Laser cutting machine for square lithium battery

A laser cutting machine and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of battery winding core damage, heavy workload, and low efficiency, so as to improve dismantling efficiency and realize automation The effect of cutting, easy recycling and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

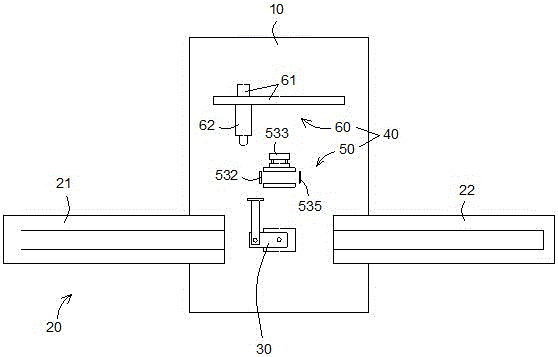

[0020] like figure 1 As shown, the square lithium battery laser cutting machine includes a working platform 10 , a conveying device 20 , a loading and unloading manipulator 30 and a laser cutting device 40 arranged on the working platform.

[0021] The conveying device 20 includes a feeding conveying device 21 positioned at the material inlet of the laser cutting device and a discharge conveying device 22 positioned at the discharge port of the laser cutting device, and the loading and unloading manipulator 30 is located between the feeding conveying device and the discharging conveying device Among them, the loading and unloading manipulator includes a four-joint robot and a battery gripper, which can rotate 360 degrees.

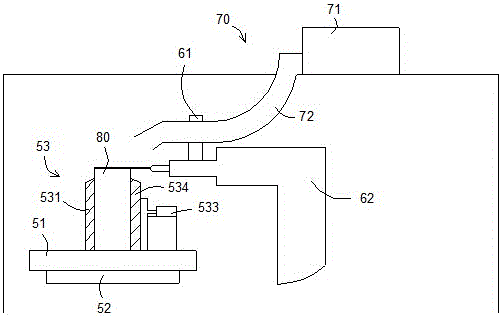

[0022] like figure 2 As shown, the laser cutting device 40 includes a clamping mechanism 50 and a cutting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com