Waste vehicle disassembly production line and corresponding process

A production line and vehicle technology, which is applied in the fields of vehicle scrap recycling, motor vehicle and solid waste removal, etc., can solve the problems of high equipment cost, low disassembly efficiency and high cost, and achieve high disassembly efficiency, fast disassembly speed, Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

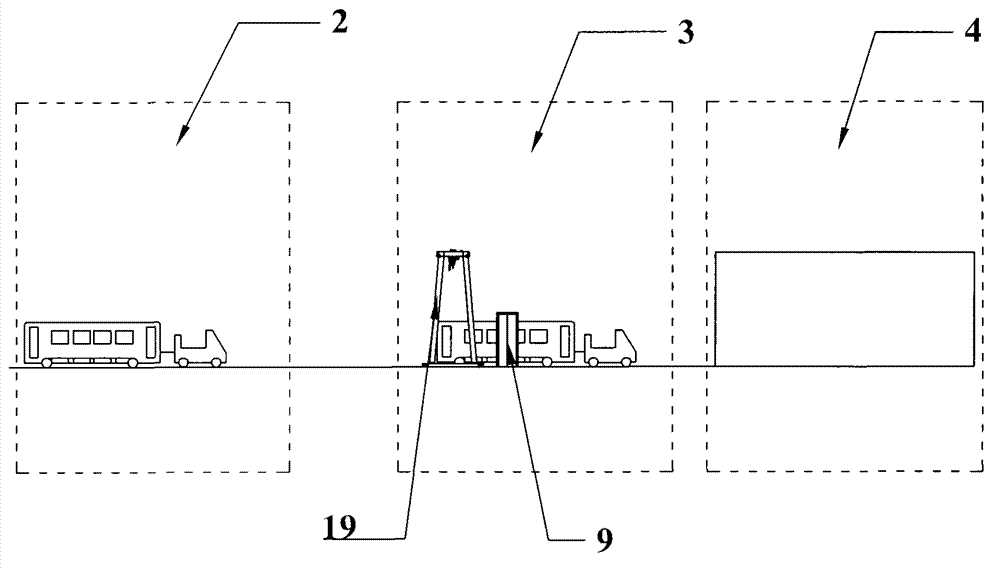

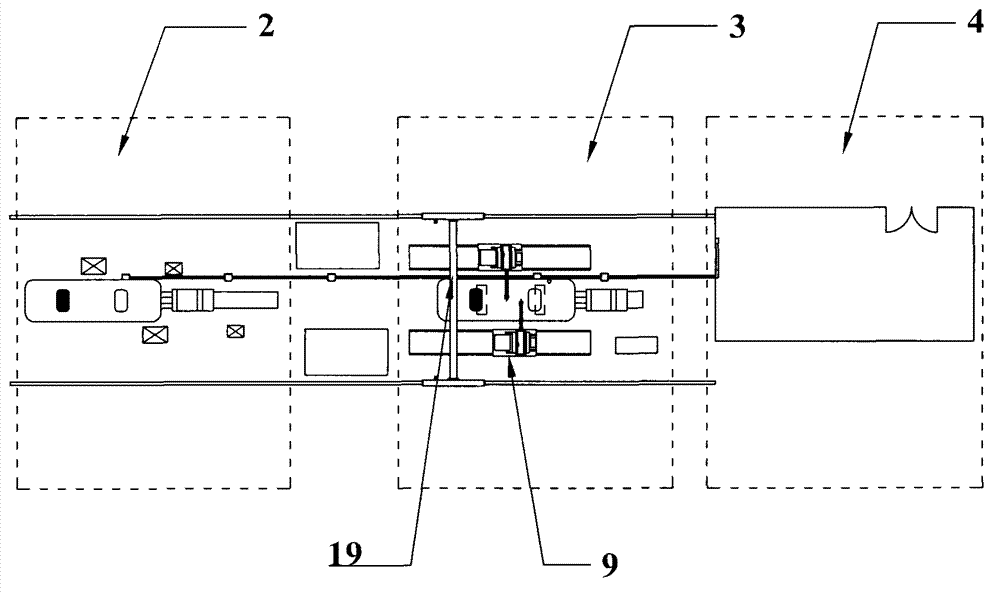

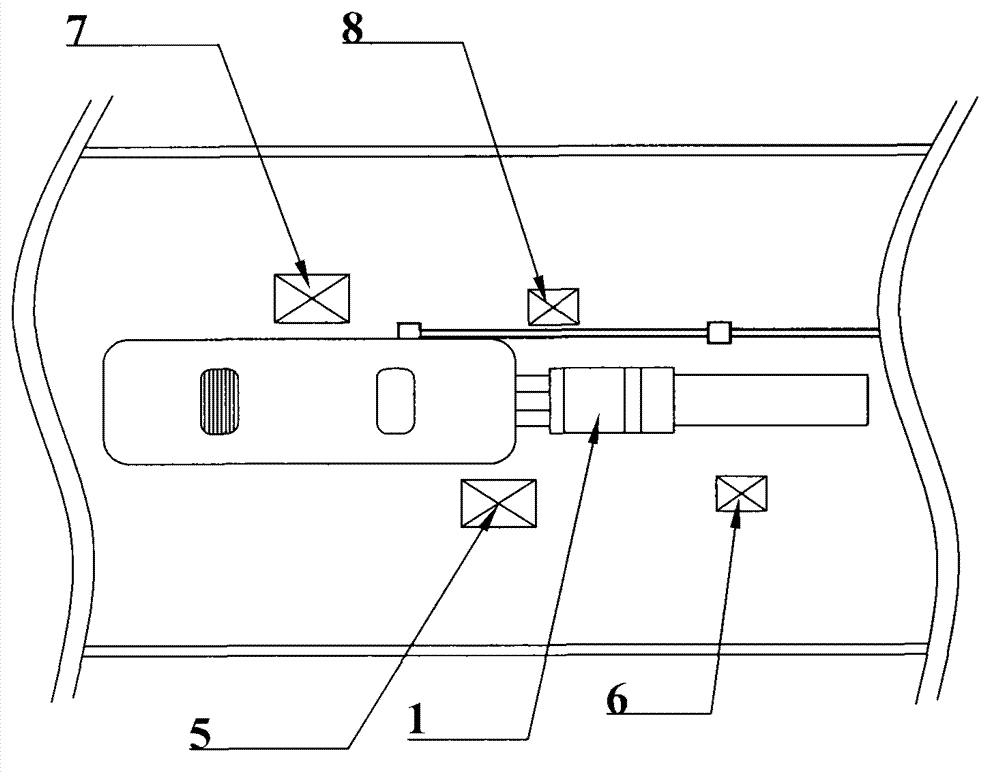

[0047] Implementation mode one: if Figure 1-6 As shown, the waste vehicle dismantling production line is provided with a tractor 1 and a chassis support assembly. The dismantling production line includes a pre-processing area 2, a semi-automatic dismantling area 3 and a refined dismantling area 4. The pre-processing area 2 includes Waste oil extraction station 5, refrigerant recovery station 6, windshield and electrical circuit dismantling station 7, interior decoration and tire dismantling station 8, and waste oil extraction station 5 is equipped with waste oil Liquid extraction equipment, refrigerant recovery station 6 is equipped with refrigerant extraction equipment, interior decoration and tire dismantling station 8 is equipped with a wind gun sleeve and a wind gun machine; the semi-automatic dismantling area 3 is located in the pre-processing area 2 Downstream position, the semi-automatic dismantling area 3 is equipped with semi-automatic dismantling equipment, chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com