Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Meet welding process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

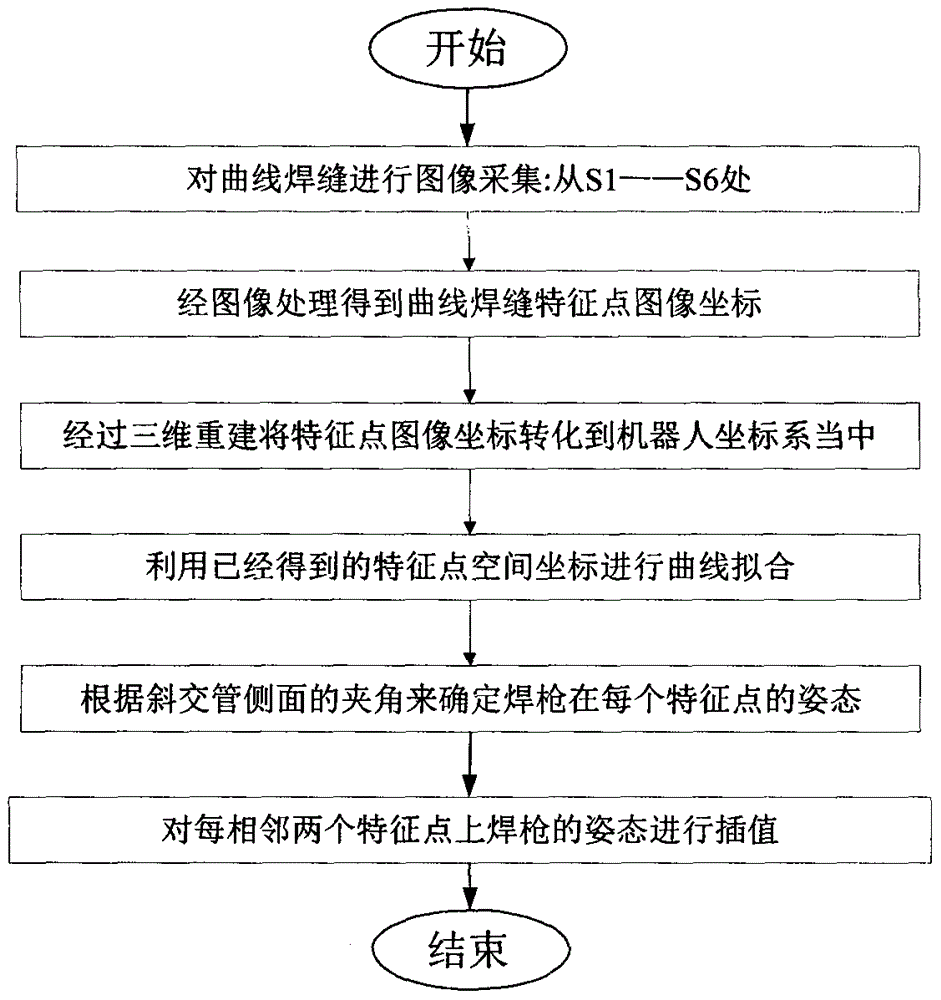

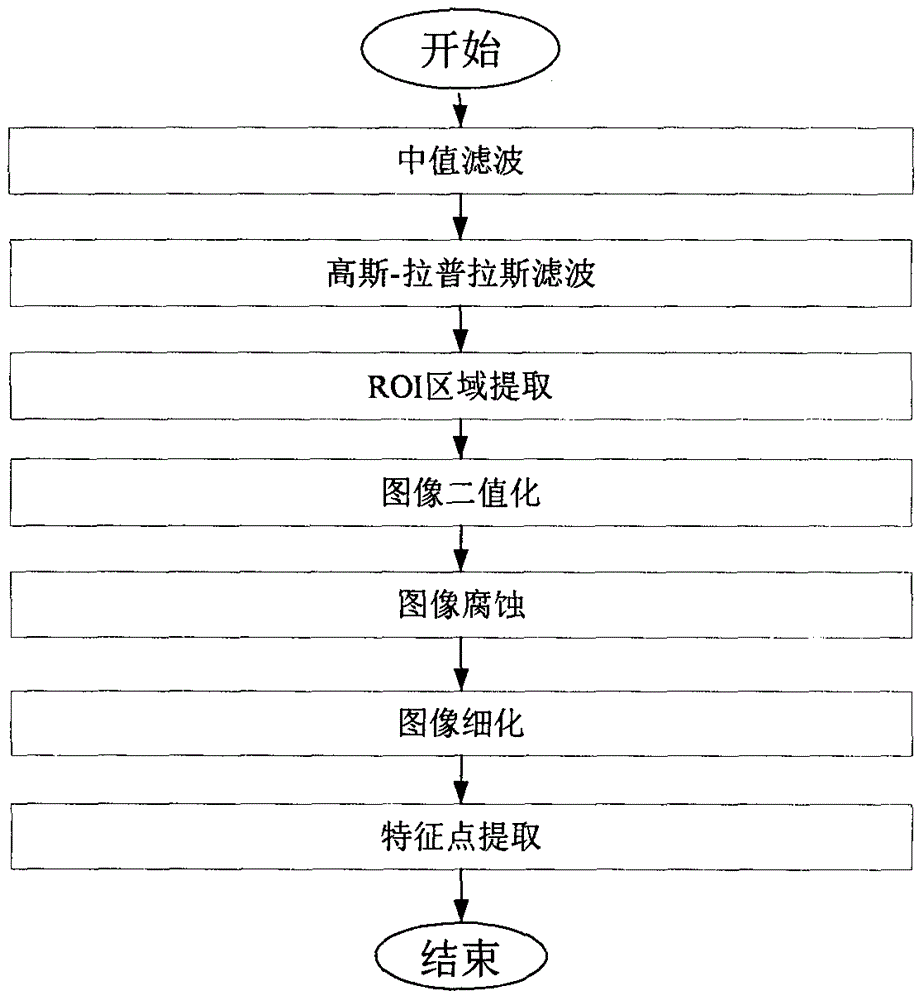

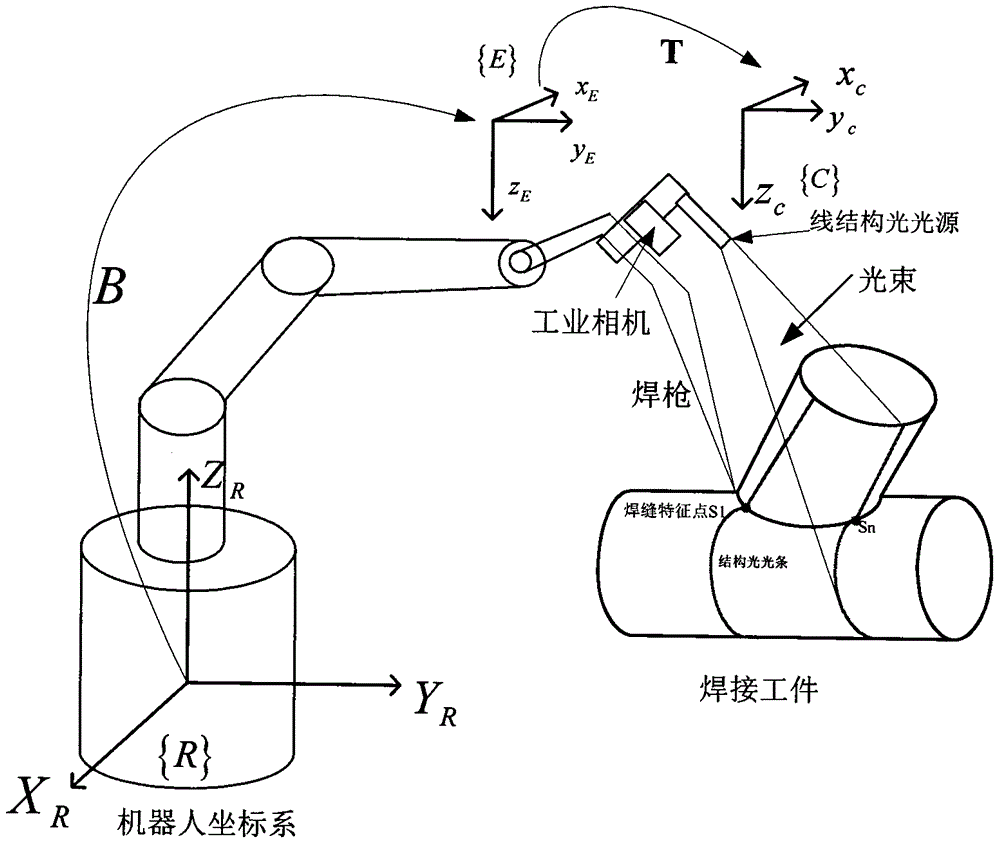

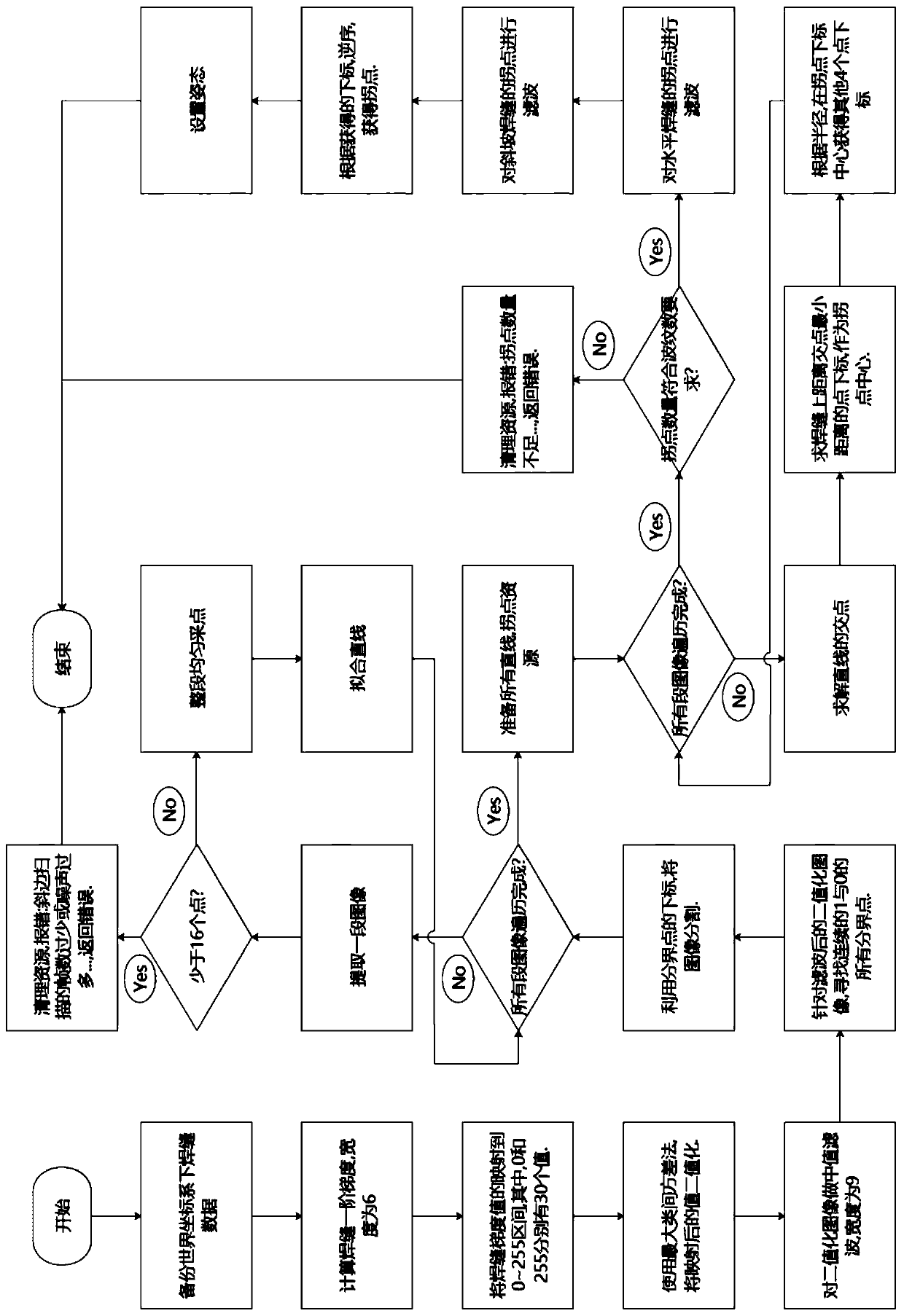

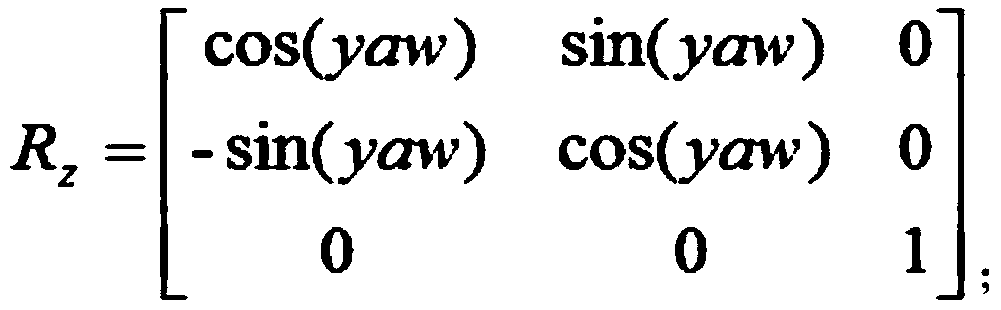

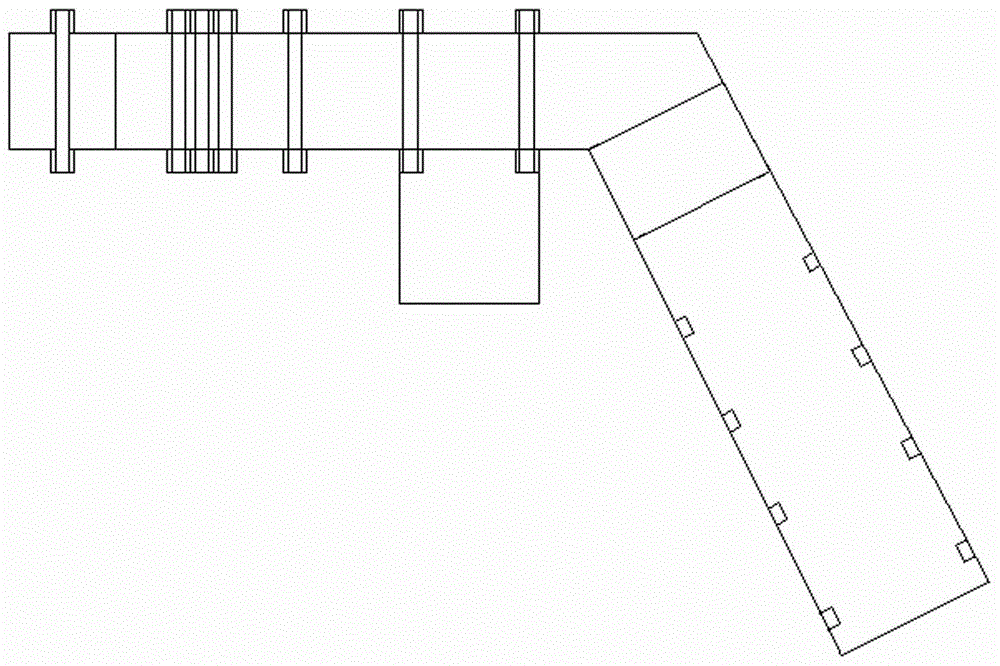

Curve welding seam welding technology based on line structured light

InactiveCN106425181AAchieving identifiabilityAchieve weldingWelding/cutting auxillary devicesAuxillary welding devicesTracking modelEngineering

The invention discloses a curve welding seam welding technology based on line structured light and oriented to an oblique crossed tube. According to the method, machine version and robot kinematics are combined very well, so that the problems that the process of obtaining curve welding seam feature points is not flexible, and a curve track model are difficult to establish are solved. The curve welding seam welding technology comprises the following steps of: firstly, controlling a six-degree-of-freedom robot, enabling a robot end to drive an industrial camera to shoot a curve welding seam image with the line structured light; and then, carrying out a series of image pre-treatment and feature point extraction work to obtain space coordinates of all feature points of a curve welding seam, and fitting through a B sample curve, and finally obtaining a smooth space curve. Besides, the gesture of a welding gun can be changed in real time according to included angles at the two sides of a workpiece when the welding gun is used for welding a curve, so that the welding process and welding requirements are improved better.

Owner:NANJING UNIV OF TECH

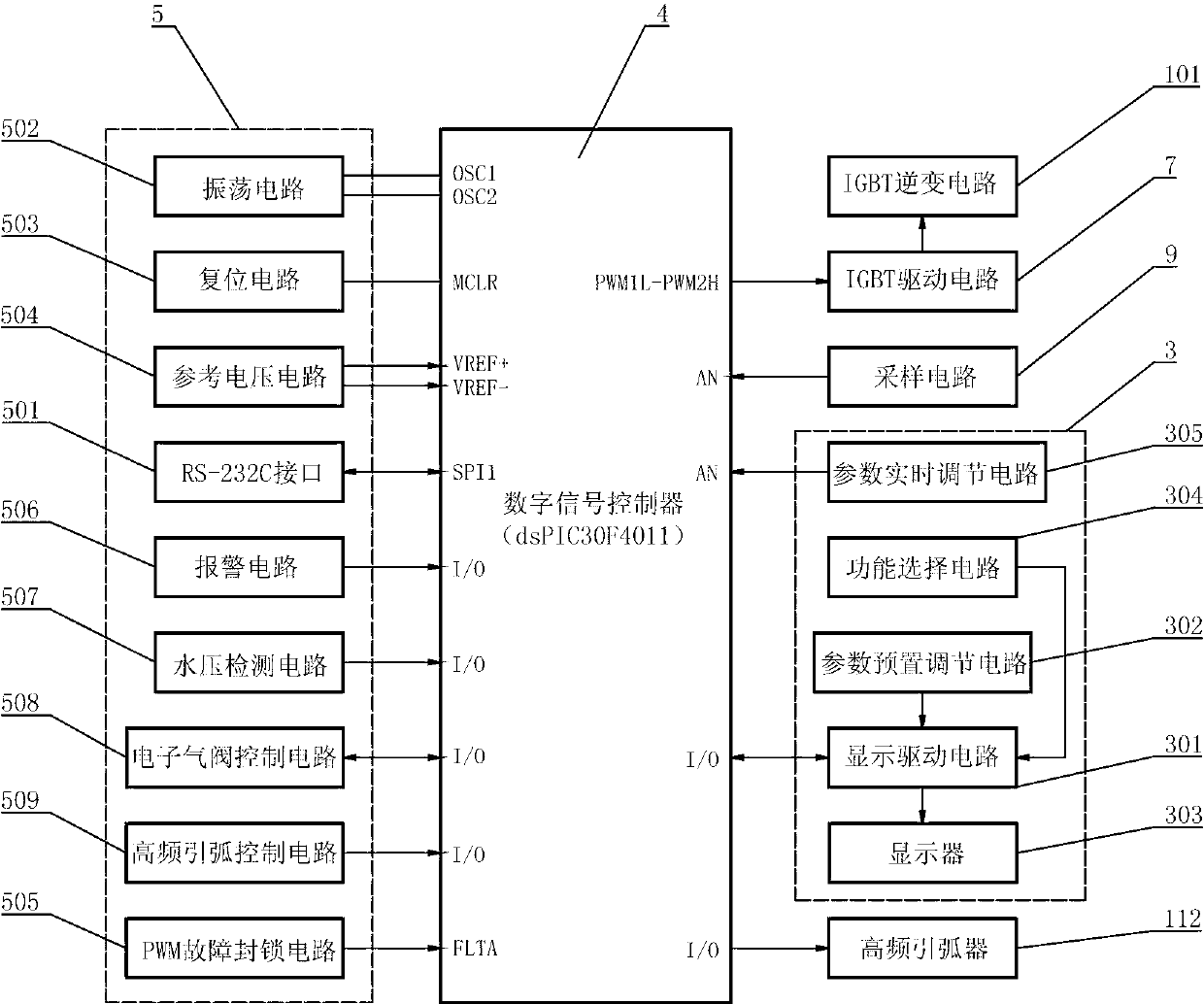

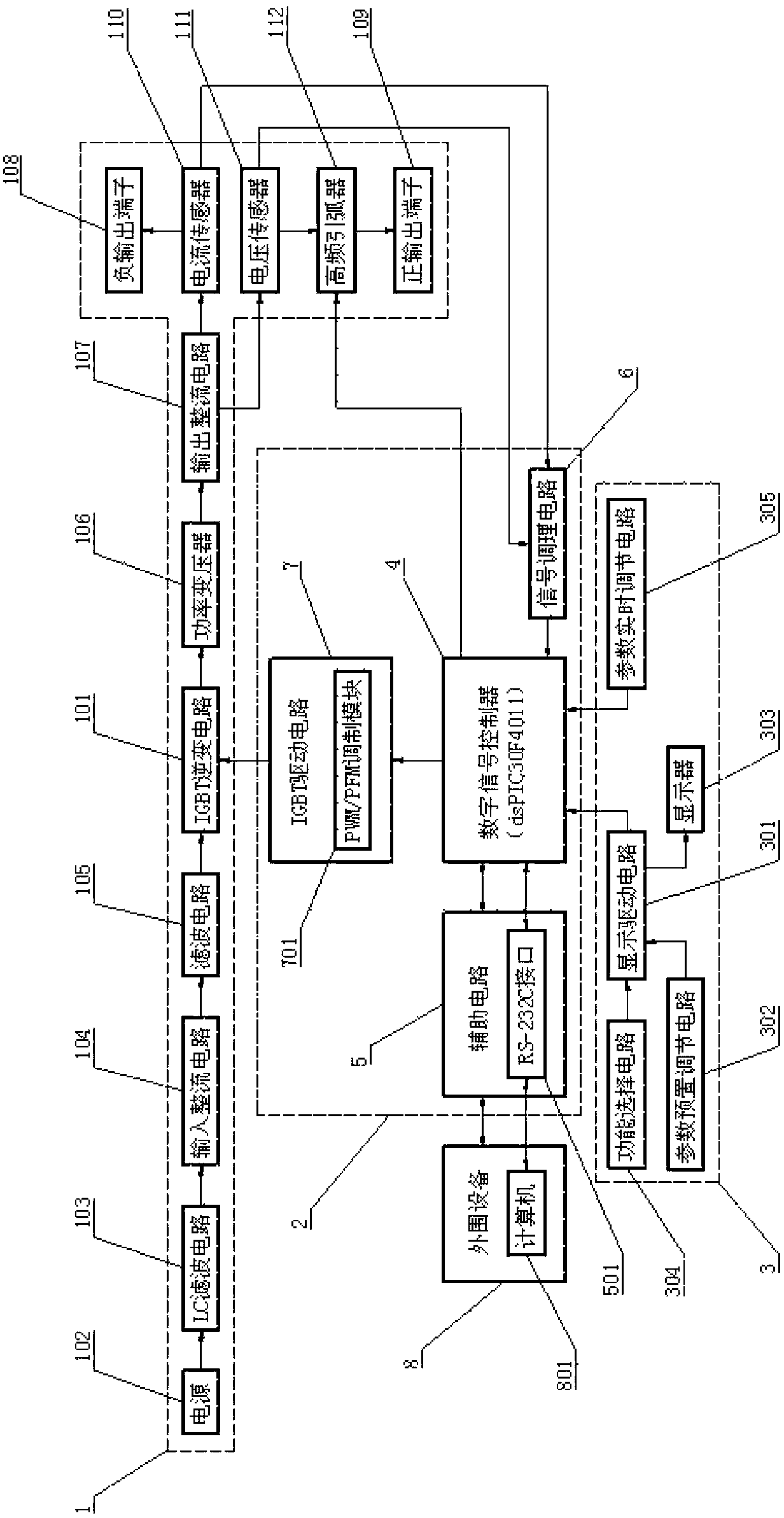

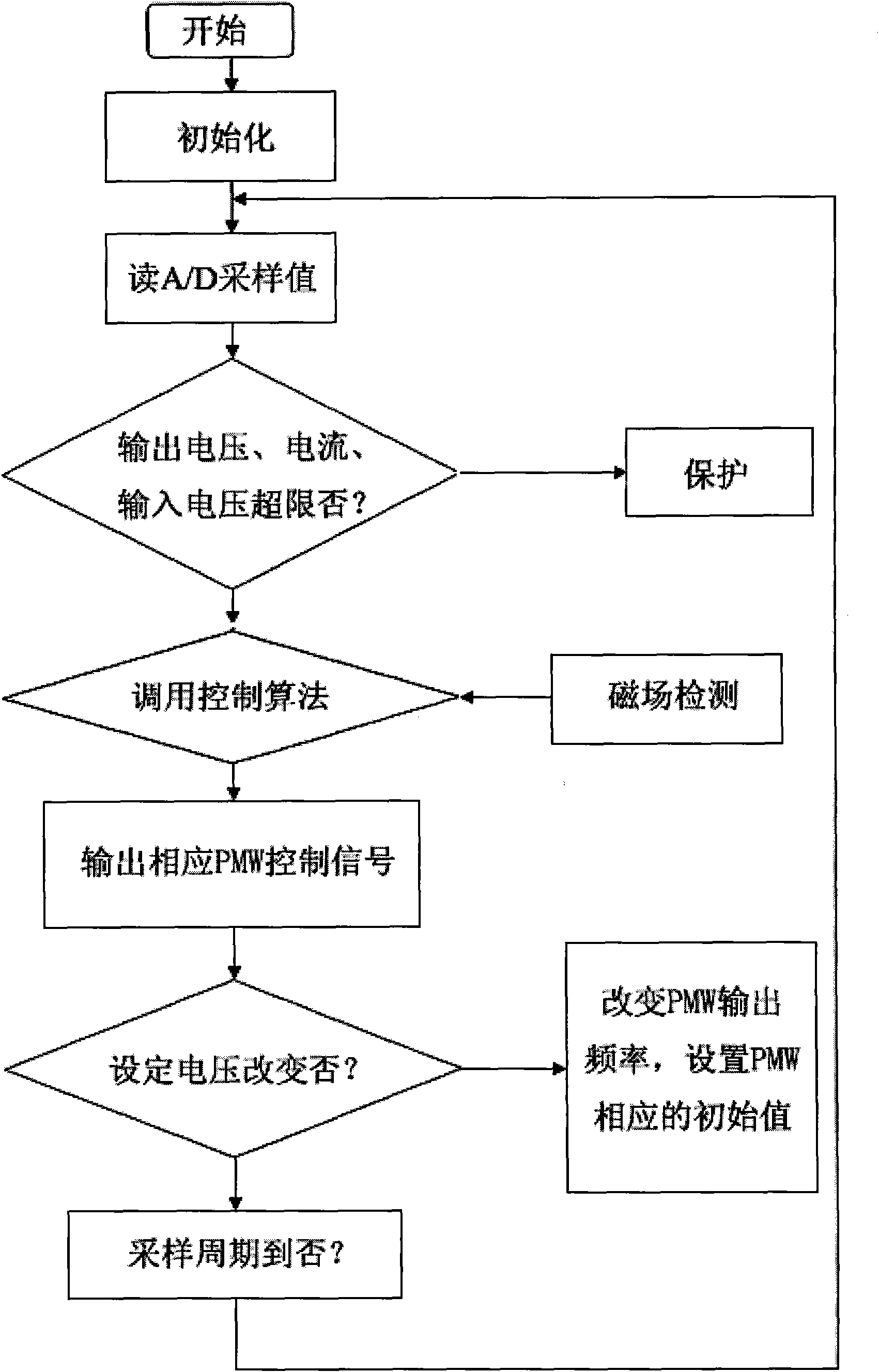

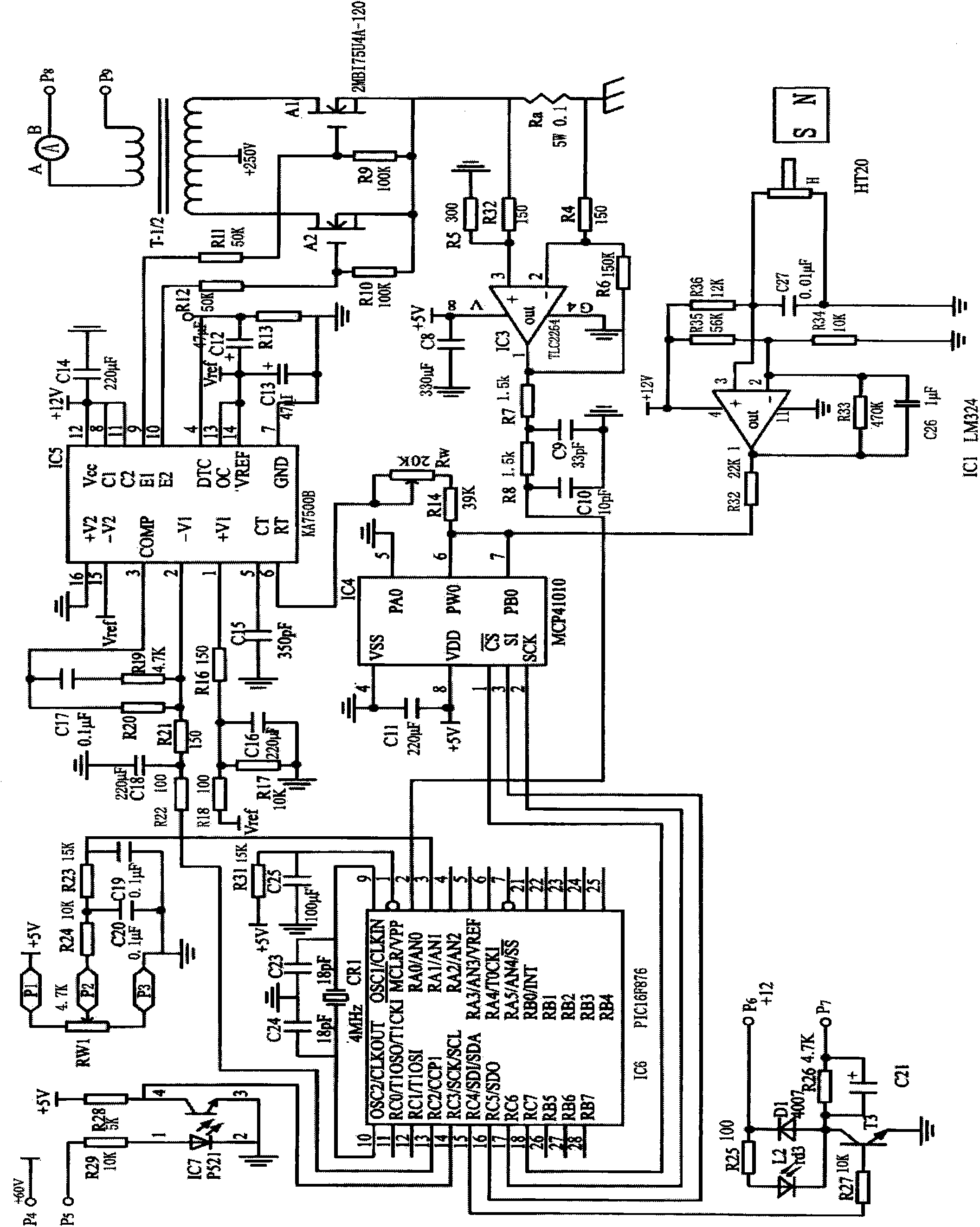

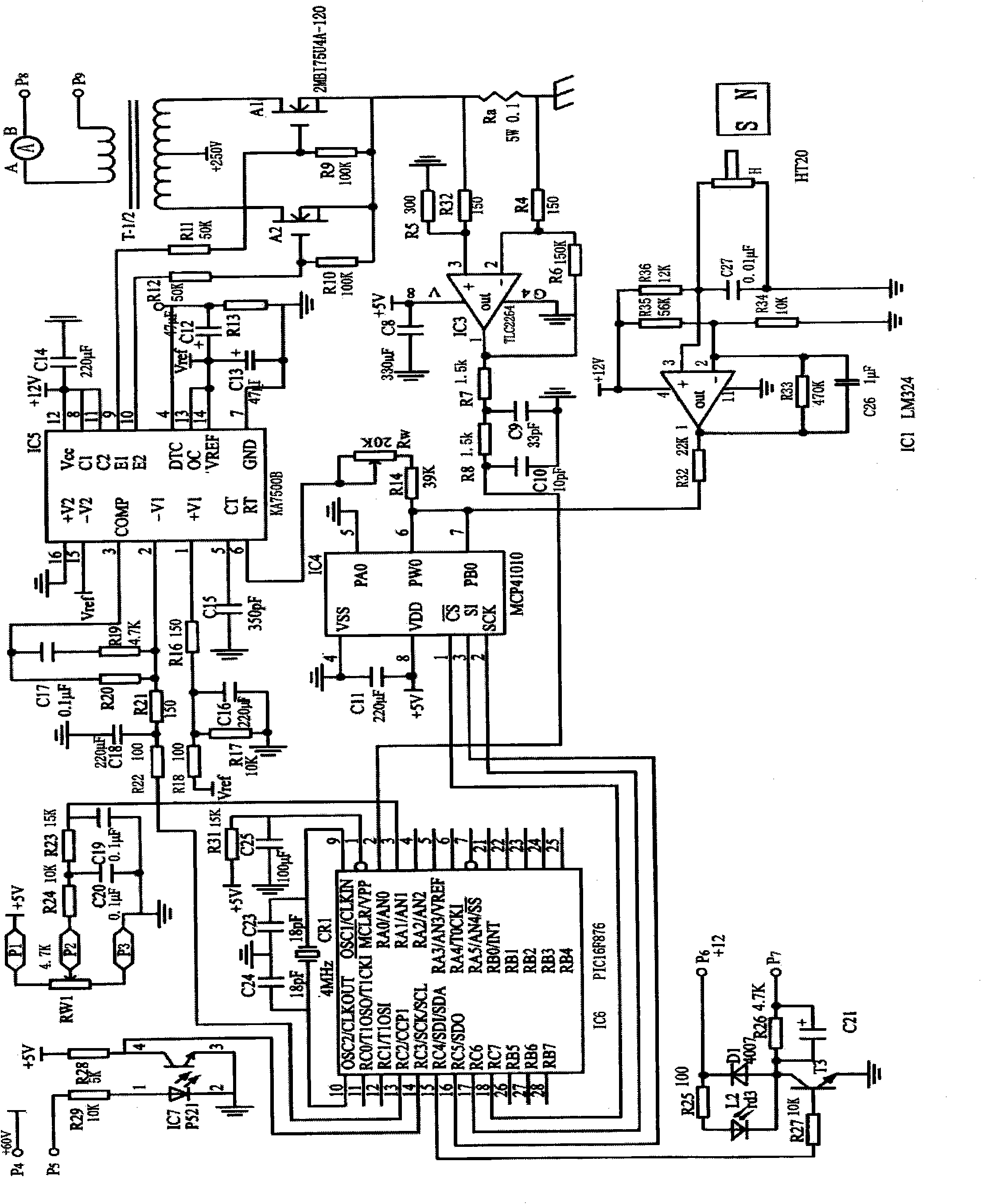

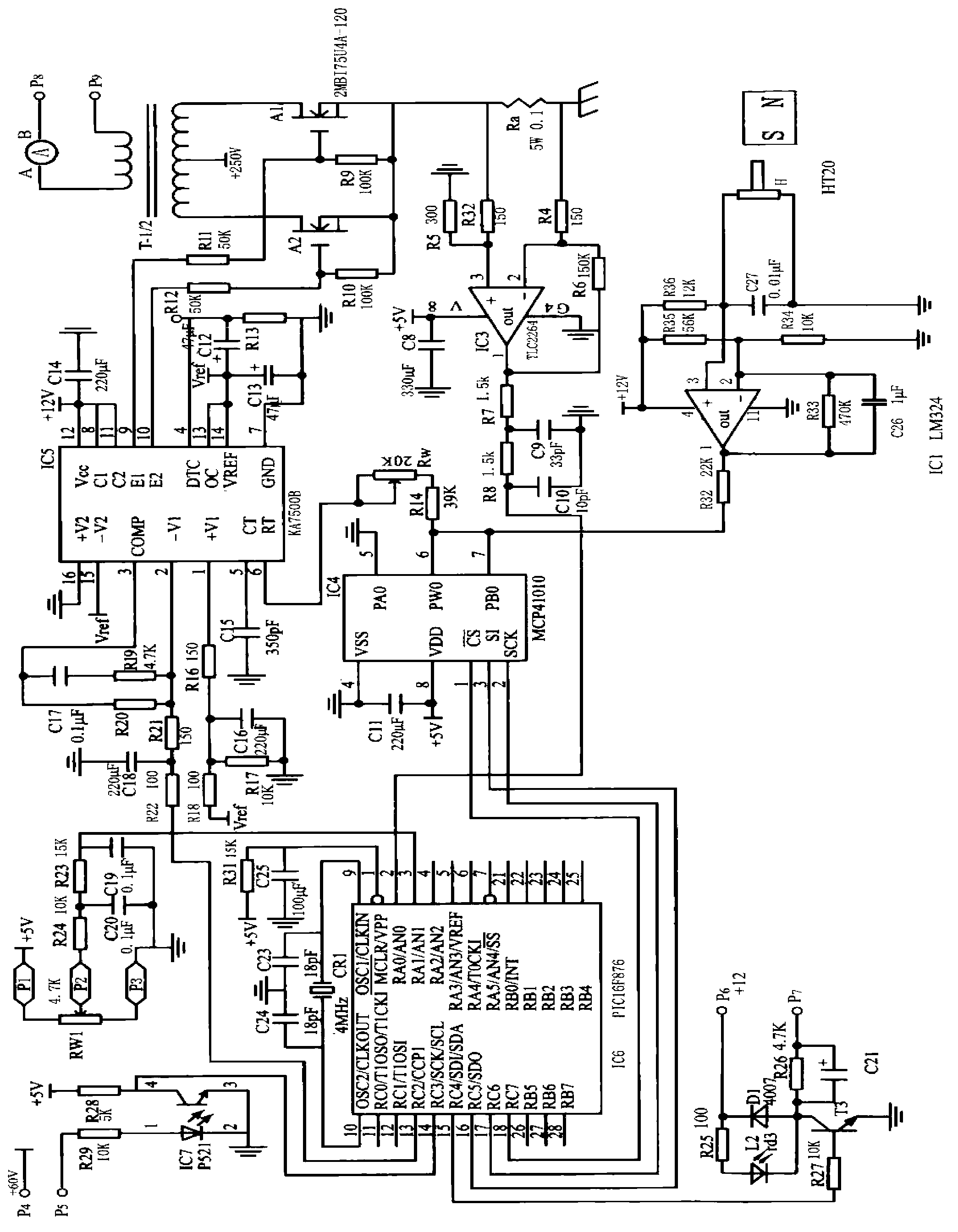

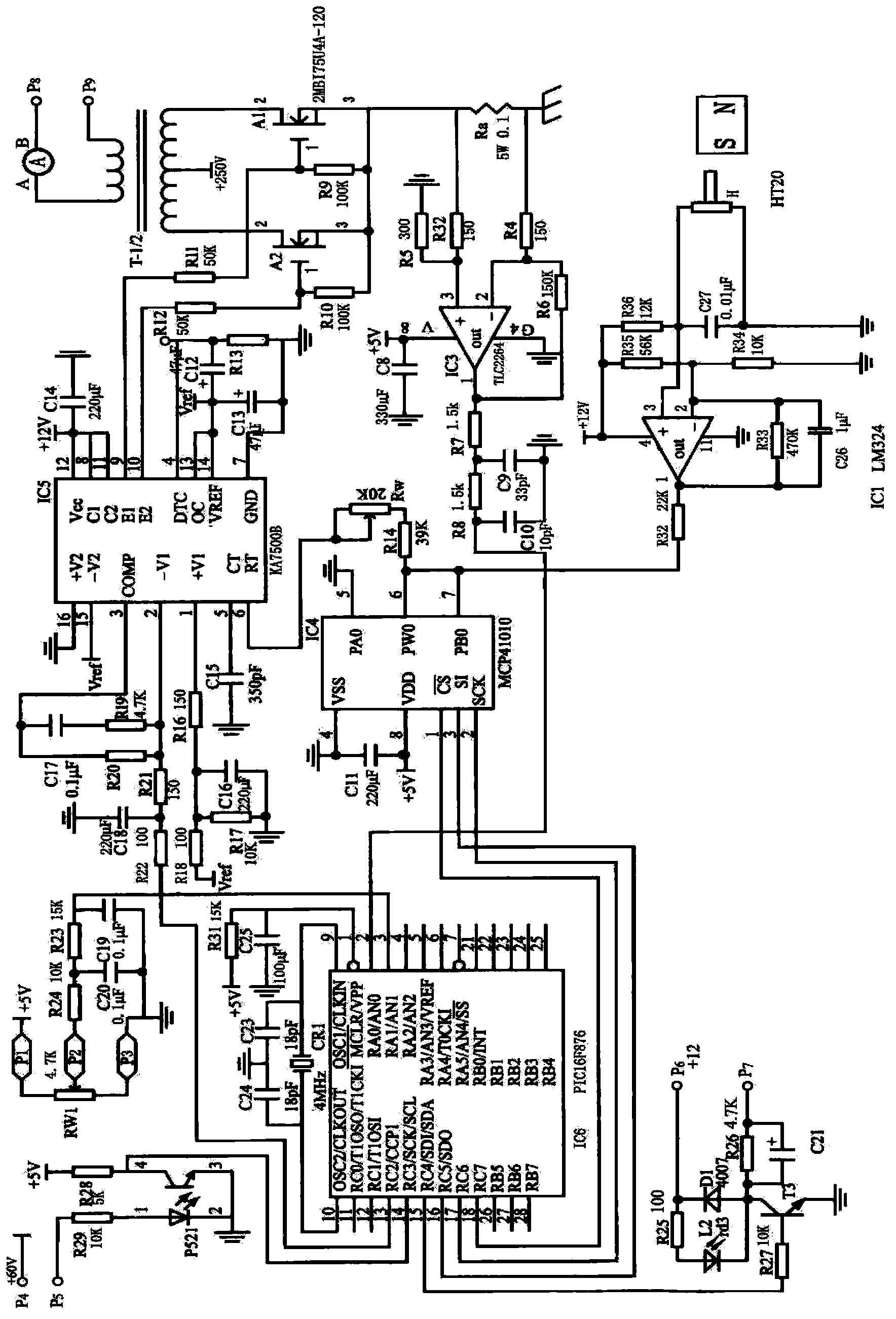

Digitally-controlled multifunctional inverted arc welding machine

ActiveCN102922091AFast dynamic responseAccurate static performanceArc welding apparatusSignal conditioning circuitsControl system

The invention relates to an inverted arc welding machine and particularly relates to a digitally-controlled multifunctional inverted arc welding machine which has high working efficiency and fast dynamic response. The digitally-controlled multifunctional inverted arc welding machine comprises a main circuit system (1) of an IGBT (Insulated Gate Bipolar Translator) inverting circuit (101), a digital control system (2) and a man-machine switching system (3), wherein the digital control system (2) adopts a digital signal controller (4) as a core control unit and further comprises an auxiliary circuit (5) connected with the digital signal controller (4), a signal conditioning circuit (6) for processing collected data of the main circuit system (1), and an IGBT driving circuit (7) for carrying out driving control on the IGBT inverting circuit (101); the type of the digital signal controller (4) is dsPIC30F4011 and the digital signal controller (4) is connected with the IGBT inverting circuit (101) through the IGBT driving circuit (7); and the digital signal controller (4) is used for adjusting and controlling the main circuit system (1).

Owner:甘肃居立门业有限责任公司

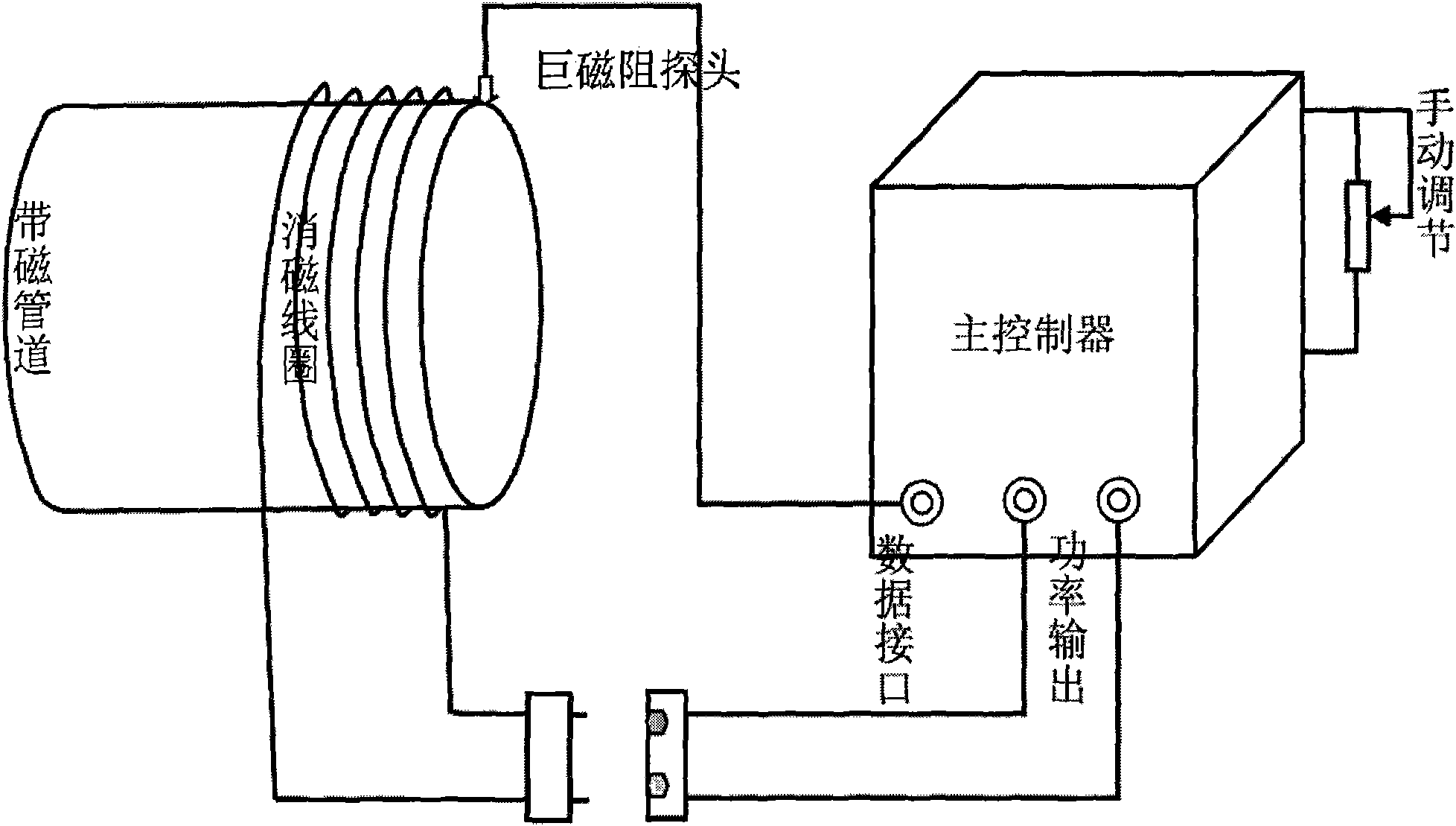

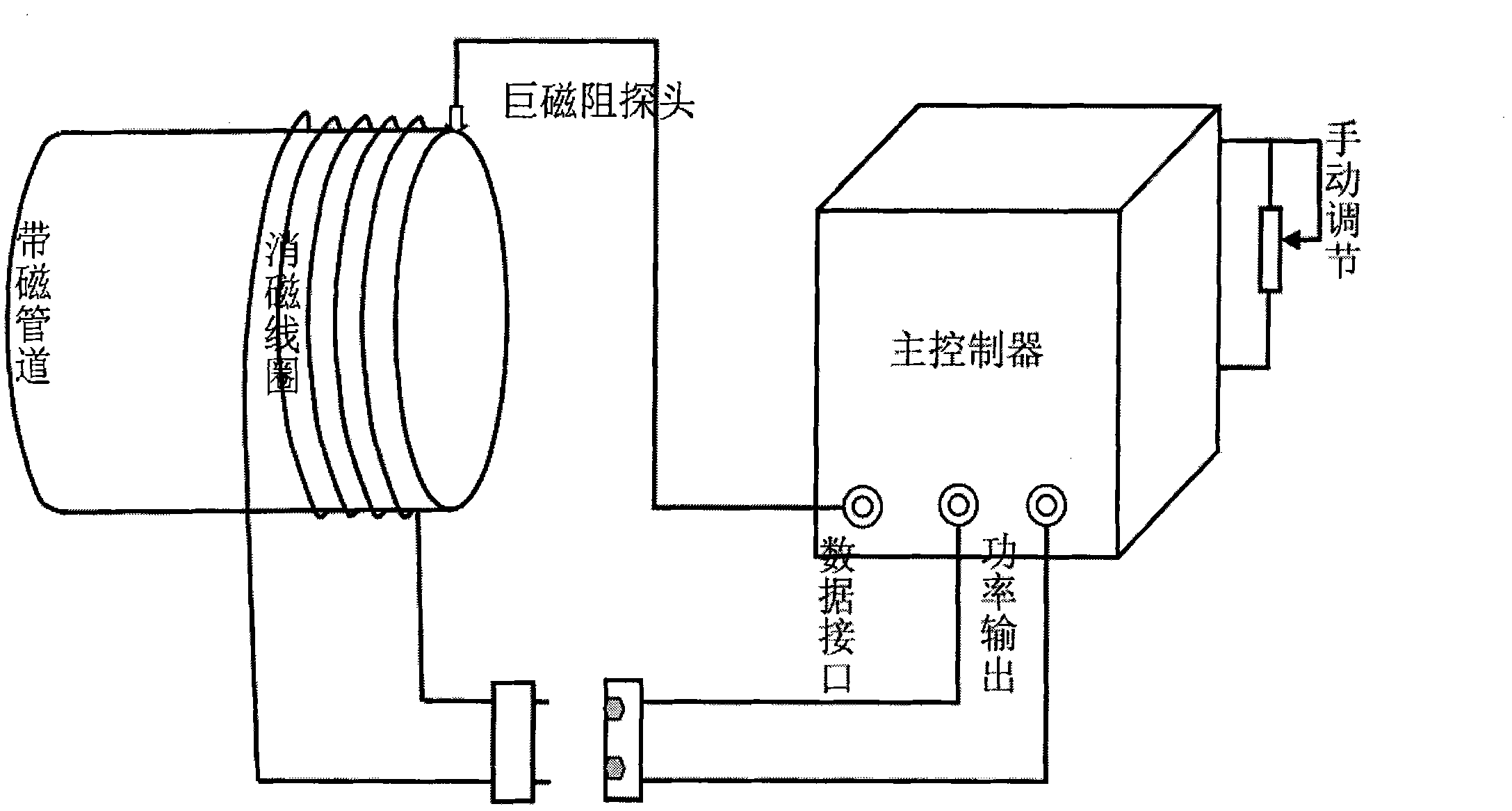

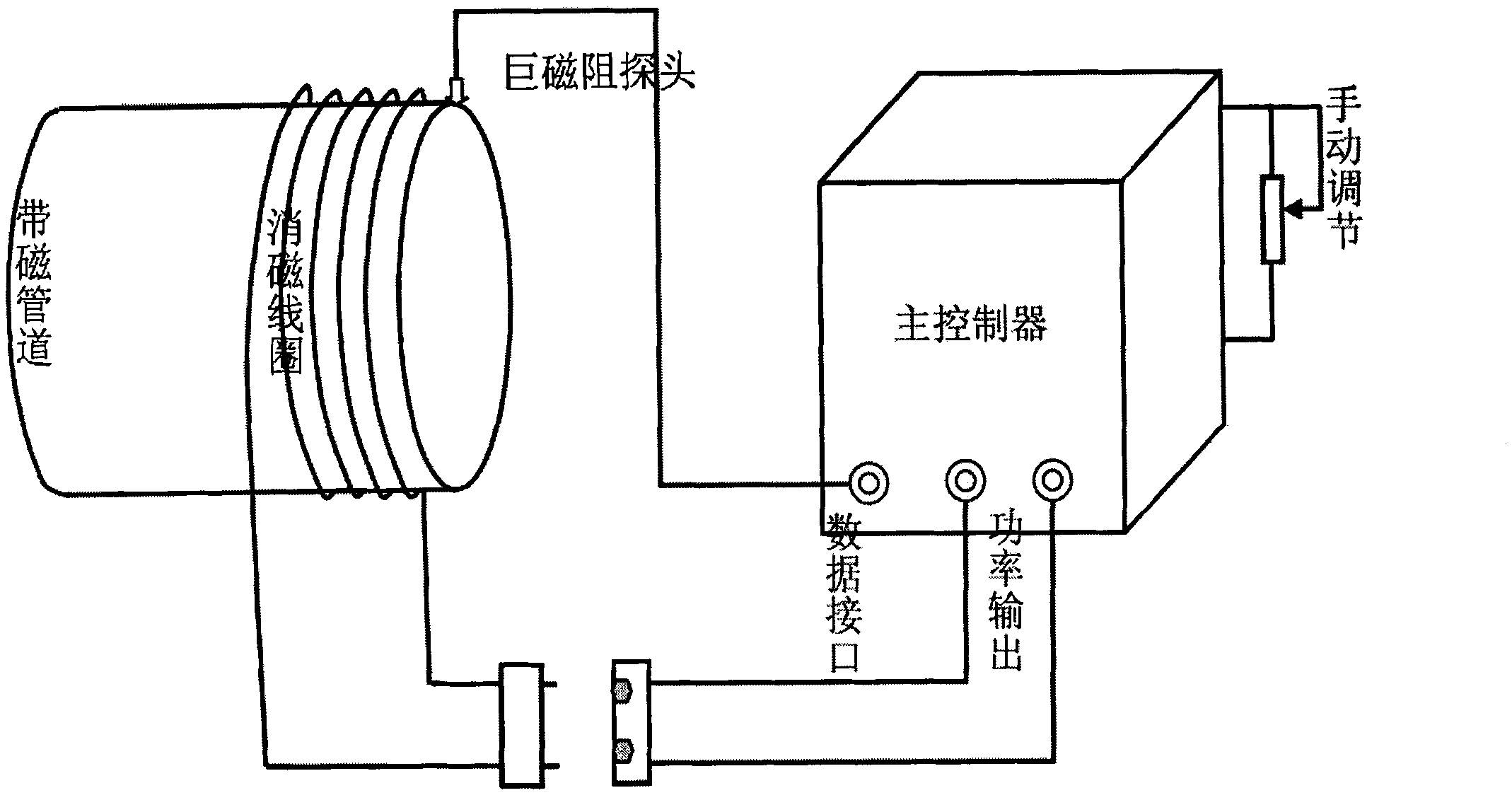

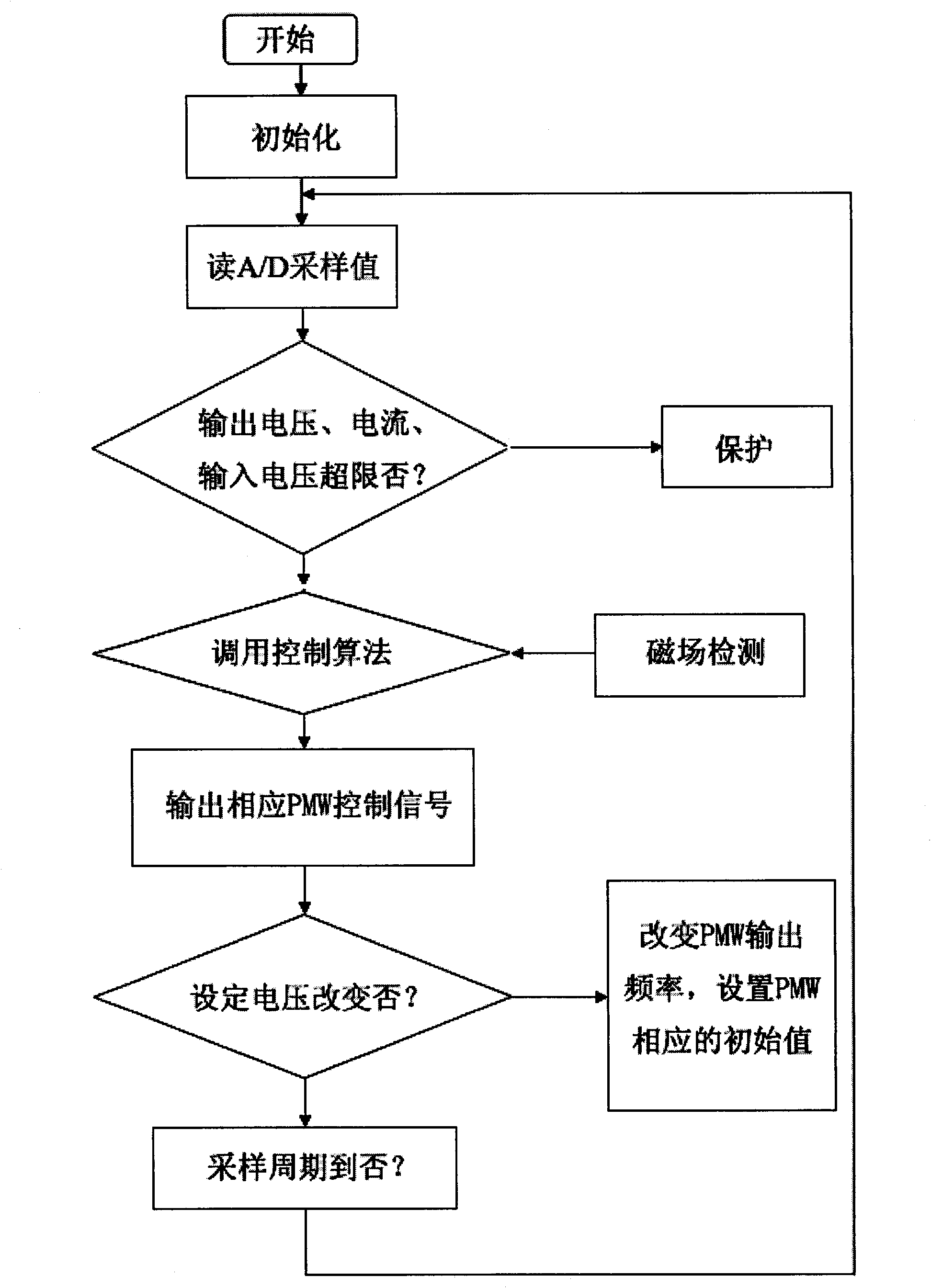

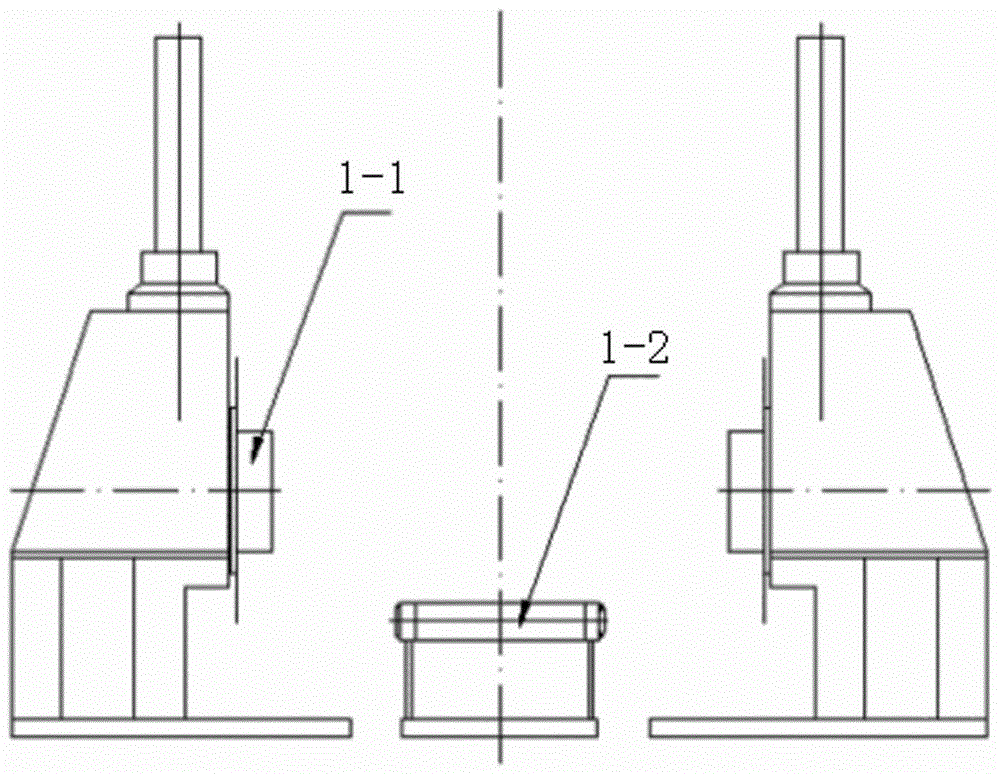

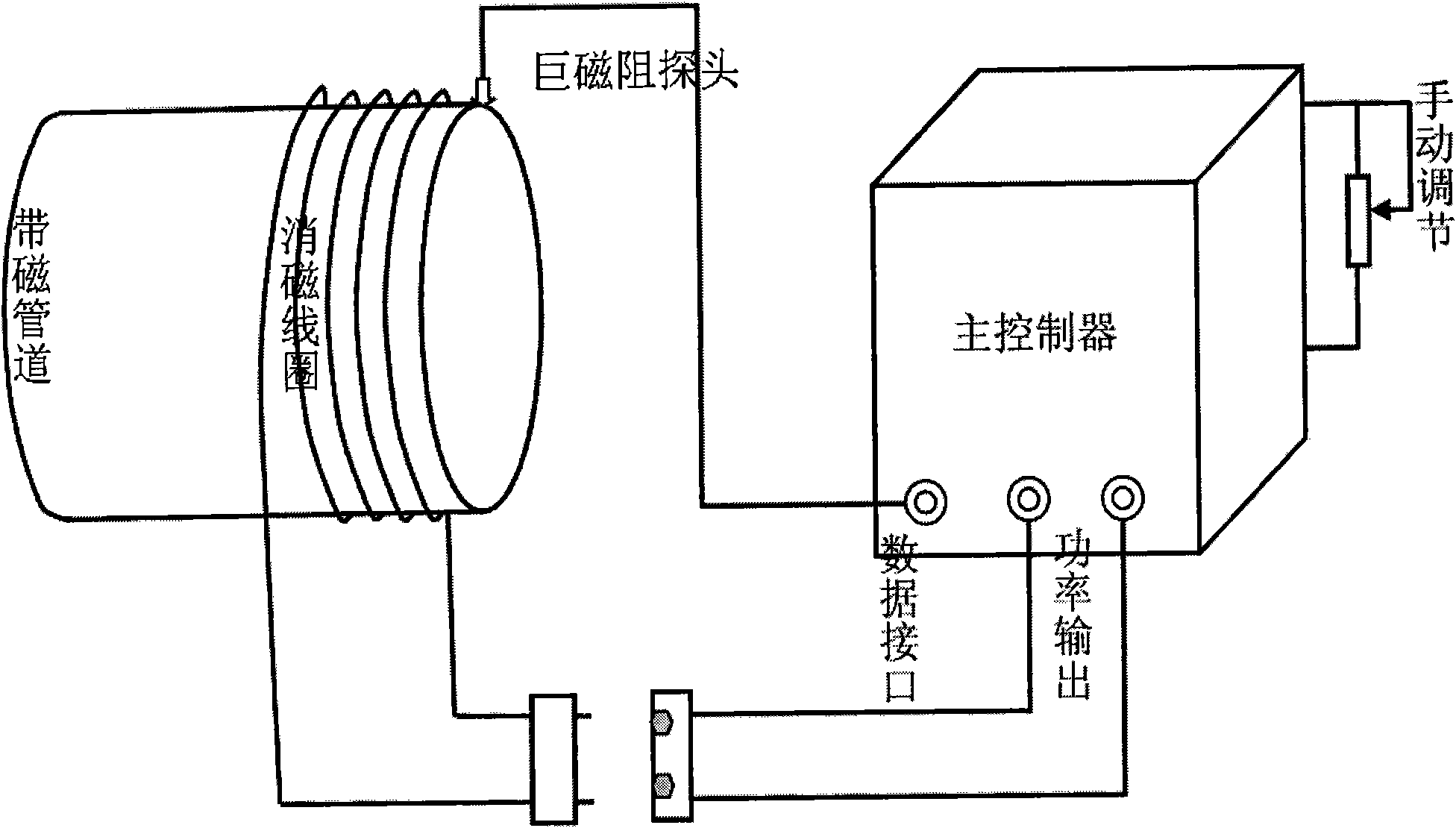

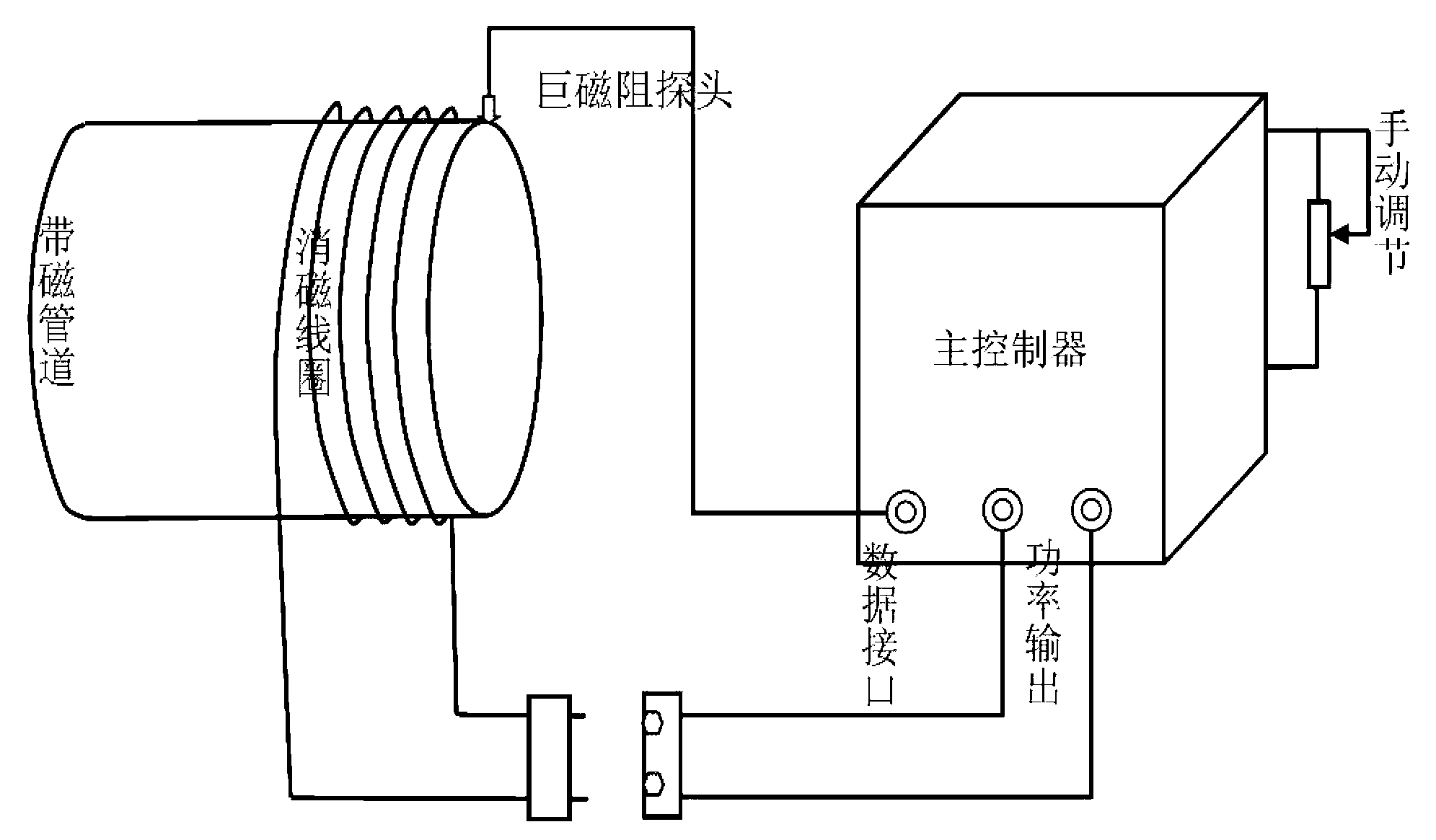

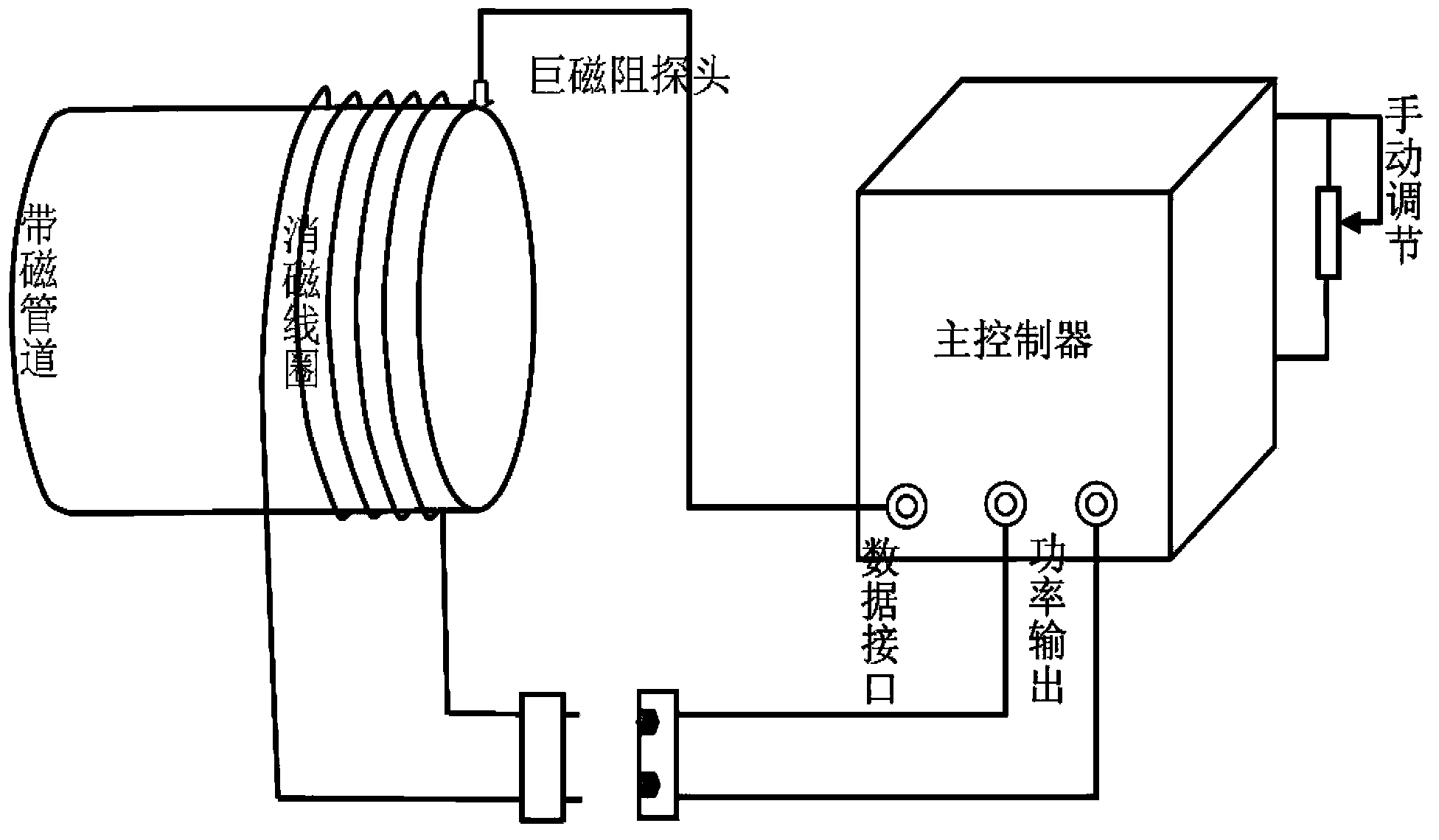

Pipeline port hysteresis buffer demagnetization method and demagnetizer

ActiveCN102403083AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisEngineering

The invention discloses a pipeline port hysteresis buffer demagnetization method and a demagnetizer and relates to the technical field of pipeline systems. Demagnetization coils are wound at a port of a pipeline to be demagnetized; a giant magneto-resistance probe is fixed at an outer edge of the port of the pipeline; the giant magneto-resistance probe is connected with a data interface of a maincontroller of the demagnetizer; and the demagnetization coils are connected with a power output end of the main controller. The method comprises the following steps that: the main controller picks upa signal of the giant magneto-resistance probe and measures the size and direction of the remanence of the pipeline; according to the size and direction of the remanence of the pipeline and differences of materials, the main controller automatically calculates output parameters and controls a circuit part to convert a power frequency alternating current of 50 Hz into a high frequency alternating current of 20 to 45 kHz; and the main controller performs voltage reduction and rectification and controls a power supply to generate the size and direction of a required current so as to obtain a magnetic field of which the size is equal to that of the remanence of the pipeline and the direction is opposite to that of the remanence of the pipeline. Compared with the conventional demagnetization product, the demagnetizer has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed, good demagnetization effect and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

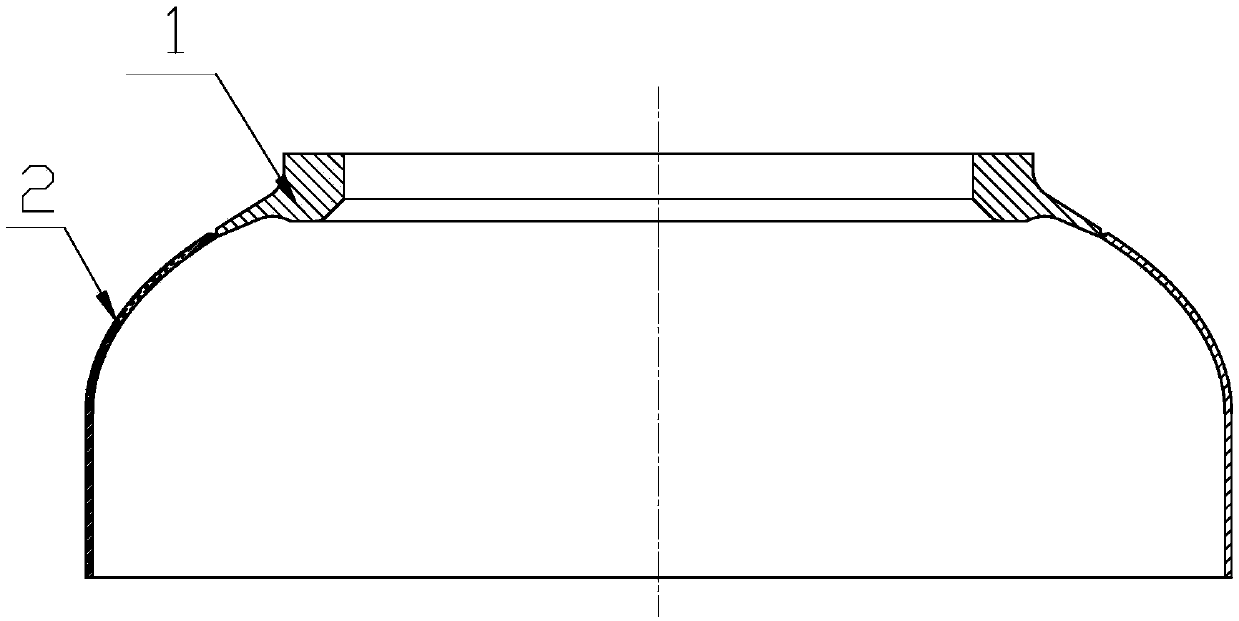

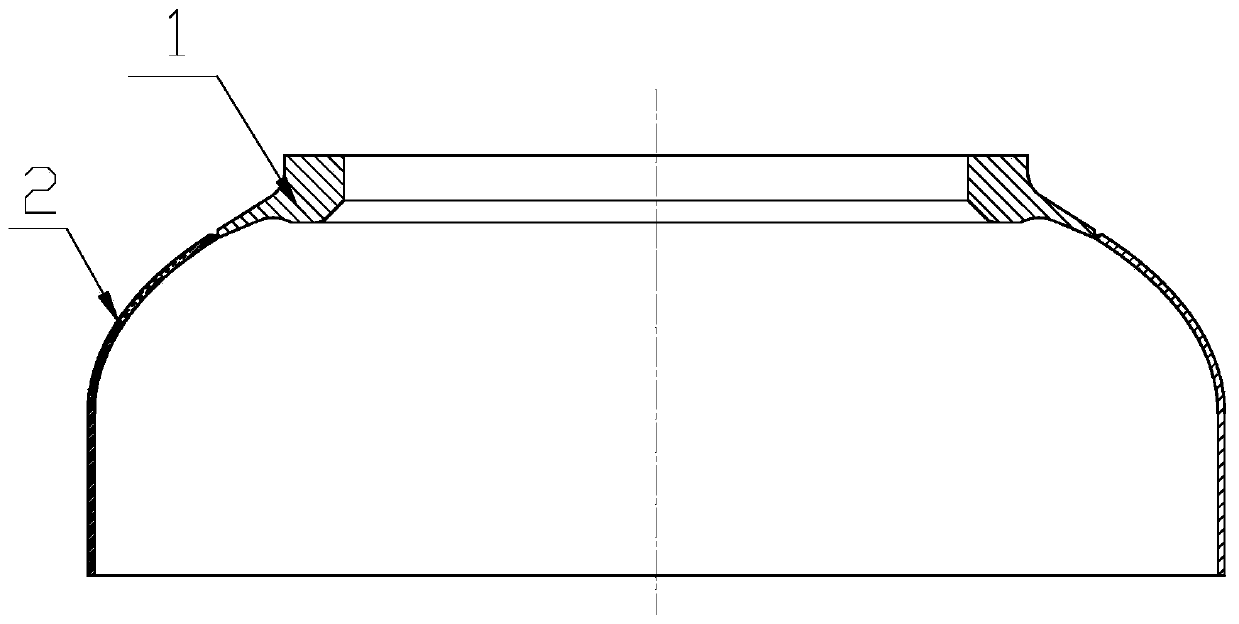

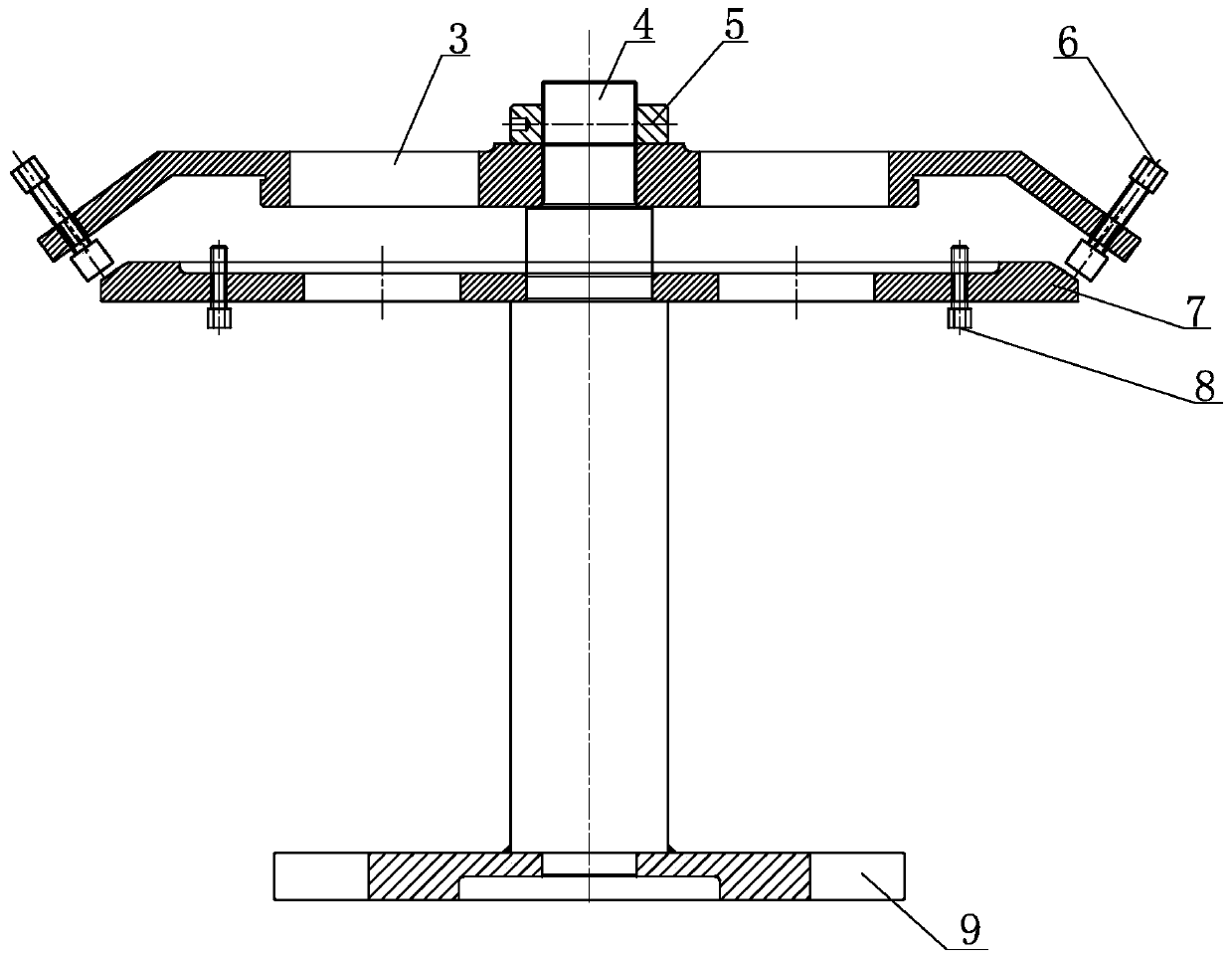

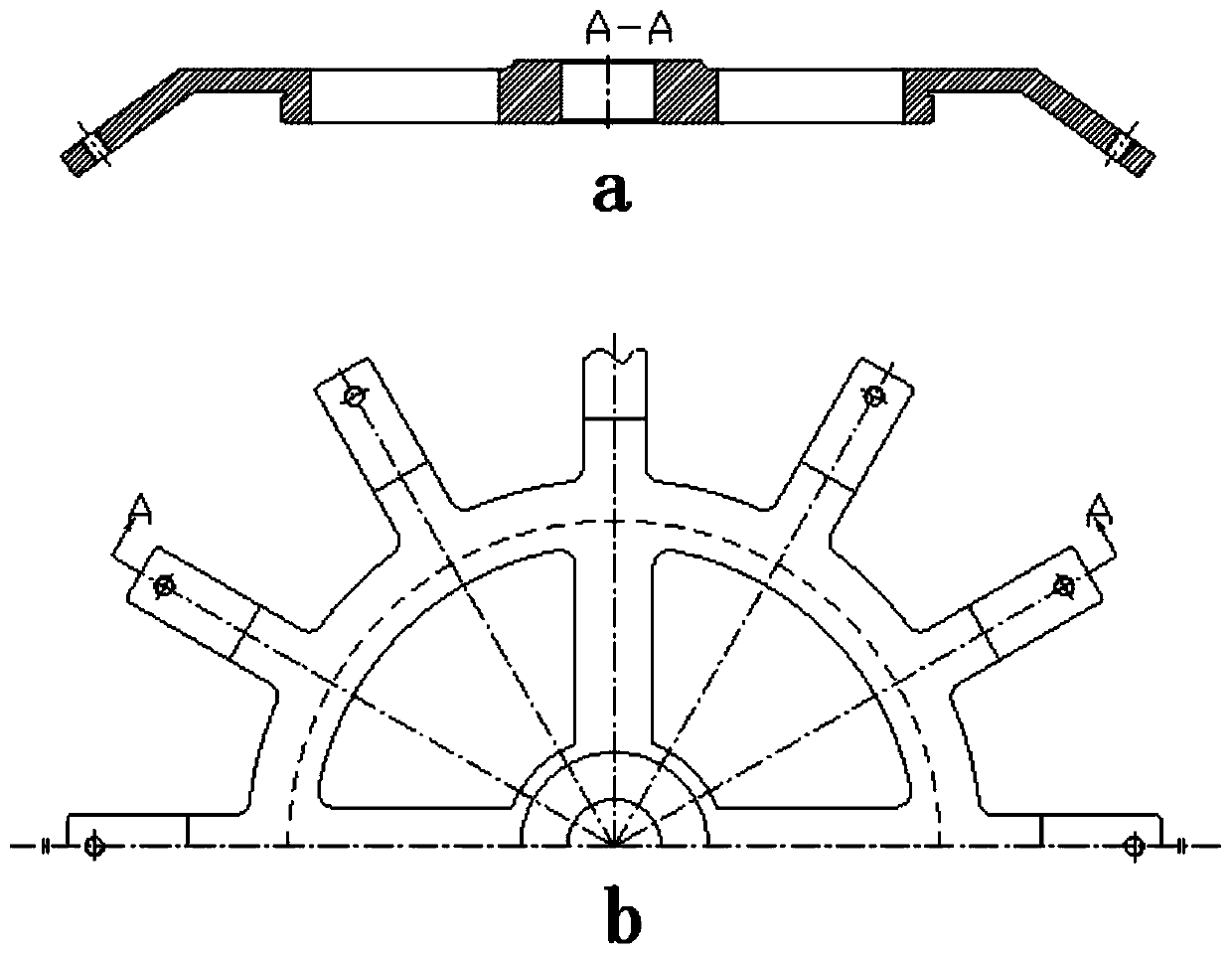

Tool for welding assembly of end socket and flange

ActiveCN107931943AAdjust flatnessAdjust the amount of welding anti-deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCushion

The invention provides a tool for welding assembly of an end socket and a flange. The upper portion of a main shaft is sleeved with a pressing plate and a cushion plate, and the pressing plate is madeto be located above the cushion plate. The end of each mounting rod on the circumference of the pressing plate is provided with an alignment tolerance adjusting bolt, and push heads on the alignmenttolerance adjusting bolts correspond to the end socket supporting faces of the edge of the upper surface of the cushion plate. Raised height adjusting bolts are mounted on the cushion plate. A plurality of radially-extending supporting rods are arranged on the surface of the outer circumference of the cushion plate, and the edge of the upper surface of each supporting rod is an arc face matched with the surface of an inner arc of the end socket. Mounting holes for the raised height adjusting bolts are formed in the supporting rods correspondingly. According to the tool for welding assembly ofthe end socket and the flange, before-welding assembly of ellipsoidal holed end sockets of various thicknesses and diameters and the flange can be achieved, and the assembly quality meets the weldingtechnological requirement. The size phi of an inner hole of the related flange is 100-1000 mm, the diameter phi of the end socket is 300-2000 mm, and the assembly sizes of the all types of flanges andend sockets can meet the welding technological requirement.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

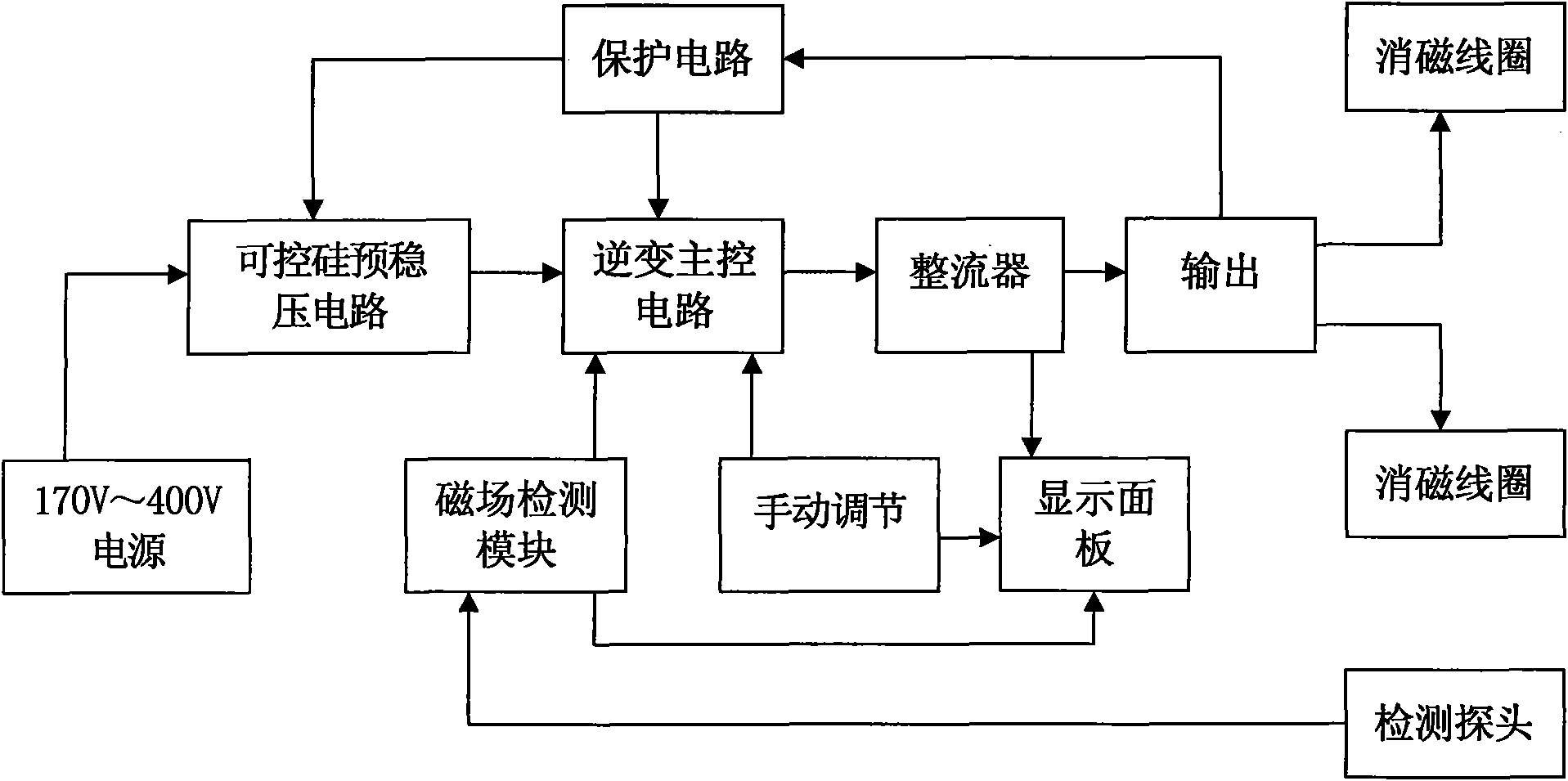

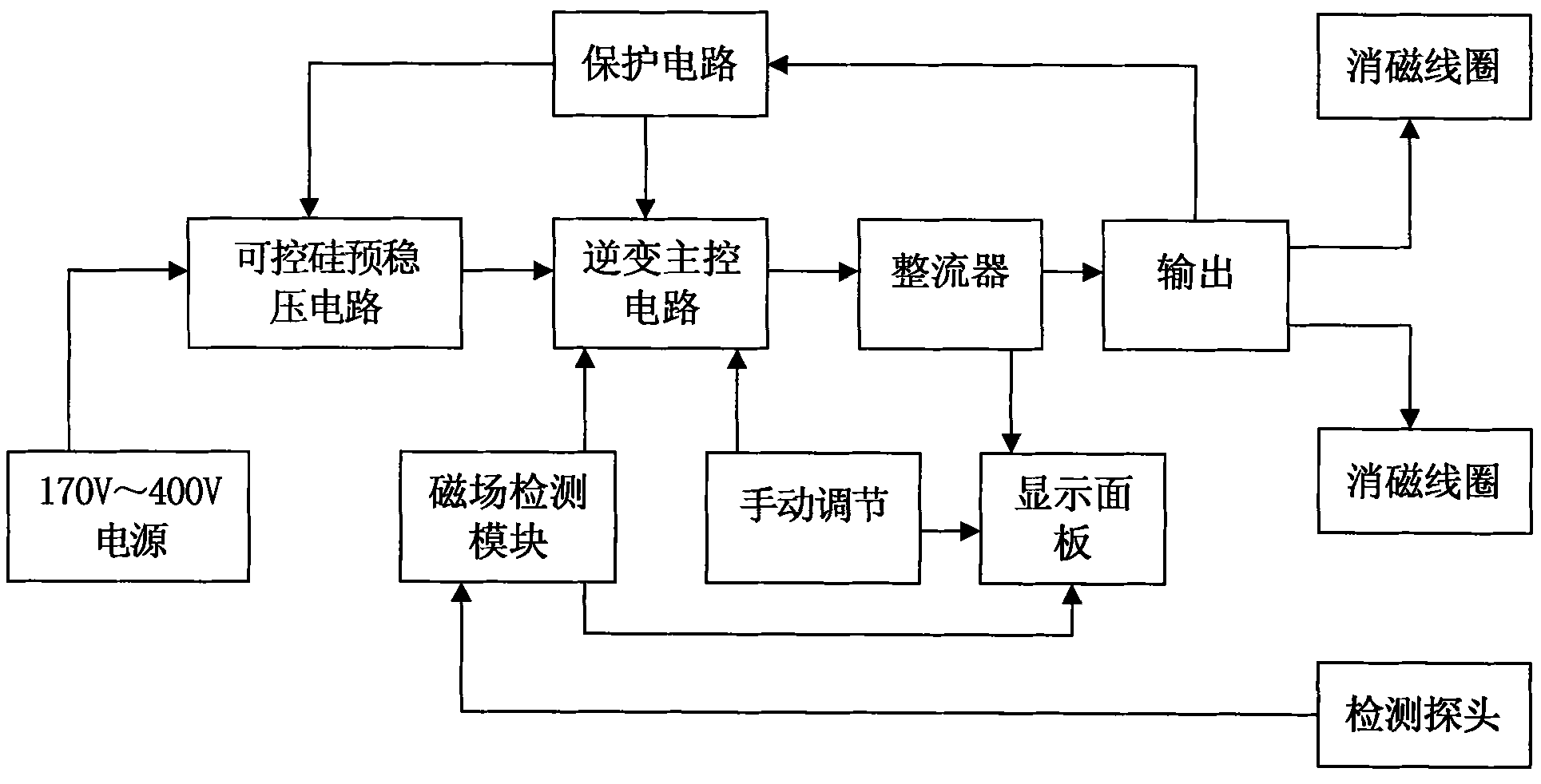

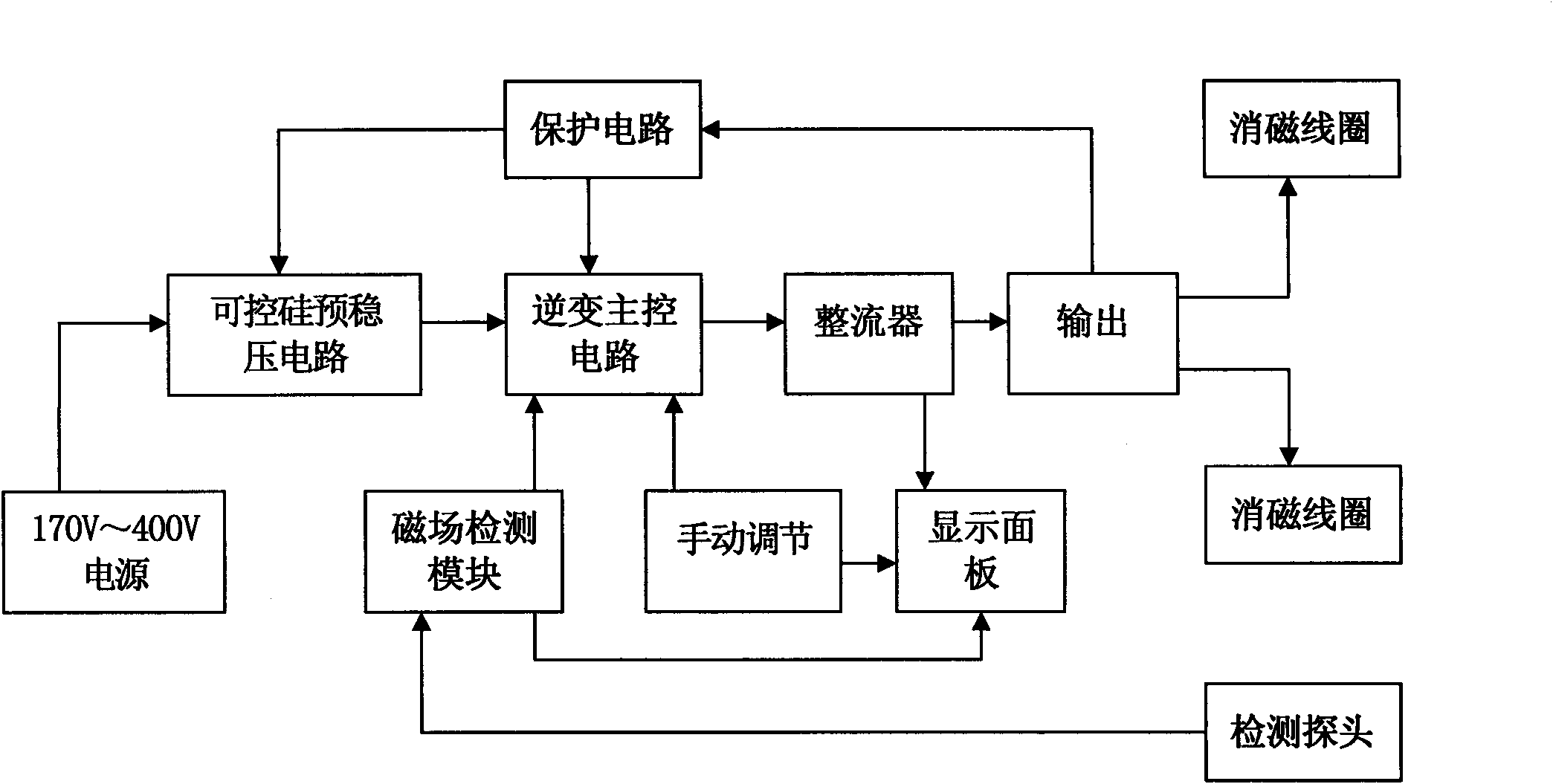

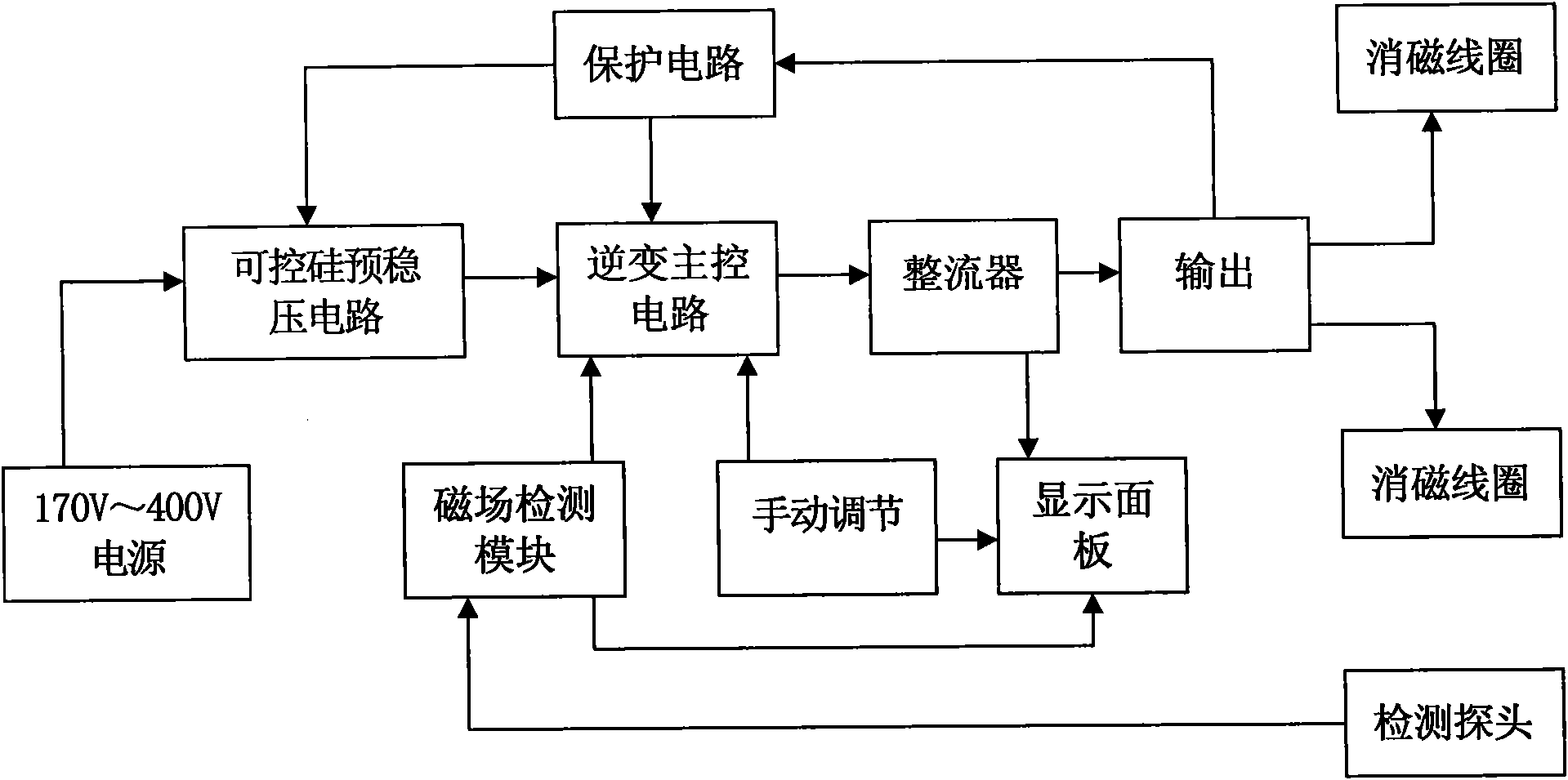

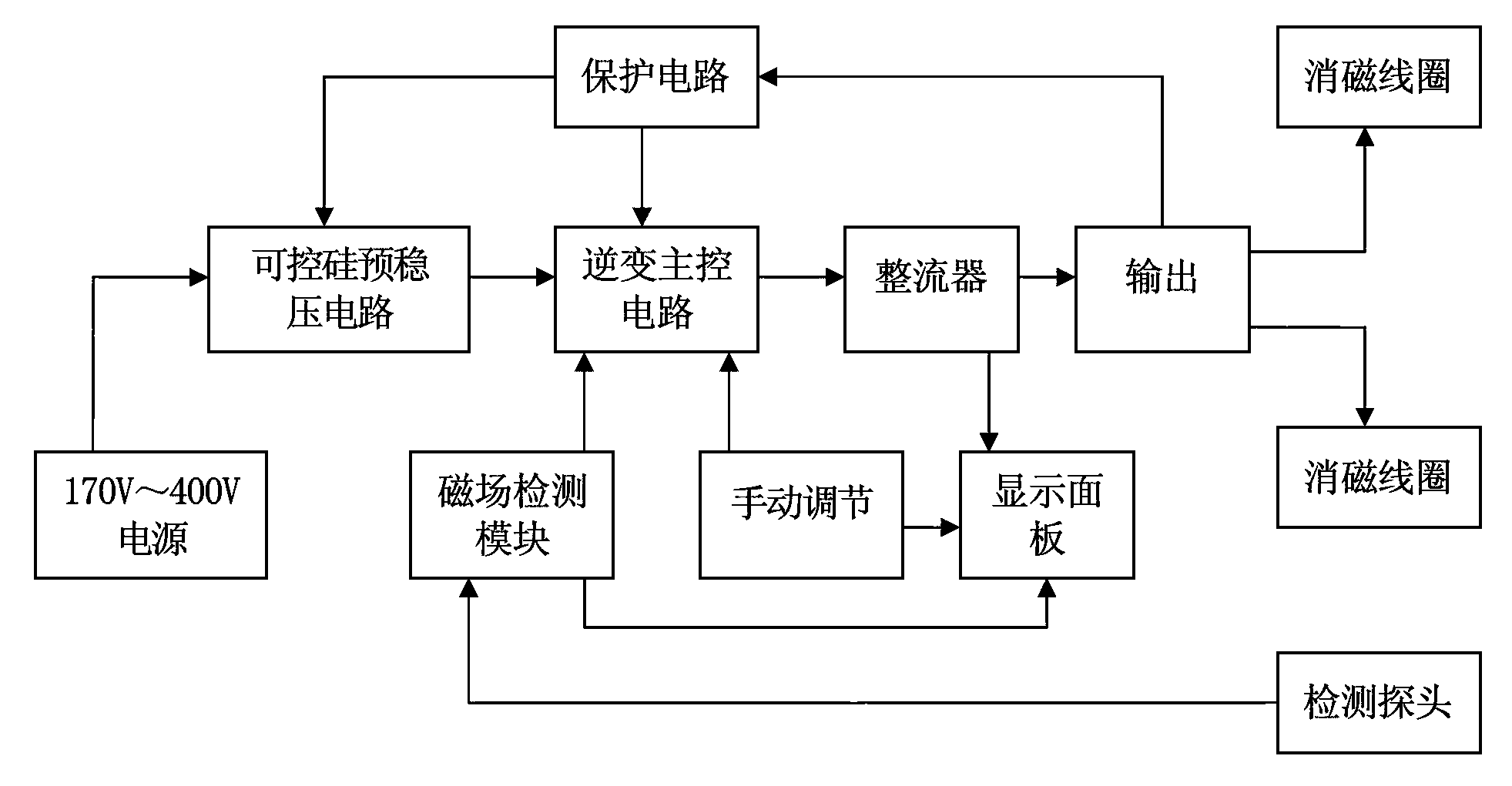

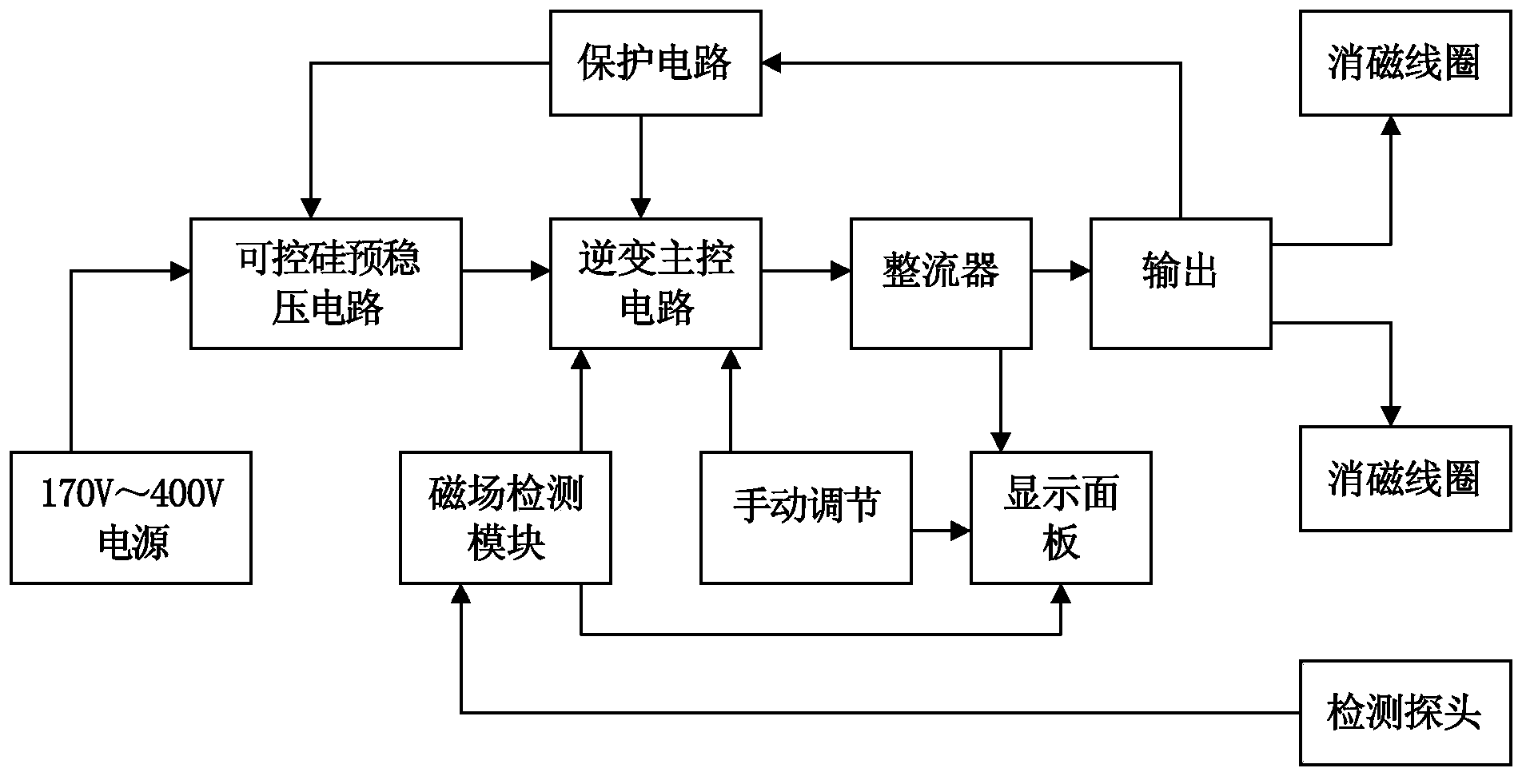

Pipeline port hysteresis buffer demagnetization controller

ActiveCN102403085AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisControl manner

The invention discloses a pipeline port hysteresis buffer demagnetization controller and relates to the technical field of pipeline systems. The pipeline port hysteresis buffer demagnetization controller consists of a silicon-controlled voltage pre-stabilizing circuit, an inversion main control circuit, a rectifier, a regulator, a magnetic field detection module, a display panel and a protection circuit, wherein a power supply from a power grid is connected with the silicon-controlled voltage pre-stabilizing circuit; the output of the silicon-controlled voltage pre-stabilizing circuit is connected with the inversion main control circuit, and the manual regulation output which is connected with the display panel is also connected with the inversion main control circuit; the output, which is connected with the output of a detection probe, of the magnetic field detection module is also connected with the inversion main control circuit; the output of the inversion main control circuit is connected with the rectifier; one of three paths of output of the rectifier is connected with the protection circuit, and the output of the protection circuit is connected with the silicon-controlled voltage pre-stabilizing circuit and the inversion main control circuit; one path of output of the rectifier is connected with the display panel; and another path of output of the rectifier is connected to demagnetization coils (1 and 2). Compared with the conventional demagnetization product, the pipeline port hysteresis buffer demagnetization controller has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed and good demagnetization effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hysteresis-damping demagnetizing method for pipeline port

ActiveCN102403084AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesDemagnetizing deviceHysteresis

The invention discloses a hysteresis-damping demagnetizing method for a pipeline port, relating to the technical field of pipeline systems. In the method, a demagnetizing coil is wound on the port of a pipeline to be demagnetized, a giant magneto-resistive probe is fixed at an outer edge of the pipeline port and is connected with a data interface of a main controller of a demagnetizing device, the demagnetizing coil is connected with a power output end of the main controller, and then, the method is implemented according to the following steps of: picking up a signal of the giant magneto-resistive probe by the main controller, and measuring the magnitude and the direction of residual magnetism of the pipeline; according to the differences in the magnitude, the direction and the materials of the residual magnetism of the pipeline, automatically calculating an output parameter and controlling a circuit part to covert power-frequency alternating current of 50Hz into high-frequency alternating current of 20-45kHz; and reducing voltage, rectifying current, and controlling the magnitude and the direction of the current required for generating a power source to obtain a magnetic field which is identical to the residual magnetism of the pipeline in magnitude and opposite to the residual magnetism of the pipeline in direction. Compared with the traditional demagnetizing technology, thedemagnetizing method disclosed by the invention has the advantages of advanced control manner, reliability in operating, rapidness in demagnetizing and good demagnetizing effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preheating welding equipment

InactiveCN108705187AAdapt to welding preheating requirementsEasy to manageWelding accessoriesTorchHigh intensity

The invention relates to preheating welding equipment. The preheating welding equipment comprises an arc welding machine and a movable platform. The arc welding machine is arranged on the movable platform. The arc welding machine and the movable platform are connected through a connecting arm. The connecting arm is further connected with a multi-head heating torch. The arc welding machine and themulti-head heating torch are arranged in the same axial direction, and the multi-head heating torch is connected with an air linkage pipe. The preheating welding equipment has the beneficial effects that the arc welding machine and the multi-head heating torch are arranged in the same axial direction, high efficiency and safety can be achieved, management is convenient, input is little, the preheating welding equipment can conduct synchronous construction with welding, the high-strength steel welding preheating requirement is met, and accordingly the welding technology and welding quality requirements are met.

Owner:SHANGHAI COSCO KAWASAKI HEAVY IND STEEL STRUCTURE

Flux-cored wire gas-shielded vertical upward welding process method

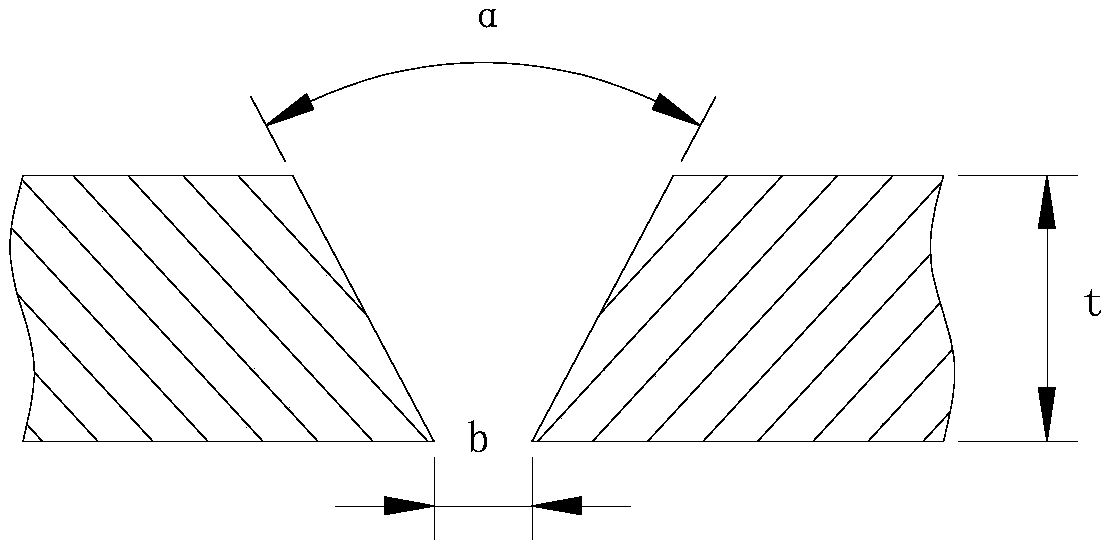

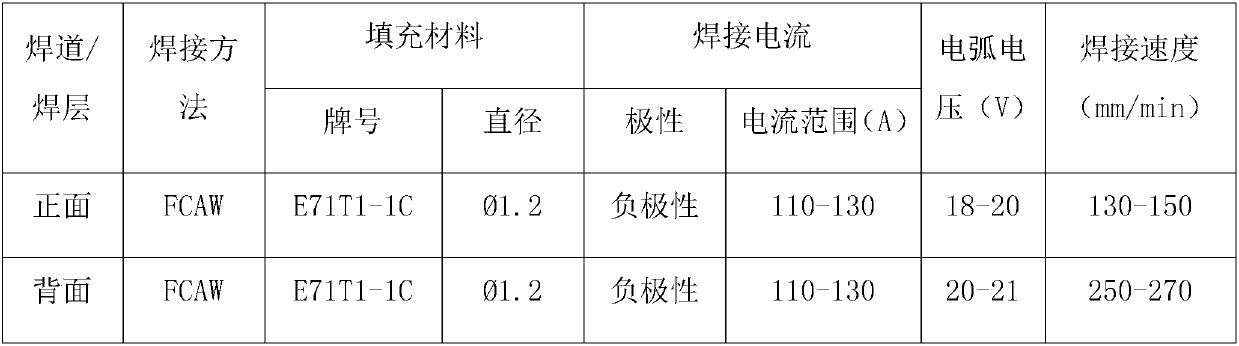

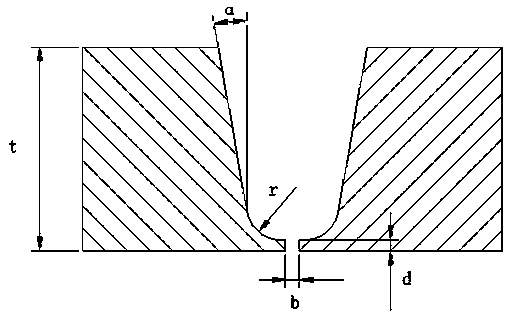

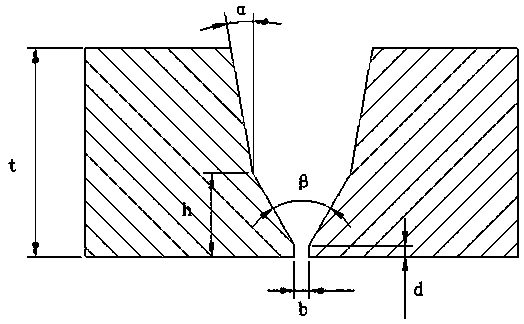

InactiveCN107813034AMeet welding process requirementsImprove docking automationArc welding apparatusMetal working apparatusThin walledSelf protection

The invention discloses a flux-cored wire gas-shielded vertical upward welding process method. The process method starts from butt joint of a vertical weld of a thin-wall plate in a vertical barrel project, the selected research range of the wall thickness is 6-10 mm, and a self-protection flux-cored wire single-sided water-cooled copper liner forced forming welding process method is adopted. Theprocess method comprises the following steps that a V-shaped groove is formed in a vertical weld plate first, an angle alpha of the groove is 60 + / - 2.5 degrees, a gap b is 4 + / - 0.5 mm, a blunt edged is 0 + / - 0.5 mm, misalignment tolerance c is less than or equal to 1.5 mm, a back face is formed by adding a water-cooled copper liner in a forced mode, and the welding gun position, welding parameters and the like are adjusted and controlled, so that single-face welding is carried out and double-face forming are realized, and the back face of the flux-cored wire is free of gouging. According tothe flux-cored wire gas-shielded vertical upward welding process method, the problem that welding quality and efficiency are influenced due to the fact that automatic welding and single-face weldingdouble-face forming are difficult to realize in the vertical barrel thin wall plate in the industry is solved, and double improvement of welding quality and efficiency of the vertical welding of the vertical barrel thin-wall plate is realized.

Owner:NANJING AUTO ELECTRIC

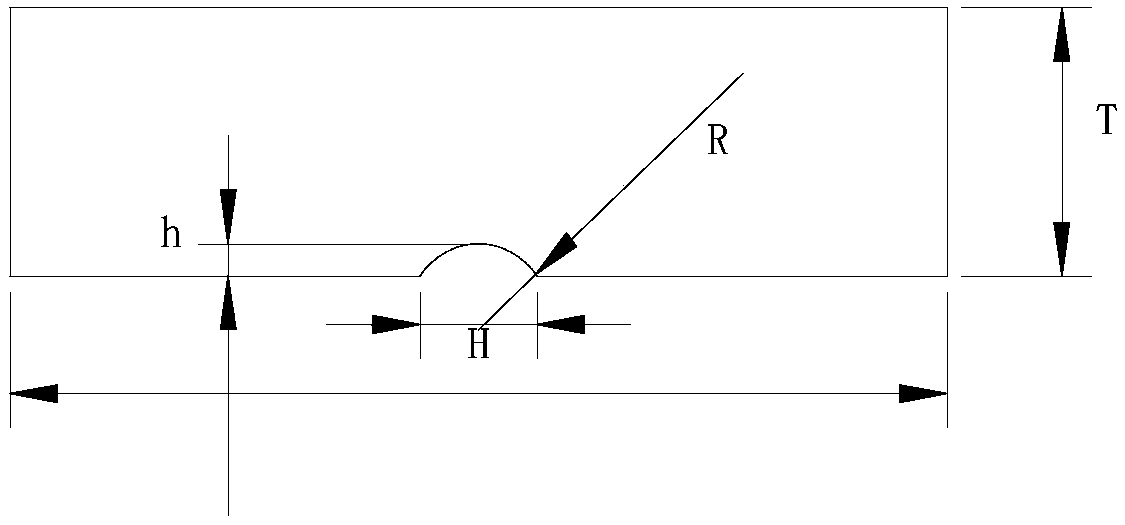

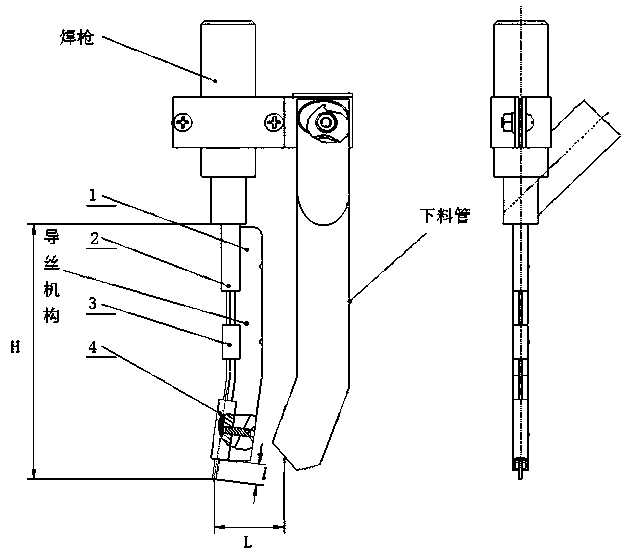

Thick-wall pipe narrow slope SAW automatic welding process and welding machine head

ActiveCN107671398AReduce manufacturing costReduce fillingElectrode supporting devicesWelding processEngineering

The invention discloses a thick-wall pipe narrow slope SAW automatic welding process and a welding machine head. The process comprises the following steps: the process is started with thick-wall pipes; the wall thickness research range is selected within 22-60 mm; emphasis aiming at double V grooves and U-shaped grooves, forms and sizes of narrow grooves are set according to the groove specifications of the thick-wall pipes based on different standards (such as ASME, national standard or European standard); meanwhile, according to the defined forms of the narrow grooves, a thick-wall pipe narrow groove novel SAW welding machine head of automatic welding equipment is designed; a novel SAW welding gun mainly comprises two parts of a welding wire guide mechanism and an unloading device; the wire guide smoothness and the unloading smoothness are guaranteed; and the effect of fluxes protecting welding lines is excellent. The thick-wall pipe narrow slope SAW automatic welding process solvesthe problems of limitation of the thick-wall pipes by the sizes of grooves and welding machine heads on industry and influence on the welding quality and efficiency, reduces the welding line metal filling quantity in welding of the thick-wall pipes, improves the welding efficiency, reduces the pipe production cost, and realizes dual improvement of the welding quality and efficiency of the thick-wall pipes.

Owner:南京奥特自动化有限公司

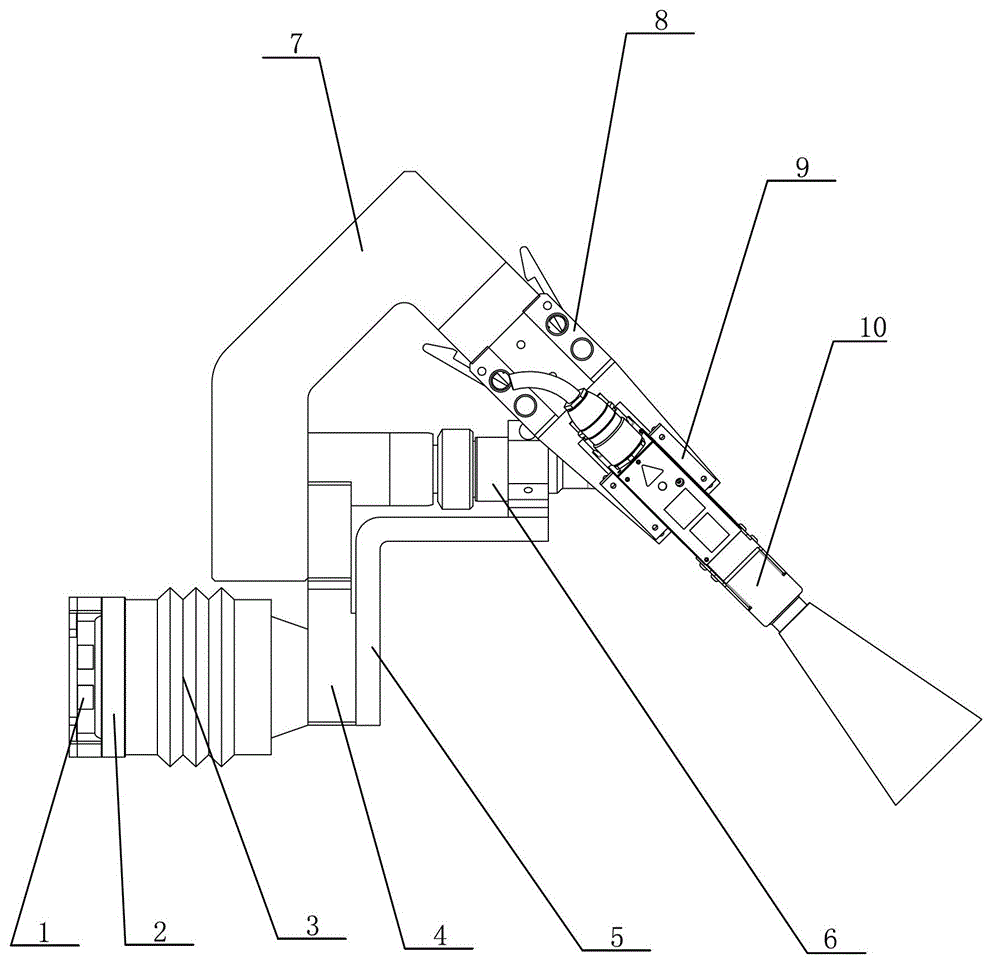

Laser tracking device

InactiveCN104002072AEasy to assemble and disassembleFirmly connectedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser tracker

The invention discloses a laser tracking device, which relates to the technical field of welding tracking. According to the laser tracking device, a gun-clamping block is connected with one end of a flange disc, the other end of the flange disc is connected with an anti-collision sensor, the anti-collision sensor is fixedly connected with one end of a holder by virtue of a first panel, and the other end of the holder is connected with a gun neck; the first panel is connected with a second panel; a laser tracker assembly comprises an installation seat, a laser fixation seat and a laser tracker, the installation seat is connected with the second panel and the laser fixation seat, and the laser fixation seat is connected with the laser tracker. The laser tracking device is simple in structure, convenient to operate, convenient to detach, and capable of being taken off independent; moreover, more than two welding guns can be held, and the angles of the welding guns can be adjusted, thus saving equipment cost, and improving the accuracy of welding.

Owner:REIS ROBOTICS KUSN

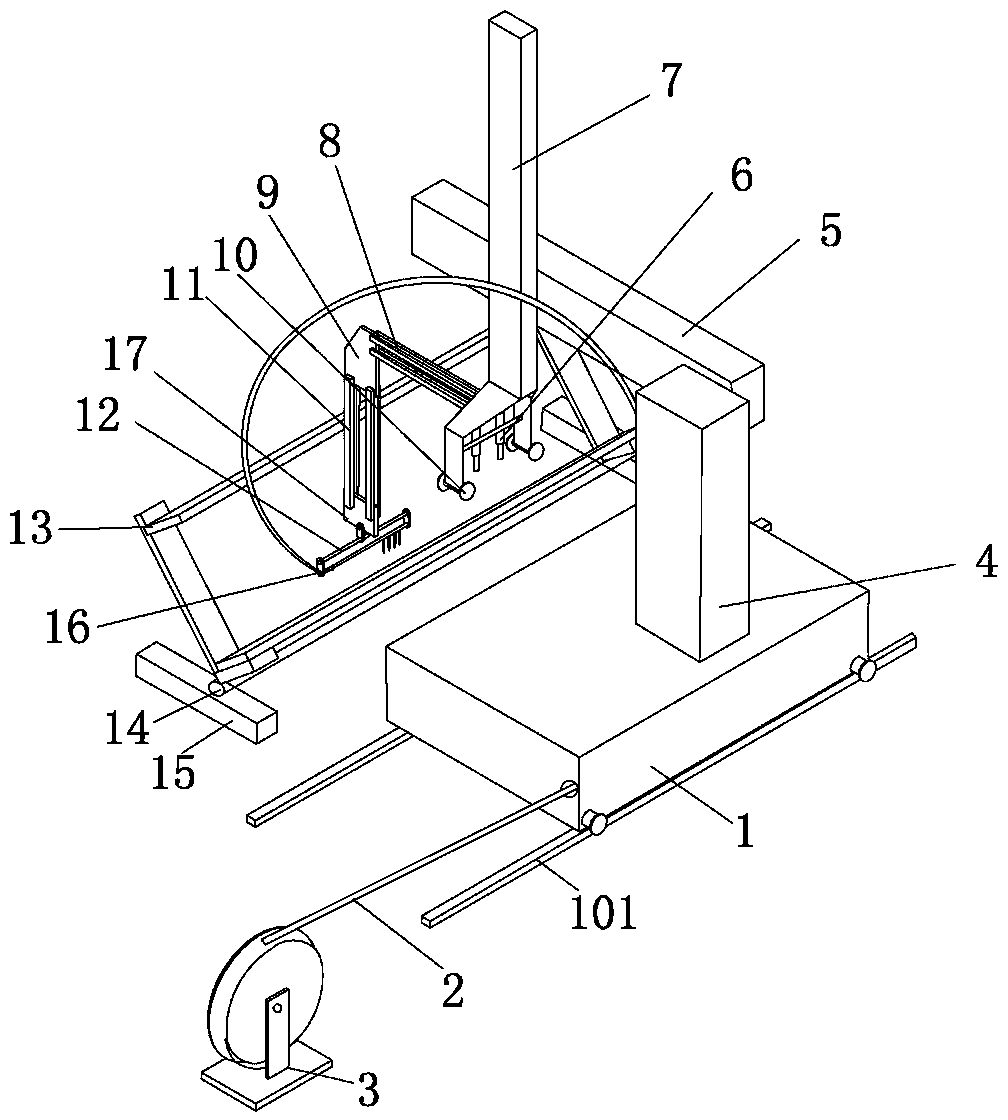

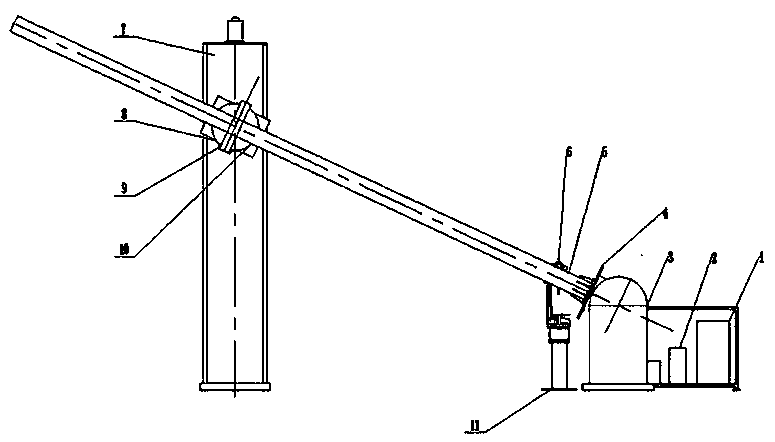

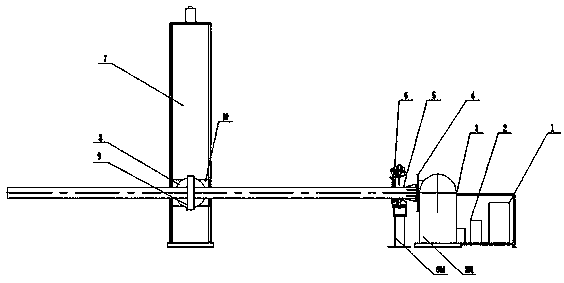

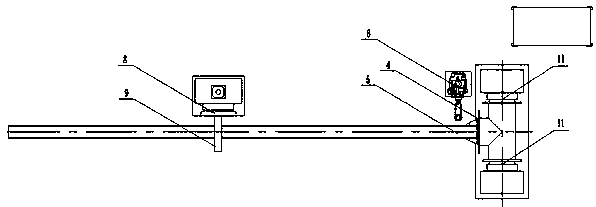

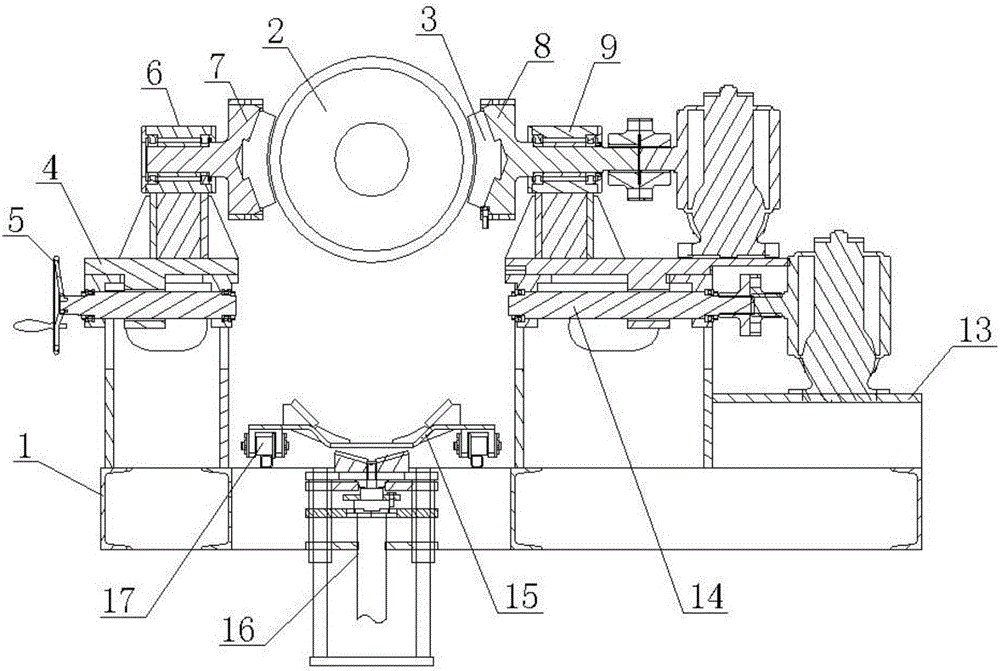

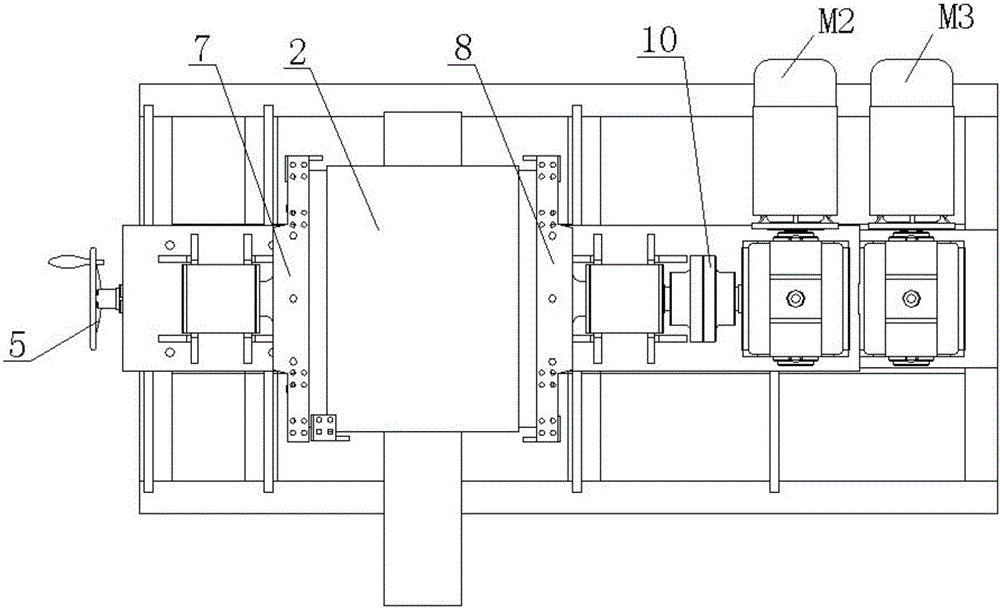

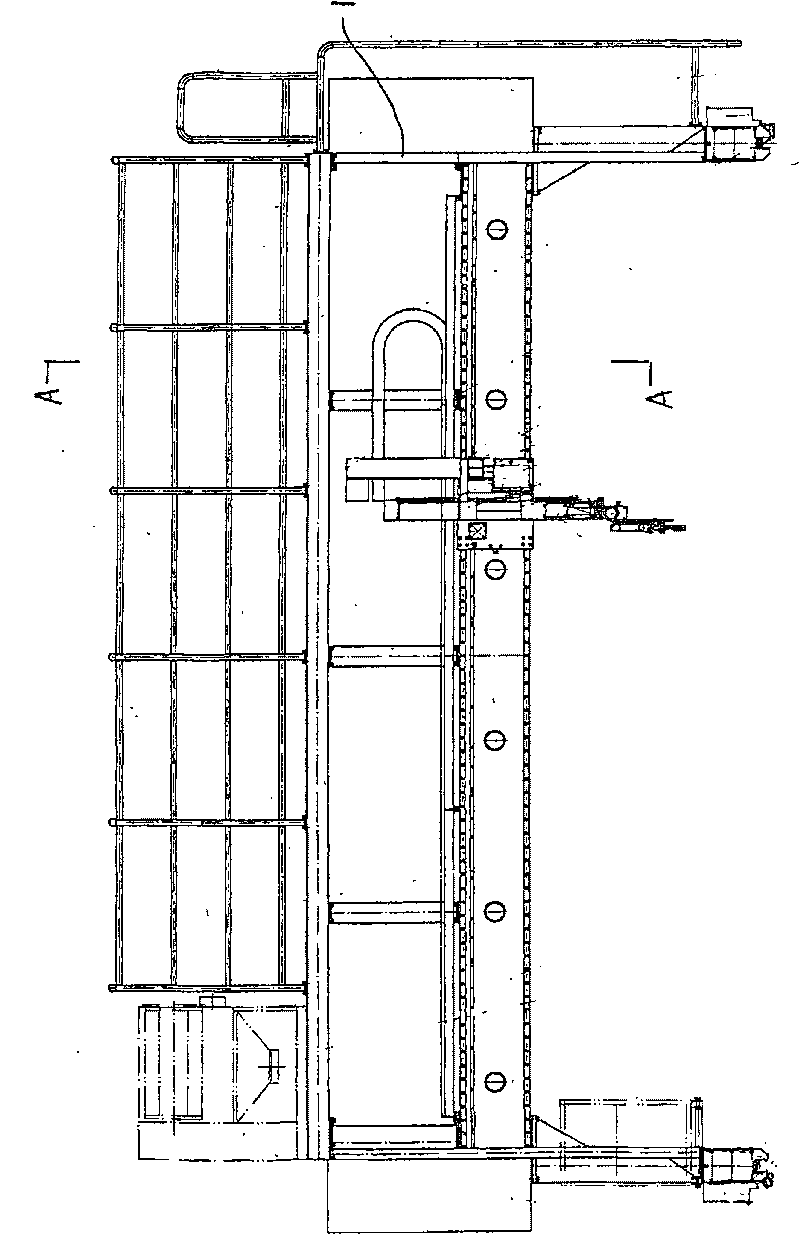

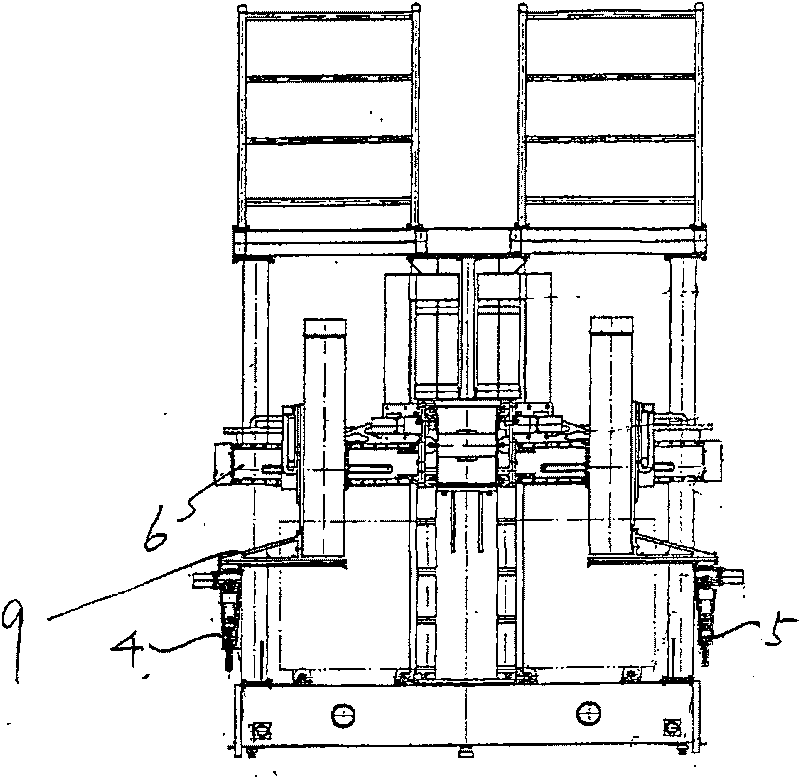

Welding displacement tool for robot automatic welding and welding method

PendingCN109719453AMeet welding process requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRotating disc

The invention provides a welding displacement tool for robot automatic welding and a welding method. The problem that thin and long workpieces can freely rotate and turn over by being driven by a displacement machine is solved so as to ensure that the workpieces reach the angle needed by ship welding. The welding displacement tool for robot automatic welding comprises a displacement machine, a welding robot, a workpiece clamping mechanism and a workpiece. The displacement machine comprises a support, a rotating disc rotationally arranged on the support and displacement machine rotary supportsarranged on the two sides of the support. The welding robot is arranged on the base and located on one side of the displacement machine. The workpiece clamping mechanism comprises a supporting frame,a walking connecting disc, a clamping device, a workpiece rotary support and a vertical walking mechanism, the walking connecting disc is mounted on the supporting frame, the workpiece rotary supportis connected to the walking connecting disc, the walking connecting disc is driven by the vertical walking mechanism to move up and down along the supporting frame, and the clamping device is rotationally arranged on the workpiece rotary support. One end of the workpiece is arranged on the rotary disc, and the other end of the workpiece is connected with the clamping device.

Owner:山东时代新纪元机器人有限公司

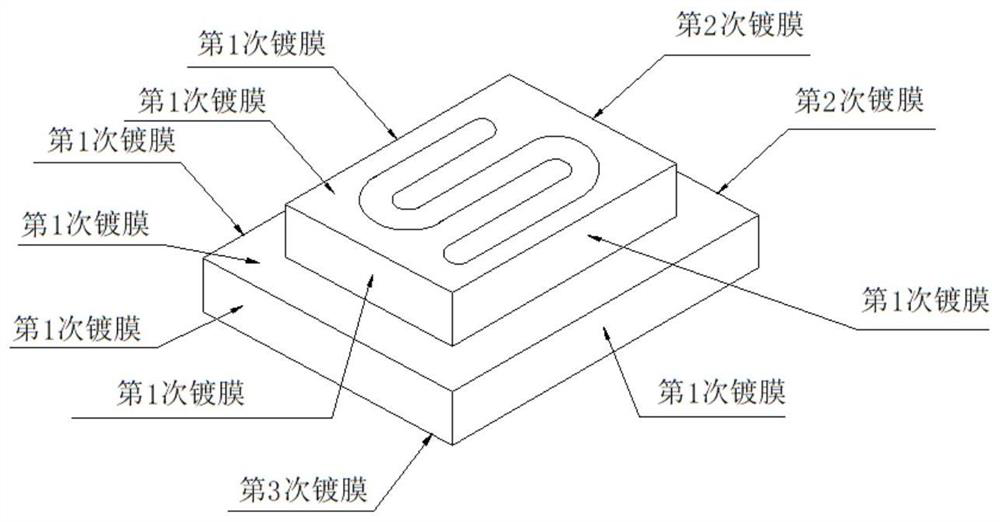

Splicing coating method for semiconductor part

ActiveCN112063972AEnsure consistencyMeet the requirements of the subsequent welding processVacuum evaporation coatingSputtering coatingCoated surfaceSemiconductor

The invention provides a splicing coating method for a semiconductor part. The method comprises the following steps: shielding the surface, making contact with a clamp in coating equipment, of the semiconductor part by adopting a protective film; coating the treated semiconductor part, and controlling the coating temperature and power to finish the coating of the non-shielding surface; attaching the protective film to the coated surface, and removing the original shielding protective film; and repeating the coating of the non-shielding surface, and removing the protective film on the coated surface after the coating is completed until the semiconductor part with the fully-coated surface is obtained. According to the method, the whole surface of the semiconductor part can be coated in a splicing coating manner, and particularly, the non-coating surface is shielded firstly, so that the consistency of coating in different sequences can be ensured, and the requirements of a subsequent welding process are met; and coating parameters are correspondingly adjusted according to selected semiconductor part materials, crystal grain change can be avoided, the strength performance of the part is guaranteed, and the method is suitable for different kinds of products and wide in application range.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

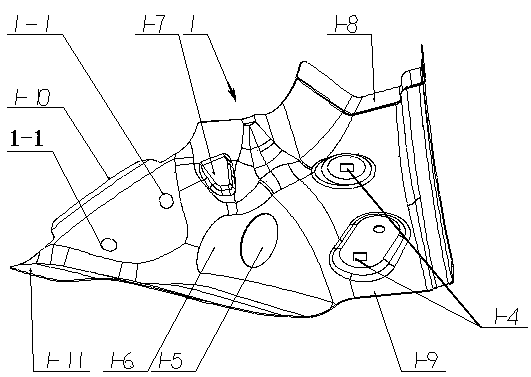

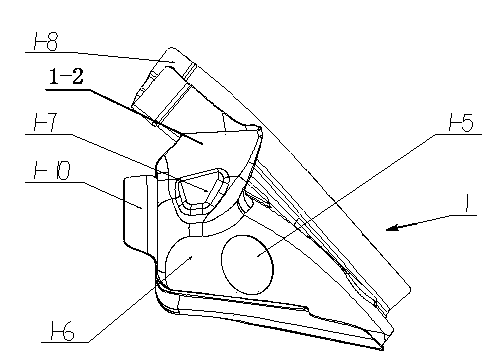

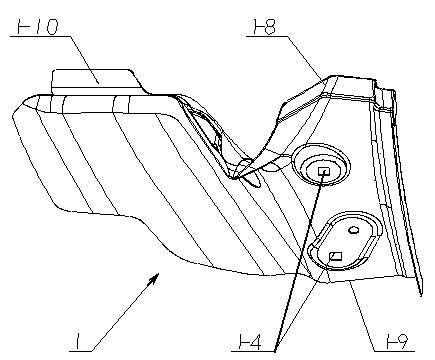

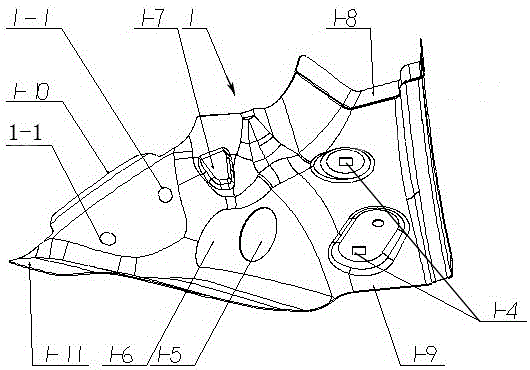

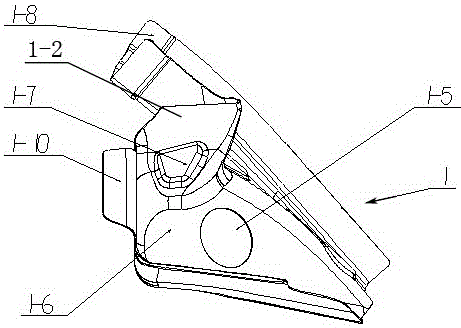

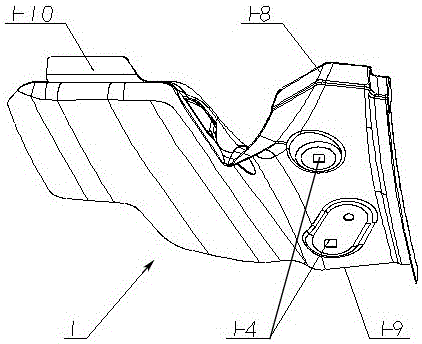

Taillight support of hatchback

ActiveCN103625354ASatisfy the requirement of too long front and back distance in shapeHigh strengthOptical signallingEngineering

The invention relates to a taillight support of a hatchback. A first turned edge is arranged on a support body and matched with the lower surface of a light, a second turned edge is arranged on the right portion of the support body and matched with the profile of an upper gutter channel on a rear pillar, a third turned edge is arranged on the right portion of the lower side edge of the support body and matched with the profile of a lower gutter channel on the rear pillar, a fourth turned edge is arranged on the upper portion of the left side edge of the support body and matched with the profile of the side wall, and a fifth turned edge is arranged on the lower portion of the left edge of the support body and matched with the profile of the side wall. Adjusting holes are formed in the left portion of the support body, and installation holes are formed in the right portion of the support body. A via hole is formed in the middle of the support body, and a reinforcement component is arranged on the periphery of the via hole. The strength of the taillight support of the hatchback can be reinforced, the taillight support and a rear pillar plate are combined to form a rear pillar cavity which is complete and smooth, and therefore the strength of the tail of a whole hatchback body is improved, uniformity of the taillight support is guaranteed, and requirements for a welding technology are met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

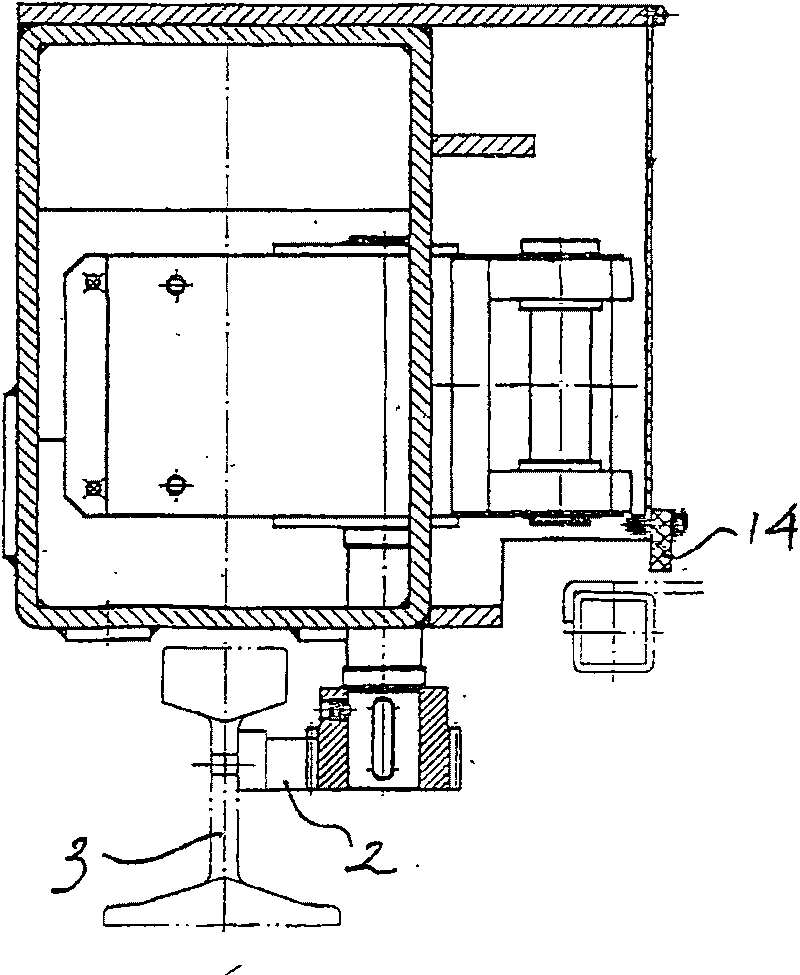

Overturning device for alternating-current traction motor rotor

InactiveCN106736078AMeet welding process requirementsReduce turnaround timeWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryTraction motor

The invention provides an overturning device for an alternating-current traction motor rotor. The overturning device comprises a second lead screw transmission mechanism (14), a left clamping piece (7) and a right clamping piece (8), wherein the left clamping piece (7) and the right clamping piece are erected oppositely. A relatively-rotatable movable connecting structure is formed between the left clamping piece (7) and a left bearing seat (6). A relatively-rotatable movable connecting structure is formed between the right clamping piece (8) and a right bearing seat (9). A sliding seat in the second lead screw transmission mechanism (14) is fixedly connected with the right bearing seat (9) and a lead screw is driven by a motor. The right clamping piece (8) is driven by the motor and does reciprocating rectilinear motion relative to the left clamping piece (7) and is driven by the motor and does rotating motion relative to the right bearing seat (9). By the adoption of the overturning device, the motor rotor overturning working time can be shortened, the motor rotor overturning working efficiency is improved, the labor intensity of working staff is lowered effectively, and the overturning device has the remarkable beneficial effects of being easy to operate, convenient to use, safe, reliable and the like.

Owner:CHENGDU CRRC ELECTRIC MOTOR CO LTD

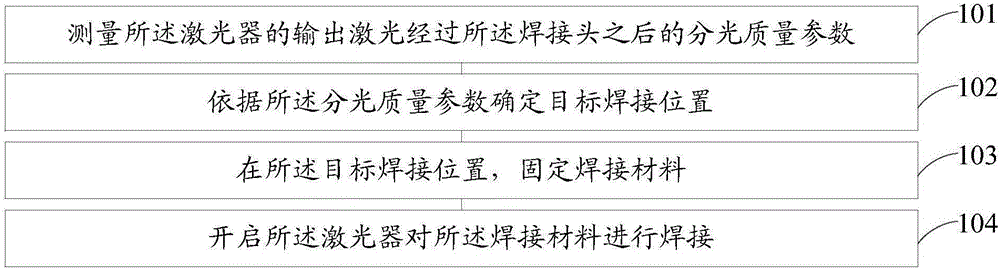

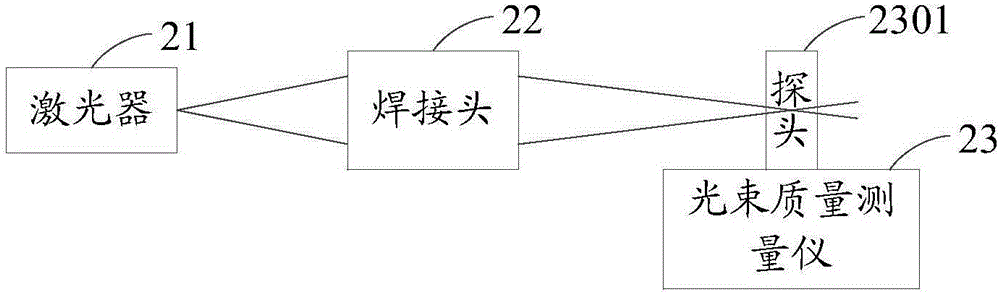

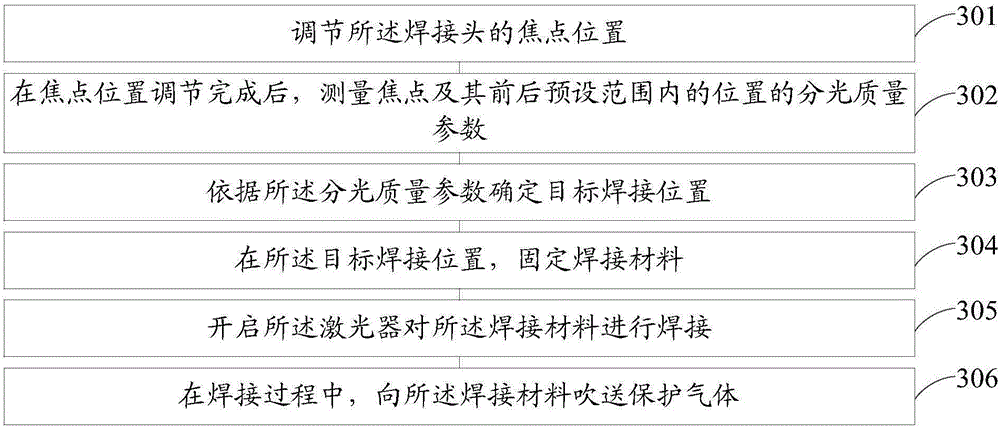

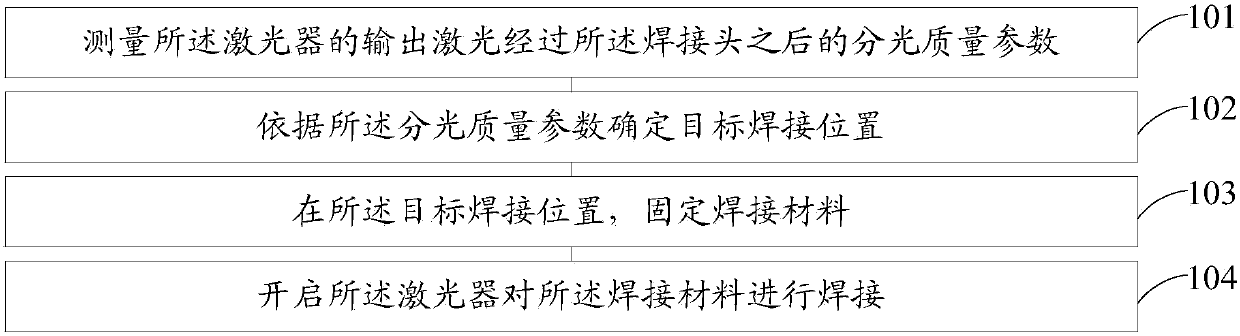

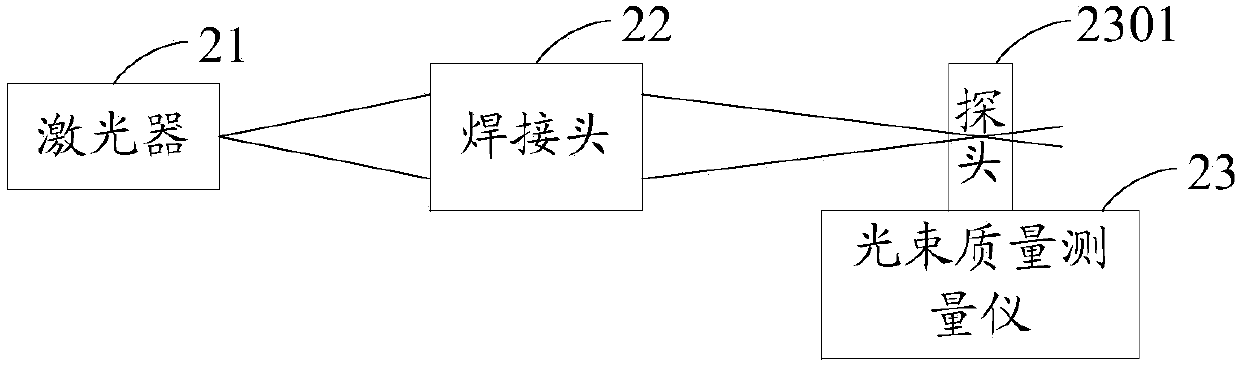

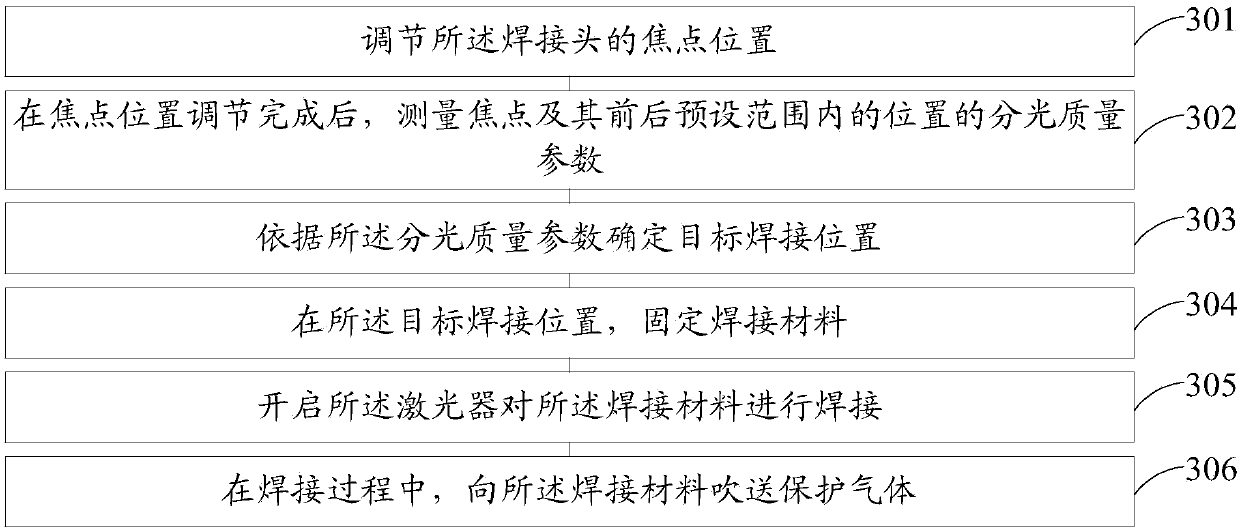

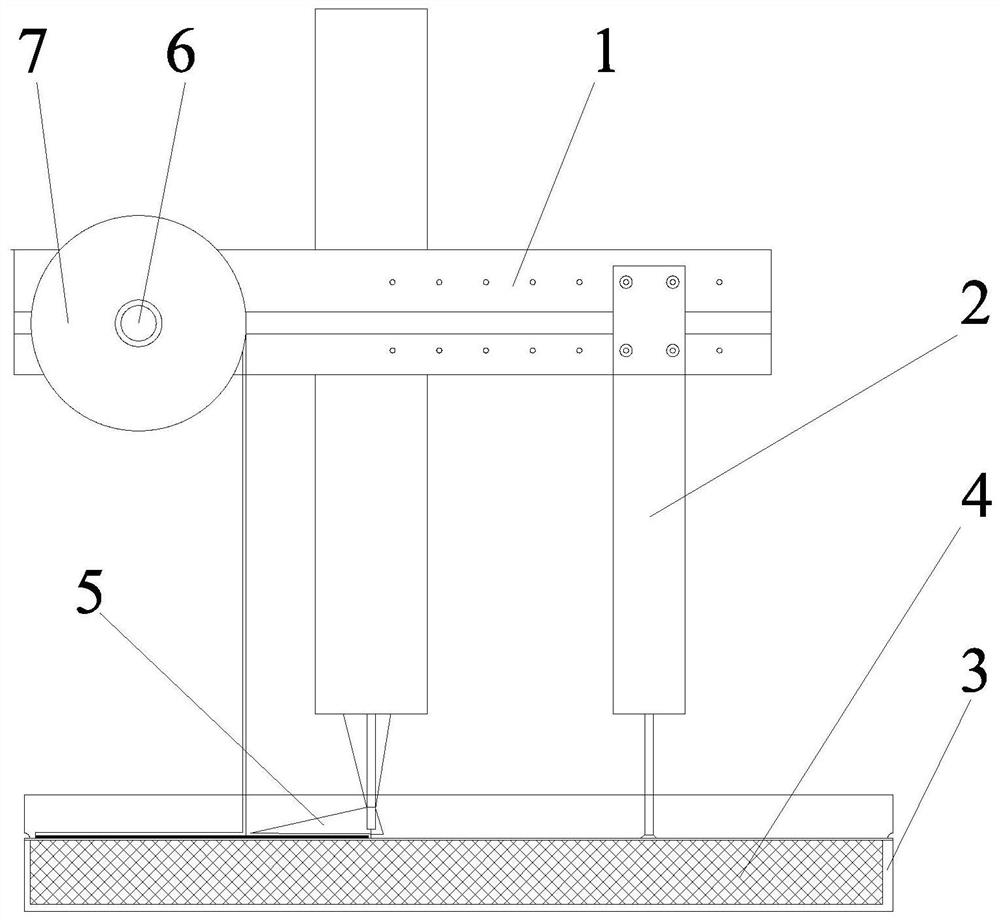

Laser welding technology, device and equipment

ActiveCN106001919AMeet welding process requirementsLaser beam welding apparatusLight beamEngineering

The embodiment of the invention provides a laser welding technology. A laser device and a welding head are adopted for welding. The welding head is provided with a double-beam lens used for splitting a single beam into double beams. The method comprises the steps that beam split mass parameters generated after an output laser of the laser device passes through the welding head are measured; the target welding position is determined according to the beam split mass parameters; a welding material is fixed at the target welding position; and the laser device is started to weld the welding material. In the embodiment, the double-beam lens is arranged in the welding head, the double-beam laser is formed after the laser passes through the welding head, the welding material is welded through the double-beam laser at the target welding position, a welding line of the welding material is in a U shape, and the requirement of the electromagnetic valve welding technology is met.

Owner:MAXPHOTONICS CORP

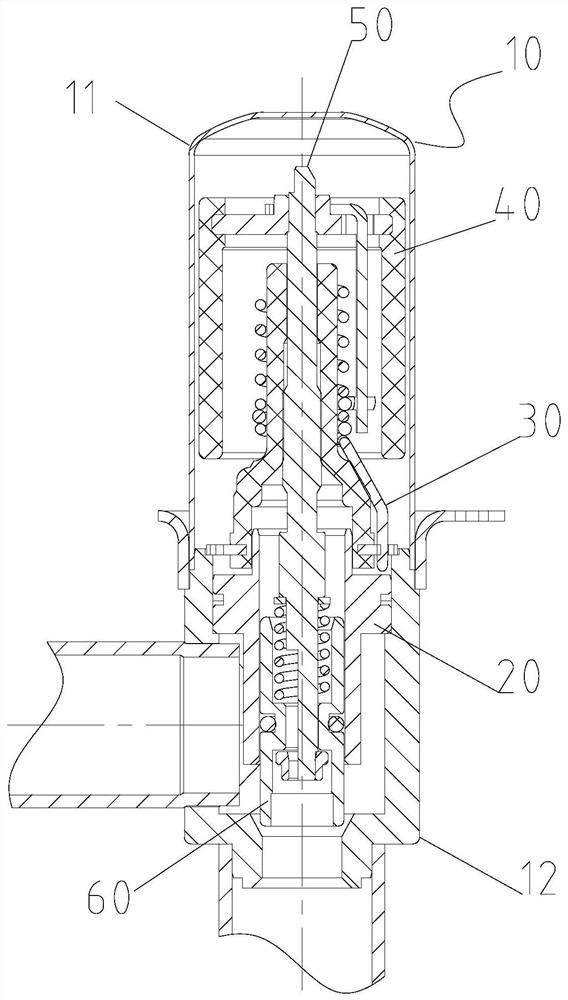

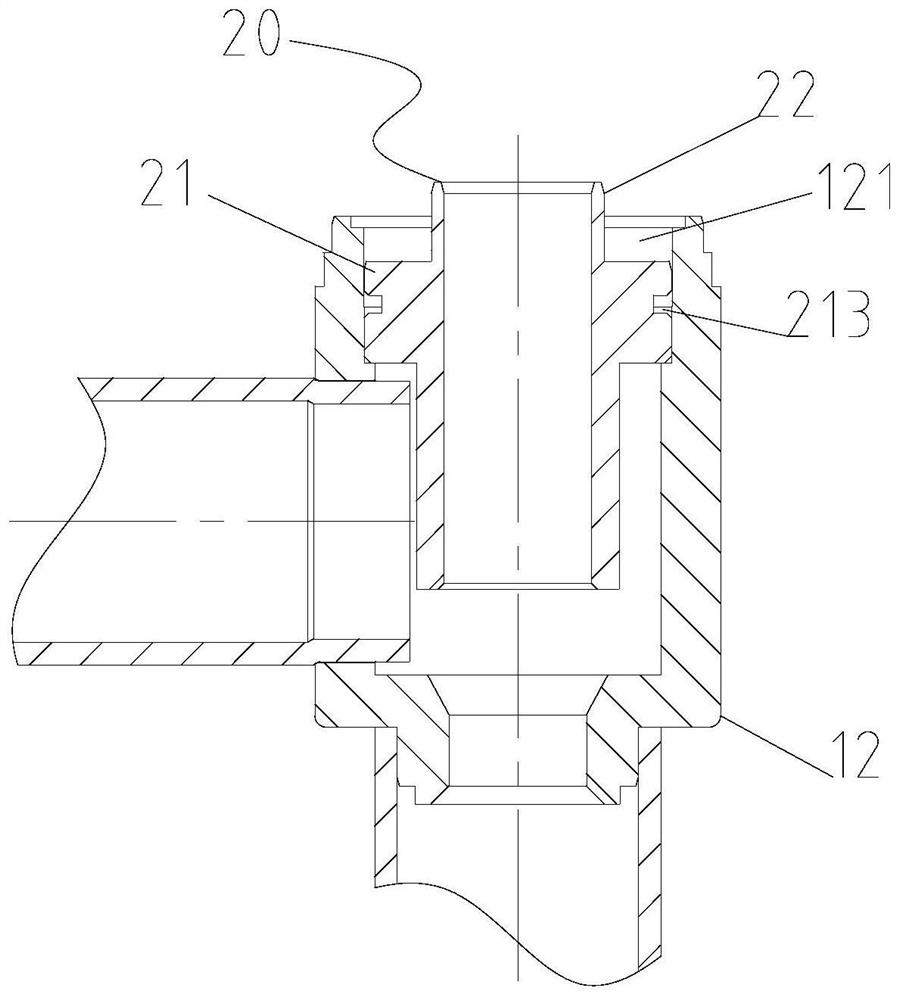

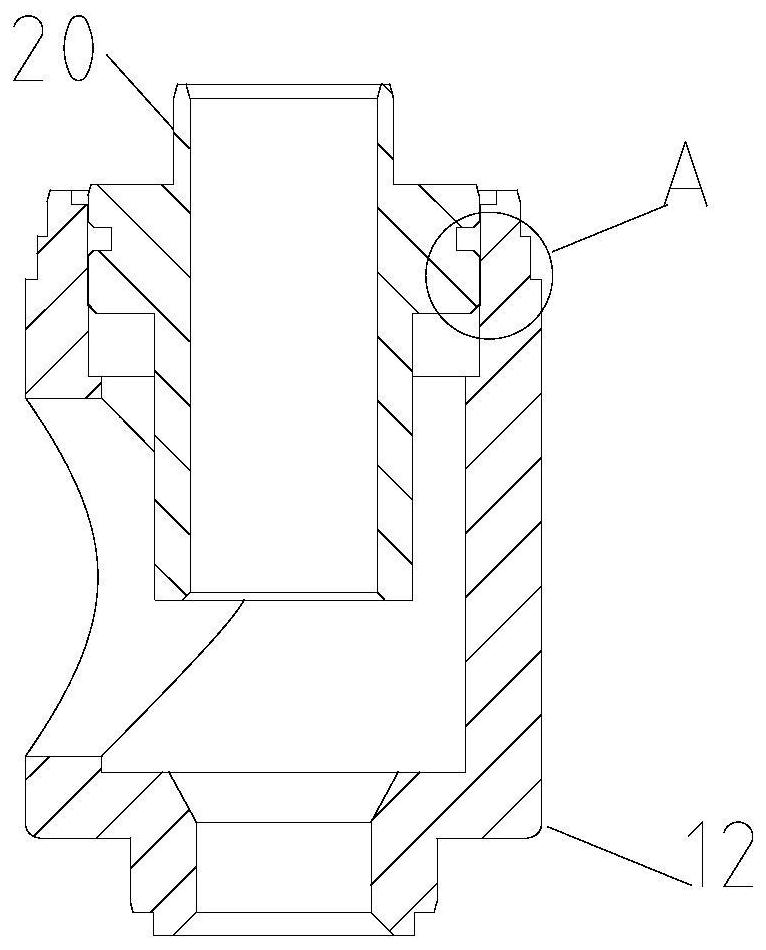

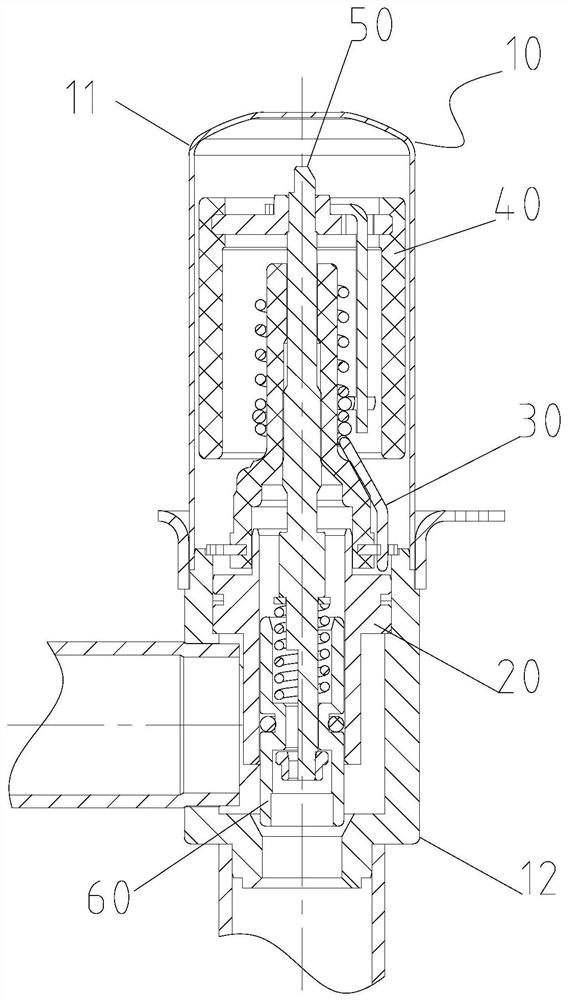

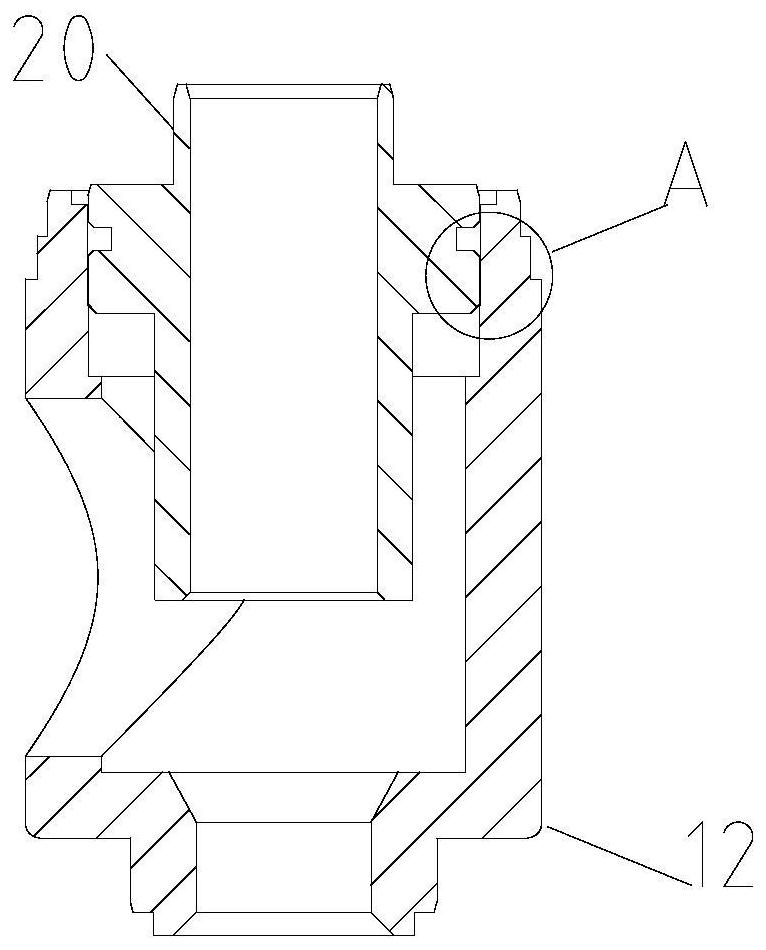

Electronic expansion valve

ActiveCN112576769APressing will not affectGuaranteed coaxialityLift valveValve housingsEngineeringElectronic expansion valve

The invention provides an electronic expansion valve. The electronic expansion valve comprises a shell, a guide sleeve, a rotor, a screw rod and a valve needle assembly; the guide sleeve is arranged in the shell; the rotor is rotatably arranged in the shell; the screw rod is arranged in the shell, and the rotor is in driving connection with the screw rod; the valve needle assembly is movably arranged in the shell, and one end of the screw rod is connected with the valve needle assembly so as to drive the valve needle assembly to move axially through the screw rod; and a guide section and a press-fitting section which communicate with each other are arranged between the inner wall of the shell and the outer wall of the guide sleeve, the distance between the guide sleeve located on the guidesection and the shell is larger than the distance between the guide sleeve located on the press-fitting section and the shell, a welding ring groove is further formed between the inner wall of the shell and the outer wall of the guide sleeve, and the welding ring groove communicates with the guide section. Through the technical scheme provided by the invention, the problem of low coaxiality in the prior art can be solved.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

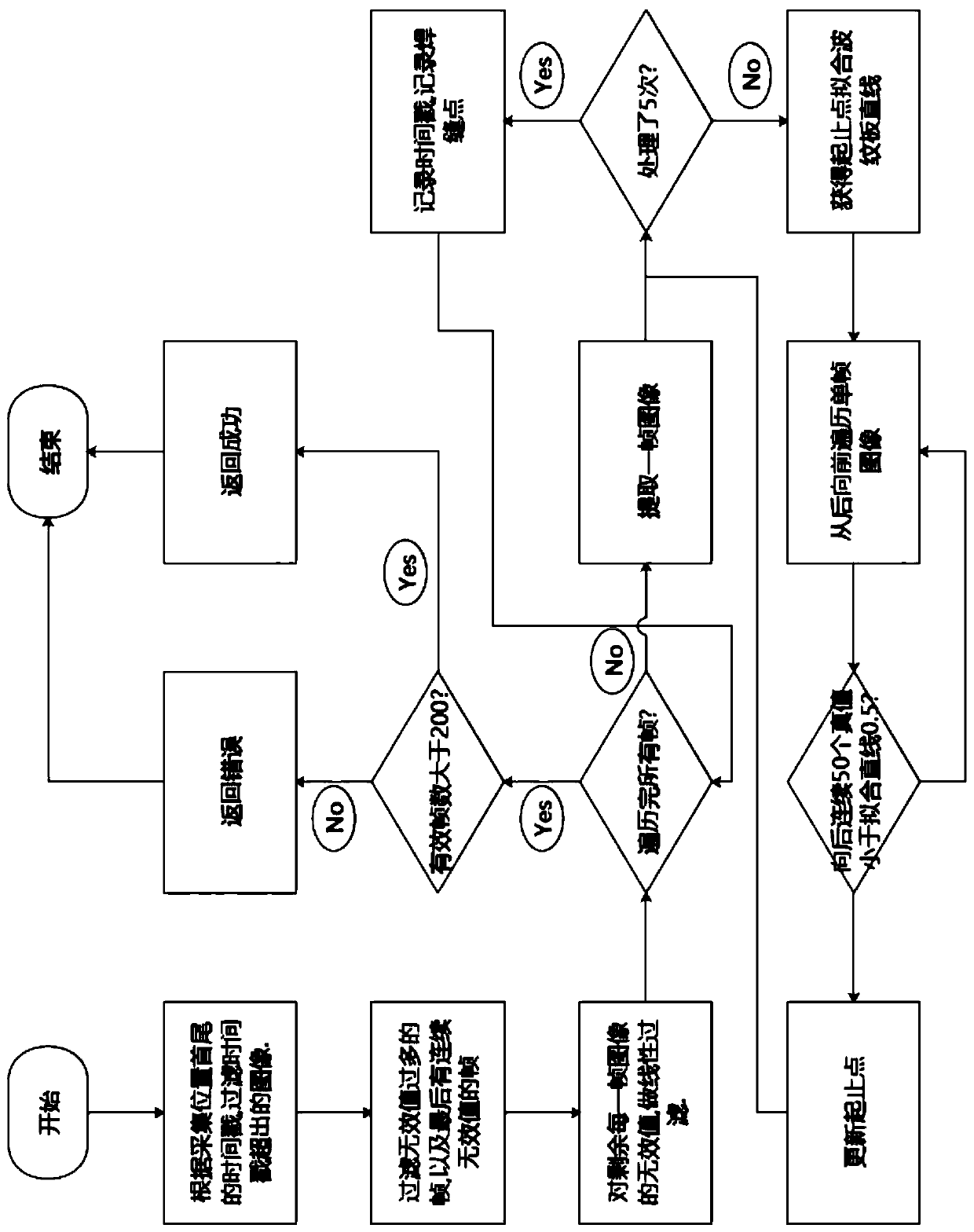

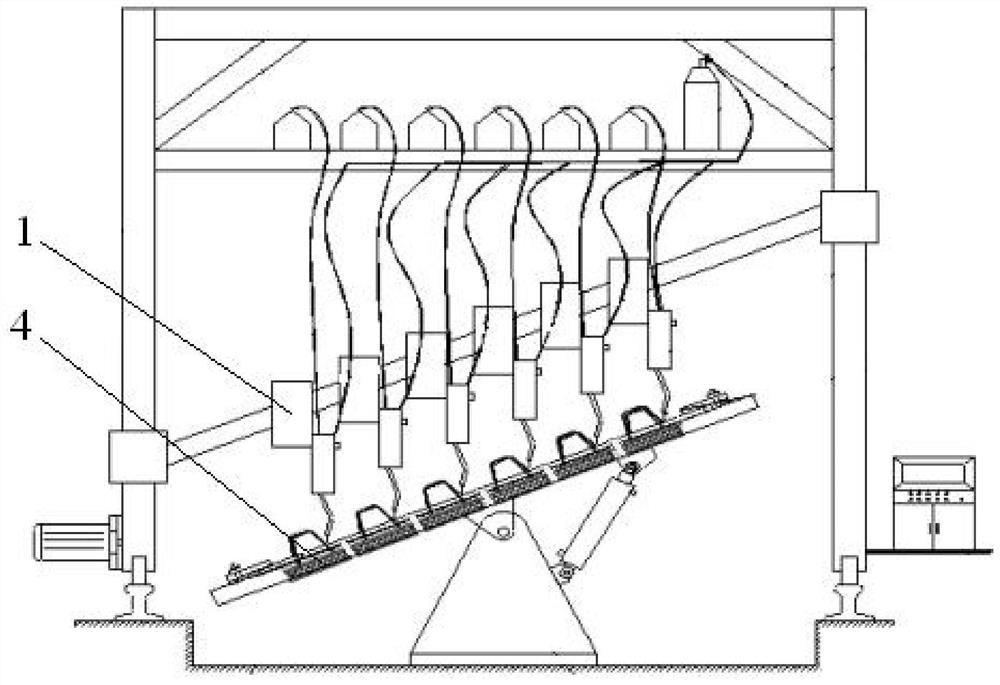

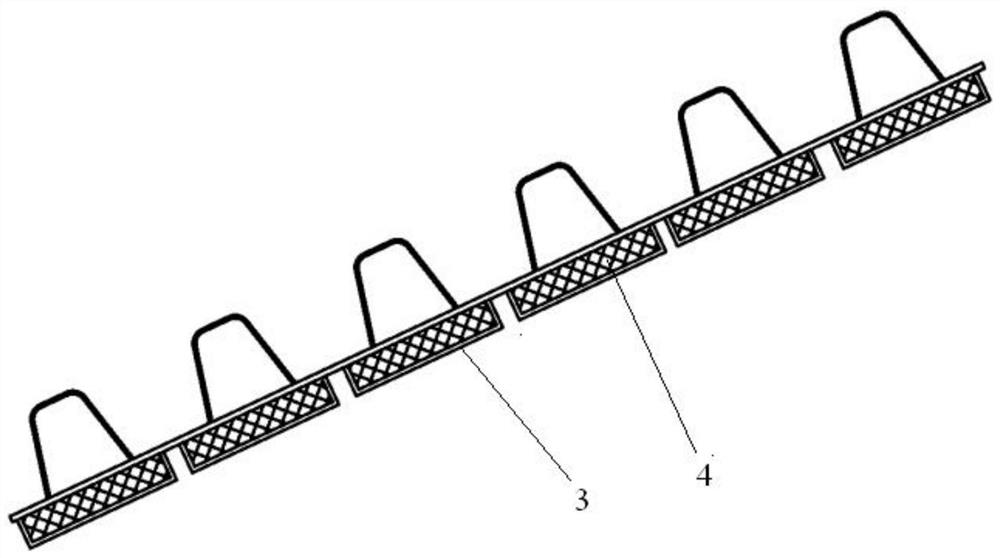

Tracking system and method for outer shaft of corrugated plate

ActiveCN110695494AMeet welding process requirementsWelding accessoriesControl engineeringPersonal computer

The invention discloses a tracking system and method for an outer shaft of a corrugated plate. The tracking method for the outer shaft of the corrugated plate comprises the following steps that S1, the point TCP of a robot is calibrated; S2, the robot, an industrial personal computer, a laser displacement sensor and a PLC module form a local area network; S3, the gun posture, the safety point andthe transition point of the robot are demonstrated; S4, the direction vector of a sliding table is calculated; S5, the world coordinate system of a camera and the robot is calibrated; S6, parameter initial setting is carried out according to the position of corrugations of the corrugated plate so as to divide the area and form the area boundary; and S7, the operation procedure of the robot is started, track planning and track compensation are automatically carried out within the preset deviation range, and therefore batched production is carried out according to the confirmed welding process.According to the tracking system and method for the outer shaft of the corrugated plate, track planning and track compensation are automatically carried out, and the welding process requirement with the process precision ranging from 0.5 mm to 1 mm is met.

Owner:创想智控科技(成都)有限公司

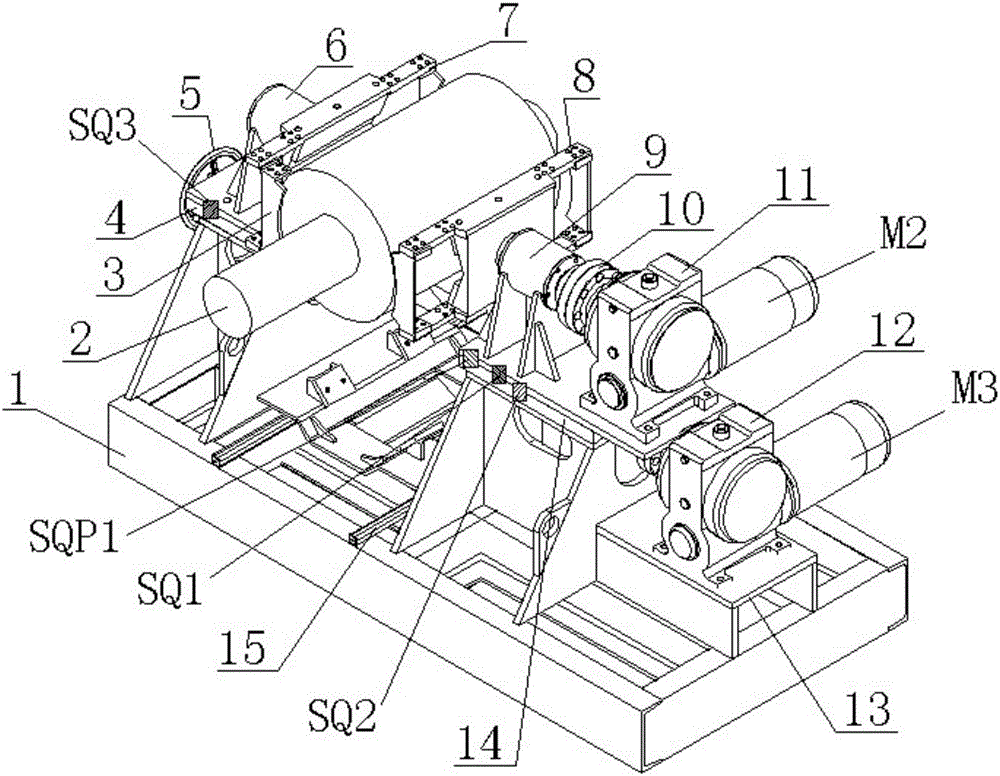

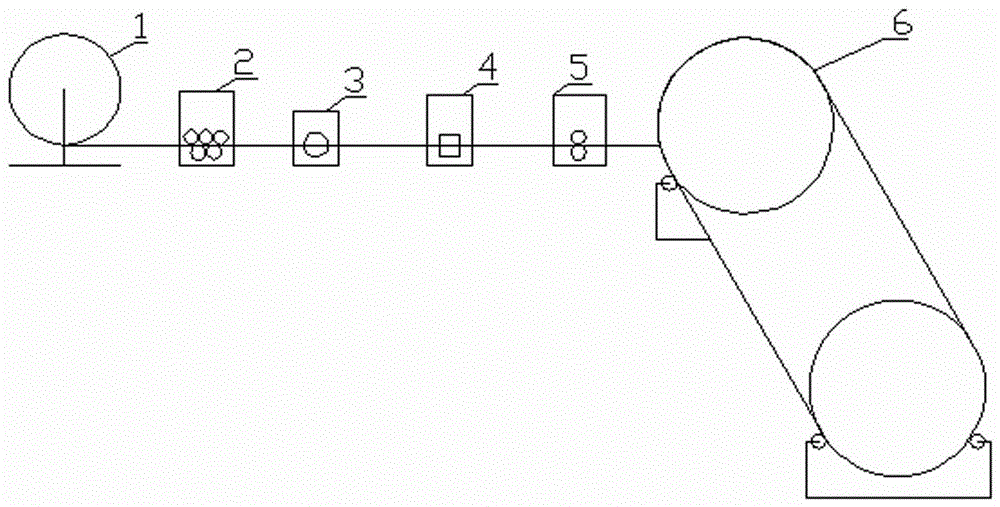

Spiral automated welding rolling machine for tanks

InactiveCN105665571AIncrease productivityReduce production capacityHollow articlesSheet steelEngineering

The invention discloses a spiral automated welding rolling machine for tanks. The spiral automated welding rolling machine for the tanks comprises a steel plate decoiling device, a steel plate leveling device, a steel plate edge cutting device, a groove machining device, a conveying device and a cylinder rolling device which are sequentially arranged and mounted, and a welding mechanical arm is arranged on one side of the cylinder rolling device. When in use, firstly the steel plate decoiling device decoils a roller-shaped steel plate, the steel plate leveling device levels the steel plate, the steel plate edge cutting device cuts the steel plate, the groove machining device machines the steel plate, the conveying device conveys the steel plate into the cylinder rolling device, and finally, the cylinder rolling device and the welding mechanical arm finish welding and cutting of internal and external gaps of a tank body. The spiral automated welding rolling machine for the tanks implement integration of six steps of decoiling, leveling, edge cutting, rolling, welding and cutting in a tank body manufacturing process, so that the production efficiency is improved, the production area and labors in the production process are reduced, and an oil tank manufacturing process is changed from multiple-operation and multiple-labor coordinative production into automated production.

Owner:保定长空石油工业股份有限公司

Pipeline port hysteresis buffer demagnetizer

ActiveCN102403086AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisControl manner

The invention discloses a pipeline port hysteresis buffer demagnetizer and relates to the technical field of pipeline systems. The pipeline port hysteresis buffer demagnetizer mainly comprises a silicon-controlled voltage pre-stabilizing circuit, an inversion main control circuit, a rectifier, a regulator, a magnetic field detection module, a display panel, a protection circuit and demagnetization coils, wherein a power supply from a power grid is connected with the silicon-controlled voltage pre-stabilizing circuit; the output of the silicon-controlled voltage pre-stabilizing circuit is connected with the inversion main control circuit, the manual regulation output which is connected with the display panel is also connected with the inversion main control circuit, the output, which is connected with the output of detection probe, of the magnetic field detection module is connected with the inversion main control circuit; the output of the inversion main control circuit is connected with the rectifier; the rectifier has three paths of outputs: one of three paths of output of the rectifier is connected with the protection circuit, and the output of the protection circuit is connected with the silicon-controlled voltage pre-stabilizing circuit and the inversion main control circuit; one path of output of the rectifier is connected with the display panel; and another path of output of the rectifier is connected to the demagnetization coils (1 and 2). Compared with the conventional demagnetization product, the pipeline port hysteresis buffer demagnetizer has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed and good demagnetization effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A tool for welding assembly of head and flange

ActiveCN107931943BGuaranteed clearanceGuaranteed flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention provides a tool for welding assembly of an end socket and a flange. The upper portion of a main shaft is sleeved with a pressing plate and a cushion plate, and the pressing plate is madeto be located above the cushion plate. The end of each mounting rod on the circumference of the pressing plate is provided with an alignment tolerance adjusting bolt, and push heads on the alignmenttolerance adjusting bolts correspond to the end socket supporting faces of the edge of the upper surface of the cushion plate. Raised height adjusting bolts are mounted on the cushion plate. A plurality of radially-extending supporting rods are arranged on the surface of the outer circumference of the cushion plate, and the edge of the upper surface of each supporting rod is an arc face matched with the surface of an inner arc of the end socket. Mounting holes for the raised height adjusting bolts are formed in the supporting rods correspondingly. According to the tool for welding assembly ofthe end socket and the flange, before-welding assembly of ellipsoidal holed end sockets of various thicknesses and diameters and the flange can be achieved, and the assembly quality meets the weldingtechnological requirement. The size phi of an inner hole of the related flange is 100-1000 mm, the diameter phi of the end socket is 300-2000 mm, and the assembly sizes of the all types of flanges andend sockets can meet the welding technological requirement.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

A kind of laser welding process, device and equipment

ActiveCN106001919BMeet welding process requirementsLaser beam welding apparatusLight beamEngineering

Owner:MAXPHOTONICS CORP

A hatchback car tail light bracket

ActiveCN103625354BSatisfy the requirement of too long front and back distance in shapeHigh strengthOptical signallingEngineering

The invention relates to a taillight support of a hatchback. A first turned edge is arranged on a support body and matched with the lower surface of a light, a second turned edge is arranged on the right portion of the support body and matched with the profile of an upper gutter channel on a rear pillar, a third turned edge is arranged on the right portion of the lower side edge of the support body and matched with the profile of a lower gutter channel on the rear pillar, a fourth turned edge is arranged on the upper portion of the left side edge of the support body and matched with the profile of the side wall, and a fifth turned edge is arranged on the lower portion of the left edge of the support body and matched with the profile of the side wall. Adjusting holes are formed in the left portion of the support body, and installation holes are formed in the right portion of the support body. A via hole is formed in the middle of the support body, and a reinforcement component is arranged on the periphery of the via hole. The strength of the taillight support of the hatchback can be reinforced, the taillight support and a rear pillar plate are combined to form a rear pillar cavity which is complete and smooth, and therefore the strength of the tail of a whole hatchback body is improved, uniformity of the taillight support is guaranteed, and requirements for a welding technology are met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Diesel engine base, engine base frame automatically welding workstation

InactiveCN101239431BImprove welding efficiencyAvoid injuryWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses an exclusive automatic welding machine for a diesel engine base and a base frame thereof, comprising a gate frame mounted on guide rails by using a propel unit, welding guns moving on the beam are provided on the two sides of the gate frame beam rails, each welding gun comprises a transverse arm provided with moving rails, a transversely moving block moving along the transverse arm is disposed on the transverse arm, longitudinal guide rails are provided on the transversely moving block, a lifting arm is connected with the longitudinal rails with a lifting mode, the lower end of the lifting arm is connected to the triangularly supporting type welding gun connection frame, a swing unit driven by a servo motor is disposed at the lower portion of the triangularly supporting type welding gun connection frame, a laser welding joint tracing sensor for cooling the auto water cooling welding gun and controlling welding gun moving position by a mechanical controller is provided at the end of the swing unit. The invented machine is provided with a reasonable structure and good working performance.

Owner:NANTONG SANJIU WELDING MACHINE

Pipeline port hysteresis buffer demagnetizer

ActiveCN102403086BOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisComputer module

The invention discloses a pipeline port hysteresis buffer demagnetizer and relates to the technical field of pipeline systems. The pipeline port hysteresis buffer demagnetizer mainly comprises a silicon-controlled voltage pre-stabilizing circuit, an inversion main control circuit, a rectifier, a regulator, a magnetic field detection module, a display panel, a protection circuit and demagnetization coils, wherein a power supply from a power grid is connected with the silicon-controlled voltage pre-stabilizing circuit; the output of the silicon-controlled voltage pre-stabilizing circuit is connected with the inversion main control circuit, the manual regulation output which is connected with the display panel is also connected with the inversion main control circuit, the output, which is connected with the output of detection probe, of the magnetic field detection module is connected with the inversion main control circuit; the output of the inversion main control circuit is connected with the rectifier; the rectifier has three paths of outputs: one of three paths of output of the rectifier is connected with the protection circuit, and the output of the protection circuit is connected with the silicon-controlled voltage pre-stabilizing circuit and the inversion main control circuit; one path of output of the rectifier is connected with the display panel; and another path of output of the rectifier is connected to the demagnetization coils (1 and 2). Compared with the conventional demagnetization product, the pipeline port hysteresis buffer demagnetizer has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed and good demagnetization effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A bridge steel automatic welding machine

ActiveCN109590581BAchieve insulation effectMeet welding process requirementsWelding/soldering/cutting articlesWelding accessoriesWater vaporEngineering

The invention provides an automatic welding machine for bridge steel, which includes a sliding track, a drying gun, a heating tank and a heating sheet, each side wall of the gas shielded welding machine is provided with a sliding track, and each sliding track faces the traveling direction of the door frame There is a drying gun at one end of the machine, the heating groove is set on the inner side of the frame of the hydraulic swing tire frame, and the heating sheet is arranged in the heating groove, so that the position of the workpiece heated by the drying gun can be adjusted as the drying gun slides on the sliding track, not only You can use the drying gun to remove the water vapor on the surface of the workpiece, and you can also adjust the temperature of the preheated workpiece when it reaches the welding torch, so that the temperature of the workpiece during welding is an ideal temperature, and after the welding is completed, the heating sheet will also heat the workpiece. It achieves the effect of heat preservation, which is beneficial to the formation of weld seams during the welding process of the plates, and can meet the requirements of the welding process and has good practicability.

Owner:WUCHUAN HEAVY ENG

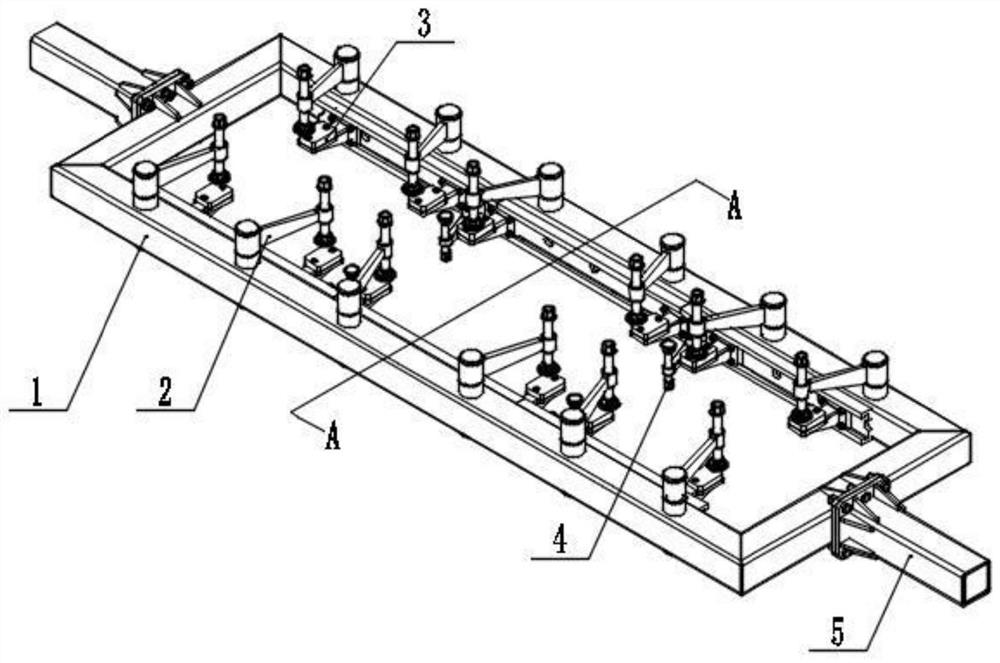

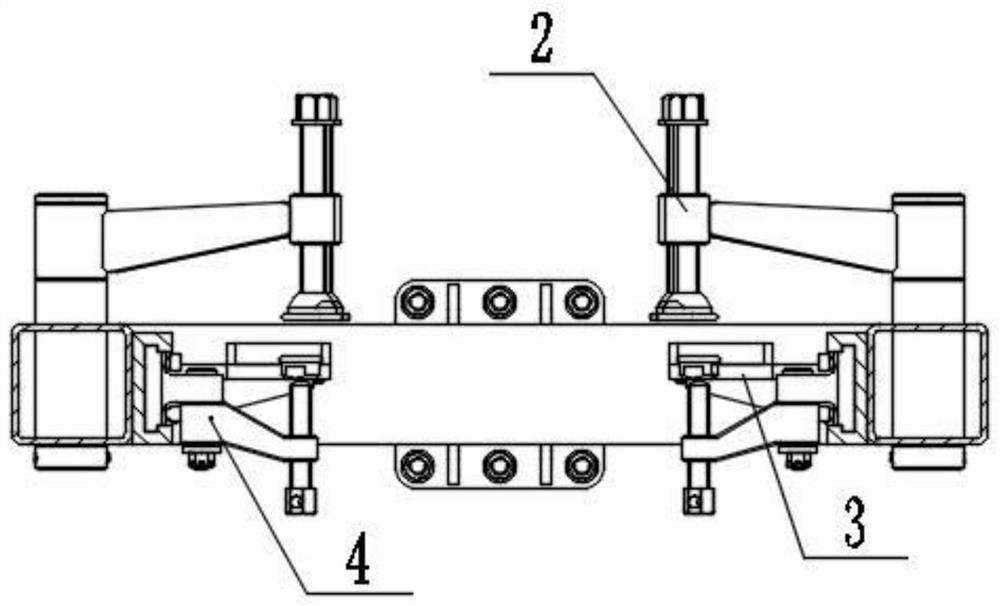

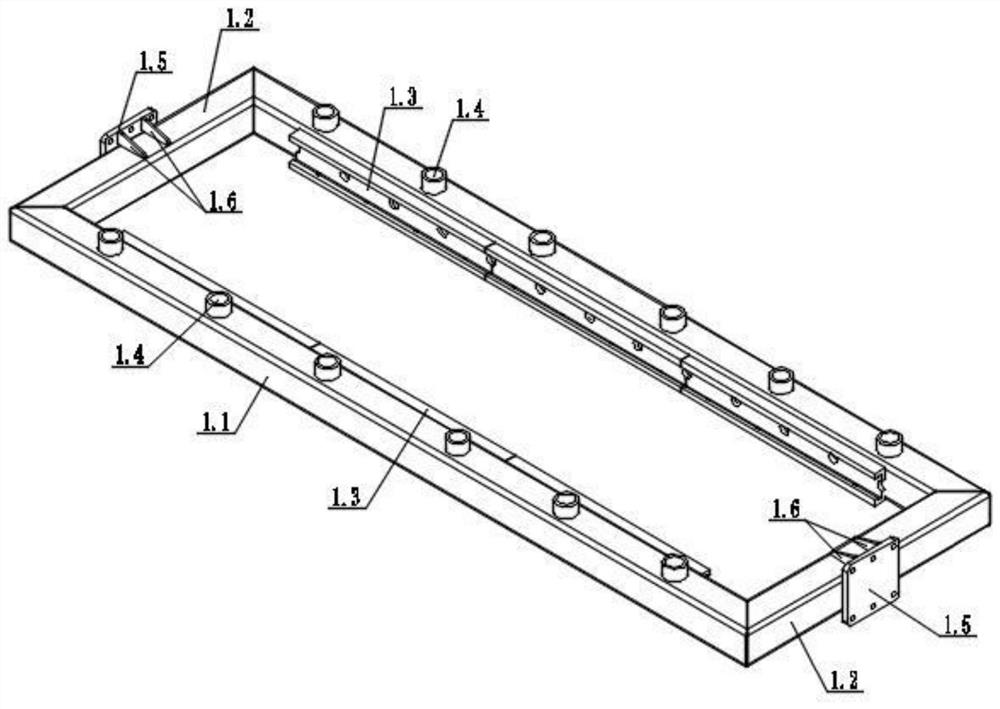

Railway vehicle traction beam assembling and welding tool

PendingCN112548476ABeneficial for feasibility and convenienceImprove versatilityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamCantilever

The invention provides a railway vehicle traction beam assembling and welding tool. The railway vehicle traction beam assembling and welding tool comprises a frame (1), workpiece clamping assemblies and welding base plate clamping assemblies, wherein the workpiece clamping assemblies and the welding base plate clamping assemblies are arranged on the frame (1). The workpiece clamping assemblies areused for clamping and fixing workpieces (6) and comprise cantilever clamping mechanisms (2) and supporting assemblies (3), and the cantilever clamping mechanisms (2) and the supporting assemblies (3)are arranged in a one-to-one correspondence mode. The welding base plate clamping assemblies are used for clamping welding base plates (7) to back welding seams of the workpieces (6) and comprise welding base plate pressing mechanisms (4). The railway vehicle traction beam assembling and welding tool comprises at least one set of workpiece clamping assembly and at least one set of welding base plate clamping assembly which are arranged on the frame, clamping of the workpieces is achieved through the workpiece clamping assemblies, the welding base plates are clamped at the back welding seams of the workpieces through the welding base plate clamping assemblies, and the welding process requirement of the workpieces is met.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

Pipeline port hysteresis buffer demagnetization controller

ActiveCN102403085BOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisComputer module

The invention discloses a pipeline port hysteresis buffer demagnetization controller and relates to the technical field of pipeline systems. The pipeline port hysteresis buffer demagnetization controller consists of a silicon-controlled voltage pre-stabilizing circuit, an inversion main control circuit, a rectifier, a regulator, a magnetic field detection module, a display panel and a protection circuit, wherein a power supply from a power grid is connected with the silicon-controlled voltage pre-stabilizing circuit; the output of the silicon-controlled voltage pre-stabilizing circuit is connected with the inversion main control circuit, and the manual regulation output which is connected with the display panel is also connected with the inversion main control circuit; the output, which is connected with the output of a detection probe, of the magnetic field detection module is also connected with the inversion main control circuit; the output of the inversion main control circuit is connected with the rectifier; one of three paths of output of the rectifier is connected with the protection circuit, and the output of the protection circuit is connected with the silicon-controlled voltage pre-stabilizing circuit and the inversion main control circuit; one path of output of the rectifier is connected with the display panel; and another path of output of the rectifier is connected to demagnetization coils (1 and 2). Compared with the conventional demagnetization product, the pipeline port hysteresis buffer demagnetization controller has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed and good demagnetization effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

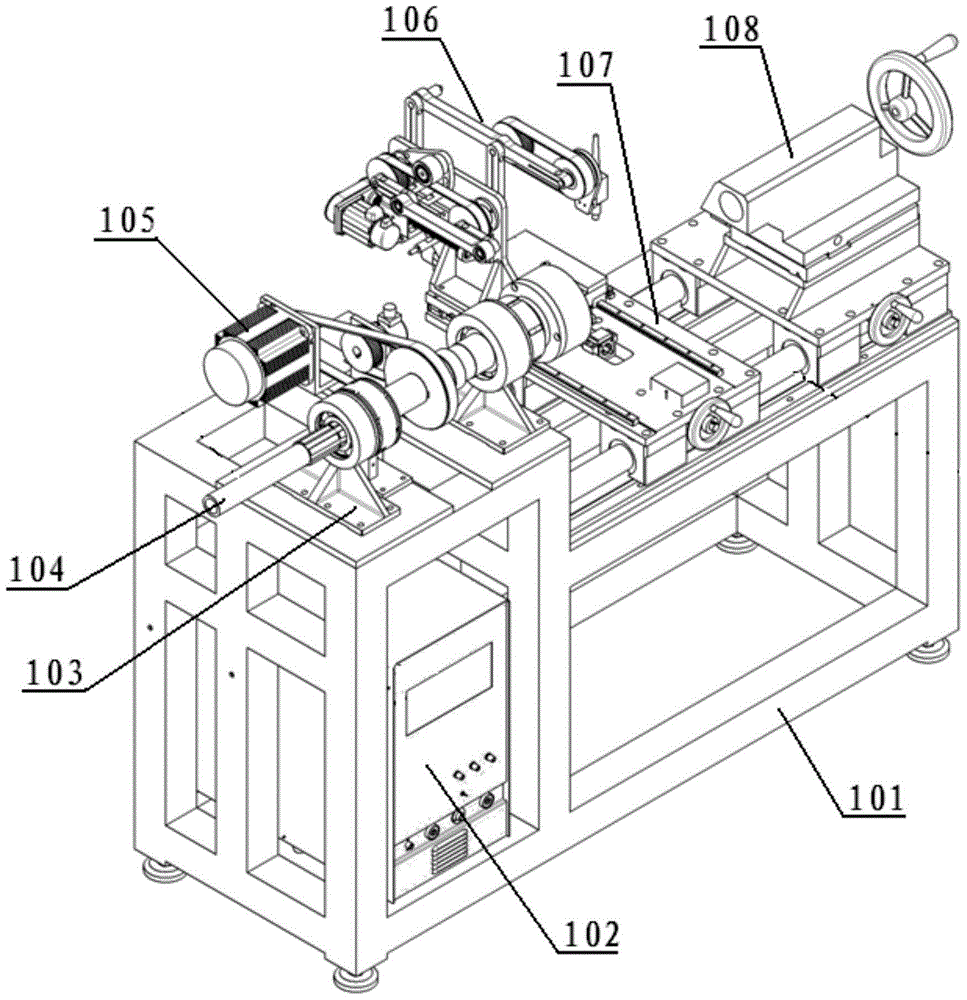

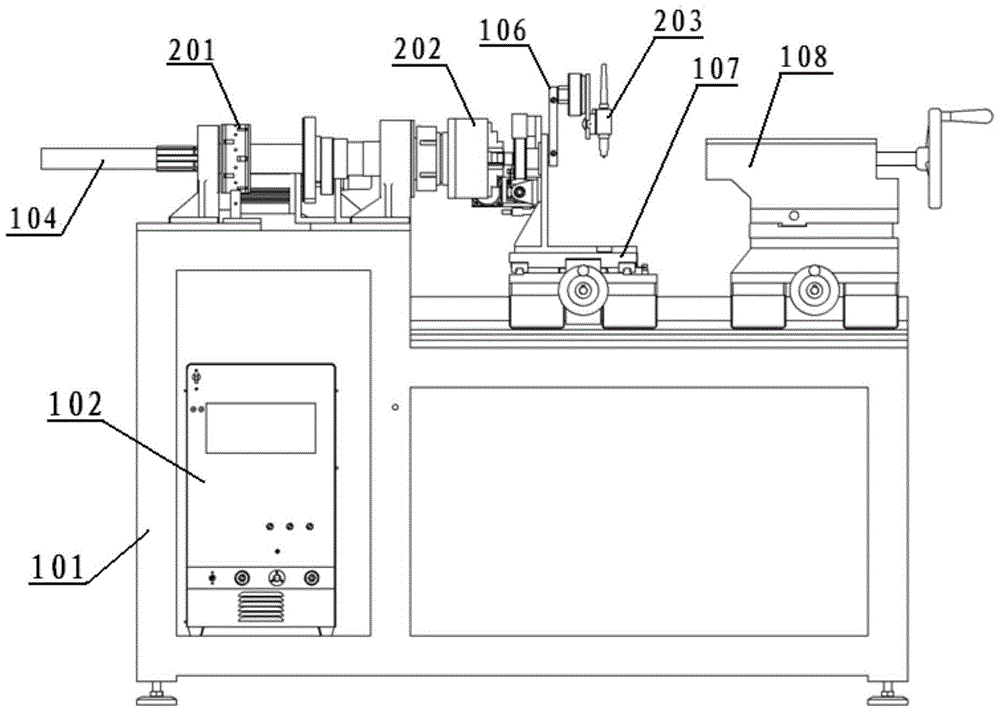

CNC Welding Bed for Realizing NC Welding of Plane Convex Weld

ActiveCN103612054BMeet welding process requirementsWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention relates to the field of mechanical devices, in particular to a numerical control welding lathe for achieving numerical control welding of a planar convex profile welding seam. The numerical control welding lathe for achieving numerical control welding of the planar convex profile welding seam comprises an A axis which controls a workpiece to be welded to rotate around an X axis, a Y axis and an A' axis which controls a welding gun to rotate around the welding tip of the welding gun. According to the numerical control welding lathe, compared with a welding lathe in the prior art, the attitude angle of the welding gun can be adjusted in real time in the moving process along the welding seam according to the curvature change of the welding seam, and therefore the welding technological requirement is met.

Owner:BEIJING POLYTECHNIC

Electronic expansion valve

ActiveCN112576769BPressing will not affectGuaranteed coaxialityLift valveValve housingsEngineeringMechanical engineering

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com