Drilling machine for spherical outer surface of bearing outer ring

A technology of bearing outer ring and outer spherical surface, which is applied in the field of bearing processing, and can solve problems such as high cost, low labor cost, clamping deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

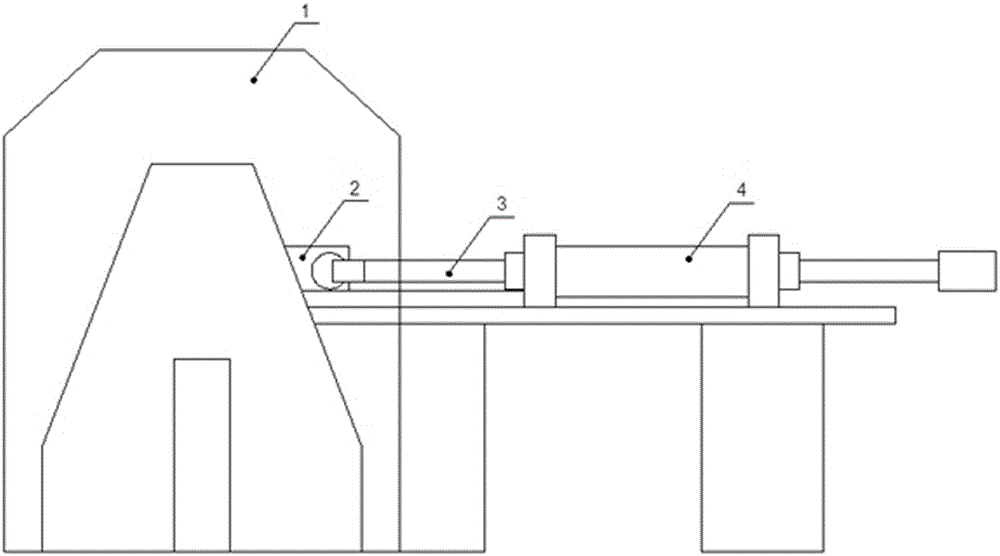

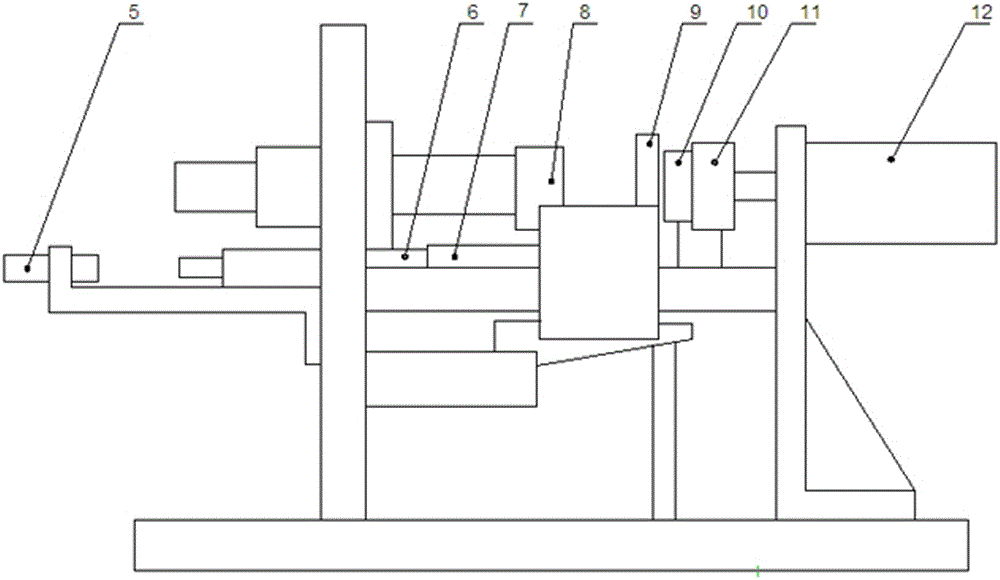

[0018] When the drilling machine 1 is working, the workpiece 10 to be drilled is delivered to the support frame 2 through the feed channel. After the workpiece 10 falls to the support frame 2, the push cylinder 4 pushes the push rod 3 to translate and drives the support frame 2 to move laterally. ; When the workpiece 10 moves to the same axis as the cylindrical boss of the movable chuck 11 and the static chuck 8, the sensor 5 touches the movement of the clamping cylinder 12, and the cylinder piston pushes the movable chuck 11 to make a linear motion, and the movable chuck 11 moves The set cylindrical boss is embedded in the outer ring of the bearing to cooperate with the clamping rod 9, and the clamped workpiece moves to the static chuck 8. When the front end of the workpiece contacts the static chuck 8, the clamping rod 9 is embedded in the static chuck 8 In the groove, the movable chuck 11 and the static chuck 8 rely on their axial positioning to perform axial positioning and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com