Mechanical arm

一种机械手臂、臂部的技术,应用在机械人领域,能够解决不利使用机械手臂、成本高、机械手臂制作成本高等问题,达到减少机械手臂需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical contents and features of the present invention will be described in detail below by referring to the enumerated embodiments in conjunction with the accompanying drawings.

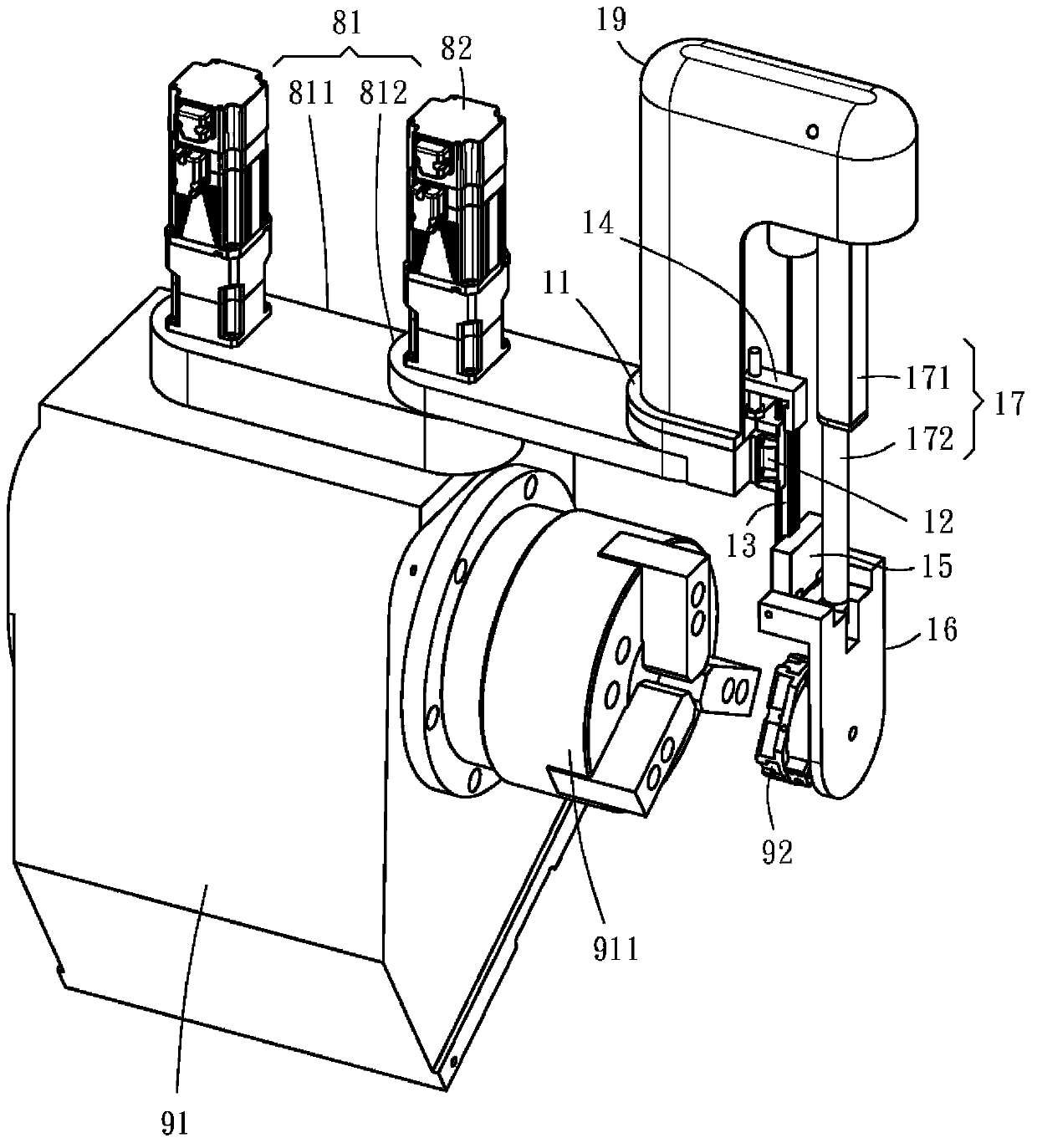

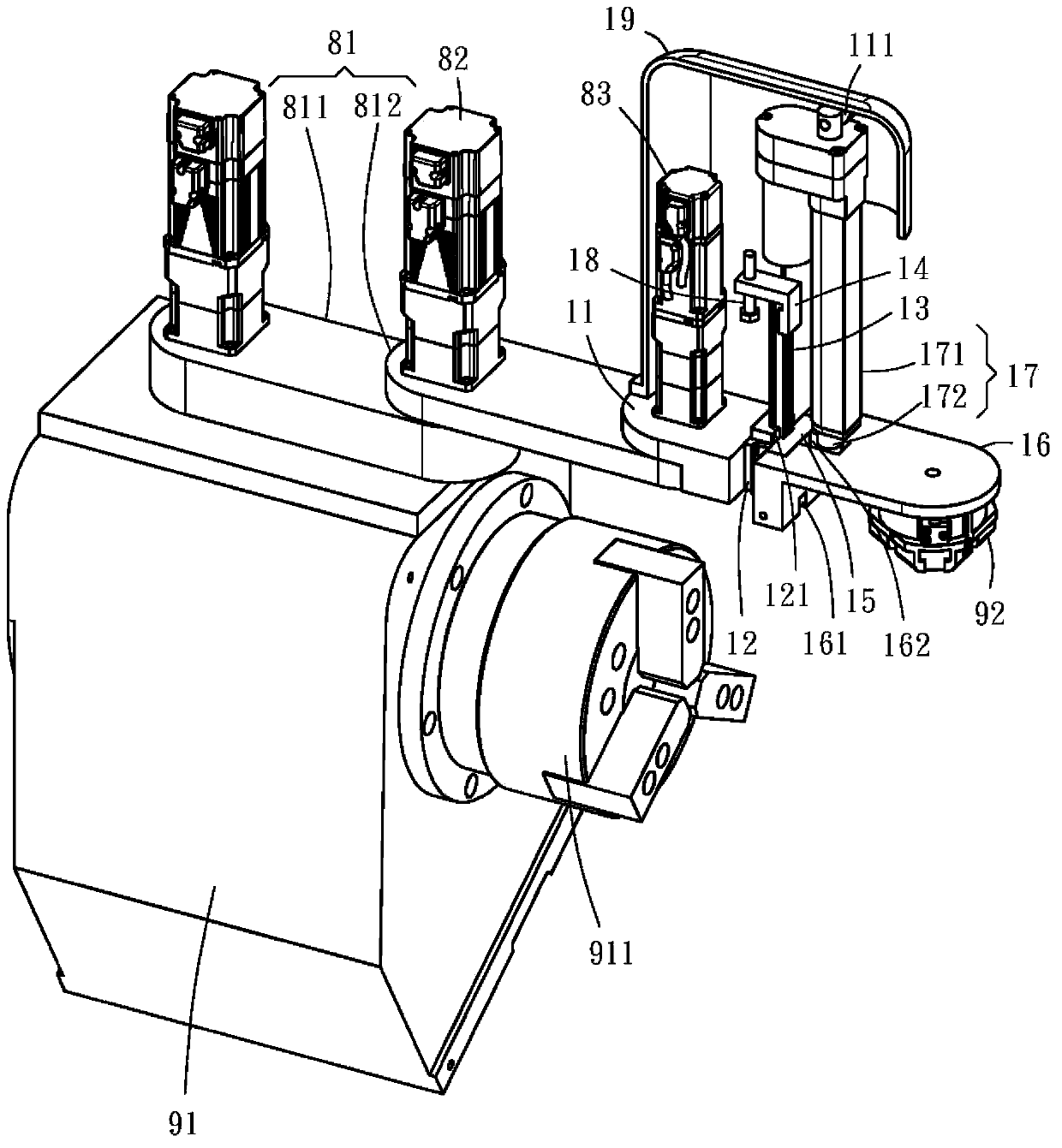

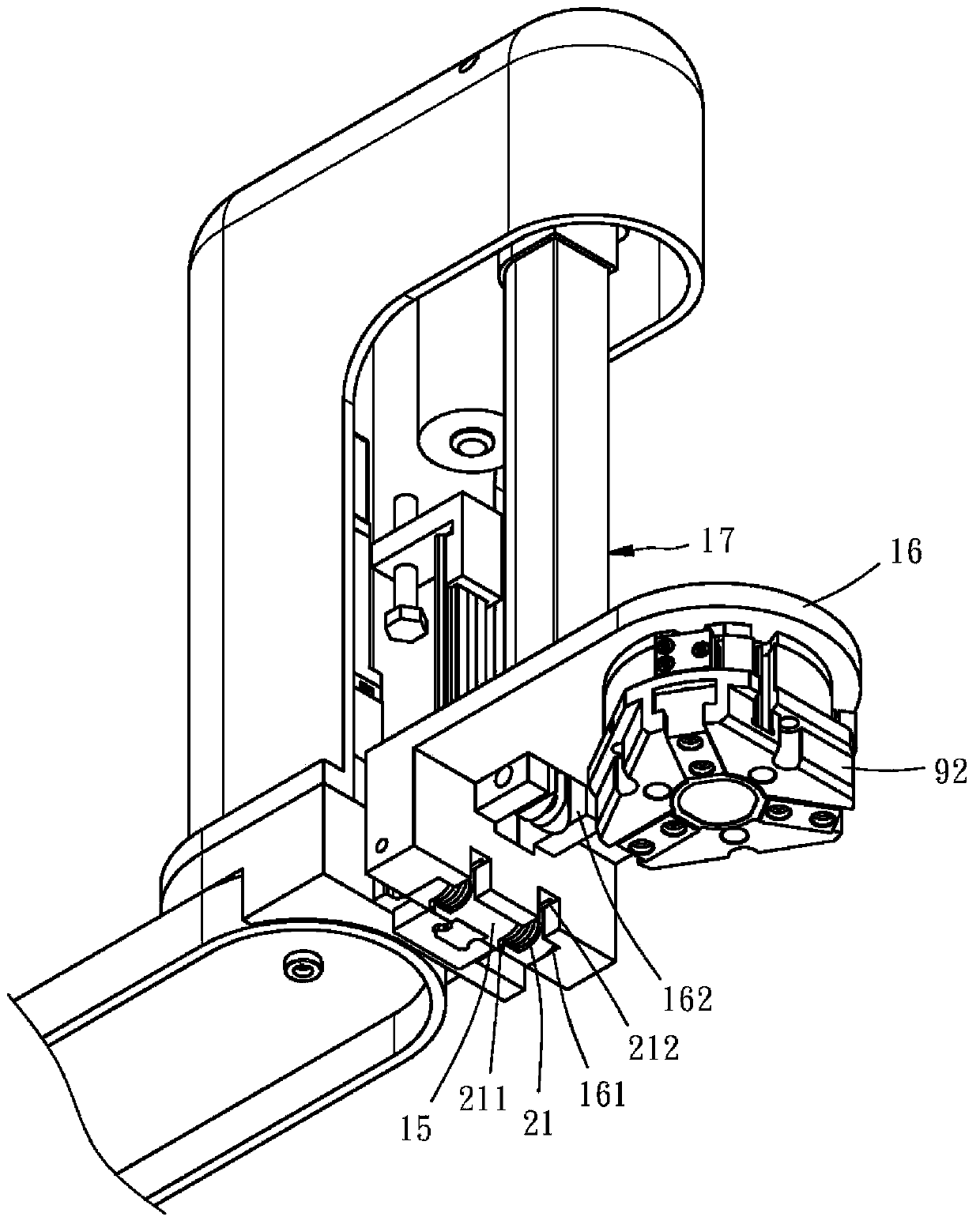

[0017] Please see first Figure 1 ~ Figure 3 , The mechanical arm provided by an embodiment of the present invention includes an arm 11 , a fixing part 12 , a sliding part 13 , a stopper 14 , a connecting part 15 , a wrist 16 and a driving device 17 .

[0018] Explain first here, in order to make the operation of the present invention appear more clearly, take the present invention is arranged on a moving arm 81 as an example, and this moving arm 81 has a first segment 811 and a second segment that are pivotally connected to each other 812 , wherein the first section 811 is pivotally connected to a processing machine 91 and can swing relative to the processing machine 91 . It should also be noted that the present invention is not limited to be installed on the moving arm 81 , and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com