Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

370results about "Automatic workpiece supply/removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

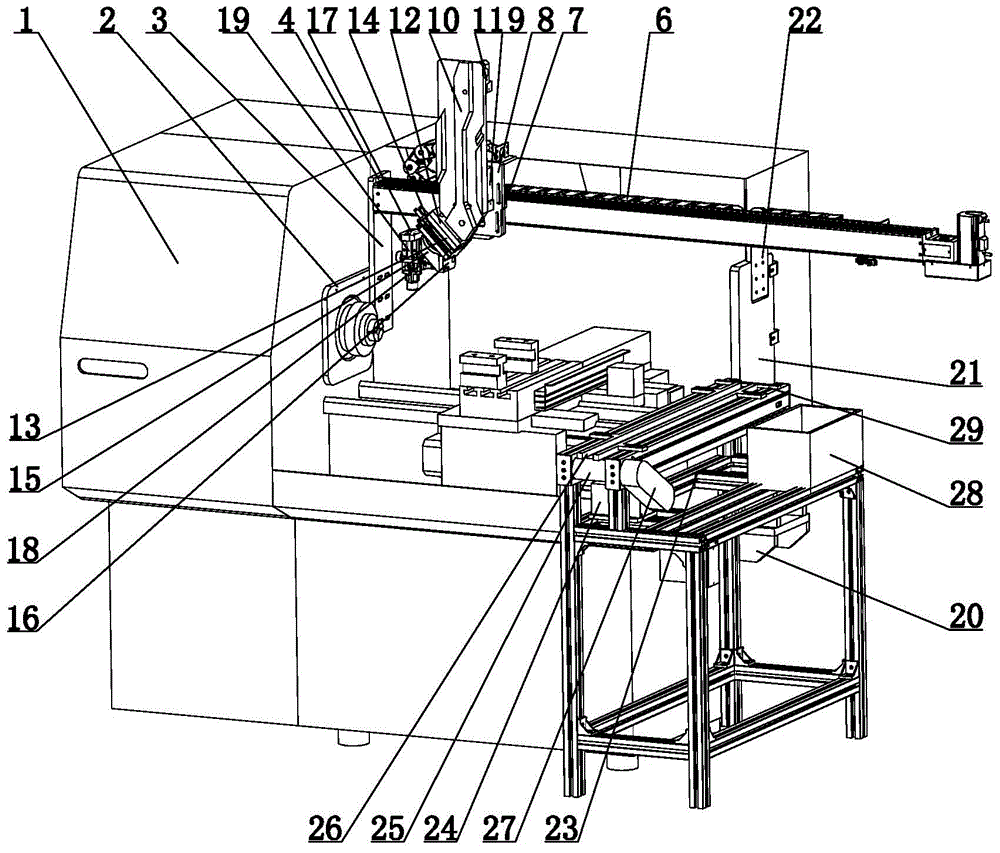

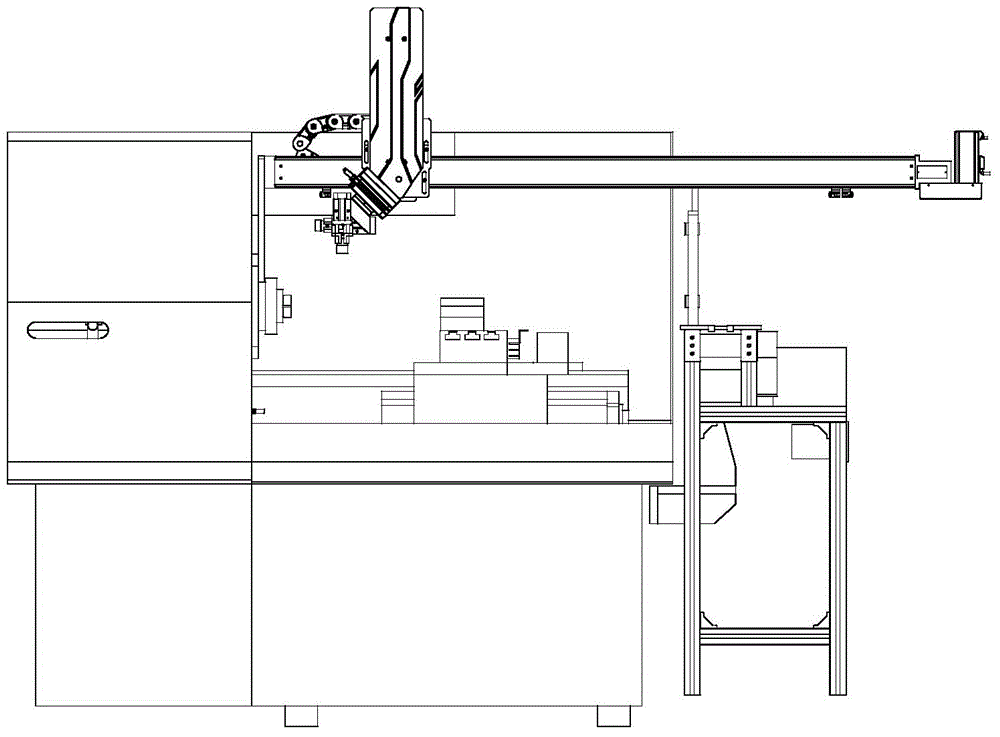

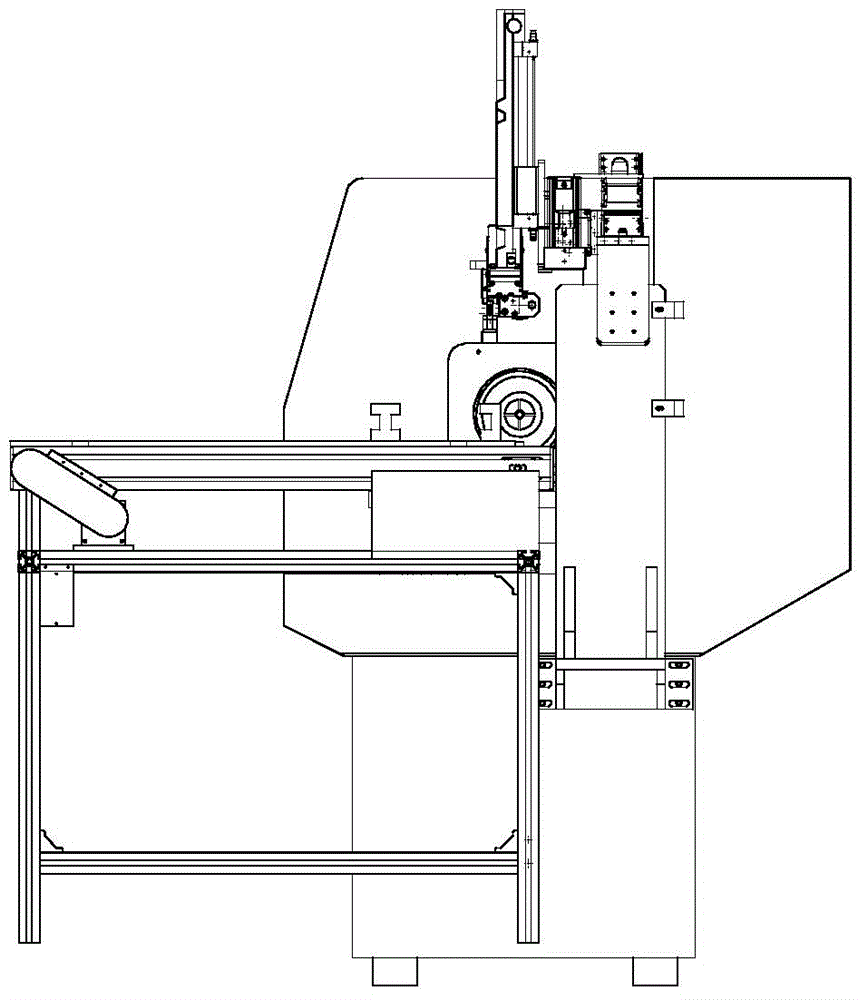

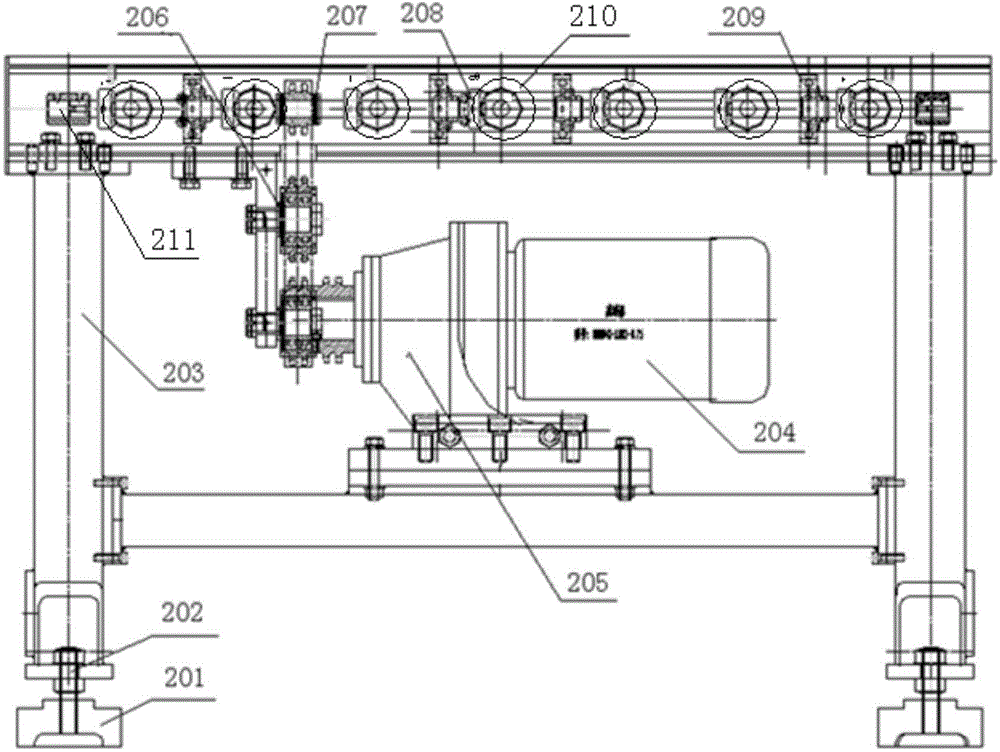

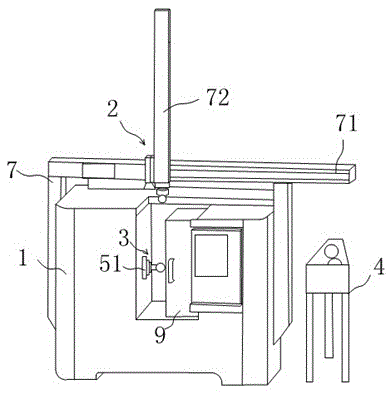

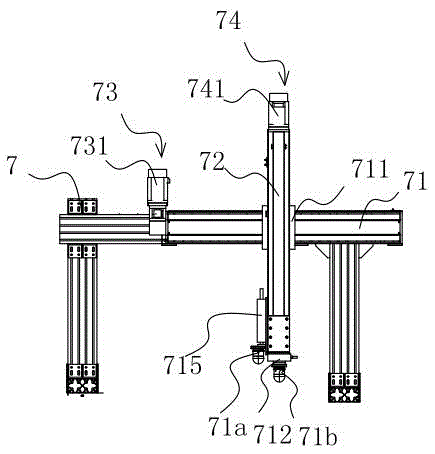

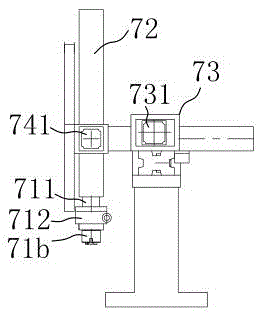

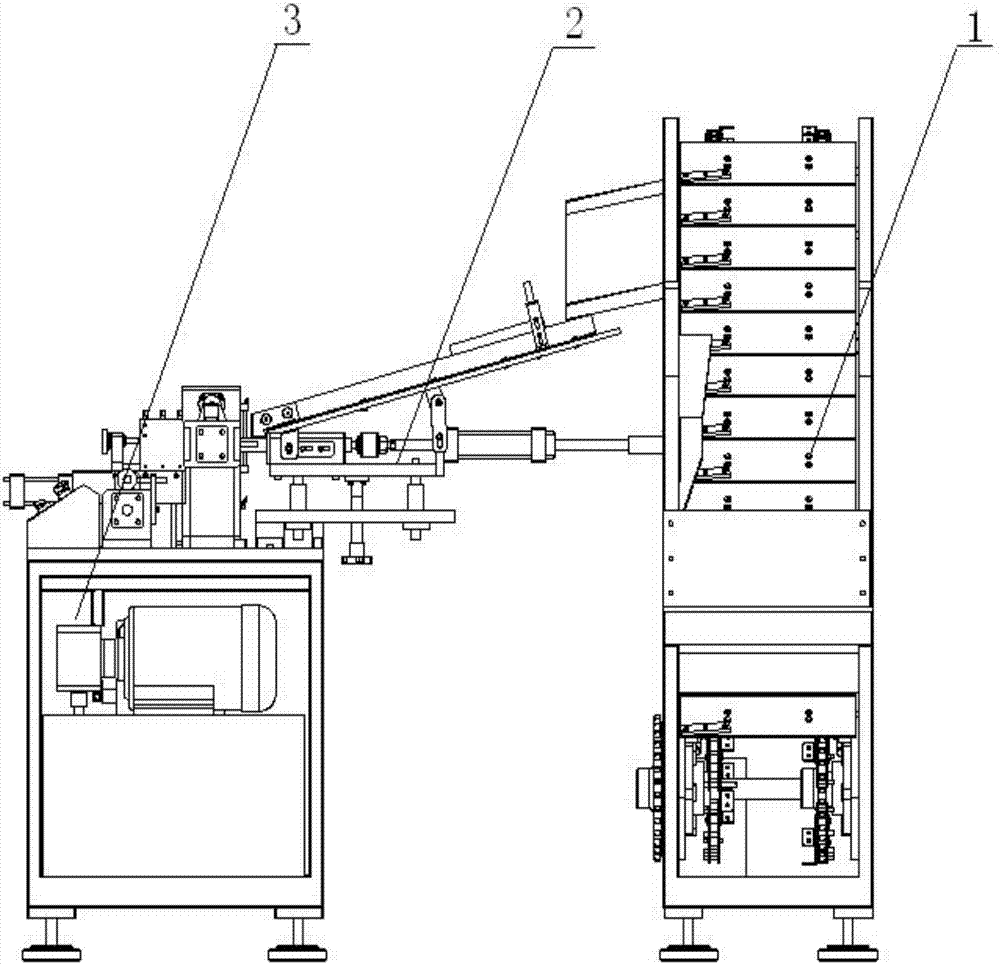

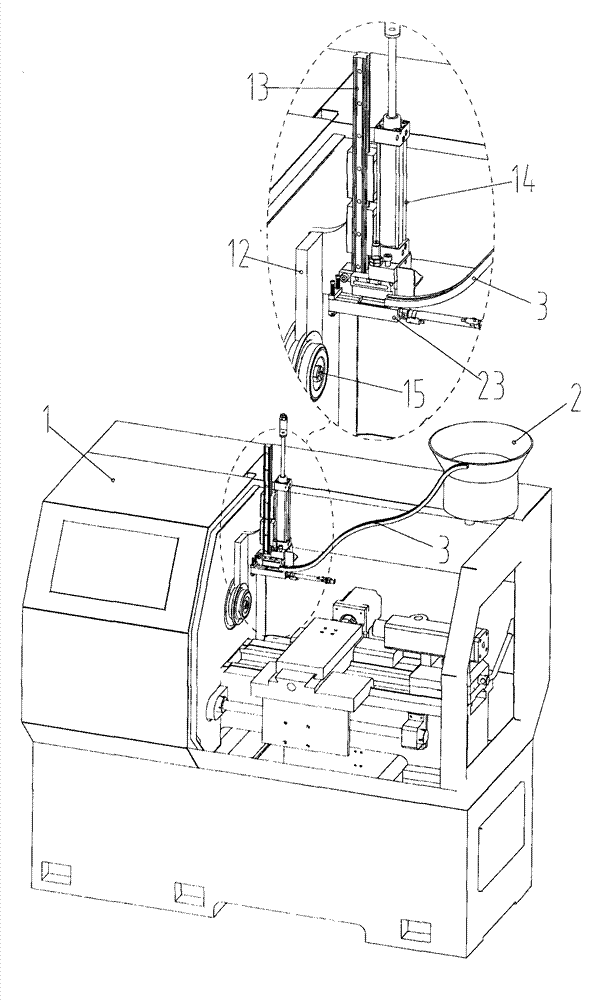

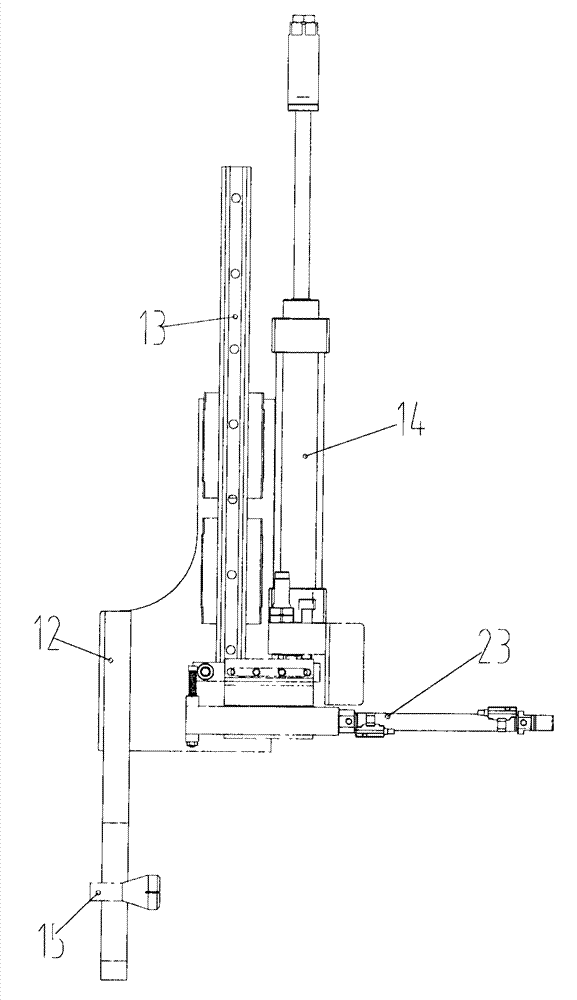

Automatic feeding device of sliding table mechanical arm

ActiveCN104972143AEasy to installEasy maintenanceAutomatic conveying/guiding stockAutomatic workpiece supply/removalRobot handEngineering

The invention relates to a mechanical transmission device, in particular to an automatic feeding device of a sliding table mechanical arm. The automatic feeding device of the sliding table mechanical arm comprises a machine tool body, an electronic sliding table and the sliding table mechanical arm. A spindle headstock is arranged on the inner wall of the machine tool body. A spindle fixing plate is arranged on the spindle headstock. A spindle sliding table support is arranged on the spindle fixing plate. A sliding table fixing plate is arranged on the upper portion of the spindle sliding table support. The right portion of the electronic sliding table is arranged on a sliding table support plate. A sliding table dragging plate connected with the electronic sliding table is arranged on the outer wall of the electronic sliding table. A sliding table mechanical arm is arranged on the sliding table dragging plate and comprises a mechanical arm moving plate, a rodless cylinder and a rodless cylinder fixing plate. The automatic feeding device of the sliding table mechanical arm has the beneficial effects that a rotation mode is novel and exquisite, work is precise, and efficiency is high; mechanical operation is adopted, and product uniformity is high and stable

Owner:宁波麦科斯机器人科技有限公司

Automatic loading and unloading manipulator of drum type brake assembling line

InactiveCN104476155AGuaranteed stabilityAction in place and preciseProgramme-controlled manipulatorAutomatic workpiece supply/removalControl systemElectrical control

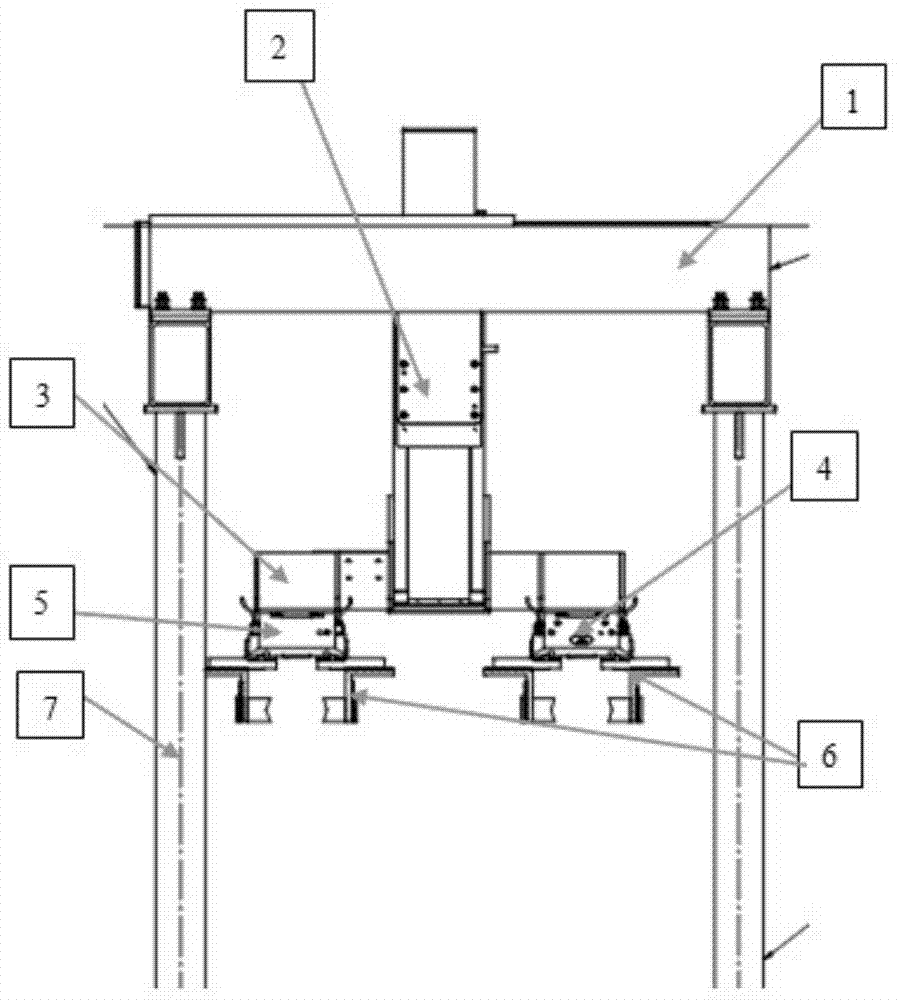

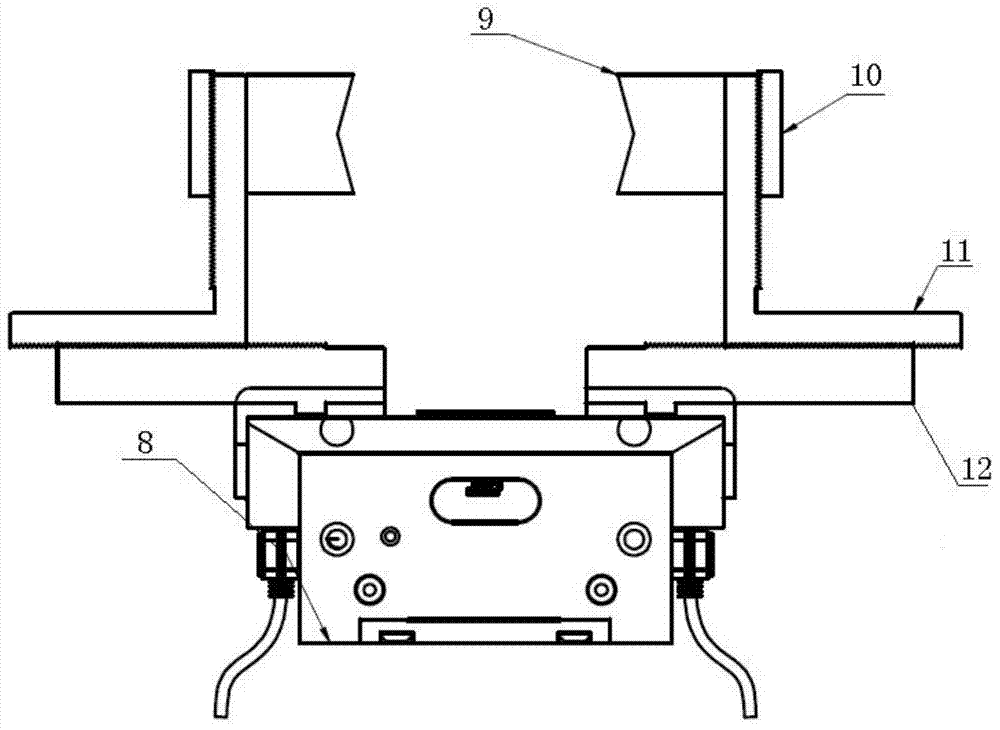

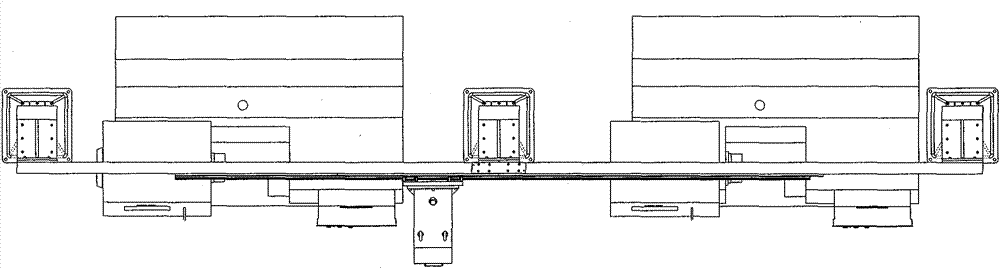

The invention discloses an automatic loading and unloading manipulator of a drum type brake assembling line. By the adoption of a portal type dual-station automatic loading and unloading dual-manipulator linkage mode, the automatic loading and unloading manipulator is characterized in that two manipulators are simultaneously used for carrying out loading, carrying and unloading control on workpieces at two stations; a system mainly comprises a portal frame and two automatic manipulators, wherein the two automatic manipulators are provided with lifting cylinders, clamping cylinders, carrying translationing cylinders, unloading rollerways, jacking cylinders, stop cylinders and PLC (programmable logic control) electrical control systems; the portal frame is divided into three stations, namely an assembling station, a turning station and an unloading jacking rollerway, and a pneumatic control manipulator finishes processing, clamping / releasing, rising / falling and translationing carrying of a brake assembly; unloading adopts rollerway conveying, and the workpieces are automatically conveyed and unloaded in turn through the jacking mechanism. According to the automatic loading and unloading manipulator, the automation degree and the processing efficiency of processing production are improved; three workers are reduced to one person, and the production processing cost is greatly lowered.

Owner:十堰市华迪汽车零部件有限公司

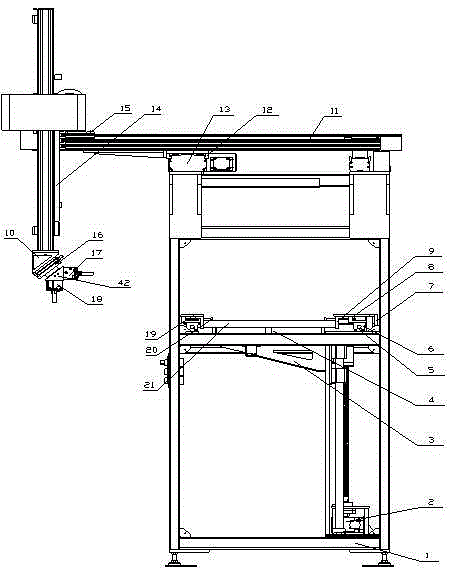

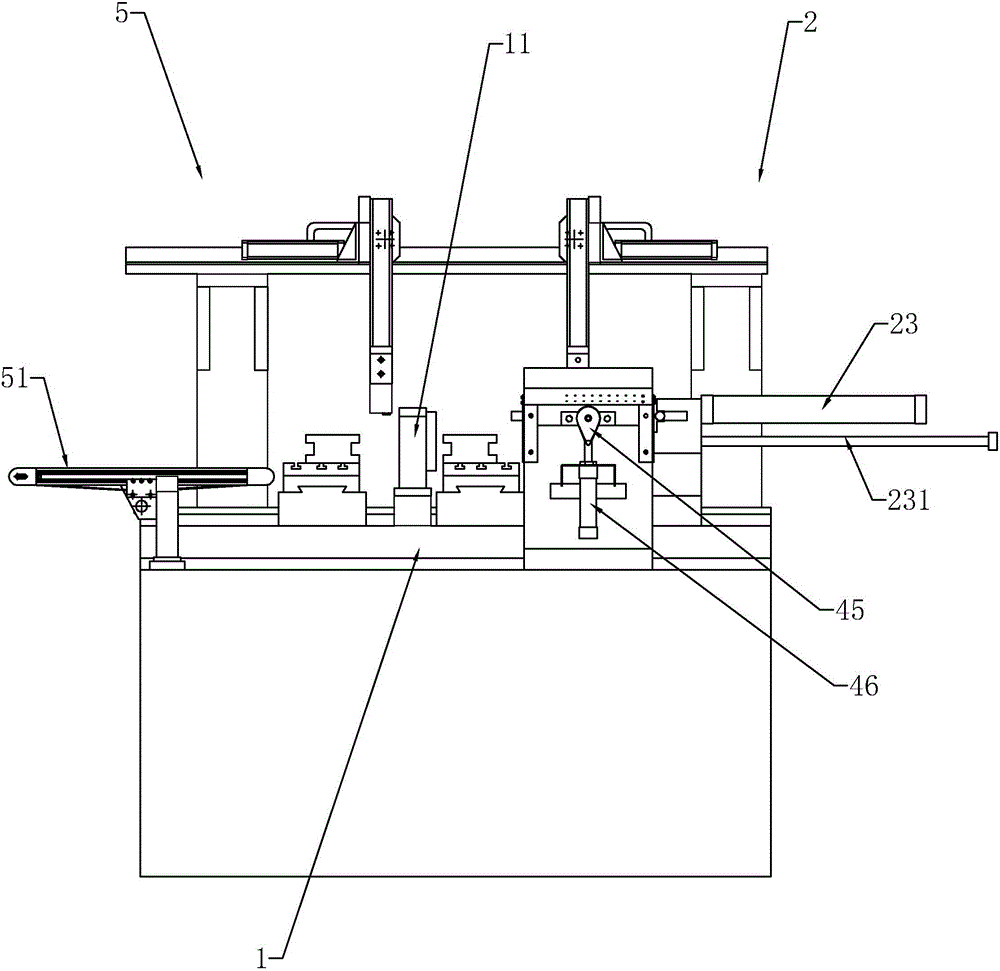

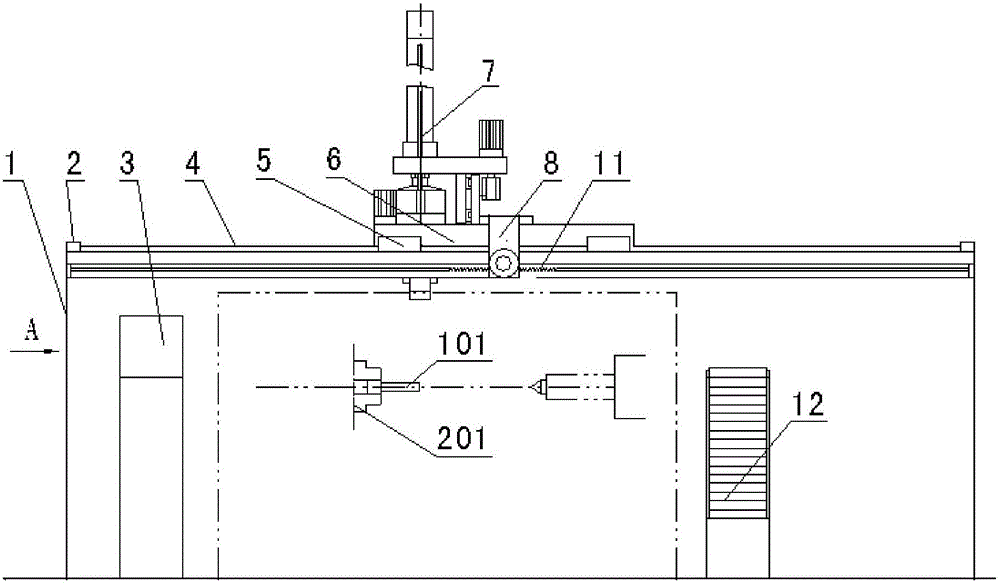

Automatic feeding and discharging device applied to numerically-controlled machine tool

InactiveCN103921162ARealize automatic loading and unloading processingEasy to operateAutomatic workpiece supply/removalMetal working apparatusHand graspNumerical control

The invention belongs to the technical field of machine tools, and provides a feeding and discharging device capable of being automatically operated on a numerically-controlled machine tool. The device is provided with a door frame, the door frame is provided with a transverse module which perpendicularly moves on the door frame, a vertical module which moves left and right is arranged on the transverse module, the two sets of modules are formed in a crossing mode and driven by a servo motor, a feeding hand grasp device and a discharging hand grasp device are arranged on the transverse module through a connecting wrench, material grasping fingers are arranged on the feeding hand grasp device and the discharging hand grasp device, the material grasping fingers are controlled through a grasp control component to clamp and loosen a workpiece, a door type internal-arranged mechanical arm is adopted, the servo motor is adopted to drive a lead screw, a sliding table and the mechanical arm, automatic feeding and discharging of the workpiece can be achieved, two fingers are adopted by each hand grasp device for conducting parallel clamping, the fingers can be adjusted, clamping of workpieces of different specifications is achieved, the double grasps can work at the same time, and the production efficiency is improved by double.

Owner:BAOJI FENGDE MACHINERY MFG

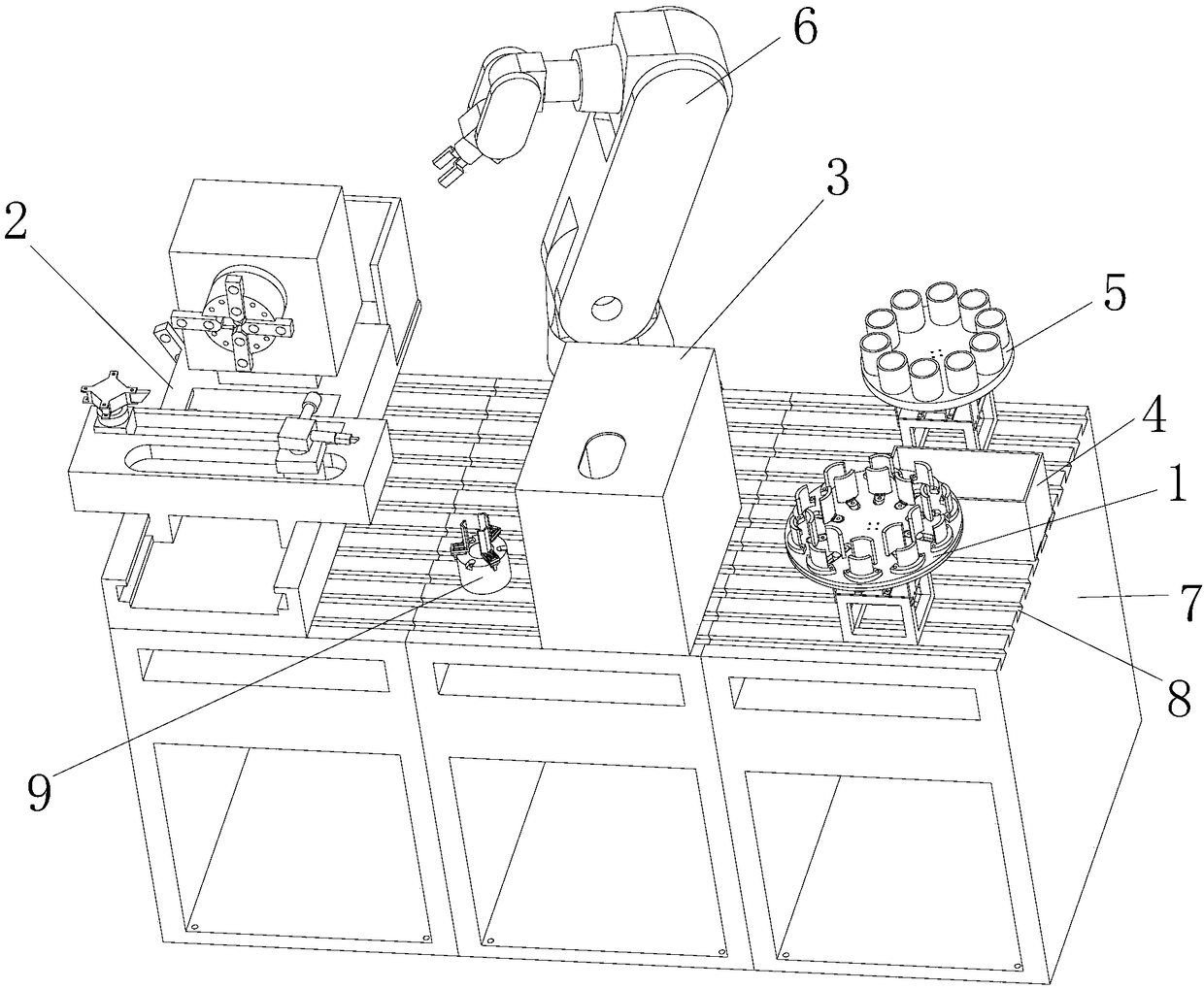

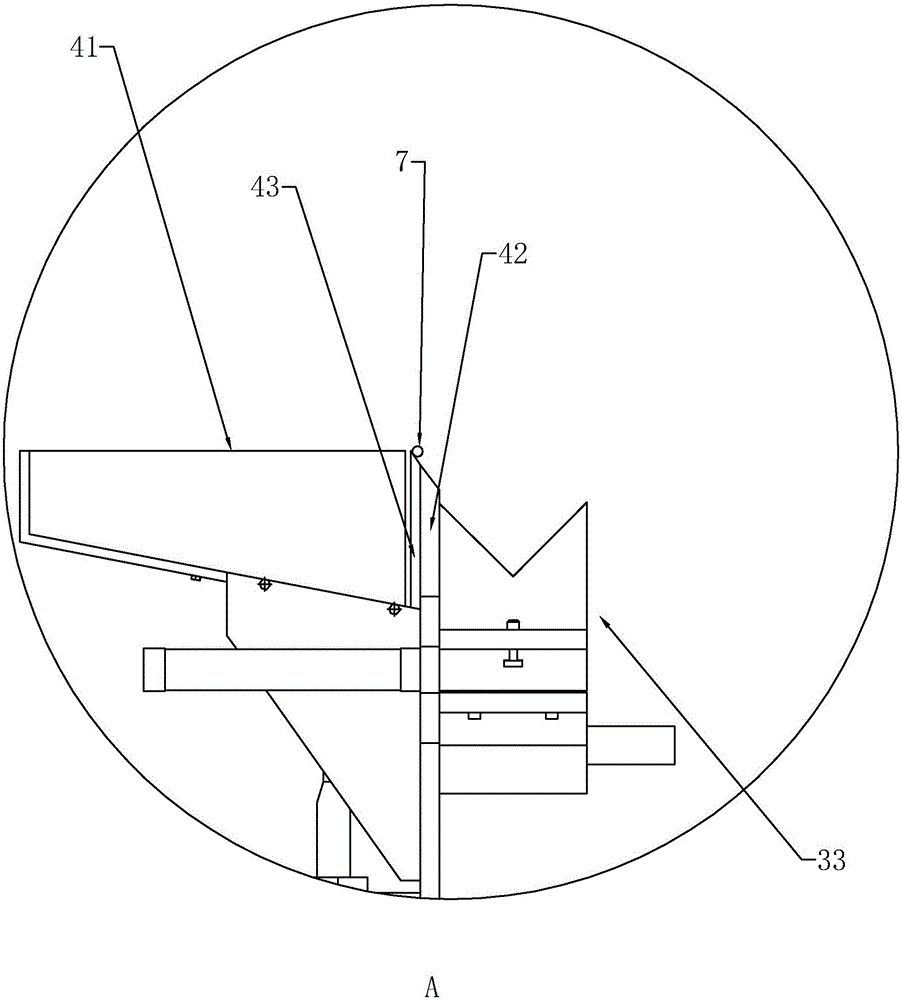

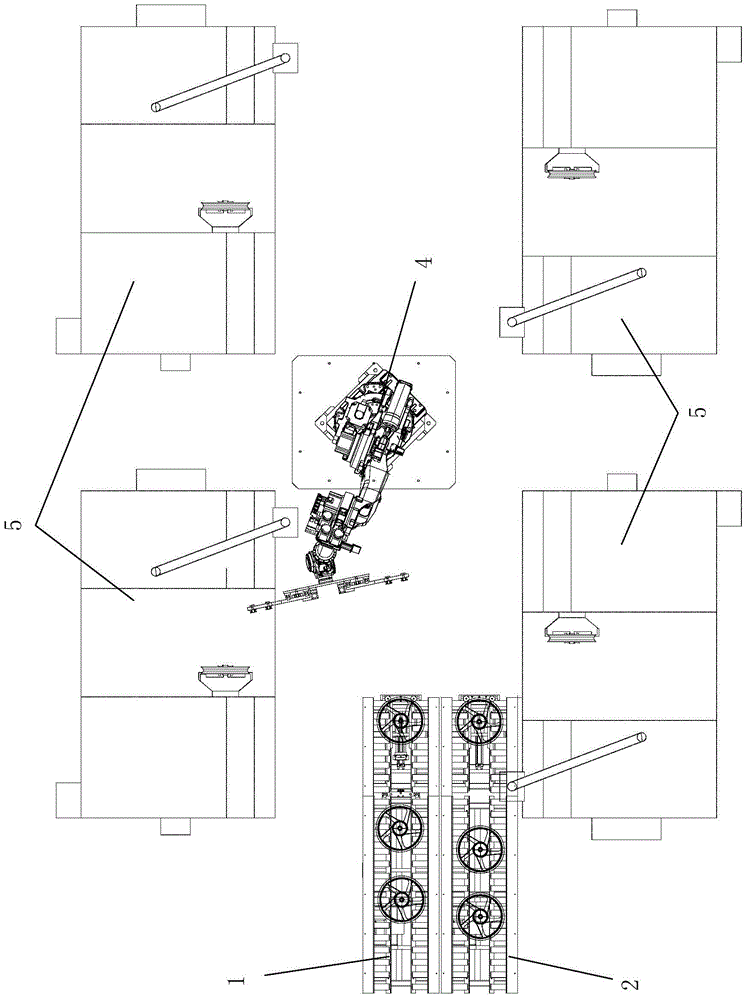

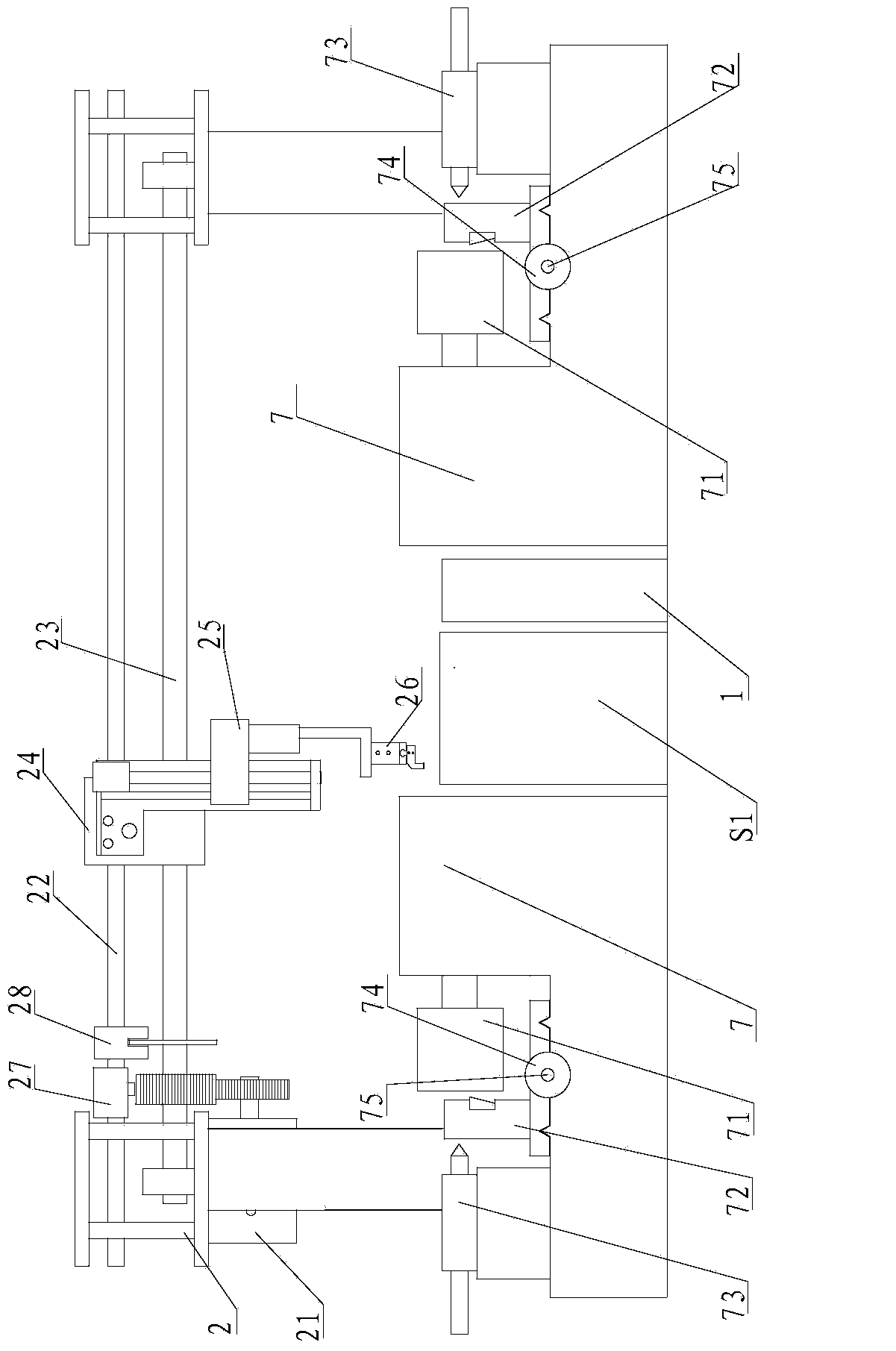

Robot-based automatic feeding and discharging system

InactiveCN103921158AAutomatic workpiece supply/removalMetal working apparatusNumerical controlEngineering

The invention relates to a robot-based automatic feeding and discharging system comprising a mechanical portion and a control portion. The mechanical portion comprises a feeding unit, a column and beam unit, a lathe unit, a robot unit, a steering unit and a discharging unit. The feeding unit comprises a feeding workbench, a feeding servo motor, the feeding bench is provided with the feeding servo motor, and the output shaft of the feeding servo motor is connected to a feeding synchronous belt wheel through a feeding conveying belt. The lathe unit comprises a first lathe and a second lathe which are used for completing a first processing procedure and a second processing procedure in workpiece processing. The system is capable of arraying and accurately positioning workpieces according to a preset manner, clamping the workpieces to a numerically-controlled machine tool for processing through different procedures, and fetching the workpieces and placing into a finished product box after the processing is completed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Robotic arm

ActiveUS20150033898A1Reduce in quantityEasy to moveProgramme-controlled manipulatorMechanical apparatusRobotic armMechanical engineering

In order to reduce the cost of robotic arm, the invention provides a robotic arm, which includes an arm member having a first pivot connection portion, a locating member affixed to the arm member, a sliding member movably mounted at the locating member, a stop member affixed to the sliding member, a wrist member having a second pivot connection portion pivoted to the sliding member and a third pivot connection portion movable relative to the second pivot connection portion, and a driving device including a body member pivoted to the first pivot connection portion and an extension member pivoted to the third pivot connection portion of the wrist member and movable relative to the body member. Using the locating member, the sliding member, the stop member and the wrist member to match with the driving device, the robotic arm achieves the effect of moving and swinging and cost reduction.

Owner:HIWIN TECH

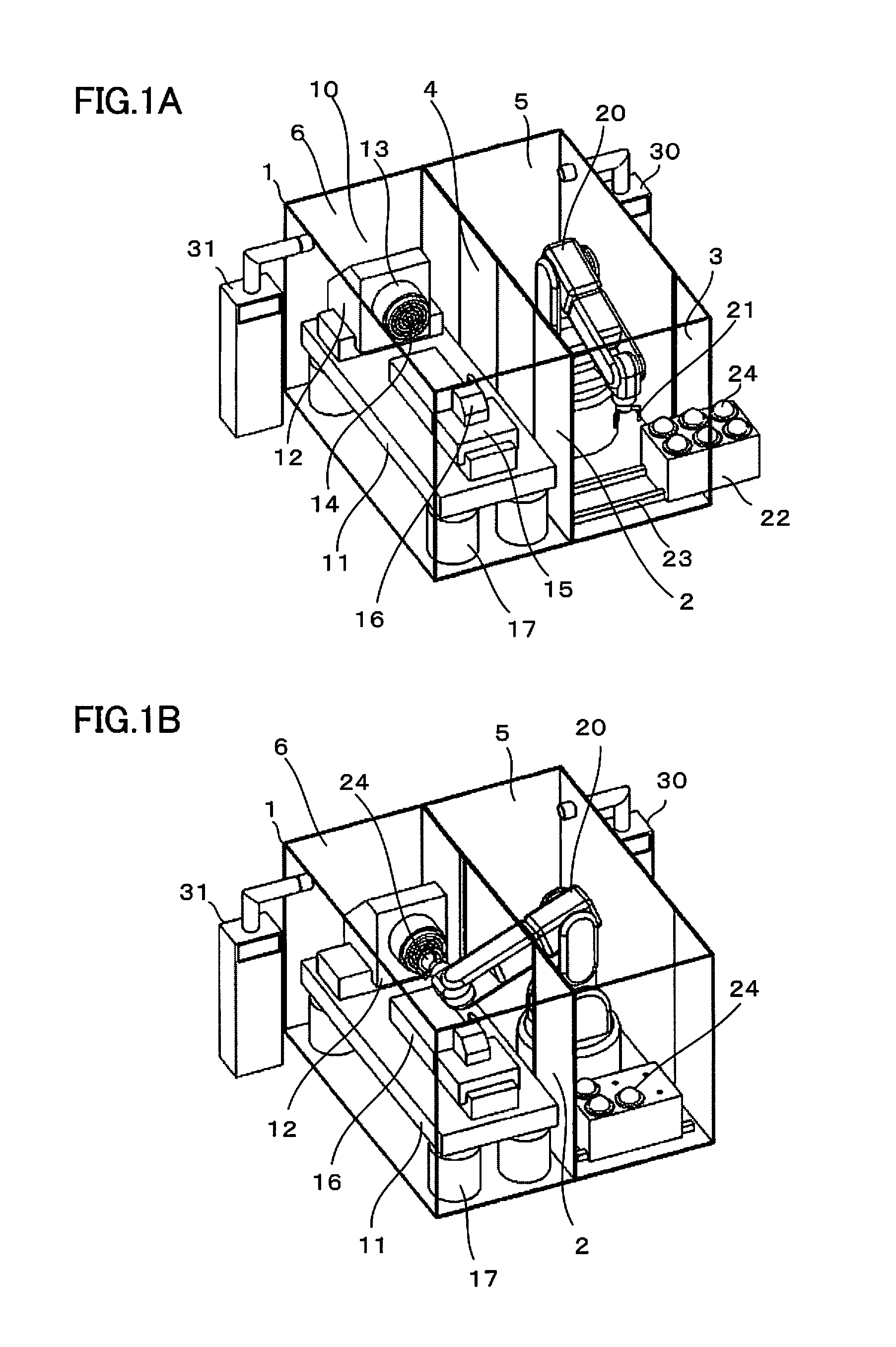

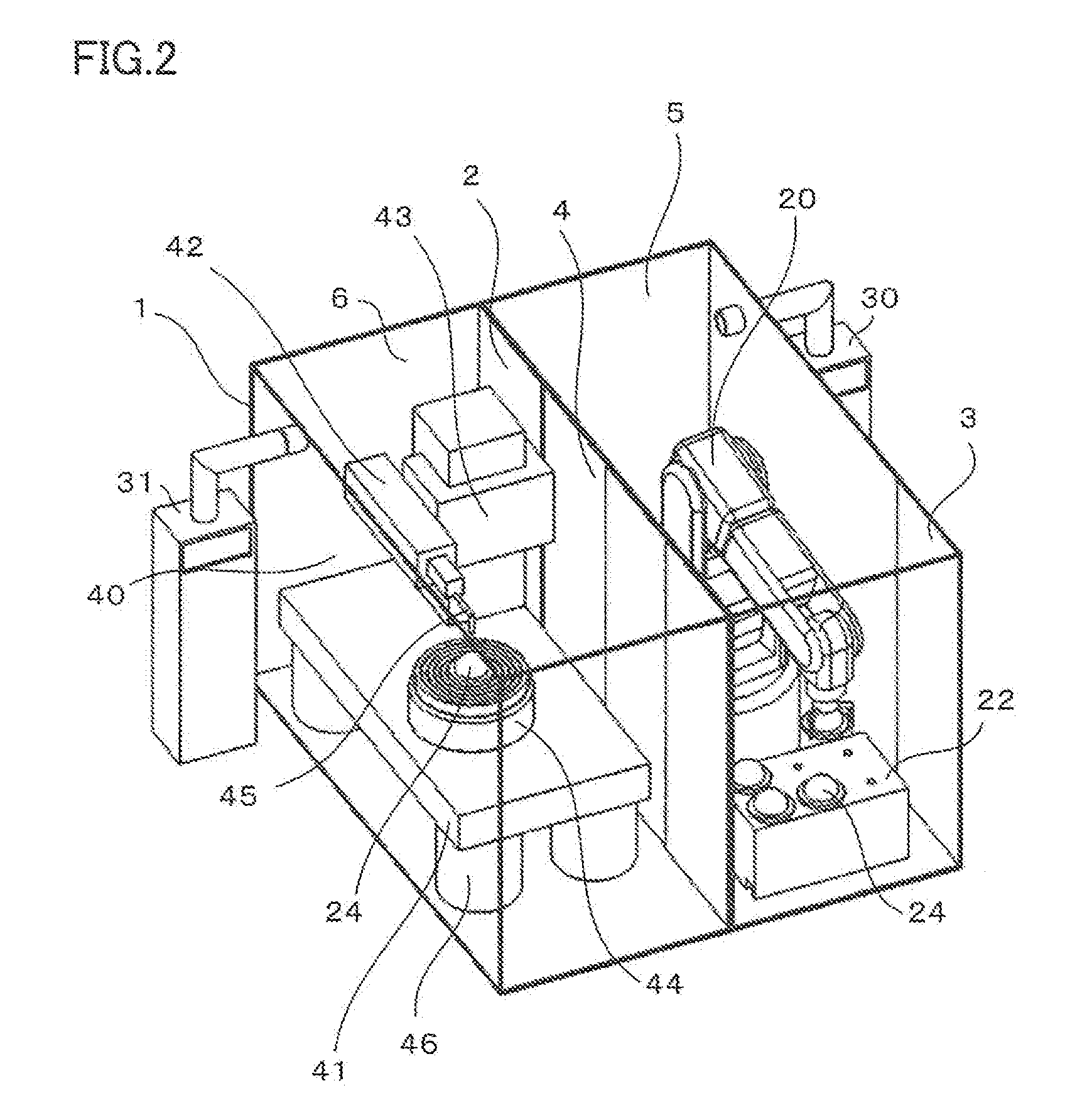

System capable of immediately performing operation on workpiece

ActiveUS20160214805A1Reduce variationProgramme-controlled manipulatorAutomatic workpiece supply/removalMeasurement deviceControl engineering

A precision machining / measurement device and a robot that conveys a workpiece to the device are covered by a cover, and a space covered by the cover is partitioned by a partition cover into a space where the precision machining / measurement device is installed and a space where the robot is installed. When a temperature inside the space where the robot is installed falls within a predetermined temperature range, a door provided in the partition cover is opened, and the robot supplies the workpiece to the precision machining / measurement device through the opened door.

Owner:FANUC LTD

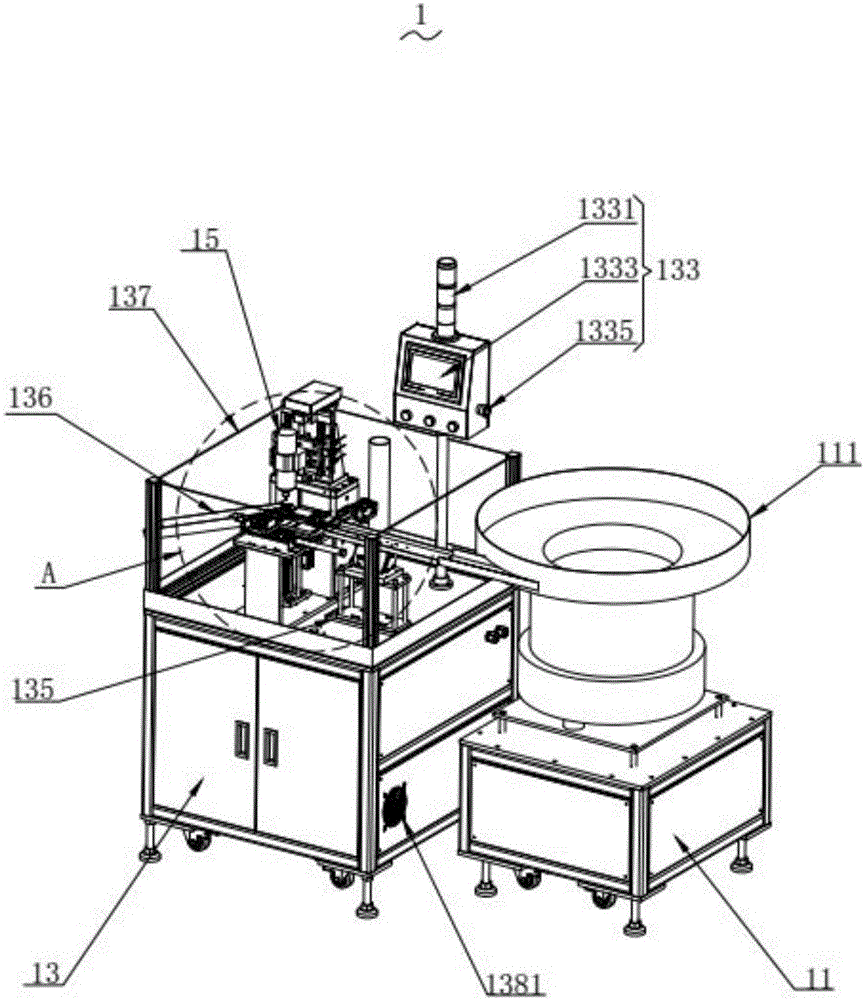

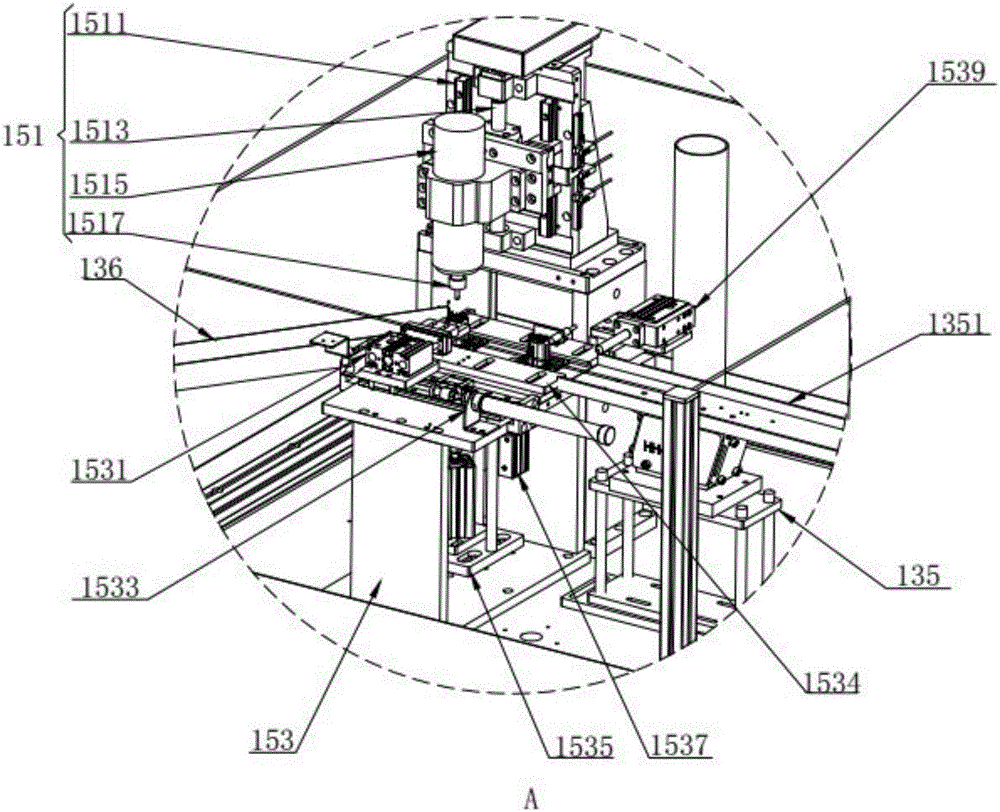

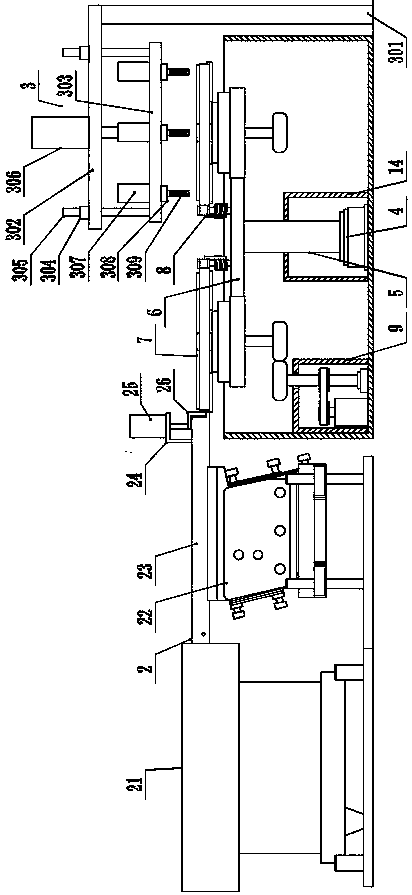

Front type automatic material supplying manipulator system of numerical control lathe

ActiveCN105345039ACompact structureSmall footprintProgramme-controlled manipulatorAutomatic workpiece supply/removalNumerical controlRobotic arm

The invention relates to a front type automatic material supplying manipulator system of a numerical control lathe. The front type automatic material supplying manipulator system comprises a rack, an automatic material supplying unit arranged in the rack, an X-axis mechanical arm unit, a Y-axis mechanical arm unit, a Z-axis mechanical arm unit and a pneumatic claw unit. The X-axis mechanical arm unit comprises an X-axis arm assembly provided with an X-axis sliding block connecting plate, and the X-axis sliding block connecting plate is provided with an X-axis servo motor assembly. The Y-axis mechanical arm unit comprises a Y-axis arm assembly which is provided with a Y-axis sliding block connecting plate and a Y-axis servo motor assembly. The Z-axis mechanical arm unit comprises a Z-axis sliding block connecting plate which is provided with a Z-axis arm assembly and a Z-axis servo motor assembly. After the adoption of the structure, integration of automatic material supplying, feeding and discharging is achieved, the structure is compact, the occupied space is reduced, the problem that a material supplying structure is separated from a feeding structure and a discharging structure is solved, and the front type automatic material supplying manipulator system is high in production efficiency and automation degree.

Owner:江苏久誉远智能科技有限公司 +1

Automatic array drilling machine

ActiveCN105834480AReasonable design structureGuaranteed uptimeAutomatic workpiece supply/removalMetal working apparatusMulti machineEngineering

The invention provides an automatic array drilling machine. The automatic array drilling machine comprises a feeding table and a workbench. The feeding table is provided with a vibration disc. The workbench is provided with an automatic drilling system assembly and an operation system. The vibration disc communicates with the automatic drilling system assembly through a linear vibration track. The automatic drilling system assembly comprises a drill bit mechanism and a drilling platform. The drill bit mechanism is arranged above the drilling platform. The drill bit mechanism comprises a high-speed electric spindle and a drill bit driven by the high-speed electric spindle. The drilling platform is provided with a material guide rail, a pushing air cylinder used for pushing an object to be machined into the portion below the drill bit, and a clamping air cylinder for stabilizing the object. The object to be machined arrives at the part of the material guide rail in the automatic drilling system assembly through the vibration disc via the lineation vibration track, and under pushing of the pushing air cylinder, the object to be machined arrives at the portion below the drill bit of the drill bit mechanism. The one-time machining automatic cycle is finished for four seconds through the automatic array drilling machine, about 20,000 PCS can be produced every day (24 hours), one person can operate multiple machines without operation of specially-assigned persons, and the machining efficiency is high.

Owner:FIND TECH SHENZHEN

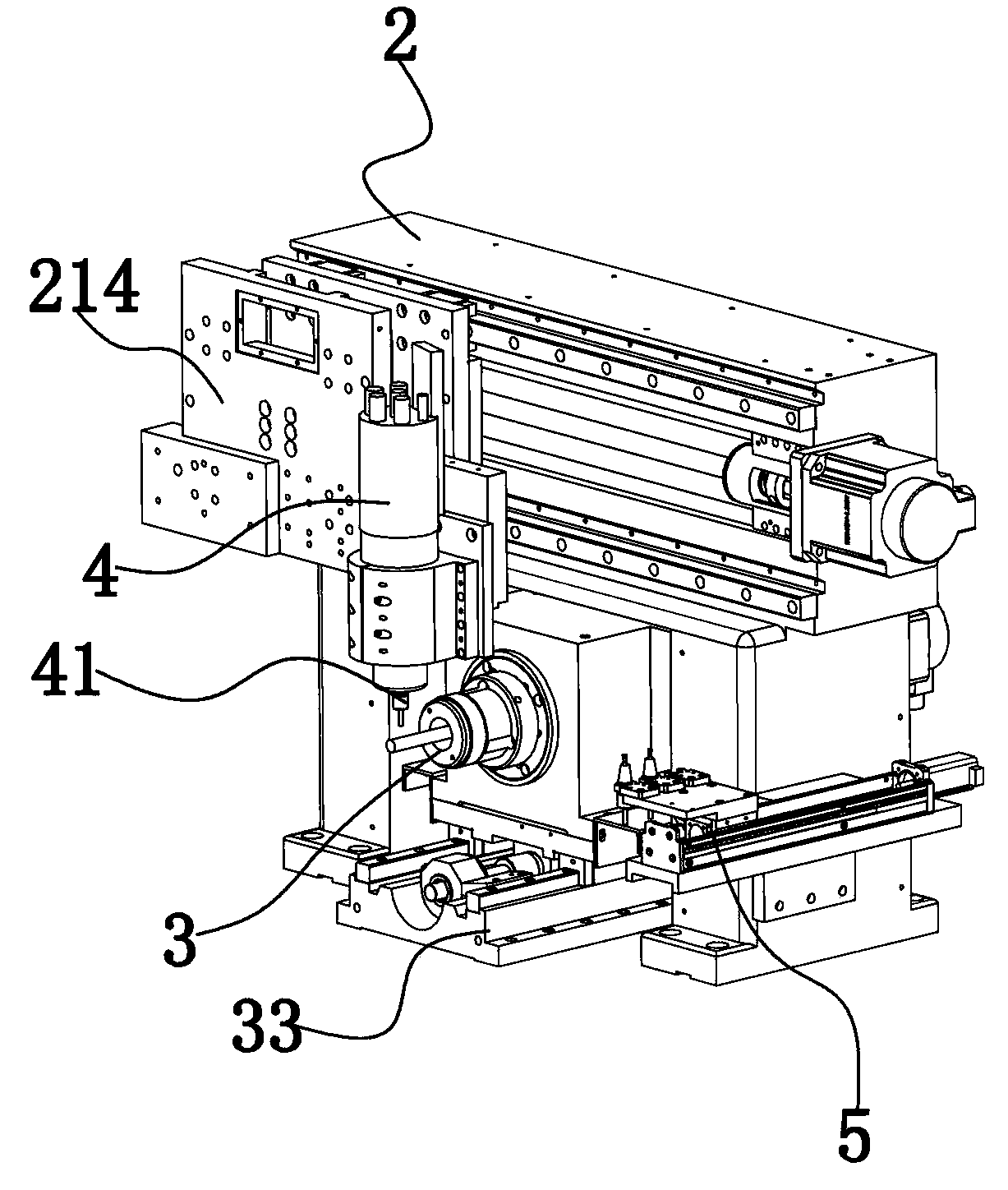

Machining device of shaft parts

InactiveCN108714701AAutomatically judge whether it is qualifiedRealize fully automatic feed processingAuxillary equipmentAutomatic workpiece supply/removalEngineeringMachining

The invention discloses a machining device of shaft parts. The device comprises a feeding disc, a lathe, a detection mechanism, a defective product area, a material discharging disc and a mechanical arm, wherein the feeding disc is used for containing the shaft parts to be machined; the lathe is used for machining the shaft parts; the detection mechanism is used for detecting whether the shaft parts meet a machining requirement or not; the defective product area is used for containing the shaft parts which do not meet the machining requirement through detection; the material discharging disc is used for containing the shaft parts which meet the machining requirement through detection; and the mechanical arm is used for grabbing the shaft parts to be machined from the feeding disc and sequentially conveying the shaft parts to the lathe and the detection mechanism, if the shaft parts do not meet the machining requirement through detection, the shaft parts are placed in the defective product area, if the shaft parts meet the machining requirement through detection, the shaft parts are placed in the material discharging disc. According to the device, only the shaft parts, machining diagrams with a DWG format of the shaft parts and an allowed machining error need to be provided, and full-automatic feeding machining, detection and material discharging can be realized.

Owner:GUANGZHOU UNIVERSITY

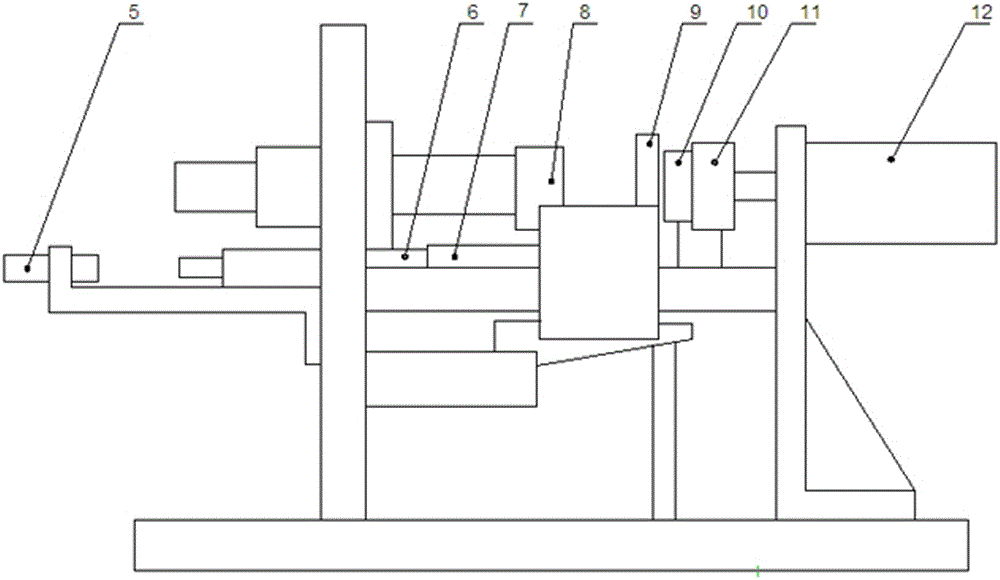

Numerical control double-end lathe

ActiveCN105665749AFix as soon as possiblePut into production as soon as possibleAutomatic workpiece supply/removalMetal working apparatusNumerical controlMechanical engineering

The invention discloses a numerical control double-end lathe, and solves the problems of slow loading and unloading speed and low efficiency of a lathe. The numerical control double-end lathe comprises a base plate provided with chucks, and is characterized in that the chucks are provided with loading mechanisms for feeding the chucks one by one and unloading mechanisms for unloading the chucks one by one; the loading mechanisms include wide air jaws and ejector rods; the wide air jaws are provided with rollers for clamping and guiding materials; the ejector rods push the materials to the chucks along the rollers; the unloading mechanisms include conveying belts for outputting the materials, and clamping air jaws for unloading the chucks; the clamping air jaws feed the materials to the conveying belts; power sources for driving the conveying belts are mounted on the lower belt surfaces of the conveying belts; and the power sources slide in the belt directions to achieve the effect of effectively improving the lathe loading and unloading efficiency.

Owner:WENLING KEYU AUTOMATION EQUIP CO LTD

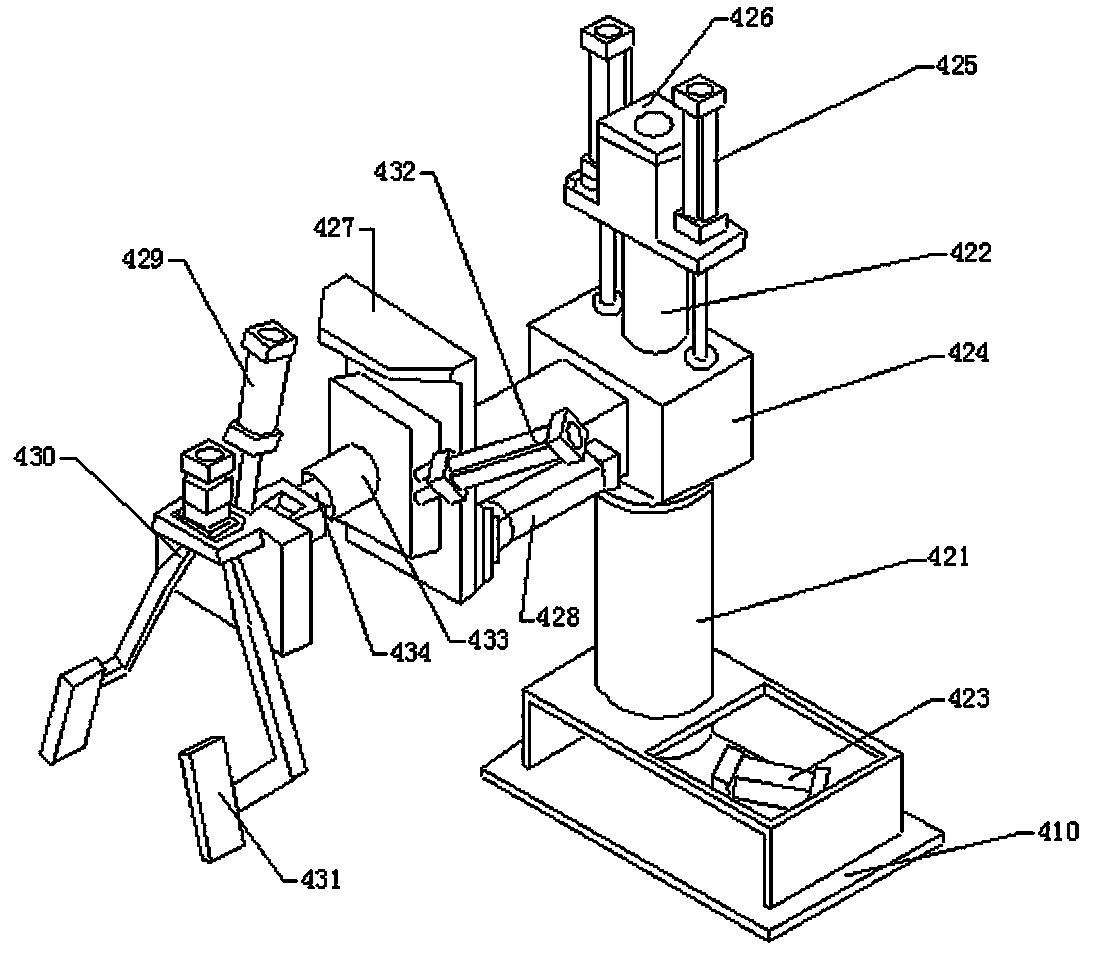

Robot and system for feeding and discharging high-pressure pipe joint parts and operation method implemented by robot and system

InactiveCN103909439ARealize automatic loading and unloadingReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusNumerical controlControl engineering

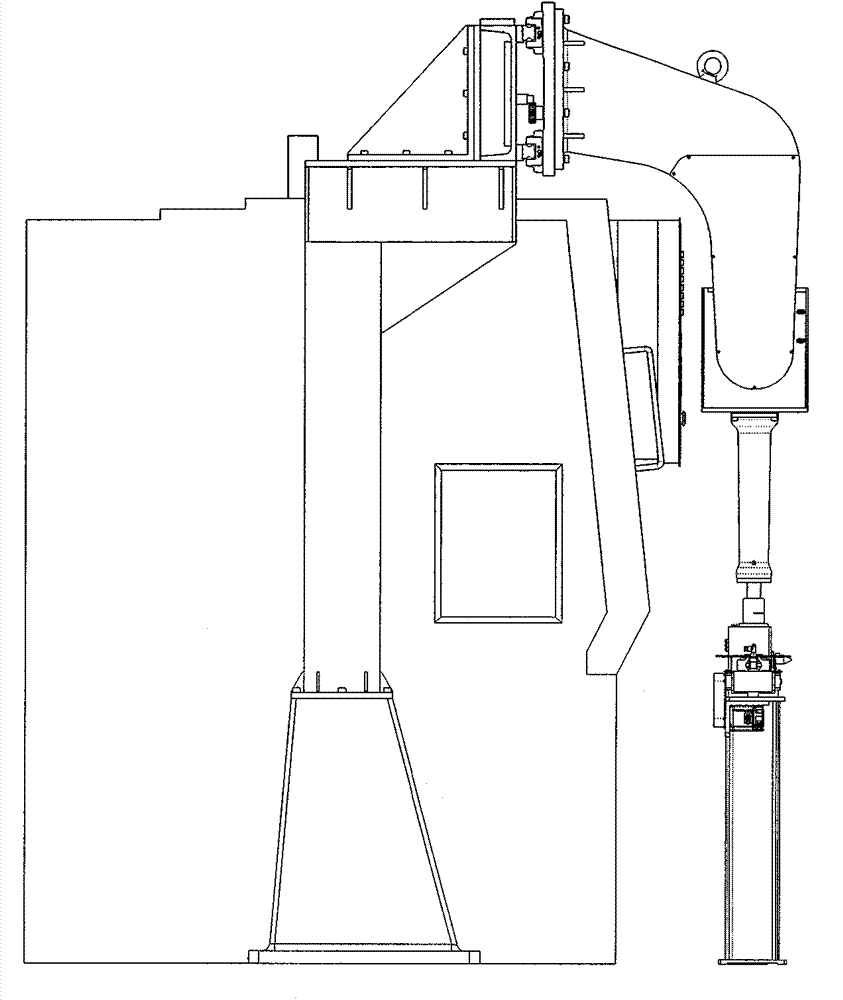

The invention discloses a robot for feeding and discharging high-pressure pipe joint parts. The robot comprises a base, an upright column, a support and a head. The base comprises legs and ball guide rails, and the ball guide rails are arranged on the upper portions of the legs, the upright column is vertically arranged at the upper ends of the ball guide rails, and ball sliders are arranged at the bottom of the upright column and horizontally and linearly move along the ball guide rails; the support which is respectively perpendicular to the ball guide rails and the upright column is arranged at the top of the upright column, a lead screw transmission gear is arranged on the support, and a lead screw nut of the lead screw transmission gear is connected with the head; the head comprises a seat and a feeding and discharging end actuator, and the feeding and discharging end actuator is mounted on the seat. The invention further discloses a system for feeding and discharging the high-pressure pipe joint parts. The robot and the system have the advantages that the system for feeding and discharging the high-pressure pipe joint parts is matched with a numerical-control machine tool, so that the high-pressure pipe joint parts can be automatically fed and discharged when switched over at machining stations in thread machining procedures, and automatic and unattended feeding and discharging effects can be realized in the machining procedures.

Owner:NANTONG AMC MACHINERY

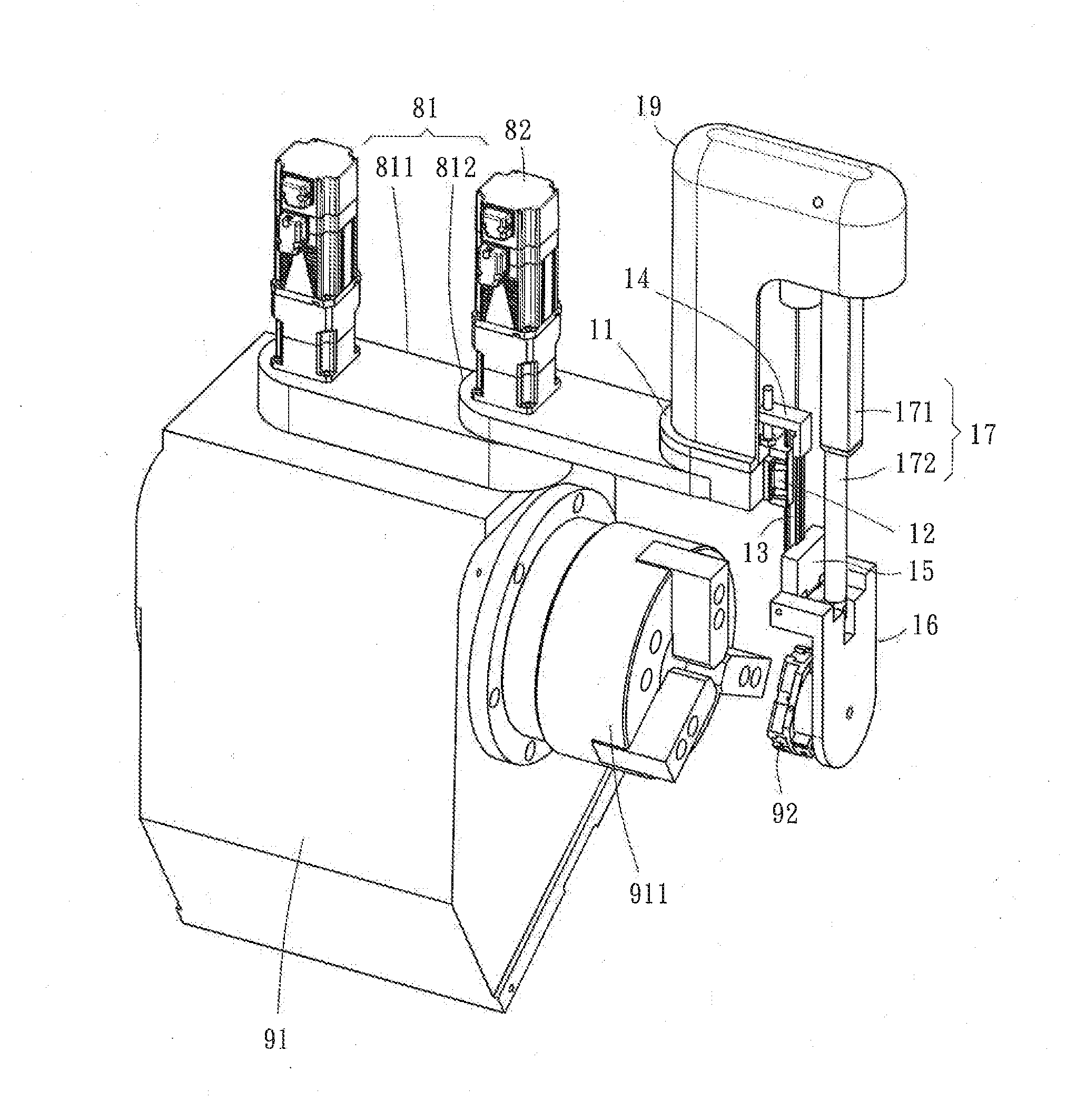

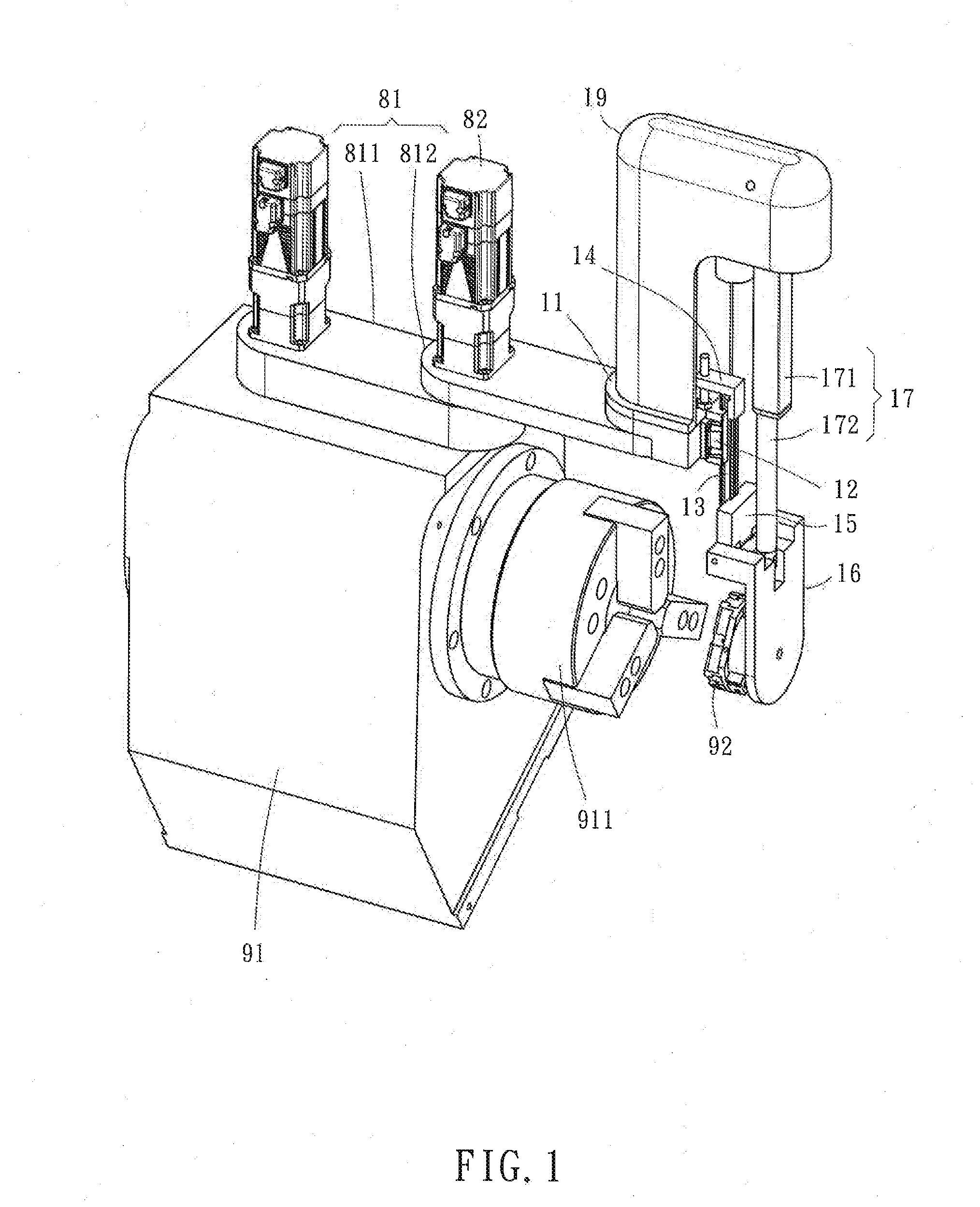

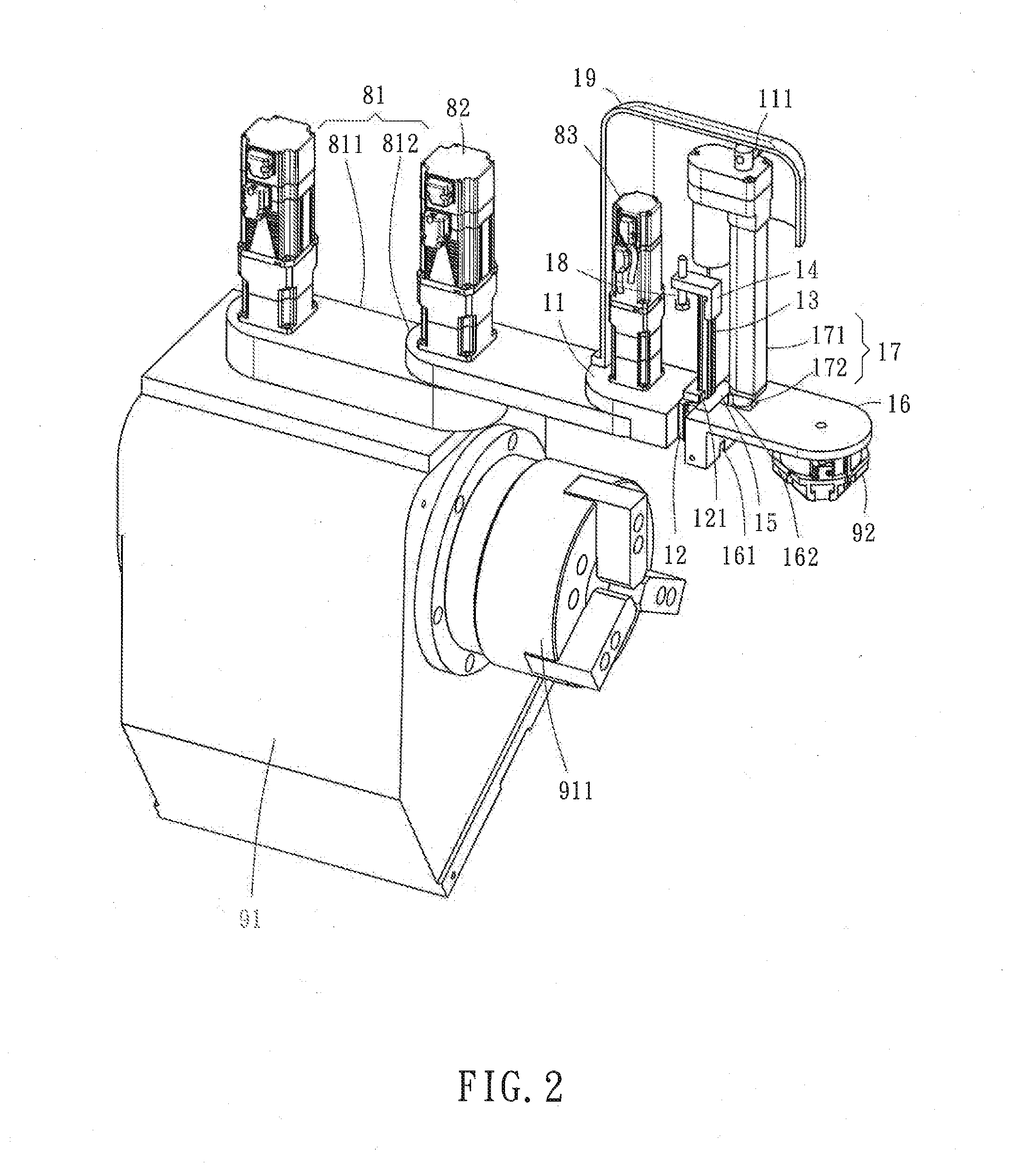

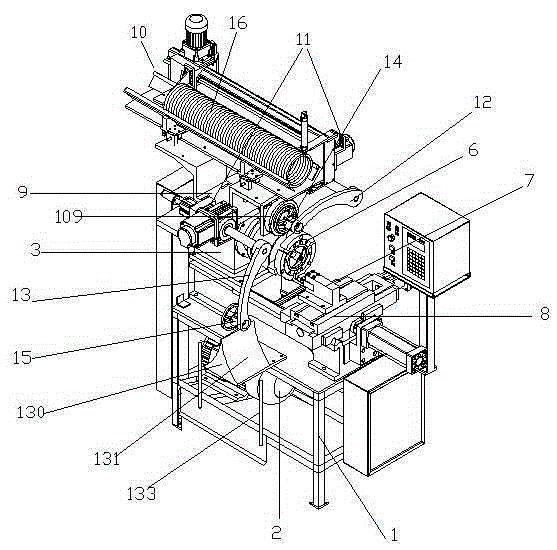

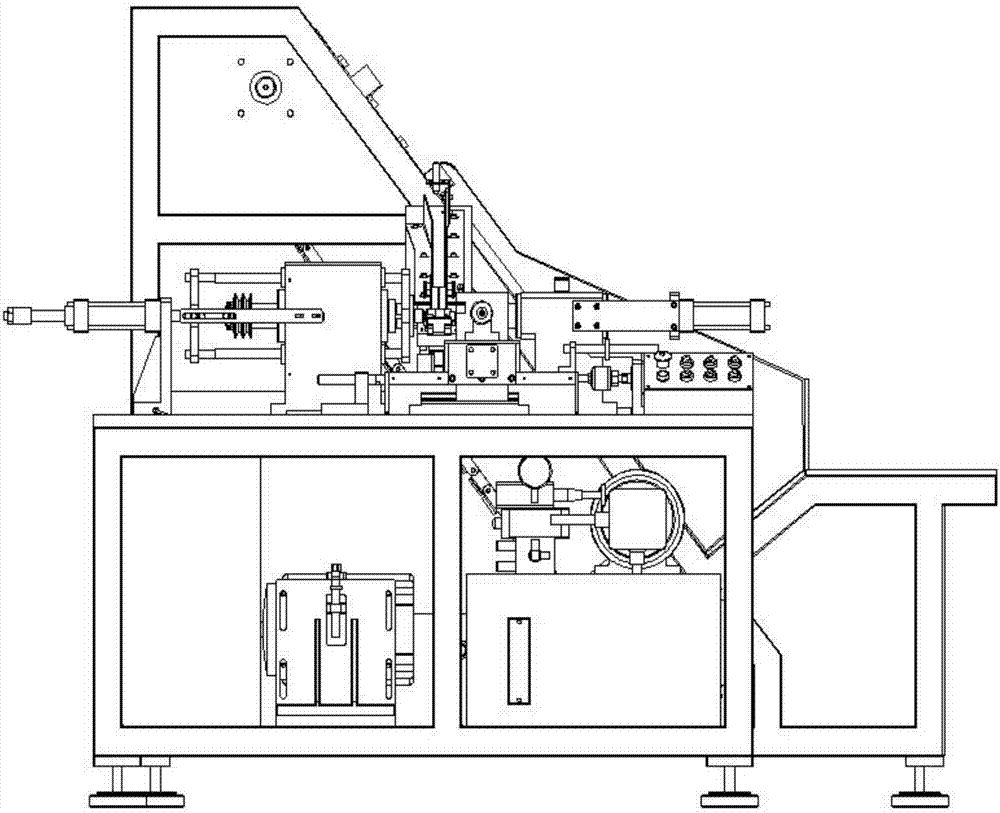

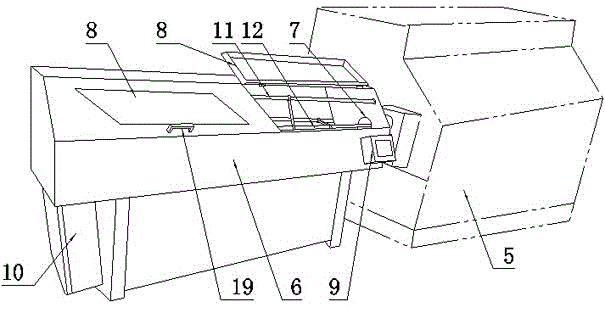

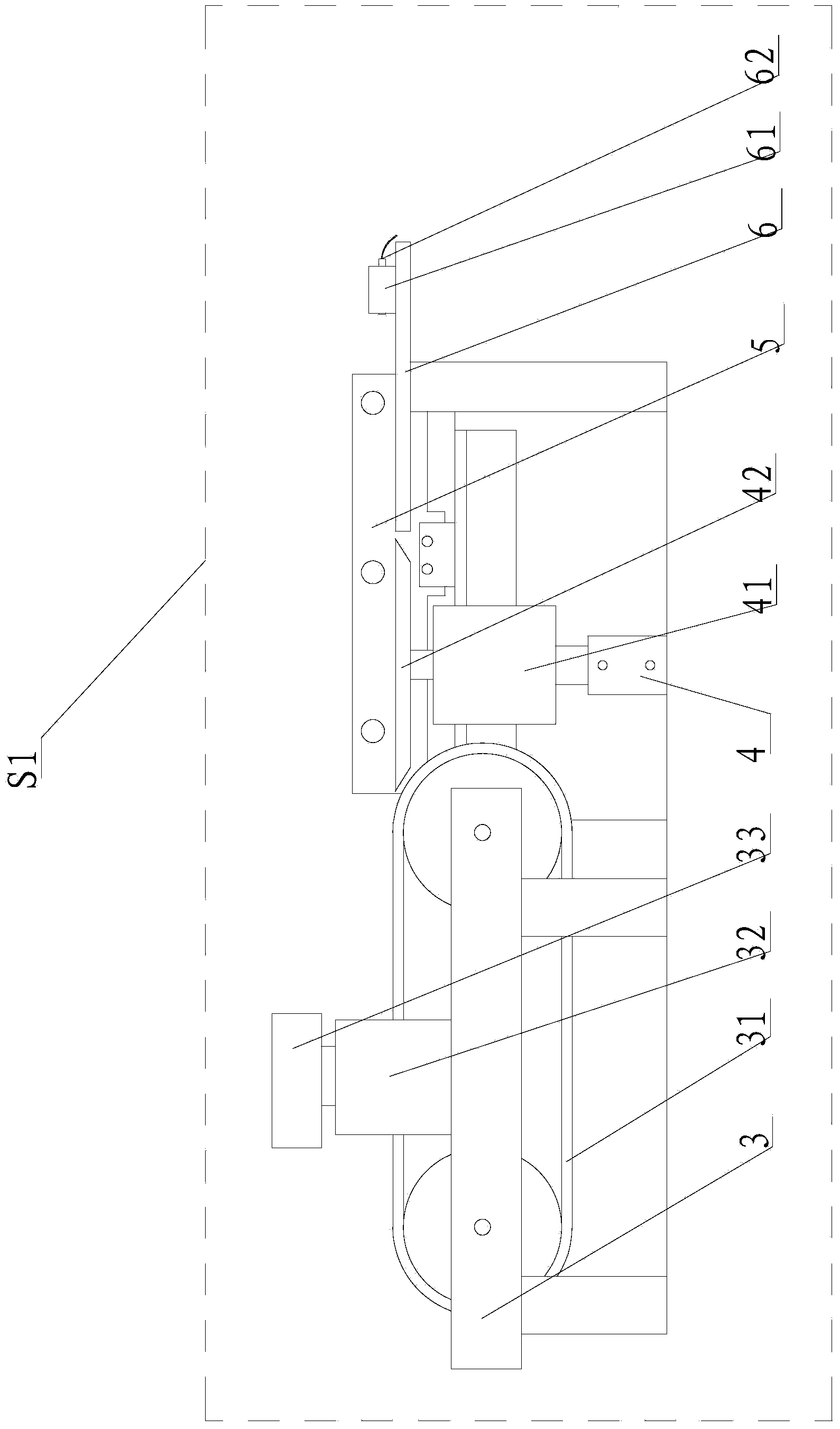

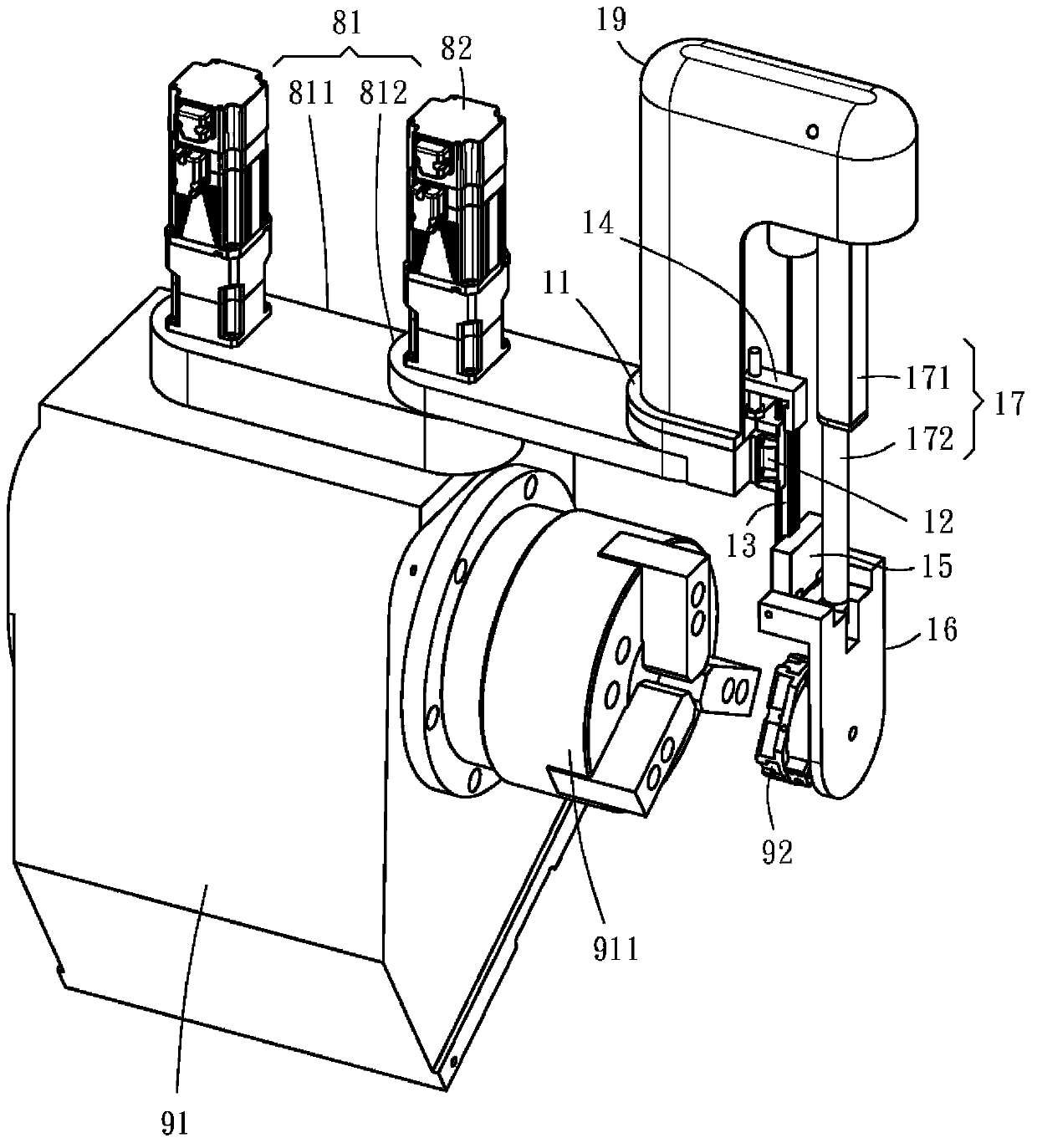

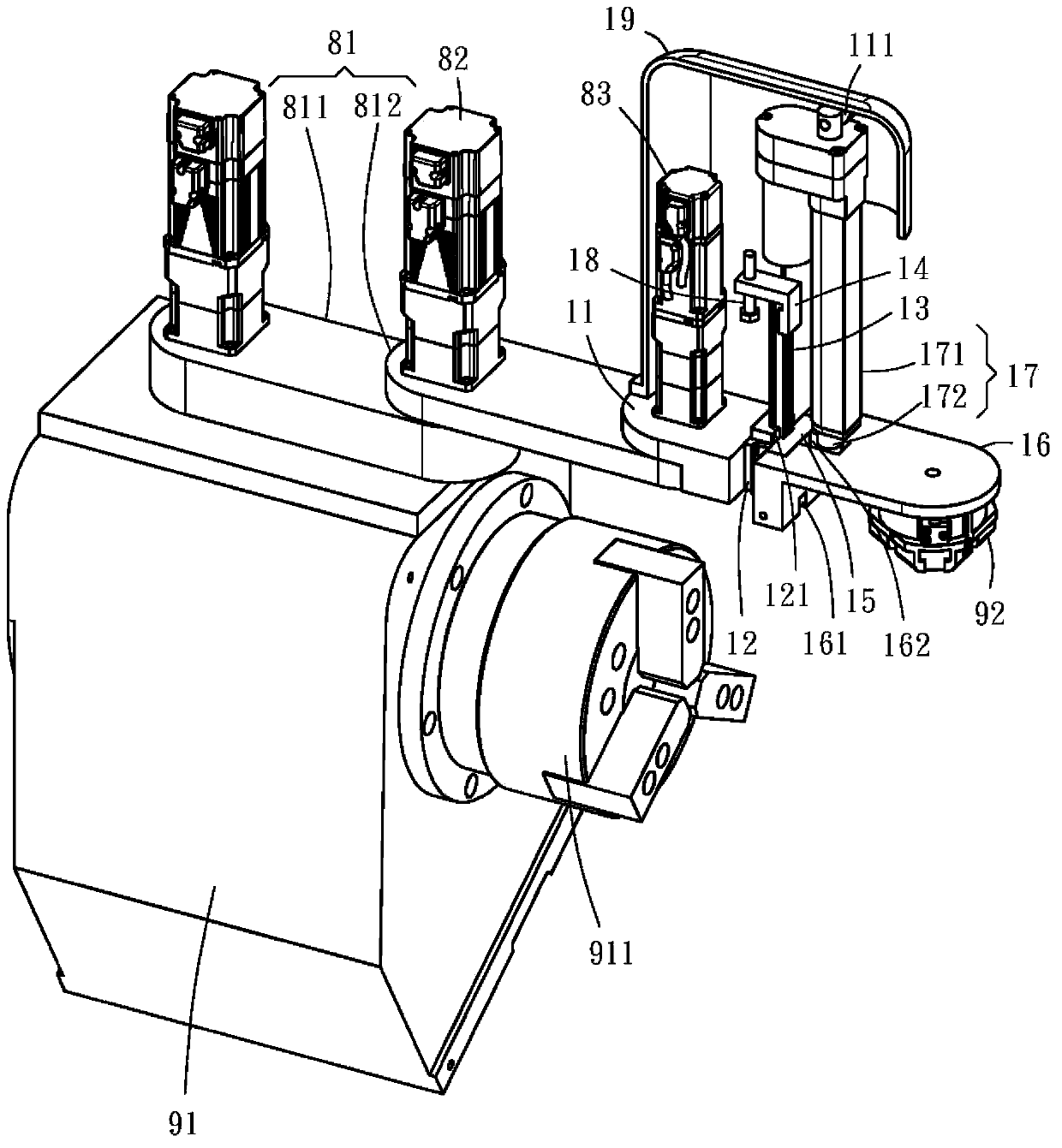

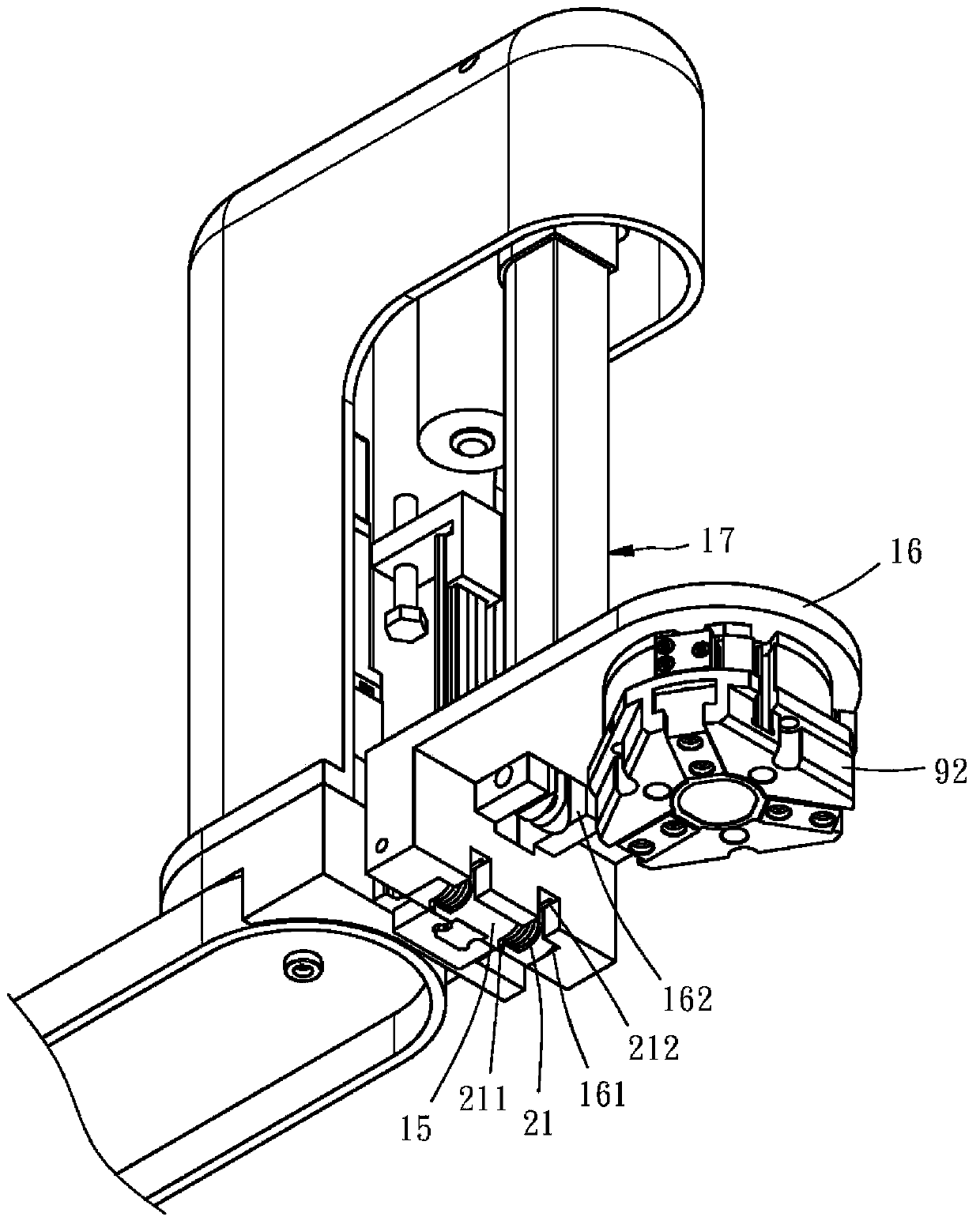

Fully-automatic cutting device for piston ring

ActiveCN105414564ARealize automatic cuttingImprove cutting accuracyPiston ringsAutomatic workpiece supply/removalEngineeringFully automatic

The invention relates to the technical field of piston ring cutting and discloses a fully-automatic cutting device for a piston ring. The fully-automatic cutting device comprises a frame, a main motor ad a lathe head box, wherein a spindle is arranged in the lathe head box; a belt pulley is arranged at one end of the spindle, and a piston ring positioning chuck is arranged at the other end of the spindle; a knife rest is arranged at the other end of the top of the frame; a connecting base is arranged at the upper side of the lathe head box; a feeding mechanism is arranged on the connecting base; a discharging end of the feeding mechanism is provided with a stopping cylinder; a positioning sleeve is arranged on the side surface of the connecting base; a rotating arm driving assembly is arranged on the connecting base and positioned on each of two sides of the feeding mechanism, wherein a feeding arm is connected to one rotating arm driving assembly, and a discharging arm is connected to the other rotating arm driving assembly; a feeding chunk is arranged at the outer end of the feeding arm; a discharging chuck is arranged at the outer end of the discharging arm; an automatic knife advance mechanism is arranged on the bottom of the knife rest; a distribution frame is arranged at a position, right below the discharging chuck, of the frame. The fully-automatic cutting device is high in cutting efficiency and high in cutting precision while used for cutting the piston ring.

Owner:上海谊奥汽配有限公司

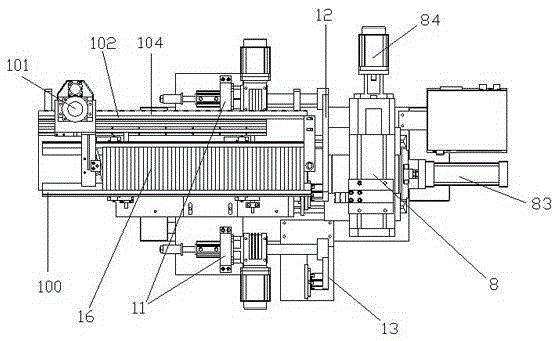

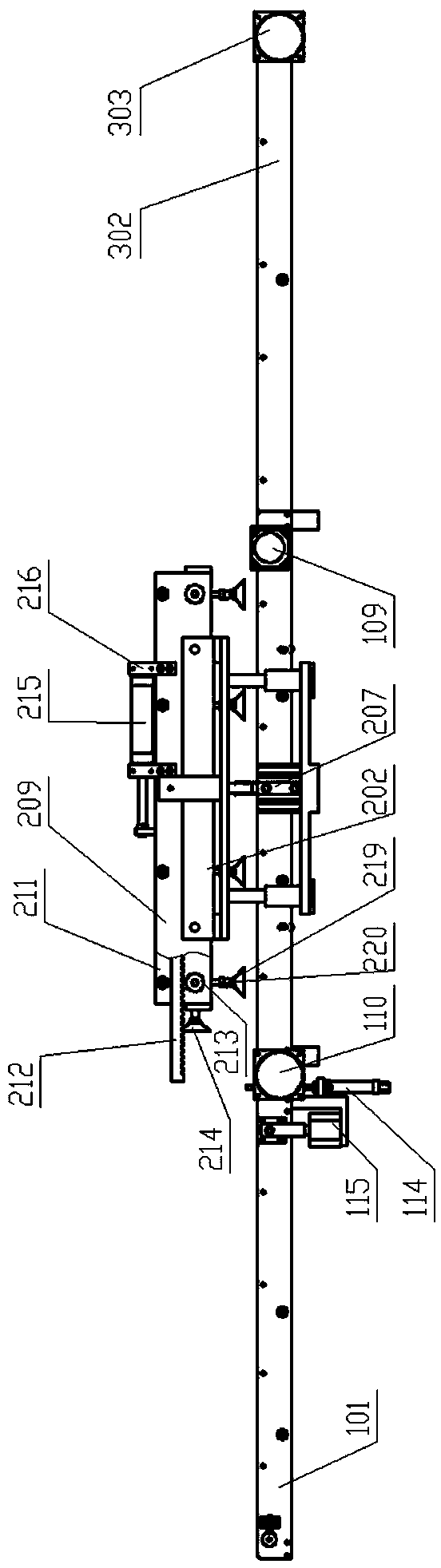

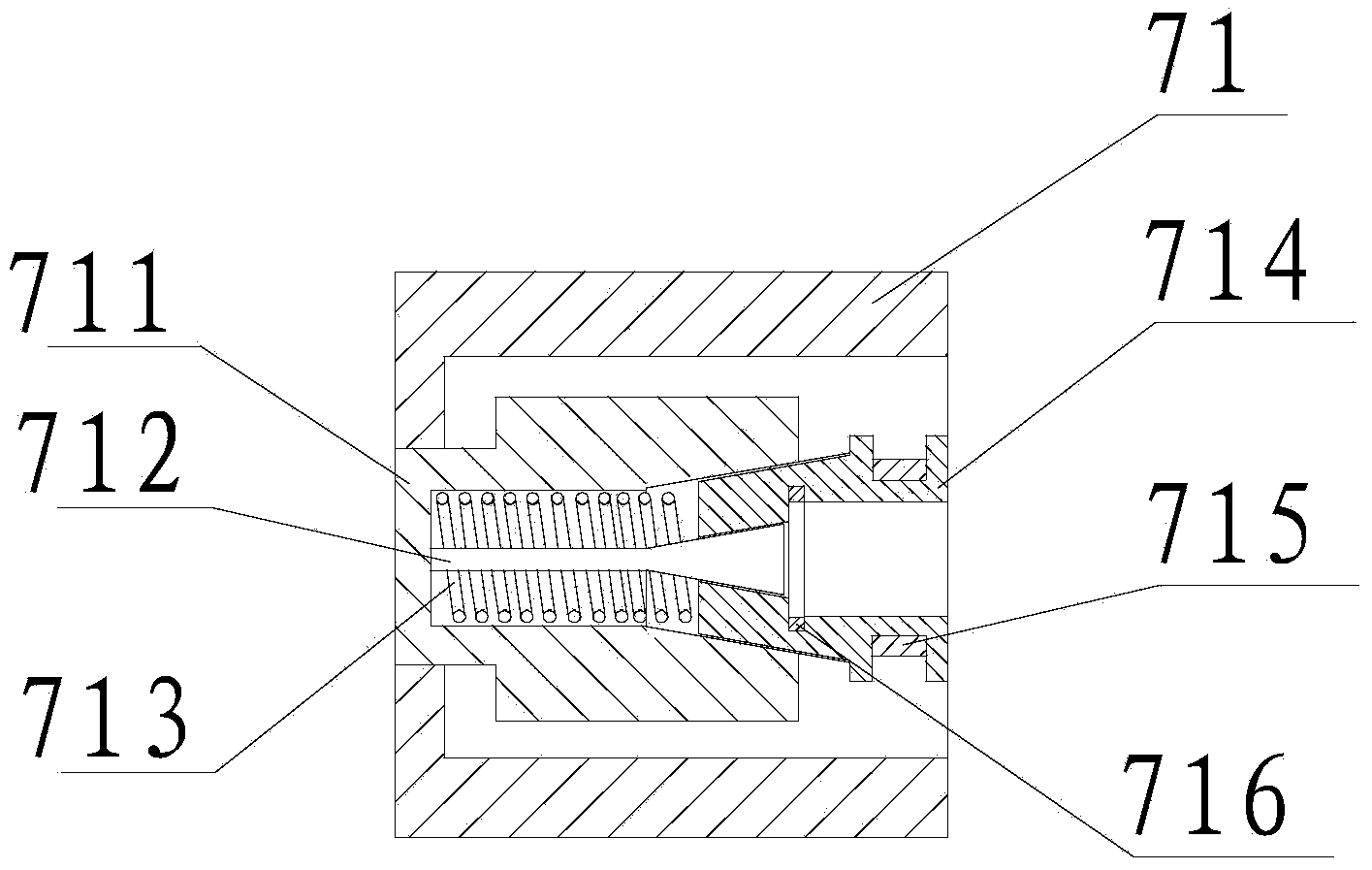

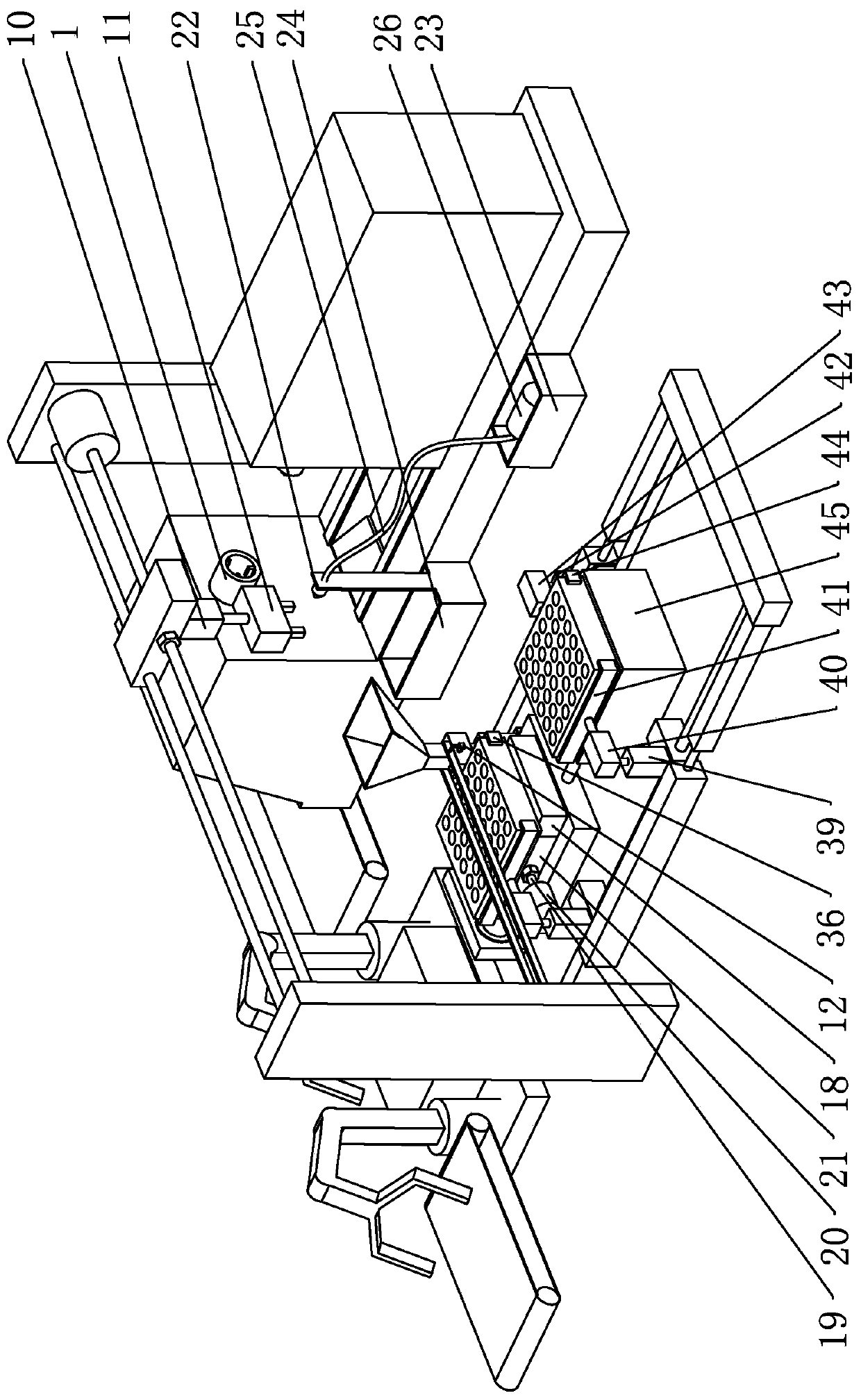

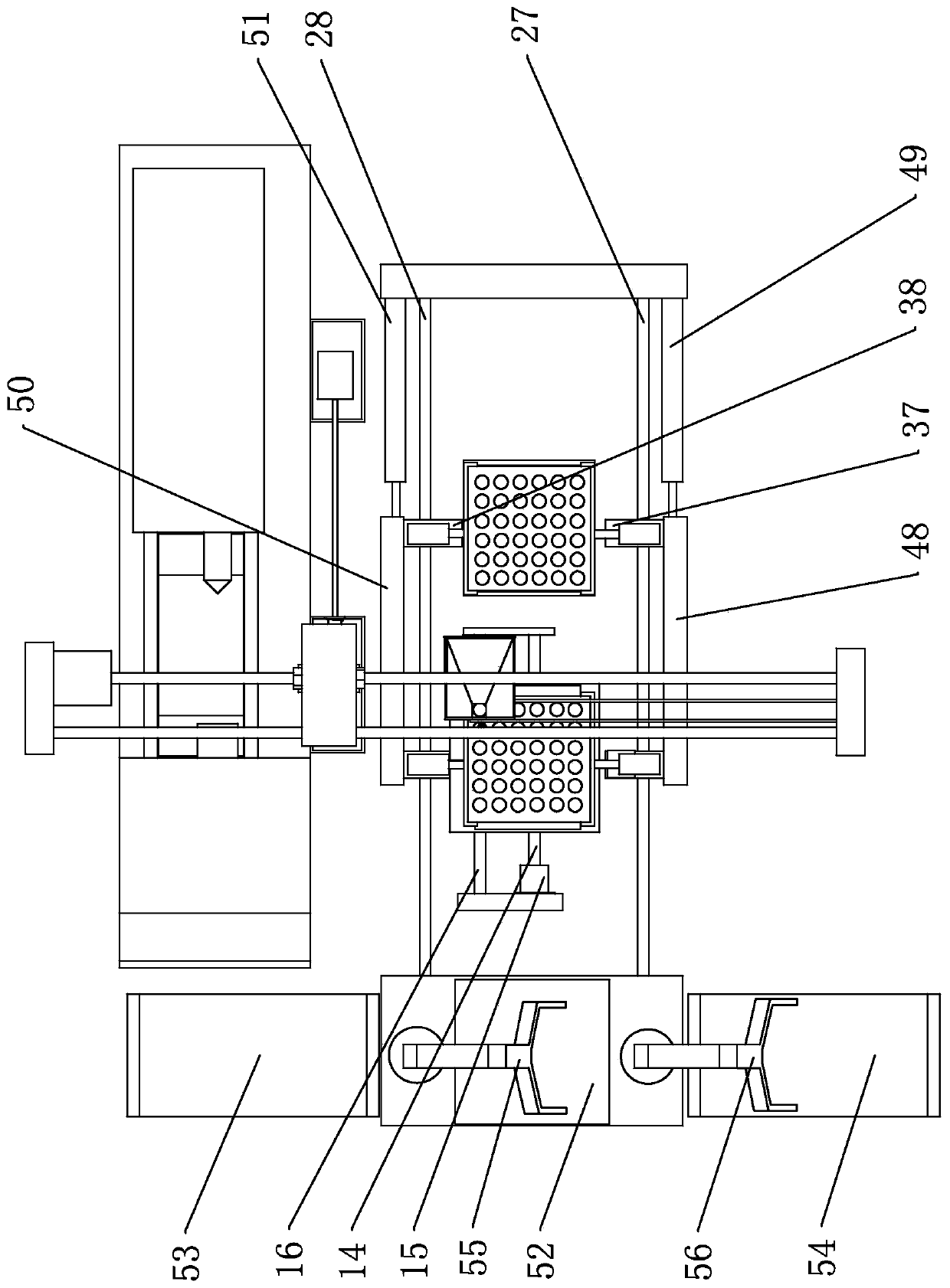

Full-automatic numerical control lathe for turning steel balls

InactiveCN105598475AGuaranteed stabilityReasonable designTailstocks/centresAutomatic workpiece supply/removalNumerical controlSteel ball

The invention relates to a full-automatic numerical control lathe for turning steel balls. The full-automatic numerical control lathe for turning steel balls solves the problems than an existing full-automatic numerical control lathe is low in precision, low in efficiency and the like. The full-automatic numerical control lathe comprises a machine tool which is provided with a truss assembly used for transferring a workpiece and a machining and clamping device used for machining the workpiece, and the truss assembly is located above the machining and clamping device. A workpiece feeding device is arranged on one side of the machine tool. The full-automatic numerical control lathe is characterized in that a clamping disk assembly is connected with a main shaft capable of driving the clamping disk assembly to rotate. The clamping disk assembly comprises a clamping disk base, a plurality of clamping claws which are evenly distributed in the circumferential direction and can stretch and retract in the axial direction of the clamping disk base are arranged in the clamping disk base in a penetrating mode, and an arc-shaped clamping concave face is arranged at the outer end of each clamping claw. The full-automatic numerical control lathe for turning steel balls has the advantages that precision and efficiency are high, energy consumption is low, the lathe is safe and reliable, and full-automatic feeding and discharging machining can be achieved.

Owner:JIANGSU BOSUNMAN IND EQUIP

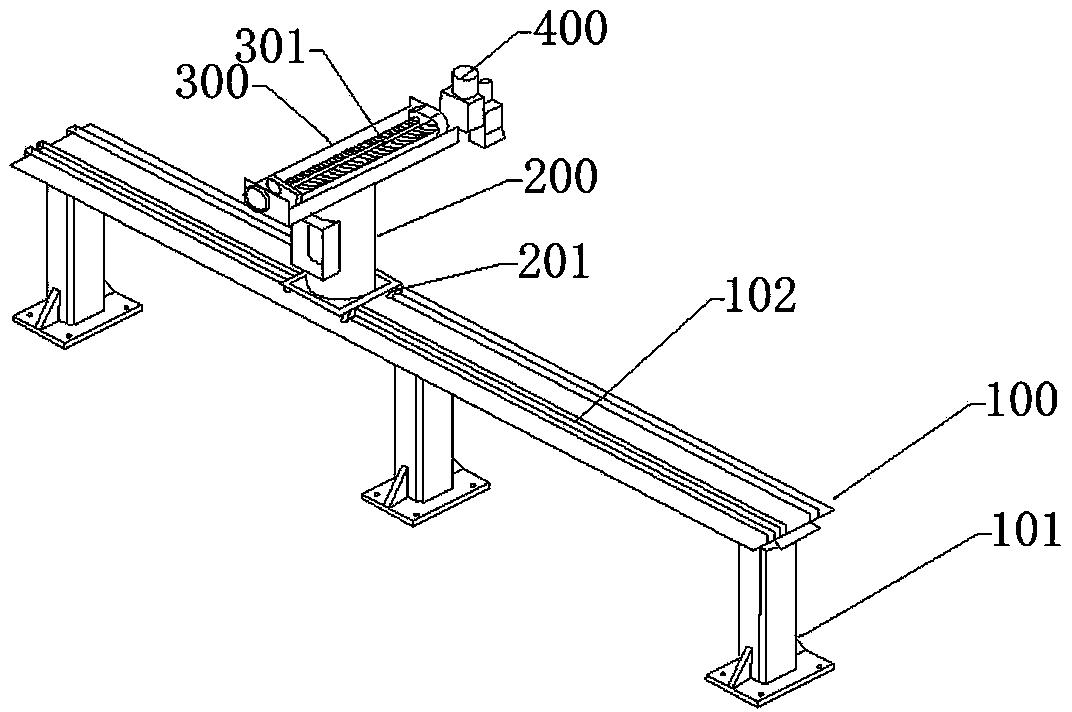

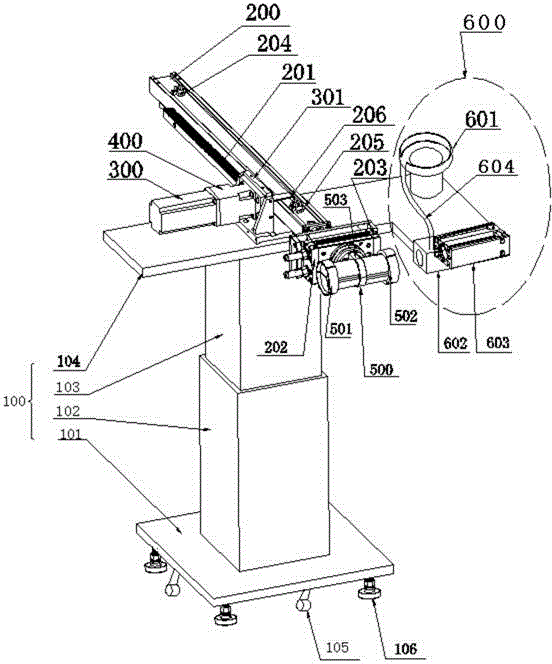

Automatic mechanical arm

ActiveCN104607992AReduce work accidentsImprove efficiencyAutomatic workpiece supply/removalGrinding feedersEngineeringConcertina movement

The invention belongs to the technical field of mechanical arm, and relates to an automatic mechanical arm specifically. The automatic mechanical arm comprises a rack (100), a servo motor (300) is arranged on the rack (100), a mechanical arm (200) is arranged on the rack (100), and the mechanical arm (200) conducts concertina movement driven by the servo motor (300). A fixture holder (500) is arranged at the end of the mechanical arm (200), and a feeding fixture (501) and a reclaiming fixture (502) are arranged on the fixture holder (500). A first cylinder (202) and a second cylinder (203) are arranged on the mechanical arm (200), the first cylinder (202) is used for controlling the rotation of the fixture holder (500), and the second cylinder (203) is used for controlling the horizontal moving of the fixture holder (500). The fixture holder of the mechanical arm can rotate driven by the cylinder, and the translocation of an intermittence between the feeding fixture and the reclaiming fixture is controlled correspondingly, perform bodied that needs processing and the processed elements are clamped respectively, the corresponding processing is conducted, the automatic material clamping, the feeding and reclaiming are achieved, and manual labor is replaced greatly.

Owner:SHENZHEN KING TEAM PRECISION TECH

Processing method of automatic lathe used for processing cylindrical workpieces

ActiveCN106984833AImprove processing efficiencyImprove pass rateAutomatic workpiece supply/removalMetal working apparatusEngineeringProcess operation

The invention relates to a processing method of an automatic lathe used for processing cylindrical workpieces. The processing method mainly solves the technical problems that during processing operation, a processing lathe for the cylindrical workpieces in the prior art does not have an automatic loading function, is low in efficiency for large-scale processing operation, feeding of a main shaft part in the prior art is directly driven by an oil cylinder, rigidity for positioning workpieces is not good, vibration is liable to cause during processing, and processing precision is affected. With the adoption of the technical scheme of additionally arranging an automatic loading mechanism and a positioning central spindle, the problems are solved very well, and therefore, the processing method can be used for industrial production of the automatic lathe used for processing cylindrical workpieces.

Owner:深圳市宏旺模具有限公司

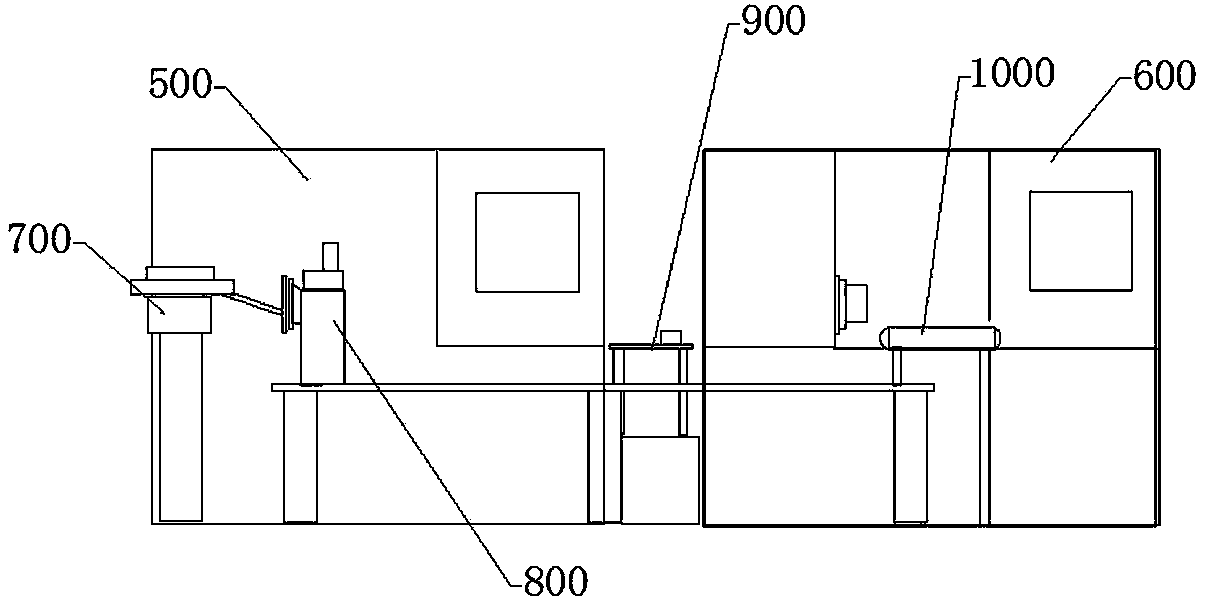

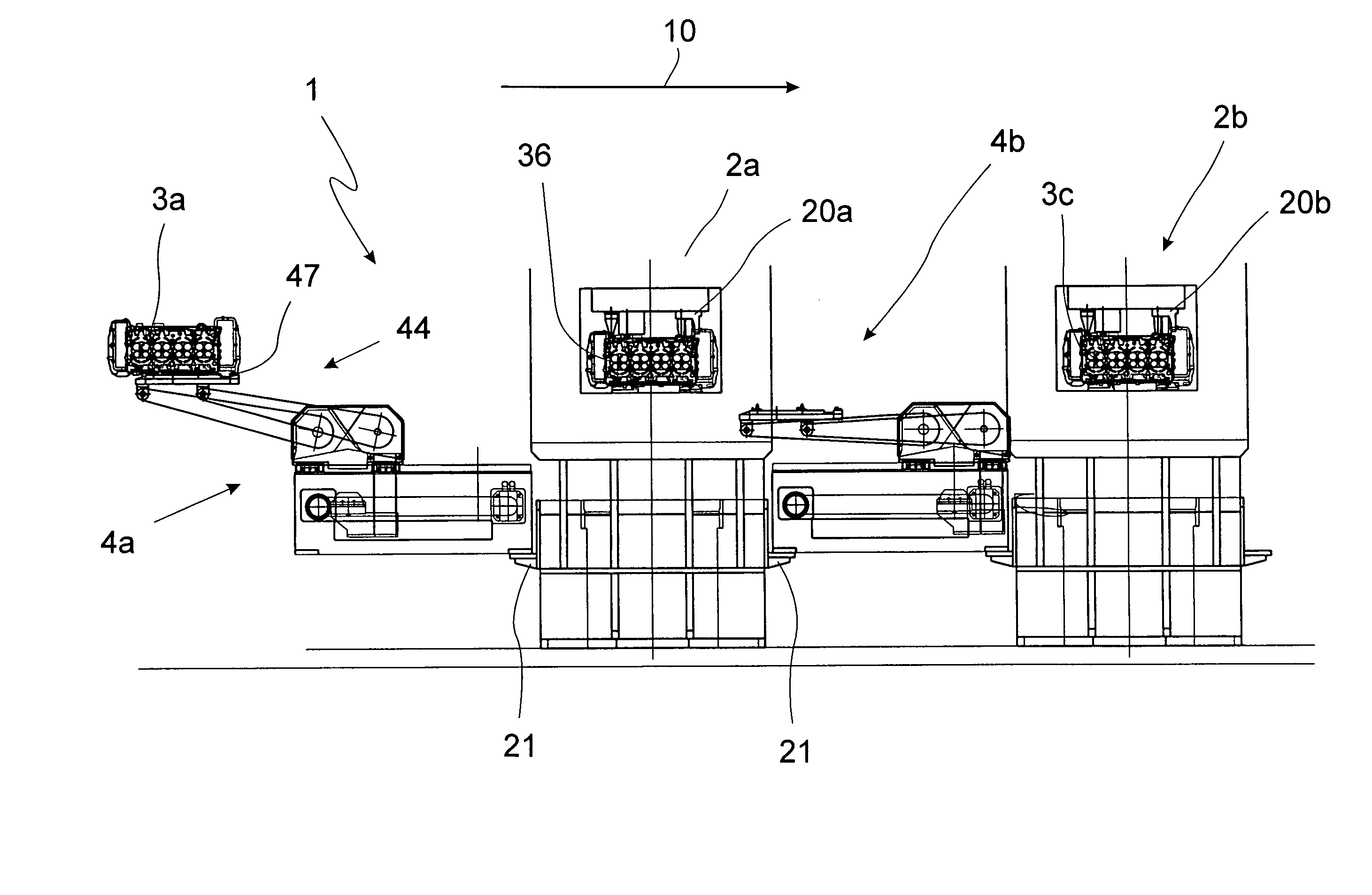

Machining line

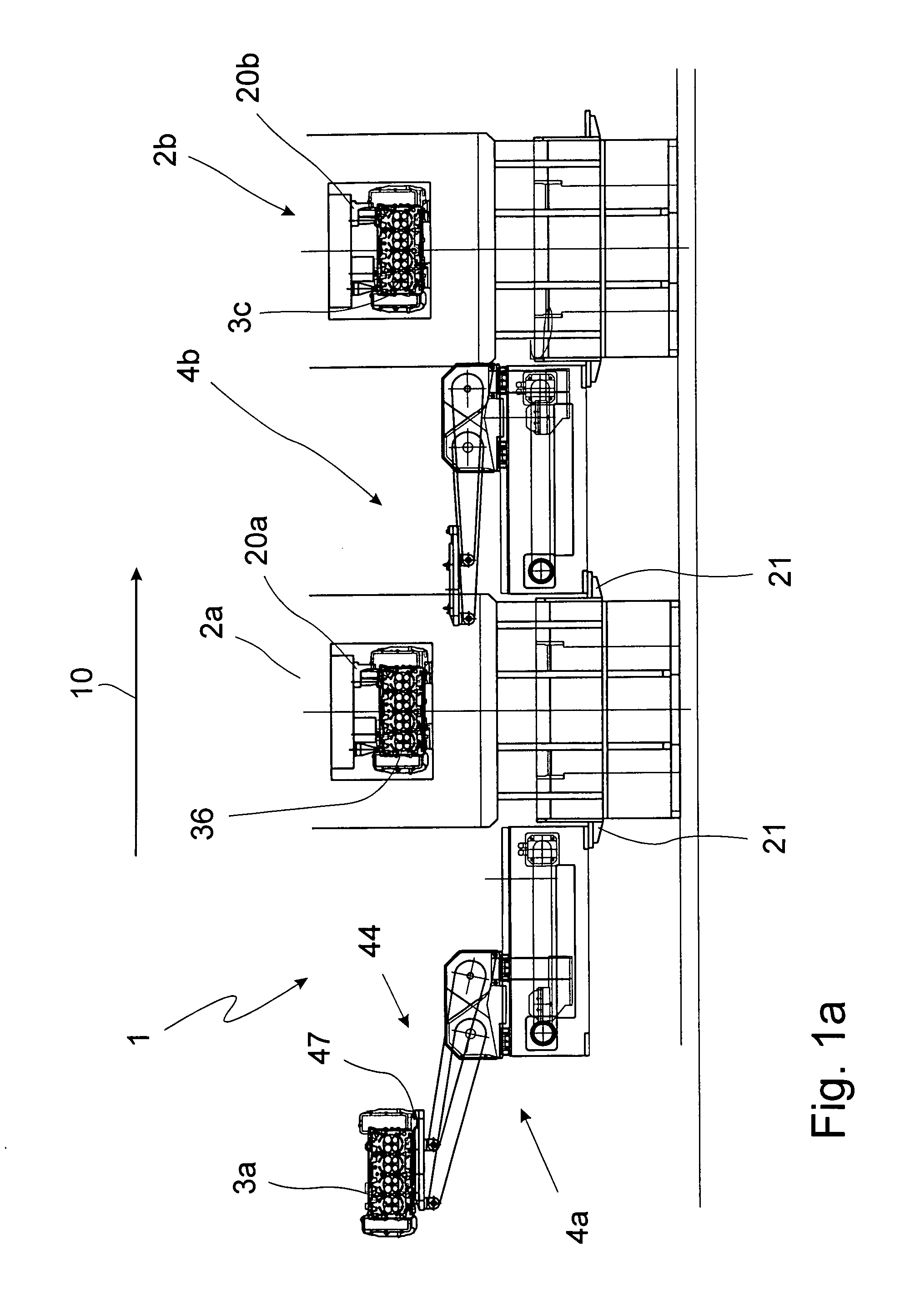

InactiveUS20080075565A1Reduce energy consumptionReduce consumptionConveyorsAutomatic workpiece supply/removalEngineeringAssembly line

The invention refers to a machining line, in particular a transfer line or assembly line, comprising a multitude of machining stations arranged one after the other in the direction of machining, and the machining station serves for machining work pieces, wherein at least one machining station is designed as special station. The invention is characterised by the fact that between two adjoining machining stations one conveying device each is provided.

Owner:GROB WERKE & K G

Full-automatic nut machining device

PendingCN111069717AHigh degree of automationIncrease productivityThread cutting machinesAutomatic workpiece supply/removalWorkbenchIndustrial engineering

The invention discloses a full-automatic nut machining device. The full-automatic nut machining device comprises a rack, a feeding mechanism and a tapping mechanism. A nut feeding chamber, a nut tapping chamber and a nut discharging chamber are arranged in the rack. A feeding station, a tapping station and a discharging station are arranged in the nut feeding chamber, the nut tapping chamber and the nut discharging chamber correspondingly. The output end of the feeding mechanism extends to the feeding station. A first protection shell is fixed in the rack. A rotary workbench is installed in the first protection shell. A rotary shaft is vertically installed on the rotary end face of the rotary workbench. The upper end of the rotary shaft extends out of the first protection shell and is fixedly provided with a rotary frame. The rotary frame is in a three-fork shape, and nut bearing mechanisms are fixed to the three ends of the rotary frame. The full-automatic nut machining device is thehighest in automation degree, and during work, automatic feeding, clamping, machining and discharging can be achieved, the production efficiency is high, and the labor cost can be remarkably reduced;and the tapping mechanism can machine four nuts on a rotary disc at the same time, feeding and tapping are not stopped, and the machining efficiency is high.

Owner:邯郸市澳嘉紧固件制造有限公司

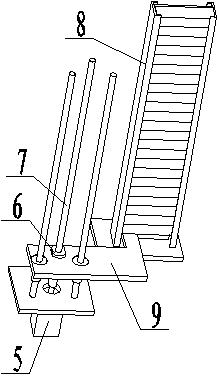

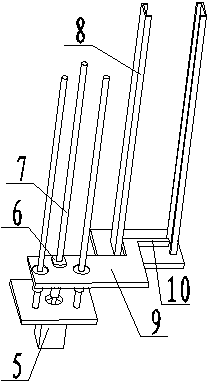

Bar feeding assisting device

ActiveCN105563215AReduce investmentReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusNumerical controlEngineering

The invention discloses a bar feeding assisting device and relates to the technical field of machining. The bar feeding assisting device comprises a lifting device and a jacking mechanism. The lifting device comprises a worktable and a lifting mechanism, a supporting rack is arranged on the worktable, bars to be machined can be erected on the supporting rack, and the lifting mechanism drives the supporting rack to move up and down so that when the bars are lifted to the highest portion, the bars can coincide with the center of a chuck of a numerical control machine tool. By means of the jacking mechanism, the bars can move to the chuck, and the bars can be placed on a feeding bracket in the numerical control machine tool. The bars are matched with the numerical control machine tool through ascending and descending of the worktable and linkage of the jacking mechanism, and the bars can be continuously cut off and discharged for subsequent machining. The bar feeding assisting device has the advantages of being simple and compact in structure, convenient to operate and high in production efficiency, capital investment of special cutting equipment for discharging is reduced, the technological process is simplified, manpower is saved, logistics transfer time between procedures is shortened, and the bar feeding assisting device is particularly suitable for being used in cooperation with the numerical control machine tool and meets the requirement for large-scale production.

Owner:XUZHOU SANHE MACHANICAL PARTS

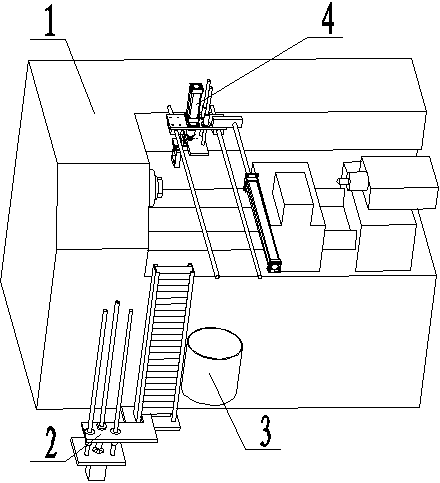

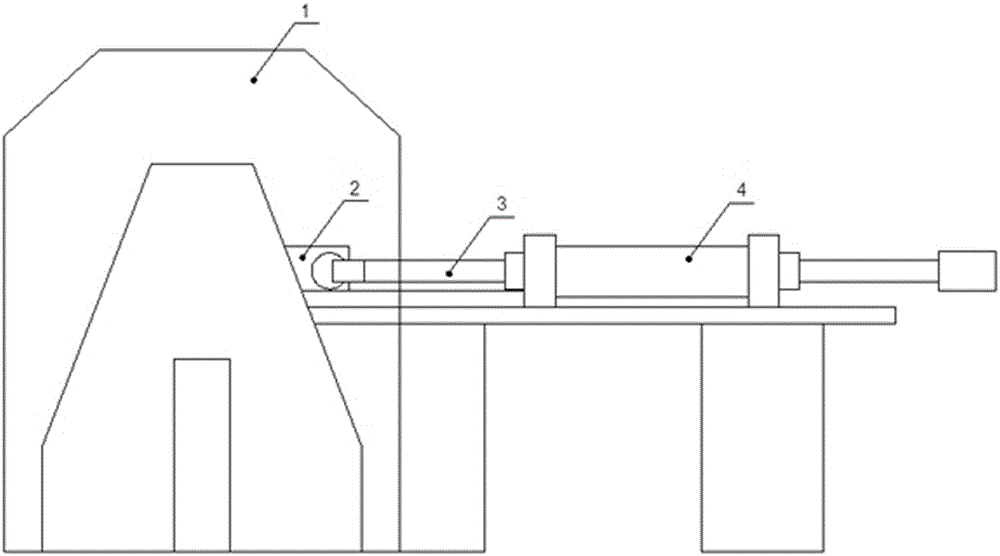

Direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system

ActiveCN104741631APrecision mechanical structureSimple loadingAutomatic workpiece supply/removalMetal working apparatusPiston rodIndustrial engineering

The invention relates to a machining device, in particular to an automatic feeding-discharging system of a numerically-controlled lathe. The direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system comprises a vibrating disc, a feeding mechanism, a discharging mechanism, a linear guide rail, a lifting air cylinder and a support. The support is fixedly connected to the numerically-controlled lathe. The linear guide rail is movably connected to the support, a lifting plate is fixedly connected with the tail end of the linear guide rail, the lifting air cylinder is fixedly connected to the support, and a piston rod of the lifting air cylinder is fixedly connected with the lifting plate. The feeding mechanism is fixedly connected to the lifting plate. A technology for achieving automatic feeding and automatic discharging of the numerically-controlled lathe is disclosed. By means of the direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system, clamping jaws widely used in the industry are omitted, a simpler and more durable direct-pushing type mechanism is developed, and the feeding process and the discharging process of workpieces on a chuck of the numerically-controlled lathe are achieved. Motions are accurate in the feeding process, and the speed is high in the discharging process.

Owner:湖北信友汽车零部件有限公司

Automatic feeding device of edging machine

ActiveCN104259490AAvoid damageImprove machining accuracyAutomatic conveying/guiding stockAutomatic workpiece supply/removalEngineeringMachining

The invention discloses an automatic feeding device of an edging machine, and belongs to the technical field of lens machining devices. The automatic feeding device comprises an input mechanism, an assembling and disassembling mechanism and an output mechanism. The assembling and disassembling mechanism comprises a double-stroke air cylinder, a pushing rod, a guide sleeve fixed plate, a guide rod, a suction cup transverse rod and a suction cup device; one end of the pushing rod is arranged at the output end of the pushing air cylinder, the other end of the pushing rod is fixedly arranged on the guide sleeve fixed plate; a guide rail mechanism is arranged on the guide sleeve fixed plate; the guide sleeve fixed plate is connected with one end of the suction cup transverse rod; a suction cup fixed block is arranged at the other end of the suction cup transverse rod; the suction cup device is arranged on the suction cup fixed block. Under action of the double-stroke air cylinder, the suction cup device conveys non-machined lens on the input mechanism to a machining position, and the edged lens are conveyed to the output mechanism. The automatic feeding device of the edging machine prevents the lens from being damaged, meanwhile, the machining precision of the lens is improved, the working efficiency is improved, and the production cost of the product is reduced.

Owner:LINHAI CITY RAUL MACHINE

Loading and unloading device for shaft processing of numerical control lathe

ActiveCN105149619AMeet processing needsReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusProduct processingTransfer mechanism

The invention discloses a loading and unloading device for shaft processing of a numerical control lathe. The loading and unloading device comprises the numerical control lathe, a rack, a loading bracket, an unloading bracket, a horizontal transfer mechanism and a mechanical arm assembly, wherein the mechanical arm assembly consists of a lifting air cylinder, a transposition holder mechanism, a sliding seat mechanism and a guide mechanism, and is mounted in an upper plane of the rack; the transposition holder mechanism consists of a mechanical arm seat plate, a bearing support, a gear ring, a clamping cylinder, a rotating shaft bolt, a transposition motor and a transposition motor gear, and is mounted in an upper plane of the horizontal transfer mechanism; the numerical control lathe is arranged in the rack; the loading bracket is arranged on one side of the numerical control lathe; the unloading bracket is arranged on the other side of the numerical control lathe. The loading and unloading device meets the requirements of the numerical control machine on shaft product processing, saves human resources, reduces the labor intensity of workers, reduces the processing cost and improves the production efficiency. In addition, the loading and unloading device can adapt to the requirements of modern automation mass production by being matched with a PLC (Programmable Logic Controller).

Owner:ANHUI MINGYAN GEAR

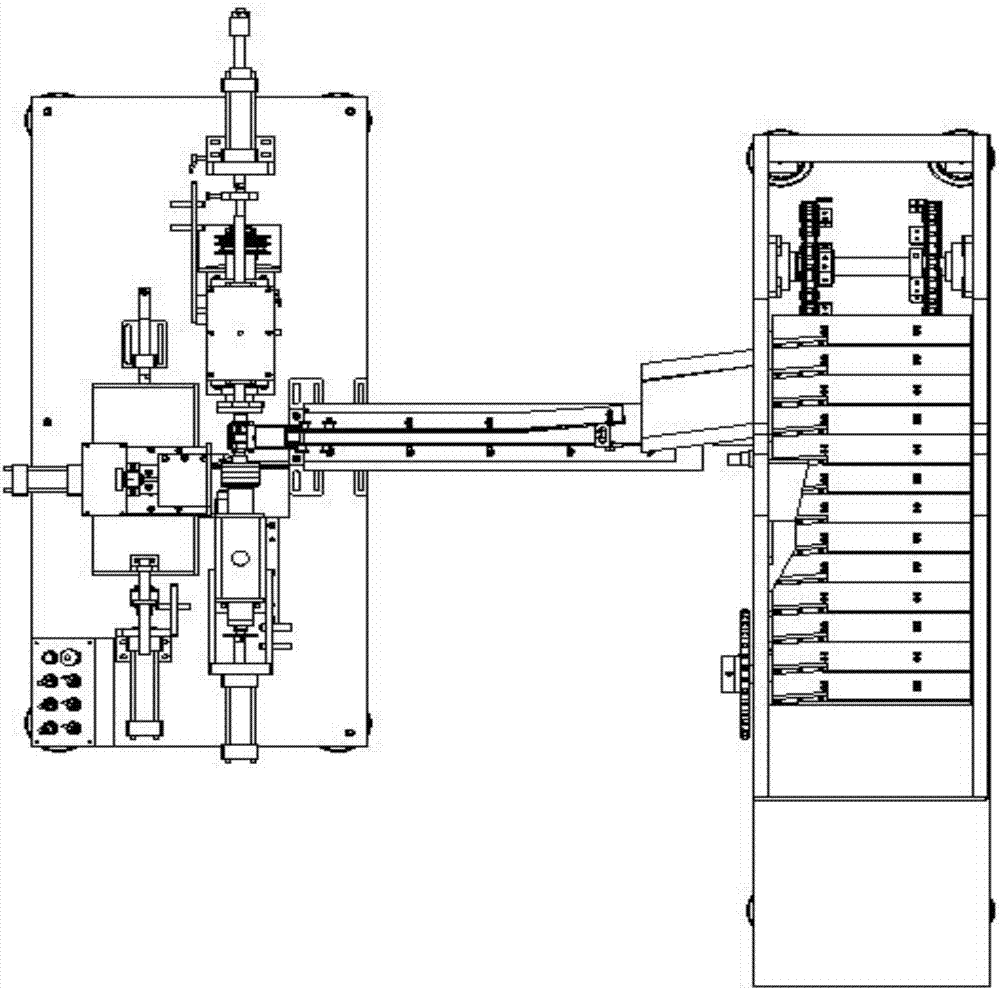

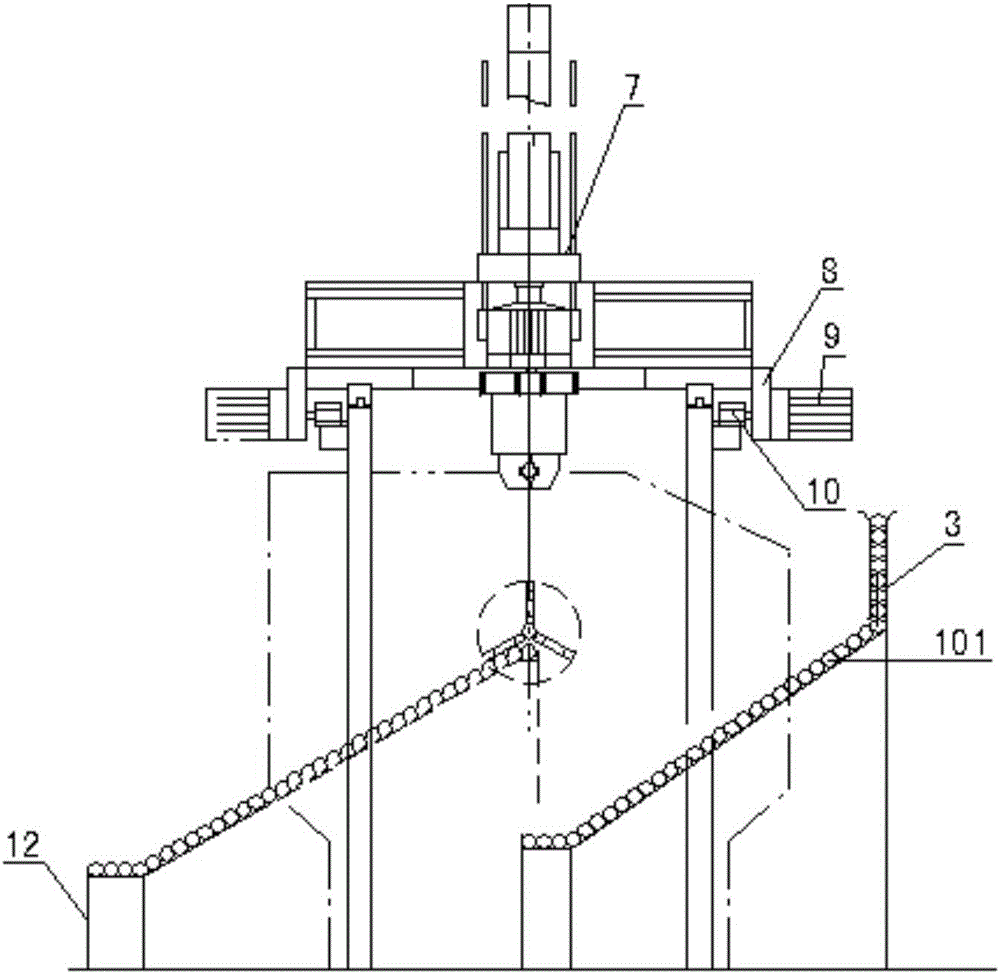

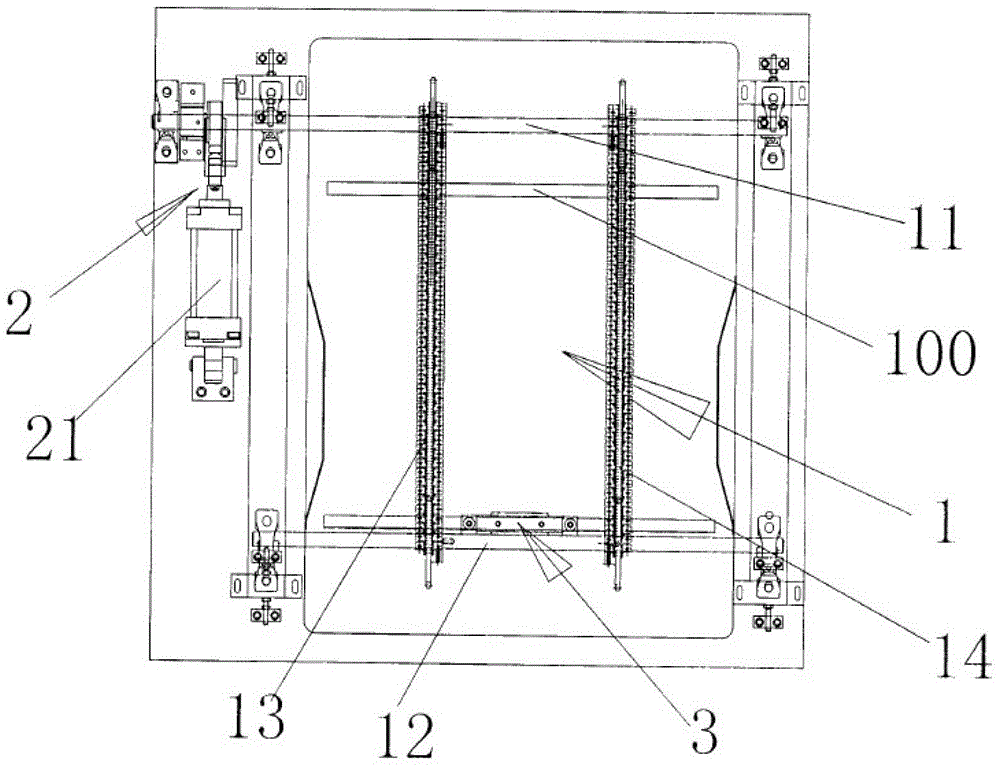

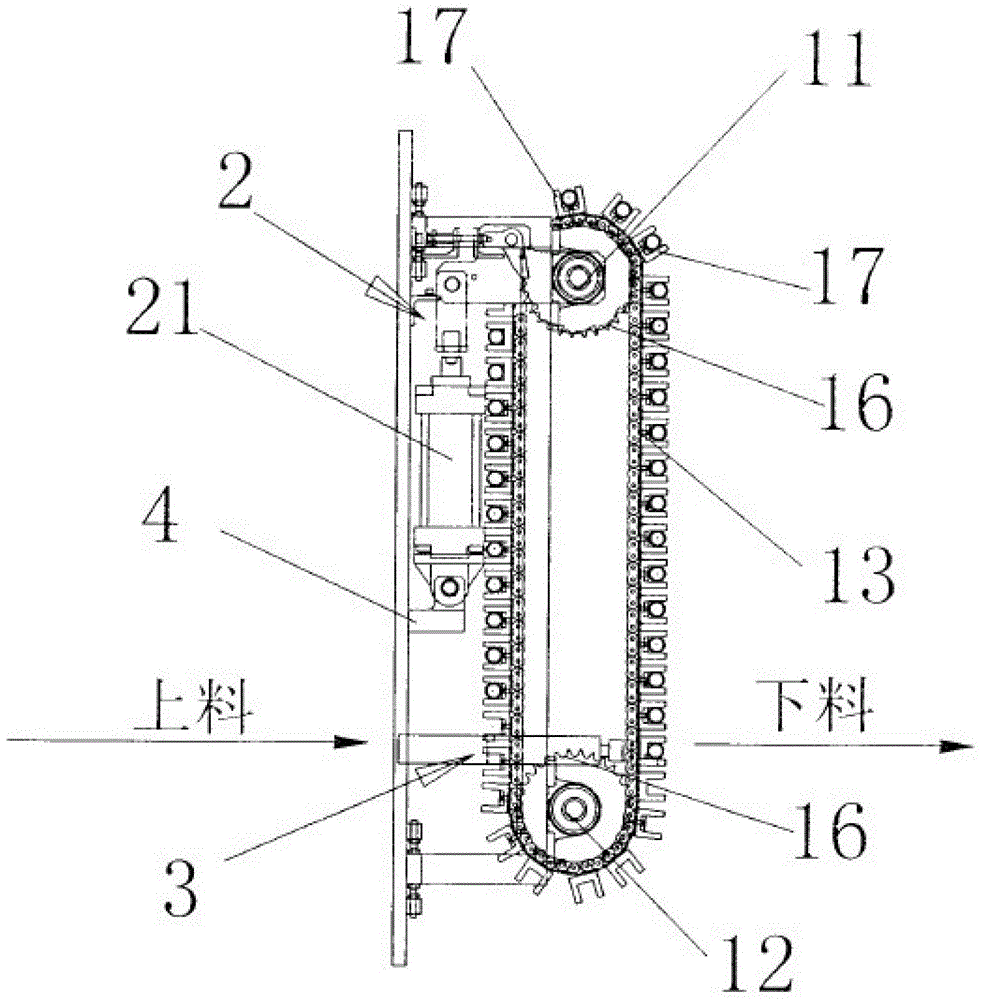

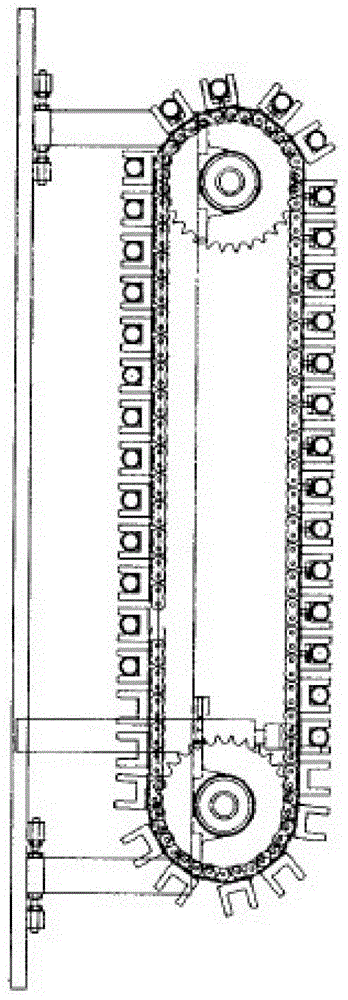

Automatic pipe discharging and feeding device

An automatic pipe discharging and feeding device comprises a discharging mechanism, a driving mechanism and a feeding mechanism, wherein pipes can be embedded in the discharging mechanism, the driving mechanism can drive the pipes on the discharging mechanism to move, and the feeding mechanism can grab and convey the pipes on the discharging mechanism. The discharging mechanism is provided with two chain rings arranged side by side, the two chain rings are installed on two spindles together through a set of chain wheels, the two spindles are arranged side by side, multiple pairs of pipe clamping dies are fixed to the two chain rings respectively, and one pipe can be embedded in the corresponding pair of pipe clamping dies. The driving mechanism is installed on one spindle and comprises a ratchet wheel, a pawl fixing plate and a driving air cylinder, wherein the ratchet wheel is fixed to the corresponding spindle, the corresponding spindle is movably sleeved with one end of the pawl fixing plate, the pawl fixing plate and the ratchet wheel are located side by side, and the driving air cylinder can drive the other end of the pawl fixing plate to swing in a reciprocating mode. The pawl fixing plate is further provided with a pawl, wherein the pawl can be meshed with the ratchet wheel in one direction and drive the ratchet wheel together with the spindle to rotate. The feeding mechanism comprises two supporting dies and a feeding air cylinder, wherein the feeding air cylinder can drive the two supporting dies to push out the pipes on the corresponding pipe clamping dies. According to the automatic pipe discharging and feeding device, the pipes can be placed continuously and conveyed out automatically, working efficiency is improved, and labor intensity is reduced.

Owner:旭东机械(昆山)有限公司

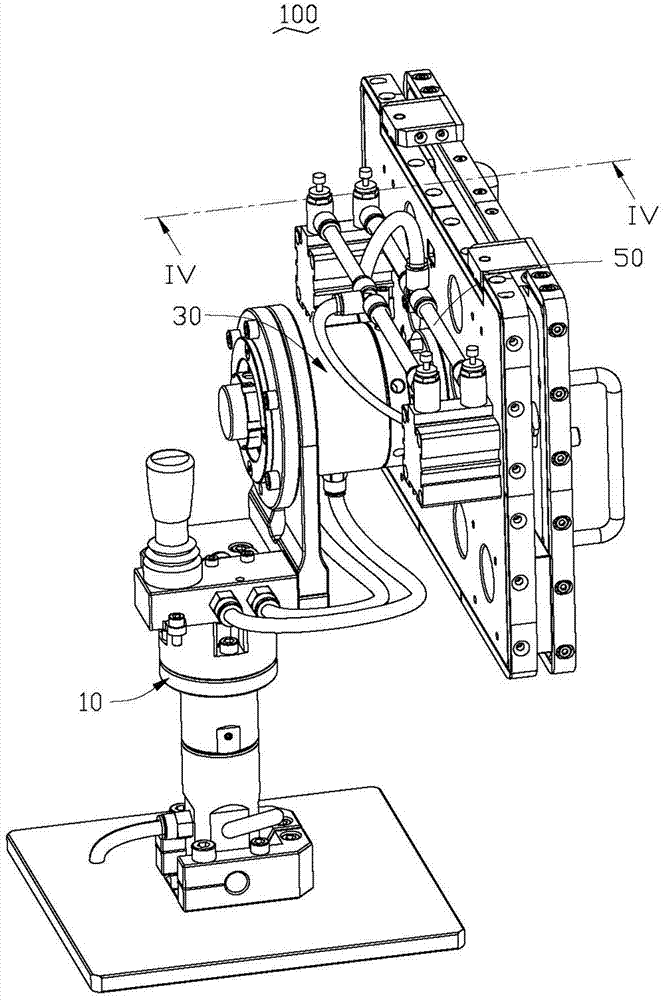

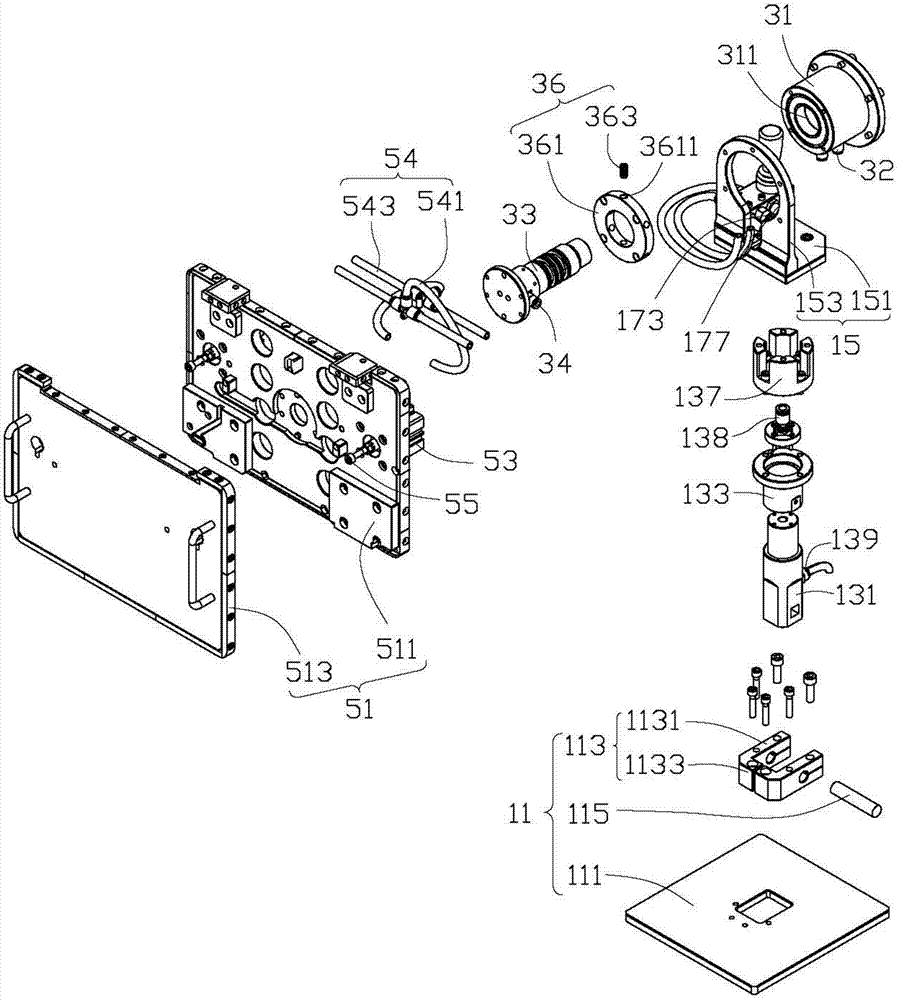

Clamping device and rotatable driving mechanism with clamping device

ActiveCN104772631AAvoid entanglementWork clamping meansAutomatic workpiece supply/removalEngineeringCircular surface

A rotary driving mechanism includes a support stand, an air feeding assembly, and a driver. The air feeding assembly includes a bearing base, a rotating member, two first ventilating joints, and two second ventilating joints. The bearing base is coupled to the support stand and defines an inner circular surface. The rotating member is rotatably received in the bearing base and resists the inner circular surface. The rotating member defines two circular grooves at an outer periphery thereof and two channels therein. Each circular groove is in fluid communication with one of the channels. The first ventilating joints are coupled to the bearing base and respectively in fluid communication with the circular grooves. The second ventilating joints are coupled to the rotating member and respectively in communication with the channels. The driver is coupled to the rotating member and in communication with the second ventilating joints.

Owner:安徽爱意爱机电科技有限公司

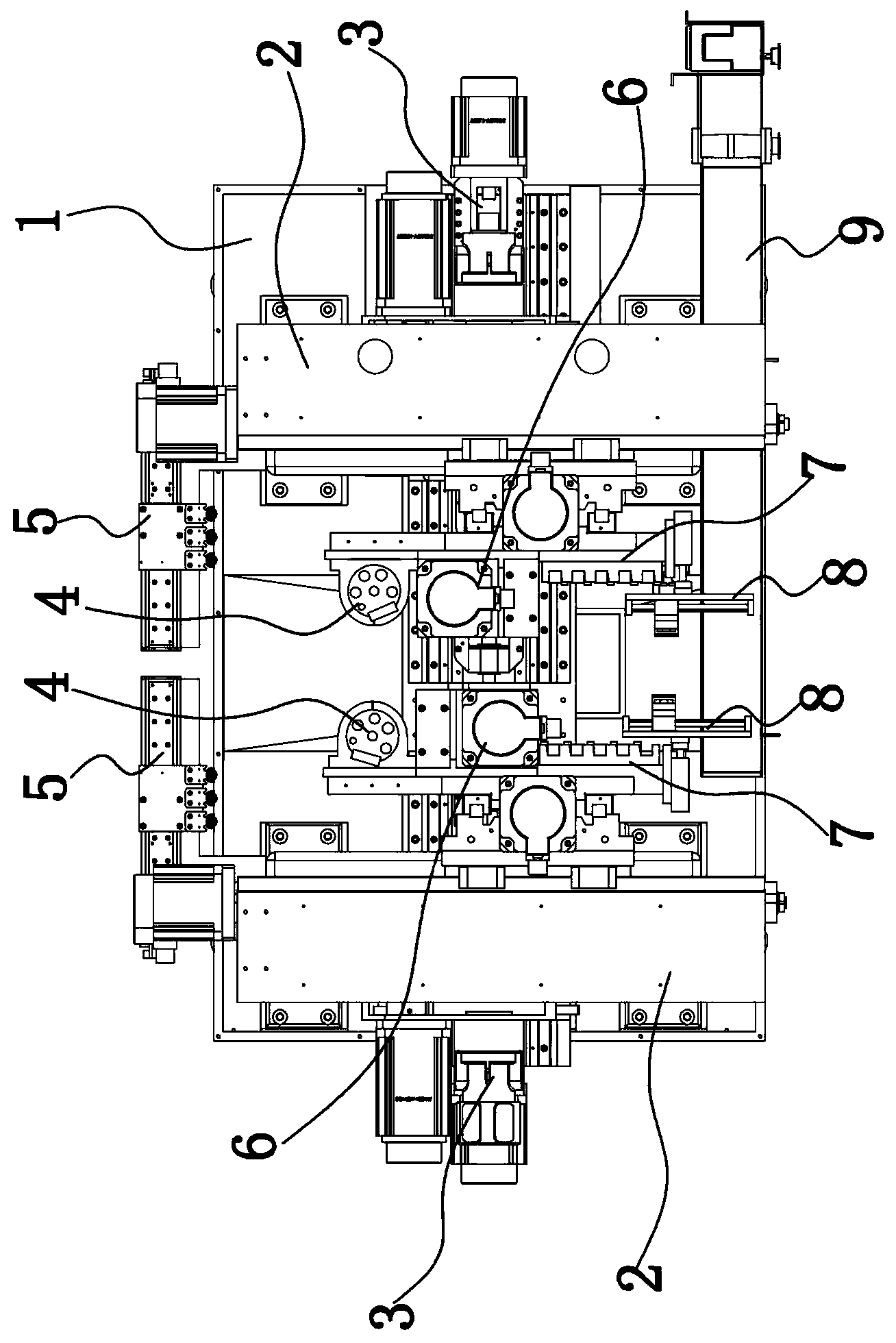

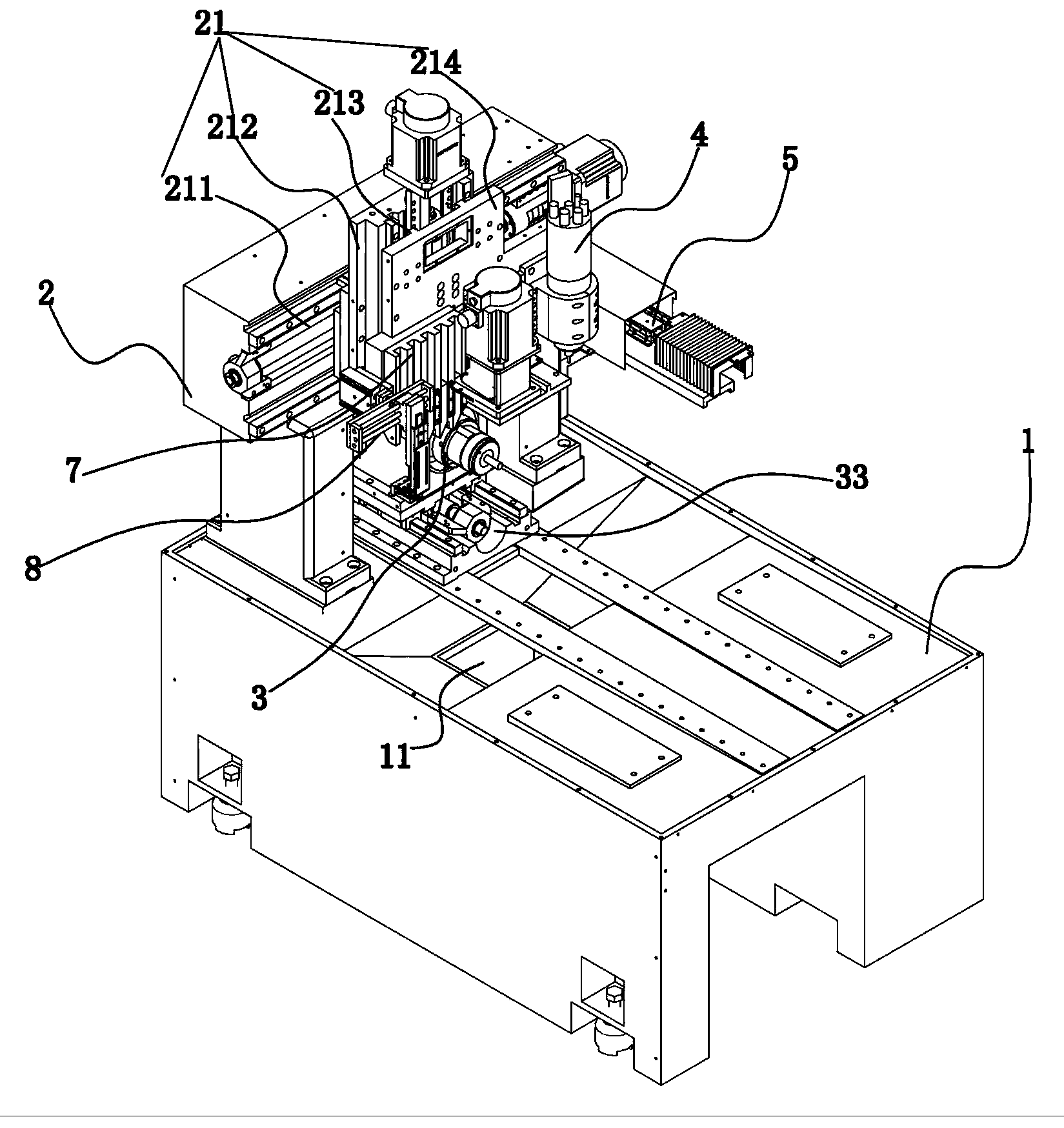

Turning-milling combination machine

InactiveCN103817529AShorten the travel distanceStable processingAutomatic workpiece supply/removalOther manufacturing equipments/toolsVertical planeTower

The invention discloses a turning-milling combination machine and belongs to the field of turning-milling machining. The turning-milling combination machine comprises a portal frame, a horizontal main shaft base, a vertical main shaft arm, a power tool tower and a row tool rest. The horizontal main shaft base is arranged in a gantry of the portal frame in a penetrating mode. A transmission mechanism is arranged on the portal frame. The vertical main shaft arm, the power tool tower and the row tool rest are arranged on the transmission mechanism, so that vertical plane moving of the vertical main shaft arm, the power tool tower and the row tool rest is achieved, and a workpiece is machined. The turning-milling combination machine is high in machining efficiency and stable in performance.

Owner:东莞市美迈士机械科技有限公司

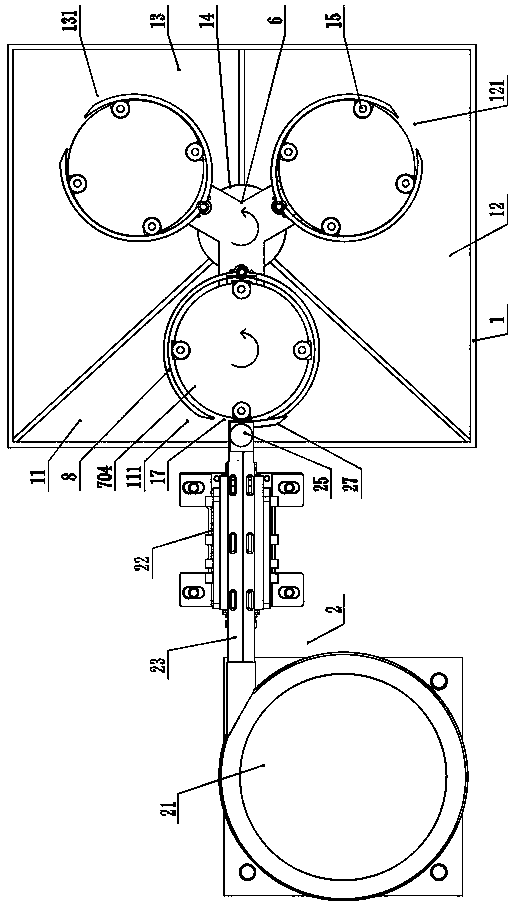

Automatic hub processing equipment and method for automatically processing hub

ActiveCN104308187ASave time at workImprove work efficiencyAutomatic workpiece supply/removalTurning machinesEngineeringManipulator

The invention provides automatic hub processing equipment and a method for automatically processing a hub. The automatic hub processing equipment comprises an inner conveying device, an outer conveying device, a manipulator and processing devices, wherein a first positioning mechanism and a first driving mechanism are arranged at the conveying tail end of the inner conveying device; the first positioning mechanism is mounted on the first driving mechanism; the first driving mechanism can drive the rotation of the first positioning mechanism; a second positioning mechanism and a second driving mechanism are arranged at the conveying head end of the outer conveying device; the second positioning mechanism is mounted on the second driving mechanism; the second driving mechanism can drive the rotation of the second positioning mechanism; a detection device is further arranged on the outer conveying device. With the adoption of the automatic hub processing equipment provided by the invention, the working time of the single working process of the manipulator is effectively shortened, so that the manipulator can be matched with at least four processing devices, the working efficiency of the manipulator is effectively improved, and the requirements of an enterprise are better met.

Owner:浙江今飞机械有限公司

Automatic feeding and discharging device for six-corner-rod numerical control lathe

InactiveCN108380908AAutomatic workpiece supply/removalMetal working apparatusNumerical controlBall screw

he invention provides an automatic feeding and discharging device for a six-corner-rod numerical control lathe. The automatic feeding and discharging device for the six-corner-rod numerical control lathe comprises a device and a manipulator device, and the device comprises a motor, a first ball screw rod, a limiting plate, a first moving plate and a device frame. The manipulator device comprises left and right cylinders, a second moving plate, upper and lower cylinders, a third moving plate, front and rear slide table cylinders, an air claw and a manipulator device machine frame. The air clawis positioned directly above the limiting plate when the left and right cylinders do not extend out of a moving rod and the front and rear slide table cylinders extend out of a moving slide table; andthe air claw faces a clamp on the numerical control lathe when the left and right cylinders extend out of the moving rod and the upper and lower cylinders extend out of the moving rod. According to the automatic feeding and discharging device, finished products can be taken out and blanks are placed in a recycled mode, and the manual action is replaced.

Owner:赵华勇

Full-automatic intelligent processing lathe of cross-axle universal joint

ActiveCN104070181AQuality assuranceHigh precisionWork clamping meansAuxillary equipmentUniversal jointTransmission belt

The invention discloses a full-automatic intelligent processing lathe of a cross-axle universal joint. The full-automatic intelligent processing lathe comprises a manipulator bracket, a transmission belt bracket, pushing mechanisms, a manipulator clamping platform and a lathe body; a pneumatic motor is mounted at the lower part of the manipulator bracket; a manipulator guide rail and a manipulator lead screw are mounted on the manipulator bracket, wherein the manipulator lead screw is in connecting fit with the pneumatic motor through a gear; a transmission belt and an industrial camera bracket are mounted on the transmission belt bracket; an industrial camera is mounted on the industrial camera bracket; a rotating platform is mounted on the right side of the transmission belt bracket; the manipulator clamping platform is mounted at the right side of the rotating platform; the pushing mechanisms are arranged at the side parts of the manipulator clamping platform and the transmission belt bracket; the lathe body is mounted at the lower part of the manipulator bracket. The full-automatic intelligent processing lathe of the cross-axel universal joint is high in efficiency, simple to operate, and flexible in application, and greatly reduces the labor intensity.

Owner:HANGZHOU ZHENGQIANG UNIVERSAL JOINT

Mechanical arm

ActiveCN104175316AReduce the need for robotic armsProgramme-controlled manipulatorMechanical apparatusMedicineRobotic arm

Owner:HIWIN TECH

Drilling machine for spherical outer surface of bearing outer ring

InactiveCN106624026AAutomatic workpiece supply/removalBearing componentsSpherical bearingEngineering

The invention provides a drilling machine for a spherical outer surface of a bearing outer ring. An automatic loading and unloading device, a clamping device, a drilling device and a PLC for system control are adopted to realize multi-procedure continuous automatic processing of loading, clamping, multi-directional drilling, unloading and the like. The drilling machine can well adapt to the requirements for multiple holes, multiple angles and adjustable positions of an insert bearing during drilling, and well meets the demand on precision of the insert bearing during drilling, and meanwhile, the drilling efficiency is improved.

Owner:张桂春

Automatic discharging mechanism used for numerically-controlled lathe

PendingCN110170662AHigh speedIncrease productivityAutomatic workpiece supply/removalMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic discharging mechanism used for a numerically-controlled lathe, and belongs to the technical field of machines. The automatic discharging mechanism used for the numerically-controlled lathe comprises a rack. An auxiliary discharging structure is arranged above a chuck. A discharging storage mechanism is arranged below the chuck and comprises a discharging hopper.A discharging pipe is connected to the bottom of the discharging hopper. A storage tray is arranged below the discharging pipe. A plurality of storage grooves are formed in the storage tray. A horizontal moving mechanism capable of driving the storage tray to move horizontally is arranged below the storage tray. The automatic discharging mechanism has the advantage of full-automatic discharging.

Owner:聊城市技师学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com