Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178 results about "Demagnetizing device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

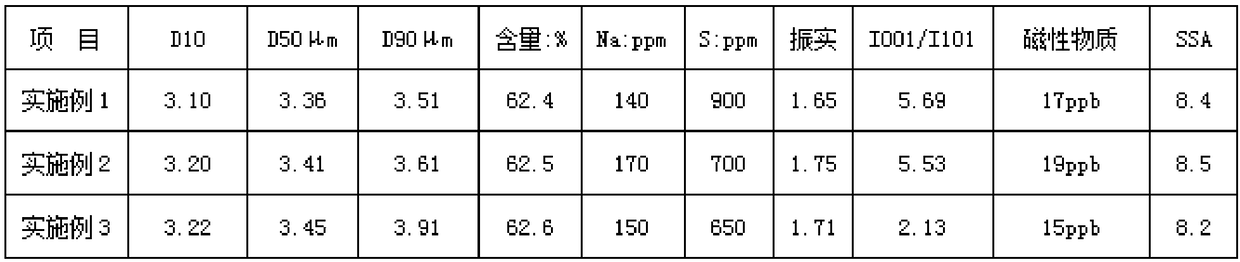

High-performance small-particle-size ternary positive electrode material precursor and preparation method thereof

ActiveCN108365214AImprove securityImprove cycle performanceCell electrodesSecondary cellsDemagnetizing deviceForeign matter

The invention provides a high-performance small-particle-size ternary positive electrode material precursor and a preparation method thereof, belonging to the technical field of positive electrode materials for lithium batteries. The precursor has a general chemical formula of NiCoMn<c>M<d>(OH)<2>, wherein M is one or more doping elements selected from the group consisting of calcium, magnesium, copper, aluminum, titanium, tantalum and niobium. The preparation method comprises the following steps: (1) preparation of a metal salt solution; (2) preparation of a complexing agent and a precipitating agent: preparing ammonia water with a concentration controlled to be 3 mol / L to 10 mol / L as the complexing agent; and (3) synthesis of the precursor. According to the high-performance small-particle-size ternary positive electrode material precursor in the invention provides, through element doping, detection and adjustment of feed concentrations and element contents with instruments andsubsequent treatment with a precise filter and a demagnetizing device, element distribution is made more uniform and accurate and the content of impurities and magnetic foreign matters in particles islower; so the purity and integrity of the crystal structure of the produced precursor are ensured, and the safety performance and cycle performance of the precursor are improved.

Owner:宁夏中色金辉新能源有限公司

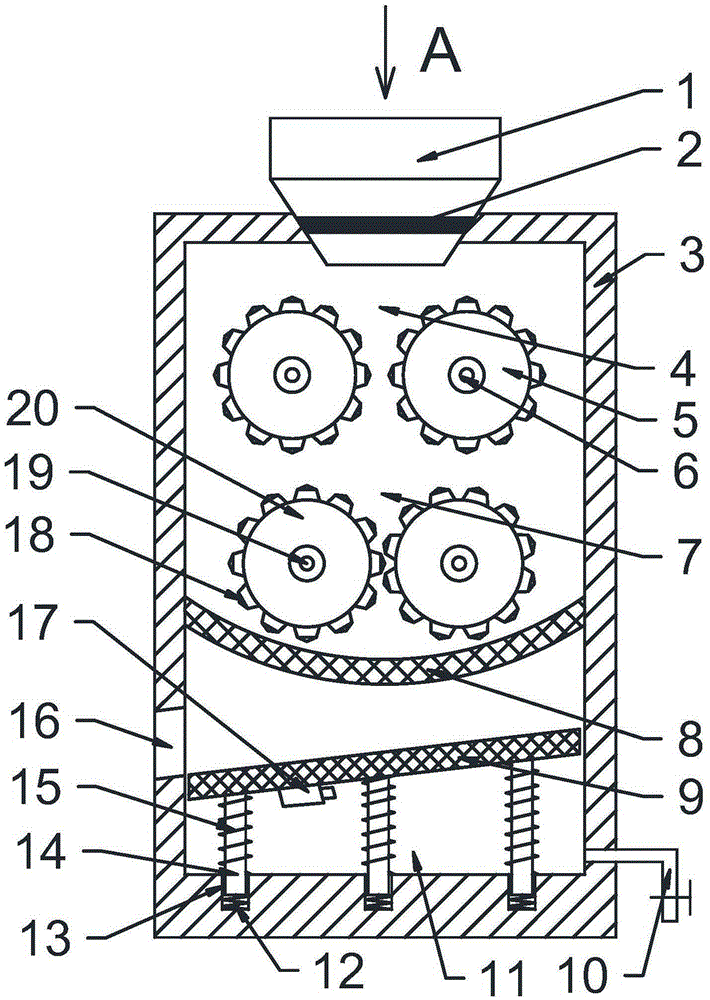

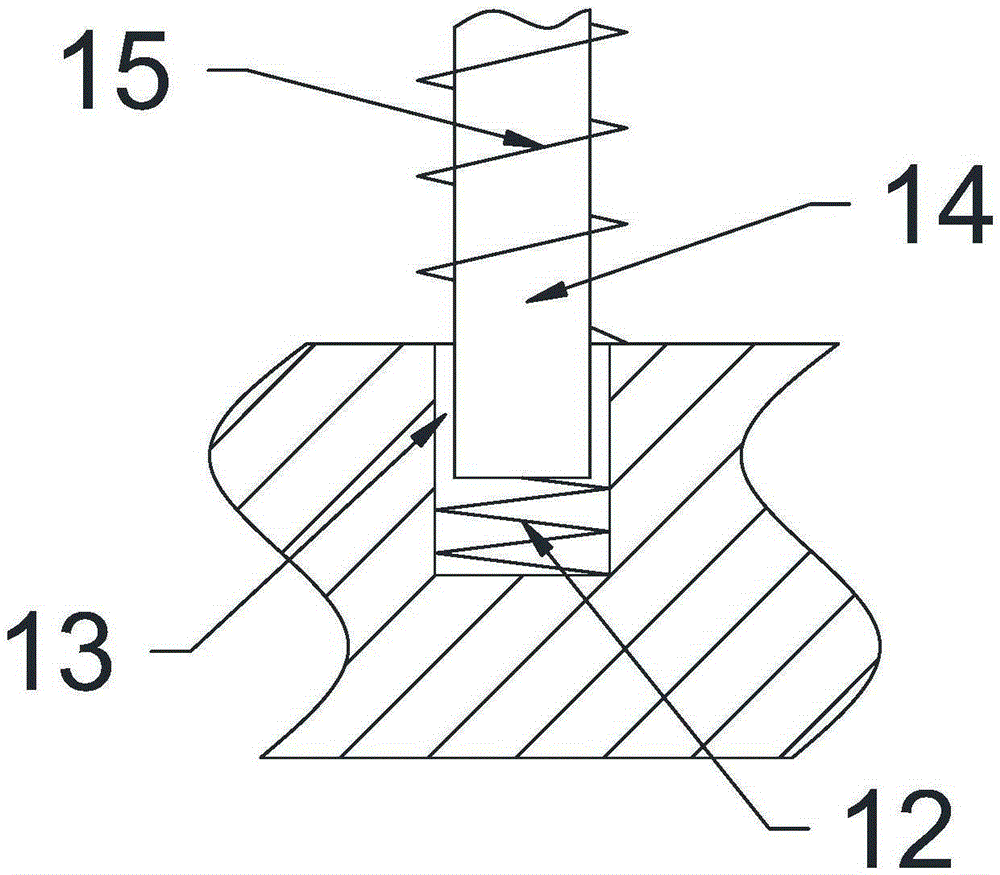

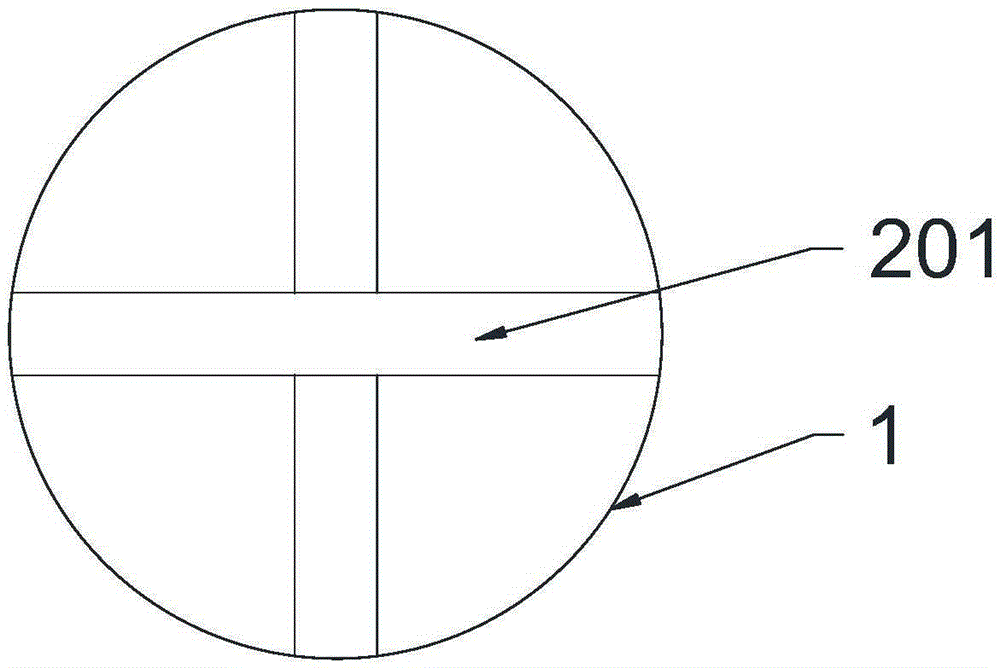

Gangue raw material processing device for insulating brick production

InactiveCN105312141AAvoid damageImprove crushing efficiencySievingScreeningDemagnetizing deviceBrick

The invention discloses a gangue raw material processing device for insulating brick production. The device comprises a crushing shell, wherein a feed hopper is arranged in the middle of the upper end part of the crushing shell; a demagnetizing device is arranged in the feed hopper, and consists of two crossed magnetic rods; two first-grade crushing rollers and two second-grade crushing rollers are arranged in the crushing shell from top to bottom; the first-grade crushing rollers coat first-grade roller shafts; the second-grade crushing rollers coat second-grade roller shafts; and multiple crushing projections are uniformly arranged on the first-grade crushing rollers and the second-grade crushing rollers. The device has the following beneficial effects: firstly, raw materials are magnetically separated to screen out iron-contained impurities so as to prevent a crushing device from being damaged; and the first-grade crushing rollers and the second-grade crushing rollers are arranged for selectively crushing incoming materials according to the volume size, so that the crushing efficiency is improved, and the crushing pressure is relieved.

Owner:嘉善远大新型墙体有限公司

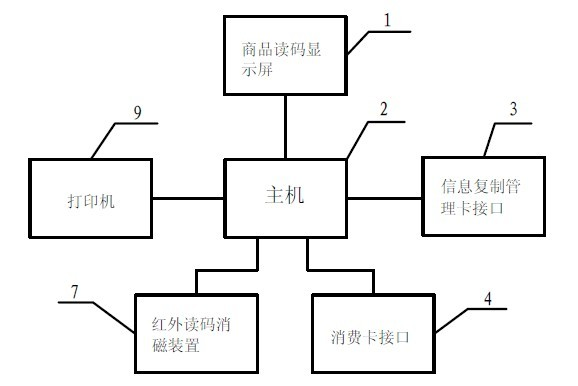

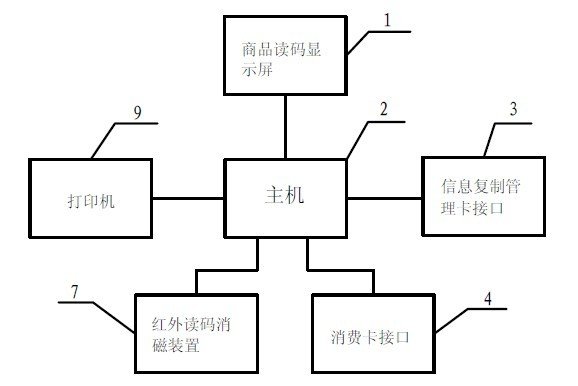

Unmanned convenience store operation system based on self-service cash register

InactiveCN107730783APrevent the situation of degaussing the anti-theft magnetic strip without pricing the commodityPlay a supervisory roleCash registersIndividual entry/exit registersDemagnetizing deviceComputer module

The invention discloses an unmanned convenience store operation system based on a self-service cash register, which comprises a showroom with weighbridges at the entrance and the exit. The showroom isinternally provided with the self-service cash register; the self-service cash register comprises a tunnel-type channel, a track, a track power device, a barcode scanning device and a demagnetizing device; the barcode scanning device and the demagnetizing device are both arranged in the tunnel-type channel; and the surface of the track is a goods placement area. A customer places the goods in thegoods placement area, the track moves and drives the goods to enter the tunnel-type channel, the goods sequentially passes through the barcode scanning device, the barcode information is read, the information is given to a PC processing module, the unit price and the unit weight corresponding to the barcode are called from a pre-stored barcode goods information database, the total price and the total weight SigmaW1...n are calculated, and n is no smaller than 1. The anti-theft magnetic strip of the goods is subjected to demagnetizing processing through the demagnetizing device away from the entrance. The weighbridges at the entrance and the exit acquire the weight difference of the customer before and after entering, the weight difference is compared with the total weight SigmaW1...n, opening and closing of a screen door at the exit are controlled according to the comparison result, and the goods can be prevented from being stolen or damaged.

Owner:安徽小豆网络科技有限公司

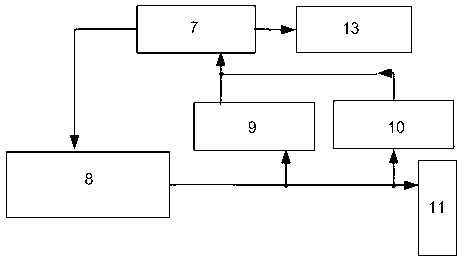

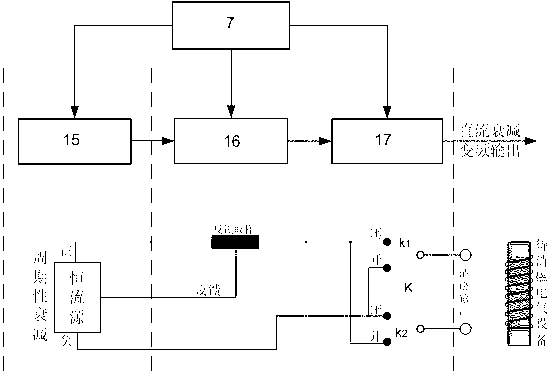

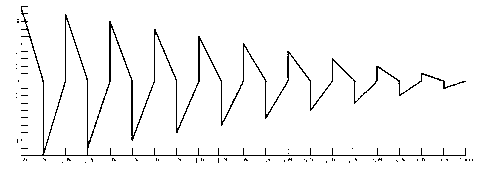

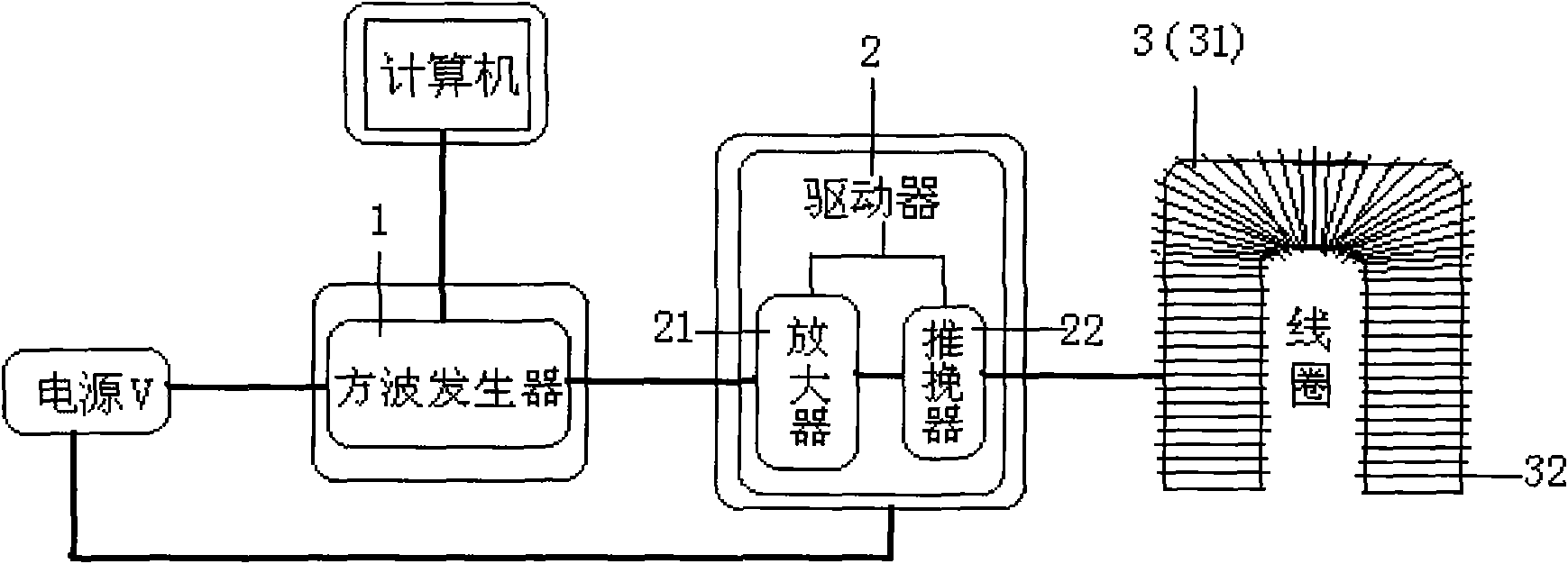

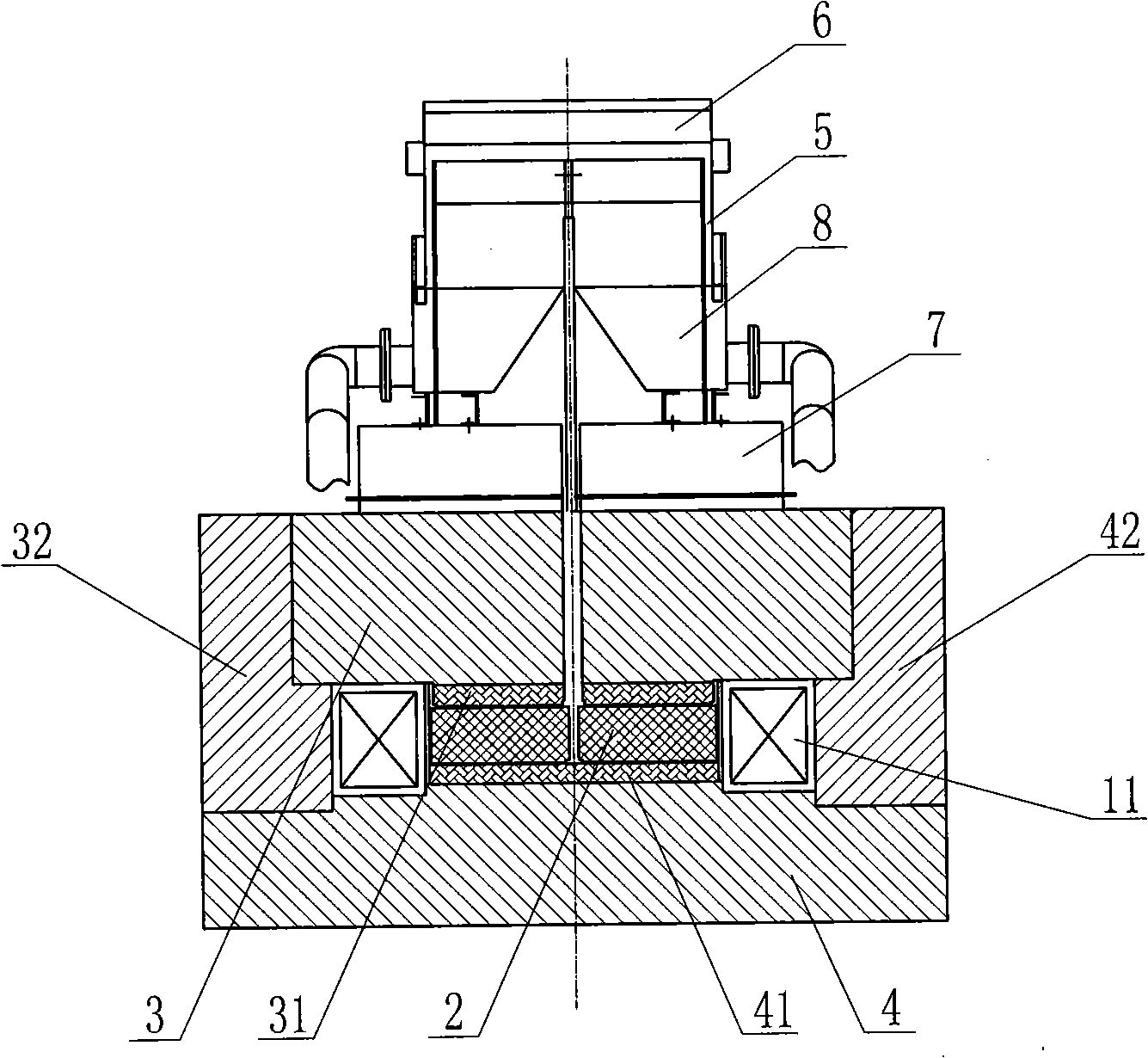

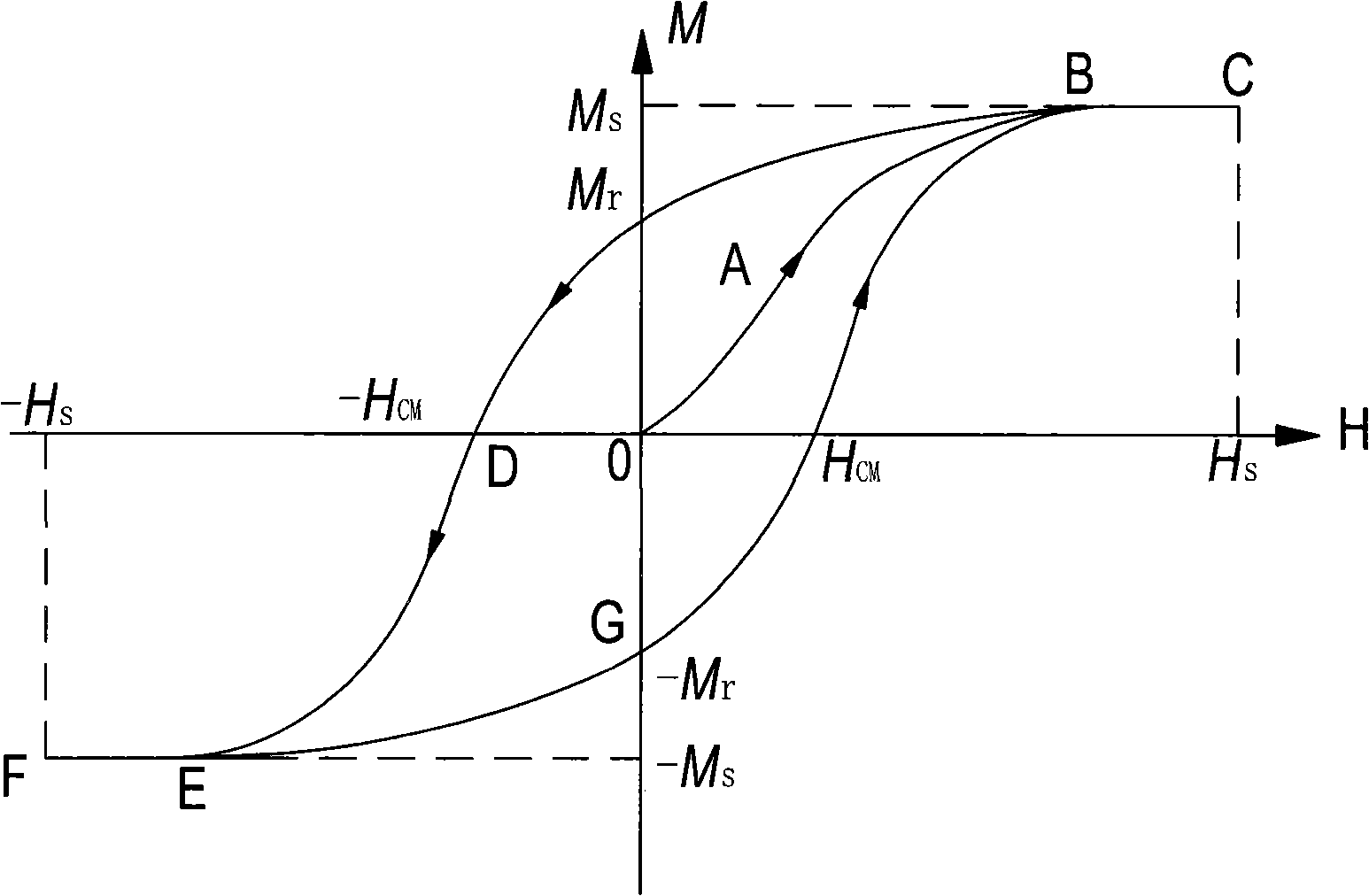

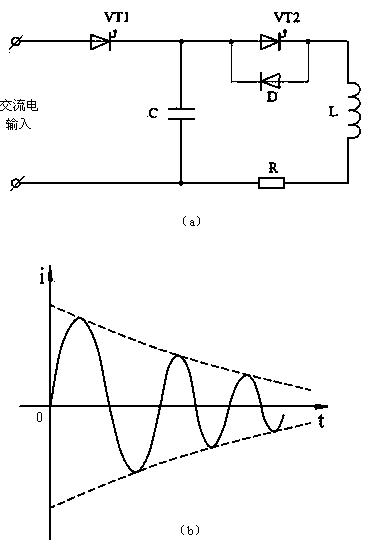

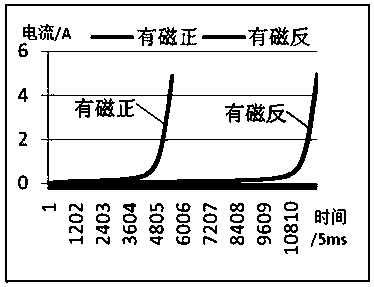

Direct-current attenuation variable-frequency demagnetizing device

ActiveCN102800458AAchieve the desired effectGuaranteed safe operationMagnetic bodiesMagnetic property measurementsDemagnetizing deviceTransformer

The invention provides a device which is used for eliminating and measuring residual magnet of a large-capacity high-voltage large-sensing electrical device of an electric power system. An innovative direct-current attenuation variable-frequency technology is adopted to produce a direct-current attenuation variable-frequency signal to demagnetize a high-voltage end of a mutual inductor and a power transformer; and simultaneously an alternative-current signal is applied to a low-voltage end of the mutual inductor and the power transformer to measure the residual magnet through a particular method. The direct-current attenuation variable-frequency demagnetizing device achieves a small size, a light weight, thorough demagnetization, rapidness in demagnetization, simpleness in measurement of residual magnet and the like. The weaknesses of an alternative-current method such as large size, heavy weight, inconvenience for on-site application, complicated structure and complexity in operation can be overcome, the effect of the alternative-current method is achieved, and the residual magnet is quantitatively measured. The safe and normal running of the power equipment can be guaranteed, and the national economic benefit can be further improved.

Owner:XIAN XU&HUI ELECTROMECHANICAL TECH CO LTD

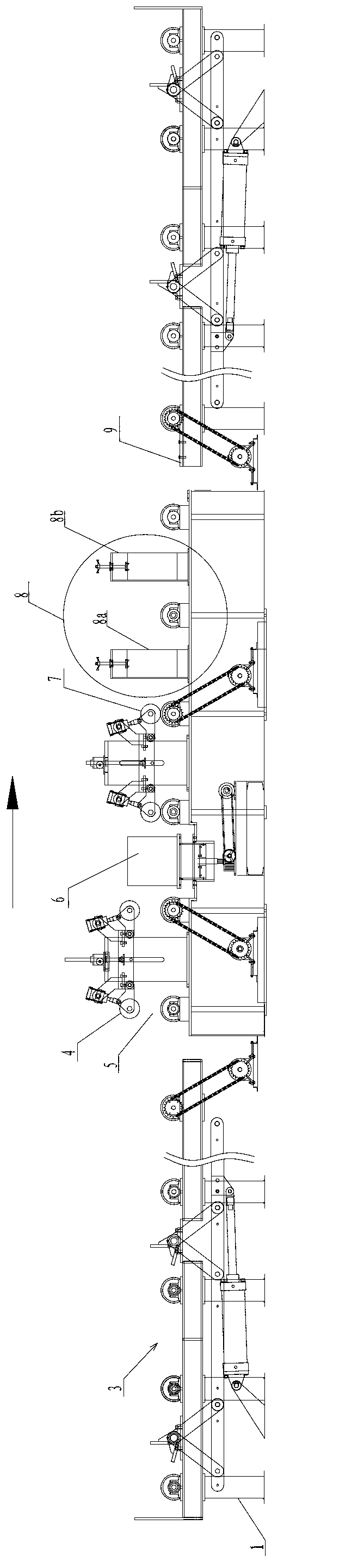

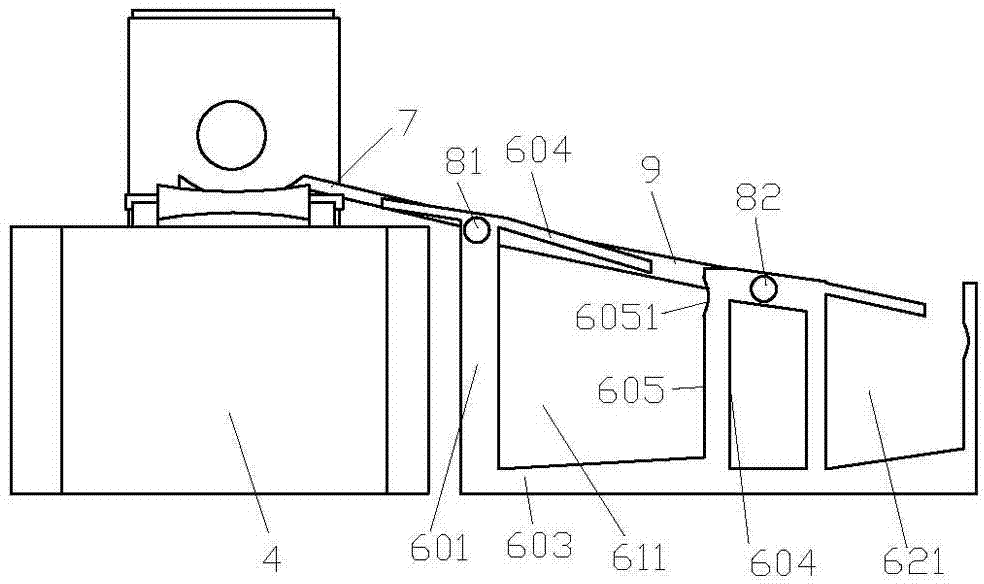

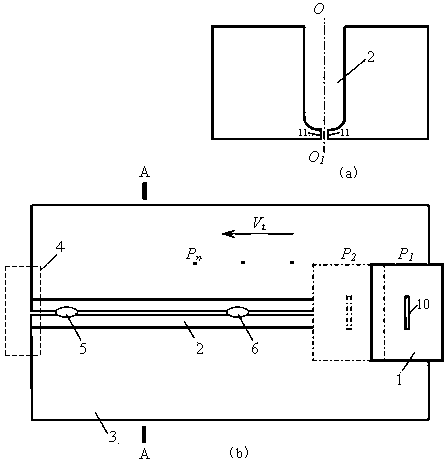

Eddy current detecting device of seamless steel tubes

InactiveCN103278559AImprove the detection rateQuality improvementMaterial magnetic variablesDemagnetizing deviceEngineering

The invention discloses an eddy current detecting device of seamless steel tubes, belonging to the technical field of tube detection. The eddy current testing device comprises a feeding platform, a conveying roller way, a first locating pinch roller, a flaw detection roller way, an eddy current testing device, a second locating pinch roller, a demagnetizing device, a marking seat and a discharging platform, which are sequentially installed on a rack, and an electric control device for controlling feeding and discharging as well as transferring, sorting and defect alarming of steel tubes. The eddy current detecting device is characterized by comprising a high frequency flaw detection device and a low frequency flaw detection device, wherein the high frequency flaw detection device comprises a high frequency magnetic saturation device A, a flaw detection probe A and a lifting device A, and the low frequency flaw detection device comprises a low frequency magnetic saturation device B, a flaw detection probe B and a lifting device B. The eddy current detecting device disclosed by the invention can be used for simultaneously detecting defects on inner and outer surfaces of tubes so as to improve the detection rate of defective steel tubes and further ensure good quality of the seamless steel tubes.

Owner:JIANGSU FANLI STEEL TUBE

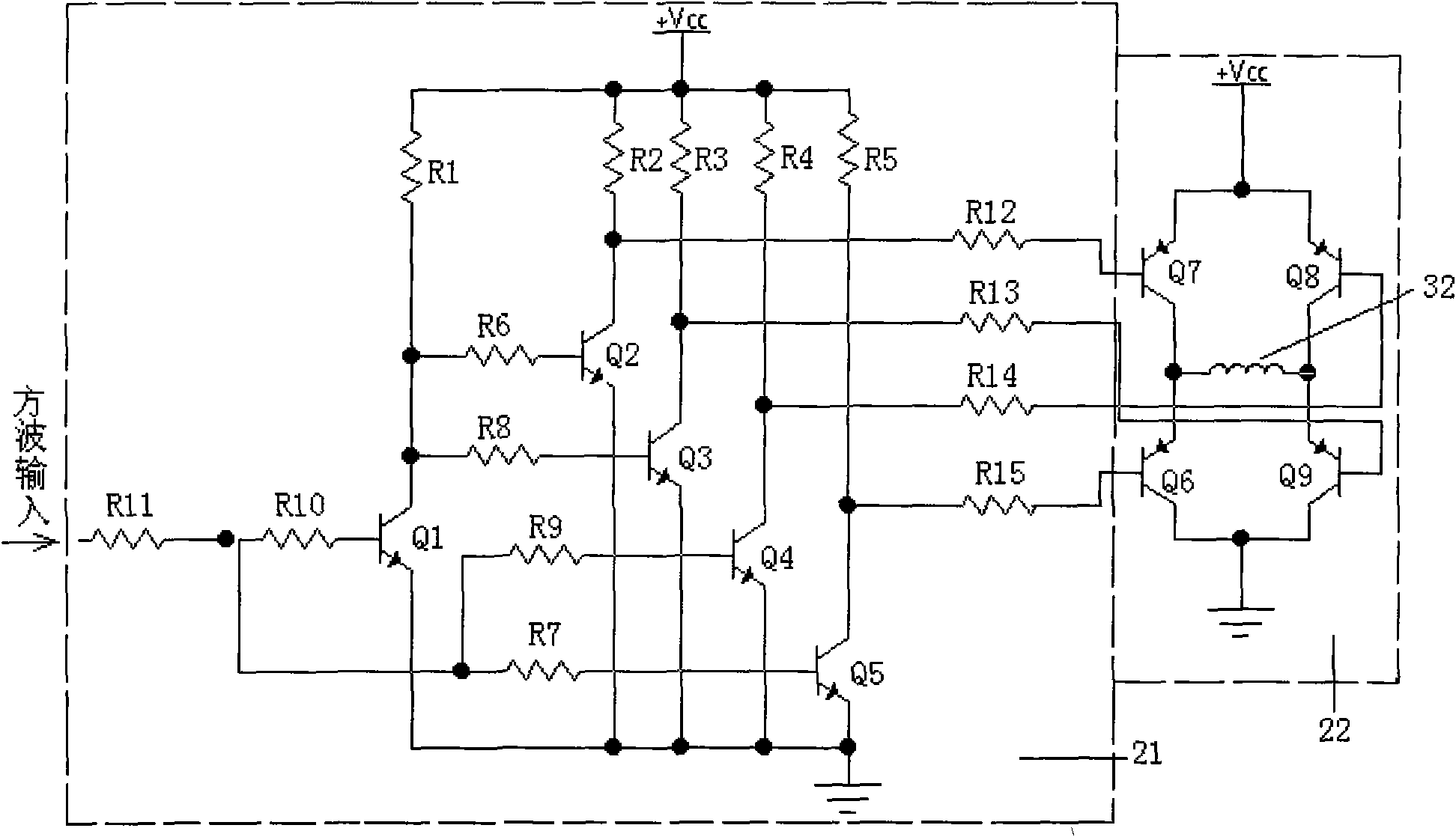

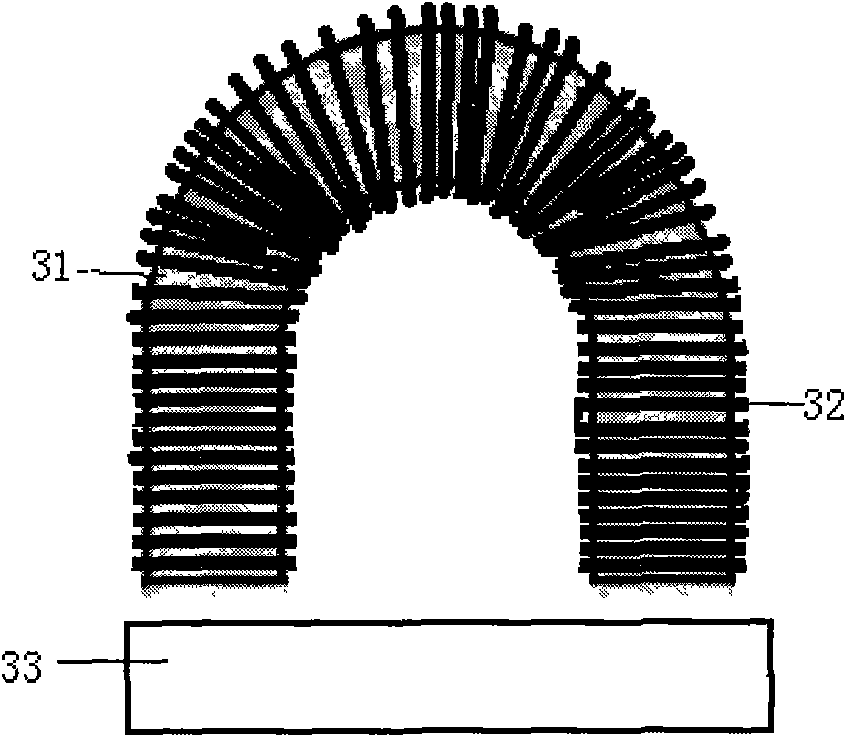

Workpiece demagnetizing method and workpiece demagnetizing device

InactiveCN101593604ANo human controlGood degaussing effectMagnetic bodiesDemagnetizing deviceSquare waveform

The invention relates to a workpiece demagnetizing method and a workpiece demagnetizing device. The method selects a square wave signal with unchanged frequency and amplitude; an amplifying circuit and a push-pull circuit are connected into a drive circuit; and the drive circuit is connected with a coil. Corresponding to the method, the demagnetizing device mainly comprises a power supply, a signal generator, a driver and a coil. An unfading alternating magnetic field generated by the method and the device can not only demagnetize a static workpiece but also can carry out continuous demagnetization on a dynamic workpiece and have wide application range; a ferrite is adopted as a magnetic core; demagnetizing current with high frequency and unchanged amplitude is conducted to the coil; the alternating magnetic field generated by the coil can disturb the residual magnetic domain of the workpiece; the demagnetizing effect is good; and the method is simple and feasible and the device has a compact structure so as to solve the difficult problem of demagnetization in the field and have practical value.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

High-efficiency steel pipe flaw detection device

InactiveCN103399086AEasy to collect and stackImprove flaw detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingDemagnetizing deviceClassical mechanics

The invention relates to the field of steel pipe flaw detection equipment and in particular relates to a high-efficiency steel pipe flaw detection device. The high-efficiency steel pipe flaw detection device comprises a detection stander, wherein a row of conveying wheels are arranged on the detection stander; liftable guide pressing wheels are arranged on the conveying wheels; flaw detection devices are arranged in the conveying directions of the conveying wheels and comprise flaw detectors and fixed boxes which are used for holding the flaw detectors and guiding steel pipes; a collection stander is also arranged at a position close to an outlet of the detection stander; a demagnetization device is arranged at an inlet of the collection stander; a row of bearing wheels positioned in the conveying directions of the conveying wheels are also arranged on the collection stander; collection frames are arranged on any one side or two sides of the bearing wheels along the conveying directions and comprise qualified product frames close to the bearing wheels and unqualified product frames away from the bearing wheels; collection rods for collecting the steel pipes are also arranged on the collection frames or the collection stander and are positioned in clearances between the bearing wheels. The high-efficiency steel pipe flaw detection device is firm in structure and very high in efficiency.

Owner:ANJI PENGDA STEEL PIPE

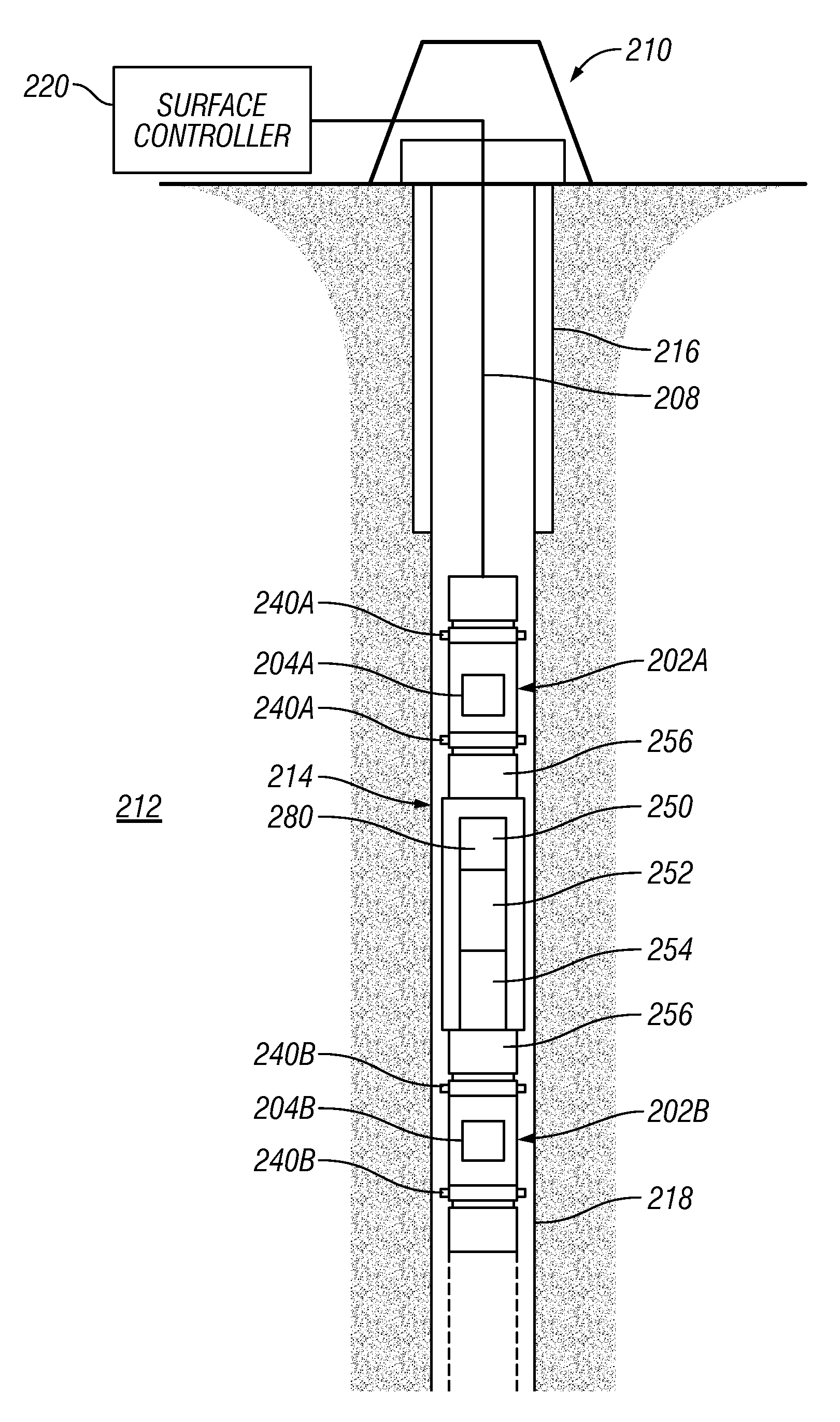

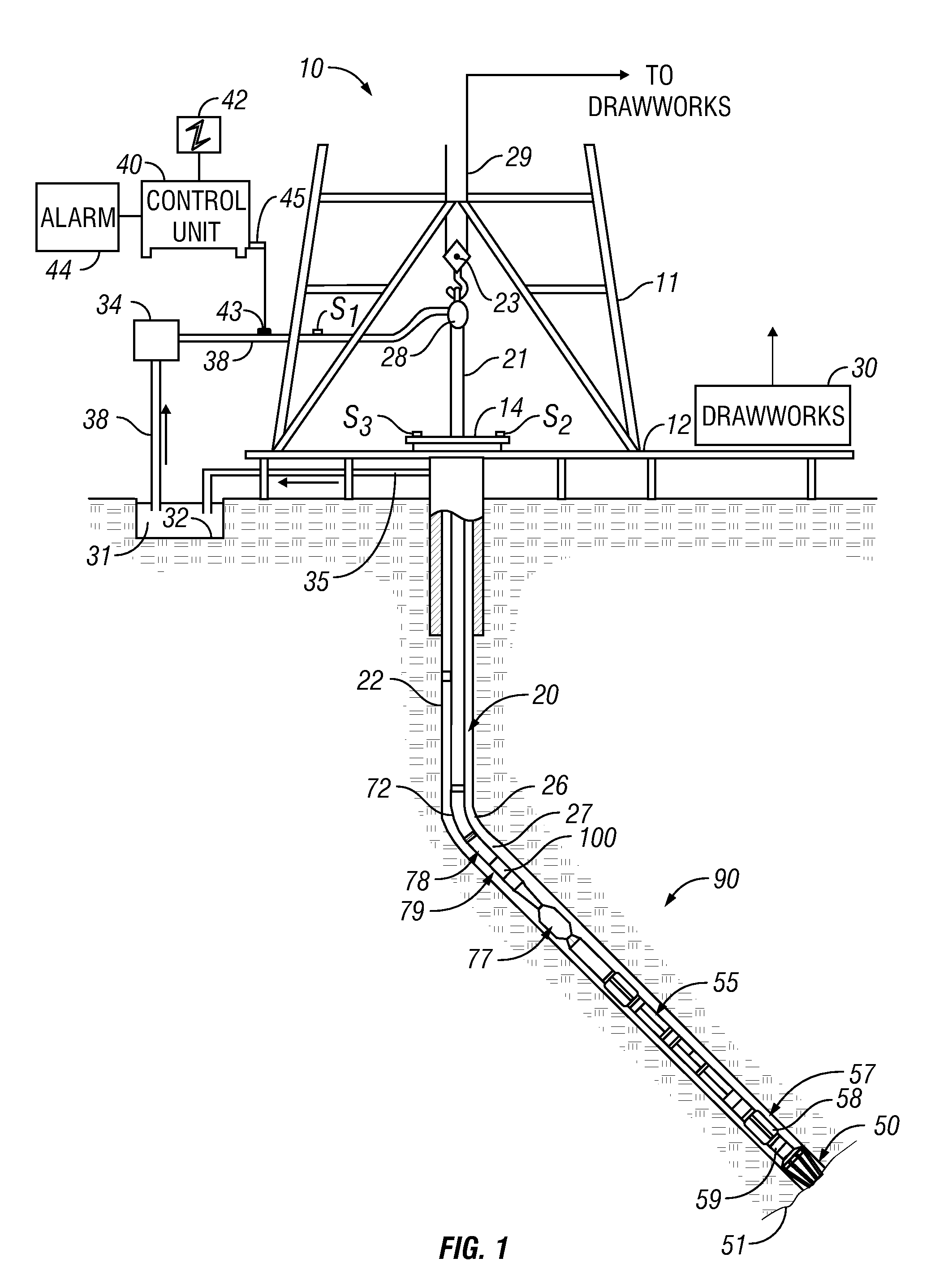

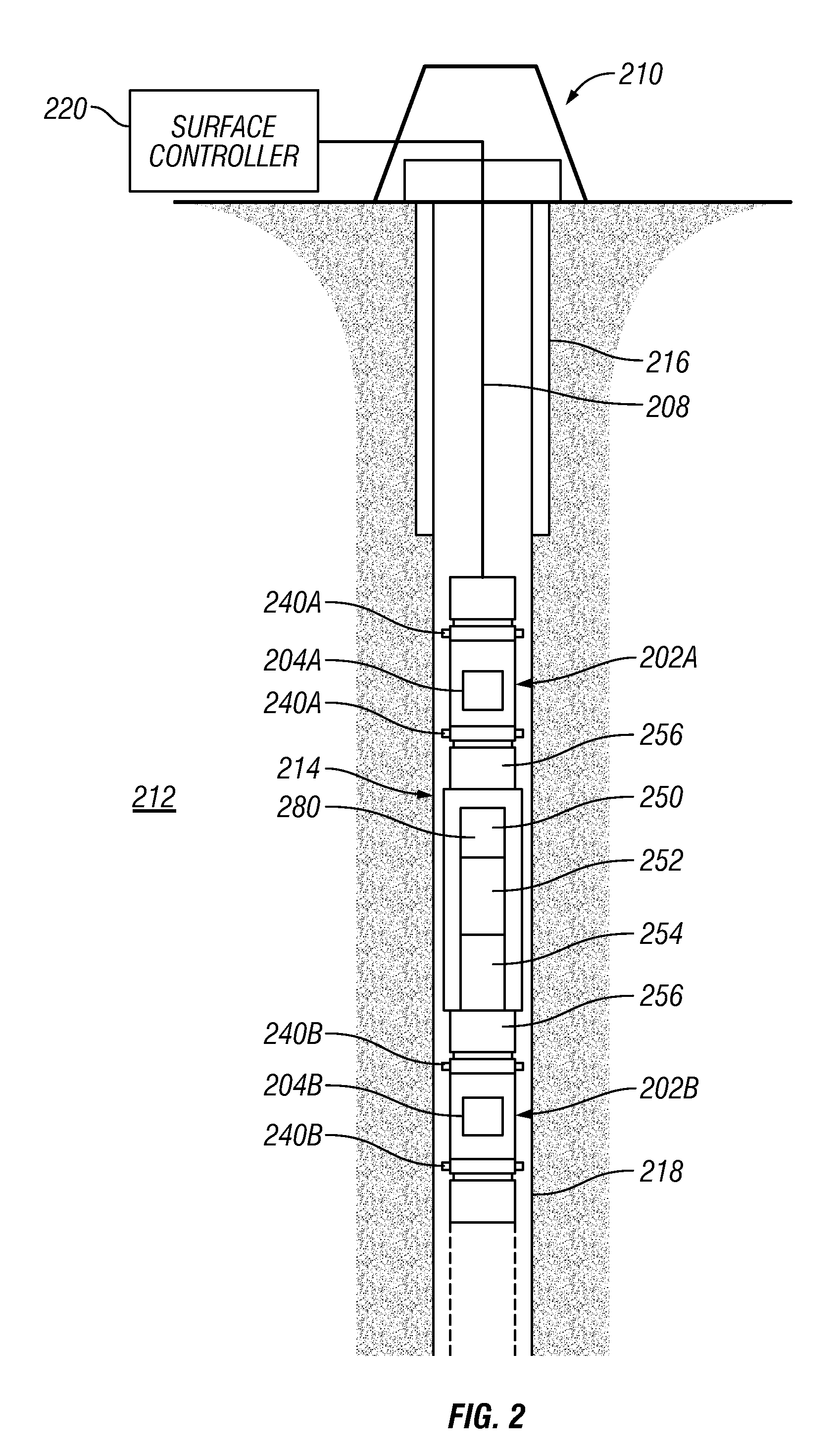

Demagnetizer to Eliminate Residual Magnetization Produced by Nuclear Magnetic Resonance Logs

InactiveUS20090015254A1Eliminate the effects ofReduce removalElectric/magnetic detection for well-loggingSurveyDemagnetizing deviceNMR - Nuclear magnetic resonance

An apparatus and method is disclosed for measuring a parameter of an earth formation surrounding a wellbore. A Nuclear Magnetic Resonance (NMR) tool and at least one second tool are conveyed in the wellbore on a wireline, the NMR tool having a magnetic influence on a region of the wellbore. The magnetic influence of the NMR tool is removed from the region of the wellbore using a demagnetizing device. The parameter of the earth formation is measured using the at least one second tool. A second demagnetizing device may be used to remove the magnetic influence of the at least one second tool from the region of the wellbore.

Owner:BAKER HUGHES INC

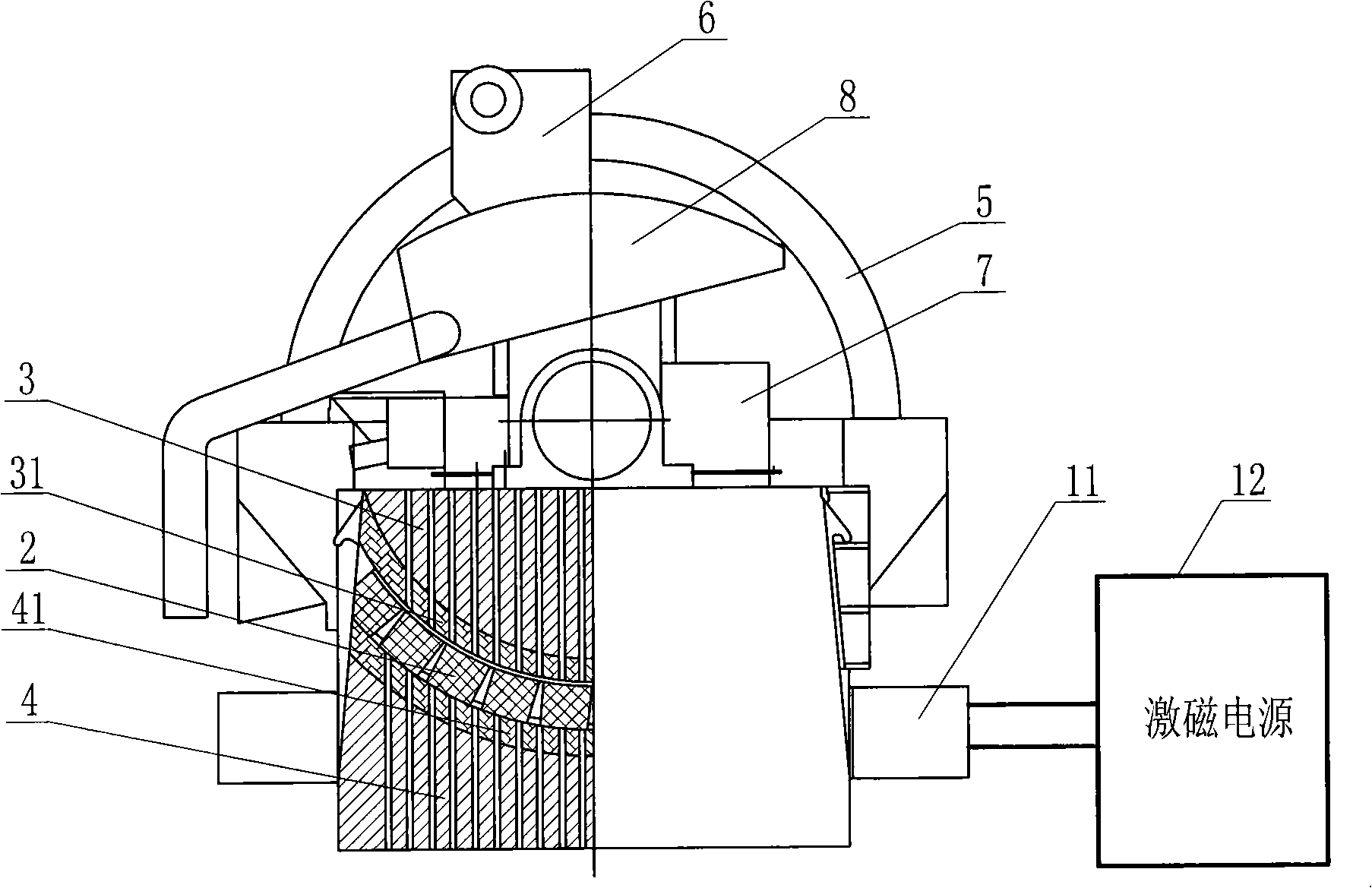

High-gradient magnetic separation machine

InactiveCN101402068AReduce energy consumptionEasy maintenanceHigh gradient magnetic separatorsDemagnetizing deviceMagnetic media

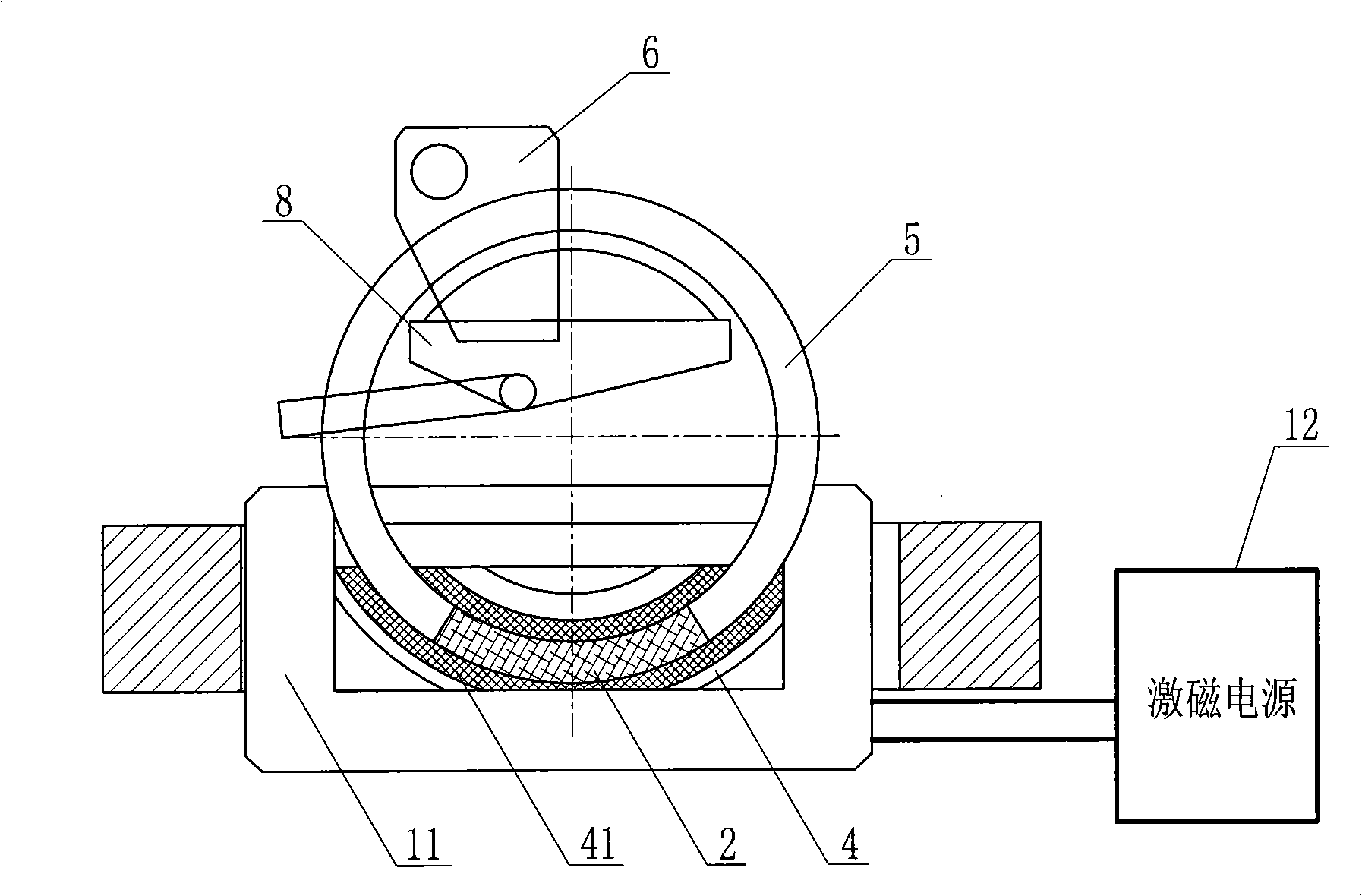

The invention discloses a high gradient magnetic separator, which comprises a separation ring and a driving device thereof, an ore feeding device, a concentrated ore discharging device and a concentrated ore collecting device, wherein the separation ring comprises a rotating ring and a concentrated magnetic medium pack, an upper magnetic yoke, an upper magnet, a lower magnetic yoke, a lower magnet, a left magnetic yoke, a right magnetic yoke, and a magnetizing and demagnetizing device which consists of magnetic coils and a magnetizing power source and can perform magnetizing and demagnetizing treatment on the upper magnet and the lower magnet respectively. The high gradient magnetic separator smartly combines a permanent magnet and a magnetizing power source to form a background magnetic field of the separator, so the high gradient magnetic separator can conveniently perform magnetizing and demagnetizing treatment on the upper magnet and the lower magnet according to the required value of the background magnetic field and then perform effective separation on ores after canceling the magnetizing power source when in work, and can perform demagnetizing treatment on an upper magnet and a lower magnet when in assembly and maintenance so as to solve the magnetic blockage problem. The high gradient magnetic separator can greatly reduce the energy consumption, and fully ensure convenient maintenance in practical production.

Owner:广东省资源综合利用研究所 +1

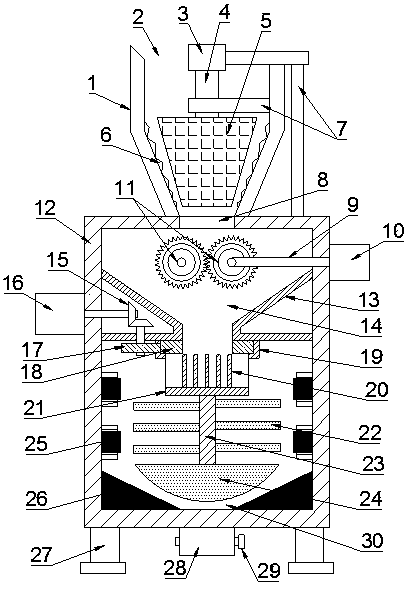

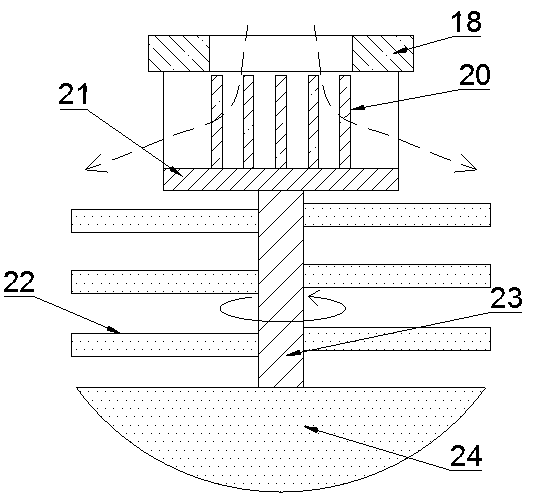

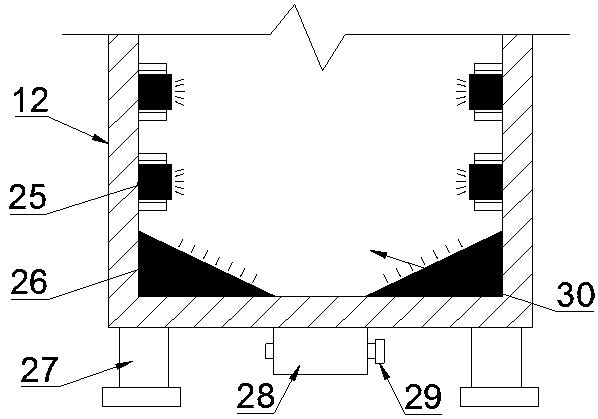

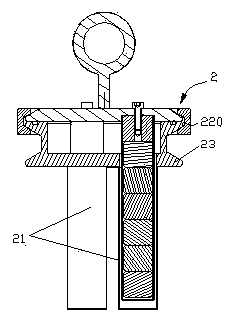

Lithium battery negative electrode smashing and demagnetizing device convenient to clean

InactiveCN109449526AAchieve smashAchieving stirringWaste accumulators reclaimingMagnetic separationDemagnetizing deviceElectrode material

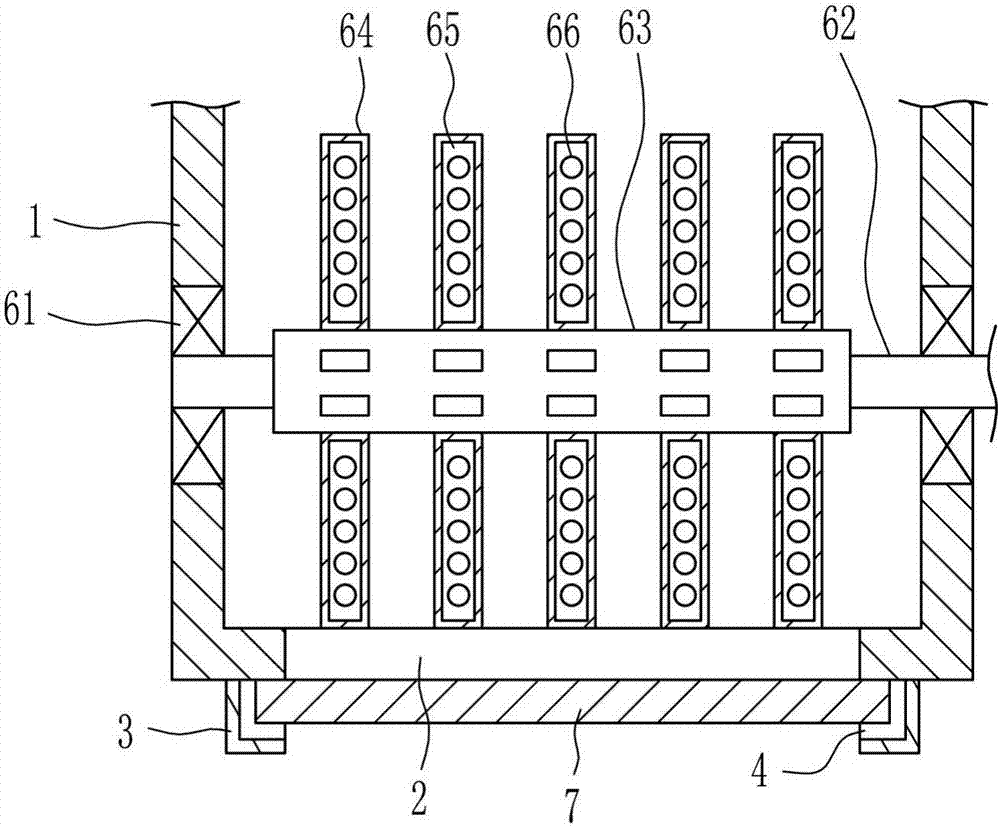

The invention discloses a lithium battery negative electrode smashing and demagnetizing device convenient to clean. The device comprises a feeding and smashing mechanism, a crushing assembly, a rotating material pushing mechanism, a negative electrode smashing box body and a demagnetizing assembly arranged in the negative electrode smashing box body; the feeding and smashing mechanism is installedon the top of the negative electrode smashing box body, a material guiding hopper is welded to the inner wall of the negative electrode smashing box body and divides the interior of the negative electrode smashing box body into a smashing cavity and a demagnetizing cavity, and the demagnetizing assembly is installed in the portion, in the demagnetizing cavity, of the negative electrode smashing box body; and the feeding and smashing mechanism smashes lithium battery negative electrodes, the crushing assembly crushes the lithium battery negative electrodes, lithium battery negative electrode materials dropping into the demagnetizing cavity are stirred in the rotating material pushing mechanism, fully demagnetized by magnetic rings and magnetic blocks and discharged by a discharge pipe. Smashing, crushing, stirring, demagnetizing and discharging operations of the lithium battery negative electrodes are achieved, the operations are convenient and fast, and the smashing and demagnetizingeffects are good.

Owner:枣庄领创新能源科技有限公司

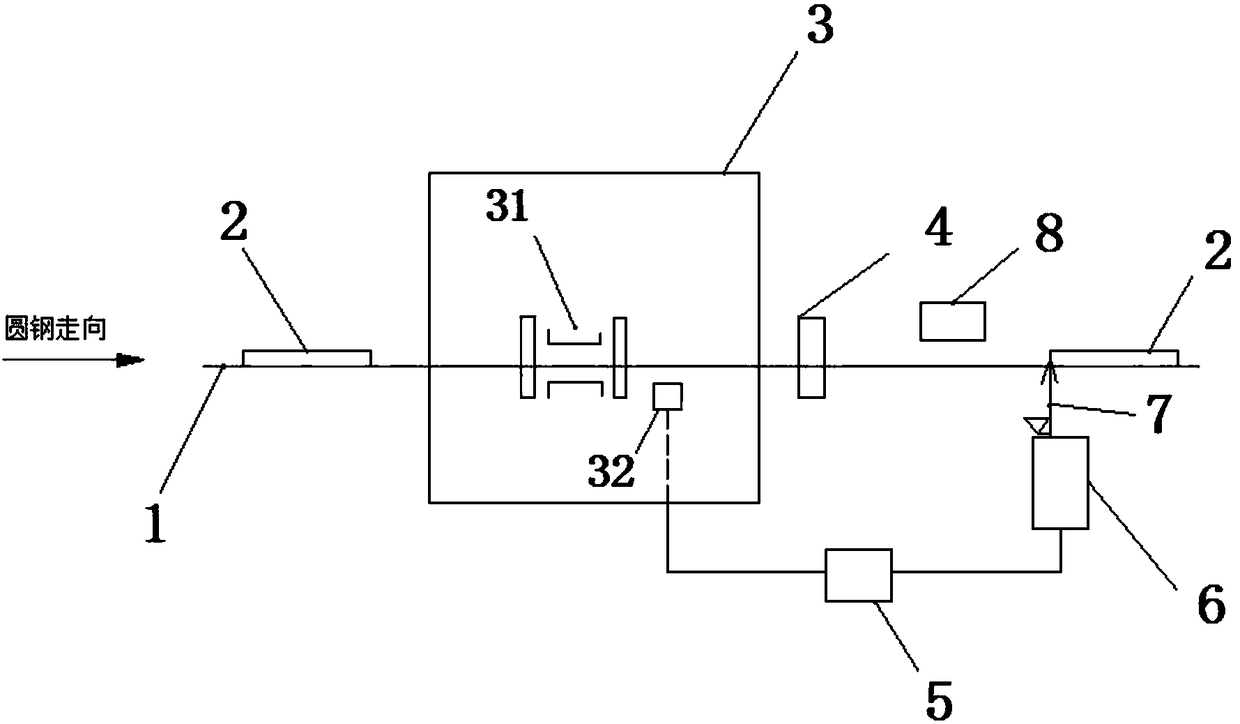

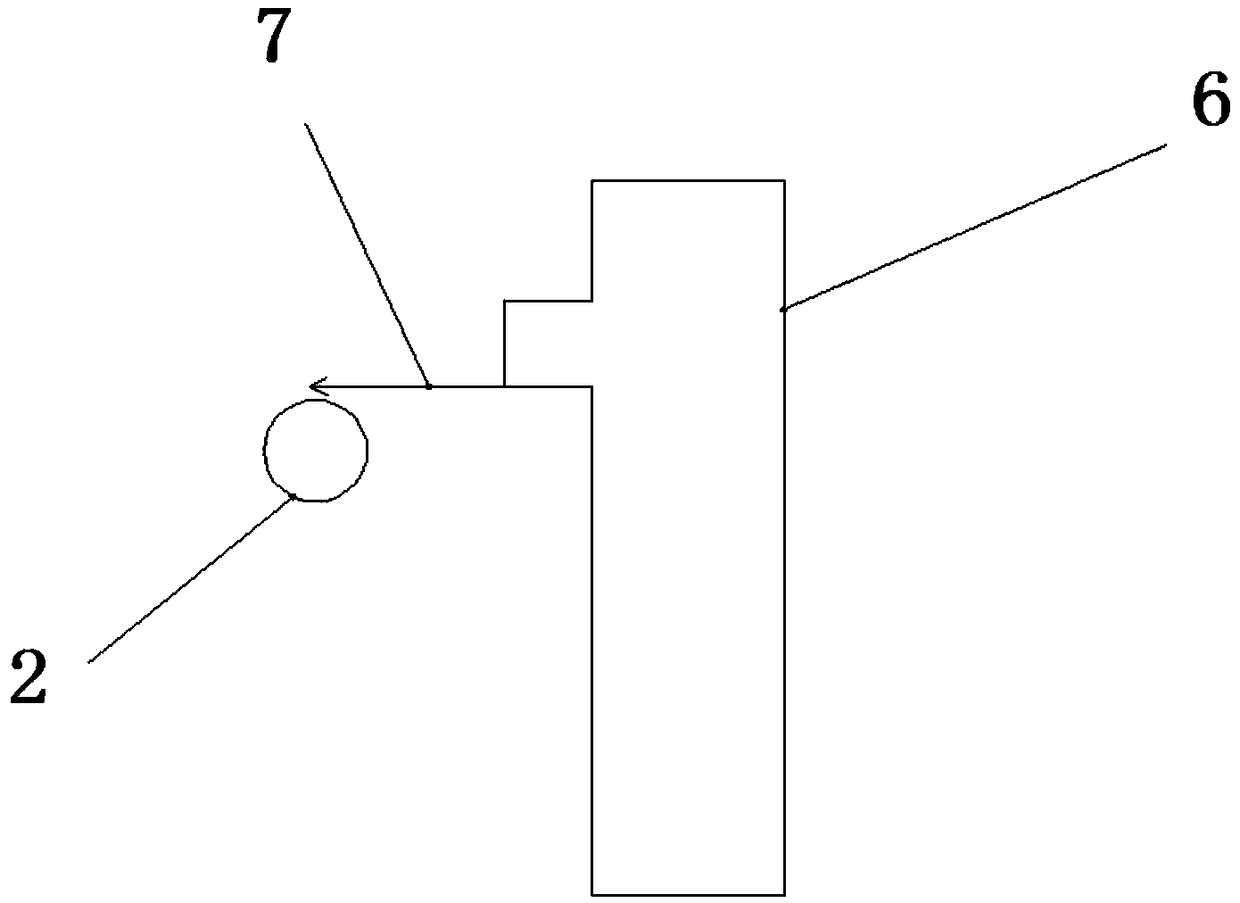

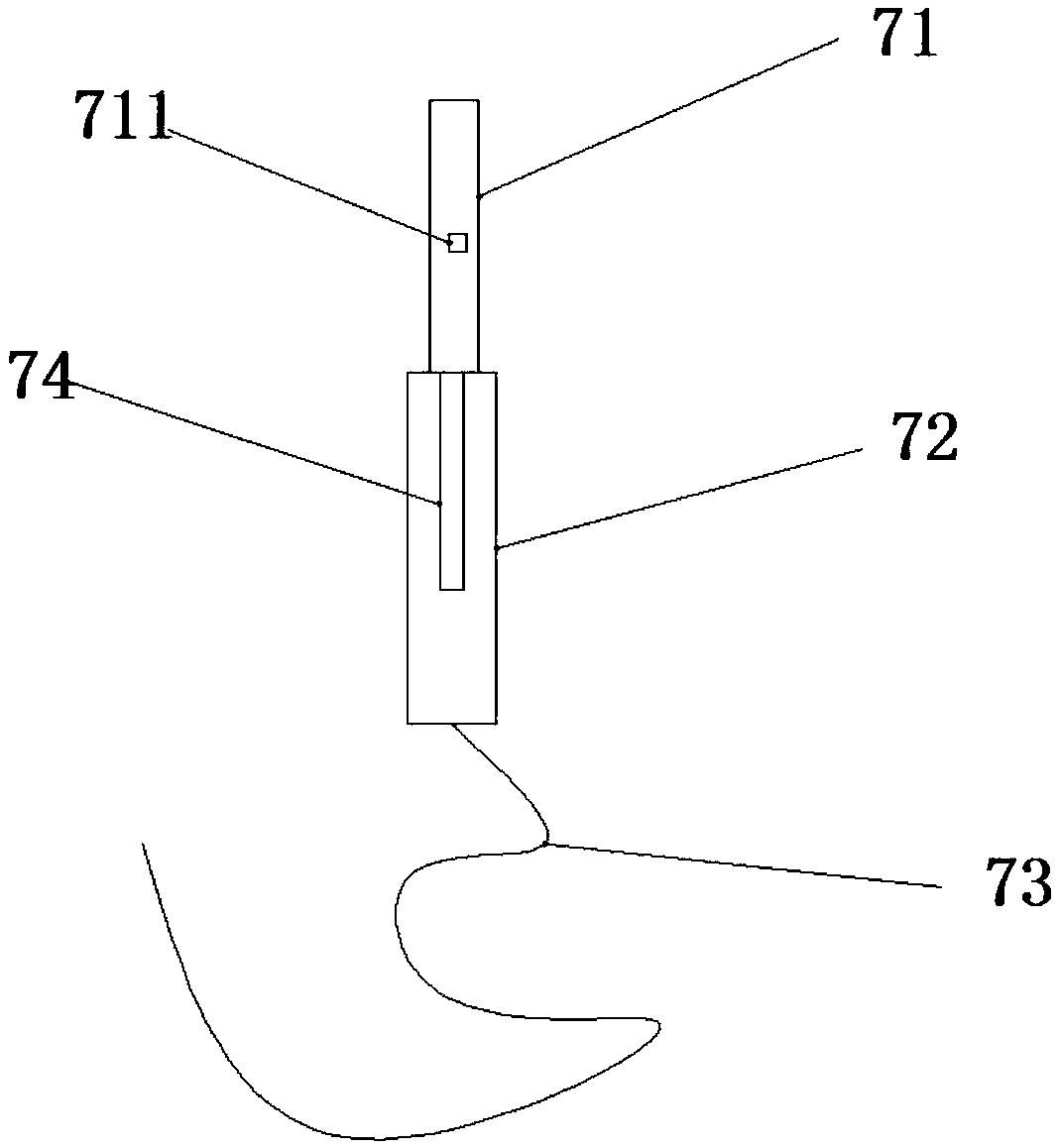

Online residual magnetism detecting device of round steel and detecting method thereof

PendingCN108614225AGood effectSave human effortMagnetic property measurementsDemagnetizing devicePropeller

The invention provides an online residual magnetism detecting device of a round steel and a detecting method thereof. The residual magnetism detecting device comprises a photoelectric detecting device, a control device, a moving device, and a sensing probe. The photoelectric detecting device is arranged above a propeller path behind a demagnetizing device and is used for detecting the position ofa round steel on a propeller path at an assembling line. The control device arranged between the photoelectric detecting device and the demagnetizing device is arranged on a device platform at one side of the propeller path. The moving device arranged behind the photoelectric detecting device is used for moving the sensing probe. The sensing probe arranged at the upper end of the moving device isused for feeding back obtained data to the control device and the control device displays a processed result at a display device. According to the online residual magnetism detecting device and the employed online automatic round steel residual magnetism detecting mode, the manpower is saved, the detection efficiency and the accuracy of the detection result are improved, and occurrence of missingdetection during the round steel residual magnetism detecting process is avoided.

Owner:DAYE SPECIAL STEEL CO LTD

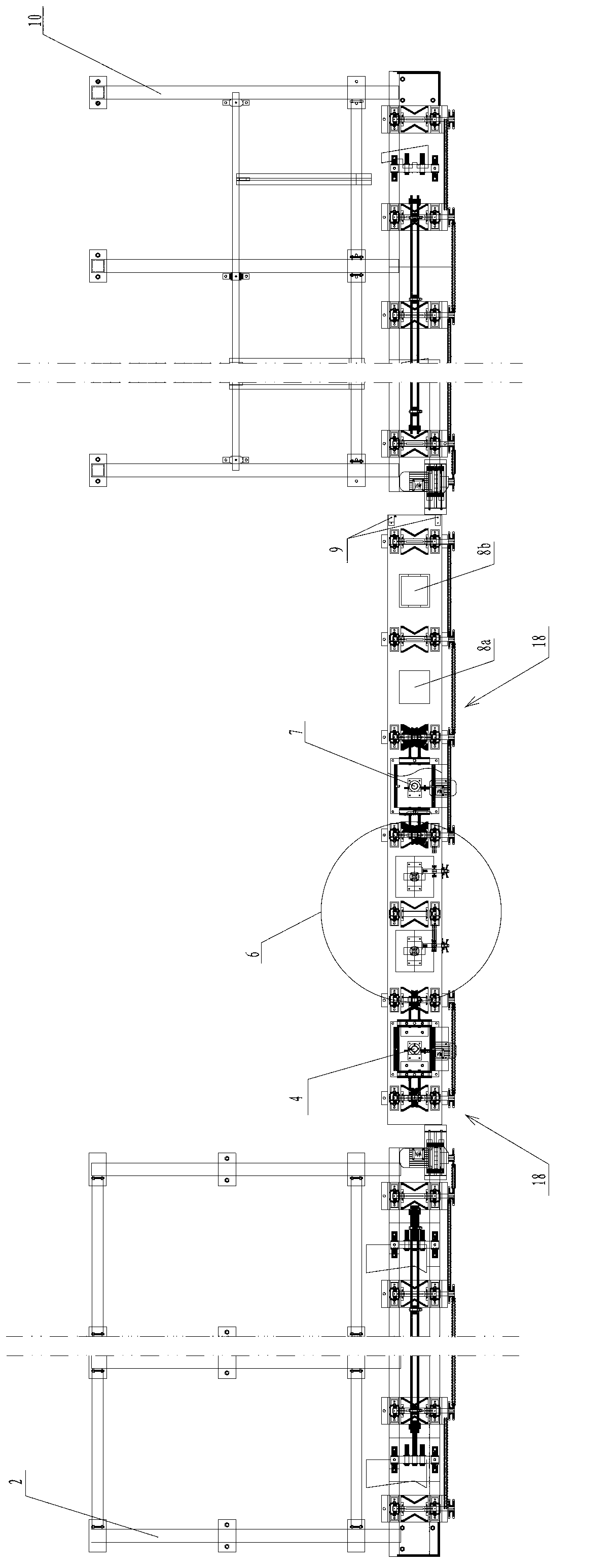

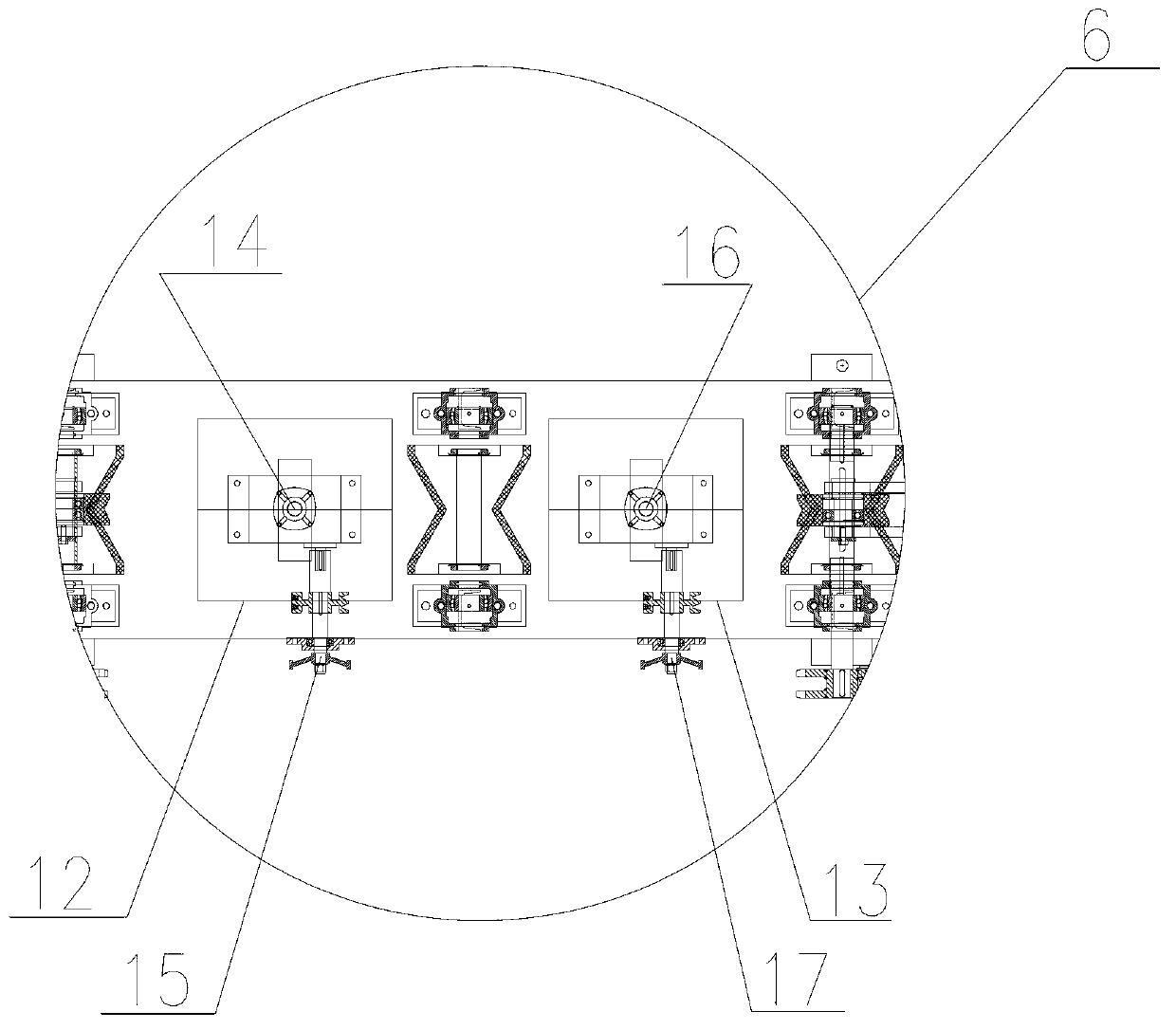

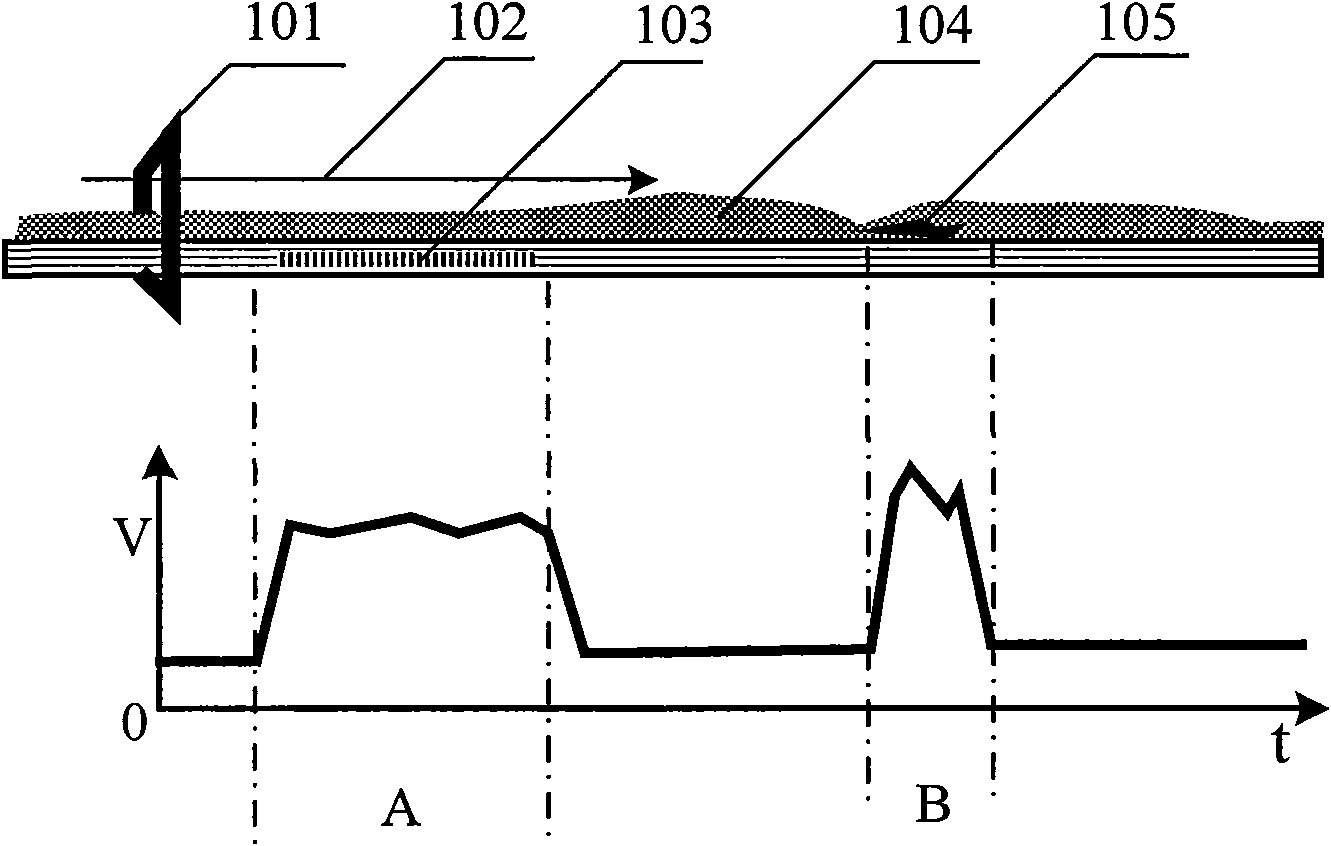

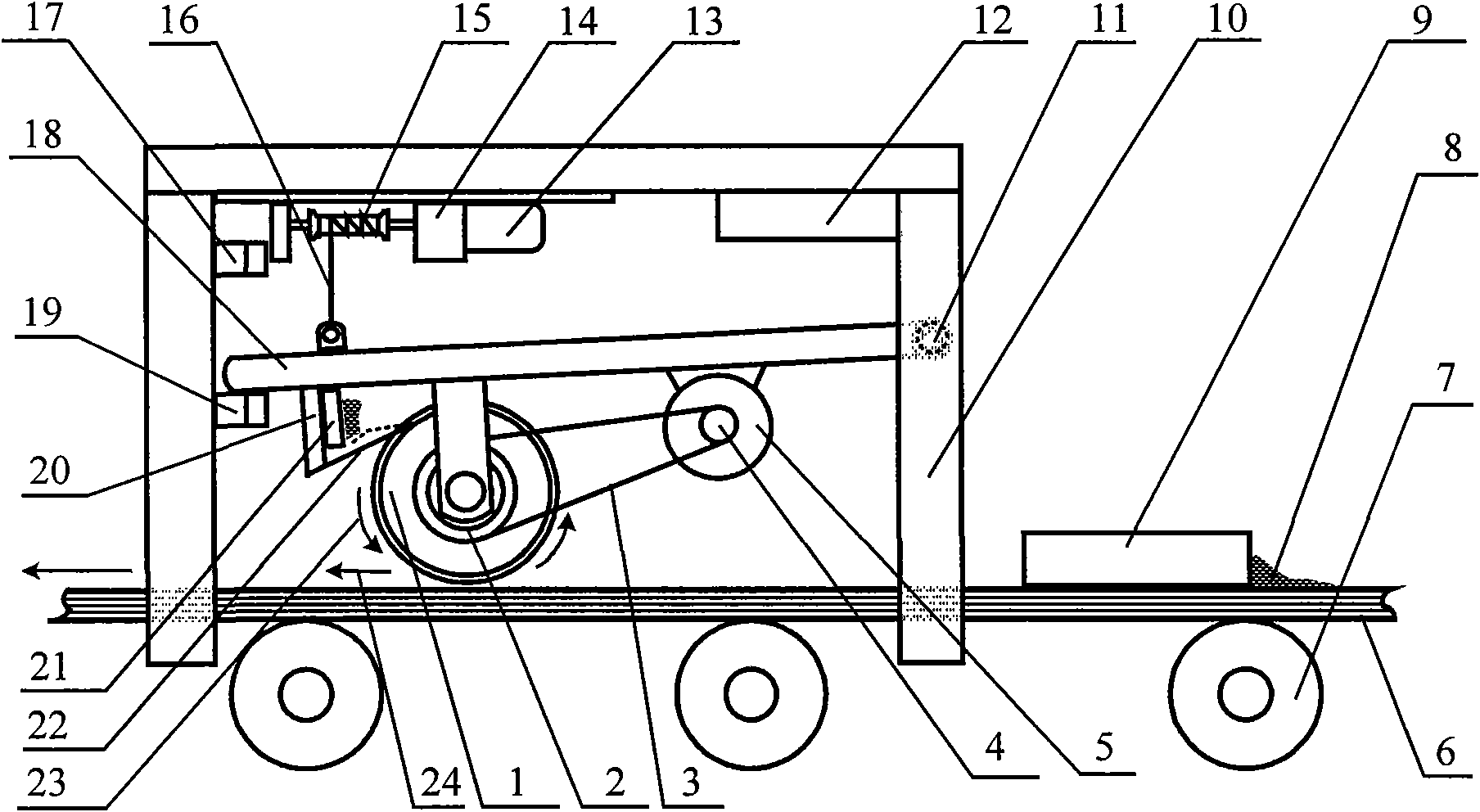

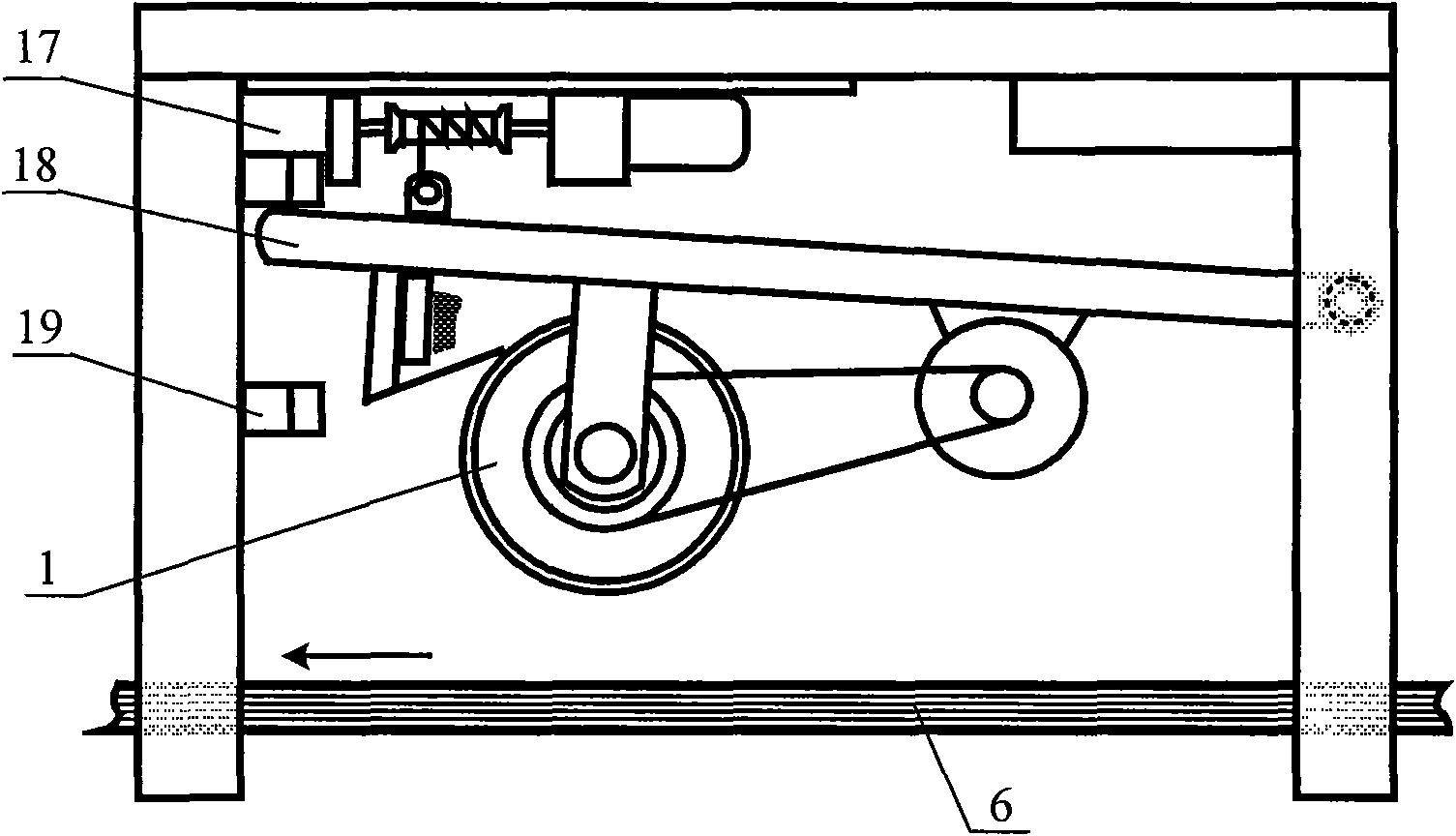

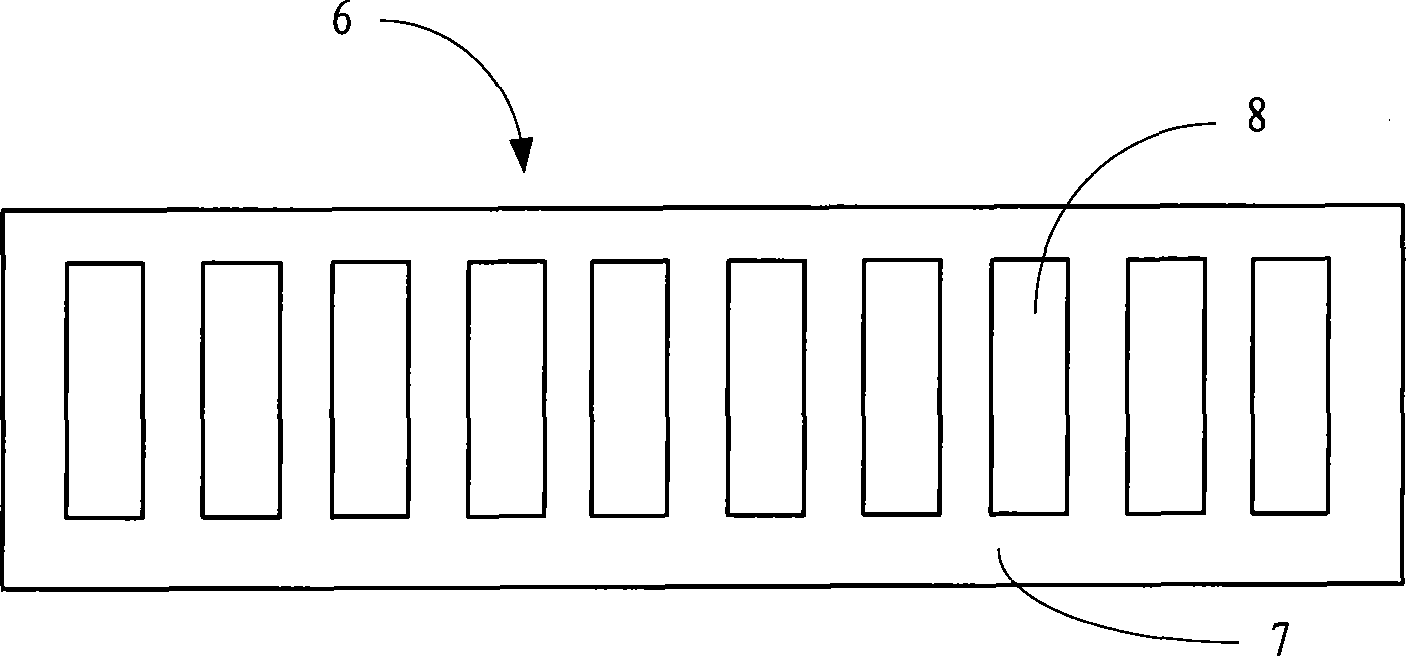

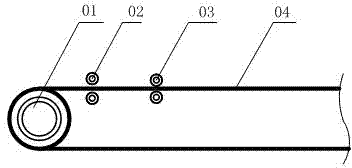

Conveyer belt multi-pole magnetic roller asynchronous demagnetizing device

ActiveCN101930822AIncrease the magnetic field strengthSolve problems interfering with metal detectorsMagnetic bodiesDemagnetizing deviceVertical bar

The invention discloses a conveyer belt multi-pole magnetic roller asynchronous demagnetizing device, which comprises a multi-pole magnetic roller (1), a magnetic roller drive motor (5), a magnetic roller framework (18), a structural frame (10), a lifting device and a controller (12), wherein the multi-pole magnetic roller is hang on the magnetic roller framework through a magnetic roller shaft, the magnetic roller drive motor drives a magnetic roller shaft transmission belt wheel (2) to rotate through a power belt wheel (4) and a transmission belt (3) so as to drive the multi-pole magnetic roller to rotate, and the multi-pole magnetic roller is positioned above a conveyer belt (6); the structural frame is positioned above a conveyer belt return plane, and a vertical bar of the structural frame is fixed on the ground; and one end of the magnetic roller framework is connected on the vertical bar of the structural frame through a rotating shaft (11), the other end of the magnetic roller framework is provided with the hoisting device, an upper stop point (17) and a lower stop point (1) with travel switches are formed on the vertical bar at the other end of the structural frame, the output of the travel switches is connected with a controller (12), and the controller controls the magnetic roller drive motor and the hoisting device. The demagnetizing device has the advantages of simple structure, low energy consumption and good demagnetizing effect.

Owner:BAOSHAN IRON & STEEL CO LTD +1

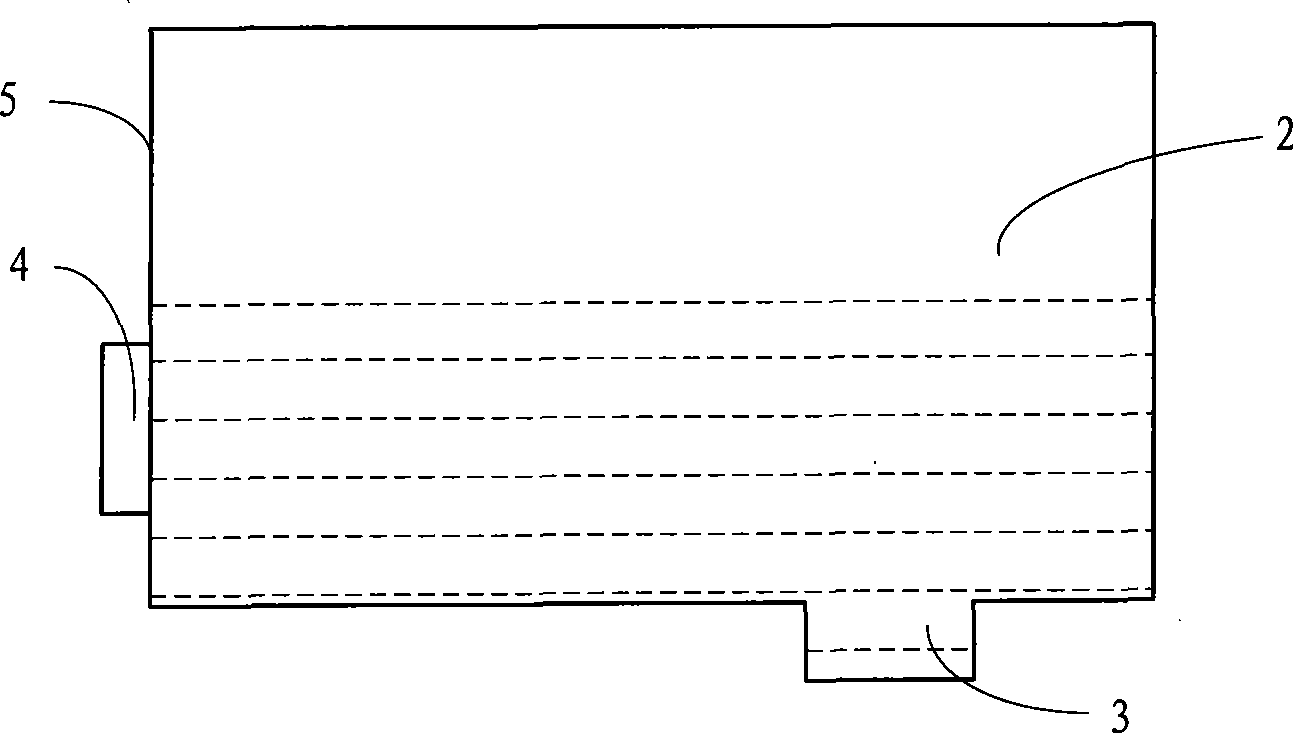

Consumable container, information processing system and information processing method

InactiveCN101544122ACorrectly judge the remaining amount of consumablesElectrographic process apparatusOther printing apparatusInformation processingRelevant information

The invention provides a consumable container, an information processing system and an information processing method. The consumable container comprises a shell and a cavity surrounded by the shell, wherein the outer wall of the shell is provided with a record strip comprising a plurality of magnetic bodies. The information processing system comprises a demagnetization device, a demagnetization controller for controlling the work of the demagnetization device, a plurality of magnetic bodies of which magnetism can be removed by the demagnetization device, and a magnetic field sensing apparatus. The information processing method comprises that: the magnetic field sensing apparatus detects the amount of the magnetic bodies with the magnetism on the record strip and transmits the detection result to a body controller; the body controller judges whether the consumable excess is enough in the consumable container, and if the consumable excess is enough, printing work begins, otherwise, warning information is sent out; and after the printing work begins, the body controller judges whether the magnetism of one magnetic body needs to be removed, and if the magnetism needs to be removed, the demagnetization device removes the magnetism of the magnetic body, otherwise, the judgment is continuous. The invention can effectively avoid occurrence of abnormal work situation because the related information of the consumable container cannot be read.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

Demagnetizing method of high-strength steel narrow-gap welding groove

ActiveCN103456457AImprove demagnetization effectImprove portabilityMagnetic bodiesArc welding apparatusDemagnetizing deviceMaterials science

The invention discloses a demagnetizing method of a high-strength steel narrow-gap welding groove. The groove residual magnetism is reduced by carrying out the technology of tack welding and run-on plate adding before welding, multiple demagnetizing operations can be carried out on a single U-shaped or double U-shaped groove by a pulse demagnetizing device according to different technologies, a moving direction of a demagnetizing device coil box can be changed after each demagnetizing operation, and the demagnetizing operations can be finished until the groove residual magnetism is reduced to a certain value. By adopting the pulse demagnetizing method and combining the demagnetizing technology of pack welding and run-on plate adding before welding, the demagnetizing effect of a large-size workpiece can be effectively increased, the portability of the demagnetizing device is good, the motion matching of the workpiece is not needed during application, the demagnetizing method is particularly suitable for carrying out the demagnetizing operation in a production field, and the engineering adaptability is strong.

Owner:JIANGSU UNIV OF SCI & TECH

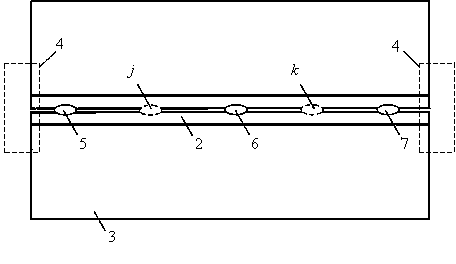

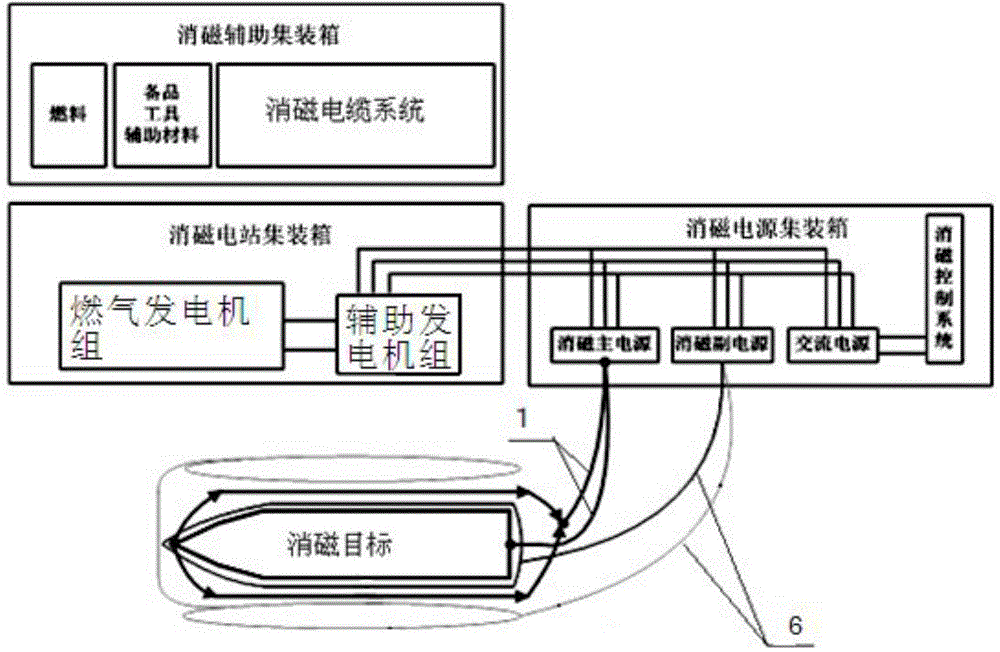

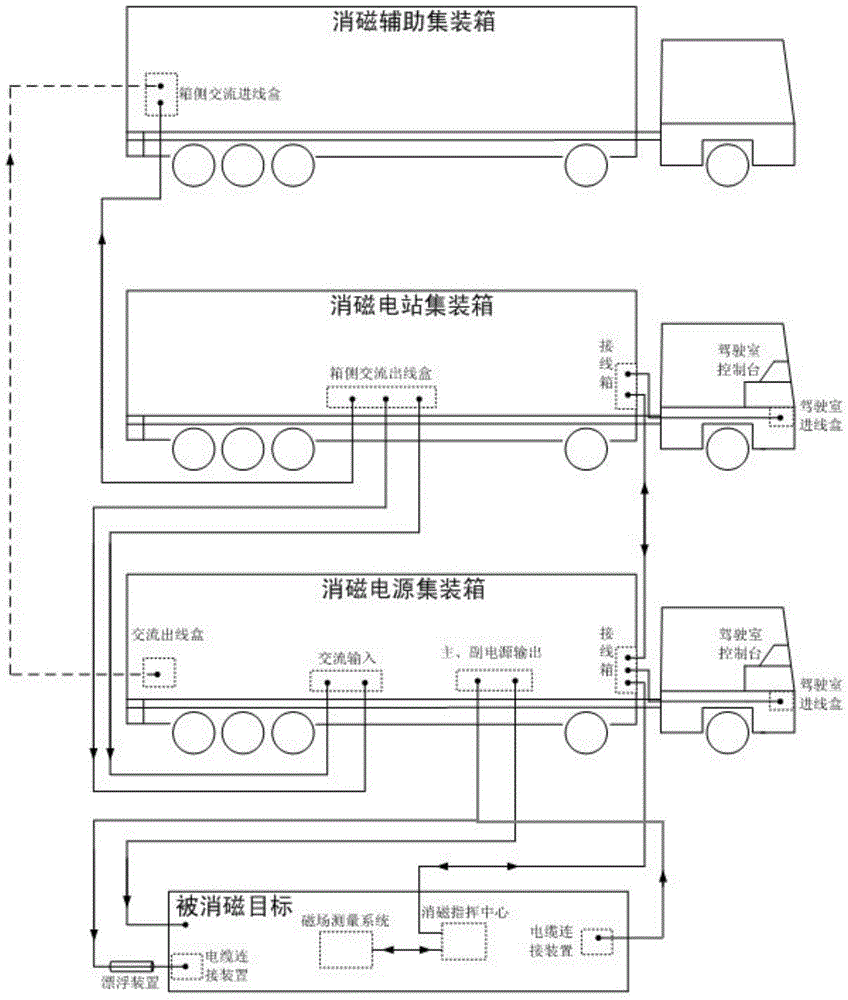

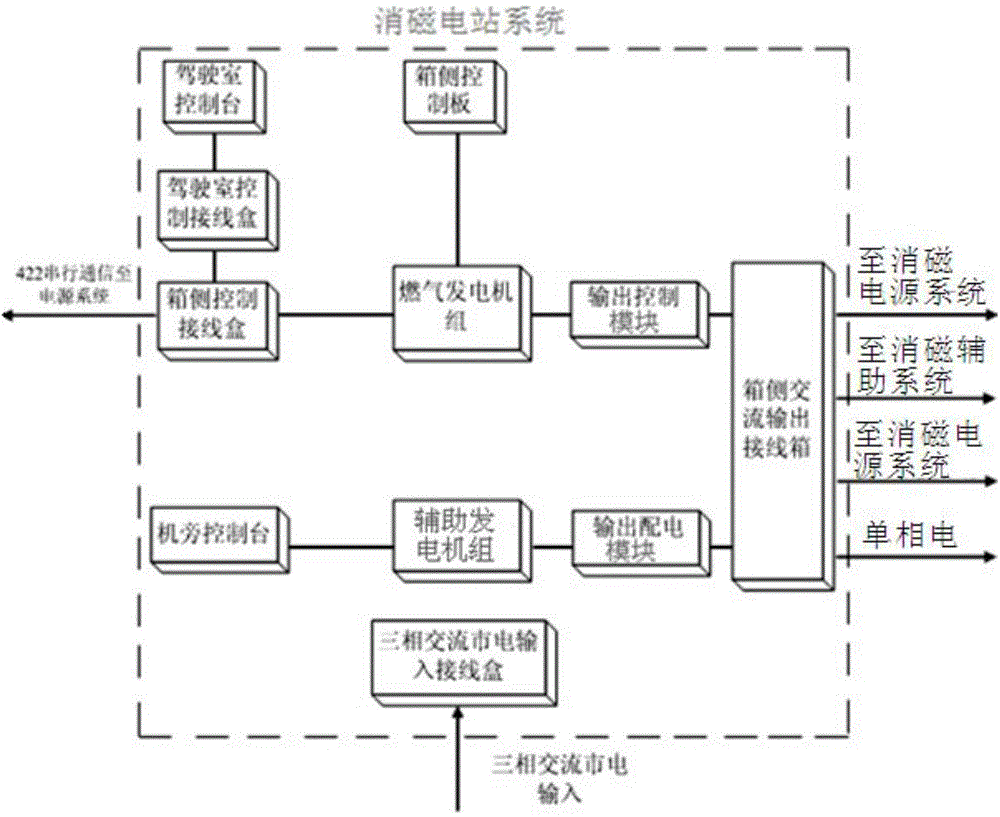

Movable demagnetizing device

InactiveCN104361974AMeet trailer transportation requirementsImprove mobilityMagnetic bodiesDemagnetizing devicePower station

The invention relates to the field of demagnetizing, and particularly provides a movable demagnetizing device, which comprises a demagnetizing power station system, a demagnetizing power source system, a special demagnetizing cable system, a magnetic field measurement system, a demagnetizing control system and a demagnetizing auxiliary system, and the demagnetizing power station system, the demagnetizing power source system, the special demagnetizing cable system, the magnetic field measurement system, the demagnetizing control system and the demagnetizing auxiliary system are integrated in three standard containers. The movable demagnetizing device can be moved when the movable demagnetizing device is carried by a container transport vehicle or a ship, and can be used for performing magnetic field measurement and remained magnetism treatment for large ferromagnetic equipment, such as ships. The movable demagnetizing device has the advantages that the manufacturing cost is relatively low, the batch production is easy, the demagnetizing speed is higher, the carrying method is flexible, the mobility and hidden property are good, the movable demagnetizing device can be applied to military and civil purposes, and the higher economic value is realized.

Owner:NAVAL UNIV OF ENG PLA

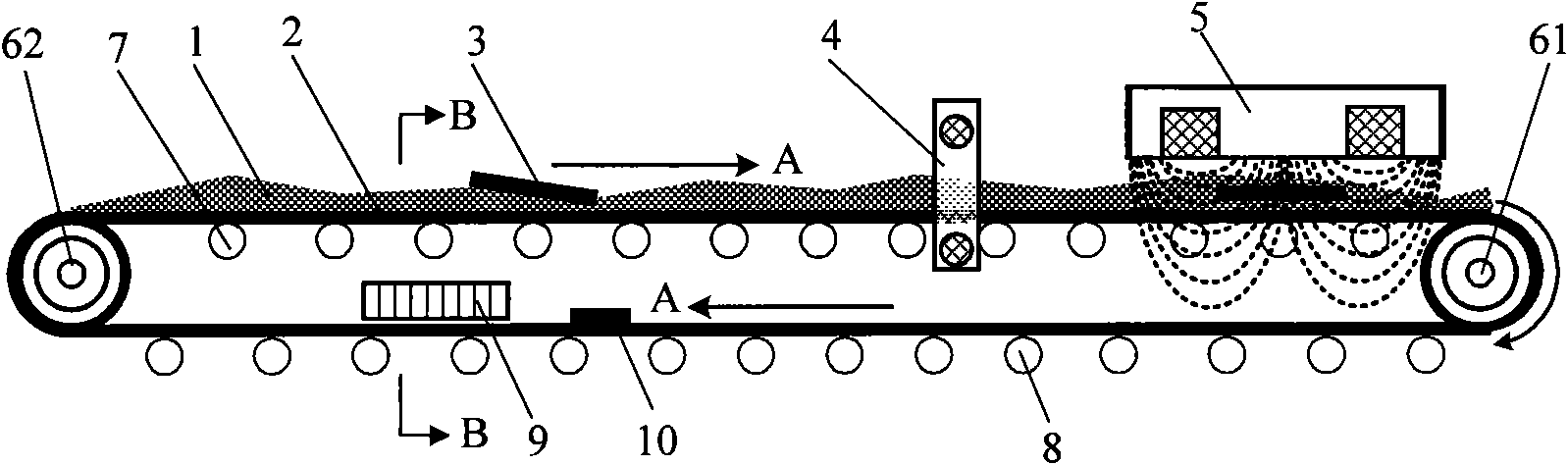

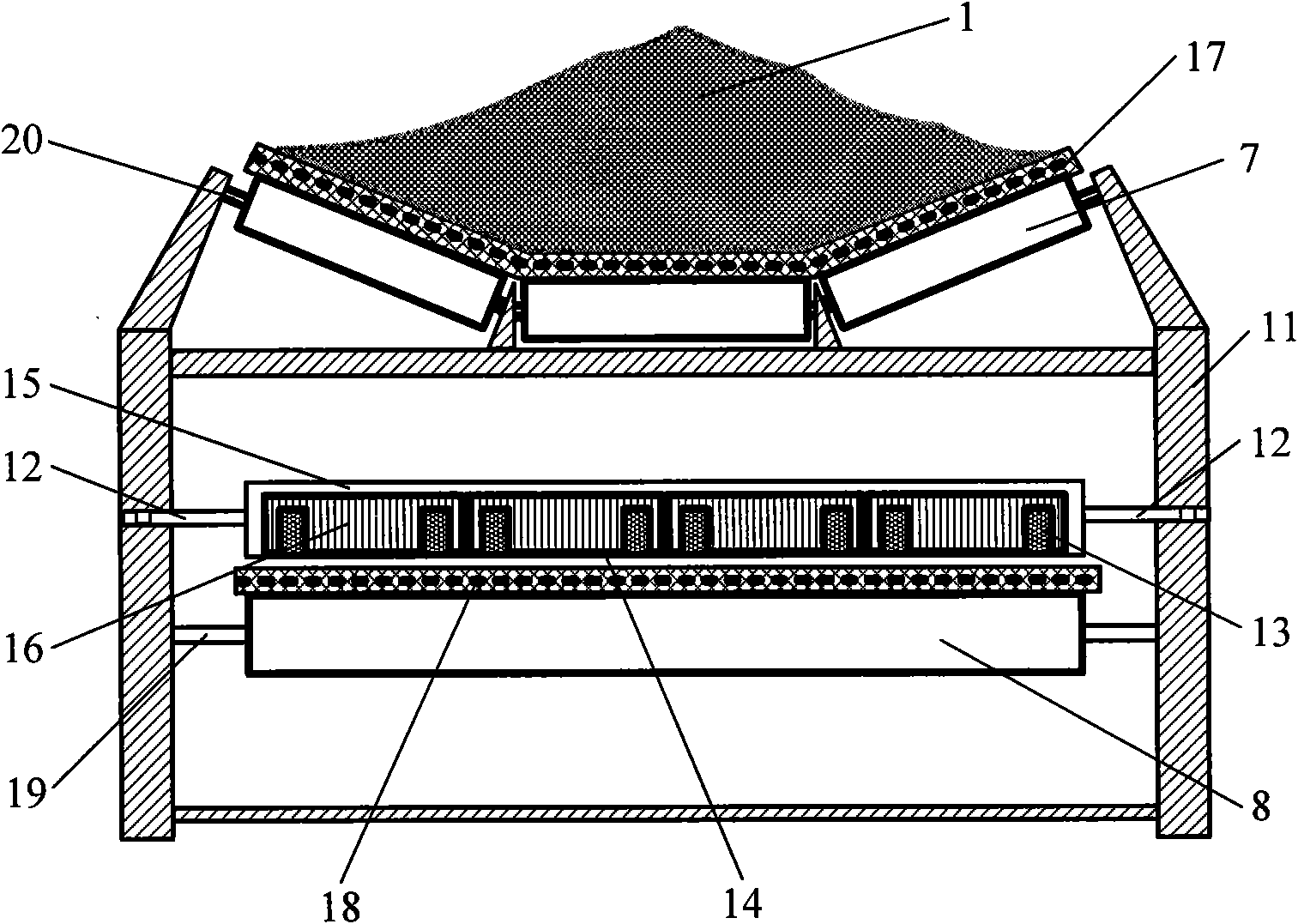

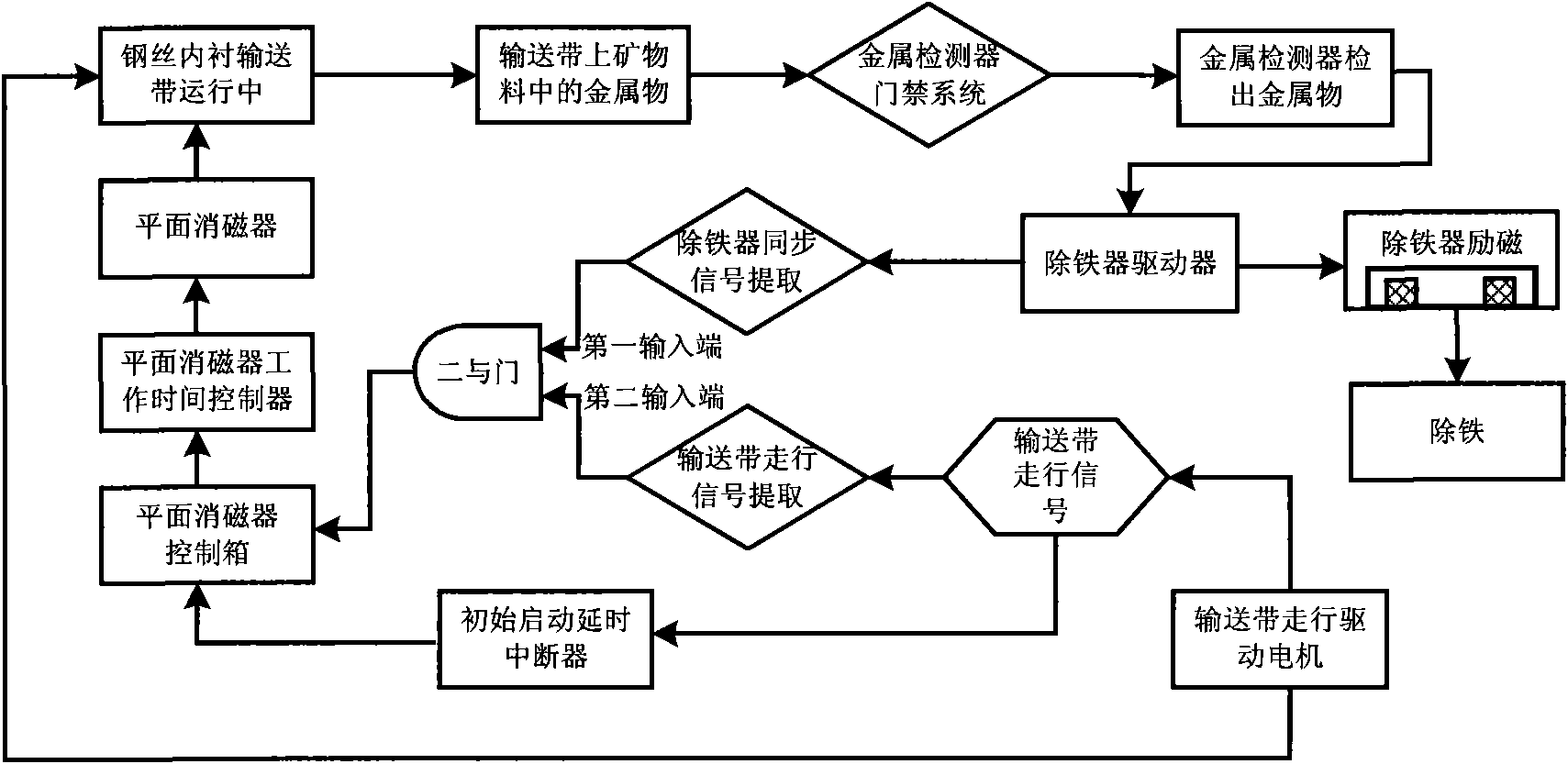

Device and method for synchronously demagnetizing steel wire lining conveyor belt

InactiveCN101552083AGuaranteed uptimeAvoid influenceConveyorsMagnetic bodiesDemagnetizing deviceStart time

The invention discloses a device and a method for synchronously demagnetizing steel wire lining conveyor belt, wherein the demagnetizing device comprises a planar demagnetizer, a planar demagnetizer controlling box and a support frame; a magnetizer is arranged in a magnet exciting coil which is positioned on a magnet exciting board and connected with the planar demagnetizer controlling box; a magnet exciting board shell is arranged on the magnet exciting board to form a cavity body; two ends of the support frame are respectively and fixedly connected with a bracket and the magnet exciting board shell, and the planar demagnetizer is fixed above a descending plane of the conveyor belt. The method comprises the following steps: an iron remover is started after metals in mineral materials are detected by a metal detector, and a signal is input into the first input end of an and gate circuit; a conveyor belt walking signal is transmitted into the second input end of the and gate circuit; the planar demagnetizer controlling box is started by an and gate circuit transmission signal; and the planar demagnetizer is controlled to demagnetize the conveyor belt after the planar demagnetizer controlling box receives a signal emitted from an initial start time-delay interrupter. The invention can entirely demagnetize the steel wire lining conveyor belt and ensures the normal operation of the metal detector.

Owner:BAOSHAN IRON & STEEL CO LTD

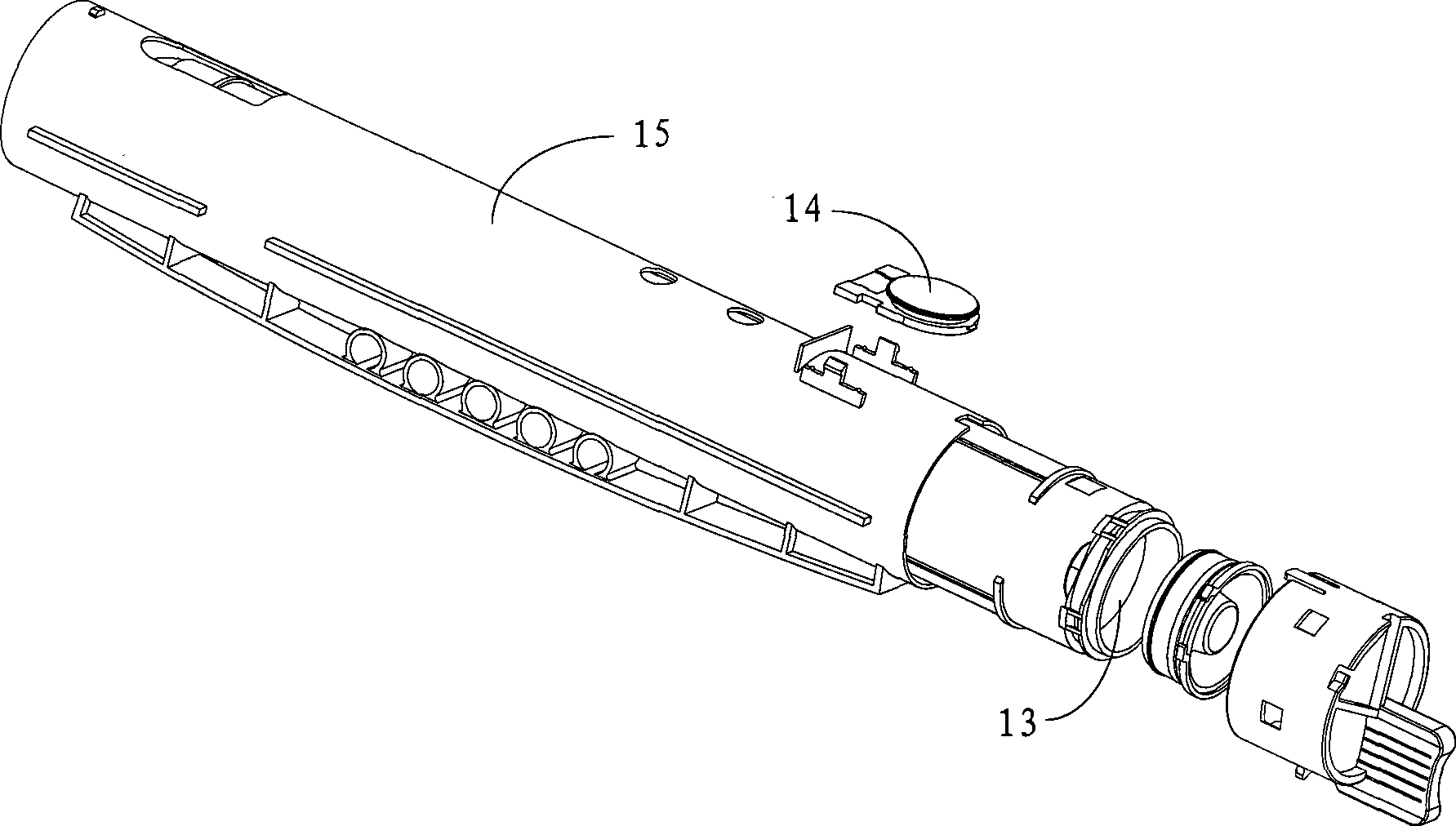

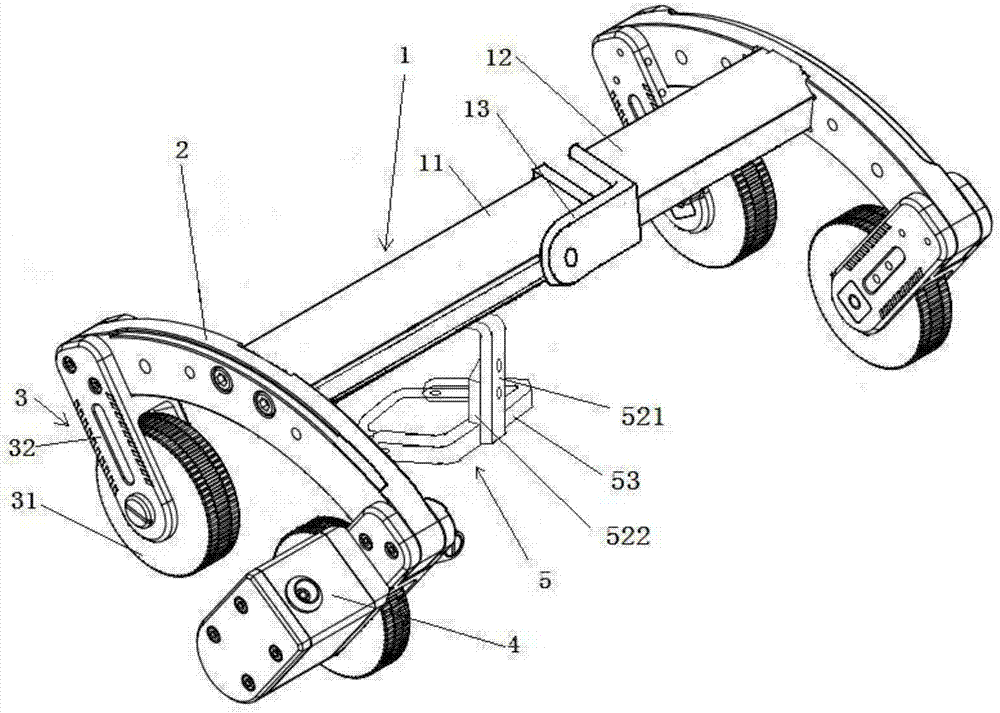

Ultrasonic scanner and detection method thereof

ActiveCN107490623AEasy to operateShort detection cycleAnalysing solids using sonic/ultrasonic/infrasonic wavesDemagnetizing deviceFillet weld

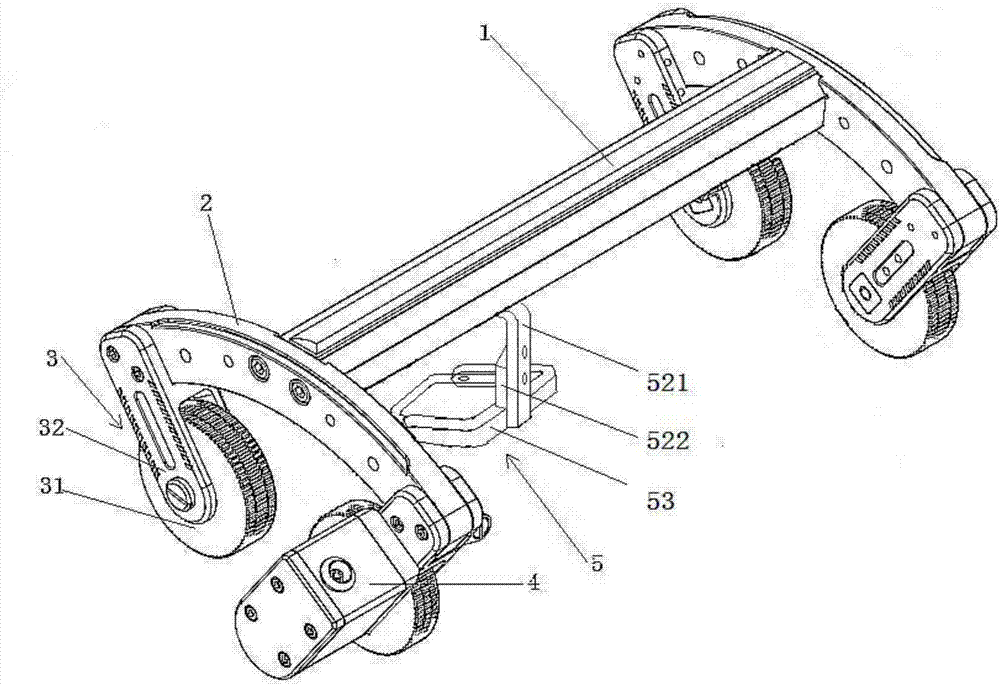

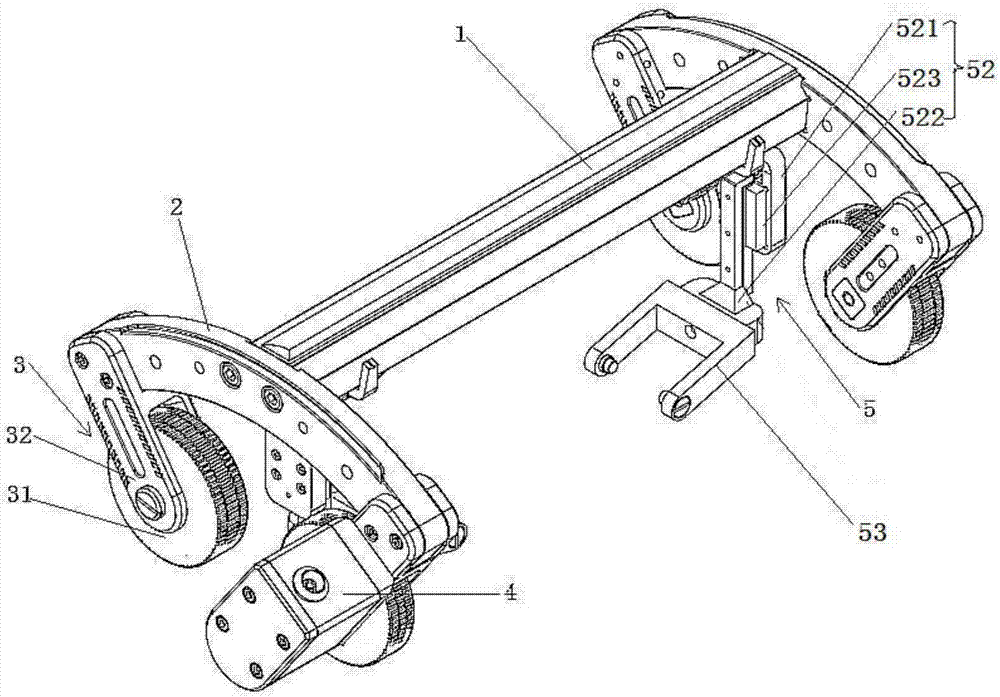

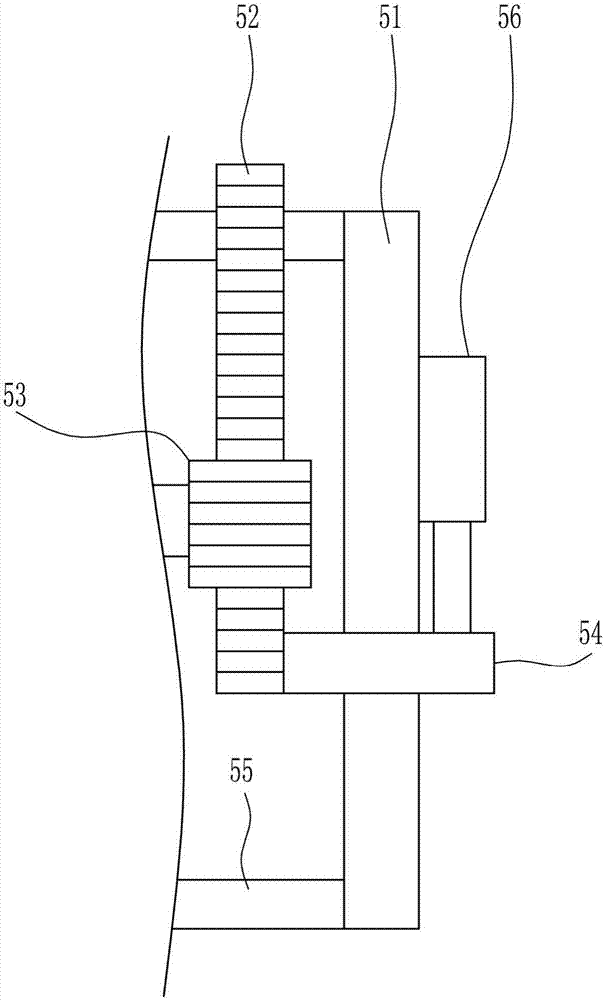

The invention belongs to the technical field of ultrasonic non-destructive detection, and relates to an ultrasonic scanner, which comprises a main beam, arc-shaped arms, magnet-wheel mechanisms, encoders and a probe loading arm. The main beam comprises a long arm, a short arm, and a connecting piece used for connecting the long arm and the short arm and capable of adjusting an included angle between the long arm and the short arm; the arc-shaped arms are connected to two end parts of the main beam; the magnet-wheel mechanisms are respectively connected to two ends of the arc-shaped arms through connecting arms; the encoders used for recording distances are arranged on the arc-shaped arms; each magnet-wheel mechanism comprises a magnetic wheel and a demagnetizing device; each connecting arm can adjust the distance and the angle between the magnetic wheels located at two ends of each arc-shaped arm; each demagnetizing device is fixed onto the corresponding connecting arm; the probe loading arm comprises a second slide block, a loading arm and a probe fixing rack; the probe loading arm can slide in a length direction of the main beam; the probe loading arm can be disassembled and replaced. The ultrasonic scanner provided by the invention can be used for simultaneously scanning three weld joints, i.e. a straight welded joint, a circumferential weld joint and a fillet weld joint, and is good in flexibility, and high in accuracy and reliability.

Owner:CHINA AERO POLYTECH ESTAB

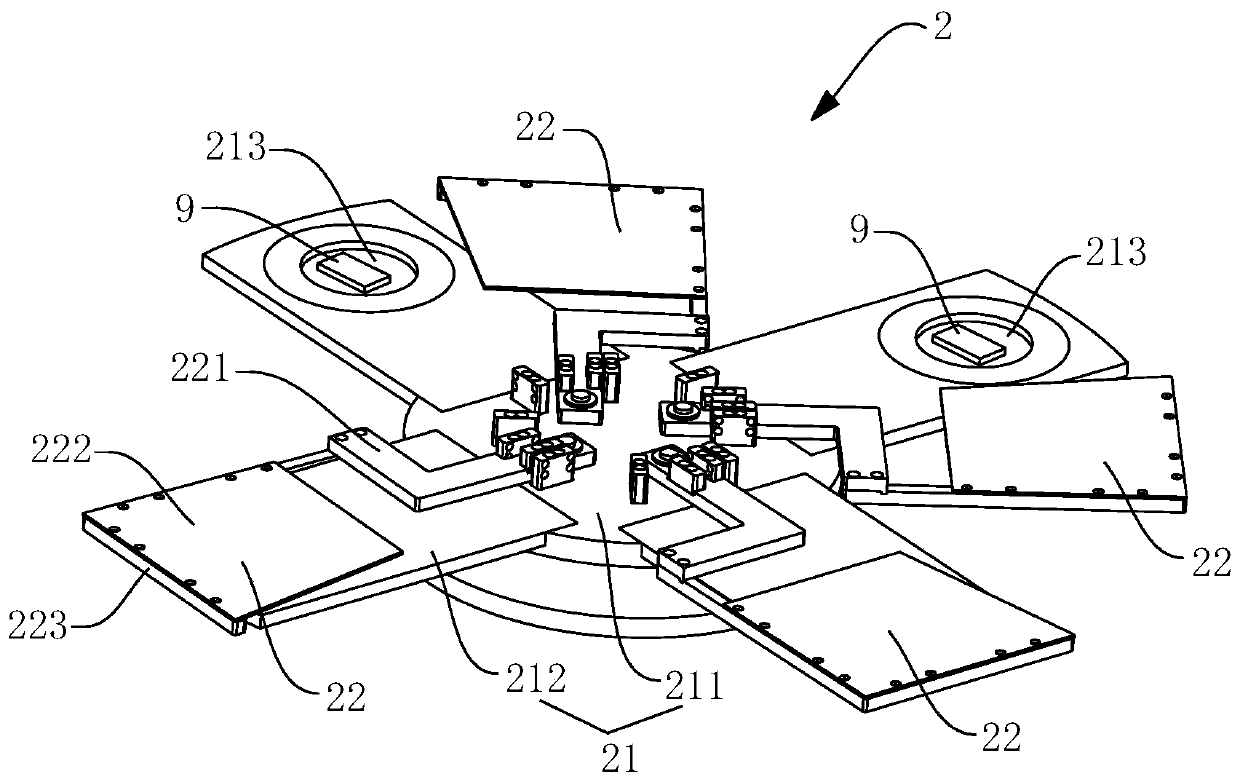

Automatic magnetizing and demagnetizing equipment of magnetic workpieces

PendingCN111128512AImprove automated processing efficiencyImprove versatilityMagnetic bodiesDemagnetizing deviceEngineering

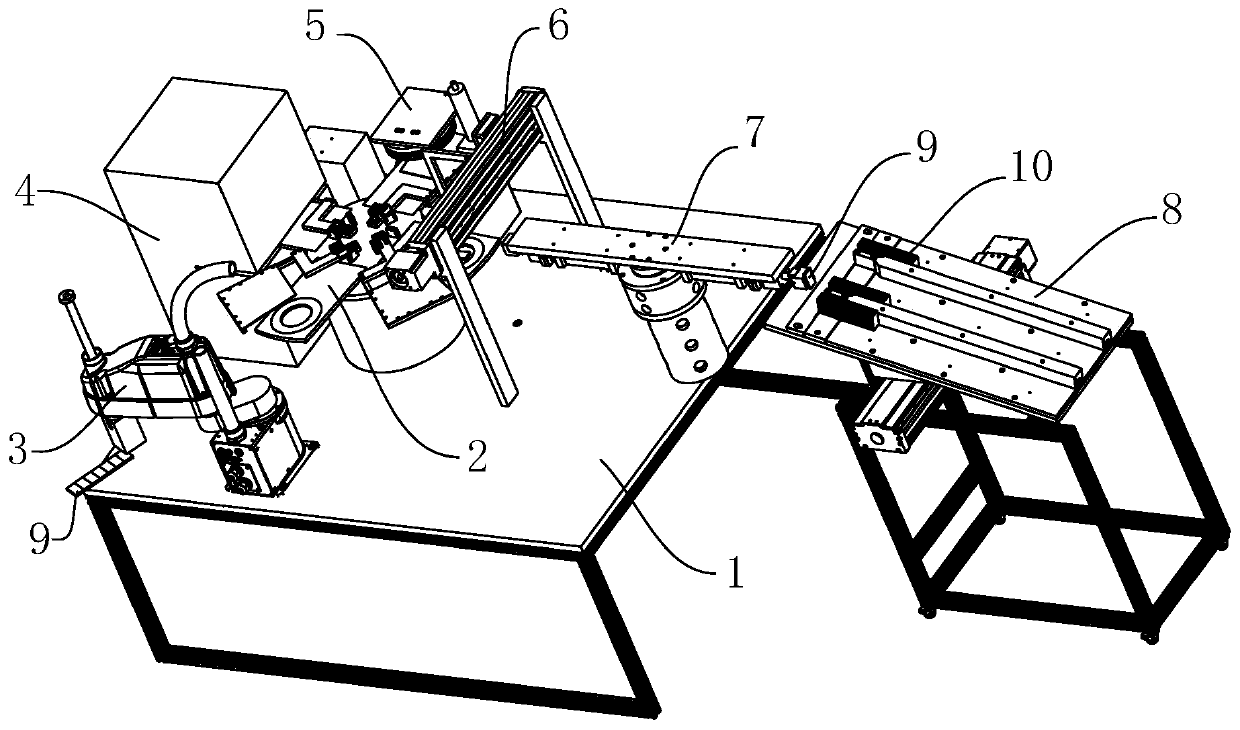

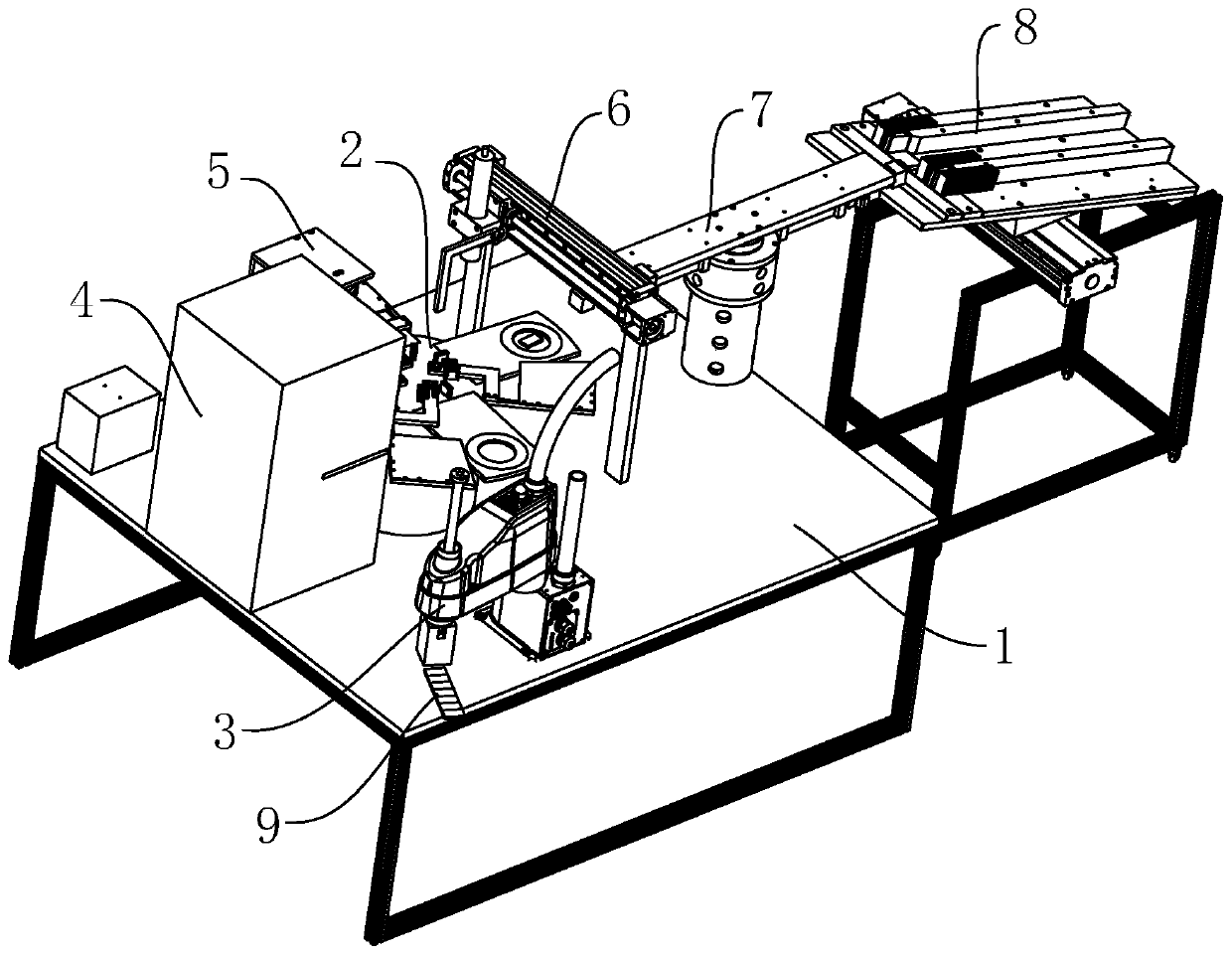

The invention discloses automatic magnetizing and demagnetizing equipment of magnetic workpieces. The equipment comprises a workpiece conveying device, a magnetizing and demagnetizing device and a workpiece processing device , wherein the workpiece conveying device is provided with a feeding station, a magnetizing and demagnetizing station and a discharging station along a conveying direction, andthe workpiece conveying device is also provided with a processing station positioned at an upstream position or a downstream position of the magnetizing and demagnetizing station; the magnetizing anddemagnetizing device is arranged at the magnetizing and demagnetizing station and includes a first permanent magnet and a second permanent magnet, and a workpiece placing space is formed between thefirst permanent magnet and the second permanent magnet; the workpiece processing device is arranged at the processing station; the workpiece conveying device bears a workpiece at the feeding station,and when a workpiece is conveyed to the magnetizing and demagnetizing station through the workpiece conveying device and enters the workpiece placing space, the workpiece is magnetized or demagnetized; and when the workpiece is conveyed to the processing station, the workpiece processing device processes the workpiece, and at the discharging station, the workpiece leaves the workpiece conveying device. According to the automatic magnetizing and demagnetizing equipment of the magnetic workpieces, the magnetic workpiece magnetizing and demagnetizing efficiency and the automatic processing efficiency of other procedures are greatly improved, and universality and accuracy are good.

Owner:茵诺麦格(杭州)自动化设备有限公司

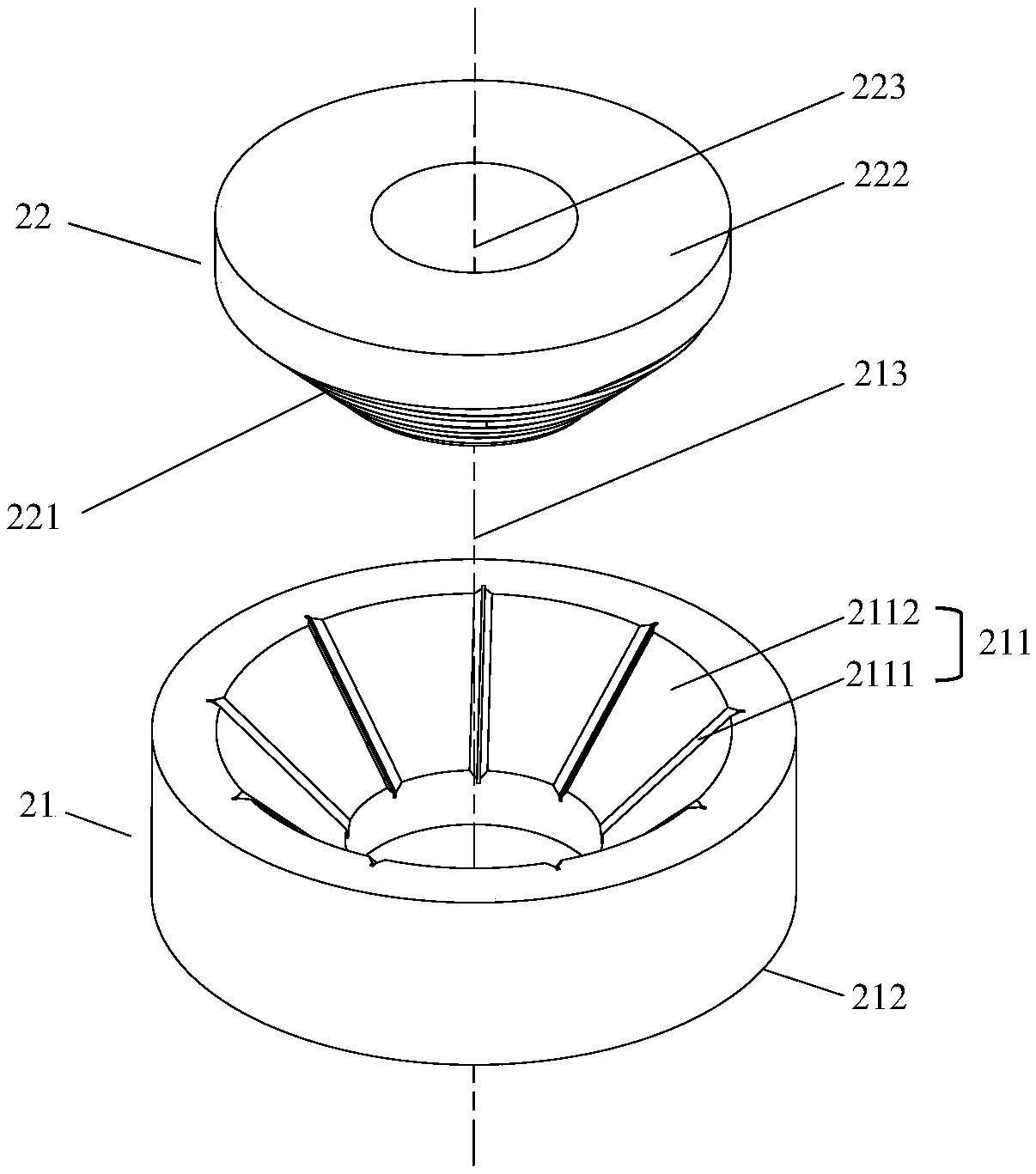

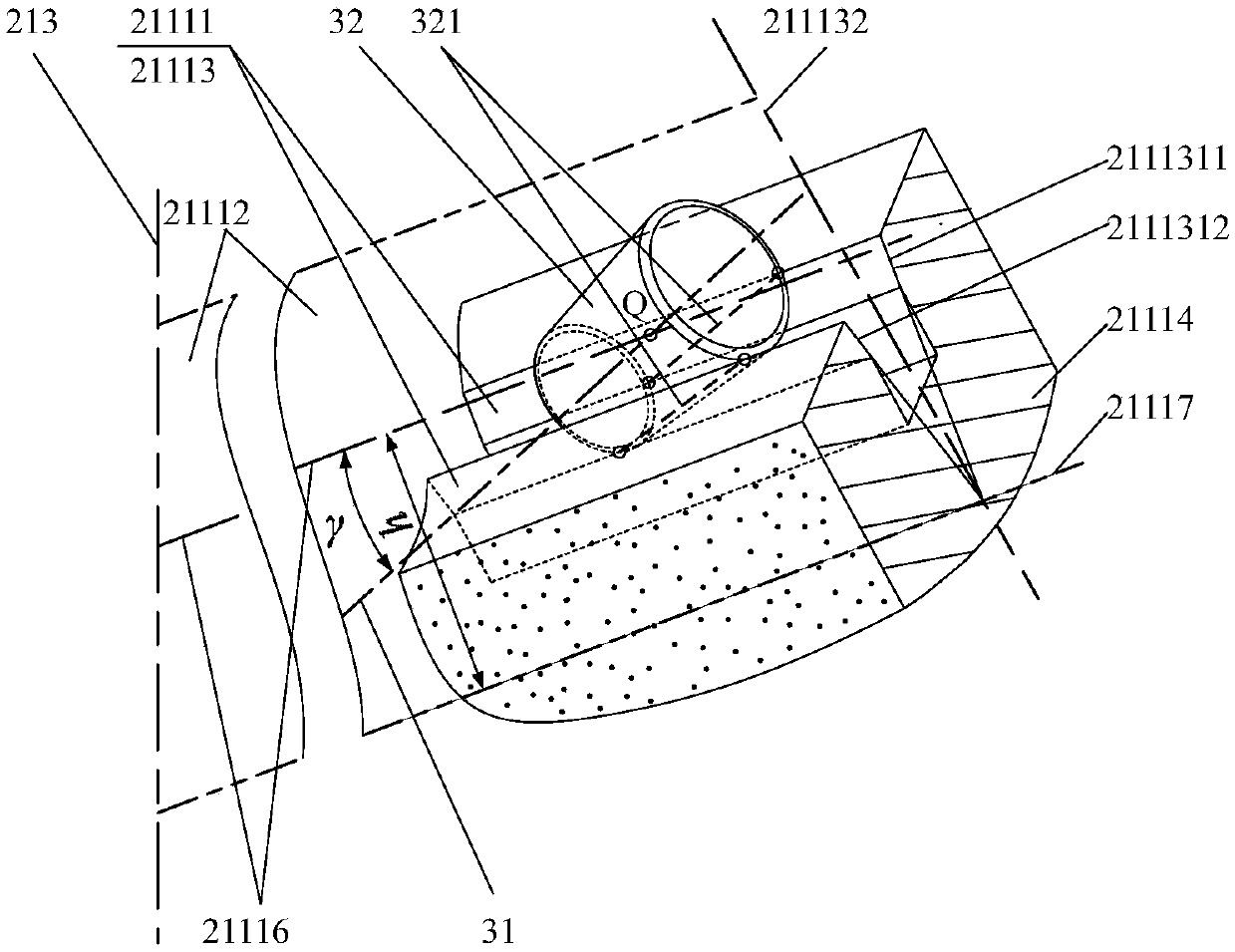

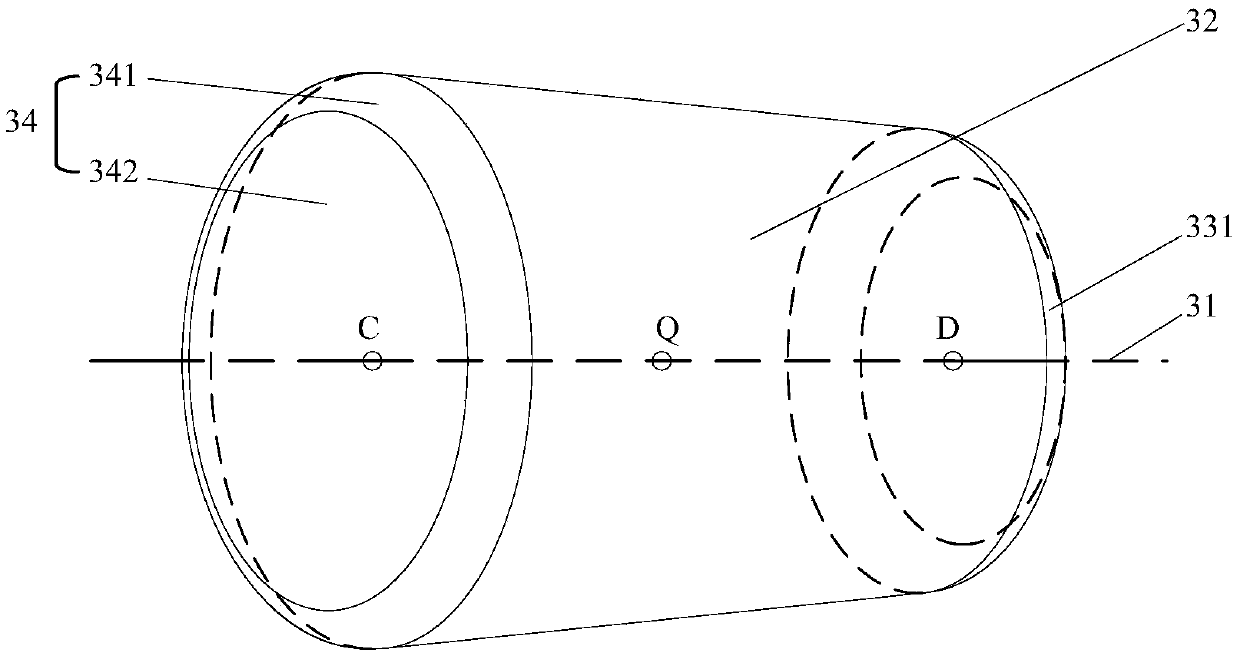

Magnetic grinding disc, equipment and method for tapered roller rolling surface finishing

PendingCN108723982AReduce removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceSurface finish

The invention discloses grinding equipment and a magnetic grinding disc kit for tapered roller rolling surface finishing of ferromagnetic materials. The grinding equipment comprises a main body, the magnetic grinding disc kit and a roller circulation disc outer system. The main body includes a base, a column, a beam, a slide table, an upper tray, a lower tray, an axial loading device and a spindledevice. The roller circulation disc outer system includes a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The magnetic grinding disc kit includes a pair of coaxial first and second grinding discs of which the front surfaces are disposed opposite to each other. The front surface of the first grindingdisc includes a set of linear grooves radially distributed on a base surface (positive conical surface) of the first grinding disc, the front surface of the second grinding disc includes one or morespiral grooves distributed in the base surface (positive conical surface) of the second grinding disc, and a ring-shaped magnetic structure is embedded inside a base body. The grinding equipment has the finishing ability of multitudinous ferromagnetic material tapered roller rolling surfaces.

Owner:TIANJIN UNIV

Remanence evaluating and demagnetizing device of power transformer and remanence evaluation and demagnetizing control methods

ActiveCN109254253AAccurate and fast degaussingDegaussing is fast and thoroughMagnetisation measurementsMagnetic bodiesDemagnetizing deviceRemanence

The invention discloses a remanence evaluating and demagnetizing device of a power transformer. In a main circuit, two ends of a switch power are respectively connected with a filter capacitor and a resistor R0 in parallel, a forward end of the switch power is connected with a main switch T5 in serial, a switch T6 and a resistor R1 serial branch, a switch 1 and a switch 2 serial branch, a switch 3and a switch 4 serial branch are connected at the rear end of the main switch T5 in parallel, a drive circuit is connected with drive ends of the main switch T5, the switch T6, the switch 1, the switch 2, the switch 3 and the switch 4, and a control circuit is connected with the drive circuit and is used for sending an instruction to the drive circuit. The device provides reference for rapid, accurate demagnetization, is more intelligent, can demagnetize rapidly and thoroughly, and greatly shortens field demagnetization time and improves demagnetization effect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +5

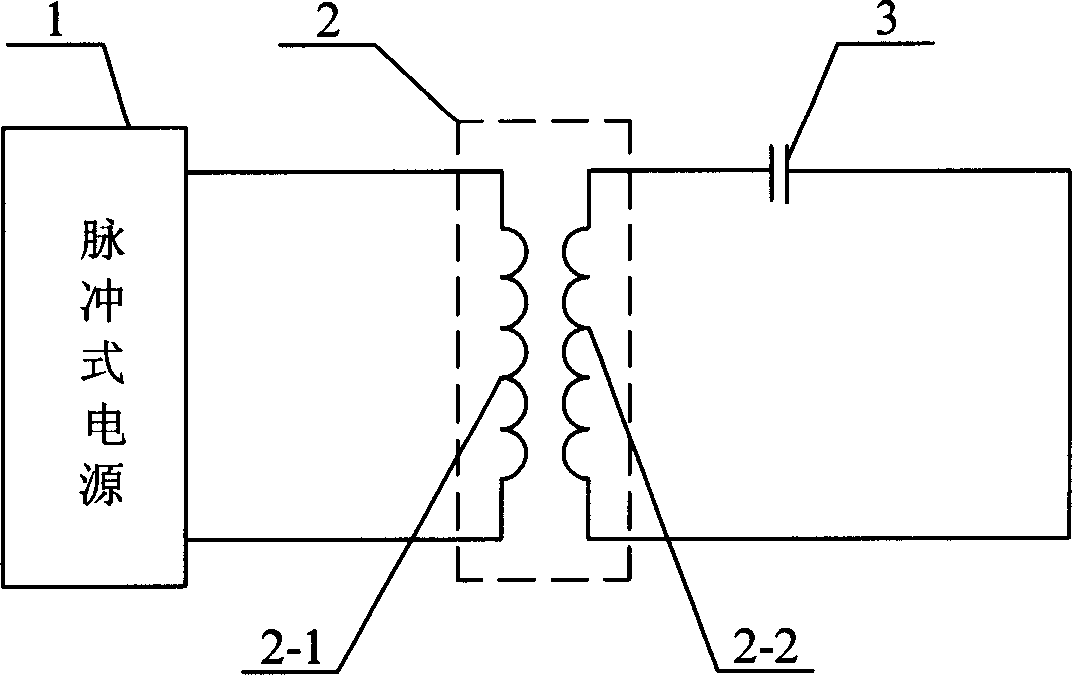

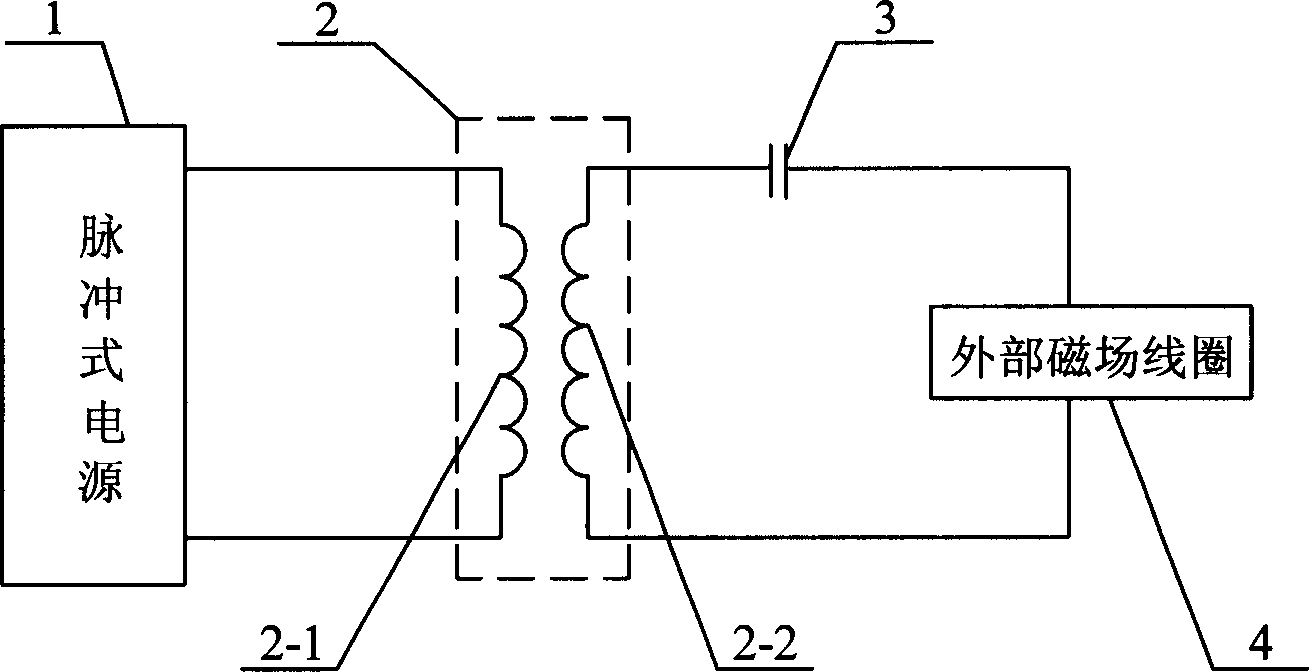

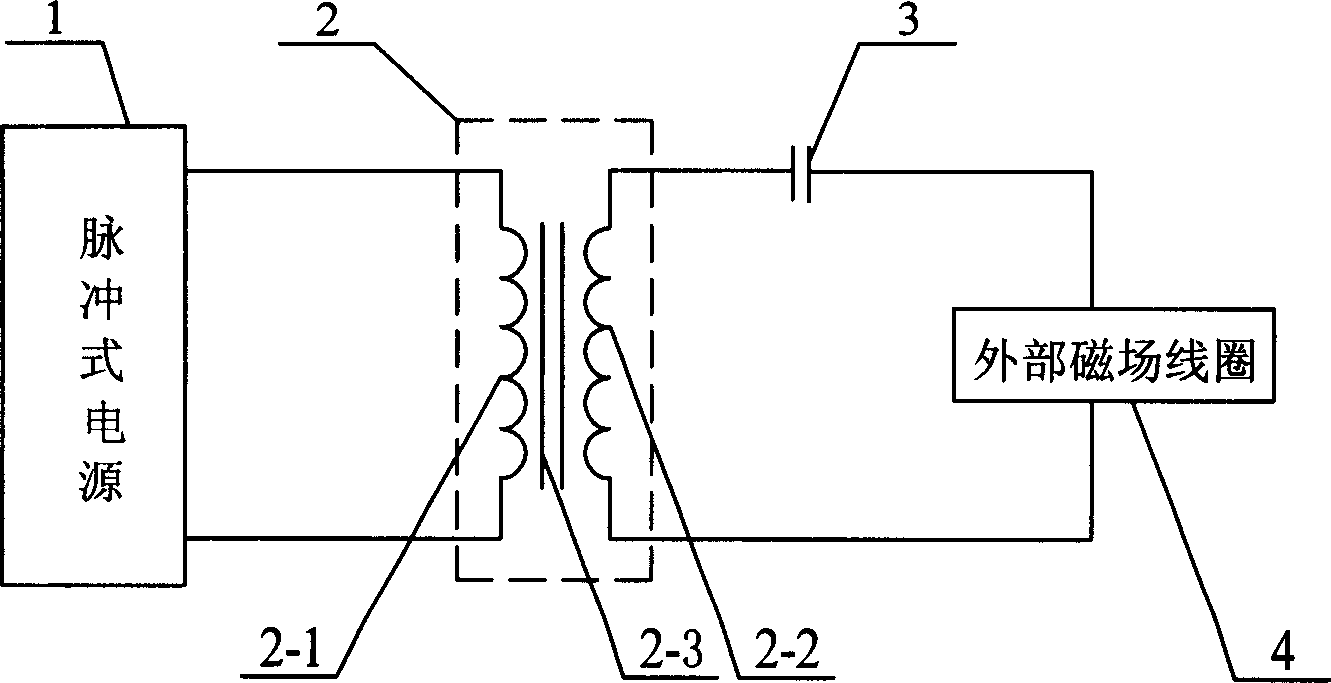

Convergent oscillation type demagnetization device

InactiveCN1664966AFree Ringing Oscillating Current IdealSimple structureMagnetic bodiesCapacitanceDemagnetizing device

The invention discloses a damping oscillation-type demagnetizing device, relating to the field of demagnetizing technique, and comprising mutual inductor and also pulse power supply as well as capacitor; wherein, the mutual inductor is a hollow mutual inductor, coiled of a primary coil and a secondary coil; and two ends of the secondary coil are connected with those of the capacitor, respectively, and two ends of the primary coil are two output ends of the pulse power supply, respectively. The invention can obtain a demagnetizing filed with enough wave number and reduction rate to completely demagnetize permanent magnet; the oscillation of the invention happens in the secondary loop, unable to be affected by high-capacity energy storage capacitor, thus obtaining idealized free damping oscillation magnetic field; and the structure of the invention is simple, and the invention is convenient to use and easy to maintain.

Owner:李志平 +1

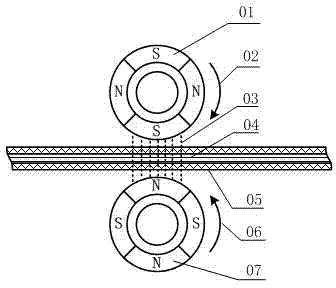

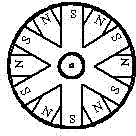

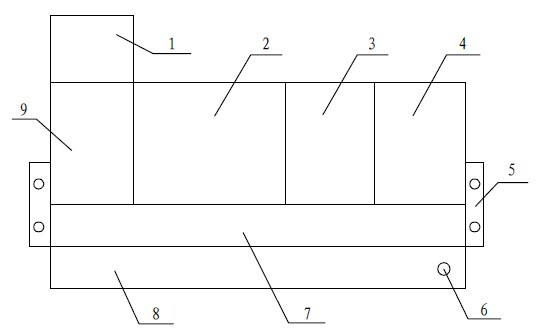

Demagnetizing method and device for steel wire lining conveyer belt by double magnetic rollers

ActiveCN102956340ASimple structureCompact structureConveyorsMagnetic bodiesDemagnetizing deviceMagnetic poles

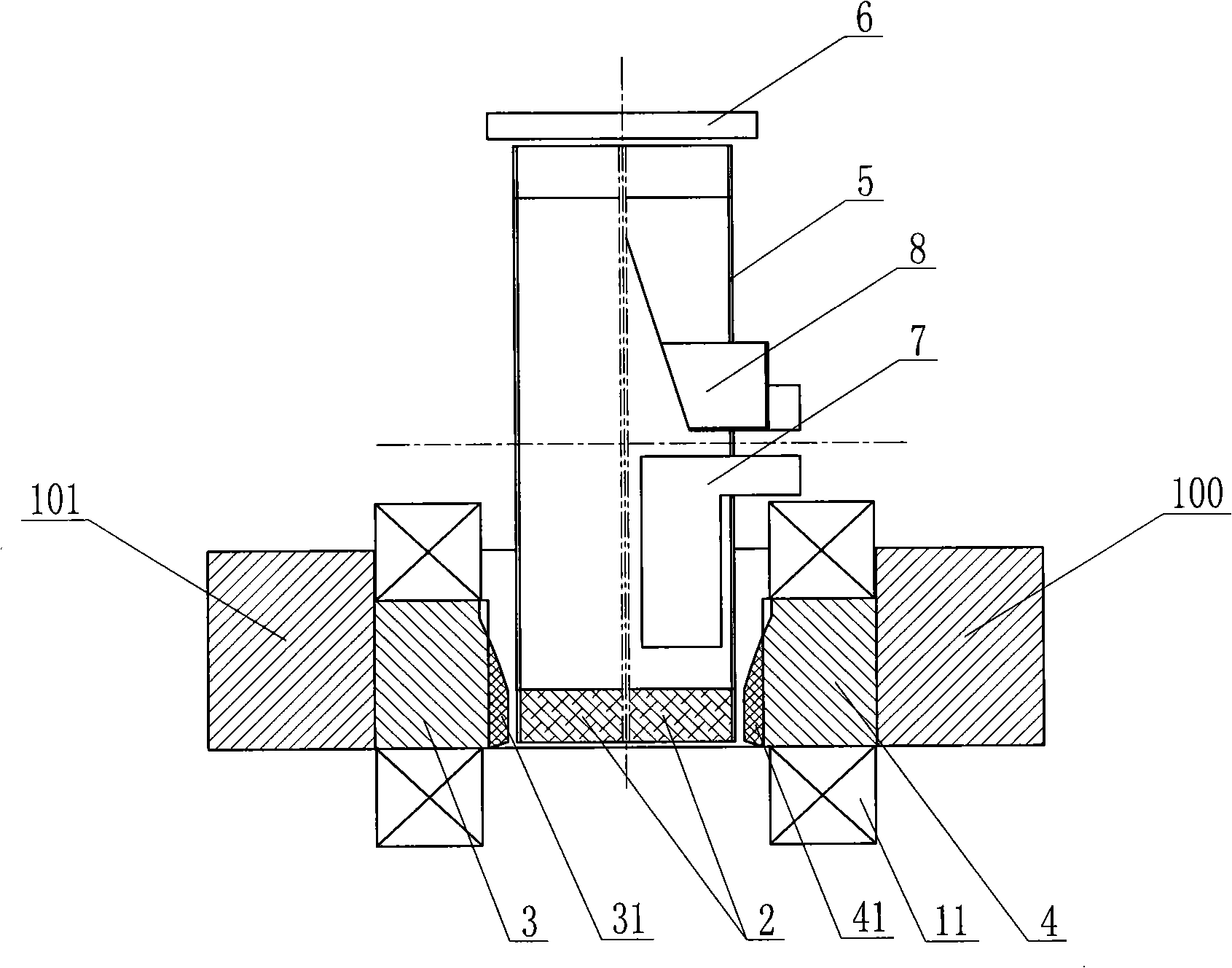

The invention relates to a demagnetizing method and device, and in particular relates to a demagnetizing method and device for a steel wire lining conveyer belt by double magnetic rollers. The demagnetizing method for the steel wire lining conveyer belt by double magnetic rollers comprises the steps of: placing two demagnetizing rollers (1 and 7) respectively above and below the steel wire lining conveyer belt (5), wherein the demagnetizing rollers are multiple-magnetic-pole magnetic rollers with adjacent heterospoles, and the diameters of the demagnetizing rollers are the same, the numbers of the magnetic poles are equal, and the magnetic densities are the same. The two demagnetizing rollers are synchronous at the same speed and rotate in opposite directions (2 and 6), and the heterospoles of the two demagnetizing rollers which rotate synchronously are opposite to each other; and the steel wire (4) lining conveyer belt moves. According to the demagnetizing method and device for the steel wire lining conveyer belt by the double magnetic rollers provided by the invention, the demagnetizing magnetic field is an alternating magnetic field which penetrates through the conveyer belt. The demagnetizing device provided by the invention is simple and compact in structure and easy to implement. Through field conduct and use, the lining steel wire of the demagnetized steel wire lining conveyer belt can be penetrated through more than 10mm, so that a demagnetizing effect is remarkable.

Owner:BAOSHAN IRON & STEEL CO LTD

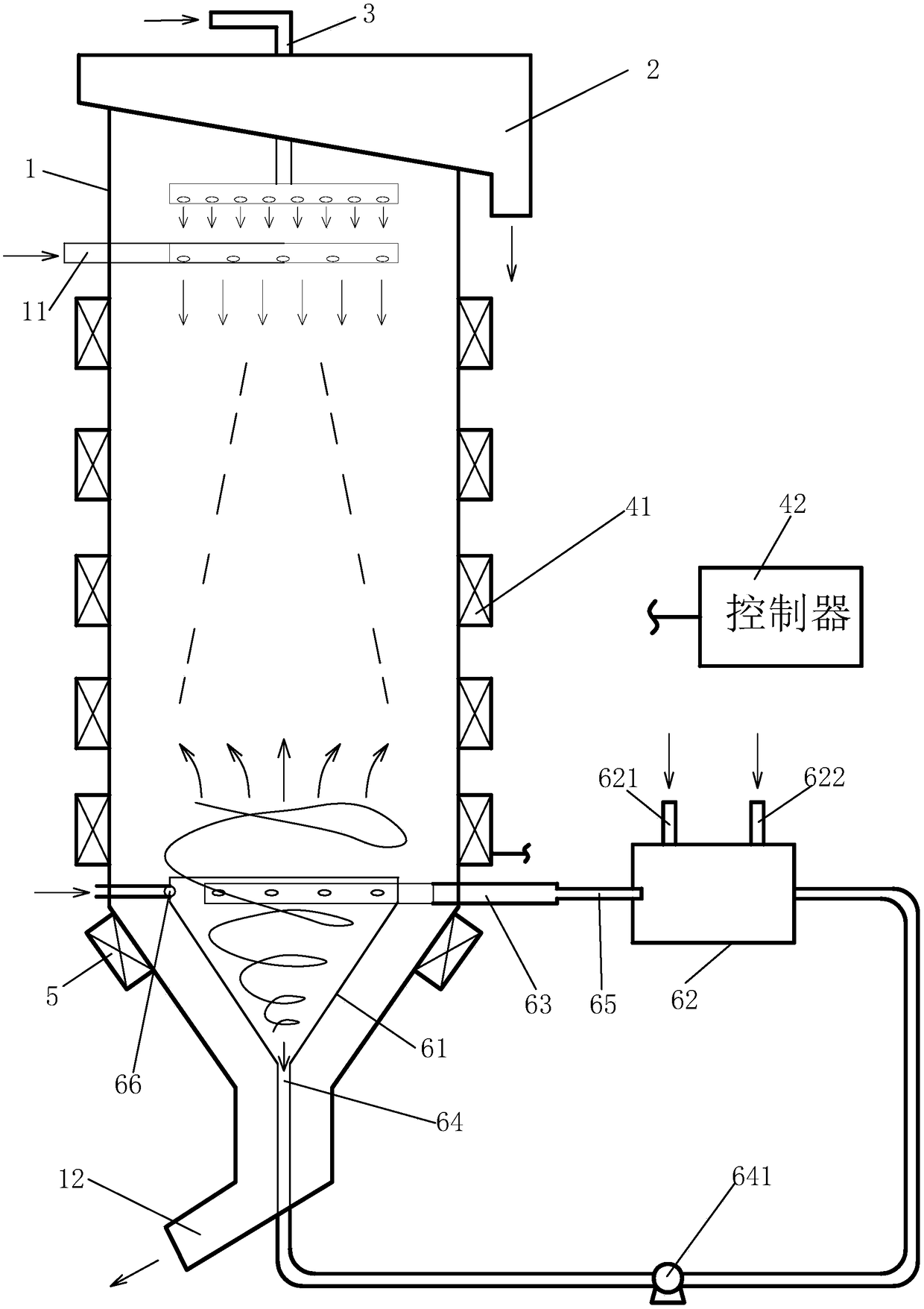

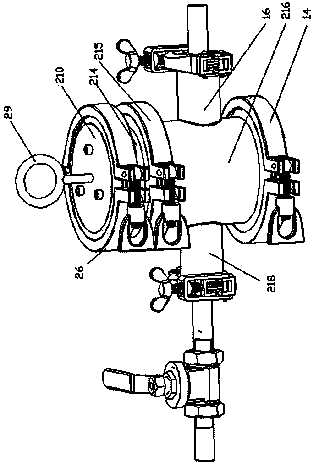

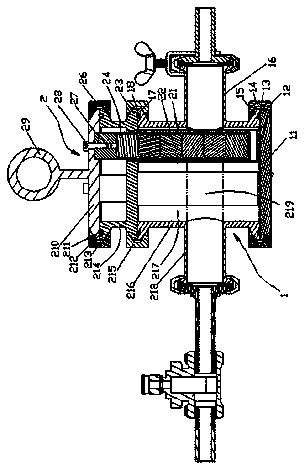

Floatation magnetic separation column device and combined type bubble generator

The invention discloses a floatation magnetic separation column device. The top of a column casing is provided with an overflow groove. The upper portion inside the column casing is provided with a spray device and an ore inlet. A pulsed magnet field and a demagnetizing device are mounted outside the column casing. The bottom of the column casing is provided with an iron ore concentrate outlet anda combined type bubble generator, wherein the combined type bubble generator comprises a conical barrel and a suction chamber. The conical barrel is arranged in the column casing in a sleeved manner,and a gap is reserved. The top of the column casing is open and communicates with the interior of the column casing. A tangential water pipe and a feeding pipe are arranged at the positions, on the upper portion of the conical barrel, inside the column casing. The bottom of the conical barrel is provided with a discharging pipe which extends out of the bottom of the column casing. The dischargingpipe is provided with a pump. The other end of the discharging pipe is connected to one side of the suction chamber. The suction chamber is provided with a gas inlet and an auxiliary agent addition opening. The other side of the suction chamber is connected with the feeding pipe of the conical barrel through a small-diameter throat pipe. The floatation magnetic separation column device is simplein structure, high in separation index and easy to operate; the grade of concrete can be remarkably raised; and by means of the combined type bubble generator, the generation quality of bubbles can beimproved, and the number of the generated bubbles can be increased; and the floatation treatment effect is improved.

Owner:JIANGSU DAFENG XINANDE MINING CO LTD

Intelligent scanning demagnetizing device

ActiveCN105513227ASolve the social problem of waiting in line to waste timeSave wagesCash registersAlarm indicatorsTablet computerDemagnetizing device

The invention relates to an intelligent scanning demagnetizing device. The intelligent scanning demagnetizing device is characterized by comprising a tablet personal computer credit card POS machine all-in-one machine, a scanning demagnetizing all-in-one machine, a bill printer, a shopping information display screen, a security door control system, a fitness equipment low-voltage power source interface, a mobile phone charging interface and a storage battery. The intelligent scanning demagnetizing device solves the social problem that time is wasted when people wait in a queue at an exit of a supermarket or a shopping mall, and the operation cost is lowered; the number of charging ports is decreased, salaries of cashiers are reduced, the problems of damage and stealing are solved, meanwhile, commodity prices of the supermarket are stabilized, the function that a consumer can go shopping while surfing the Internet is added, the consumer can achieve self-service shopping only by pushing a shopping cart with the intelligent scanning demagnetizing device, only one minute is enough from payment to the exit after shopping is completed, and the intelligent scanning demagnetizing device has the key role in transforming and updating supermarkets and large shopping malls in the future and improving the service quality, and improves happy lives of people.

Owner:徐天宏

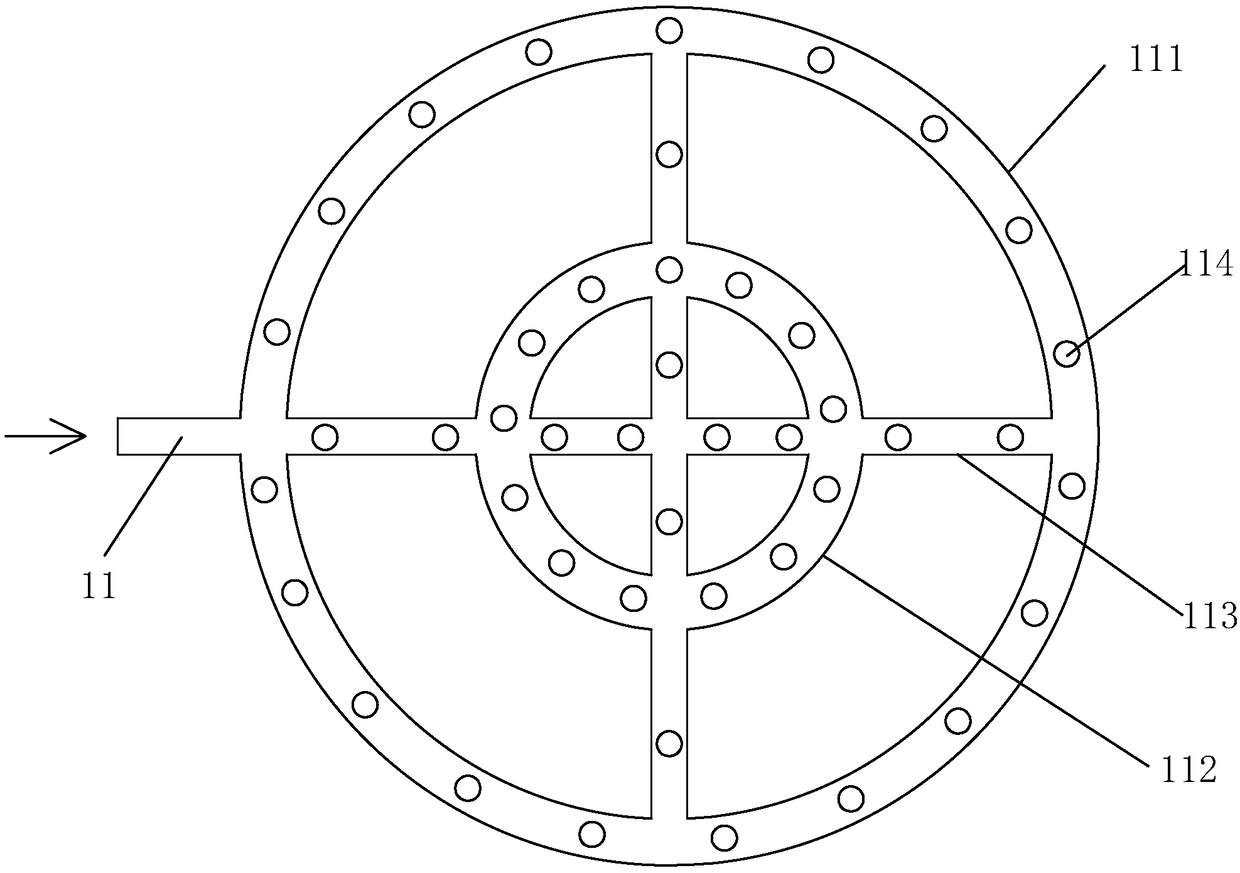

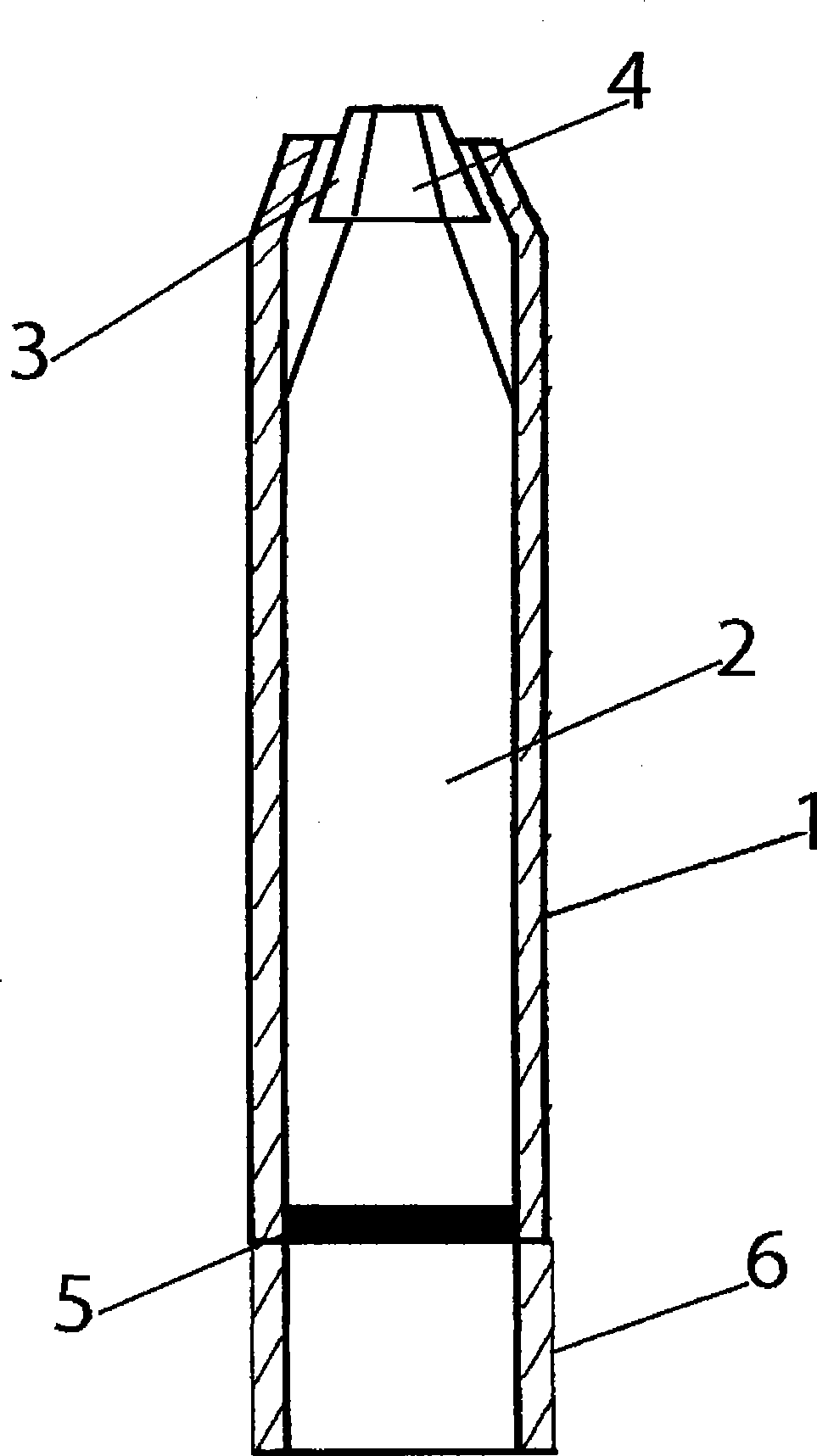

Slurry demagnetizing device for battery production

InactiveCN103506217AEfficient removalEasy to cleanMagnetic separationDemagnetizing deviceEngineering

The invention relates to a slurry demagnetizing device for battery production. The slurry demagnetizing device comprises a barrel body and a magnetic bar connection tray, wherein the barrel body comprises a barrel-shaped housing, a barrel bottom, a barrel bottom tension sleeve, a slurry inlet pipe and a slurry outlet pipe, a barrel cavity is formed in the barrel-shaped housing, the bottom of the barrel-shaped housing is hermetically connected with the upper surface of the barrel bottom, annular barrel bottom tension edges outwardly projecting are respectively arranged at the joint of the barrel-shaped housing and the barrel bottom, the magnetic bar connection tray comprises magnetic bars, a connection tray, magnetic bar covers, an upper cover, a barrel mouth tension sleeve and a tray mouth tension sleeve, the magnetic bar covers are barrel-shaped, the magnetic bars are arranged in the magnetic bar covers, at least two magnetic bar cover openings are formed in the bottom of the connection tray, the lower parts of the magnetic bar cover openings are connected with the magnetic bar covers, the magnetic bar covers are arranged in the barrel cavity and pass along a flow path of the slurry inlet pipe and the slurry outlet pipe in the barrel cavity, the magnetic bar covers and the barrel cavity are sealed, a gap is formed between the magnetic bar covers, and the magnetic bars are connected with the upper cover. The slurry demagnetizing device can effectively remove impurities adsorbed by magnets in slurry, is convenient for quick cleaning of the surfaces of the magnetic bar covers and is convenient to dismount and clean.

Owner:ZHONGSHAN TIANMAO BATTERY

Magnetic chalk

InactiveCN101417572AMagnetic lossBoard cleaning devicesNon-propelling pencilsDemagnetizing deviceEngineering

The invention relates to magnetic chalk, the main body of which is a tubular rod and the two ends of the magnetic chalk is divided into two parts, i.e., a magnetizing tube and a demagnetizing tube. The magnetizing tube is internally provided with a scrap iron room for holding scrap iron, a scrap outlet and a magnetizing device. The demagnetizing tube is provided with a demagnetizing device. An insulating layer is between the magnetizing tube and the demagnetizing tube for mutual insulation. The magnetic chalk is green and environment-friendly, non-toxic and harmless.

Owner:SHANGHAI HUANGPU DISTRICT XINLING ELEMENTARY SCHOOL

Wireless mobile paying device

ActiveCN102184605ASimplify the tedious manual charging operationPassenger flow speed increasesCash registersDemagnetizing devicePayment

Owner:浙江公原前智能科技有限公司

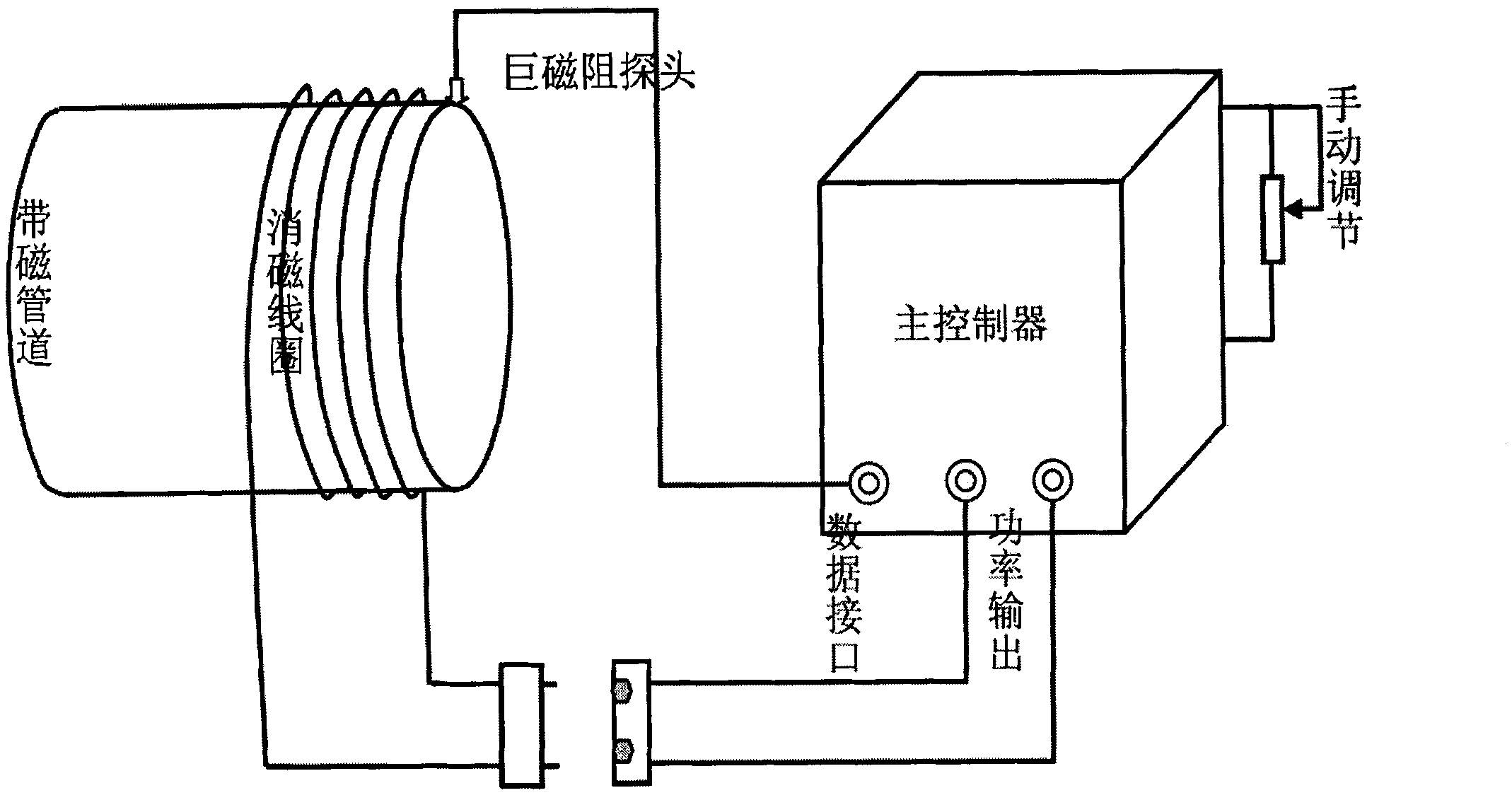

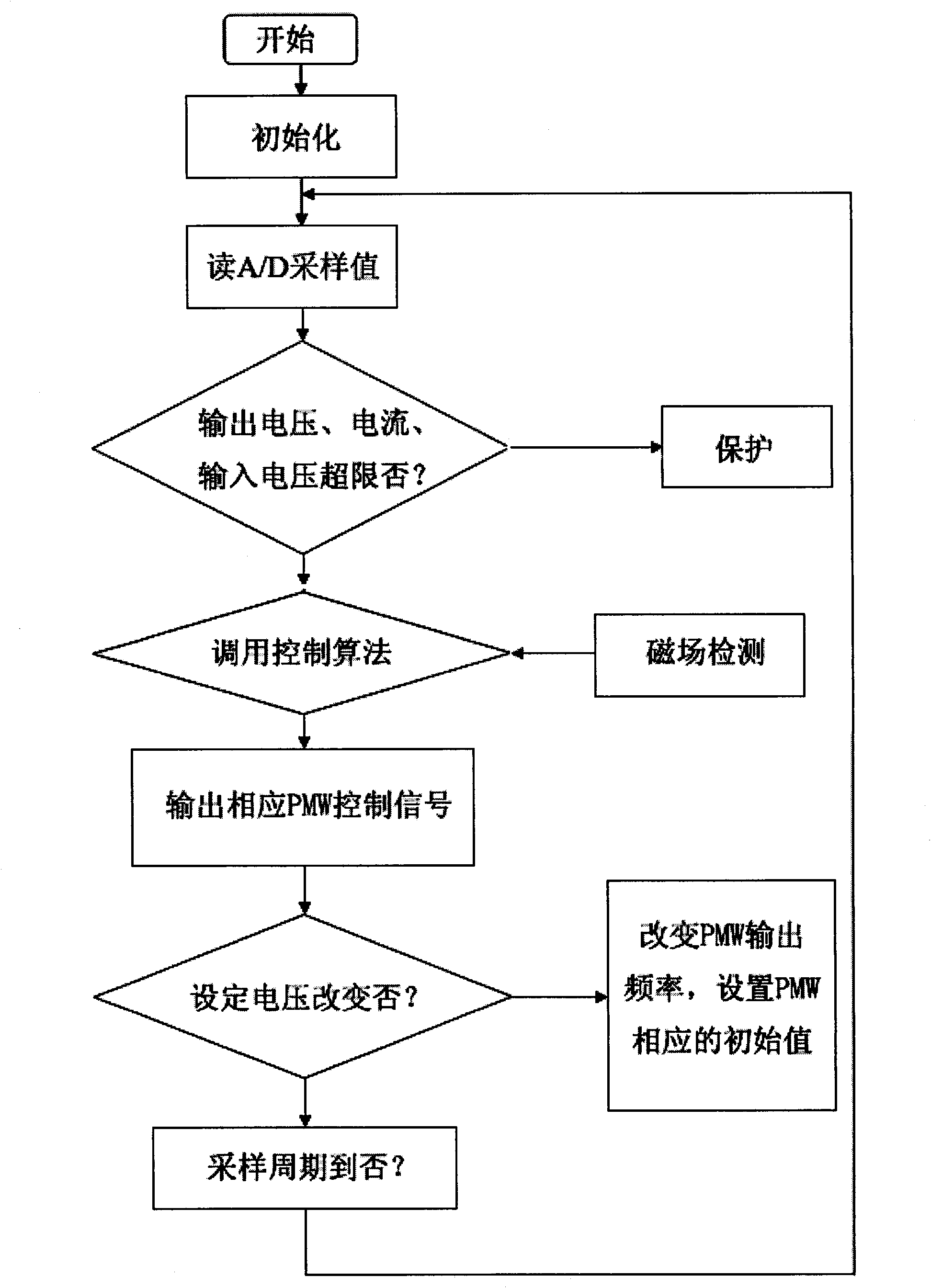

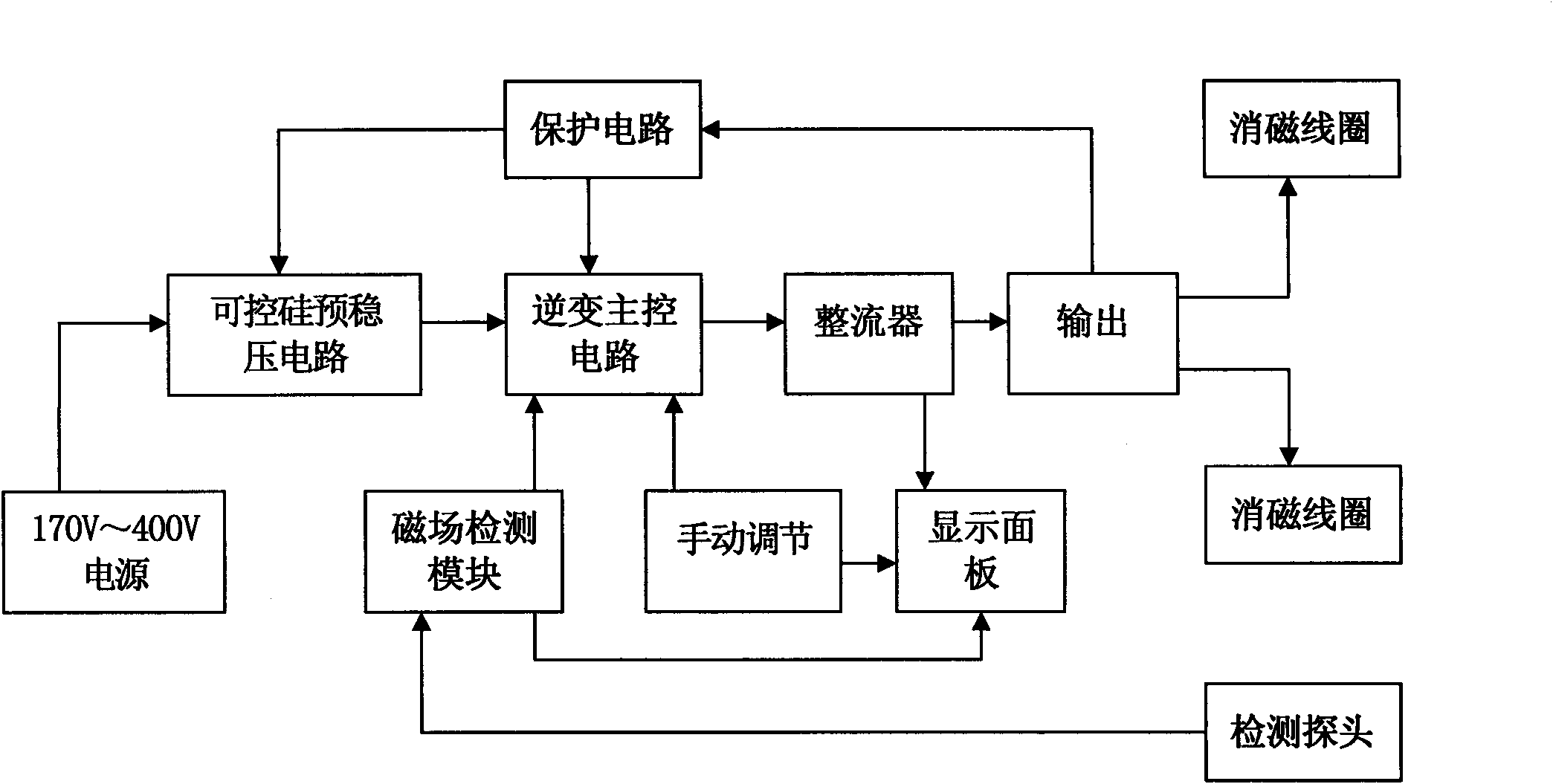

Hysteresis-damping demagnetizing method for pipeline port

ActiveCN102403084AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesDemagnetizing deviceHysteresis

The invention discloses a hysteresis-damping demagnetizing method for a pipeline port, relating to the technical field of pipeline systems. In the method, a demagnetizing coil is wound on the port of a pipeline to be demagnetized, a giant magneto-resistive probe is fixed at an outer edge of the pipeline port and is connected with a data interface of a main controller of a demagnetizing device, the demagnetizing coil is connected with a power output end of the main controller, and then, the method is implemented according to the following steps of: picking up a signal of the giant magneto-resistive probe by the main controller, and measuring the magnitude and the direction of residual magnetism of the pipeline; according to the differences in the magnitude, the direction and the materials of the residual magnetism of the pipeline, automatically calculating an output parameter and controlling a circuit part to covert power-frequency alternating current of 50Hz into high-frequency alternating current of 20-45kHz; and reducing voltage, rectifying current, and controlling the magnitude and the direction of the current required for generating a power source to obtain a magnetic field which is identical to the residual magnetism of the pipeline in magnitude and opposite to the residual magnetism of the pipeline in direction. Compared with the traditional demagnetizing technology, thedemagnetizing method disclosed by the invention has the advantages of advanced control manner, reliability in operating, rapidness in demagnetizing and good demagnetizing effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electronic information demagnetizing device

ActiveCN107256756ANot easy to corrodeExtended service lifeMagnetic bodiesDemagnetizing deviceElectronic information

The invention relates to demagnetizing devices, in particular to an electronic information demagnetizing device. The technical problem of the invention is to provide a demagnetizing device which can fully perform demagnetizing, can perform demagnetizing in a sealed environment, and can collect the demagnetized electronic devices. To solve the technical problem, the invention provides the electronic information demagnetizing device. The electronic information demagnetizing device includes a demagnetizing frame; the internal center of the demagnetizing frame is connected to a demagnetizing mechanism; a first through hole is formed in the center of an internal bottom of the demagnetizing frame; the first through hole is positioned under the demagnetizing mechanism; first fixing blocks are connected to a left side and a right side of the bottom of the demagnetizing frame; first grooves are formed in the first fixing blocks; a baffle plate is arranged in the first grooves; a left end and a right end of the baffle plates are positioned in the first grooves; and a right side of the demagnetizing frame is connected to a drive mechanism. The drive mechanism and the demagnetizing mechanism can turn over electronic devices to be demagnetized in the demagnetizing frame.

Owner:ZHEJIANG JIESHITAI ELECTRONICS

High-gradient magnetic separation machine

InactiveCN101402067AReduce energy consumptionEasy maintenanceHigh gradient magnetic separatorsDemagnetizing deviceMagnetic media

The invention discloses a high gradient magnetic separator, which comprises a separation ring and a driving device thereof, an ore feeding device, a concentrated ore discharging device and a concentrated ore collecting device, wherein the separation ring comprises a rotating ring and a concentrated magnetic medium pack, a left magnetic yoke, a left magnet, a right magnetic yoke, a right magnet, a front magnetic yoke, a rear magnetic yoke, and a magnetizing and demagnetizing device which consists of magnetic coils and a magnetizing power source and can perform magnetizing and demagnetizing treatment on the left magnet and the right magnet respectively. The high gradient magnetic separator smartly combines a permanent magnet and a magnetizing power source to form a background magnetic field of the separator, so the high gradient magnetic separator can conveniently perform magnetizing and demagnetizing treatment on the left magnet and the right magnet according to the required value of the background magnetic field and then perform effective separation on ores after canceling the magnetizing power source when in work, and can perform demagnetizing treatment on an upper magnet and a lower magnet when in assembly and maintenance so as to solve the magnetic blockage problem. The high gradient magnetic separator can greatly reduce the energy consumption, and fully ensure convenient maintenance in practical production.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com