Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

288results about How to "Improve dismantling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

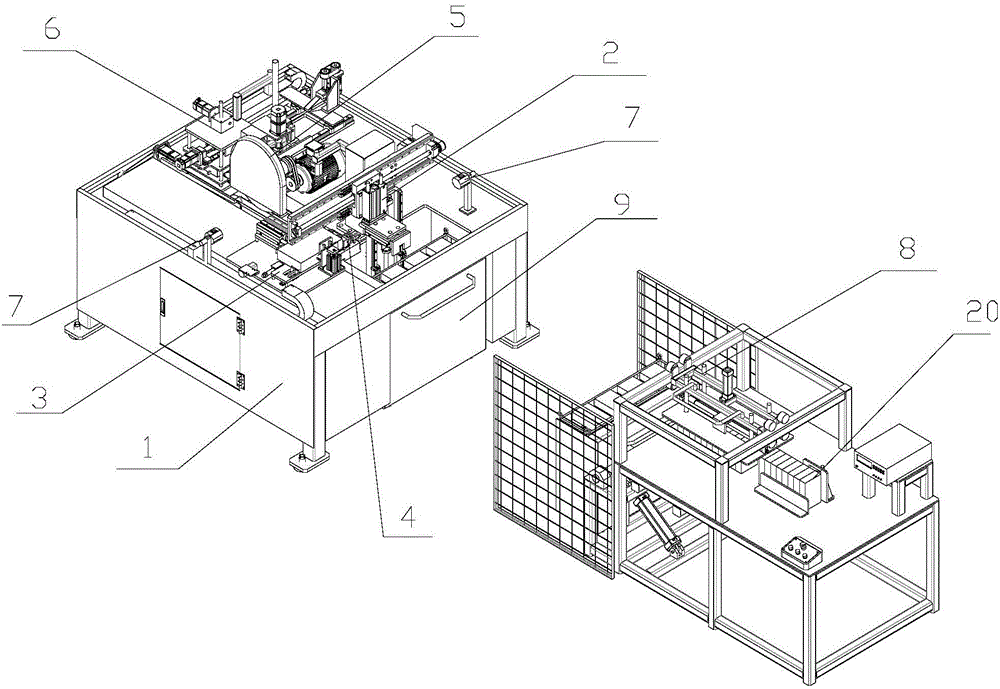

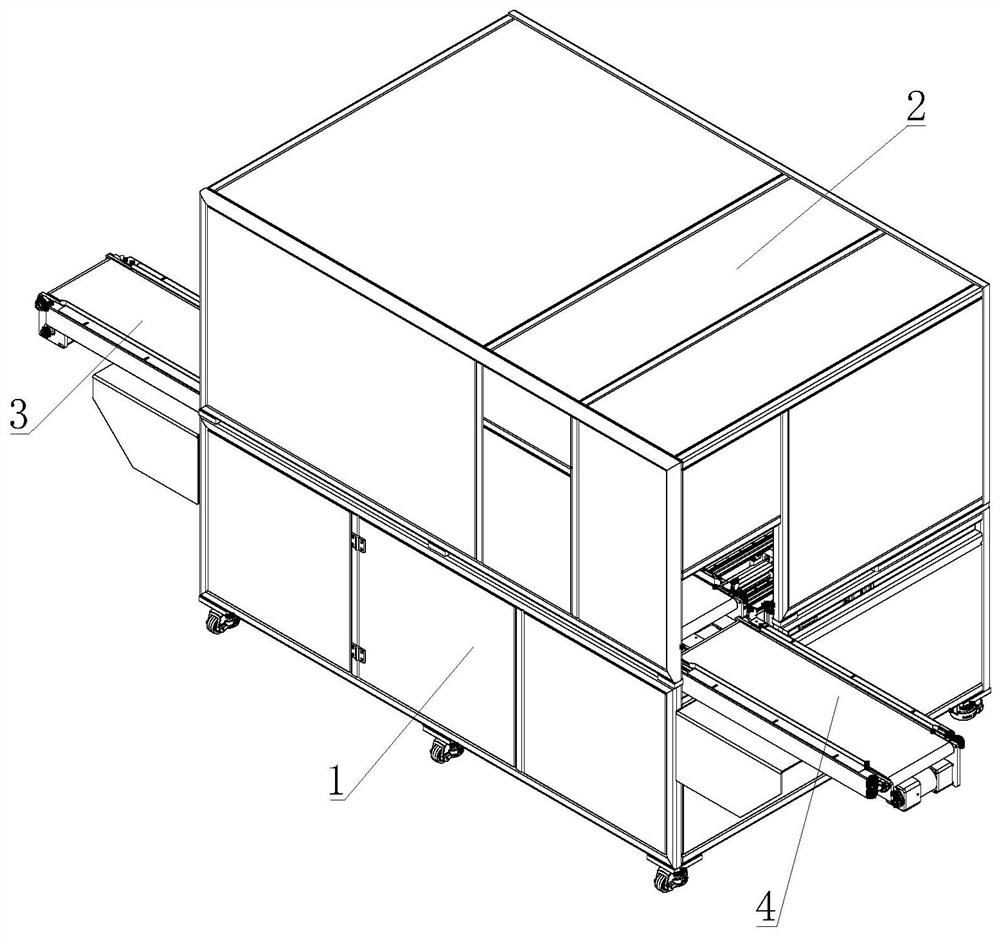

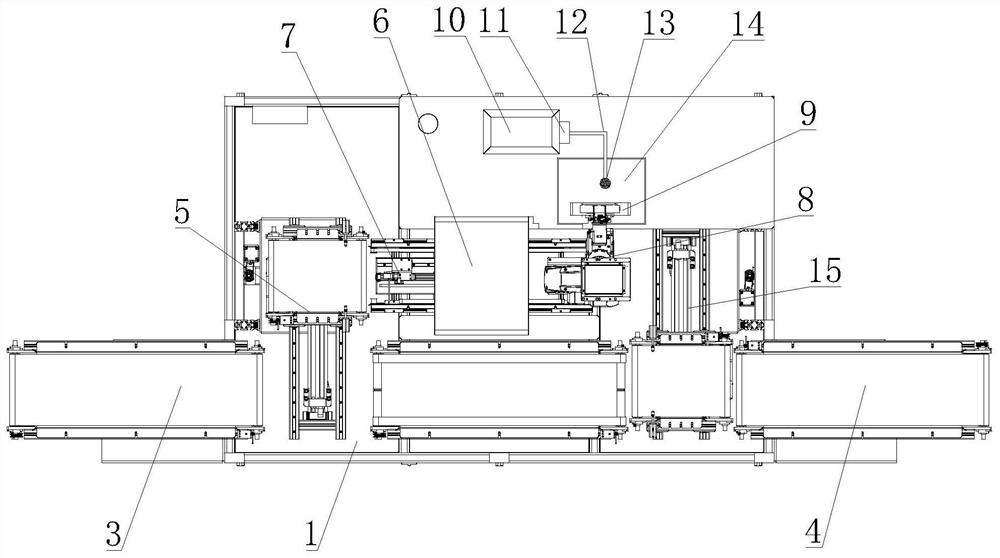

Equipment and method for automatically disassembling and recycling power battery

ActiveCN105070971AActive collectionHigh degree of automationWaste accumulators reclaimingBattery recyclingManipulatorPower battery

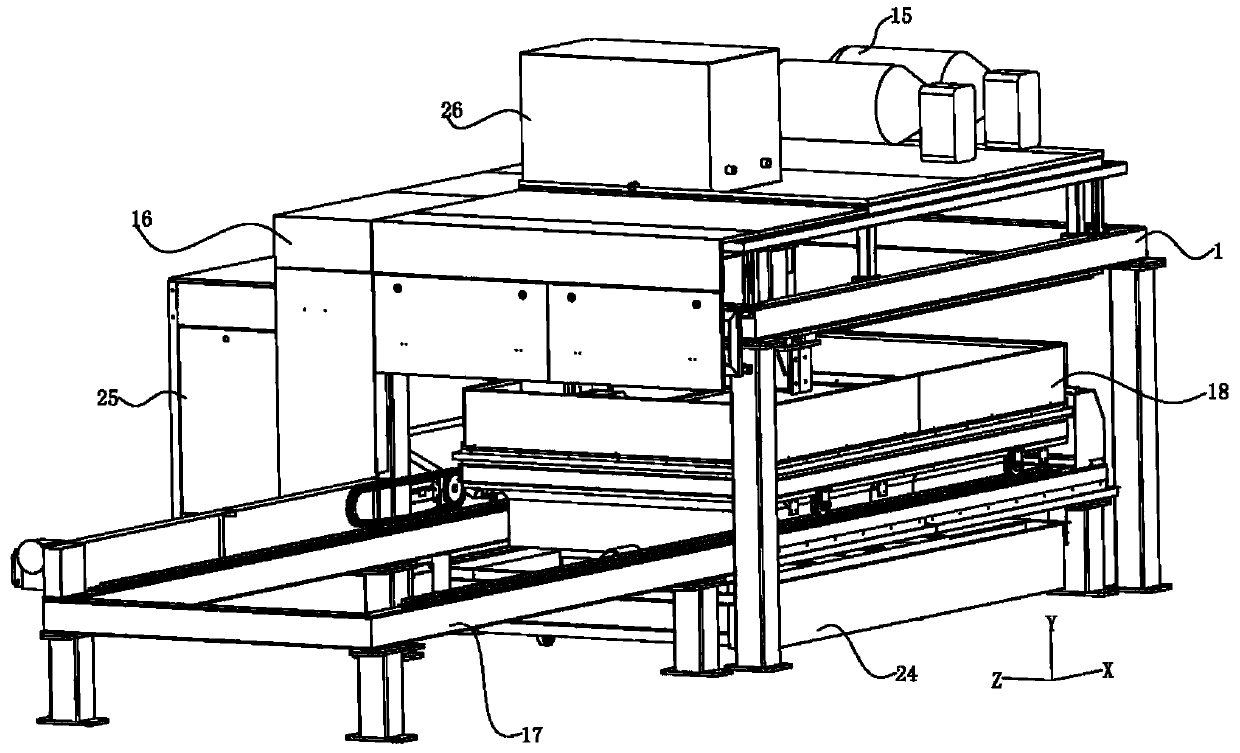

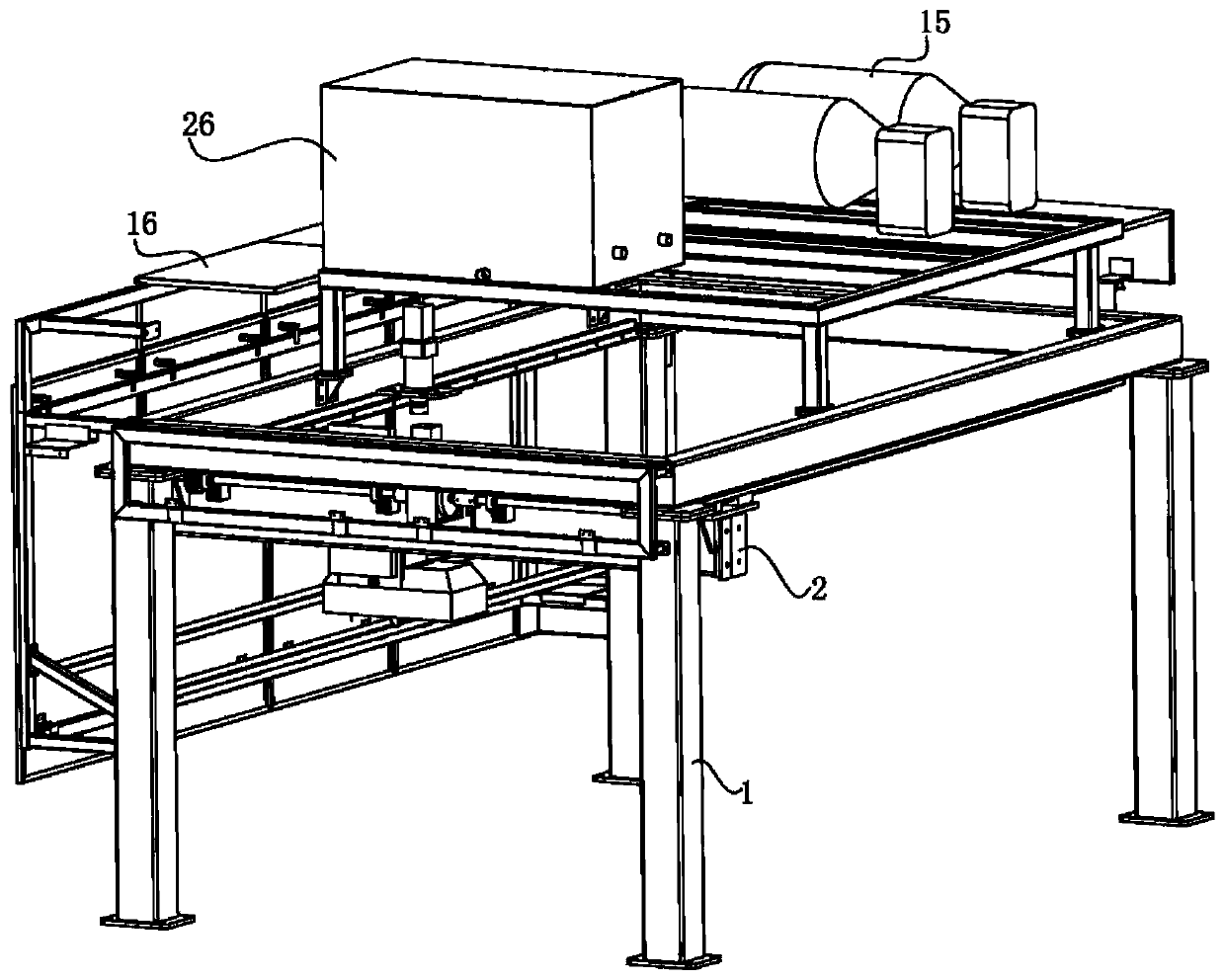

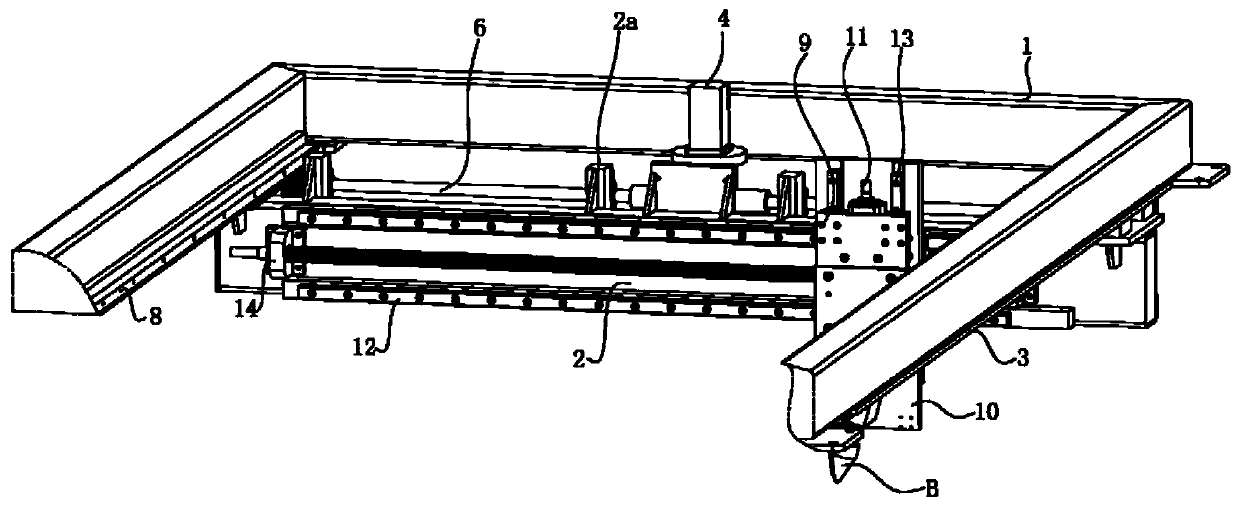

The invention discloses equipment and a method for automatically disassembling and recycling a power battery. The equipment comprises a rack, a loading bin, a loading manipulator, a horizontal mobile platform, a clamping and positioning mechanism, a cutting mechanism, a core taking mechanism, a residual energy detection system, an auxiliary loading device and a visual system; a series of automated technological process such as loading, clamping, battery head cutting, separation of a cell and a battery case, unloading and the like of the power battery can be realized, and meanwhile, visualized remote monitoring on the whole technological process is realized through matching with the visual system. Besides, the cutting mechanism and the core taking mechanism are covered with inner protection covers, the whole equipment adopts an all-closed type outer protection cover, so that noise and dust in the equipment can be effectively isolated, and safety of operators and the equipment is protected.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

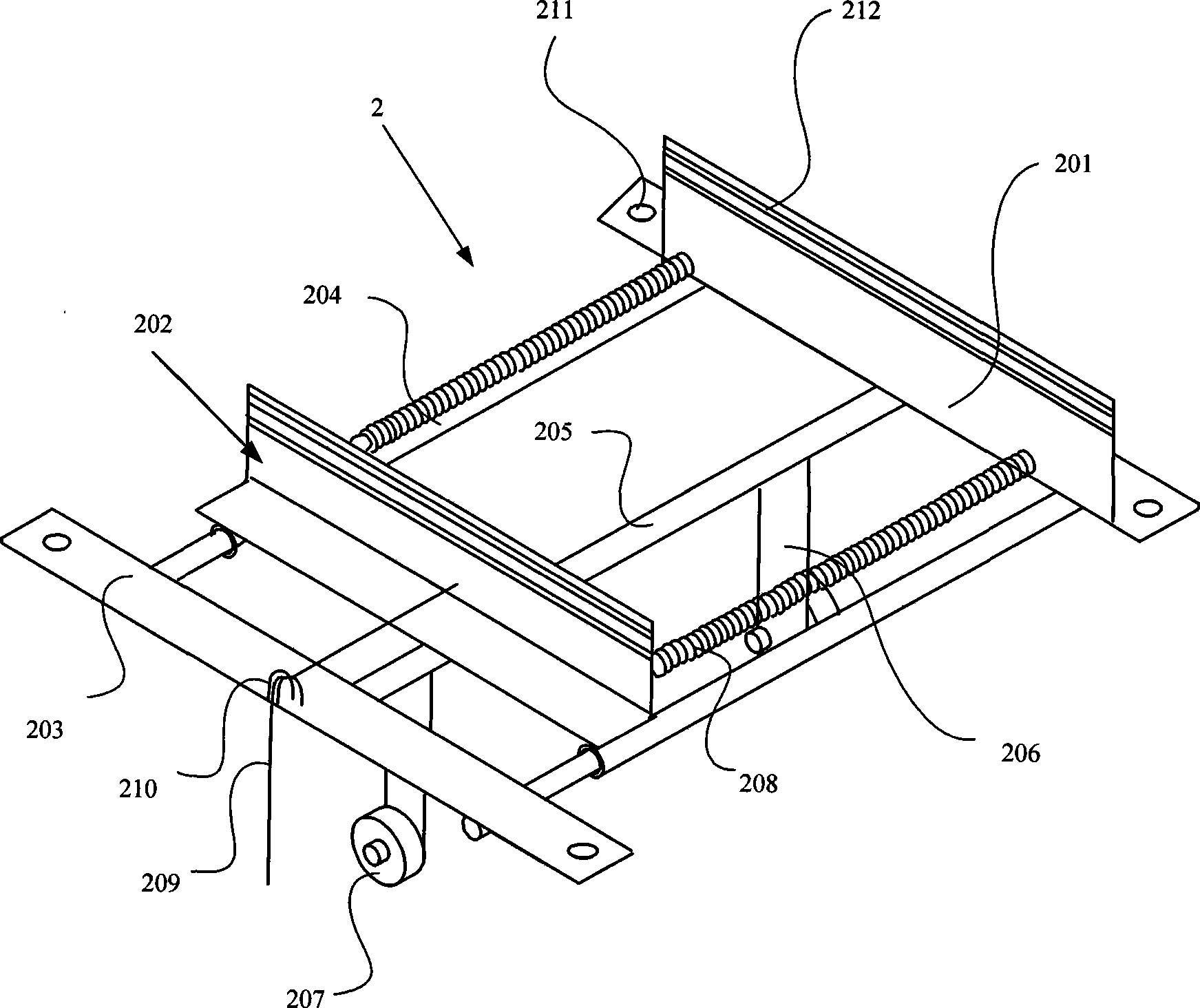

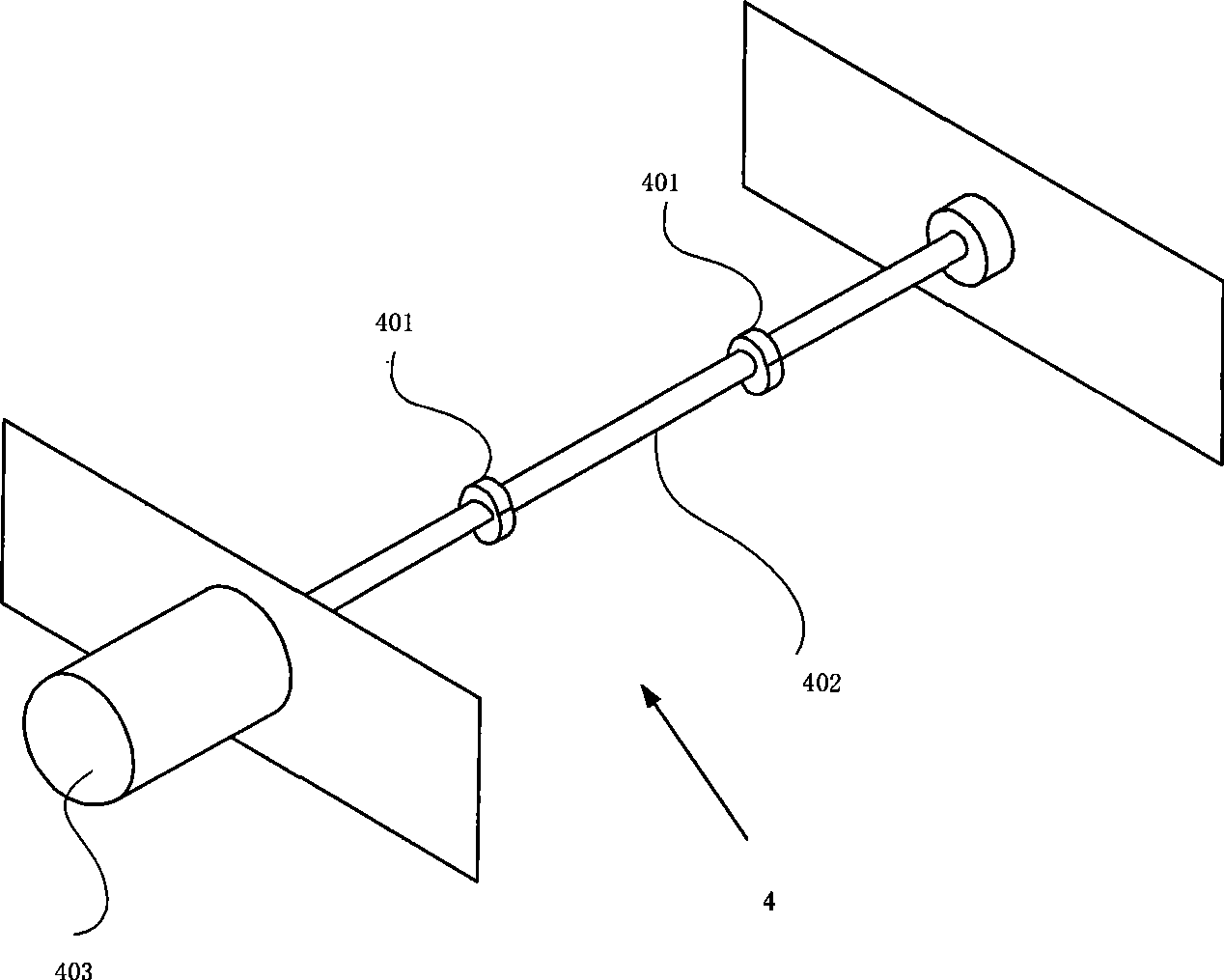

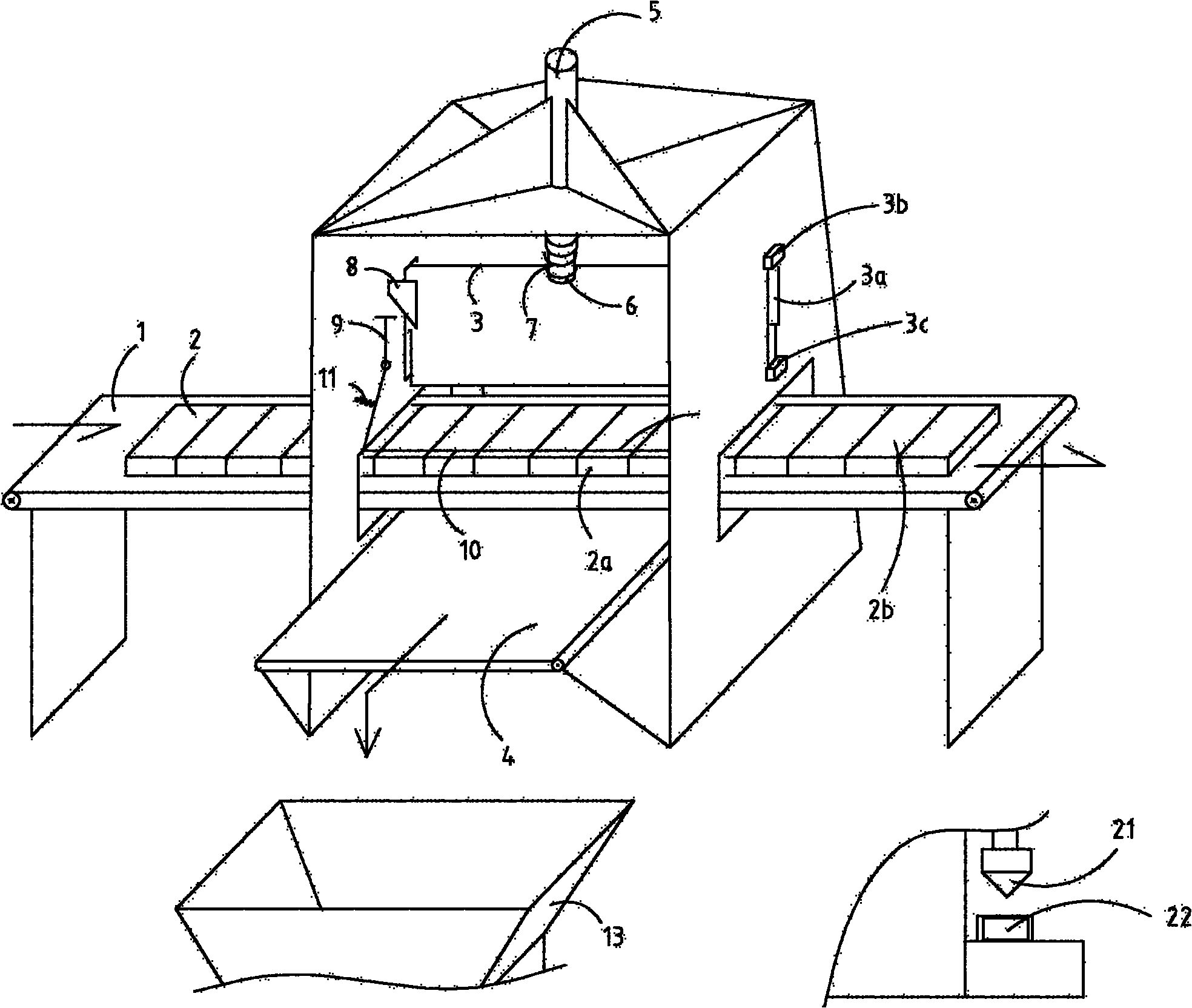

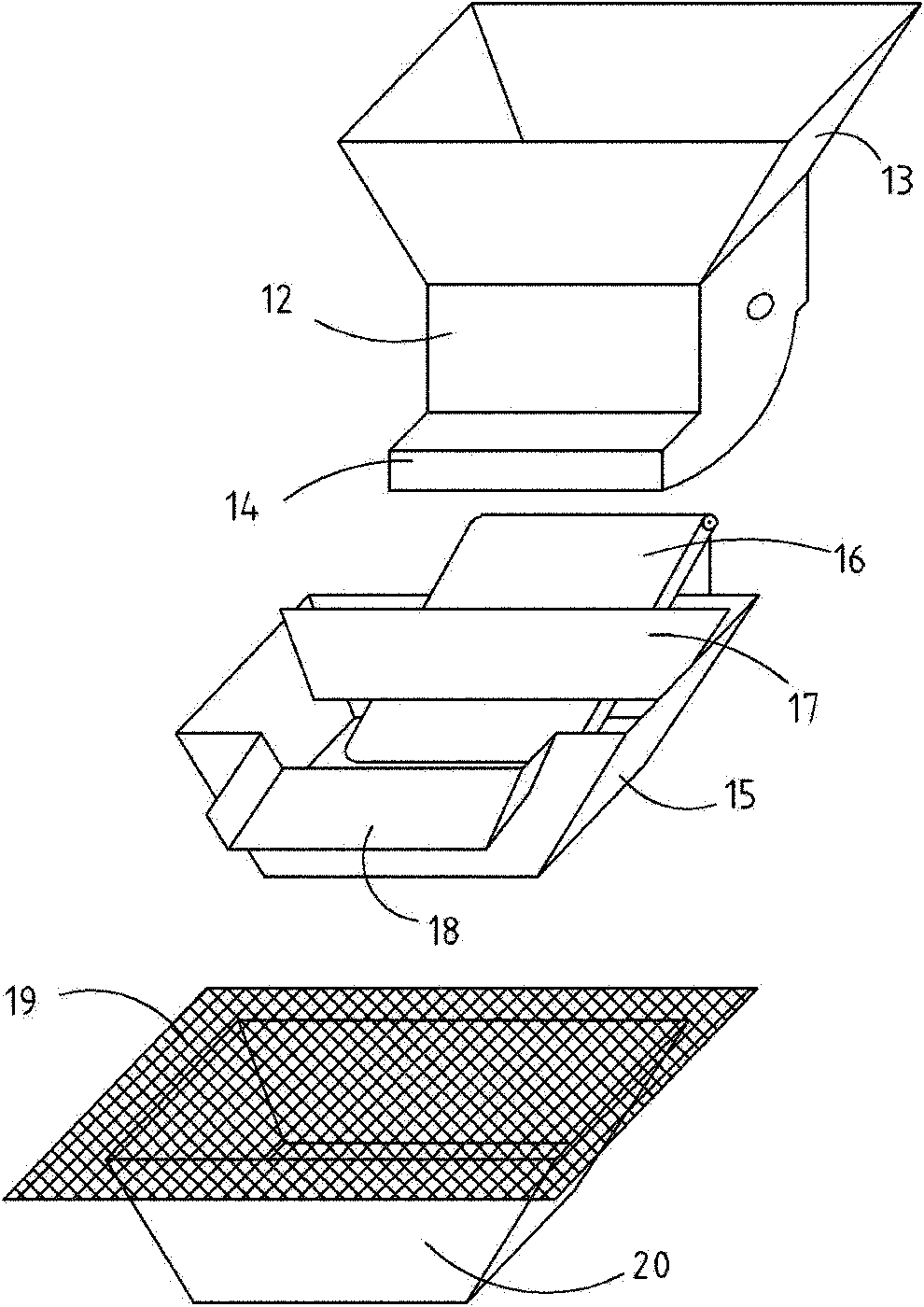

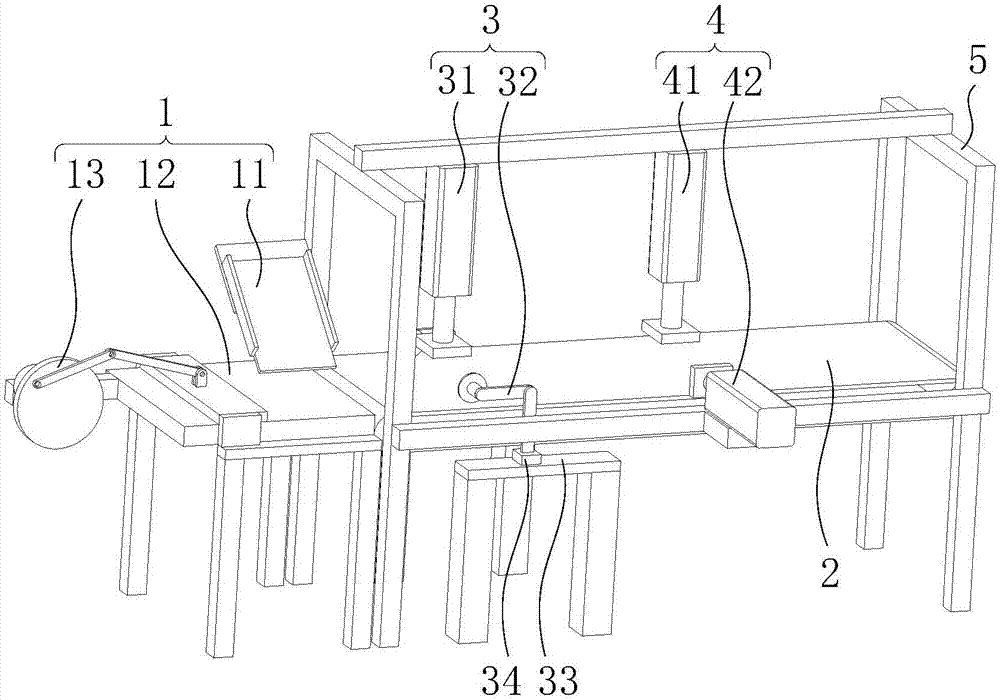

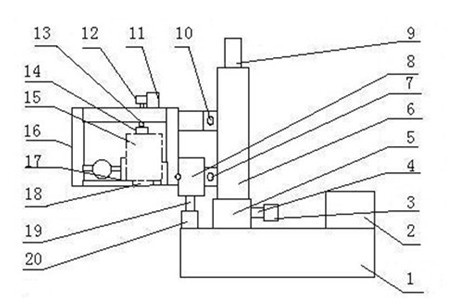

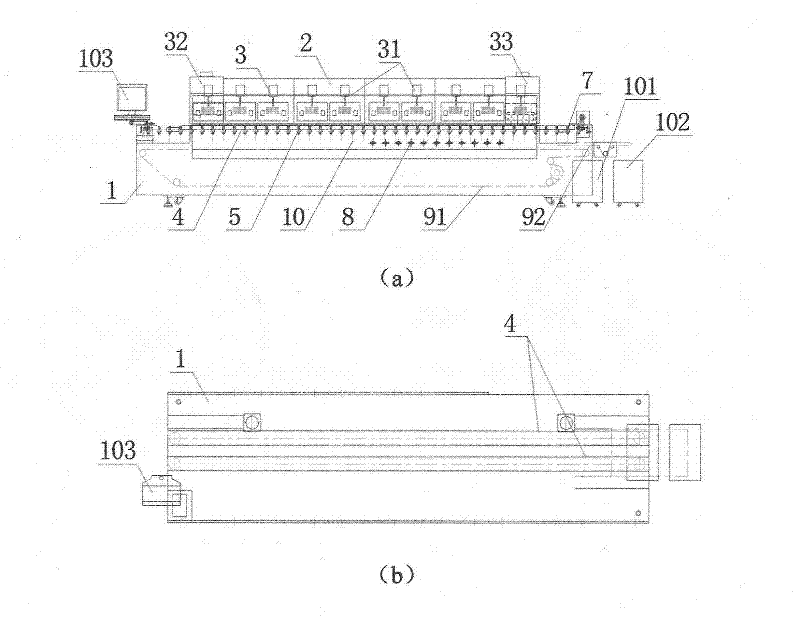

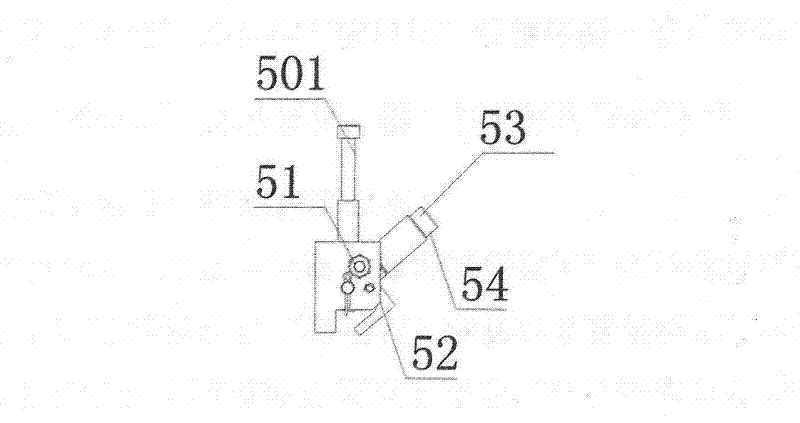

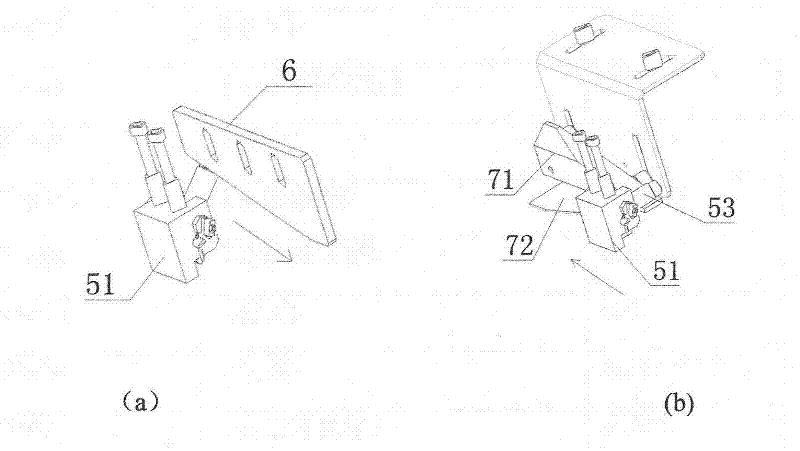

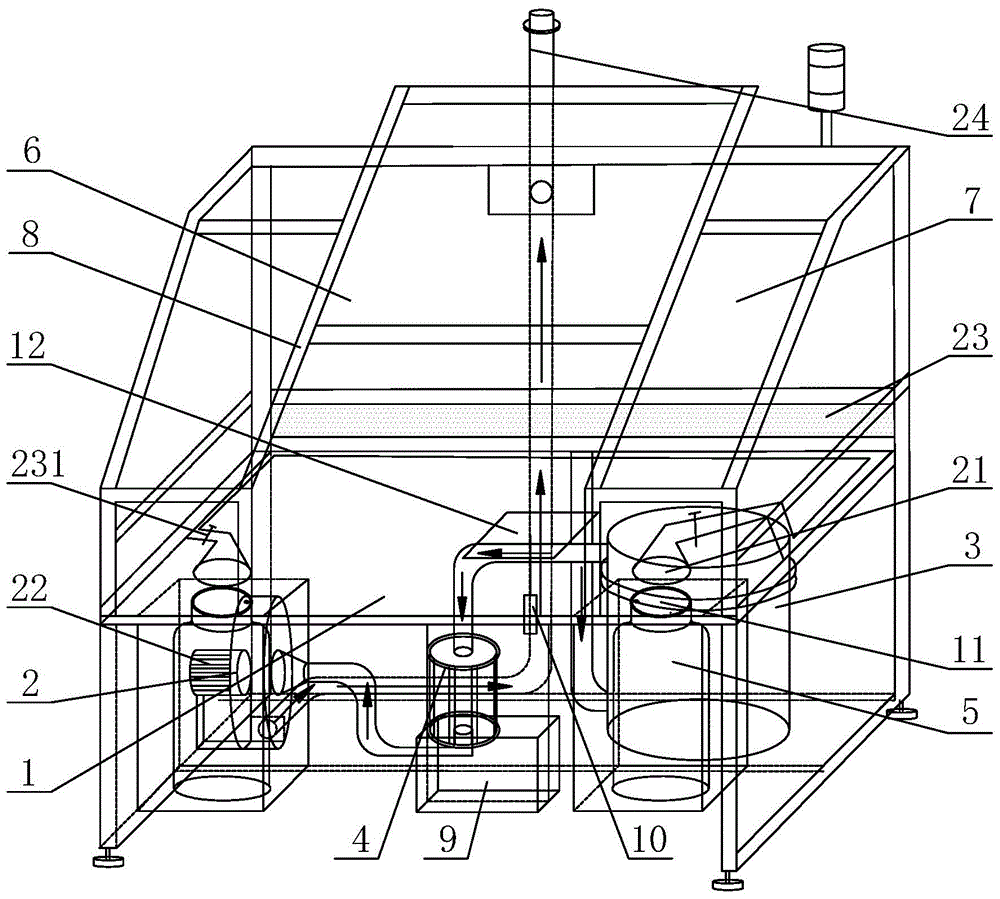

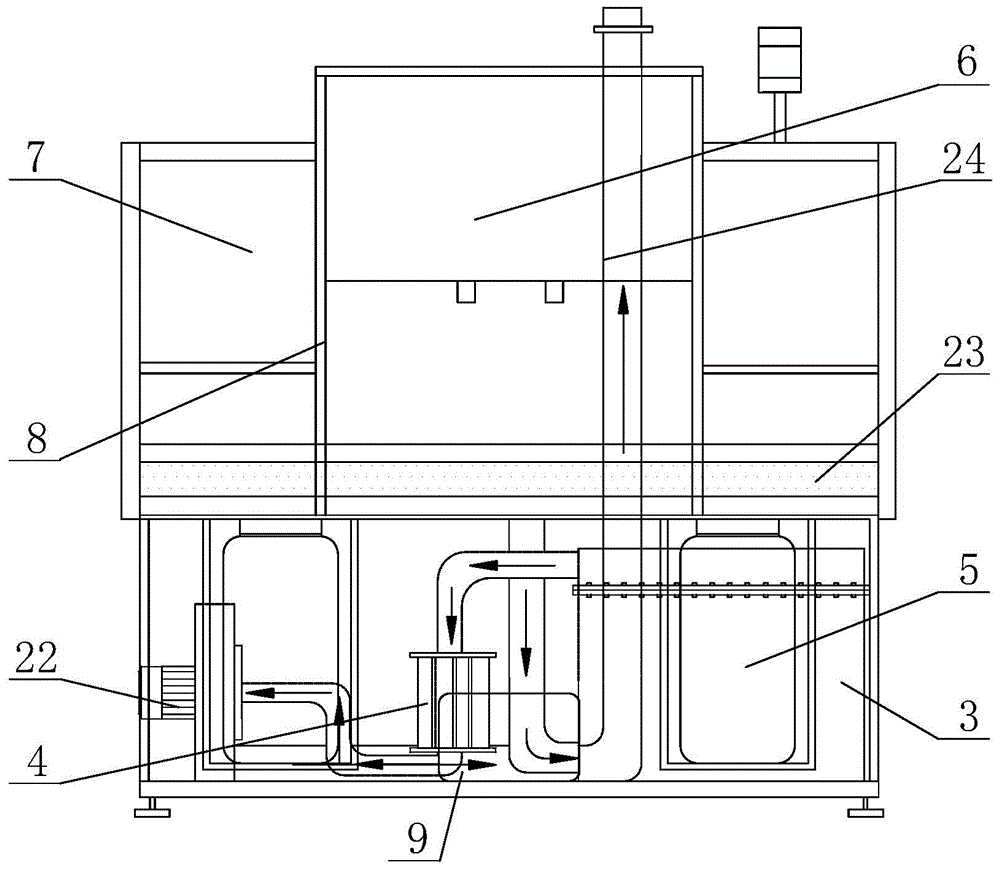

Treatment device and method for non-destructive disassembling the waste circuit board

InactiveCN101386016AFast dismantlingImprove dismantling efficiencySolid waste disposalSoldering apparatusNon destructiveFlue gas

The invention discloses a device for nondestructively disassembling and treating waste circuit boards and a method thereof. The device comprises six parts of a conveying unit, a heating and heat insulation unit, a loading and unloading unit, a vibration unit, a recovery unit and a smoke removing unit. The conveying unit conveys the circuit boards; the heating and heat insulation unit melts soldering tin on the circuit boards; the loading and unloading unit realizes rapid loading and automatic unloading of the circuit boards; the vibration unit is used for separating the soldering tin and components from the circuit boards; the recovery unit is used for realizing separation and recovery of the soldering tin and the components; and the smoke removing unit is used for filtering flue gas dust in waste gas and odor produced in the operation of the device. The device and the method thereof have the advantages of continuous operation, high disassembling efficiency, high heating speed, controllable temperature, energy saving, high nondestructive disassembling rate of the components, small volume, light weight, simple installation, low power, high automation degree and simple processing operation.

Owner:BEIHANG UNIV

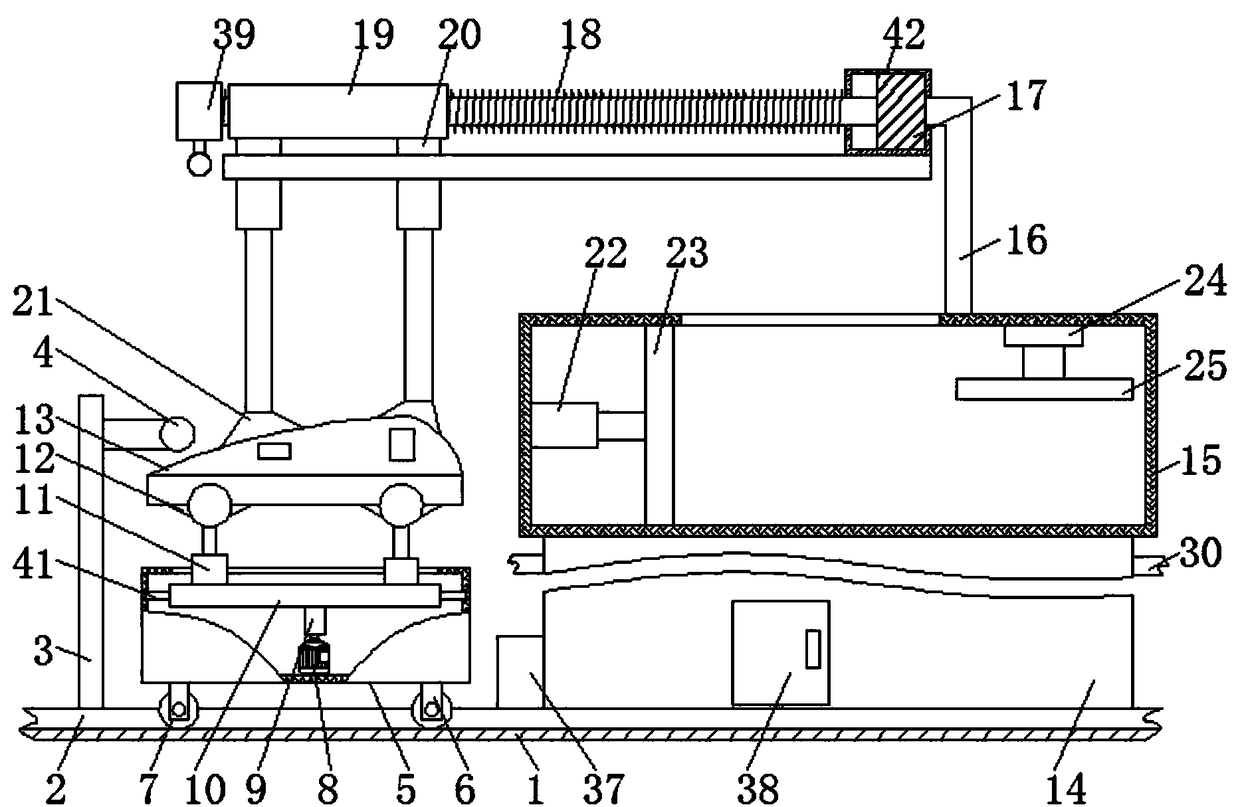

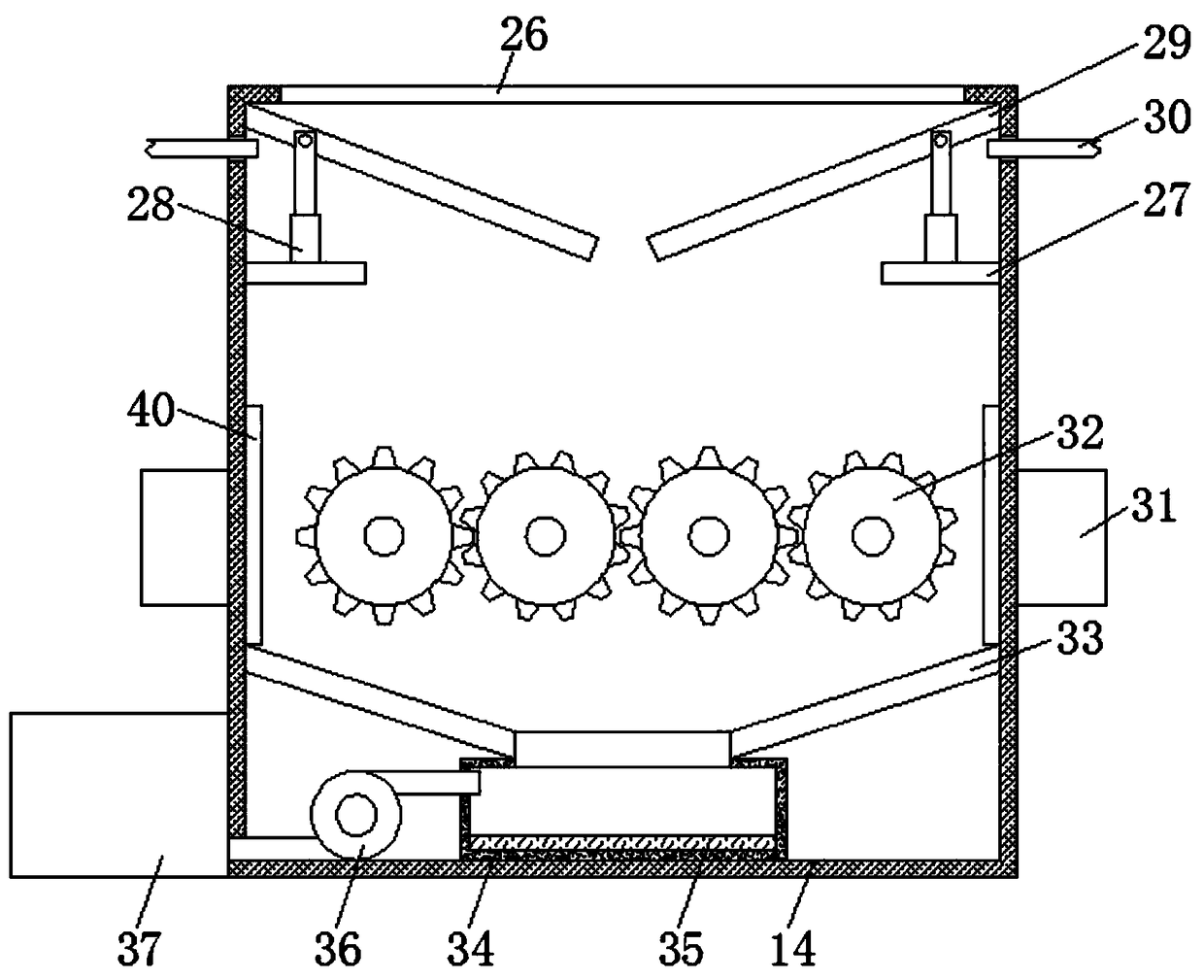

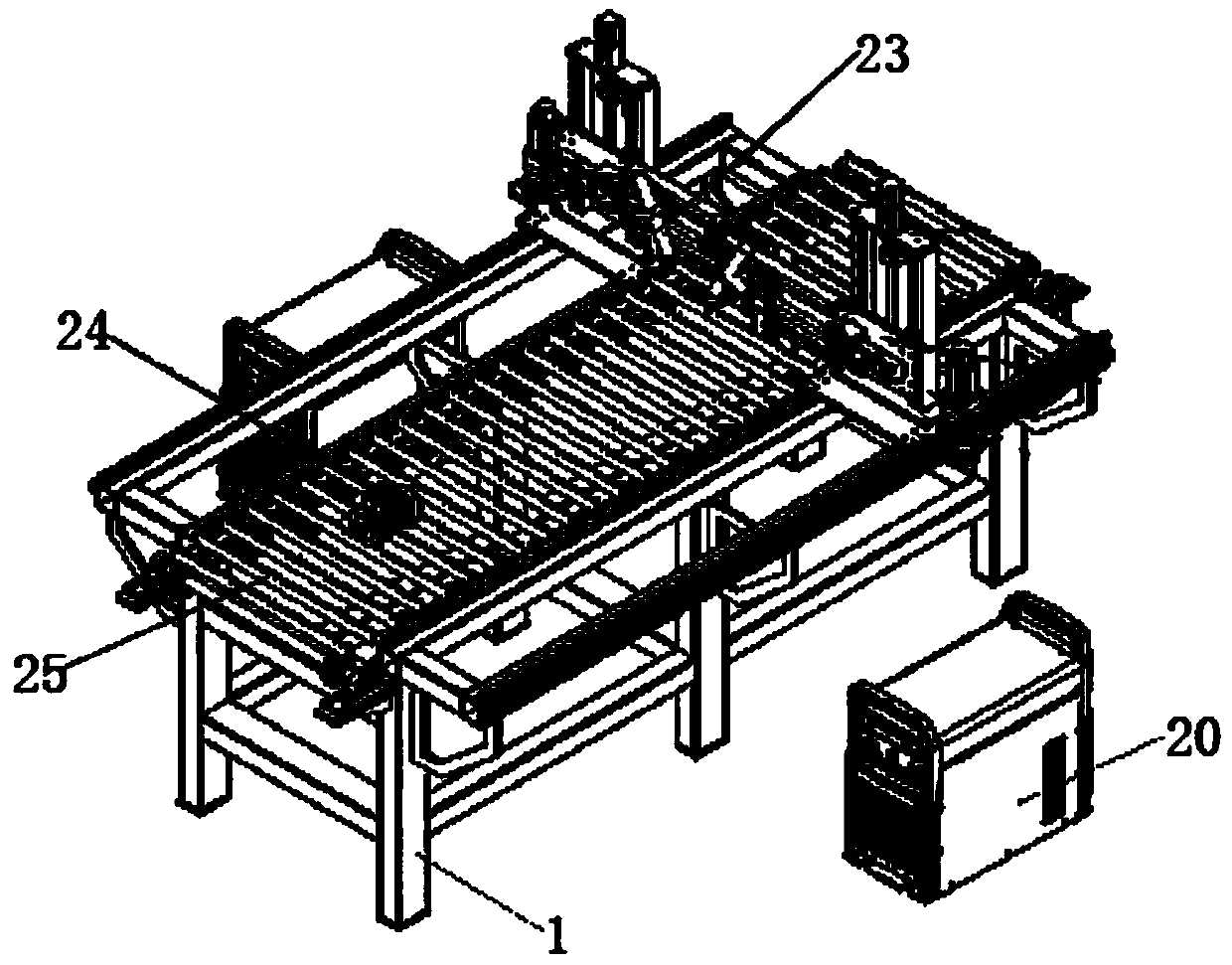

Energy-saving and environment-friendly automatic disassembly and separation system for waste batteries

InactiveCN102148414AImprove dismantling efficiencyReduce smelting energy consumptionSolid waste disposalWaste accumulators reclaimingEngineeringProduction line

The invention discloses an automatic disassembly and separation system for waste batteries. The system is characterized in that a battery conveyor belt is horizontally arranged, and all the batteries are arranged on the battery conveyor belt in a way of enabling box covers of the batteries to face the same direction and can be conveyed from left to right along with the battery conveyor belt; a cutting mechanism is arranged above the battery conveyor belt, a box cover conveyor belt is arranged below the cutting mechanism, and the conveying directions of the box cover conveyor belt and the battery conveyor belt are vertical; and a box cover crushing and separation production line is arranged at the blanking end of the box cover conveyor belt, and a body separation production line is arranged at the battery body blanking end of the battery conveyor belt. By enabling automatic cutting, breaking, sorting and other units to match organically, the full-automatic mechanical disassembly of the waste batteries can be realized.

Owner:贵州火麒麟能源科技有限公司

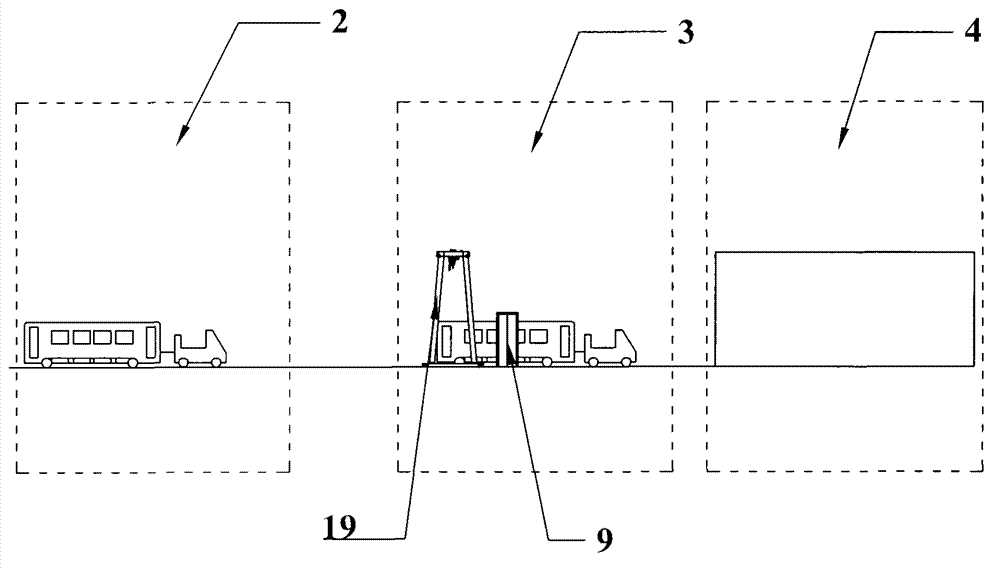

Scrapped car disassembly line

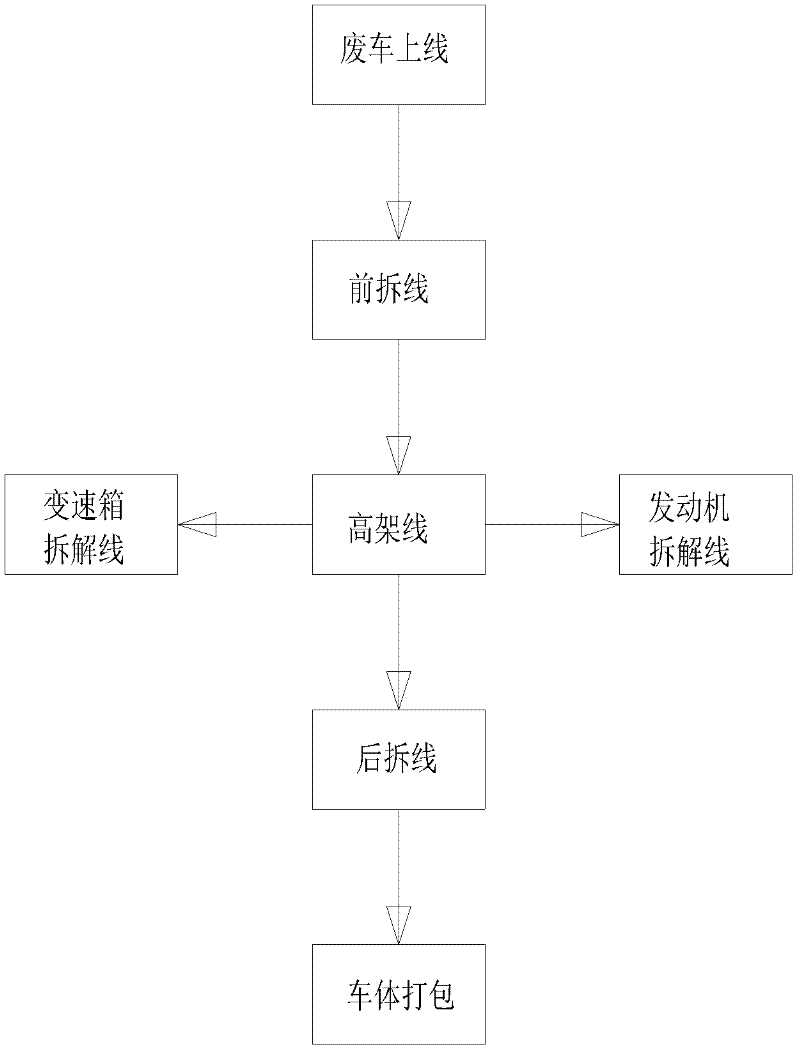

InactiveCN102556216AOptimize layoutImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalProgrammable logic controllerOn the fly

The invention discloses a scrapped car disassembly line. Along the conveying direction of scrapped cars, the scrapped car disassembly line is structurally characterized in that a feeding system is used for conveying the scrapped cars to a pre-disassembly conveying system, the pre-disassembly conveying system is used for completing preparations required by chassis disassembly and conveying the scrapped cars to an overhead conveying system, the overhead conveying system is used for disassembling the scrapped cars and conveying the disassembled scrapped cars to a post-disassembly conveying system which is used for packaging the scrapped cars, and the feeding system, the pre-disassembly conveying system, the overhead conveying system and the post-disassembly conveying system are connected with a PLC (programmable logic controller) module. The scrapped car disassembly line adopting the technical scheme has the advantages of mechanized operation, PLC module control, dynamic automated disassembly and higher disassembly efficiency, the subsystems facilitate arrangement of the whole disassembly line and are clear in division of responsibilities, corresponding parts are sequentially disassembled along with conveyance of the scrapped cars, disassembly efficiency is high, and management and adjustment are facilitated.

Owner:安徽韦尔汽车科技有限公司

Waste vehicle disassembly production line and corresponding process

InactiveCN103112519AReduce labor intensityLess investmentVehicle dissasembly recoverySolid waste disposalProduction lineRefrigerant reclamation

The invention relates to a waste vehicle disassembly production line and corresponding process. Nowadays, a relatively complete disassembly method for waste vehicles does not exist at both home and abroad. The waste vehicle disassembly production line comprises a pretreatment area and a semi-automatic disassembly area, the pretreatment area comprises a waste oil fluid extracting work station, a refrigerant recycling work station, a windshield, an electrical equipment circuit disassembly work station and an inner trim and tyre disassembly work station, wherein a waste oil fluid extracting device is arranged in the waste oil fluid extracting work station, a refrigerant extracting device is arranged in the refrigerant recycling work station, and an air gun sleeve and an air gun unit are arranged on the inner trim and tyre disassembly work station. The semi-automatic disassembly area is arranged on a downstream position of the pretreatment area, and a semi-automatic disassembly device and a material taking and carrying device are arranged in the semi-automatic disassembly area. Not only do the waste vehicle disassembly production line and the corresponding process achieve transformation from manual disassembly to mechanical disassembly, but also the size of cut material can be adjusted according to requirements, and the waste vehicle disassembly production line and the corresponding process are widely used for disassembly of various vehicles and particularly suitable for disassembling of oversize vehicles.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

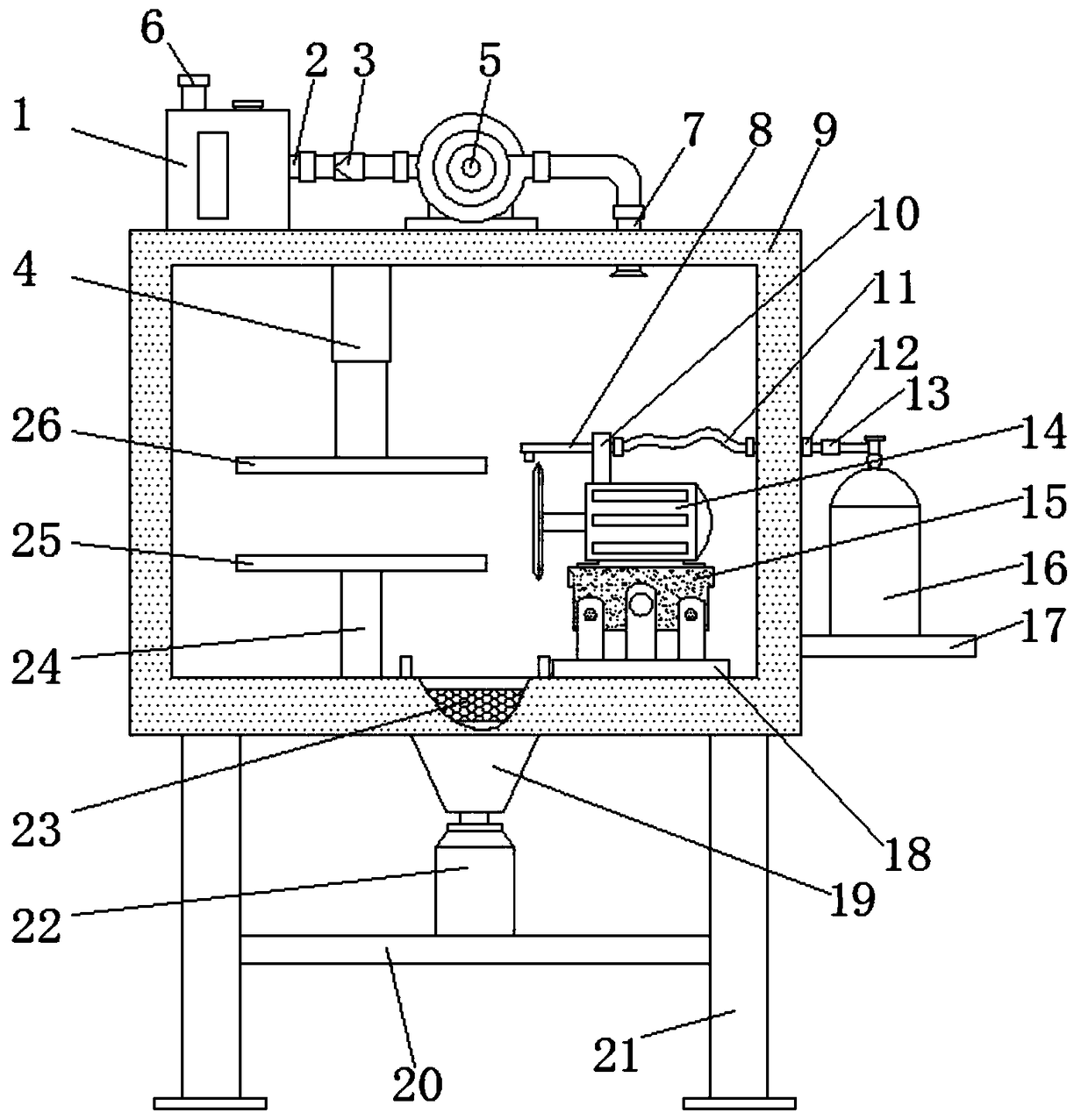

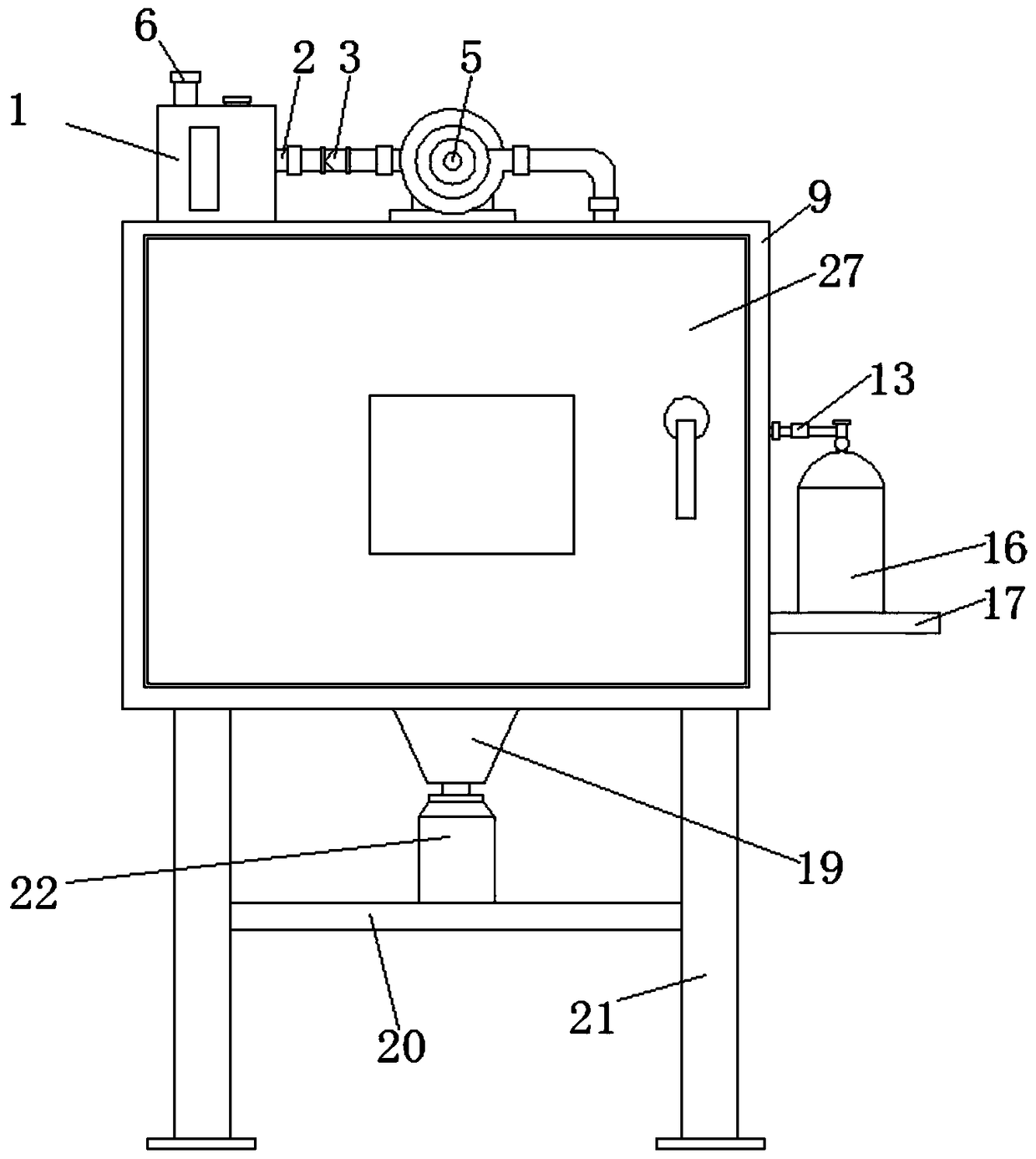

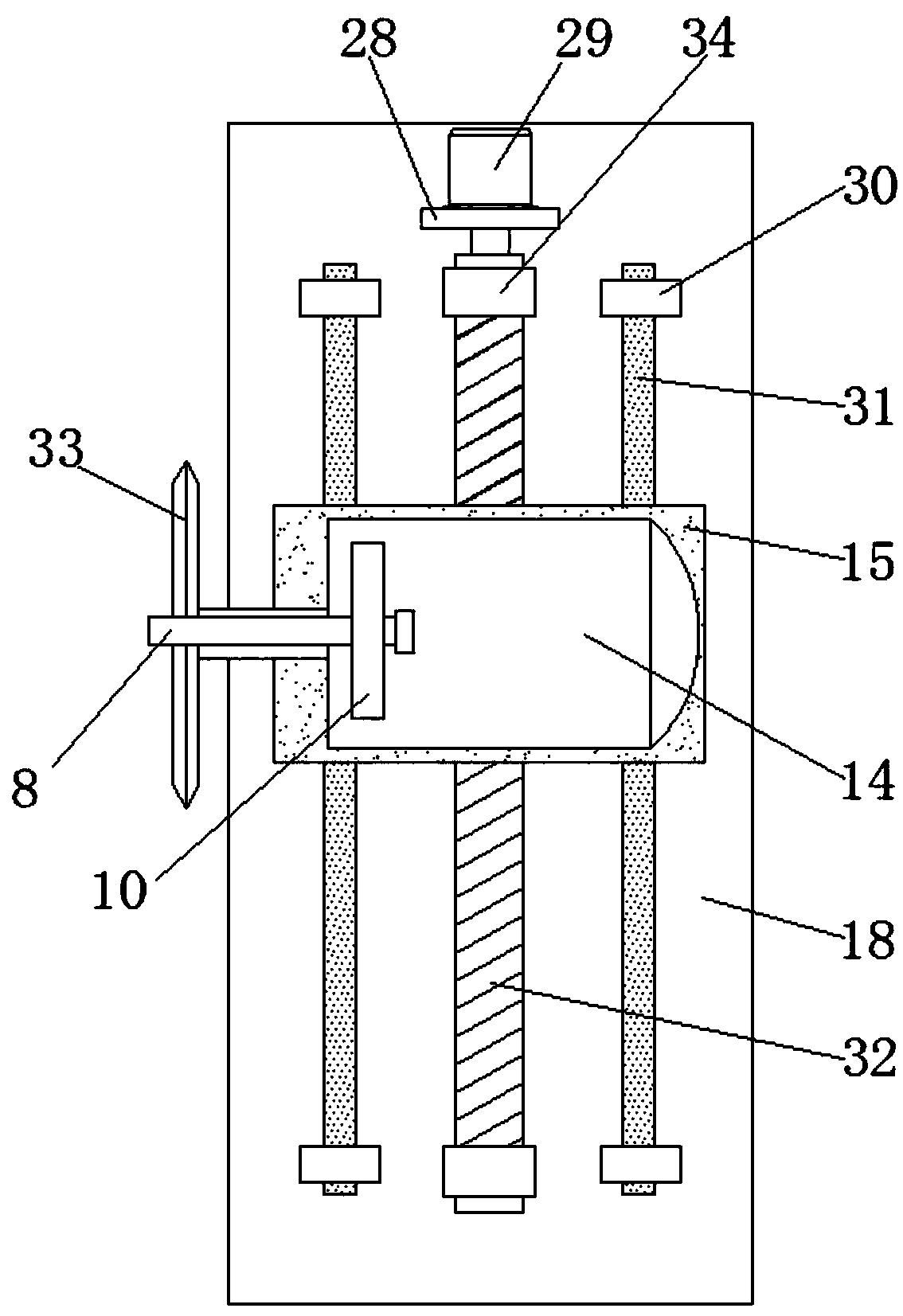

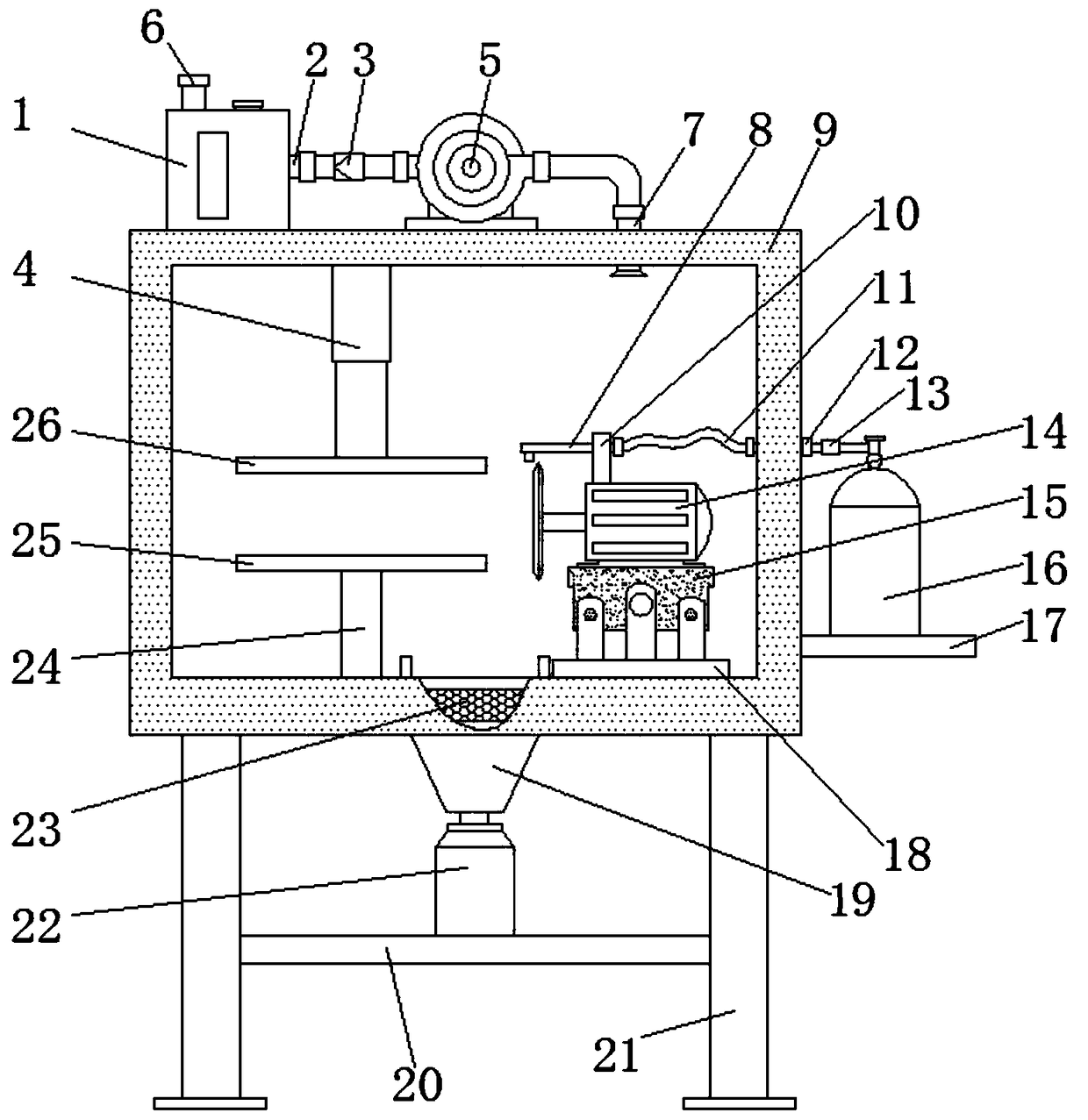

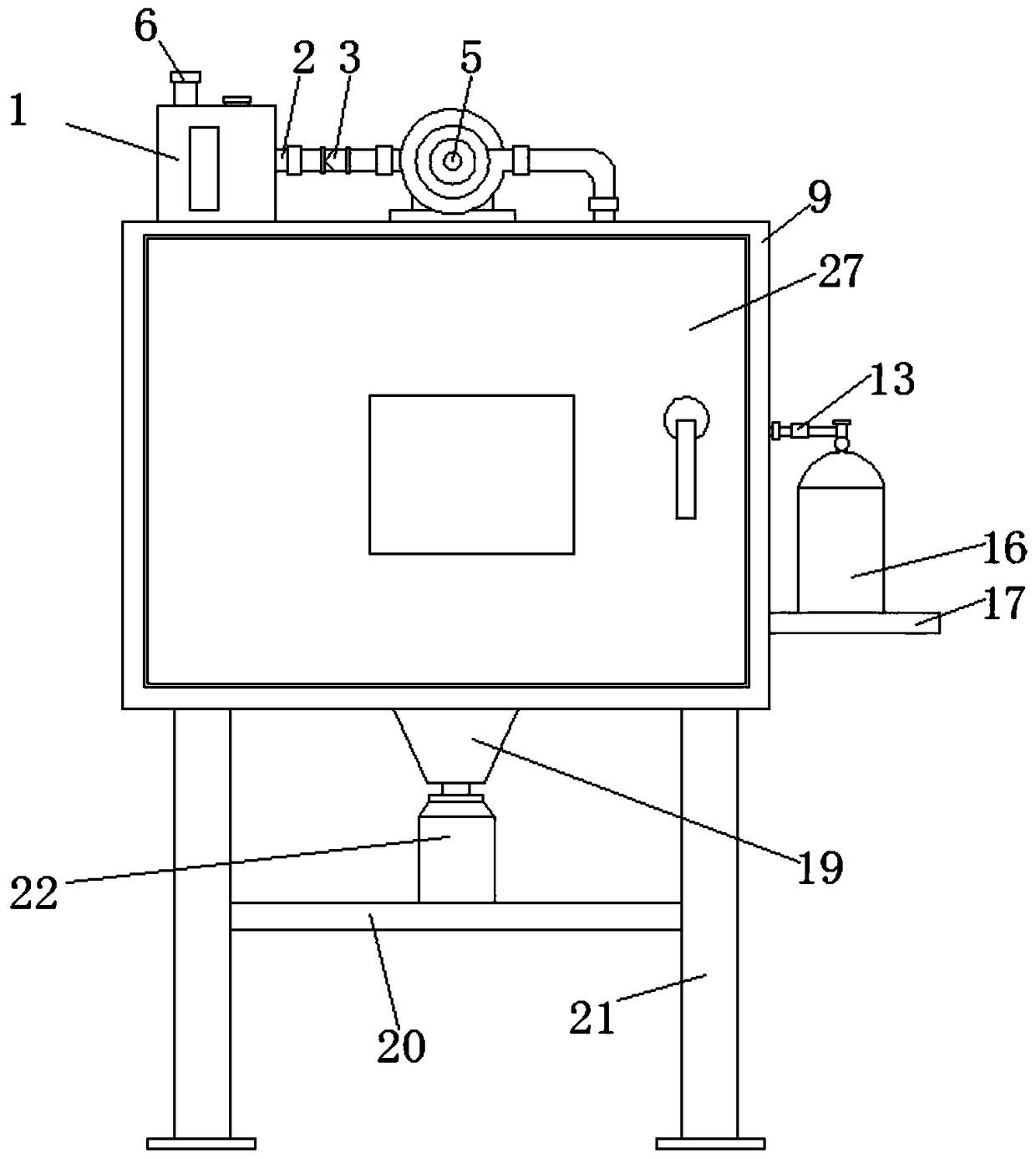

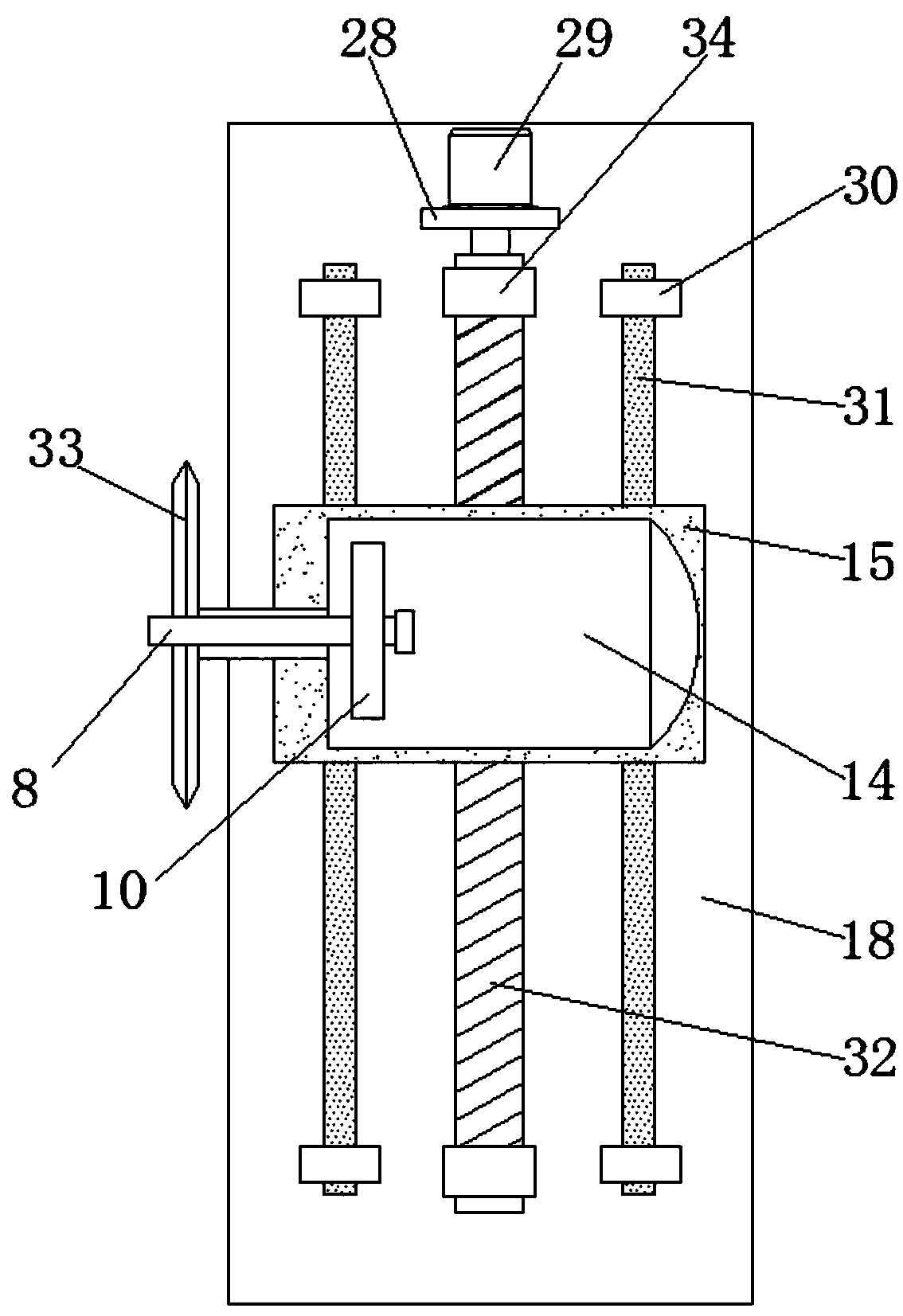

Controllable discharge safety automatic disassembly device for waste hard shell lithium ion power battery

ActiveCN109256598AAvoid Spontaneous Combustion SituationsAvoid explosive situationsSolid waste disposalWaste accumulators reclaimingSpontaneous combustionSolenoid valve

The invention belongs to the technical field of machinery, in particular to a controllable discharge safety automatic disassembly device for a waste hard shell lithium ion power battery, Including anexhaust gas filtration tank, an Intake pipe, a check valve, an air cylinder, an Outlet pipe, a suction pipe first pipe, case, a pipe fixing plate, hose, a second pipe, a solenoid valve, a first motor,a slider, a nitrogen tank, a transverse plate, a mounting plate, a funnel, a storage plate, support legs, a waste liquid collection bottle, a filter screen, a support column, a first pressure plate, asecond pressure plate, a case door, a second motor a amounting plate , second motor, a aguide rail mounting pl ate, guide rail, screws, a cutting knife and a screw mounting plate. The disassembly efficiency of the invention is high, As that liquid nitrogen cool the cutting place during the cutting of the power battery, the occurrence of the spontaneous combustion of the battery caused by excessive temperature during the cut is avoided, the battery explosion is avoided, the battery is cut in the box body, the personal safety of the dismantling personnel is facilitated, and the gas filtering mechanism avoids the pollution of the environment caused by the waste gas during the dismantling.

Owner:万华化学(烟台)电池材料科技有限公司

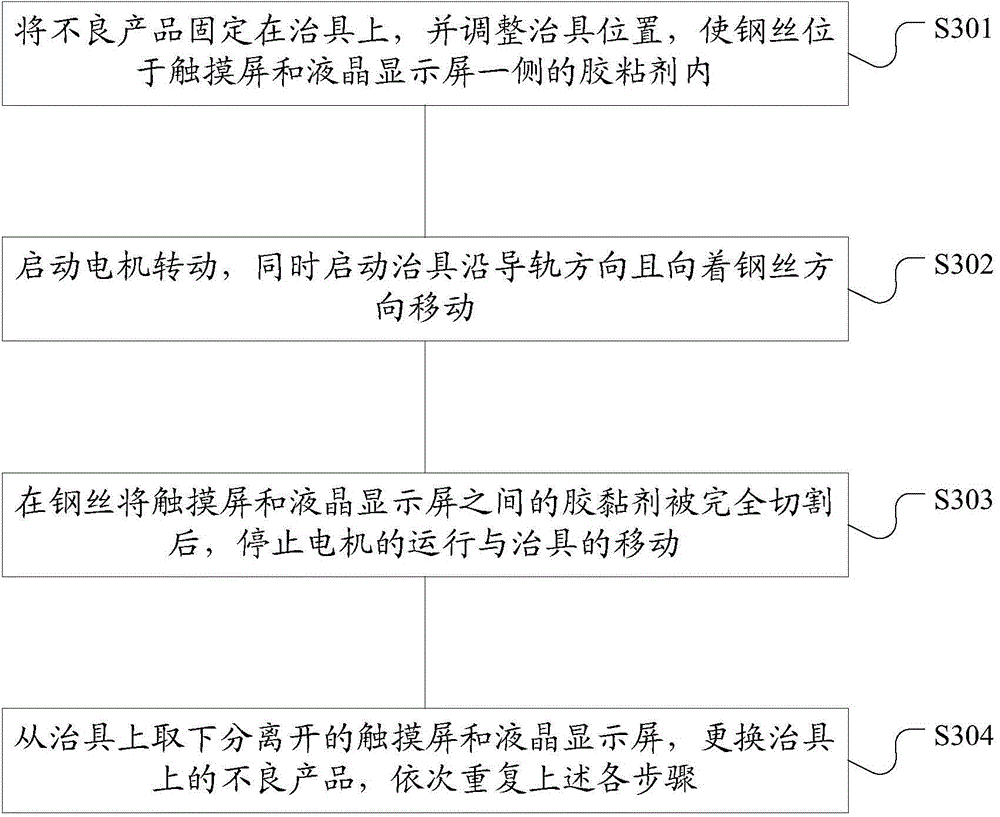

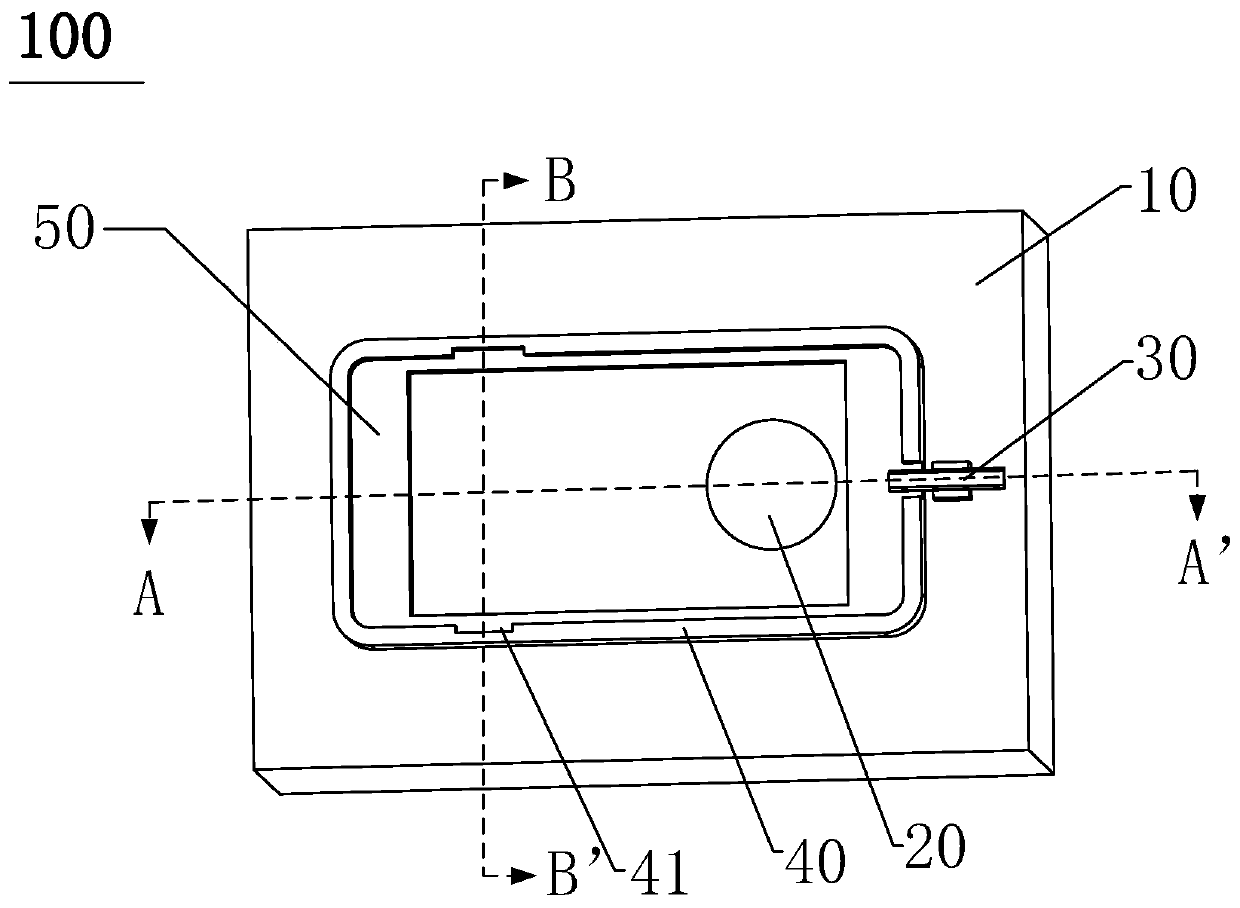

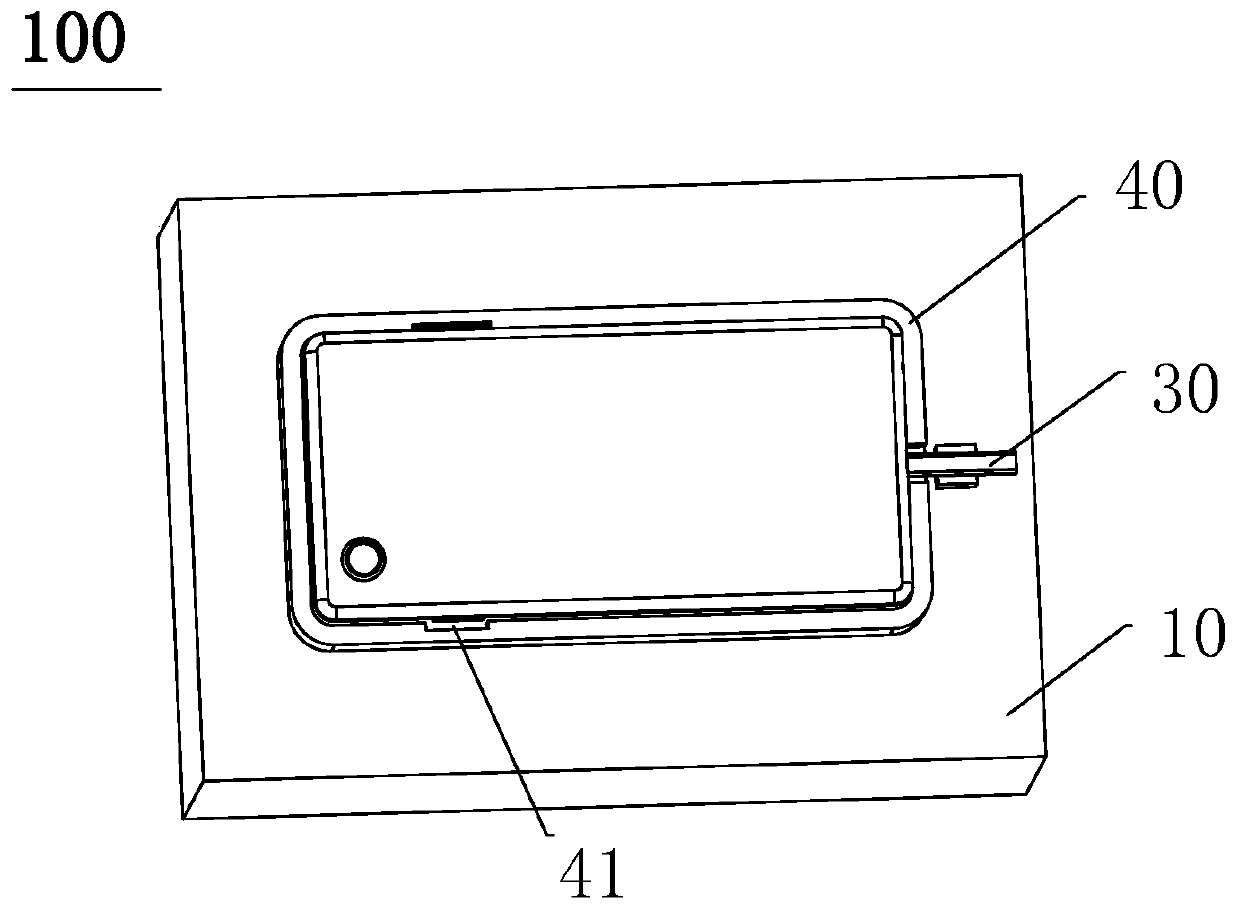

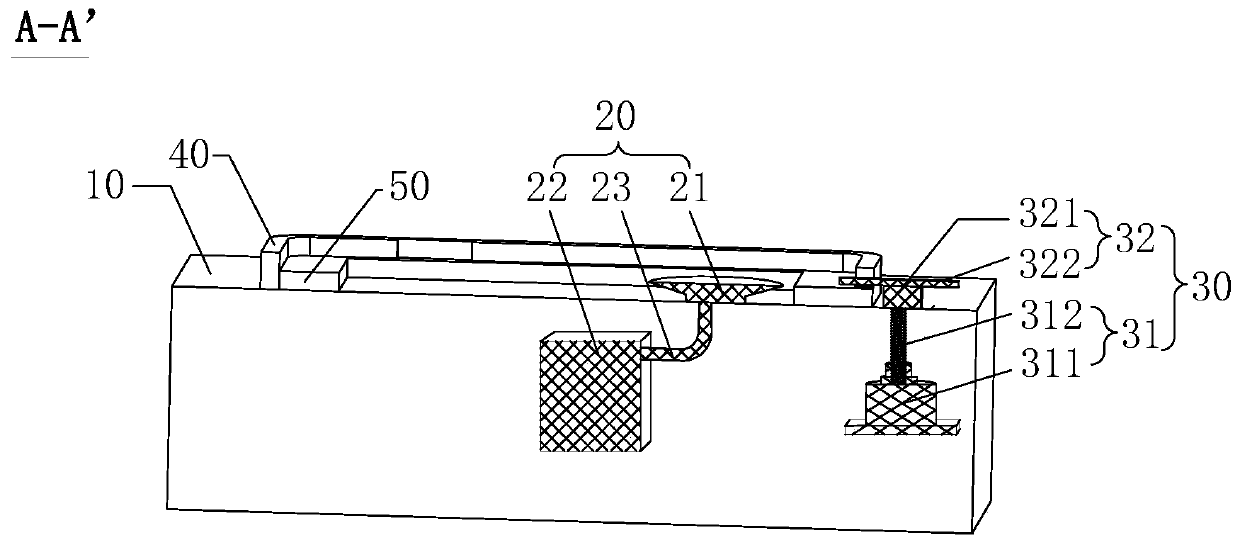

Disassembling device and disassembling method for touch screen and liquid crystal display screen

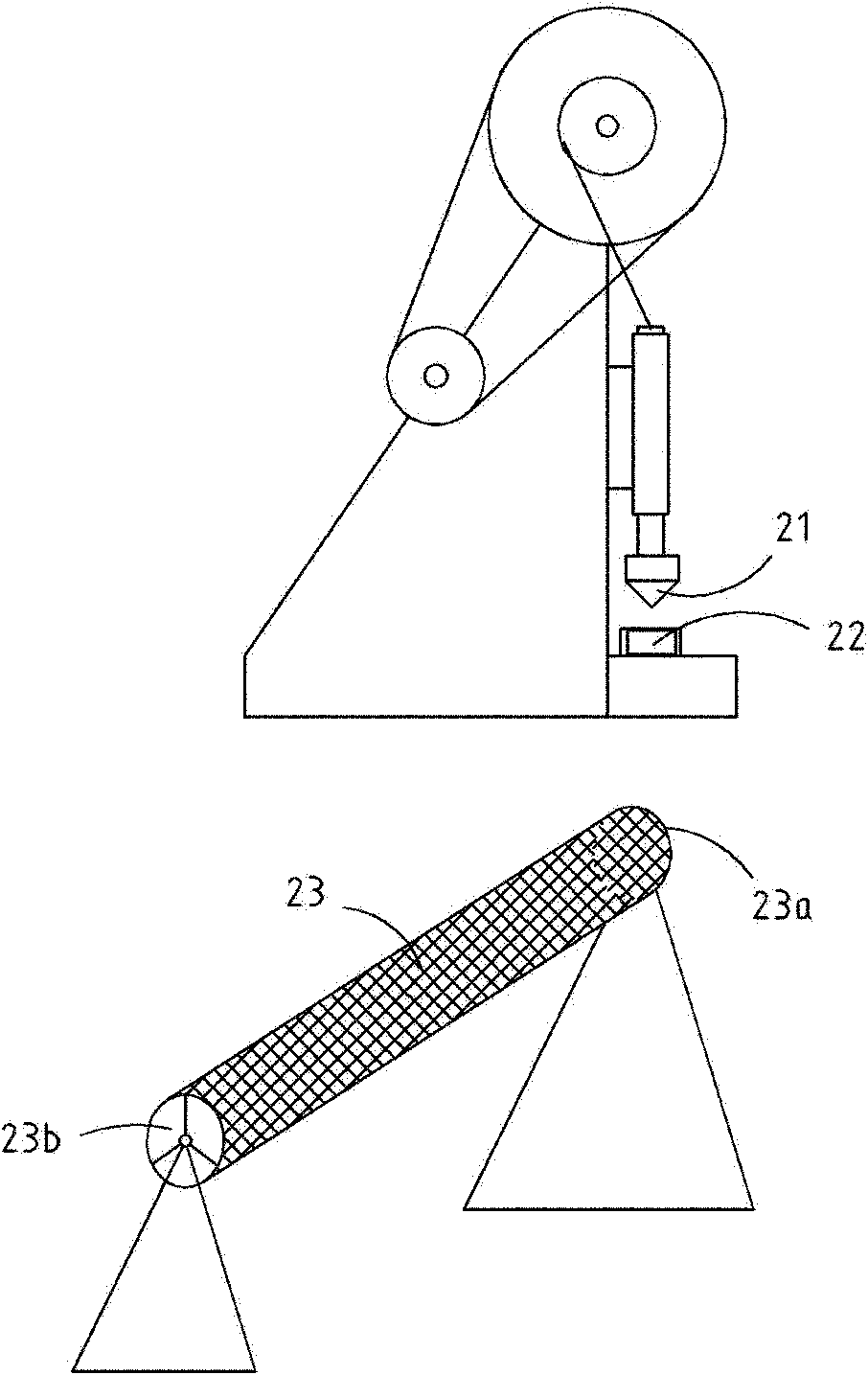

ActiveCN103552107AMovement speed is stableNo change in cutting forceMetal working apparatusBobbinLiquid-crystal display

The invention provides a disassembling device and a disassembling method for a touch screen and a liquid crystal display screen. The disassembling device comprises a working platform, a motor, a bobbin, a steel wire, a rotor, a guide rail and a jig. The invention further correspondingly provides a use method of the disassembling device. The disassembling method comprises the following steps: fixing a defect product on the jig; starting the motor; driving the bobbin to rotate under the rotating action of the motor; winding the steel wire at one end of the bobbin while releasing at the other end; driving the steel wire between the rotor and the bobbin to walk continuously; meanwhile, moving the jig towards the steel wire along the guide rail, so that the steel wire can be used for cutting an adhesive between the touch screen and the liquid crystal display screen on the jig, and the touch screen is separated from the liquid crystal display screen. The disassembling device provided by the invention is automatic mechanical equipment, and the rotating speed of the motor and the moving speed of the jig are uniform, so that the moving speed of the steel wire is kept stable, and the yields of the disassembled touch screen and liquid crystal display screen are increased relatively.

Owner:金龙机电(杭州)有限公司

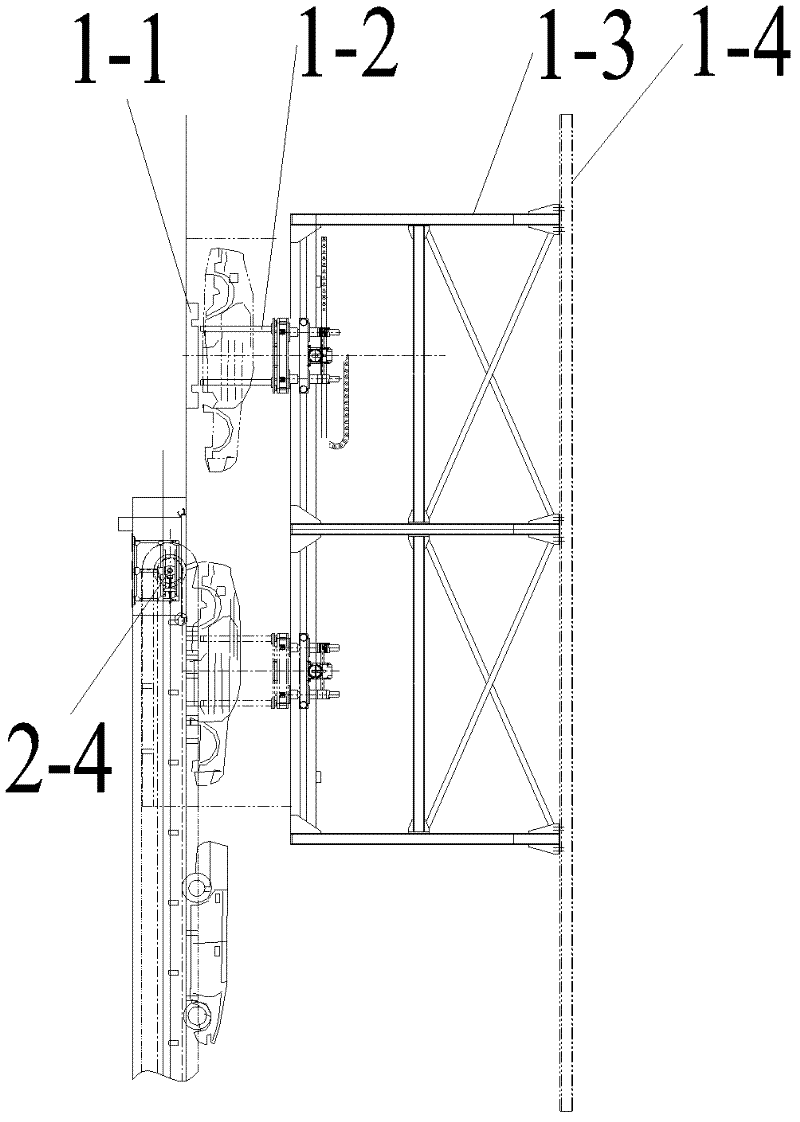

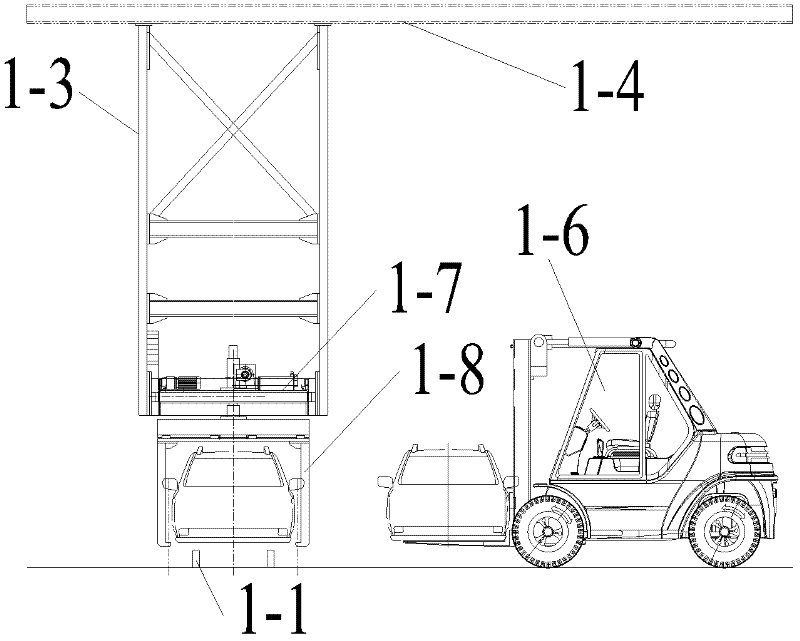

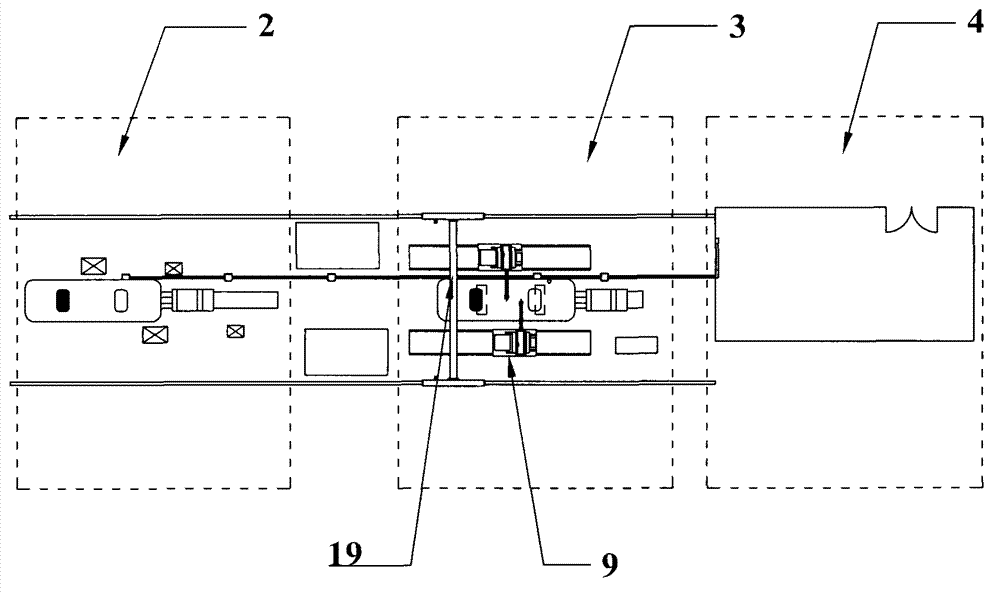

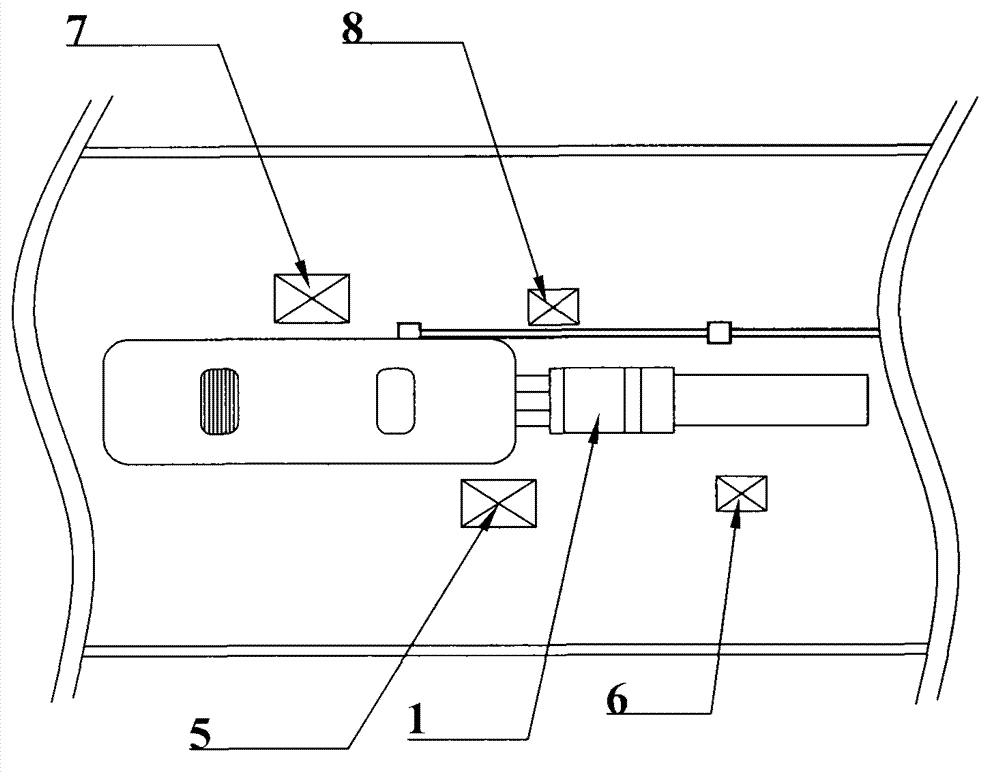

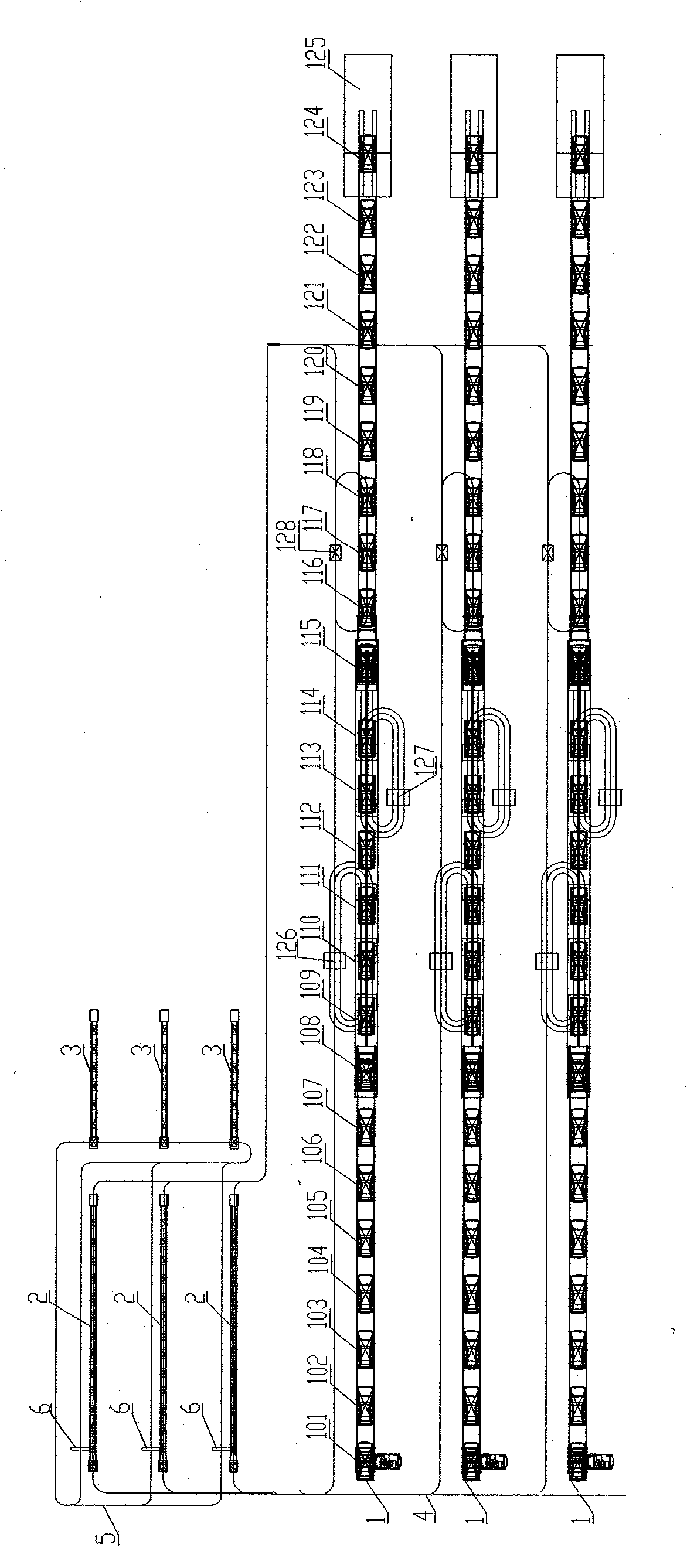

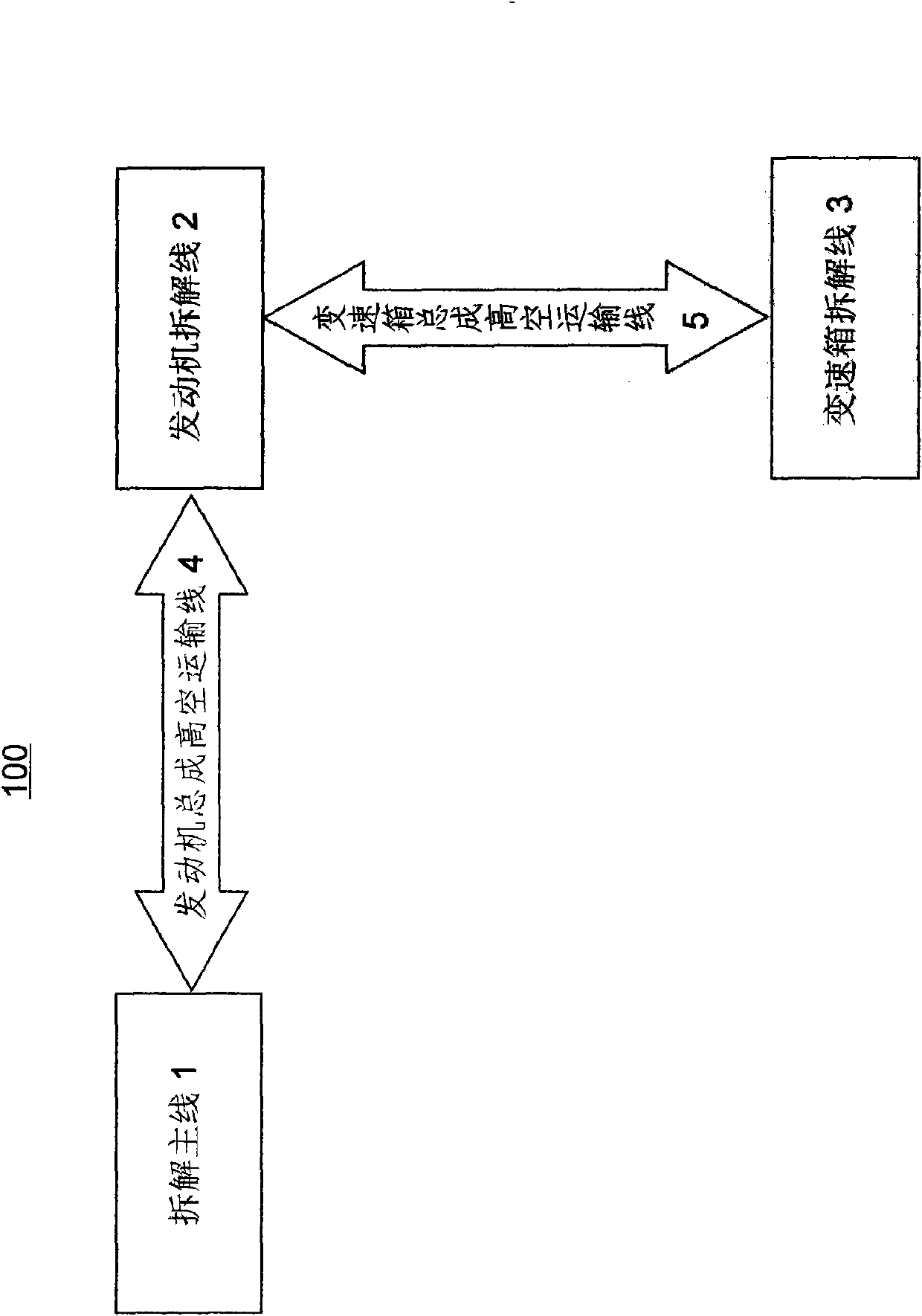

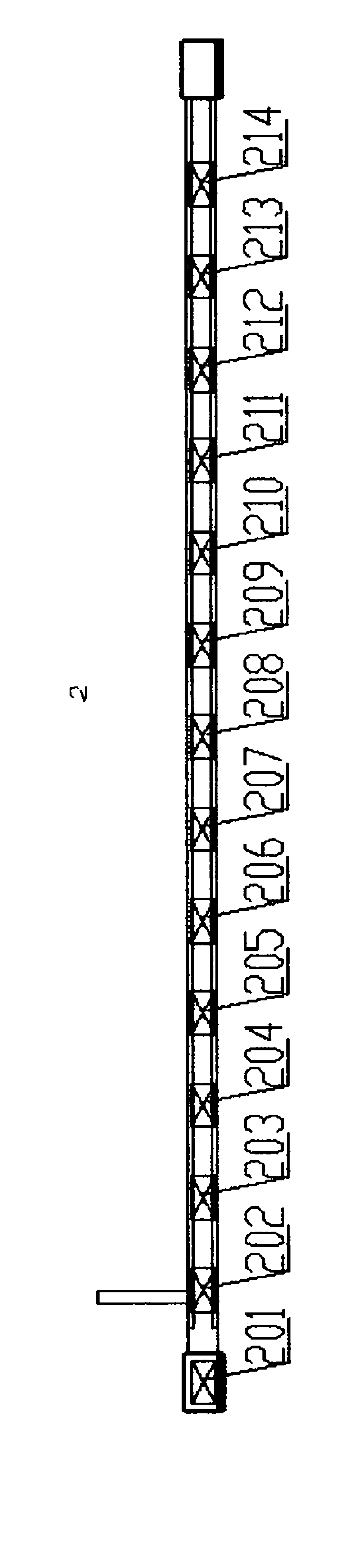

Disassembly reclamation system for scrapped motor vehicle

InactiveCN102107695AEasy to sort and recycleEasy to recycleVehicle dissasembly recoverySolid waste disposalMobile vehicleResource recovery

The invention discloses a disassembly reclamation system for a scrapped motor vehicle. By connection and operation of a main disassembly line, a high-altitude engine assembly transport line, an engine disassembly line, a high-altitude gearbox assembly transport line and a gearbox disassembly line, the purposes of large production scale and high disassembly efficiency are fulfilled; and the system is operated automatically, is convenient for reclaiming and classifying parts and favorable for resource reclamation and environmental protection, simultaneously has simple layout, and is convenient for expanding the scale.

Owner:张家港永峰泰环保科技有限公司

Scraped automobile preprocessing method and production line thereof

ActiveCN103640644AImprove displacement efficiencyImprove the orderliness of dismantlingVehicle dissasembly recoverySolid waste disposalProduction linePretreatment method

The invention discloses a scraped automobile preprocessing method and a production line thereof. The method includes the following procedures of pre-disassembling, disassembling an automobile body, disassembling a power system and packaging. The production line comprises a conveying main line and a conveying branch line. The specific procedures of the scraped automobile disassembling processes are provided; according to the steps of the specific procedures, disassembly orderliness and disassembly efficiency can be improved. An arrangement scheme of four disassembly stations is provided, the pre-disassembly station, the automobile body disassembly station and the power system disassembly station are three main disassembly procedures which are arranged according to time consumption of the disassembly steps, thus the time consumed in each procedure is basically equal. Reasonable arrangement of time and personnel is facilitated and the problem that other procedures are delayed due to the fact that one procedure is too slow is effectively solved. A conveying system which joints all procedures together is provided and the conveying main line and the conveying branch line are adopted. A lengthwise conveying plate trailer and a transverse lifting device are used so that the displacement efficiency of scraped automobiles can be effectively improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

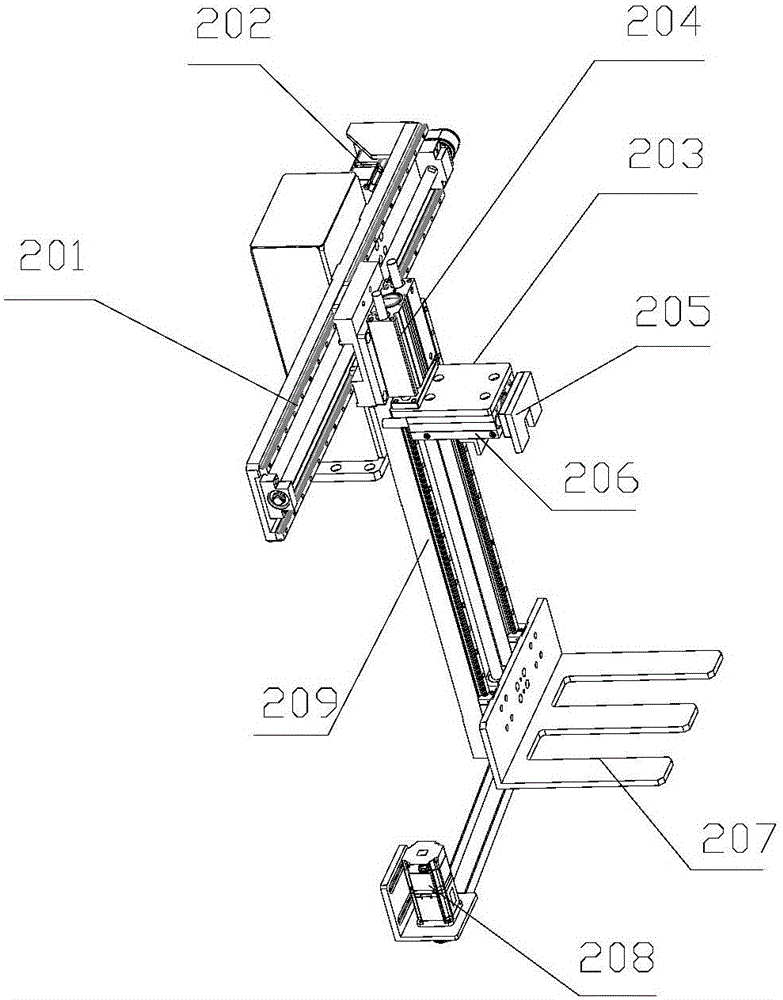

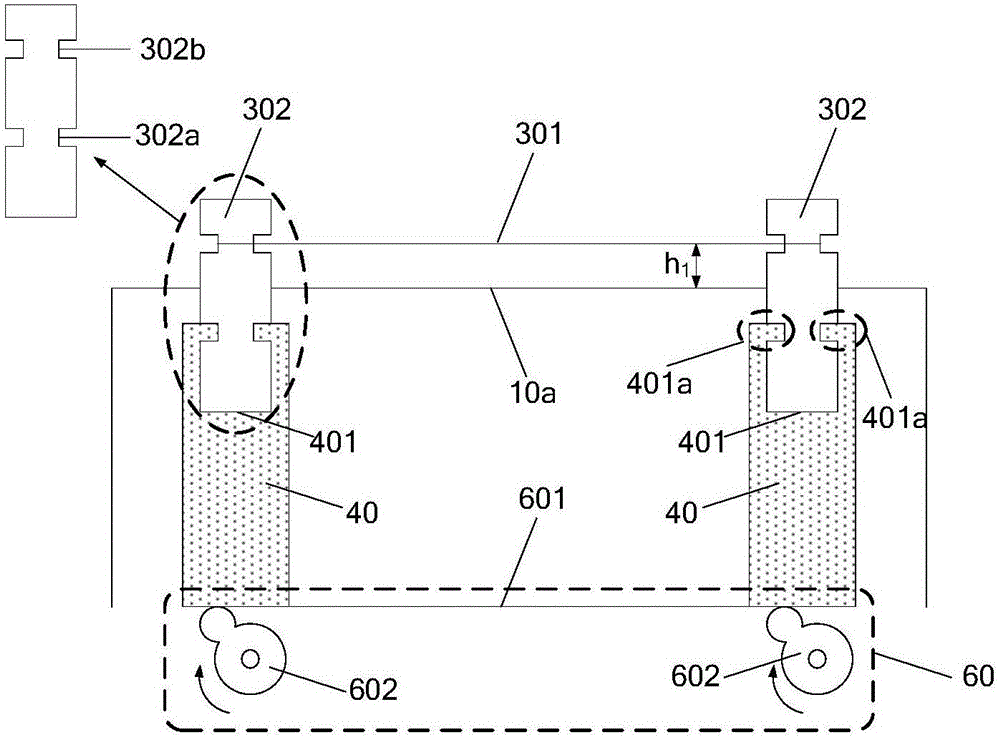

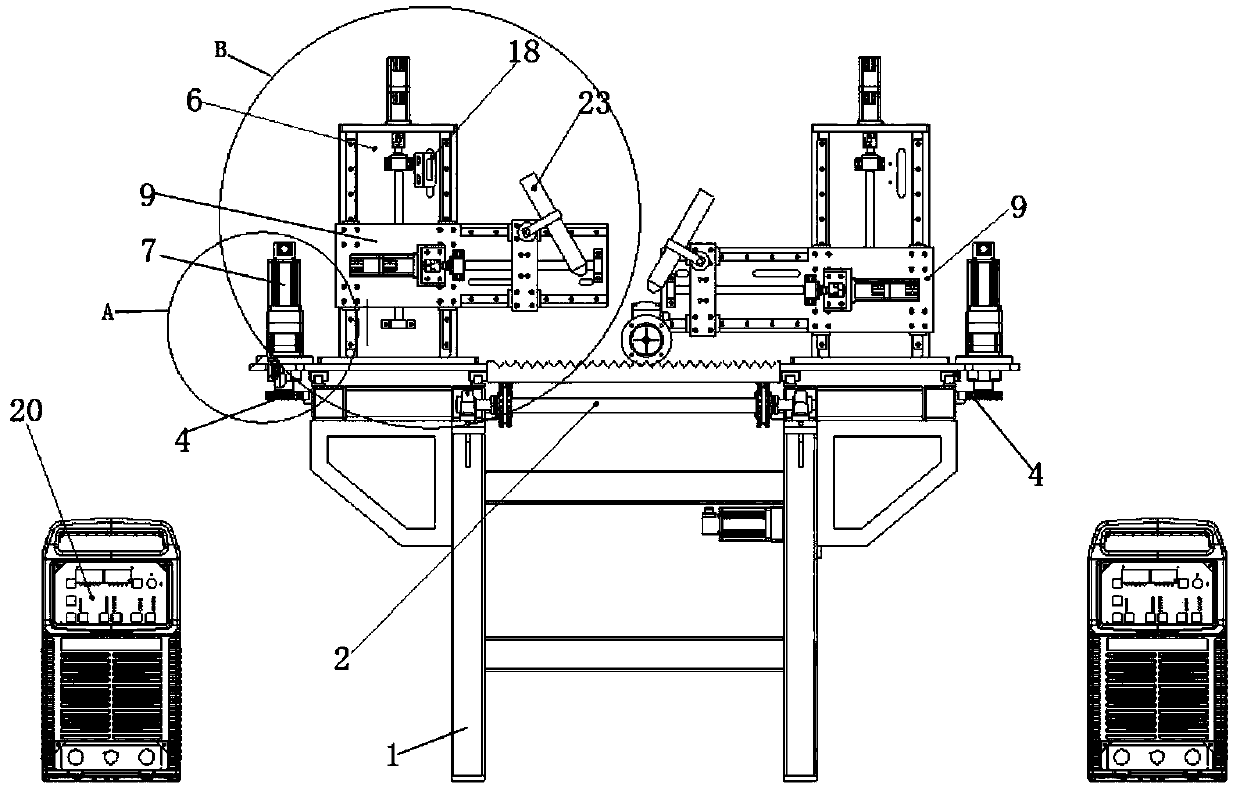

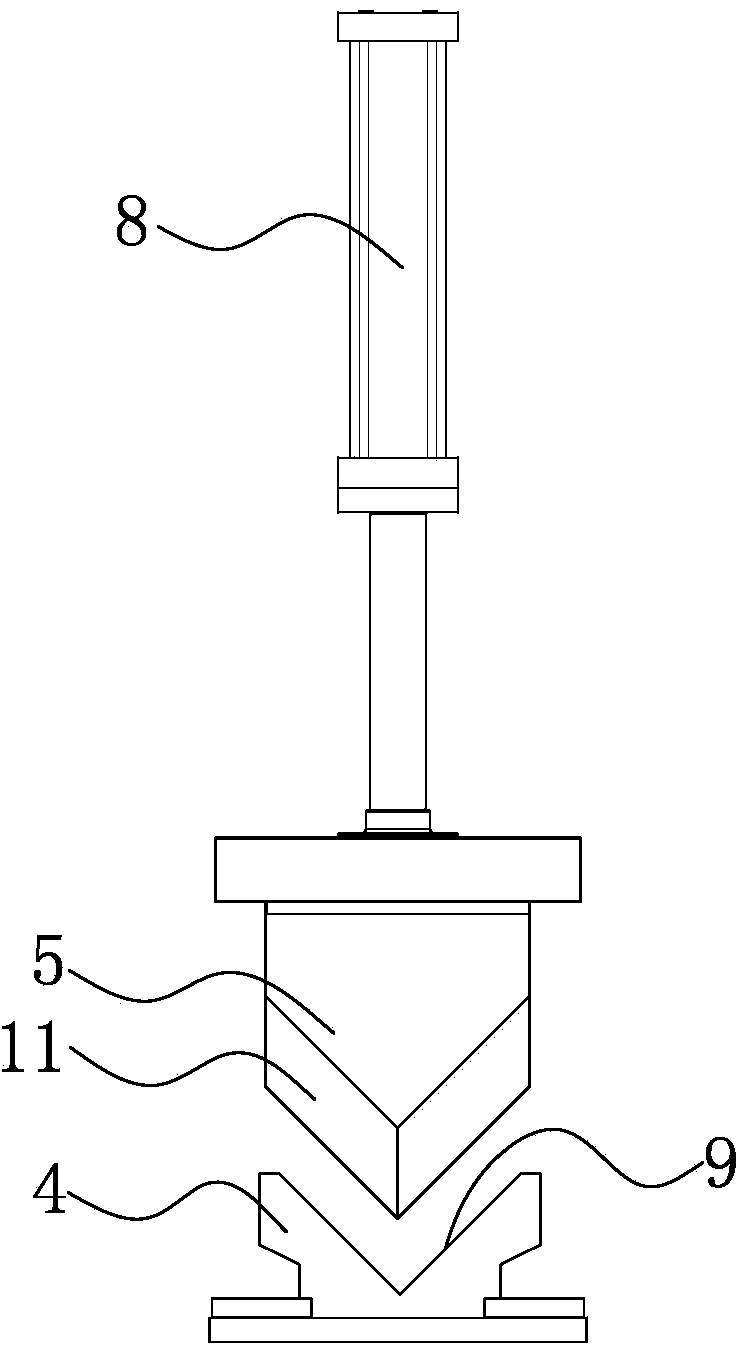

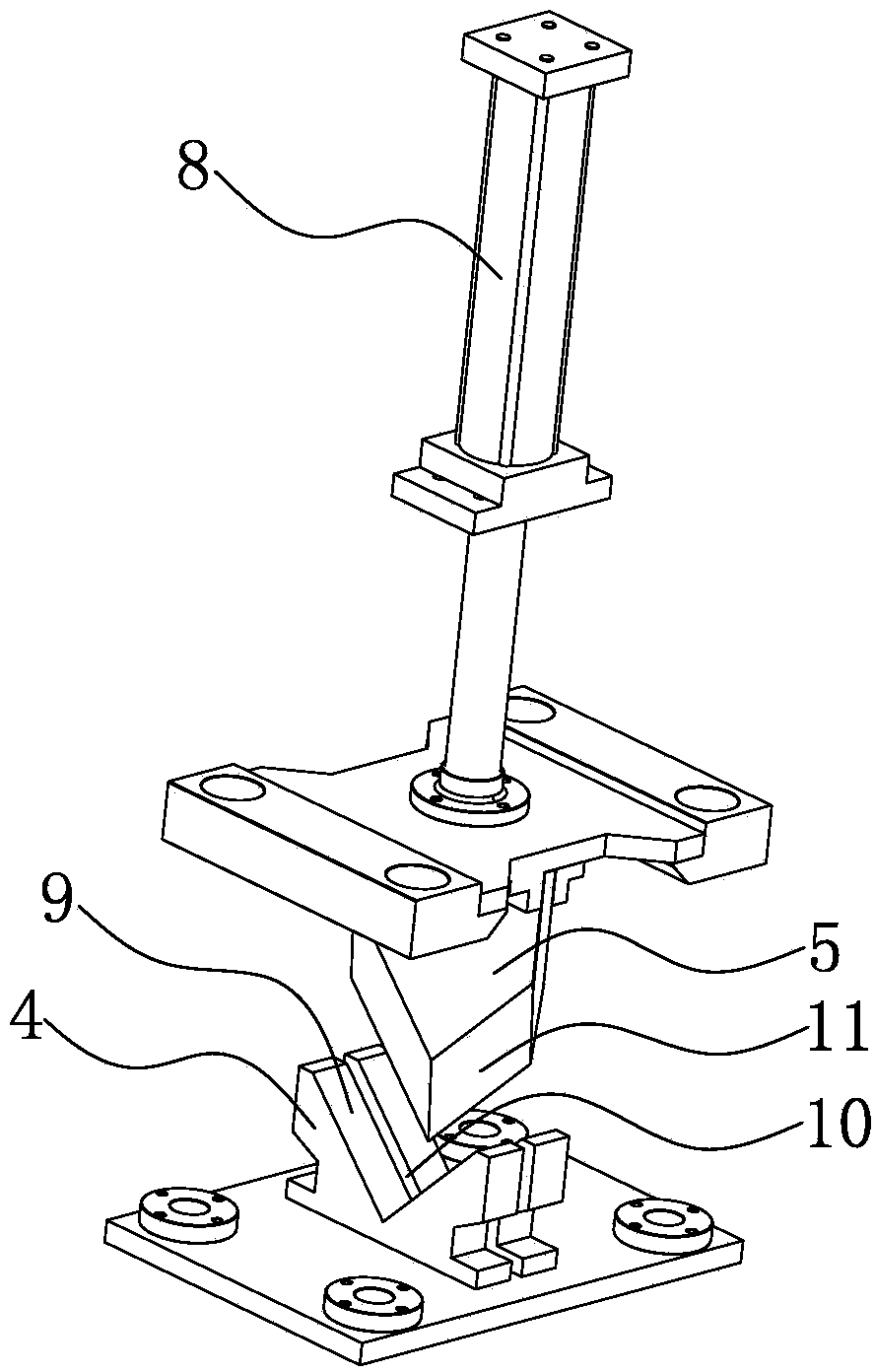

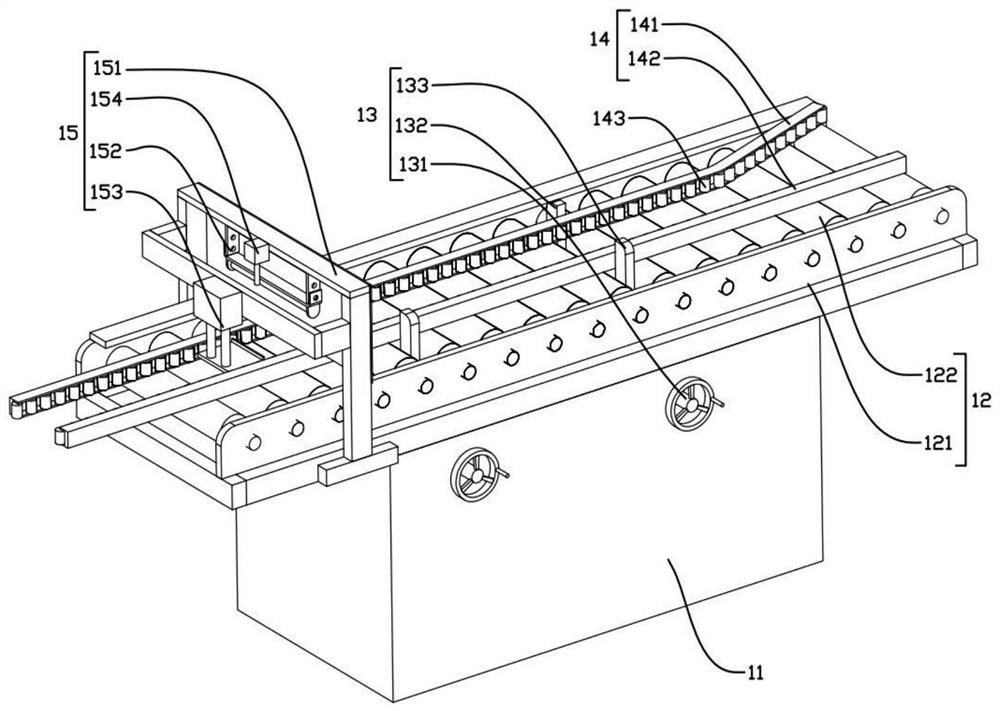

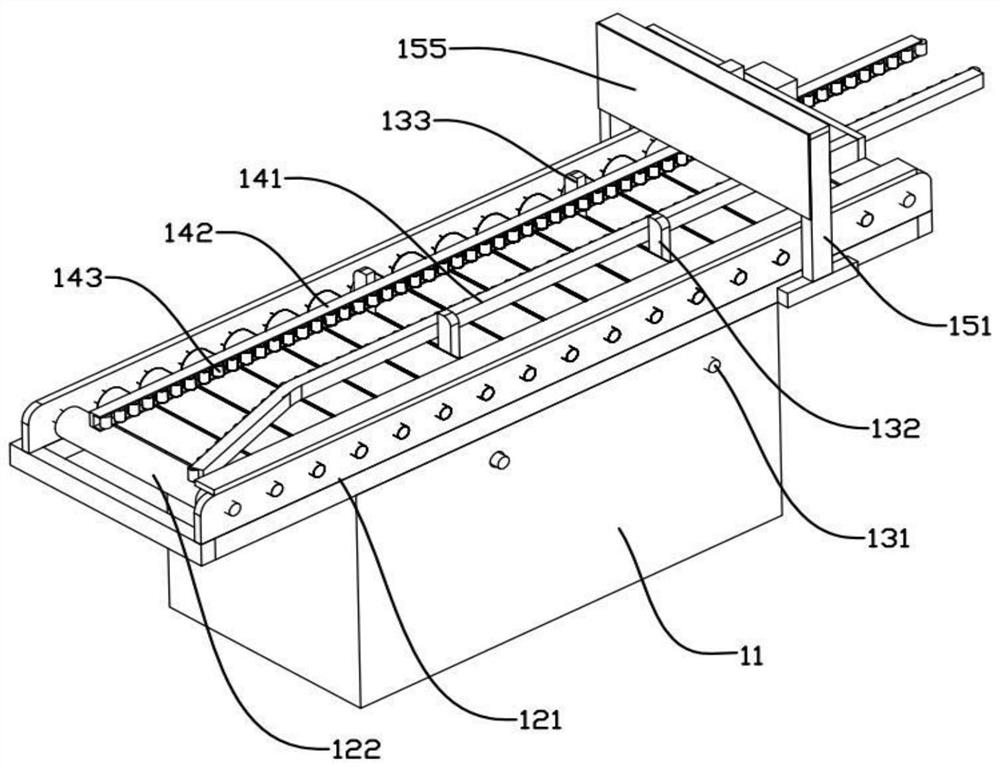

Power battery dismounting device and power battery recycling system

ActiveCN107331912AFully automatedPrevention of conditions hazardous to human healthWaste accumulators reclaimingBattery recyclingPower batteryBattery cell

The invention provides a power battery dismounting device and a power battery recycling system and relates to the technical field of recycling of power batteries. The power battery dismounting device provided by the invention comprises a charging mechanism, a material conveying mechanism, a cutting mechanism for cutting two opposite ends of a power battery and a cell pushing mechanism for pushing a battery cell out from a battery shell, wherein the charging mechanism is connected with the material conveying mechanism; the cutting mechanism and the cell pushing mechanism are arranged along a conveying direction of the material conveying mechanism; the material conveying mechanism is used for conveying the power battery to pass through the cutting mechanism and the cell pushing mechanism in sequence. The power battery dismounting device provided by the invention is applied to a power battery dismounting process and the technical problems in the prior art that the efficiency of manually dismounting the power battery is low and potential safety hazards exist are relieved.

Owner:贵州轻工职业技术学院

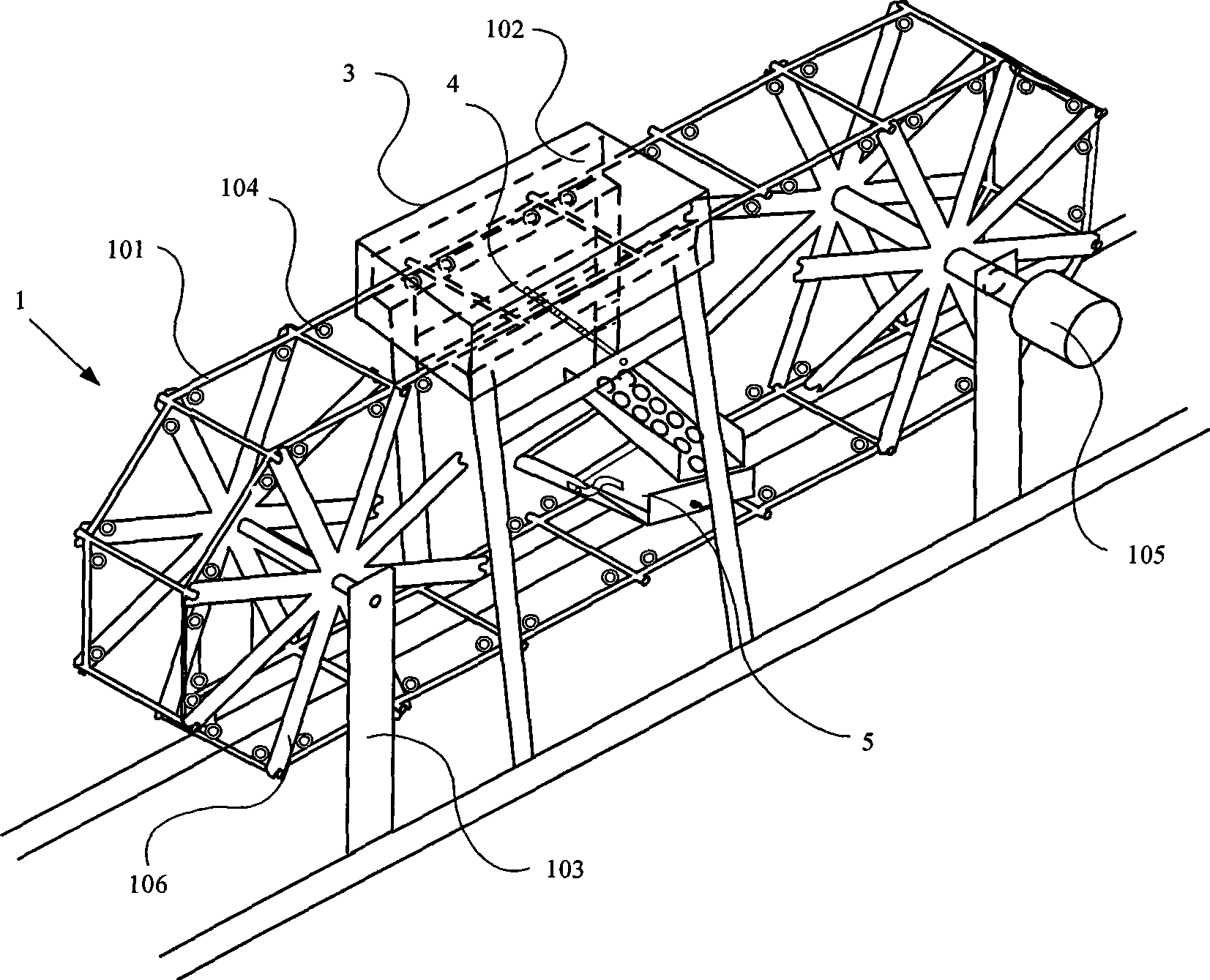

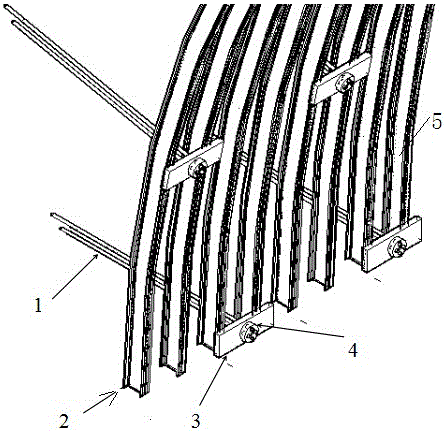

Supporting structure for large-section weak surrounding rock tunnel construction and construction method thereof

ActiveCN106401614AReduce installationSimplified temporary support removal process requirementsUnderground chambersTunnel liningSupporting systemPre stress

The invention discloses a supporting structure for large-section weak surrounding rock tunnel construction and a construction method thereof. The supporting structure comprises a steel arch which is formed by arranging a plurality of arc-shaped I steel at intervals in the tunnel direction. Grooves of the I steel are in the tunnel direction, strip-type anchor bearing plates are arranged between the adjacent I steel and firmly attached to the inner side surfaces of the arc shapes of the I steel, and anchorages are arranged on the inner side surfaces of the anchor bearing plates and connected with pre-stressed anchor cables. According to the supporting structure for large-section weak surrounding rock tunnel construction and the construction method thereof, prestress of the pre-stressed anchor cables is transmitted to the steel arch through the strand tapered anchorages and the anchor bearing plates, so that the pre-stressed anchor cables and the steel arch serve as a part of a tunnel early support together, a cable-arch combined supporting system is formed, mounting of subsequent temporary supports is reduced, the technological requirement for dismantling of the temporary supports is lowered, the support dismantling efficiency is improved, the construction safety is guaranteed, the problems that many partitions are needed, the construction space is small, many procedure links exist, and the construction organization difficulty is high during large-section weak surrounding rock tunnel construction are effectively solved, and the construction efficiency is greatly improved.

Owner:THE FIFTH ENGEERING OF CHINA RAILWAY 5TH BUREAU GROUP

Display screen disassembling device

InactiveCN109915449AImprove efficiencyHigh degree of automationFastening meansMetal-working hand toolsEngineeringElectrical and Electronics engineering

The invention provides a display screen disassembling device for electronic equipment. The display screen disassembling equipment comprises a workbench, an adsorption device and a disassembling devicebody, wherein the adsorption device is arranged on the workbench and is used for adsorbing a display screen of the electronic equipment to be disassembled, the disassembling device body is arranged on the workbench, and comprises a driving unit and a connecting rod assembly, wherein the connecting rod assembly is used for being inserted into the electronic equipment to be disassembled, and the disassembling force is applied to a shell of the electronic equipment to be disassembled under driving of a driving unit. According to the technical scheme, the disassembling efficiency of the display screen and the automation degree can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Overturning equipment for scraped car

ActiveCN102431608AAvoid operabilityAvoid security issuesVehicle dissasembly recoverySolid waste disposalLocking mechanismEngineering

Owner:SOUND ENVIRONMENTAL RESOURCES

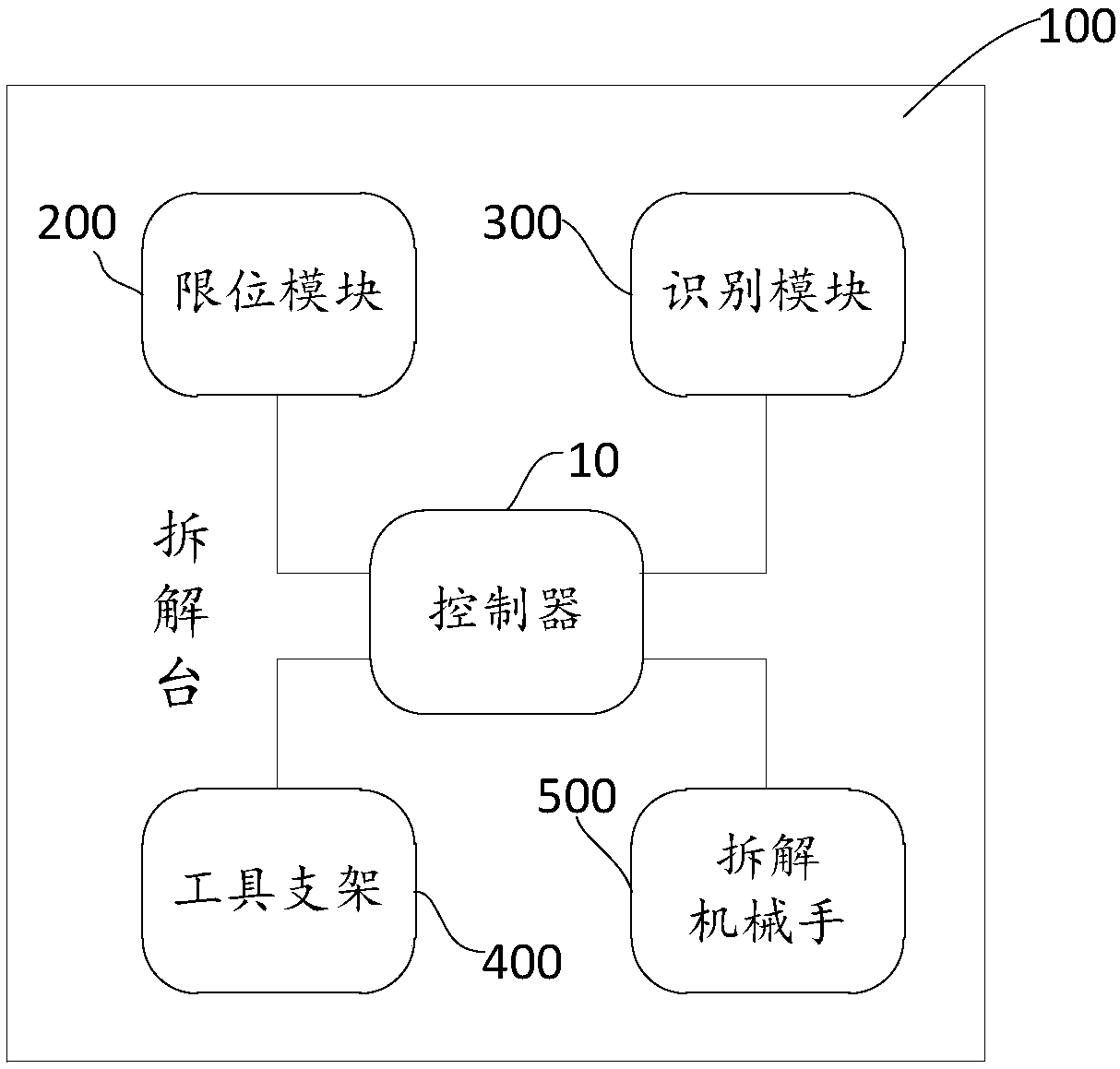

An automatic disassembling device for a battery pack

PendingCN108923091AAvoid harmHigh degree of automationWaste accumulators reclaimingSecondary cells servicing/maintenanceEngineeringManipulator

The invention relates to an automatic disassembling device for a battery pack. The device is used for automatic disassembling of a battery pack. The device includes a disassembling table used for bearing the battery pack; a limiting module used for fixing the battery pack to a preset position on the disassembling table; a recognition module used for recognizing attribute information of the batterypack; and a tool support provided with a plurality of disassembling tools. The disassembling table is also provided with a disassembling mechanical arm and a controller. The controller is electrically connected to the limiting module, the recognition module, the tool support and the disassembling mechanical arm. Through the limiting module, the recognition module and the tool support, the devicecan achieve battery pack positioning and type recognition, a corresponding tool is selected from the tool support according to the recognized type and is automatically loaded, and disassembling of thebattery pack is automatically completed under control by the controller, thus making the degree of automation high, effectively increasing the disassembling efficiency and avoiding human body harm caused by battery disassembling.

Owner:武汉动力电池再生技术有限公司

Controllable discharging and safe and automatic disassembling method for waste hard-shelled lithium-ion power battery

ActiveCN109346790AAvoid Spontaneous Combustion SituationsAvoid explosive situationsGas treatmentSolid waste disposalPower batterySpontaneous combustion

The invention belongs to the technical field of recycling of lithium-ion batteries, and particularly relates to a controllable discharging and safe and automatic disassembling method for a waste hard-shelled lithium-ion power battery. The method comprises the following steps: S1, discharging the waste hard-shelled lithium-ion power battery; S2, placing the discharged battery in step S1 in automatic battery disassembling equipment and then disassembling the battery; and S3, classifying and recycling the materials disassembled in step S2. The battery can be rapidly disassembled by the automaticbattery disassembling equipment used in the method, the disassembling efficiency is high, during cutting of the power battery, a cut position is cooled by liquid nitrogen, spontaneous combustion of the battery due to over-high temperature during cutting is avoided, explosion of the battery is also avoided, battery cutting operation is carried out in a box, thus, personal safety of a disassemblingworker is benefited, and by a gas filtering mechanism, the circumstance that the environment is polluted by waste gas generated during disassembling is avoided.

Owner:LONGNAN JINTAIGE COBALT IND CO LTD

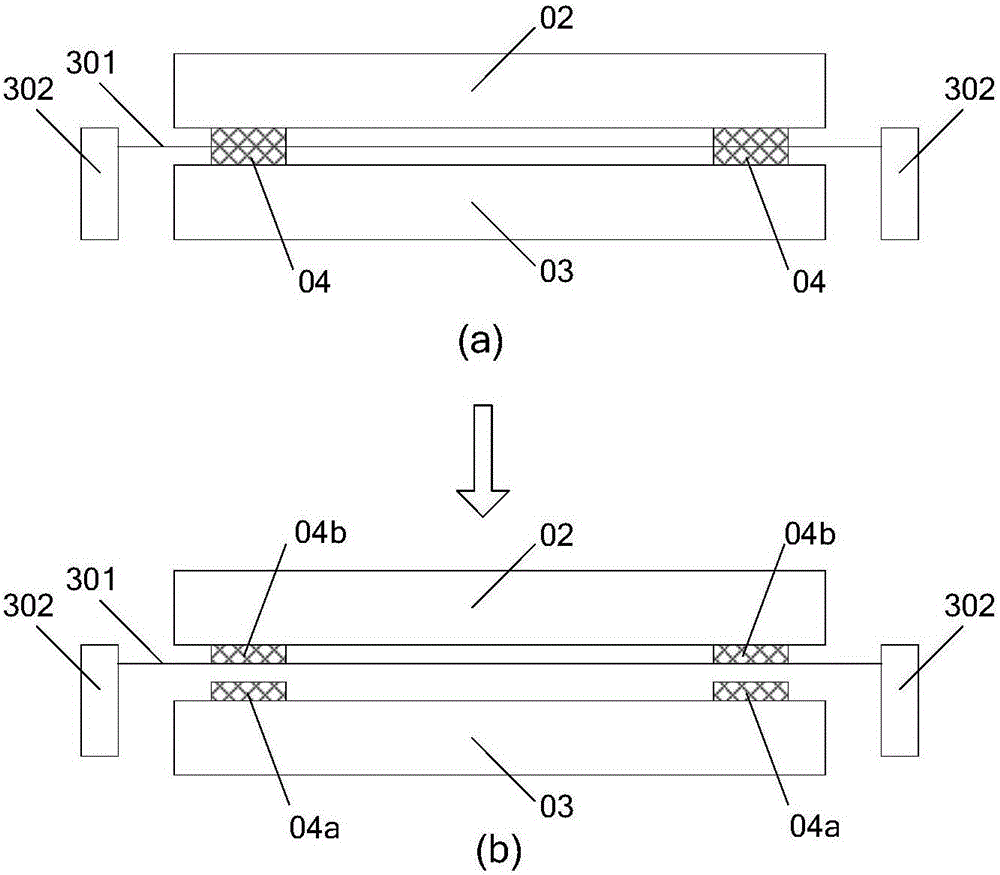

Disassembling device of display panel

InactiveCN106353901AQuick cutEasy to separateNon-linear opticsMetal-working hand toolsSurface plateEngineering

The embodiment of the invention provides a disassembling device of a display panel and relates to the technical field of display. The disassembling device can be used for conveniently and rapidly disassembling the display panel and has high disassembling efficiency and the disassembling damage rate is reduced. The disassembling device comprises a loading platform, a heating device, a panel fixing device, a cutting device and a height adjusting device, wherein the heating device is used for heating the display panel; the panel fixing device is used for fixing the display panel on the heating device; long-strip holes for communicating a cavity are formed in an upper surface of the loading platform; the long-strip holes are formed in two relative sides of the heating device; the cavity is internally provided with a supporting structure located below the long-strip holes; slide rails, which vertically correspond to the long-strip holes, are formed in the top of the supporting structure; the cutting device comprises a cutting part and slide blocks; the height adjusting device is used for adjusting the height, relative to the upper surface of the loading platform, of the cutting part; one end of each slide block is matched with the slide rails and the other ends of the slide blocks are used for fixing the cutting part and protrude] out of the long-strip holes; the cutting part can move along the long-strip holes under the driving the slide blocks, so as to cut frame sealing glue. The disassembling device is used for disassembling the display panel.

Owner:BOE TECH GRP CO LTD +1

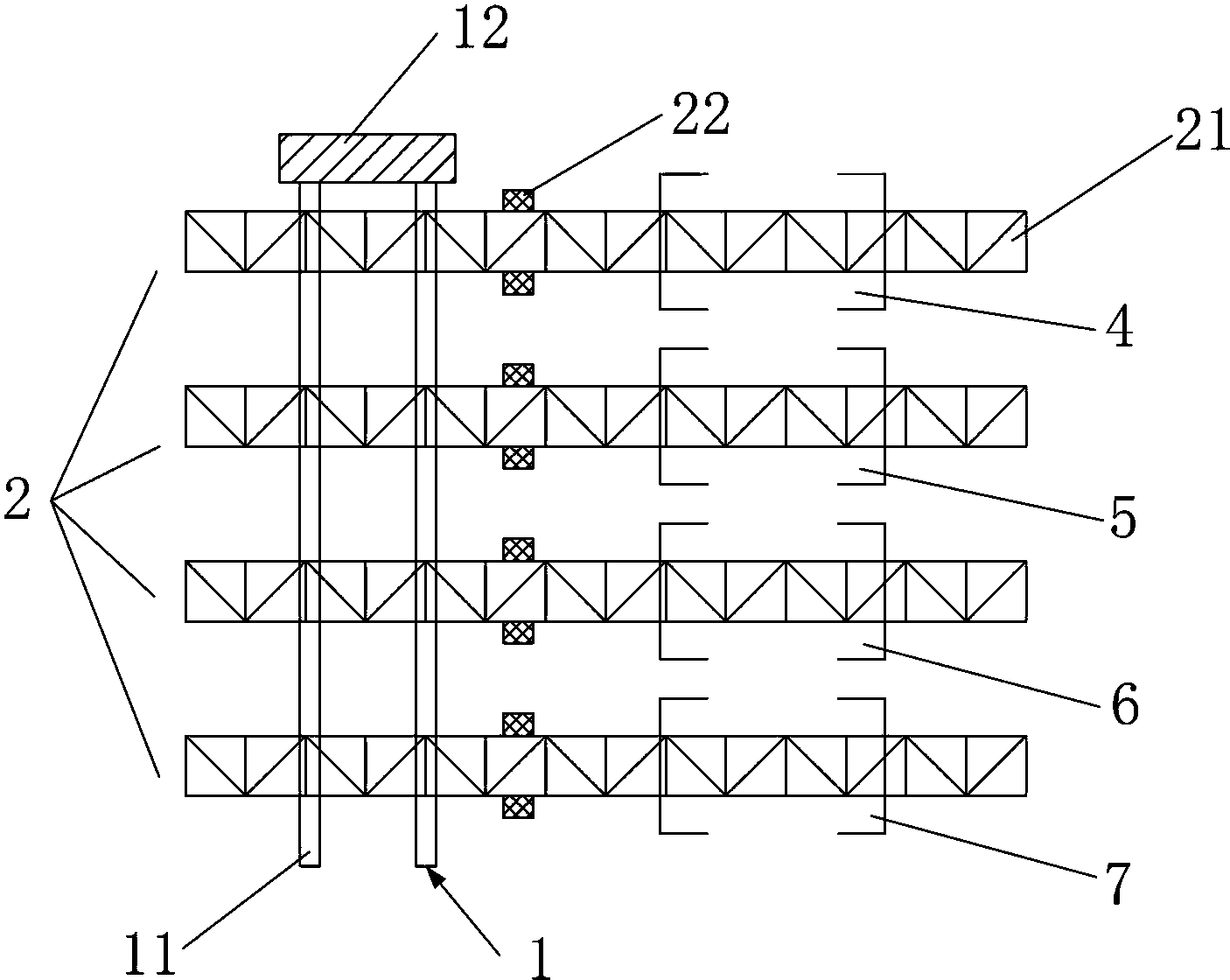

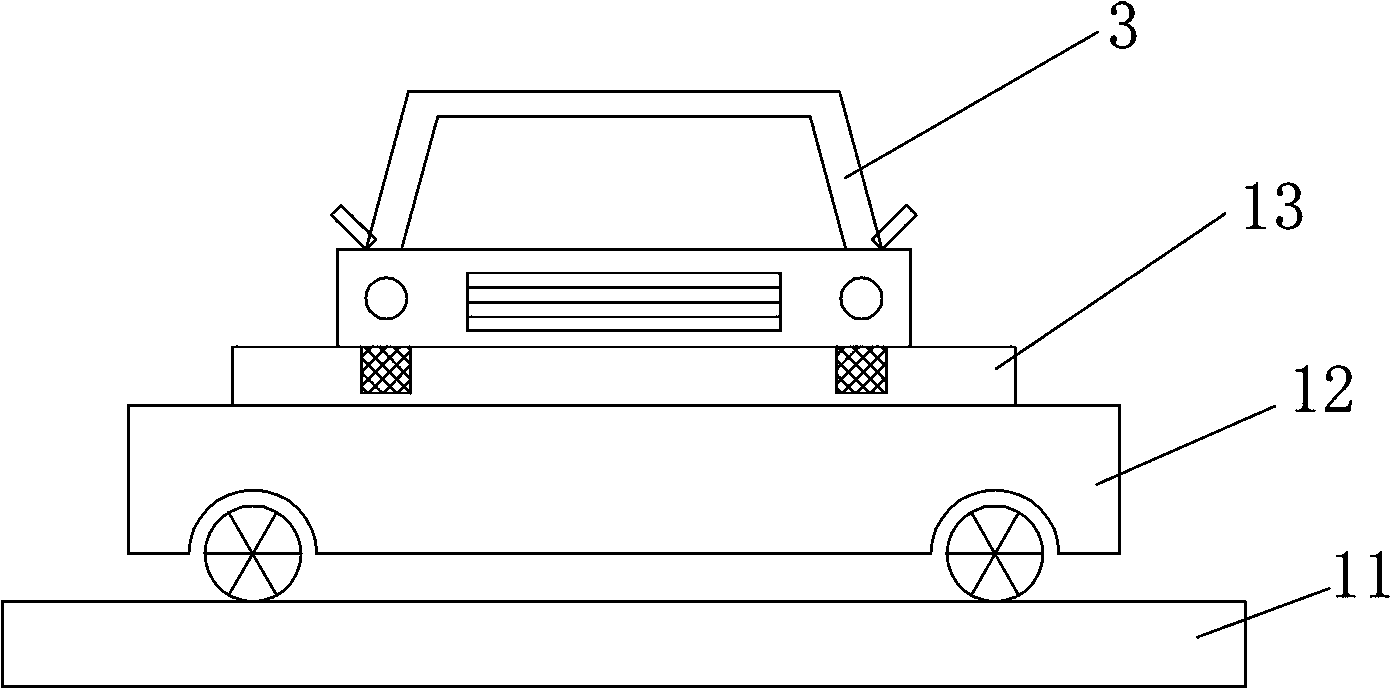

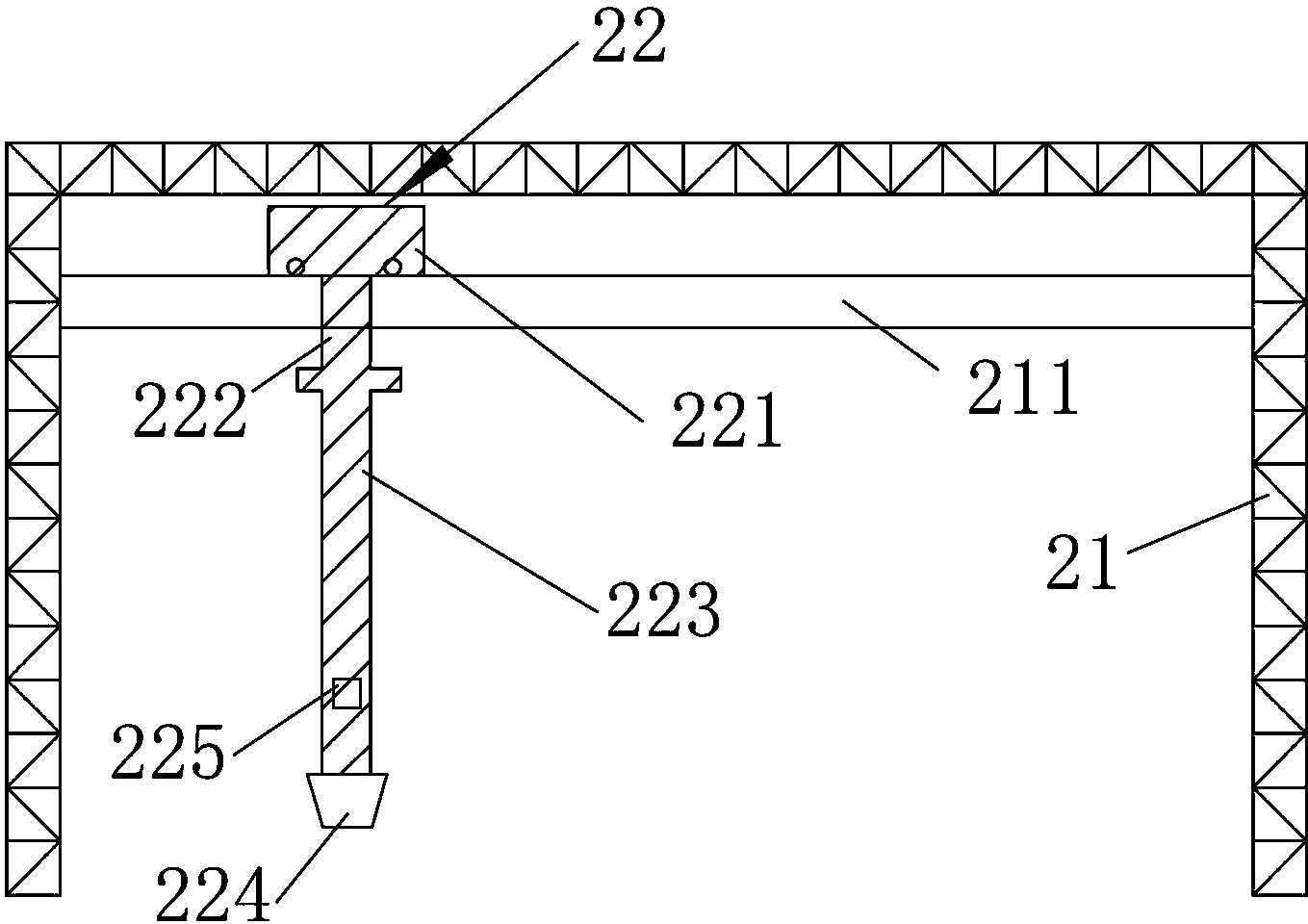

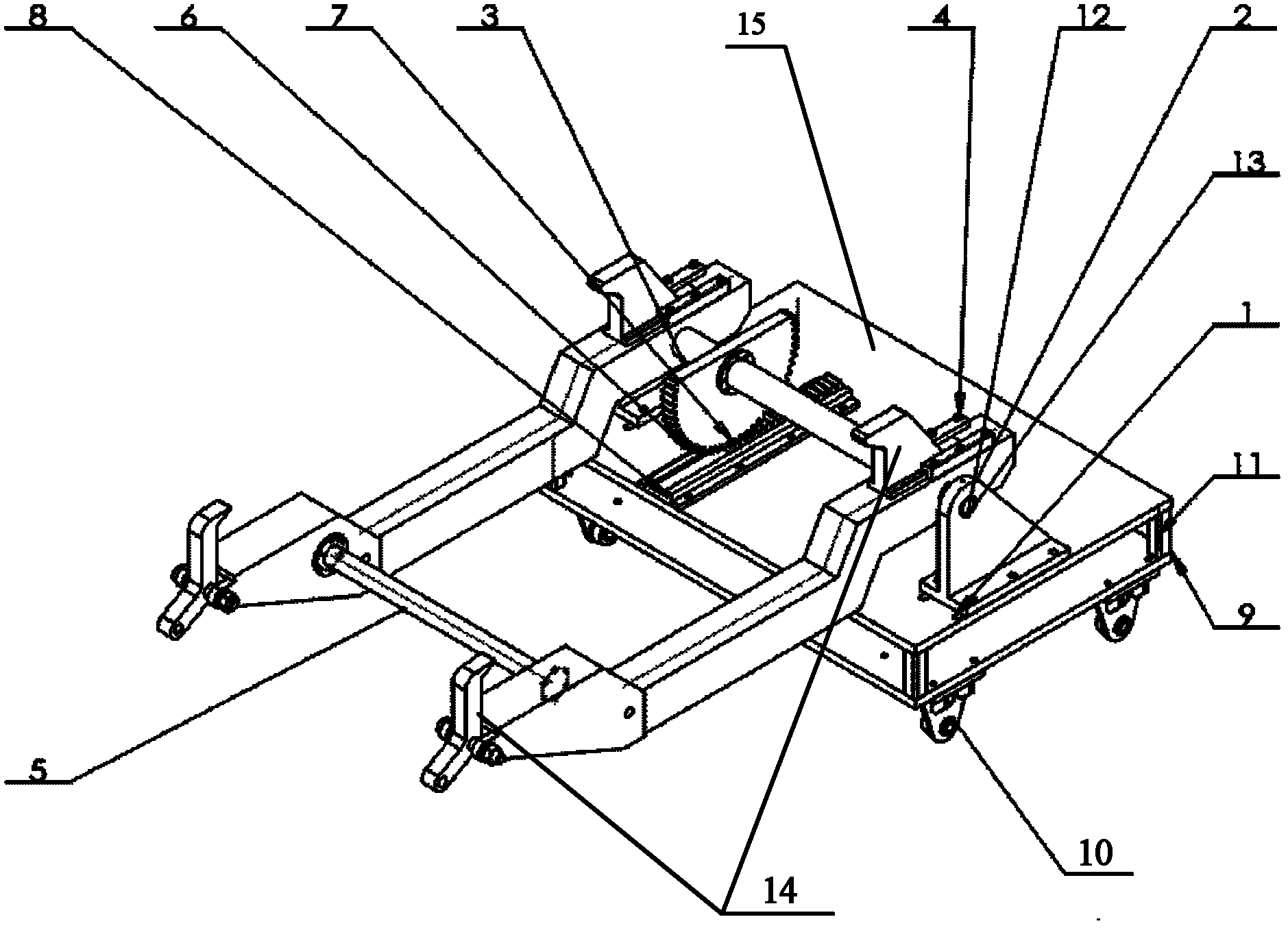

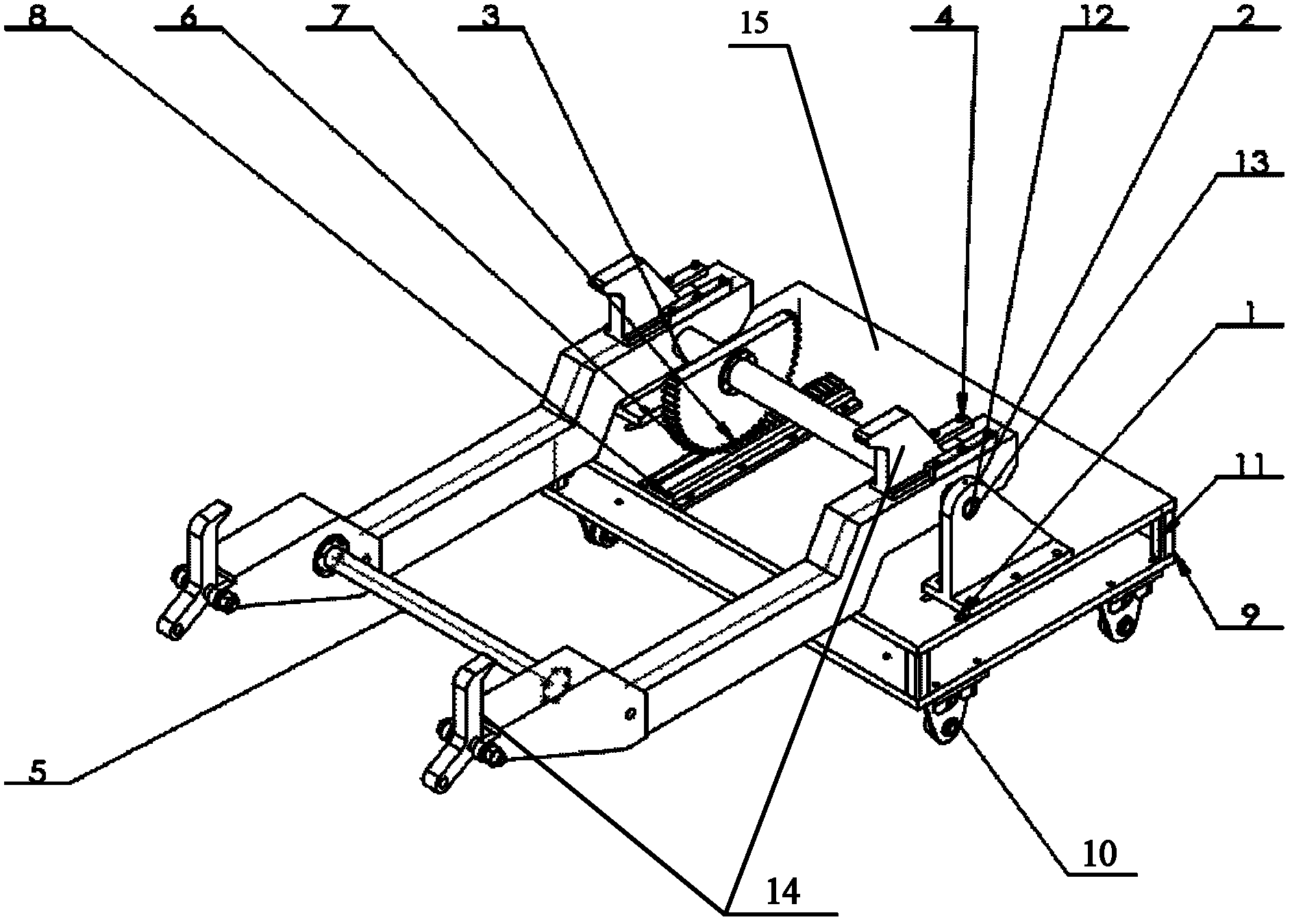

Mechanical scrapped car disassembling platform

InactiveCN102050170AEasy to disassembleReduce labor intensityVehicle dissasembly recoverySolid waste disposalEngineeringPortal frame

The invention relates to a mechanical scrapped car disassembling platform suitable for disassembling scrapped cars. The mechanical scrapped car disassembling platform comprises a base (1), a sliding carriage (6) and a portal frame (16); the top of the base (1) is provided with a first mechanical jack (5) and two guide posts (9); the sliding carriage (6) is sleeved on the two guide posts (9) emptily, and the bottom of the sliding carriage (6) is connected with the first mechanical jack (5); a first screw mandrel (13) vertically passes through the top of the portal frame (16), and the lower endof the first screw mandrel (13) is linked with a nut press block (14); the portal frame (16) is internally provided with a set of mechanism for clamping a scrapped car, the mechanism consists of a second screw mandrel (21), a long nut (23), two connecting rods (24), a movable supporting plate (17) and a handwheel (25), wherein one ends of the two connecting rods (24) are hinged with the long nut (23), and the other ends of the two connecting rods (24) are hinged with the movable supporting plate (17). The invention can realize that a plurality of parts on the scrapped car can be disassembled on the same site and station.

Owner:JIANGSU HUAHONG TECH STOCK

One-stop type disassembling process for small-sized automobile

ActiveCN108749960ASolve the problem of low disassembly efficiencyEfficient disassemblyVehicle dissasembly recoverySolid waste disposalMagnetic separatorAgricultural engineering

The invention discloses a one-stop type disassembling process for a small-sized automobile. The one-stop type disassembling process for the small-sized automobile comprises slide rails; the number ofthe slide rails is two; and slide grooves are formed in the tops of the slide rails. According to the one-stop type disassembling process for the small-sized automobile, through coordination of a cutting frame, a cutting device, an adjusting frame, rolling wheel carriers, rolling wheels, a motor, a rotating shaft, a rotating disc, a first electric telescopic rod, a first fixing disc, a treatment box, a compression box, a supporting frame, a second motor, a threaded rod, a threaded sleeve, first hydraulic rods, second fixing discs, a second hydraulic rod, a first extrusion plate, a third hydraulic rod, a second extrusion plate, driving mechanisms, crushing rollers, discharging inclined plates, a screening box, a magnetic separator, a fan, an article storage box and a material fetching device, the problem that the disassembling efficiency of the traditional one-stop type disassembling process for the small-sized automobile is low is solved; and the one-stop type disassembling process forthe small-sized automobile has the advantages that the disassembling is efficient, time and labor are both saved during disassembling, the disassembling effect is good, and the disassembling efficiency is greatly enhanced.

Owner:广东拓展资源综合利用开发有限公司

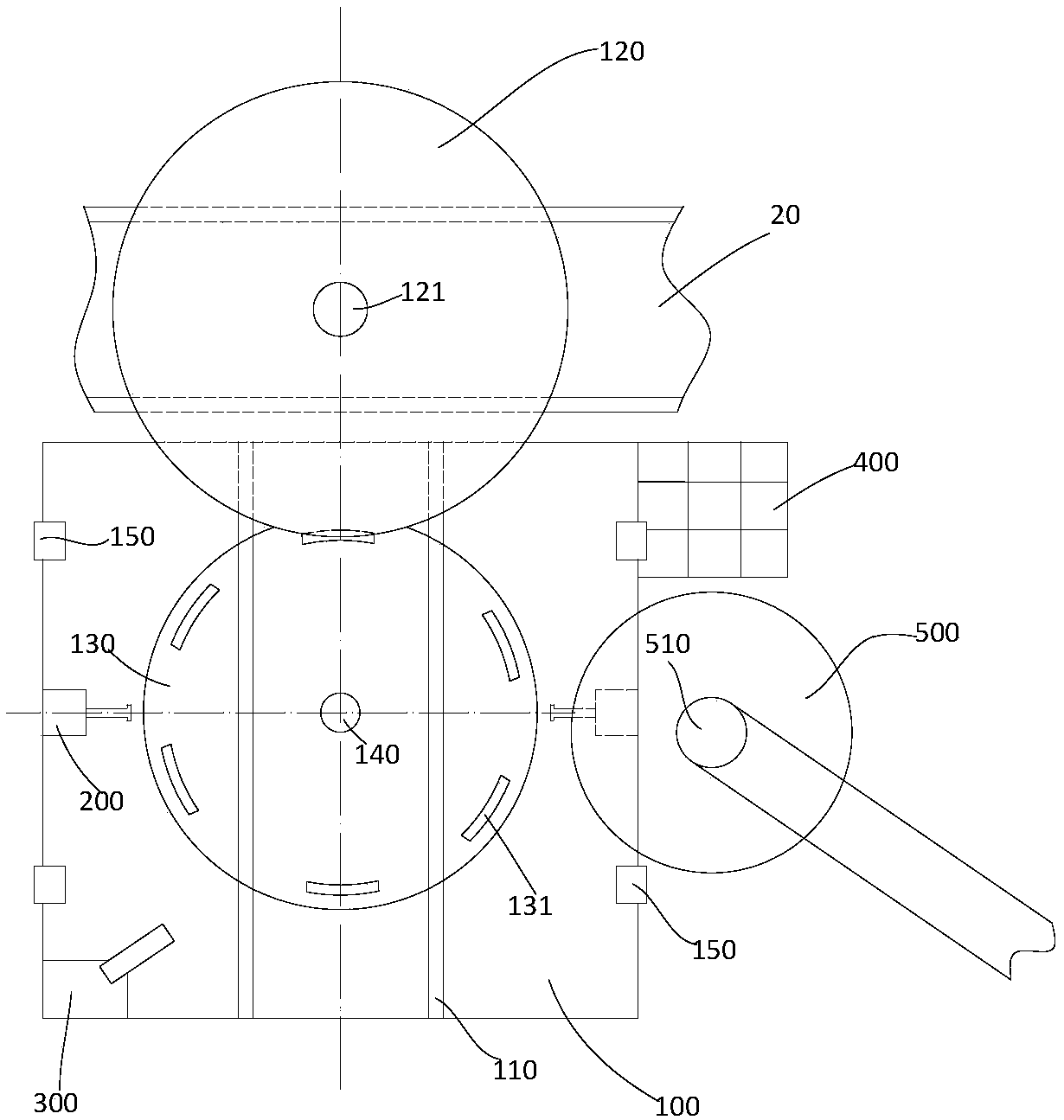

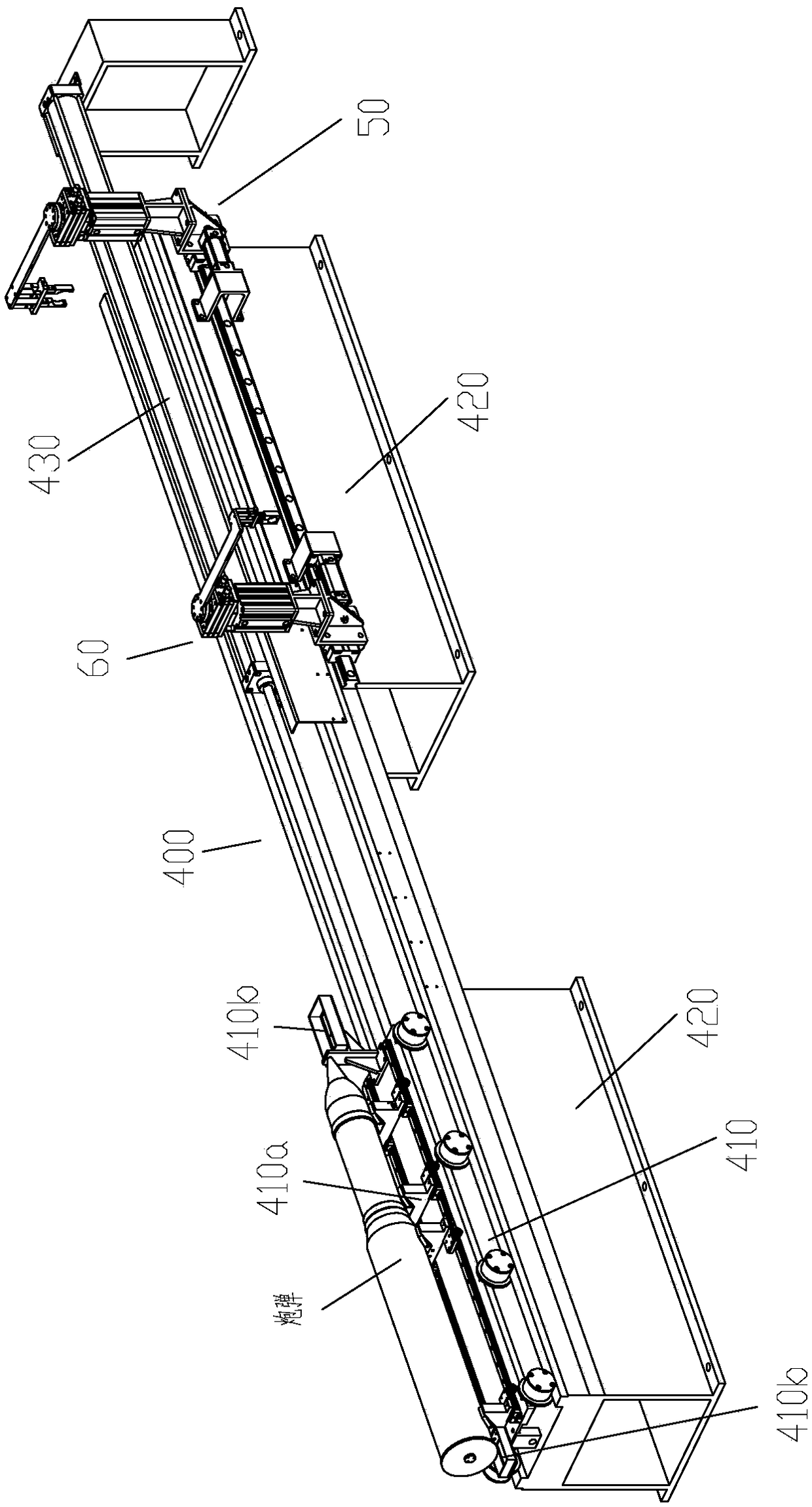

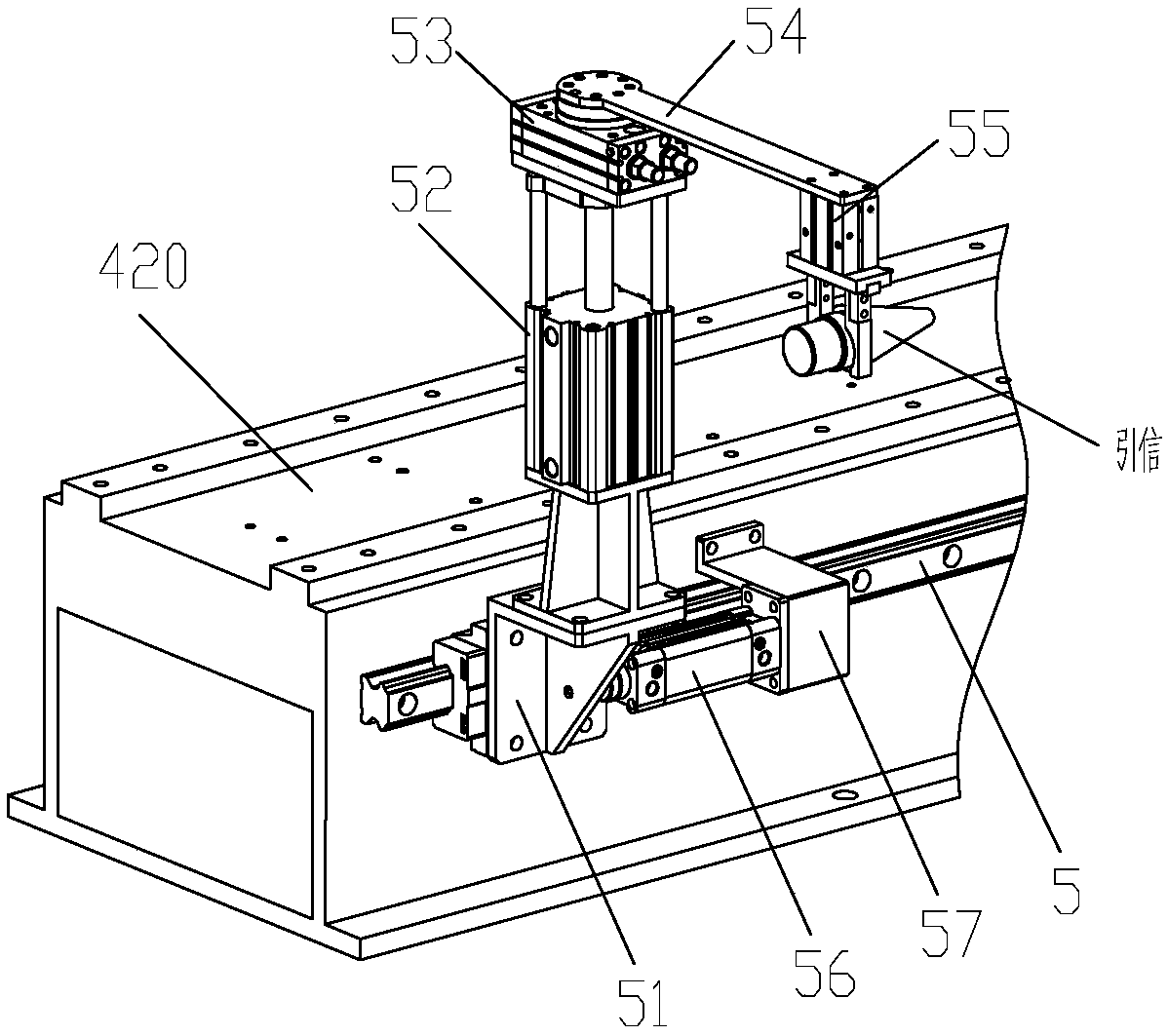

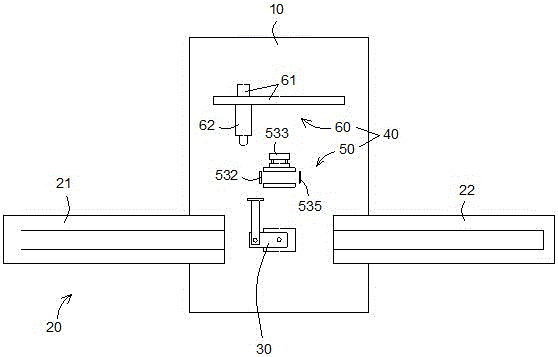

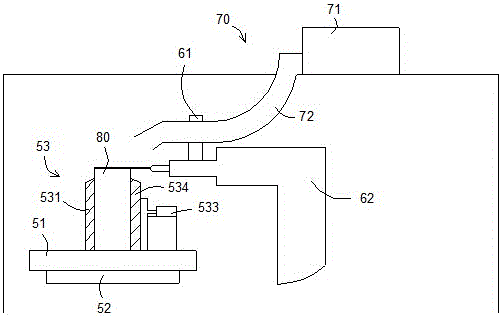

Cannonball dismantling line

The invention discloses a cannonball dismantling line. The cannonball dismantling line comprises a rotary dismantling separator and a cartridge case turning separator. The rotary dismantling separatoris used for dismantling cannonballs into fuses, bullets, cartridge cases and primers. The cartridge case turning separator is used for cutting off the bottoms of cartridge cases and separating explosives from the cartridge cases. The cartridge cases are conveyed between the rotary dismantling separator and the cartridge case turning separator through a cartridge case conveying line, a cannonballconveyor is arranged at the front end of the rotary dismantling separator, and a first truss manipulator is arranged above the combination portion of the rotary dismantling separator, the cannonball conveyor and the cartridge case conveying line. A cartridge case conveyor and an explosive conveying line are arranged at the rear end of the cartridge case turning separator. A second truss manipulator is arranged above the combination portion of the cartridge case conveying line, the cartridge case turning separator, the cartridge case conveyor and the explosive conveying line. The cannonball dismantling line has the beneficial effects that due to the reasonable configuration, the dismantling line can achieve the cannonball dismantling function and the explosive removing function and is compact in layout; and on the basis of the existing industrial control technology, automatic dismantling of cannonballs can be achieved, the cannonball dismantling line has high dismantling efficiency andgood safety, and dismantling cost is low.

Owner:重庆航天工业有限公司

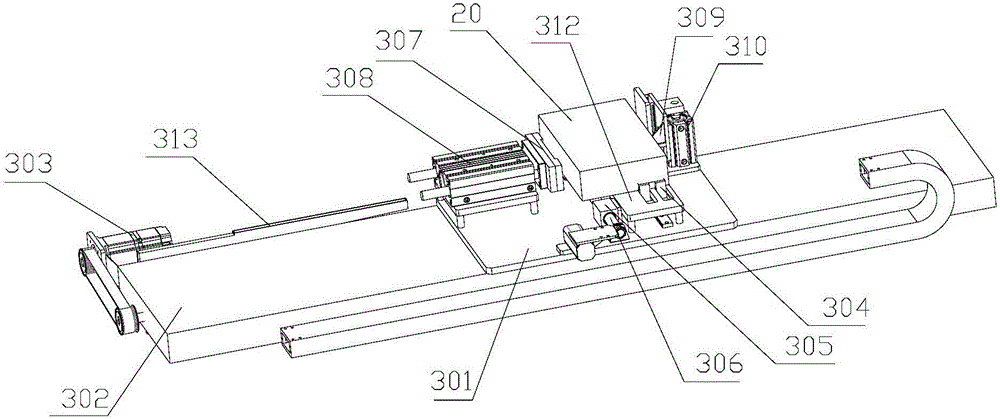

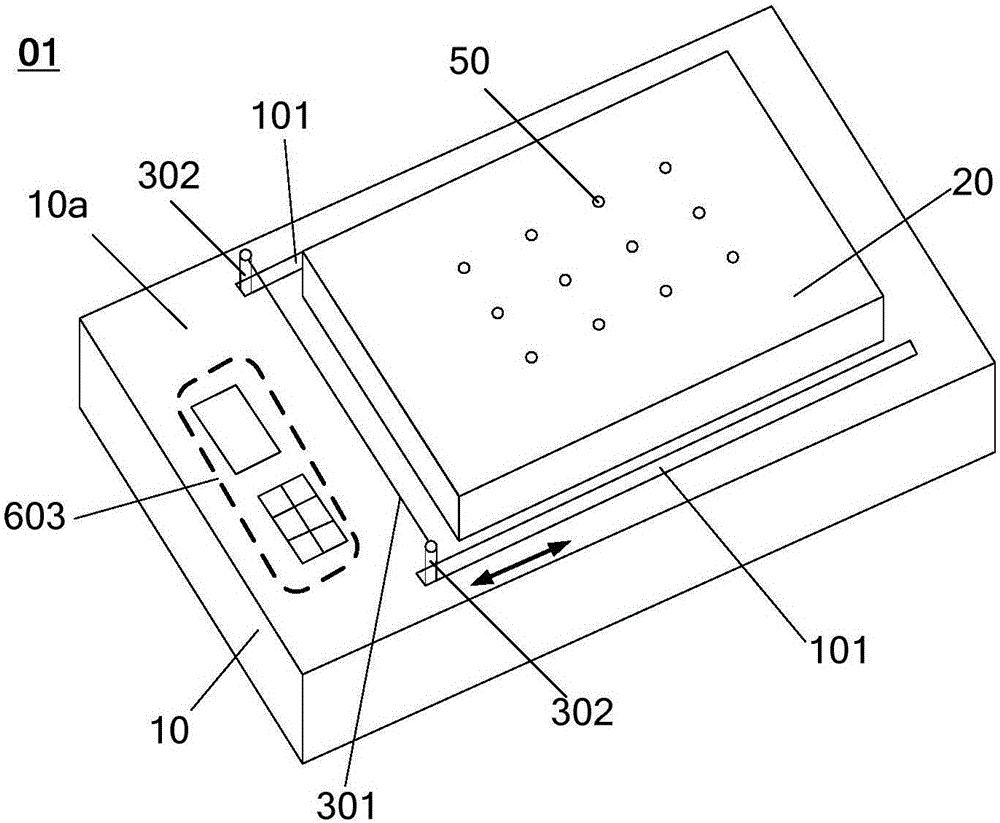

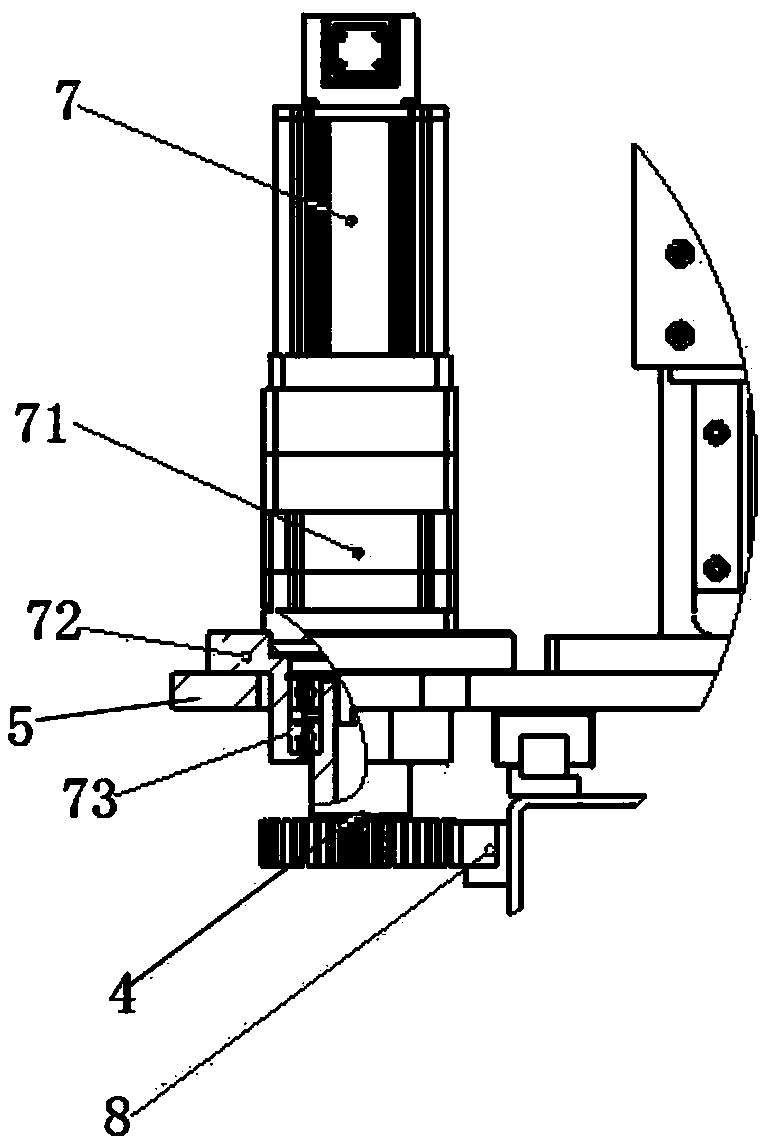

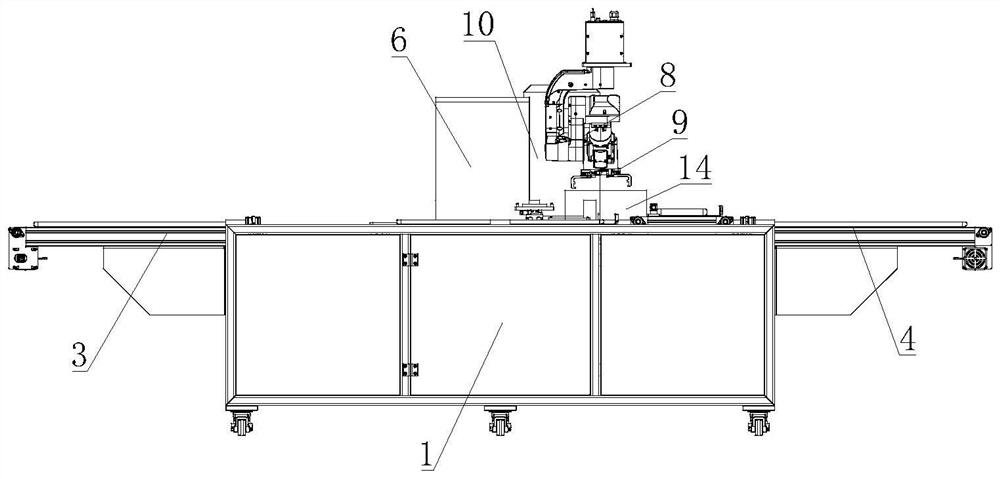

Laser cutting machine for square lithium battery

InactiveCN105935839ARealize automatic cuttingImprove dismantling efficiencyLaser beam welding apparatusPhysicsEngineering

The invention provides a laser cutting machine for a square lithium battery, which comprises a working platform, as well as conveying device, a feeding and discharging manipulator and a laser cutting device which are arranged on the working platform, wherein the laser cutting device comprises a clamping mechanism and a cutting mechanism which are arranged on the working platform. The laser cutting machine has the advantages that automatic cutting of the battery to be reworked due to air leakage is realized; the dismounting efficiency of the battery is improved obviously; and a battery reeling core can be recovered and reworked easily.

Owner:NANJING GUOXUAN BATTERY CO LTD

Disassembling device for waste motor casing

ActiveCN109551090AImprove dismantling efficiencyReduce dismantling lossSolid waste disposalPlasma welding apparatusControl systemAgricultural engineering

The invention discloses a disassembling device for a waste motor casing. The disassembling device comprises a frame, a conveying device, a cutting system, a control system and an image recognition device arranged above the frame. The conveying device, the cutting system and the image recognition device are respectively connected with the control system, the image recognition device is arranged above the conveying device, the image identification device includes an image recognition lens for automatically recognizing the external appearance of the waste motor, determining the model of the wastemotor, determining the position of the rib on the waste motor casing and determining the plasma cutting processing path, and the conveying device and the cutting system are arranged on the frame. Thedisassembling device has the characteristics of simple structure and safe and reliable work, can quickly cut the motor casing, improves the disassembly efficiency of the waste motor, improves the working environment of the motor disassembly, reduces the energy consumption, and reduces the dismantling loss of the waste motor.

Owner:JIANGSU UNIV OF TECH

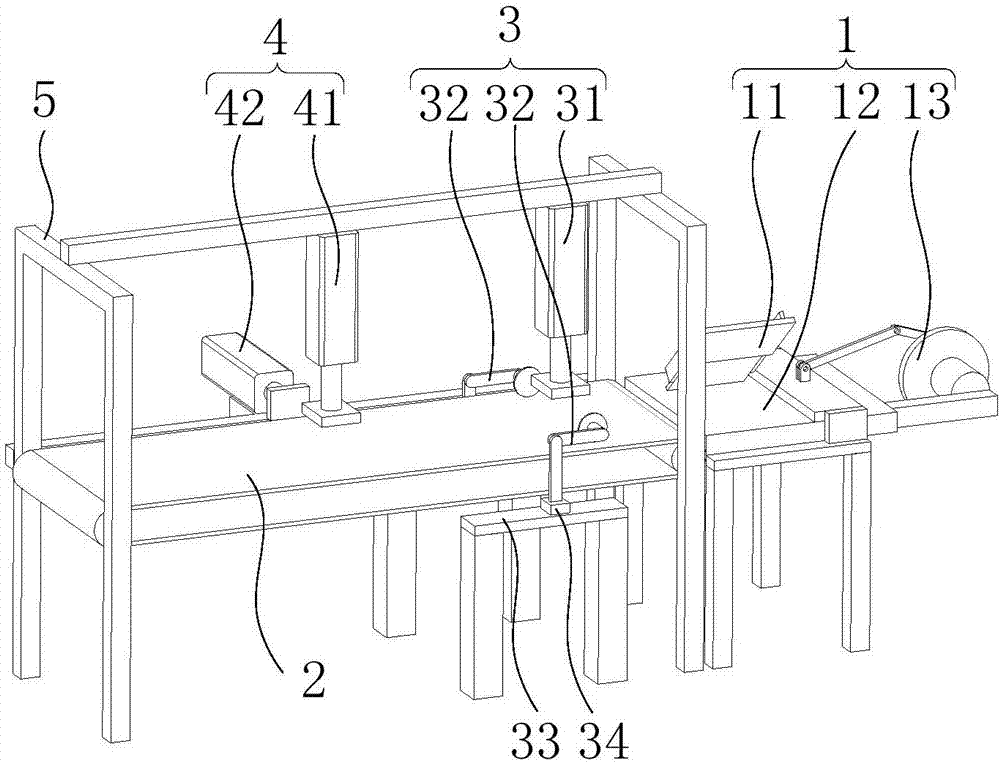

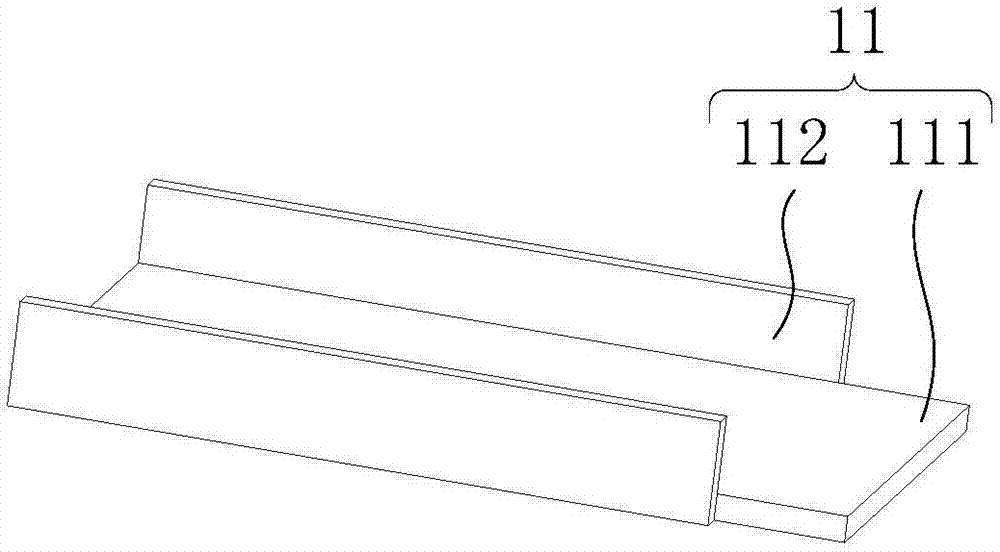

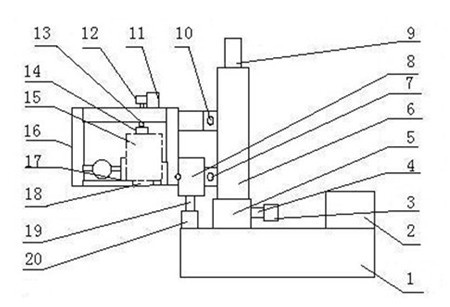

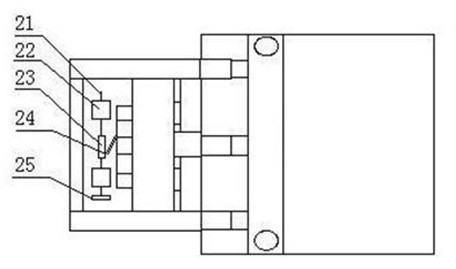

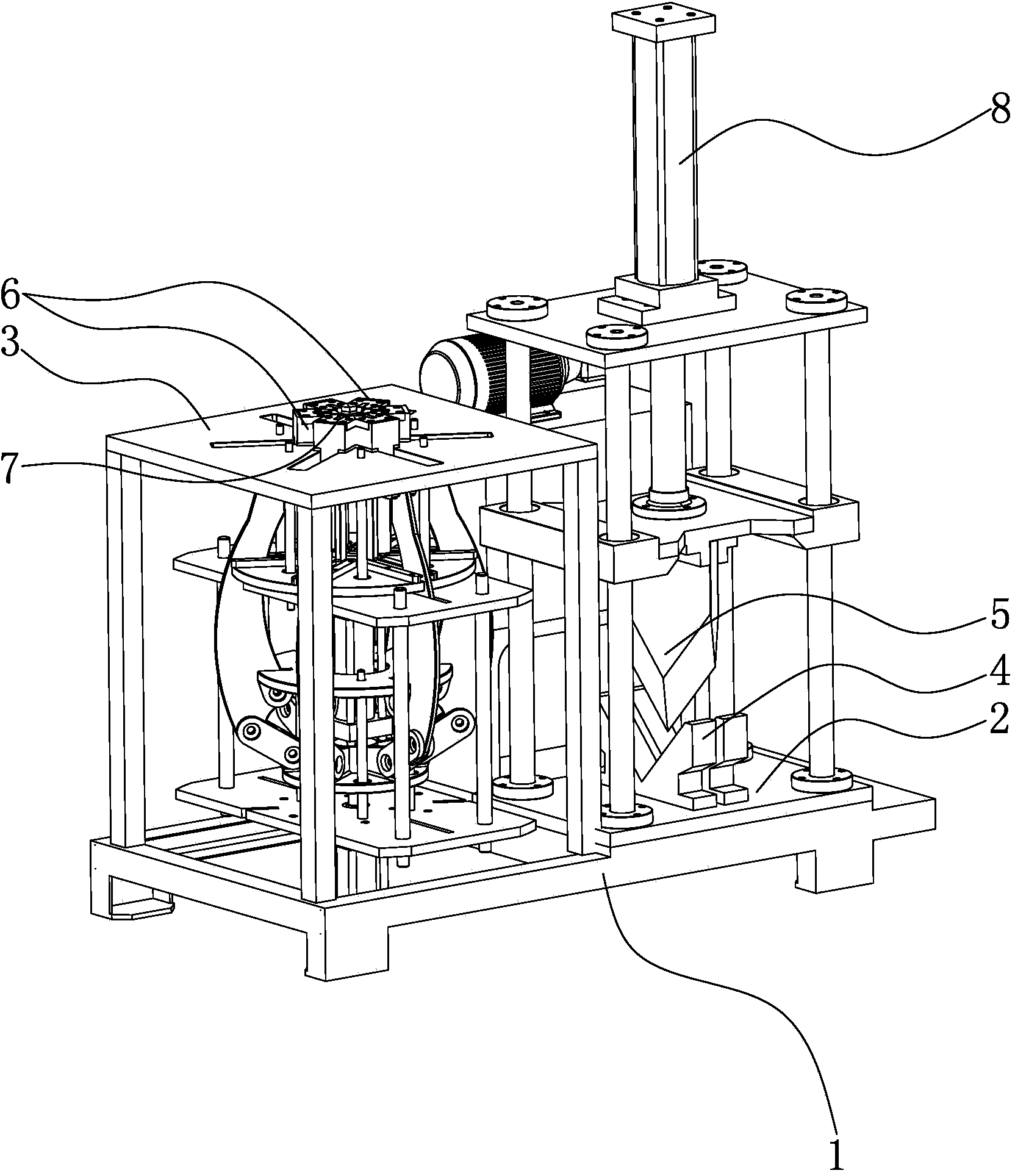

Detaching and recovery processing integrated machine and recovery processing method for waste motor

InactiveCN103978019AImprove dismantling efficiencyQuality improvementSolid waste disposalCopperConductor Coil

The invention provides a detaching and recovery processing integrated machine and a recovery processing method for a waste motor, belongs to the technical field of the detachment and recovery of the waste motor and solves the problems that the manpower and the time are wasted for detaching the waste motor, and copper windings are difficult to recycle. The integrated machine comprises a stander, wherein a cutting platform and a detaching platform are arranged on the stander, a motor stator fixing seat is detachably arranged on the cutting platform, a cutter controlled to move by a driver is arranged above the cutting platform, a plurality clamp claws are arranged on the detaching platform by surrounding the center of the detaching platform and are driven by the driving mechanism to move on the detaching platform so as to movably gather and disperse clamped objects, and motor stator thimbles driven by the driver are arranged on the clamp claws. The detaching and recovery processing integrated machine has the advantages that the detachment can be finished by virtue of twice operations, the efficiency is high, the pollution is avoided, and the like.

Owner:TAIZHOU MAYSLYNN RECYCLING EQUIP & TECHOLOGY

Waste lead-acid battery disassembling and electrolyte recycling device

InactiveCN111934046AGuaranteed stabilityPlay a protective effectWaste accumulators reclaimingBattery recyclingElectrical batteryEnvironmental engineering

The invention discloses a waste lead-acid battery disassembling and electrolyte recycling device. An upper rack is fixedly mounted on a lower rack, and shell plates are arranged on the periphery of the upper rack and the periphery of the lower rack. A feeding conveying belt and a discharging conveying belt are fixedly mounted on the two sides of the lower rack correspondingly. The feeding conveying belt is used for conveying the waste lead-acid batteries into the upper rack; the discharging conveying belt is used for conveying the waste lead-acid batteries out of the upper rack; the waste lead-acid battery is automatically carried and steered by arranging the manipulator assembly; the feeding conveying belt, the discharging conveying belt and a transfer conveying belt are arranged, the waste lead-acid batteries are automatically conveyed, workers do not need to make direct contact with the batteries in the whole conveying process, the workers are effectively protected, the clamping mechanism is arranged in a cutting machine box to clamp the waste lead-acid batteries, the stability during battery cutting is ensured, the lead screw drives the cutter to automatically move to cut and disassemble the lead-acid batteries, and the disassembling efficiency is improved.

Owner:太和县大华能源科技有限公司

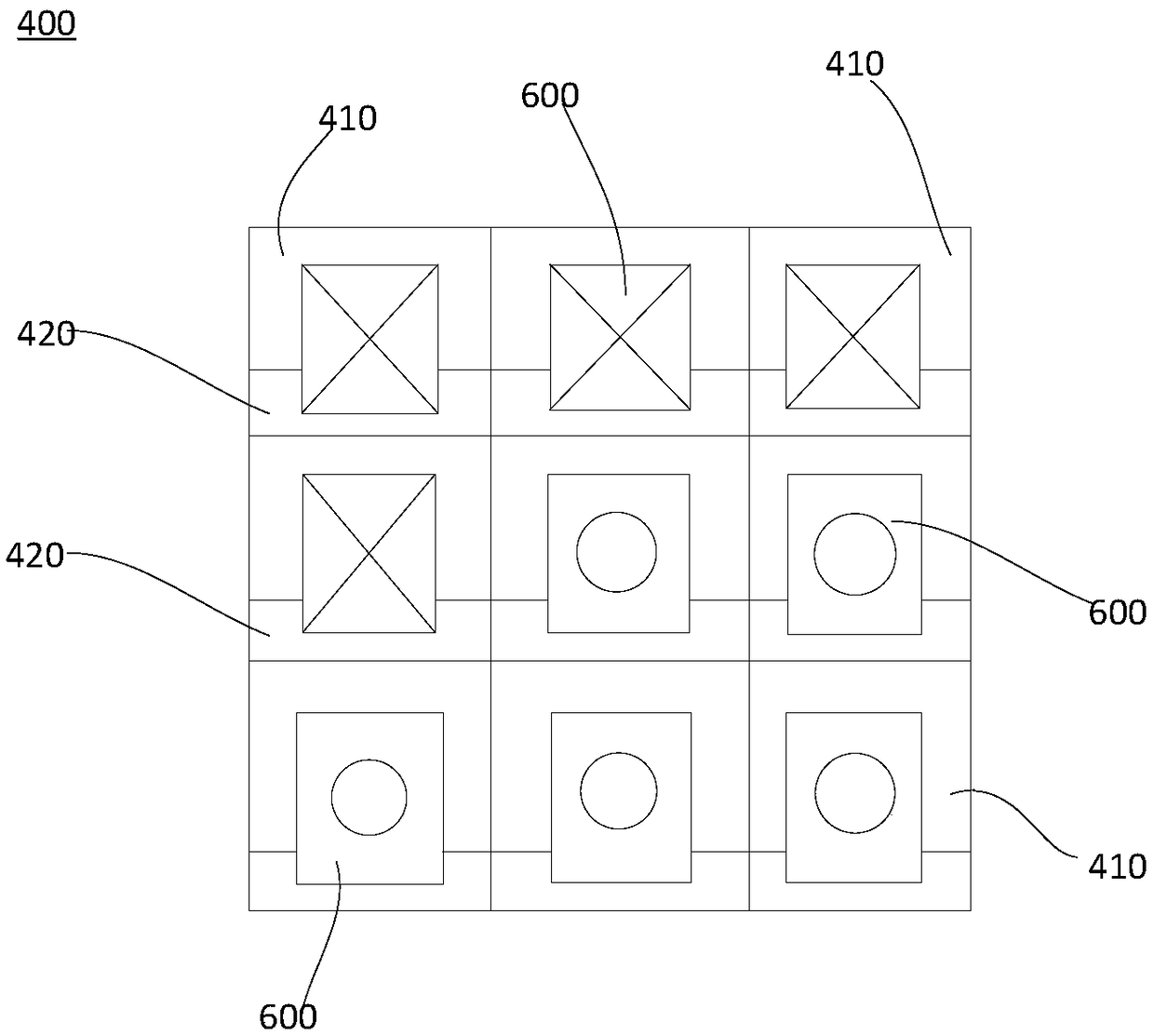

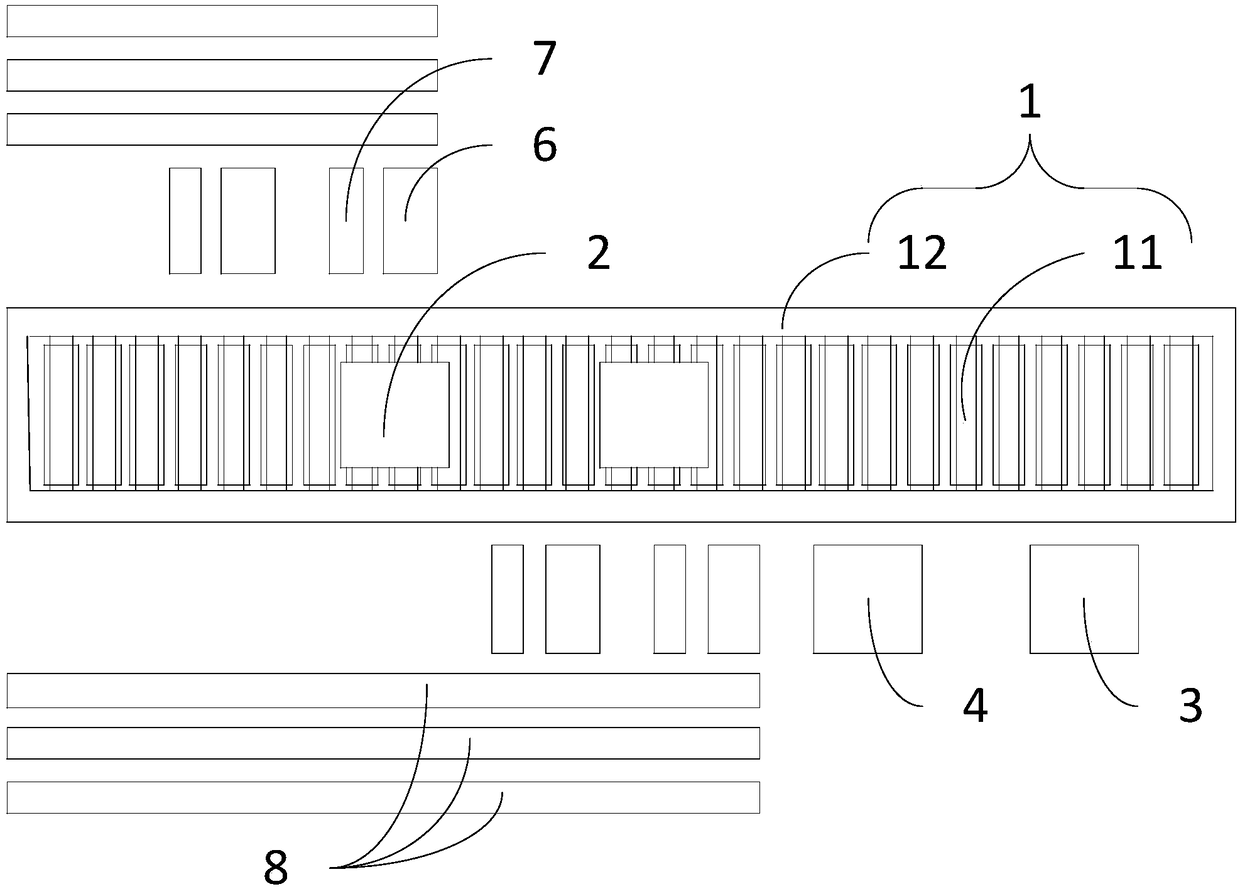

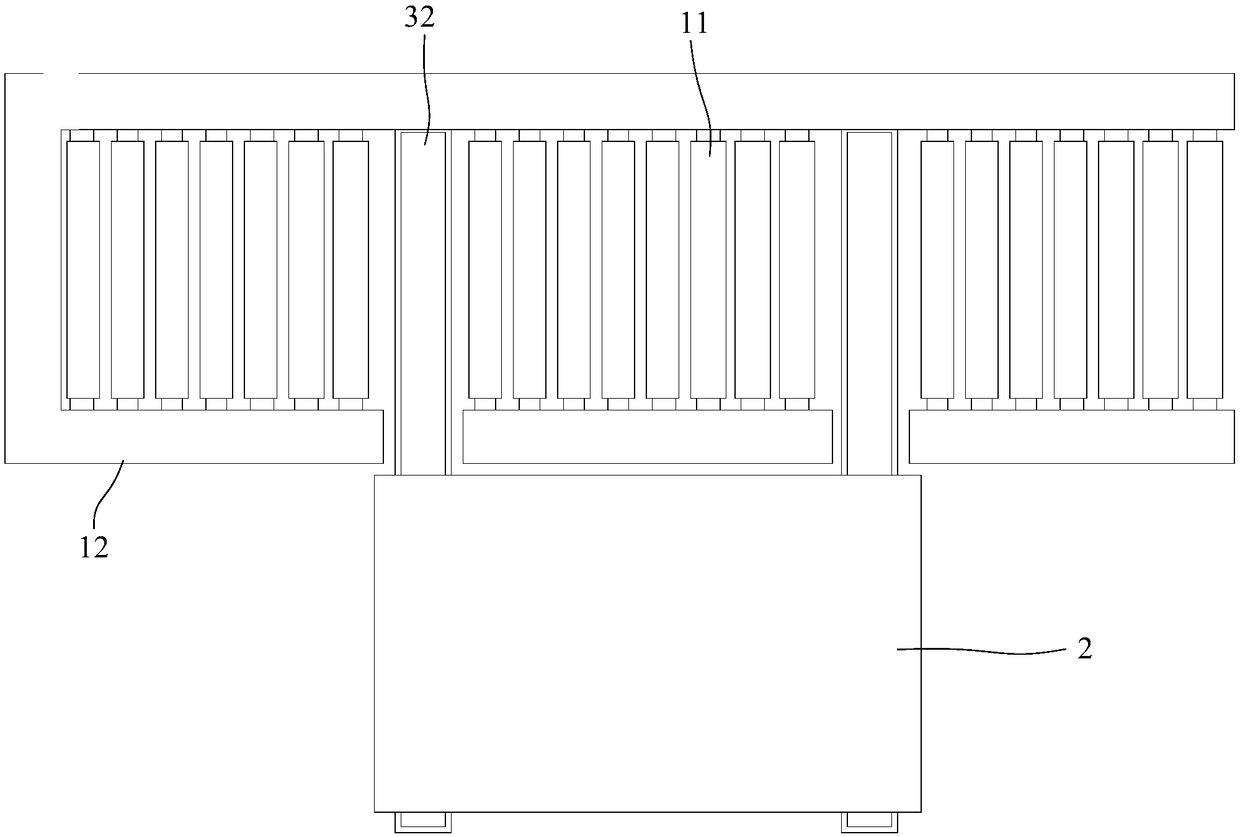

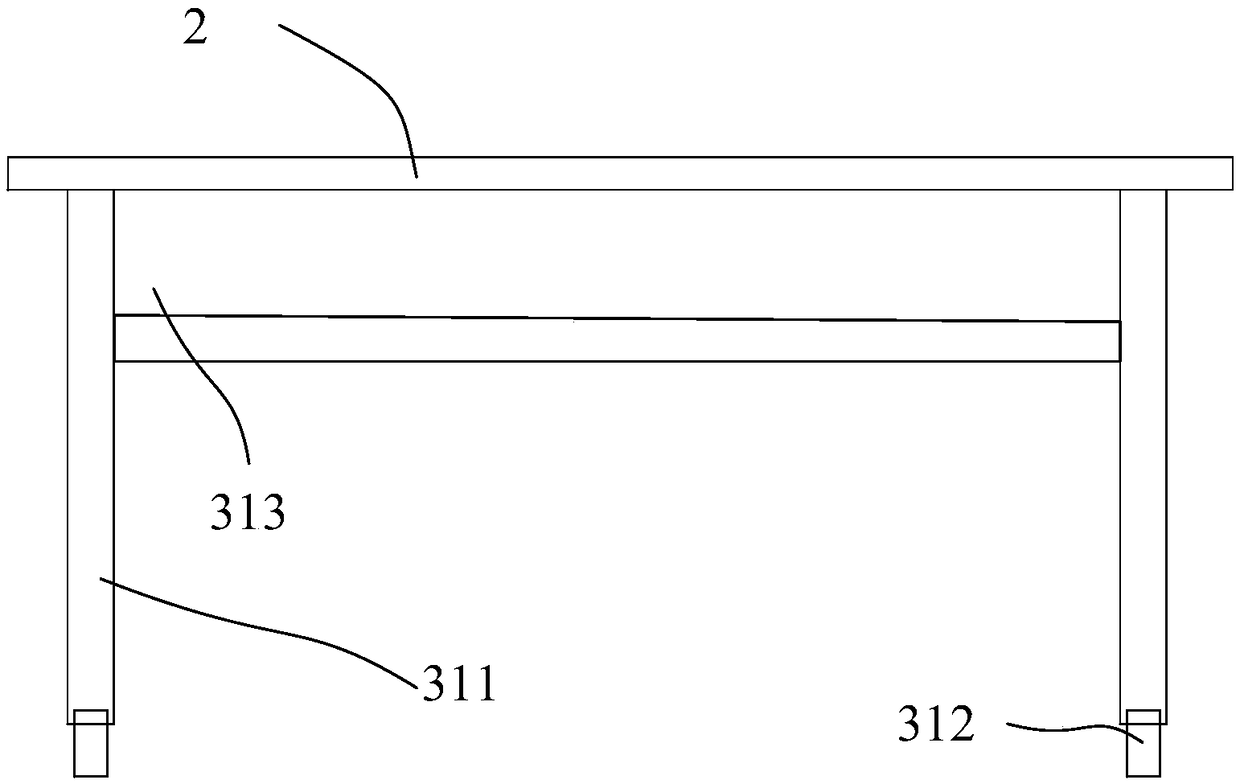

Battery pack disassembly line

PendingCN108736089AReduce labor intensityImprove dismantling efficiencyWaste accumulators reclaimingBattery recyclingAssembly lineEngineering

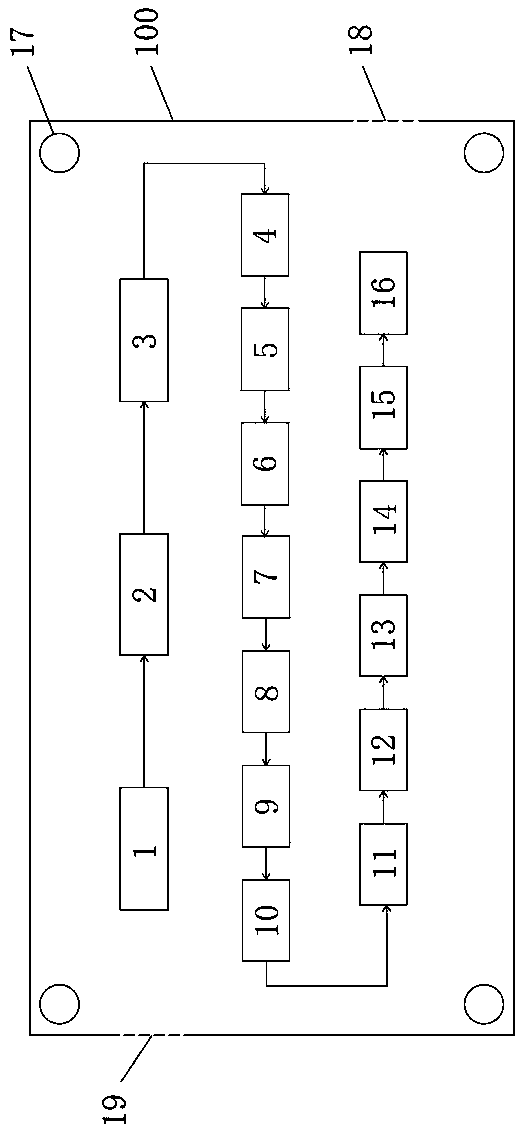

The embodiment of the invention discloses a battery pack disassembly line. The battery pack disassembly line comprises a transmission main line, a plurality of carrying plates, a feeding mechanism, aliquid pumping mechanism, a plurality of disassembly mechanisms, a plurality of detection mechanisms and a plurality of transmission branches, wherein the carrying plates are arranged on the transmission main line, the feeding mechanism, the liquid pumping mechanism and the disassembly mechanism are sequentially arranged along a transmission direction of the transmission main line, the detection mechanisms and the disassembly mechanisms are arranged in one-to-one correspondence, and three of the transmission branches are arranged asides each disassembly mechanism. Compared with the prior art,the battery pack disassembly line has the following beneficial effects that all processes, namely cooling liquid pumping, multi-stage disassembly, detection and classification, of disassembly a battery pack can be achieved by the battery pack disassembly line, no transfer is needed on a plurality of assembly line, the labor intensity of a worker is reduced, and moreover, the disassembly efficiencyis improved.

Owner:武汉动力电池再生技术有限公司

Disassembling device for photovoltaic module

PendingCN110690325AImprove dismantling efficiencyImprove broken rateFinal product manufactureSolid waste disposalEngineeringOblique angle

The invention discloses a disassembling device for a photovoltaic module. The disassembling device comprises a spraying device disposed on an upper frame. The spraying device includes: a first drivingmechanism used for driving a moving beam to move laterally along the upper frame; a nozzle for spraying a disassembling liquid for the photovoltaic module, wherein the flow direction of the liquid sprayed by the nozzle and the back surface of the photovoltaic module form a tilt angle in a non-vertical state; a support mechanism movably arranged on the moving beam; a second driving mechanism disposed on the moving beam and used for driving the support mechanism to mover longitudinally along the upper frame; a pump having an output end connected to the nozzle; and a controller used for controlling the spraying device and the photovoltaic module to move relatively according to a set path, and controlling the liquid sprayed by the spraying device to form a notch on the back surface of the photovoltaic module in order that the liquid enters the photovoltaic module at an oblique angle along the cut. The liquid with pressure is expanded inside the photovoltaic module and achieves cutting. The disassembling device has the advantage of improving disassembly efficiency.

Owner:CHANGZHOU RUISAI ENVIRONMENTAL PROTECTION TECH CO LTD

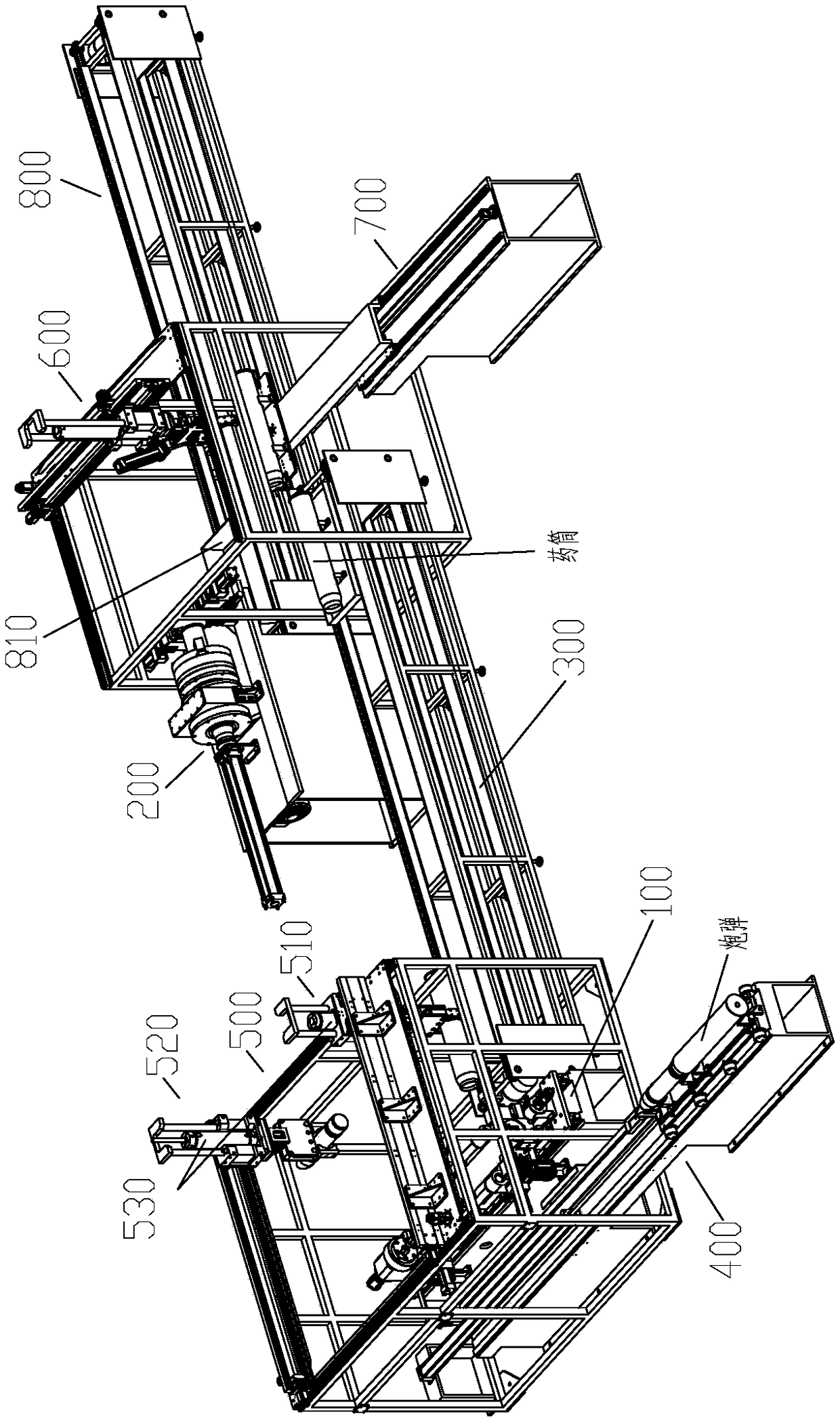

Power battery system recovery and dismantling production line based on stepwise recovery

PendingCN108110367AGuarantee the safety of lifeImprove assembly efficiencyWaste accumulators reclaimingBattery recyclingProduction linePower battery

The invention discloses a power battery system recovery and dismantling production line based on stepwise recovery. The production line is arranged in a dust-free workshop. The dismantling productionline comprises a test evaluation line, a mechanical disassembling line and a recovery and recycling line orderly connected. The test evaluation line is used for evaluating and testing the safety of abattery dismantling system to be recovered. The mechanical disassembling line is used for dismantling and recovering components of the battery system. The recovery and recycling line is used for assembling and testing the stepwise battery system. The invention provides the power battery system recovery and dismantling production line based on stepwise recovery has reasonable station layout, effectively improves the disassembling and assembling efficiency and fully realizes the stepwise use of components in the battery system.

Owner:SHENZHEN BAK BATTERY CO LTD

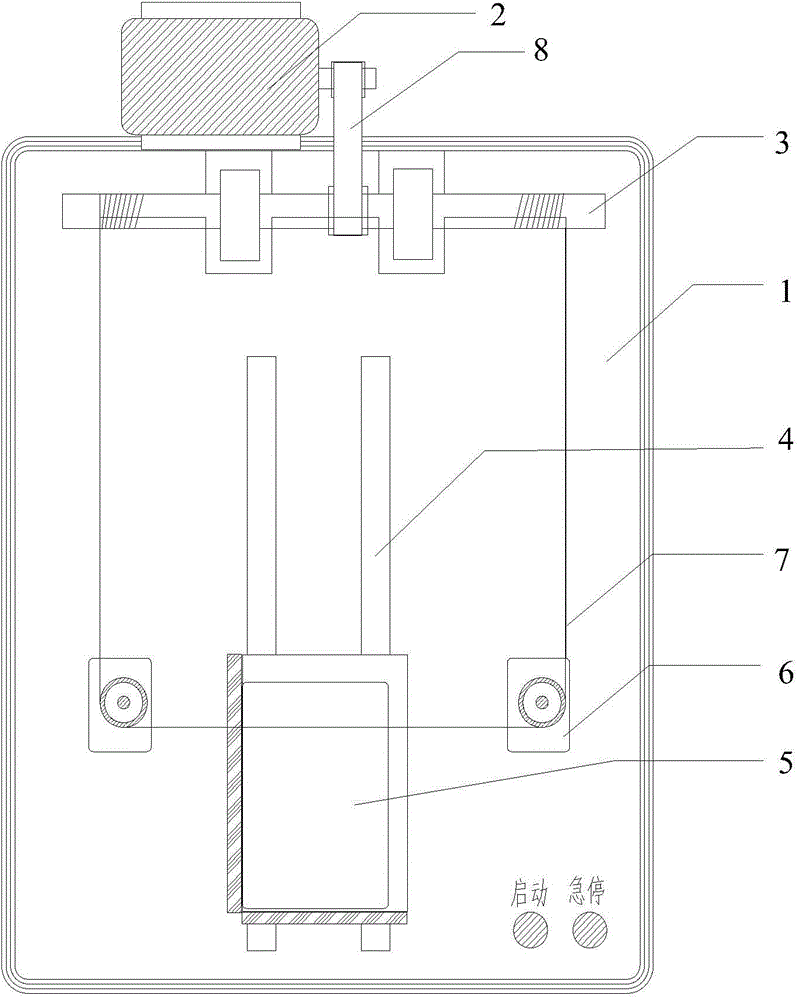

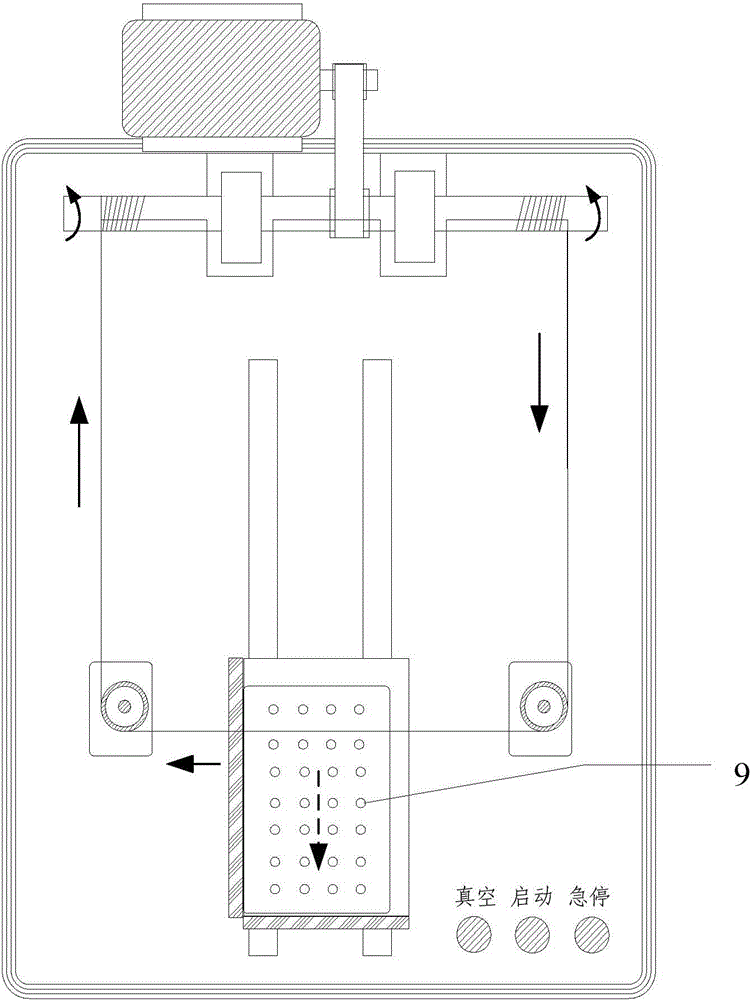

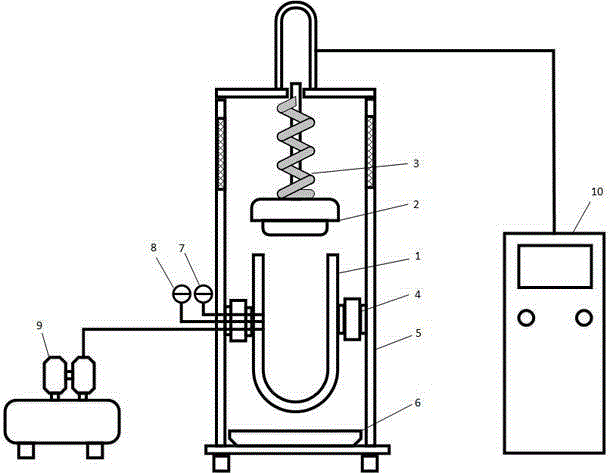

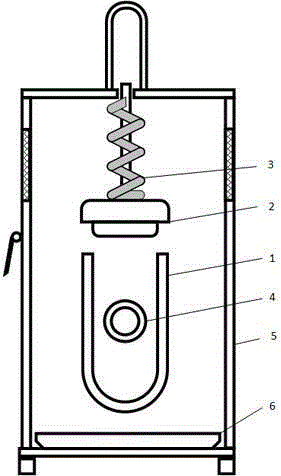

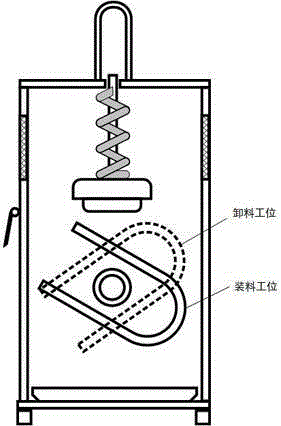

Air pressure dismantling device and method for waste mobile phone

InactiveCN105196035AGood dissociation effectImprove dismantling efficiencyMetal working apparatusElectronic control systemHazardous substance

The invention discloses an air pressure dismantling device and method for a waste mobile phone. The device comprises an air pressure tank, an air compressor and an electronic control system, wherein the air pressure tank comprises a tank body and a cover, a magnetically controlled switch is arranged between the tank body and the cover, a spring slideway is arranged above the cover, and opening and closing of the cover is controlled by the electronic control system; when the cover is closed, airtight connection is formed between the tank body and the whole cover; the air compressor is connected with the air pressure tank through a pipeline. According to the method, differential pressure inside and outside a mobile phone shell is produced, the mobile phone shell is broken from inside under the action of air pressure, and the purpose of mobile phone dismantling is achieved. The method and the device are green and environment-friendly, production of toxic and harmful substances in an implementation process is avoided, batch, efficient and environment-friendly dismantling of the waste mobile phones is realized, the waste mobile phone dismantling efficiency of an electronic waste dismantling enterprise can be greatly improved, and the labor cost is reduced.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

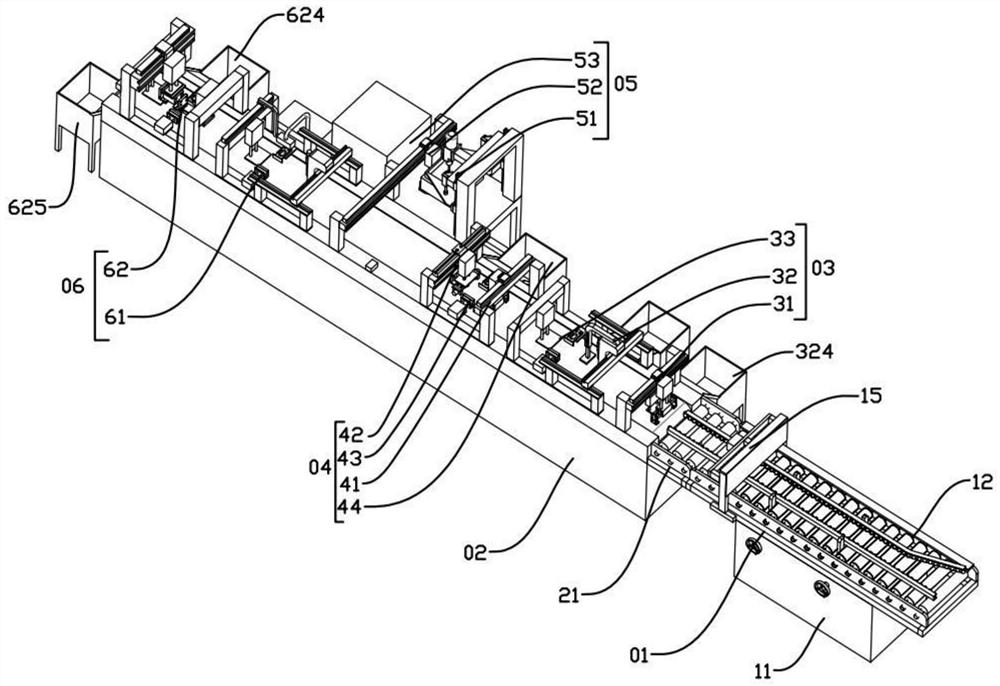

Automatic waste ammeter dismantling system

PendingCN111889729AAvoid injuryReduce manpower consumptionPositioning apparatusMetal working apparatusEnvironmental engineeringAssembly line

The invention discloses an automatic waste ammeter dismantling system which comprises a waste ammeter conveying device, an ammeter transferring device, a waste ammeter cover nail loosening device, a waste ammeter cover dismantling device, a waste ammeter circuit board perforating device and a waste ammeter circuit board dismantling device. The waste ammeter conveying device is arranged at the inlet end of the ammeter transferring device. According to the structural characteristics of a waste ammeter, the waste ammeter cover nail loosening device, the waste ammeter cover dismantling device, thewaste ammeter circuit board perforating device and the waste ammeter circuit board dismantling device are sequentially fixedly arranged on the ammeter transferring device, the waste ammeters are sequentially dismantled according to an assembly line form, and all components of the waste ammeter are recycled in a classified manner, so that manpower consumption is reduced, the dismantling efficiencyis improved, and the phenomenon that a staff is injured when the ammeter is dismantled during the production process is avoided.

Owner:YINCHUAN POWER SUPPLY COMPANY OF STATE GRID NINGXIA ELECTRIC POWER +1

Hot disassembly equipment for electronic circuit board component

InactiveCN102513634AHigh degree of automationImprove dismantling efficiencySoldering auxillary devicesEngineeringAutomation

The invention relates to circuit board treatment technology, in particular to hot disassembly equipment for an electronic circuit board component, which comprises a cabinet provided with a heating box. A heating device, an impact device and a component collecting device are arranged in the heating box. The hot disassembly equipment is characterized by further comprising a circuit board conveying device. As the hot disassembly equipment is provided with various automation devices, an operator only needs to hang a circuit board on a lifting hook on an operation platform (in front of an inlet of the temperature box), heating, impact, component collection and circuit board disassembly are automatically completed, automation degree is extremely high, the whole equipment is continuously operated, disassembly efficiency is extremely high, labor cost is greatly reduced, operation is extremely safe, and the equipment has excellent industrial prospect.

Owner:SHENZHEN TIANWEIDA ELECTRONICS +1

Disassembling device for liquid crystal display screen

ActiveCN104550183AGuaranteed absorptionIncrease flexibilitySolid waste disposalDirt cleaningLiquid-crystal displayWorking environment

The invention discloses a disassembling device for a liquid crystal display screen, relating to the technical field of production of display devices. The disassembling device of the liquid crystal display screen is of a box-type workbench; the box-type workbench comprises a workbench board, an air return system for forming a negative pressure environment and a filtering device which are arranged inside; the air return system comprises at least one air inlet hood and a centrifugal fan; the air inlet hood is arranged above the workbench board; an air inlet of the centrifugal fan is communicated with the air inlet hood through the filtering device and an air inlet pipe; an air outlet of the centrifugal fan is communicated with the outside through an air outlet pipe. The disassembling device for the liquid crystal display screen can create an independent negative pressure working environment for disassembling the liquid crystal display screen and ensure that mercury vapor can be completely absorbed, and is high in flexibility, high in safety, energy-saving and environment-friendly.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com