Processing method of automatic lathe used for processing cylindrical workpieces

A technology of automatic lathes and processing methods, applied in metal processing, metal processing equipment, automatic in/out of workpieces, etc. The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

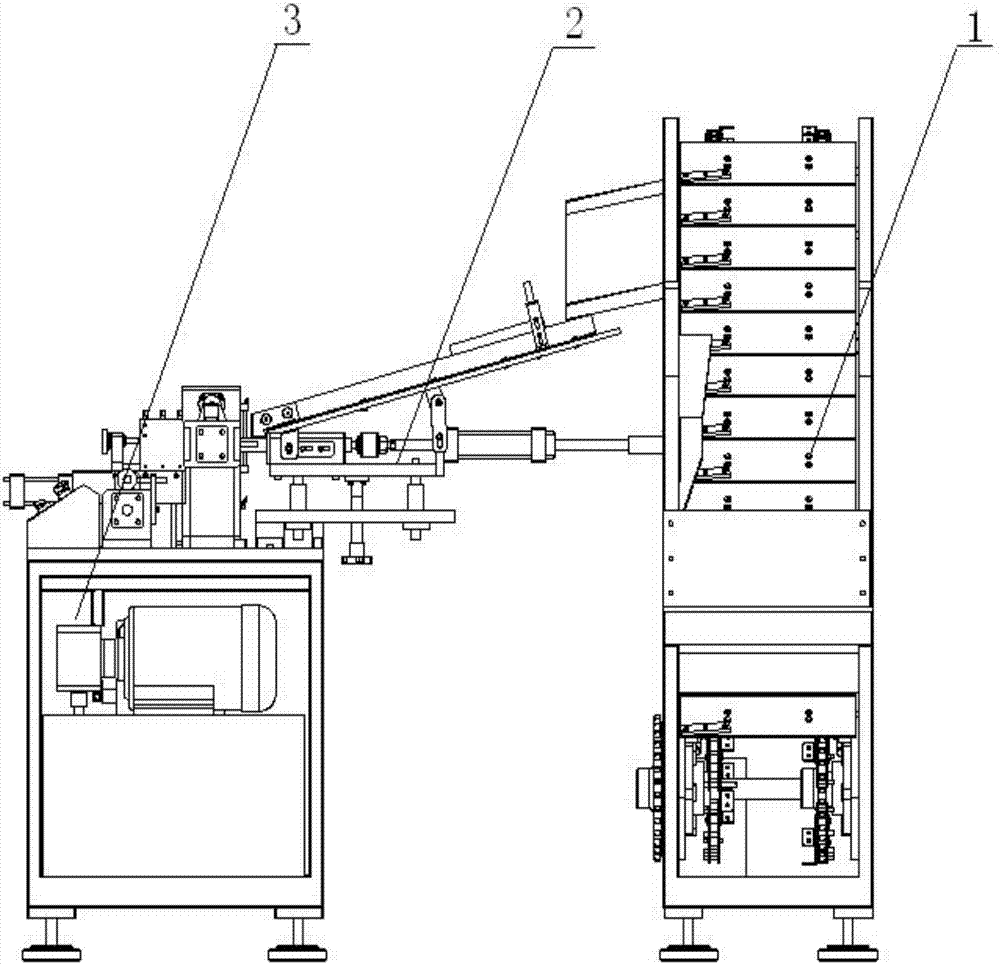

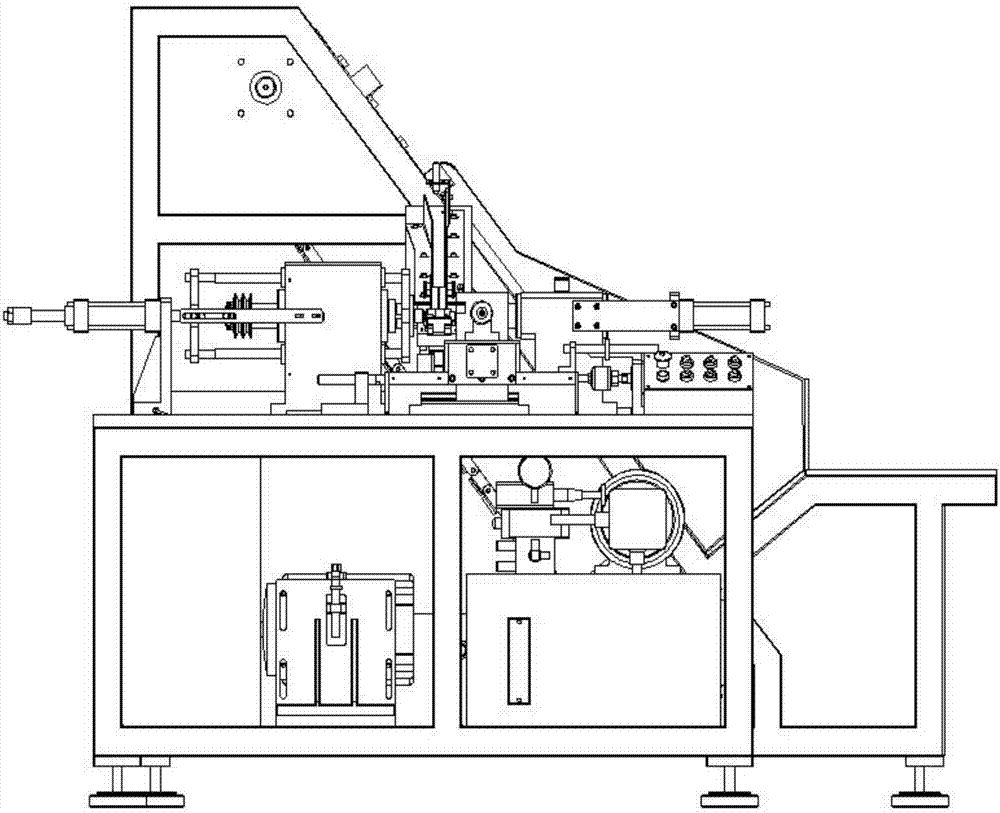

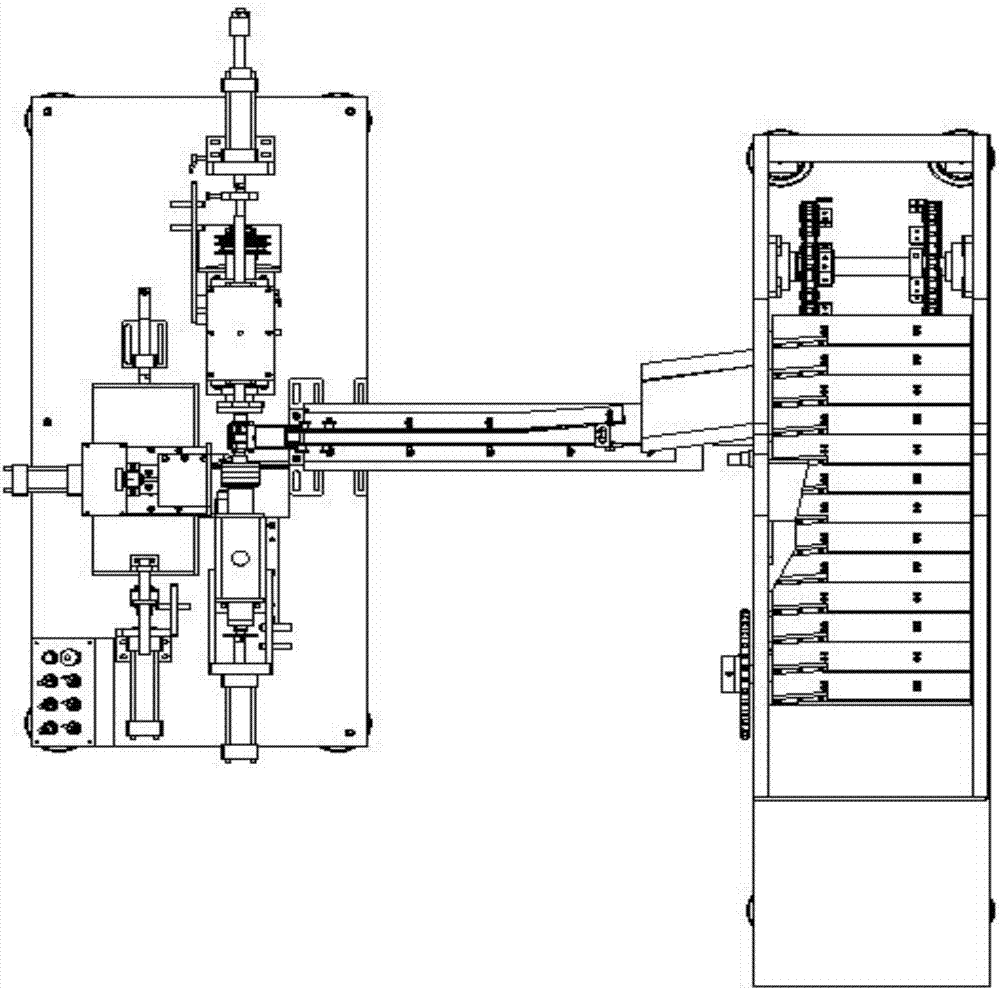

[0066] An automatic lathe for machining cylindrical workpieces, such as figure 1 As shown, it includes a pushing and clamping mechanism 2 and a turning mechanism 3, and the automatic lathe also includes an automatic feeding mechanism 1, which is arranged in parallel with the turning mechanism 3, and the pushing and clamping mechanism 2 It is located between the automatic feeding mechanism 1 and the turning mechanism 3, and is fixed on the upper surface of the turning mechanism 3 by bolts; the pushing and clamping mechanism 2 is used to send the raw materials delivered by the automatic feeding mechanism 1 into the turning mechanism 3;

[0067] In order to realize the automatic loading of the workpiece, thereby improving the processing efficiency, such as Figure 4 to Figure 8 As shown, the automatic feeding mechanism 1 includes a square tube welding material feeding bracket 4 arranged on the ground, a protective plate 10 arranged on the right side of the feeding bracket 4 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com