Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

849results about "Tool changing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

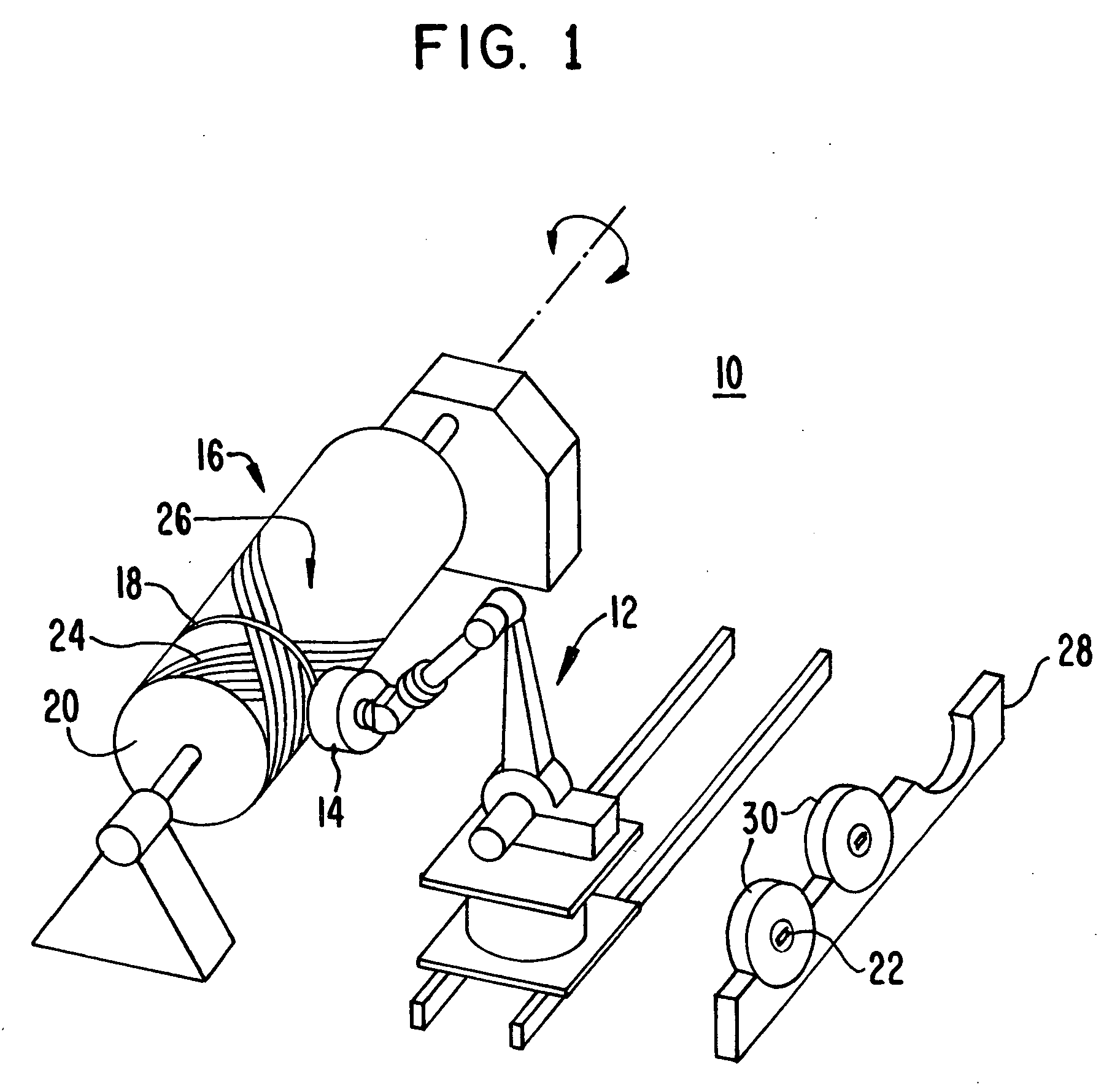

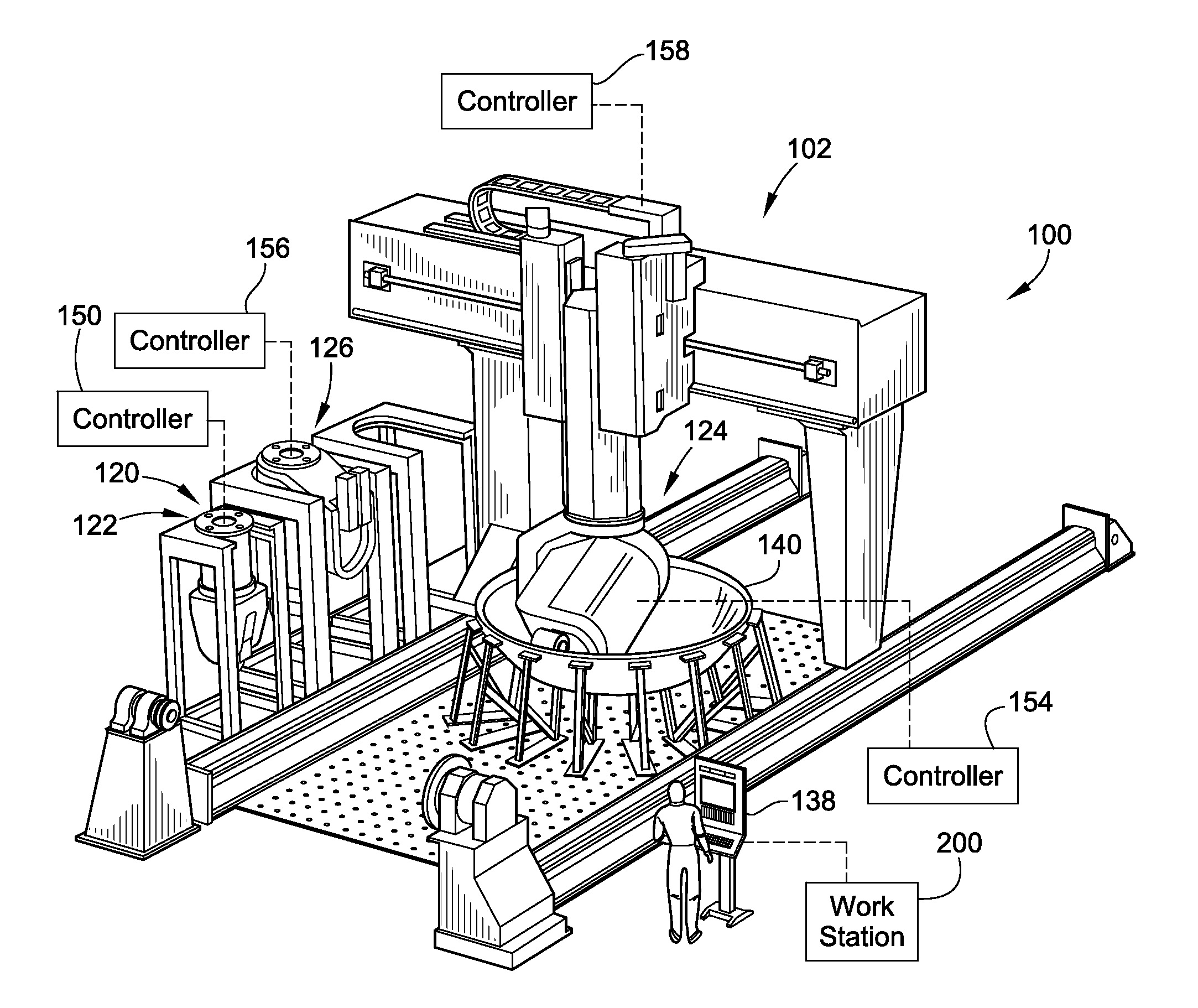

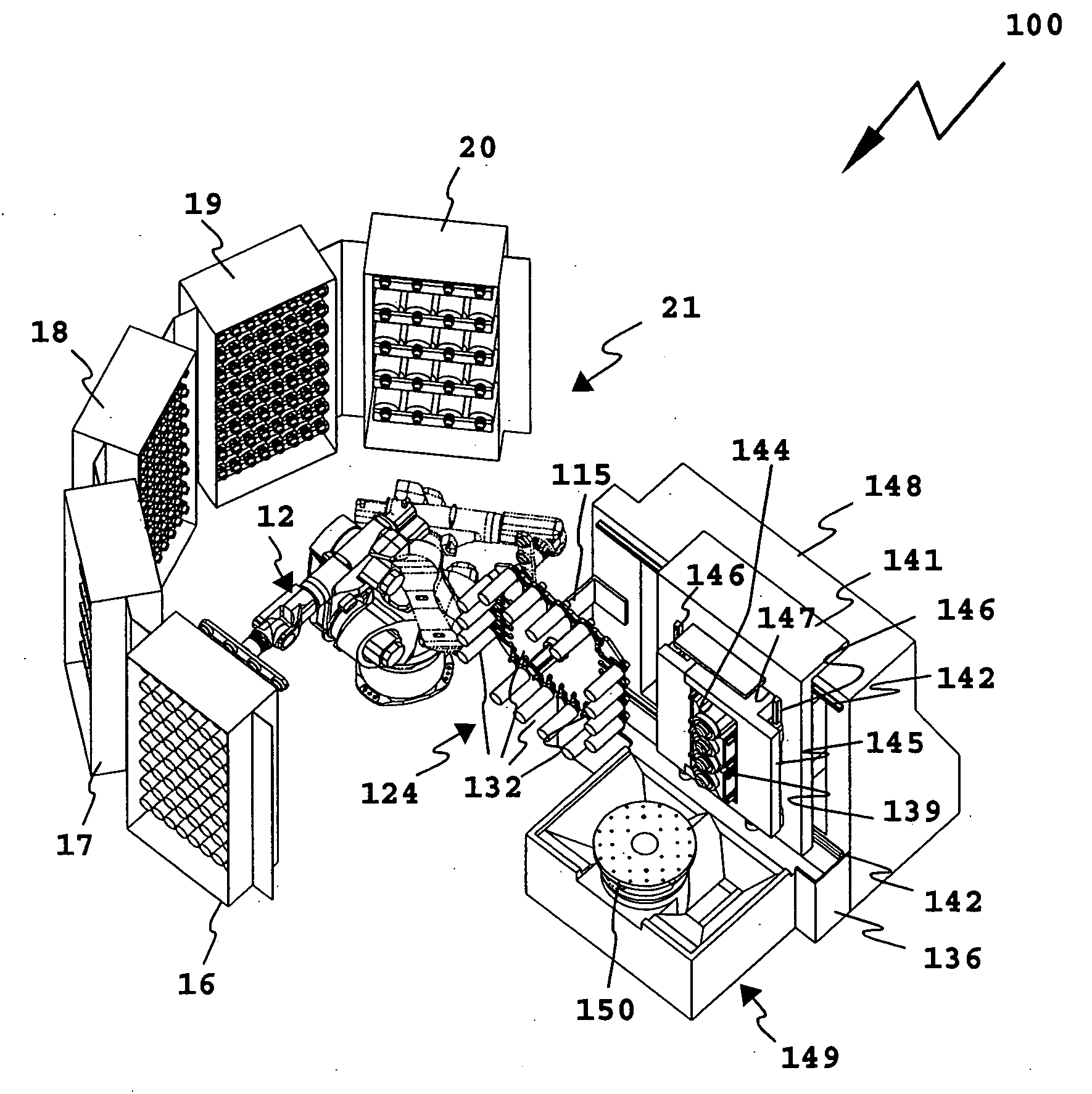

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

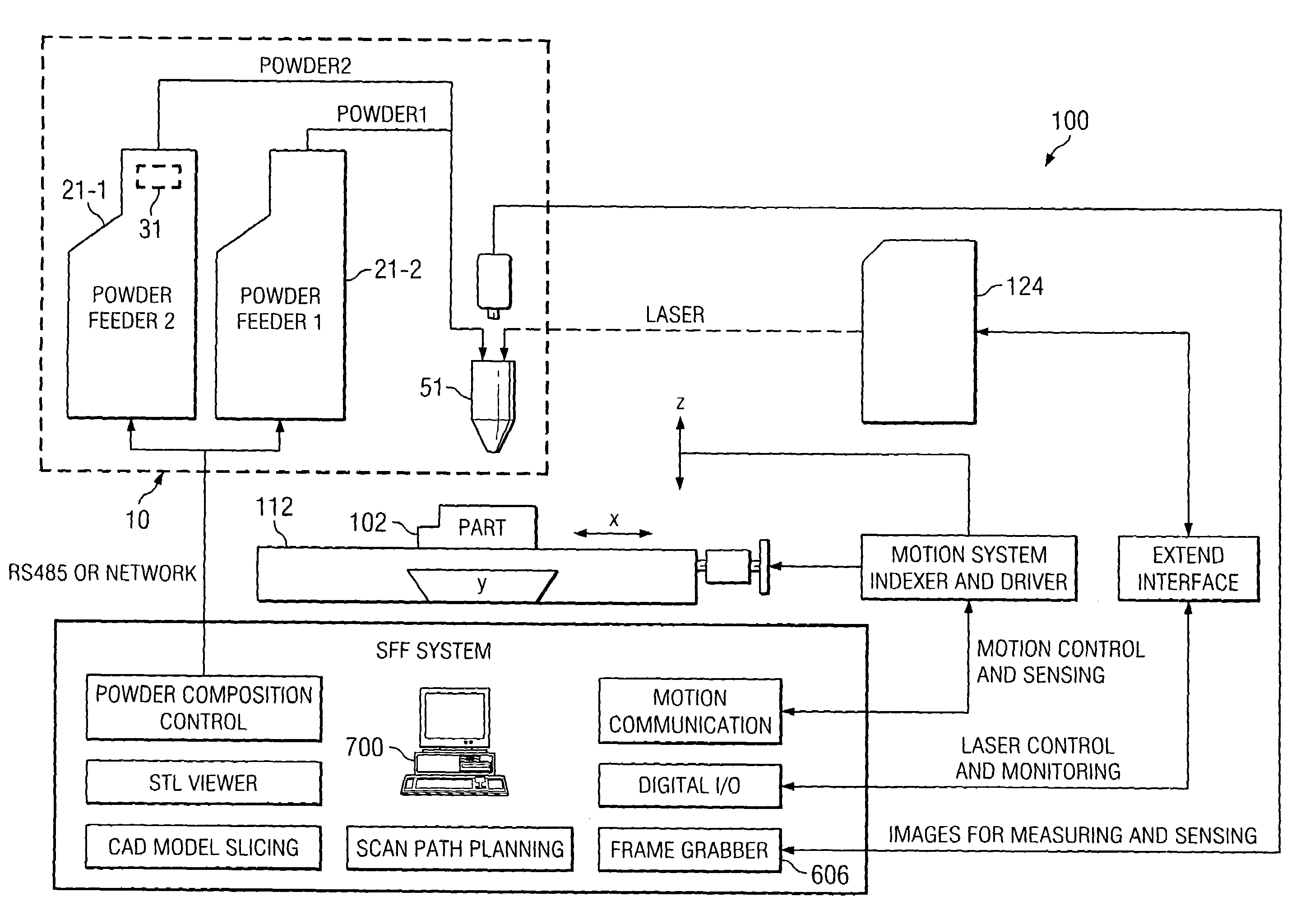

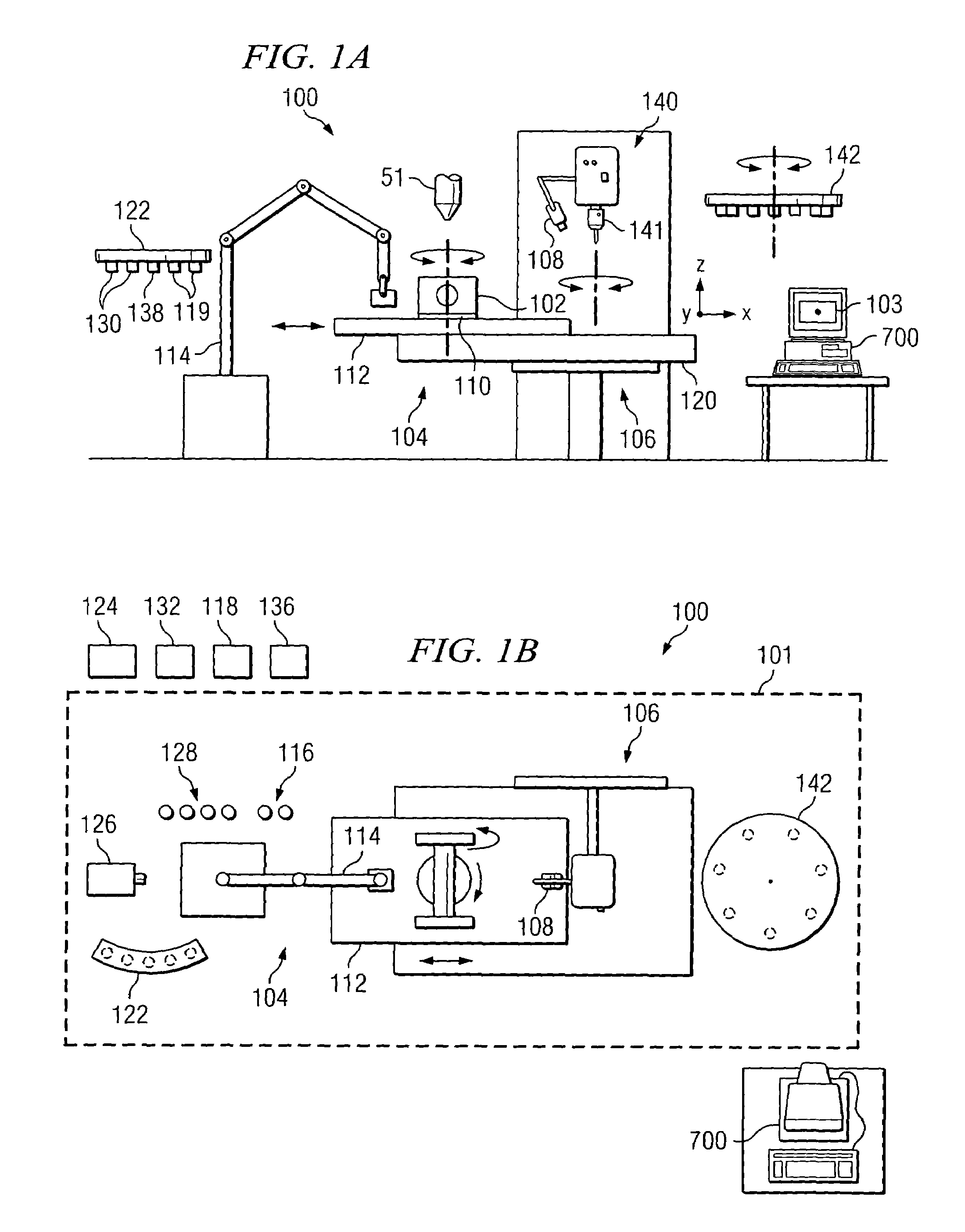

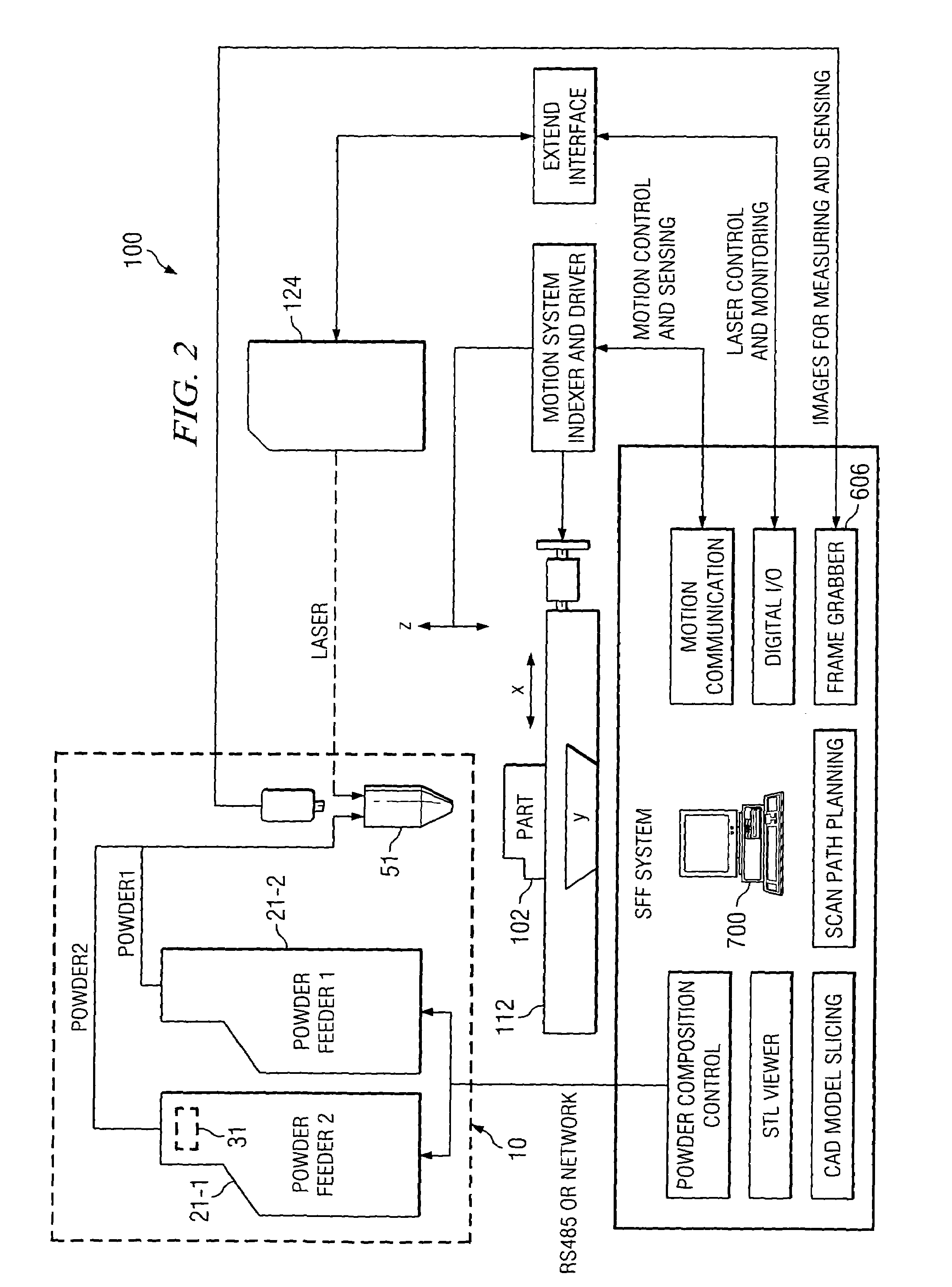

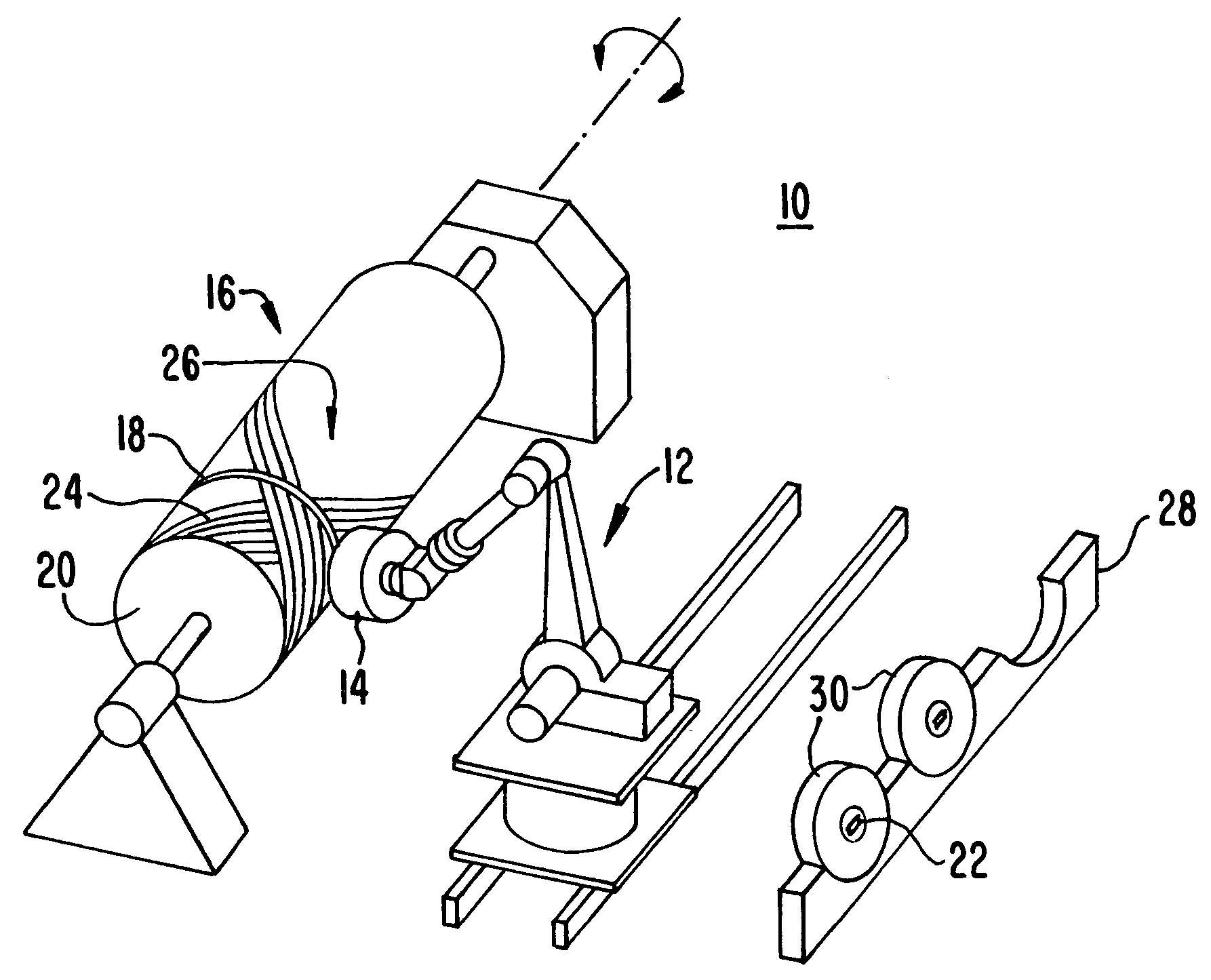

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

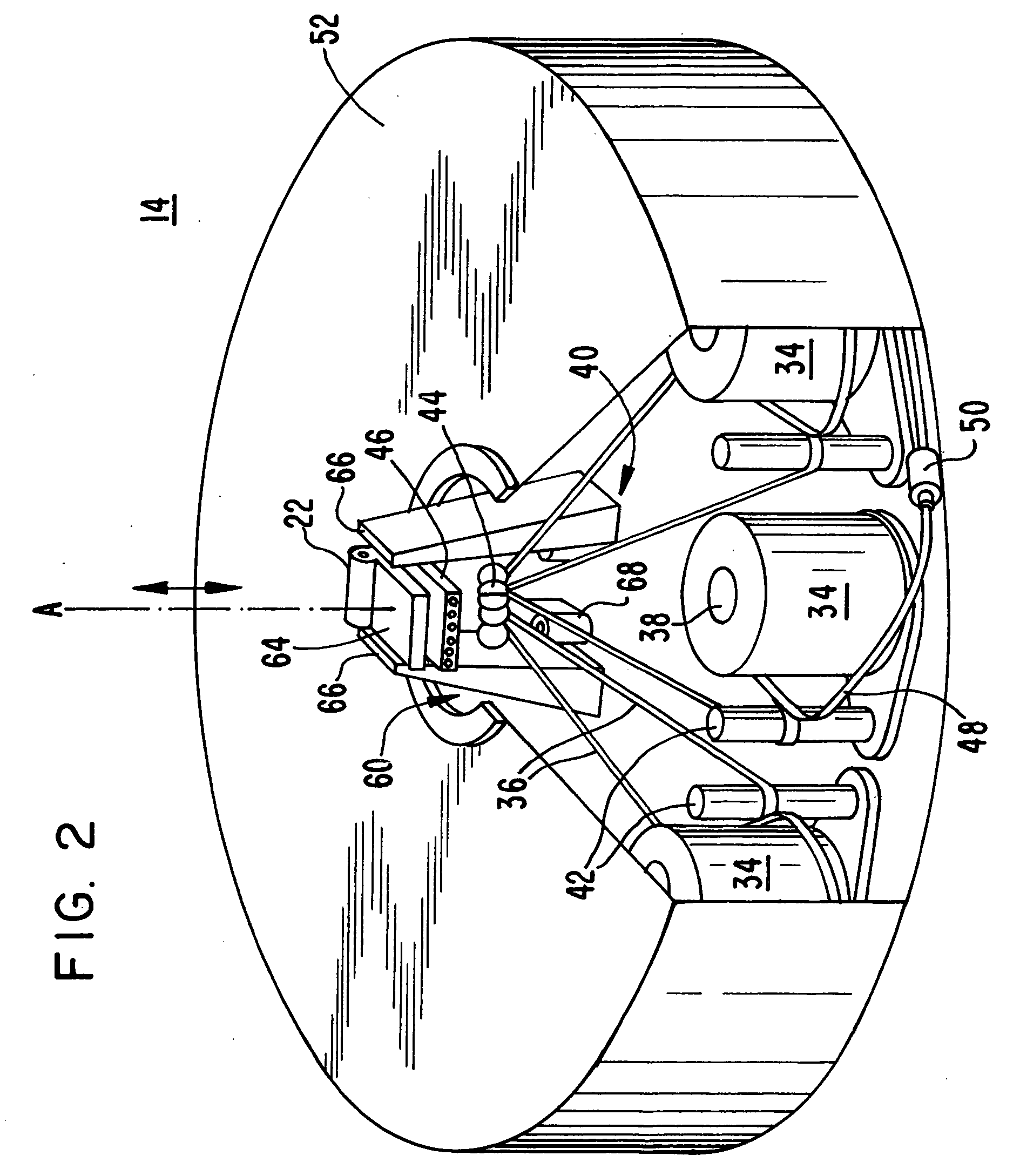

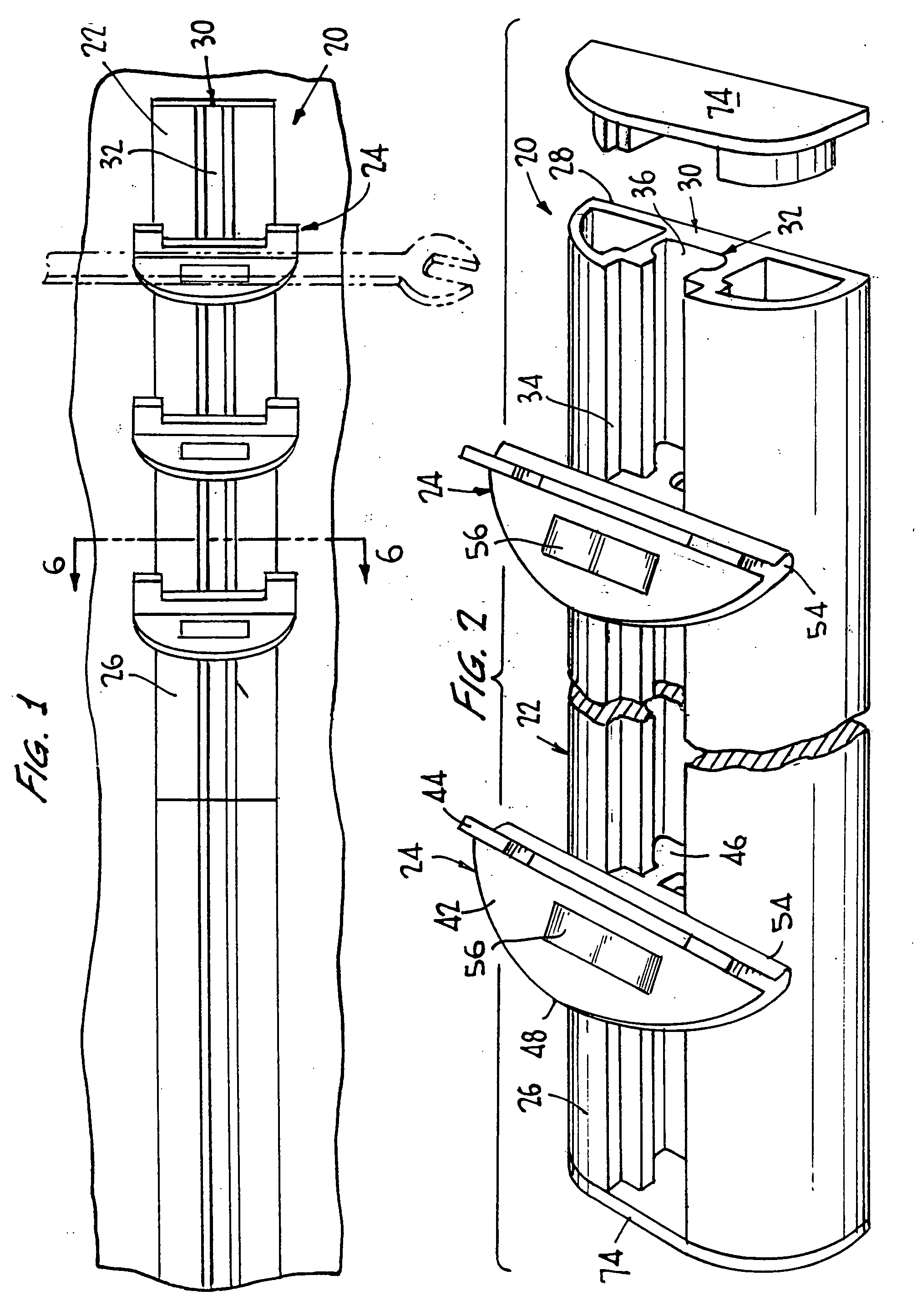

Modular head lamination device and method

A composite item is fabricated with a device. The device includes and end effector and a positioning device. The end effector places a tow. The end effector includes a spindle, compaction device, and a path. The spindle detachably secures a spool of tow and the path is disposed from the spool to the compaction device. The positioning device positions the end effector. The end effector is detachably secured to the positioning device.

Owner:THE BOEING CO

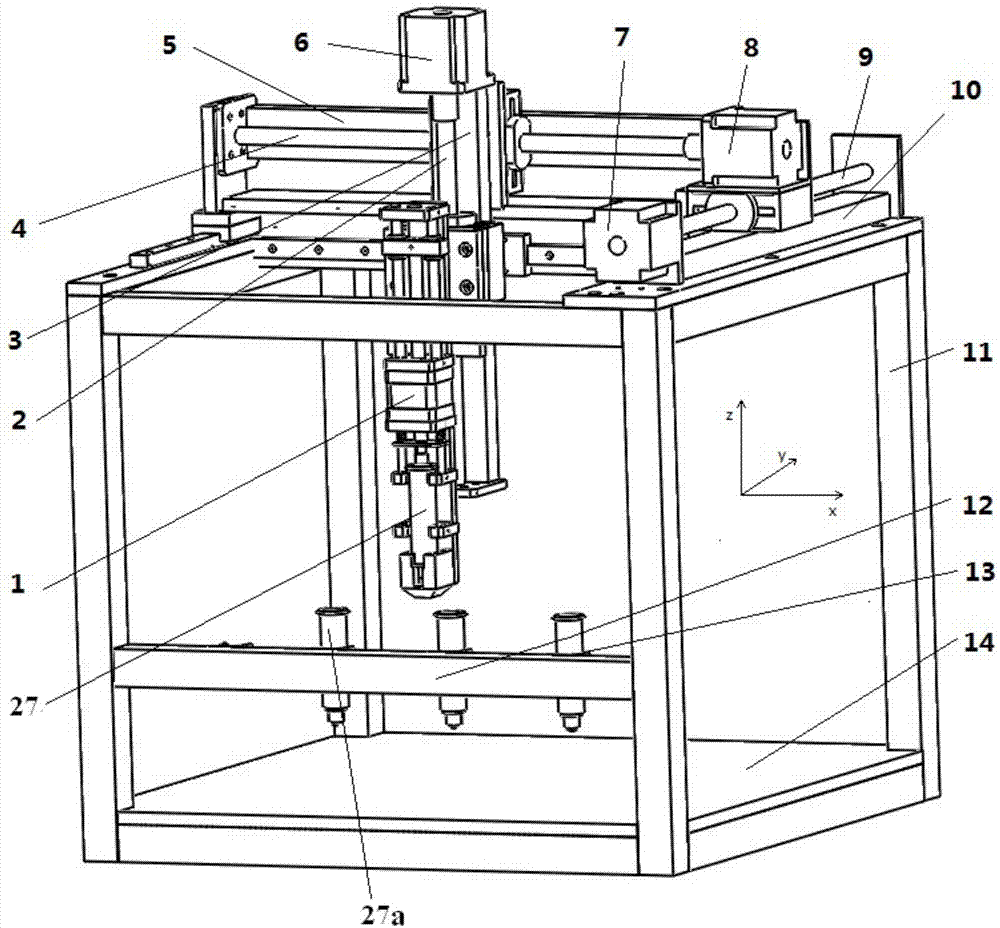

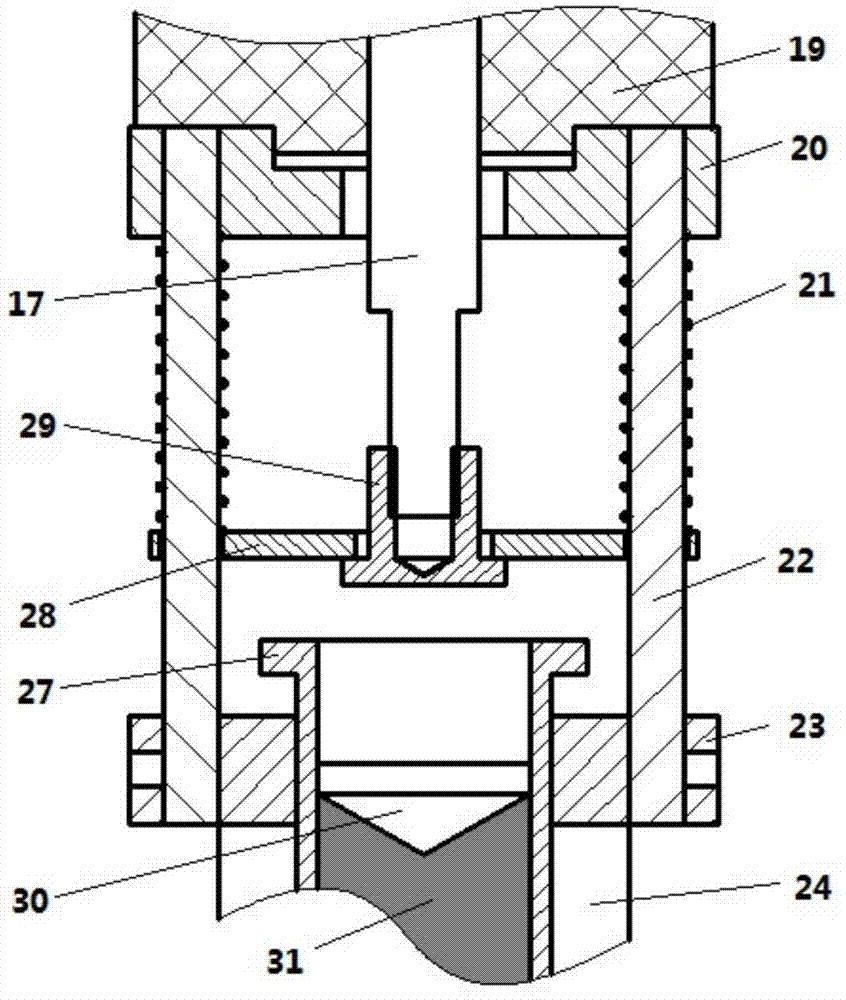

Three-dimensional printer with replaceable nozzle

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

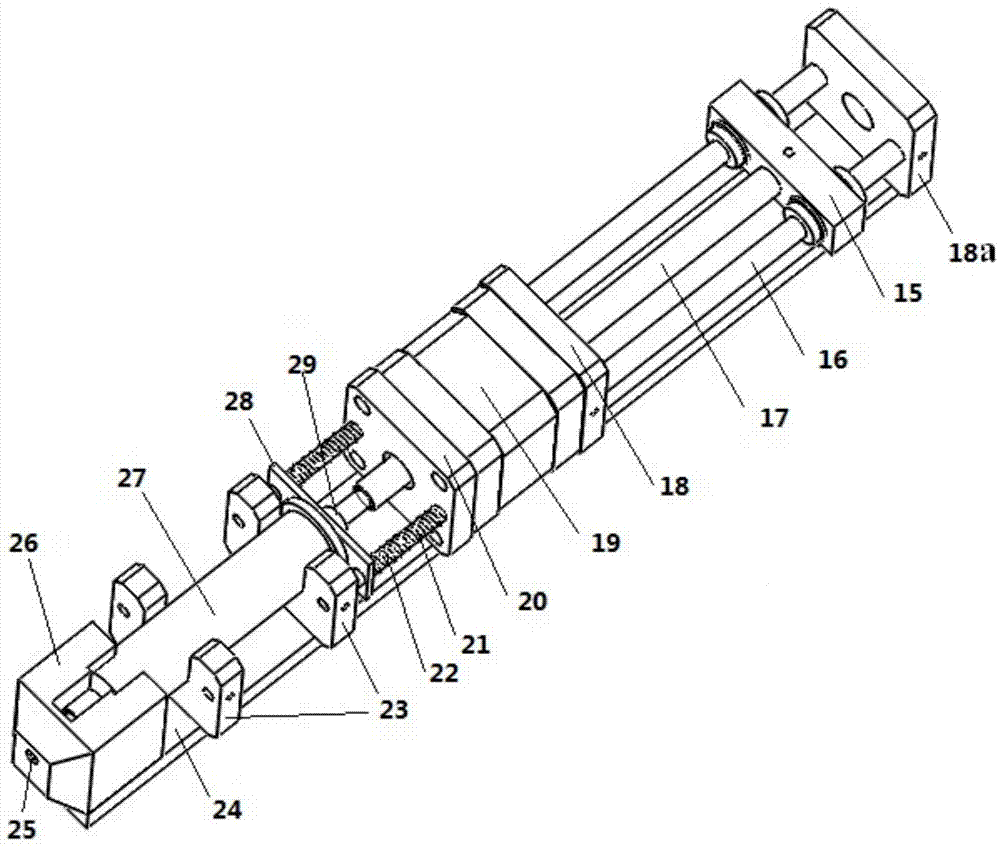

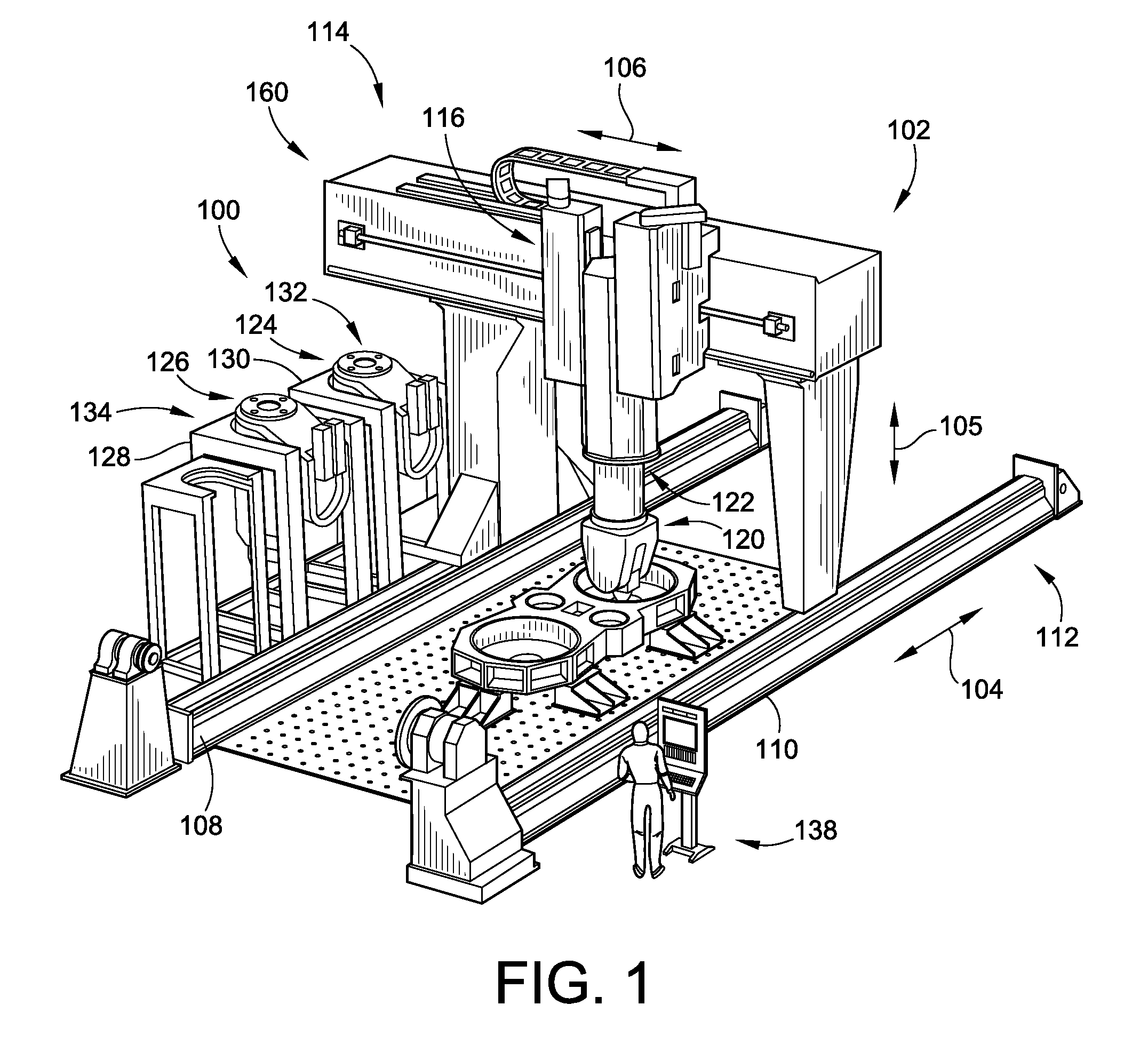

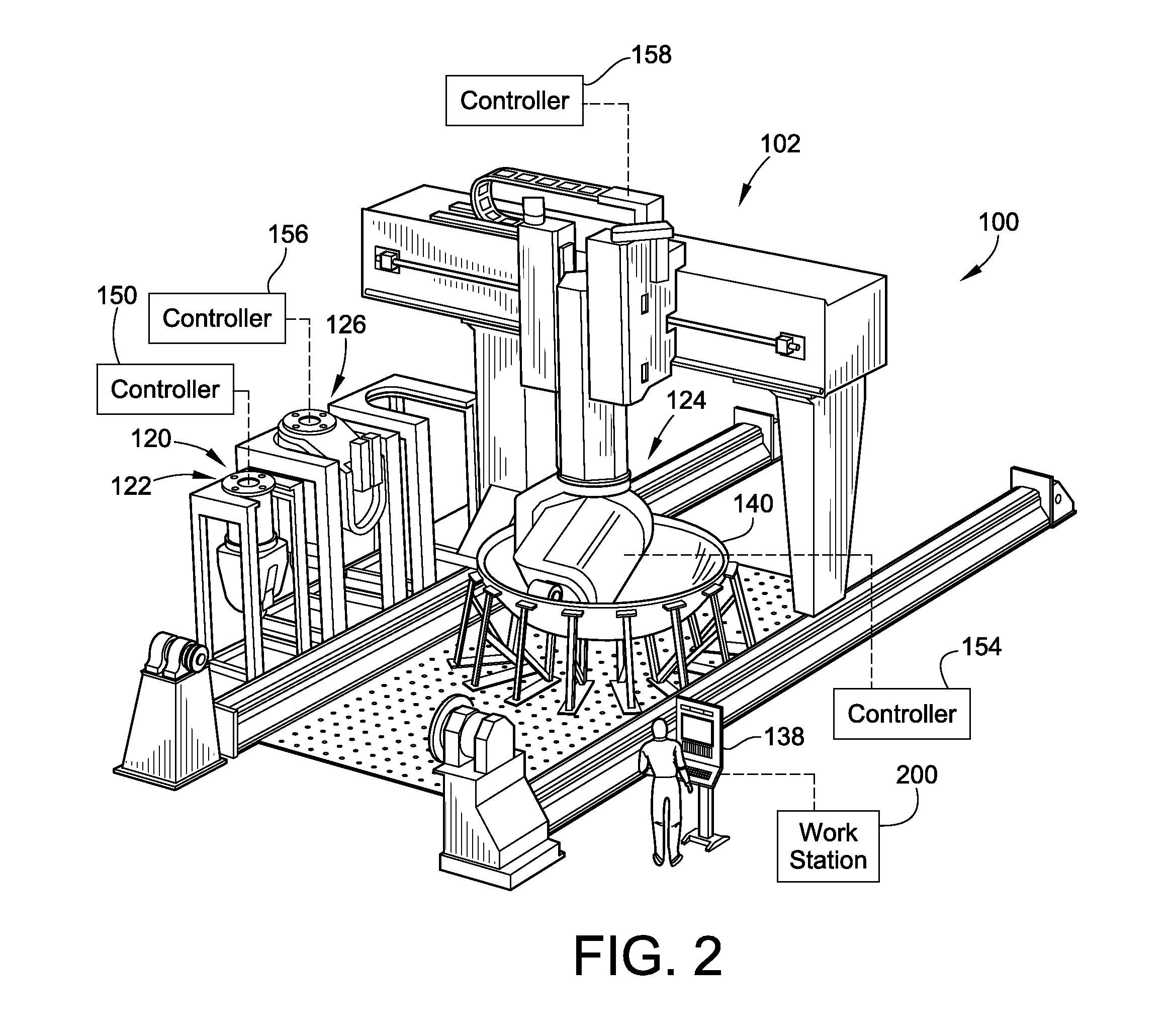

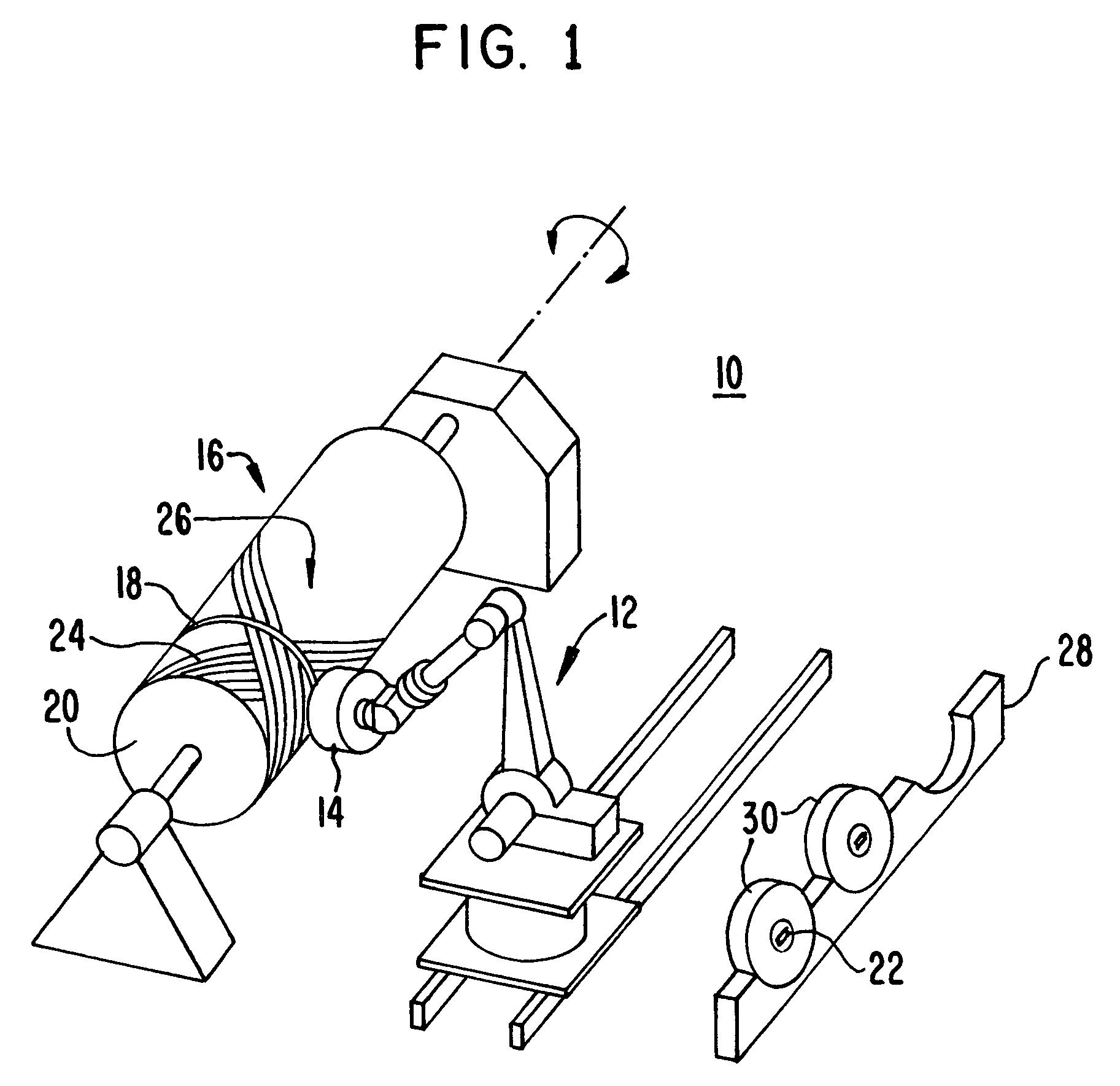

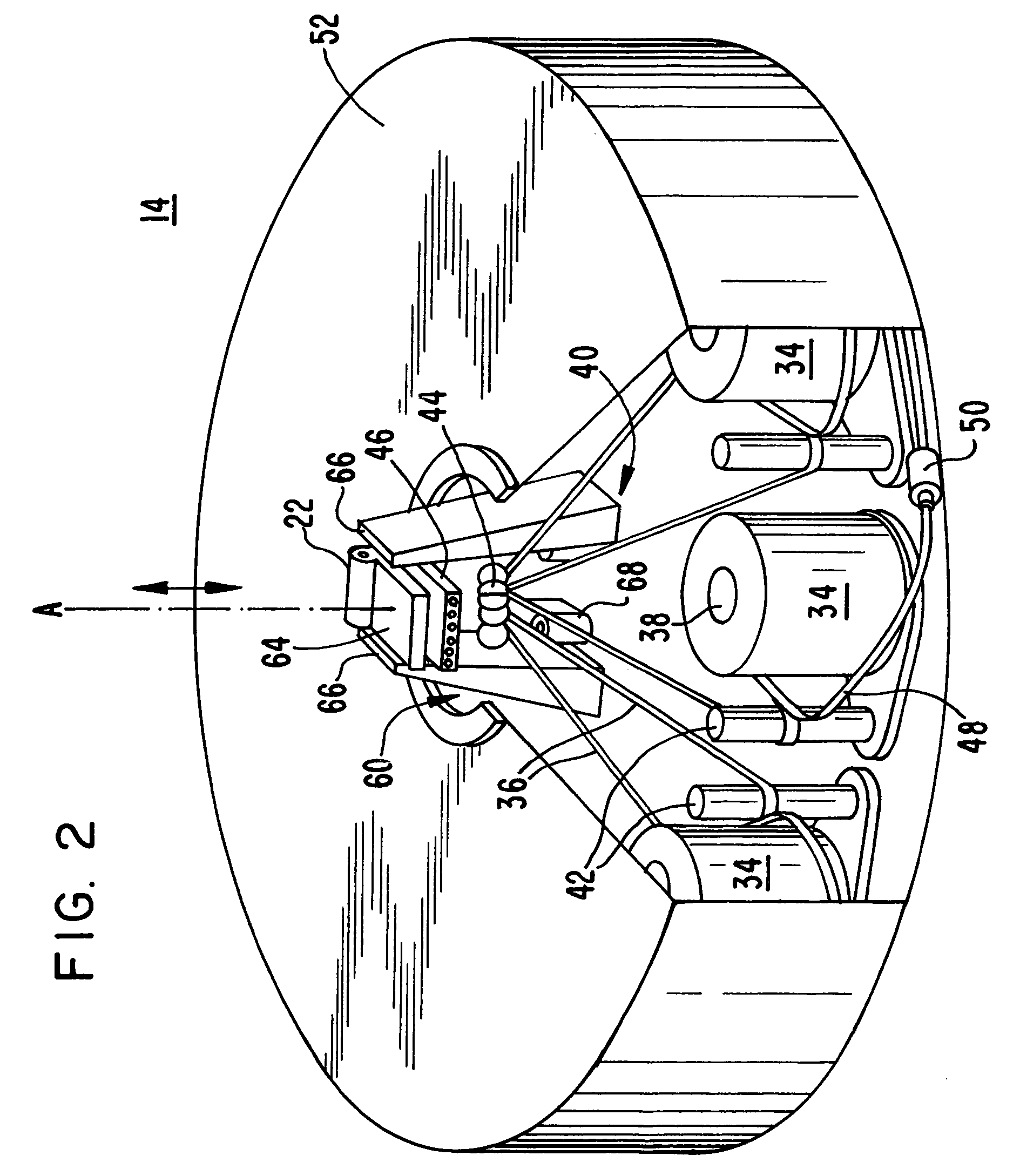

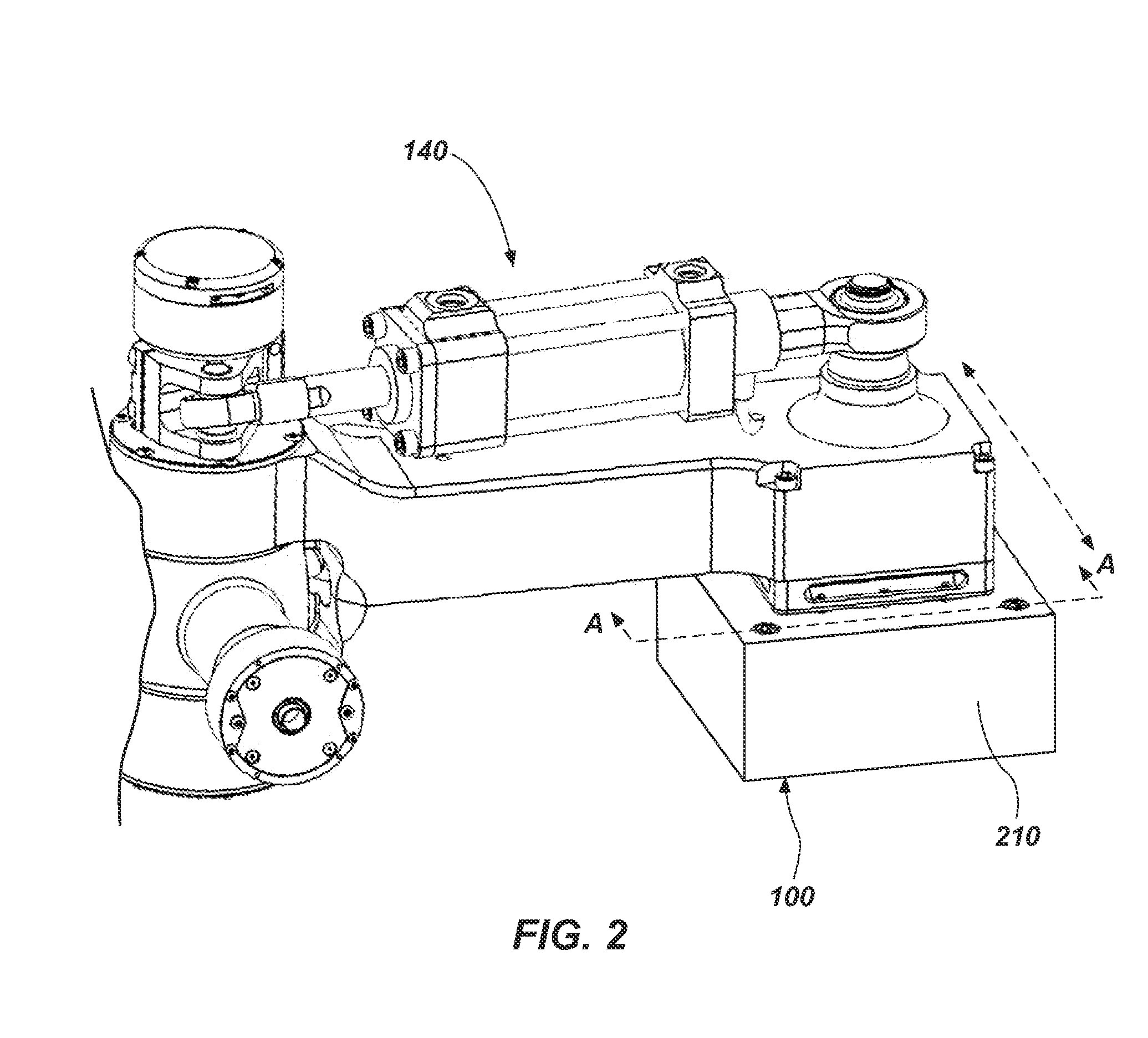

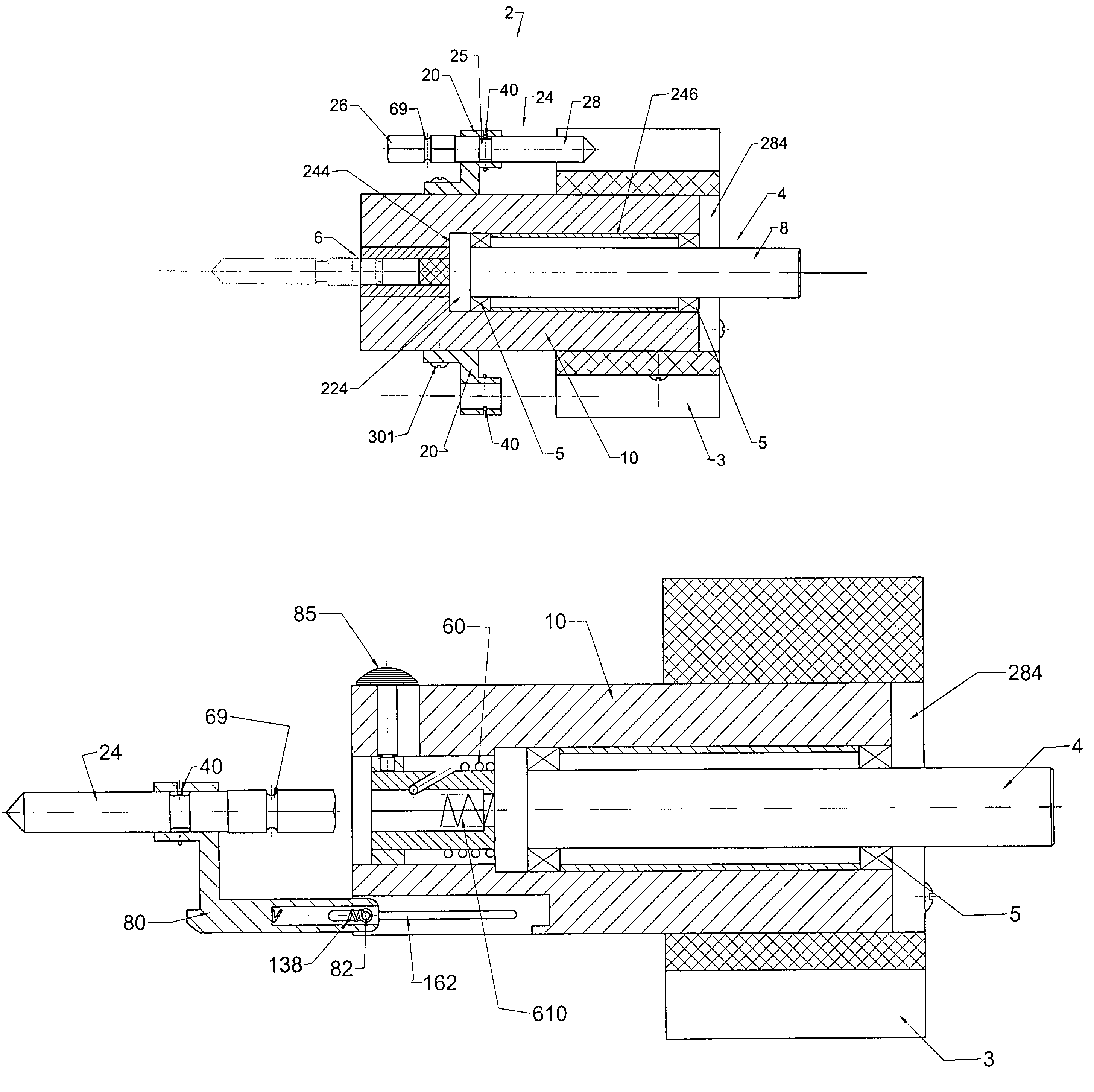

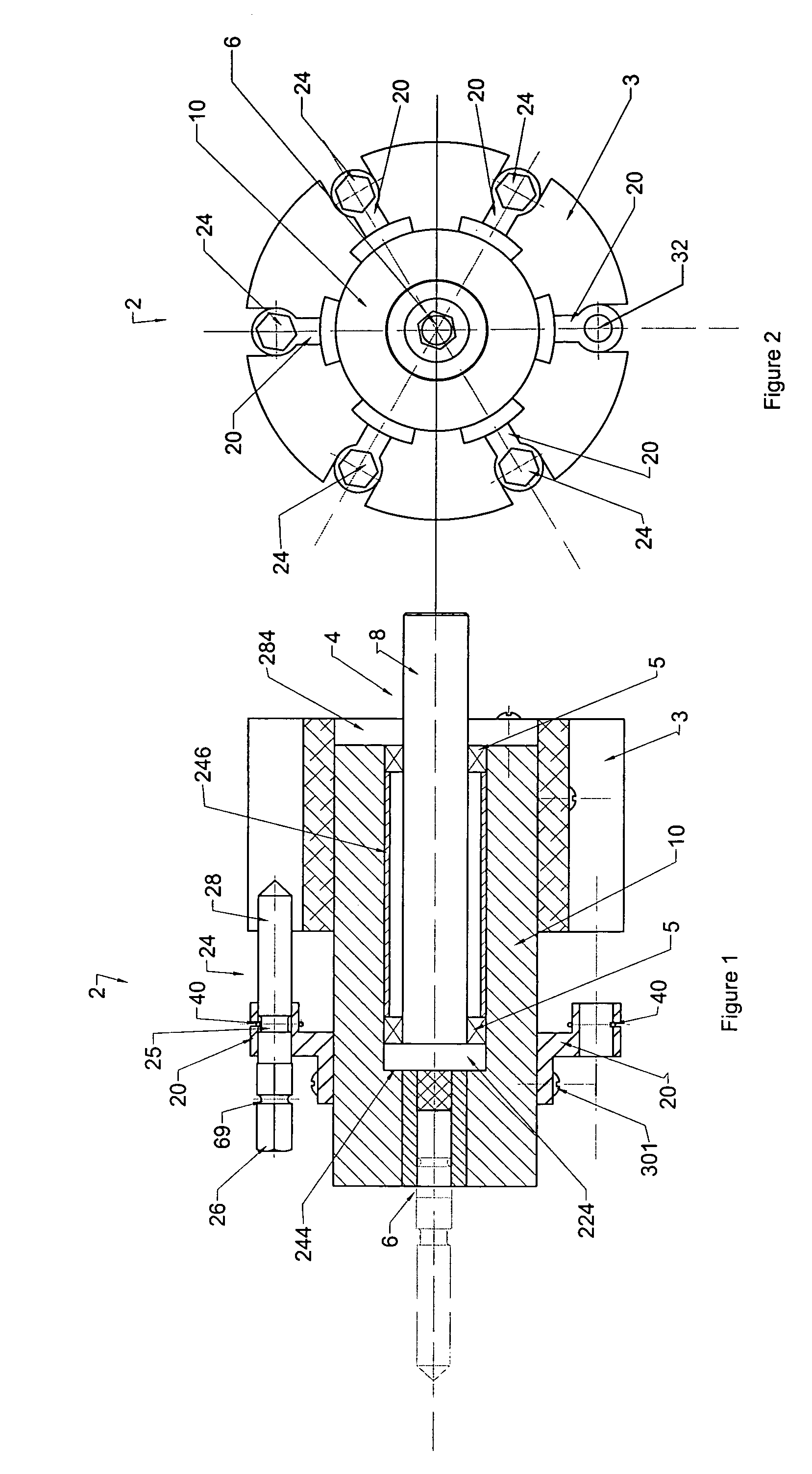

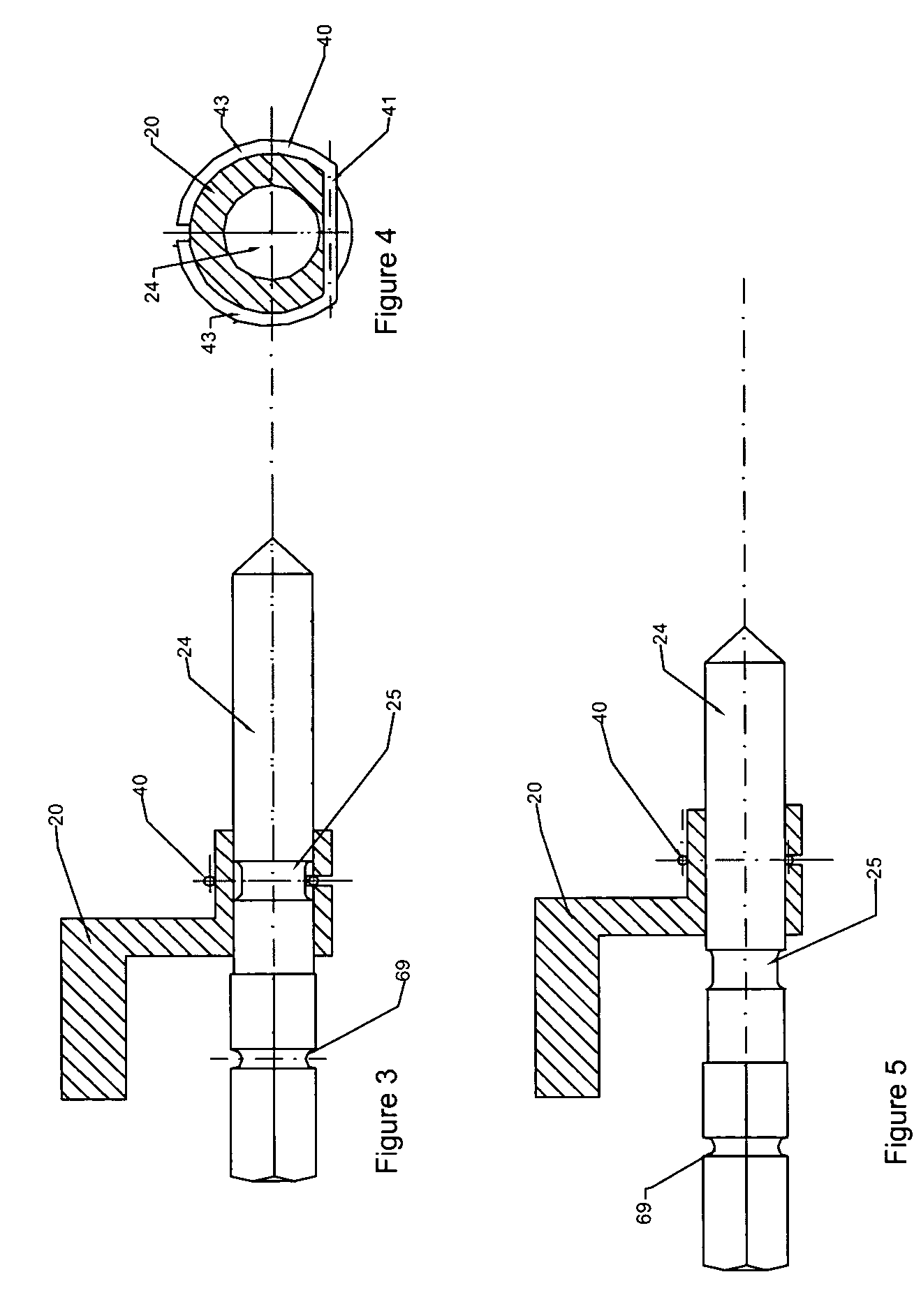

Manufacturing process and apparatus having an interchangeable machine tool head with integrated control

ActiveUS8954180B2Efficient transferAutomatic control devicesTool changing apparatusFiberDegrees of freedom

A modular manufacturing system and methods of using are provided. The modular manufacturing system includes a plurality of manufacturing heads that perform different manufacturing processes. These heads may include multi-axial machining heads, fiber placement heads including fiber tow and fiber tape lay-up heads. The heads are fixably attachable to a single positioning system that can manipulate the various heads along a plurality of different degrees of freedom relative to a tool or material blank.

Owner:INGERSOLL MACHINE TOOLS

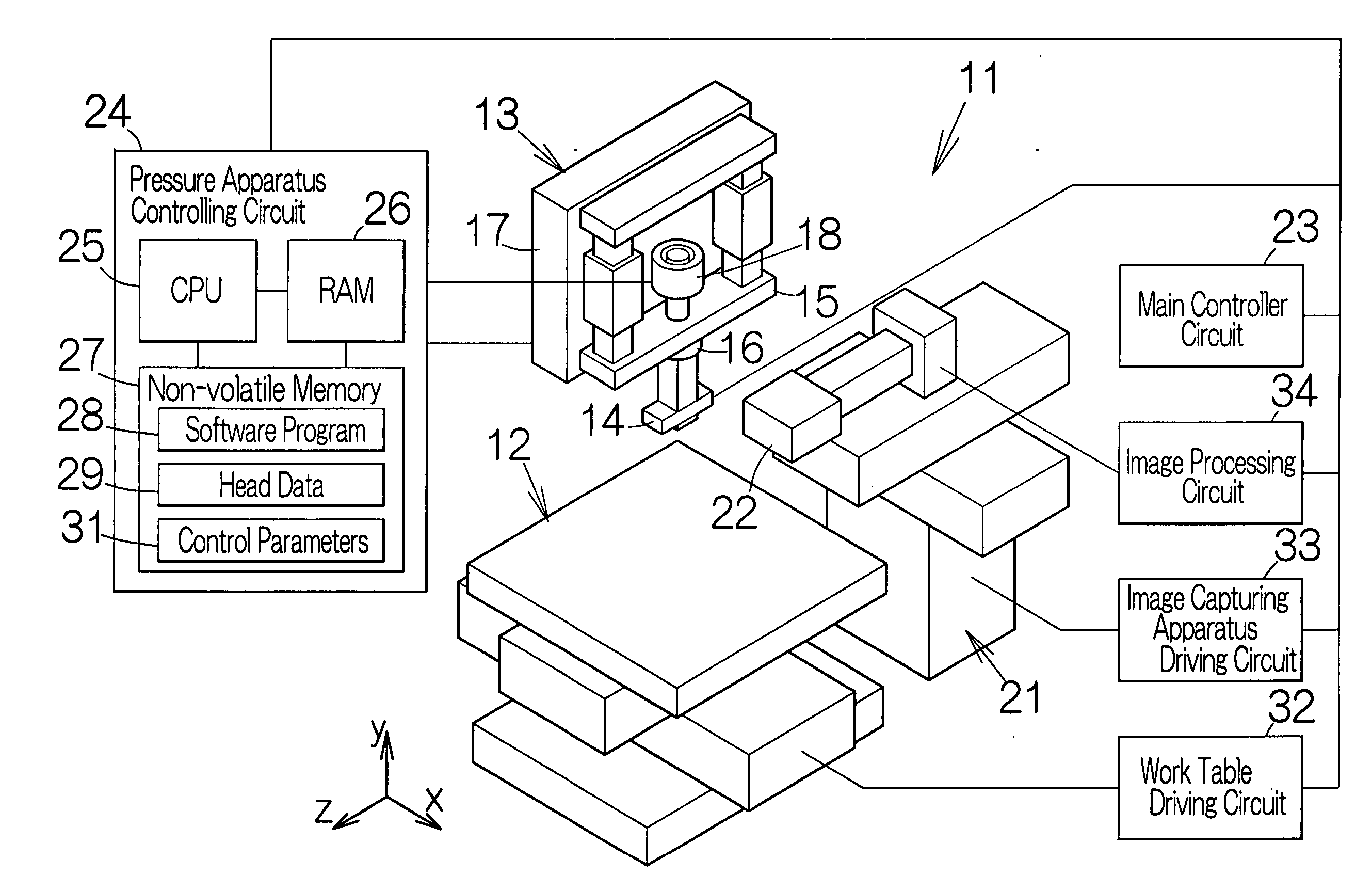

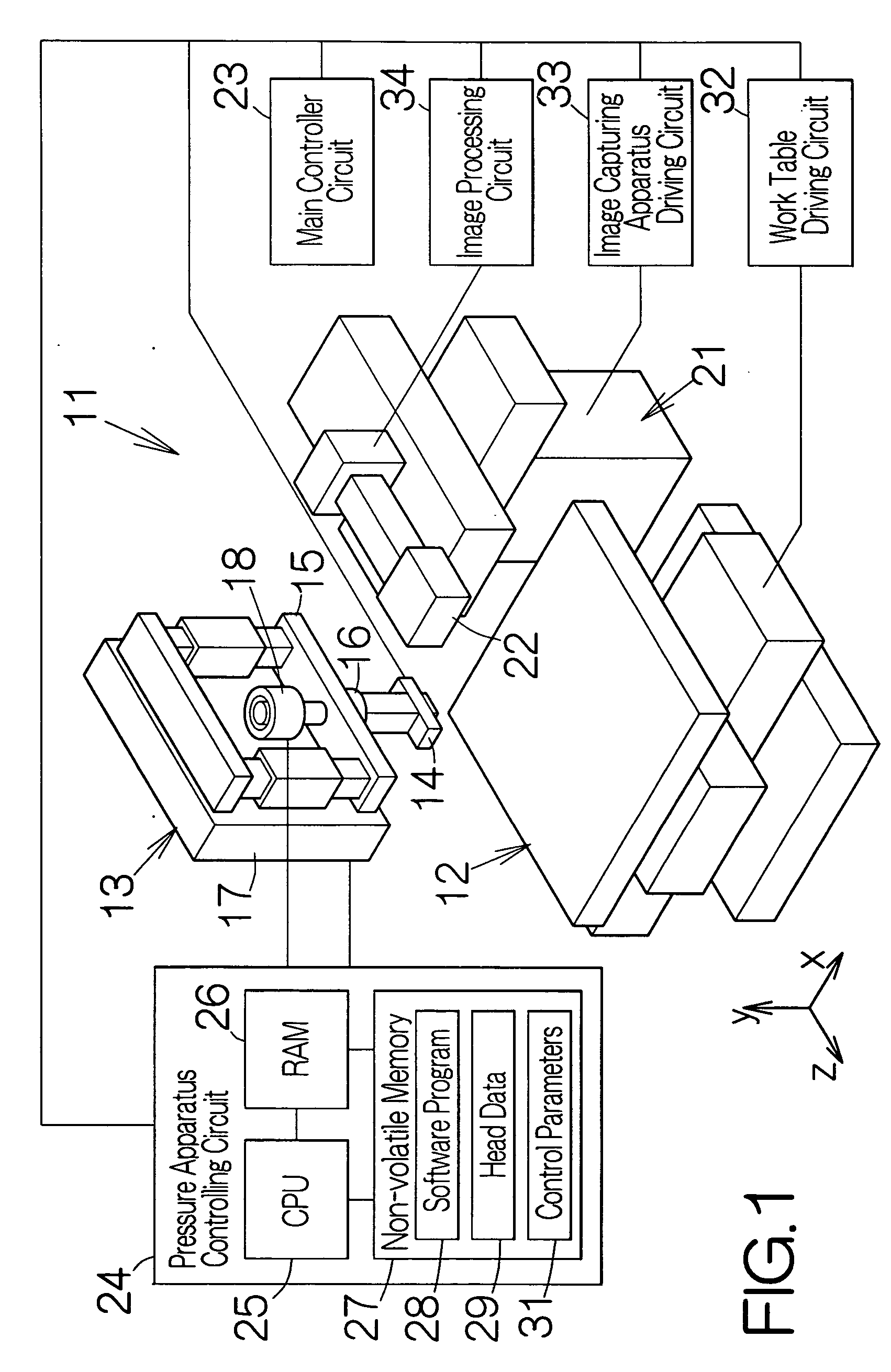

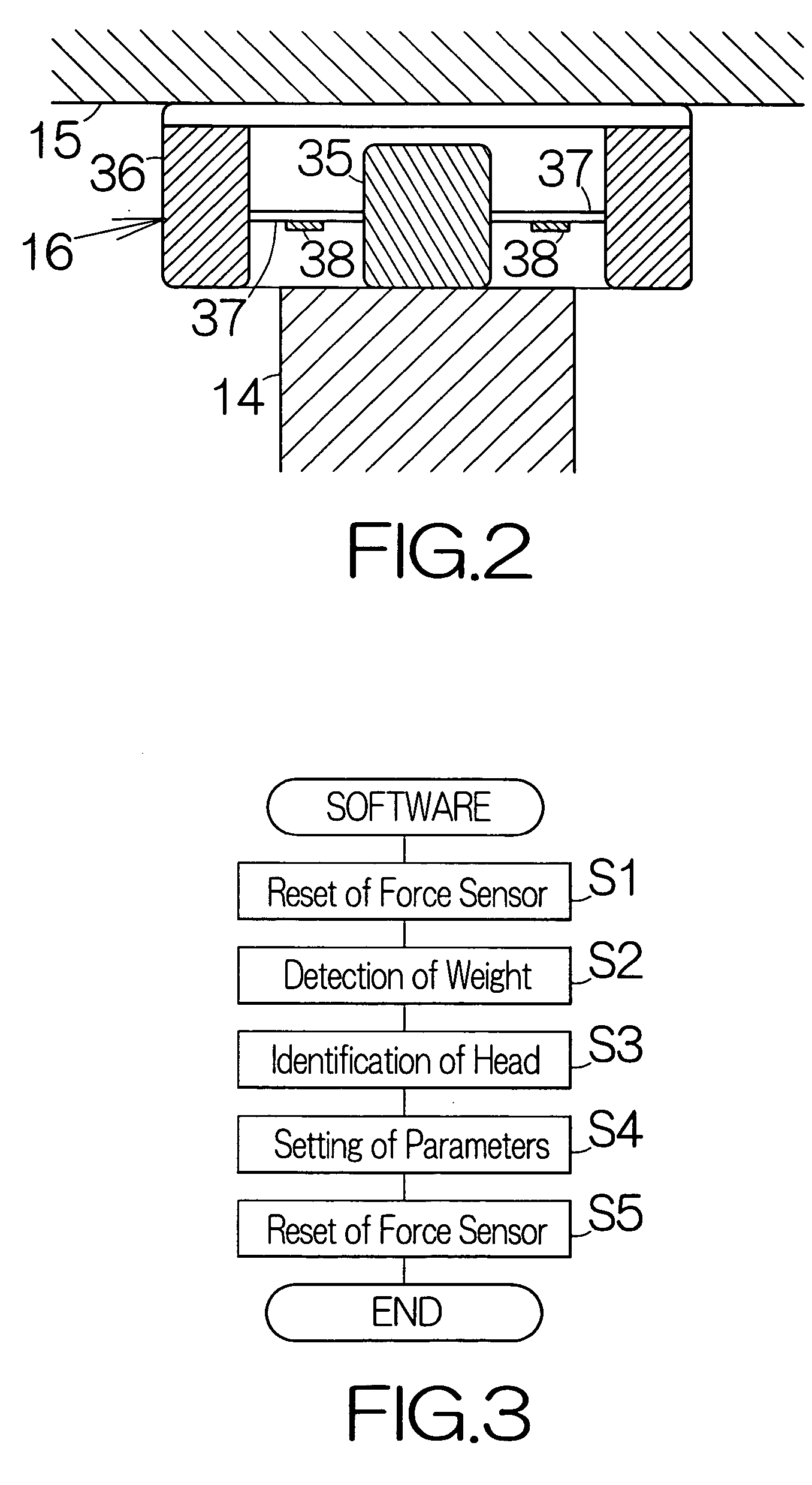

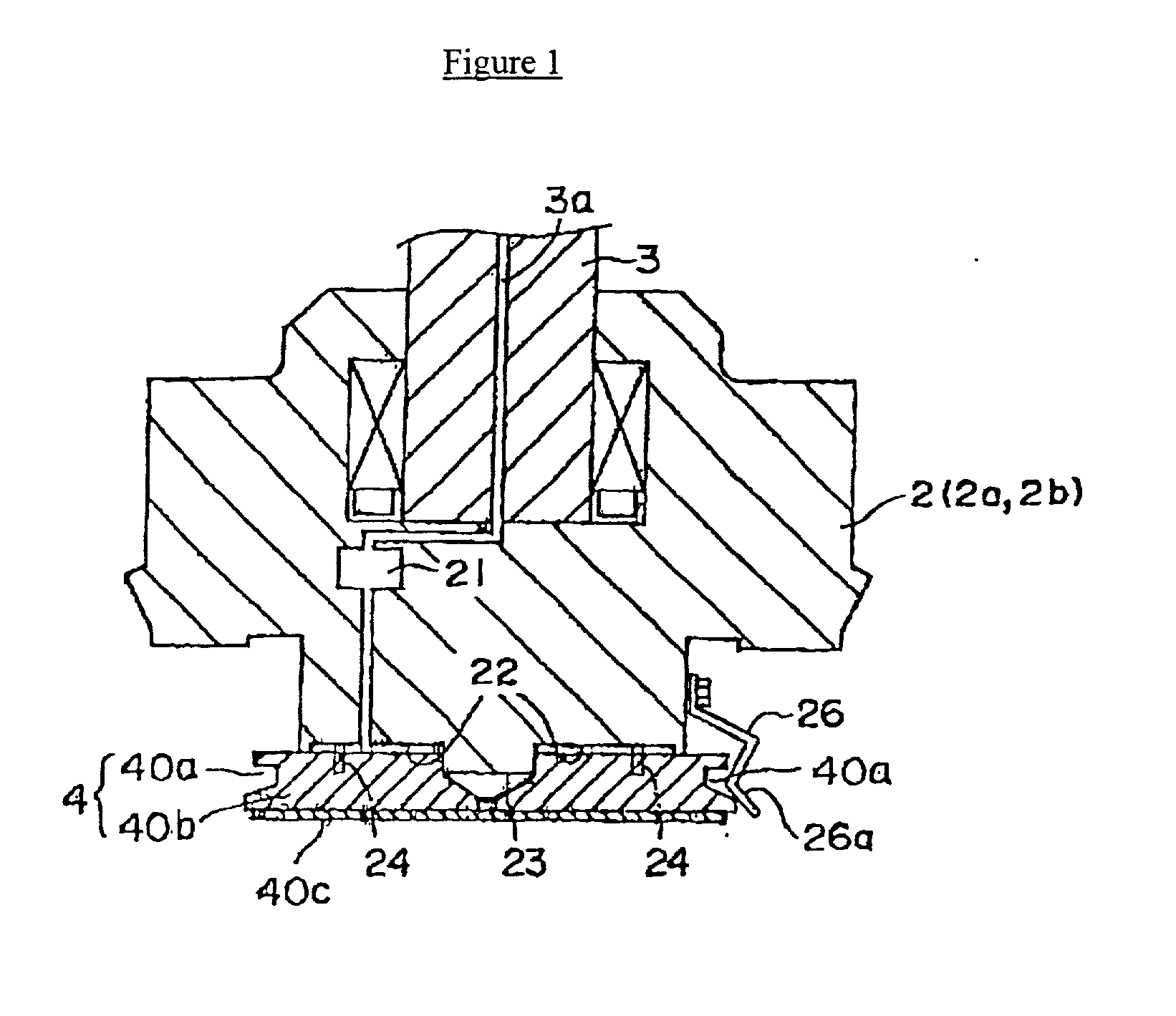

Identifying unit for working machine and pressure apparatus

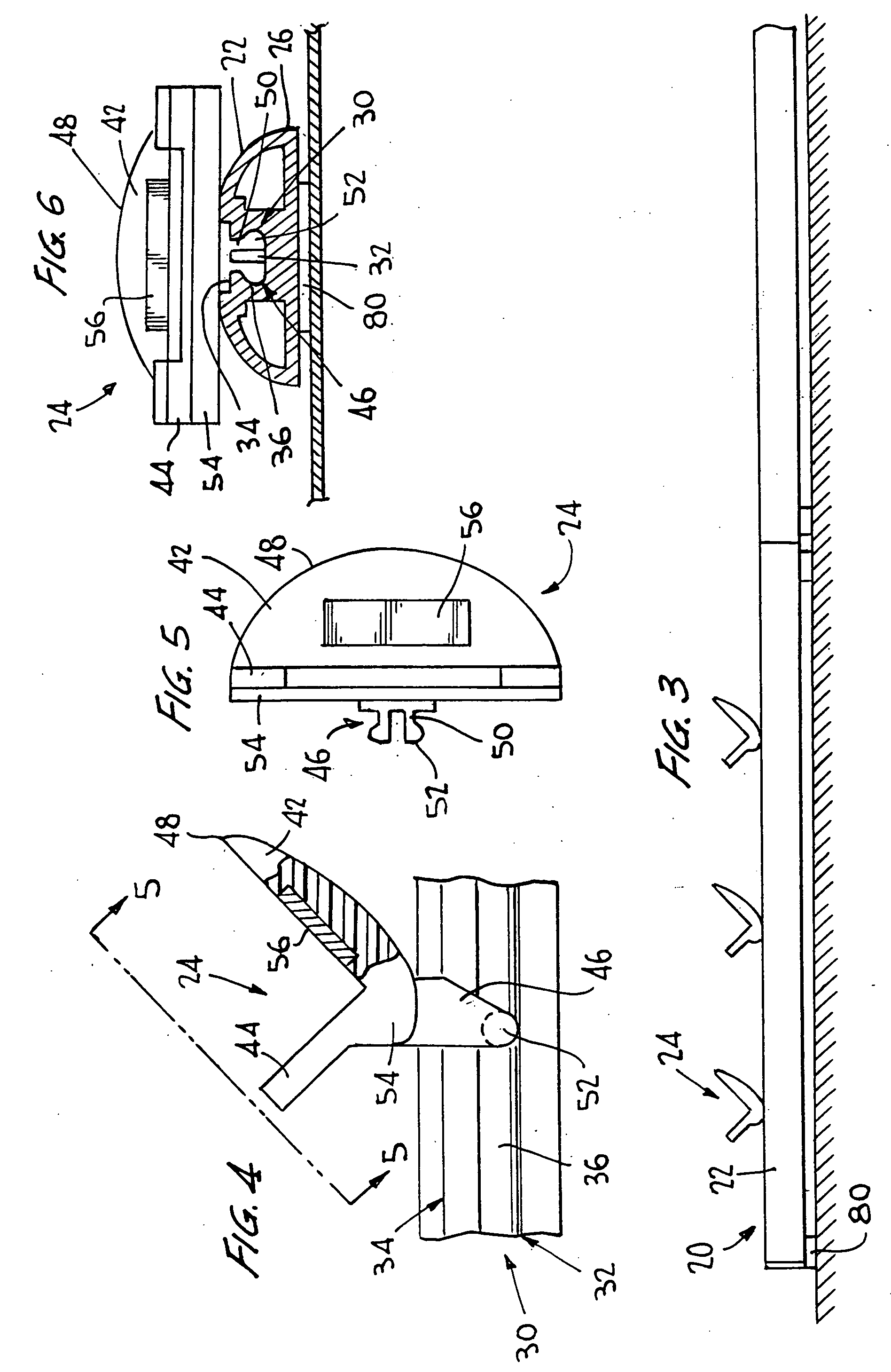

InactiveUS20060169050A1Improve accuracyReduce the hassle of operationForce measurementTool changing apparatusEngineeringForce sensor

A working machines includes an identifying unit. A force sensor detachably supports a working head in the identifying unit. A controller circuit is designed to identify the working head based on the load detected at the force sensor. When the working head is replaced with another one, the load changes in the force sensor in the identifying unit. In general, the individual working head has the specific weight. The working heads can thus be differentiated from each other based on the weight. Accordingly, the controller circuit is allowed to reliably identify the working head after the replacement with a higher accuracy based on the detected load.

Owner:FUJITSU LTD

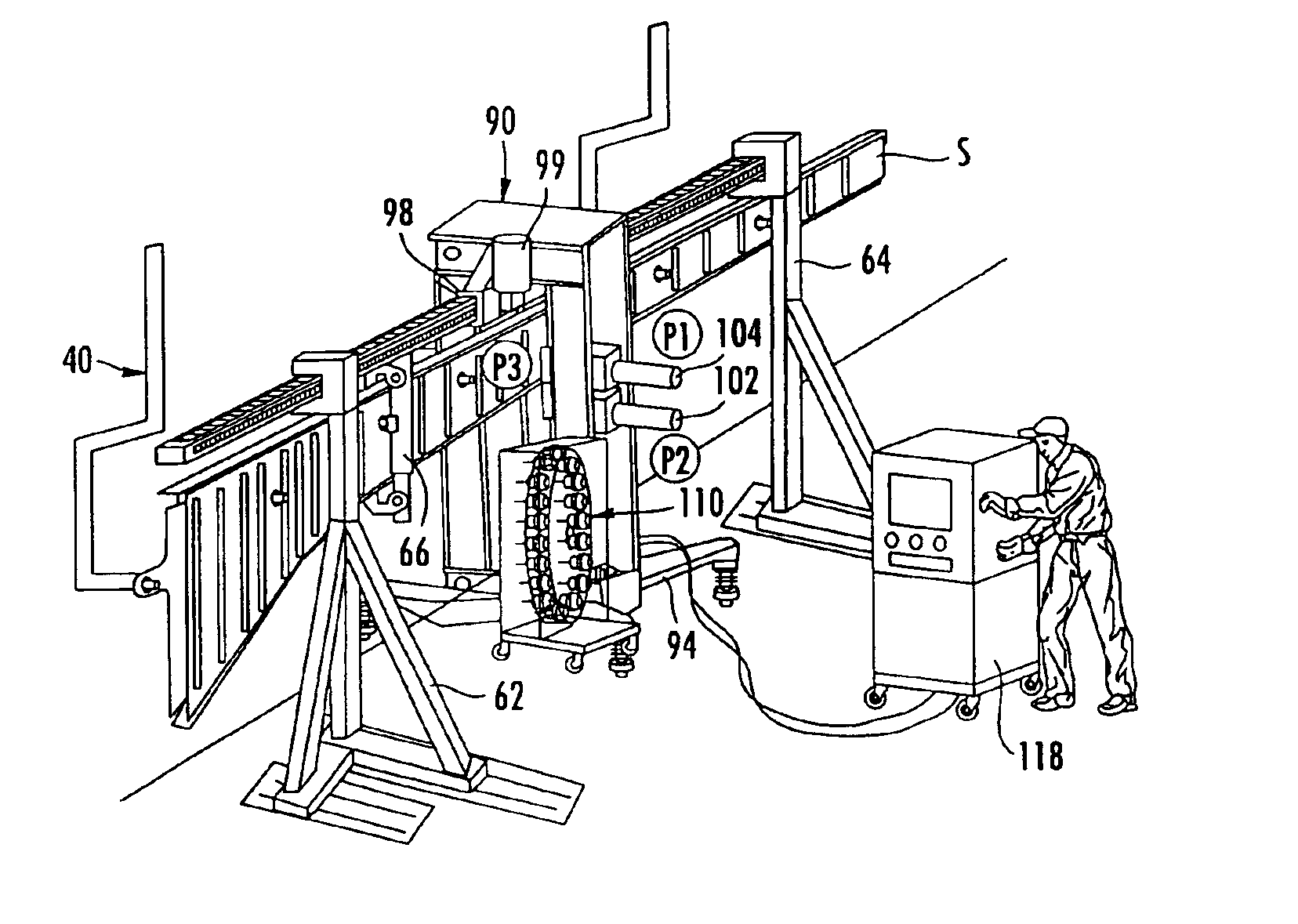

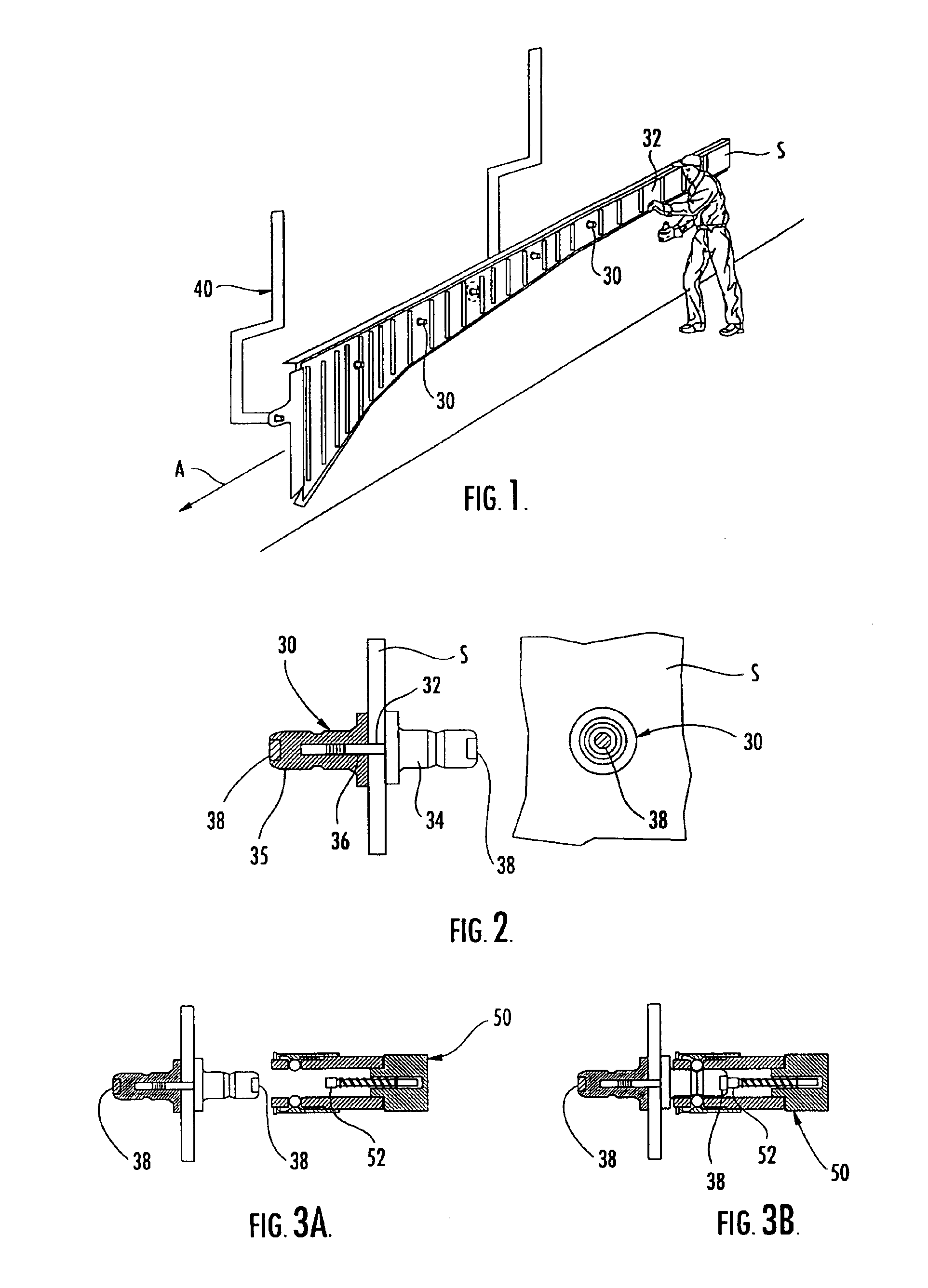

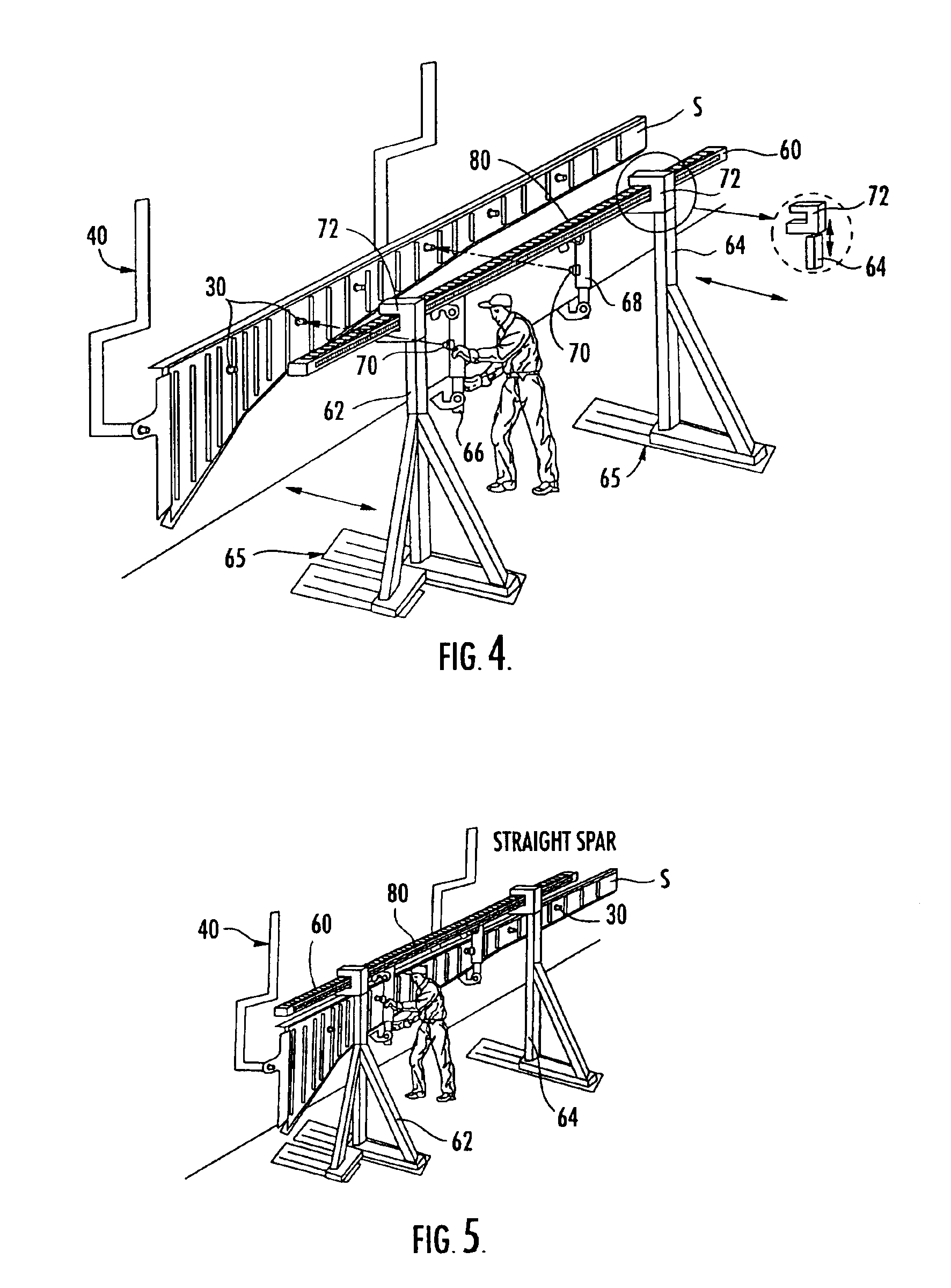

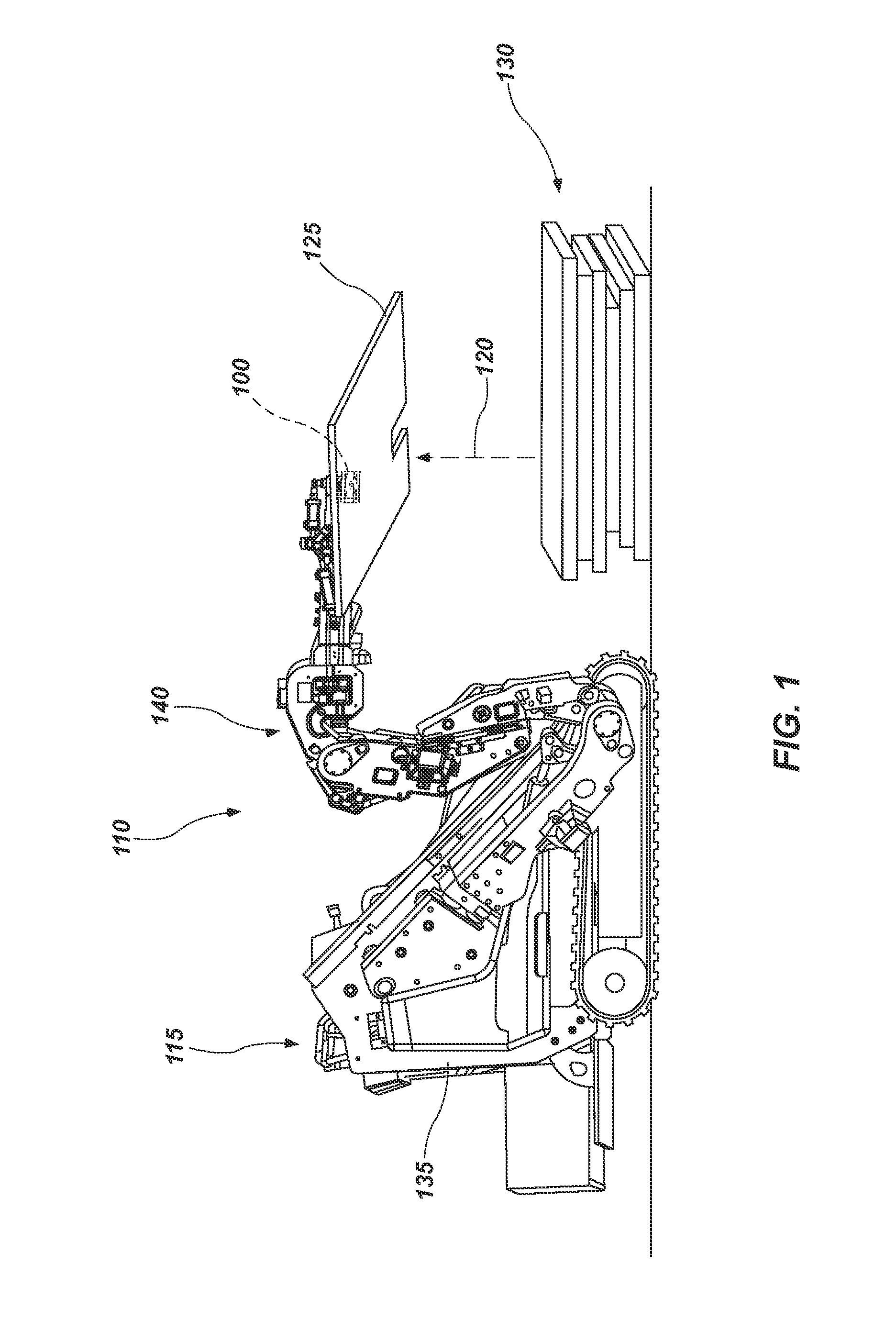

Manufacturing system for aircraft structures and other large structures

InactiveUS6855099B2Accurate locationDrilling/boring measurement devicesThread cutting machinesComputer moduleEngineering

A production system for manufacturing a workpiece comprises an index system including a plurality of index devices removably mounted on the workpiece at known longitudinally spaced locations therealong, and a longitudinally extending index member releasably engaged with at least two of the index devices such that a position and orientation of the index member are fixed relative to the workpiece by the index devices, the index member having position-indicating features distributed therealong. The production system further comprises a machine module mounted for longitudinal movement along the index member and operable to perform an operation, the machine module being operable to detect the position-indicating features on the index member and thereby determine a position of the machine module relative to the workpiece.

Owner:THE BOEING CO

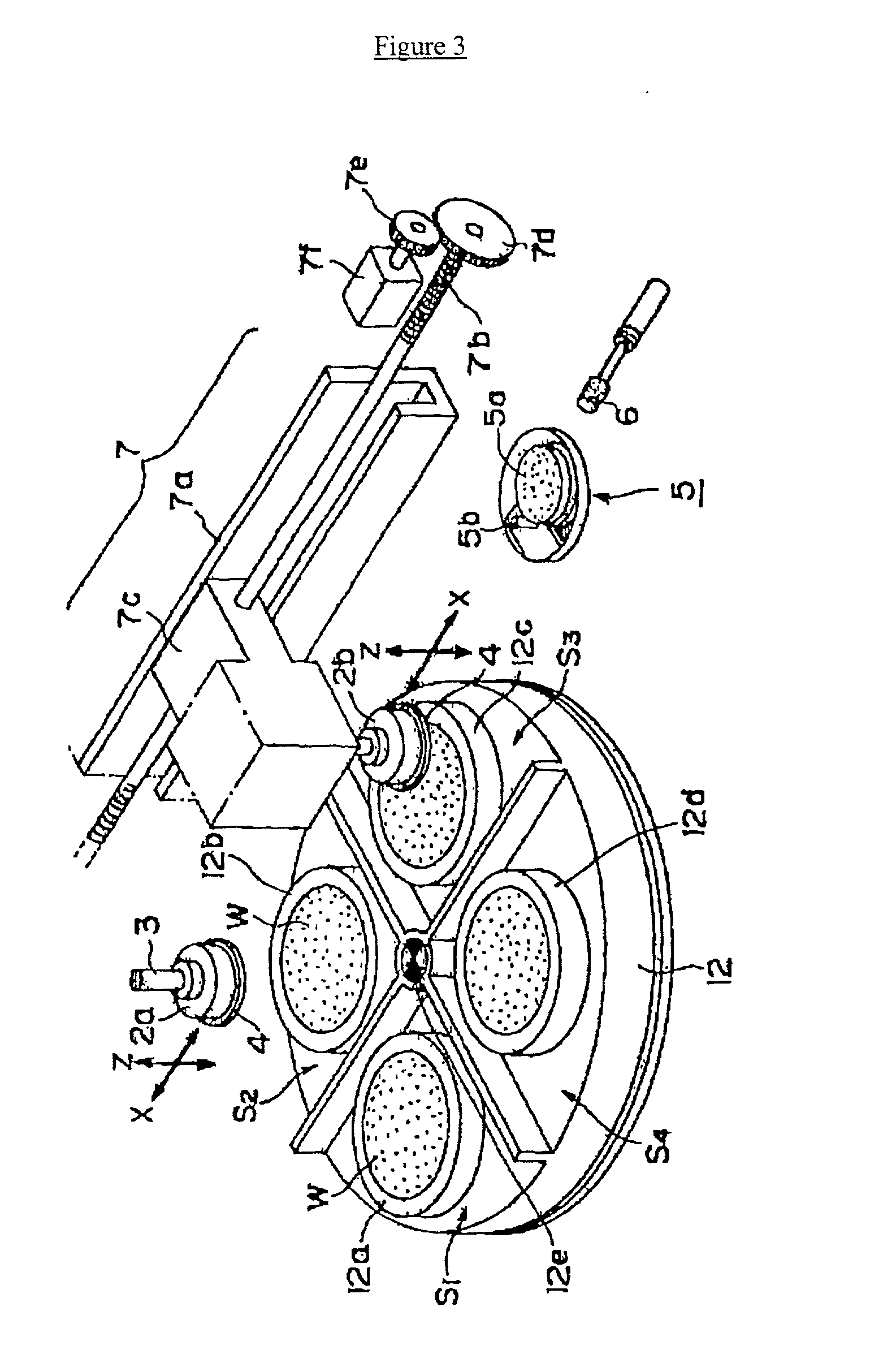

Automatic blade changing system

InactiveUS6030326AHold the blade steadilyTool changing apparatusFine working devicesEngineeringScrew thread

An automatic blade changing system of a dicing machine uses a blade which is fixed to an auxiliary stopper member provided with a thread which is engaged with a thread of a spindle. The automatic blade changing system consists of two blade holding means which hold the blade to which the stopper member is fixed and rotate the blade relatively to the spindle in the state wherein the blade is forced to the spindle, a blade accommodating means which accommodates a blade to replace the blade, a moving means for moving the blade holding means between the end of the spindle and the blade accommodating means.

Owner:TOKYO SEIMITSU

Tool holder arrangement

ActiveUS7008362B2Easy to understandDiagnosticsTool changing apparatusEngineeringIdentification system

A tool identification system has a tool holder allowing removable attachment thereto of any one of a plurality of tools; a sensor arrangement operable to sense features present on a tool attached to the tool holder; a processor operable to identify uniquely, from the sensed features, the type of the tool attached to the tool holder; and an insulation arrangement provided between the tool holder and the sensor arrangement, thereby electrically insulating the tool holder from the sensor arrangement.

Owner:PROSURGICS

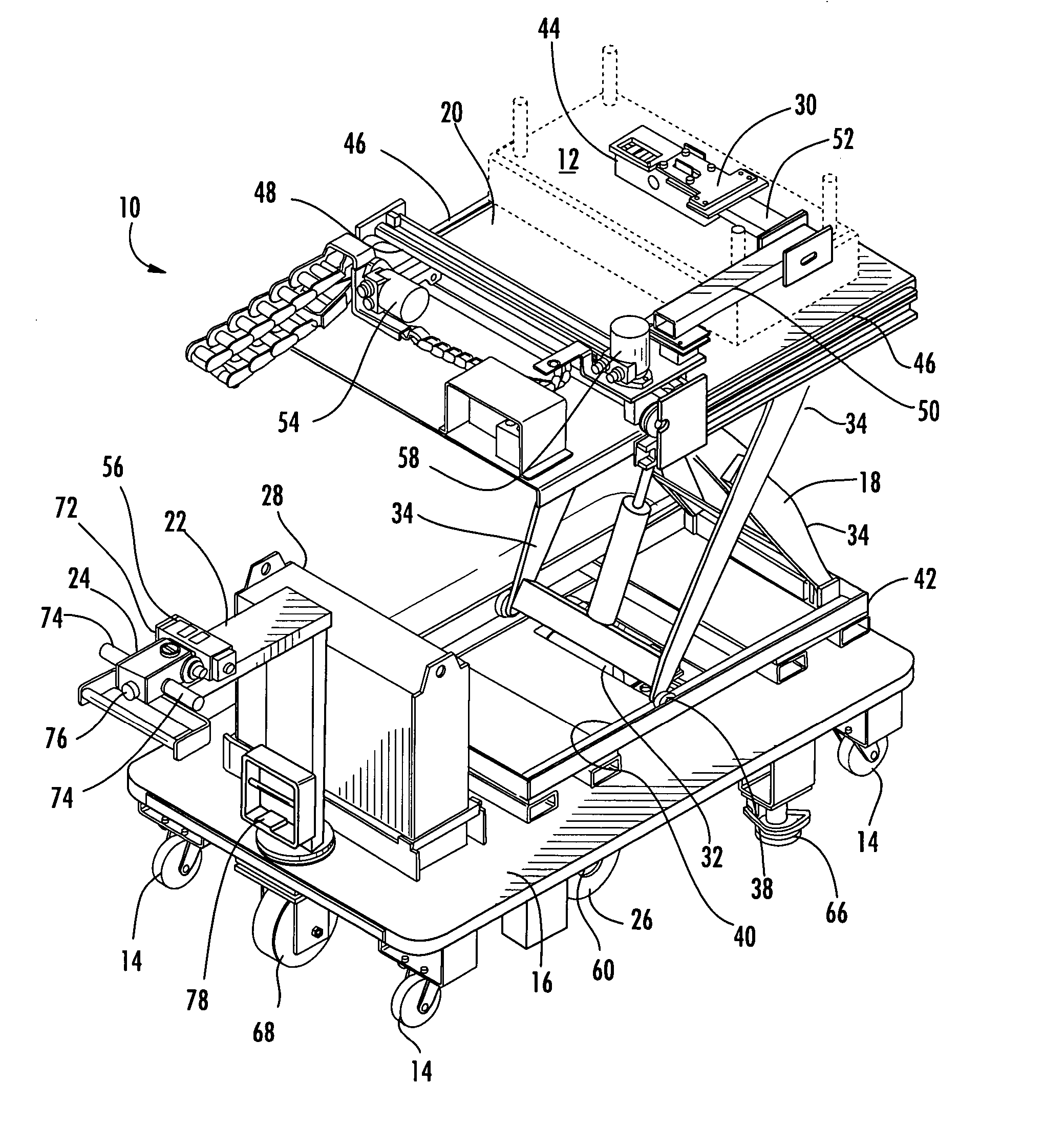

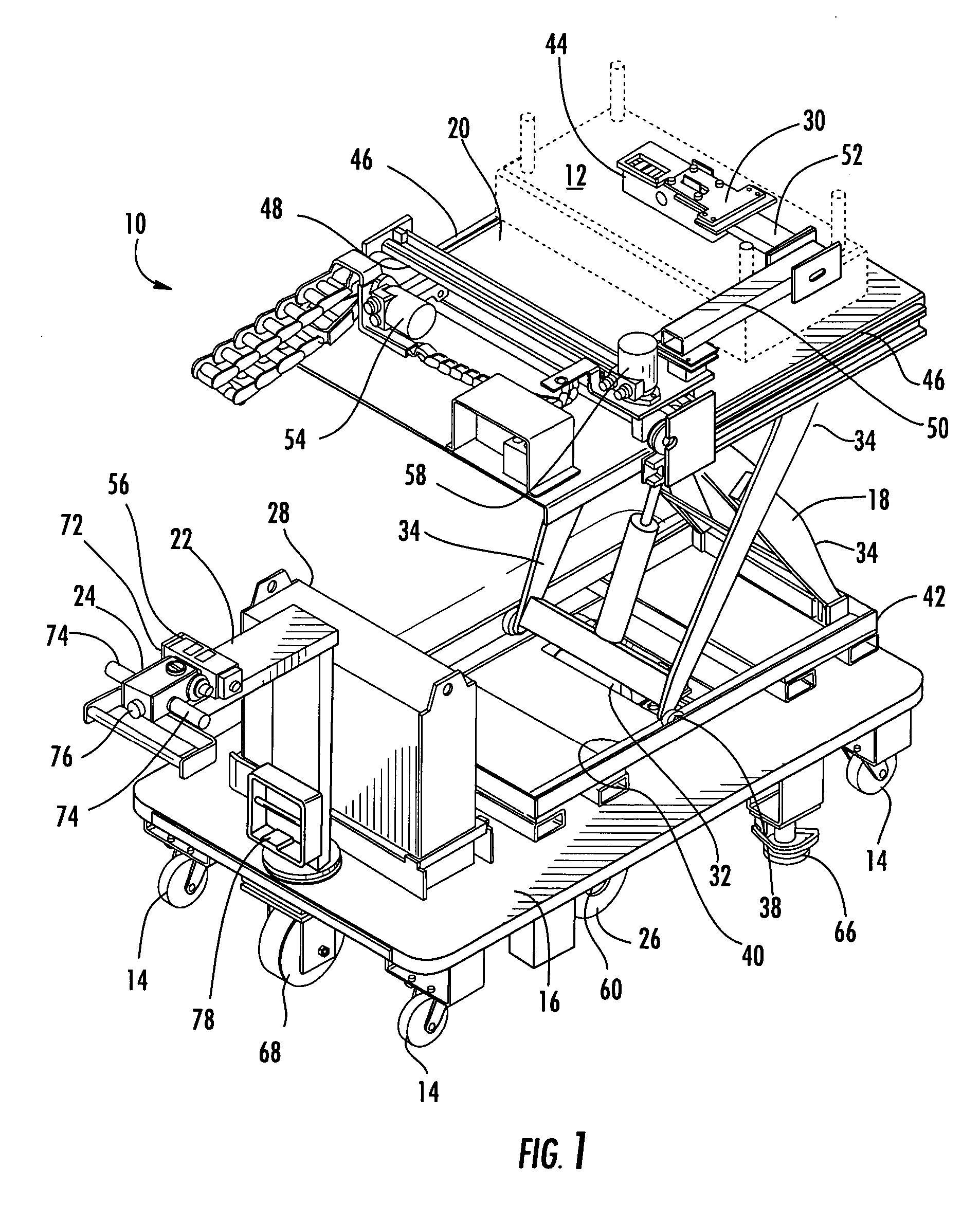

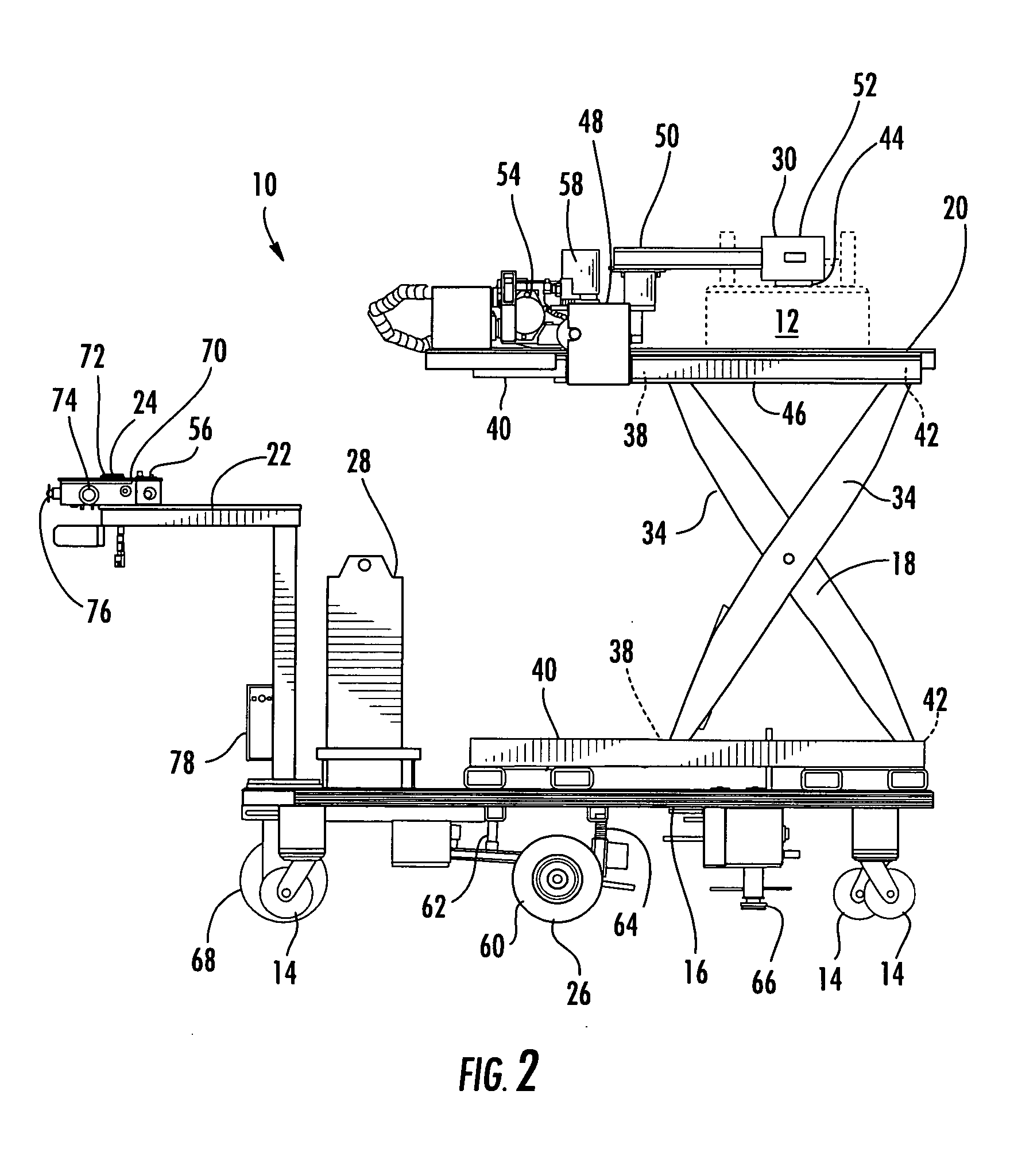

Cart for die transportation

There is provided a cart for transporting dies, molds, and similar objects. The cart includes a lift mechanism for raising and lowering a support surface to the height of the surface onto which or from which the die will be moved. The support surface includes a transfer mechanism for coupling to the die, either with an electromagnet or a suction device, to thereby slide the die as desired without damaging critical components on the exterior of the die. The cart also includes a motorized drive wheel assembly which provides a drive force in a forward or backward direction to assist the operator in moving a die that has been transferred onto the cart. The cart is powered by one or more rechargeable batteries. The cart enables a single operator to safely and conveniently remove, insert, and transport dies or other similar objects.

Owner:MULTI SHIFTER

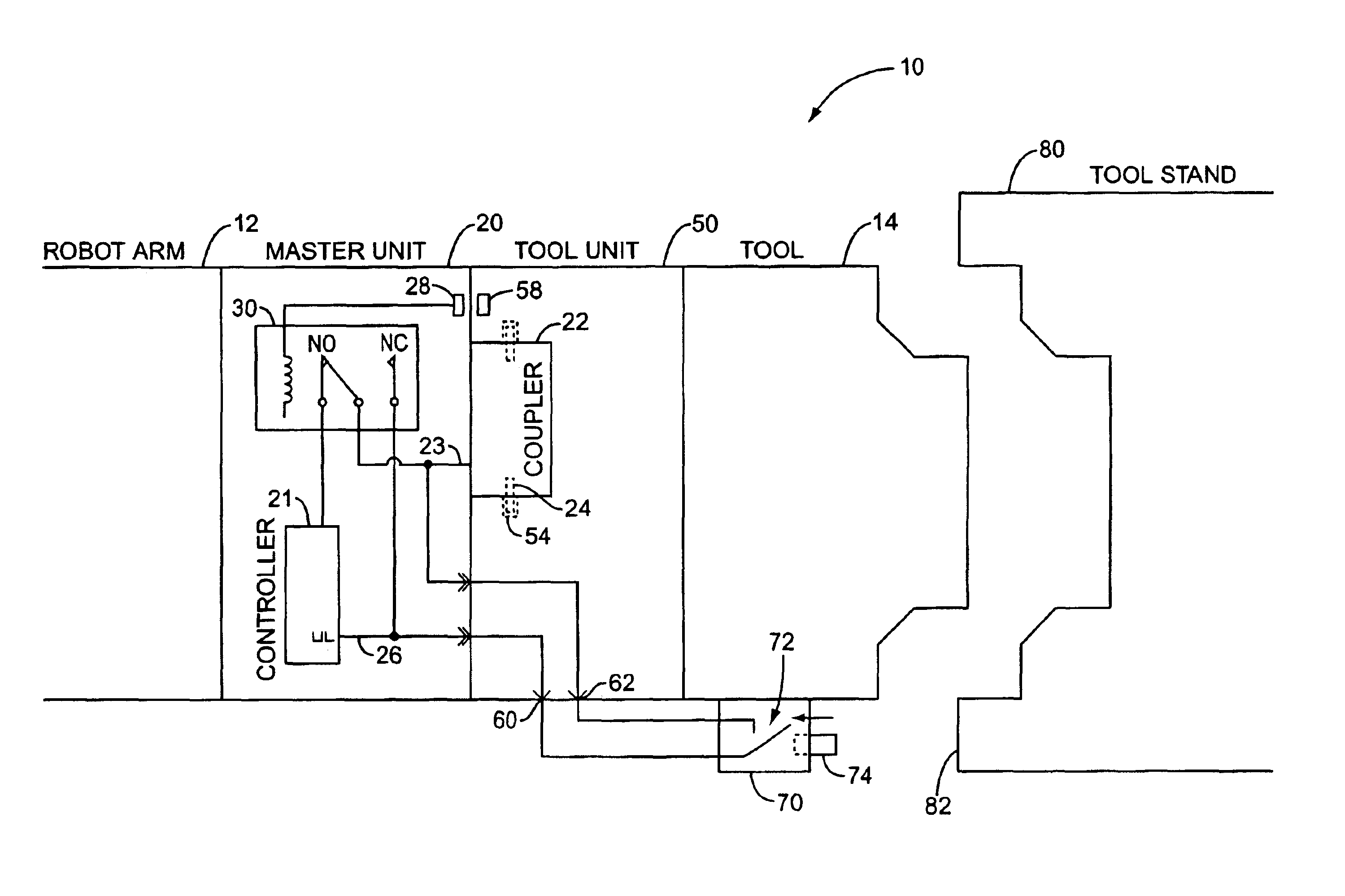

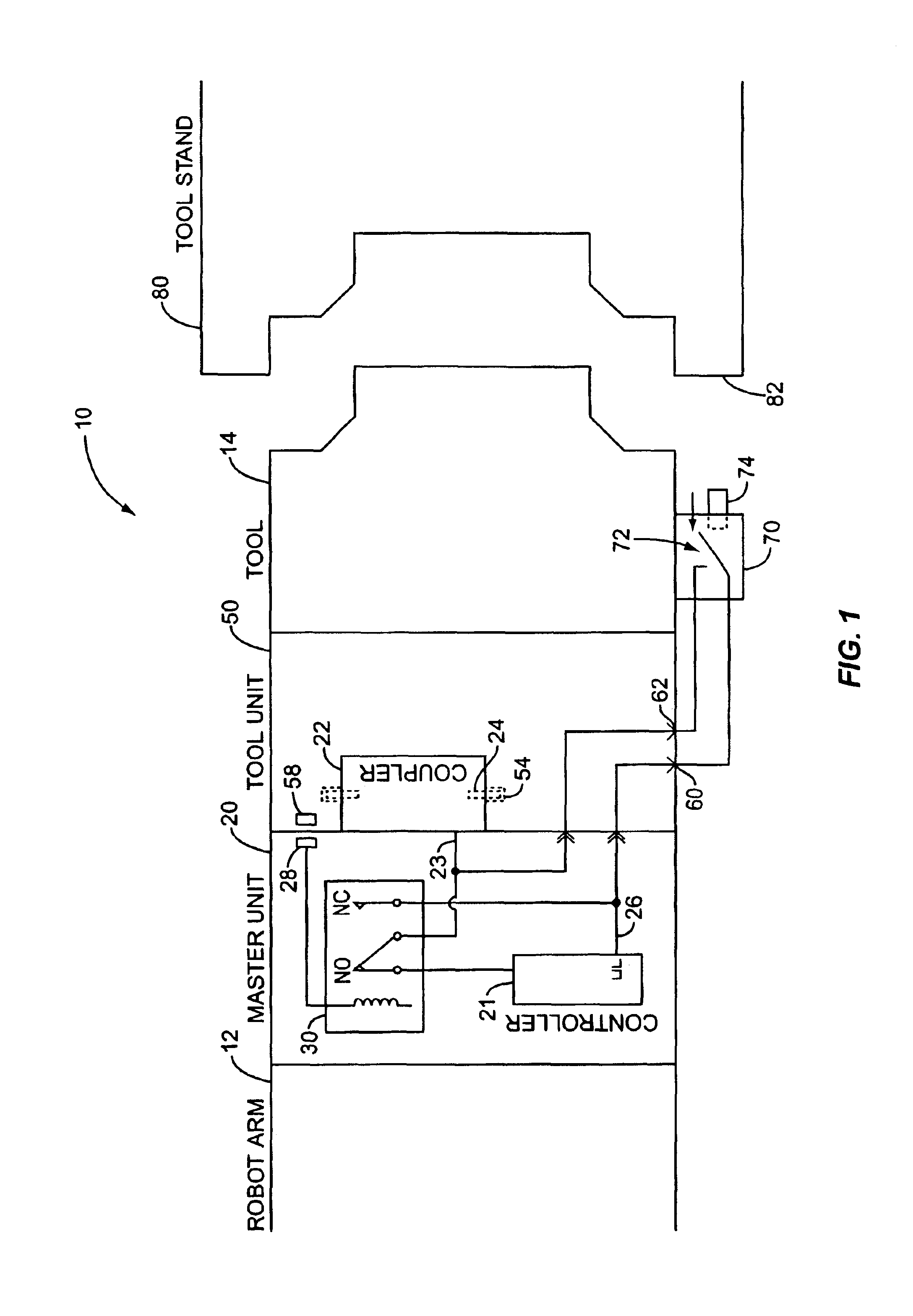

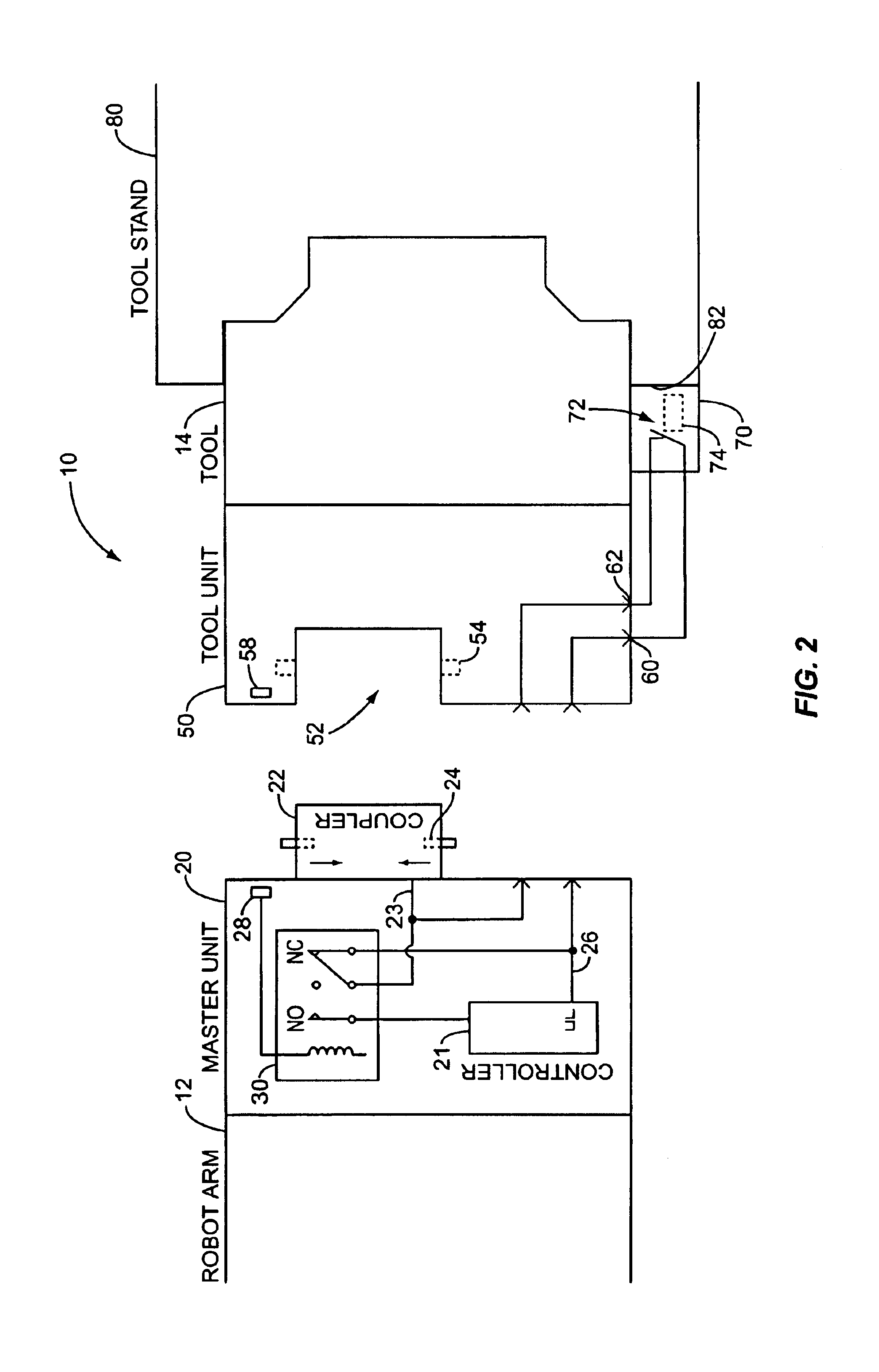

Tool side robotic safety interlock

A robotic tool changer with an improved safety interlock includes a master unit, a tool unit, and a coupler movable between coupled and decoupled positions and operative to couple the master and tool units. A circuit for actuating the coupler is associated with the tool unit, for connection to an interlock that closes when the tool is safely parked in a tool stand. The circuit enables the coupler to assume the decoupled position when the master and tool units are coupled and the circuit is closed. The robotic tool changer additionally includes a circuit operative to enable the coupler to assume the decoupled position when the master unit is decoupled from the tool unit.

Owner:ATI INDAL AUTOMATION

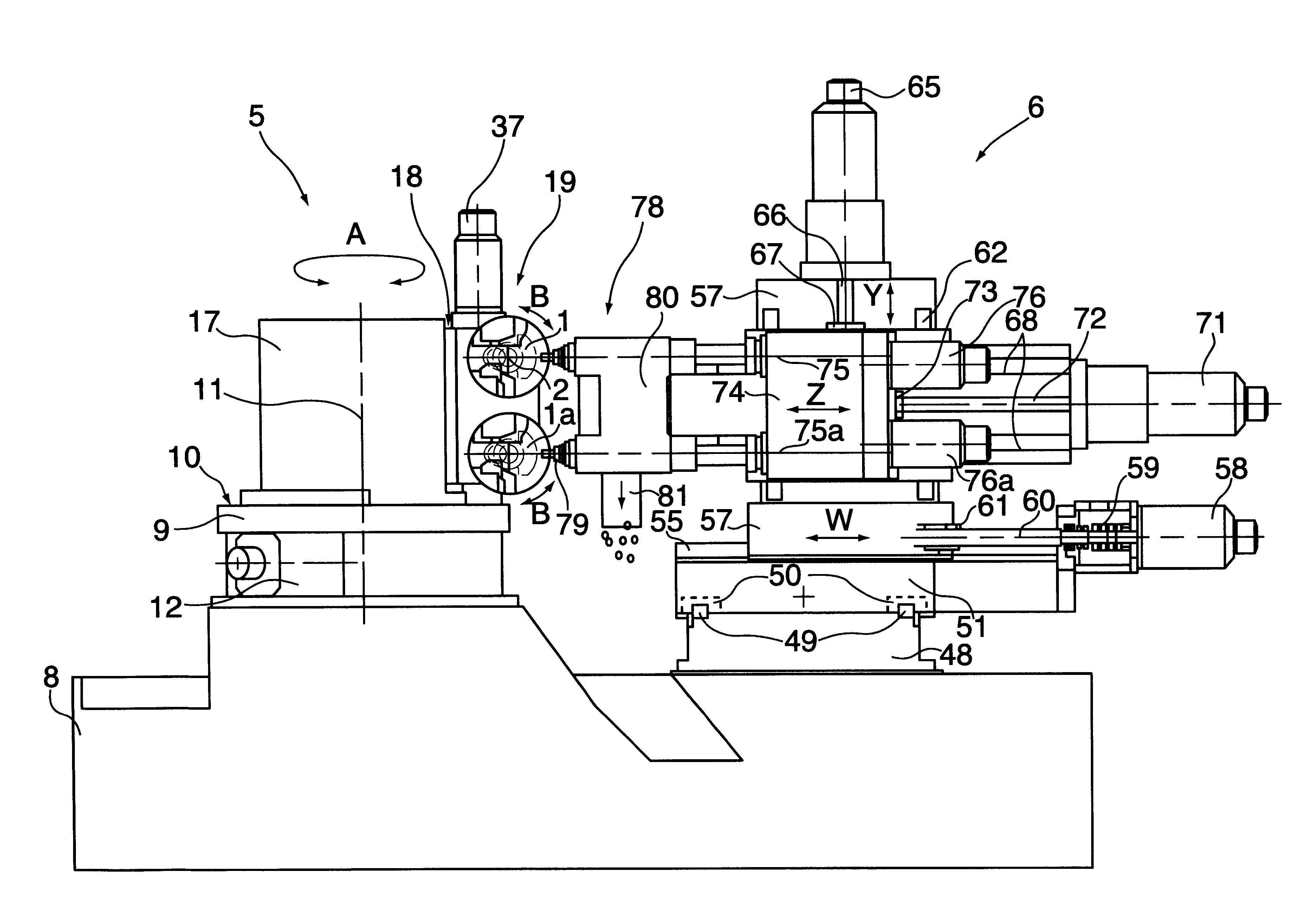

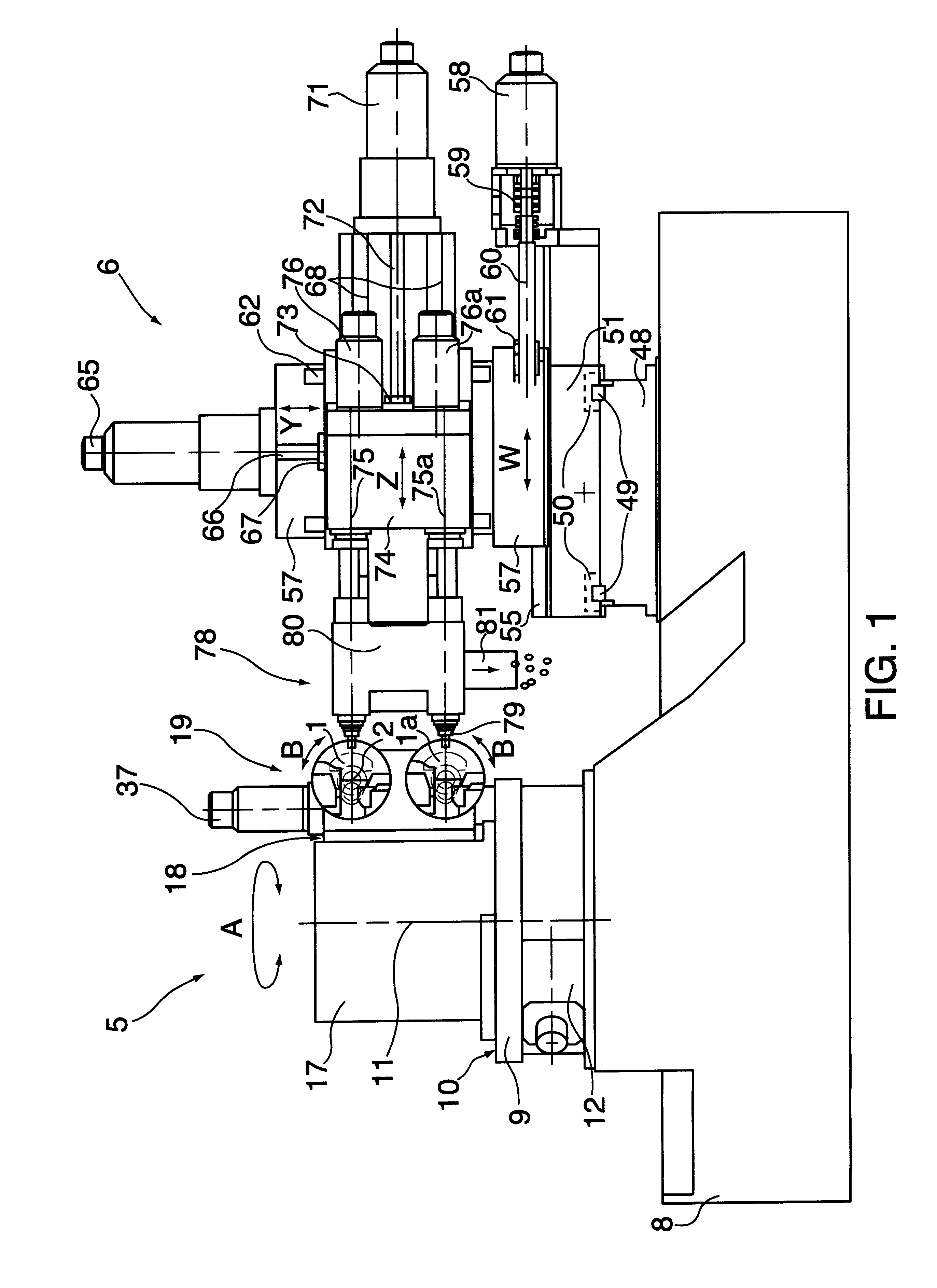

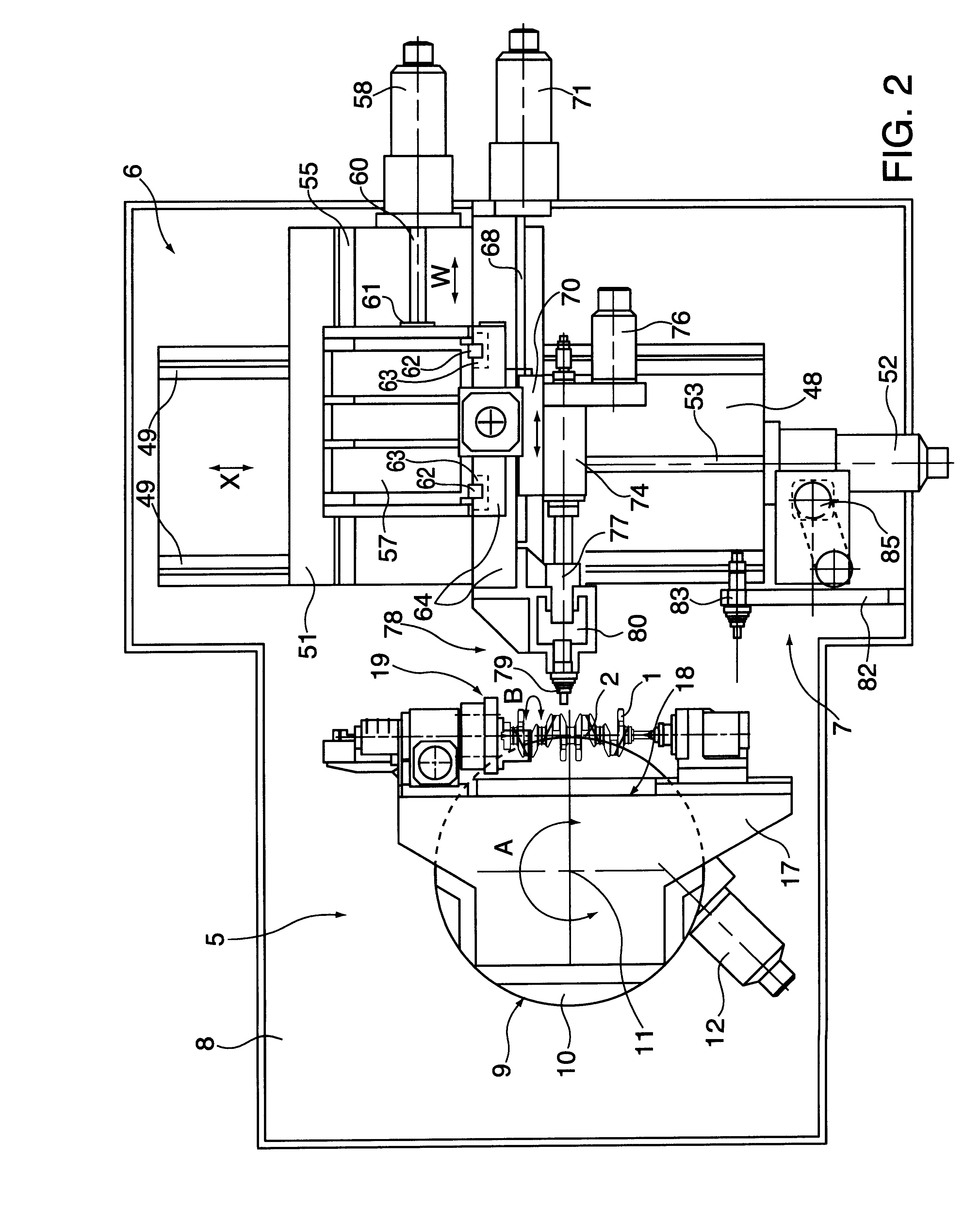

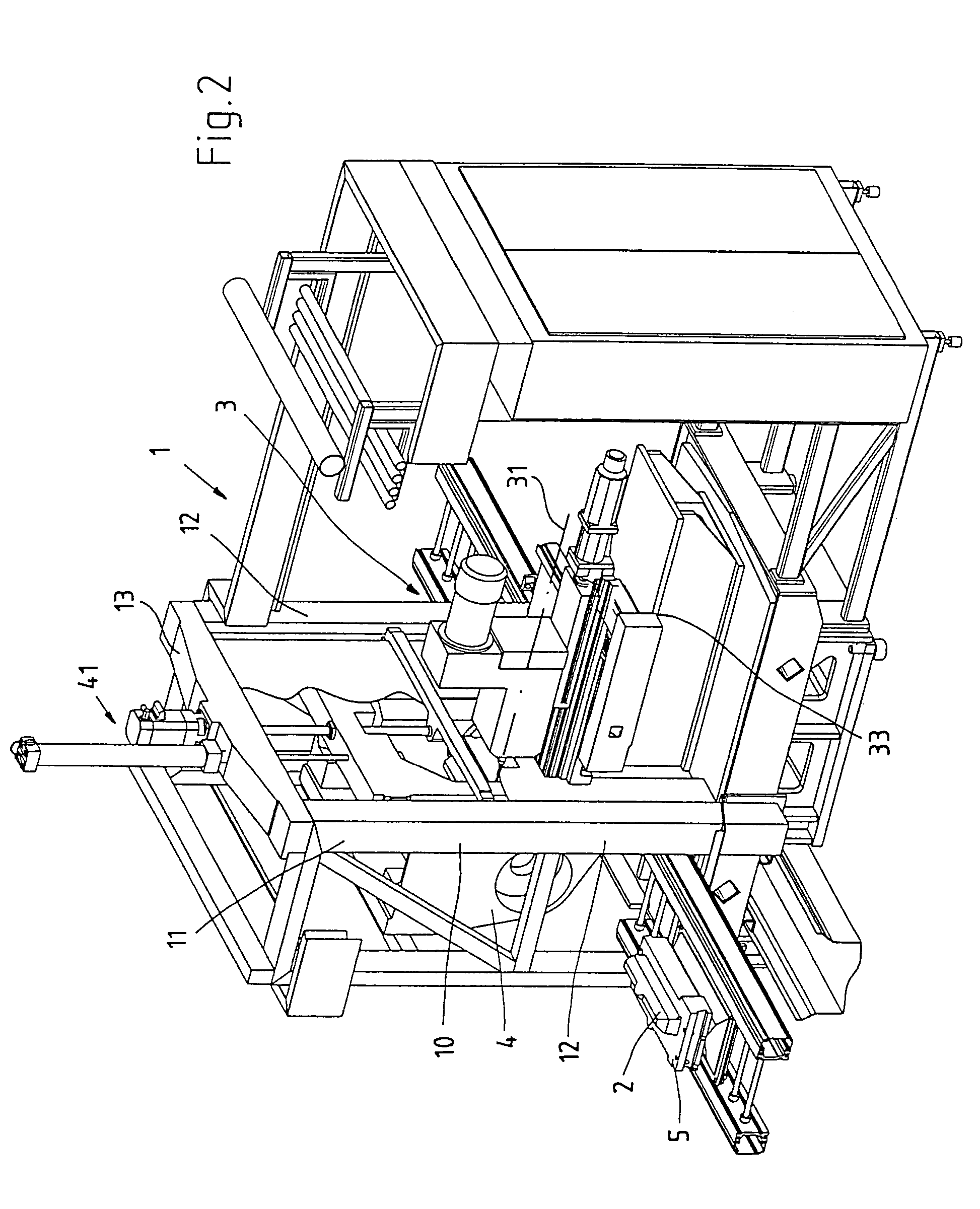

Machine for drilling oil holes in crankshafts

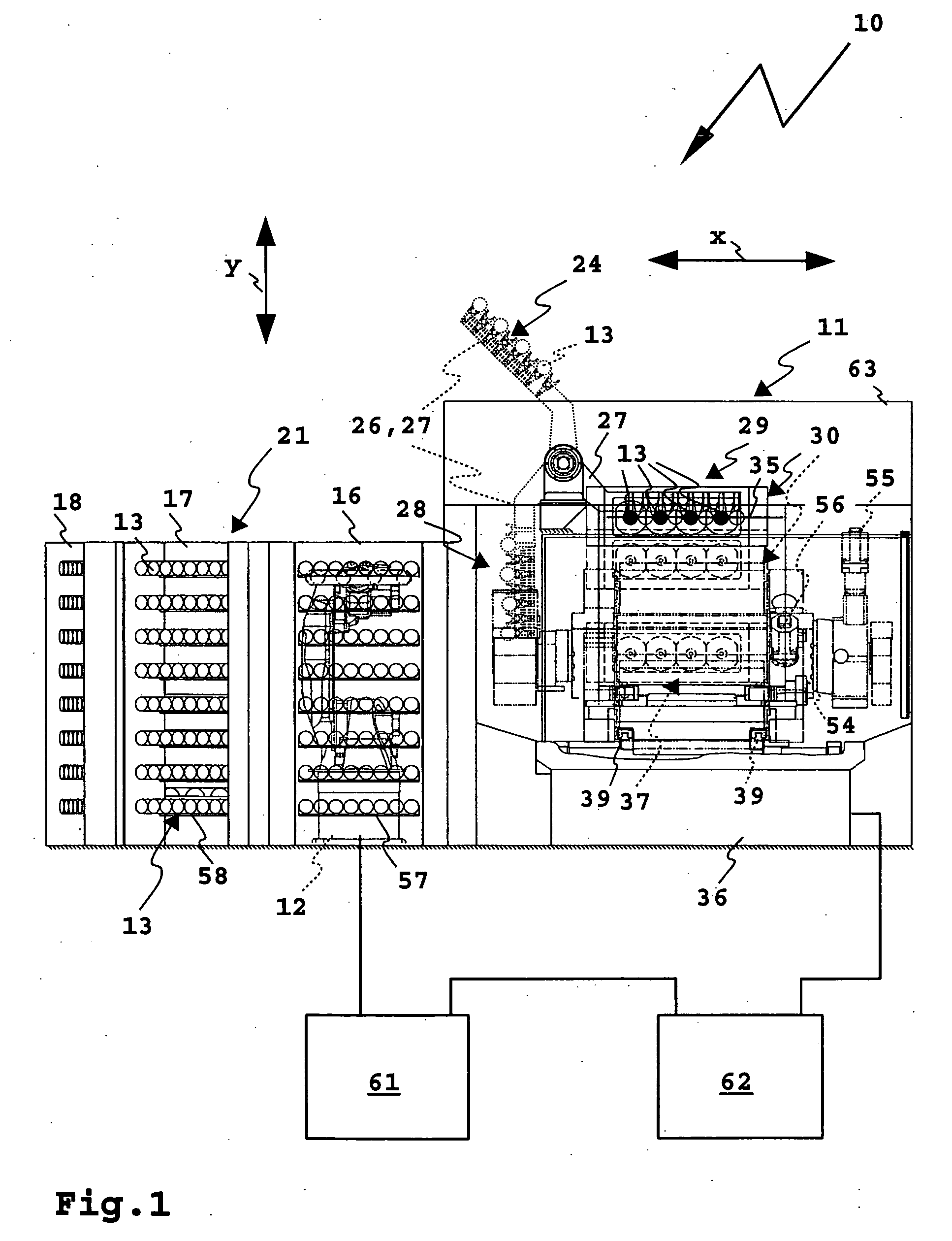

InactiveUS6203478B1Remove complicationsEliminate investmentCrankshaftsThread cutting machinesEngineeringCo ordinate

A machine for drilling oil-holes in crankshafts and the corresponding procedure. It can be used to drill one, two or more crankshafts per cycle. Each crankshaft can revolve on its own axis. The unit described is mounted on a horizontally-faced rotary table with vertical rotating axis, to place the crankshafts at different angles to the Z axis of the machining module, maintaining the horizontal position of the longitudinal axes of the crankshafts. Facing the unit is the machining module, provided with two horizontal spindles, drill tool-holders, with their corresponding guide bushings and parallel to each other, one on top of the other, at the same distance as the two crankshafts. The module has movement in three co-ordinates: axis X (horizontal-transverse), Y (vertical ) and Z (horizontal-presenting tools). A fourth axis W, (with additional module and independent action), moves parallel to Z and carries the guide bushings. It is provided with an automatic changeover, (tool+bushing or just the bushing), incorporating simultaneously the pair of spindles.

Owner:ETXE TAR SA

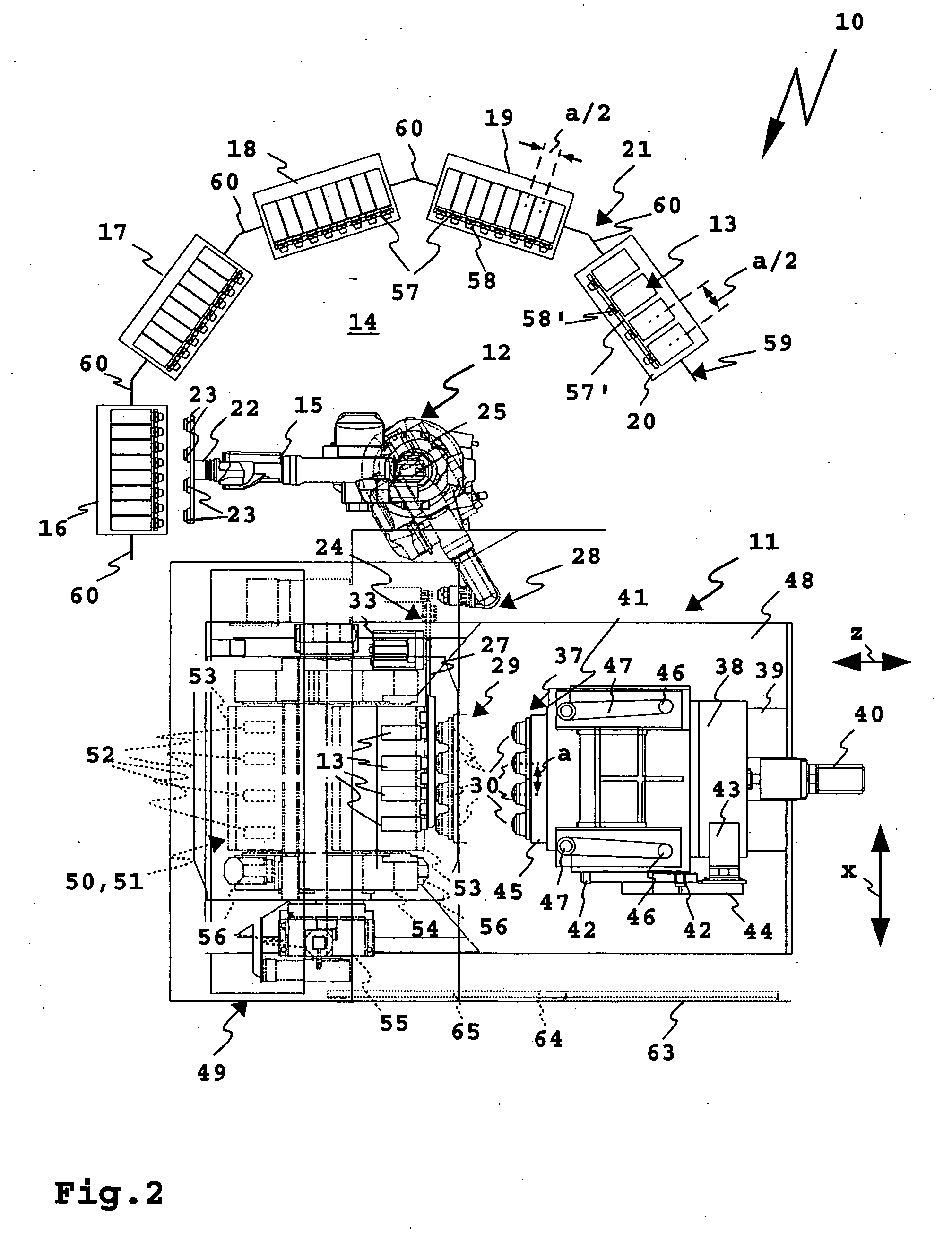

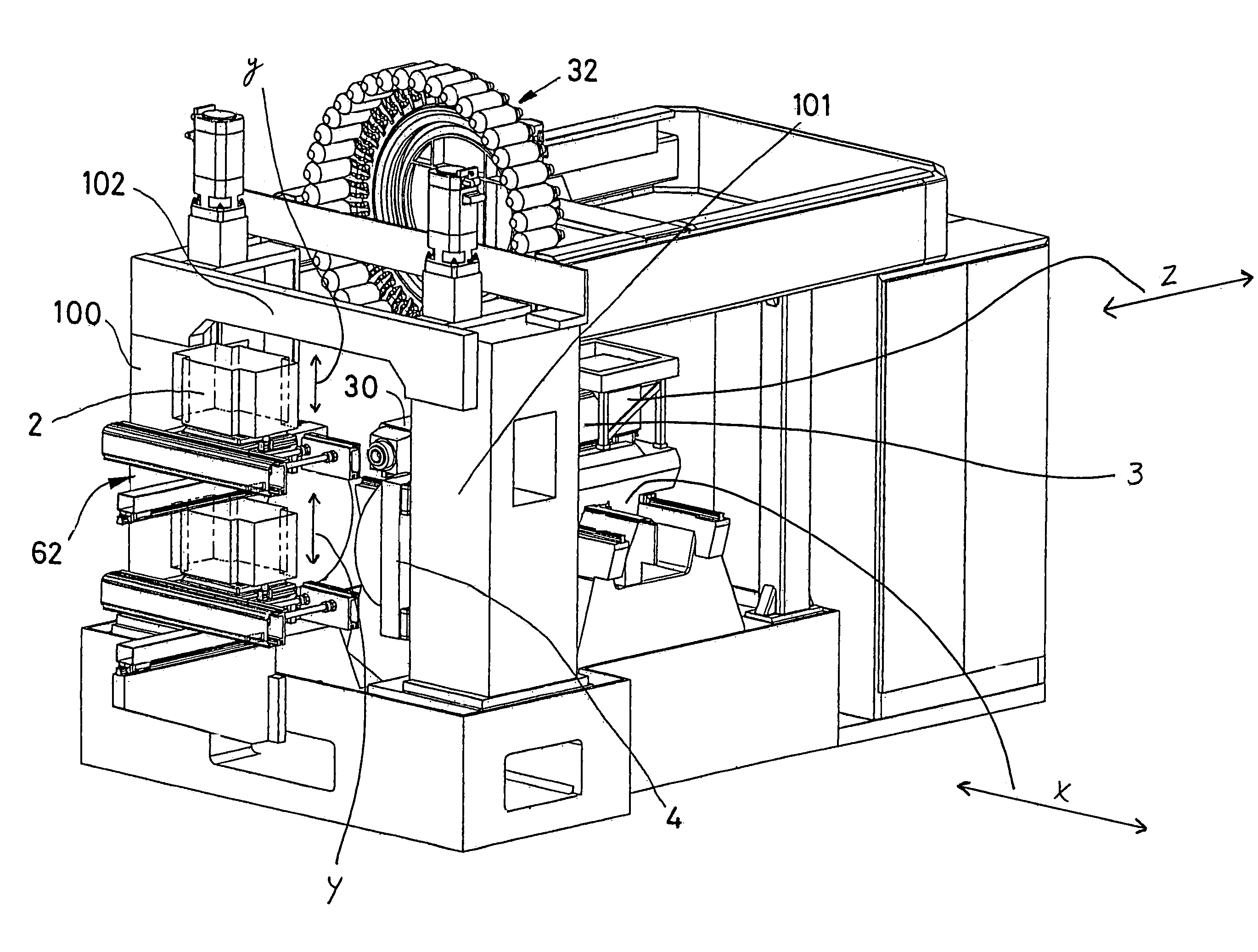

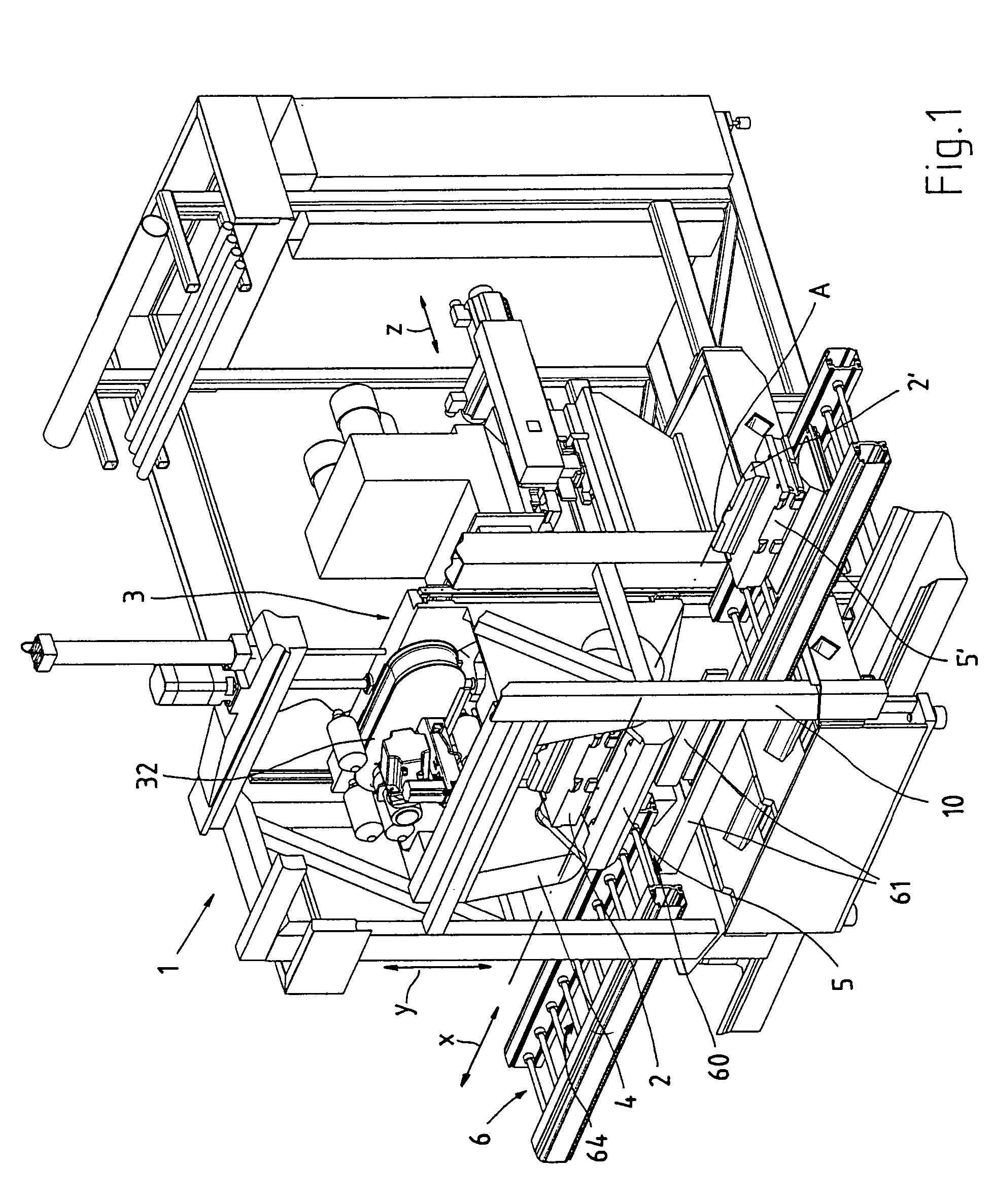

Processing machine arrangement with robot and a tool magazine

InactiveUS20070087924A1Guaranteed uptimeImprove the speed of tool changeTool changing apparatusStorage devicesEngineeringMachining

A processing machine arrangement comprises a processing machine with at least one tool spindle and with a tool magazine for offering tools to the processing machine for the machining of a workpiece. A method for the operation of such a processing machine arrangement is also provided. There is a robot with a multi-joint robot arm for providing the tool magazine with tools from a tool storage supply means and for removing spent tools from the tool magazine, and that the tool magazine includes at least one tool holder portion which is alternatingly able to be shifted, and more especially pivoted, into a robot access space for a tool change of the robot and into a spindle access space for a tool change on the at least one tool spindle such tool holder portion having at least one tool holder for holding a tool.

Owner:ALFING KESSLER SONDERMASCH

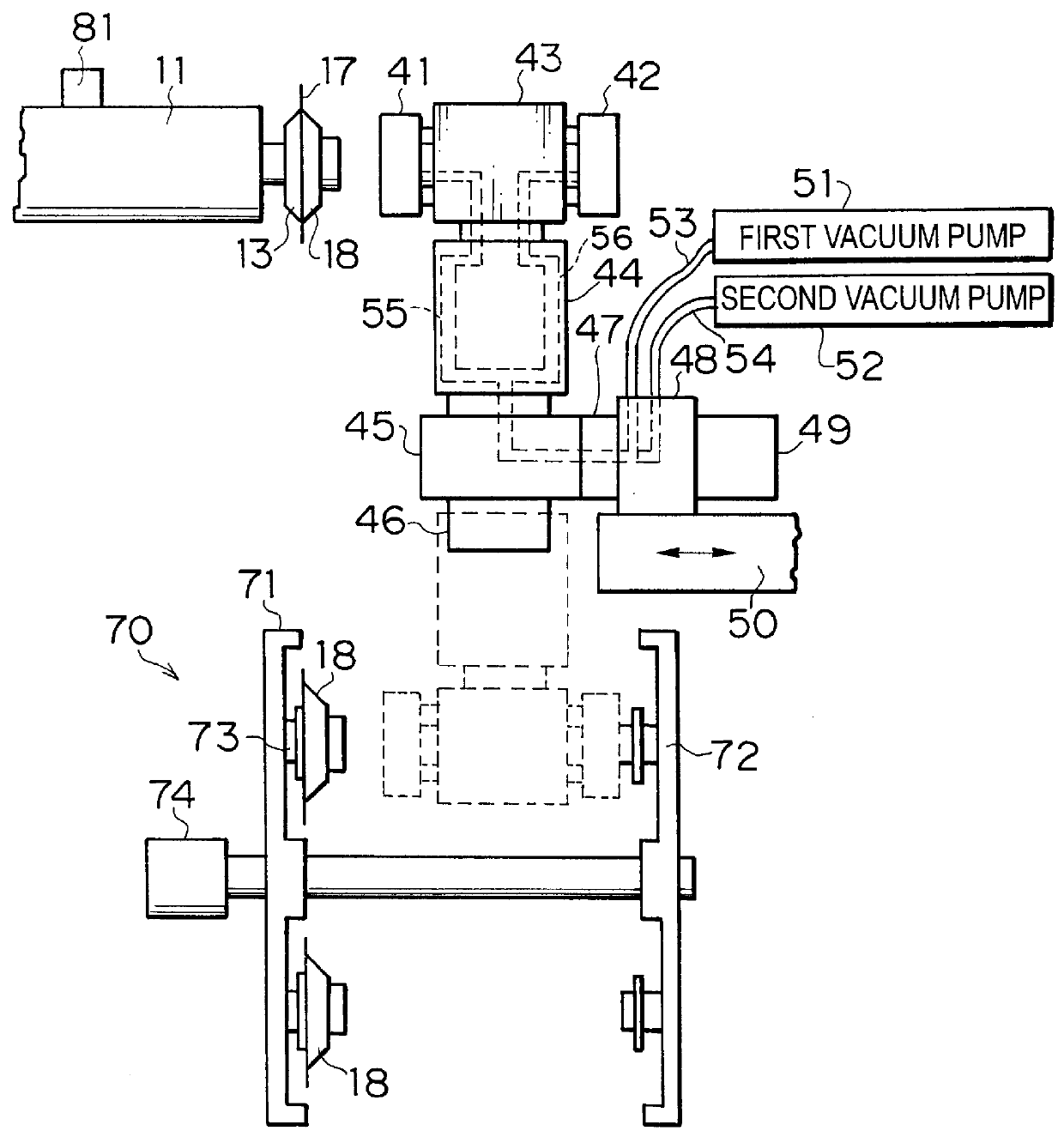

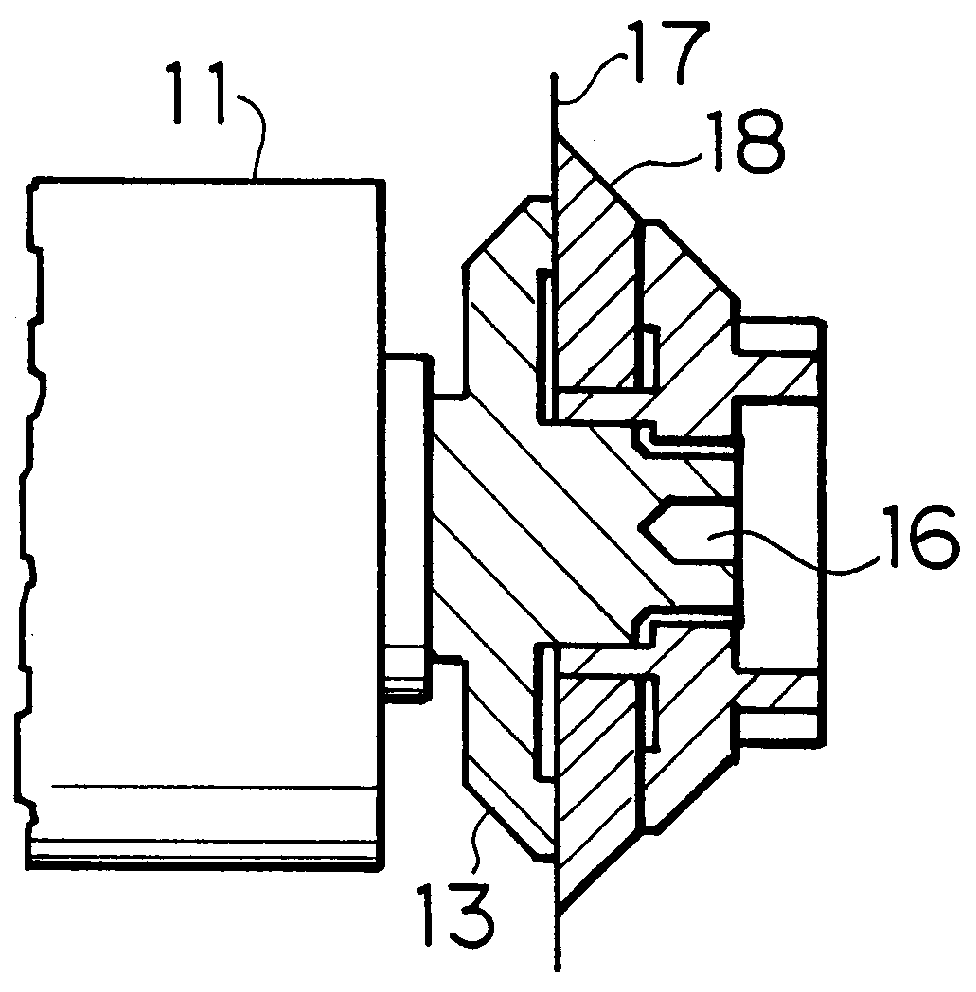

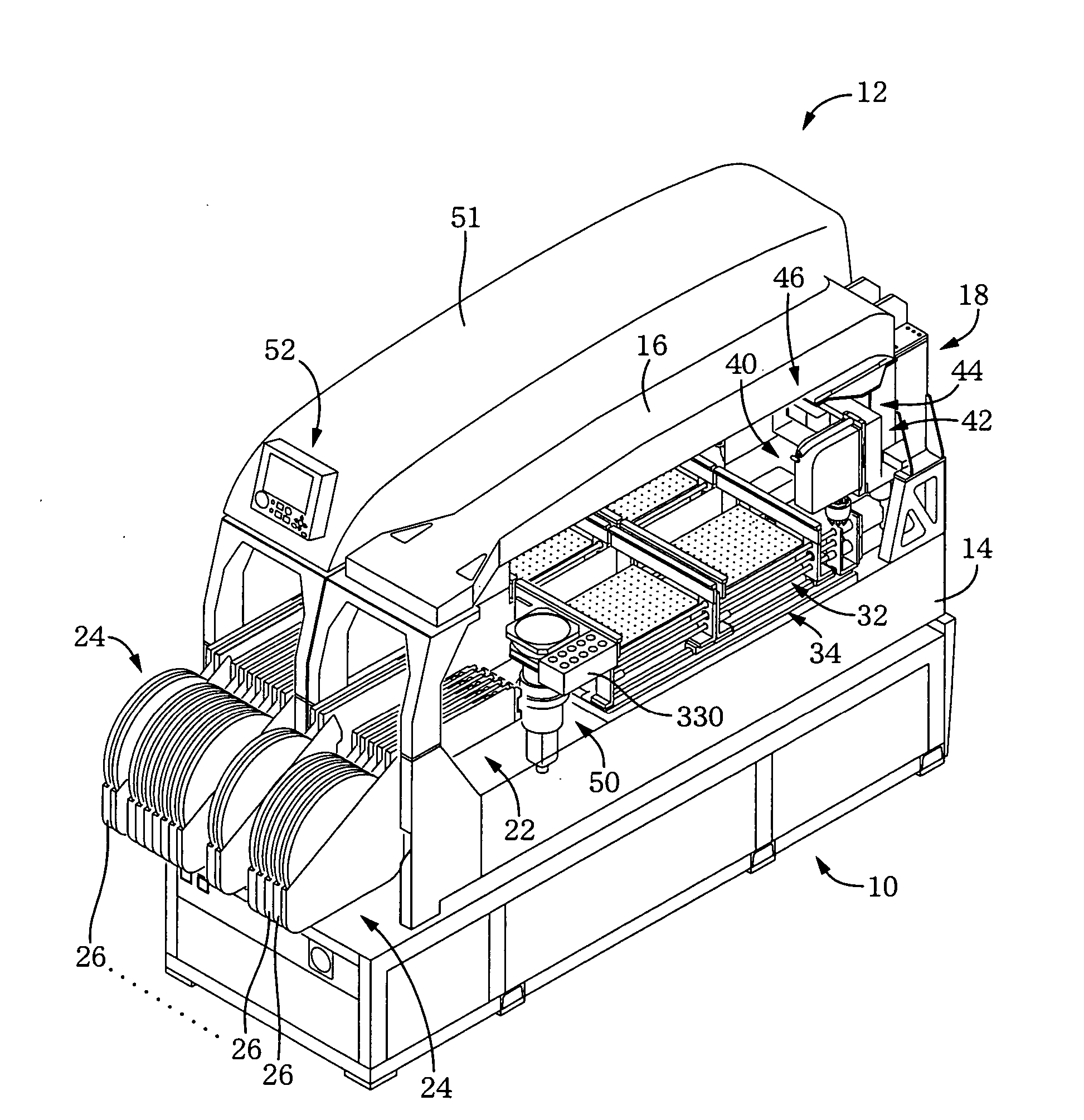

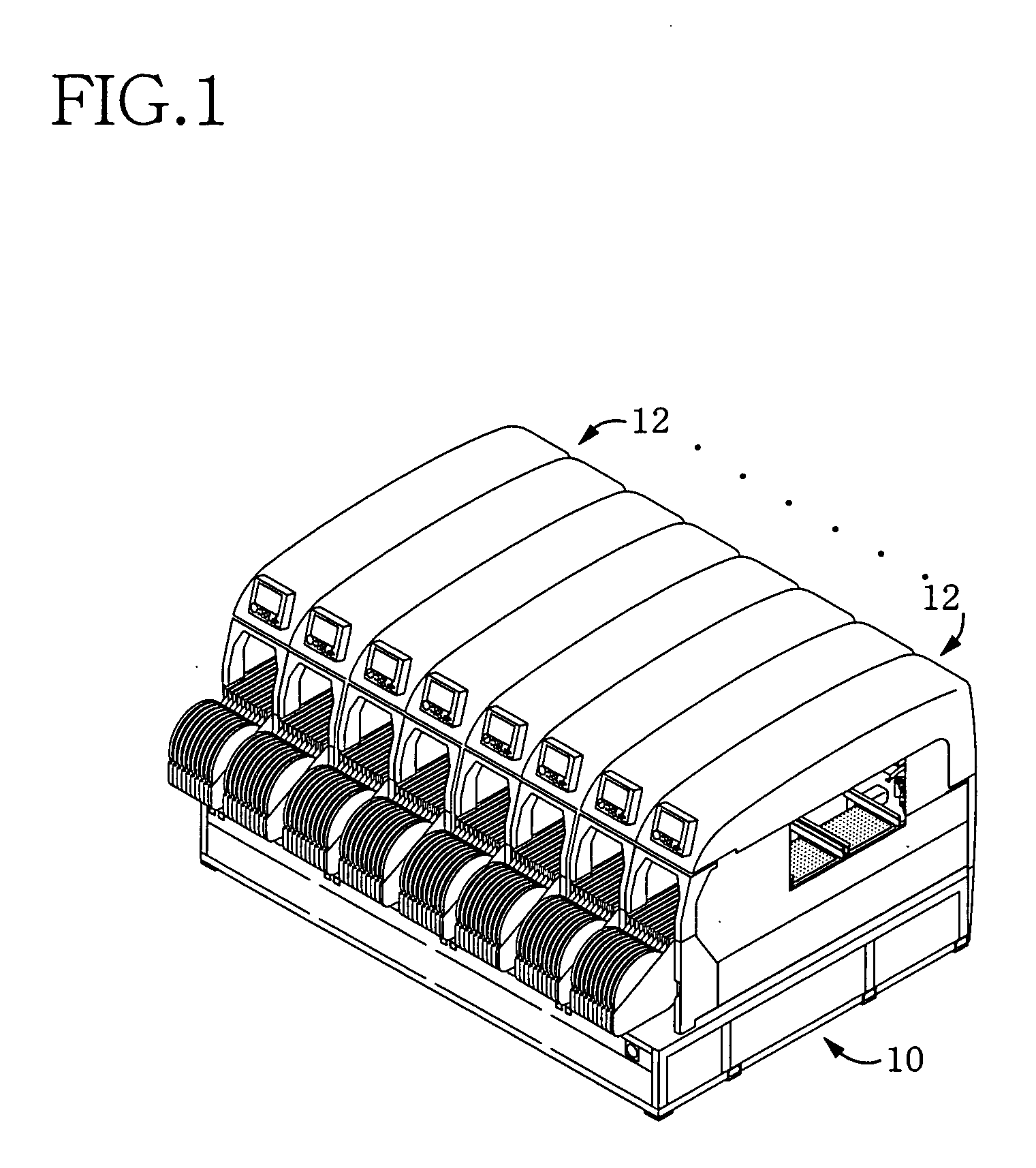

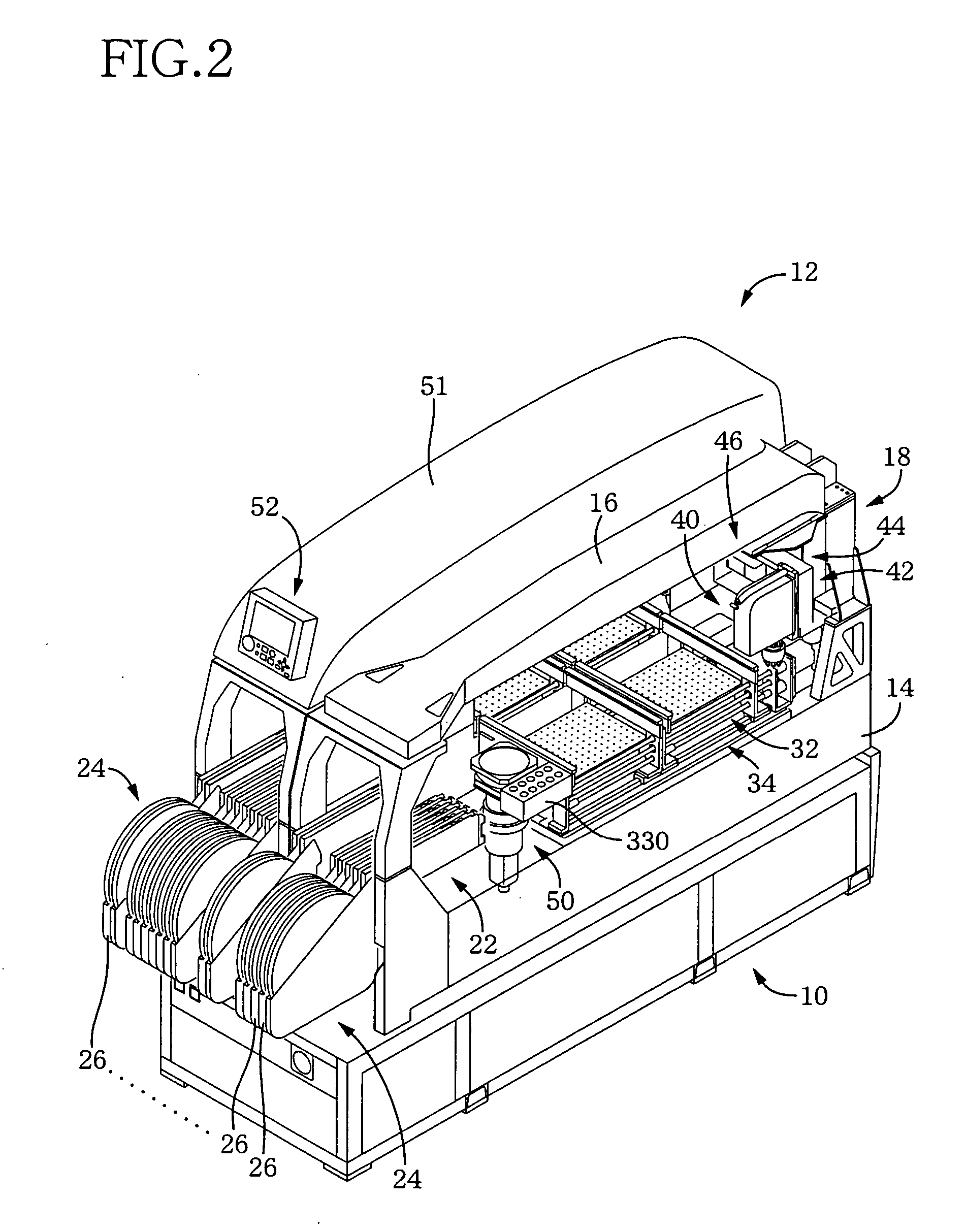

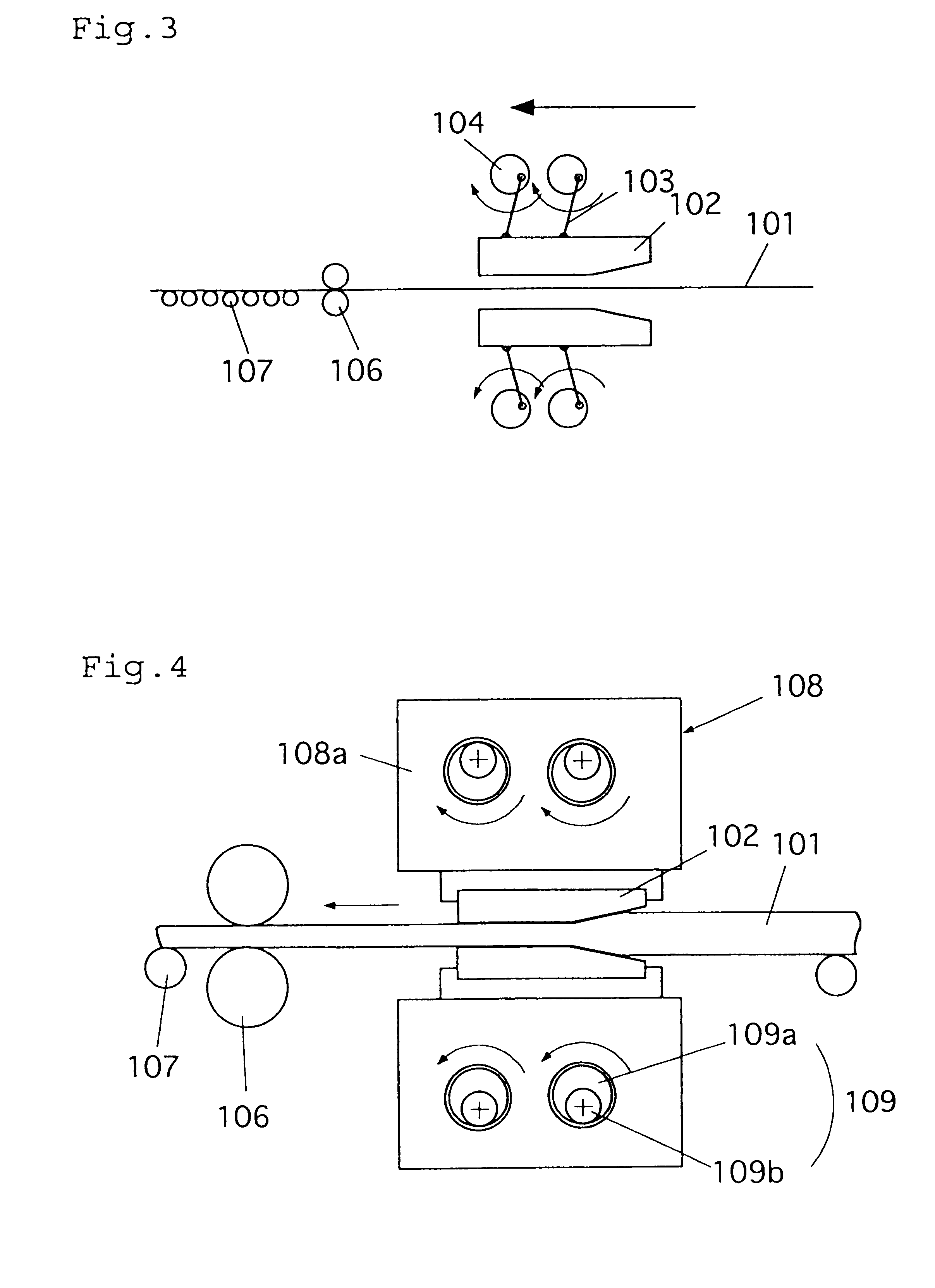

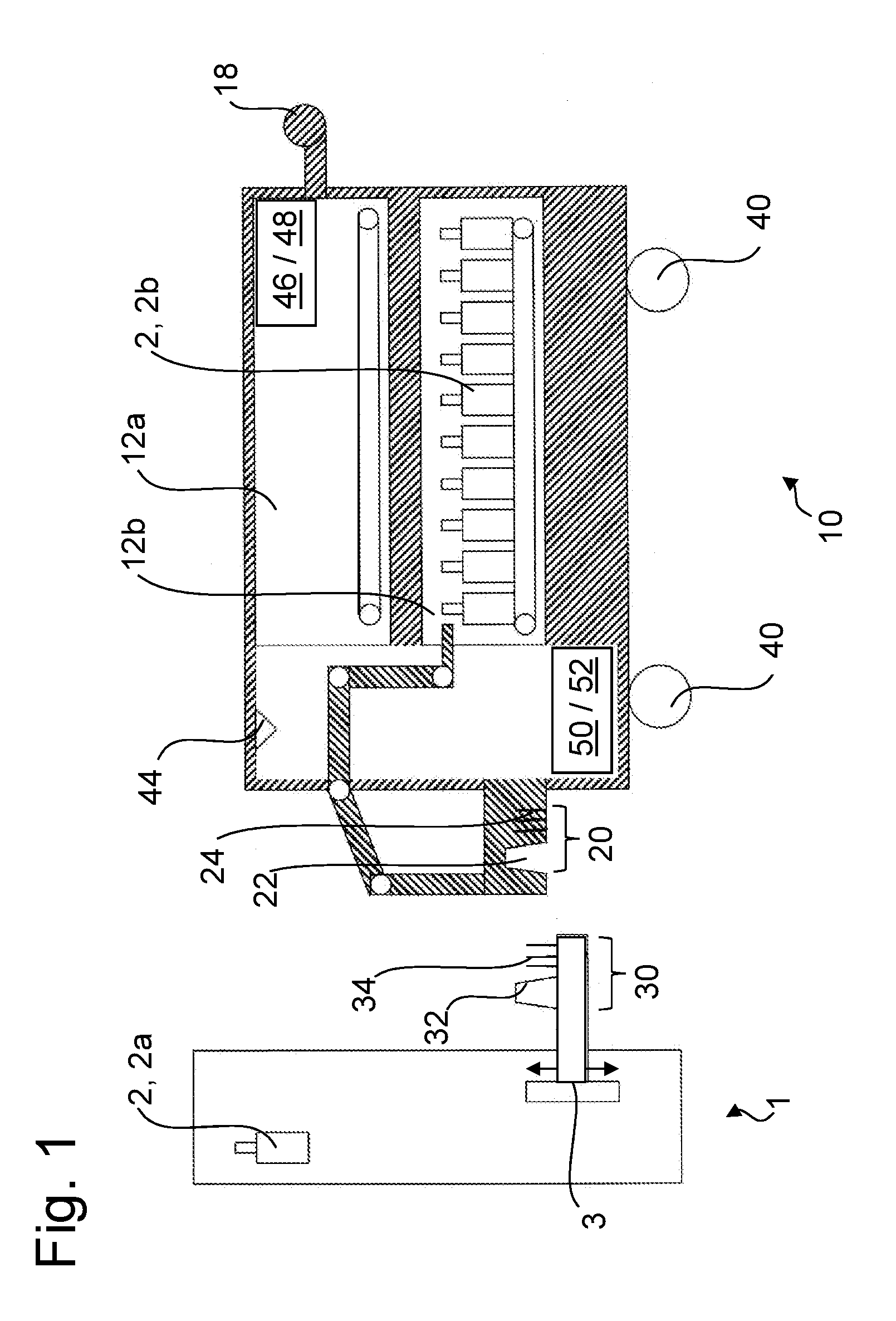

Working machine for circuit board and method of feeding component thereto

ActiveUS20060111222A1Increase the number ofEasily supplied to apparatusPrinted circuit assemblingLine/current collector detailsEngineeringBuilding construction

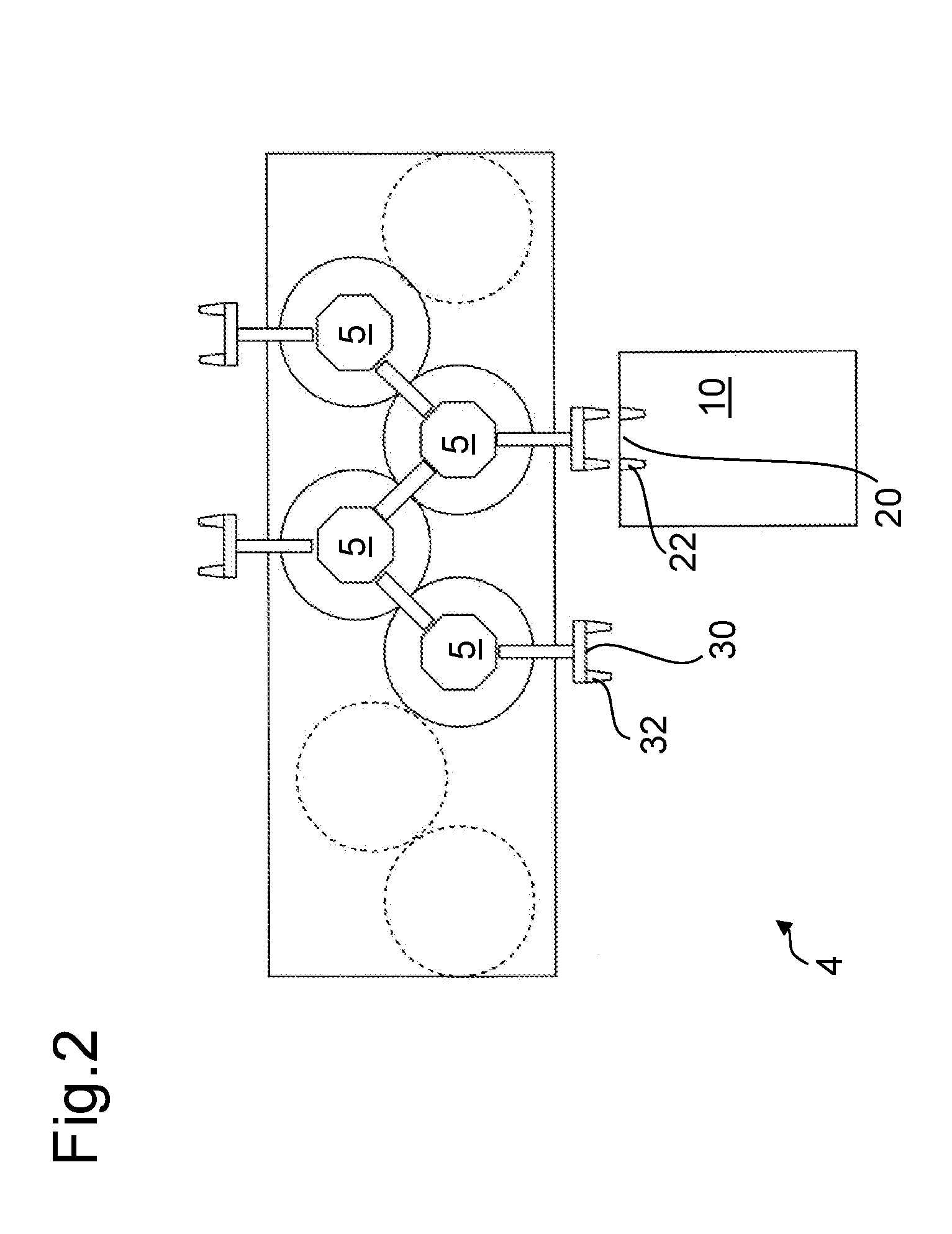

A component mounting apparatus including an exchangeable suction nozzle is easily supplied with another suction nozzle to replace the former suction nozzle. A plurality of mounting modules 12 having respective identical constructions are arranged adjacent to each other such that the mounting modules are oriented in a same direction, so that the mounting modules 12 constitute a mounting-apparatus line. When the mounting-apparatus line is reset, a mounting head 40 is used to exchange automatically suction nozzles 158 between a nozzle stocker 330 and a nozzle carrier plate 400, so that a current arrangement of suction nozzles on the nozzle stocker 330 is changed to a new arrangement of suction nozzles for the next component mounting operation. The nozzle carrier plate 400 can hold a plurality of sorts of suction nozzles 158 that are needed for the next component mounting operation but are not held by the mounting modules 12. A wiring-board conveying device 34 is used to convey sequentially the nozzle carrier plate 400 to each of the mounting modules 12 and, in a state in which the nozzle carrier plate 400 is positioned and held, one or more unnecessary suction nozzles 158 are returned to the nozzle carrier plate 400 and one or more suction nozzles 158 needed for the next mounting operation are held by one or more vacant nozzle holders.

Owner:FUJI MASCH MFG CO LTD

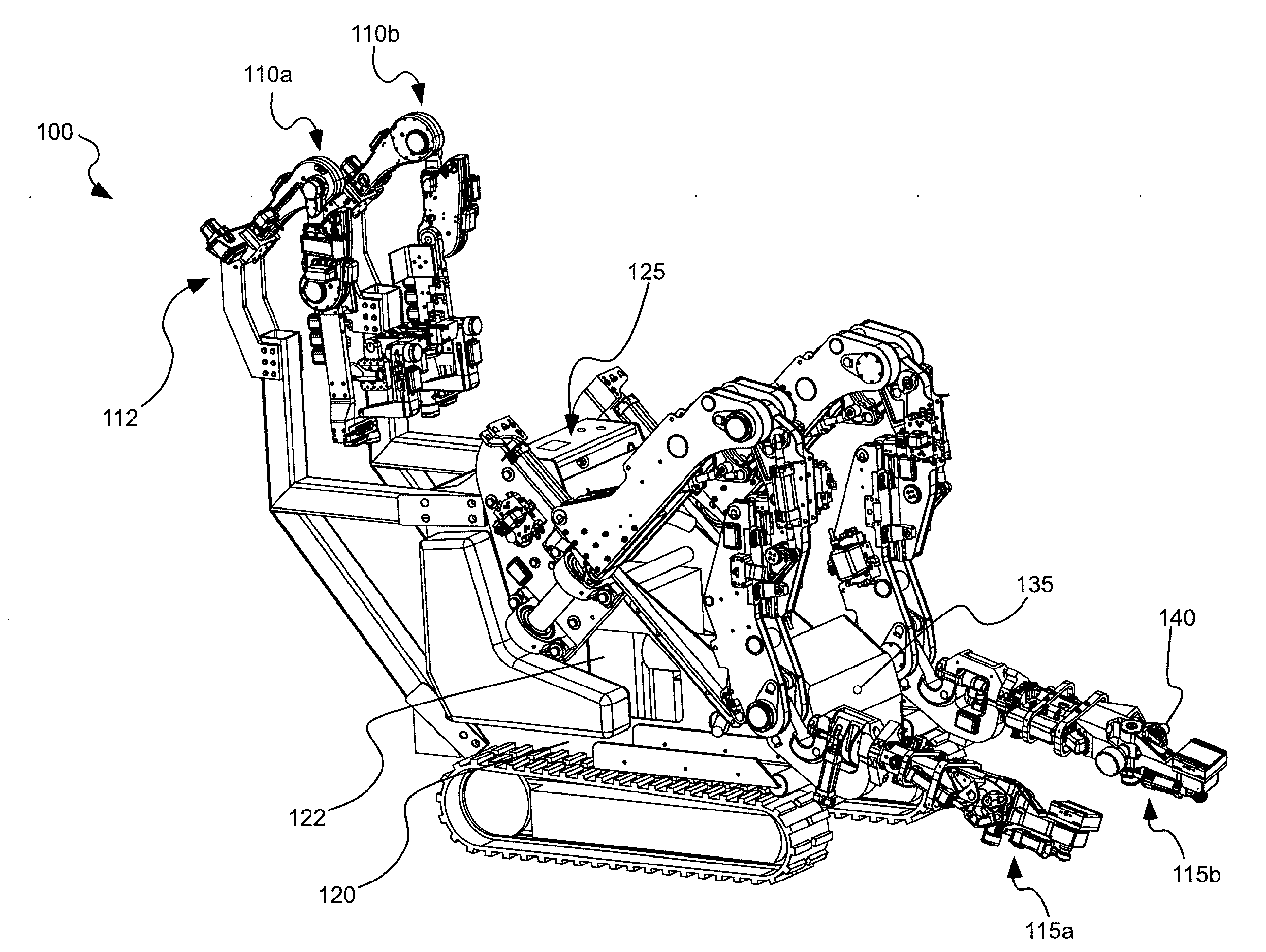

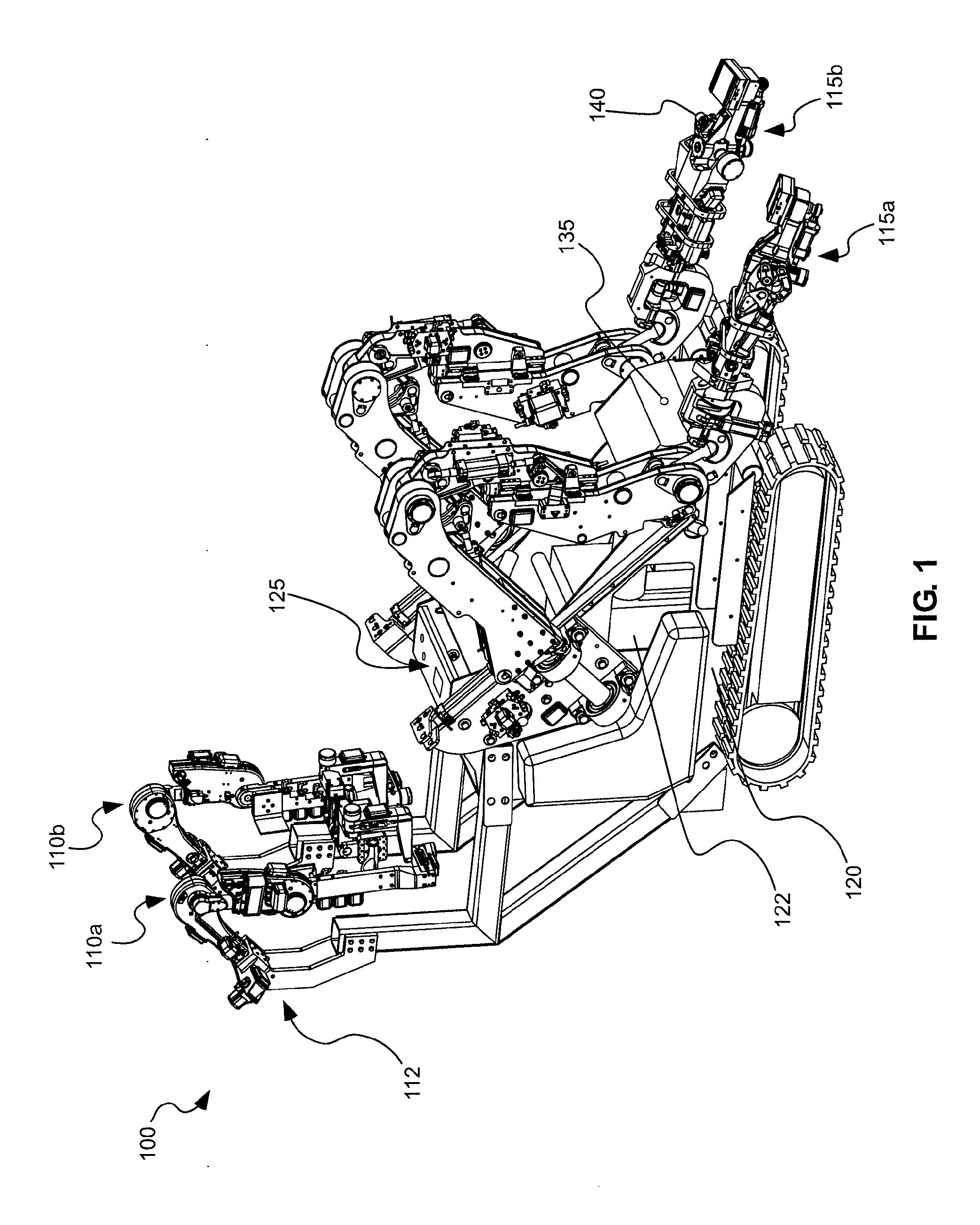

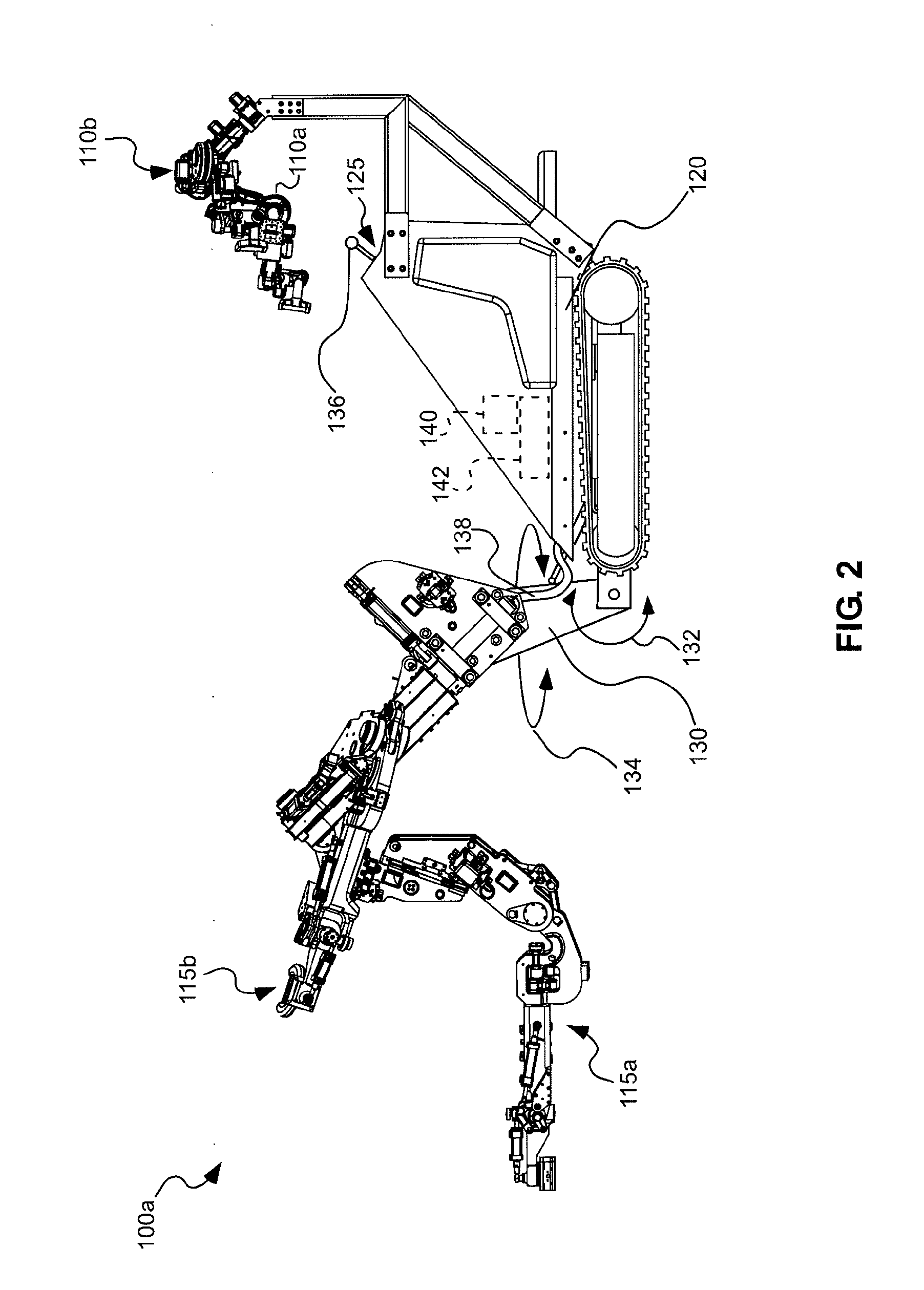

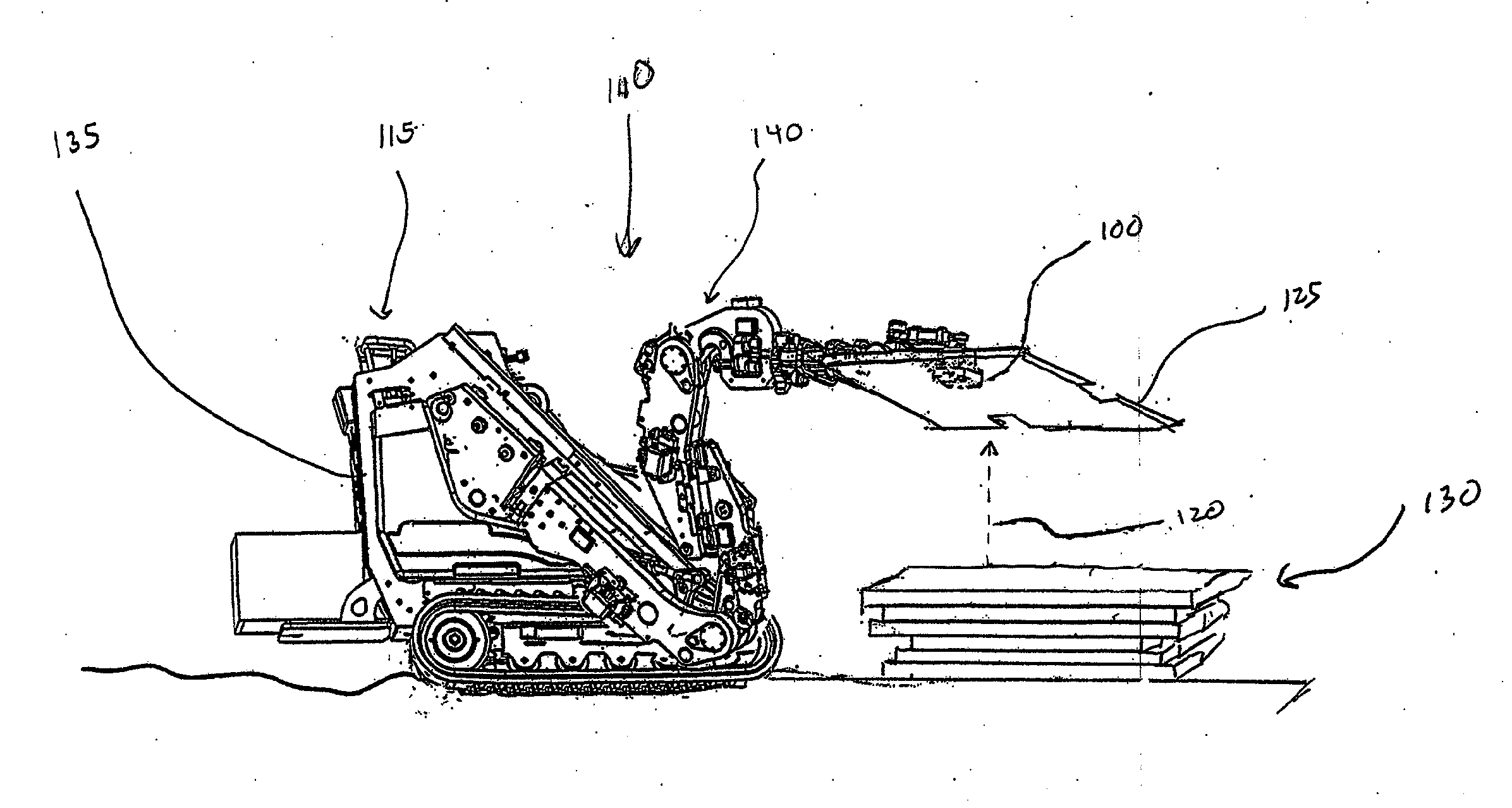

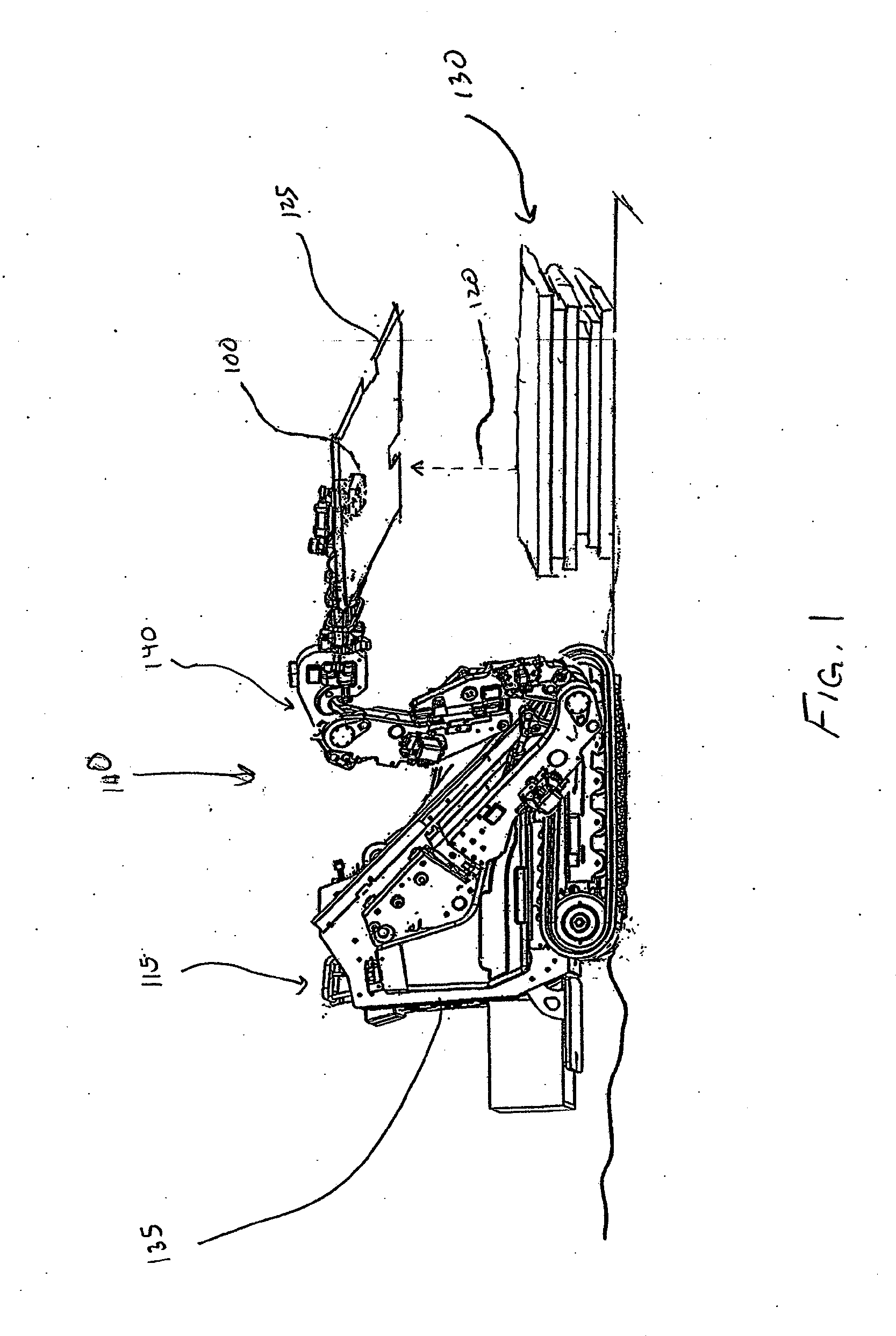

Multi-Degree of Freedom Torso Support For a Robotic Agile Lift System

A controllable robotic arm system comprises a base unit and a moveable torso coupled to the base unit. The moveable torso is capable of moving in at least one degree of freedom independently of movement of the base unit. At least one robotic slave arm is moveably coupled to the torso. A master control system is operable to control the robotic slave arm and the moveable torso. The master control system includes an input interface by which a user can cause control signals to be communicated to the robotic slave arm and the moveable torso.

Owner:SARCOS LC

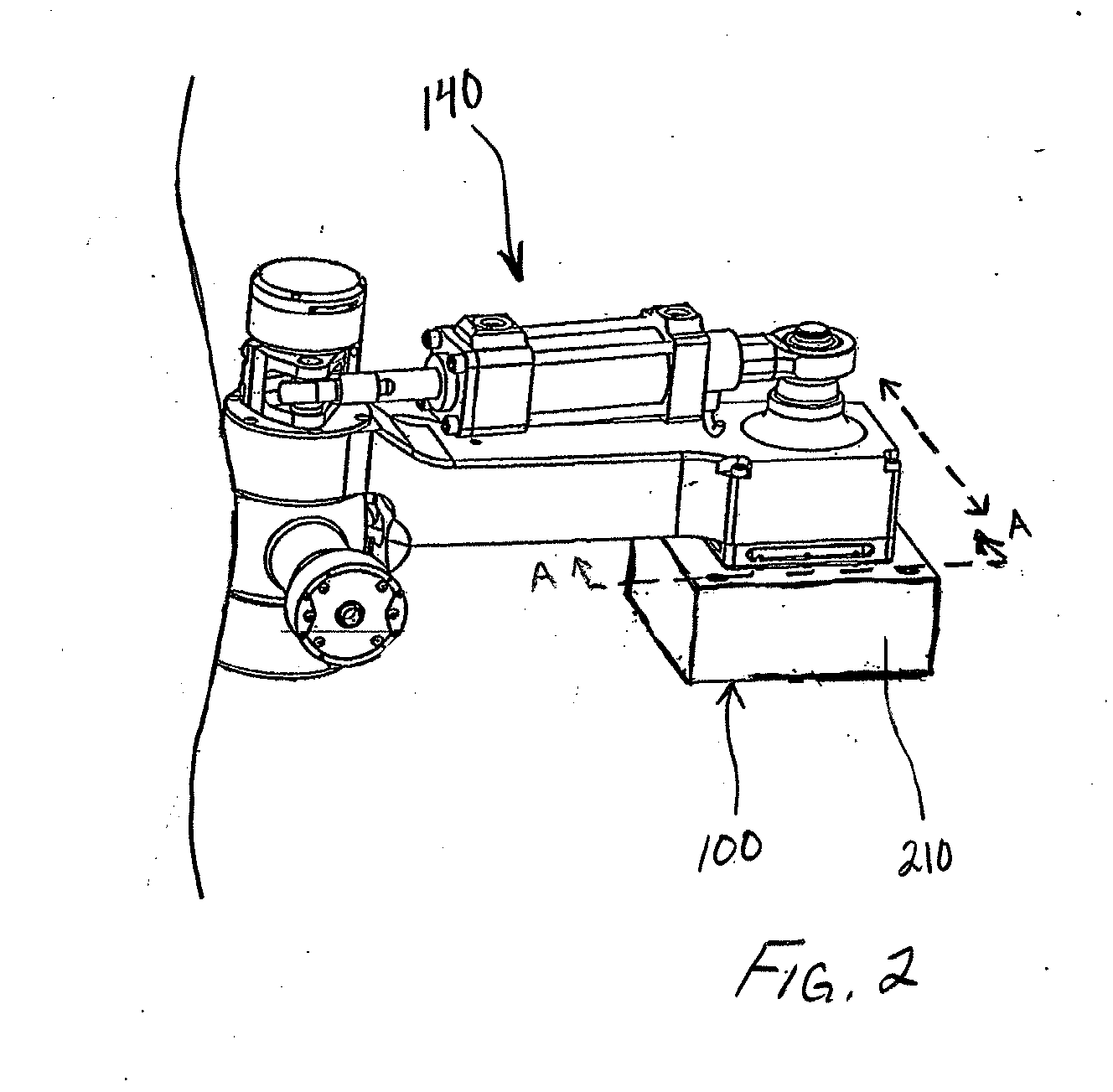

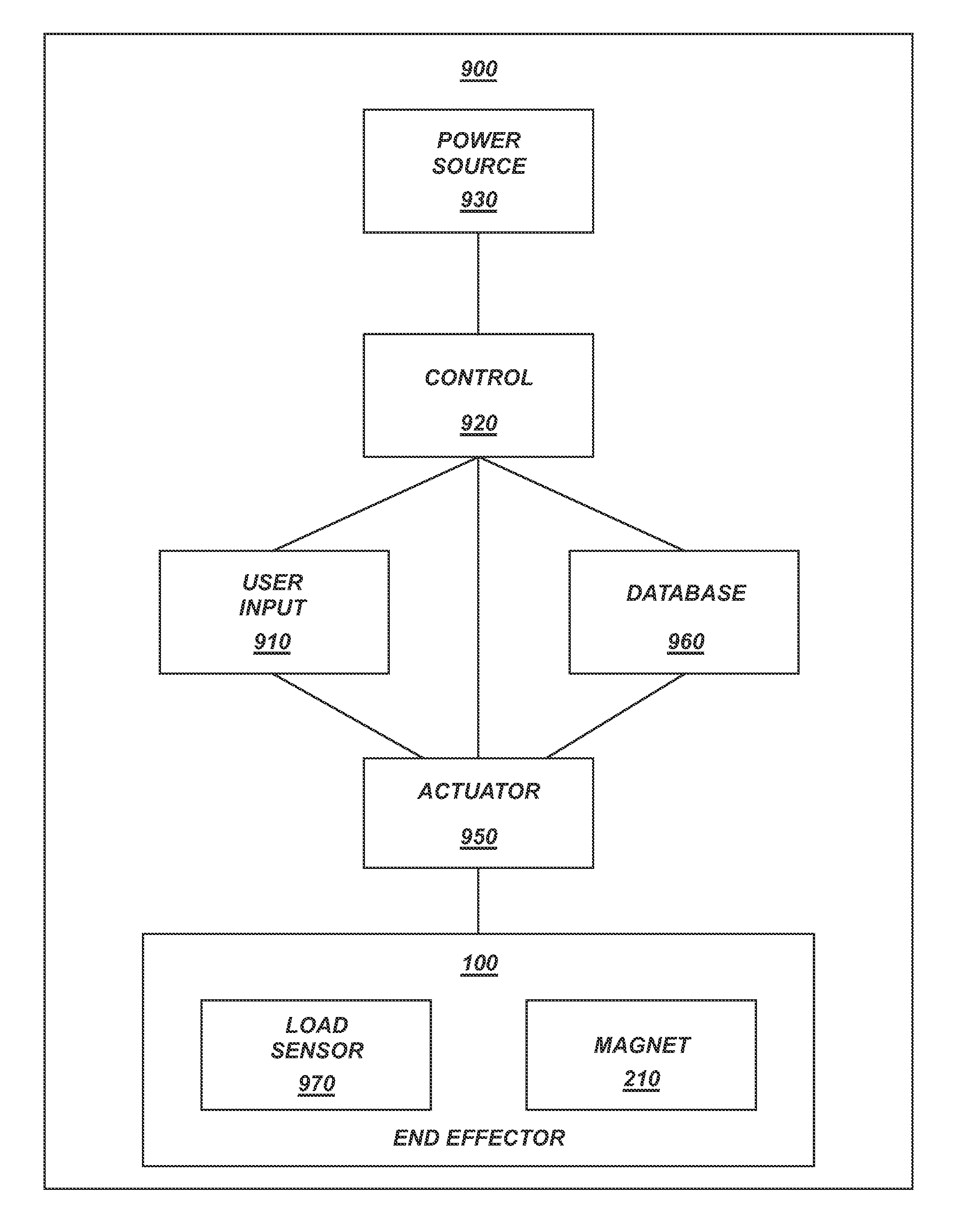

Variable Strength Magnetic End Effector For Lift Systems

A device and method for adjusting the magnetic strength of a magnetic end effector for lift systems is described. The magnetic end effector is capable of lifting discriminate payloads by selectively varying the strength of the magnetic forces output by the magnetic end effector. An actuator can be operatively coupled to the variable strength magnet end effector, wherein the actuator is selectively actuatable to control the adjustment of the variable strength magnet. The actuator may also be configured to maintain the variable strength magnet at a desired magnetic force output strength once achieved for any given amount of time.

Owner:SARCOS LC

Modular head lamination device and method

A composite item is fabricated with a device. The device includes and end effector and a positioning device. The end effector places a tow. The end effector includes a spindle, compaction device, and a path. The spindle detachably secures a spool of tow and the path is disposed from the spool to the compaction device. The positioning device positions the end effector. The end effector is detachably secured to the positioning device.

Owner:THE BOEING CO

Polishing device and polishing pad component exchange device and method

InactiveUS20010041650A1High frequencyEasy to operateGrinding wheel securing apparatusSupport wheelsRelative displacementMechanical engineering

A polishing device includes a wafer chuck mechanism which retains a wafer while its plane to be polished faces upward, a polishing pad component which possesses a polishing plane which polishes the wafer, a polishing head, and a shift mechanism which enables a relative displacement of said polishing pad component in relation to the wafer. A fixation and retention mechanism fixes and retains said polishing pad component to the polishing head in a detachable fashion while its polishing plane faces downward. The displacement distance of the shift mechanism ranges from the polishing position of the wafer to the exchange position of the polishing pad component, so that the polishing pad component is automatically exchanged.

Owner:NIKON CORP

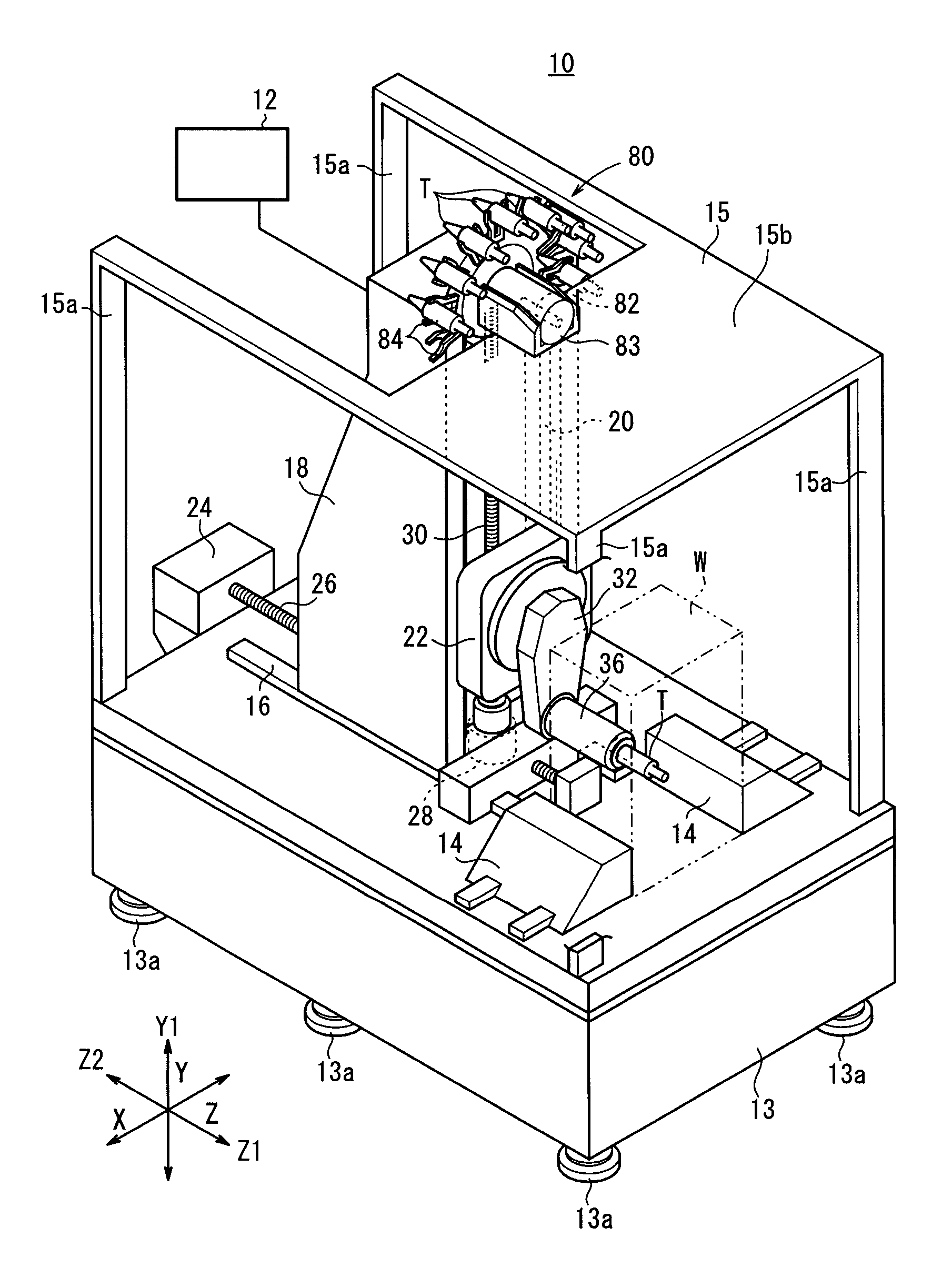

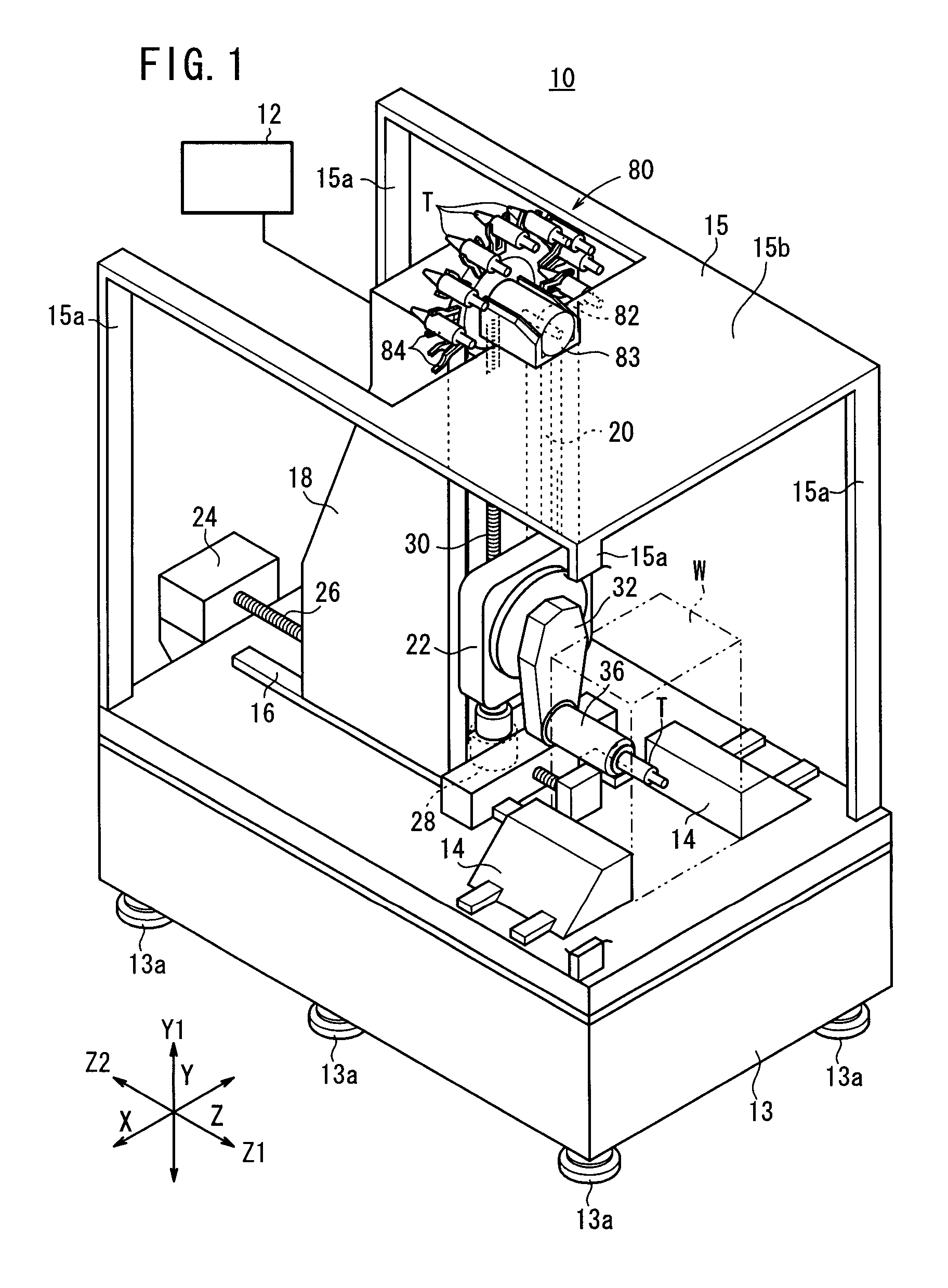

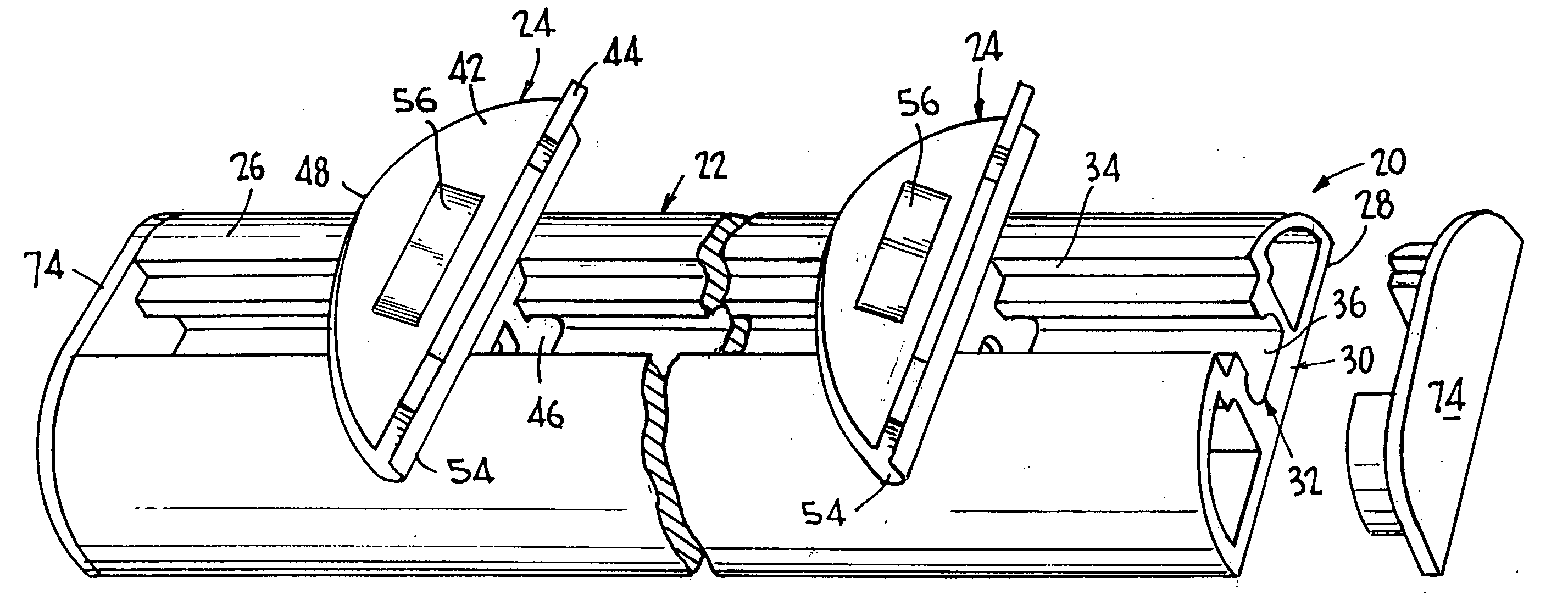

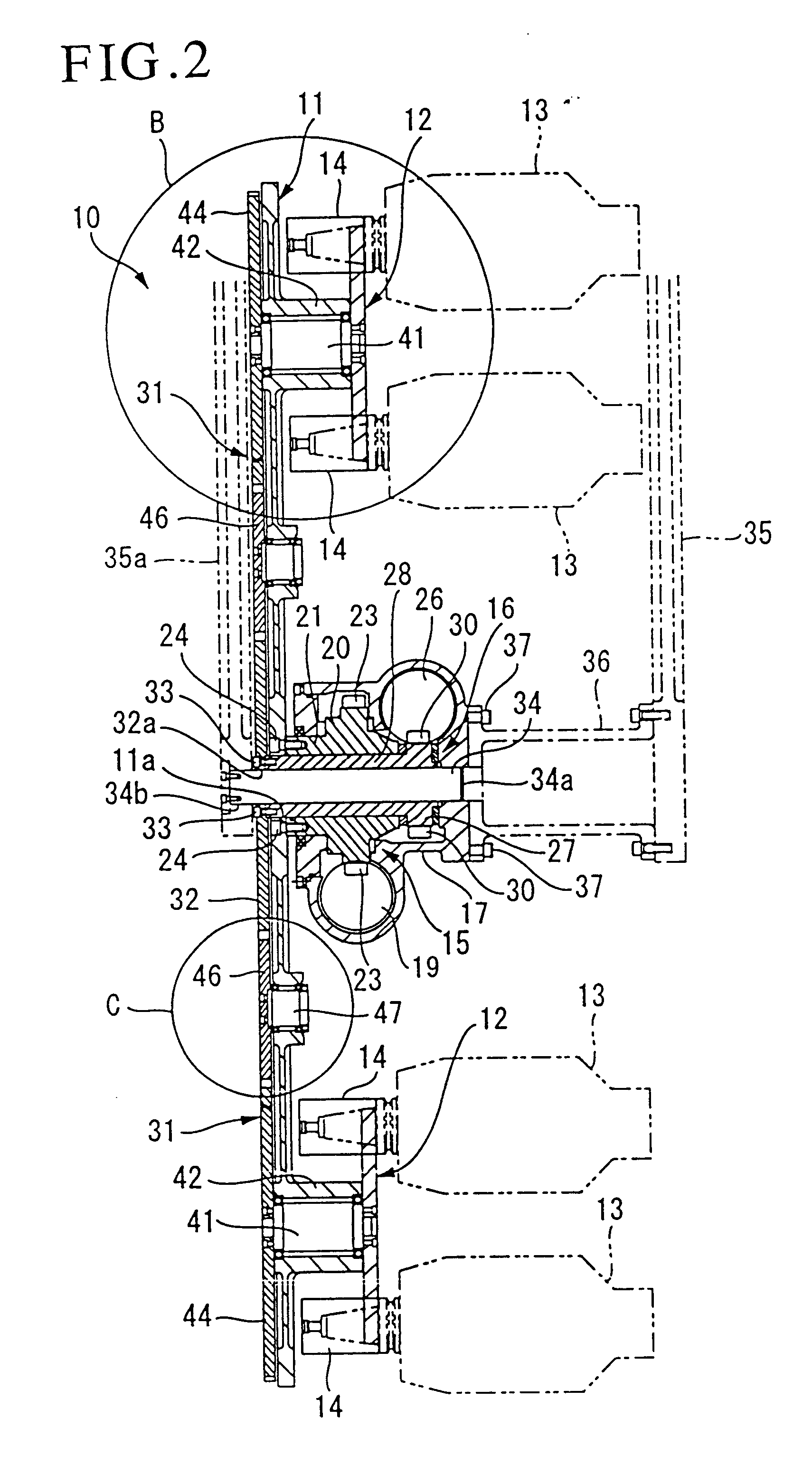

Machine tool and method of controlling machine tool

InactiveUS20090053004A1Compact structureImprove space efficiencyAttachable milling devicesTool changing apparatusVertical planeEngineering

A machine tool (10) has a Z table (18) sliding in the Z direction in a horizontal plane, a support body (22) provided on the Z table (18) and sliding in the vertical direction, a rotation arm (32) supported at the support body (22) and endlessly rotatable in a vertical plane facing work (W), an arm motor (34) for rotating the rotation arm (32), a processing spindle (36) rotatably supported and placed at a position of a distance R from the center C of rotation of the rotation arm (32), and a spindle motor (38) for rotating the processing spindle (36).

Owner:HONDA MOTOR CO LTD

Tool holder

InactiveUS20060234846A1Easy accessSmall sizeTool changing apparatusWork tools storageEngineeringWrench

A tool holder having at least one holding member with a fastener to secure at least one tool, such as a wrench or the like, on the tool holder is described. The tool holder has a body and at least one holding member with at least one fastener therein or thereon, wherein the fastener is preferably a magnet. The body is substantially elongated and has a securing member which may be substantially centered along the length of the body. The holding member(s) operatively connect to or about the body, preferably by connecting to or about the securing member of the body. The securing member is preferably a channel or a T-shaped extension member. The holding member(s) may be adjustable along the securing member or permanently fixed to the securing member such as to form a unitary tool holder so that the holding member(s) may accommodate any suitable size tool on the tool holder.

Owner:E Z RED

Variable strength magnetic end effector for lift systems

A device and method for adjusting the magnetic strength of a magnetic end effector for lift systems is described. The magnetic end effector is capable of lifting discriminate payloads by selectively varying the strength of the magnetic forces output by the magnetic end effector. An actuator can be operatively coupled to the variable strength magnet end effector, wherein the actuator is selectively actuatable to control the adjustment of the variable strength magnet. The actuator may also be configured to maintain the variable strength magnet at a desired magnetic force output strength once achieved for any given amount of time.

Owner:SARCOS LC

Receiver-puncturing device with translating puncturing devices

InactiveUS20140121085A1Less audible noiseReduce power consumptionAutomatic control devicesTool changing apparatusEngineeringPuncturing

Apparatus for selectively puncturing a moving receiver includes puncturing devices, each with two parallel puncturing wheels and a pressure wheel. A drive mechanism rotates the puncturing wheels or pressure wheel of two or more puncturing devices so that the rotating puncturing wheels engage the moving receiver to puncture the moving receiver parallel to its feed direction in the puncturing areas. A transport mechanism selectively moves the plurality of puncturing devices perpendicular to the feed direction of the receiver. A controller receives a job specification including two or more specified puncture locations and causes the transport mechanism to laterally position two or more of the plurality of puncturing devices to puncture the moving receiver in the specified puncture locations. A rotatable turret with various shaft segments can be arranged so that perforating devices can be moved on and off the shaft segments.

Owner:EASTMAN KODAK CO

Apparatus and method for changing dies

The die changing apparatus for a plate reduction press machine, comprises an upper die support holder 28a and a lower die support holder 28b that are arranged vertically on opposite sides of a transfer line, and support holder guide rails 31 installed on the upper die support holder and extending substantially horizontally in the lateral direction of the transfer line, and an upper die 29a and a lower die 29b are mounted on the upper and lower die support holders, respectively using the rollers onto the dies, fixing devices 30 that fix the upper and lower dies on the upper and lower die support holders, respectively, die fastening members 38 which are placed on each side of the upper and lower dies, opposite each other in such a manner that they can be fastened to both dies, and a die changing mechanism that can move one of the die fastening members in a direction perpendicular to the transfer line.

Owner:JFE STEEL CORP +2

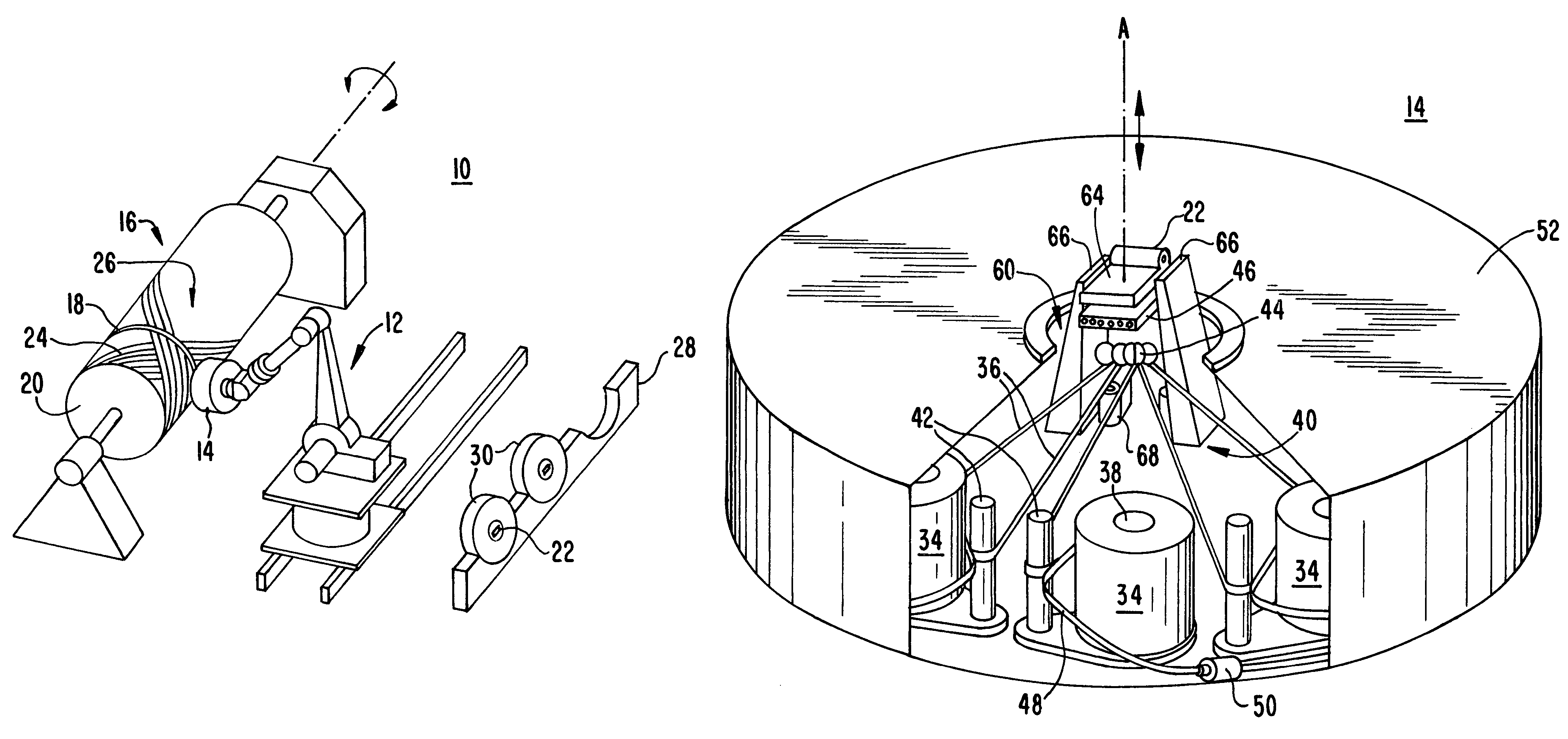

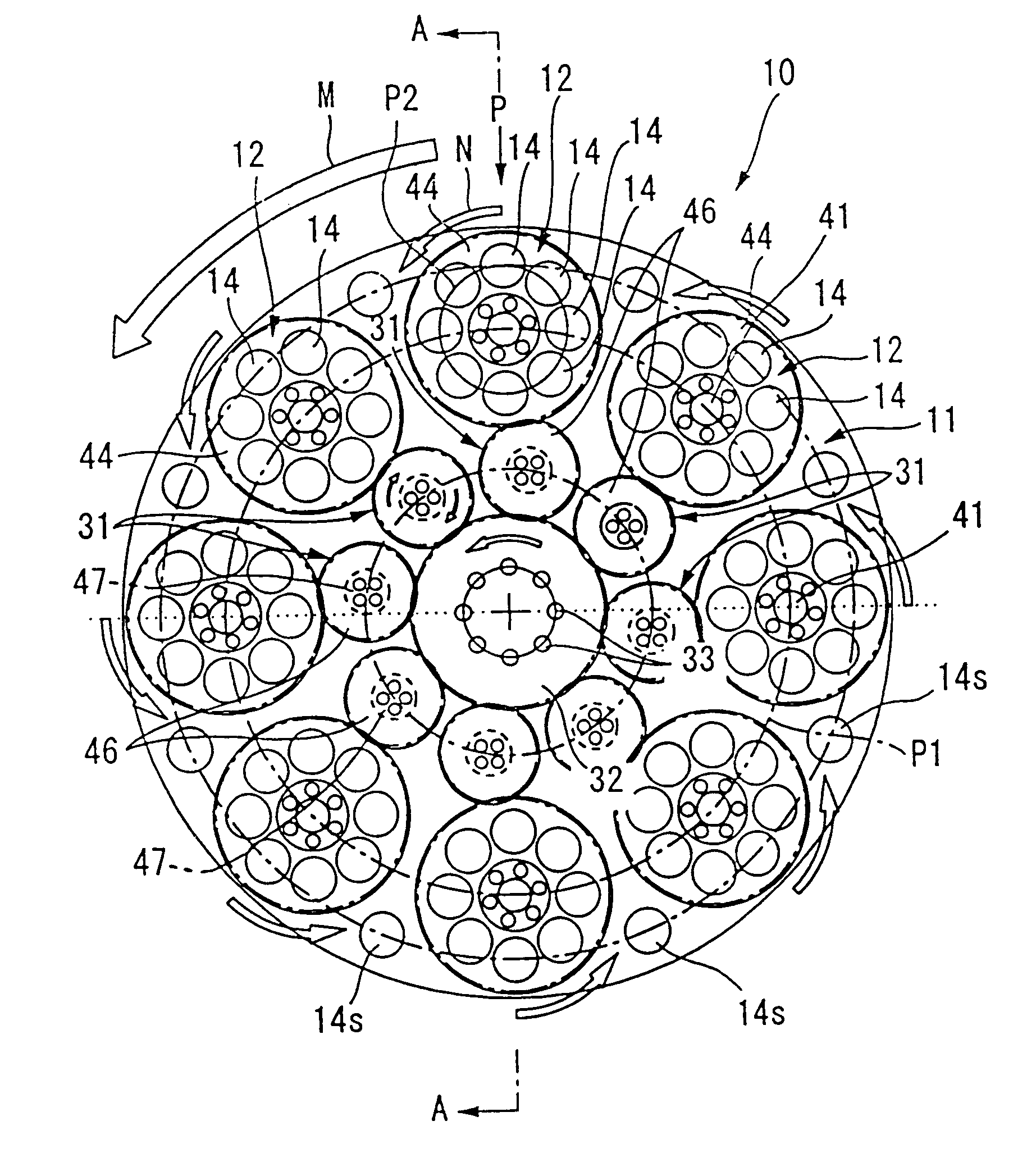

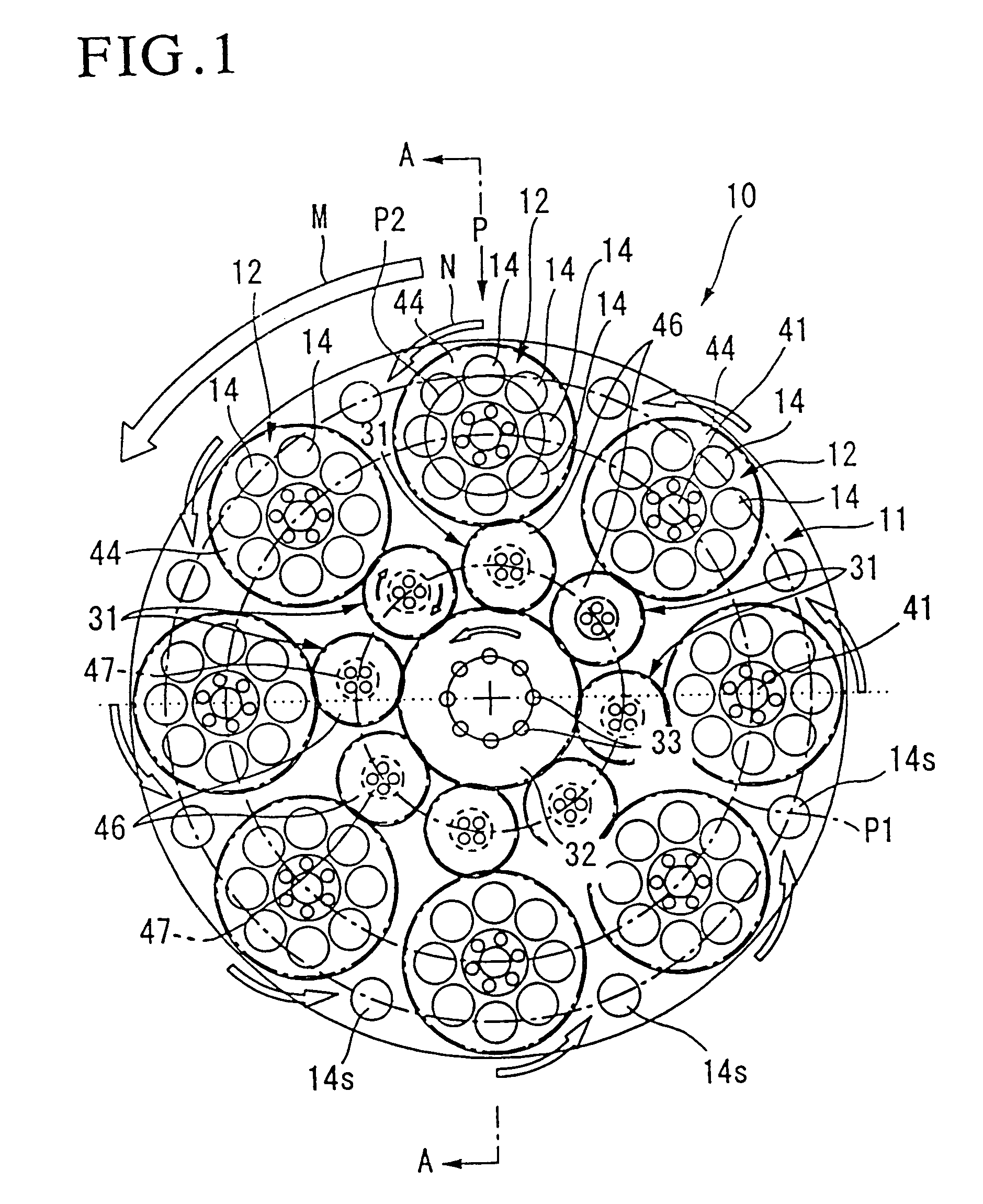

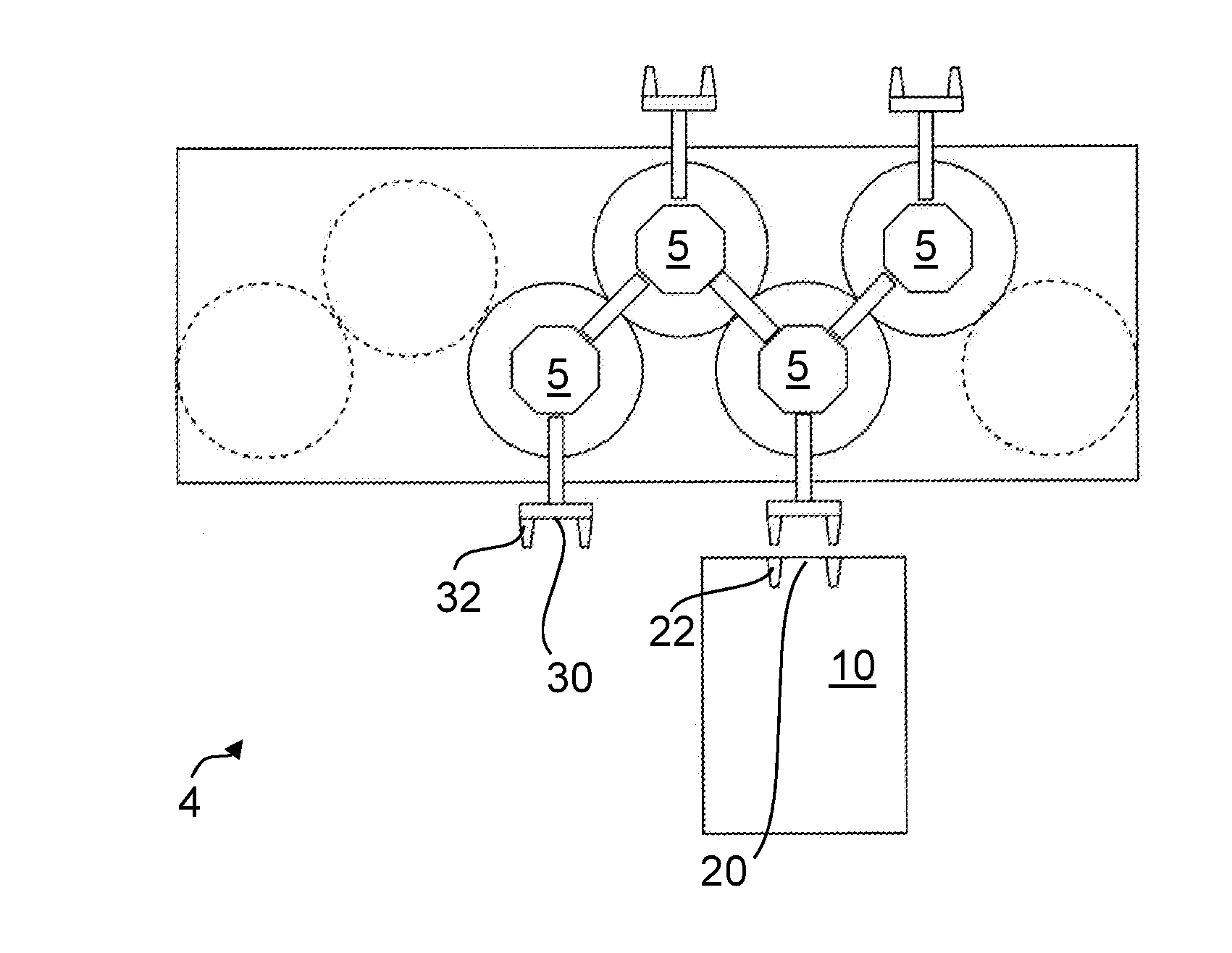

Tool Magazine

InactiveUS6716146B2Small sizeEfficient comprehensive utilizationMechanical apparatusPrecision positioning equipmentEngineeringMachining

A automatically indexing tool magazine, of the type attached to machining centers that incorporate an automatic tool change function, able to hold a relatively large number of tools in a compact space as means of improving space efficiency. The tool magazine is comprised of a rotatable main table and multiple sub-tables rotatably attached to the main table in a uniformly spaced radial pattern, each sub-table being equipped with a number of tool pots likewise arranged in a uniformly spaced radial pattern. The tool pots serve as containers into which machining tools can be inserted or removed. The main table and sub-tables are rotatably indexed by means of respective main table and sub-table indexing mechanisms. The tool pot holding the tool designated for removal is transported to a tool removal position through the rotational indexing movement of the main table and appropriate sub-table.

Owner:SANKYO SEISAKUSHO

Drill accessory

A tool for a power drill allows fast and convenient loading and unloading of a screw bit, drill bit, or other implement. The user preferably loads the tool with the necessary implements which are then carried with the tool. Each received implement is movable from a storage position to an in use position in drive engagement with the power drill or power screwdriver. The desired implements can rapidly be changed from one to the other, while the implements are retained on the tool.

Owner:BAI LI KUN

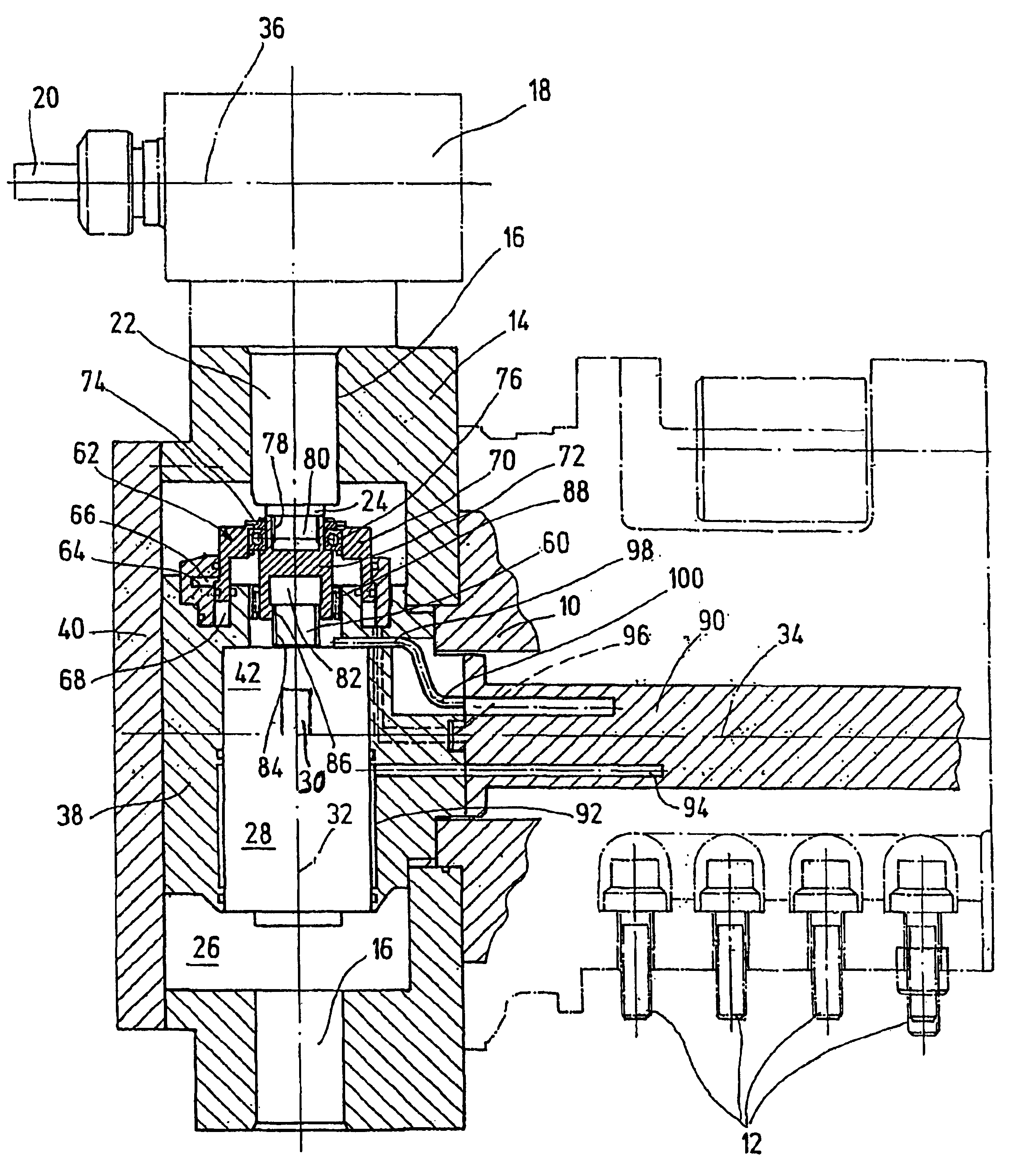

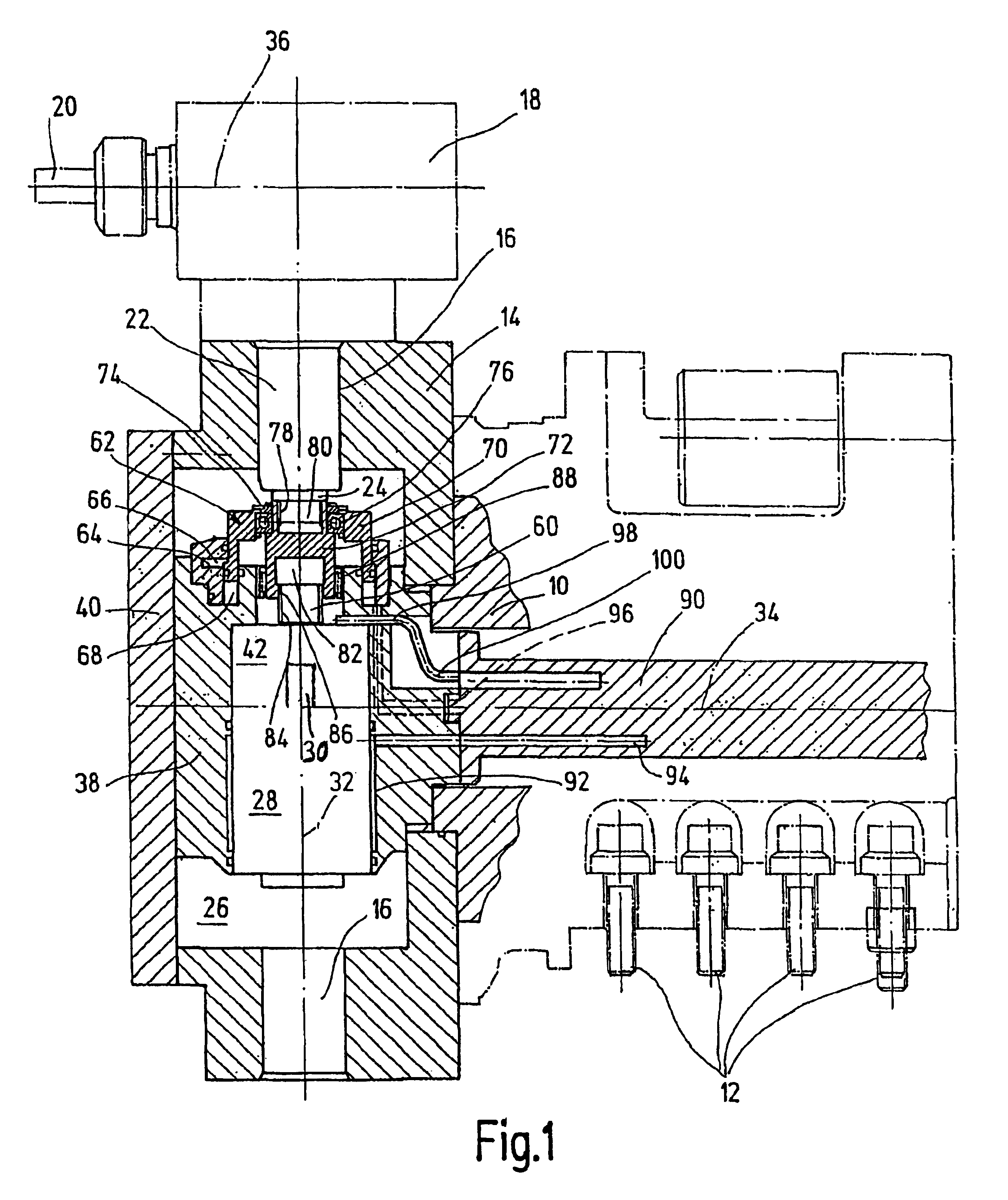

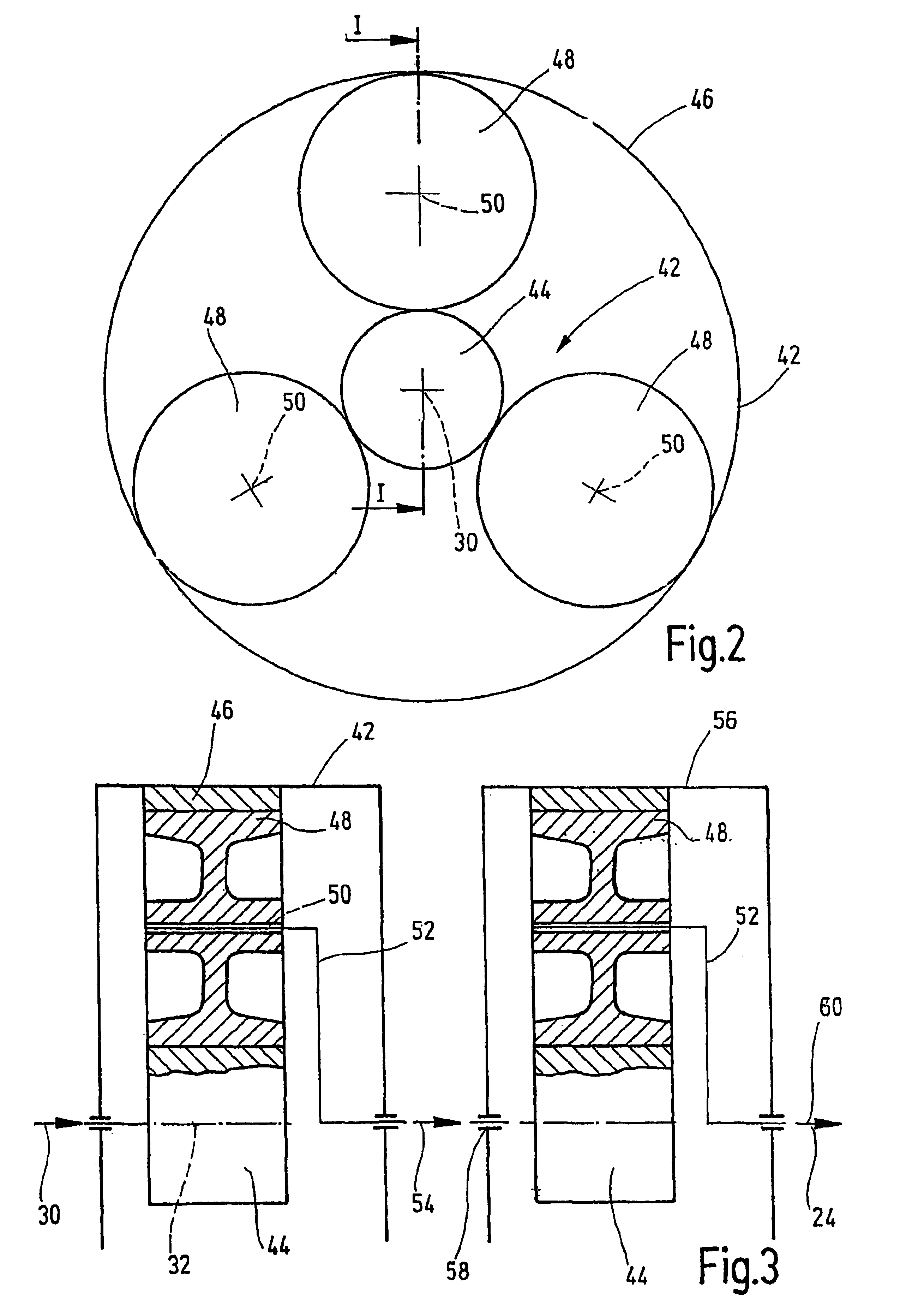

Tool turret

InactiveUS6925694B2Less structural spaceReduce maintenance costsMechanical apparatusThread cutting machinesElectric driveDrive motor

A tool turret includes a housing (10) for connection to a machine tool, and an electric drive motor (28). A tool disk (14), is mounted to rotate relative to the housing (10) about a longitudinal axis (34), may be fixed in selected angular positions, and has recesses (16) for machining tools (18). At least one rotating machining tool (18) may be driven by the drive motor (28) using shafts (24, 30), extending perpendicular to the longitudinal axis forming the swiveling axis of the tool disk (14). The electric drive motor (28) is arranged within the tool disk (14). The driveshaft (30) from the electric drive (28) is aligned with the driveshaft (24) for the machining tool (18), and is aligned with the driveshaft (24) for the machining tool (18) or extends parallel to it. An economical drive design for machining tools on a tool turret is achieved, with a small installation volume.

Owner:ZEITFRACHT GMBH & CO KGAA

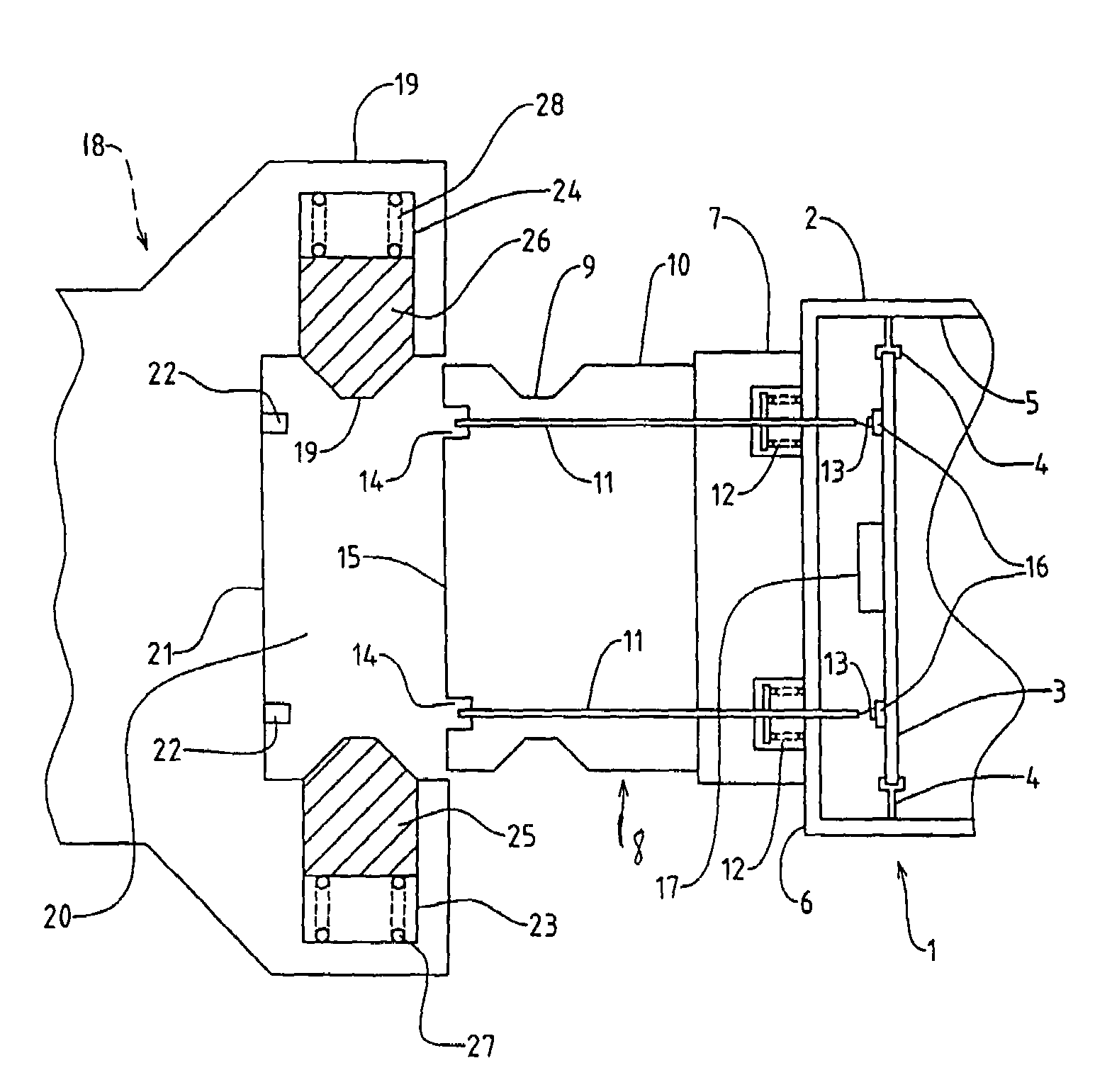

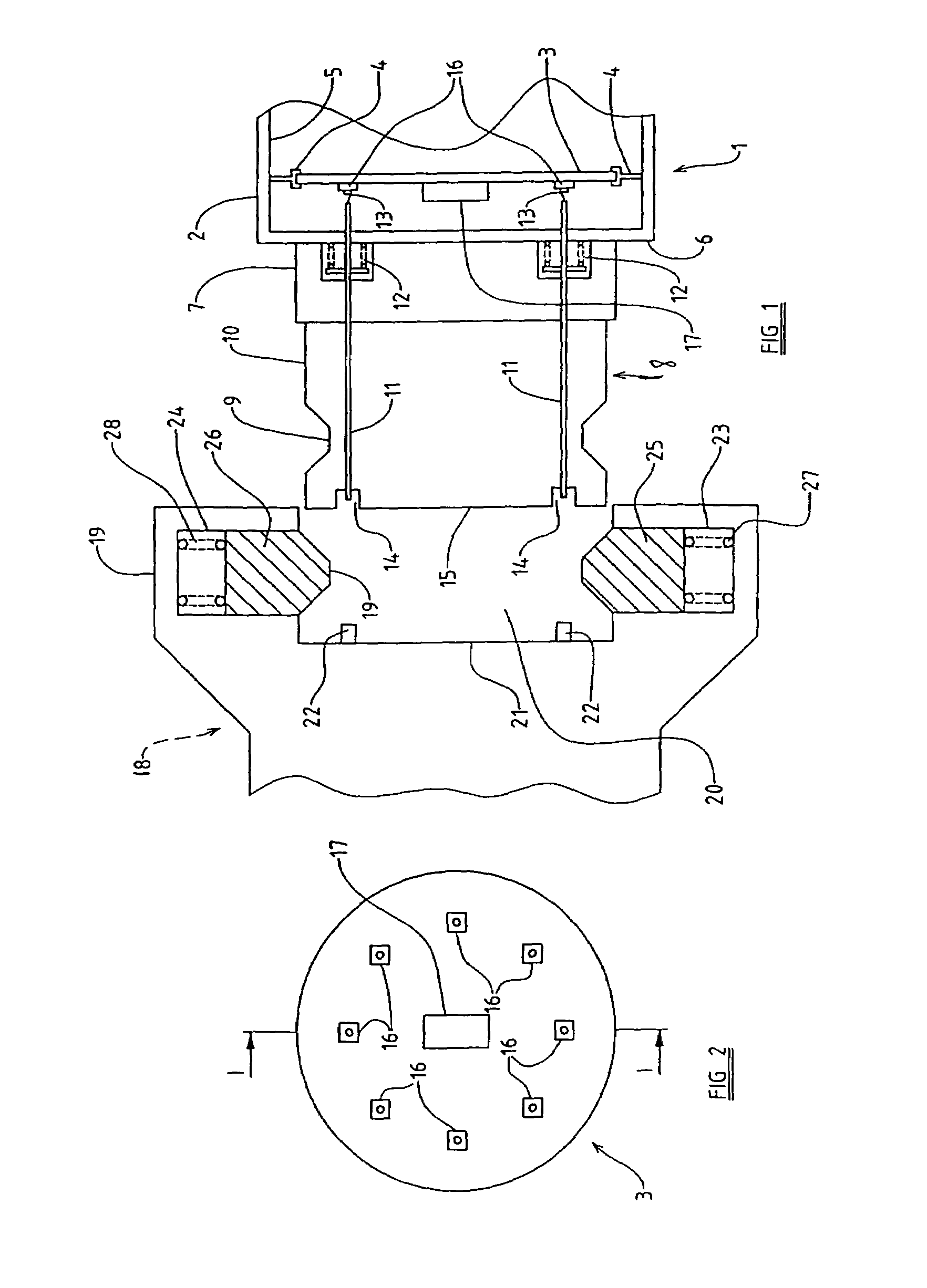

Machining station

ActiveUS7150706B2Low production costMeasurement/indication equipmentsTool changing apparatusEngineeringMachining

A machining station, at least one machining unit, in particular a tool spindle, being provided for the machining of workpieces. The workpiece is approached to a discharge point and picked up there by a workpiece carriage. The workpiece carriage moves the workpiece for a machining to the machining unit or moves the workpiece during its machining through the machining unit.

Owner:GROB WERKE & K G

Container treatment system and handling device

InactiveUS20140305076A1Easy to detectEasy to identifyPackage sterilisationTool changing apparatusIndustrial engineeringTreatment system

A container treatment system (1, 13) that has at least two working areas (AP). Each of the working areas (AP) respectively comprises at least one exchangeable working tool (2) and / or one adaptable format part. Furthermore, the container treatment system (1, 13) comprises at least one handling device (10) which is movable, in particular drivable, to the at least two working areas (AP), which handling device (10) can be connected selectively to any of the respective working areas (AP), in particular using centering means (22, 32), and which handling device (10) comprises tools for exchanging the working tools (2) and / or for adapting the format parts of the respective working area (AP). The invention further relates to a handling (10) device for exchanging working tools (2) and / or for adapting the format parts of at least two different working areas (AP) of a container treatment system (1, 13).

Owner:KRONES AG

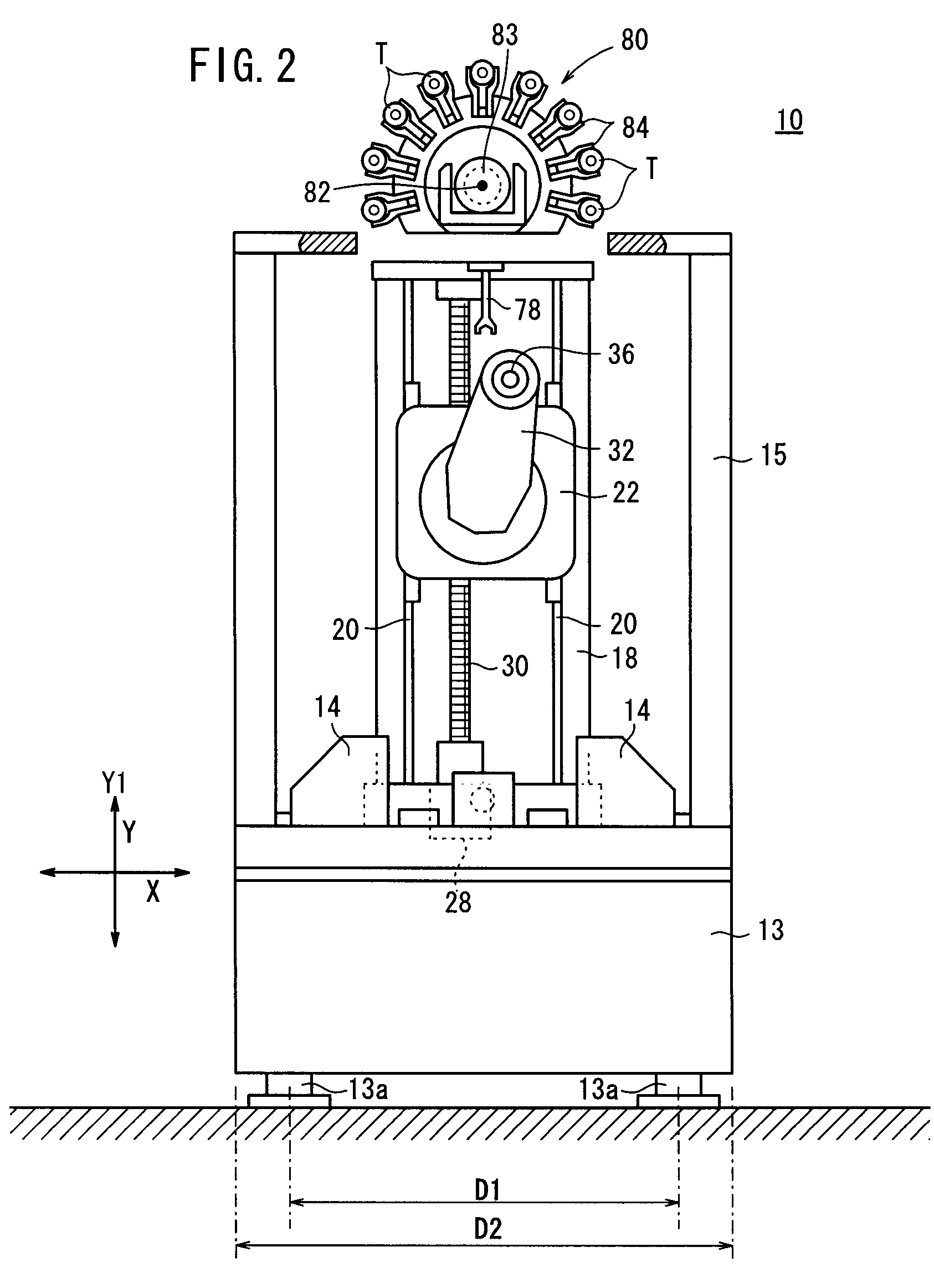

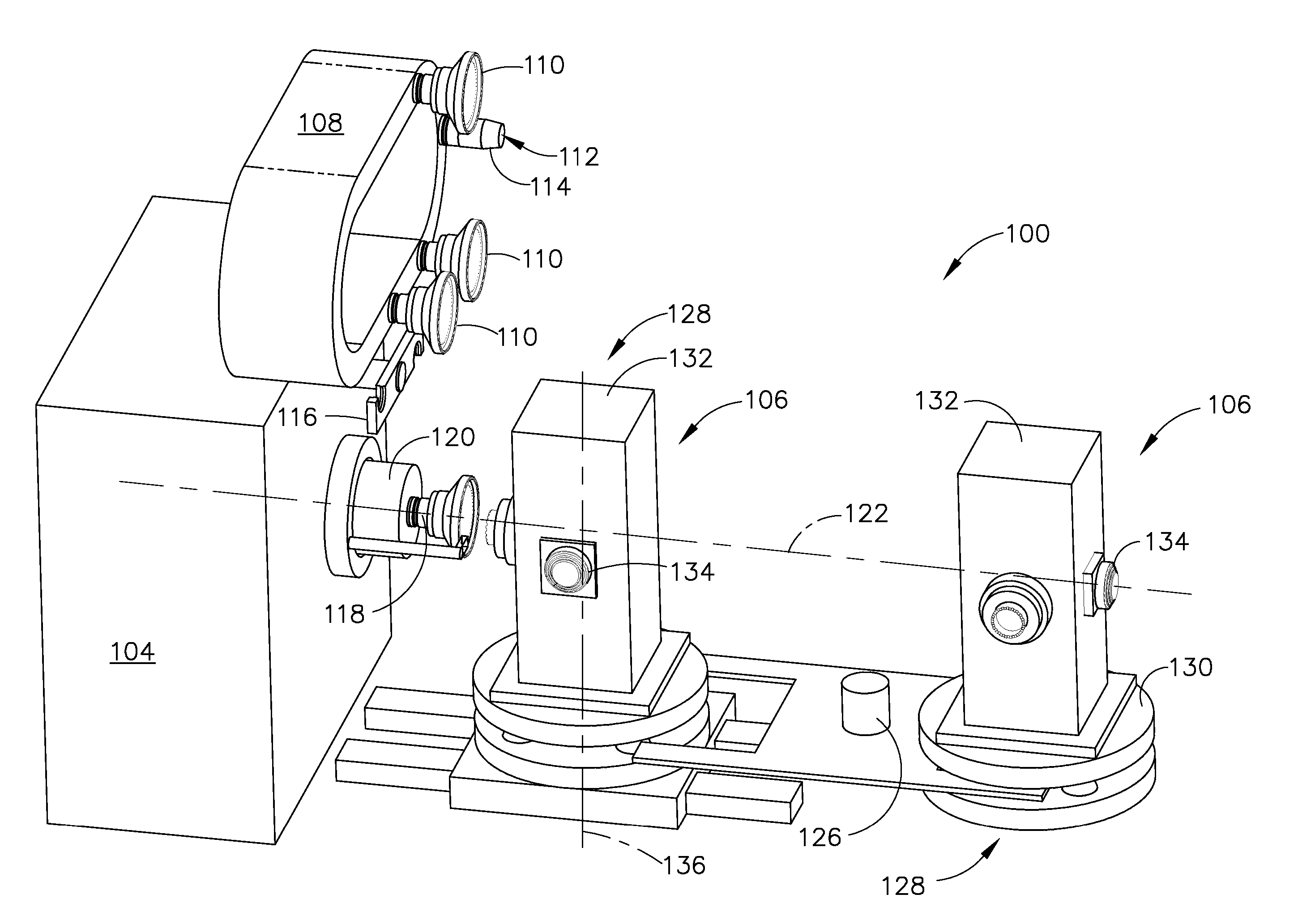

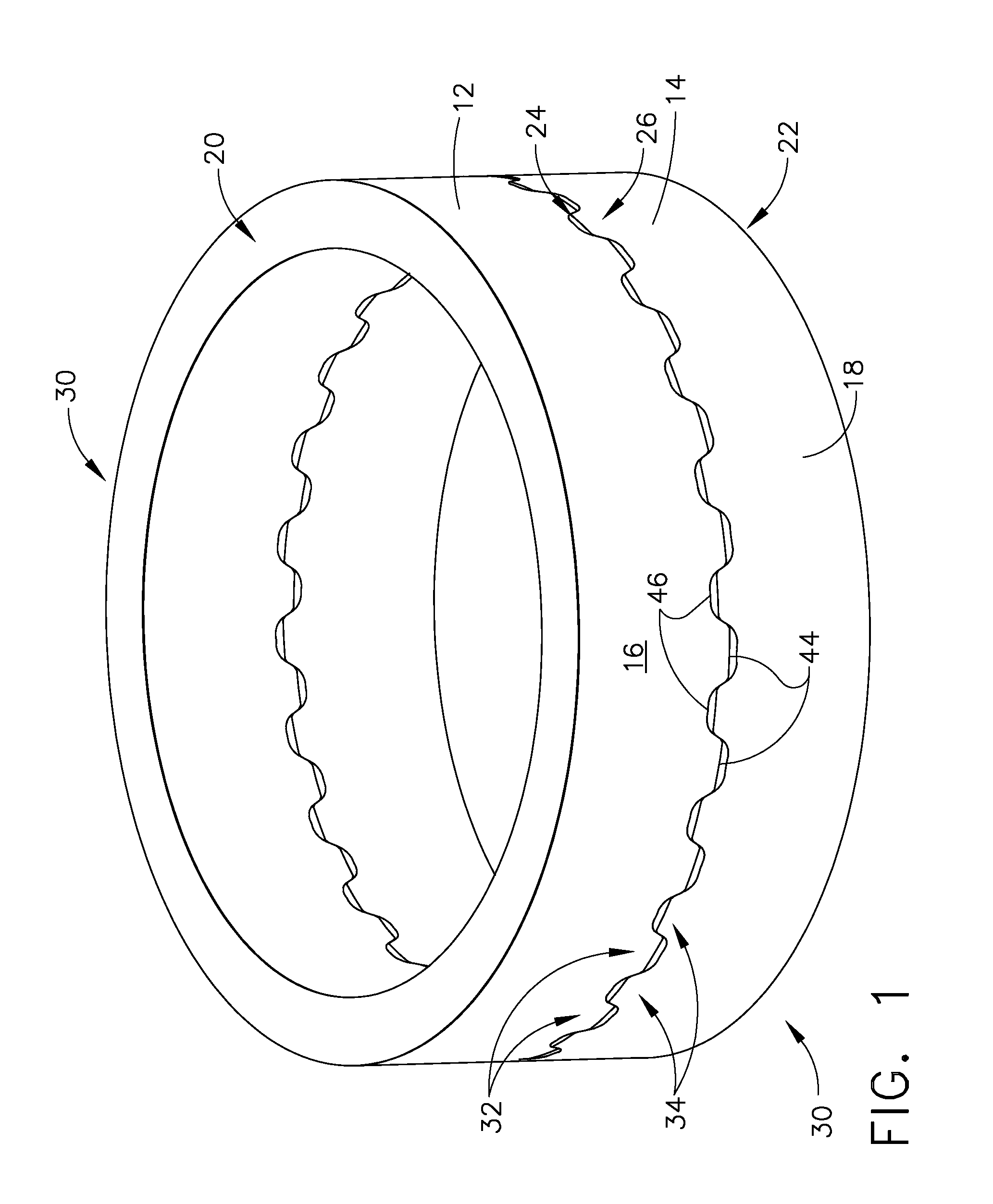

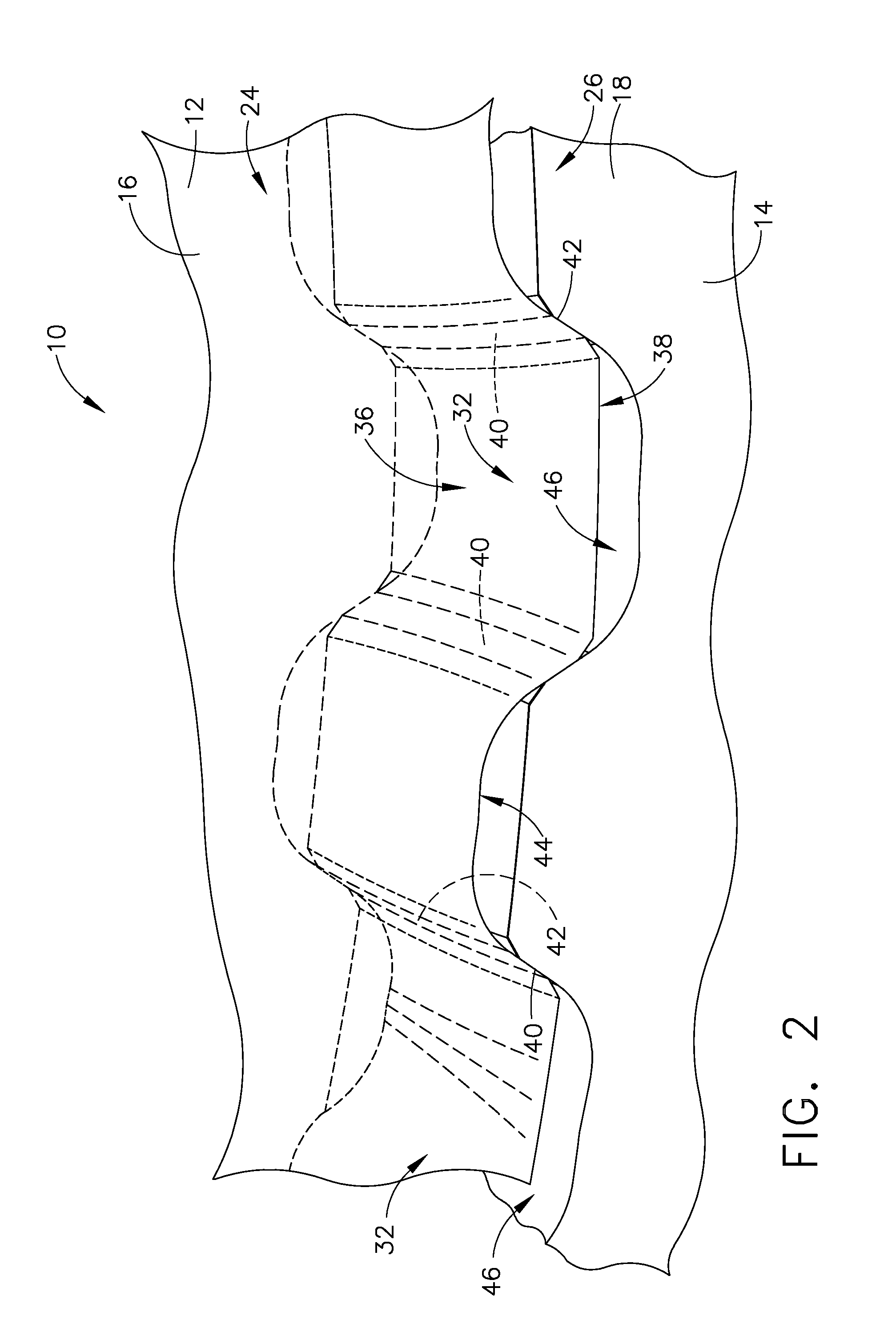

Methods and apparatus for machining a coupling

A method facilitates fabricating a coupling including a first annular coupling member and a second annular coupling member. The method comprises coupling the first coupling member to a machine assembly that includes a plurality of grinding wheels coupled to a tool storage member, machining a plurality of troughs in the first coupling member using at least one of the plurality of grinding wheels, such that at least one projection is defined between adjacent troughs, coupling the second coupling member to the machine assembly, and machining a plurality of troughs in the second coupling member using at least one of the plurality of grinding wheels, such that the second coupling member is configured to rotatably couple to the first coupling member.

Owner:GENERAL ELECTRIC CO

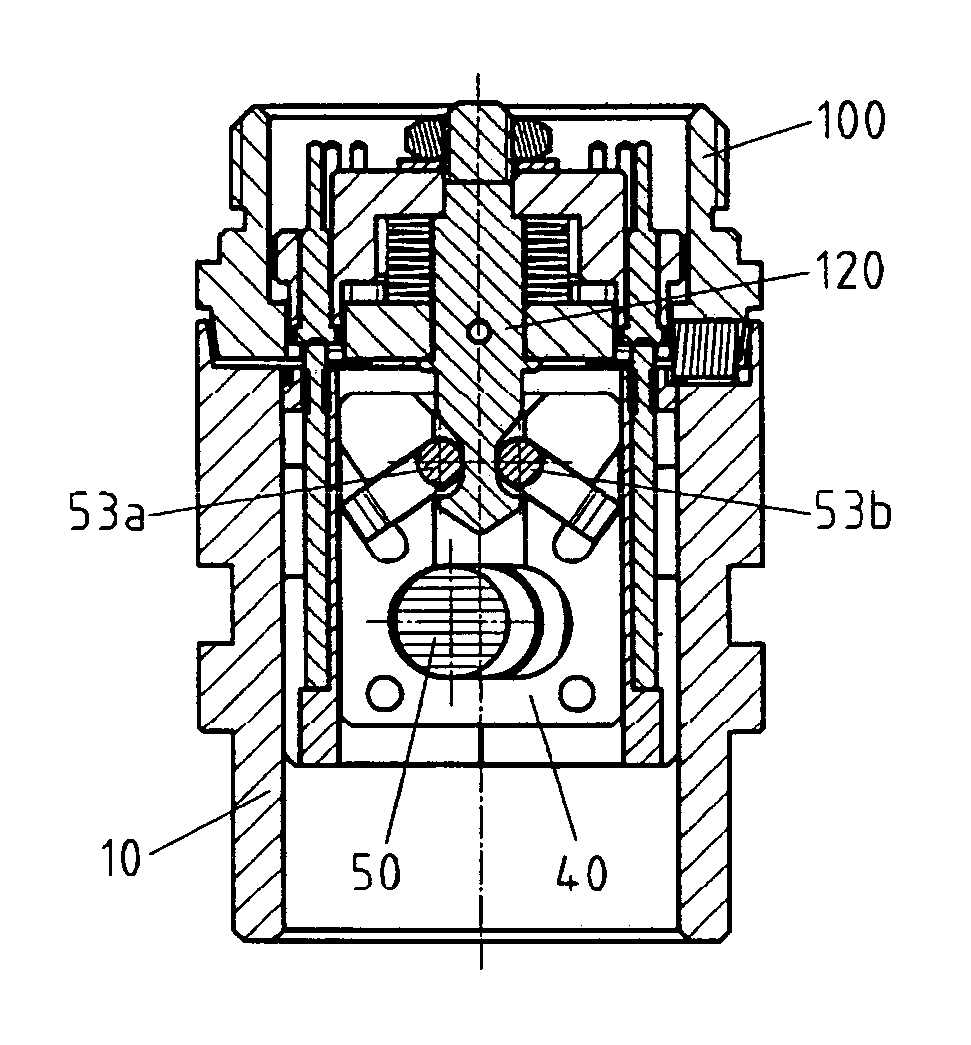

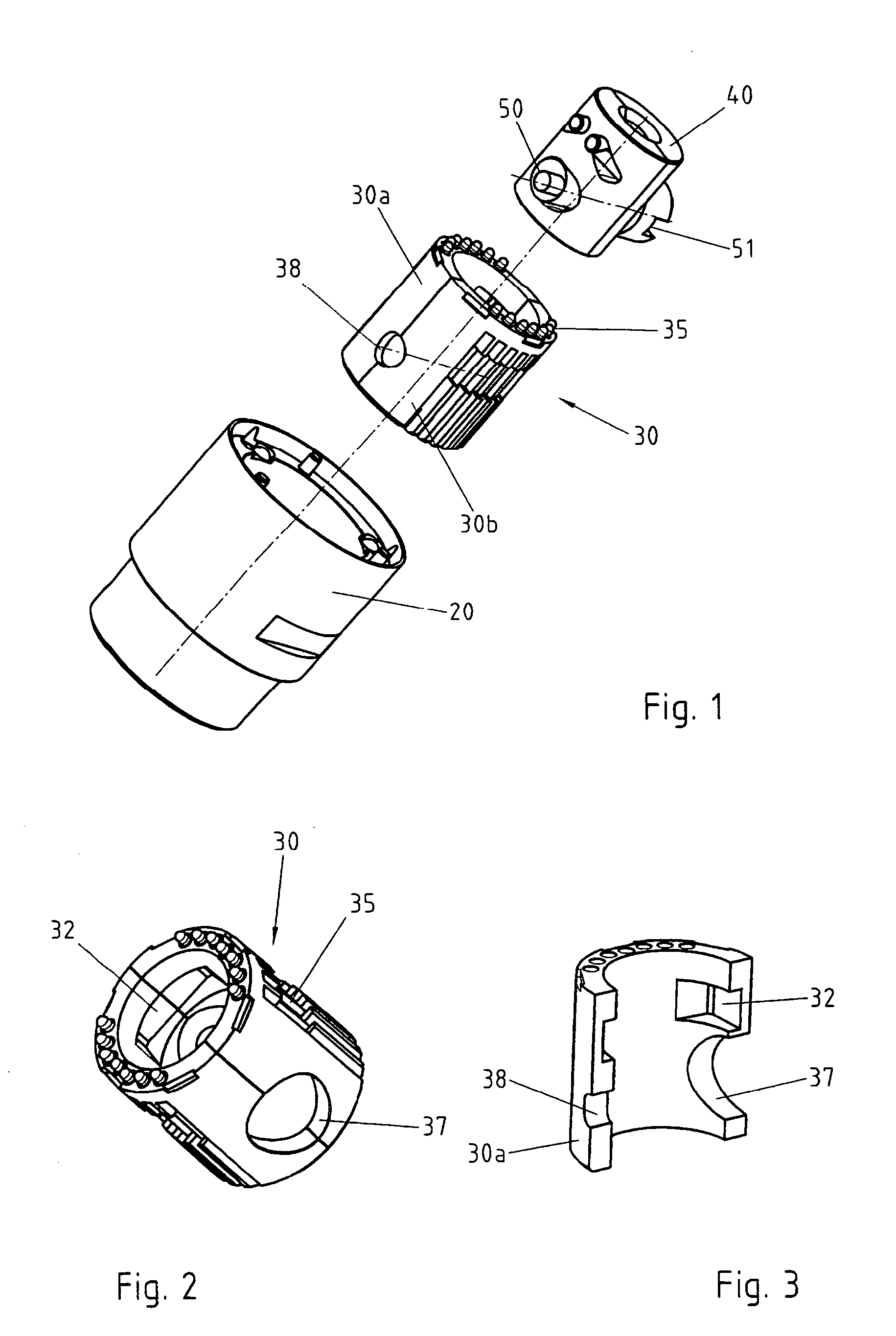

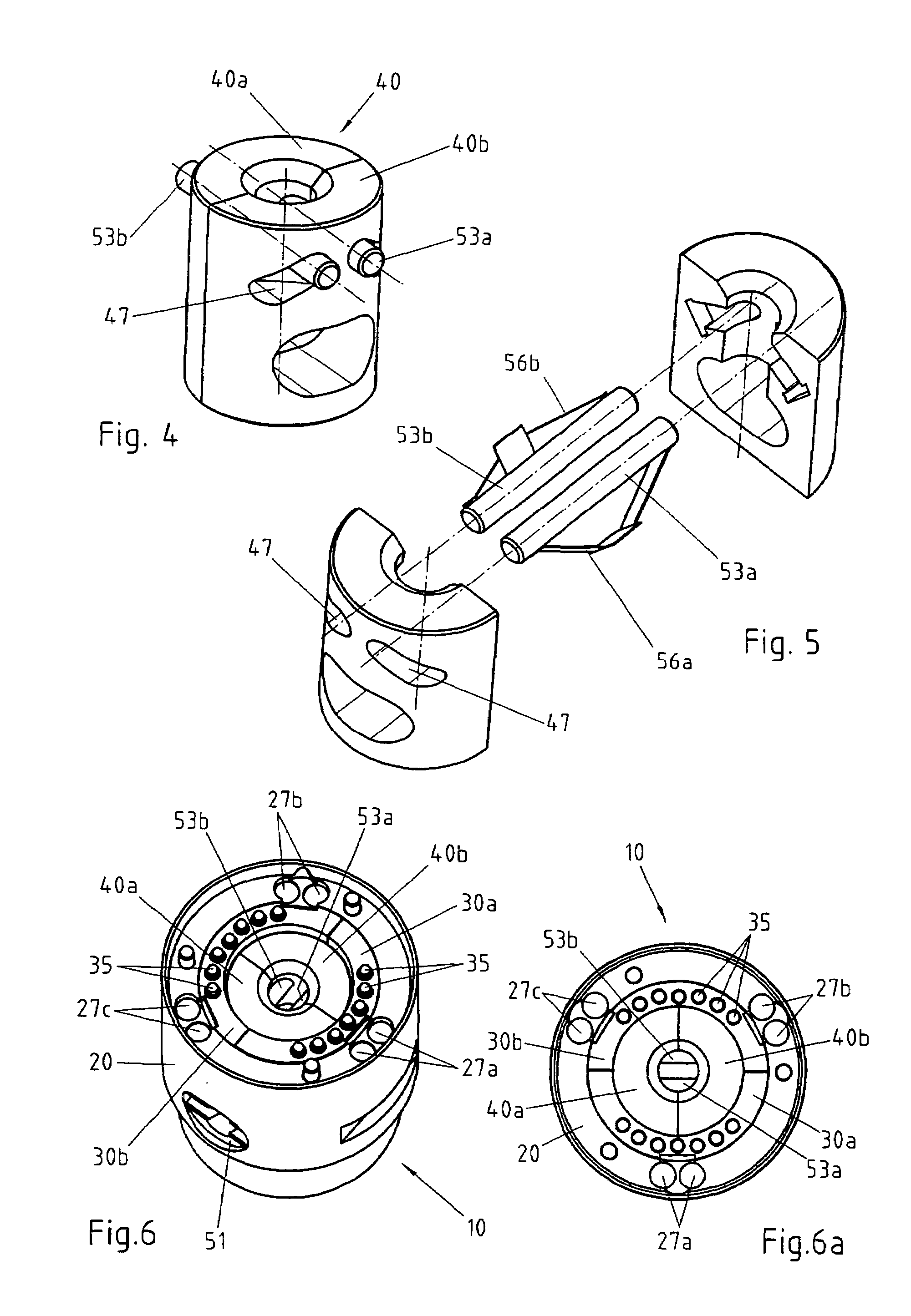

Tool-switching device

Tool-switching device for a machine for measuring coordinates wherein the tool is fastened on the tool-carrier and held by the action of elements exerting an axial force. The locking force is taken over symmetrically by the elements of a Boys connection, which increases the repeatability of the connection; in one embodiment, two pins or spheres are driven by a sliding bushing provided with two “V”-shaped slits or with two lateral gorges. In the subsequent embodiments, the pins are replaced by spheres, by levers or by a stirrup.

Owner:TESA SE

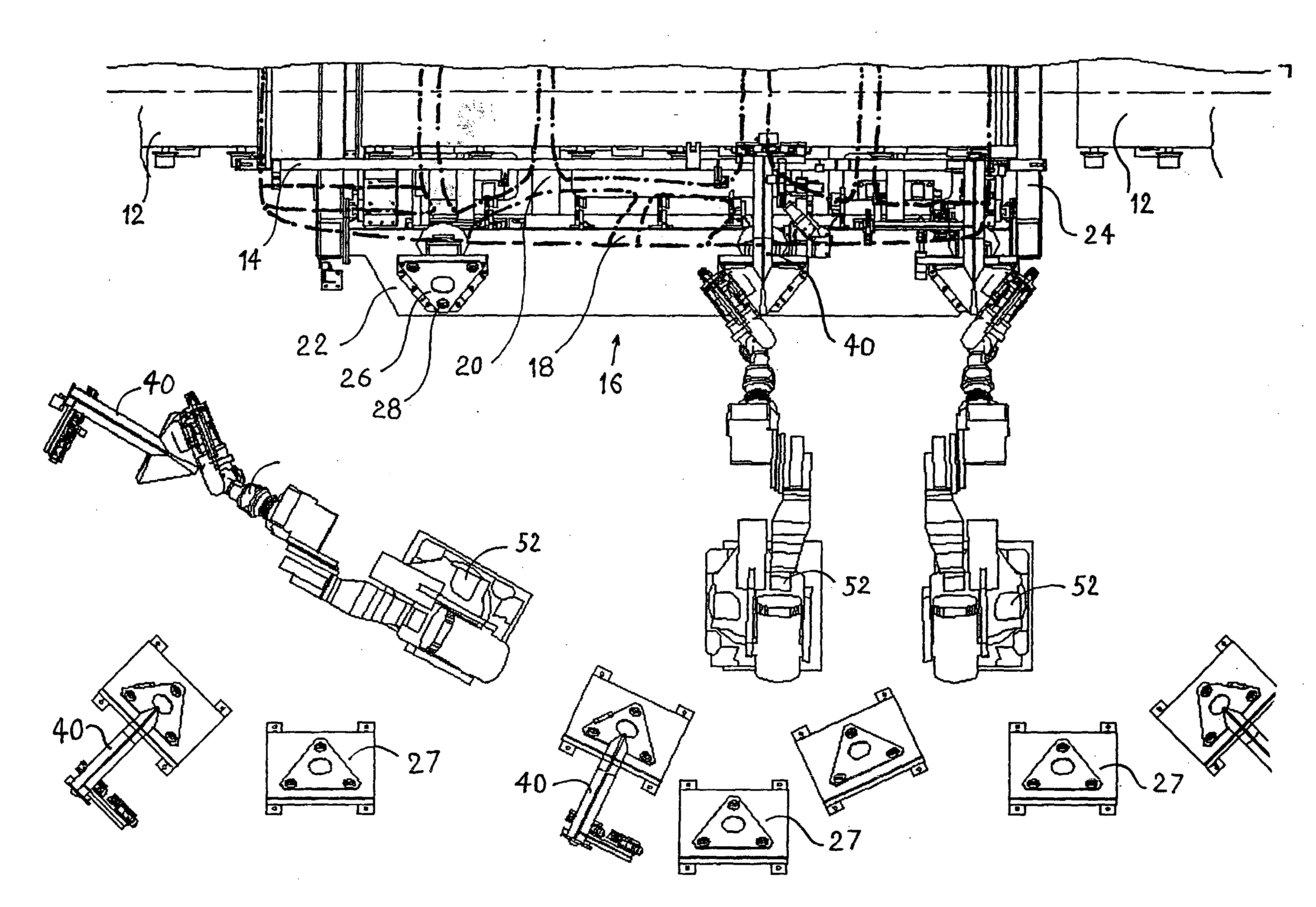

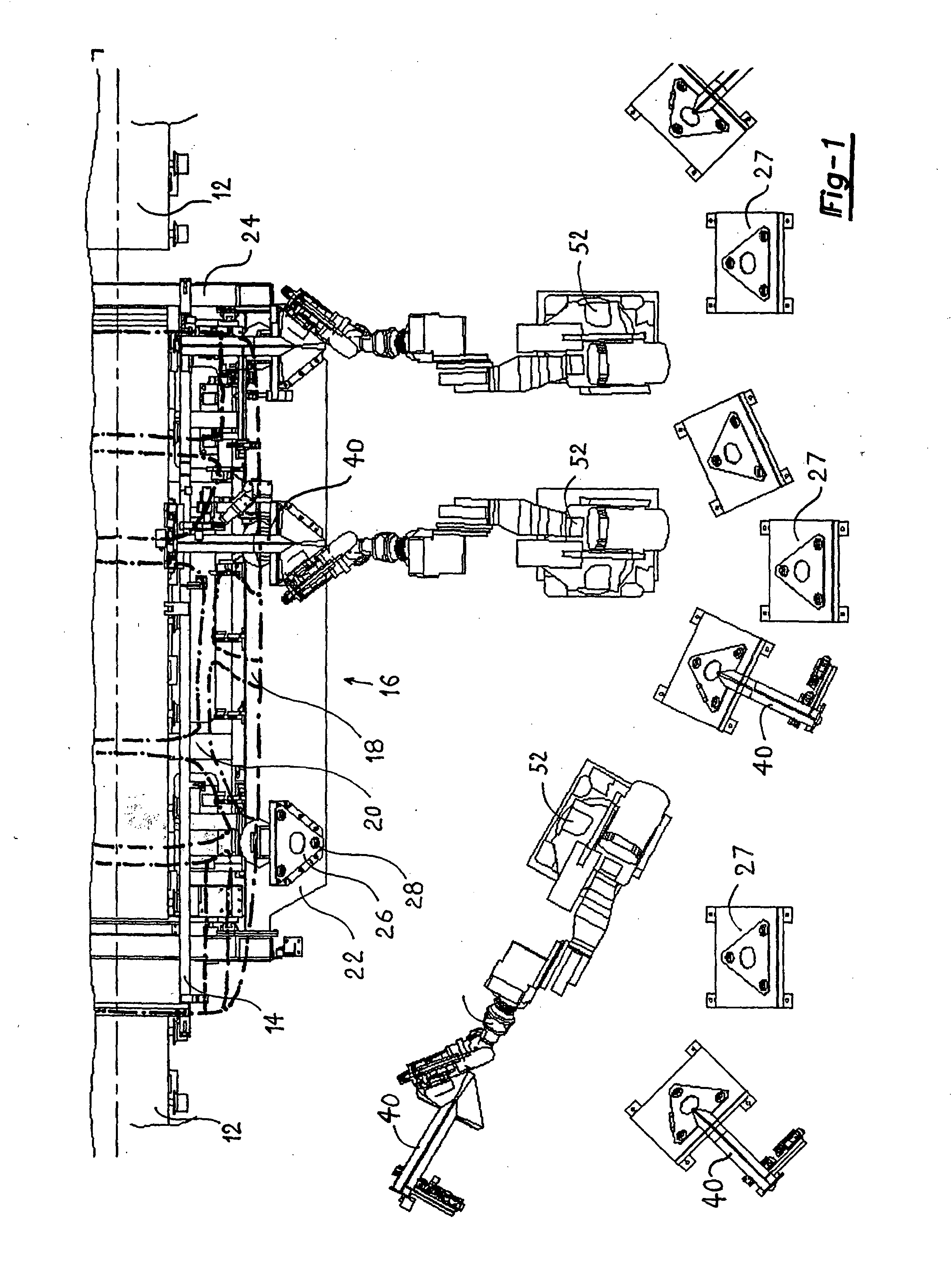

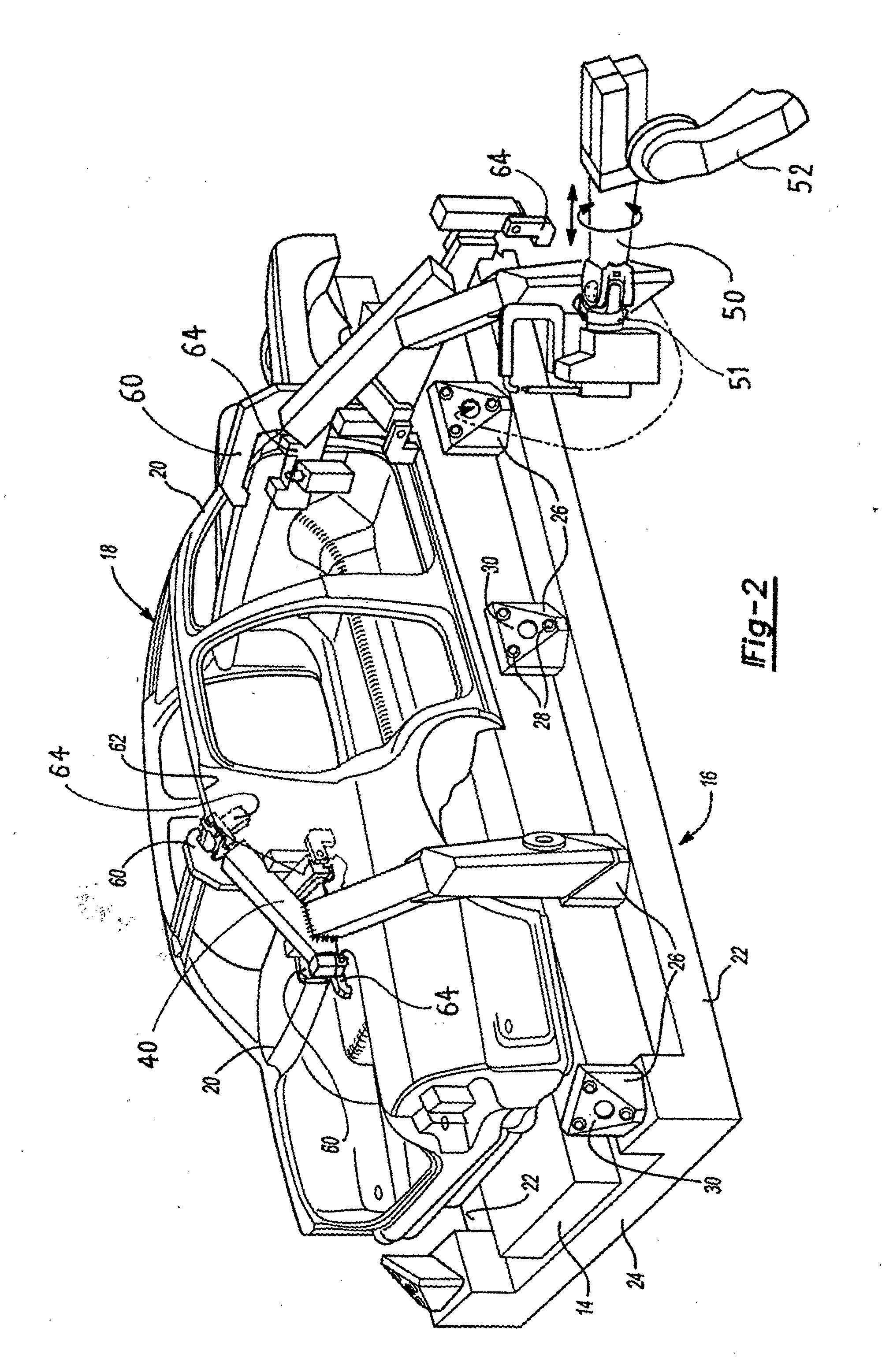

Automotive vehicle framing system

ActiveUS20050060862A1Maximize accessibilityInexpensive to assembleWelding/cutting auxillary devicesAssembly machinesDocking stationVehicle frame

A vehicle framing system for framing an automotive vehicle body from a plurality of separate body components wherein the body components each include a reference surface. The system includes an assembly station having spaced-apart frame members positioned so that, when a vehicle carrier supporting the vehicle body components is positioned at the assembly station, the frame members extend along opposite sides of the vehicle carrier. At least two docking stations are secured to each frame member at predetermined locations. A robot mounts its associated tool arm with a docking station. At least one set of reference block and framing clamp is secured to each tool arm and these framing clamps maintain the reference surfaces of the vehicle body components against the reference blocks to hold the vehicle components at a predetermined position relative to each other. After each robot positions each associated tool arm with the docking station, the robot disengages from the tool arm and then welds the body components together by a welding gun carried by the robots.

Owner:VALIANT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com