Electric melting magnesium furnace shell cooling device and method

A technology of cooling device and fused magnesia furnace, which is applied to furnace cooling devices, furnaces, furnace components, etc., can solve the problems of no unitized structure, unfavorable application and promotion, inconvenient installation and maintenance, etc., so as to reduce the welding workload, The effect of avoiding the risk of passing through the furnace and having good operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

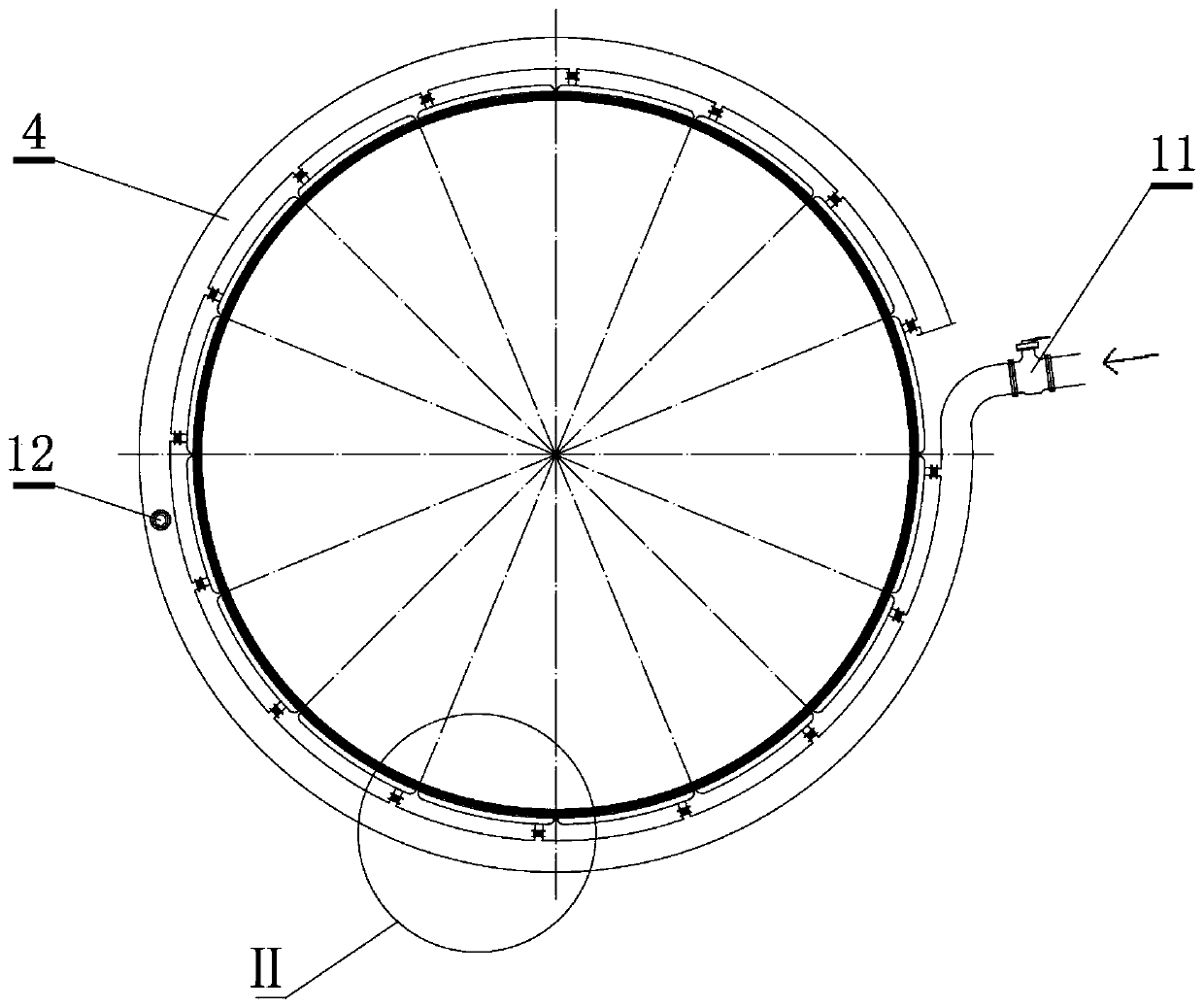

[0038] Such as Figure 1-Figure 3 As shown, the fused magnesium furnace shell cooling device of the present invention includes an upper furnace shell cooling device and a lower furnace shell cooling device. The upper furnace shell cooling device and the lower furnace shell cooling device are respectively composed of a plurality of independent cooling devices. Each cooling unit 3 is connected to the water inlet main pipe 4 through the corresponding water inlet branch pipe 10, and the water outlet main pipe 2 is connected through the corresponding water outlet branch pipe 13; the cooling unit 3 is connected with a plurality of bolts welded on the furnace shell 1. 7 is connected and fixed by a nut 6 and a disc spring 5, and a flexible thermal pad 9 is filled between the cooling unit 3 and the furnace shell 1; the water inlet main pipe 4 and the outlet main pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com