Hydraulic-digger obstruction-avoiding control system and method

A technology of hydraulic excavator and control method, applied in the operation method of excavator/dredger, earthmoving machine/shovel, construction, etc., can solve the problems of inconvenient observation, causing accidents, losses, etc., to improve self-safety and site safety, avoid accidents, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

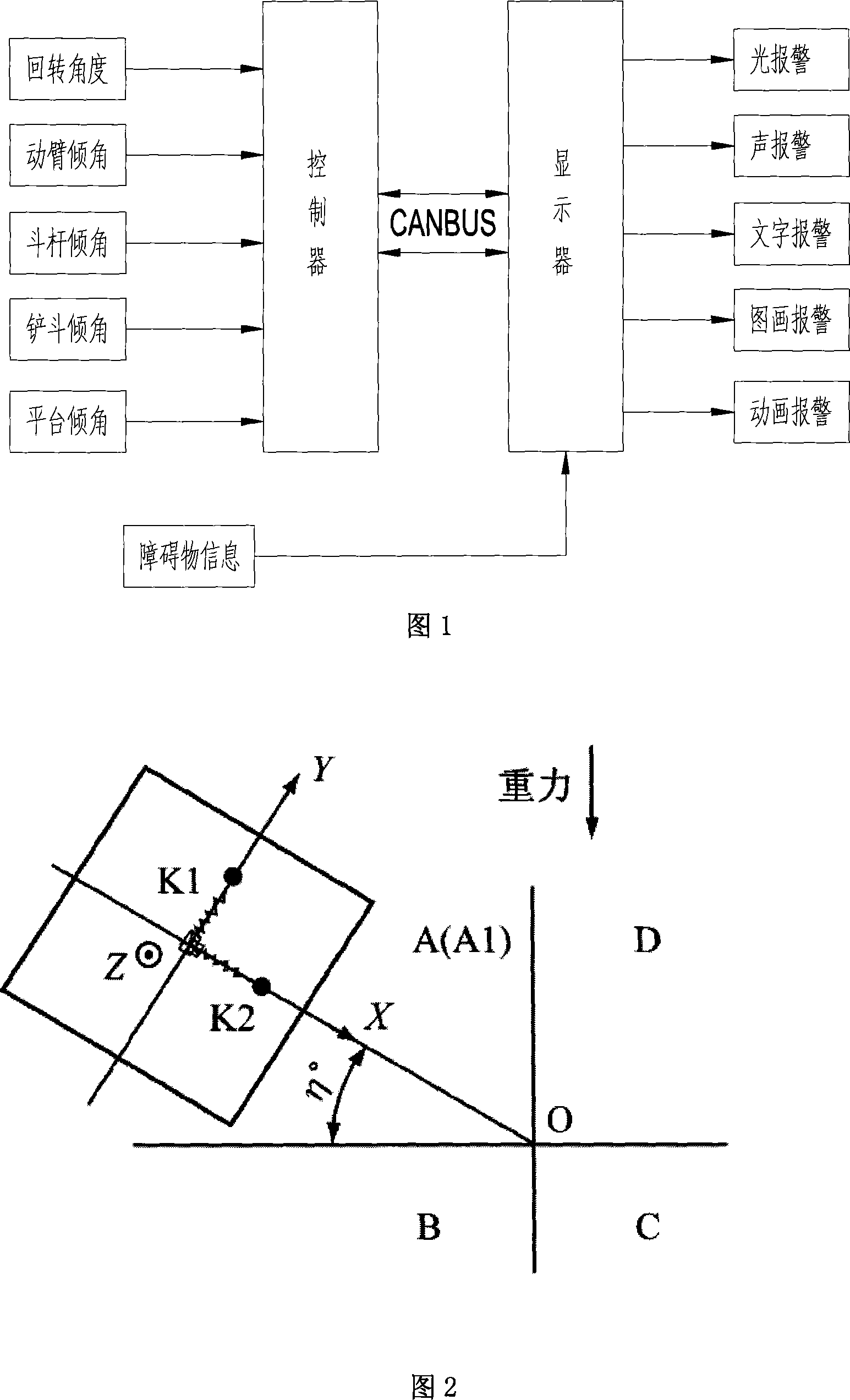

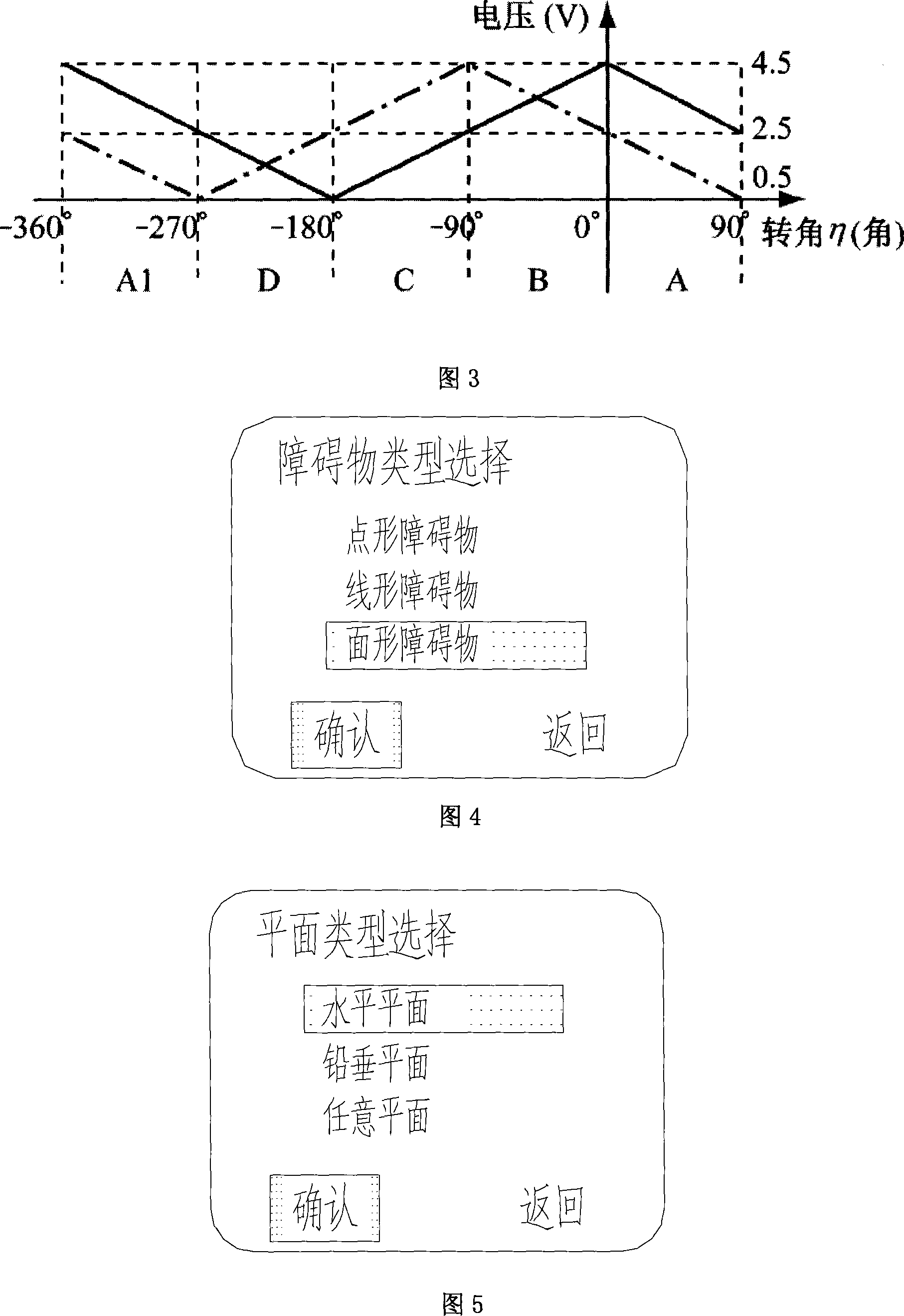

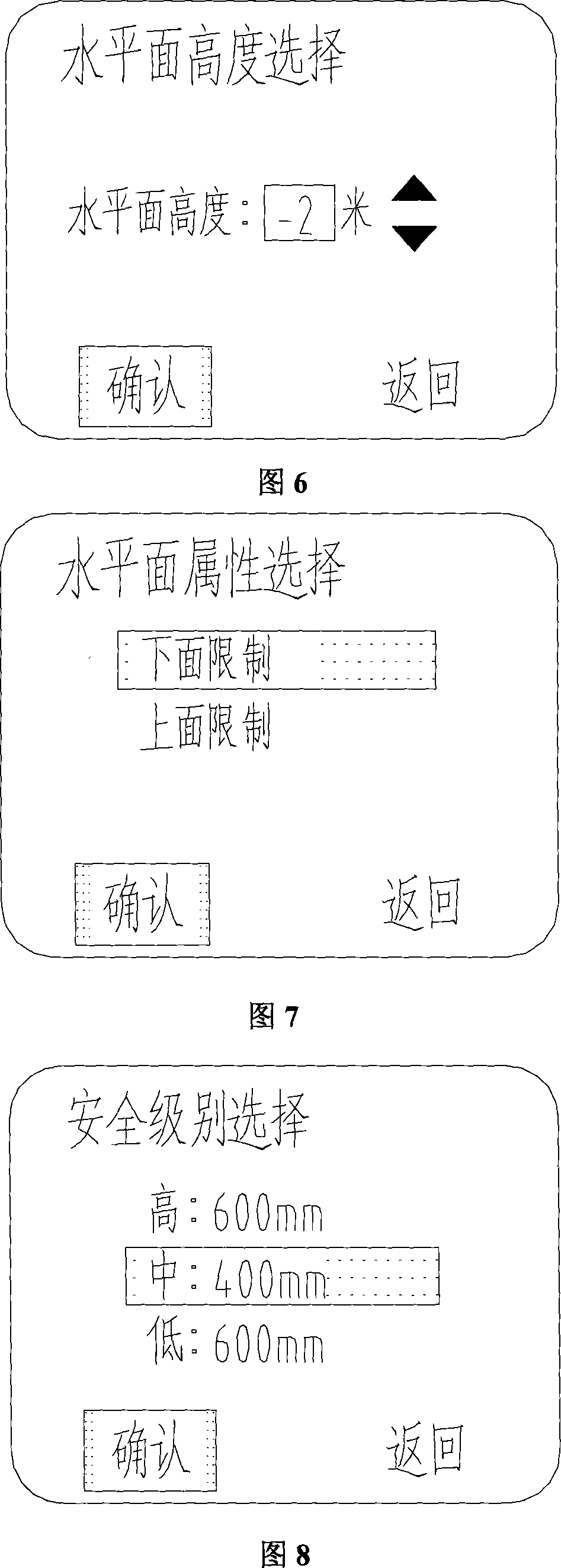

[0033] Embodiment 1: Referring to accompanying drawings 1 to 8, an obstacle avoidance control system and method for a hydraulic excavator, the method includes the following steps:

[0034] (1) Setting the restricted area for excavation, the restricted area for excavating is obtained after increasing the preset safety distance by classifying obstacles as one or a combination of point-shaped obstacles, linear obstacles, and surface-shaped obstacles;

[0035] (2) Obtain the status of the boom, stick, bucket and working platform of the excavator through the sensor, and obtain the position parameters of the working device of the excavator;

[0036] (3) Calculate the distance between the working device of the excavator and the excavation restricted area. When the distance is less than the critical value, an alarm signal is sent. The critical value is set to 2. When the distance is less than the corresponding critical value, an alarm signal of the corresponding level is sent. Alarm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com