Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

227results about How to "Improve pitting resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

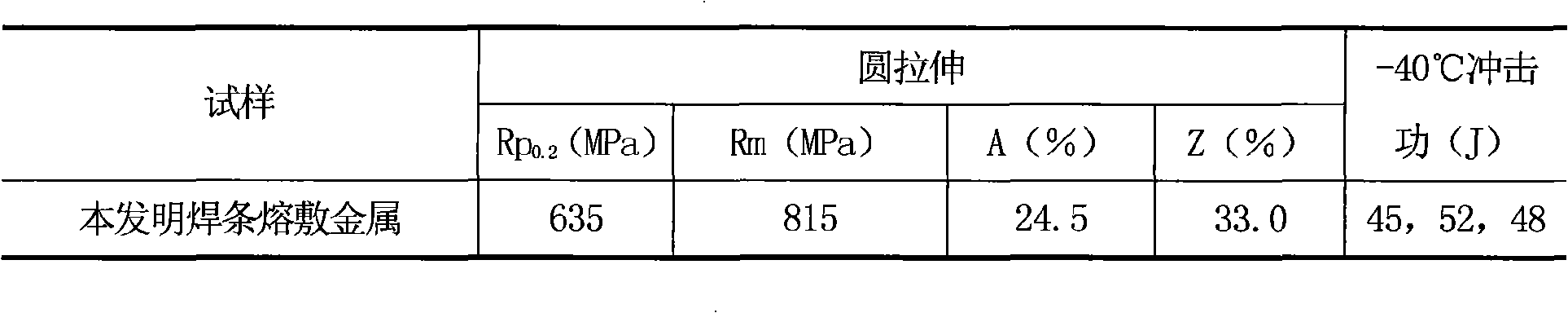

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

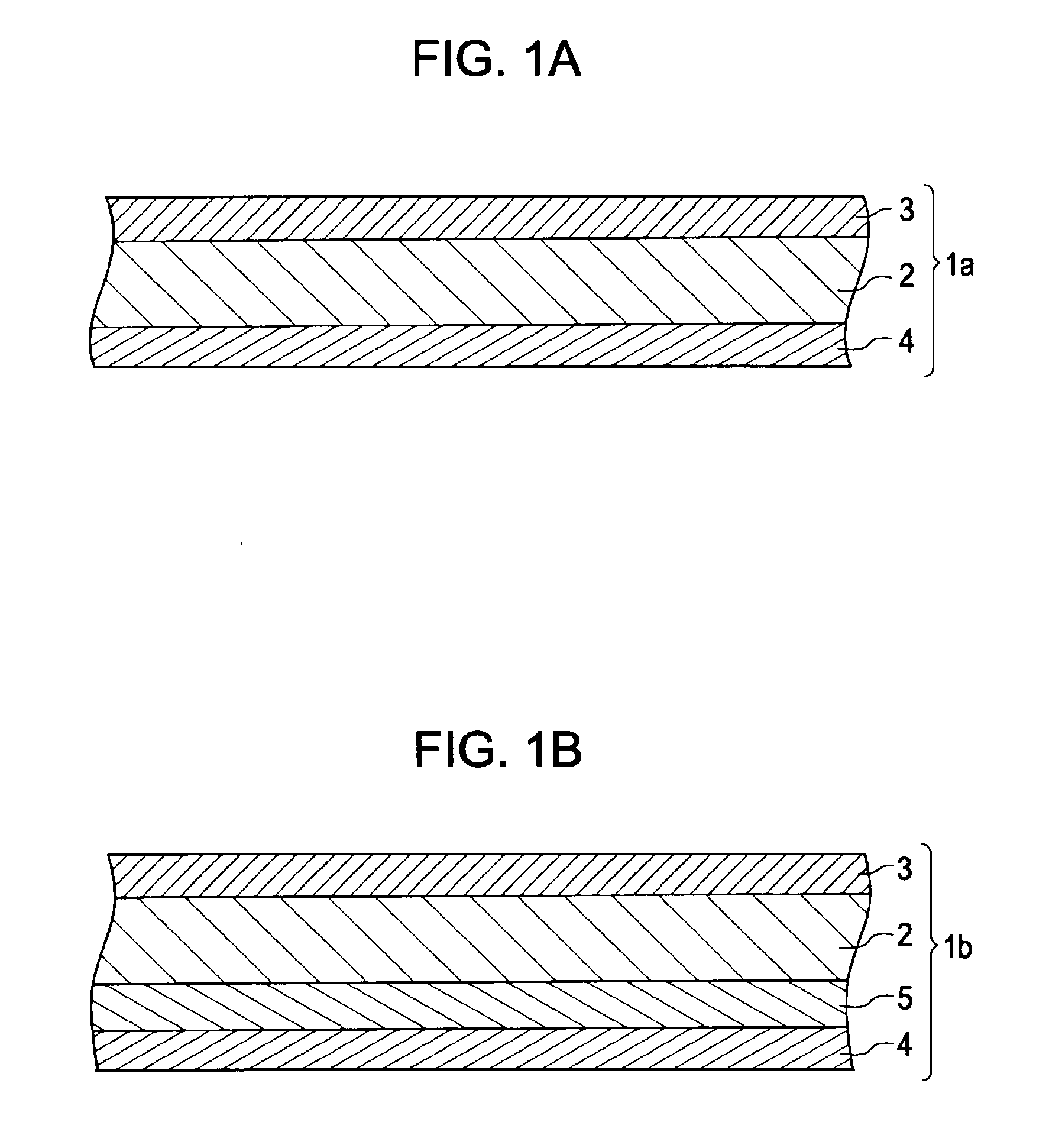

Aluminum alloy clad sheet for heat exchanger

InactiveUS20100183897A1Prevent deterioration in brazeabilityInhibit deteriorationWelding/cutting media/materialsCoatingsImpurityMaterials science

An aluminum alloy clad sheet for heat exchangers includes a core layer, a sacrificial layer disposed on one side of the core layer, and a brazing layer of an Al—Si alloy disposed on the other side of the core layer, wherein the core layer contains Si: 0.15% to 1.6% by mass, Mn: 0.3% to 2.0% by mass, Cu: 0.1% to 1.0% by mass, Ti: 0.02% to 0.30% by mass, and the remainder of Al and incidental impurities, and the sacrificial layer contains Zn: 4.0% to 10.0% by mass, Cr: 0.01% to 0.5% by mass, and the remainder of Al and incidental impurities.

Owner:KOBE STEEL LTD

Aluminium alloy profile for building template, and preparation method thereof

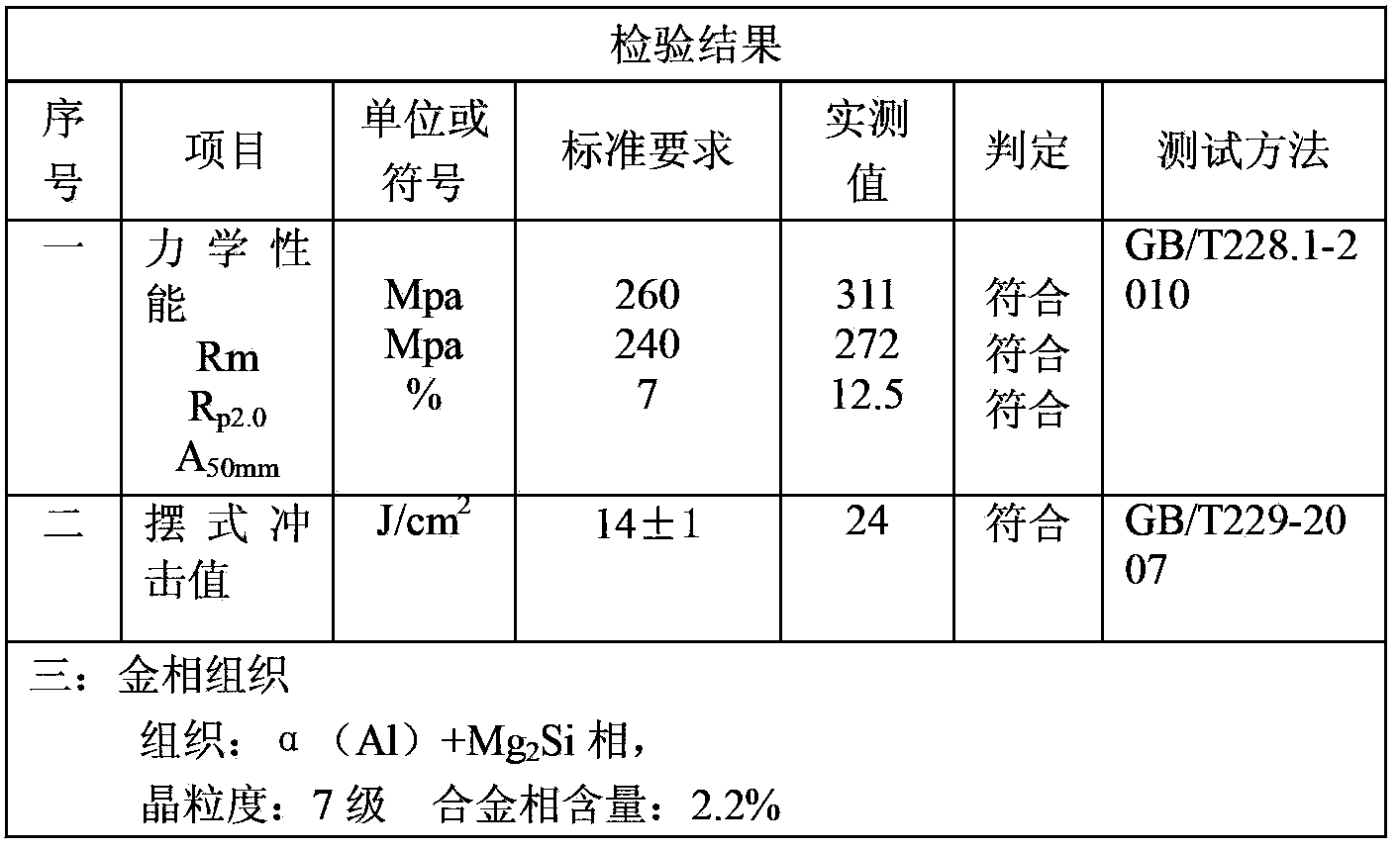

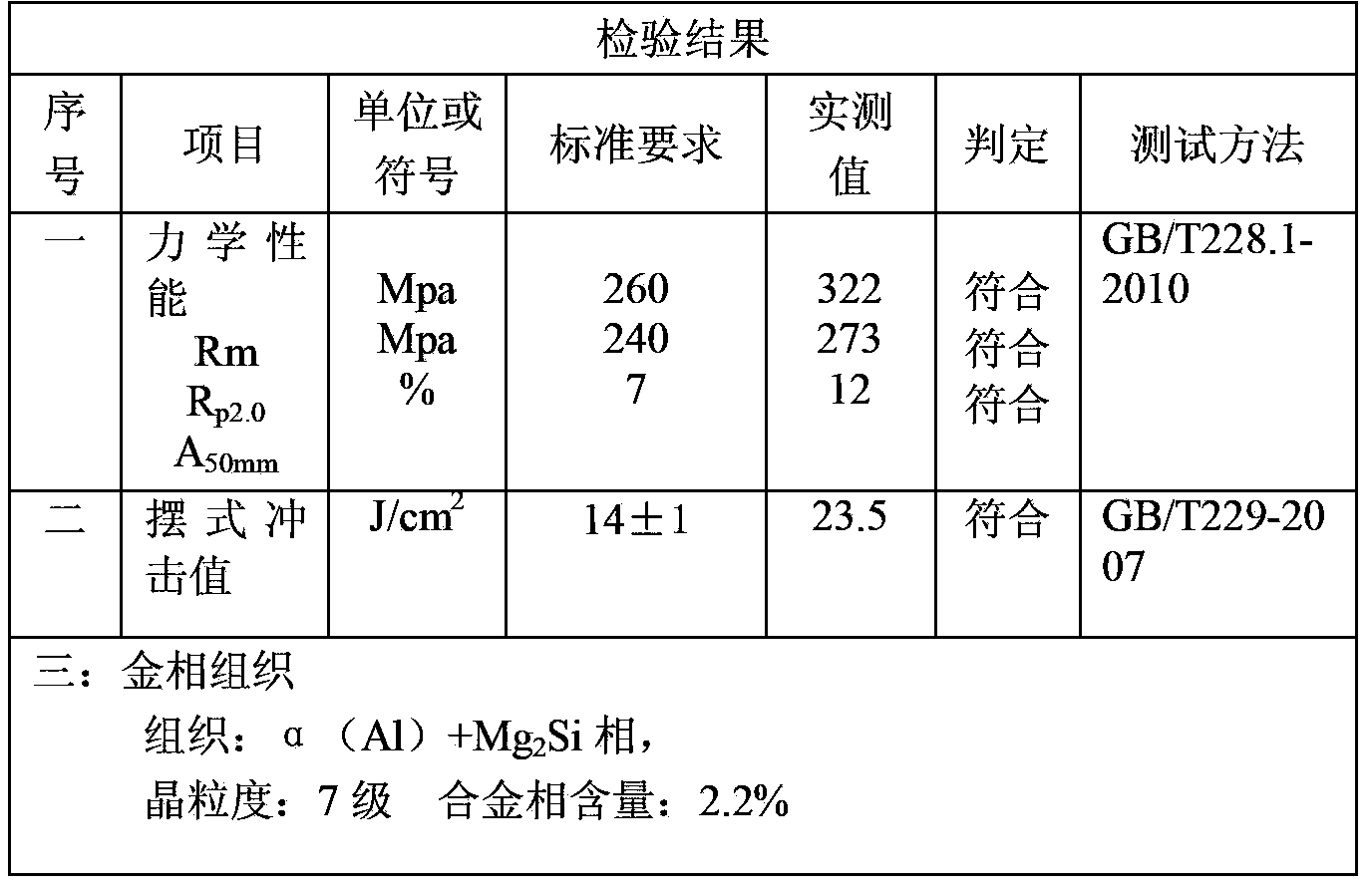

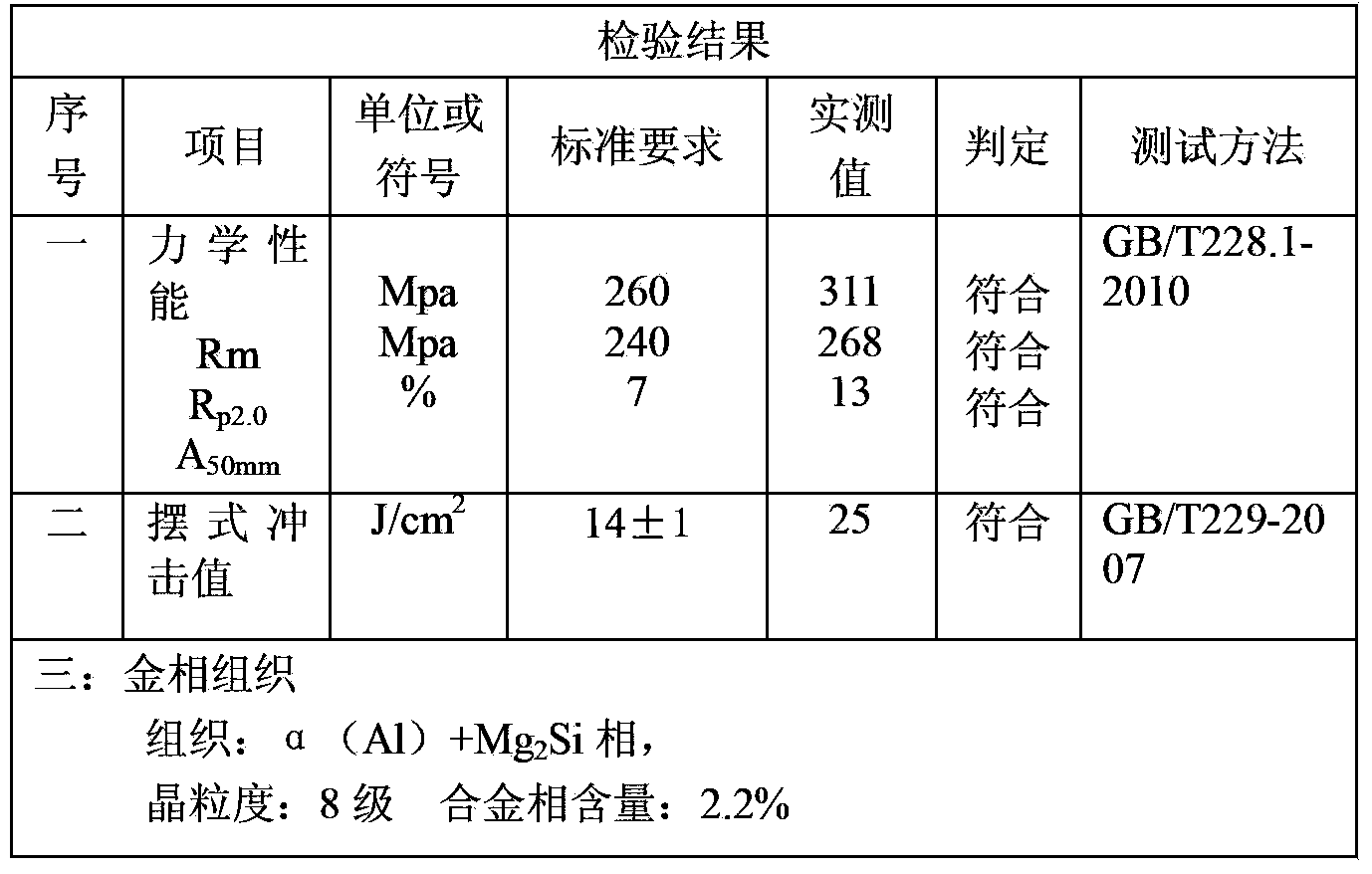

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

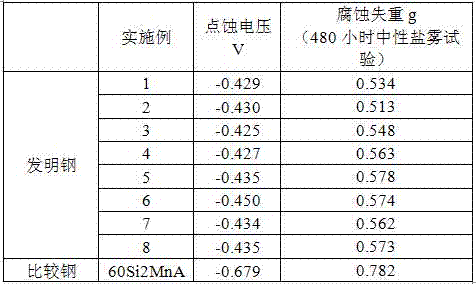

Duplex stainless steel and manufacturing method thereof

The invention relates to duplex stainless steel. The duplex stainless steel comprises the following chemical components in percent by weight: 0.01-0.08% of C, 0.2-1.0% of Si, 1.5-3.5% of Mn, 19.0-21.0% of Cr, 1.2-2.8% of Ni, 0.08-0.18% of N, less than or equal to 0.5% of Mo, less than or equal to 1.0% of W, less than or equal to 1.0% of Cu and the balance of Fe and inevitable impurities; PREN (Pitting Resistance Equivalent Number) is 20-24, the martensitic temperature Md formed by strain induction is 60-130 DEG C. A manufacturing method comprises the following steps of: selecting vacuum induction smelting in an electric furnace, argon oxygen decarburization (AOD) or electric furnace, argon oxygen decarburization (AOD), external refining and LF (Ladle Furnace) smelting; carrying out die casting or continuous casting on molten steel, controlling the superheat degree to be 20-50 DEG C in die casting, matching with fast cooling, preventing nitrogen from escaping, and controlling the overheat degree to be 20-50 DEG C and the plate blank casting speed to be 0.8-2m / min; and putting a die-casting blank or a continuous casting blank into a heating furnace for heating to 1100-1250 DEG C, preserving the heat for 0.5-1.5 hours, processing the die-casting blank or the continuous casting blank on a forging production line or a hot-rolling mill group to the needed thickness, then carrying out annealing at the speed of 0.5-2.5min / mm and the temperature of 1030-1150 DEG C. The obtained duplex stainless steel has excellent corrosion resistance and TRIP effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

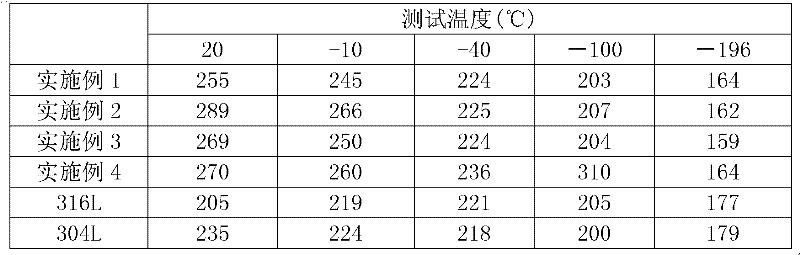

Austenitic stainless steel medium-thick plate and manufacture method thereof

ActiveCN101724789AGood strengthGood corrosion resistance and ductilityMetal rolling arrangementsRare-earth elementAustenitic stainless steel

The invention relates to an austenitic stainless steel medium-thick plate which comprises the following components in percentage by weight: no more than 0.04 percent of C, 0.3-0.9 percent of Si, 1-2 percent of Mn, no more than 0.010 percent of S, no more than 0.04 percent of P, 16-22 percent of Cr, 8-14 percent of Ni, no more than 4 percent of Mo, 0.04-0.30 percent of N, 0.0010-0.0030 percent of B, smaller than 0.30 percent of one or more rare-earth elements, such as Ce, Dy, Y and Nd, 1-10 percent of high-temperature ferrite delta and the balance of ferrum and unavoidable impurities. The manufacture method of the austenitic stainless steel medium-thick plate comprises the following steps of: smelting; hot rolling; heating and preserving the temperature of the alloy and then carrying out 4-10 passes of rolling in a recrystallization area at 1,250-1,050 DEG C; water-cooling the recrystallization area by 20-40 DEG C / s to 700-950 DEG C, rolling 3-5 rounds in the temperature interval and water-cooling to room temperature; carrying out low-temperature annealing heat treatment at 900-1,050 DEG C; washing with acid and then obtaining the austenitic stainless steel medium-thick plate with excellent strength.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

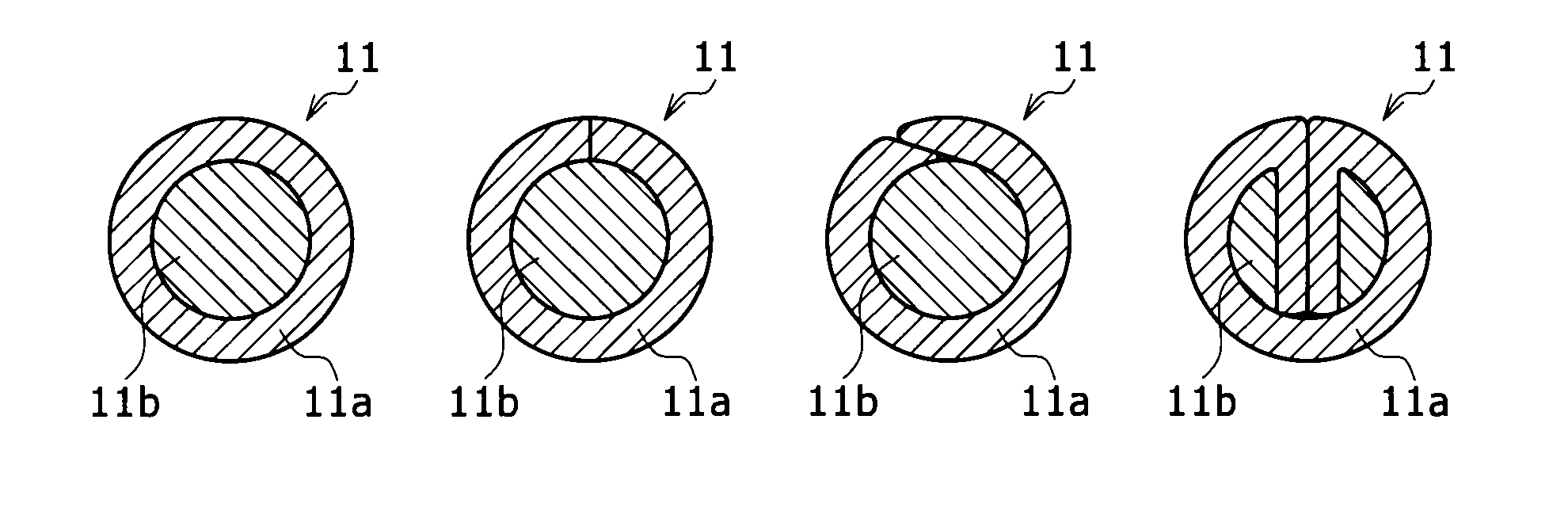

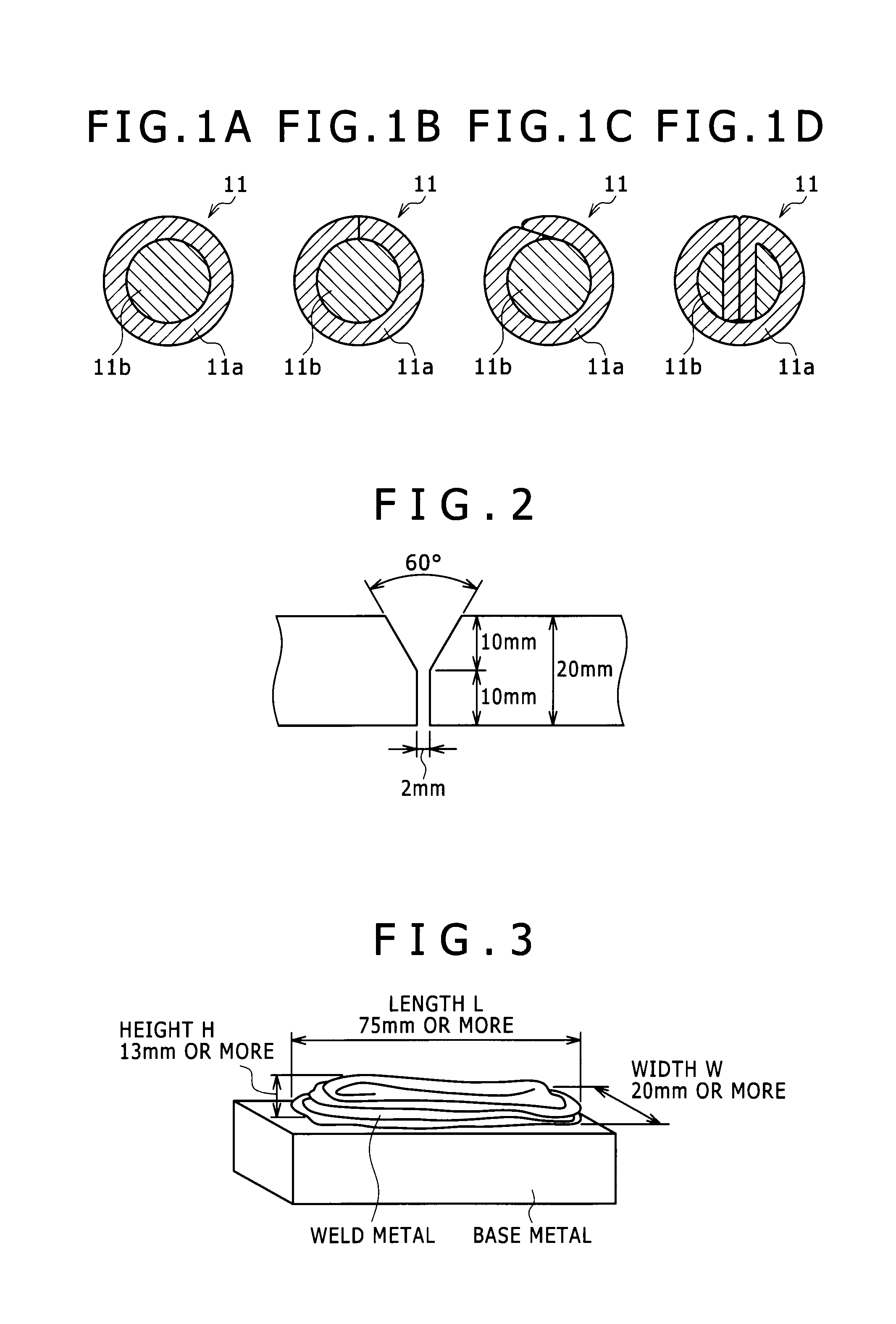

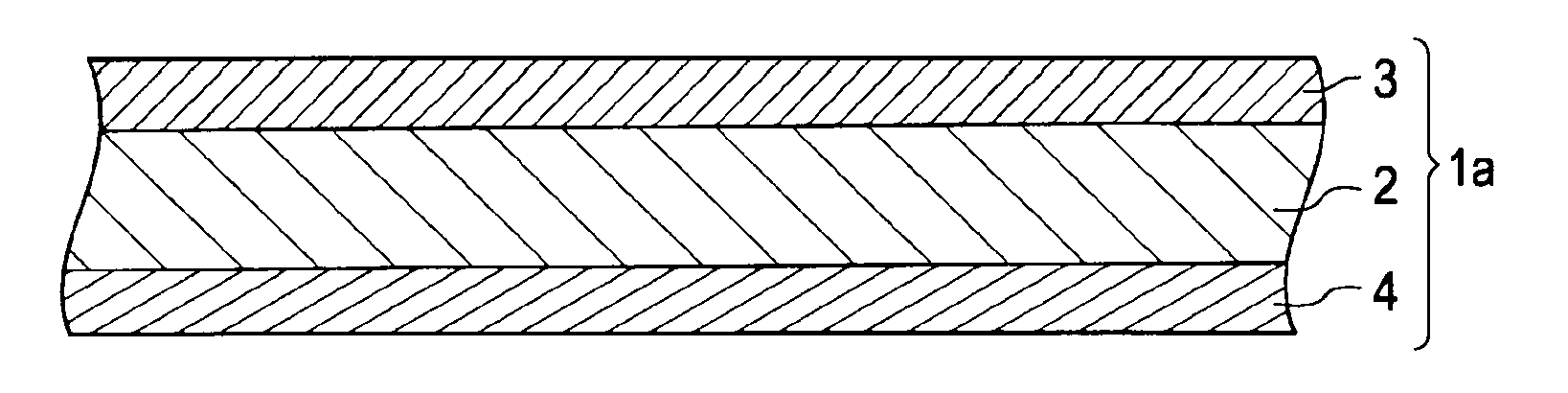

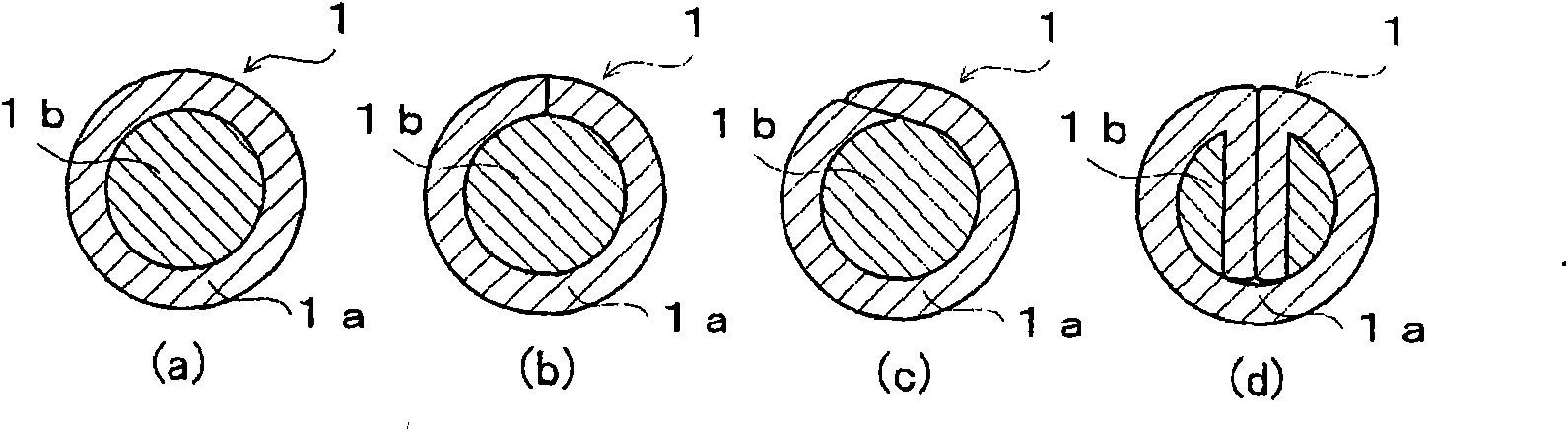

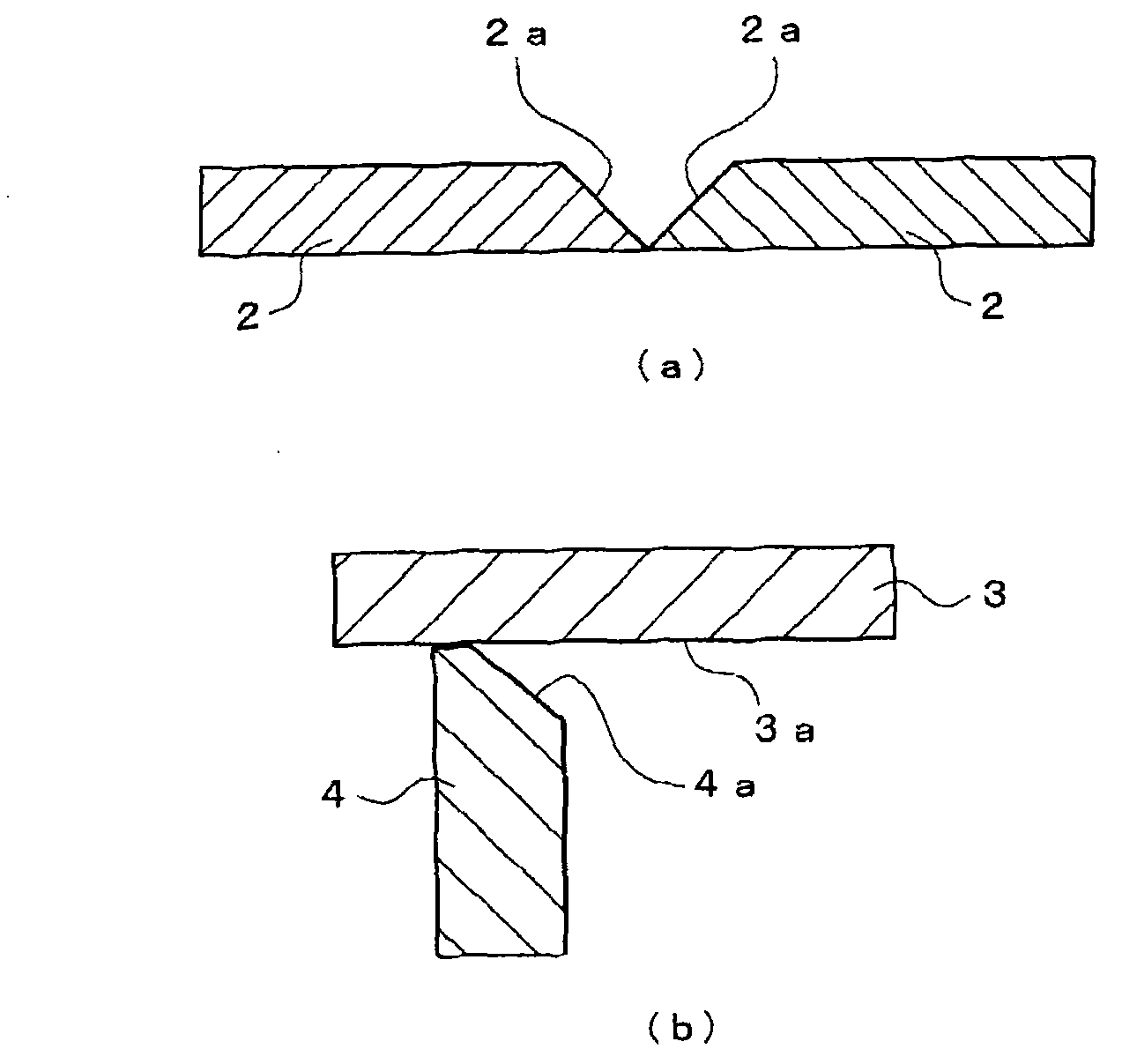

Flux-cored wire for stainless steel arc welding

ActiveCN102091881AImprove pitting resistanceImprove low temperature toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementFluoride

A flux-cored wire for stainless steel arc welding including an outer sheath made of stainless steel and flux filled up in the outer sheath contains, as percentage to the total mass of the wire, Cr: 22.0-30.0 mass %, Ni: 6.0-12.0 mass %, Mo: 2.0-5.0 mass %, N: 0.20-0.35 mass %, TiO2: 4.0-9.0 mass %, SiO2: 0.1-2.0 mass %, ZrO2: 0.5-4.0 mass %, total of Li2O, Na2O and K2O: 0.50-1.50 mass %, metal fluoride in terms of fluorine amount: 0.10-0.90 mass %, and rare earth element component: 0.10-1.00 mass %, limits C to 0.04 mass % or below, W to 4.0 mass % or below, Cu to 2.0 mass % or below, Bi2O3 to 0.01 mass % or below, and limits oxides other than the above to 3.0 mass % or below. With such a composition, it is possible to obtain a weld bead which is excellent in the weldability in welding in all attitudes and is more excellent in the low temperature toughness while keeping excellent pitting corrosion resistance in arc welding of duplex stainless steel and the like.

Owner:KOBE STEEL LTD

Manufacturing process of pump body casting of super duplex stainless steel centrifugal pump

InactiveCN102626769AReduce manufacturing costReduce maintenance costsFoundry mouldsFoundry coresFuranTemperature control

The invention provides a manufacturing process of a pump body casting of a super duplex stainless steel centrifugal pump. The manufacturing process comprises steps of sand mould prefabricating, material smelting, casting, sand shakeout and heat treatment, wherein a runner core in a sand mould is composed of chromite furan resin sand of which the outer layer is filled with quartz furan resin sand;in material smelting, super duplex stainless steel material ZG00Cr25Ni7Mo4N is used, the chemical composition, ferrite content and PREN (Pitting Resistance Equivalent) value of molten steel are undercontrol and the casting temperature is from 1540 DEG C to1560 DEG C; after sand shakeout, forced air cooling is carried out, spray cooling is further carried out on the thick and large part of the casting, and after a casting system and a dead head are removed, the heat treatment is carried out. The pump body casting of a super duplex stainless steel centrifugal pump, which is manufactured by using the manufacturing method, has the advantages that the manufacturing and maintenance cost is reduced, abrasion resistance and pitting resistance are improved and the service life is prolonged.

Owner:遵义拓特铸锻有限公司

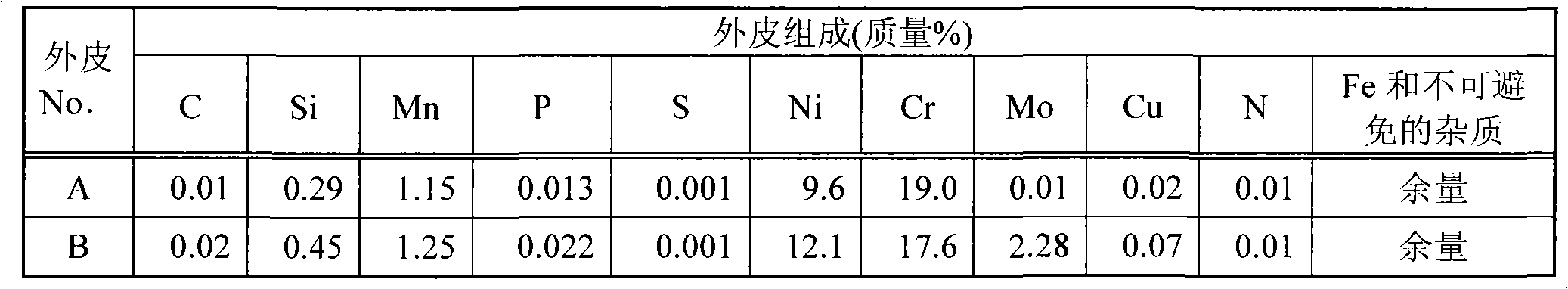

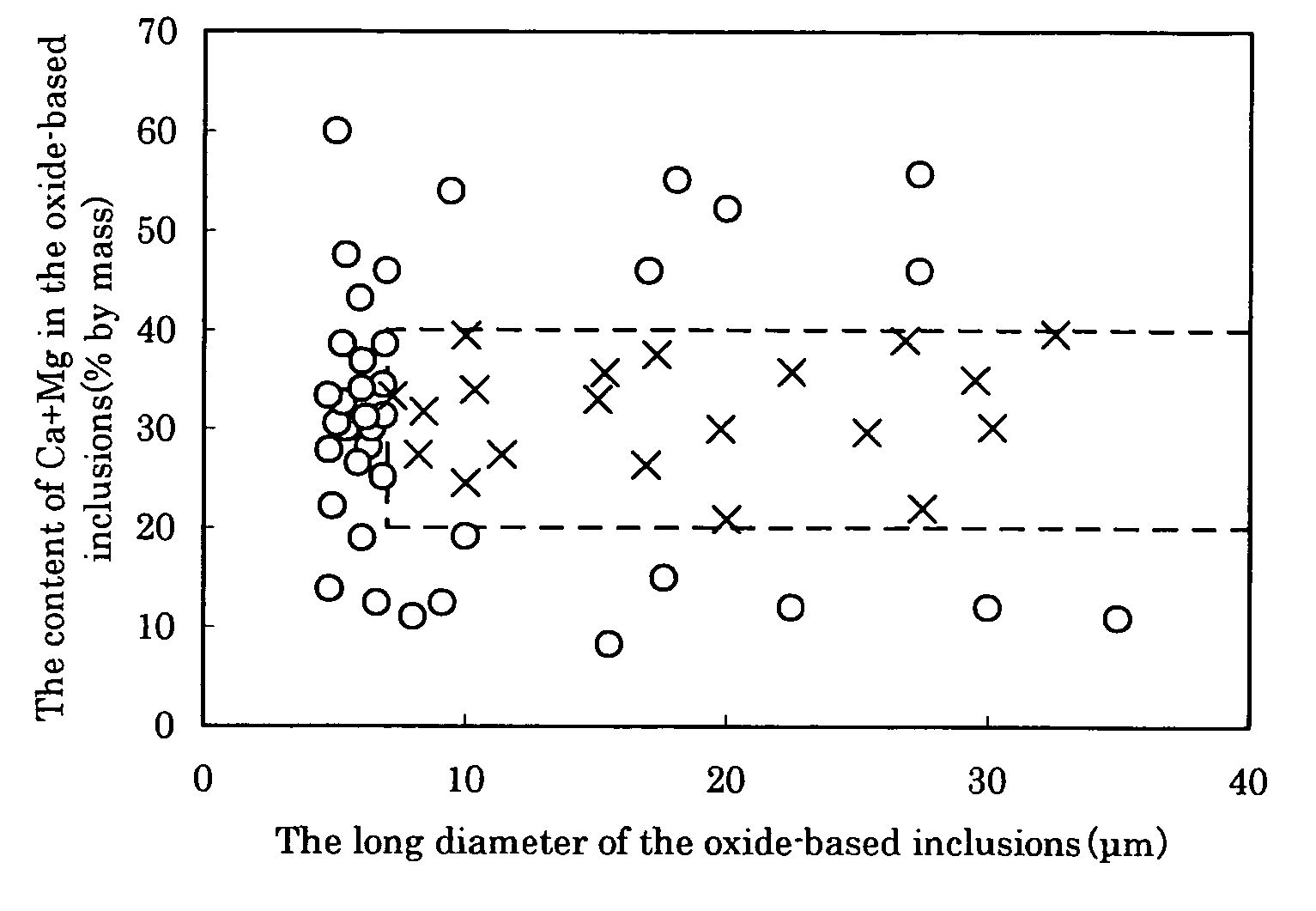

Duplex stainless steel and manufacturing method thereof

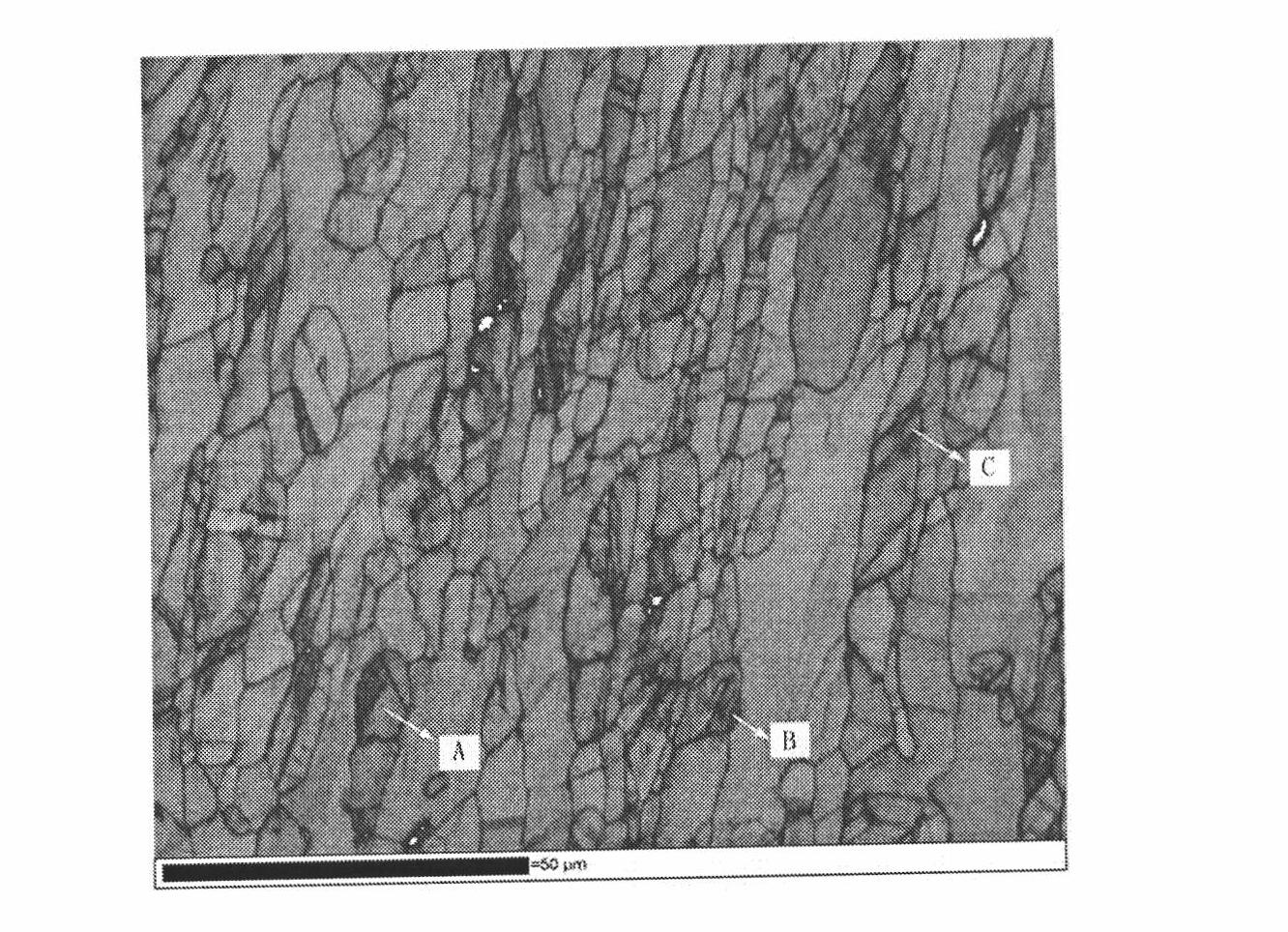

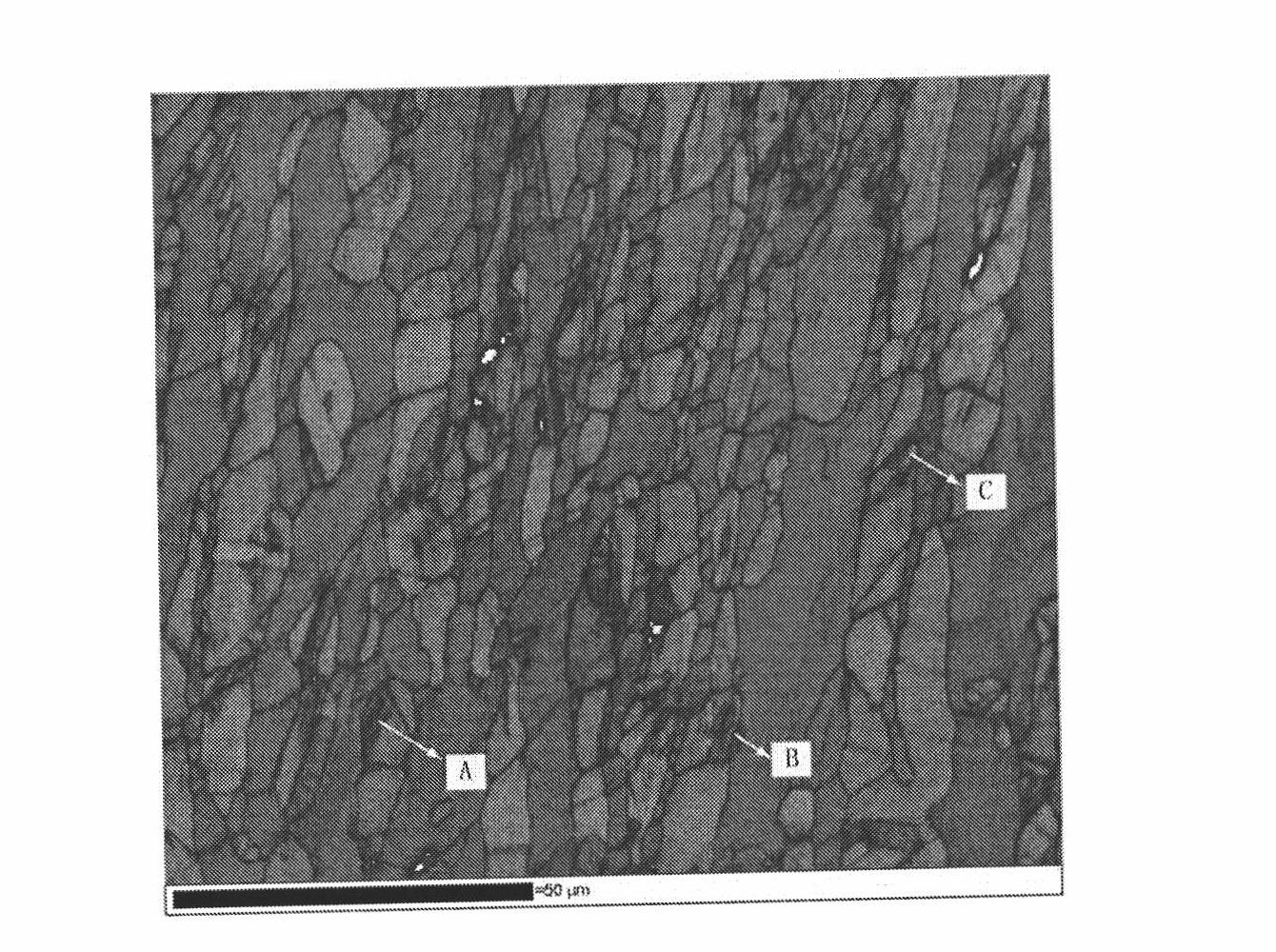

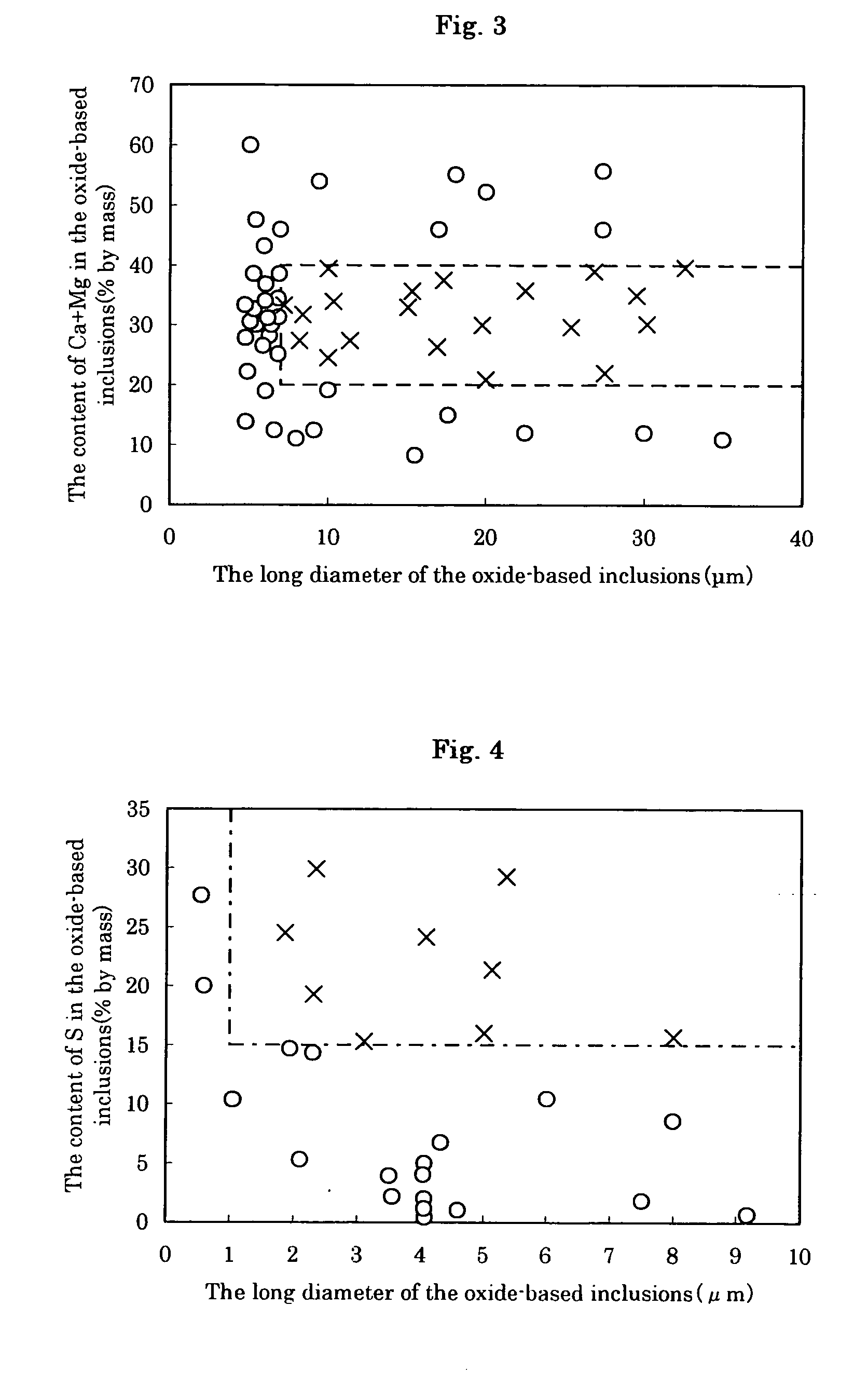

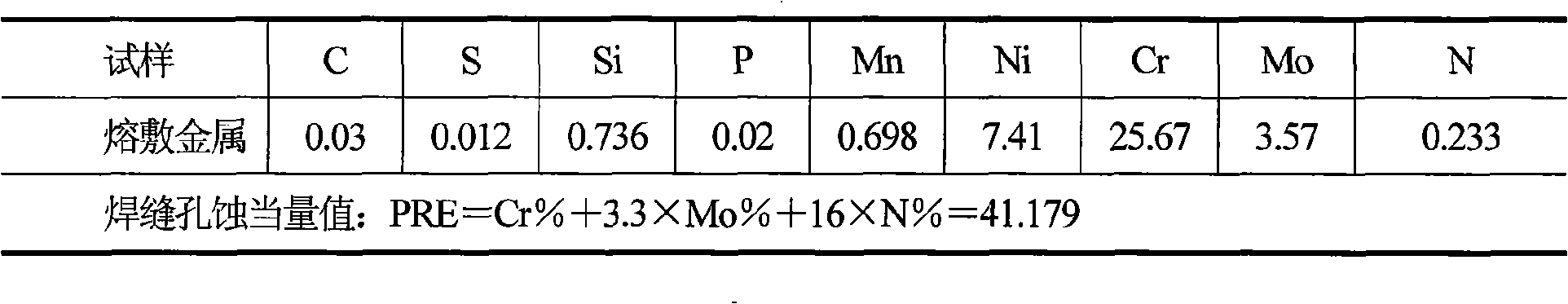

ActiveUS20050211344A1Good resistanceImprove the immunityFurnace typesQuenching agentsLongest DiameterOxide

A duplex stainless steel containing C, Si, Mn, P, S, Al, Ni, Cr, Mo, N (nitrogen, O (oxygen), Ca, Mg, Cu, B, and W, and the balance Fe and impurities, where a number of oxide-based inclusions, which have a total content of Ca and Mg of 20 to 40% by mass and also have a long diameter of not less than 7 μm, is not more than a 10 per 1 mm2 of the cross section perpendicular to the working direction, or further, the number of oxide-based inclusions, which have a content of S of not less than 15% by mass and also have a long diameter of not less than 1 μm, is not more than 10 per 0.1 mm2 of the cross section perpendicular to the working direction. Particularly, the contents of Cu, B and W are desirably 0.2 to 2%, 0.001 to 0.01%, and 0.1 to 4% by mass, respectively.

Owner:NIPPON STEEL CORP

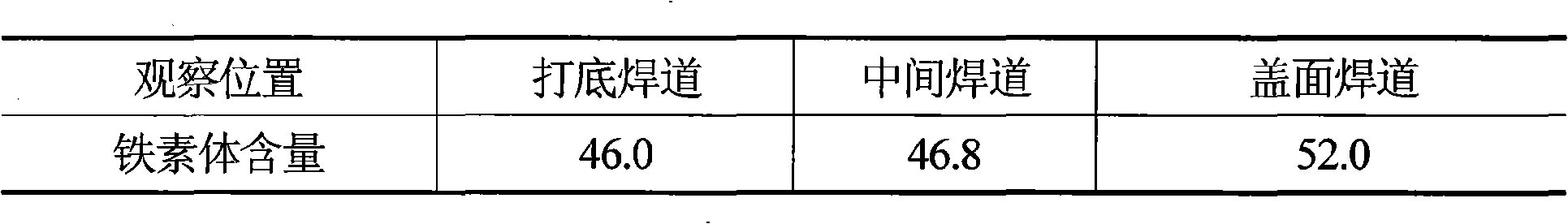

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

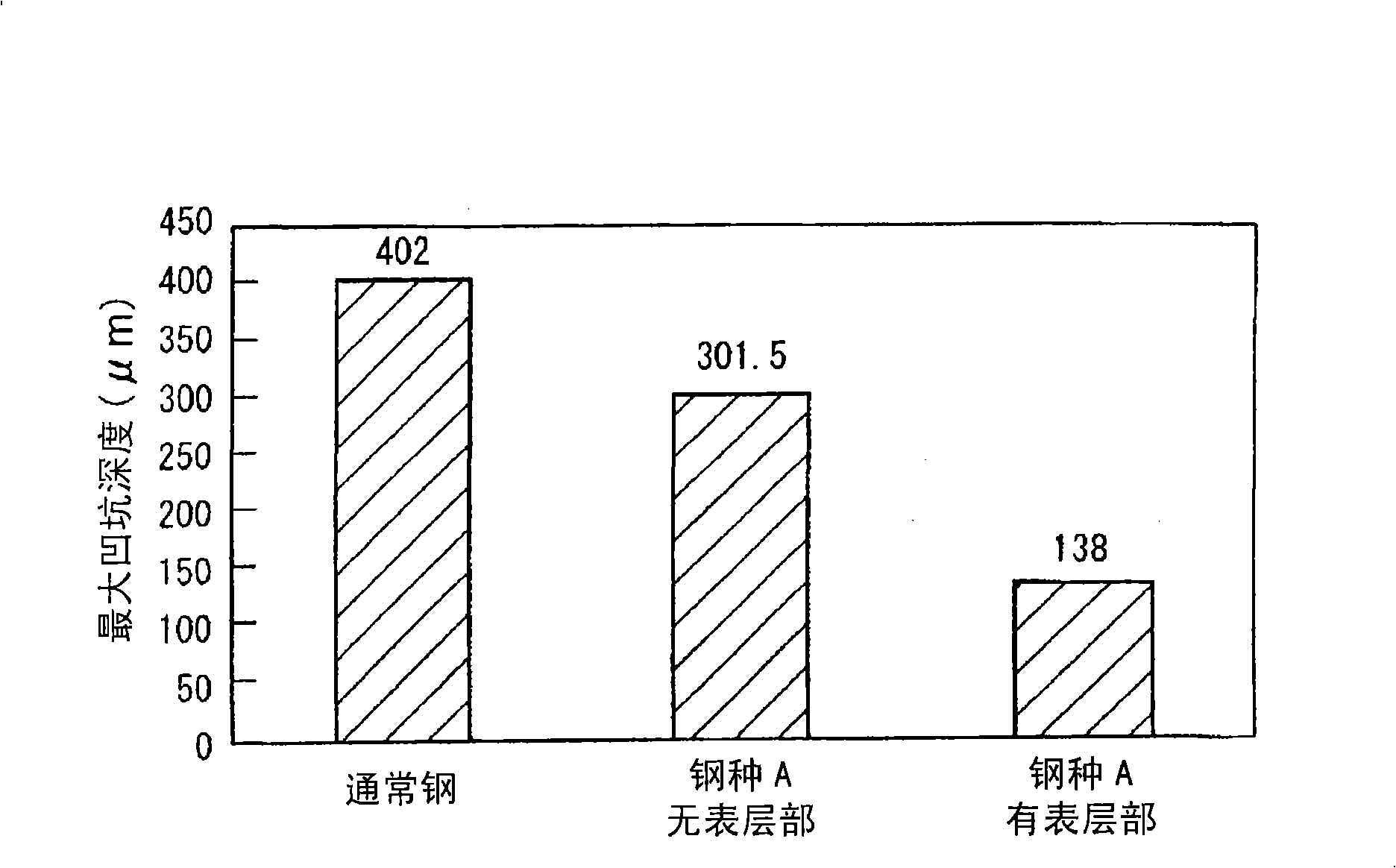

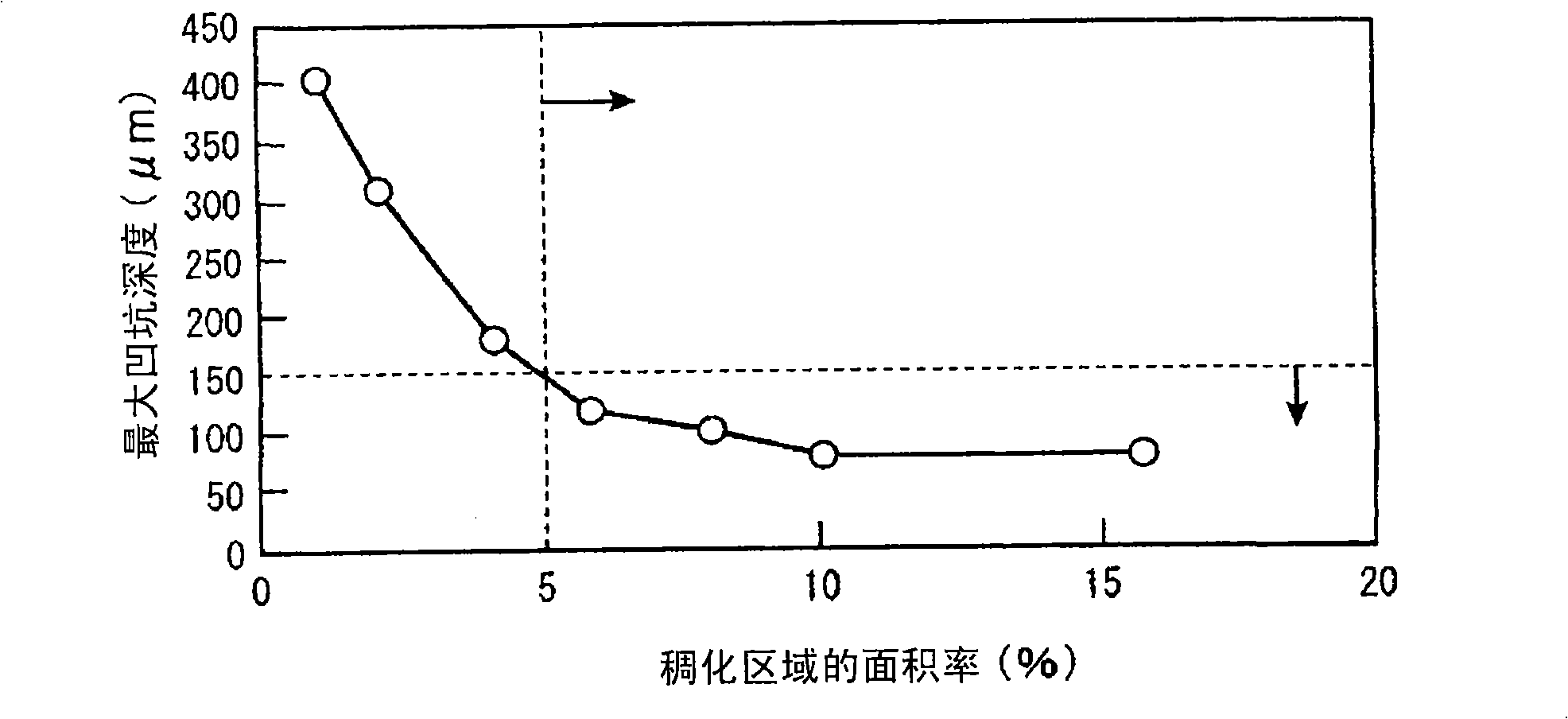

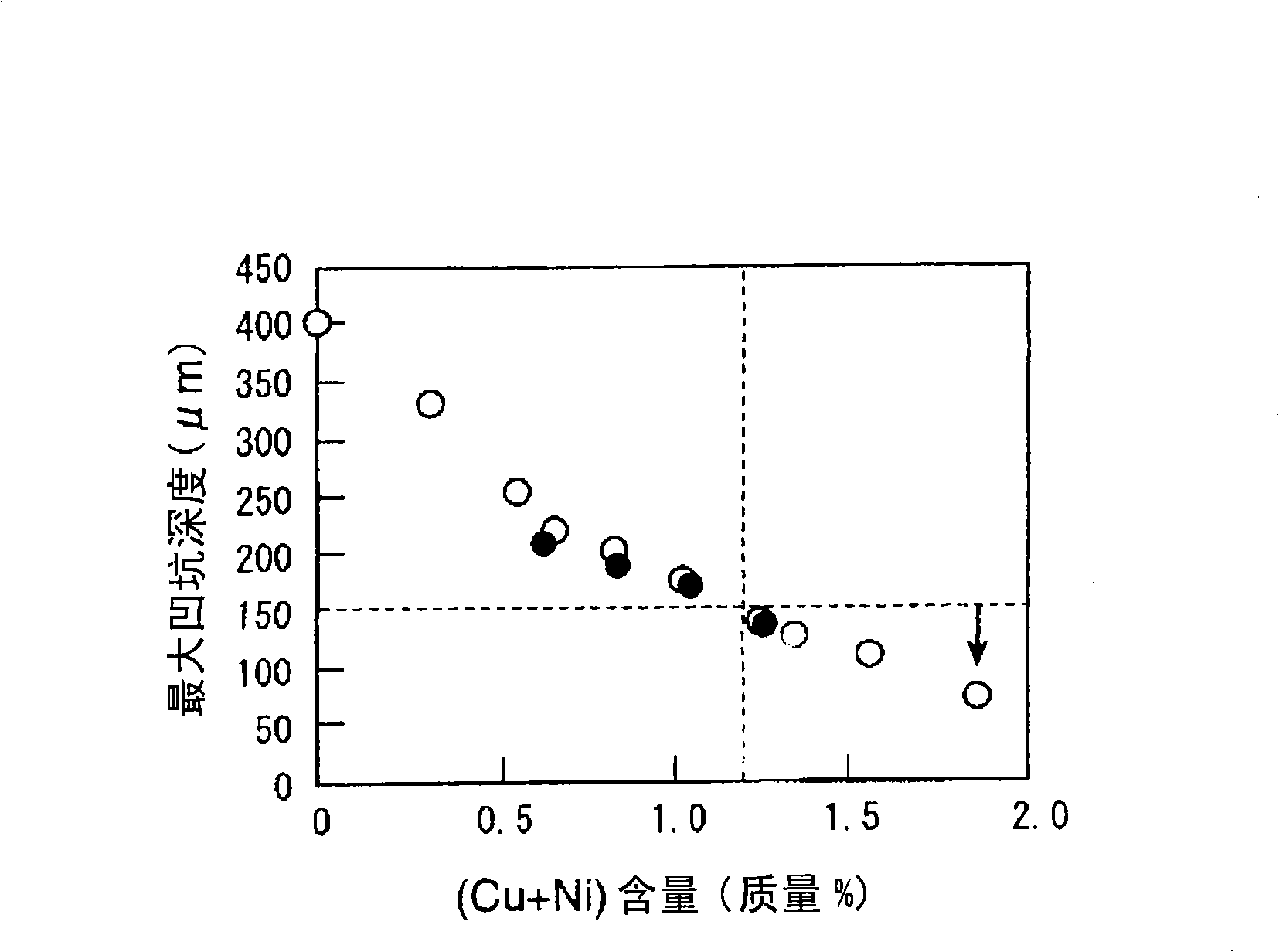

Steel plate having superior pitting corrosion resistance and manufacturing method thereof

InactiveCN101298645AExcellent resistance to pitting corrosionExcellent pitting resistanceSteel platesChemical composition

A steel plate of the invention contains C: 0.03-0.2%, Si: 0.05-0.5%, Mn: 0.4-1.8%, P: less than 0.04%, S: less than 0.040%, Al: 0.01-0.10%, N: 0.002-0.0080%, Cu: 0.1-0.5% and Ni:0.1-0.50%, at old austenite grain bound with depth 10 mu m away from the surface of the steel plate, an enrichment area having total content of Cu and Ni more than 1.2% is present, and the area rule of the enrichment area in the section of the plate thickness is more than 5%. According to the structure, even if painting dressing and electric protection are not implemented, practical pitting tolerance is excellent, which is exerted when applied in the crude oil storage tank.

Owner:KOBE STEEL LTD

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

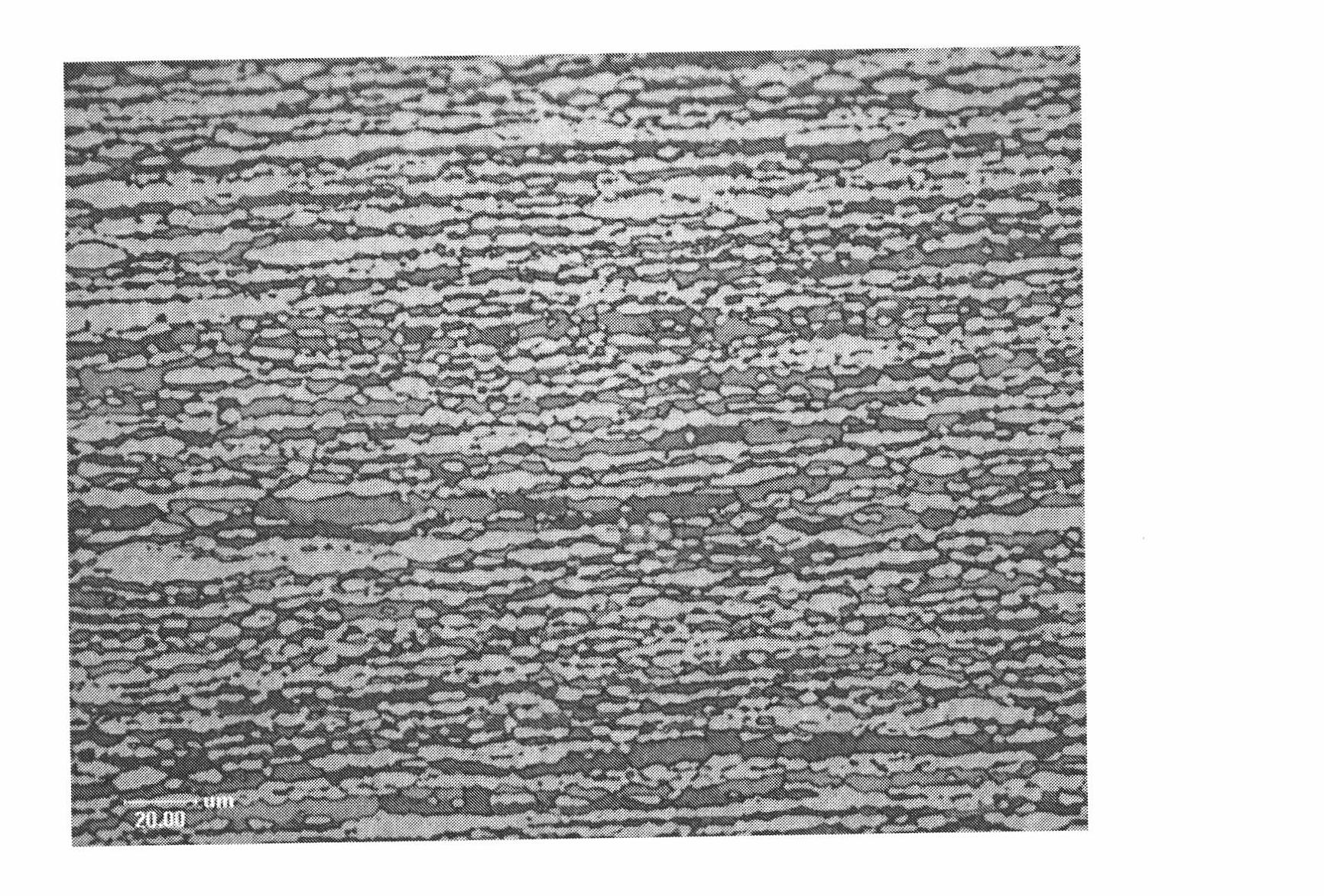

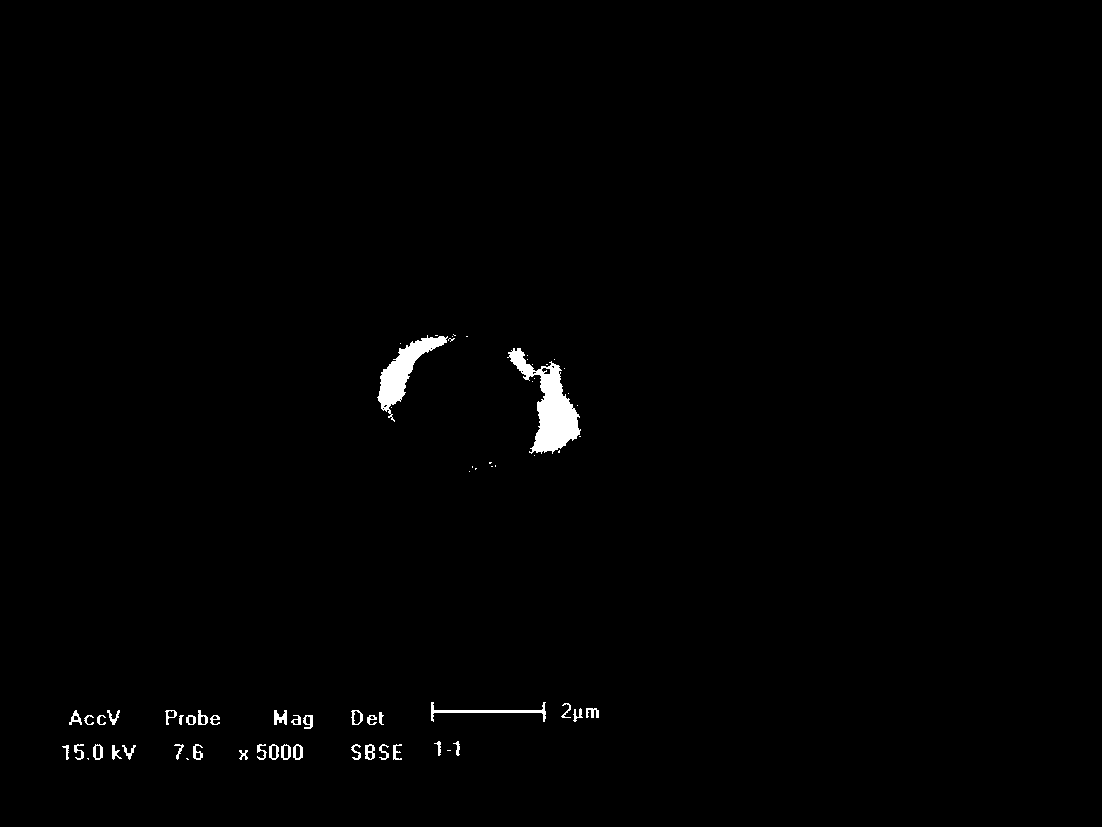

Abnormally segregated stanniferous low-clearance ferritic stainless steel and preparation method thereof

The invention discloses abnormally segregated stanniferous low-clearance ferritic stainless steel and a preparation method thereof, and belongs to the technical field of metallurgy. The stainless steel comprises the following components in percentage by weight: 0.005-0.03% of C, 0.2-0.4% of Si, 0.2-0.5% of Mn, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 14-16% of Cr, less than or equal to 0.01% of N, 0.1-0.4% of Sn, Nb, Ti and / or V and the balance of iron and inevitable impurities; the tensile strength is 445-451MPa; the pitting potential is 202-240mV. The preparation method comprises the following steps: (1) smelting and casting a blank according to set components; (2) heating to be 1150+ / -10 DEG C, carrying out heat preservation for 1-3 hours, and subsequently hot-rolling to make a hot-rolled steel plate; (3) annealing at 900+ / -10 DEG C for 2-3 hours, cooling to room temperature, pickling and then cold-rolling to make a cold-rolled steel plate; (4) heating to 800+ / -10 DEG C and carrying out normalizing treatment to obtain the abnormally segregated stanniferous low-clearance ferritic stainless steel. By adopting the method disclosed by the invention, the production cost of the stainless steel can be greatly lowered, the process is simple, and a product is high in strength, hardness and corrosion resistance.

Owner:NORTHEASTERN UNIV

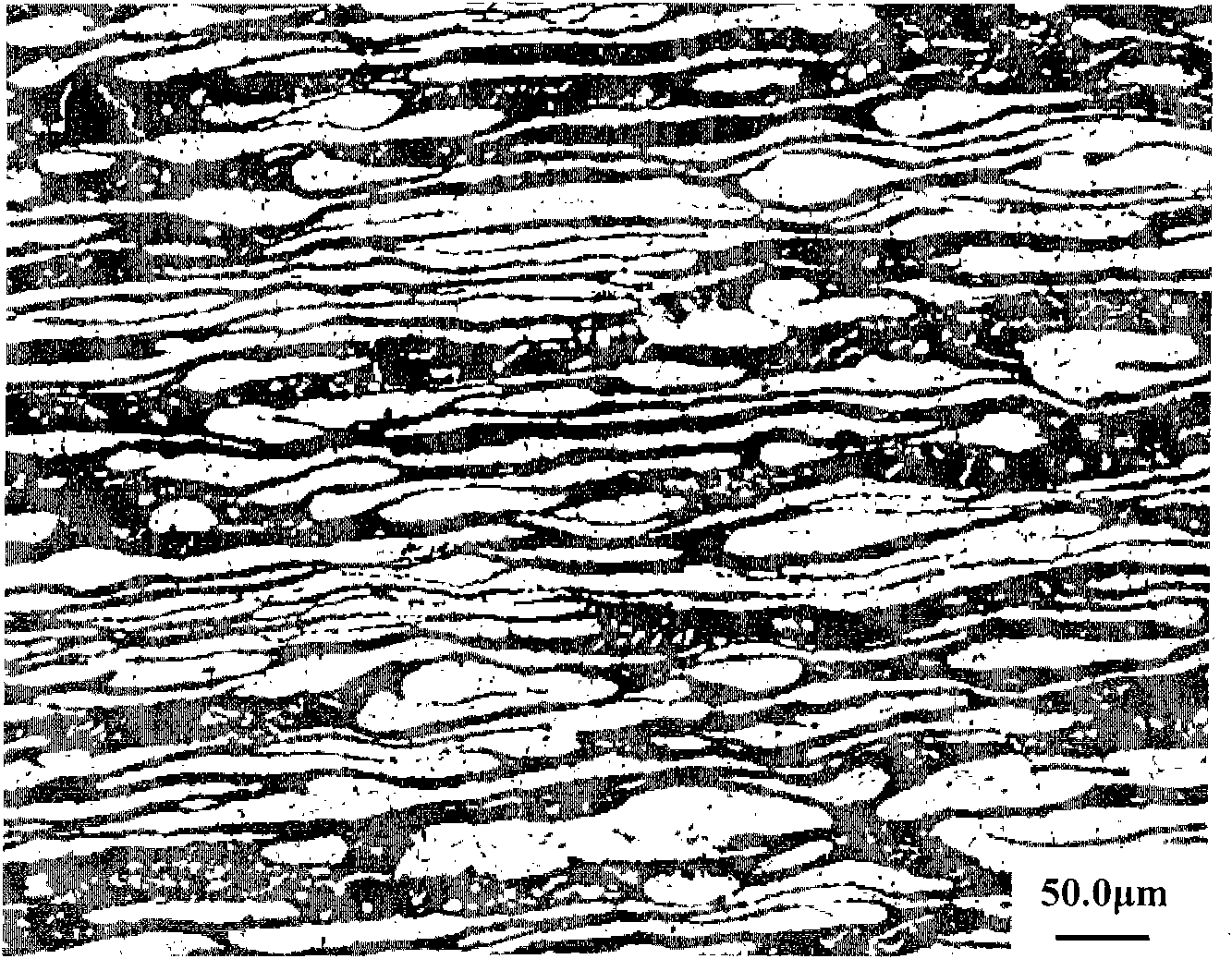

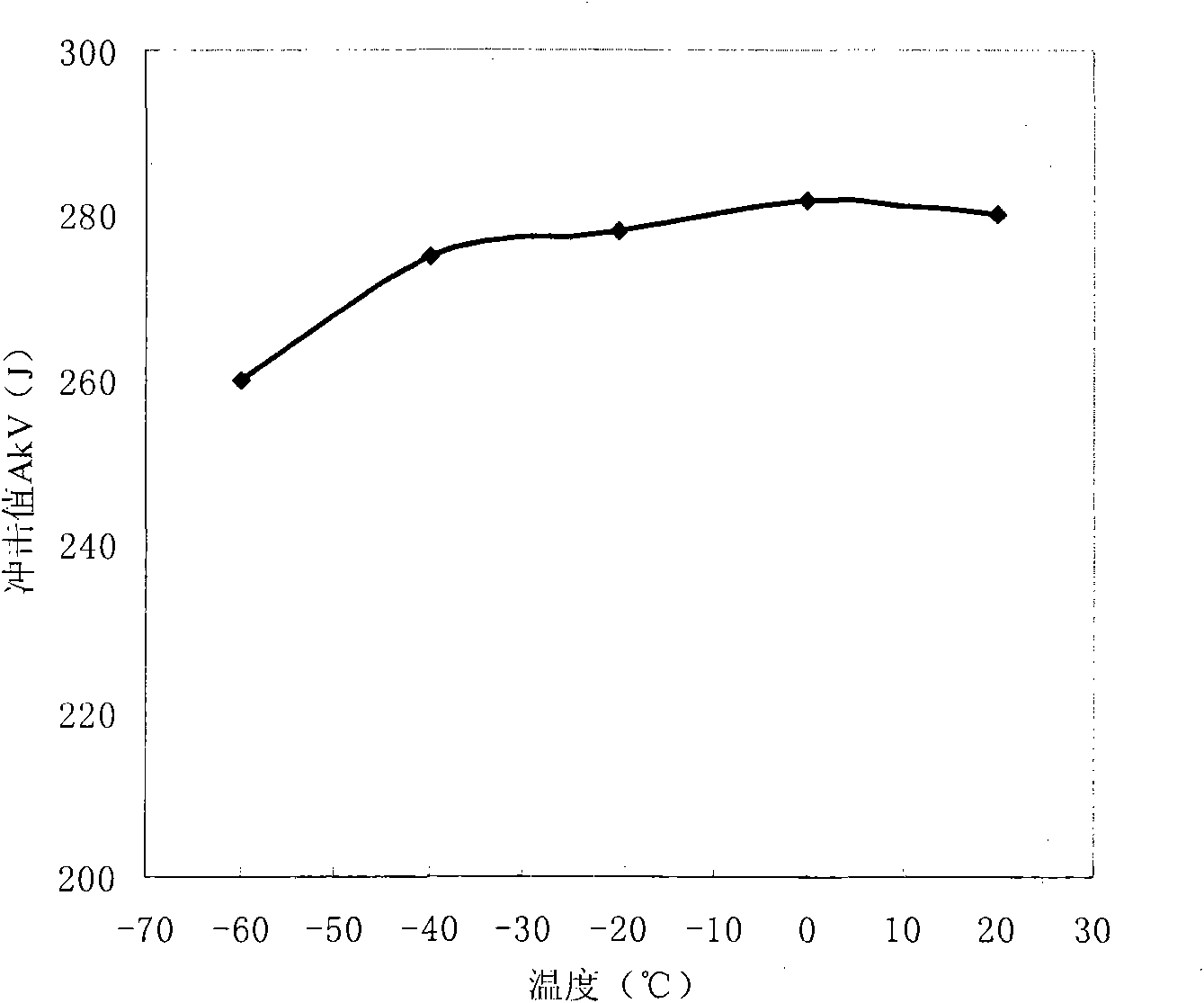

Duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and manufacturing method thereof

InactiveCN101684542AImprove solubilityDecreased low temperature toughnessChemical compositionRoom temperature

The invention discloses a duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and a manufacturing method thereof. The duplex stainless steel comprisesthe following components in mass percentage: 0.01-0.10% of C, 0.2-1.0% of Si, more than 0% and less than 1.5% of Mn, 20.0-22.0% of Cr, 1.8-4.0% of Ni, 0.08-0.2% of N, more than 0% and less than 0.5% of Mo, less than or equal to 1.0% of one or more than one of W and Cu and the balance Fe and inevitable impurities. The invention controls Mn content below 1.5% until zero and simultaneously adjusts the content of elements of N, Ni and the like to ensure that steel has high strength, favourable corrosion resistance and favourable impact toughness at room temperature and low temperature when steel contains no or small amount of noble element Mo; meanwhile, the duplex stainless steel has low cost and small hot working difficulty, can be largely applied in the fields of buildings along the coast,petrochemical industry and the like and can replace 304 austenitic stainless steel of which the nickel content is above 8% at room temperature and lower temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Duplex stainless steel thin strip and near-net shaping preparation method thereof

The invention provides a duplex stainless steel thin strip and a near-net shaping preparation method thereof, and belongs to the technical field of steel alloy materials. The duplex stainless steel thin strip comprises, by mass, 0.0001%-0.03% of C, 18%-22% of Cr, 5%-7% of Mn, 0.3%-0.45% of N, 0.0001%-0.1% of Ni, and the balance iron and other inevitable impurities. The preparation method includes the steps that (1) smelting is carried out under nitrogen; (2) molten steel is guided out along with rotation of crystallizing rollers to form a cast strip, and the cast strip is cooled to the room temperature through water; (3) hot rolling is carried out for 1-2 passes, and the strip is cooled to the room temperature through water; (4) the hot-rolled stainless steel thin strip is subjected to acid pickling; (5) the stainless steel thin strip is cold-rolled; and (6) a finished product is obtained after solution annealing. The duplex stainless steel thin strip prepared through the method has a good corrosion property; the initial as-cast structure is refined, and a good property can be obtained in subsequent processing; according to the preparation method, segregation of elements is restrained, and the alloy elements can be distributed more evenly after subsequent rolling and solution annealing; cost is low, and the production process is simple and easy to operate.

Owner:NORTHEASTERN UNIV

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

Nitrided steel member and manufacturing method thereof

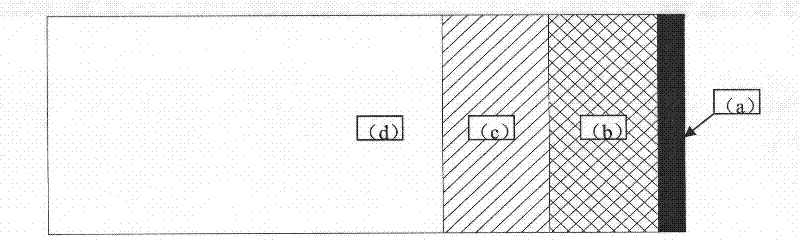

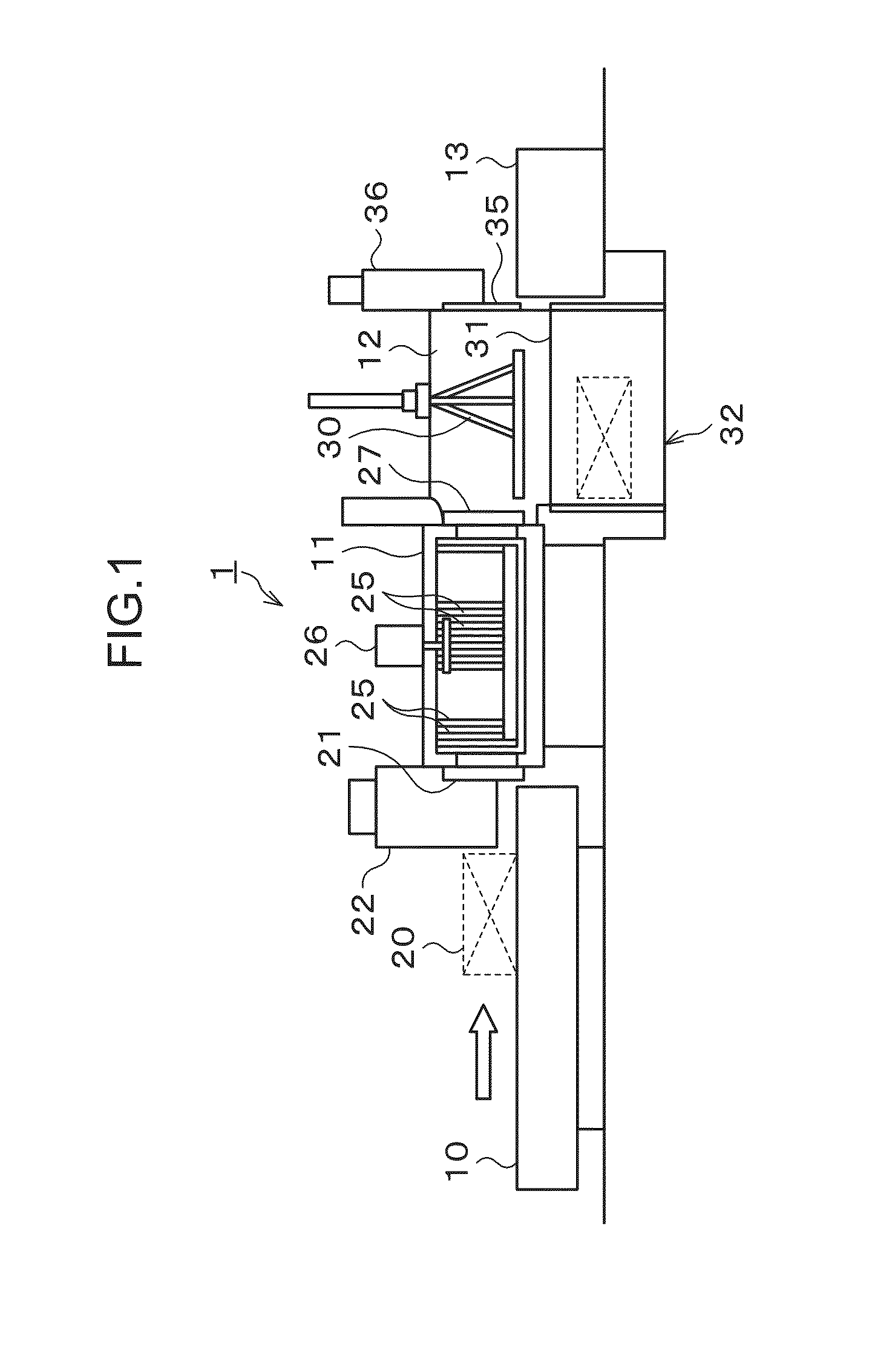

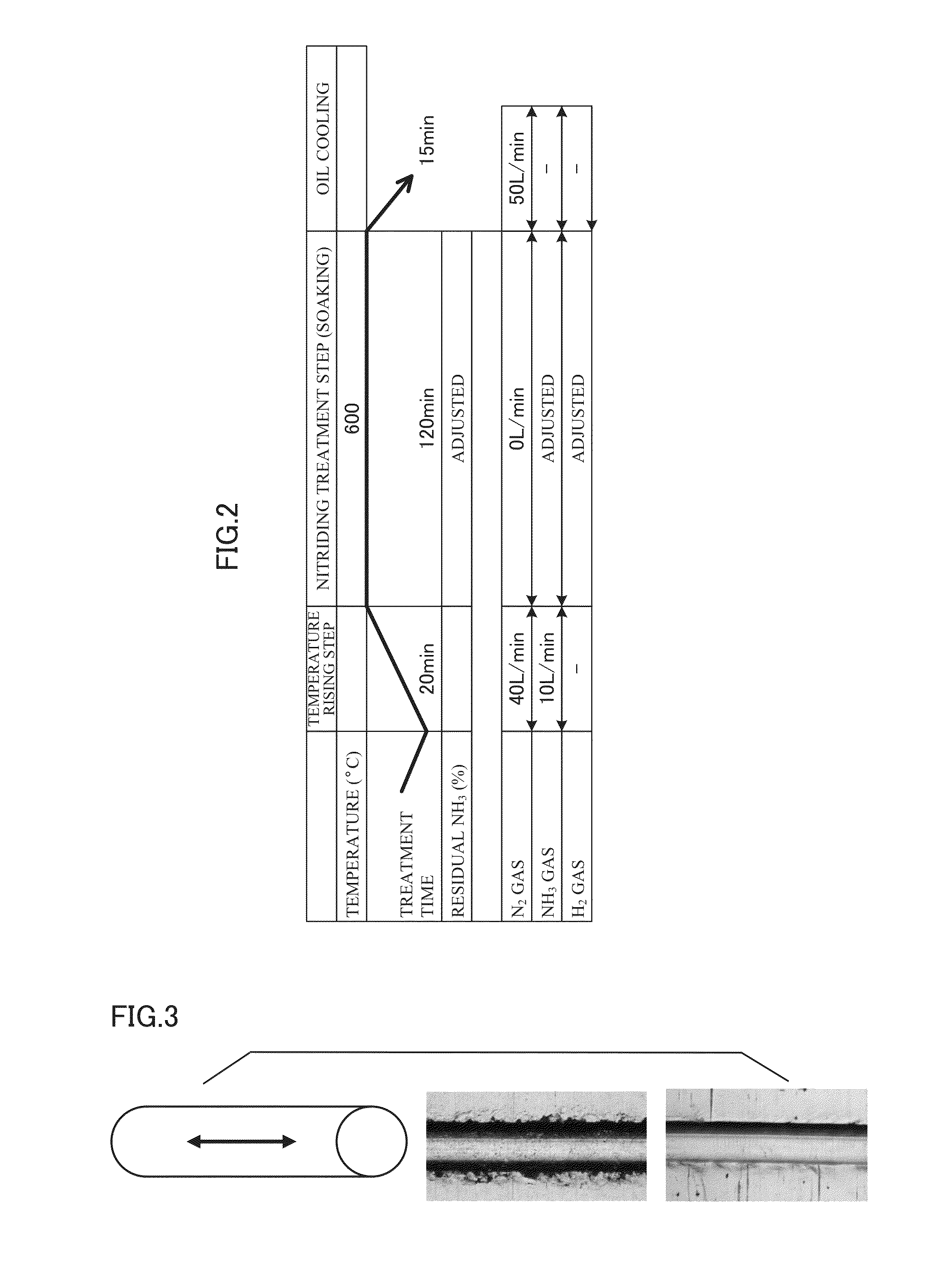

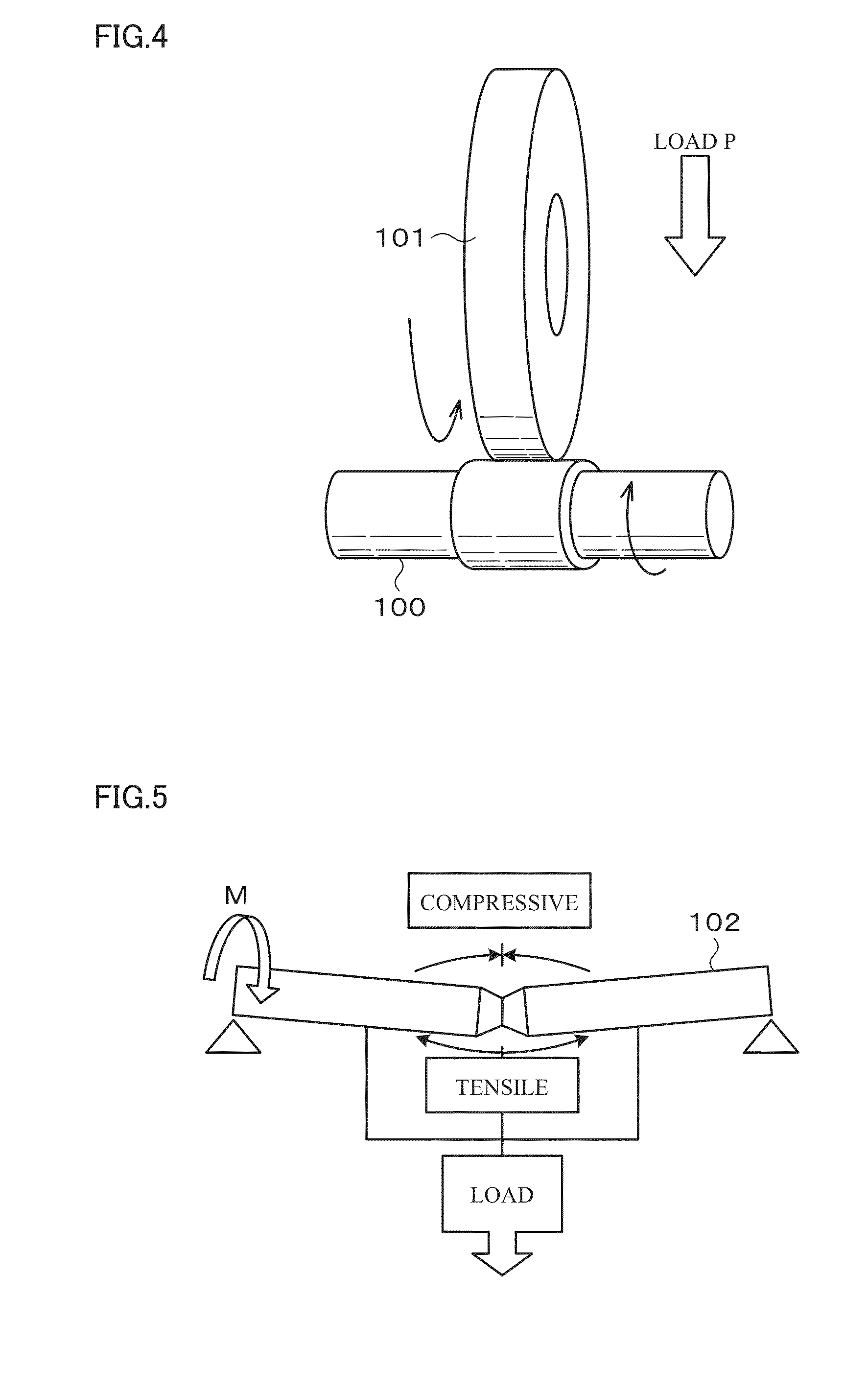

ActiveUS20150053311A1Improve pitting resistanceEasy to bendSolid state diffusion coatingFurnace typesIron nitrideX-ray

A nitrided steel member including an iron nitride compound layer formed on a surface of a steel member having predetermined components, wherein: in X-ray diffraction peak intensity IFe4N (111) of a (111) crystal plane of Fe4N and X-ray diffraction peak intensity IFe3N (111) of a (111) crystal plane of Fe3N, which are measured on a surface of the nitrided steel member by X-ray diffraction, an intensity ratio expressed by IFe4N (111) / {IFe4N (111)+IFe3N (111)} is 0.5 or more; Vickers hardness of the iron nitride compound layer is 900 or less, Vickers hardness of a base metal immediately under the iron nitride compound layer is 700 or more, and a difference between the Vickers hardness of the iron nitride compound layer and the Vickers hardness of the base metal is 150 or less; and a thickness of the iron nitride compound layer is 2 to 17 μm.

Owner:DOWA THERMOTECH +2

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

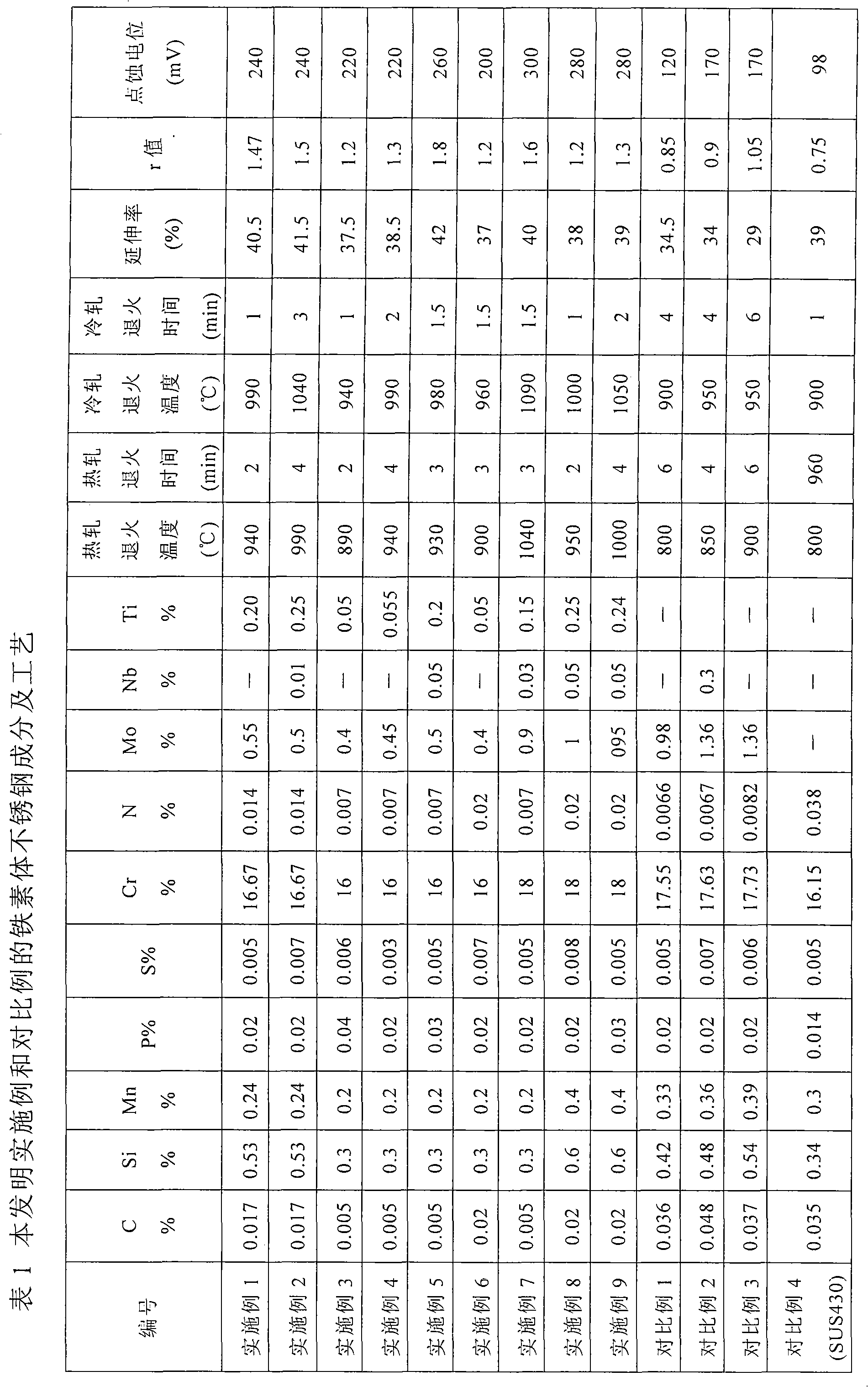

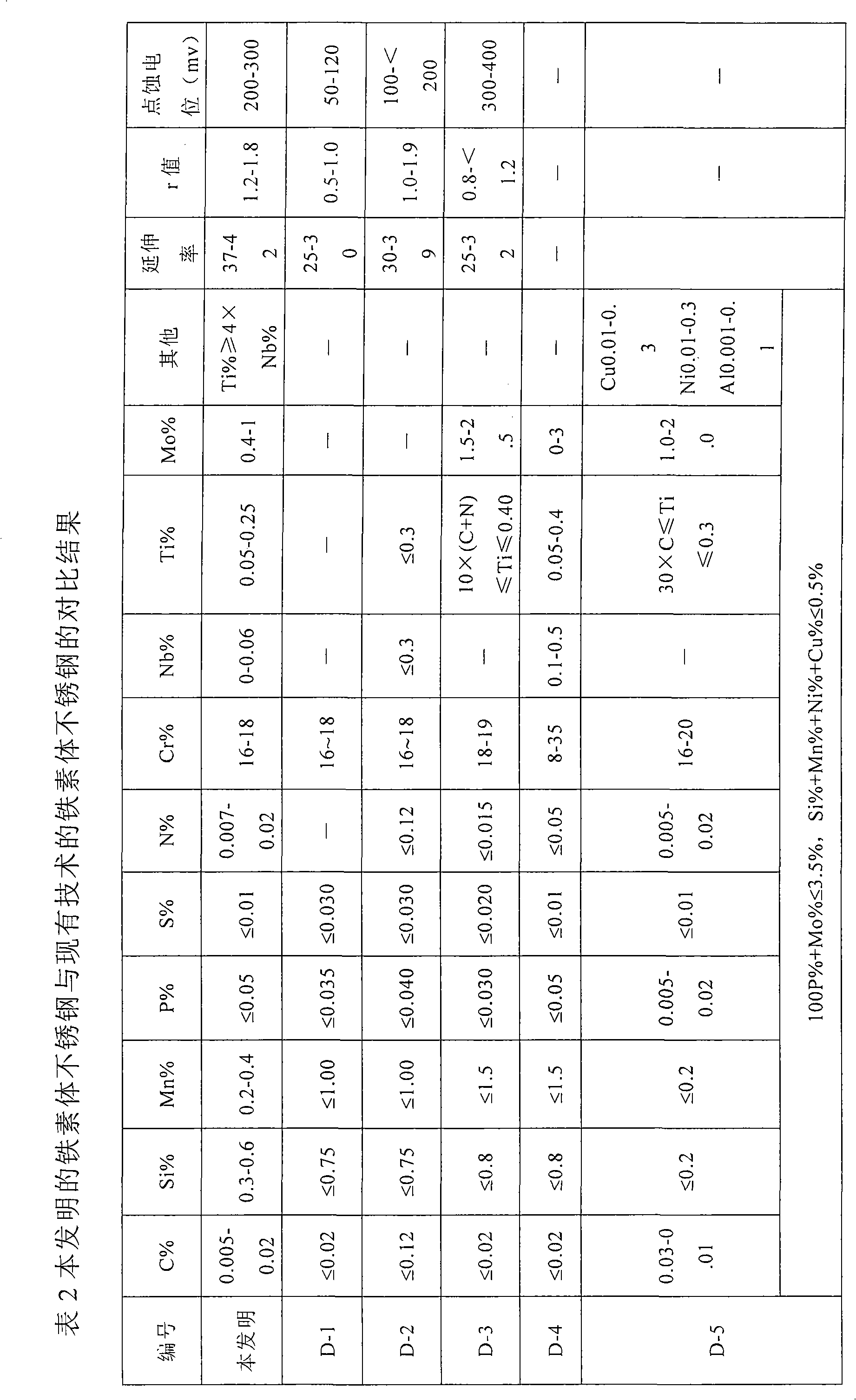

Ferrite stainless steel and manufacturing method thereof

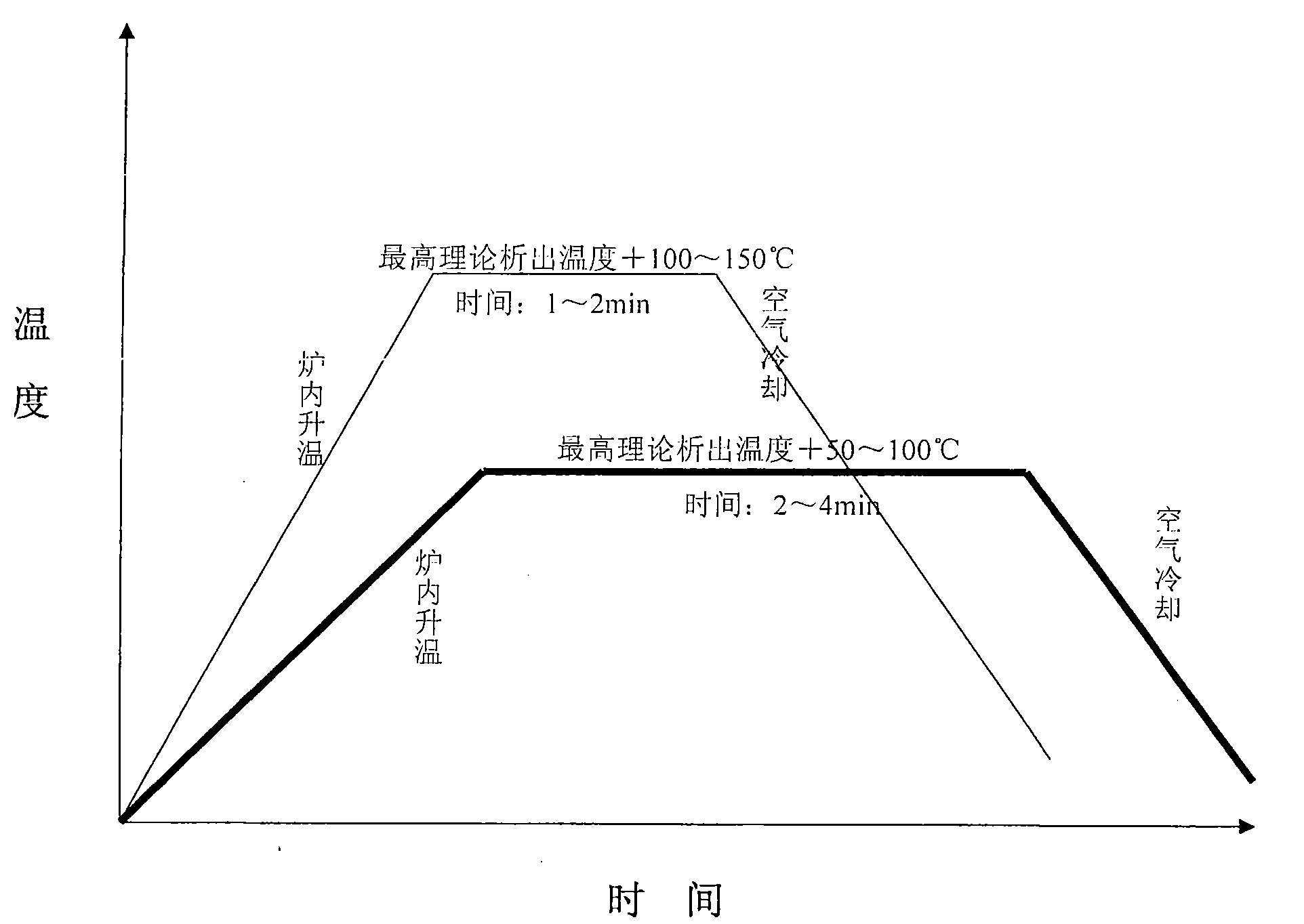

Ferrite stainless steel comprises the following components in percentage by weight: less than or equal to 0.02 percent of C, 0.30 to 0.60 percent of Si, 0.20 to 0.40 percent of Mn, less than or equal to 0.01 percent of S, less than or equal to 0.05 percent of P, 1.60 to 18.0 percent of Cr, less than or equal to 0.02 percent of N, 0.4 to 1 percent of Mo, 0 to 0.06 percent of Nb, 0.05 to 0.25 percent of Ti and the balance of Fe and inevitable impurities, wherein Ti is more than or equal to 4*Nb. The method for manufacturing the ferrite stainless steel comprises the following steps: smelting by an electric furnace-AOD-VOD three-step method; performing casting, hot rolling, annealing and acid washing, cold rolling and annealing and acid washing processes; calculating theological precipitationtemperatures of M23C6, sigma phase and chi phase according to a Thermo-calc phase diagram and taking a maximum value x DEG C of the precipitation temperatures of three precipitated phases, wherein the hot rolling and annealing temperature is equal to the highest theological temperature x DEG C plus 50 to 100 DEG C, and the annealing time is between 2 and 4 minutes; and the cold rolling and annealing temperature is equal to the highest theological temperature x DEG C plus 100 to 150 DEG C, and the annealing time is between 1 and 3 minutes; and performing air cooling after annealing. Prepared Mo-containing ferrite stainless steel has excellent corrosion resistance and moldability, and can be widely applied in household appliance industry.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

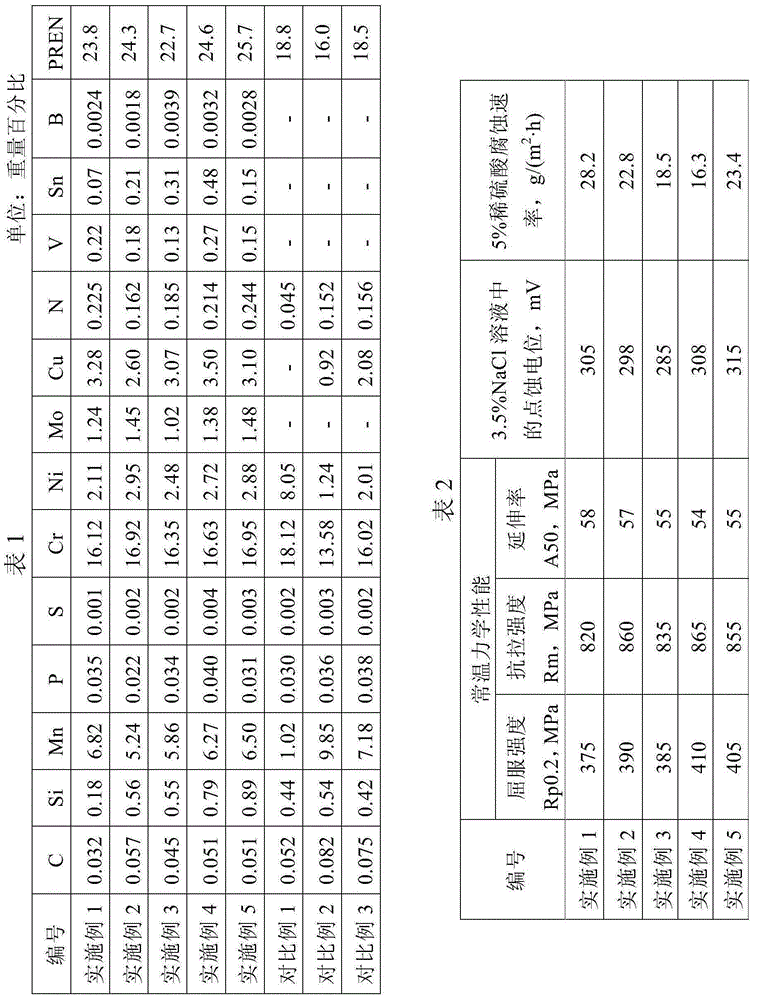

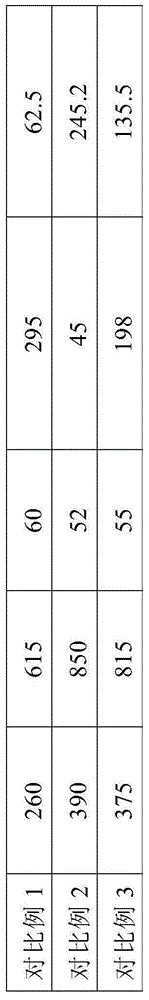

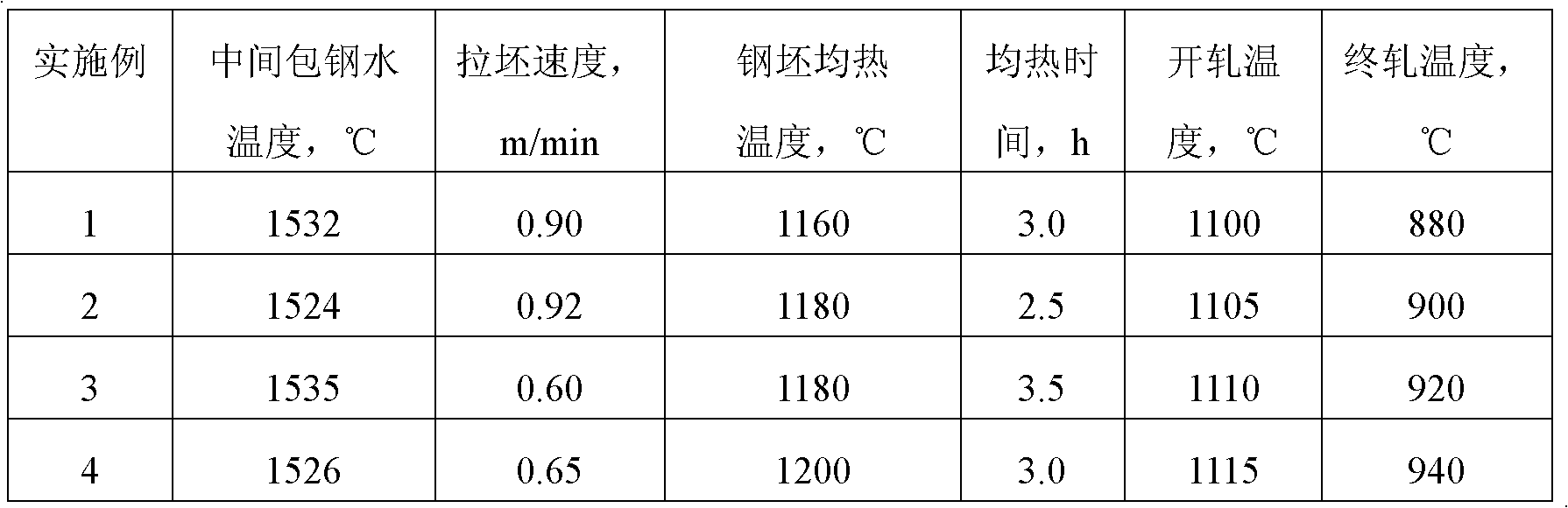

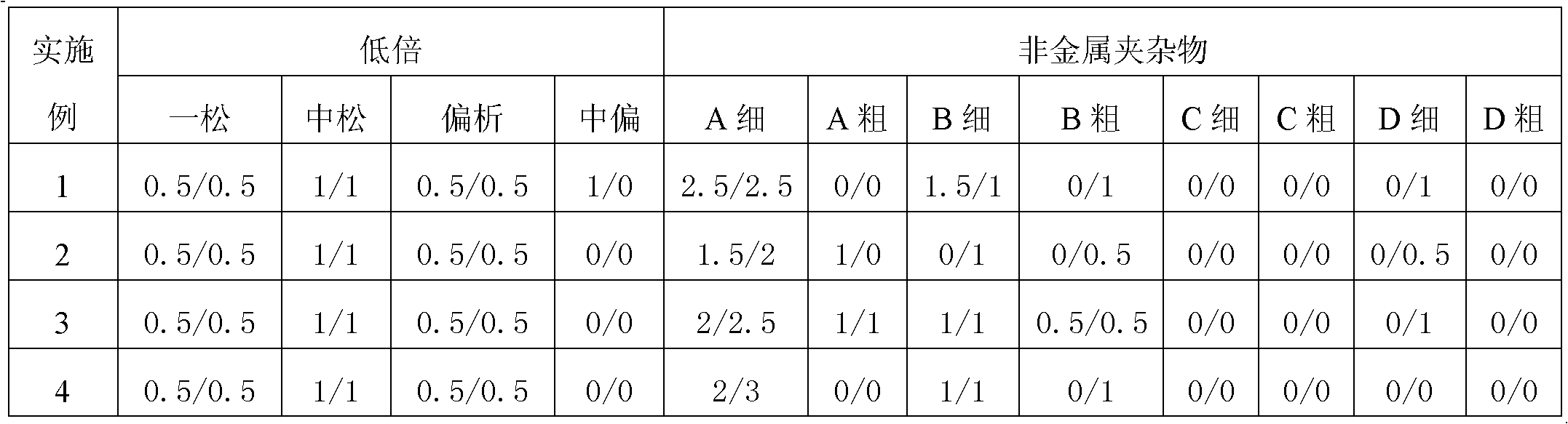

Acid rain corrosion-resistant austenitic stainless steel and manufacturing method thereof

InactiveCN106319391AImprove the corrosion resistance of dilute sulfuric acidHigh strengthChemical compositionRoom temperature

The invention relates to acid rain corrosion-resistant austenitic stainless steel and a manufacturing method thereof. The acid rain corrosion-resistant austenitic stainless steel comprises the chemical components in percentages by weight: 0.03-0.06% of C, 0.1-1.0% of Si, 5.0-7.0% of Mn, less than or equal to 0.06% of P, less than or equal to 0.01% of S, 16.0-17.0% of Cr, 2.0-3.0% of Ni, 1.0-1.5% of Mo, 2.5-3.5% of Cu, 0.15-0.25% of N, 0.1-0.3% of V, 0.05-0.5% of Sn, 0.001-0.005% of B and the balance of Fe and inevitable impurities, wherein the condition is satisfied as follows: (Cr+3.3Mo+16N) is greater than or equal to 22 but less than or equal to 26. A purpose of improving the capacity of resisting acid rain corrosion of the material is achieved with relatively low cost. The corrosion rate of the steel in a 5% diluted sulfuric acid is less than or equal to 30g / (m<2>.h), and the room temperature tensile strength is greater than or equal to 800MPa, and the steel can partially replace 304 stainless steel to use.

Owner:BAOSTEEL STAINLESS STEEL

MnCr carburized gear steel and its production method

The invention relates to a MnCr carburized gear steel and its production method, the MnCr carburized gear steel comprises the following components by mass percentage: 0.25-0.30% of C, less than or equal to 0.12% of Si, 0.60-0.80% of Mn, 0.80-1.10% of Cr, less than or equal to 0.035% of P, 0.020-0.050% of S, 0.020-0.055% of Al, less than or equal to 20ppm of [O] and the balance of Fe and inevitable impurities. By using an electric furnace smelting, the end point [C] is 0.10-0.15%, [P] is less than or equal to 0.015%, [Si] is less than or equal to 0.05%, and the tapping temperature is 1630-1680DEG C. The method comprises the steps of LF refining, adjusting slag by using carbon powder; feeding aluminum line, calcium line and sulfur line; vacuum treating; soft blowing argon; continuously casting a blank, controlling the tundish temperature at 1520-1540 DEG C, and strictly controlling the casting speed according to different blank types. The isothermal temperature, heating time and rolling temperature can be strictly controlled during the rolling process; thereby a hot-rolled round steel is prepared.

Owner:LAIWU IRON & STEEL GRP

Thermal treatment method used for improving duplex stainless steel welded structure

InactiveCN102560065AImprove pitting resistanceControl volumeFurnace typesHeat treatment furnacesHeat-affected zoneElectrical impulse

The invention discloses a thermal treatment method used for improving a duplex stainless steel welded structure, which comprises the following steps: 1) heating by an electric oven at the temperature lower or close to duplex stainless steel phase transition when a duplex stainless steel weld seam and a heat affected zone are heated by a thermal treatment technology, simultaneously carrying out electric pulse heating; 2) insulating for 10-60 minutes after heating, cooling with three phases, wherein in a first phase, the temperature of the welded structure is 850 DEG C and the cooling speed is controlled at 1-30 DEG C / s, simultaneously providing pulse current; in a second phase: the temperature is decreased to 800-500 DEG C, the cooling speed is controlled at 5-50 DEG C / s, and the cooling speed is greater than that of the first phase; in a third phase: the temperature is decreased below 500 DEG C and the cooling speed is controlled more than 30 DEG C / s. The thermal treatment for duplex stainless steel welded seam and the heat affected zone can control the volume fraction and existence form of ferrite, avoid the precipitation of a brittleness phase in ferrite / austenite, ferrite / ferrite crystal boundary, and enhance the capability of pitting corrosion resistance of the duplex stainless steel.

Owner:WENGFU (GRP) CO LTD

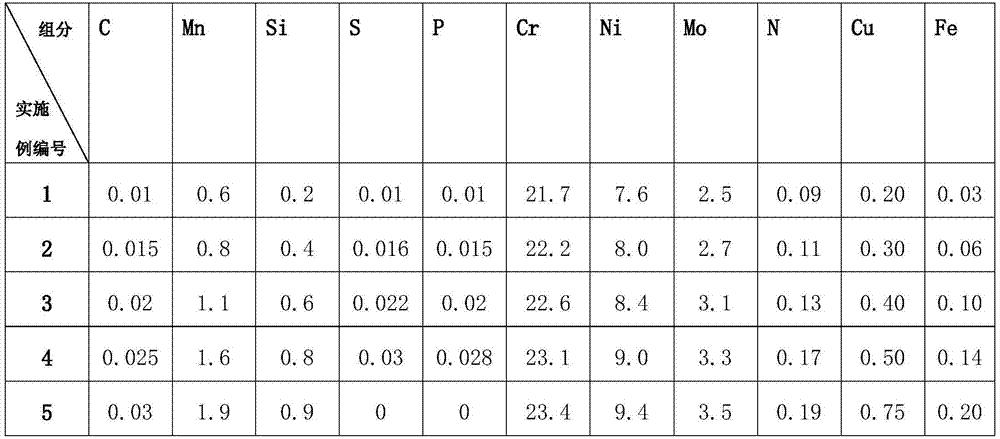

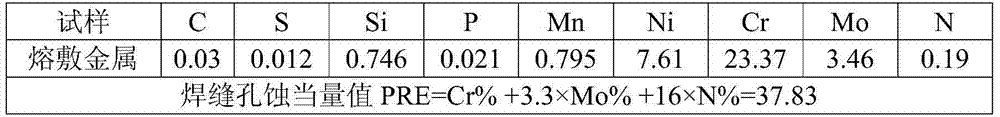

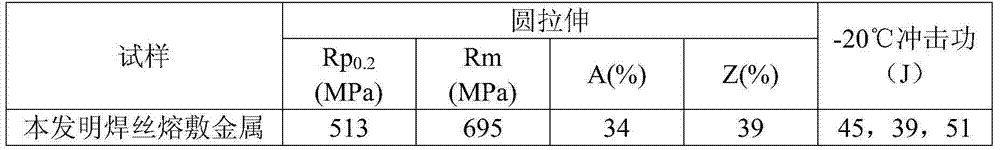

Kernel I-grade 2209 double-phase stainless steel welding wire and manufacturing method

InactiveCN104759784ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaDouble phaseStress corrosion cracking

The invention discloses a kernel I-grade 2209 double-phase stainless steel welding wire and a manufacturing method. The kernel I-grade 2209 double-phase stainless steel welding wire is prepared from the following components in percentage by mass: 0 to 0.03% of C, 0.5 to 2.0% of Mn, 0 to 0.90% of Si, 0 to 0.03% of S, 0 to 0.03% of P, 21.5 to 23.5% of Cr, 7.5 to 9.5% of Ni, 2.5 to 3.5% of Mo, 0.08 to 0.20% of N, 0 to 0.75% of Cu, and the balance of Fe. According the kernel I-grade 2209 double-phase stainless steel welding wire, alloy elements in an alloy system are reasonably mixed, so that the welding wire is high in process performance and mechanical performance, small in splashing, high in deslagging performance, outstanding in stress corrosion cracking resistance and pitting resistance; the alloy system is designed, so that the stable phase ratio of the weld joint metal is ensured; the manufacturing method is high in strength and high in plasticity of the manufactured welding wire.

Owner:JIANGSU UNIV OF SCI & TECH

Corrosion resistant spring steel for high-speed railway spring rods and production method thereof

InactiveCN106947921AMeet the mechanical performance requirementsImprove corrosion resistanceTemperature controlChemical composition

The invention discloses a corrosion-resistant spring steel for high-speed railway spring bars and a production method thereof. The chemical composition and mass percentage of the corrosion-resistant spring steel are as follows: C: 0.50-0.60%, Si: 1.40-2.20%, Mn : 0.70~1.00%, Cr: 0.36~0.50%, Ni: 0.36~0.60%, Cu: 0.26~0.50%, P: 0.015~0.030%, S≤0.015%, and the balance is Fe and unavoidable impurity elements. The production method includes converter smelting, LF refining, VD vacuum degassing, continuous casting, continuous casting slab heating, and rolling processes; in the converter smelting process, the C content at the control end point is ≥0.08%, and the tapping temperature is controlled at 1640±30°C. The invention satisfies the requirements of the standard on the mechanical properties of the spring steel under the conventional production process conditions of the spring steel through proper component design. After the spring is made according to the existing high-speed railway spring production process, the corrosion resistance of the steel body is significantly improved, and it has broad application prospects.

Owner:SHIJIAZHUANG IRON & STEEL

Precipitation-hardening martensitic stainless steel for surgical operation and heat treatment process thereof

ActiveCN103866198AImprove antibacterial propertiesImprove mechanical propertiesSurgical operationChemical composition

The invention discloses precipitation-hardening martensitic stainless steel for a surgical operation and a heat treatment process thereof, and belongs to the technical field of stainless steel material. The stainless steel comprises the following chemical composition: not more than 0.07 wt% of C, not more than 1.00 wt% of Si, not more than 1.00 wt% of Mn, not more than 0.040 wt% of P, not more than 0.030 wt% of S, 3.00-5.00 wt% of Ni, 15.0-17.5 wt% of Cr, 3.5-5.5 wt% of Cu, 0.05-0.15 wt% of N, 0.15-0.45 wt% of Nb, and the balance Fe. After the stainless steel is subjected to special heat treatment, a copper-rich phase can be precipitated evenly and dispersedly in a stainless steel matrix, and thus the stainless steel is endowed with an antibacterial function. The stainless steel solves the problem of bacterial infection caused by the use of stainless steel tools in a conventional surgical operation, is widely applied in various stainless steel appliances such as scalpels, surgical scissors, surgical forceps, intestinal forceps and curettes used in the surgical operation in the medical clinical field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anti-chlorine ion corrosion Ni-Cr nano composite coating and preparing method and use

InactiveCN1782138AImprove protectionGood resistance to Cl ion corrosionElectrolytic coatingsHydration reactionNicr alloy

The present invention discloses a kind of chlorine ion corrosion resisting nanometer composite Ni-Cr coating and its preparation and application. The nanometer composite Ni-Cr coating is prepared with nanometer metal Ni and Cr powder with Cr content of 4-15 wt%. The preparation process of the nanometer composite Ni-Cr coating is to electroplate Ni and Cr onto Ni substrate through conventional electric co-deposition. The nanometer composite Ni-Cr coating has obviously higher corrosion resistance than NiCr alloy with similar Cr content and composite Ni-Cr coating with micron Cr grains in similar content. The present invention has simple technological process, low cost, and compact and homogeneous coating. The nanometer composite Ni-Cr coating, when set in water solution containing Cl ion, will form hydrated Cr containing oxide and hydroxide to resist corrosion of Cl ion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

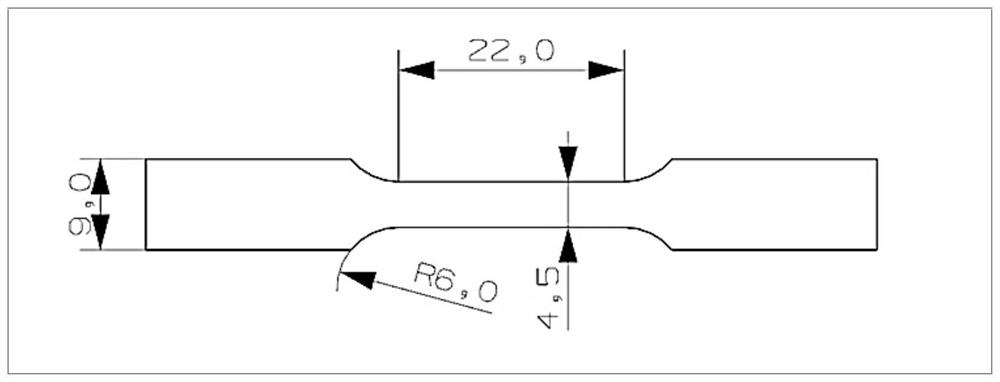

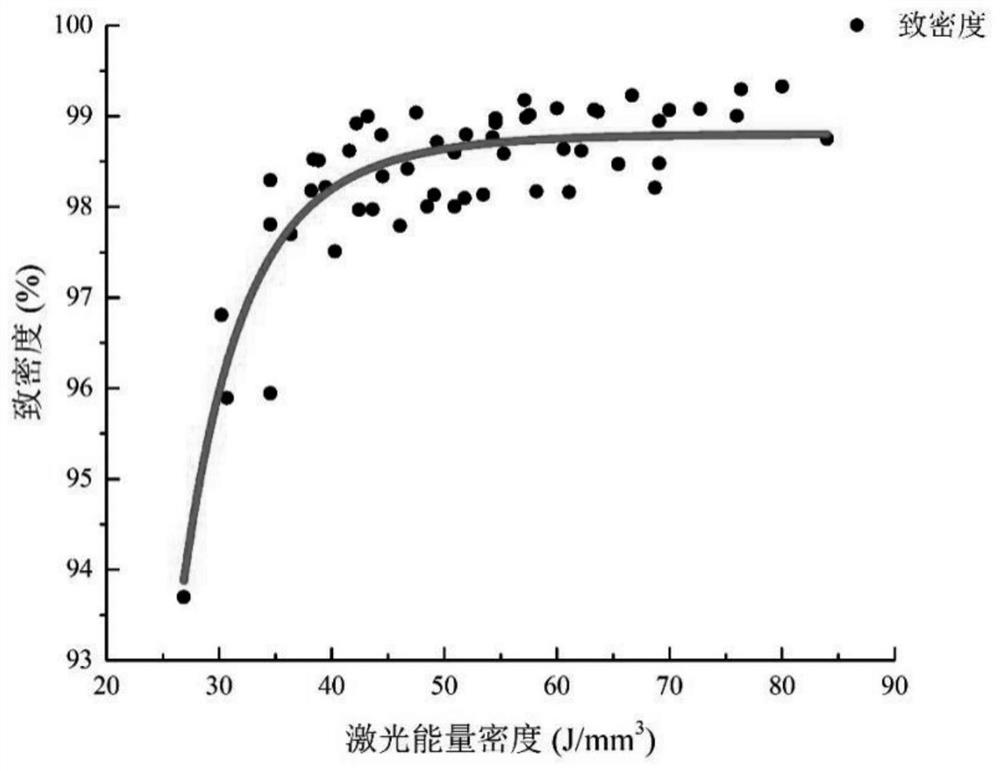

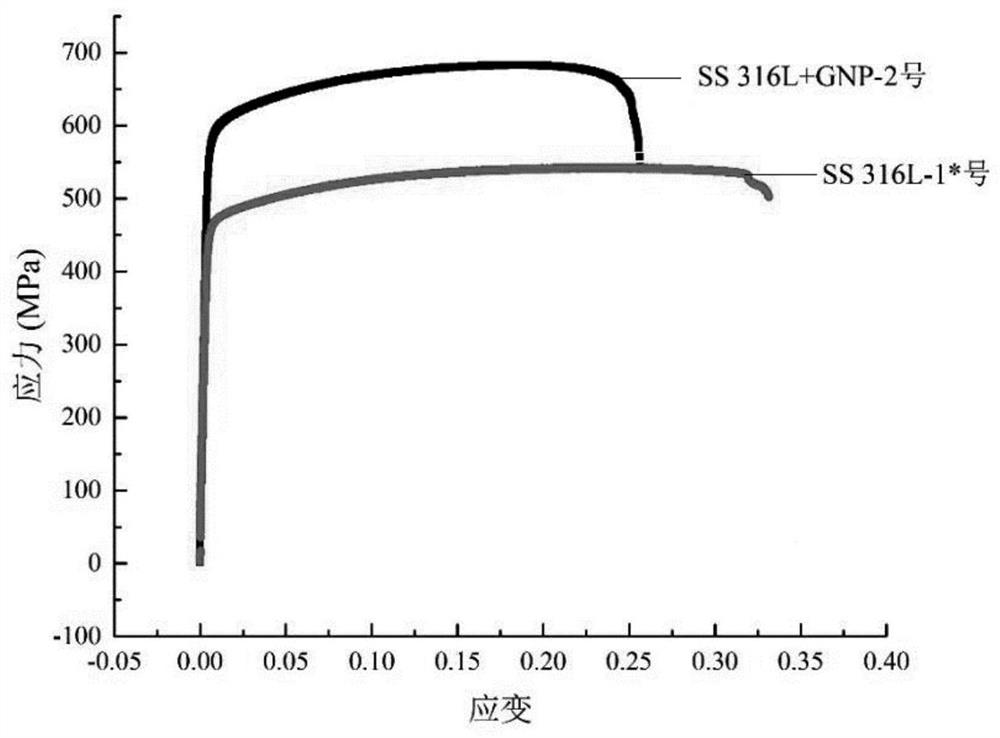

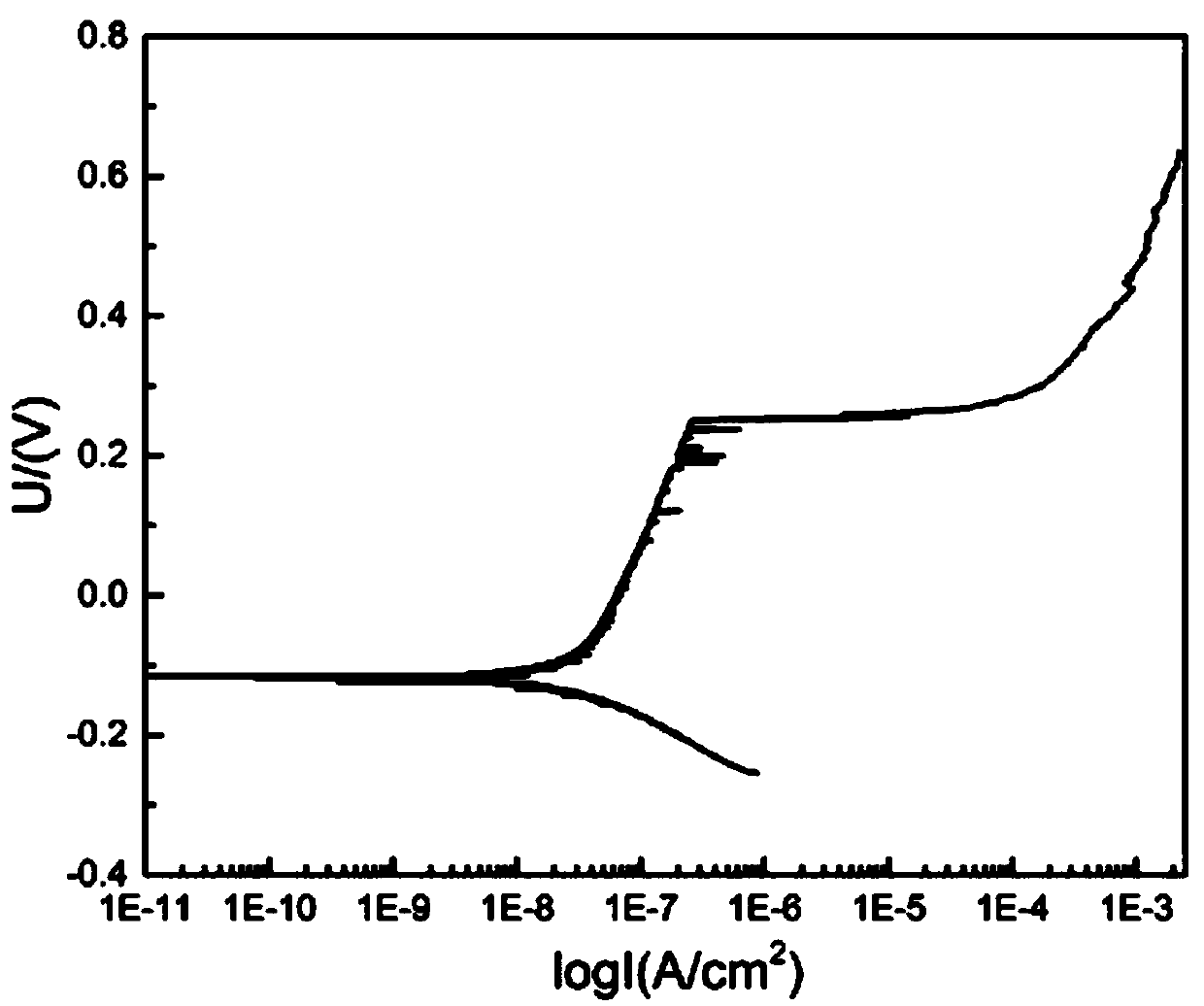

Preparation method for graphene-316L stainless steel based on selective laser melting

ActiveCN112453395AHigh yield strengthHigh tensile strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSS - Stainless steel

The invention discloses a preparation method for graphene-316L stainless steel based on selective laser melting. The preparation method comprises the following steps that graphene powder and 316L powder are mixed to obtain 316L and graphene mixed powder; then, the mixed powder is subjected to selective laser melting block forming, the optimal technological parameters are obtained through analysisof density, mechanical properties, electrochemical corrosion and metallographic and microcosmic appearance, the exposure time is 100 microseconds, the dot pitch is 50 micrometers, the power is 210 W,the laser energy density is 49.35 J / mm < 3 >, and compared with pure 316L stainless steel, the graphene / 316 L stainless steel sample under the optimal technological parameters has the advantages thatthe yield strength is improved by 28%, the tensile strength is improved by 26%, and the corrosion resistance is improved.

Owner:TIANJIN UNIV

High-strength stainless steel, heat treatment process and forming member

InactiveCN109594022AImprove pitting resistanceImprove plastic toughnessProcess efficiency improvementRoom temperatureCarbide

The invention relates to high-strength stainless steel, a heat treatment process and a forming member. The high-strength stainless steel is prepared from the following components according to weight percent: 0.2 to 0.35% of C, 0.7 to 3.50% of Mn, 0.6 to 2.0% of Si, 11 to 17% of Cr, less than or equal to 0.20% of Nb, less than or equal to 0.20% of Ti and the balance of Fe and impurities. The heat treatment process comprises the following steps of (a) heating the high-strength stainless steel to 1000 to 1200 DEG C, and then insulating for 1 to 3600 s; (b) cooling the high-strength stainless steel treated in the step (a) below 100 DEG C; and (c) heating the high-strength stainless steel treated in the step (b) to 150 to 400 DEG C, then insulating for 10 to 10000 s, and then cooling to room temperature in any cooling mode. The forming member is made of the high-strength stainless steel, and the microstructure of the forming member is composed of 5% to 30% of retained austenite, 70% to 95%of martensite, less than 1% of Nb and Ti carbide and less than 2% of Cr carbide in an area.

Owner:IRONOVATION MATERIALS TECH CO LTD

Hot-dipping Zn-Al-Mg coating steel plate with excellent dip plating performance, and production method

InactiveCN108588491AImprove wettabilityImprove pitting resistanceHot-dipping/immersion processesFurnace typesSheet steelSolution element

The invention provides a hot-dipping Zn-Al-Mg coating steel plate with an excellent dip plating performance, and a production method. A coating contains 1 to 5 percent of Al, 1 to 3 percent of Mg, less than or equal to 0.0104 percent of Fe, 0.1 to 1 percent of Si, 0.01 to 1 percent of Ce, and the balance Zn and inevitable impurities. Compared with the prior art, according to the hot-dipping Zn-Al-Mg coating steel plate with the excellent dip plating performance, and the production method provided by the invention, through designing the plating solution element content, adding 0.1 to 1 percentof Si and 0.01 to 1 percent of Ce, and controlling Al to be 1 to 5 percent, the infiltrating performance of a plating solution and a substrate is improved, and a large number of iron elements are prevented from being brought into zinc liquid so as to cause an adverse effect, so that the coating is uniform and fine in microstructure. The designed plating solution adapts to a steel plate for a common household appliance and has a good infiltrating effect on the surface of the steel plate; and in addition, through optimizing annealing and hot-dipping processes, the coating formed on the surface of the steel plate is fine and uniform in microstructure without skip plating or shrinking and is remarkably improved in pitting corrosion resistance.

Owner:MAANSHAN IRON & STEEL CO LTD

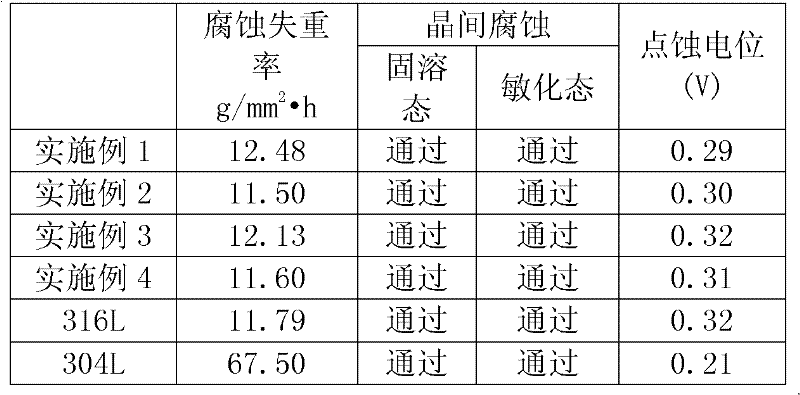

Low-cost austenitic stainless steel with excellent corrosion resistance

ActiveCN102330033AImprove pitting resistanceImprove corrosion resistanceAustenitic stainless steelAustenite

The invention discloses low-cost austenitic stainless steel with excellent corrosion resistance, which comprises the following chemical elements in mass percentage: smaller than or equal to 0.04% of C, 16.00-19.00% of Cr, 8.00-10.00% of Ni, 0.50-1.50% of Mo, 2.10-4.50% of Cu, 0.02-0.08% of N, smaller than or equal to 0.80% of Mn, 1.30-2.50% of Si, smaller than or equal to 0.04% of P, smaller thanor equal to 0.005% of S, 0.0010-0.0040% of B and the balance of Fe and other inevitable impurities, and the ratio of Si to Mn is 2.5 to 4. The corrosion resistance and mechanical properties of the austenitic stainless steel are far better than those of 304L or approach or reach the level of 316L austenitic stainless steel, but the cost is lowered by 20-30% as compared with that of the 316L austenitic stainless steel.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

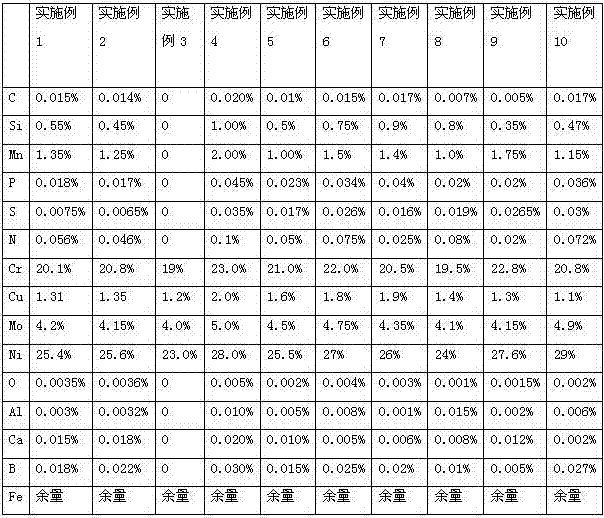

Superaustenitic stainless steel and preparing method thereof

ActiveCN107058905ASolve the smelting and continuous casting technologyImprove corrosion resistanceCopperAustenite

The invention provides superaustenitic stainless steel and a preparing method thereof. The superaustenitic stainless steel is prepared in the following percent by weight: smaller than or equal to 0.020% of C, smaller than or equal to 1.00% of Si, smaller than or equal to 2.00% of Mn, smaller than or equal to 0.045% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.1% of N, 19.0-23.0% of Cr, 1.2-2.0% of Cu, 4.0-5.0% of Mo, 23.0-28.0% of Ni, smaller than or equal to 0.0050% of O, smaller than or equal to 0.010% of Al, smaller than or equal to 0.020% of Ca, smaller than or equal to 0.030% of B and the balance of Fe. The method adopts a protection process of smelting superaustenitic stainless steel mother liquid by adopting a Consteel electric furnace and an intermediate frequency furnace, AOD, LF and continuous casting of a sheet billet, and can smelt the high-Ni, high-Cr, high-Mo, Cu-containing and low-C superaustenitic stainless steel, and both the surface quality and internal quality of the continuous casting billet are good.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com