Tracking system and method for outer shaft of corrugated plate

A corrugated plate, coordinate system technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that the weld seam tracker cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention discloses a corrugated plate external axis tracking method and a corrugated plate external axis tracking system. The specific implementation of the present invention will be further described below in combination with preferred embodiments.

[0052] It is worth mentioning that the (high-speed) laser displacement sensor involved in the patent application of the present invention can be defined as the camera (industrial camera) involved in the patent application of the present invention, which is the same concept and is hereby declared.

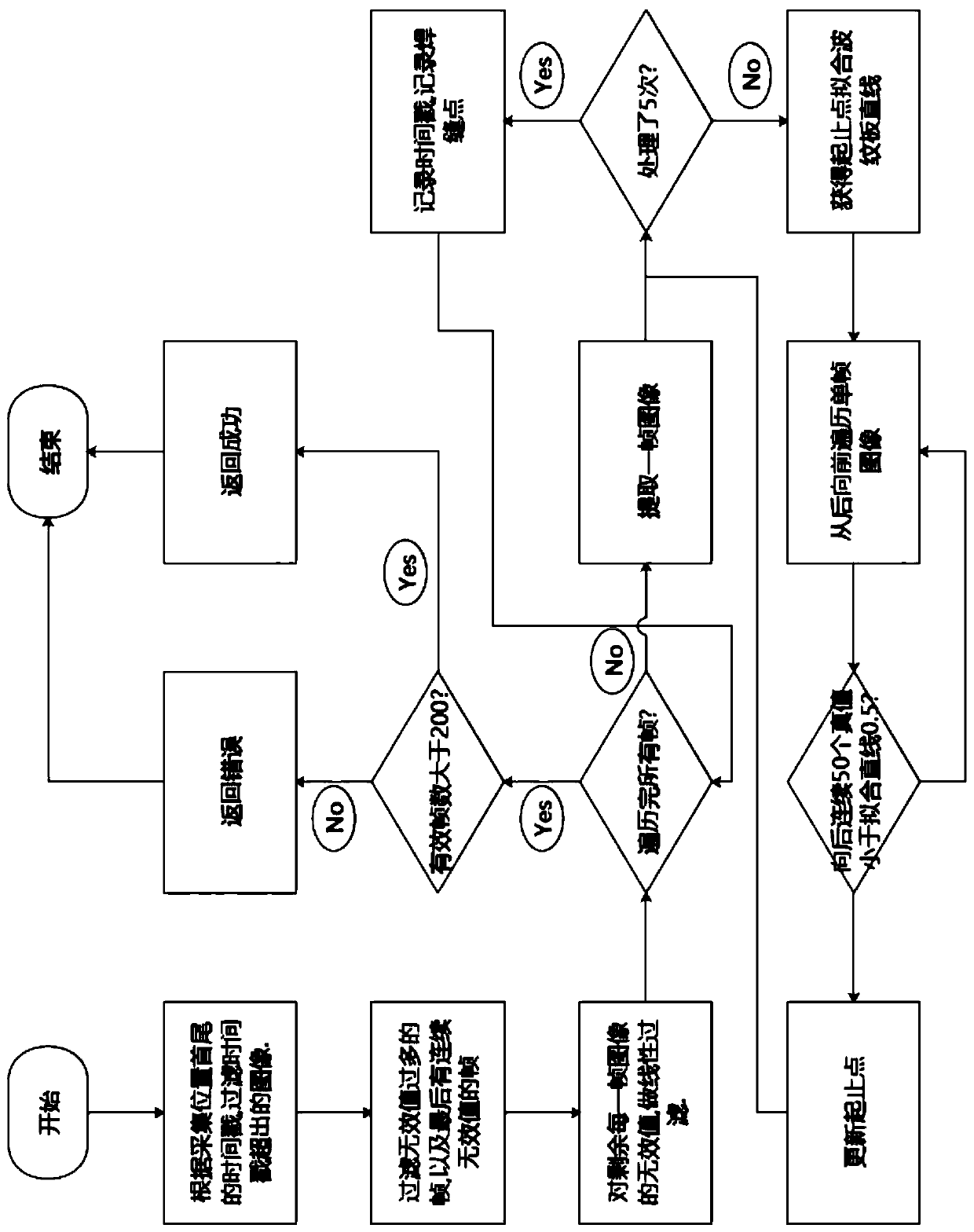

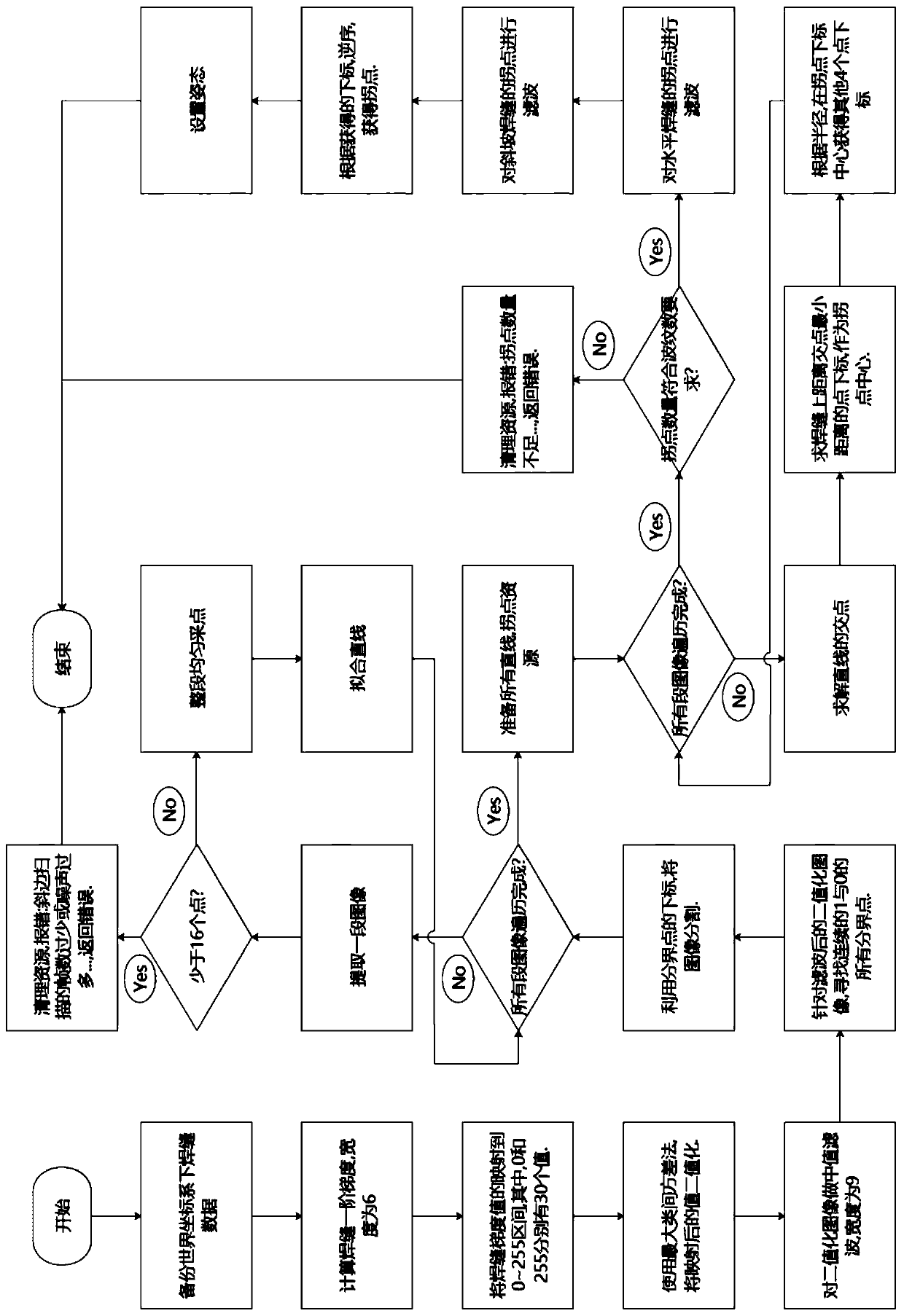

[0053] see attached Figure 1 to Figure 2 , figure 1 A partial flow of a corrugated plate external axis tracking system and method thereof is shown, figure 2 A partial flow of the corrugated plate external axis tracking system and method thereof is shown.

[0054] preferred embodiment.

[0055] Preferably, the method for tracking the external axis of the corrugated plate includes the following steps:

[0056] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com