Robot flexible curved surface milling processing production device

A technology of milling processing and production equipment, which is applied in the direction of metal processing equipment, manipulators, milling machine equipment, etc., can solve the problems of increasing production costs, achieve the effects of improving production efficiency, optimizing time beats, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

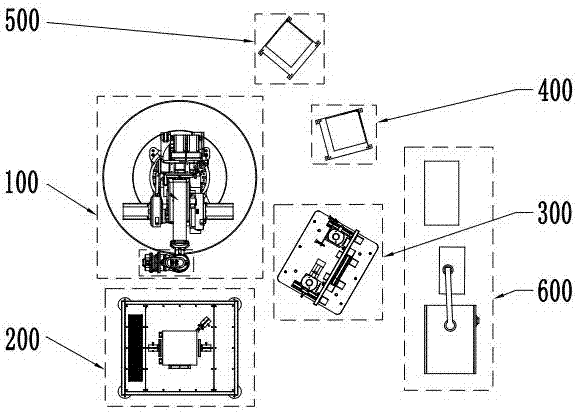

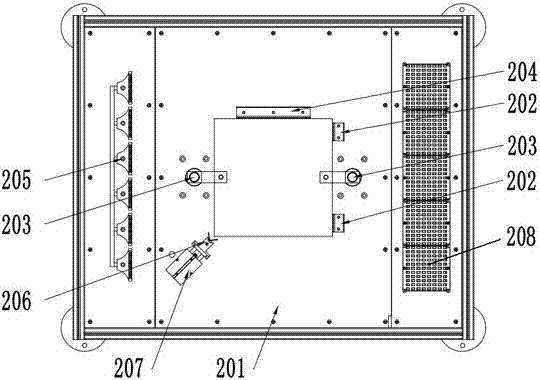

[0027] Such as Figure 1 to Figure 6 As shown, the present invention includes: industrial robot assembly 100, workbench 200, tool support 300, upper feed bin 400, lower feed bin 500 and control system 600; workbench 200, tool support 300, upper feed bin 400 and lower feed bin 500 are dispersedly arranged around the robot assembly 100, and the control system 600 is located on the right side of the tool holder 300;

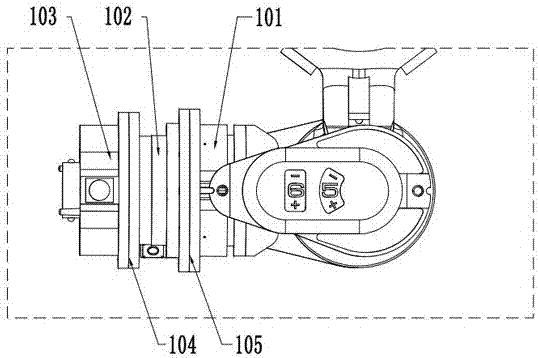

[0028] Wherein, the industrial robot assembly 100 includes an industrial robot 101, a force sensor 102, a robot side quick changer 103, one end of the force sensor is connected to the industrial robot, and the other end is connected to the robot side quick changer; Realize the connection between the force sensor and the robot side quick change and the industrial robot, specifically, the robot side quick change 103 and the connection flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com