Welding device for air-conditioning cross-flow fans

A cross-flow blade and welding device technology, which is applied in the field of air-conditioning cross-flow blade processing equipment, to achieve the effects of convenient feeding and retrieving, reasonable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

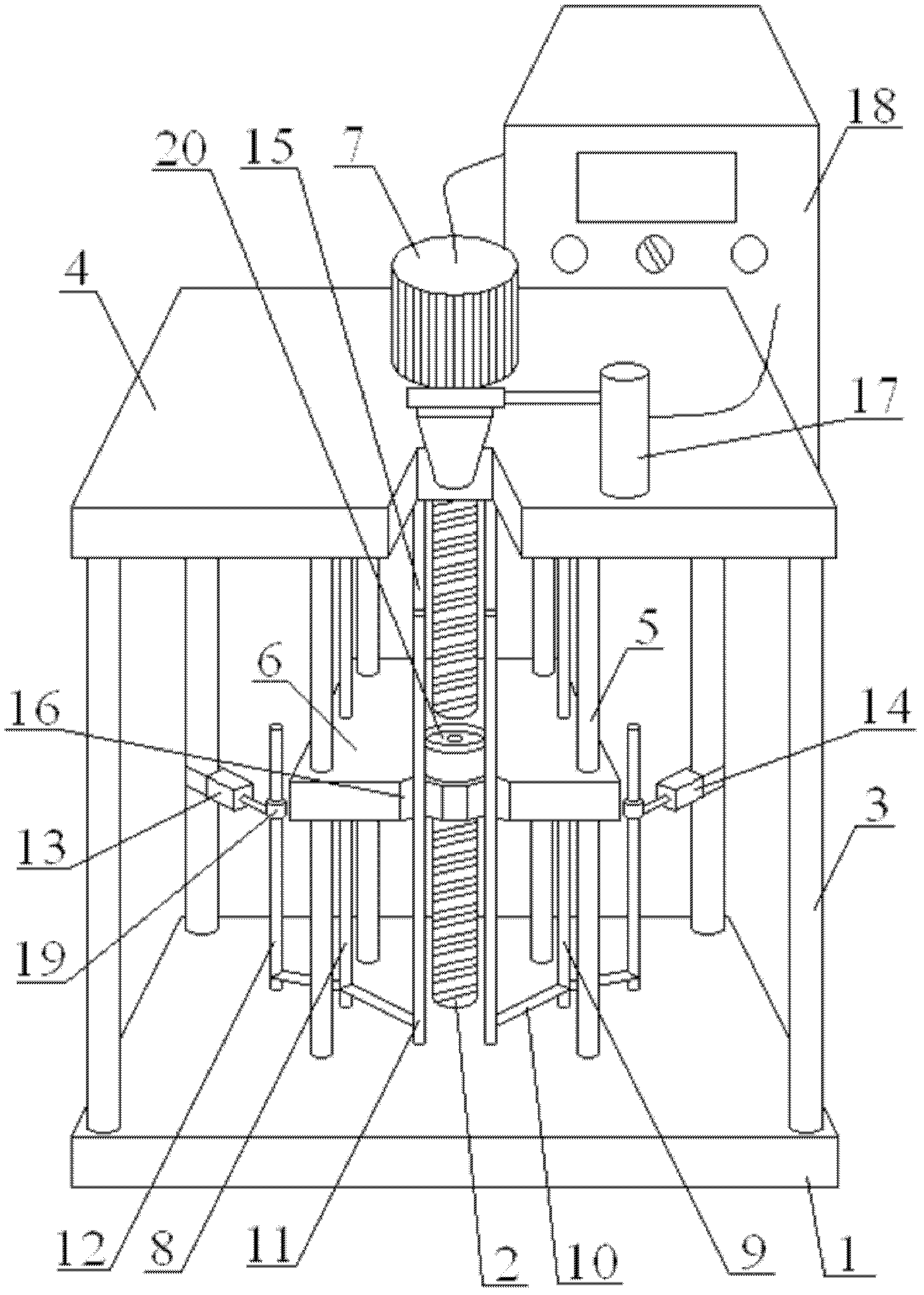

[0017] see figure 1 , an air conditioner cross-flow fan blade welding device, including a base 1, a screw rod 2 is installed on the base 1, four support rods 3 are fixedly installed around the base 1, and a top plate is fixedly installed on the ends of the four support rods 3 4. Four guide rods 5 are fixedly installed on the base 1 around the lead screw 2, and a worktable 6 is installed on the four guide rods 5 through sliding fit. The workbench 6 is provided with screw holes, and the screw rod 2 passes through The screw holes on the workbench 6 are screwed together, the top plate 4 is equipped with a servo motor 7, and the servo motor 7 is connected to the screw rod 2 in transmission, and the workbench 6 moves along the four guide rods 5 with the rotation of the screw rod 2 , move down;

[0018] Between the base 1 and the top plate 4 on both sides of the workbench 6, left and right straight rods 8,9 are rotated and installed respectively. Straight rods 11,12, left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com