Movable power transmission network transformer maintenance station

A technology for network transformers and maintenance stations, which is applied to motor vehicles, electrical components, transport objects, etc., can solve the problems of inconvenient daily maintenance and fault maintenance of transformers, and achieve the effect of multi-functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in conjunction with the following examples.

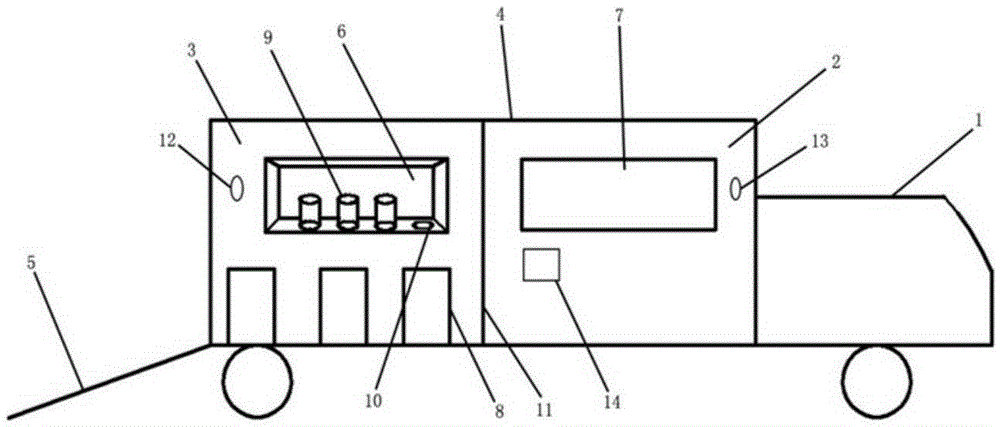

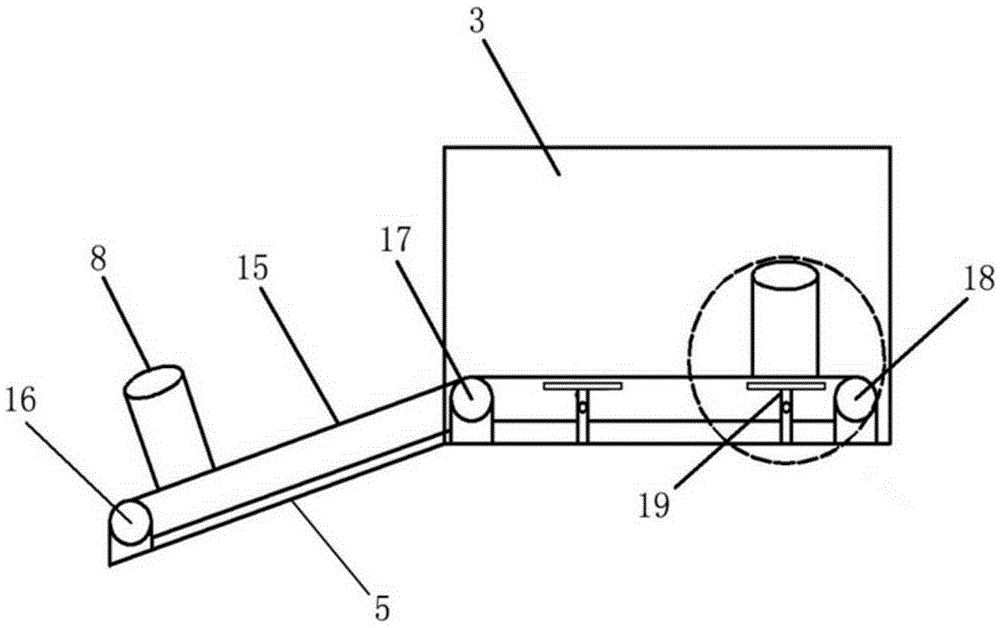

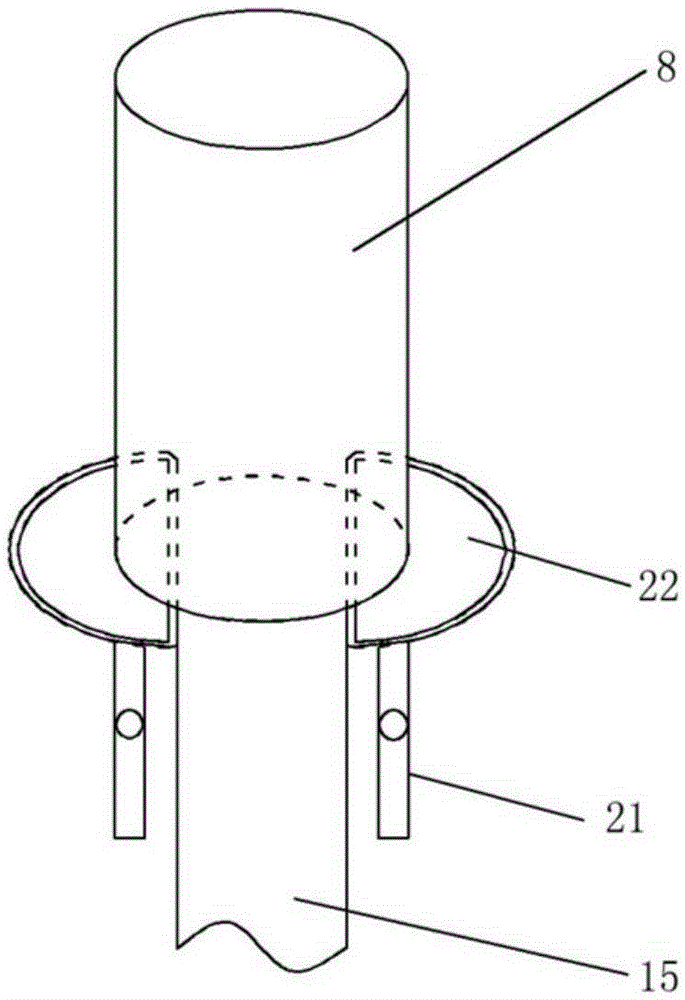

[0030] Such as figure 1 The movable transmission network transformer repair station shown in the figure includes traction unit 1, maintenance tool compartment 2, and oil tank compartment 3, and the three are connected in sequence, and the maintenance tool compartment 2 and oil tank compartment 3 are separated by a separation plate 11 , due to the inflammable and explosive characteristics of the transformer oil, the gap between the isolation plate 11 and the inner wall of the compartment is tightly sealed with a fireproof material. The top cover 4 of the overhaul tool compartment 2 can be opened by remote control, and the top cover 4 is provided with a solar heat collector, and the solar heat collector is used to supply power to the storage battery.

[0031] The side of the overhaul tool compartment 2 is provided with a common tool cabinet 7 sunken to the interior of the compartment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com