Inner supporting device for storage tank tank-sealing circular seam friction stir welding and method thereof

A technology of friction stir welding and storage tanks, which is applied in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc. It can solve the problems that the welding requirements cannot be realized, and achieve the effect of light weight, convenient disassembly and assembly, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

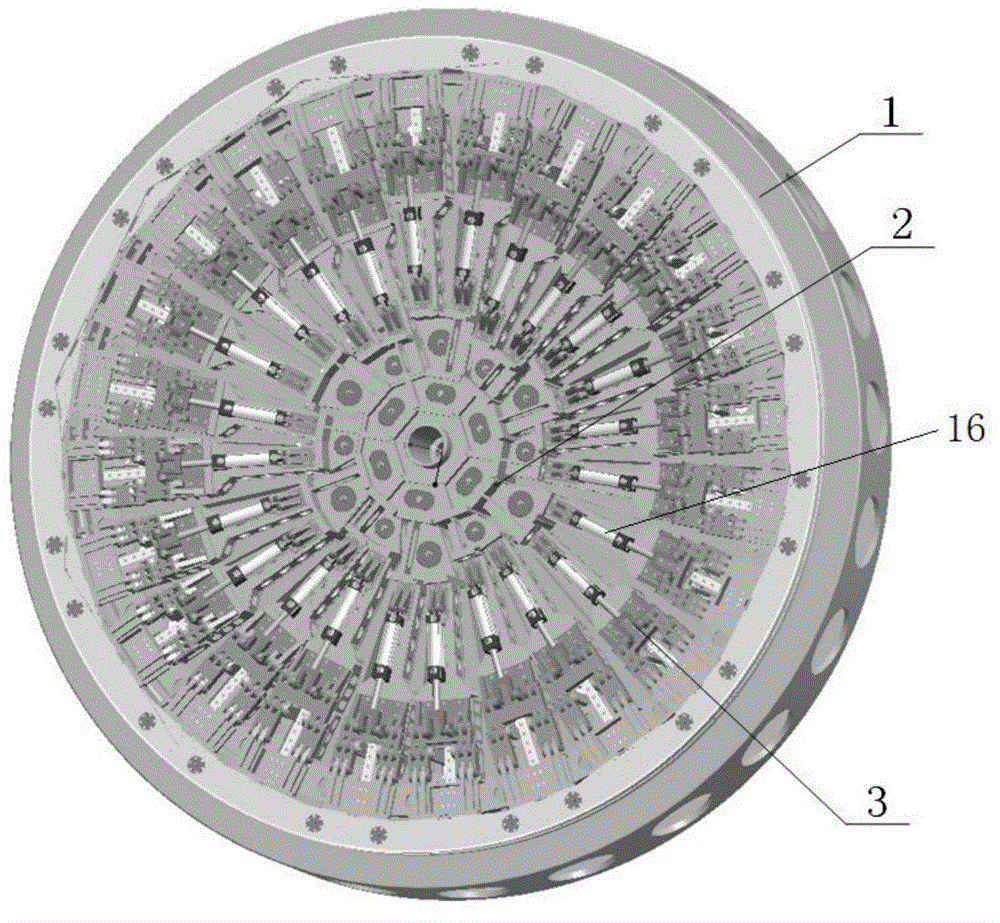

[0027] like figure 1 As shown, a friction stir welding internal support device for tank sealing circular seam according to the present invention, its special main body is a spliced support ring 2, and 24 pneumatic support blocks are evenly distributed on the circumference of the spliced support ring 2 3;

[0028] like figure 2 As shown, the center of the splicing support ring 2 is a snap ring 4, and the periphery of the snap ring 4 is connected to an annular structure formed by connecting 6 ring petals 5; The seat 6 is connected to a certain number of connecting beams 7, wherein, one end of each supporting seat 6 is connected to the ring petal 5, and the other end is correspondingly connected to two connecting beams 7; each connecting beam 7 is connected to a connecting block 8; every two phases Adjacent connecting blocks 8 form a ring structure by connecting one ring seat 9 . That is, the periphery of the annular structure formed by the connection of six ring petals 5...

Embodiment 2

[0033] A kind of internal support method of the friction stir welding of the storage tank sealing circular seam using the internal support device described in embodiment 1, such as Image 6 As shown, it includes the following steps:

[0034] (a) Push the splicing support ring 2 and the 24 pneumatic struts 3 on it to the bottom of the tank barrel section 10; connect the two air circuit connecting plates 12 and push them to the rear end of the splicing support ring 2 to assemble and lock them;

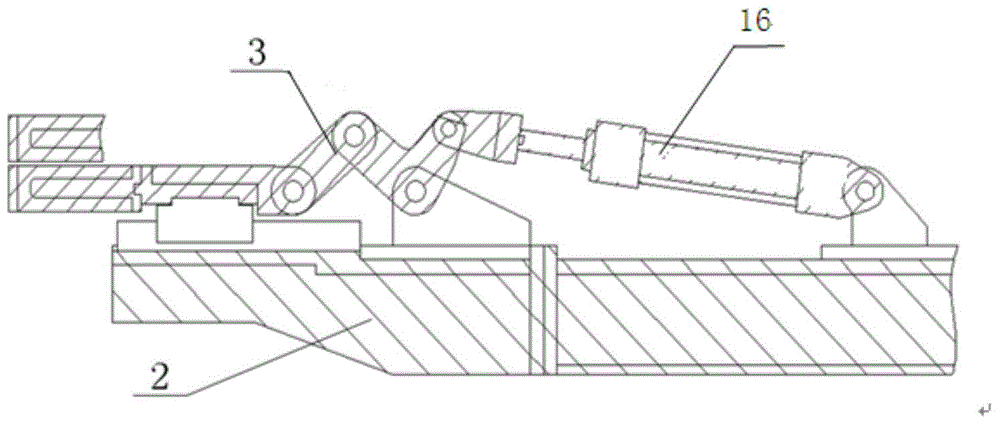

[0035] (b) After docking the tank bottom 11 with the tank barrel section 10, the cylinder 16 pushes the pneumatic struts 3 to move outward along the radial direction of the splicing support ring 2, so that 24 pneumatic struts 3 connect the tank bottom 11 and Friction stir welding is performed after the tank section 10 is braced;

[0036] (c) After the friction stir welding is completed, first disassemble the two gas circuit connecting plates 12 and take them out from the manhole flange;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com