Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Reduce smelting energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

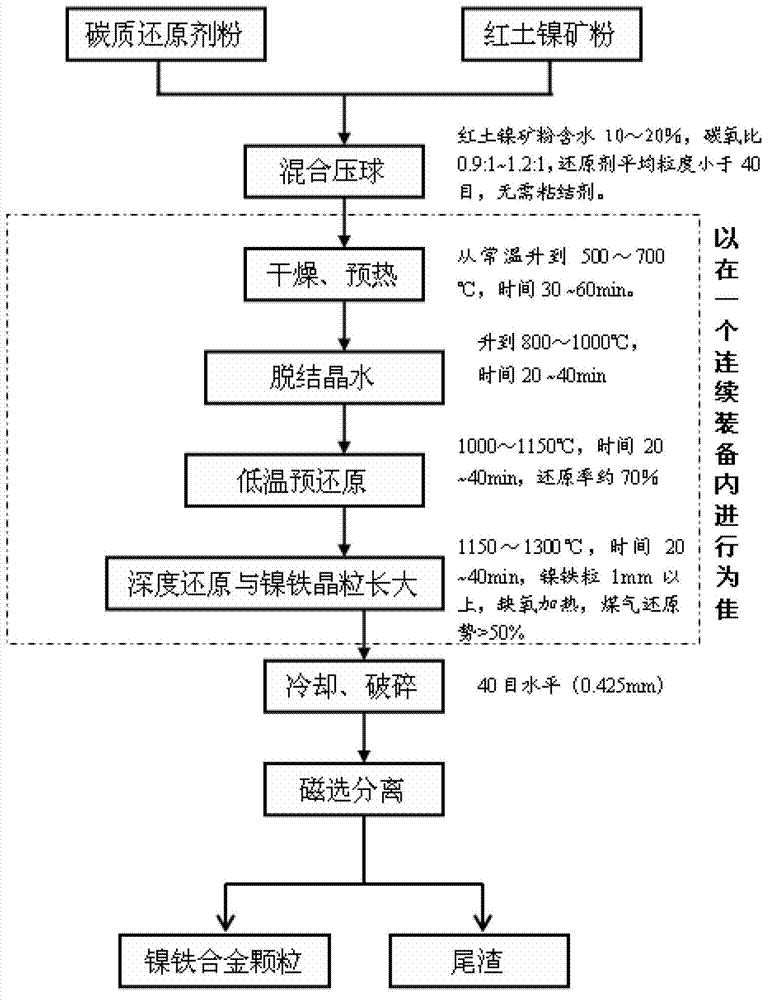

Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

The invention provides a method for producing nickel-iron alloy by smelting a red earth nickel mineral at a low temperature and belongs to the field of preparation of non-ferrous metallurgy. A process flow is as follows: after the red earth nickel mineral and a carbon reducing agent are molded, molding raw materials are subjected to drying, pre-heating and crystallization water removing; pre-reduction, deep reduction and growth of nickel-iron alloy grains are carried out; and after a cooling step, the separation of the nickel-iron alloy and furnace dregs is realized in a magnetic selection manner. Compared with the prior art, the method has the advantages of being low in reaction temperature, low in energy consumption, easy to obtain the high-quality nickel-iron alloy grains, simple in preparation process and low in production cost.

Owner:NEW METALLURGY HI TECH GRP

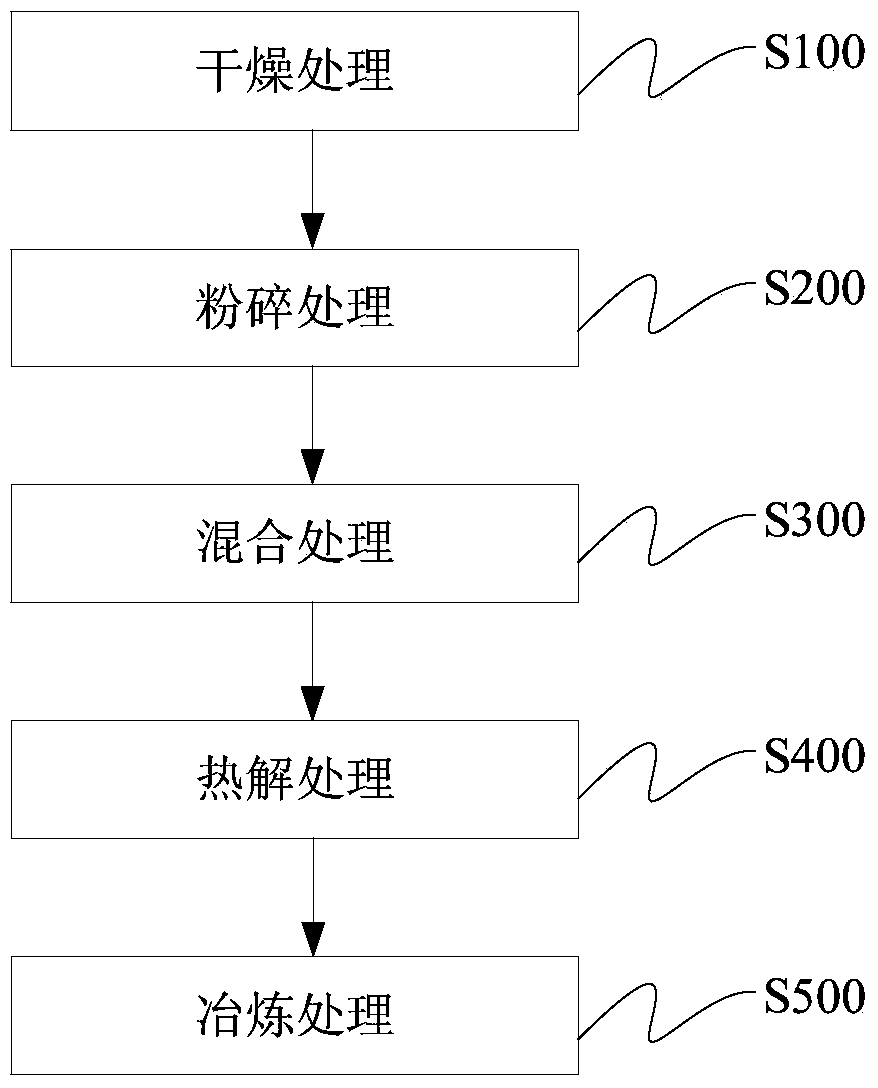

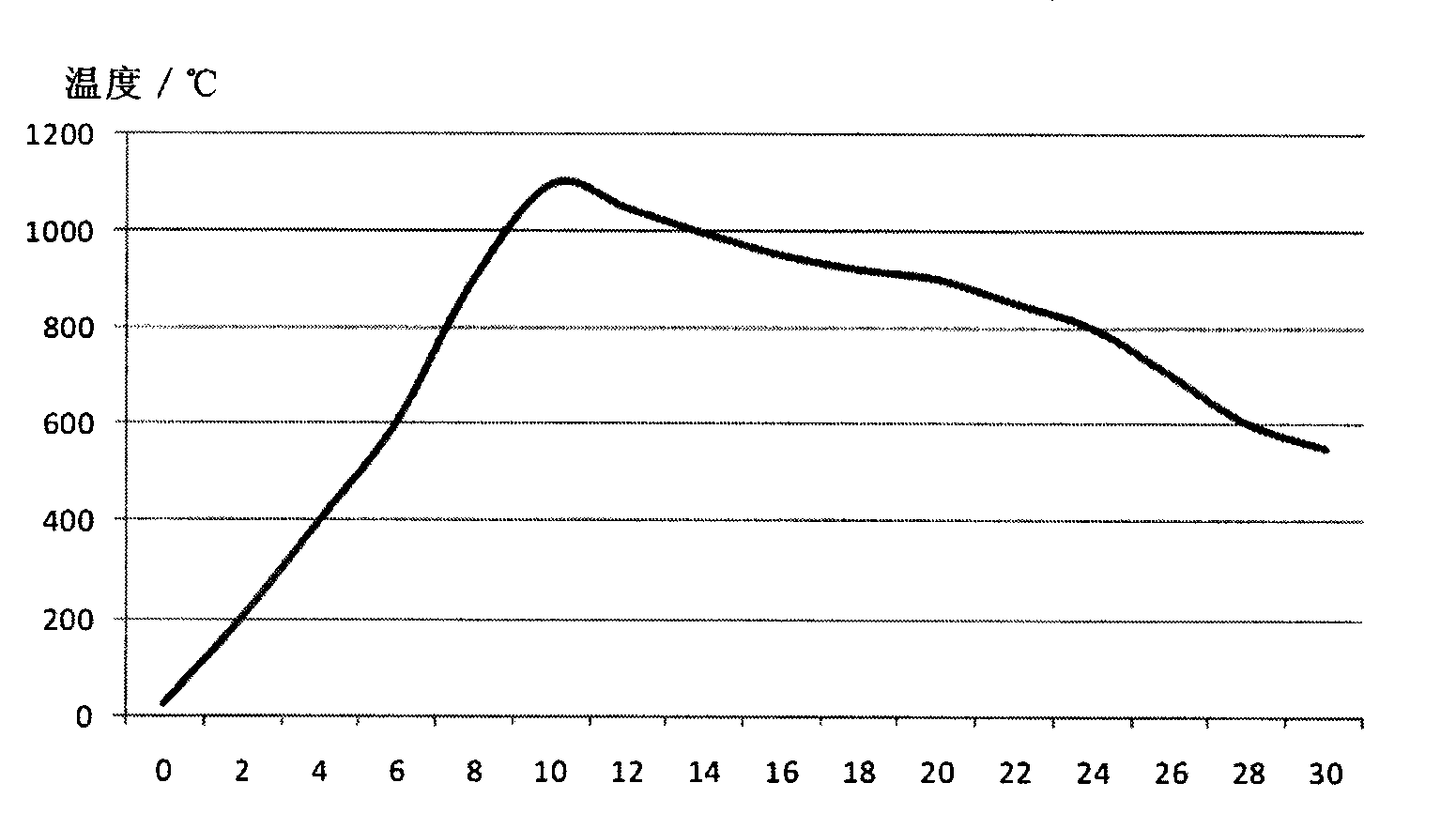

Method for preparing calcium carbide

InactiveCN103708456AIncrease profitIncrease productivityCalcium carbideElectric arc furnaceForming gas

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; forming the mixture to obtain a lump material; pyrolyzing the lump material to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into an arc furnace at the temperature of not lower than 450 DEG C to perform smelting in the arc furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

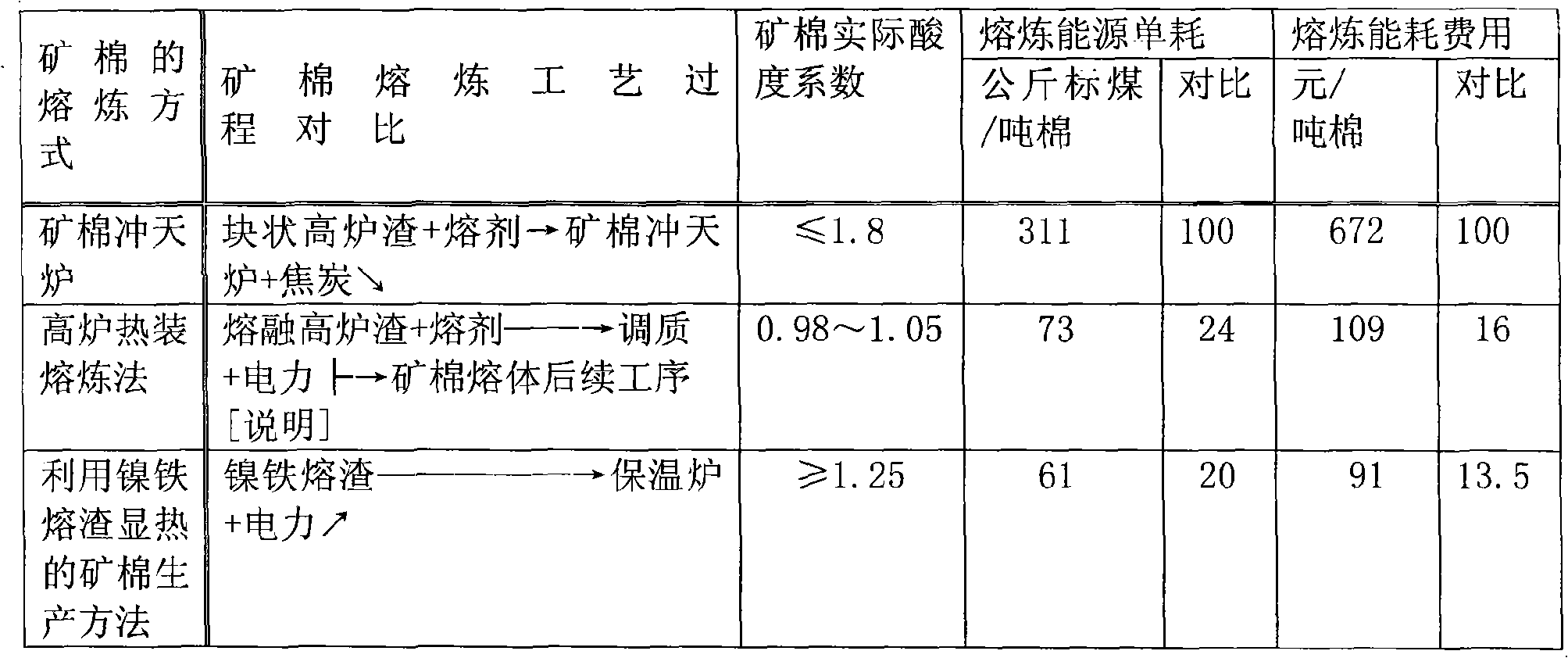

Method for preparing mineral wool by using ferronickel dross sensible heat

InactiveCN101293731AReduced service lifeMeet quality requirementsGlass making apparatusThermal insulationCotton fibre

The invention relates to the technical filed of mineral cotton production, which is a method for producing mineral cotton by using the sensible heat of ferronickel slag. The method includes the following steps: laterite-nickel ore is adopted as basic material, and the ferronickel slag with the temperature of 1450 to 1500 DEG C and acidity coefficient being equal to or more than 1.25 is poured into a power thermal insulation furnace with the capacity being 15 tons without adding any fusing agent; the temperature of melts is adjusted and kept within the range of 1350 to 1400 DEG C; then the melts with adjusted temperature are correctly led to a four-roller centrifugal machine by a water-cooling controllable head piece and a diversion trench so as to lead the ferronickel slag to be directly transformed into the mineral cotton fiber with high quality. Electrode materials in the power thermal insulation furnace are metal or carbon.

Owner:杨铧 +1

Preparation method for titanium-nickel memory alloy sheet

InactiveCN107805741ASolve the problem of poor plasticity at room temperatureEliminates press-in defectsMechanical propertyImpurity

The invention belongs to the field of nonferrous metal processing, and provides a preparation method for a titanium-nickel memory alloy sheet. The preparation method mainly comprises the steps of smelting, annealing, forging, hot rolling, cold rolling and annealing, acid pickling and inspection; a vacuum induction furnace graphite crucible is adopted for smelting in the smelting step, firstly, a small amount of Ti-Ni mother alloys with the same mass percent as smelting materials is prepared and is placed in the vacuum induction furnace graphite crucible, after power is supplied and smelting iscompleted, a Ti-Ni alloy molten pool is formed, melting the ni alloy molten pool, then crushed materials of sponge titanium and electrolytic nickel are slowly added into the molten pool for smelting,and a titanium-nickel ingot is formed, wherein the chemical components of the titanium-nickel ingot is ensured to comprise 54.5%-55.5% of Ni, less than or equal to 0.04% of C, less than or equal to 0.005% of H, less than or equal to 0.050% of O, less than or equal to 0.04% of N and the balance Ti. According to the method, the problem of poor plasticity of a common titanium-nickel memory alloy sheet at the room temperature is solved, defects of cracking, peeling, folding, oxidizing and impurity pressing are overcome, the mechanical property is improved, meanwhile, the cost is reduced, and theyield during batch production is improved.

Owner:BAOJI BOXIN METAL MATERIALS

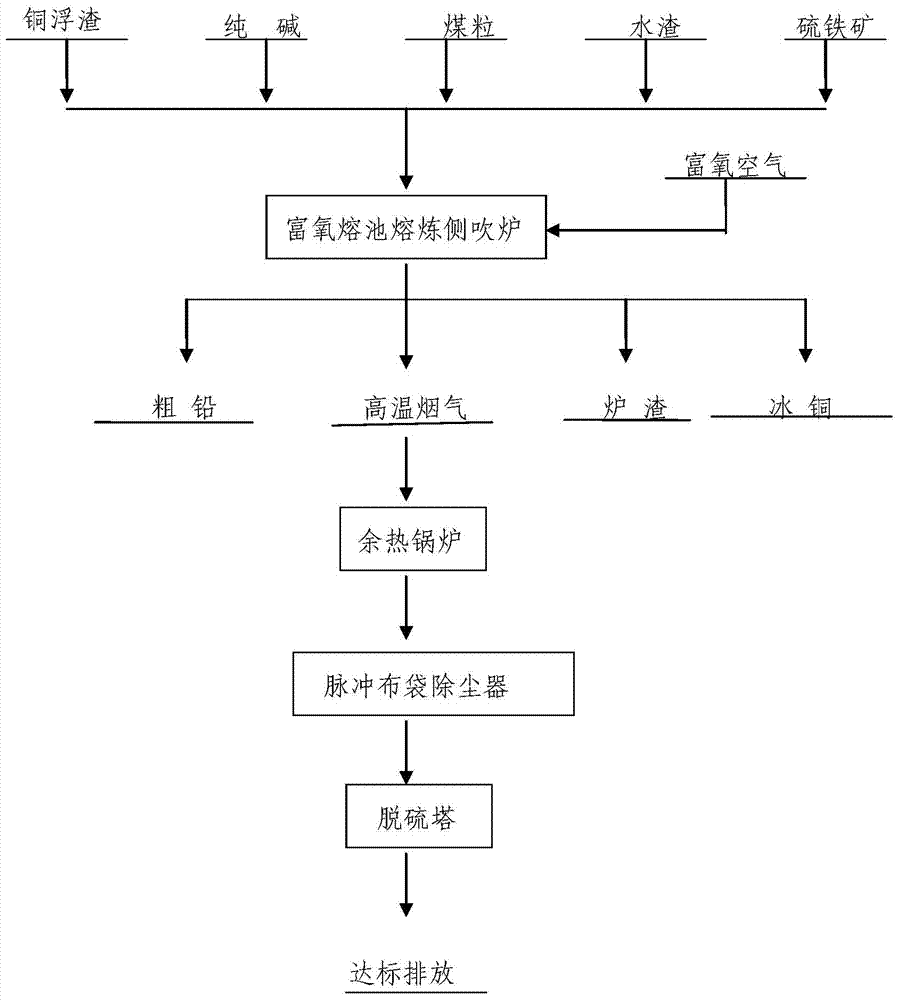

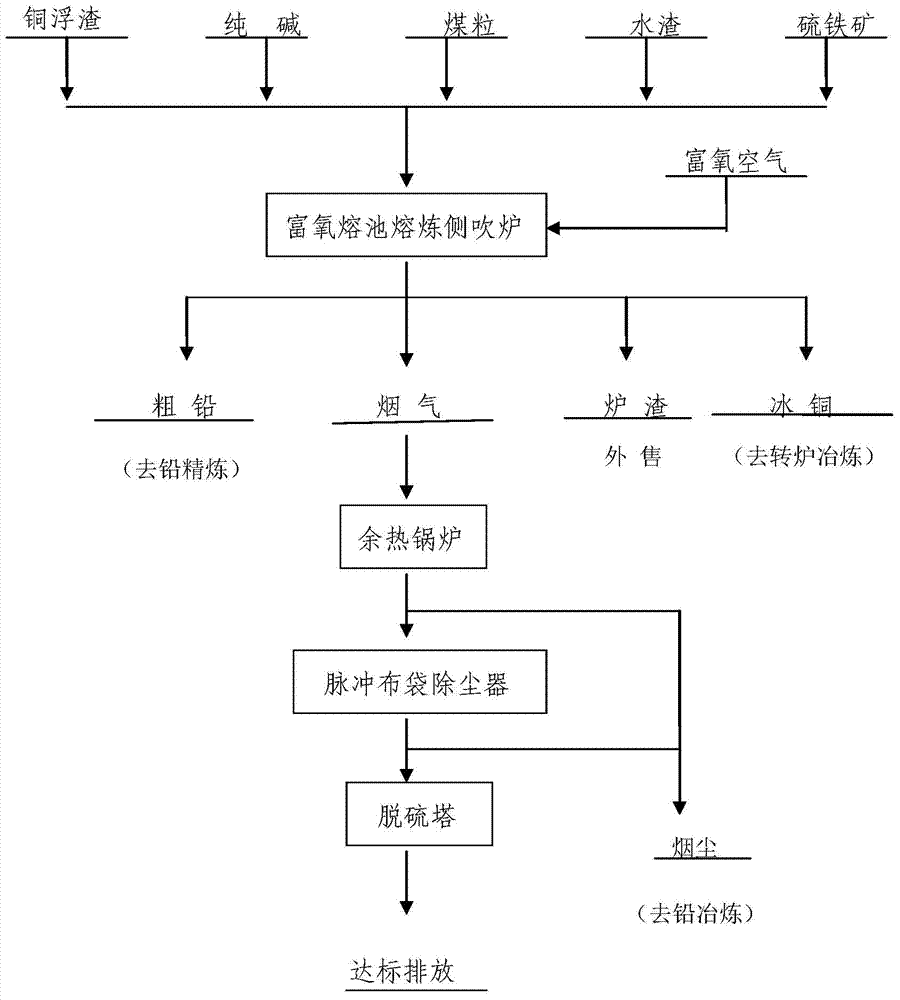

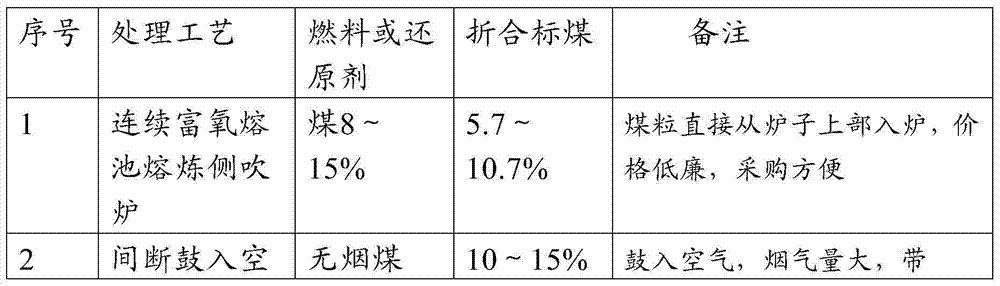

Method for treating copper dross

ActiveCN103924094AImprove melting efficiencyHigh direct metal recovery rate and recovery rateProcess efficiency improvementAutomatic controlPyrite

The invention provides a method for treating copper dross. According to the method, copper dross is treated by using an oxygen enrichment molten pool smelting side blowing furnace, coal granules are adopted as a reducing agent and fuel, copper dross, pure alkali, pyrite and water granulated slag are adopted for blending, together with the coal granules, are fed into the furnace from the feeding hole of the oxygen enrichment molten pool smelting side blowing furnace through a belt, and are blown into an oxygen enrichment air smelting pool for smelting so as to obtain crude lead, copper matte, furnace slag and high-temperature flue gas. By adopting the method provided by the invention, continuous feeding is achieved; due to adoption of a DCS automatic control technique, the working intensity of operators is low, the flushing and casting environment is good, the side blowing treatment bed is high in capacity, the efficiency of the smelting pool is high, the metal recycling rate is high, and the smelting energy consumption is low.

Owner:JIYUAN WANYANG SMELTING GROUP

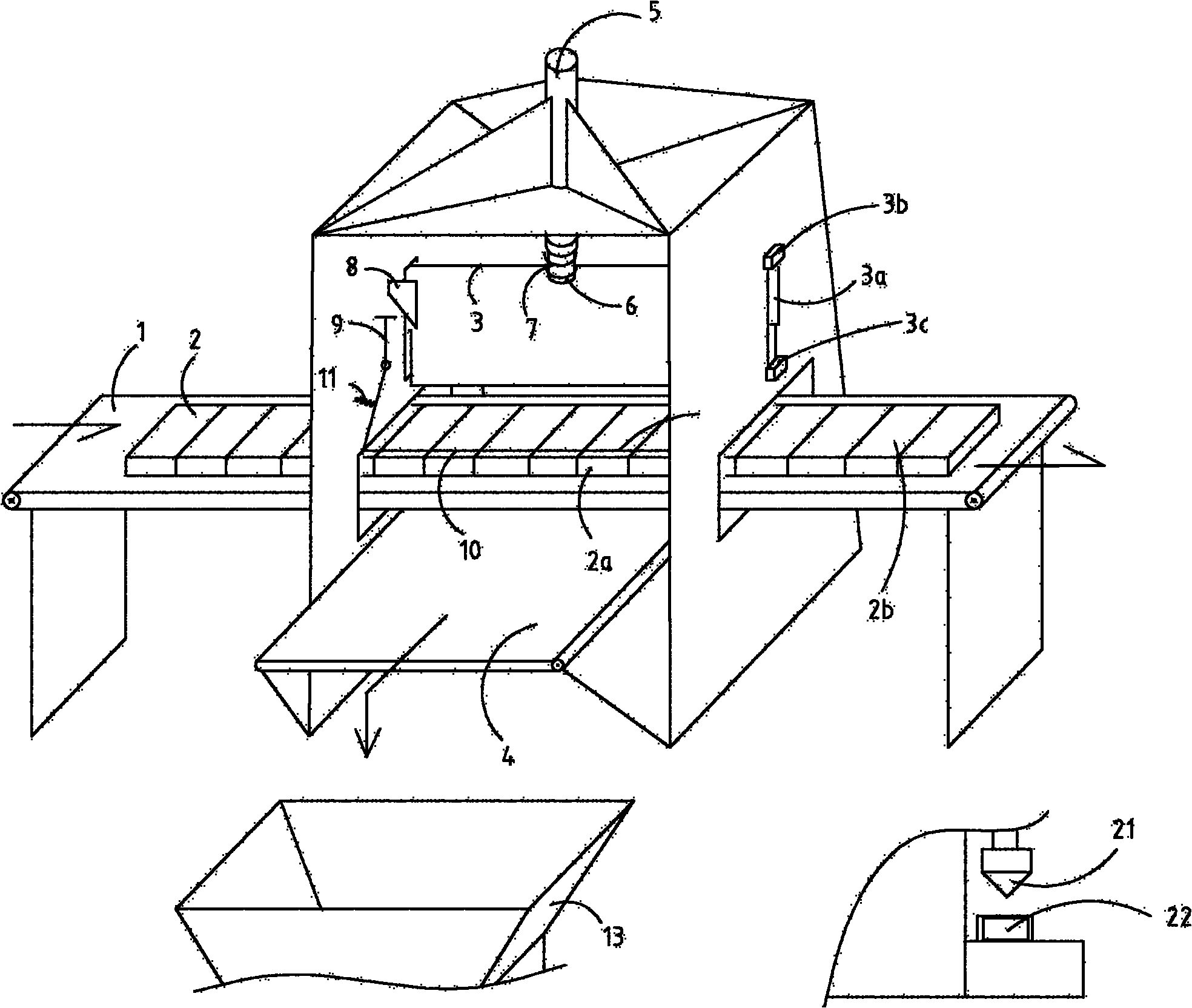

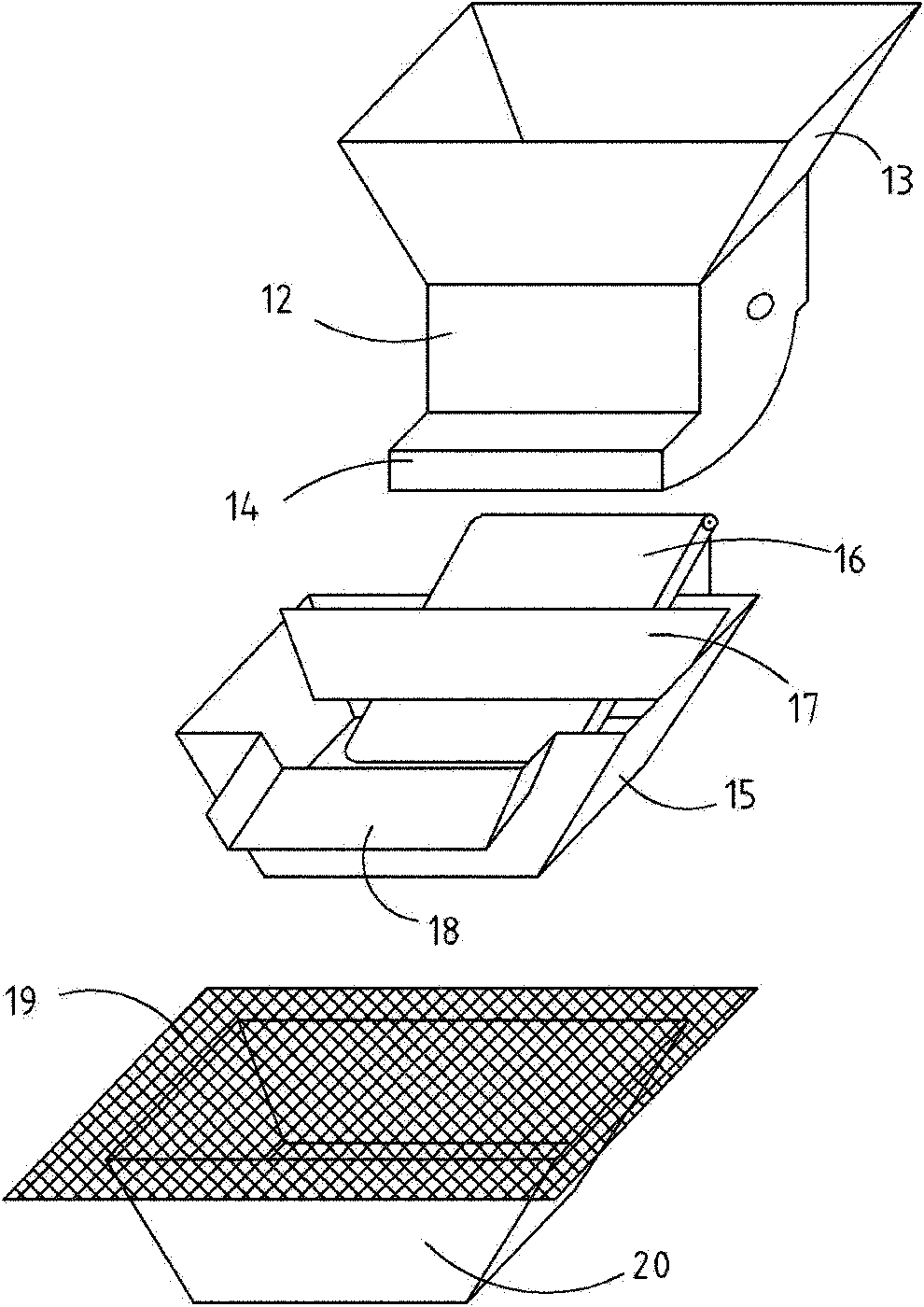

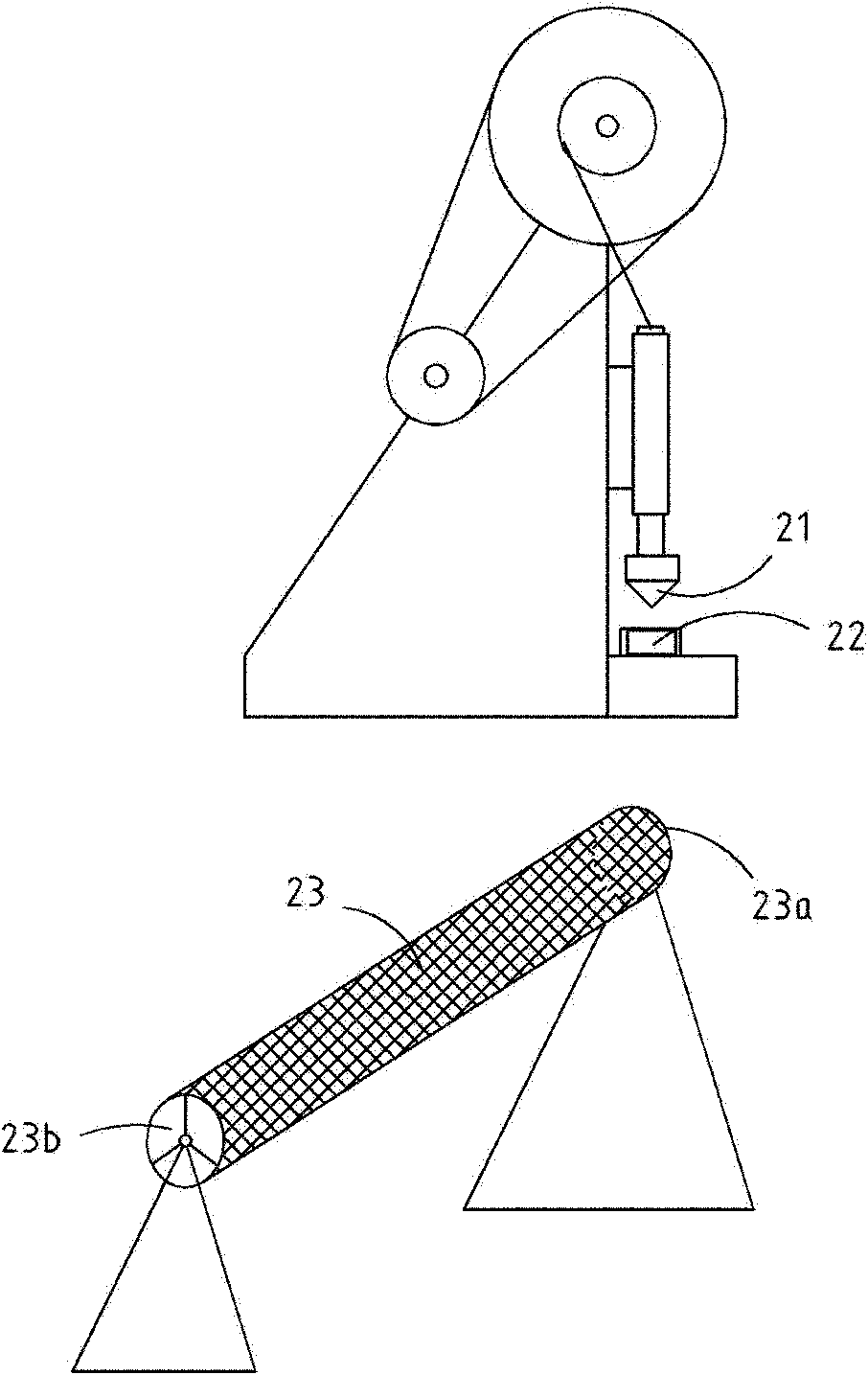

Energy-saving and environment-friendly automatic disassembly and separation system for waste batteries

InactiveCN102148414AImprove dismantling efficiencyReduce smelting energy consumptionSolid waste disposalWaste accumulators reclaimingEngineeringProduction line

The invention discloses an automatic disassembly and separation system for waste batteries. The system is characterized in that a battery conveyor belt is horizontally arranged, and all the batteries are arranged on the battery conveyor belt in a way of enabling box covers of the batteries to face the same direction and can be conveyed from left to right along with the battery conveyor belt; a cutting mechanism is arranged above the battery conveyor belt, a box cover conveyor belt is arranged below the cutting mechanism, and the conveying directions of the box cover conveyor belt and the battery conveyor belt are vertical; and a box cover crushing and separation production line is arranged at the blanking end of the box cover conveyor belt, and a body separation production line is arranged at the battery body blanking end of the battery conveyor belt. By enabling automatic cutting, breaking, sorting and other units to match organically, the full-automatic mechanical disassembly of the waste batteries can be realized.

Owner:贵州火麒麟能源科技有限公司

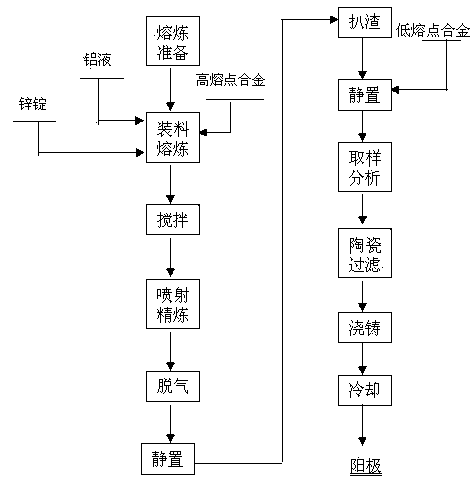

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

Method for preparing calcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; pyrolyzing the mixture to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into a gas smelting furnace at the temperature of not lower than 450 DEG C to perform smelting in the gas smelting furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Pretreatment method for chromium powder ore used for smelting production of ferrochrome alloy

The invention provides a pretreatment method for a chromium powder ore used for smelting production of a ferrochrome alloy. The method comprises the steps of 1) mixing the chromium powder ore with a fluxing agent, a reducing agent and a fuel to obtain a mixture; and 2) sintering the mixture to obtain a sintered material. The method is short in process flow and low in sintering cost and is simple and practicable, and production of powder ore pollutions is not easy, so that relatively cheap powder chromium ore can be fully used, smelting consumption can be decreased greatly, and further smelting cost of the ferrochrome is reduced. The sintered material obtained by the sintering treatment method can be directly introduced into an ore smelting electric arc furnace for smelting after smashing. The method can enhance reducibility of furnace charging materials, reduce energy consumption and decrease usage proportion of other auxiliary materials such as coke, silica and the like in the smelting furnace charging materials. At the same time, possibility of reversing materials is greatly decreased, production security is increased and probability of production accidents is reduced greatly.

Owner:中国中化股份有限公司 +1

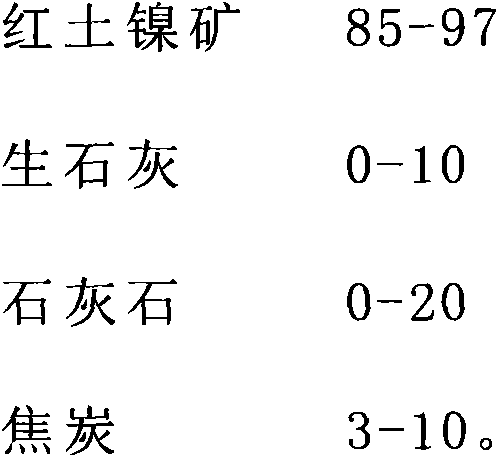

Method for treating laterite-nickel ore

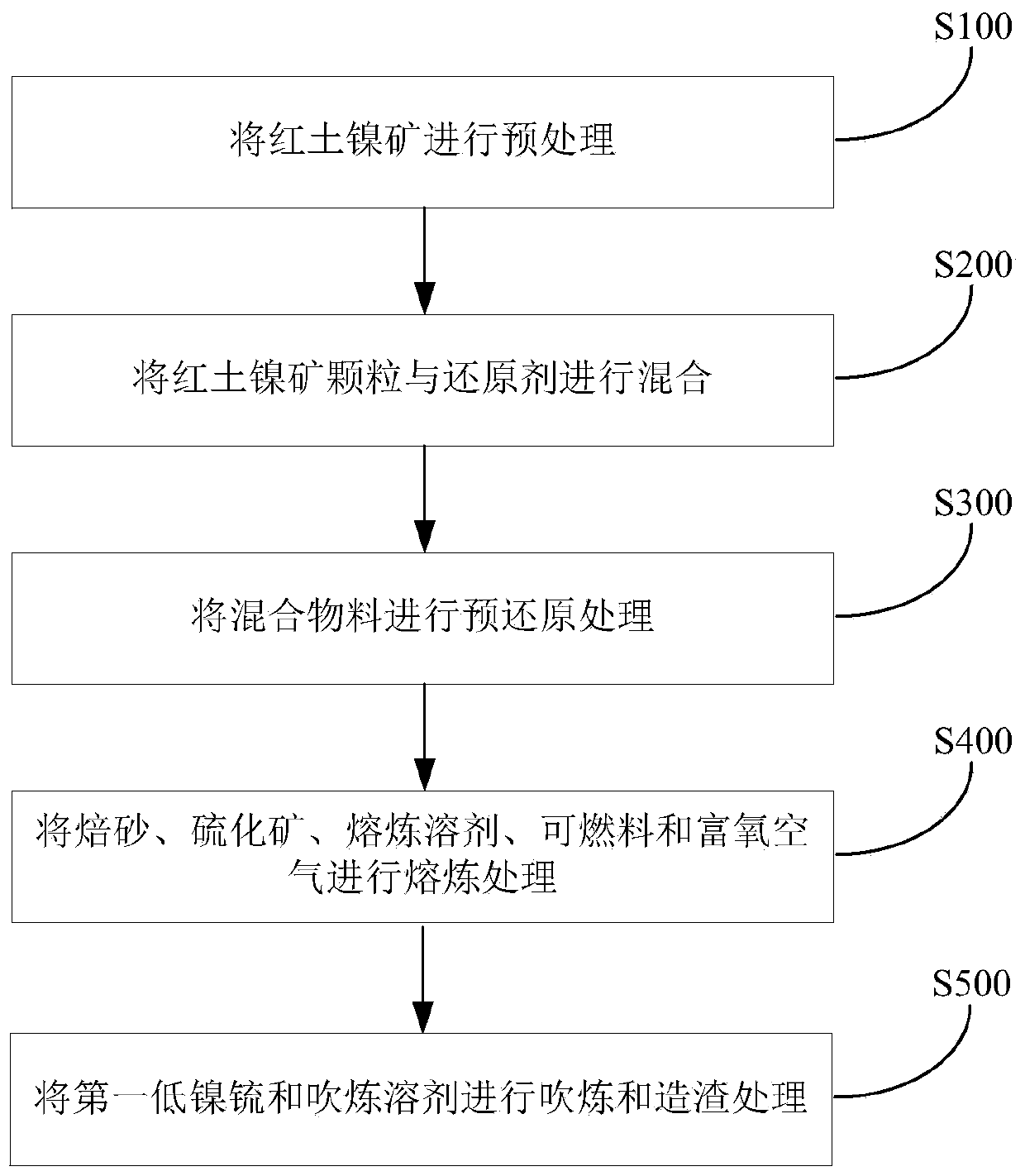

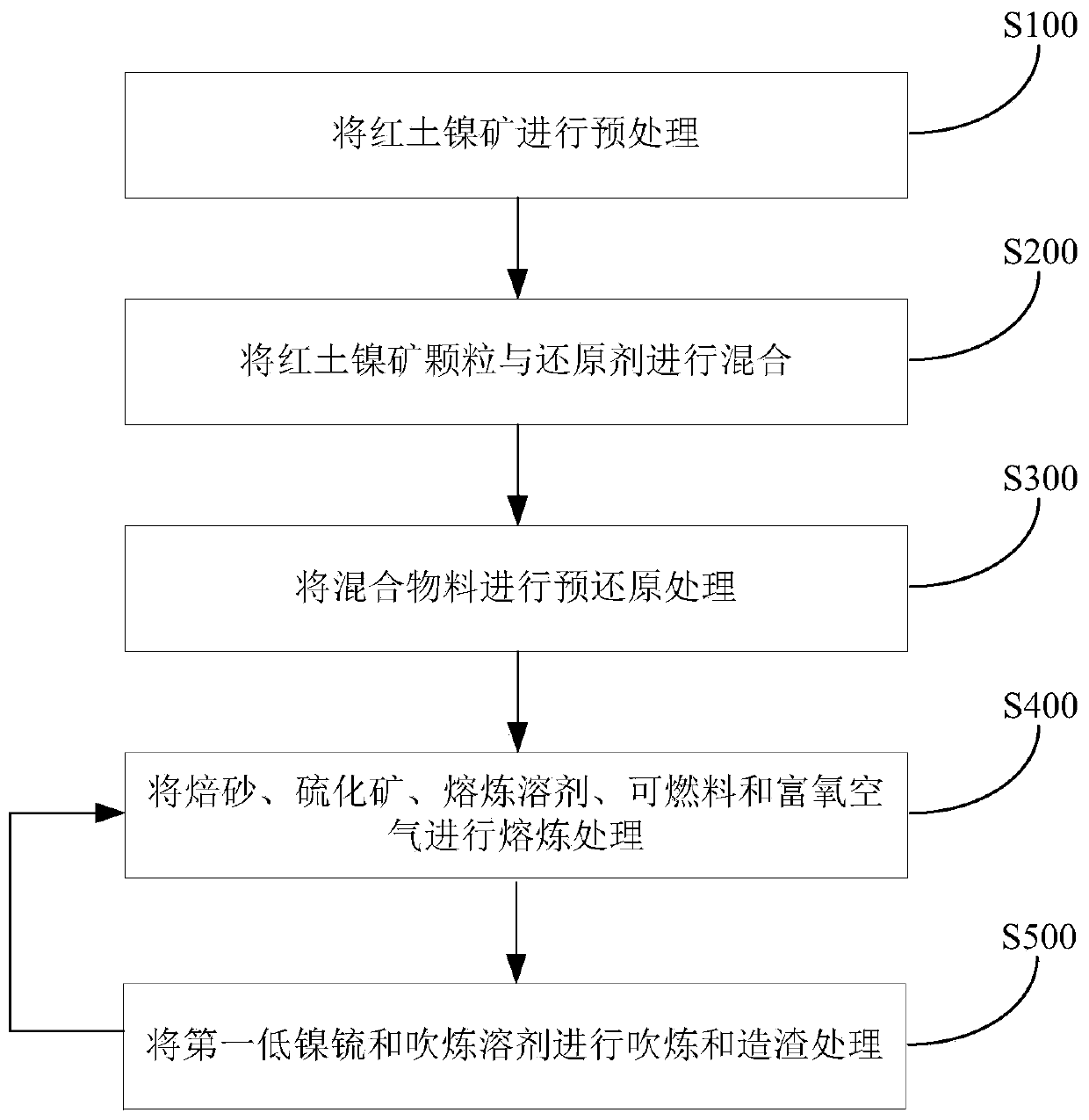

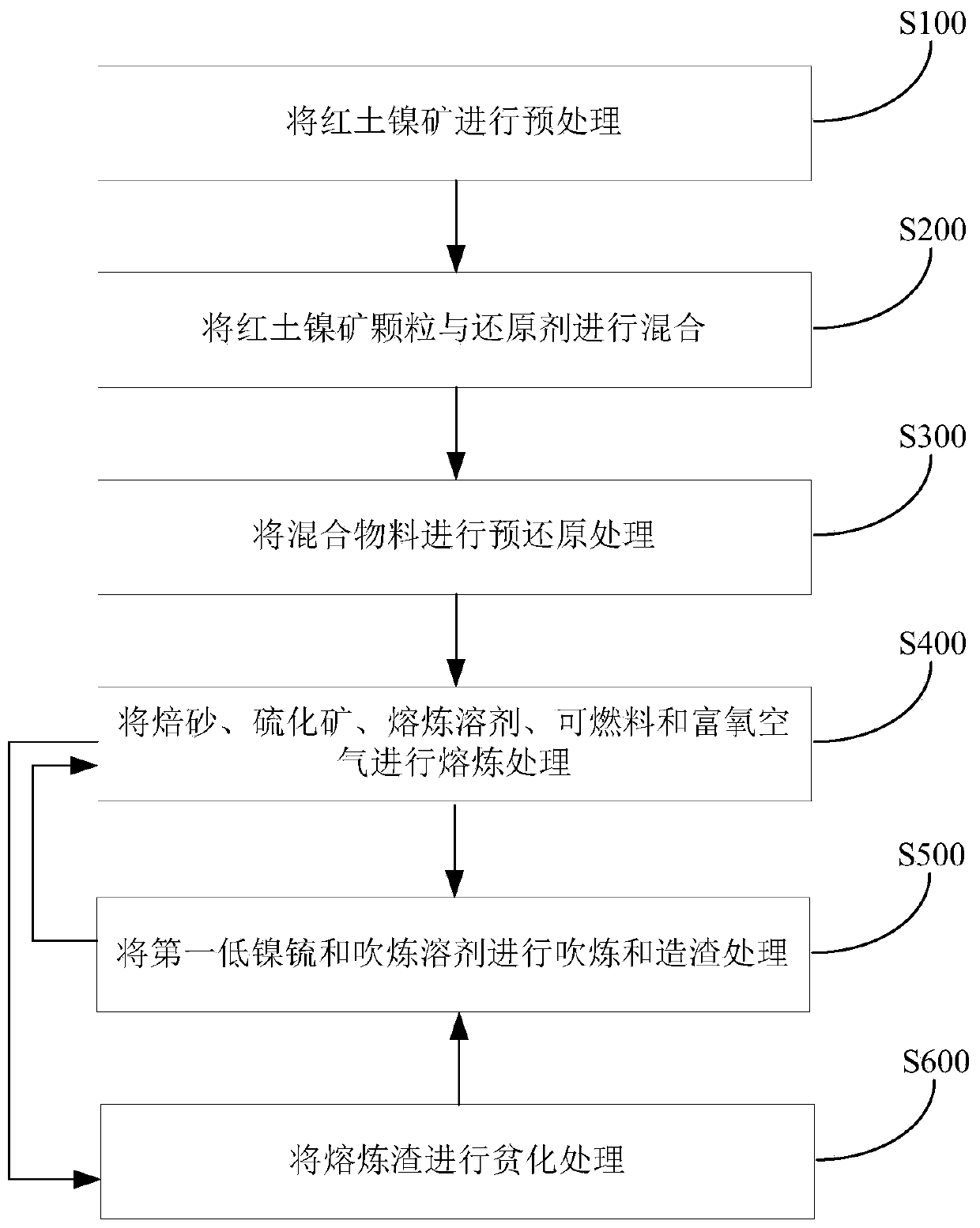

The invention discloses a method for treating laterite-nickel ore. The method comprises the following steps of: (1) pretreating the laterite-nickel ore to obtain laterite-nickel ore particles; (2) mixing the laterite-nickel ore particles with a reducing agent to obtain a mixed material; (3) pre-reducing the mixed material to obtain roasted ore; (4) smelting the roasted ore, sulfide ore, a smeltingsolvent, combustible and oxygen-enriched air to obtain first low-nickel matte and smelting slag; and (5) blowing and slagging the first low-nickel matte and a blowing solvent to obtain high-nickel matte and blowing slag. The method is high in efficiency, low in energy consumption and high in metal recovery rate when used for treating the laterite-nickel ore.

Owner:CHINA ENFI ENGINEERING CORPORATION

Pouring process for extrusion casting

InactiveCN1546257ASolve large burning lossSolve the problem of many solidification defectsAlloyCasting

The invention refers to a kind of pressing founding and casting method, which is used to produce colored alloy foundry goods. The realizing method is: the alloy fusant enters the pressure room through batch casting device and casting aperture sliding block, after the casting, the gate sliding block closes the pressure room, the indenter up runs, the alloy fusant is formed, pressure maintained, condensed under pressure. The efficiency is high, the quality is good, and the process reclaiming rate is high.

Owner:CHONGQING UNIV

Superaustenitic stainless steel and preparing method thereof

ActiveCN107058905ASolve the smelting and continuous casting technologyImprove corrosion resistanceCopperAustenite

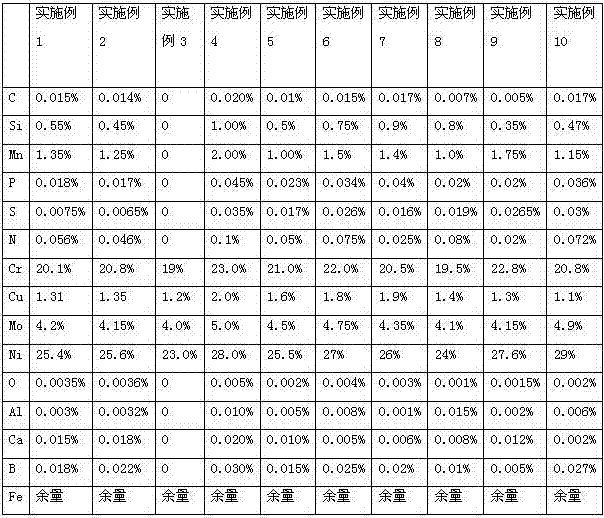

The invention provides superaustenitic stainless steel and a preparing method thereof. The superaustenitic stainless steel is prepared in the following percent by weight: smaller than or equal to 0.020% of C, smaller than or equal to 1.00% of Si, smaller than or equal to 2.00% of Mn, smaller than or equal to 0.045% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.1% of N, 19.0-23.0% of Cr, 1.2-2.0% of Cu, 4.0-5.0% of Mo, 23.0-28.0% of Ni, smaller than or equal to 0.0050% of O, smaller than or equal to 0.010% of Al, smaller than or equal to 0.020% of Ca, smaller than or equal to 0.030% of B and the balance of Fe. The method adopts a protection process of smelting superaustenitic stainless steel mother liquid by adopting a Consteel electric furnace and an intermediate frequency furnace, AOD, LF and continuous casting of a sheet billet, and can smelt the high-Ni, high-Cr, high-Mo, Cu-containing and low-C superaustenitic stainless steel, and both the surface quality and internal quality of the continuous casting billet are good.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

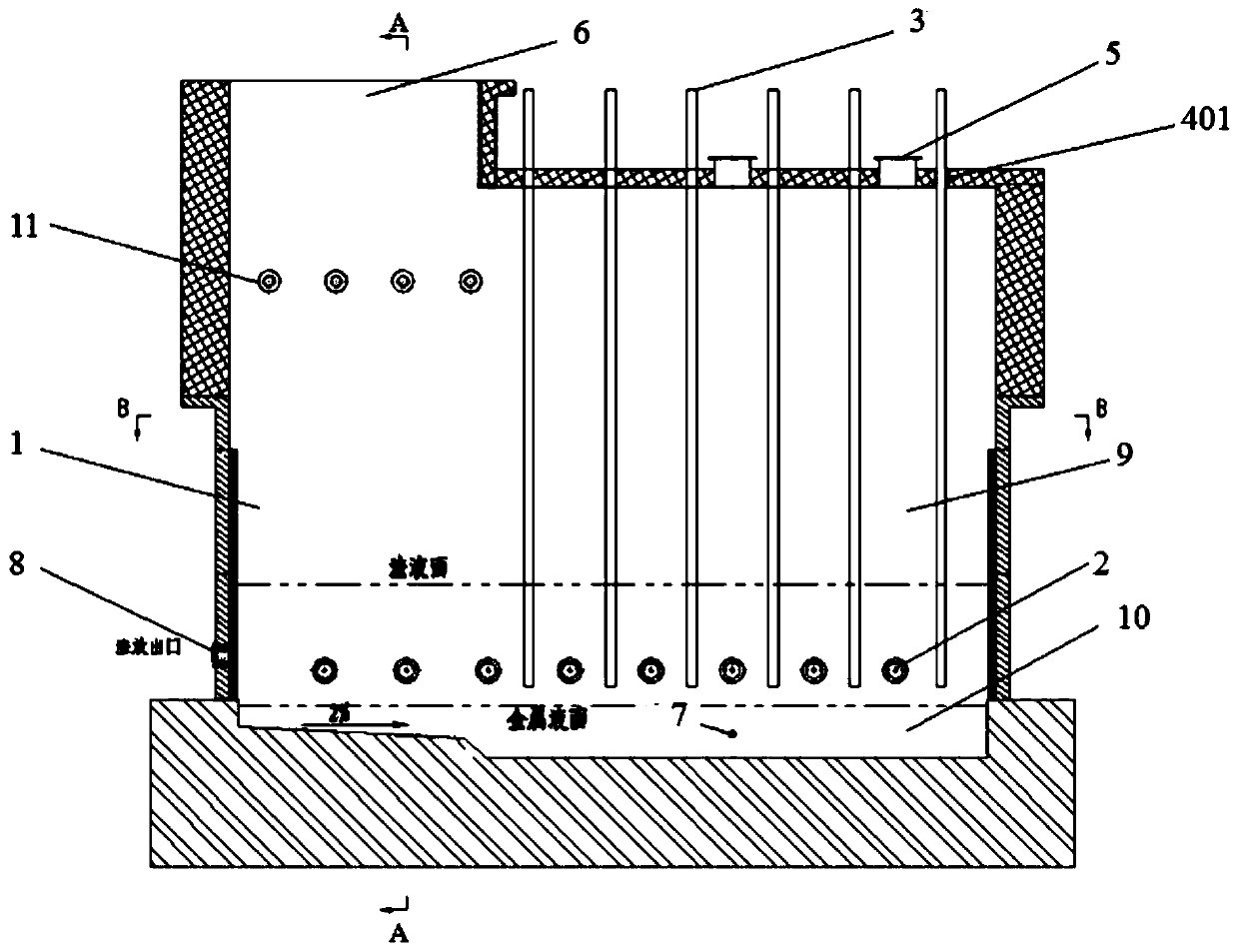

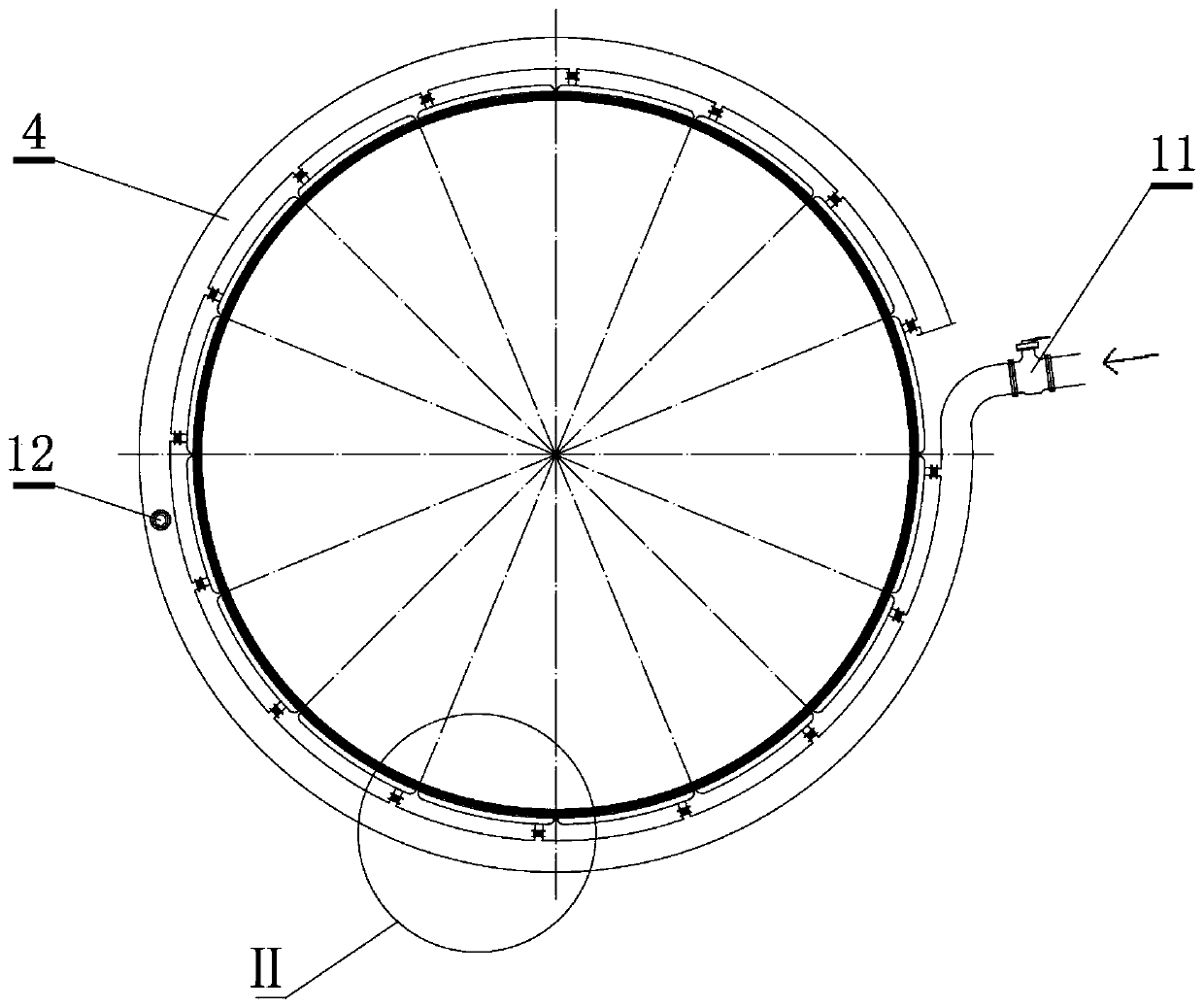

Process for co-production of nickel pig iron and rock wool products by using laterite-nickel ore

InactiveCN104004873AMeet acidity requirementsReach the viscosity requirementGlass making apparatusHot meltLaterite

The invention relates to a process for co-production of nickel pig iron and rock wool products by using laterite-nickel ore. The process comprises the following steps: by taking laterite-nickel ore as a primary material, preparing nickel pig iron and hot melt by smelting of a submerged arc furnace; screening out the hot melt of which the temperature is 1450-1580 DEG C and the acidity coefficient is 1.6-1.9; injecting the screened hot melt into a holding furnace or injecting into an insulting can to inject into the holding furnace in a roping manner; keeping the temperature inside the holding furnace at 1400-1500 DEG C; guiding the hot melt in the holding furnace into a four-roll centrifugal machine by virtue of a controllable head piece and a diversion trench; preparing the rock wool products by a rock wool product production process. Co-production of the nickel pig iron and the rock wool products is achieved by the preparation process, energy consumption in the production process of the rock wool products just is 1 / 4 of that of the traditional rock wool product production process when the energy consumption for smelting the nickel pig iron is greatly reduced, no exhaust gas is discharged, and the production cost of the rock wool products is greatly reduced.

Owner:SHANDONG WEIYE ENERGY SAVING NEW MATERIALS COMPANY +1

Method for smelting ferro-nickel through smelting reduction of laterite-nickel ore

The invention relates to a method for smelting ferro-nickel through smelting reduction of laterite-nickel ore and belongs to the technical field of ferroalloy. Firstly the laterite-nickel ore and lump coal are uniformly mixed according to the mass ratio of (40-50):(1-2) to obtain a mixture; then the mixture is added into a pre-heater, and is dried and pre-reduced at the temperature of 900-1100 DEG C to obtain hot mineral powder; the hot mineral powder, the powdered coal and a fusing agent are uniformly mixed and then subjected to smelting reduction for 3-8h under the condition of feeding oxygen-rich hot air and at the temperature of 1400-1600 DEG C; the ferro-nickel and furnace slag can be obtained after the reaction ends. Compared with the existing roasting reduction smelting method, preheating and pre-reducing are achieved synchronously in the method, so that the process is optimized; in addition, the oxygen-rich hot air is fed during the process of smelting reduction, so that the energy consumption of the smelting is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Composite adhesive for metallurgical pellet and production method thereof

The invention discloses a composite adhesive for a metallurgical pellet and a production method thereof, relates to an adhesive used in a metal smelting process and a method for producing the adhesive, and aims to provide an adhesive for favorably improving the metal smelting performance of subsequent smelting and reducing the smelting energy consumption and the emission of pollution gases. The composite adhesive for the metallurgical pellet comprises organic powder and bentonite, wherein the mass ratio of the organic powder to the bentonite is 1:1; the organic powder comprises a dispersant and an organic adhesive in percentage by mass: 95-99.5 percent of dispersant and 0.5-5 percent of organic adhesive. In order to produce the composite adhesive, the three steps of taking the materials, manufacturing the organic powder and manufacturing the composite adhesive are required.

Owner:LIAONING JINSHI TECH GROUP

Aluminum alloy ingot for high-zinc car and production method thereof

The invention discloses an aluminum alloy ingot for a high-zinc car and a production method thereof. The aluminum alloy ingot comprises the following components by weight percent: 1.5% to 4.0% of Cu, 10.5% to 12.0% of Si, 0.05 to 0.35% of Mg, 0% to 2.5% of Zn, 0% to 1.1% of Fe, 0% to 0.5% of Mn, 0% to 0.5% of Ni, 0% to 0.2% to Sn, 0% to 0.25% of other trace elements and the balance of Al. The gas-containing and slag-containing quantity of the aluminum alloy ingot is far below the industry level. The aluminum alloy ingot is homogeneous in alloy components, accurate to control, high in zinc content proportion and high in alloy intensity. The production method has the advantages of being low in cost as well as stable and controllable in production quality, and cannot generate pollution.

Owner:YE CHIU METAL RECYCLINGCHINALTD

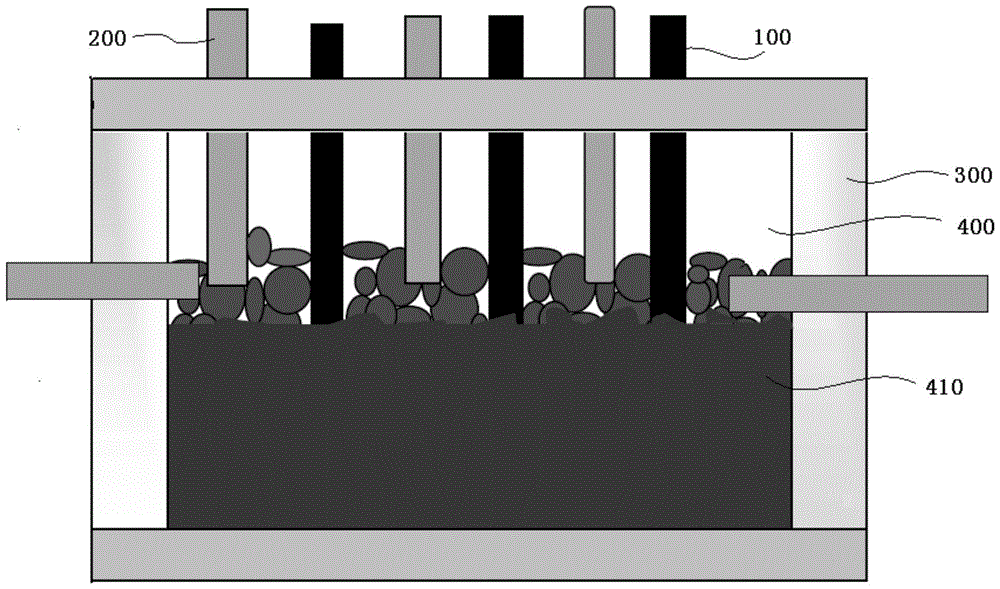

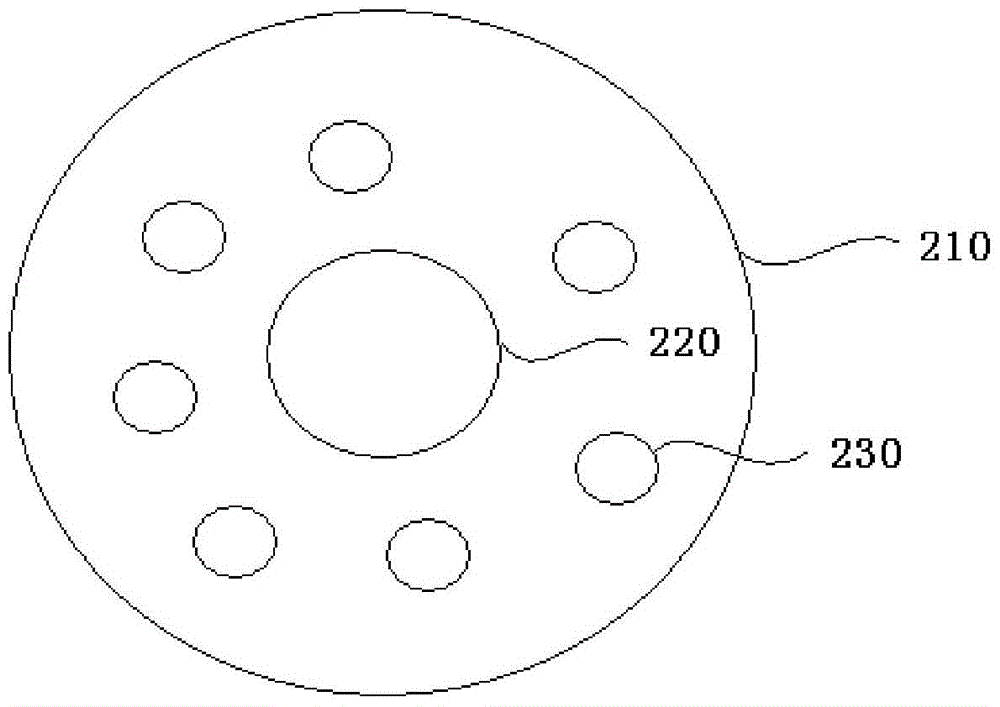

Calcium carbide furnace and method for preparing calcium carbide

The invention discloses a calcium carbide furnace and a method for preparing calcium carbide. The calcium carbide furnace comprises a furnace body, a plurality of electrodes and a plurality of spray guns. A calcium carbide production space is defined in the furnace body. The electrodes are embedded in the calcium carbide production space through the top wall and / or the side wall of the furnace body and are suitable for providing heat for the calcium carbide production space. The spray guns are embedded in the calcium carbide production space through the top wall and / or the side wall of the furnace body and are suitable for providing coal dust and oxygen for the calcium carbide production space so that heat generated through combustion of the coal dust and the oxygen can be supplied to the calcium carbide production space. Due to the fact that the spray guns are reasonably arranged between the electrodes on the top wall and / or the side wall of the furnace body of the calcium carbide furnace, heat in the calcium carbide furnace is evenly distributed.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

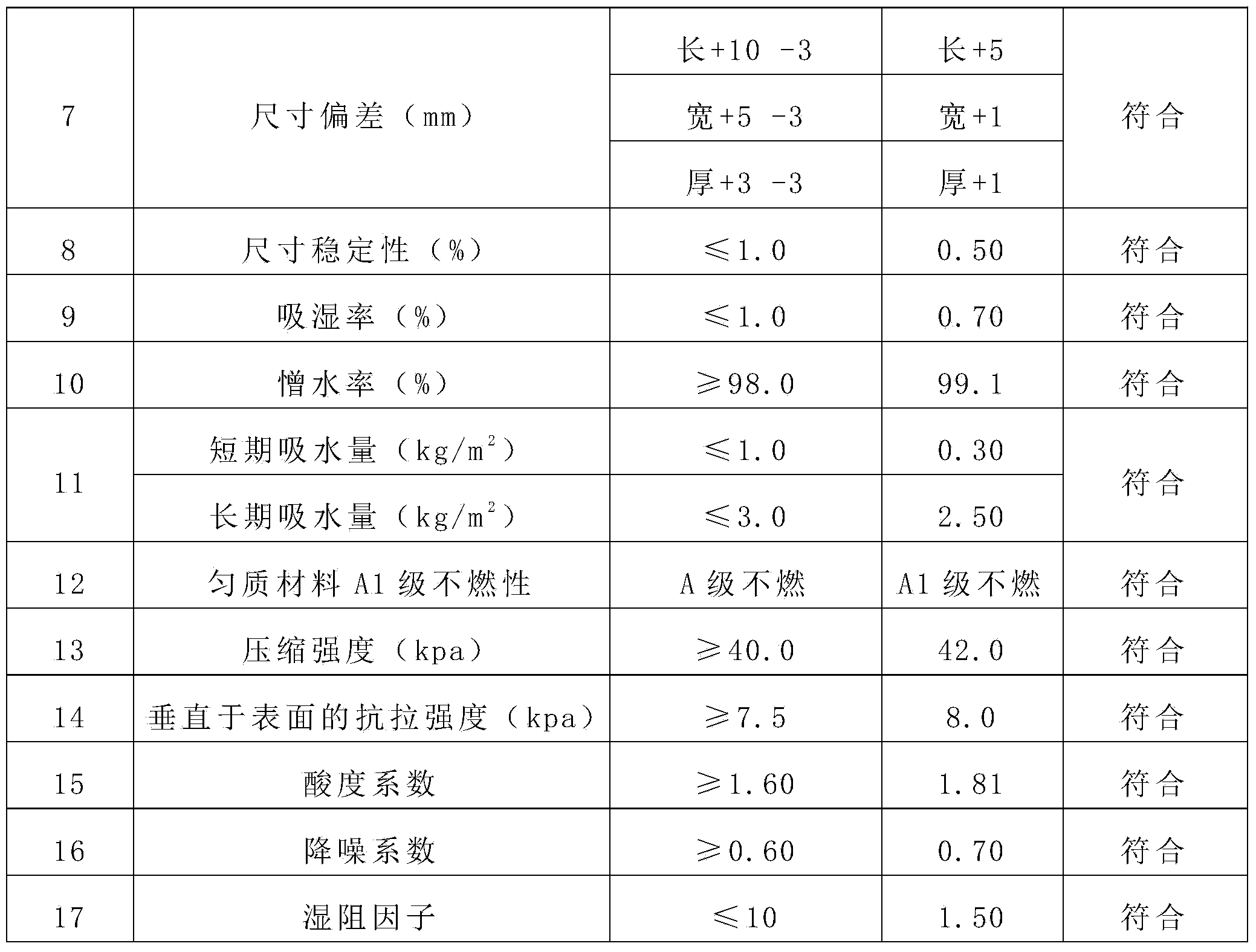

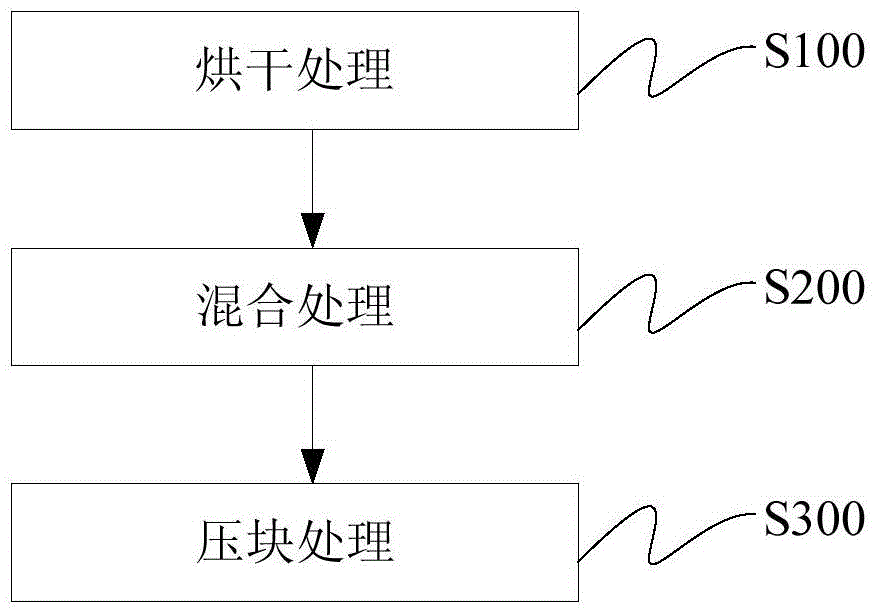

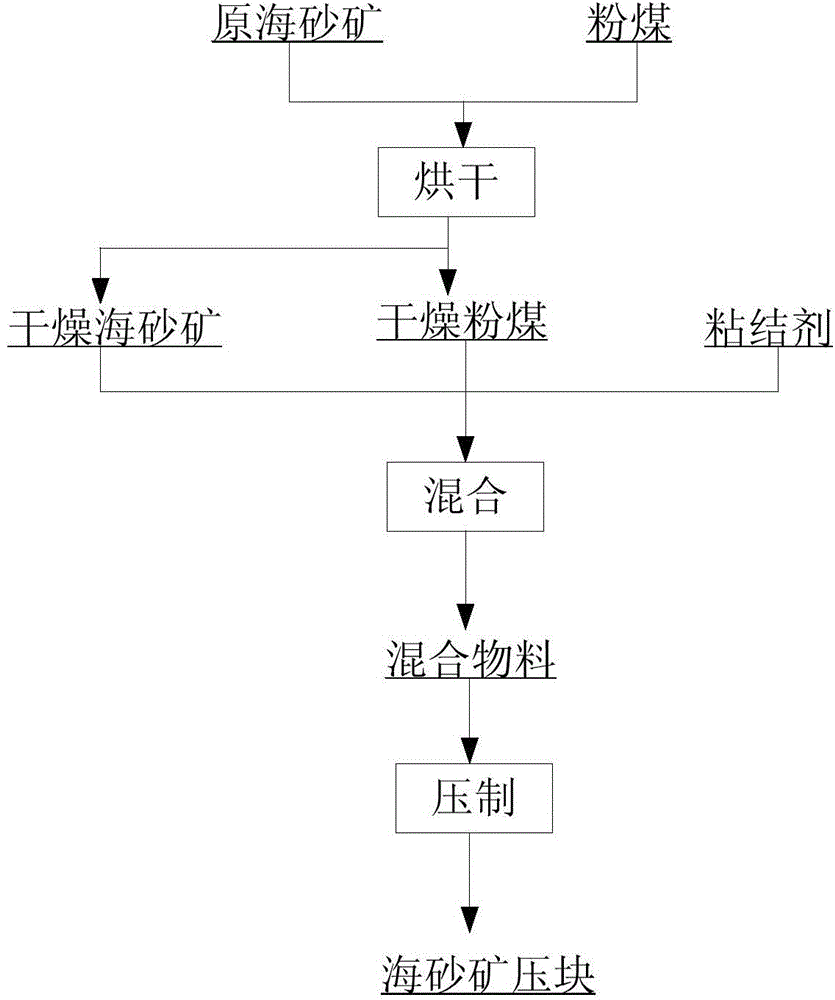

Pretreatment method of marine placer

InactiveCN104593590AImprove smelting efficiencyReduce smelting energy consumptionFluidised-bed furnacesPretreatment methodEngineering

The invention provides a pretreatment method of marine placer. The pretreatment method comprises the steps of performing drying treatment on the raw marine placer and pulverized coal to obtain dry marine placer and dry pulverized coal, mixing the dry marine placer, the dry pulverized coal and a binder to obtain a mixture, and pressing the mixture to obtain a marine placer briquette. The pretreatment method is capable of effectively preparing the marine placer into the marine placer briquette, and then the efficiency and the yield of preparing direct reduction iron from the marine placer can be improved remarkably.

Owner:张诚 +1

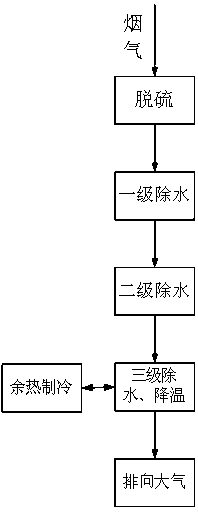

Sintering desulfurization and white smoke removal system and technological process of sintering desulfurization and white smoke removal system

ActiveCN103432861AEffective desulfurization treatmentReduce energy consumptionDispersed particle separationFlue gasTower

The invention discloses a sintering desulfurization and white smoke removal system and a technological process of the sintering desulfurization and white smoke removal system, which can be used for mainly solving the problems that a method for treating 'white smoke' is high in energy consumption, cannot achieve energy conservation and emission reduction, and the like in the prior art. The sintering desulfurization and white smoke removal system comprises a desulfurization tower (3) and a smoke discharging chimney (1) arranged at the top of the desulfurization tower (3). The sintering desulfurization and white smoke removal system is characterized by also comprising a dehumidifying system connected with the smoke discharging chimney (1), wherein a flap valve (2) used for switching a communicating state of the smoke discharging chimney (1) and the dehumidifying system is also installed on the smoke discharging chimney (1) and positioned above the joint of the smoke discharging chimney (1) and the dehumidifying system. According to the sintering desulfurization and white smoke removal system and the technological process, the desulfurization treatment is firstly carried out, then three-step gradually strengthened dehydration treatment is carried out, and finally cooling treatment is carried out, so that flue gas can be effectively dehumidified, and the energy consumption of the sintering desulfurization and white smoke removal system is greatly reduced due to the technology of firstly dehydrating and then cooling.

Owner:CHINA MCC5 GROUP CORP

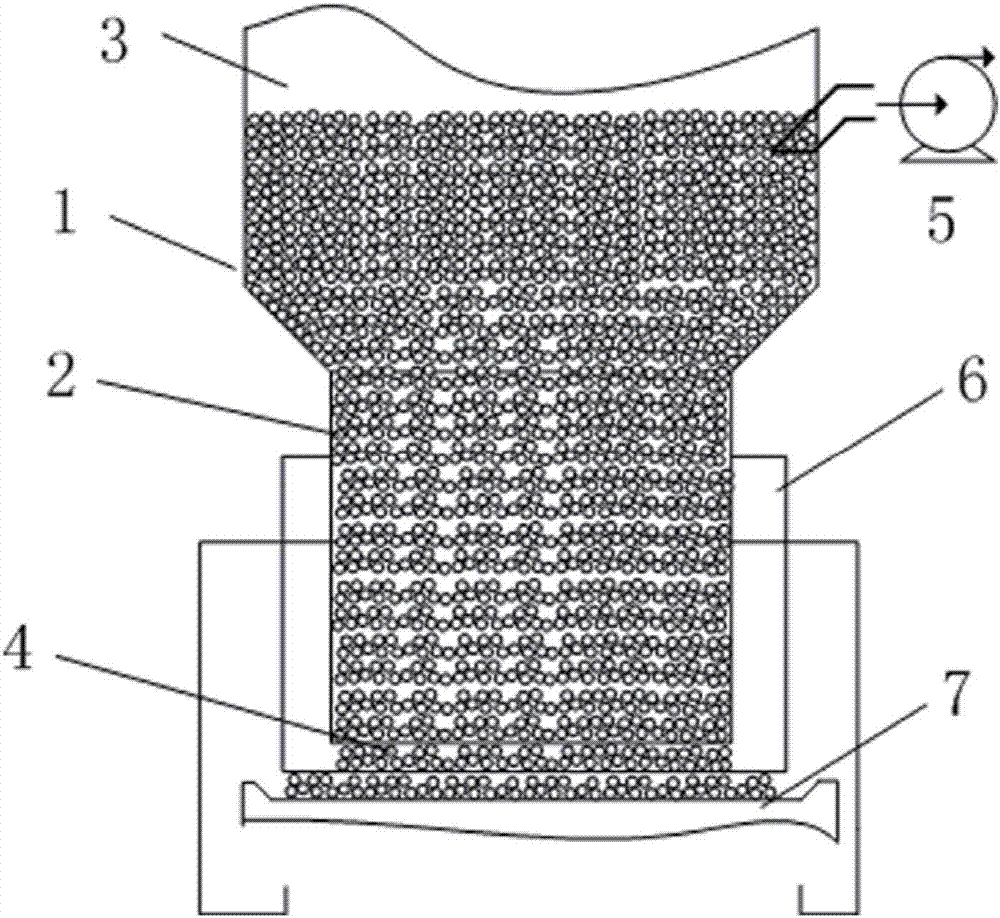

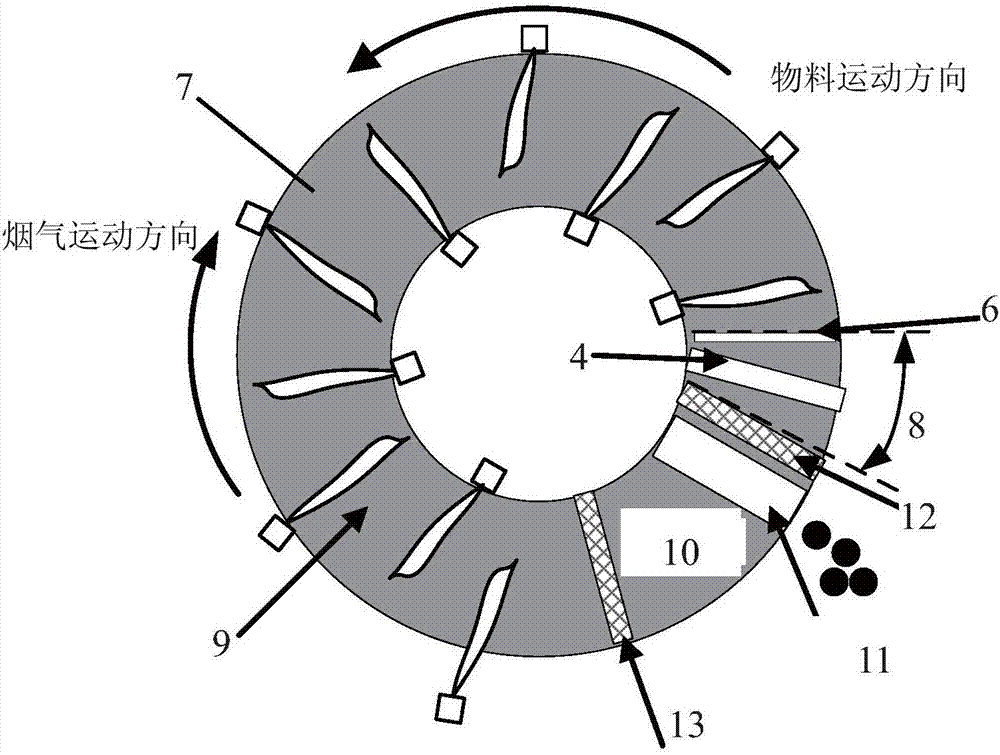

Rotary hearth furnace

The invention relates to a rotary hearth furnace. The rotary hearth furnace comprises an annular furnace body, an annular hearth, a heat power engineering system, a discharge mechanism, a distributionmechanism and a smoke discharge mechanism. The rotary hearth furnace effectively solves low CO utilization rate, and meanwhile, fully uses the smoke afterheat; more CO participates in indirect reduction; materials are preheated by the smoke afterheat; compared with a traditional rotary hearth furnace technology, the rotary hearth furnace can reduce adding of the material carbon dosage, effectively reduces the smelting energy consumption, and reduces the production cost; and the angle of a high-temperature reduction area is increased, so that the reduction time is prolonged, the reduction effect is improved, and meanwhile, the treatment capacity of the rotary hearth furnace is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

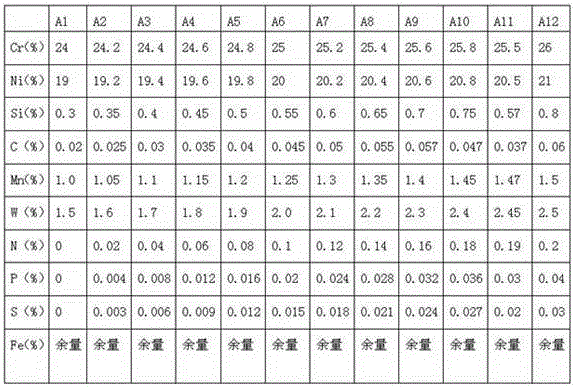

High-temperature-resistant austenitic stainless steel for furnace pipe

InactiveCN105803318AShort smelting cycleReduce smelting energy consumptionElectric furnaceProcess efficiency improvementSS - Stainless steelAustenite

The invention relates to high-temperature-resistant austenitic stainless steel for a furnace pipe. The high-temperature-resistant austenitic stainless steel comprises the following components in percentage by mass: 24-26% of Cr, 19-21% of Ni, 0.3-0.8% of Si, 0.02-0.06% of C, 1.0-1.5% of Mn, 1.5-2.5% of W, less than or equal to 0.2% of N, less than or equal to 0.04% of P, less than or equal to 0.03% of S and the balance of Fe. According to the high-temperature-resistant austenitic stainless steel, high-temperature creep resistance and oxidation resistance which are better than those of 310 heat-resistant stainless steel are provided; and the high-temperature-resistant austenitic stainless steel can be used for a longer time at a temperature above 1000 DEG C.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

New process for smelting tin in side-top-blowing molten pool and smelting furnace

ActiveCN111235388ASolution to short lifeExtend your lifeCharge treatment typeCrucible furnacesFlue gasEthylene

The invention discloses a new process for smelting tin in a side-top-blowing molten pool and a smelting furnace, and belongs to the technical field of metal smelting. By adopting the new new process for smelting the tin in the side-top blowing molten pool, the oxygen enrichment concentration is high, amount of air entering a furnace is reduced, the concentration of pollutants such as sulfur dioxide in flue gas is improved, subsequent desulfurization treatment is facilitated, emission of the pollutants is greatly reduced, less heat is taken away by the flue gas, and smelting comprehensive energy consumption is reduced; a top wall spray gun shortens the blow-in time, the molten pool is rapidly manufactured, a tin-iron alloy layer at the bottom is moved and stirred up and down to serve as a reducing agent to participate in a weak reduction reaction in next stage, the consumption of reducing coal is reduced, ethylene is not generated, and the crude tin refining technological process is shortened; the oxygen-enriched air strongly stirs the molten pool, and metallurgical dynamic conditions are strengthened to the maximum extent, unit hearth area treatment capacity is improved, and tin recovery rate is high. The smelting furnace adopted by the novel process for smelting the tin in the side-top blowing molten pool can be used for rapidly manufacturing the molten pool, and is high in oxygen enrichment concentration, low in energy consumption, small in flue gas emission and long in service life of a furnace body.

Owner:CINF ENG CO LTD

Method for preparing ultrapure iron concentrate powder from common grade iron mine

The invention belongs to the technical field of metallurgy, and particularly relates to a method for preparing ultrapure iron concentrate powder from a common grade iron mine. The method comprises the following steps: grinding and enriching the iron mine to obtain common grade iron miner powder in which TFe accounts for 58%-65%, then adding sodium hydroxide solution, mixing, performing desilicication reaction, washing with water, filtering, and drying to obtain ultrapure iron concentrate powder in which TFe accounts for 69.0%-71.5%. According to the method, low-cost available industrial sodium hydroxide replaces poor coking coal resources, so that the reduction cost of iron mine can be lowered, melting energy consumption can be reduced, carbon emission is reduced, and the energy-saving and environment-friendly purposes can be reduced; and the sodium hydroxide solution reacts with SiO2, silicon content in the iron mine is greatly reduced and the iron grade is improved.

Owner:唐竹胜

Method for producing ferronickel through reduction smelting of laterite-nickel ore flash furnace

The invention relates to the technical field of pyrometallurgy, in particular to a method for producing ferronickel through reduction smelting of a laterite-nickel ore flash furnace, which is short inflash reduction smelting time, high in speed, high in production efficiency, energy-saving and environment-friendly, and the reduction time is within one minute. Iron in the slag is reduced to prepare the iron-containing semi-steel alloy; remelting of said alloy is carried out to form qualified molten steel, meanwhile, submerged arc furnace slag is also obtained; the submerged arc furnace slag can serve as cement clinker to be conveyed to a cement plant to produce high-quality cement. The process is simple, the flow is short, qualified molten steel can be smelted and recycled, cement can be manufactured, economic benefits are good, environmental protection is facilitated, and hot materials subjected to multi-stage cyclone drying and pre-reduction directly enter a rotary kiln to be roasted; on one hand, the material buffering effect is achieved, and the material blocking problem caused when the hot materials directly enter the rotary kiln can be avoided; and on the other hand, throughfurther pre-reduction roasting of the rotary kiln, agglomeration of the materials can be achieved, and equipment and operation safety problems caused by direct feeding of the powdery materials into the furnace is avoided.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

Direct reduction ironmaking method by electric furnace

InactiveCN102703635AShort processReduce manufacturing costElectric furnaceElectric arc furnaceEconomic benefits

The invention discloses a direct reduction ironmaking method by an electric furnace, belonging to the technical field of ferrous metallurgy. An outlet of a multistage reactor is connected with an inlet of the electric furnace, coal powder is put into the electric furnace and heated, generated coal gas ascends and is introduced into the multistage reactor, iron ores are put into a first stage reactor of the multistage reactor after being treated by pelletizing and sequentially pass through the multistage reactor, an iron ore pellet obtained from the multistage reactor is then sent into the electric furnace, and finally the iron ore pellet is heated by the electric furnace and also reacted with the coal powder so as to obtain molten iron after ionmaking by the electric furnace. By developing the technology, the smelting energy consumption can be dramatically lowered, the operation conditions and smelting economic and technical indexes are improved, the economic benefit is increased, and the resource is effectively utilized.

Owner:KUNMING UNIV OF SCI & TECH

Technique for coproducing nickel pig iron and rock wool product from lateritic nickel ores

InactiveCN104726711AMeet acidity requirementsReach the viscosity requirementGlass making apparatusHot meltLaterite

The invention relates to a process for co-production of nickel pig iron and rock wool products by using laterite-nickel ore. The process comprises the following steps: by taking laterite-nickel ore as a primary material, preparing nickel pig iron and hot melt by smelting of a submerged arc furnace; screening out the hot melt of which the temperature is 1450-1580 DEG C and the acidity coefficient is 1.6-1.9; injecting the screened hot melt into a holding furnace or injecting into an insulting can to inject into the holding furnace in a roping manner; keeping the temperature inside the holding furnace at 1400-1500 DEG C; guiding the hot melt in the holding furnace into a four-roll centrifugal machine by virtue of a controllable head piece and a diversion trench; preparing the rock wool products by a rock wool product production process. Co-production of the nickel pig iron and the rock wool products is achieved by the preparation process, energy consumption in the production process of the rock wool products just is 1 / 4 of that of the traditional rock wool product production process when the energy consumption for smelting the nickel pig iron is greatly reduced, no exhaust gas is discharged, and the production cost of the rock wool products is greatly reduced.

Owner:SHANDONG WEIYE ENERGY SAVING NEW MATERIALS COMPANY +1

Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

Owner:NEW METALLURGY HI TECH GRP

Electric melting magnesium furnace shell cooling device and method

PendingCN110763019AImprove interchangeabilityEasy to install on siteFurnace cooling arrangementsIncreasing energy efficiencyEngineeringMaterials science

The invention relates to an electric melting magnesium furnace shell cooling device and method. The device comprises an upper furnace shell cooling device and a lower furnace shell cooling device. Theupper furnace shell cooling device and the lower furnace shell cooling device are respectively composed of a plurality of independent cooling units. Each cooling unit is connected with a water inletmain pipe through a corresponding water inlet branch pipe, and is connected with a water outlet pipe through a corresponding water outlet branch pipe. The cooling units are fixedly connected with a plurality of bolts welded to a furnace shell through nuts and disc-shaped springs. Spaces between the cooling units and the furnace shell are filled with flexible heat conduction pads. The device is composed of the plurality of cooling units with a unified structure, and the cooling units and the furnace shell are detachably connected, so that not only can the furnace shell be effectively protected,but also the mounting and maintenance are very convenient; and the upper furnace shell cooling device and the lower furnace shell cooling device are put into operation at different phases according to the temperature rise characteristic in the electric melting magnesium production process, so that energy is saved, and synergistic effects are realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Formula of steel and iron refining slag system

The invention provides a formula of a steel and iron refining slag system. The formula comprises lime, fluorite and aluminum particles to form a calcium oxide-calcium fluoride-silicon dioxide-aluminumoxide slag system. Therefore, the formula achieves the beneficial effects that in the steel and iron refining process, related ores are added into molten steel according to the formula, so that the melting point of the slag system is reduced, the fluidity of slag is improved, the deoxidation of the molten steel and the adsorption of inclusions is further optimized, and the smelting energy consumption is reduced under the condition that the molten steel component meets the technical requirements of silicon, aluminum, oxygen and the like.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

Method for preparing calcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; forming the mixture to obtain a lump material; pyrolyzing the lump material to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into an arc furnace at the temperature of not lower than 450 DEG C to perform smelting in the arc furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com