Robot and system for feeding and discharging high-pressure pipe joint parts and operation method implemented by robot and system

A technology of robots and pipe joints, which is applied in the field of machine tool loading and unloading devices and high-pressure pipe joint loading and unloading systems, which can solve the problems that cannot meet the production requirements of enterprises and the needs of front-line workers, workers cannot concentrate, and labor intensity is high. problems, to achieve the effect of enhancing system adaptability and flexibility, compact structure, and high transmission progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

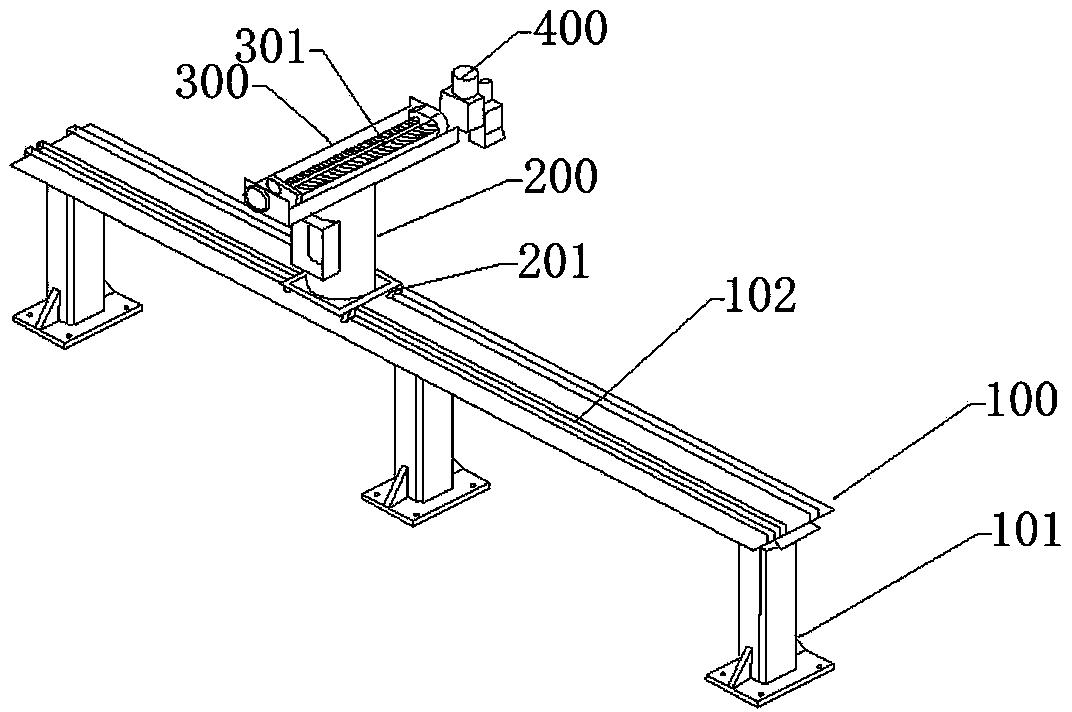

[0054] Such as figure 1 A loading and unloading robot for high-pressure pipe fittings is shown, including a base 100, a column 200, a support 300 and a machine head 400;

[0055] The base 100 is composed of a foot 101 and a ball guide rail 102 arranged on the top of the foot 101;

[0056] The column 200 is vertically arranged on the upper end of the ball guide rail 102, and the bottom of the column 200 is provided with a ball slider 201, which moves linearly along the ball guide rail 102 in the horizontal direction;

[0057] A support 300 perpendicular to the ball guide rail 102 and the column 200 is provided on the top of the column 200, a screw drive 301 is provided on the support 300, and the screw nut of the screw drive 301 is connected to the machine head 400;

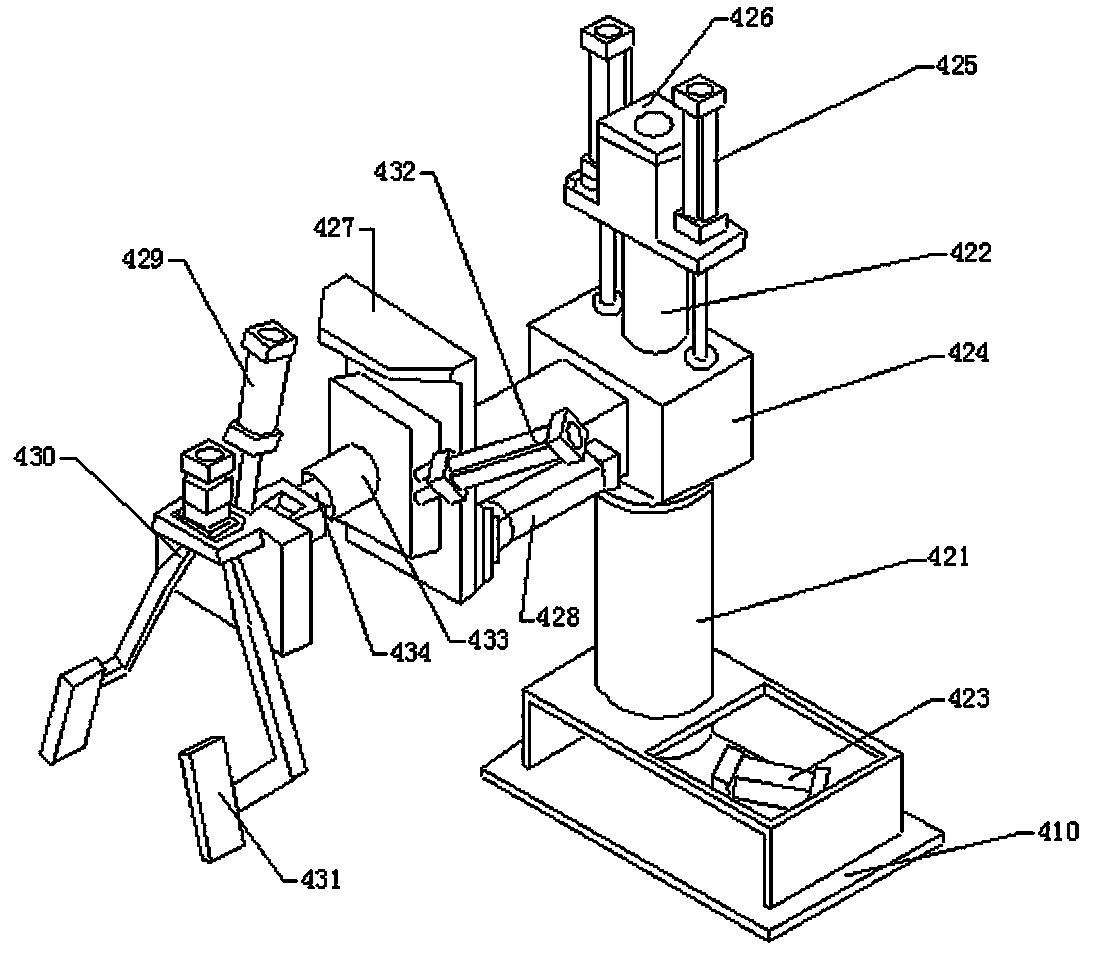

[0058] The machine head 400 includes a machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com