Mine site oil sands processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

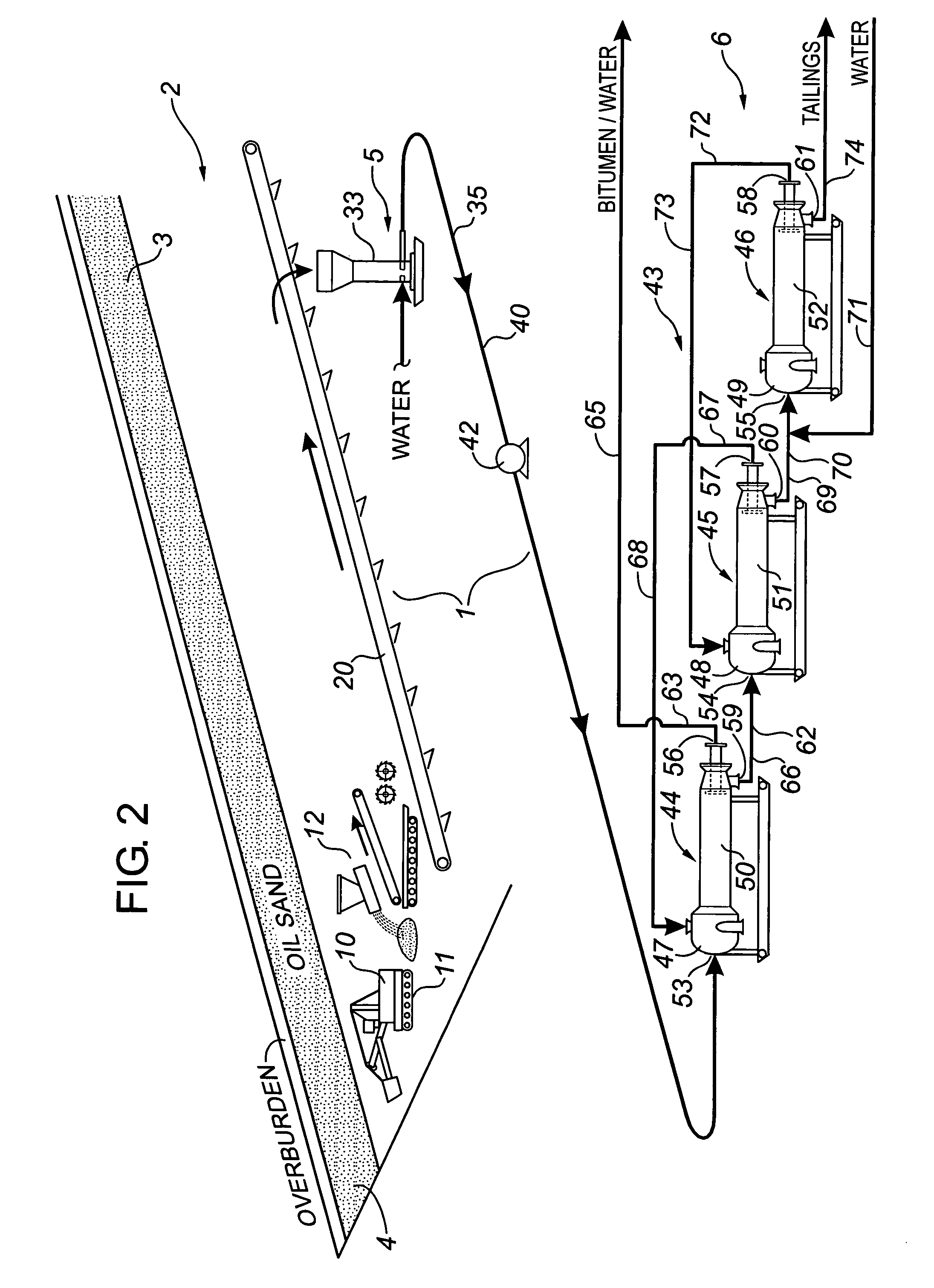

[0058] A process line 1 in accordance with the invention comprises a series of operatively connected processing units located at a mine site 2. The mine site 2 is positioned on a body of mineable oil sand 3, such as exists in the Fort McMurray region of Alberta. The mine site 2 has one or more mine faces 4, a slurry preparation location 5, a desanding location 6 and a tailings retention facility 7. As the mine faces 4 advance, one or both of the locations 5, 6 will periodically advance as well. As shown in FIG. 4, a plurality of process lines 1 may be in use on the mine site 2.

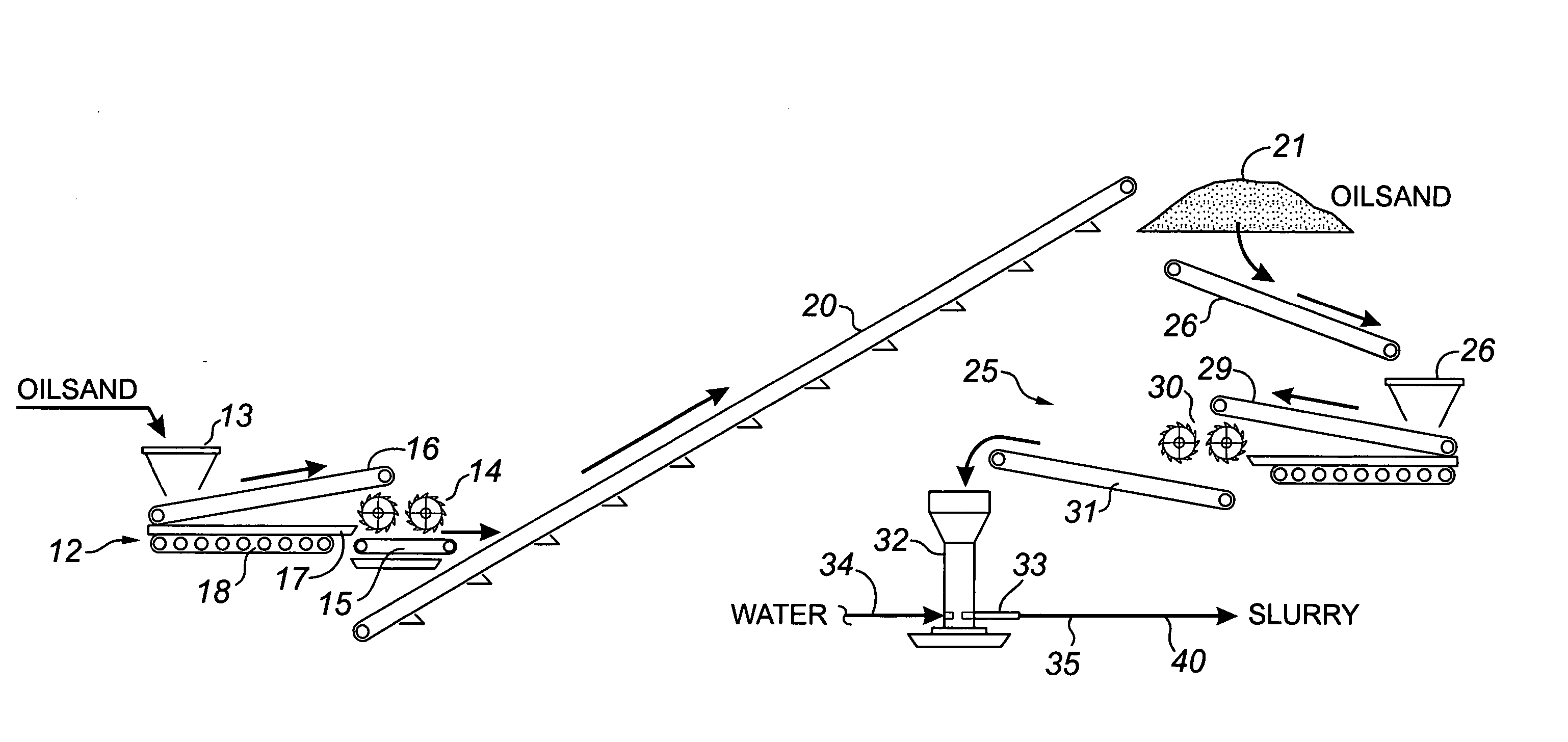

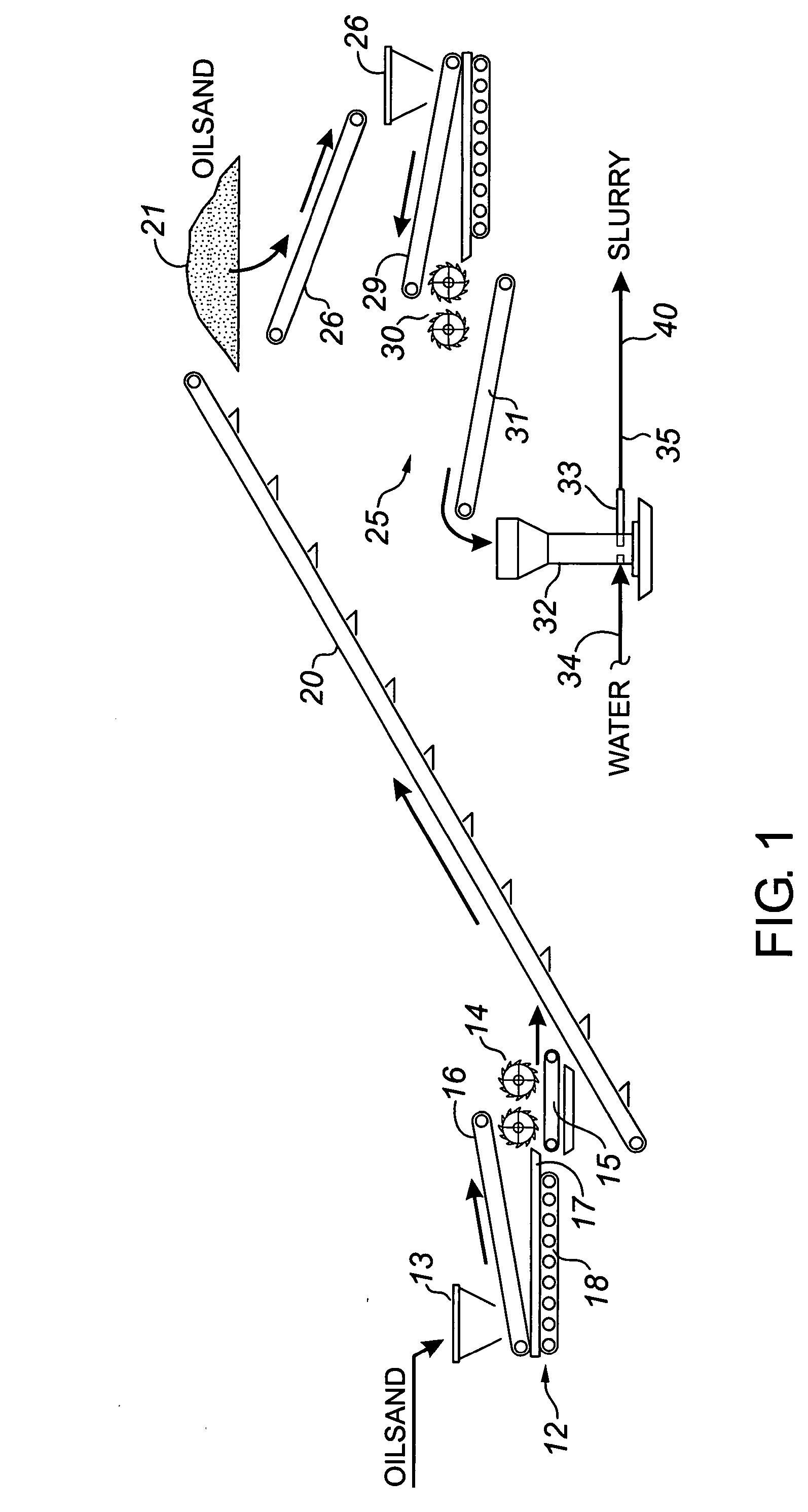

[0059] In the preferred embodiment (as shown in FIGS. 1 and 2), each process line 1 comprises: [0060] A mobile mining shovel 10, which is mounted on driven tracks 11. The shovel 10 is positioned at the mine face 4 for excavating the oil sand 3. It is operative to advance along the mine face 4. Otherwise stated, the shovel 10 provides mobile excavating means for advancing along the mine face 4 and excavating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com