Welding device and method for superconducting lines

A welding device and superconducting wire technology, applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of insufficient heating temperature, small heat capacity, large temperature fluctuation, large dispersion of welding quality, etc., and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

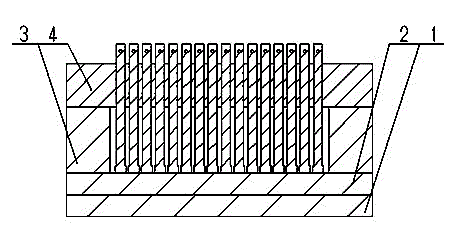

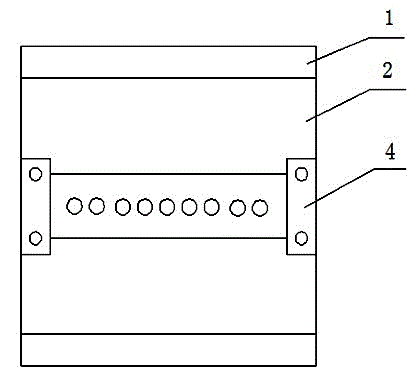

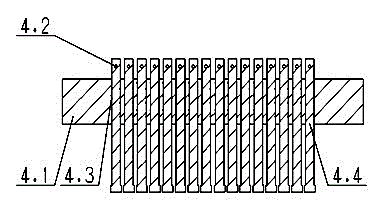

[0029] Example 1: Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it is a basic embodiment of a superconducting wire welding device, which includes a heating unit 1, a welding table 2, a heat insulation pad 3 and a pressing unit 4 with a support 4.1; the welding table 2 is fastened On the heating unit 1; the heating unit 1 is provided with a heater and a temperature regulator, and the temperature is precisely adjusted and controlled through a temperature feedback signal; the pressing unit 4 is installed on the welding table 2; the pressing unit 4 also includes: The pressing piece 4.4 on the support body 4.1 is used to apply pressure to the welding joint, and the heat insulation pad 3 is located between the welding table 2 and the support body 4.1. The above-mentioned welding table 2 provides a welding operation plane, which reaches thermal equilibrium with the heating unit 1 after heat conduction and temperature control, and then performs welding operations...

Embodiment 2

[0030] Example 2: is an optimized embodiment. Such as figure 1 As shown in -4, the difference from Example 1 is that the support body 4.1 is a beam, and the pressing member 4.4 is rod-shaped, and there are several; the axes of several holes on the support body 4.1 point to the welding table 2 for the mounting hole of the compression rod; the compression spring 4.3 is sleeved on the compression part 4.4. Compression spring 4.3 Adjust the pressure of the compression member by selecting springs and spring lengths with different stiffness coefficients 4.4 The pressure on the superconducting wire welding joint or the superconducting wire and conventional conductor welding joint, or use hydraulic pressure to achieve the required pressure during the welding process .

Embodiment 3

[0031] Example 3: is another optimized embodiment. The difference from the above-mentioned embodiment 2 is that the pressing member 4.4 is a pressing plate, which is slidably connected with the supporting body 4.1. The pressing unit 4 also has a gravity block added to the support body 4.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com