Superaustenitic stainless steel and preparing method thereof

A kind of austenitic stainless steel, super technology, applied in the field of super austenitic stainless steel and its preparation, can solve the problems that the continuous casting slab production process has yet to be developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of super austenitic stainless steel, the steps are as follows:

[0038] (1), Consteel electric furnace and intermediate frequency furnace together smelt super austenitic stainless steel mother liquor;

[0039] The composition of Consteel electric furnace mother liquor is as follows according to weight percentage: C>0.5%, Si≤1.0%, Cr: 1-5%, Ni: 25-35%, P<0.007%, and the balance is Fe; the tapping temperature is controlled at 1490 ~1550°C; Consteel electric furnace mother liquor can be made of stainless steel waste, high-quality scrap steel, and ferronickel. Before smelting, the raw materials can be preheated to 500-600°C to reduce smelting costs. During the smelting process, oxygen can be blown and lime and white clouds can be added appropriately. The proportion of stone and adding appropriate calcium fluoride slag to reduce the content of P.

[0040] The intermediate frequency furnace is used to smelt ferrochromium and ferromolybdenum alloys. The c...

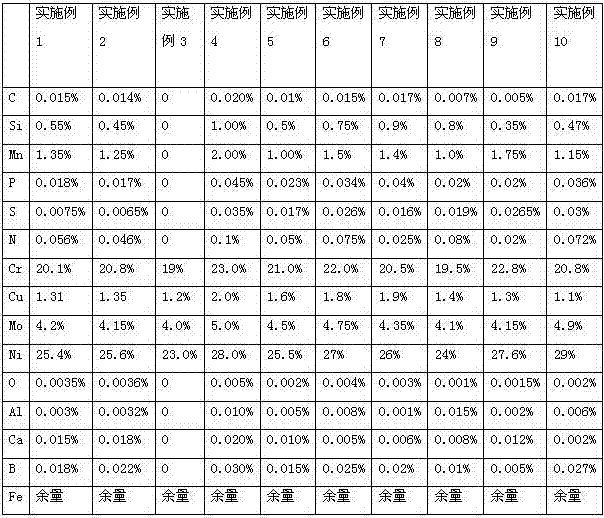

Embodiment example 1

[0045] The implementation examples are described below.

[0046] The composition of Consteel electric furnace mother liquor is as follows according to weight percentage: C: 1.39%, Si: 0.08%, P: 0.005%, Cr: 1.25%, Ni: 28.9%, the balance is Fe, and the tapping temperature is controlled at 1510°C. Through oxygen blowing decarburization in AOD furnace, nitrogen blowing and composition adjustment, LF furnace refining and microalloy addition, the composition of molten iron is finally adjusted to: C: 0.015%, Cr: 20.1%, Si: 0.55%, Ni: 25.4% , Mn: 1.35%, Mo: 4.2%, N: 0.056%, P: 0.018%, O: 0.0035%, S: 0.0075%, Al: 0.003%, Ca: 0.015%, B: 0.018%, Cu: 1.31% , the balance being Fe. The tapping temperature of the AOD furnace is 1510°C, the weak blowing time of the LF furnace is 32min, the feeding SiCa line is 380m, the B line is 22m, the hanging ladle temperature is 1450°C, the continuous casting tundish temperature is controlled at 1425°C, the penetration nozzle depth is 125mm, and the con...

Embodiment example 2

[0048] The implementation examples are described below.

[0049] The composition of Consteel electric furnace mother liquor is as follows according to weight percentage: C: 1.41%, Si: 0.06%, P: 0.006%, Cr: 1.15%, Ni: 28.5%, the balance is Fe, and the tapping temperature is controlled at 1505°C. Through oxygen blowing decarburization in AOD furnace, nitrogen blowing and composition adjustment, LF furnace refining and microalloy addition, the composition of molten iron is finally adjusted according to weight percentage: C: 0.014%, Cr: 20.8%, Si: 0.45, Ni: 25.6%, Mn: 1.25%, Mo: 4.15%, N: 0.046%, P: 0.017%, O: 0.0036%, S: 0.0065%, Al: 0.0032%, Ca: 0.018%, B: 0.022%, Cu: 1.35%, The balance is Fe. AOD tapping temperature is 1515°C, LF furnace weak blowing time is 35min, feeding SiCa line is 400m, B line is 25m, hanging ladle temperature is 1445°C, continuous casting tundish temperature is controlled at 1426°C, penetration nozzle depth is 125mm, continuous casting speed is 0.85m / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com