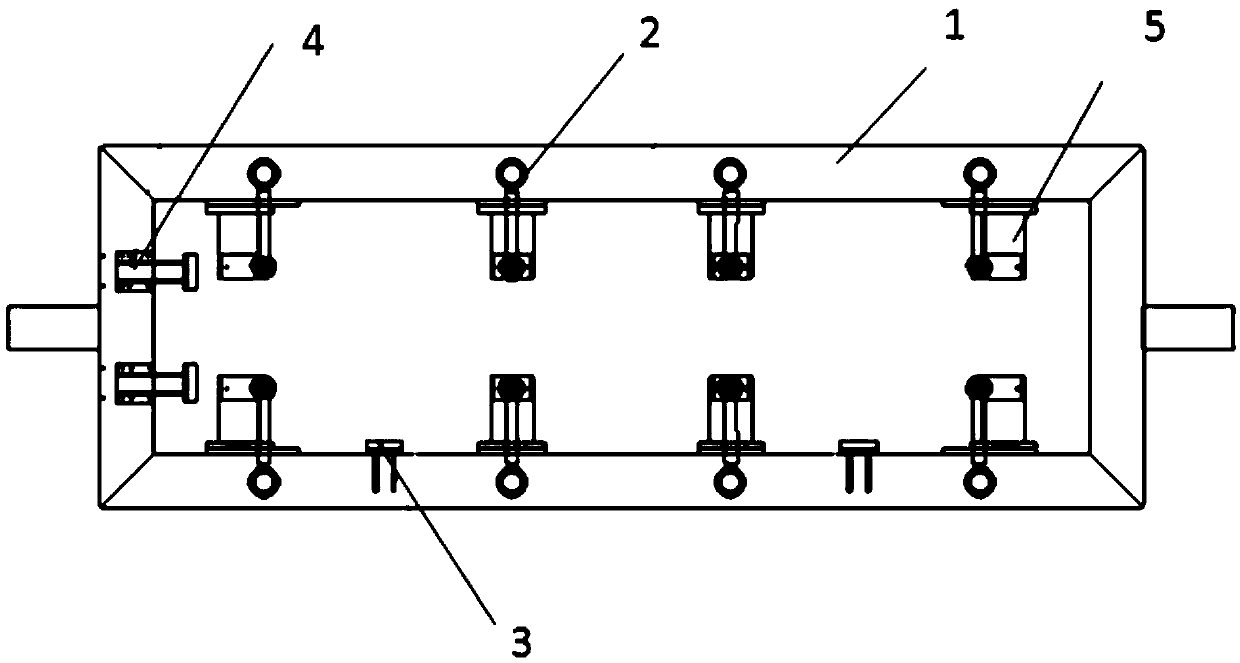

Inner supporting device for storage tank tank-sealing circular seam friction stir welding and method thereof

ActiveCN104400213AMeet welding needsReduce work intensityDomestic vesselsWelding/soldering/cutting articlesEngineeringMechanical engineering

The invention provides an inner supporting device for storage tank tank-sealing circular seam friction stir welding and a method thereof. A splicing supporting ring is arranged as a device main body; a plurality of pneumatic supporting blocks are uniformly connected with the circumference of the splicing supporting ring; each of the pneumatic supporting blocks is respectively connected with a cylinder; the pneumatic supporting blocks are driven to stretch along a radial direction of the splicing supporting ring by the cylinders; air pipes and valves of all the cylinders are uniformly arranged on an annular structure which is formed by connecting two air-path connecting plates; a positioning ring is arranged on one side of the splicing supporting ring; positioning pin shafts are arranged on the positions, corresponding to a clamping ring, a ring petal, a supporting base, a connecting beam, a connecting block and a ring base of the splicing supporting ring, on the positioning ring. According to the device and the method, the welding requirement of the storage tank tank-sealing circular seam is efficiently and quickly met; after the welding, the inner supporting device can be conveniently taken out of a manhole flange with a diameter being 350mm; after the inner supporting device is taken out, the whole device is high-efficiently reset on the positioning ring and is prepared for the next use.

Owner:CAPITAL AEROSPACE MACHINERY +2

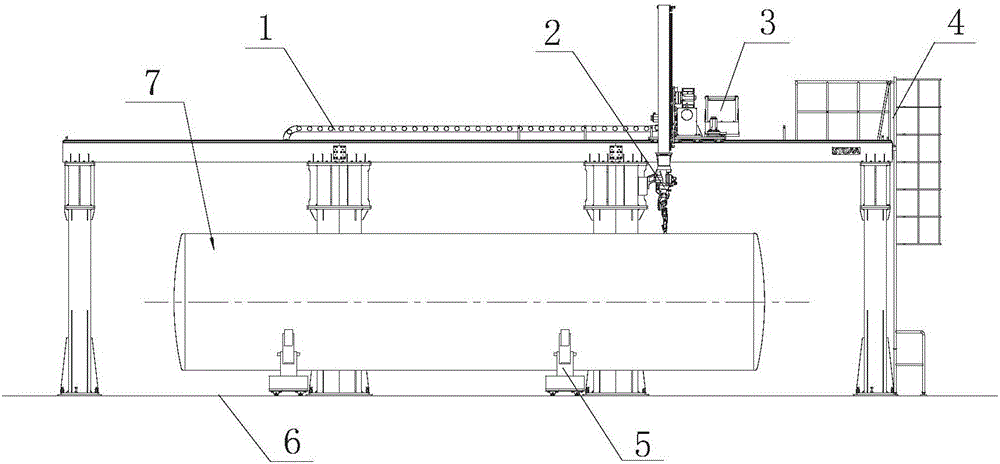

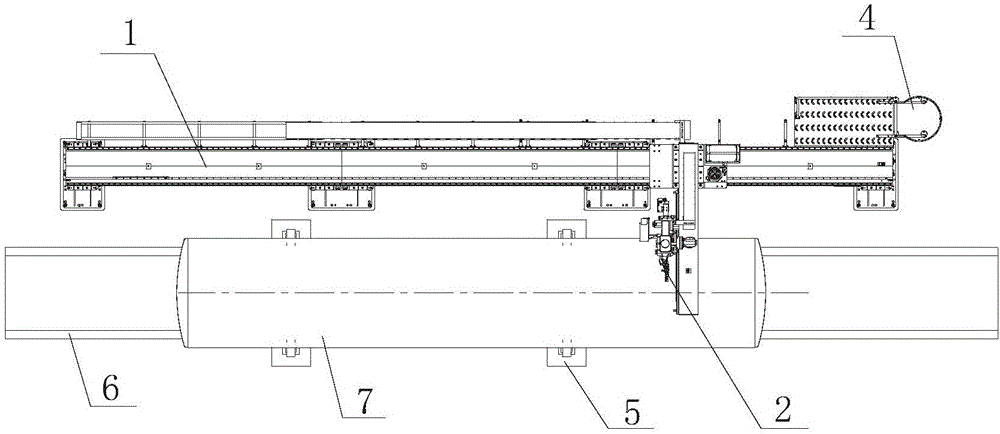

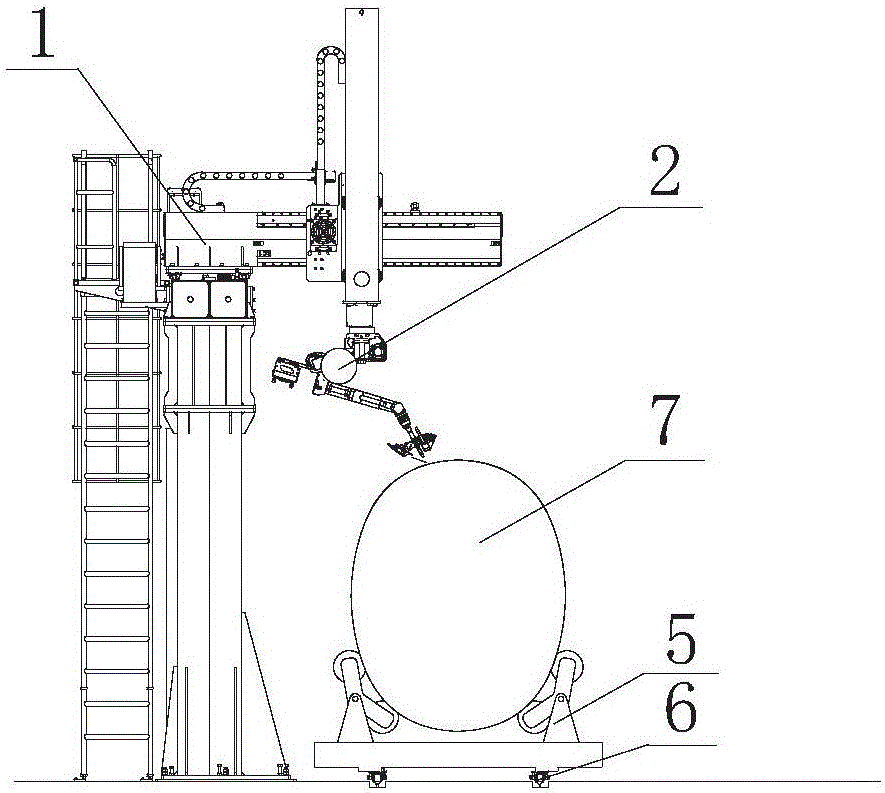

Robot welding system for elliptical tank body circumferential weld

InactiveCN106425177AAchieve weldingAchieving different angles/positionsWelding/cutting auxillary devicesAuxillary welding devicesEllipseWelding power supply

The invention relates to a robot welding system, in particular to a robot welding system of an elliptical tank body circumferential weld. The robot welding system of the elliptical tank body circumferential weld comprises an XYZ triaxial sky rail traveling mechanism, a robot welding system, a welding power supply, a servo roller frame reversal positioner and a positioner traveling track, the servo roller frame reversal positioner can be arranged on the positioner traveling track in a sliding mode, and the XYZ triaxial sky rail traveling mechanism is arranged on one side of the positioner traveling track. The robot welding system is arranged on the XYZ triaxial sky rail traveling mechanism, is connected with the welding power supply and can make rectilinear motion in the X-axis, Y-axis and Z-axis directions. According to the robot welding system of the elliptical tank body circumferential weld, through the XYZ triaxial rectilinear motion of the robot welding system, workpieces are driven to make irregular rotary motion, and the welding of the workpieces at various angles is achieved in combination with a robot welding gun.

Owner:斯图加特航空自动化(青岛)有限公司

Welding device and method for superconducting lines

ActiveCN102941387AAchieve weldingApply pressure evenlyLine/current collector detailsHeating appliancesTemperature controlEngineering

The invention relates a welding device and method for superconducting lines. The welding device comprises a heating unit, a welding bedplate, heat insulation blocks and a pressing unit with a support body, wherein the welding bedplate is fastened on the heating unit; the heating unit is provided with a heater and a temperature adjustor; the pressing unit is mounted on the welding bedplate and further comprises pressing pieces and the heat insulation blocks; and the pressing pieces are mounted on the support body and used for pressing a welding head, and the heat insulation blocks are arranged between the welding bedplate and the support body. The welding device and method for the superconducting lines provided by the invention have the advantages of having a large temperature-controlled range, being high in precision, being capable of meeting the temperature control requirement on the welding of the superconducting lines, and further being capable of improving welding quality and alleviating welding dispersiveness through reducing the thickness of a welding layer, enlarging welding area, lowering welding resistance and reducing artificial operation factors.

Owner:中国船舶重工集团公司第七一二研究所

Automatic welding machine

InactiveCN102794555AHigh degree of automationImprove welding efficiencyResistance electrode holdersControl systemAutomation

The invention relates to an automatic welding machine. The automatic welding machine comprises a working platform, one or more welding mechanisms arranged on the working platform and a control system for controlling the welding mechanisms. The automatic welding machine is characterized in that the welding mechanism comprises a central electrode and a plurality of moving electrodes arranged at the periphery of the central electrode, wherein each moving electrode comprises a sliding rail, a moving electrode block and a moving electrode cylinder; the moving electrode block can be arranged on the sliding rail in a sliding manner; the moving electrode cylinder is used for driving the electrode block to slide upwards; the central electrode and the moving electrodes are respectively connected with two electrodes of a power supply; and the moving electrode cylinder is connected with the control system. The automatic welding machine has the advantages that a plurality of workpieces or a plurality of welding parts of the same workpiece can be welded automatically and simultaneously, the automation degree is high, the use is convenient and the welding efficiency is high.

Owner:伟业精密科技(惠州)有限公司

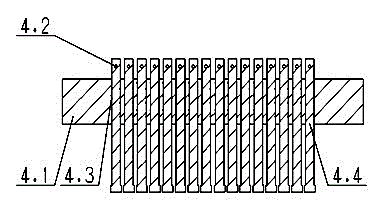

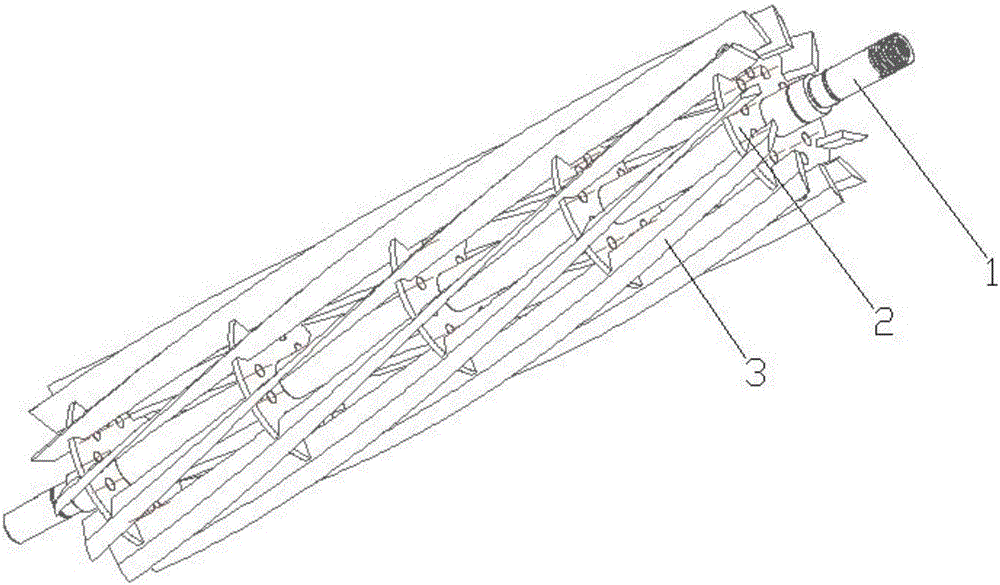

Grass-cutting hob, cutter welding tool of grass-cutting hob and manufacturing method of grass-cutting hob

ActiveCN106392422AImprove welding efficiencyImprove welding precisionWelding/cutting auxillary devicesLawn-mowersLawnManufacturing engineering

The invention discloses a grass-cutting hob, a cutter welding tool of the grass-cutting hob and a manufacturing method of the grass-cutting hob, and belongs to the field of lawn machines and manufacturing processes of the lawn machines. By means of the grass-cutting hob, the cutter welding tool and the manufacturing method, the problem that existing grass-cutting hob manufacturing methods are high in cost or poor in quality is solved. The grass-cutting hob comprises cutters. Multiple insertion grooves are formed in each cutter. The corresponding insertion grooves are formed in each cutter with the circle center of the surface of the cutter as the central point according to an array with the angles between items being a. Positioning holes are formed in the cutters. The cutter welding tool of the grass-cutting hob comprises a base and multiple supporting plates perpendicularly arranged on the base at equal intervals. A cutter positioning block is arranged on one side of each supporting plate. The cutter positioning blocks correspond to the positioning holes. The manufacturing method of the grass-cutting hob mainly includes the step that the cutters are welded through the combination of the improvement mentioned above. The grass-cutting hob, the cutter welding tool and the manufacturing method mainly have the beneficial effect that on the premise of not increasing the production cost, the production efficiency and the quality of the grass-cutting hob are improved.

Owner:MAANSHAN GREEN FRIEND MACHINE MFG

Universal welding tool for sleeper beam of subway rail vehicle and welding method thereof

PendingCN109676299ASave tuning timeImplement anti-morphingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a universal welding tool for a sleeper beam of a subway rail vehicle, comprising a frame, a sleeper beam pressing device, a longitudinal limiting device, a transverse limiting device and a reference adjusting device; the sleeper beam pressing device is arranged on the frame to press the sleeper beam, the longitudinal limiting device is arranged on the frame to limit the sleeper beam in a longitudinal direction, the transverse limiting device is arranged on the frame to limit the sleeper beam in a transverse direction, the reference adjusting device is positioned on the inner side surface of the frame, and the reference adjusting device corresponds to the sleeper beam pressing device one by one to adjust the placing height of the sleeper beam. The invention relates toa welding method for a sleeper beam of a subway rail vehicle, which comprises the following steps of adjusting too before welding, welding and assembling the sleeper beam, and standing after weldingto eliminate stress. The welding tool provided by the invention has a simple structure, novel design, convenient operation and strong universality; double functions of workpiece positioning and welding deformation reduction are simultaneously realized by matching the welding method, and the production efficiency is greatly improved.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

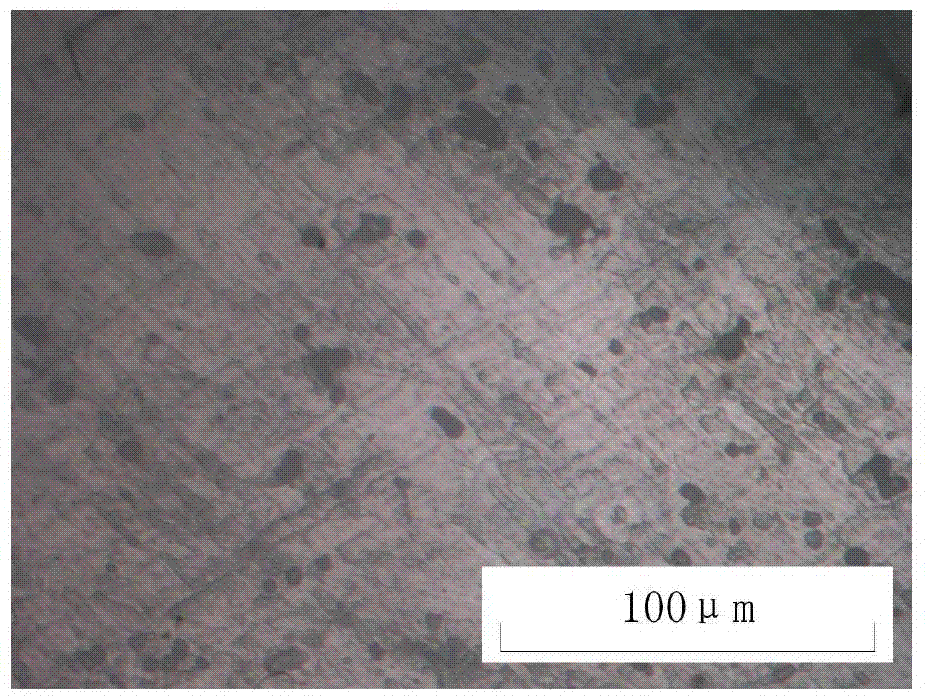

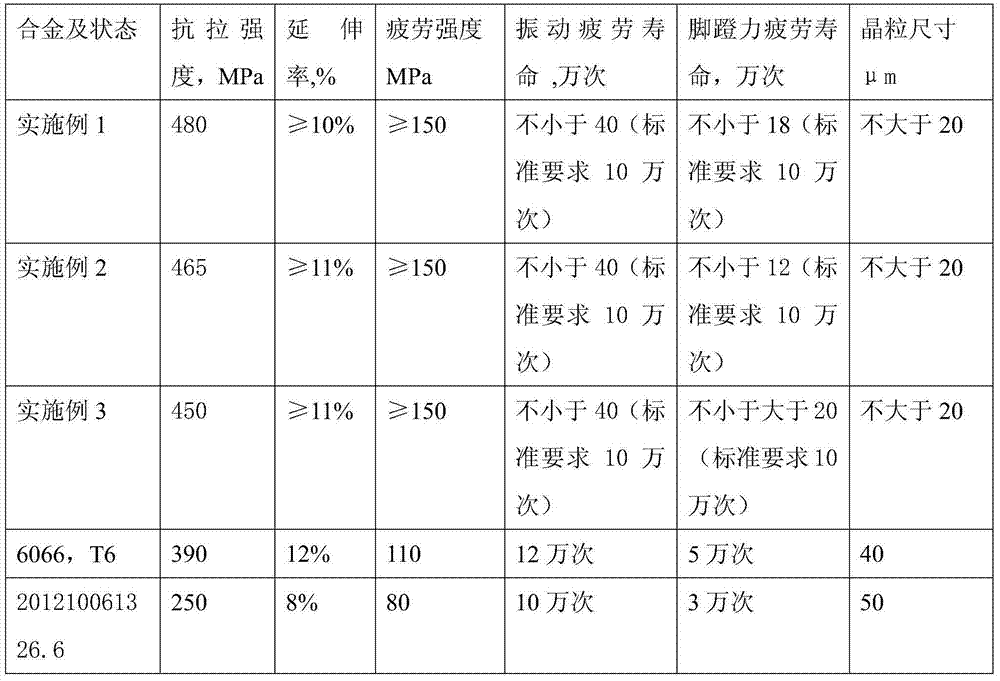

Aluminum alloy for bicycle frame tube and preparation method thereof

The invention discloses an aluminum alloy for a bicycle frame tube and a preparation method thereof, wherein the aluminum alloy aims at solving the technical problems that the intensity of the existing aluminum alloy which is used for manufacturing the bicycle frame tube is not good or the welding process property is not good or the safe reliability is not good. The aluminum alloy comprises the following components according to weight percentage 0.8-1.6% of Mg, 0.8-1.8% of Si, 0.7-1.2% of Cu, 0.6-1.4% of Mn, 0.10-0.30% of Cr, 0.1-0.6% of Er, 0.08-0.20% of Zr, and the balance Al and inevitable impurities. The aluminum alloy provided by the invention have the beneficial effects that the intensity of the aluminum alloy is good, the plasticity is good, the light weight of a bicycle is realized, the intensity of the bicycle frame tube which is made of the aluminum alloy is greater than 450MPa, and the extending ratio can be kept to be more than 10%; the welding property and the extrusion property are excellent, the welding requirements on the extrusion moulding of the bicycle frame tube and a frame are met, and the aluminum alloy can smoothly pass the European standard safety test.

Owner:TIANJIN GOLDEN WHEEL BICYCLE GRP +1

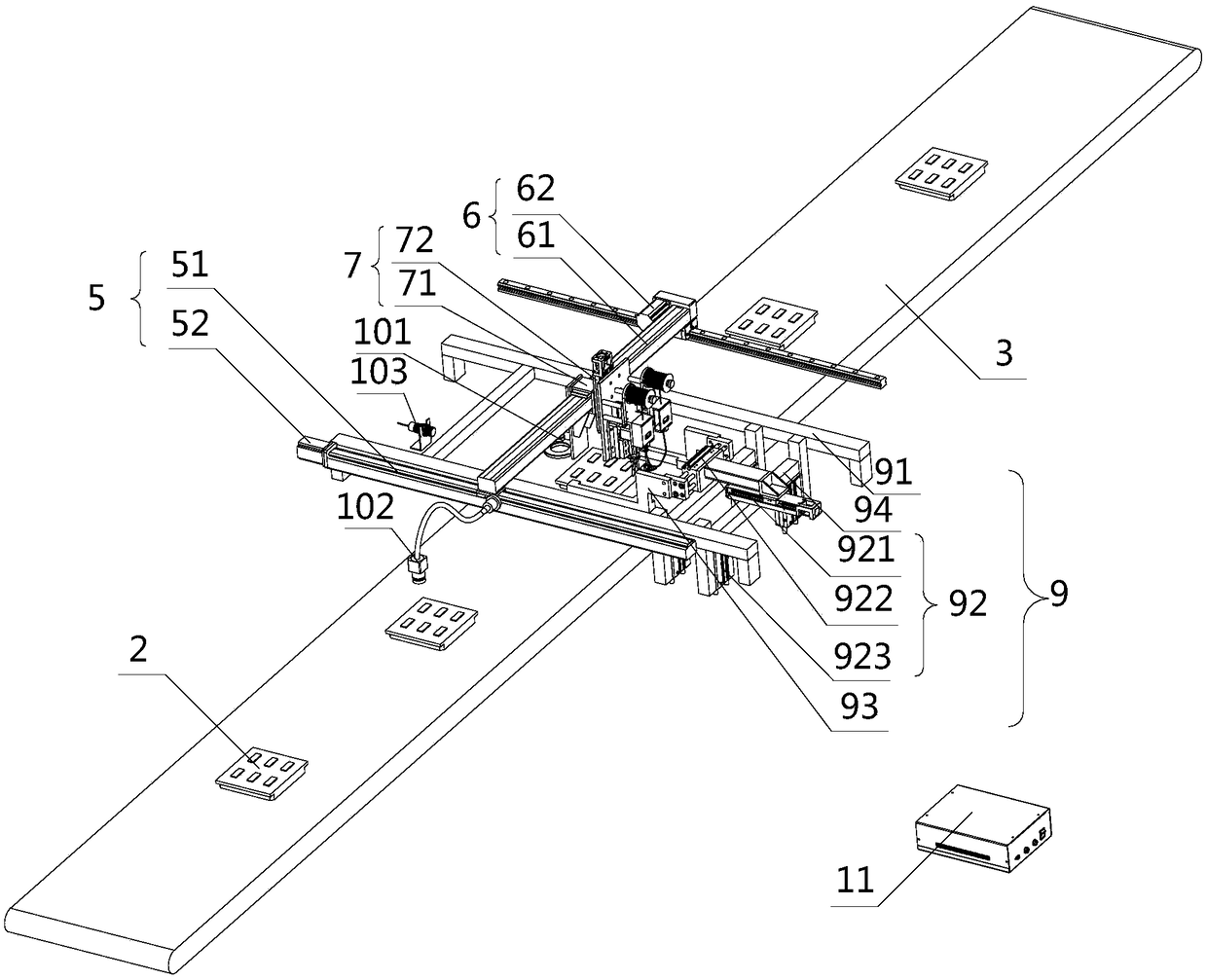

Intelligent welding system and method

PendingCN109332840AReduce manual debugging workloadImprove work efficiency and product qualityMetal working apparatusSoldering auxillary devicesAssembly lineWorkload

The invention relates to an intelligent welding system and method. The system comprises an assembly line, an industrial personal computer, a moving platform, a clamping assembly, a visual system and awelding assembly, wherein the visual system, the clamping assembly and the welding assembly are arranged on the moving platform; the assembly line, the moving platform, the clamping assembly, the welding assembly and the visual system are electrically connected with the industrial personal computer; the clamping assembly can clamp a circuit board moving on the assembly line so as to arrive at thepreset position; and the welding assembly can be used for welding the circuit board clamped by the clamping assembly. According to the intelligent welding system and the method provided by the invention, the visual system acquires image information of the circuit board moving to the preset position, the industrial personal computer recognizes welding pad information on the circuit board, weldingpulse information is generated by combining pre-stored printing information, and the circuit board clamped by the clamping assembly is automatically welded, so that the previous artificial debugging workload is greatly reduced, the working efficiency and the product quality are improved, the welding parameters cannot be adjusted aiming at circuit boards of different circuit structures, and the intelligent degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

Automatic welding process for aluminum alloy sheets

PendingCN112756883ARealize clamping and fixingImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesAluminium alloyMaterials science

The invention relates to the technical field of aluminum alloy sheet machining, in particular to an automatic welding process for aluminum alloy sheets. The automatic welding process comprises the following steps that the angle between a first base and a second base in welding equipment is adjusted according to different-angle welding requirements of two sets of aluminum alloy sheets, telescopic rods on two sides are synchronously controlled and started to stretch out and draw back, and corresponding driving racks are driven to stretch out and draw back back and forth on an L-shaped bottom plate. According to the automatic welding process for the aluminum alloy sheets, a clamping mechanism is arranged and used in cooperation with an adjusting assembly, the aluminum alloy sheets of different sizes and located between two sets of clamping rods can be effectively clamped and fixed, and therefore the stability of the aluminum alloy sheets during automatic welding is improved; and by arranging a rotating assembly, the angle between the first base and the second base can be flexibly changed, and therefore the welding requirements of the two sets of aluminum alloy sheets at different angles can be met.

Owner:杨康艺

Low-temperature lead-free solder

ActiveCN108971793AEliminate pollution problemsHas thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaEnvironmental resistanceOvervoltage

The invention discloses low-temperature lead-free solder and used for welding electrical contact materials. The low-temperature lead-free solder comprises, by mass percent, 30%-65% of Bi, 15%-50% of Sn and 15%-45% of In. To improve the mechanical performance of the alloy solder and improve the oxidation resistance, the wettability and the like, one or more of microelements including Ag, Zn, Al, Cu, Ga, P and the like is appropriately added. The melting point of the low-temperature solder is controlled within the range of 75 DEG C-100 DEG C, is used for removing damage of welding temperature toa welded object in the welding process and has the advantages that the melting temperature is low, during welding, the binding rate with copper foil is high, the loss tangent value of a capacitor issmall, the partial discharging performance and the overvoltage and large current resistance of the capacitor are improved, the cost is relatively low, no lead exists and the low-temperature lead-freesolder is more environmentally friendly. The low-temperature lead-free solder is especially suitable for welding heat sensitive elements, semiconductor elements with semiconductor manner refrigeratingelements and the like.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

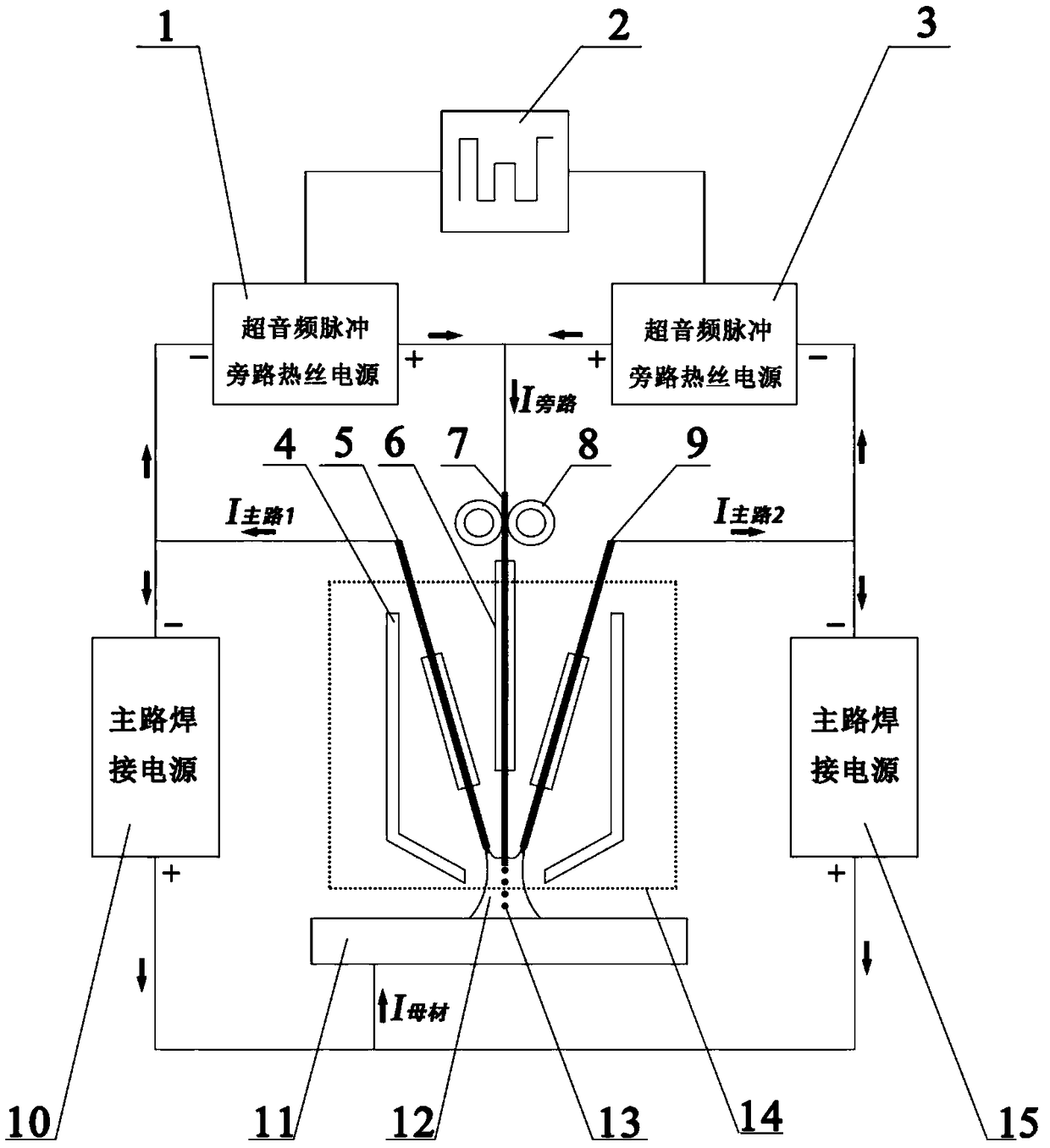

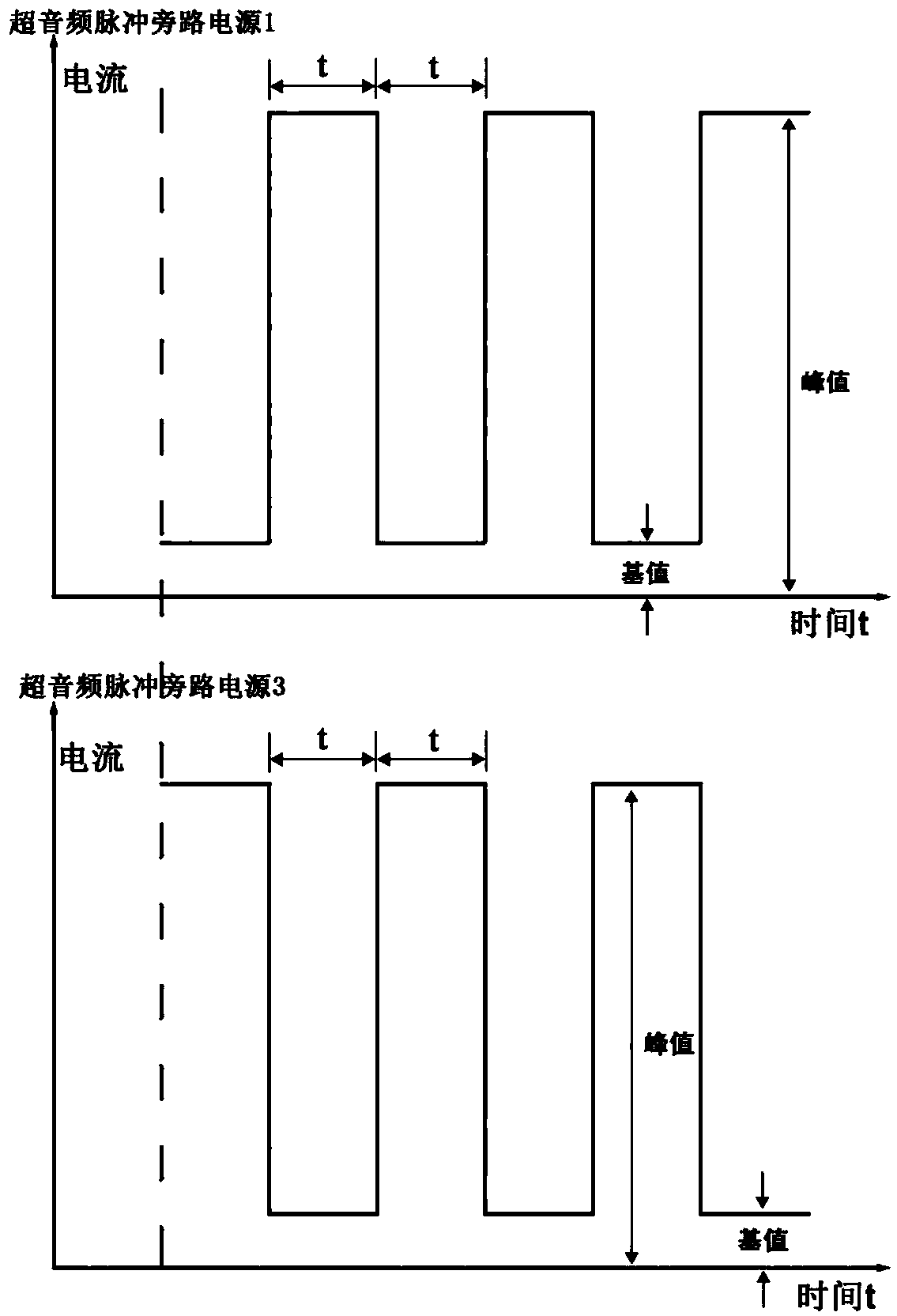

Welding molten drop transition control device based on ultrasonic frequency pulse double-tungsten-electrode coordination and control method

ActiveCN109365965AFor precise controlSave spaceAdditive manufacturing apparatusWelding accessoriesDirectivityCoordinate control

The invention provides a welding molten drop transition control device based on ultrasonic frequency pulse double-tungsten-electrode coordination and a control method. A welding wire is arranged on the center of a conductive nozzle of a welding gun, the upper end of the conducive nozzle is connected with a wire feeder, tungsten electrodes are arranged on the two sides of the conductive nozzle, a protection air cover is arranged on the outer sides of the tungsten electrodes, a positive electrode of a first ultrasonic frequency bypass heating wire power source and a positive electrode of a second ultrasonic frequency bypass heating wire power source are connected to a welding wire, negative electrodes of the ultrasonic frequency bypass heating wire power sources are connected with negative electrodes of main welding power sources and the tungsten electrodes, and the positive electrode of the first main welding power source and the positive electrode of the second main welding power source are connected to parent metal. The ultrasonic frequency pulse coordination control manner is used, the molten drop transition passive control manner is changed into an active control manner, the molten drops are forced to generate ultrasonic frequency vibration, the molten drops are promoted to be dropped, the molten drop transition frequency and the molten drop size can be precisely controlled,space of a welding gun is saved, the welding directivity is eliminated, the whole size of the welding gun is reduced, and the flexibility and the accessibility of the welding gun can be improved.

Owner:HARBIN ENG UNIV

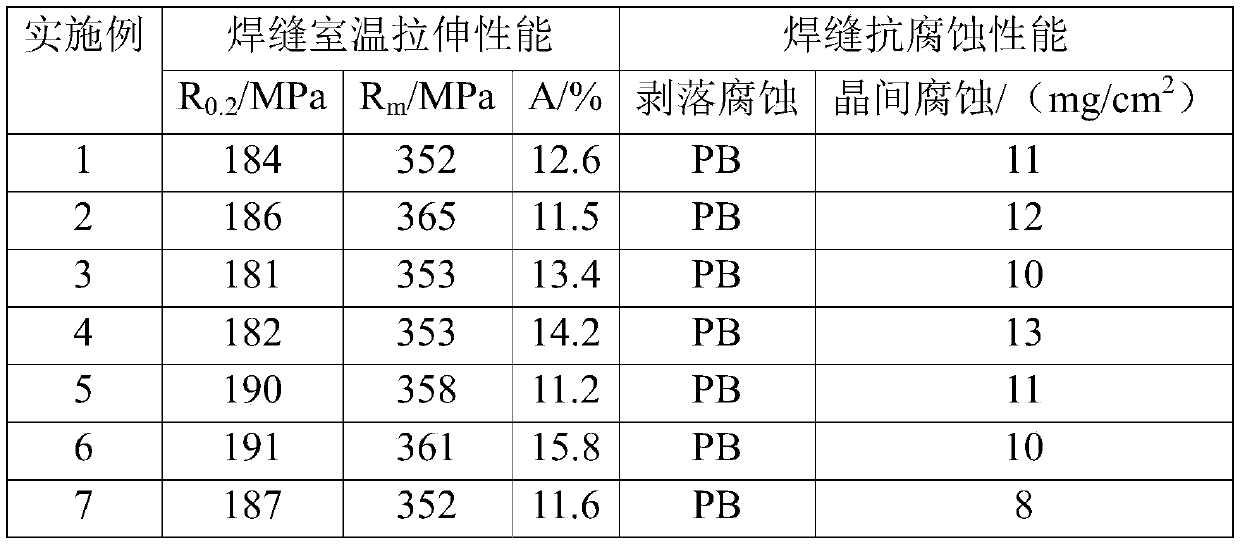

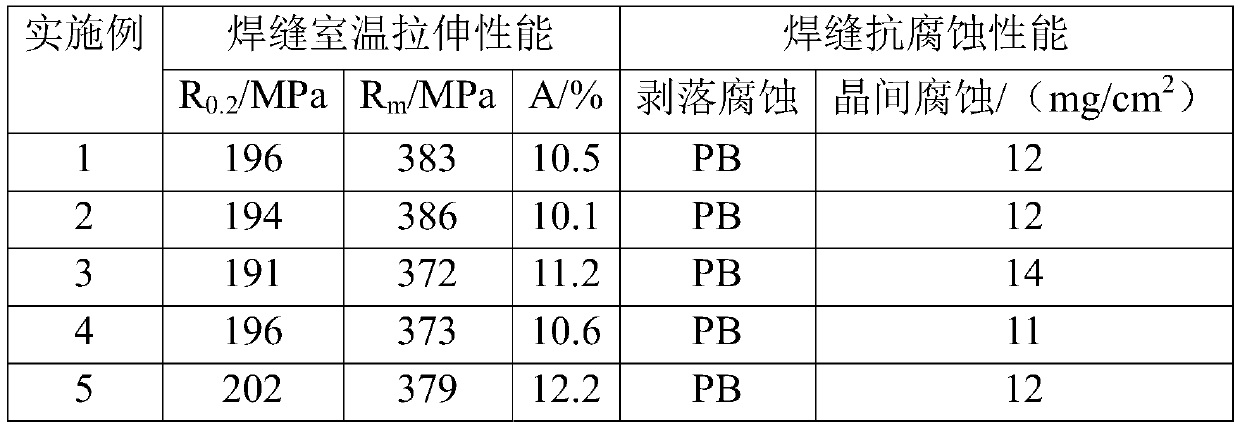

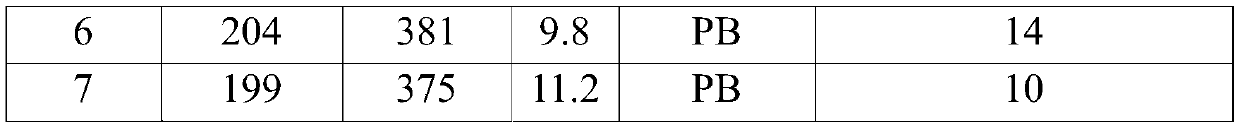

High-strength and corrosion-resistant Al-Mg-Zr aluminum alloy welding stick and preparation method thereof

ActiveCN109955003AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaZincUltimate tensile strength

The invention discloses a high-strength and corrosion-resistant Al-Mg-Zr aluminum alloy welding stick and a preparation method thereof. The proportion of alloy elements in an Al-Mg-Zr alloy is controlled in an optimized manner, and meanwhile, powder preparation, hot isostatic pressing, extrusion, continuous extrusion and drawing processes are adopted for preparing the welding stick with the fine crystalline grains, uniform structure and the good comprehensive performance. The novel alloy welding stick has the good formability and the low hot cracking tendency in the TIG or MIG welding formingprocess, a welding joint has the high strength and excellent corrosion resistance, the welding stick can be used for welding corrosion-resistant Al-Mg series alloys and high-strength Al-Zr-Mg series alloys, welding requirements of all-aluminum ship and warship bodies and armor protection decks are met, and the application prospects are broad.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

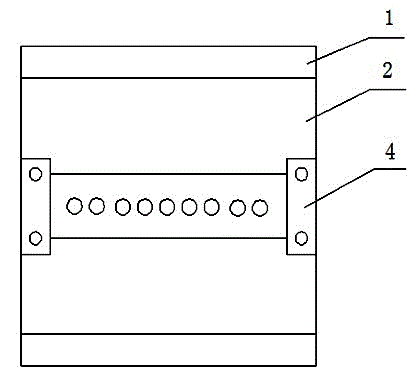

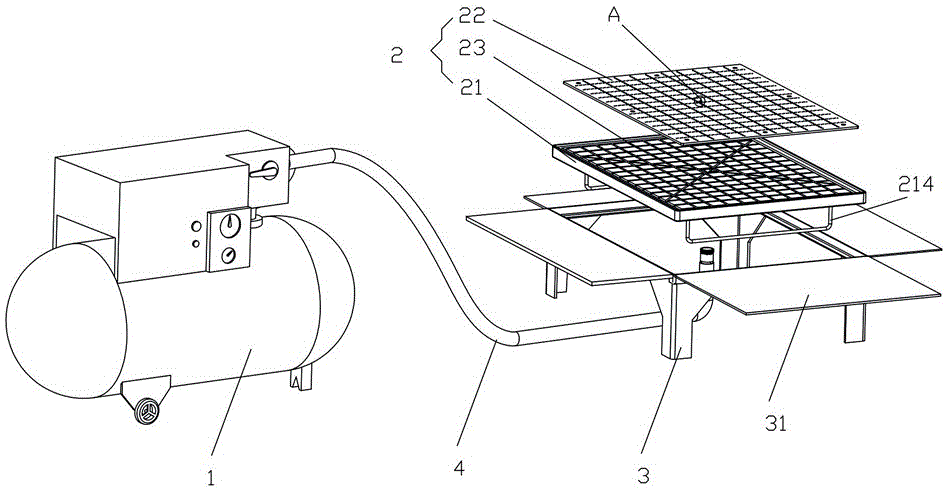

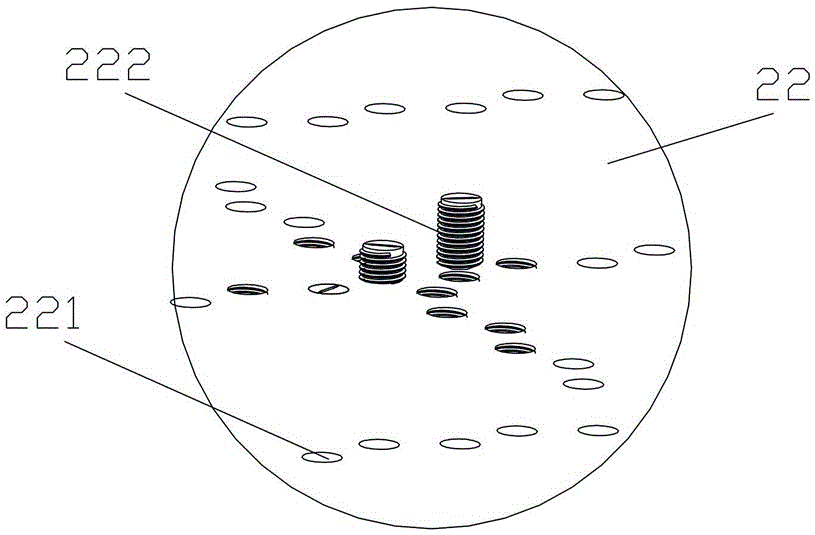

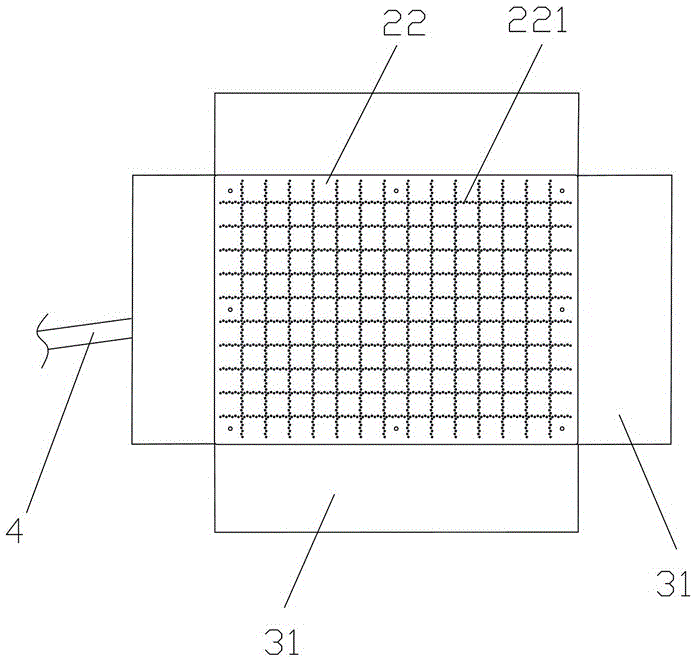

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

Welding positioner special for upper and lower square butt joint welding seams of excavator movable arms and using method of welding positioner

ActiveCN103624468AMeet the needs of weldingSolve bottlenecksWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses a welding positioner special for upper and lower square butt joint welding seams of excavator movable arms and a using method of the welding positioner. The welding positioner and the using method solve the bottleneck problem in the operation of welding the movable arms. Due to welding of the square butt joint welding seams of the movable arms, the welding can be well combined with a welding device, mechanization of the welding is achieved, and production efficiency and welding quality are improved. The problems that at present, production efficiency is low and product quality cannot be ensured are solved. Meanwhile, the labor intensity of workers is reduced, and the production cost is greatly reduced. Above all, safe and civilized production is achieved, and field management is also facilitated. The welding positioner special for the upper and lower square butt joint welding seams of the excavator movable arms can complete the welding of movable arms of different types and end the situation that no device is used for welding the movable arms.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

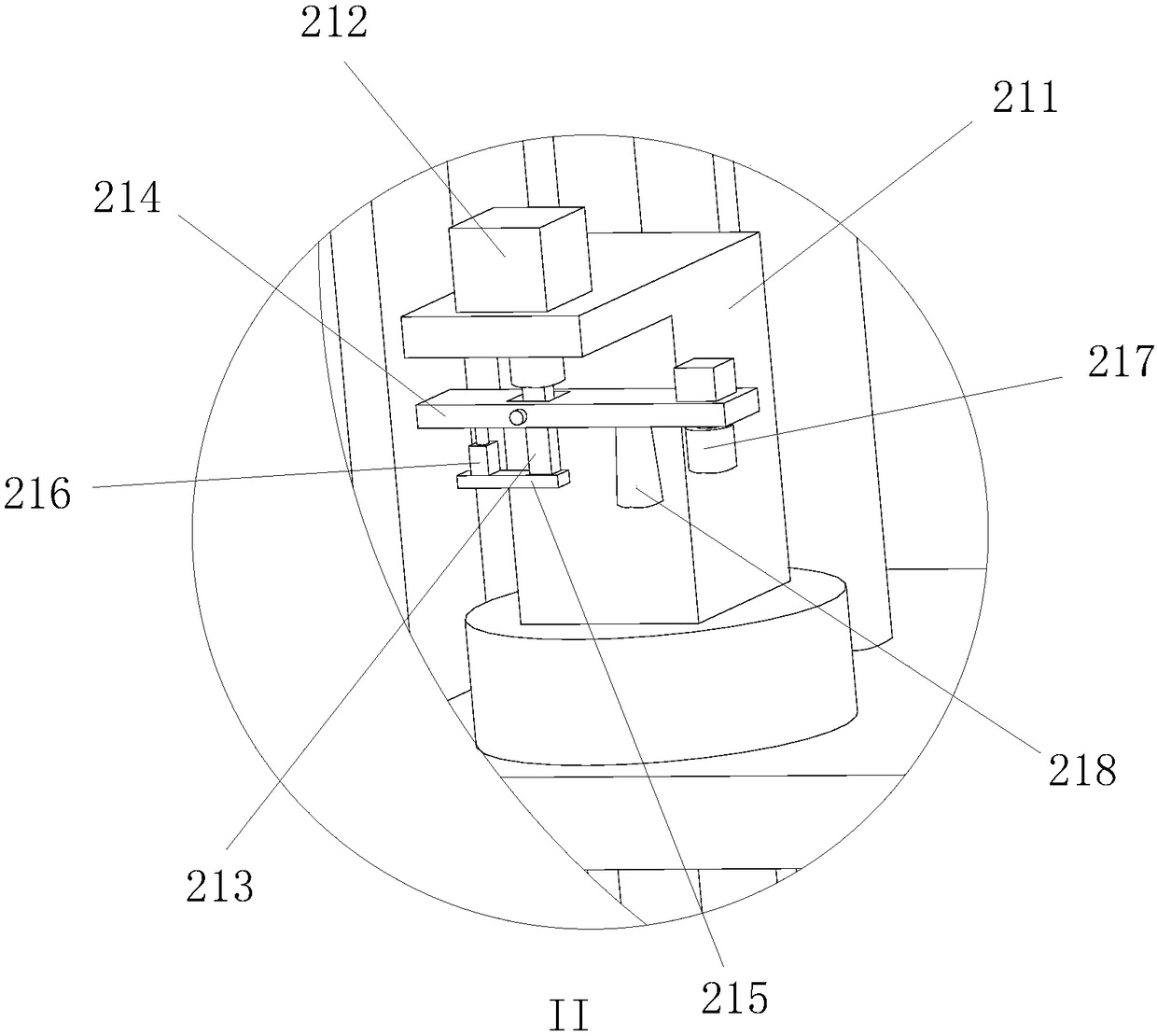

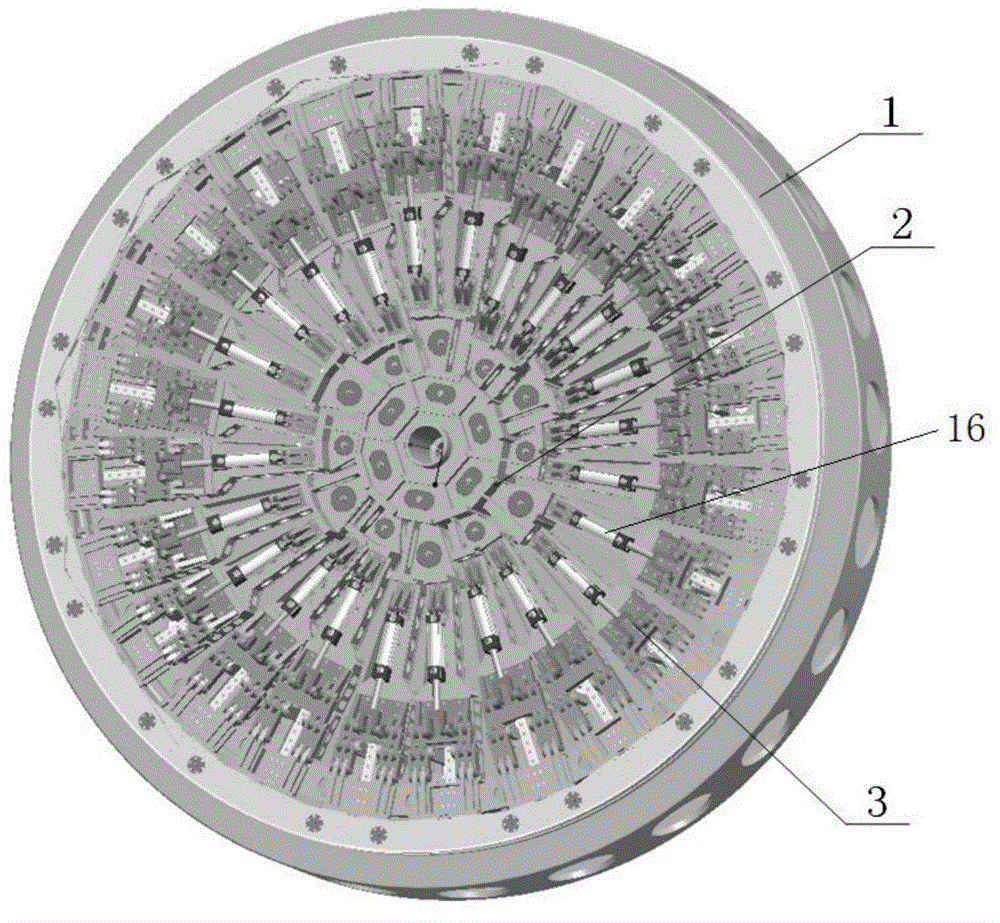

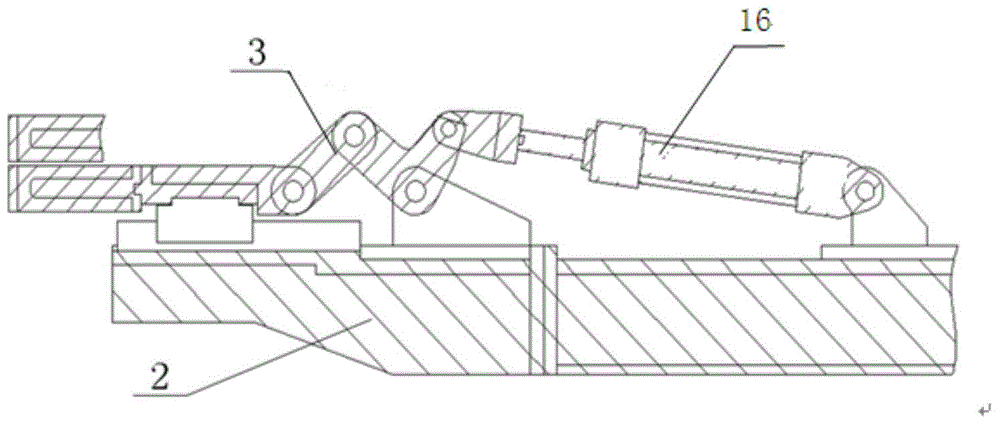

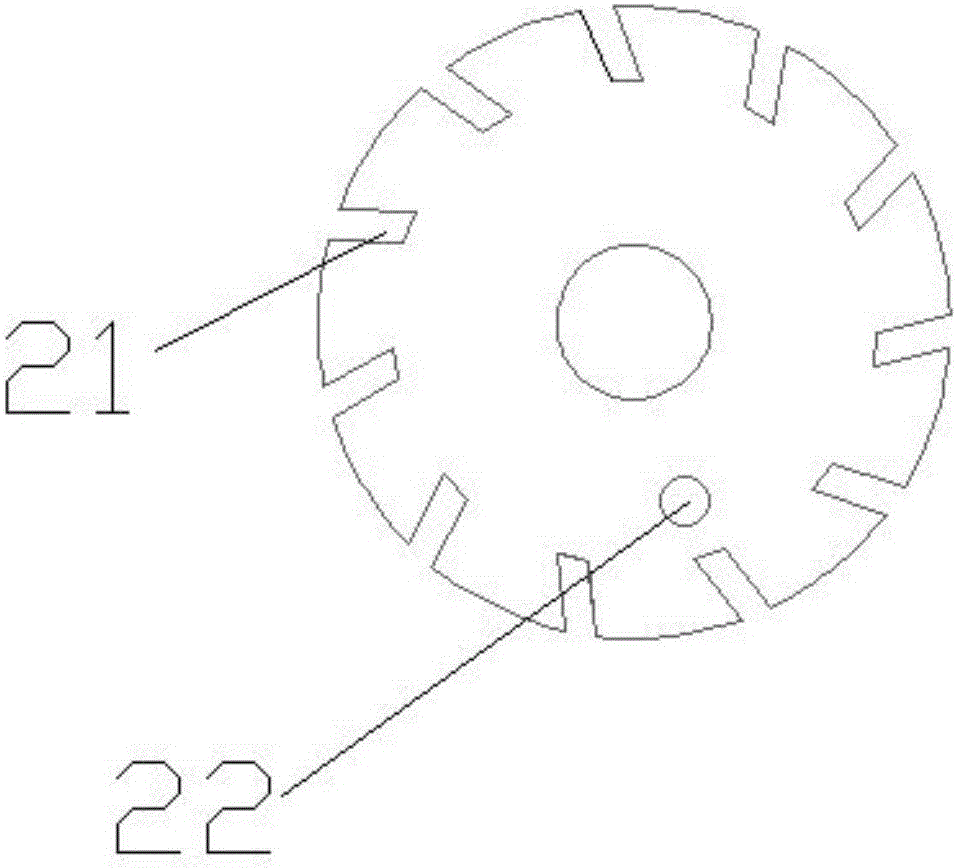

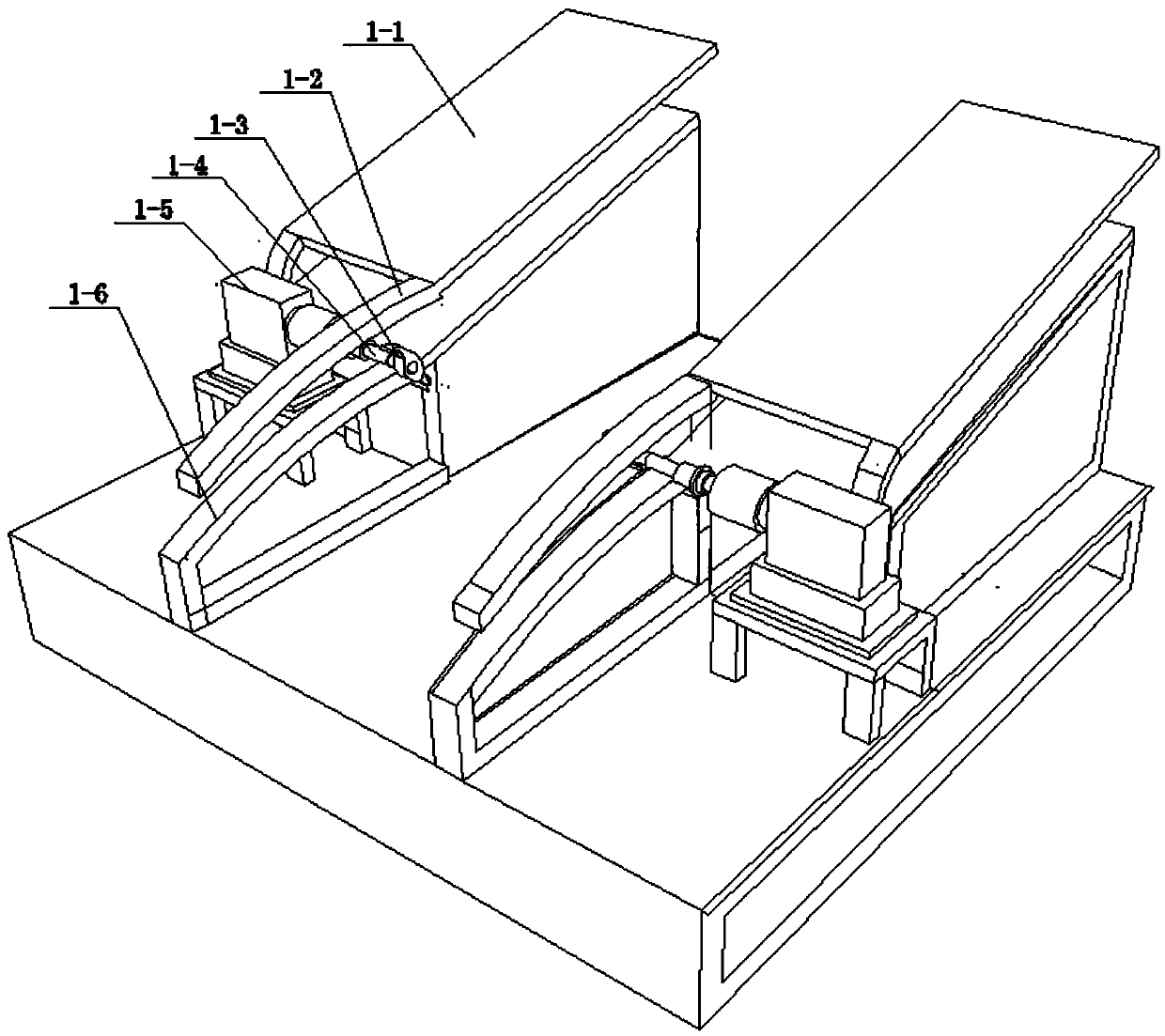

Full-automatic tube sheet welding tool platform

ActiveCN110102948ASave welding learning timeMeet the needs of bonding and weldingWelding/cutting auxillary devicesAuxillary welding devicesCircular discRadiation mode

The invention discloses a full-automatic tube sheet welding tool platform. A working table is provided with a plurality of strip-shaped track grooves, tube sheet clamping mechanisms are arranged in the strip-shaped track grooves correspondingly, and a drive mechanism is arranged in a machine box; the upper end of a curvy swing arm is fixedly connected with a round disc, and the lower end of the curvy swing arm is movably hinged to a telescopic mechanism; a rotating shaft penetrates through the round disc, a clamp base sleeves the rotating shaft, and the clamp base is provided with a pluralityof clamping servo drive modules in a radiation mode; the first side of a L-shaped clamping block is located at the tip of the telescopic movable end, the second side of the L-shaped clamping block islocated on the side surface of the side, back to the round disc, of the telescopic movable end, and the second side of the L-shaped clamping block is further fixedly connected with a clamping stop block. The full-automatic tube sheet welding tool platform is used for welding practical teaching of tube sheets and tube sheets, plates and plates and the tube sheets and the plates, the welding assembling efficiency and welding assembly precision are improved, the labor intensity is relieved, welding operators quickly clamp workpieces in practical teaching and welding skill competitions, and the welding position is flexibly adjusted for welding operation.

Owner:合肥哈工库讯智能科技有限公司

Laser welding device

ActiveCN103170745APrecise angle of rotationEffectively control the rotation angleWelding/cutting auxillary devicesAuxillary welding devicesLinear motionSpot welding

The invention relates to a laser welding device comprising a worktable, a weld fixing device and a control device, wherein the weld fixing device comprises a fixing plate, a vertical plate, a connecting plate, a first motor, a rotating shaft, a workpiece fixing structure, a second motor and a lead screw; the rotation motion of the workpiece fixing structure is controlled through the first motor; and the rotating speed of the workpiece fixing structure is determined by the rotating speed of an output shaft of the first motor. According to the invention, the rotating speed of the first motor can be set to a preset value, so that the accurate rotation angle of the workpiece fixing structure is guaranteed; in addition, the lifting motion of the workpiece fixing structure is realized through driving the lead screw by using the second motor and cooperating with a lead screw nut; the circular motion of the second motor can be transformed into accurate linear motion through the cooperation of the lead screw and the lead screw nut, so that the control of the lifting height can be realized through controlling the rotating speed of the second motor; and therefore, the weld fixing device is capable of effectively controlling the rotation angle and the lifting height of the workpiece fixing structure and welding spots are uniformly distributed during multiple-spot welding.

Owner:HANS LASER TECH IND GRP CO LTD

Welding device for air-conditioning cross-flow fans

The invention discloses a welding device for air-conditioning cross-flow fans, which comprises a base, a top plate, a lead screw, a plurality of support rods, a plurality of guide rods, a worktable, a left cylinder and a right cylinder. The lead screw penetrates through a screw hole on the worktable and is screwed with the screw hole, a motor in transmission connection with the lead screw is mounted on the top plate, a left straight rod and a right straight rod are arranged on two sides of the worktable, a front straight rod and a rear straight rod are laterally arranged in the front and at the back of the left straight rod and the right straight rod respectively, the front end of a piston rod of the left cylinder and the front end of a piston rod of the right cylinder are respectively rotatably matched with the rear straight rod through clamp rings, a clamp seat is fixedly mounted on the worktable, a plurality of stop rods are arranged on the rear side of the clamp seat, the side fronts of the left straight rod and the right straight rod and the front straight rod are respectively clamped in notches on the side wall of the worktable, and a welder is mounted on the top plate. The welding device is reasonable and reliable in structure and low in cost, not only can meet the requirements on welding air-conditioning cross-flow fans with different lengths and diameters, but also can facilitate manual discharging and taking, and improves welding precision and efficiency.

Owner:滁州市成业机械制造股份有限公司

Orthohexagonal crystal silicon solar wafer and solar battery manufactured thereby

InactiveCN102945868ATrim reductionIncrease profitPolycrystalline material growthSingle crystal growth detailsSilicon solar cellEngineering

The invention discloses an orthohexagonal crystal silicon solar wafer, which comprises an orthohexagonal silicon wafer, and the orthohexagonal silicon wafer is a sheet body formed by an inscribed regular hexagon of the cross section of a cylindrical crystal silicon rod. The invention also discloses a solar battery manufactured by the orthohexagonal crystal silicon solar wafer, and the orthohexagonal silicon wafer is manufactured into an orthohexagonal solar battery by adopting the manufacture process of a crystal silicon solar battery. The silicon wafer is orthohexagonal, so that the cut-off flaw-piece materials of the crystal silicon rod are greatly reduced, the utilization ratio of the crystal silicon rod is improved, the return quantity is reduced and the manufacturing cost is saved. The orthohexagonal solar battery has increased effective area and improved output power, realizes seamless splicing of battery components manufactured into the battery and the limited arrangement area of the components as far as possible, and satisfies the requirement for welding the battery components.

Owner:JA SOLAR

Flange disc high-accuracy butt welding device

InactiveCN109514143ARealize automatic deliveryPrecise automatic dockingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention relates to a flange disc high-accuracy butt welding device which comprises a loading mechanism, a butt welding fixing mechanism and an unloading and loading mechanism; the left side andthe right side of a positioning supporting body of the butt welding fixing mechanism are provided and connected with the loading mechanism and the unloading and loading mechanism respectively; the loading mechanism enables a steel pipe to be loaded onto the positioning supporting body of the butt welding fixing mechanism; flanges are accurately in butt welding to the two ends of the steel pipe through the butt welding fixing mechanism; and after butt jointing is finished, transferring and loading are performed on the steel pipe after butt jointing is finished through an unloading component andthe loading component of the unloading and loading mechanism. The flange disc high-accuracy butt welding device is simple in structure, accurate in butt jointing and less in needed labor force and greatly improves the production efficiency.

Owner:天津市源泉钢塑管有限公司

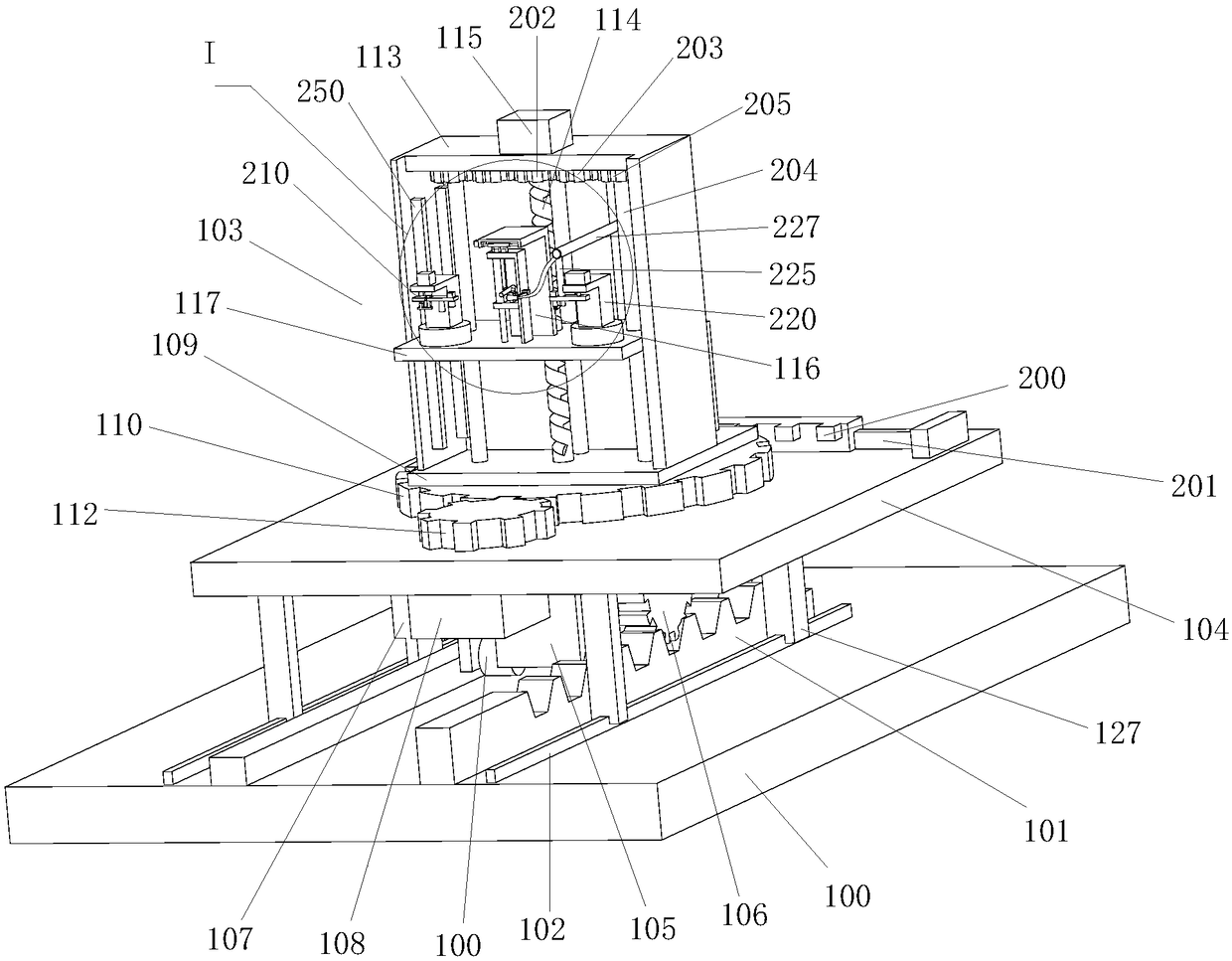

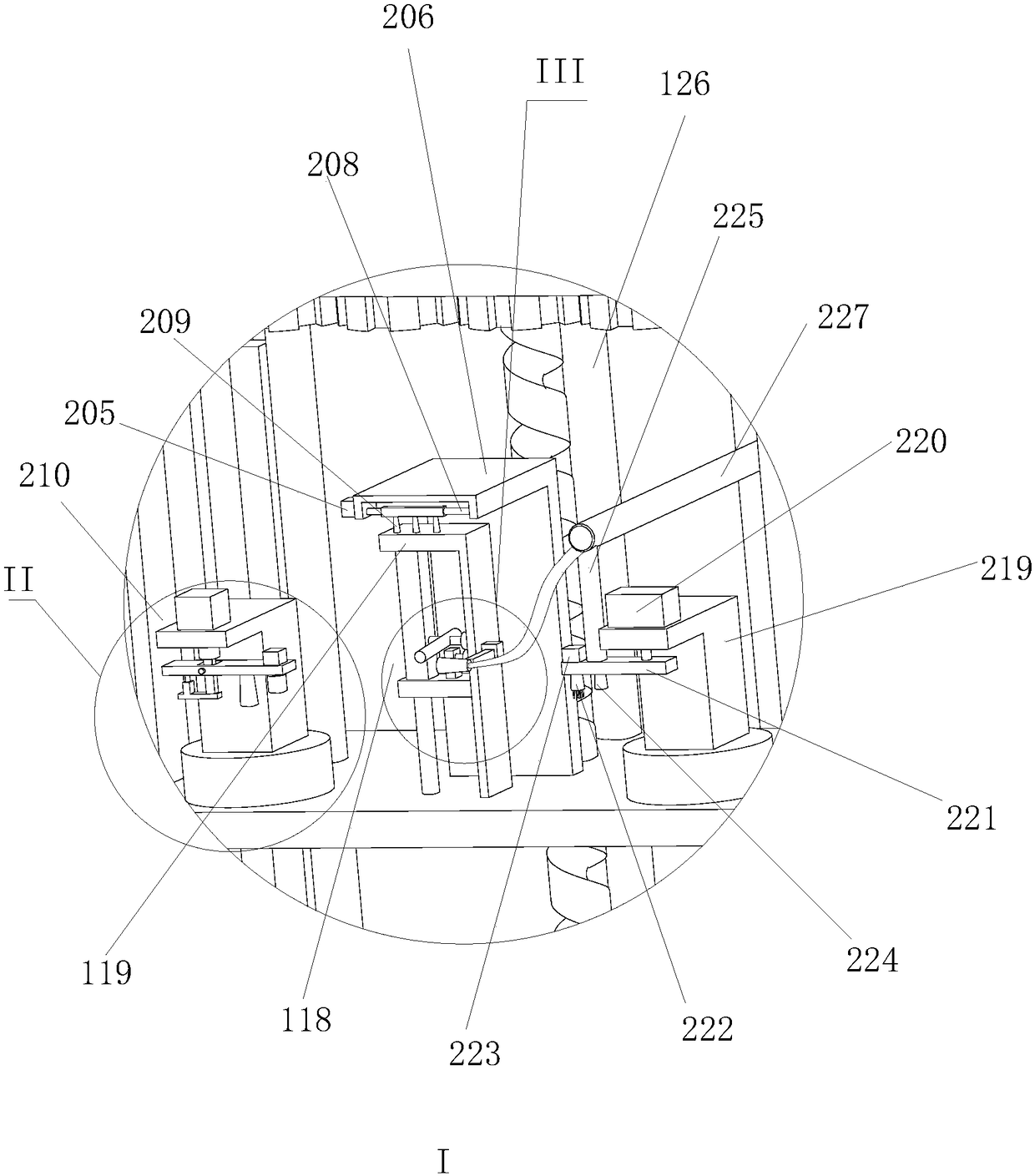

Variable-angle automatic spot welding device moving along with profiling track

ActiveCN103028875AAvoid interferenceGuarantee the function of cycle continuous operationWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingUltimate tensile strength

The invention discloses a variable-angle automatic spot welding device moving along with a profiling track, which is used for realizing the automatic welding on an arc profile workpiece. The variable-angle automatic spot welding device moving along with the profiling track comprises a base, workpiece locating mechanisms, a welding machine, a welding machine space angle adjusting mechanism, a welding machine rotating mechanism, a welding machine movable driving mechanism and a profiling track seat, wherein the welding machine is fixedly arranged on the upper surface of the welding machine space angle adjusting mechanism through a welding machine fixing seat, the welding machine space angle adjusting mechanism is in assembling with the welding machine rotating mechanism, the welding machine rotating mechanism is arranged between the welding machine space angle adjusting mechanism and the welding machine movable driving mechanism, the welding machine movable driving mechanism and the profiling track seat are positioned on the base, and the left side and the right side on the upper surface of the base are symmetrically provided with the workpiece locating mechanisms. According to the variable-angle automatic spot welding device moving along with the profiling track, disclosed by the invention, the automation degree is high, the operation is simple, the labor intensity of an operator can be reduced, the working efficiency and the welding quality can be increased, the variable-angle automatic spot welding device has the characteristics similar to those of a mechanical arm, the input cost is lower, and the maintenance is more convenient.

Owner:长城汽车股份有限公司平湖分公司

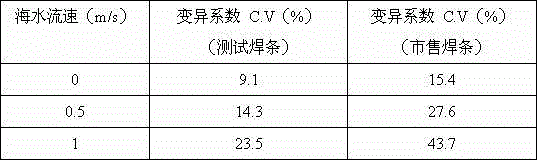

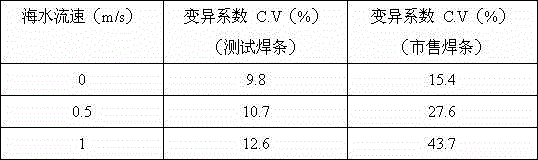

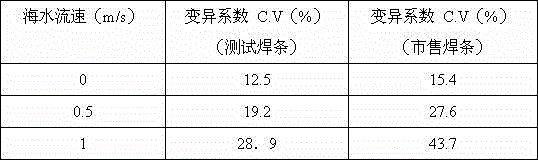

High-stability coating for underwater wet welding rod

InactiveCN104874939ASmooth startStable arc burningWelding/cutting media/materialsSoldering mediaSolid componentCoating

The invention discloses a high-stability coating for an underwater wet welding rod. The coating is prepared by mixing a solid component and a liquid component, wherein the mass of the added liquid component is 15%-20% of that of the solid component; the solid component is prepared from raw materials in percentage by mass as follows: 45%-55% of rutile, 10%-16% of fluorite, 5%-8% of marble, 4%-8% of ferromanganese, 8%-15% of nickel powder, 8%-10% of cryolite and 0%-2% of cesium nitrate; the liquid component adopts potassium-sodium water glass with the potassium-sodium ratio being 3:1 at the temperature of 20 DEG C. According to the high-stability coating for the underwater wet welding rod, arc strike can be performed smoothly under the conditions that the water depth doesn't exceed 20 meters and the water velocity is not higher than 1.2 m / s, continuous stable combustion is realized, an electric arc extinguishing phenomenon is avoided, the strength is higher than or equal to 400 MPa, and the welding requirements of a non-structural member are basically met.

Owner:青岛哈工海洋工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com