Workpiece demagnetizing method and workpiece demagnetizing device

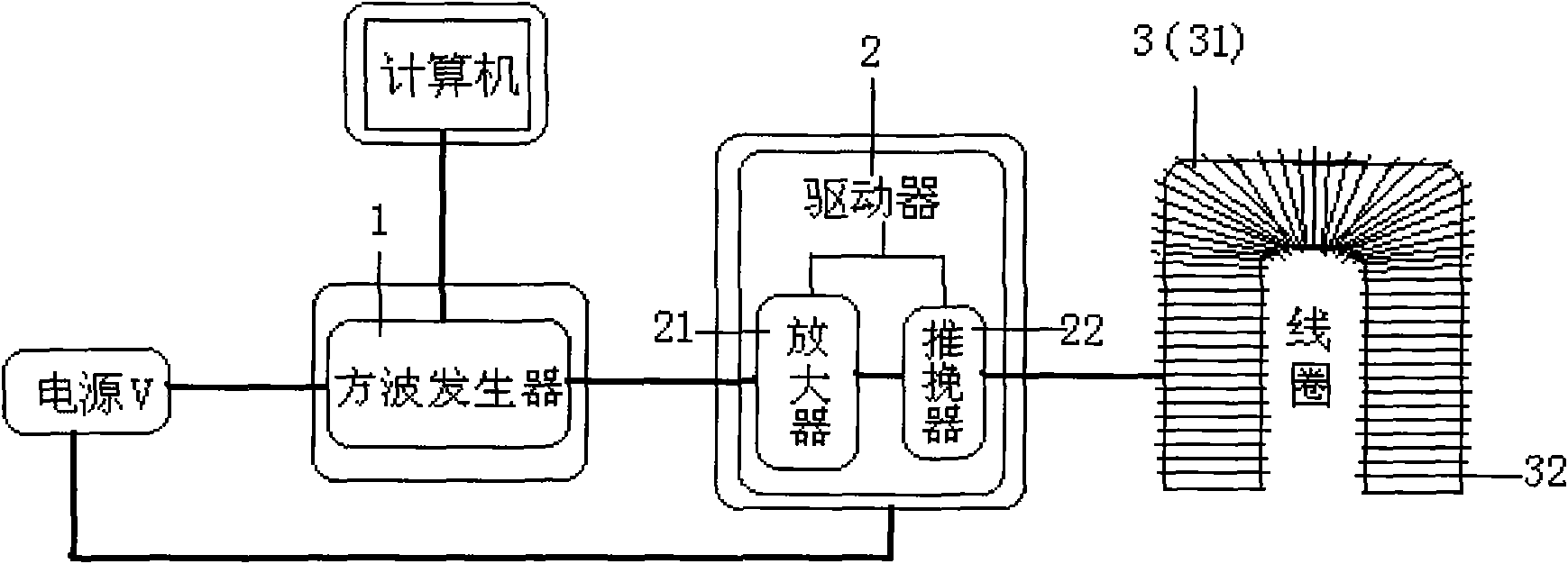

A degaussing method and a technology of a degaussing device, which are applied in the field of degaussing, can solve problems such as unsatisfactory degaussing effect and failure to be used in real applications, and achieve the effects of good degaussing effect, compact structure, and reduced device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

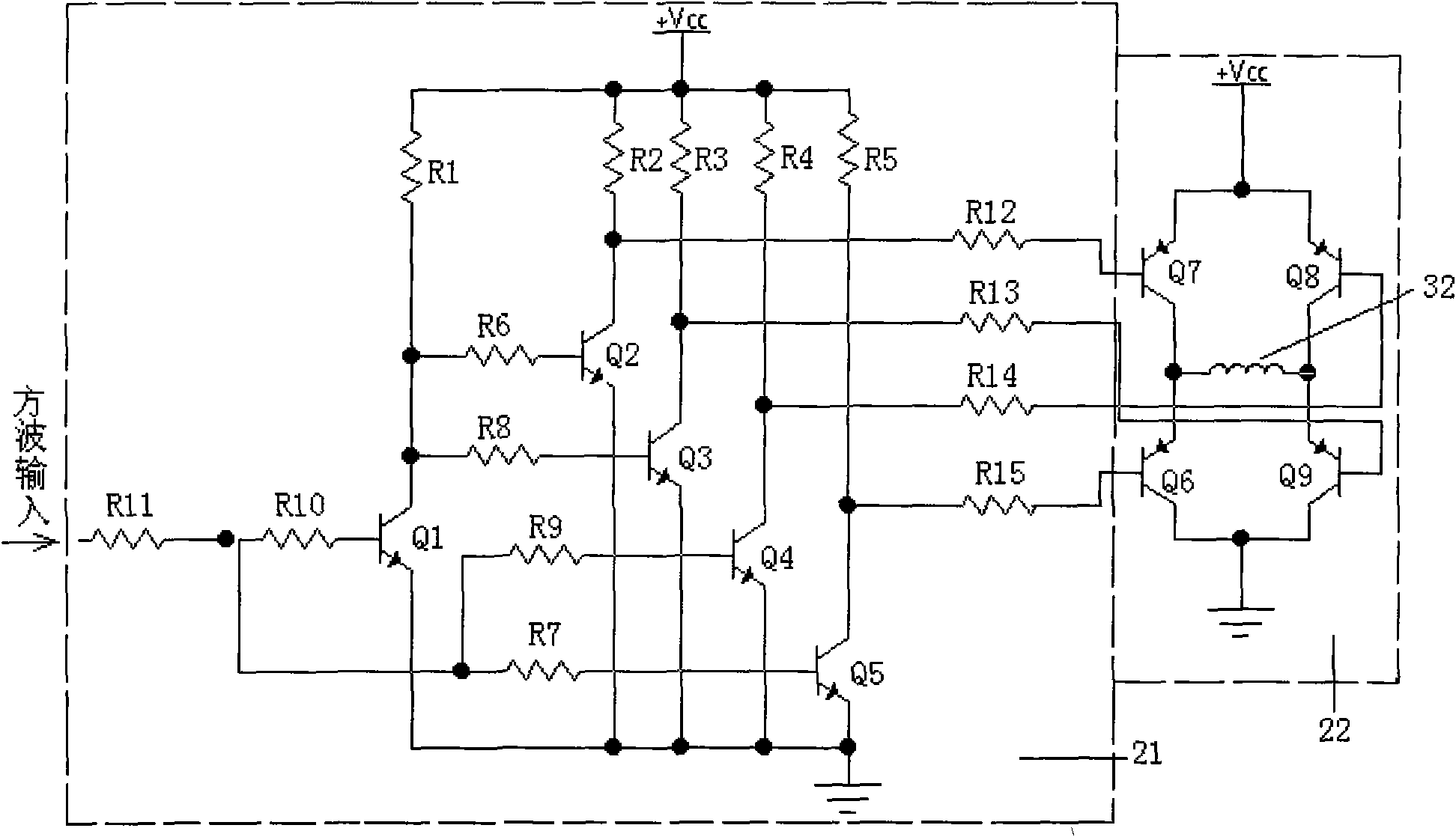

Method used

Image

Examples

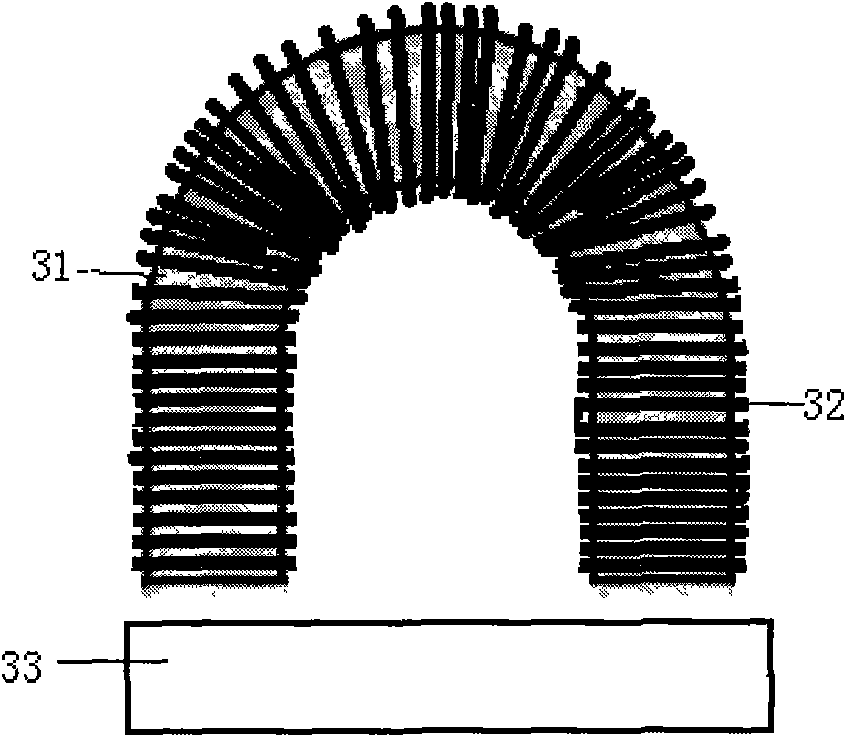

example 1

[0031] After testing, the residual magnetism in a certain section of the workpiece is 100Gs, and the relative movement speed of the workpiece is 1.5m / s. The design degaussing magnetic field is 300Gs, the square wave frequency is 600Hz, and the power supply is 24V DC; ferrite selection: the initial permeability is greater than 2200, the shape is a large semi-circular ring, the cross-section is 10mm×20mm, and the effective degaussing area is 20mm×30mm; coil The copper wire diameter is selected as 0.56mm, and the number of turns is 320 turns. After degaussing, the residual magnetism of this section of the workpiece is less than 1Gs after testing.

example 2

[0033] After testing, the residual magnetism in a certain section of the workpiece is 200Gs, and the relative movement speed of the workpiece is 1.5m / s. The design degaussing magnetic field is 300Gs, the square wave frequency is 600Hz, and the power supply is 24V DC; ferrite selection: the initial permeability is greater than 2200, the shape is a large semi-circular ring, the cross-section is 10mm×20mm, and the effective degaussing area is 20mm×30mm; coil The copper wire diameter is selected as 0.56mm, and the number of turns is 320 turns.

[0034] After degaussing, the residual magnetism of this section of the workpiece is less than 1Gs after testing.

example 3

[0036] After testing, the residual magnetism of a section of the workpiece is 800Gs, and the relative movement speed of the workpiece is 1.2m / s. The design degaussing magnetic field is 2000Gs, the square wave frequency is 400Hz, and the power supply is 60V DC; ferrite selection: the initial permeability is greater than 2200, the shape is U-shaped, the cross-section is 30mm×70mm, and the effective degaussing area is 70mm×80mm; coil selection The diameter of the copper wire is 1.40 mm, and the number of turns is 860 turns.

[0037] After degaussing, the residual magnetism detected in this section of the workpiece is less than 1Gs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com