High-strength stainless steel, heat treatment process and forming member

A technology for forming components and high strength, applied in the field of heat treatment process and forming components, high-strength stainless steel, can solve the problem of stability of performance without realizing the problem of corrosion resistance decline, quenching temperature has great influence on performance, narrow process window, etc. problems, to achieve the effects of improved plastic toughness, high strength and plasticity, and a large process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

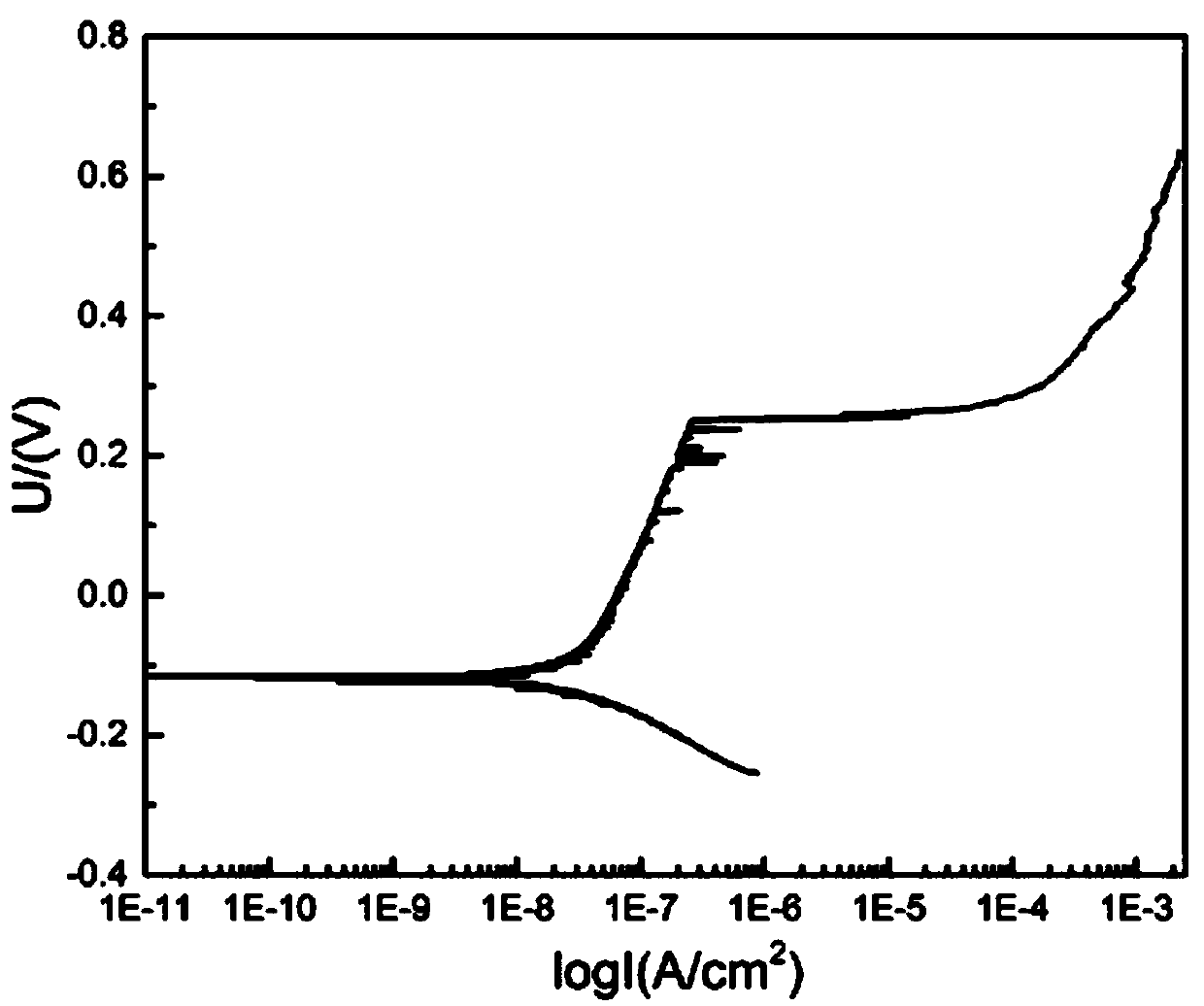

Image

Examples

Embodiment Construction

[0034] The high-strength stainless steel of the present invention comprises: 0.2-0.35% of C, 0.7-3.50% of Mn, 0.6-2.0% of Si, 11.0-17.0% of Cr, less than or equal to 0.20% of Nb, less than or equal to 0.20% %Ti. Among them, the C content is preferably 0.2-0.3%, the Cr content is preferably 12.0-14%, the Nb content is preferably less than or equal to 0.10%, and the Ti content is preferably less than or equal to 0.10%. One or more of the group consisting of: 2.0% or less Mo; 1.0% or less W; 1.0% or less V; 3.0% or less Cu; 4.0% or less Ni; 0.4% or less Zr. The balance is Fe and impurities.

[0035] The content range of each chemical component will be described respectively below.

[0036] C: 0.20~0.35%, preferably 0.2~0.3%

[0037] In the steel of the present invention, carbon is the most important strengthening element, which improves the strength through solid solution strengthening and dispersion precipitation strengthening. In addition to being a strengthening element, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com