Convergent oscillation type demagnetization device

A damping and demagnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problem of insufficient wavenumber demagnetization magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

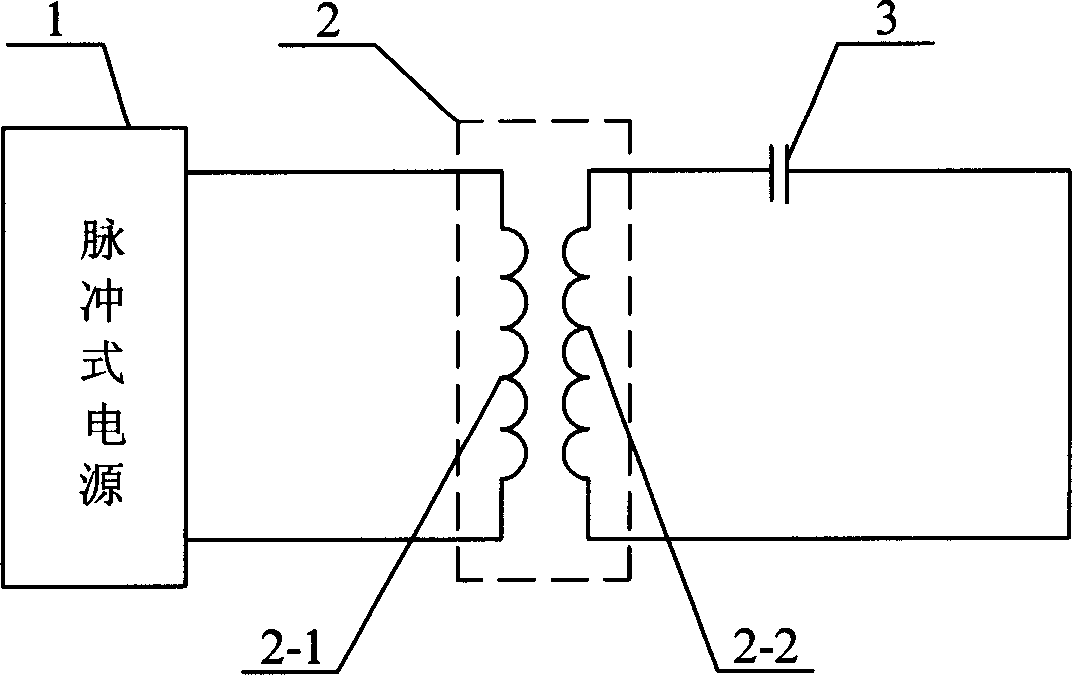

[0005] Specific implementation mode one: combine figure 1 Describe this embodiment, it is made up of pulse type power supply 1, mutual induction coil 2, capacitor 3; The ends are respectively connected to the two ends of the capacitor 3, and the first and the ends of the coil 2-1 are respectively connected to the two output ends of the pulse power supply 1. This embodiment enables the ideal demagnetization of the permanent magnets, magnetic powders and workpiece materials that need to be demagnetized in the mutual induction coil 2 . The front-end pulsed power supply 1 can be a specially designed pulsed power supply, or an existing pulsed magnetizing power supply can be utilized. The demagnetizing field in the mutual inductance coil 2 is also an ideal orientation magnetic field, which can be used for magnetic field orientation of powder and permanent magnetic material forming magnetic field orientation and demagnetization after orientation in the cavity or mold in the coil.

specific Embodiment approach 2

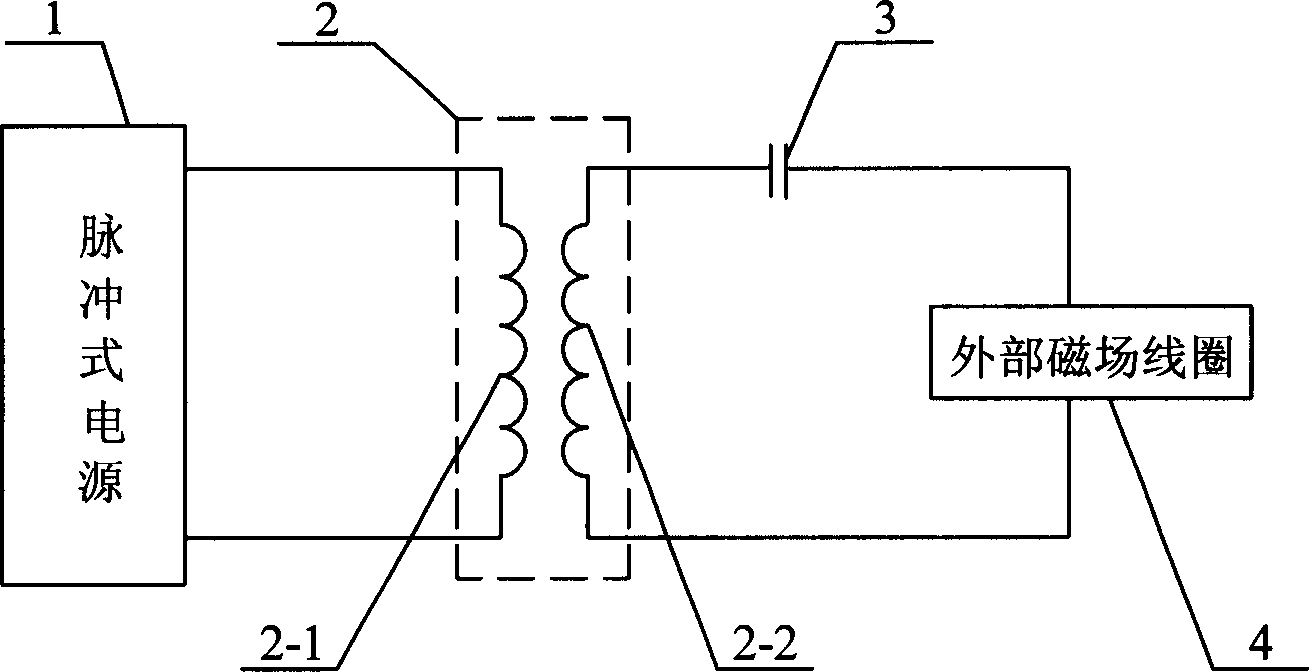

[0006] Specific implementation mode two: combination figure 2 Describe the present embodiment, present embodiment adds external magnetic field coil 4 on the basis of specific embodiment one; One end of external magnetic field coil 4 is connected with one end of coil 2-2, and the other end of external magnetic field coil 4 is connected with one end of capacitor 3, The other end of the capacitor 3 is connected to the other end of the coil 2-2; other components and connections are the same as those in the first embodiment. The external magnetic field coil 4 in this embodiment may be a solenoid or a magnetizing seat and coils of various structures including a multi-pole magnetizing seat. In this embodiment, the external magnetic field coil 4 is used to demagnetize the placed permanent magnets, magnetic powder and workpiece materials that need to be demagnetized.

specific Embodiment approach 3

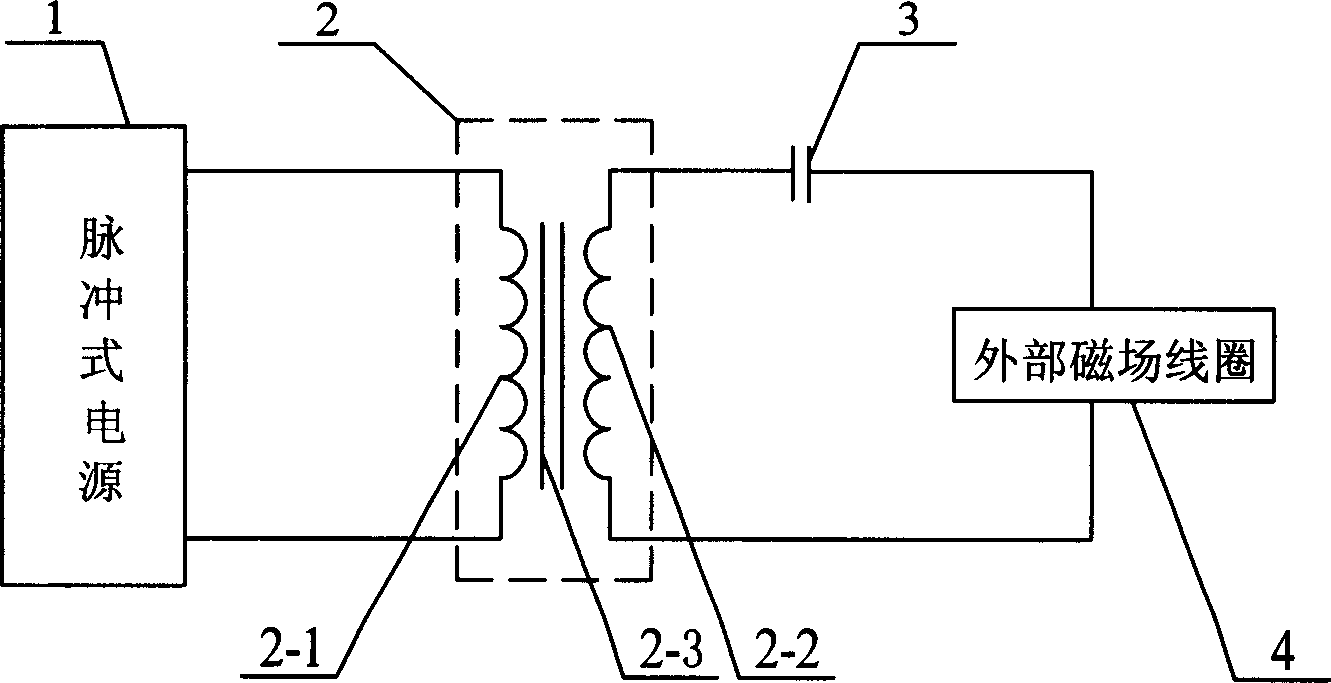

[0007] Specific implementation mode three: combination Figure 4 This embodiment will be described. On the basis of Embodiment 1, this embodiment adds an external magnetic field coil 4 ; the external magnetic field coil 4 is connected in parallel with the capacitor 3 . Other compositions and connections are the same as in the first embodiment. The external magnetic field coil 4 may be magnetizing seats and coils of various structures including multi-pole magnetizing seats.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com