Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

623results about "Vehicle with endless chains/belts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

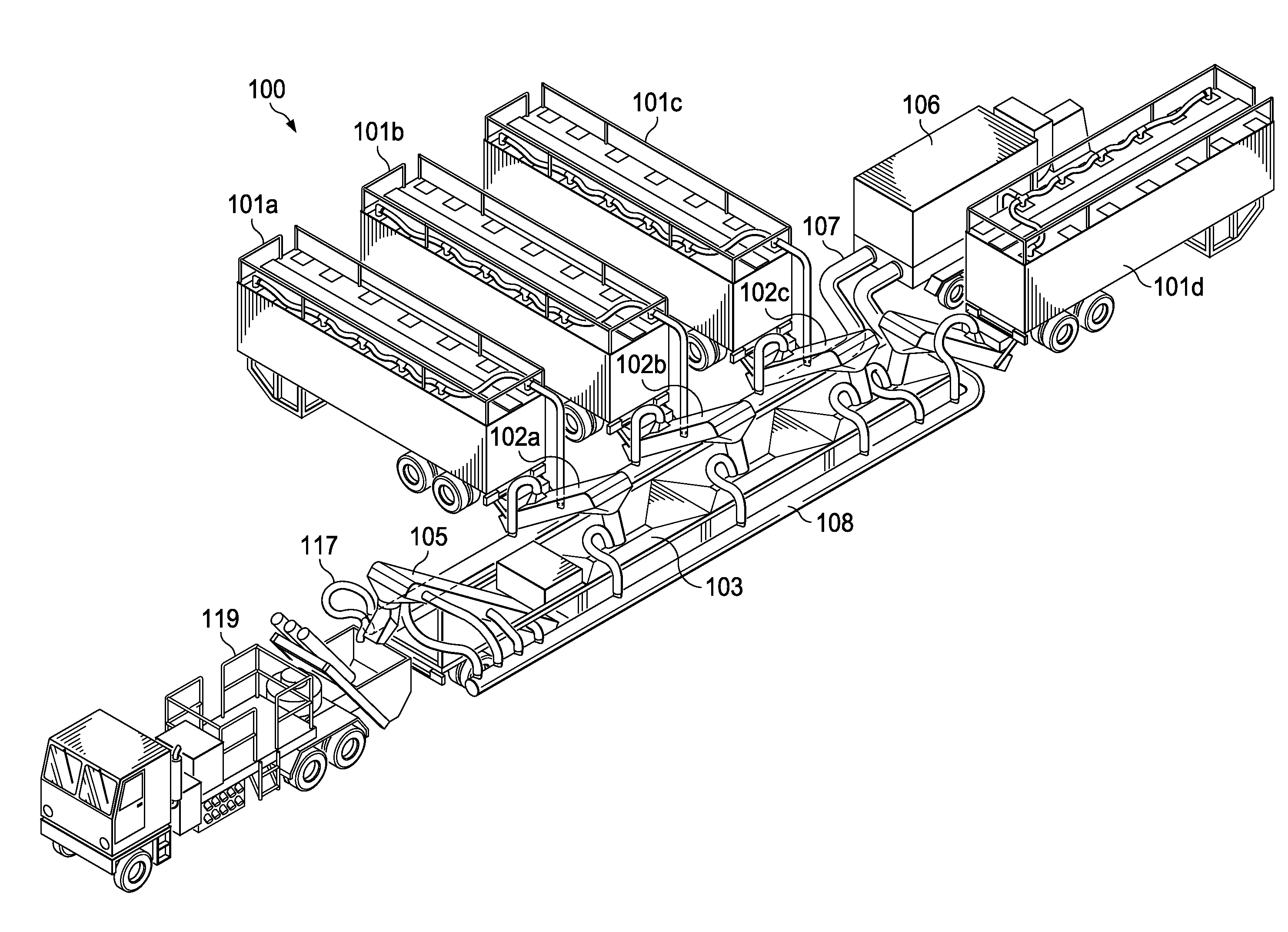

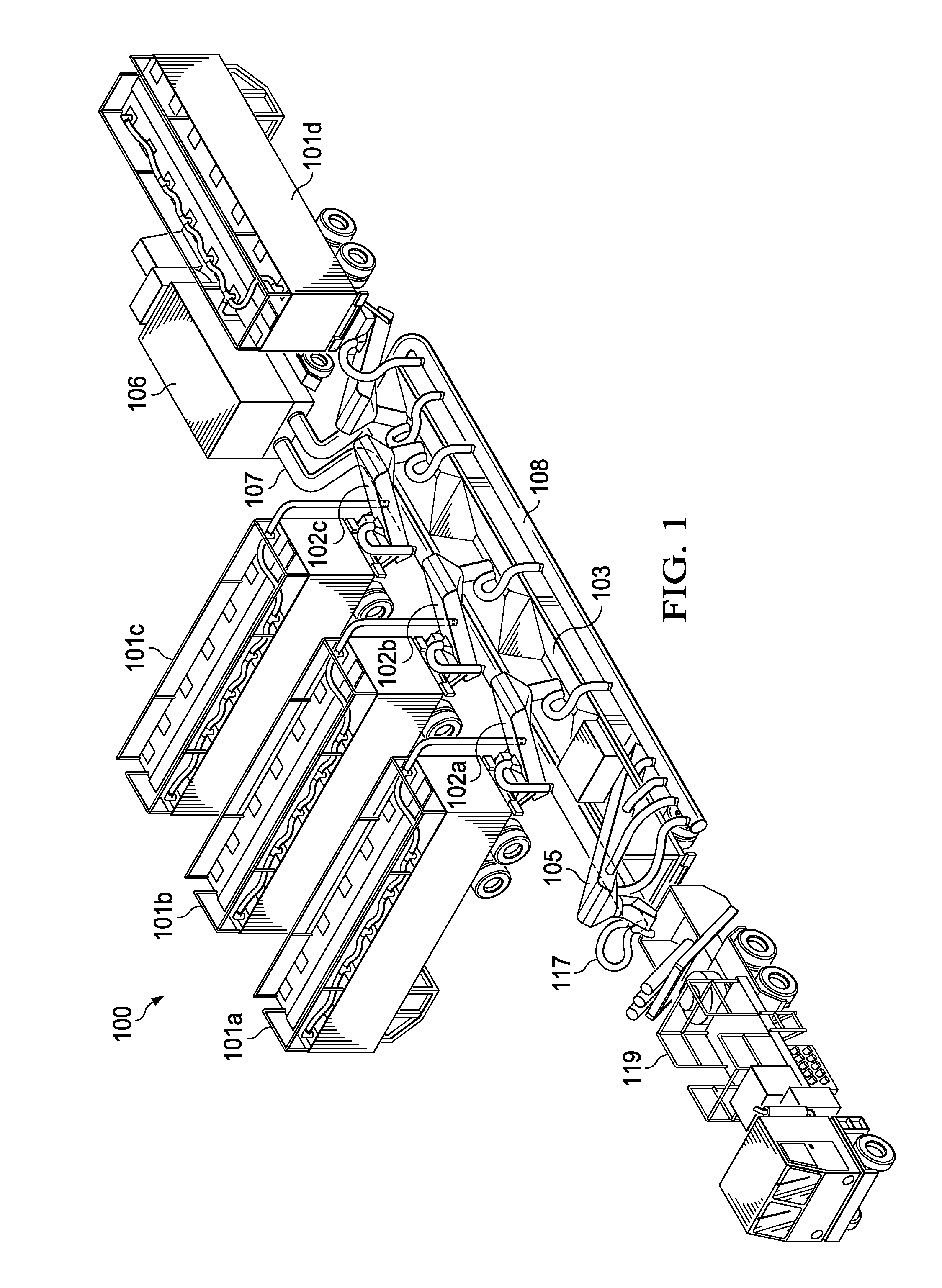

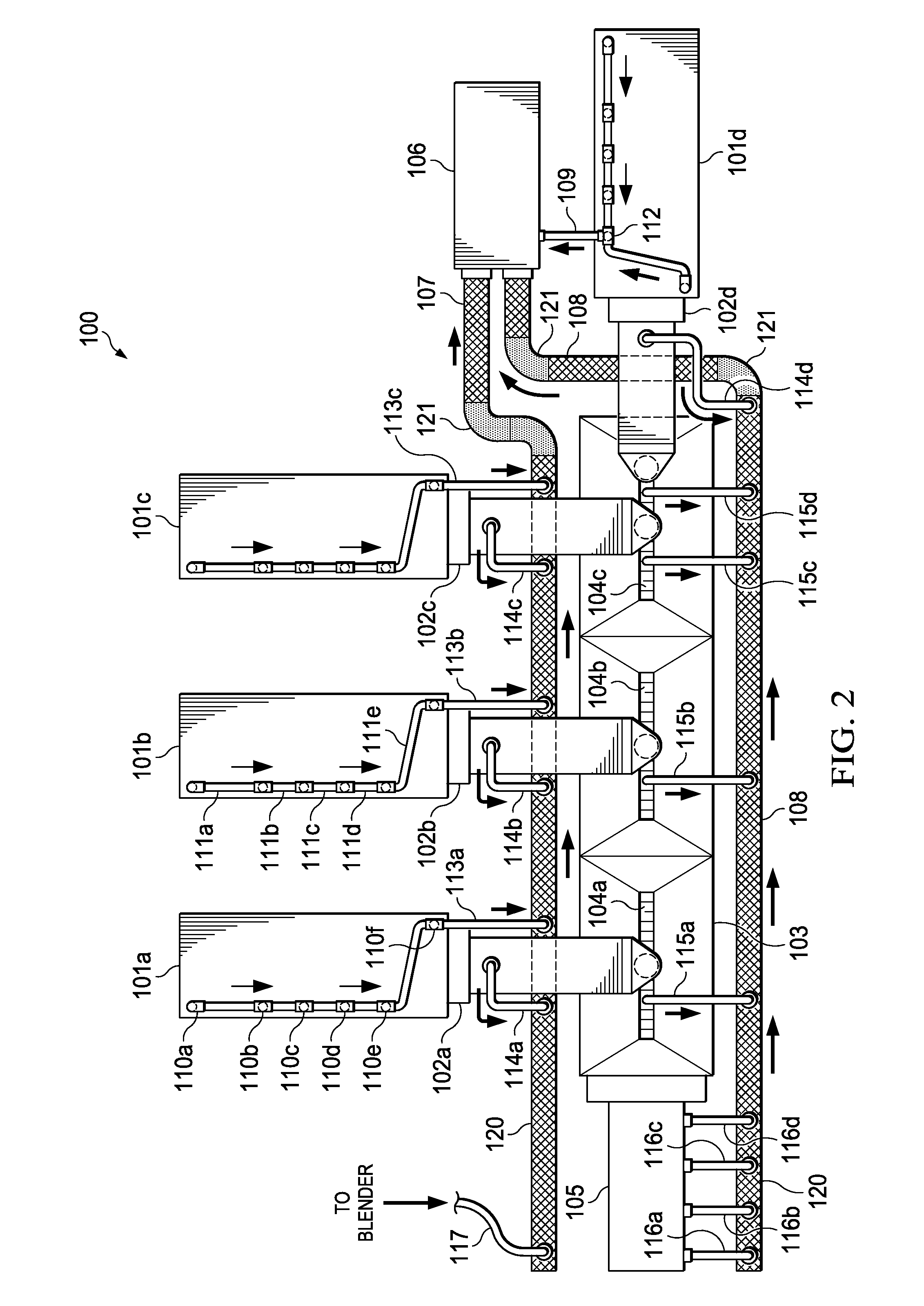

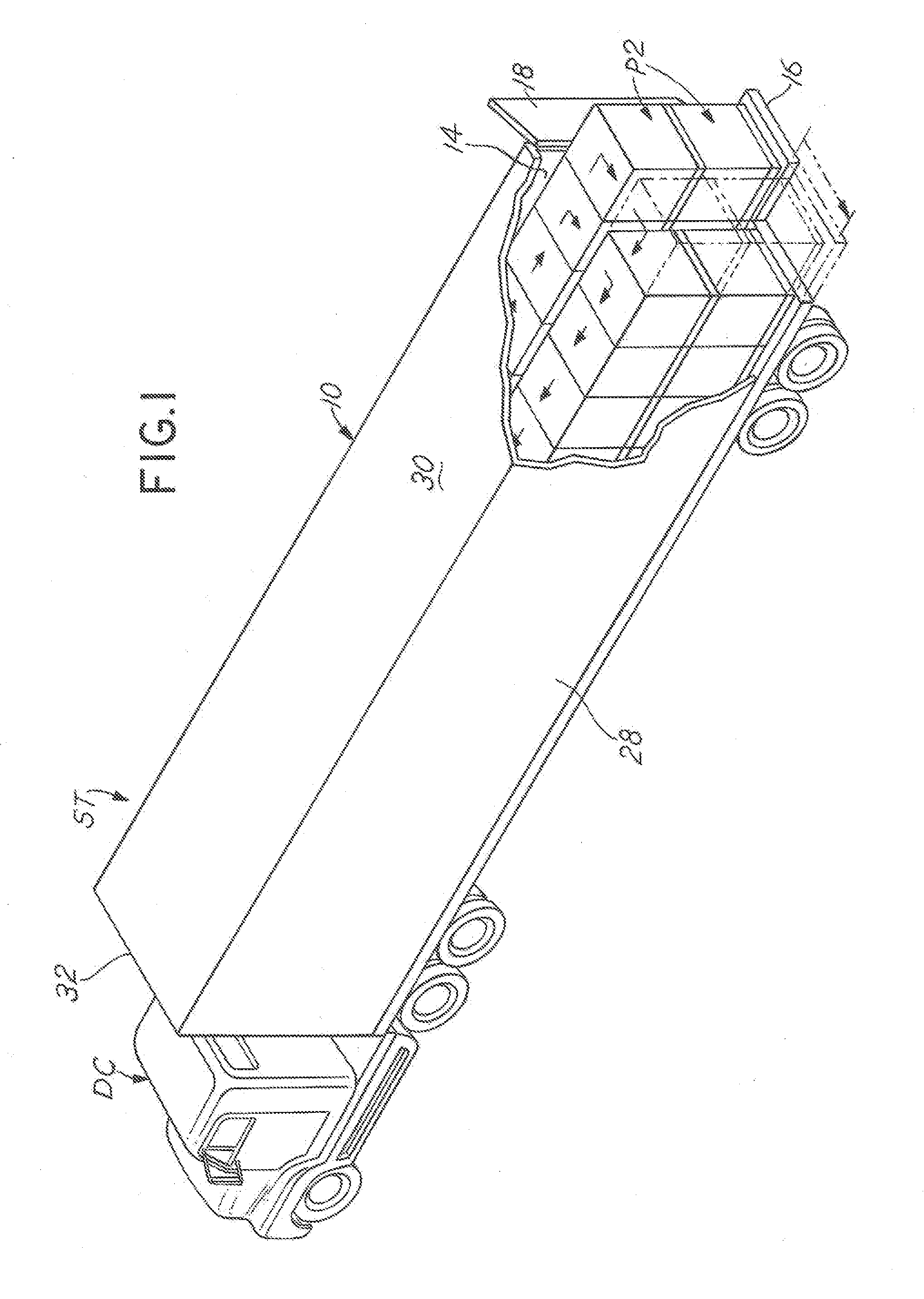

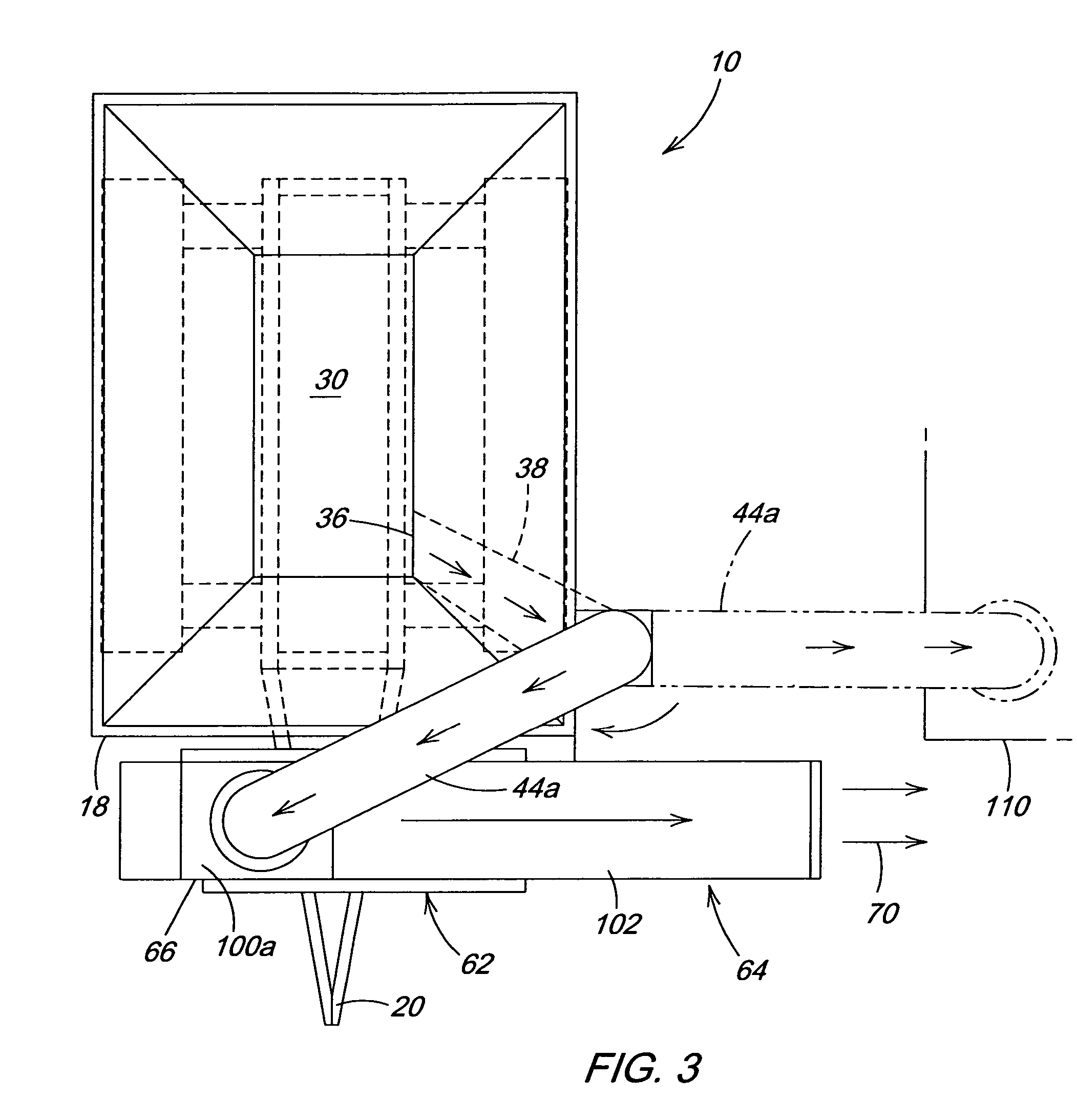

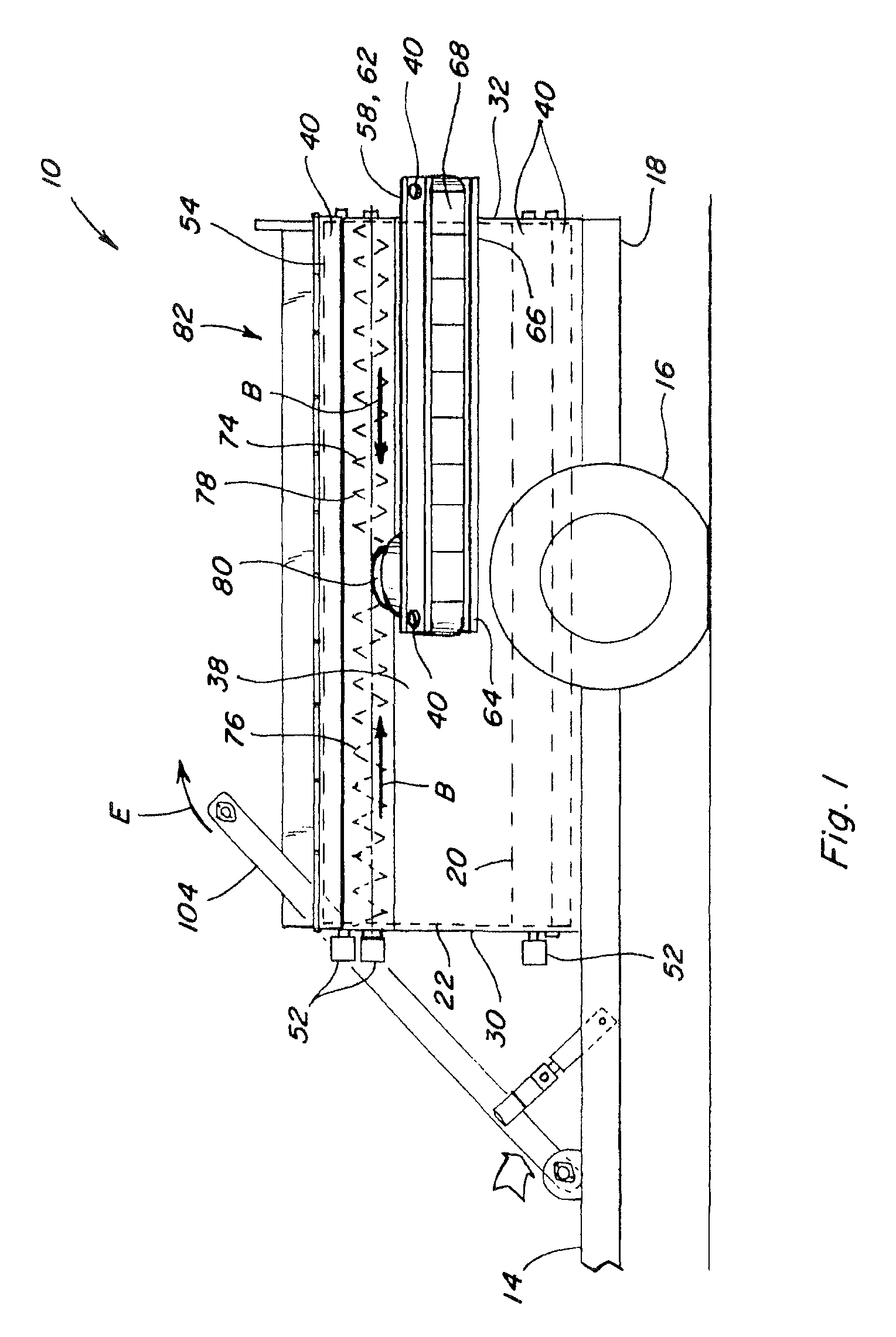

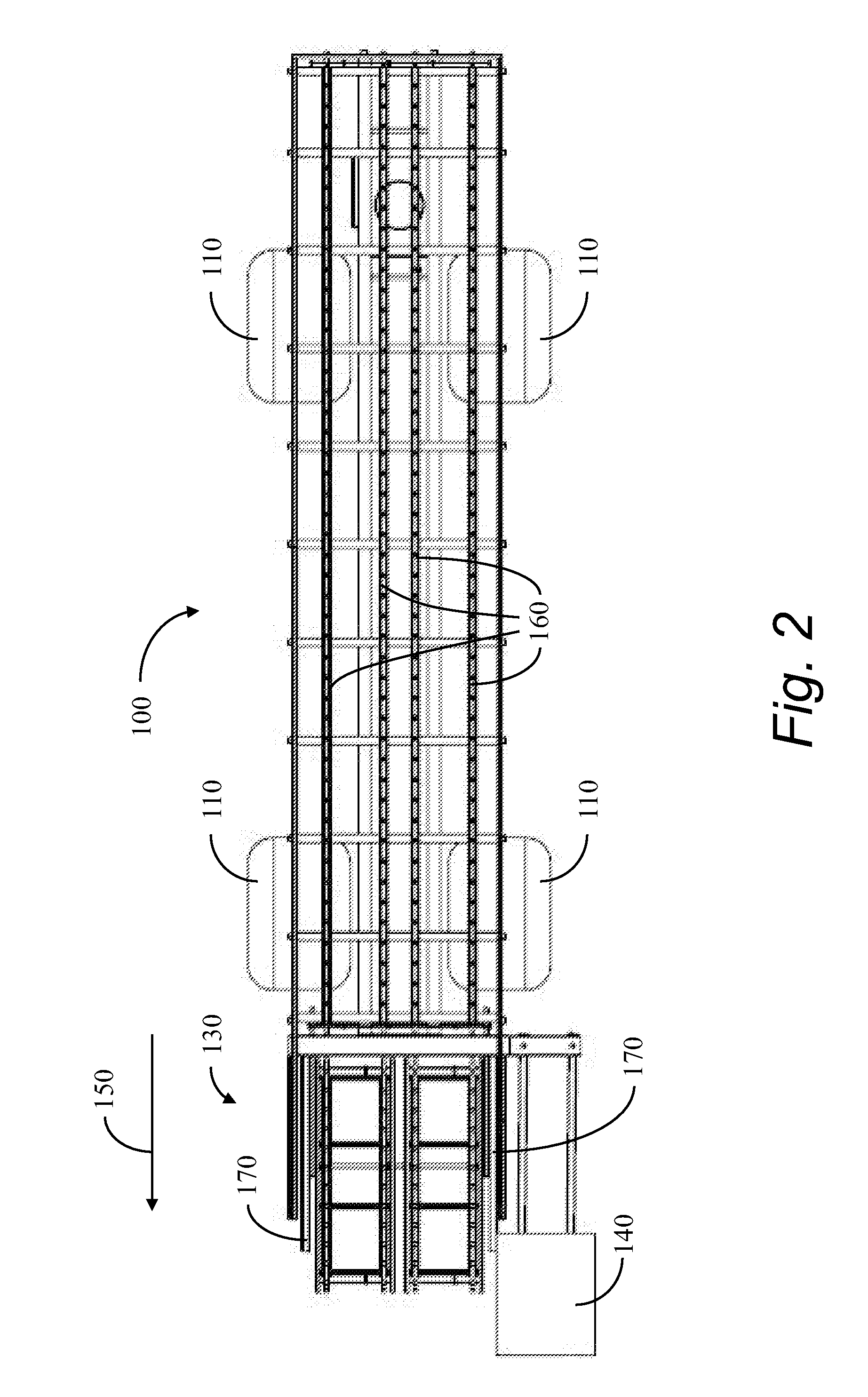

Systems and methods for controlling silica dust during hydraulic fracturing operations

ActiveUS8881749B1Improve flexibility and efficiencyEfficient and flexible systemMechanical cleaningPressure cleaningEngineeringHydraulic fracturing

A system for controlling silica dust generated during the transfer of frac sand from a storage container through a conveyor system includes a system of conduits having a plurality of inlets for collecting silica dust generated at selected points along the conveyor system. An air system pneumatically coupled to the system of conduits generates a negative pressure at each of the inlets to induce the collection of silica dust at the selected points along the conveyor.

Owner:SIERRA DUST CONTROL

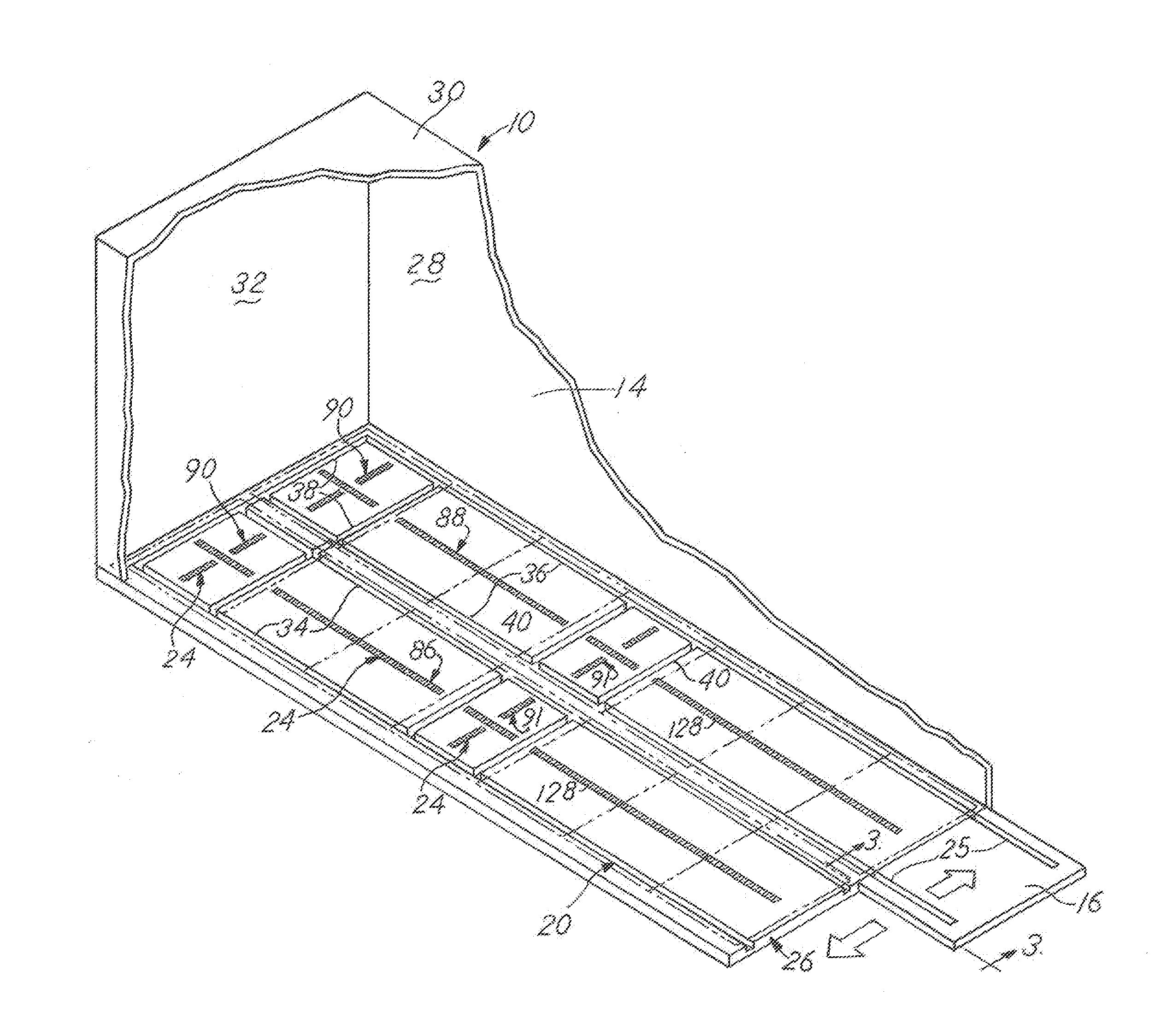

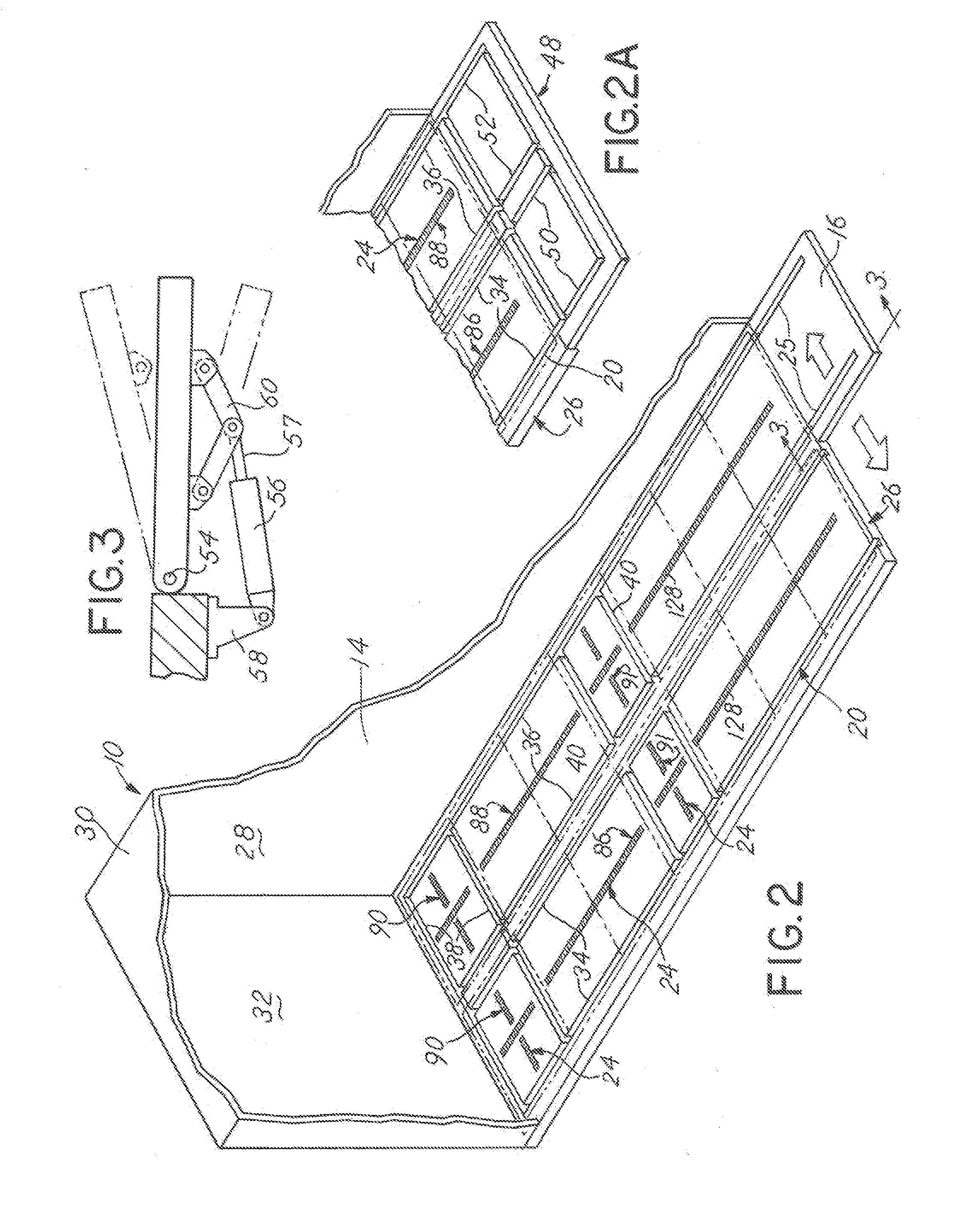

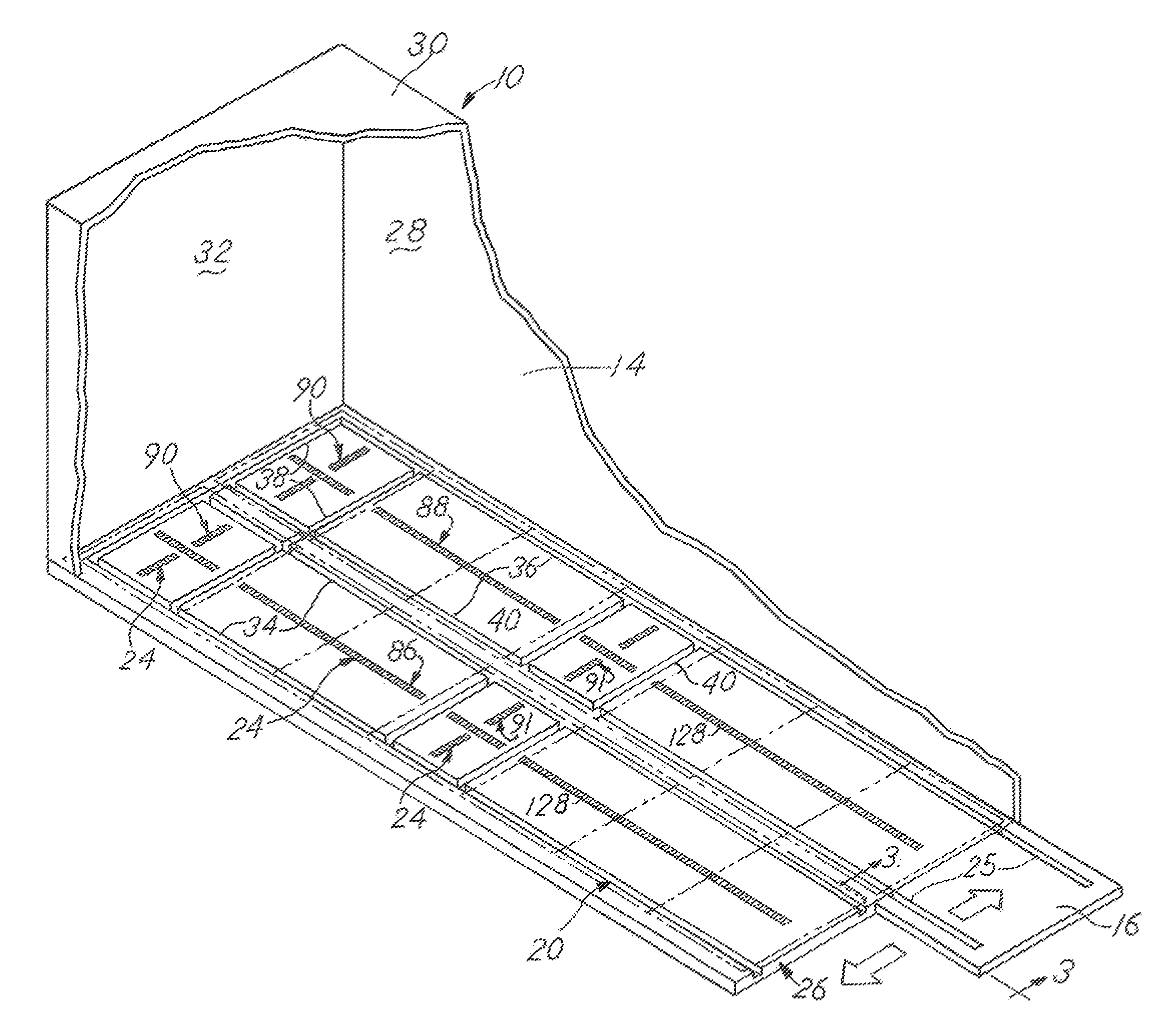

Apparatus and System for Facilitating Loading and Unloading Cargo from Cargo Spaces of Vehicles

A vehicle cargo space includes a rear lift gate moveable between opened and closed positions to allow movement of palletized containers into and out of the cargo space. The cargo space has a substantially horizontal floor with first and second sets of laterally spaced, parallel, longitudinal tracks. The tracks extend from the front to the lift gate at the rear of the cargo space. At least one set of tracks is positioned transverse to the longitudinal tracks. The tracks slidably support cargo container pallets. A system of actuators, guides and locks enable programmed movement of the pallets along the tracks into and out of the cargo space as well as within the cargo space.

Owner:JKC DEV

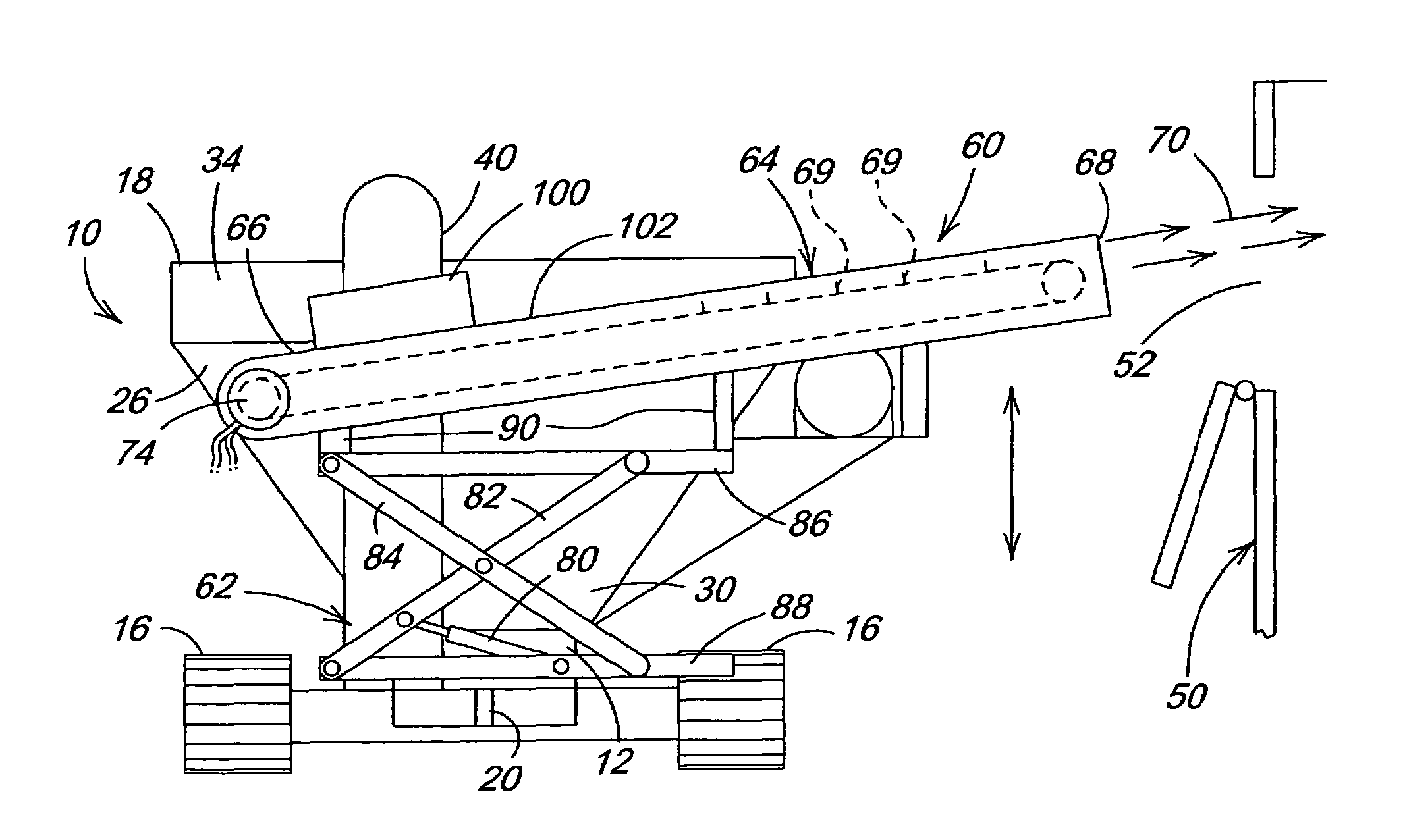

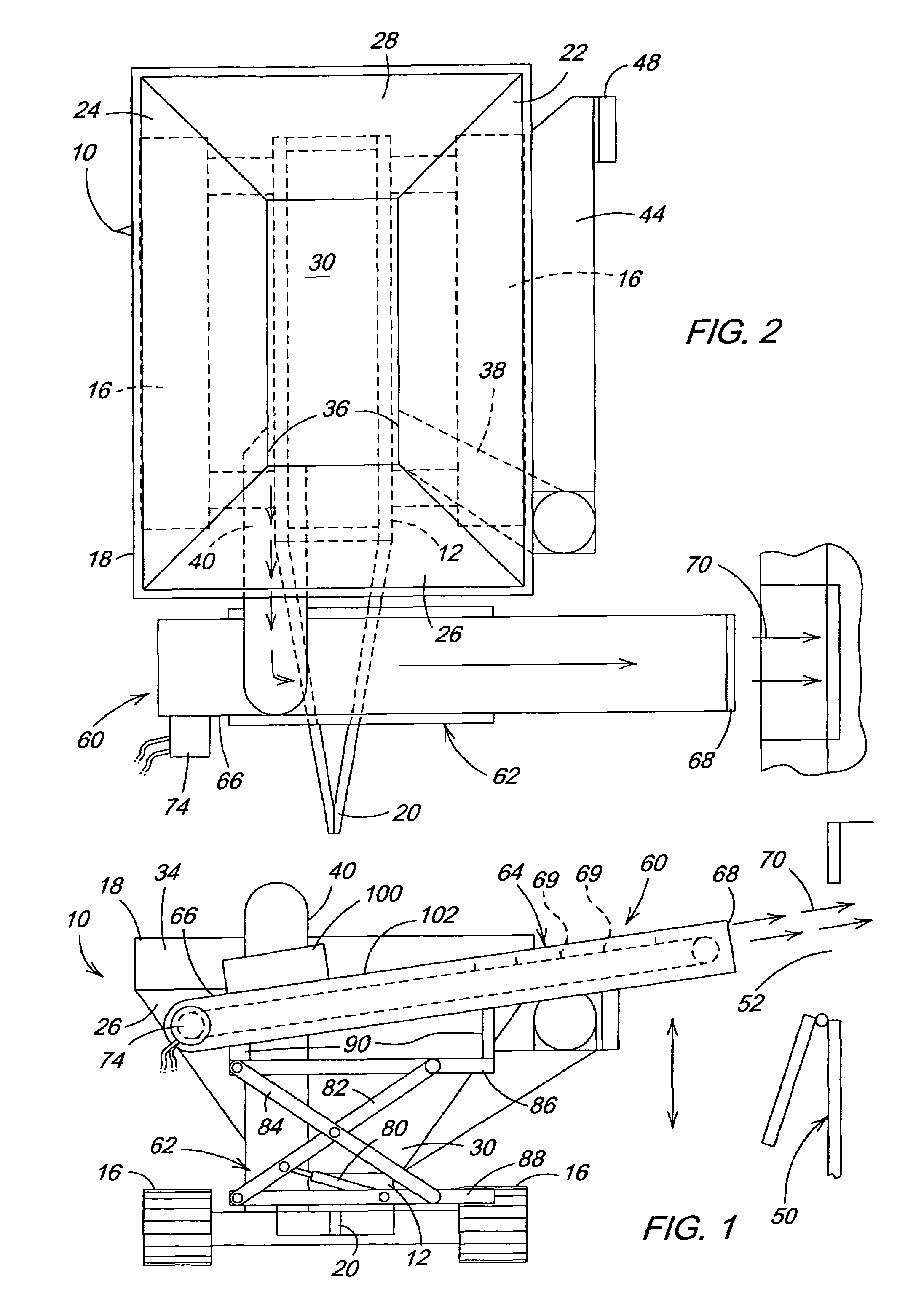

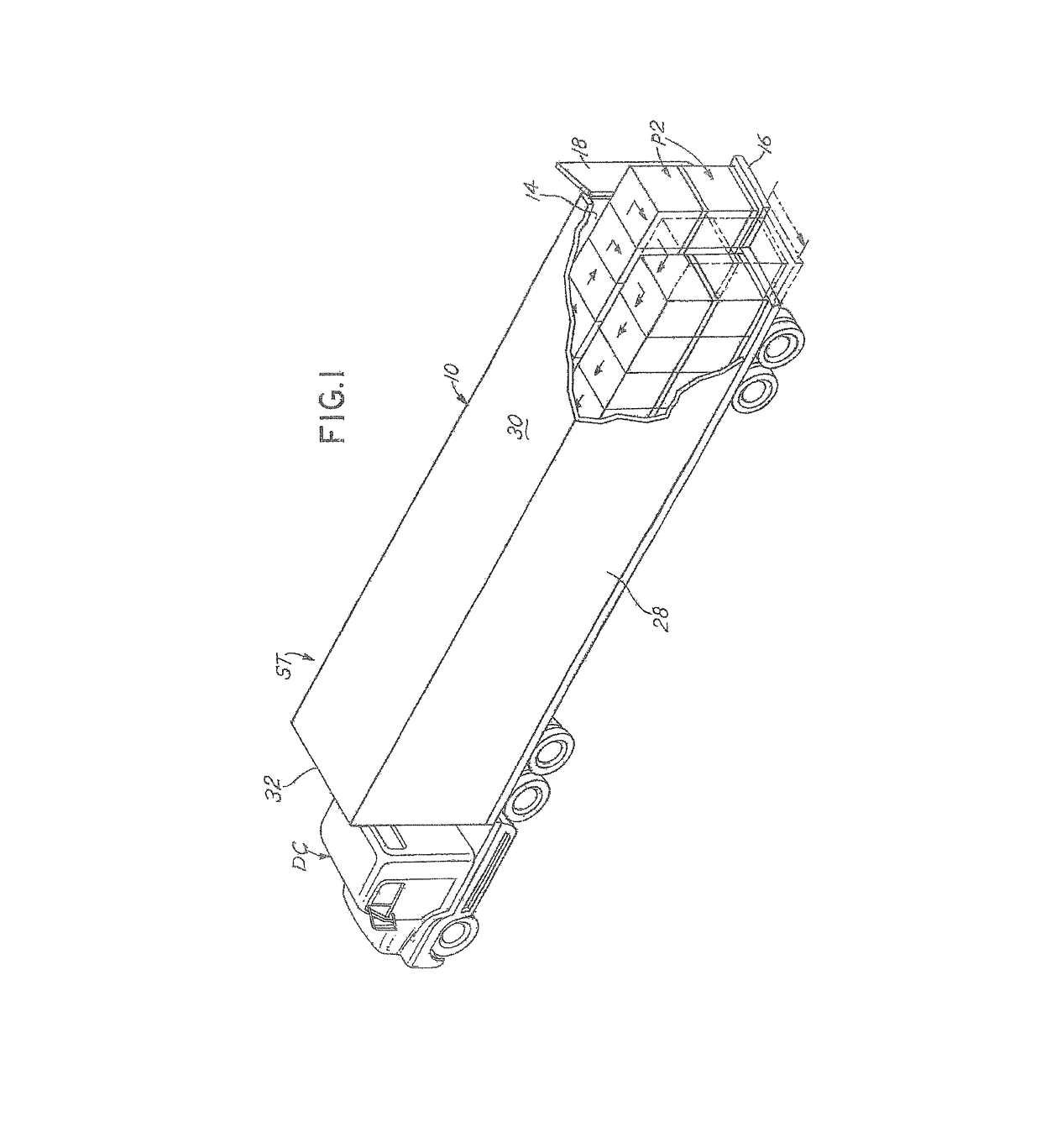

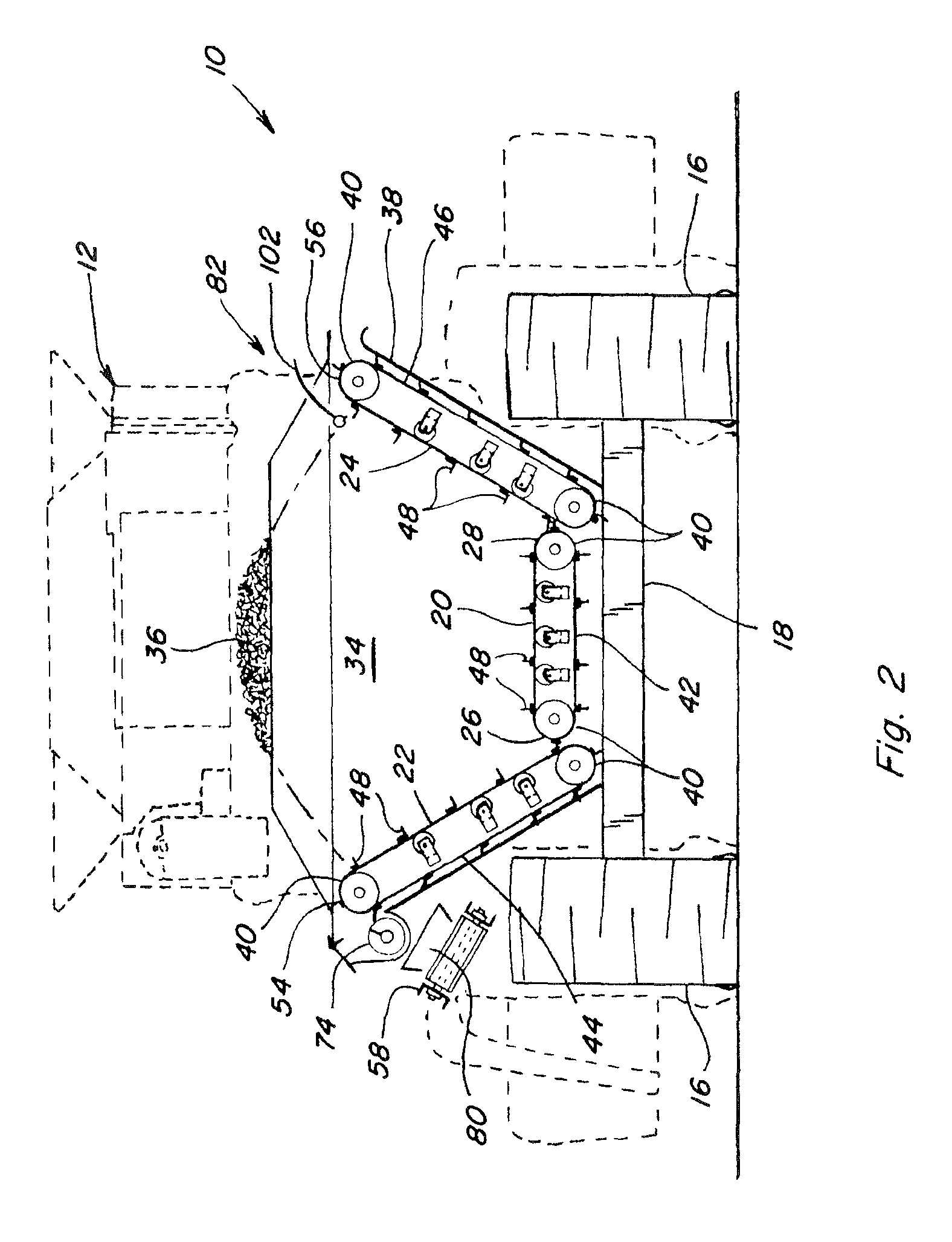

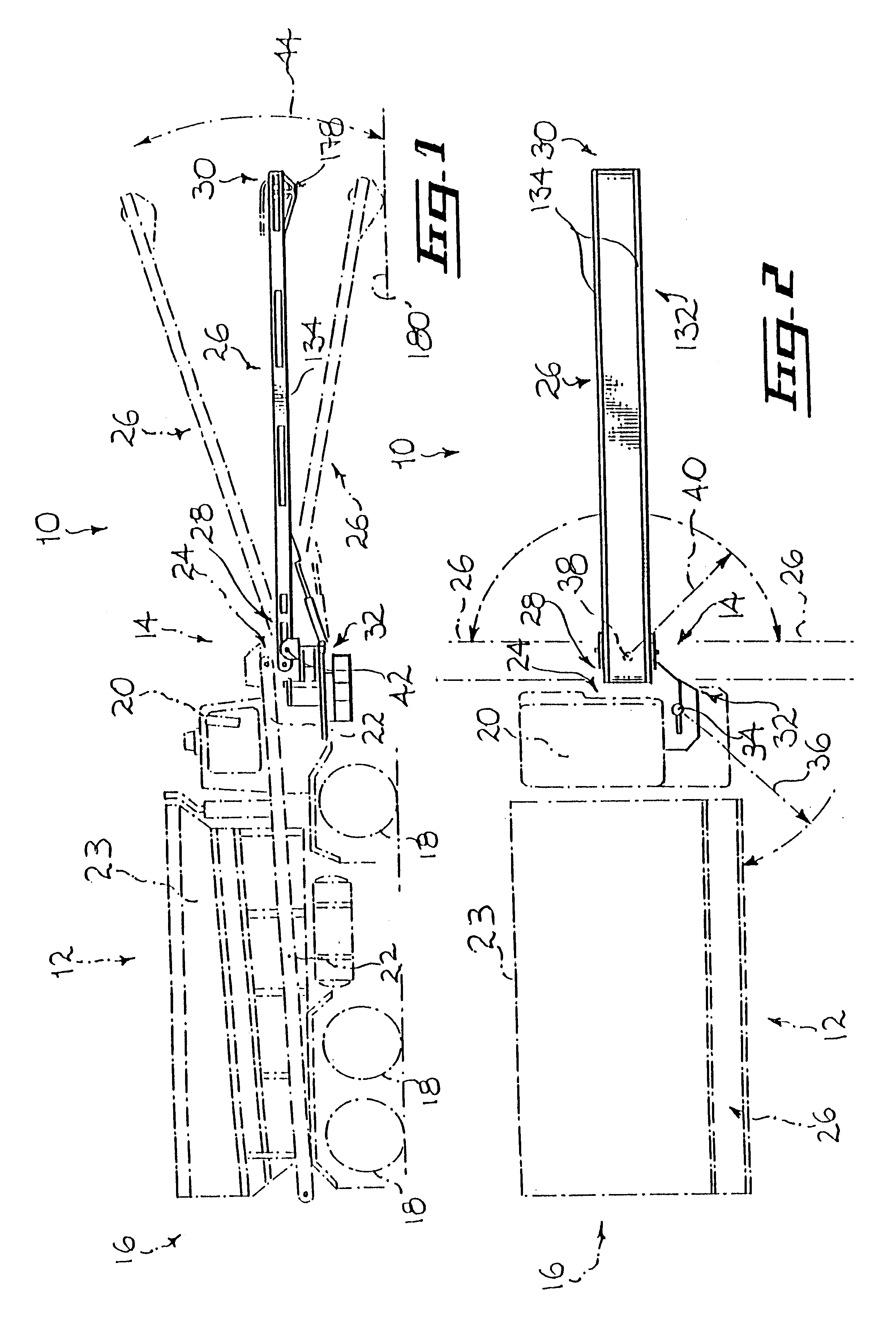

Grain cart with intermodal container loader

InactiveUS7540700B2Easy loadingReduce processingLoadersRefuse receptaclesEngineeringCircular segment

Owner:DEERE & CO

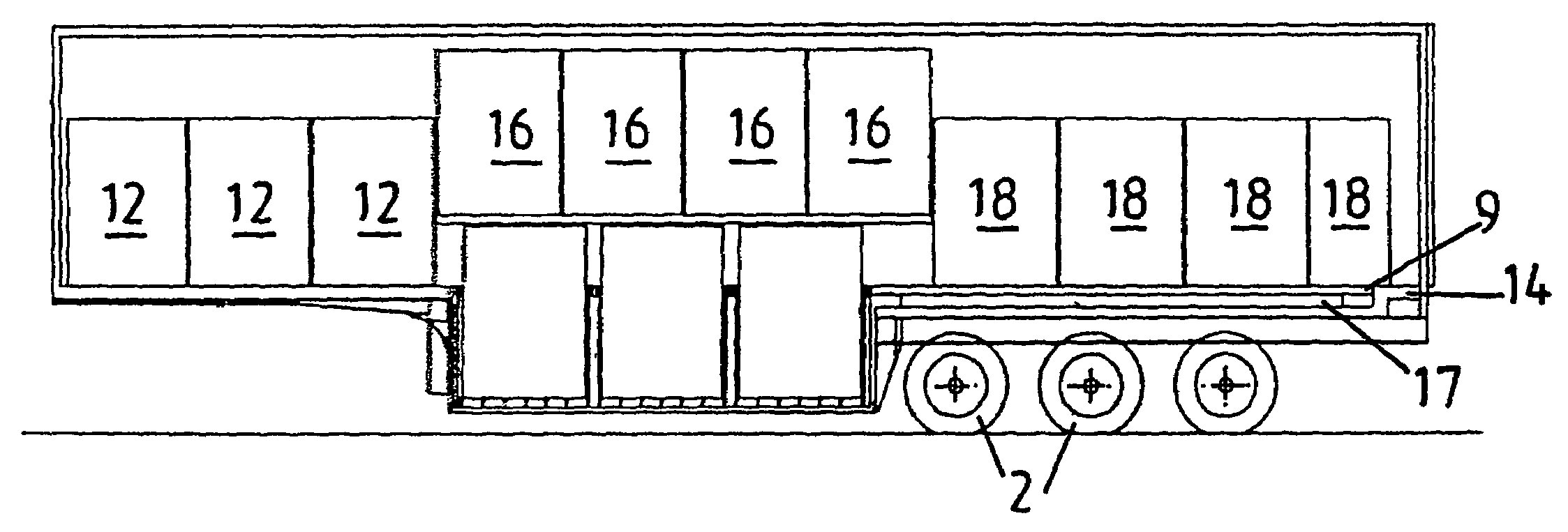

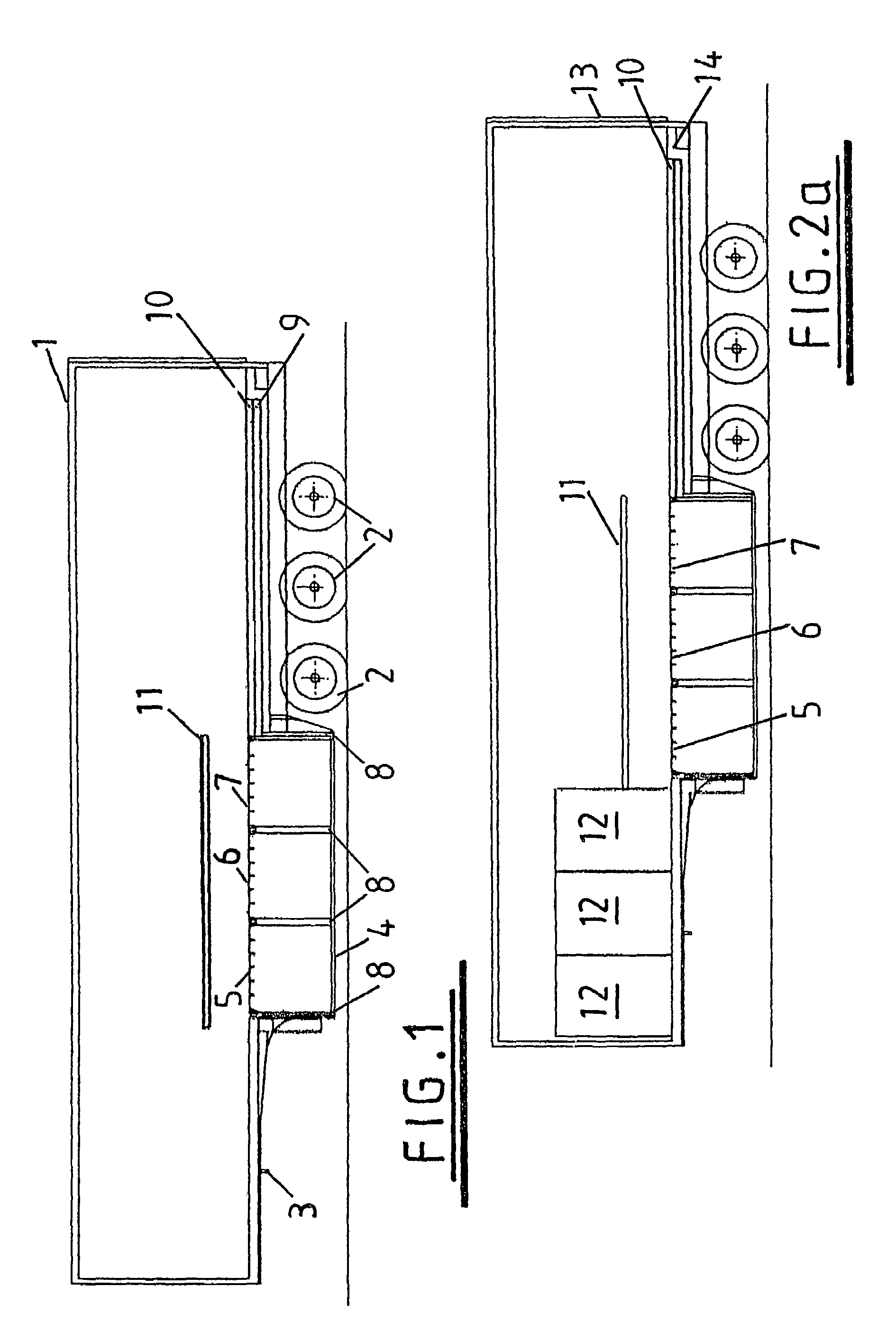

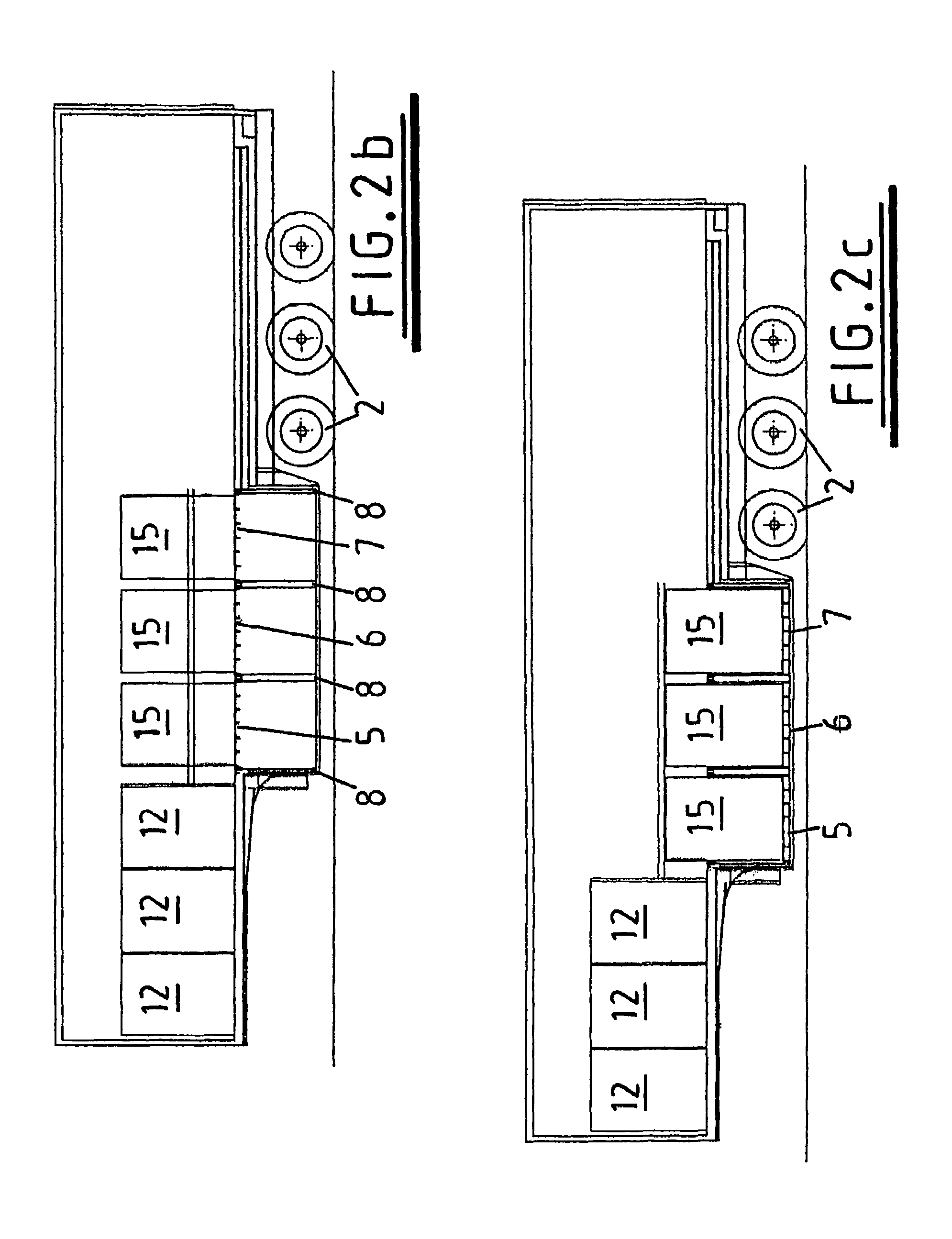

Vehicles and trailers incorporating moveable load carrying platforms

InactiveUS7665788B2Avoiding any significant reduction in the internal width of the vehicle availableSimple and robust mechanismPortable braking systemSuperstructure subunitsMarine engineeringLoad carrying

Owner:MIDDLEGATE MARKETING LTD

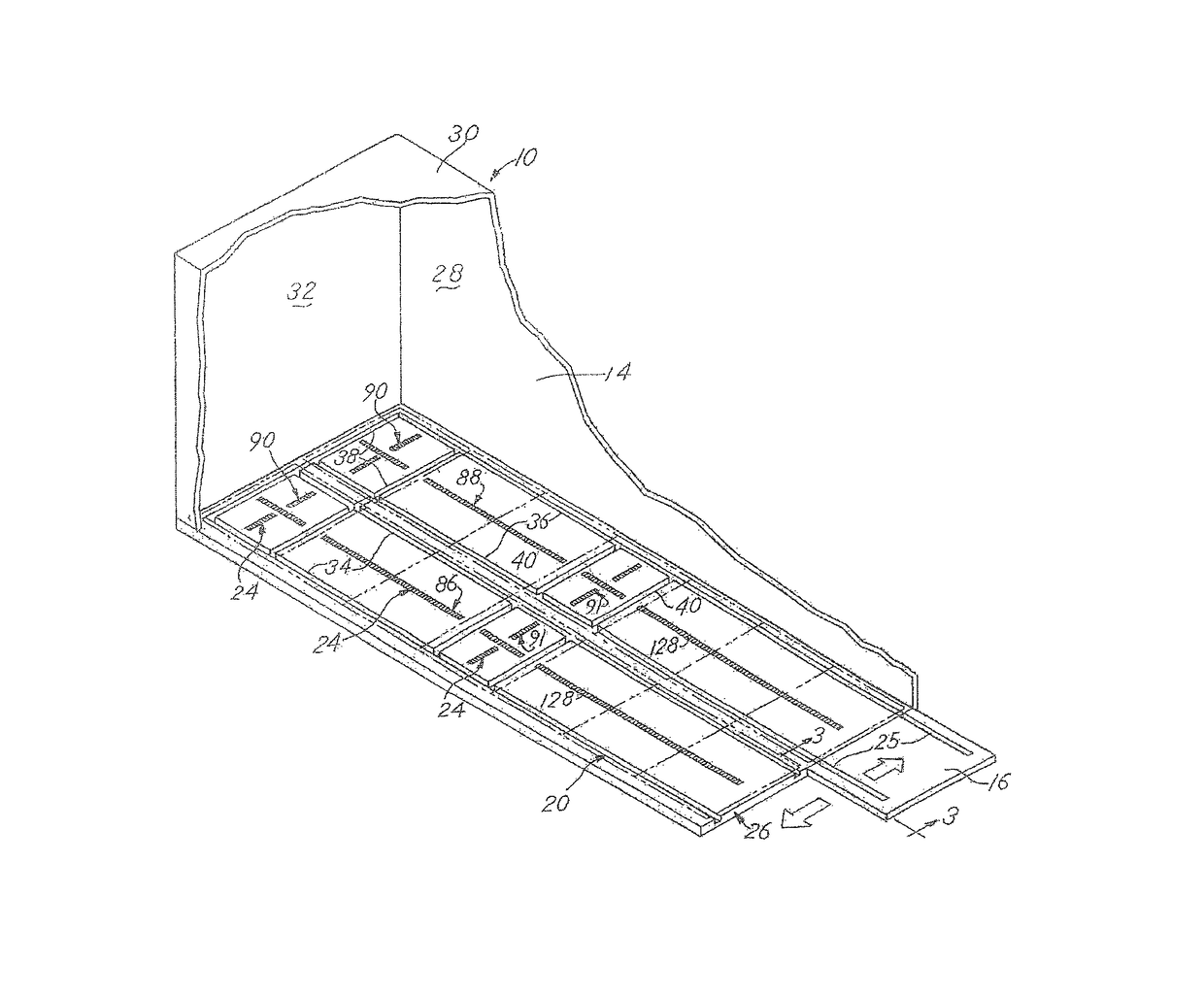

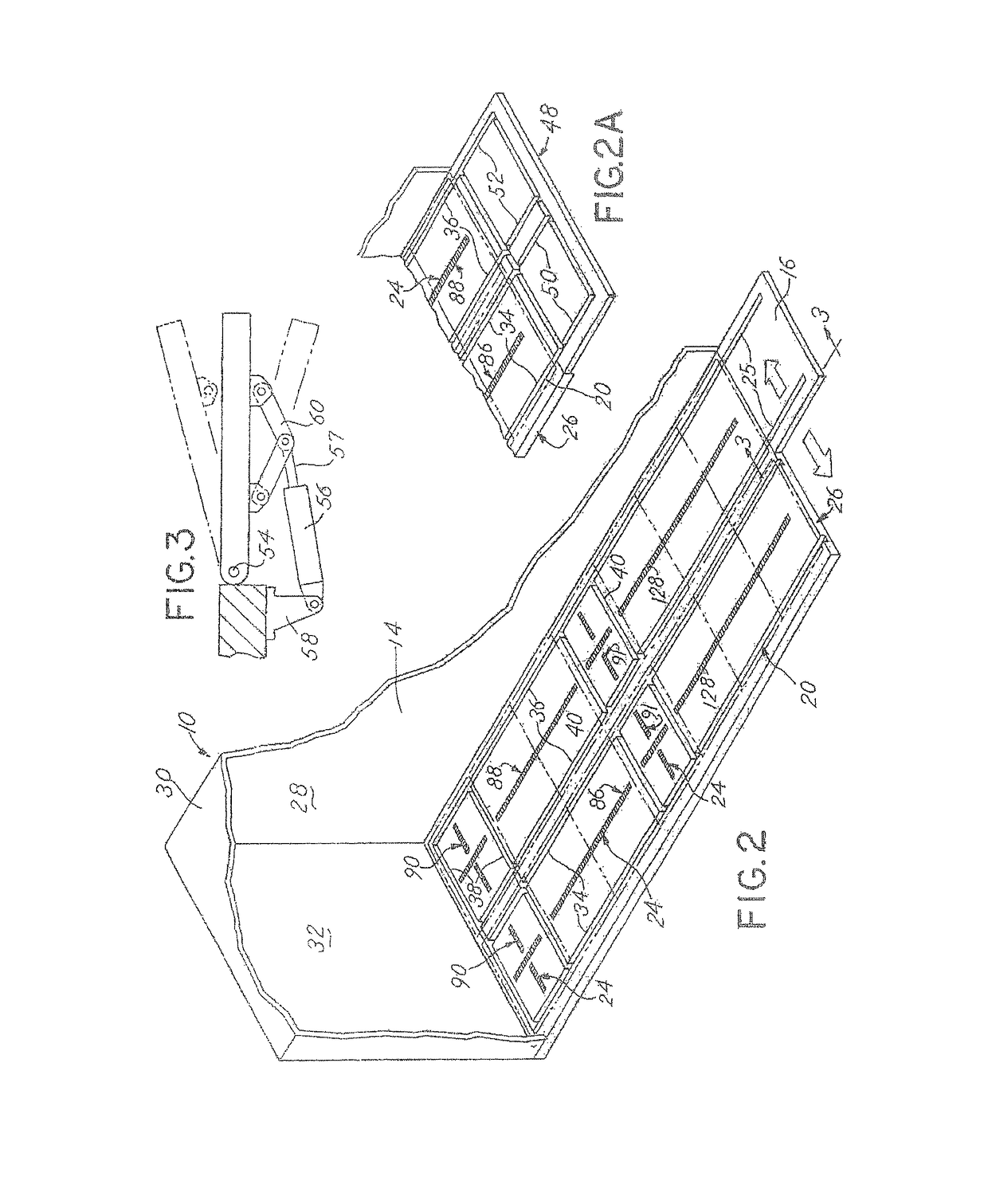

Apparatus and system for facilitating loading and unloading cargo from cargo spaces of vehicles

ActiveUS9630545B1Easy to changeAvoid undesired dispersionVehicle with raised loading platformVehicle with rollersEngineeringActuator

A cargo space includes a rear lift gate moveable between opened and closed positions to allow movement of palletized containers into and out of the cargo space. The cargo space has a substantially horizontal floor with first and second sets of laterally spaced, parallel, longitudinal tracks. The tracks extend from the front to the lift gate at the rear of the cargo space. At least one set of tracks is positioned transverse to the longitudinal tracks. The tracks slidably support cargo container pallets. A system of actuators, guides and locks enable programmed movement of the pallets along the tracks into and out of the cargo space as well as within the cargo space.

Owner:JKC DEV

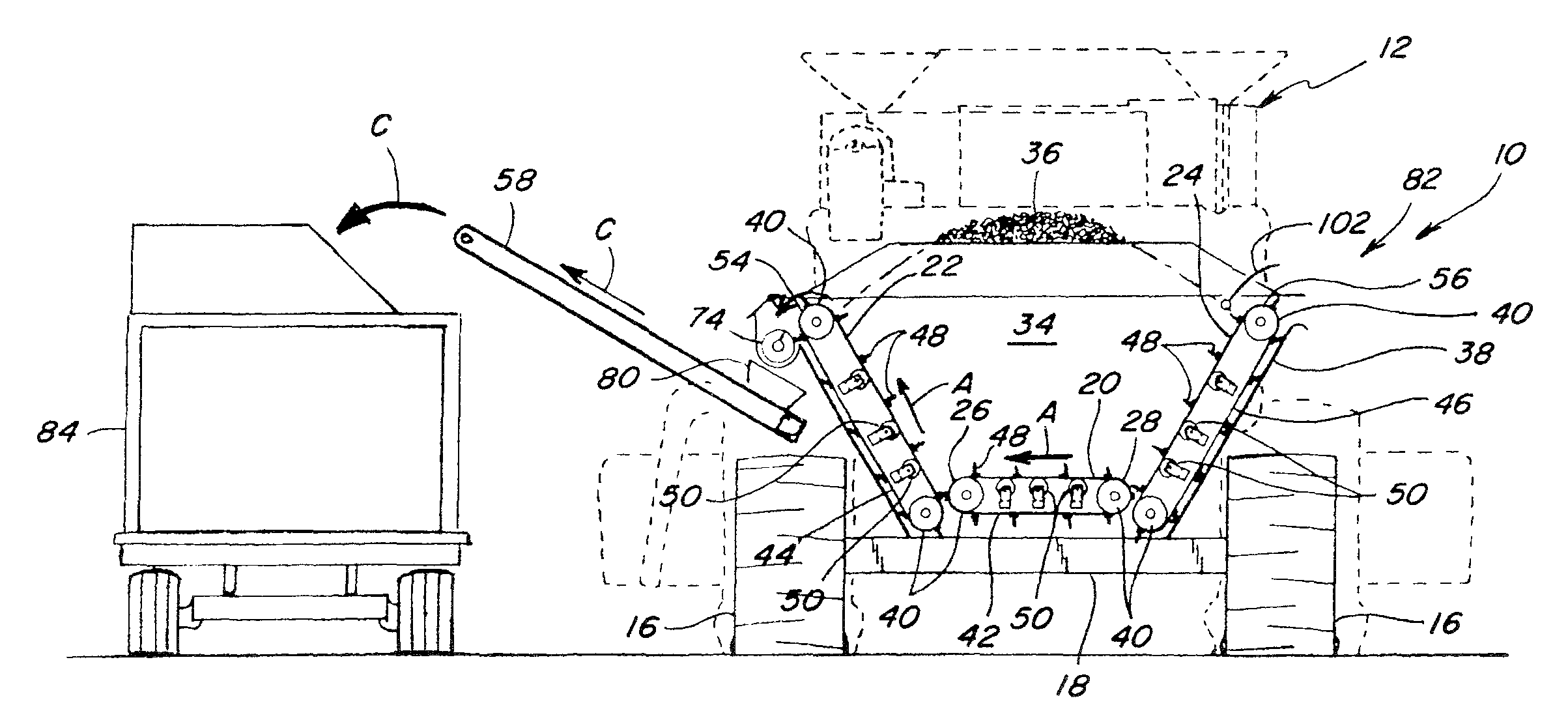

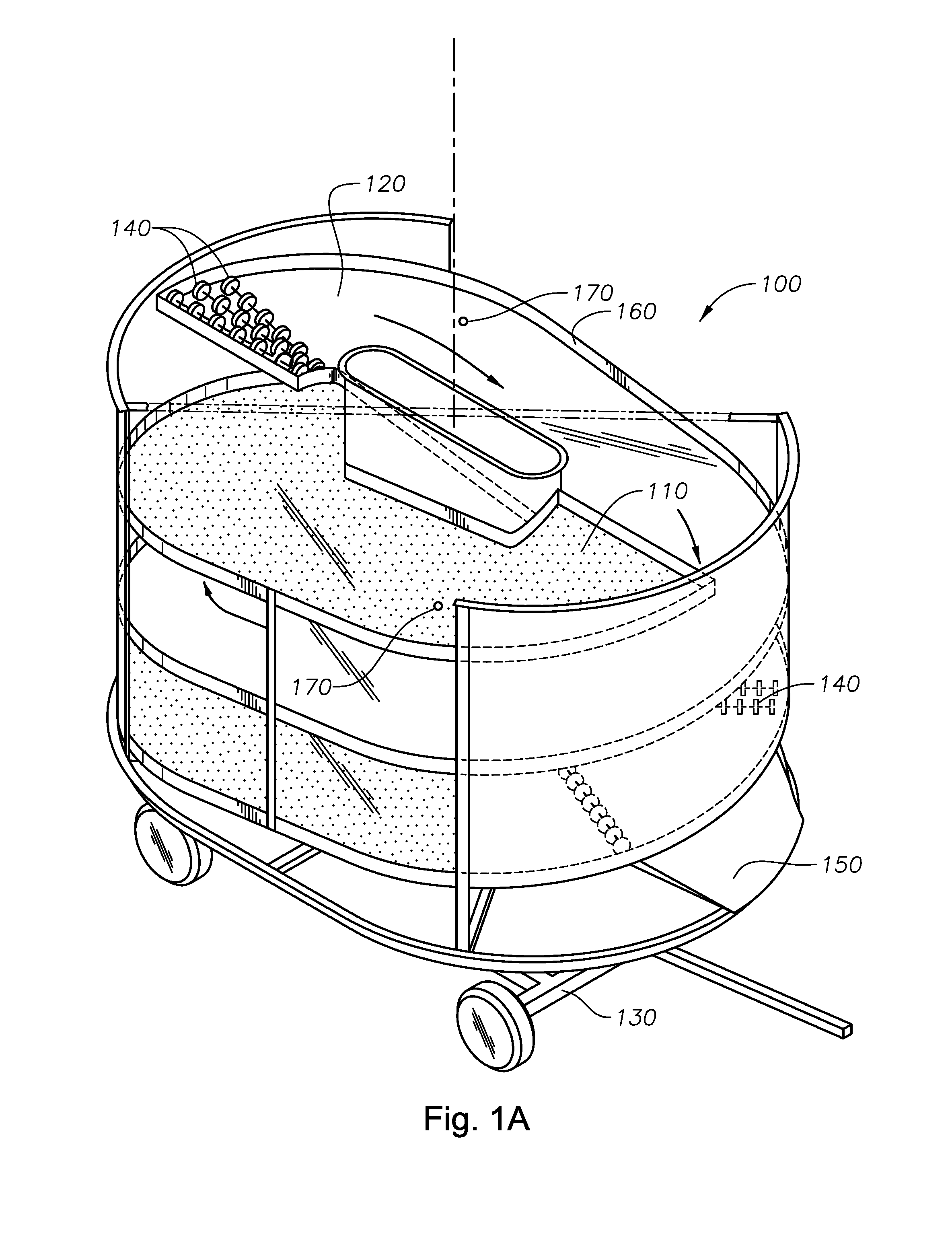

Bulk Materials Cart Having Dual Unload Capability

The bulk materials cart has a dual unload system including at least two inclined belt conveyors bounding an enclosed cavity. A first belt conveyor is operable for conveying bulk materials from the cavity to an unloading conveyor extendable from that side of the cart. A second belt conveyor is operable for conveying bulk materials upwardly and over another side of the cart. The dual unload system is automatically operable in a first mode operating the first belt conveyor and the unloading conveyor for conveying the bulk materials away from the cart, and in a second mode operating the second belt conveyor for conveying the bulk materials over the side of the cart.

Owner:BLUE LEAF I P

Baggage cart handling system

A system for holding one or more bags. The system includes a cart, a first chute disposed on the cart, and a second chute also disposed on the cart. The first chute includes a first edging along each side of the first chute. The second chute includes a second edging along each side of the second chute. The second chute is intertwined with the first chute. The system may further include a third chute and a fourth chute disposed on the cart. The third chute may include a third edging along each side of the third chute, and the fourth chute may include a fourth edging along each side of the fourth chute. The top and bottom of the first chute and the top and bottom of the second chute are positioned on opposite ends of the cart at about 180 degrees apart, while the top and bottom of the third chute and the top and bottom of the fourth chute are positioned on opposite ends of the cart at about 180 degrees apart.

Owner:AMERICAN AIRLINES INC

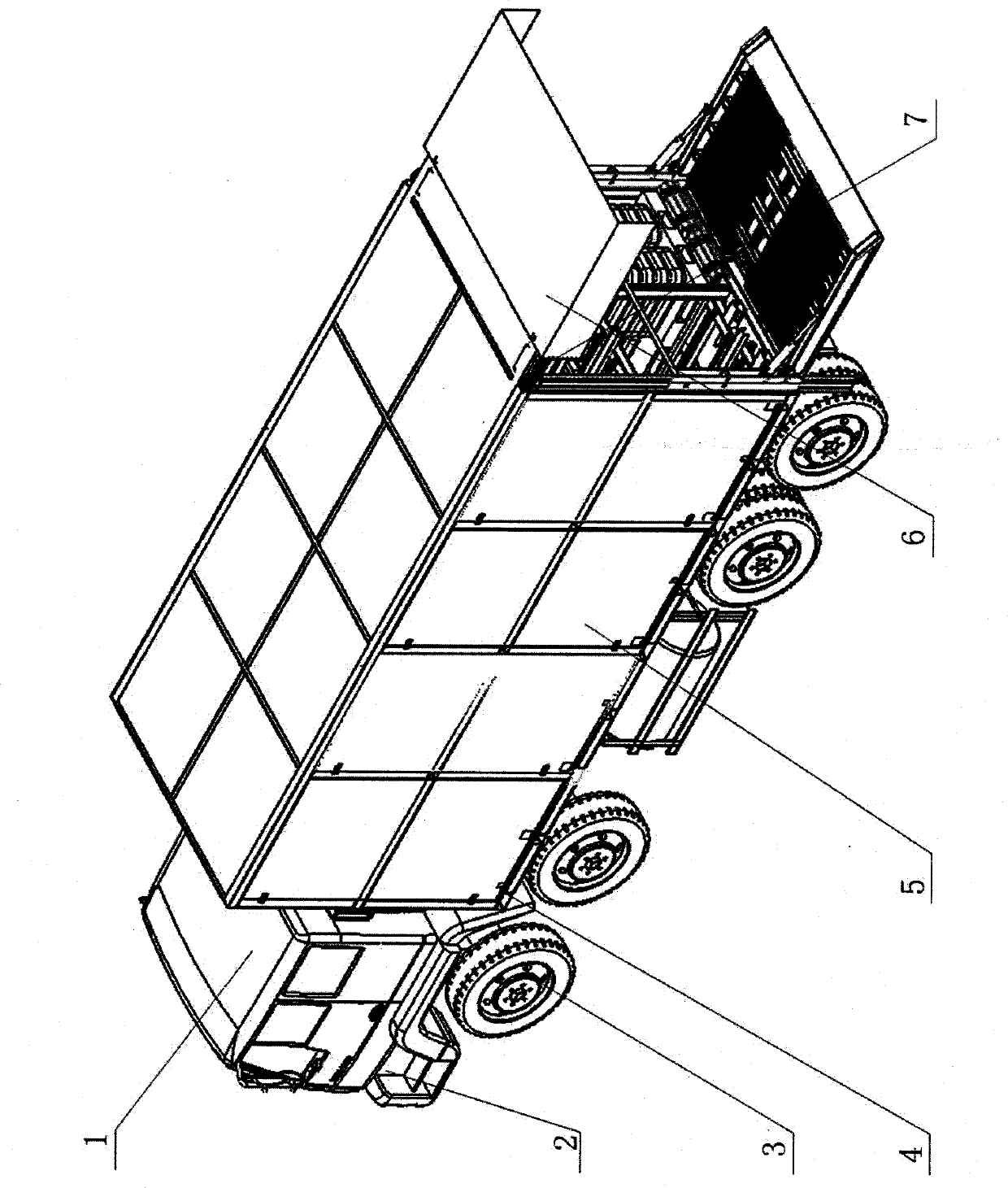

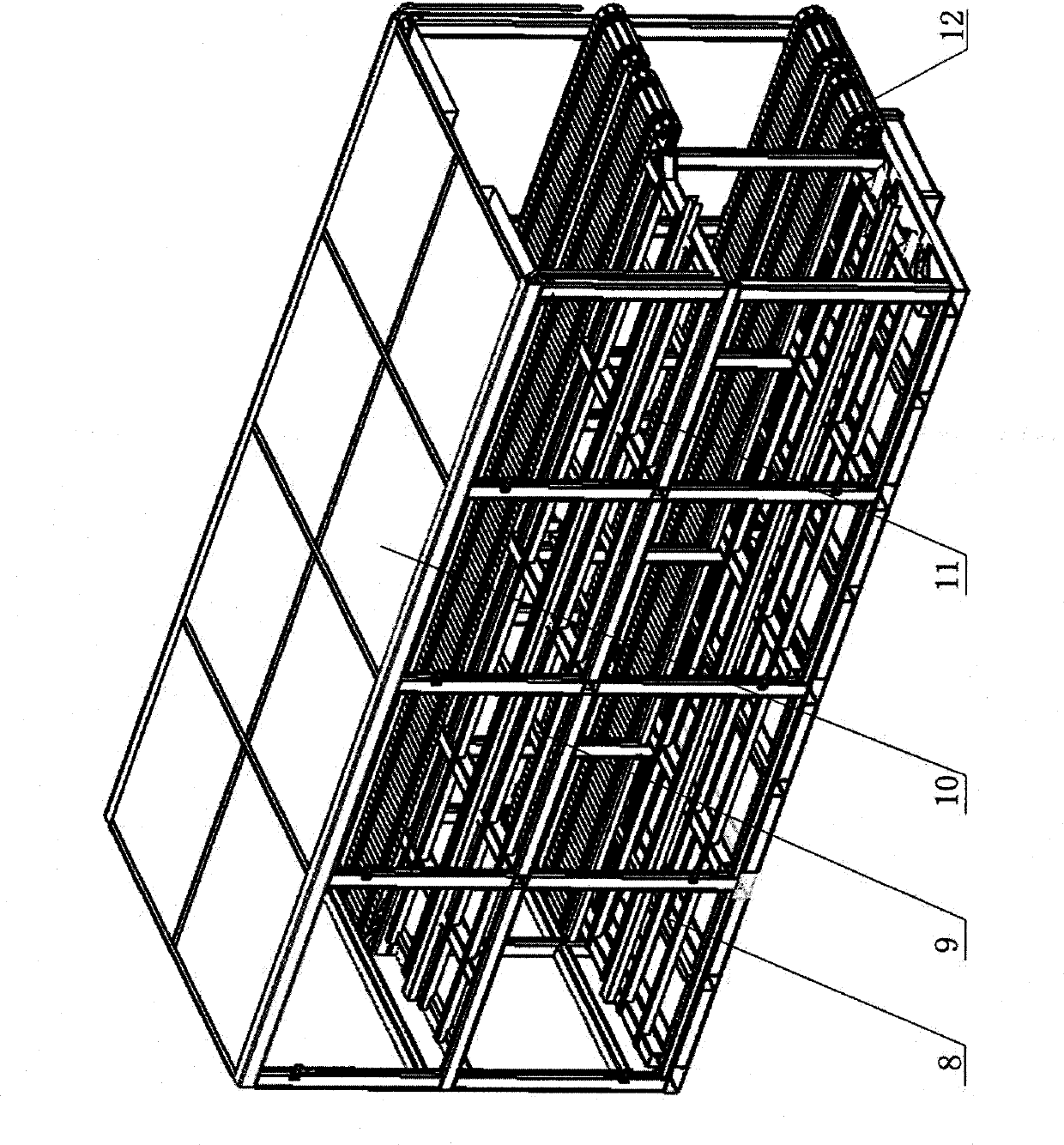

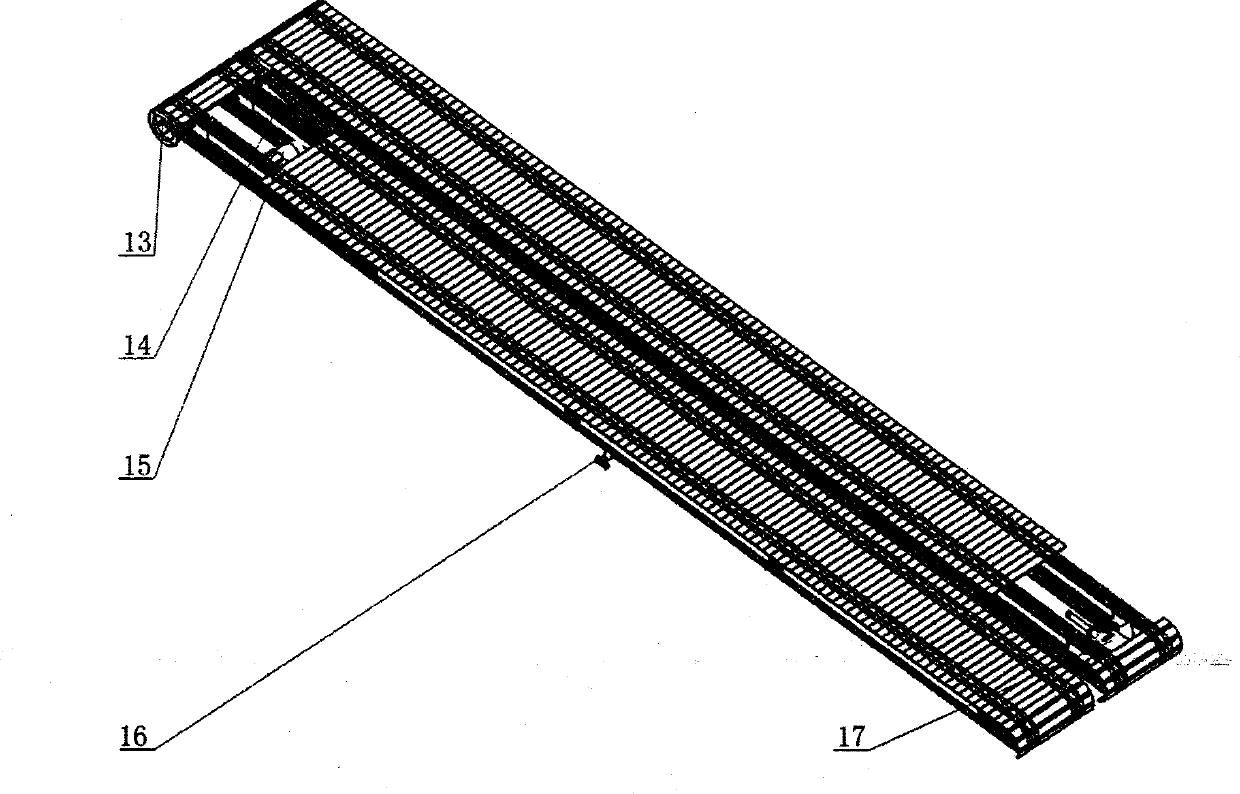

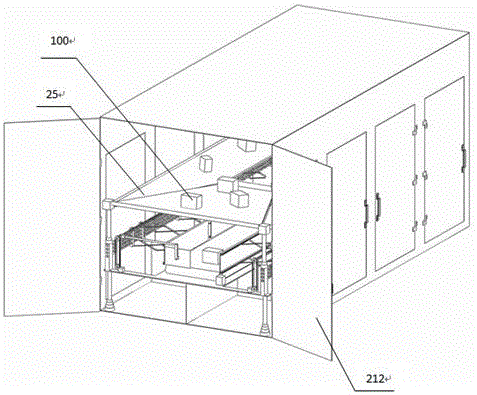

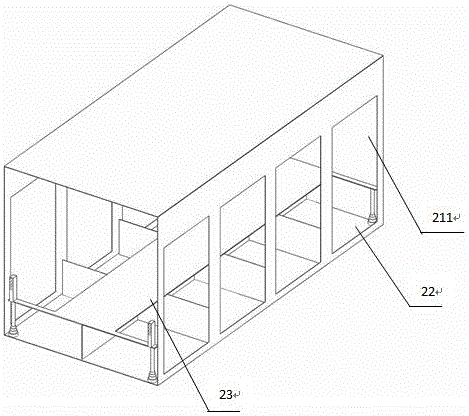

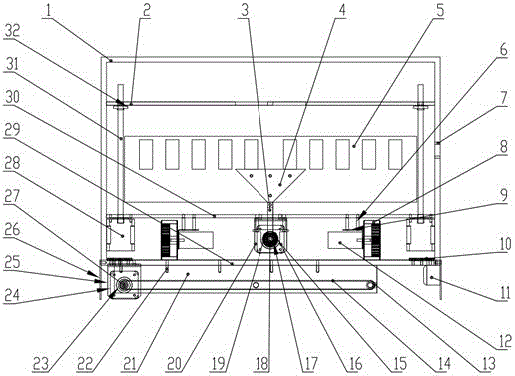

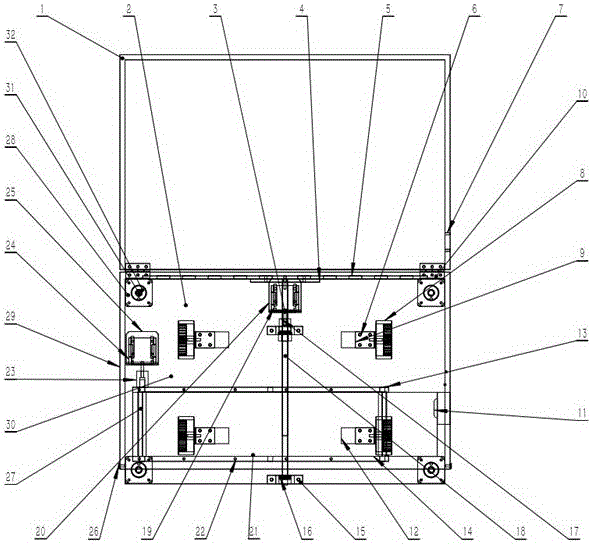

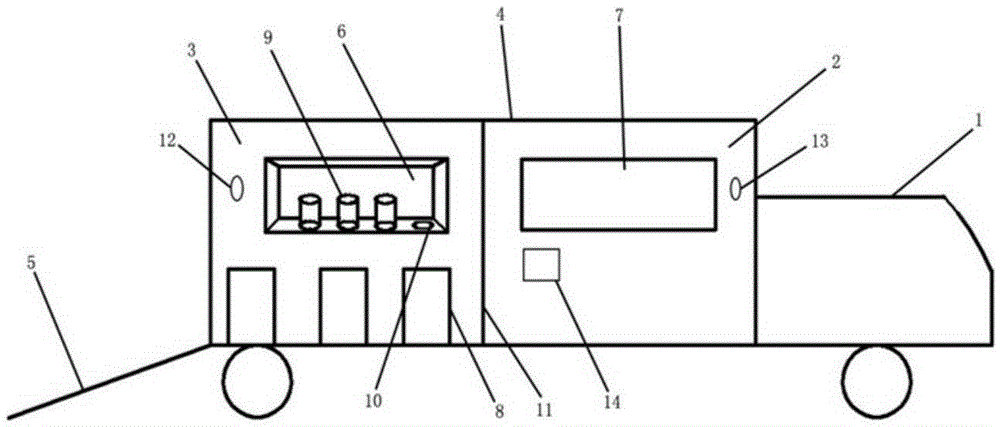

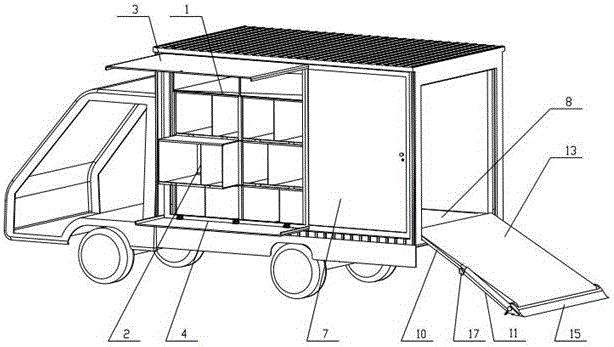

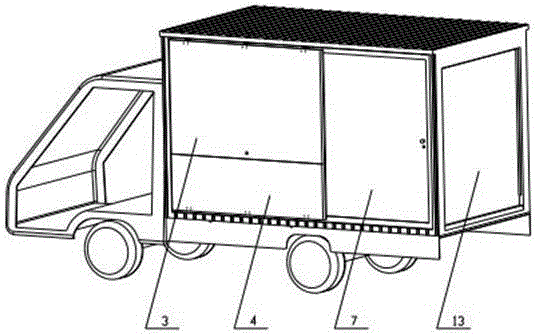

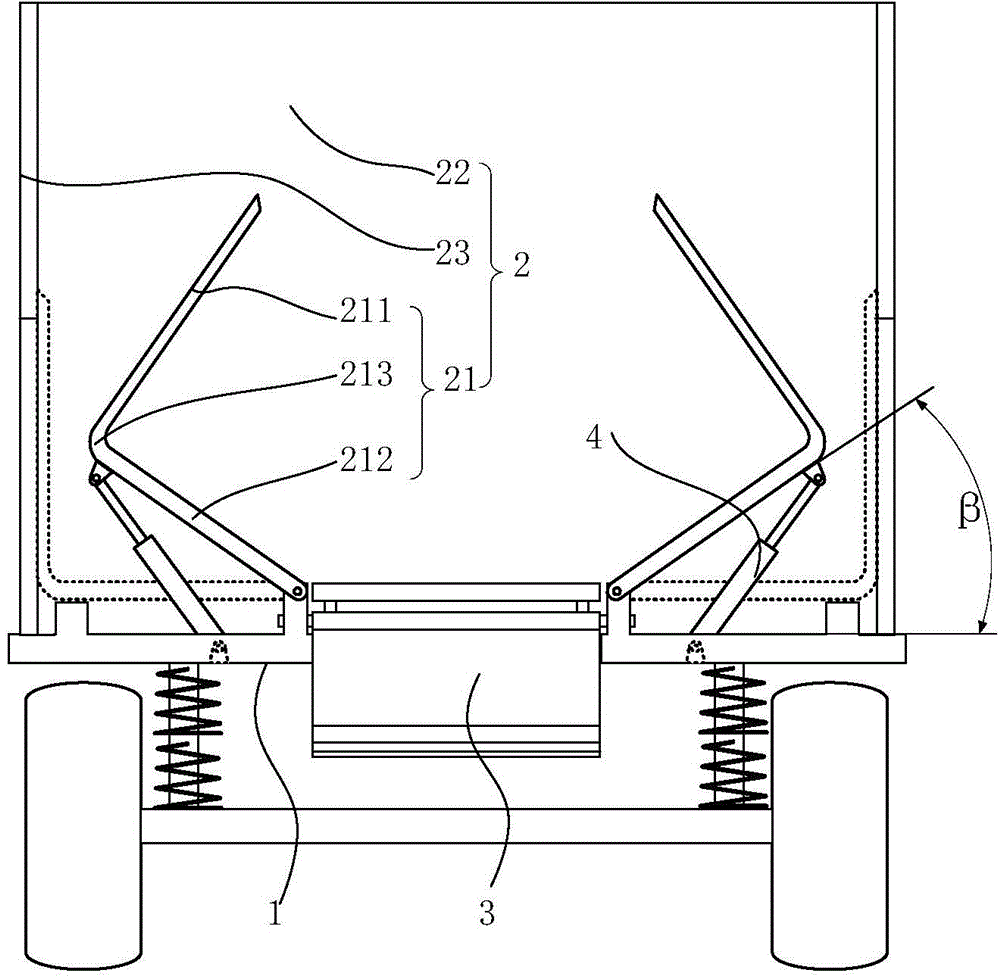

Automatic loading and unloading logistics vehicle

InactiveCN103661068AHigh degree of automationCompact structureLoad securingVehicle with endless chains/beltsVehicle frameControl system

An automatic loading and unloading logistics vehicle comprises a vehicle frame, a vehicle compartment, an automatic conveying system, a tail plate system and a hydraulic control system. The vehicle frame is mainly composed of a cab, a chassis, wheels and a transmission. The vehicle compartment is mainly composed of a lower-layer framework, an upper-layer framework, side doors, a tail door, a tail door oil cylinder and a vehicle roof. The automatic conveying system is installed on the lower-layer framework and the upper-layer framework in the vehicle compartment, the tail plate system is installed on the tail portion of the vehicle compartment, and therefore automatic loading and unloading of goods can be achieved. A bundling system is arranged in the vehicle compartment, and therefore the goods can be fixed and released conveniently. The hydraulic control system supplies power to an automatic loading and unloading system and the tail plate system. According to the automatic loading and unloading logistics vehicle, the automatic degree of the logistics vehicle in the process of loading and unloading the goods is improved by adding the automatic conveying system and the goods loading and unloading system on the basis of an existing logistics vehicle, and the automatic loading and unloading logistics vehicle has the advantages of being compact in structure, high in automation degree, high in conveying ability, suitable for the logistics field, and the like.

Owner:CHONGQING SHENGHE LOGISTICS

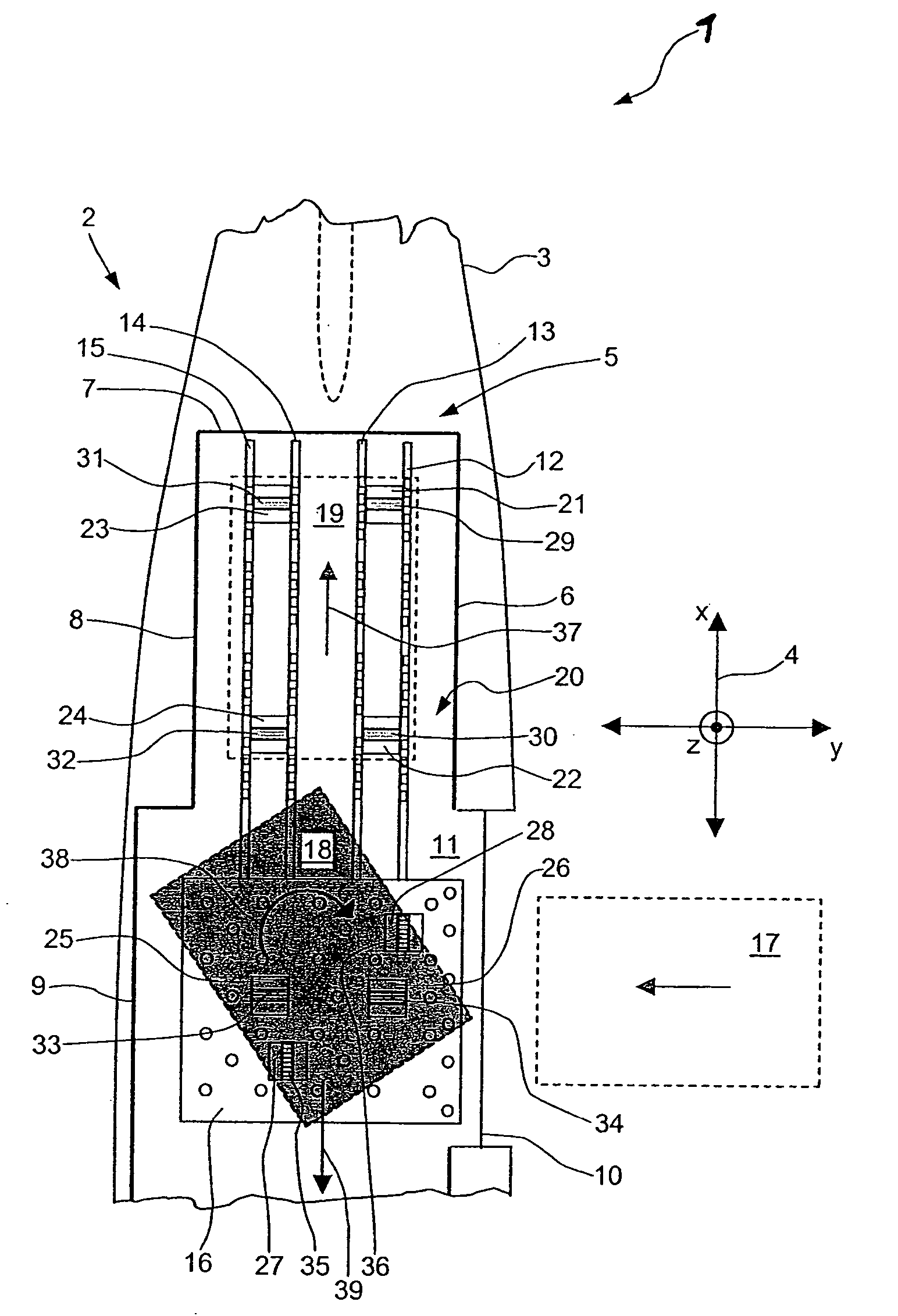

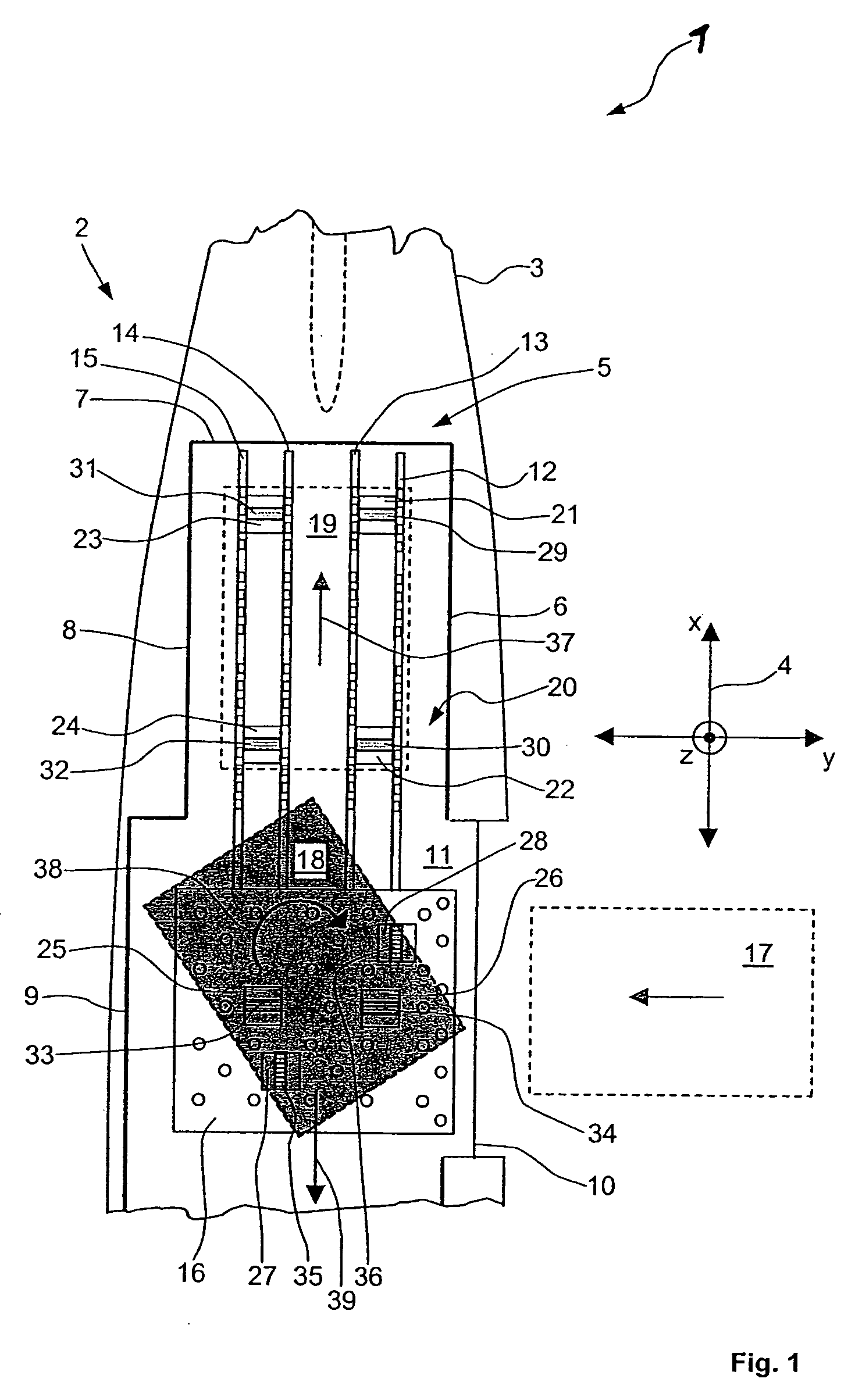

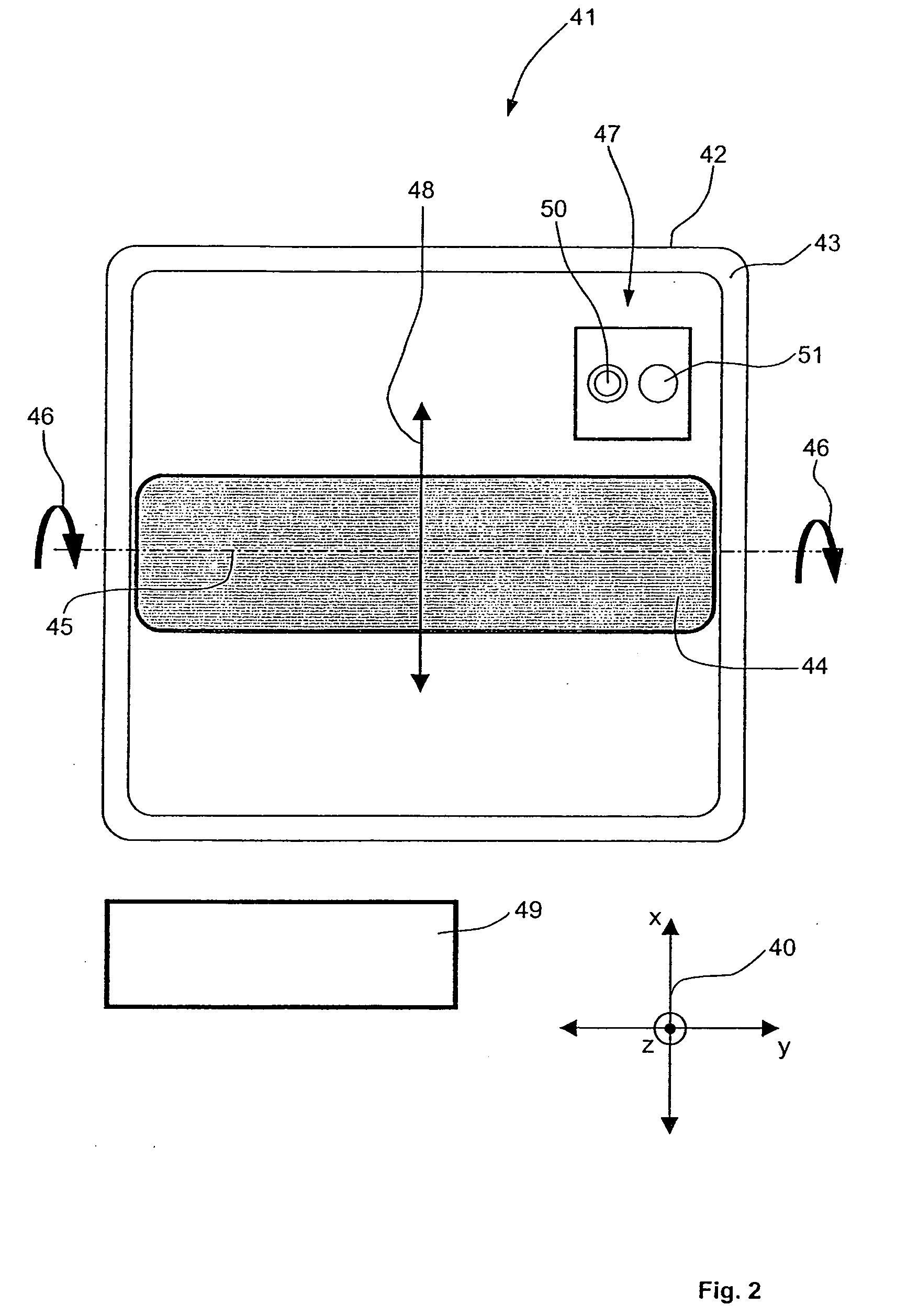

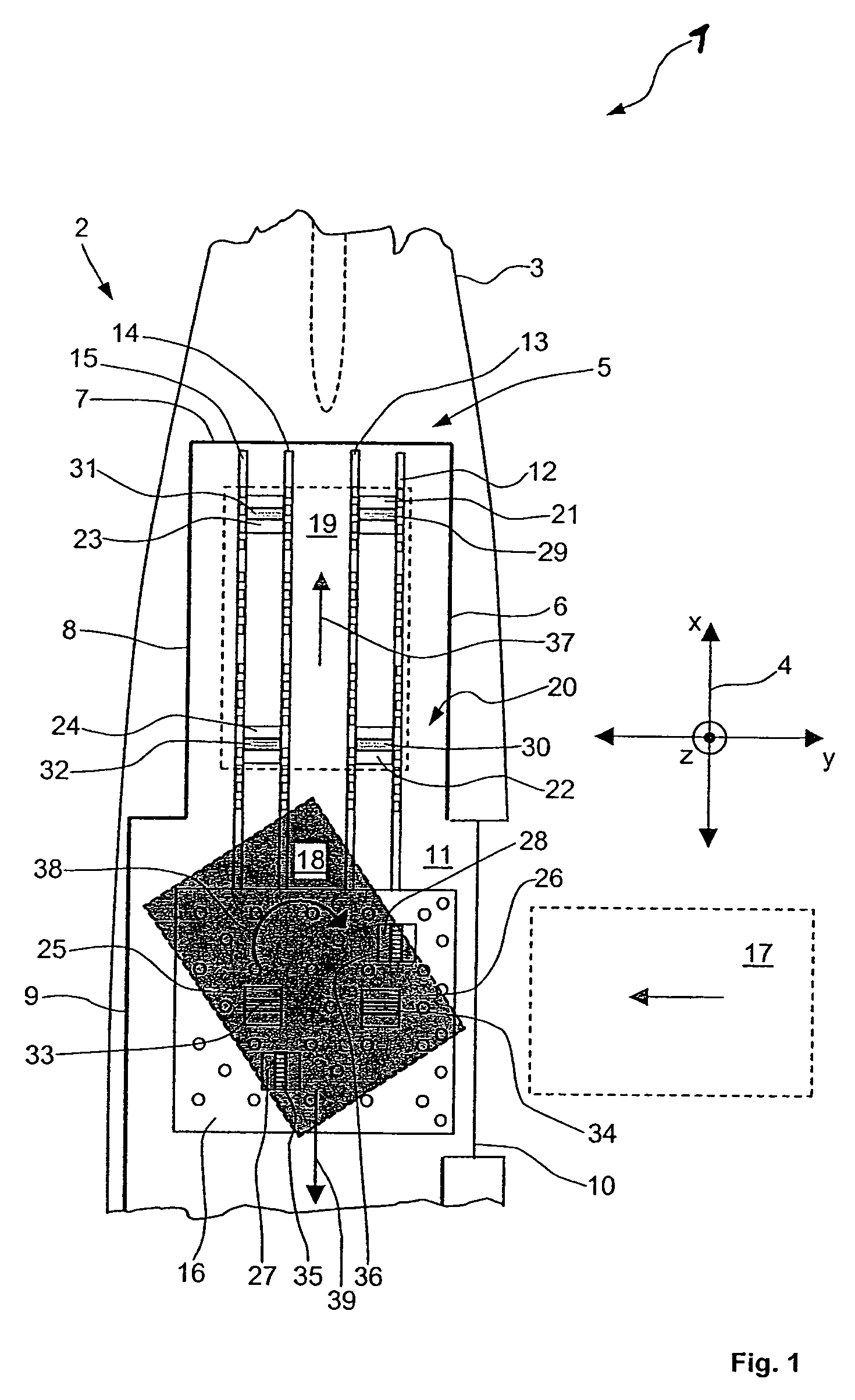

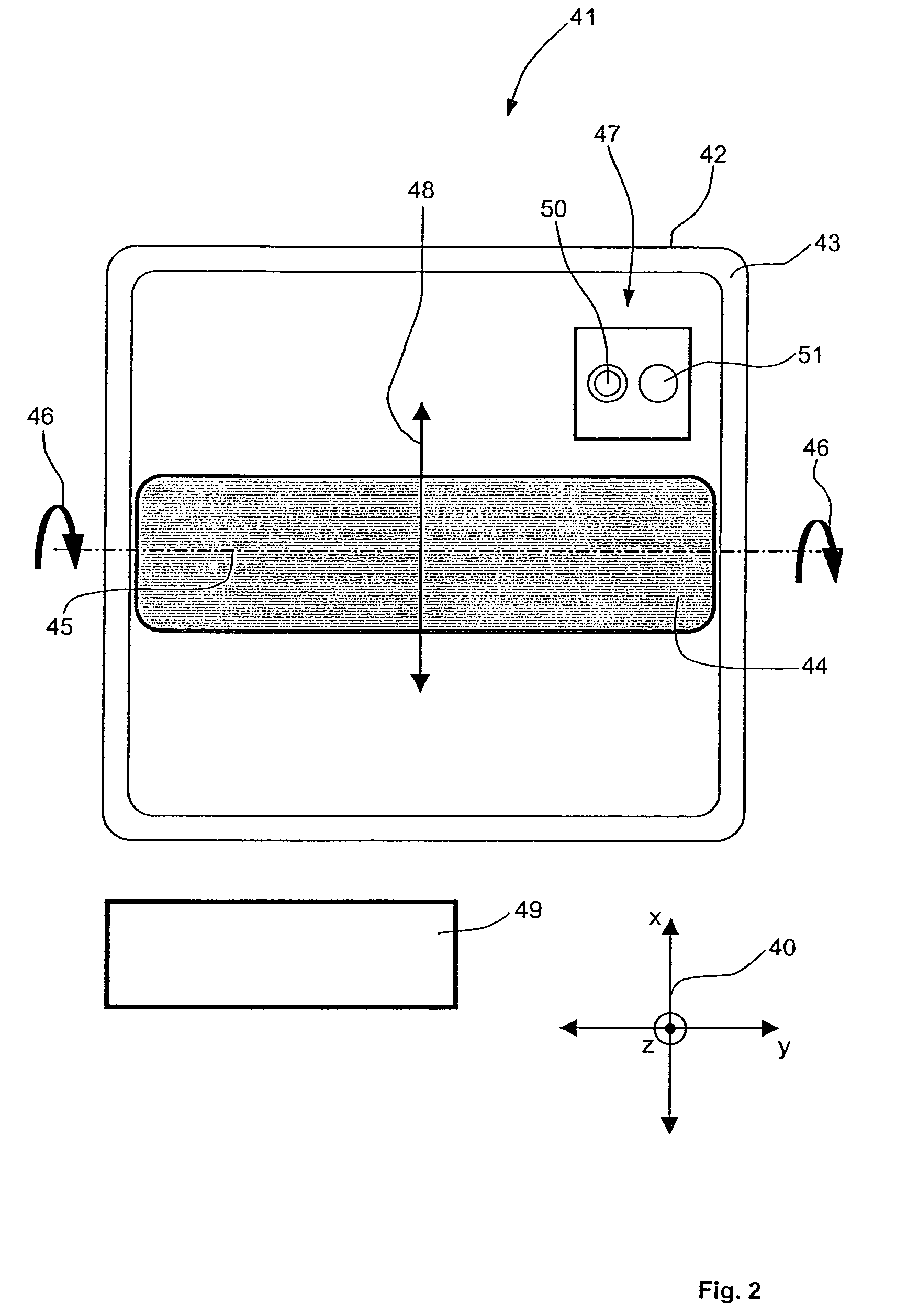

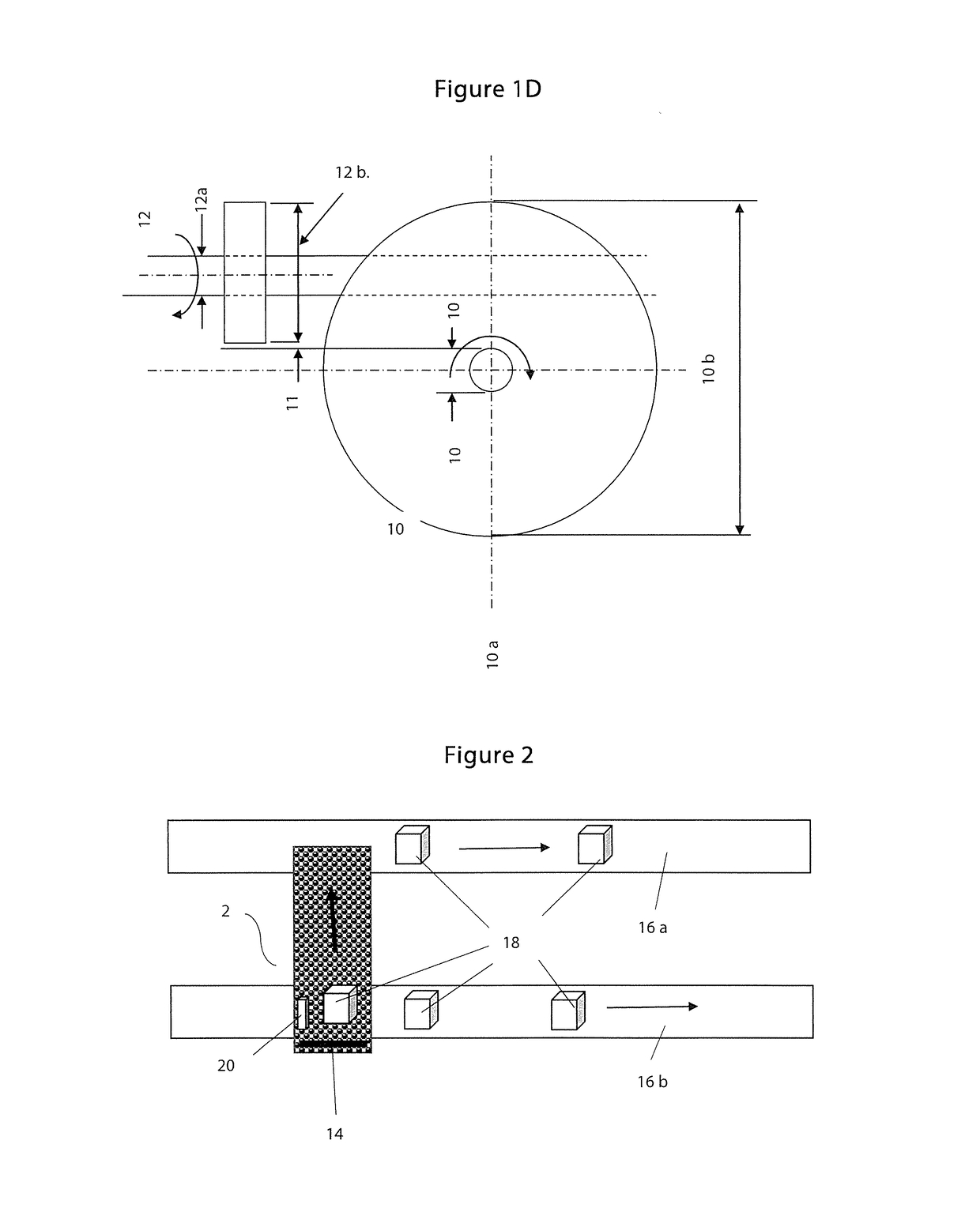

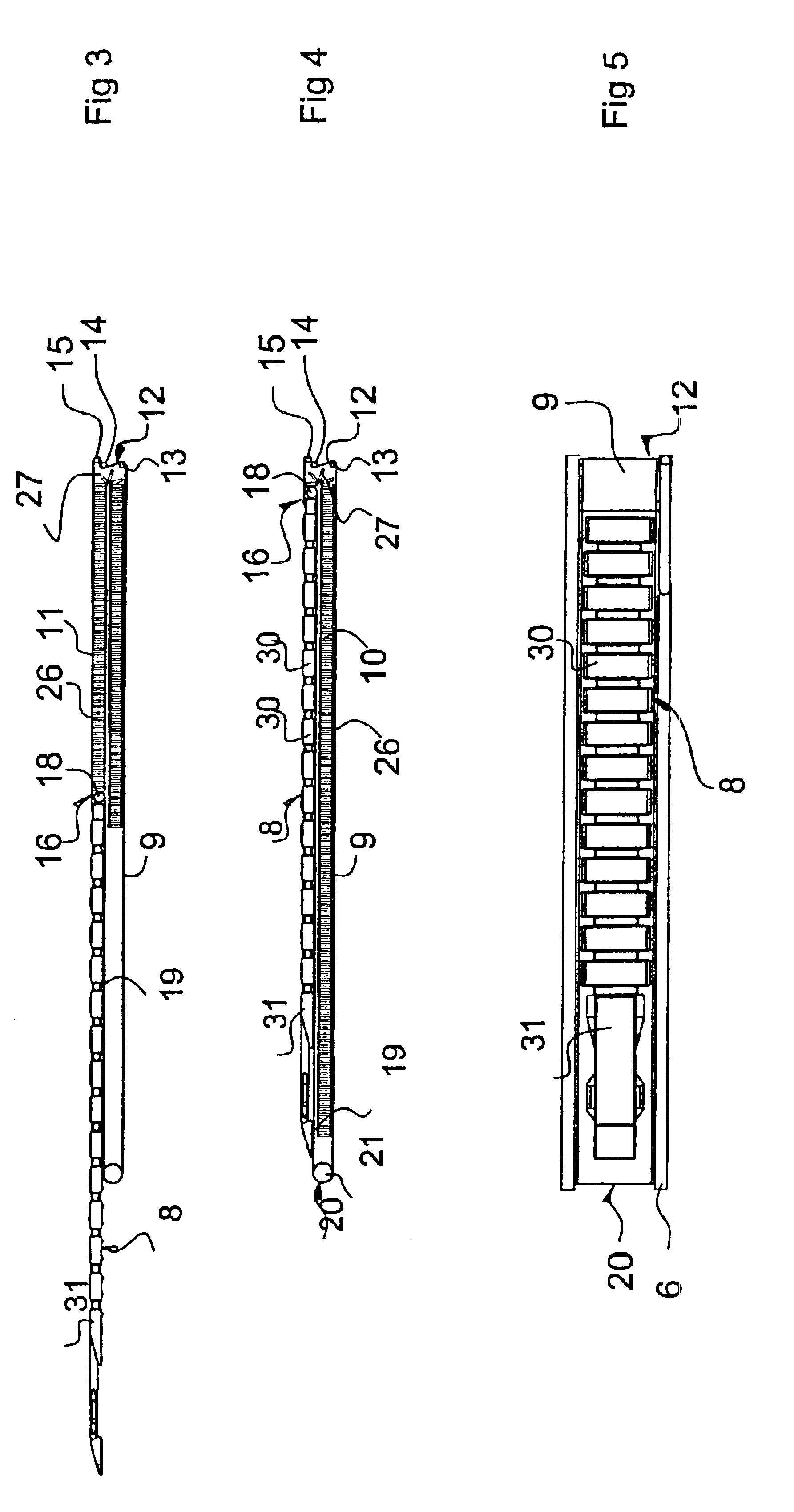

Loading device for the at least partially automated loading and unloading of a cargo hold on transport equipment as well as a conveying system

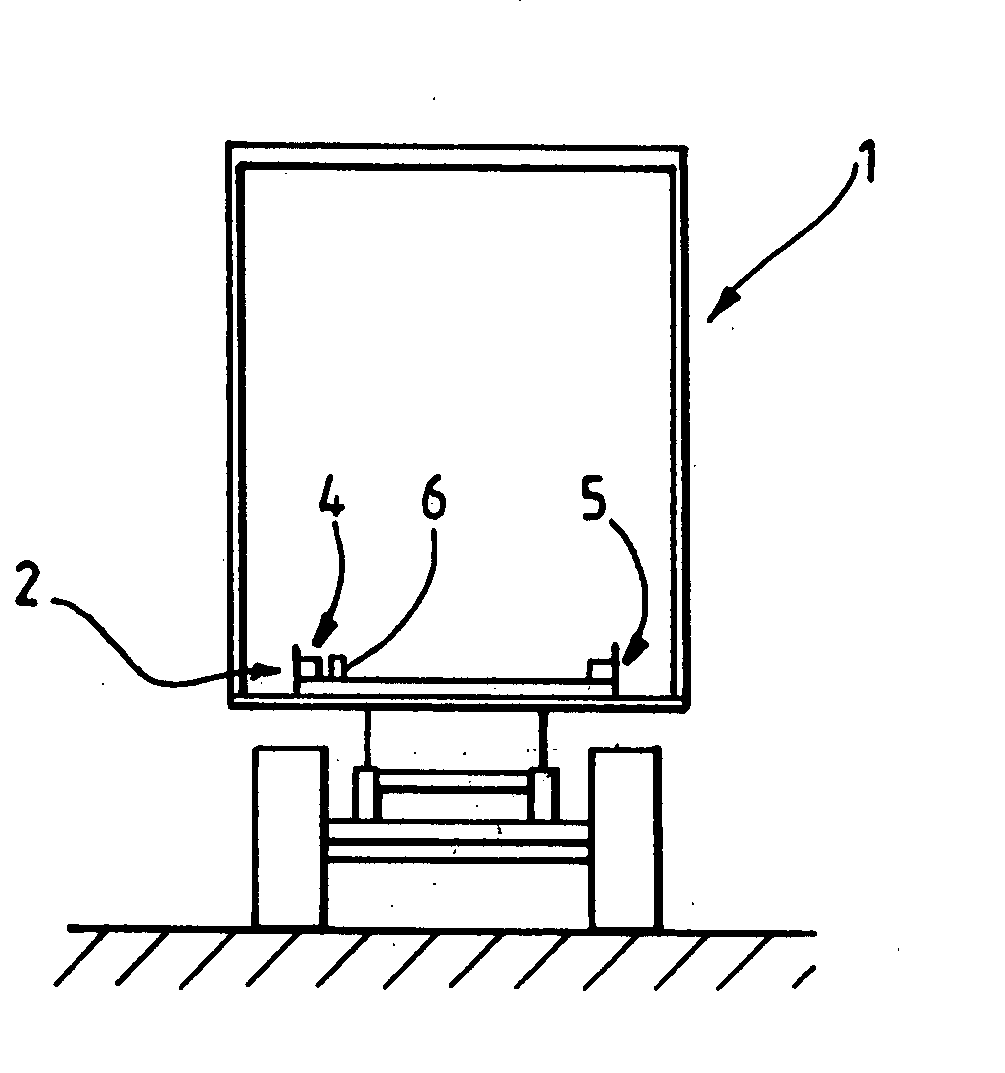

InactiveUS20060186271A1Reduce failure rateEasy to controlFreight handlingVehicle with endless chains/beltsClosed loopMechanical engineering

The invention relates to a loading device 1 for the at least partially automated loading and unloading of a cargo hold 5 on transport craft, in particular a cargo hold 5 on an aircraft, with at least one conveying system 21-28, 41 for positioning cargo units 17, 18, 19 in the area of a floor space 11 of the cargo hold 5, and with at least one guiding element, as well as at least one movement aid in the area of the floor space 11 of the cargo hold 5. According to the invention, each conveying system 21-28, 41 has at least one sensor 47, wherein the sensor 47 or sensors can detect the presence of a cargo unit 17, 18, 19 in the area of the conveying system 21-28, 41 without contact, and at least the position of a cargo unit 17, 18, 19 on the floor space 11 can be determined in at least two spatial dimensions without contact. The sensors or sensor 47 that determine the position of a cargo unit 17, 18, 19 on the floor space 11 of the cargo hold 5 of an aircraft in at least two spatial dimensions make it possible in particular to control rotating movements of the cargo units 17, 18, 19 in the area of the respective conveying systems 21-28, 41 of the loading device 1 by an open and / or closed loop controller 49. Further, the contactless sensors enable a largely maintenance-free and at least partially automated operation of the loading device 1. In addition, the invention relates to a conveying system 21-28, 41, in particular for a loading device 1 for the at least partially automated loading and unloading of a cargo hold 5 on transport craft, in particular a cargo hold 5 on an aircraft, with at least one conveying unit, in particular with at least one driven transport roller 29-36, 44.

Owner:AIRBUS OPERATIONS GMBH

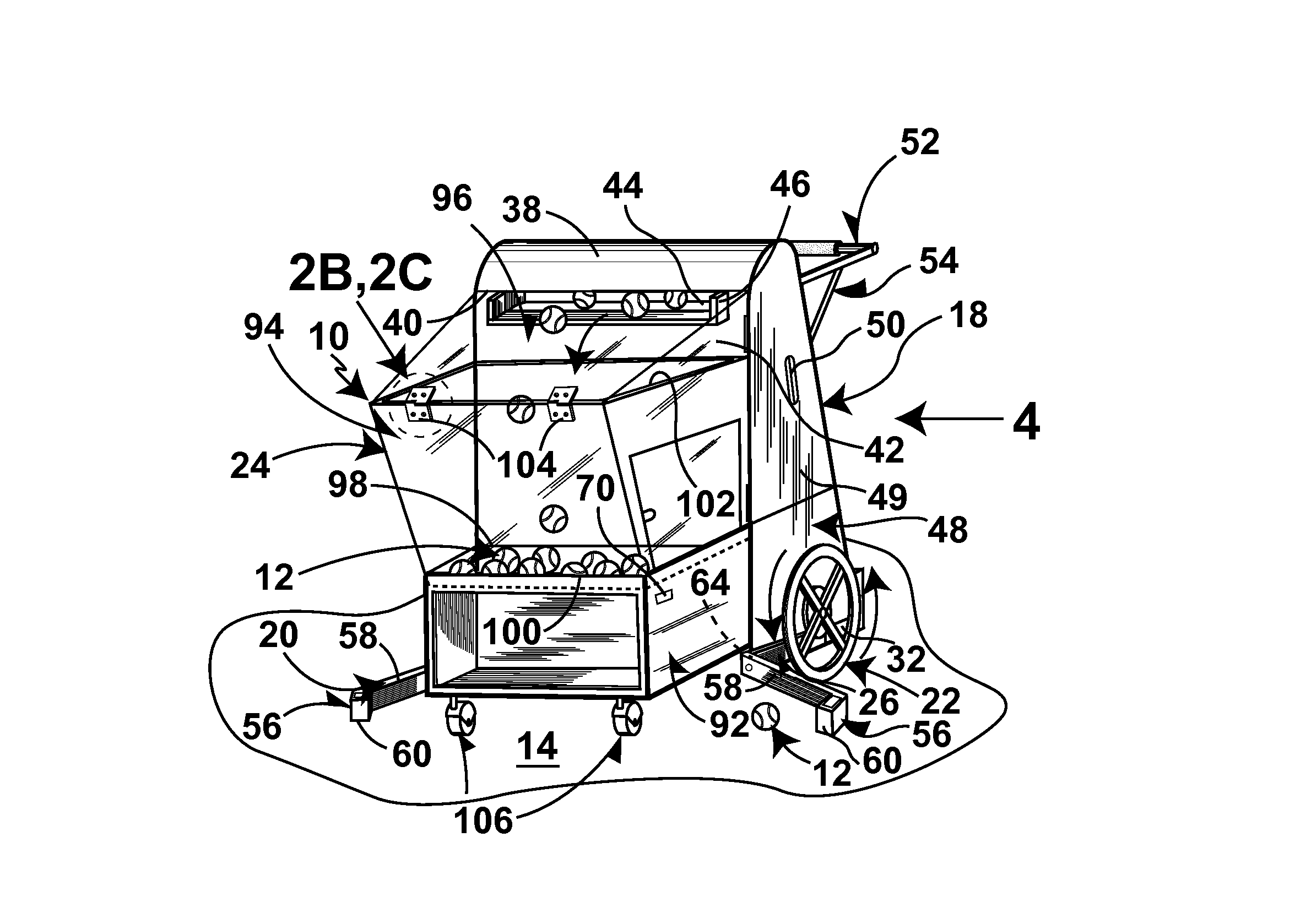

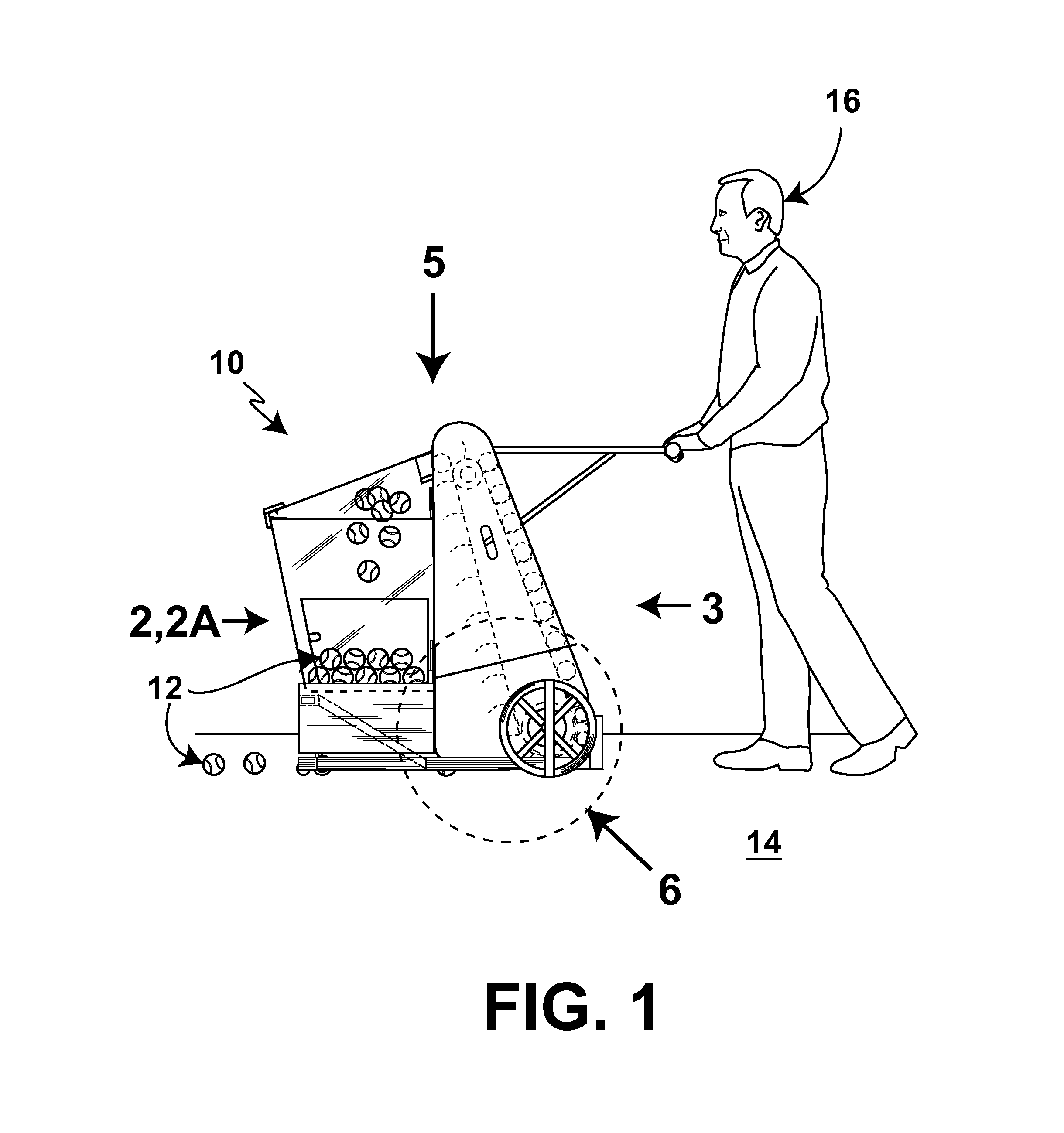

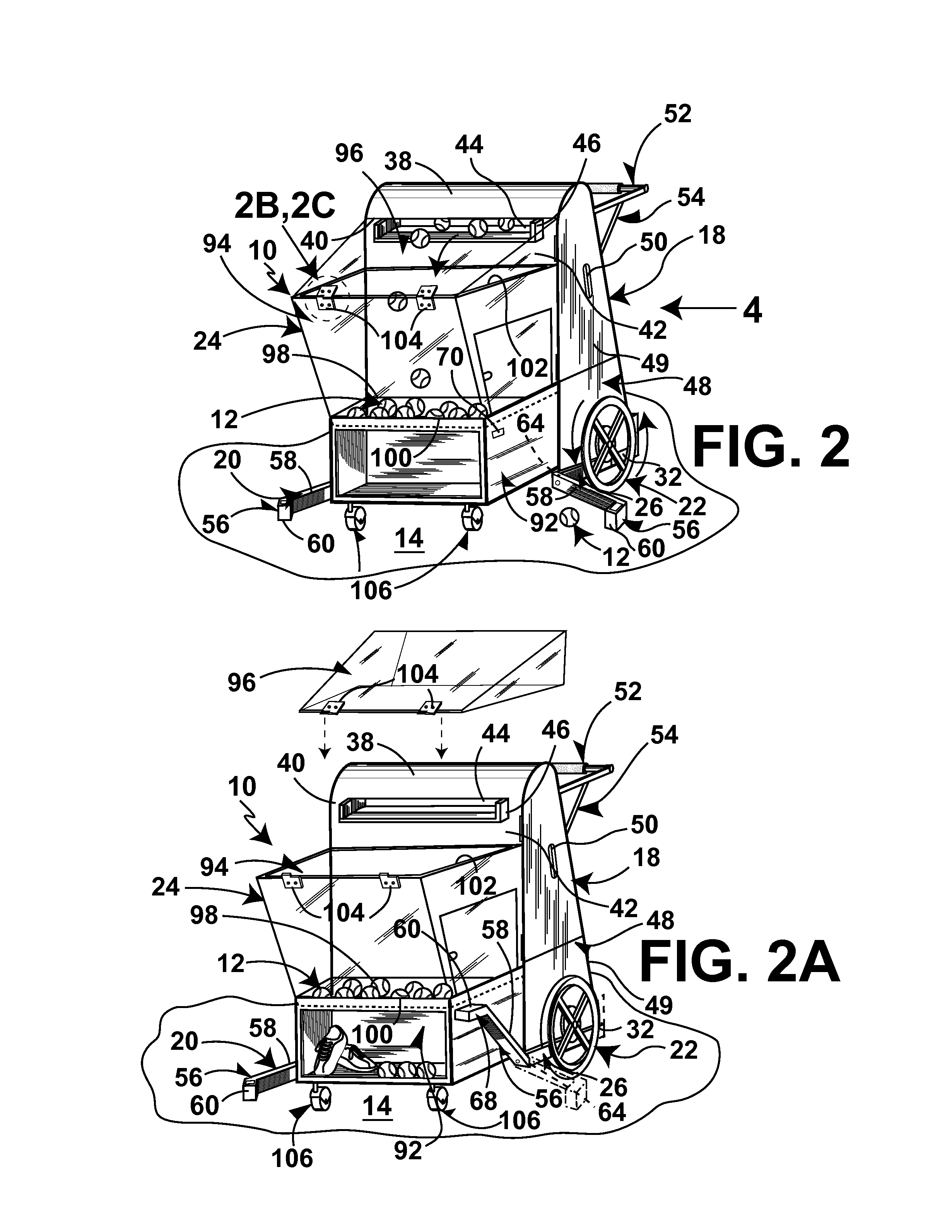

Combination tennis ball cart and mower

A cart that collects tennis balls on the ground when manually pushed by a user and stores the tennis balls once collected. The cart includes a housing, a gathering assembly, a conveyor assembly, and a receptacle. The housing is manually pushed by the user. The gathering assembly is operatively connected to the housing, and gathers the tennis balls on the ground. The conveyor assembly is operatively connected within the housing. The receptacle is disposed against the housing, and stores the tennis balls elevated thereto by the conveyor assembly that have been gathered by the gathering assembly.

Owner:NASH NOVAK MR +1

Vehicle

InactiveCN105905019AEffective use of timeEasy to sortSortingVehicle with endless chains/beltsEngineeringMechanical engineering

The invention discloses and relates to a vehicle for transporting and sorting goods. The vehicle comprises a sorting device. The sorting device comprises a compartment, a cavity, a conveyor, a detector, a sorter and a support device. Regional doors are arranged on the compartment, the cavity is fixedly arranged on a compartment baseboard, the cavity is partitioned into multiple accommodation chambers which are not communicated, and the accommodation chambers are matched with the regional doors; the conveyor is fixedly arranged on the upper part of the cavity and used for transporting goods; the detector is arranged in the compartment, is capable of detecting the goods on the conveyor and sends goods information in a way of signals; the sorter is fixedly arranged in the compartment, is capable of receiving the signals sent by the detector, and sorts the goods on the conveyor into the specified accommodation chambers according to the signals; the support device is arranged on the upper end of the conveyor, an opening allowing the goods to pass is formed in the support device, and the goods can enter through the opening to reach the conveyor. Through the design, goods can be sorted and traced in the transporting process and thus the efficiency is improved.

Owner:HEBEI AGRICULTURAL UNIV.

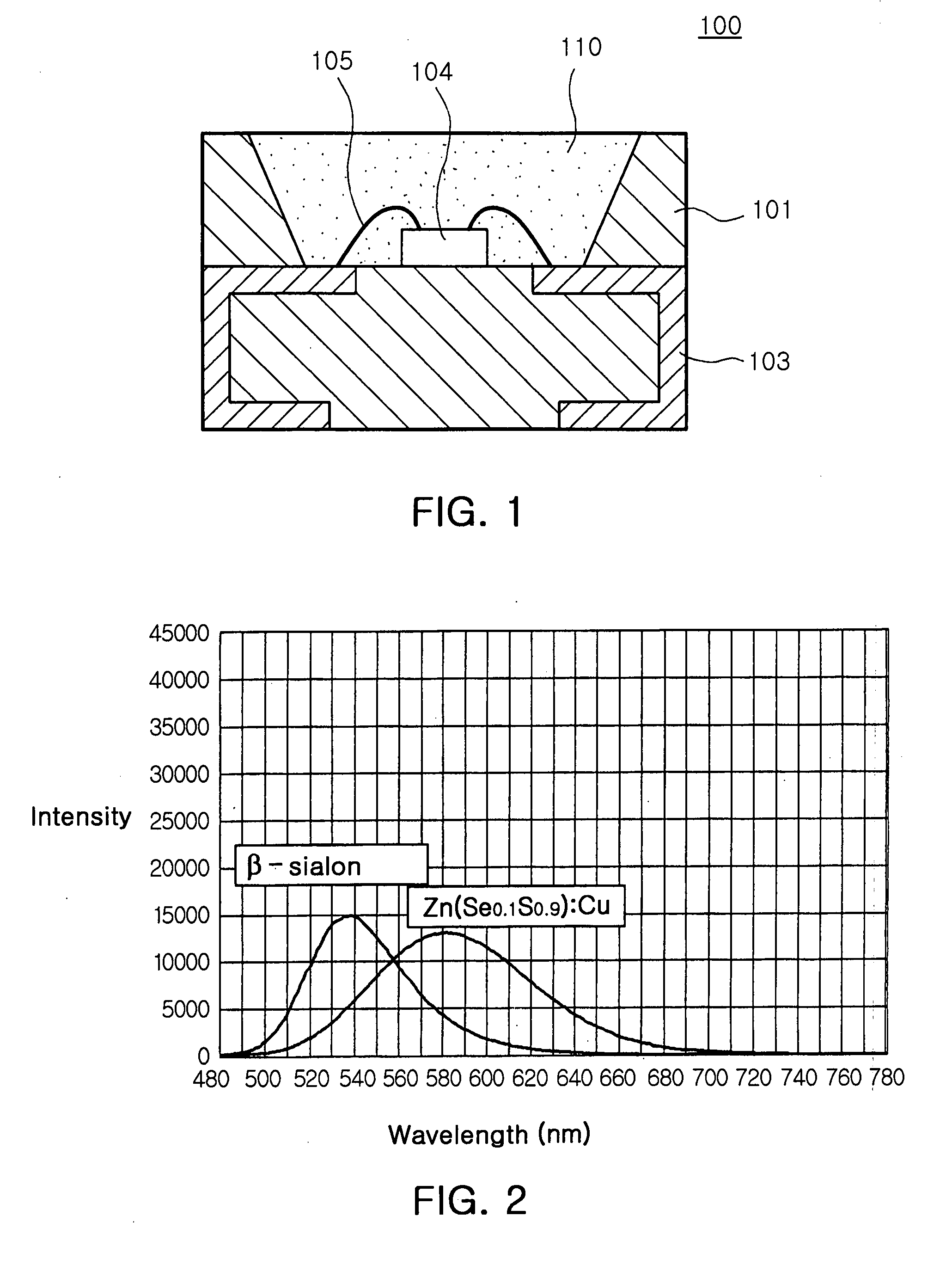

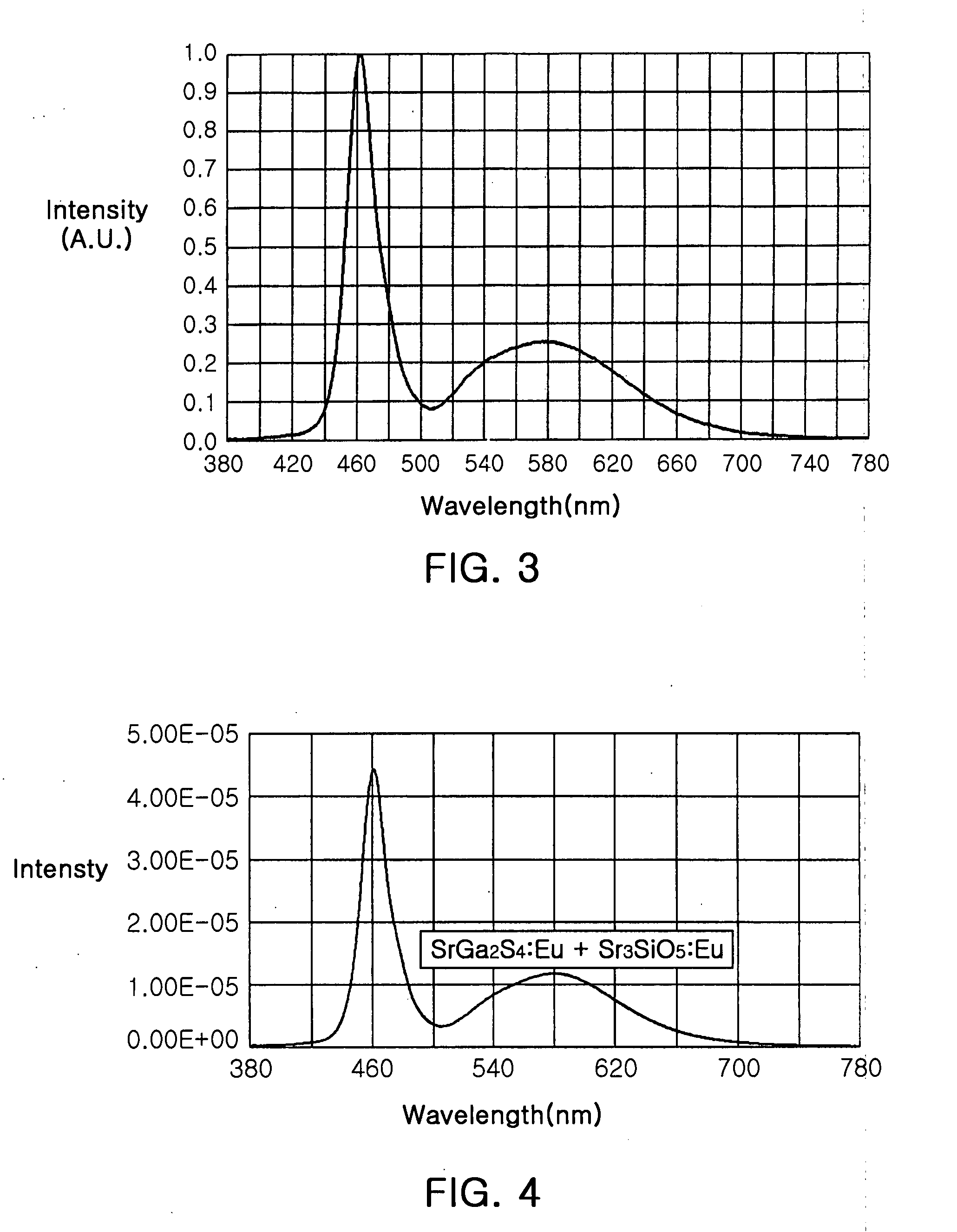

White light emitting device

ActiveUS20070194695A1Increase rangeConveyorsDischarge tube luminescnet screensWavelength rangeWhite emission

A white light emitting device capable of expanding the wavelength range of a blue LED used for realizing white light. The white light emitting device according to the present invention includes a blue LED and a mixture of orange phosphor and green phosphor disposed above the blue LED.

Owner:SAMSUNG ELECTRONICS CO LTD

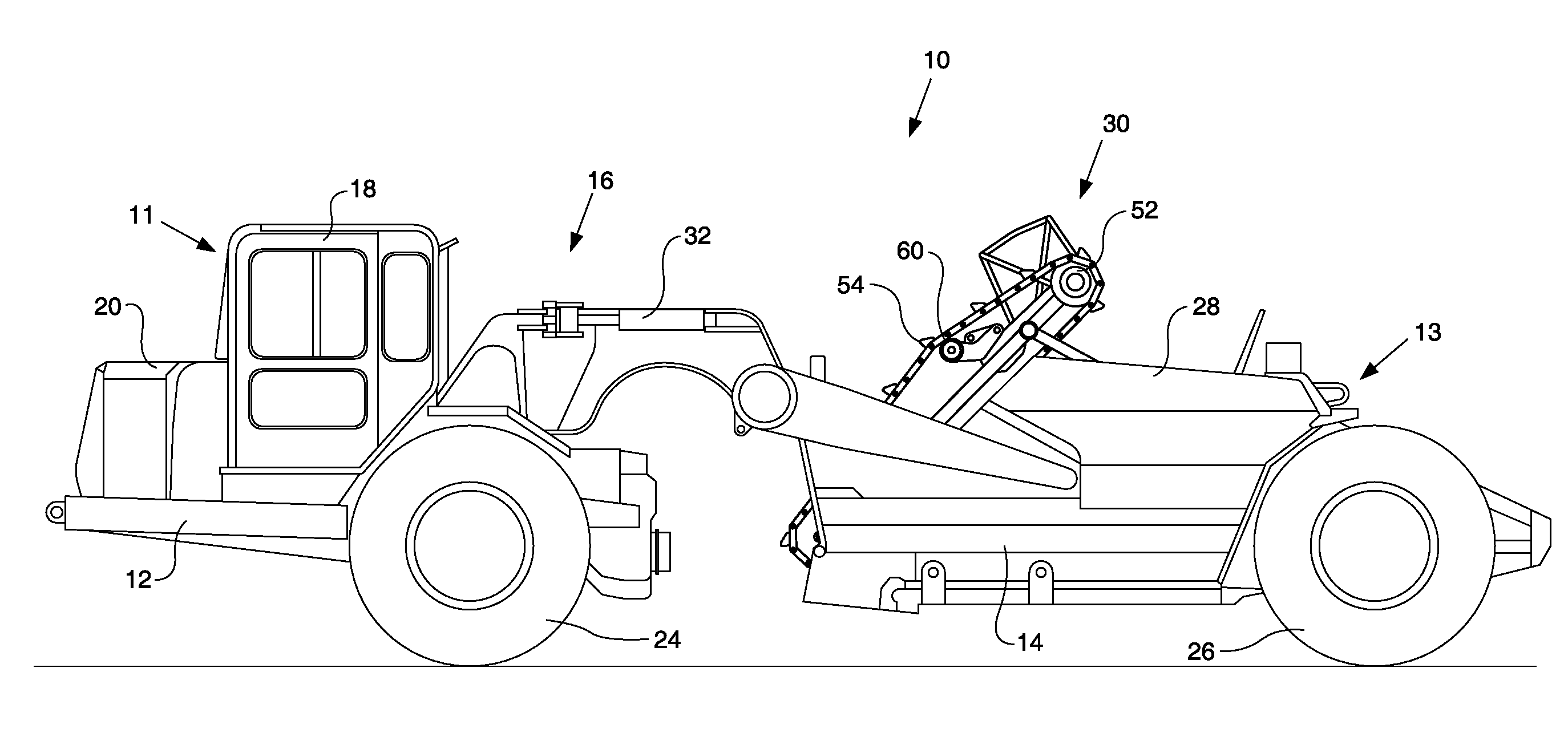

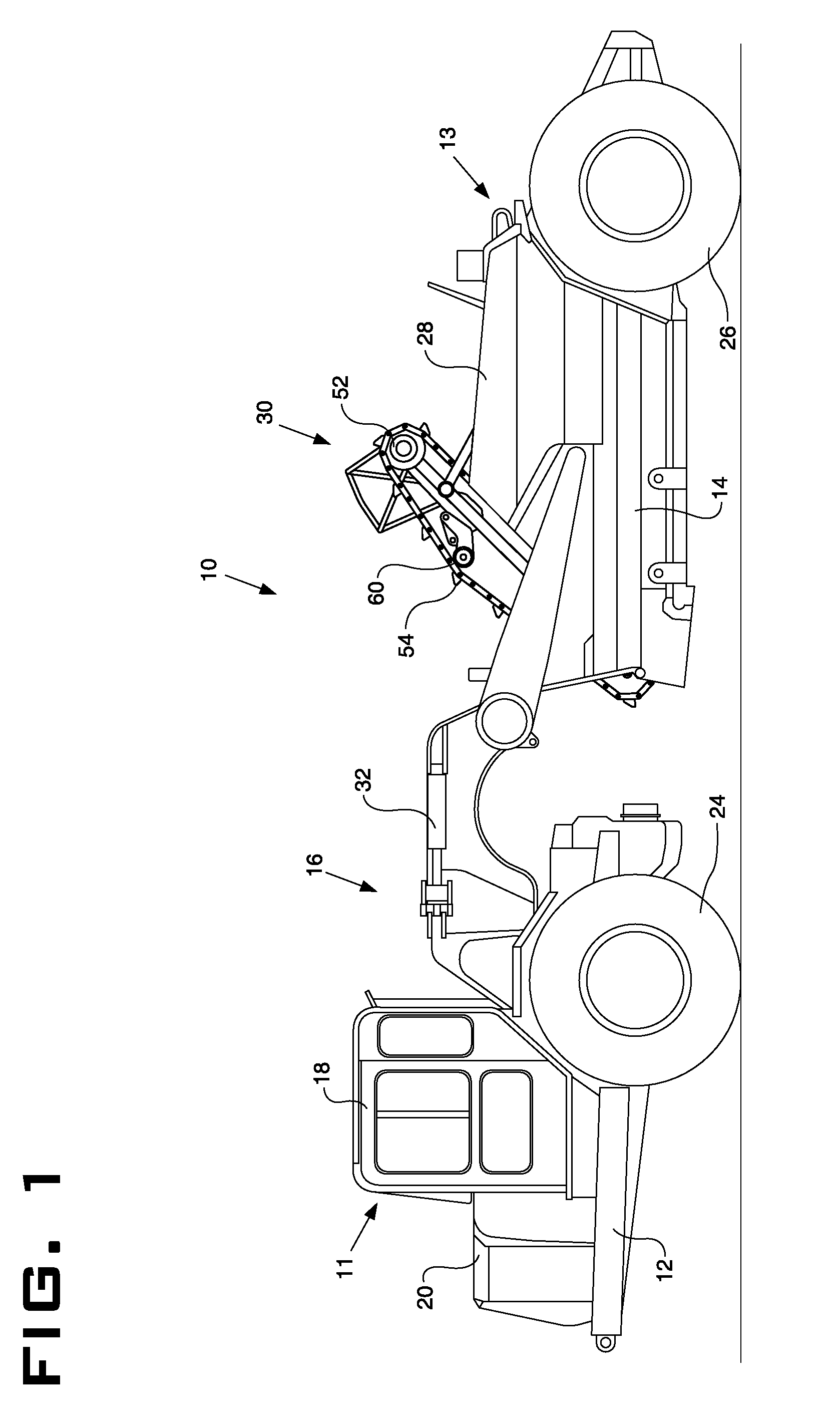

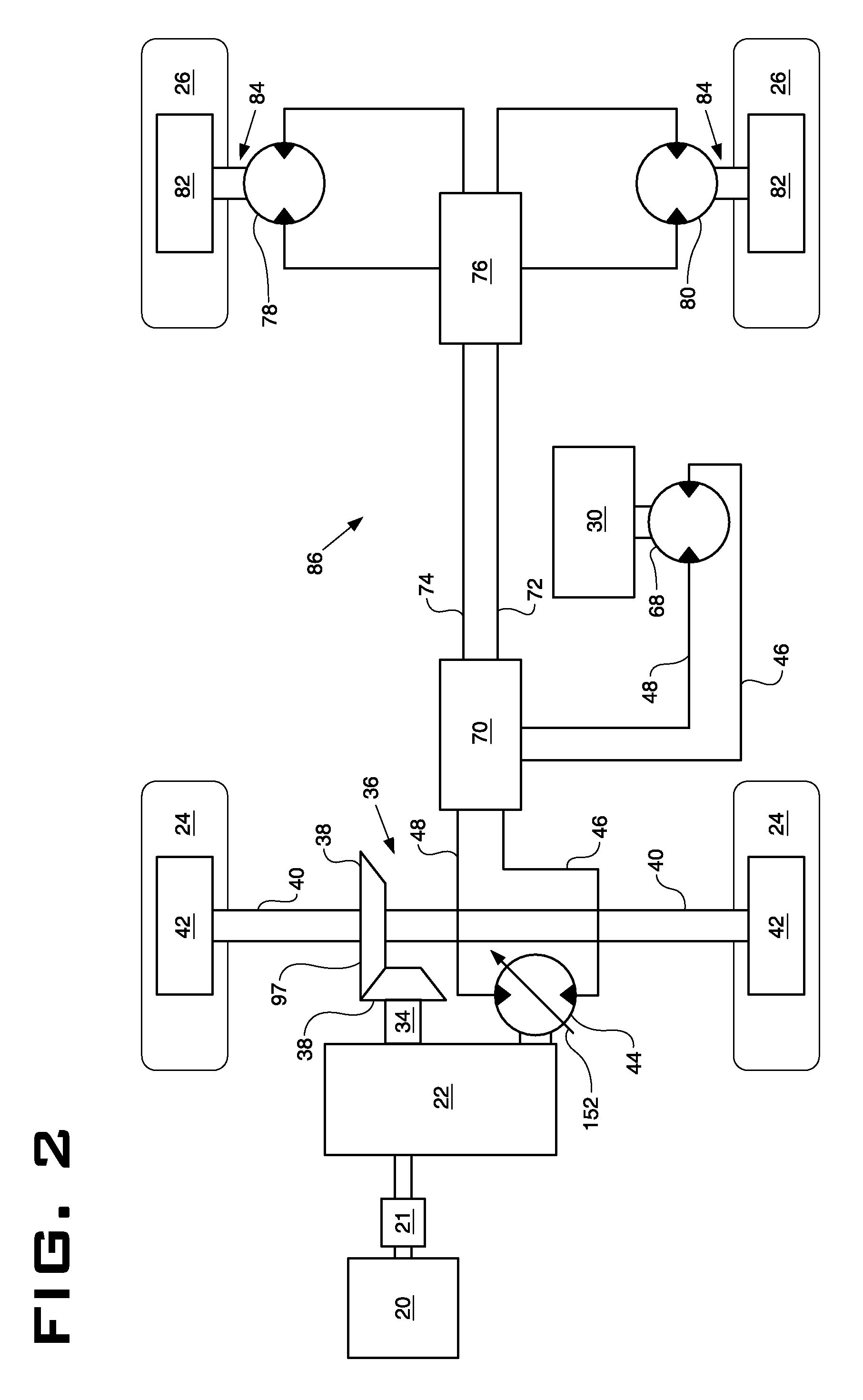

Wheel tractor scraper rear wheel drive assist and method of operation

ActiveUS20100018727A1Machines/dredgers working methodsAgricultural machinesWheel tractor-scraperDrive motor

A wheel tractor scraper having a rear wheel drive assist, the wheel tractor scraper includes a tractor portion pivotally coupled to a rear scraper portion, the rear scraper portion having a bowl for hauling material and a fluid powered work tool configured to assist in loading the bowl, the work tool powered by a fluid pump connected to a fluid operated work tool motor. The rear wheel drive assist includes a fluid operated drive motor coupled to the rear wheels of the machine, a diverter valve having a first position at which fluid flow is delivered from the pump to the work tool motor and a second position at which fluid flow is delivered from the pump to the drive motor, and a controller being configured to control the diverter valve to engage the rear wheel drive assist. The machine may be operated by engaging the pump and work tool motor, and then actuating the diverter valve to the second position to divert flow from the work tool motor to the drive motor.

Owner:CATERPILLAR INC

Bale Picking Truck

Biomass may become an important source of combustible fuel in the future. For biomass, such as switchgrass, to be economically viable as a fuel, the processes required to take the plant material from a green, growing plant in the field to an energy dense package must be efficient. A self-propelled bale picking truck simplifies and speeds bale collecting, stacking, and staging for loading onto a truck for transport over the road.

Owner:KELDERMAN GARY L

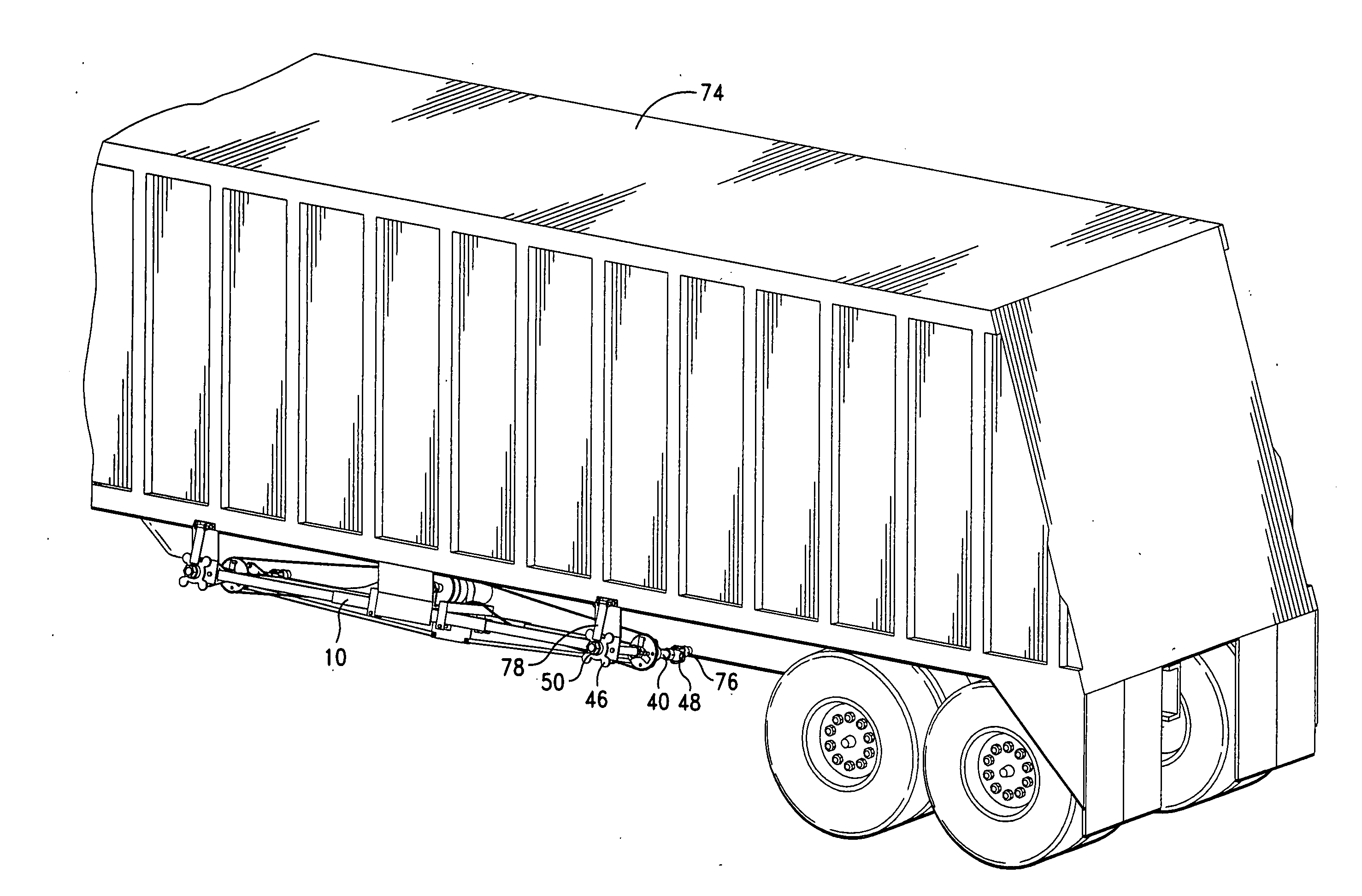

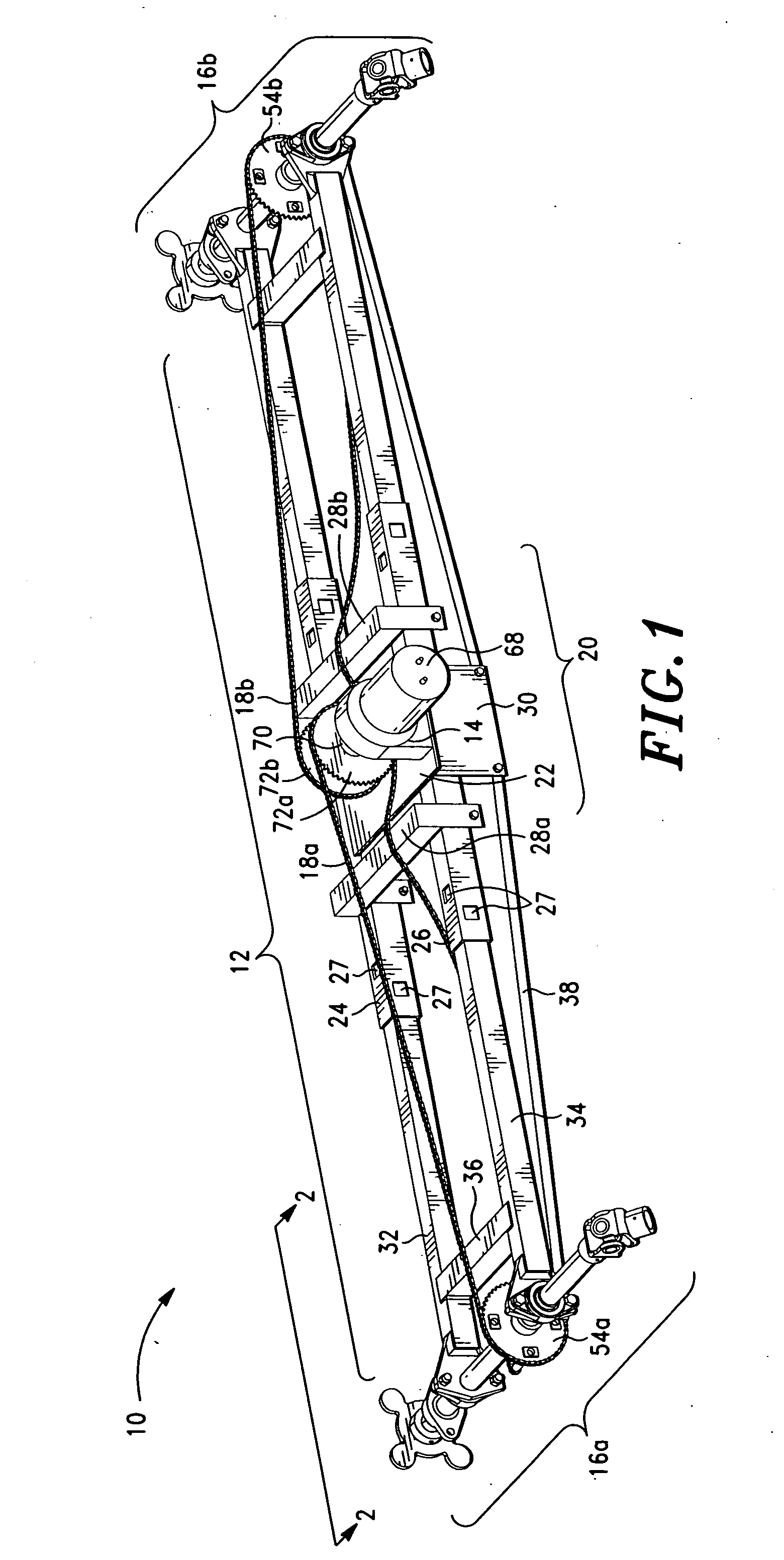

Apparatus for operating commodity trailer hopper trap doors

InactiveUS20050168047A1Simple and safe operationEliminate needHopper carsVehicle with endless chains/beltsElectric machineryEngineering

An apparatus for operating first and second commodity trailer hopper trap doors is provided that includes a support frame extending between first and second ends, first and second driveshaft assemblies attached at each end of the support frame, a motor assembly attached to the support frame, and first and second linking mechanisms coupled between the motor assembly and the first and second driveshaft assemblies such that the motor assembly is operable to move the first and second linking mechanisms and thereby rotate the first and second driveshaft assemblies, thus operating the commodity trailer hopper trap doors. Various embodiments of the apparatus are provided.

Owner:GRIER RALPH ELLIS

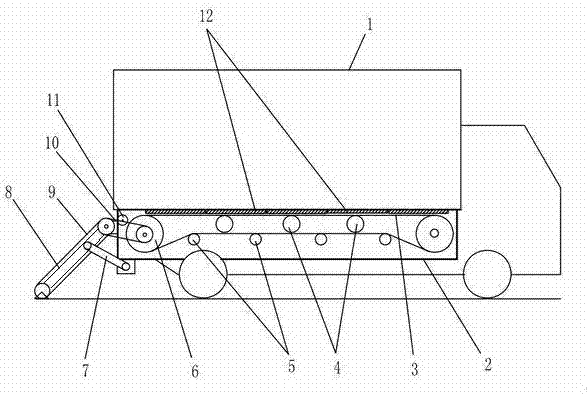

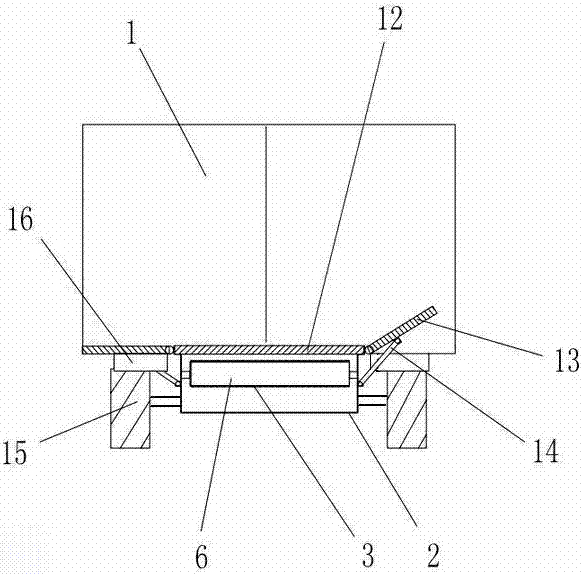

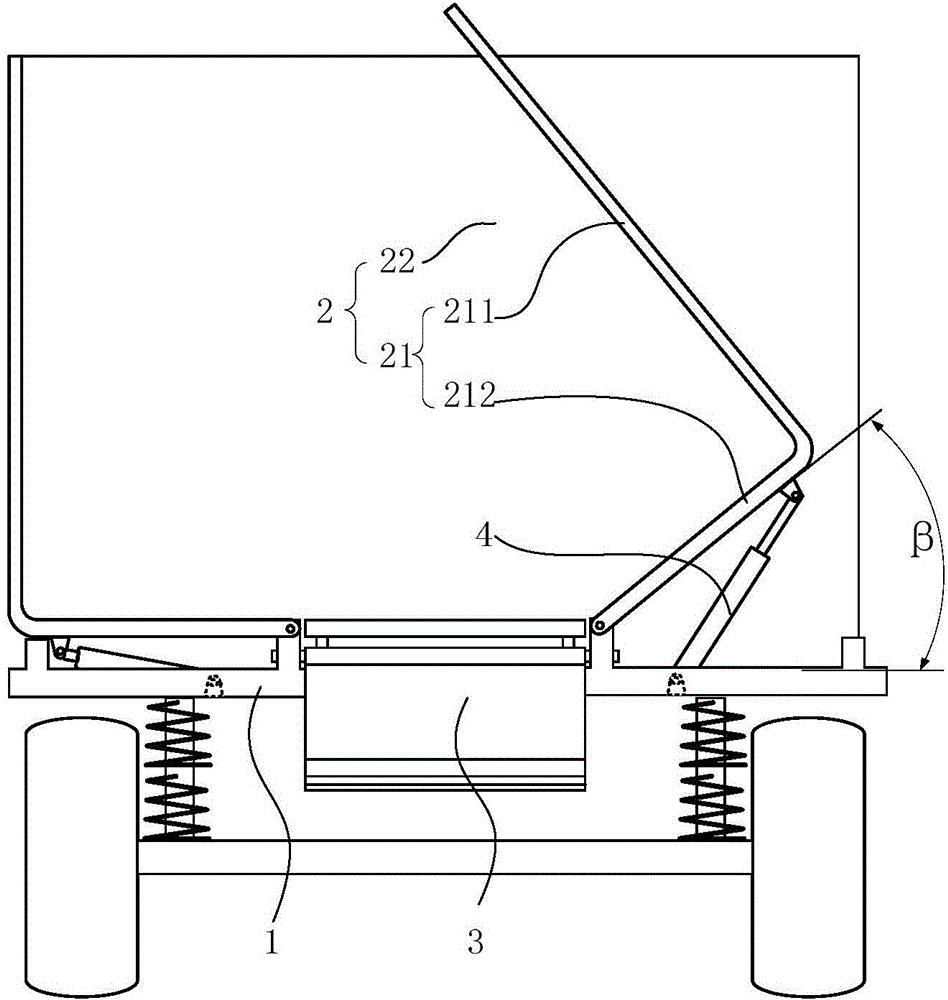

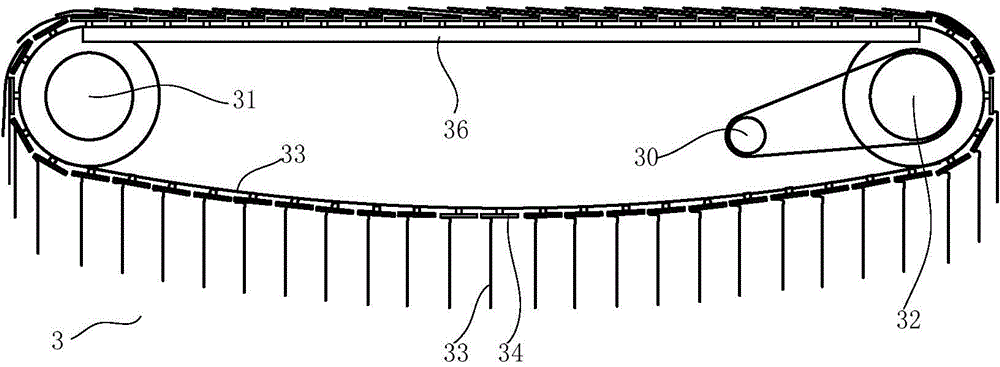

Auto-handling carriage of truck

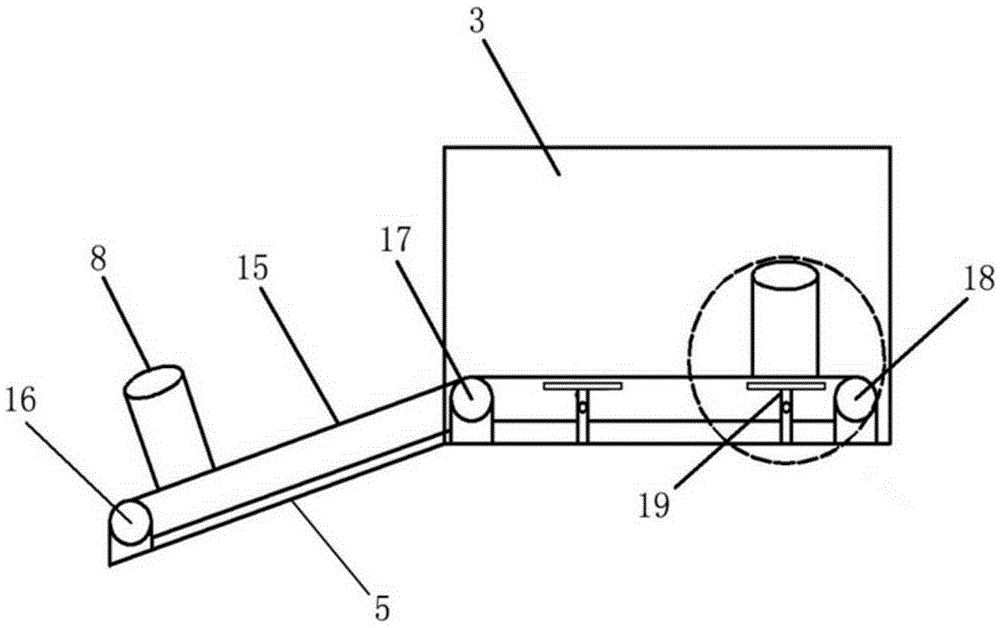

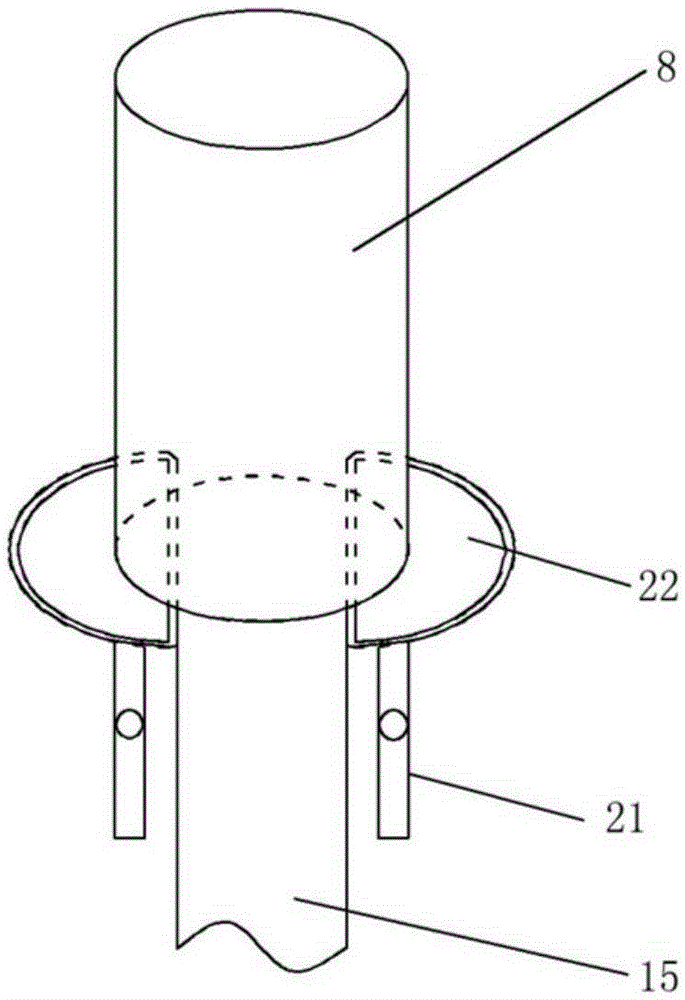

PendingCN107244278AReduce labor intensityImprove loading and unloading efficiencyVehicle with endless chains/beltsVehicle with loading rampHydraulic cylinderDrive wheel

An auto-handling carriage of a truck is characterized in that a bottom box is mounted between the bottom of a carriage body and girders, a bottom box cover plate is arranged at the open end of the bottom box, and the girders at two ends of the bottom box cover plate are connected with movable bottom plates through hinges respectively; when the movable bottom plates on two sides are horizontal, the movable bottom plates are supported by the girders, and the bottom box cover plate and the movable bottom plates in horizontal state form a carriage body bottom plate; a conveyer belt is arranged in the bottom box in front-rear direction of the carriage body and sleeves driving wheels at front and rear ends; an auxiliary goods carrier is mounted at the rear end of the carriage body, one end of the auxiliary goods carrier is fixed to the carriage body through a rotary shaft, the other end of the auxiliary goods carrier is a free end, and the auxiliary goods carrier is connected with a goods lifting hydraulic cylinder; an auxiliary conveyer belt is arranged on the auxiliary goods carrier, and a driving shaft of the auxiliary conveyer belt is connected with the driving wheels of the conveyer belt through a transmission belt. The auto-handling carriage has the advantages that by handling goods via the conveyer belt, labor intensity of people can be greatly decreased, and handling efficiency can be greatly improved; the auto-handling carriage is novel in structure and good in goods handling convenience.

Owner:郭华

Loading device for the at least partially automated loading and unloading of a cargo hold on transport equipment as well as a conveying system

InactiveUS7604204B2Reduce failure rateEasy to controlFreight handlingVehicle with endless chains/beltsEngineeringMechanical engineering

A loading device 1 for loading and unloading of a cargo hold having at least one conveying system for positioning cargo units in the area of a floor space of the cargo hold, and with at least one guiding element guiding the conveying, and a movement aid in the area of the floor space 11 of the cargo hold 5 enabling rotation and movement of the cargo unit. Sensors detect the presence of a cargo unit in the area of the conveying system without contact the position of a cargo unit on the floor space is determined in at least two spatial dimensions without contact. The sensors make it possible to control rotating movements of the cargo units in the area of the respective conveying systems by a controller.

Owner:AIRBUS OPERATIONS GMBH

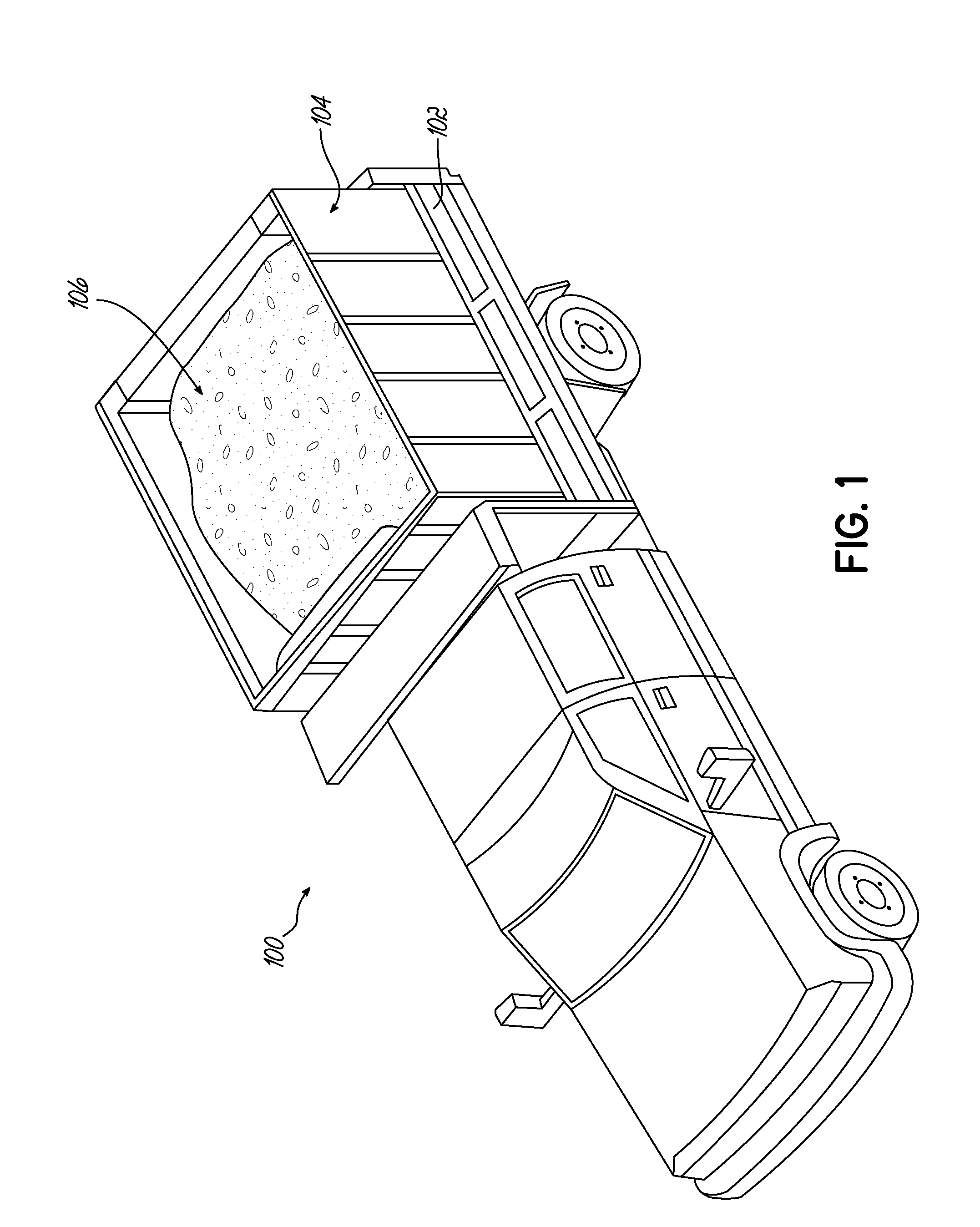

Bulk material unloading and distribution

The disclosure shows an exemplary system for unloading and distributing bulk materials. In one embodiment, a powered conveyor system including a conveyor belt is coupled with the bed of a truck. There may be one or more wings attached to the truck bed for directing the flow of a bulk material from the truck with the conveyor system. Various other embodiments implement different types of vehicles for transporting bulk material.

Owner:PARTNERS & INNOVATION

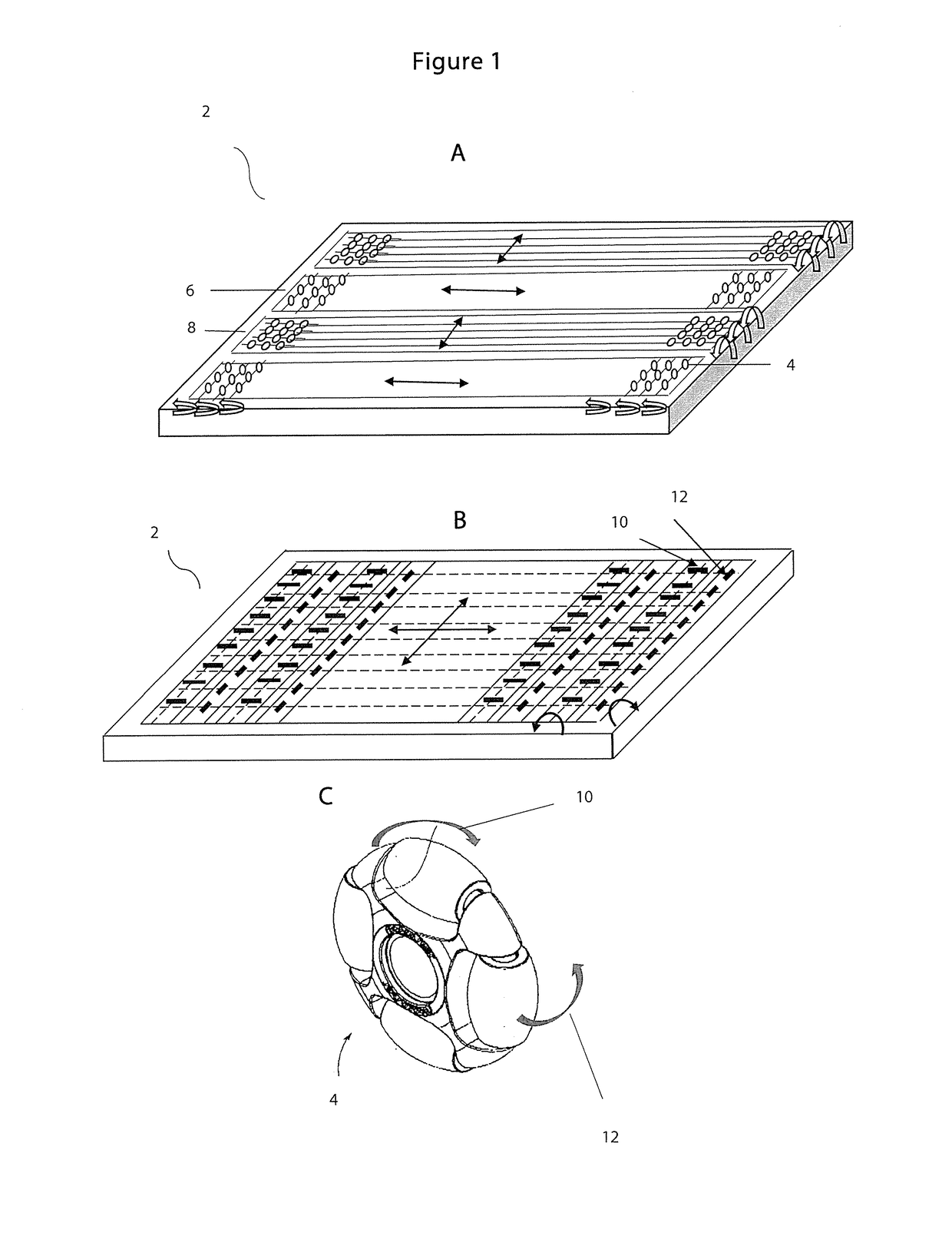

Platform for baggage cart and baggage handling system and method of using the same

The present invention relates to baggage handling systems and in particular a platform for moving baggage in multiple directions and methods of using the same with baggage carts and a baggage handling system to reduce human interaction and intervention with the baggage and for tracking of baggage.

Owner:CYCLECT ELECTRICAL ENG

Apparatus for loading and unloading aircrafts

InactiveUS6893200B2Effective controlEasy to replaceFreight handling installationsRefuse transferringMechanical engineeringAirplane

Owner:MV INVEST APS

Express carrying truck bed convenient for loading and unloading as well as automatic code scanning

InactiveCN105774624ALarge working spaceQuick loading and unloadingVehicle with endless chains/beltsTransportation itemsTruckAutomatic control

The invention discloses an express carrying truck bed convenient for loading and unloading as well as automatic code scanning. The express carrying truck bed consists of a truck bed body, a vehicle-mounted transportation mechanism, a telescopic type conveying mechanism, a control mechanism, a code scanner, a side door, side door connection members and side door supporting members, wherein upper and lower two bearing plates are arranged in the truck bed body, and the space in the truck bed can be reasonably adjusted according to carried cargoes; the side door of the truck bed can be opened and is provided with the supporting members; the telescopic type conveying mechanism is arranged on the outer edge of the side door and protrudes out of the side door of the truck bed; a pushing plate in the truck bed body can push a cargo onto the telescopic type conveying mechanism under the driving of an automatic control stepping motor transmission mechanism; the code scanner is arranged on the telescopic type conveying mechanism and is used for automatically scanning the cargo conveyed to identify and store cargo information. The express carrying truck bed realizes automatic control over express cargo loading and unloading processes, so that the cargo conveying, sorting and code scanning efficiency is greatly improved, the labor intensity of cargo loading and unloading during express transportation is effectively relieved, and the safety is improved.

Owner:XIANGTAN UNIV

Vehicle dispensing system

A flowable material delivering vehicle in combination with a material dispensing system including a fixed conveyor extending continuously from a position located adjacent a vehicle container outlet aperture to a position located adjacent a vehicle cab front end. A dispensing adapter is attached to the vehicle for receiving a portion of the flowable material when the latter emanates from the fixed conveyor. In one embodiment, the dispensing adapter includes a pivotable conveyor pivotally attached to the vehicle and a configuring mechanism. The configuring mechanism allows the pivotable conveyor to pivot between a stowed configuration wherein it lies in a generally proximal and parallel relationship relative to an edge of the vehicle and a working configuration wherein the pivotable conveyor extends away from the vehicle so as to allow discharging of the flowable material away from the vehicle. In another embodiment, the dispensing adapter includes a dispensing chute defining a chute inlet end positioned adjacent the fixed conveyor discharge section, a laterally and downwardly extending chute body and a chute outlet end positioned laterally relative to the vehicle.

Owner:YAHOO INC

Apparatus and system for facilitating loading and unloading cargo from cargo spaces of vehicles

A vehicle cargo space includes a rear lift gate moveable between opened and closed positions to allow movement of palletized containers into and out of the cargo space. The cargo space has a substantially horizontal floor with first and second sets of laterally spaced, parallel, longitudinal tracks. The tracks extend from the front to the lift gate at the rear of the cargo space. At least one set of tracks is positioned transverse to the longitudinal tracks. The tracks slidably support cargo container pallets. A system of actuators, guides and locks enable programmed movement of the pallets along the tracks into and out of the cargo space as well as within the cargo space.

Owner:JKC DEV

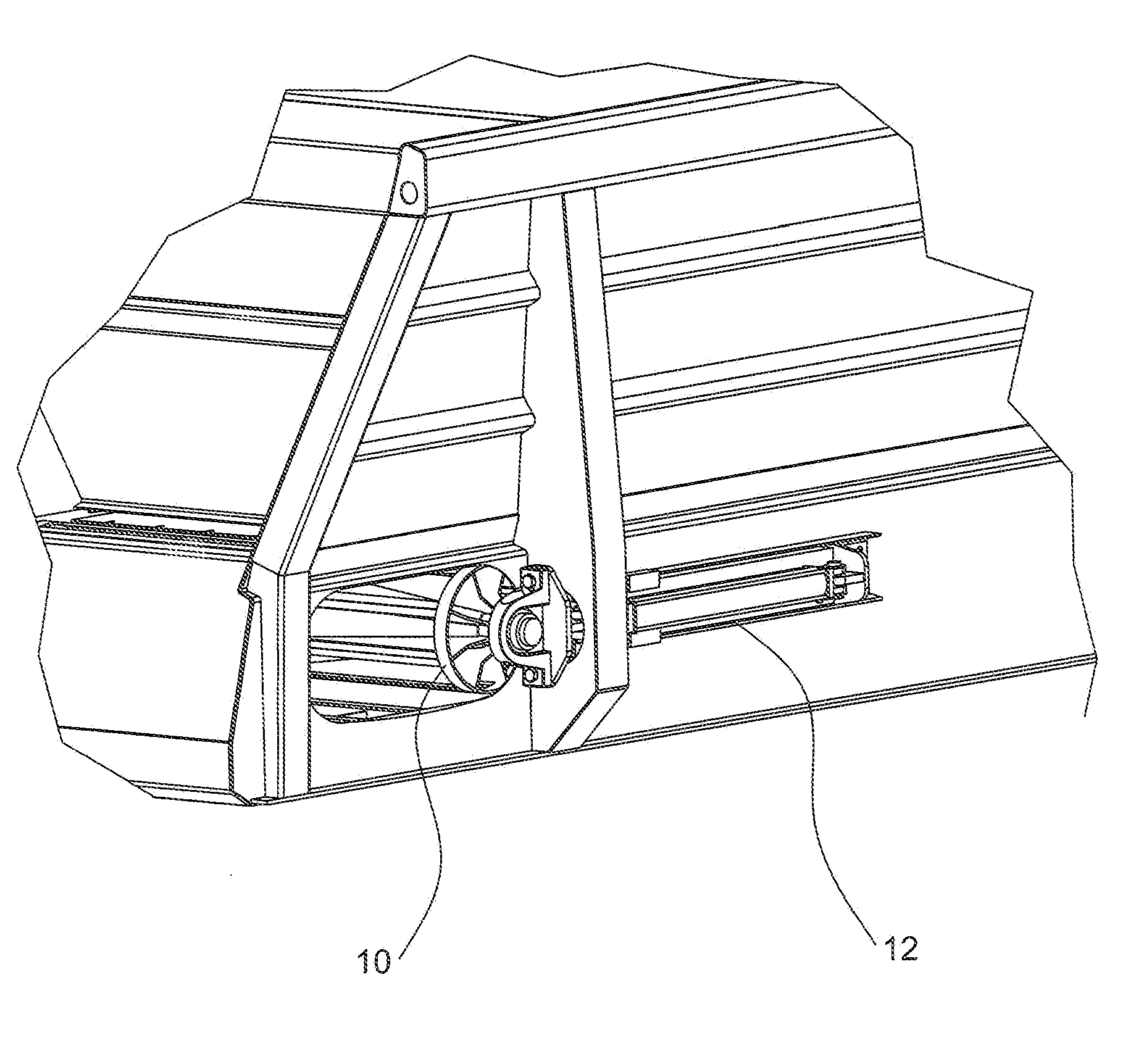

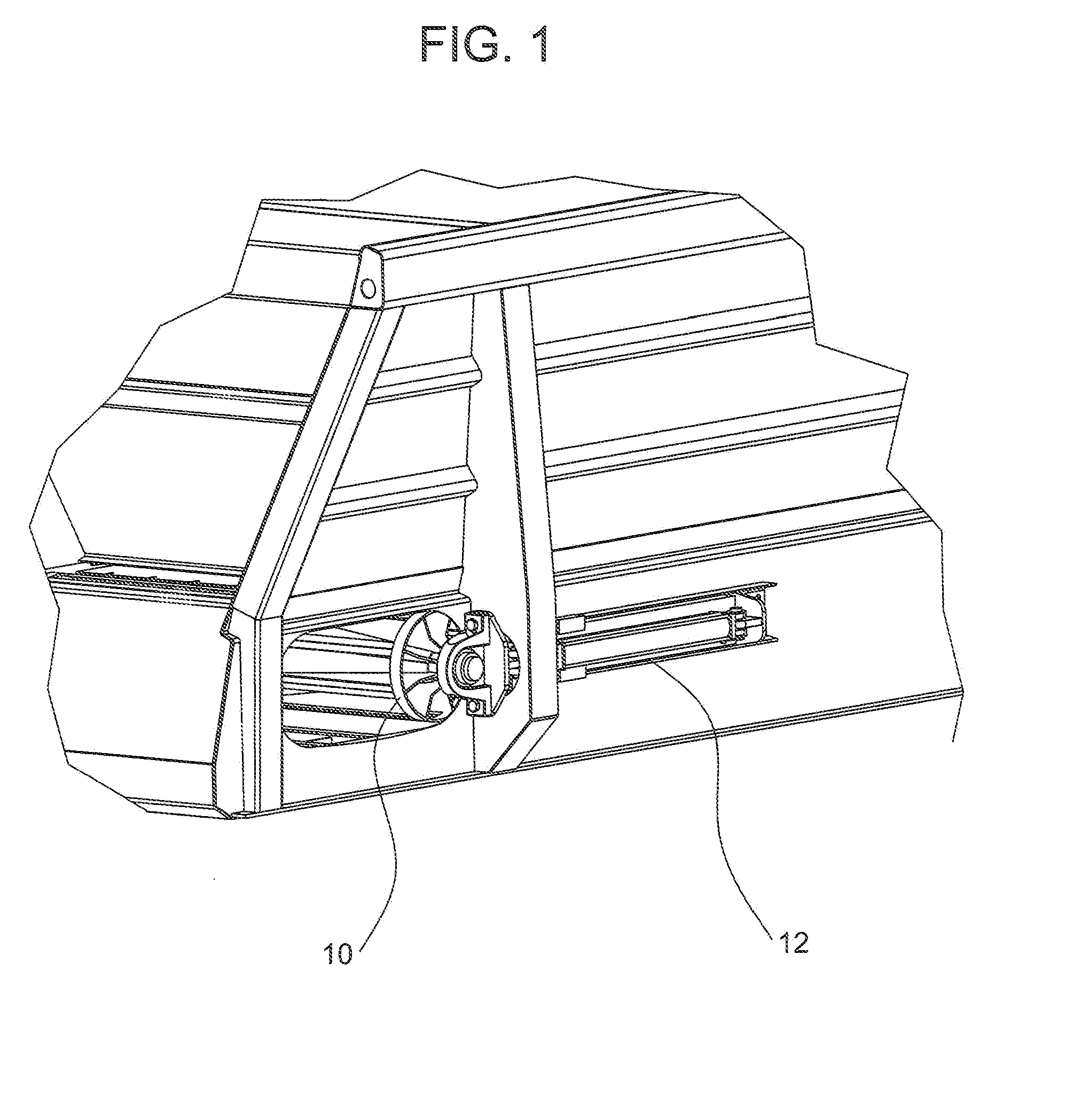

Conveyor system for vehicle

A conveyor system for a vehicle includes a belt auto-tensioning system that tensions the belt prior to belt movement but not necessarily during loading. Also included are a belt guidance system and a belt anti-slippage system. A fourth system aspect is a floating drive connection system with square or non-linear adaptor. Several benefits are obtained by using the conveyor system disclosed. Also provided are a method of using the conveyor system and a method of constructing a vehicle system combination conveyor.

Owner:HENDERSON PRODS

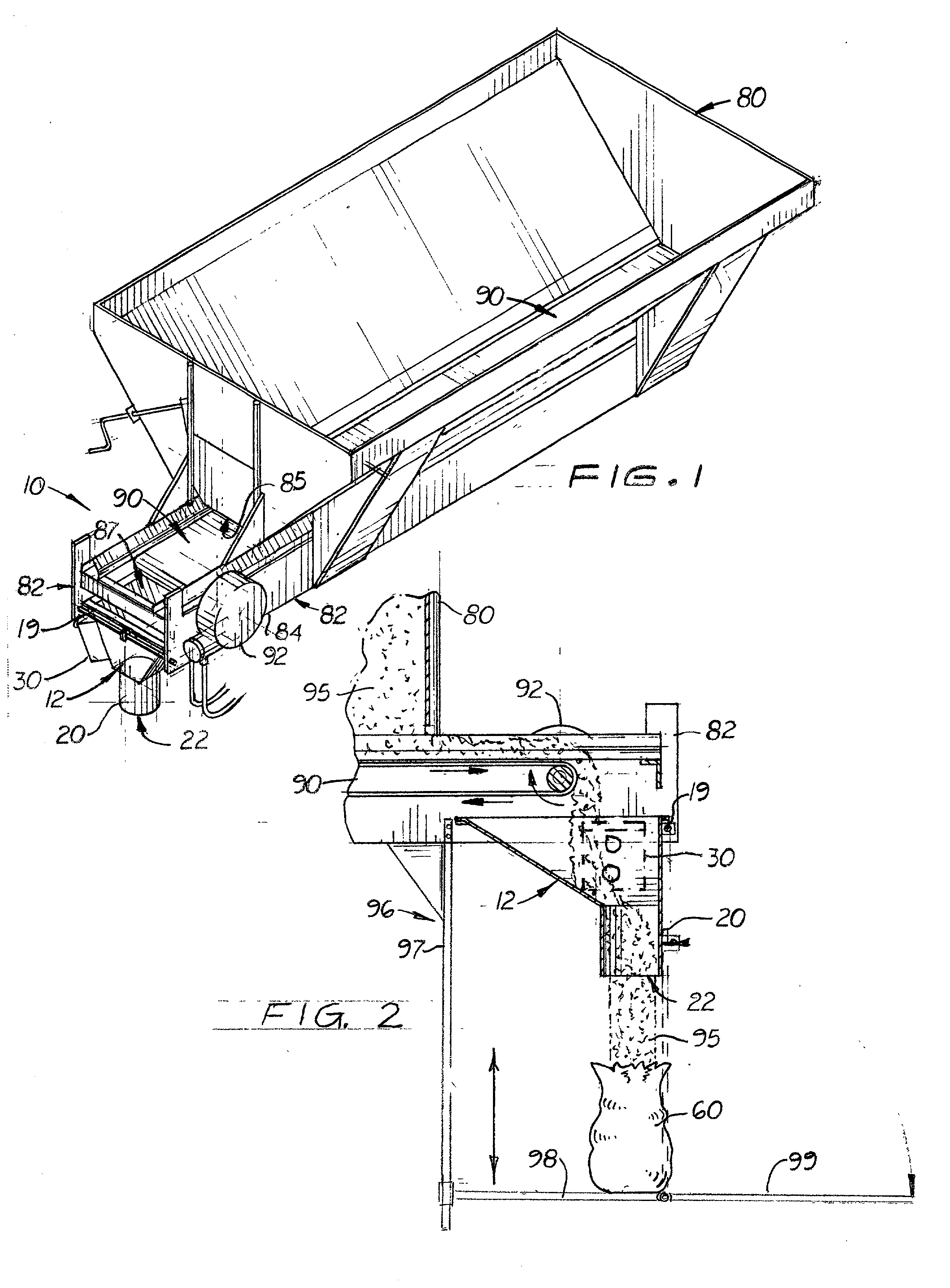

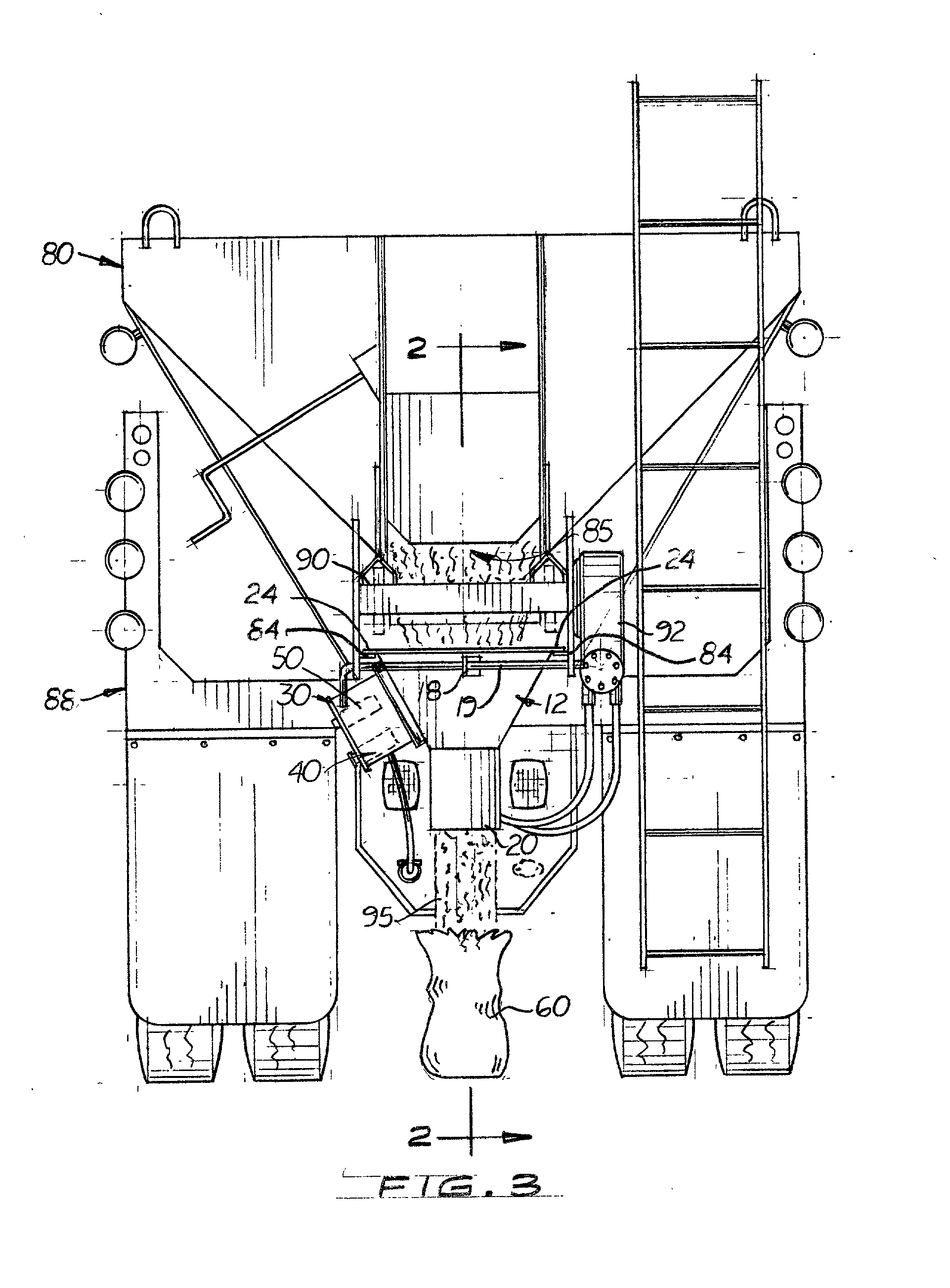

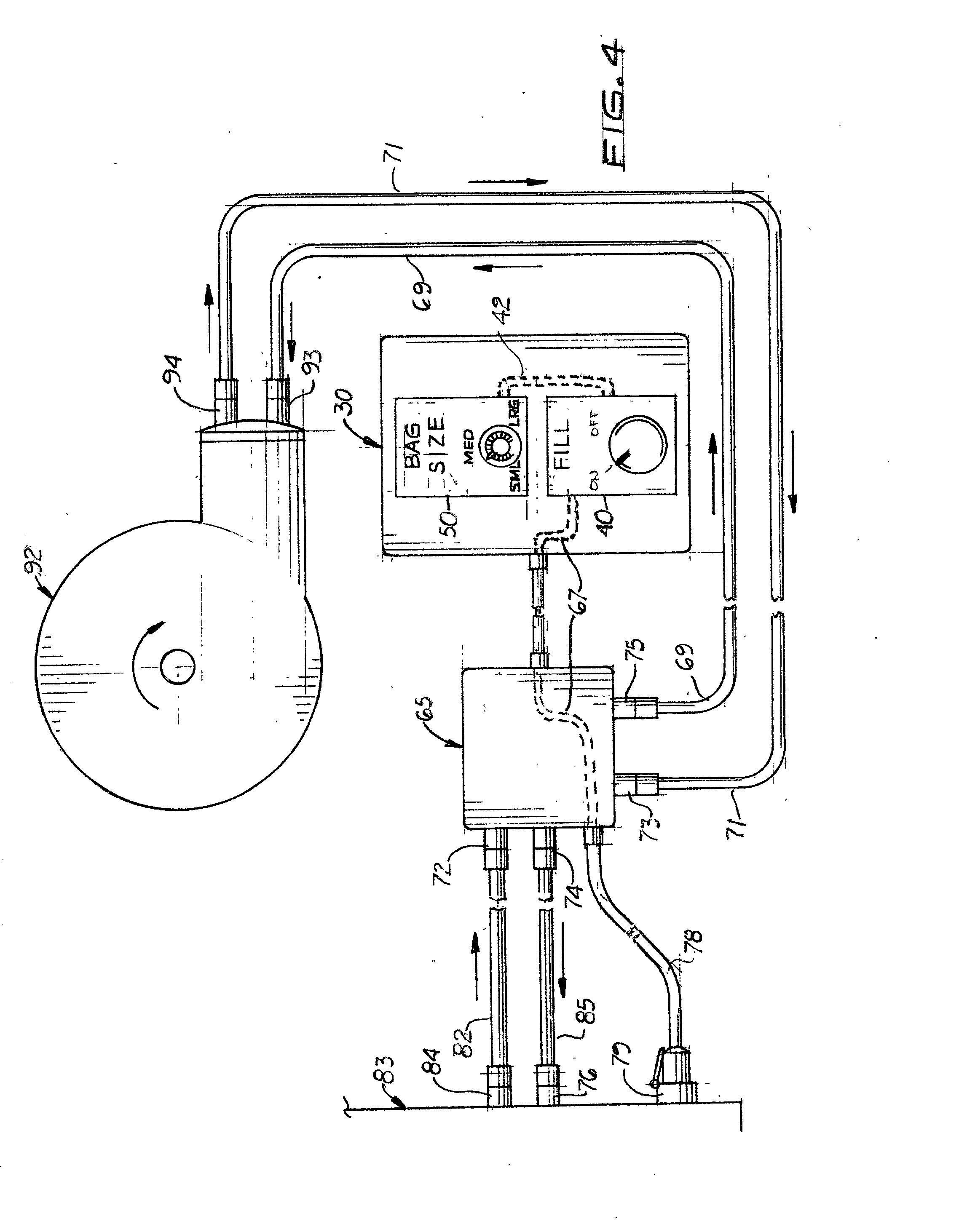

Sanding truck sandbagging apparatus

A sandbagging manufacturing apparatus designed to be used with standard sanding trucks normally used with a broadcast spreader. The truck includes a large hopper with a hydraulically controlled conveyor belt located longitudinally inside the large hopper that delivers sand to a rear opening. Located below the rear opening is rigid framework used to hold the broadcast spreader. The apparatus includes a small hopper selectively attached to the framework below the hopper's rear opening. The small hopper is designed to slide into brackets formed on the framework so that the small hopper and broadcast spreader may be easily exchanged. A vertically aligned chute is attached to the small hopper through which sand falls to fill sandbags. The apparatus also includes a control box designed to control the operation of the conveyor belt. Located in the control box is an adjustable electric timer that controls the length of time the conveyor belt is activated which, in turn, controls the amount of sand delivered to the hopper's rear opening area. A main on-off switch is provided on the outside surface of the control box, which controls activation of the conveyor belt and the timer.

Owner:MALONE MORRIS J +2

Movable power transmission network transformer maintenance station

InactiveCN105291940APrecise positioningRealize automatic deliveryItem transportation vehiclesVehicle with endless chains/beltsTransformerDiesel generator

A movable power transmission network transformer maintenance station comprises a traction part, an overhaul tool and instrument compartment and an oil tank compartment, wherein an oil tank conveying and positioning device is arranged in the oil tank compartment and can achieve automatic conveying and accurate positioning of an oil tank. In addition, the space utilization rate of the compartments can be maximized while necessary tools and instruments for maintenance of a power transmission network transformer are provided by reasonably arranging the positions and structures of a hydraulic oil station, a diesel generator, a storage battery, a special tool stepped cabinet, a common tool cabinet and an elevator for aerial operation. Multi-functionalization of the maintenance station is achieved by applying a fingerprint identifier, an electronic cipherer, a solar thermal collector and other modernized means. The novel movable power transmission network transformer maintenance station can meet the demand for remote transformer maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Novel intelligent express delivery vehicle

ActiveCN106515542AItem transportation vehiclesVehicle with endless chains/beltsDelivery vehicleEngineering

The present invention discloses a novel intelligent express delivery vehicle which can classify, and load and unload expresses in advance according to the size and the delivery address. The novel intelligent express delivery vehicle comprises a small express storage area, a large express storage area, a loading and unloading device and a control device. The purposes of standardized delivery, and efficient loading and unloading are realized. A compartment is divided into different zones, different expresses are arranged at different storage zones, thus the space utility rate of the compartment is greatly improved, and the waste of human resources is decreased. The expresses stacked in disorder originally are arranged in an orderly manner according to the size and the delivery address, an expansion partition storage portion, a large express storage portion and a retractable storage table portion are designed for irregular expresses, a multi-purpose door is designed for the different zones used for storing different expresses, the loading and unloading device is designed for relatively heavy expresses, intelligentization is realized through control and analysis of the control device by combining a sensor, and higher convenience and humanization are realized.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Conveyor system

A conveyor system for loading pallets into and out of a vehicle comprises an accumulating conveyor and an airbag rail. The accumulating conveyor is constituted by a pair of chain rails for supporting and conveying pallets into and out of a vehicle. The airbag rail is positioned between the chain rails and adjacent to one of the chain rails. The airbag rail is constituted by a base beam, a lift beam and an airbag positioned between the two beams. The arrangement is such that, with the chain rails and the base beam fixed to the floor of a vehicle, the airbag can be inflated to raise the lift beam so as to lift an edge portion of a pallet supported by the two chain rails out of contact with said one chain rail.

Owner:AUTOMATION CONVEYORS

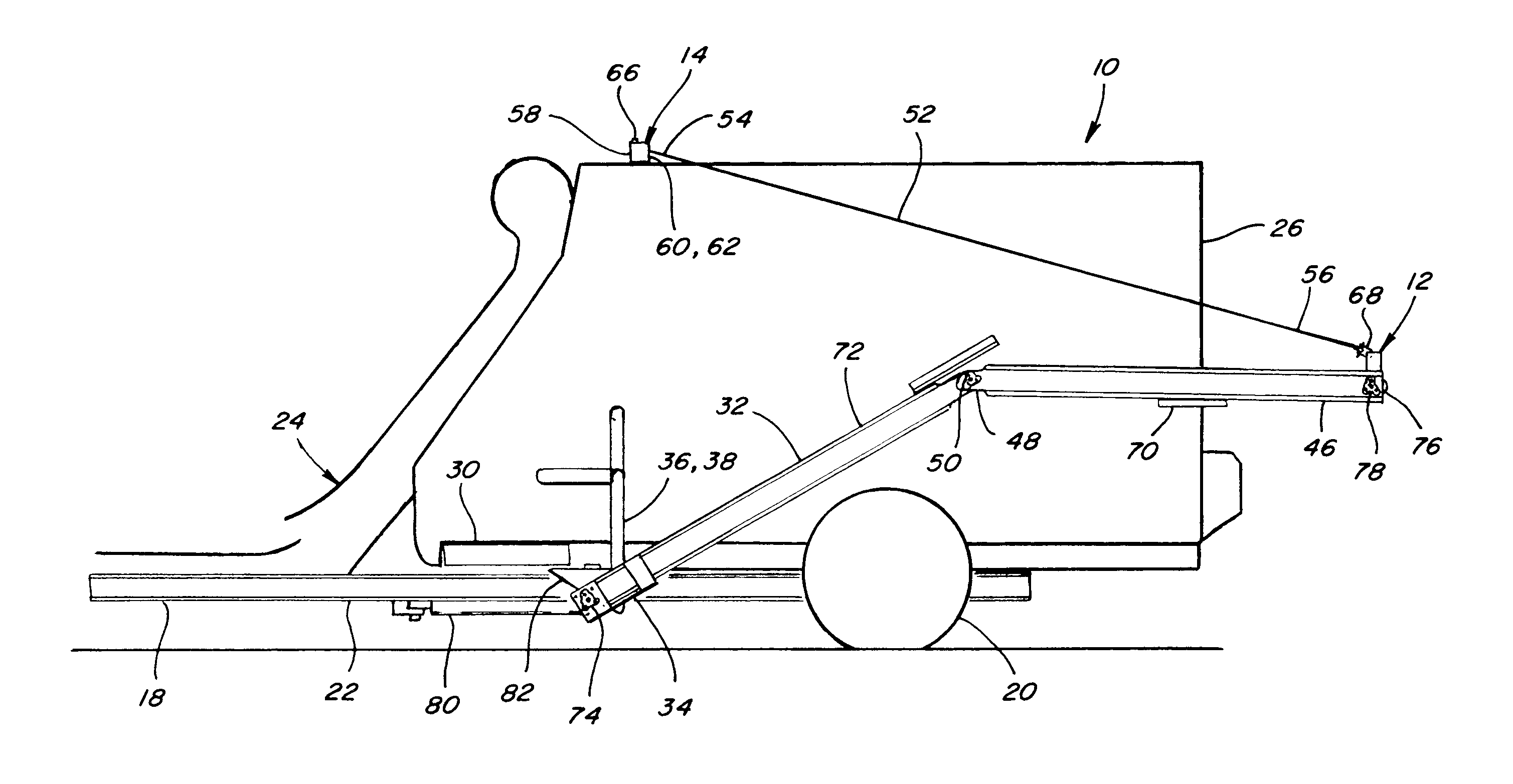

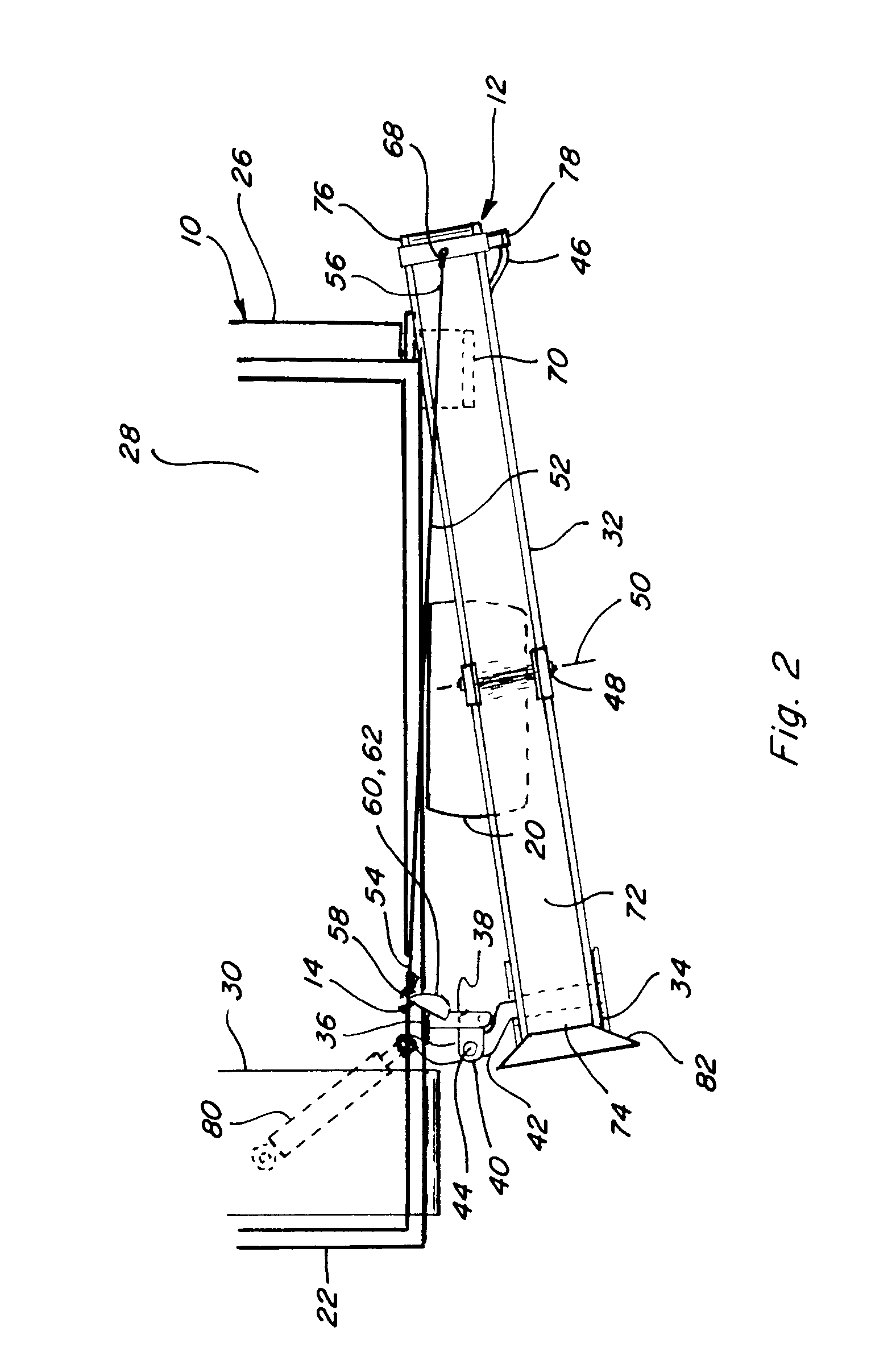

Unloader system with cam operated raise system

The unloader system has a conveyor and a raise system having an elongate support element including a flexible first end portion and an opposite second end, the first end portion being connected to a support structure at a location higher than a first end of the conveyor, and the second end being connected to the conveyor at a location therealong adjacent to a free end thereof. A cam element is disposed on the support structure in a path of movement of the flexible first end portion of the support element such that as the conveyor is pivoted from the stored position toward the operating position the flexible first end portion will conformingly engage or bend about the cam element to raise the free end of the conveyor. The conveyor can include an elbow which is straightened by this action for raising the free end.

Owner:BLUE LEAF I P INC

Novel self-dumping tractor-semitrailer

ActiveCN103950402AIncreased payload capacityLow costVehicle with endless chains/beltsVehicle with tipping movementHydraulic motorVehicle frame

The invention relates to transport equipment, in particular to a tractor-semitrailer with a dumping device. The tractor-semitrailer comprises a frame 1, a compartment arranged on the frame and the dumping device, wherein the dumping device comprises a driven chain wheel and a driving chain wheel arranged on the front and rear ends of the frame, a hydraulic motor connected with the driving chain wheel, and two drive chains surrounding the driven chain wheel and the driving chain wheel. The tractor-semitrailer is different from the traditional technology in that outer plates of the drive chains are divided into two kinds, namely conventional outer plates and special-shaped outer plates, more than one conventional outer plate is arranged between two special-shaped outer plates, circumferential outer circles of rollers of the chains protrude out of the upper and lower edges of inner plates or the conventional outer plates, plate lugs with outer planes higher than the circumferential outer circles of the rollers are arranged on the special-shaped outer plates, a supporting plate is fixed on each plate lug, a rubber track is fixed on each supporting plate, and two guide rails fixed on the frame are used for supporting the rollers. Compared with the prior art, supporting rolls are abandoned by the invention, the structure is simplified, and the manufacturing cost is reduced.

Owner:烟台恒驰挂车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com