Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Provide space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

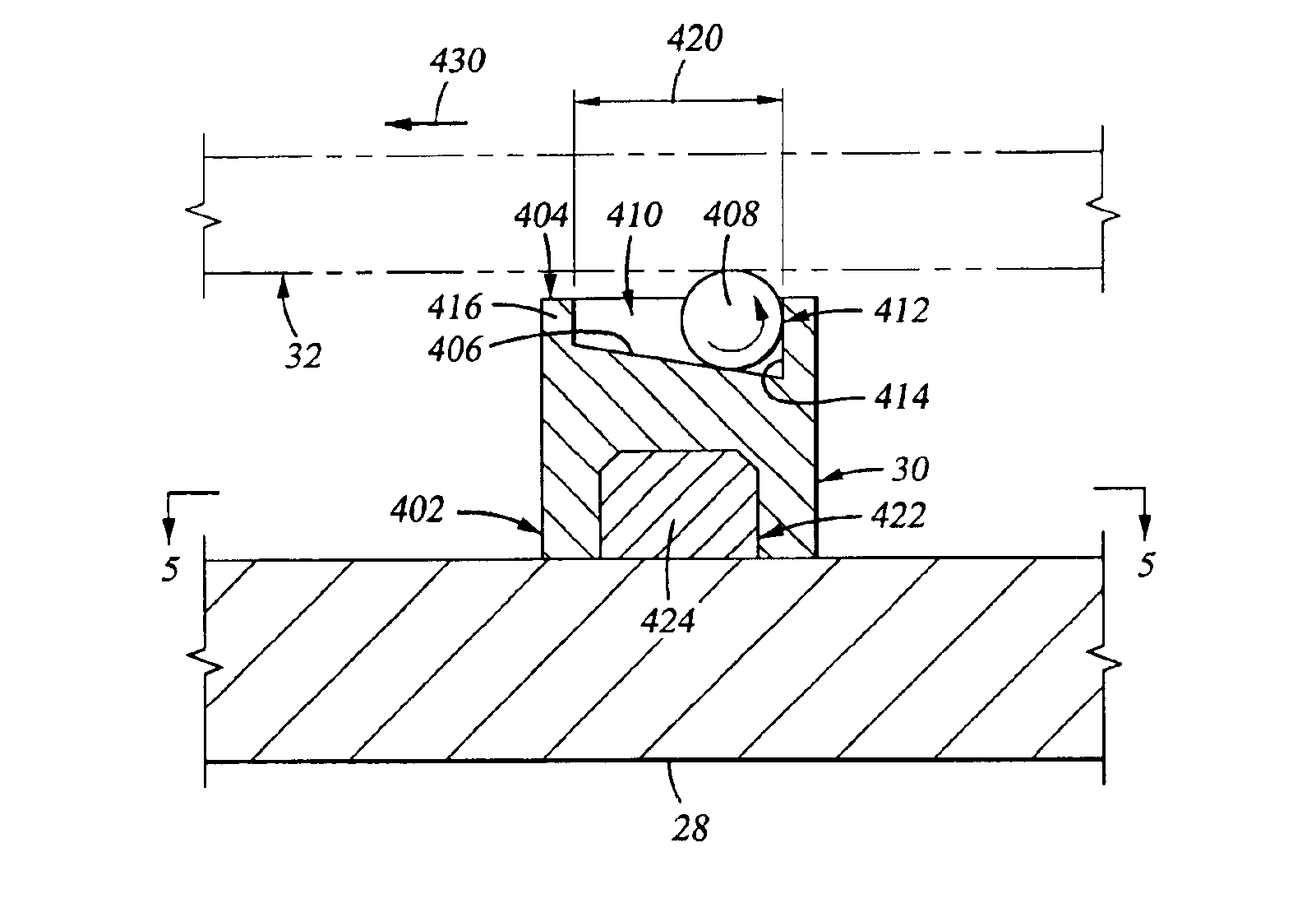

Substrate support

InactiveUS6917755B2Minimize damageProvide spaceDrying solid materials with heatMuffle furnacesSupport surfaceEngineering

An apparatus for supporting a substrate is described that has a ball adapted to minimize damage between the substrate support and the substrate supported thereon. In one embodiment, an apparatus for supporting a substrate includes ball disposed on an inclined ball support surface. The ball support surface is adapted to bias the ball toward one side of the ball support surface thereby providing space for the ball to roll as the substrate supported thereon changes in length when exposed to thermal influences. In another embodiment, the apparatus further comprises a cage adapted to capture the ball to the ball support surface.

Owner:APPLIED MATERIALS INC

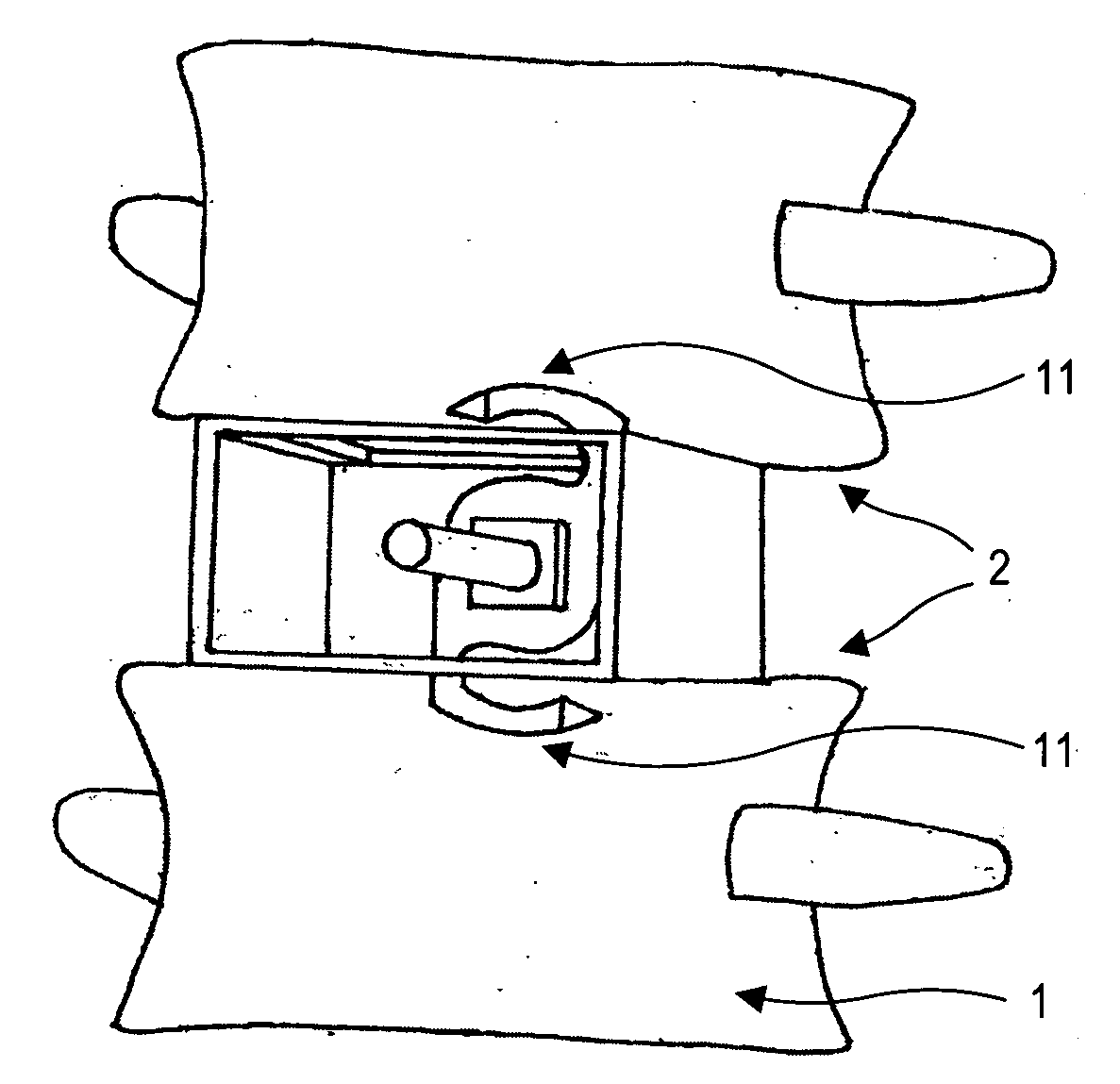

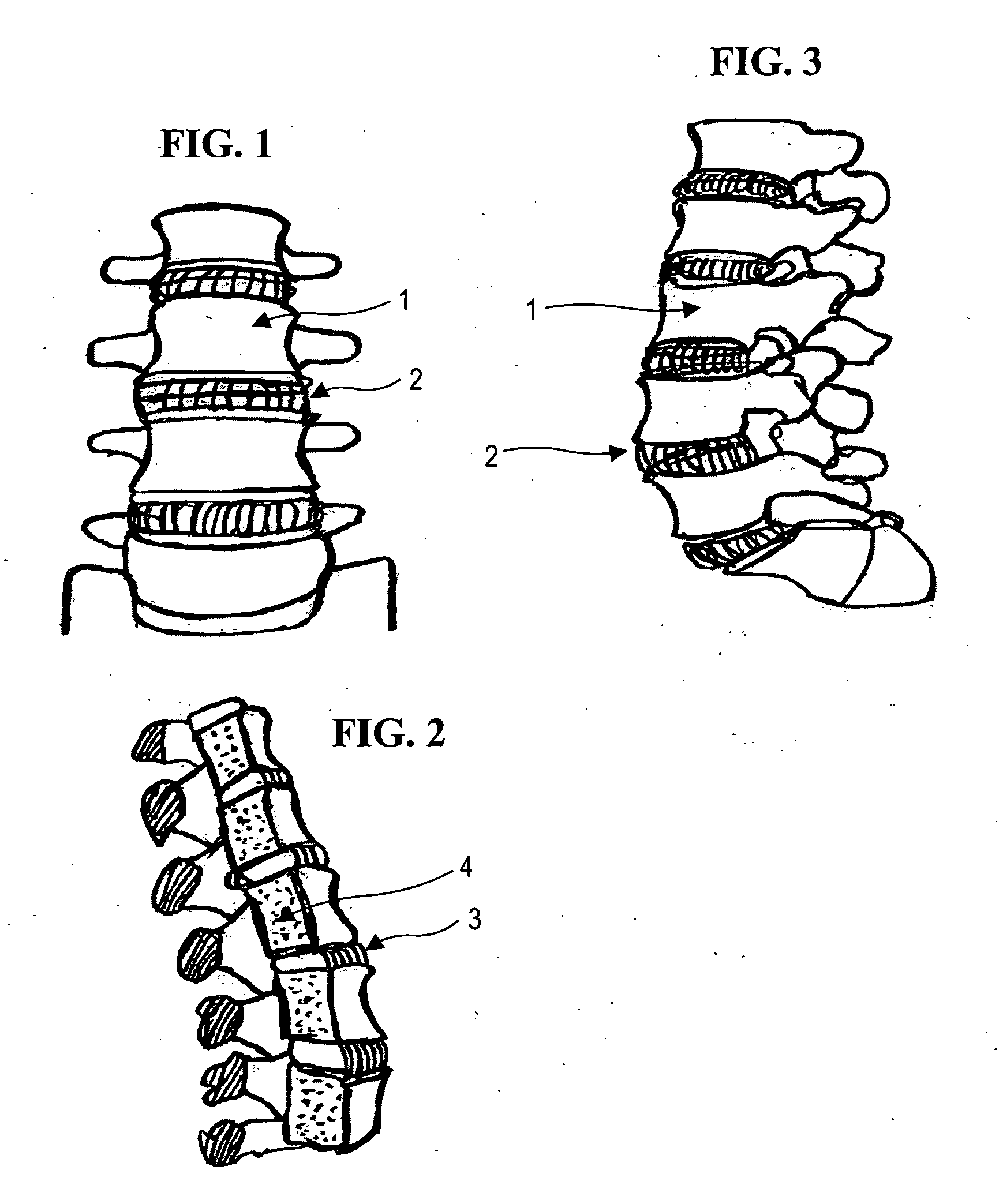

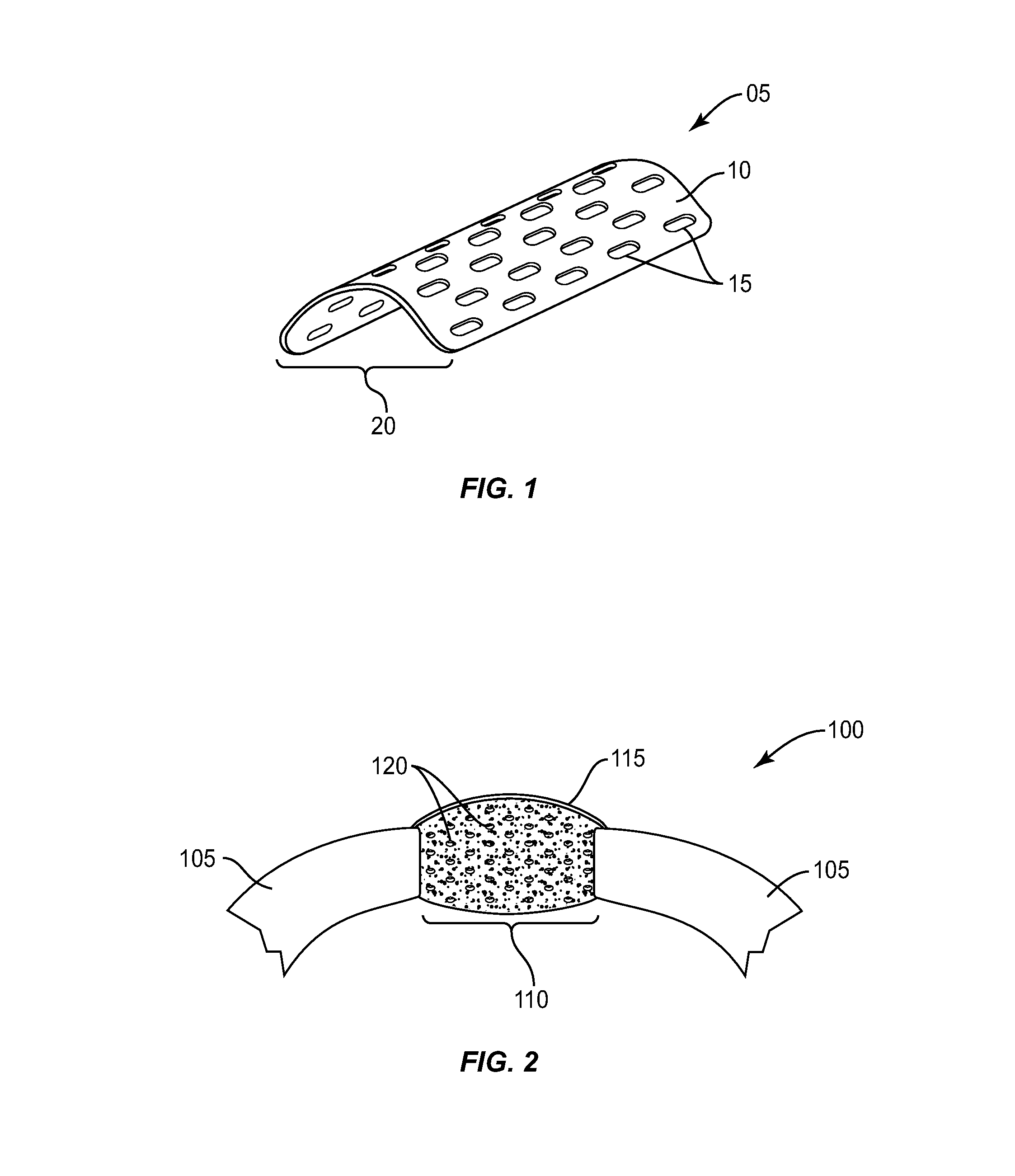

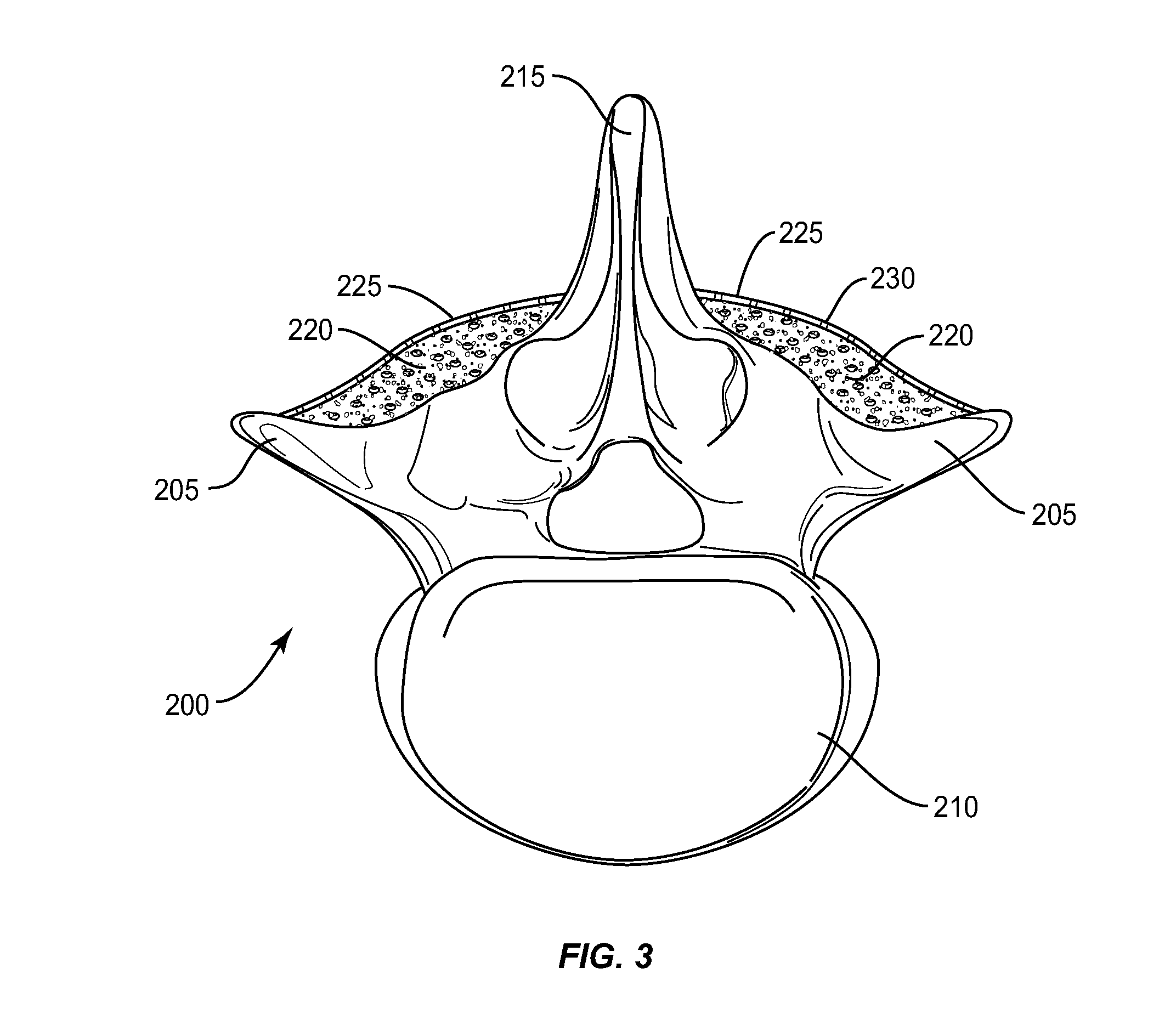

Apparatus and method for anterior intervertebral spinal fixation and fusion

ActiveUS20080132949A1Enhance bony fusionImprove fusionInternal osteosythesisJoint implantsVertebraSpinal locomotion

A spinal fixation and fusion device that includes a housing with leading deep surface conforming to the posterior aspect of the intervertebral disk and trailing outer surface conforming to the anterior surface of the disk, weight bearing sides and the top and bottom surfaces with plurality of openings enabling ingrowths of bone. The device further includes a shaft running from the center of the deep surface and perpendicular to the deep surface of the housing to the center of the outer surface of the housing and affixed at least to the deep surface of the housing, and a flat metal member threaded onto the shaft with sharp leading edge which upon clockwise or counterclockwise rotation about the axis of the shaft will break the endplate, hook into the vertebra and rigidly secure the vertebra to the entire device preventing separation of the vertebra from the device during spinal motion.

Owner:INT SPINAL INNOVATIONS +2

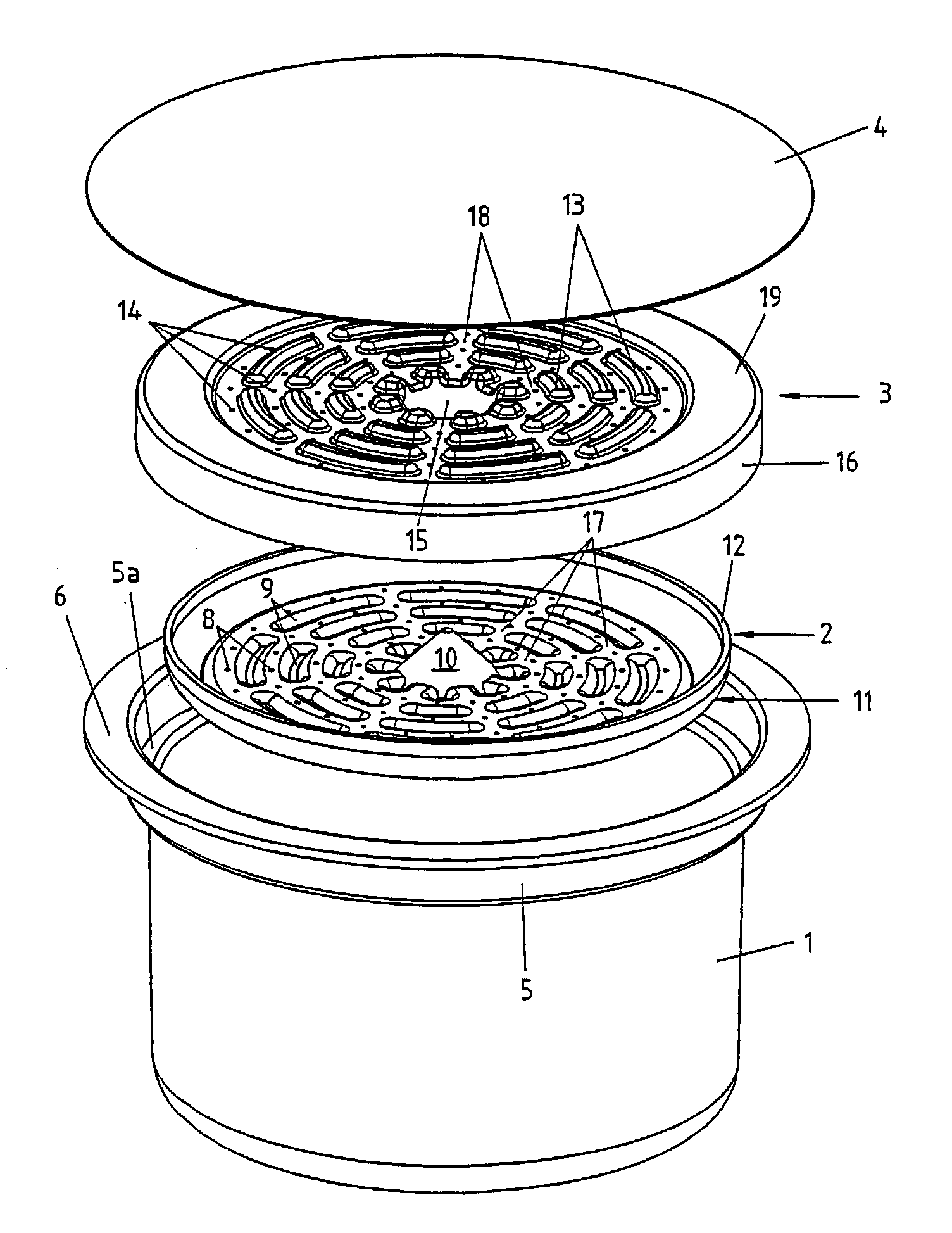

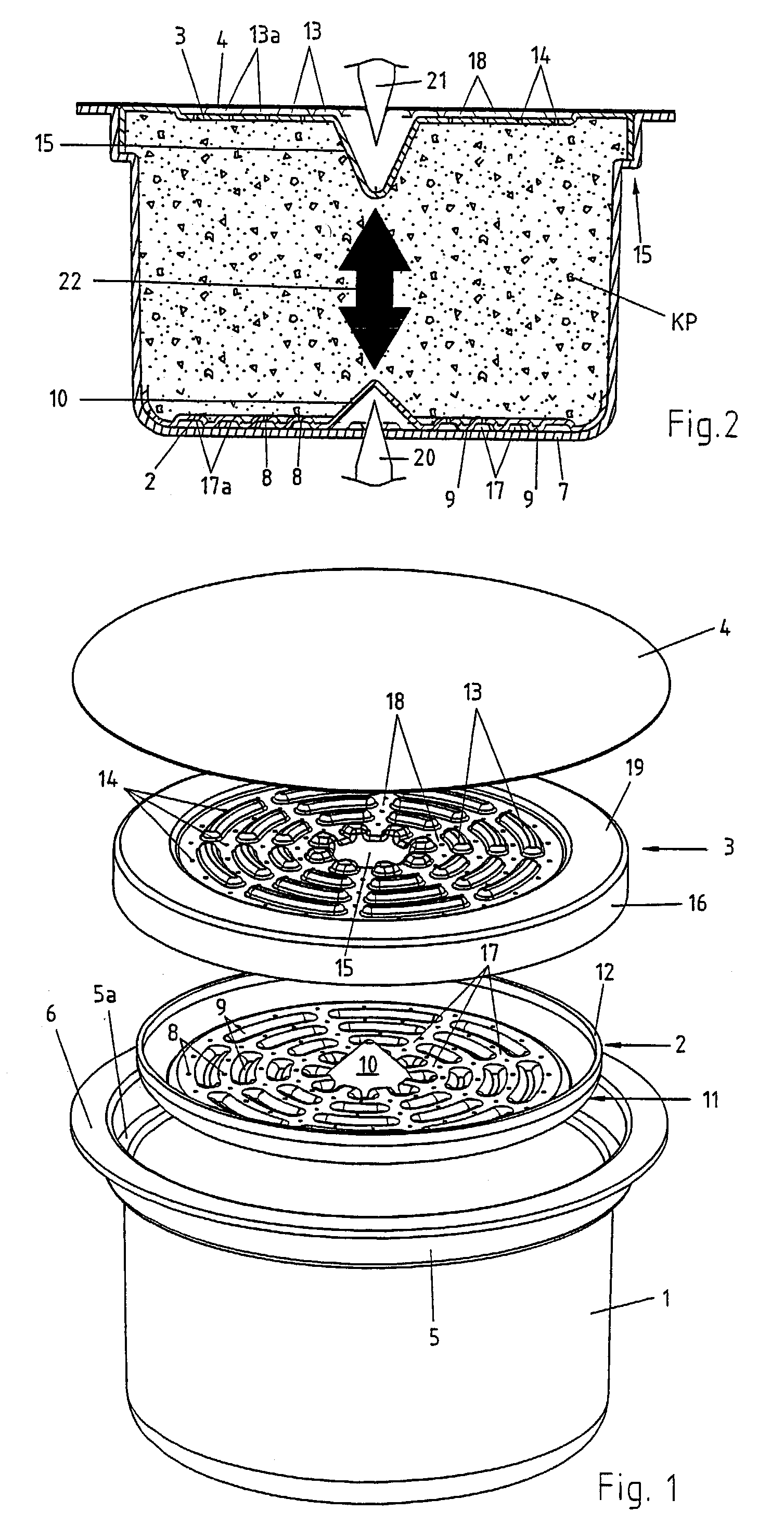

Cartridge containing a single serving of a particulate substance for preparing a beverage

ActiveUS7543527B2Provide spacePrevent escapeReady-for-oven doughsBeverage vesselsEspresso coffeeEngineering

A cartridge containing a single serving of a particulate substance extractable by means of water for preparing a beverage, preferably an espresso coffee beverage is disclosed. Between the bottom of the cartridge and the particulate substance as well as between the particulate substance and the cover of the cartridge, in each case a fluid director member is provided, having a plurality of small openings. The one close to the cover serves as a water distribution member for distributing the water, fed into the cartridge through a central opening pierced therein, evenly over the particulate substance, and the one close to the bottom serves as a beverage collection member to lead the beverage to a central opening pierced into the bottom of the cartridge. Both director members are provided with a recess directed towards the interior of the cartridge, allowing the penetration of a piercing member without damage to the director members.

Owner:CAFFITAL SYST SPA

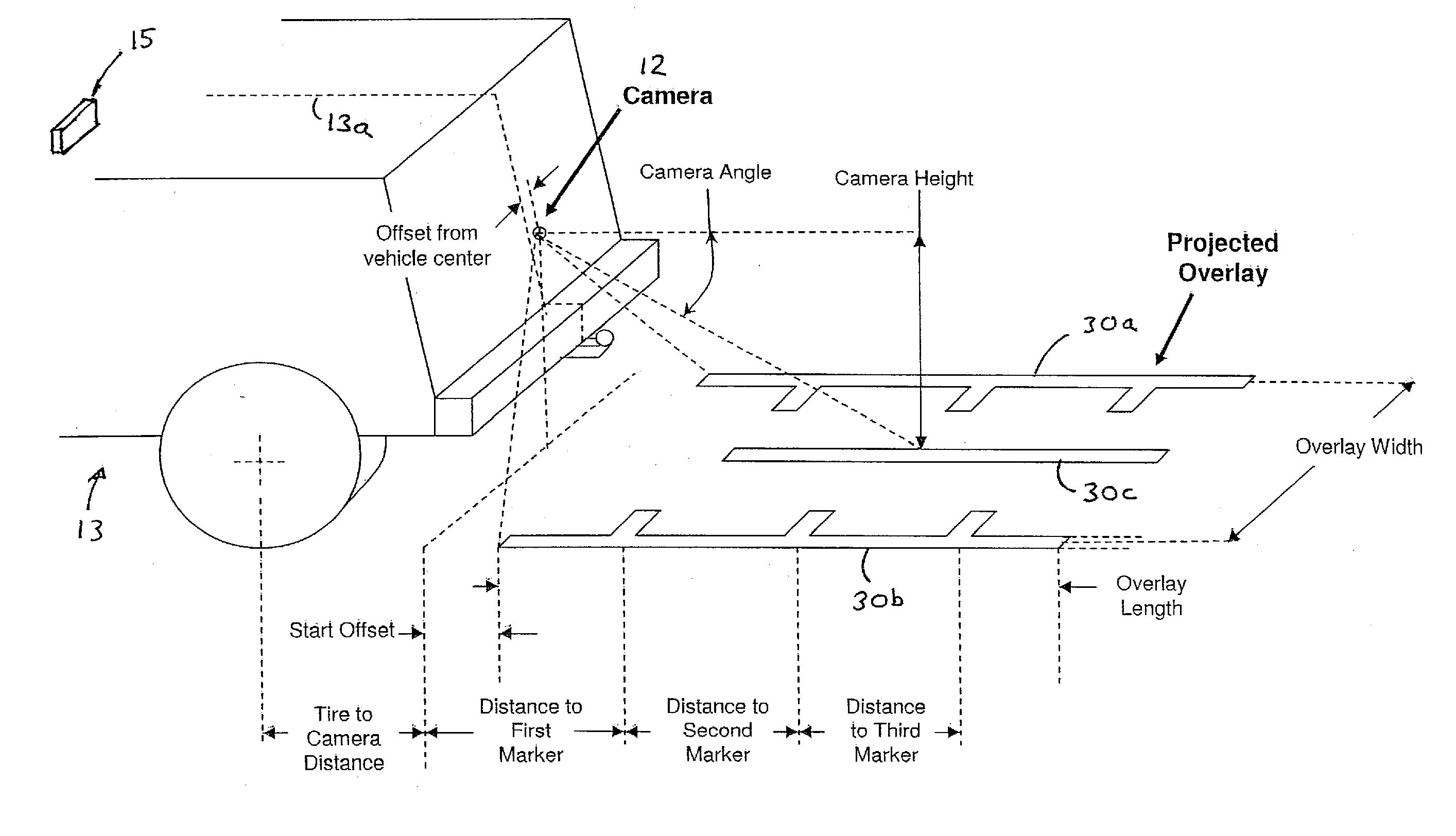

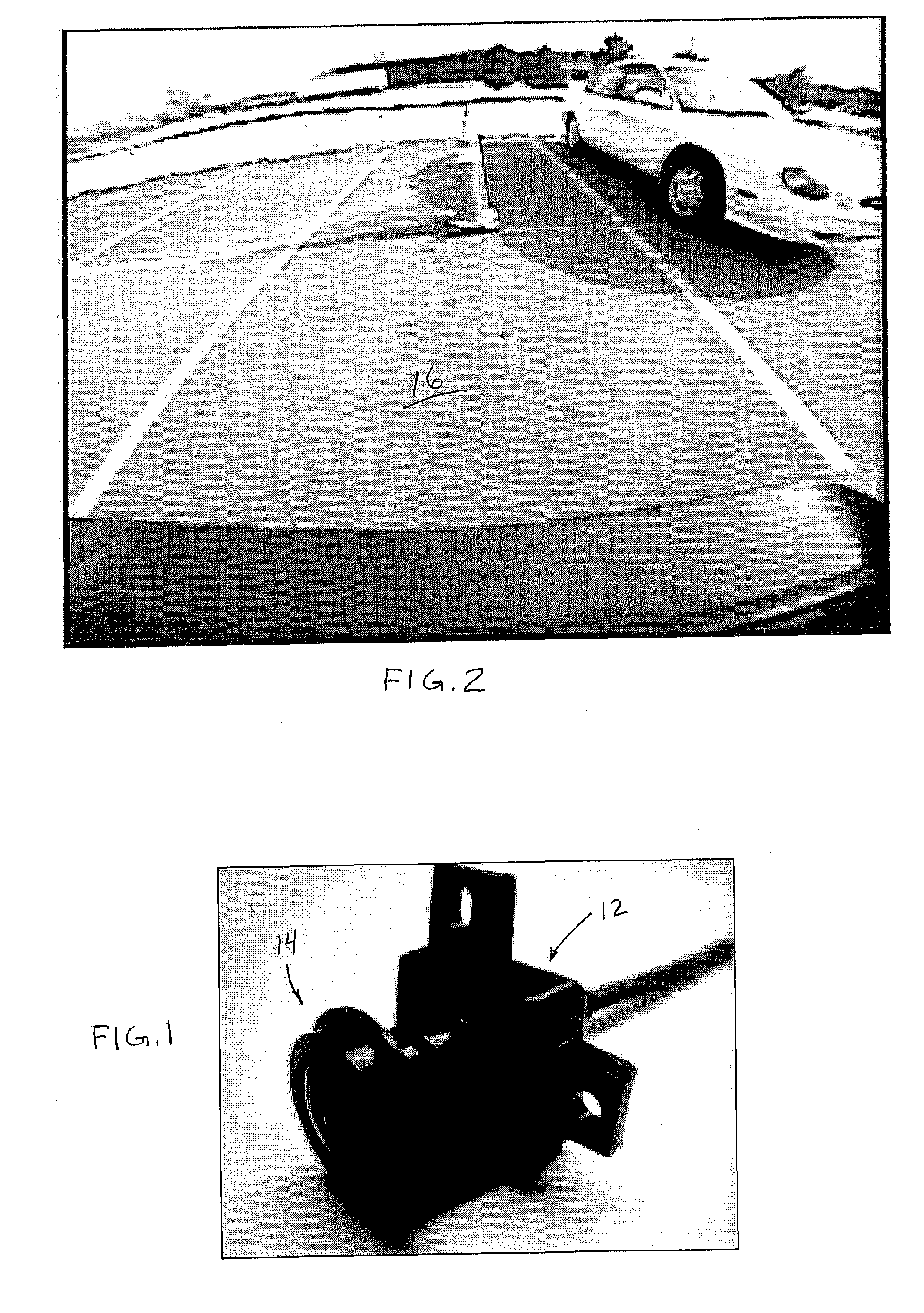

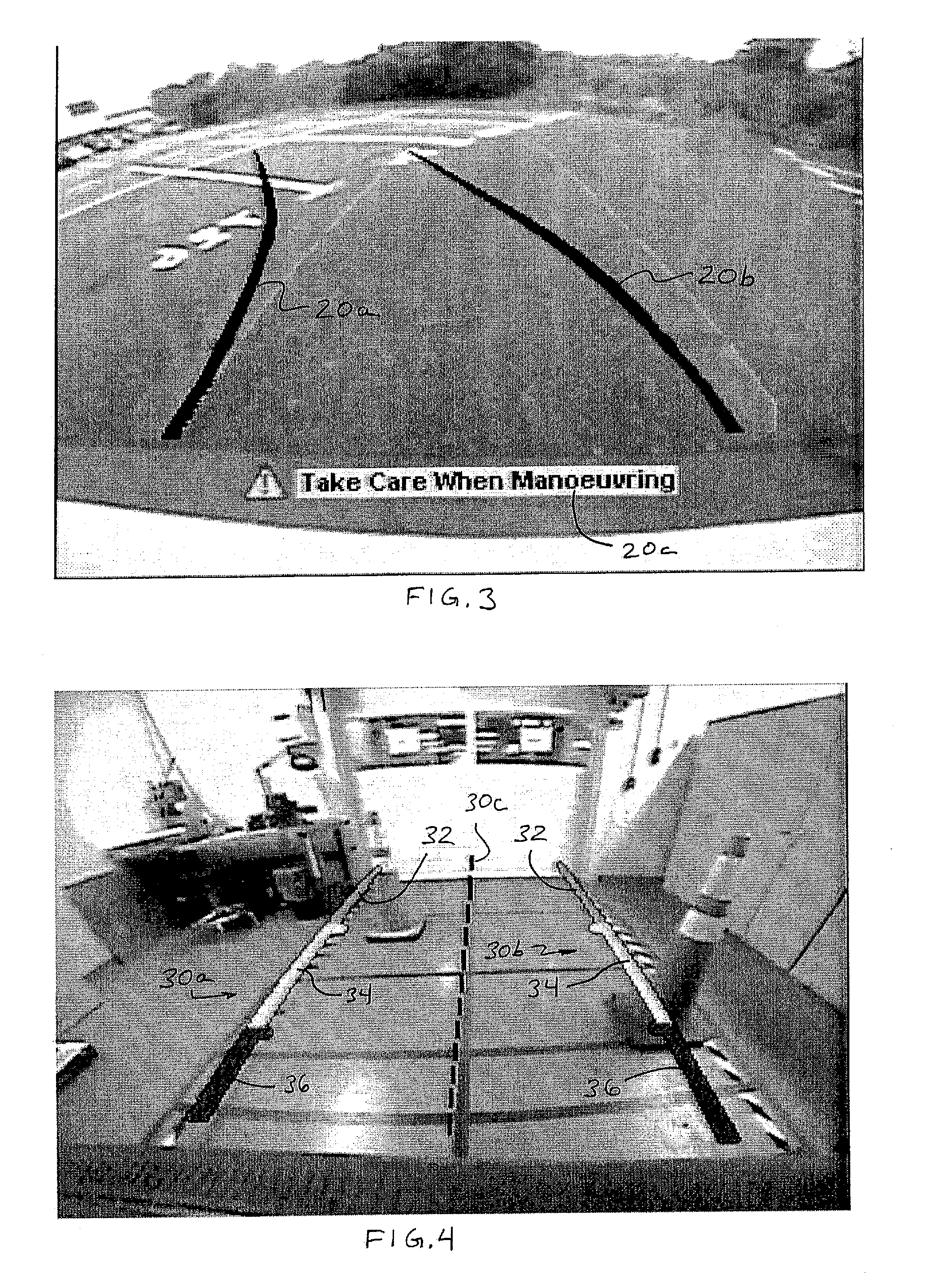

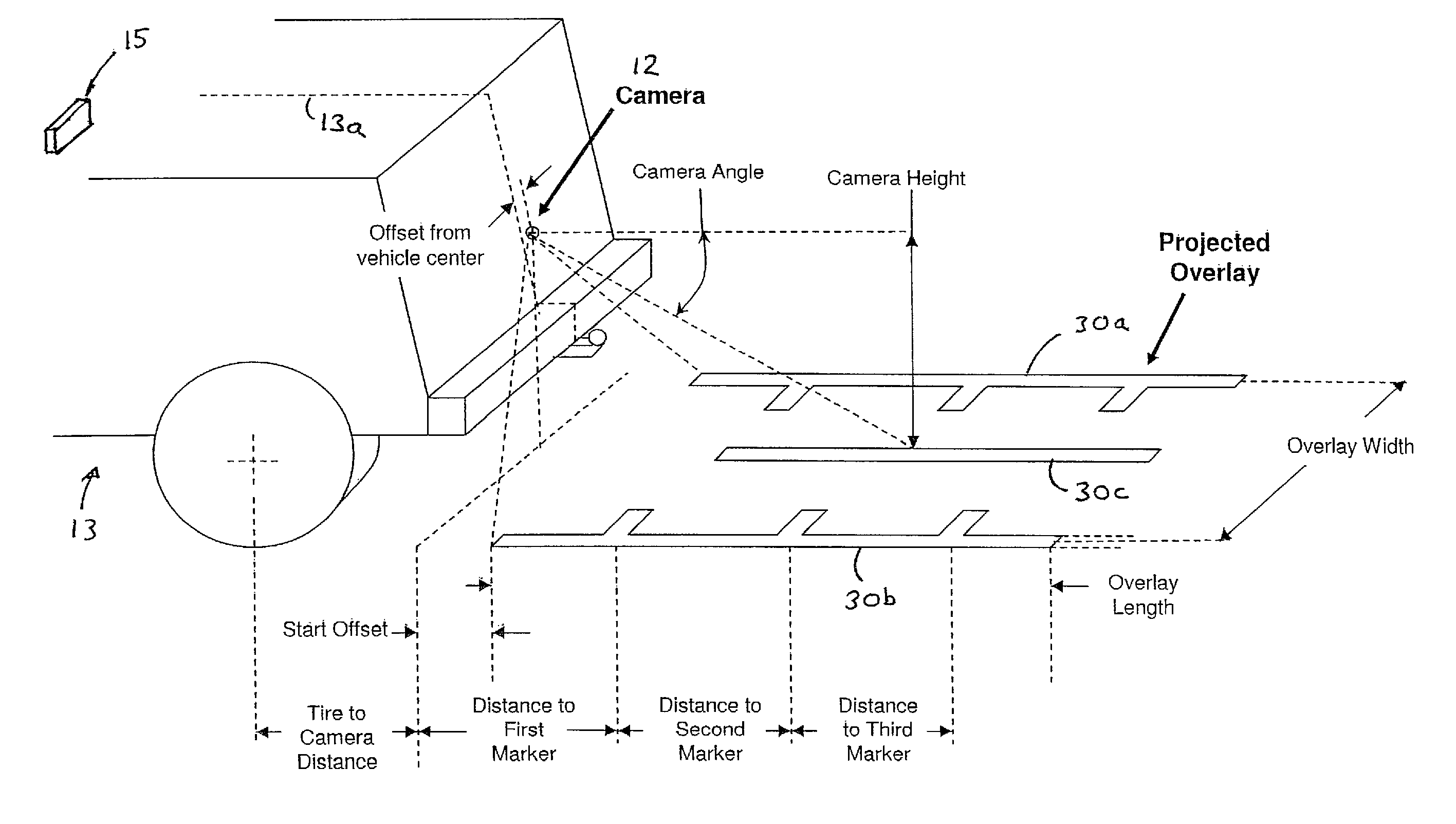

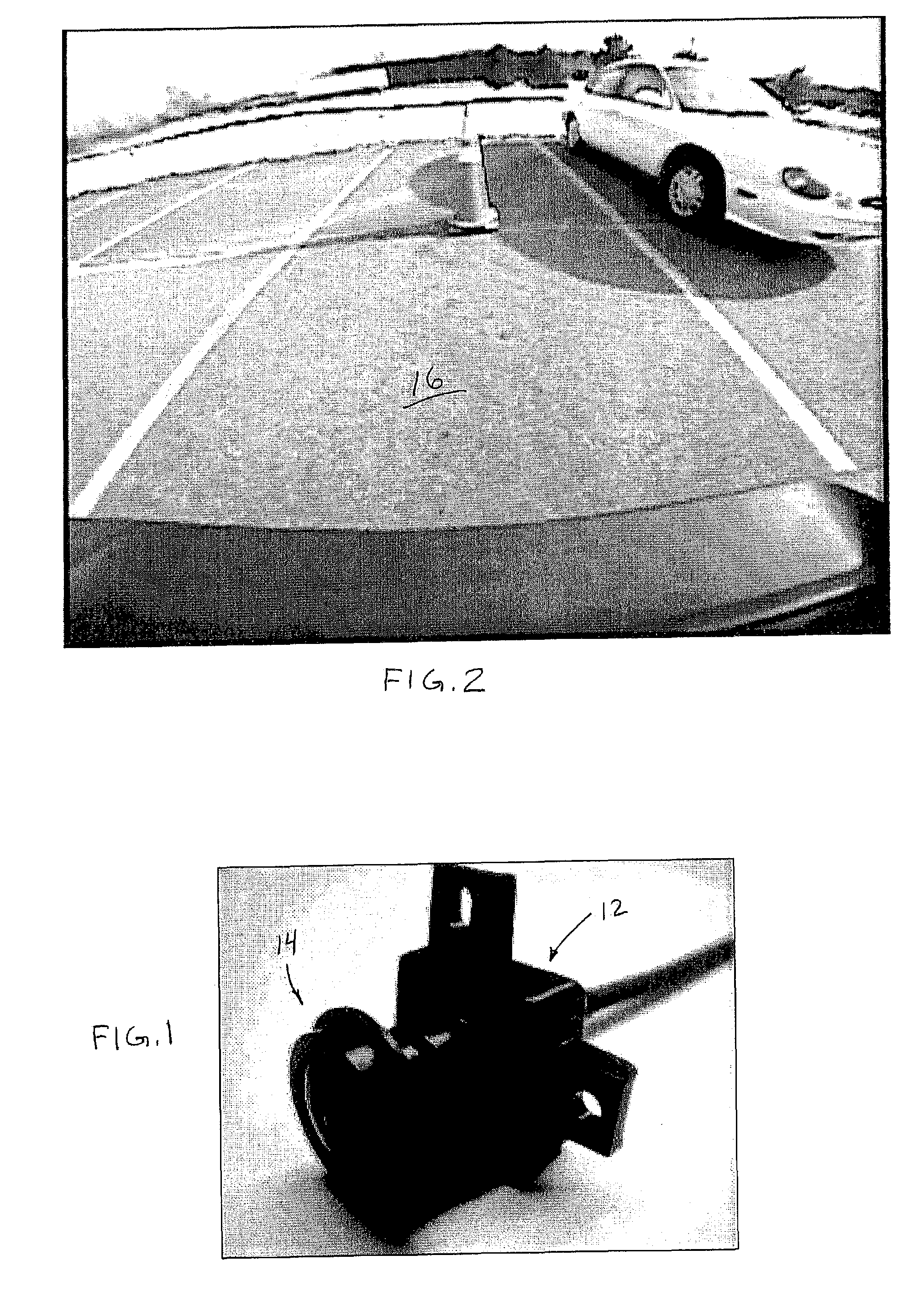

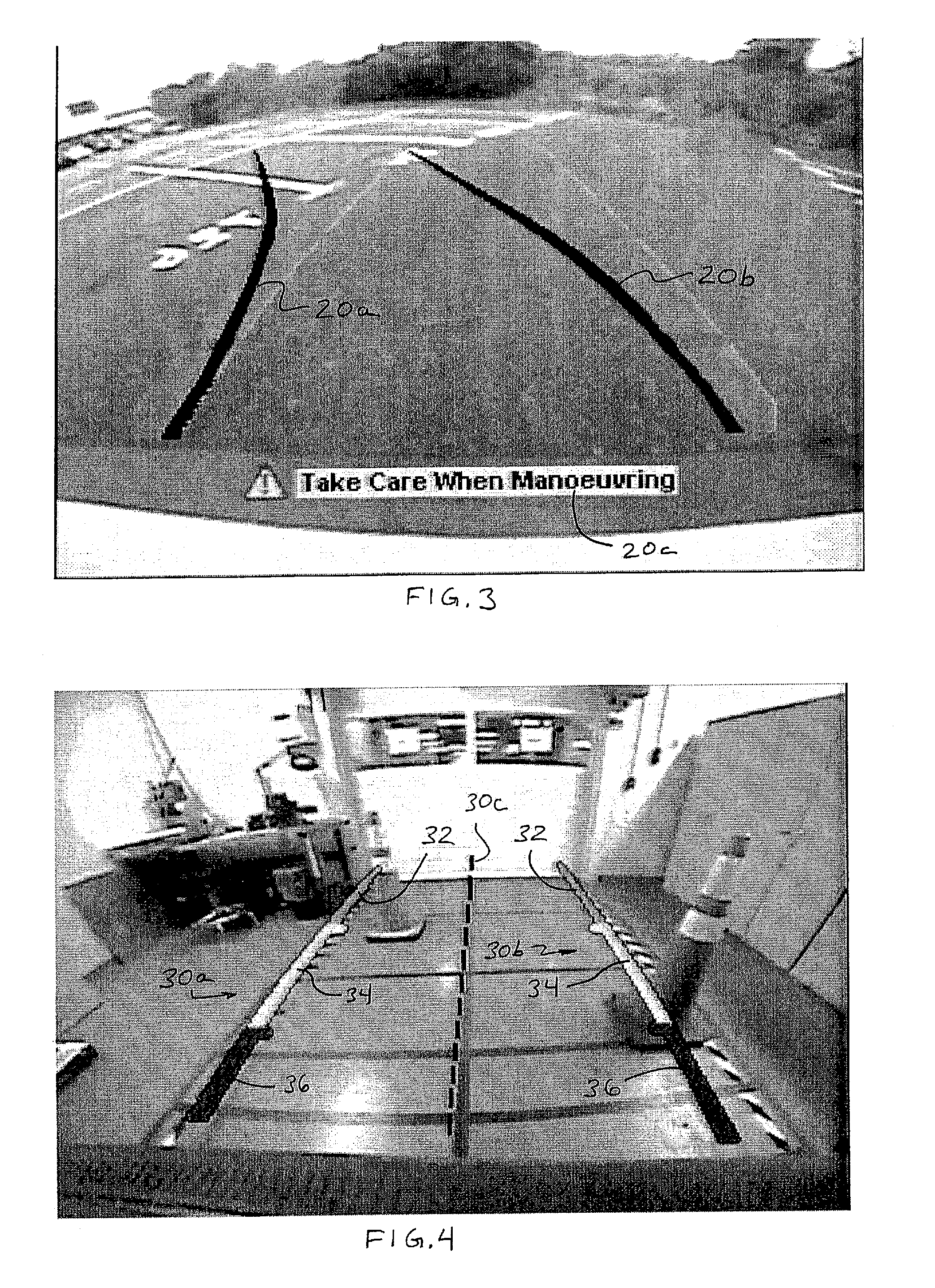

Imaging System for Vehicle

ActiveUS20100265048A1Enhancing exterior visibilityIncrease awareness2D-image generationPneumatic tyre reinforcementsGraphicsDisplay device

An imaging system for a vehicle includes an imaging sensor (12) and a display device (15) for displaying images representative of image data captured by the imaging sensor. The imaging sensor (12) has a rearward field of view when mounted at the vehicle. The imaging system generates a plurality of graphic overlays (130a, 130b, 130c) on the displayed images to enhance the driver's cognitive awareness of an object rearward of the vehicle. The graphic overlays comprises a plurality of graphic overlay segments. The graphic overlay segments convey three dimensional information to a person viewing the displayed images and the graphic overlays. The imaging system may adjust at least one of a color, an intensity and a rate of flashing of at least one of the plurality of graphic overlay segments in response to an object being detected rearward of the vehicle and within a distance threshold.

Owner:MAGNA ELECTRONICS

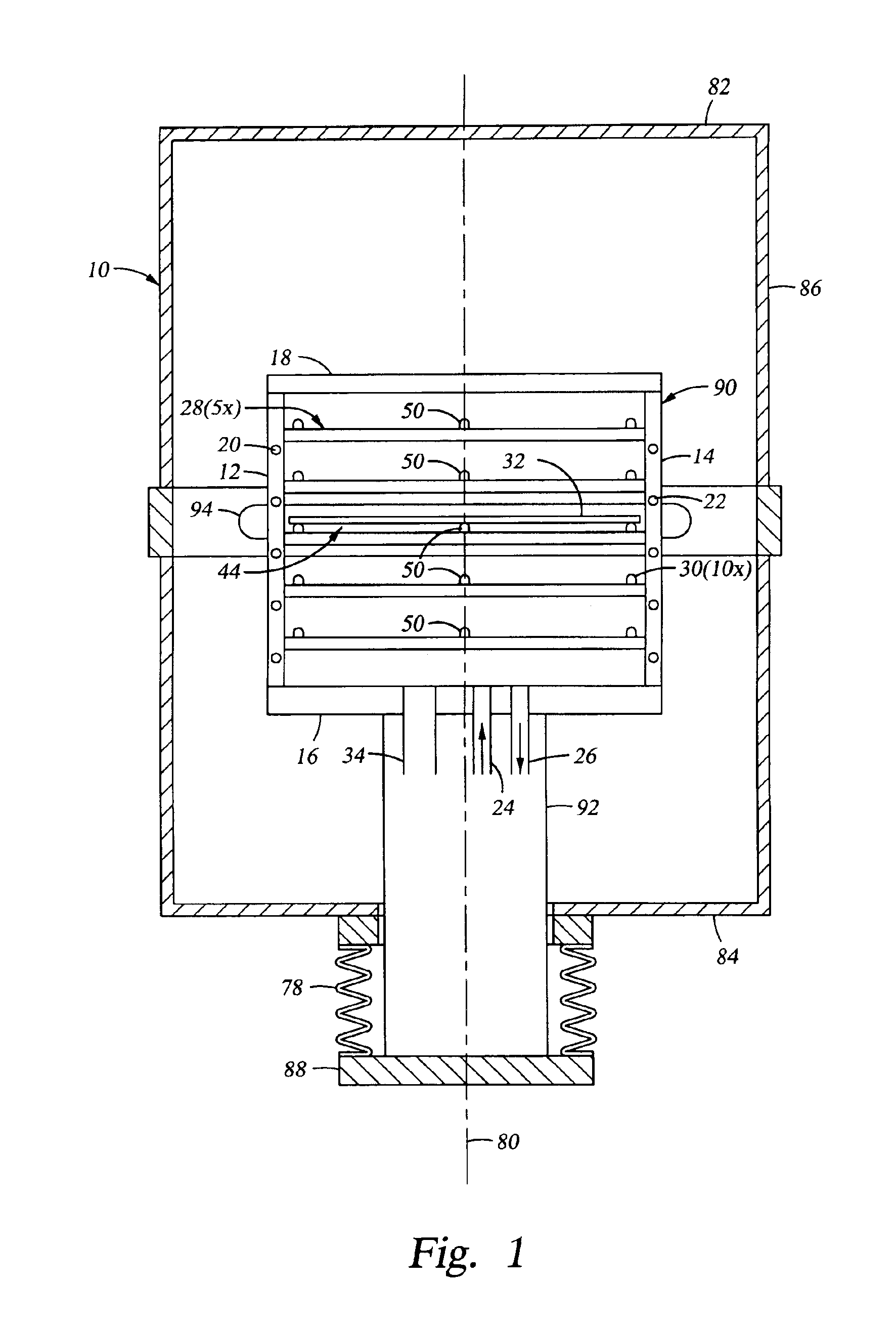

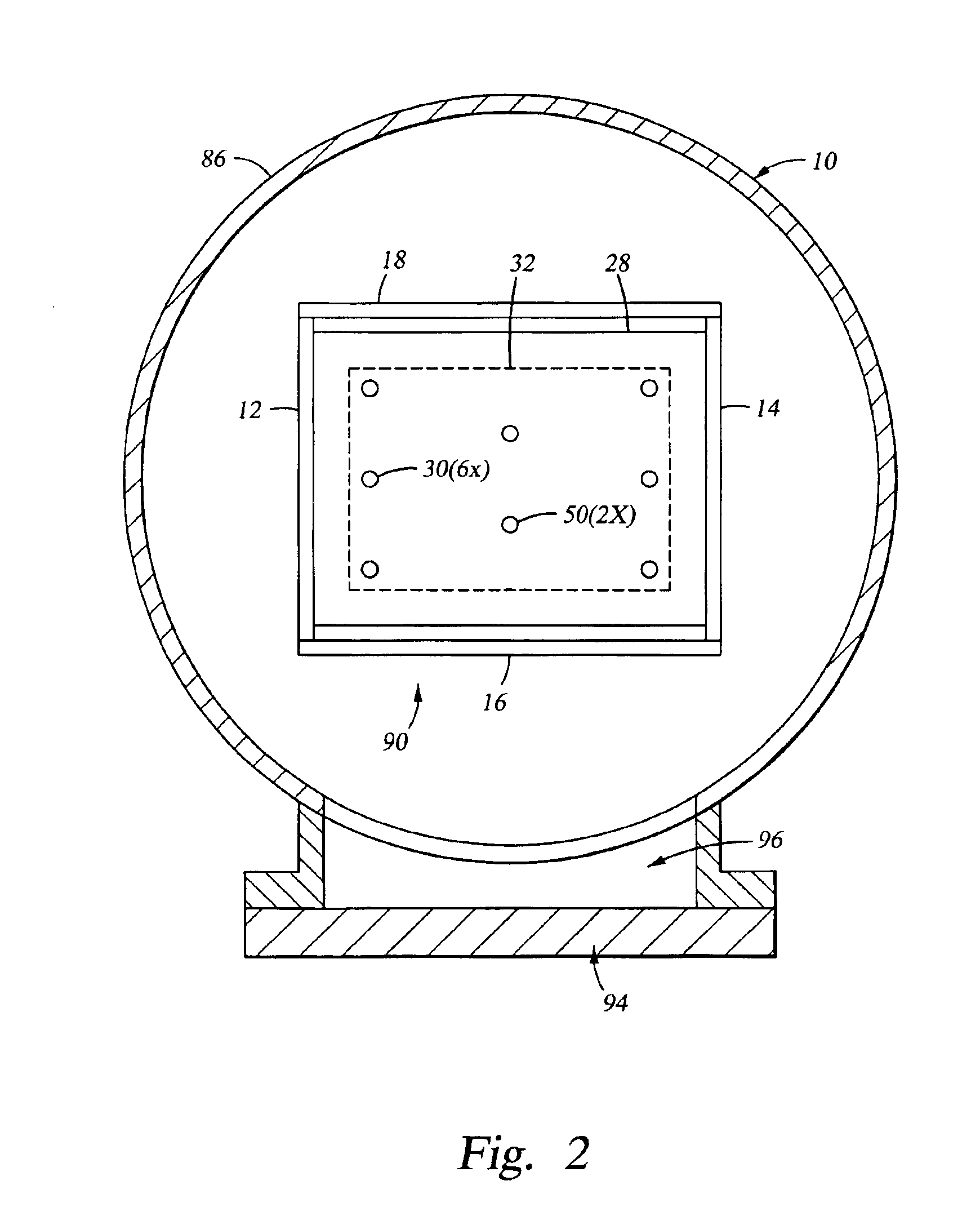

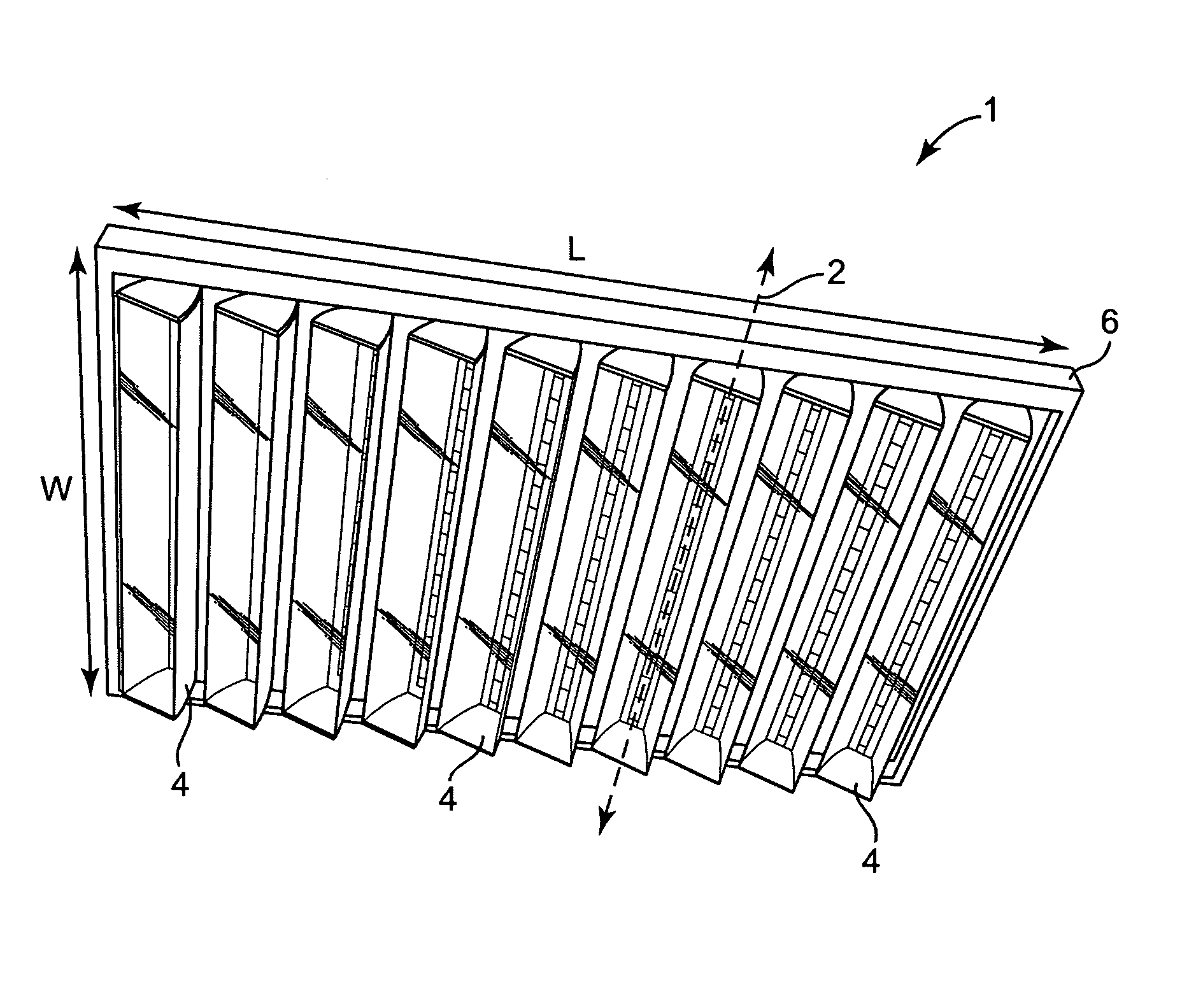

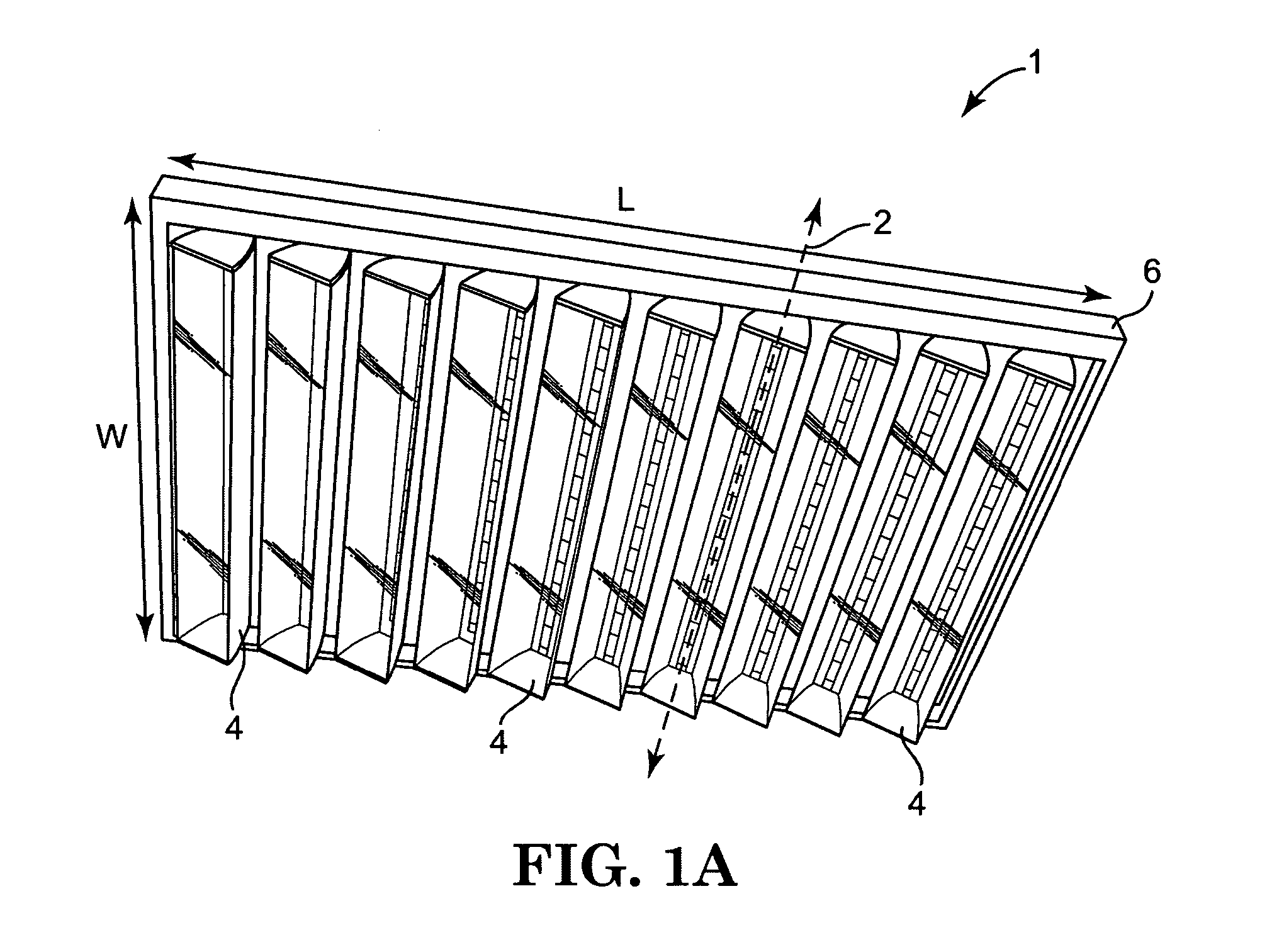

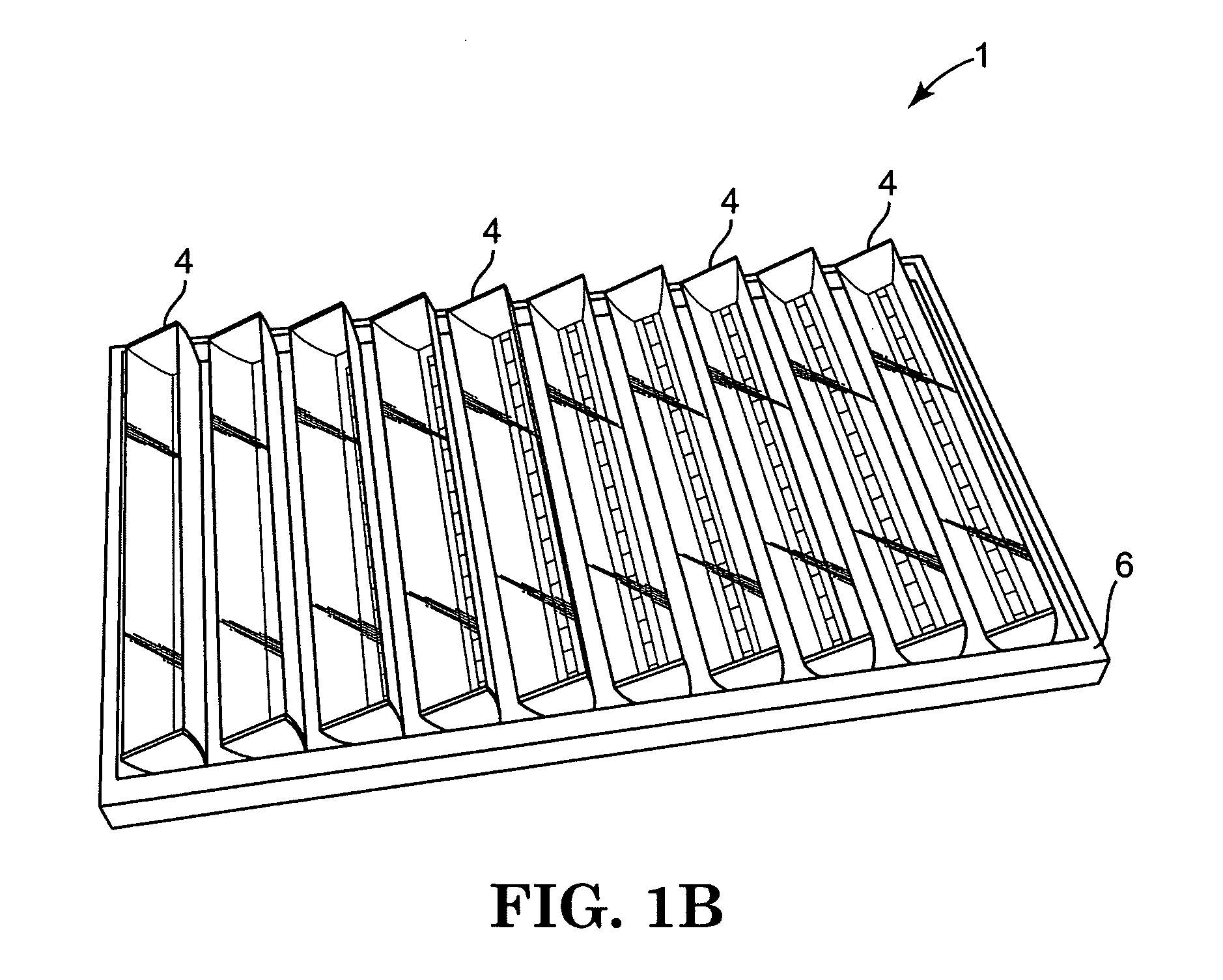

Concentrating solar panel and related systems and methods

InactiveUS20070193620A1Low profileSuitable for rooftop installationPhotovoltaic supportsSolar heating energyTelecommunicationsMarket acceptance

The present invention relates to photovoltaic concentrating modules and related concentrating solar systems and methods. In particular, the present invention relates to concentrating modules, especially modules having a convenient size and market acceptance of traditional flat photovoltaic solar panels.

Owner:SOLIANT ENERGY INC

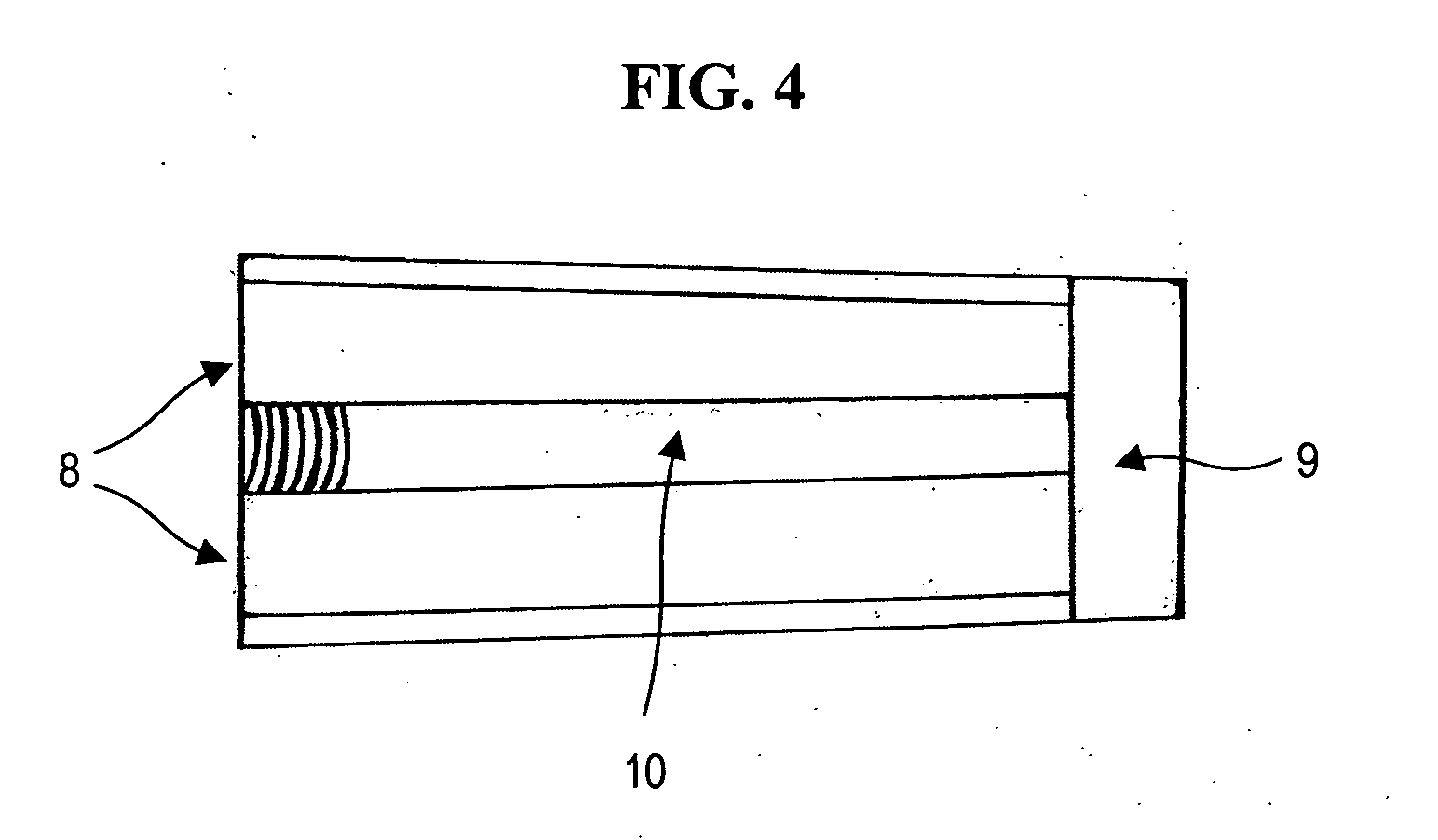

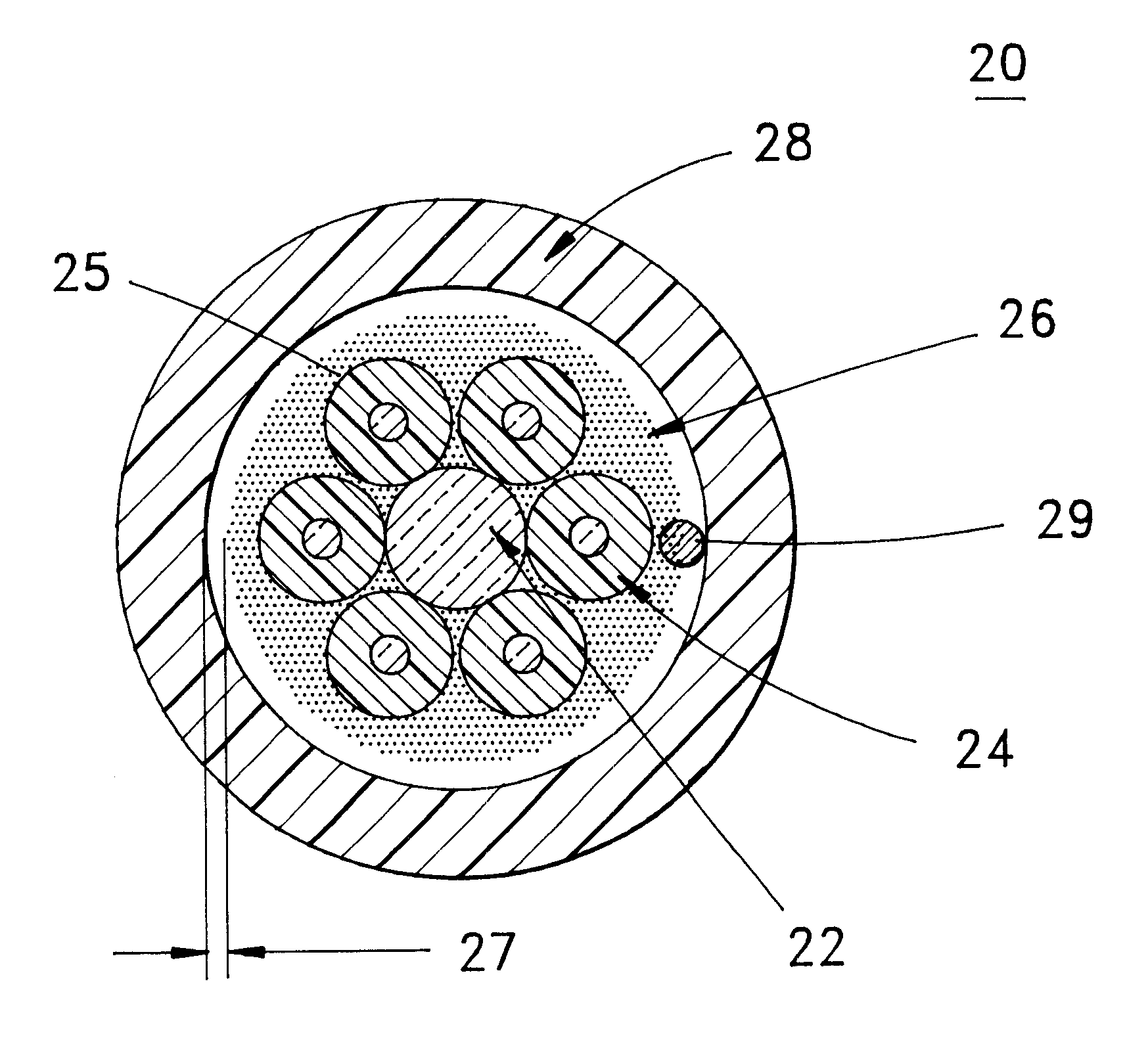

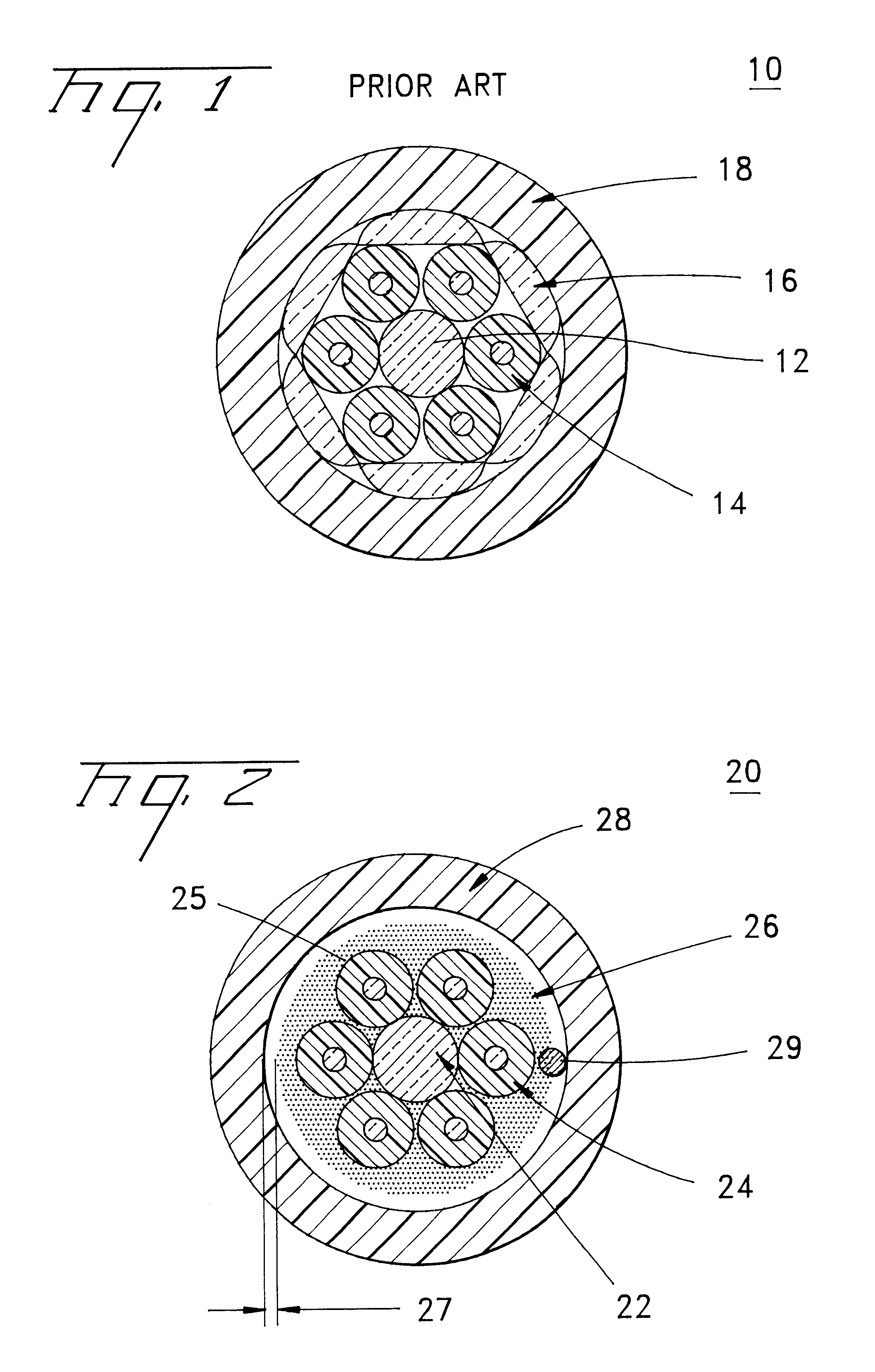

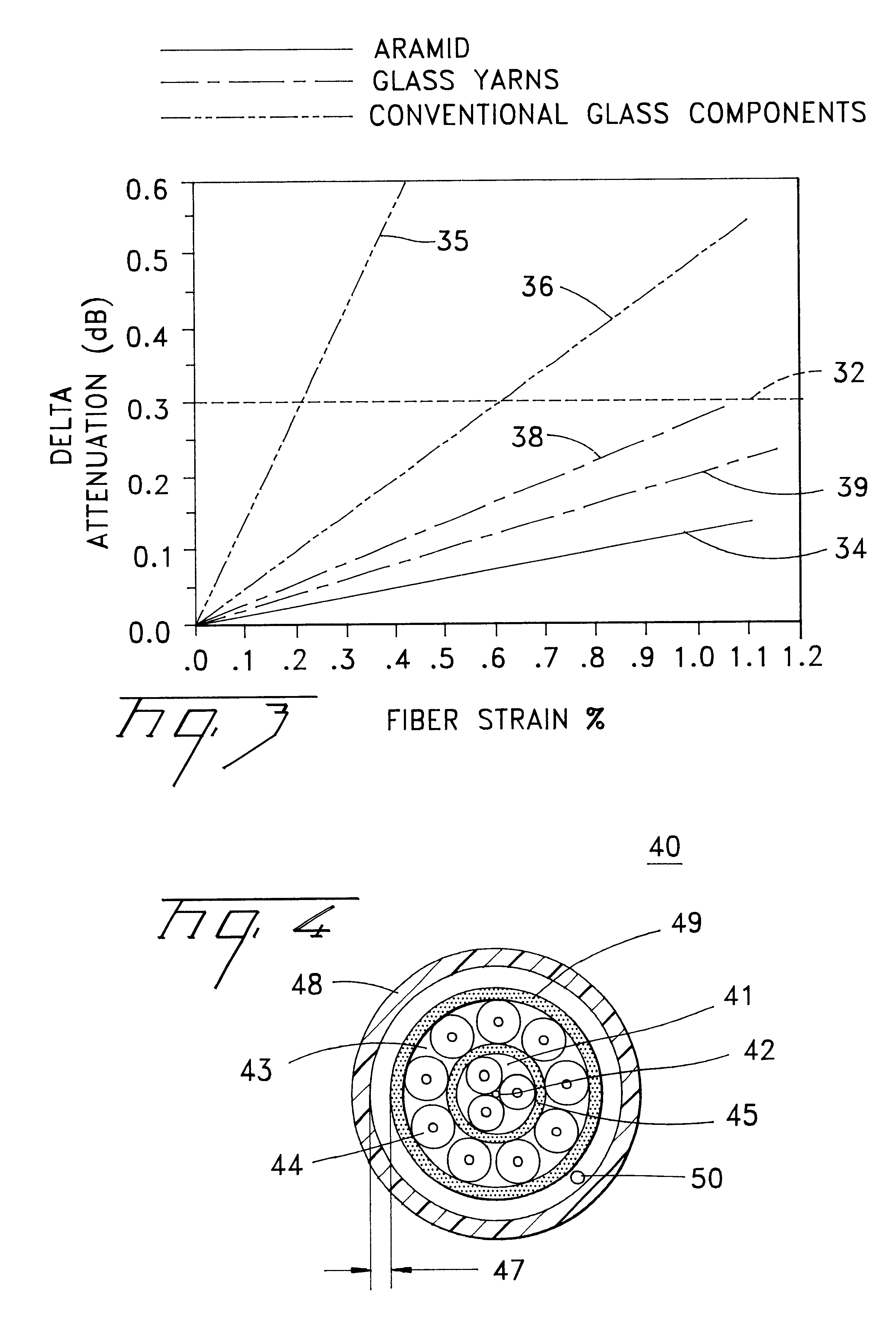

Fiber optic cables with strength members and methods of making the same

A fiber optic cable and method of manufacturing the same include at least one optical fiber component and at least one strength member disposed adjacent to said at least one optical fiber component. The at least one strength member includes a yarn and a jacket generally surrounding said at least one optical fiber component and said at least one strength member. The yarn includes a coating system having a percentage by weight, based on the dry weight of said yarn, of about 2.0% or less. Other embodiments can include a delta attenuation of about 0.3 dB or less over the range of about 0% to about 1.0% of optical fiber strain, a peak cable core pull-out force of about 1 newton or less, or a space disposed between a cable core and the jacket.

Owner:CORNING OPTICAL COMM LLC

Imaging system for vehicle

ActiveUS8451107B2Improve visibilityEasy to explain2D-image generationProjectorsGraphicsDriver/operator

An imaging system for a vehicle includes an imaging sensor (12) and a display device (15) for displaying images representative of image data captured by the imaging sensor. The imaging sensor (12) has a rearward field of view when mounted at the vehicle. The imaging system generates a plurality of graphic overlays (130a, 130b, 130c) on the displayed images to enhance the driver's cognitive awareness of an object rearward of the vehicle. The graphic overlays comprises a plurality of graphic overlay segments. The graphic overlay segments convey three dimensional information to a person viewing the displayed images and the graphic overlays. The imaging system may adjust at least one of a color, an intensity and a rate of flashing of at least one of the plurality of graphic overlay segments in response to an object being detected rearward of the vehicle and within a distance threshold.

Owner:MAGNA ELECTRONICS INC

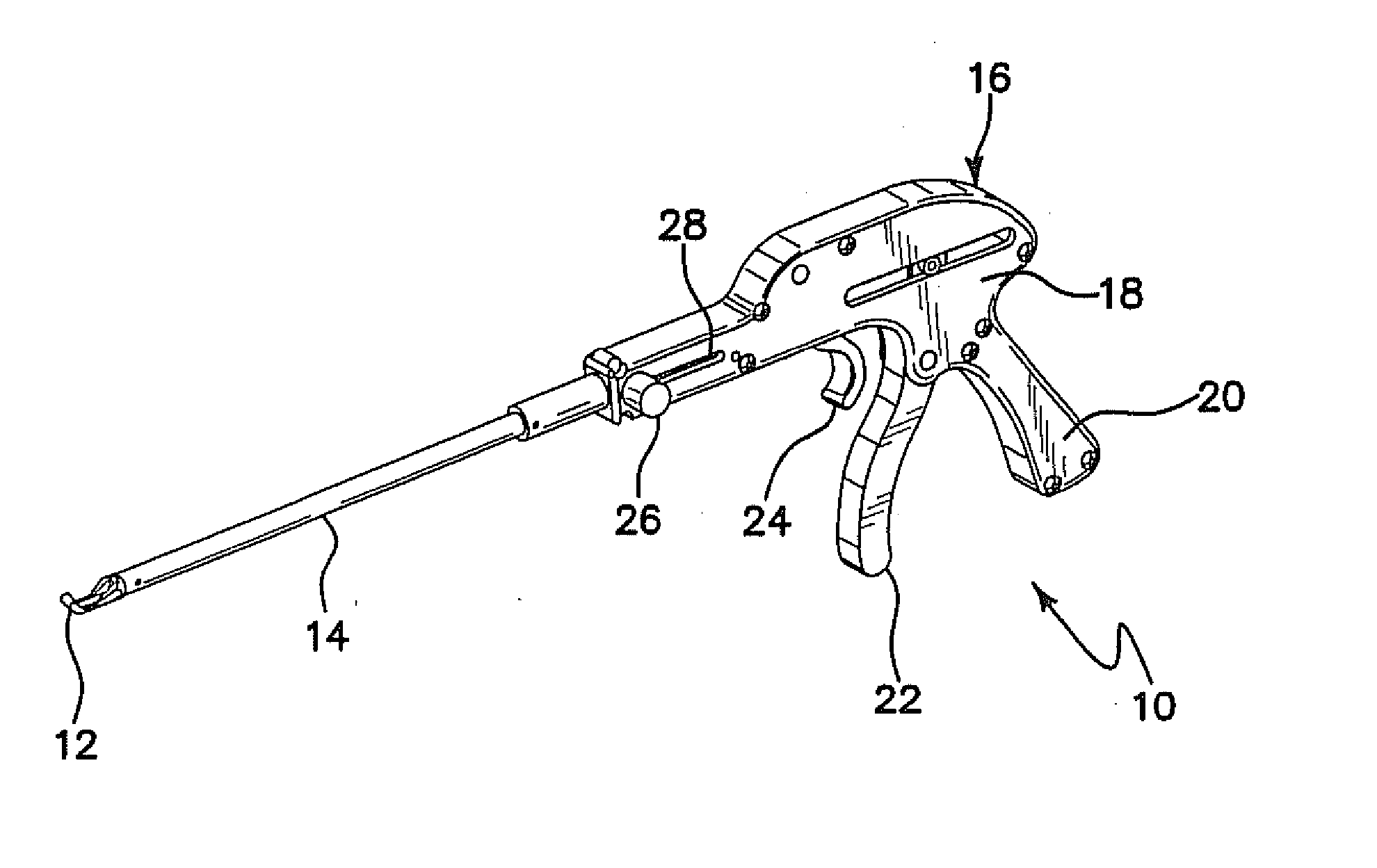

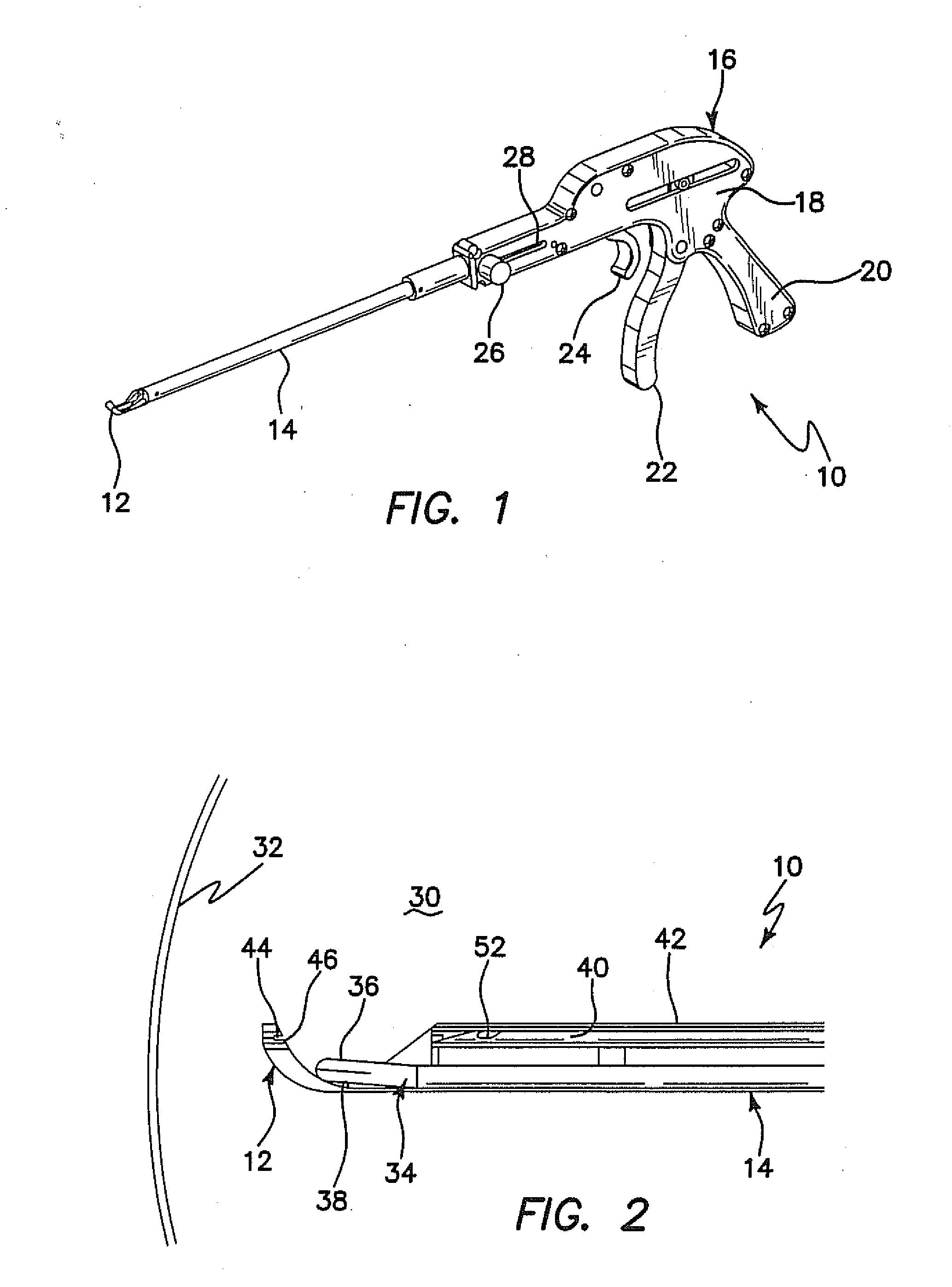

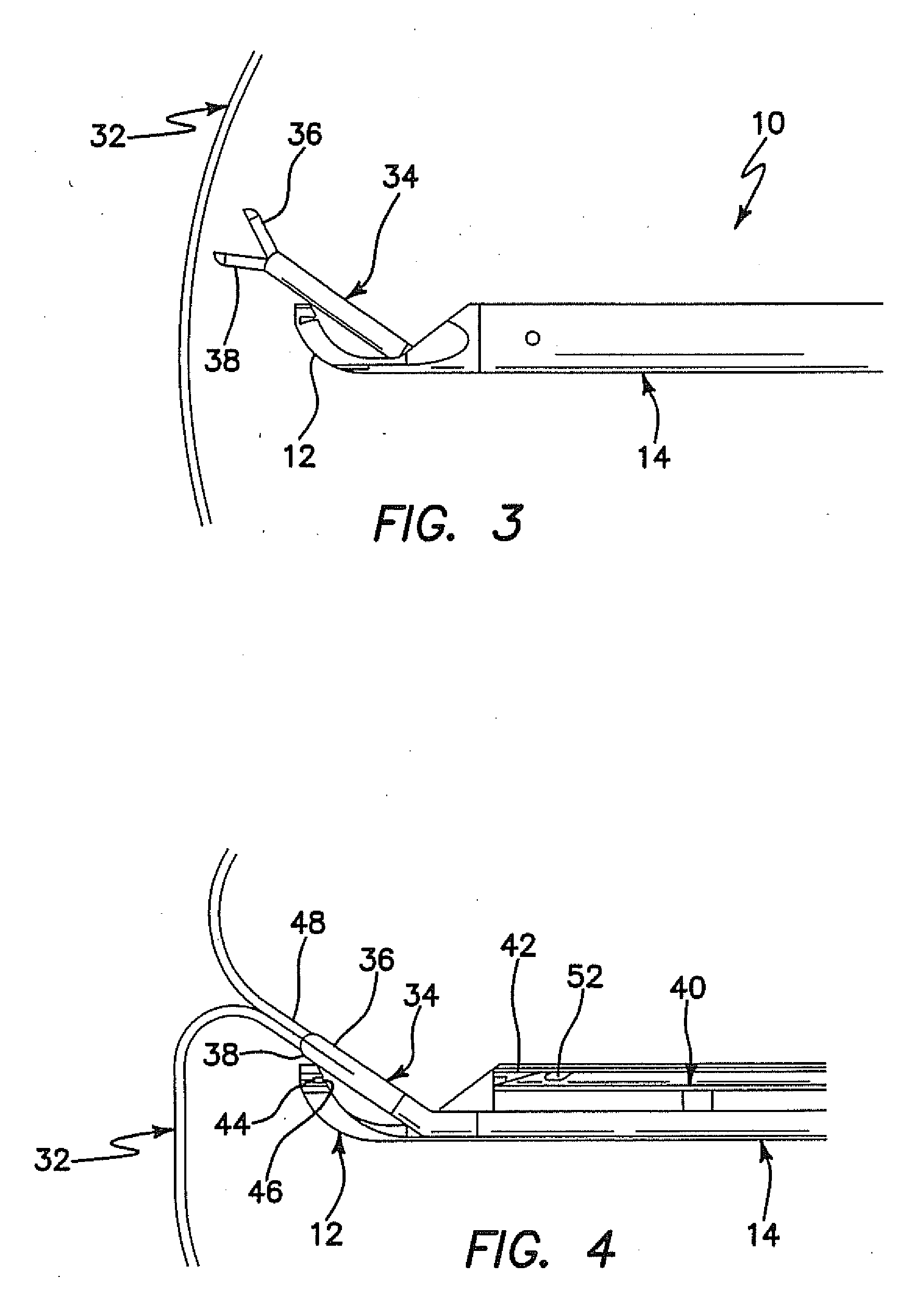

Arthroscopic soft tissue plication systems and methods

InactiveUS20080077162A1Reduce loading forceReduce load forceSuture equipmentsSurgical needlesSurgical siteSoft tissue

A system and method for repairing soft tissue comprises introducing an instrument having a shaft into an operative site, such as a human shoulder. Then, a flexible grasper is advanced from the instrument to capture a portion of soft tissue. The flexible grasper is then retracted so that the captured tissue lies in a pathway for a needle in the instrument. The needle is advanced along the pathway through the captured tissue, and then a portion of suture is captured with the needle, distally of the captured tissue. The needle is retracted proximally through the captured tissue, to thereby pass the suture therethrough and plicate the tissue. The plicated tissue is then released from the grasper.

Owner:CAYENNE MEDICAL INC

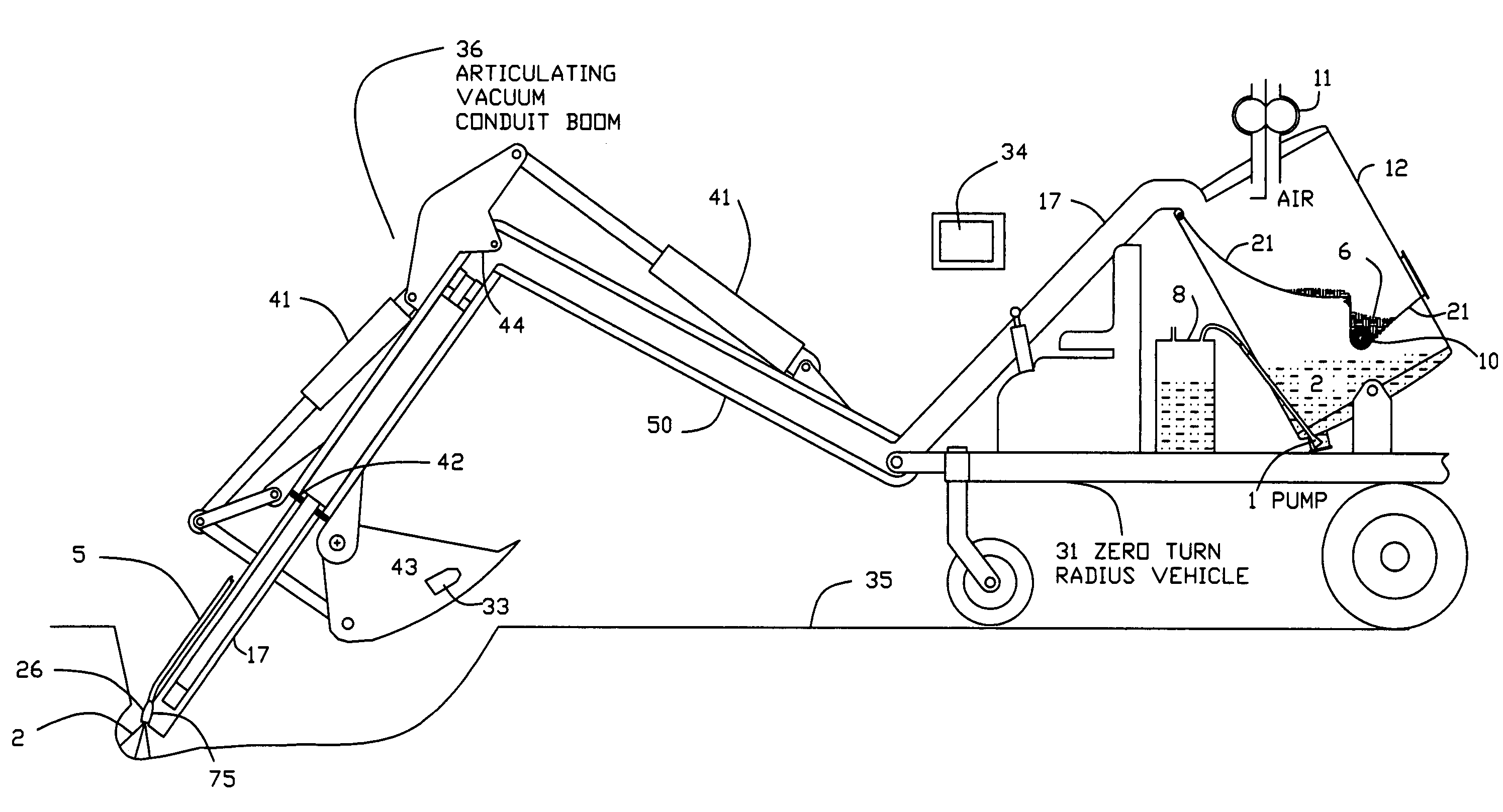

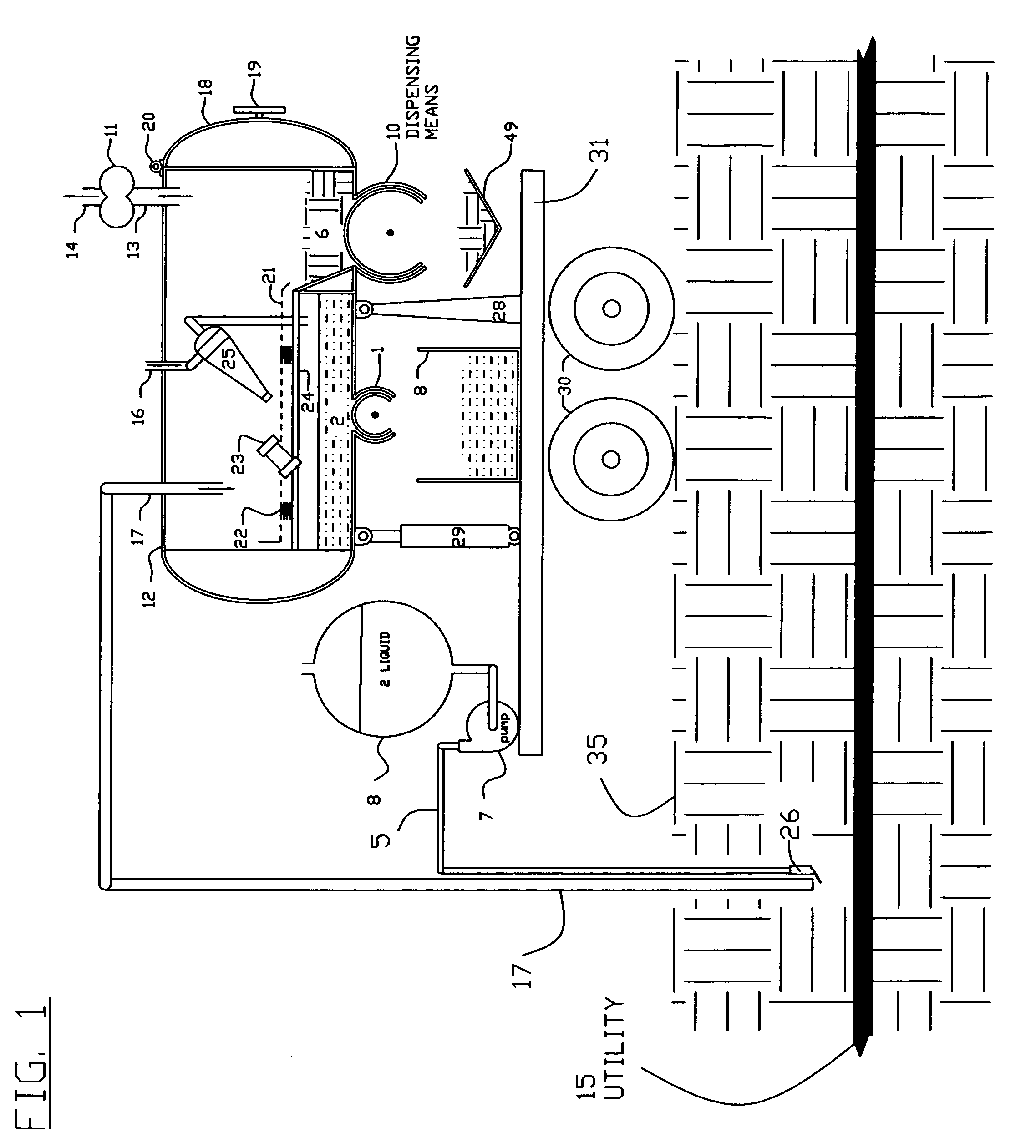

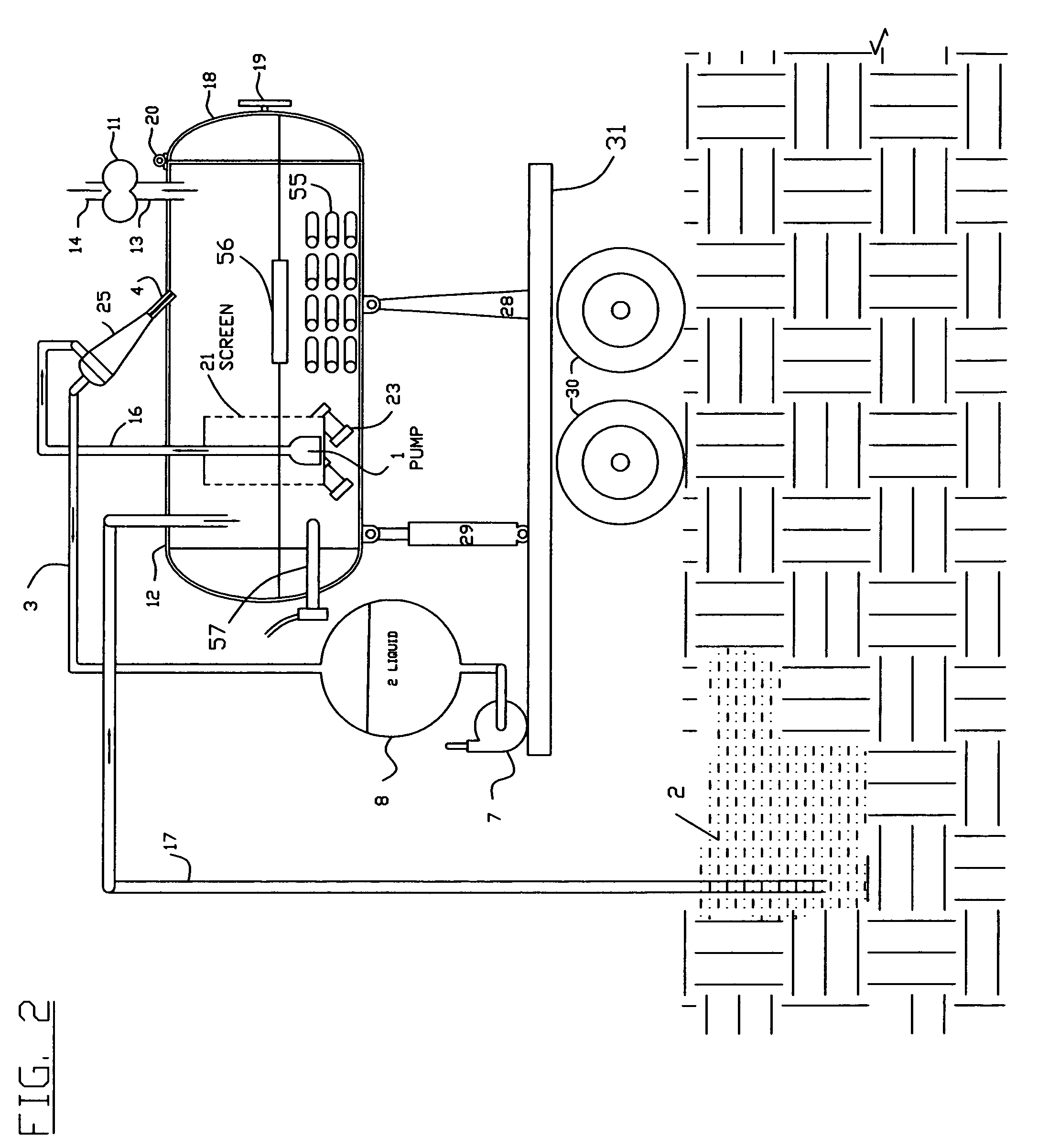

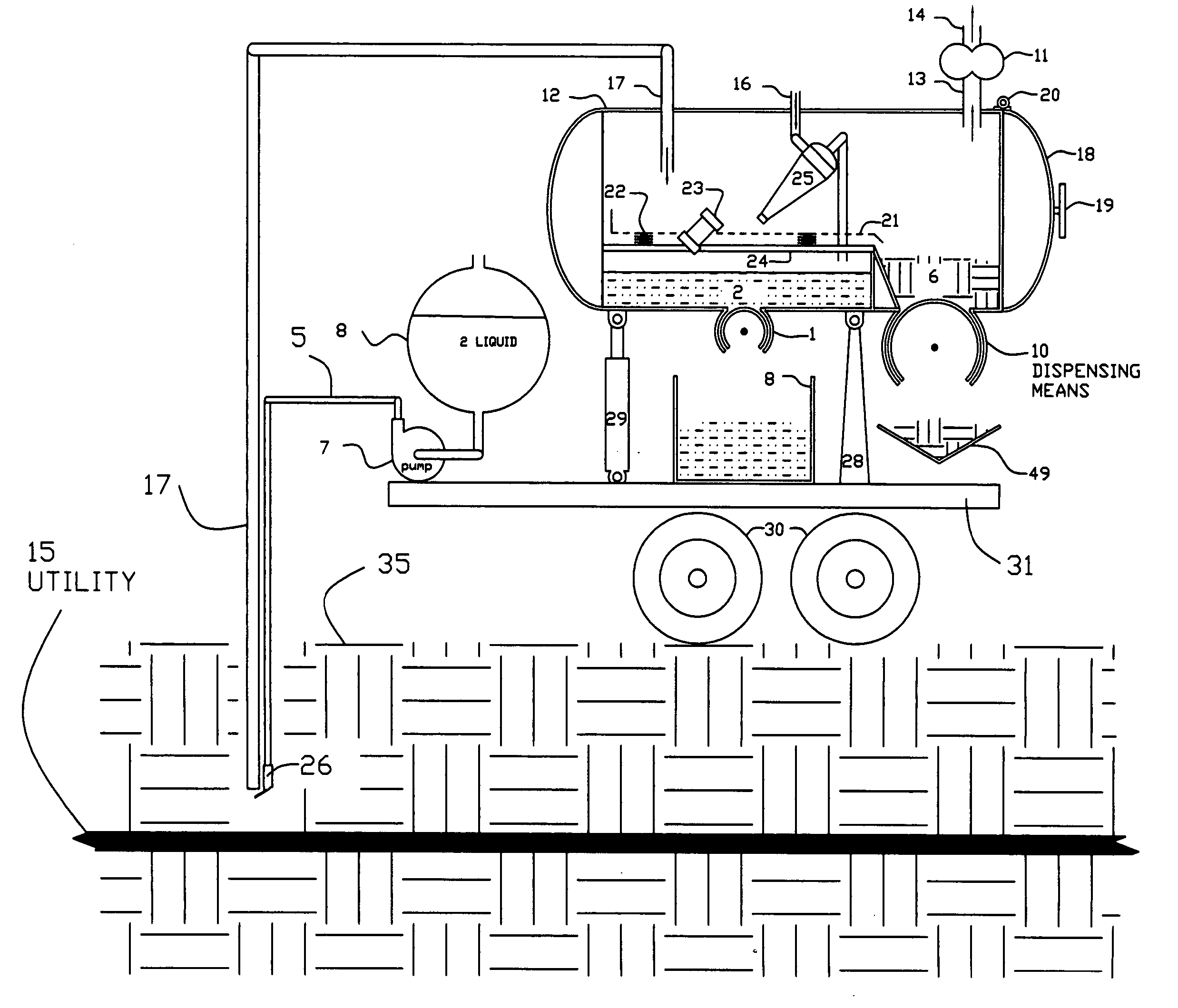

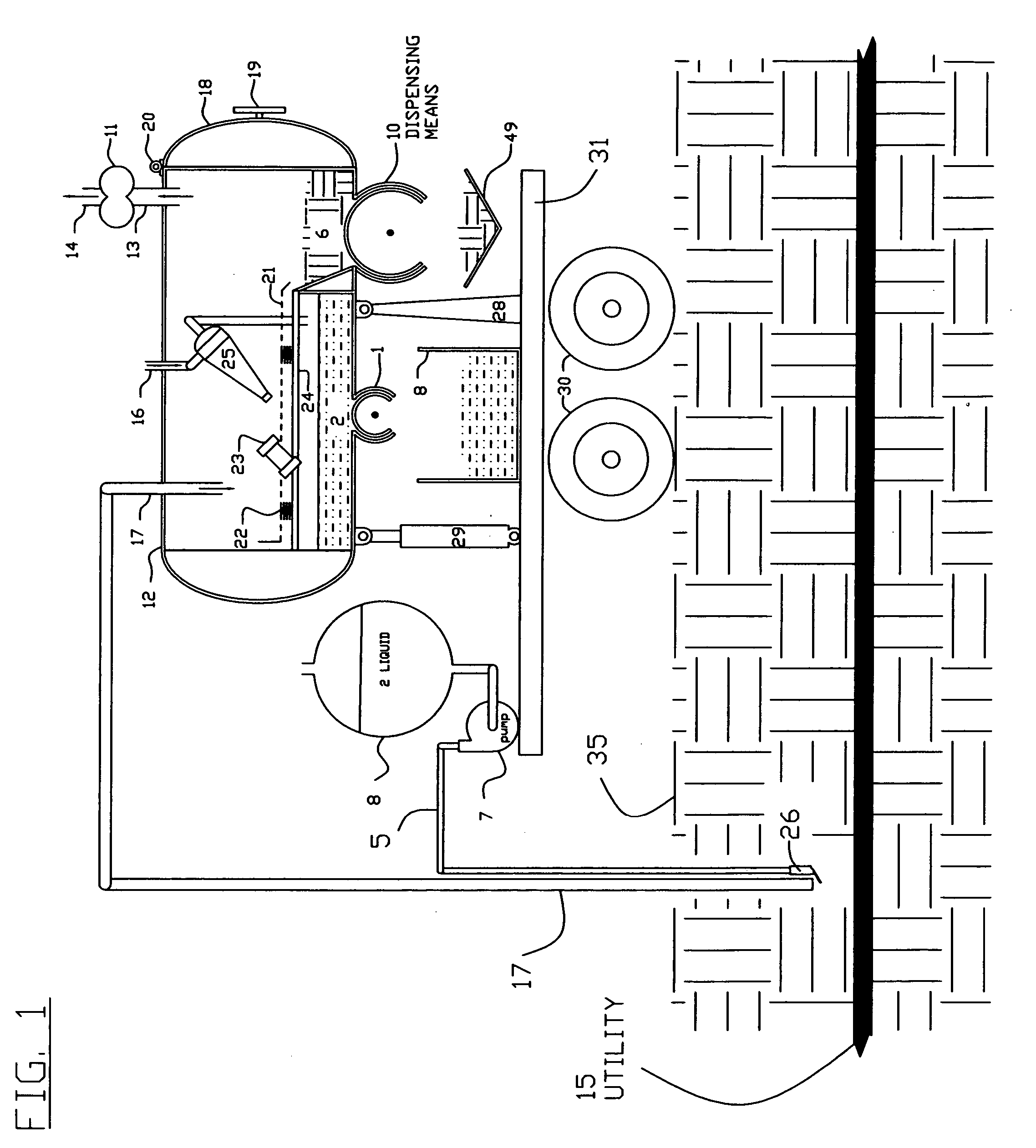

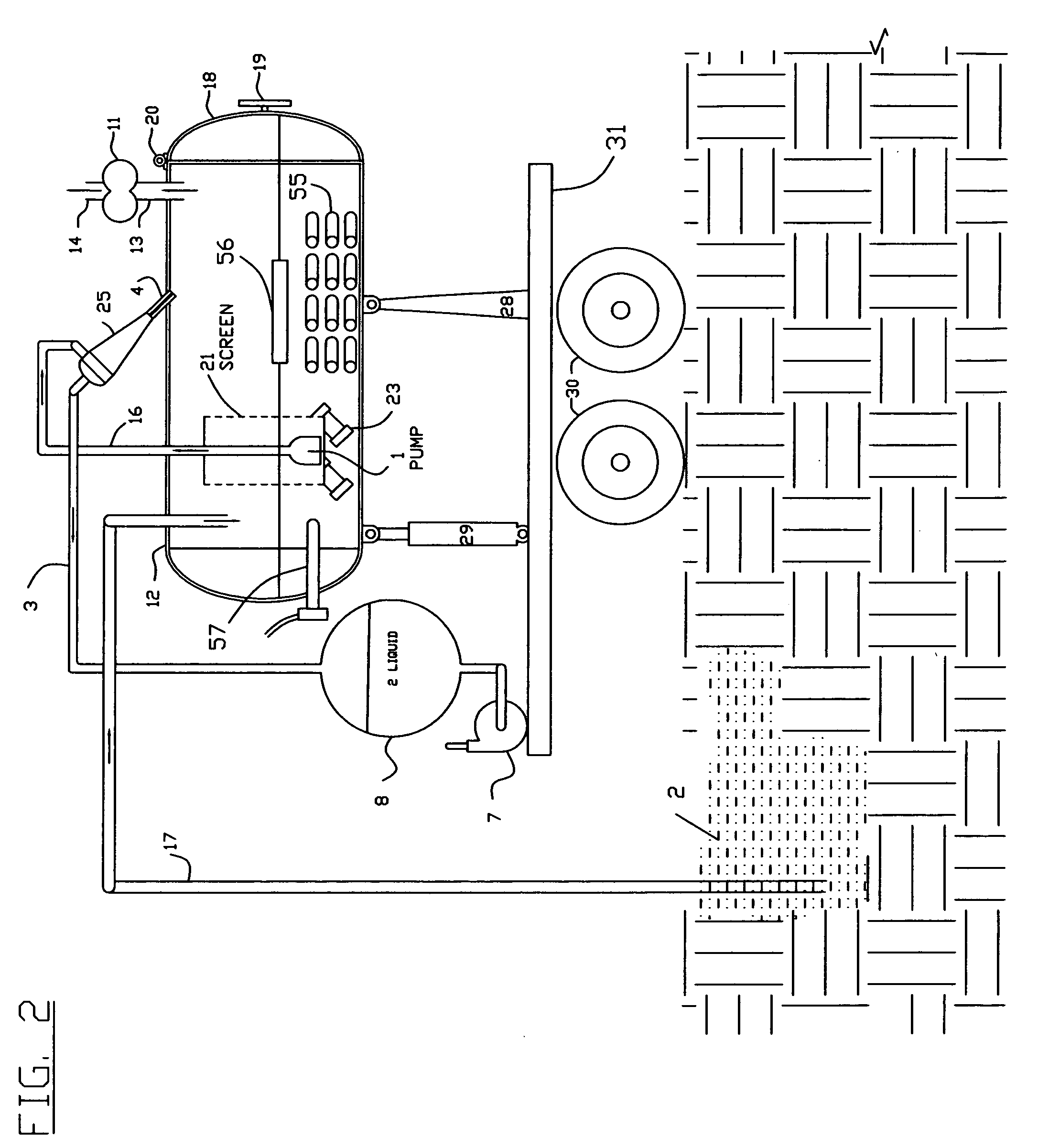

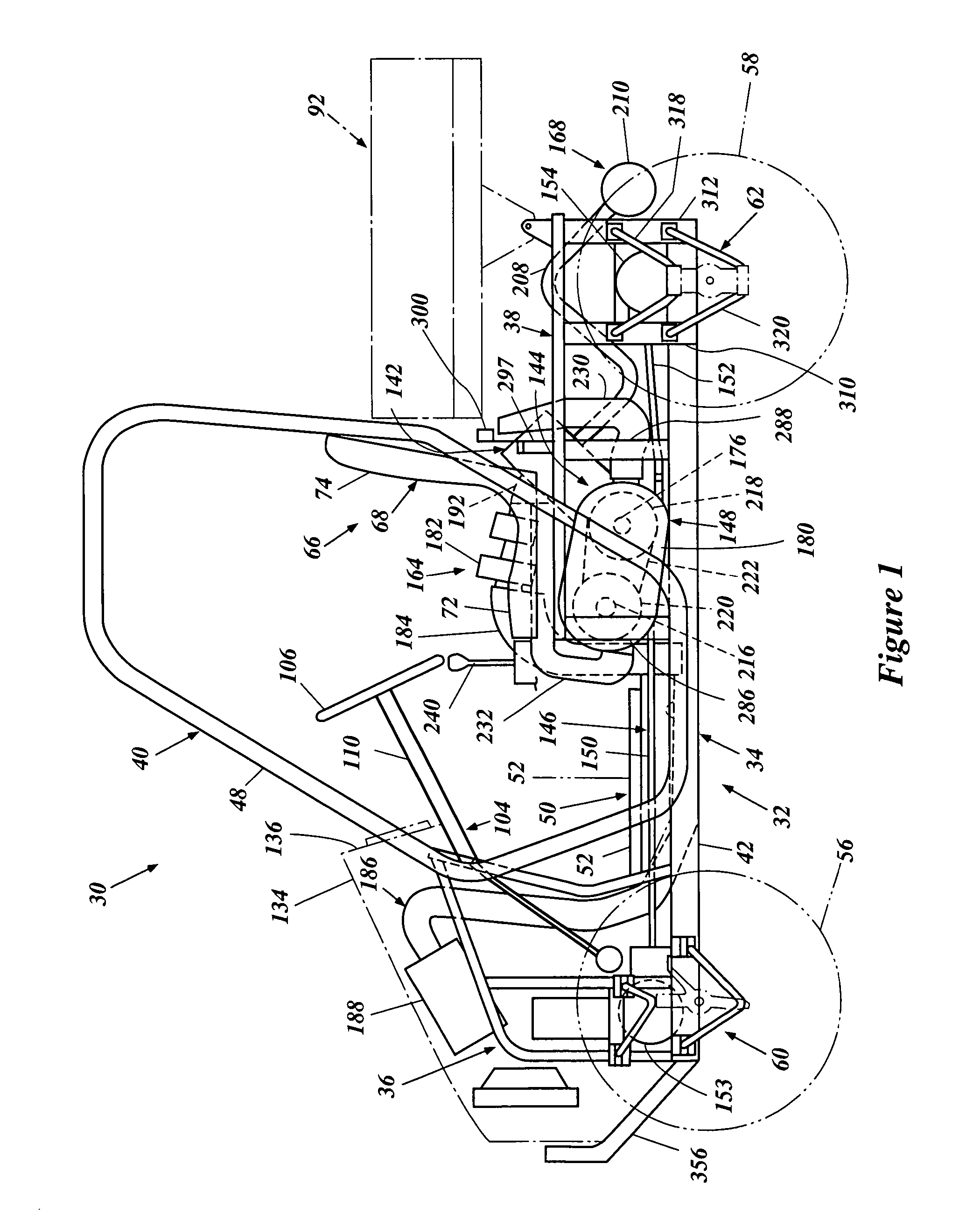

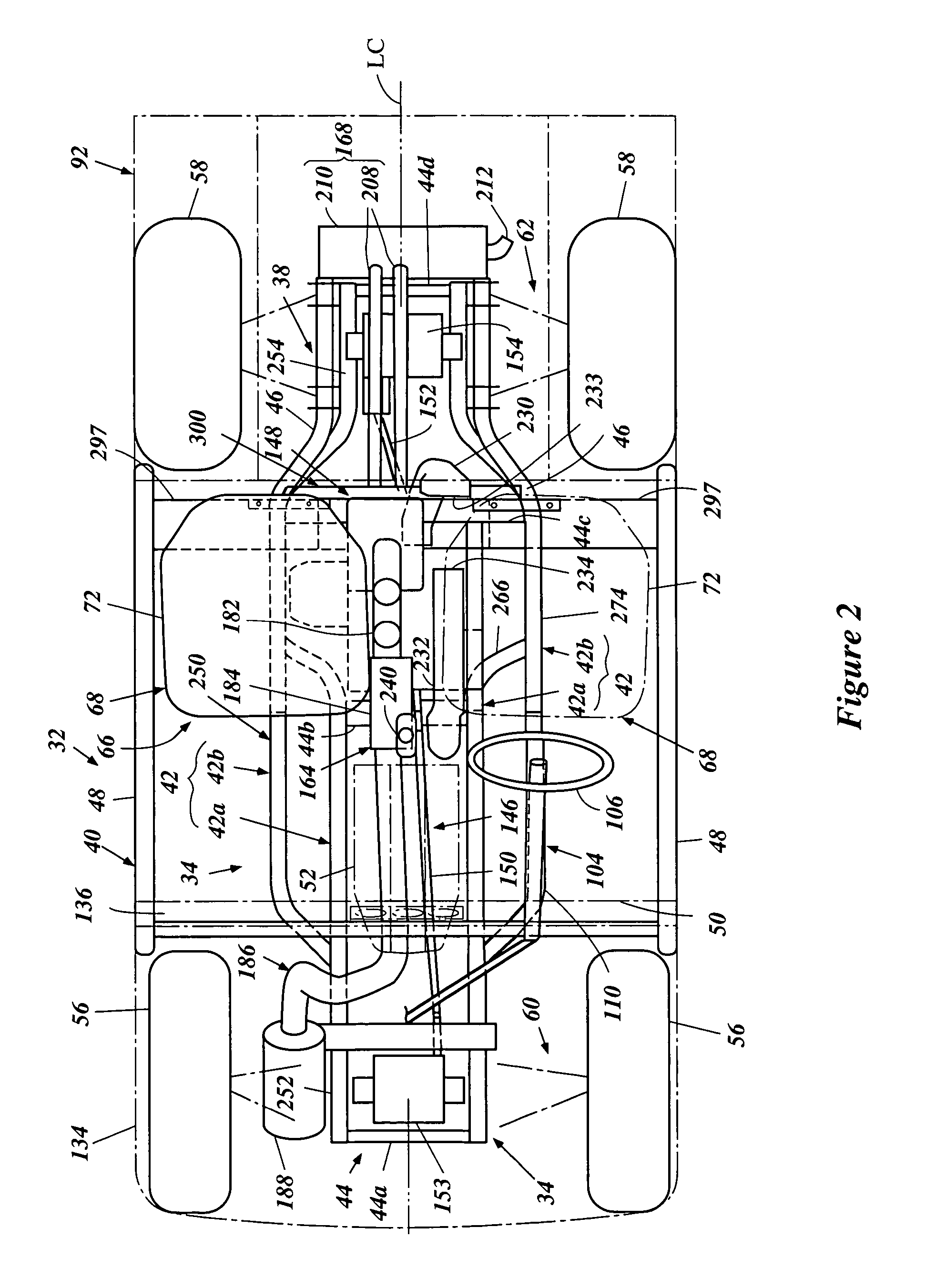

Mobile vacuum boring and excavation method

InactiveUS7644523B2Improve structural strengthProvide spaceMachines/dredgers working methodsMining devicesWater storageSolid mass

Owner:BUCKNER LYNN ALLAN

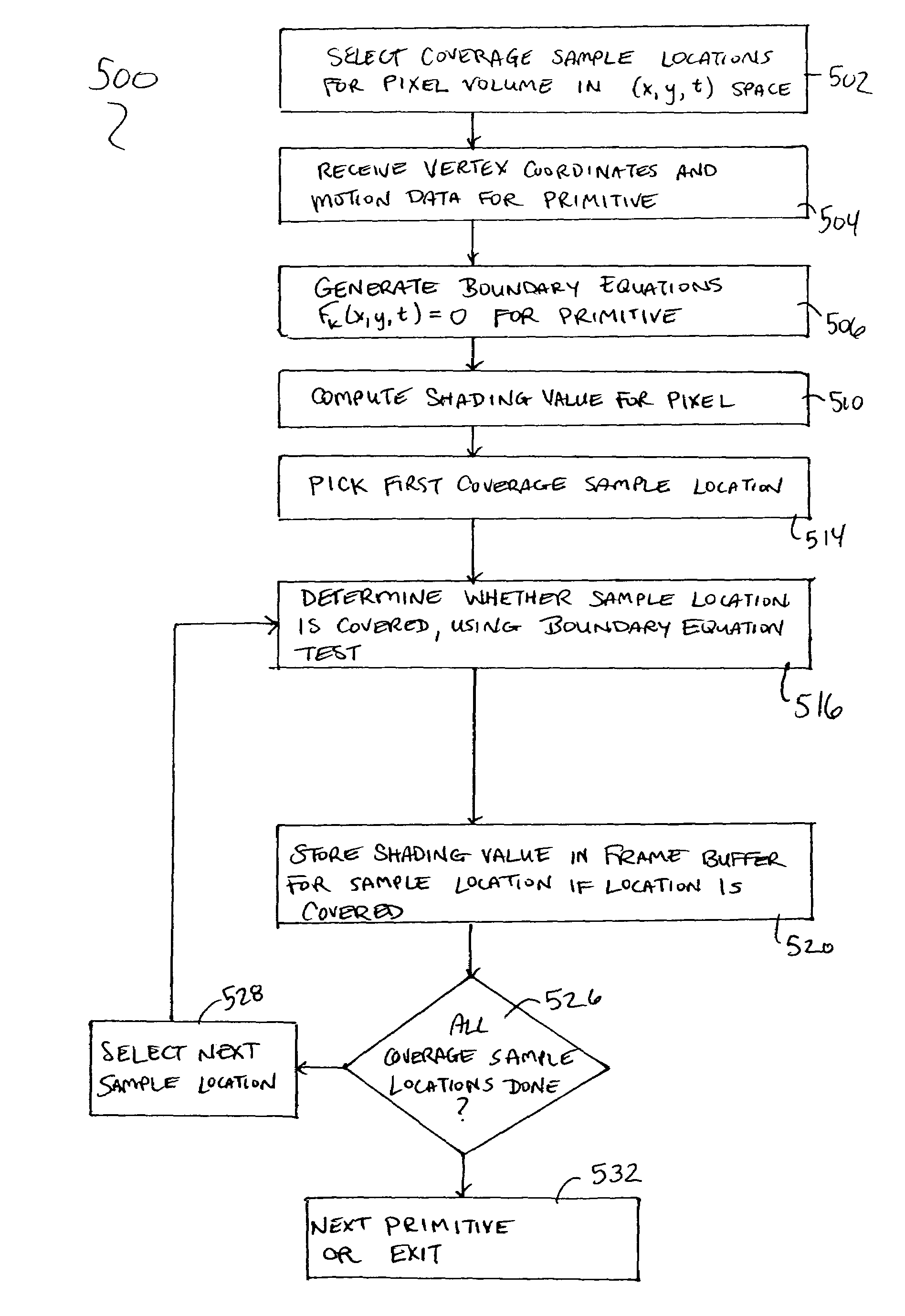

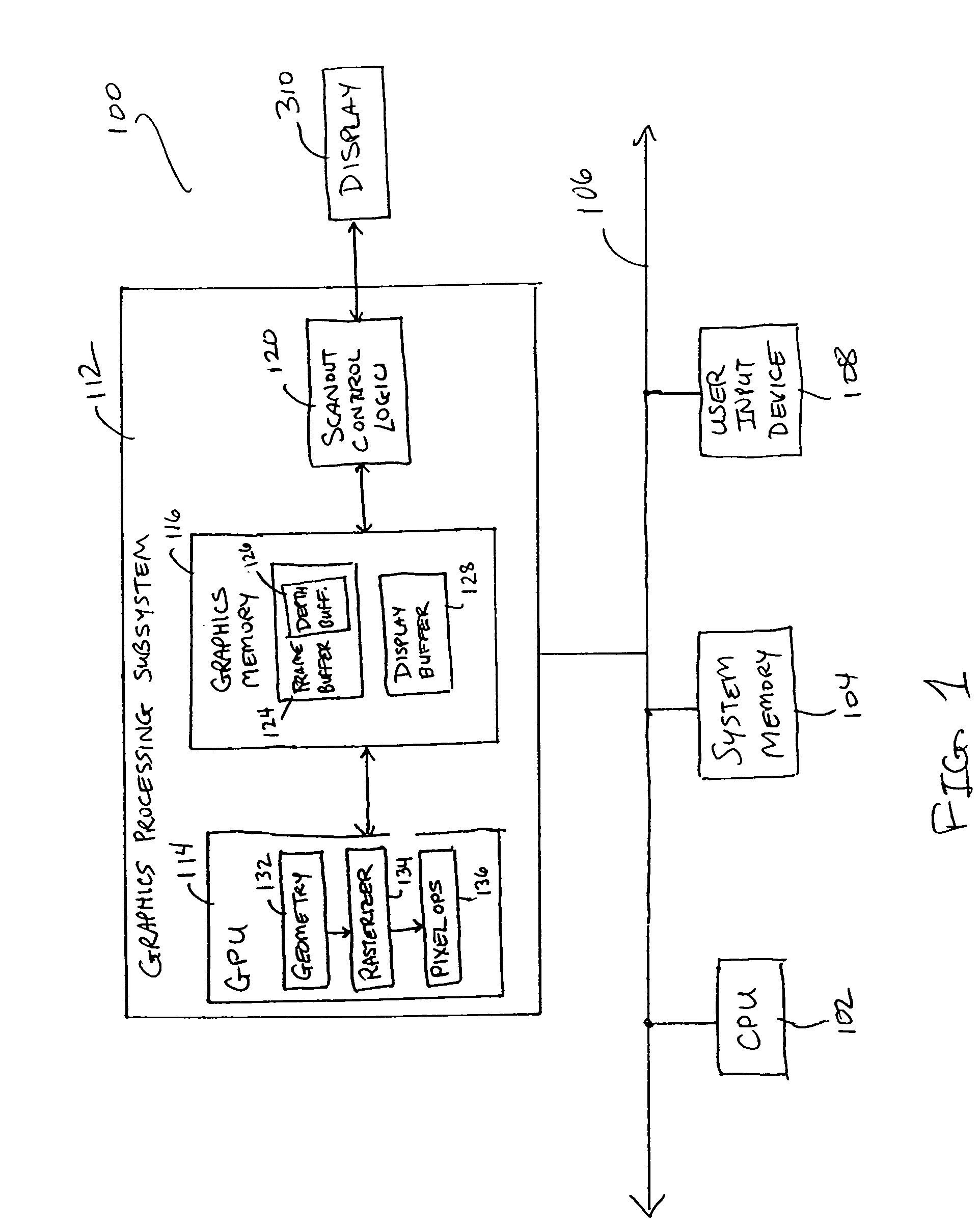

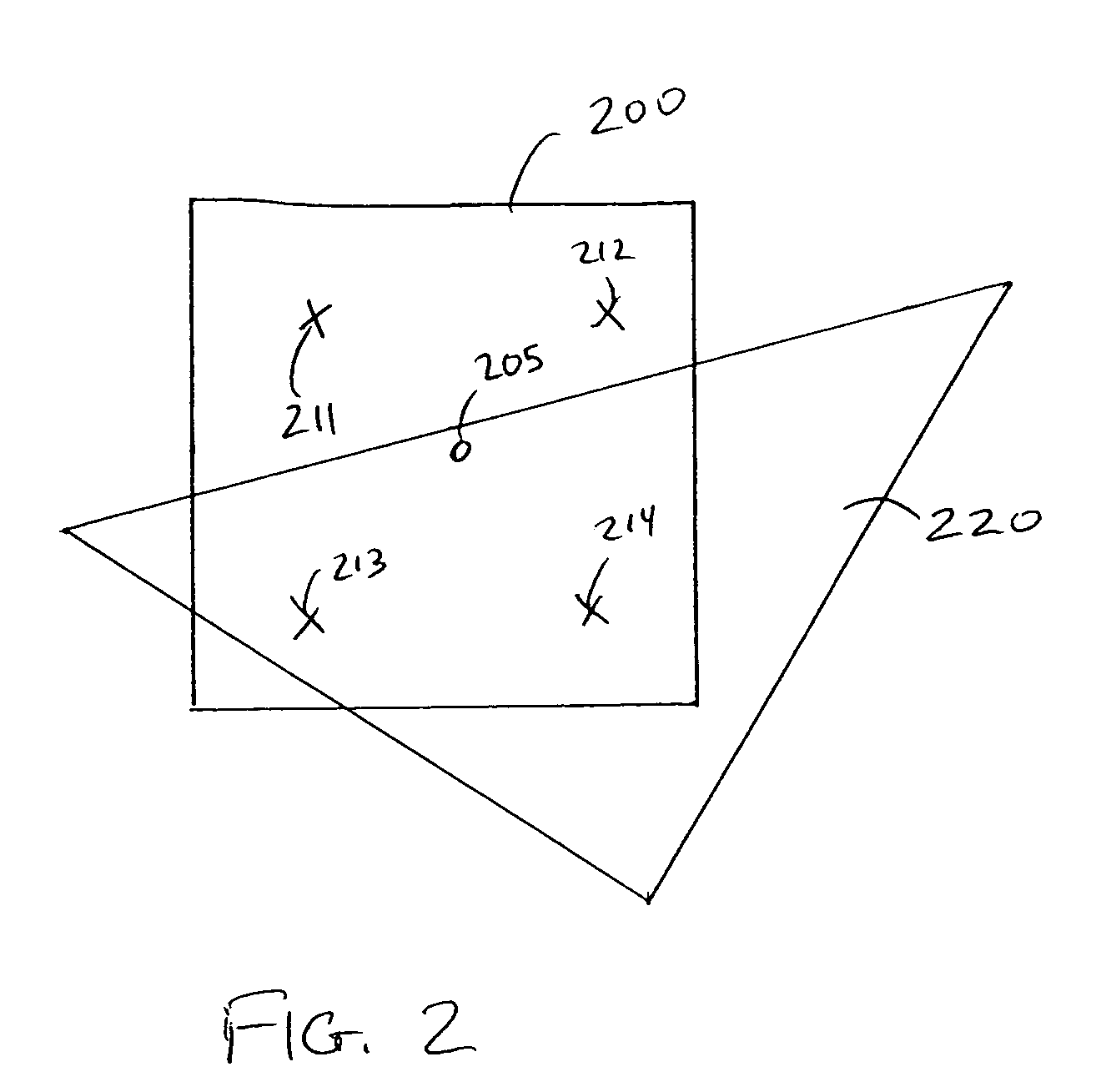

Temporal antialiasing in a multisampling graphics pipeline

ActiveUS7446780B1Provide space2D-image generationCathode-ray tube indicatorsGraphicsBoundary equation

Owner:NVIDIA CORP

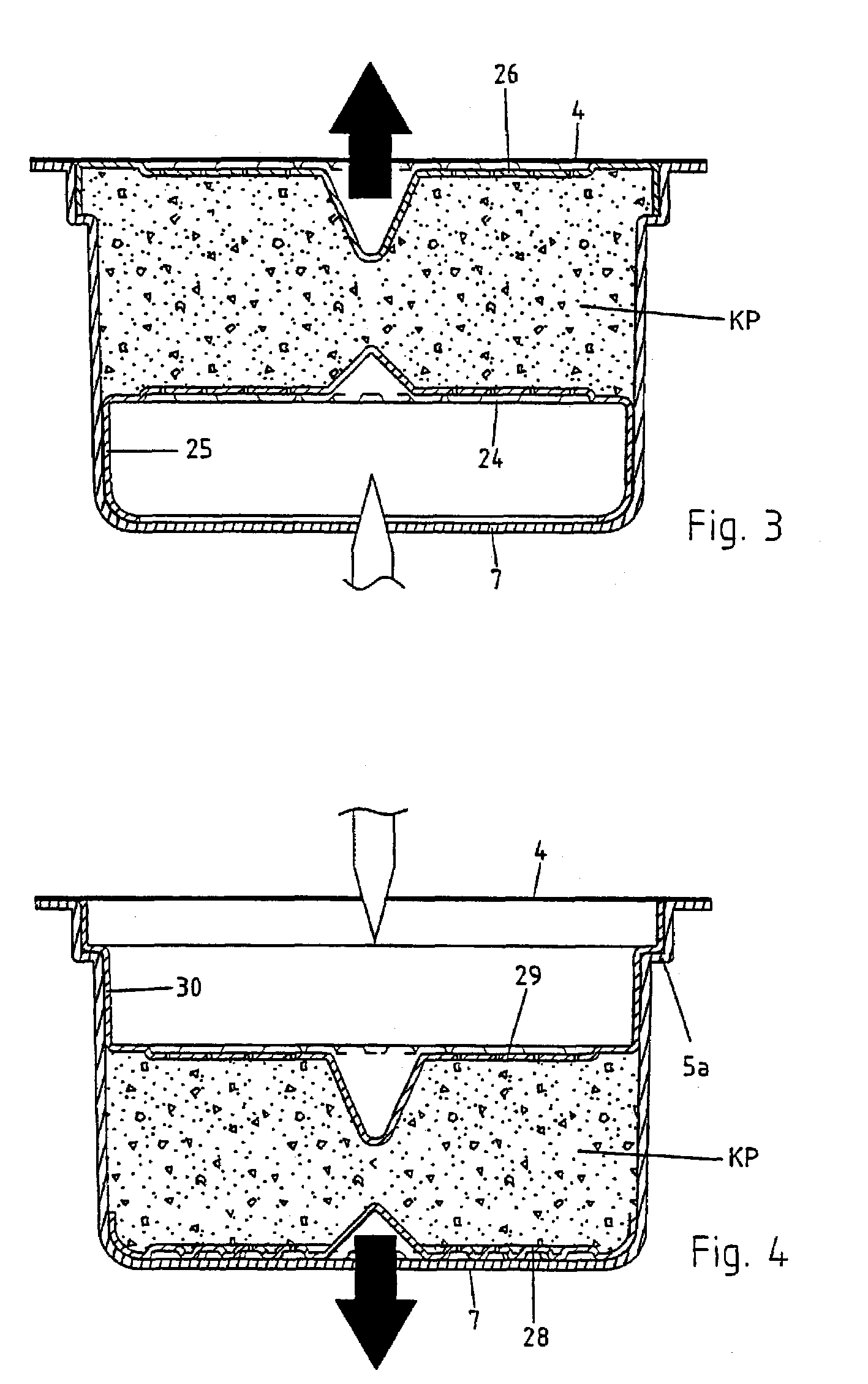

Mobile vacuum boring and mud recovery method with the debris tank inclined & water storage below

InactiveUS20060032095A1Improve structural strengthProvide spaceMachines/dredgers working methodsMining devicesRecovery methodWater storage

A mobile vacuum boring and mud recovery method comprising a device which will create a vacuum condition within a vacuum container and the vacuum container is mounted on an incline to provide space beneath it to locate a water storage container, and having a vacuum conduit to transport a liquid and or solid particles into the vacuum container. The inclined vacuum tank facilitates gravitational assistance in both separation of liquids & solids as well as unloading debris. A dispensing device may be added to dispense a liquid or a solid from the vacuum container without eliminating the vacuum environment within the vacuum container, and said vacuum container having the ability to fill, store and dispense its contents simultaneously. The vacuum container may further comprises a means to separate a liquid from solids. The vacuum conduit articulated boom used to transport debris into the vacuum container may have the added feature or attachments chosen from an earth digging bucket, a telescoping vacuum conduit, sensor to locate buried utilities, monitors and controls to operate the attachments an their function, water spray nozzle, man hole cover remover cutting tool grinding tool, saw, blasting tool, surface cleaning tool, demolition tool, torque wrench, tractor to pull vacuum hose, jetter nozzle, or camera and power source to operate them. The above described vacuum system may be mounted on a variety of mobile platforms, chosen from but not limited to a trailer, truck, skid steer, fork lift, track hoe, railroad car, or zero turn radius vehicle which may have the added feature of being convertible between a powered vehicle & a trailer.

Owner:BUCKNER LYNN ALLAN

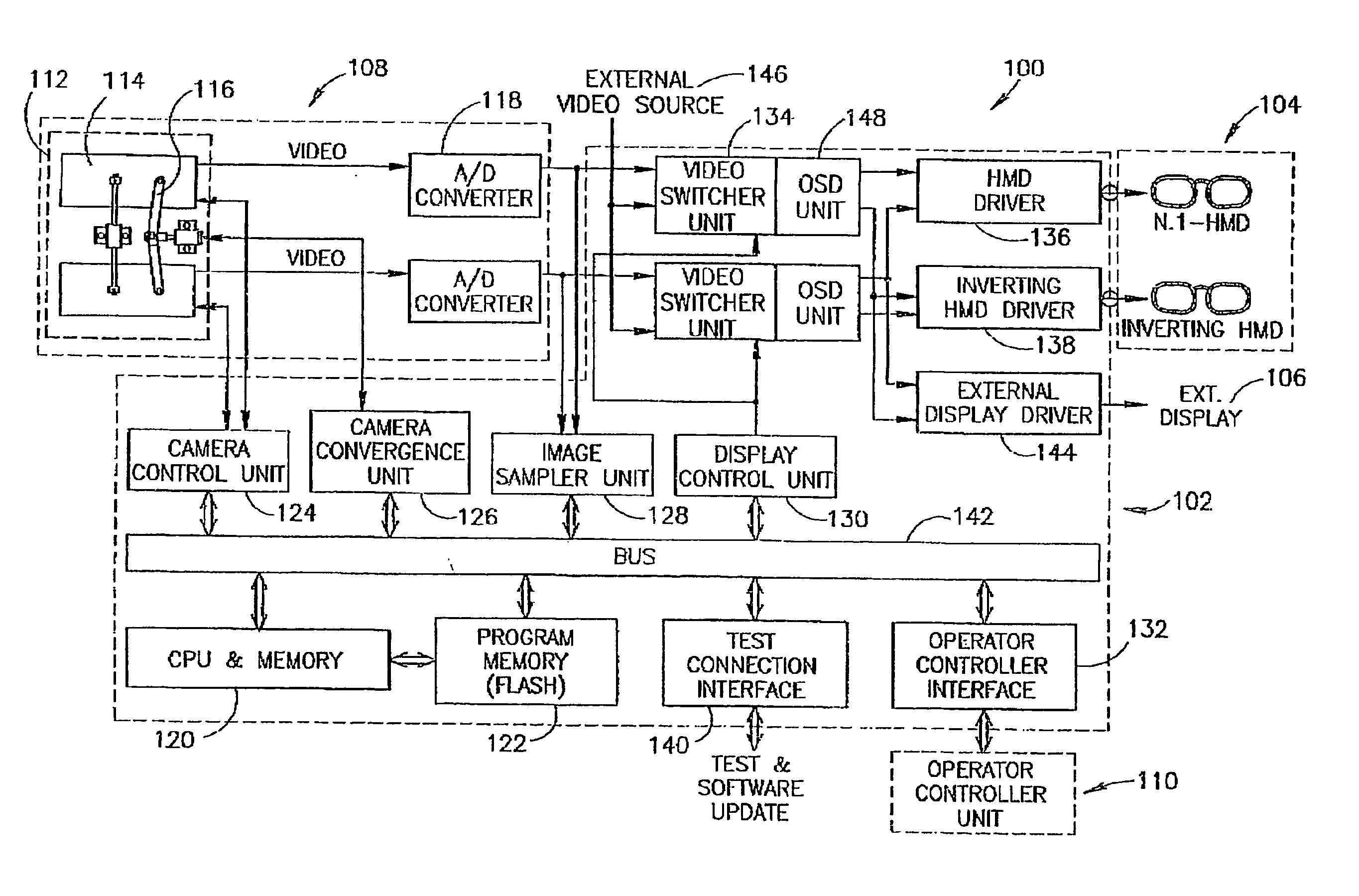

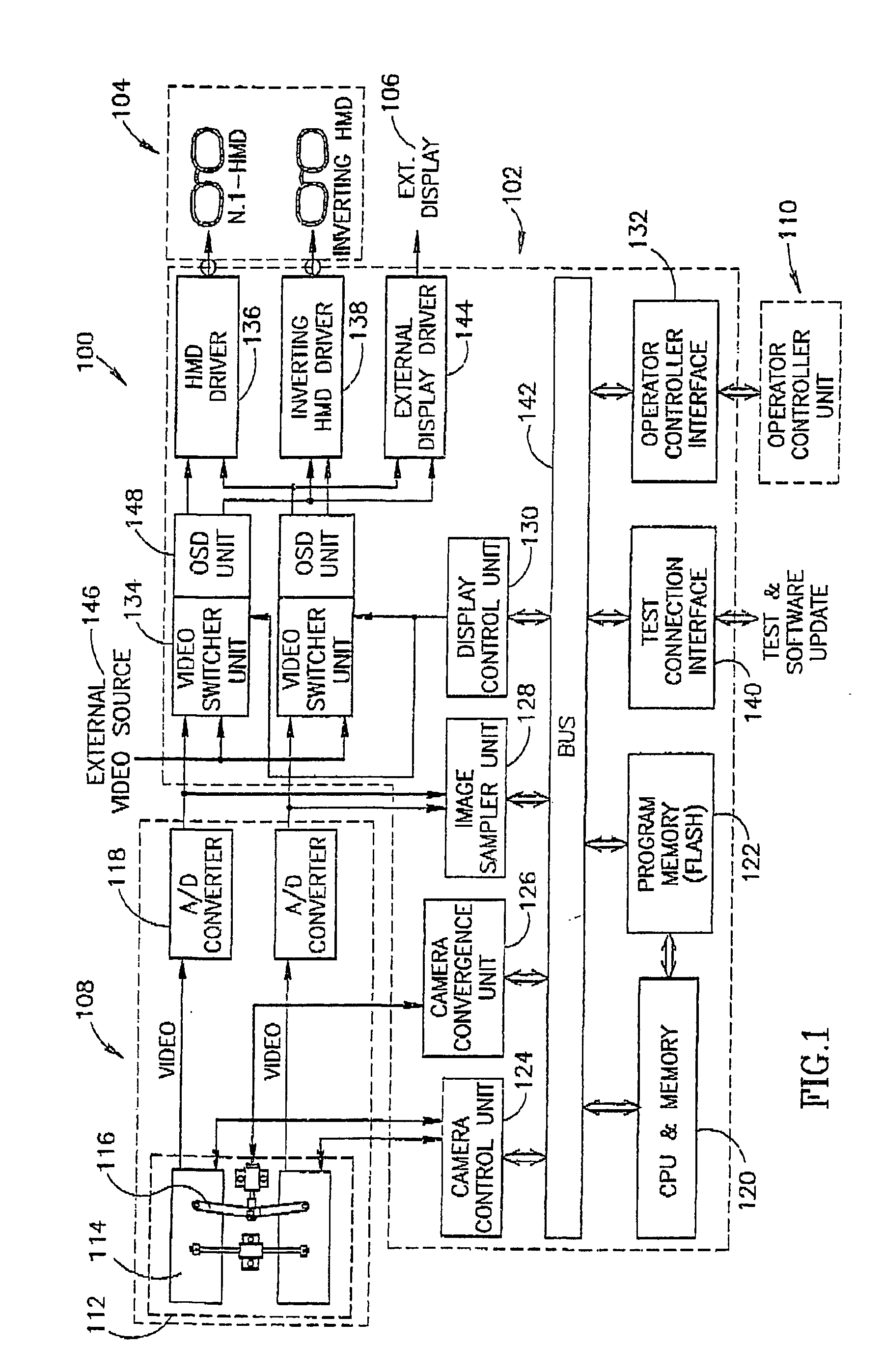

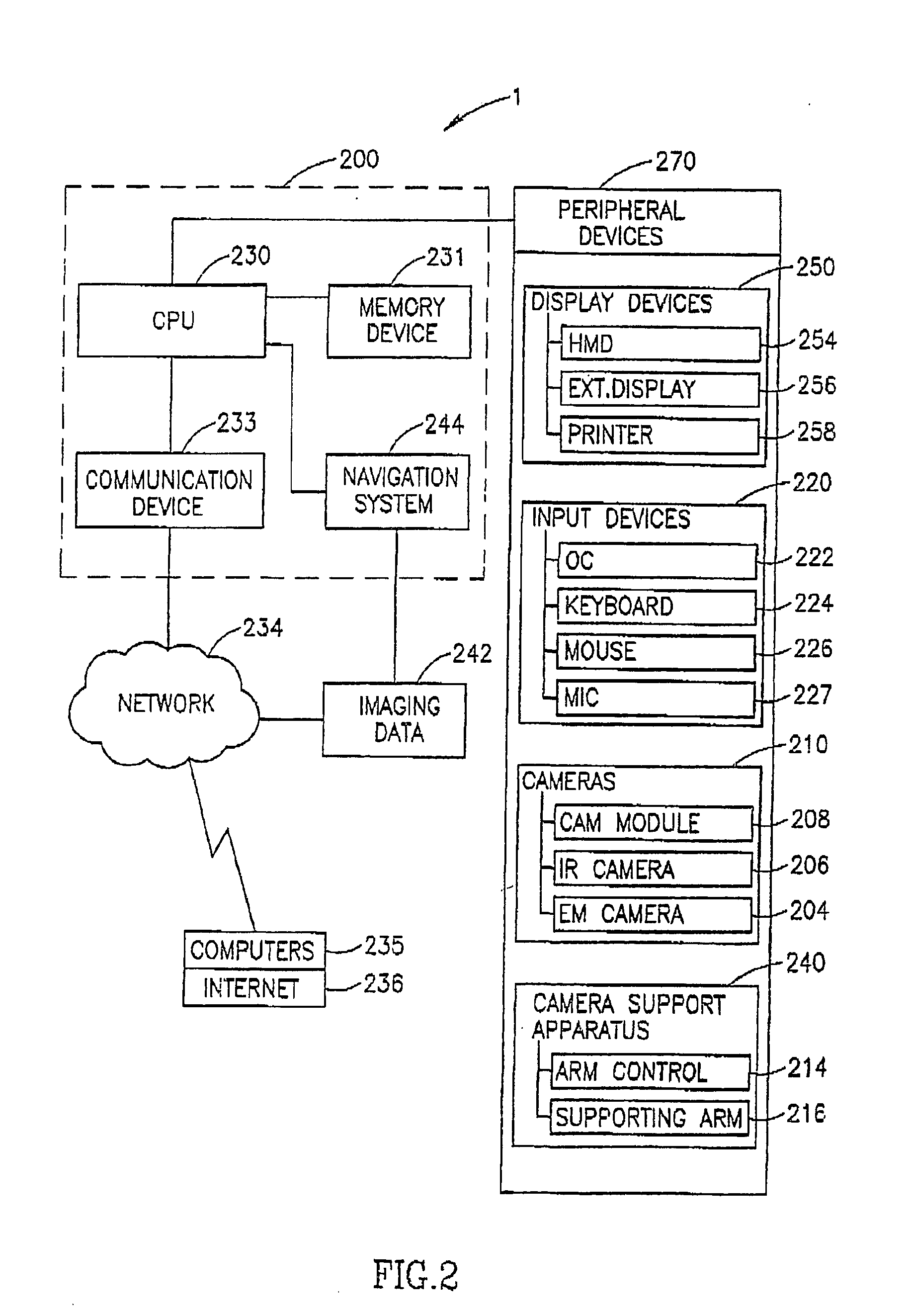

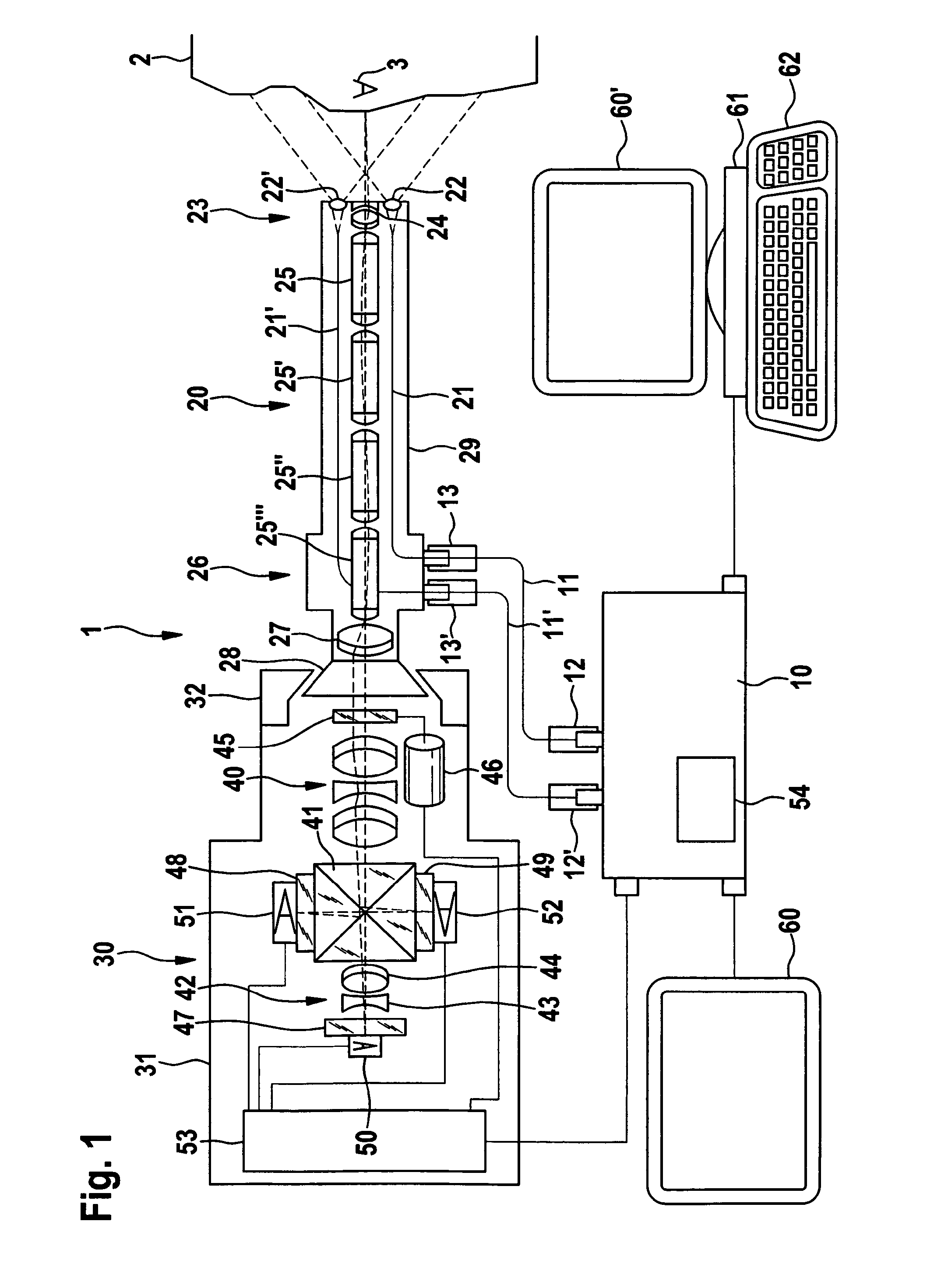

Stereoscopic video magnification and navigation system

InactiveUS20050090730A1Accurate informationImprove ergonomicsDiagnostic recording/measuringSensorsStereoscopic videoDisplay device

An apparatus and method for providing stereoscopic magnified observation enabling an operator to perform surgical procedures without having to remove his eyes from the operating field comprising a head mounted display for provding the operator with stereoscopic magnified images in an operating field, a camera module for providing stereoscopic magnified images, an operator controller unit for enabling an operator to control the operation of the apparatus; and an interface processing unit for processing and dynamically presenting the stereoscopic magnified images in an operating field.

Owner:FRENI BREMBO SPA

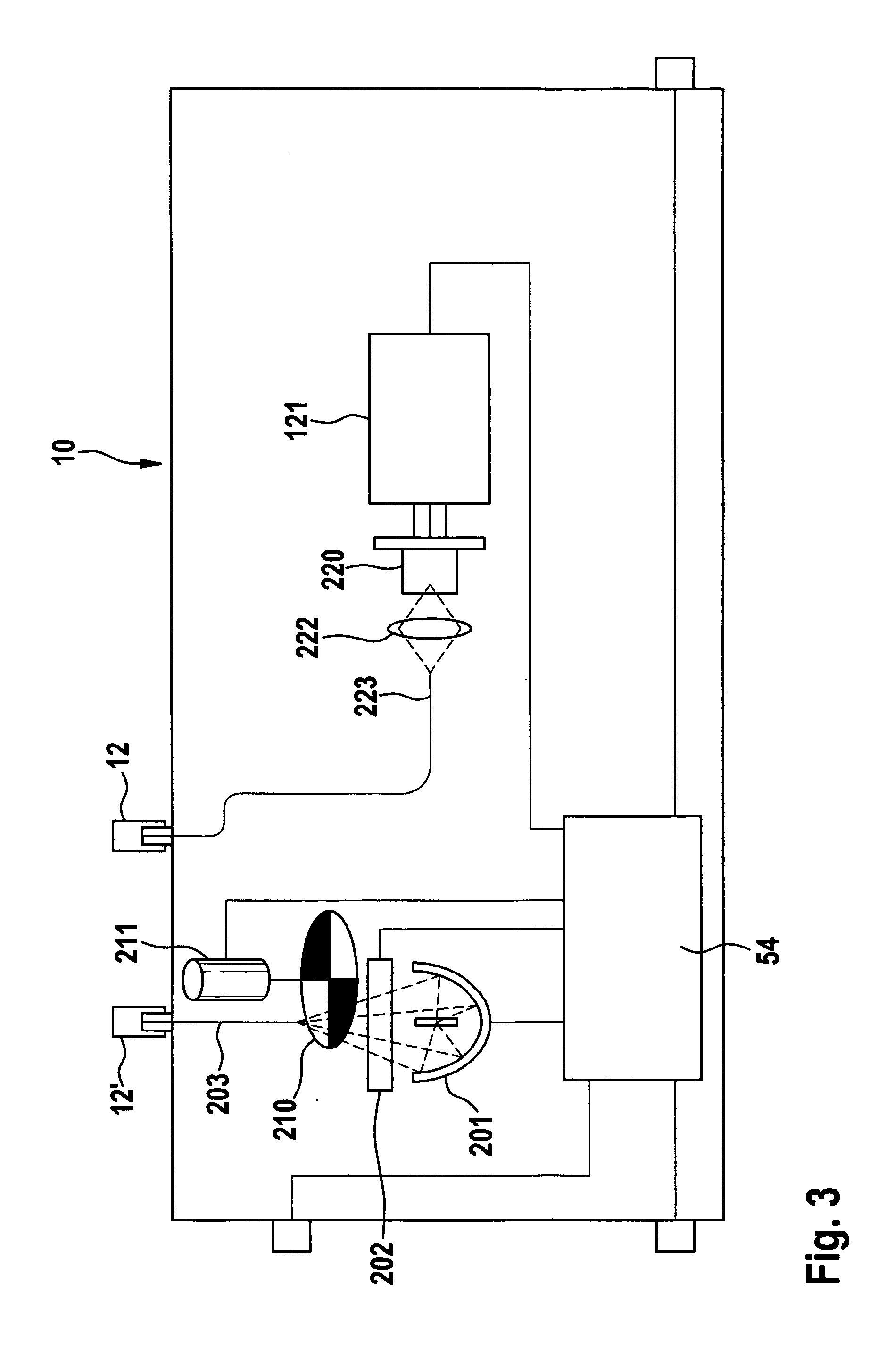

Laser-to-fiber coupling

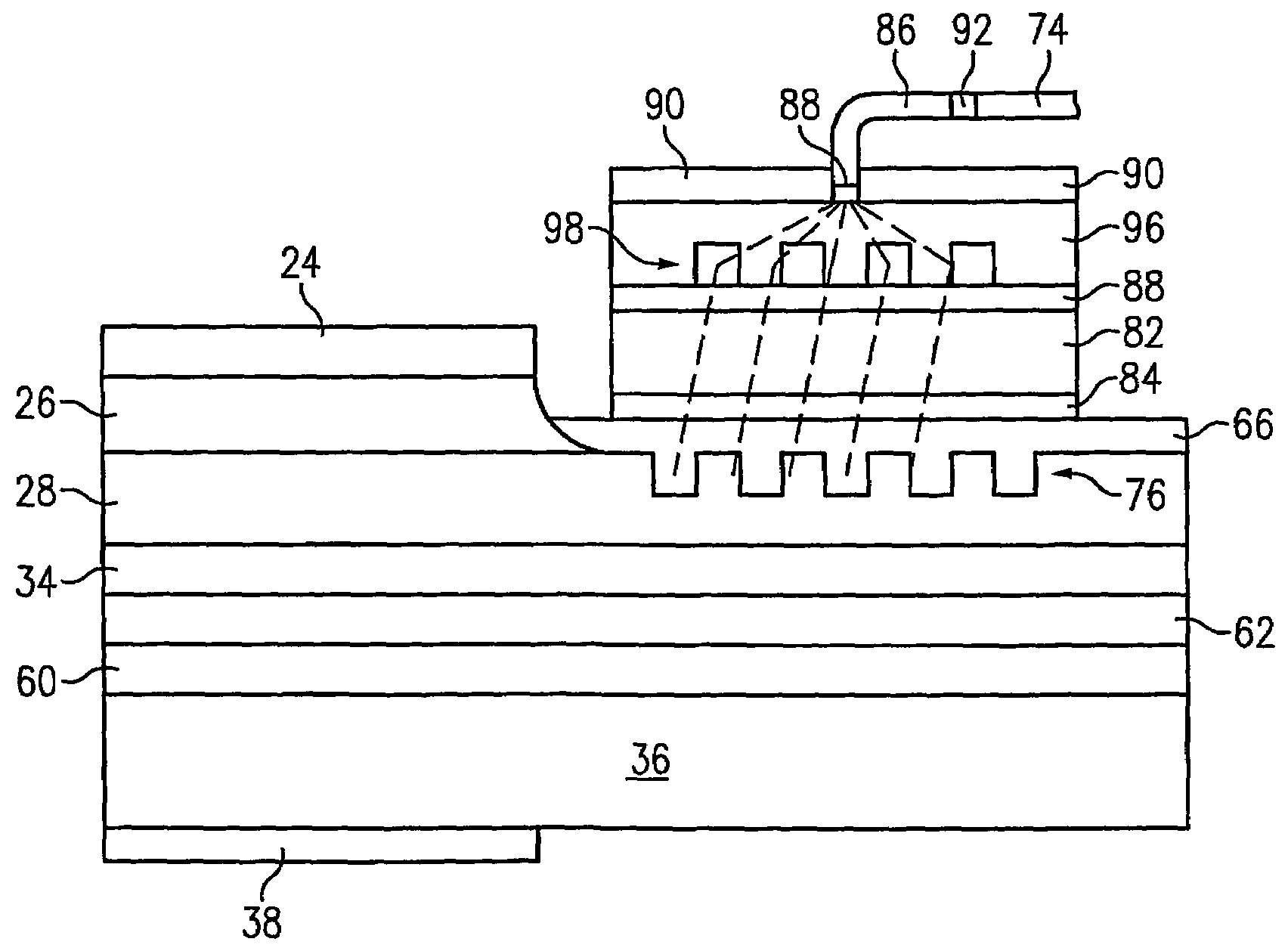

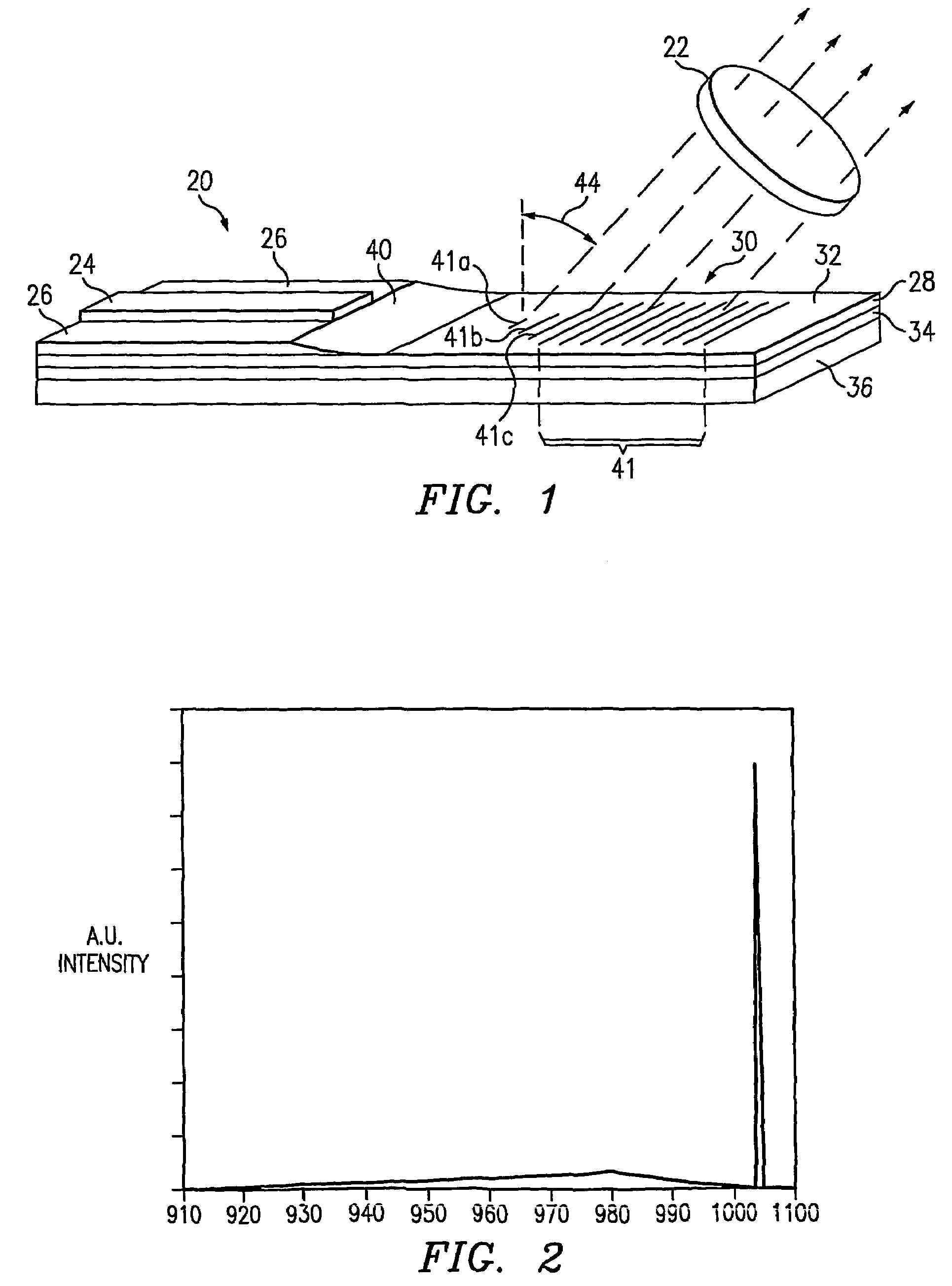

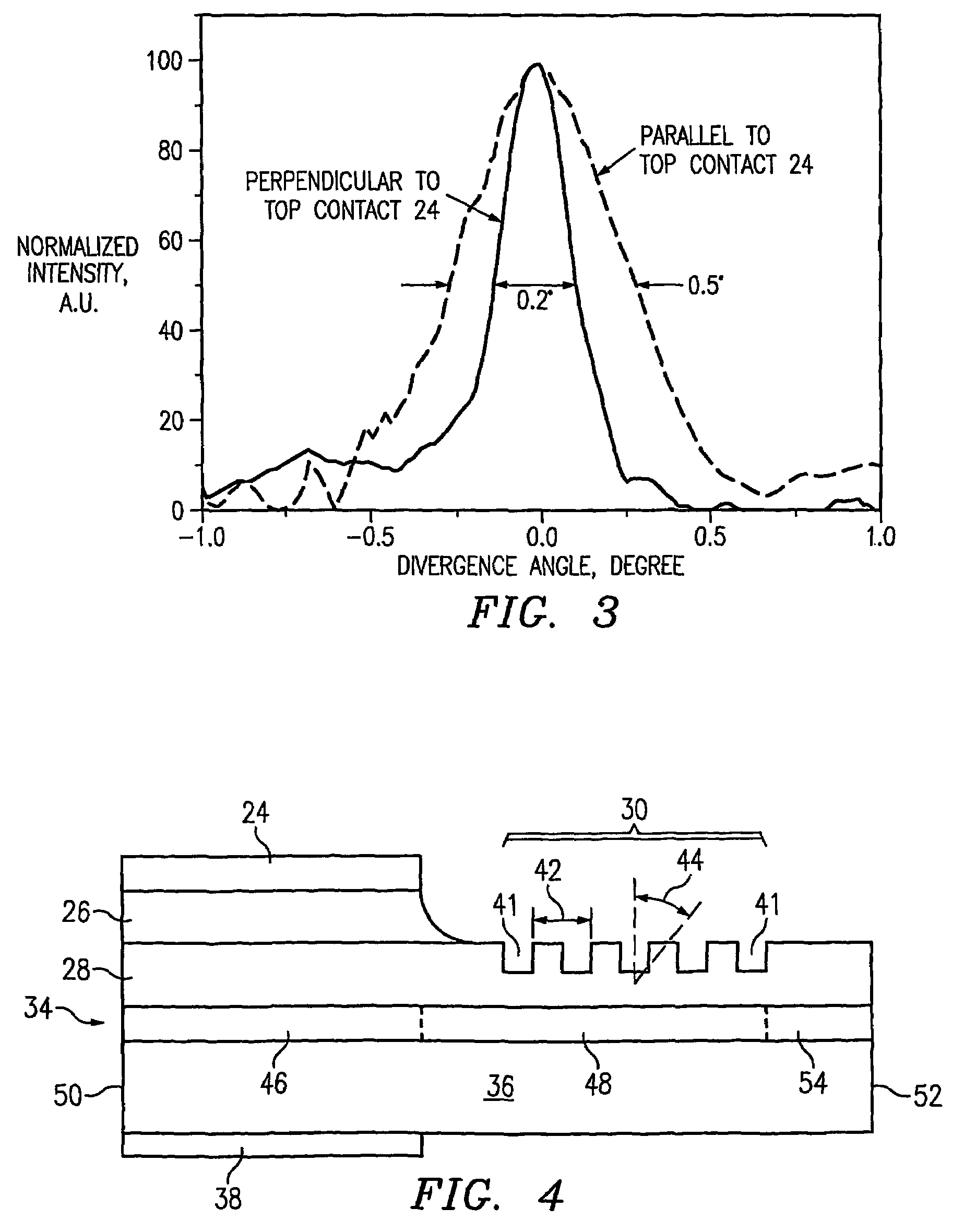

InactiveUS7194016B2Reducing and even eliminating needLower assembly costsLaser optical resonator constructionOptical resonator shape and constructionFacetLaser diode

Our wafer scale processing techniques produce chip-laser-diodes with a diffraction grating (78) that redirects output light out the top (88) and / or bottom surfaces. Generally, a diffraction grating (78) and integrated lens-grating (78) are used herein to couple light from the chip to an output fiber (74), and the lens-grating (78) is spaced from the diffraction grating (76). Preferably the diffraction grating (76) and integrated lens grating (78) are also used to couple light from the output fiber (74) back to the active region of the chip. The integrated lens-grating (78) can be in a coupling block (82). The use of a coupling block (82) can eliminate “facet-type damage”. A coupling block (82) is generally used herein to couple light from the chip to an output fiber (74), and preferably to couple feedback reflected from the fiber (74) back to the chip.

Owner:RES FOUND OF THE CENT FLORIDA UNIV OF THE +1

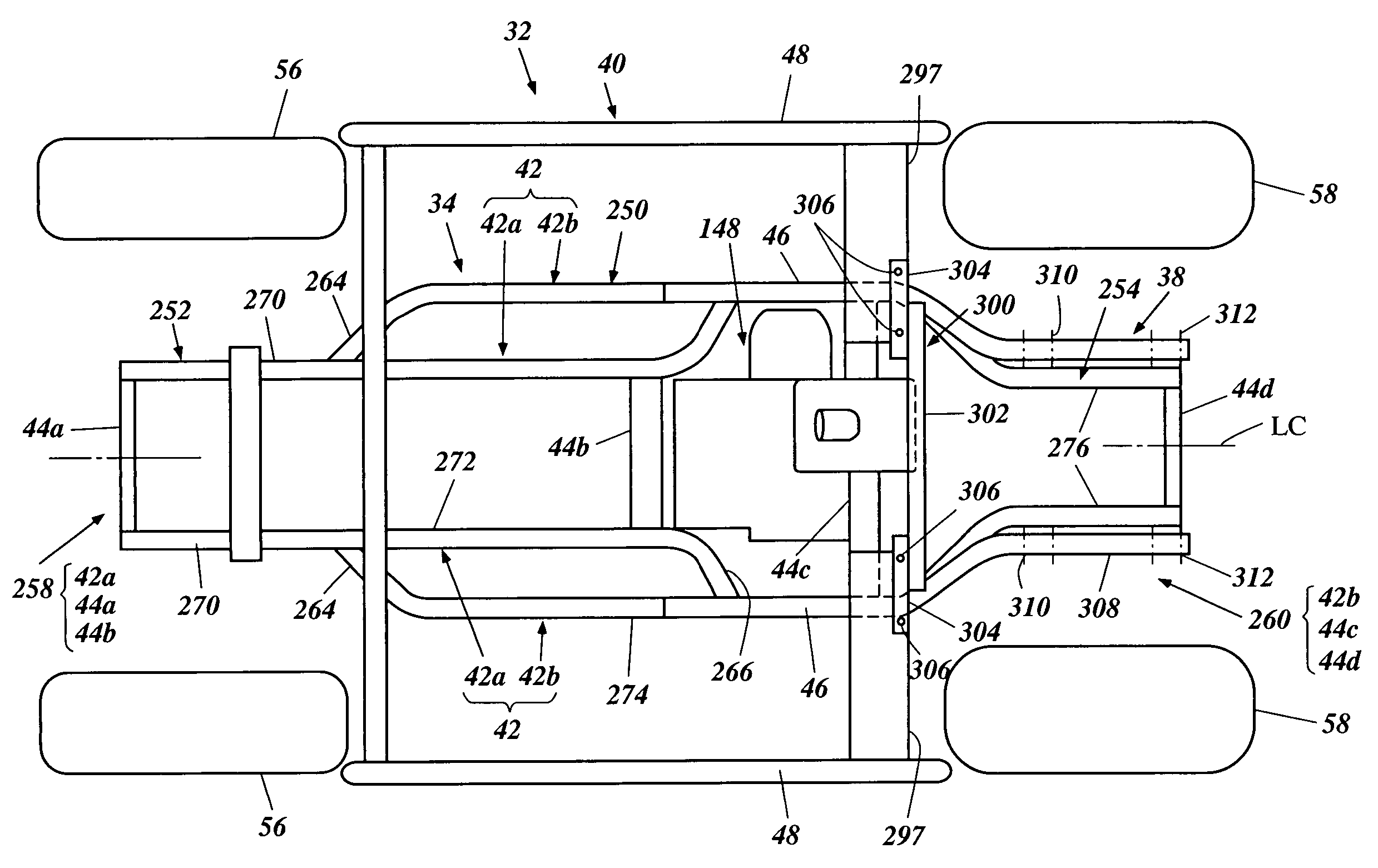

Frame arrangement for off-road vehicle

ActiveUS7650959B2High frame strengthEnhanced engine protectionVehicle body-frame connectionsElectric propulsion mountingVehicle frameMultiple frame

An off-road vehicle includes a frame and four wheels that support the frame. An engine powers the wheels. The engine is mounted on the frame. The frame includes multiple frame members that surround the engine. One of the frame members disposed behind the engine is detachably affixed to the rest of the frame members. The frame members are divided into first and second groups. The first and second groups are offset fore to aft relative to each other and overlap with each other in a rear section of the first group and in a front section of the second group. The rear section of the first group defines a bent portion coupled with the second group. The front section of the second group defines a bent portion coupled with the first group.

Owner:YAMAHA MOTOR CO LTD +1

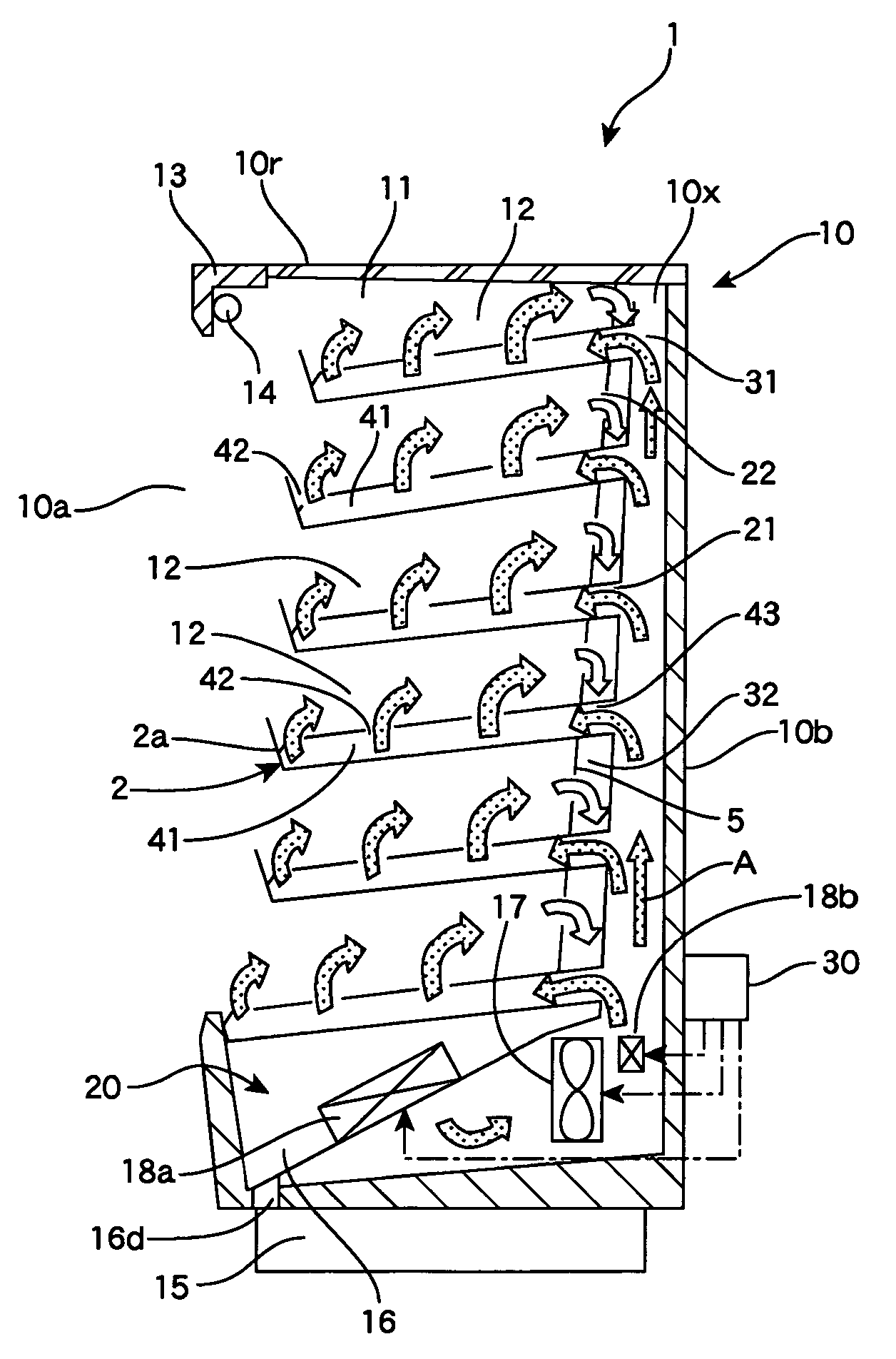

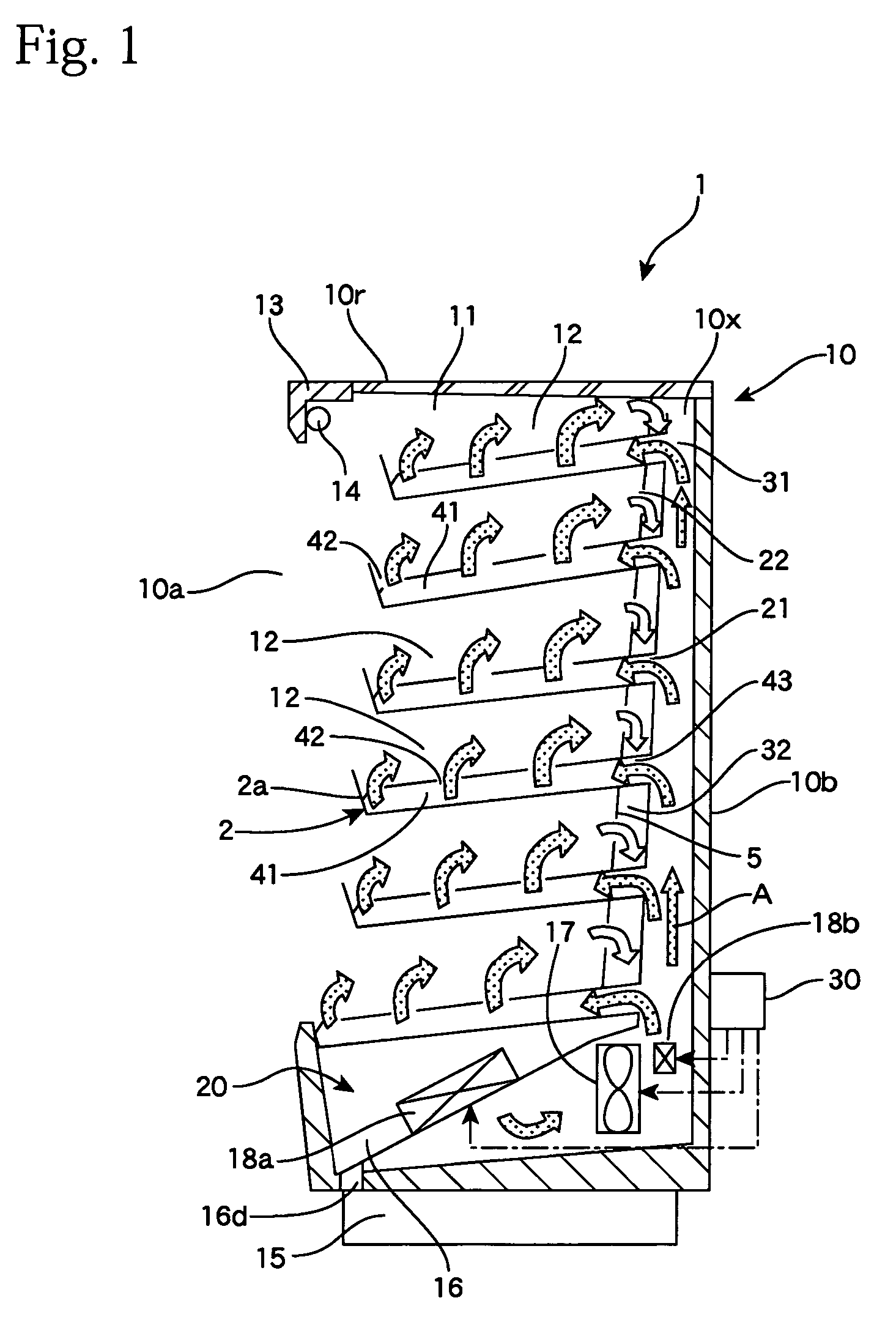

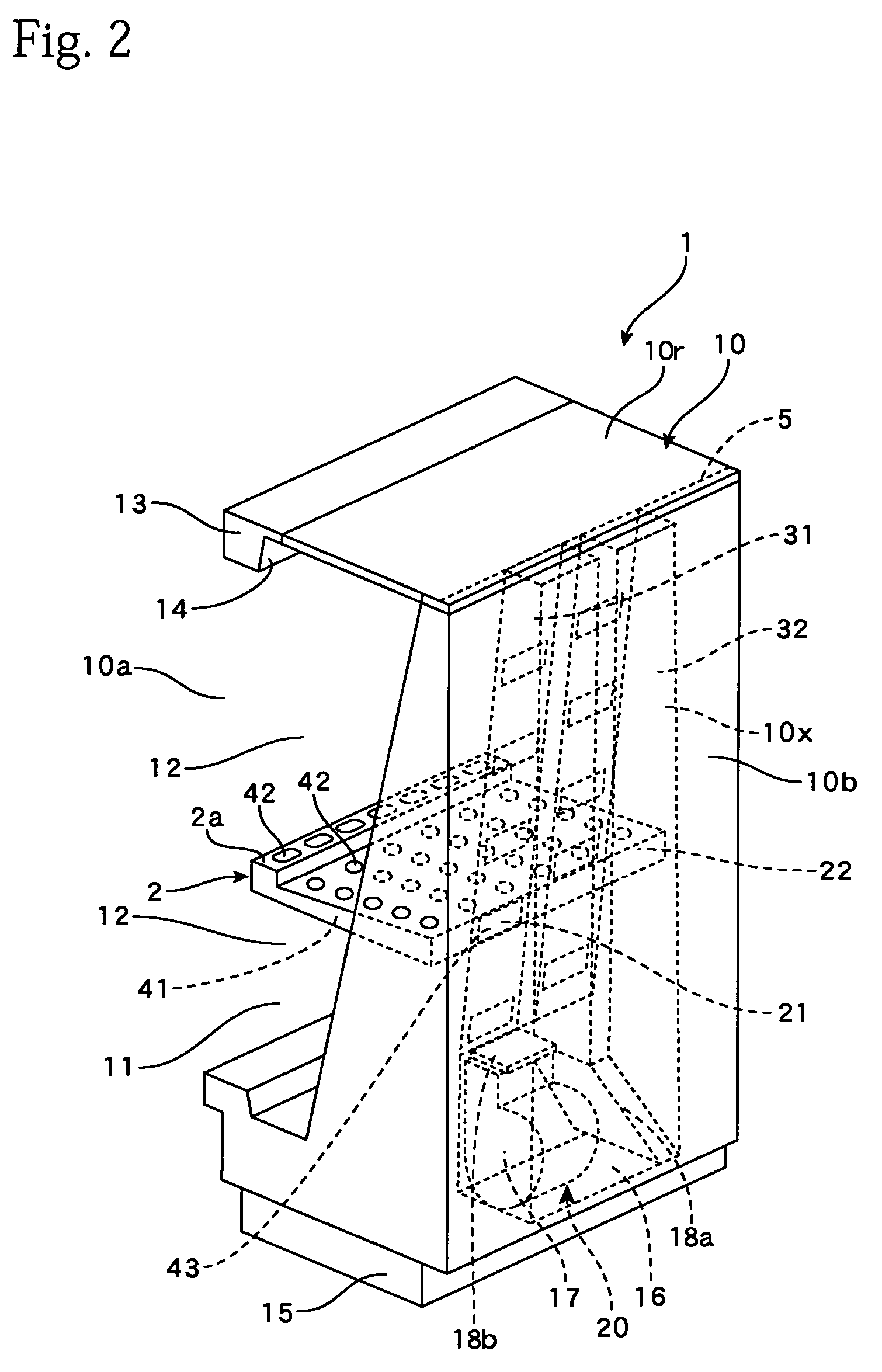

Storage device

InactiveUS7137438B2Improve efficiencyEffective spaceShow cabinetsDomestic refrigeratorsCold airEngineering

A storage apparatus is provided that comprises a display case part with an inside thereof being dividable into a plurality of zones, a supply duct that is connected to supply openings for supplying conditioning air for controlling environmental conditions to the plurality of zones respectively, and an exhaust duct that is connected to exhaust openings for taking in air from the plurality of zones. In this storage apparatus, conditioning air such as cold air or hot air is circulated in the respective zones, and the environmental conditions can be adjusted efficiently in zone basis. Therefore, in a storage apparatus equipped with an open-type display case part, it is possible to dispense with an air curtain covering the entire open side, so that a storage apparatus with a high storage capacity is provided.

Owner:GLOSTER

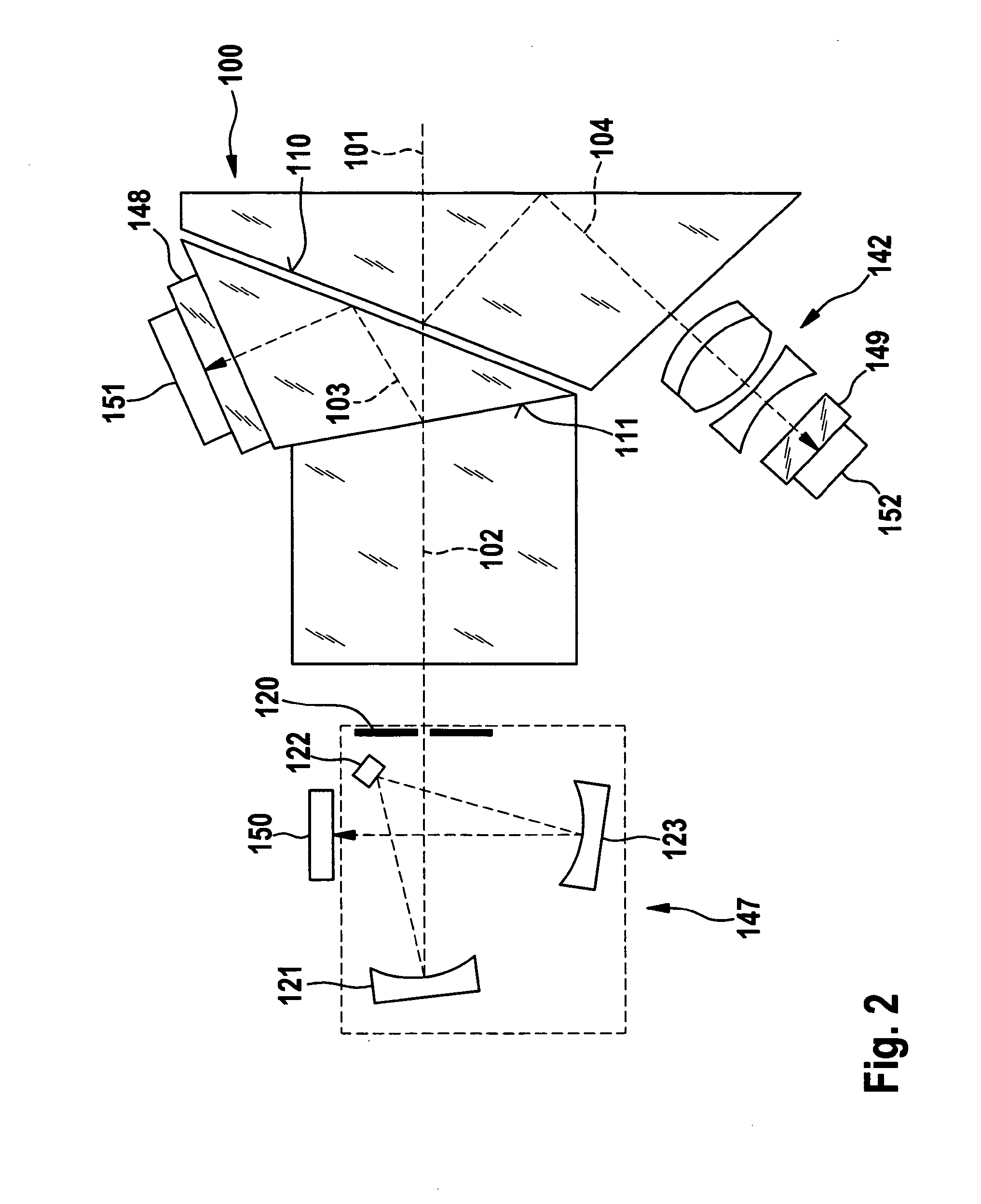

Apparatus and method for fluorescent imaging

InactiveUS20090266999A1Economical and easy to operateSimple electronic meansOptical radiation measurementRadiation measurementExcitation beamSolid state detector

An apparatus and method for fluorescent imaging. The apparatus includes a light-generating means for generating at least one modulated fluorescence excitation beam, a light retransmitting means for retransmitting the fluorescence excitation beam onto an area that is to be examined, a light-imaging means for imaging a fluorescent beam from the area to be examined onto a first image sensor, a control and evaluation means for controlling the light-generating means to power the first image sensor and for evaluating the data supplied by the first image sensor to generate a fluorescent image, where the fluorescent excitation beam may be continuously modulated, the first image sensor is a solid state detector that may be powered phase-sensitively, and the data supplied by the first image sensor contain pixel by pixel phase information on the fluorescent beam.

Owner:STORZ ENDOSKOP PROD GMBH

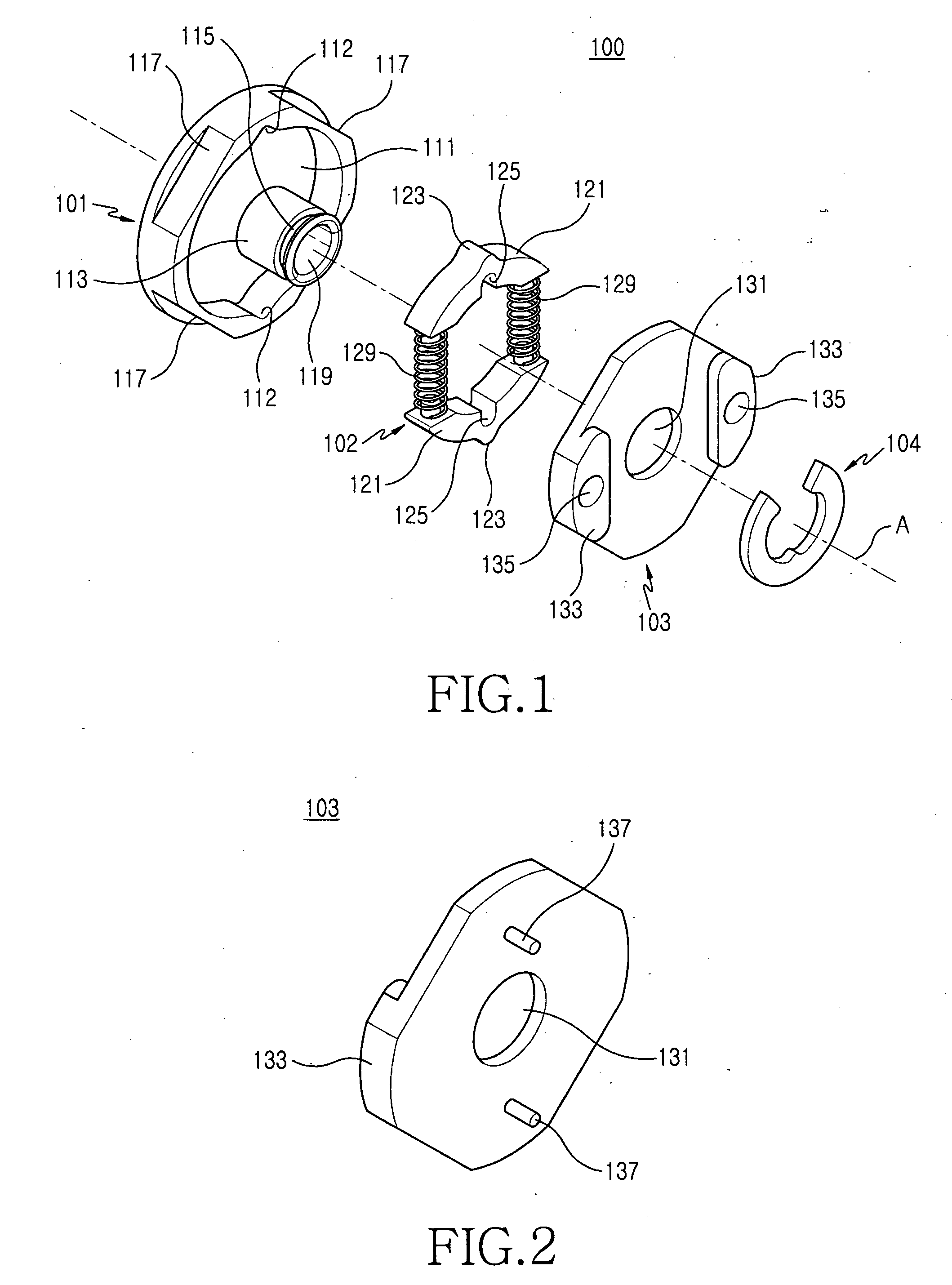

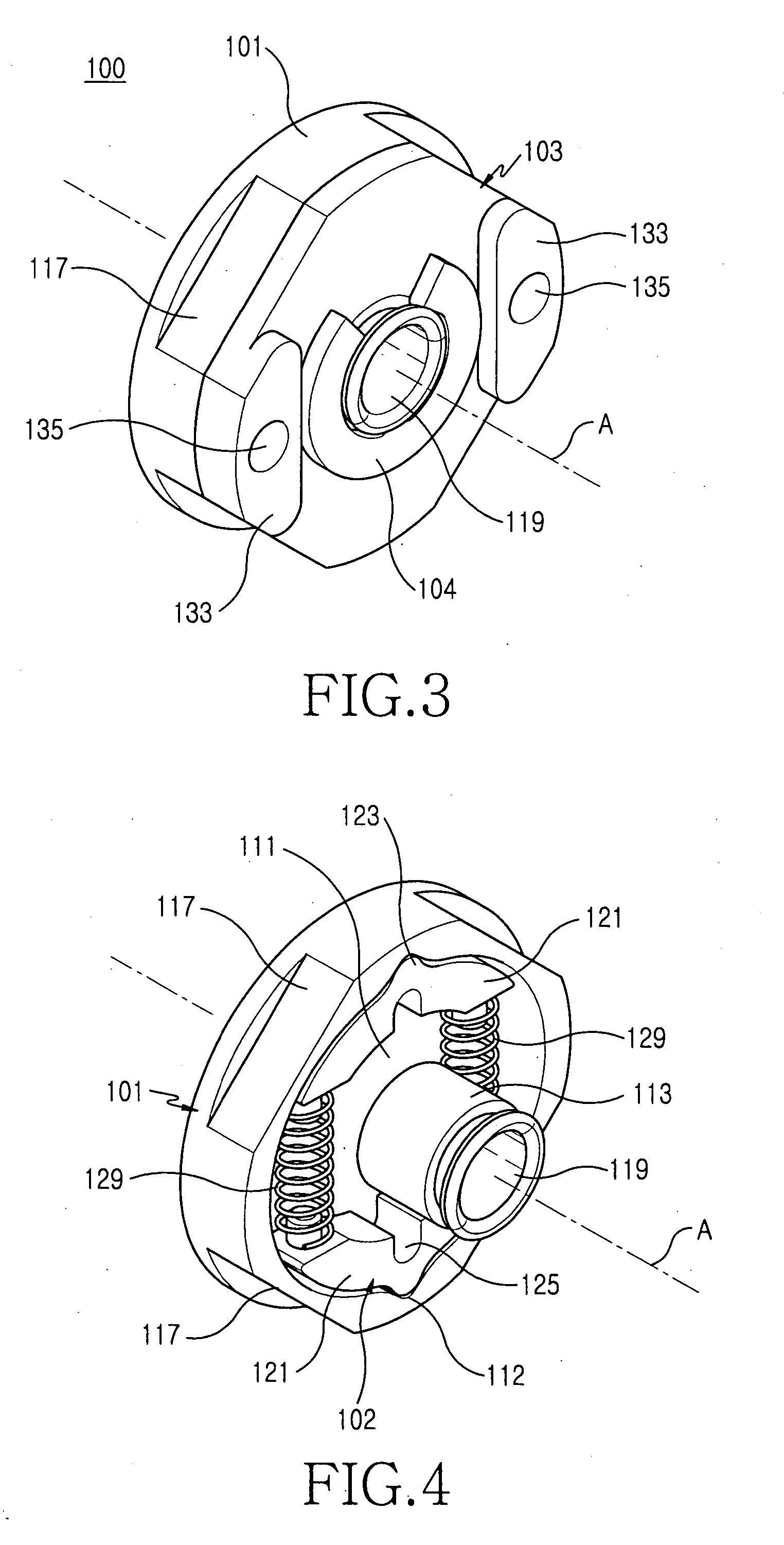

Hinge device for portable terminal and portable terminal having the same

A hinge device for a portable terminal rotatably couples a first housing to a second housing of a portable terminal. The hinge device includes a first hinge cam fixed to one of the housings of the portable terminal and a second hinge cam fixed to the other one of the housings of the portable terminal. The first hinge came has a cam groove on a surface, and the second hinge cam is rotatably received in the cam groove to generate friction with an inner wall of the cam groove. The hinge device has a reduced length and can occupy a smaller area in the portable terminal. Further, the hinge device allows the separate housing to be installed to the portable terminal while maintaining the shape of the portable terminal so that the separate housing slidably moves, thereby allowing increased design flexibility for the portable terminal. Furthermore, since the hinge device requires a small space in the portable terminal, the design specifications of the portable terminal may be easily changed.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Toner containing metallic flakes and method of forming metallic image

The present invention relates to a porous toner particle with encapsulated metallic flakes. The porous particle containing metallic flakes can be useful for reproduction of a metallic hue upon fusing to a substrate, preferably golden or silvery hue, and for manufacturing of printed circuits, by a printing process, especially electrophotography.

Owner:EASTMAN KODAK CO

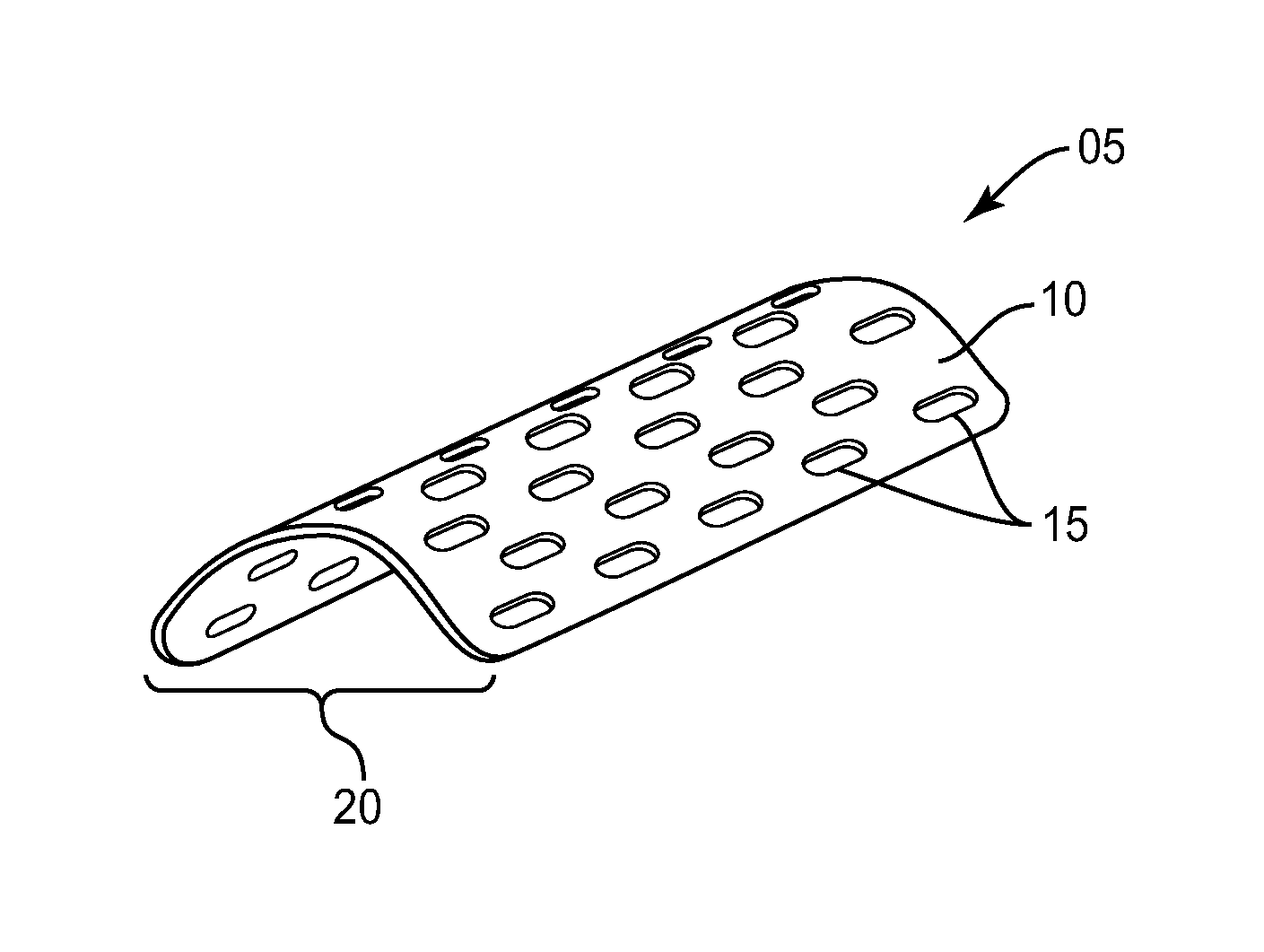

Bio-Remodable Bone Augmentation device and method

ActiveUS8900617B2Promote bone growthKeeps tissue disruption to a minimumOrganic active ingredientsPeptide/protein ingredientsBone tissueImplanted device

A bio-remodable augmentation device including an implantable member configured for maintaining space in a bone defect. The implantable member is formed from a bio-remodable composite having structural properties so as to aid in the generation of new bone tissue and eventually be reabsorbed in the newly formed bone tissue. This structural and bio-remodable implant reduces, if not eliminates, the need to remove the implantable member from the patient once new bone tissue is formed. A kit including the implantable devices and bone growth material is disclosed. Methods of use are also disclosed.

Owner:WARSAW ORTHOPEDIC INC

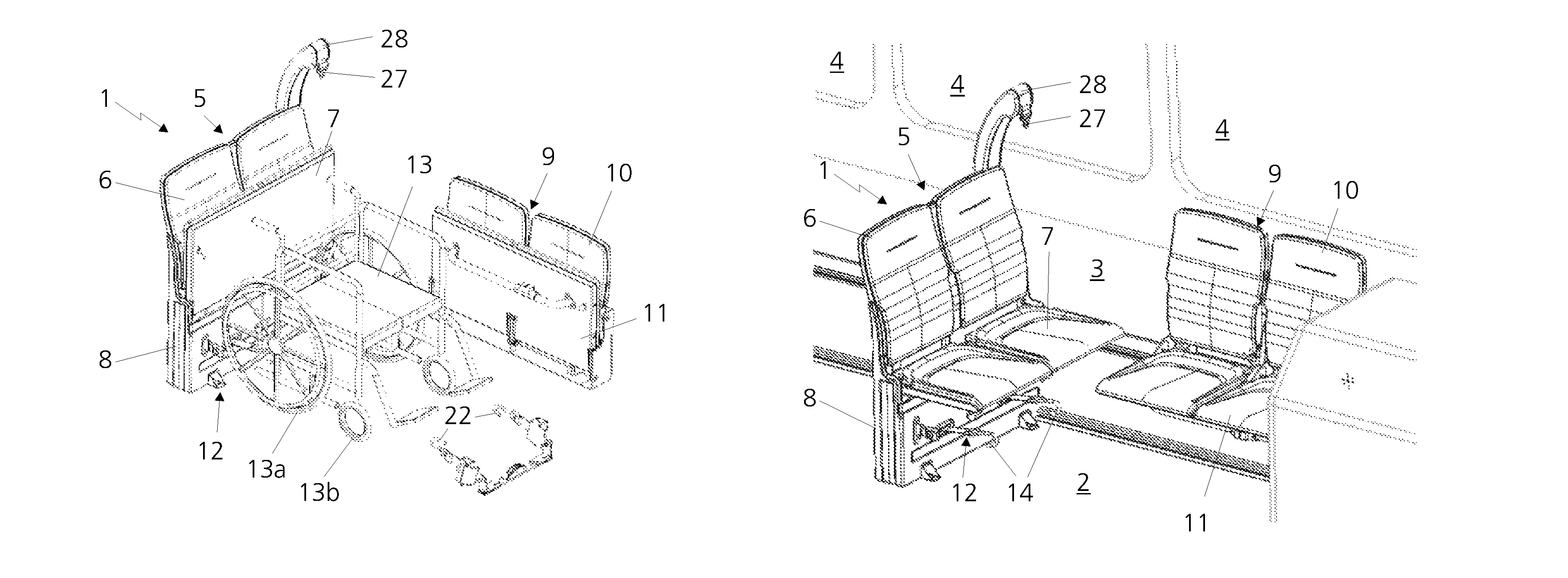

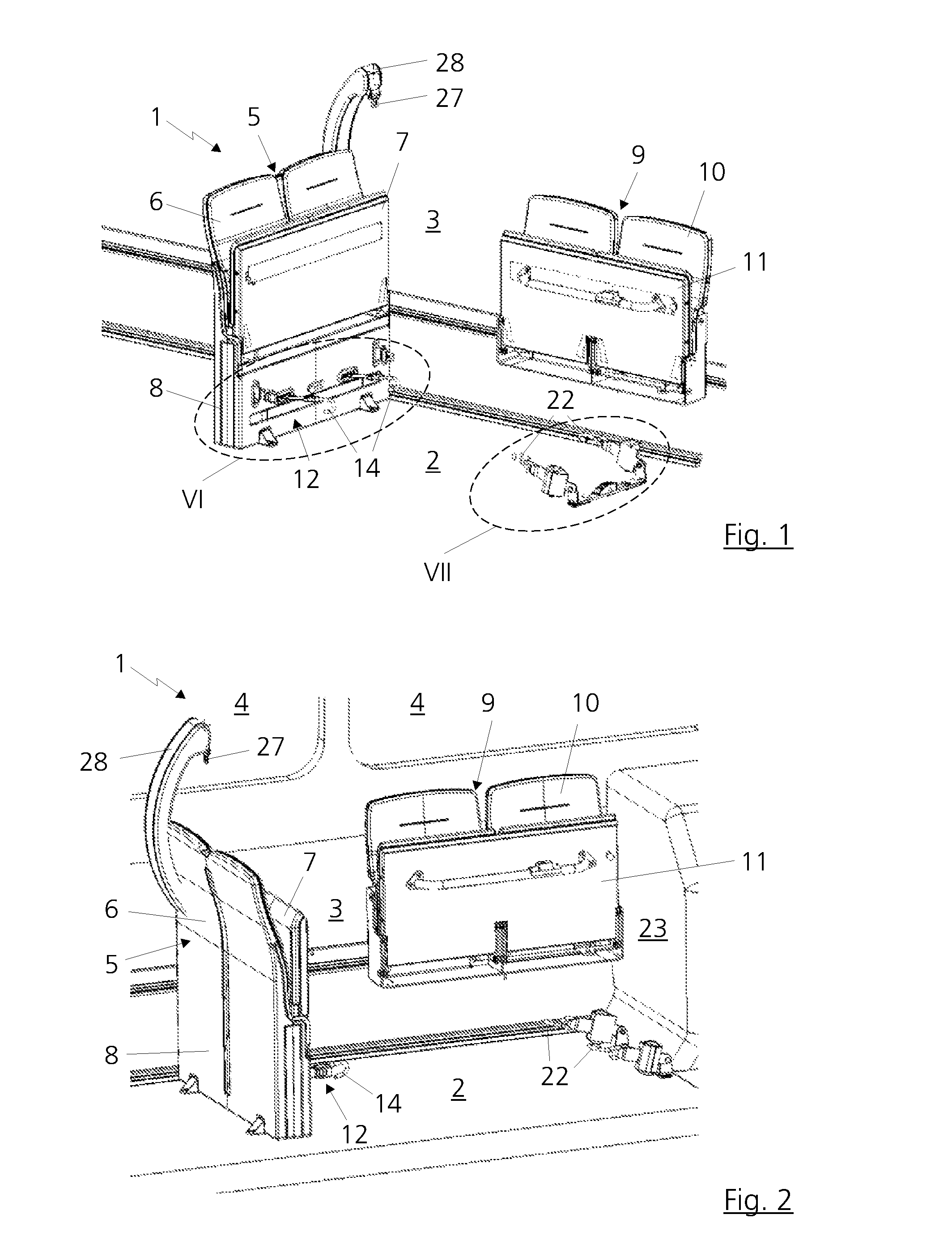

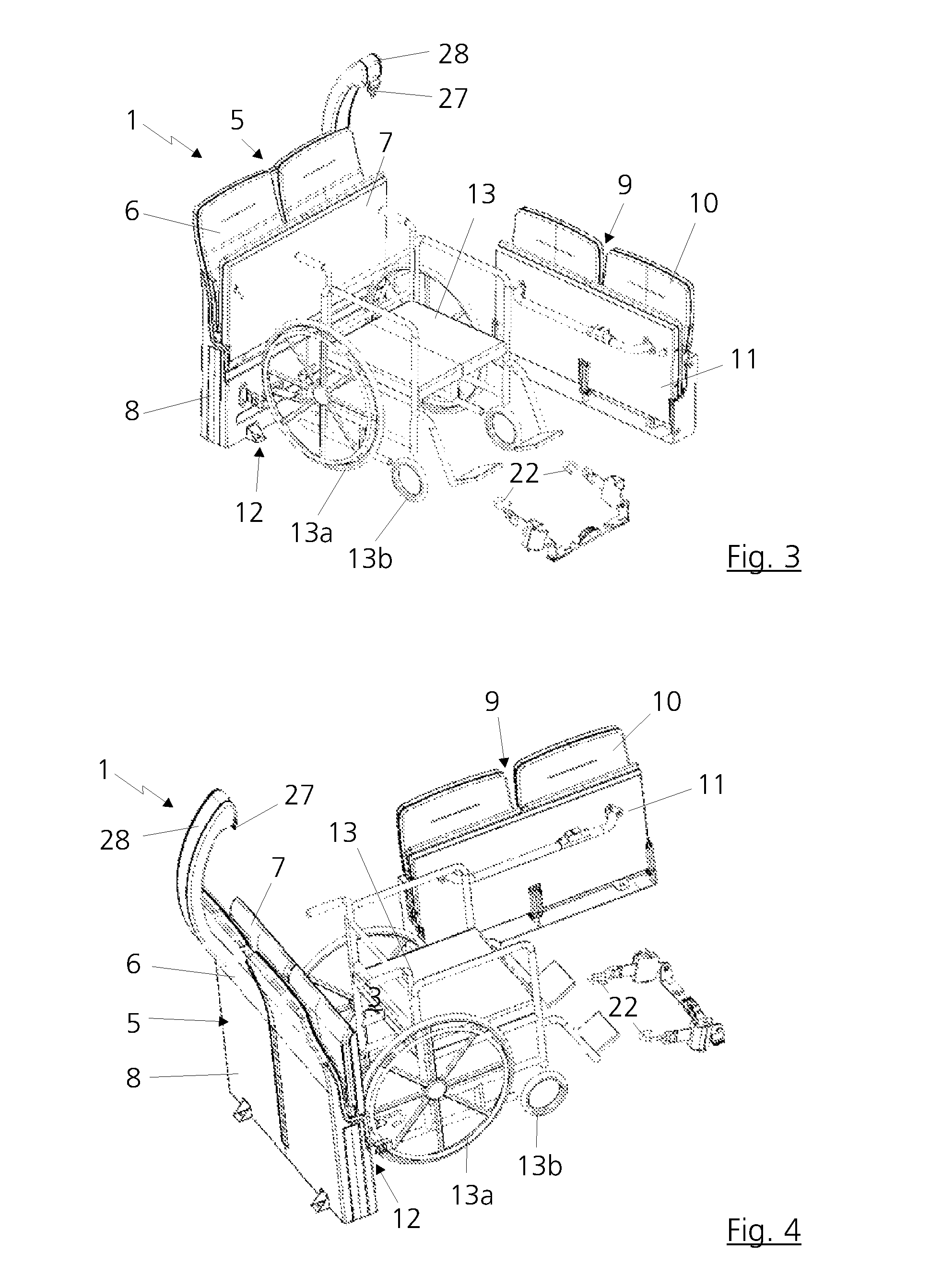

Double folding seat for a vehicle

InactiveUS8911188B1Easy to lockSufficient securityFlexible elementsLoad securingWheelchair userEngineering

The invention relates to a double folding seat for a vehicle, particularly a public transportation vehicle such as a bus or a train, with a bench seat positioned in the direction of travel of the vehicle that has a backrest and a seating surface that can be folded between a home position and a sitting position, with a retaining device for holding a wheelchair or the like that has at least two hooks arranged in extension of the backrest and mounted on a wall supported on a floor of the vehicle, which hooks can be tightened by respective tightening members and loosened by respective loosening members, with a safety belt for the wheelchair user and with a covering for the tightening members and loosening members.

Owner:FRANZ KIEL

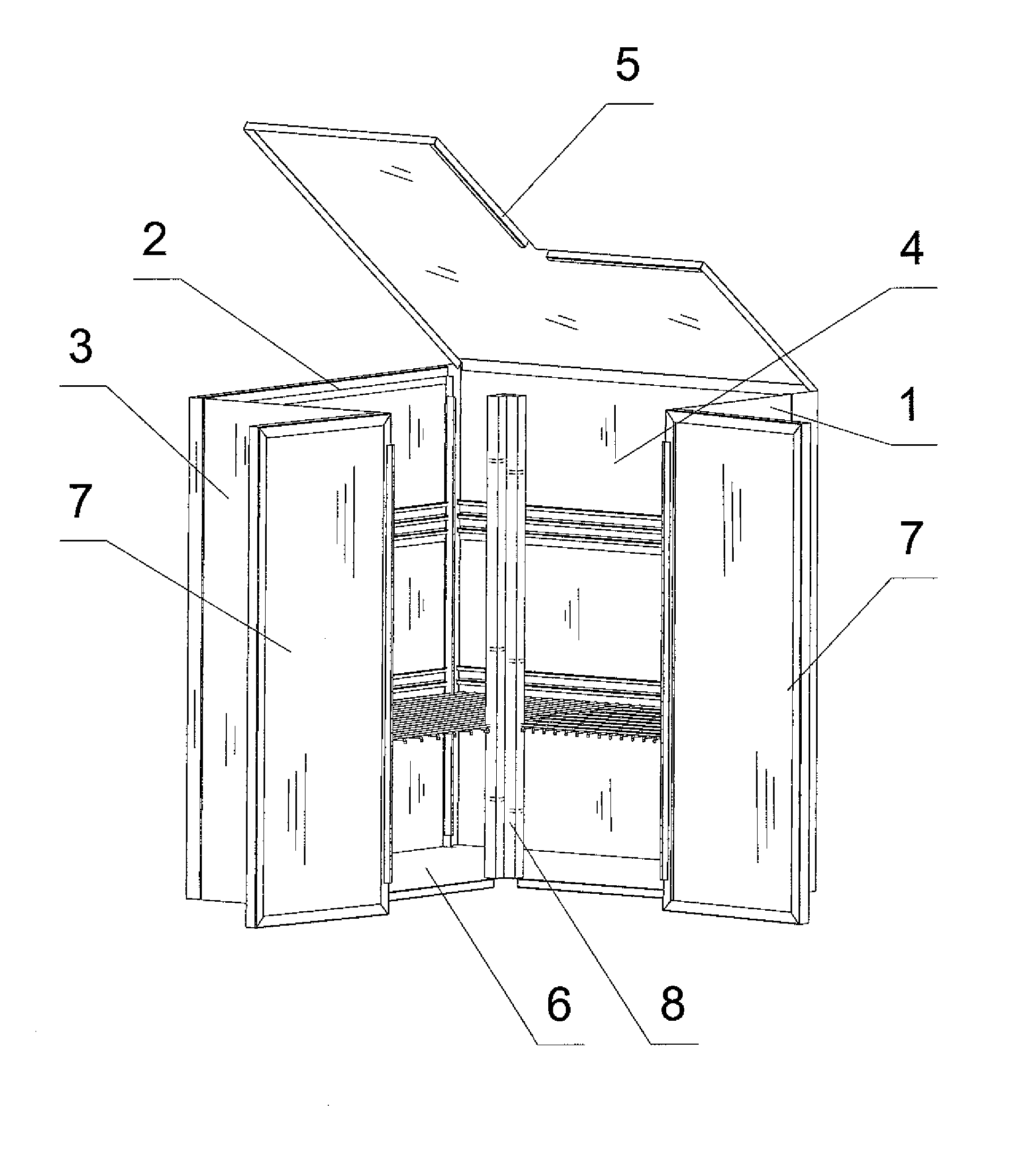

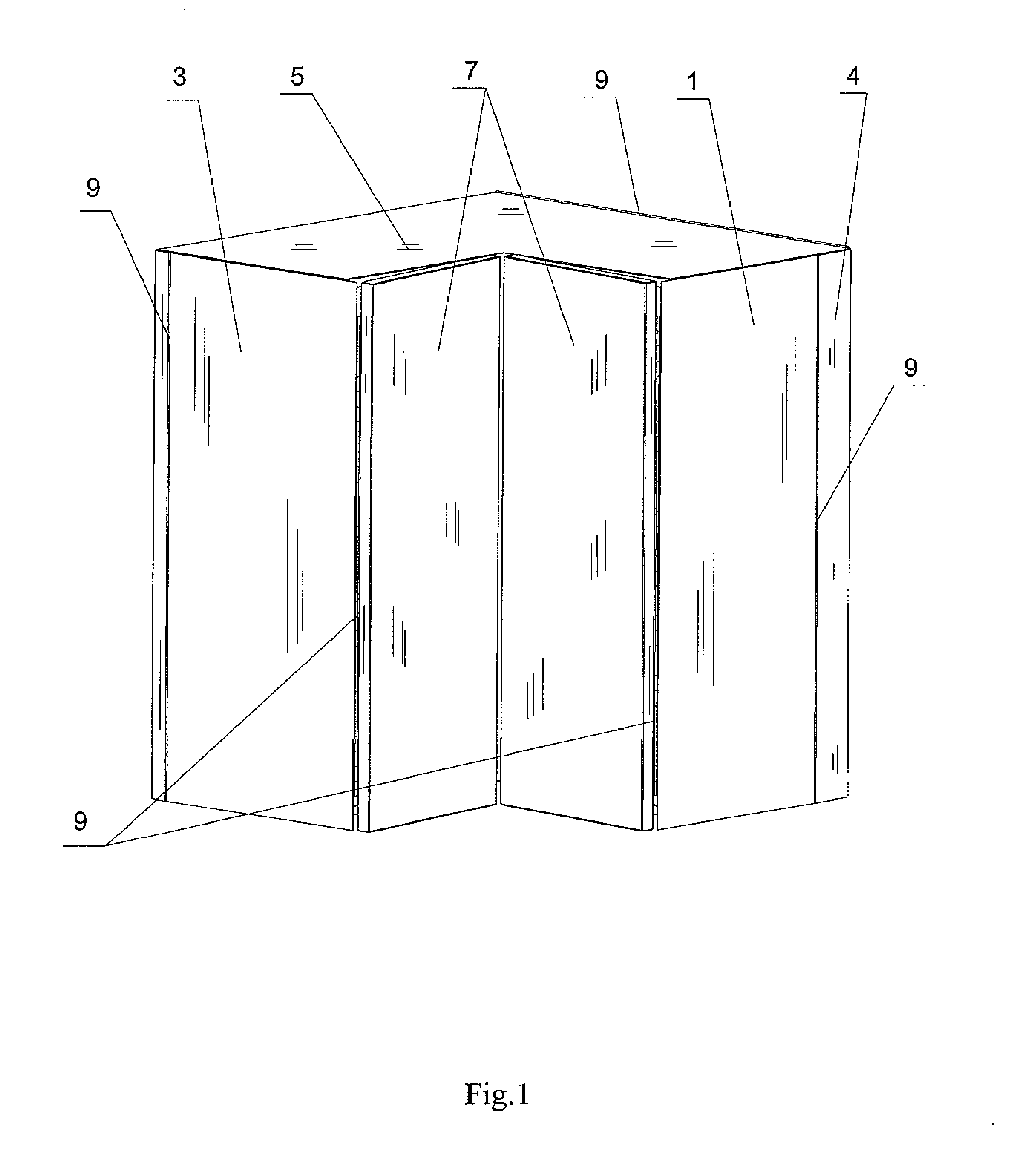

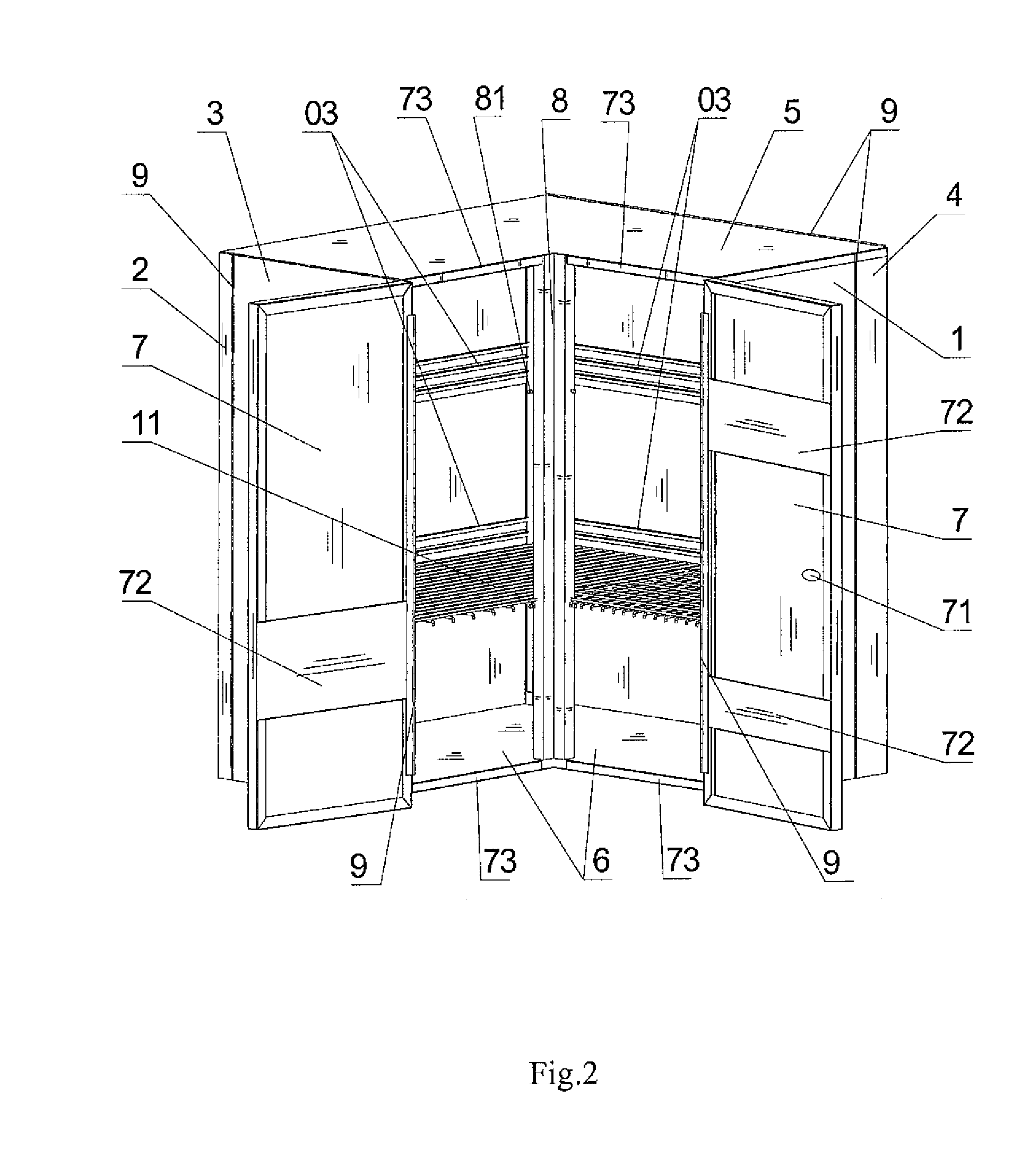

Tool cabinet

InactiveUS20080012455A1Simple structureEasy to assembleFolding cabinetsDismountable cabinetsEngineeringBackplane

A tool cabinet including an upper cover, a bottom board, a case body and a shelf accessory. The case body includes rotatably interconnected case boards, which are foldable with each other. The upper cover and the bottom board are loosely rabbetted into the case body. Without disconnecting each case board, each case board can be folded only by pulling out the pin in the upper cover, turning over the upper cover, then taking out the shelf and the upright column, releasing the block rabbeting, and folding the case boards. It is done after the shelf and the upright column are placed into a predetermined space of the right board and the back board during the folding process. It is very simple and convenient. Hence, it is convenient to carry the tool cabinet after it is folded. In another embodiment, a tool cabinet is also constructed with hinged panels and doors that after assembly can be easily folded into a compact unit for storage or shipping.

Owner:JINHUA ZHENFEI TOOLS

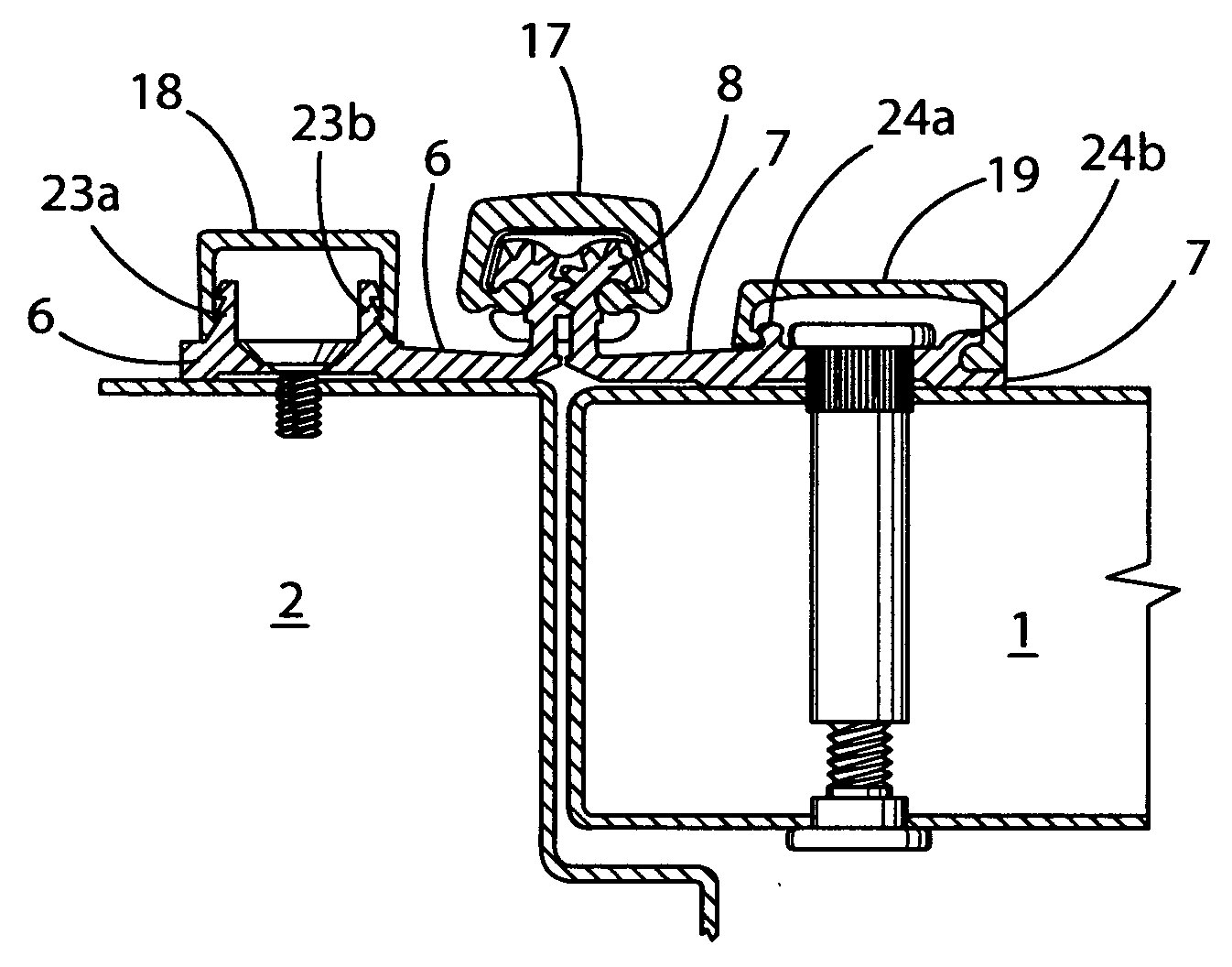

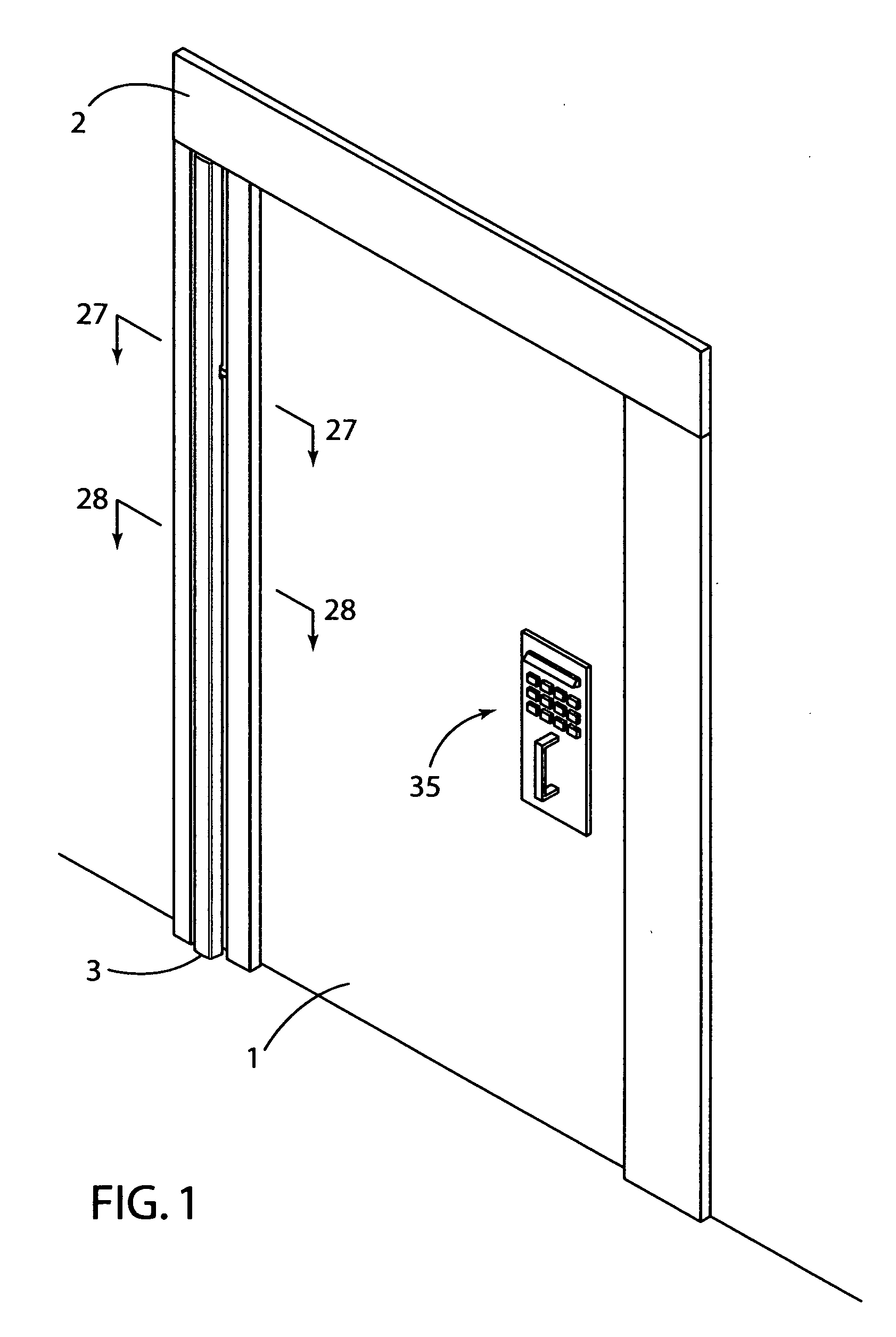

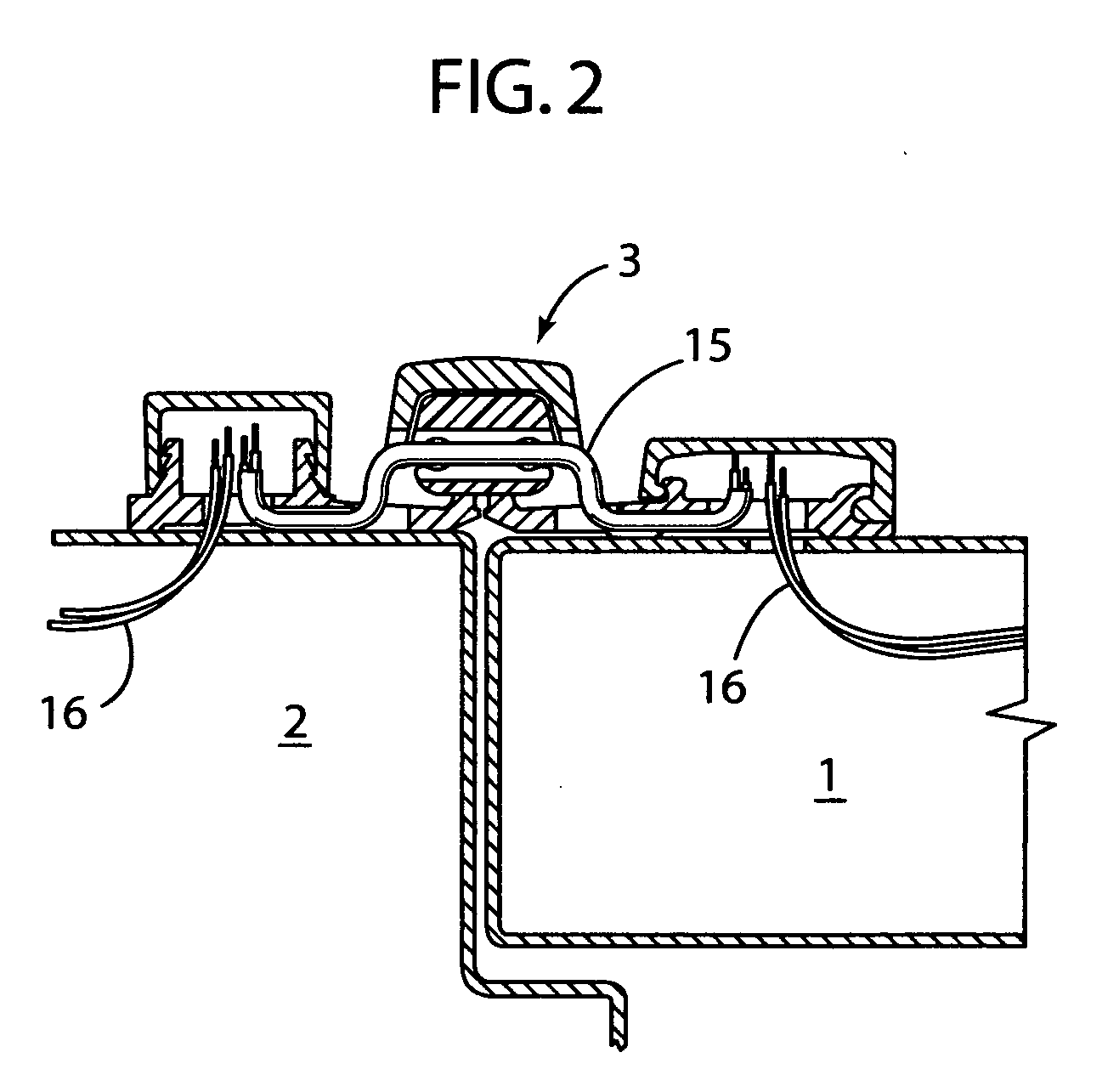

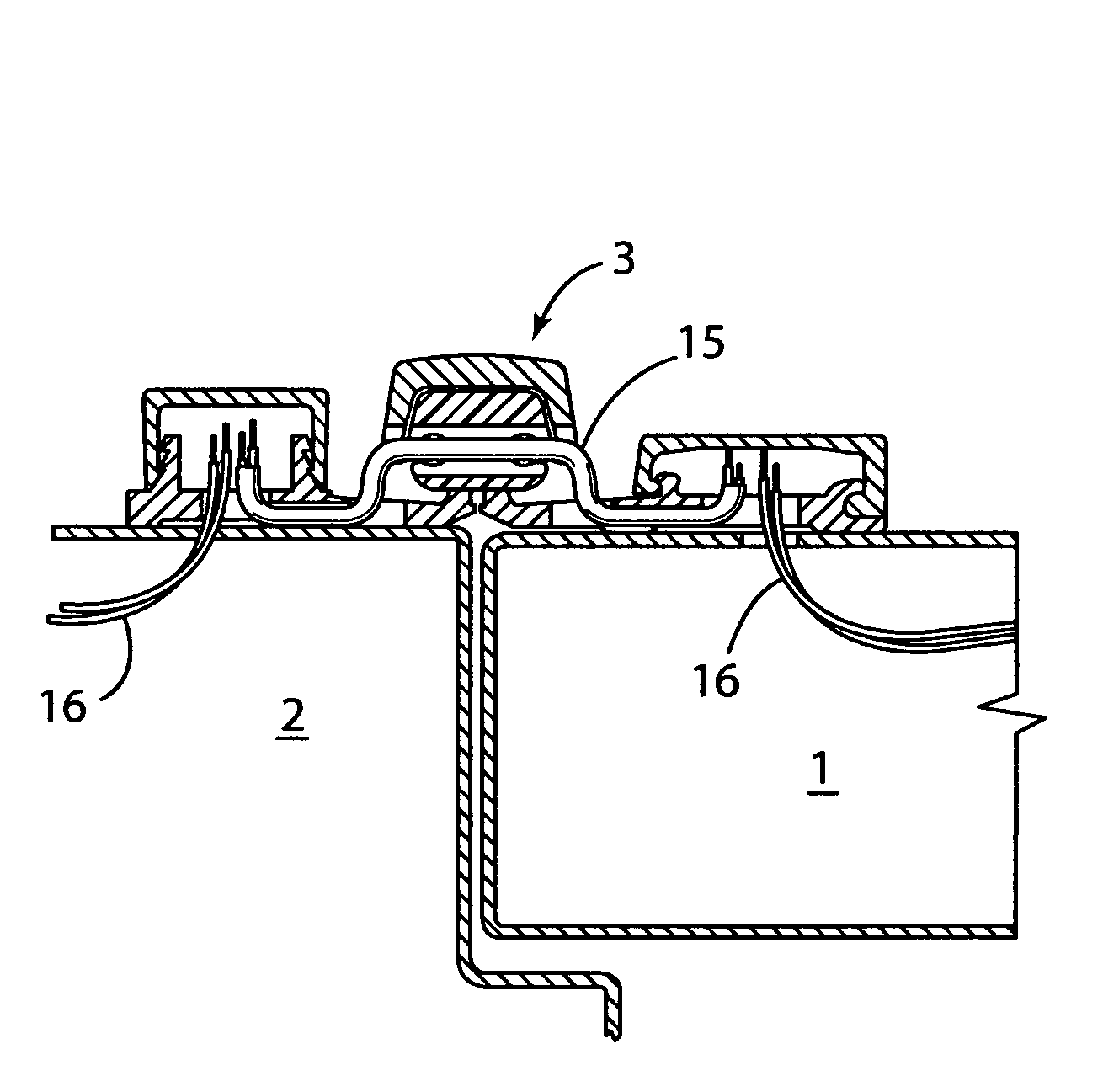

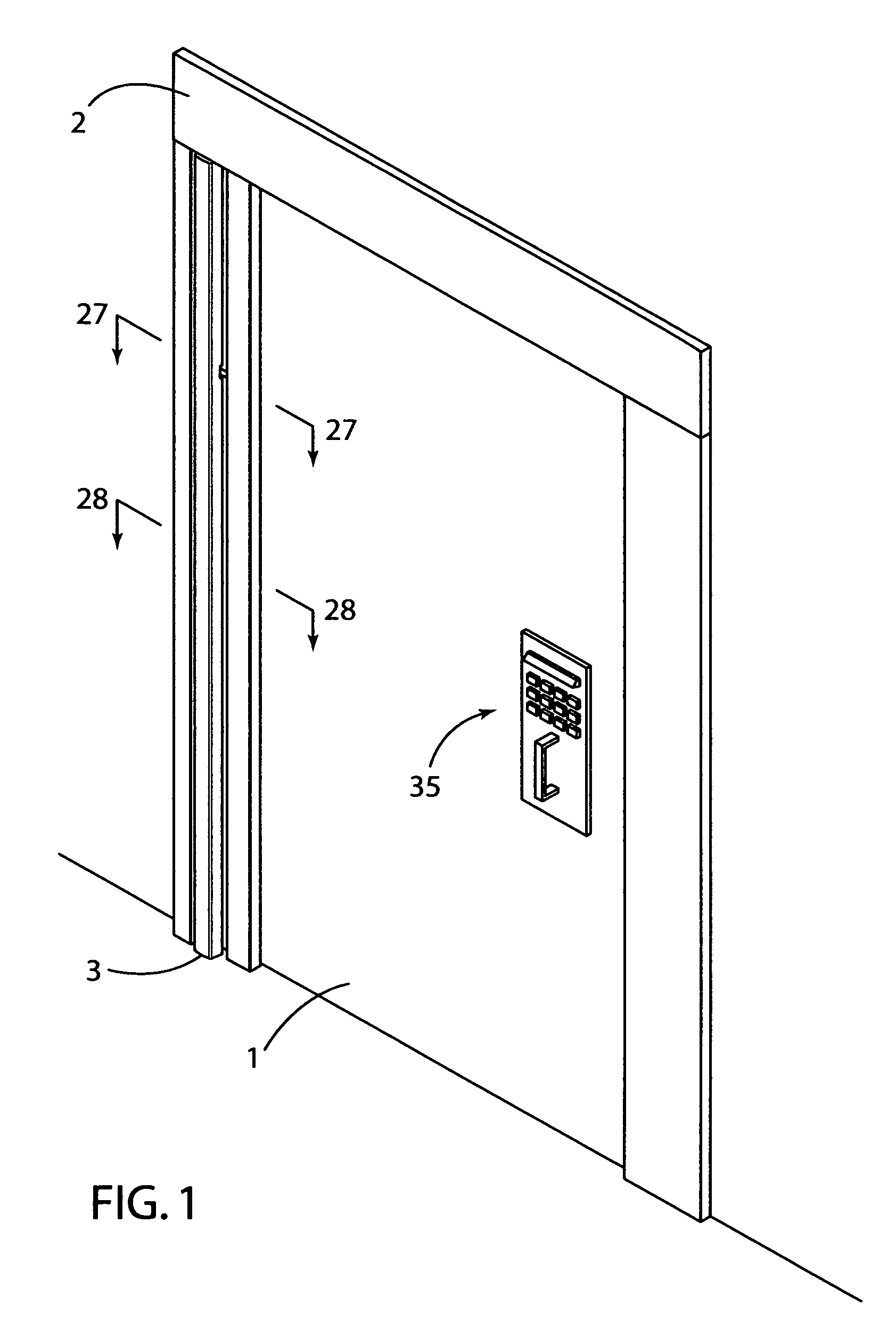

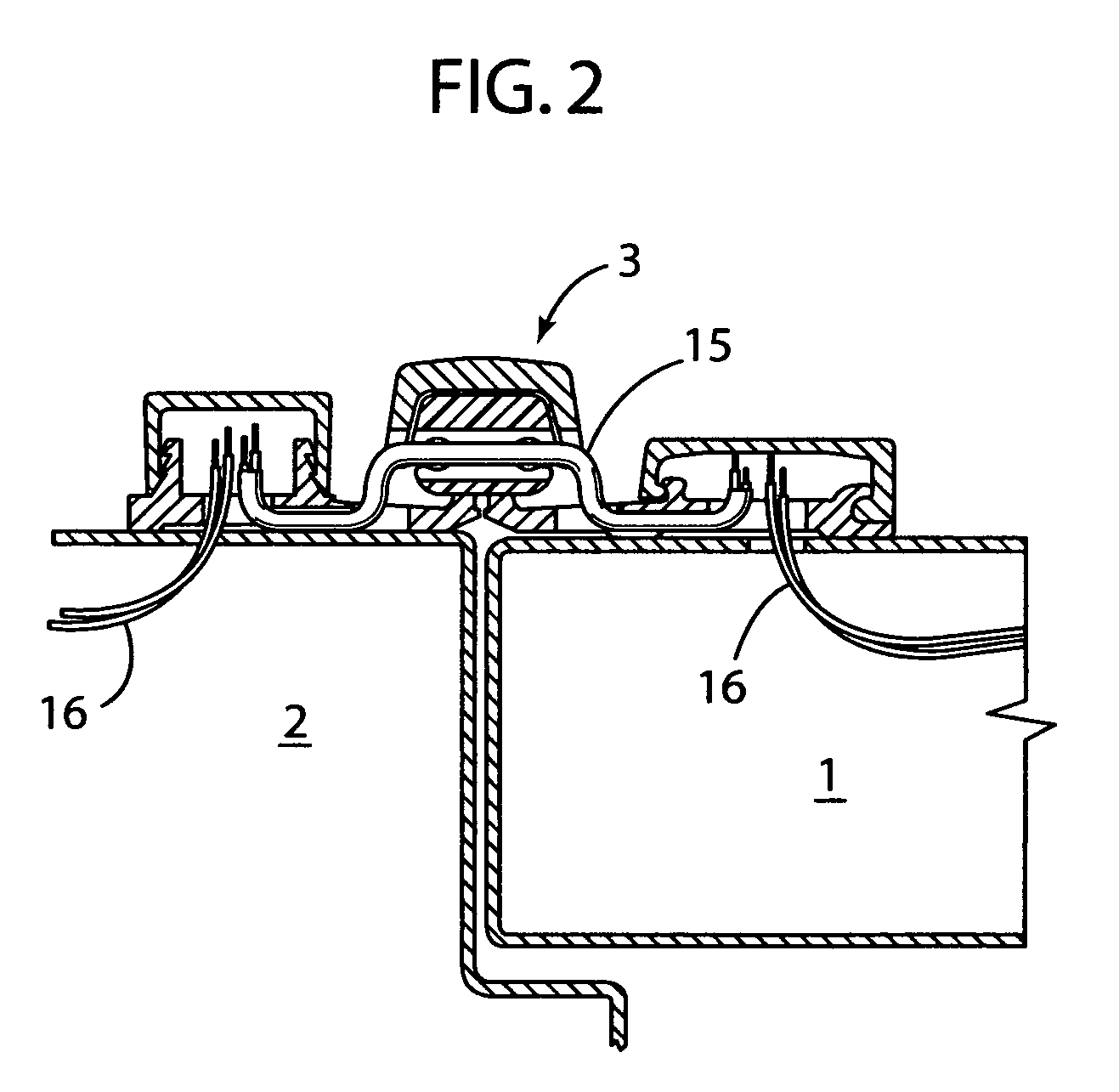

Hinge with electrical wiring

ActiveUS20090313790A1Less exposureReduce wearElectrically conductive connectionsRotary current collectorEngineeringSurface mounting

A geared full surface mounted continuous hinge with a hole in a thrust bearing supporting the hinge, said hole adapted to accommodate a flexible tube containing electrical wiring and thereby facilitate the passage of electric current from a frame to appliances in a door connected to the frame using the hinge.

Owner:SELECT PRODS

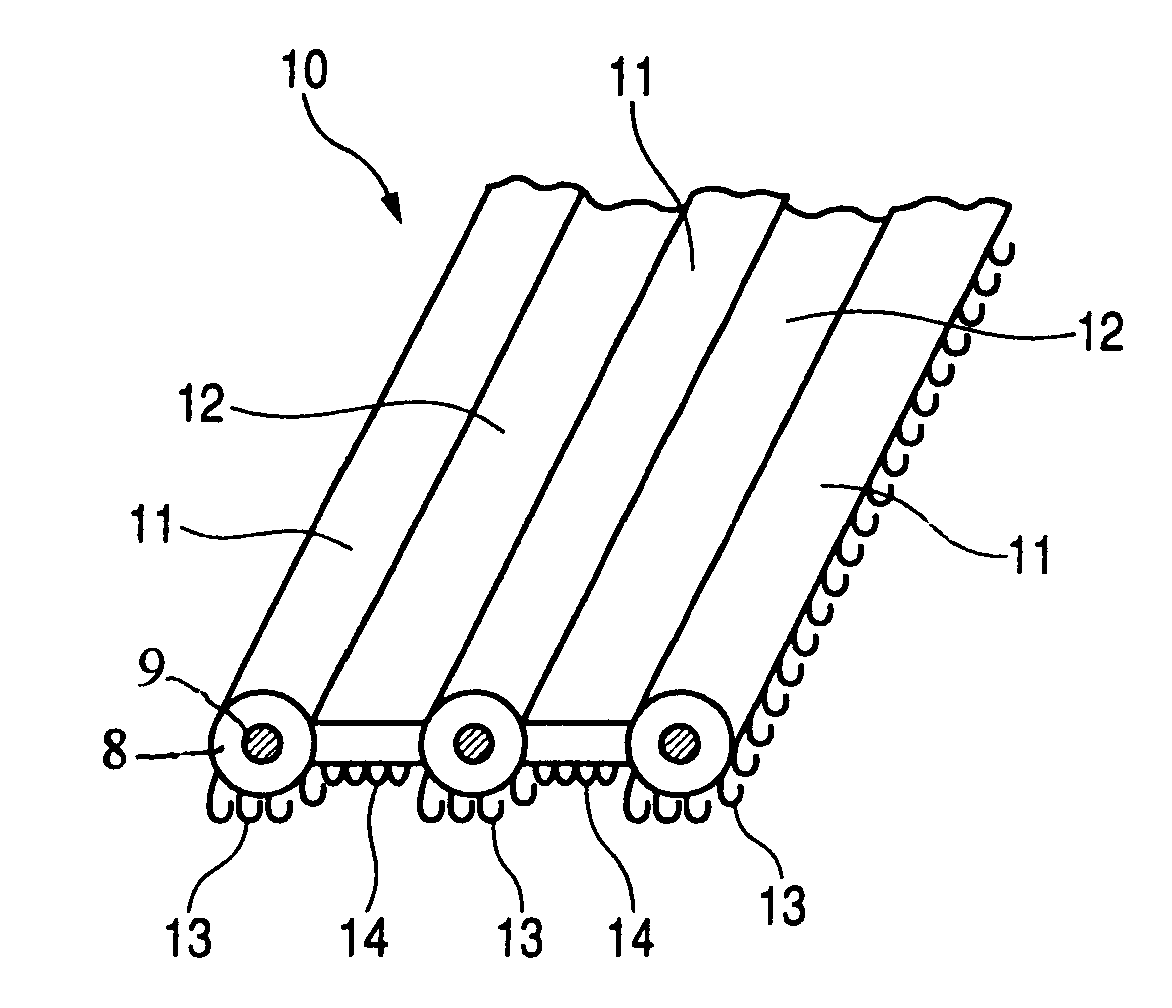

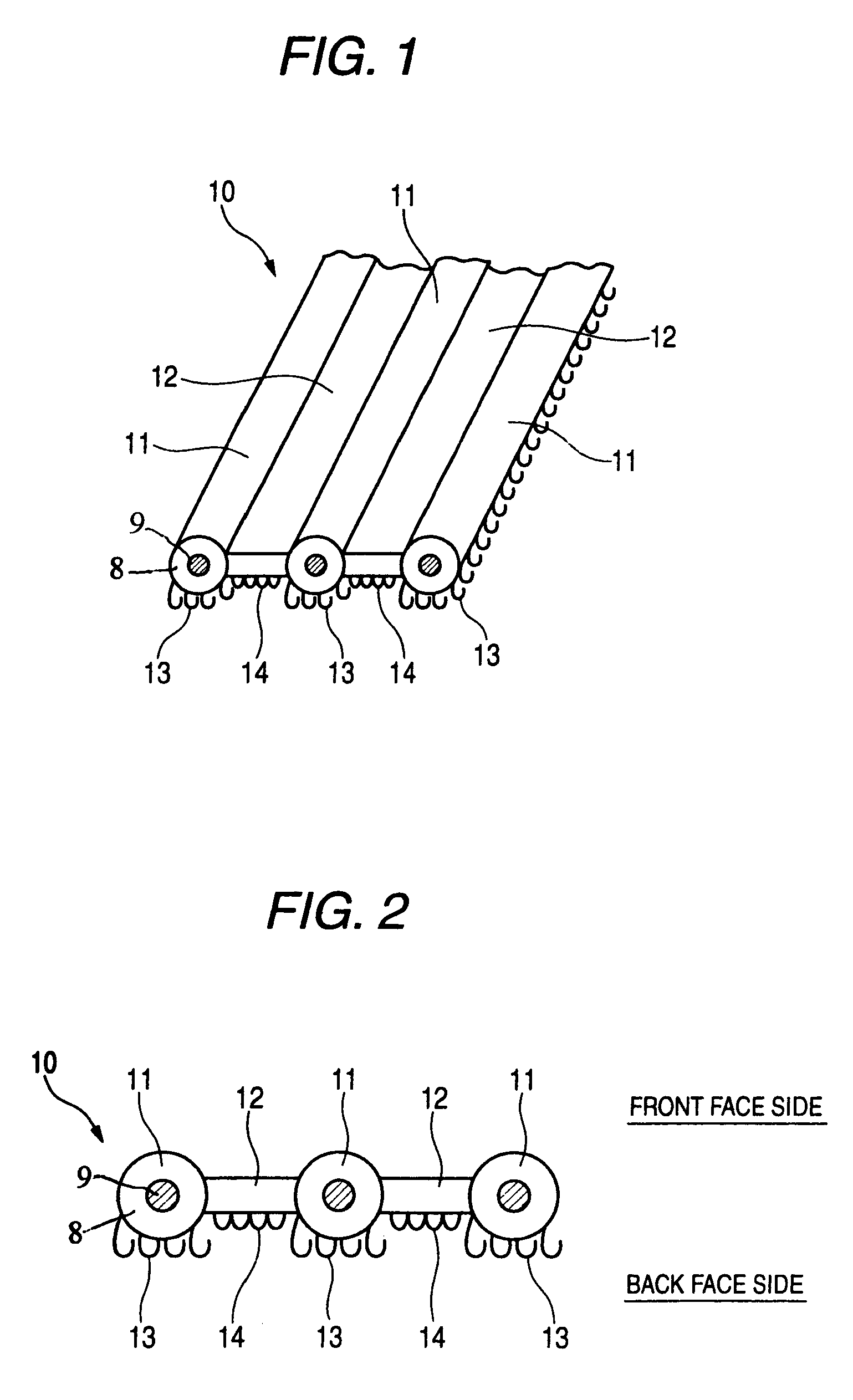

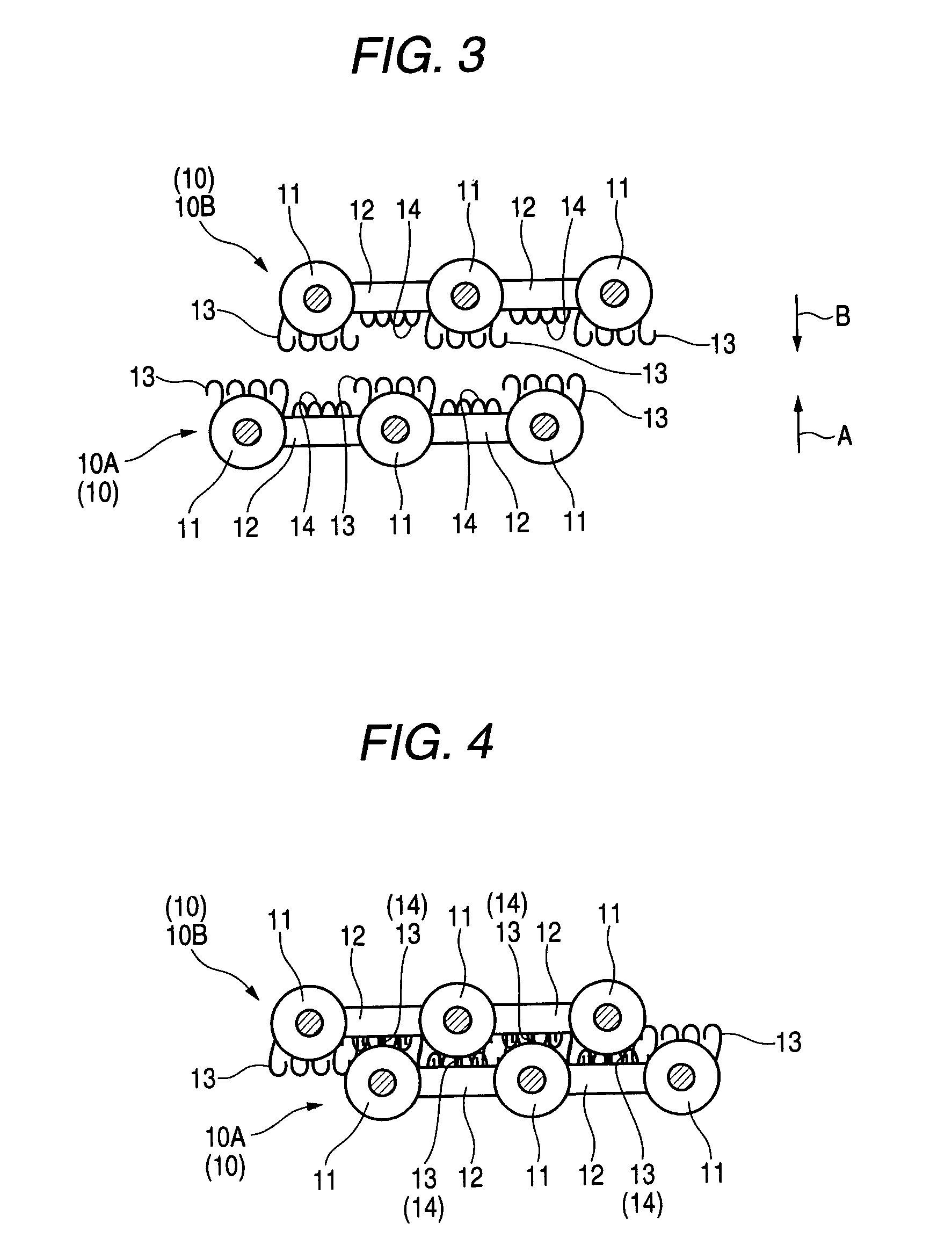

Wire harness including hook and loop shaped attaching members and a method of attaching a wire harness using the same

ActiveUS7204704B2Provide spaceEngagement/disengagement of coupling partsContact member assembly/disassemblyElectrical conductorEngineering

A wire harness includes an insulating member that contains a conductor therein, the conductor extending along one direction, and the insulating member having a front face and a back face that is opposed to the front face and a plurality of hook-shaped members and a plurality of loop-shaped members that are provided on at least one of the first face and the back face of the insulating member. The hook-shaped members are engageable to loop shaped members of a mating wire harness to be laminated to the wire harness. The loop-shaped members are engageable to hook shaped members of the mating wire harness.

Owner:YAZAKI CORP

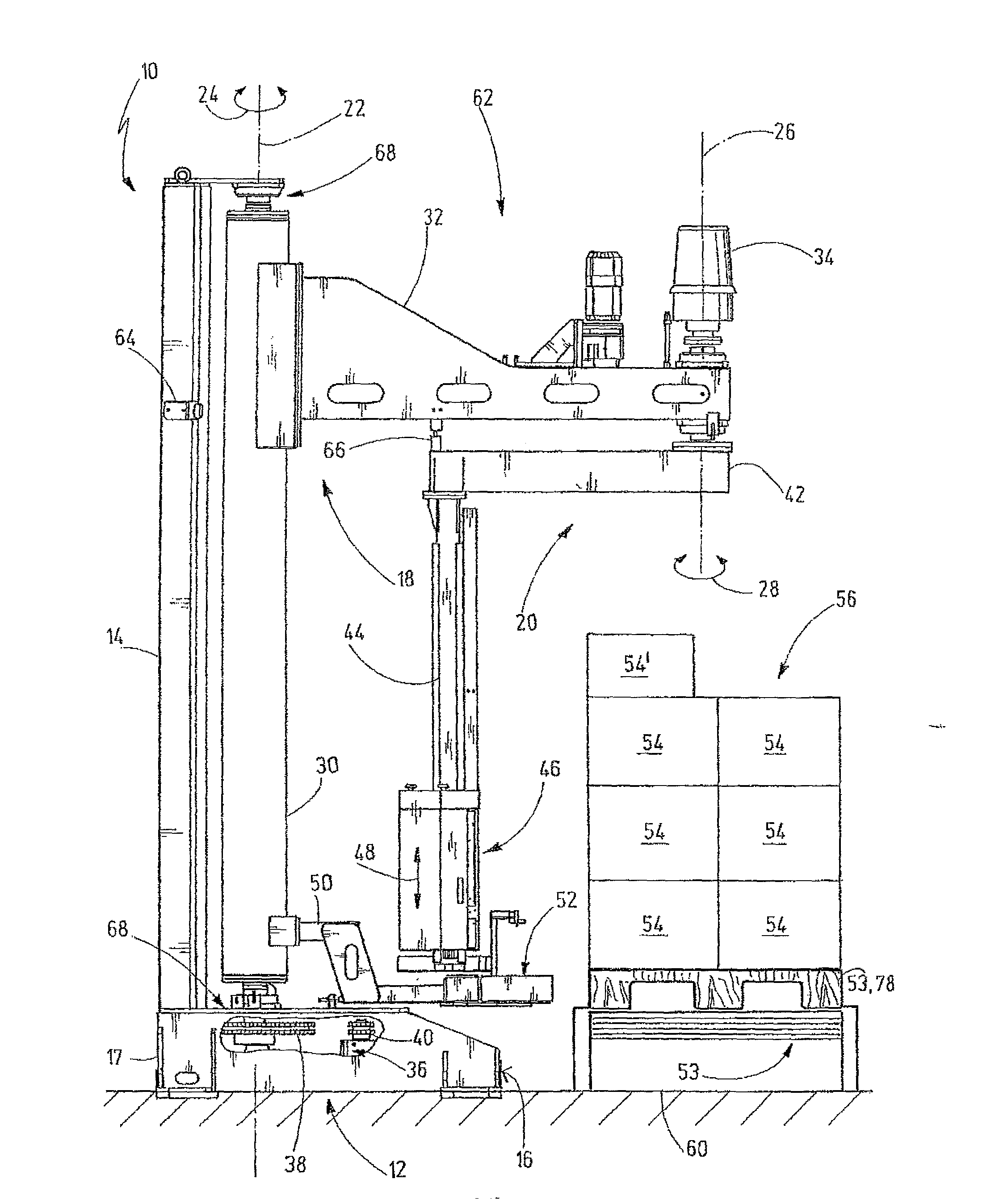

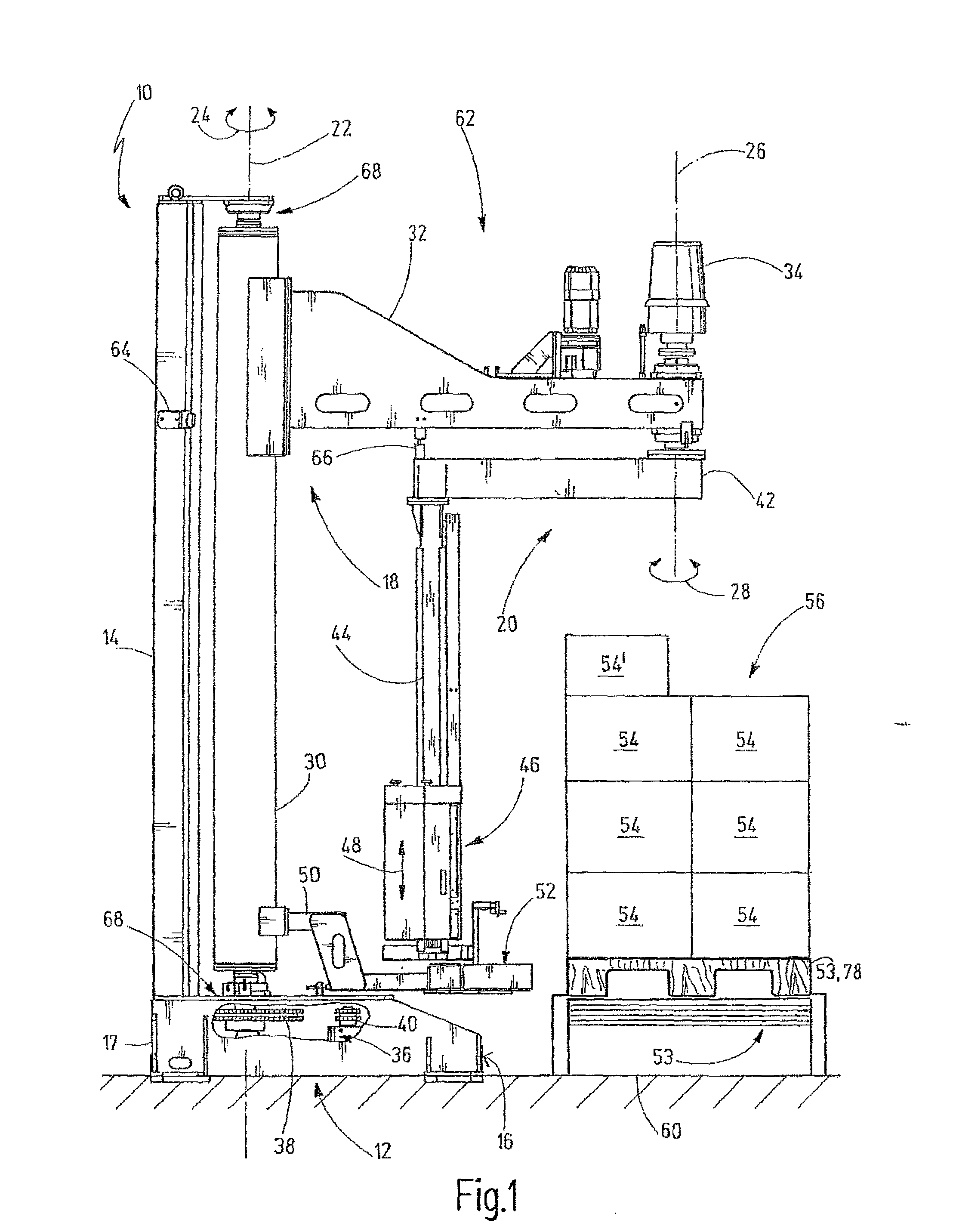

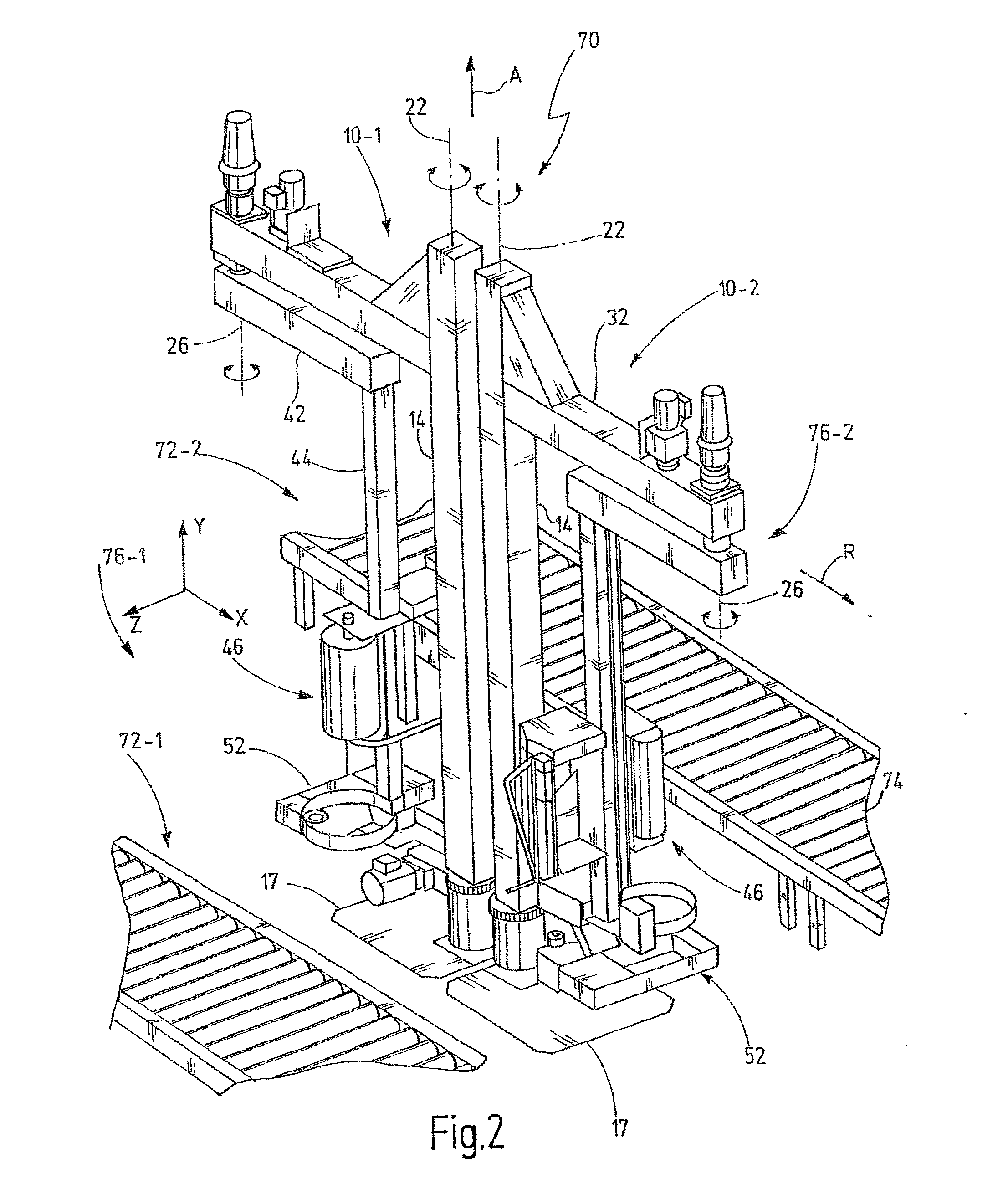

Packing station and method for automated loading of piece goods on a load carrier including subsequent foil wrapping

InactiveUS20130199133A1Prevent movementProvide spaceWrapping material feeding apparatusWeb rotation wrappingEngineeringMechanical engineering

An automated packing station for automated loading of load carriers with piece goods and for automated wrapping a stack with a foil, comprising: a fixedly arranged packing robot; and a rotational-arm winding device arranged adjacent to the packing robot and comprising a frame which is adapted to absorb forces which occur during the wrapping of the stack with the foil, and to forward the forces to an environment of the packing station.

Owner:SSI SCHFER NOELL GMBH LAGER UND SYSTTECHN

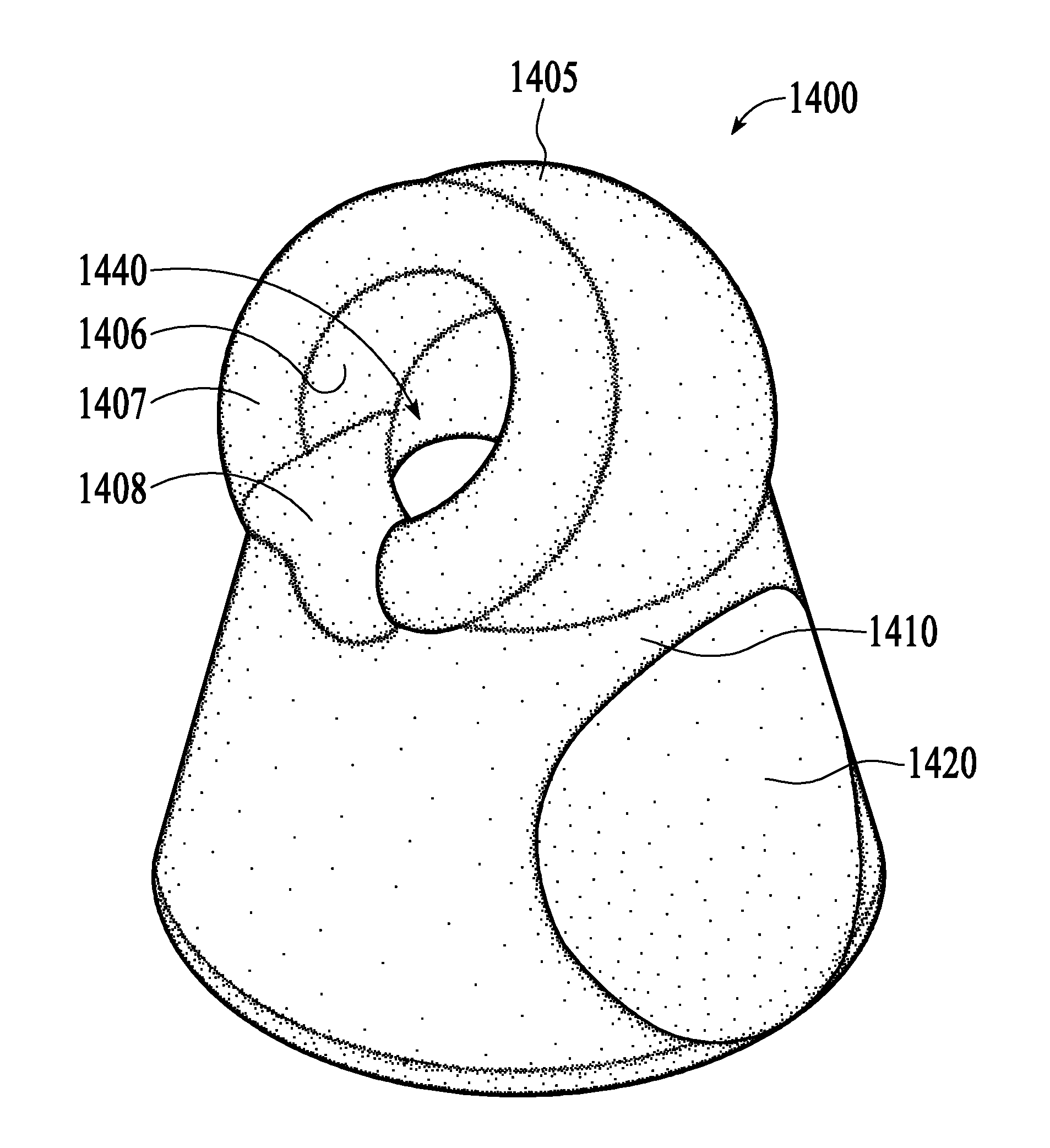

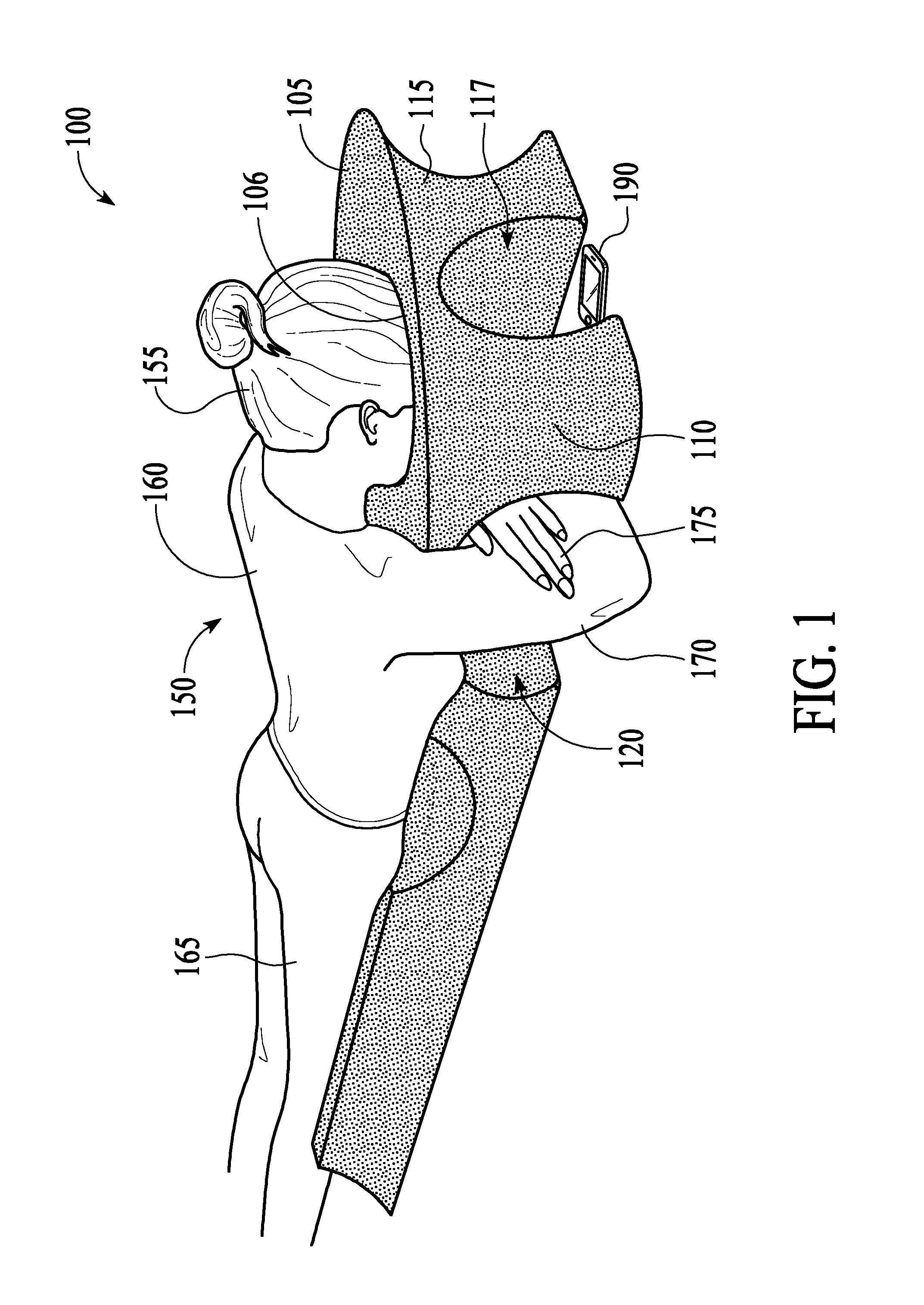

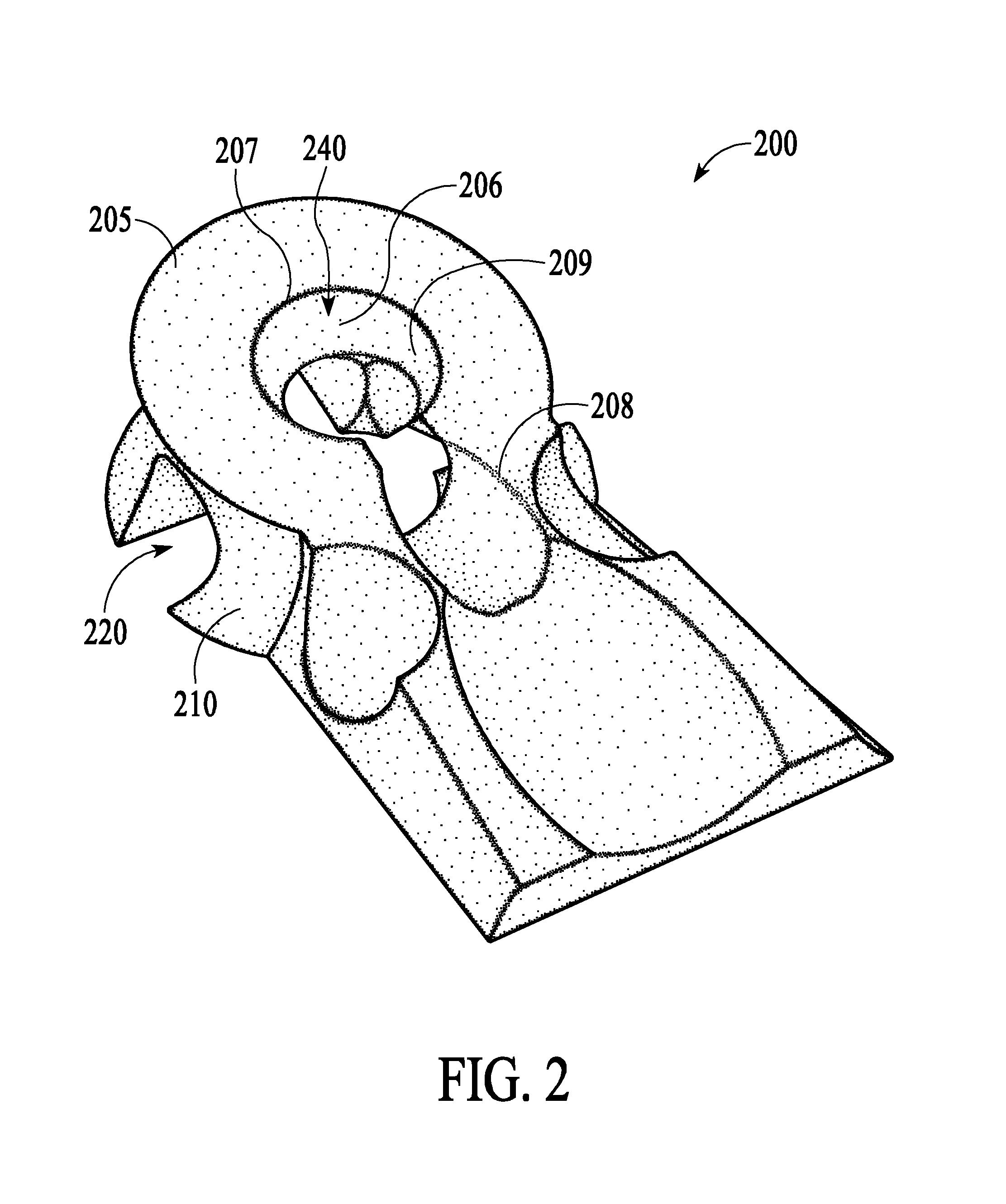

Pillow structure

A supporting pillow structure for a user to sleep or to perform sedentary activity facing down toward the pillow structure with the user's hands and arms placed underneath their face. The pillow structure includes a top opening substantially on the top surface of the pillow structure for the user's face to lean into the pillow structure, at least two side openings in the side of the pillow structure for the user to insert the user's arms into the pillow structure and place the user's arms underneath their head or body comfortably and to increase airflow for the user to breathe comfortably while resting, and a cavity in the middle of the pillow structure for airflow between the openings and for placing objects within the pillow structure, allowing the user to perform tasks requiring minimal physical activity while remaining comfortable and sedentary for an extended period of time. Embodiments of the pillow structure may be configured to provide users with comfort and support while the user is seated leaning forward on an airplane or at a desk or table or while the user is lying facing down on a substantially level surface such as a bed.

Owner:PILLOWVISION

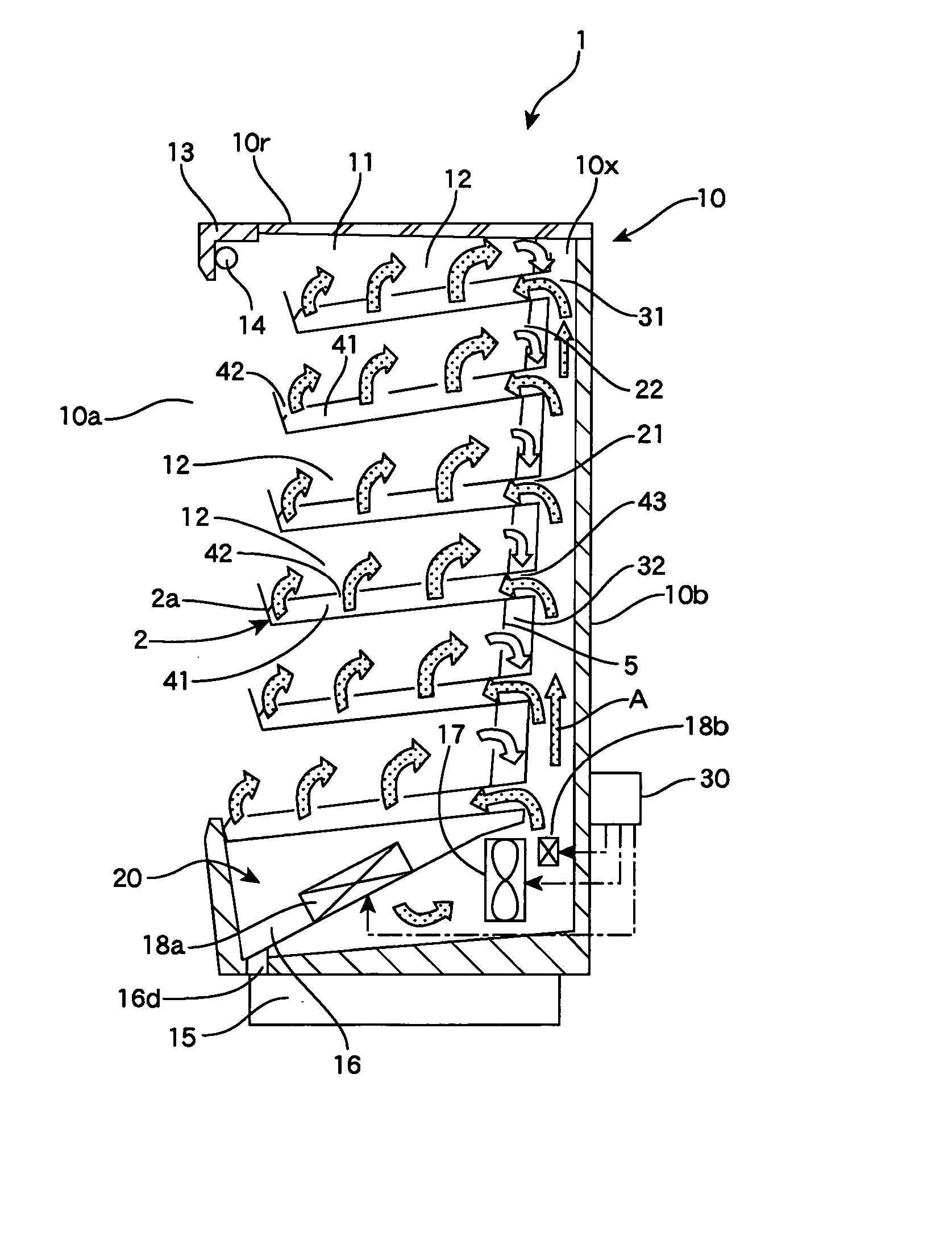

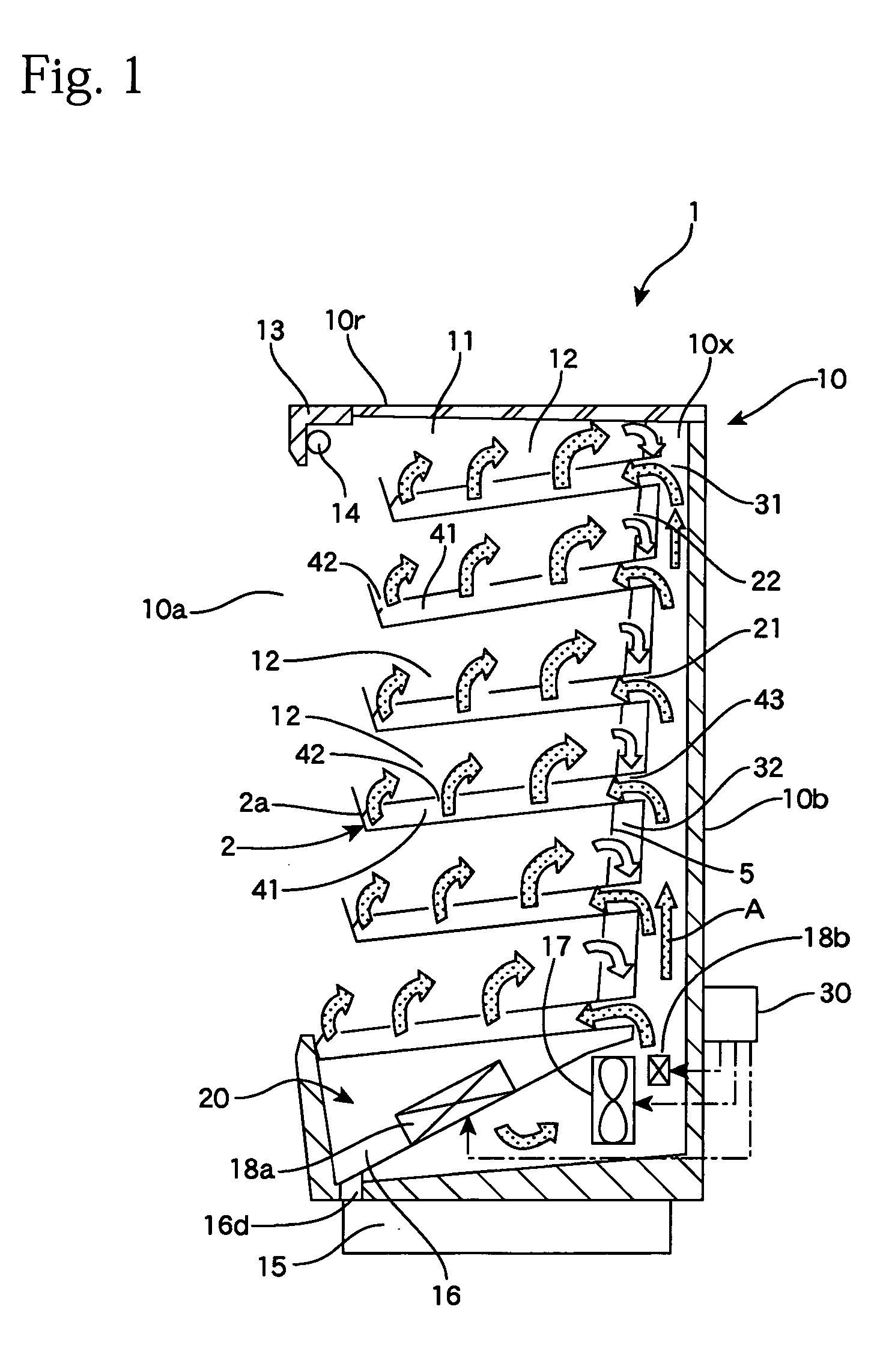

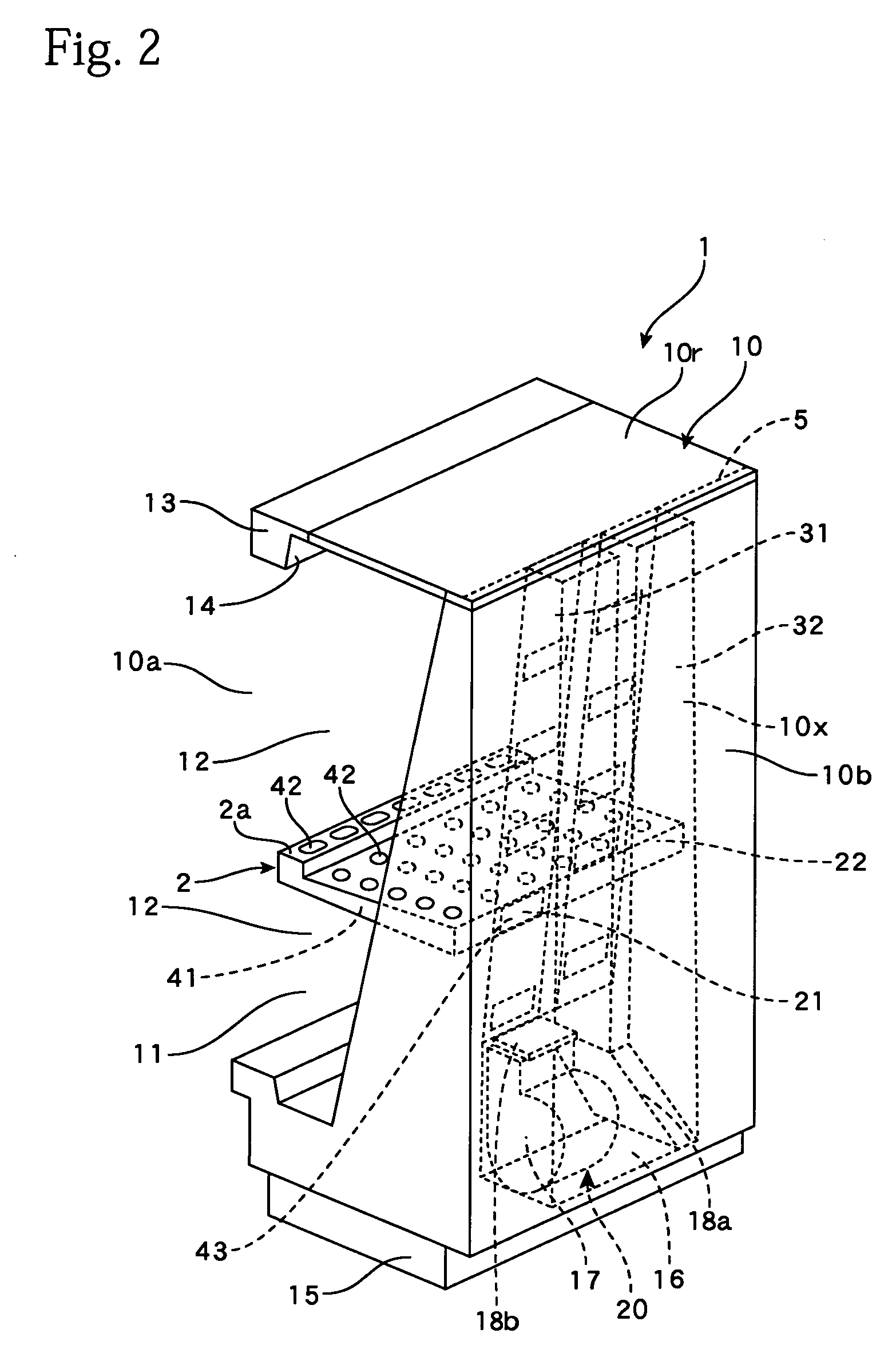

Storage device

InactiveUS20050061758A1Improve efficiencyEffective spaceShow cabinetsDomestic refrigeratorsCold airEngineering

A storage apparatus is provided that comprises a display case part with an inside thereof being dividable into a plurality of zones, a supply duct that is connected to supply openings for supplying conditioning air for controlling environmental conditions to the plurality of zones respectively, and an exhaust duct that is connected to exhaust openings for taking in air from the plurality of zones. In this storage apparatus, conditioning air such as cold air or hot air is circulated in the respective zones, and the environmental conditions can be adjusted efficiently in zone basis. Therefore, in a storage apparatus equipped with an open-type display case part, it is possible to dispense with an air curtain covering the entire open side, so that a storage apparatus with a high storage capacity is provided.

Owner:GLOSTER

Hinge with electrical wiring

ActiveUS8307509B2Easy accessReduce exposureElectrically conductive connectionsRotary current collectorPower flowSurface mounting

A geared full surface mounted continuous hinge with a hole in a thrust bearing supporting the hinge, said hole adapted to accommodate a flexible tube containing electrical wiring and thereby facilitate the passage of electric current from a frame to appliances in a door connected to the frame using the hinge.

Owner:SELECT PRODS

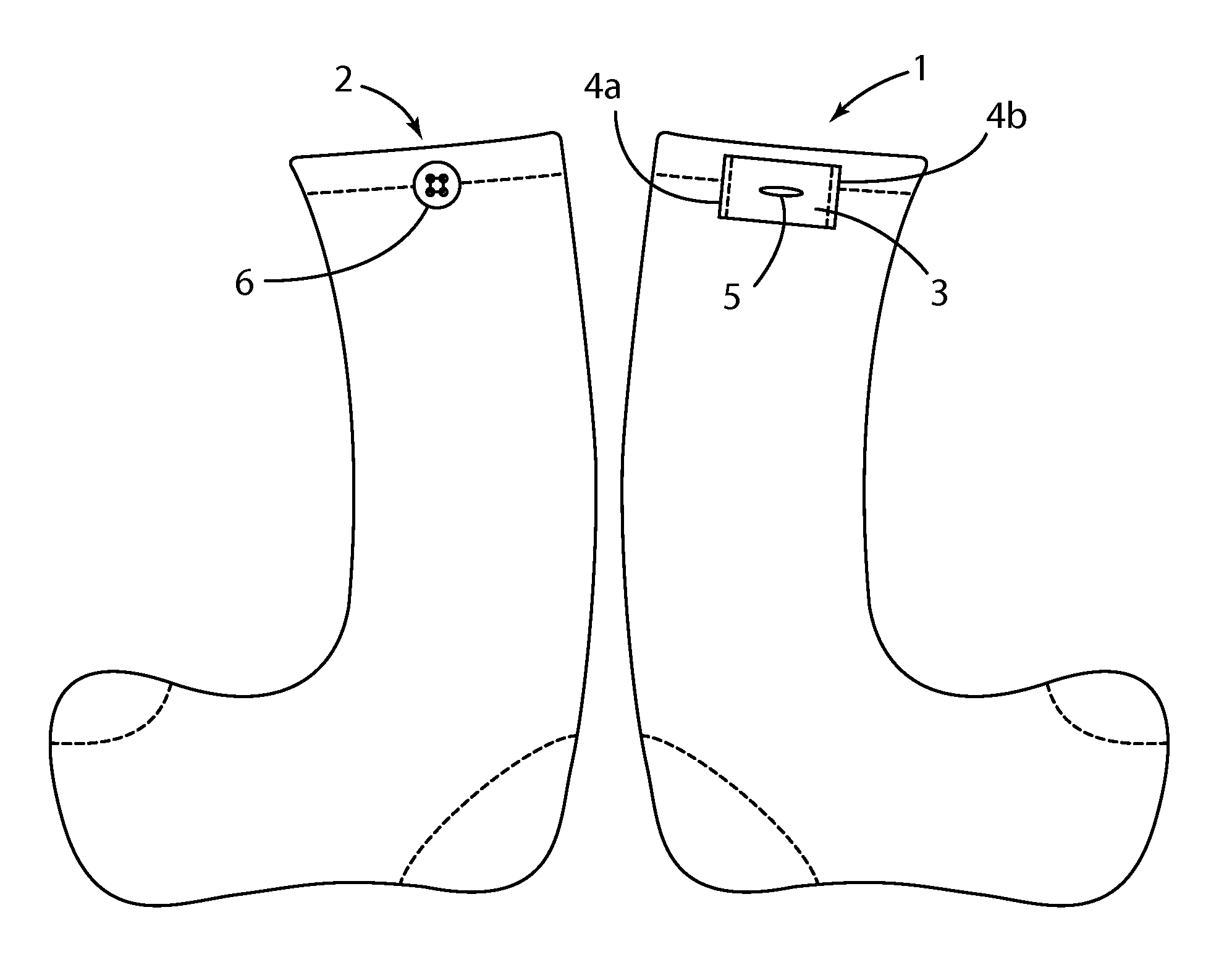

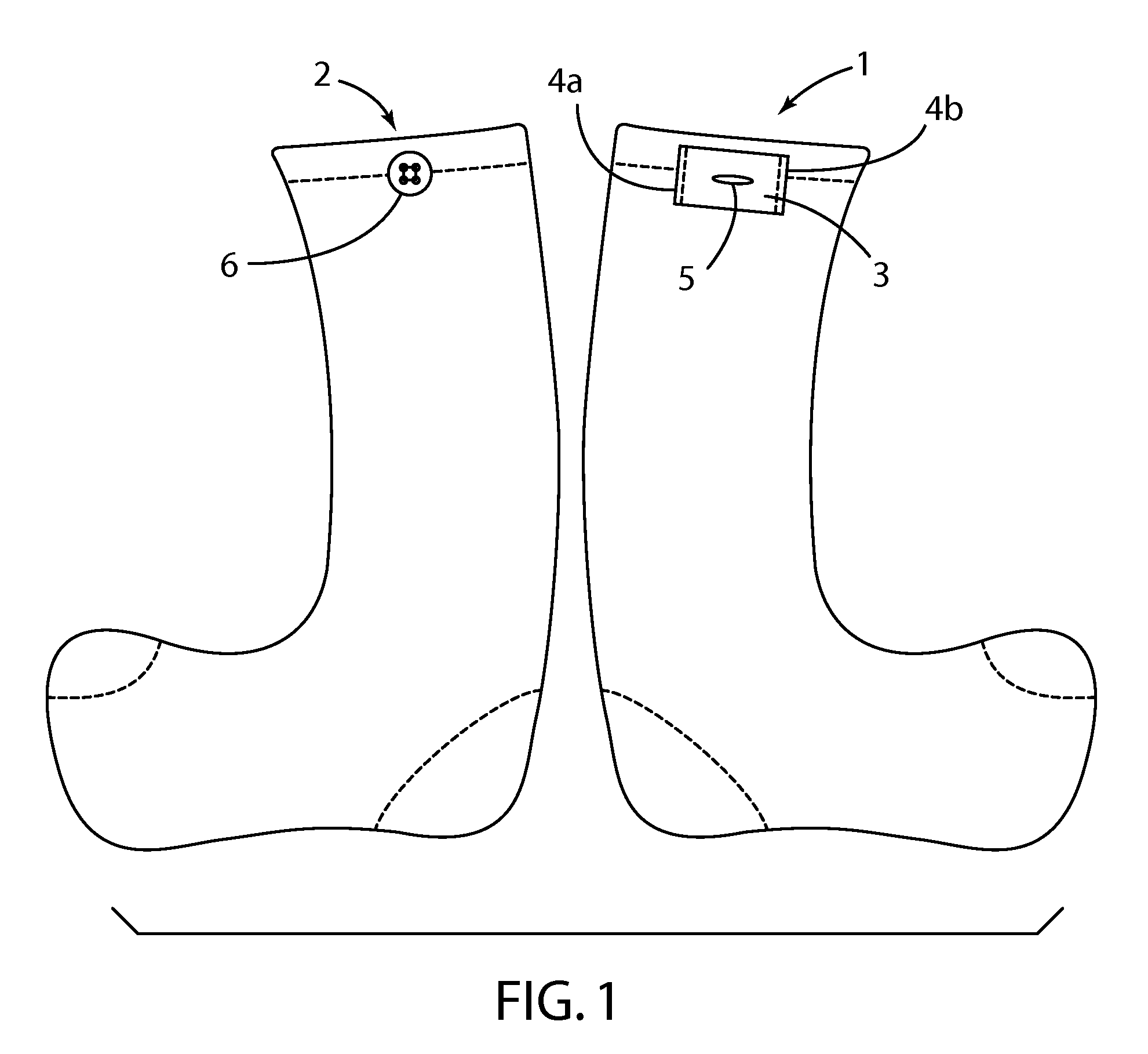

Washing socks

InactiveUS20140090149A1High strengthAvoid separationInsolesPanty-hoseEngineeringMechanical engineering

A combination and a method for keeping the individual members of a pair of socks together during repeated laundering or storage employing a button on a locally reinforced portion of one sock of a pair of socks and a locally reinforced elasticized opening in the other sock in the pair of socks, the opening adapted to receive and secure the button.

Owner:ANDONIAN JOSEPH KOORKIN

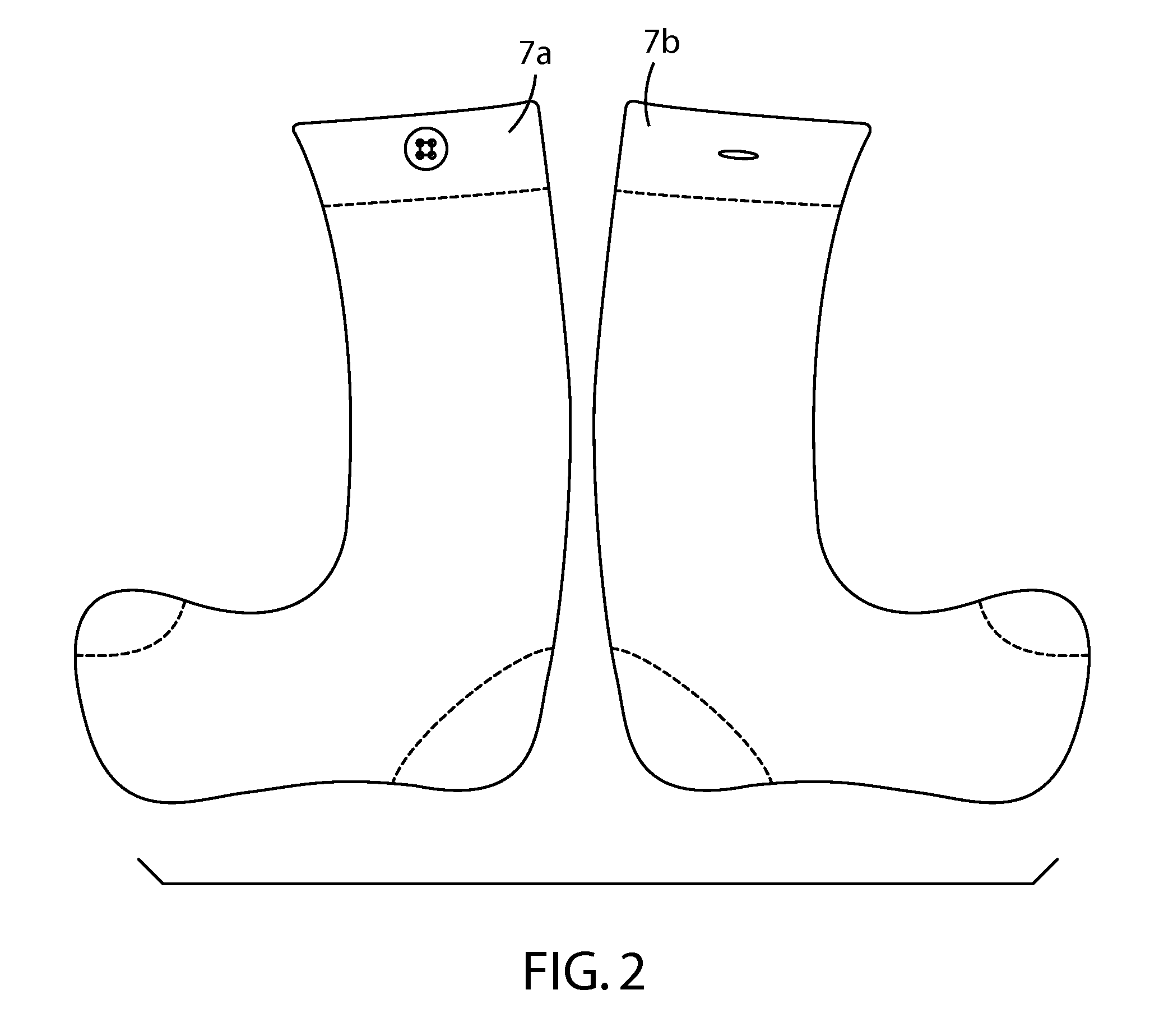

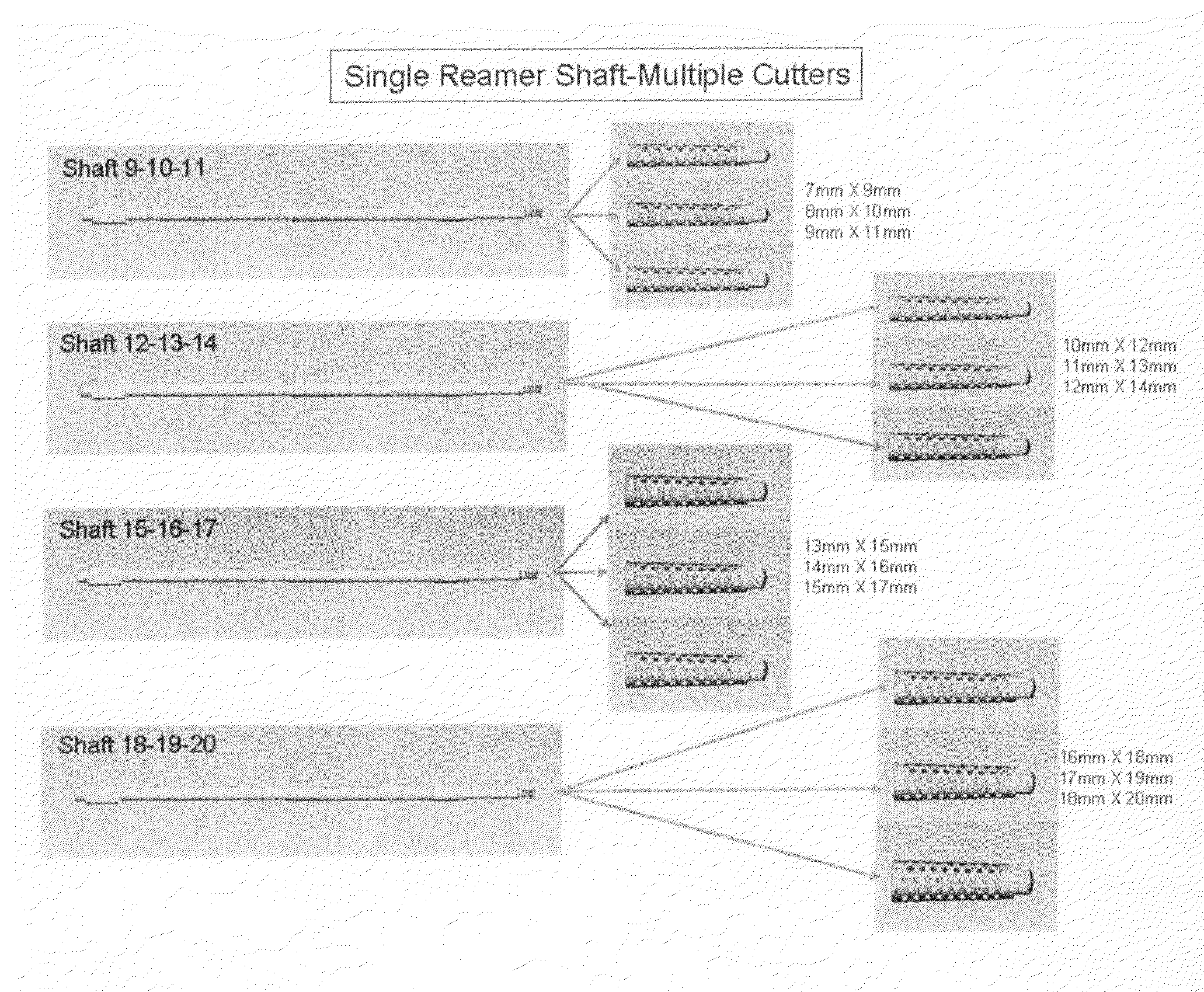

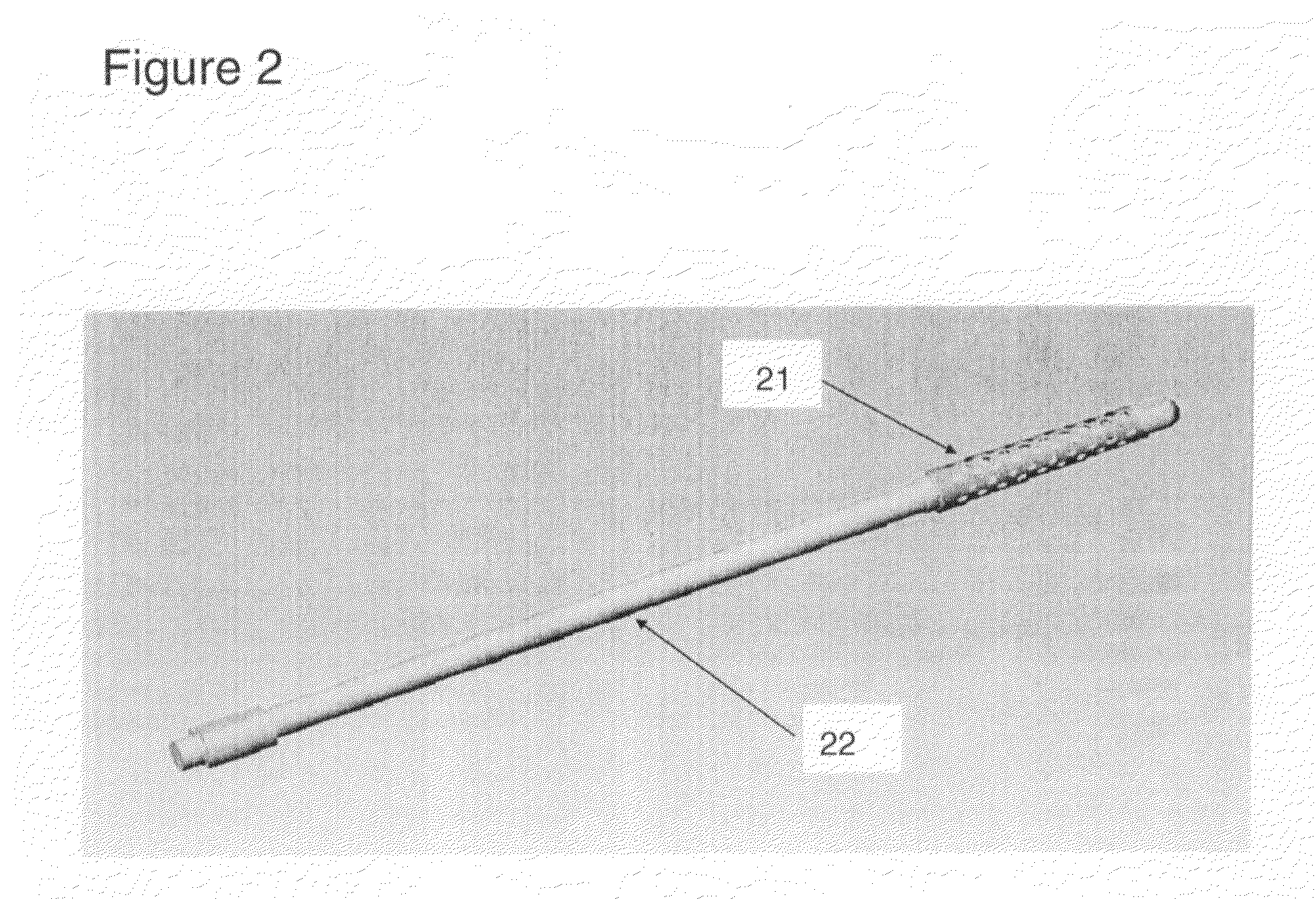

Hollow reamer for medical applications

A reamer for medical applications includes a shaft portion and a disposable hollow cutter assembly. The shaft portion having an elongated body with a distal end and a proximal end. The distal end has a coupling portion appointed for attachment of the reamer to a drilling device, and the proximal end has a threaded portion. The hollow cutter assembly includes: a disposable hollow cutter sleeve portion and a pilot tip. The disposable hollow cutter sleeve has an outer surface and a hollow construction, and is preferably appointed for a single, one-time use. Alternatively, the cutter sleeve is used more than once before it is discarded. In addition, the disposable hollow cutter sleeve portion has a plurality of cutting teeth and a plurality of apertures on the outer surface. The pilot tip having a threaded inner surface and is attached to the disposable hollow cutter sleeve portion. The disposable hollow cutter assembly is adapted to slide over the proximal end of the elongated shaft portion and extend over a portion of the elongated body thereof, thereby enabling the pilot tip to be threaded with the threaded portion of the proximal end of the shaft portion.

Owner:LRS SCI & TECH LLC

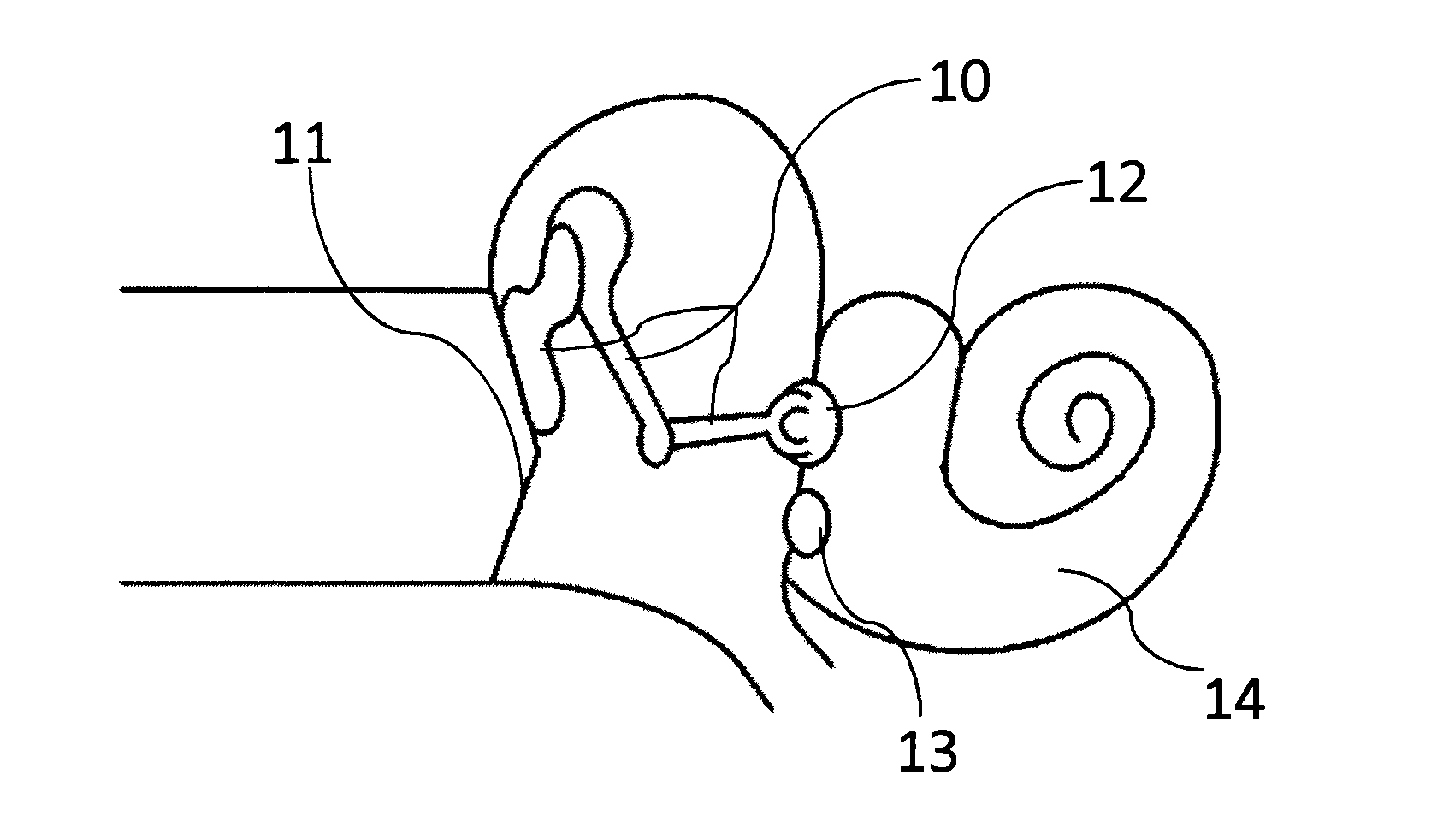

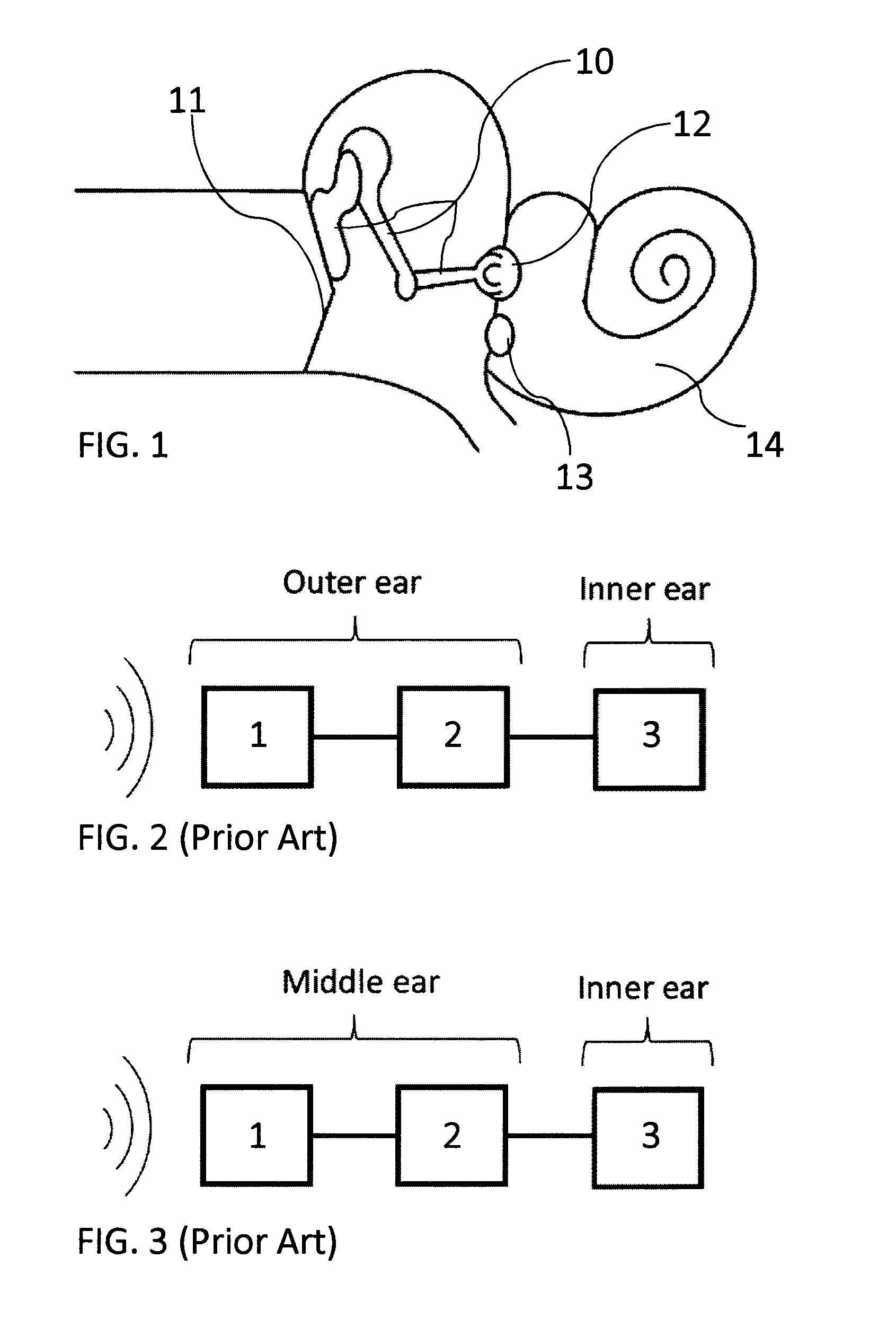

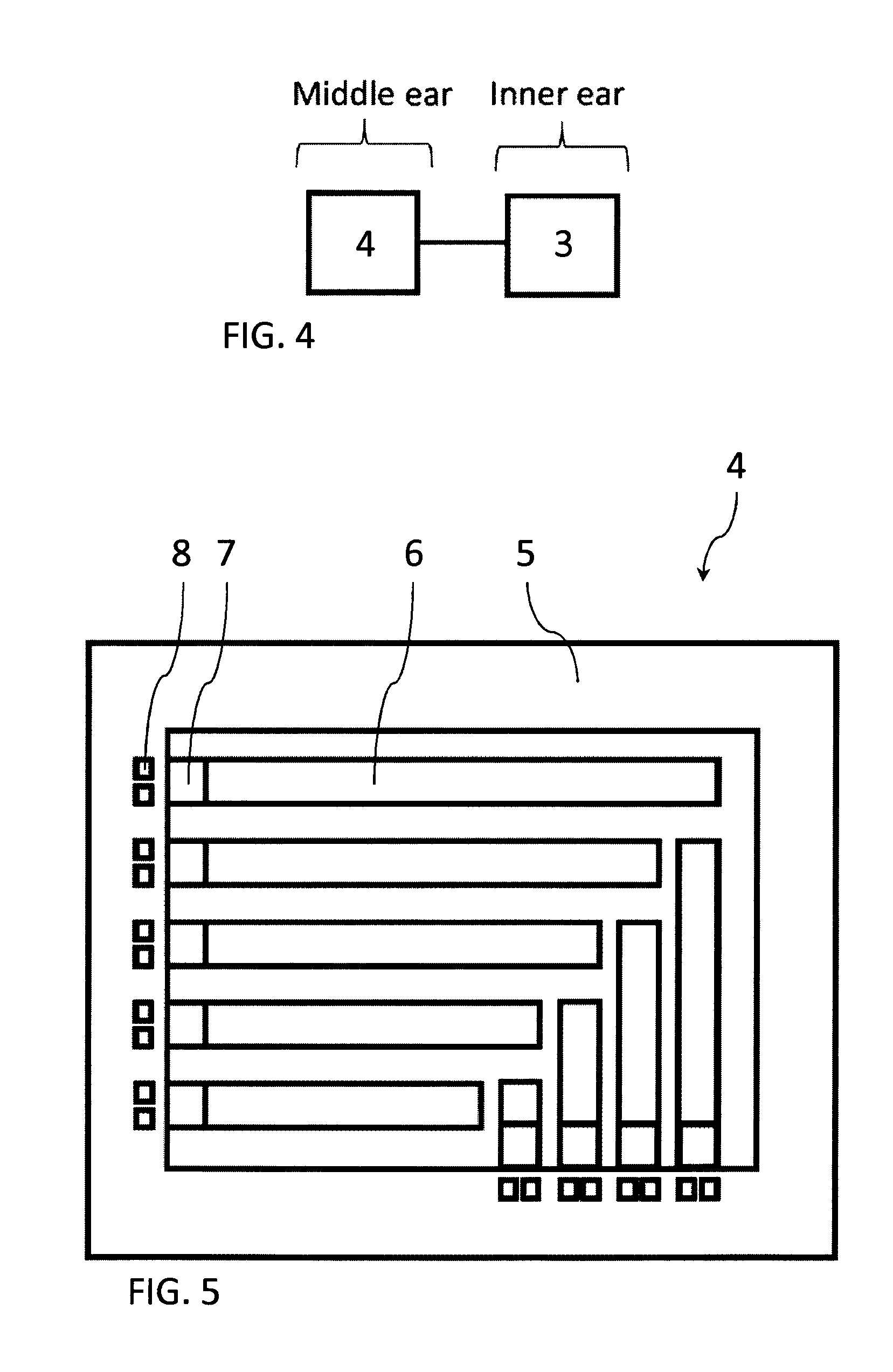

Energy harvesting cochlear implant

ActiveUS20140303688A1Reduce needHigh voltage output potentialElectrotherapyPiezoelectric/electrostriction/magnetostriction machinesElectricityManufacturing technology

The invention is related to a totally implantable cochlear implant having a transducer which is a piezoelectric vibration energy harvester to be mounted on the ossicular chain or the tympanic membrane to detect the frequency of oscillations and generate the required voltage to stimulate the relevant auditory nerves. The invention enables patients' continuous access to sound, since it eliminates the outside components of conventional cochlear implants. The invention also eliminates the problem of battery need, since the transducer generates voltage required to stimulate auditory nerves from the vibrations of ossicular chain. The transducer is fabricated using Microelectromechanical Systems (MEMS) fabrication techniques. The invention incorporates of two main parts, a transducer acting both as a frequency detector and an energy harvester, and electrodes to stimulate the auditory nerve inside the cochlea.

Owner:KULAH HALUK +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com