Front type automatic material supplying manipulator system of numerical control lathe

A technology of automatic material feeding and CNC lathe, which is applied in the direction of program-controlled manipulators, manipulators, and automatic in/out of workpieces. High efficiency and reduced footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

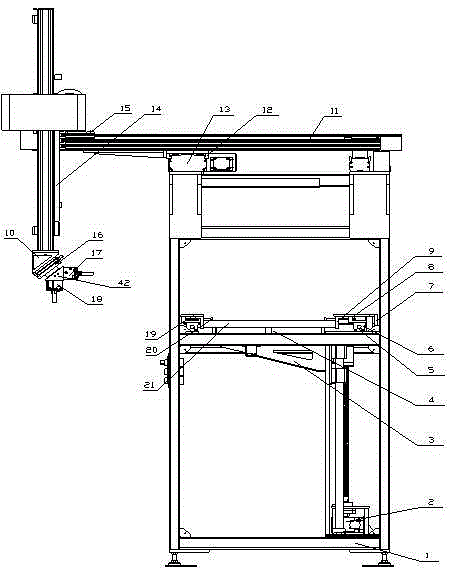

[0015] Such as Figure 1 ~ Figure 3 Shown is a front-mounted CNC lathe automatic feeding manipulator system, including a frame 1, an automatic feeding unit A inside the frame 1, and an X-axis mechanical arm unit B on the top of the frame 1 , a Y-axis robot unit C is arranged on the X-axis robot unit B, a Z-axis robot unit D is arranged on the Y-axis robot unit C, and a Z-axis robot unit D is arranged on the Z-axis robot unit An air gripper unit E is provided on D, and the X-axis mechanical arm unit B includes an X-axis arm assembly 13 installed on the top of the frame 1, and an X-axis slider connection is provided on the X-axis arm assembly 13. Plate 12, an X-axis servo motor assembly is provided on the X-axis slider connecting plate 12; the Y-axis mechanical arm unit C includes a Y-axis arm assembly 11 fixed to the X-axis slider connecting plate 12, The Y-axis arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com