Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1638results about How to "Improve solderability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

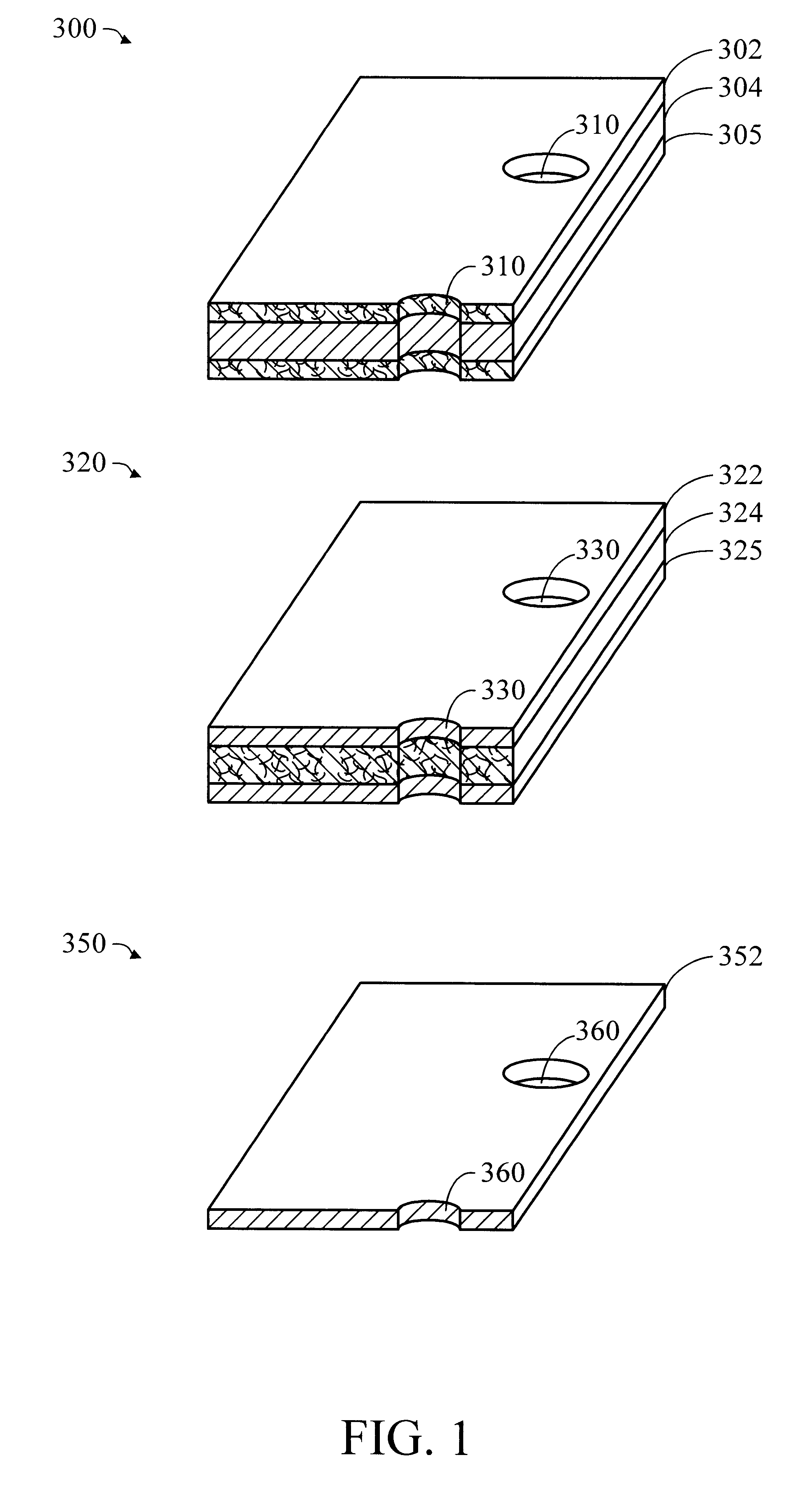

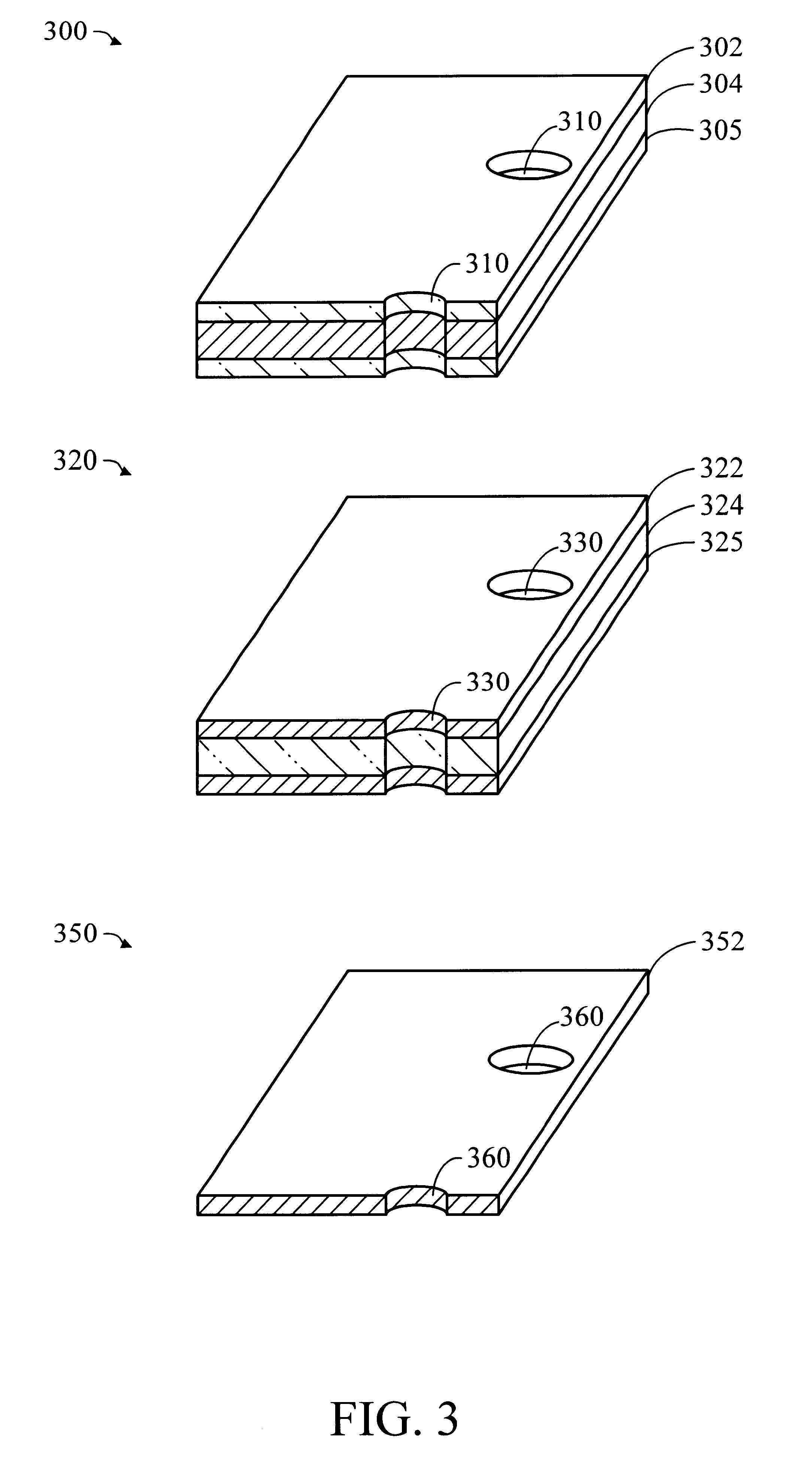

Low CTE power and ground planes

InactiveUS6329603B1Easily fractureImprove solderabilityPrinted circuit aspectsElectrical connection printed elementsGround planeHigh conductivity

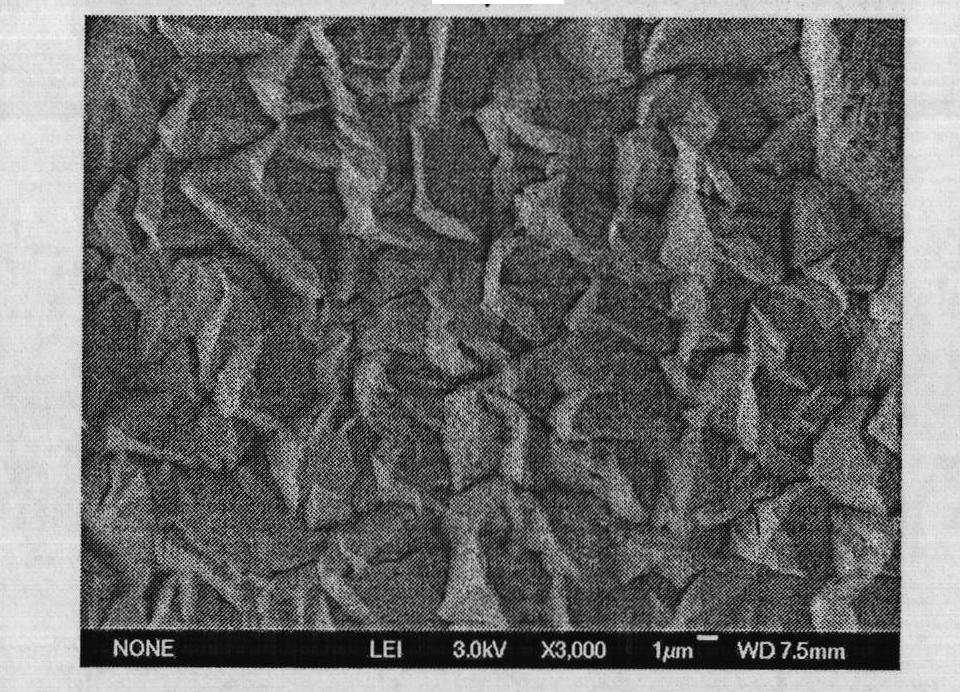

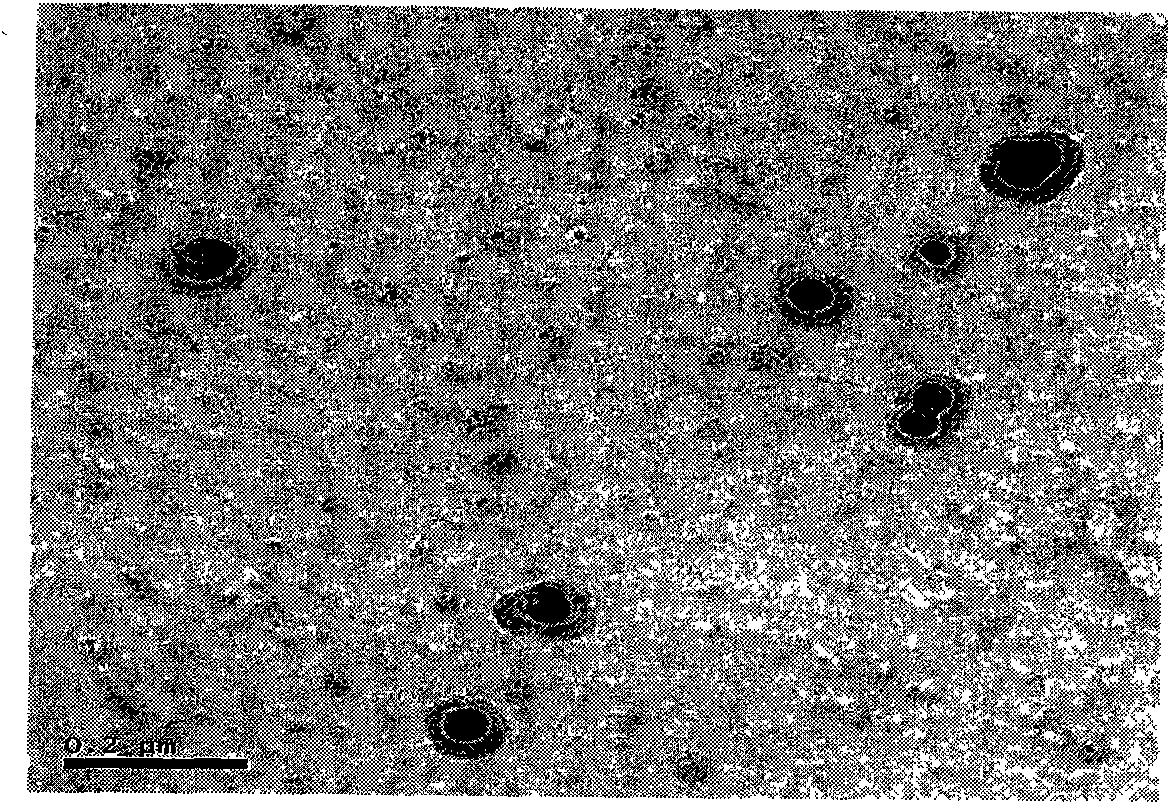

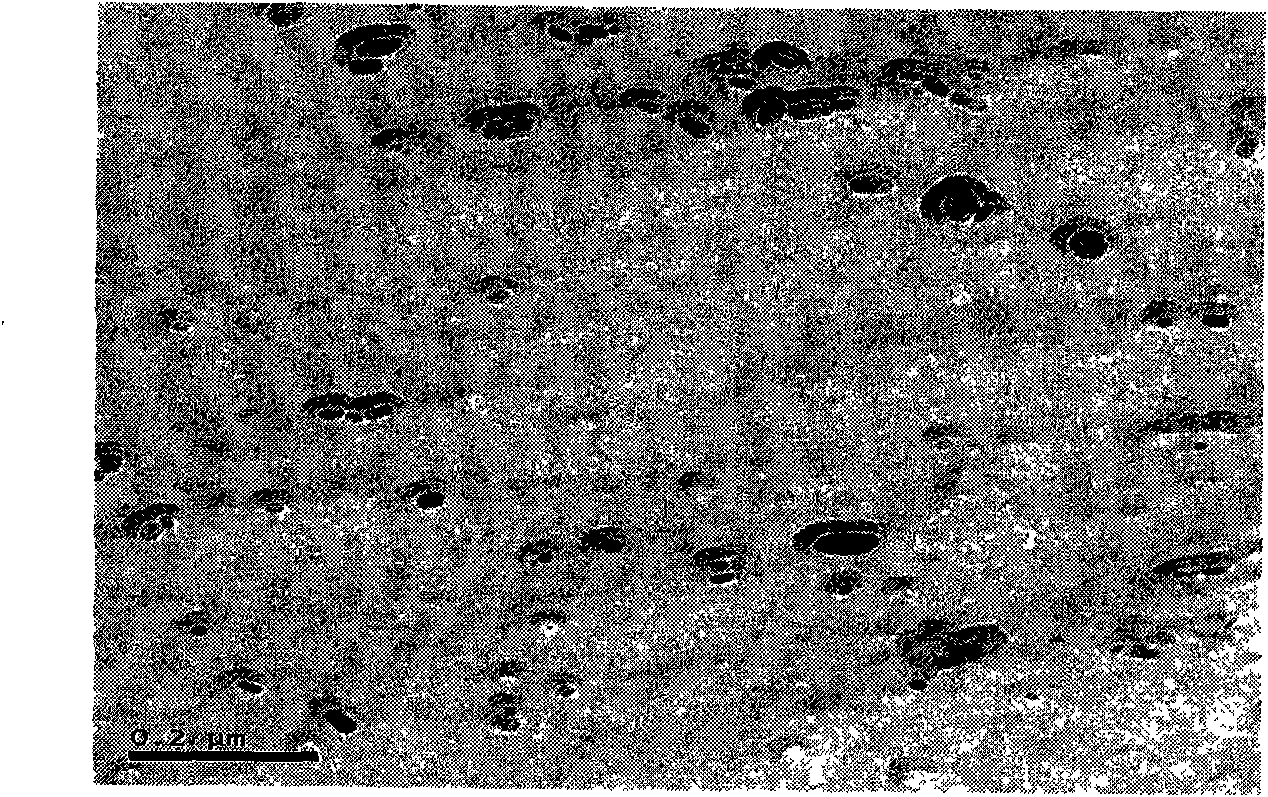

Conductive materials that have low coefficients of thermal expansion (CTEs) and that are used for power and ground planes are disclosed. Fibrous materials (such as carbon, graphite, glass, quartz, polyethylene, and liquid crystal polymer fibers) with low CTEs are metallized to provide a resultant conductive material with a low CTE. Such fibers may be metallized in their individual state and then formed into a fabric, or these materials may be formed into a fabric and then metallized or a combination of both metallizations may be used. In addition, a graphite or carbon sheet may be metallized on one or both sides to provide a material that has a low CTE and high conductivity. These metallized, low CTE power and ground planes may be laminated with other planes / cores into a composite, or laminated into a core which is then laminated with other planes / cores into a composite. The resultant composite may be used for printed circuit boards (PCBs) or PCBs used as laminate chip carriers.

Owner:GLOBALFOUNDRIES INC

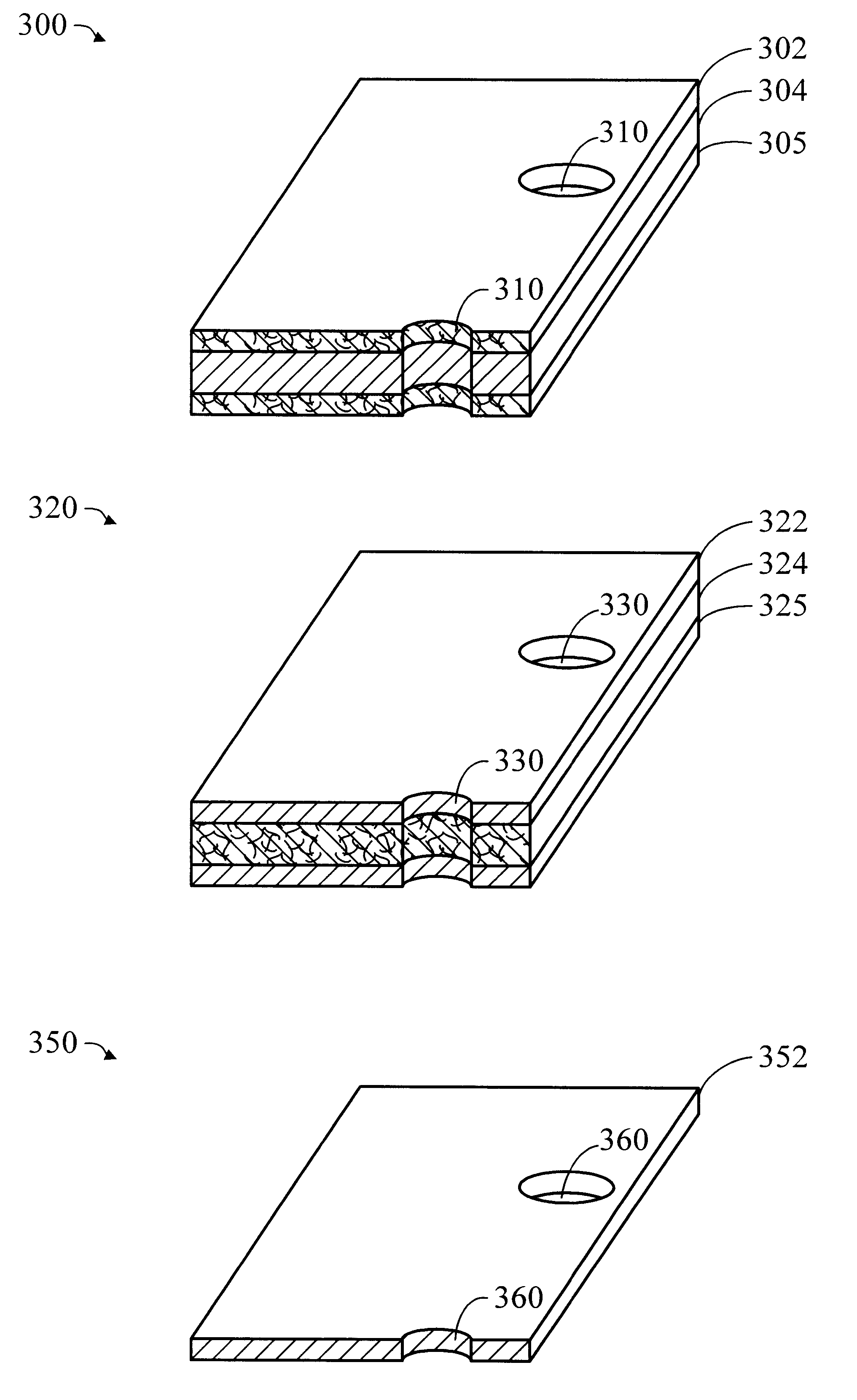

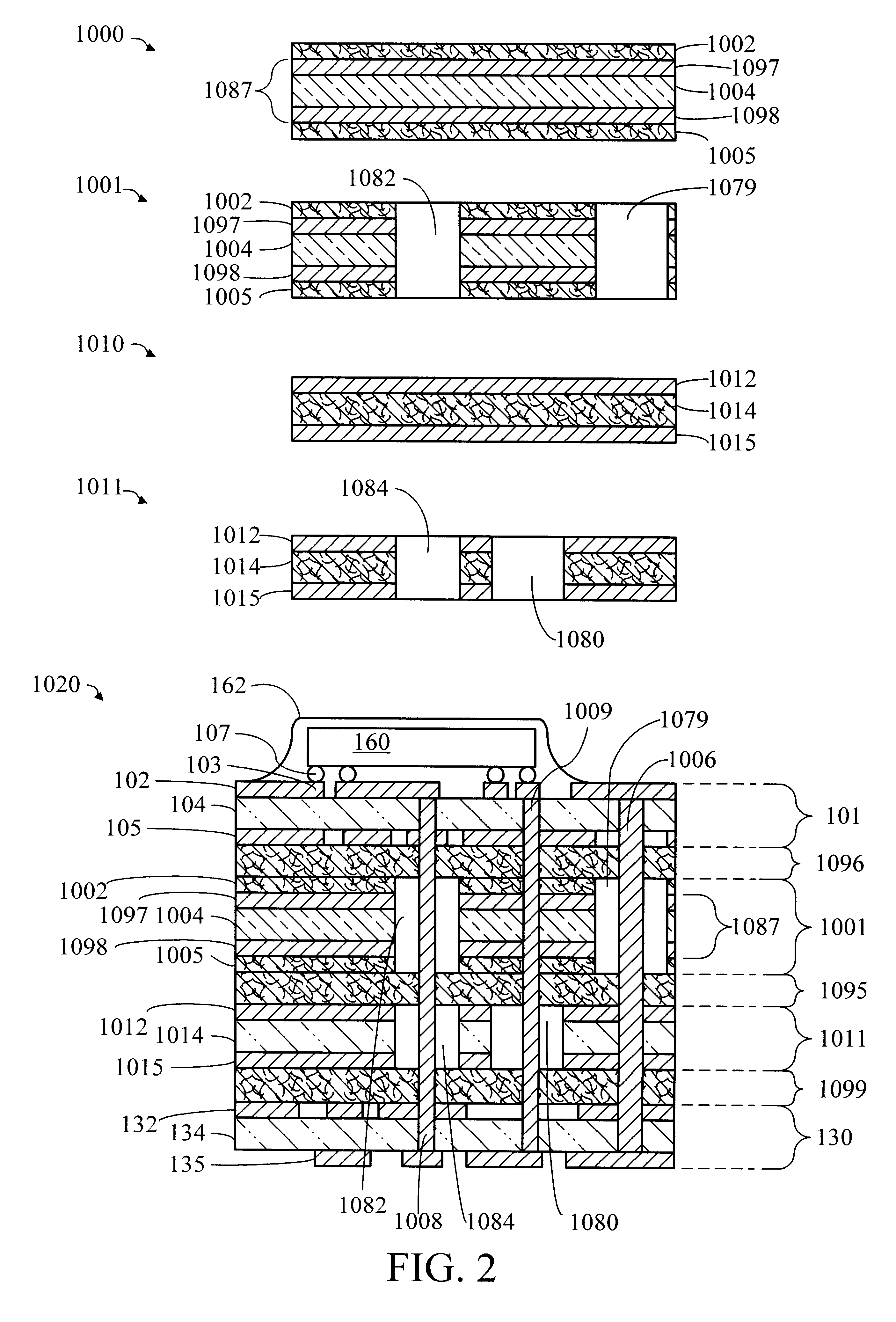

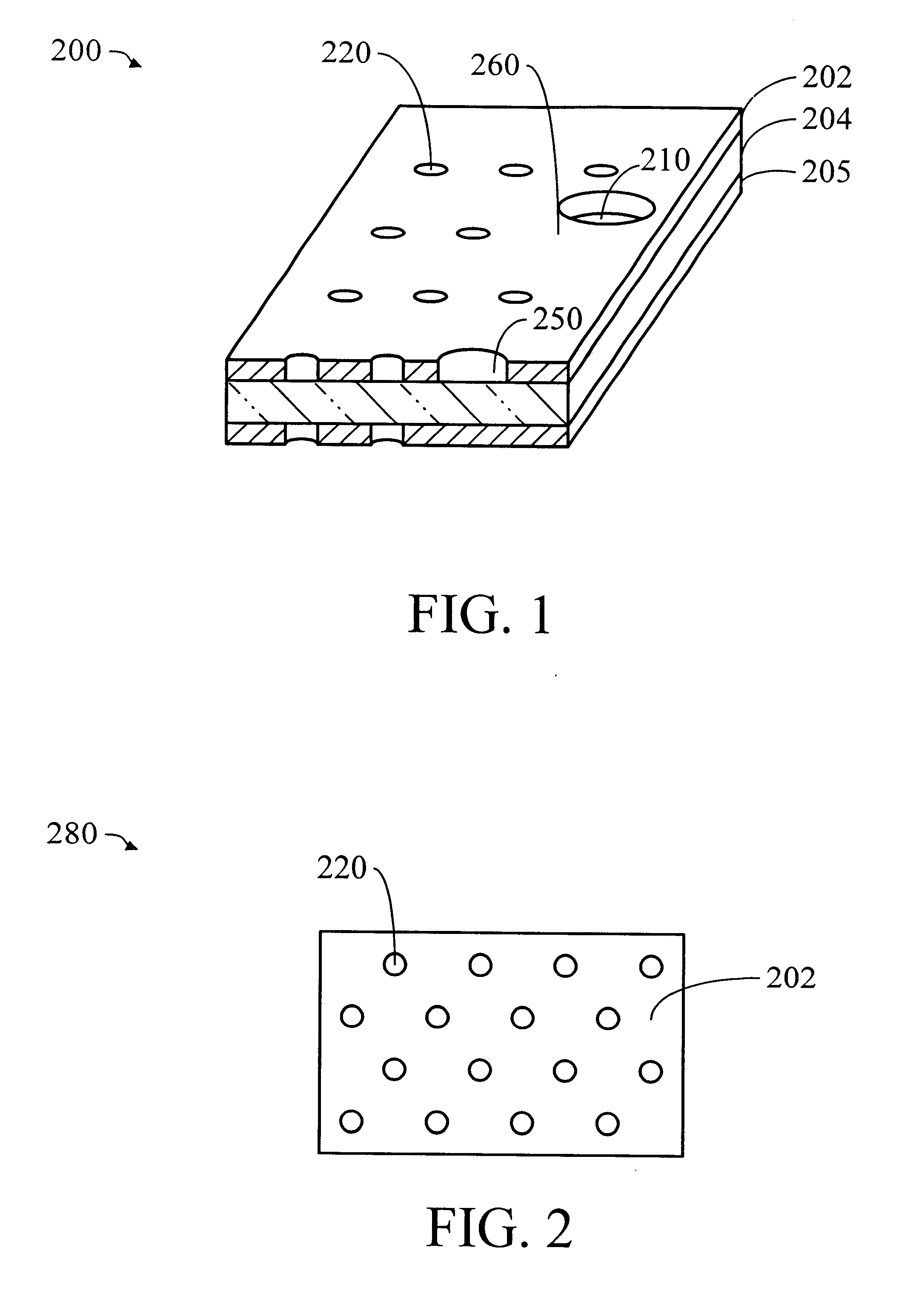

Porous power and ground planes for reduced PCB delamination and better reliability

InactiveUS6613413B1Decrease failureReduce failurePorous dielectricsPrinted circuit secondary treatmentSolventGround plane

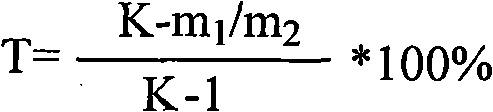

Power and ground planes used in Printed Circuit Boards (PCBs) having porous, conductive materials allow liquids (e.g., water and / or other solvents) to pass through the power and ground planes, thus decreasing failures in PCBs (or PCBs used as laminate chip carriers) caused by cathodic / anodic filament growth and delamination of insulators. Porous conductive materials suitable for use in PCBs may be formed by using metal-coated organic cloths (such as polyester or liquid crystal polymers) or fabrics (such as those made from carbon / graphite or glass fibers), using metal wire mesh instead of metal sheets, using sintered metal, or making metal sheets porous by forming an array of holes in the metal sheets. Fabrics and mesh may be woven or random. If an array of holes is formed in a metal sheet, such an array may be formed with no additional processing steps than are performed using conventional PCB assembly methods.

Owner:GLOBALFOUNDRIES INC

Method for producing high strength aluminum alloy welded structures

The present invention relates to a method for fabricating lightweight alloy feedstock for welded structures. Specifically, the method for producing the tubular stock proposed in the present invention enables a bicycle manufacturer to readily weld a lightweight yet high strength bicycle frame. The properties attained in the final product allow the bicycle manufacturer to reduce the overall weight of the bicycle without sacrificing durability.

Owner:TRI KOR ALLOYS

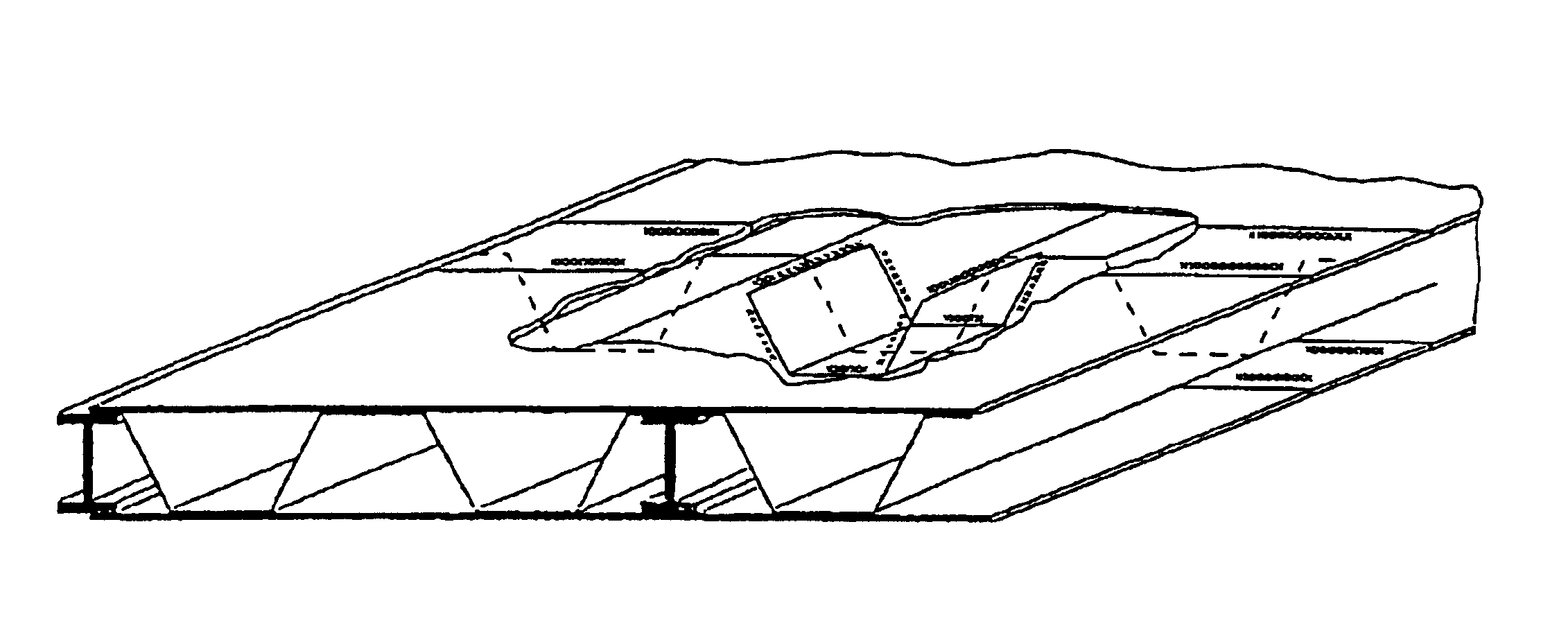

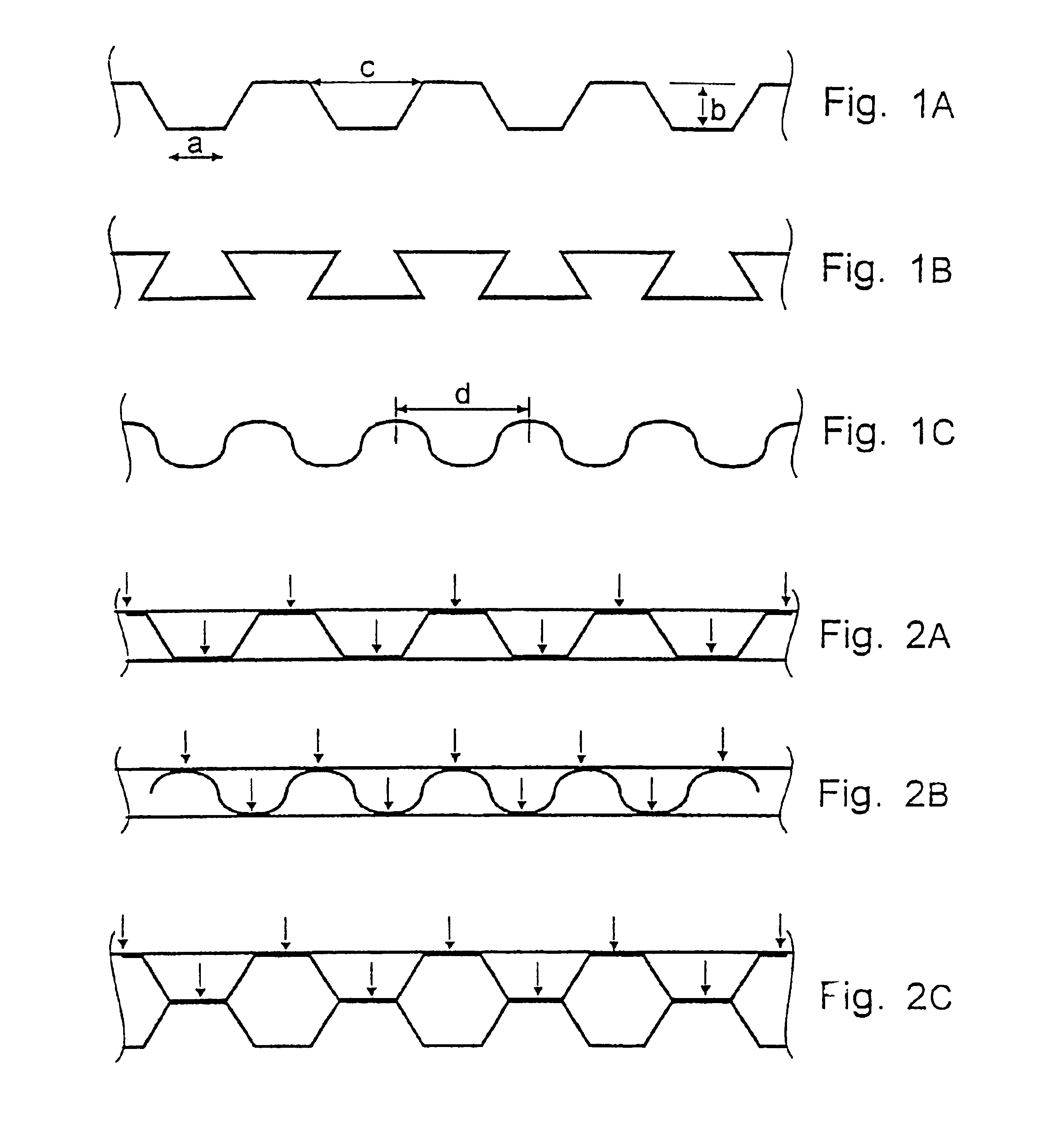

Composite aluminium panel

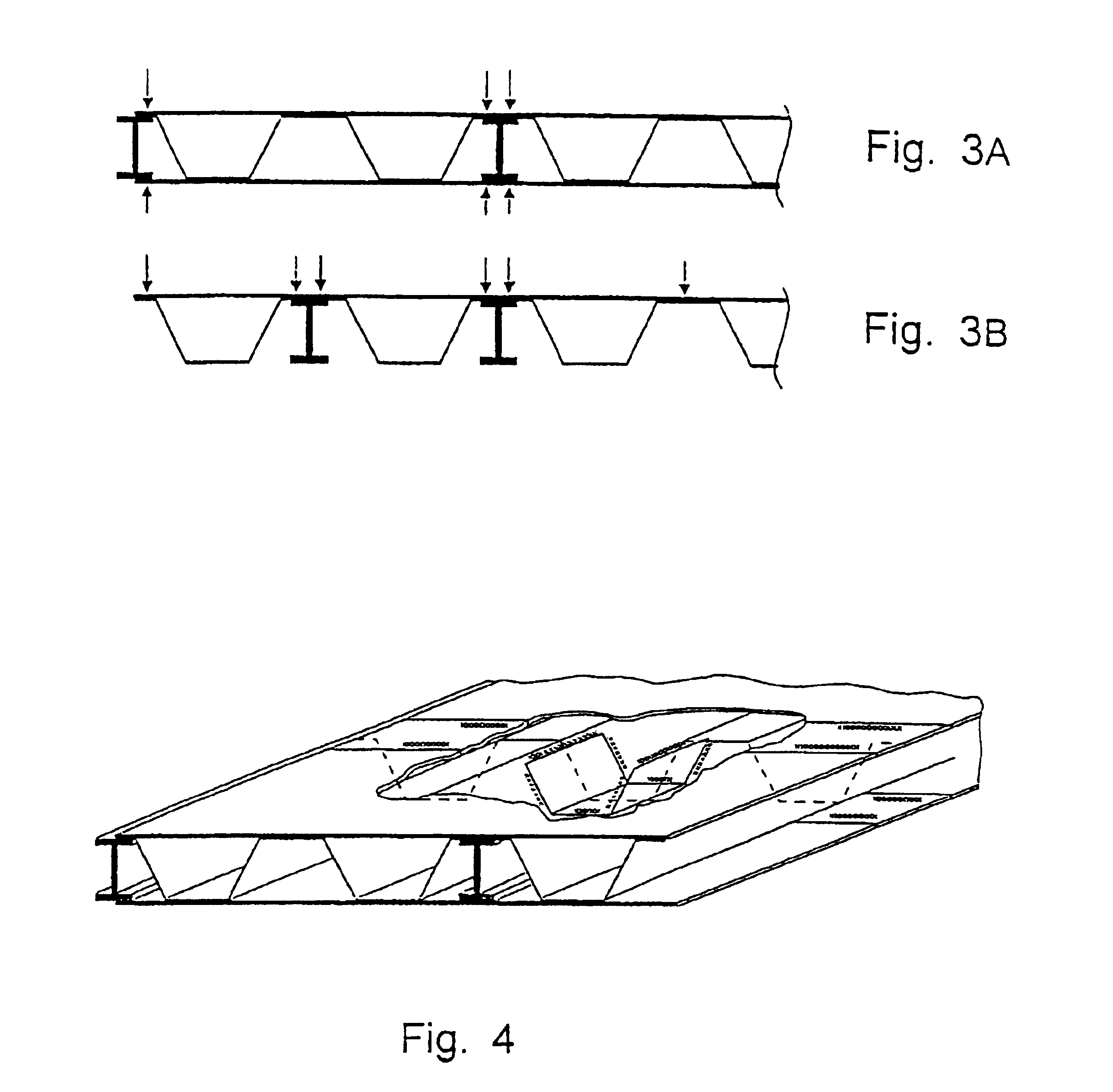

InactiveUS6848233B1Improve corrosion resistanceReliable and easy to manufactureNon-magnetic metal hullsLayered product treatmentParallel plateMaterials science

A composite aluminium panel comprising two parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is made from an aluminium alloy rolled sheet of composition (in weight percent): Mg 1.5-6.0, Mn 0.3-1.4, Zn 0.4-5.0, Fe up to 0.5, Si up to 0.5, Zr up to 0.30; optionally one or more of Cr 0.05-0.3, Ti 0.01-0.20, V 0.05-0.25, Ag 0.05-0.40, and Cu up to 0.40; and other elements up to 0.05 each, 0.15 total, with a balance of Al; and having in an H-condition or in an O-condition a ratio of PS / UTS in the range of 0.4 to 0.9 and having good roll formability.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

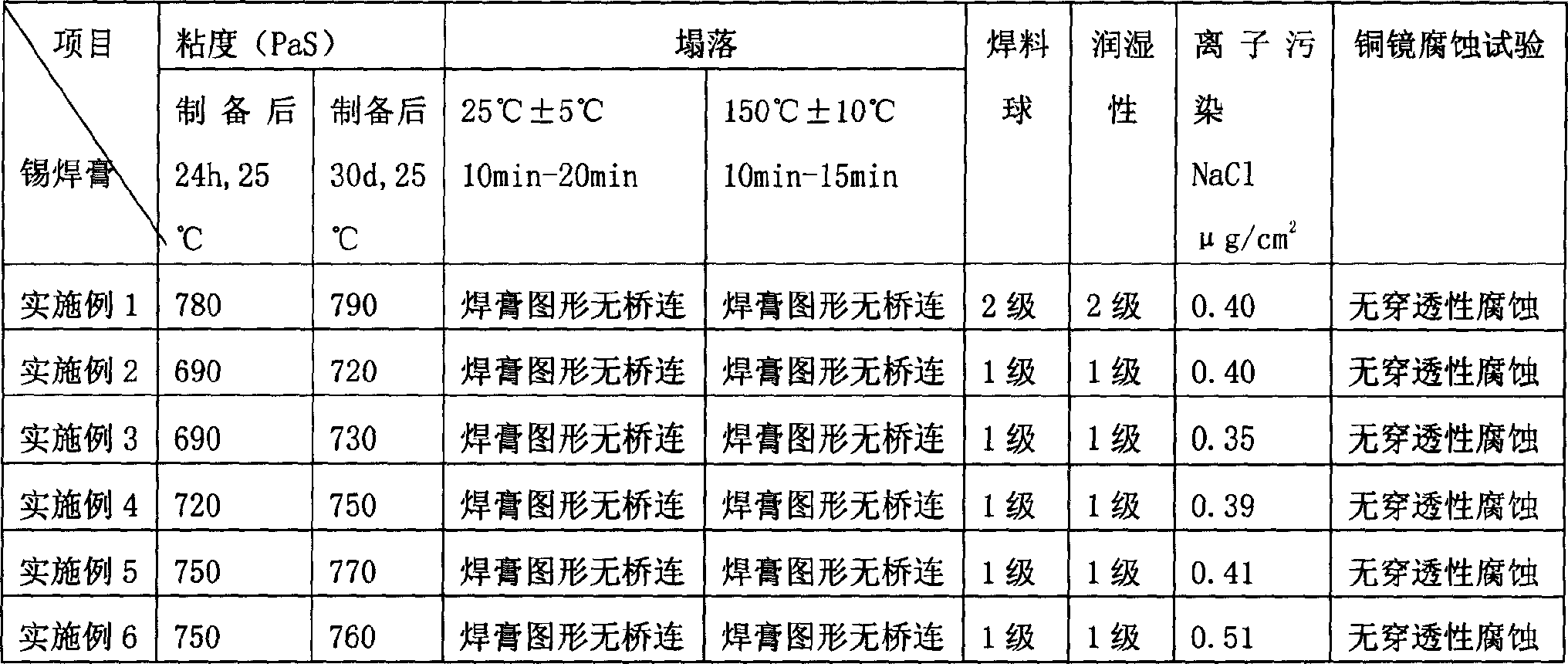

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Leadless tellurate low melting glass used as cementation phase in electronic slurry

The leadless tellurate low melting glass is used as binder phase for preparing electron paste. Said glass is mixed with functional powder to produce composite powder, which is then dispersed in organic solution to prepare thick paste, i.e. electron paste, used for making various kinds of electron devices. Said low melting glass, during sintering, melts-out and takes effect of adhering. The sintering temperature is between 350-600deg.C when making electron device. The components of the glass are (mass percentages): TeO2 10-90%,V2O5 0-40%,SiO2 0-5%,B2O3 0-5%,ZnO 0-10%,Bi2O3 0-20%,Sb2O3 0-8%,Al2O3 0-4%,SnO2 0-6%,Ag2O 0-10%,BaO 0-5%,MgO+CaO 0-5%.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Lead-free alloy solder containing rare-earth and more alloy components

InactiveCN1346728ALower melting temperatureAdjust mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementChemical composition

A lead-free alloy solder containing rare-earth elements and multiple other elements for electronic package contains Ag (0.1-5 wt.%), Cu (0.1-1 wt.%), Bi (0.1-8 wt.%), In (0.1-7.5 wt.%), Sb (0-8 wt.%), the mixture of La and Ce or the mixture of La, Ce and one or both of Pr and Nd (0.01-2 wt.%) and Sn (the balance). It has liquidus temp less than 210 deg.c (even 190 deg.C or lower), less than 15 deg.c for liquidus and solidus temp difference, at least 60 MPa of yield strength, at least 18% of elongation percentage, excellent wetting ability, and high soldering quality.

Owner:DALIAN UNIV OF TECH

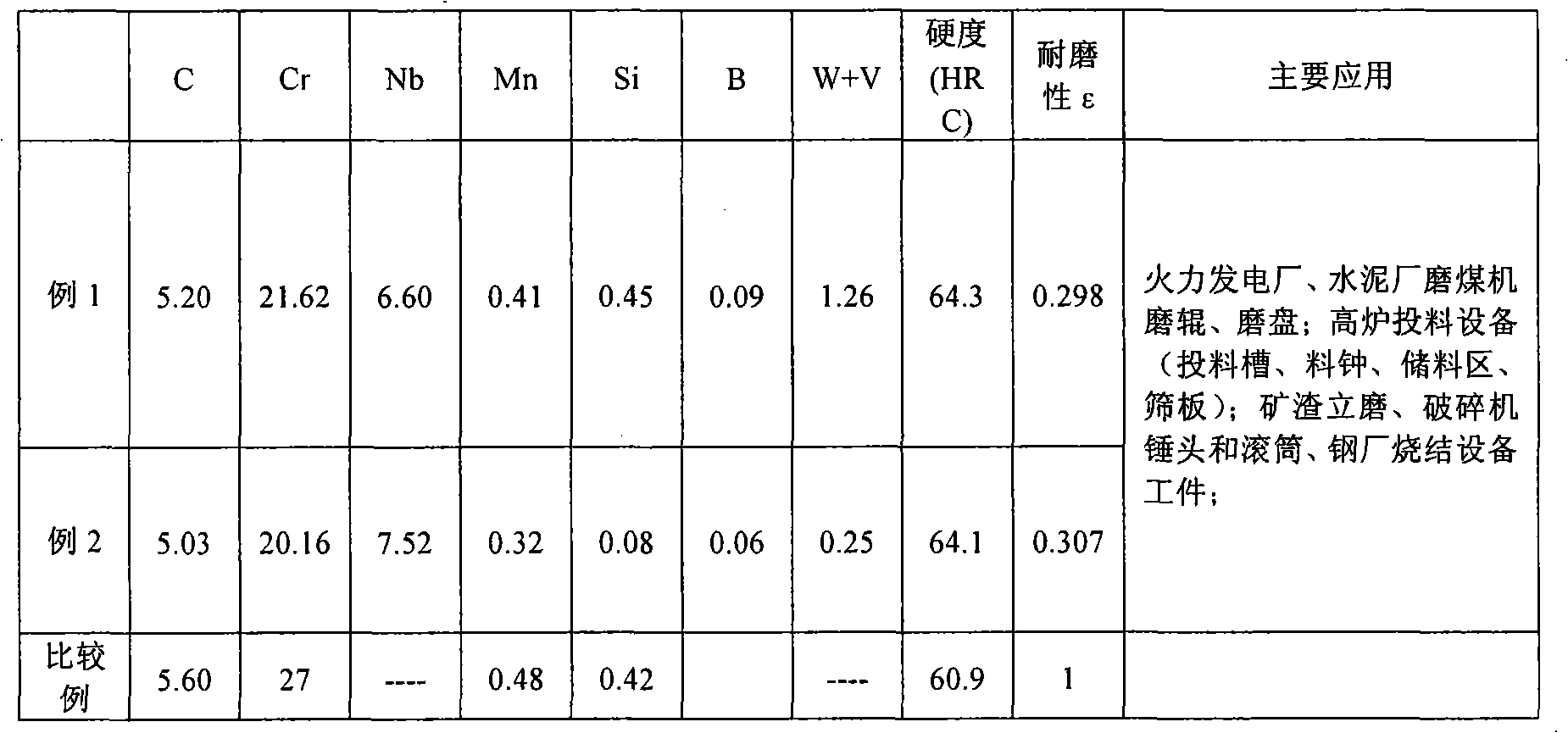

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Cast Aluminium Alloy

Cast aluminium alloys comprising 1.0-8.0% in weight magnesium (Mg), >1.0-4.0% in weight silicon (Si), 0.01-<0.5% in weight scandium (Sc), 0.005-0.2% in weight titanium (Ti), 0-0.5% in weight of at least one element or selected from the group consisting of zirconium (Zr), hafnium (Hf), molybdenum (Mo), terbium (Tb), niobium (Nb), gadolinium (Gd), erbium (Er) and vanadium (V), 0-0.8% in weight manganese (Mn), 0-0.3% in weight chromium (Cr), 0-1.0% in weight copper (Cu), 0-0.1% in weight zinc (Zn), 0-0.6% in weight iron (Fe), 0-0.004% in weight beryllium (Be), and the remainder of aluminium with further impurities to an individual maximum of 0.1% in weight and totally maximally 0.5% in weight.

Owner:EADS DEUT GMBH +1

Lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics and preparation method thereof

ActiveCN102751000AAchieve lead-freeImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceSlurry

The invention discloses a lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics. The lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics is prepared from the following raw materials in percentage by weight: 50 to 75 percent of conducting silver micro powder, 0.5 to 5 percent of inorganic additive, 1 to 15 percent of lead-free glass powder and 15 to 45 percent of organic carrier. The lead-free and cadmium-free electrode silver slurry is technologically advantaged in that a boron-bismuth-silicon-zinc-titanium glass system is designed, the traditional lead-containing glass can be completely substituted, a lead-free product is realized, the system glass can react with a piezoelectric ceramic substrate to form a firm interface between an electrode and the substrate, and the adhesion force of the interface is more than 15N / mm<2>.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

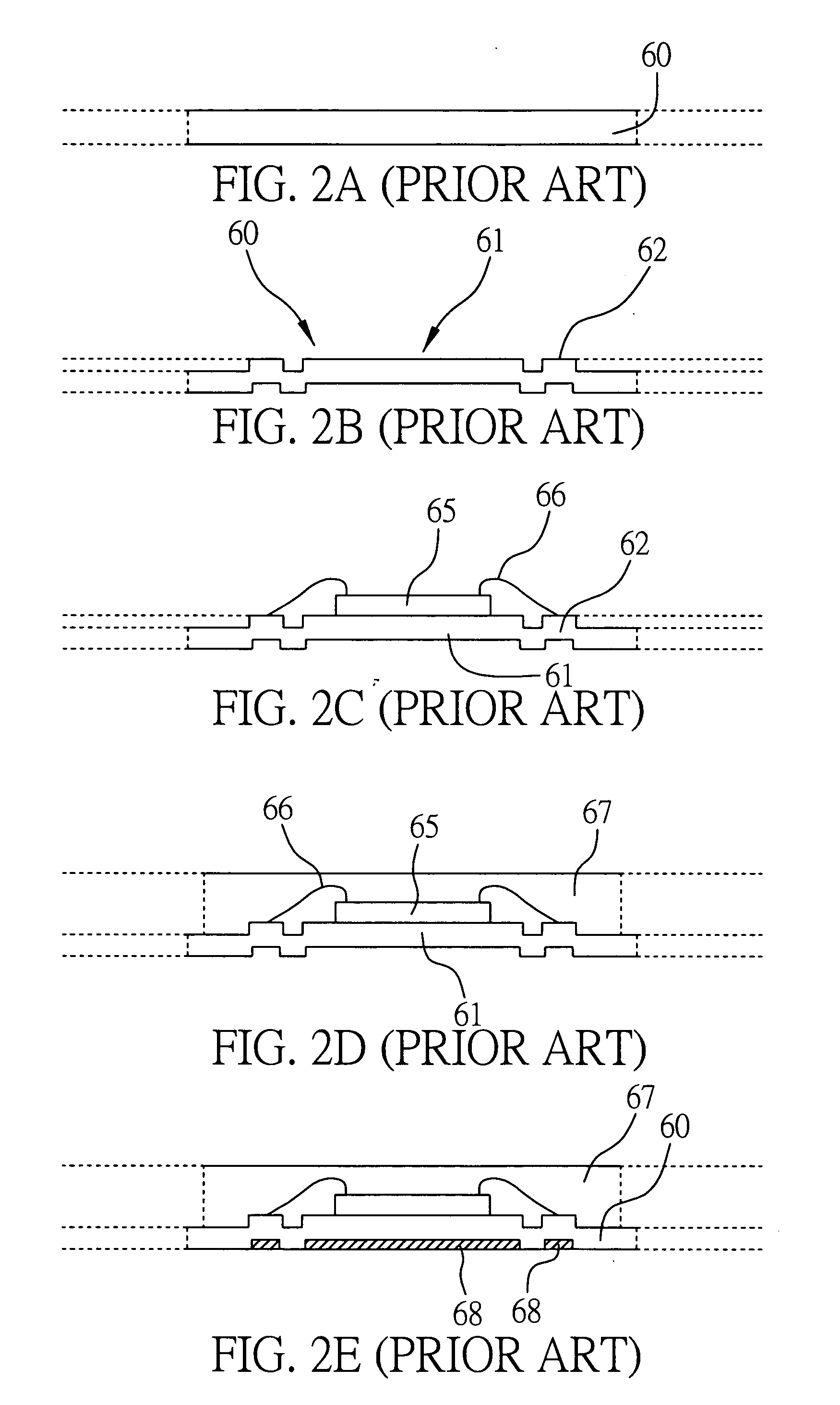

Method of manufacturing quad flat non-leaded semiconductor package

InactiveUS20070059863A1Improve production yieldGood solderabilitySemiconductor/solid-state device detailsSolid-state devicesResistElectrically conductive

A method of manufacturing a quad flat non-leaded semiconductor package is provided. A metal plate is prepared and is defined with predetermined positions of a plurality of electrically conductive pads. A resist layer is formed on the metal plate, and a plurality of openings are formed in the resist layer and correspond to the predetermined positions of the electrically conductive pads. A solderable metal plated layer is formed in each of the openings of the resist layer. The resist layer on the metal plate is removed. A portion of the metal plate, which is not covered by the metal plated layers, is etched using the metal plated layers as a mask. A chip is mounted on the metal plate and is electrically connected to the electrically conductive pads. A molding process is performed such that the chip and the metal plate are encapsulated by an encapsulant.

Owner:SILICONWARE PRECISION IND CO LTD

Lead-free halogen-free tinol and preparation process

ActiveCN1876311AImprove compatibilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention discloses a leadless and no-halogen tonal, comprising following components with percent by weight: alloy powder 80-98 and welding flux 2-20; said alloy powder is one of SnAgCu, SnAgNi, SnAgBiCu, SnAgBiSb, SnCu and SnAg; said welding flux concludes following components with percent by weight: modified resin antioxidant 30-60, organic acid activating agent 5-15, thixotropic agent 4-14, plasticizing agent 2-6, plasticizing agent 0.4-2, inhibitor 0.1-0.5 and organic solvent 20-40; said modified resin antioxidant comprises following components with percent by weight: modified rosin resin 80-90, anti-oxidant 2-8, and reducer 2-8. The tonal is characterized by good thixotropic behavior, no oxidation, no dry welding and no short circuit.

Owner:BEIJING XINLI MACHINERY

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

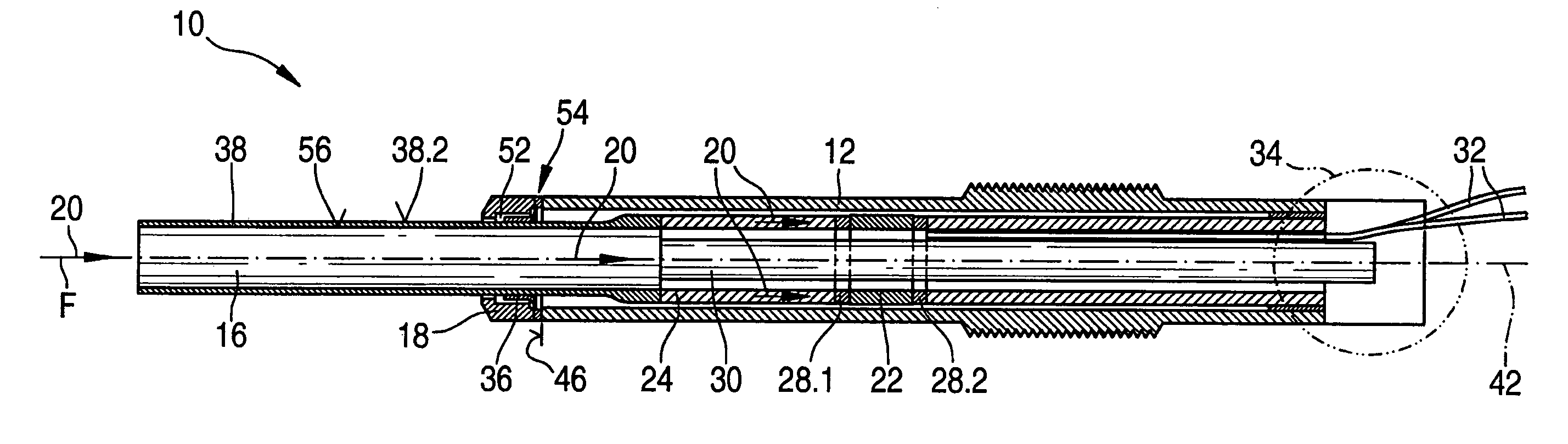

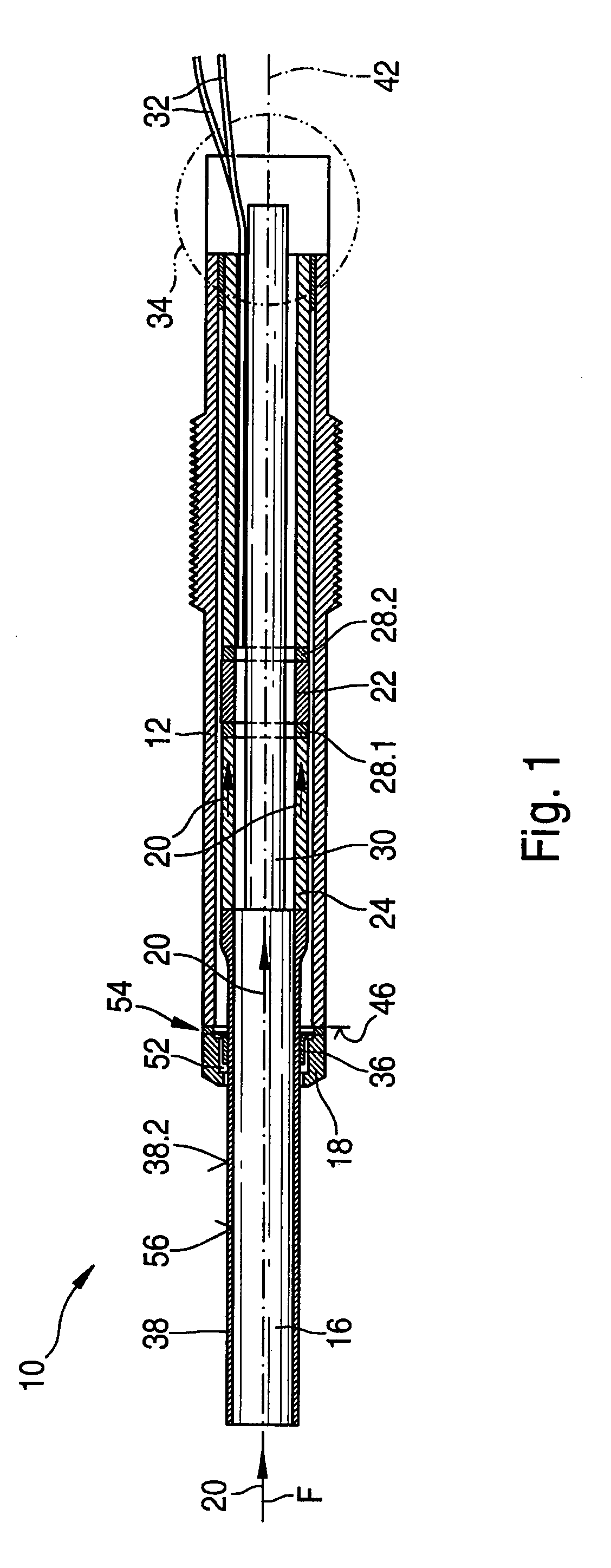

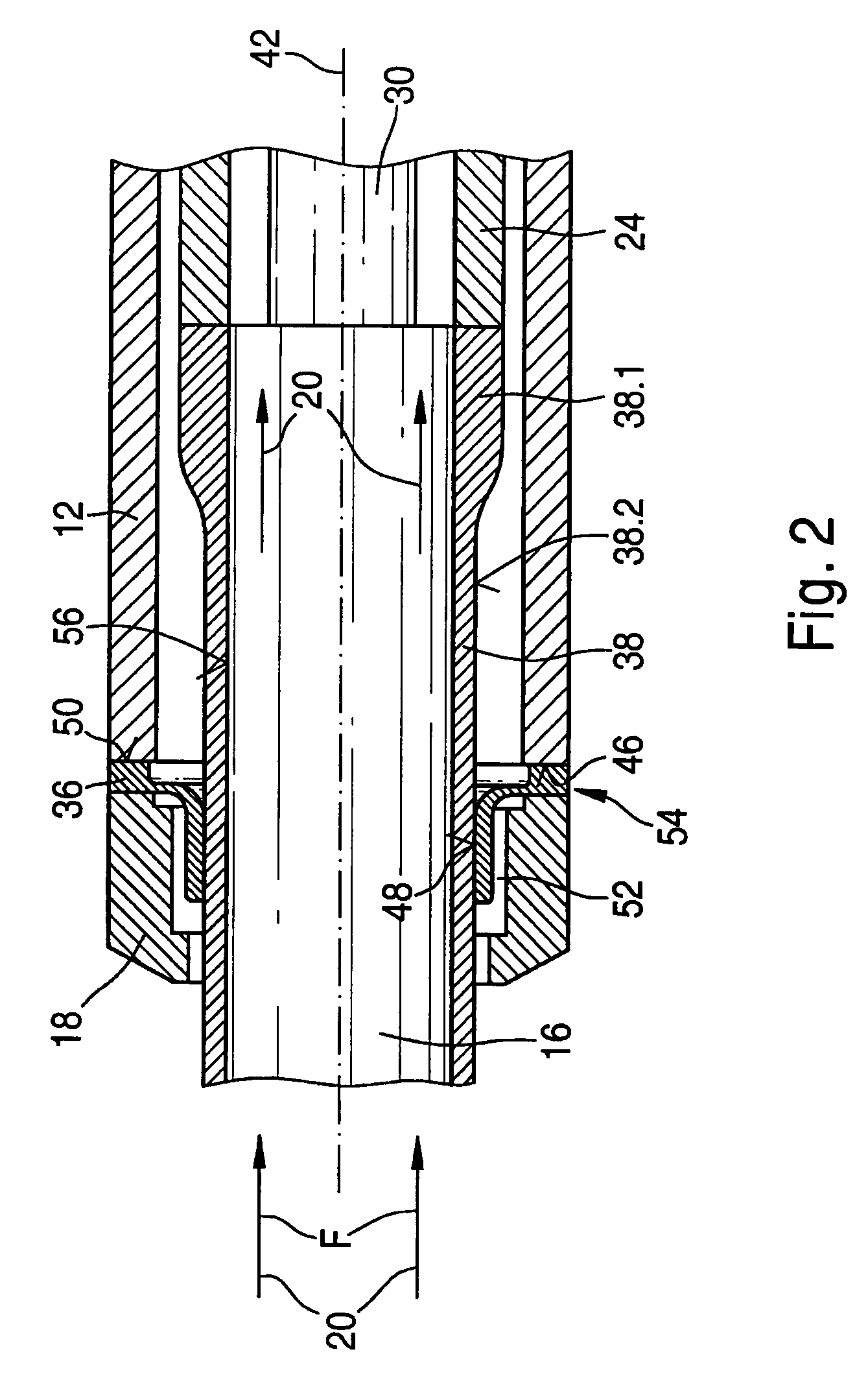

Pencil-type glow plug having an integrated combustion chamber pressure sensor

InactiveUS7581520B2Improve fatigue strengthAvoid failureIncandescent ignitionLamp incadescent bodiesCombustion chamberDiaphragm seal

A pencil-type glow plug for a self-igniting internal combustion engine is described. The pencil-type glow plug includes a plug body in which a combustion chamber pressure sensor is integrated, and a bar-shaped heating element that protrudes out from the plug body at one end, into the combustion chamber of the internal combustion engine. A force-measuring element of the combustion chamber pressure sensor is accommodated behind the heating element, which moves axially under the influence of force. The force-measuring element is sealed against combustion chamber gases by a steel diaphragm made of a stainless precipitation-hardened maraging steel.

Owner:ROBERT BOSCH GMBH

Water-soluble soldering flux dedicated for lead-free solder

InactiveCN1836825AImprove solderabilityImprove performanceWelding/cutting media/materialsSoldering mediaOrganic acidWater soluble

The water soluble soldering flux specially for lead-free soldering material consists of boric acid and organic acid activator 5.0-10.0 wt%, non-ionic surfactant or cationic surfactant 0.1-1.0 wt%, co-solvent 8.0-20.0 wt%, filming agent 0.1-1.0 wt%, corrosion retardant 0.1-0.5 wt%, except deionized water. The compounding process includes the following steps: mixing co-solvent and partial deionized water, adding filming agent under stirring, adding the rest deionized water, activator and surfactant after dissolving, adding corrosion retardant while stirring to dissolve, stilling, and filtering to obtain the filtrate as the soldering flux. The water soluble soldering flux has excellent soldering assisting performance on lead-free soldering material, environment friendship and other advantages.

Owner:BEIJING UNIV OF TECH

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

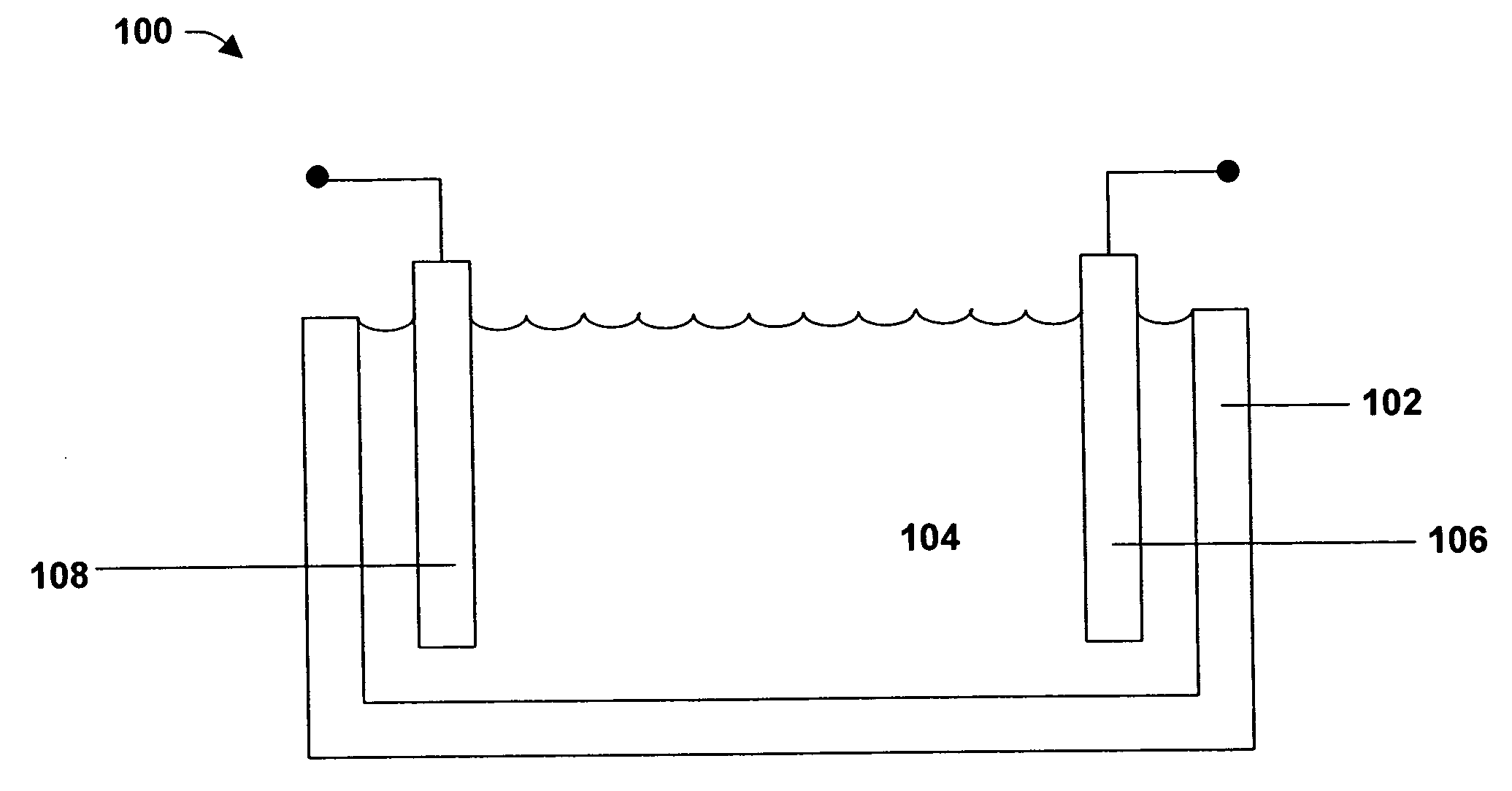

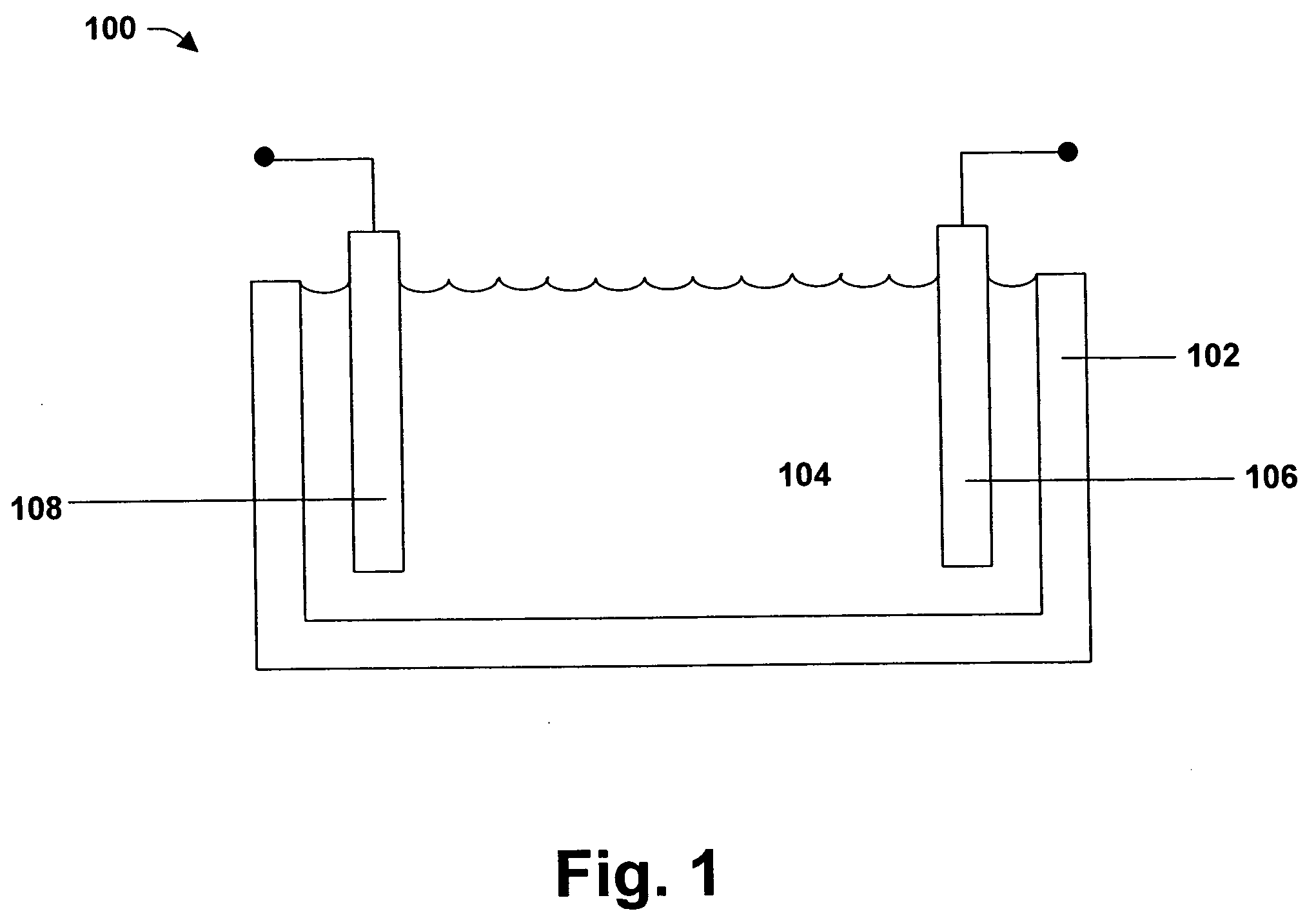

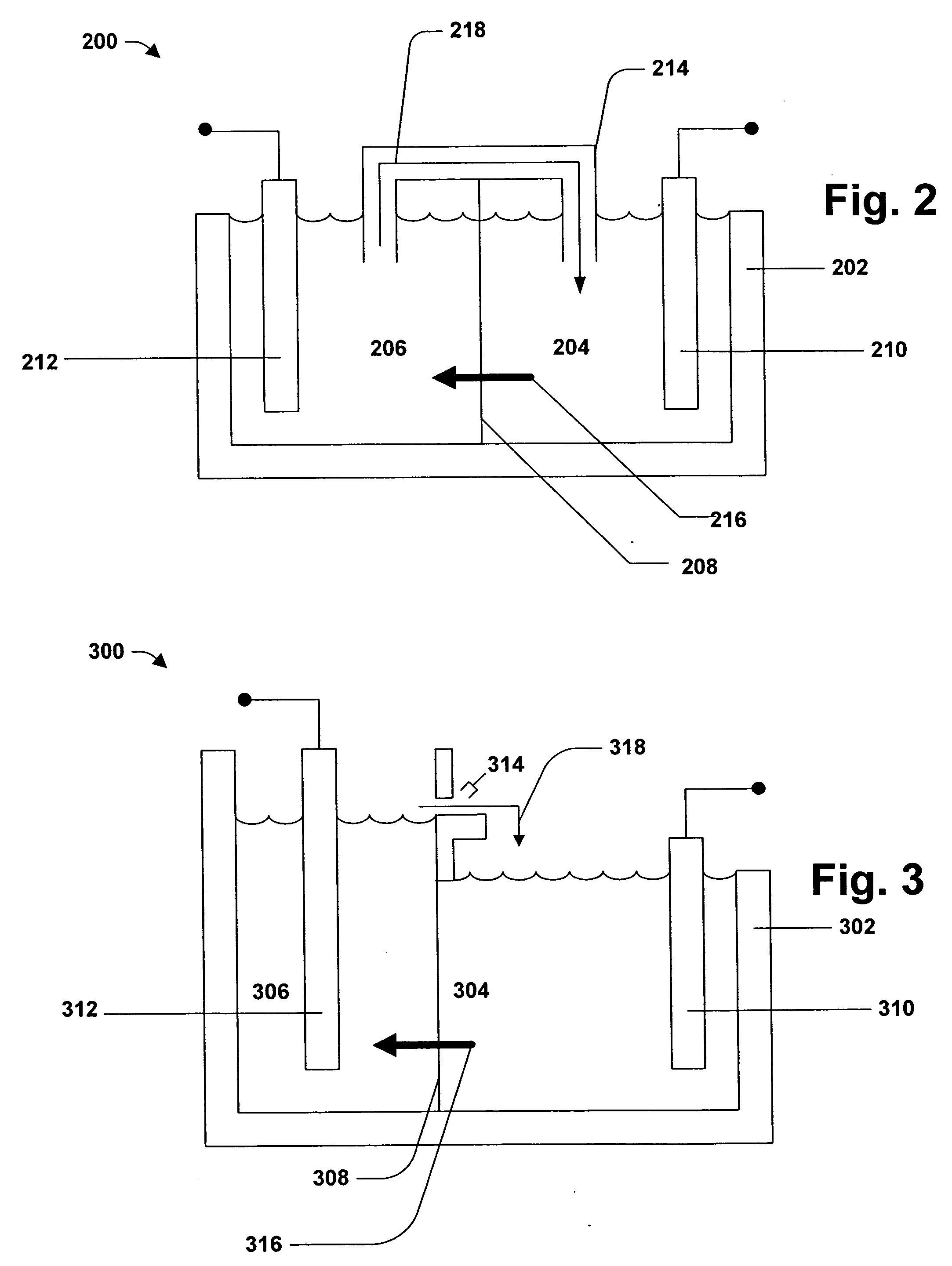

Tin alloy electroplating system

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. The system for plating a tin alloy contains an electrochemical cell containing an anode, the cathode, and an electroplating bath. The electroplating bath contains water, an acid, at least one nitrogen-containing heterocyclic complexing agent, an ionic alloy metal, and ionic tin. The methods involve applying a current to the electroplating bath whereby a tin alloy forms on the cathode.

Owner:TASKEM

Magnet valve for a slip-controlled hydraulic vehicle brake system

InactiveUS6189985B1Fast and economical production processImprove solderabilityOperating means/releasing devices for valvesBraking action transmissionSolenoid valveVehicle brake

A rodlike magnet valve having a magnetic part which is surrounded by a coil for actuating the valve. The magnet valve can be inserted into a receiving bore of a hydraulic block of a slip-controlled vehicle brake system. For fast, economical manufacture of the magnet valve, the magnet valve has a rotationally symmetrical base body, which has a through bore and a securing flange, as an extruded part without undercuts or tapered features. Along with the advantage of enabling fast, inexpensive manufacture of its base body, the magnet valve has the further advantage that the base body can be made from an economical reforming steel, which can be readily welded for fluid-tight mounting of a valve dome.

Owner:ROBERT BOSCH GMBH

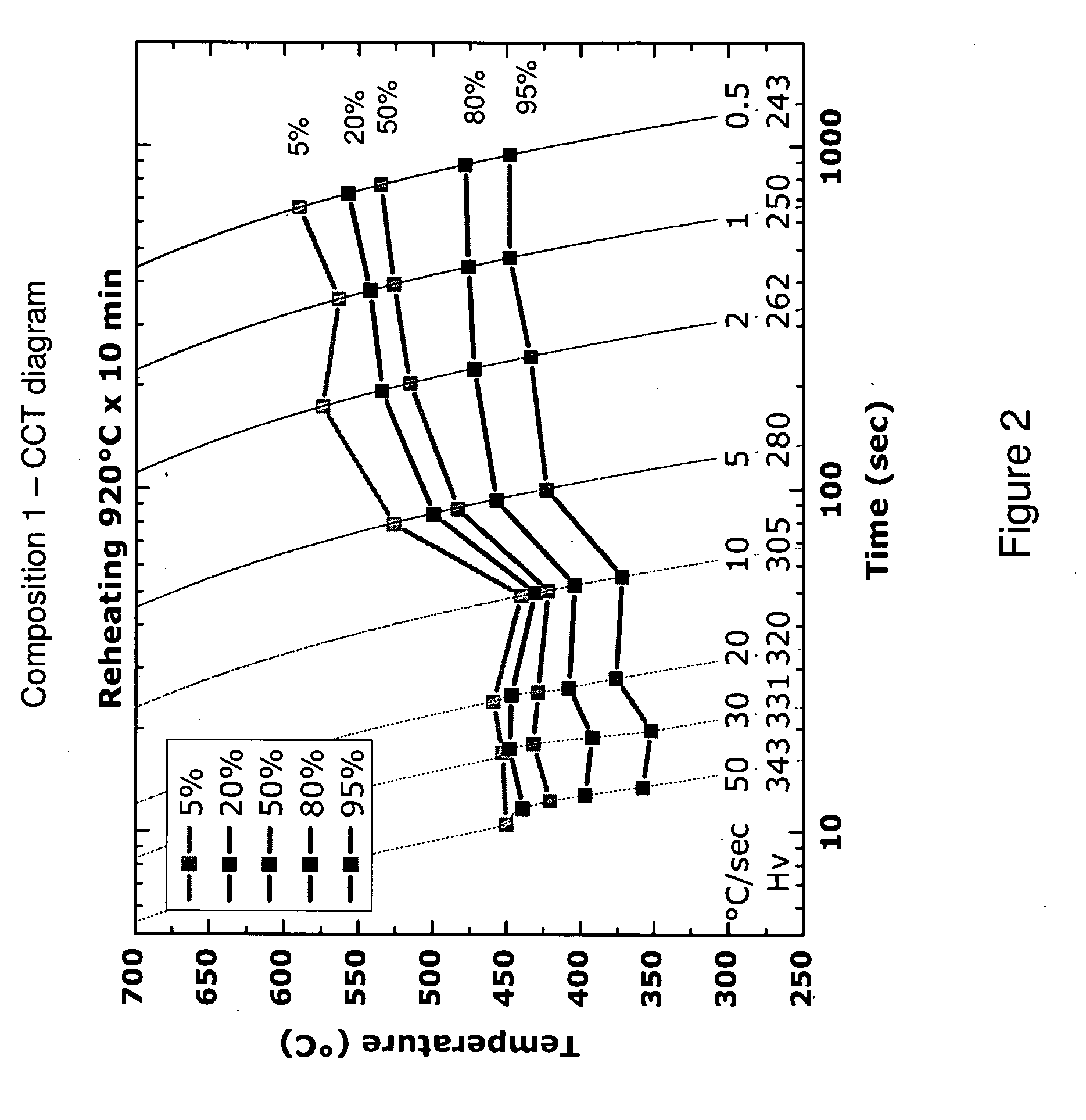

Bainitic steels with boron

InactiveUS20100319814A1Improve toughnessImprove solderabilityFurnace typesHeat treatment process controlHigh intensityTitanium

Steel compositions contain micro-alloying additions of boron and titanium, with yield strength of at least 100 ksi (690 MPa), excellent toughness and good weldability. Boron additions are used to increase hardenability. Strong nitride formers, such as titanium, may be added to the steel composition in order to prevent boron nitrides from forming. These compositions may be cooled from hot rolling in air or using accelerated cooling. After air cooling, the composition may be quenched or quenched and tempered. The compositions are suitable for high strength line pipes (for example, X100 in API 5L standard) and other applications.

Owner:TENARIS CONNECTIONS

Austenitic stainless steel

An austenitic stainless steel with minimized deformation by heating and cooling treatment after cold working, which consists of, % by mass, C: 0.03% or less, Si: 2 to 4%, Mn: 0.1 to 2%, P: 0.03% or less, S: 0.03% or less, Ni: 9 to 15%, Cr: 15 to 20%, N: 0.02 to 0.2%, Nb: 0.03% or less, each of Mo and Cu or a total of Mo and Cu: 0.2 to 4%, and the balance Fe and impurities, and satisfies the following formulas (1) and (2). This steel can also have good weldability when the following formula (3) is also satisfied in addition to the formulas (1) and (2);16.9+6.9Ni+12.5Cu−1.3Cr+3.2Mn+9.3Mo−205C−38.5N−6.5Si−120Nb≧40 (1)450−440(C+N)−12.2Si−9.5Mn−13.5Cr−20(Cu+Ni)−18.5Mo≦−90 (2)8.2+30(C+N)+0.5Mn+Ni−1.1(1.5Si+Cr+Mo)+2.5Nb≦−0.8 (3)wherein each element symbol in the formulas (1), (2) and (3) represents the content, % by mass, of each element included in the steel.

Owner:NIPPON STEEL CORP

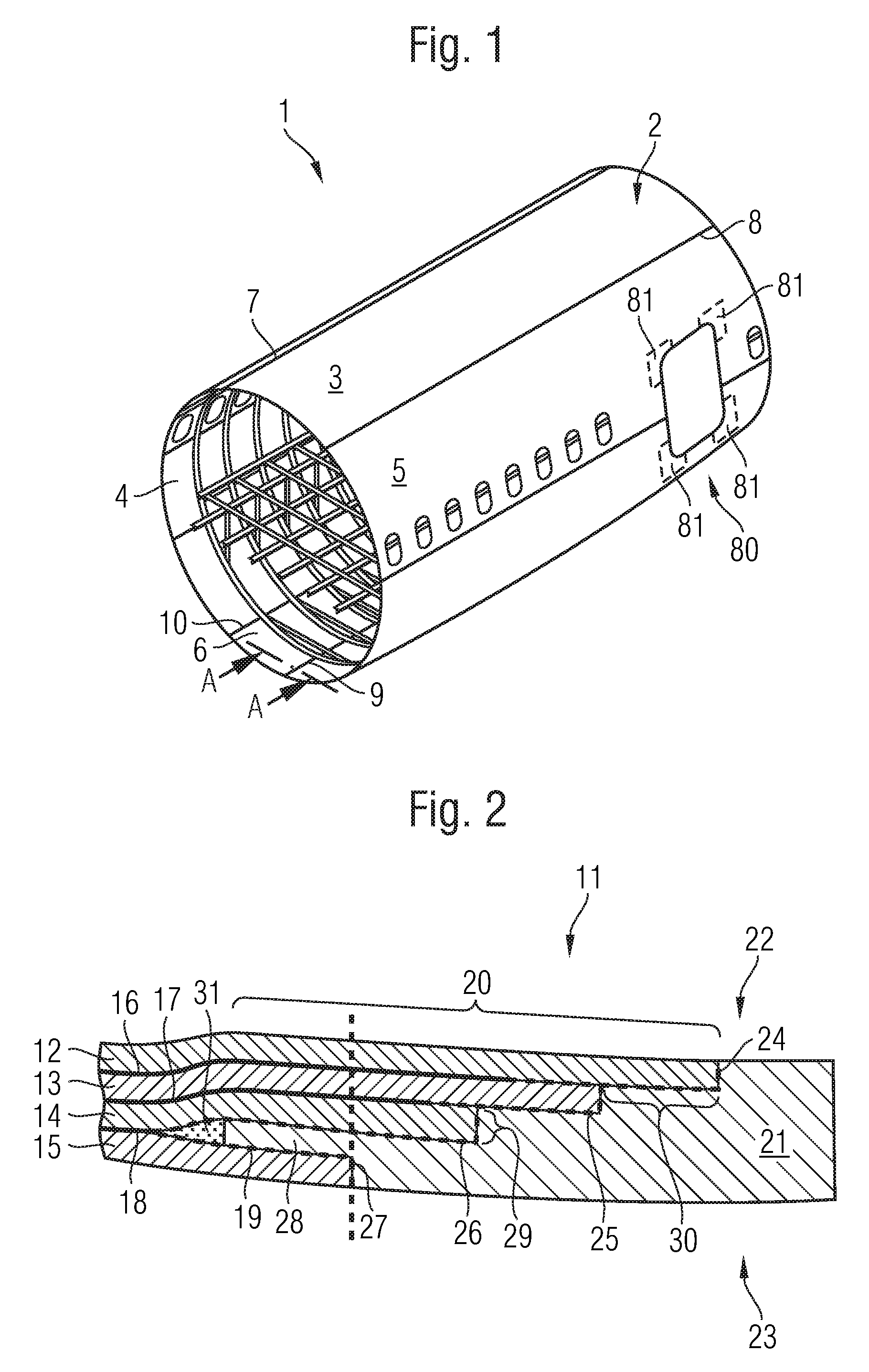

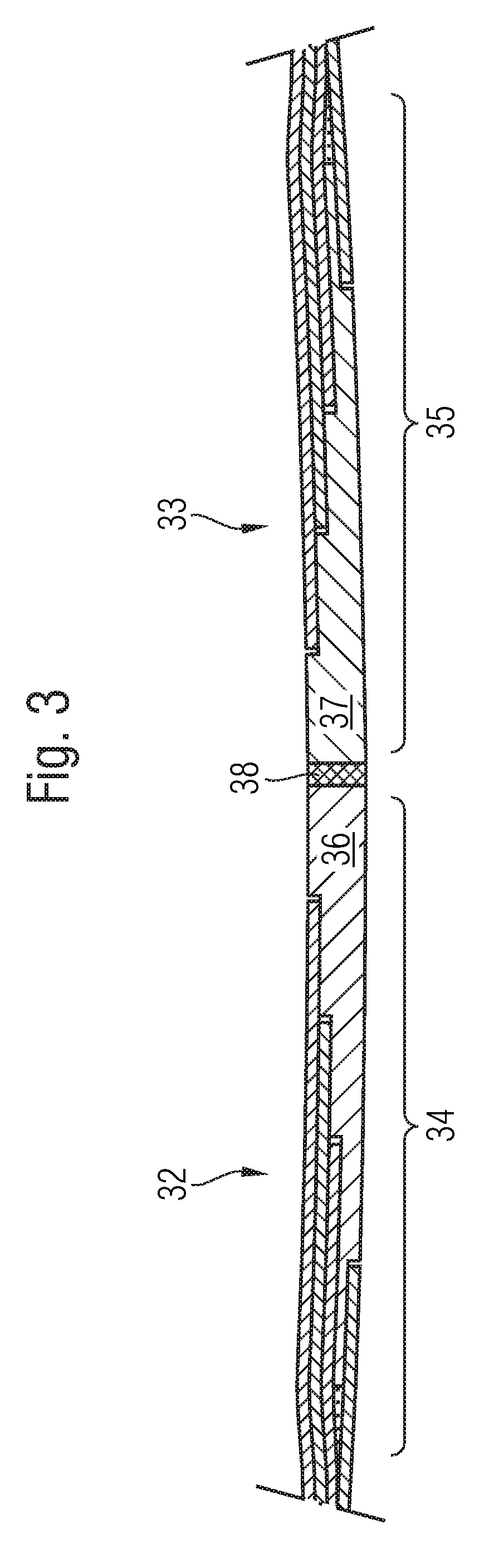

Laminate sheet, in particular for fuselage skin sheets for aircrafts

InactiveUS20080292849A1Improve welding qualityAvoid placingFuselage framesCellulosic plastic layered productsGlass fiberMetallurgy

A laminate sheet, in particular for use as a fuselage skin includes thin aluminium alloy sheets layered on top of one another with each two aluminium alloy sheets being adhesively bonded to one another at least in regions by an adhesive layer which includes at least one unidirectional fibreglass insert impregnated with a curable synthetic resin.

Owner:AIRBUS OPERATIONS GMBH

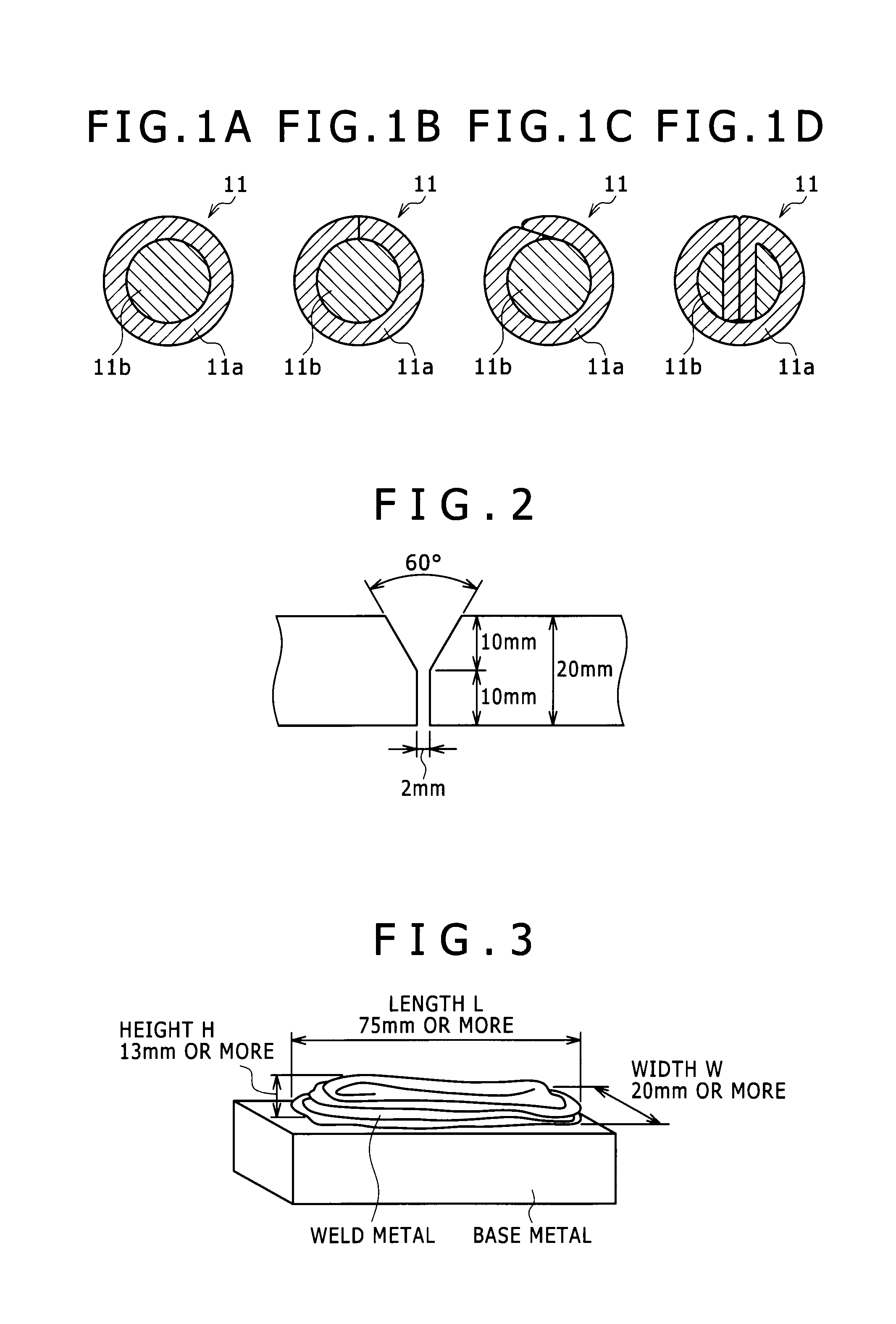

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

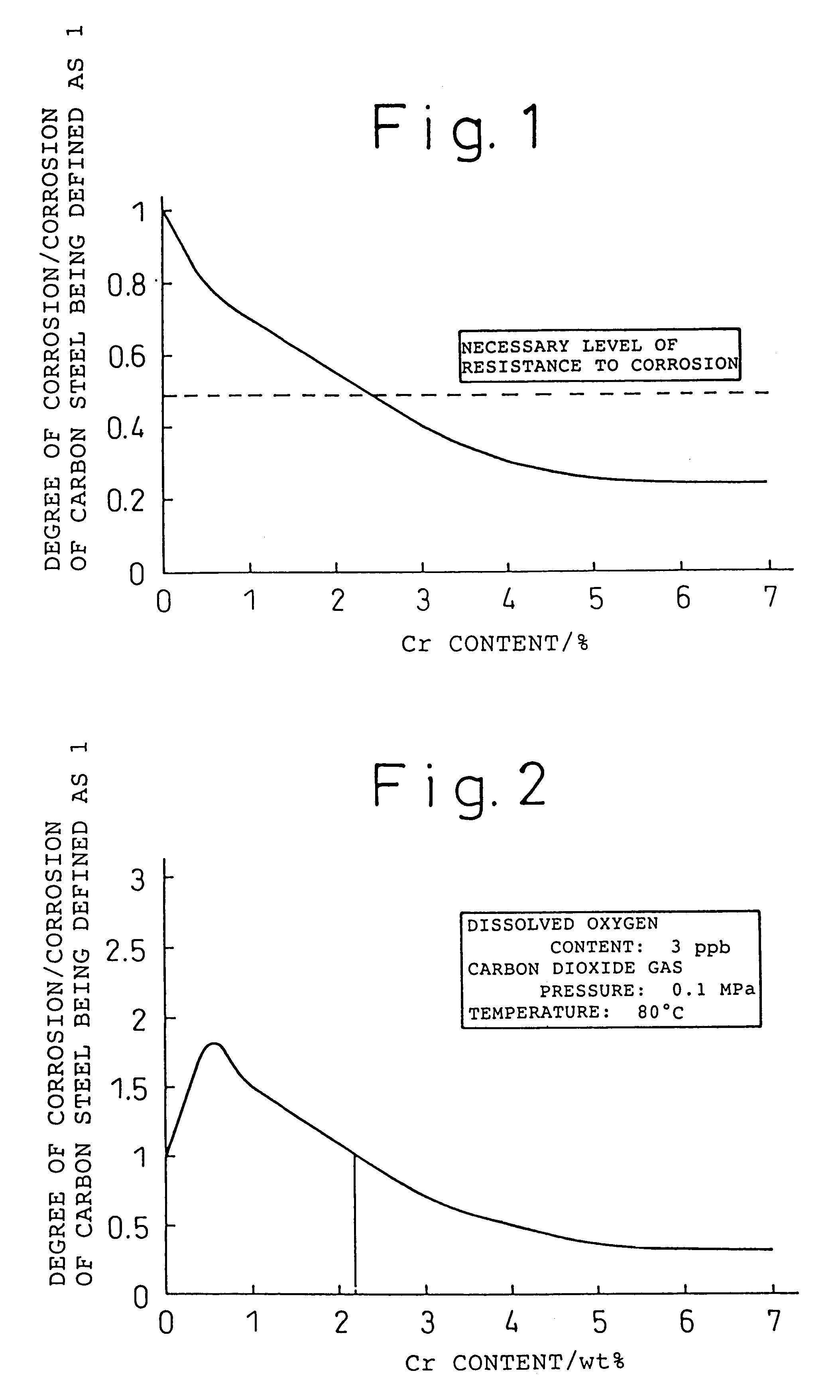

Corrosion resisting steel and corrosion resisting oil well pipe having high corrosion resistance to carbon dioxide gas

InactiveUS6248187B1Excellent in resistance to corrosionHigh strengthMartensiteUltimate tensile strength

An object of the present invention is to provide a corrosion resistant steel excellent in strength and low temperature toughness as well as resistance to corrosion by carbon dioxide and seawater, and most suitable for oil well steel pipes and line pipes for production and transportation of gas, petroleum, etc. used in the field of energy, or a steel for plants, and corrosion resistant oil well steel pipes. The corrosion resistant steel and the corrosion resistant oil well steel pipes comprise, based on weight, up to 0.30% of C, up to 1.0% of Si, 0.2 to 2.0% of Mn, 2.1 to less than 5.0% of Cr, up to 0.03% of P, up to 0.02% of S, up to 0.10% of Al, up to 0.015% of N, optionally containing Cu, Ni, Mo, Ti, Nb and B, and the balance of Fe and unavoidable impurities, and have a martensitic structure as their metallic structure.

Owner:NIPPON STEEL CORP

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

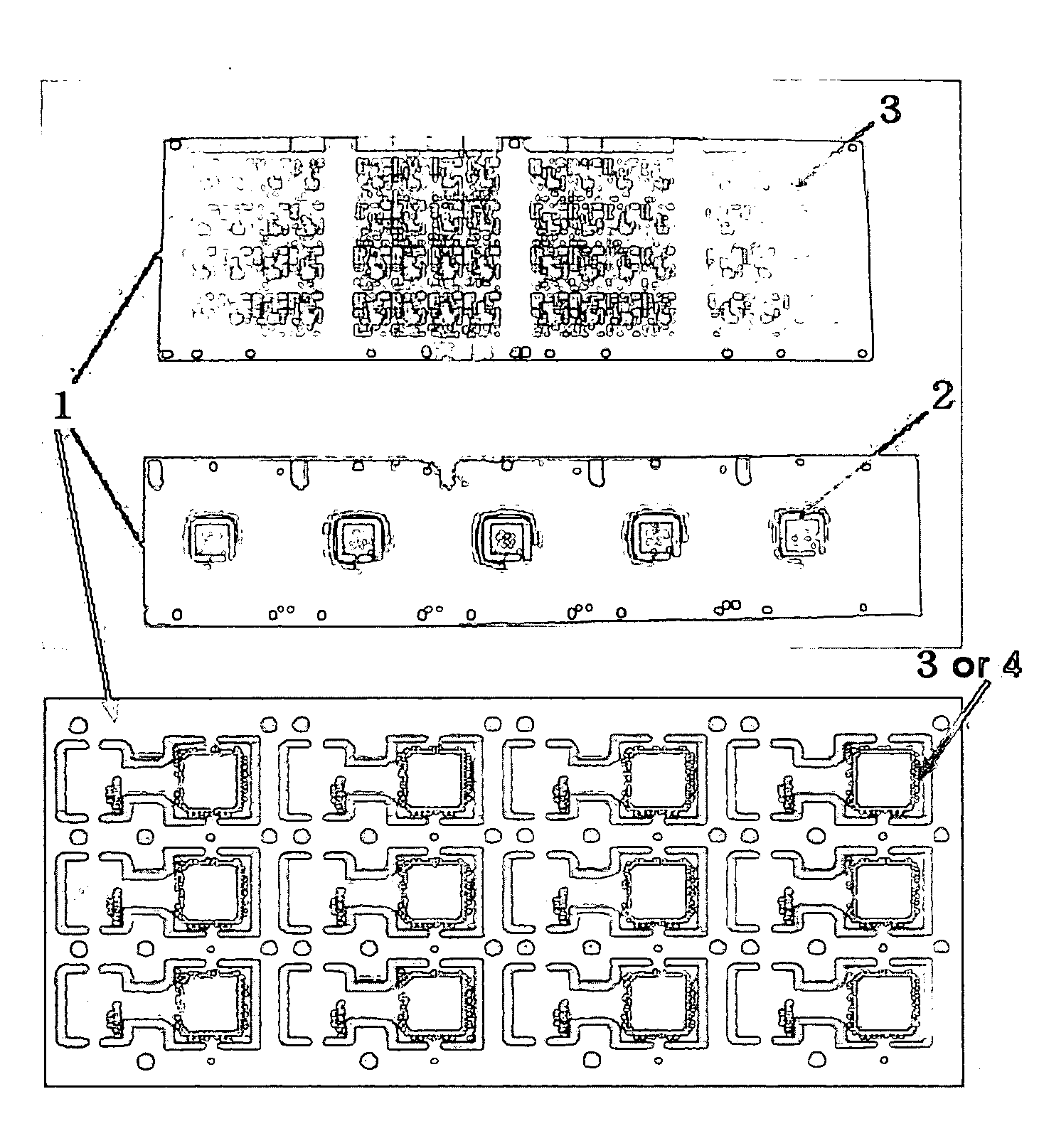

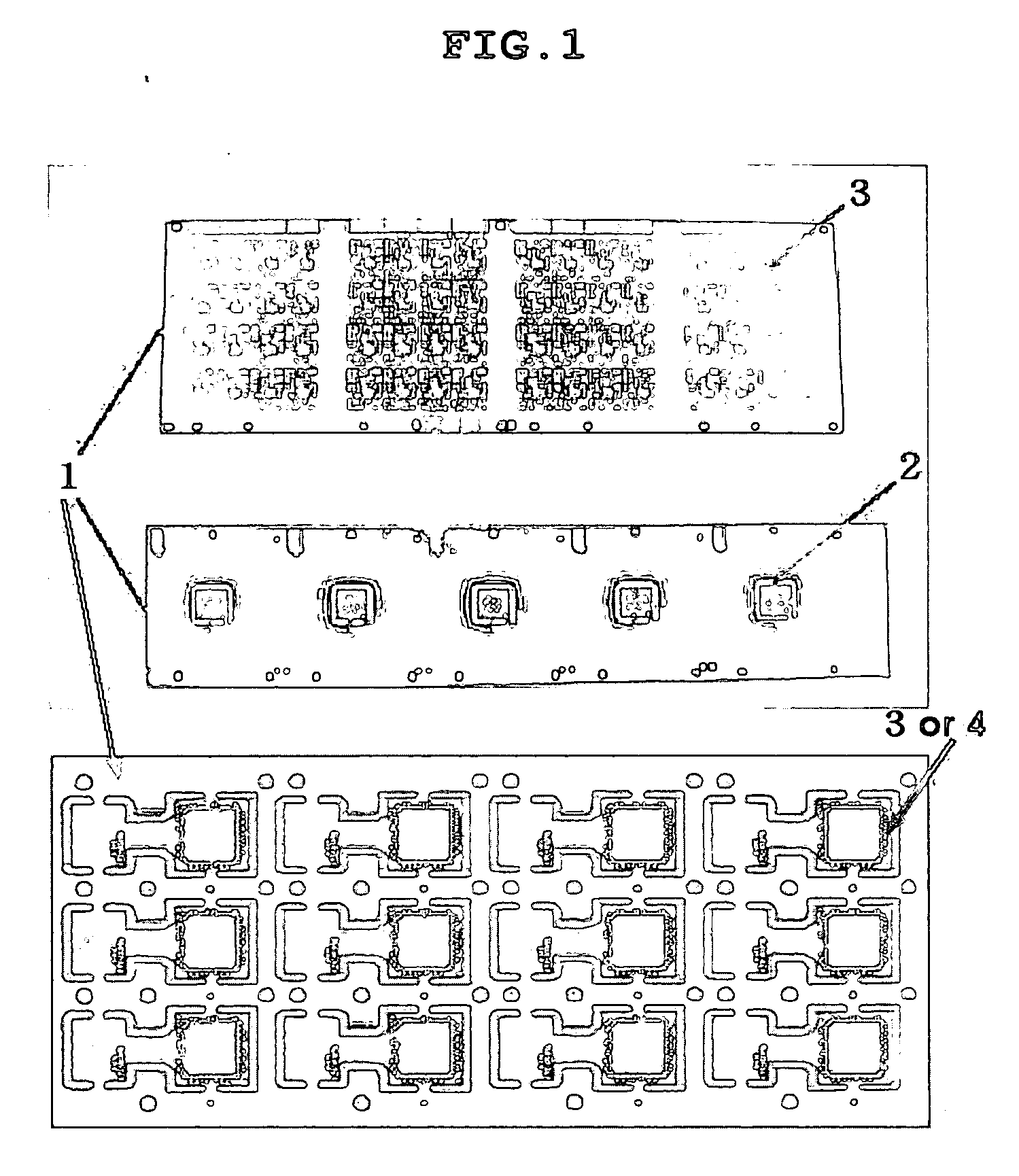

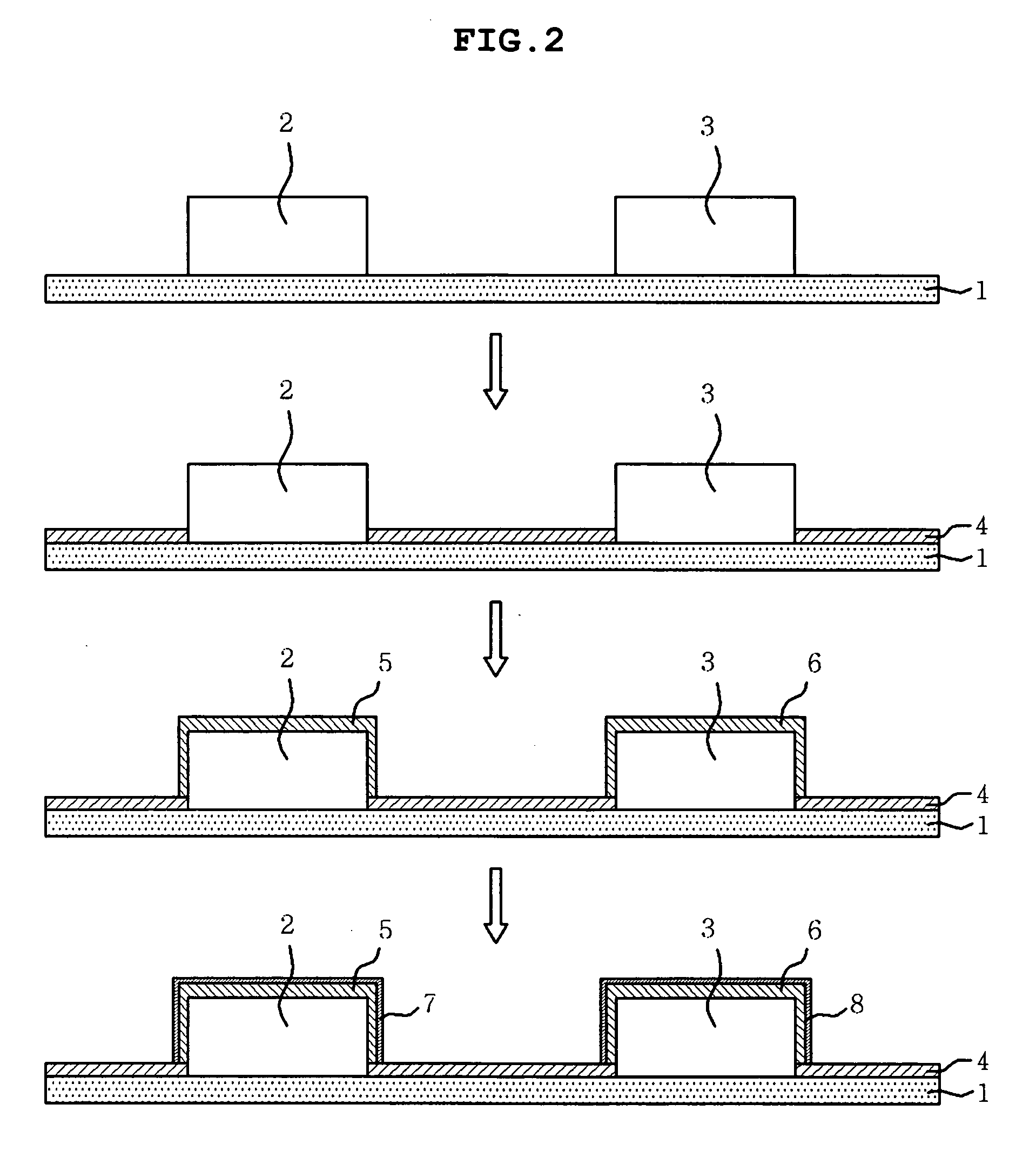

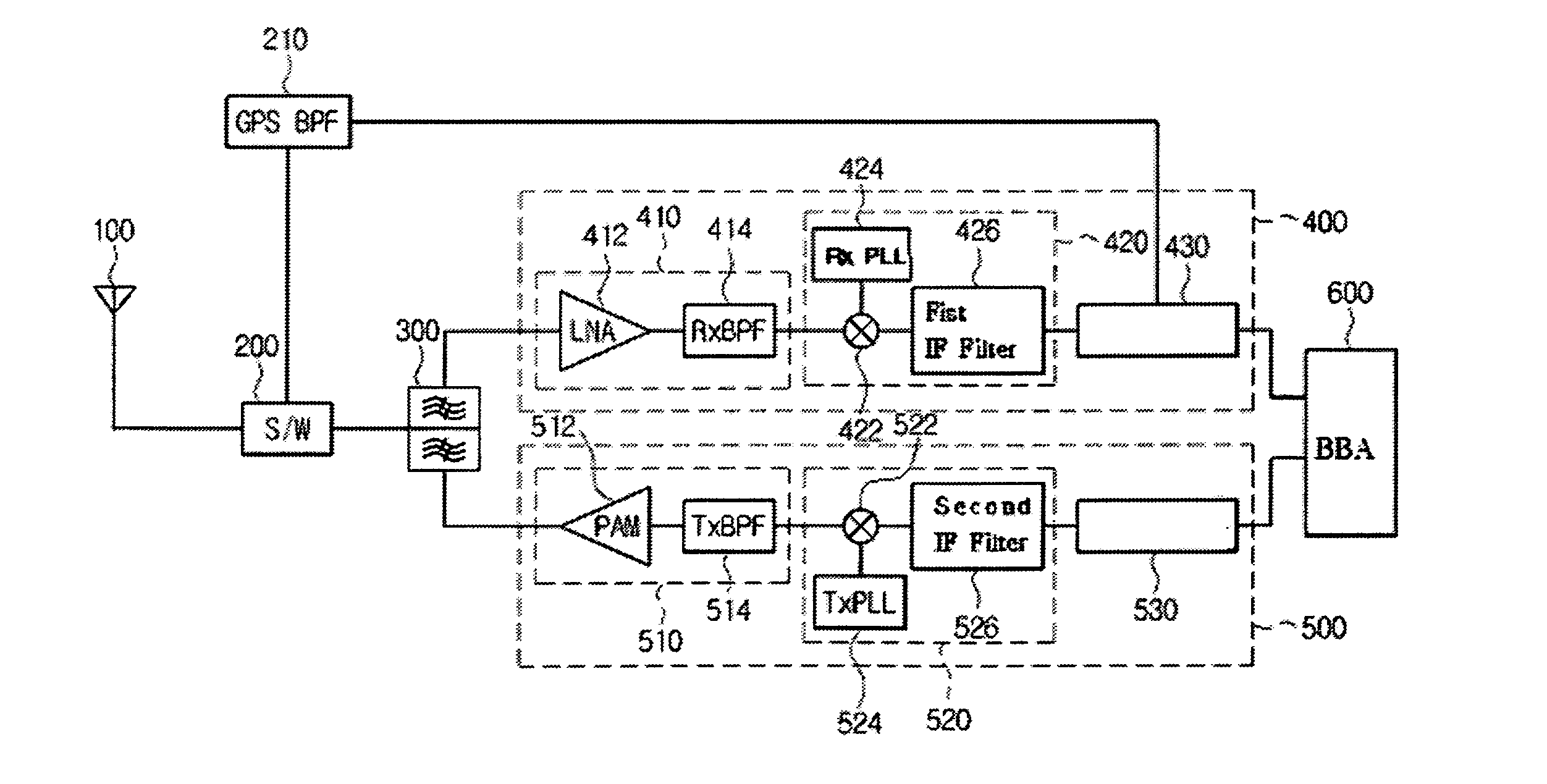

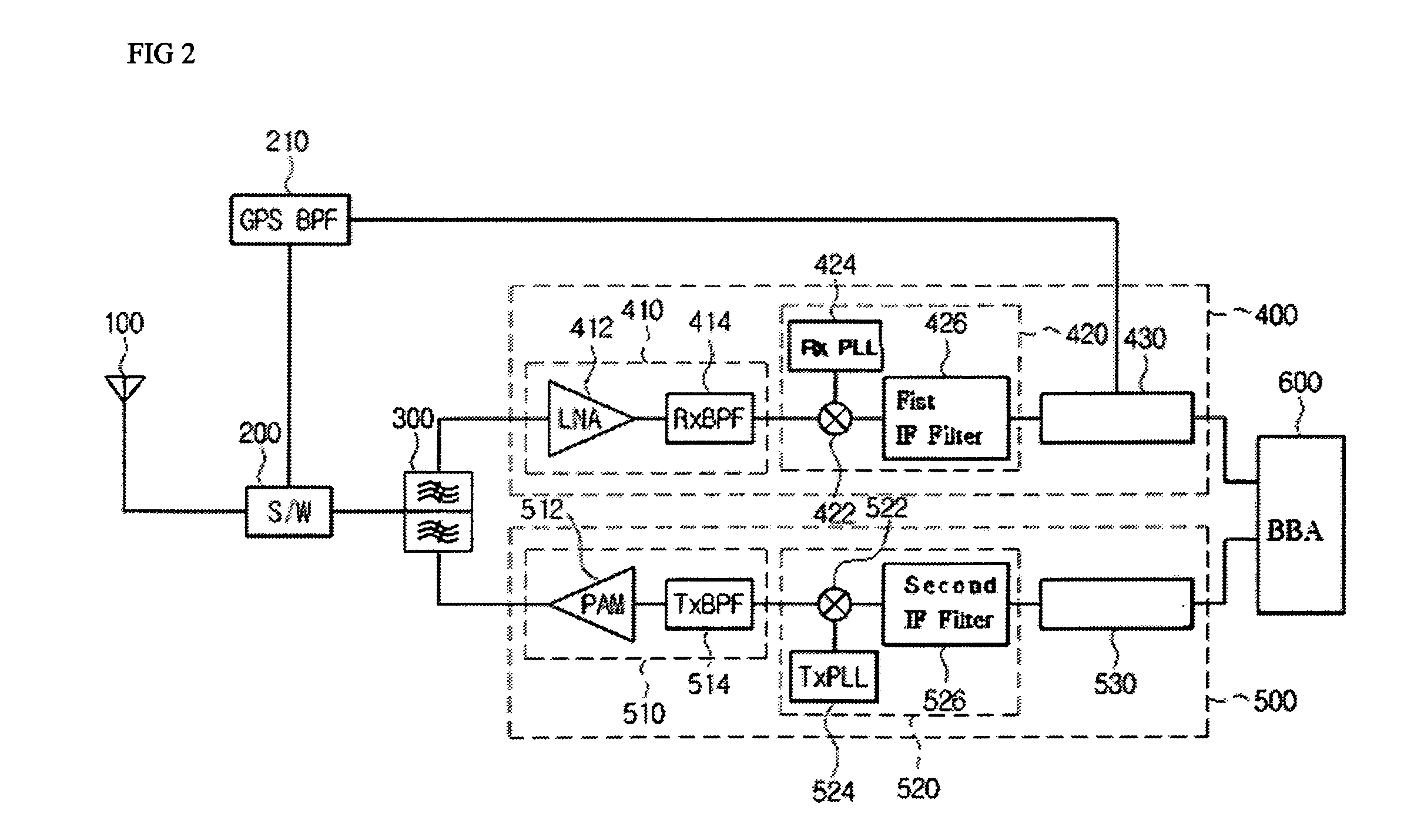

Front end module

ActiveUS20070058748A1Efficient arrangementMade smallModulated-carrier systemsSolid-state devicesEngineeringGround pattern

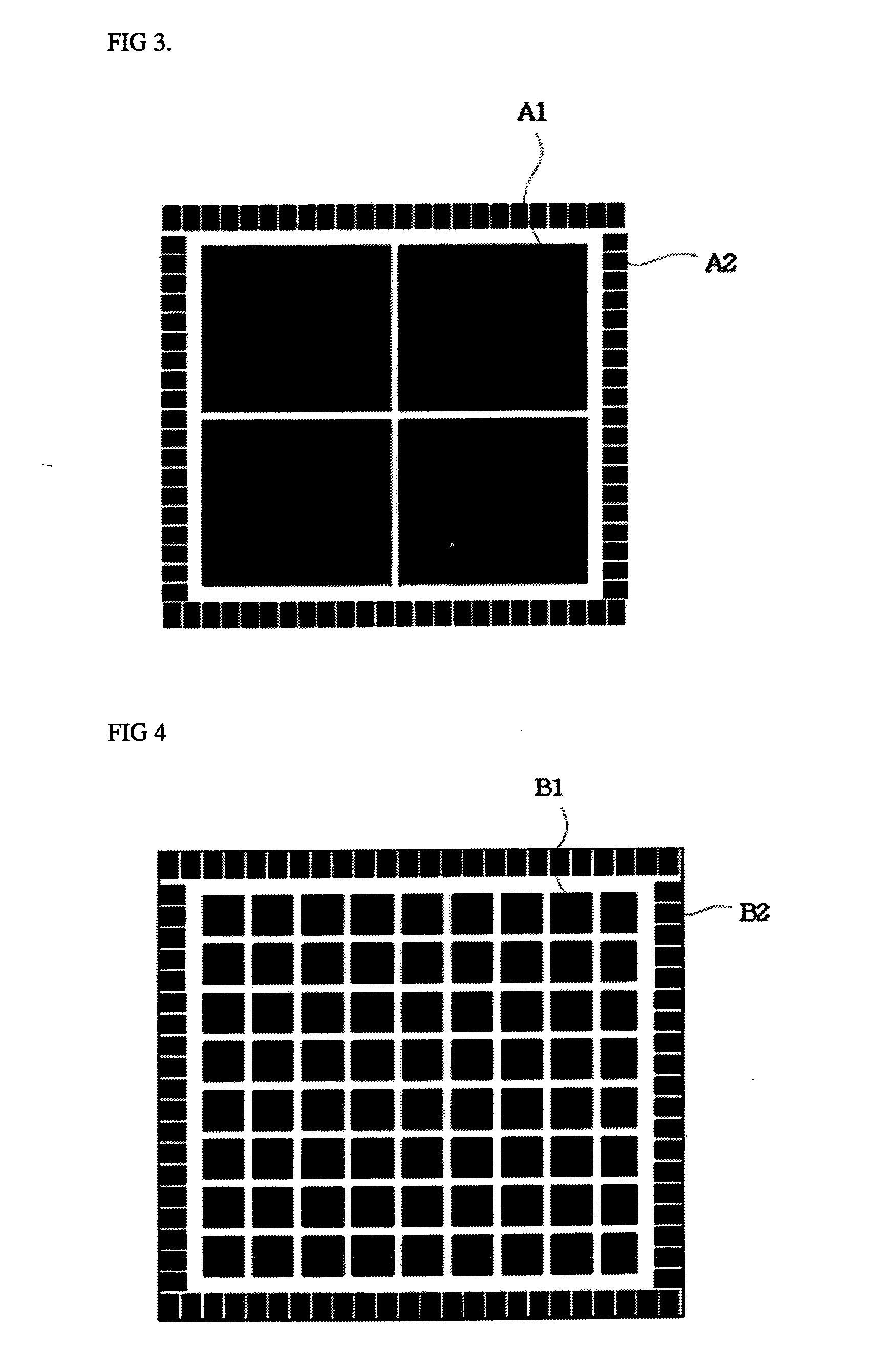

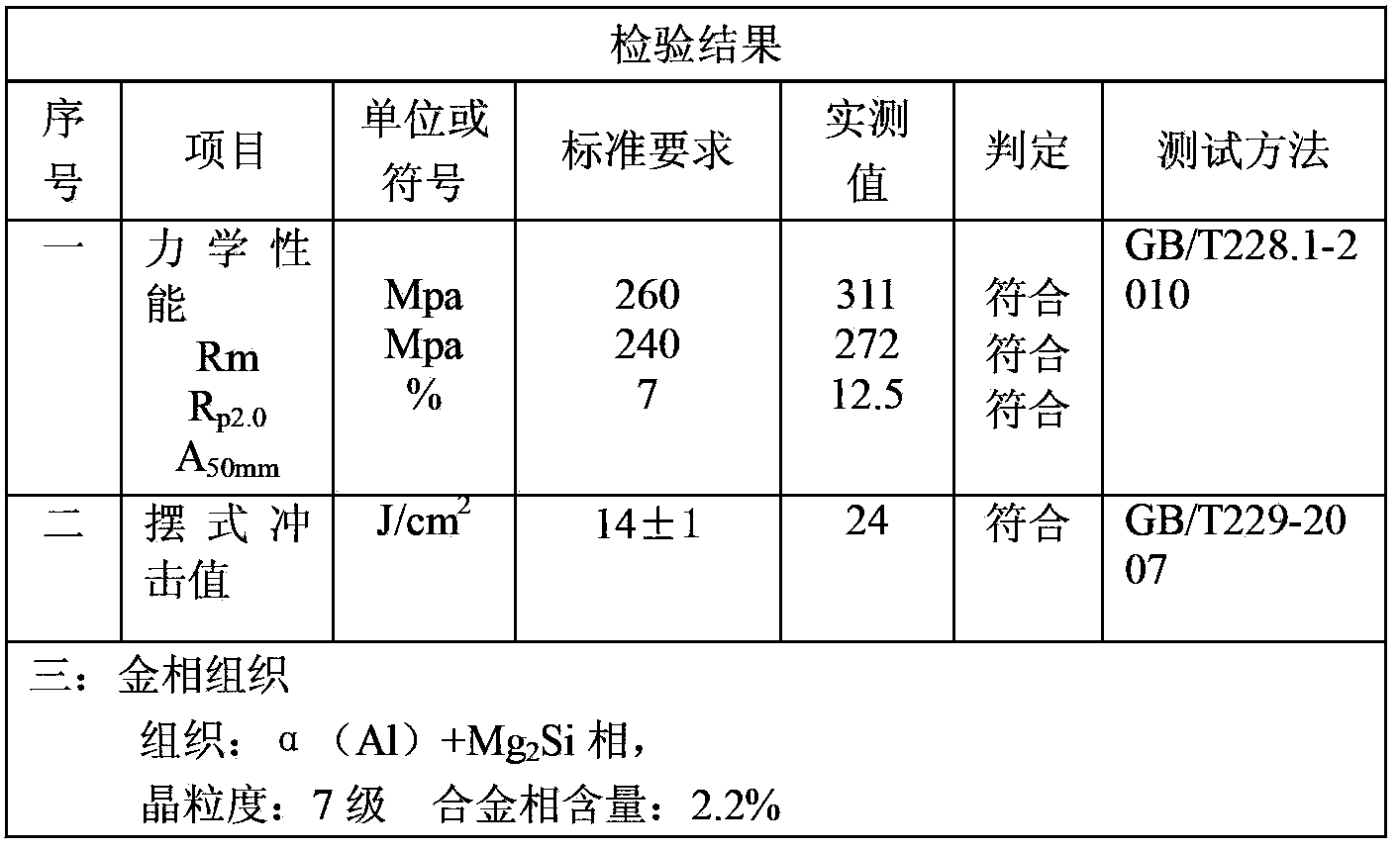

A front end module having a multilayered structure is provided. The front end module includes a transmitter, a receiver, and a duplex unit. A ground layer is provided with an ground pattern having a plurality of separated blocks on a surface of a substrate of the front end module.

Owner:LG INNOTEK CO LTD

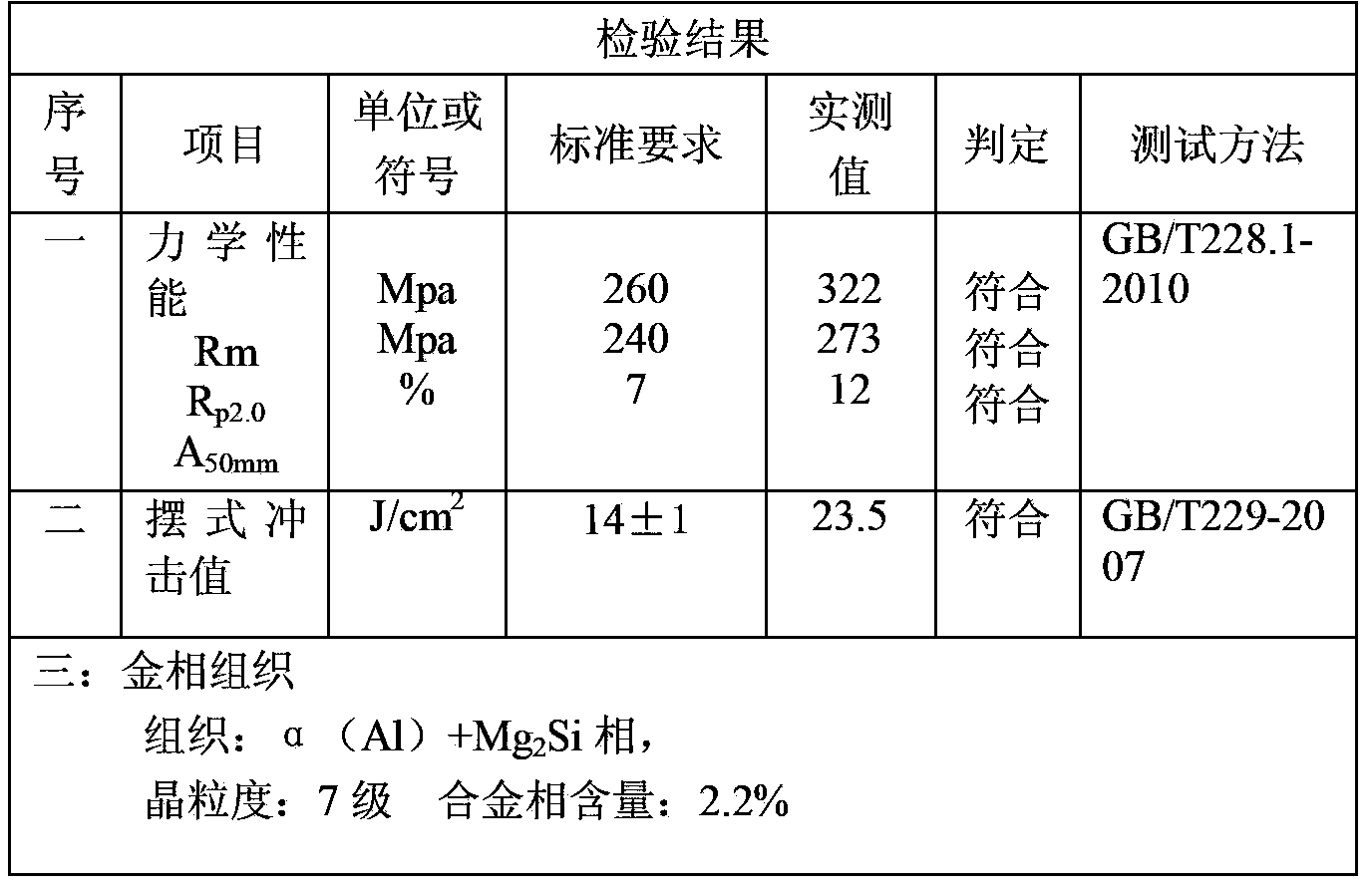

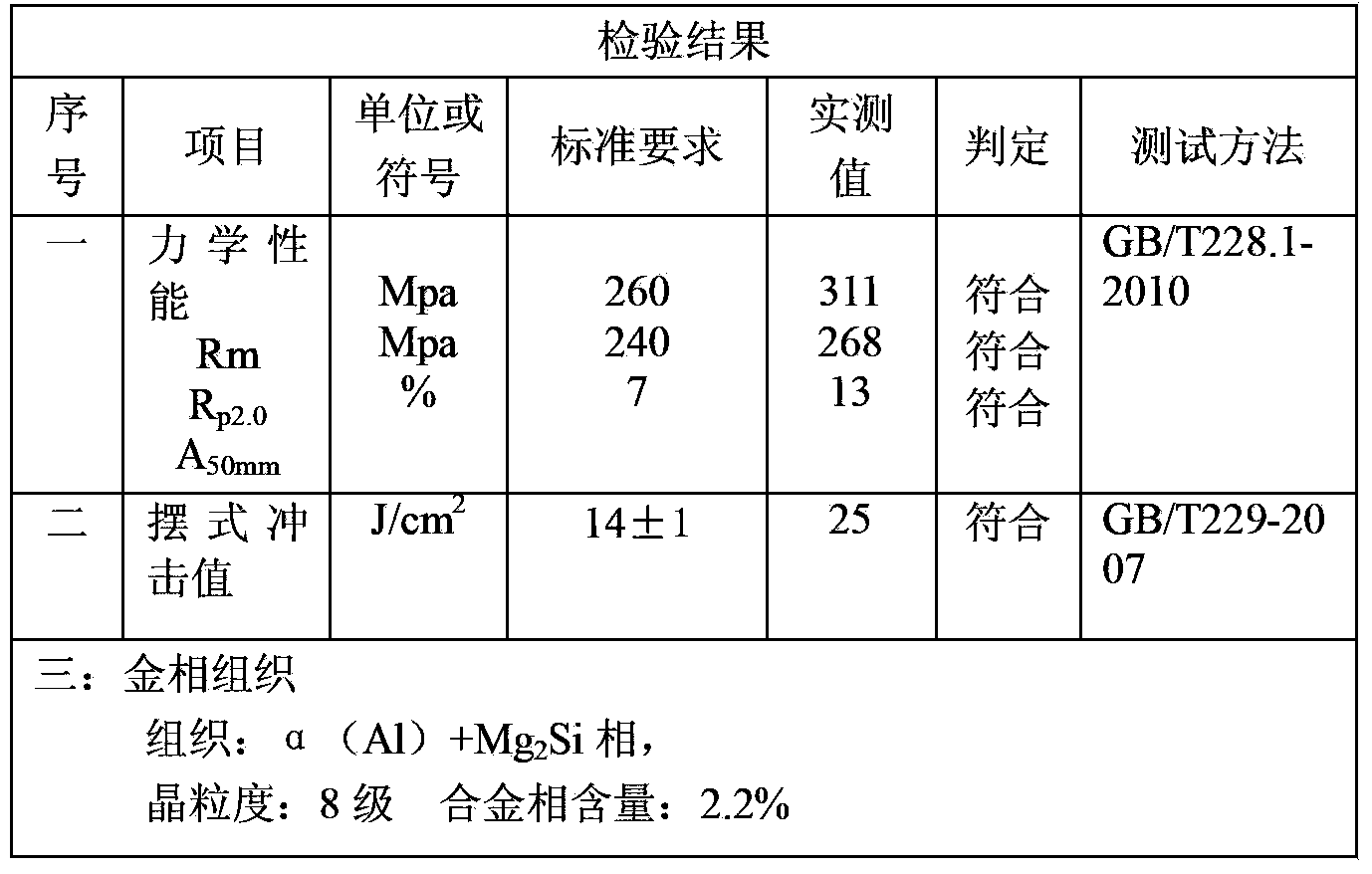

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

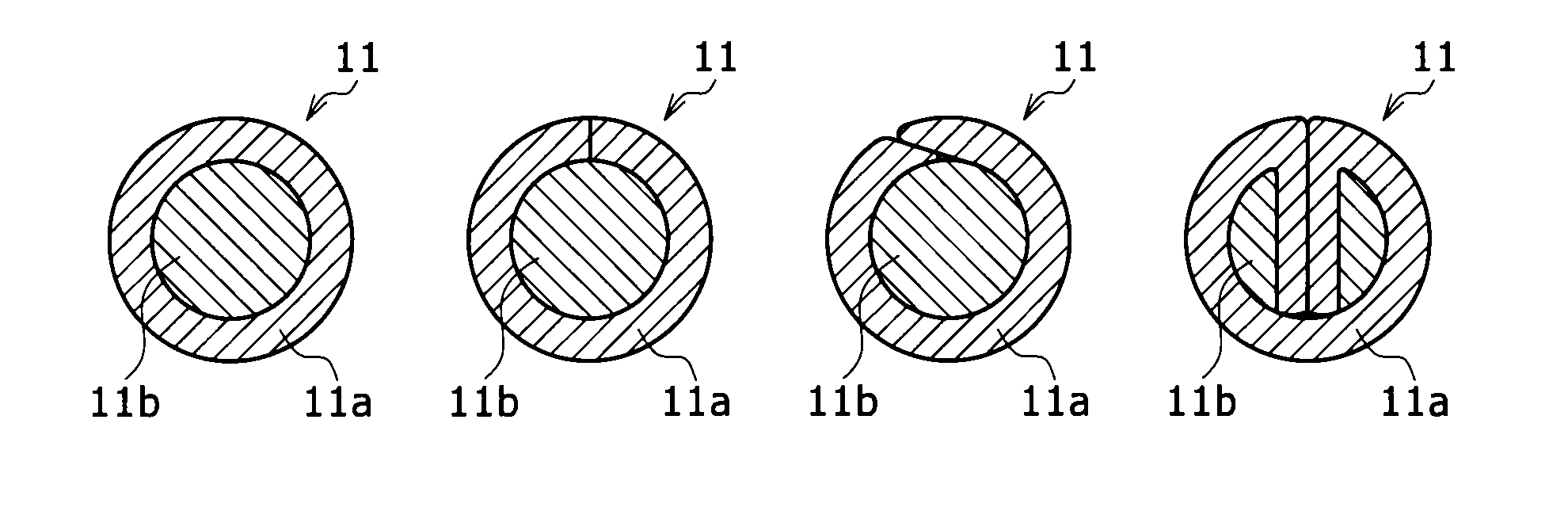

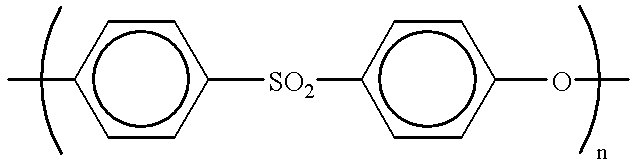

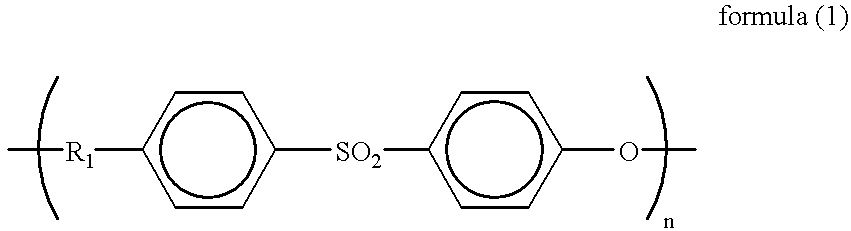

Multilayer insulated wire and transformers made by using the same

InactiveUS6329055B1Good effectLowered in electric propertyPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolymer sciencePolyetherimide

There is disclosed a multilayer insulated wire which comprises a conductor and solderable extrusion-insulating layers made up of two or more layers for covering the conductor, wherein at least one insulating layer is formed by a mixture comprising 100 parts by weight of a resin (A), of at least one selected from the group consisting of polyetherimide resins and polyethersulfone resins, 10 parts by weight or more of a resin (B), of at least one selected from the group consisting of polycarbonate resins, polyarylate resins, polyester resins, and polyamide resin, and 15 to 200 parts by weight of an inorganic filler (C). There is also disclosed a transformer which utilizes the multilayer insulted wire. The multilayer insulated wire is excellent in heat resistance, solderability, high-frequency characteristic, and coilability, and it is favorably suitable for industrial production. Further, the transformer utilizing the multilayer insulated wire is excellent in electrical properties and high in reliability, since when used at high frequencies, electric properties are not lowered and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

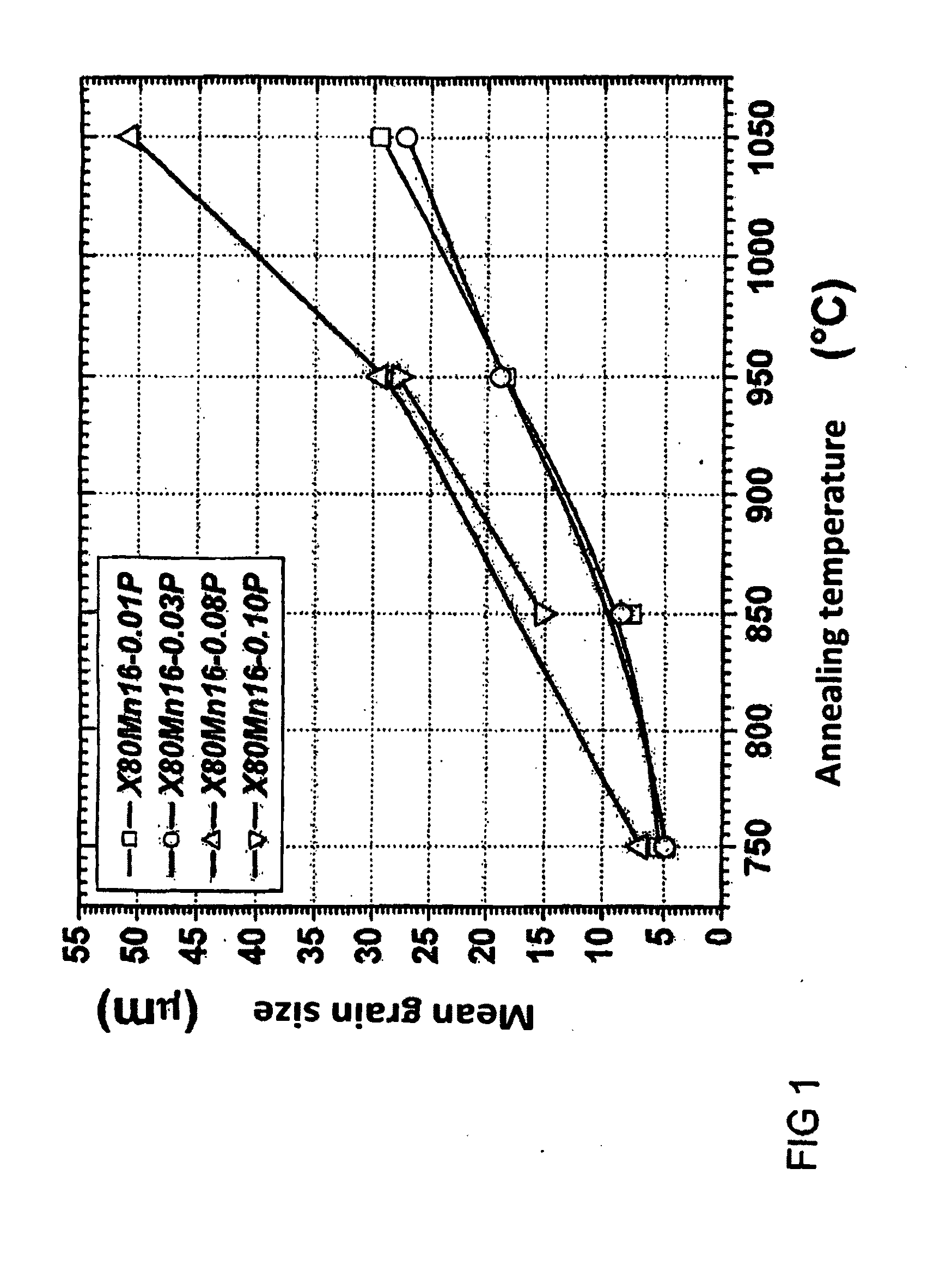

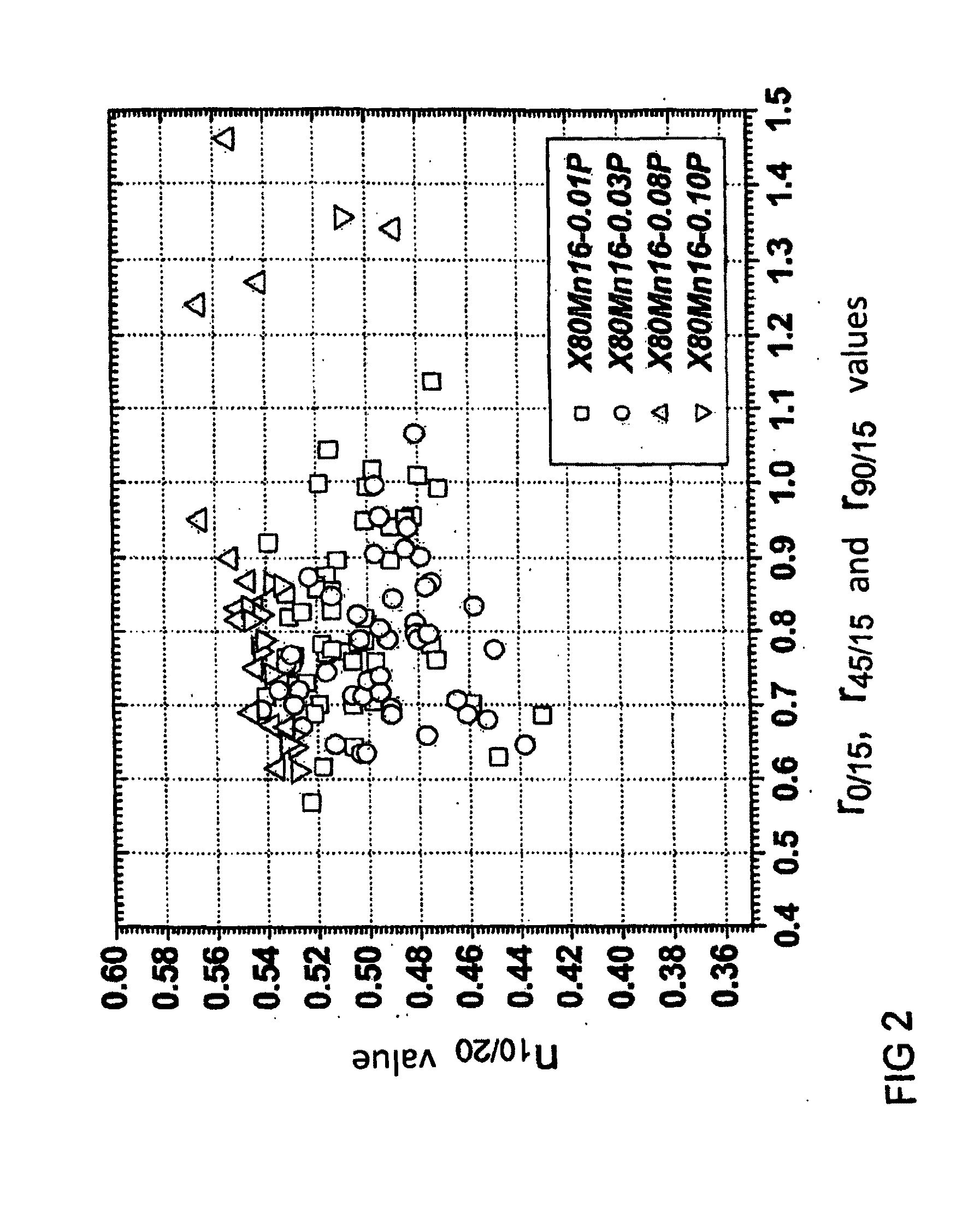

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

Seawate-corrosive-resisting steel and its production

Seawater-corrosion-resisting steel consists of C 0.04-0.10wt%, Si 0.40-0.50wt%, Mn 0.75-1.30wt%, Nb<=0.020wt%, Ti<=0.025wt%, Al 0.015-0.040wt%, Cu 0.20-0.50wt%, Cr<=0.95wt%, Mo<=0.25wt%, Ca 0.0015-0.0040wt%, P<=0.020wt%, S<=0.005wt%, O<=0.0040wt%, N<=0.0060wt%, H<=0.00025wt%, F and impurities residues. It has excellent mechanical and welding performances and corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

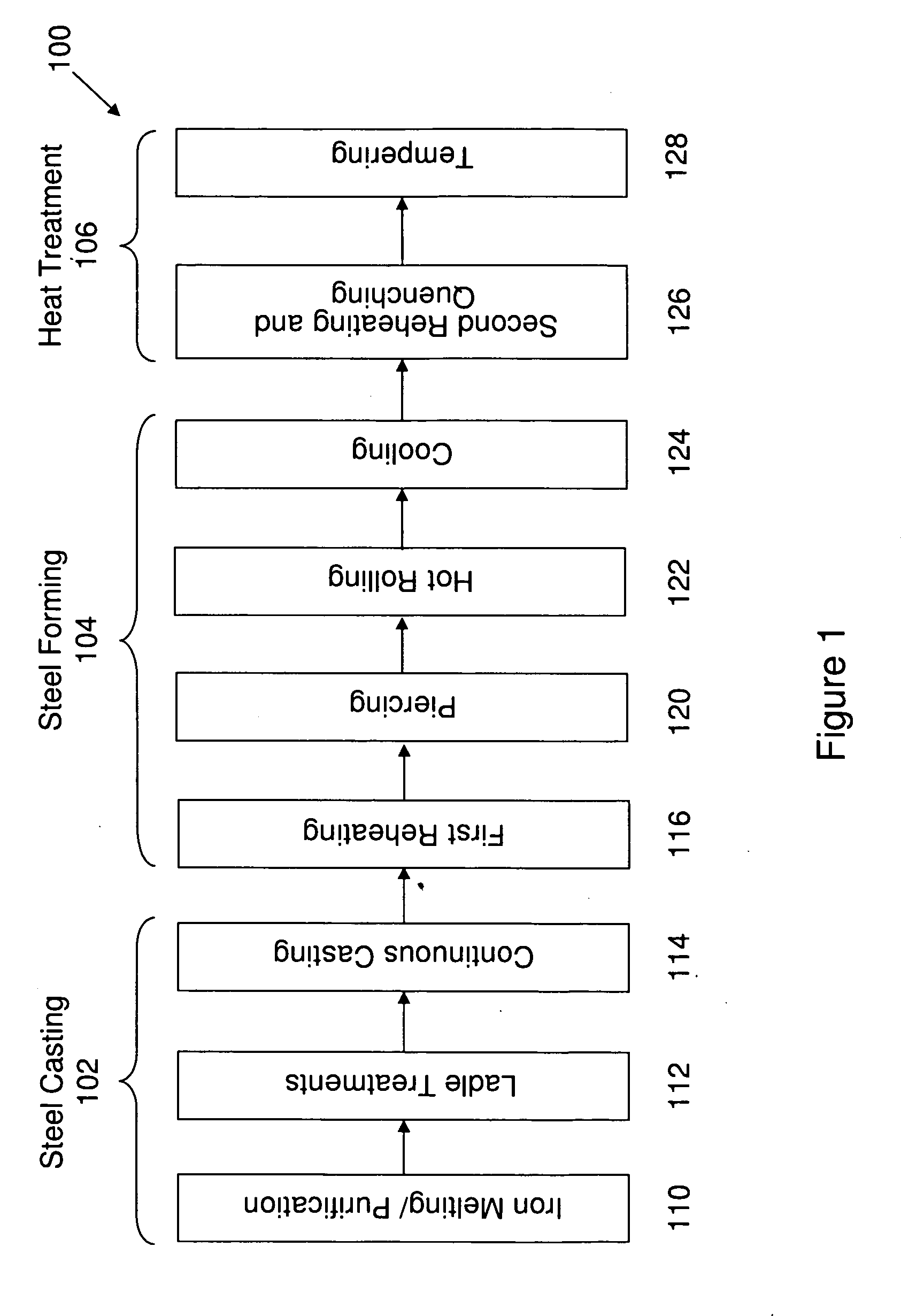

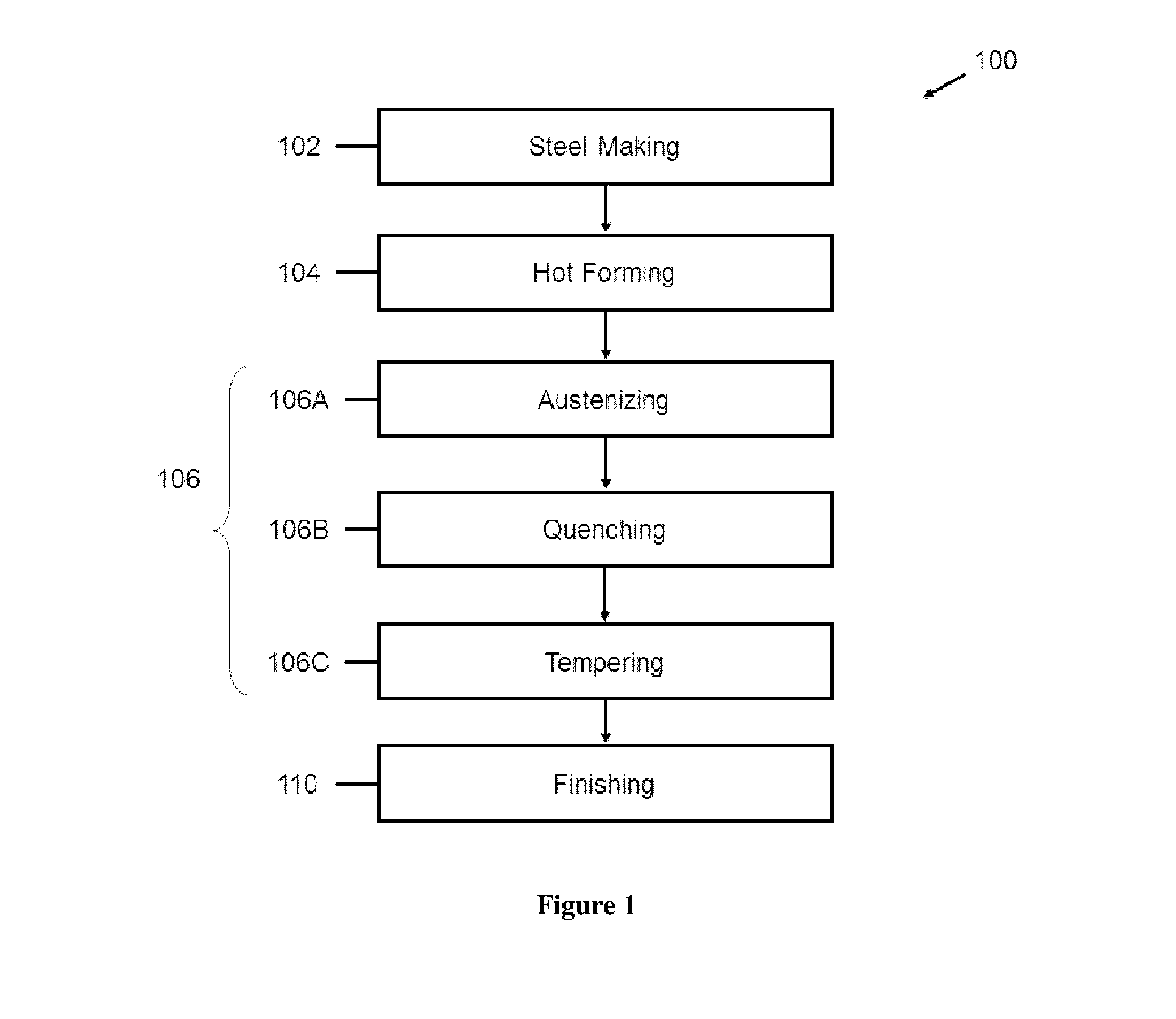

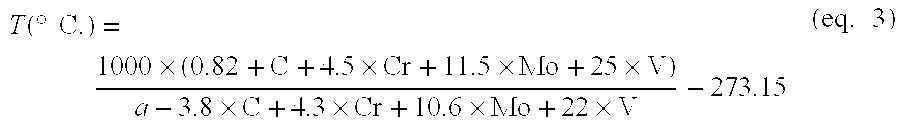

High strength medium wall quenched and tempered seamless steel pipes and related method for manufacturing said steel pipes

ActiveUS20140299236A1Good low temperatureImprove solderabilityFurnace typesHeat treatment process controlSteel tubeChemical composition

Disclosed herein are embodiments of a seamless quenched and tempered steel pipe which can have a wall thickness WT higher than or equal to 6 mm and lower than or equal to 35 mm. Some embodiments of the steel pipe can have a chemical composition comprising C, Mn, Si, Cr, Ni, Mo, Al, N, Ca, Nb, Ti, V, Zr, and Ta based on the composition weight, the remaining being iron and impurities. In some embodiments, wherein (V+Nb) content is lower than 0.07 wt %; defining a first parameter P1=(60×C)+Cr+[5×e(35×Mo / WT)]+50×(V+Nb), the chemical composition satisfies a first condition P1≦14.5.

Owner:DALMINE SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com