Loading and unloading device for shaft processing of numerical control lathe

A technology of CNC lathes and shafts, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high labor intensity, low production efficiency, aggravating the burden and trouble of enterprises, and improve production efficiency, reduce Processing cost and the effect of reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

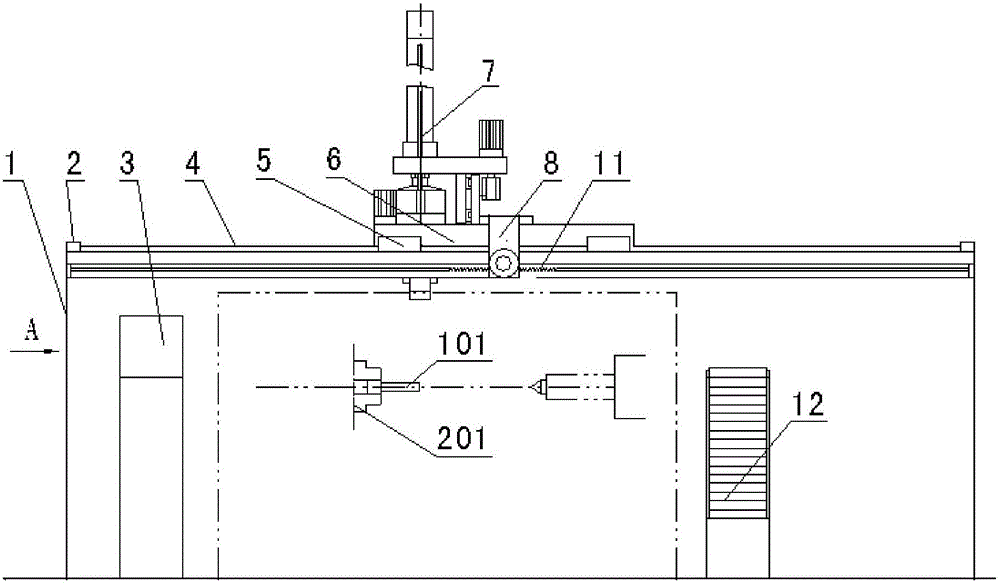

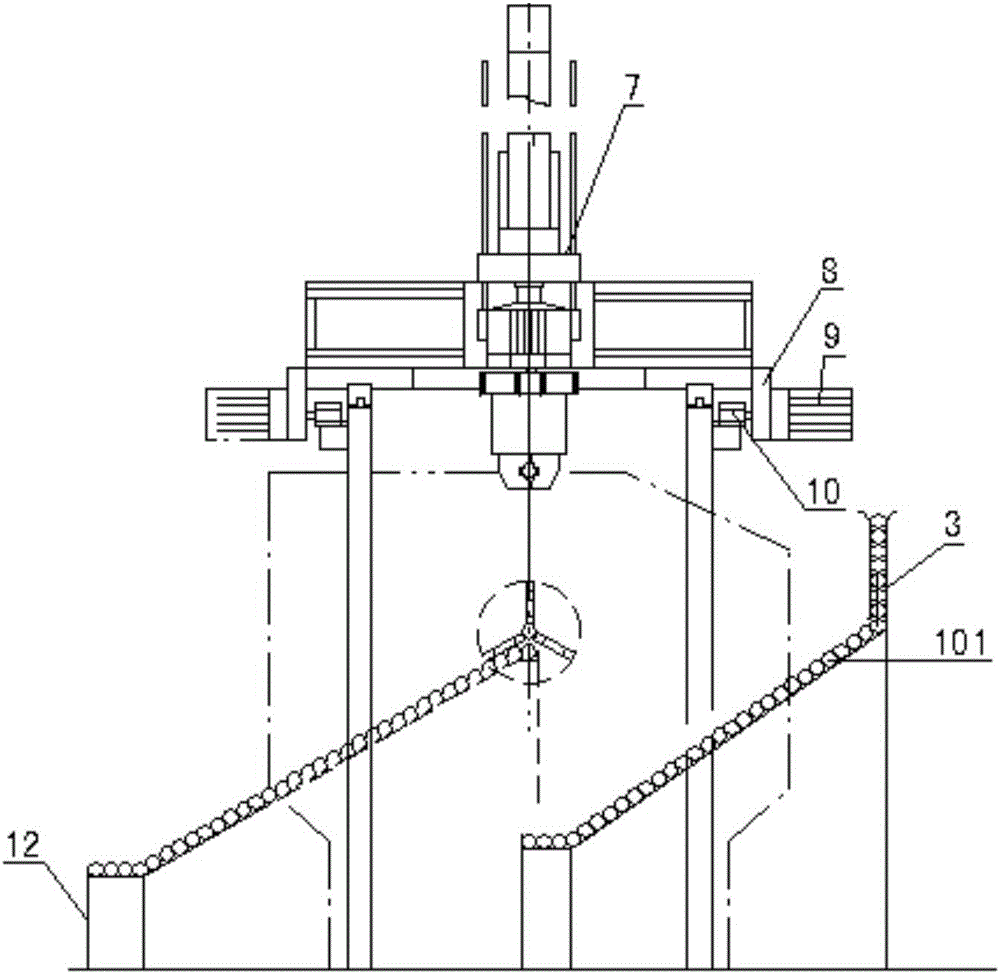

[0015] Such as figure 1 , 2 As shown, a loading and unloading device for CNC lathe shaft processing includes a CNC lathe, a frame, a loading rack, an unloading rack, a horizontal transfer mechanism and a mechanical arm assembly. The horizontal transfer mechanism is composed of a guide rail installed vertically on the upper plane of the frame 1, a track seat 6 arranged on the guide rail by a guide rail seat 5 and a track motor 9 installed on the track seat by a track motor seat 8, and a longitudinal level The track rack installed on the plane on the frame below the guide rail constitutes; the gear 10 on the output shaft of the track motor 9 is meshed with the track rack 11.

[0016] Such as image 3 As shown, the mechanical arm assembly is composed of a lifting cylinder, an indexing clamp mechanism, a slide mechanism and a guide mechanism. The indexing clamp mechanism is composed of a mechanical arm seat plate, a bearing seat, a ring gear, a clamping cylinder, a rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com