Robot-based automatic feeding and discharging system

A technology of automatic loading and unloading and robotics, which is applied in the direction of automatic in/out of workpieces, metal processing machinery parts, maintenance and safety accessories, etc., and can solve problems such as low manual clamping accuracy, high labor costs, and long production cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

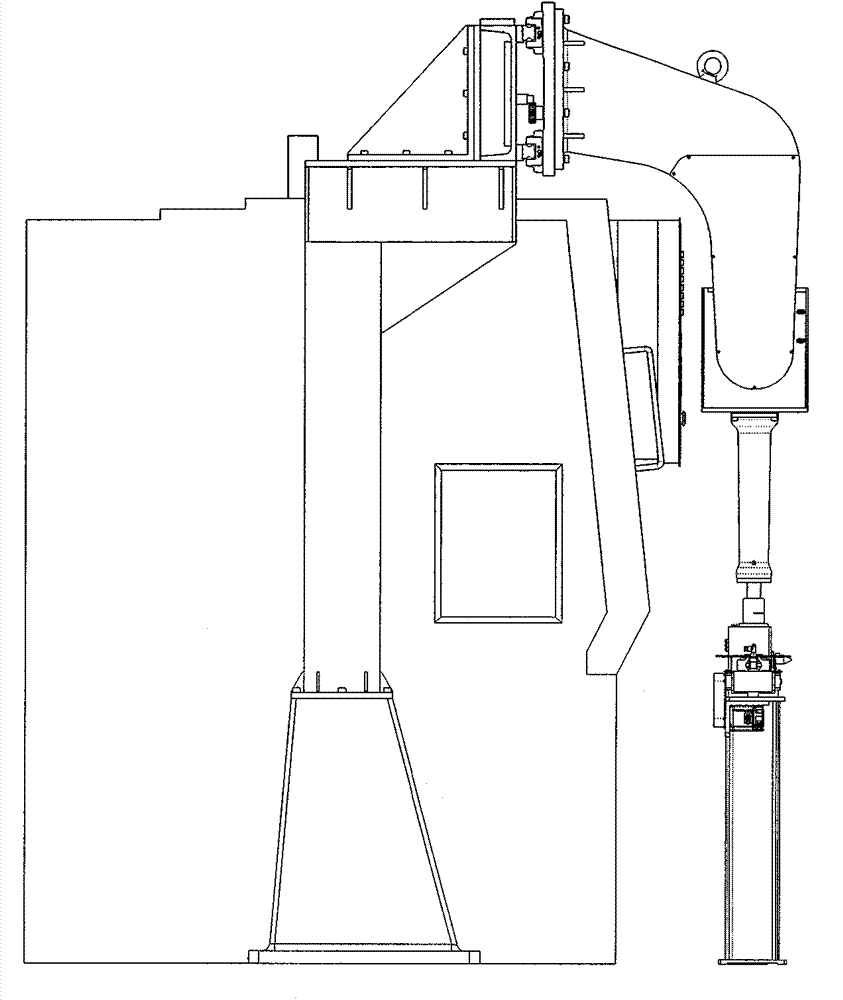

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0030] The invention is based on the automatic loading and unloading system of the robot, which can arrange and accurately position the workpieces in a predetermined manner, clamp the workpieces to the CNC machine tool for processing in different procedures, and remove the workpieces and place them in the finished product box when the workpieces are processed. middle.

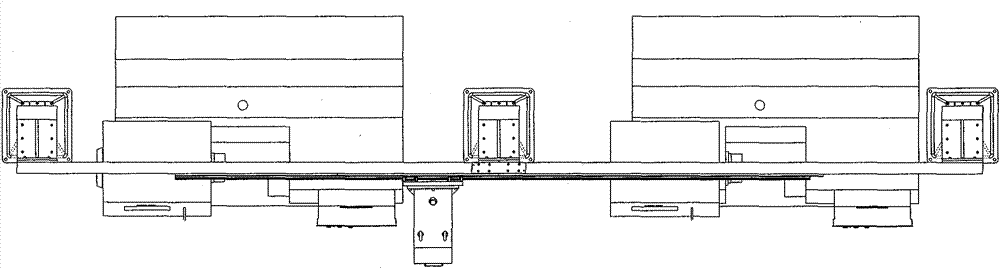

[0031] see figure 1 As shown, it is a front view structural schematic diagram of the robot-based automatic loading and unloading system of the present invention, which includes a mechanical part and a control part, and the mechanical part includes a feeding unit 1, a column beam unit 2, a machine tool unit 3, a robot unit 4, Turn to unit 5 and unloading unit, wherein,

[0032] The feeding unit 1 includes a channel steel, a feeding table, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com