Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

287results about "Machines/dredgers working methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the excavation of buried waste

ActiveUS7114880B2Preventing particulate emissionMachines/dredgers working methodsFouling preventionRadioactive contaminationEnvironmental engineering

Disclosed is a method of excavating large quantities of non-homogenous radioactive contaminated waste, desirably without releasing radioactive contaminated dust or exposing personnel to its hazards. The excavation of buried waste is performed in the presence of a suppression fluid that coats the waste and captures and retains particles so that they do not become airborne. Use of this suppression fluid technique allows larger mechanized excavation equipment to be used to perform the work. This keeps workers away from the waste. The waste is excavated and placed inside large steel boxes, such as a roll-off box, by the excavator. The suppression fluid covers the waste in the boxes and prevents particulate emissions from the waste.

Owner:CARTER JR ERNEST E

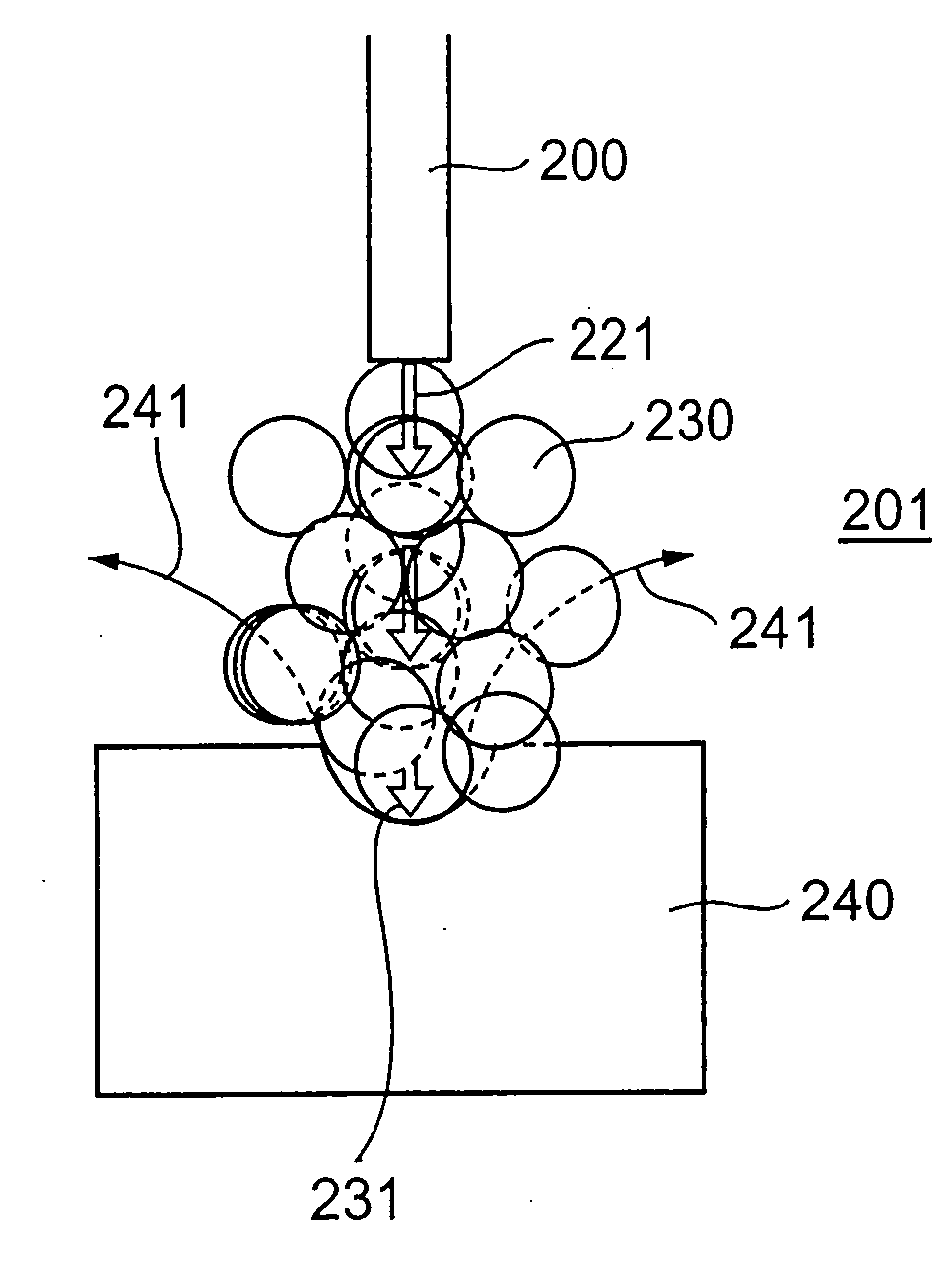

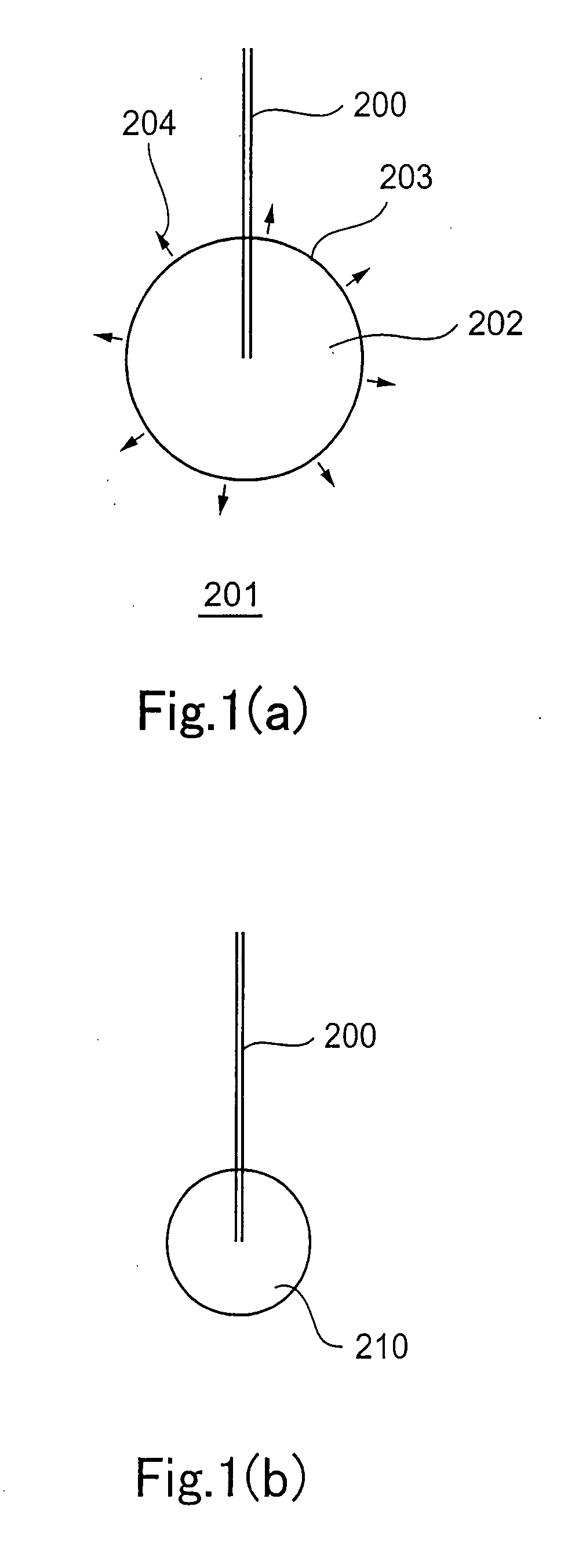

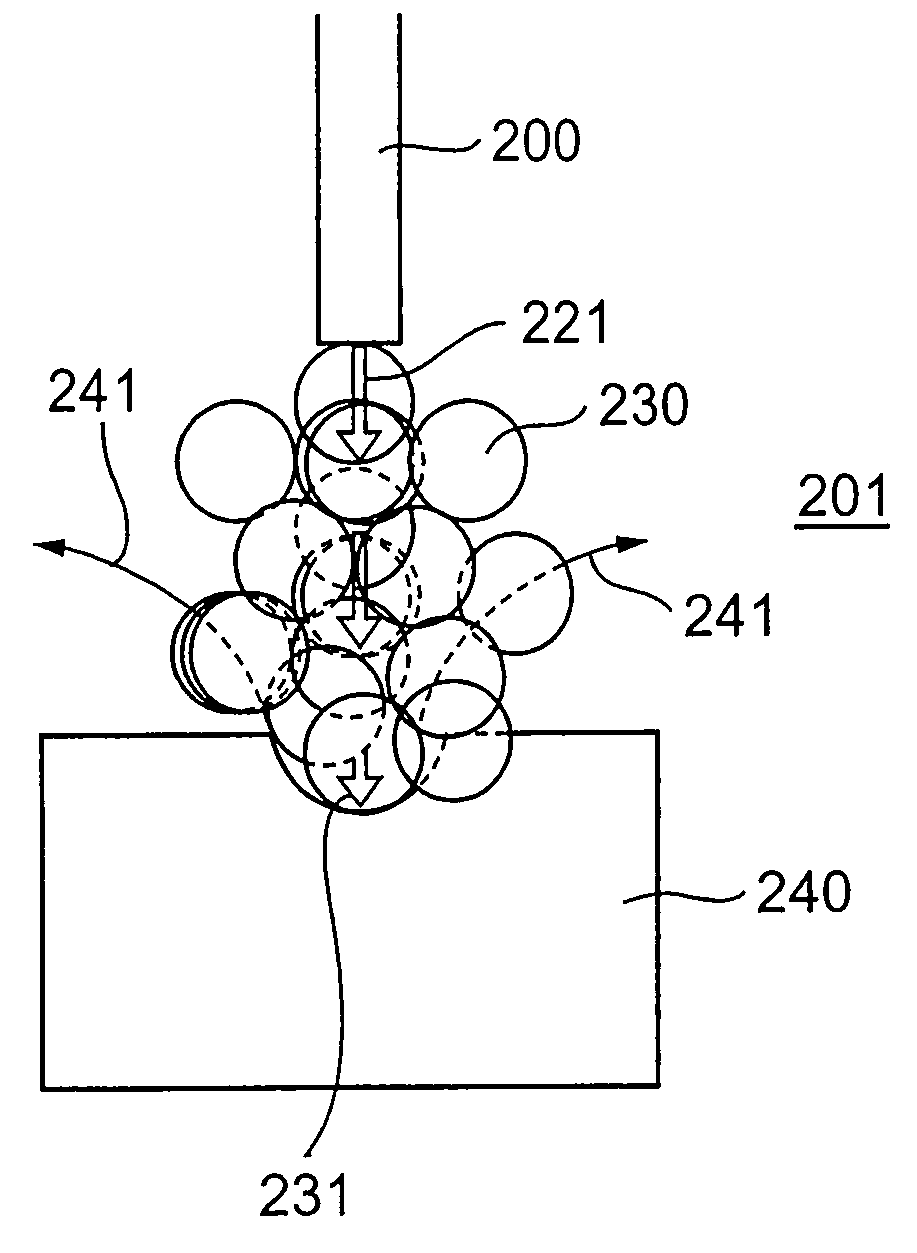

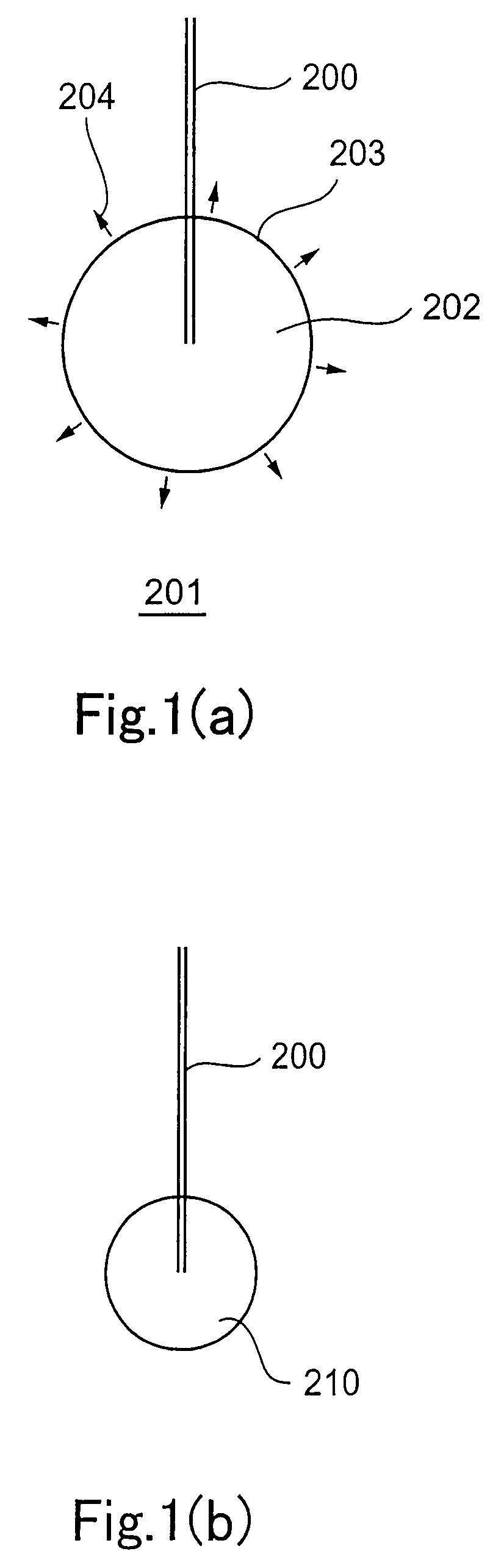

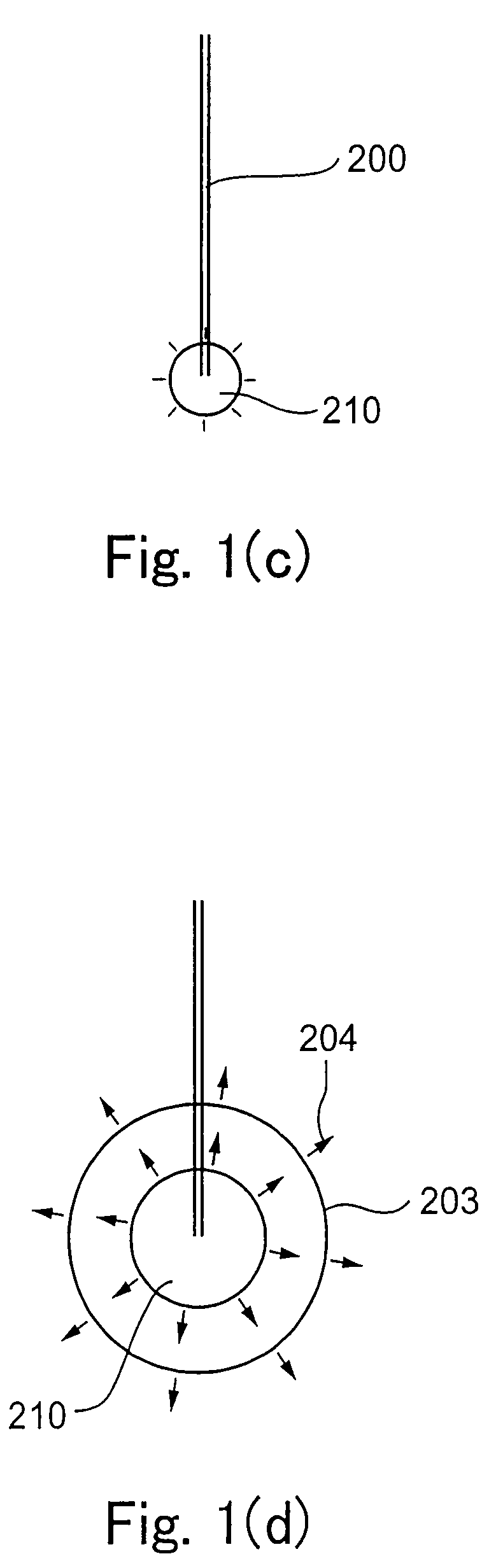

Method and device for excavating submerged stratum

InactiveUS20090126235A1Reduce energy transferReduce loadMachines/dredgers working methodsMechanical machines/dredgersAbsorptanceLaser induced bubble

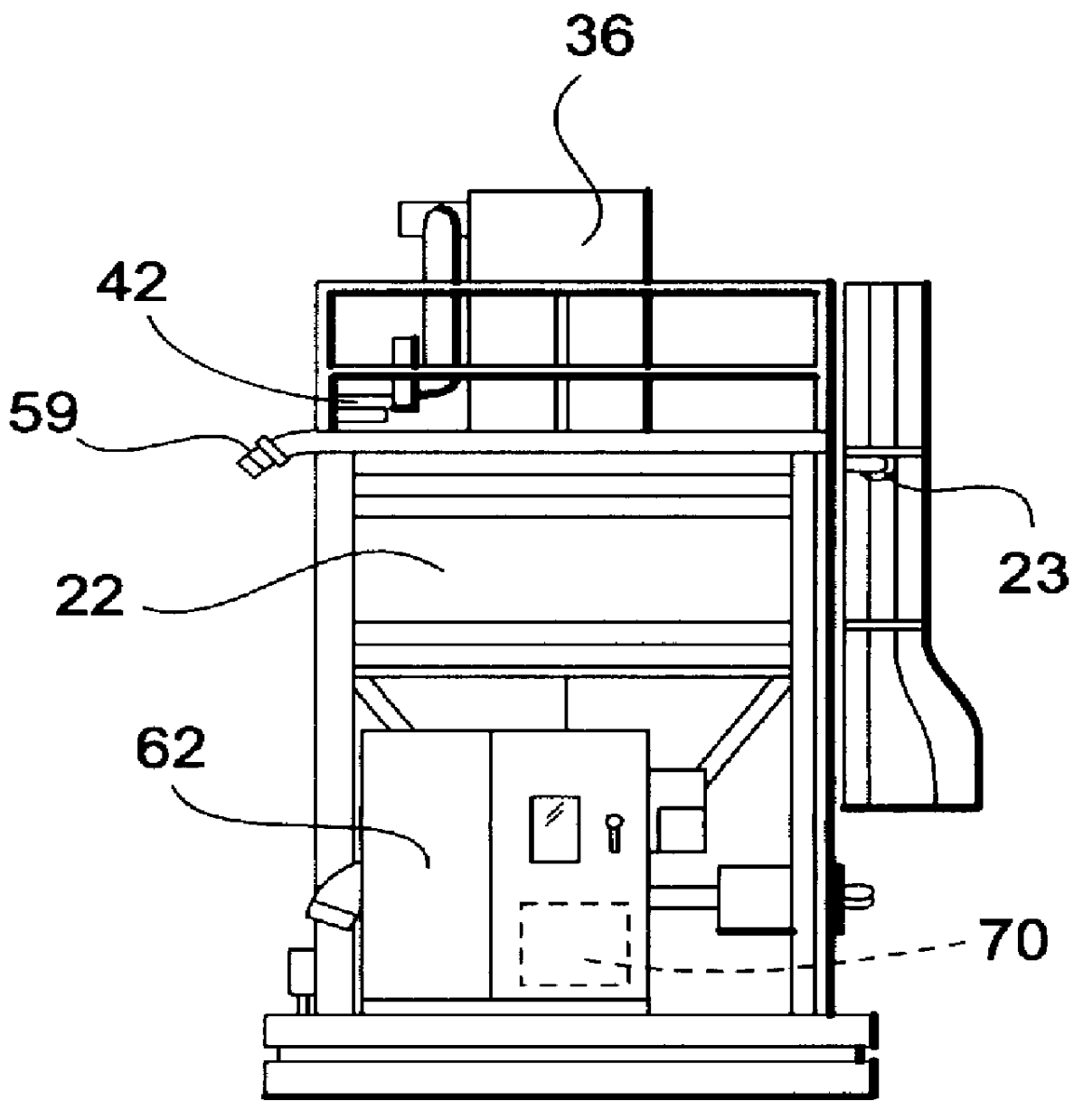

An excavation technique for a stratum capable of excavating a submerged stratum such as a layer containing an underground resource by using laser irradiation in liquid is provided. In this technique, a laser beam transmitted through laser transmission means 20 is irradiated in liquid 90 in form of a laser beam having a wavelength with high absorptance of the liquid 90 by laser-induced bubble generation means 35, generating a bubble flow 36, thus excavation of a submerged stratum may be carried out by using a laser-induced destruction effect. Moreover, a laser beam 41 having low absorptance of the liquid 90 is irradiated by laser irradiation means 39 and passed through the bubble flow 36, thereby applying a thermal effect to a stratum to destroy rock and excavate the stratum. The destruction effect and the thermal effect also may be cooperatively worked.

Owner:JAPAN DRILLING CO LTD +2

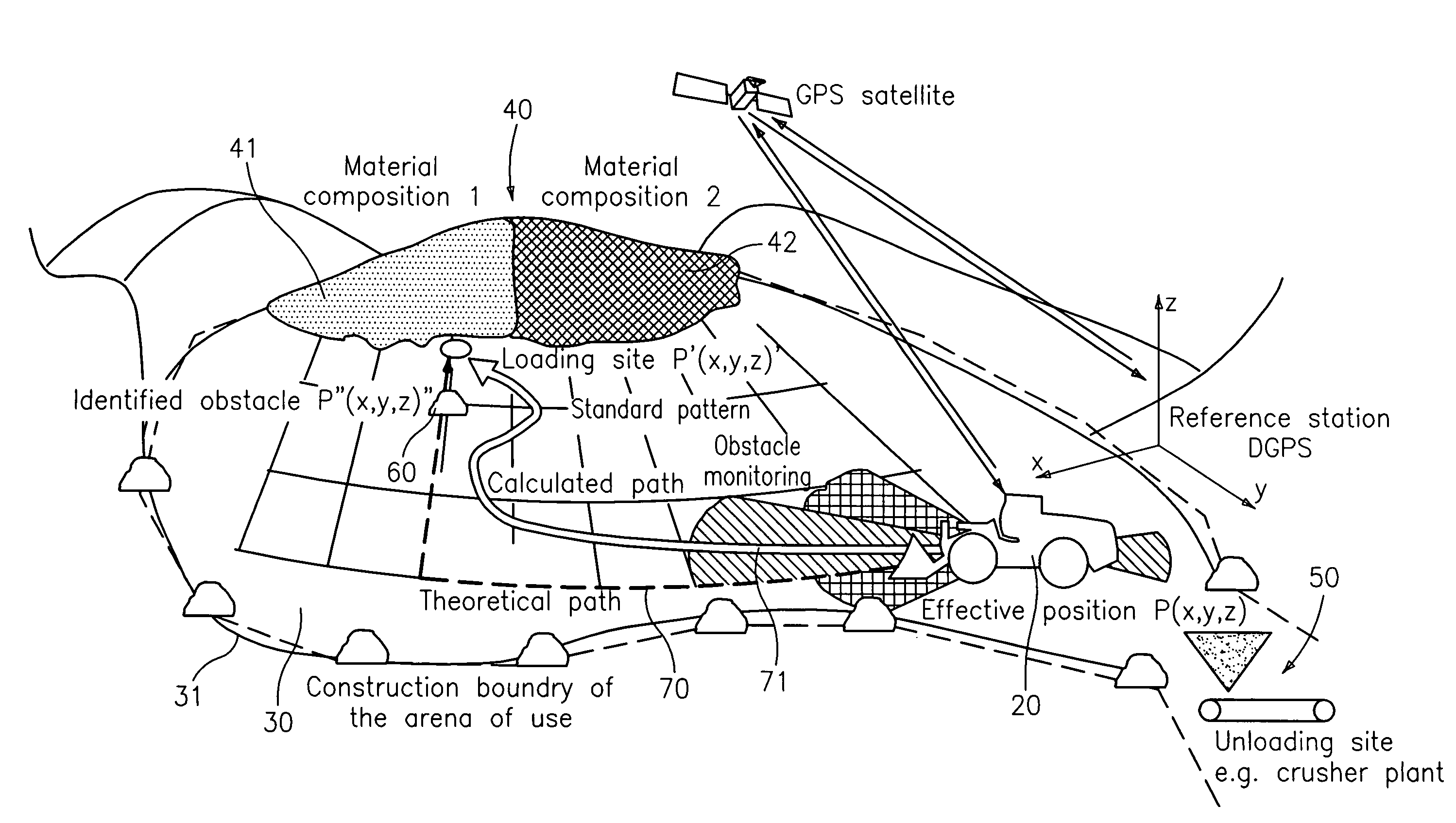

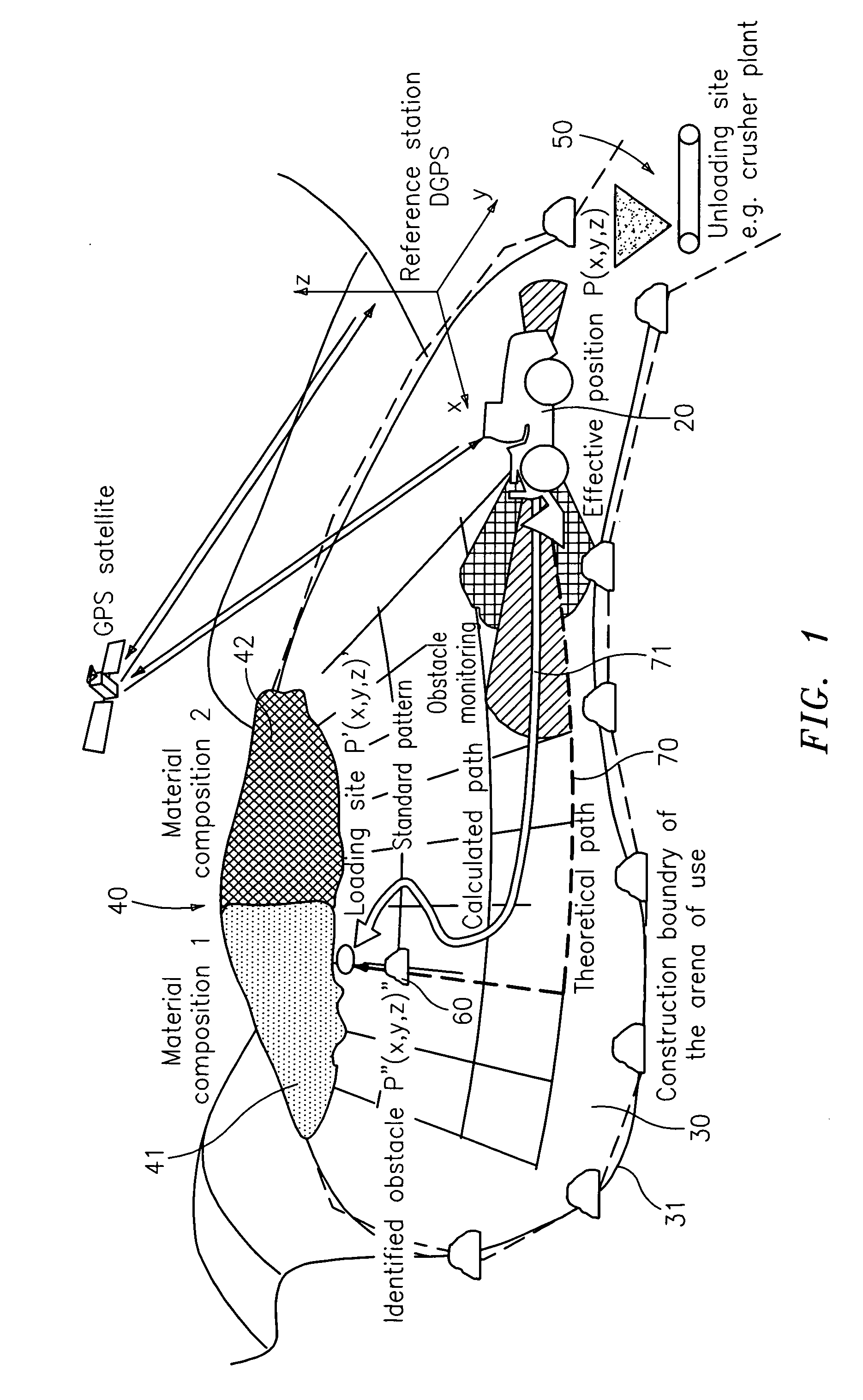

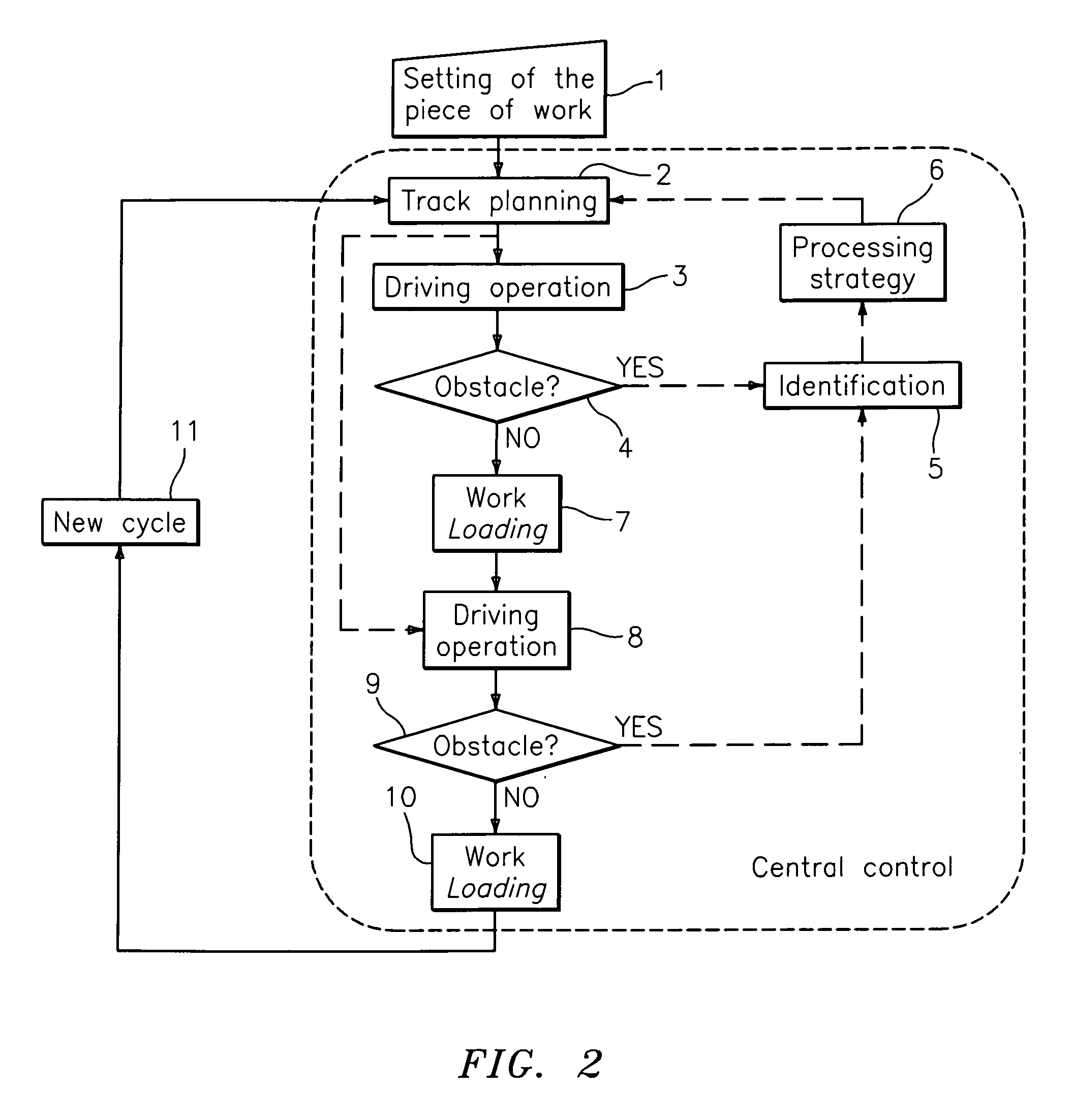

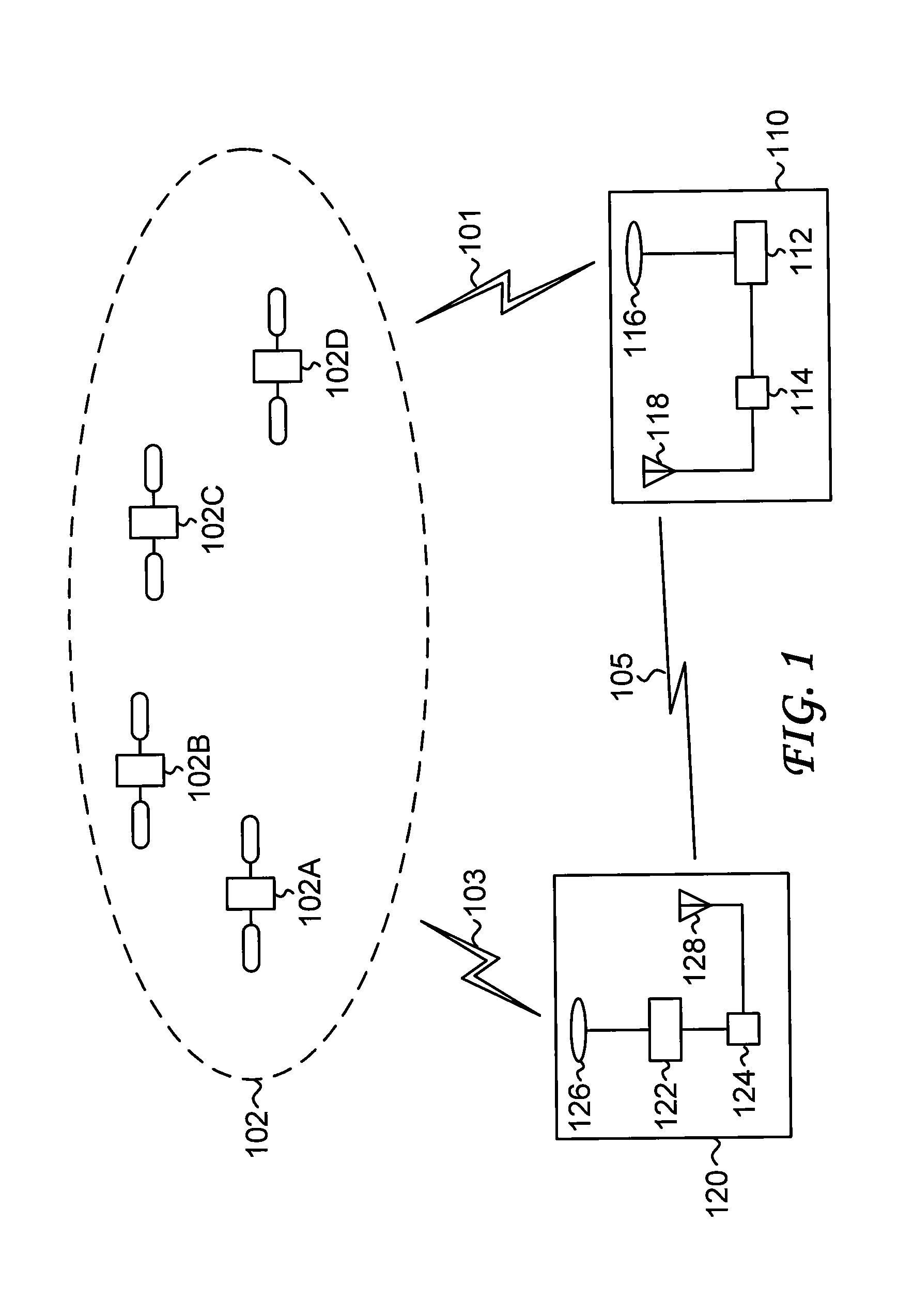

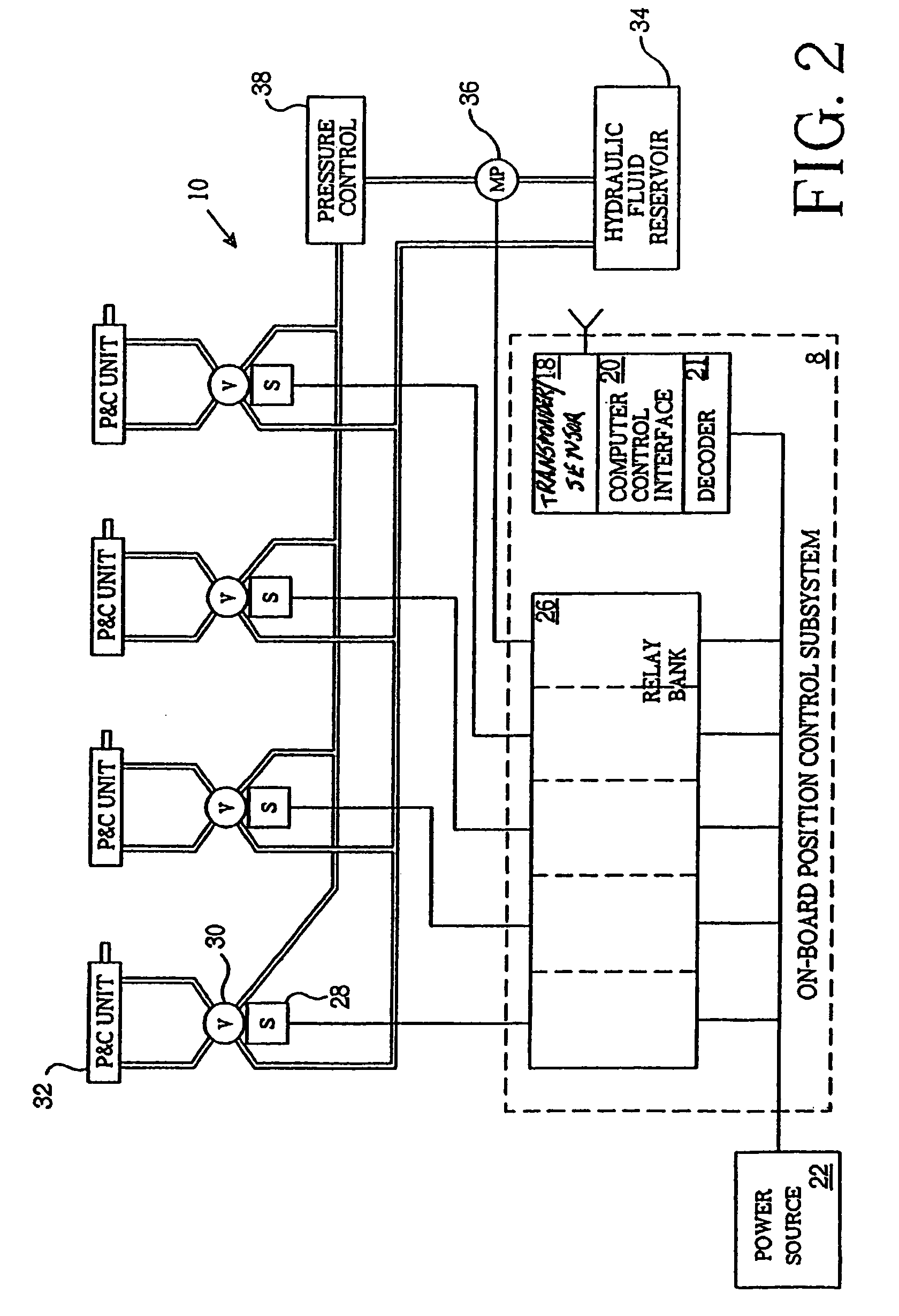

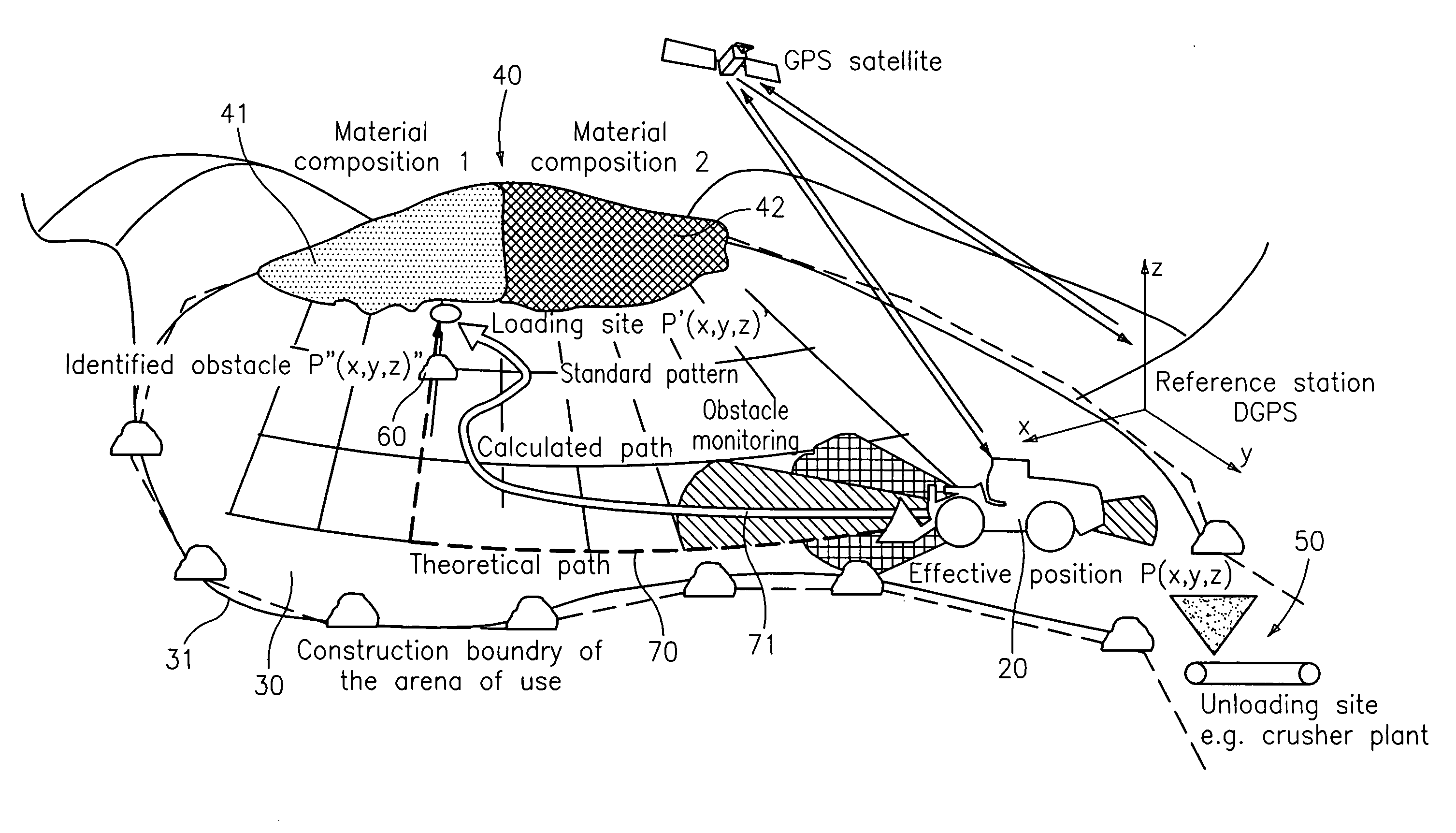

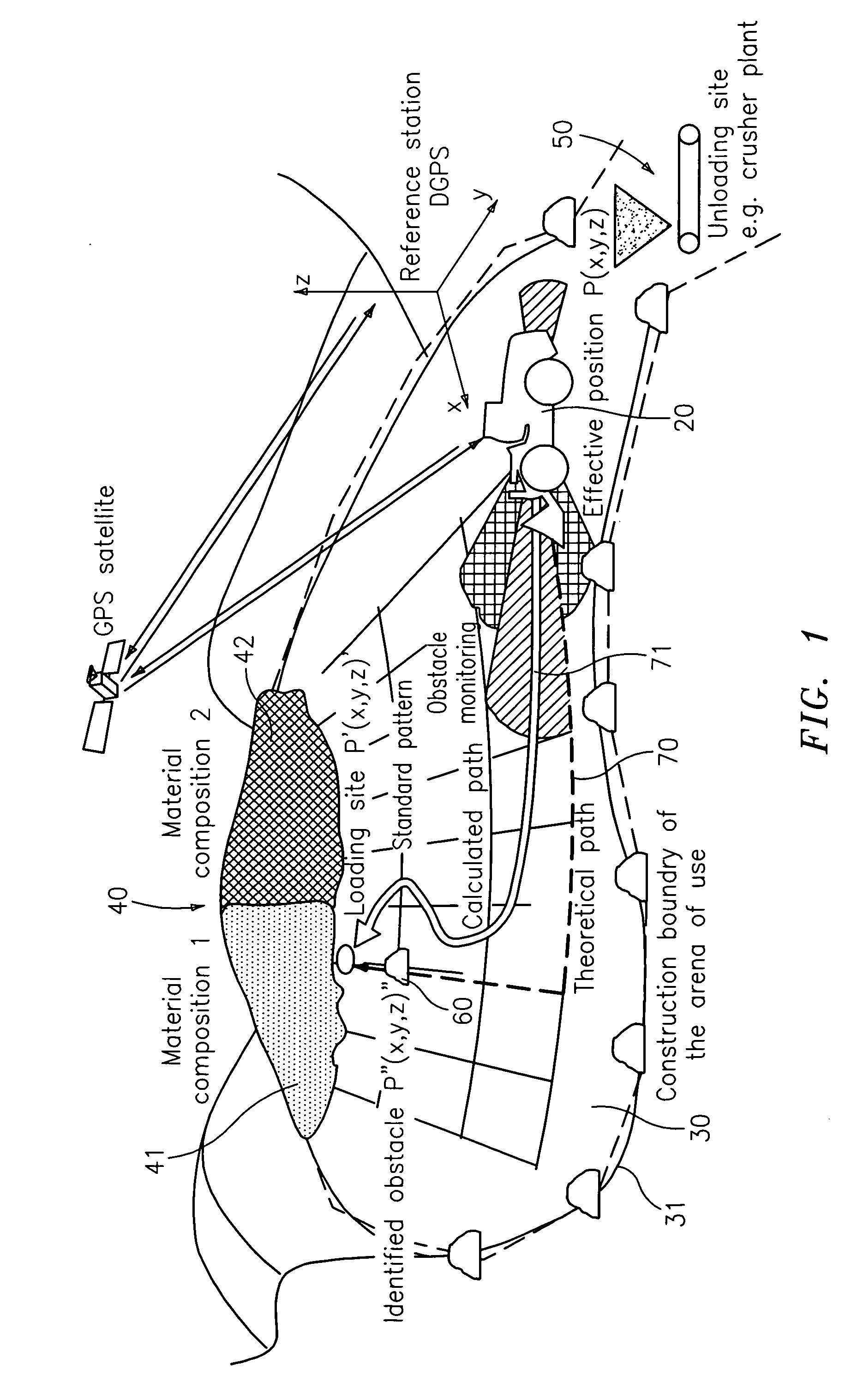

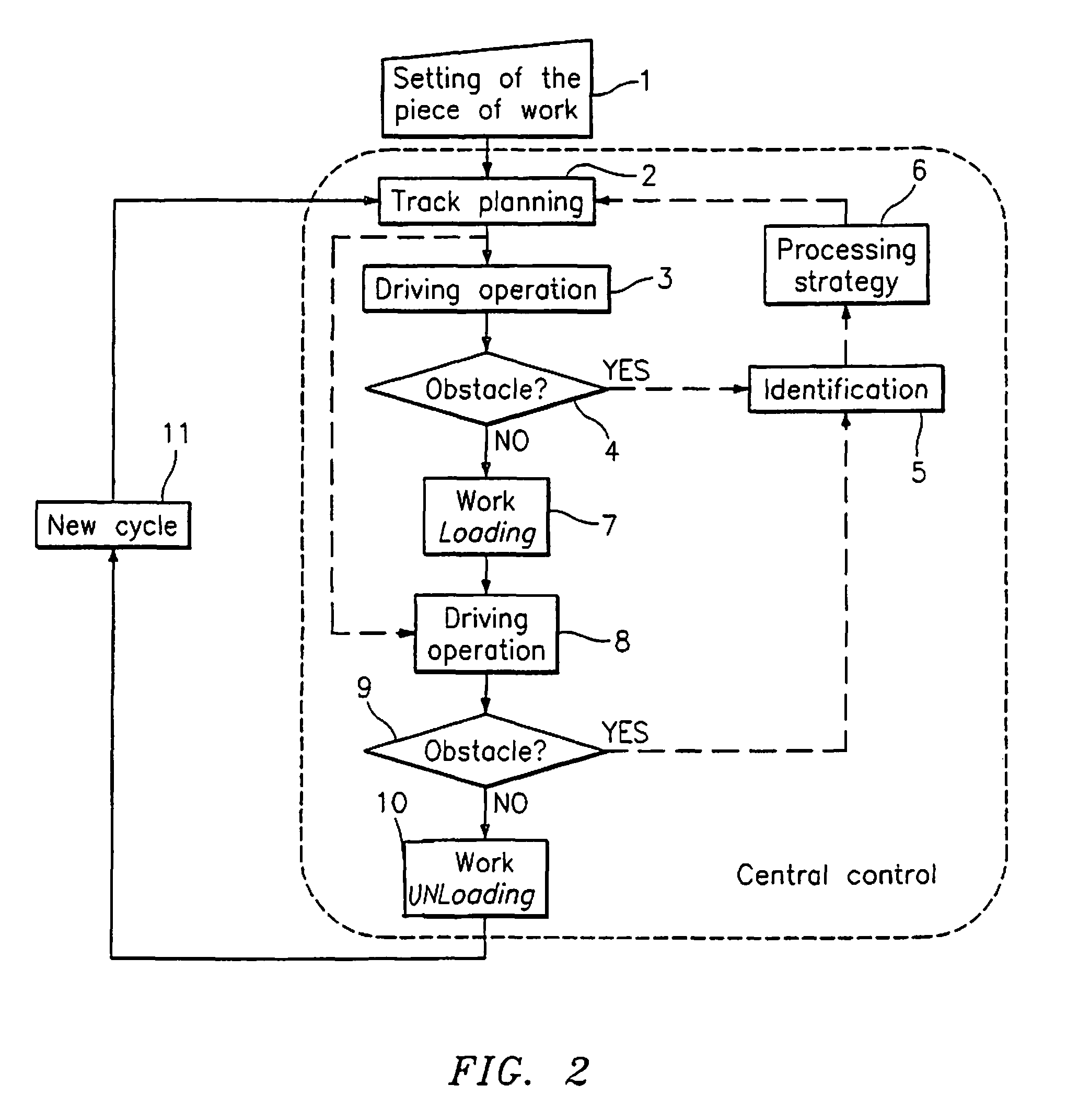

System for the automatic movement of material

InactiveUS20090076674A1Guaranteed automatic operationMachines/dredgers working methodsDigital data processing detailsEngineeringMobile device

The present invention relates to a system for the automatic movement of material in a working area comprising at least one movable piece of equipment, wherein the system has a control for the automatic movement of the piece of equipment with an automatic recognition of obstacles. In accordance with the invention, the control has a first obstacle processing function which moves an obstacle in the working area automatically using the movable piece of equipment; and / or in that the control has a second obstacle processing function which automatically removes an obstacle from the working area using the movable piece of equipment.

Owner:LIEBHERR WERK BISCHOFSHOFEN GES

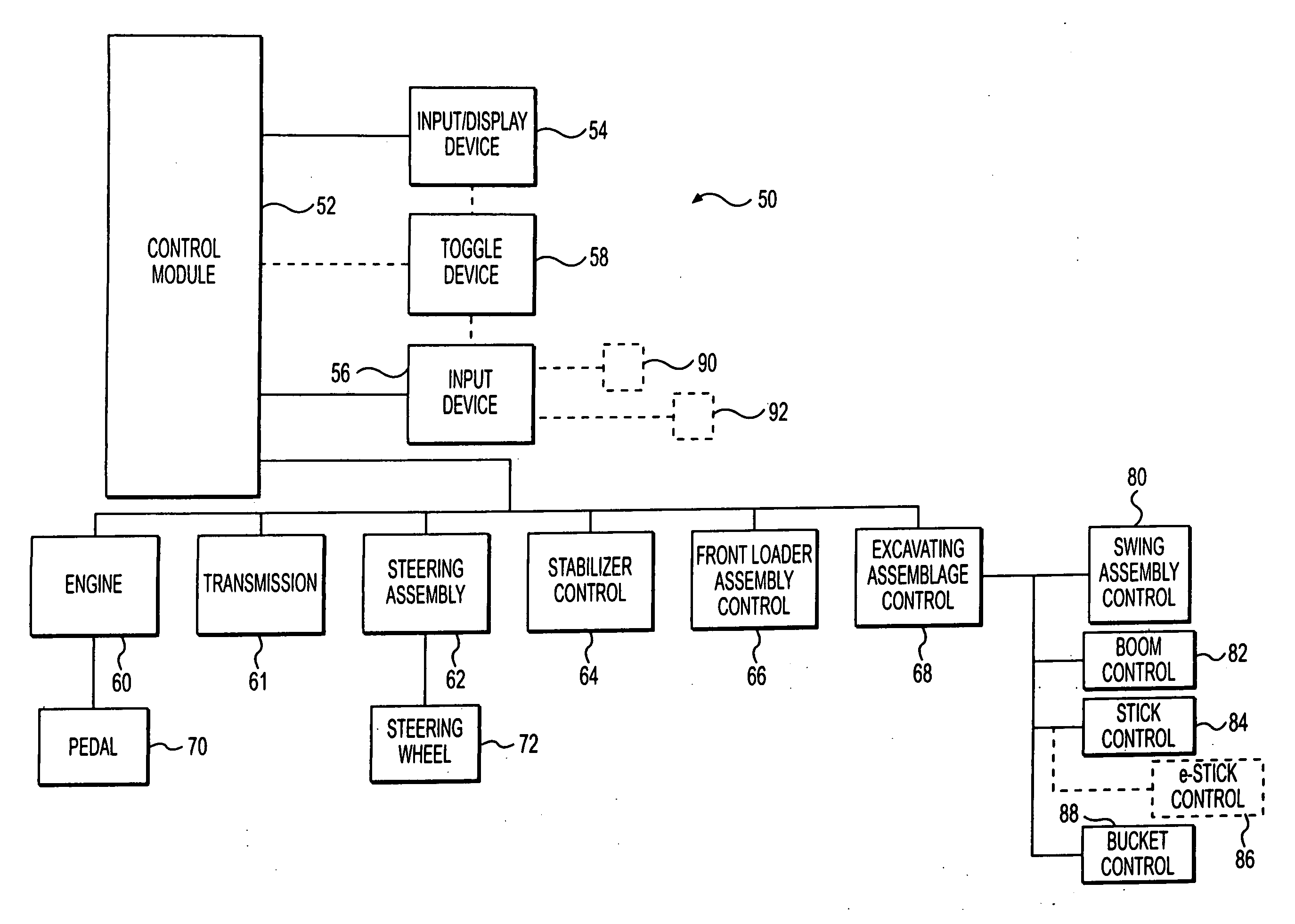

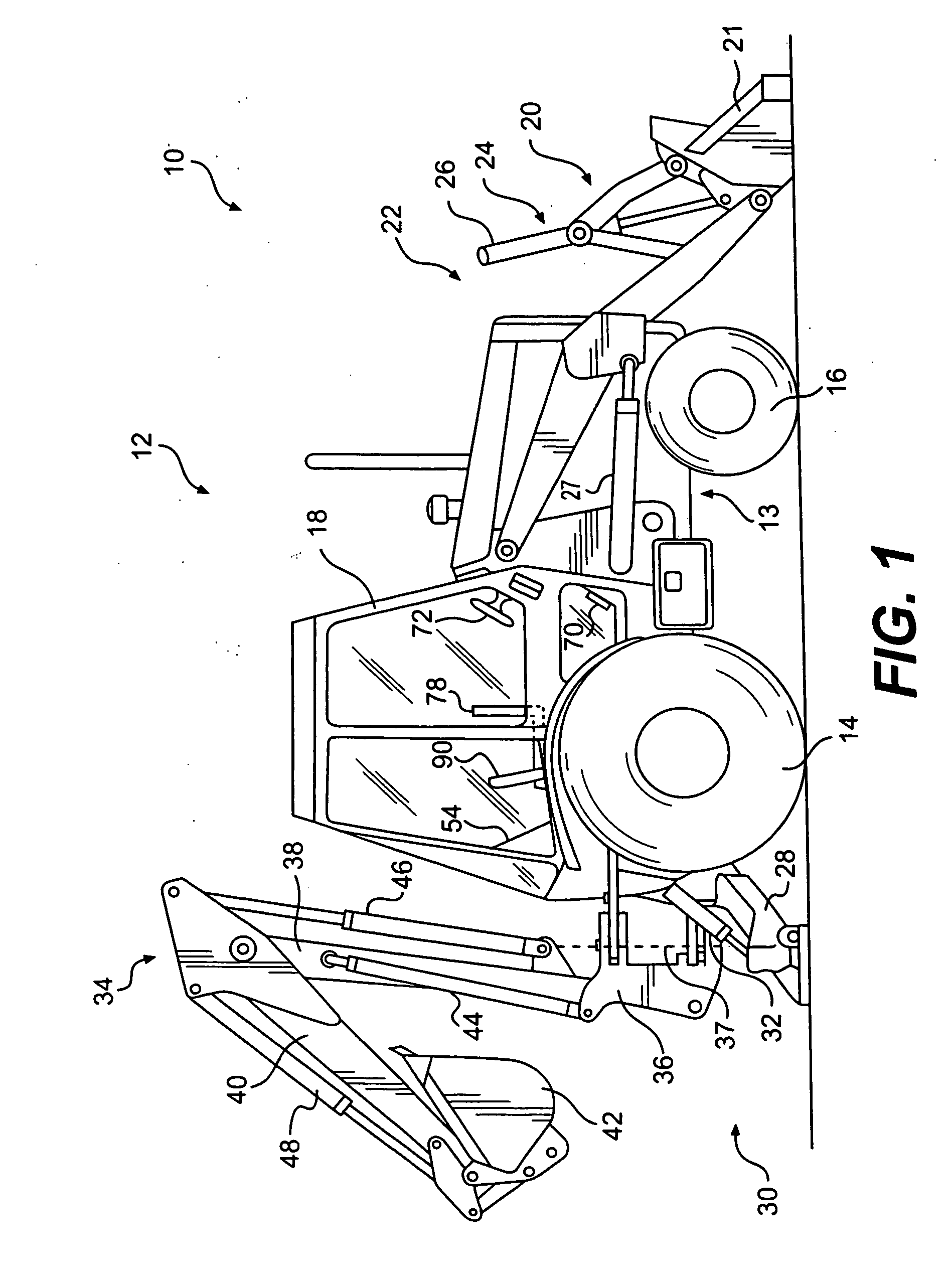

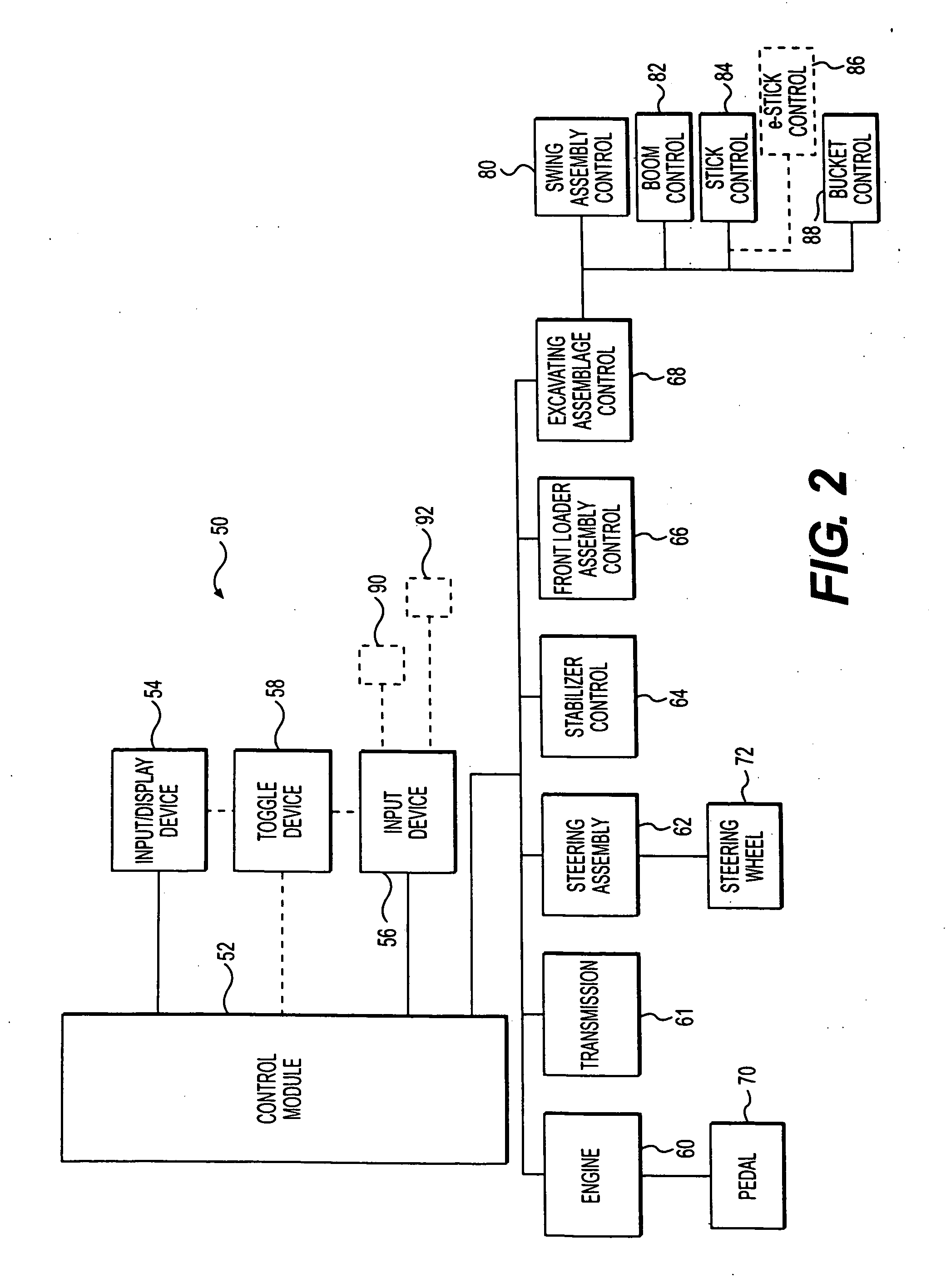

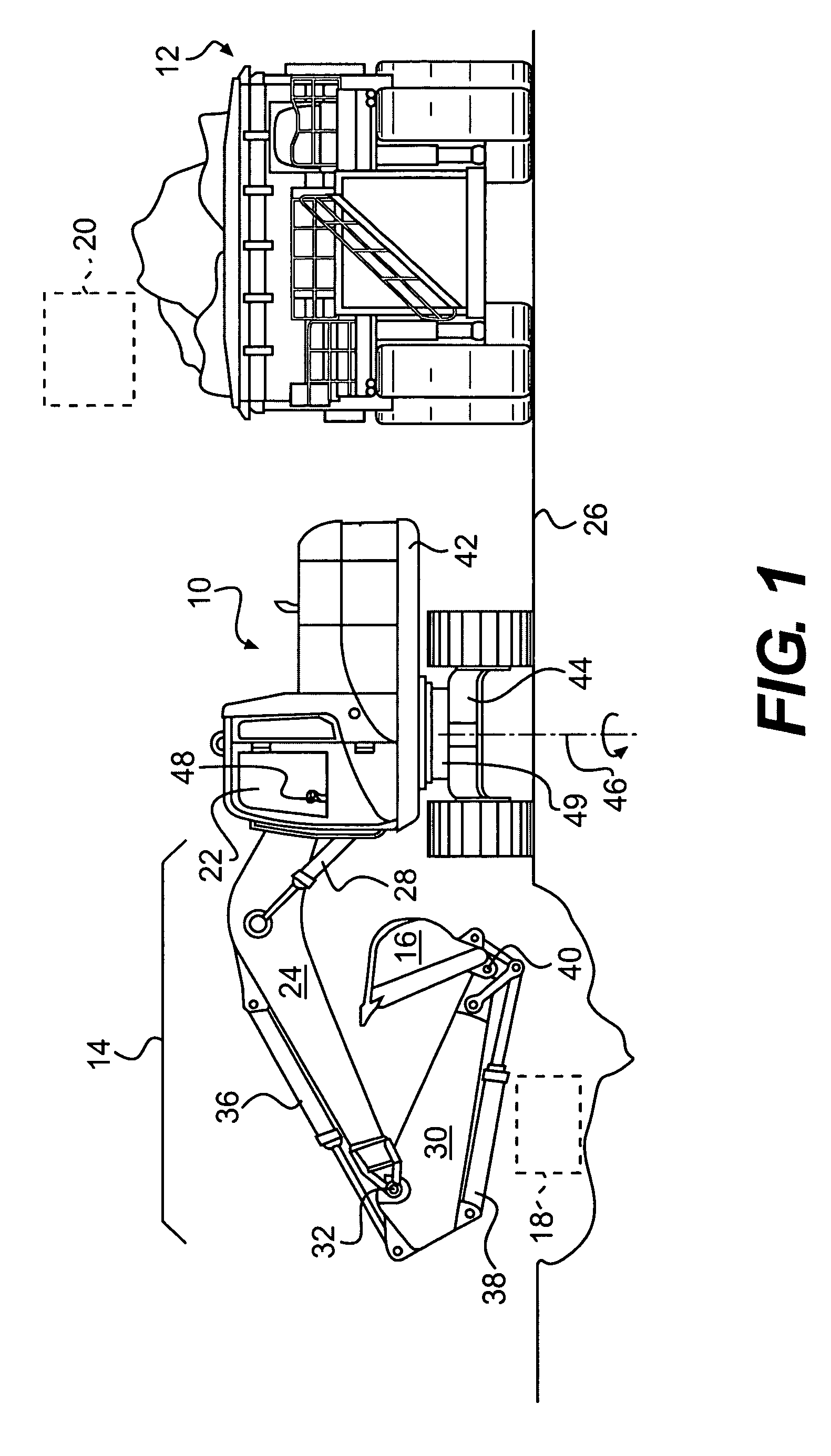

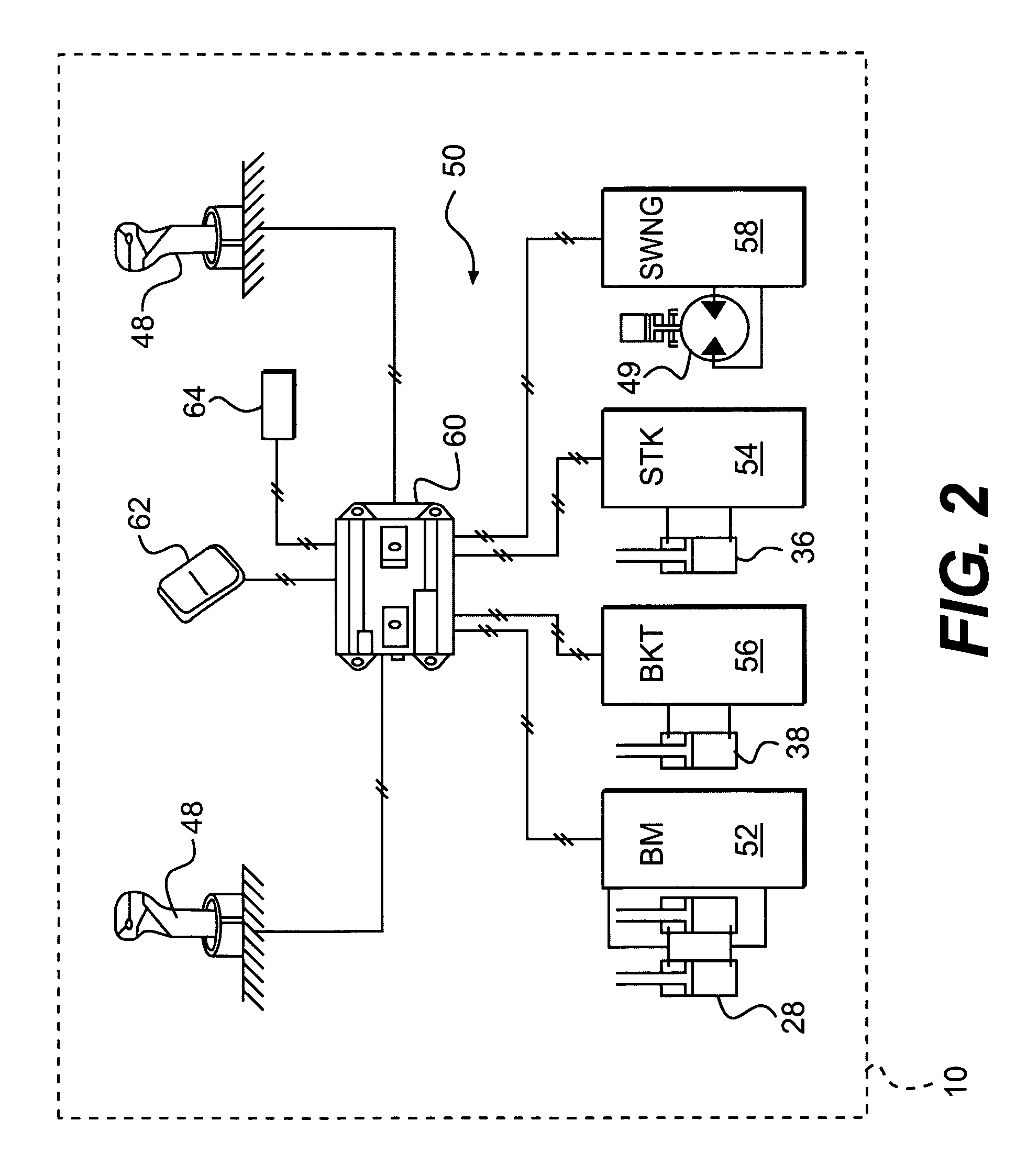

Method of changing operating characteristics of an implement

InactiveUS7017674B2Machines/dredgers working methodsMechanical machines/dredgersProduction rateComputer module

Changing operating characteristics of an implement can expand the capabilities of and enhances the productivity of the implement. The disclosed method and apparatus for changing operating characteristics of an implement comprises, providing the operating characteristics of the implement with a predetermined operational range consisting of a plurality of values, connecting the implement with a work machine, sending a first input signal identifying the operational range to an electronic control module, operating the implement at a first value within the operational range, sending a second input signal relating to a second value within the operational range to the electronic control module, and sending an output signal from the electronic control module to one of the work machine and the implement to change from the first value to the second value.

Owner:CATEPILLAR SARL

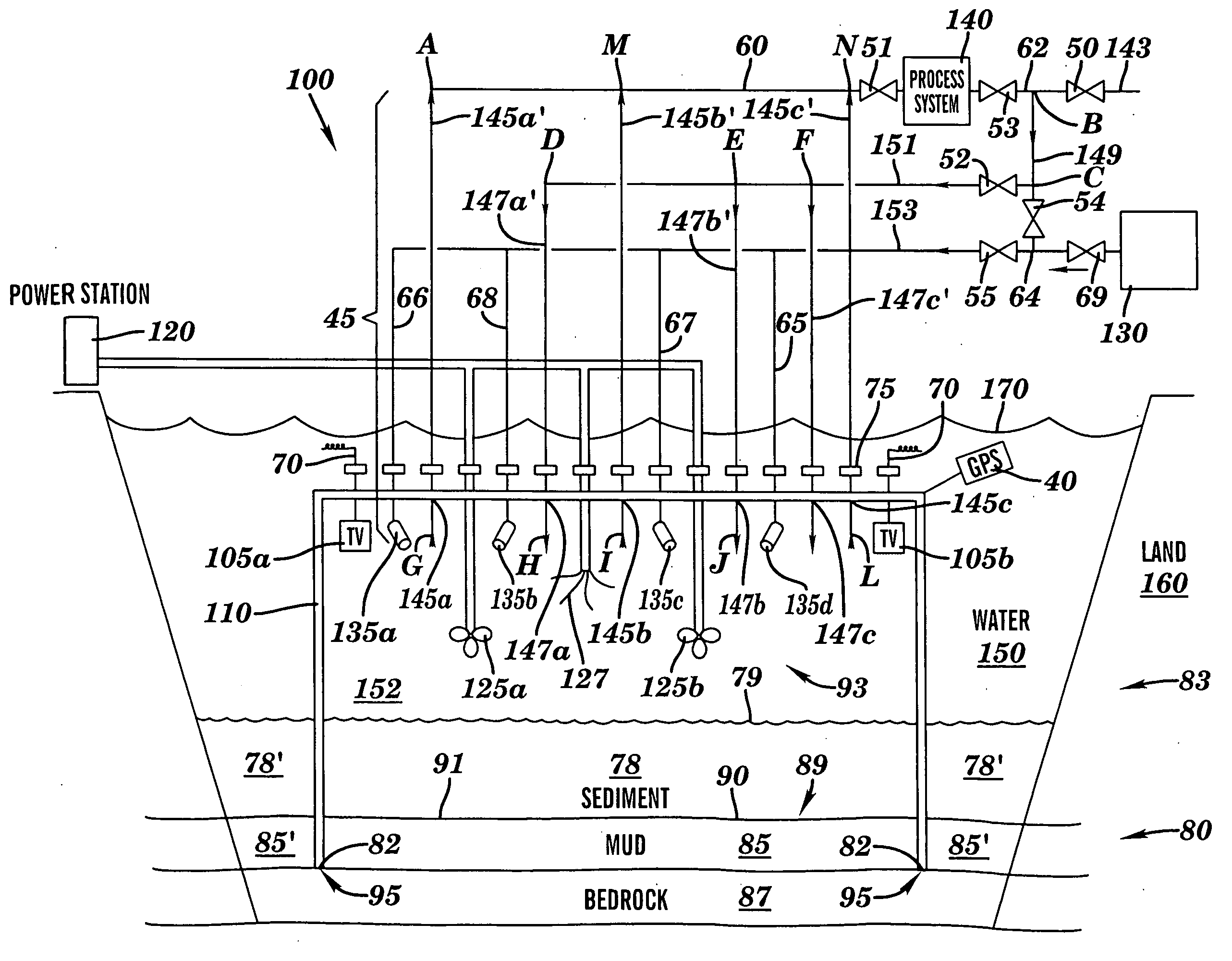

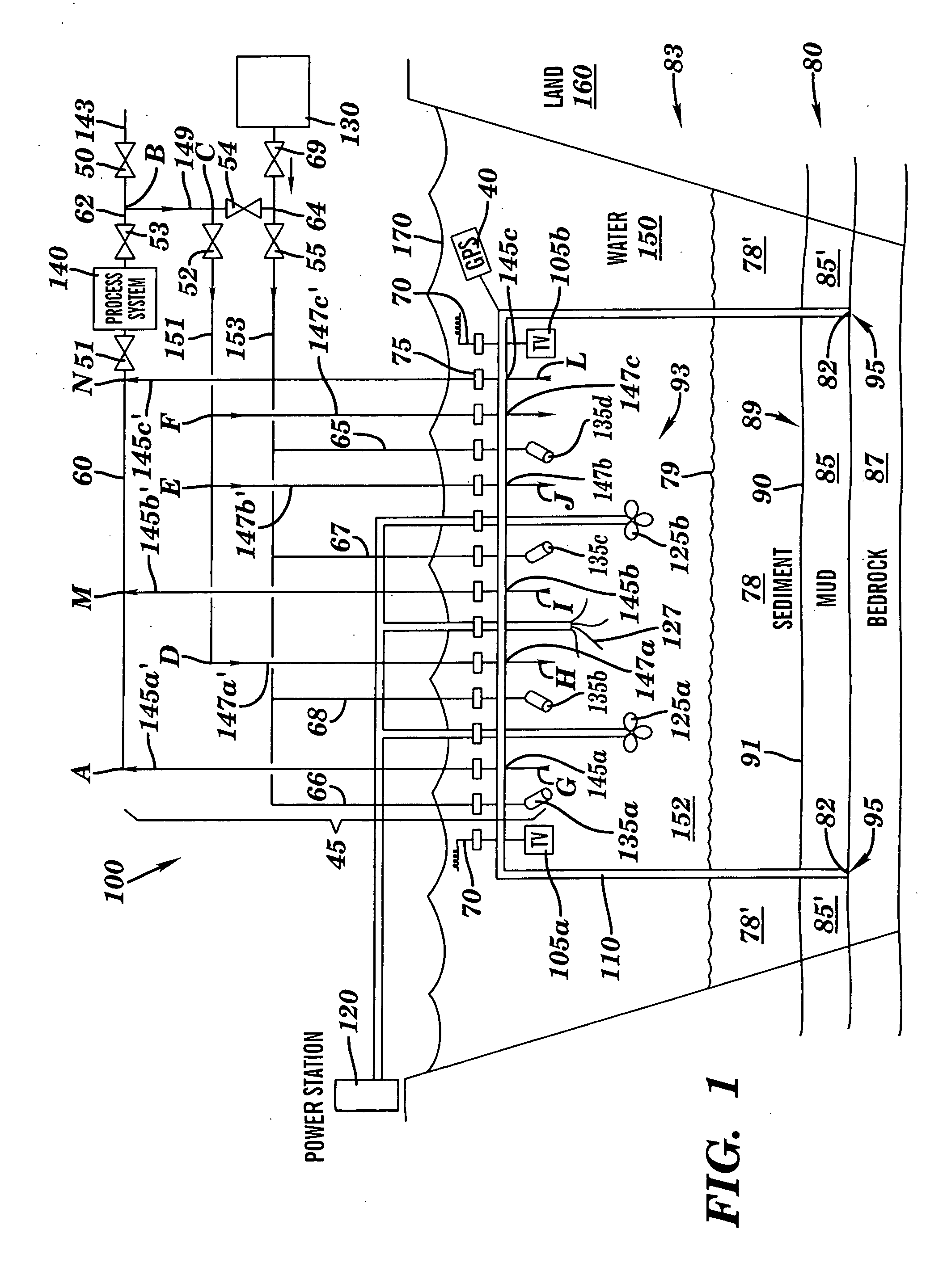

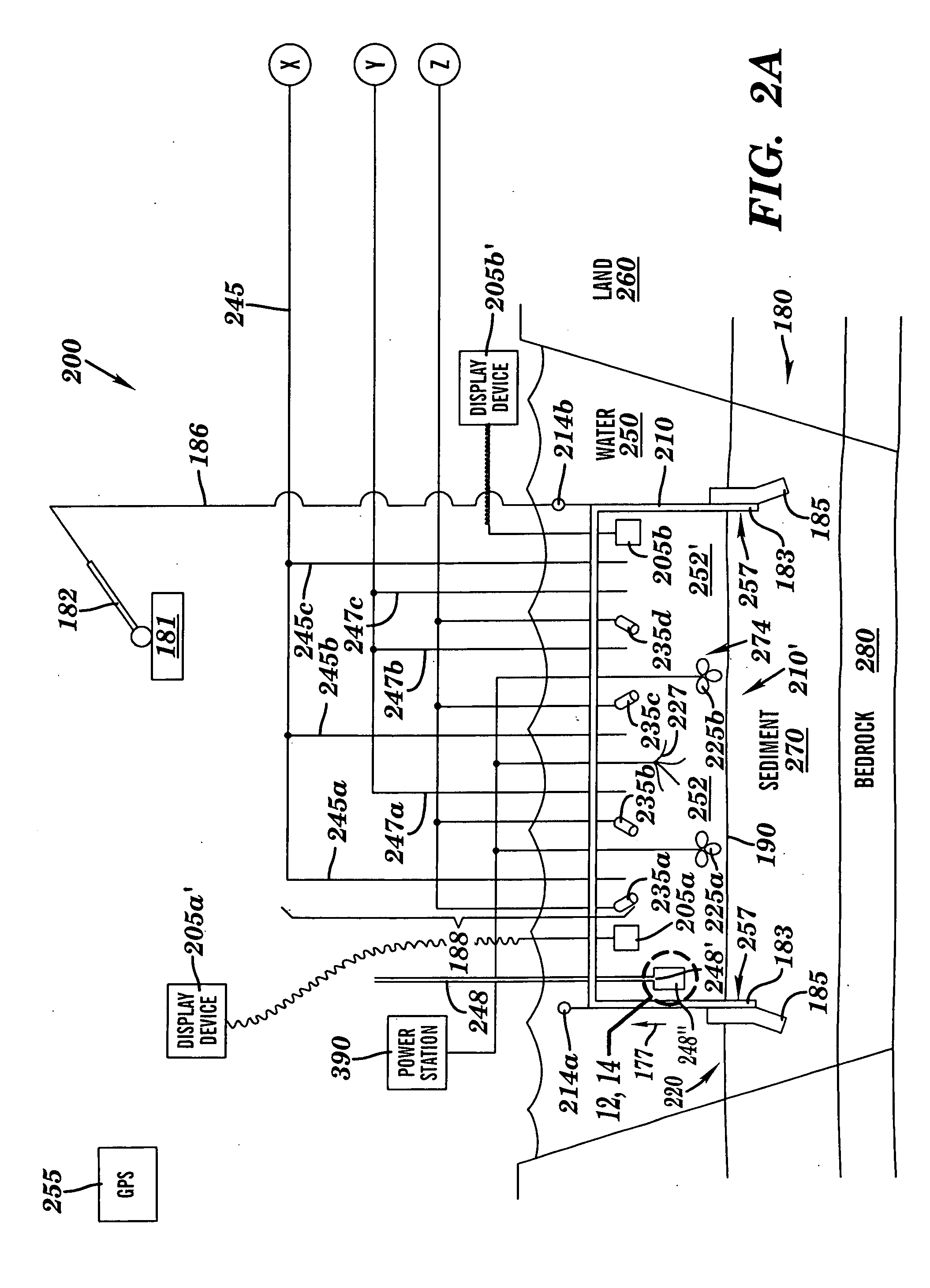

Apparatus, system and method for remediation of contamination

ActiveUS20050045556A1Promote plant growthImprove the growing environmentMachines/dredgers working methodsGeneral water supply conservationMarine engineeringCompound (substance)

An apparatus, system and method for removing and treating contaminated materials on a bottom of a body of water and introducing growth packets to revitalize the treated bottom of the body of water. The structure may comprise a vessel with an open face. The vessel may be lowered down to the bottom of the body of water with the face facing down. As a result, the vessel and the bottom form an isolated space. The structure may comprise at least one agitating device(s) for stirring up the materials inside the vessel so as to form a mixture containing the sediment materials which in turn contain the contaminants. Multiple at least one pipe(s) may be coupled to the vessel for transporting the mixture out of the vessel for processing (filtering, treating with chemicals, etc.) so as to neutralize or eliminate the contaminants in the mixture. Then, the treated mixture can be returned to the inside of the vessel via the at least one pipe(s).

Owner:AIR & EARTH

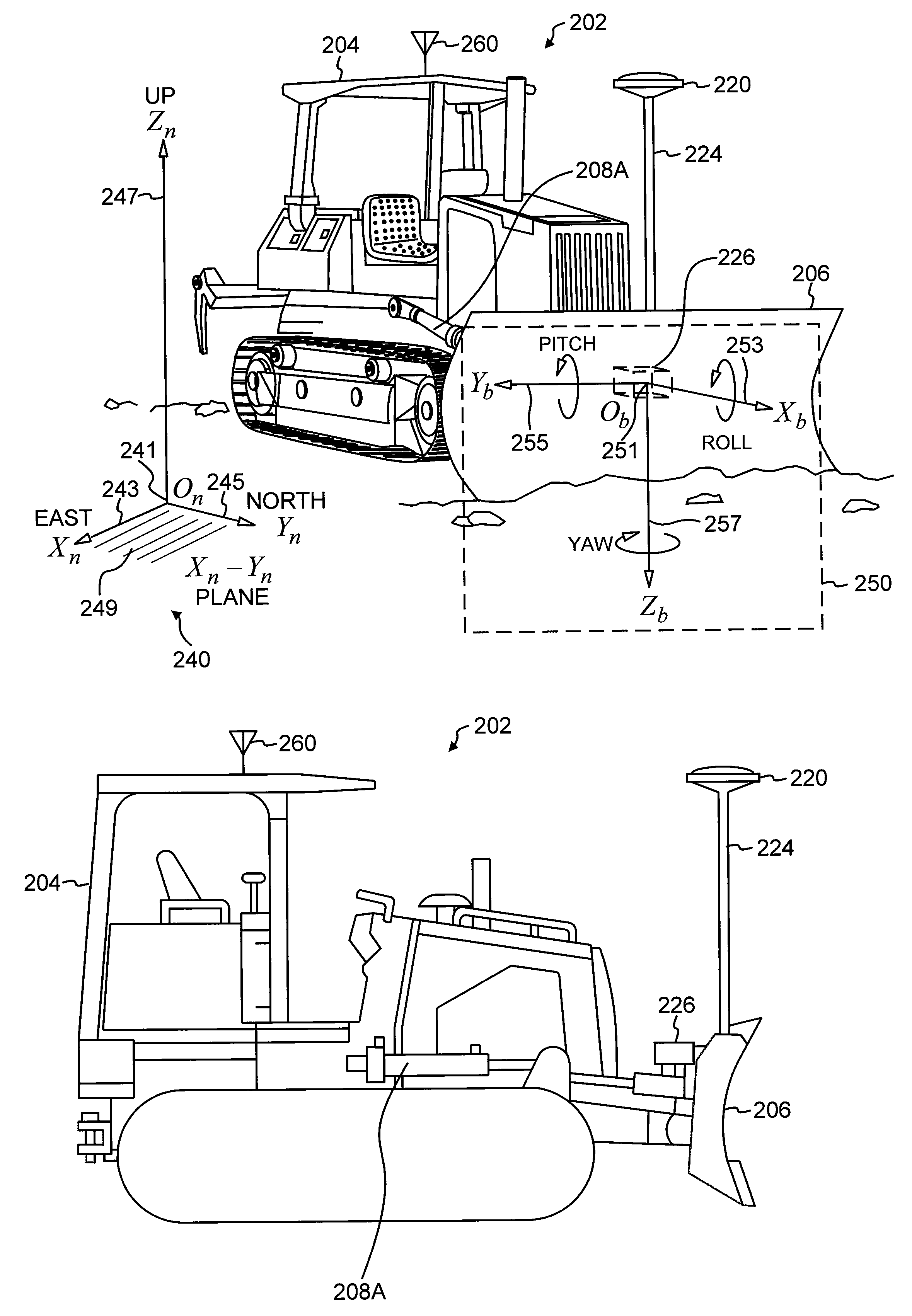

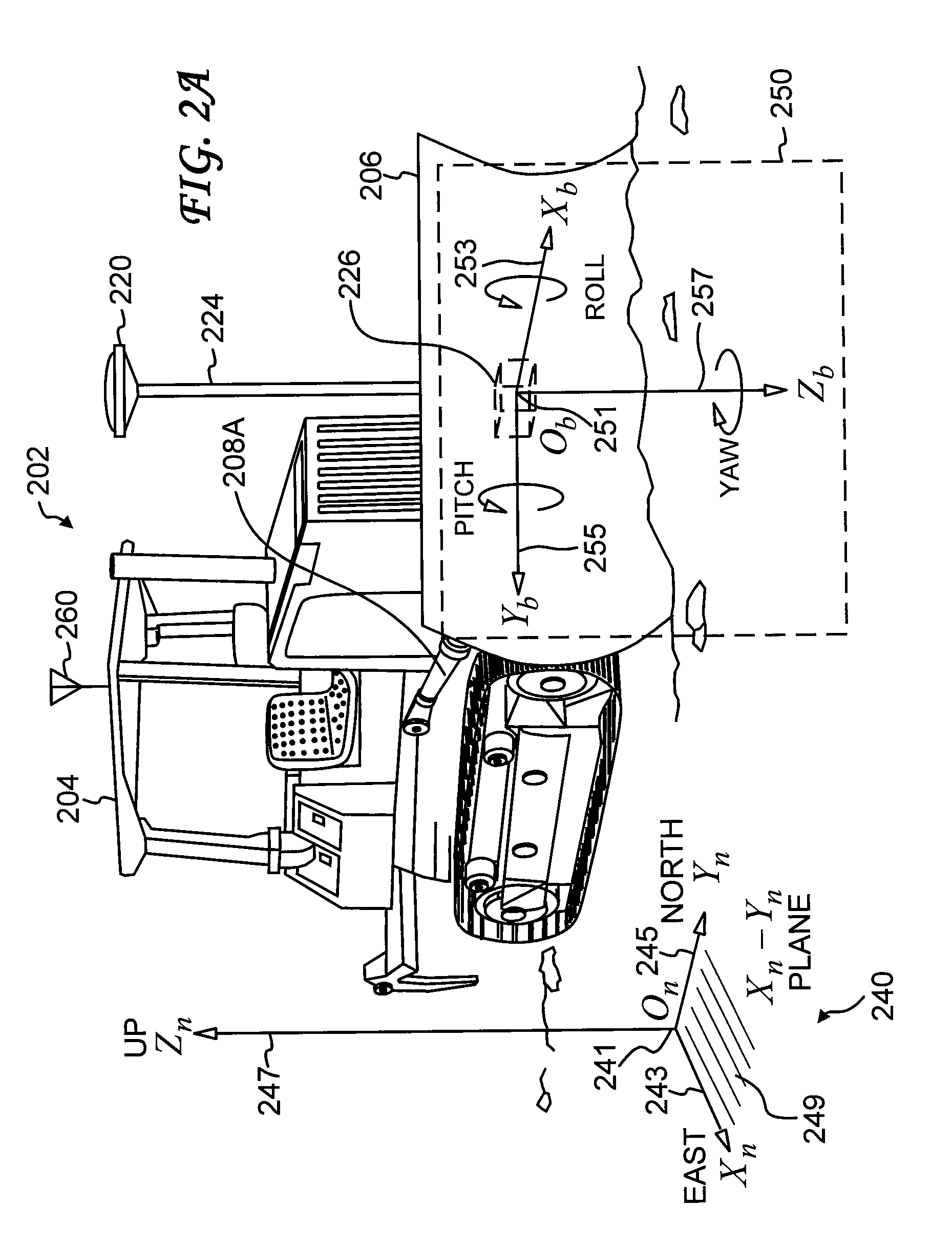

Automatic Blade Control System during a Period of a Global Navigation Satellite System ...

InactiveUS20120059554A1Easy to controlMachines/dredgers working methodsAnalogue computers for trafficTerrainAutomatic control

For precision grading of terrain by a dozer, the dozer blade can be automatically controlled based on measurements from a combination of a global navigation satellite system real-time kinematic mode (GNSS RTK) system and inertial sensors. At least one GNSS sensor and at least one inertial sensor are mounted on the dozer. Control algorithms are based on blade elevation and blade slope angle. During a period of GNSS RTK system outage, control of blade elevation is not available. Blade control is maintained by switching to control algorithms based on blade slope angle and blade pitch angle. Blade slope angle and blade pitch angle are controlled based on extrapolated target values of blade slope angle and blade pitch angle. The extrapolated target values of the angles are extrapolated from target values of the angles prior to the GNSS RTK system outage with the use of a distance travelled by the dozer.

Owner:TOPCON POSITIONING SYST INC

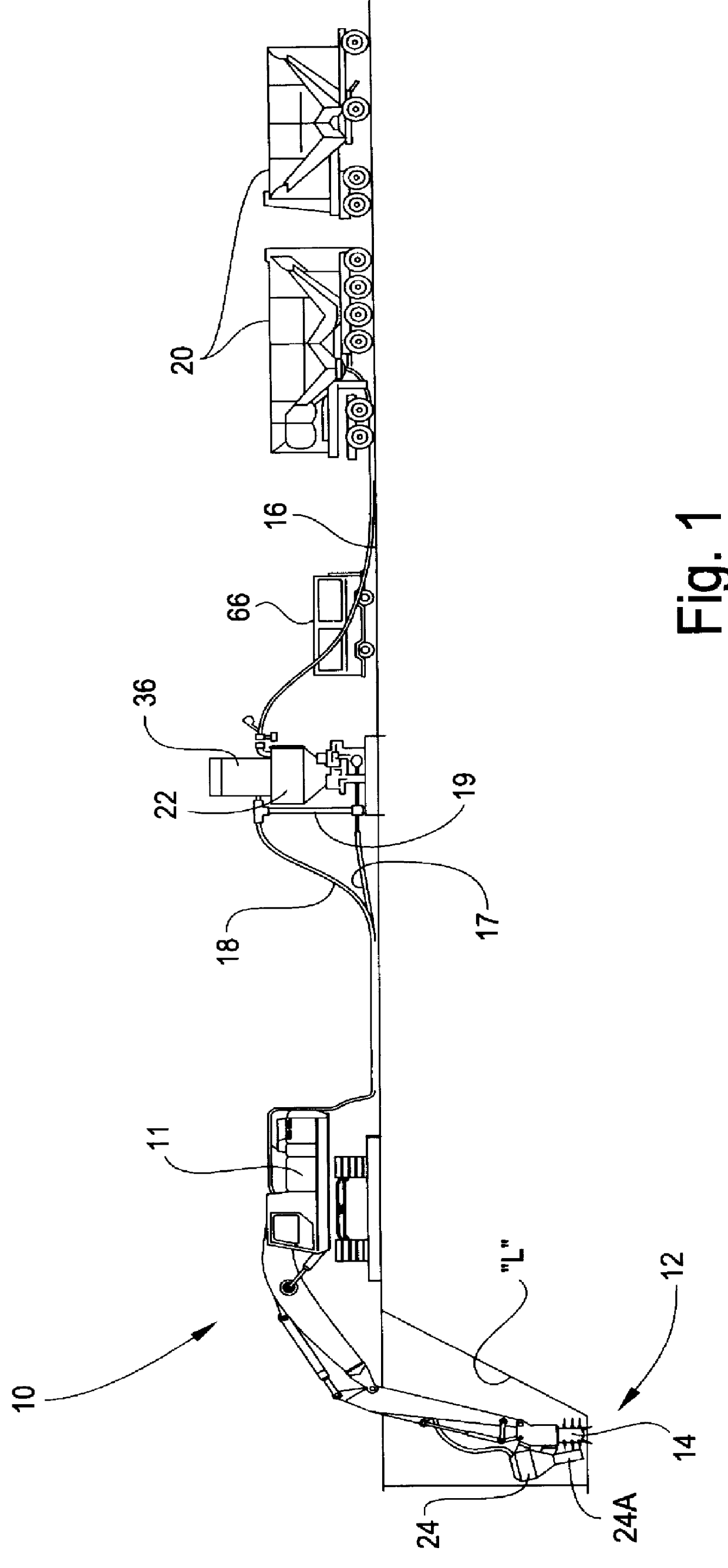

Material delivery system

InactiveUS6152656AReduce the amount requiredMachines/dredgers working methodsMechanical machines/dredgersLine tubingEngineering

A material delivery system conveys material from a supply location at or above an area surface to a working location below the area surface. The delivery system includes a supply hopper located at the supply location and having an inlet for receiving material to be conveyed and an outlet for discharging material. An injection hopper is adapted for mounting on a movable working arm of a self-propelled vehicle, and has an inlet for receiving material and an outlet for discharging material. The arm of the vehicle carries the injection hopper below the area surface to the working location. A supply line is connected to the outlet of the supply hopper and to the inlet of the injection hopper for conveying material from the supply location to the working location.

Owner:J A JONES ENVIRONMENTAL SERVICES

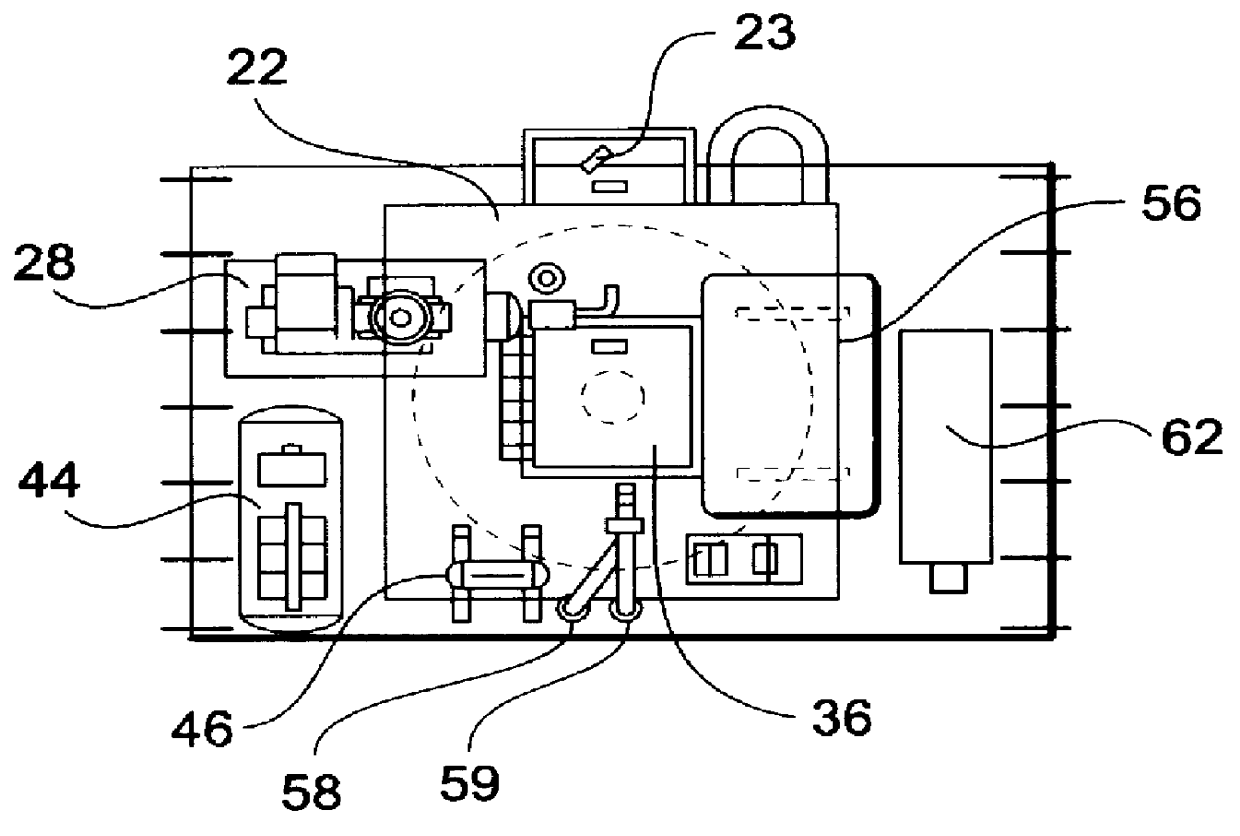

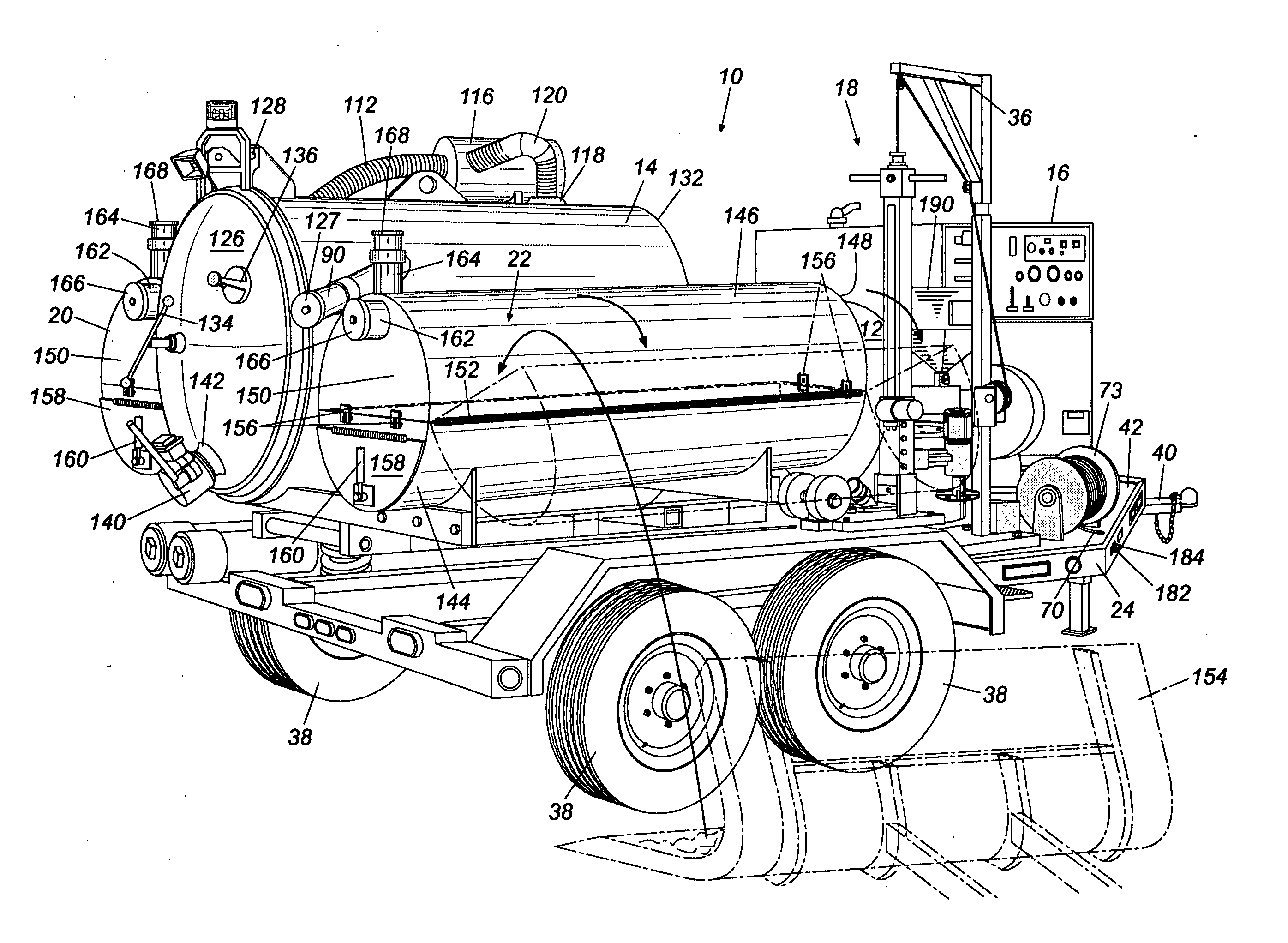

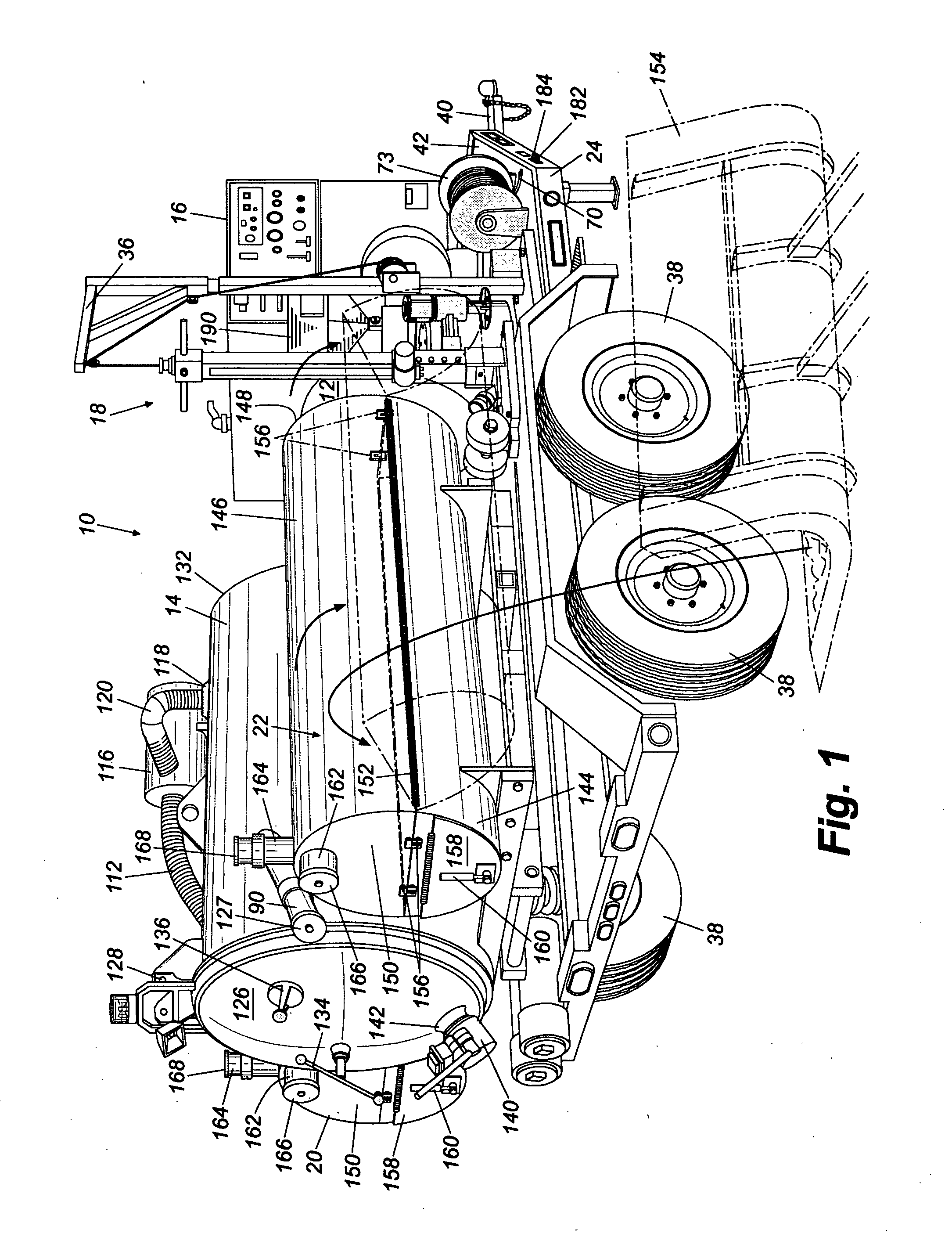

Digging and backfill apparatus

ActiveUS7484322B2Machines/dredgers working methodsMechanical machines/dredgersEngineeringVacuum pump

Owner:VERMEER MFG CO

Method and device for excavating submerged stratum

InactiveUS7802384B2Machines/dredgers working methodsMechanical machines/dredgersAbsorptanceLaser induced bubble

An excavation technique for a stratum capable of excavating a submerged stratum such as a layer containing an underground resource by using laser irradiation in liquid is provided. In this technique, a laser beam transmitted through laser transmission means 20 is irradiated in liquid 90 in form of a laser beam having a wavelength with high absorptance of the liquid 90 by laser-induced bubble generation means 35, generating a bubble flow 36, thus excavation of a submerged stratum may be carried out by using a laser-induced destruction effect. Moreover, a laser beam 41 having low absorptance of the liquid 90 is irradiated by laser irradiation means 39 and passed through the bubble flow 36, thereby applying a thermal effect to a stratum to destroy rock and excavate the stratum. The destruction effect and the thermal effect also may be cooperatively worked.

Owner:JAPAN DRILLING CO LTD +2

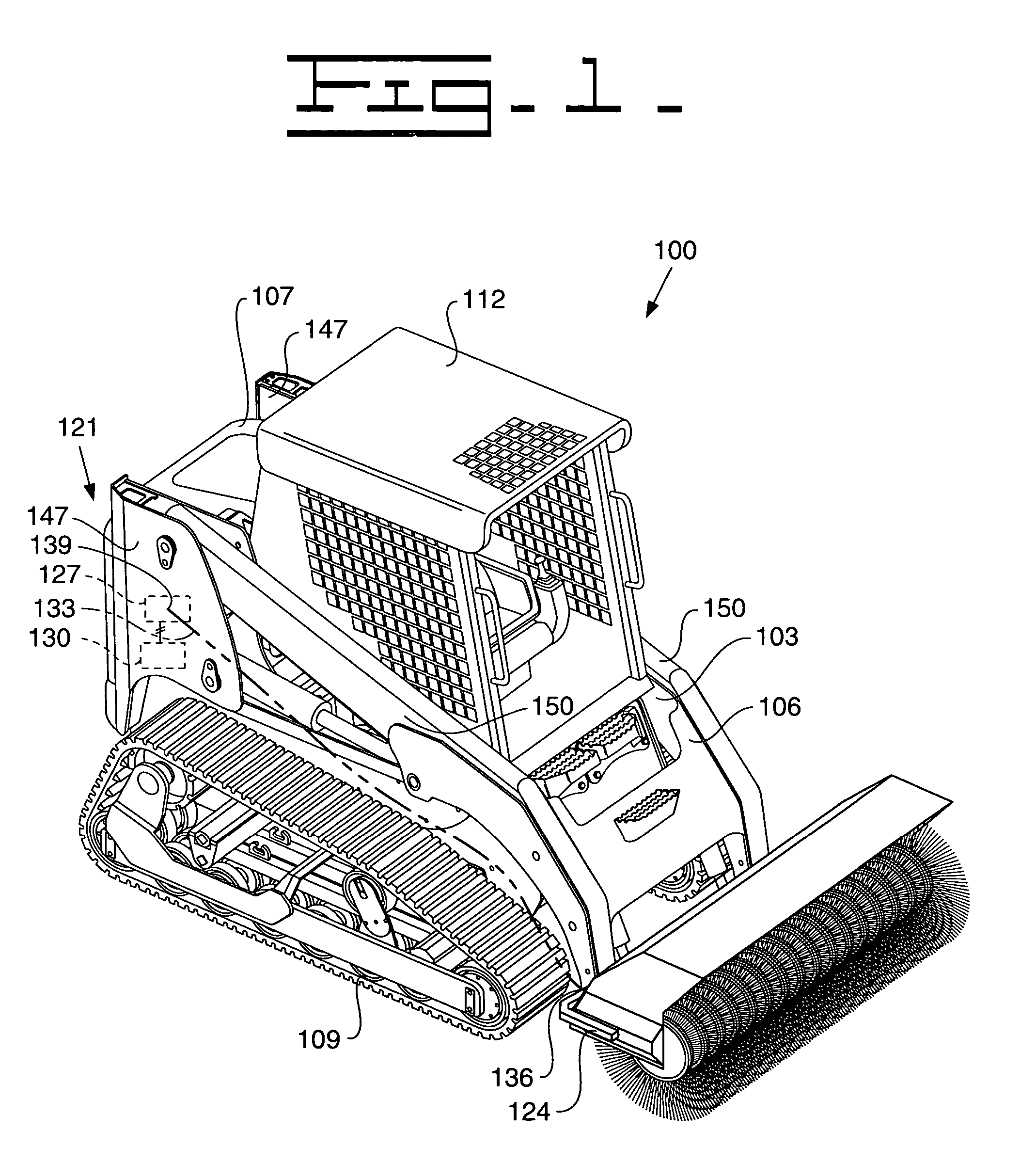

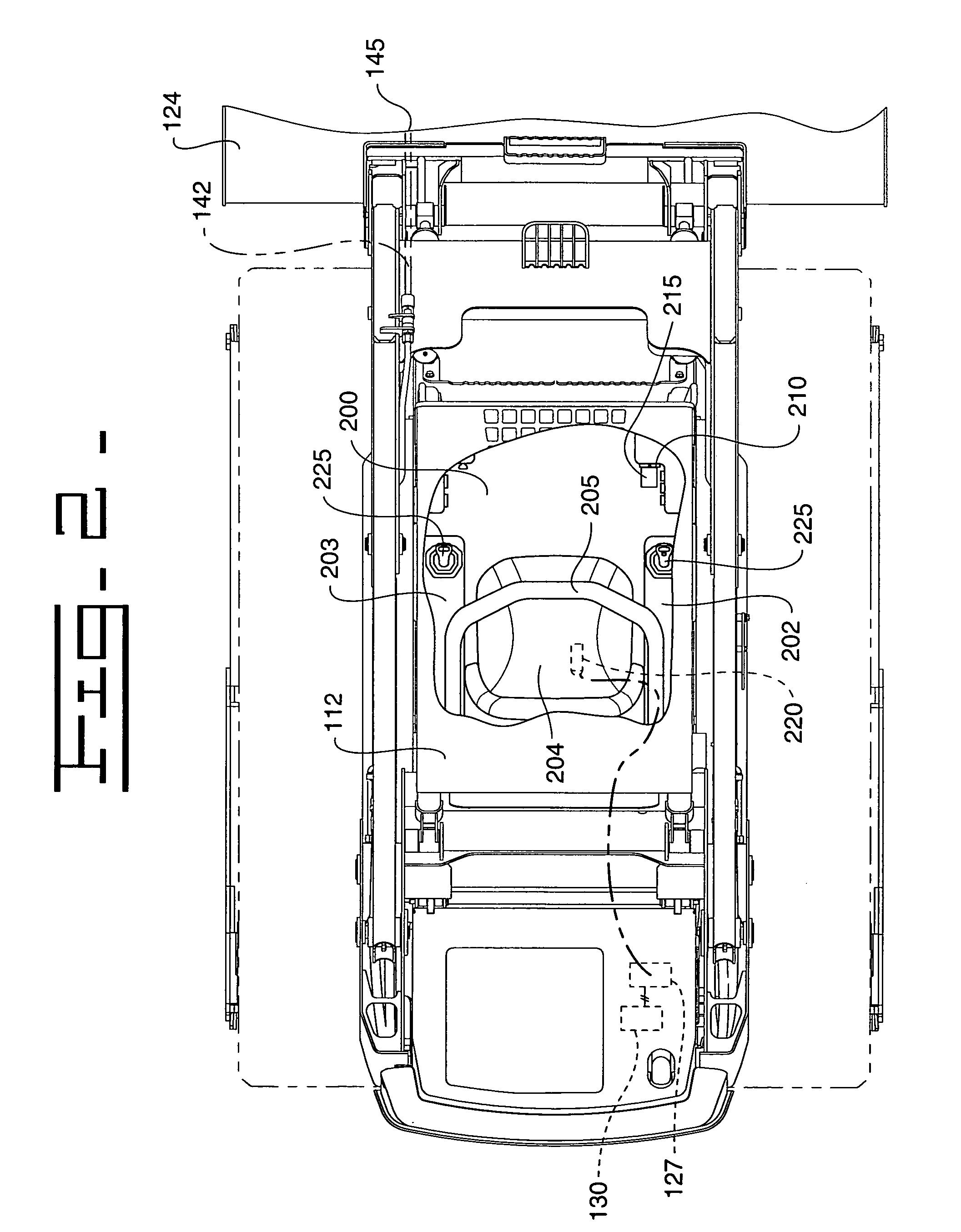

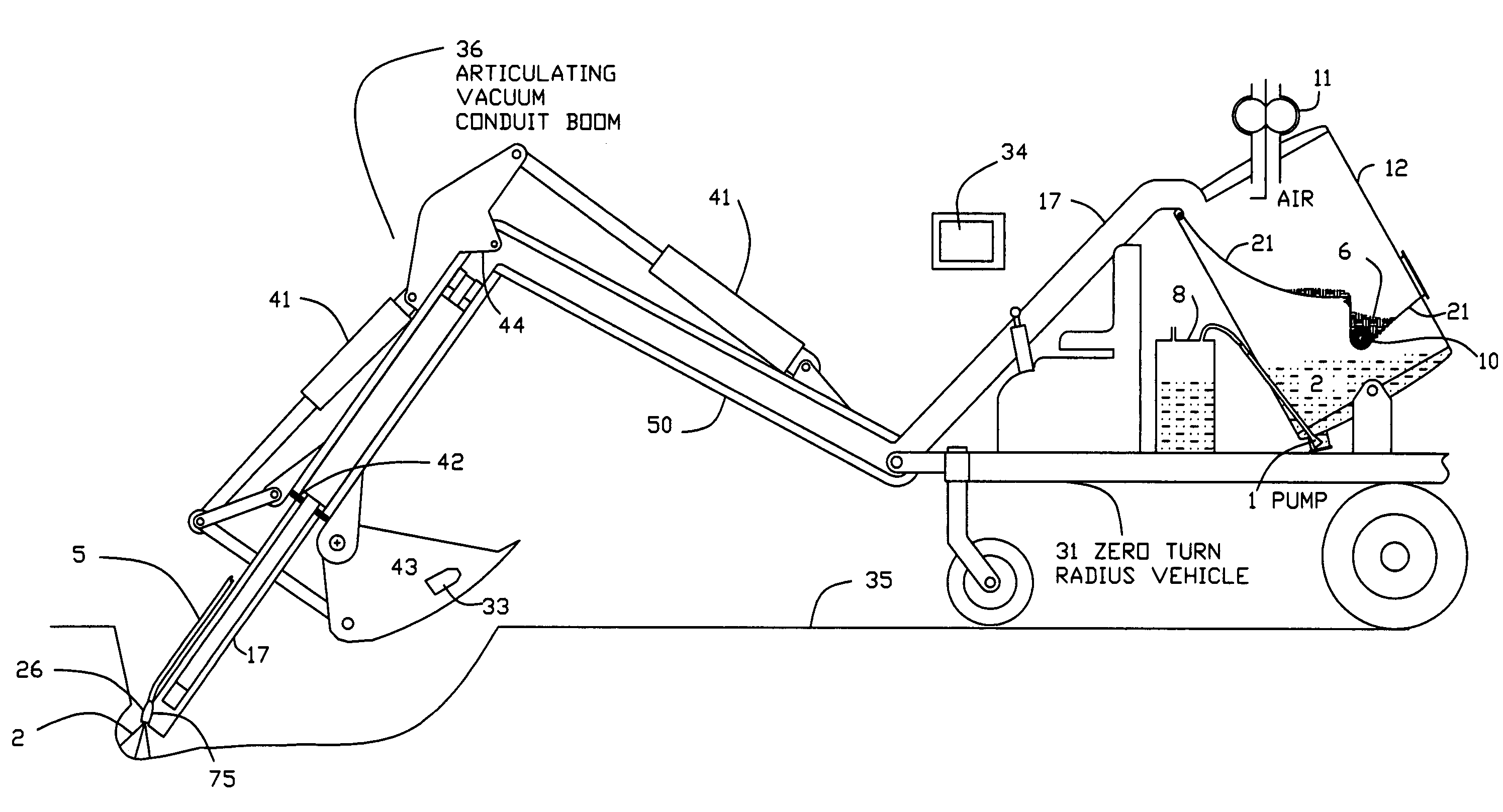

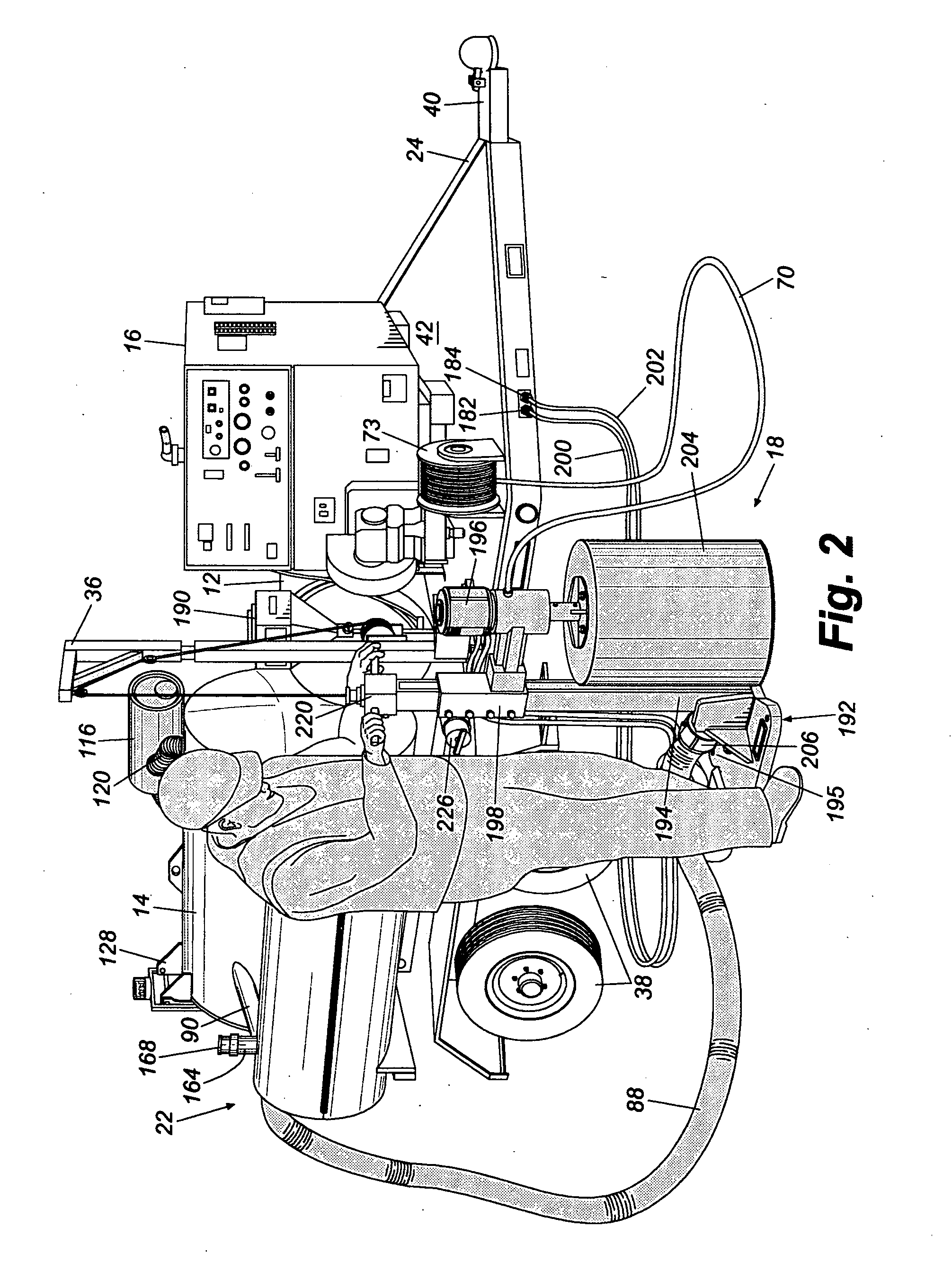

Mobile vacuum excavation attachment for vehicle

InactiveUS20100095559A1Improve structural strengthMachines/dredgers working methodsLoading/unloading vehicle arrangmentSpray nozzleEngineering

A mobile, platform mounted excavator which may include a vacuum container and a device which will create a vacuum condition within the vacuum container. A water container, water pump, hoses and spray nozzles may be mounted on the platform and may be used for cleaning, jettering out conduits, and loosening earthen material. An articulated boom may be pivotably mounted on the platform and the articulated boom may have the added feature of having a means for coupling and supporting in stabilizing in place, auxiliary tools which are useful for accessing, servicing or repairing in ground utilities. The mobile platform mounted systems may have sensors to measure the physical quantities of the service or repair operation. A data logger, a PLC, an RFID, a camera, a GPS, a utility mapping program and wireless communication may be used for documenting, displaying and storing data related to a utility servicing operation. The above described mobile platform system may be mounted to a variety of vehicles.

Owner:BUCKNER LYNN A

Automated machine repositioning in an excavating operation

InactiveUS20080127531A1Machines/dredgers working methodsAnalogue computers for trafficMachine controlComputer module

A method of repositioning a machine during an excavating operation from a first machine position to a second machine position is provided. A target distance to the second machine position is selected. An operator input device configured to send a control input signal to a control module to initiate a repositioning phase is activated. During a repositioning phase, the machine is moved toward the second position while an operator maintains control of movement. A determination is made when the machine has traveled the target distance. The machine is stopped under automated machine control at the second machine position.

Owner:CATERPILLAR INC

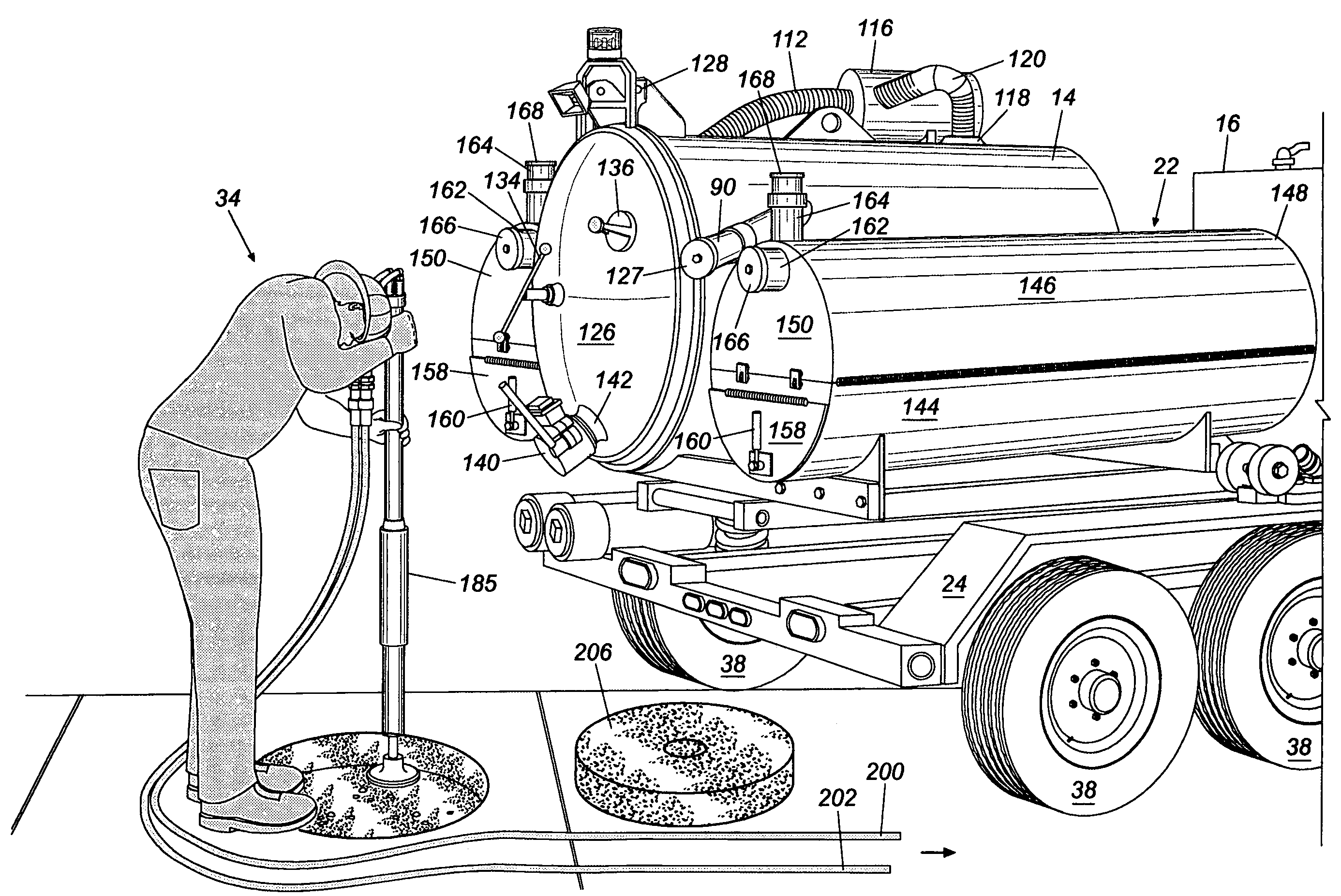

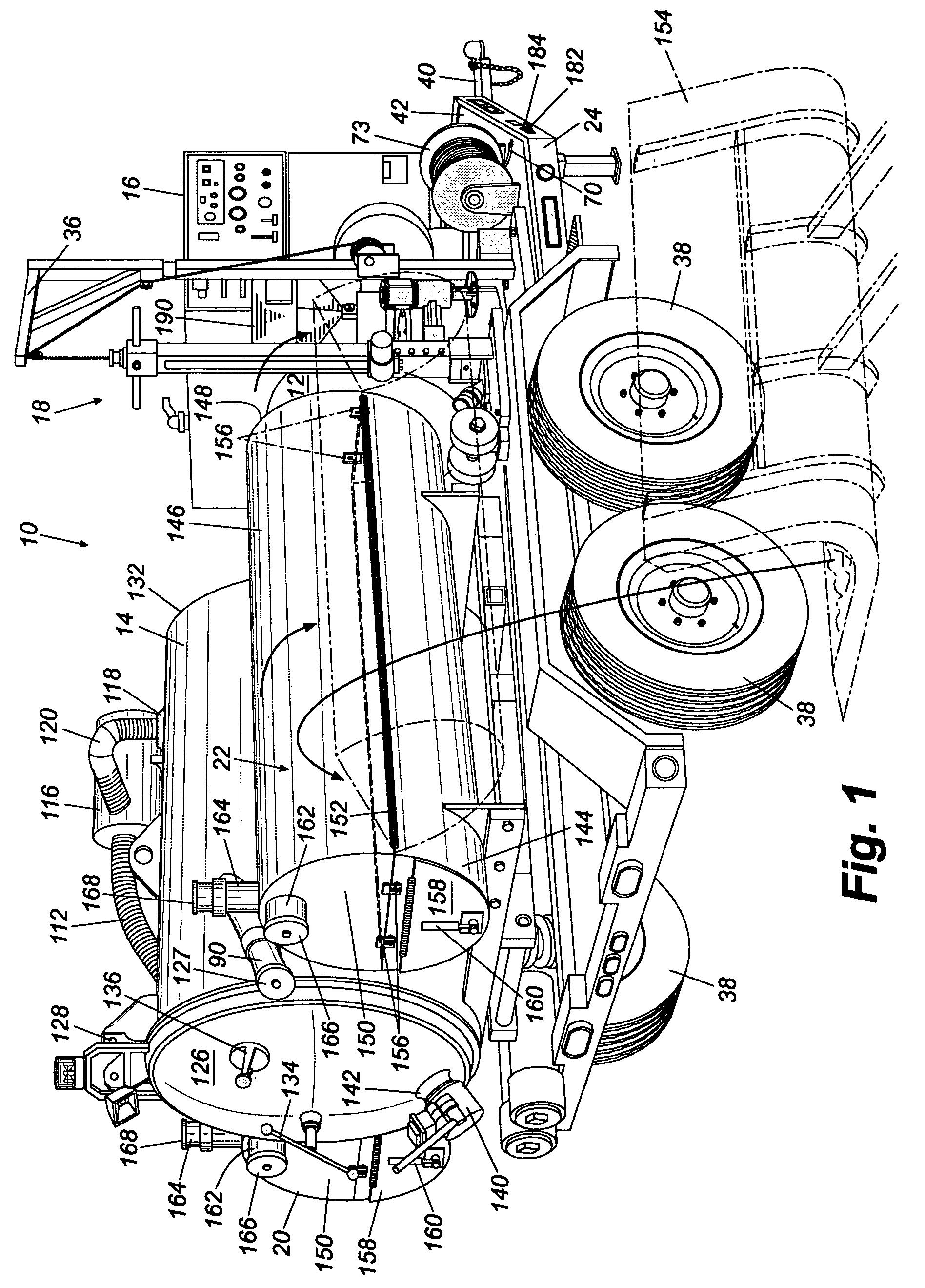

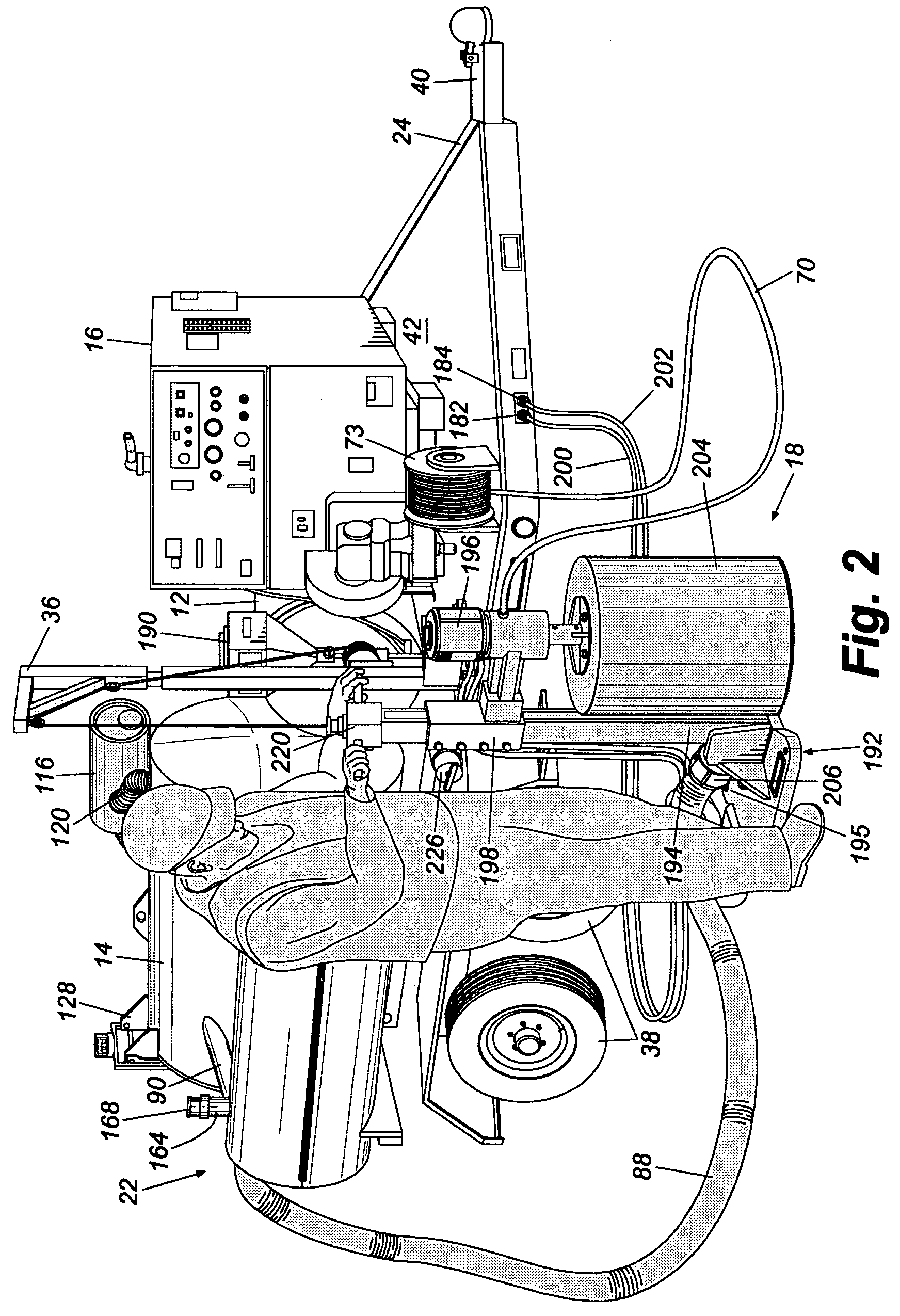

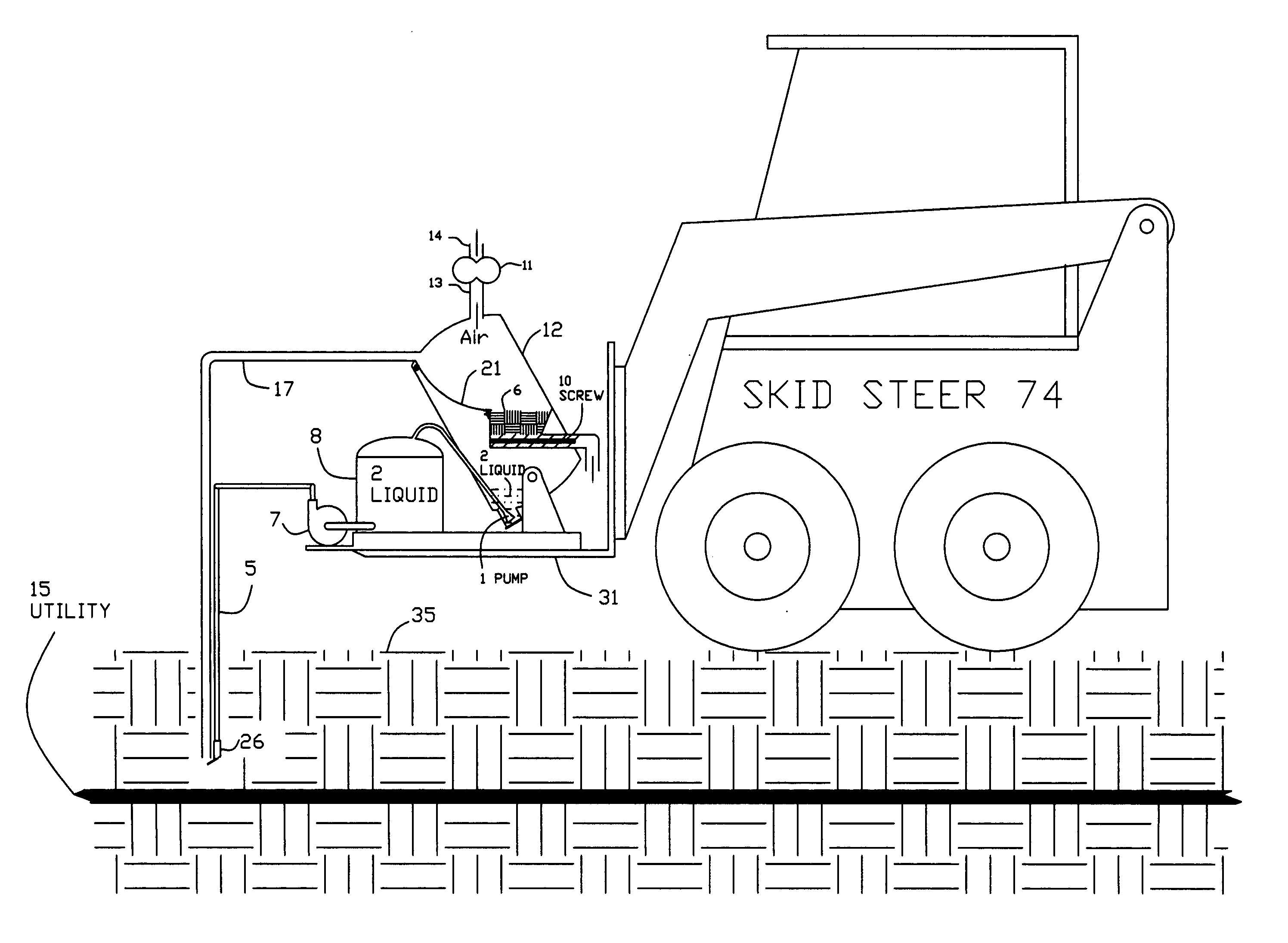

Mobile vacuum boring and excavation method

InactiveUS7644523B2Improve structural strengthProvide spaceMachines/dredgers working methodsMining devicesWater storageSolid mass

Owner:BUCKNER LYNN ALLAN

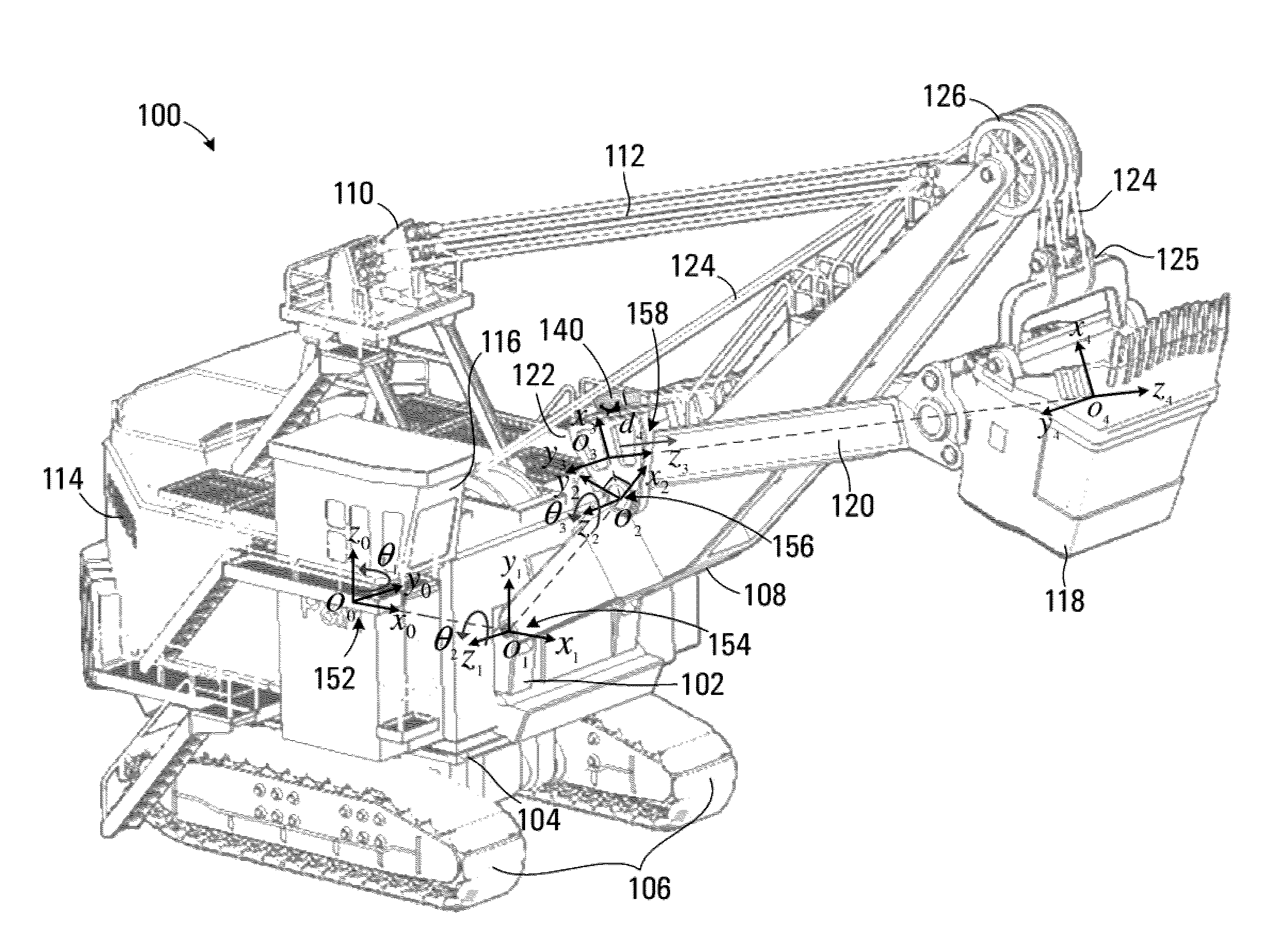

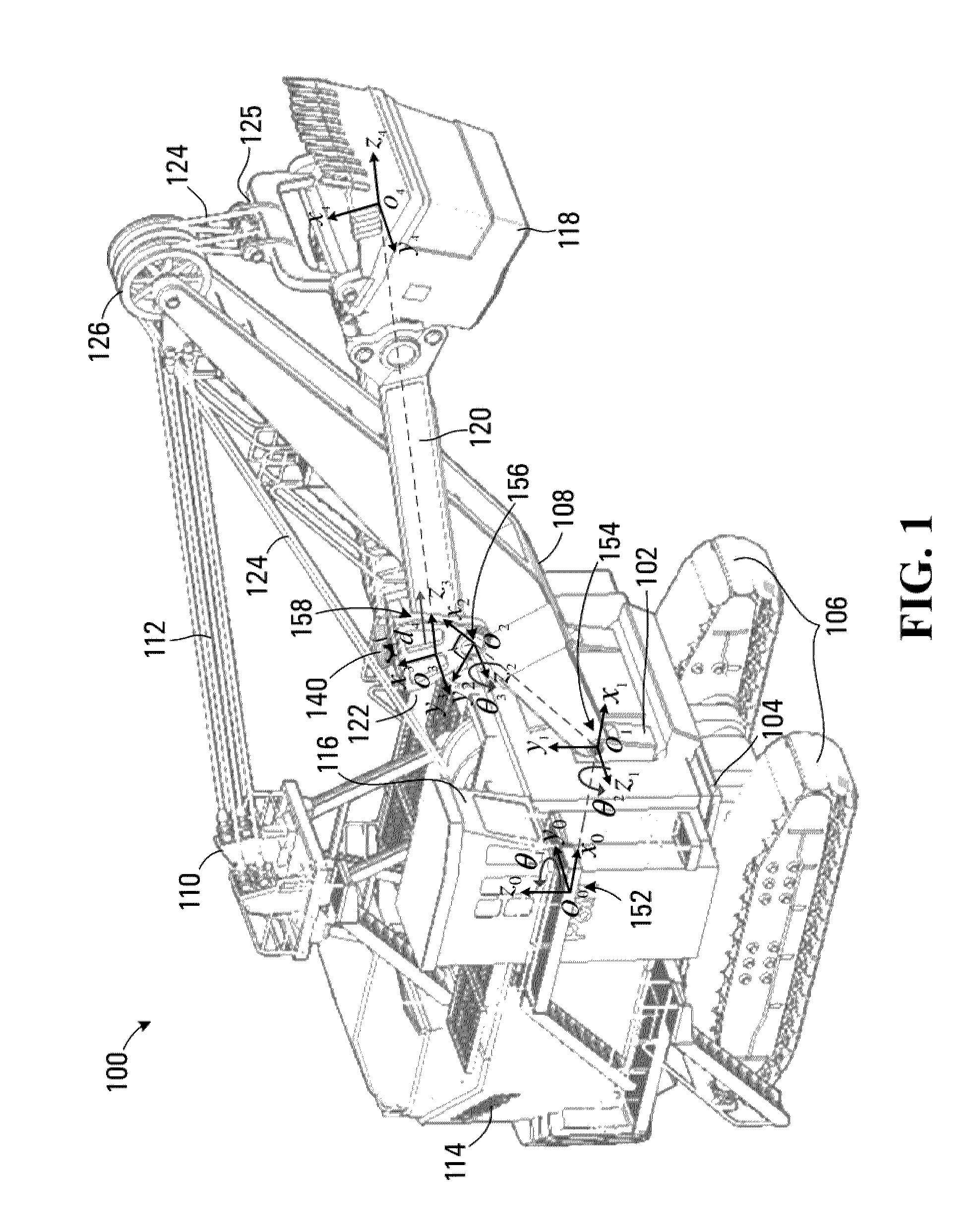

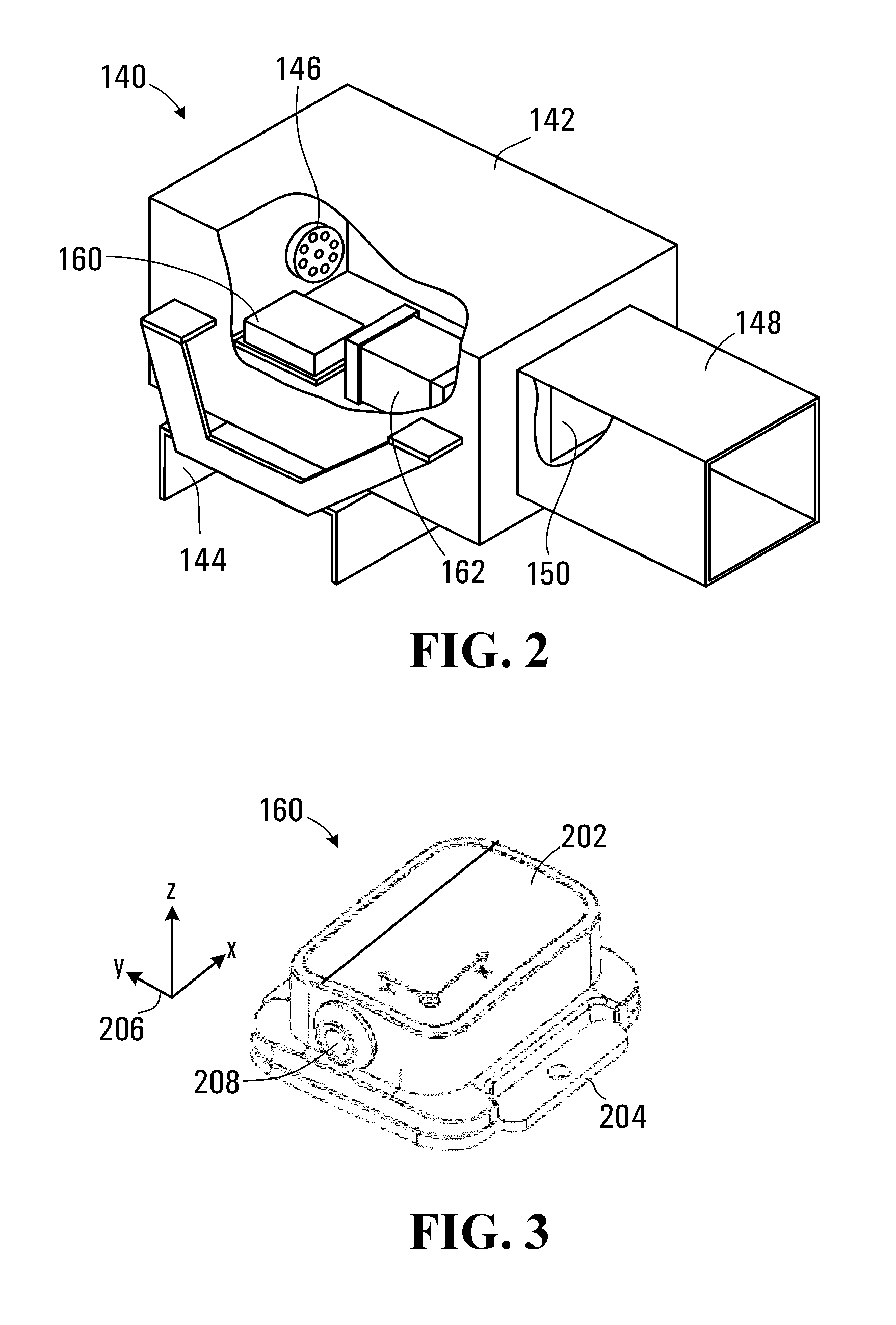

Method and apparatus for determining a spatial positioning of loading equipment

ActiveUS20120308354A1Machines/dredgers working methodsMechanical machines/dredgersSpatial positioningEngineering

An apparatus, method and sensor apparatus for determining a spatial positioning of loading equipment is disclosed. The loading equipment has an operating implement for loading a payload, the operating implement being coupled to a support for movement relative to the support. The apparatus includes an orientation sensor disposed on the support and being operable to produce an orientation signal representing an orientation of the support. The apparatus also includes a displacement sensor operable to produce a displacement signal representing a displacement of the operating implement relative to the support. The apparatus further includes a processor circuit operably configured to receive the orientation signal and the displacement signal, use a kinematic model of the loading equipment to compute a spatial positioning of the loading equipment, and produce an output signal representing the spatial positioning.

Owner:MOTION METRICS INT CORP

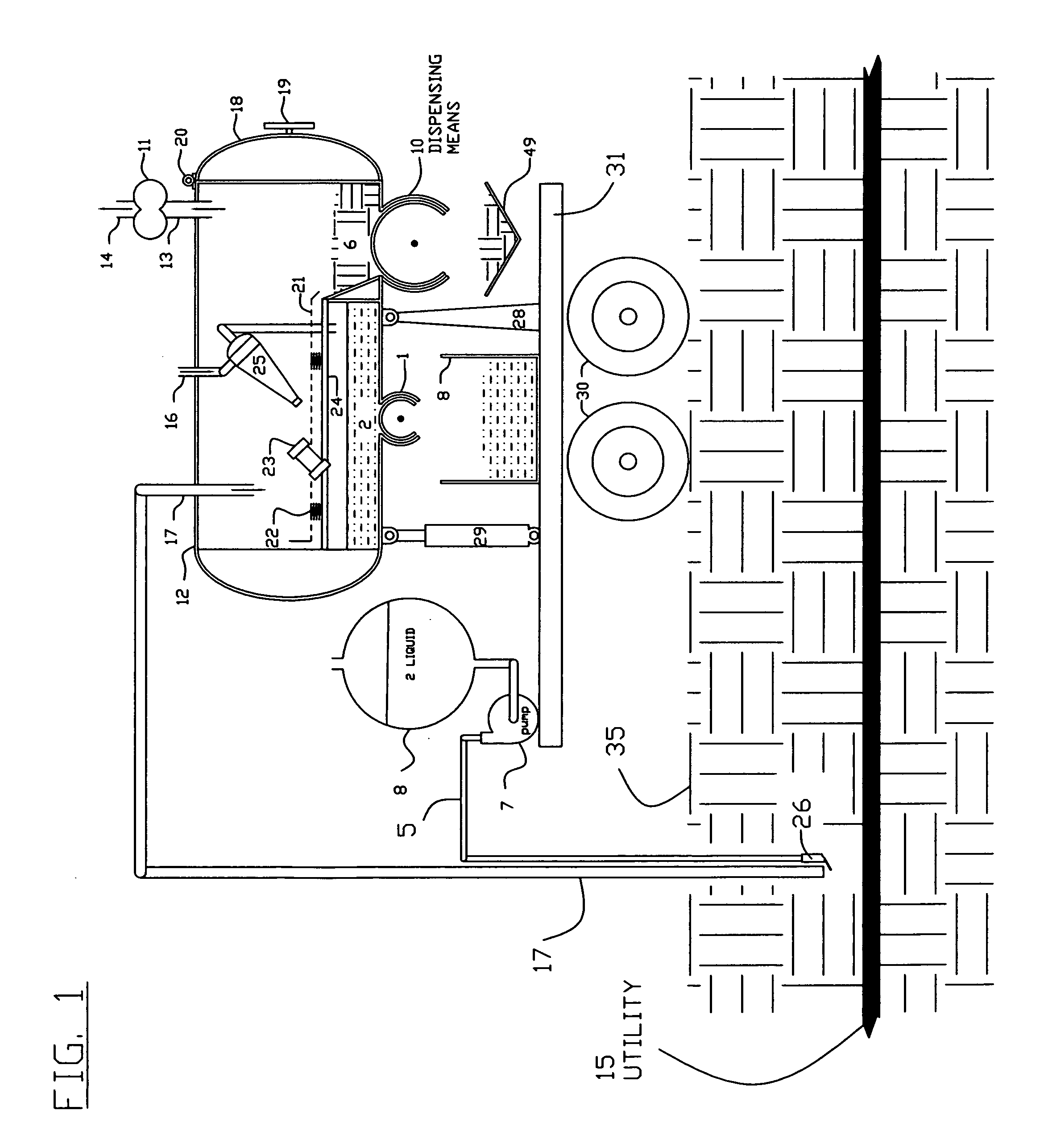

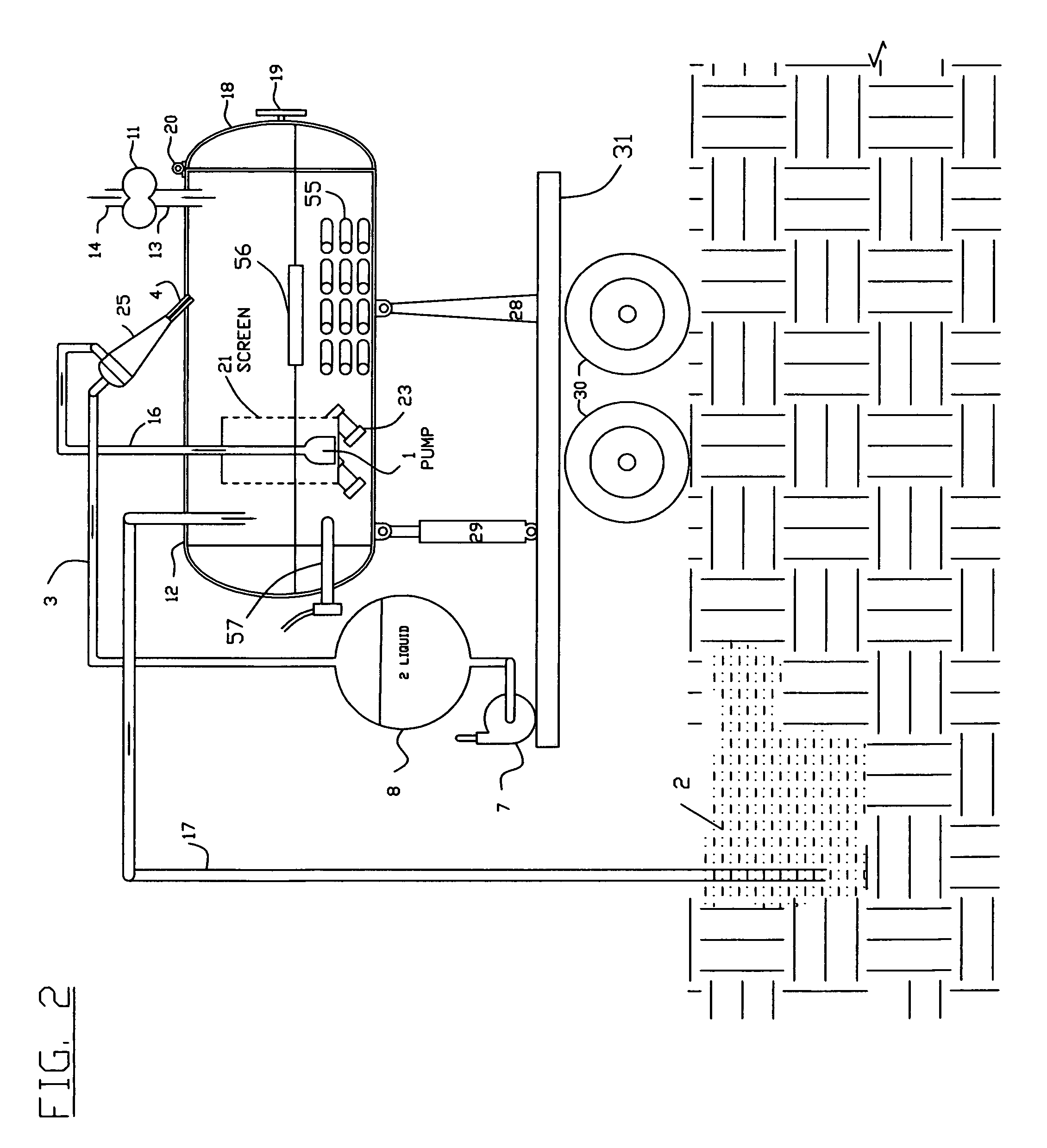

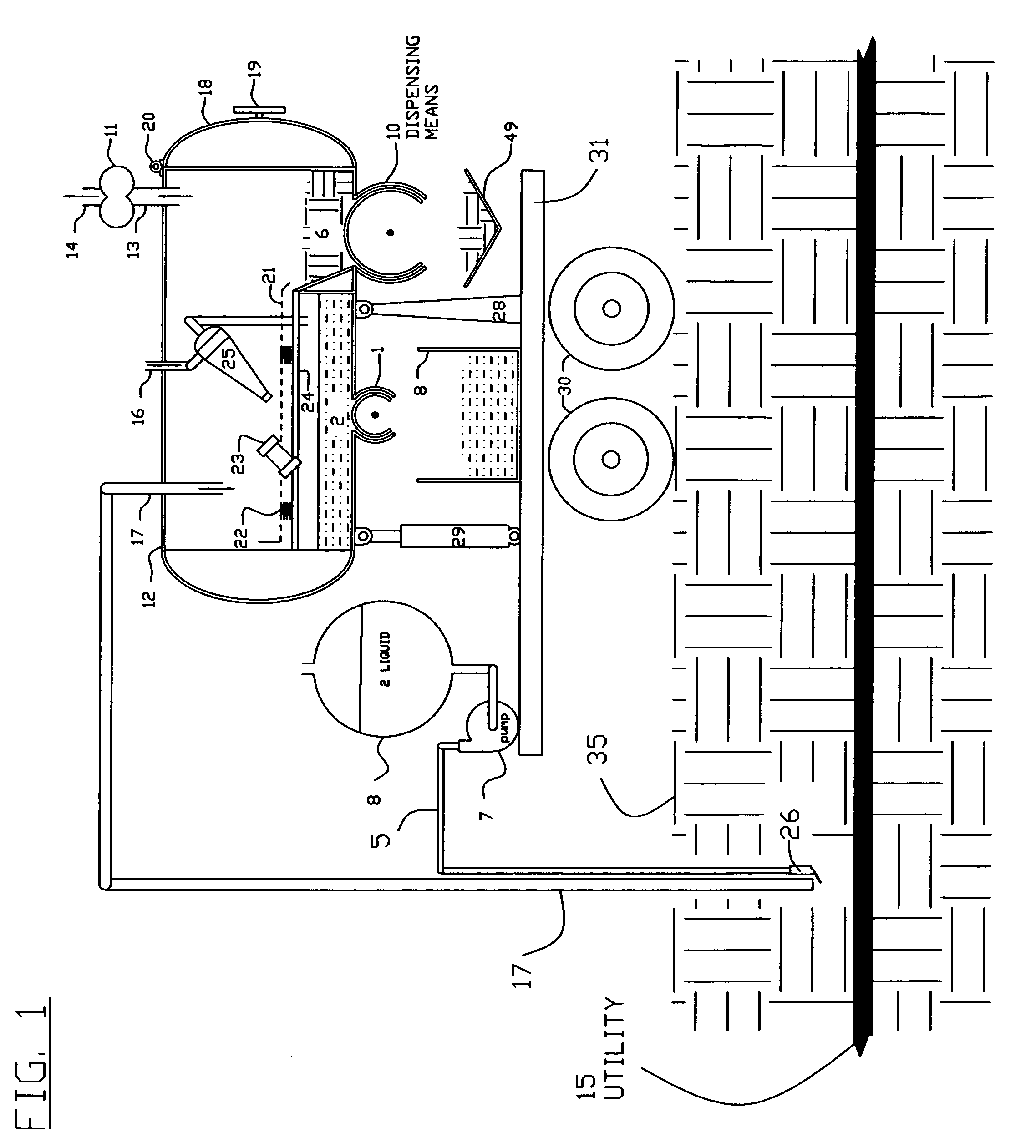

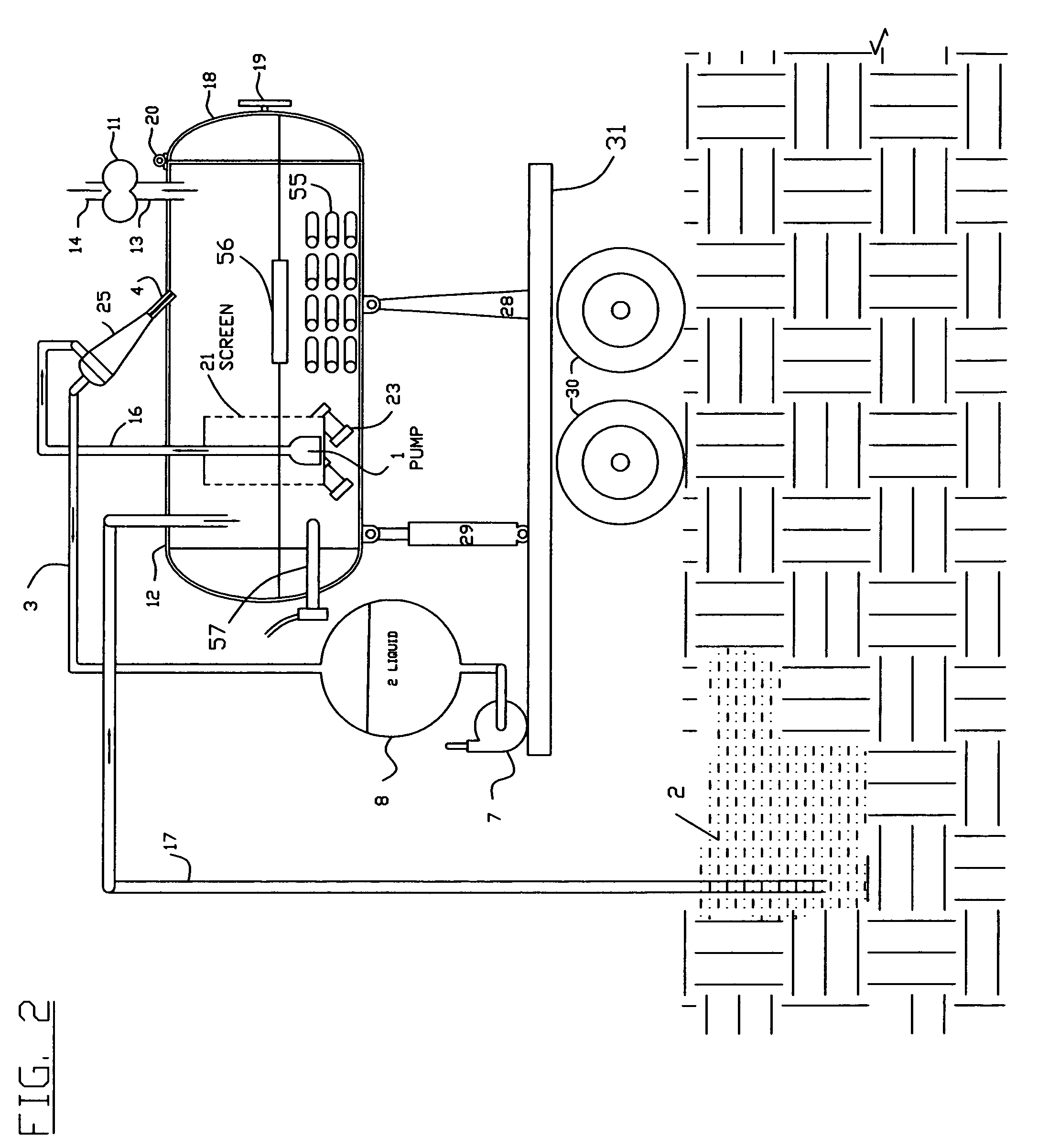

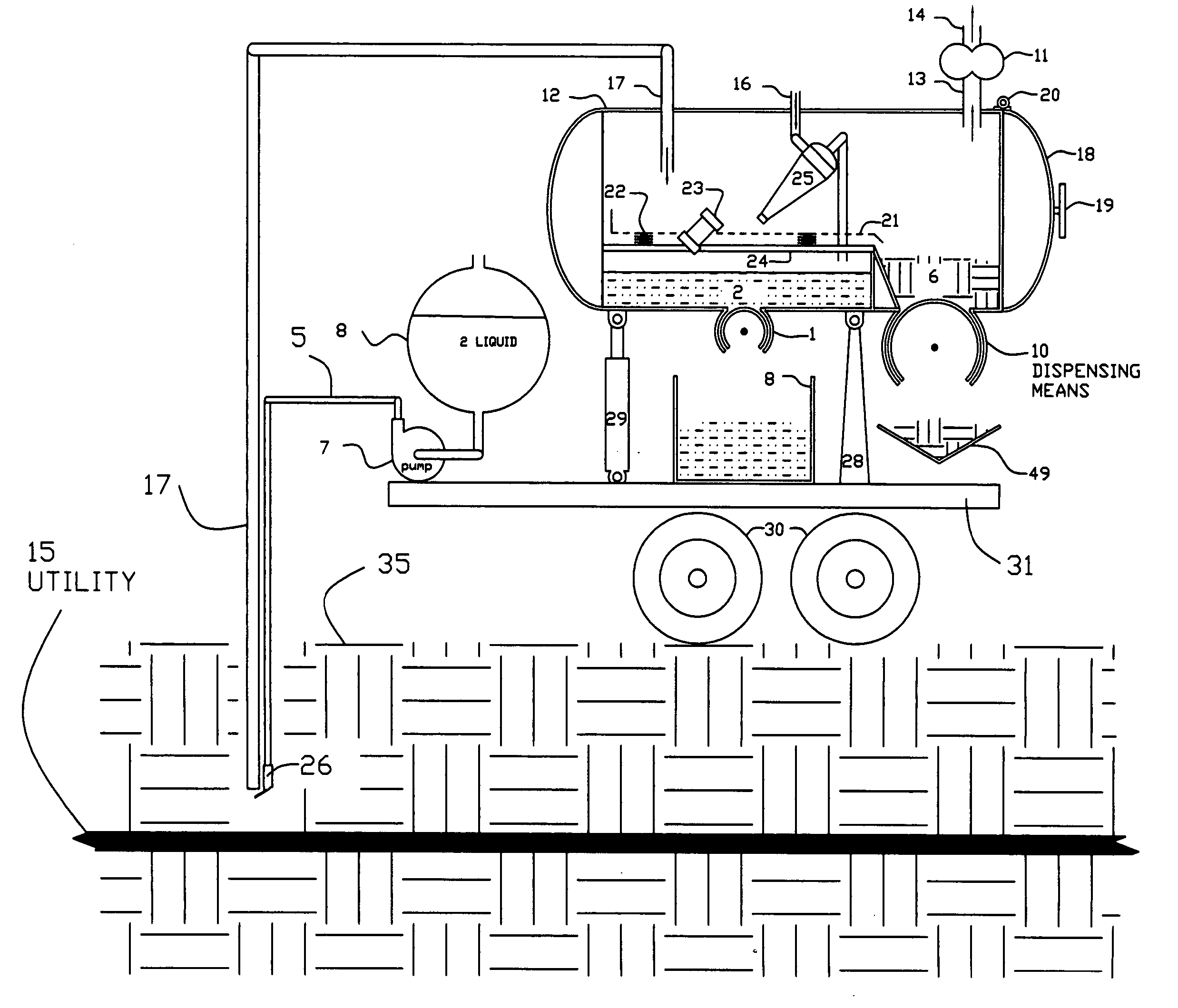

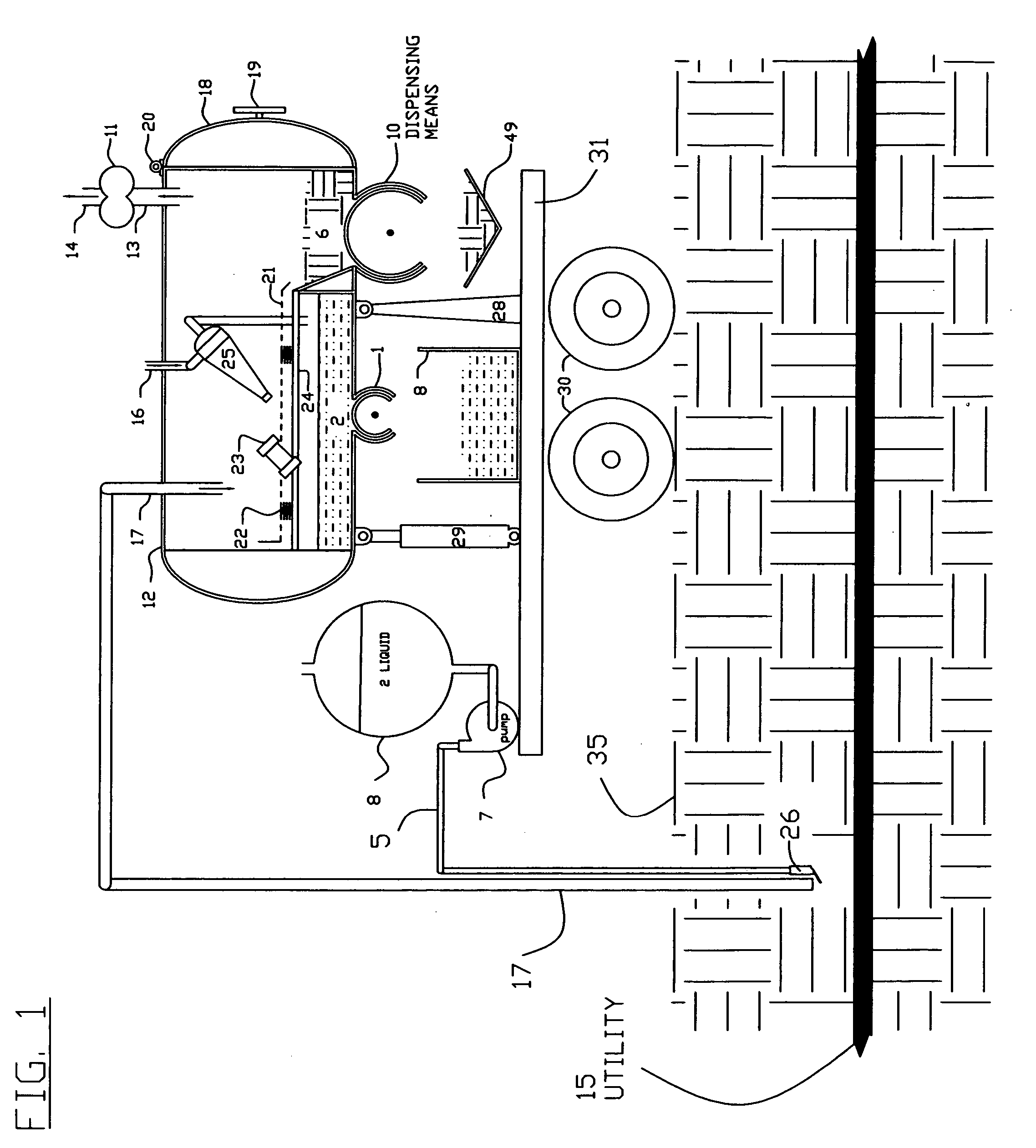

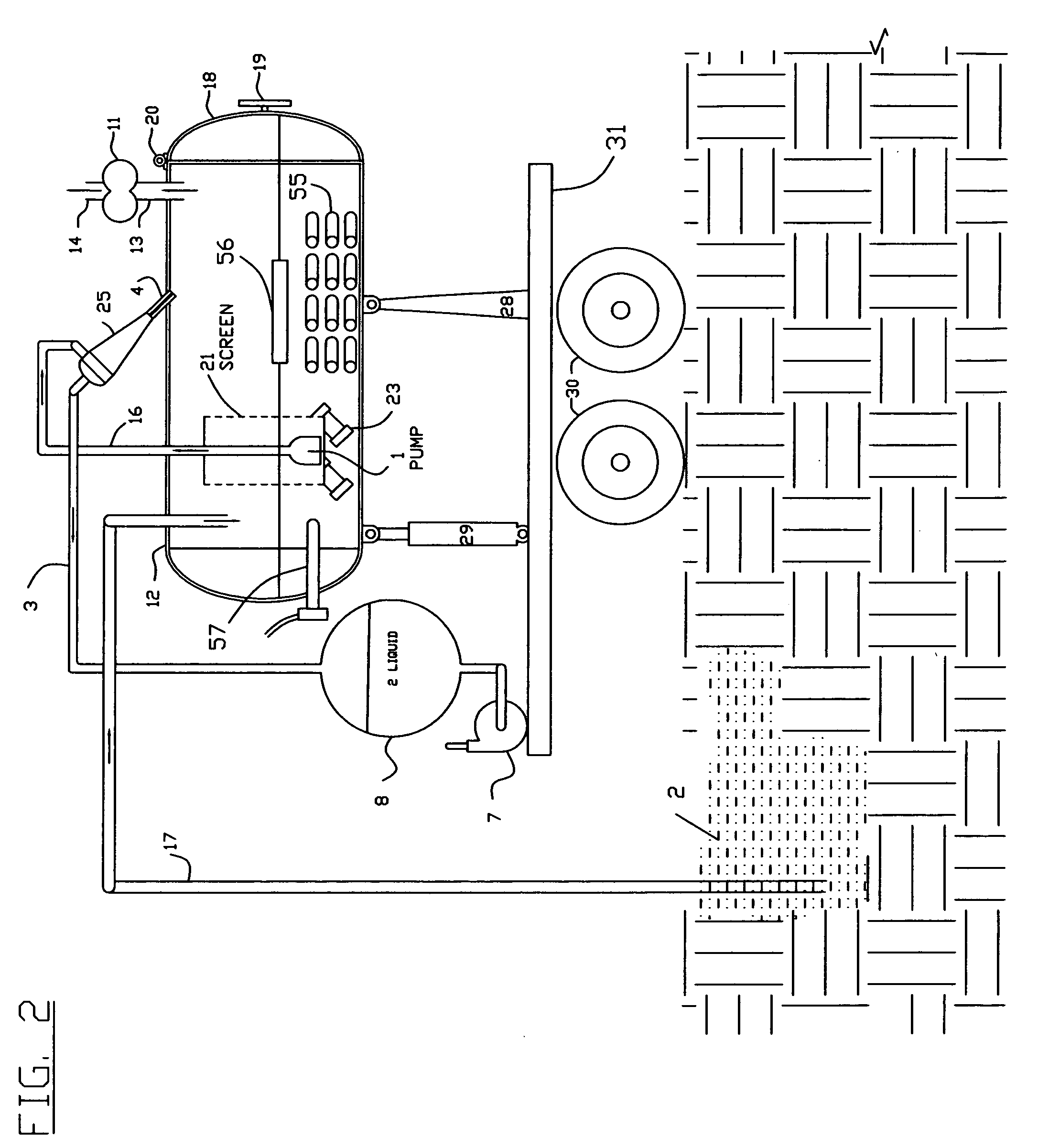

Mobile vacuum boring and mud recovery method with the debris tank inclined & water storage below

InactiveUS20060032095A1Improve structural strengthProvide spaceMachines/dredgers working methodsMining devicesRecovery methodWater storage

A mobile vacuum boring and mud recovery method comprising a device which will create a vacuum condition within a vacuum container and the vacuum container is mounted on an incline to provide space beneath it to locate a water storage container, and having a vacuum conduit to transport a liquid and or solid particles into the vacuum container. The inclined vacuum tank facilitates gravitational assistance in both separation of liquids & solids as well as unloading debris. A dispensing device may be added to dispense a liquid or a solid from the vacuum container without eliminating the vacuum environment within the vacuum container, and said vacuum container having the ability to fill, store and dispense its contents simultaneously. The vacuum container may further comprises a means to separate a liquid from solids. The vacuum conduit articulated boom used to transport debris into the vacuum container may have the added feature or attachments chosen from an earth digging bucket, a telescoping vacuum conduit, sensor to locate buried utilities, monitors and controls to operate the attachments an their function, water spray nozzle, man hole cover remover cutting tool grinding tool, saw, blasting tool, surface cleaning tool, demolition tool, torque wrench, tractor to pull vacuum hose, jetter nozzle, or camera and power source to operate them. The above described vacuum system may be mounted on a variety of mobile platforms, chosen from but not limited to a trailer, truck, skid steer, fork lift, track hoe, railroad car, or zero turn radius vehicle which may have the added feature of being convertible between a powered vehicle & a trailer.

Owner:BUCKNER LYNN ALLAN

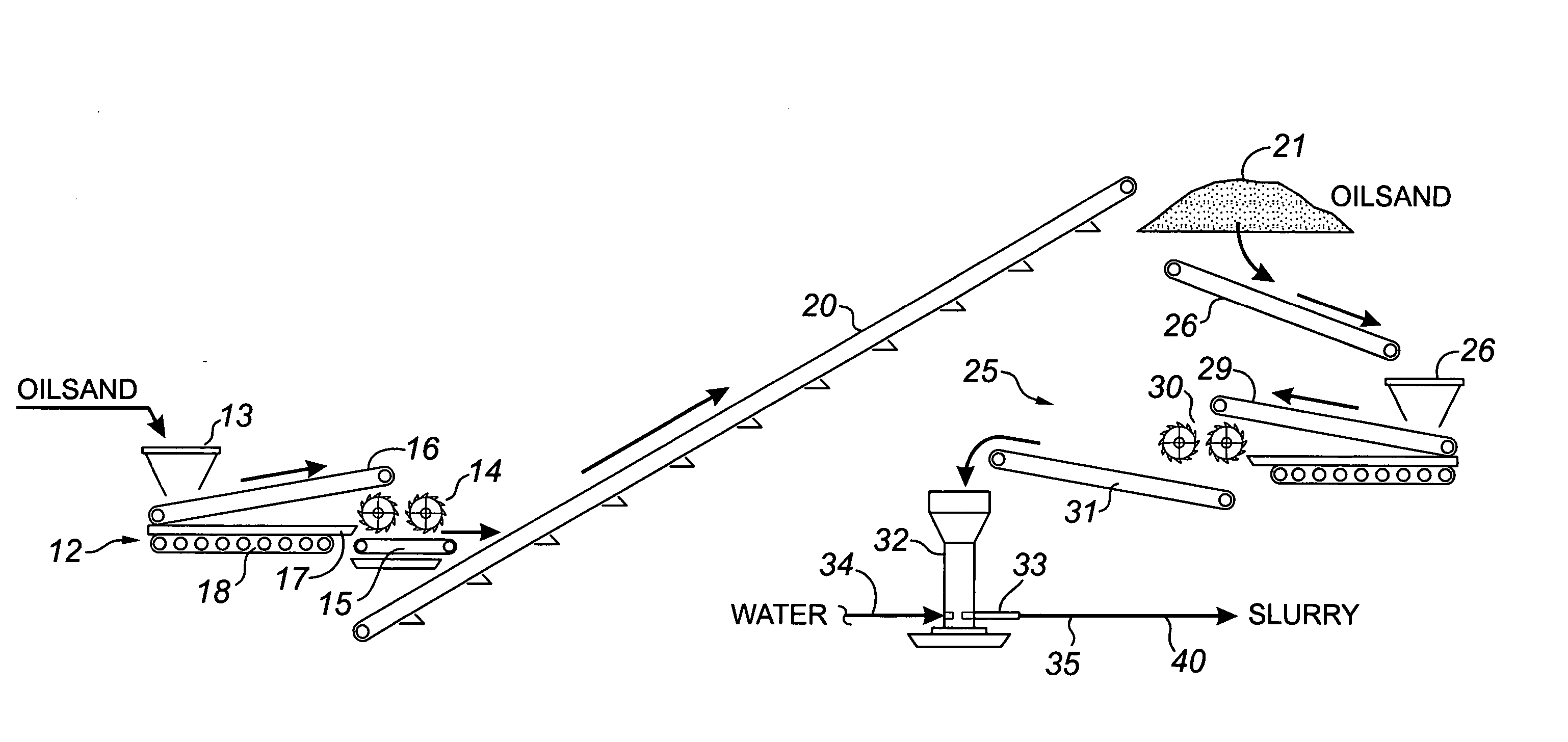

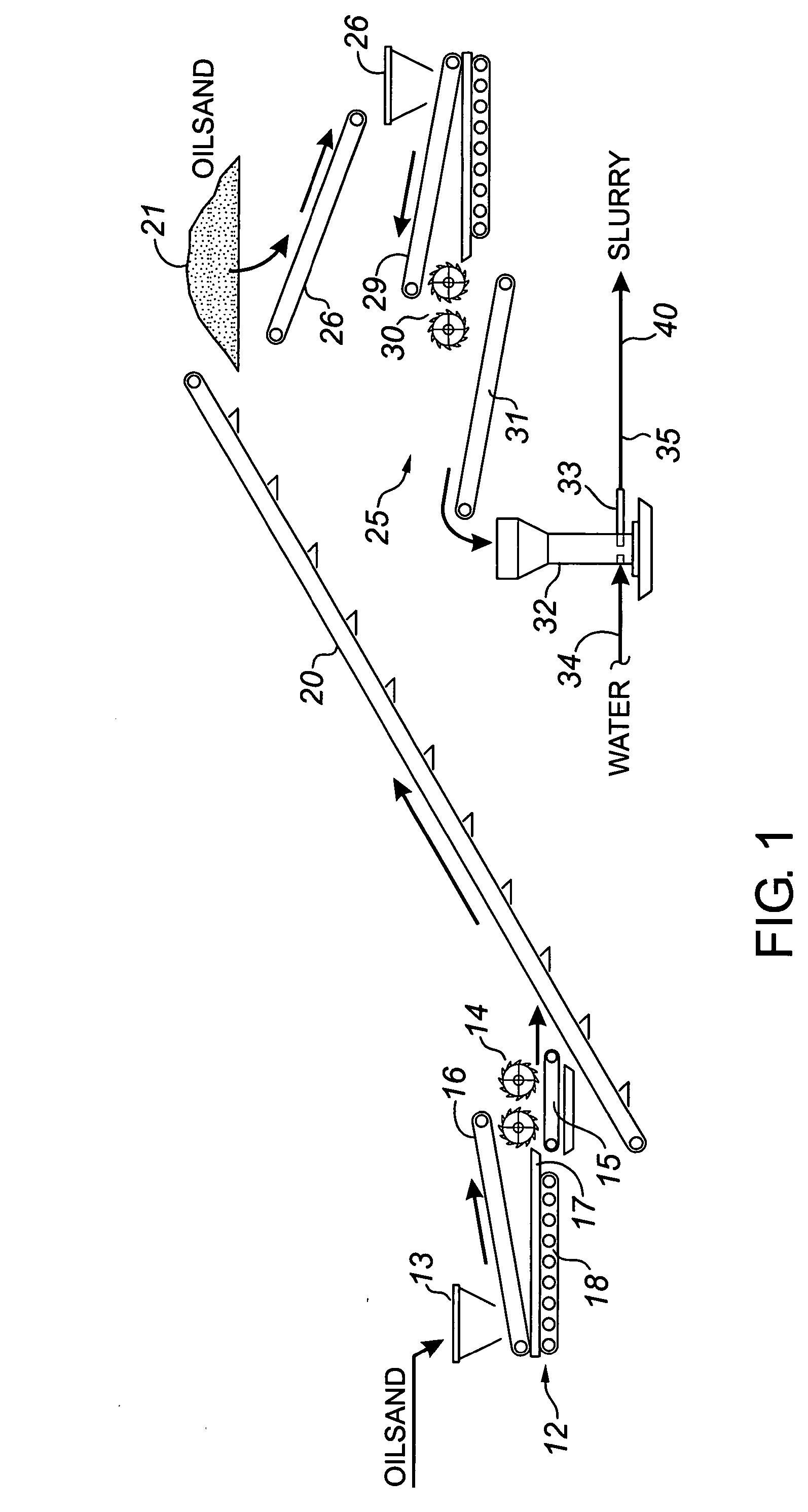

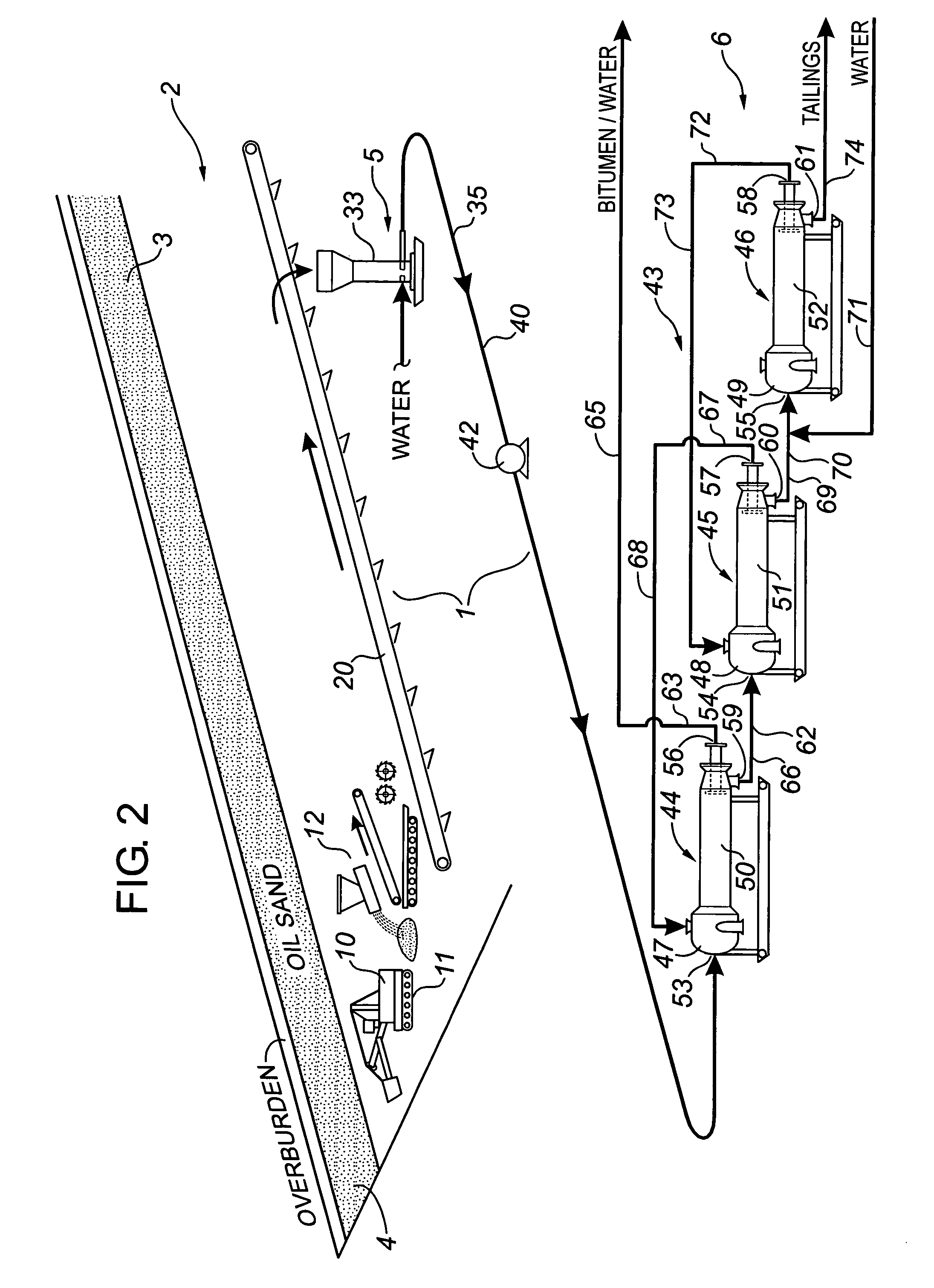

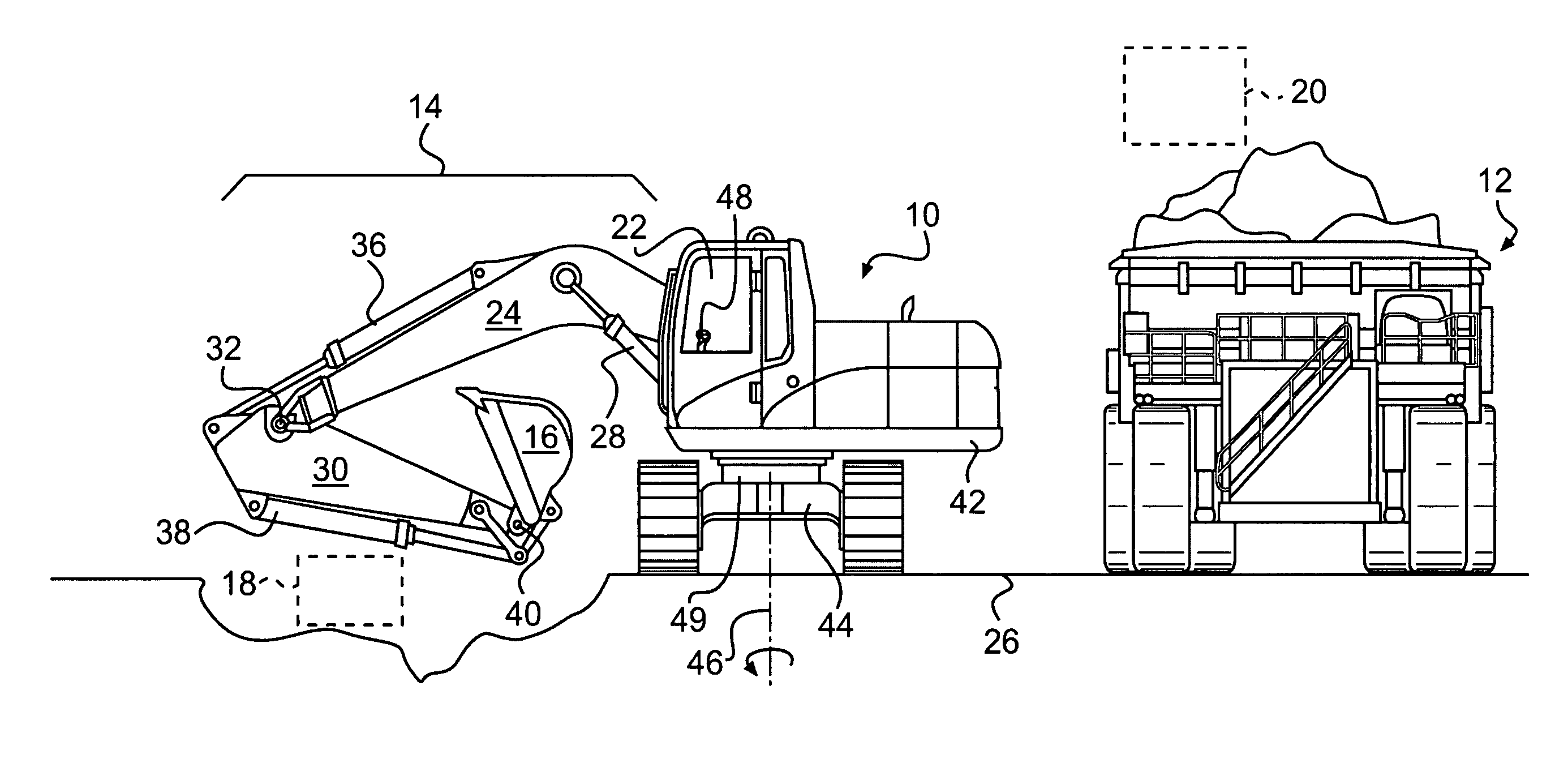

Mine site oil sands processing

InactiveUS20050134102A1Increase probabilityMachines/dredgers working methodsUnderground miningShovelCrusher

A process line comprising a combination of mobile and relocatable equipment units is provided at an oil sand mine site. The process line may comprise: a mobile shovel; a mobile bin and double roll crusher; a relocatable conveyor belt extending along the mine face; a relocatable slurry preparation assembly, such as a secondary crusher and jet pump; a pipeline; and a relocatable desanding circuit of separators. The process line conducts the following steps: mining the oil sand; crushing it to conveyable size; conveying it to a slurry preparation location; further crushing it to slurrying size and mixing it with heated water to produce a pumpable, aerated oil sand slurry; transporting and conditioning the slurry in the pipeline; desanding it to produce a product comprising bitumen and water and tailings; depositing tailings in a retention facility; and removing the product from the mine site in a pipeline.

Owner:CANADIAN OIL SANDS CANADIAN OIL SANDS

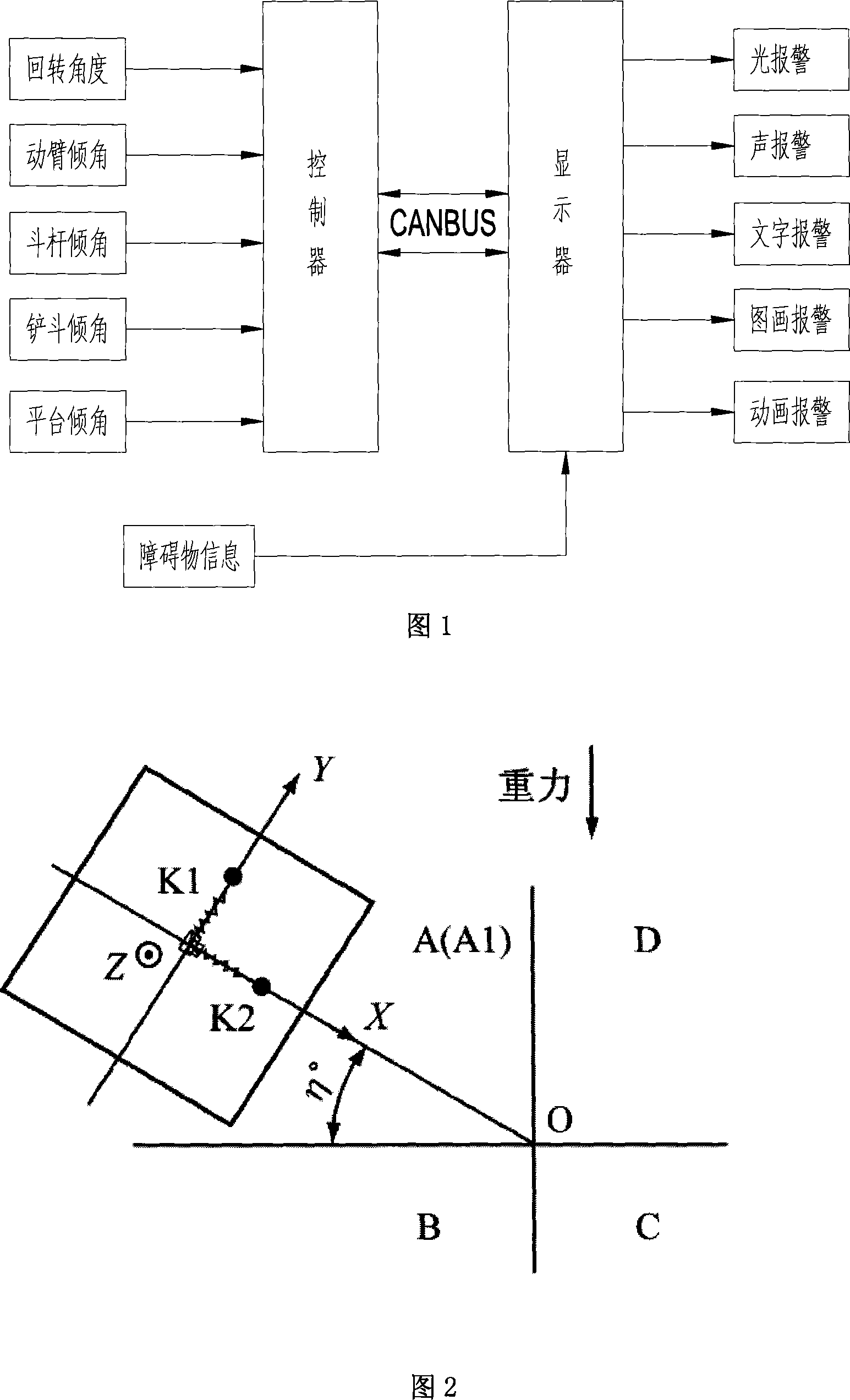

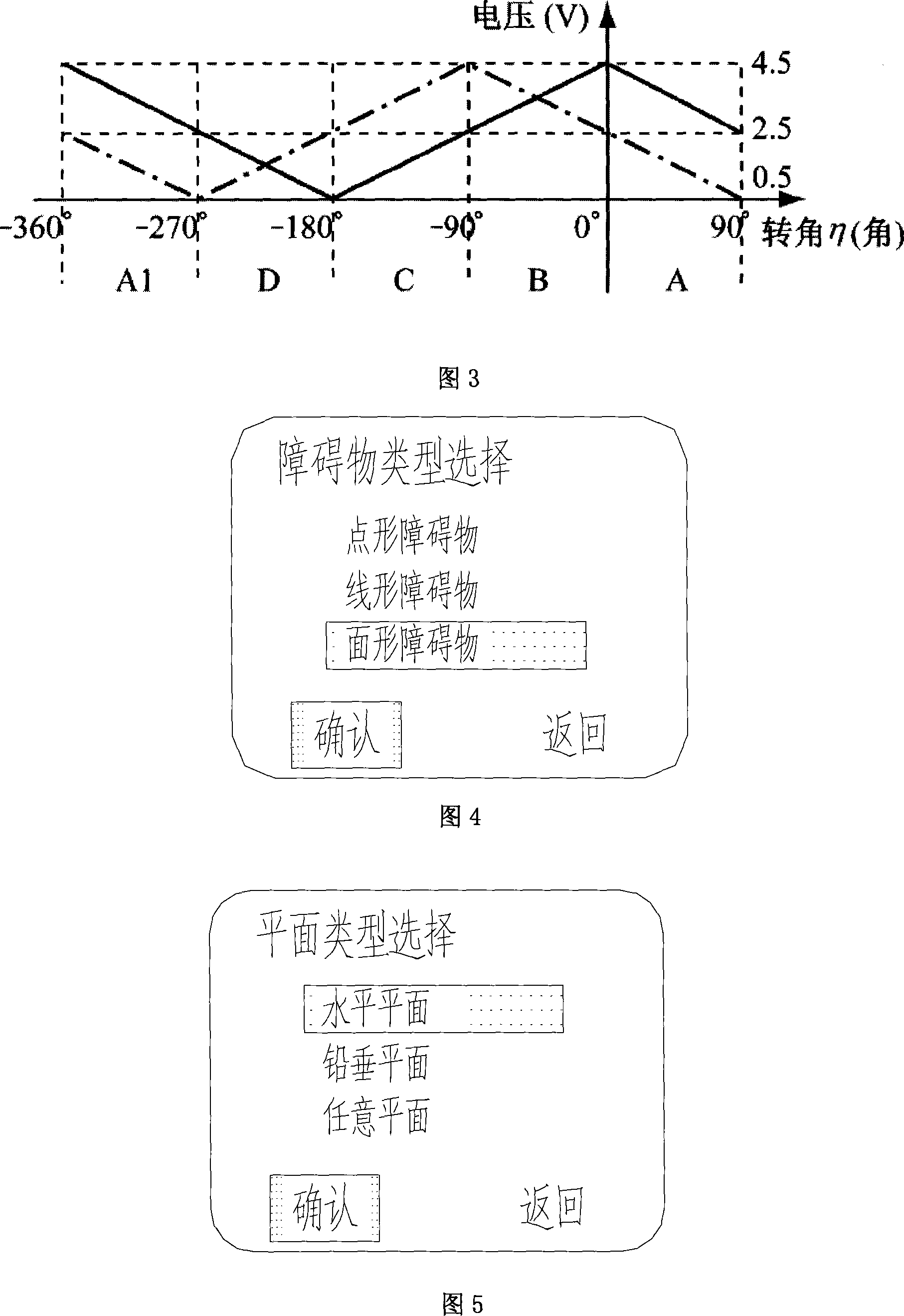

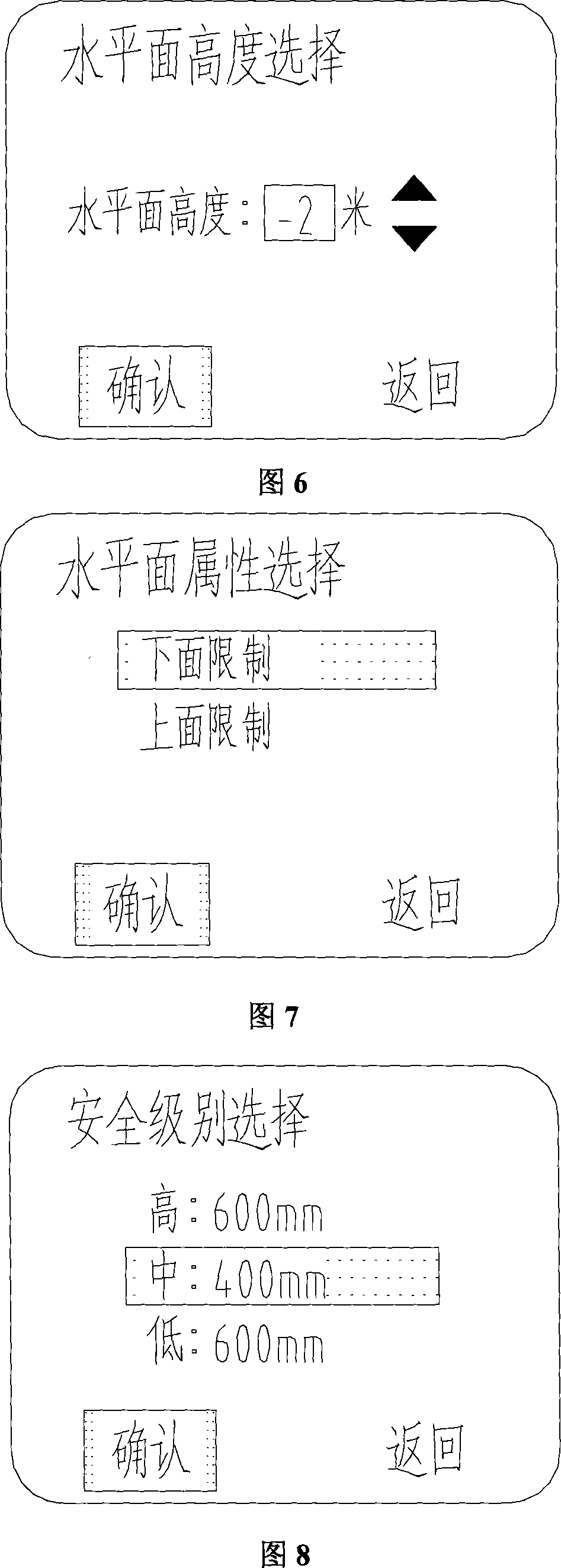

Hydraulic-digger obstruction-avoiding control system and method

InactiveCN101070706AImprove digging reliabilityAvoid accidentsMachines/dredgers working methodsControl systemPosition angle

This invention discloses a hydraulic pressure excavator to evade bonds control system and the method. Including the following step: (1) hypothesis unearths the forbidden area; (2) gains the excavator through the sensor of move arm, the bucket arm, the scoop and the working platform condition; (3) computation excavator work installs and unearths the forbidden area the distance, when this distance being smaller than marginal value, sends out the alarm; (4) redundant step (2), (3), until excavator engine off when up to; The system including input device's load module, uses in examining the excavator work, walking the setting position angle sensor, the inclination angle sensor, various sensors' output signal after the sensor interface module and the controller connection, is equipped with the comparison module the controller as well as the early-warning installation. This invention the online data which and the critical number comparison obtains through various sensors, the definite excavator's active status, realizes in the excavator work process by this to the obstacle avoidance function, avoids the accident occurring.

Owner:SANY HEAVY MACHINERY

Digging and backfill apparatus

ActiveUS20060117612A1Improved drillingImproved backfill systemMachines/dredgers working methodsMechanical machines/dredgersEngineeringVacuum pump

A mobile digging and backfill system for removing and collecting material above a buried utility. The system comprises a mobile chassis, a collection tank mounted to the chassis, a water pump mounted to the chassis for delivering a pressurized liquid flow against the material for loosening the material at a location, a vacuum pump connected to the collection tank so that an air stream created by the vacuum pump draws the material and the fluid from the location into the collection tank, and at least one backfill reservoir mounted to the chassis for carrying backfill for placement at the location.

Owner:VERMEER MFG CO

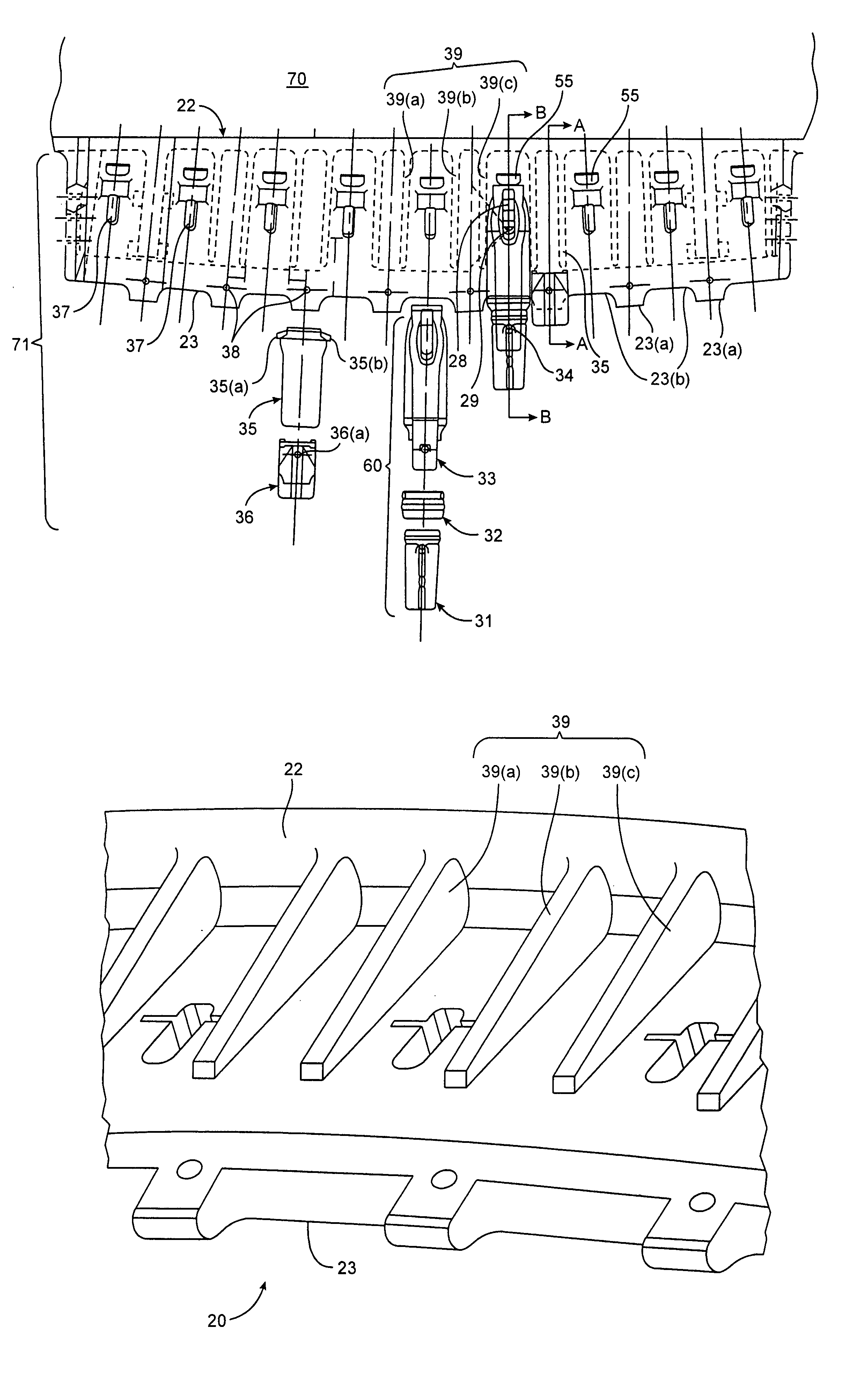

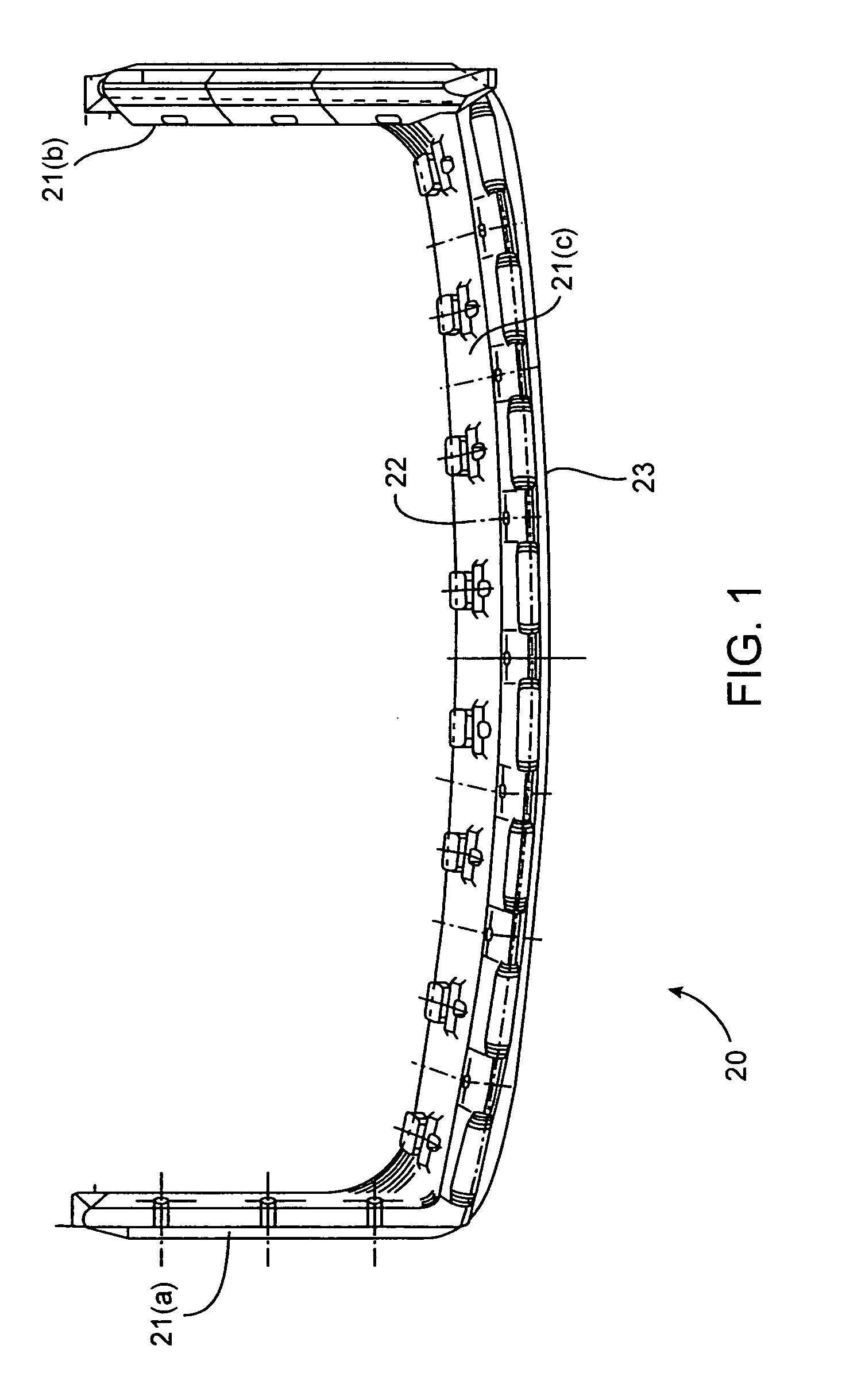

Lip assembly

InactiveUS6952892B1Reduce wearExtended service lifeMachines/dredgers working methodsEngineeringMechanical engineering

A lip assembly is disclosed. The lip assembly comprises a lip having an upper surface, a lower surface, a front portion, and a rear portion. A plurality of holes is disposed between the front portion and the rear portion. The lip also includes support members. Each support member is disposed adjacent to a hole within the plurality of holes and is positioned to inhibit movement of a tooth assembly coupled to the hole. A plurality of tooth assemblies extend away from the lip and are respectively coupled to the lip via the plurality of holes. The lip assembly may be used with an excavation bucket body.

Owner:BIERWITH ROBERT S

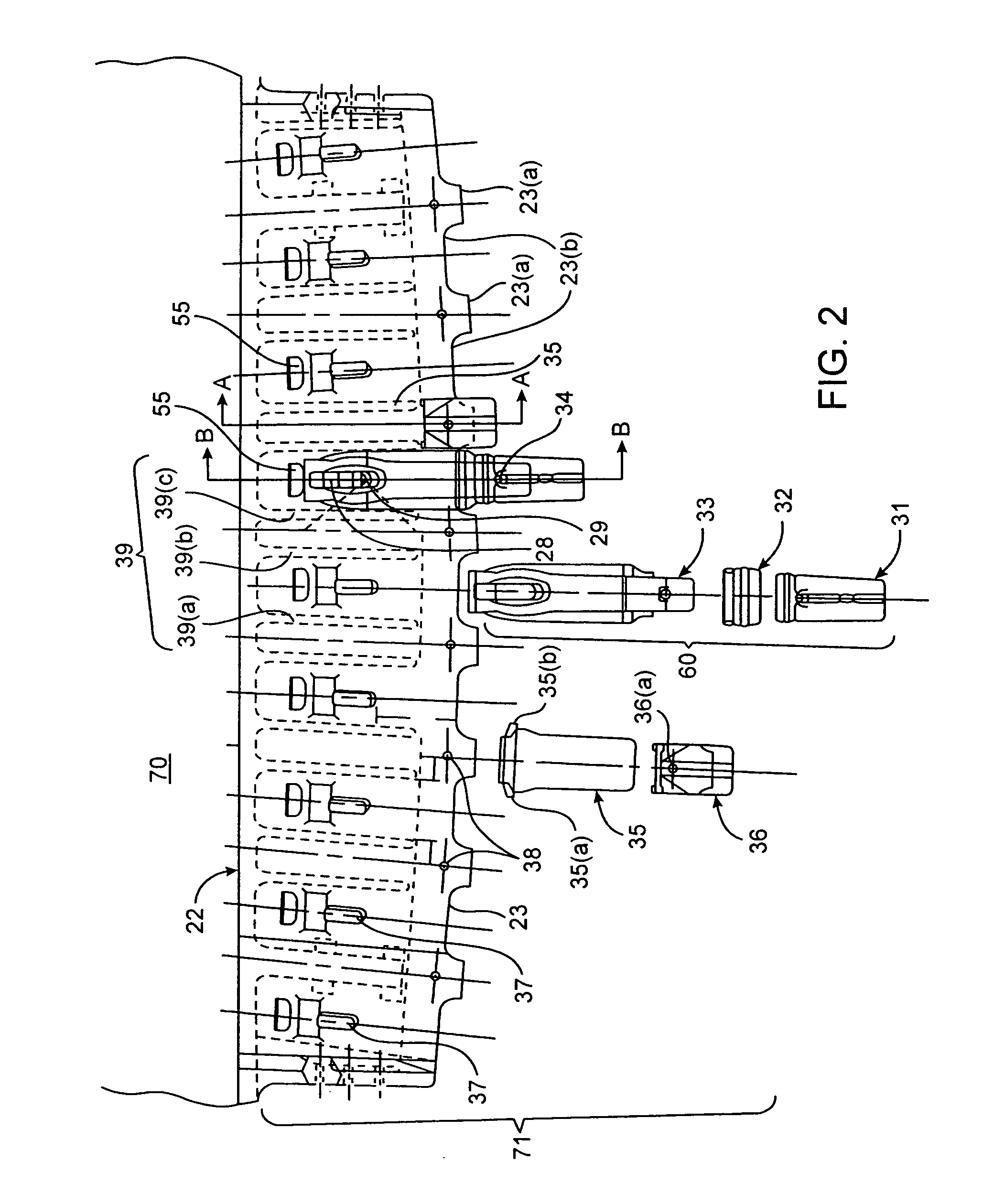

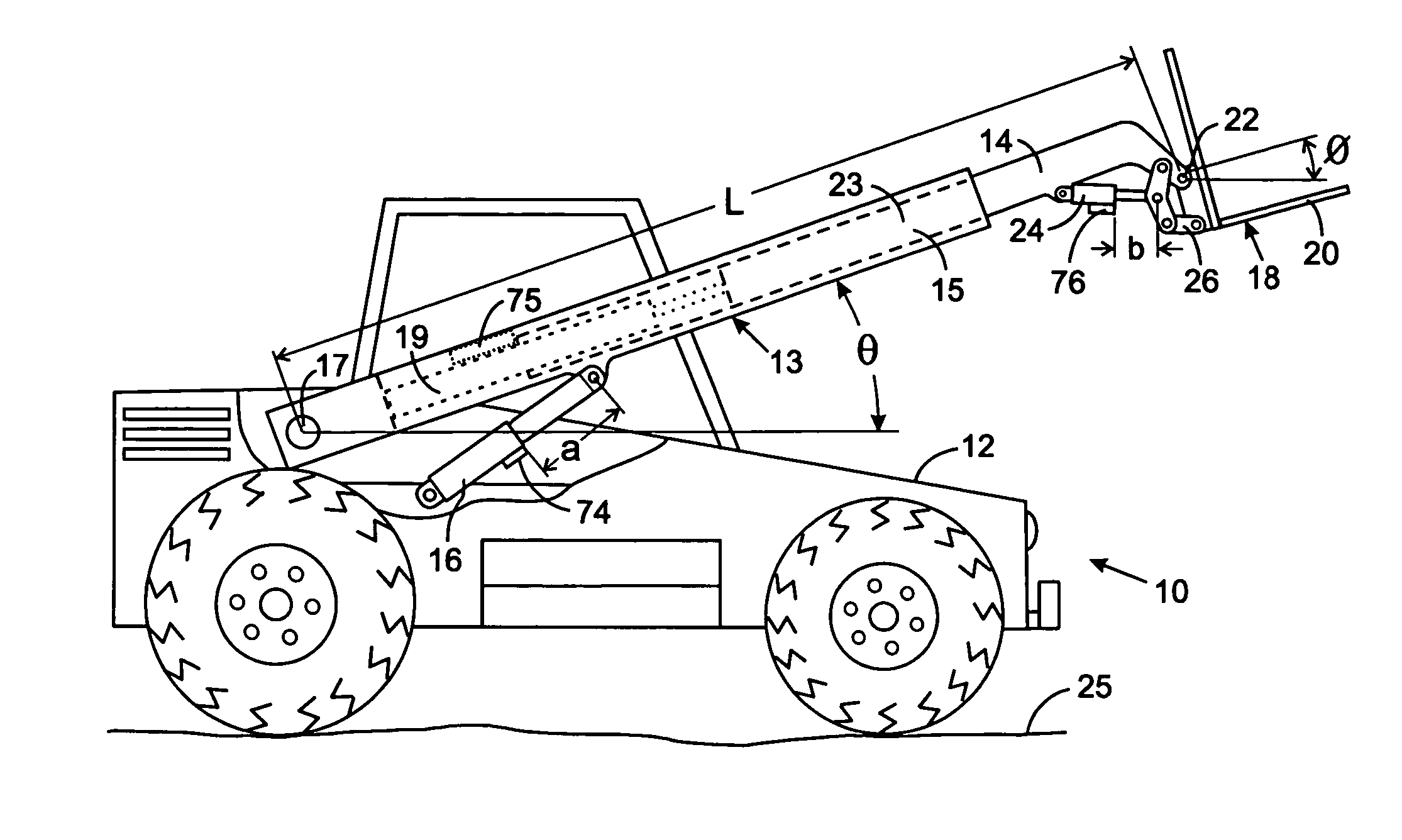

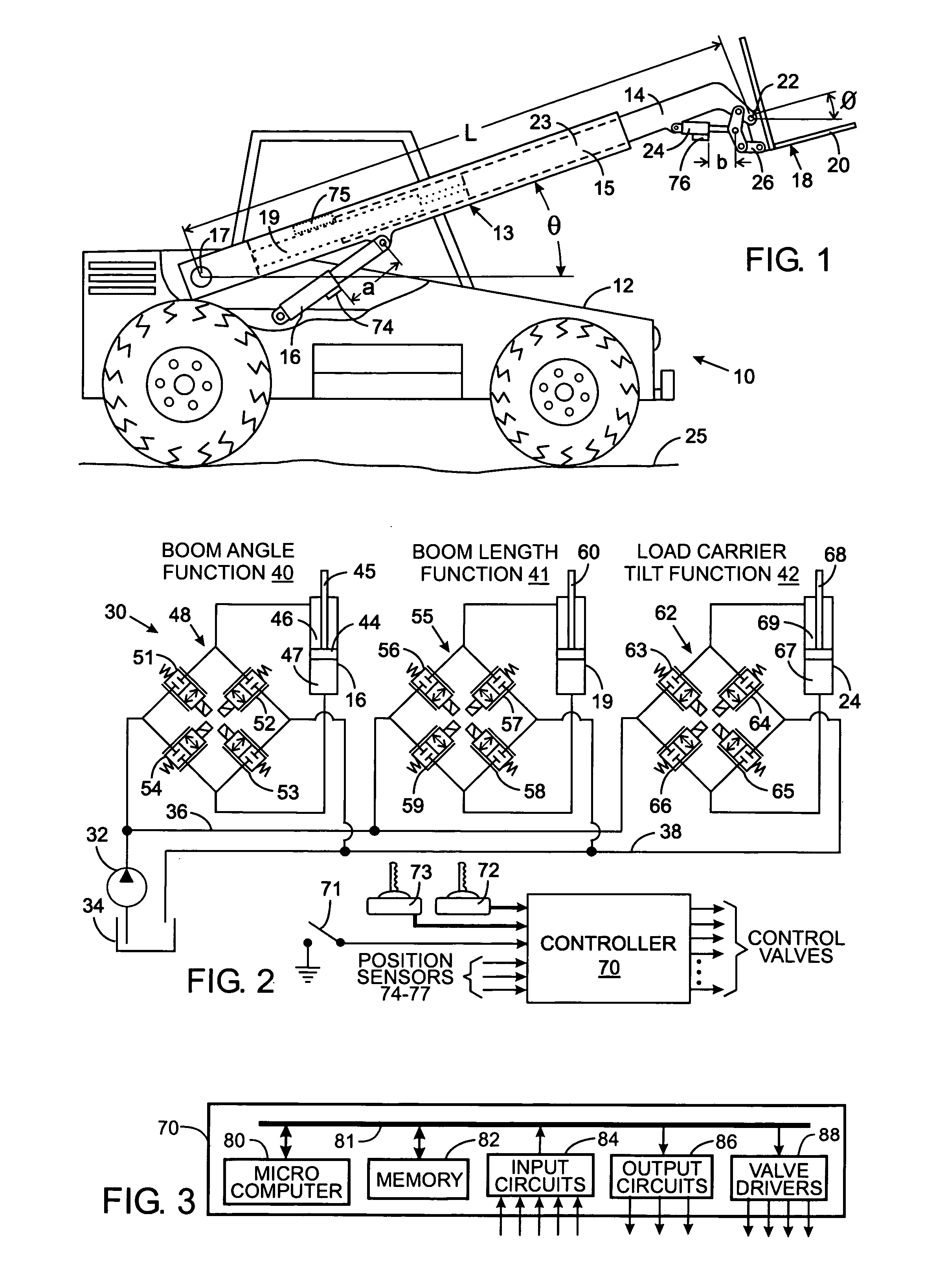

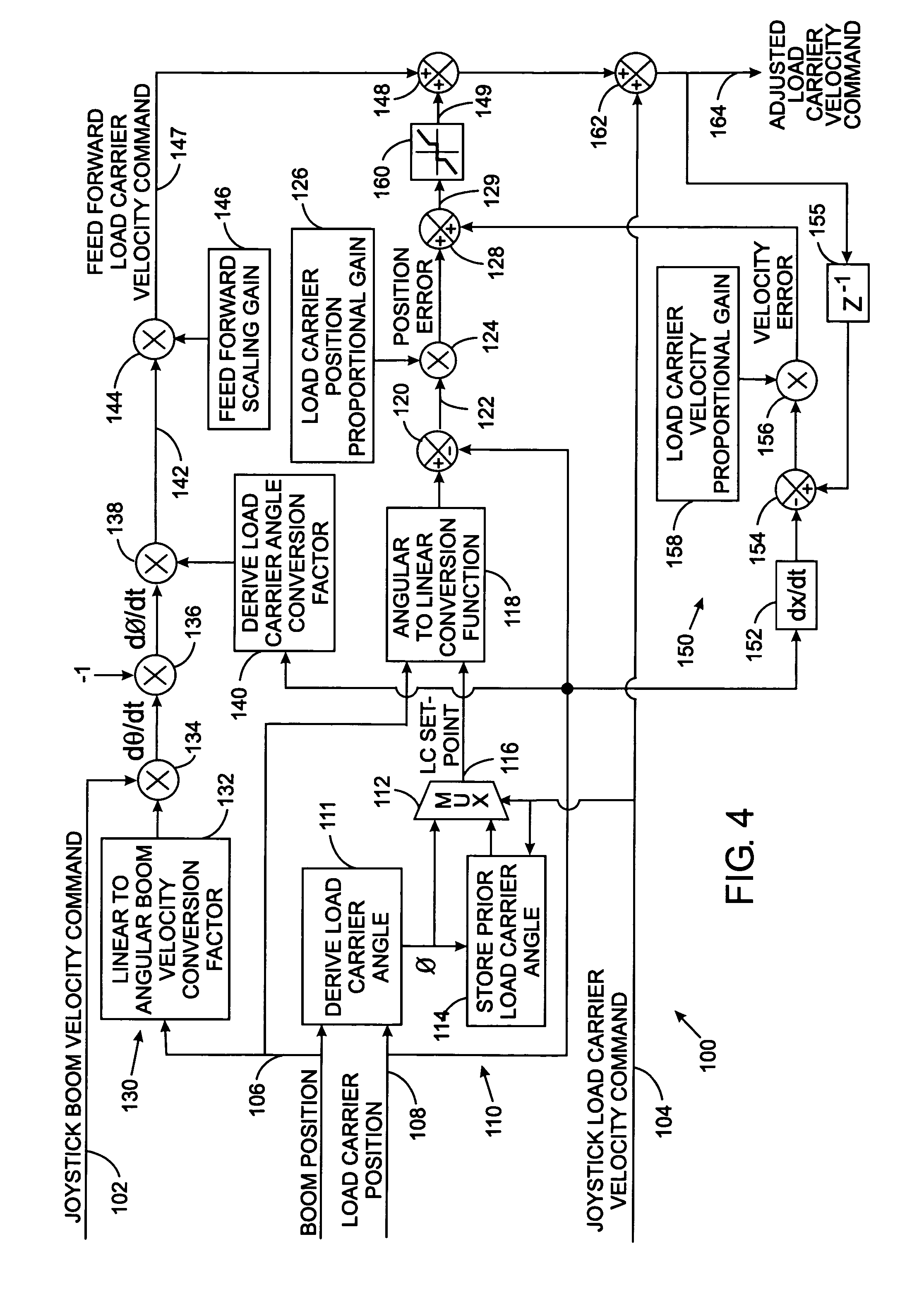

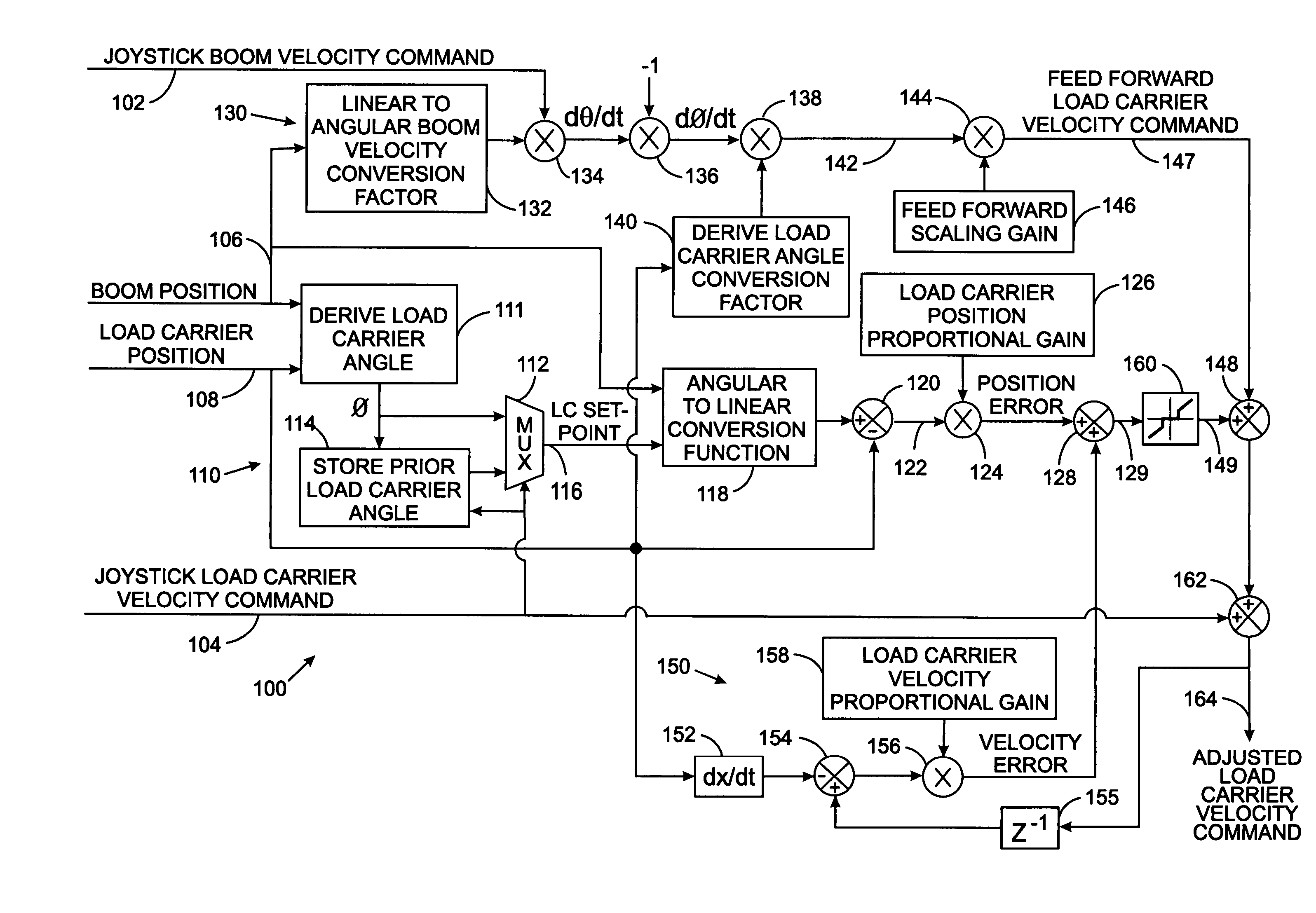

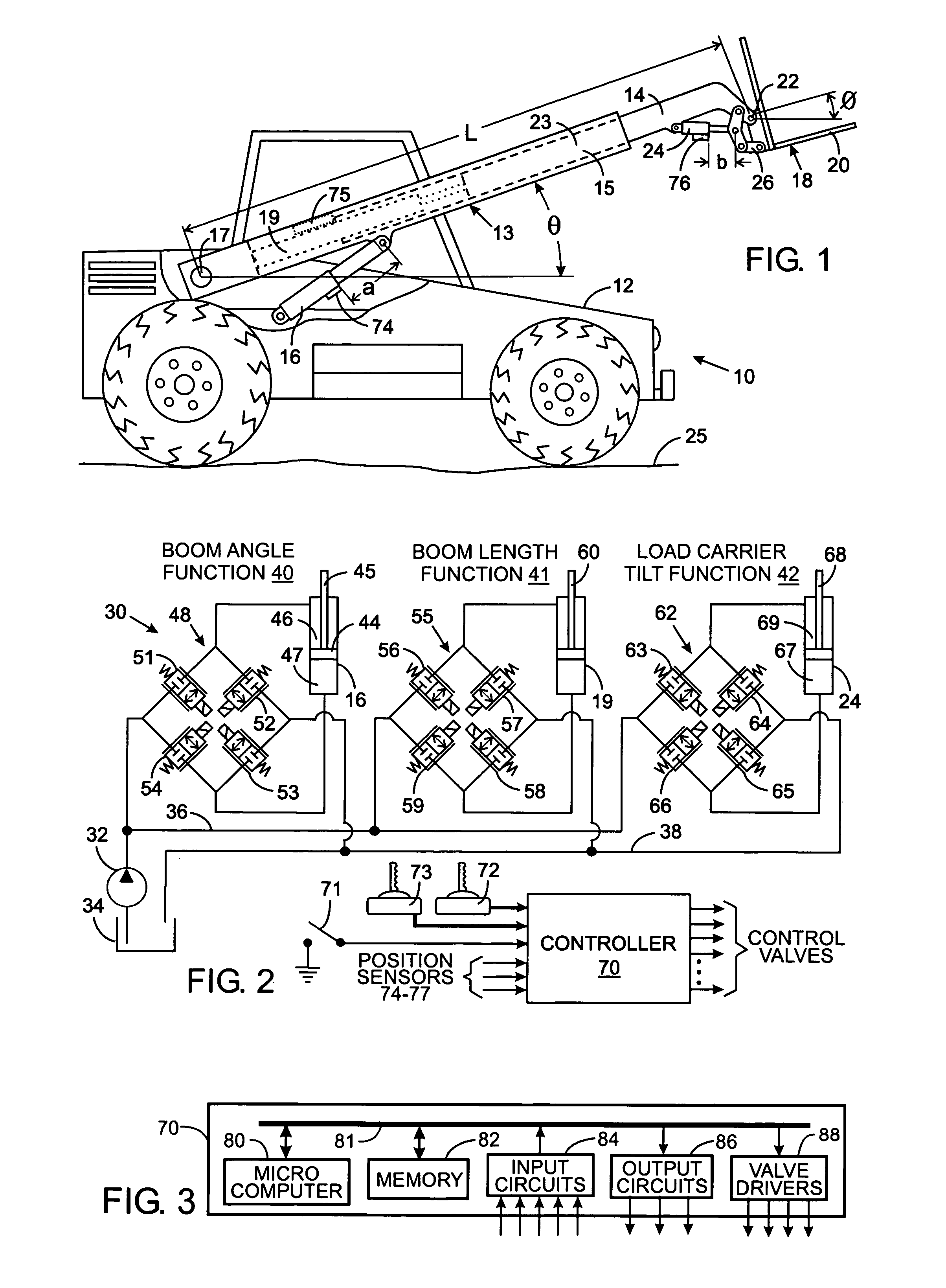

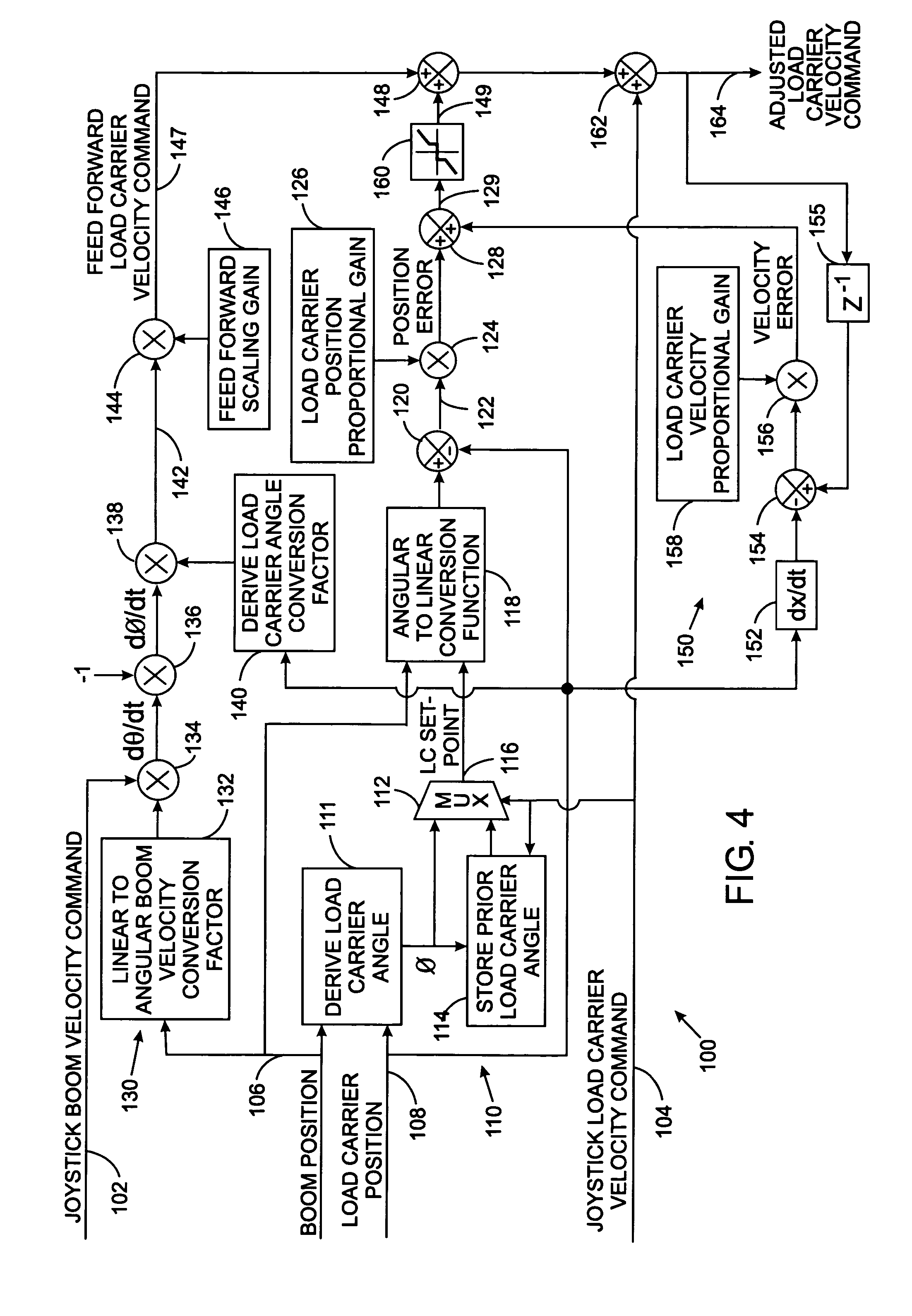

Automatic hydraulic load leveling system for a work vehicle

InactiveUS20050210713A1Programme-controlled manipulatorMachines/dredgers working methodsLinear motionMachine control

A machine has a boom, that is pivotally raised and lowered by a first cylinder, and has a load carrier that is pivoted at the end of the boom by a second cylinder. As a machine operator commands movement of the boom, the position of the load carrier is automatically altered by a controller to prevent a load from falling off the load carrier. The load carrier position with respect to the boom is altered in response to the amount of boom motion to maintain a constant position relationship between the load carrier and a chassis of the machine. Although the boom and load carrier move through different angular positions, the machine control is expressed in terms of the linear motion of the first and second cylinders.

Owner:HUSCO INT INC

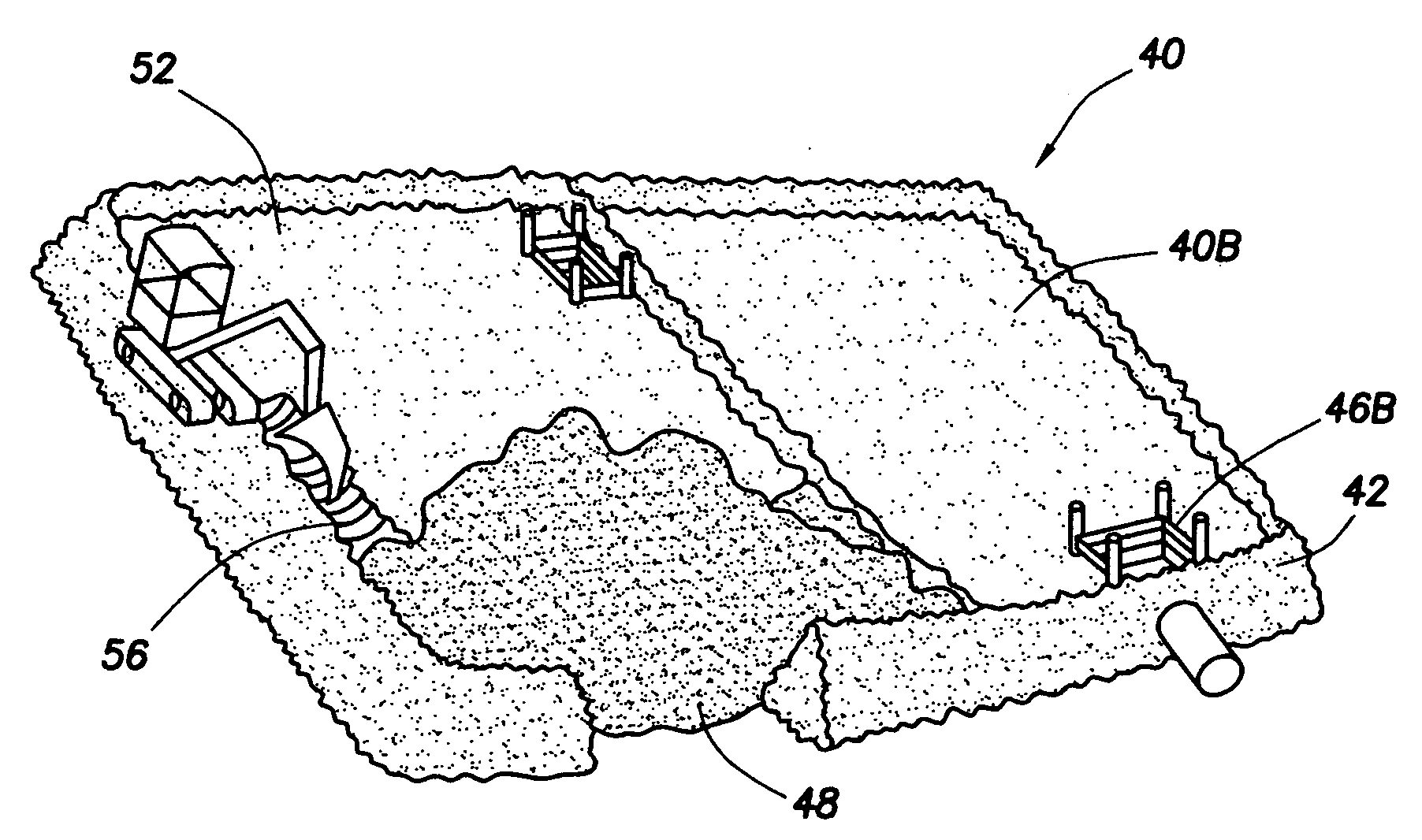

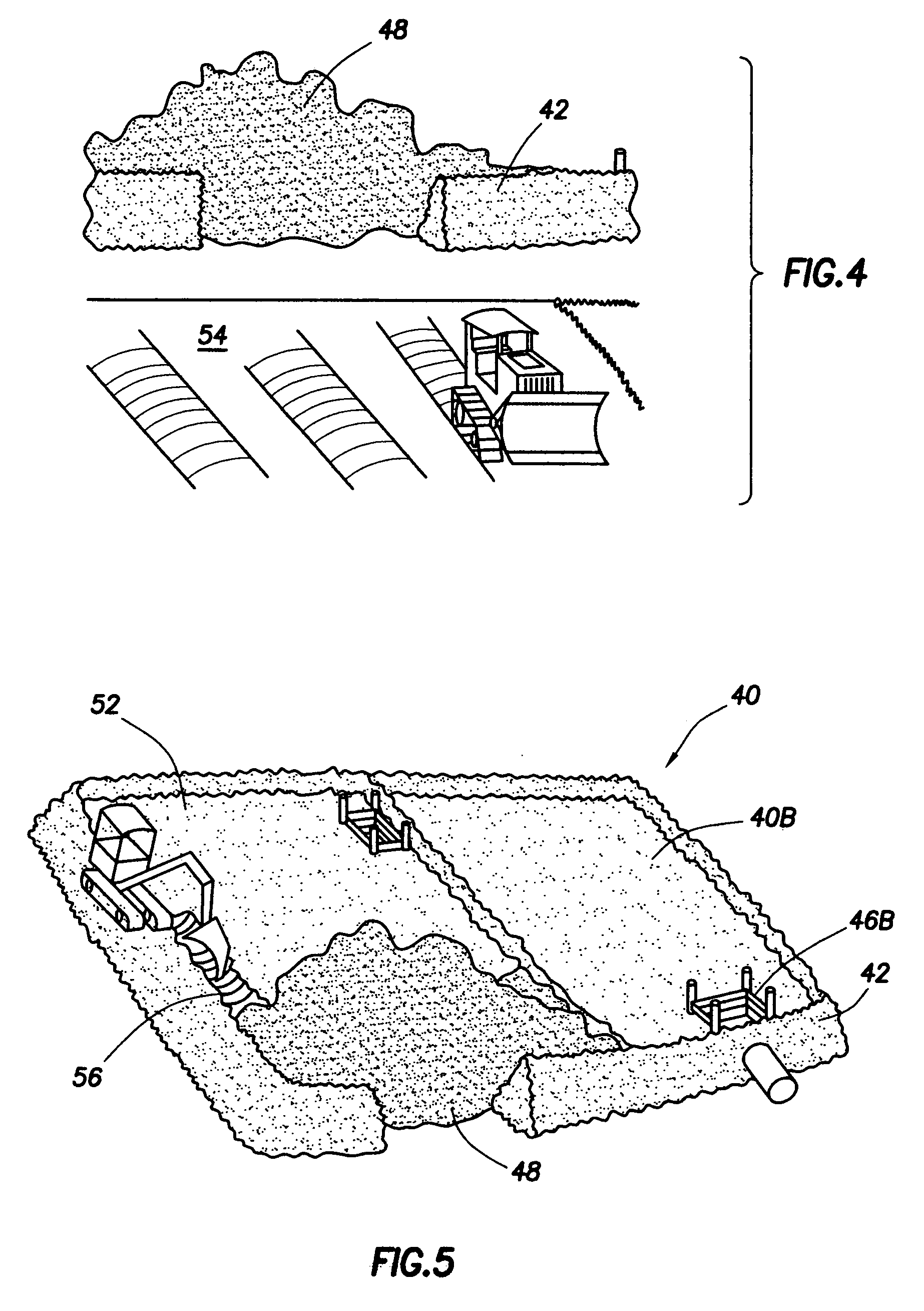

Method for reclaiming hydraulically dredged material

InactiveUS20090148238A1Machines/dredgers working methodsSolid waste disposalProcess regionEngineering

A method for reclaiming hydraulically dredged material from a dredge reclamation area (DRA) having particular application for reclaiming hydraulically dredged virgin / new cut earthen material. The method involves the construction of training dikes and weirs in the DRA for draining water from saturated silts within the DRA and drying clay in the DRA in either a separate processing area or within the confines of the DRA by windrowing and by mechanical manipulation of the clay. The silts are then dried in the same way and mixed with the dried clay, either in a separate processing area or within the DRA. The resulting reclaimed material can meet industry standard density tests of 95% standard Proctor along with removing the moisture content to a 2%± of optimum moisture or better for use as structural or regular fill.

Owner:SMITH TROY A

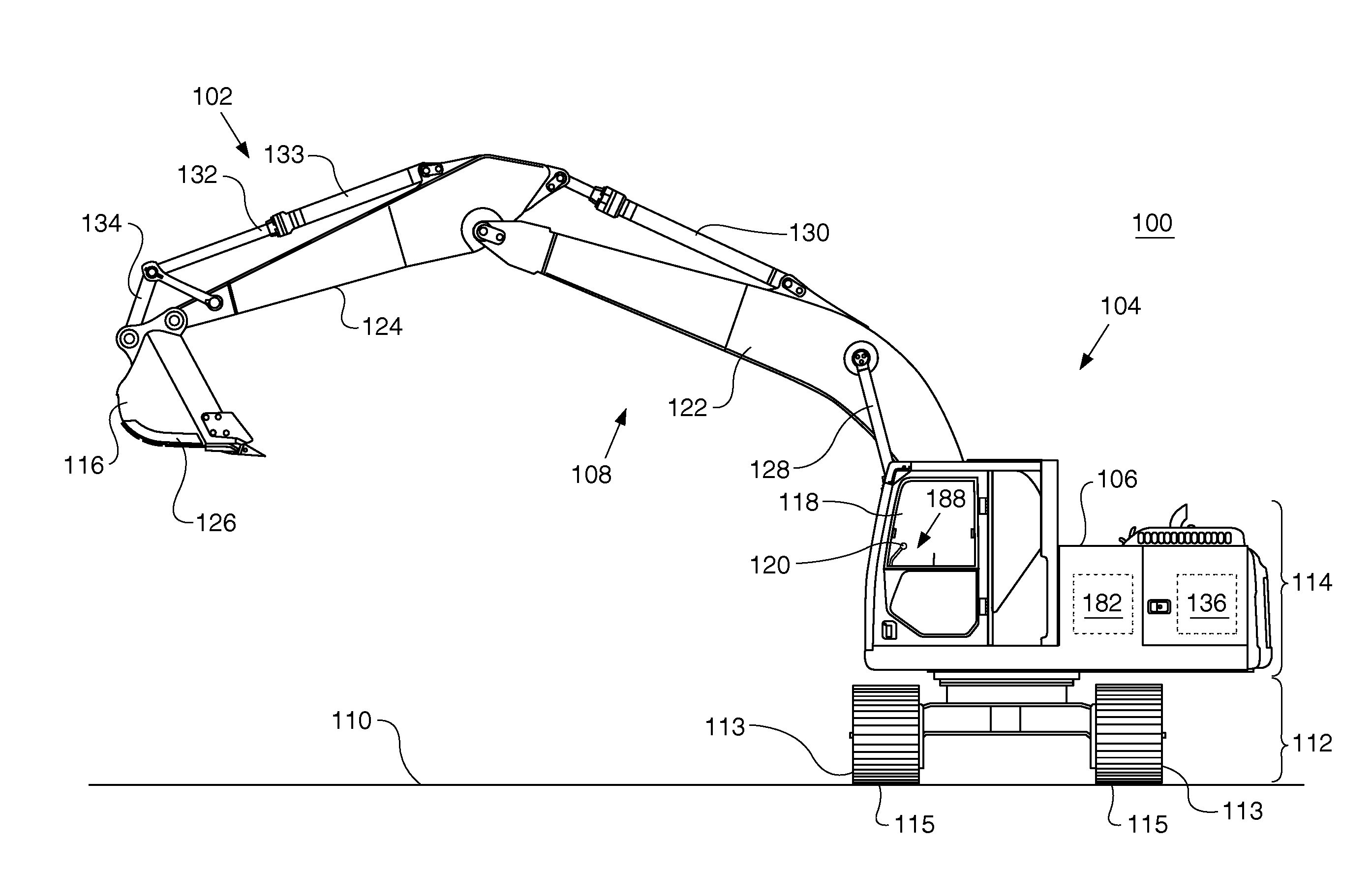

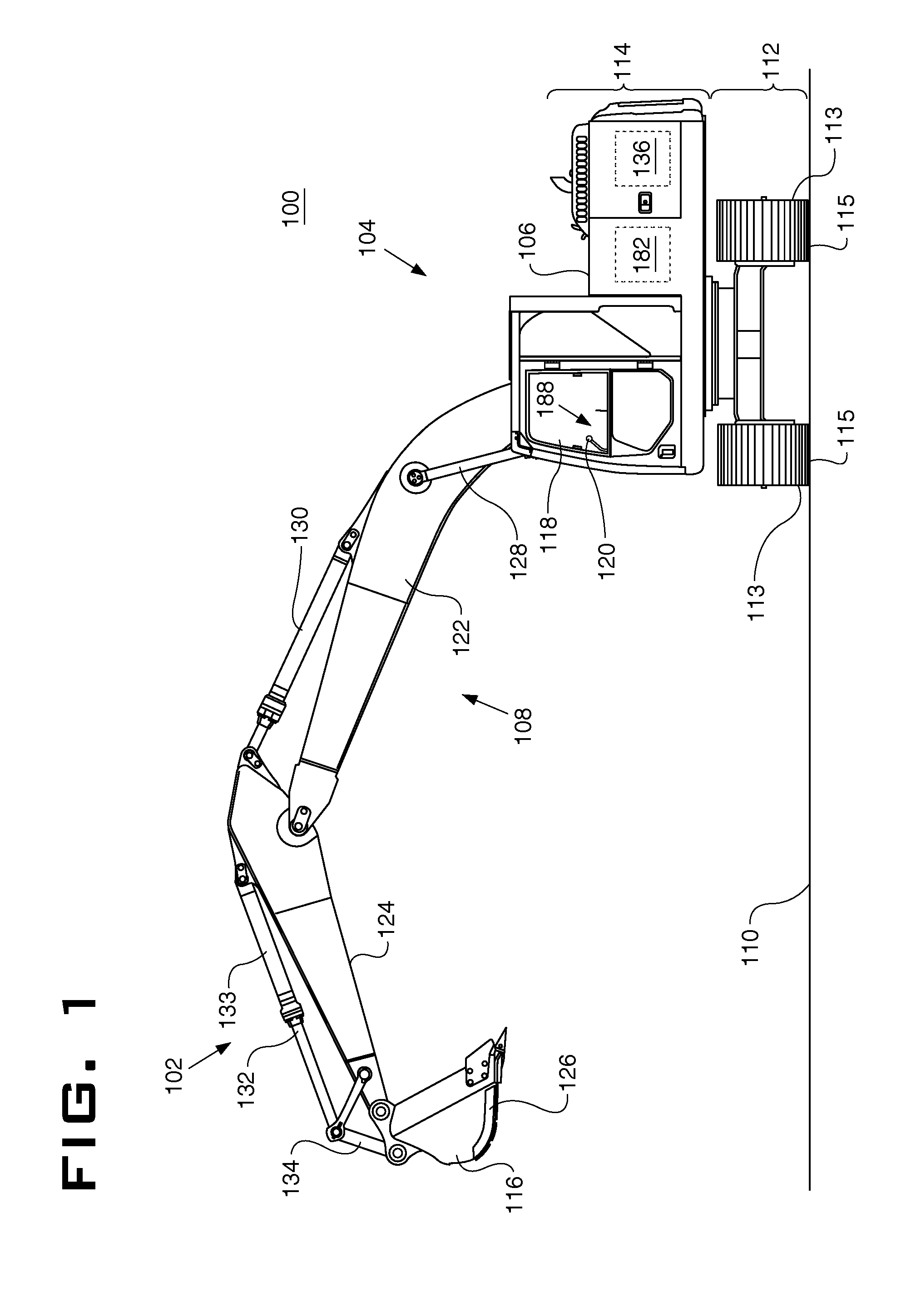

Semi-autonomous excavation control system

ActiveUS7934329B2Machines/dredgers working methodsAnalogue computers for trafficControl systemInput device

An excavation control system for a machine is disclosed. The excavation control system may have a tool, at least one operator input device configured to provide manual control over movement of the tool, and a controller in communication with the at least one operator input device. The controller may be configured to receive an input related to an operator desired tool location, and determine that an operator is manually controlling movement of the tool toward the operator desired tool location. The controller may be further configured to automatically assume control over movement of the tool toward the operator desired tool location based on the determination.

Owner:CATERPILLAR INC

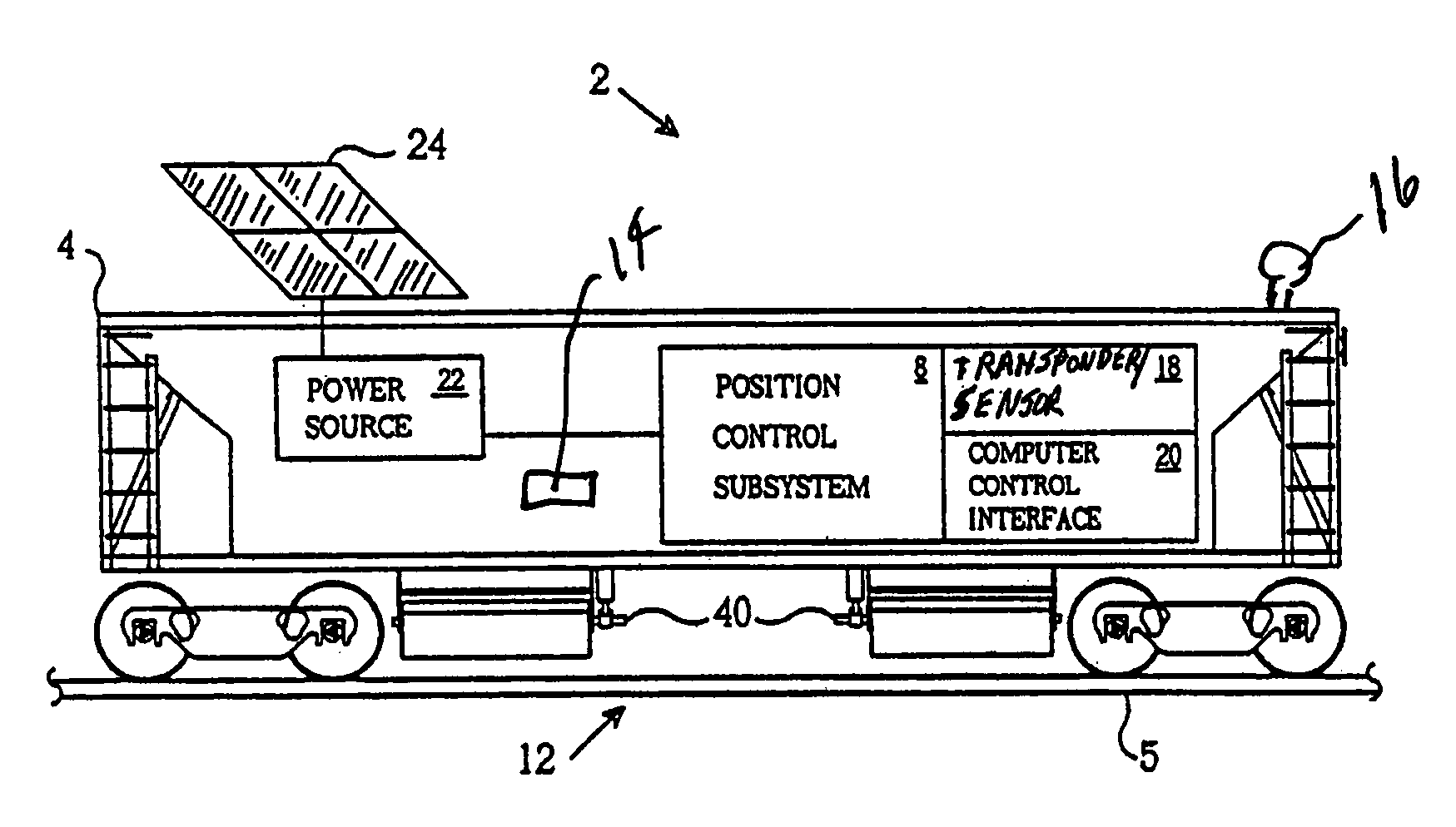

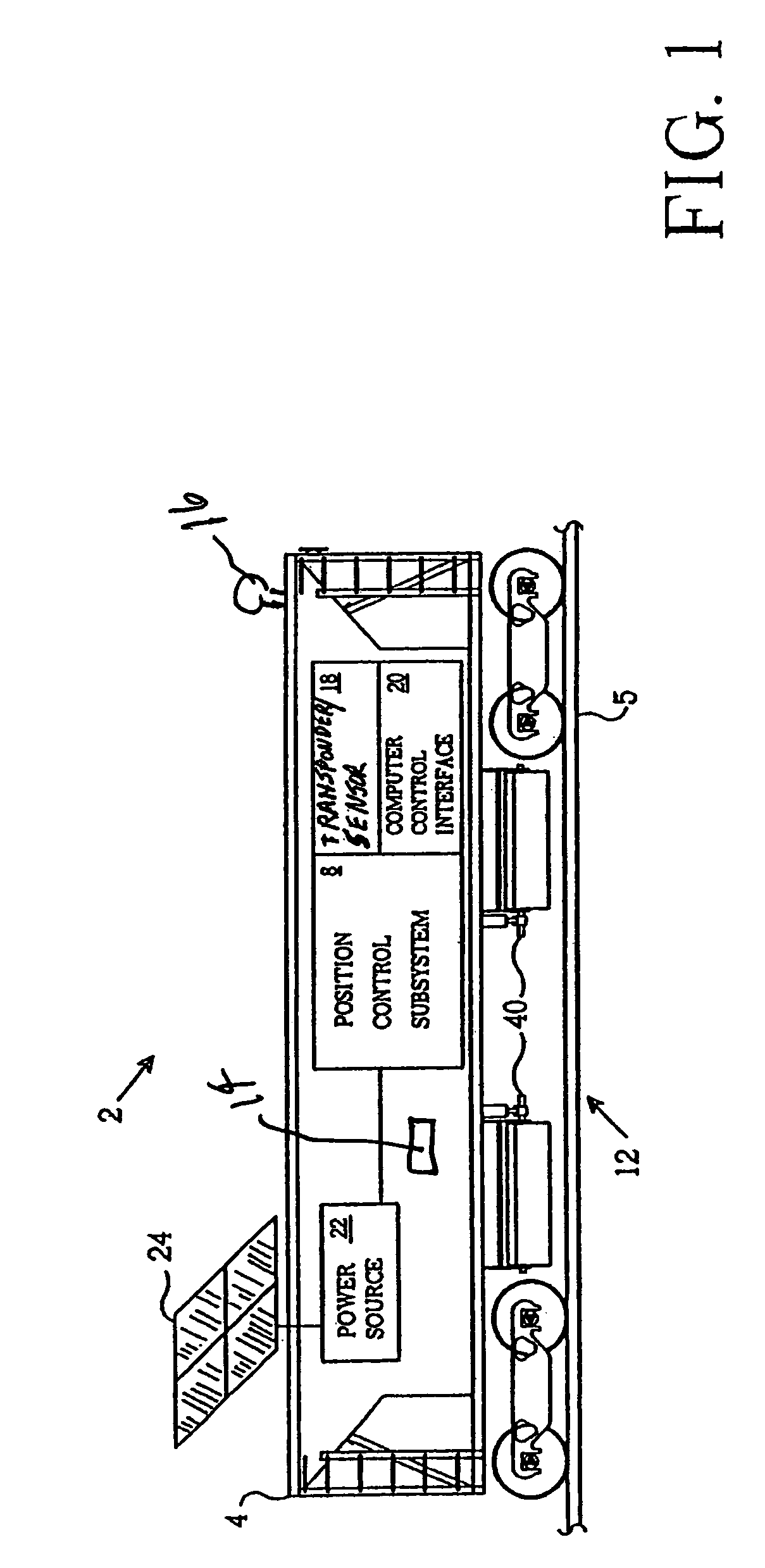

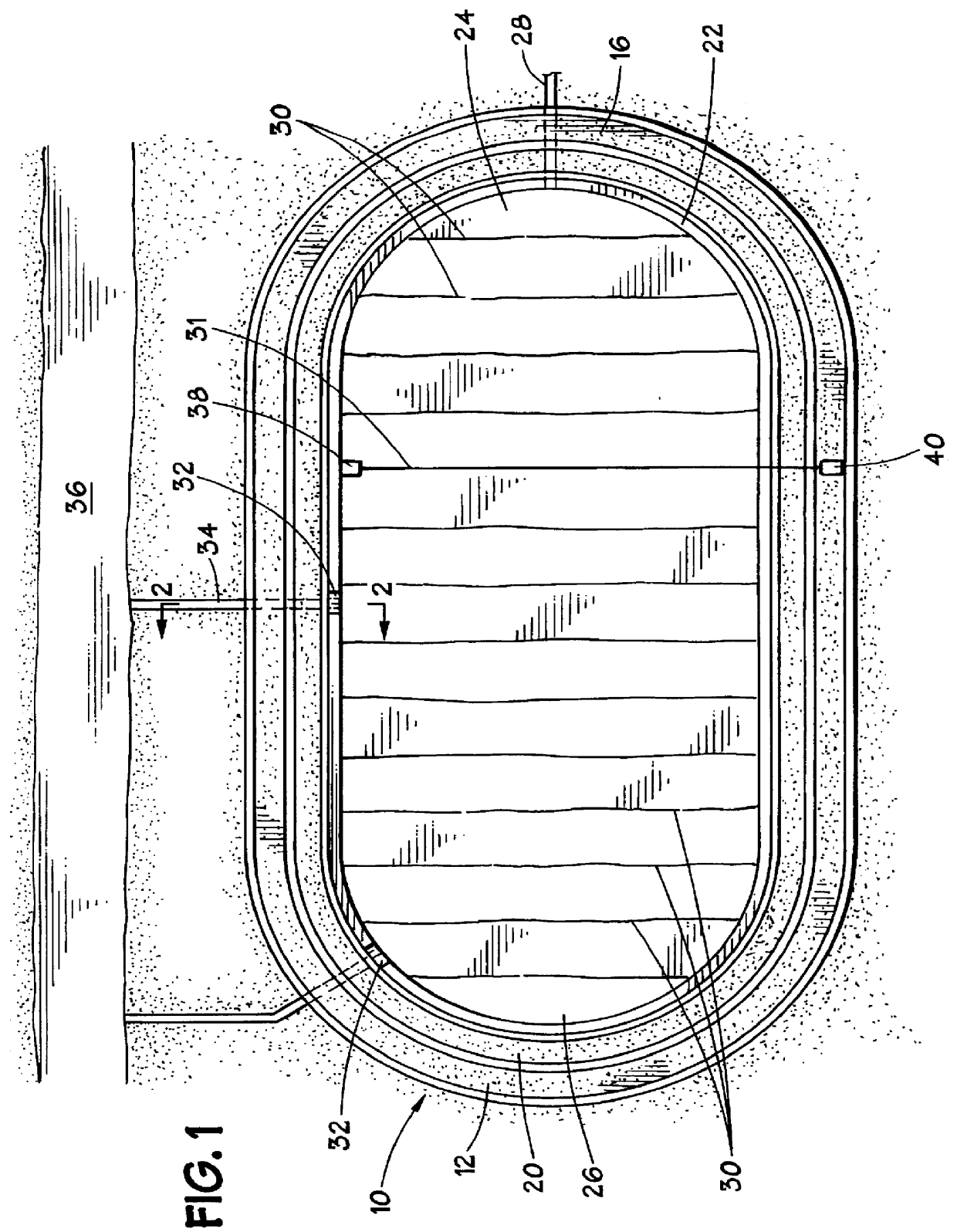

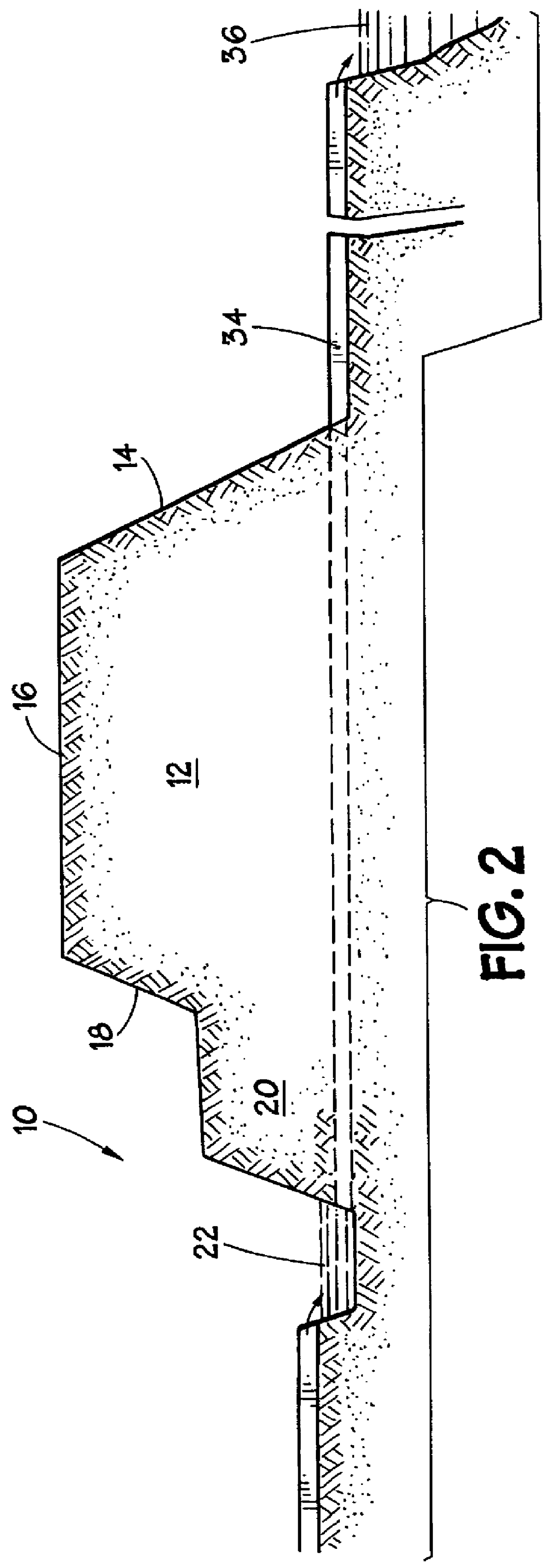

Method and apparatus for applying railway ballast

ActiveUS7152347B2Control spreadImprove accuracyMachines/dredgers working methodsBallastwayLaser technologyRadar

A method and apparatus for spreading ballast along railways makes use of an inertial measurement system to determine where to apply ballast from a hopper car. A variety of techniques can be used to determine the location and speed of the ballast spreading train, including manual or automated visual techniques, laser technology, radar technology, radio frequency transponders, magnetic sensor, thermal imaging and aerial photogrammetry. The invention also contemplates “on the fly” surveys and terrain profiling using lasers or radar.

Owner:HERZOG CONTRACTING

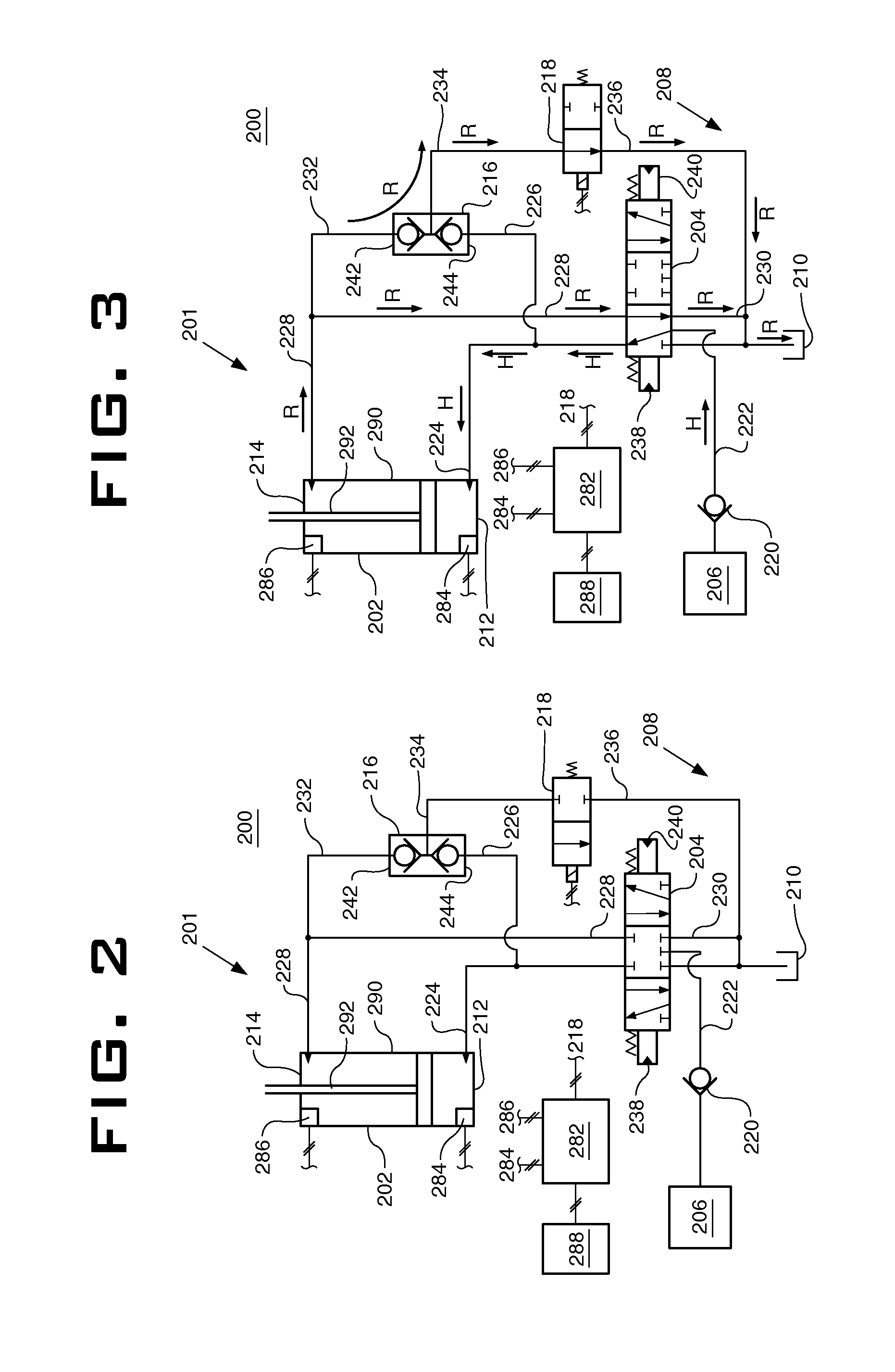

Work implement control system

ActiveUS20130129460A1Machines/dredgers working methodsServomotor componentsHydraulic cylinderControl system

A control system for a work implement on a machine is disclosed including a first hydraulic circuit, a second hydraulic circuit, and a controller. The first hydraulic circuit includes a hydraulic cylinder assembly, a pressurized fluid source, and a fluid tank. The hydraulic cylinder assembly includes a head end, a rod end, a cylinder, and a rod. The pressurized fluid source and the fluid tank are selectively connected to the head end or the rod end. The second hydraulic circuit includes a valve configured to receive a connection to tank signal and selectively connect the head end or the rod end to the fluid tank. The controller is configured to generate the connection to tank signal.

Owner:CATERPILLAR INC

Automatic hydraulic load leveling system for a work vehicle

InactiveUS7093383B2Programme-controlled manipulatorMachines/dredgers working methodsLinear motionMachine control

A machine has a boom, that is pivotally raised and lowered by a first cylinder, and has a load carrier that is pivoted at the end of the boom by a second cylinder. As a machine operator commands movement of the boom, the position of the load carrier is automatically altered by a controller to prevent a load from falling off the load carrier. The load carrier position with respect to the boom is altered in response to the amount of boom motion to maintain a constant position relationship between the load carrier and a chassis of the machine. Although the boom and load carrier move through different angular positions, the machine control is expressed in terms of the linear motion of the first and second cylinders.

Owner:HUSCO INT INC

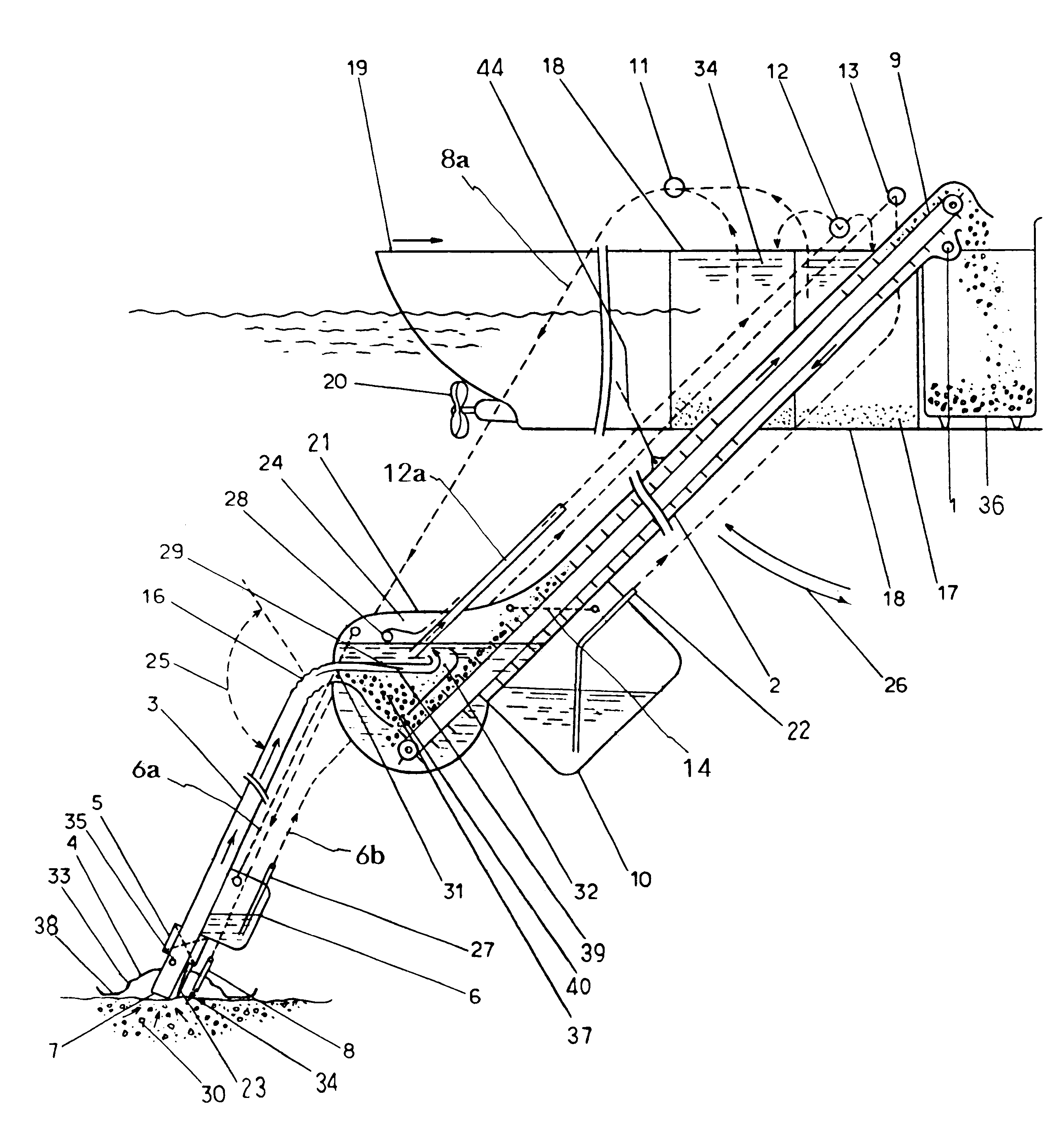

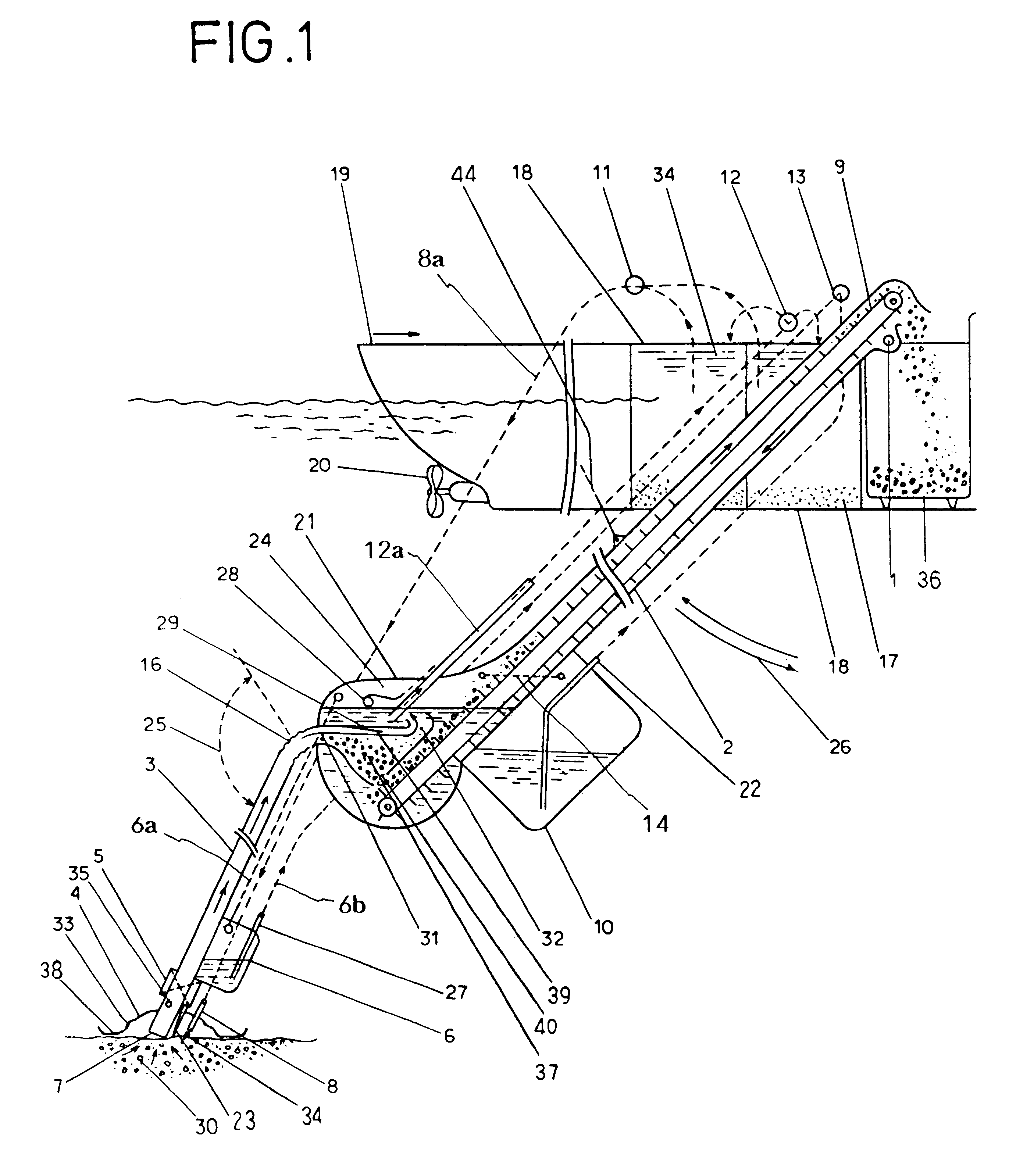

Dredging method and dredging apparatus

A dredging method and a dredging apparatus which can efficiently suck large quantities of sand and gravels deposited on the bottom of dams, rivers, harbors, etc., convey them with as much saved energy as possible, and can prevent diffusion of turbid water. To achieve these objects, the apparatus includes a case laid down into the water in communication with the atmosphere. A suction pipe having a suction portion at the lower end thereof is connected to this case. The apparatus further includes a drain pump for draining water in the case and forming a level difference between the water level in the case and the external water level A container is removably disposed at an intermediate portion of the suction pipe. The sand and gravels are sucked from the suction pipe into the container by the siphon principle due to the level difference between the external water level and the water level in the container, and the container is cut off and the sand and gravels are taken out when the container is full.

Owner:MOBURON DESIGN OFFICE

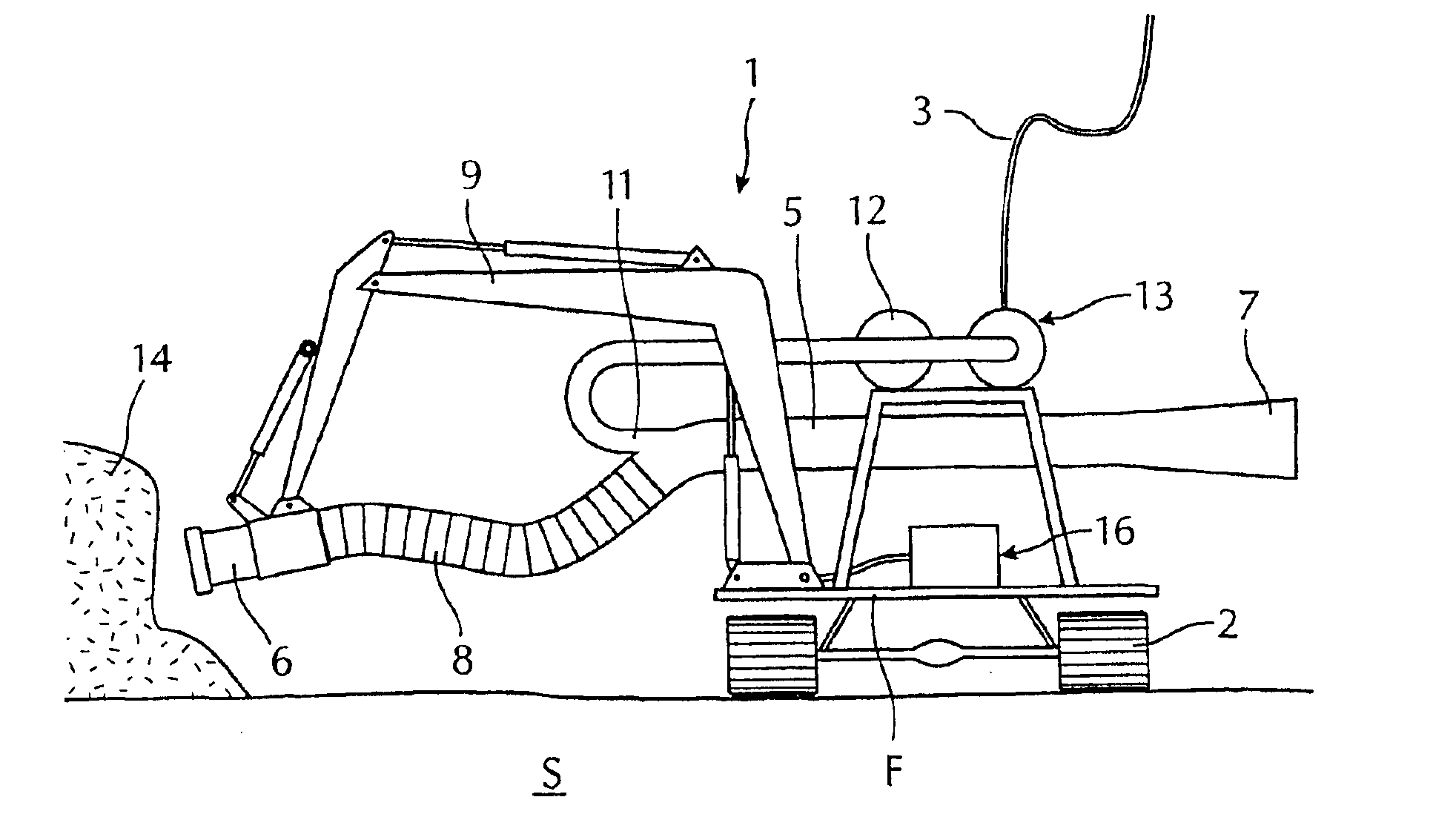

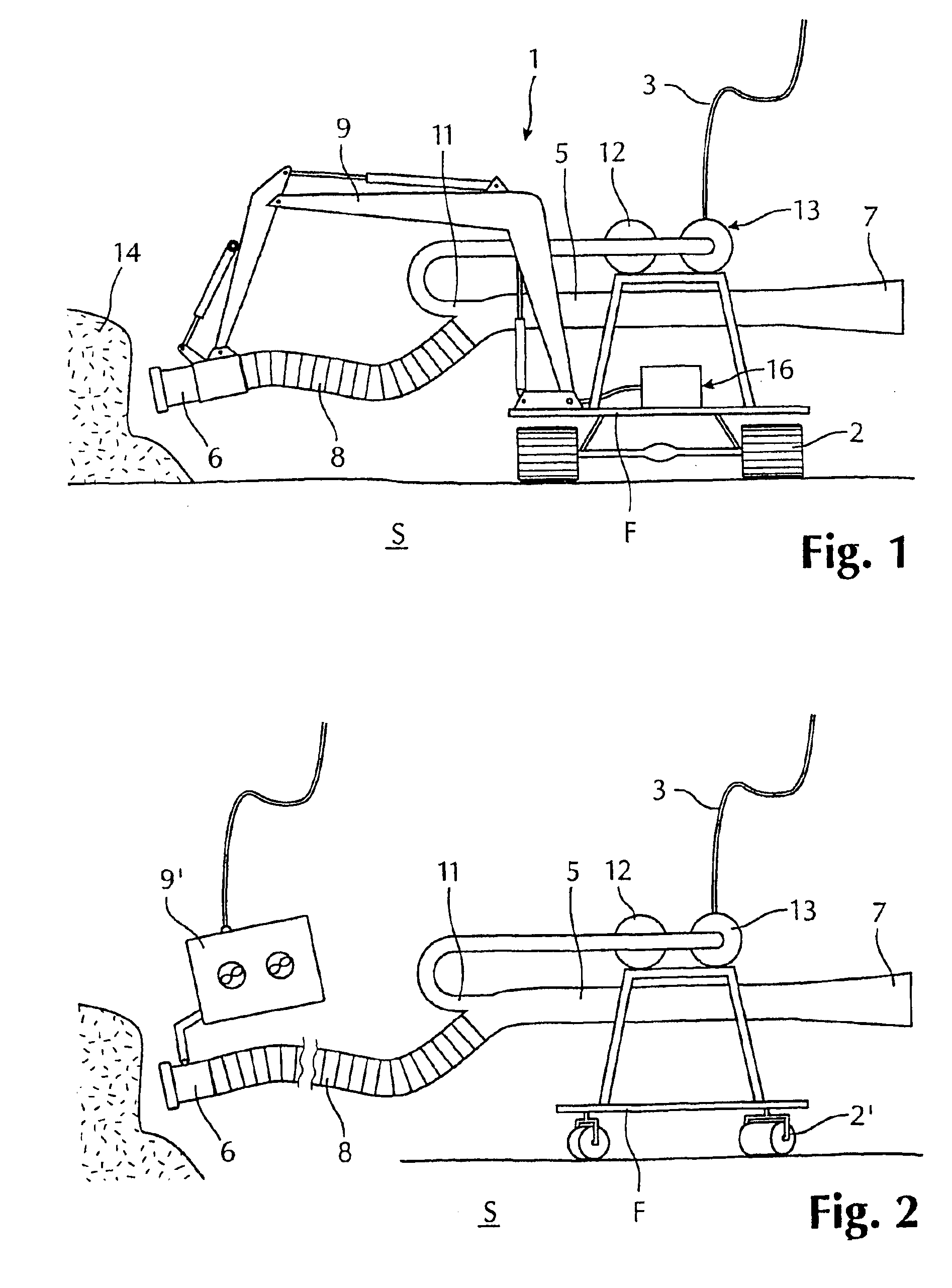

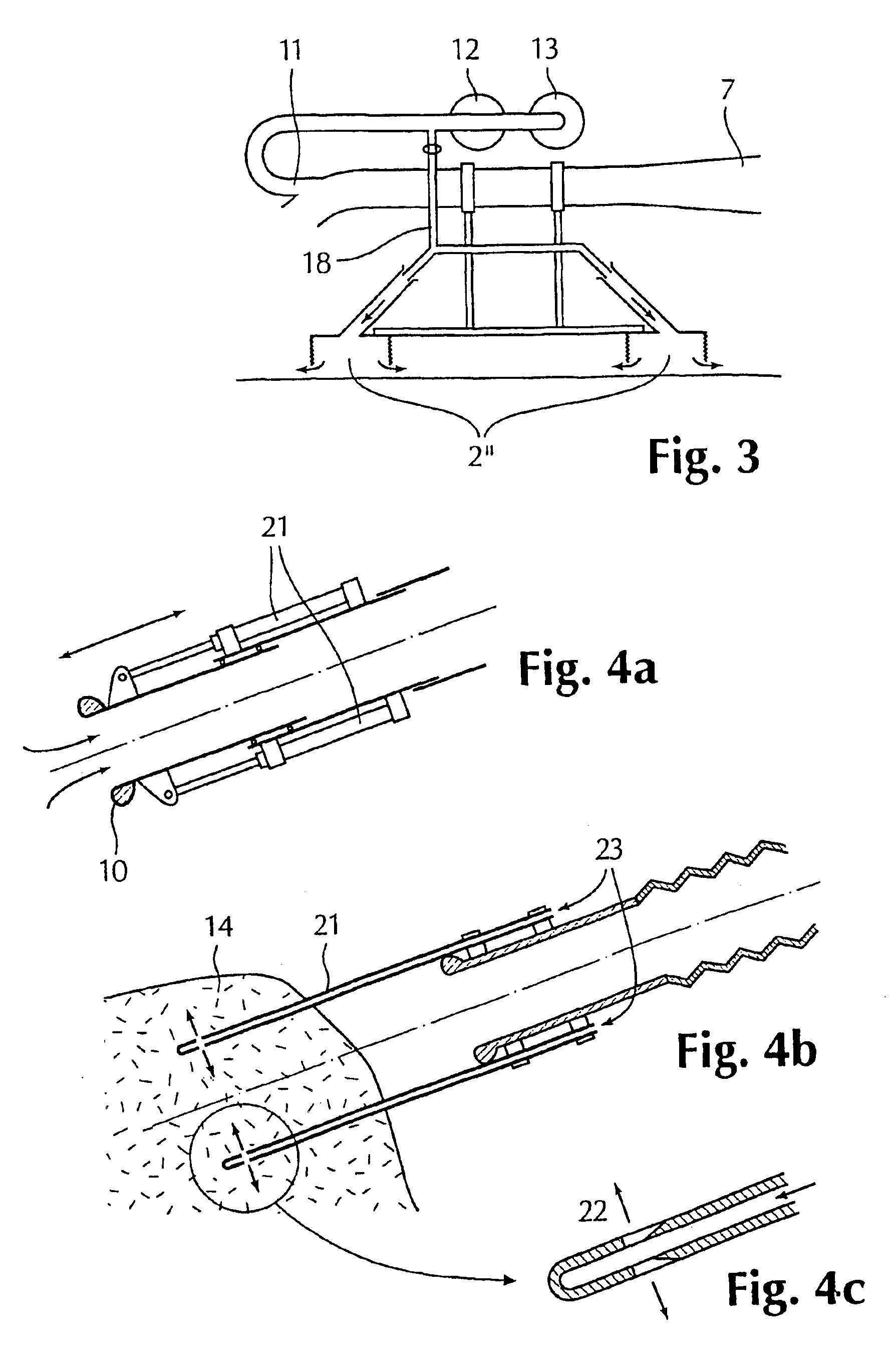

Method and device for subsea dredging

InactiveUS6868625B2Wide range of usesEasy to moveMachines/dredgers working methodsMechanical machines/dredgersManipulatorSediment

Method and device for moving subsea rocks and sediments, particularly at significant depths, for example in connection with removal of protective rocks around subsea installations where maintenance is to be conducted. The device includes a rigid or at least partly flexible tubing thorough which masses may be transported with the aid of a pressure gradient produced by an ejector nozzle arranged externally in relation to the tubing, and fed with water from a water pump. The device further includes a chassis adapted to be transported along the sea bottom. The required power is supplied through a cable from the surface, while the tubing preferably is remotely controlled by a manipulator.

Owner:FOSSURA

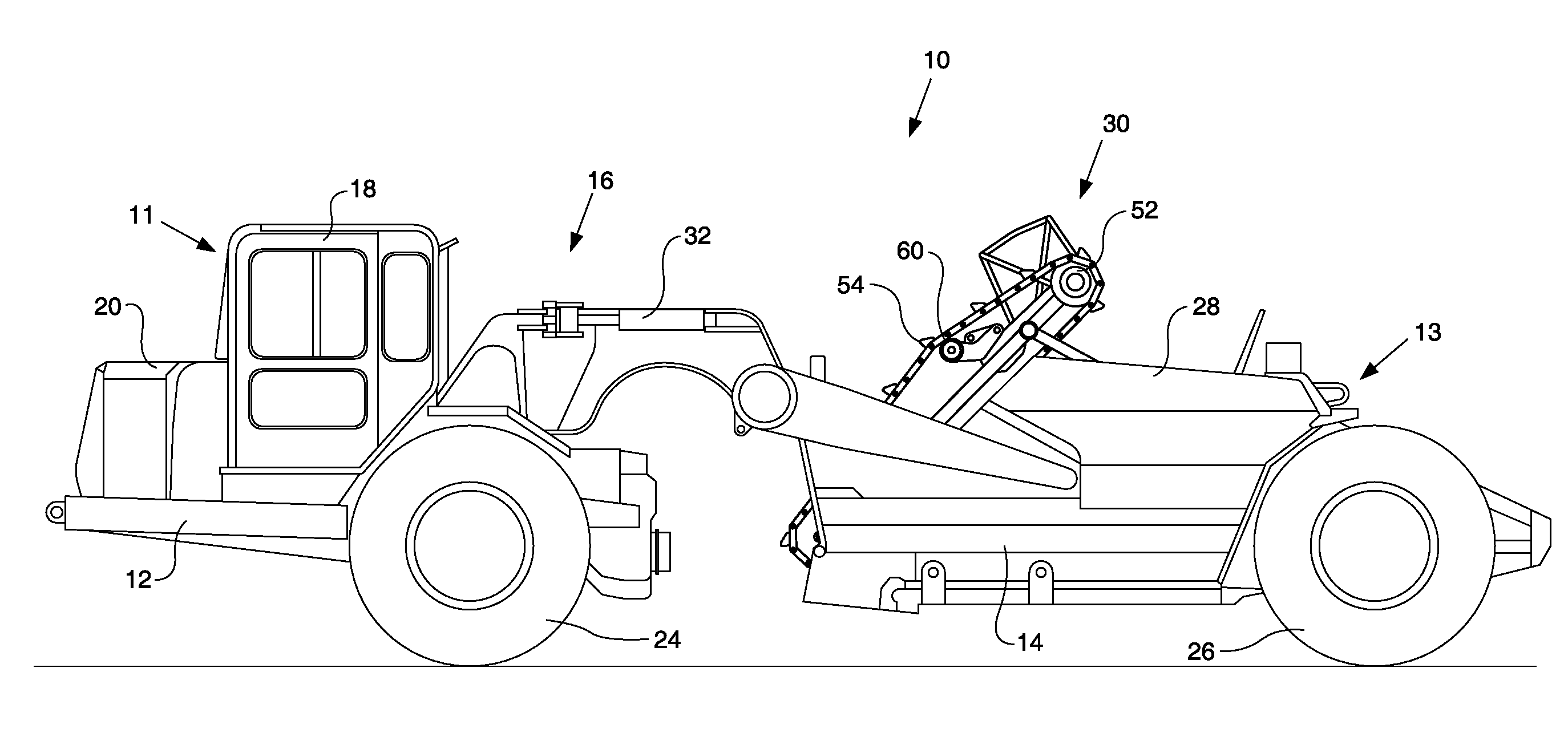

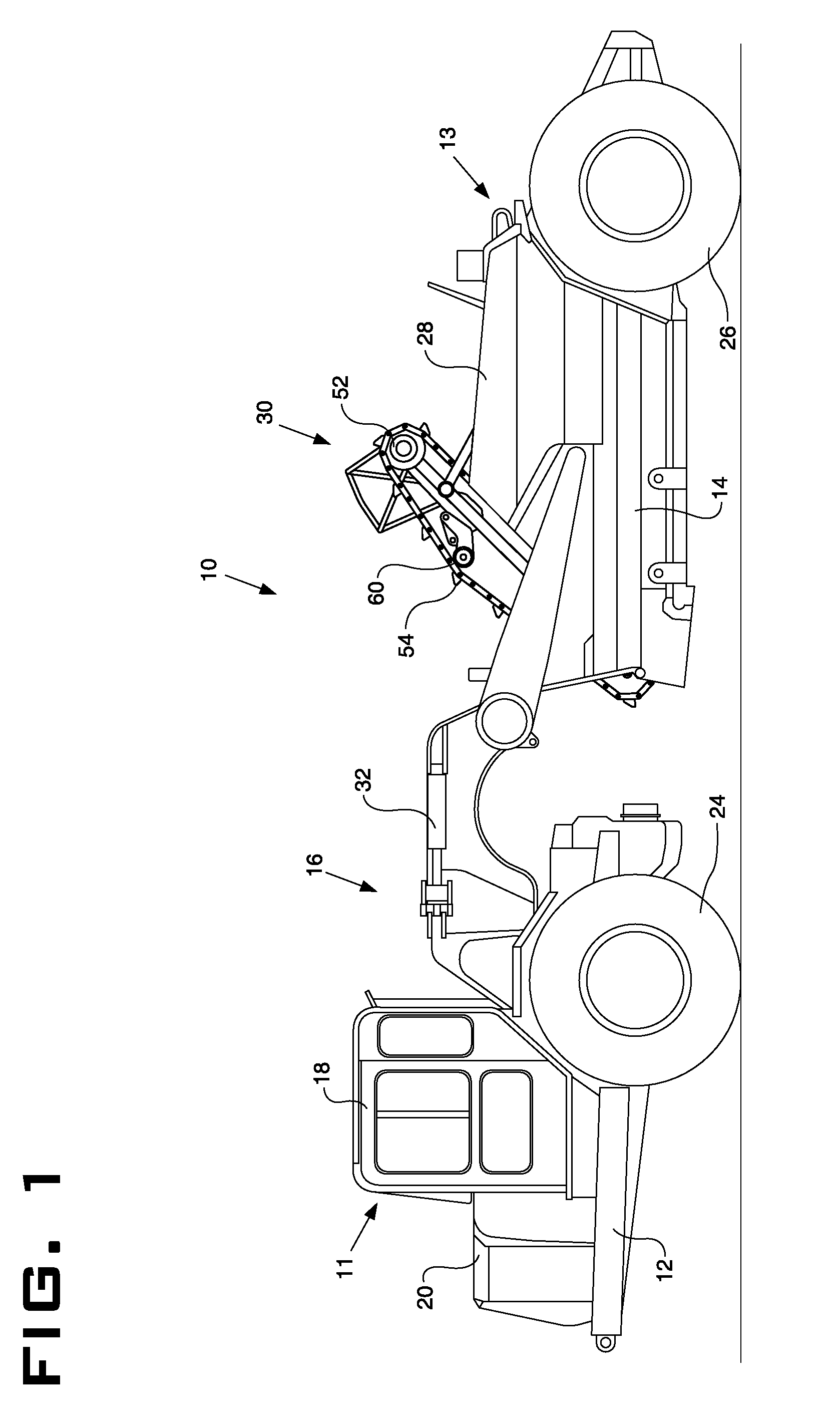

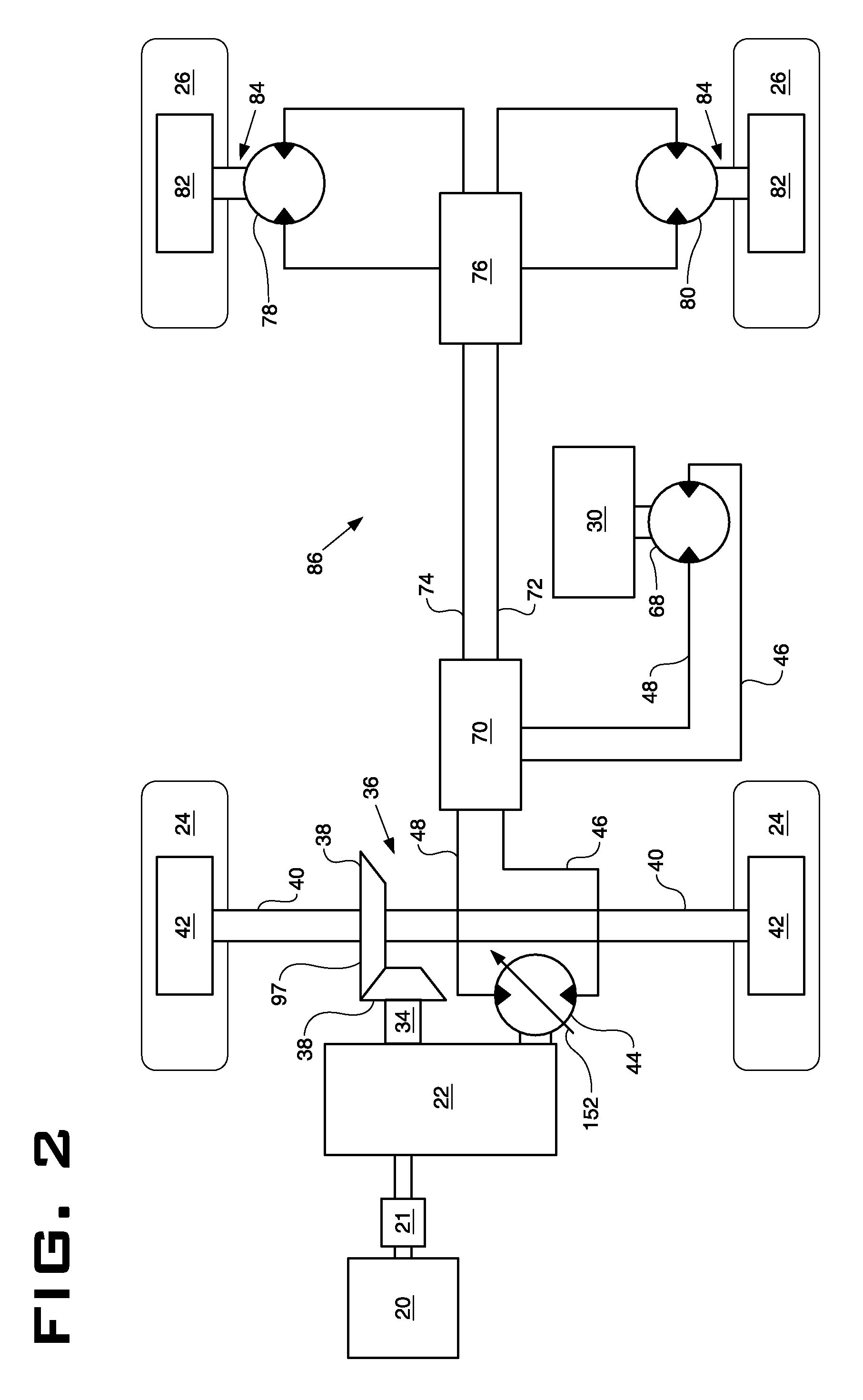

Wheel tractor scraper rear wheel drive assist and method of operation

ActiveUS20100018727A1Machines/dredgers working methodsAgricultural machinesWheel tractor-scraperDrive motor

A wheel tractor scraper having a rear wheel drive assist, the wheel tractor scraper includes a tractor portion pivotally coupled to a rear scraper portion, the rear scraper portion having a bowl for hauling material and a fluid powered work tool configured to assist in loading the bowl, the work tool powered by a fluid pump connected to a fluid operated work tool motor. The rear wheel drive assist includes a fluid operated drive motor coupled to the rear wheels of the machine, a diverter valve having a first position at which fluid flow is delivered from the pump to the work tool motor and a second position at which fluid flow is delivered from the pump to the drive motor, and a controller being configured to control the diverter valve to engage the rear wheel drive assist. The machine may be operated by engaging the pump and work tool motor, and then actuating the diverter valve to the second position to divert flow from the work tool motor to the drive motor.

Owner:CATERPILLAR INC

System for the automatic movement of material

InactiveUS8364353B2Guaranteed automatic operationMachines/dredgers working methodsAnalogue computers for trafficMobile deviceMechanical engineering

The present invention relates to a system for the automatic movement of material in a working area comprising at least one movable piece of equipment, wherein the system has a control for the automatic movement of the piece of equipment with an automatic recognition of obstacles. In accordance with the invention, the control has a first obstacle processing function which moves an obstacle in the working area automatically using the movable piece of equipment; and / or in that the control has a second obstacle processing function which automatically removes an obstacle from the working area using the movable piece of equipment.

Owner:LIEBHERR WERK BISCHOFSHOFEN GES

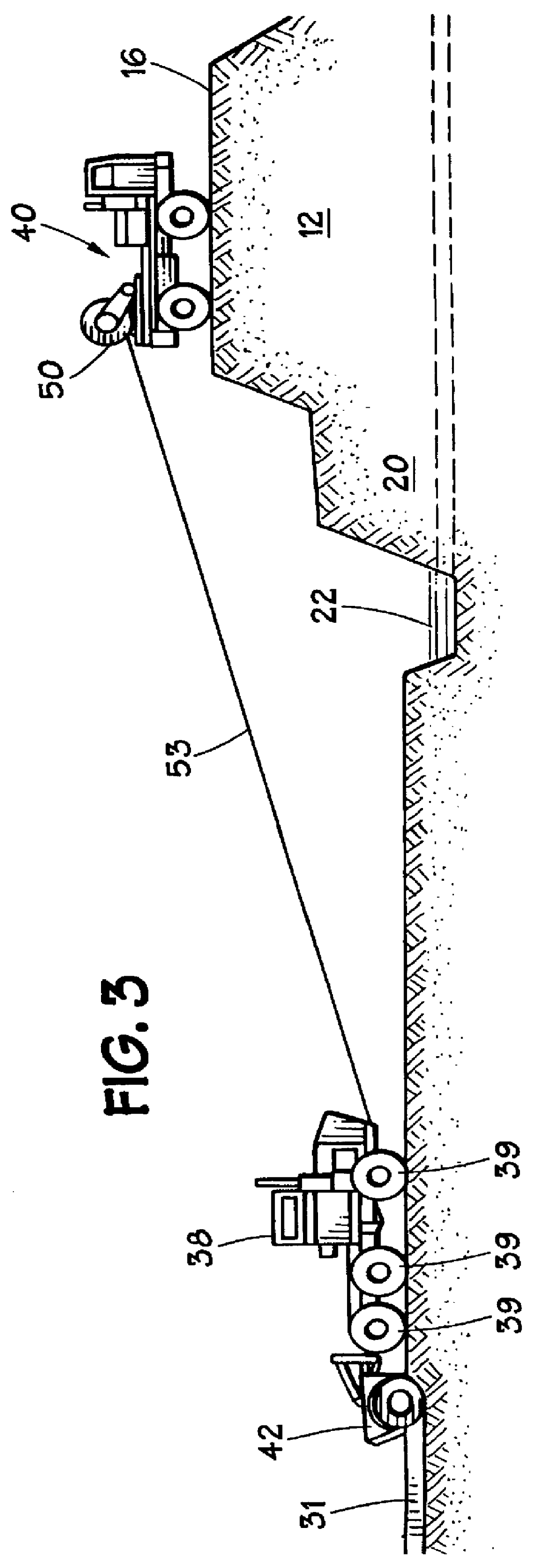

Containment area process

InactiveUS6119375ASludge treatment by de-watering/drying/thickeningMachines/dredgers working methodsDewateringBerm

Effective techniques and equipment are described for maintaining and improving dredge disposal sites. In one aspect, the use of winching equipment is described to move a digging vehicle within a containment area for effective creation of ditching to permit substantial dewatering and drainage of the dredge spoil to dry it. Substantially dried spoil is removed from the containment area pit using amphibious scraper equipment. The substantially dried spoil may then be used to build up the berm surrounding the dredge pit.

Owner:WILCO MARSH BUGGIES & DRAGLINES

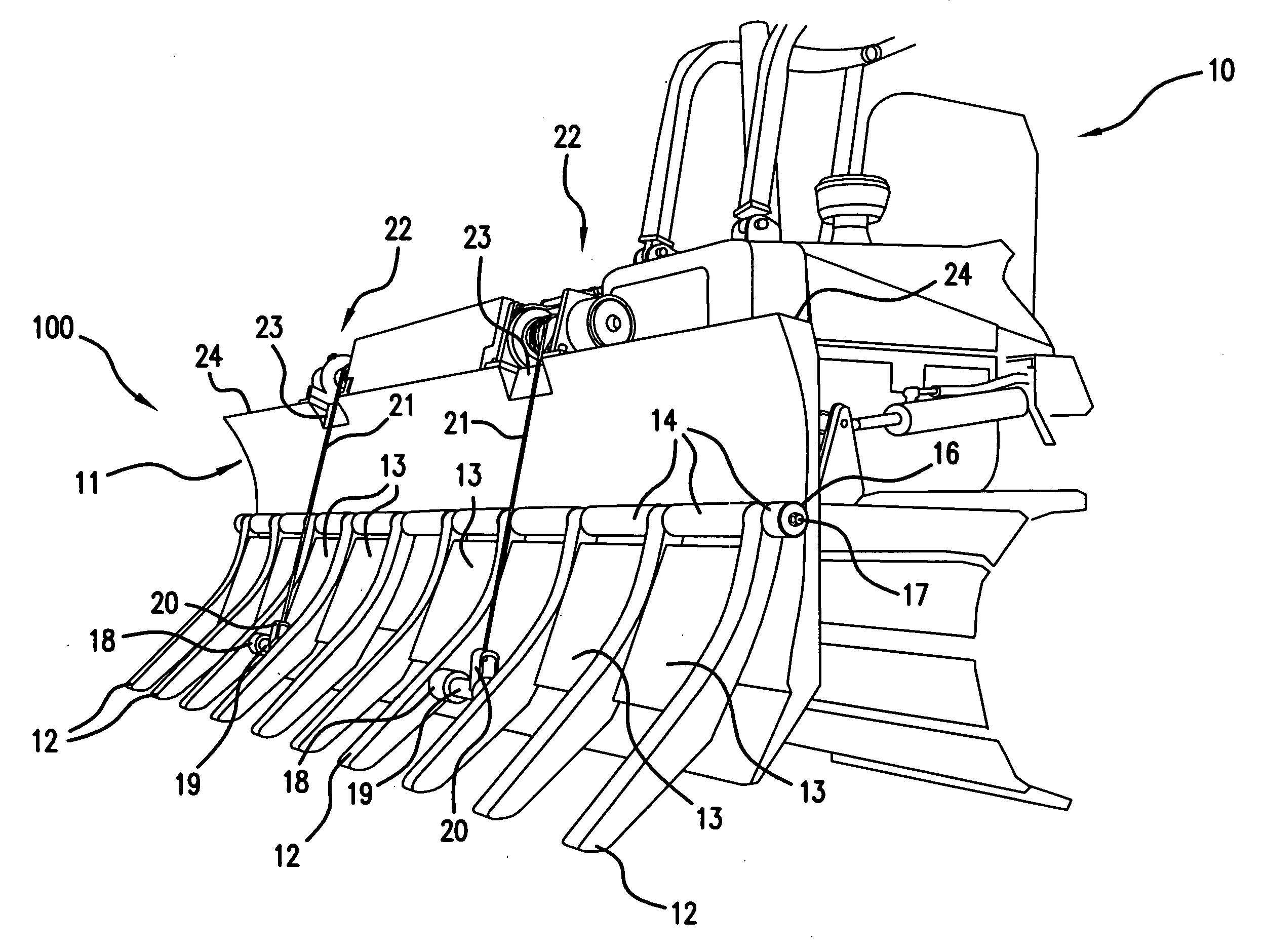

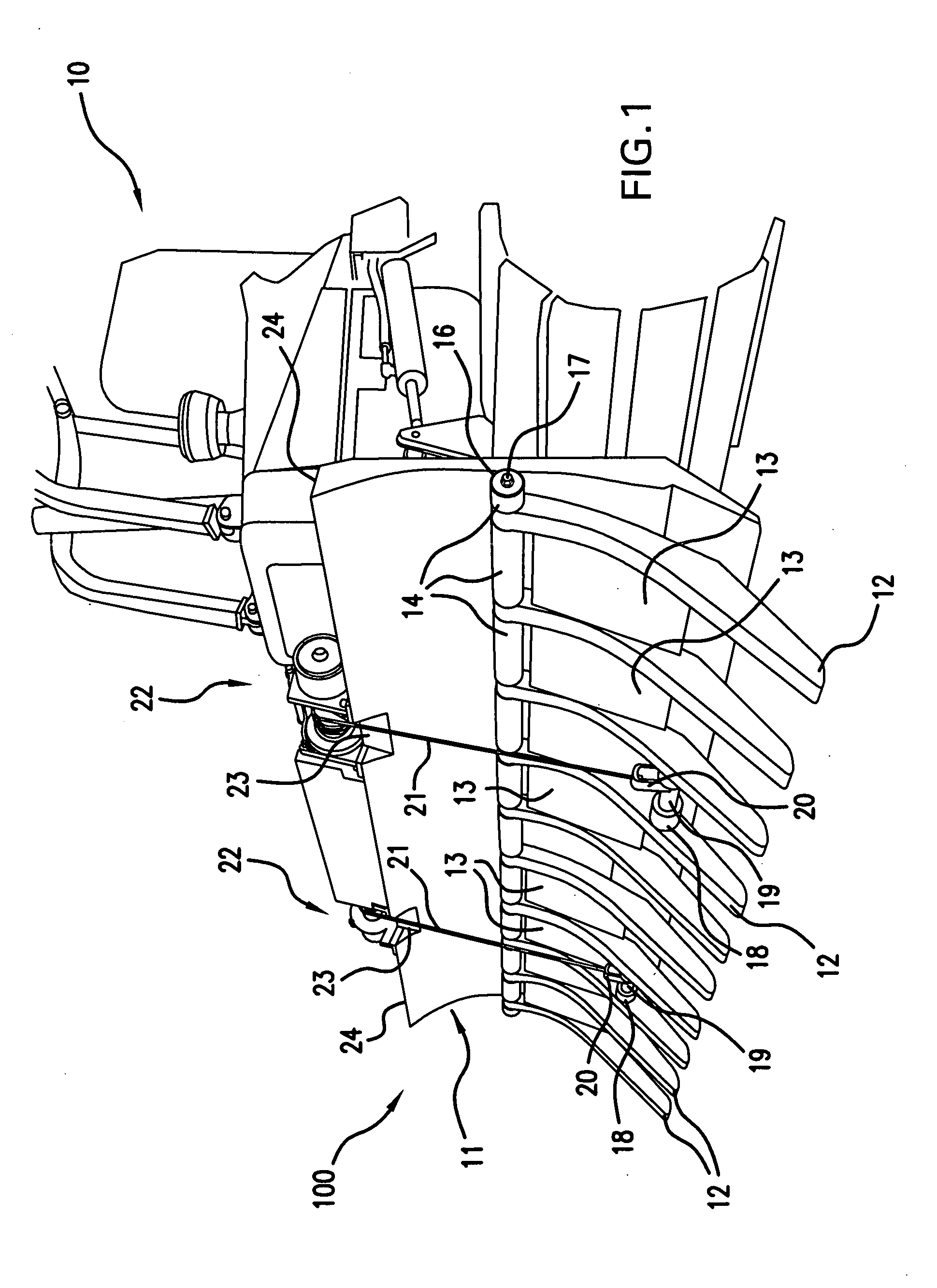

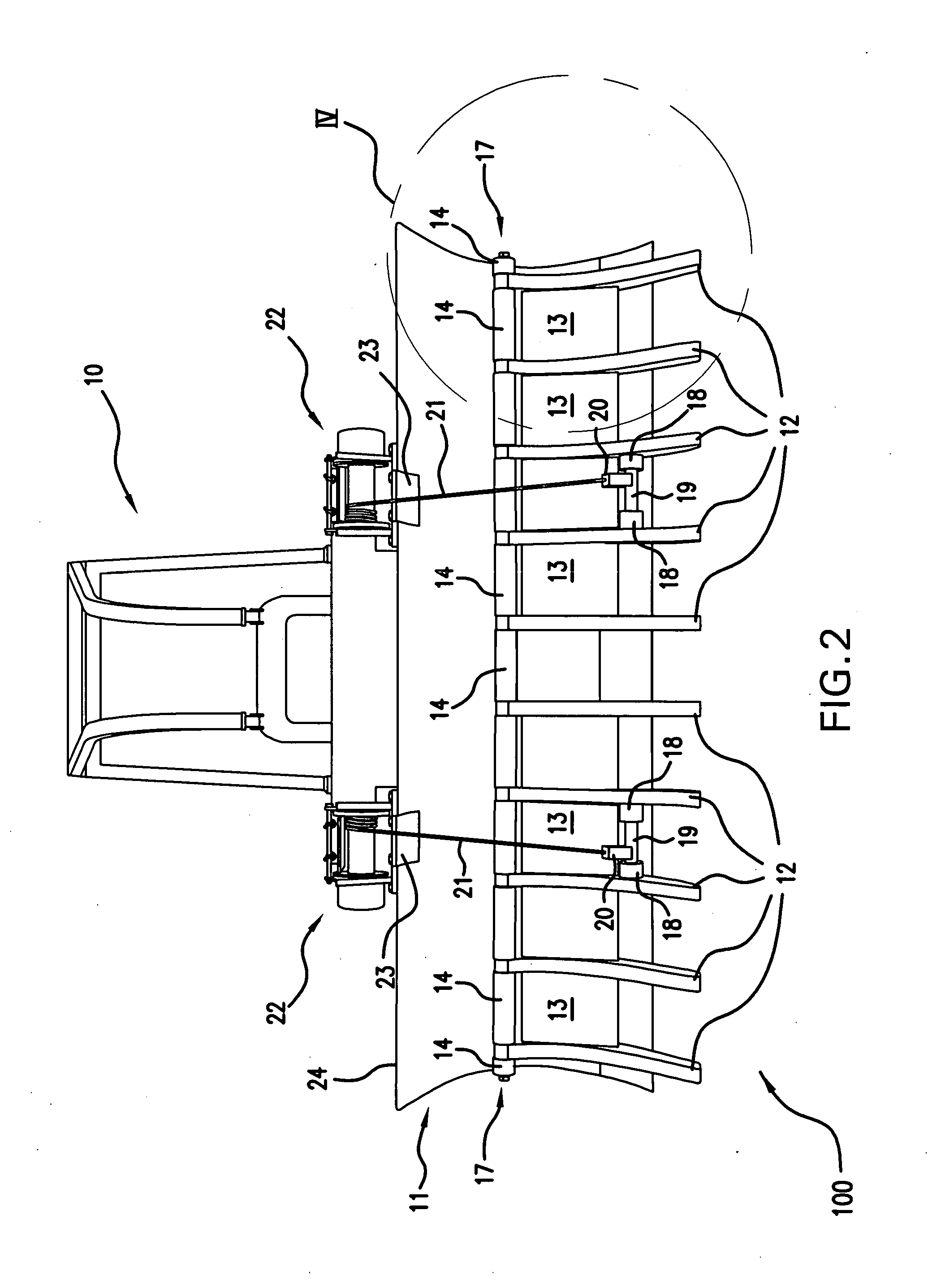

Land Clearing Rake

The invention is a land clearing rake that is typically mounted on a moldboard on a conventional bulldozer. The land clearing rake pivots about a shaft that is horizontally connected to the front of the moldboard. The rake is comprised of teeth connected to each other by heavy-duty plates between each of the teeth. The teeth may be arranged in one or more sections wherein the sections can be simultaneously raised or lowered by winches mounted on the moldboard. The winches are remotely controlled from the operator's seat. Thus, the land clearing rake is capable of being quickly raised or lowered by the operator while the earth moving equipment is moving back to prepare for another forward move. The ability to quickly transition between raking and grading modes significantly improves the efficiency of land clearing operations.

Owner:PARRISH MARLIN

Popular searches

Transportation and packaging Contaminated soil reclamation Portable shielded containers Radioactive decontamination Material analysis by optical means Vibration drilling Chemical conversion by chemical reaction Nuclear radiation detection Material analysis using wave/particle radiation Disloding machines

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com